Portable steam heat accumulator

A heat accumulator, mobile technology, applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of potential safety hazards, inconvenient assembly, affecting the surrounding environment, etc., to improve the mixed heat exchange. Efficiency, improved transportation safety, improved safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

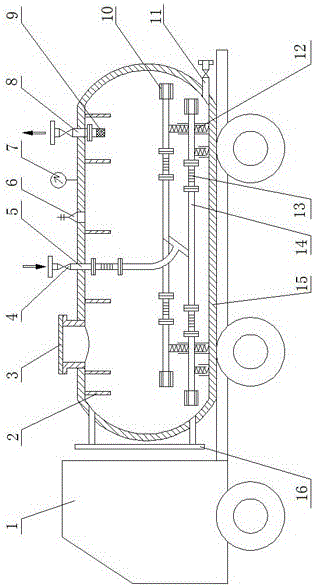

[0019] The specific implementation of the mobile steam heat accumulator is as follows:

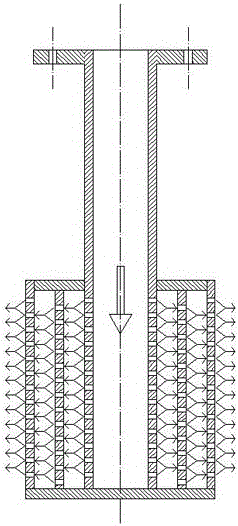

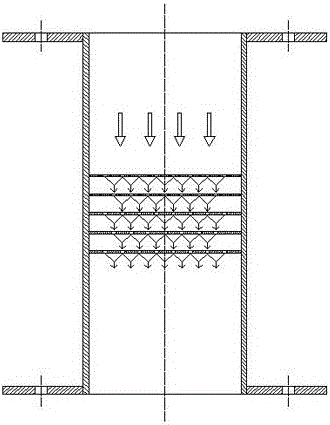

[0020] First weld the elliptical head and the cylindrical body together, and install manholes on the cylindrical body; then connect the pressure reducer to the intake pipe and the H-shaped branch pipe through the flange, and the noise reducer to the H-shaped branch pipe through the flange. The pipe end of the branch pipe is connected, and the noise reducer is as close as possible to the bottom of the steam heat storage tank shell. The inlet pipe and the H-shaped branch pipe are connected in an arc shape, and the steam inlet pipe and the H-shaped branch pipe are fixed on the steam heat storage tank shell through a damping shock absorber. The bottom surface of the inside of the steam storage tank; the anti-vibration plate is welded on the inner upper part of the steam heat storage tank shell; then the adjustable safety valve, stop valve and exhaust pipe are installed on the steam heat storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com