Patents

Literature

90results about How to "Reduce flue gas temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

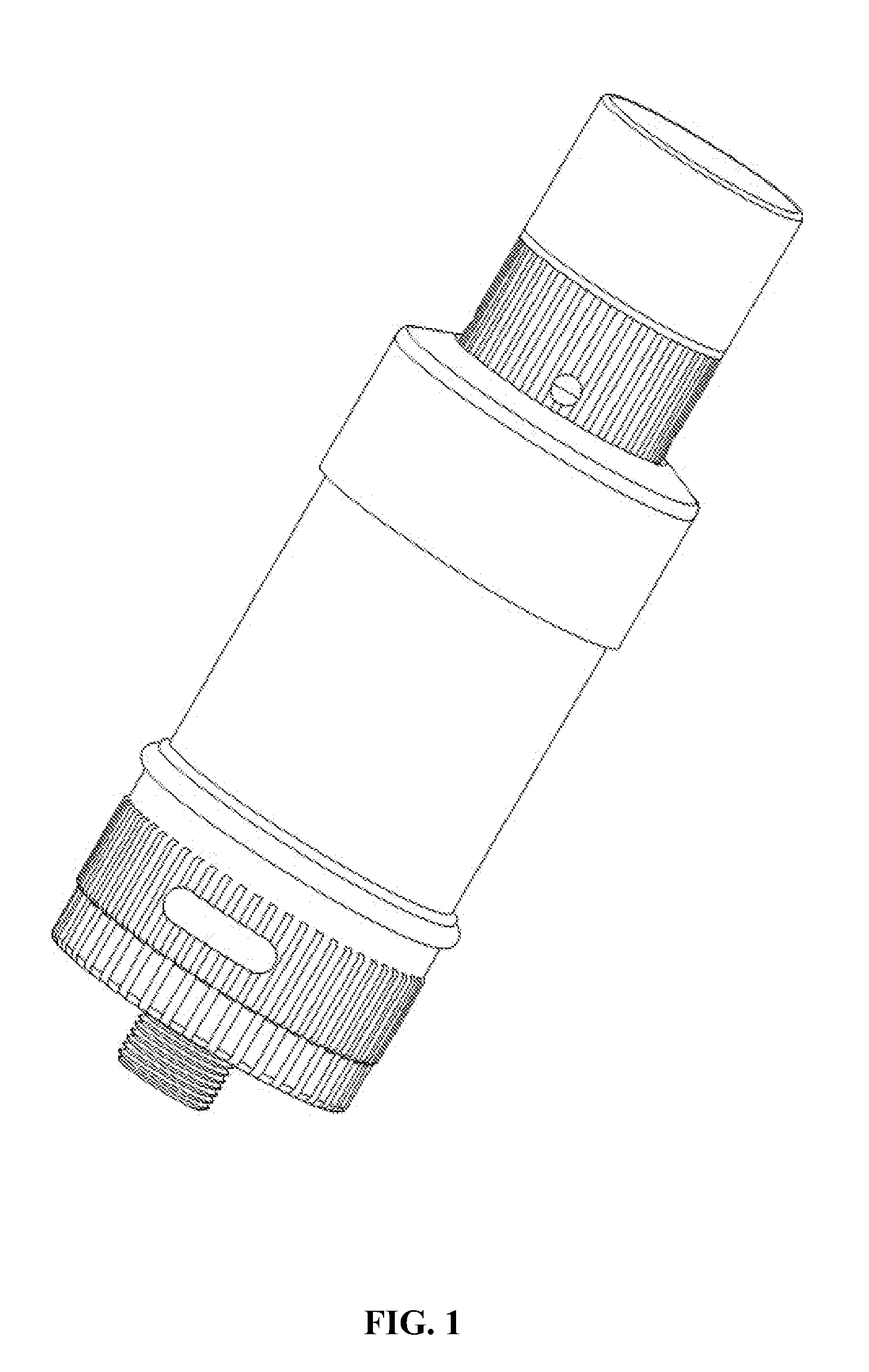

Electronic cigarette

ActiveUS20160295920A1Easy to operateImprove compatibilityTobacco devicesOhmic-resistance heatingEngineeringElectronic cigarette

An electronic cigarette, including: a cigarette holder assembly; a fixing seat assembly; an atomization assembly; a gas flow control assembly; and a glass housing. The cigarette holder assembly is made of metal. The fixing seat assembly operates to fix the glass housing and to regulate an air flow. The atomization assembly is disposed inside the glass housing. The heating wires are disposed inside the atomization assembly. The cigarette holder assembly is connected to the fixing seat assembly in the manner of plugging. The glass housing is connected to a middle support via a fixing jaw. The atomization assembly is assembled with the gas flow control assembly using screw threads to form an integrated structure, and the integrated structure of the atomization assembly and the gas flow control assembly is then assembled with the fixing seat assembly.

Owner:LIU TUANFANG

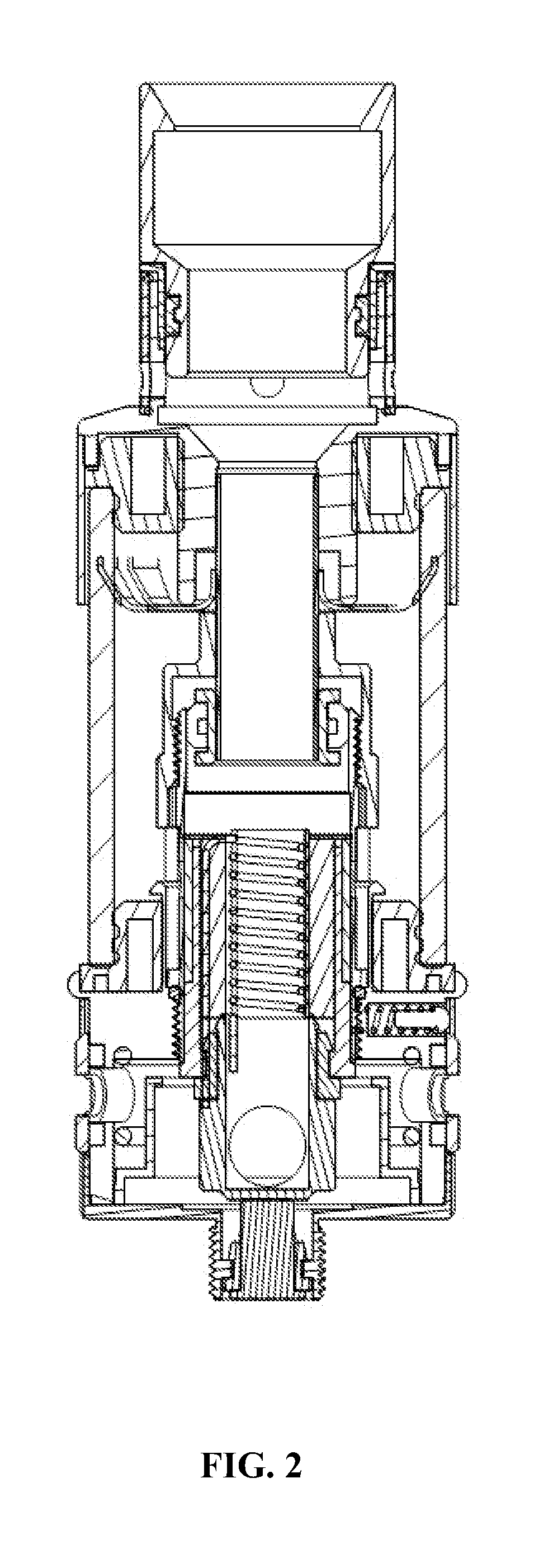

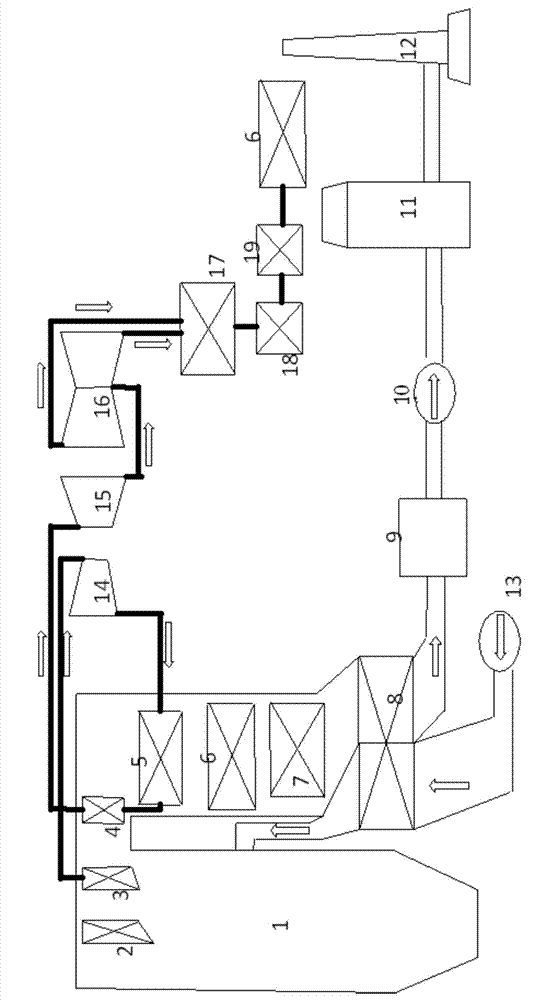

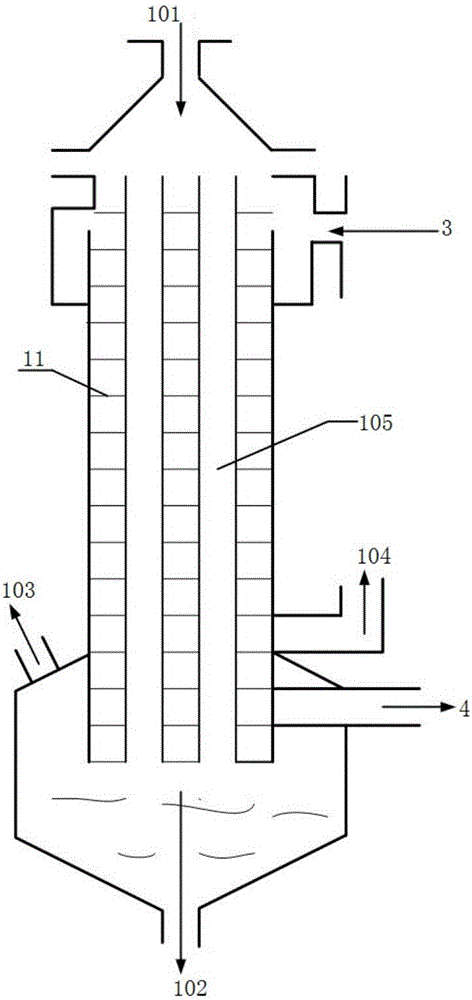

Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

ActiveCN105526576AReduce flue gas temperatureLower exhaust gas temperatureSteam engine plantsSteam boilersSuperheaterHigh pressure

The invention discloses a coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system which comprises a low-temperature regenerator, a precooler, a main compressor, a re-compressor, a high-temperature regenerator, a boiler, a high-pressure turbine, a low-pressure turbine and an electric generator. The boiler is composed of a combustion channel, a main heat exchange channel and a tail flue in the smoke flowing direction, wherein the combustion channel, the main heat exchange channel and the tail flue are communicated in sequence; a water-cooled wall and a reheating water-cooled wall are sequentially arranged in the combustion channel in the smoke flowing direction; a high-temperature superheater and a high-temperature reheater are sequentially arranged in the main heat exchange channel in the smoke flowing direction; a baffle, a coal economizer and a low-temperature coal economizer are sequentially arranged in the tail flue in the smoke flowing direction, and a low-temperature reheater and a lower-temperature superheater are arranged on the two sides of the baffle. According to the coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system, optimal combining of the coal-fired boiler and the supercritical carbon dioxide Brayton cycle can be achieved, and the heat exchange efficiency of the high-temperature regenerator, the thermal efficiency of the boiler and the efficiency of the power generation system are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

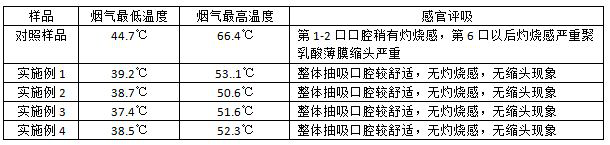

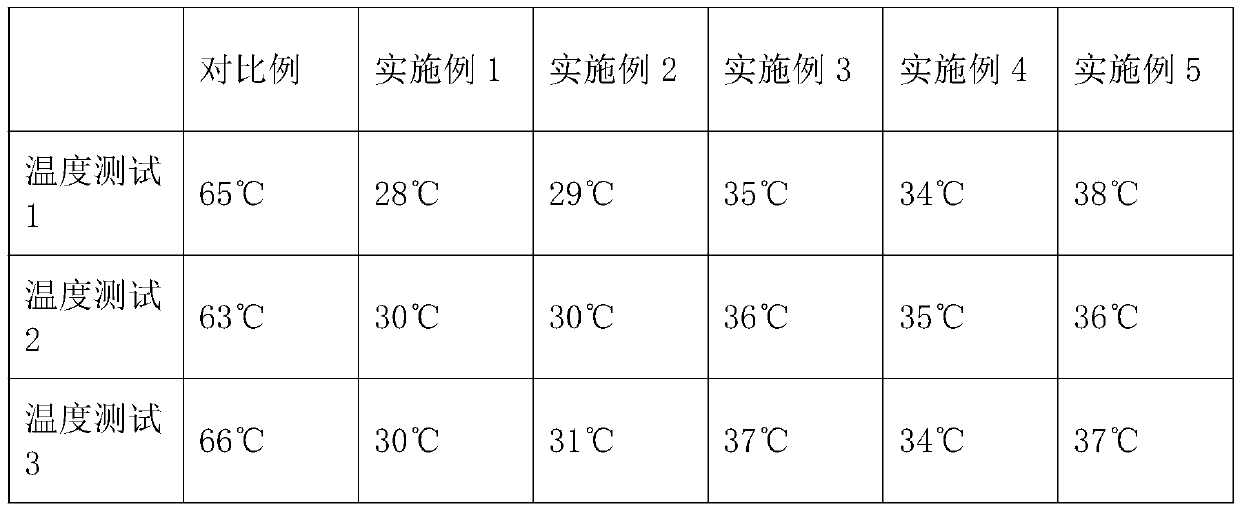

Cigarette filter stick with function of reducing main stream smoke temperature of cigarette

ActiveCN106690415AThe processing technology is simple and effectiveReduce flue gas temperatureTobacco smoke filtersAlcoholPolyethylene glycol

The invention relates to a cigarette filter stick with a function of reducing the main stream smoke temperature of a cigarette. The filter stick is added with heat-absorption gel, wherein the heat-absorption gel is prepared from the following components in parts by weight: 30-70 parts of propylene glycol, 30-60 parts of polyethylene glycol and 5-15 parts of hexadecyl alcohol. Compared with the prior art, the cigarette filter stick has the advantages that the cigarette or tobacco product which is not burnt by heating uses the cigarette filter stick, the smoke temperature can be reduced by 1.0-8.0 DEG C, the smoking comfortable feeling of the cigarette and tobacco product which is not burnt by heating can be improved.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

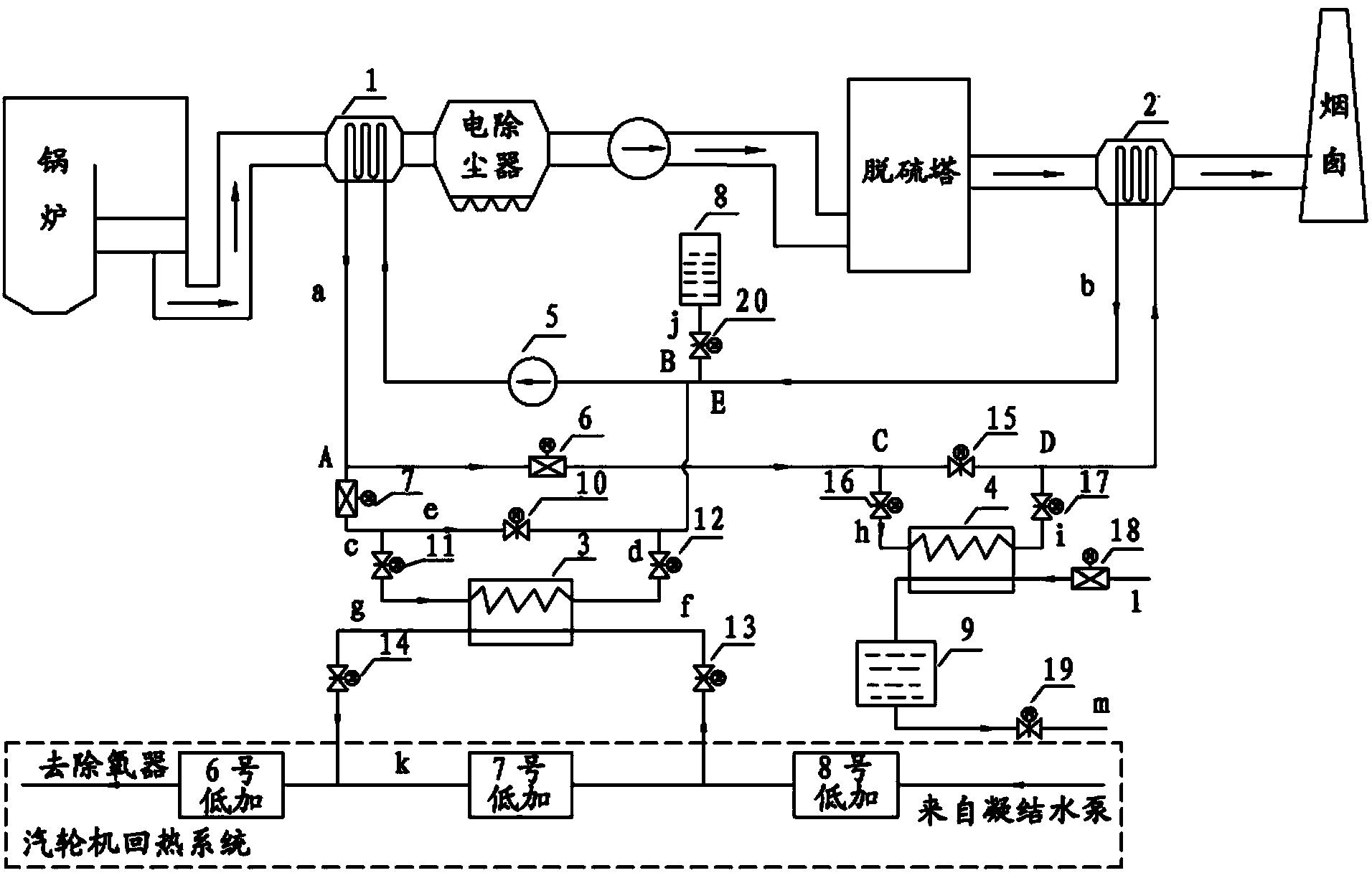

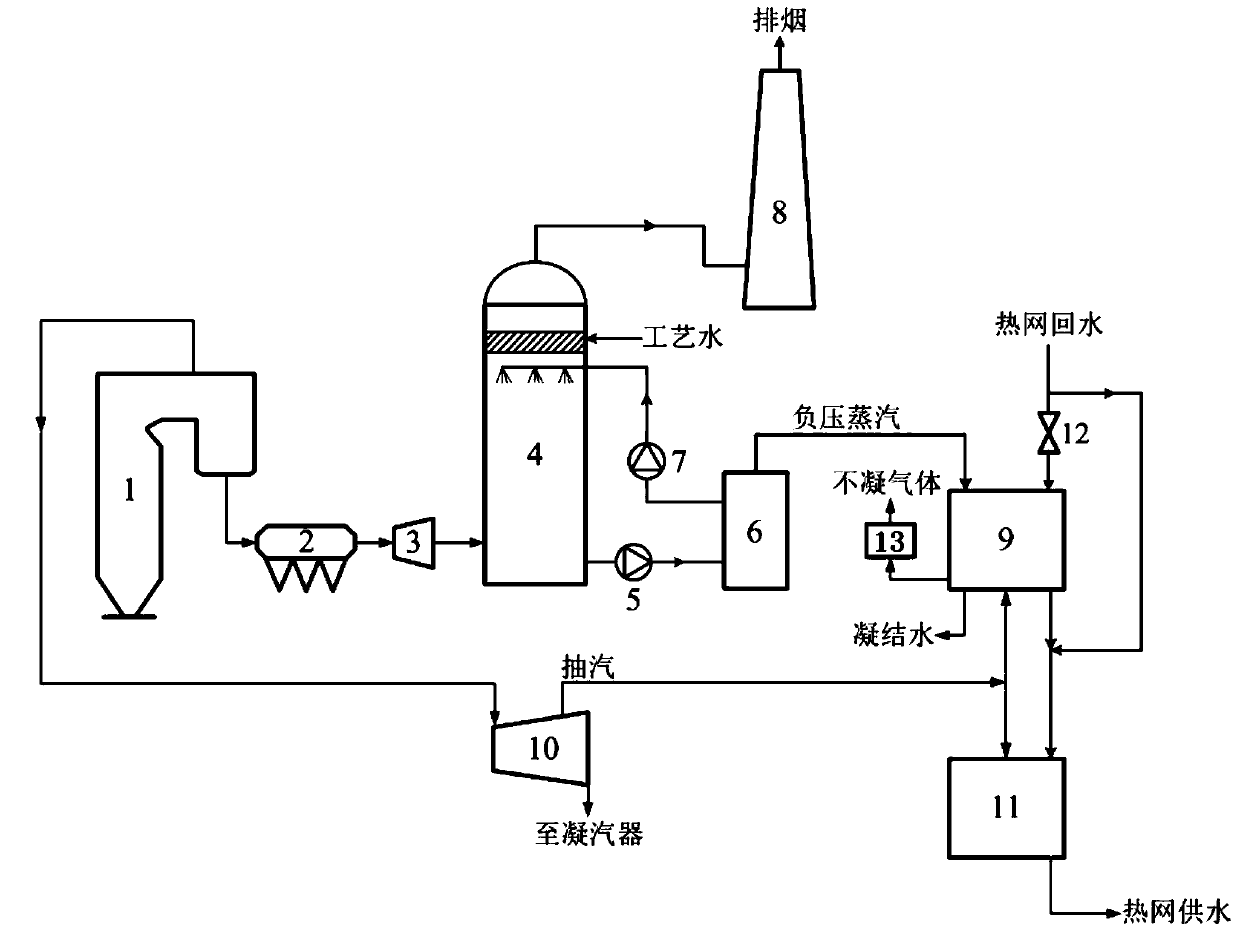

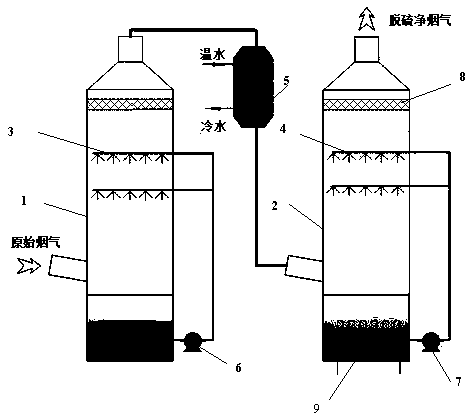

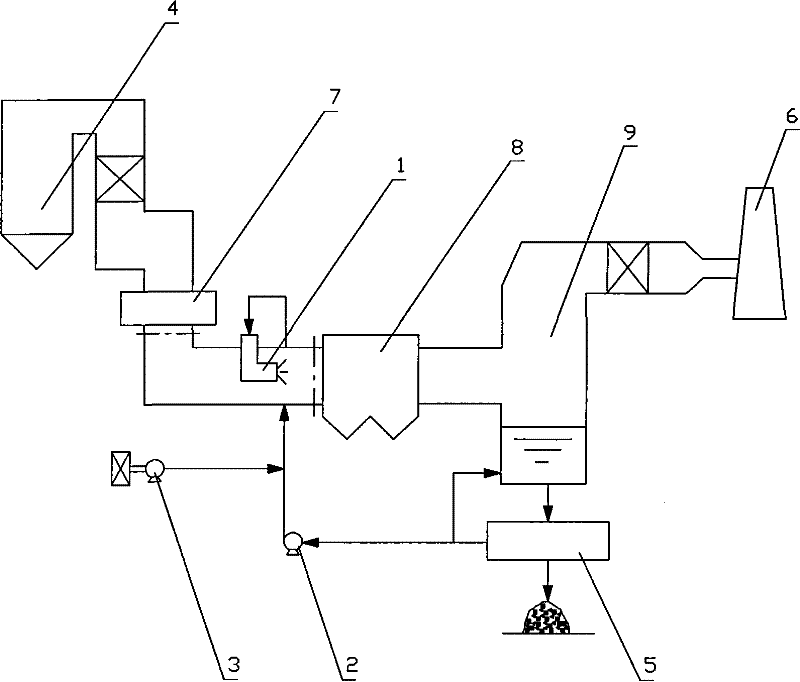

Smoke waste heat comprehensive utilization device and method

InactiveCN104048307AAvoid Low Temperature CorrosionReduce investment in anti-corrosionCombustion technology mitigationFeed-water heatersFlueChiller

The invention discloses a smoke waste heat comprehensive utilization device and a smoke waste heat comprehensive utilization method. The device comprises a smoke cooler, a smoke heater and a closed circulation pump, wherein the smoke cooler is arranged on a flue of the smoke outlet of a boiler air pre-heater; the smoke heater is arranged on a flue of the smoke outlet of a desulphurization tower; the water outlet of the smoke cooler and the water inlet of the smoke heater are connected by a first pipeline, and the water outlet of the smoke heater and the water inlet of the smoke cooler are connected by a second pipeline, so that a closed circulation water main circuit is formed; the closed circulation pump is arranged on the closed circulation water main circuit. According to the smoke waste heat comprehensive utilization device and the smoke waste heat comprehensive utilization method, waste heat of the boiler discharged smoke of a thermal generator set is mainly used as a heat source to heat pure smoke of the smoke outlet of a wet desulphurization tower, the operation is stable, safe and environment-friendly, and the energy-saving and environment-friendly effects are excellent.

Owner:舒少辛 +1

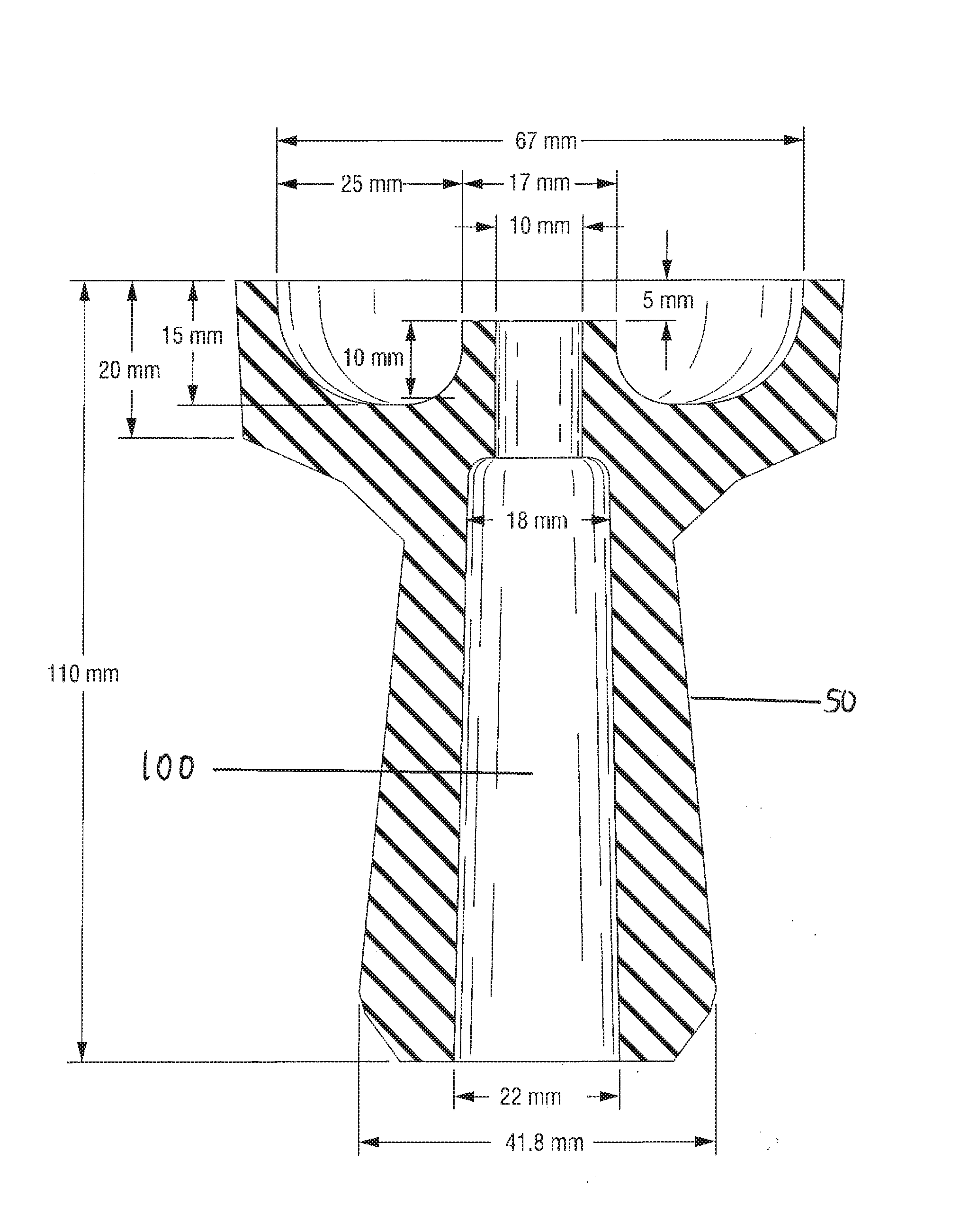

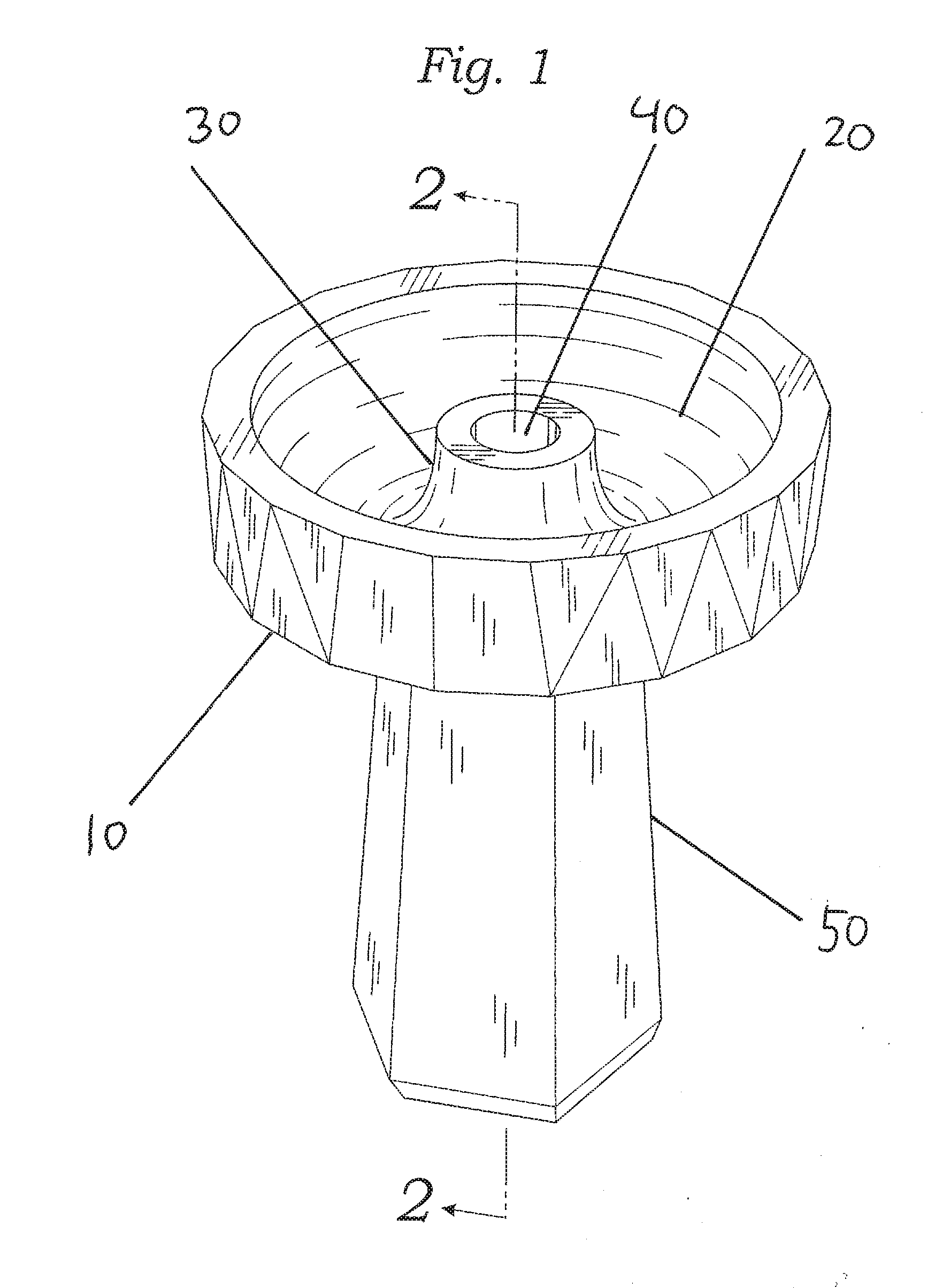

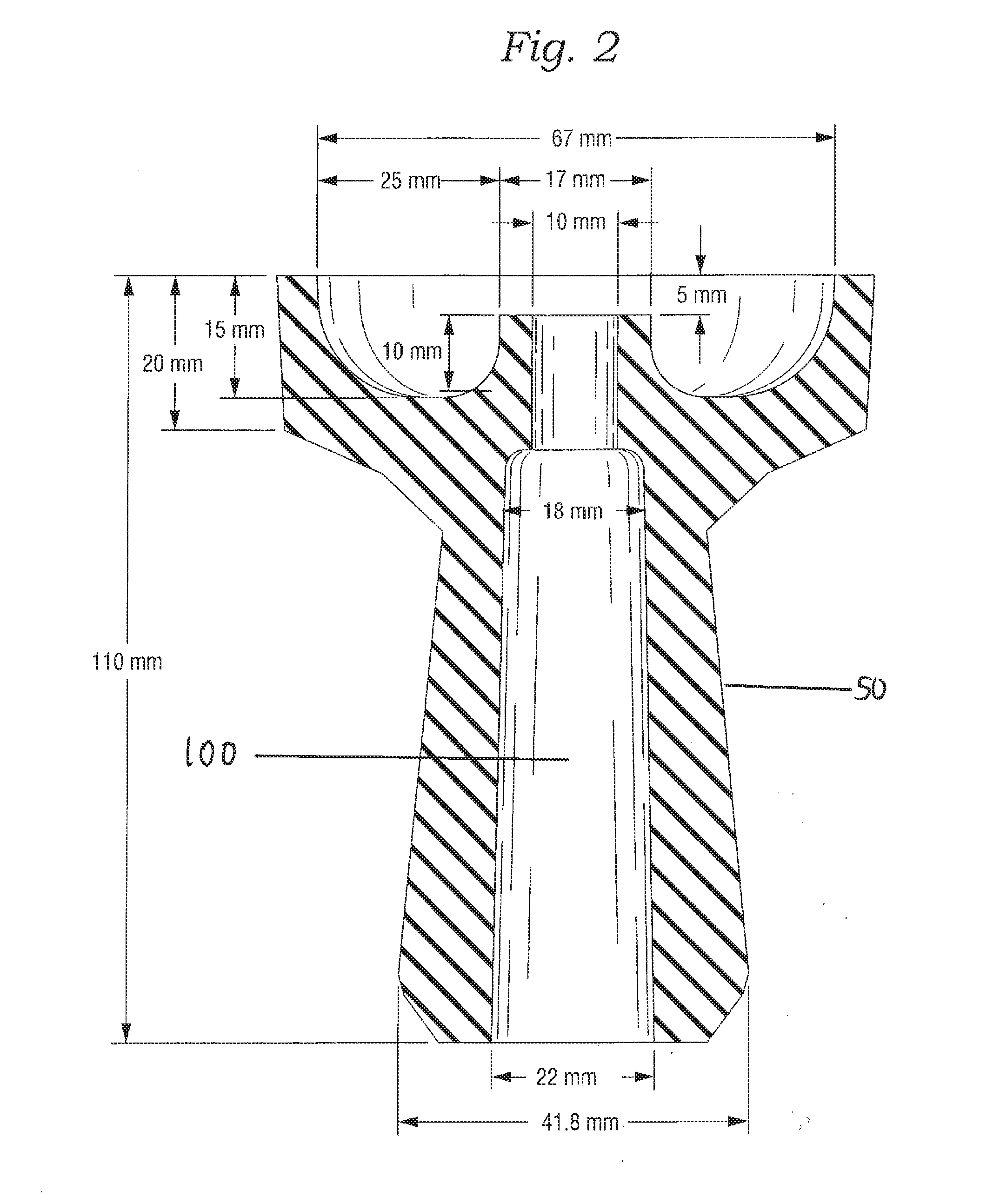

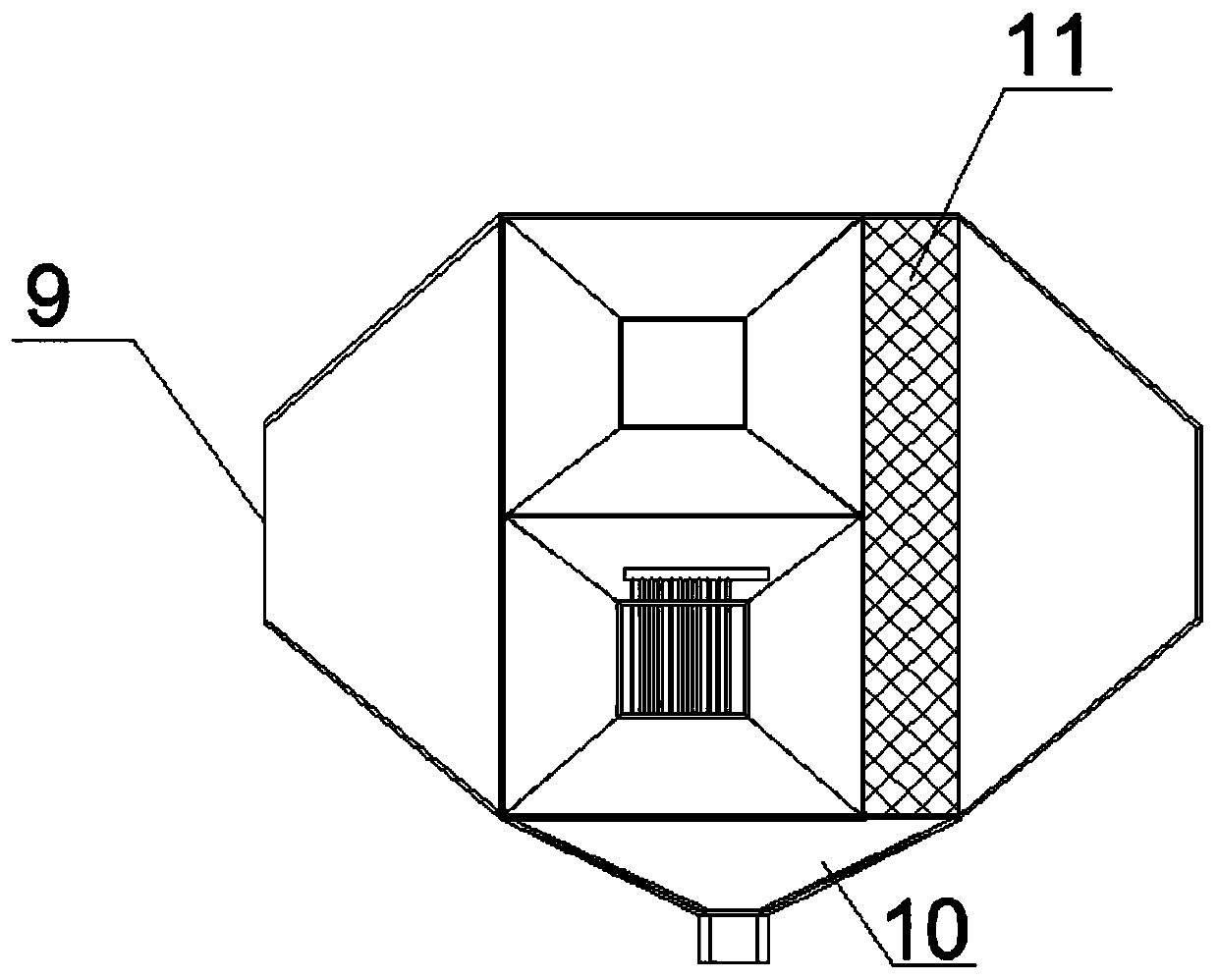

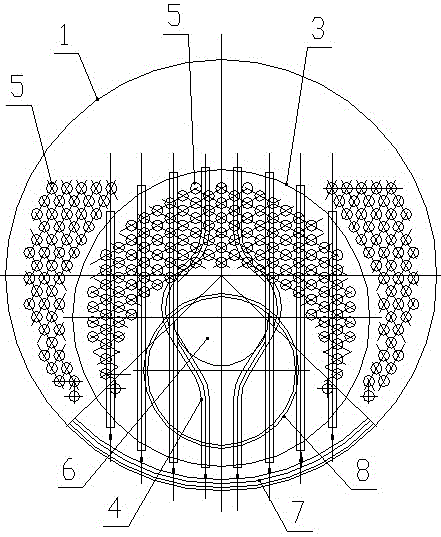

Hookah bowl

InactiveUS20170055570A1Improve experienceDecrease temperature of smokeTobacco pipesFlavorEngineering

A hookah bowl for a hookah is disclosed. The hookah bowl has a raised circular structure in center of the bowl, which has an opening at the apex. A concave area having one or more compartments is defined between inner walls of the upper bowl and the raised circular structure. As the opening is placed at the apex, the liquid in the additive laced tobacco does not leak into the stem or base of the hookah. An alternative embodiment discloses an option to hold multiple flavors of tobacco. The hookah bowl also has a hexagonal shaft extending substantially below the raised circular structure. A diametrically growing airway conduit is defined from the apex of the raised circular structure through the shaft and till distal end of the shaft for increasing the surface area the hot flavored smoke has to traverse before entering into the base of the hookah containing water.

Owner:ELHALWANI WAEL SALIM

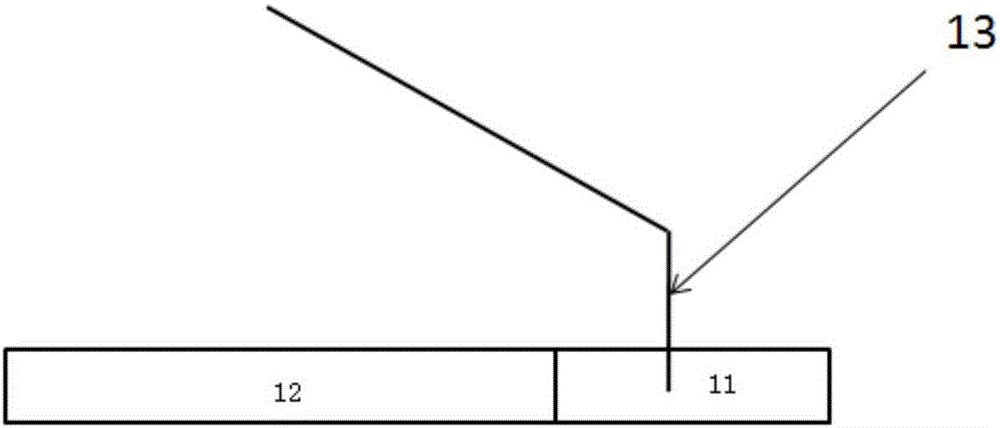

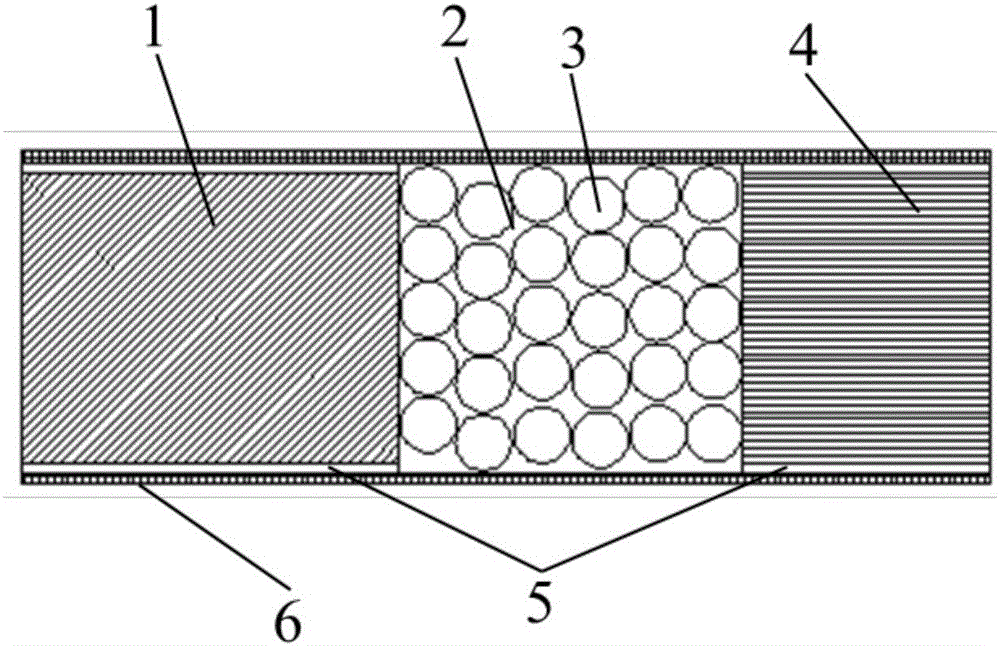

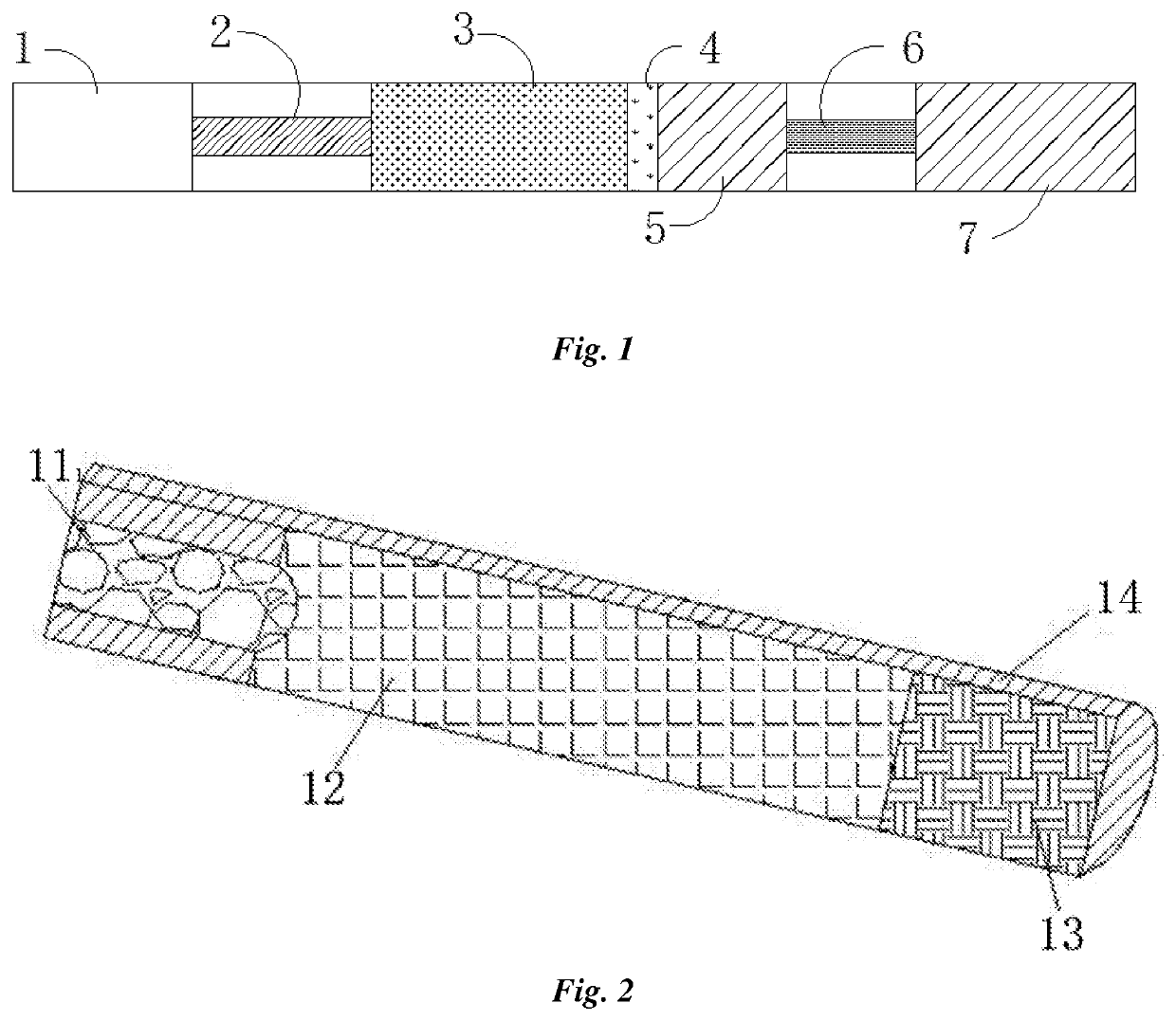

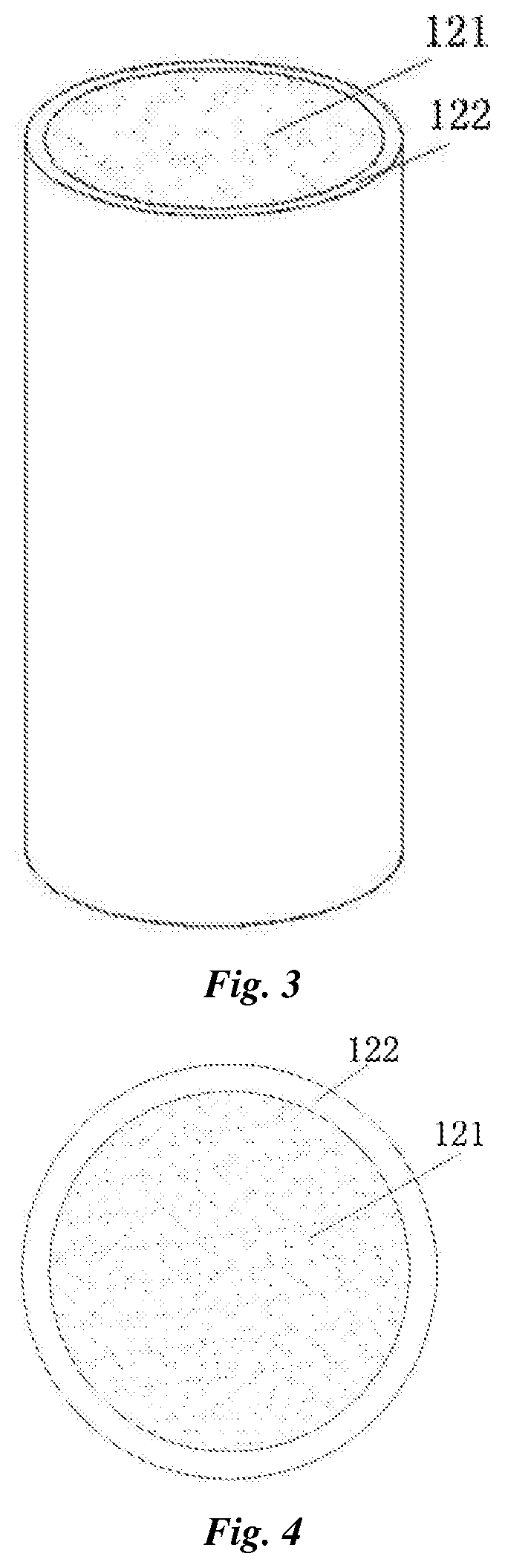

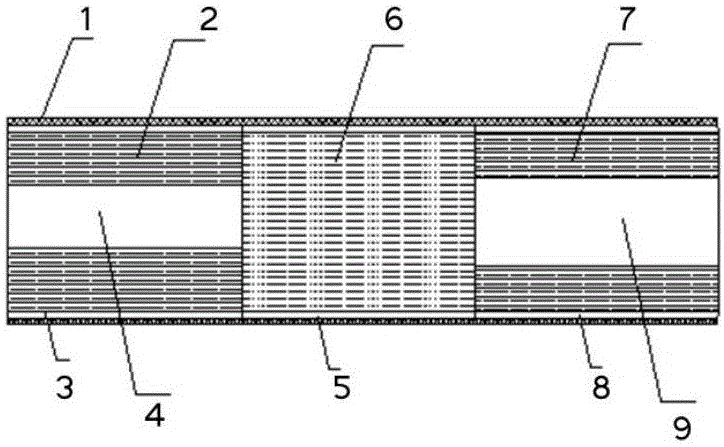

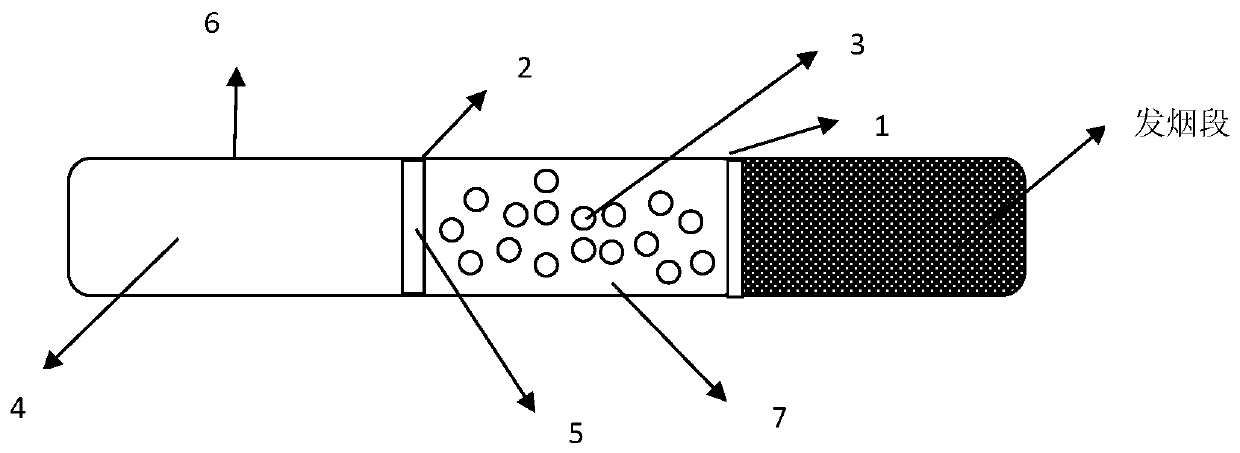

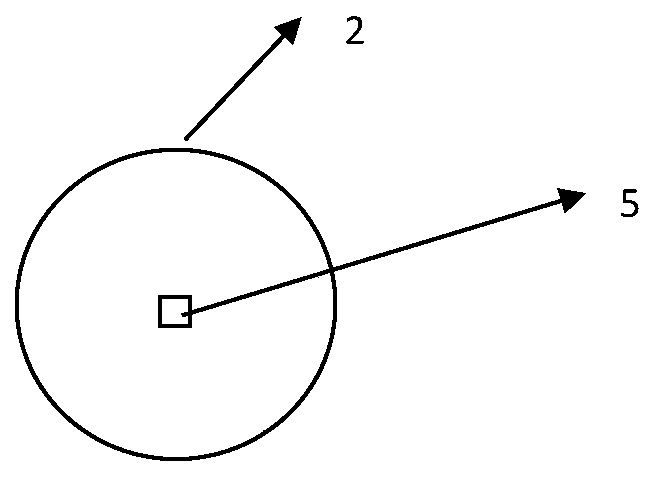

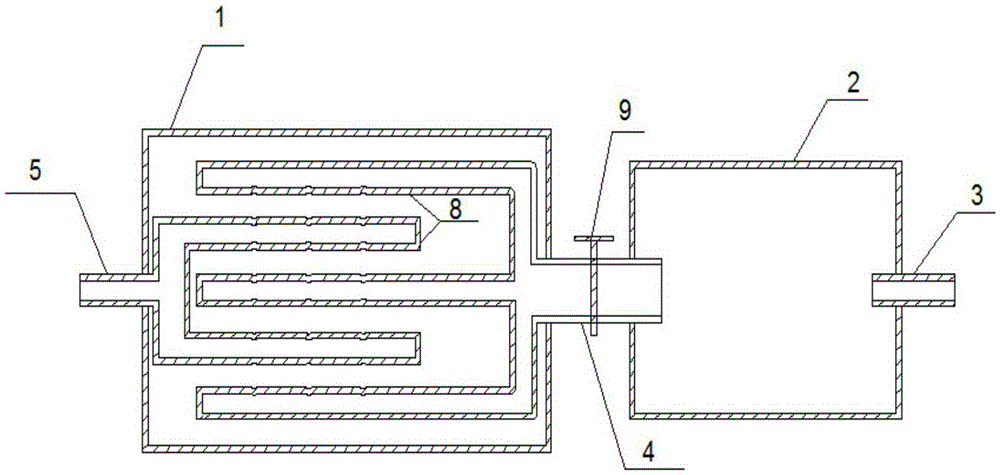

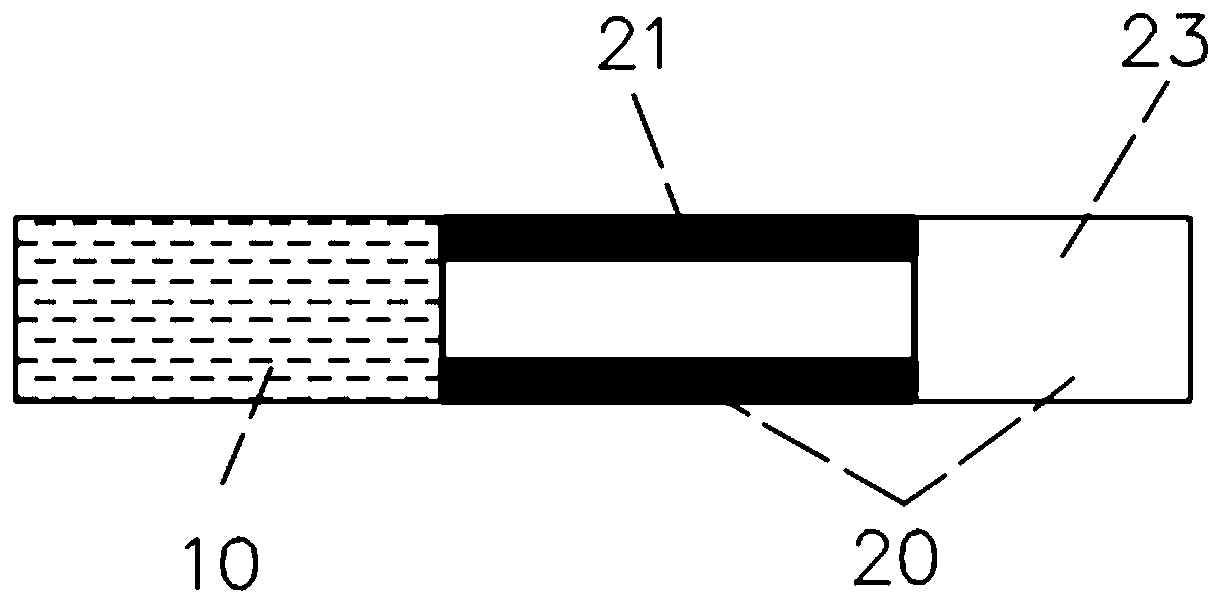

Three-component-unit compounding filter tip rod

InactiveCN105077576AReduce flue gas temperatureReduce suction resistanceTobacco smoke filtersFilling materialsSmoke

The invention provides a three-component-unit compounding filter tip rod. The three-component-unit compounding filter tip rod comprises three component units including a solid filter (1), a cavity (2) and a filter (4) which are sequentially arranged from the near lip end to the far lip end, wherein a piece of first forming paper (5) covers the outer side of the solid filter (1); a piece of first forming paper (5) covers the outer side of the filter (4); then, the three component units are compounded and formed through a piece of second forming paper (6); and the cavity (2) is filled with filling materials (3). The three-component-unit compounding filter tip rod has the effects of lowering the smoke gas temperature, increasing the smoke quantity, reducing the sucking resistance, reducing the CO content in the smoke gas and the like.

Owner:CHINA TOBACCO YUNNAN IND

Flue gas waste heat utilization system of thermal power plant

InactiveCN104266171AAchieve recyclingReduce heat lossCombustion processIndirect carbon-dioxide mitigationAir preheaterPlate heat exchanger

The invention discloses a flue gas waste heat utilization system of a thermal power plant. The system comprises an air pre-heater, a first heat exchanger, an electric dust collector, a second heat exchanger, a desulfurizing tower and a chimney. The flue gas inlet and outlet of the first heat exchanger are communicated with the flue gas inlet and outlet of the electric dust collector and the flue gas inlet and outlet of the air pre-heater through pipelines respectively, the flue gas inlet and outlet of the electric dust collector are communicated with the flue gas inlet and outlet of the second heat exchanger, and the flue gas inlet and outlet of the desulfurizing tower are communicated with the chimney and the flue gas inlet and outlet of the second heat exchanger respectively; the cold source outlet and inlet of the first heat exchanger are communicated with a cold source device through pipelines; the air inlet of the second heat exchanger is communicated with the air, and the air outlet of the second heat exchanger is communicated with an air inlet of the air pre-heater through a pipeline, and the air outlet of the air pre-heater is communicated with the hearth of a thermal power plant furnace through a pipeline. The system is capable of recovering the flue gas waste heat, desulfurizing water is saved, and power consumption of an air guiding fan and electric dust collector is reduced.

Owner:GUODIAN LONGYUAN ENERGY SAVING TECH +1

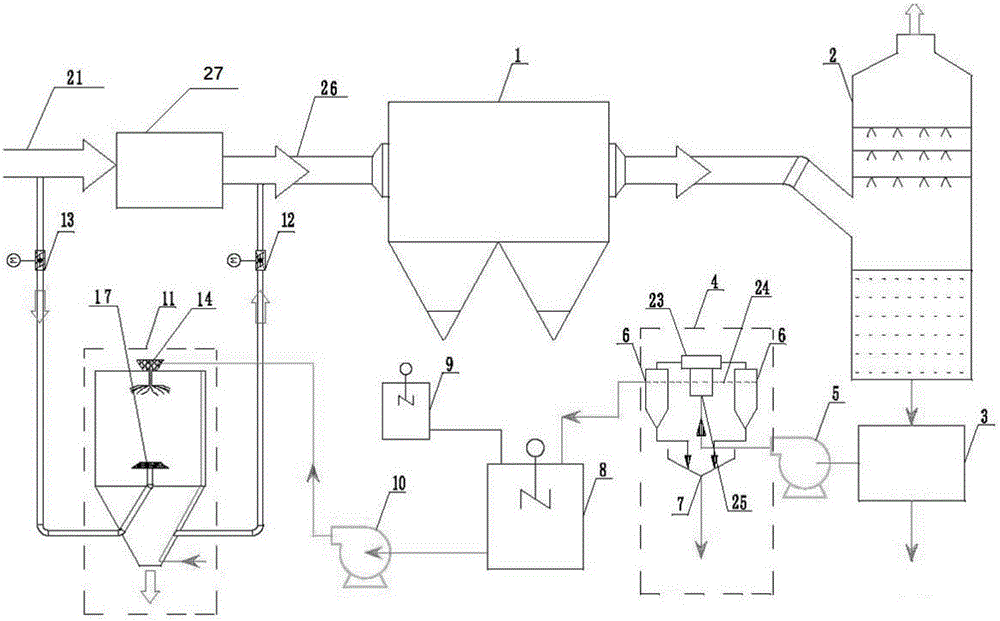

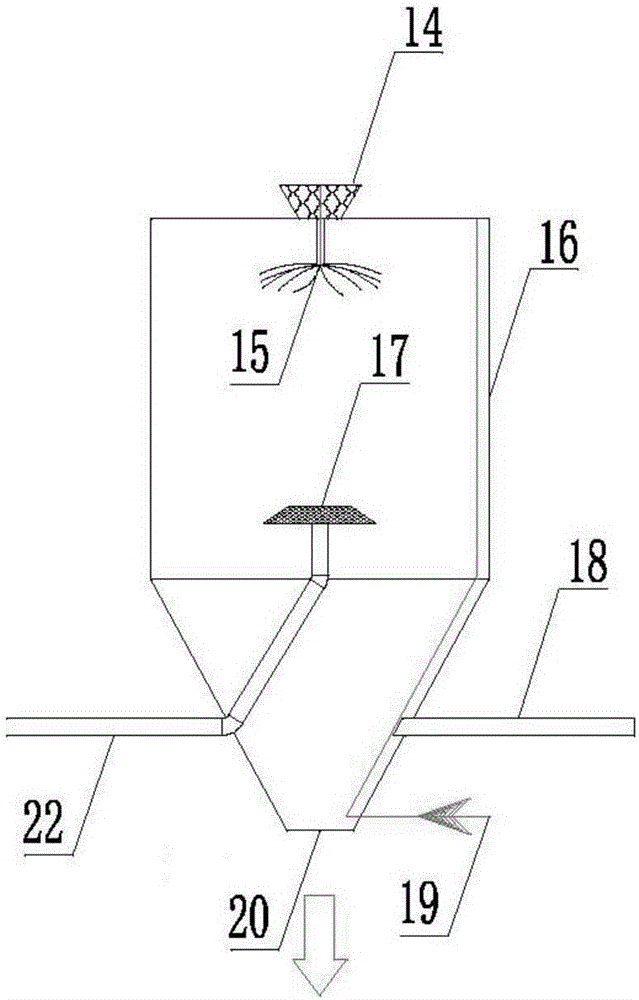

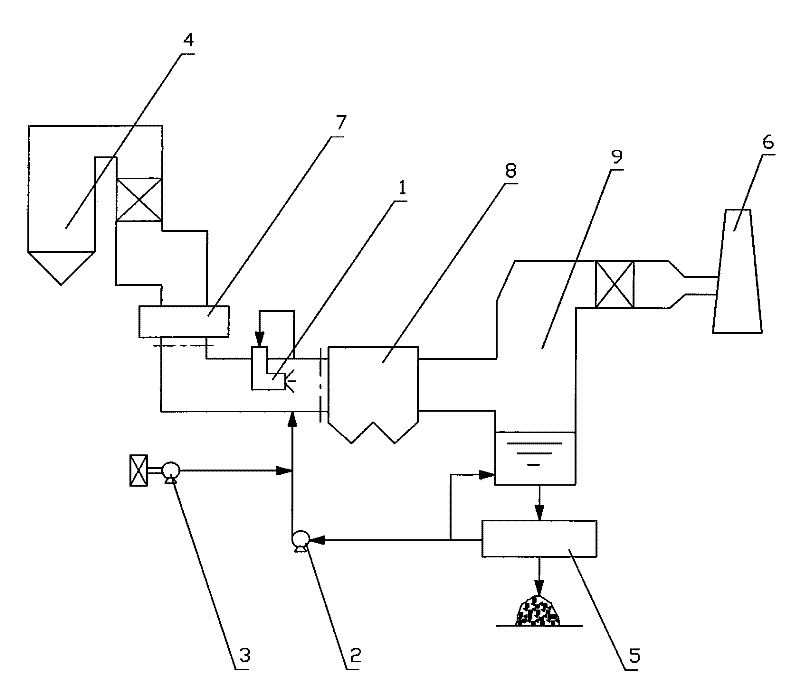

Zero-release coupling humidifying dust-removing synergizing system and method for desulfurization wastewater

PendingCN106630358AAvoid poor evaporationImprove dust removal efficiencyWater/sewage treatment by centrifugal separationElectrostatic separationAir preheaterCyclone

The invention relates to a zero-release coupling humidifying dust-removing synergizing system and a zero-release coupling humidifying dust-removing synergizing method for desulfurization wastewater. The zero-release coupling humidifying dust-removing synergizing system comprises a desulfurizing tower, a gypsum dewatering system, a wastewater cyclone, a wastewater box, a rotary spraying and evaporating tower and a dust remover, wherein wastewater treated through the gypsum dewatering system is treated through the wastewater cyclone; afterwards, one part underflows to the desulfurizing tower to be repeatedly utilized; one part overflows to a wastewater box to be collected; the wastewater is conveyed to a rotary sprayer to be atomized; an atomized fog drop descends, is regressively in contact with a high-temperature fume which is introduced from the front of an air pre-heater; a solid particle in the evaporated wastewater and the fume integrally descend to the lower part of a rotary evaporating tower, and enter a front flue of the dust remover through an outlet flue of the rotary evaporating tower; the wastewater passes through the dust remover in a form of purified water vapor to enter the desulfurizing tower. The zero-release coupling humidifying dust-removing synergizing system and the zero-release coupling humidifying dust-removing synergizing method are high in wastewater treatment stability, and are not influenced by the load of a unit; the investment and running expenses are low; the water consumption and the energy consumption are reduced; the fume humidity is increased while the zero release of the wastewater is realized; the dust removal efficiency of the dust remover is improved.

Owner:ZHEJIANG UNIV

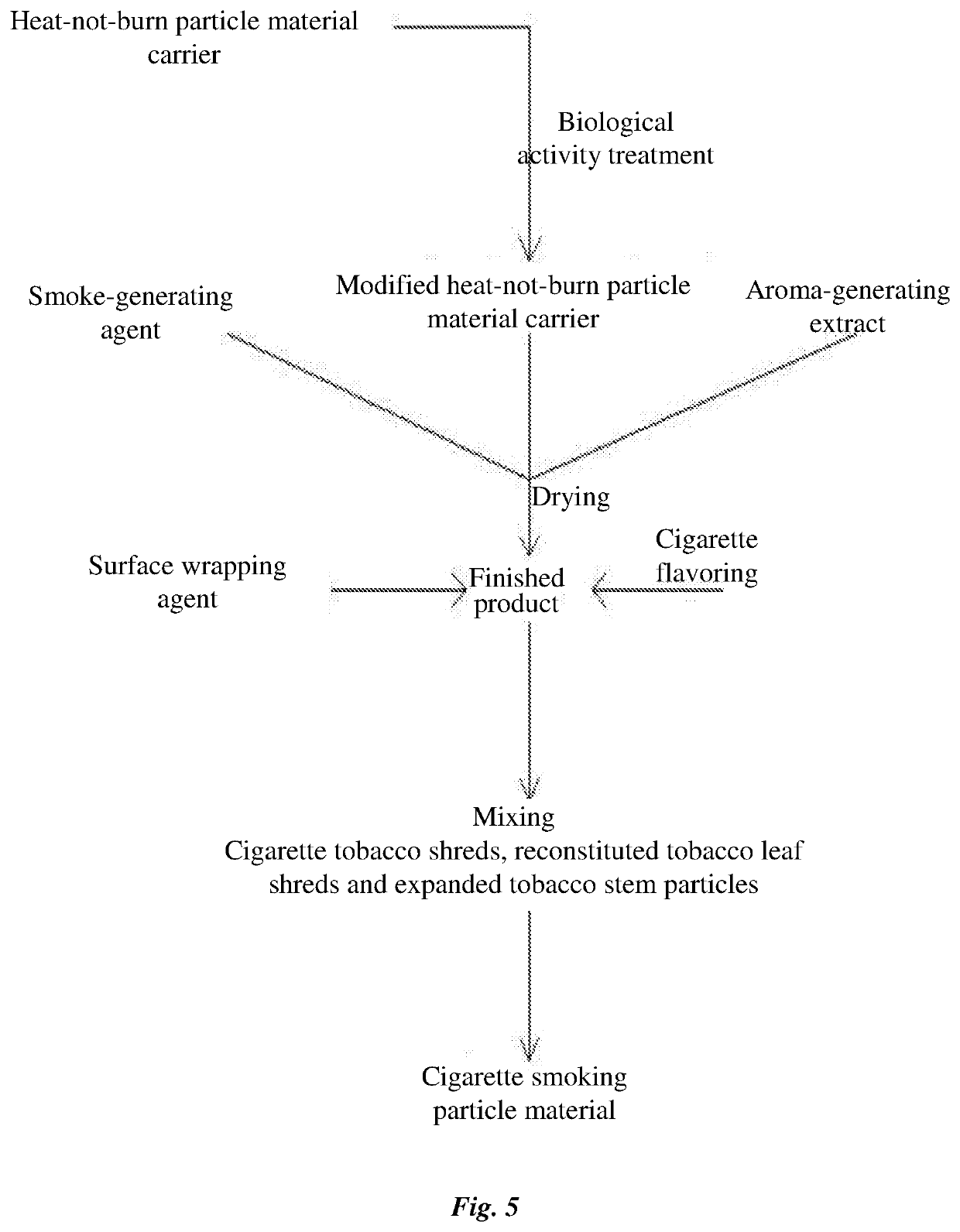

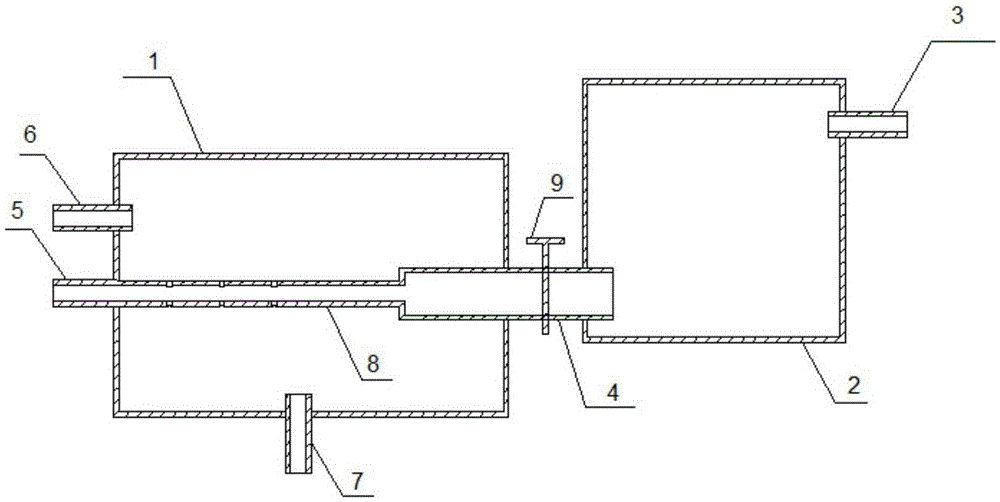

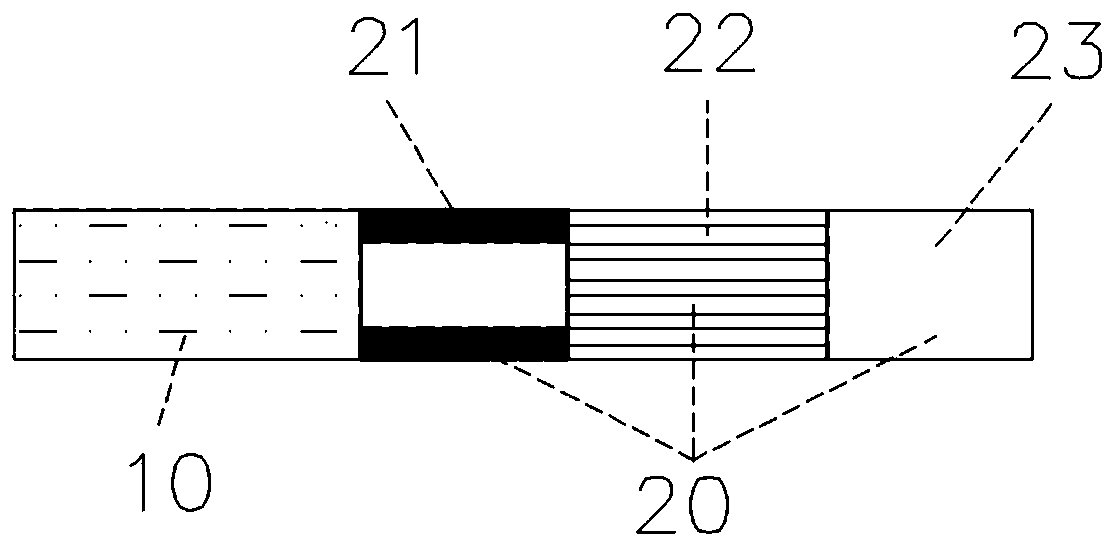

Integrally-formed Heat-not-burn Smoking Article and Manufacturing Method therefor

PendingUS20200229487A1Simple manufacturing processSimple formatAdditive manufacturing apparatusTobacco treatmentMechanical engineeringComposite material

An integrally-formed heat-not-burn smoking article and a manufacturing method therefor, wherein the smoking article comprises a lip-proximal end and a lip-distal end, and the smoking article is formed by integrally filling a piece of forming paper having a constant thickness, from the lip-distal end to the lip-proximal end, with four or more different unit sections comprising a filter unit, a gel cooling aroma-carrying unit, a hollow special particle unit, a hollow supporting unit, a cavity unit, a blocking sheet unit and a smoking unit. The manufacturing method involves corresponding integral filling, with the manner of the filling comprising positioned filling in with independent units and integral filling in with combined units. The present invention can reduce the temperature of smoke, reduce a burning, hot and spicy feeling caused by the smoke entering the oral cavity, improve the feeling of a smoking experience.

Owner:YUNNAN XIKE TECH CO LTD

Oily sludge drying and burning integrated treatment technology

InactiveCN106746470AAchieve reductionRealize resourcesSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisBurn unitsFlue gas

The invention discloses an oily sludge drying and burning integrated treatment technology and belongs to the technical field of oily sludge treatment. The oily sludge drying and burning integrated treatment technology is characterized by comprising the following steps of feeding; drying: repeatedly drying oily sludge through a high-temperature flue gas drying unit in an air drying mode and concentrating and collecting the dried sludge; pyrolysing: separating out pyrolysis gas, generating pyrolysis coke, exhausting the pyrolysis gas, congealing, concentrating and collecting the pyrolysis gas and conveying the pyrolysis coke into a burning unit; burning: burning the pyrolysis coke in a fluidized mode, utilizing a multidirectional air supply mode to adjust burning temperature of the pyrolysis coke and exhausting burned flue gas into a flue gas treating unit; treating flue gas: desulfurizing and denitrifying the flue gas. The oily sludge drying and burning integrated treatment technology disclosed by the invention forms an integrated treatment system with drying, pyrolyzing, burning, treating flue gas and recycling the flue gas integrated and achieves reduced and recycled comprehensive utilization of the oily sludge and emission reducing comprehensive utilization of pollutant.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

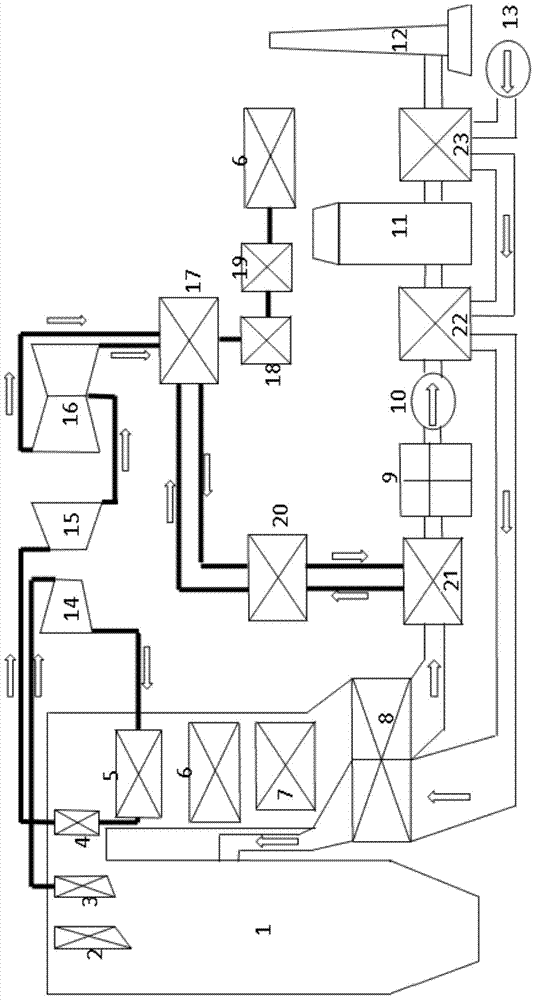

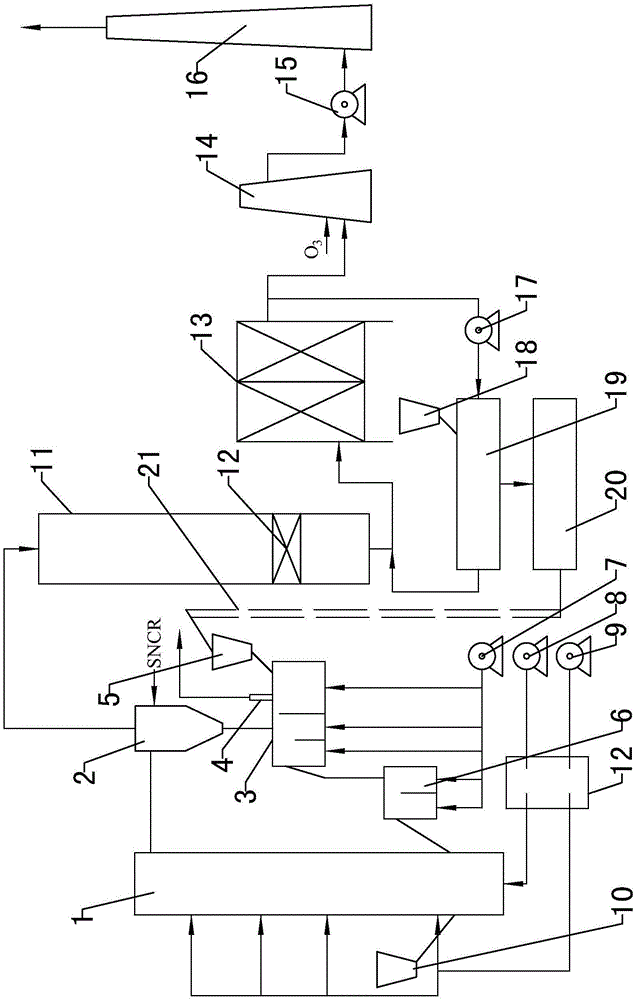

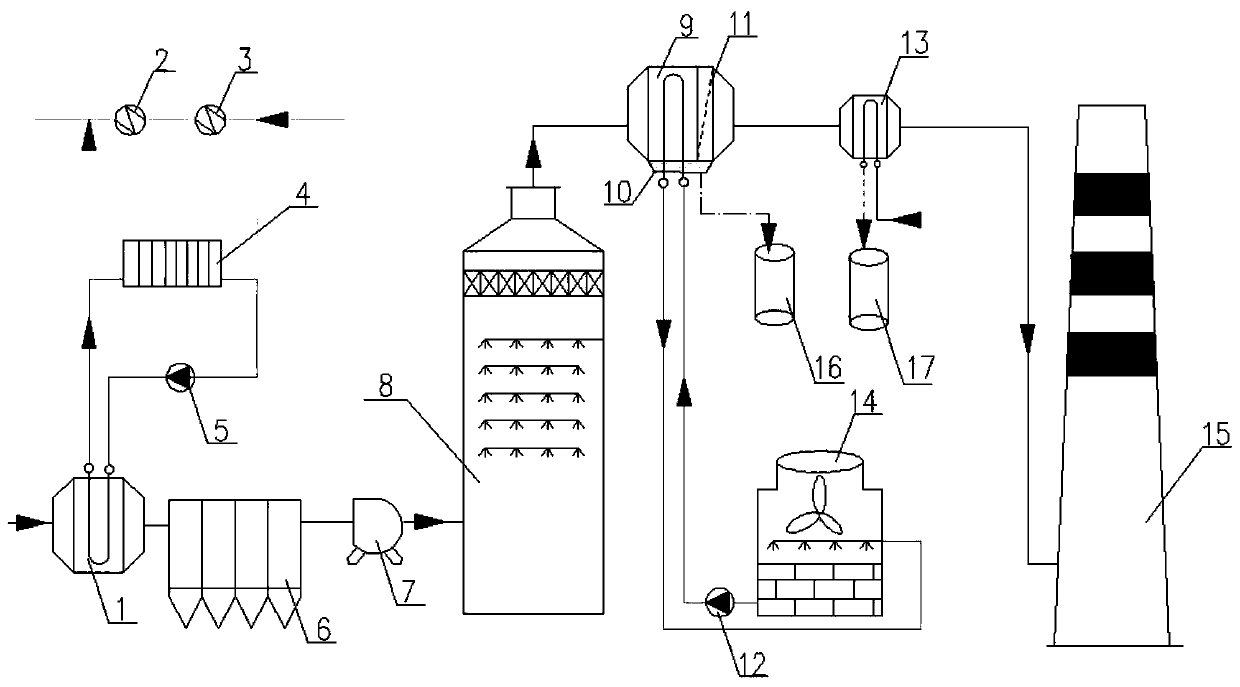

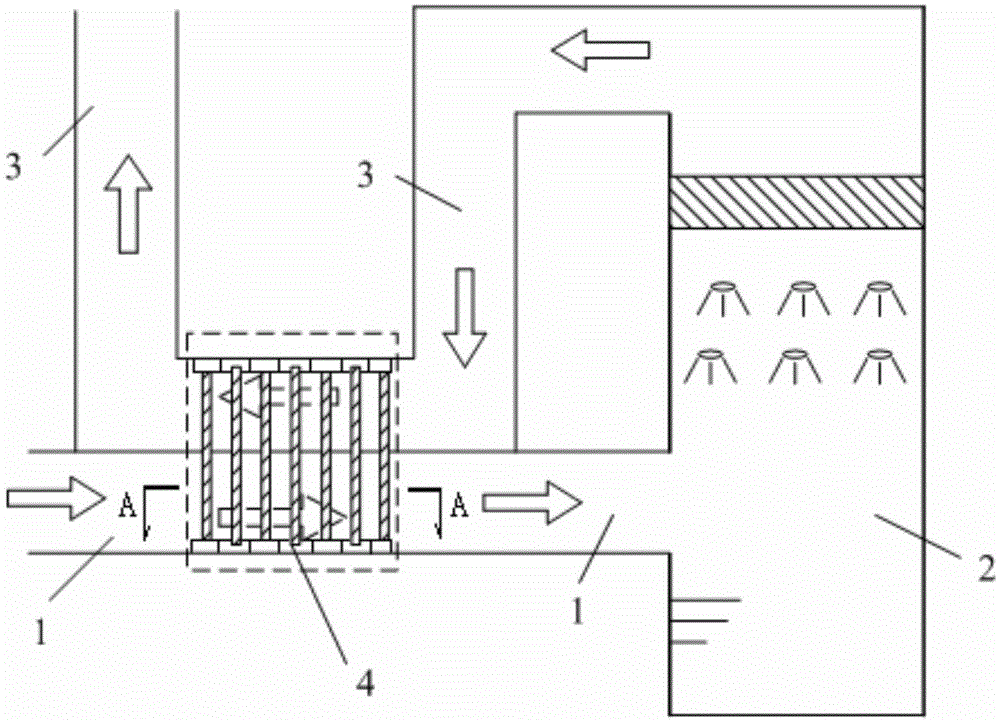

System and method for recovering and utilizing waste heat of smoke after wet desulphurization

PendingCN110425902AImprove utilization efficiencyIncrease heating capacityMachines/enginesCombustion technology mitigationEngineeringAbsorption heat pump

The invention discloses a system and method for recovering and utilizing waste heat of smoke after wet desulphurization. The system comprises a coal-fired boiler, a wet desulphurization tower, a flashevaporation tower, an absorbing type heat pump, a steam turbine and a heating net heater. A smoke outlet of the coal-fired boiler communicates with a smoke inlet of the wet desulphurization tower. Asteam outlet of the coal-fired boiler is connected with a steam inlet of the steam turbine. A steam drawing opening is formed in the middle portion of the steam turbine and communicates with the heating net heater and the absorbing type heat pump. An outlet of the bottom of the wet desulphurization tower communicates with an inlet of the flash evaporation tower through a first slurry pump. A coldslurry outlet of the flash evaporation tower communicates with an inlet in the upper portion of the wet desulphurization tower through a second slurry pump. A negative pressure steam outlet of the flash evaporation tower is connected with a negative pressure steam inlet of the absorbing type heat pump. The system can recover heat of desulfurization slurry in the wet desulphurization tower, the waste heat of the smoke after desulphurization is recovered in depth, the energy utilization efficiency is improved, the heat supply ability of a unit is improved, and the system has remarkable economicbenefits.

Owner:HUANENG POWER INT INC +1

Preparation method of polylactic acid cooling modified tow filter stick

PendingCN111789285AHigh melting pointImprove heat resistanceTobacco smoke filtersPolymer scienceTobacco product

The invention belongs to the technical field of tobacco product production. The invention provides a preparation method of a polylactic acid cooling modified tow filter stick. The preparation method comprises the following steps: uniformly mixing polylactic acid master batch, SEBS and PP, carrying out online melt polymerization reaction at 140-200 DEG C, carrying out screw extrusion through a screw, cooling, carrying out melt spinning, drafting, curling, drying, shaping to obtain polylactic acid tows, and carrying out filter stick molding on a conventional filter stick machine. Compared with the traditional polylactic acid tow filter stick, the polylactic acid cooling modified tow filter stick prepared by the invention has the advantages that the melting point is higher; the heat resistance is greatly improved, the head shrinking phenomenon is avoided in the heating non-combustion tobacco product, meanwhile, the smoke temperature is remarkably reduced, the problems that the heating non-combustion tobacco product is high in smoke temperature, high in hot pricking feeling and poor in smoking comfort are solved, and the method is suitable for industrial production.

Owner:HUBEI CHINA TOBACCO IND +1

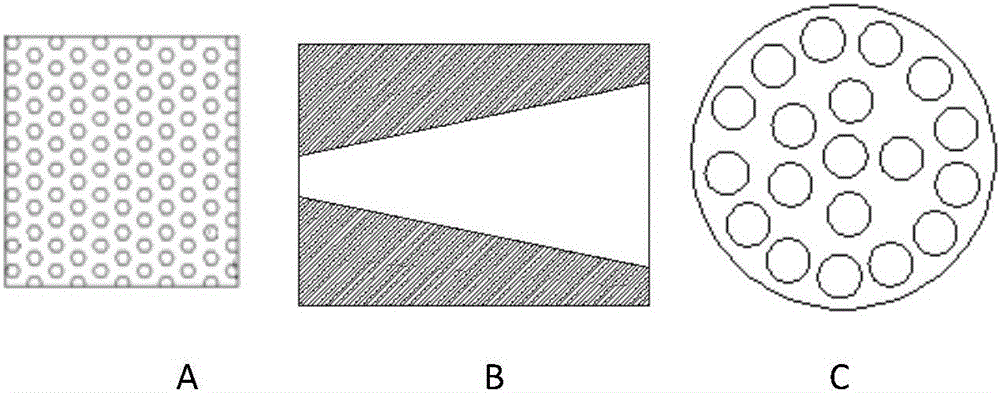

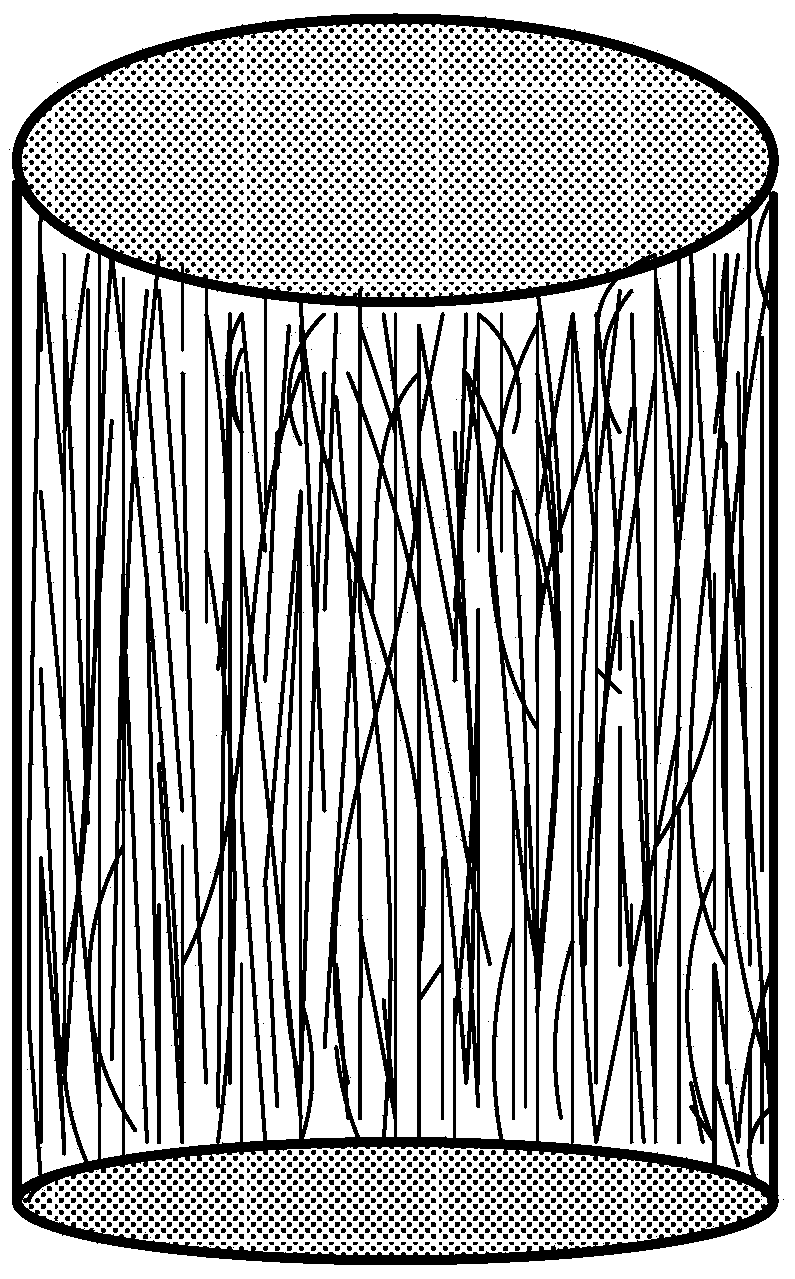

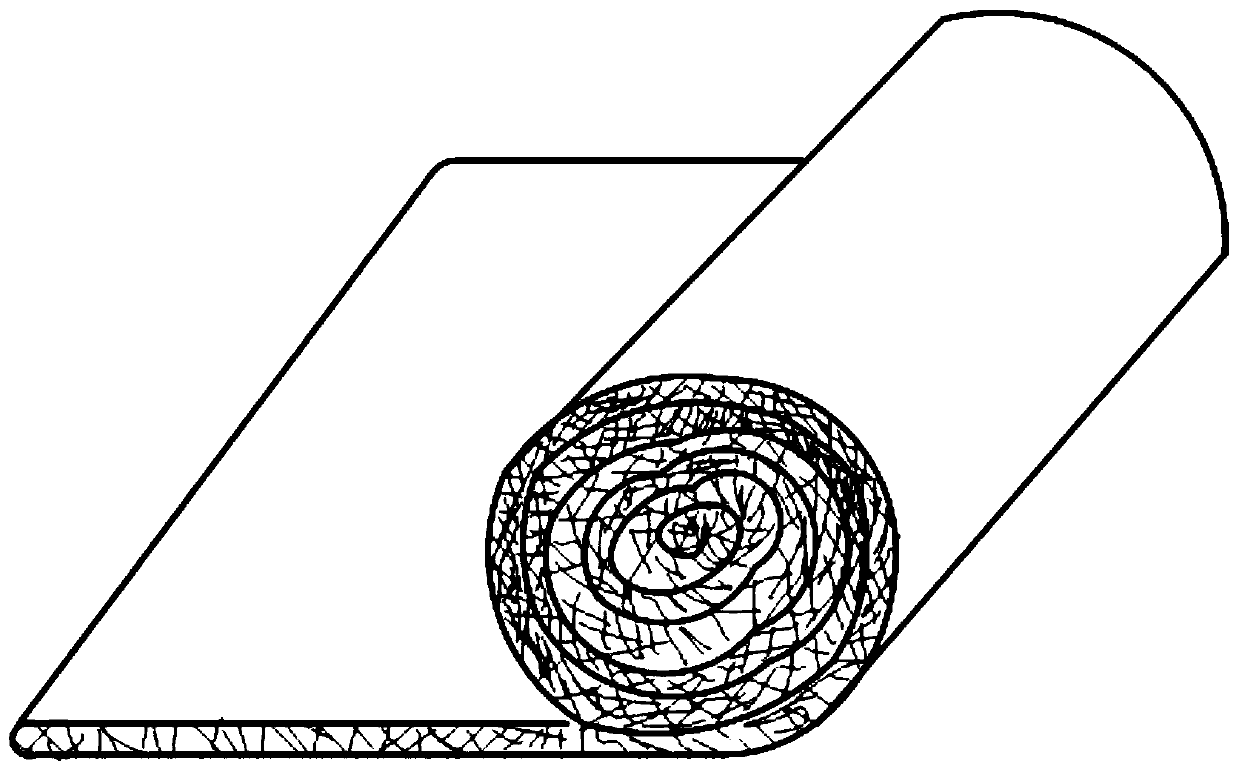

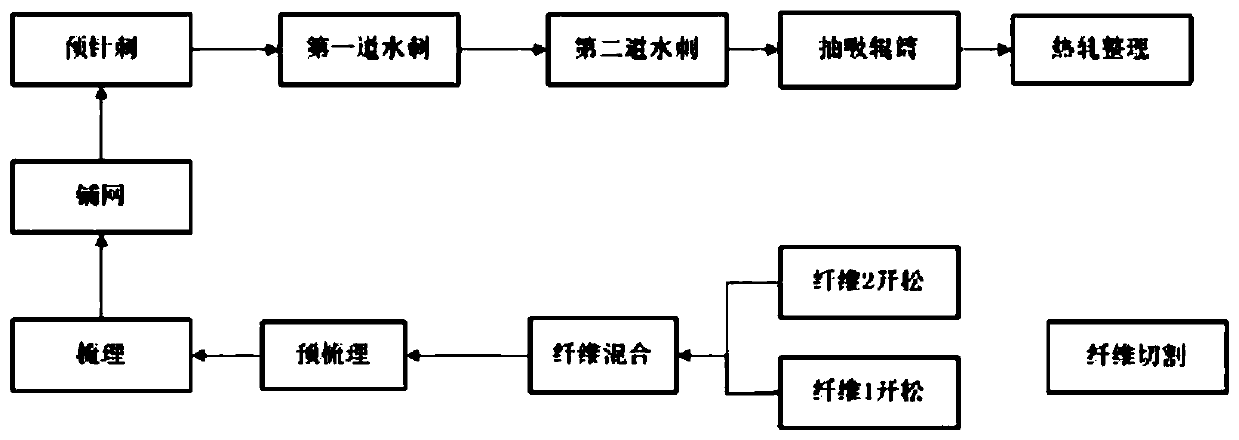

Composite acetate fiber non-woven material applicable to cigarette filters and preparation method and application of composite acetate fiber non-woven material

PendingCN110616505AHigh tensile strengthStrong heat conduction and heat absorption capacityCarbon fibresTobacco smoke filtersAbsorption effectPolylactic acid

The invention relates to a composite acetate fiber non-woven material applicable to cigarette filters and a preparation method of the composite acetate fiber non-woven material. The composite acetatefiber non-woven material is prepared by mixing acetate fiber and other fibers, wherein the other fibers is one, two or three of polylactic acid fibers, metal fibers and carbon fibers. The composite acetate fiber non-woven material comprises 5-99wt% of cellulose acetate fibers and 1-95wt% of non-acetate-fiber material. The preparation method includes: opening the cellulose acetate fibers, mixing with the non-acetate-fiber material, carding, lapping, and performing spunlace to obtain the acetate fiber non-woven material. The acetate fiber non-woven material has a certain heat absorption effect and certain filtering performance and can lower smoke temperature and filter harmful components in smoke. After fiber mixing, the tensile strength of the non-woven material is enhanced, and the strength requirement of the cigarette filters produced by the non-woven material can be satisfied. The composite acetate fiber non-woven material can be used to produce incombustible cigarette filters.

Owner:NANTONG CELLULOSE FIBERS CO LTD +2

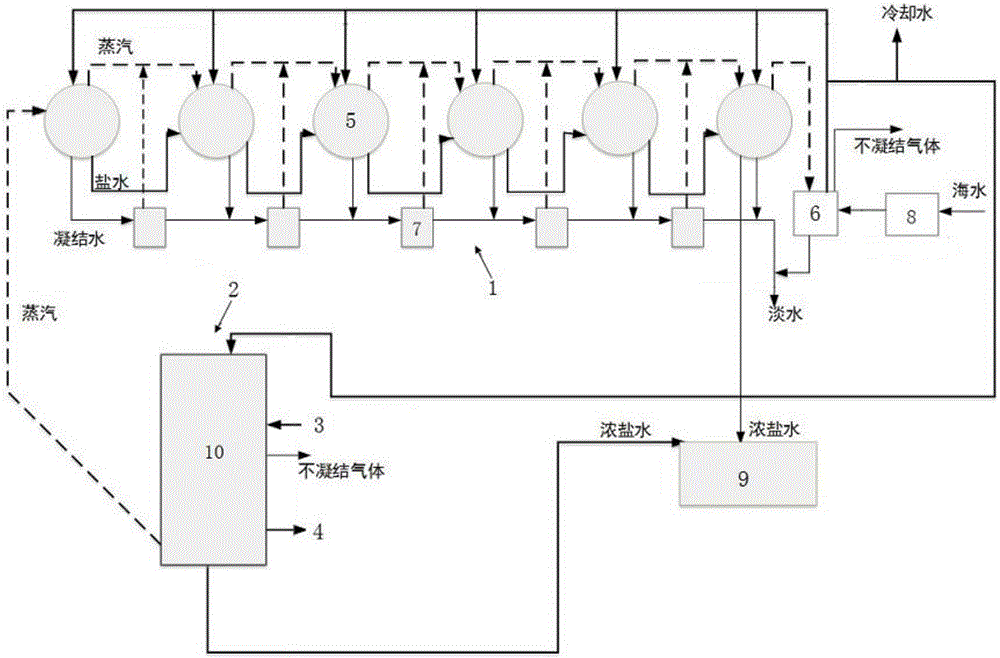

Multiple-effect distillation seawater desalination system adopting power station waste heat

InactiveCN105692750AReduce fresh water costsReduce flue gas temperatureGeneral water supply conservationSeawater treatmentSeawaterSaline water

The invention relates to a multiple-effect distillation seawater desalination system adopting power station waste heat. Seawater is pretreated through a pretreatment system and then sent to a condenser, and seawater flowing out of the condenser is divided by a pipeline to enter an N-effect evaporator and a heat exchanger; meanwhile, seawater is heated by the heat exchanger by means of low-temperature smoke, smoke waste heat is recovered to obtain steam, steam is introduced into a first-effect evaporator to provide a heat source for multiple-effect distillation seawater desalination, desalted water is obtained through desalination treatment of seawater by means of the low-temperature multiple-effect distillation technique, condensation of steam flowing out of a final-effect evaporator and seawater preheating are conducted by means of the condenser, and strong brine in the N-effect evaporator and the heat exchanger is sent to a salt chemical engineering technological unit. By recycling low-temperature smoke waste heat of coal-fired power plants, low-cost seawater desalination production is achieved, and secondary pollution is avoided in the whole process.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

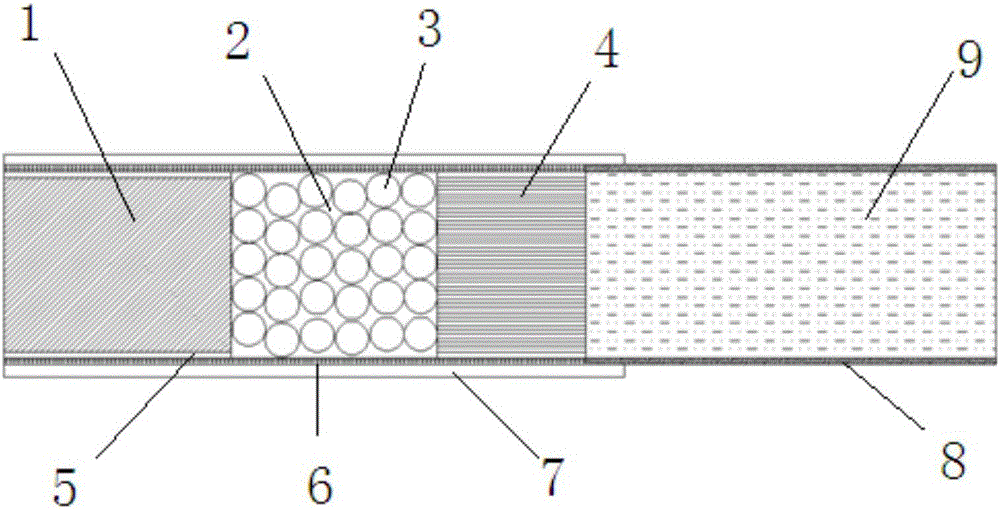

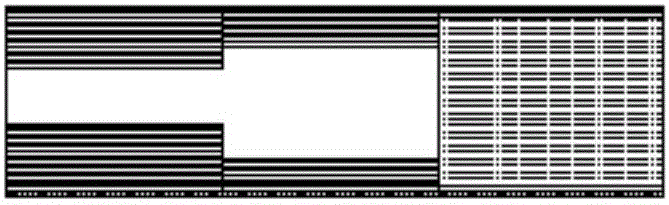

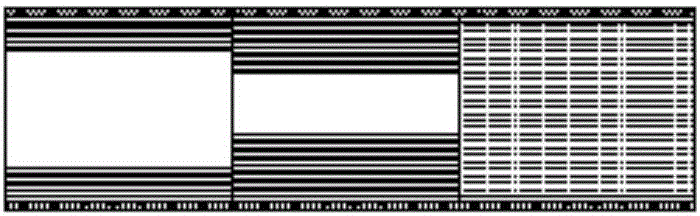

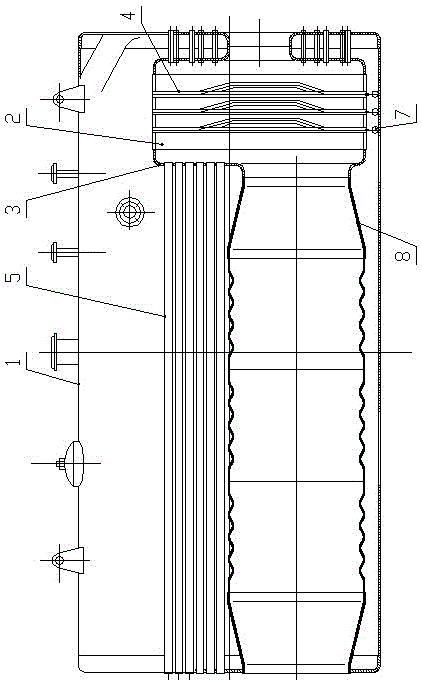

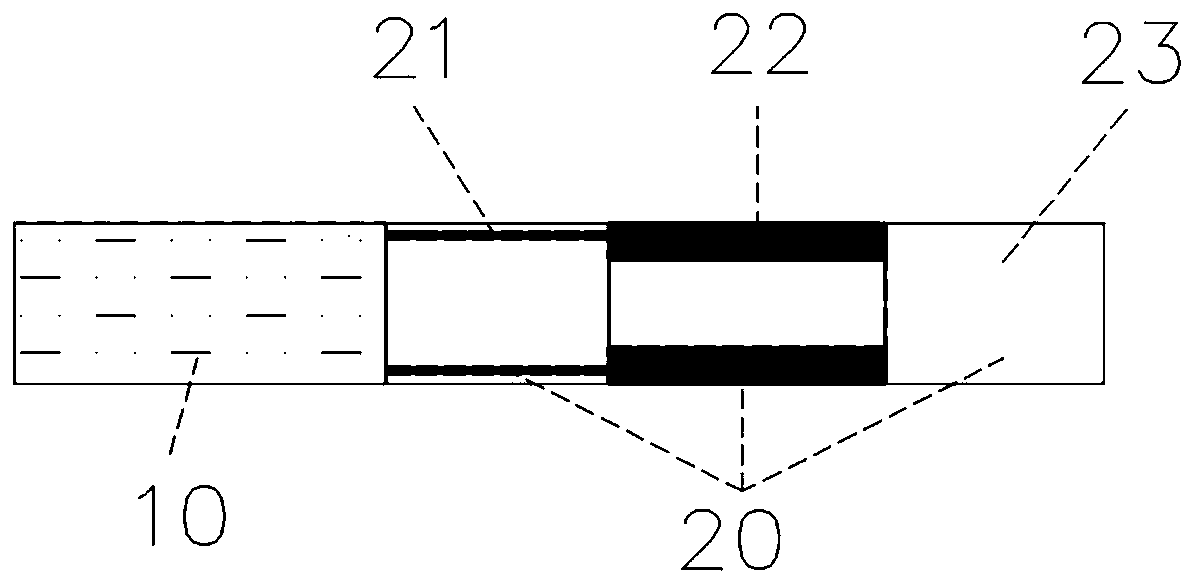

Composite filter tip and application of composite filter tip in heating and incombustible cigarette

InactiveCN105996119AReduce flue gas temperatureImprove pumping sensationCigar manufactureTobacco smoke filtersComposite filterEngineering

The invention belongs to the technical field of cigarettes and particularly relates to a composite filter tip. The composite filter tip comprises a tobacco rod (6), a first hollow filter (2) and a second hollow filter (7), wherein the tobacco rod (6) is formed by wrapping a tobacco material with first tipping paper (5); the first hollow filter (2) is formed by wrapping a polymer fiber material with third tipping paper (3) and is provided with a first hollow cavity (4); the second hollow filter (7) is formed by wrapping a polymer fiber material with fourth tipping paper (8) and is provided with a second hollow cavity (9); the tobacco rod (6), the first hollow filter (2) and the second hollow filter (7) are connected and are wrapped with second tipping paper (1), and the composite filter tip is obtained. The invention further discloses an application of the composite filter tip in reducing the content of aldehyde substances in smoke of the heating and incombustible cigarette.

Owner:CHINA TOBACCO YUNNAN IND

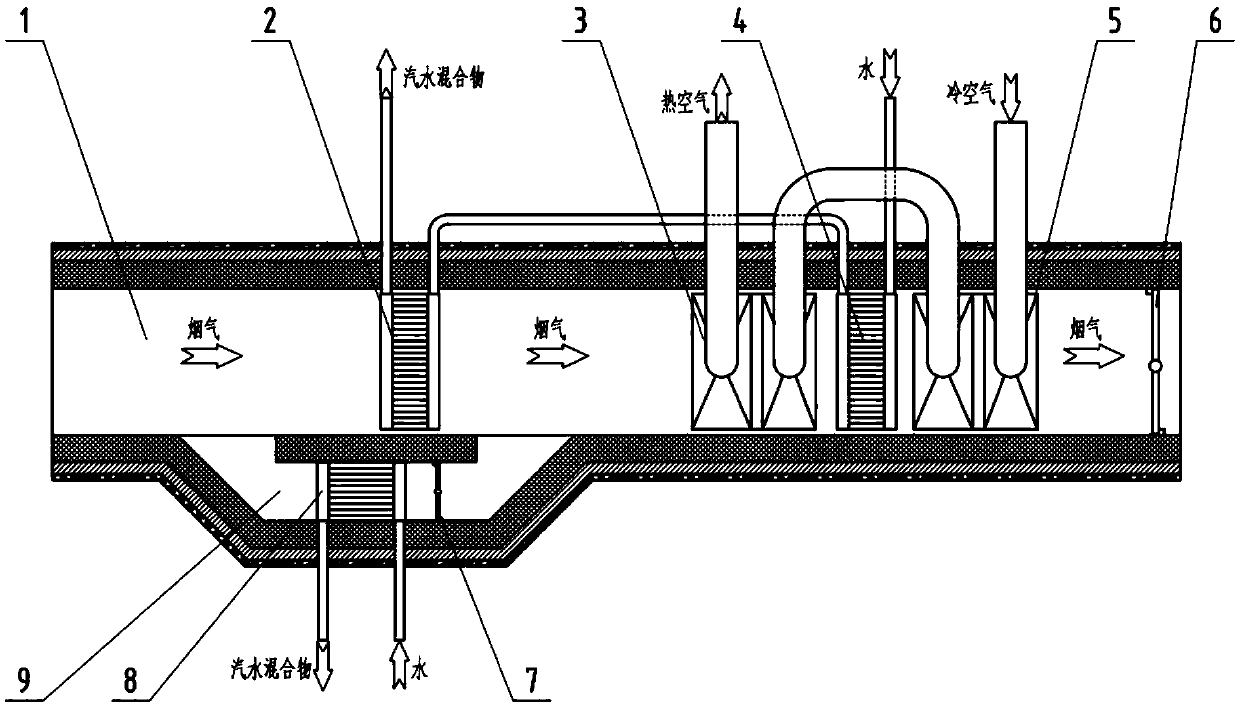

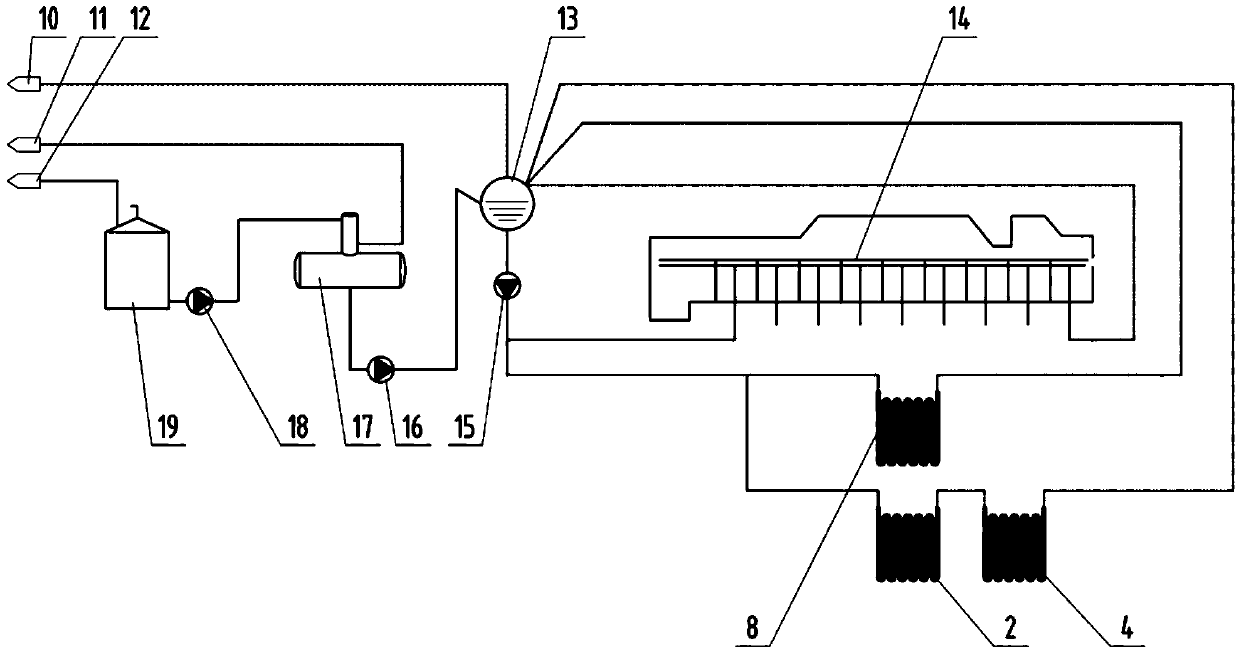

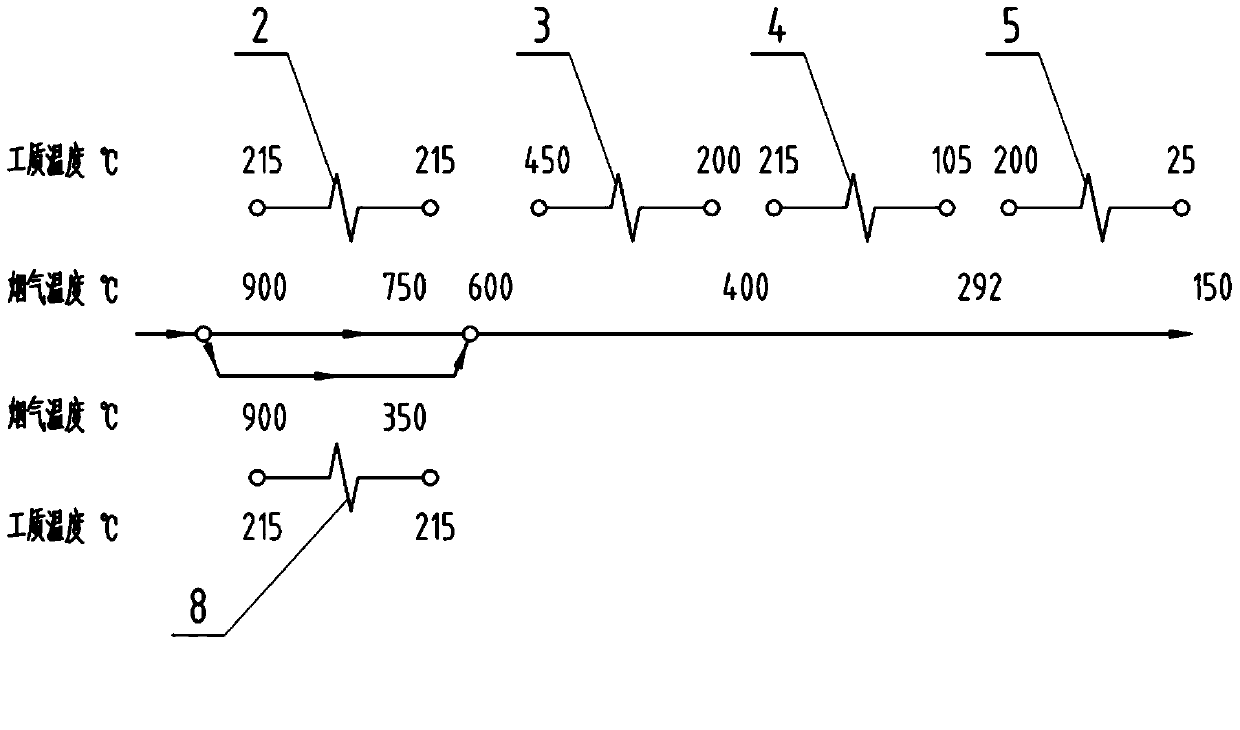

Waste heat recovery system of steel rolling heating furnace

ActiveCN103994667AIncrease the heating areaImprove utilization efficiencyCombustion processEnergy industryWater sourceRecuperator

A waste heat recovery system of a steel rolling heating furnace comprises a main flue, wherein a second-level evaporator, a second-level air heat exchanger, a first-level evaporator and a first-level air heat exchanger are sequentially arranged in the main flue in the smoke flow direction. The firsts-level air heat exchanger is provided with a cold air inlet and is connected with the second-level air heat exchanger in series, wherein the second-level air heat exchanger is provided with a hot air outlet. The first-level evaporator is provided with a water source inlet and is connected with second-level evaporator in series, wherein the second-level evaporator is provided with a steam and water mixture outlet. An auxiliary flue used for regulating the amount of smoke passing through the second-level air heat exchanger is arranged in the position where the outer side of the main flue and the second-level evaporator are arranged in parallel, wherein an auxiliary flue evaporator and an auxiliary flue damper are sequentially arranged in the auxiliary flue in the smoke flow direction. The two levels of evaporators are arranged in the main flue, and therefore the steam heating area is effectively enlarged; the air heat exchangers and the evaporators are arranged in a staggered mode, the first-level air heat exchanger is arranged at the most tail end of the main flue, the temperature difference is ensured in the heat exchange process due to the arrangement method, and heat exchange efficiency is effectively improved.

Owner:XI AN JIAOTONG UNIV

Deep smoke purification system for removing smoke plume through waste heat and method of system

PendingCN109939556AReduce moisture contentReduce the temperatureDispersed particle separationCooling towerSmoke plume

The invention provides a deep smoke purification system for removing smoke plume through waste heat and a method of the system, and belongs to the field of environmental protection. The problems of anexisting method are solved that the resistance of a smoke channel is large, the running and investment cost is high, and only visual pollution can be solved. A smoke outlet of a boiler is sequentially connected with a smoker cooler, a dust remover, a desulfurizing tower, a smoke condenser, a steam reheater and a chimney; condensation circulation water at a condensation circulation water outlet ofa cooling tower / induced draft tower flows back to the cooling tower / induced draft tower through a smoke condensation circulation water pump and the smoke condenser; a cooling circulation water outletof a condensate heater is connected with a cooling circulation water inlet of the smoke cooler, and a cooling circulation water outlet of the smoke cooler is connected with a cooling circulation water inlet of the condensate heater; a condensate forming branch, entering an eighth lower heater, in the boiler is connected with a condensate inlet of the condensate heater, a condensate outlet of thecondensate heater is connected with a condensate outlet of a seventh lower heater, and a condensate outlet of the eighth lower heater is connected with a condensate inlet of the seventh lower heater;a condensate outlet of the steam reheater is connected with a condensate system.

Owner:山西华仁通电力科技股份有限公司

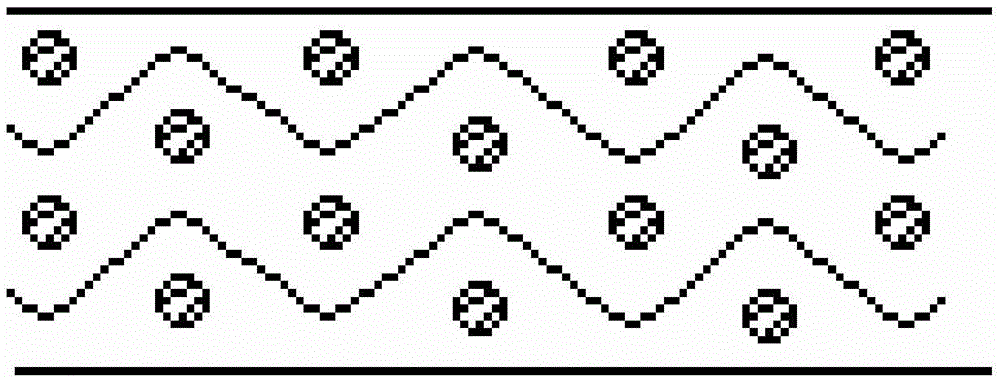

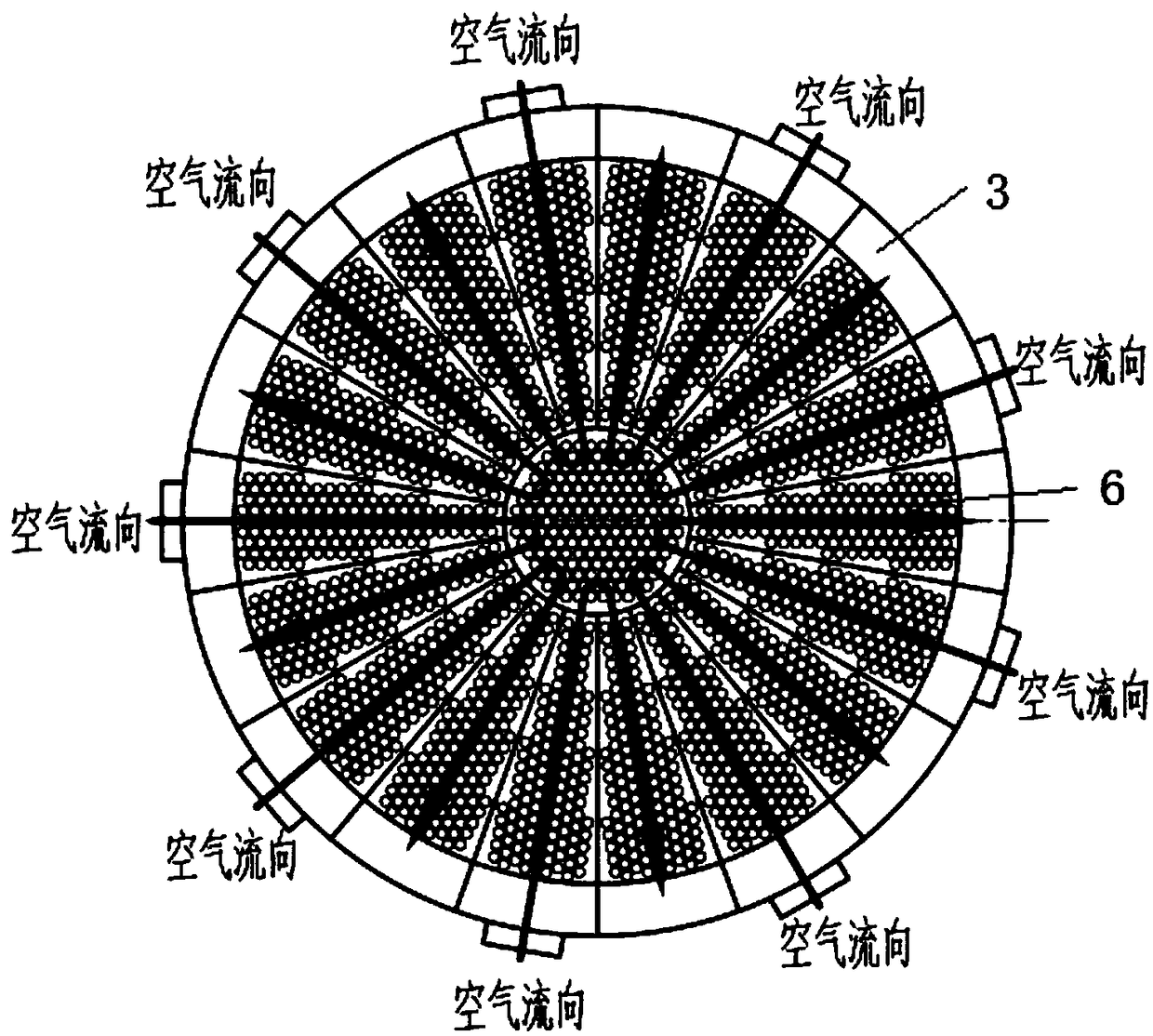

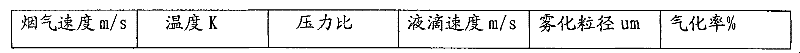

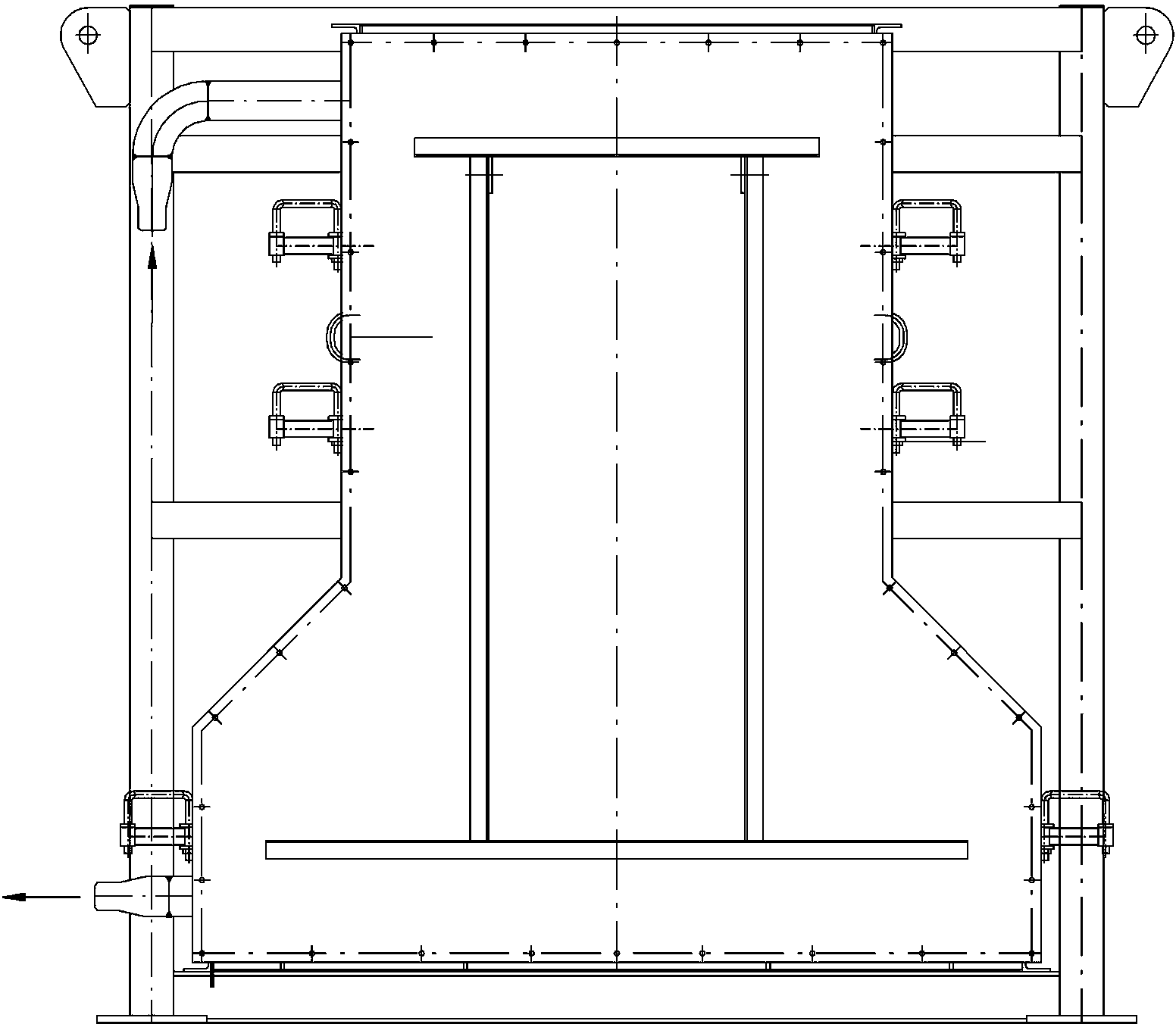

Integrated heat exchange device for wet desulphurization system

ActiveCN105889959AReduce the temperatureIncrease lift heightIndirect heat exchangersWork performanceFlue gas

The invention provides an integrated heat exchange device for a wet desulphurization system. The wet desulphurization system is provided with an inlet flue, an outlet flue and a desulphurization tower. The inlet flue and the outlet flue are provided with a horizontal intersection segment which comprises multiple columns of hot tube bundles. Each column of hot tube bundles comprises a plurality of hot tubes distributed linearly and evenly. The heat absorbing ends of the hot tubes extend into the inlet flue, and the heat release ends of the hot tubes extend into the outlet flue. Each column of hot tube bundles and the adjacent hot tube bundles are distributed in parallel in a staggered mode. Heat of flue gas in a high-temperature segment is used for heating flue gas in a low-temperature segment, an external heat source is not needed, work performance of the system is improved, diffusion of flue gas emission is promoted, and engineering construction investment and occupied area are reduced. Compared with a traditional GGH system and various heat exchange devices replacing the GGH system, the integrated heat exchange device is simple and light in structure, the number of corresponding flue supporting structures can be reduced, overall operation of a heat exchange system is not affected when single hot tubes break down, and stability is high.

Owner:DATANG ENVIRONMENT IND GRP

Device and method for promoting double-tower double-cycle wet desulfurization system to remove fine particulate matters and sulfur trioxide acid mist

InactiveCN108434960AReduce the temperatureEasy to buildCombination devicesGas treatmentProcess engineeringEnvironmental engineering

The invention provides a device and a method for promoting a double-tower double-cycle wet desulfurization system to remove fine particulate matters and sulfur trioxide acid mist. The device mainly consists of a pre-washing tower, a flue gas heat exchanger and a desulfurization tower. The method mainly comprises the following steps: enabling dusty flue gas to first enter the pre-washing tower andthen react with desulfurization washing liquid in the tower for realizing mass and heat transfer so as to reduce the temperature of the flue gas and approach to the super-saturation state; after that,cooling the flue gas at an outlet of the pre-washing tower by means of the flue gas heat exchanger arranged between the two towers, enabling the flue gas to reach a super-saturation state, enabling the PM2.5 / SO3 acid mist to be condensed and grow up, and partially removing the PM2.5 / SO3 acid mist; after part of the PM2.5 / SO3 acid mist is removed by means of the pre-washing tower and the heat exchanger, enabling the PM2.5 / SO3 acid mist to enters the desulfurization tower to be in contact with the lower-temperature desulfurization washing liquid so as to enable the flue gas undergo secondary super-saturation, enabling the PM2.5 / SO3 acid mist which is not removed to be secondarily condensed and grow up, removing the rest PM2.5 / SO3 acid mist by washing with the desulfurization washing liquid,and carrying out interception and capture by means of a dimister of the desulfurization tower.

Owner:SOUTHEAST UNIV

Heating surface of high-temperature high-pressure natural circulating dry coke quenching residual heat boiler

InactiveCN101037604AIncrease heat absorptionImprove water cycle safetyCoke quenchingSpray coatingEngineering

The invention relates to a heating surface of high temperature and high pressure natural circulation dried coke quenching exhaust-heat boiler, which includes a pipe bundle of front-wall water-cooling wall. Character of the invention is: the pipe bundle of the front-wall water-cooling wall is drawn sparsely to form crust block pipe and educed to boiler ceiling for increasing caloric receptivity and security for water circulation of the front-wall water-cooling wall; the crust block pipe in inlet combustion ashes chamber of the exhaust-heat boiler is made of metal spray coating anti-wear pipe. Advantages of crust block pipe employed by the coke quenching exhaust-heat boiler are: 1. increasing caloric receptivity and security for water circulation of the front-wall water-cooling wall; 2. simplifying pipe structure of leading-out pipe of the front-wall water-cooling wall; 3. reducing flue-gas temperature at import of second level superheater, and guaranteeing operation security of the superheater.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

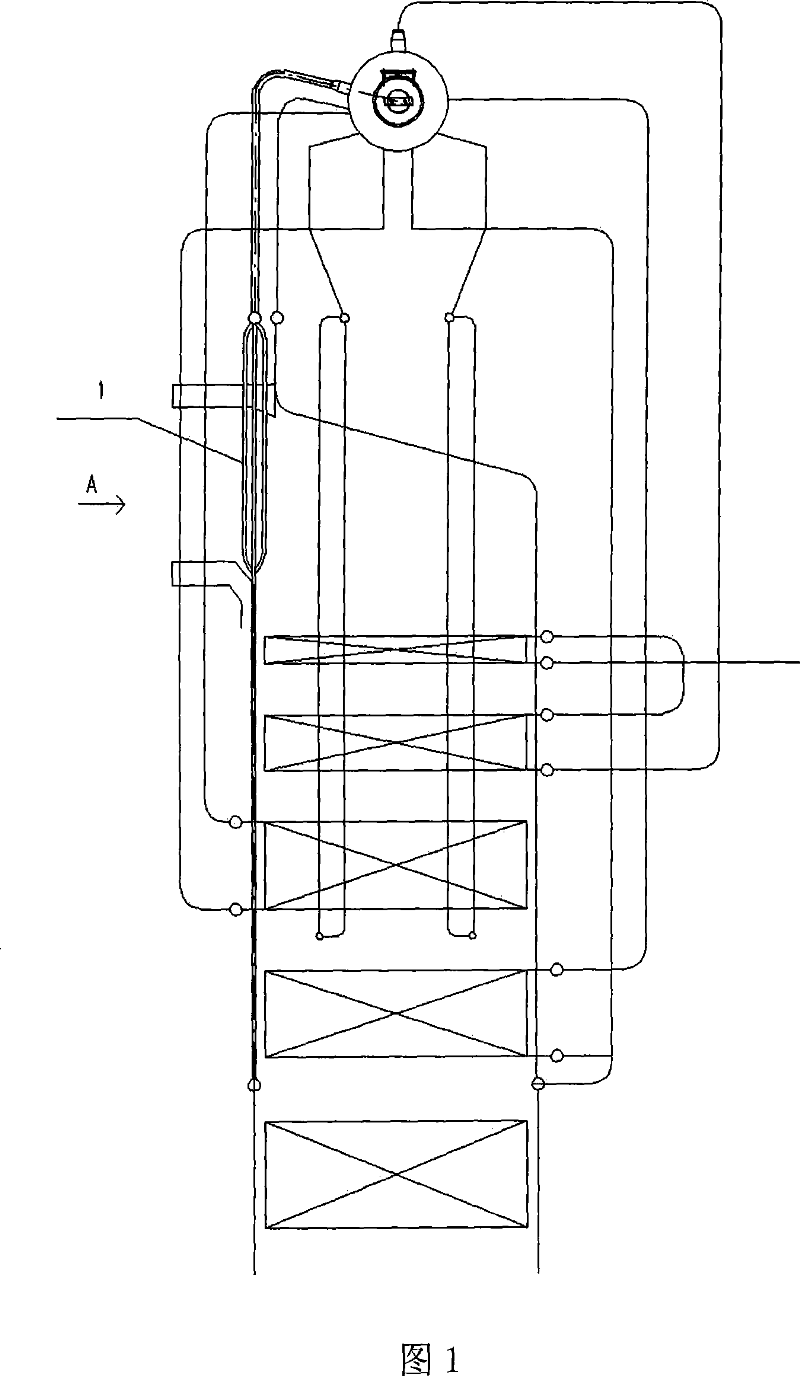

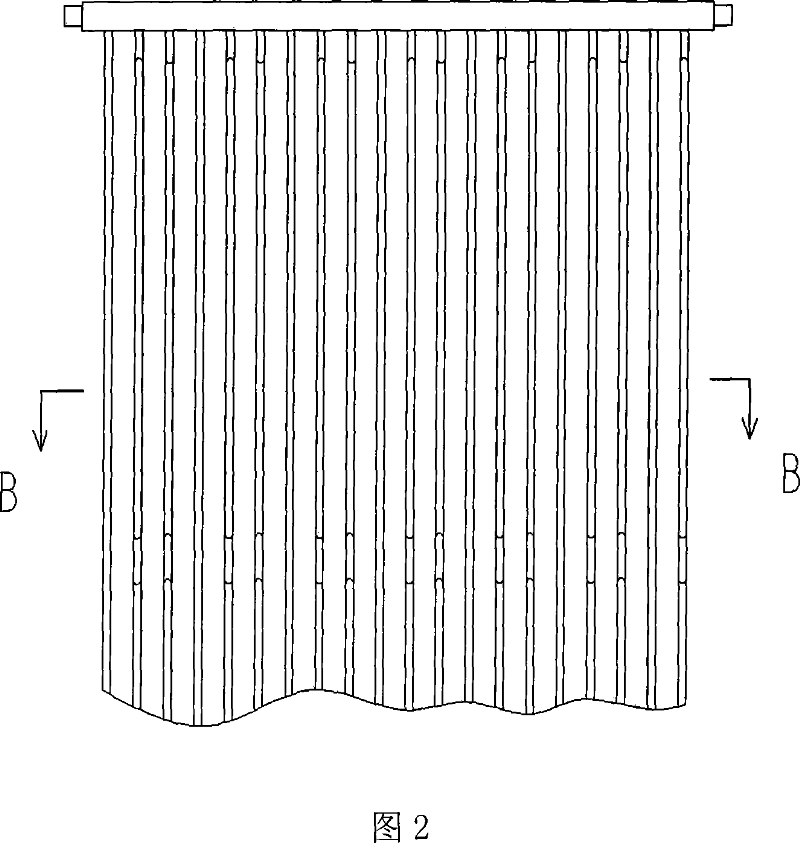

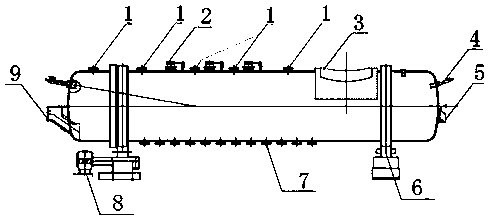

Double wet back cooling device for horizontal internal combustion multi-pass boiler

ActiveCN103939881BReduce flue gas temperatureImprove the operating environmentSteam boilersSteam boilers componentsCombustionWater circulation

A horizontal double-wet-back cooling device for an internal combustion multi-return-stroke boiler comprises a tempering reversing chamber arranged in a boiler barrel. The two ends of the tempering reversing chamber are respectively provided with a tube board. Smoke tubes in the boiler barrel are respectively arranged on the tube boards in a penetrating mode and communicated with the inner portion of the tempering reversing chamber. Conversion heat-exchanging tubes are vertically arranged in the tempering reversing chamber from top to bottom. The two ends of each conversion heat-exchanging tube respectively stretch out of the tempering reversing chamber. The middles, in the center of the tempering reversing chamber, of the conversion heat-exchanging tubes are respectively bent outwards so that a repairing channel can be formed. The lower surface inside the boiler barrel is provided with water supplying injection tubes of an arc structure and each water supplying injection tube is provided with an injection opening vertically corresponding to a lower port of the corresponding conversion heat-exchanging tube. The horizontal double-wet-back cooling device is reasonable in design and simple in structure; temperature of smoke in the tempering reversing chamber is reduced; the operation environment of the tube boards is improved; the water supplying injection tubes are arranged, so that water circulation of the conversion heat-exchanging tubes is prevented from being deteriorated.

Owner:董磊

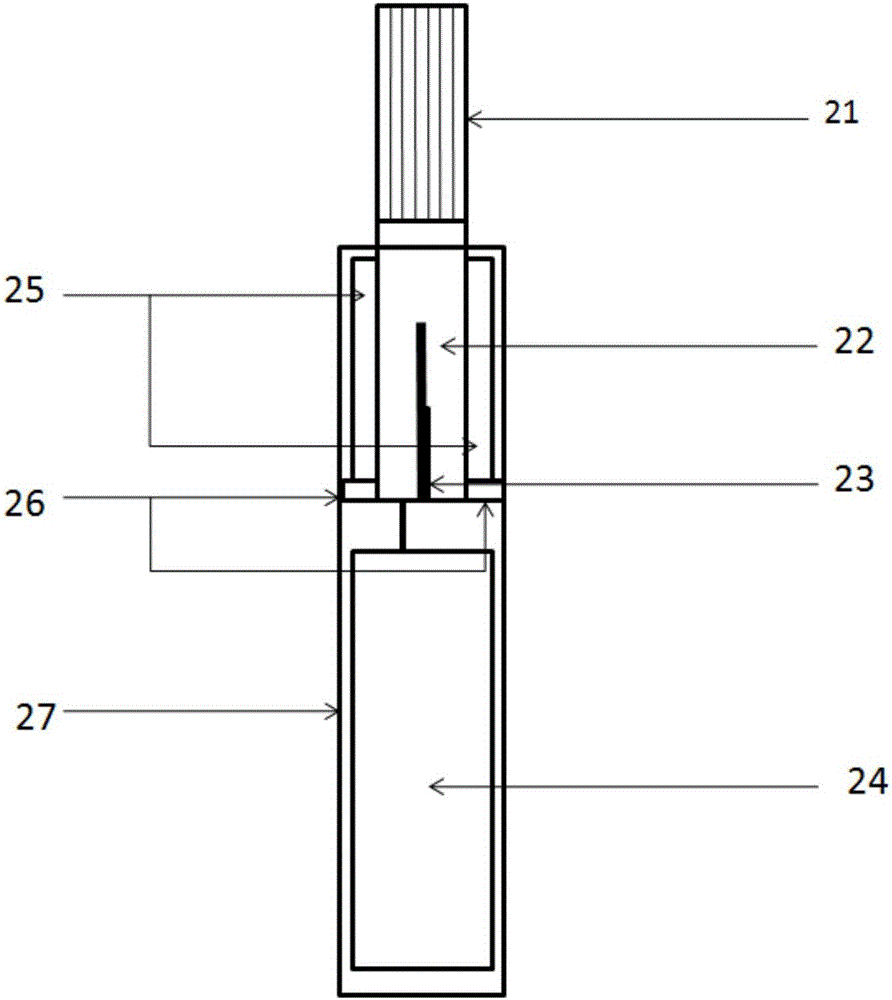

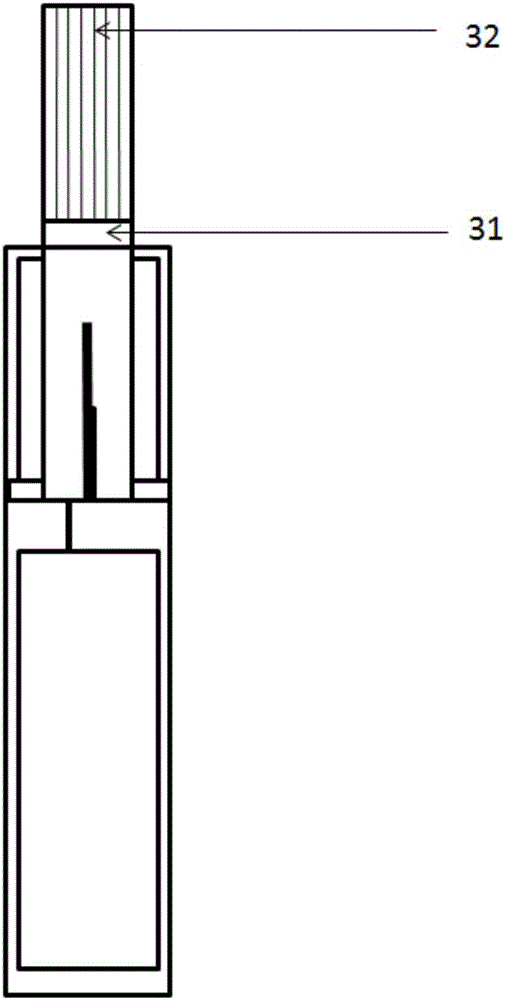

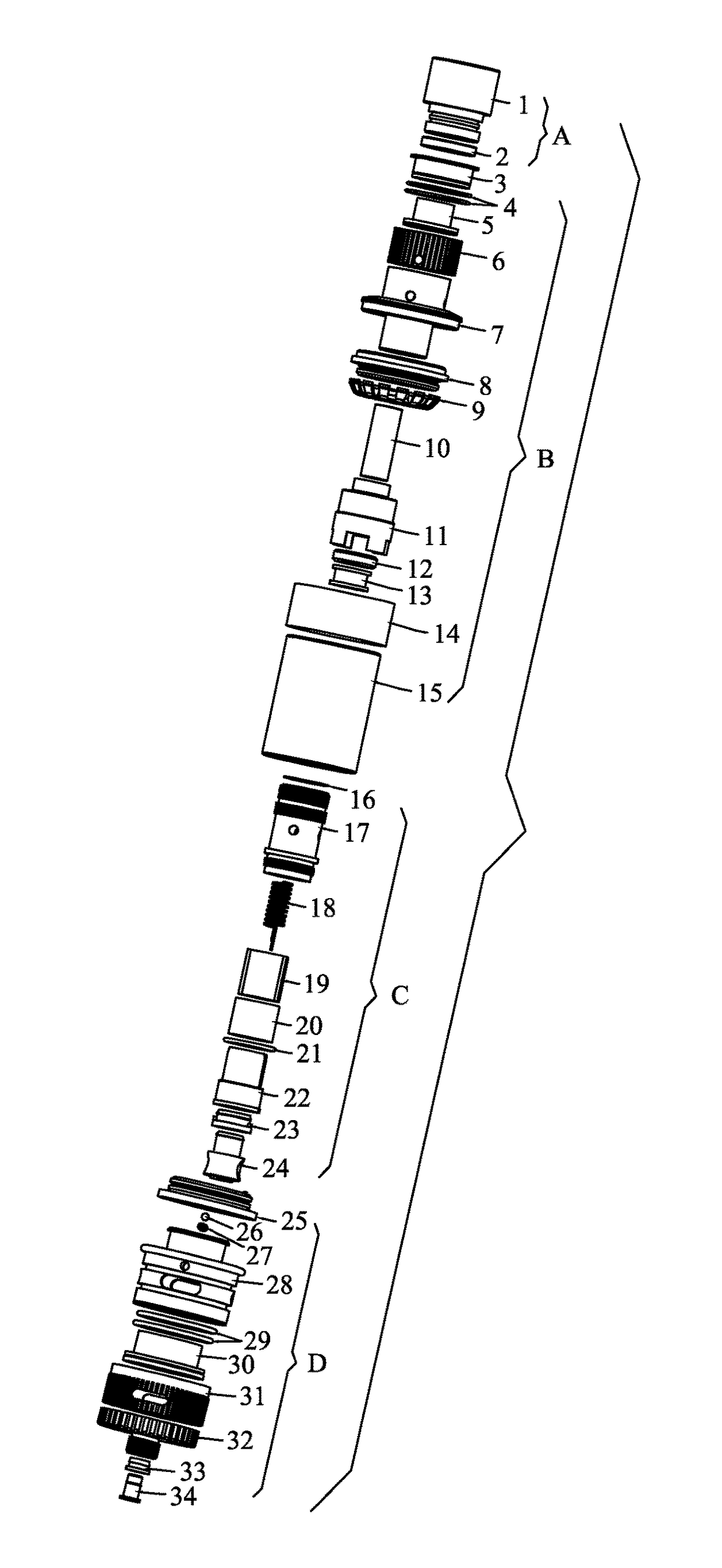

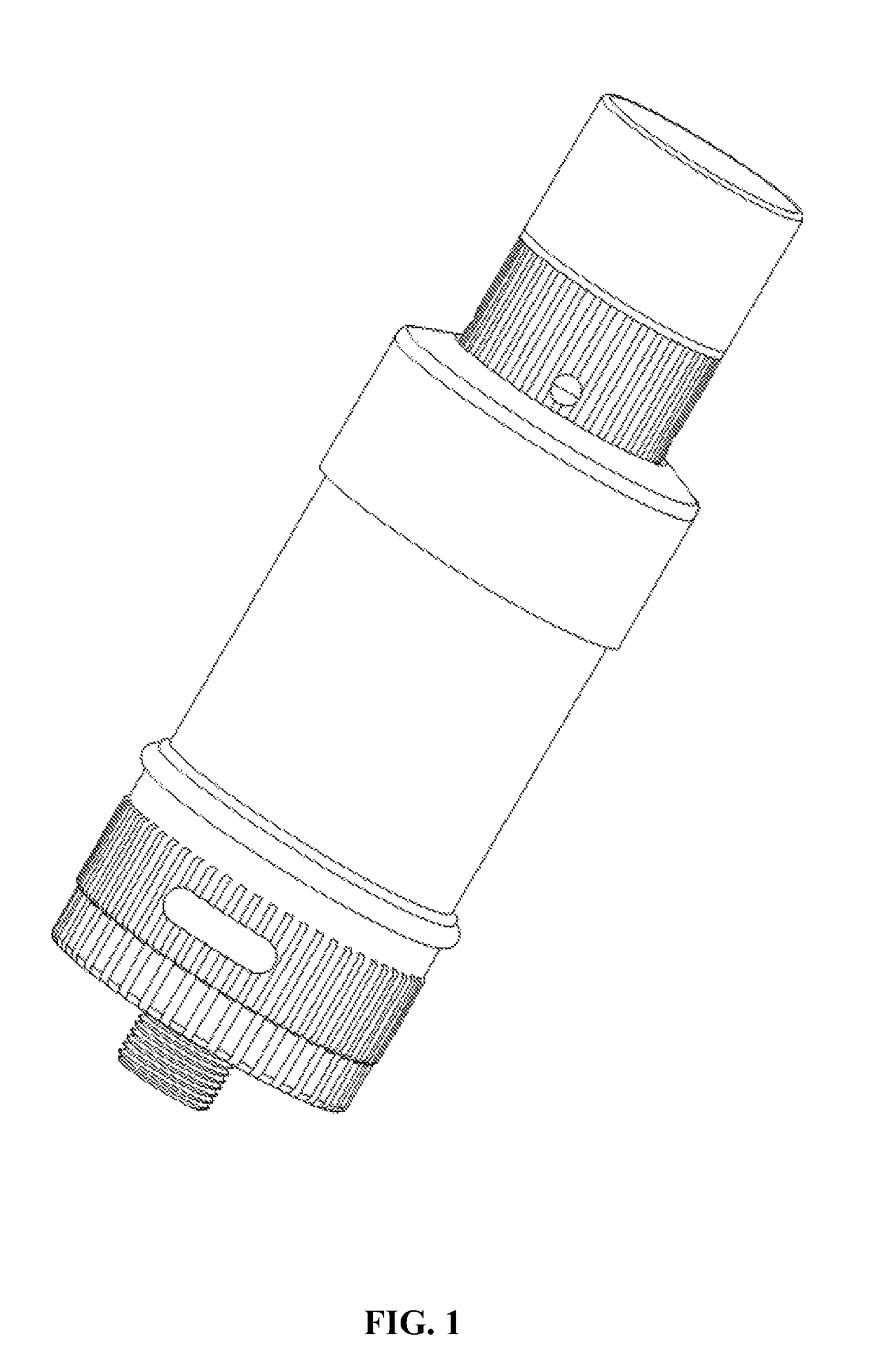

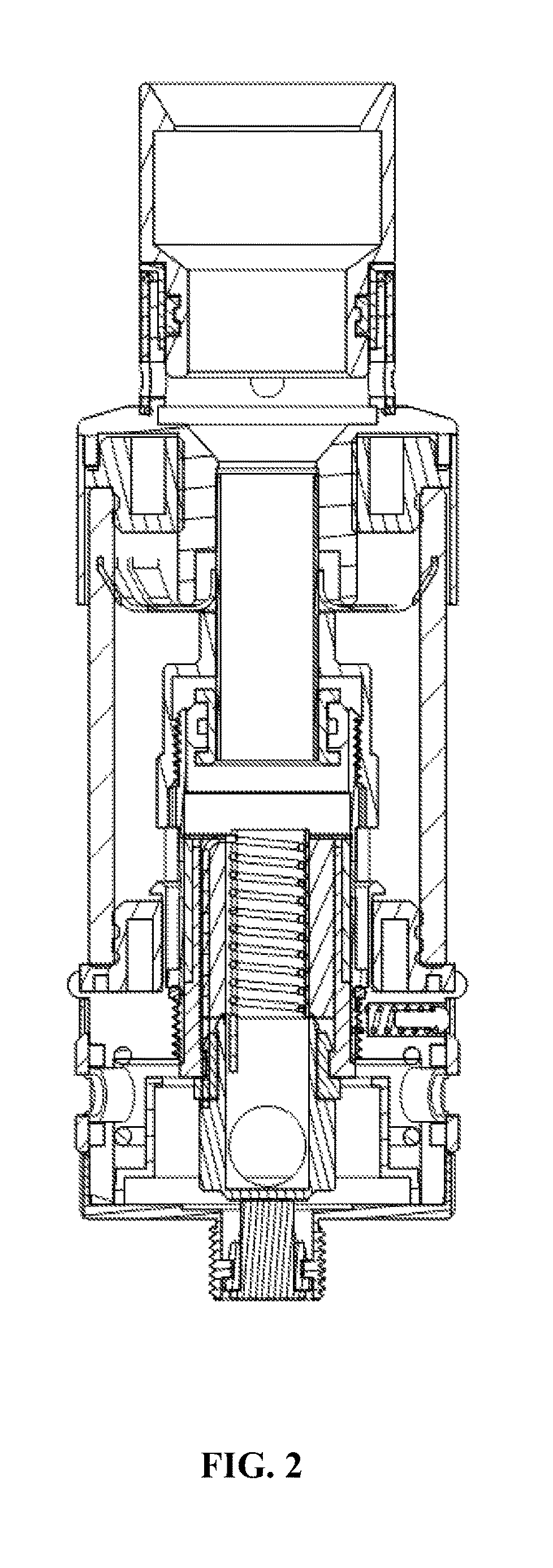

Electronic cigarette

ActiveUS9788577B2Easy to operateImprove compatibilityTobacco devicesOhmic-resistance heatingElectronic cigaretteScrew thread

An electronic cigarette, including: a cigarette holder assembly; a fixing seat assembly; an atomization assembly; a gas flow control assembly; and a glass housing. The cigarette holder assembly is made of metal. The fixing seat assembly operates to fix the glass housing and to regulate an air flow. The atomization assembly is disposed inside the glass housing. The heating wires are disposed inside the atomization assembly. The cigarette holder assembly is connected to the fixing seat assembly in the manner of plugging. The glass housing is connected to a middle support via a fixing jaw. The atomization assembly is assembled with the gas flow control assembly using screw threads to form an integrated structure, and the integrated structure of the atomization assembly and the gas flow control assembly is then assembled with the fixing seat assembly.

Owner:LIU TUANFANG

Tobacco cartridge flavoring and cooling filter tip and preparation method thereof

The invention relates to a tobacco cartridge flavoring and cooling filter tip and a preparation method thereof. The tobacco cartridge flavoring and cooling filter tip comprises a paper tube, a sealingfilter sheet, a spacing filter sheet and a filter tip body, wherein the sealing filter sheet and the spacing filter sheet are sequentially fixed in the paper tube at intervals, so that the paper tubeis divided into a sealing part, a partition part and a flavoring cavity; and the flavoring cavity is filled with flavor substances, including but not limited to sustained-release flavor microspheres,gel flavors, solid particle flavors, nano microcapsule flavors, nano microcapsule formed paper and the like. According to the tobacco cartridge flavoring and cooling filter tip, the paper tube, the sealing filter sheet, the spacing filter sheet, the flavoring cavity and the filter tip body are arranged, and tipping paper is connected with a smoke formation section. The flavoring cavity is clampedbetween the sealing filter sheet and the spacing filter sheet; the flavoring cavity is filled with the flavor substances; the flavoring cavity has the functions of realizing flavoring and reducing the temperature of smoke, so that an inlet is not hot, the smoke flavors are rich, and the experience of various different flavors is brought.

Owner:广东神农烟科技术有限公司

Opposite spraying type impinging stream oily fume purification device

InactiveCN105396396AReduce concentrationAvoid fire riskGas treatmentUsing liquid separation agentFlue gasFire risk

The invention provides an opposite spraying type impinging stream oily fume purification device. The device comprises a purification tank and a water storage tank, wherein one side of the purification tank is welded with one side of the water storage tank through a pipeline; an oily fume gas inlet and a purified gas discharge port are formed in the other side of the purification tank, and the purified gas discharge port is located above the oily fume gas inlet; a purification tank drainage port is formed in the bottom of the purification tank, an oily fume gas and water impinging area is formed in the middle of the purification tank, a first jet pipe and a second jet pipe which are embedded into each other are arranged in the impinging area, the first jet pipe and the second jet pipe are oppositely arranged in the same plane, distributed in a staggered manner and both provided with jet holes, one side of the first jet pipe is connected with an oily fume inlet, the other side of the first jet pipe is sealed through a pipeline, one side of the second jet pipe is connected with a water storage tank water outlet of the water storage tank, and the other side of the second jet pipe is sealed through a pipeline. The opposite spraying type impinging stream oily fume purification device has the benefits as follows: the flue gas temperature and the flue gas emission concentration in a gas duct are remarkably reduced; the fire risk is reduced, and the air quality is improved; the device is simple and convenient to mount, maintain and operate.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

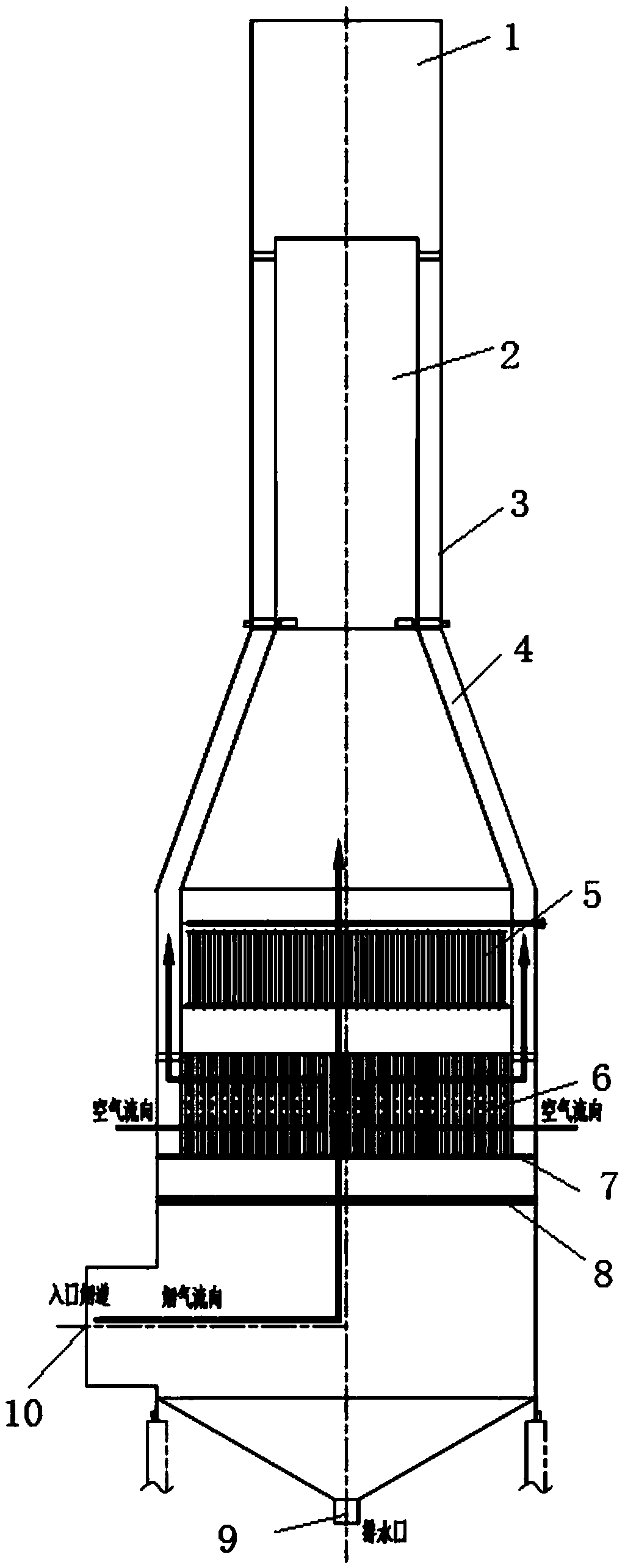

Wet desulphurization tail smoke white removing tower and application

PendingCN109200741AReduce water contentReduce flue gas temperatureGas treatmentDispersed particle separationPulp and paper industryTower

The invention relates to a wet desulphurization tail smoke white removing tower. The white removing tower comprises a tower body, a water outlet, an inlet smoke channel, flow homogenizing devices, condensation sections, a draught fan, a demisting section, an inner cylinder and a top outlet, the water outlet is coaxially communicated with the bottom of the tower body, the top outlet is coaxially communicated with the top of the tower body, the flow homogenizing devices are coaxially arranged on the part, above the water outlet, of the tower body at intervals, the condensation sections are coaxially arranged on the part, above the flow homogenizing devices, of the tower body at intervals, the outer sides of the lower bottom faces of the condensation sections are tightly connected with the inner wall of the tower body through a sealing plate, and the inner cylinder is coaxially arranged in the part, between the condensation sections and the top outlet, of the tower body. The white removing tower can reduce the water content in the smoke and the smoke temperature after wet desulphurization, so that no white smoke plume capable of being recognized by naked eyes does not exist in the smoke exhausted into the air, the investment and the operation maintenance of the white removing system are greatly reduced, the benefits are improved, and the purposes of energy conservation and emission reduction are achieved.

Owner:AEROSPACE ENVIRONMENTAL ENG

Top and bottom composite blowing molten bath smelting technology and device

InactiveCN108754175AAvoid enteringReduce flue gas temperatureRotary drum furnacesCrucible furnacesDecompositionSlag

The invention provides a top and bottom composite blowing molten bath smelting technology and device. A plurality of spray gun insert holes are formed in the top of a furnace body. Feeding inlets anda floss hole are formed in the top of the furnace body and formed in the left and right ends of the furnace body correspondingly. Spray gun insert holes are formed in the bottom of the furnace body. Aslag tap and a copper-matte tap are formed in the two sides of the furnace body correspondingly. A nozzle is formed above the slag tap. The top and bottom composite blowing molten bath smelting technology and device have the advantages that a top blowing unit is additionally arranged at the top of the furnace body, elemental sulfur which is produced due to copper concentrate decomposition and cannot participate in oxidizing reaction completely fully reacts in a smelting furnace, a large amount of the elemental sulfur is prevented from entering a flue gas system, the boiler inlet flue gas temperature is decreased, a coking situation is alleviated, the molten bath smelting heat efficiency is improved, and meanwhile, top blowing high-speed airflow is utilized for reducing the phenomenon ofmelt splashing caused by bottom blowing.

Owner:DONGYING FANGYUAN NONFERROUS METALS +3

Cigarette wrapper and cigarette

InactiveUS20030034042A1Reduce the chance of spontaneous combustionReduce flue gas temperatureNon-fibrous pulp additionNatural cellulose pulp/paperCalcium carbonateEngineering

A cigarette has a tobacco section in which cut tobacco is wrapped with a cigarette wrapper, a filter section connected to one end of the tobacco section, and a tip paper integrally connecting the tobacco section to the filter section in a manner to cover the proximal end portion of the tobacco section and the filter section and provided with ventilation holes formed in a circumferential direction in positions apart from the smoking end of the filter section. The tobacco section has a rod length of 30 to 46 mm, and a cut tobacco filling density of 180 to 270 mg / cm3. The cigarette wrapper has a basis weight of 17 to 21 g / m2, a mixing ratio of a calcium carbonate filler of 16 to 25% by weight, and a calcium carbonate content of 3 g / m2 or more. The cigarette provides at least six puffs under a standard smoking condition.

Owner:JAPAN TOBACCO INC

Aerosol cooling filtration unit and low-temperature cigarette

InactiveCN110292207AReduce flue gas temperatureReduce filterTobacco devicesThermodynamicsComposite film

The invention relates to the technical field of heat-not-burn cigarettes, in particular to an aerosol cooling filtration unit and a low-temperature cigarette. The aerosol cooling filtration unit is ahollow pipe or a honeycomb-shaped empty pipe made of an organosilicon material in an injection molding or extrusion molding mode, or is a cylinder provided with a longitudinal multi-channel structureand formed by organosilicon composite film sheets in an embossing, folding or gathering mode, and or is a hollow pipe formed by organosilicon composite film sheets wound through a spiral technology. The aerosol cooling filtration unit adopts the organosilicon material with cooling and heat absorbing functions, the temperature of aerosol can be decreased through the effect of absorbing a lot of heat by the organosilicon material, the physical properties of the organosilicon material are stable, thus adhesion and collapse are not likely to occur in the aerosol passing process, longitudinal channels are always kept smooth, smooth flowing of the aerosol is kept, and the smoking experience feeling of a user is effectively improved.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

Spray evaporation treatment method of wet method flue gas desulfurization wastewater in thermal power station

ActiveCN101844819BOvercomes highly corrosive effectsIncrease humidityDispersed particle separationWater/sewage treatmentEvaporationTreatment system

Owner:WUHAN TIANHE TECH

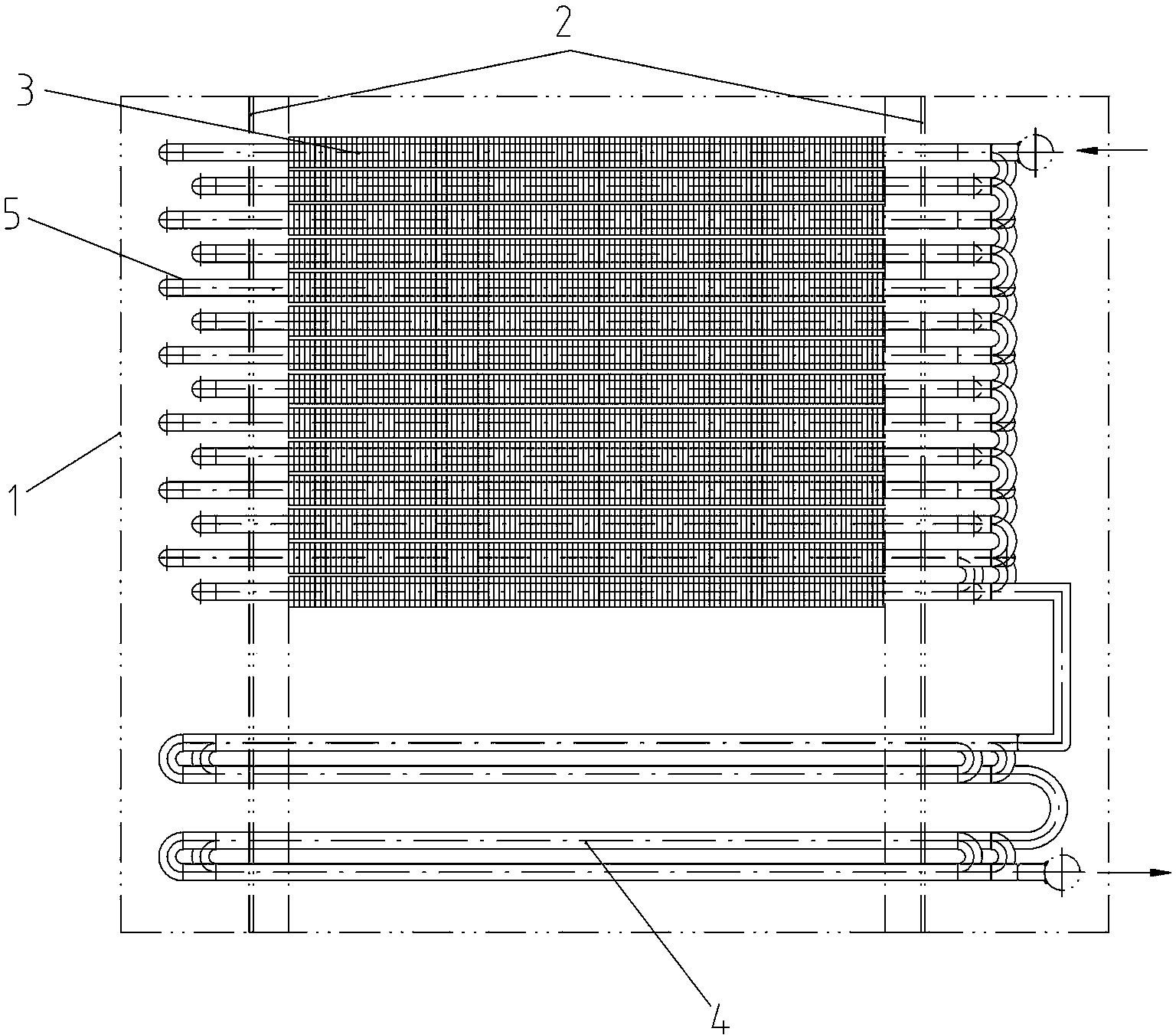

Coal economizer with H-type ribbed tubes

InactiveCN103644560AIncrease the heating areaHigh strengthTubular elementsFeed-water heatersEngineeringCoal

The invention discloses a coal economizer with H-type ribbed tubes. The coal economizer aims at improving the use effect to the maximum degree. The coal economizer with the H-type ribbed tubes comprises a shell, end plates, an H-type ribbed tube set, a plain tube set, tube sleeves and a sealing comb-shaped plate, wherein the plain tube set is arranged in the space in the lower portion inside the shell, the H-type ribbed tube set is arranged in the space in the upper portion inside the shell, the H-type ribbed tube set is connected with the plain tube set through an elbow tube, the end plates are used for supporting the H-type ribbed tube set and the plain tube set, the tube sleeves are welded to the end plates, and the sealing comb-shaped plate is welded to the positions of strip-shaped groove openings to prevent smoke leakage. The coal economizer with the H-type ribbed tubes is an upgraded product of an existing plain tube coal economizer and an existing circular spiral ribbed tube coal economizer, and can be widely applied to industrial boiler systems in the efficient and energy-saving technical field.

Owner:SHANGHAI XINYE BOILER HIGH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com