Patents

Literature

301results about "Boiler drums/headers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

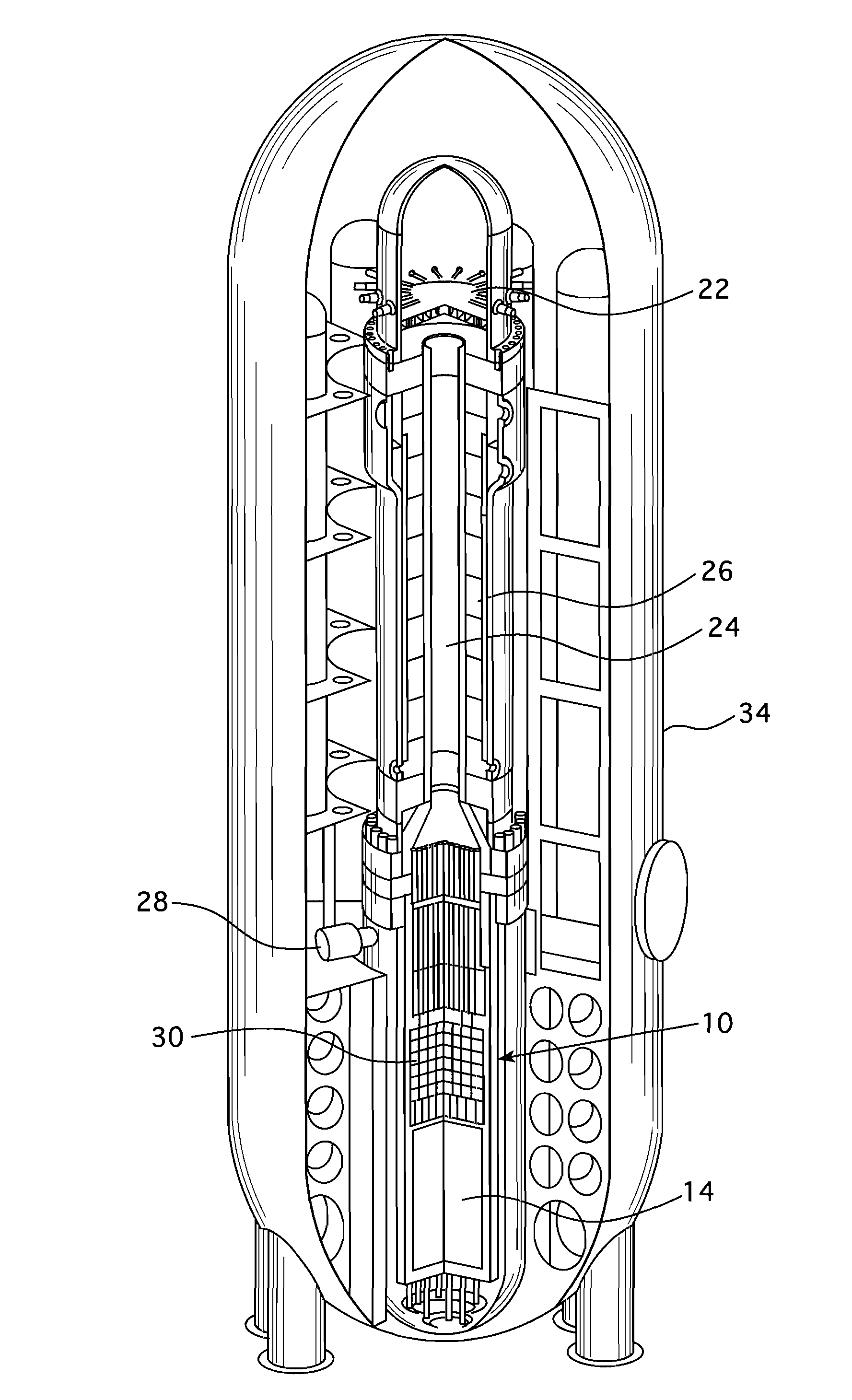

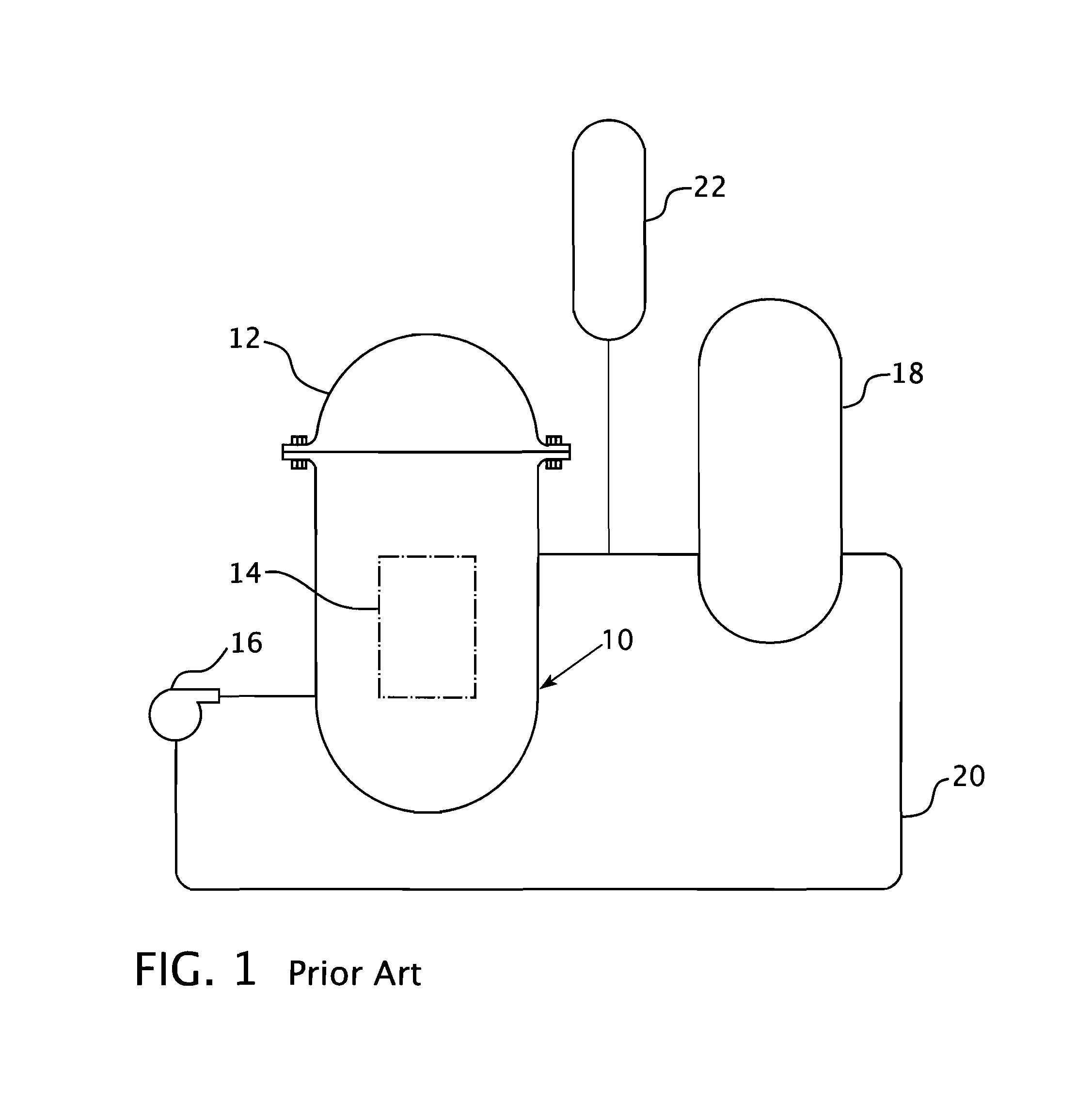

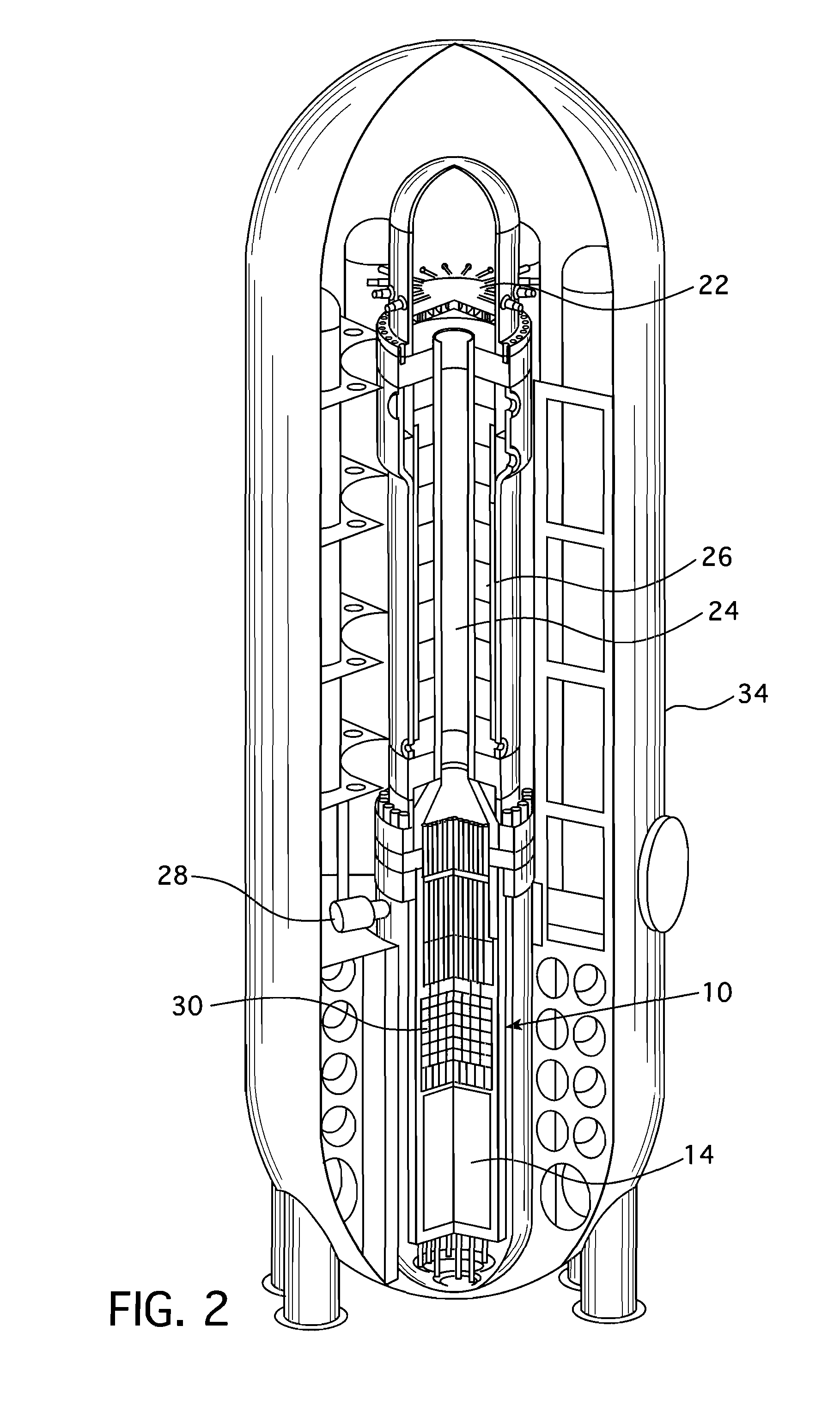

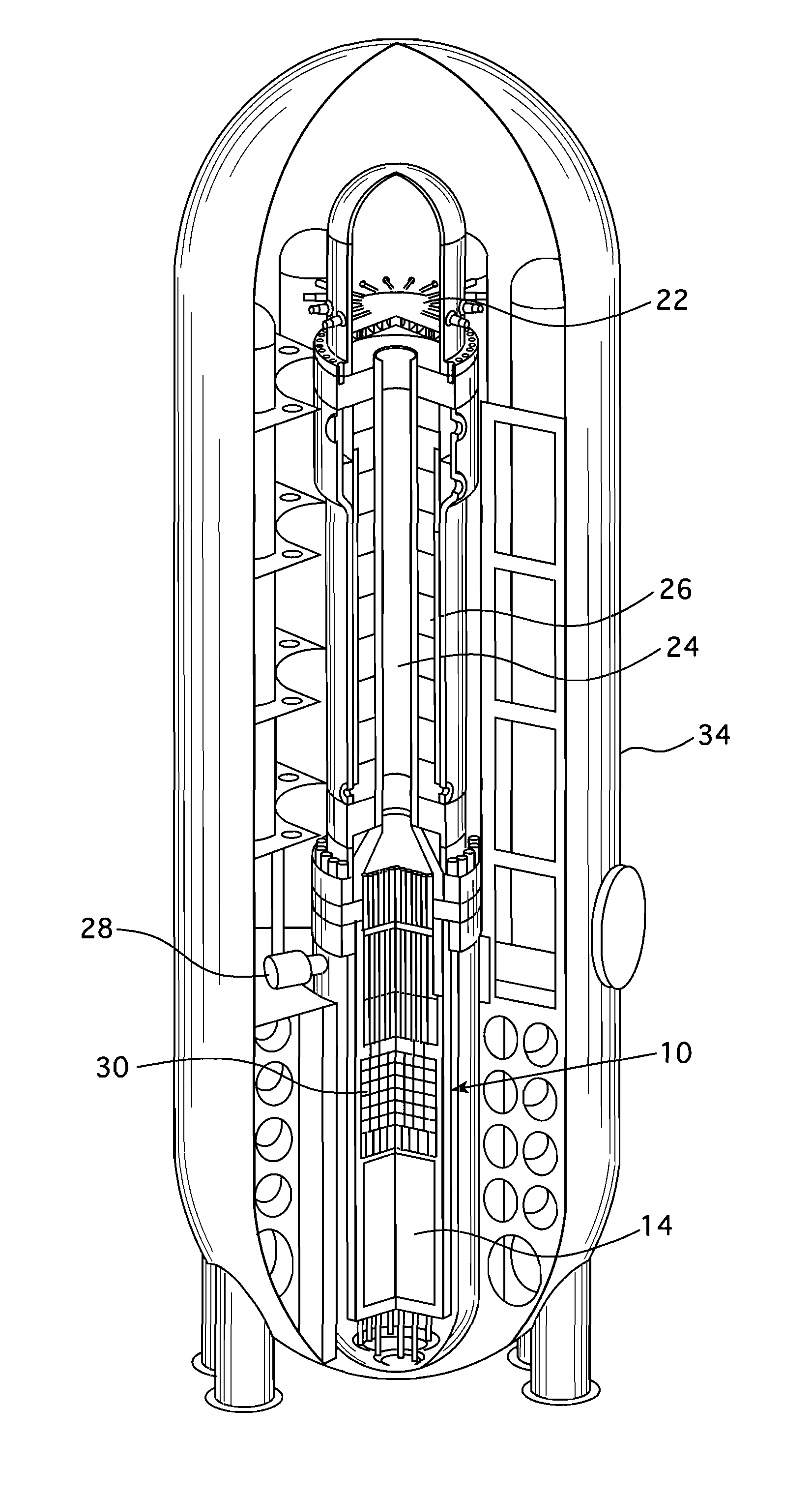

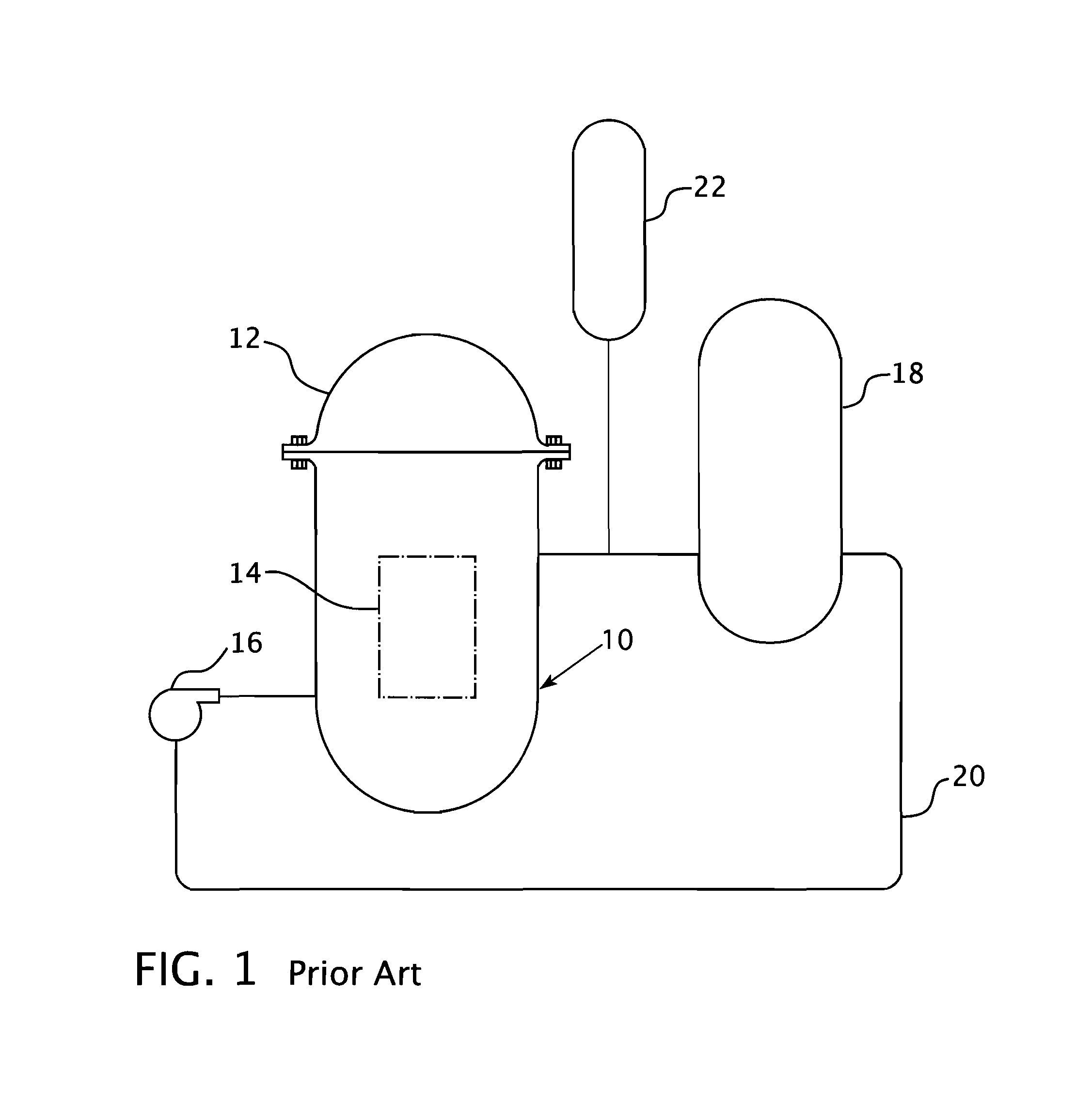

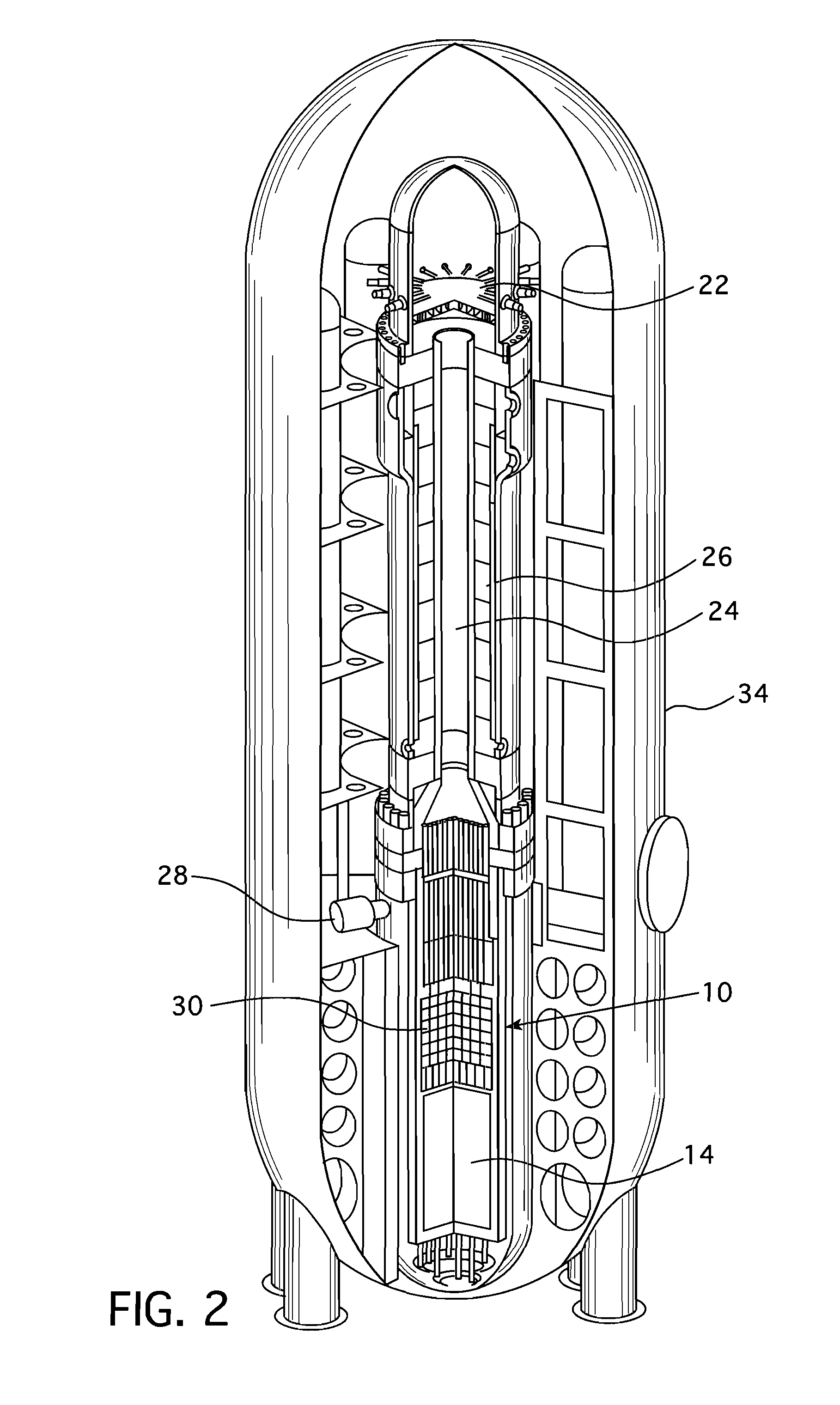

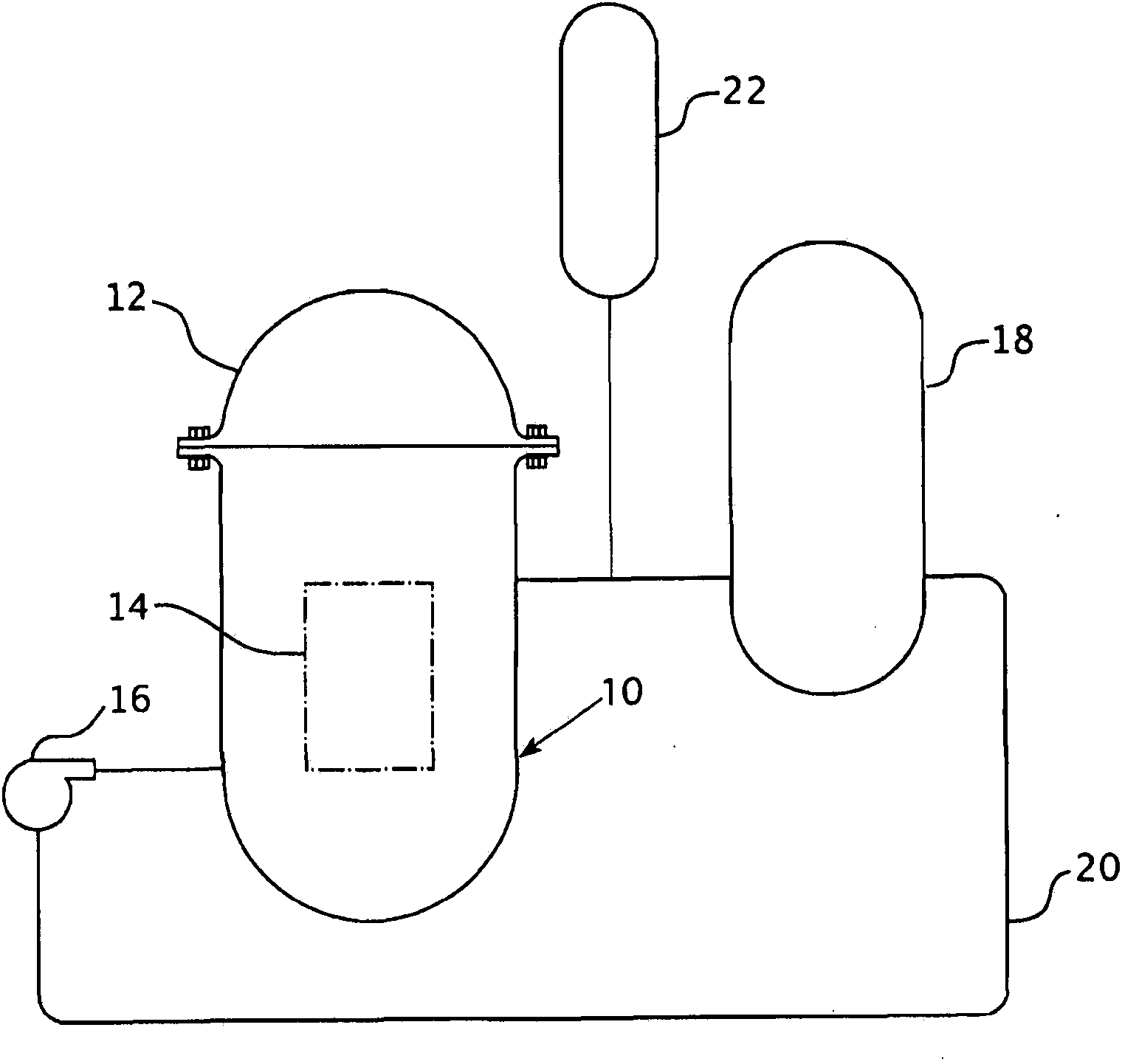

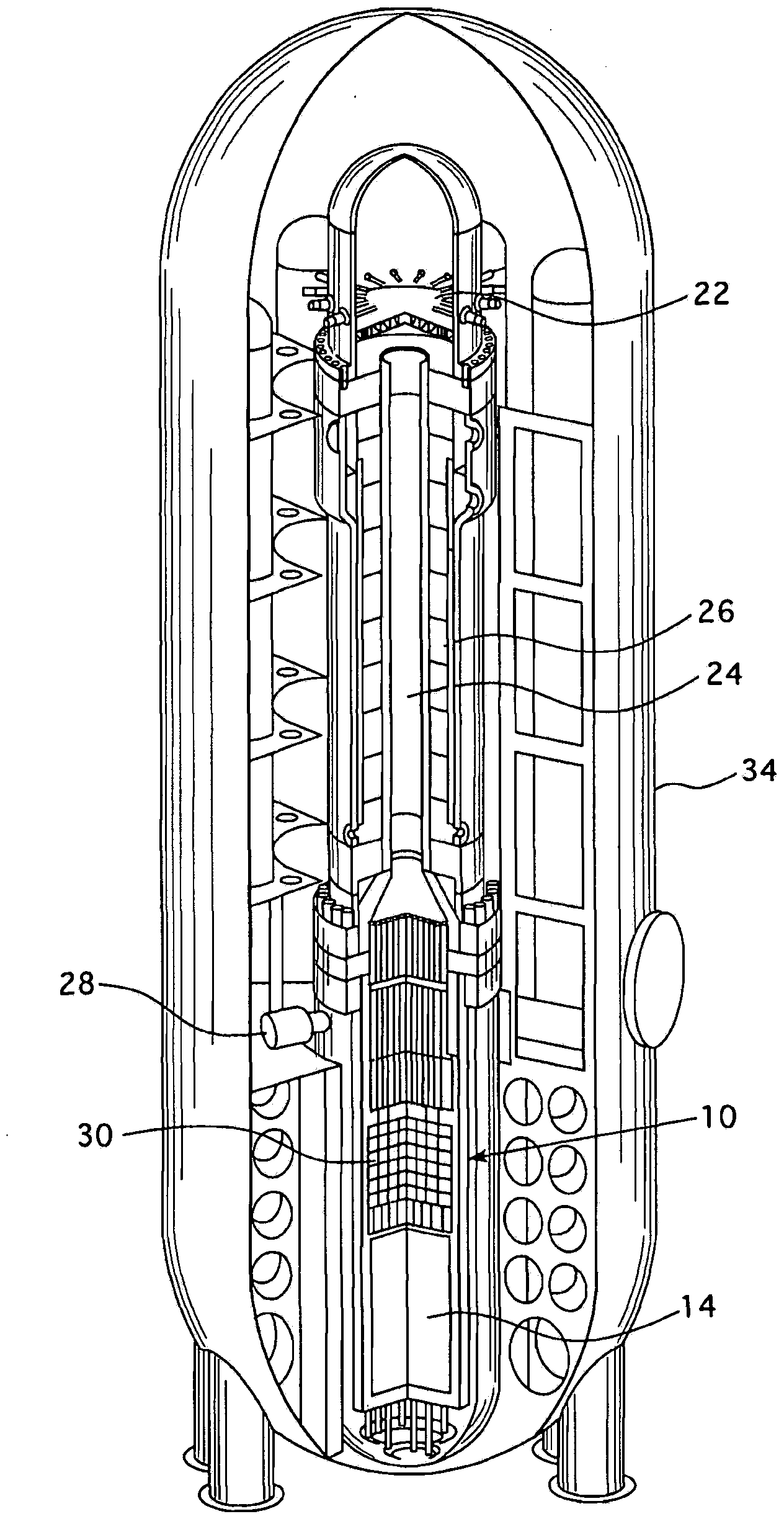

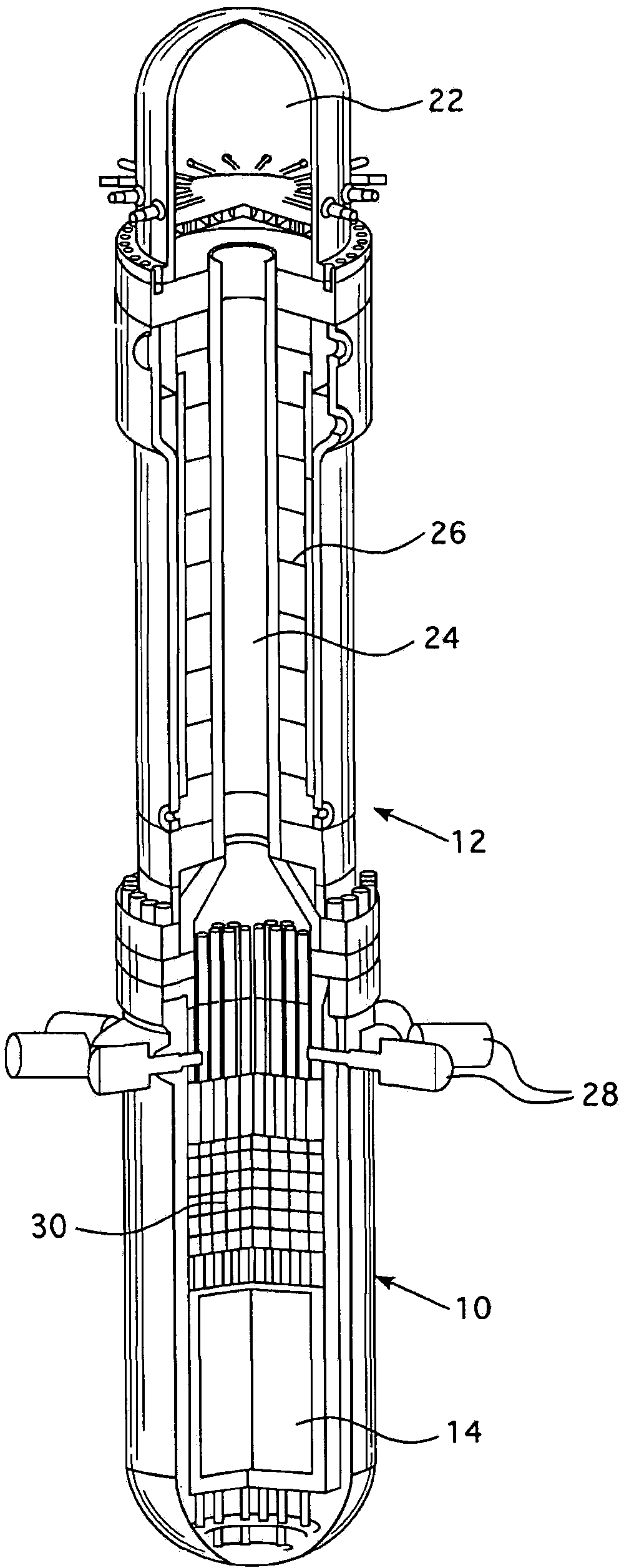

Pressurized water reactor compact steam generator

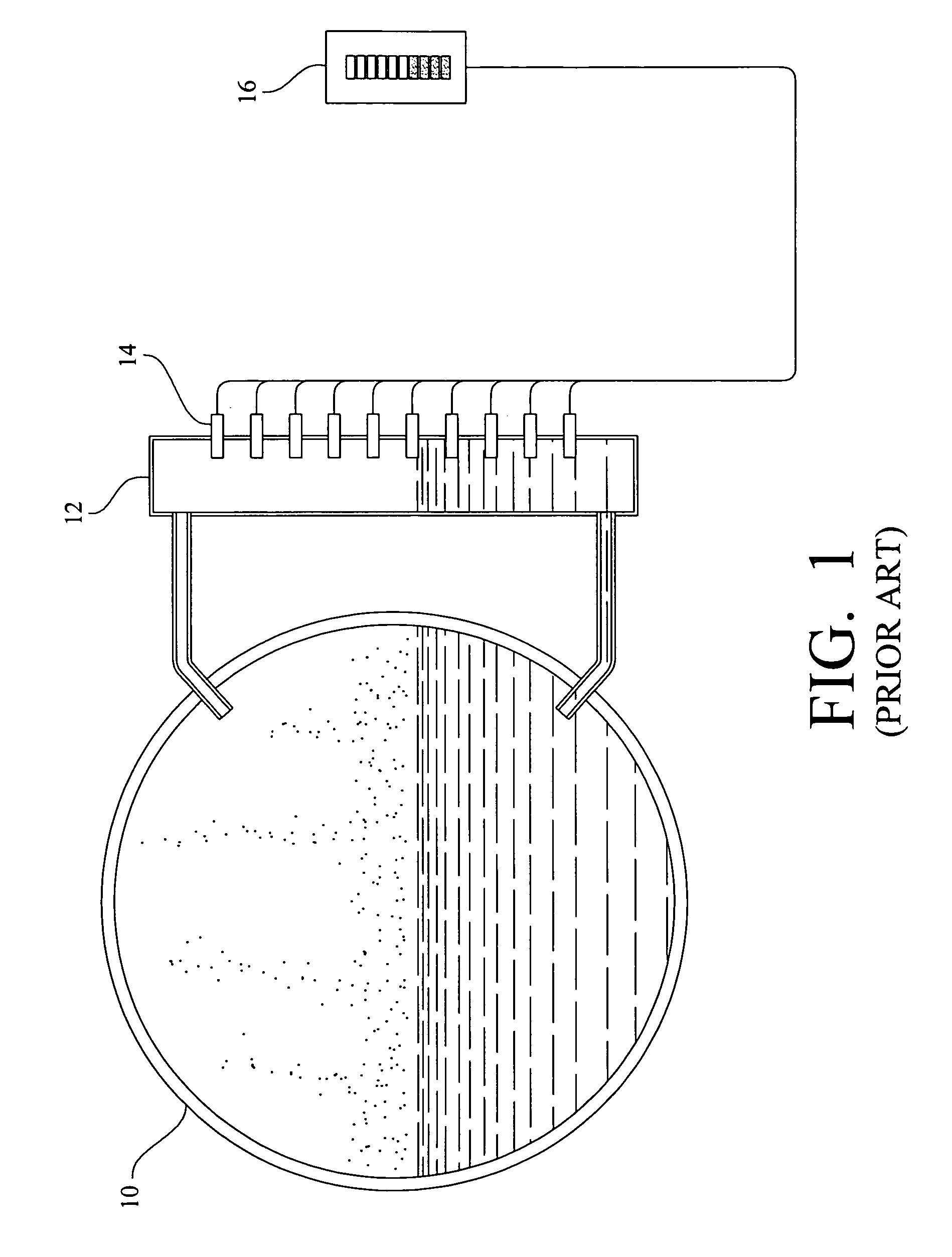

ActiveUS20130336442A1Facilitate natural recirculation of recirculatingBoiler drums/headersIntegral reactorsPressurized water reactorSteam drum

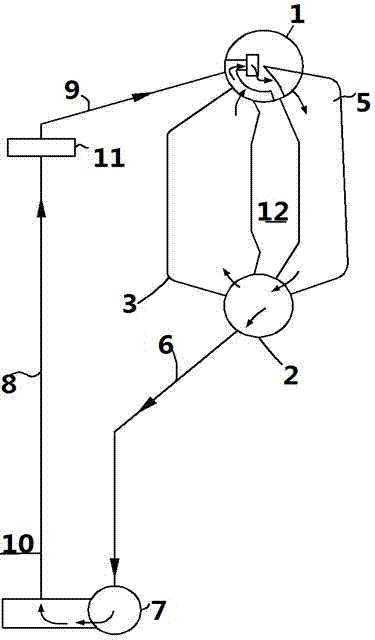

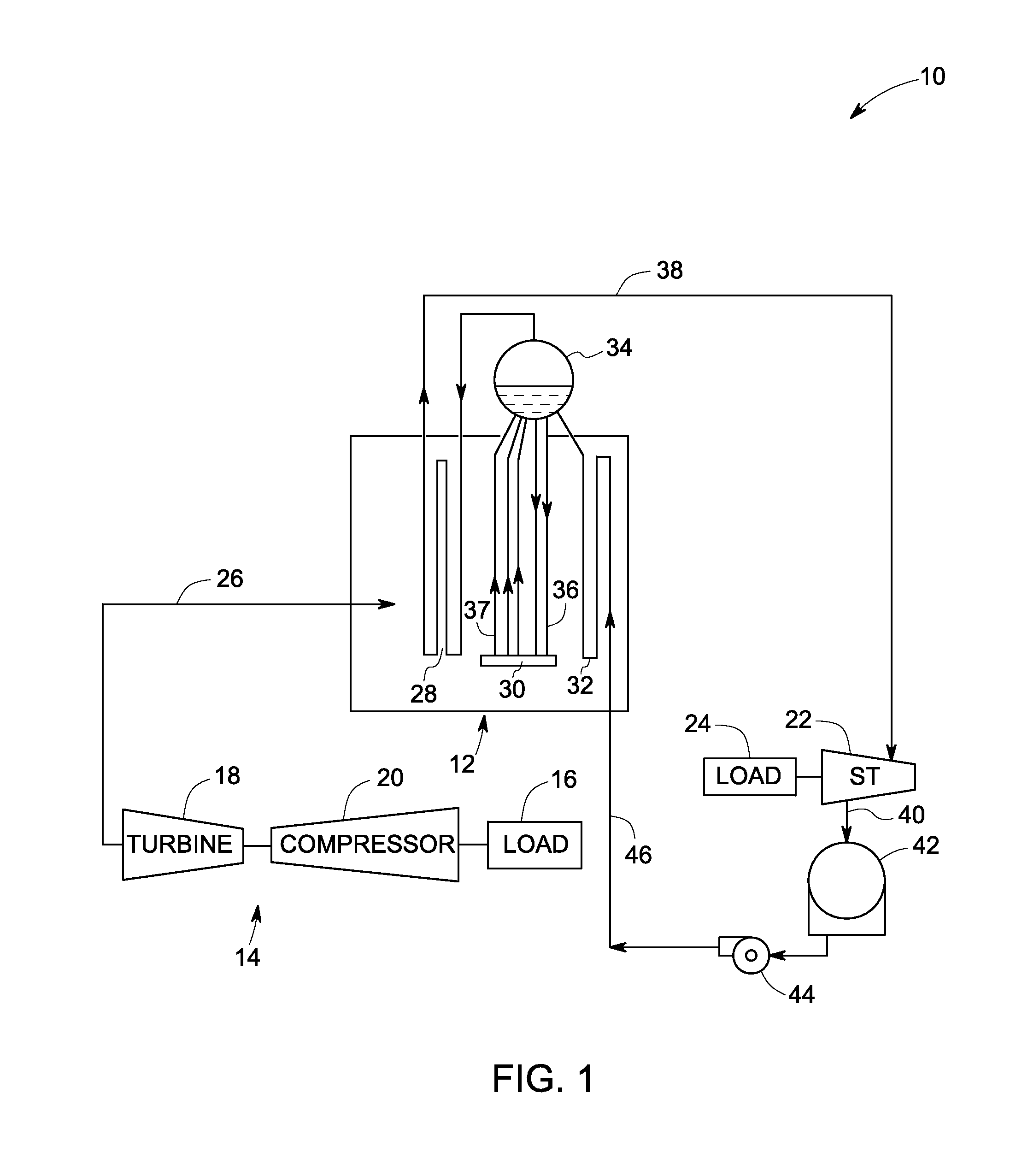

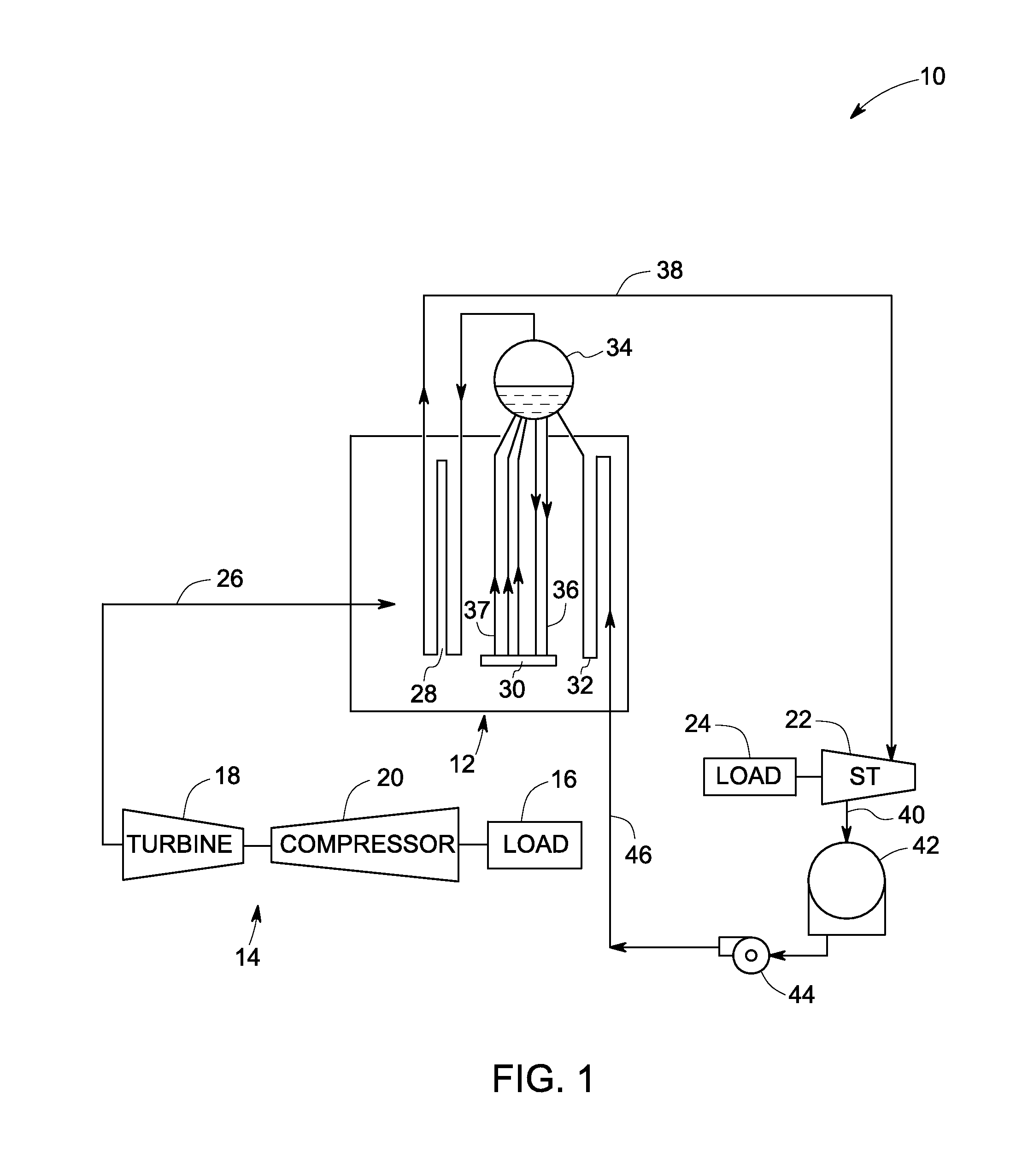

A steam generator system for a pressurized water reactor which employs an external to containment steam drum and recirculation loop piping. The steam generator system changes the arrangement of a typical pressurized water reactor recirculation steam generator by relocating the functions of steam separation and feedwater preheating outside of the reactor coolant system. The steam generator system and thermal hydraulic conditions are selected in order to minimize the size of the steam generator heat exchanger component volume inside of the containment. The external steam drum component can be isolated in accident conditions when desired and is used as a source of secondary fluid inventory for improved decay heat removal capability and tolerance for loss of feedwater events. Thus, the steam generator component volume inside of the containment is reduced and the amount of maintenance required for the reactor coolant system components are similarly reduced.

Owner:WESTINGHOUSE ELECTRIC CORP

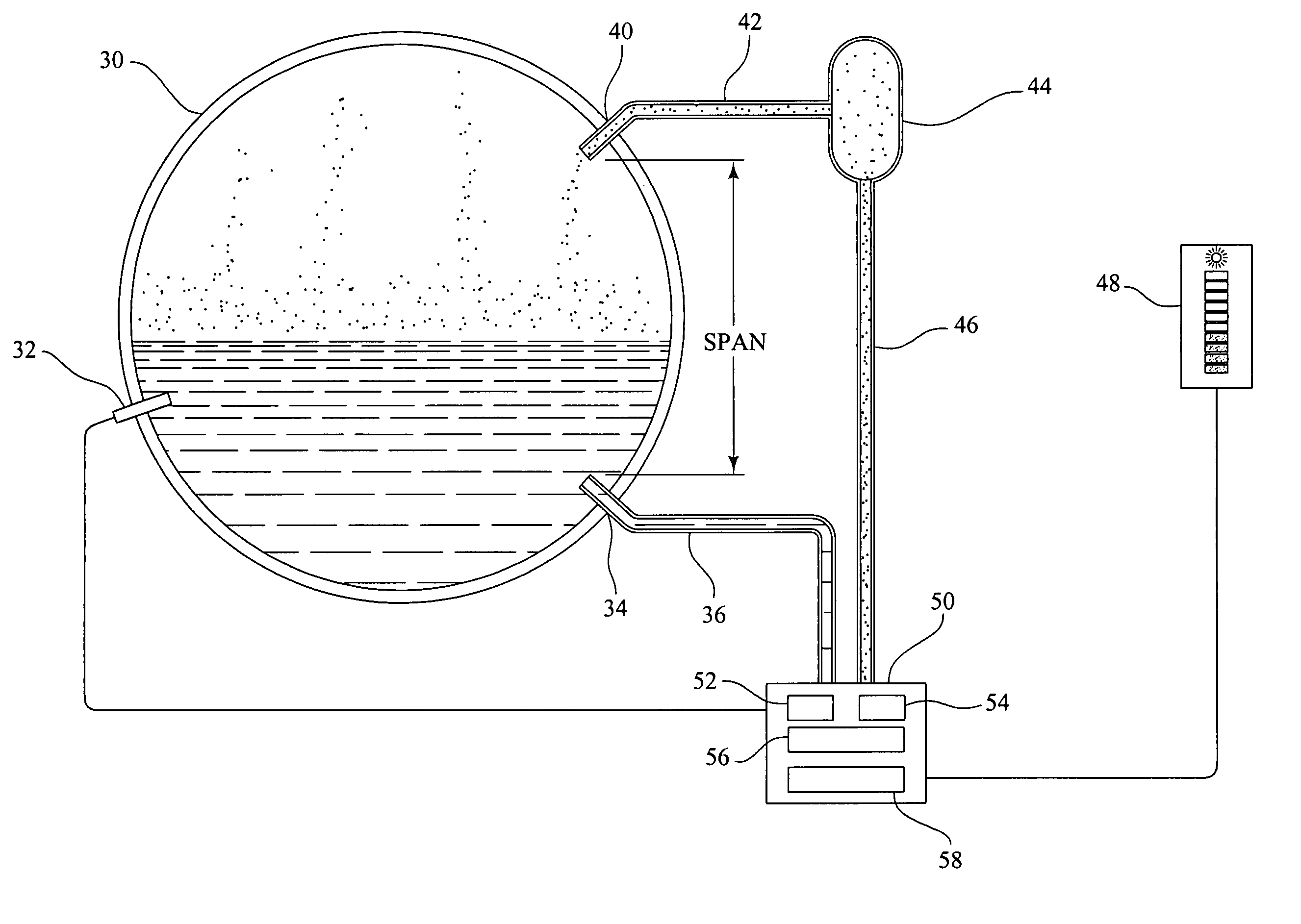

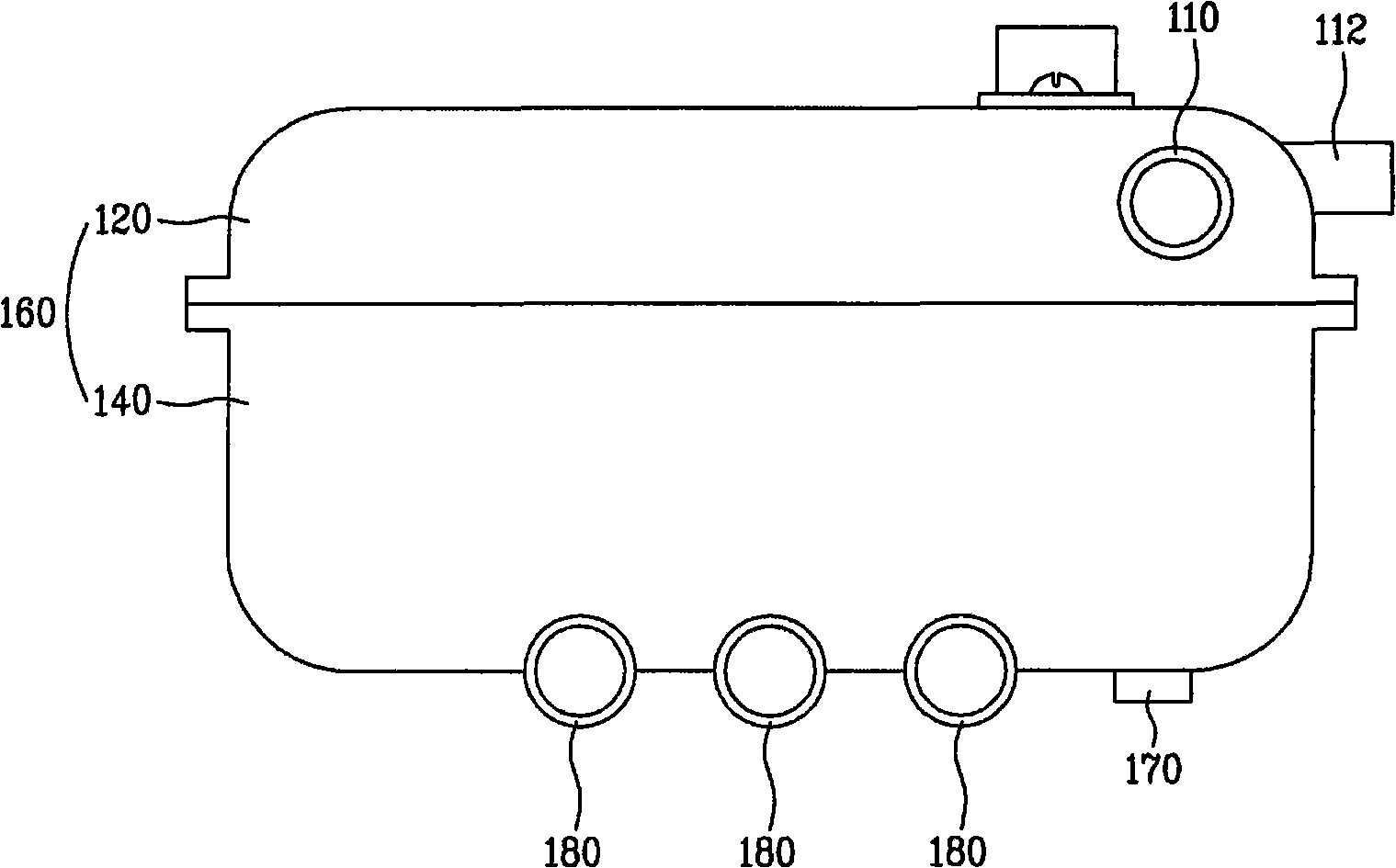

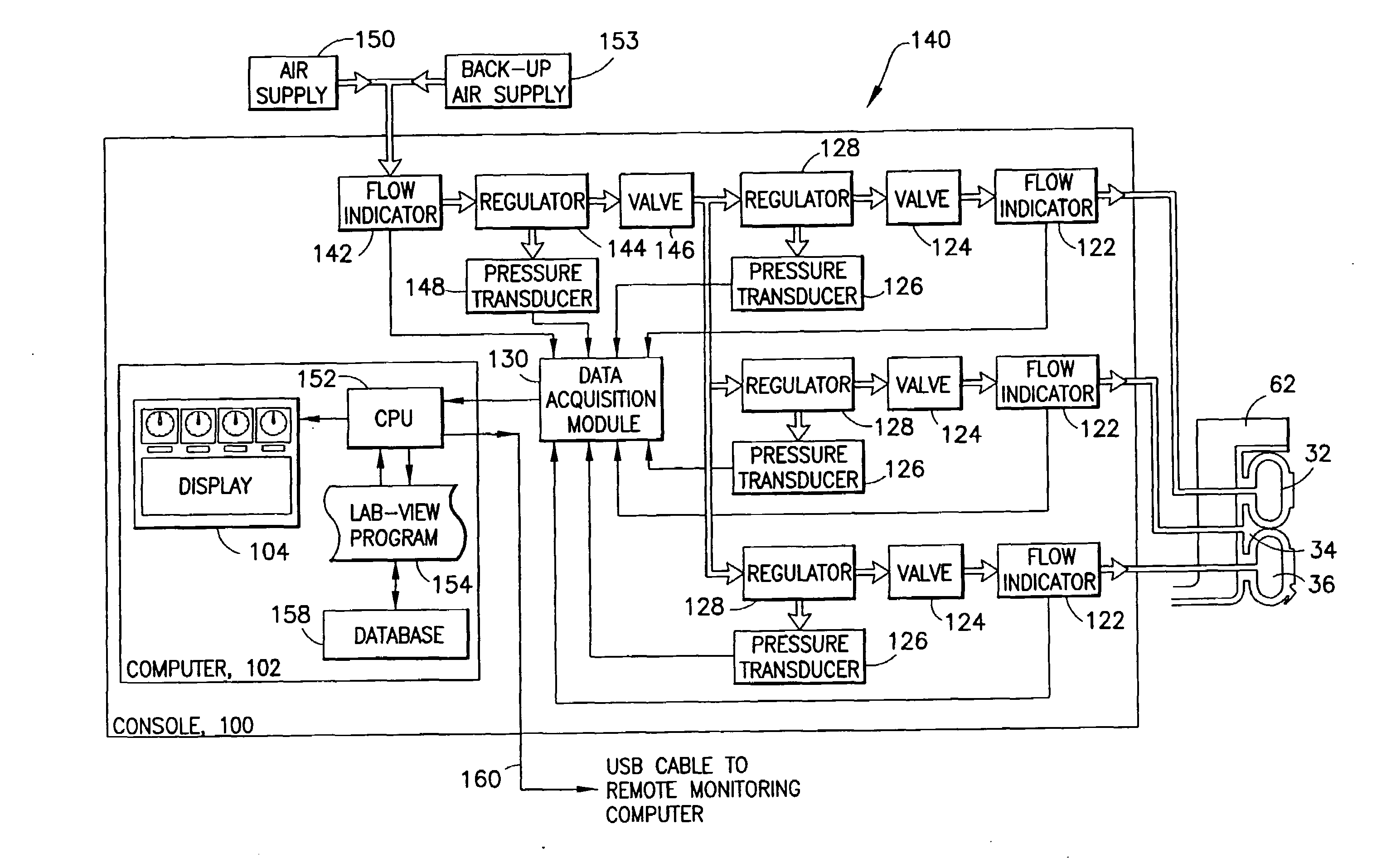

Apparatus and method for determining a liquid level in a steam drum

An apparatus for determining a density-compensated liquid level in a vessel containing a mixture of liquid and vapors comprises a temperature sensor which produces a signal that is proportional to the temperature of the mixture; and a processing apparatus that includes one or more pressure sensors that allow for a measurement of an operating pressure and a differential pressure between the mixture in the vessel and a constant reference leg. The processing apparatus further includes an integral microprocessor for calculating the respective specific gravities of the liquid and vapor portions of the mixture based on the operating pressure, and then computing the density-compensated liquid level in the vessel based on such calculations of specific gravity and the differential pressure.

Owner:VOGT POWER INT

Steam generator

PendingCN101290111AIncrease the heating areaImprove the heating effectBoiler drums/headersSteam generation heating methodsEngineeringHeating effect

Owner:NANJING LG PANDA APPLIANCES

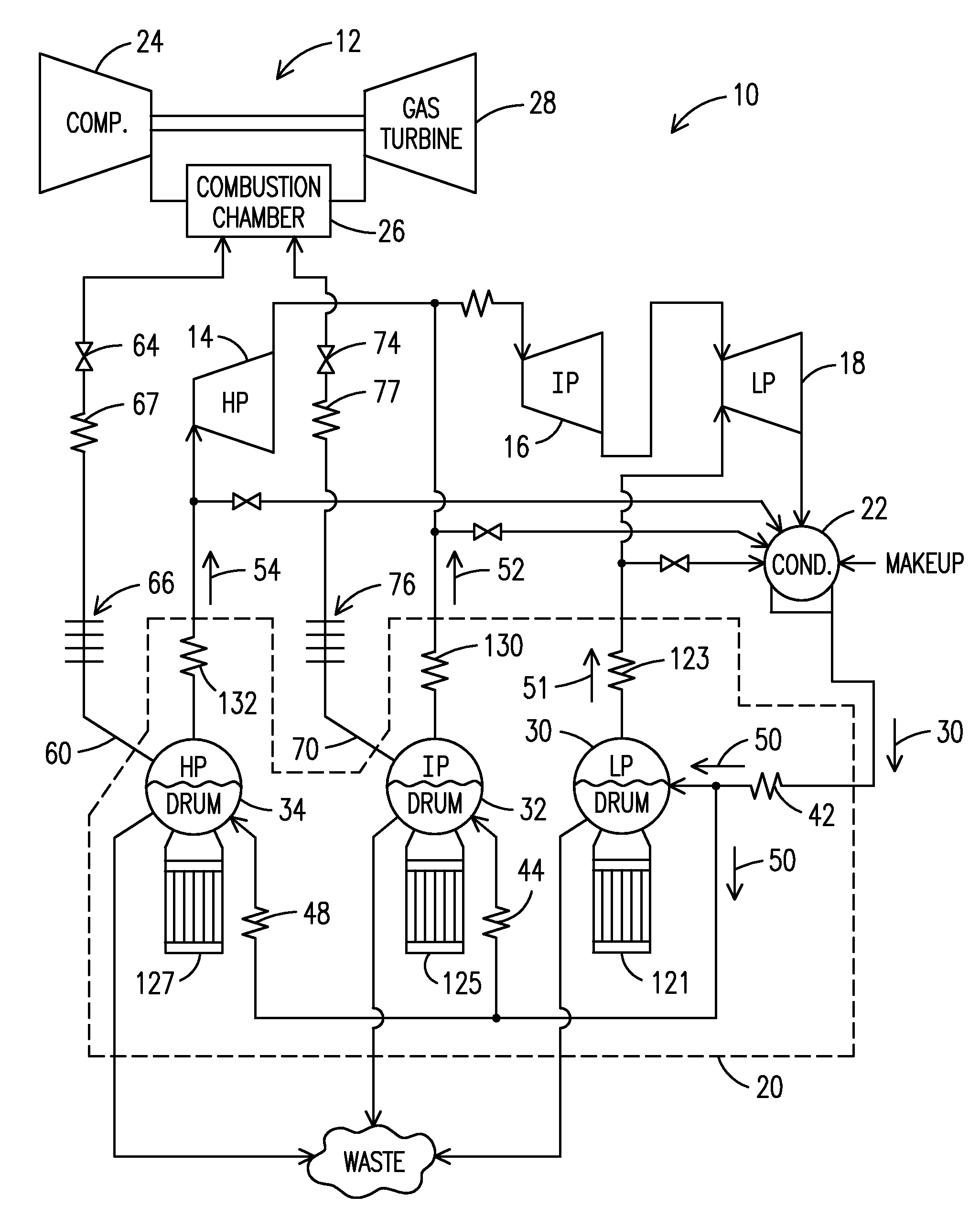

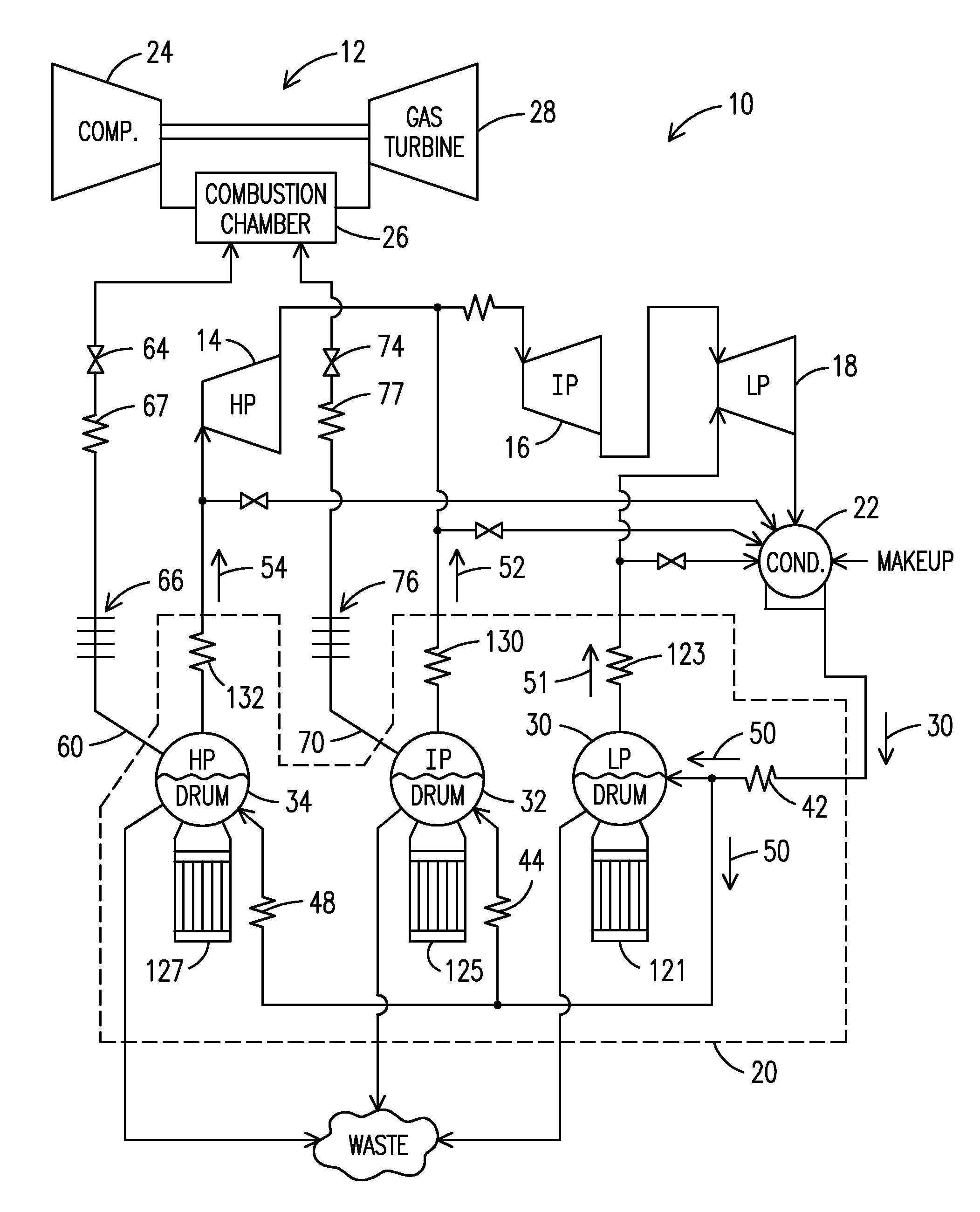

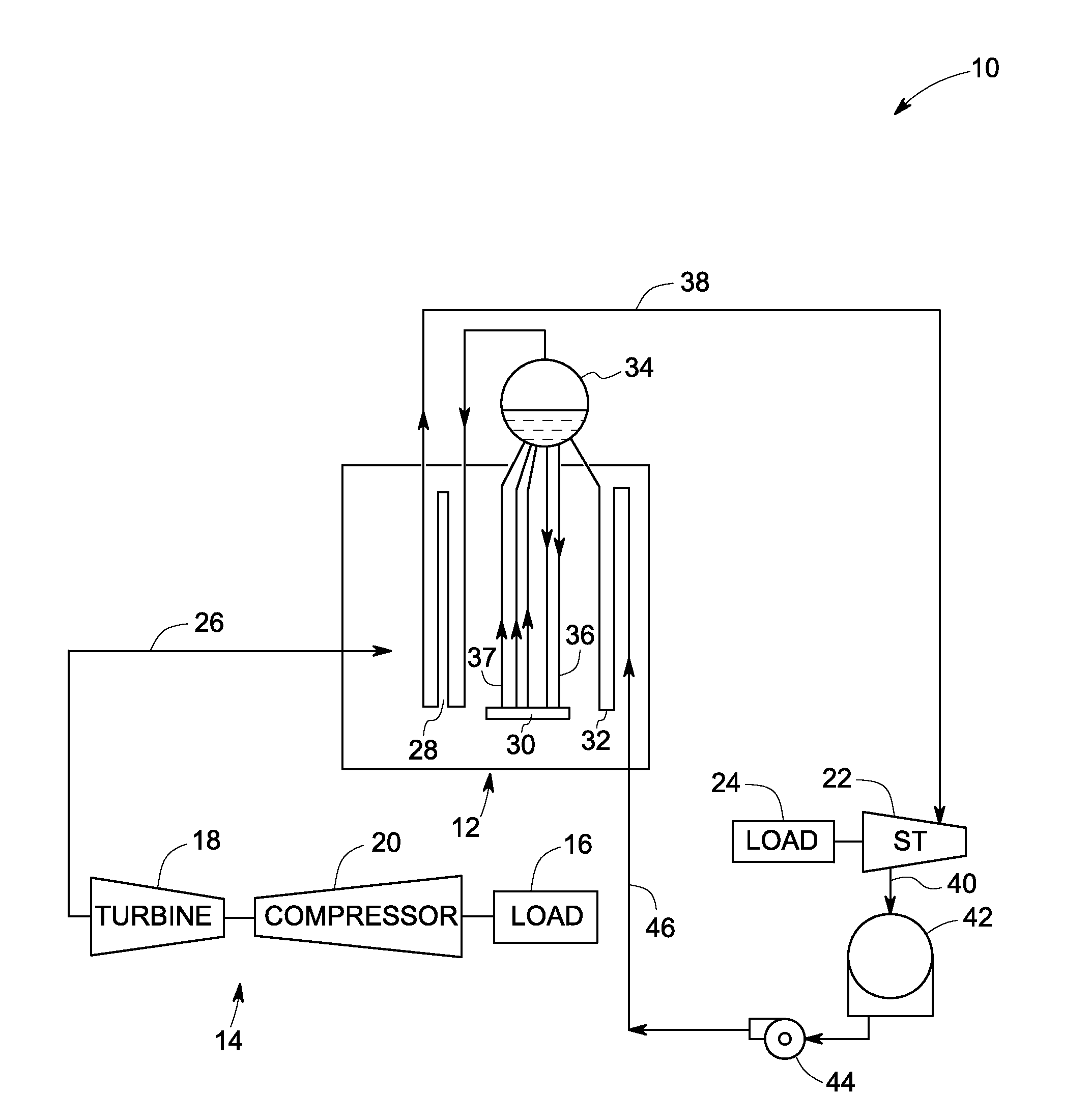

Method for Removal of Entrained Gas in a Combined Cycle Power Generation System

A combined cycle power generation system (10) includes a steam turbine (14, 16, 18), a combustion system (12) including a compressor (24), a combustion chamber (26), a gas turbine (28), and a HRSG (20) to generate steam with energy from the combustion turbine. A flow line (60, 70) passes superheated steam into the combustion chamber. In an associated method a first source of power is provided via a combustion process having a variable reaction temperature in a first turbine. A second source of power is provided via a second turbine. Components of the system are placed in a mode of increasing power output with steam generated from the HRSG, during which a portion of the steam is provided into a combustion chamber associated with operation of the second turbine.

Owner:SIEMENS AG

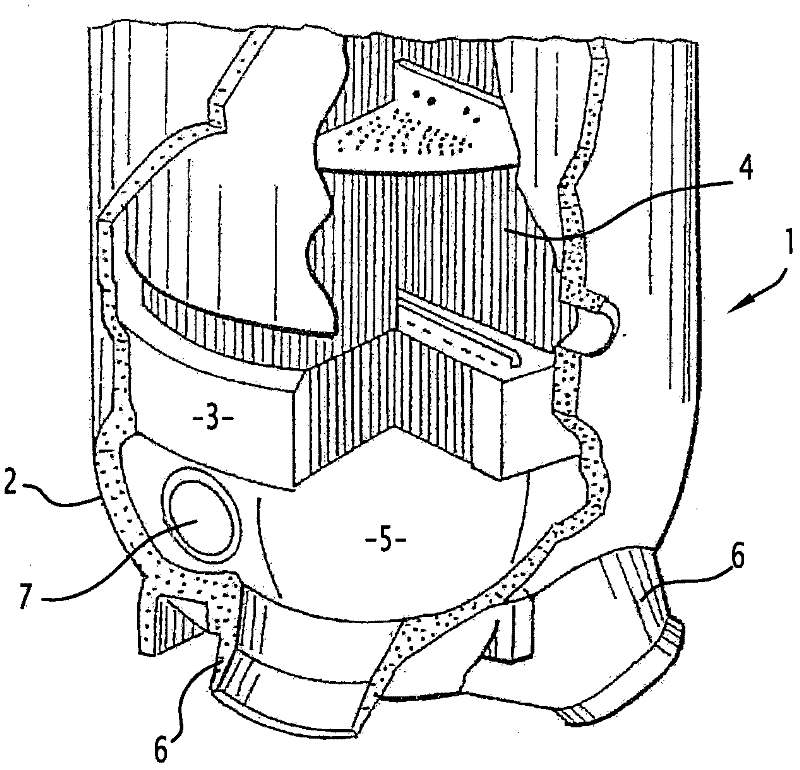

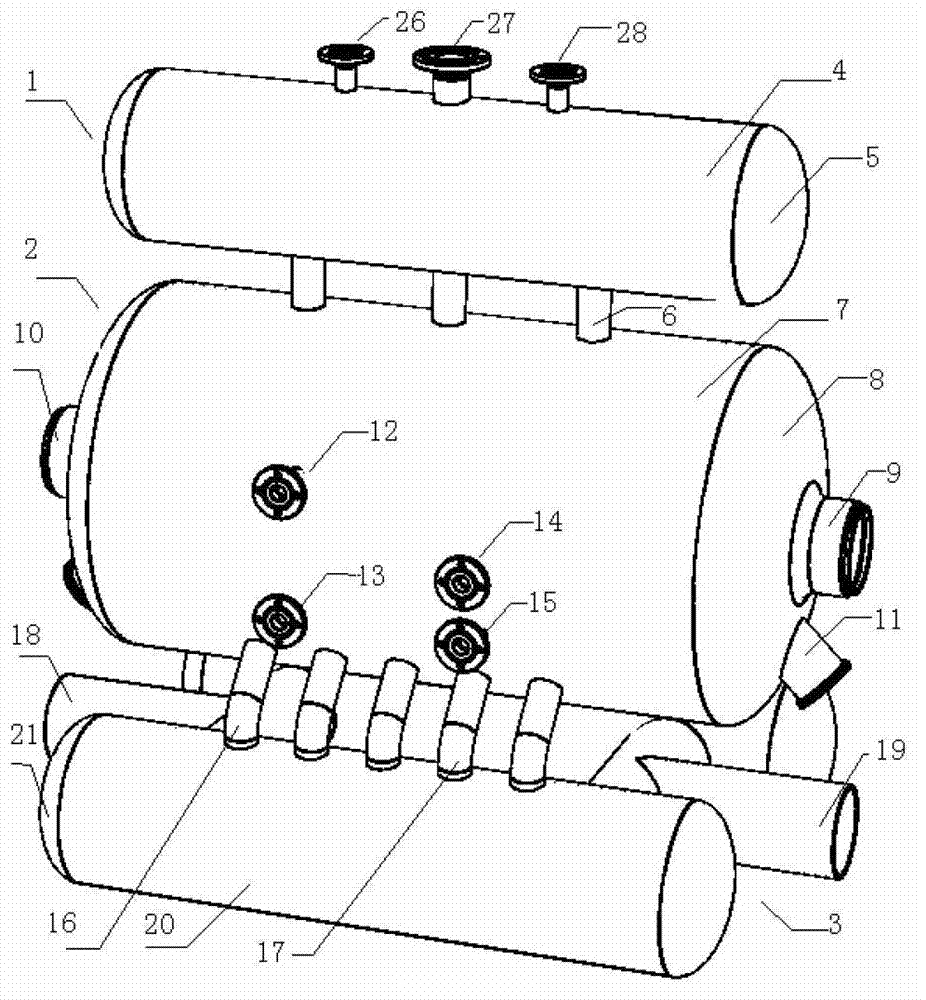

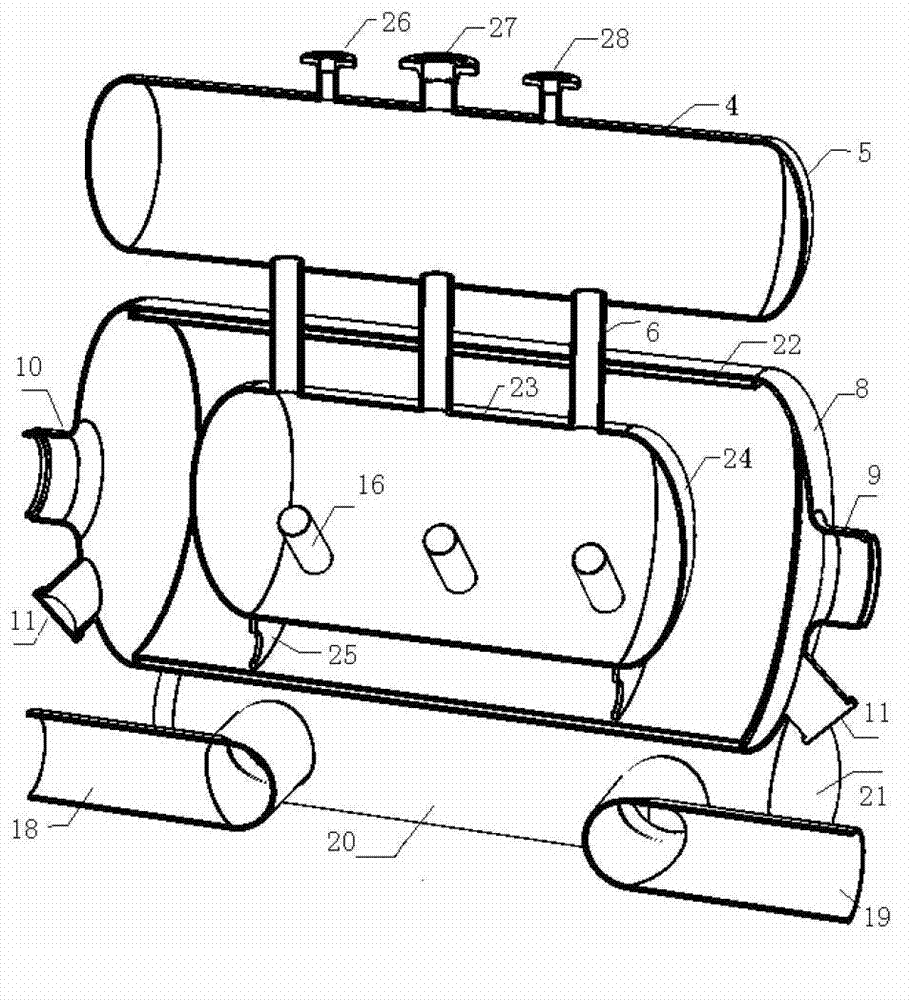

Steam boiler provided with three boiler cylinders

ActiveCN106949450ADirect useDirect use to avoidBoiler drums/headersSteam boilersEngineeringHeat transfer

The invention provides a steam boiler provided with three boiler cylinders. The steam boiler provided with the three boiler cylinders comprises the first boiler cylinder, the second boiler cylinder and the third boiler cylinder, wherein the first boiler cylinder is located on the upper portion, the second boiler cylinder is located in the middle, and the third boiler cylinder is located on the lower portion; and the first boiler cylinder and the second boiler cylinder are connected through a first ascending pipe and a descending pipe, the second boiler cylinder and the third boiler cylinder are connected through the descending pipe, and the third boiler cylinder and the first boiler cylinder are connected through a second ascending pipe. According to the steam boiler provided with the three boiler cylinders, the three boiler cylinders are arranged so that all heat can be sufficiently used, heat transfer is enhanced, and the heat utilization rate is increased.

Owner:扬州华大锅炉有限公司

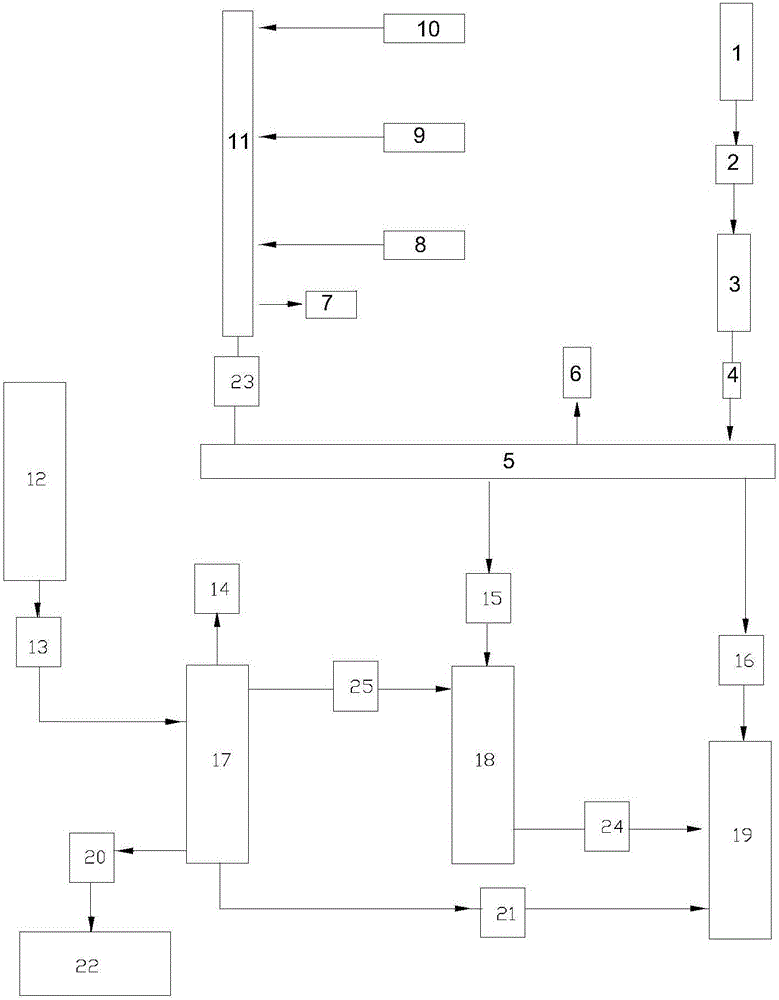

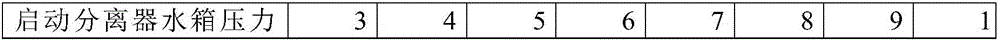

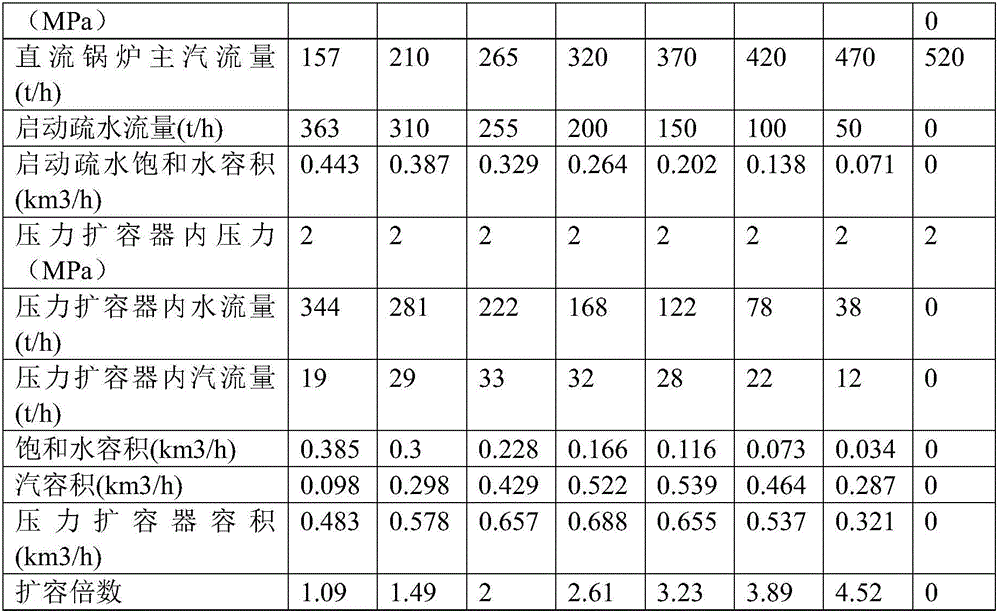

Once-through boiler starting system and method

ActiveCN106016230AReduce capacityLow reliabilityBoiler drums/headersLiquid degasificationWater storage tankAtmospheric air

The invention discloses a once-through boiler starting system and method. The system comprises a separator water storage tank, a pressure flash vessel, a high-pressure heater, a deaerator, a boiler side auxiliary steam header, a turbine side auxiliary steam header, a boiler reheater and a unit drainage groove. An outlet of the separator water storage tank is connected with an inlet of the pressure flash vessel. The pressure flash vessel is provided with two steam outlets, one steam outlet exhausts steam into atmosphere, and the other steam outlet exhausts steam to the high-pressure heater steam side. The pressure flash vessel is provided with two water outlets, one water outlet drains water to the deaerator, and the other water outlet drains water to the unit drainage groove. The boiler reheater supplies the steam to the boiler side auxiliary steam header, and the boiler side auxiliary steam header communicates with the turbine side auxiliary steam header. According to the method, by means of the pressure flash vessel, the water amount and the heat amount of once-through boiler starting drainage are recycled, and the temperature of boiler water supply is raised. The boiler reheater is used for supplying the steam to the boiler auxiliary steam header, dependency of unit starting on external steam is reduced, the steam exhausted to a condenser by means of a bypass is reduced, and the effects of saving energy and cost are achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

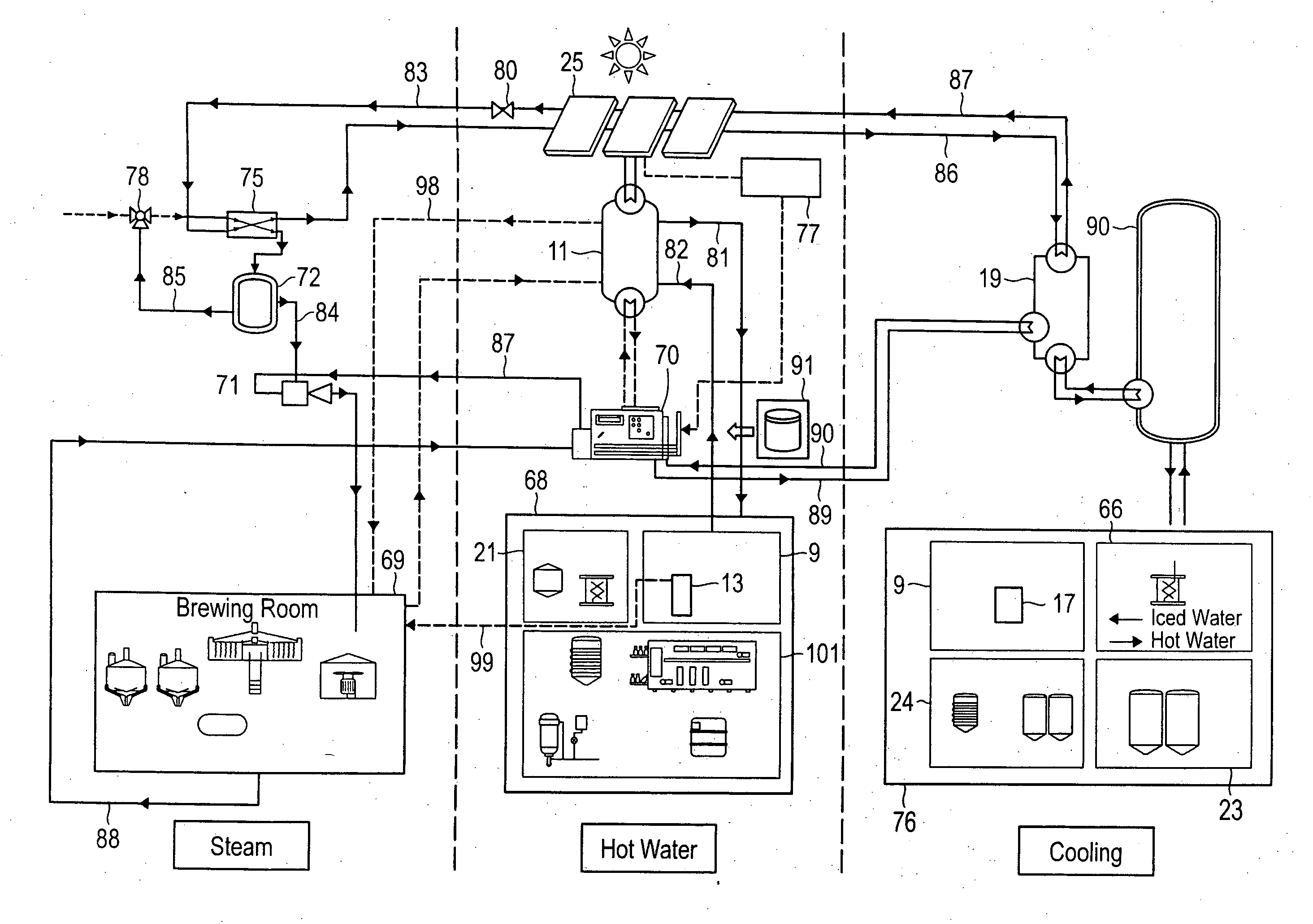

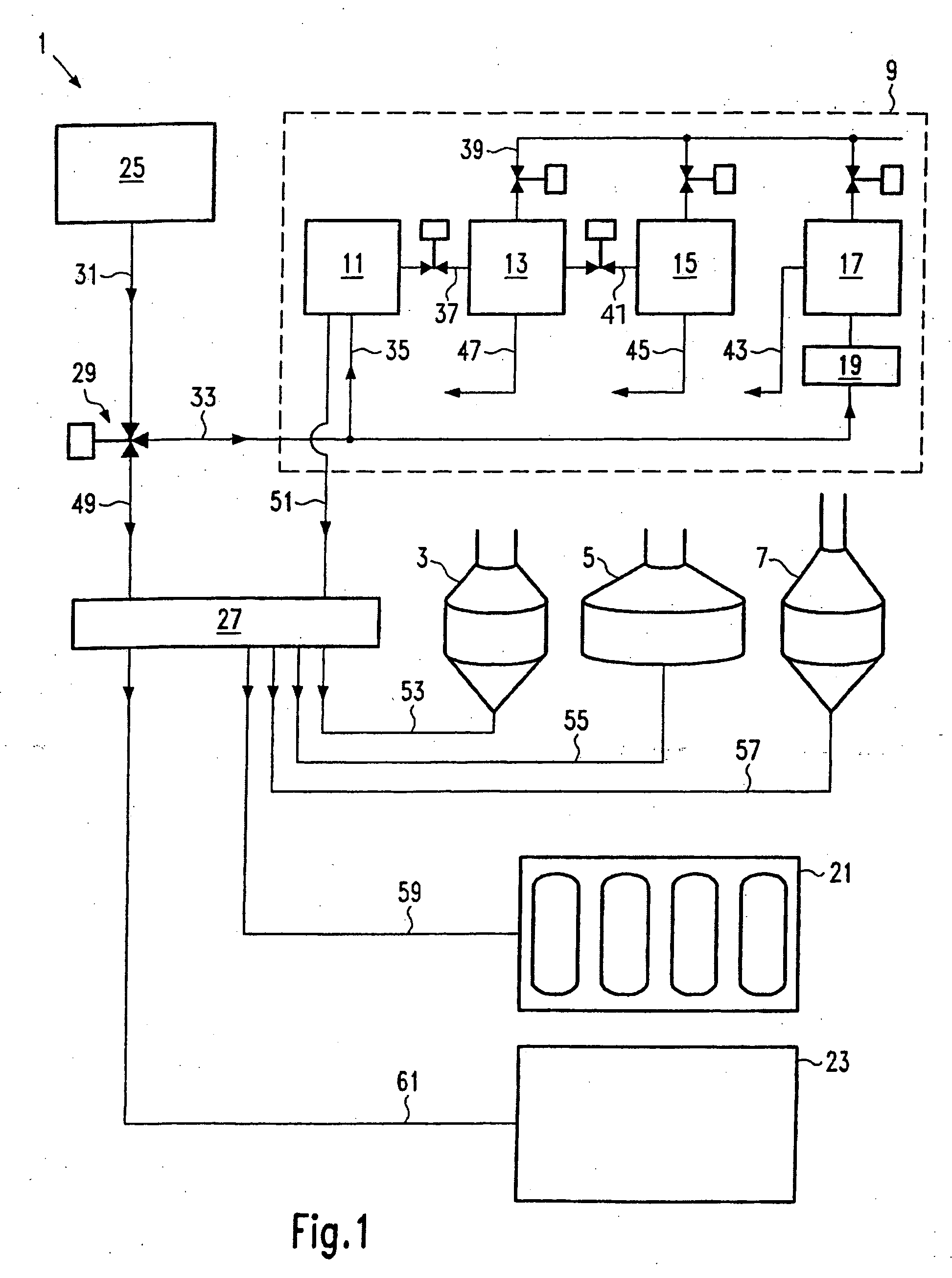

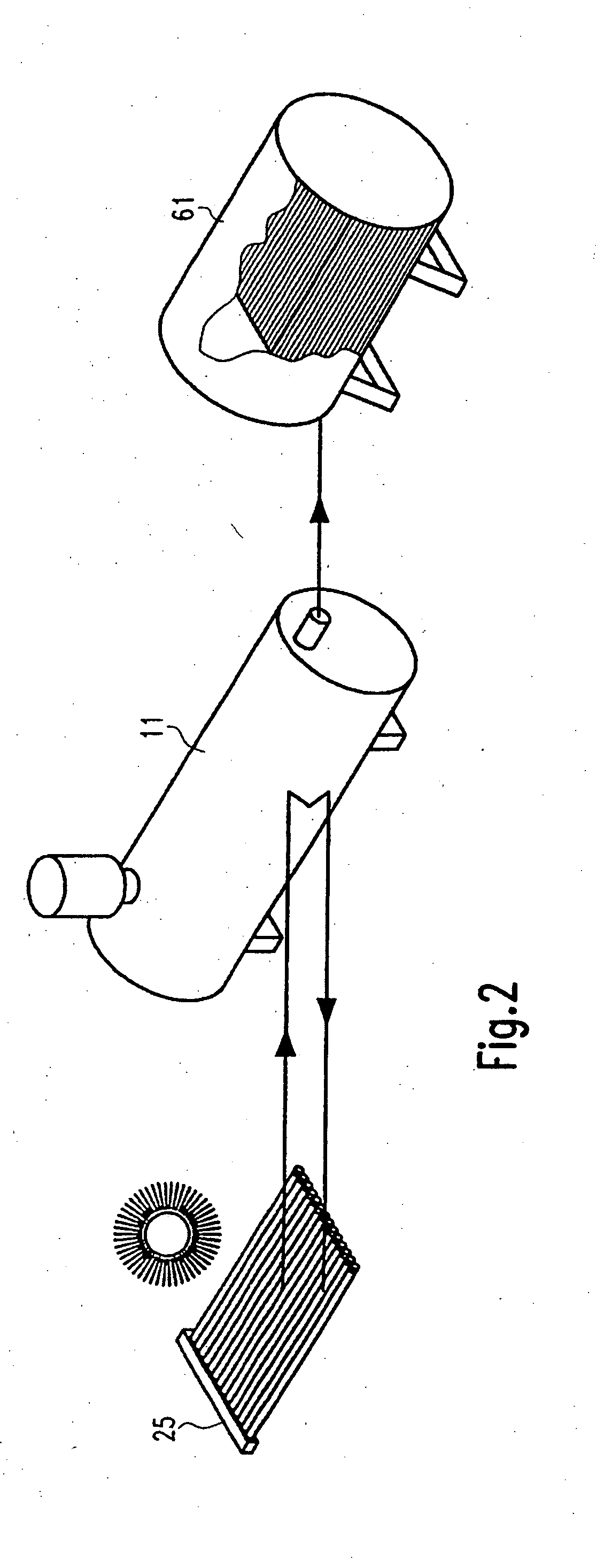

Brewery plant and method

InactiveUS20090148556A1Increase supplyReduce thermal energyBoiler drums/headersSolar heating energyThermal energyEngineering

A brewery plant with at least one mash container, a lauter tun, a wort pan and a water housing, wherein at least part of the thermal energy requirement of the brewery is covered with solar collectors, and the solar collectors directly or indirectly heat a fluid. Also, a brewing method where the thermal energy requirement for at least of a part of the brewing process stages is at least partially covered with a fluid heated directly or indirectly by solar collectors.

Owner:KRONES AG

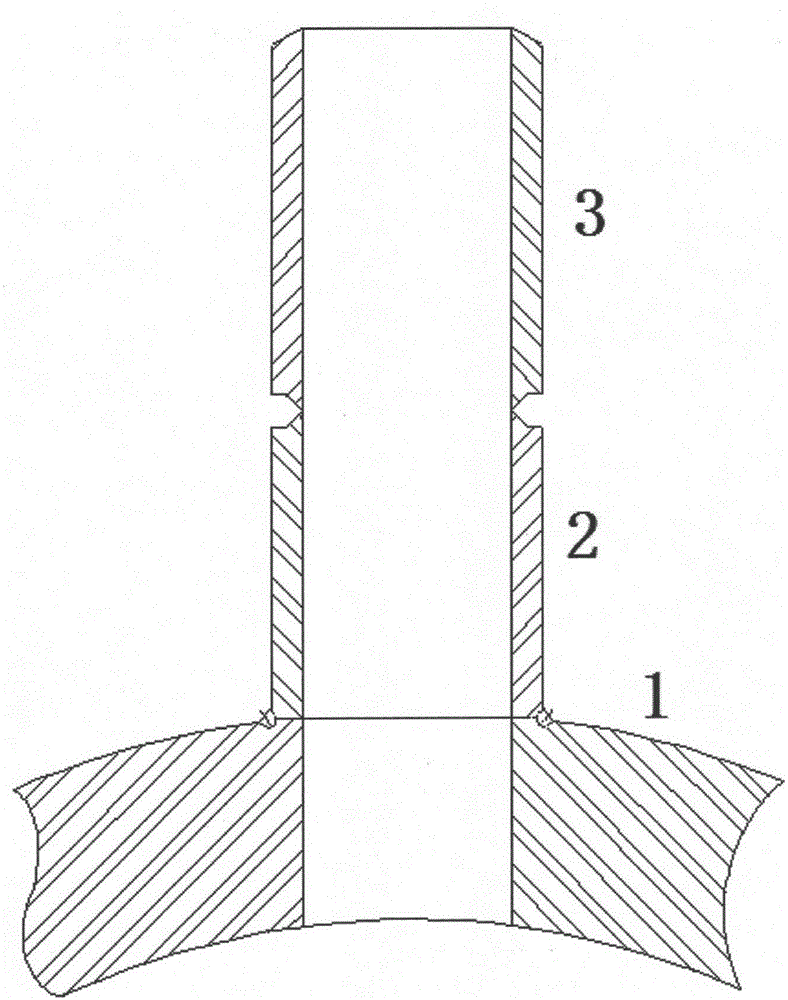

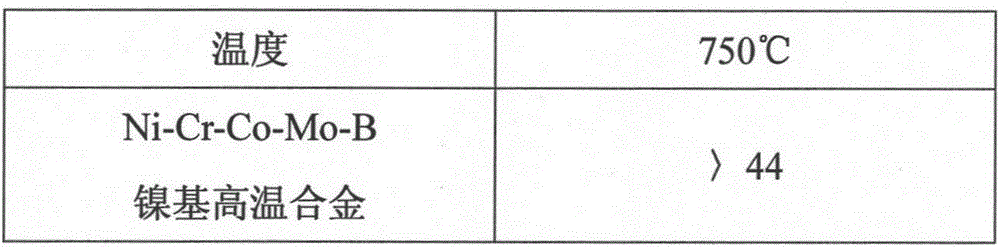

Header of ultra supercritical boiler unit at 700 DEG C

InactiveCN105066096AExcellent high temperature oxidation performanceGood practical valueBoiler drums/headersSteam boilersEngineeringHot Temperature

The invention relates to a header of an ultra supercritical boiler unit at 700 DEG C. The header comprises a header body and a tube base, wherein one end of the tube base and the header body are welded together; the other end of the tube base and a finishing super-heater or a finishing super-heater tube are welded together; the header is characterized in that the header body is made from a Ni-Cr-Co-Mo-B nickel-based high-temperature alloy large-diameter tube; the tube base is made from a Ni-Cr-Co-Mo-B nickel-based high-temperature alloy small-diameter tube. The invention provides a novel super-heater outlet header or a reheater outlet header applied to an ultra supercritical unit of which the steam parameter is 700 DEG C, and the header is made from the Ni-Cr-Co-Mo-B nickel-based high-temperature alloy large-diameter tube. The material is excellent in high-temperature oxidation property and excellent in practical value.

Owner:SHANGHAI BOILER WORKS

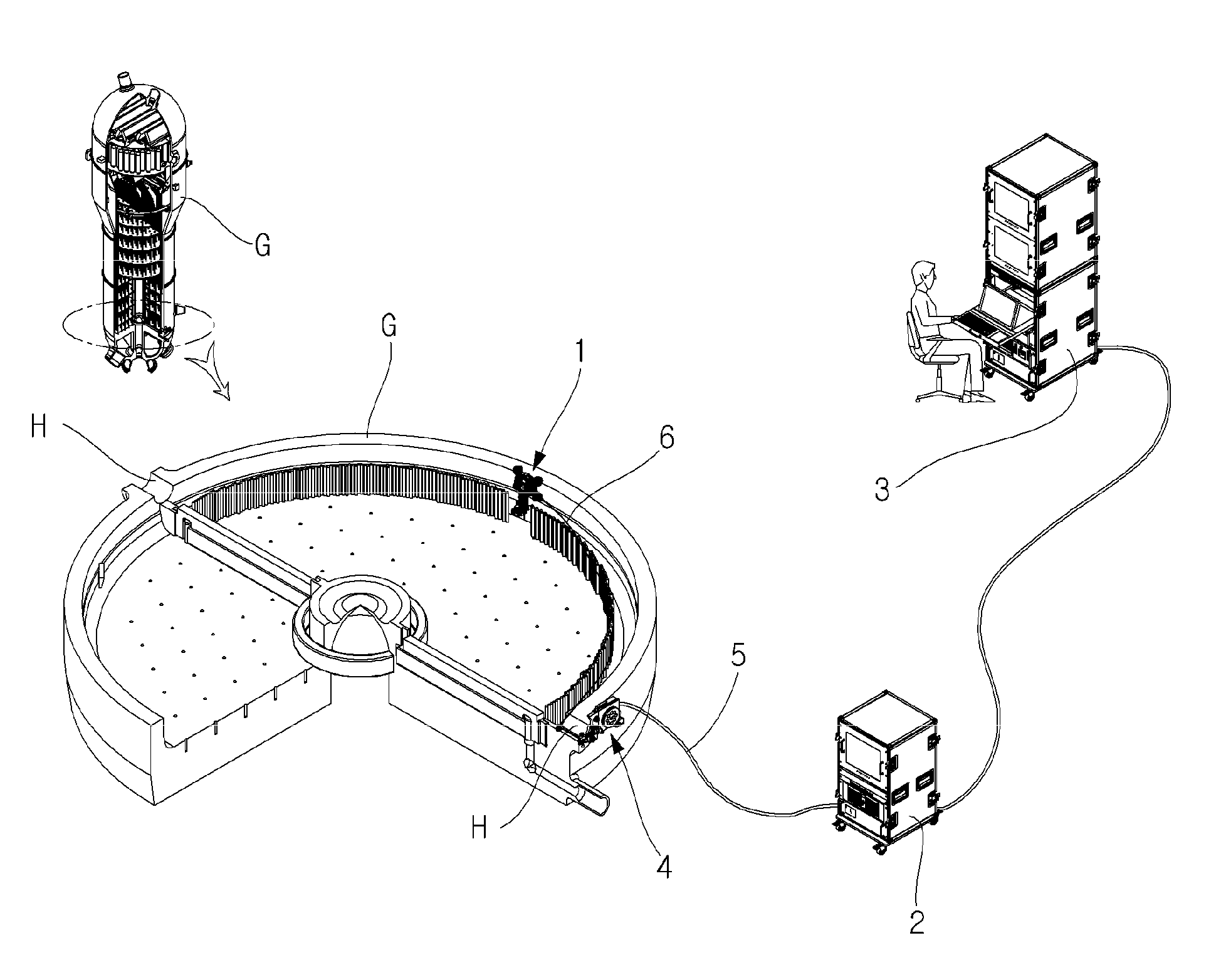

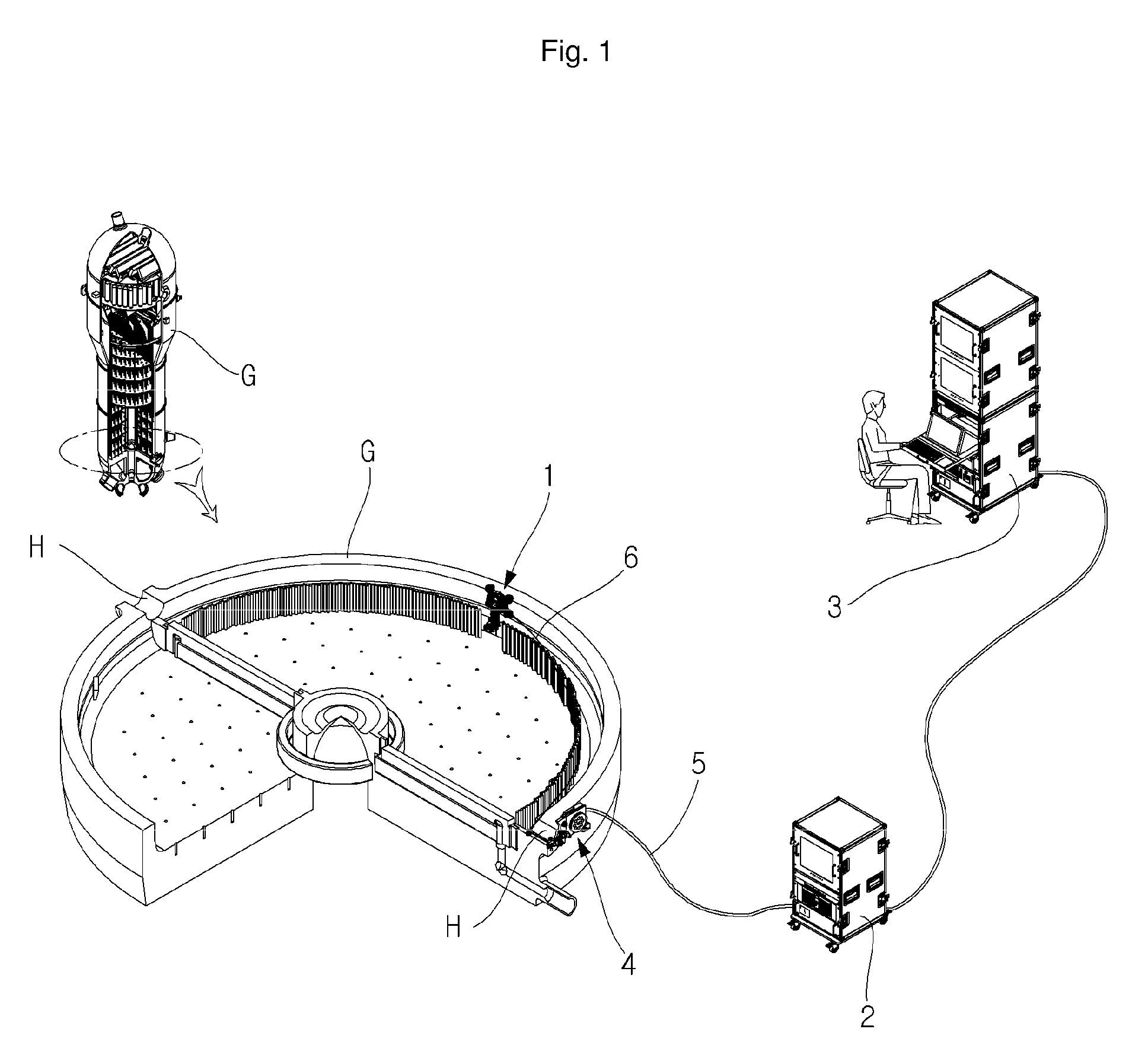

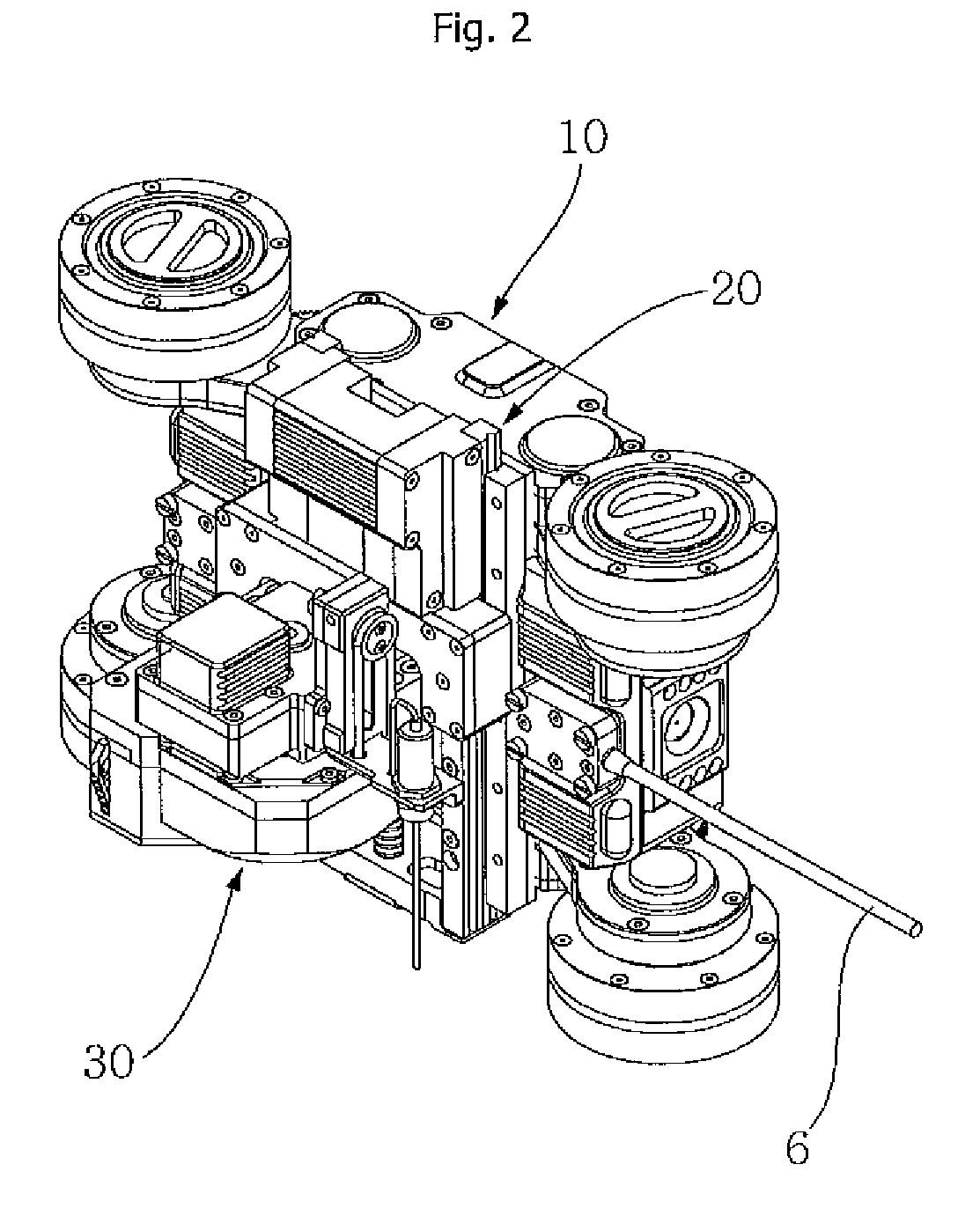

Apparatus for visually inspecting and removing foreign substance from gap of heat tube bundle in upper part of tube sheet of second side of steam generator

An apparatus that visually inspects a state of sludge and foreign substances found between steam generator bundles positioned at an upper portion of a tube sheet of a steam generator of a nuclear power plant using a visual inspector mounted in a robot moving on an inner wall surface of the steam generator for removing the foreign substances.

Owner:KOREA PLANT SERVICE & ENG CO LTD

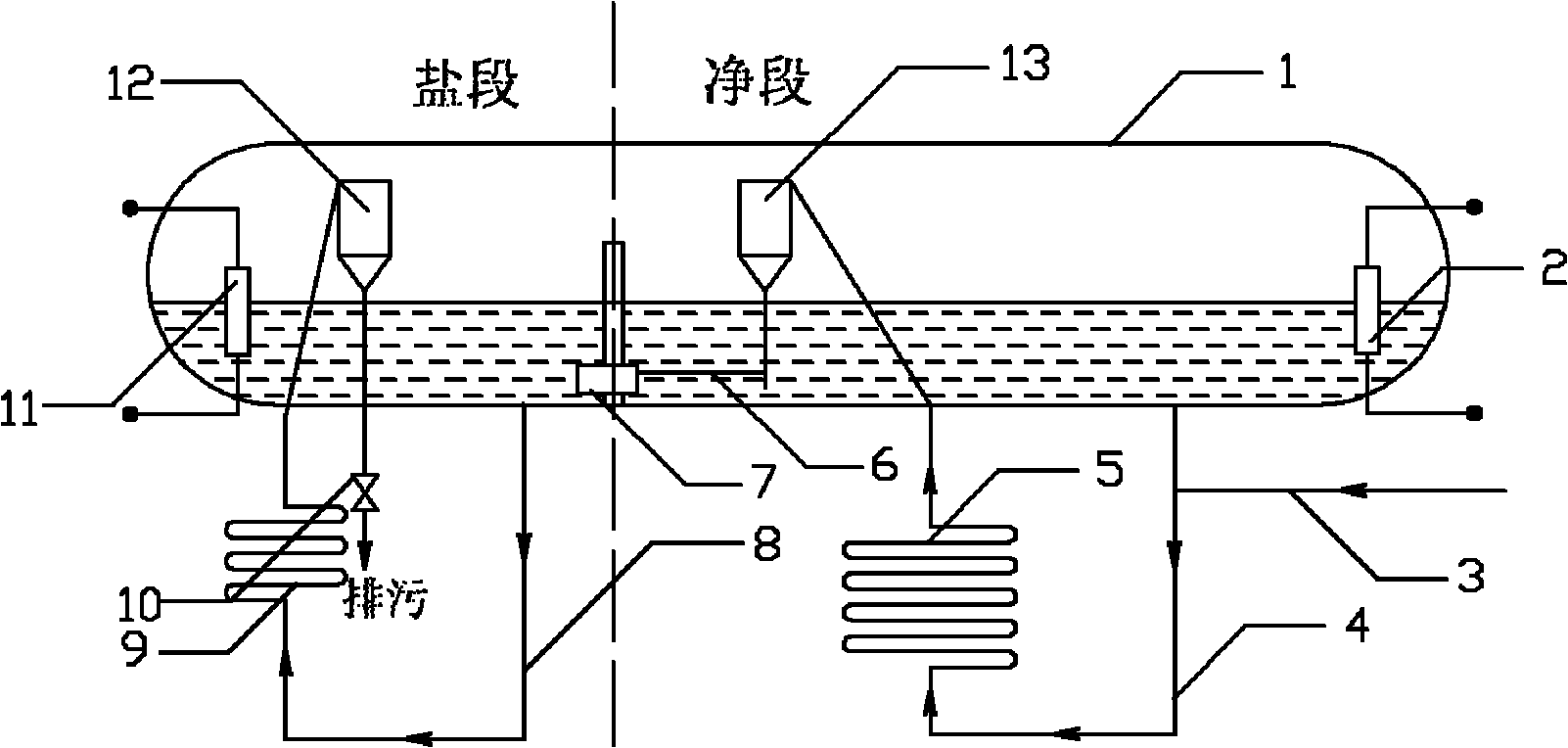

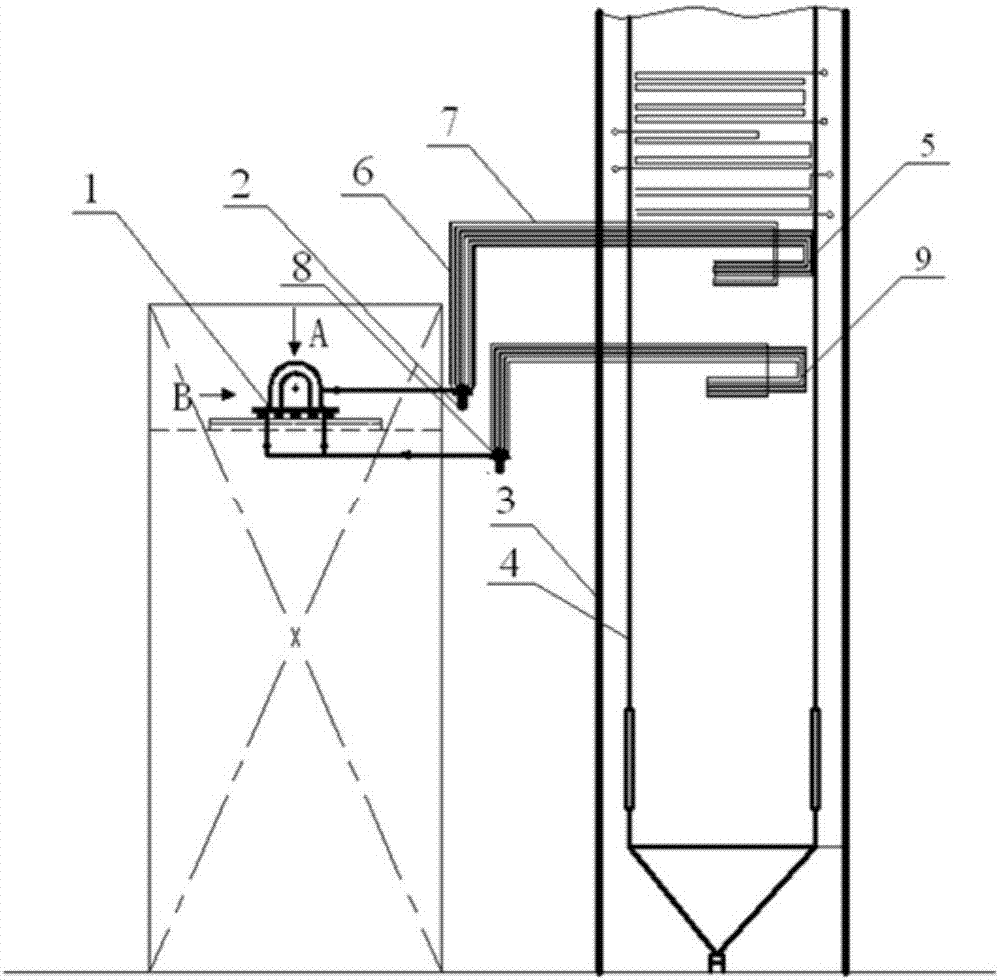

Natural circulating steam injection boiler fed with high salt-containing softened water and water circulating method

ActiveCN101979917ASmooth circulationReduced hydrodynamic safetyBoiler drums/headersBoiler cleaning apparatusBoiler blowdownSoftened water

The invention discloses a natural circulating steam injection boiler fed with high salt-containing softened water and a water circulating method, and belongs to the fields of natural circulating steam pocket water power technology and stage evaporation technology. A steam pocket is divided into a net section and a salt section, boiler feed water is directly introduced into a vertical down pipe of the net section of the steam pocket, and the evaporation heating surface of the net section is arranged on the heating surface of a hearth. The feed water of the salt section of the steam pocket is supplied by the boiler water of the net section, the evaporation heating surface of the salt section is arranged in a flue at the tail of the boiler, and the sewerage is directly led out by a steam-water separation device on the salt section of the boiler. The blow-down rate of the boiler is 5 to 15 percent, and the evaporation capacity of the salt section is 5 to 40 percent of the total evaporation capacity. Under the same blow-down rate, the boiler water of the net section and salt section heating surfaces of the boiler has low salt content; the heating surfaces have good corrosion resistance, hydrodynamic characteristic and safe heat transfer; and the heating surface of the salt section is convenient for overhauling. The fuel of the boiler can be coal, oil, natural gas and other combustible solids, and is suitable for high-capacity thick oil thermal recovery steam injection boilers.

Owner:TSINGHUA UNIV

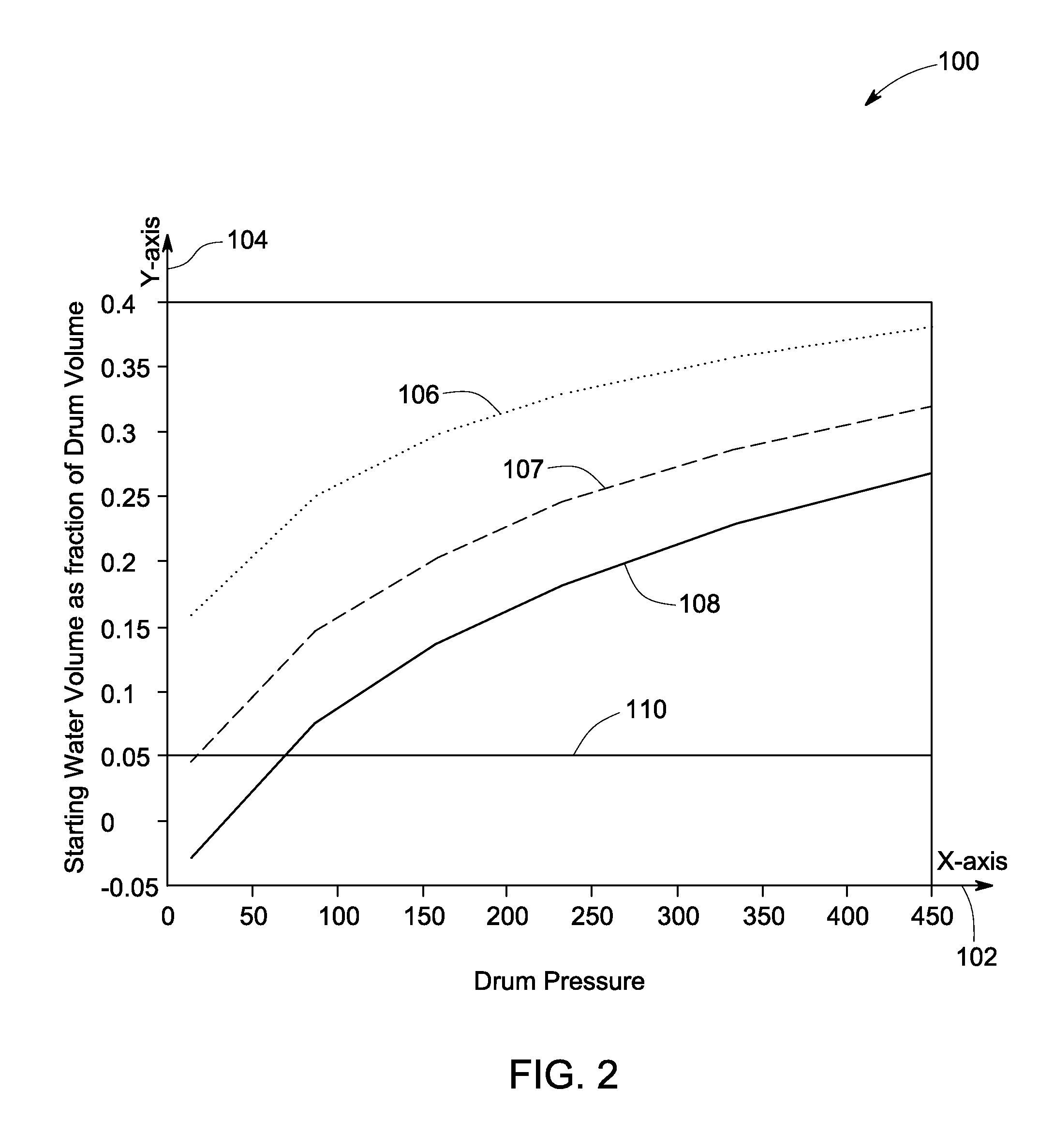

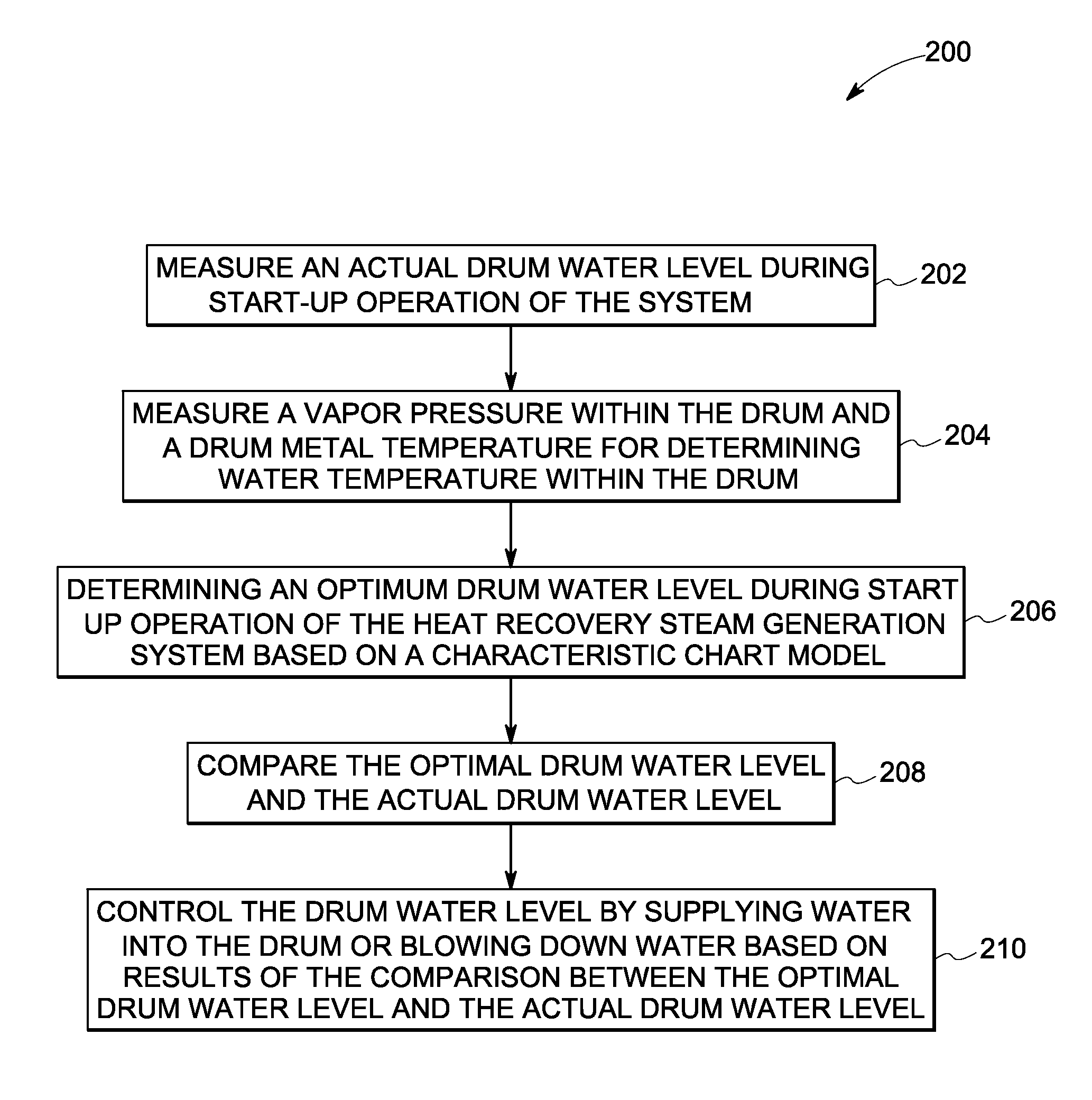

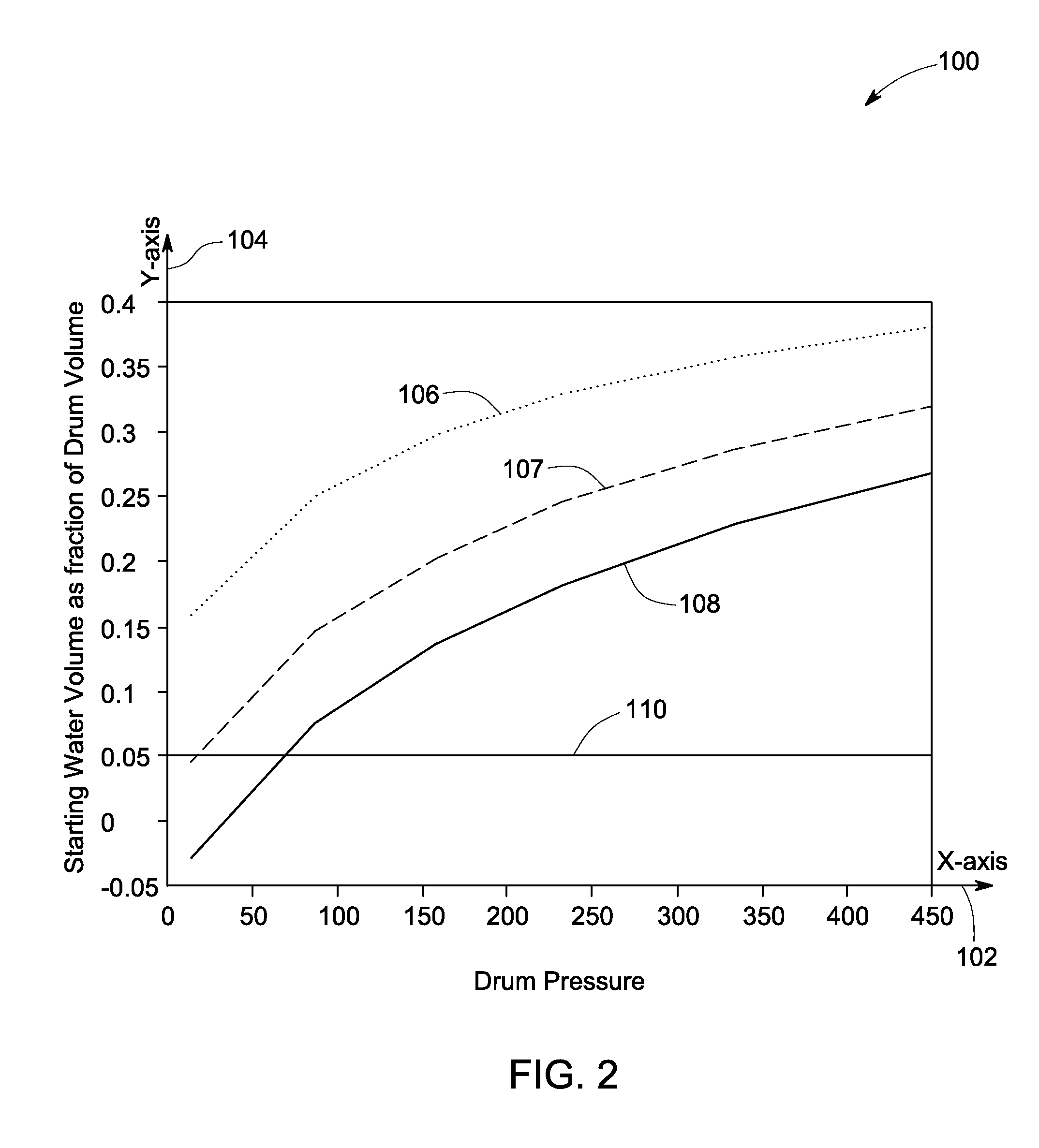

Method and system for safe drum water level determination in a combined cycle operation

A method for controlling a water level of a drum of a heat recovery steam generation system for a combined cycle power plant is provided. The method includes determining an optimum drum water level during start up operation of the heat recovery steam generation system based on a characteristic chart model. The characteristic chart model is generated based on a plurality of vapor pressures of the drum and a plurality of temperatures of drum metal at the time of the start up operation of the heat recovery steam generation system.

Owner:GENERAL ELECTRIC CO

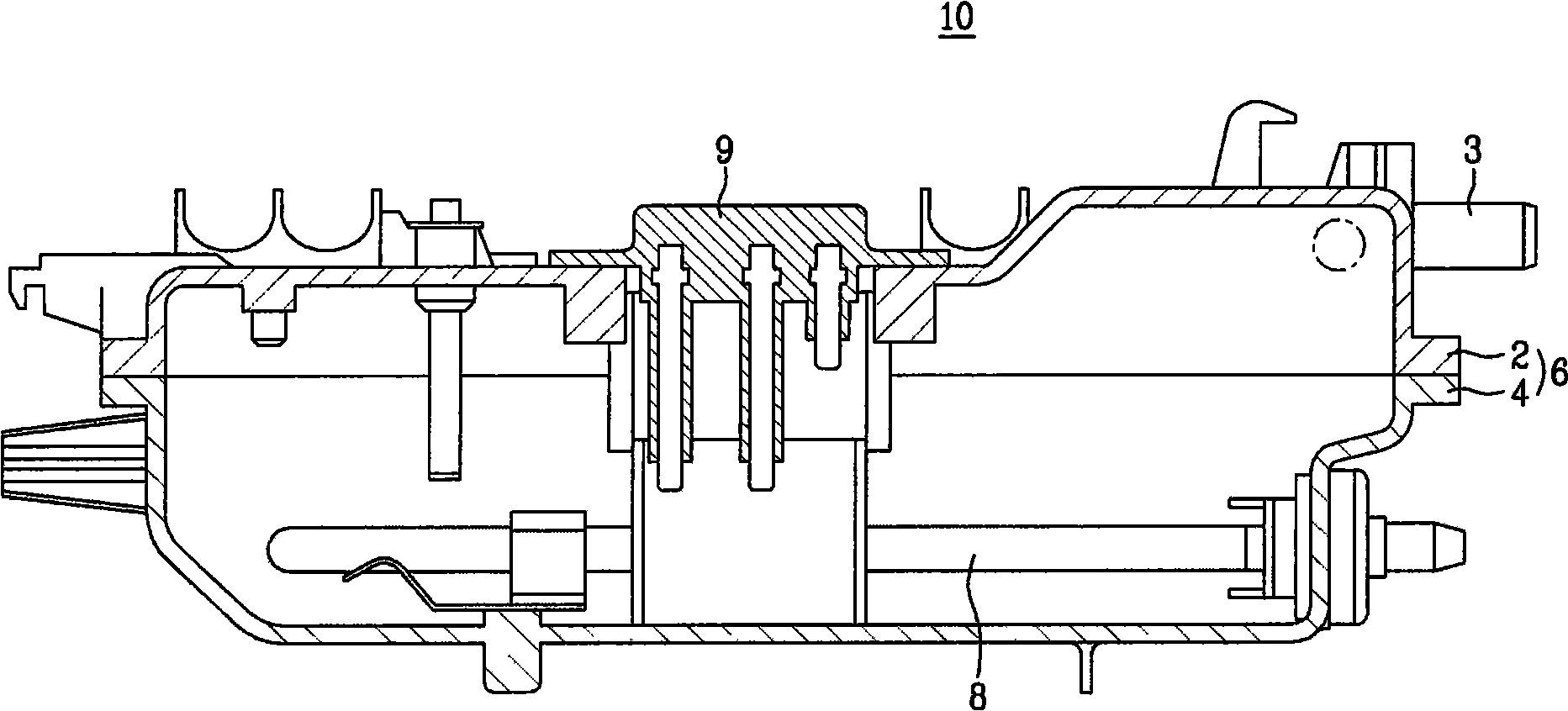

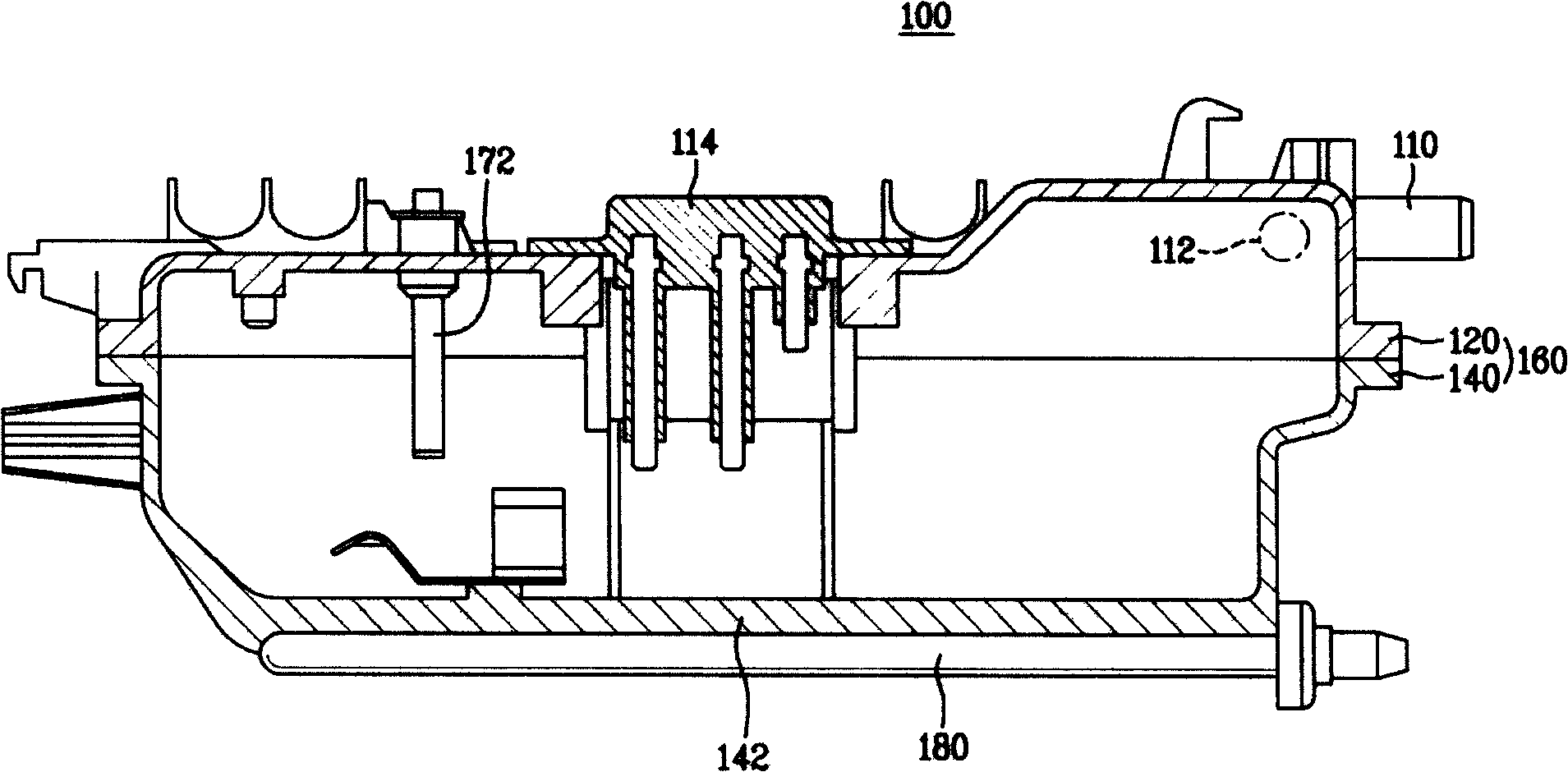

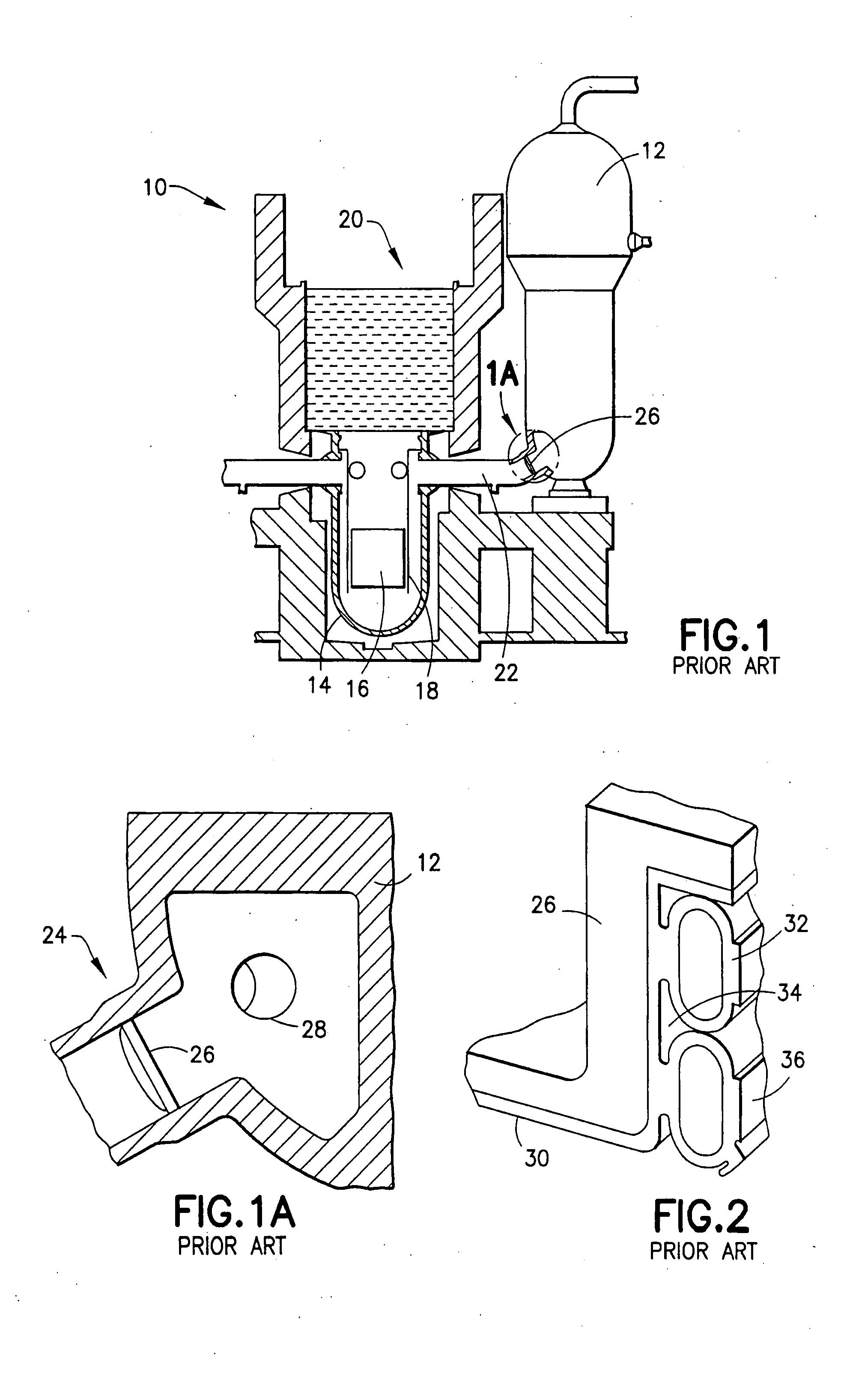

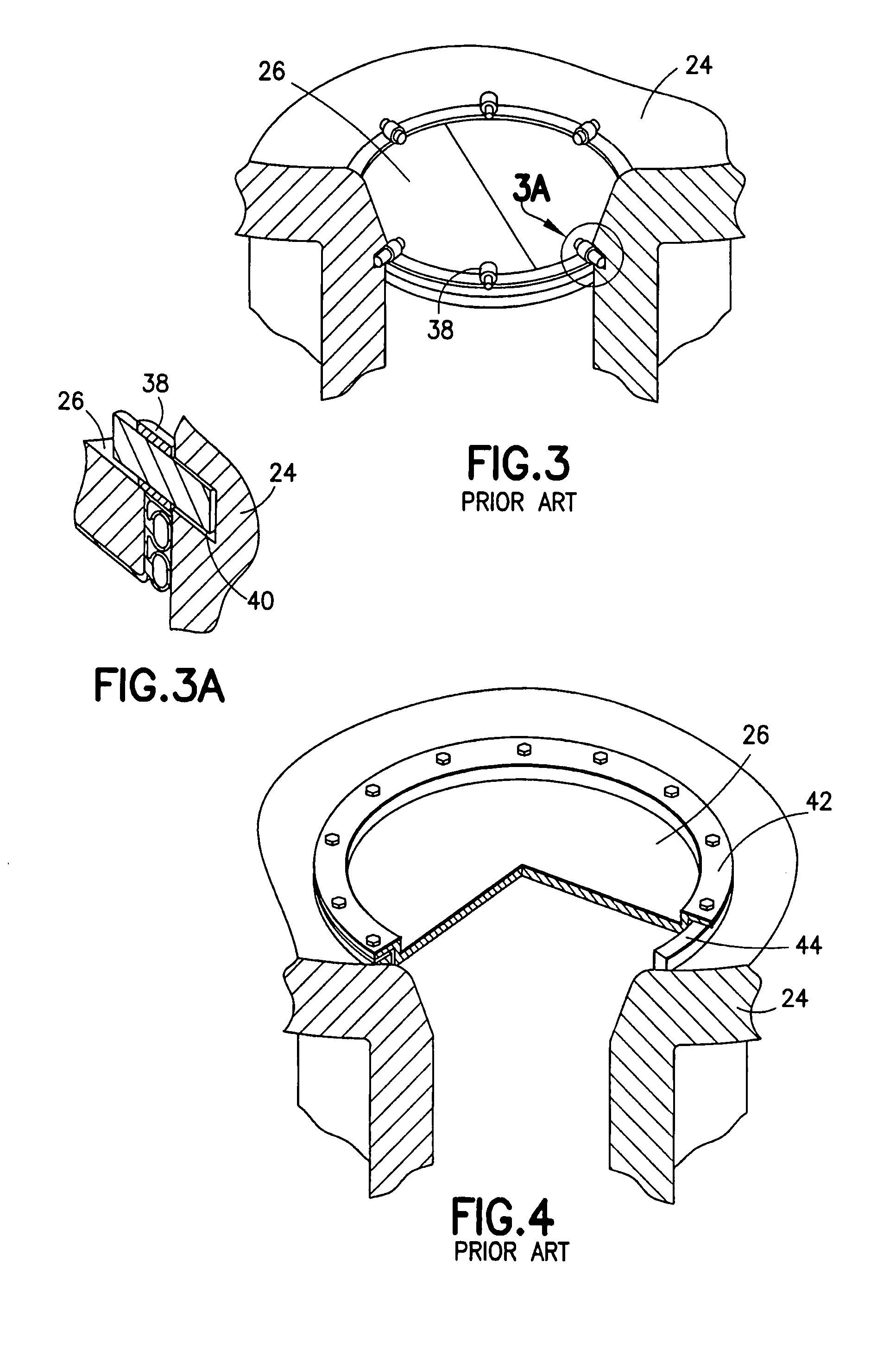

Steam generator nozzle dam and method for installing and removing steam generator nozzle dam

InactiveUS20080179042A1Prevent rotationAvoid excessive rotationBoiler drums/headersRing springsAbutmentEngineering

The present invention includes an apparatus for watertight sealing of a steam generator nozzle and methods for installing the apparatus. The apparatus comprises a nozzle dam, a nozzle dam attachment ring, and a seal. The attachment ring is provided in an interior of the nozzle and has a plurality of retaining tabs and a nozzle dam landing. The nozzle dam is adapted for insertion into the attachment ring and abutment against the nozzle dam landing. The nozzle dam has a plurality of radial protrusions adapted to interlock with the retaining tabs for fixing the nozzle dam in the attachment ring upon rotation of the nozzle dam in the attachment ring. The seal covers at least one side of the nozzle dam for effecting a seal between the nozzle dam and the attachment ring. The present invention also provides methods and apparatus for the pressurization and control of nozzle dam seals.

Owner:CURTISS WRIGHT FLOW CONTROL SERVICE

Header of 620-DEG C steam parameter ultra supercritical unit boiler

InactiveCN105066098AReduce wall thicknessMeet manufacturing requirementsBoiler drums/headersSuperheaterEngineering

The invention relates to a header of a 620-DEG C steam parameter ultra supercritical unit boiler. The header of the 620-DEG C steam parameter ultra supercritical unit boiler comprises a header main body and a pipe seat, wherein one end of the pipe seat is welded with the header main body, and the other end of the pipe seat is welded with a final-stage superheater or final-stage reheater pipe. The header is characterized in that the header main body is made by a 9Cr-3W-3Co large-diameter pipe, the pipe seat is made by a 9Cr-3W-3Co small-diameter pipe, the inner diameter of the pipe seat is larger than 35mm, and Ni-based alloy is welded on the inner wall of the pipe seat except the region which is 15-20mm away from the header. The header provided by the invention is a novel superheater outlet header or reheater outlet header applied to the 620-DEG C steam parameter ultra supercritical unit boiler, and the 9Cr-3W-3Co large-diameter pipe is used as the material. The high-temperature oxidation performance of the material is great, and the practical value is high.

Owner:SHANGHAI BOILER WORKS

Immediate response steam generating system and method

The method of generating immediate and thereafter continuous steam is used in a steam generating system comprising a steam accumulator, a steam outlet connected to the steam accumulator, an outlet valve at the steam outlet, and a quick response steam generator unit connected to the steam accumulator. The method comprises the steps of providing latent steam in the steam accumulator, opening the outlet valve to allow latent steam in the steam accumulator to exit through the steam outlet, feeding water to the steam generator unit, heating the water fed to the steam generator unit while the latent steam exits through the steam outlet and, before the latent steam has entirely exited the steam accumulator, generating steam with the steam generator unit to feed the steam accumulator and controlling the steam flow rate through the steam outlet to maintain it at a value which is essentially not greater than the steam flow rate from the steam generator unit to the steam accumulator. The steam generating system is capable of generating immediate and thereafter continuous steam from an initial steam generator unit cold condition due to the steam accumulator providing steam at the steam outlet while the steam generator unit heats the water fed therein.

Owner:ENERO INVENTIONS

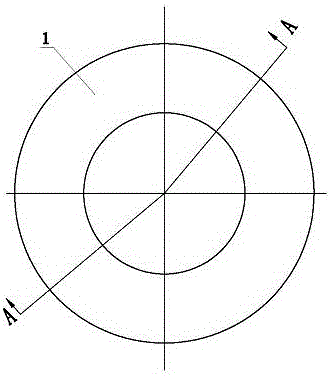

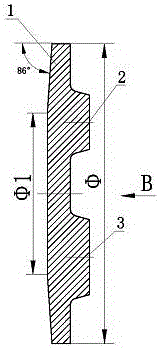

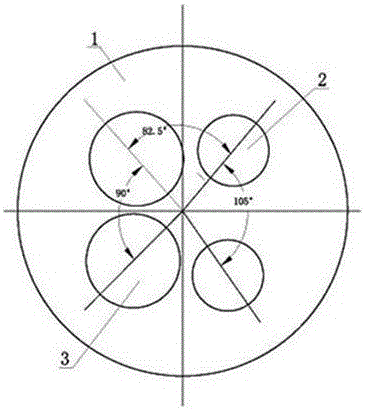

Integrated seal head slab of pressure vessel for nuclear power and forge molding method thereof

InactiveCN105921655AImprove mechanical propertiesImprove uniformityBoiler drums/headersMetal-working apparatusReduction rateNuclear power

The invention discloses an integrated seal head slab of a pressure vessel for nuclear power. The slab comprises a slab main body which is of a circular plate-shaped structure; two manhole circular truncated cones and two tube hole circular truncated cones are arranged on one face of the slab main body while the other face of the slab main body is a large-cone-angle circular truncated cone. The ratio of the upper base diameter phi1 of the large-cone-angle circular truncated cone of the slab main body (1) to the outer diameter phi of the slab main body is as follows: phi1 / phi=1 / (1.80-1.90). The cone angle of the large-cone-angle circular truncated cone on the slab main body is 170-175 degrees. The forge molding method of the slab comprises the following steps: ingot heating; forging stock blanking; forging stock upsetting and drawing-out, wherein the upsetting and drawing-out ratio is 3.0-3.5; die forge molding; and thermal treatment of the slab. The every-time upsetting reduction rate in forging stock upsetting is 24-30%; the every-time drawing-out reduction rate in forging stock drawing-out is 24-30%. According to the invention, integral forge molding of the seal head slab can be realized, and a forge piece is uniform and compact in tissue and intact in metal streamline, so that forging of a seal head finished product is further facilitated and the mechanical property is improved.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

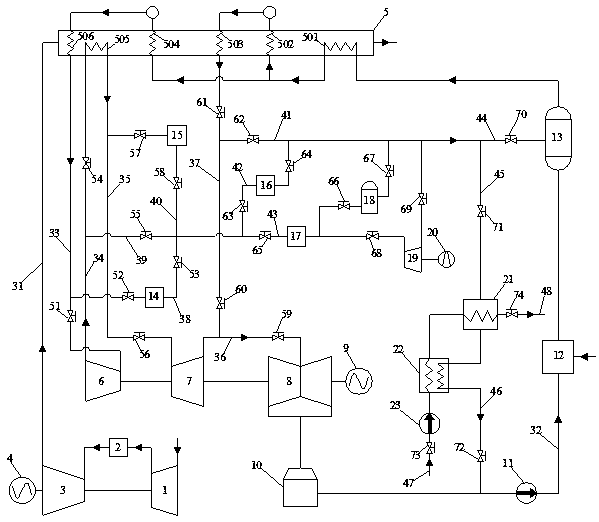

Combined circulating device based on coupling of heat supply and electric power peak regulation and operating method thereof

ActiveCN109855147AImproved thermoelectric decoupling capabilityGuaranteed heating needsBoiler drums/headersLiquid degasificationElectrolysisEnergy gradient

The invention relates to a combined circulating device based on coupling of heat supply and electric power peak regulation and an operating method thereof, and belongs to the technical field of combined heat and power generation. The combined circulating device comprises a gas turbine unit and a steam turbine unit; based on the energy gradient utilization principle, integrated design of differentsteam extraction modes is conducted, the operating capacity of a thermal electrolysis coupler of a combined circulating unit is effectively improved, and the heating requirements of residents are ensured; and meanwhile, a steam heat storage system is coupled with the combined circulating unit, collaborative matching of electric power peak regulation and heat supply of the combined circulating unitis achieved, and moreover, the electric power peak regulation capacity of the combined circulating unit operating in the pure solidification working condition is improved. After the combined circulating device is applied, the working capacity loss in the heat supply process is effectively reduced while the external heat supply capacity of the combined circulating unit is deeply exploited, in addition, the current severe electric power peak regulation policy requirements are met, the deep peak regulation capacity of a thermal power generating unit is achieved, the requirement of a power grid for unit peak regulation is met, and the high practical application value is achieved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

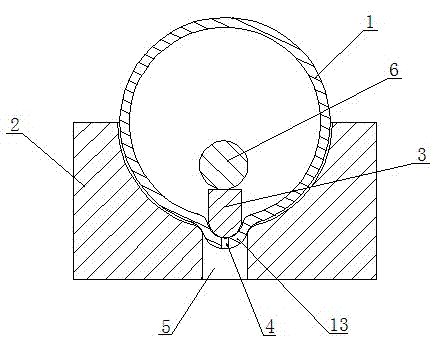

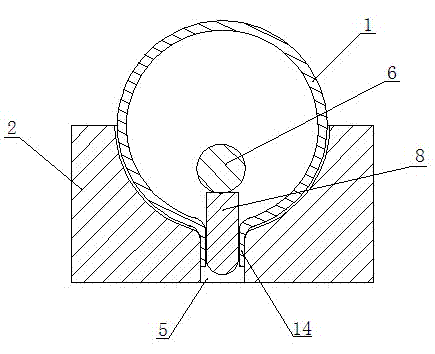

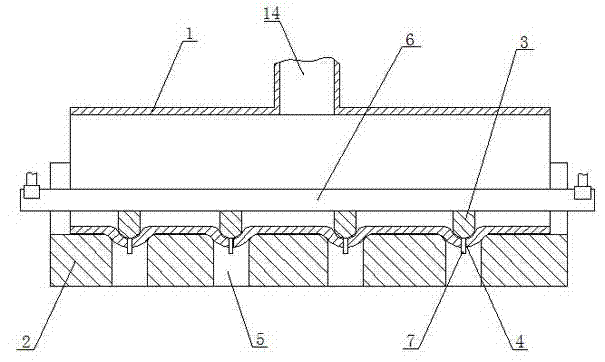

Molding process of header body

ActiveCN102773675AUniform sizeQuality improvementFluid heatersBoiler drums/headersIngotHeating furnace

The invention provides a molding process of a header body, comprising the following steps of manufacturing a circular pipe by using a steel ingot, adding into a heating furnace to be treated and carrying out turning machining to form a header main body pipe; determining the position of each branch pipe connector on the header main body pipe, and drilling a positioning hole; sending into the heating furnace to be heated and taking out; upwards putting a semicircular surface provided with a positioning hole and downwards putting the semicircular surface into water for cooling; then placing on a die and ejecting a convex bag at the position of the positioning hole in the pipe wall of the header main body pipe; drawing the convex bag by utilizing a chambering die core to form a pipe wall blank of the branch pipe connector, and finishing to form a connector pipe of the branch pipe connector; and carrying out annealing treatment on the header body, detecting, brushing paint and leaving from a factory. The pipe connector and the header body are connected to form an integral structure and are connected in a seamless manner so that the tightness is good; and with the adoption of a process for cooling one surface after heating, the header main body pipe does not deform and the whole size of a machined header body is uniform.

Owner:河南光大管业有限公司

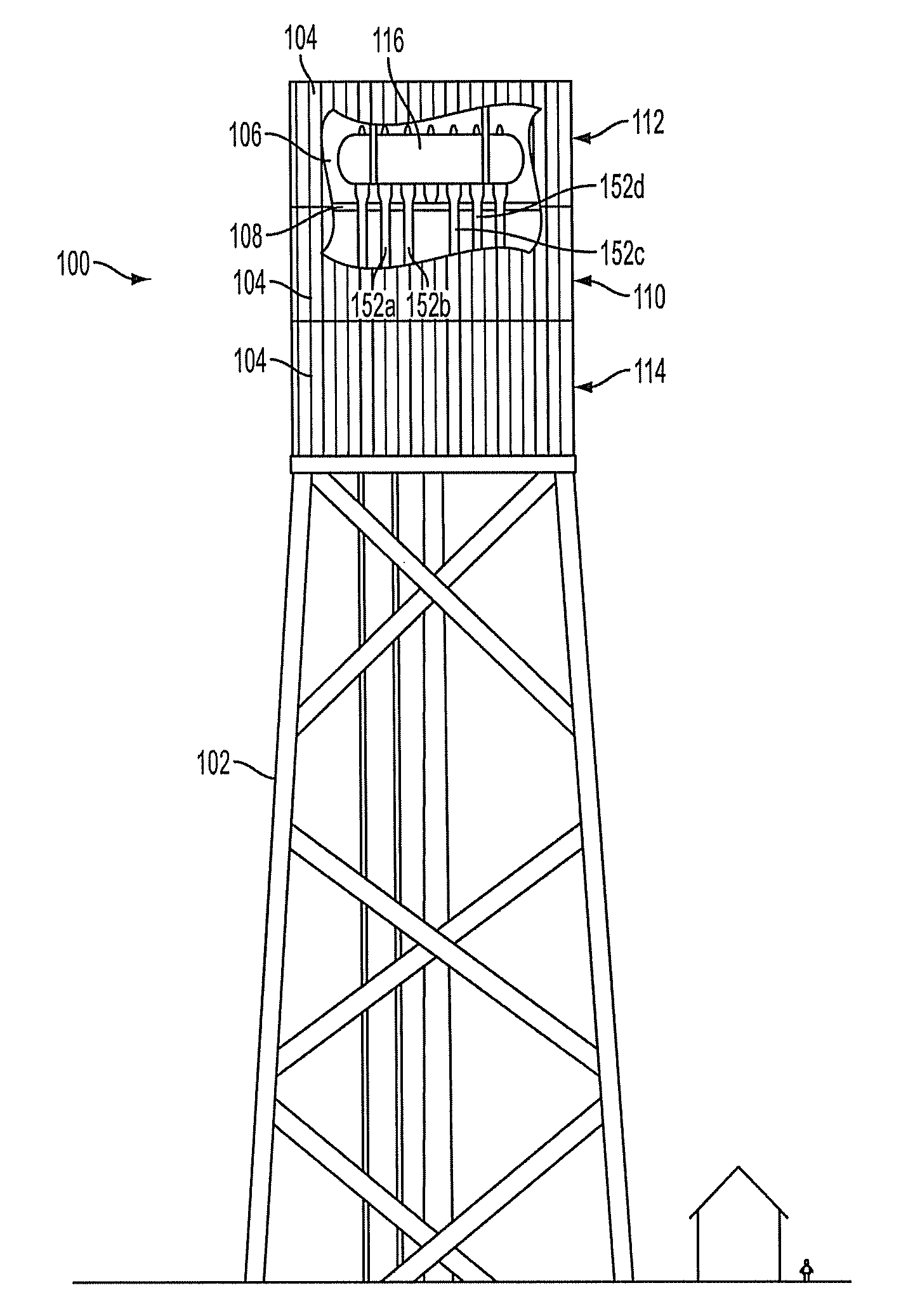

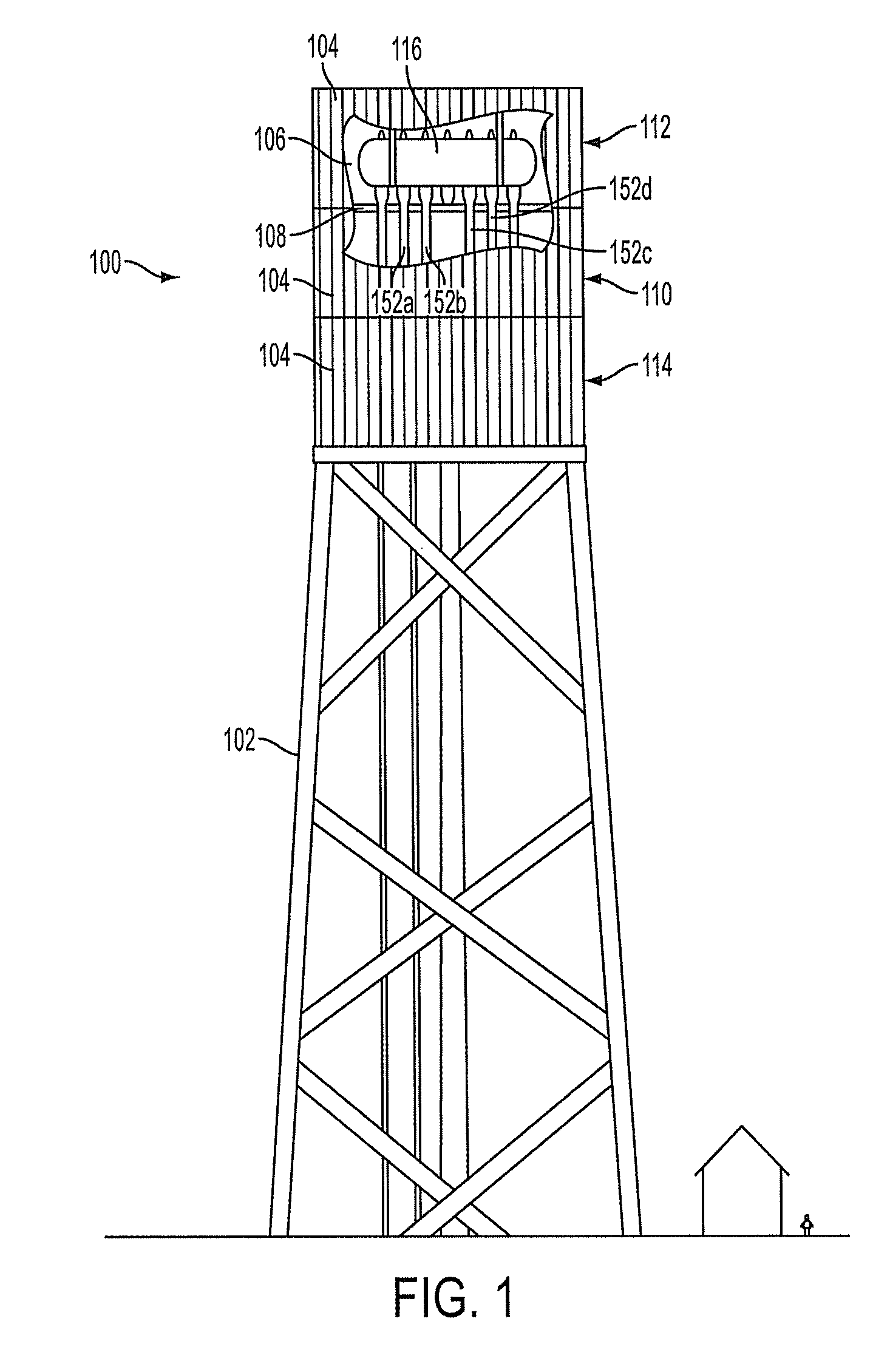

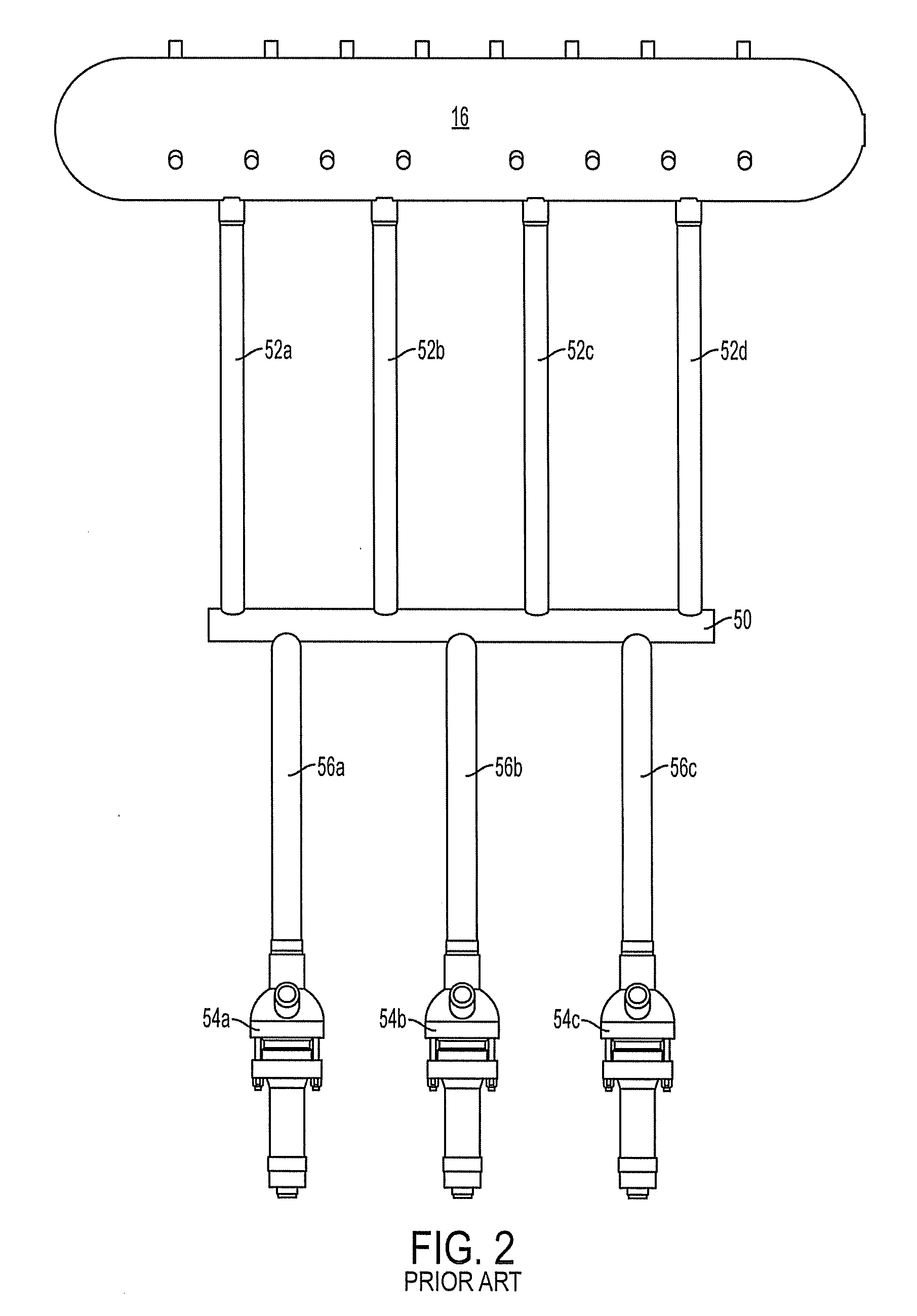

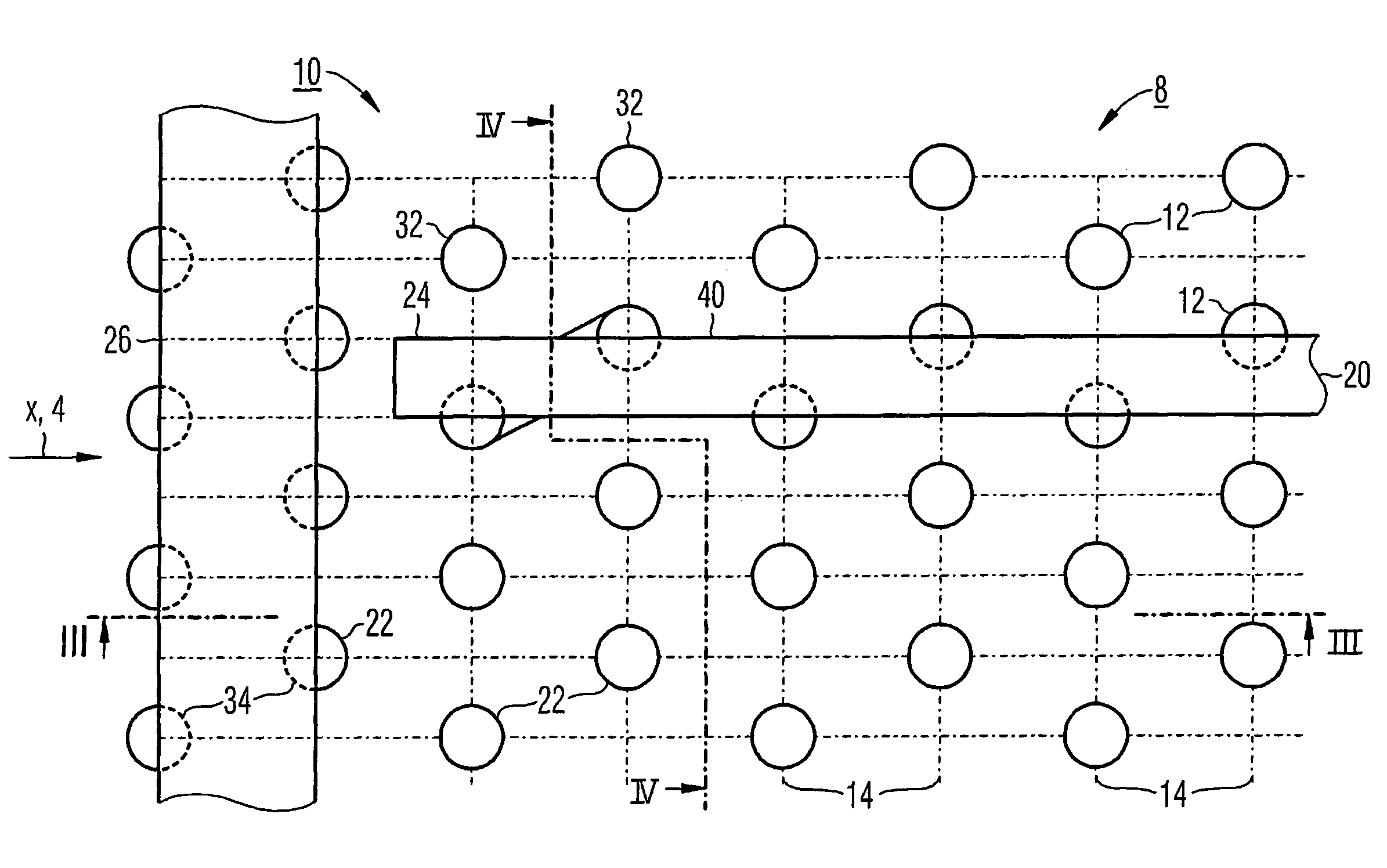

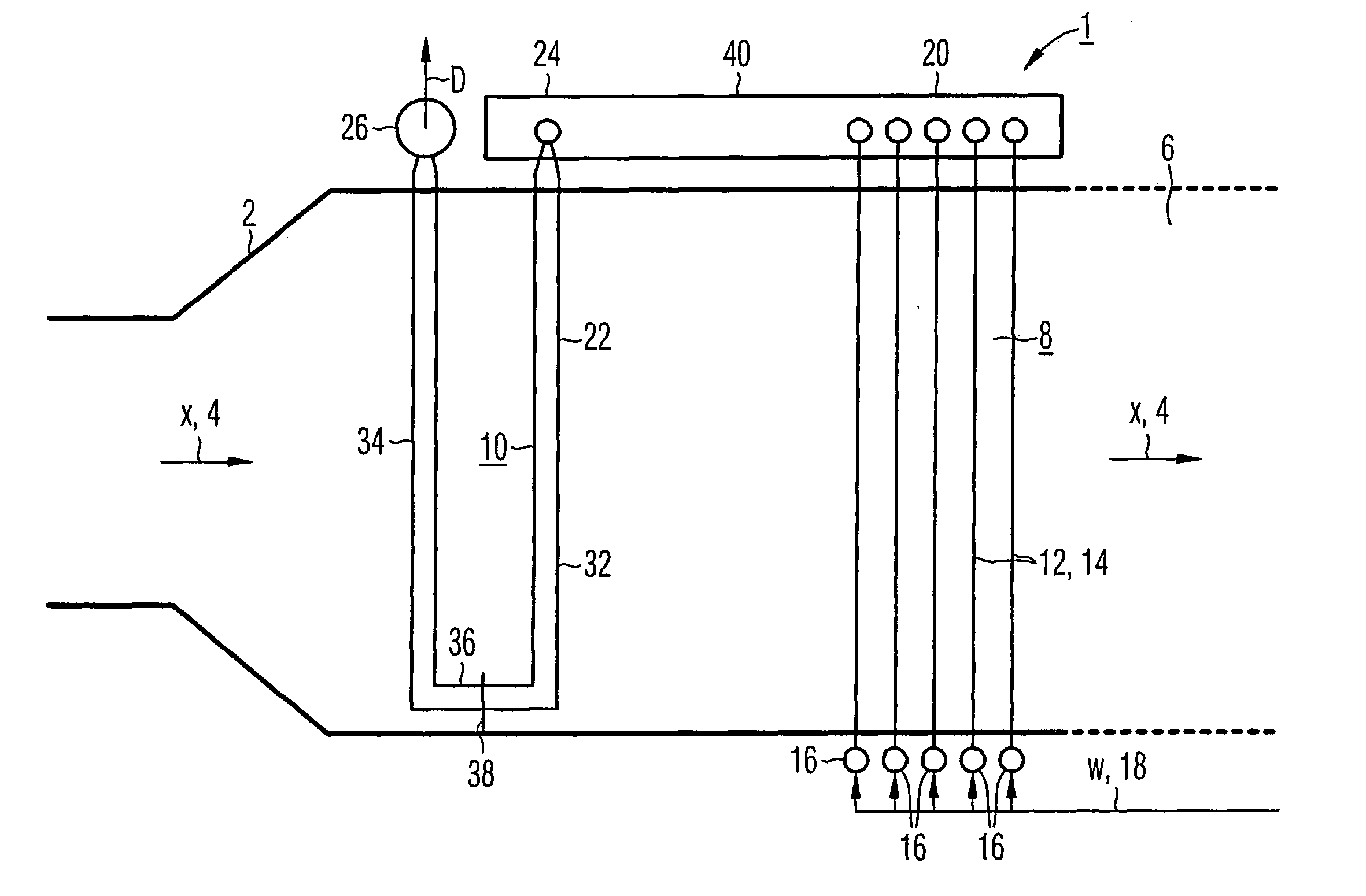

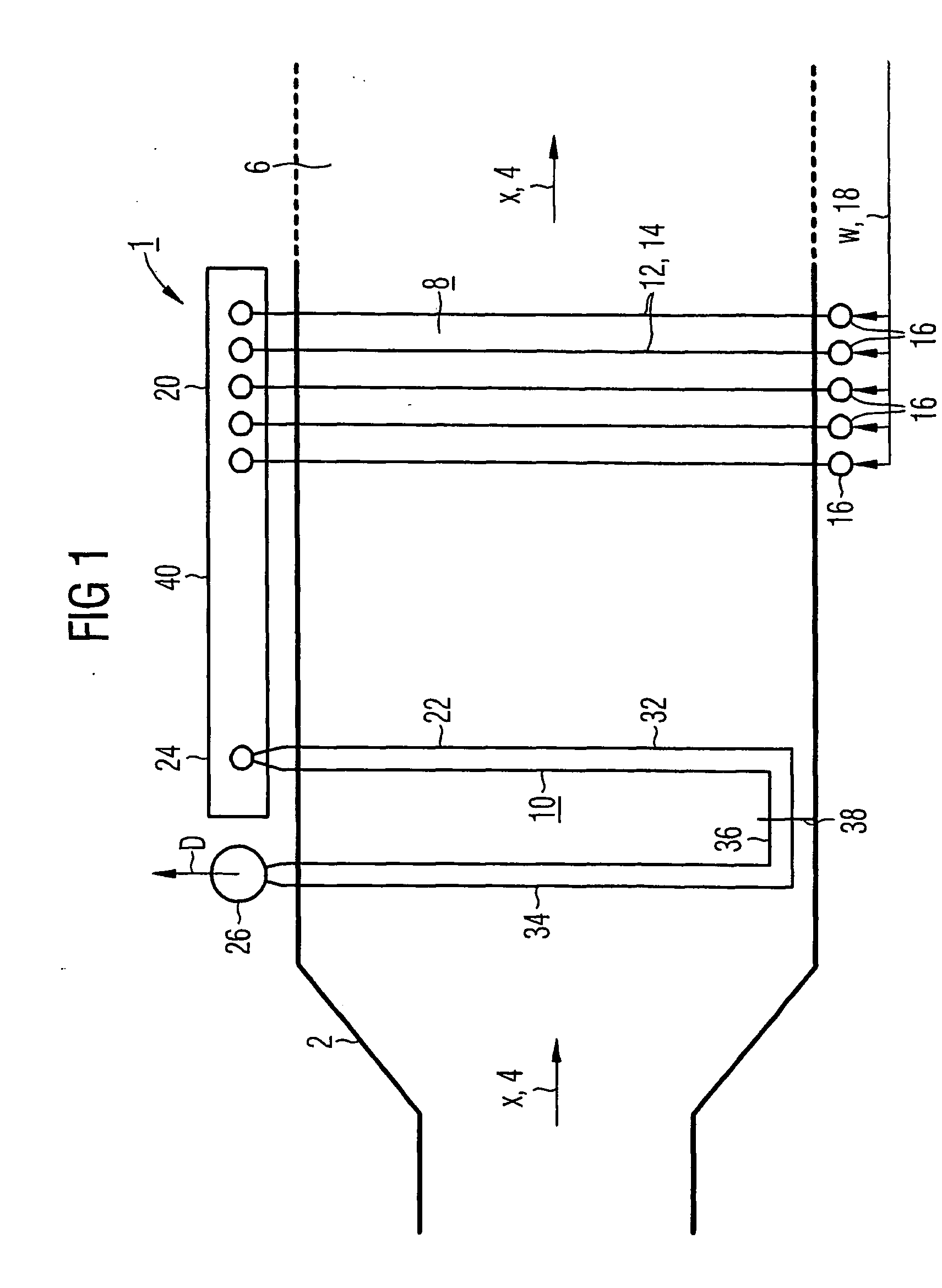

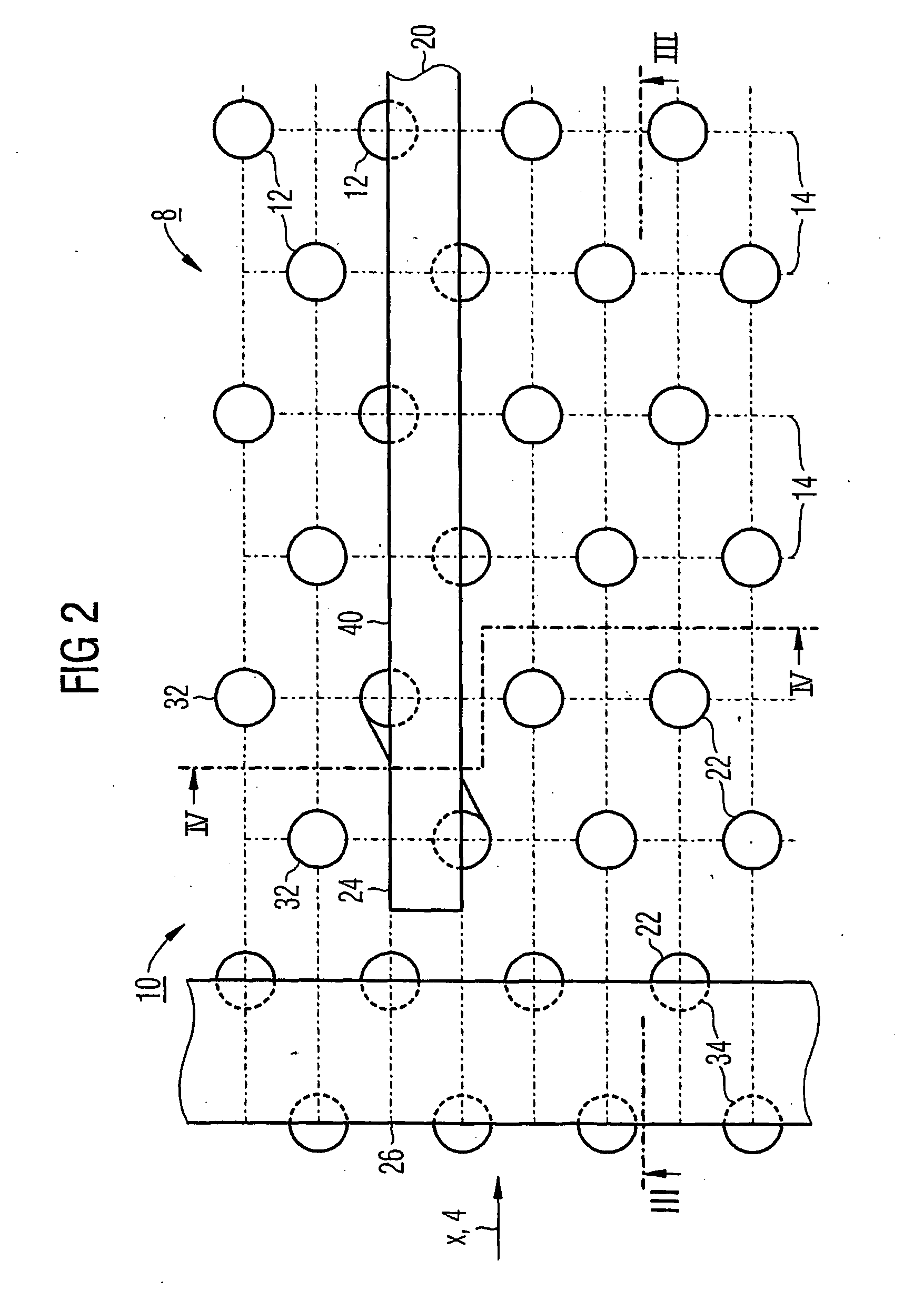

Piping, header, and tubing arrangements for solar boilers

A header system for fluid circulation in a boiler includes a header configured to conduct fluid therethrough for circulating fluids in a boiler. A plurality of suction lines are connected in fluid communication with the header. Each suction line is configured and adapted to connect a respective pump in fluid communication with the header. A plurality of downcomers are connected in fluid communication with the header. Each downcomer is configured and adapted to connect the header in fluid communication with a steam drum. The header, suction lines, and downcomers are configured and adapted to draw substantially equal amounts of fluid from each of the downcomers even when flow is uneven among the suction lines. A plurality of cascaded headers can fluidly connect the circulation header to a steam generator. The plurality of cascaded headers is configured and adapted to provide a substantially equal flow to panels of the steam generator.

Owner:BABCOCK POWER SERVICES

Pipeline connecting system with turbine and boiler arranged compactly

PendingCN107091127ALess investmentReduce total pressure lossBoiler drums/headersWater-tube boilersPipe fittingShortest distance

The invention discloses a pipeline connecting system with a turbine and a boiler arranged compactly. The pipeline connecting system at least comprises a boiler with a boiler heating face and boiler outlet headers, the high-position turbine and pipeline systems connected between the boiler outlet headers and the high-position turbine. The boiler outlet headers are close to the high-position turbine, a boiler heating face pipe bundle (a heating face pipe bundle boiler outer section) connected with each boiler outlet header is arranged to be in an L shape comprising a horizontal section and a perpendicular section. Heat expansion and heat stress of the systems, between the boiler and the turbine, of the boiler outlet headers are absorbed through pipe bundles connected to the boiler outlet headers, short-distance connection of high-temperature and high-pressure steam pipelines between the turbine and the boiler can be achieved, the use amount of high-temperature and high-pressure pipeline materials, bends and other pipe fittings is substantively reduced, pressure losses and heat dissipation losses of the high-temperature and high-pressure steam pipeline systems are reduced in a real sense, finally, the investment of the pipeline systems is saved, and economical efficiency of a unit is improved as well.

Owner:冯煜珵

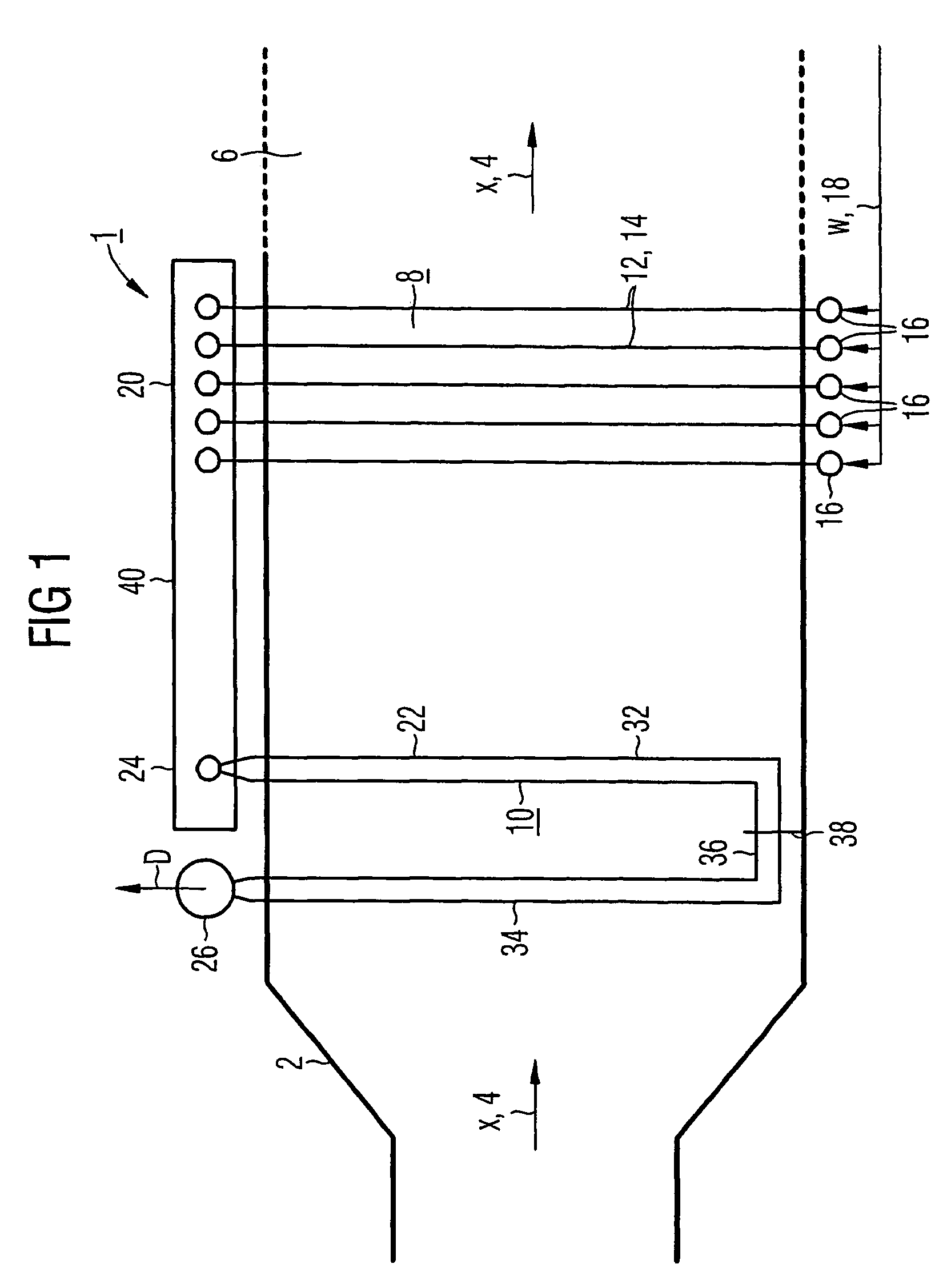

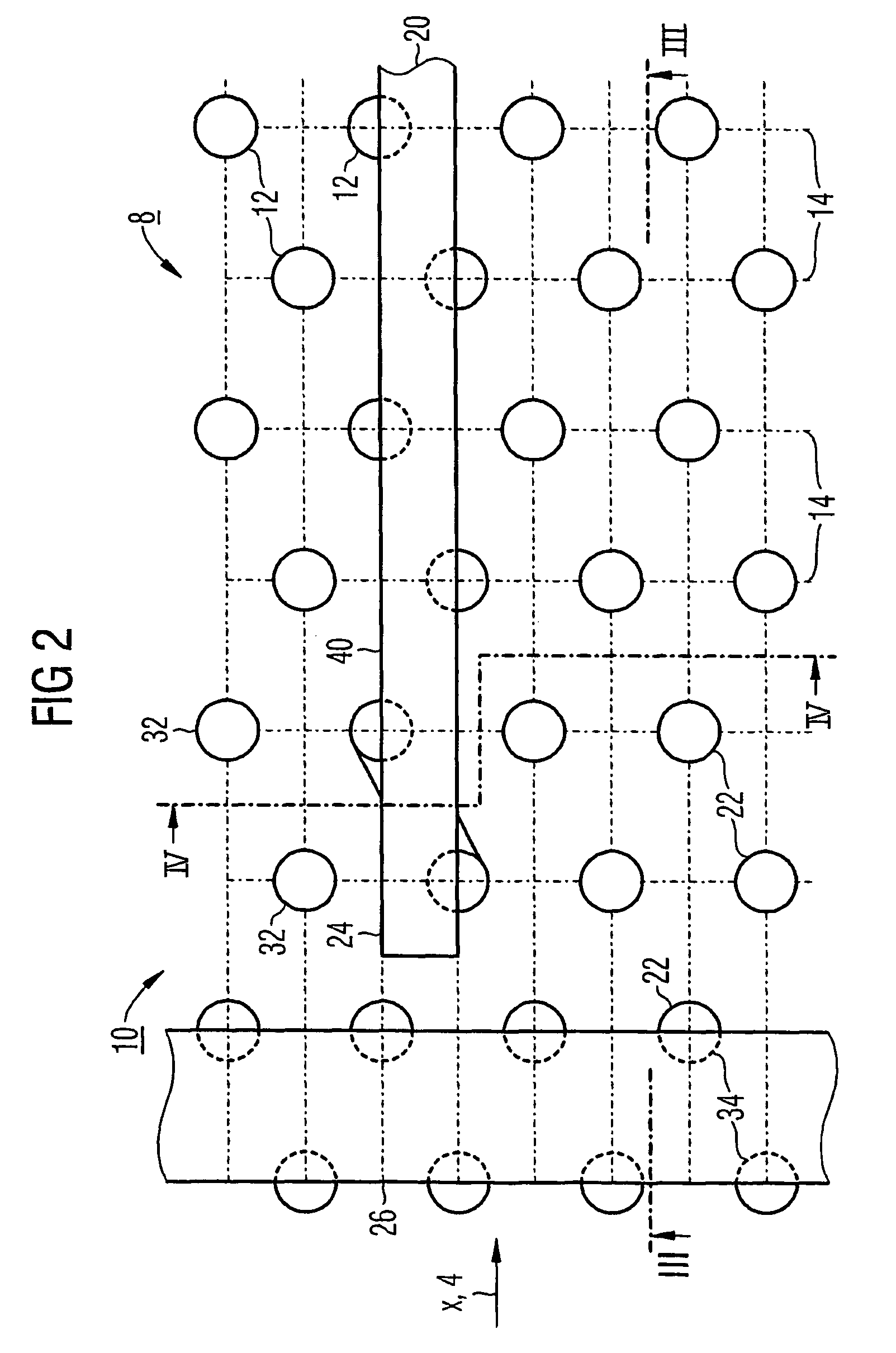

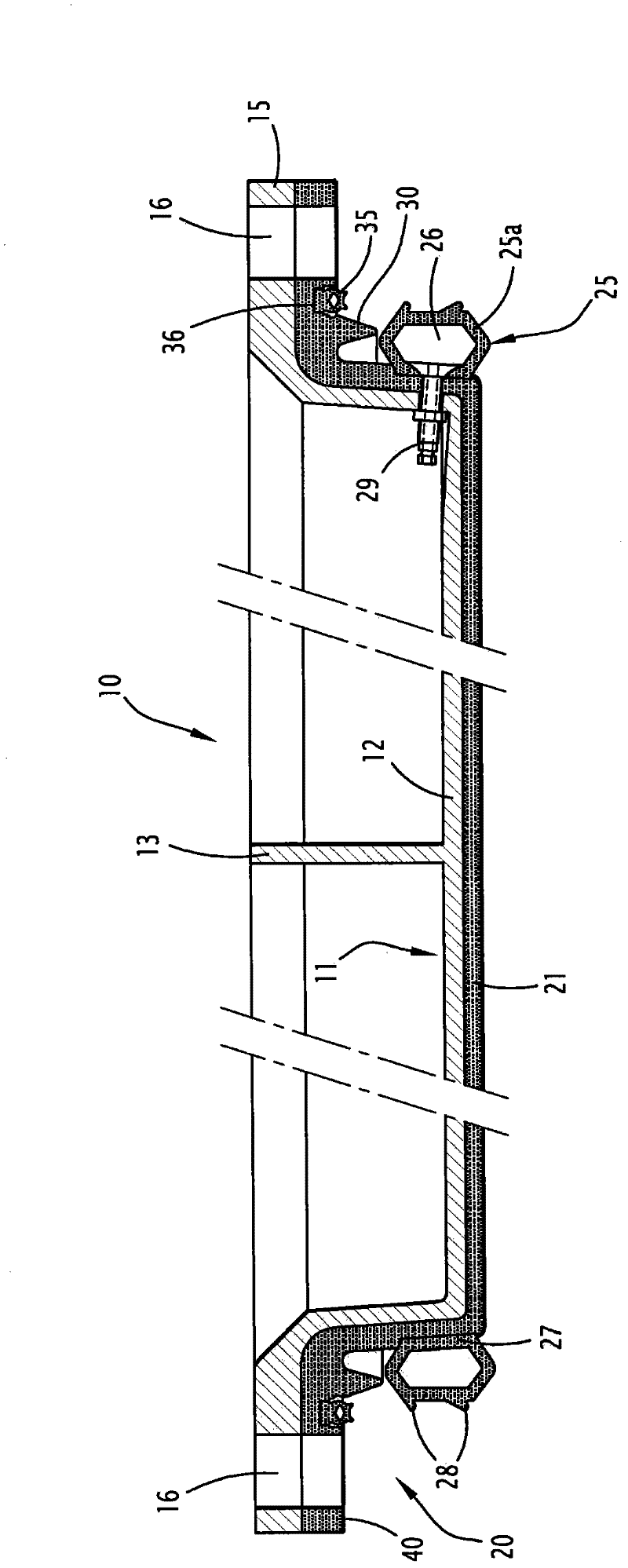

Horizontally assembled steam generator

InactiveUS7428374B2High degreeLow constructionBoiler drums/headersWater circulationEngineeringProduct gas

Disclosed is a steam generator in which a continuous evaporating heating area is disposed within a heating gas duct that is penetrated in a nearly horizontal direction by a heating gas. Said continuous evaporating heating area comprises a number of steam-generating pipes that are connected in parallel and are penetrated by a flowing medium and is configured such that a steam-generating pipe which is heated more than another steam-generating pipe of the same continuous evaporating heating area has a higher throughput of the flowing medium than said other steam-generating pipe. The aim of the invention is to create a steam generator which provides a particularly high degree of stability of flow during operation of the continuous evaporating heating area while keeping the structural complexity and design comparatively simple. Said aim is achieved by means of a discharge collector which is mounted downstream of the steam-generating pipes of the continuous evaporating heating area on the side of the flowing medium, and the longitudinal axis of which is located essentially parallel to the direction of the heating gas.

Owner:SIEMENS AG

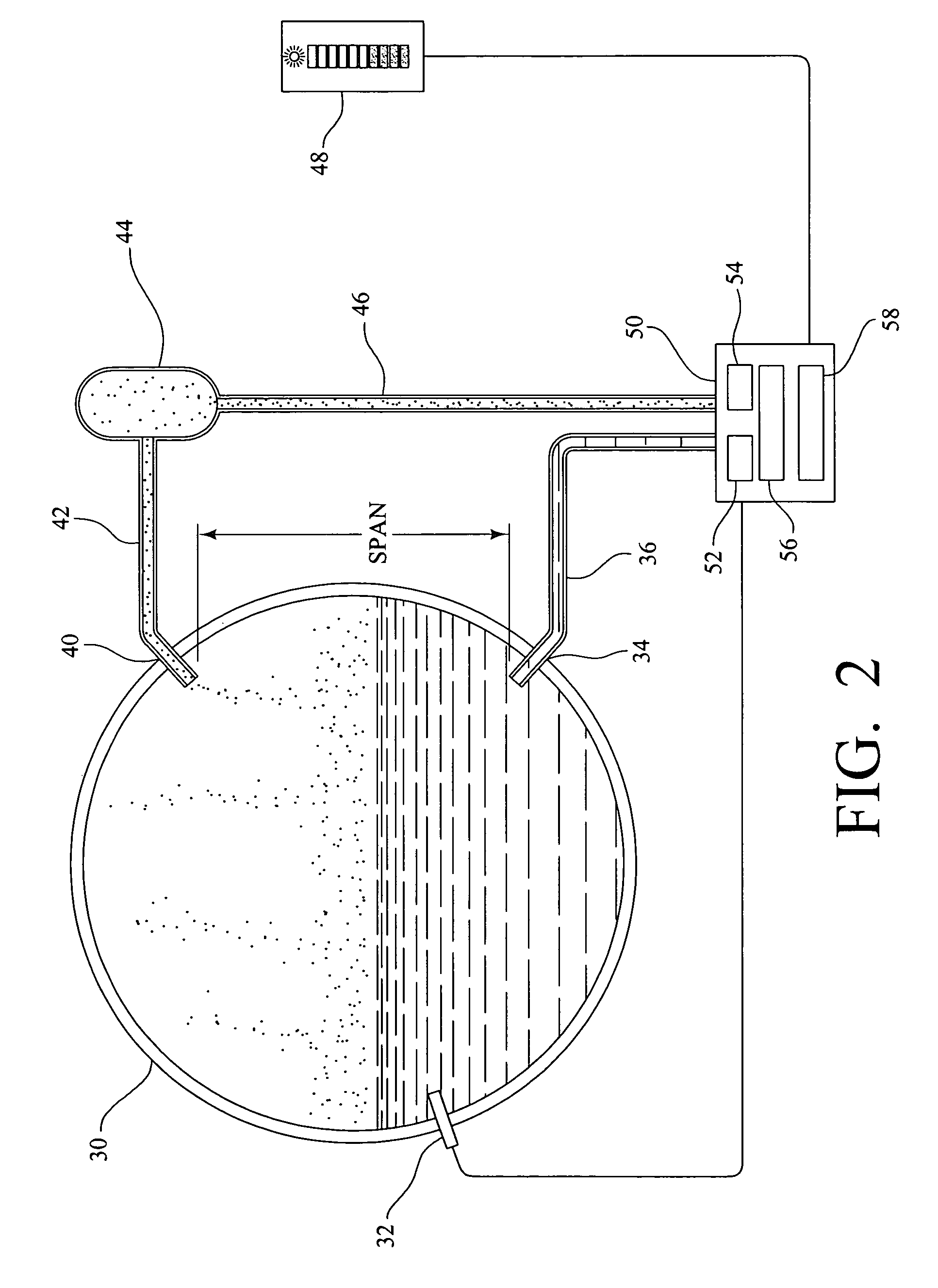

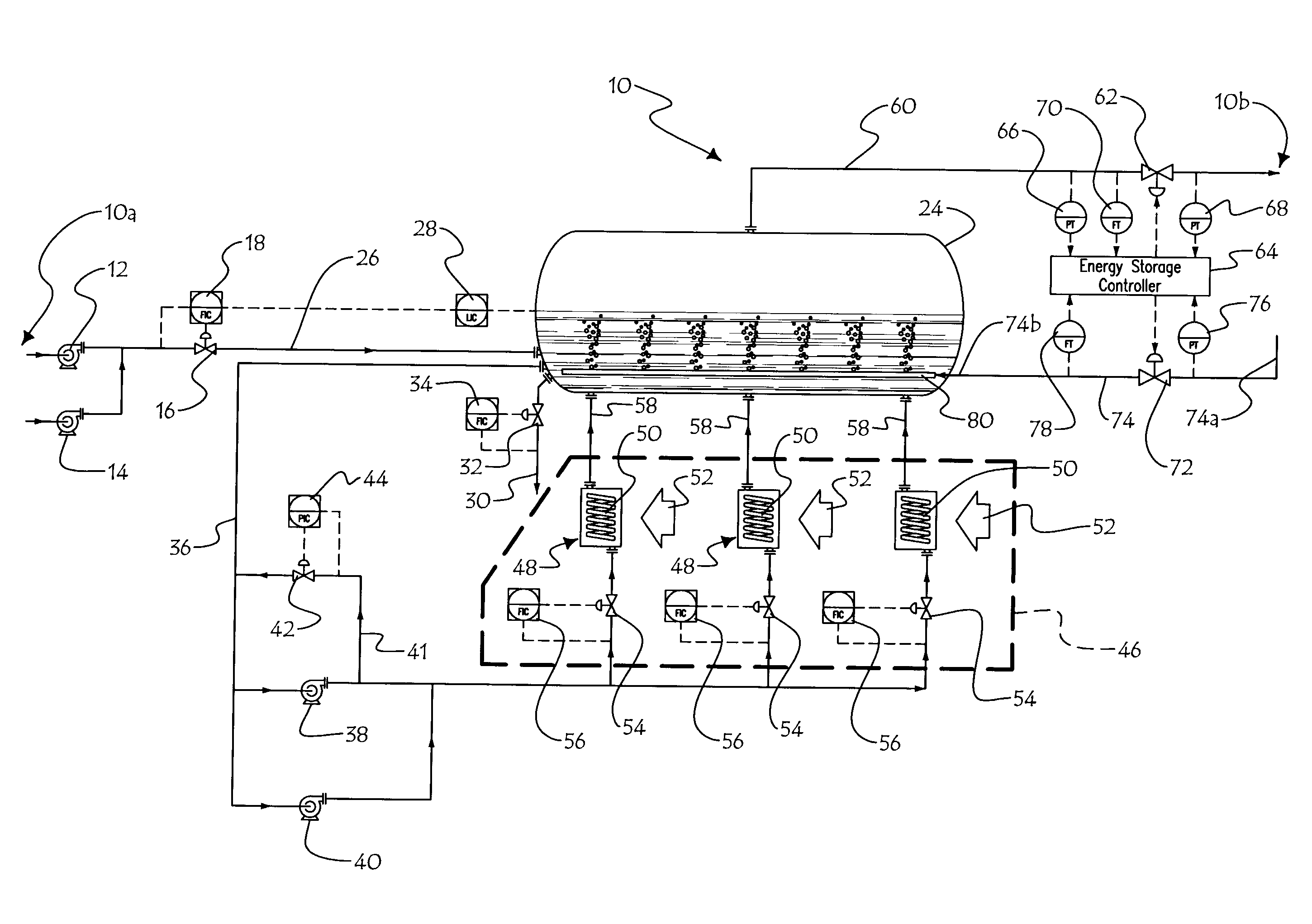

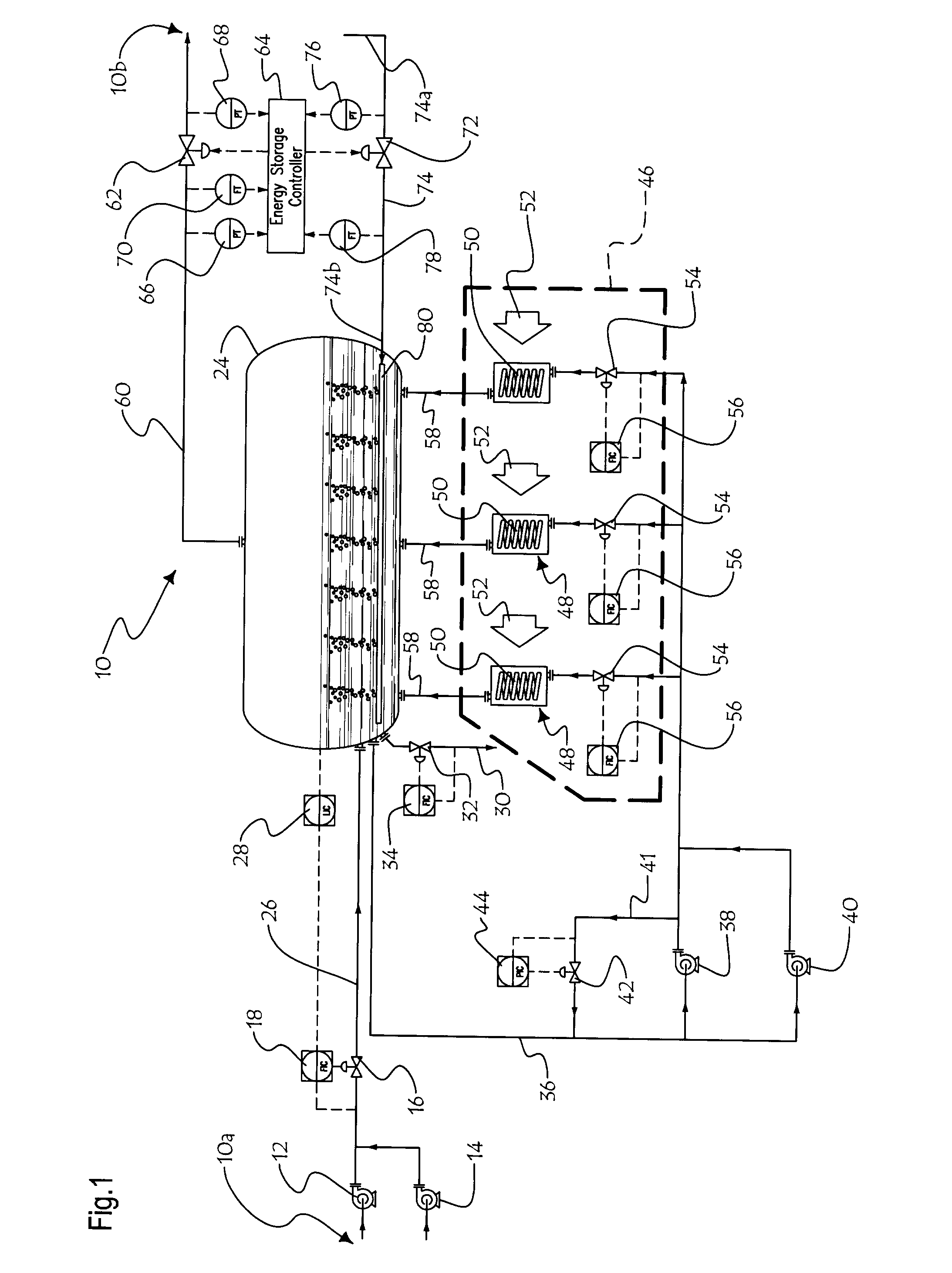

Pressurized water reactor compact steam generator

A steam generator system for a pressurized water reactor which employs an external to containment steam drum and recirculation loop piping. The steam generator system changes the arrangement of a typical pressurized water reactor recirculation steam generator by relocating the functions of steam separation and feedwater preheating outside of the reactor coolant system. The steam generator system and thermal hydraulic conditions are selected in order to minimize the size of the steam generator heat exchanger component volume inside of the containment. The external steam drum component can be isolated in accident conditions when desired and is used as a source of secondary fluid inventory for improved decay heat removal capability and tolerance for loss of feedwater events. Thus, the steam generator component volume inside of the containment is reduced and the amount of maintenance required for the reactor coolant system components are similarly reduced.

Owner:WESTINGHOUSE ELECTRIC CORP

Method and system for safe drum water level determination in a combined cycle operation

A method for controlling a water level of a drum of a heat recovery steam generation system for a combined cycle power plant is provided. The method includes determining an optimum drum water level during start up operation of the heat recovery steam generation system based on a characteristic chart model. The characteristic chart model is generated based on a plurality of vapor pressures of the drum and a plurality of temperatures of drum metal at the time of the start up operation of the heat recovery steam generation system.

Owner:GE INFRASTRUCTURE TECH INT LLC

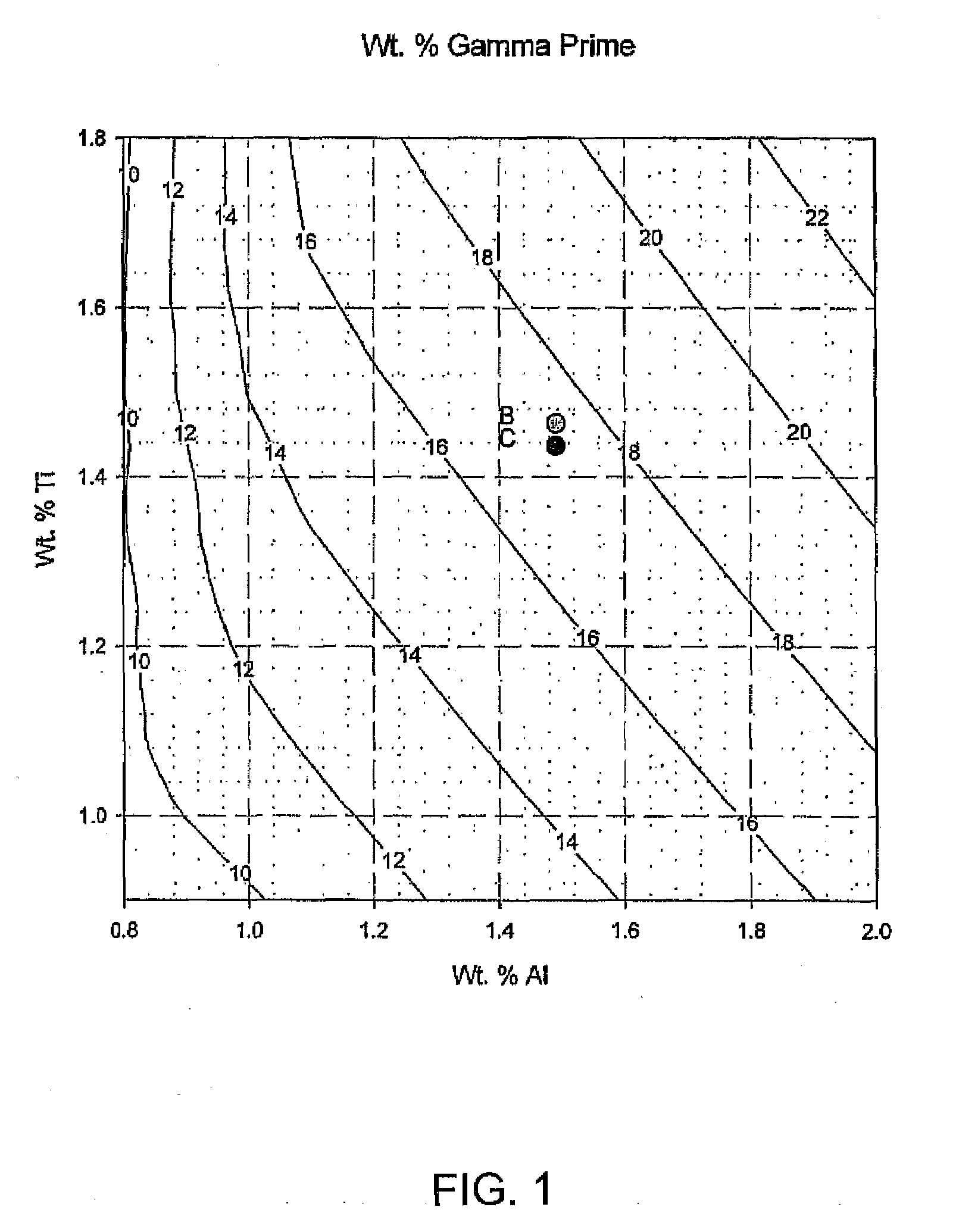

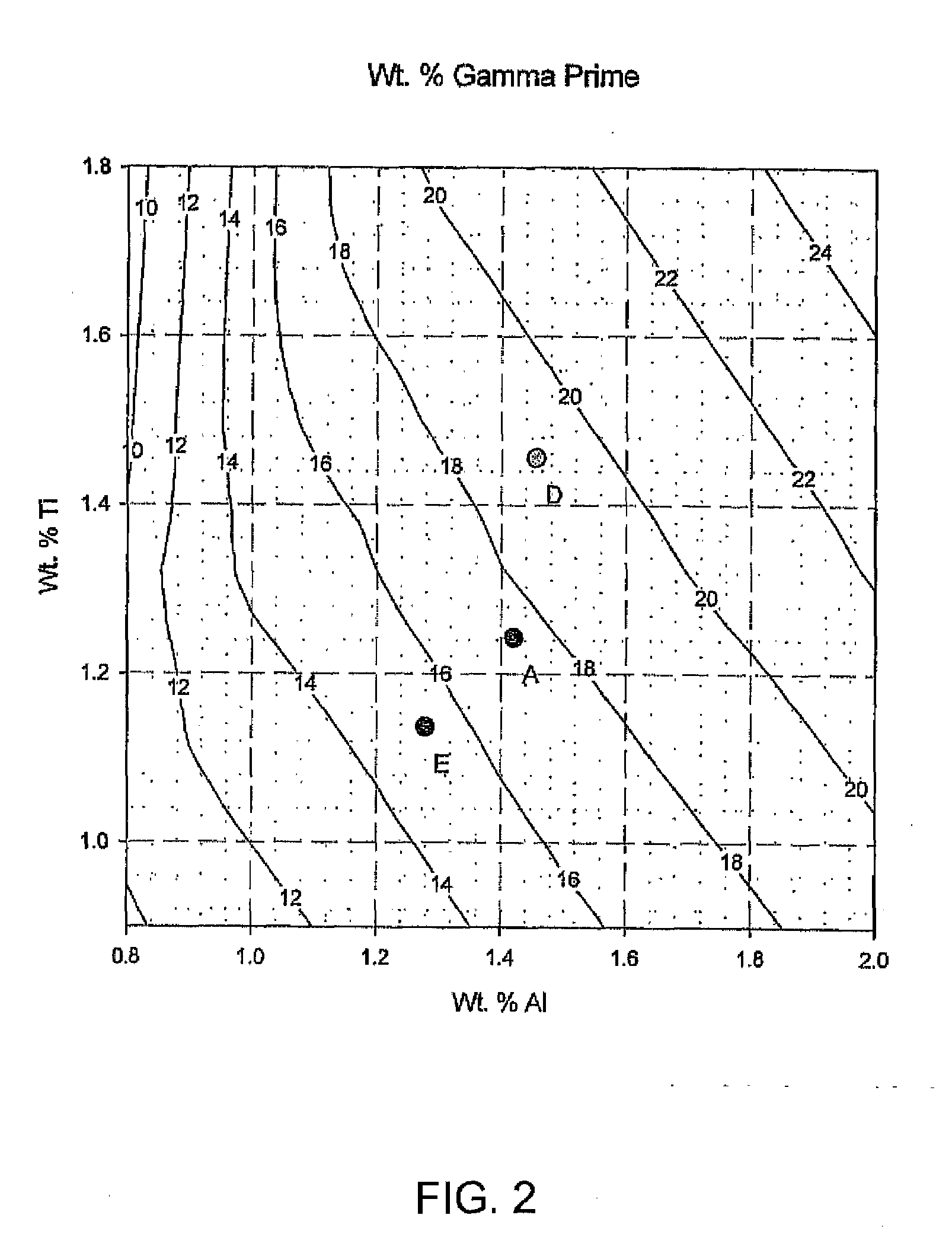

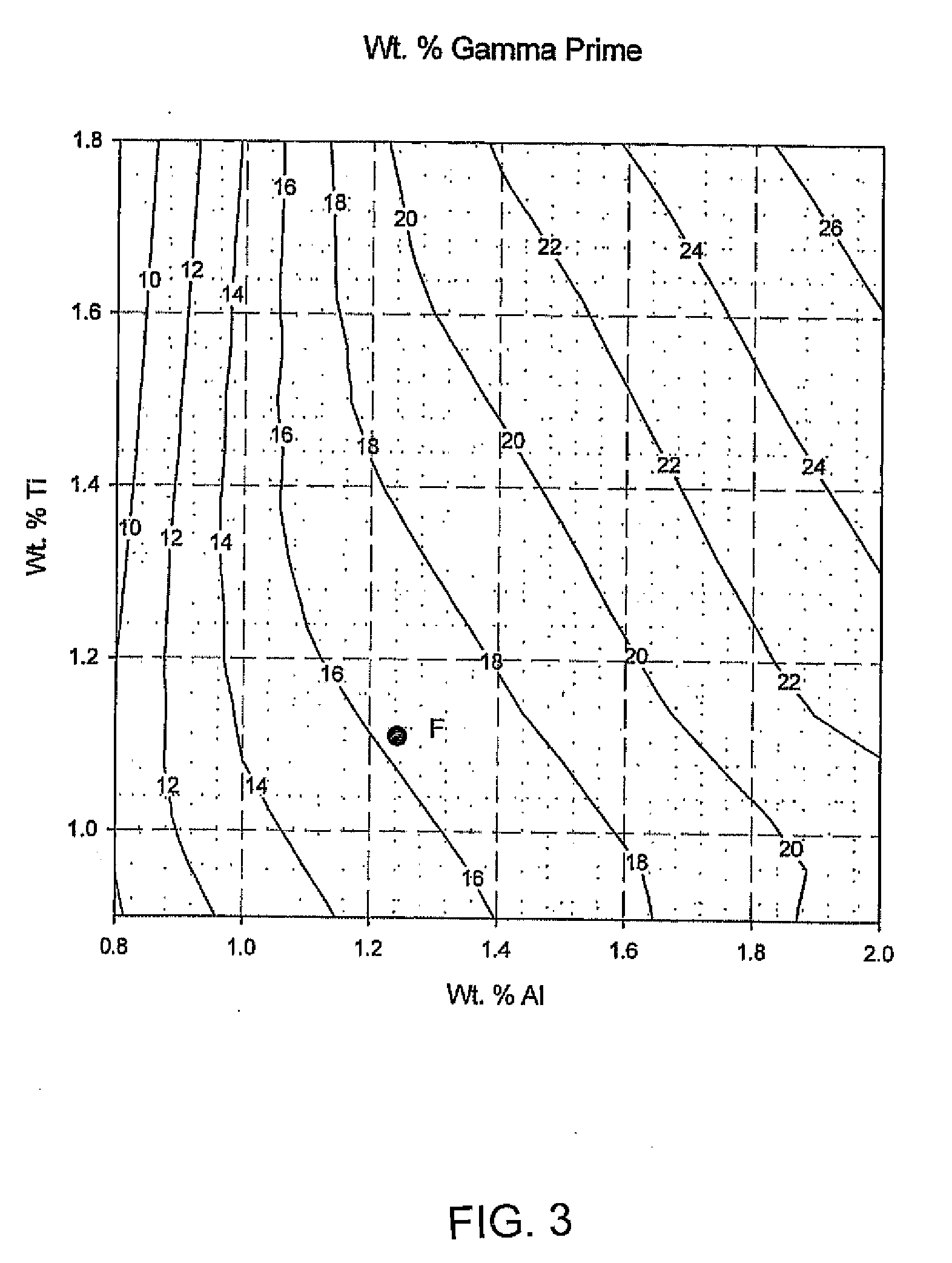

Ultra Supercritical Boiler Header Alloy and Method of Preparation

A high temperature, high strength Ni—Co—Cr alloy possessing essentially fissure-free weldability for long-life service at 538° C. to 816° C. contains in % by weight about: 23.5 to 25.5% Cr, 15-22% Co, 1.1 to 2.0% Al, 1.0 to 1.8 % Ti, 0.95 to 2.2% Nb, less than 1.0% Mo, less than 1.0% Mn, less than 0.3% Si, less than 3% Fe, less than 0.3% Ta, less than 0.3% W, 0.005 to 0.08% C, 0.01 to 0.3% Zr, 0.0008 to 0.006% B, up to 0.05% rare earth metals, 0.005% to 0.025% Mg plus optional Ca and the balance Ni including trace additions and impurities. The strength and stability is assured at 760° C. when the Al / Ti ratio is constrained to between 0.95 and 1.25. Further, the sum of Al+Ti is constrained to between 2.25 and 3.0. The upper limits for Nb and Si are defined by the relationship: (% Nb+0.95)+3.32(% Si)<3.16.

Owner:HUNTINGTON ALLOYS CORP (US)

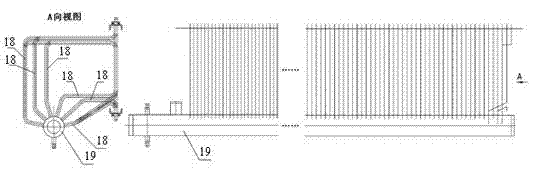

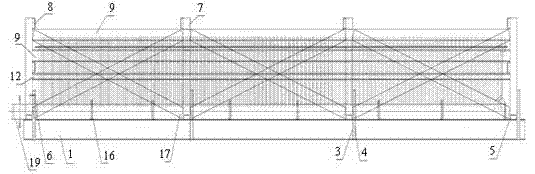

Multifunctional header assembly frame

ActiveCN102390047AGuaranteed assembly accuracyEasy to assembleBoiler drums/headersBoiler supporting/setting arrangementsAssembly lineEngineering

Owner:SHANGHAI BOILER WORKS

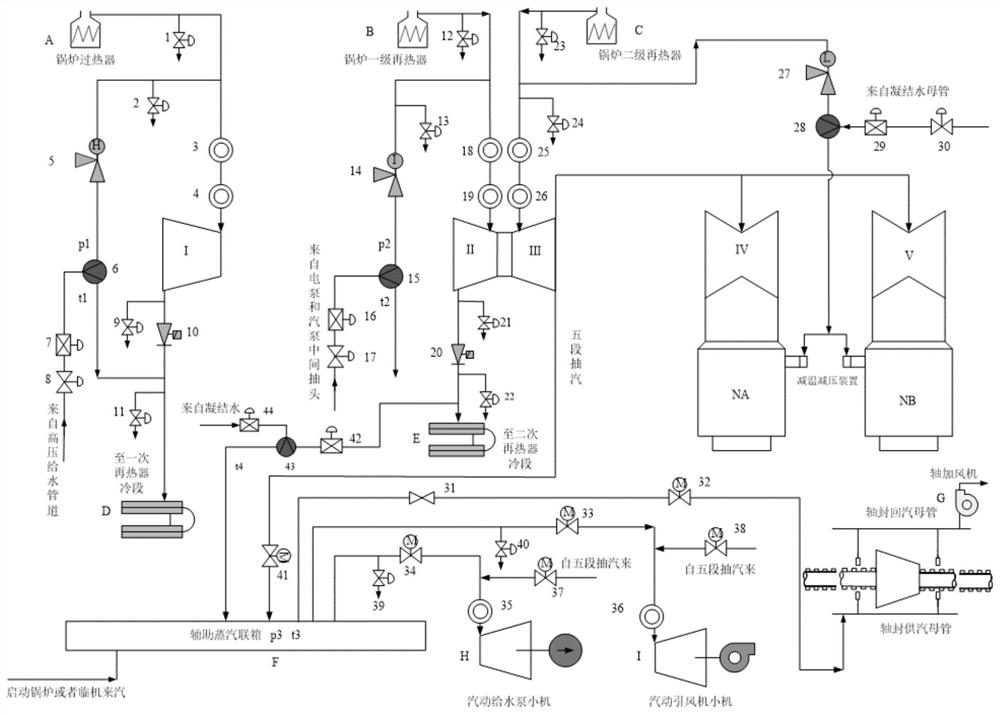

Method for controlling system under steam protection mode after MFT of secondary reheat unit boiler

PendingCN111981458AReduce wasteAchieve the design effectBoiler drums/headersSuperheating controlAutomatic controlSteam trap

A method for controlling a system under a steam protection mode after master fuel trip (MFT) of a secondary reheat unit boiler. The method includes the following steps that (1) a control target of thesteam protection mode is specified; (2) judging conditions of automatic triggering and automatic exit of the steam protection mode are set; (3) automatic control over high-pressure, medium-pressure and low-pressure three-stage bypasses and attemperation water thereof under the steam protection mode are explicitly described; (4) the control logic of a feed pump small machine and an induced draft fan small machine under the steam protection mode is described in detail; (5) pressure control of an auxiliary steam header and action conditions of a steam trap group under the steam protection modeare further described; and (6) supply of a shaft seal is preferentially considered under the steam protection mode, and meanwhile, control over a condensed water system and an auxiliary steam system is taken into consideration. The entire control process becomes accurate automatic adjustment from coarse manual control. The method has great significance in achieving energy conservation and consumption reduction of a thermal power generating unit, rapid recovery of accident shutdown and improvement of the automation degree of a unit.

Owner:XIAN THERMAL POWER RES INST CO LTD

Pressurized water reactor compact steam generator

A steam generator system for a pressurized water reactor which employs an external to containment steam drum and recirculation loop piping. The steam generator system changes the arrangement of a typical pressurized water reactor recirculation steam generator by relocating the functions of steam separation and feedwater preheating outside of the reactor coolant system. The steam generator system and thermal hydraulic conditions are selected in order to minimize the size of the steam generator heat exchanger component volume inside of the containment. The external steam drum component can be isolated in accident conditions when desired and is used as a source of secondary fluid inventory for improved decay heat removal capability and tolerance for loss of feedwater events. Thus, the steam generator component volume inside of the containment is reduced and the amount of maintenance required for the reactor coolant system components are similarly reduced.

Owner:WESTINGHOUSE ELECTRIC CORP

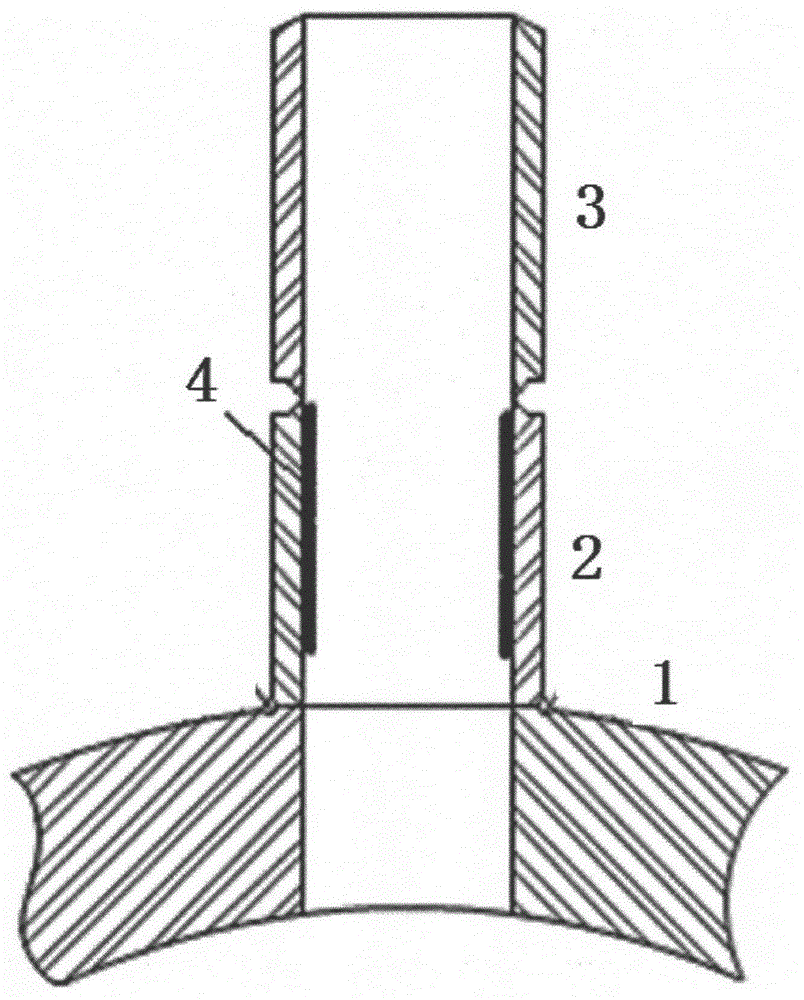

Sealed stopper for an opening in a junction tubing between a housing and a pipe, and method for implementing said stopper

ActiveCN102348923AReduce intervention timeBoiler drums/headersNuclear energy generationEngineeringMechanical engineering

Owner:FRAMATOME ANP

Horizontally assembled steam generator

InactiveUS20050257753A1High degreeLow constructionBoiler drums/headersWater circulationProduct gasSteam generation

Disclosed is a steam generator in which a continuous evaporating heating area is disposed within a heating gas duct that is penetrated in a nearly horizontal direction by a heating gas. Said continuous evaporating heating area comprises a number of steam-generating pipes that are connected in parallel and are penetrated by a flowing medium and is configured such that a steam-generating pipe which is heated more than another steam-generating pipe of the same continuous evaporating heating area has a higher throughput of the flowing medium than said other steam-generating pipe. The aim of the invention is to create a steam generator which provides a particularly high degree of stability of flow during operation of the continuous evaporating heating area while keeping the structural complexity and design comparatively simple. Said aim is achieved by means of a discharge collector which is mounted downstream of the steam-generating pipes of the continuous evaporating heating area on the side of the flowing medium, and the longitudinal axis of which is located essentially parallel to the direction of the heating gas.

Owner:SIEMENS AG

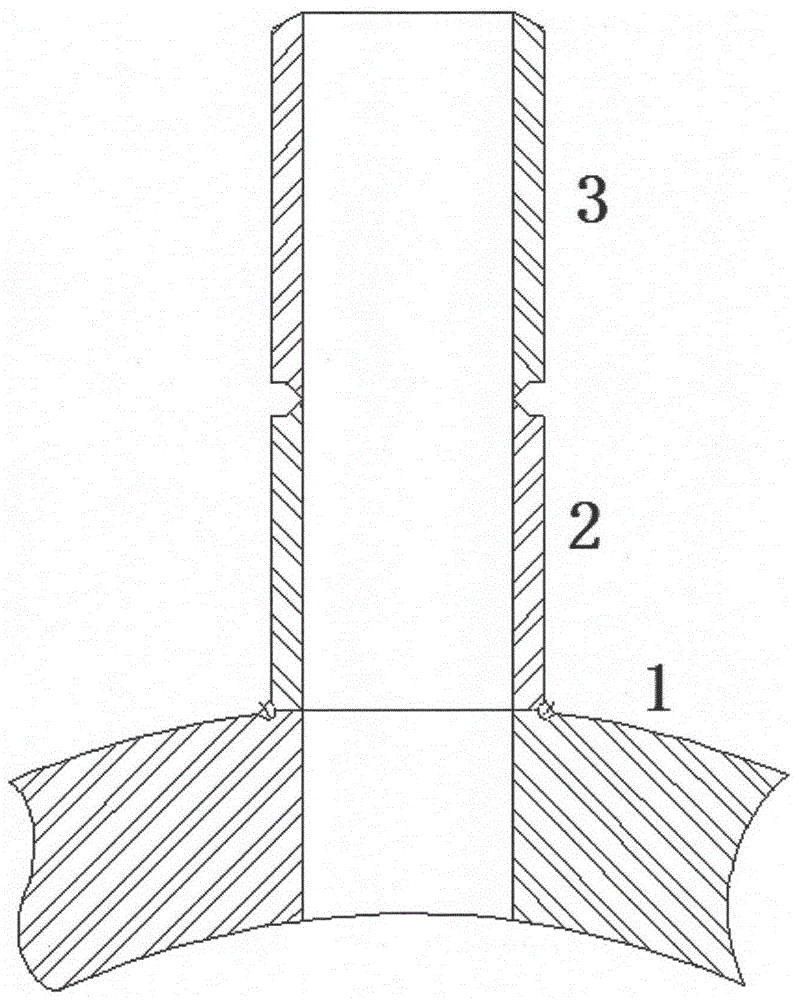

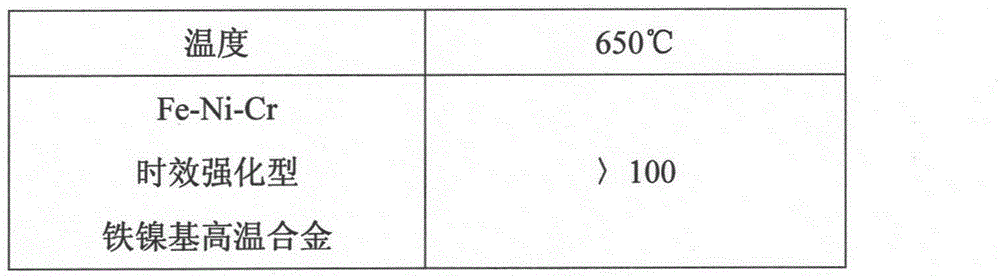

Header of ultra supercritical unit boiler in above 620 DEG C

InactiveCN105003902AExcellent high temperature oxidation performanceGood practical valueBoiler drums/headersSuperheaterEngineering

The invention relates to a header of an ultra supercritical unit boiler in above 620 DEG C. The header comprises a header body and a tube base. One end of the tube base is welded with the header body, and the other end is welded with the pipe of a finishing superheater or a finish-stage reheater. The header is characterized in that the header body is manufactured by a Fe-Ni-Cr ageing strengthening type Fe-Ni matrix high-temperature alloy large-diameter tube, and the tube base is manufactured by a Fe-Ni-Cr ageing strengthening type Fe-Ni matrix high-temperature alloy small-diameter tube. The invention provides the superheater or reheater outlet header applied in steam parameter ultra supercritical unit boiler in above 620 DEG C, and the material is the Fe-Ni-Cr ageing strengthening type Fe-Ni matrix high-temperature alloy large-diameter tube. The material is excellent in high-temperature oxidizability, and has excellent practical value.

Owner:SHANGHAI BOILER WORKS

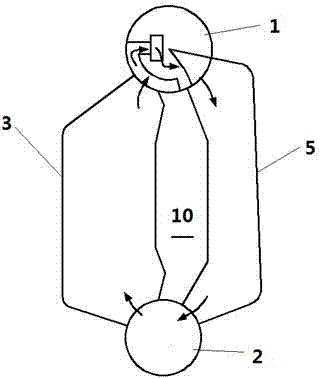

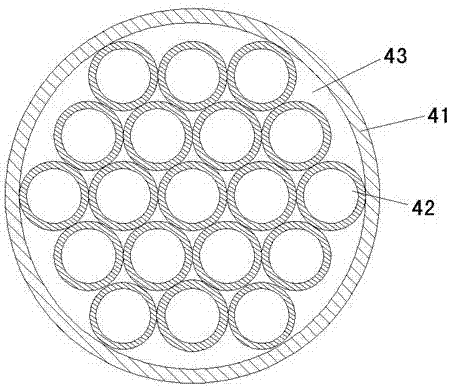

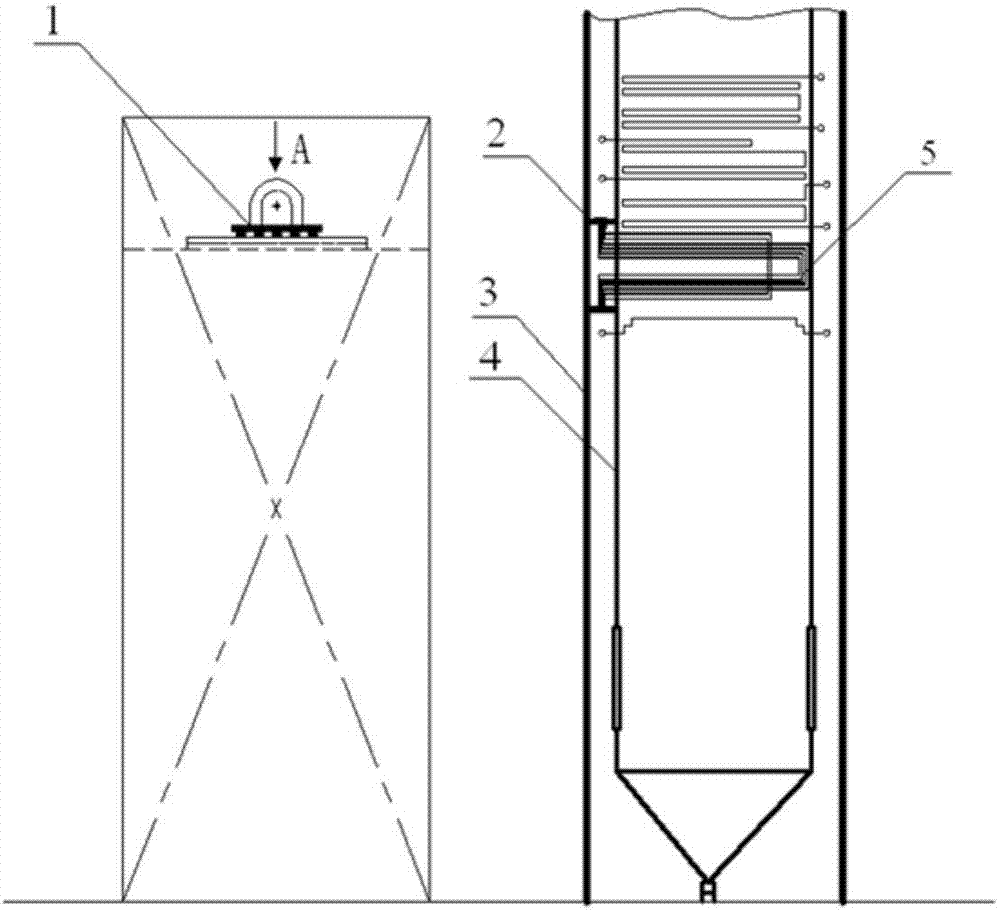

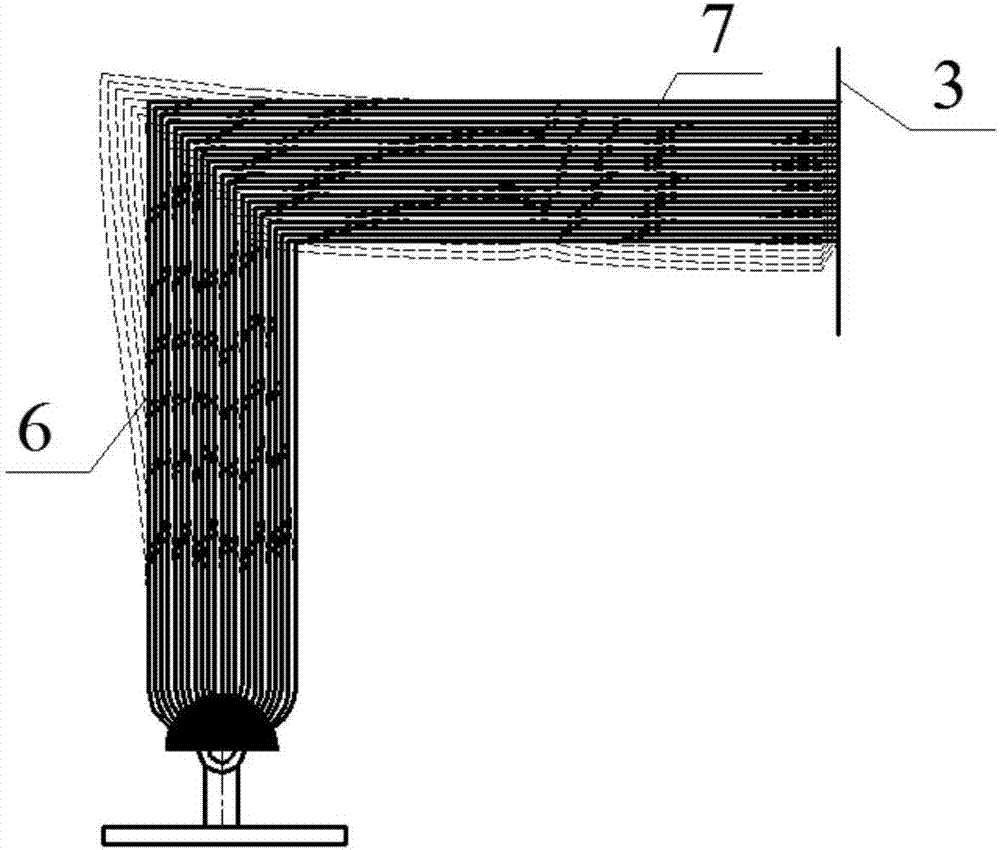

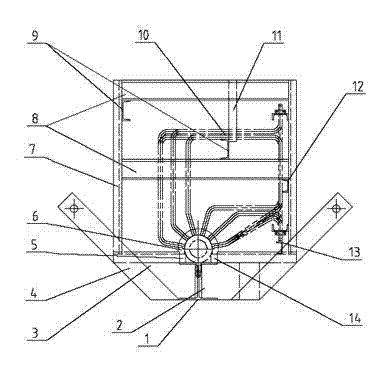

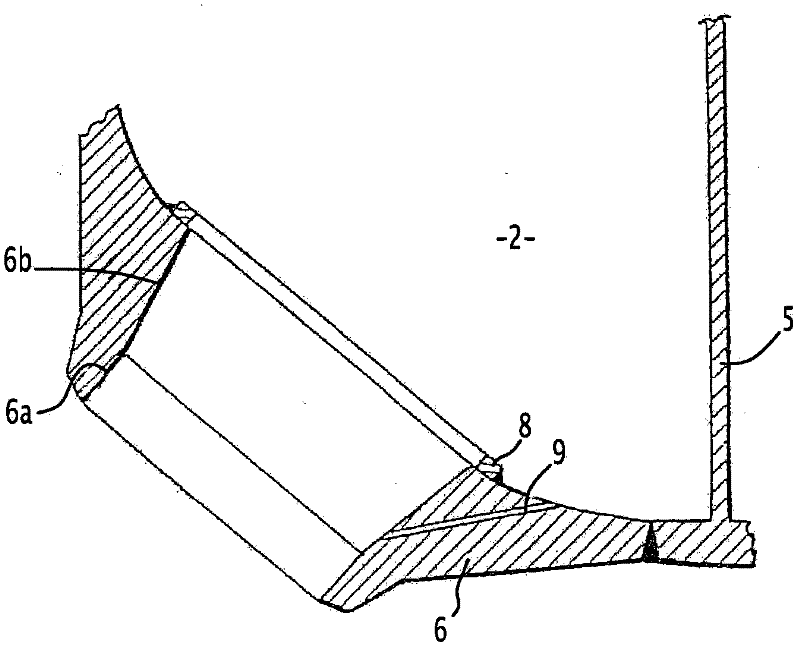

Fused salt steam generator

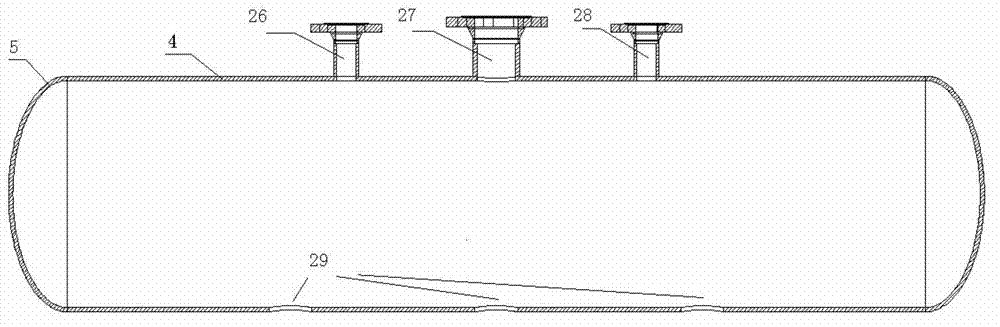

A fused salt steam generator is composed of a steam pocket (1), a steam generation tank (2) and a lower collection pipe (3), wherein the steam pocket (1) is located at the upper part of the fused salt steam generator, the steam generation tank (2) is located at the middle part of the fused salt steam generator, the lower collection pipe (3) is located at the lower part of the fused salt steam generator and below the steam generation tank (2); and the lower collection pipe (3) supports the fused salt steam generator. The steam pocket (1) is composed of a steam pocket end enclosure (5), a steam pocket shell body (4), a steam outlet (27), a pressure connector (26) and a safety valve connector (28); the steam generation tank (2) is composed of a steam generation tank outer shell (7), a steam generation tank inner shell (36), a hand hole (11) and a steam generation tank end enclosure (8). The steam generation tank inner shell (36) is connected with the steam pocket (1) through a steam ascending pipe (6). The lower collection pipe (3) is composed of a lower collection pipe inlet (18), a lower collection pipe outlet (19), a lower connection pipe shell body (20), a lower connection pipe end enclosure (21), an auxiliary heat exchange medium pipeline (34), a phase change material (35), etc.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

Popular searches

Steam generator primary side Cooling arrangement Steam boilers components Reactor fuel susbtances Machines/engines Liquid fuel feeders Special data processing applications Level indicators by physical variable measurement Level indicators by pressure measurement Fluid pressure measurement by mechanical elements

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com