Patents

Literature

42 results about "Steam accumulator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A steam accumulator is an insulated steel pressure tank containing hot water and steam under pressure. It is a type of energy storage device. It can be used to smooth out peaks and troughs in demand for steam. Steam accumulators may take on a significance for energy storage in solar thermal energy projects. An example is the PS10 solar power tower plant near Seville, Spain and one planned for the "solar steam train" project in Sacramento, California.

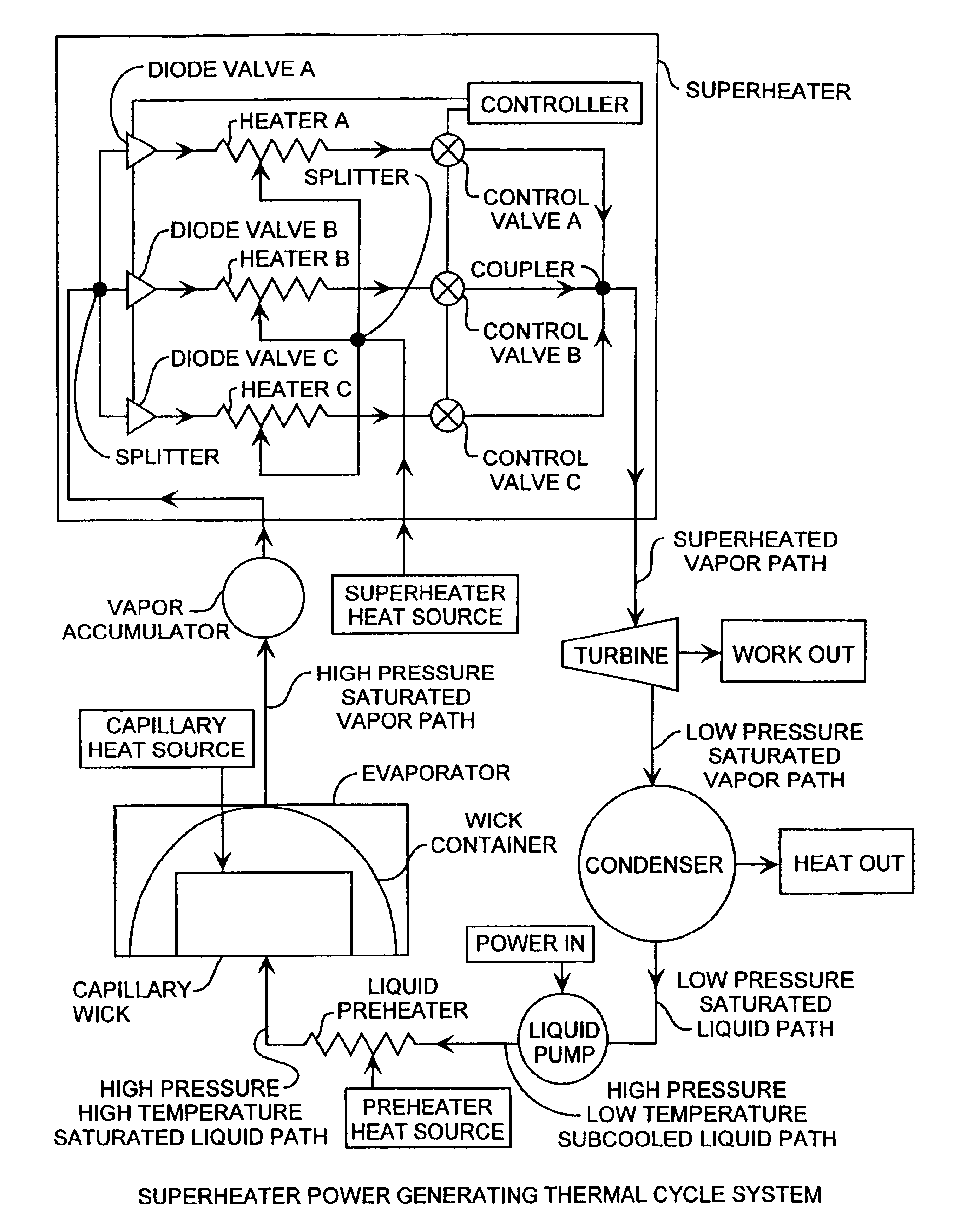

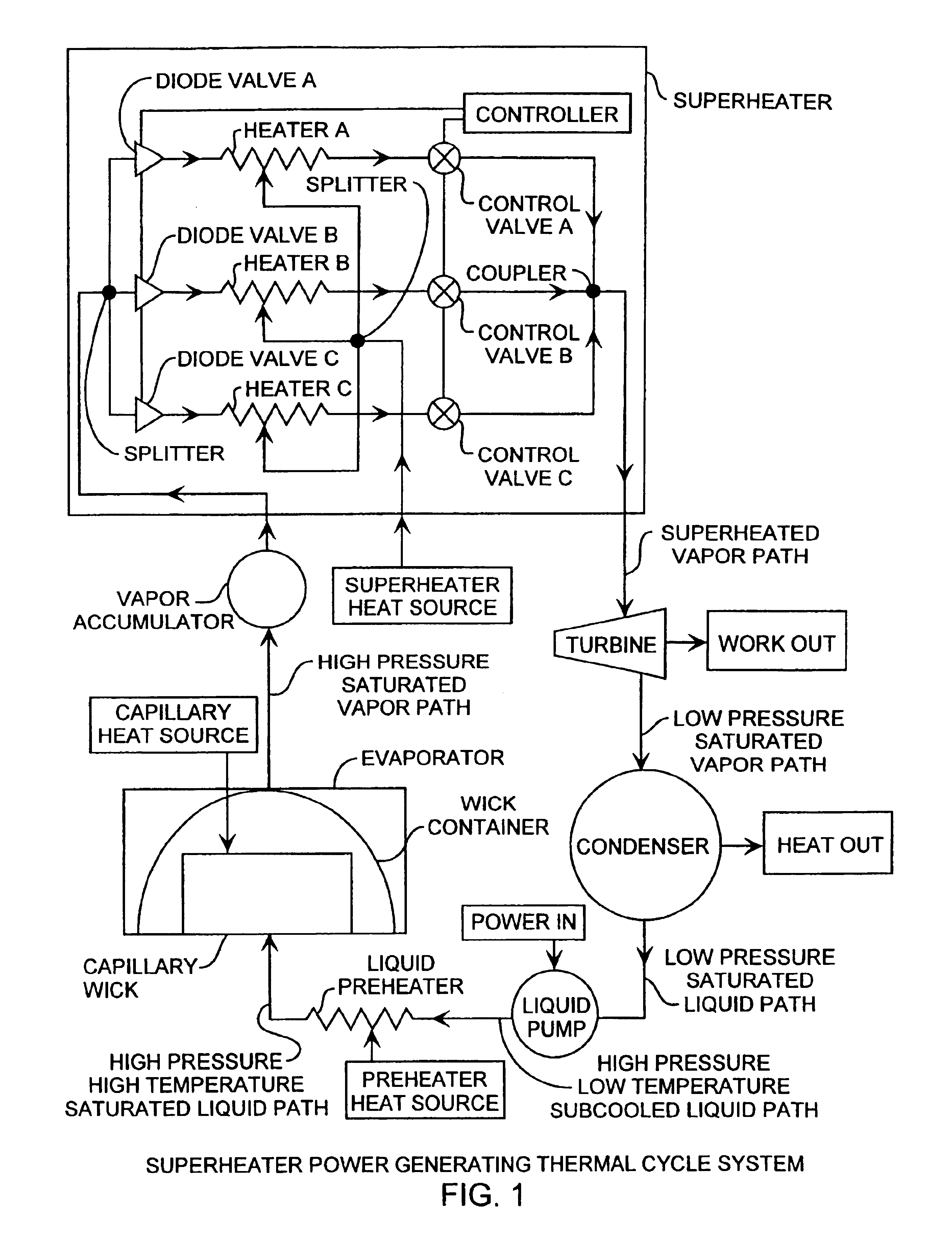

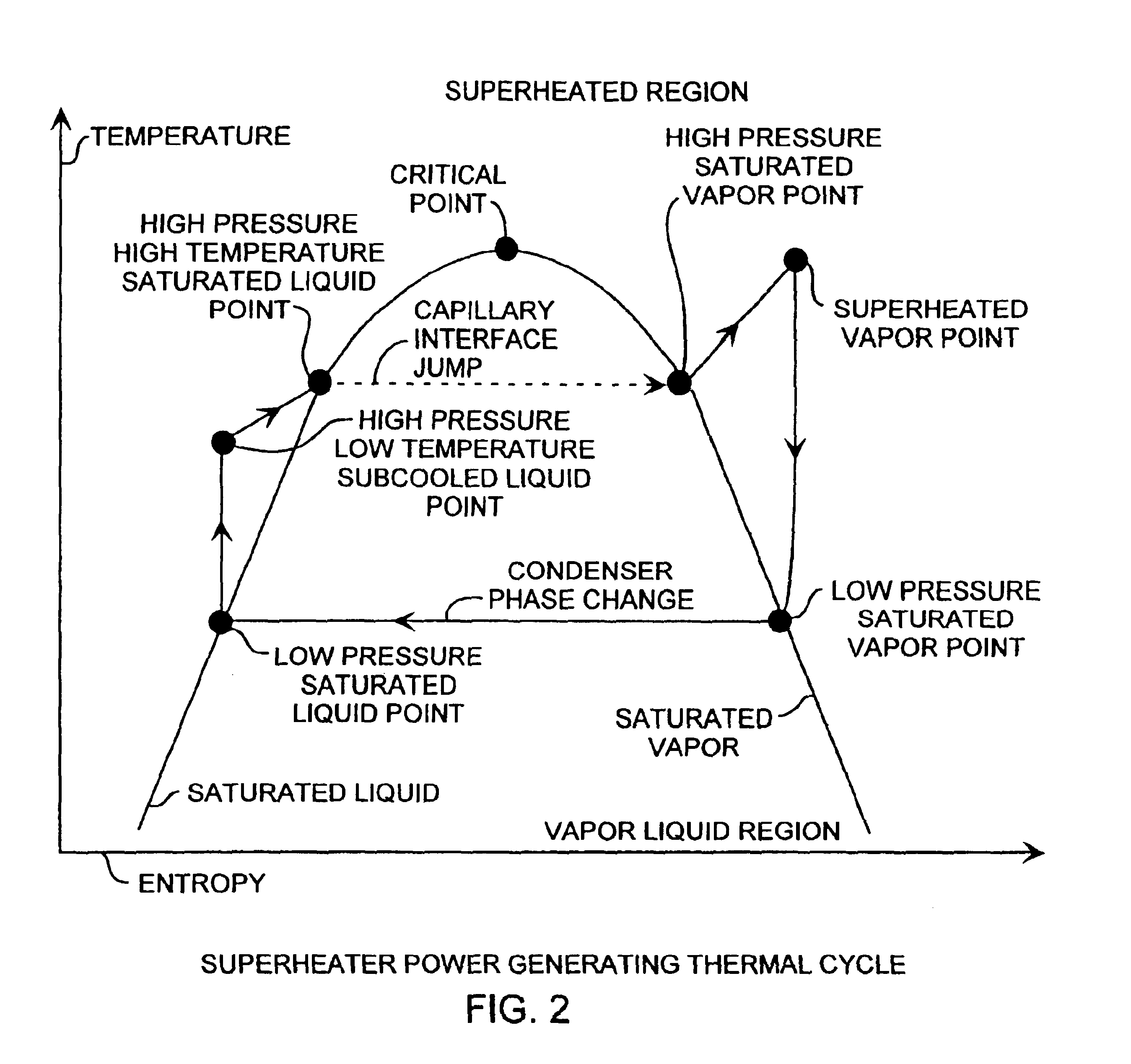

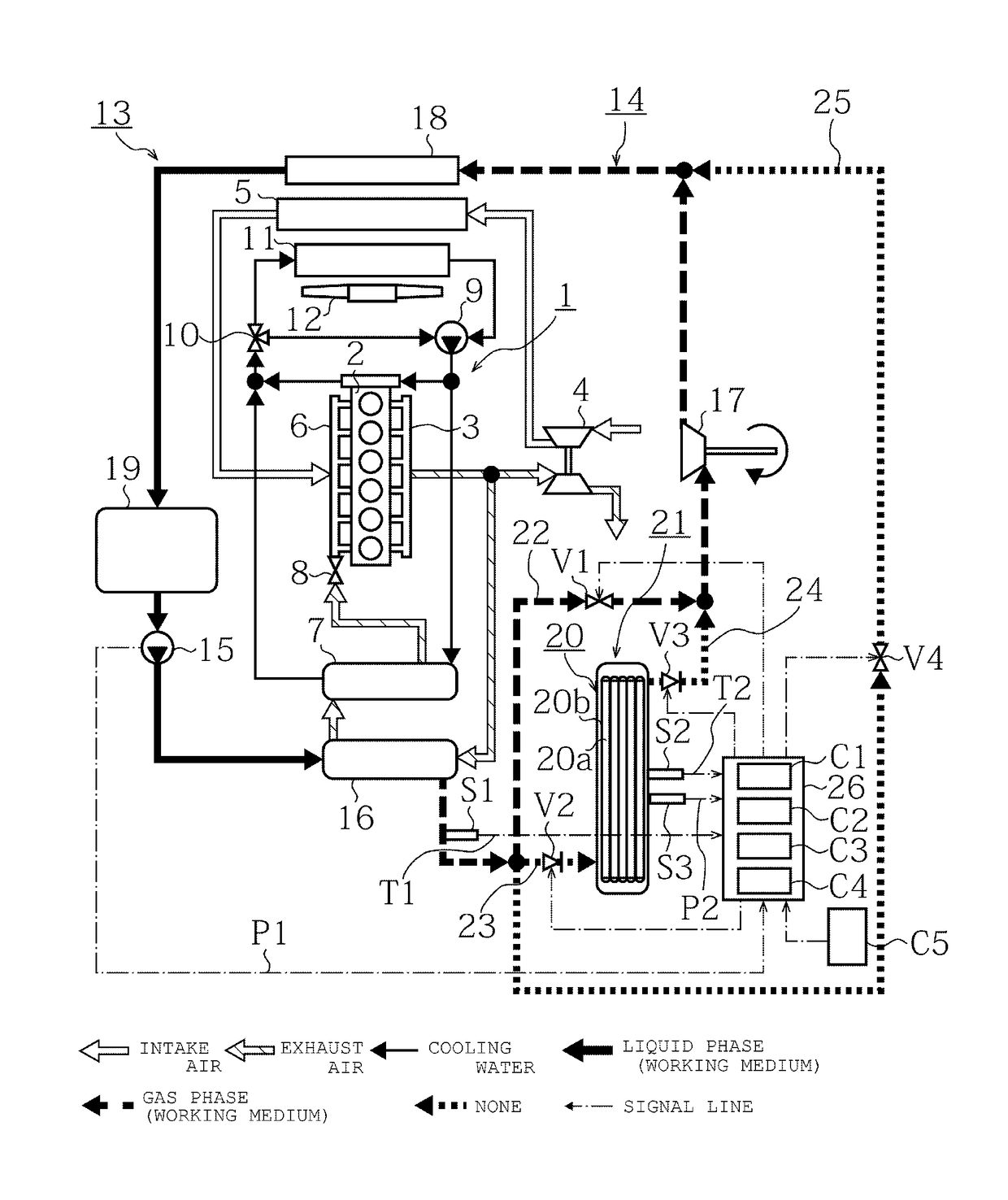

Superheater capillary two-phase thermodynamic power conversion cycle system

InactiveUS6918254B2Power generationImprove efficiencyIndirect heat exchangersSteam engine plantsThermal energyThermal energy storage

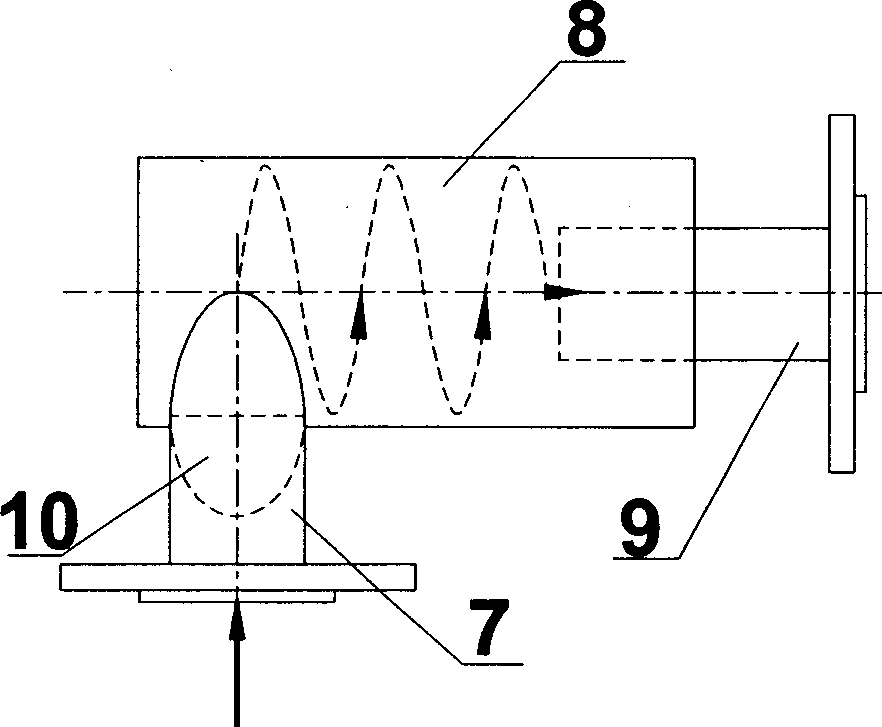

A two-phase thermodynamic power system includes a capillary device, vapor accumulator, superheater, an inline turbine, a condenser, a liquid pump and a liquid preheater for generating output power as a generator. The capillary device, such as a loop heat pipe or a capillary pumped loop, is coupled to a vapor accumulator, superheater, the inline turbine for generating output power for power generation, liquid pump and liquid preheater. The capillary device receives input heat that is used to change phase of liquid received from the liquid preheater, liquid pump and condenser into vapor for extra heating in the superheater used to then drive the turbine. The power system is well suited for space applications using a radioisotope, active nuclear or solar heat source. The system can use waste heat from various dynamic or static power systems as a heat source and waste heat from spacecraft components such as electronics as a heat source. These heat sources can be used separately or in any combination. The power system can be combined with thermal energy storage devices when operated with heat sources that are not steady state. Heat sources are useful for driving the capillary wick, superheater and liquid preheater for increased power efficiency and long lifetime operation. The power system is well suited for space receiving heat from a heat source to produce useful mechanical energy. A superheater in combination with a liquid pump and preheater are implemented for use with the evaporator for improved thermal efficiency while operating at maximum cycle temperatures well below other available power conversion cycles.

Owner:THE AEROSPACE CORPORATION

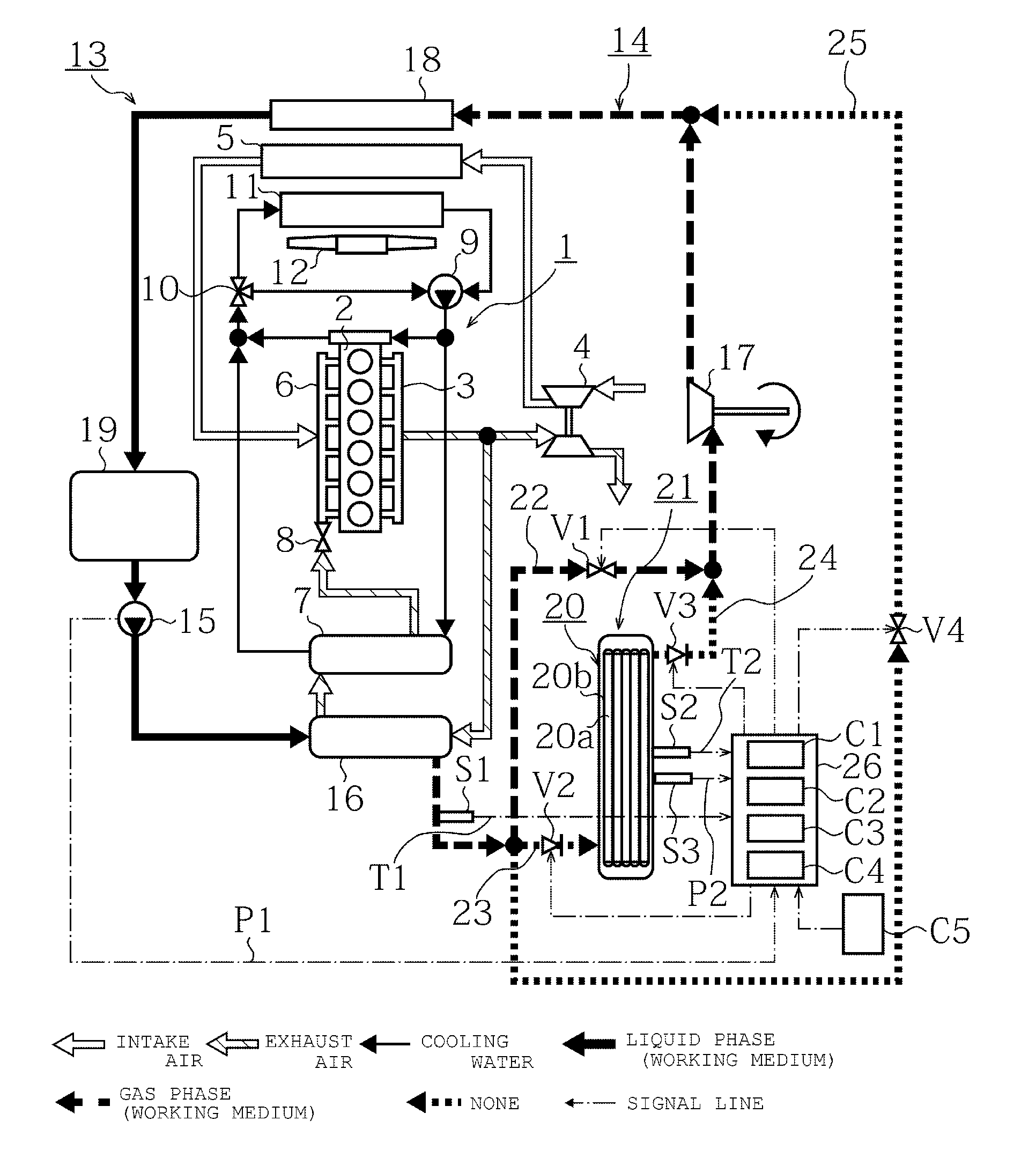

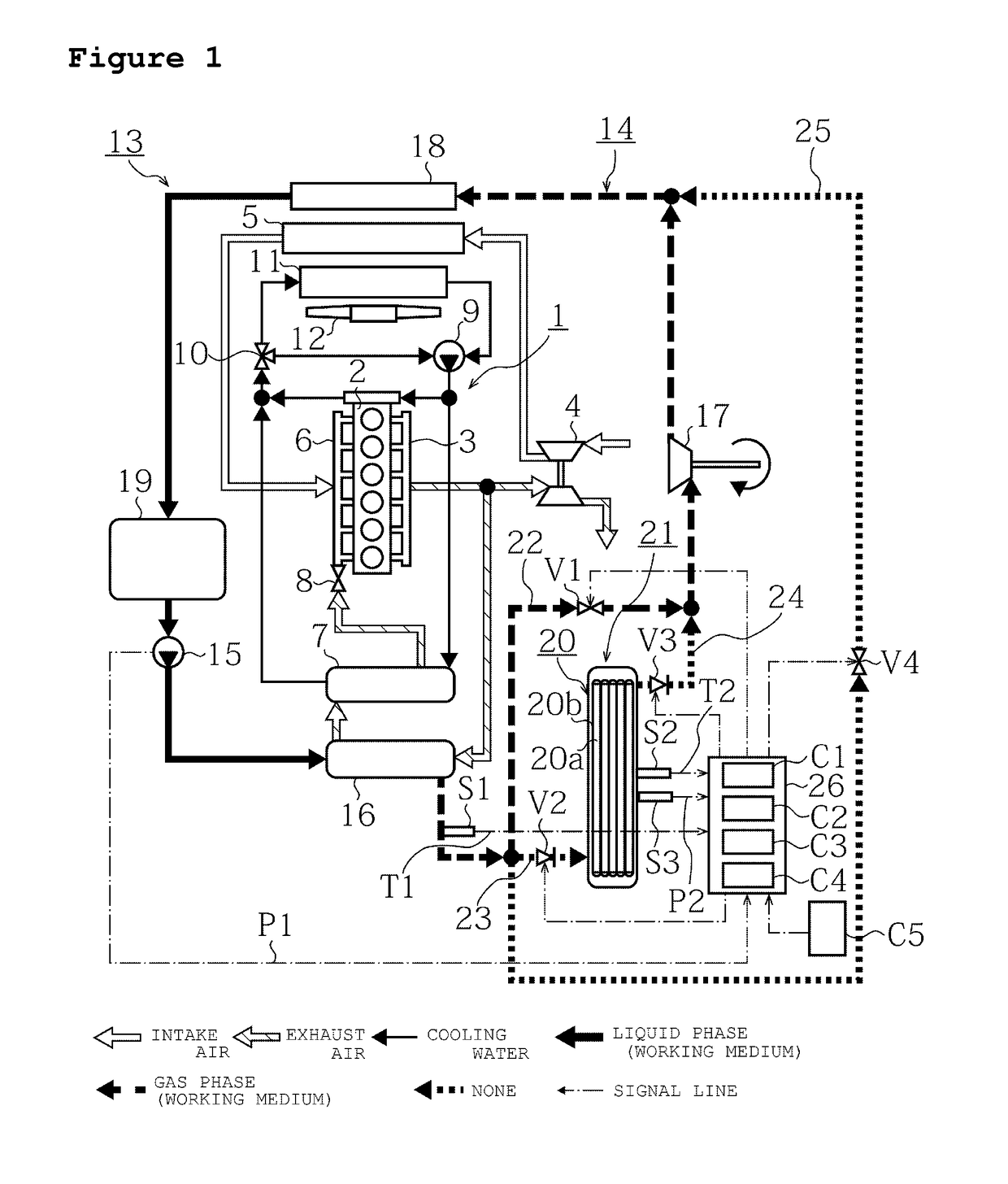

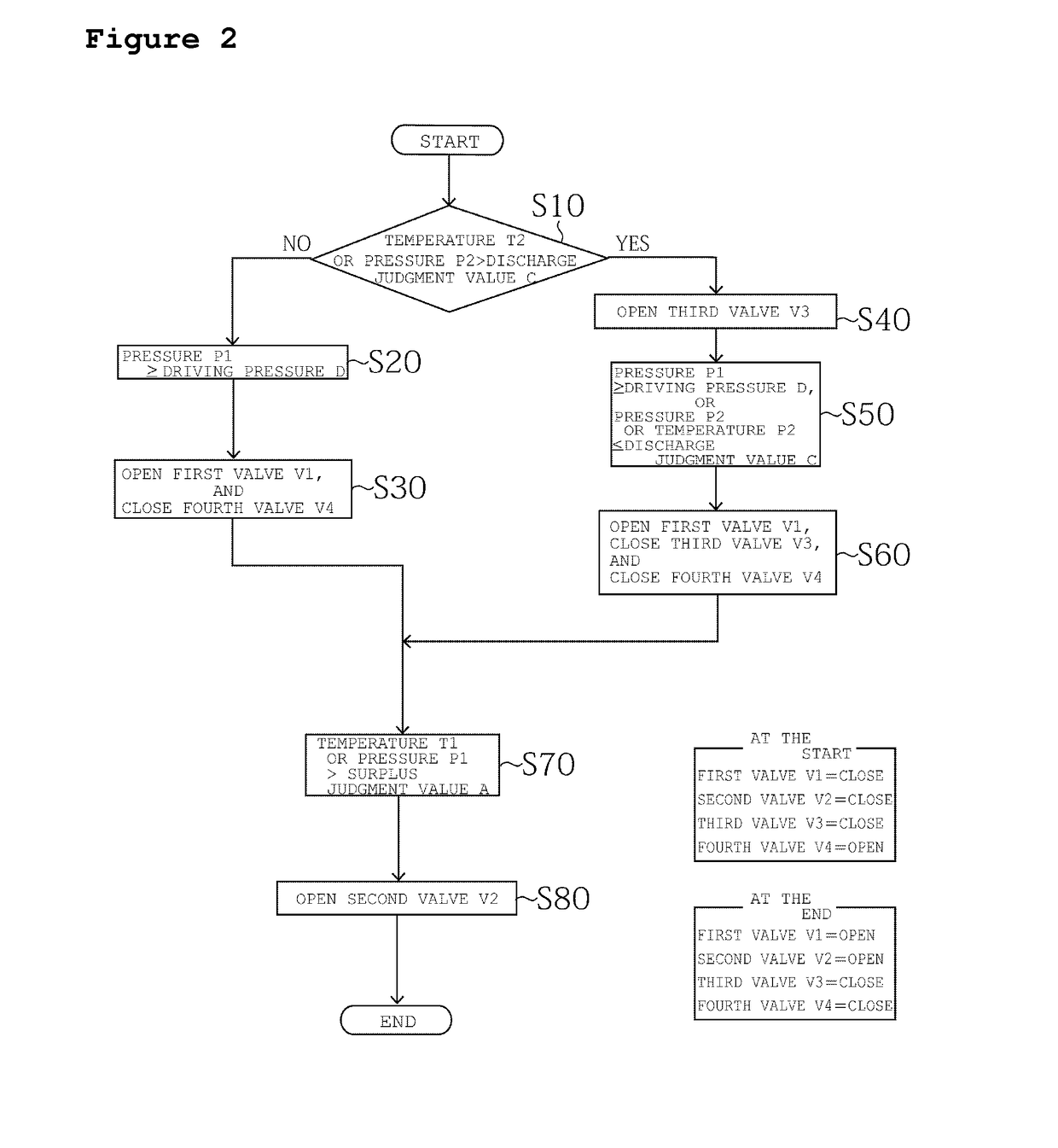

Exhaust heat recovery device for internal combustion engine and exhaust heat recovery method for internal combustion engine

ActiveUS20150275698A1Easy to useImprove fuel efficiencyInternal combustion piston enginesExhaust apparatusRecovery methodExternal combustion engine

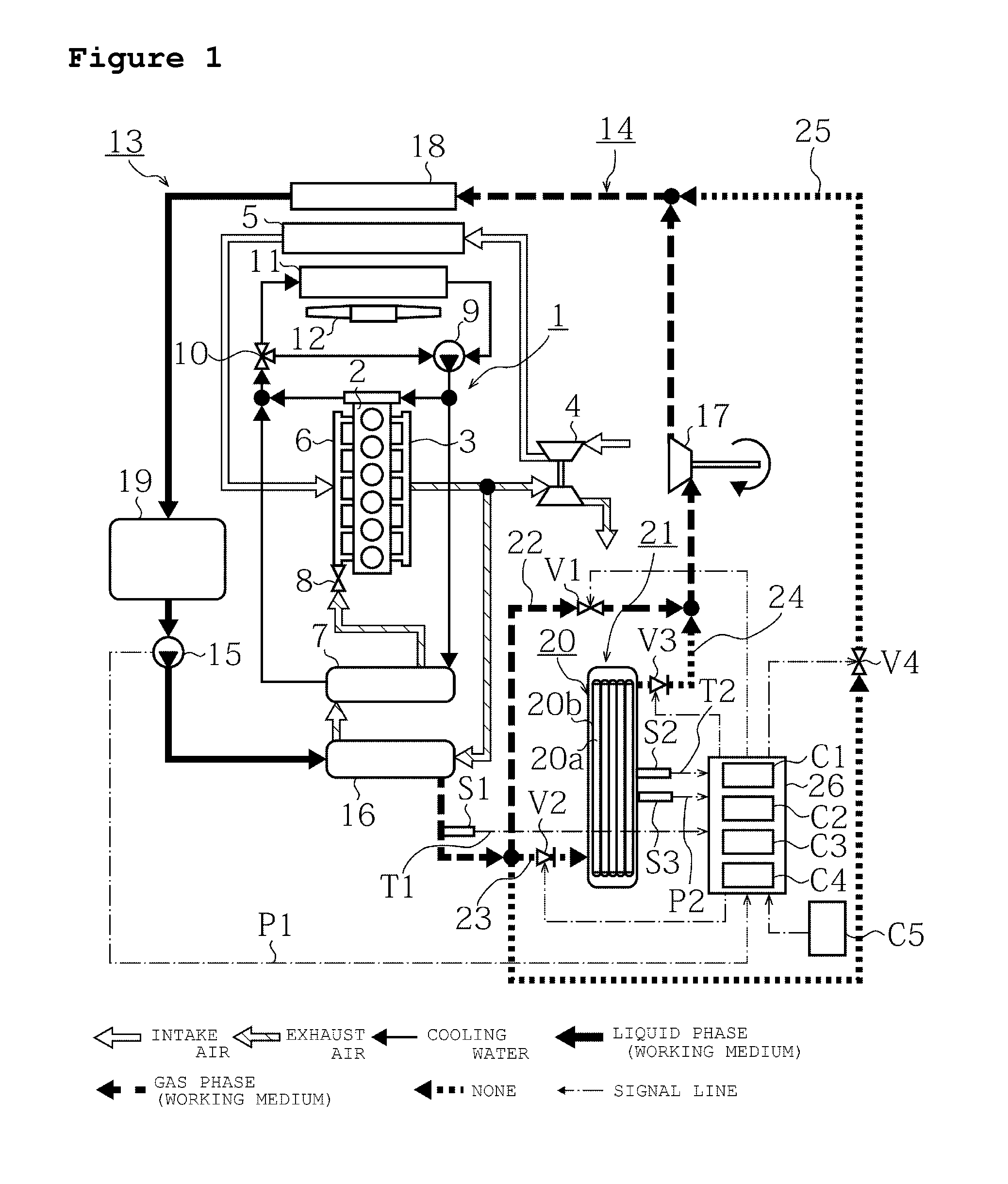

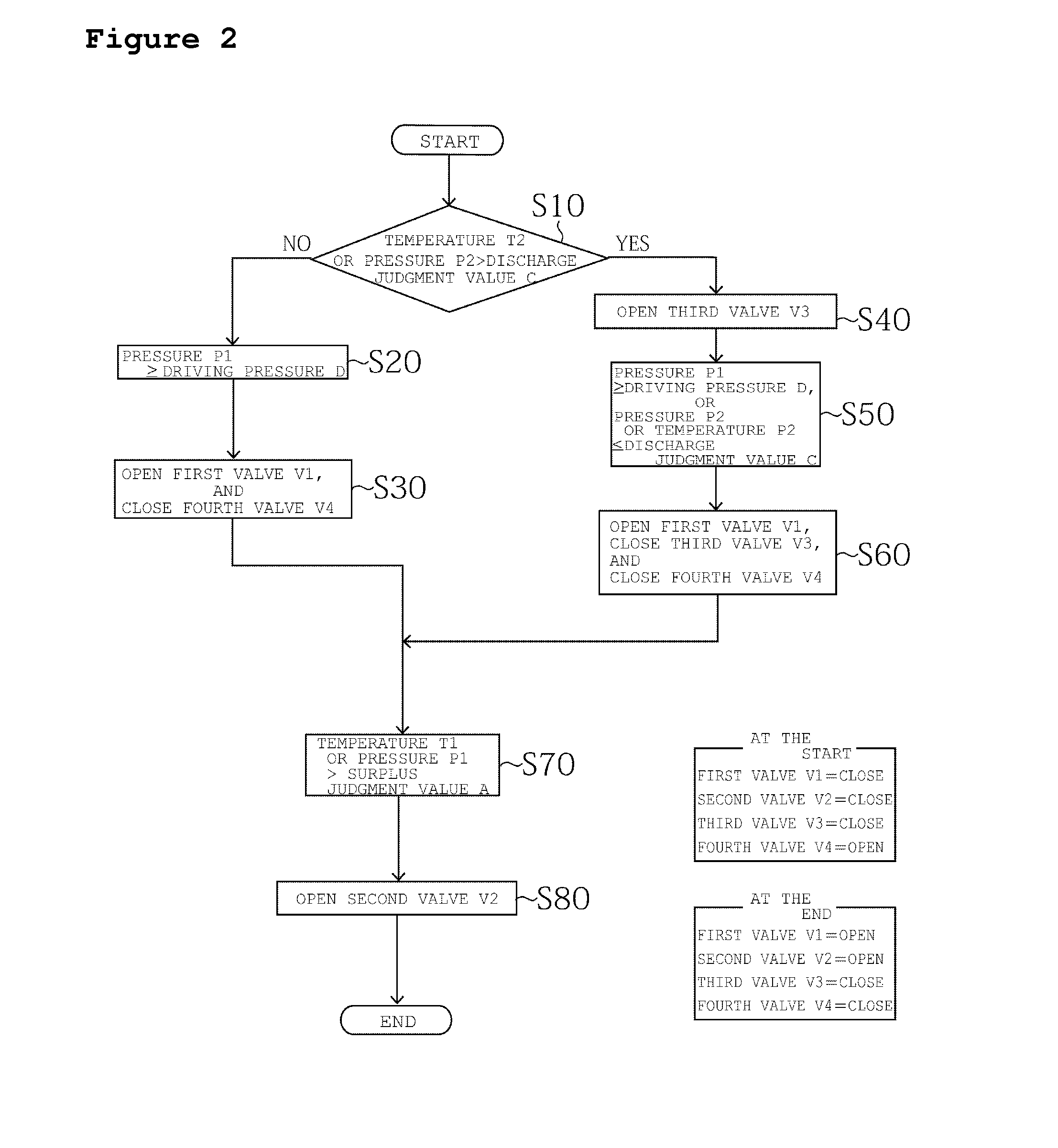

An exhaust heat recovery device for an engine including a Rankine cycle, including a steam accumulator that stores a surplus of a working medium for driving a turbine, and a leveling line that discharges the stored surplus working medium from the steam accumulator to the turbine, when the turbine cannot output predetermined power only with the working medium flowing out from a boiler, and levels the power outputted from the turbine. Since the power outputted from the turbine can be leveled without reduction of the power, even if the working medium cannot vaporize with the boiler immediately after start-up, immediately before stop, or during a low-load operation of the engine, exhaust heat from the engine can be efficiently used.

Owner:ISUZU MOTORS LTD

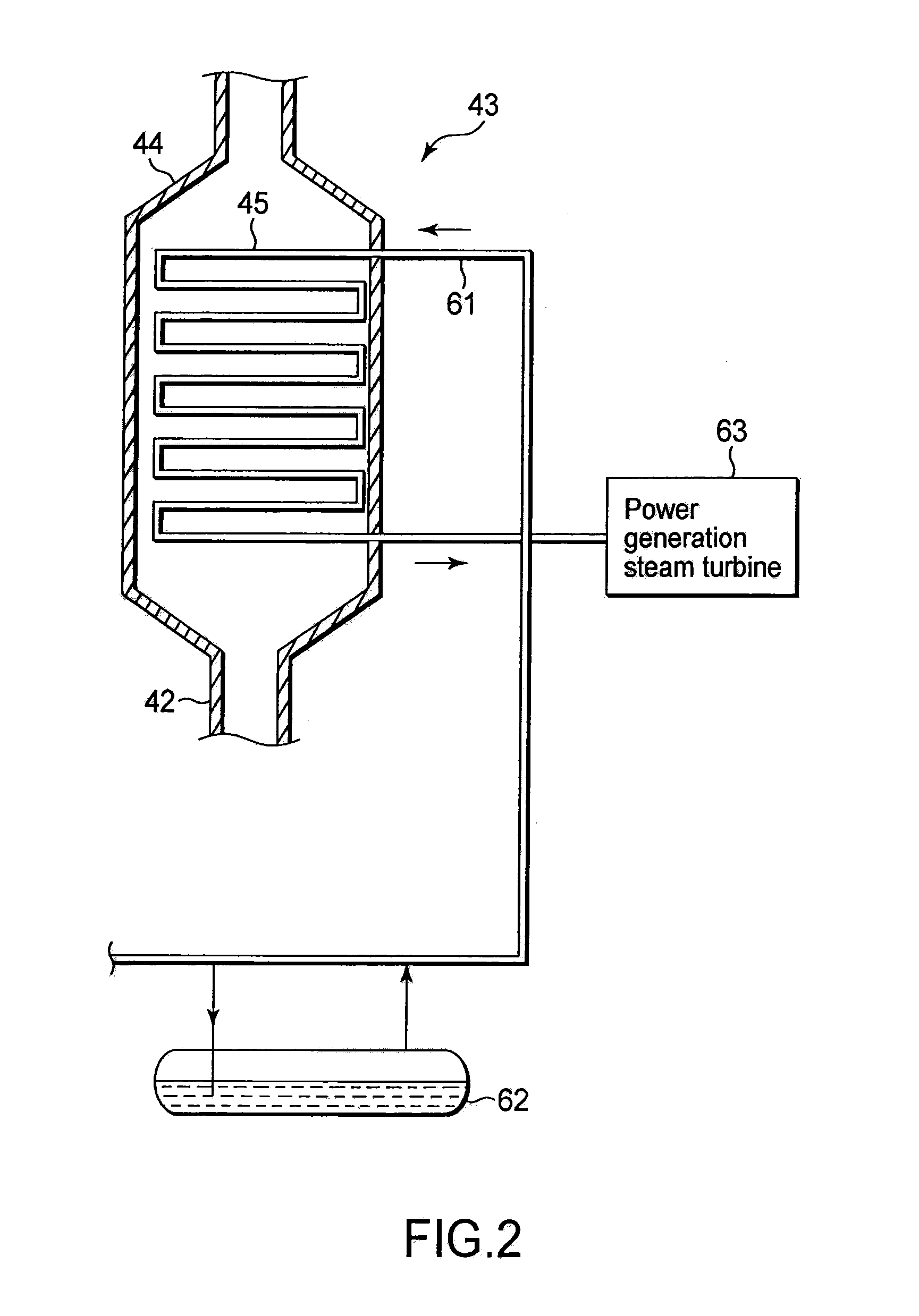

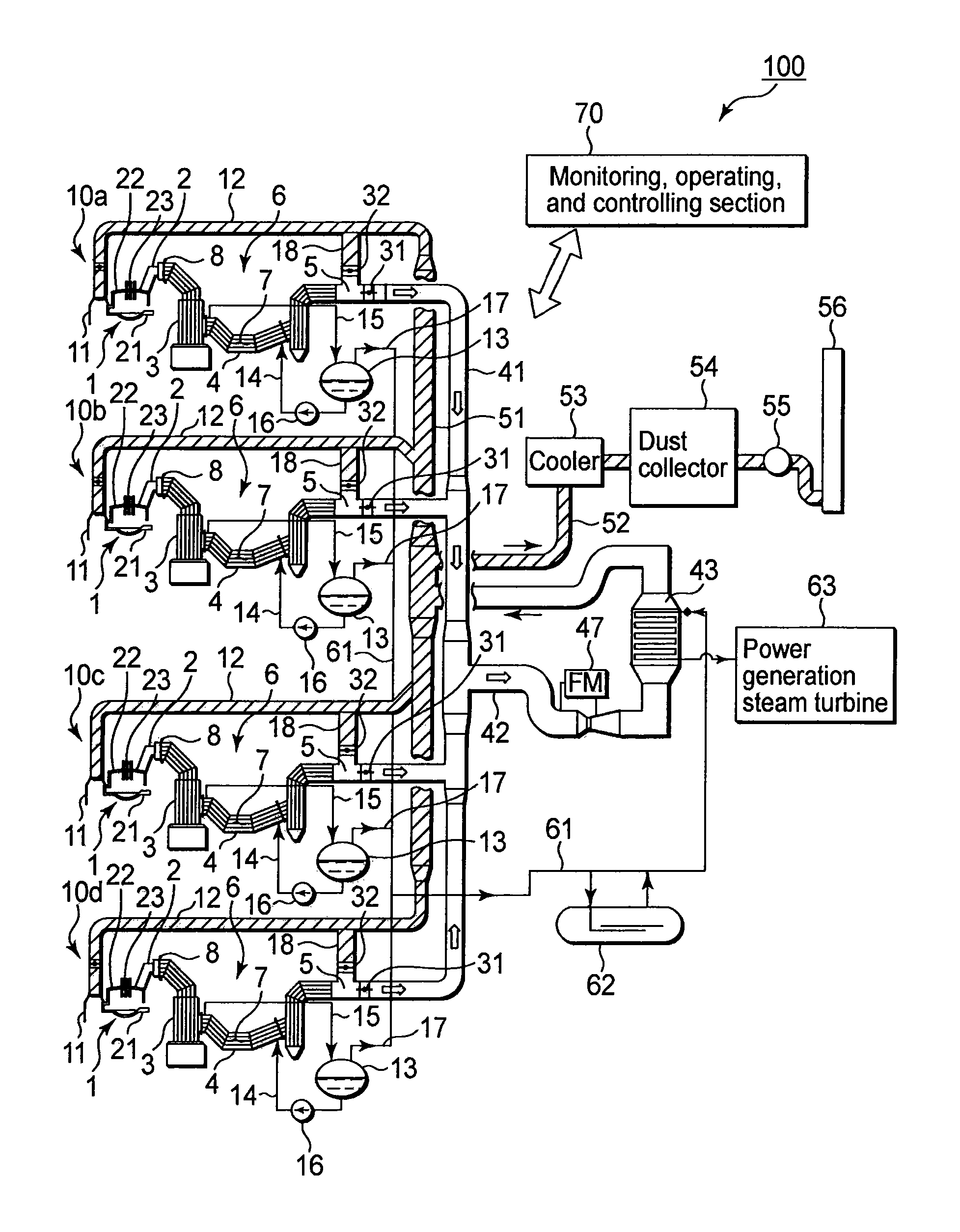

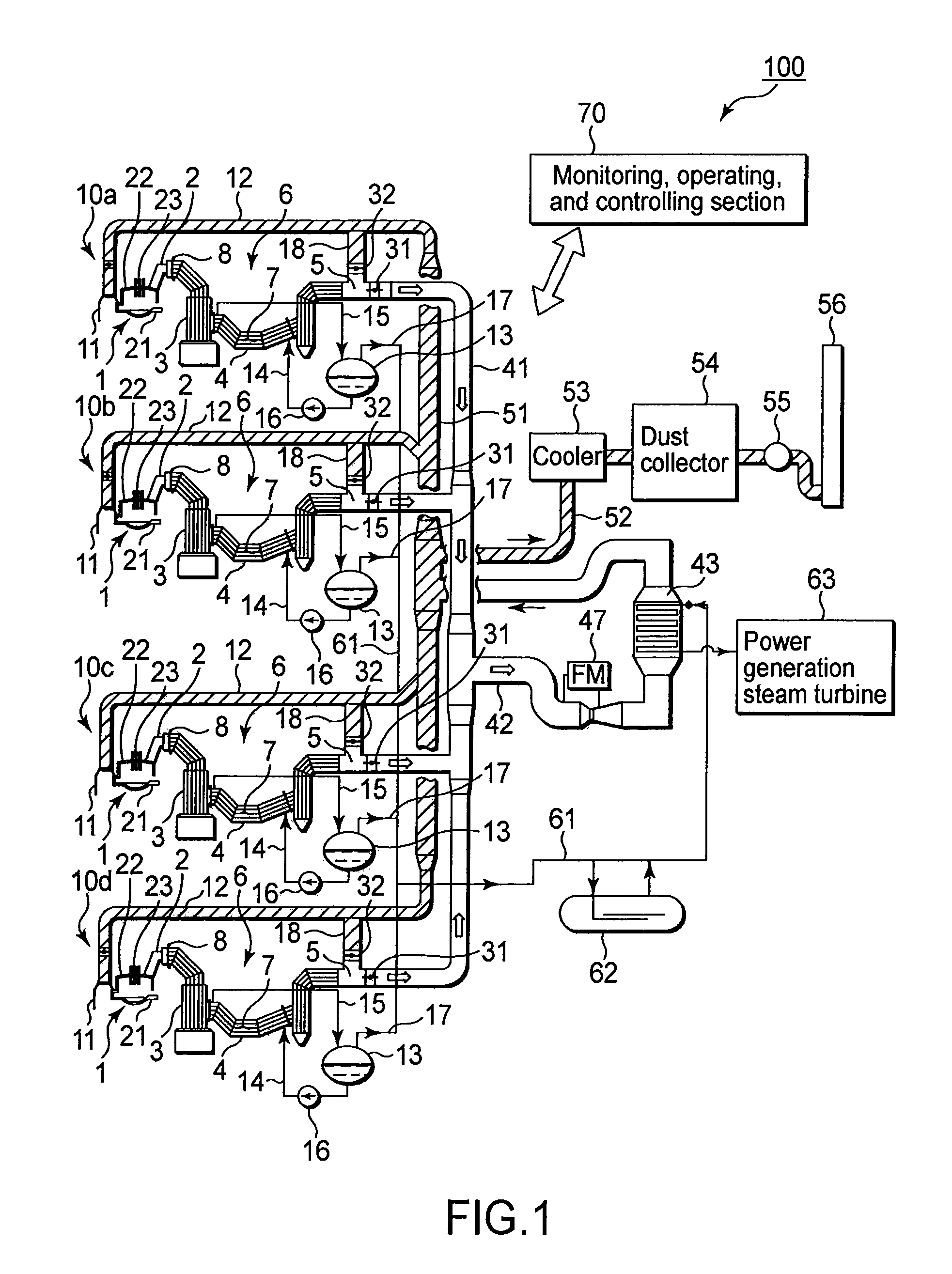

Waste heat recovery structure for steel making electric arc furnaces, steel making electric arc furnace facility, and waste heat recovery method for steel making electric arc furnaces

ActiveUS20120320941A1Minimize changesEffective recoverySteam generation heating methodsRecovering materialsWaste heat recovery unitRecovery method

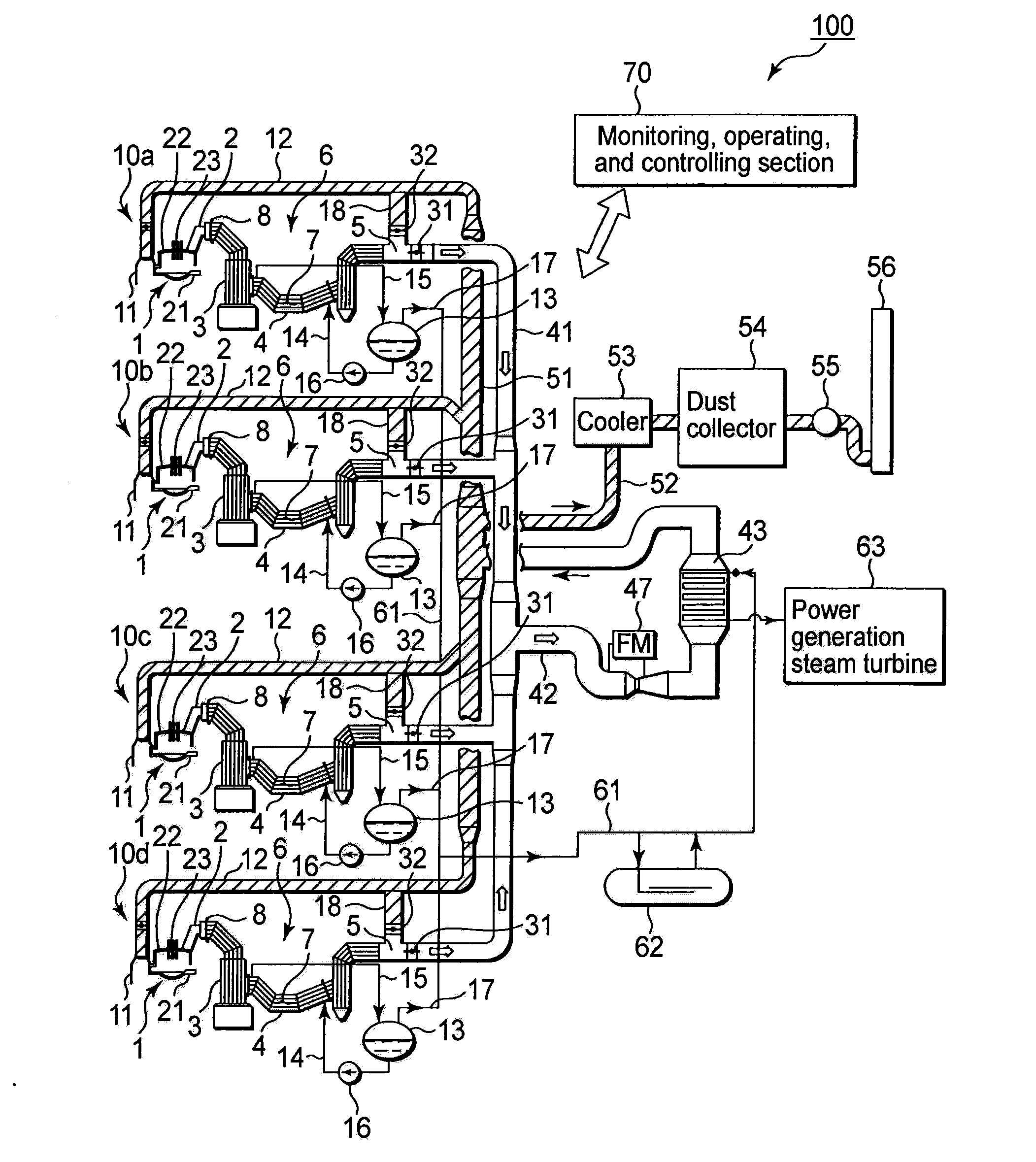

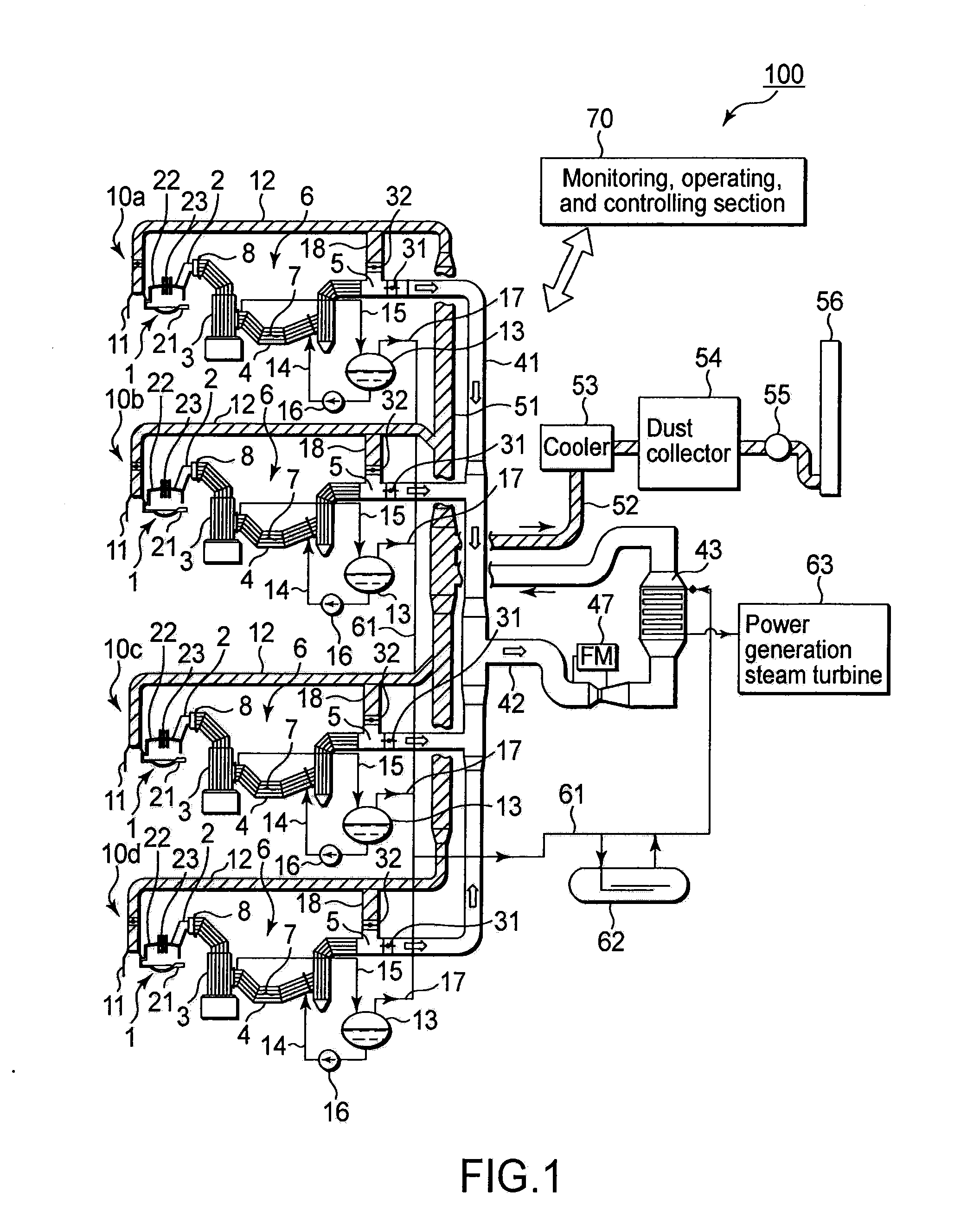

A waste heat recovery structure includes a first exhaust gas flow path provided to each of steel making electric arc furnaces to discharge exhaust gas thereinto; a waste heat boiler disposed on the first exhaust gas flow path to recover waste heat as saturated steam from exhaust gas; a steam accumulator configured to store steam formed by confluence of saturated steam parts, each generated by the waste heat boiler; a steam super heater configured to turn steam into superheated steam by heating; a second exhaust gas flow path configured to lead exhaust gas from the waste heat boiler to the steam super heater to use it for superheating; a third exhaust gas flow path configured to discharge exhaust gas from the waste heat boiler not through the steam super heater; and a switching device configured to switch flow paths between the second and third exhaust gas flow paths.

Owner:JP STEEL PLANTECH CO

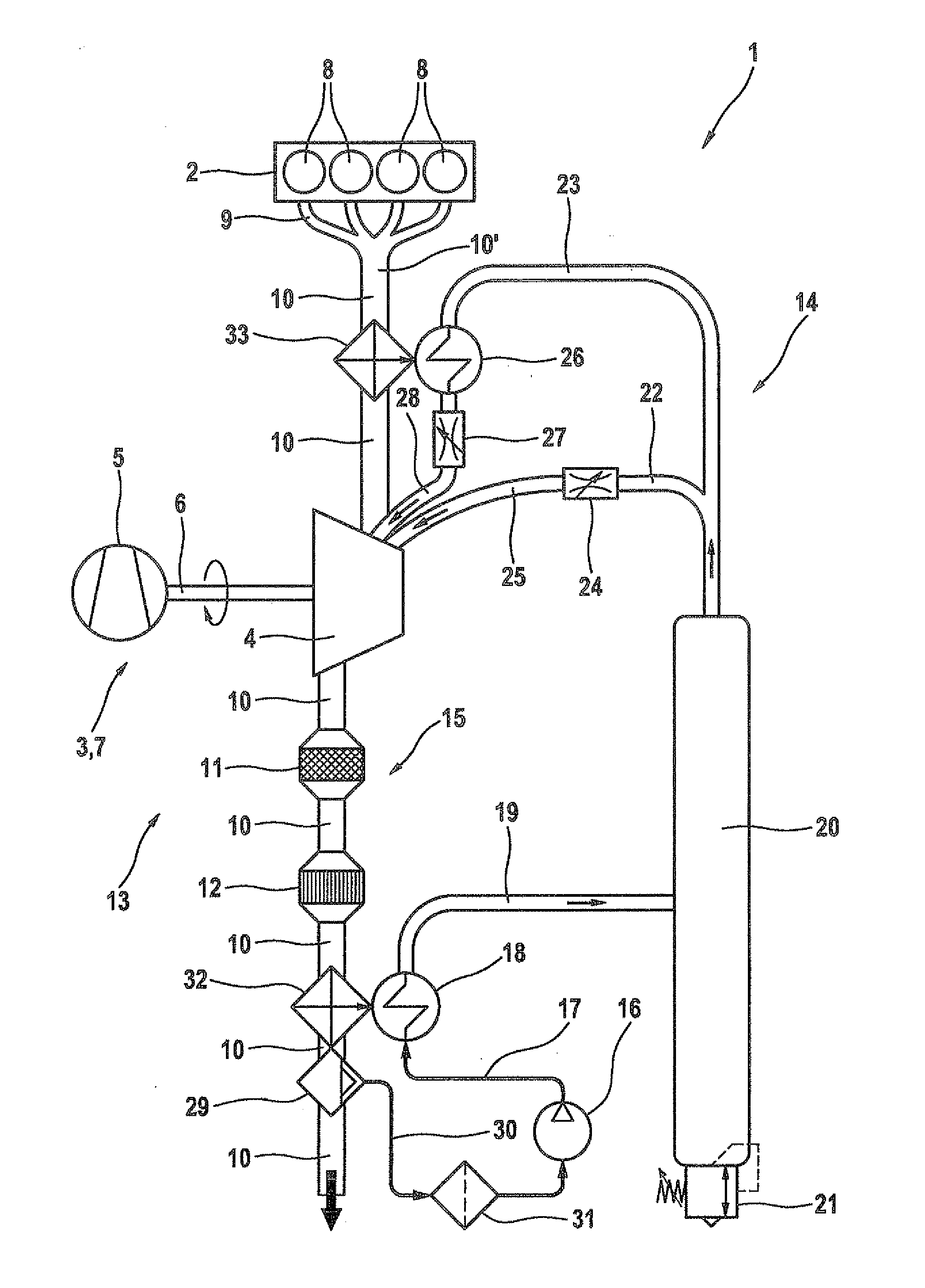

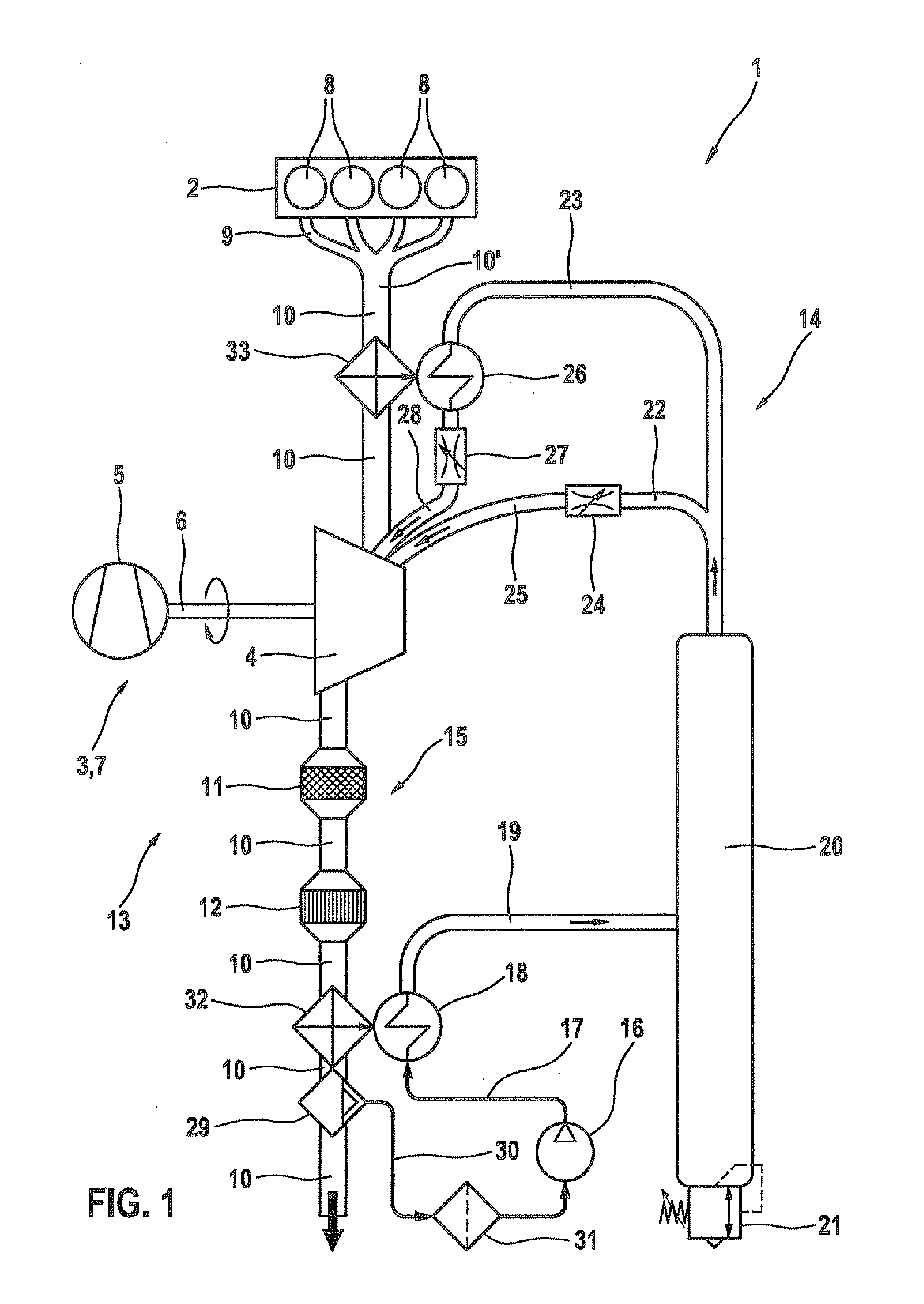

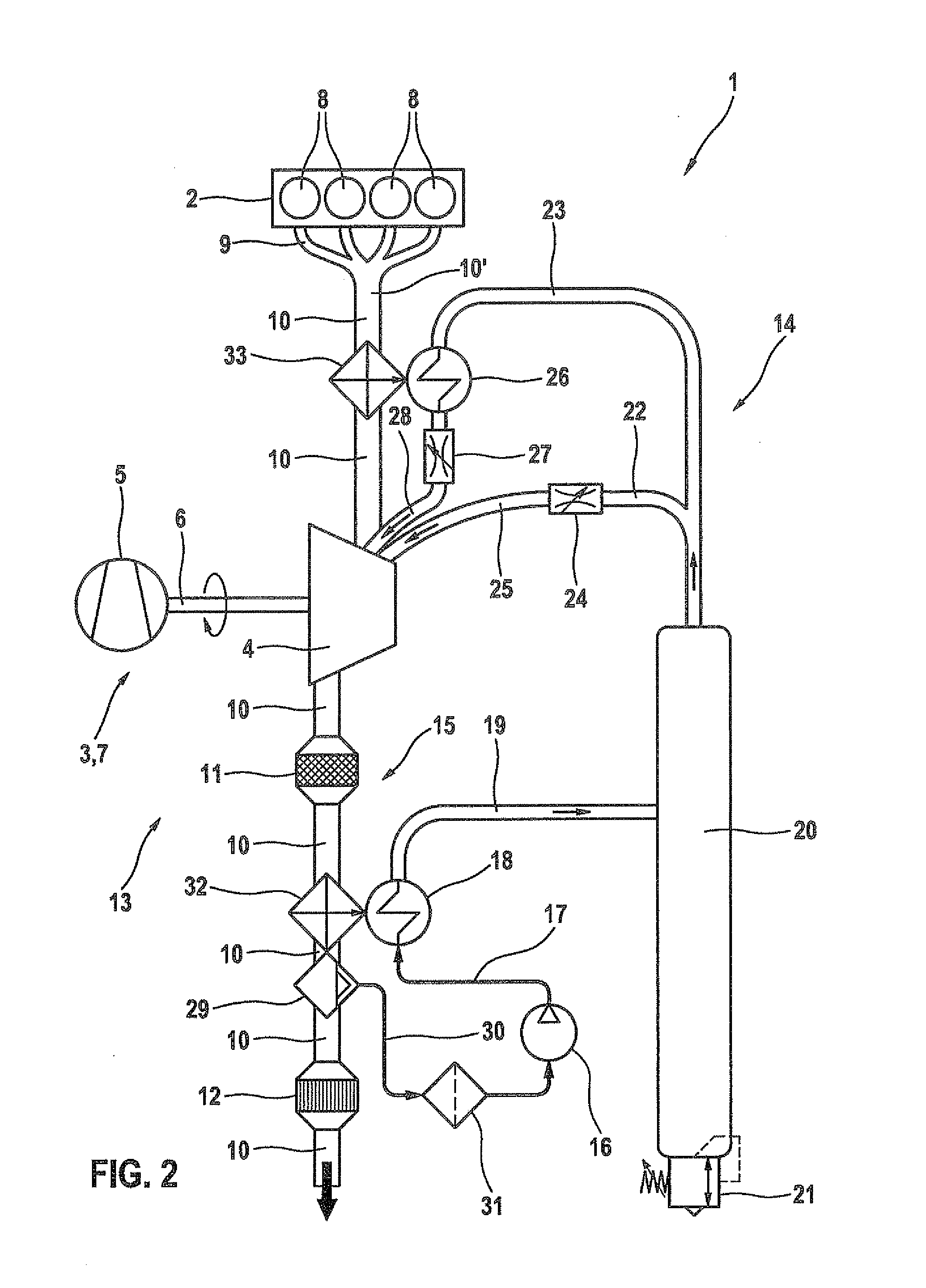

Driving device

InactiveUS20120260654A1Improve combustionImprove efficiencyInternal combustion piston enginesExhaust apparatusThermal energySteam pressure

A driving device having a charging device for increasing the pressure and the mass flow of the combustion air of an internal combustion engine, and having a steam generator for evaporating a fluid using thermal energy drawn from the exhaust gas of the internal combustion engine. The steam generator is connected to a steam accumulator, and the charging device is an exhaust gas turbocharger whose drive turbine can be acted on at least partly both by exhaust gas and also by steam from the steam accumulator, the steam pressure and / or steam mass flow of the steam supplied to the exhaust gas turbocharger being capable of being regulated and / or controlled.

Owner:ROBERT BOSCH GMBH

Immediate response steam generating system and method

The method of generating immediate and thereafter continuous steam is used in a steam generating system comprising a steam accumulator, a steam outlet connected to the steam accumulator, an outlet valve at the steam outlet, and a quick response steam generator unit connected to the steam accumulator. The method comprises the steps of providing latent steam in the steam accumulator, opening the outlet valve to allow latent steam in the steam accumulator to exit through the steam outlet, feeding water to the steam generator unit, heating the water fed to the steam generator unit while the latent steam exits through the steam outlet and, before the latent steam has entirely exited the steam accumulator, generating steam with the steam generator unit to feed the steam accumulator and controlling the steam flow rate through the steam outlet to maintain it at a value which is essentially not greater than the steam flow rate from the steam generator unit to the steam accumulator. The steam generating system is capable of generating immediate and thereafter continuous steam from an initial steam generator unit cold condition due to the steam accumulator providing steam at the steam outlet while the steam generator unit heats the water fed therein.

Owner:ENERO INVENTIONS

Catch water of varying pressure steam accumulator

InactiveCN1424553AEqual speedReduce wateringHeat storage plantsSteam separation arrangementsEngineeringSteam accumulator

A separation device of steam and water for heat accumulator in change pressure type sets flute pipe with non-uniform hole at upper part of the heat accumulator and to set in parallel with shaft centre of it connects screw dewaterer at outlet flange of steam output main pipe as steam input pipe of the screw dewaterer to be connected with dewaterer cylindrical body in tangential direction, steam output pipe to be inserted into cylindrical body for fixing, steam input pipe baffle to be set in the steam input pipe in tilt to block a half area of flowing for steam stream. The device can decrease a lot of water contained in the steam o f heat accumualtor in change pressure to raise effectively the quality of steam.

Owner:SHANGHAI JIAO TONG UNIV

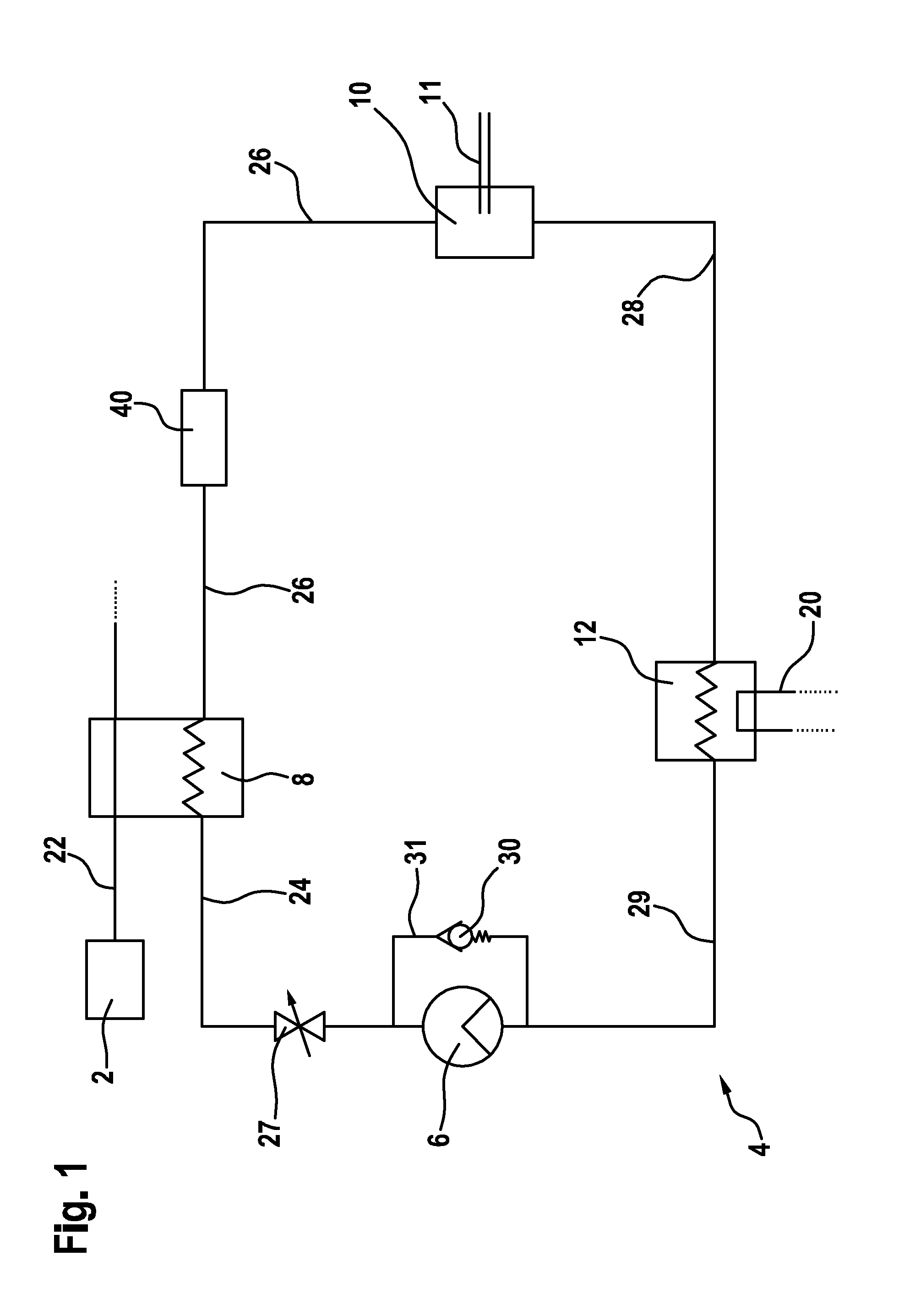

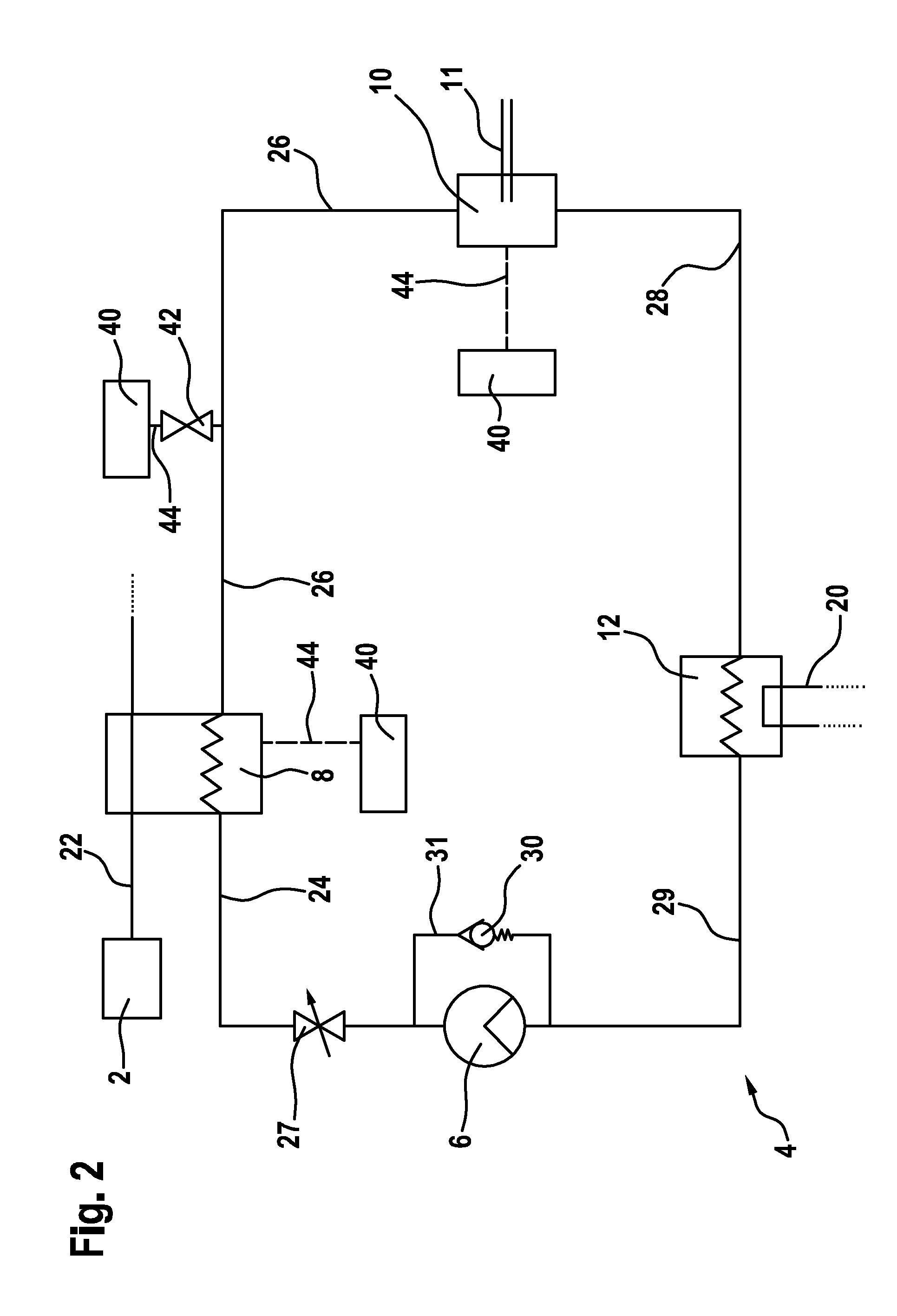

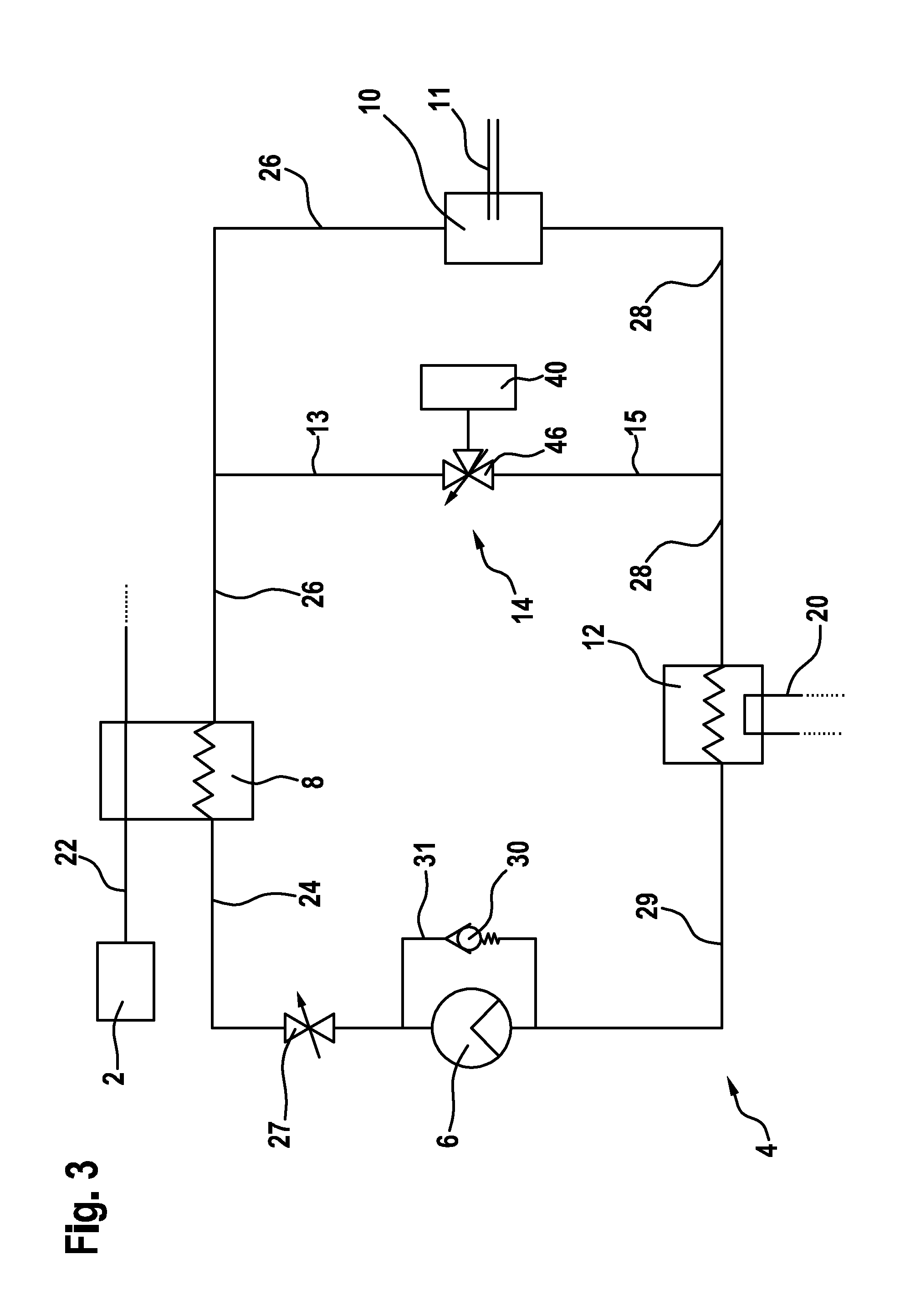

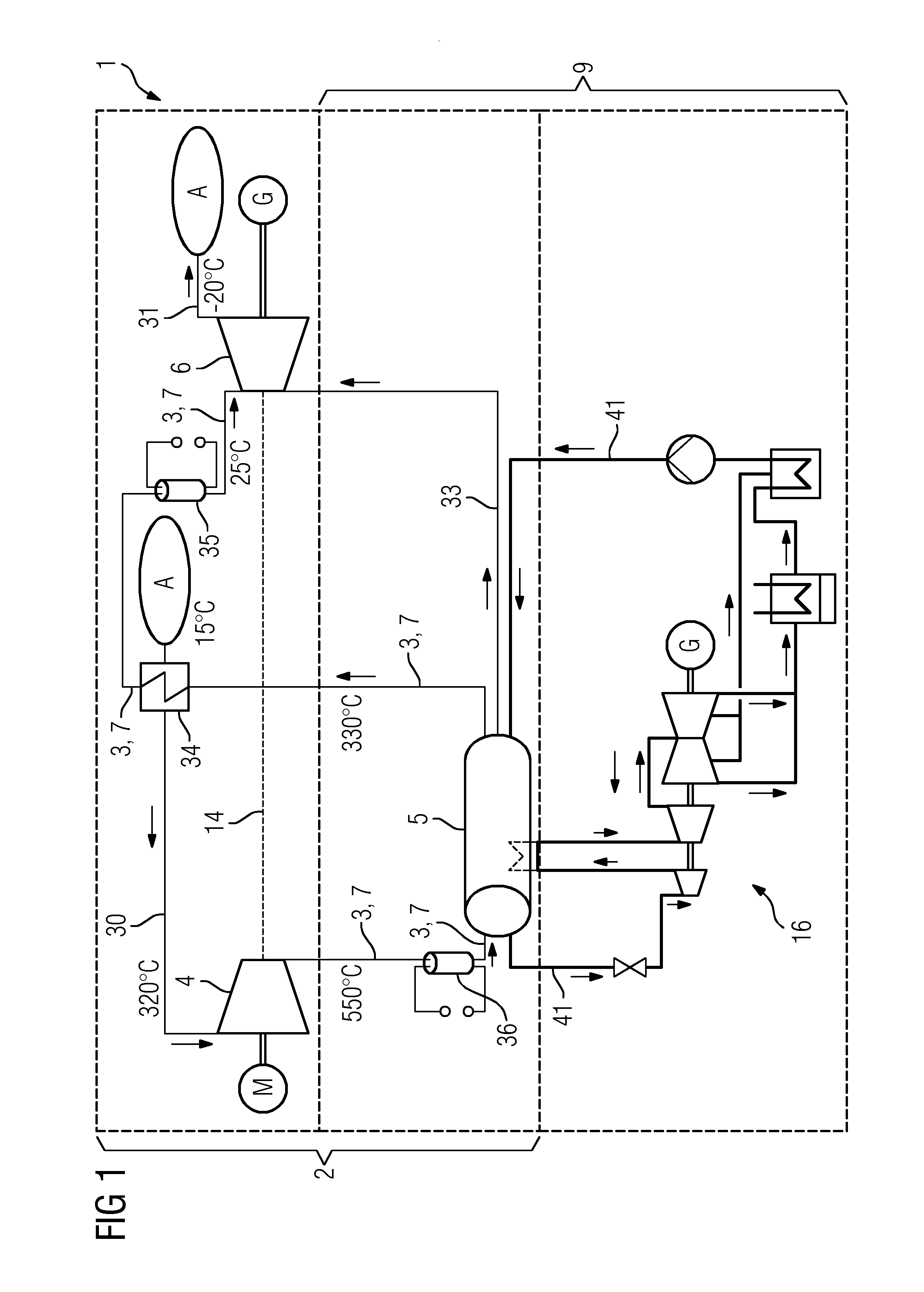

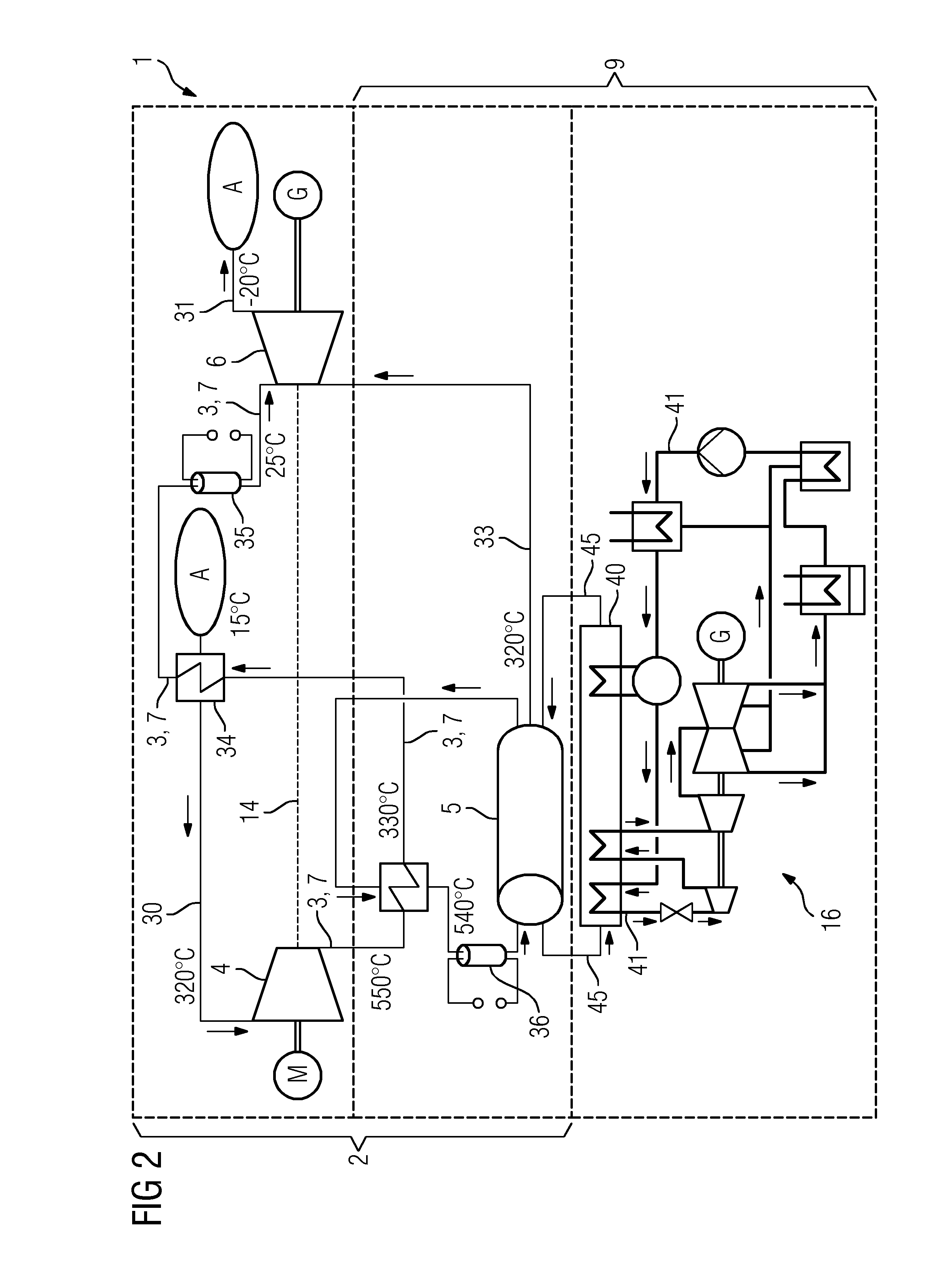

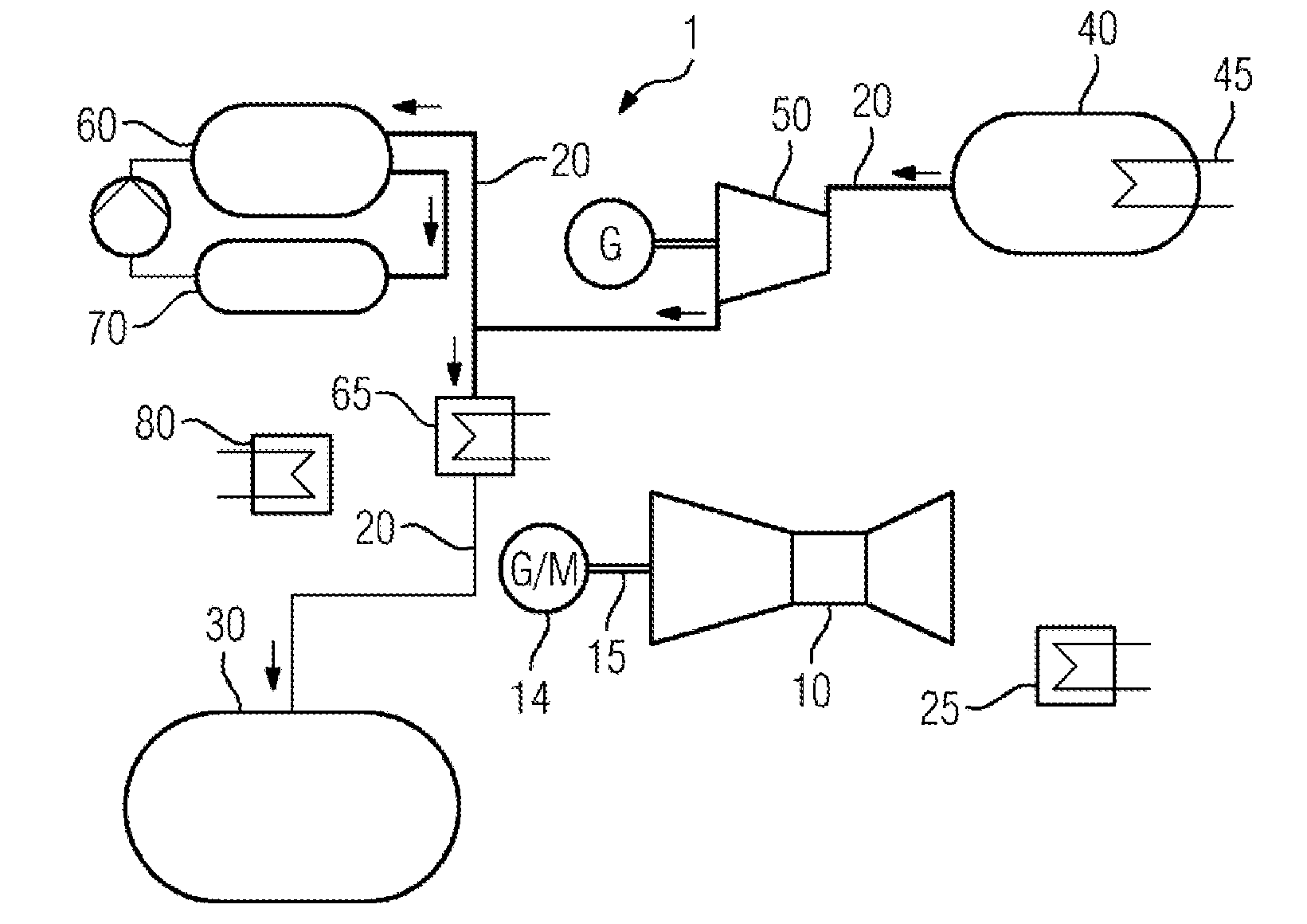

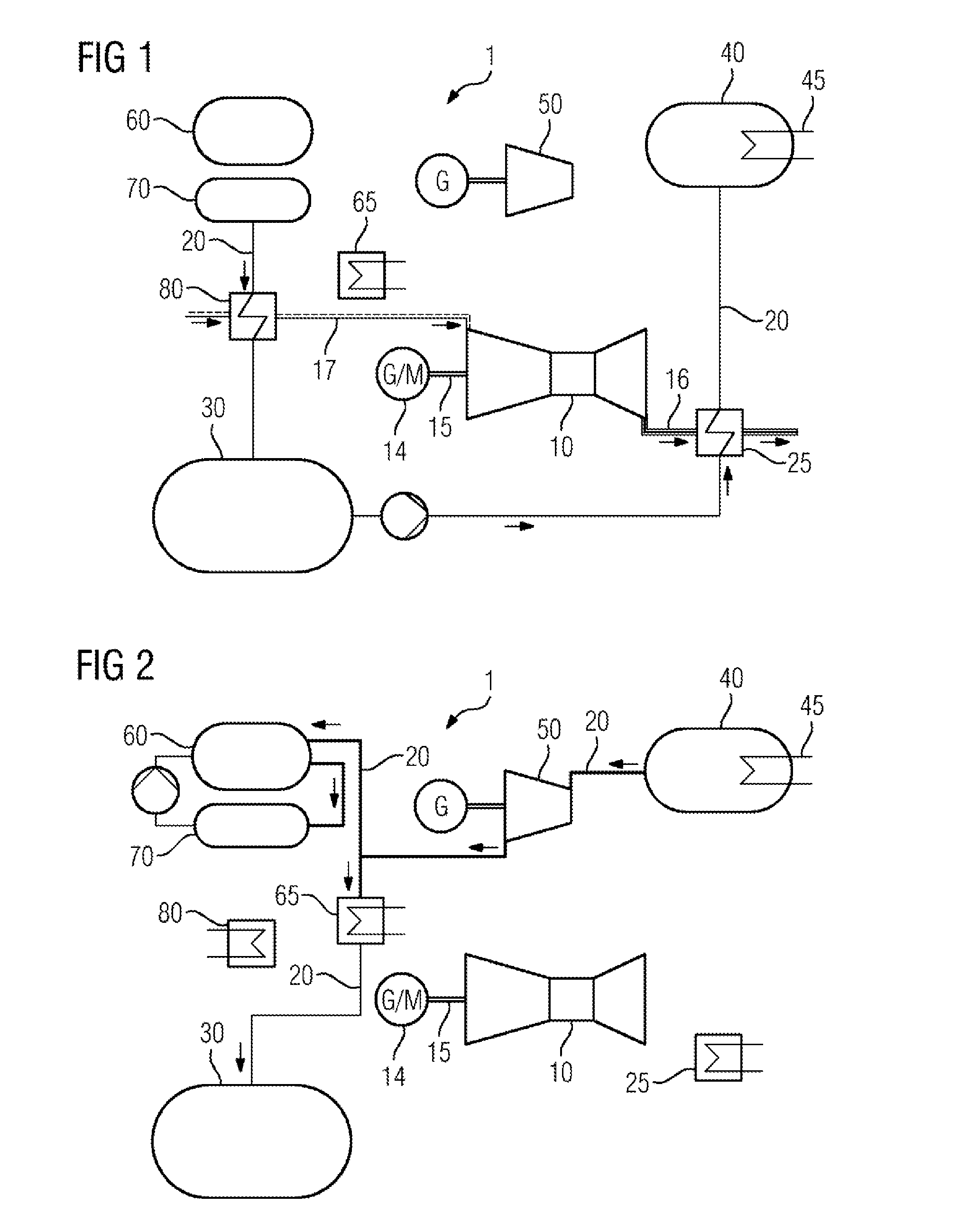

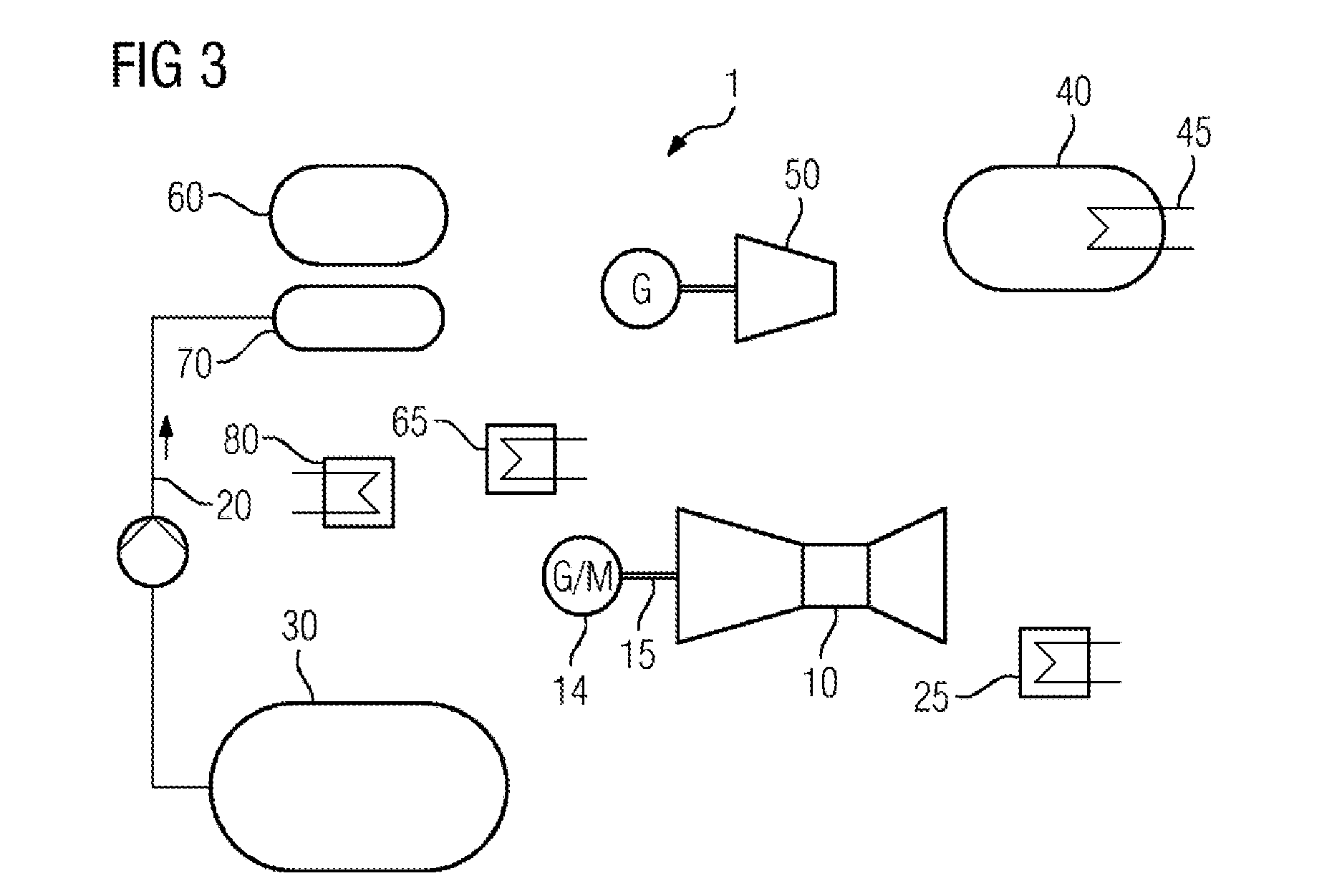

Device and method for the recovery of waste heat of an internal combustion engine

InactiveUS20130192225A1Convenient ArrangementReduce heatSteam generation heating methodsCombustion enginesEngineeringInternal combustion engine

The invention relates to a device and a method for the recovery of waste heat from an internal combustion engine (2). A feed pump (6), a heat exchanger (8), an expansion engine (10) and a capacitor (12) are arranged in a circuit (4) containing a circulating working medium. A steam accumulator (40) for storing the vaporous working medium is also arranged in the circuit (4).

Owner:ROBERT BOSCH GMBH

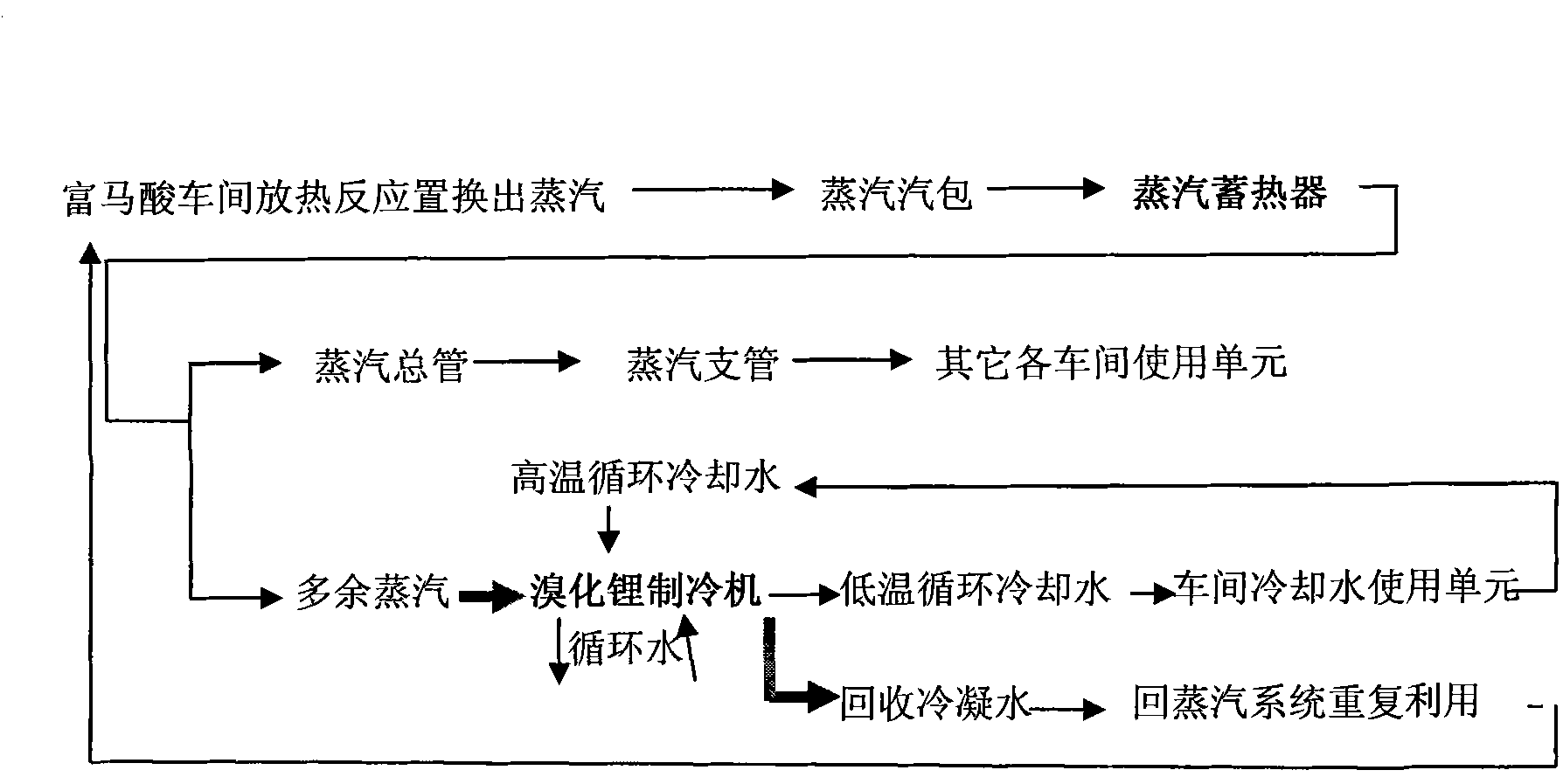

Waste heat comprehensive utilization device during the production process of fumaric acid

ActiveCN101987816AImprove cooling effectImprove efficiencyOrganic chemistryChemical industryThermal energyLithium bromide

The invention provides a waste heat comprehensive utilization device during the production process of fumaric acid, and belongs to waste heat recycling equipment. The waste heat comprehensive utilization device comprises a steam pocket communicated with steam displaced through exothermic reaction in a fumaric acid workshop, a steam header pipe and a steam branch pipe which are connected with other steam application workshops for production of the fumaric acid, wherein, a steam pocket pipe is connected with a steam accumulator; the steam header pipe is connected on the steam accumulator; and the steam accumulator is connected with a lithium bromide refrigerating machine via another pipe. In the invention, by adding the steam accumulator, steam load and heat accumulation can be stabilized; the excessive steam is taken as a driving heat source; the lithium bromide refrigerating machine is used for producing low-temperature circulating cooling water for cooling use in the workshops; and meanwhile steam condensate is recycled so that thermal energy and water resource can be utilized maximally, thus saving energy and production cost.

Owner:宜兴市前成生物有限公司

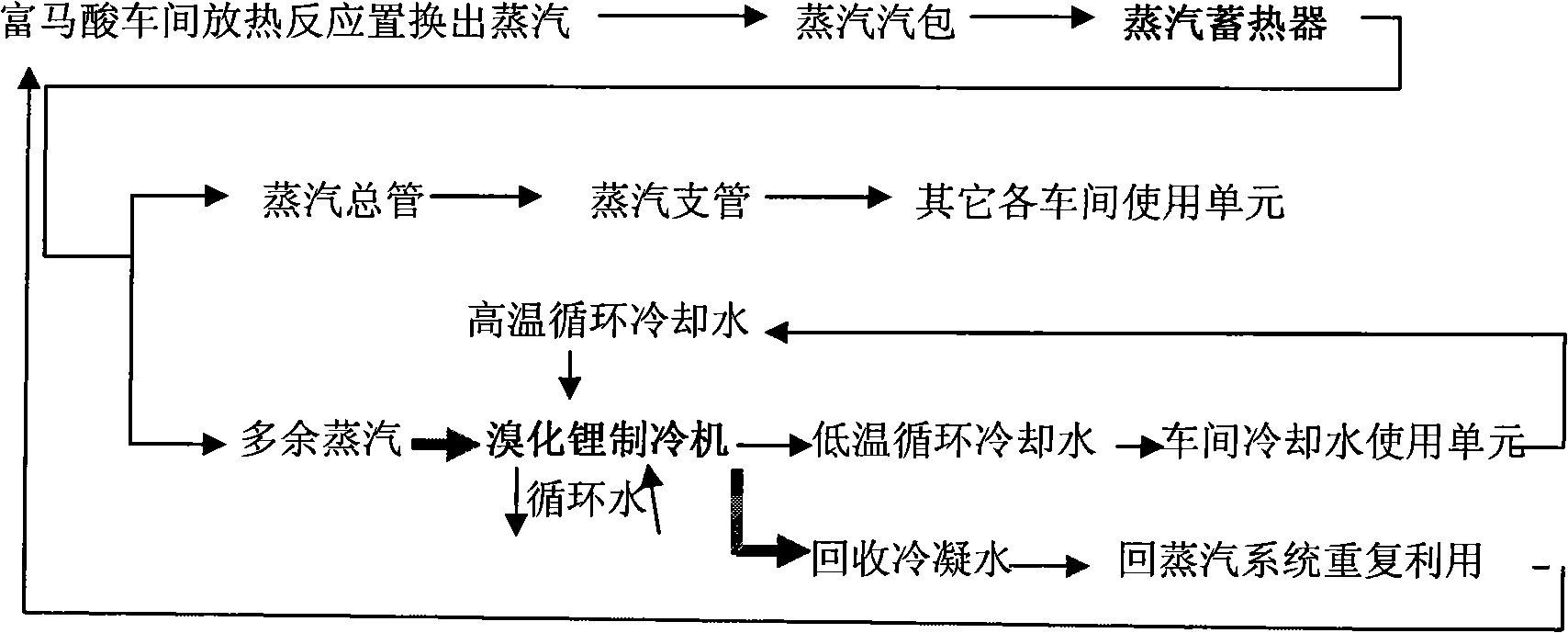

Afterheat recycling device for continuous cast secondary cooling section

ActiveCN102773441AImprove securityImprove cooling effectEnergy industryIncreasing energy efficiencyThermal energyMolten salt

The invention discloses an afterheat recycling device for a continuous cast secondary cooling section. The afterheat recycling device comprises an afterheat recycling system and a steam generation system, wherein the afterheat recycling system comprises an intermediate-temperate salt bath pool (3) in which a roller shaft (2) is arranged and an intermediate-temperate salt dissolving furnace (5) connected with the intermediate-temperate salt bath pool; according to the afterheat recycling system, molten salt is used as a heat exchange medium; the steam generation system comprises a water tank (9), a water feed pump (10), a deaerator (11), a heat exchanger (6), a steam pocket (12) and a steam accumulator (13); and the heat exchanger is respectively connected with the intermediate-temperate salt bath pool and the intermediate-temperate salt dissolving furnace of the afterheat recycling system. By adopting the system, the afterheat recycling device for the continuous cast secondary cooling section can convert heat energy of steel billets into steam heat energy and is high in heat energy recycling rate.

Owner:南京东方源环境科技有限公司 +1

Energy storage installation with open charging circuit for storing seasonally occurring excess electrical energy

ActiveUS20140338330A1Improve efficiencyAvoid disadvantagesSteam accumulatorsSteam engine plantsThermal energyEngineering

An energy storage device for storing thermal energy, with a charging circuit for a working gas, is provided, having a compressor, heat accumulator and expansion turbine, the compressor and expansion turbine arranged on a common shaft, and the compressor connected on the outlet side to the inlet of the expansion turbine via a first line for the working gas, the heat accumulator wired into the first line, wherein the compressor is connected on the inlet side to a line, which is open to the atmosphere, and the expansion turbine is connected on the outlet side to a line, which is open to the atmosphere such that a circuit open to the ambient air is formed, wherein the expansion turbine is connected to the heat accumulator via a line for a hot gas such that the working gas in the expansion turbine can be heated by heat from the heat accumulator.

Owner:SIEMENS AG

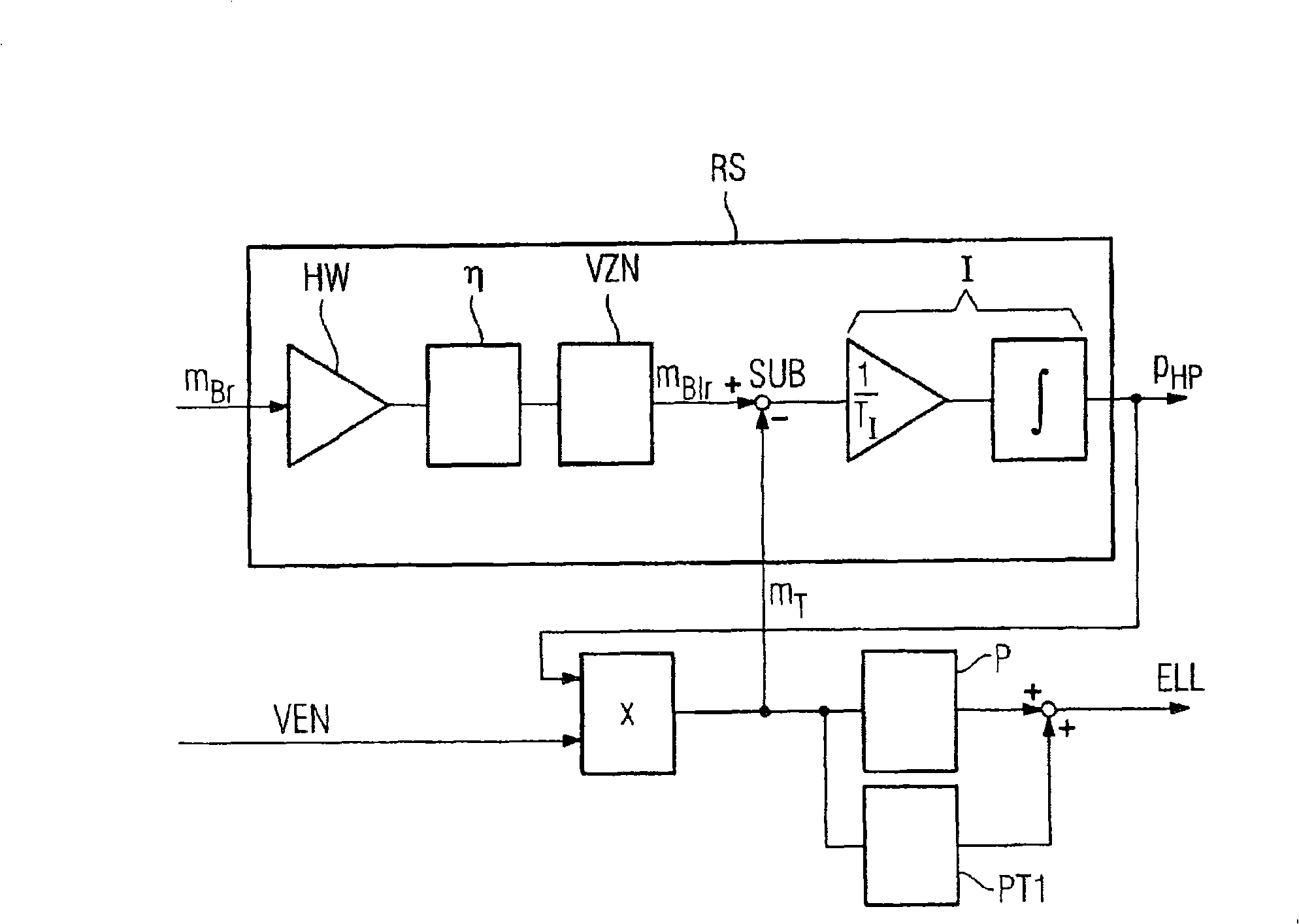

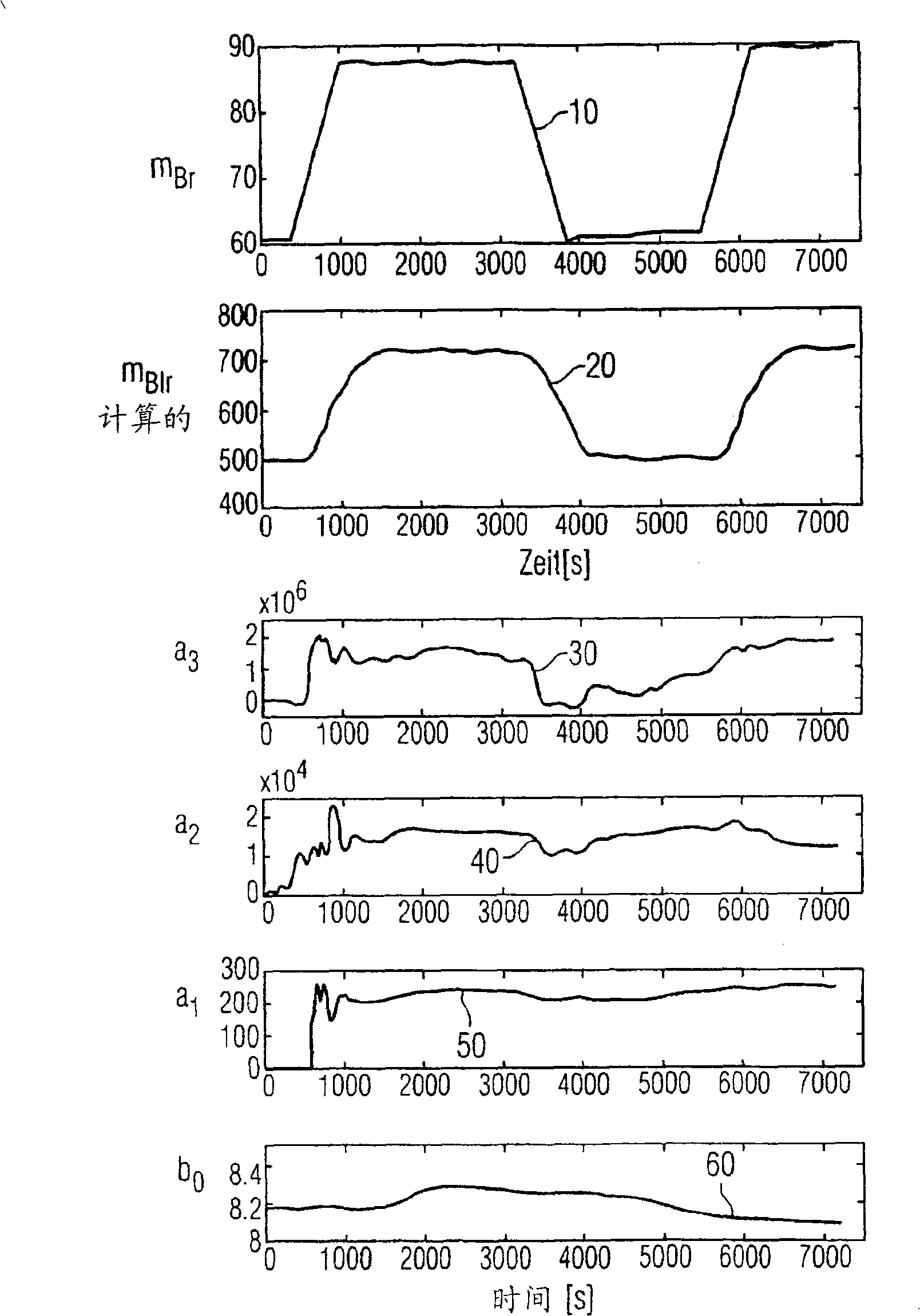

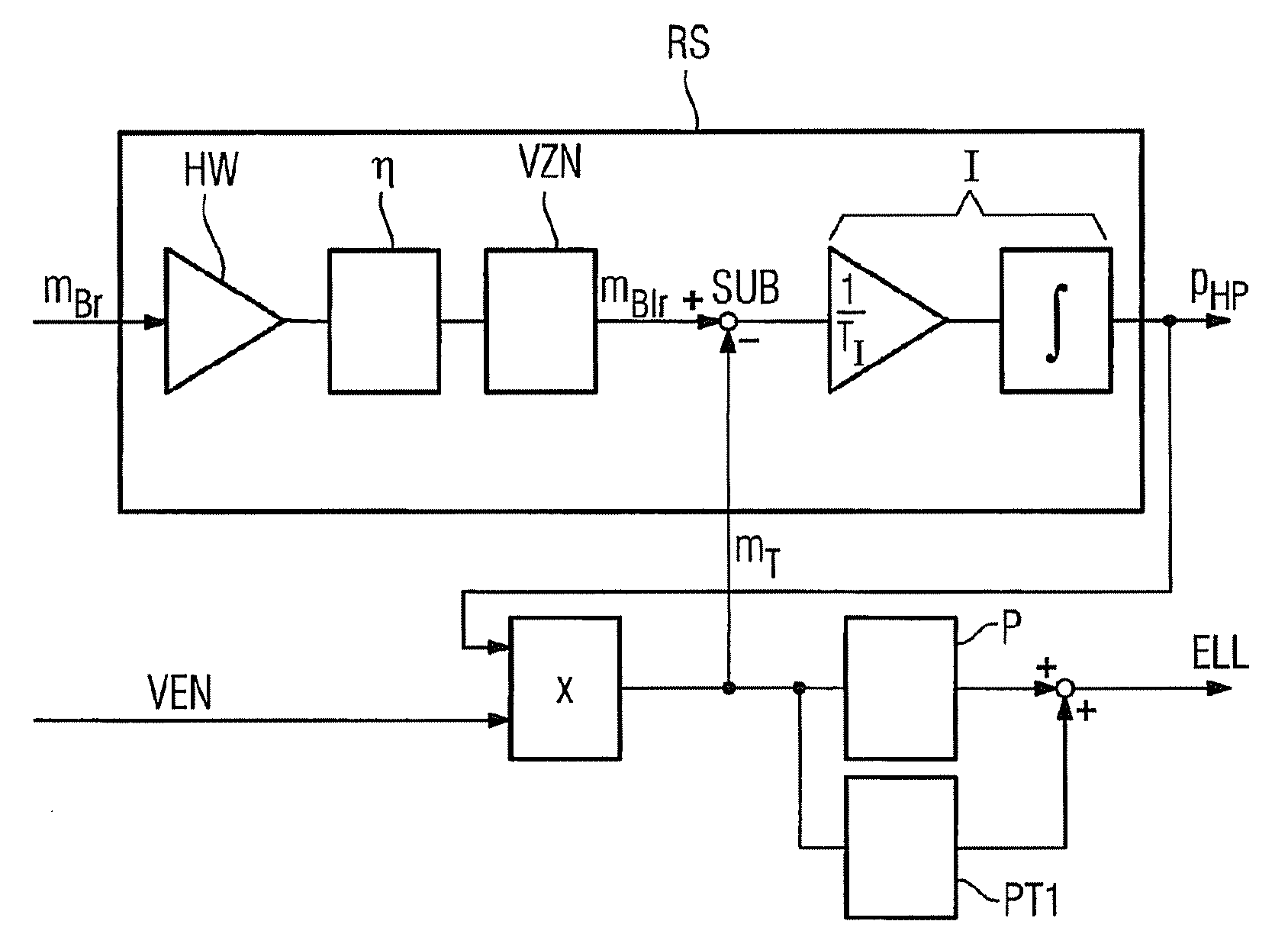

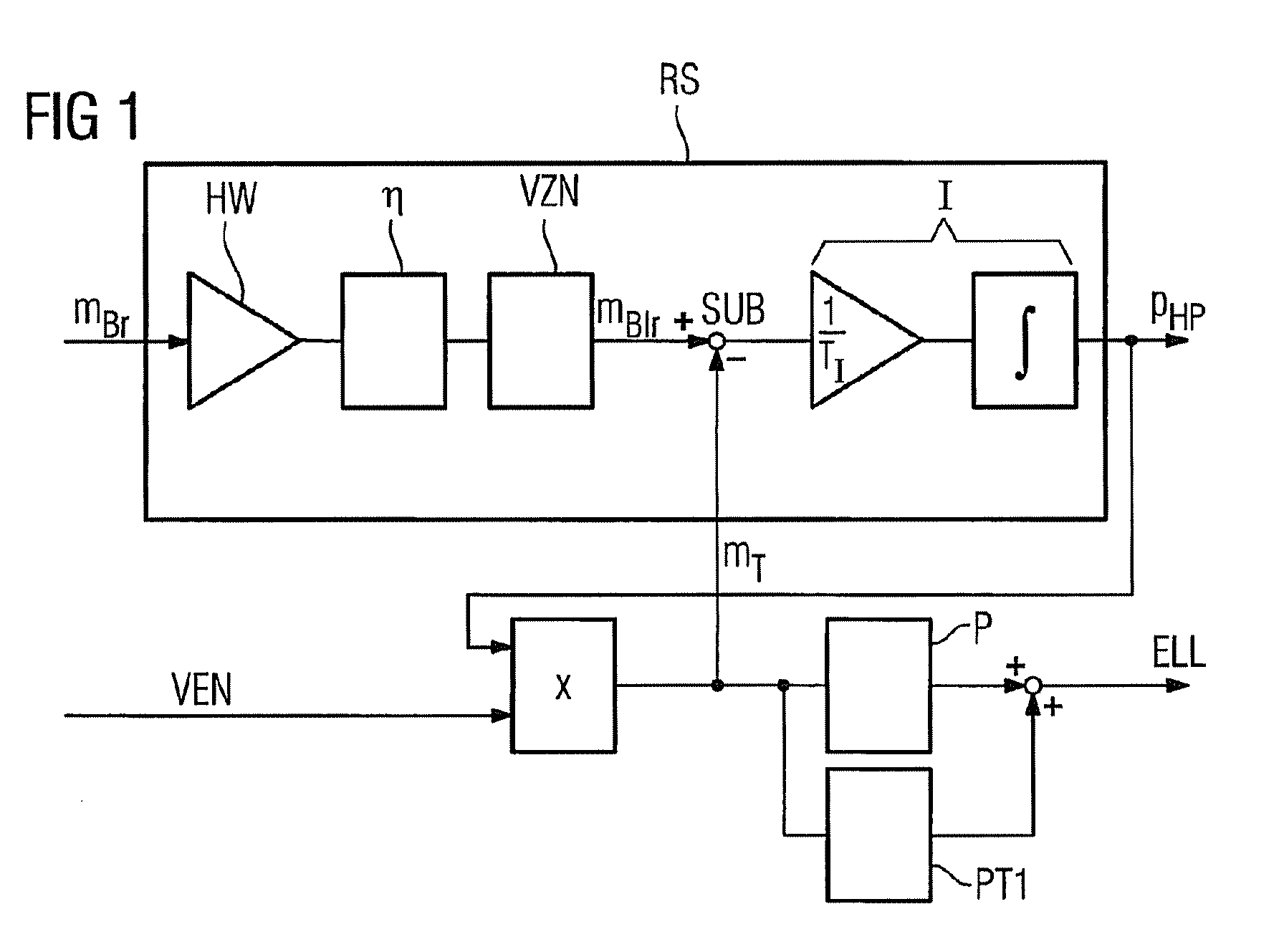

Method and device for the identification of a delay-susceptible control path, control device, and computer program product

InactiveCN101529347AImprove adjustment qualityReduce energy consumptionProgramme controlComputer controlTemporal changeSteam pressure

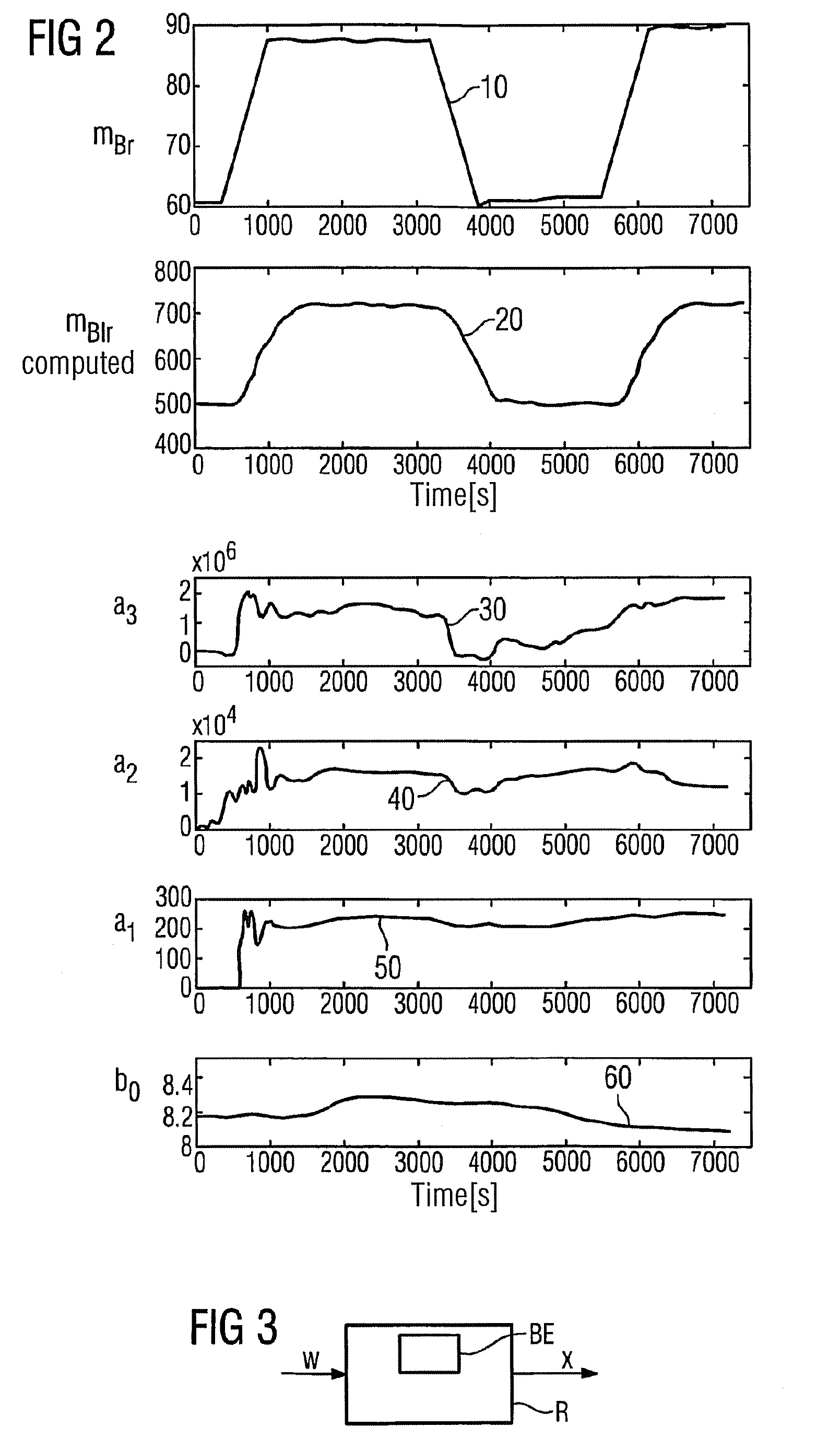

The invention relates to a method for identifying a delay-susceptible control path in the control of a steam generator, and a device constructed for carrying out the method. A model structure of the steam generator is specified, consisting of an unknown time-variable Nth-order delay element and a known integrator. Also used for the identification are measurements of the fuel mass flow, the turbine steam mass flow, and the live steam pressure which arises in the steam accumulator behind the steam generator after the removal of the turbine steam mass flow. Using these online measurements and the model structure, the live steam mass flow at the output of the steam generator is derived by calculation. In this way, the input value and the output value of the Nth-order delay element (VZN) are determined in such a way that, using an estimation method, the parameters of a continuous transmission function of the Nth-order delay element (VZN) are also determined online. The estimated parameters are then converted into the time constants of a delay element with N independent time constants. In a following step, the relevant time constant for the delay element of the specified model structure is determined by comparison of the N independent time constants.

Owner:SIEMENS AG

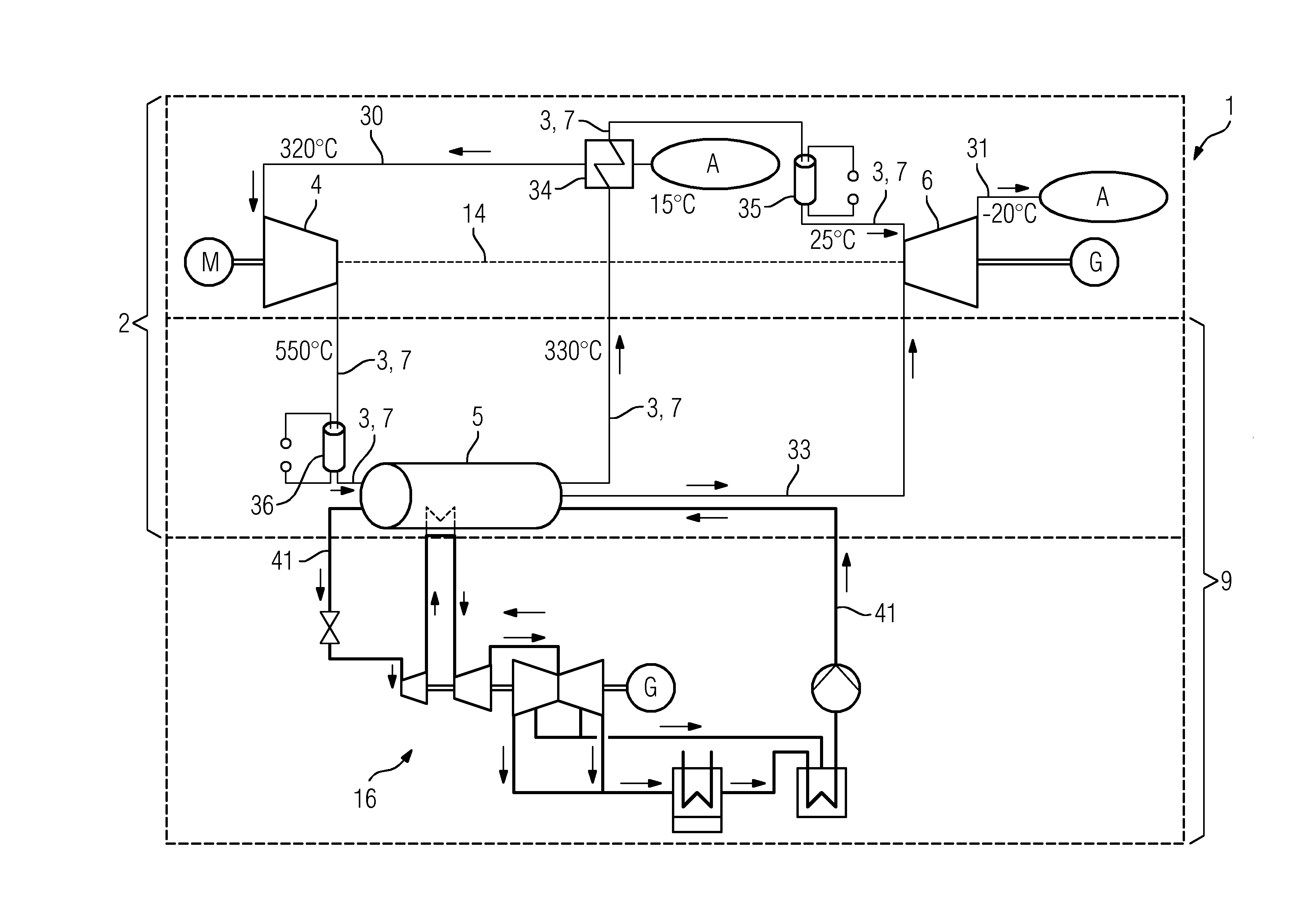

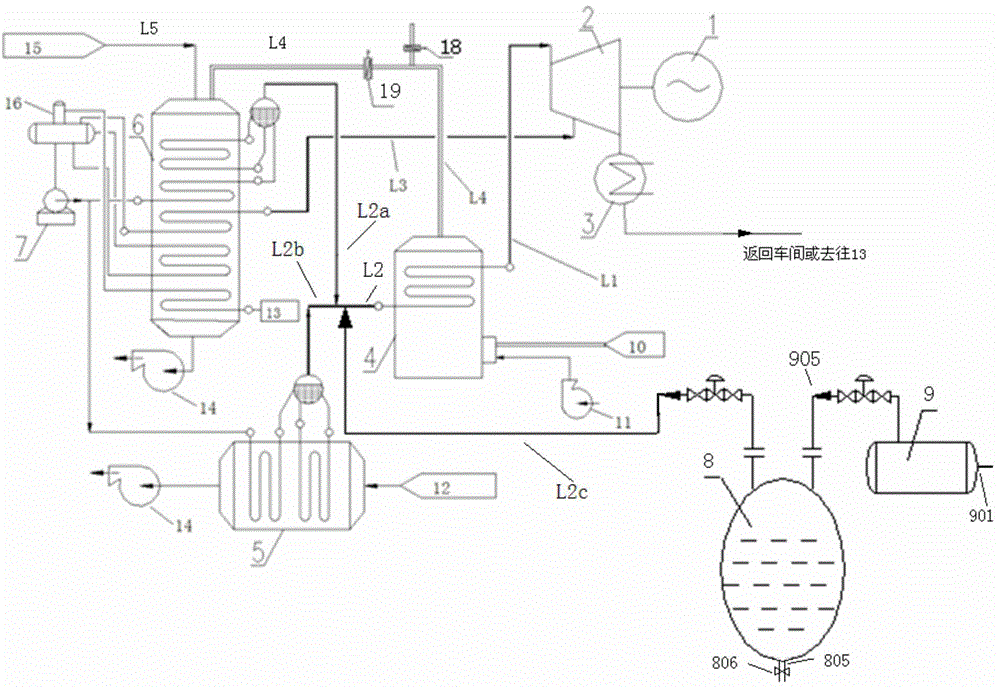

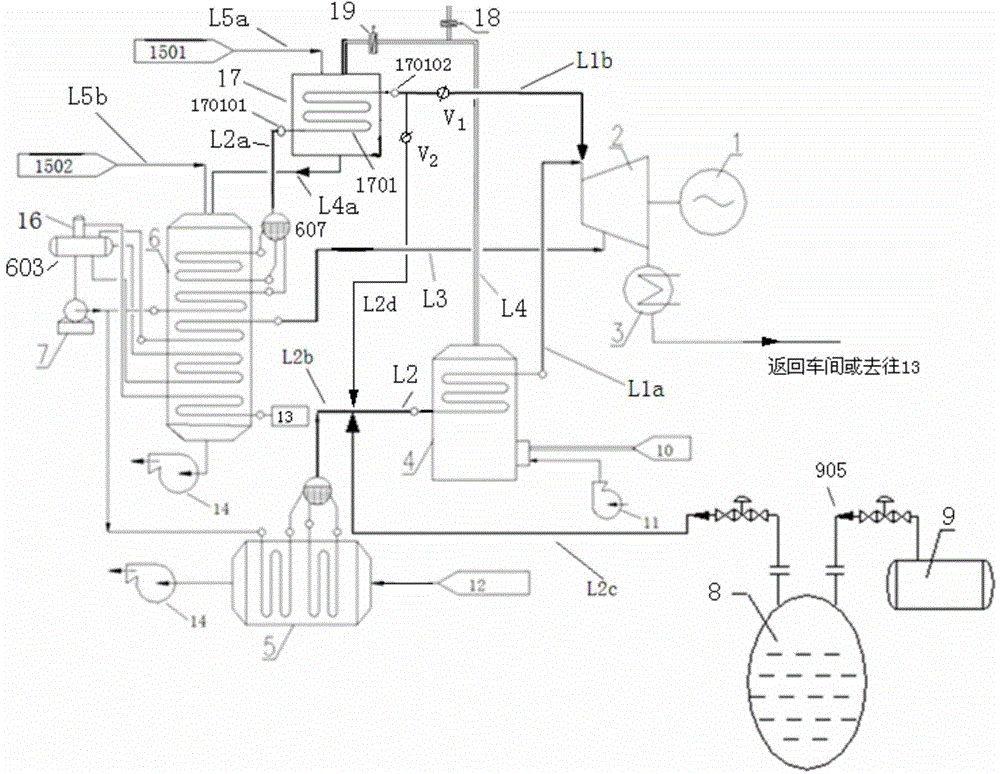

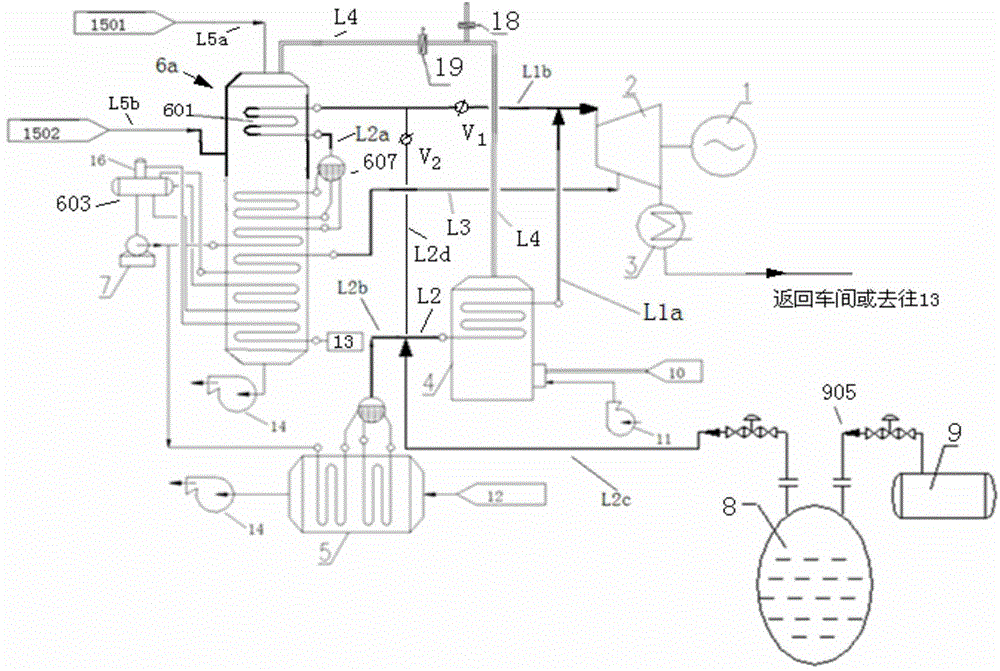

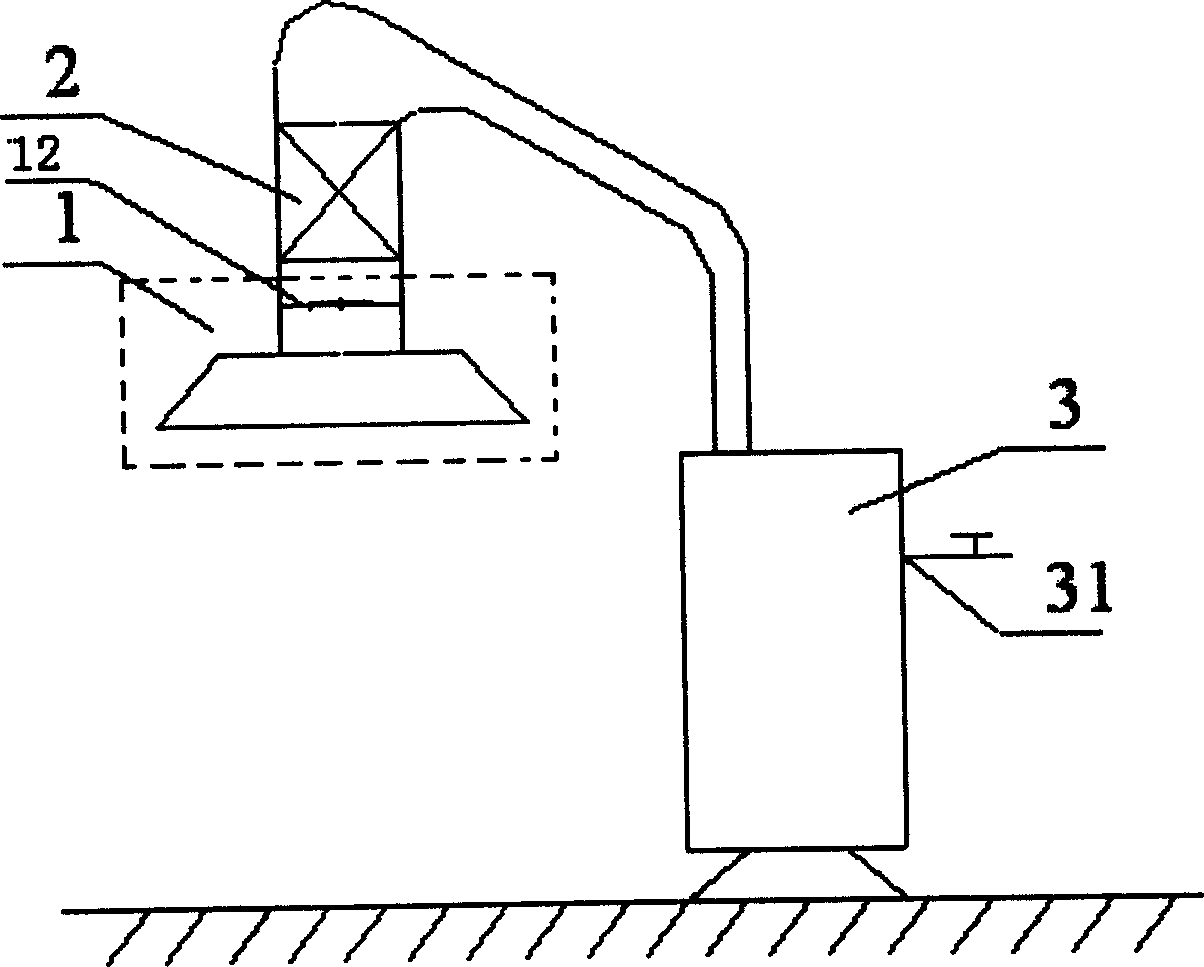

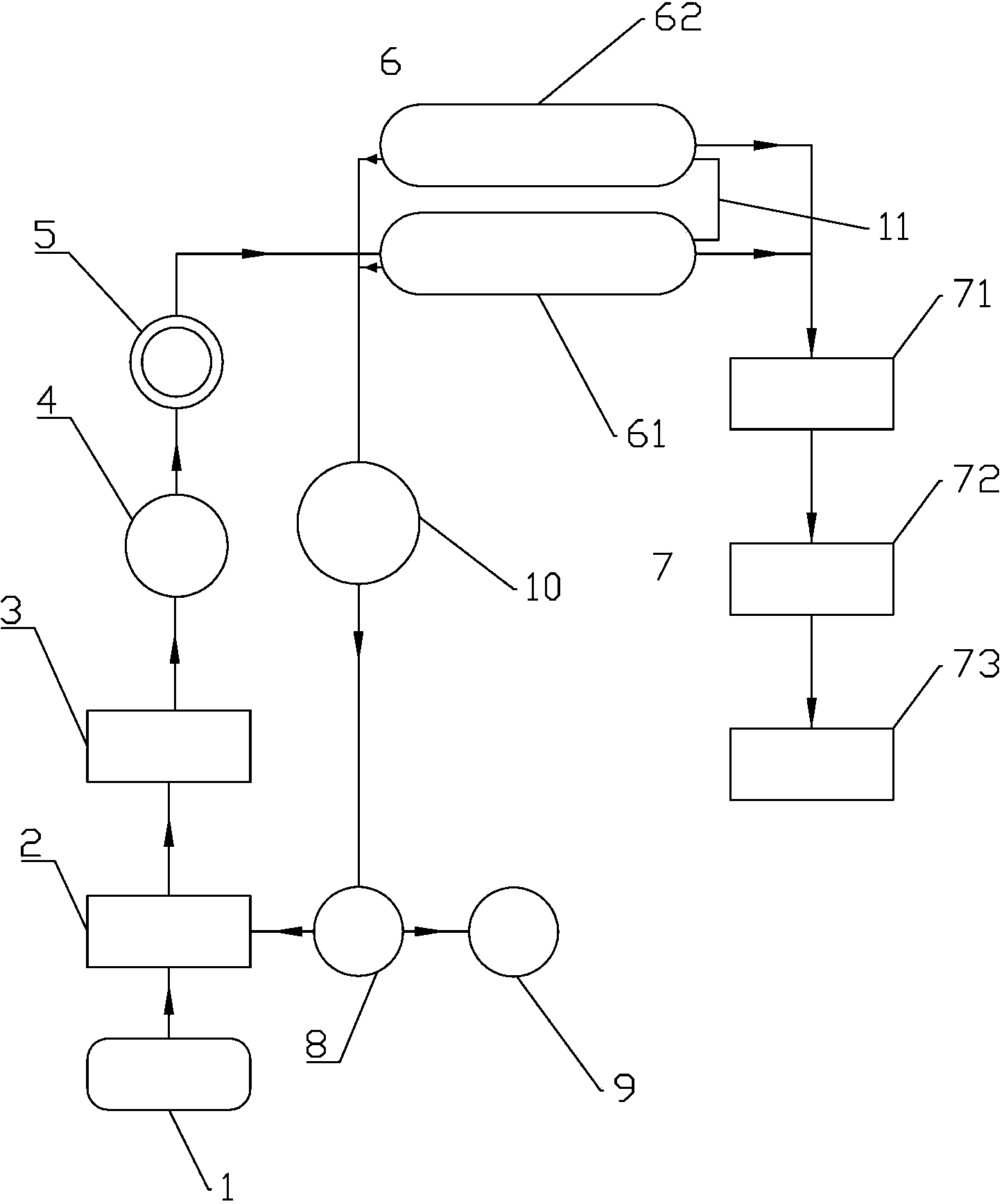

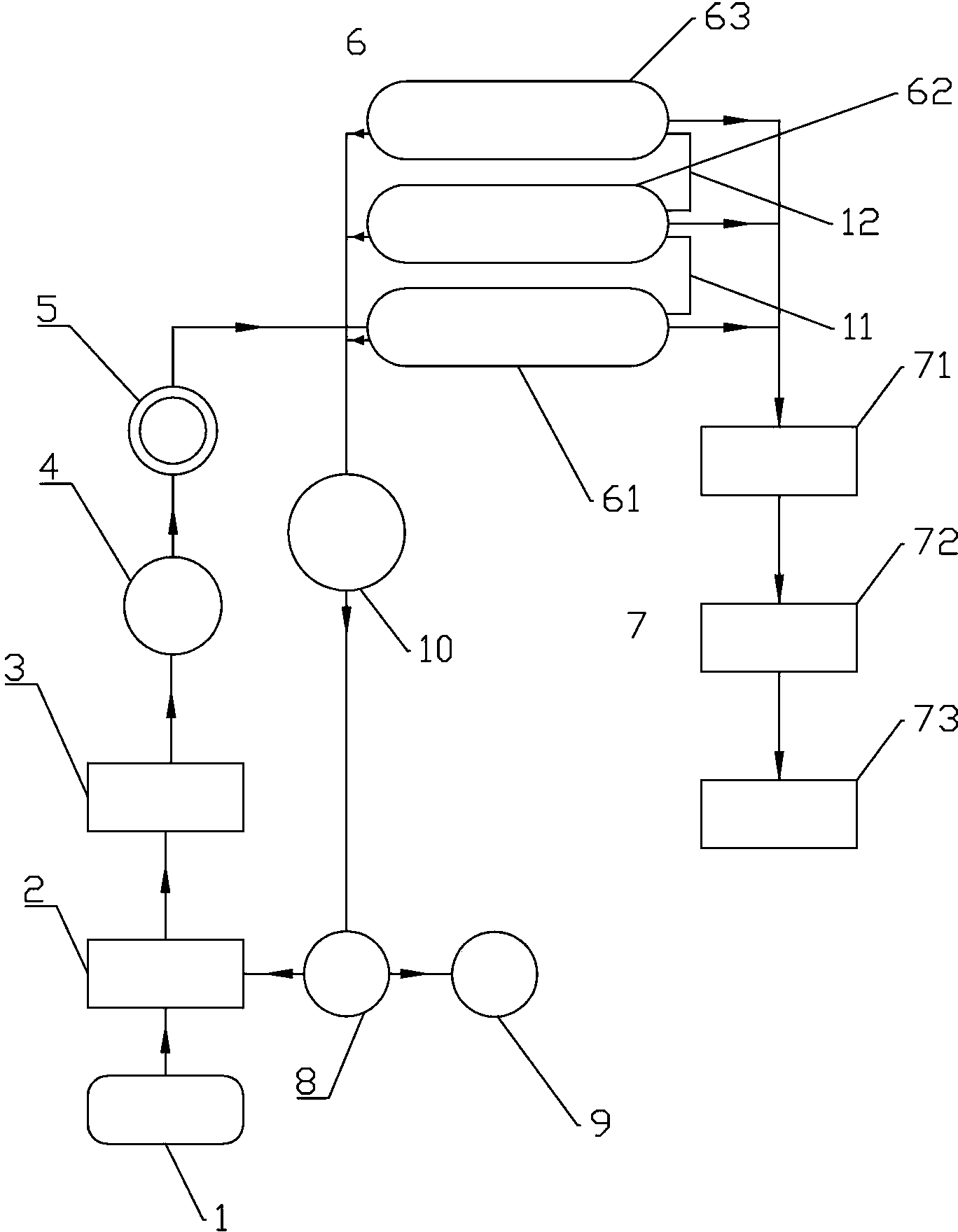

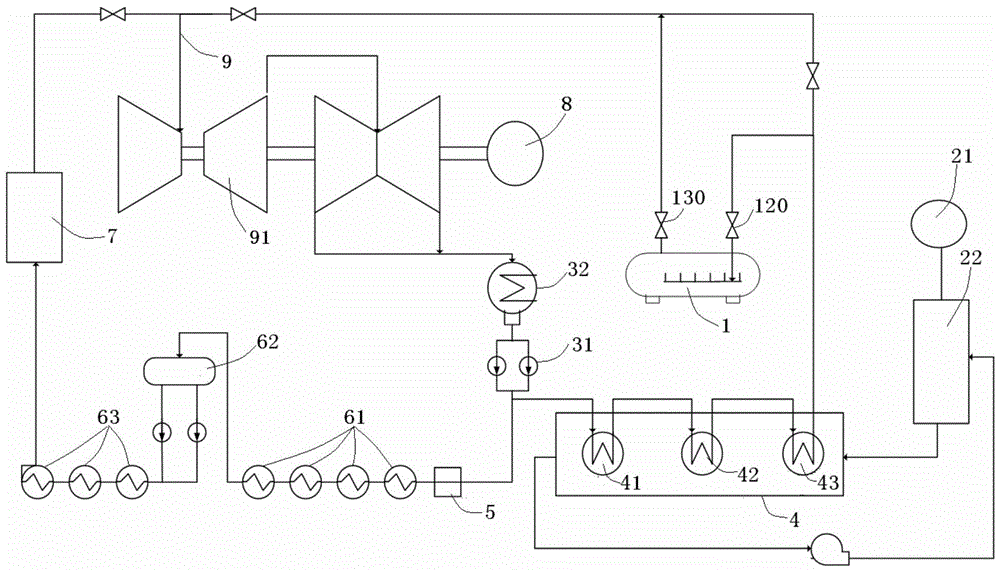

Coal gas, converter steam and sintering waste heat combined power generation device and waste heat utilization method

InactiveCN104807338ALow temperature requirementParameter stabilityManufacturing convertersIncreasing energy efficiencyCombustionSeries compensation

The invention relates to a coal gas, converter steam and sintering waste heat combined power generation device which comprises a generator 1, a turbine 2, a condenser 3, an over-heat compensation combustion furnace 4, a waste heat boiler 5 of a sintered smoke exhaust pipe, a waste heat boiler 6 of a circular cooler, a steel converter drum 9 and a steam accumulator 8 of the converter, wherein low parameter over-heated steam generated by the waste heat boiler 6 of the circular cooler is connected with a steam compensation opening 202 of the turbine, high parameter saturated steam generated by the waste heat boiler 5 of the sintered smoke exhaust pipe and the steam accumulator 8 of the converter enters into a main steam inlet 201 of the turbine through the over-heat compensation combustion furnace 4, and a rotary shaft 204 of the turbine 2 is connected with or drives a rotary shaft of the generator 1. The coal gas, converter steam and sintering waste heat combined power generation device provided by the invention has the advantages that residual coal gas, sintered waste heat and converter steam of an iron and steel plant are comprehensively utilized, the utilization ratio of waste heat is high, the system is flexible, the outage rate of a steam turbine unit is low, and the investment and operation costs are low.

Owner:HUNAN ZHONGYE CHANGTIAN ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

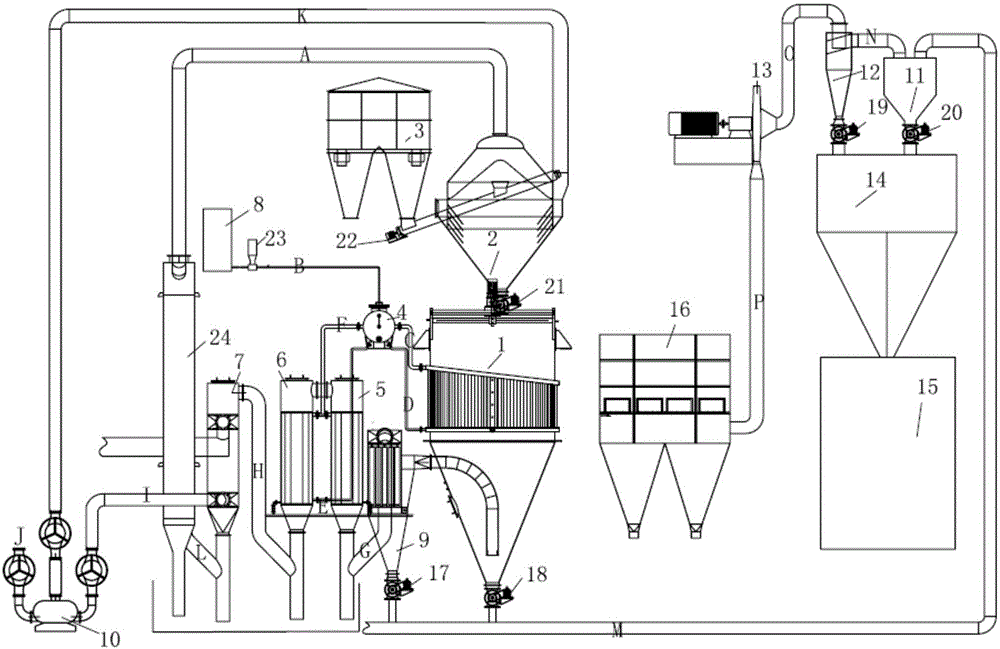

Biomass gasification equipment

ActiveCN105087069AReduce the temperatureReduce fine ash contentCombustible gas productionSoftened waterIntercooler

The invention provides biomass gasification equipment, which comprises a biomass gasifier body, a biomass filter, a biomass bin, a steam accumulator tank, a gas water heat exchanger, a fuel gas heat exchanger, a softened water tank, a wire-wove bag-type dust collector, a Roots blower, a tar cooling intercooler, a biomass charcoal bin accumulator tank, a cyclone dust collector, a biomass charcoal bin and automatic packaging system. By adopting the biomass gasification equipment provided by the invention, the temperature of fuel gas can be effectively lowered, and by making full use of the heat of high temperature fuel gas, substantial by-product steam is generated, and meanwhile, due to the fact that the wire-wove bag-type dust collector and the biomass filter are arranged, a fine ash content in the fuel gas in a high temperature zone is sufficiently reduced, and a condition is provided for subsequent cleaner tar removal in the fuel gas, and the secondary pollution problem of a water washing method is effectively avoided.

Owner:盐城汇百实业有限公司

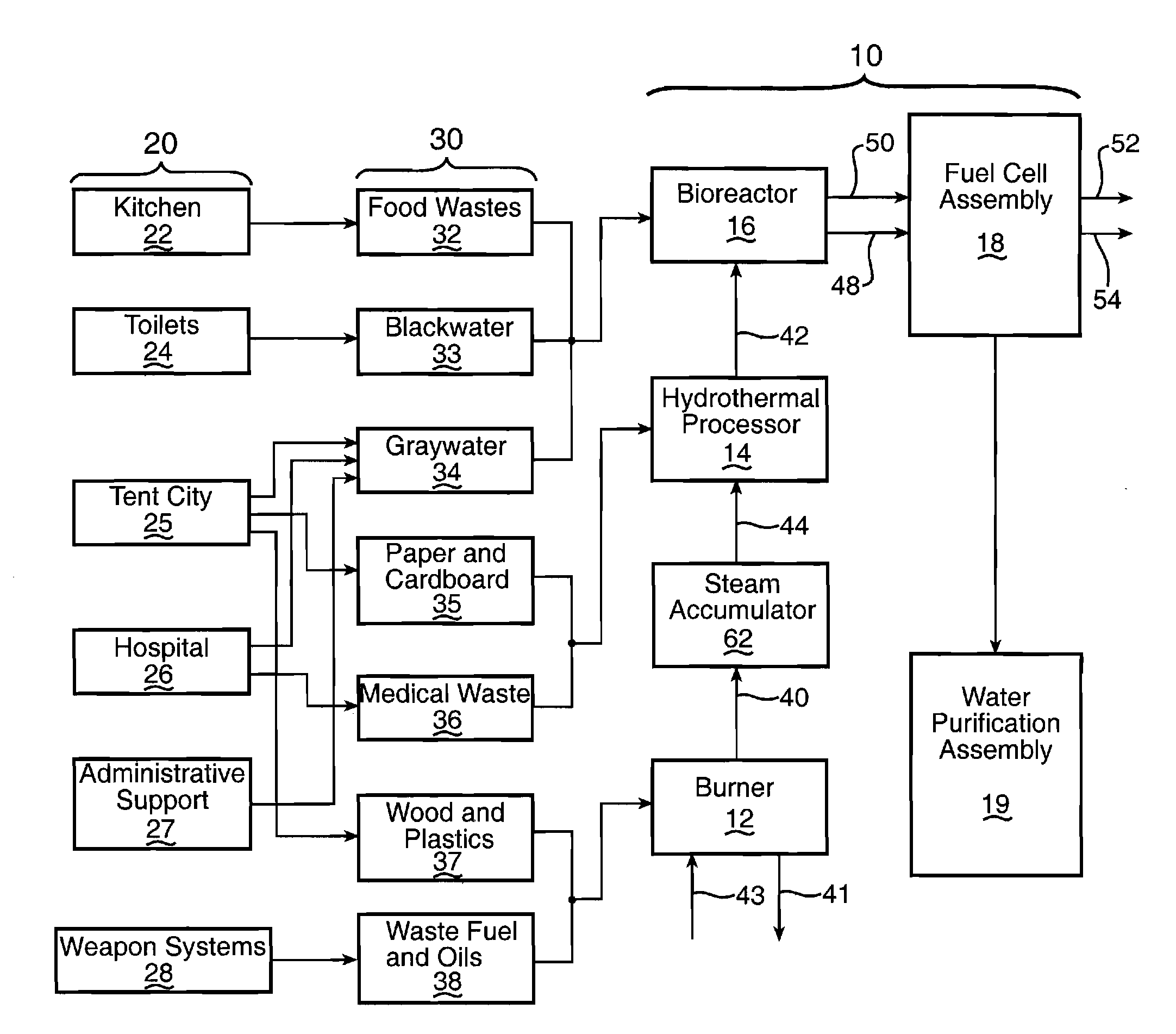

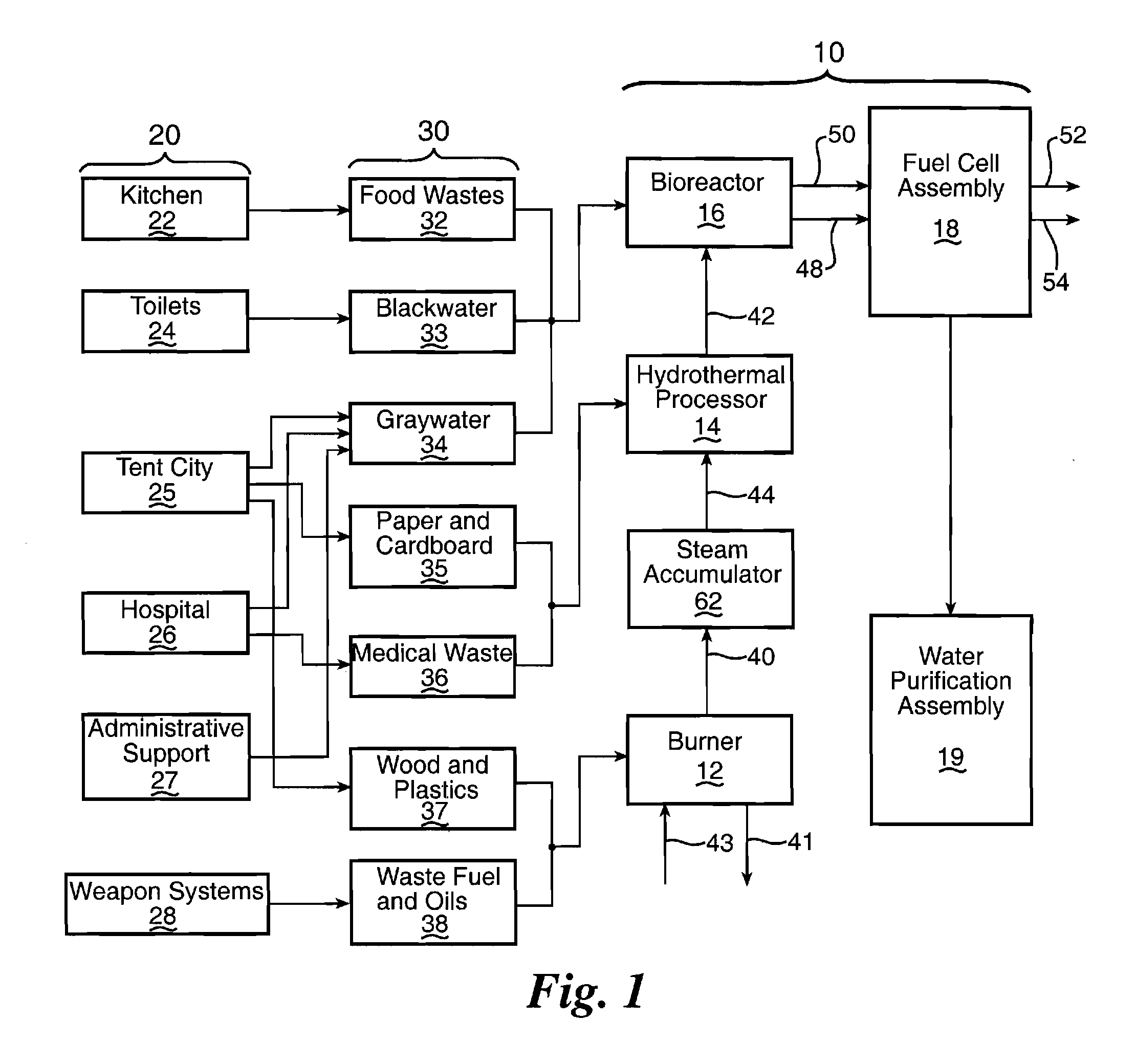

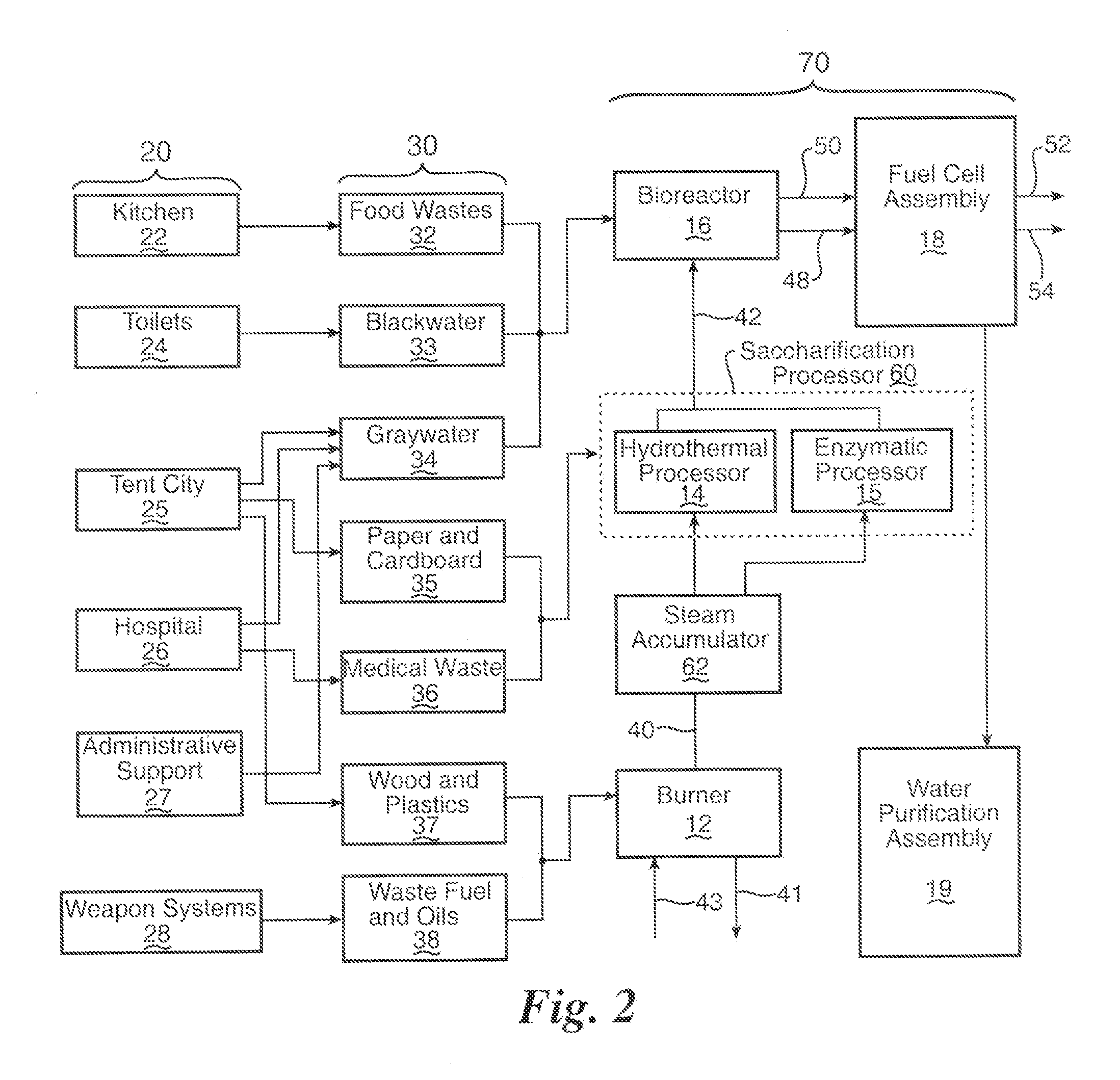

Method for consolidated waste management and resource recovery

InactiveUS8114663B1Maximize synergySystem versatilityBioreactor/fermenter combinationsBiological substance pretreatmentsCardboardOperational system

A waste management and resource recovery system that uses the different waste streams from typical waste sources as fuel or feedstock for its subsystems that, in turn, produce fuel, feedstock or energy for other subsystems such that all the different waste streams are effectively managed. The subsystems include a gas burner for solid and fuel wastes that supplies heat to a hydrothermal processor for saccharification of paper and cardboard. The resulting saccharification broth, along with kitchen wastes and blackwater, are supplied to a bioreactor using dark fermentation to produce hydrogen and volatile fatty acids. The hydrogen and volatile fatty acids are supplied to hydrogen and microbial fuel cells to produce electrical energy for operating the system and potable water. A steam accumulator is added to provide sufficient temperatures and pressures to reach the necessary thermodynamic states for the saccharification process. An enzymatic saccharification processor may also improve the saccharification process.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Expanded gas power plant for energy storage

InactiveUS20150252726A1Great expenditureEasy to useSteam accumulatorsGas turbine plantsEngineeringHeat treated

A method for operation of a gas power plant, and to a gas power plant of this type, comprising a gas turbine, which is connected to a generator that can also be operated as a motor and which is thermally coupled to a water vapour circuit by way of a first heat exchanger are provided. The method includes: operating the generator as a motor in such a way that a heated gas flow is discharged from the gas turbine; thermally treating of water in the water vapour circuit via the first heat exchanger by the heated gas flow; storing of the water thermally treated in this way in a vapour accumulator; operating a steam turbine with water vapour taken from the vapour accumulator; diverting of the water vapour after interaction with the steam turbine into a vapour chamber for condensation; and collecting of the condensed water in a condensate reservoir.

Owner:SIEMENS AG

Electro-thermal steam heat accumulator

InactiveCN104676570ALess investmentSmall footprintSteam generation heating methodsThermal energyElectricity

The invention discloses an electro-thermal steam heat accumulator. The heat accumulator comprises a steam accumulator cylinder, wherein most of part in the heat accumulator cylinder is used for storing water or saturated water; a steam space is formed on the upper side of the water; an electric heating element is arranged in the stored water; the heat accumulator is provided with a water inlet pipe orifice, a water level gauge, a steam outlet, and related pipe fittings, pressure, temperature, safety, thermal insulation, water supply, drainage, maintenance hole and electrical control auxiliary devices for constituting the heat accumulator. The heat accumulator is mainly characterized in that the electro-thermal steam heat accumulator operates at full load and the heat energy is stored in the electro-thermal steam heat accumulator when social electric load is at valley, and steam is output outwards or heat is supplied by the electro-thermal steam heat accumulator when the social electric load is at peak. The electro-thermal steam heat accumulator has the main advantages that a user using off-peak electricity does not need to arrange a steam heat accumulator and an electric steam boiler side by side to save a large amount of investment and avoid resource waste, particular save energy for the country and reduce the cost for the user.

Owner:赵联众

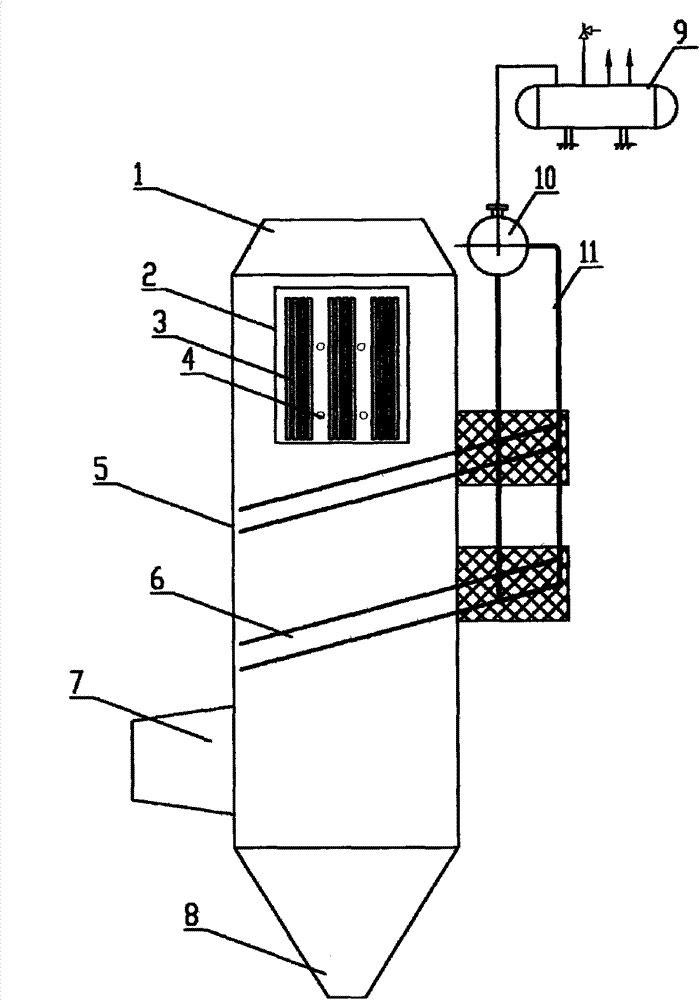

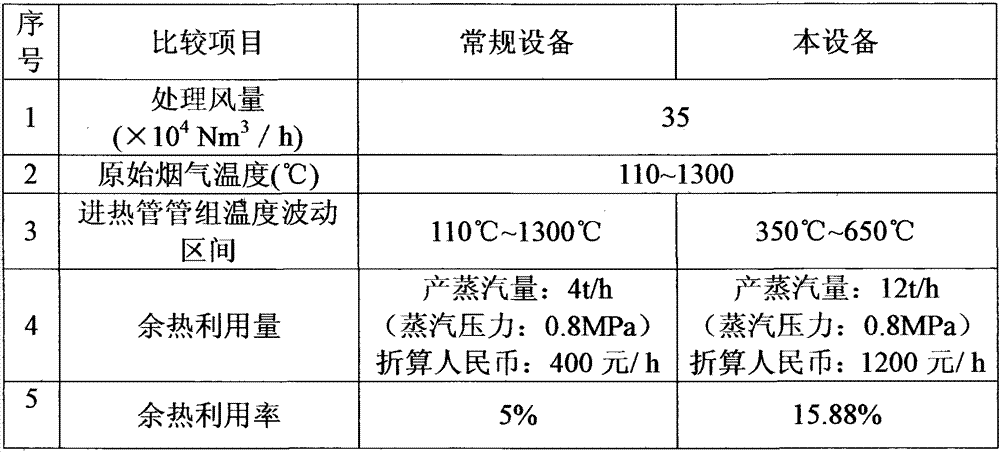

Heat exchange set for flue gas waste heat recovery

InactiveCN104729307AReduce the temperatureReduce peakEnergy industryIncreasing energy efficiencyShock waveCarbon composites

A heat exchange set for flue gas waste heat recovery comprises a flue gas inlet, a heat-accumulating temperature homogenizer, a flue gas passage, a heat pipe bank, a flue gas outlet, an ash hopper, a circulation pipe, a steam drum and a steam accumulator. The heat exchange set is characterized in that the top of the flue gas passage is provided with the flue gas inlet, the outside of the bottom of the flue gas passage is provided with the flue gas outlet, the bottom of the flue gas passage is provided with the ash hopper, the heat pipe bank is disposed within the flue gas passage and is connected with the steam drum through the circulation pipe, the steam drum is connected with the steam accumulator through a pipe, the steam drum is disposed on the top of the outside of the flue gas passage, the heat-accumulating temperature homogenizer is disposed at the upper end of the heat pipe bank in the flue gas passage, the heat-accumulating temperature homogenizer comprises carbon-carbon composite accumulating members and a shock wave ash-remover, and the shock wave ash-remove is disposed among the carbon-carbon composite accumulating members segment by segment. The heat exchange set has the advantages that heat in the flue gas can be recovered to the maximum extent, investment on waste heat utilization equipment is lower and the waste heat utilization equipment is more stable.

Owner:JIANGSU HONGHUA HEAVY IND

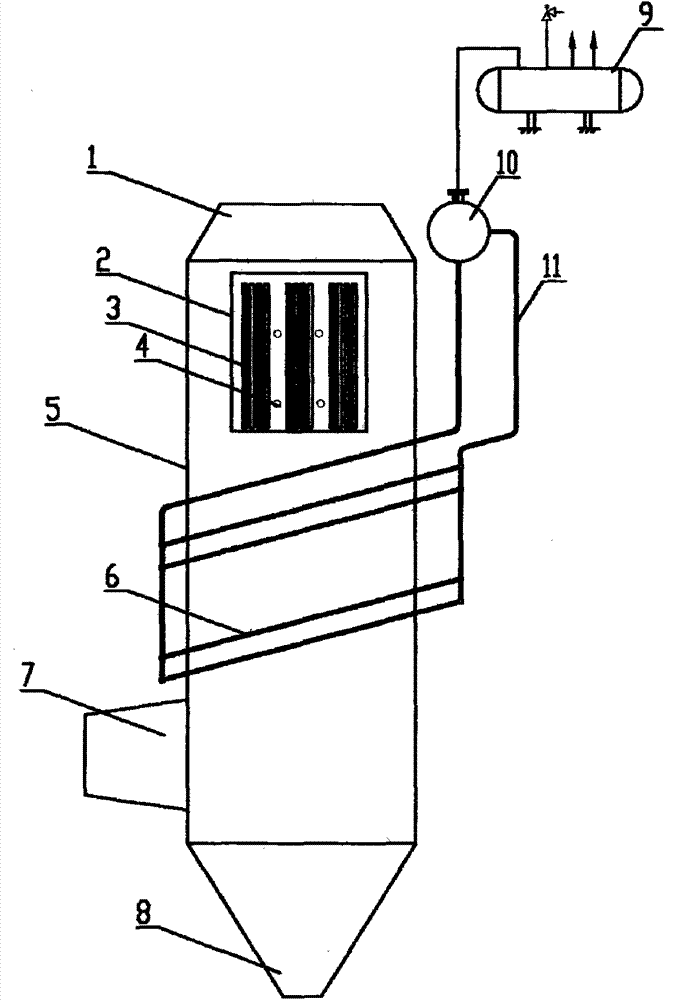

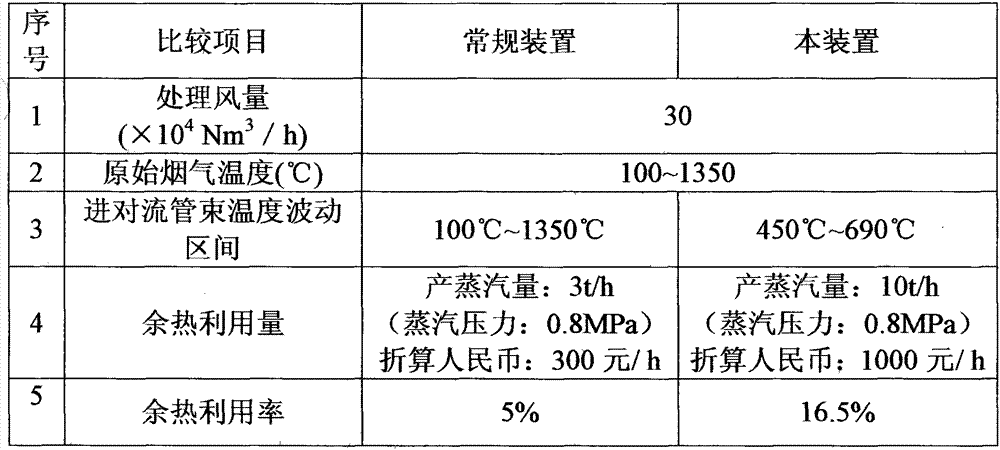

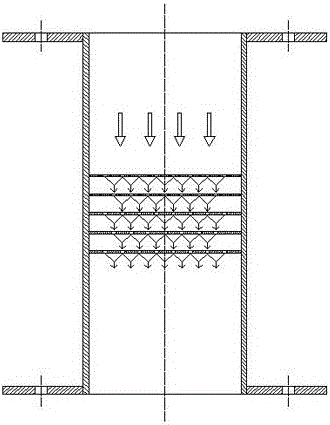

Convection-bank heat exchange set for flue gas waste heat recovery

InactiveCN104729306AReduce the temperatureReduce peakEnergy industryIncreasing energy efficiencyCarbon compositesShock wave

A convection-bank heat exchange set for flue gas waste heat recovery comprises a flue gas inlet, a heat-accumulating temperature homogenizer, a flue gas passage, a convection pipe bank, a flue gas outlet, an ash hopper, a circulation pipe, a steam drum and a steam accumulator. The convection-bank heat exchange set is characterized in that the top of the flue gas passage is provided with the flue gas inlet, the outside of the bottom of the flue gas passage is provided with the flue gas outlet, the bottom of the flue gas passage is provided with the ash hopper, the convection pipe bank is disposed in the flue gas passage and is connected with the steam drum through the circulation pipe, the steam drum is connected with the steam accumulator through a pipe, the steam drum is disposed on the top of the outside of the flue gas passage, the heat-accumulating temperature homogenizer is disposed at the upper end of the convection pipe bank within the flue gas passage and comprises carbon-carbon composite accumulating members and a shock wave ash-remover, and the shock wave ash-remover is disposed among the carbon-carbon composite accumulating members segment by segment. The convection-bank heat exchange set has the advantages that heat in the flue gas can be recovered to the maximum extent, investment on waste heat utilization equipment is lower and the waste heat utilization equipment is more stable.

Owner:JIANGSU HONGHUA HEAVY IND

Exhaust heat recovery device for internal combustion engine and exhaust heat recovery method for internal combustion engine

ActiveUS9657602B2Easy to useIncrease powerInternal combustion piston enginesExhaust apparatusRecovery methodLow load

An exhaust heat recovery device for an engine including a Rankine cycle, including a steam accumulator that stores a surplus of a working medium for driving a turbine, and a leveling line that discharges the stored surplus working medium from the steam accumulator to the turbine, when the turbine cannot output predetermined power only with the working medium flowing out from a boiler, and levels the power outputted from the turbine. Since the power outputted from the turbine can be leveled without reduction of the power, even if the working medium cannot vaporize with the boiler immediately after start-up, immediately before stop, or during a low-load operation of the engine, exhaust heat from the engine can be efficiently used.

Owner:ISUZU MOTORS LTD

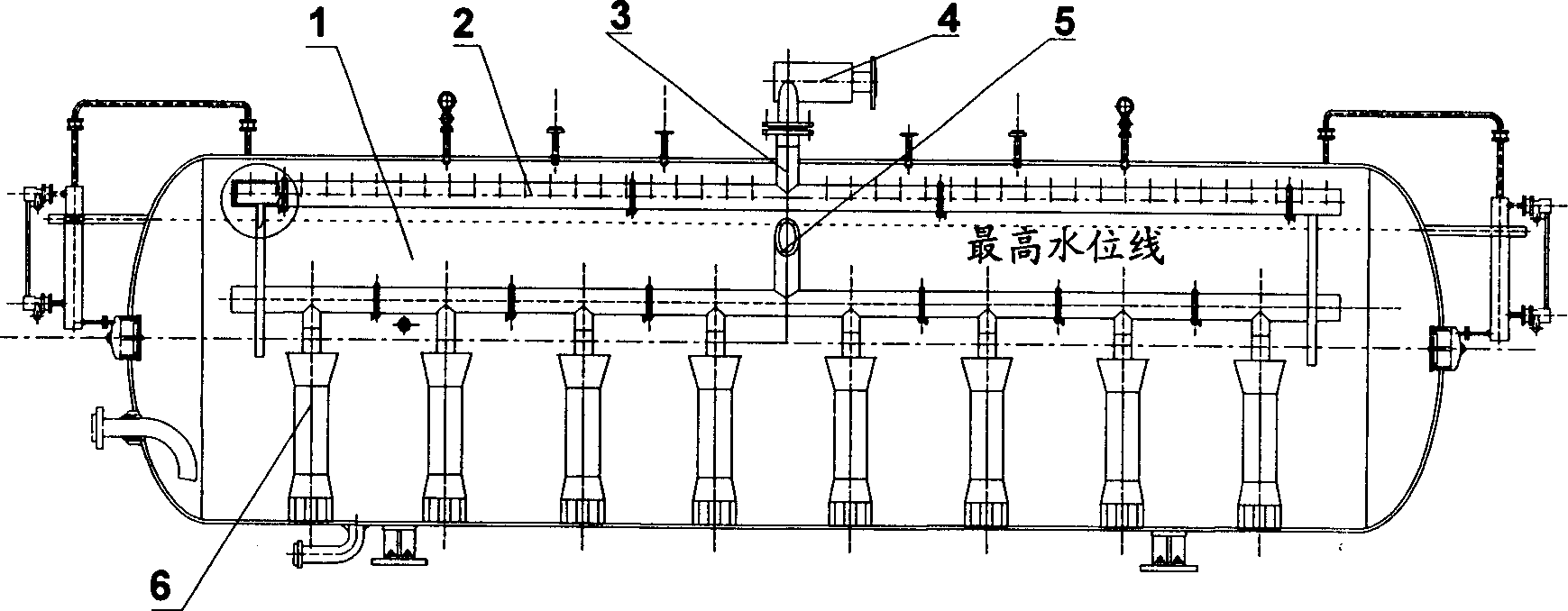

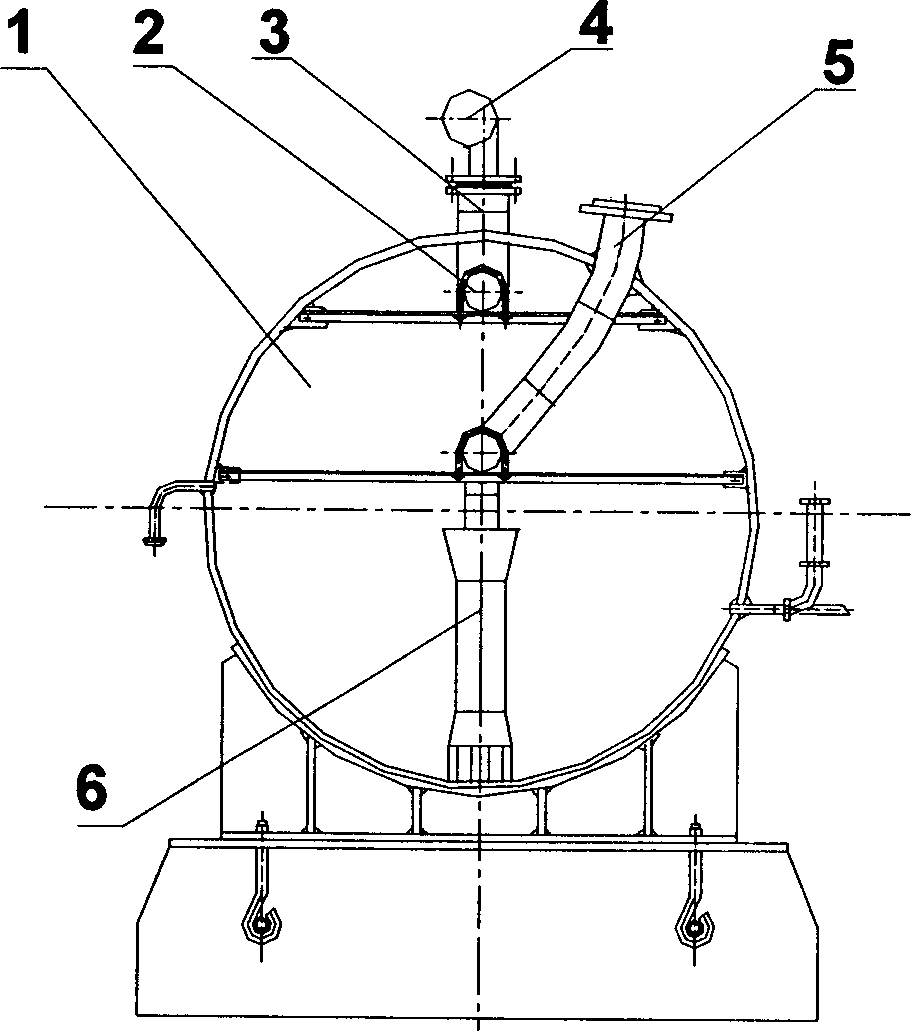

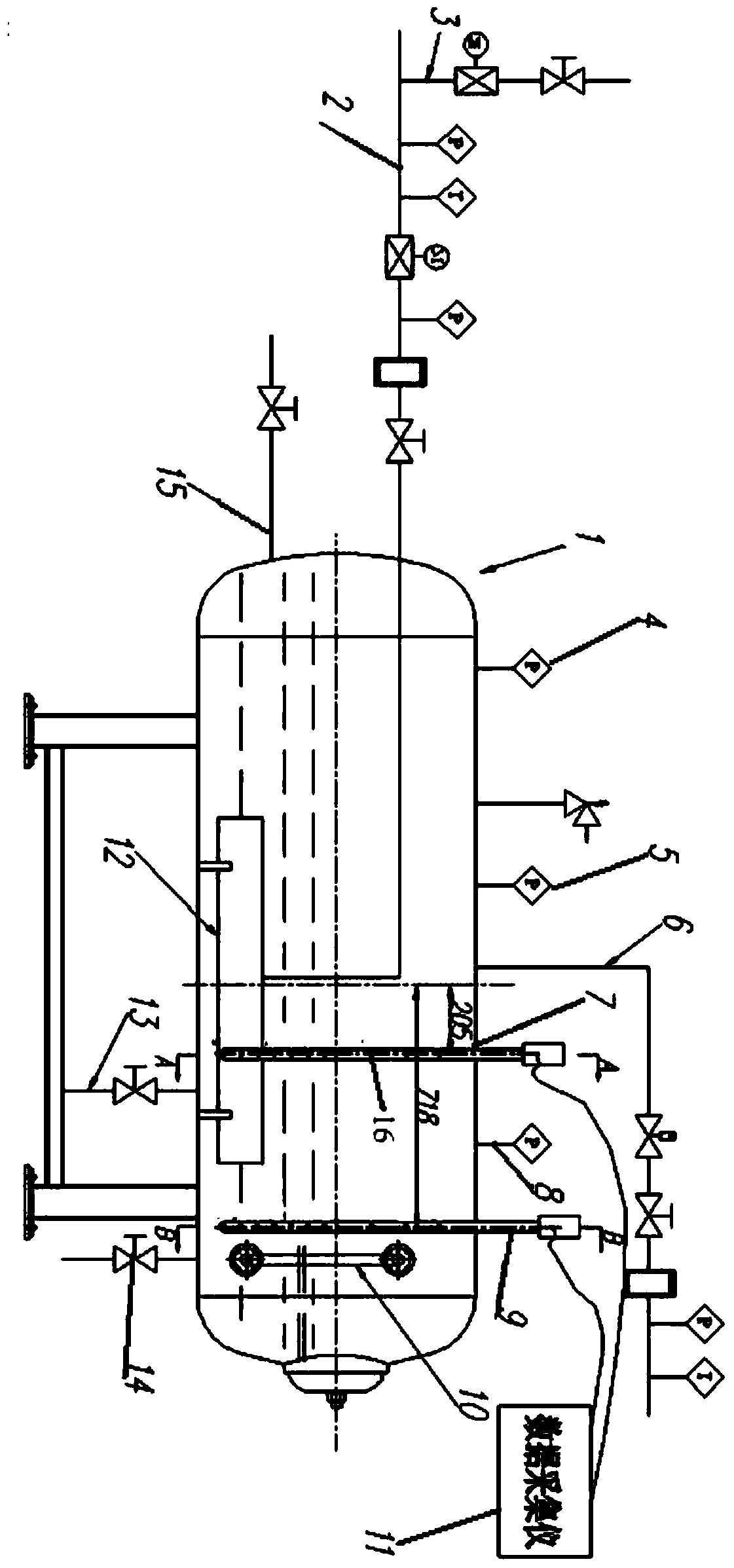

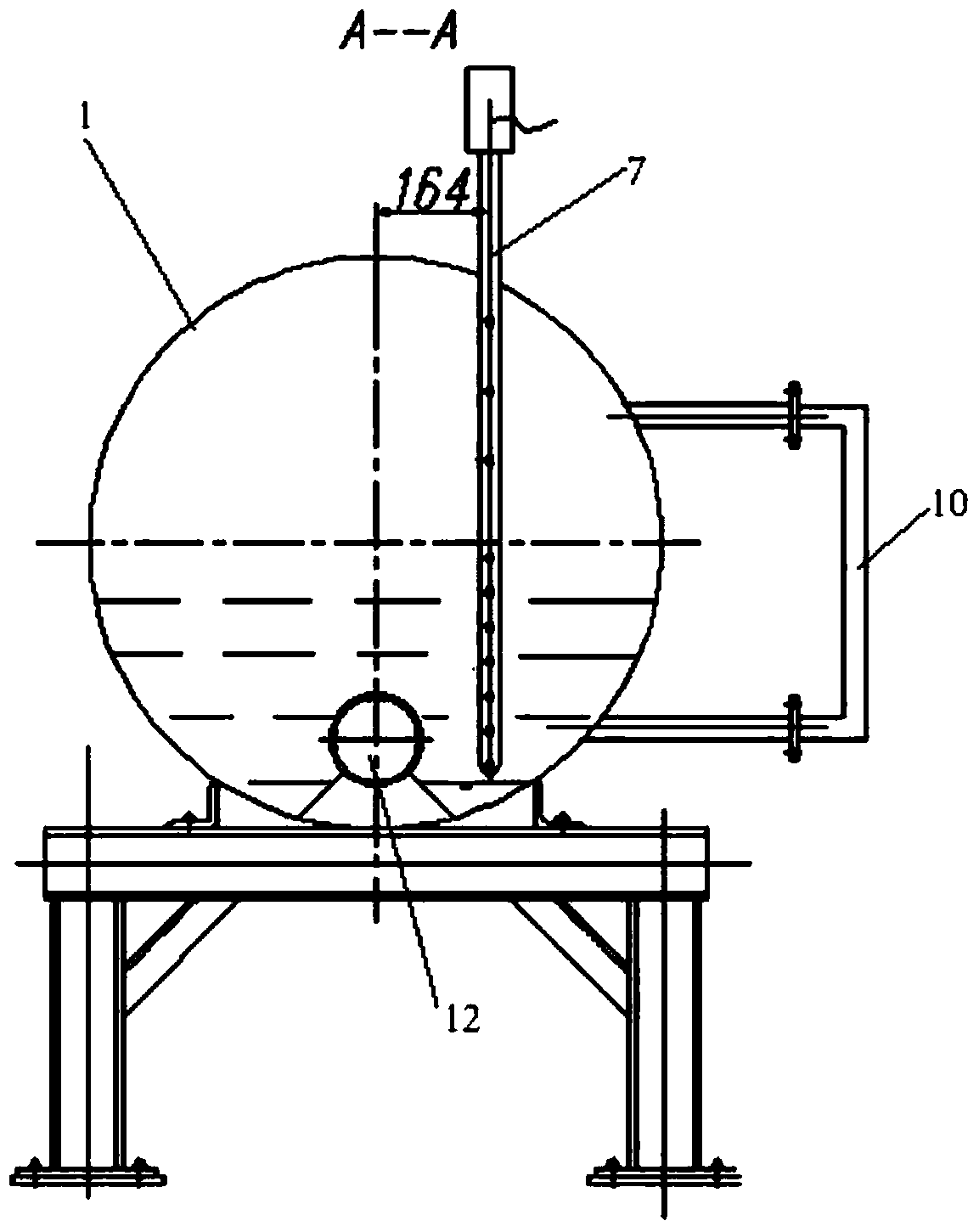

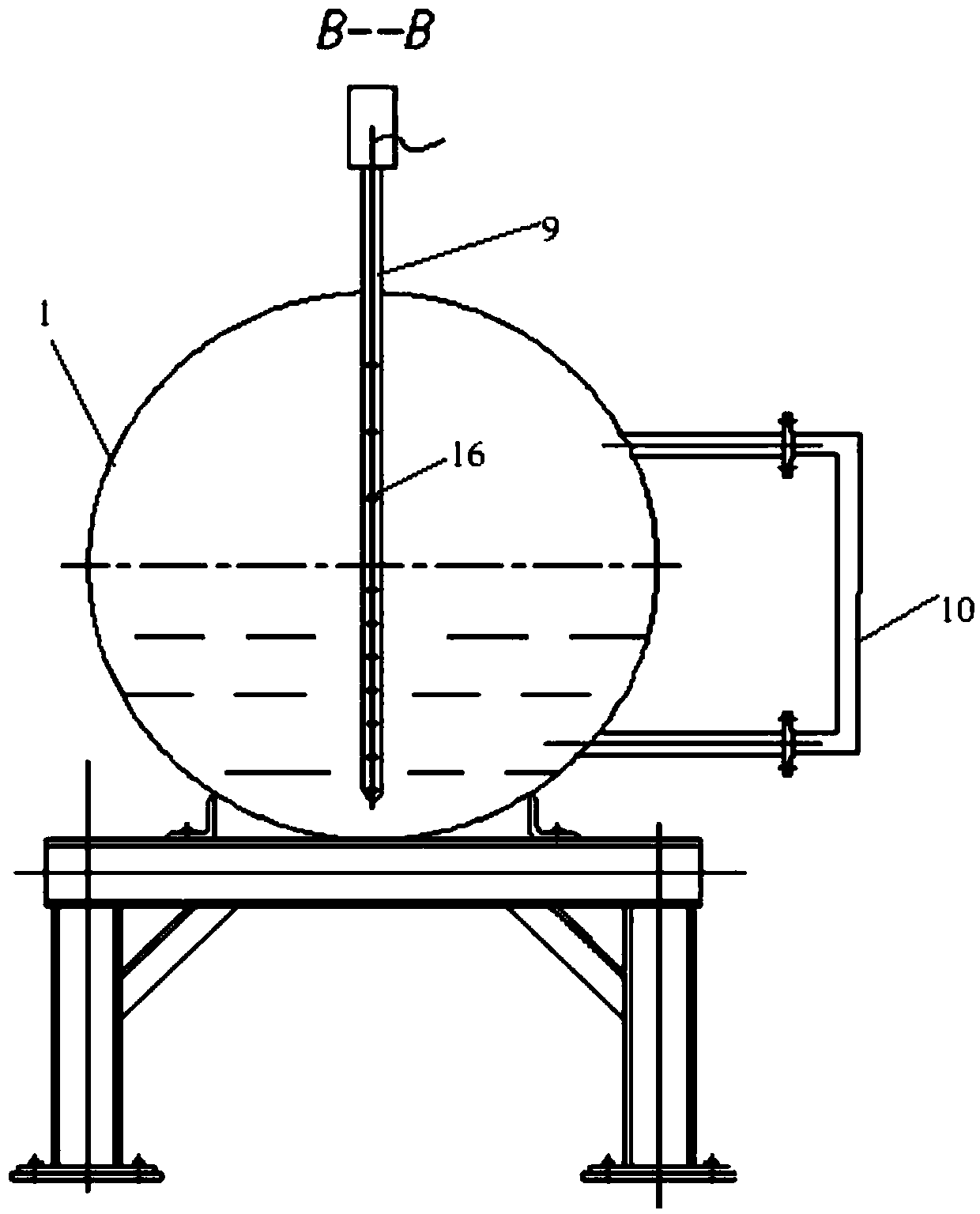

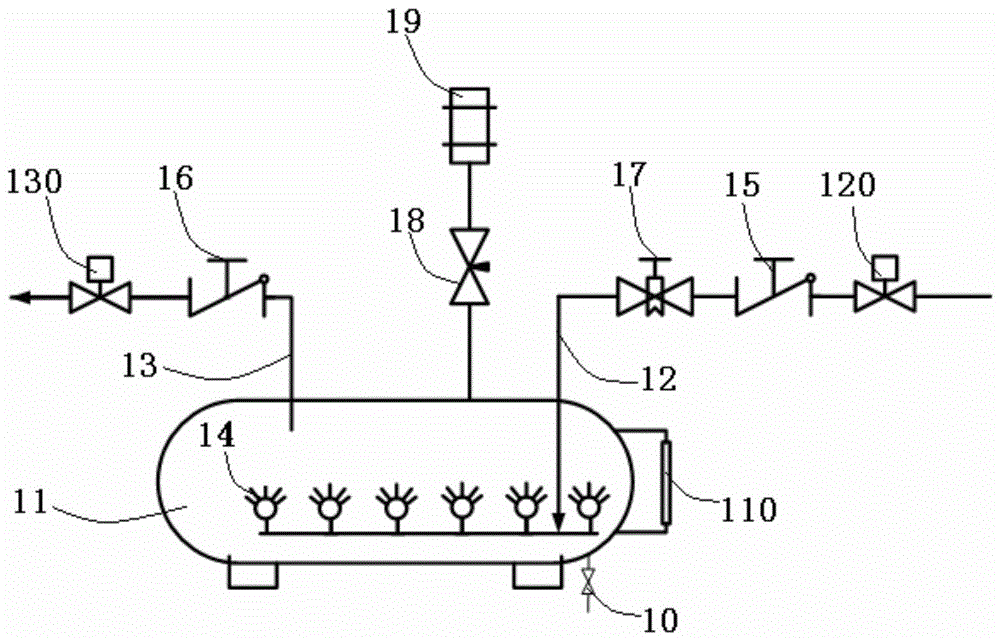

Temperature nonuniformity measuring device for marine steam accumulator

InactiveCN104111271AReal temperature distributionRealistic representation of temperature distributionMaterial heat developmentWater dischargeExternal data

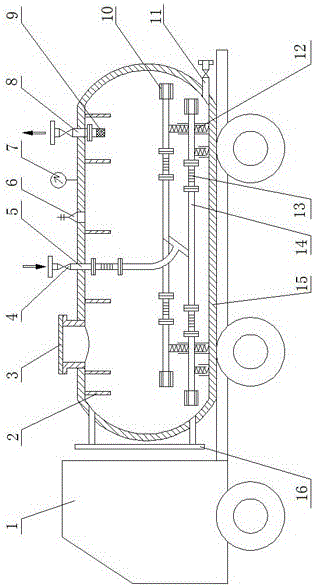

The invention discloses a temperature nonuniformity measuring device for a marine steam accumulator. The temperature nonuniformity measuring device comprises a cylindrical marine steam accumulator barrel body, wherein the cylindrical marine steam accumulator barrel body is horizontally arranged; a water space steam header is arranged in the lower part of the marine steam accumulator barrel body and connected with an external bypass pipeline through a steam filling pipeline; three sensors and a steam discharge pipeline are arranged on the outer upper part of the marine steam accumulator barrel body; one end of each of two multipoint thermocouples is arranged in the marine steam accumulator barrel body, and the other ends of the two multipoint thermocouples extend out of the marine steam accumulator barrel body and are connected with an external data collector through signal lines; one thermocouple is arranged beside the water space steam header, and the other thermocouple is far from the water space steam header; a water level indicator is arranged on the steam accumulator barrel body, and a water discharge pipeline and a pollution discharge pipeline are arranged at the bottom of the steam accumulator barrel body; a water replenishing pipeline is connected to the steam accumulator barrel body. The temperature nonuniformity measuring device has the beneficial effect of simplicity, and by using the device, the temperature distribution in the accumulator can be conveniently and really displayed.

Owner:HARBIN ENG UNIV

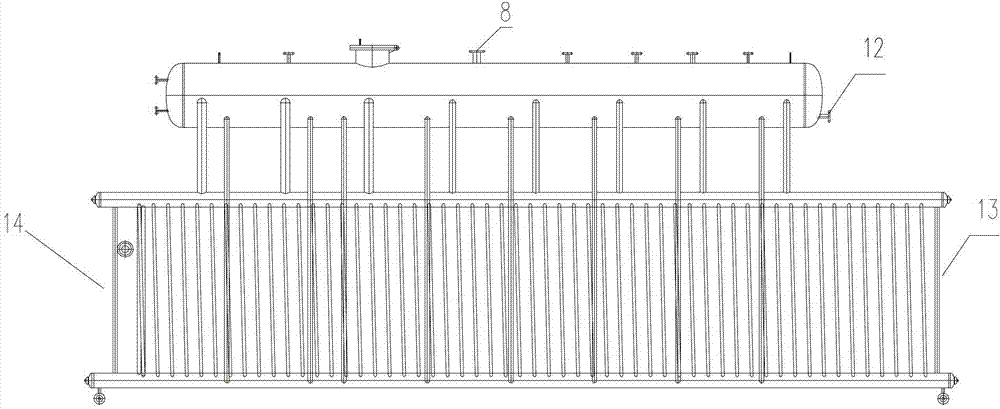

Radiant waste-heat steam generator for tunnel brick kiln

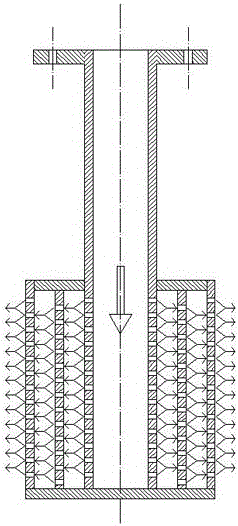

InactiveCN102966939AFast coolingIncrease economic incomeEnergy industryIncreasing energy efficiencySuperheaterEngineering

The invention relates to a radiant waste-heat steam generator for a tunnel brick kiln, which comprises a radiant evaporator pipe bank, a radiant superheater pipe bank, a rising header pipe, a descending header pipe, a riser pipe, a downcomer and a steam accumulator; a plurality of the radiant evaporator pipe banks and a plurality of the radiant superheater pipe banks constitute a heat-transfer surface, the radiant evaporator pipe banks and the radiant superheater pipe banks are arranged in a staggered manner, the radiant evaporator pipe banks are rear-mounted, and the radiant superheater pipe banks are front-mounted; an inlet and an outlet of the radiant evaporator pipe bank are connected to one end of the rising header pipe and one end of the descending header pipe respectively, and the other end of the rising header pipe and the other end of descending header pipe are connected to the steam accumulator; and an inlet of the radiant superheater pipe bank is connected with a steam outlet of the steam accumulator, and high-temperature superheated steam is drained from an outlet of the radial superheater pipe bank. The radiant waste-heat steam generator for the tunnel brick kiln has the advantages that the cooling rate of bricks can be increased, the production efficiency can be improved, meanwhile, a lot of radiant heat of 900-1000 DEG C released from the fired bricks is recovered, and the effects of energy conservation and emission reduction are achieved.

Owner:TIANJIN HUANENG THERMAL EQUIP

Waste heat recovery structure for steel making electric arc furnaces, steel making electric arc furnace facility, and waste heat recovery method for steel making electric arc furnaces

ActiveUS9157336B2Effective recoveryAvoid temperature fluctuationsExhaust gas handlingIncreasing energy efficiencyRecovery methodElectric arc furnace

A waste heat recovery structure includes a first exhaust gas flow path provided to each of steel making electric arc furnaces to discharge exhaust gas thereinto; a waste heat boiler disposed on the first exhaust gas flow path to recover waste heat as saturated steam from exhaust gas; a steam accumulator configured to store steam formed by confluence of saturated steam parts, each generated by the waste heat boiler; a steam super heater configured to turn steam into superheated steam by heating; a second exhaust gas flow path configured to lead exhaust gas from the waste heat boiler to the steam super heater to use it for superheating; a third exhaust gas flow path configured to discharge exhaust gas from the waste heat boiler not through the steam super heater; and a switching device configured to switch flow paths between the second and third exhaust gas flow paths.

Owner:JP STEEL PLANTECH CO

Cooking oil smoke degradation conversion device

InactiveCN1593724ADegradation hasPollution-free treatmentDomestic stoves or rangesLighting and heating apparatusCombustible gasEngineering

The invention relates to a kind of culinary-soot degradation conversion system for resolving culinary soot, which contains an aspirator of soot. In soot mobility channel that formed in the aspirator of soot, there is a soot degradation device in passing form. In the outlet of passing soot degradation device, there is a steam accumulator connecting with it, in the top of which has an outlet of flammable gas. Compared with the technique by now, the invention has the features as follows: it uses the aspirator of soot for collecting culinary soot, and also it sets the passing soot degradation device in the soot mobility channel. In the result of such structures, it can make the culinary soot contact with the soot degradation device, and then they degrade into the flammable gas burn that can burn into the substances such as water. So the invention has the ability of degrading the culinary soot, and also realizes the pollution-free treatment of culinary soot.

Owner:NANJING UNIV

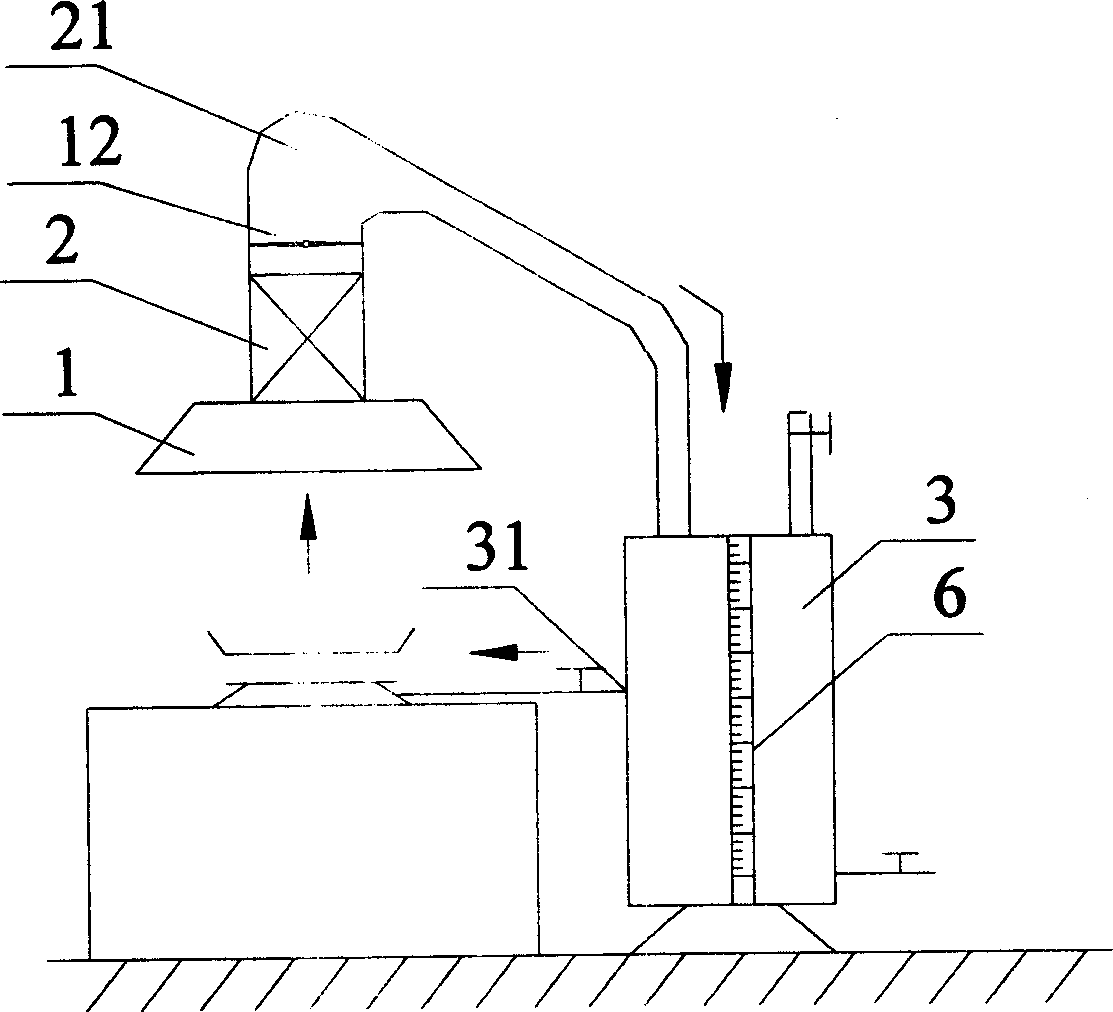

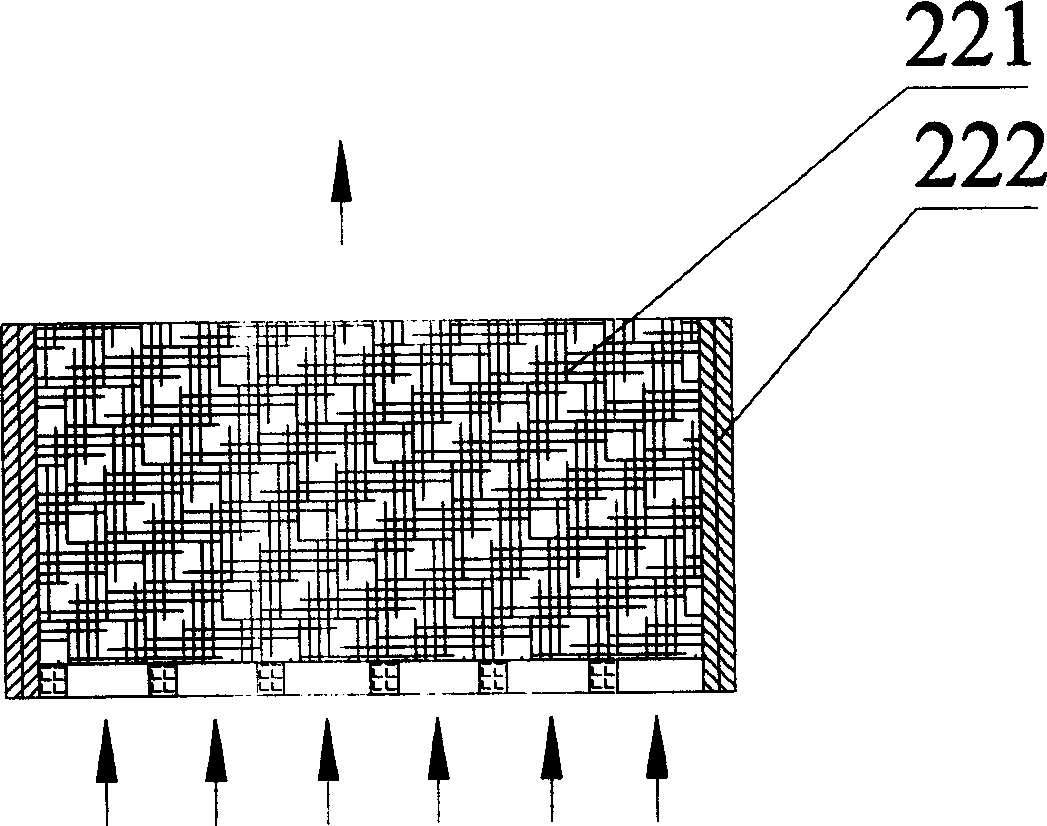

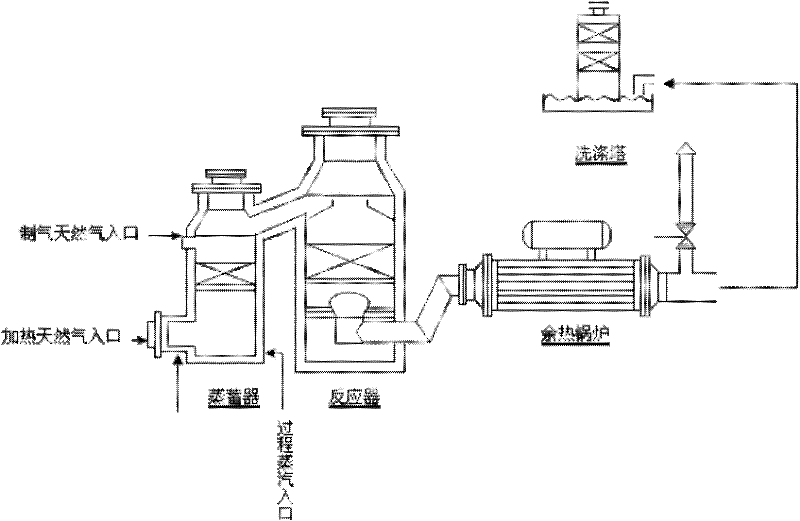

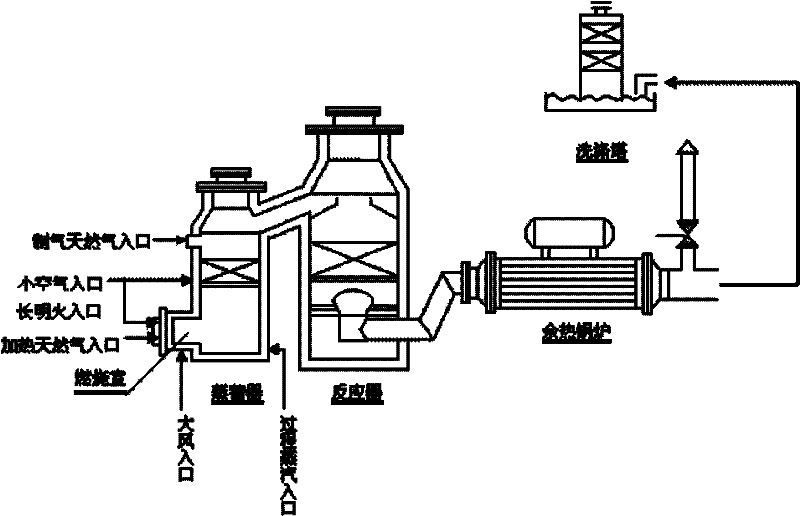

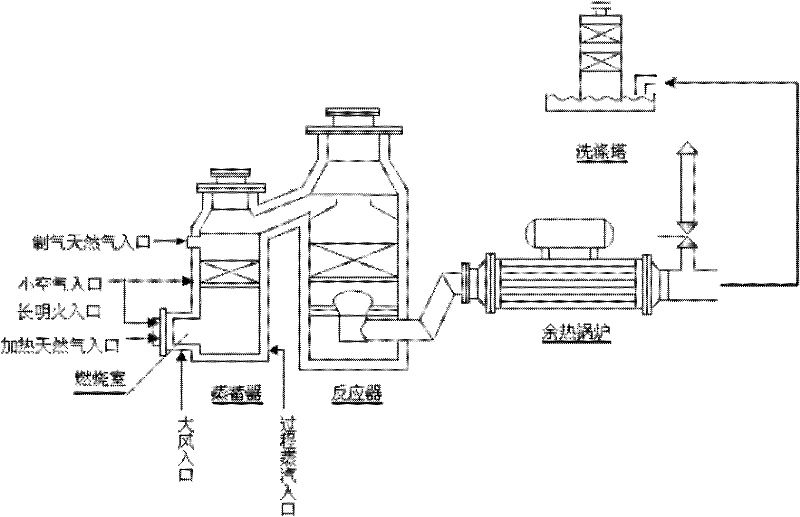

Normal pressure intermittent natural gas reforming process and device

InactiveCN102199461AIncrease temperatureImprove conversion efficiencyHydrogenGaseous fuelsProcess engineeringEngineering

The invention relates to a normal pressure intermittent natural gas reforming process and a normal pressure intermittent natural gas reforming device, and belongs to the field of reforming natural gas. The normal pressure intermittent natural gas reforming process is characterized in that: the gas-reforming process comprises the step of introducing a small amount of air from the bottom part of a steam accumulator of a two-barrel type natural gas reforming furnace; and by adding a small amount of air, the temperature of a catalytic bed is raised, a certain amount of waste gas is generated, and the heat value of the reforming gas is decreased. In the normal pressure intermittent natural gas reforming process and the device thereof, a small amount of air is added in the gas-reforming process to raise the temperature of the catalytic bed, and simultaneously under the action of the added air, the obtained finished product of reforming gas contains the generated waste gas, so that the heat value of the reforming gas is decreased; and when the flow rate of the natural gas to be processed is high, a lengthened open fire device is added, a small amount of air with a higher flow rate is added and reformed together with the natural gas after combustion and the amount of water gas in the reforming gas is increased under the condition of guaranteeing the quality of the reforming gas, so that the aim of decreasing the heat value of the reforming gas is achieved, the conversion efficiency of natural gas in cities is improved, and the energy is saved.

Owner:上海吴淞煤气制气有限公司

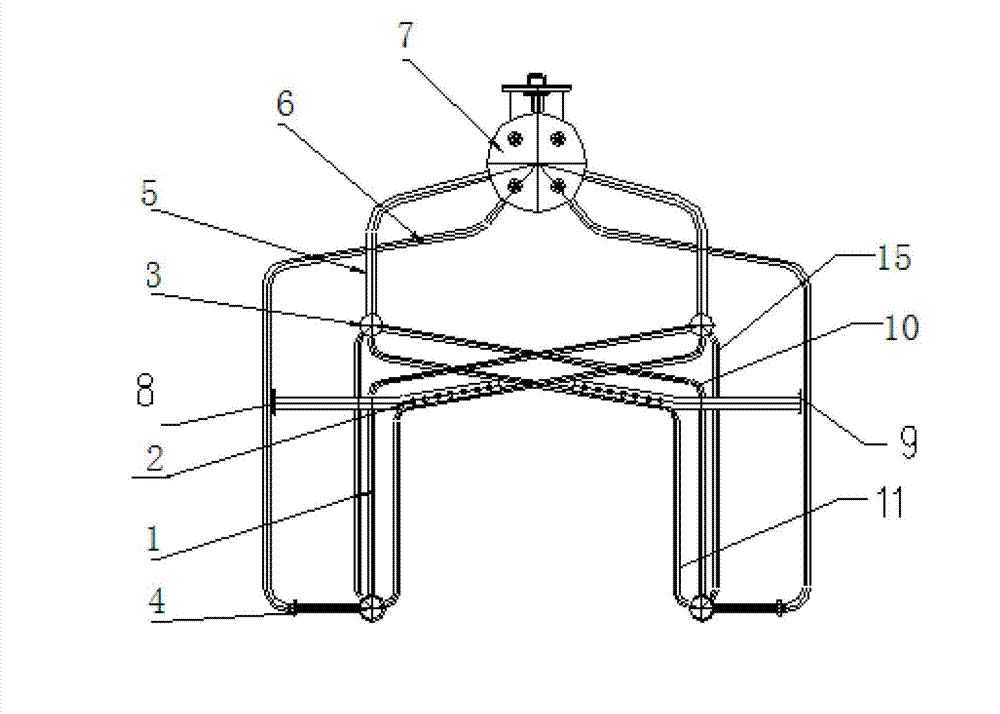

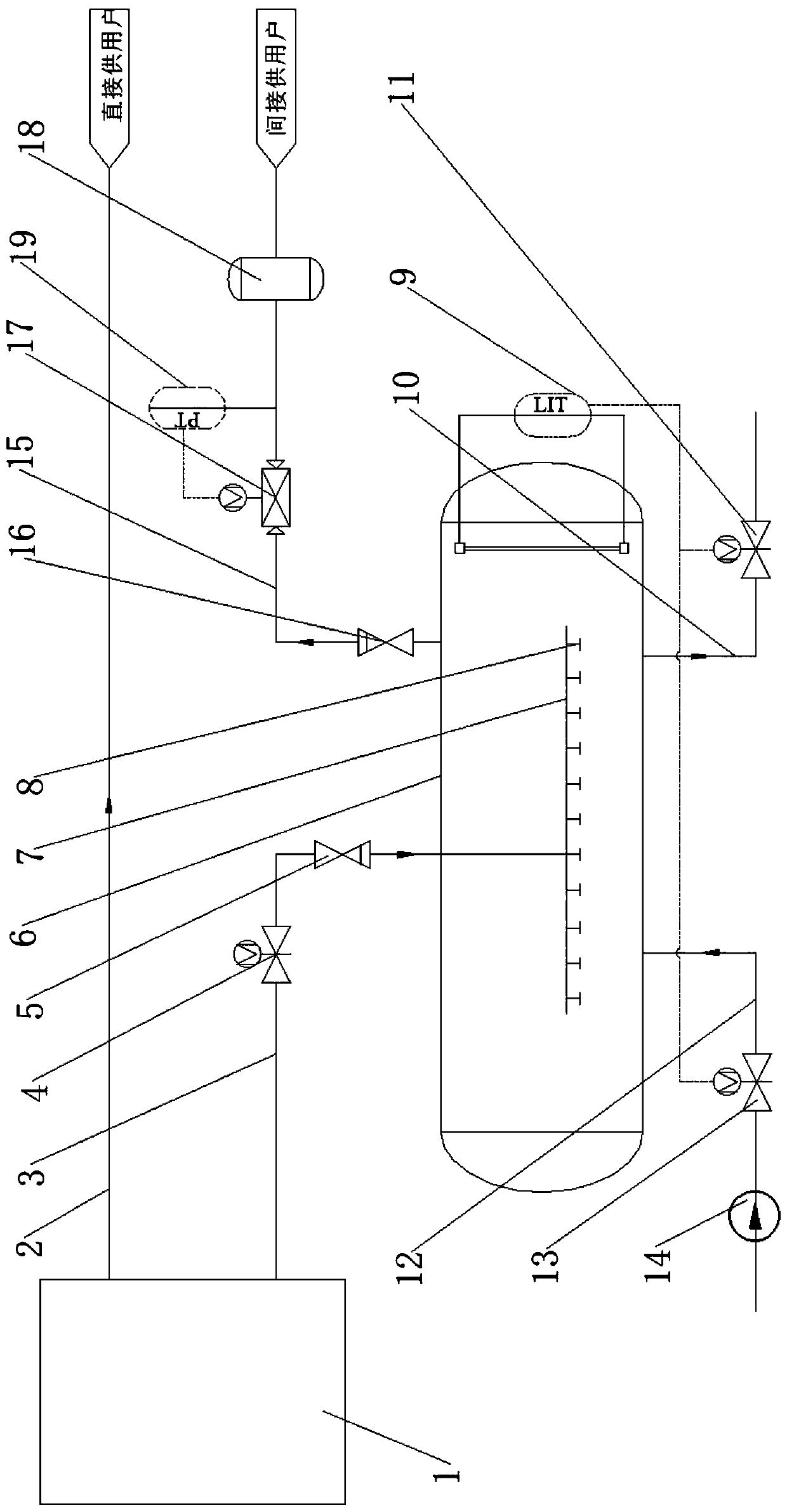

Steam energy accumulating system for accumulating heat through off-peak electricity

PendingCN111271694APrevent backflowSmall footprintSteam separation arrangementsBoiler controlProcess engineeringCheck valve

A steam energy accumulating system for accumulating heat through off-peak electricity comprises an electric steam boiler, a direct steam supply pipeline, a heat accumulating pipeline, a heat accumulating pipeline electric valve, a heat accumulating pipeline check valve, a steam distributing pipeline, a heating pipe, a liquid level transmitter, a drainage pipeline, a drainage pipeline electric valve, a water replenishing pipeline, a water replenishing pipeline electric valve, a make-up water pump, a heat releasing pipeline, a heat releasing pipeline check valve, an electric adjusting valve, a steam-water separator and a pressure transmitter. The tail end of the heat accumulating pipeline is connected in a steam heat accumulator. The heating pipe is connected to the steam distributing pipeline. The make-up water pump is connected with the water replenishing pipeline electric valve, and the heat releasing pipeline is connected with the steam accumulator. The heat releasing pipeline checkvalve, the electric adjusting valve, the steam-water separator and the pressure transmitter are mounted on the heat releasing pipeline in sequence. The steam energy accumulating system is small in occupied space and low in operation cost, water is adopted as a medium to store high-temperature high-pressure steam generated by off-peak electricity, and the steam is released for use at an electricityconsumption peak. The steam energy accumulating system can be widely used for the field of industrial and civil steam.

Owner:QINGDAO DANENG ENVIRONMENTAL PROTECTION INC

Method and device for the identification of a delay-susceptible control path, control device and computer program product

InactiveUS20100268500A1Quality is easy to controlEasy mappingProgramme controlComputer controlIntegratorEstimation methods

A method for identifying a delay-susceptible control path in the control of a steam generator and a device constructed for carrying out the method are provided. A model structure of the steam generator is specified, consisting of an unknown time-variable Nth-order delay element and a known integrator. Also used for the identification are measurements of the fuel mass flow, the turbine stream mass flow, and the live stream pressure which arises in the steam accumulator behind the steam generator after the removal of the turbine steam mass flow. Using these online measurements and the model structure, the live steam mass flow at the output of the steam generator is derived by calculation. In this way, the input value and the output value of the Nth-order delay element are determined and, using an estimation method, the parameters of a continuous transmission function of the Nth-order delay element are also determined online.

Owner:SIEMENS AG

Energy distribution system of low valley electric steam heat accumulator

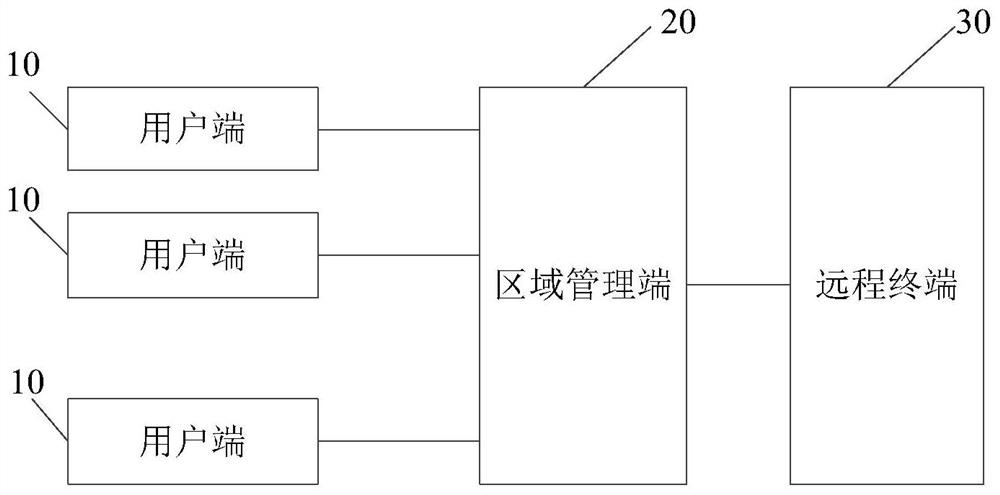

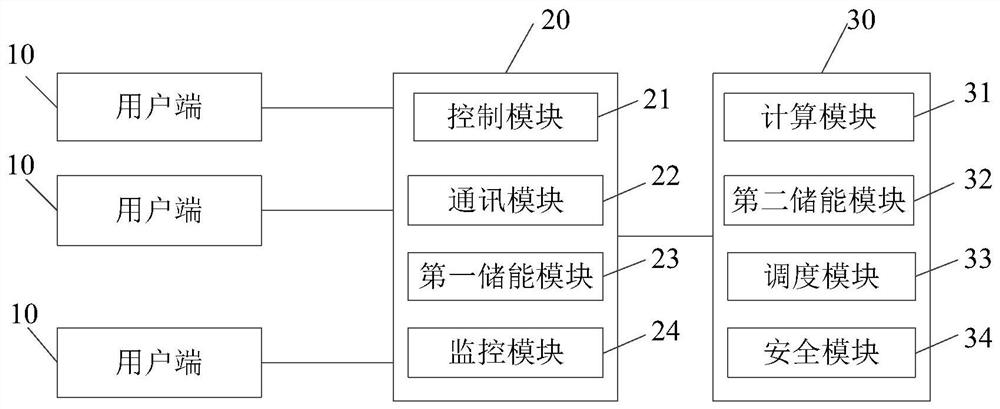

The invention provides an energy distribution system for a low-valley electric steam heat accumulator, including: multiple user terminals, a regional management terminal and a remote terminal, wherein the user terminal is used to collect energy consumption information of users; the regional management terminal is used to collect user The energy consumption information is sent to the remote terminal; the remote terminal is used to convert and store the energy according to the user's energy consumption information during off-peak electricity, and distribute the converted and stored energy to the regional management terminal; the regional management terminal is also used to The user's energy consumption information distributes the energy allocated by the remote terminal to multiple user terminals for use by multiple user terminals. In the system of the present invention, the remote terminal converts and stores energy according to the user's energy consumption information during low-peak electricity, and distributes the converted energy to the regional management terminal. When the user terminal uses energy, the regional management terminal The user's energy consumption information is used for energy allocation, so as to store as much as used, and avoid energy waste to the greatest extent.

Owner:JIANGSU ELECTRIC POWER CO +2

Portable steam heat accumulator

InactiveCN104833252BHas a buffering effectAvoid direct flushingHeat storage plantsItem transportation vehiclesEngineeringReducer

Owner:ZHENGZHOU UNIV

Garbage treating method

InactiveCN102319718BNo pollution in the processIncrease profitSolid waste disposalThermodynamicsProcess engineering

Owner:GOWIN ENTERPRISES

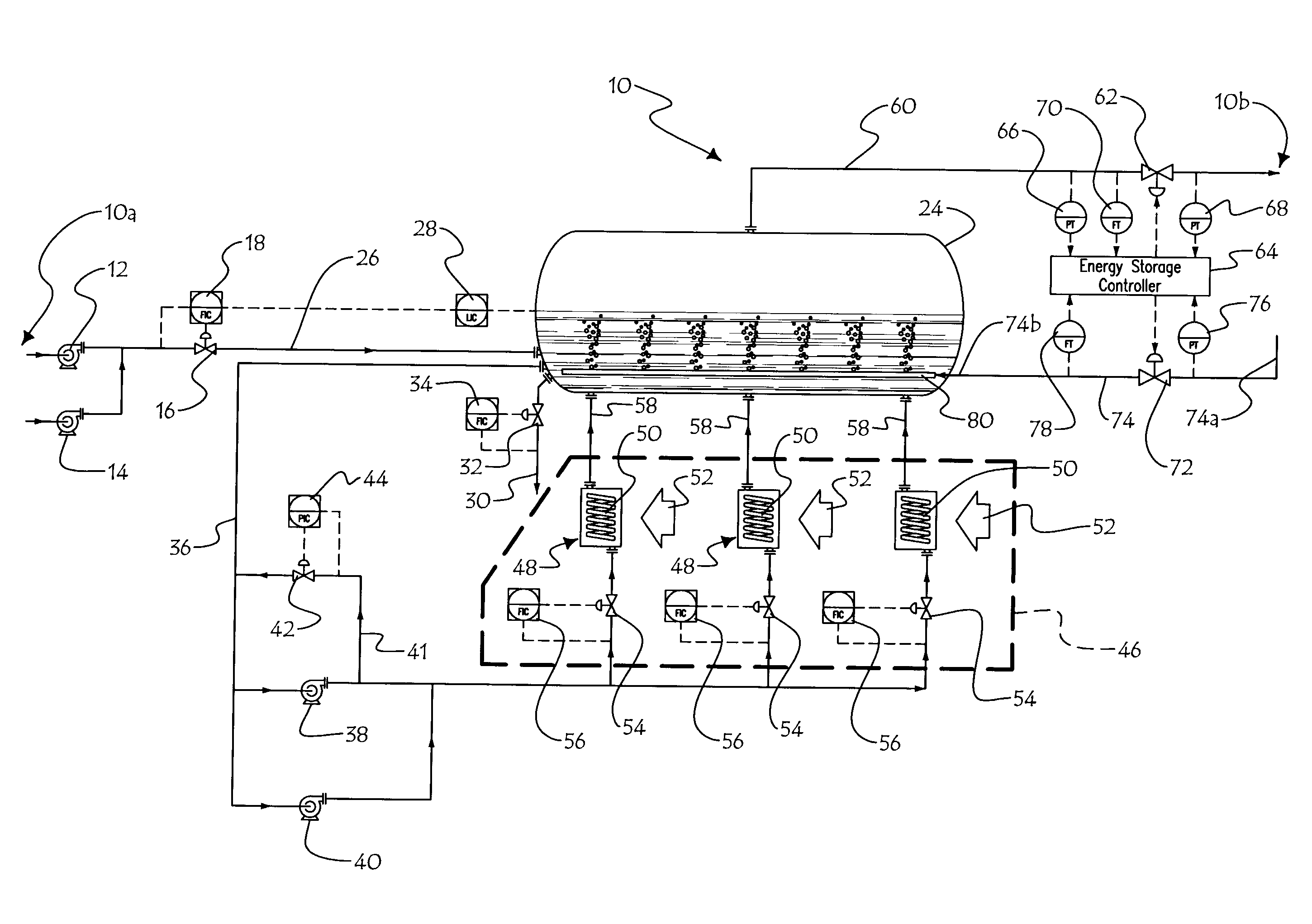

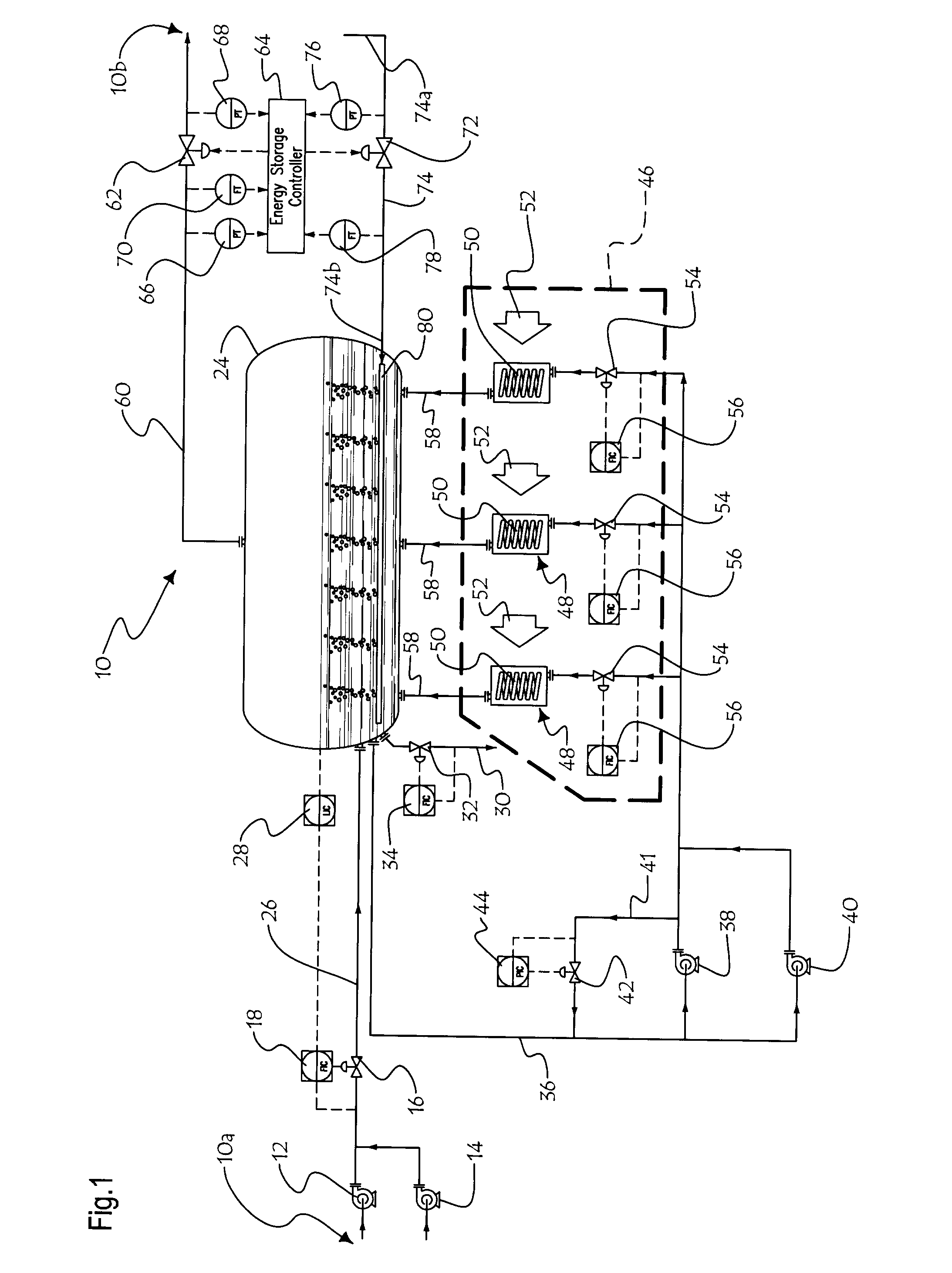

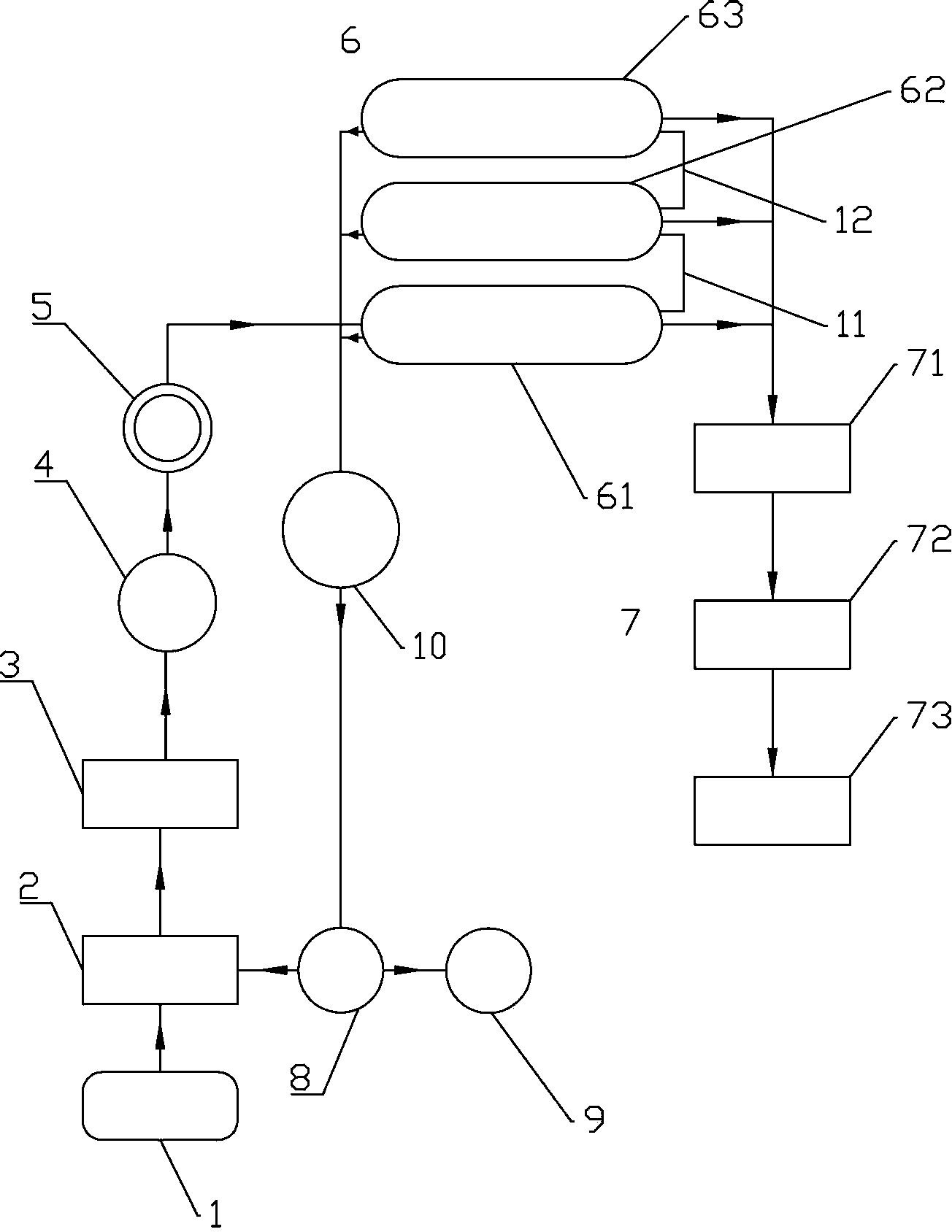

Power Generation Systems Including Steam Heat Accumulators

ActiveCN104265586BEfficient use ofReduce pollutionFrom solar energySteam engine plantsEngineeringSuperheated steam

The invention provides a power generation system comprising a steam heat accumulator. The power generation system comprises a disc-type solar energy system and a coal-fired power generation system which are connected together in parallel; the superheated steam of the disc-type solar energy system and that of the coal-fired power generation system both go into a main steam pipeline and are used for propelling the generator of a turbo generator unit; the steam heat accumulator is mounted between the disc-type solar energy system and a main steam pipeline; when the solar energy system supplies sufficient steam, the solar energy supplied steam is divided into two branches, wherein one branch goes into the main steam line, while the other branch goes into the steam heat accumulator; when the steam supplied by the solar energy system is insufficient, the steam heat accumulator generates secondary steam which directly goes into the main steam line to cover the shortage of the steam supplied by the disc-type solar energy system. The power generation system is used for solving the safety problem of frequency adjustment of the power generation system to cope with the fluctuation of the disc-type solar energy system by use of the steam heat accumulator, and therefore, the overall efficiency of the power generation system is improved, the energy source is saved and a new choice is provided for efficient utilization of the solar energy.

Owner:GUODIAN LONGYUAN POWER TECH ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com