Comprehensive utilization method for recycling industrial hazardous wastes

A technology for resource utilization and hazardous waste, applied in chemical instruments and methods, selenium/tellurium compounds, photographic technology, etc., can solve the problems of single solution of metal lead recovery technology, waste of secondary resources of copper smelting smoke, etc., and achieve easy governance. , The effect of high equipment utilization and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

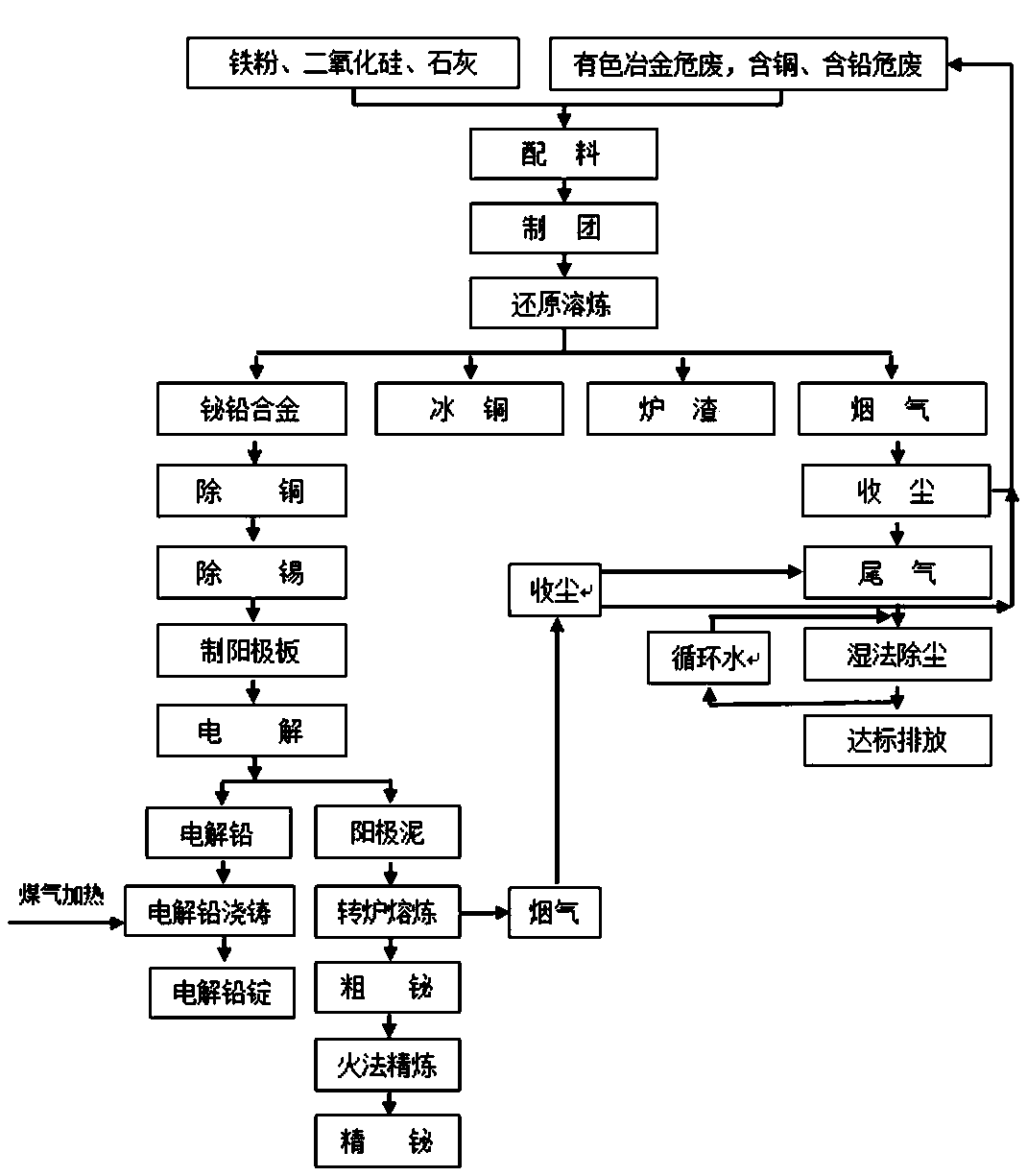

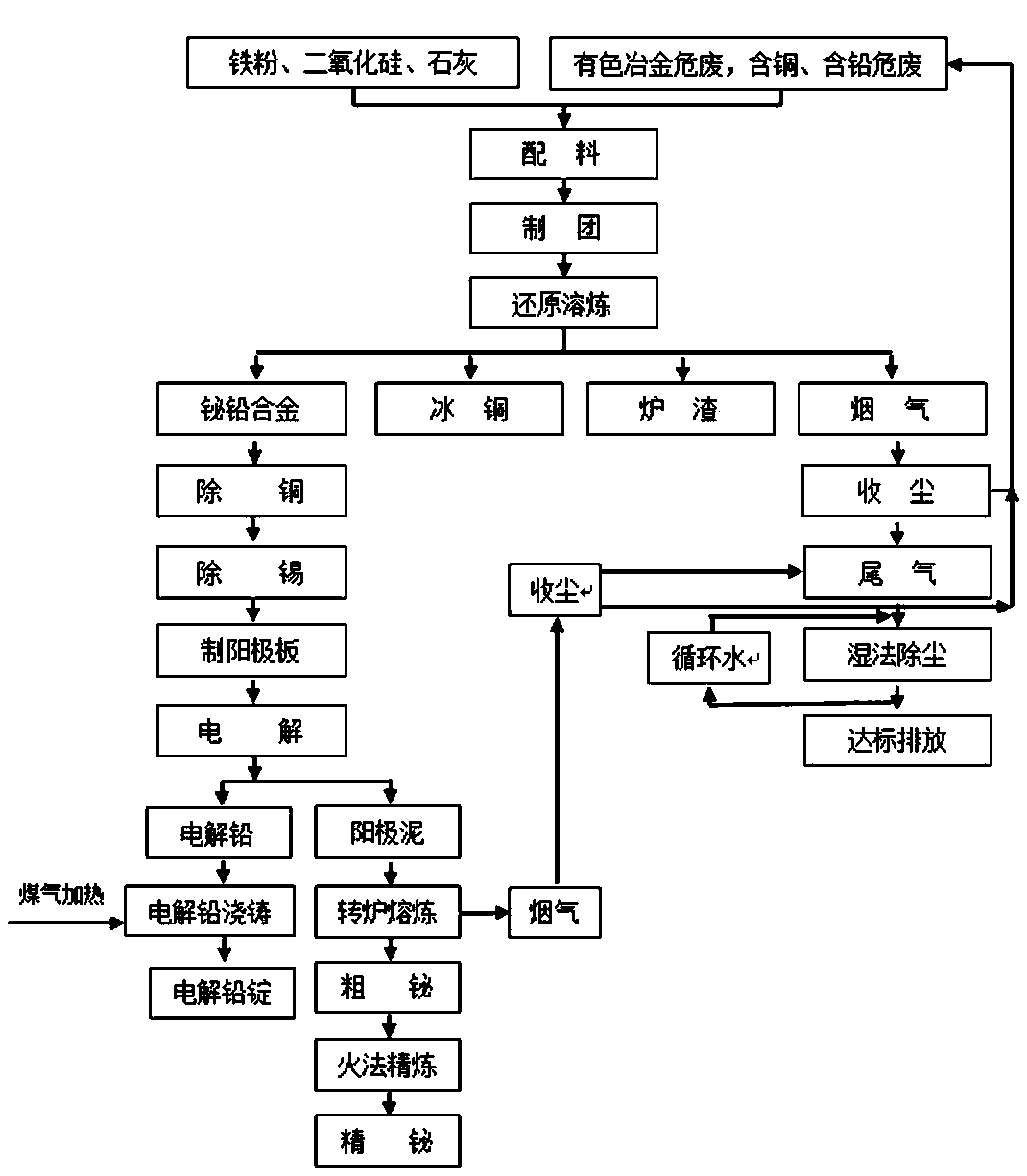

[0034] see figure 1 , a method for comprehensive utilization of industrial hazardous waste resources, comprising the following steps;

[0035] (1) Ingredients: a) According to the chemical composition of non-ferrous metallurgical hazardous waste, copper-containing hazardous waste, and lead-containing hazardous waste, use non-ferrous metallurgical hazardous waste or copper-containing hazardous waste or lead-containing hazardous waste to make charge, and the prepared charge contains Bismuth (Bi) 1-10%, tin (Sn) 0.5-5%, copper (Cu) 1-10%, lead (Pb) 8-20%; b) Add iron, silicon and Calcium material, the material ratio is: iron: silicon: calcium = 20-40: 15-25: 10-20, the silicon is silicon dioxide, and the calcium is lime.

[0036] (2) Group making: Press the prepared charge in the pellet making machine into charge balls or charge bricks with a relative density of 50-60%. The diameter of the charge balls is φ10-15cm; the size of the charge bricks is 6 ×12×24cm, the prepared furna...

Embodiment 2

[0053] The difference between Embodiment 2 and Embodiment 1 is: (1) Ingredients: a) According to the chemical composition of non-ferrous metallurgical hazardous waste, copper-containing hazardous waste and lead-containing hazardous waste, non-ferrous metallurgical hazardous waste and copper-containing hazardous waste and / or Hazardous lead waste is mixed in a certain proportion to make charge, and the prepared charge contains bismuth (Bi) 1-10%, tin (Sn) 0.5-5%, copper (Cu) 1-10%, lead (Pb) 8-20% %; b) According to the chemical composition of the charge, iron, silicon and calcium materials are added in proportion, and the material ratio is: iron: silicon: calcium = 20-40: 15-25: 10-20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com