Light source heating atomizer and electronic cigarette employing same

A technology of heating atomization and light source, which is applied in the fields of tobacco, smoker’s supplies, applications, etc. It can solve the problems of shortening the service life of electric heating wires, concentrated heating temperature, and unevenness, so as to improve the atomization effect, service life, and heating area Large, uniform temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

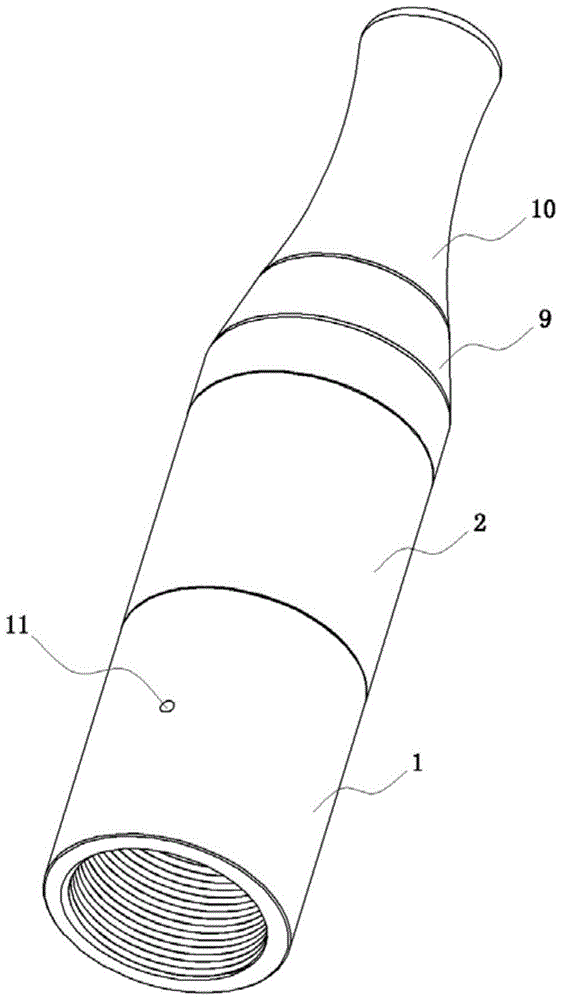

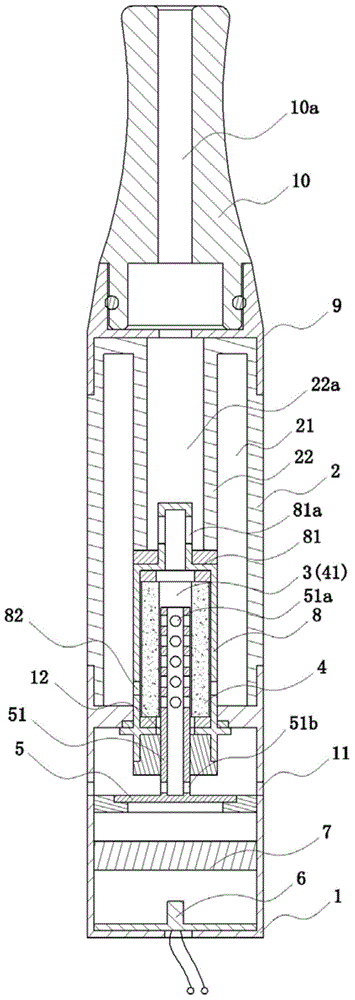

[0027] Embodiment one: as attached Figure 7 The light source heating atomizer shown includes a housing 1 , a container 2 , an atomizing chamber 3 , a penetrating element 4 , a metal heating element 5 , a light source generator 6 and a lens group 7 .

[0028] The housing 1 is the shell of the entire atomizer, an air outlet 11 is installed at the upper end of the housing 1, and an air inlet 12 is provided at the lower end of the housing 1; the container 2 is installed inside the housing 1, and the inside of the container 2 forms a The atomization chamber 3 is formed between the outer surface of the container 2 and the inner surface of the housing 1 in the accommodation chamber 21 containing the smoking substance (such as smoke oil, etc.), and the air inlet hole 12 is connected to the bottom of the atomization chamber 3 .

[0029] The permeable member 4 is interposed between the atomization chamber 3 and the container 2, specifically, the two ends of the permeable member 4 are ...

Embodiment 2

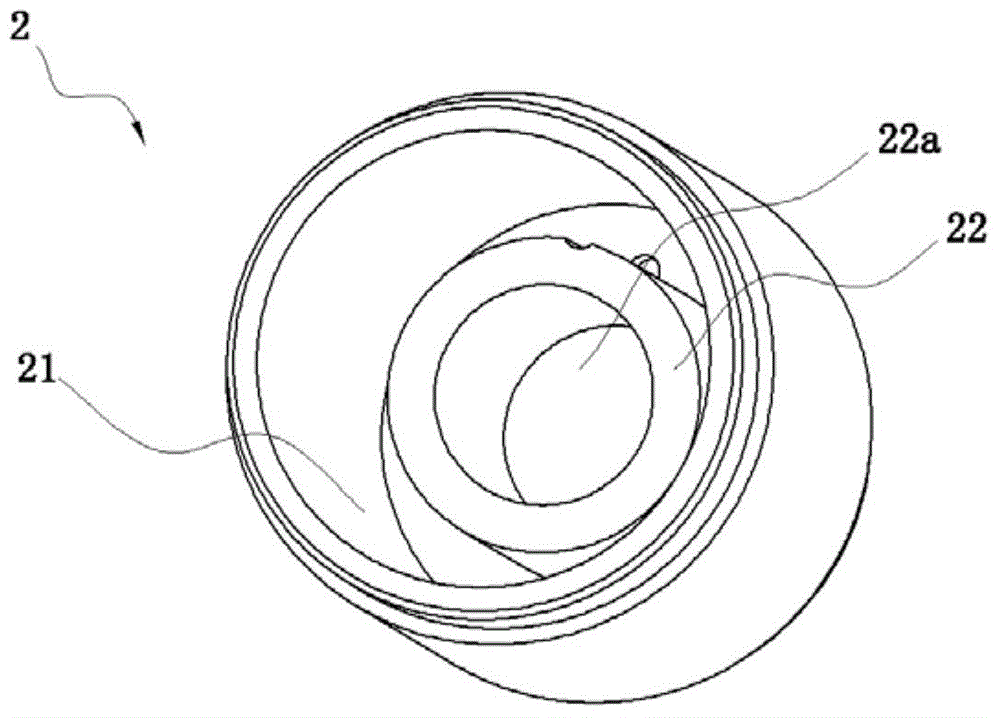

[0033] Embodiment two: as attached figure 1 And attached figure 2 The light source heating atomizer shown includes a housing 1 , a container 2 , an atomizing chamber 3 , a penetrating element 4 , a metal heating element 5 , a light source generator 6 and a lens group 7 .

[0034] in:

[0035] The housing 1 has an air inlet 11 and an air outlet 12 ; both the air inlet 11 and the air outlet 12 communicate with the atomizing chamber 3 .

[0036] The housing 1 is connected with a cylindrical mounting piece 8, as attached Figure 5 And attached Figure 6 shown. Specifically, the first end of the mounting member 8 is fixedly connected to the inside of the housing 1 .

[0037] The penetrating part 4 is accommodated and fixed inside the mounting part 8, specifically, the mounting part 8 is assembled from a left mounting part and a right mounting part, and the penetrating part 4 can be accommodated and fixed inside the mounting part 8 after assembly .

[0038] The lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com