Coal economizer with H-type ribbed tubes

A technology of finned tubes and economizers, applied in tubular elements, feed water heaters, preheating, etc., can solve the problems of unsatisfactory wear resistance, no extended heating surface, easy to form dust, etc., to reduce cutting processing Quantity, cost reduction, large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A coal economizer using H-shaped finned tubes of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

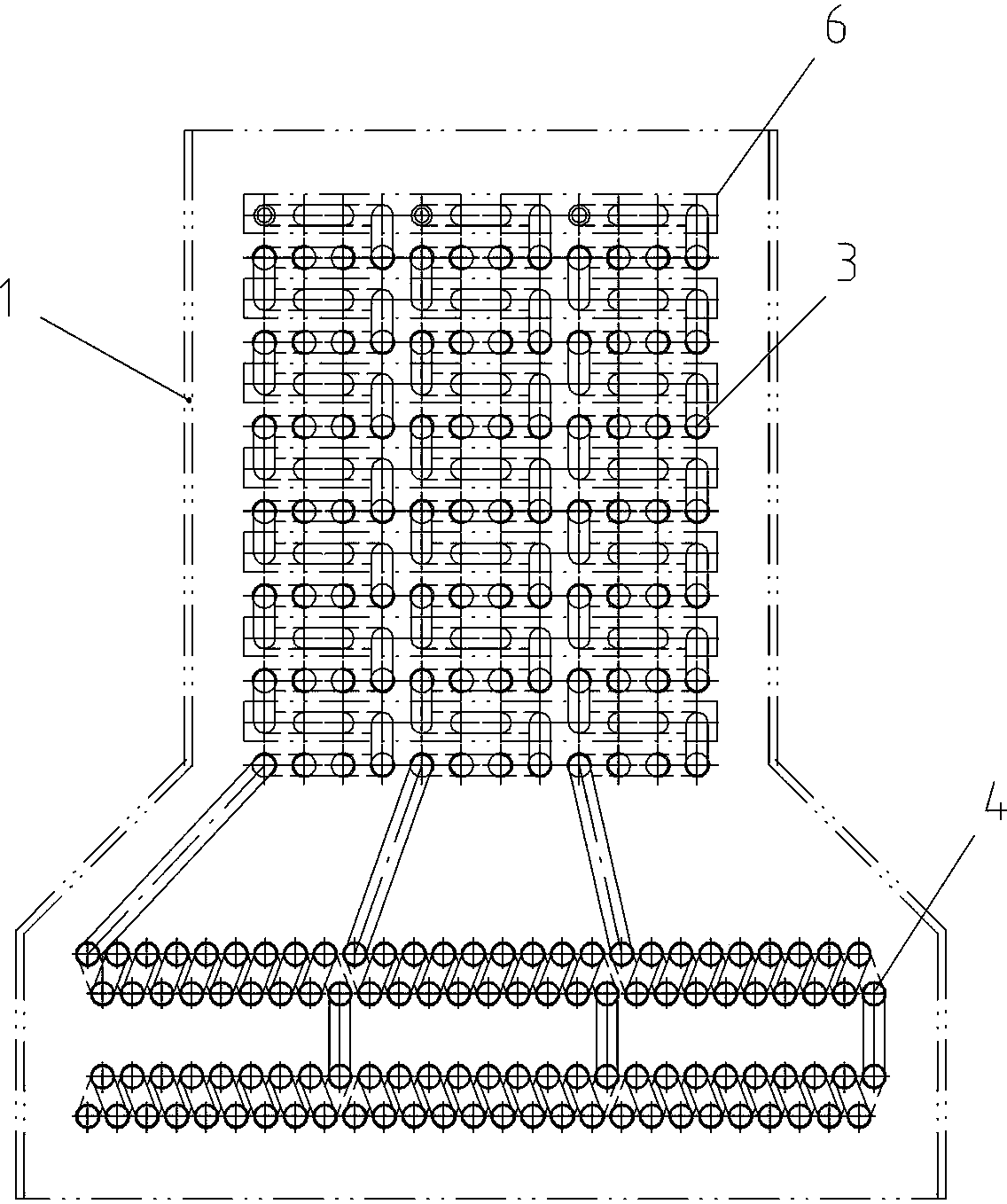

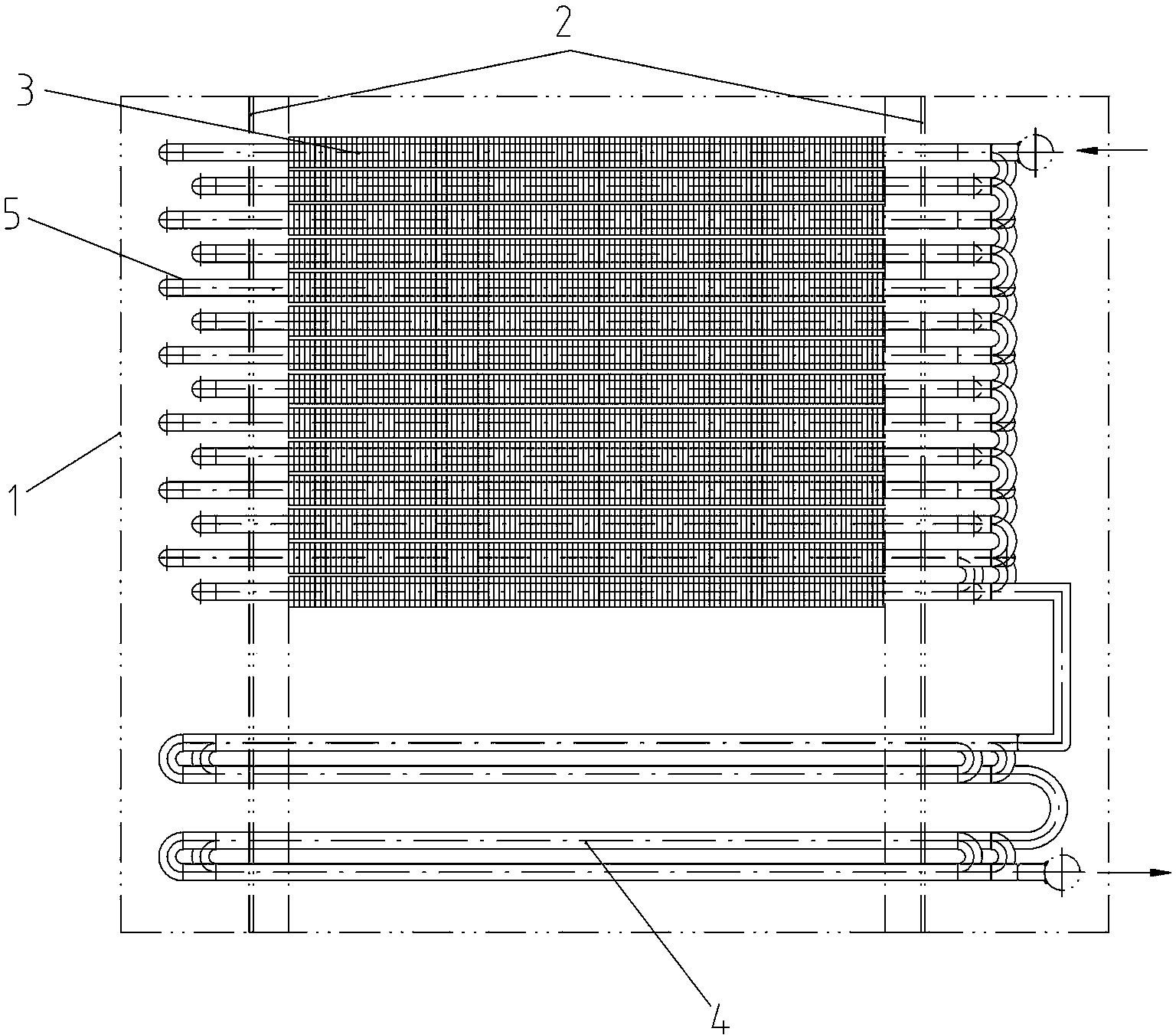

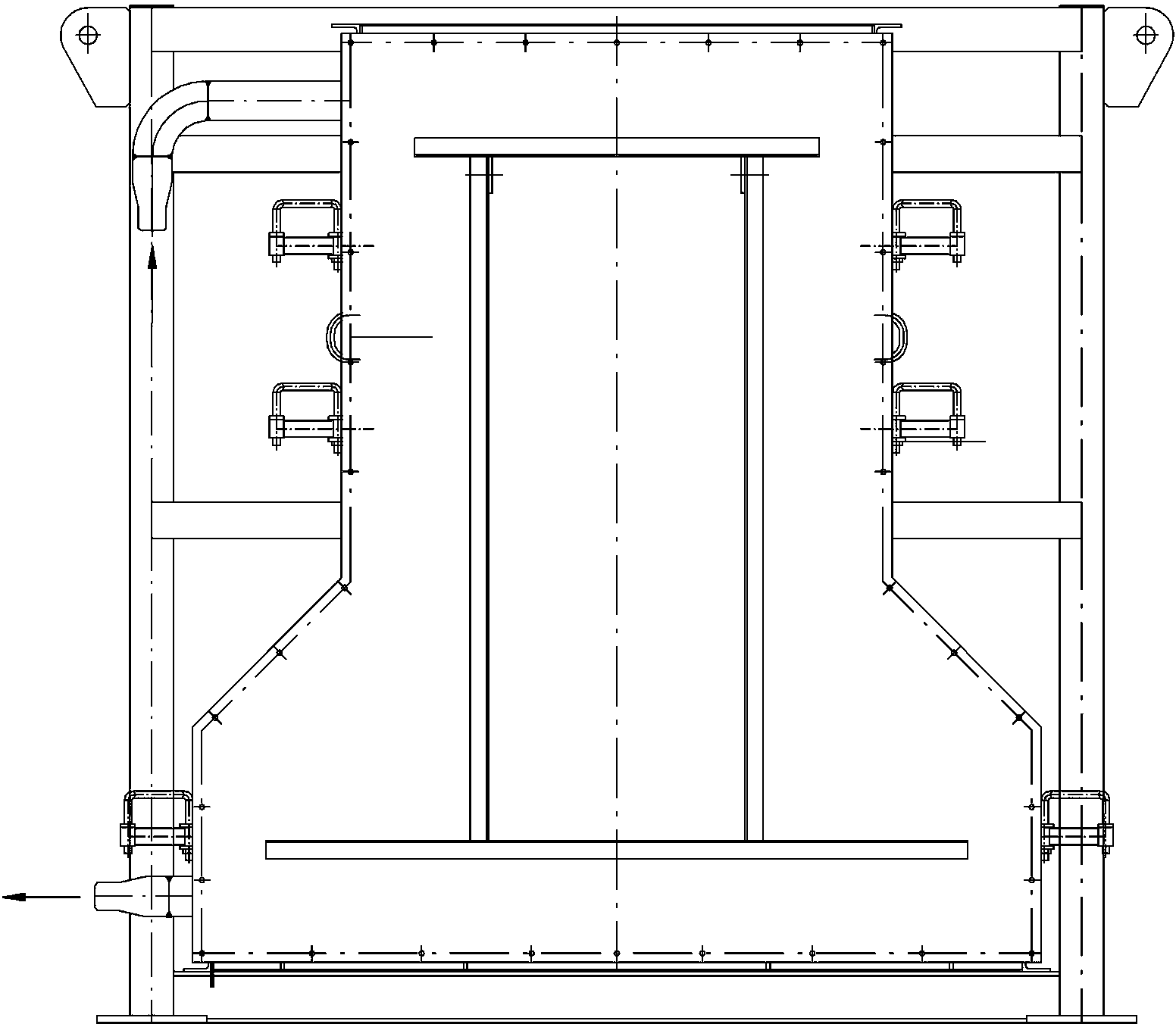

[0022] as attached Figure 1-12 Shown: A new type of economizer using H-shaped finned tubes, including economizer shell 1, end plate 2, H-shaped finned tube group 3, bare tube group 4, pipe sleeve 5 and sealing comb plate 6. The light tube group 4 is arranged in the lower space of the housing 1, and the H-shaped fin tube group 3 is arranged in the upper space. The two tube groups are connected by elbows, and the end plate 2 is used to support the two parts of the tubes. group, weld the pipe sleeve 5 on the end plate, and weld the sealing comb plate 6 to the strip notch to prevent the leakage of smoke; the fins in the H-shaped finned pipe group (such as Figure 5 , Image 6 As shown), two fins with circular arcs in the middle are symmetrically welded to the light pipe to form a finned tube. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com