Patents

Literature

84results about How to "Avoid wild swings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

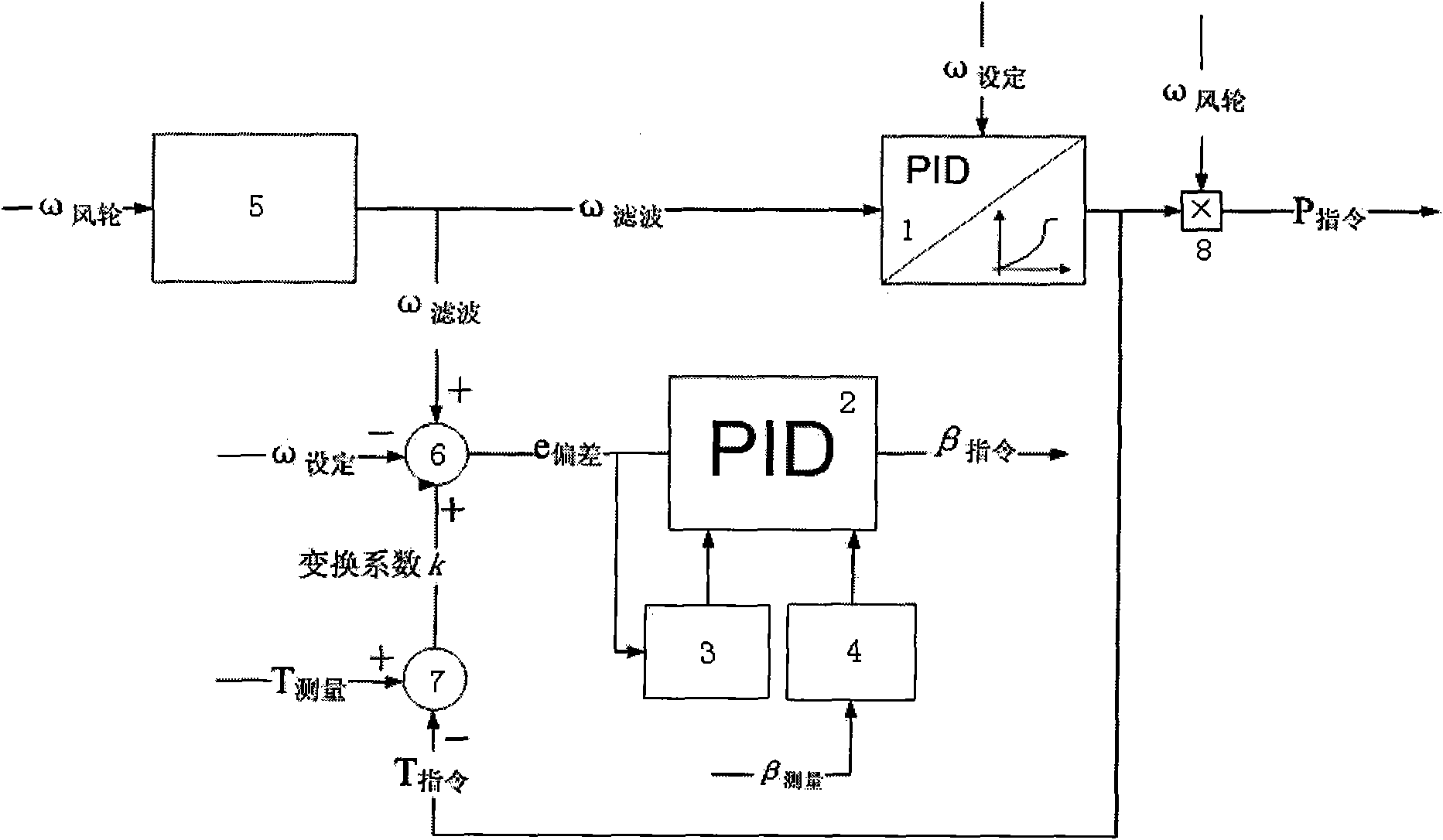

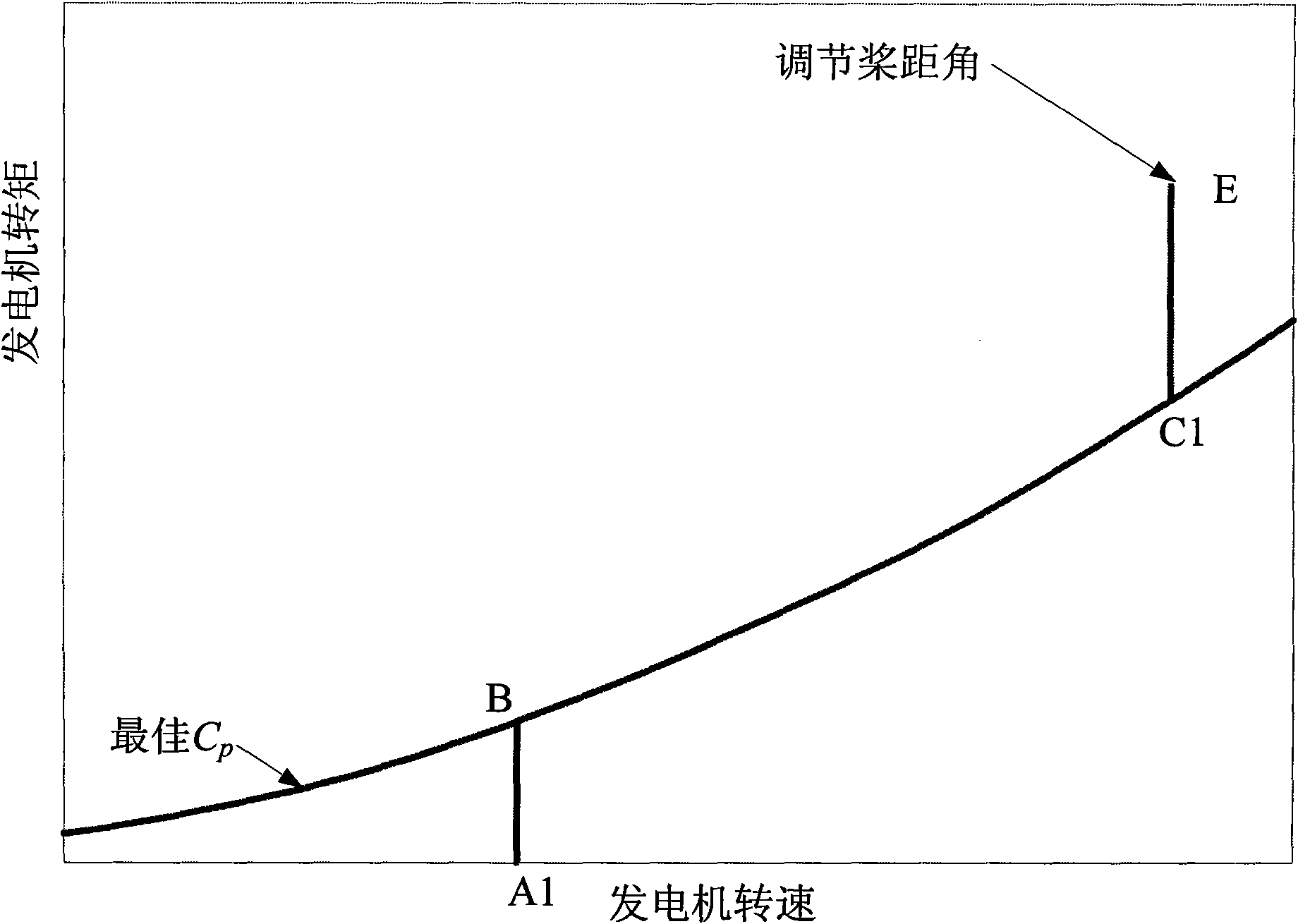

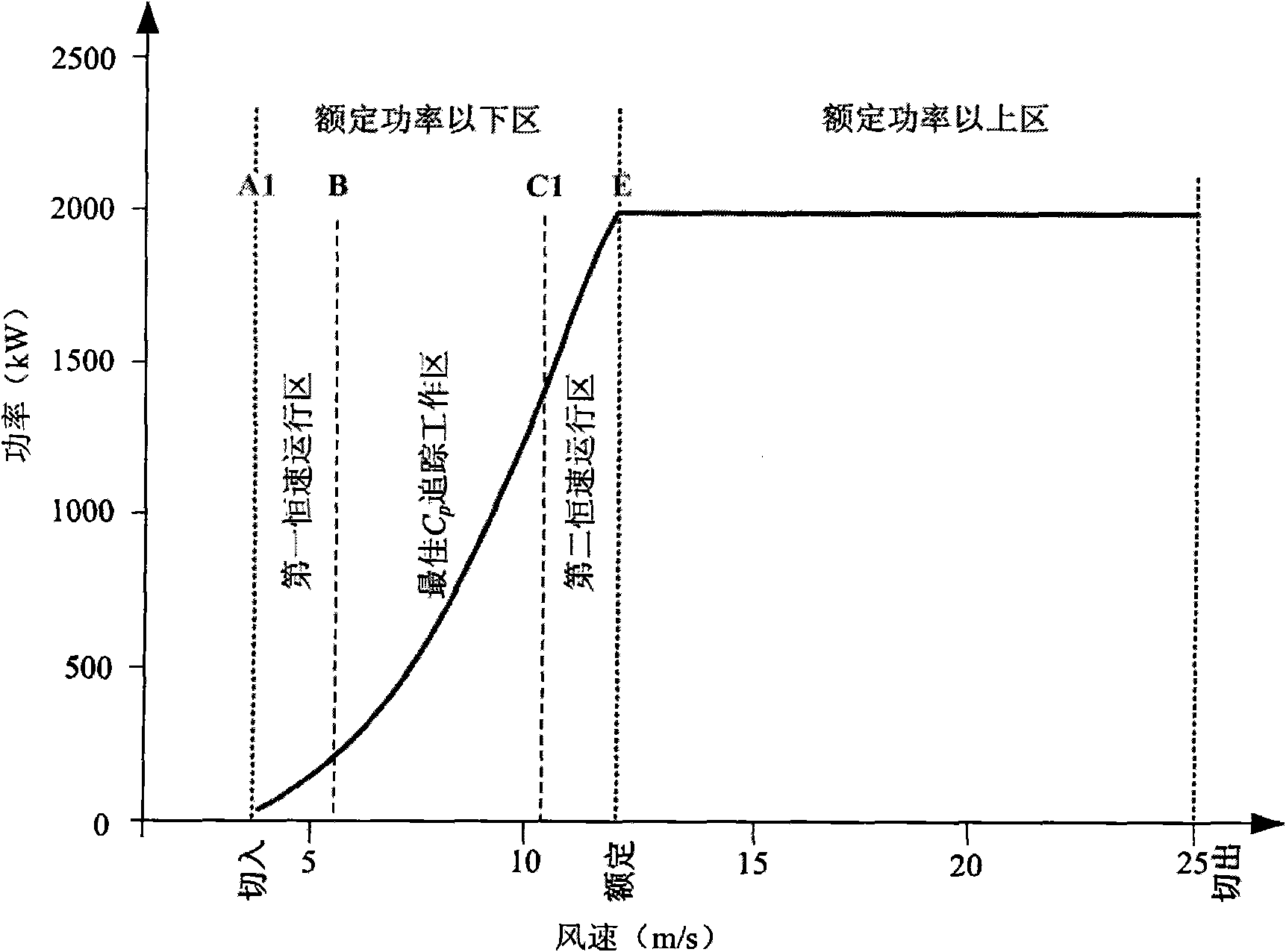

Megawatt wind generating set combination control policy

InactiveCN101660489AAvoid mutual interferenceSwitching is smooth and responsiveWind motor controlMachines/enginesPower qualityControl theory

The invention relates to a megawatt wind generating set combination control policy. When the wind speed of a wind generator fluctuates at rated wind speed, a torque control policy and feather control policy simultaneously remain in operation state, so as to realize undisturbed switching between a feather PID controller and a torque PID controller. The invention makes the best of the integral saturation characteristic of PID algorithm, so that switching between the torque PID controller and the feather PID controller is smooth and sensitive, mutual interference between the feather controller and the torque controller in the previous switch mode switching process while only one controller is ensured to operate at the same time, drastic fluctuation of wind generator power when the wind speedfluctuates at the rated wind speed is avoided, further load impact is reduced, electric energy quality is improved, reliability of the wind generating set is improved, and operation performance of the wind generating set is improved.

Owner:南京智昊置业有限公司

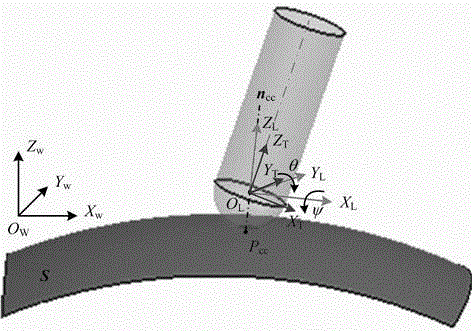

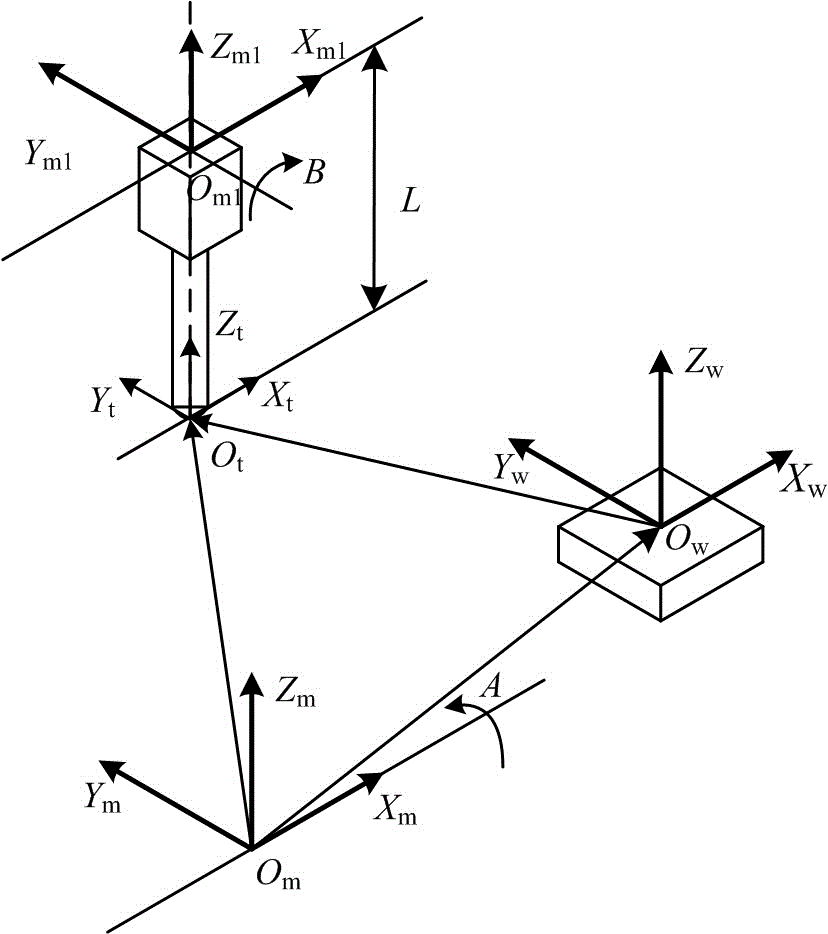

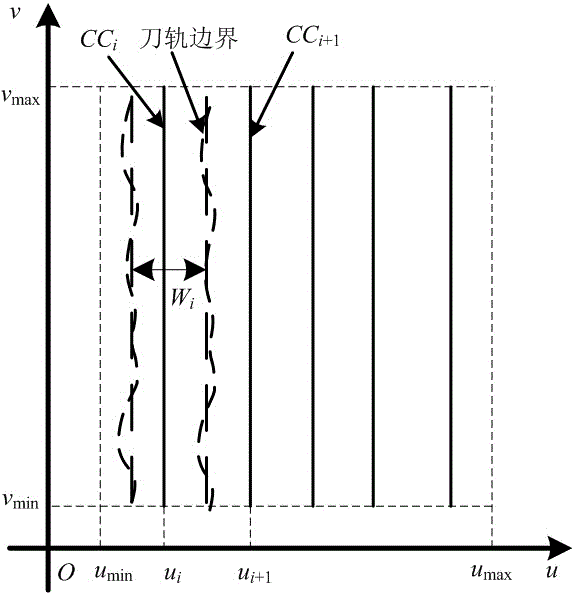

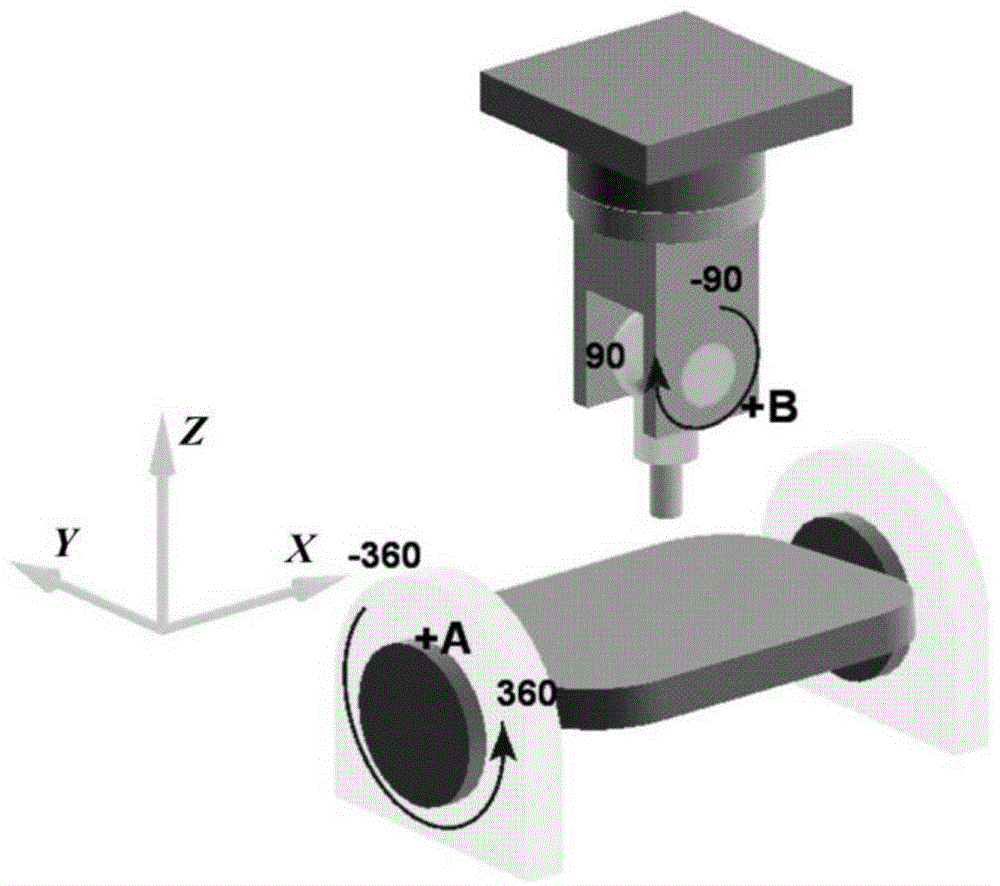

Ball-end cutter multi-axis machining cutter axis vector optimization method

ActiveCN104102171AImprove processing efficiencyImprove processing qualityNumerical controlCutter locationStructural engineering

The invention discloses a ball-end cutter multi-axis machining cutter axis vector optimization method. The method includes the following steps that: at first, a relationship equation between cutter location optimization variables and cutter location data is constructed, and at the same time, a movement transformation equation between the cutter location data and machine tool rotation axis angles is constructed, and therefore a relationship equation between the cutter location optimization variables and the machine tool rotation axis angles can be derived; then, a cutter axis vector computational formula of ball-end cutter multi-axis machining complex curved surfaces can be obtained through solving the above equations; and finally, the ball-end cutter multi-axis machining cutter axis vector optimization method is rendered based on the above steps. With the ball-end cutter multi-axis machining cutter axis vector optimization method adopted, large fluctuation of machine tool rotation axes in a machining process can be avoided, and the movement of the machine tool axes is more stable and smooth, and therefore, machining quality and machining efficiency of the curved surfaces can be improved. The ball-end cutter multi-axis machining cutter axis vector optimization method has a certain practical application value.

Owner:SHANDONG UNIV OF TECH

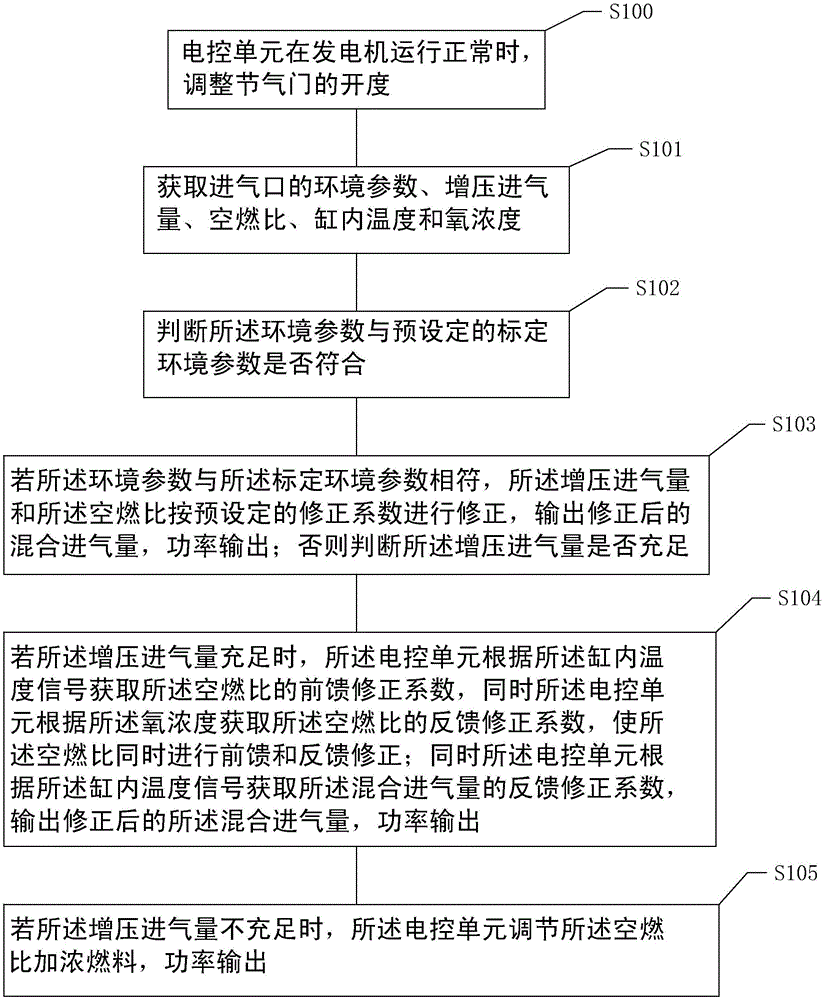

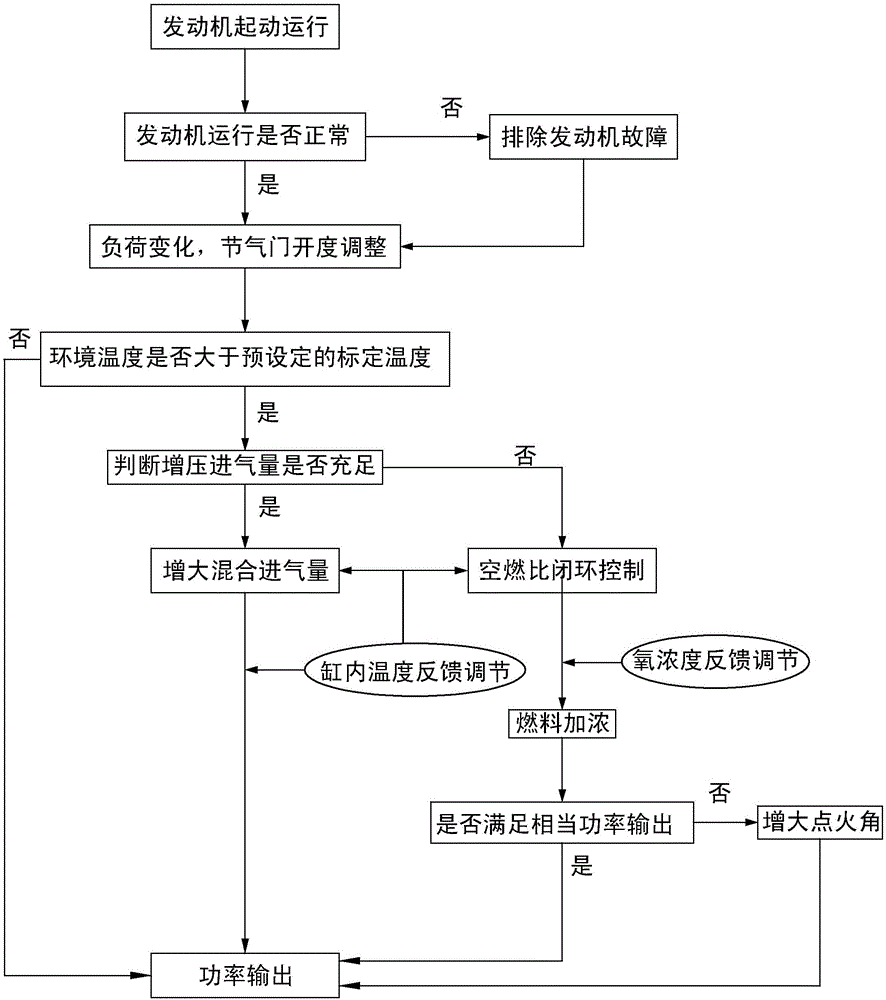

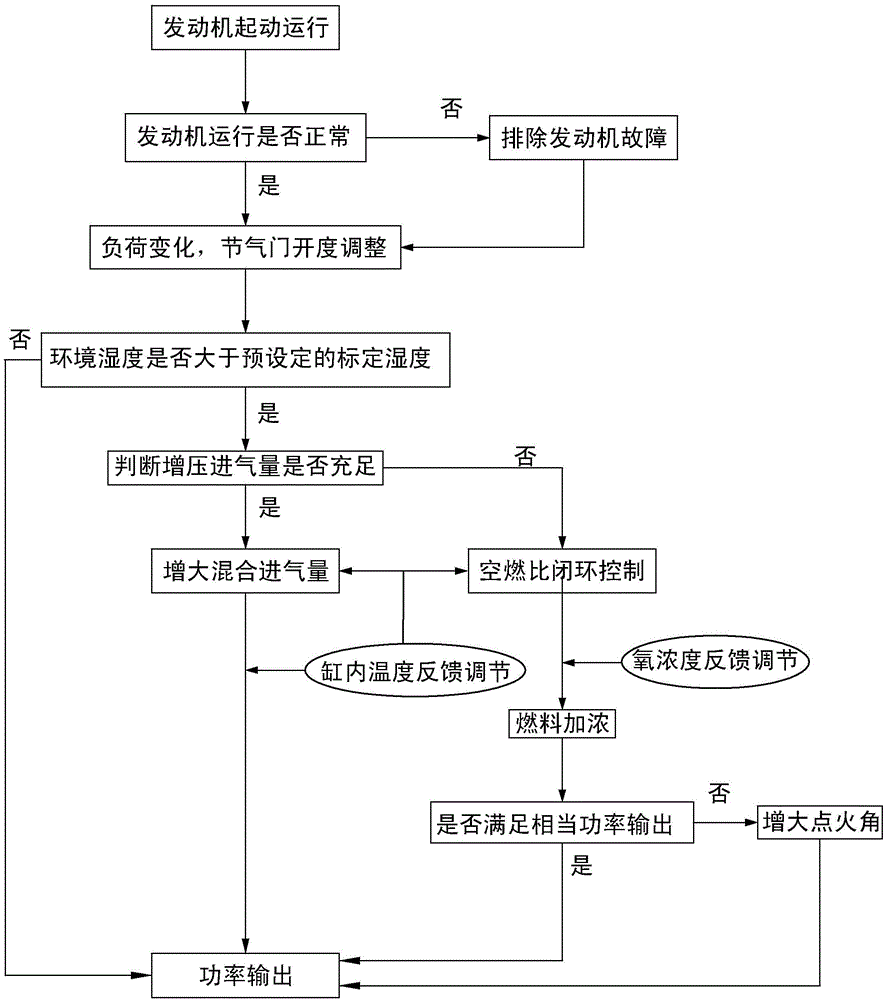

Environmental compensation closed-loop control method and system for natural gas engine

ActiveCN106121843AAvoid wild swingsRealize closed-loop precise controlElectrical controlMachines/enginesLoop controlControl system

The invention discloses an environmental compensation closed-loop control method and system for a natural gas engine. The control method includes the steps that by comparing the environmental parameters of a gas inlet of the engine with the preset standard environment parameters, when the engine is in the nonstandard environment, an electric control unit obtains the feedforward correction coefficients of the boosting gas inflow and the air-fuel ratio according to the temperature in a cylinder, meanwhile the feedback correction coefficient of the mixed gas inflow is obtained according to the temperature in the cylinder, and finally the equivalent power output is obtained, so that the engine can work normally under any environment. The control system is characterized in that an atmospheric environment sensor is additionally arranged on the gas inlet, an intra-cylinder temperature sensor is arranged in the air cylinder, boosting air inflow feedforward and feedback control, air-fuel ratio feedforward control and mixed gas inflow feedback control can be achieved, and finally under any environment, the engine adopting the environmental compensation closed-loop control method and system can achieve the purposes that the inflow of mixed air entering the air cylinder can be controlled and corrected quickly and precisely, and equivalent power output is reached.

Owner:WEICHAI XIGANG NEW ENERGY POWER

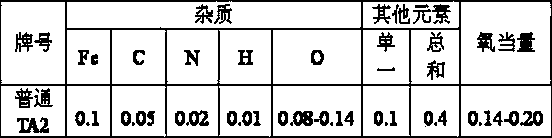

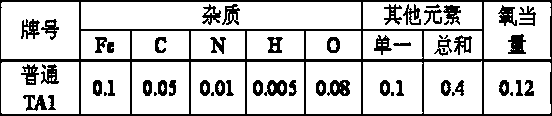

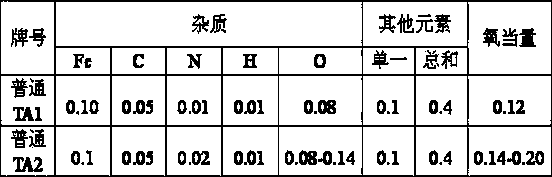

Method for melting titanium scraps and pure titanium wastes of thin titanium plates by electron beam cold hearth melting furnace

InactiveCN103866130AAvoid high and low density inclusionsClear high and low density inclusionsProcess efficiency improvementTitaniumIngot

The invention discloses a method for melting titanium scraps and pure titanium wastes of thin titanium plates by an electron beam cold hearth melting furnace, and relates to methods for melting pure titanium by electron beam cold hearth melting furnaces. The method comprises the following steps: preparing raw materials; selecting and proportioning; mixing by a mixer; vacuumizing and melting the vacuumized raw materials by the electron beam cold hearth melting furnace to obtain slab ingot formed by recovering and melting the wastes. According to the method, the utilization rate of the block-shaped titanium wastes is effectively increased, the process is simplified, the cost is reduced, high-and-low-density impurities in the wastes are effectively removed, and the waste recovering and melting quality is improved.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

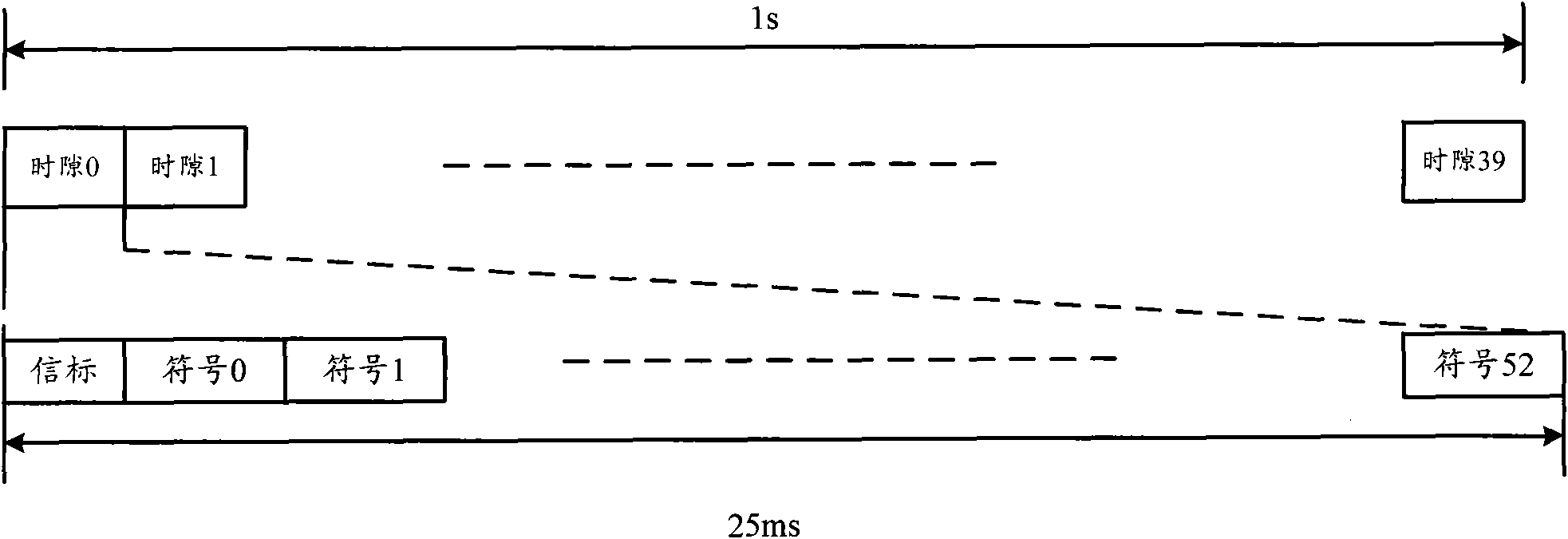

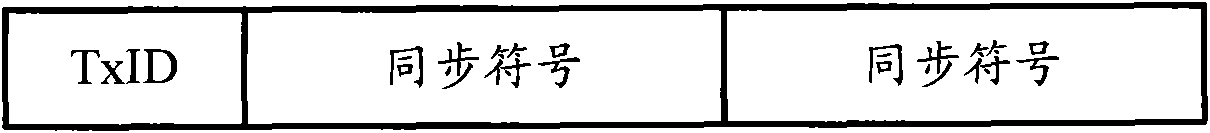

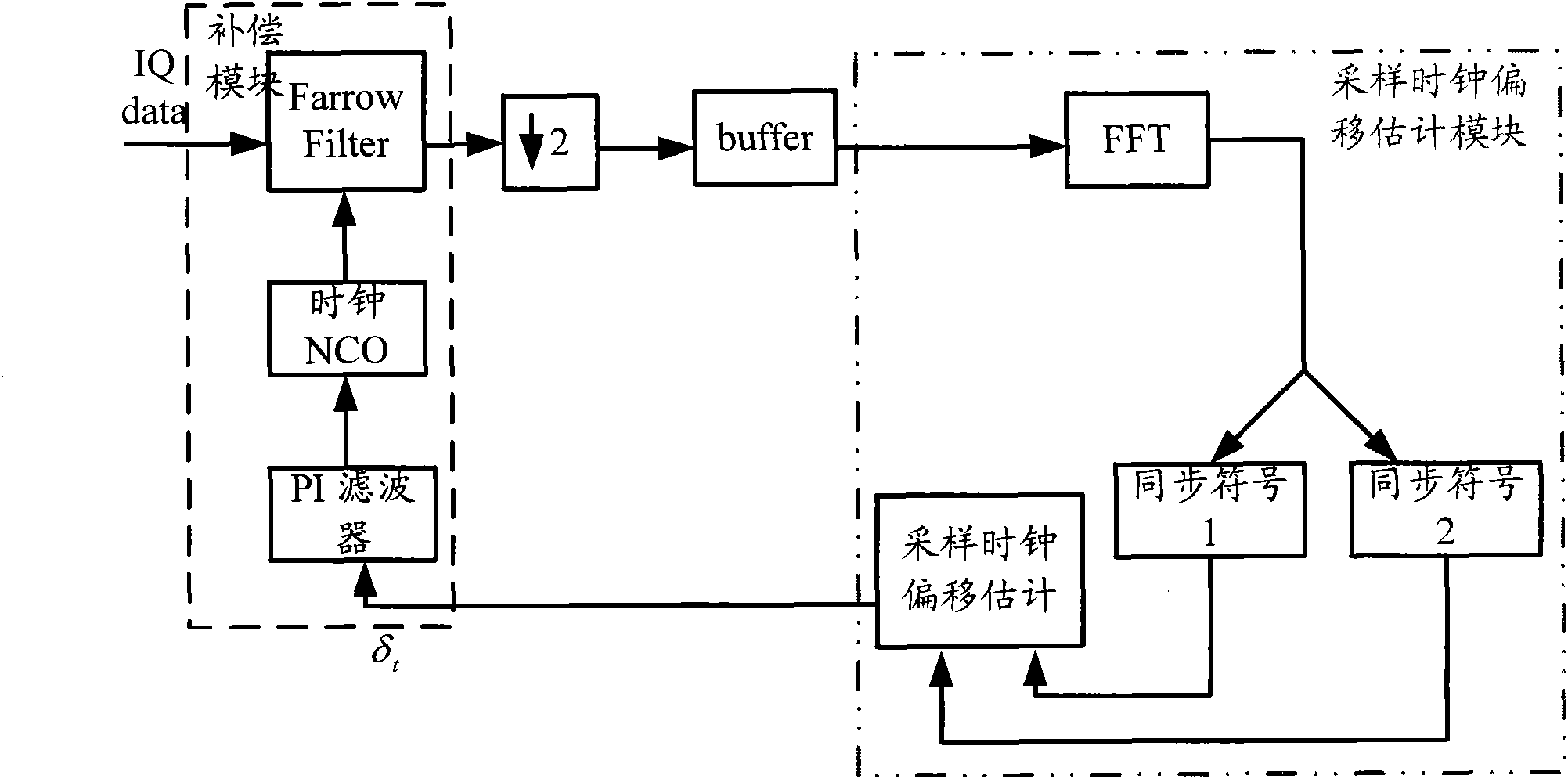

Method for estimating and compensating sampling clock offset and receiving device

ActiveCN101841509AFast adjustmentGuaranteed robustnessMulti-frequency code systemsStable stateTwo step

The invention relates to the field of communication, in particular to a method for estimating and compensating a sampling clock offset and a receiving device. In the invention, a sampling clock offset is estimated and comprehended by two steps. In the first step, the sampling clock offset is sampled according to two synchronous symbols in a time slot and compensated in the next time slot according to an estimating result; and in the second step, the sampling clock offset of every two adjacent data symbols in the time slot is finely estimated by utilizing the continuous pilot frequency symmetry of the data symbols and the sampling clock offset of the currently received data symbols is compensated according to a current estimating result after the sampling clock offset of every two adjacent data symbols is estimated every time. By the invention, the adjusting speed is greatly improved, and the system can rapidly enter a stable state.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

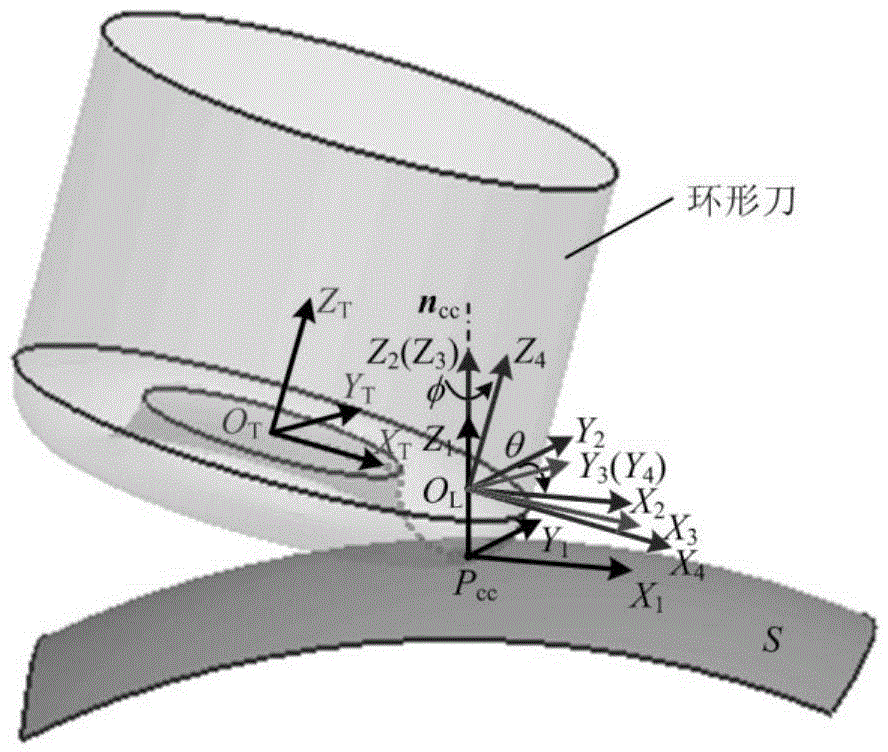

Tool path generating method for multi-axis machining complex curved surface of constraint circular tool based on motion of machine tool

ActiveCN104678888AImprove processing efficiencyImprove processing qualityTotal factory controlNumerical controlNumerical controlTransformation equation

The invention discloses a tool path generating method for a multi-axis machining complex curved surface of a constraint circular tool based on the motion of a machine tool. The method explains by taking head and table five-axes numeric control machine tools as an example and comprises the following steps: firstly, establishing a relation equation between a tool position design variable and tool position data as well as a motion transformation equation between the tool position data and a rotating shaft of the machine tool, and further deducing a relation equation between the tool position design variable and the rotating shaft of the machine tool; secondly, analyzing and discussing the equations, and deducing a formula of solving another two variables by using any two variables in a known equation set, thereby obtaining a tooth position calculation formula for the multi-axis machining complex curved surface of the constraint circular tool; on the basis, giving out the basic principle and the calculation flow of a tooth path generation algorithm for the multi-axis machining complex curved surface of the constraint circular tool. The test result shows that by using the algorithm, great change of the rotating shaft of the machine tool can be avoided, the feed speed of a motion shaft of the machine tool is improved, and higher processing quality of the curved surface can be obtained; the algorithm has certain actual application value.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

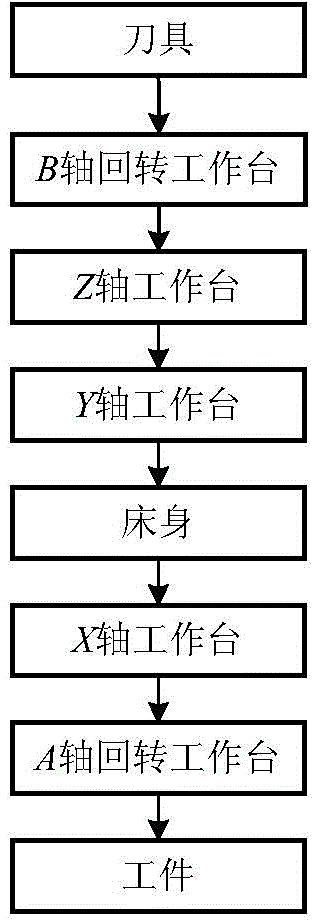

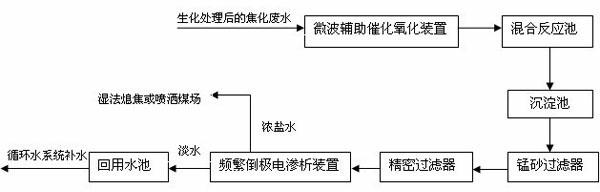

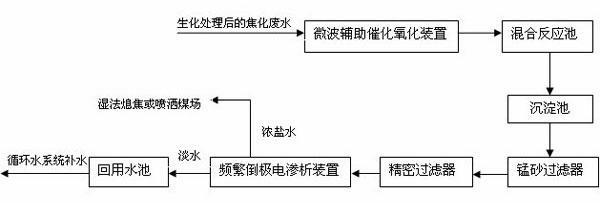

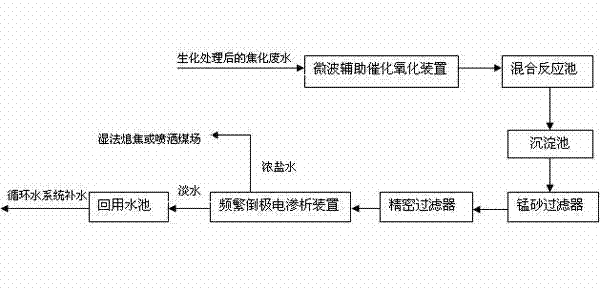

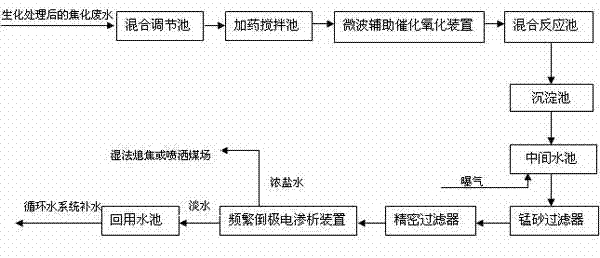

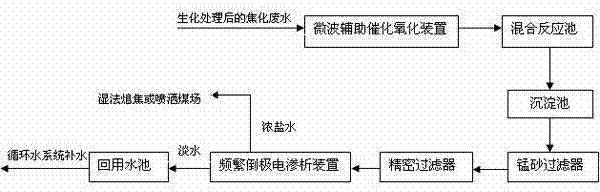

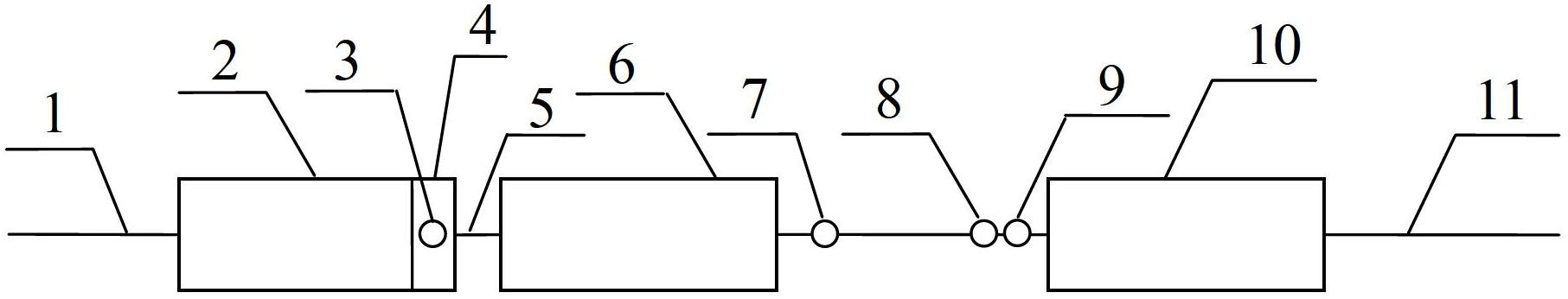

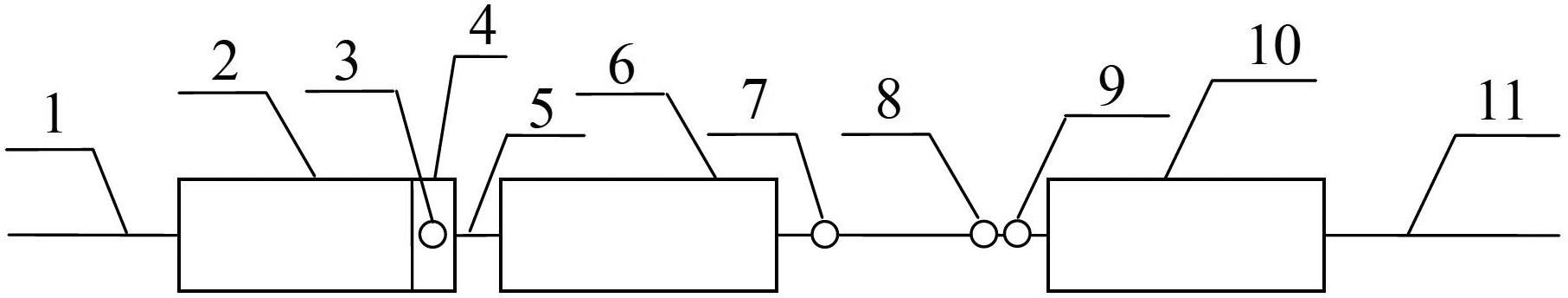

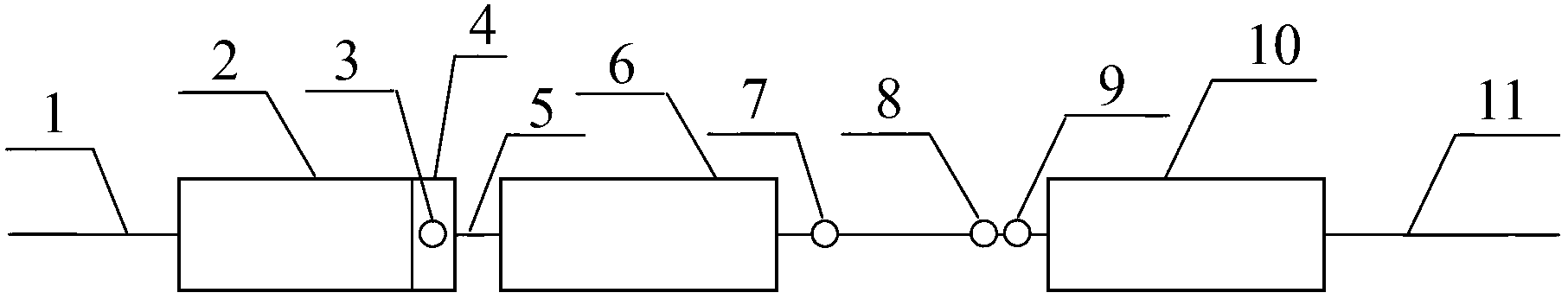

Coking wastewater advanced treatment system and process

InactiveCN102120663AStrong resistance to hydrolysisAvoid easy cloggingDispersed particle separationMultistage water/sewage treatmentCatalytic oxidationProcess engineering

The invention relates to a coking wastewater advanced treatment system, comprising a microwave-assisted catalytic oxidation device, a mixing reaction pool, a sedimentation pool, a manganese sand filter, a precision filter and a frequent electrode reverse electrodialysis device, wherein the microwave-assisted catalytic oxidation device is used for carrying out catalytic oxidation treatment on coking wastewater subjected to A / O (Anoxic / Oxic) biochemical treatment; the mixing reaction pool is connected with the microwave-assisted catalytic oxidation device and the sedimentation pool; the manganese sand filter is connected with the sedimentation pool and the precision filter; and the frequent electrode reverse electrodialysis device is connected with the precision filter. The advanced treatment process provided by the invention can be used for coking wastewater advanced treatment and simultaneously has a high-efficiency pretreatment and economic and proper type desalting system.

Owner:中电恒德环保投资有限公司

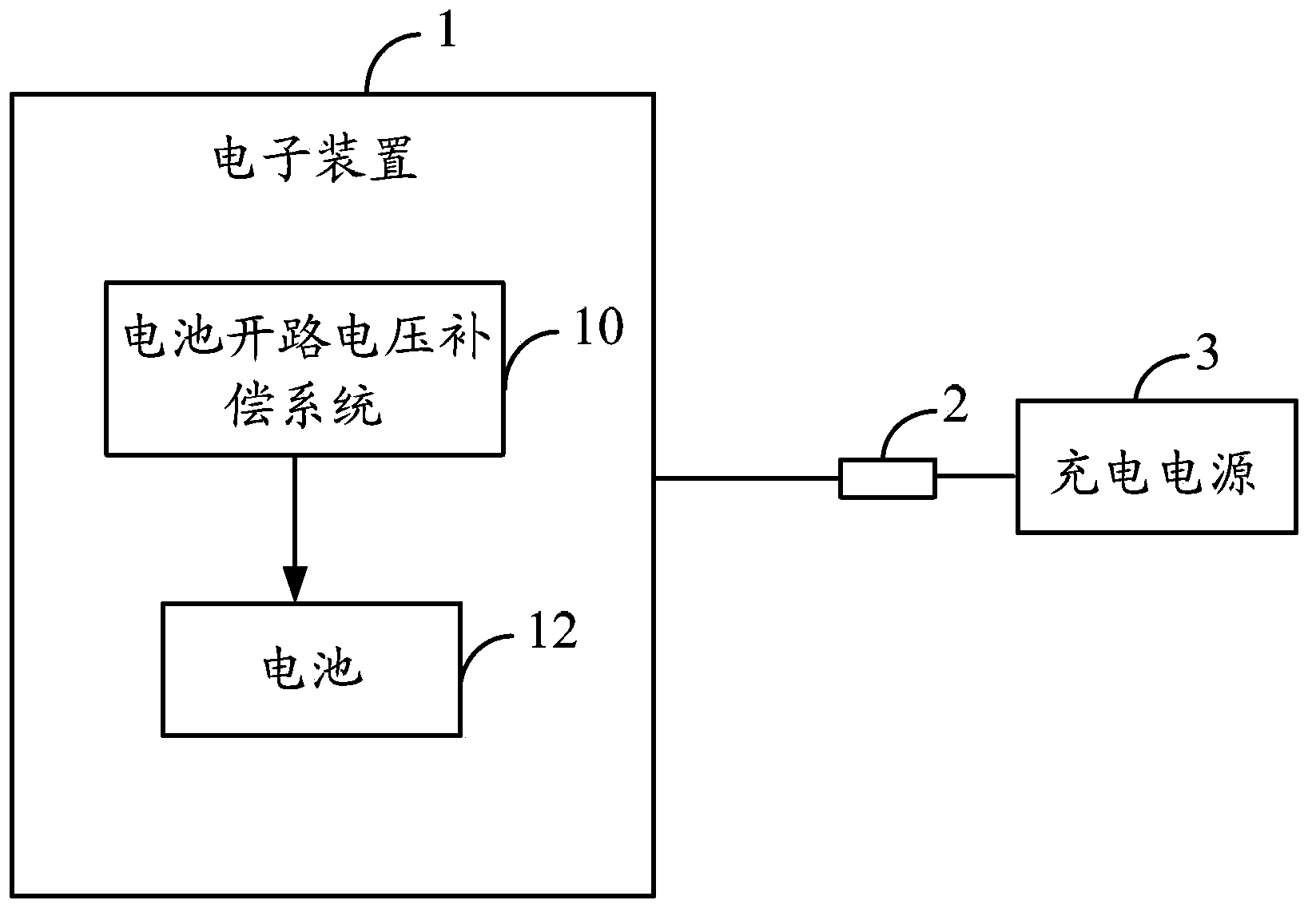

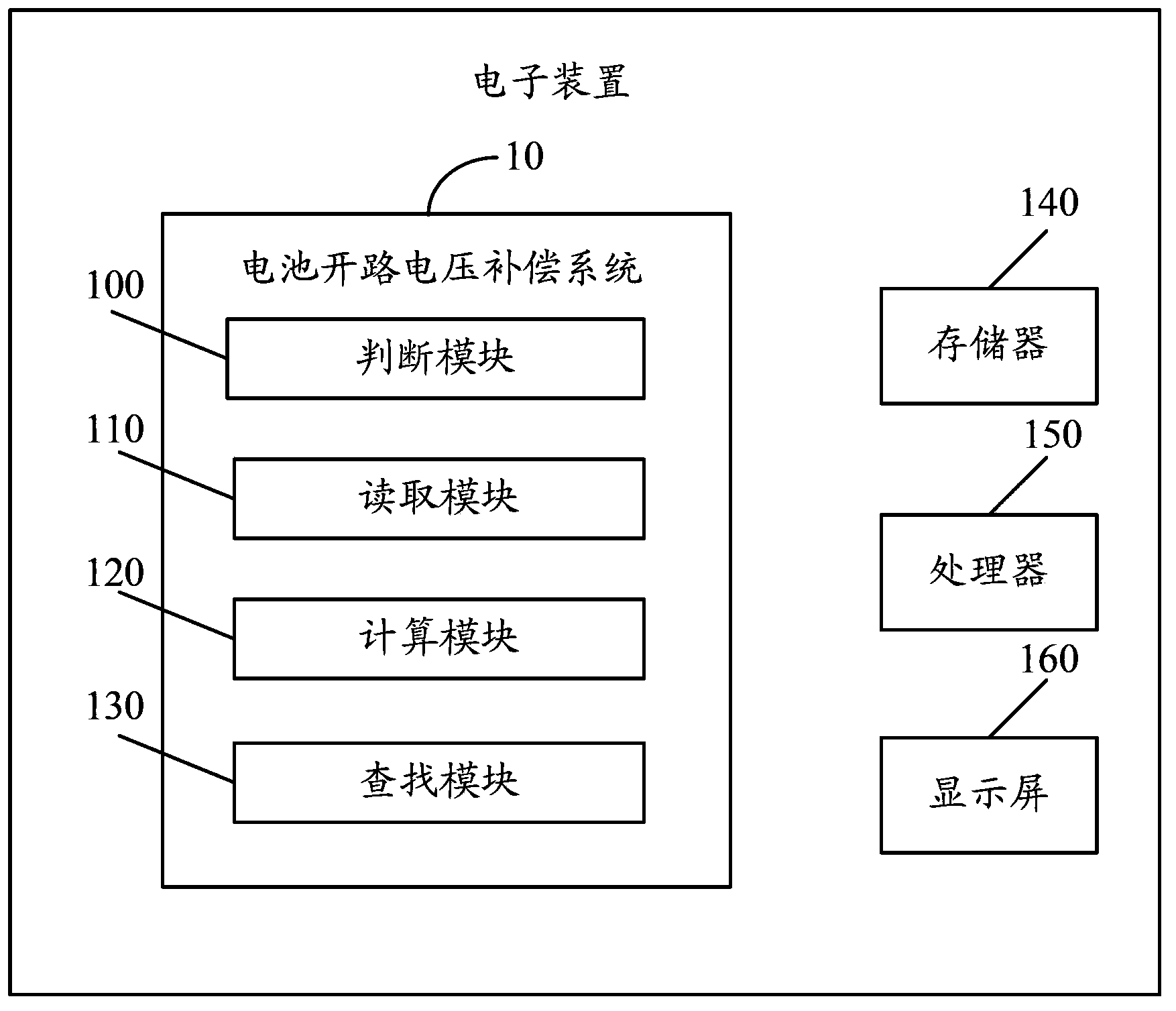

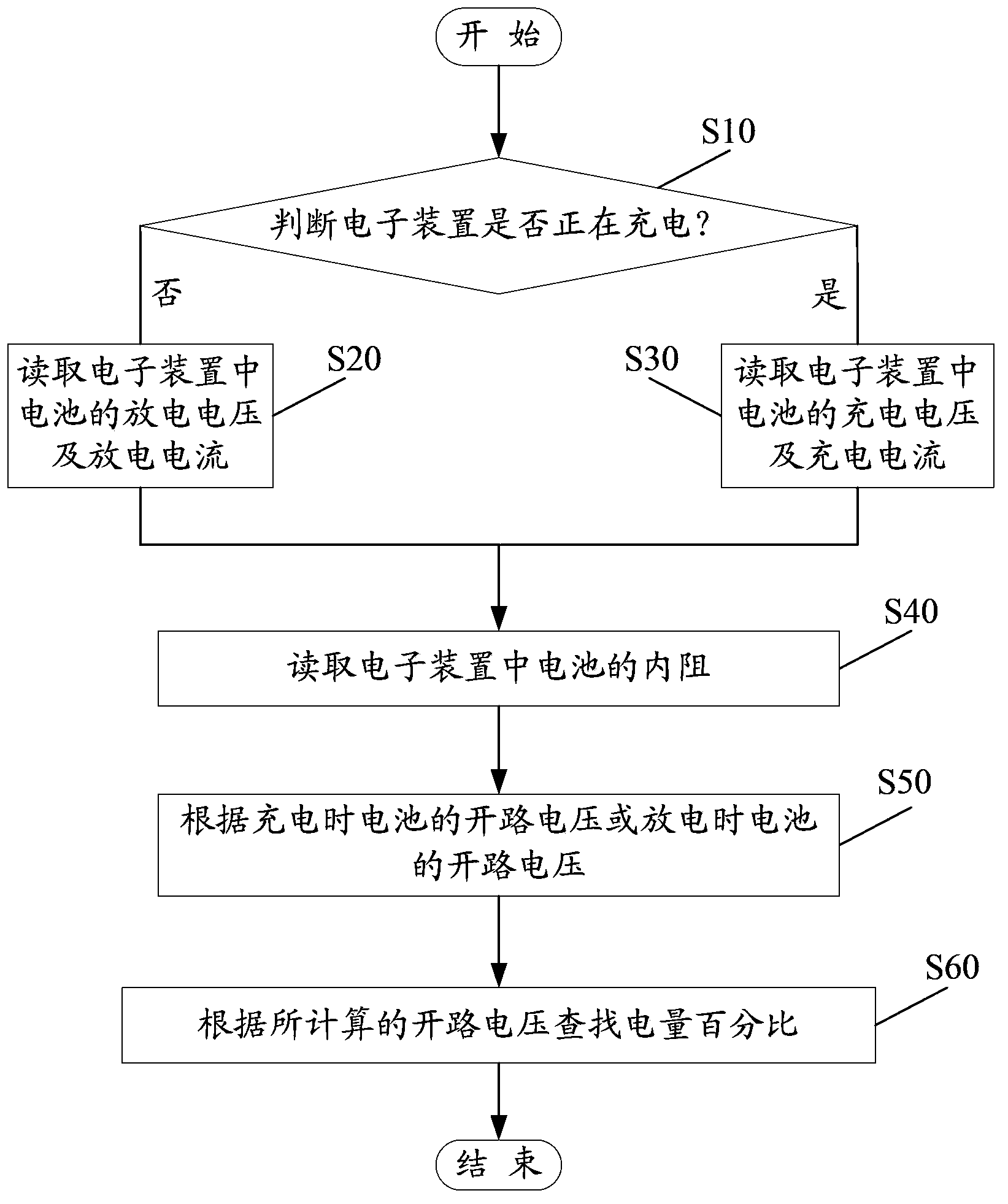

Cell open-circuit voltage compensation system and cell open-circuit voltage compensation method

InactiveCN103576091AAccurate battery percentageAvoid wild swingsCurrent/voltage measurementElectrical testingCharge currentInternal resistance

An electronic device being used to calculate an open circuit voltage of a battery built in the electronic device. The electronic device reads a charging voltage and a charging current, a discharging voltage and a discharging current. The electronic device calculates the open circuit voltage of the battery according to the charging voltage, the charging current and the resistance if the battery is charging. The electronic device calculates the open circuit voltage of the battery according to the discharging voltage, the discharging current and the resistance if the battery is discharging.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

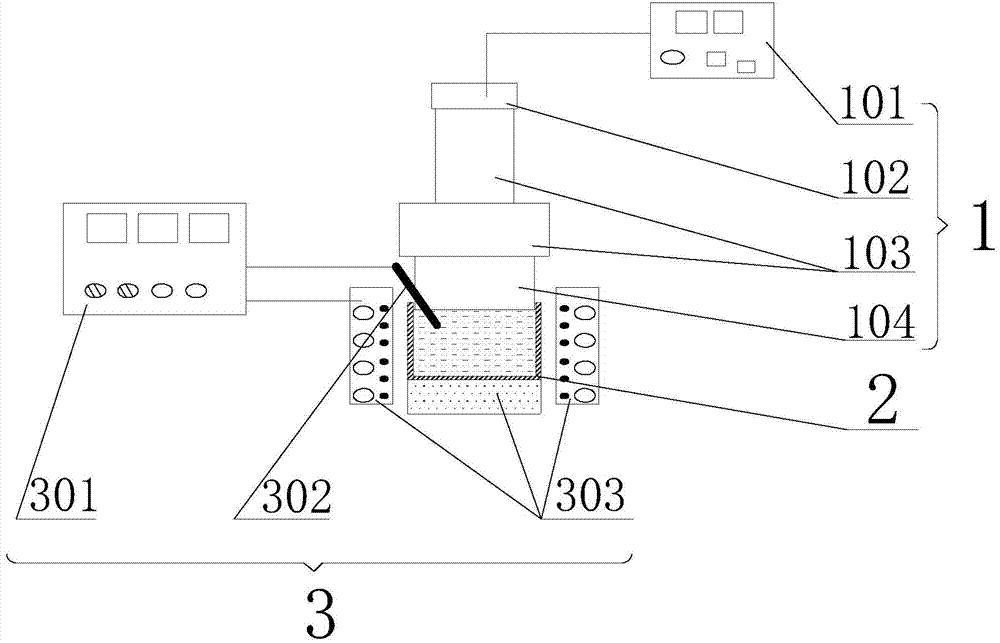

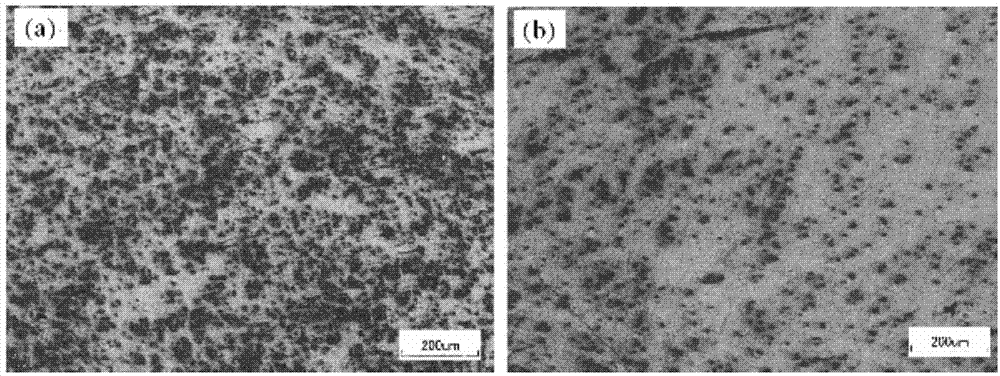

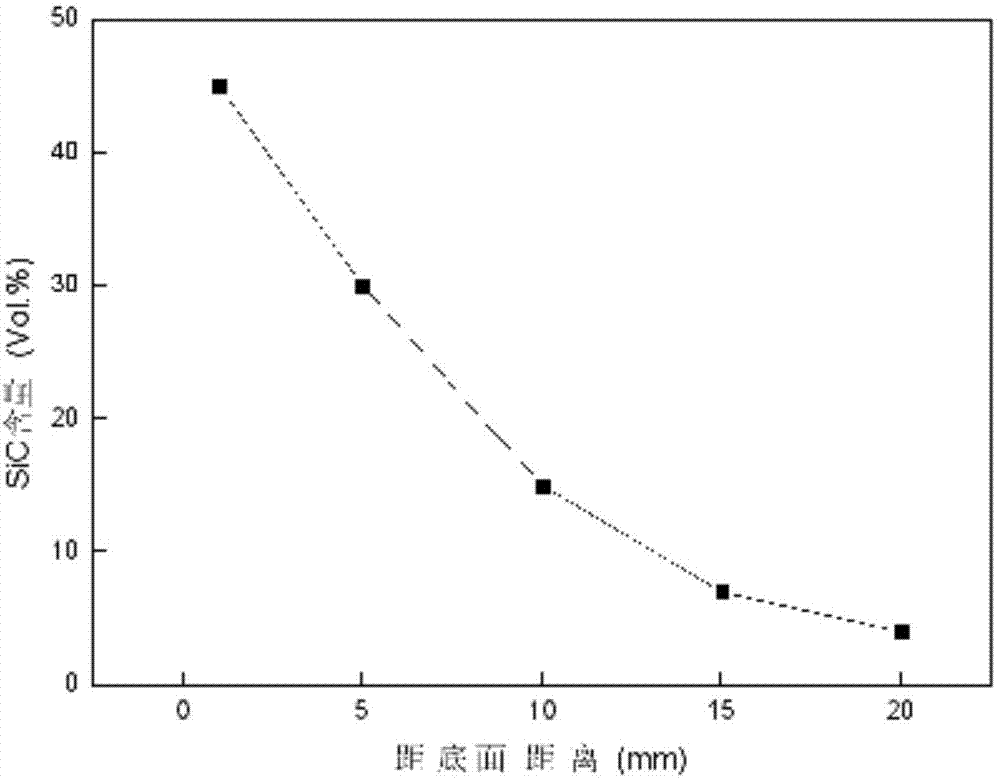

As cast condition large gradient material preparation method and utilization device thereof

The invention belongs to the field of materials, in particular to an as cast condition large gradient material preparation method and a utilization device thereof. The large gradient material preparation method comprises the steps of selecting alloy materials with semi-solid temperature ranges, heating the alloy materials and enabling the alloy materials to be completely melted so as to obtain alloy melt; feeding 6-60% of enhanced phase particles into the alloy melt, and then applying ultrasonic vibration on the alloy melt and the enhanced phase particles; reducing the temperature of the alloy melt to the alloy semi-solid temperature range, and enabling the solid fraction in the solid-liquid mixture to be 6-61%; after applying ultrasonic stationary fields on the solid-liquid mixture for 2-1200s, cooling the solid-liquid mixture, and obtaining the as cast condition large gradient material after solidification. According to the as cast condition large gradient material preparation method, the enhanced phase particles and the alloy melt are mixed evenly, the viscosity of the alloy melt is adjusted, and the motion resistance of the enhanced phase particles in the alloy melt is increased, so that gradient distribution of the enhanced phase particles in a large range of the alloy material can be achieved.

Owner:SOUTHWEST JIAOTONG UNIV

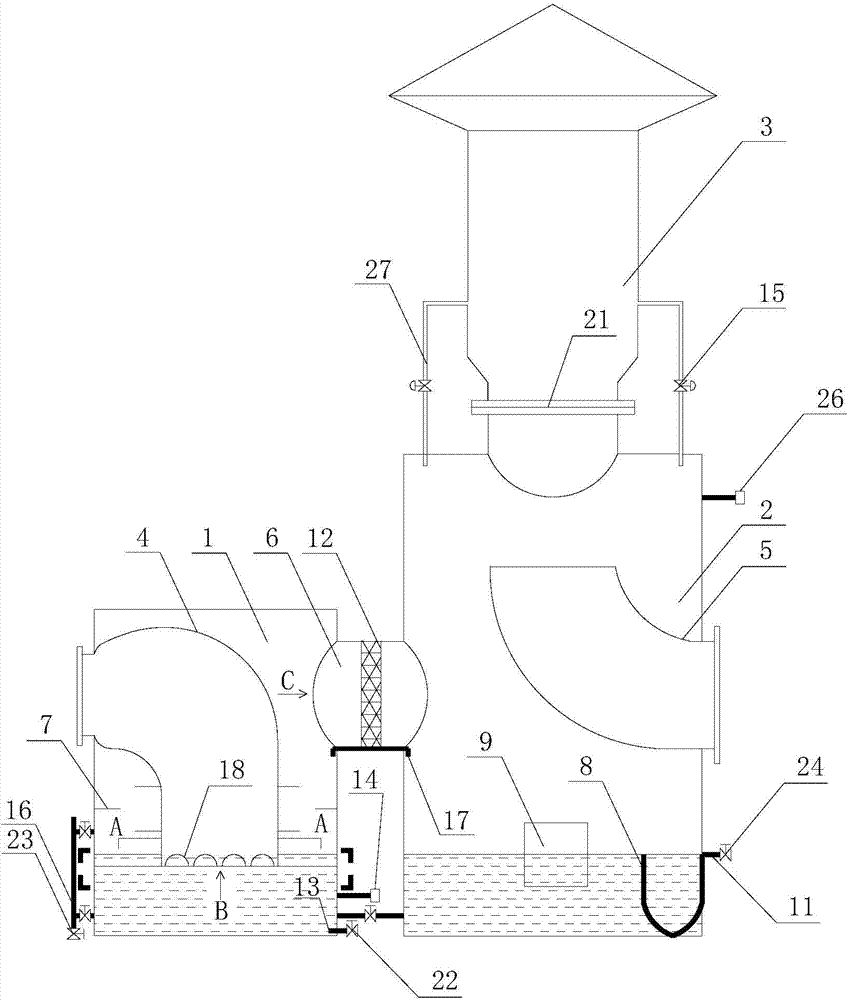

Water sealing fire retardance explosion venting device

The invention discloses a water sealing fire retardance explosion venting device which comprises a fire retardance device and an explosion venting machine. The fire retardance device comprises a fire retardance barrel body, an air inlet pipe, an air outlet pipe and a water filtering metal ring net. One end of the air inlet pipe is placed out of the fire retardance barrel body, the other end of the air inlet pipe extends into the fire retardance barrel body and is inserted to the position below a sealing water liquid level, and the water filtering metal ring net is arranged above the sealing water liquid level and is arranged outside the air inlet pipe in a sleeving mode. The explosion venting machine comprises an explosion venting barrel body, an exhaust pipe and an explosion venting pipe. The exhaust pipe and the explosion venting pipe are communicated with the explosion venting barrel body. The fire retardance barrel body is communicated with the explosion venting barrel body through the air outlet pipe and a communication pipe arranged at the bottom. An explosion piece is arranged in the explosion venting pipe. An air outlet end pipe opening of the air inlet pipe is sealed. An exhaust hole is formed in the side wall, placed below the sealing water liquid level, of the air inlet pipe. The exhaust hole is connected with an air guiding pipe. Air guiding holes for air discharging are distributed in the air guiding pipe. The instability and the acute fluctuation of the liquid level caused when air is discharged from the device exhaust pipe can be avoided, water level control is convenient, and the safety and the reliability of the device are improved.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

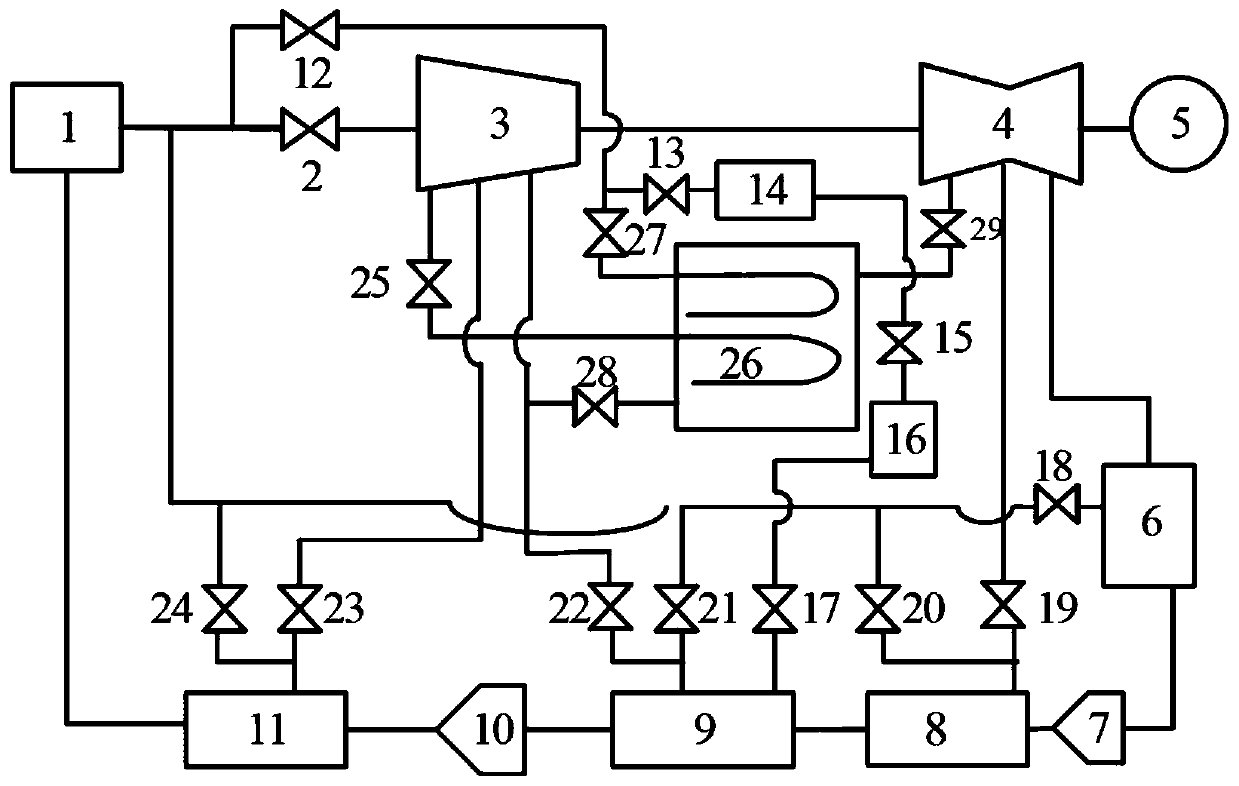

Pressurized water reactor nuclear power unit secondary circuit thermodynamic system self-adaptive steam supply system and method

PendingCN110259532AReduce startup timeSafe and stable operationNuclear energy generationSteam generator primary sideStart stopPressurized water reactor

The invention discloses a pressurized water reactor nuclear power unit secondary circuit thermodynamic system self-adaptive steam supply system and method. By means of the system and the method, a main steam bypass can be self-adaptively put into use or cut out to supply a heating steam source to a low-pressure heater, a deaerator and a high-pressure heater according to secondary circuit thermodynamic parameters in the unit start-stop and normal running process, the defect of long-time hot stand-by duty of an auxiliary boiler is avoided, energy cascade recycling is achieved, meanwhile the reliability, stability and safety are high, and the power consumption is low.

Owner:XIAN THERMAL POWER RES INST CO LTD

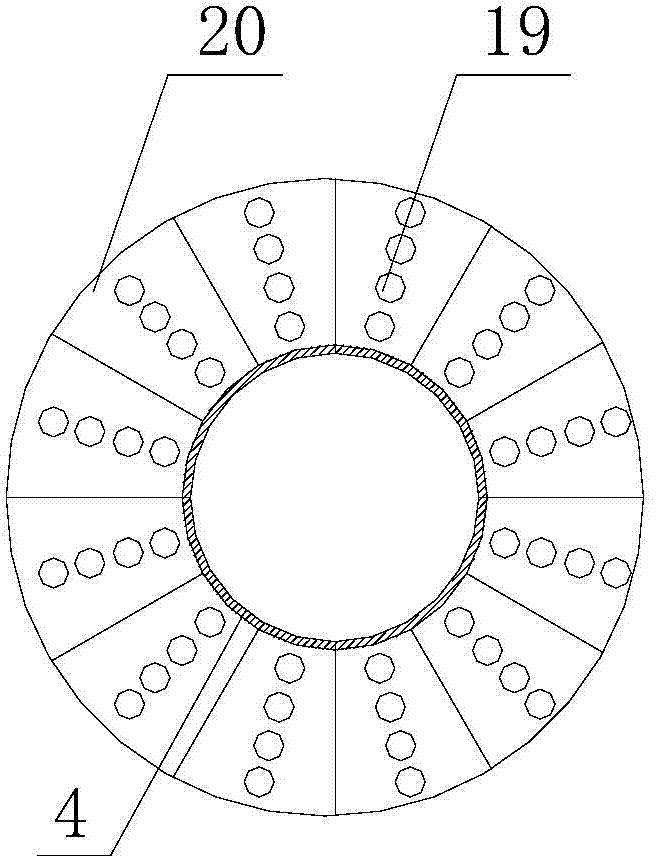

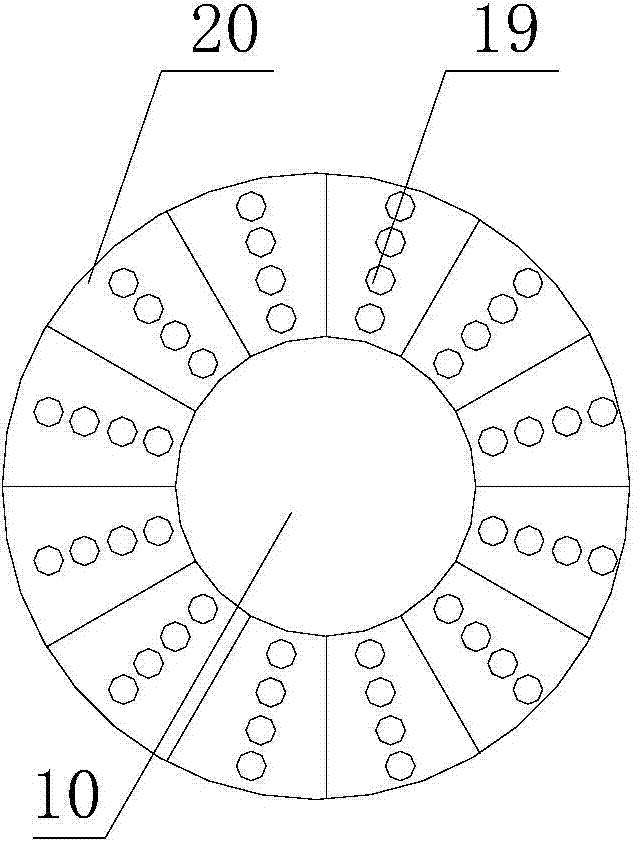

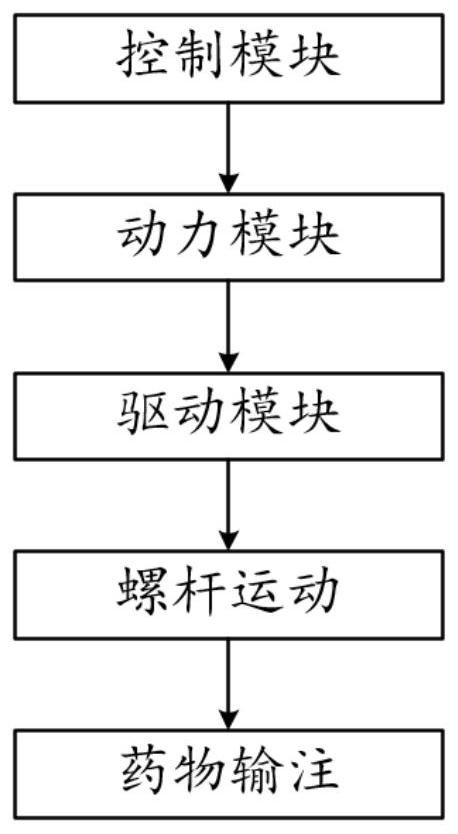

Medicine infusion device having multiple infusion modes

ActiveCN111939387AImprove experiencePrecise control levelAutomatic syringesMedical devicesMedication infusionPharmacy medicine

The invention discloses a medicine infusion device having multiple infusion modes. The medicine infusion device comprises a medicine storage unit, a piston, a screw rod, a driving module, a power module and a control module; the piston is arranged in the medicine storage unit; the piston is connected with the screw rod; the driving module at least comprises a first driving unit and a second driving unit, which are matched with each other to operate; the second driving unit drives the screw rod to advance; the power module is connected with the first driving unit; the control module is connected with the power module; and the control module controls the power module to apply different acting forces to the first driving unit, so that the first driving unit has multiple different operation modes, and the infusion device has multiple different unit infusion amounts or infusion rates. A user can select different infusion modes to infuse medicines, so that the user experience is enhanced.

Owner:MEDTRUM TECH

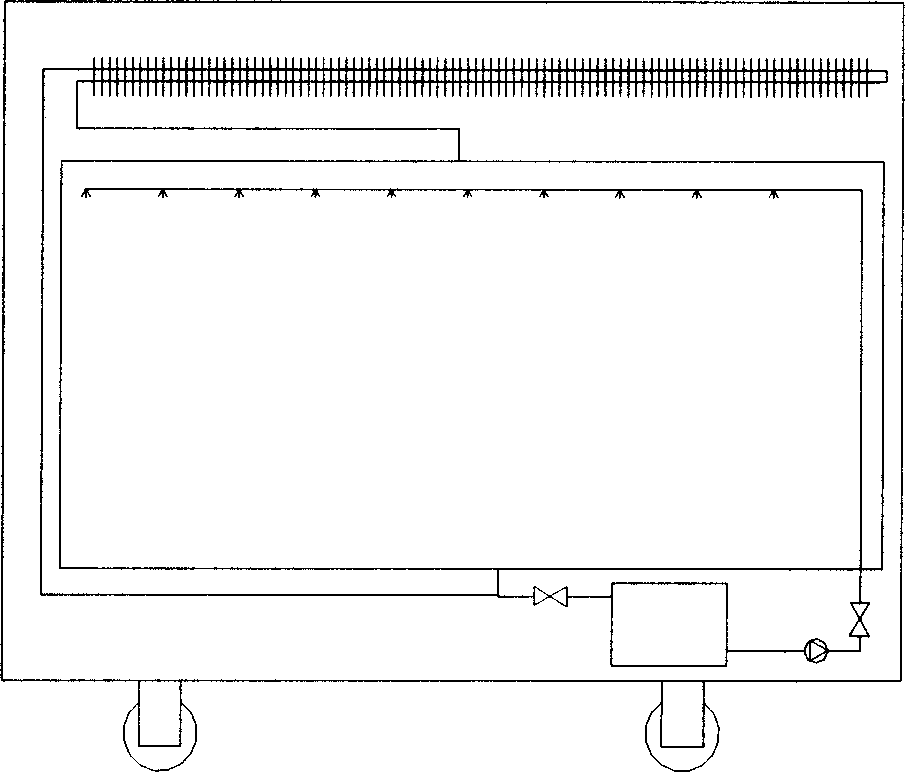

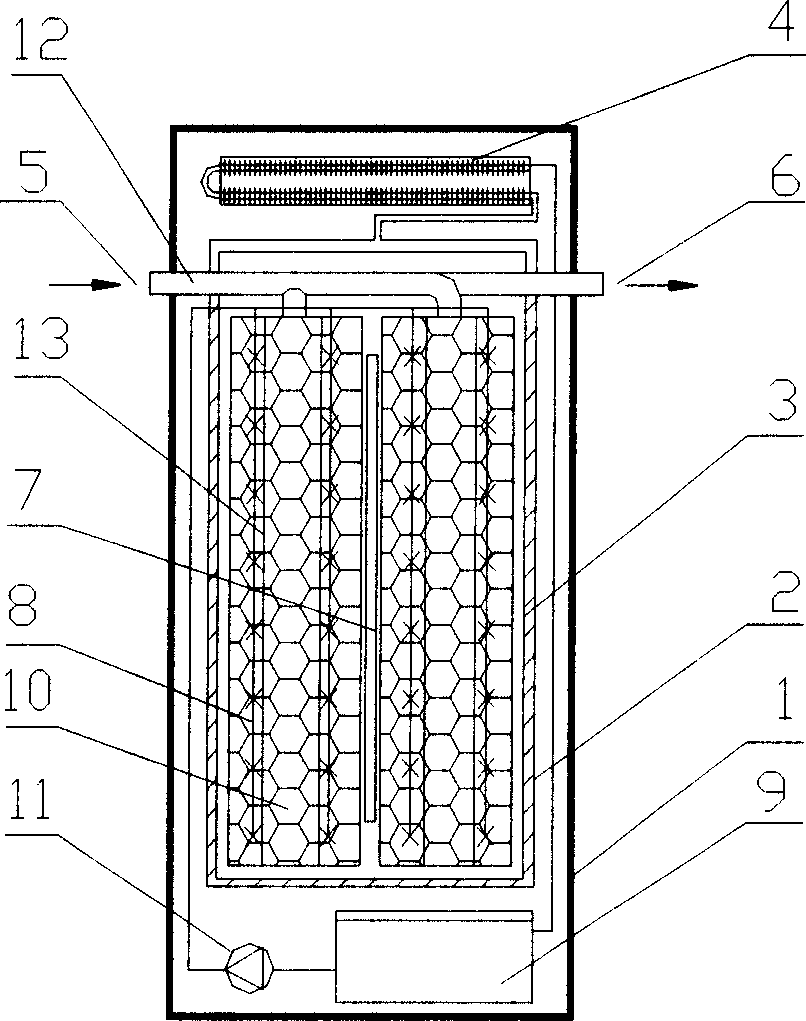

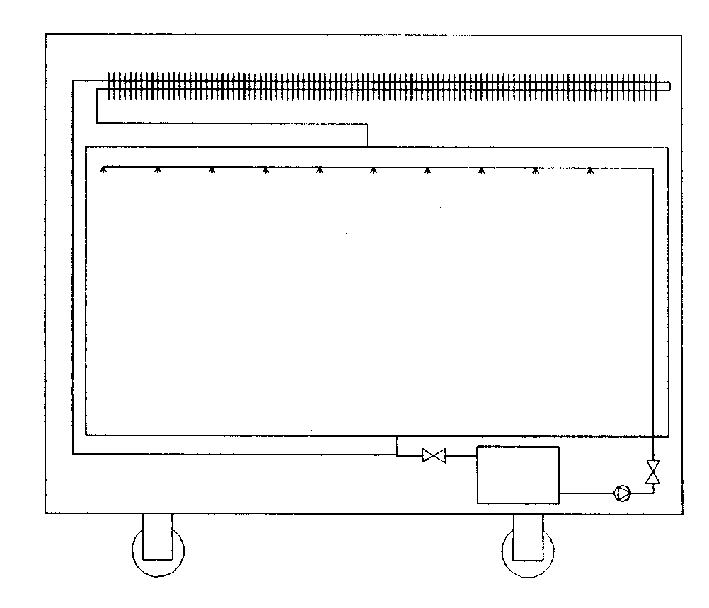

Adsorption type heat-storage electric-warming method and device thereof

InactiveCN1529095AHigh heat storage densityThe system is safe and reliableLighting and heating apparatusElectric heating systemSorptionElectric heating

The invention is a kind of sorption heat reservation electric heating method and the device, it carries on sorption heat reservation by using sorption heat in sorption process with sorption agent and sorption media, using the difference in price of electricity of peak and valley, uses the electrically heats and makes the sorption agent to desorbing the sorption media, and reserves the electricity energy as heat energy mode, the sorption media is frozen in the condensator and discharged into the room, the frozen sorption media is stored in the water storage box; opens the valve in daylight, the sorption media is sprayed onto the sorption bed with liquid type, and discharges the accumulate energy at night into the room, realizes heat reservation at night, and heat supplying in daylight. The device is made up of box, condensator, wind channel, sorption device, liquid storage device, pump, sorption channel, the sorption device connects with the condensator, and the liquid storage device.

Owner:SOUTH CHINA UNIV OF TECH

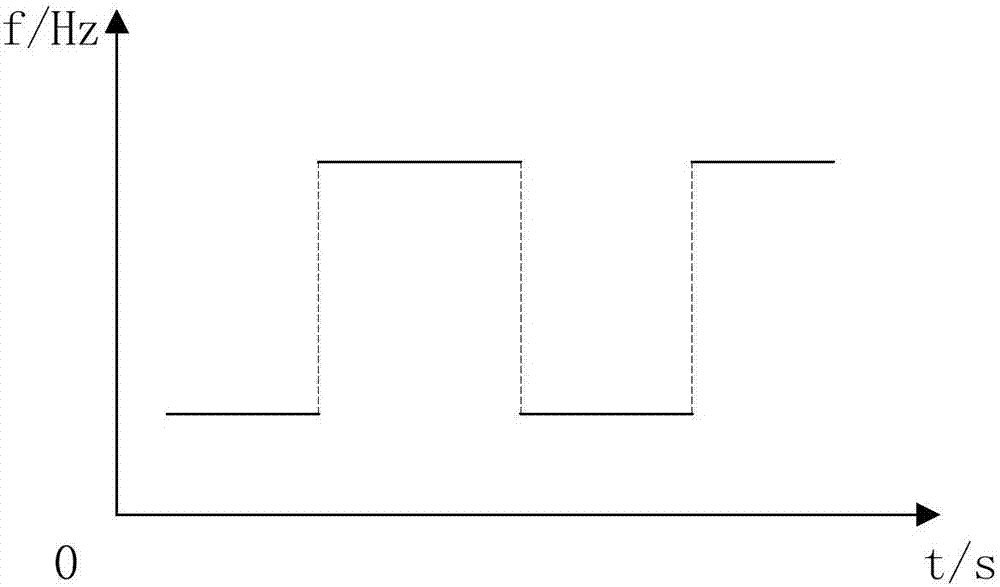

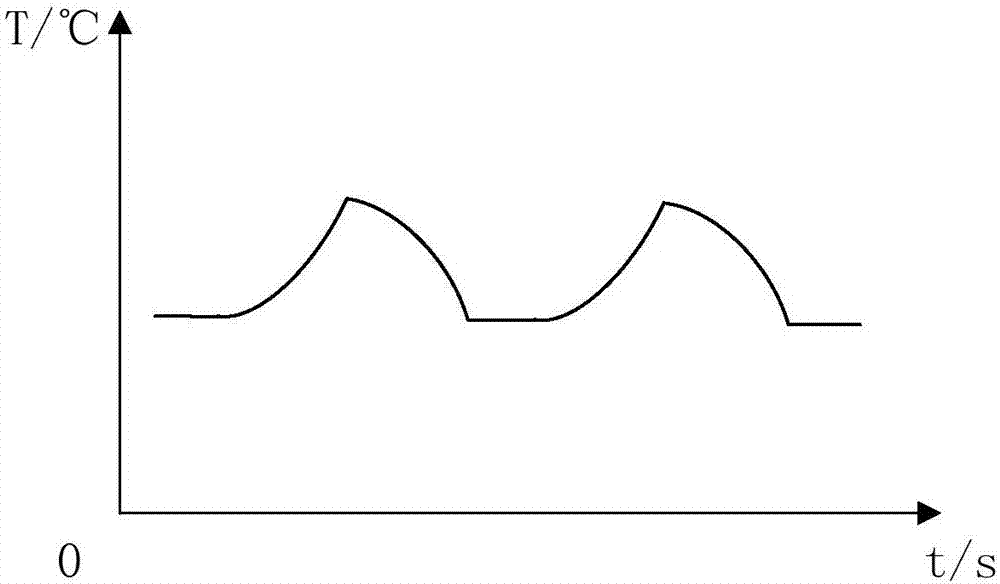

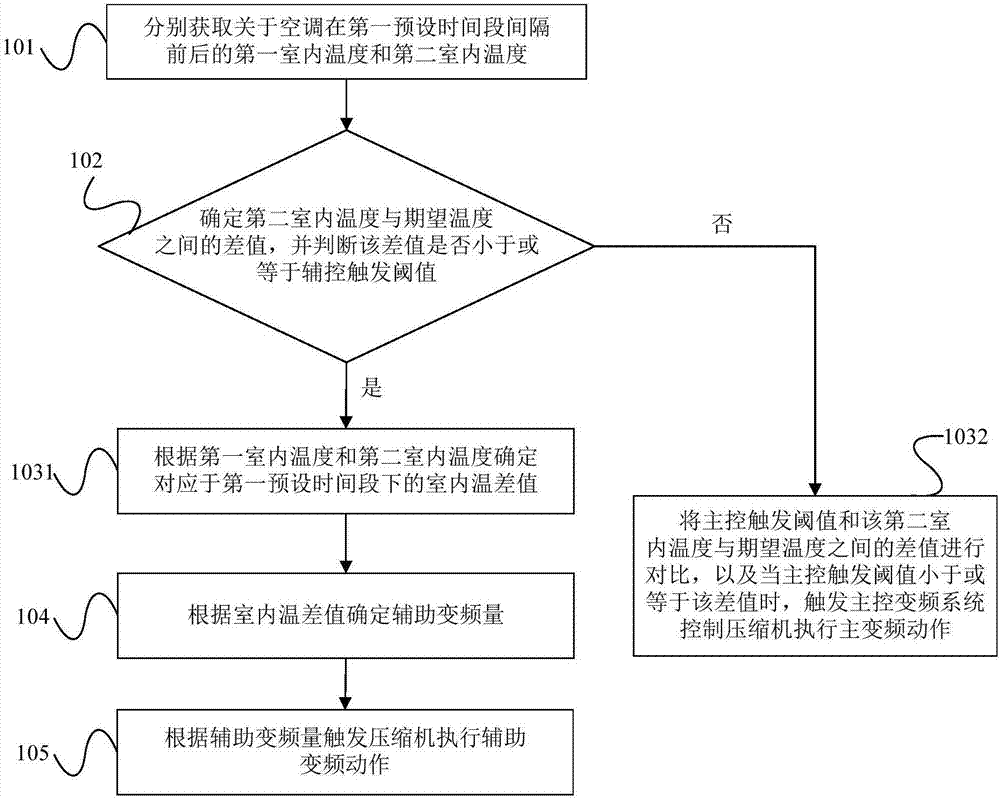

Auxiliary frequency converting control method and system of air conditioner and variable frequency air conditioner

InactiveCN107062536AReduce startup frequencyImprove comfortMechanical apparatusSpace heating and ventilation safety systemsControl systemEngineering

The invention relates to the technical field of air conditioners and discloses an auxiliary frequency converting control method and system of an air conditioner and the variable frequency air conditioner. The auxiliary frequency converting control method of the air conditioner comprises the steps that the first indoor temperature and the second indoor temperature before and after a first preset time period of the air conditioner are acquired, and the second indoor temperature is compared with an expected temperature; when the difference value between the second indoor temperature and the expected temperature is not larger than an auxiliary control triggering threshold value, the indoor temperature difference value corresponding to the first preset time period is determined according to the first indoor temperature and the second indoor temperature, wherein the auxiliary control triggering threshold value is smaller than a main control triggering threshold value triggering the main frequency converting control system to execute main frequency converting control actions; the auxiliary frequency converting amount is determined according to the indoor temperature difference; and according to the auxiliary frequency converting amount, a compressor is triggered to execute frequency converting actions. The correction of the frequency of the compressor is achieved according to the temperature rising and decreasing of the indoor temperature, and the temperature fluctuation caused after the indoor temperature reaches a user set temperature is prevented.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

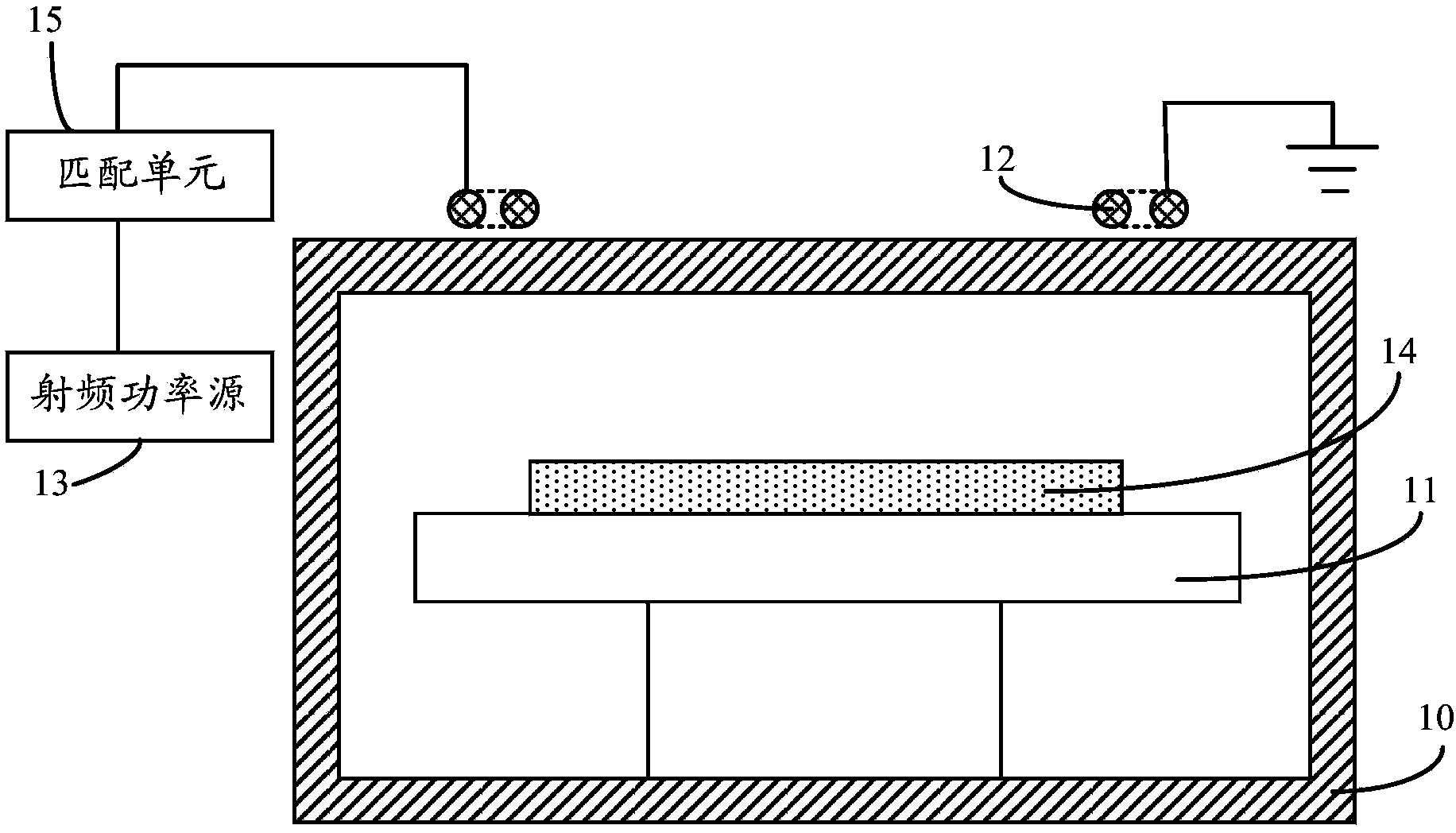

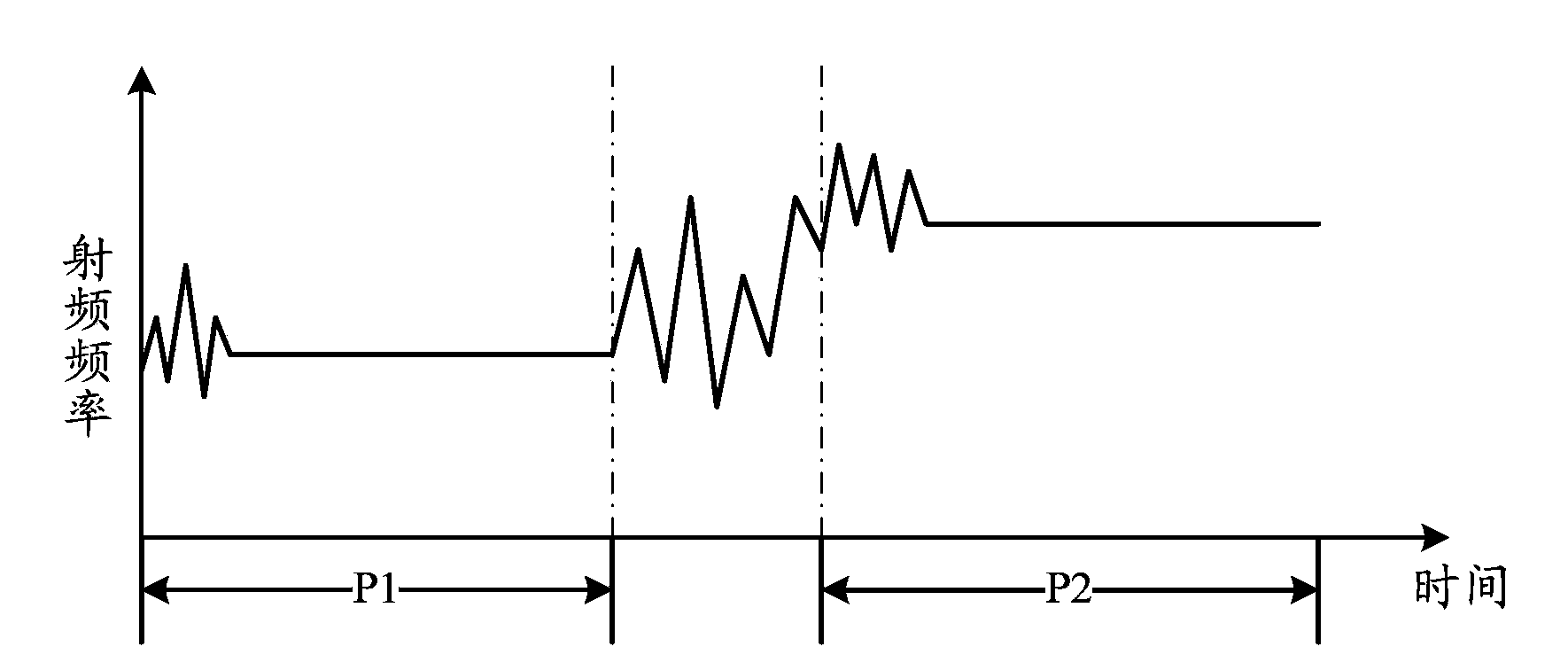

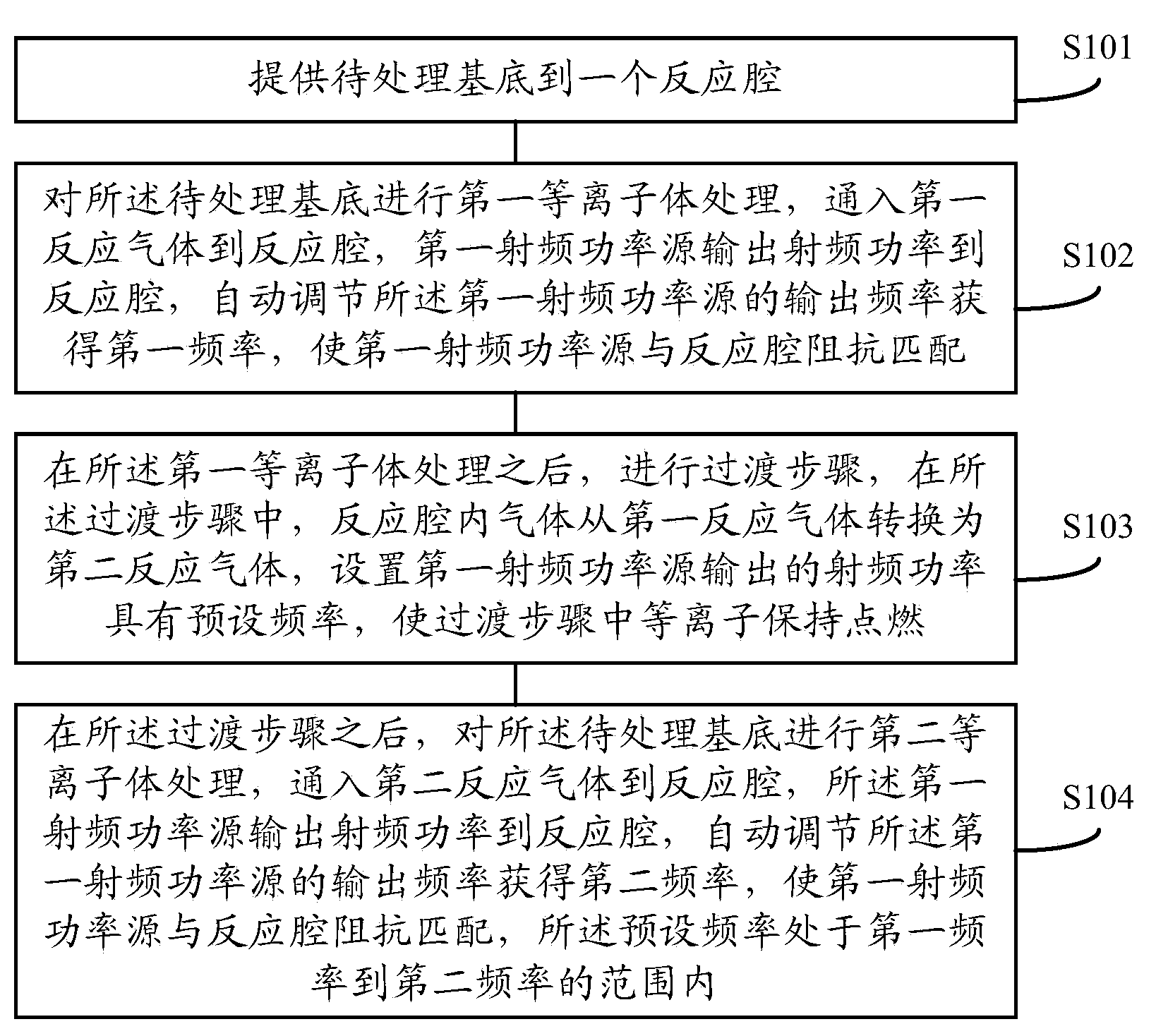

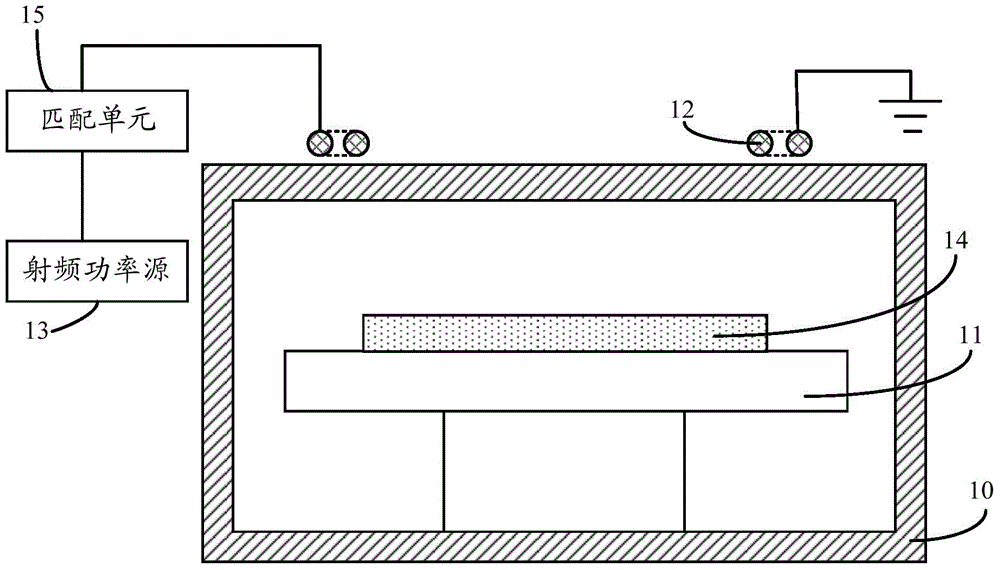

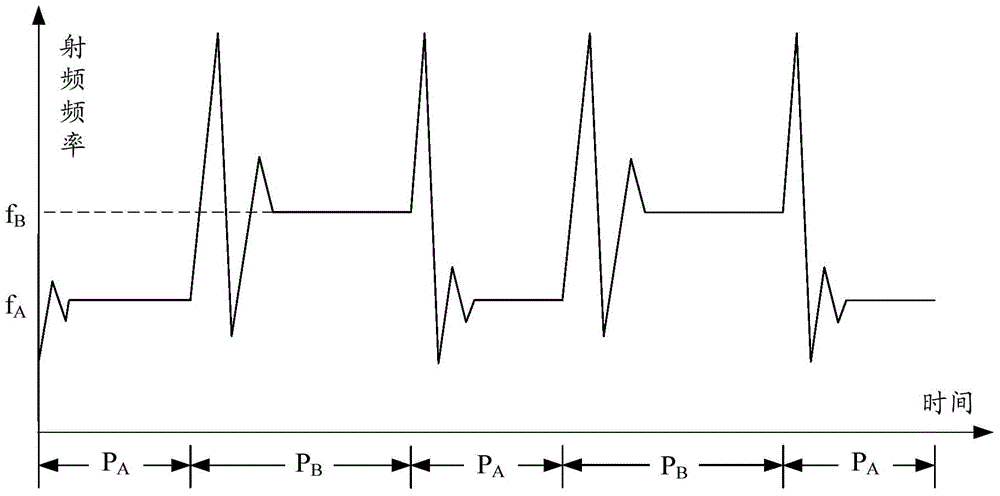

Plasma treatment method

ActiveCN103474328AEasy to handleGuaranteed continuous ignitionElectric discharge tubesSemiconductor/solid-state device manufacturingImpedance matchingRadio frequency

A plasma treatment method comprises the steps of performing first plasma treatment to a substrate to be treated, leading first reaction gas into a reaction cavity and enabling a first radio-frequency power source to output radio-frequency power to the reaction cavity, wherein the output frequency of the first radio-frequency power source is the first frequency; performing second plasma treatment to the substrate to be treated, leading second reaction gas into the reaction cavity, enabling the first radio-frequency power source to output radio-frequency power to the reaction cavity, automatically adjusting the output frequency of the first radio-frequency power source to obtain the second frequency and enabling the first radio-frequency power source to be in impedance match with the reaction cavity. A transition step is further included between the first plasma treatment step and the second plasma treatment step, the gas in the reaction cavity is converted into second reaction gas from first reaction gas, and the radio-frequency power output by the first radio-frequency power source has the preset frequency ranging from the first frequency to the second frequency so that the plasma ignition can be kept. The plasma treatment method can keep plasmas stable, and the treatment quality is improved.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

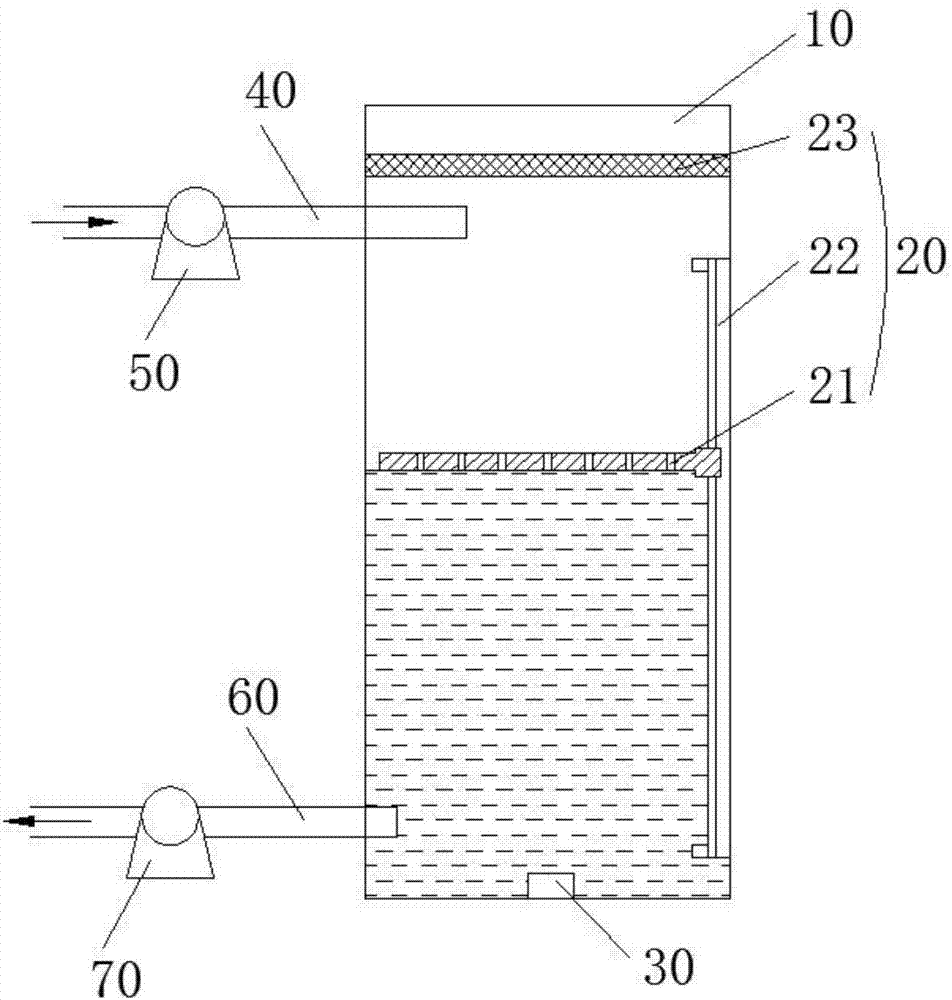

Coking wastewater advanced treatment system and process

InactiveCN102120663BStrong resistance to hydrolysisAvoid easy cloggingDispersed particle separationMultistage water/sewage treatmentCatalytic oxidationProcess engineering

The invention relates to a coking wastewater advanced treatment system, comprising a microwave-assisted catalytic oxidation device, a mixing reaction pool, a sedimentation pool, a manganese sand filter, a precision filter and a frequent electrode reverse electrodialysis device, wherein the microwave-assisted catalytic oxidation device is used for carrying out catalytic oxidation treatment on coking wastewater subjected to A / O (Anoxic / Oxic) biochemical treatment; the mixing reaction pool is connected with the microwave-assisted catalytic oxidation device and the sedimentation pool; the manganese sand filter is connected with the sedimentation pool and the precision filter; and the frequent electrode reverse electrodialysis device is connected with the precision filter. The advanced treatment process provided by the invention can be used for coking wastewater advanced treatment and simultaneously has a high-efficiency pretreatment and economic and proper type desalting system.

Owner:中电恒德环保投资有限公司

Feedwater treatment and disinfection process by converting multipoint free chlorine into chloramine

ActiveCN102659266APrevent nitrificationImprove stabilityMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processChloramine BChemical oxygen demand

The invention belongs to control of feedwater treatment and disinfection by-products and particularly relates to a feedwater treatment and disinfection process by converting multipoint free chlorine into chloramine. On the basis of structures of precipitation-disinfection process stages of original conventional feedwater treatment processes of a conventional drinking water treatment plant, chlorine is fed for disinfection at two or three points, ammonia nitrogen is required to be fed at once after chlorine is feed at the last point, and accordingly, treated water can be disinfected further byconverting the free chlorine into chloramine in place. By the feedwater treatment and disinfection process, disinfection by-products can be effectively controlled, the COD (chemical oxygen demand) can be reduced to a great extent, and the feedwater treatment and disinfection process have great action on preventing forming of biomembranes of a filter tank and nitration of a pipe net is realized. Meanwhile, chlorine feed quantity can be adjusted flexibly according to the characteristics of water quality by means of multipoint chlorine feeding, and accordingly, severe fluctuation of residual chlorine quantity and ammonia nitrogen feed quantity is reduced, and safe and stable water supply of large and mid-size cities can be guaranteed effectively.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Tartary buckwheat sweet dumplings capable of controlling blood glucose and making method

InactiveCN106136029AFreeze fastWith flowing textureFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentFiberFood industry

The invention belongs to the field of quick-frozen food industry, and particularly relates to tartary buckwheat sweet dumplings capable of controlling blood glucose and a making method. The mass dosage ratio of sweet dumpling wrappers to sweet dumpling stuffing is (1.5-3.5):1; the sweet dumpling stuffing is made from 25%-45% of maltitol, 15%-30% of sesame seeds, 205-30% of vegetable oil, 5%-15% of common wheat flour, 8%-15% of water and 0.2%-10% of olive oil, wherein the percentage content sum of all the components is 100%; the sweet dumpling wrappers are made from 45%-75% of glutinous rice flour, 20%-50% of tartary buckwheat powder, 2.5%-10% of wheat starch and additives comprising, by total mass of the glutinous rice flour, the tartary buckwheat powder and the wheat starch, 2%-10% of vegetable oil, 0.1%-2.5% of wheat dietary fiber powder, 0.5%-0.75% of a quick-frozen sweet dumpling modifying agent and 55%-80% of water. The sweet dumplings are soft, glutinous, fine and smooth in mouthfeel, fragrant and sweet in sesame seed stuffing and low in blood glucose increasing index and can effectively help a diabetic patient to better control the postprandial blood glucose.

Owner:CHENGDU BAOWEI CONTROL SUGAR FOOD CO LTD

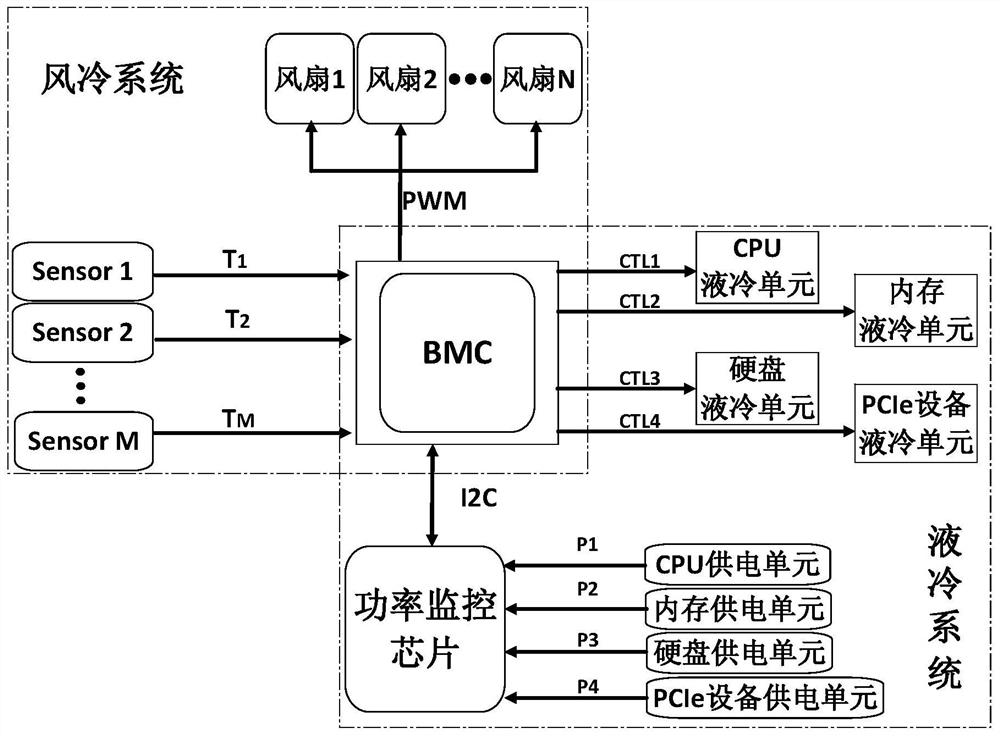

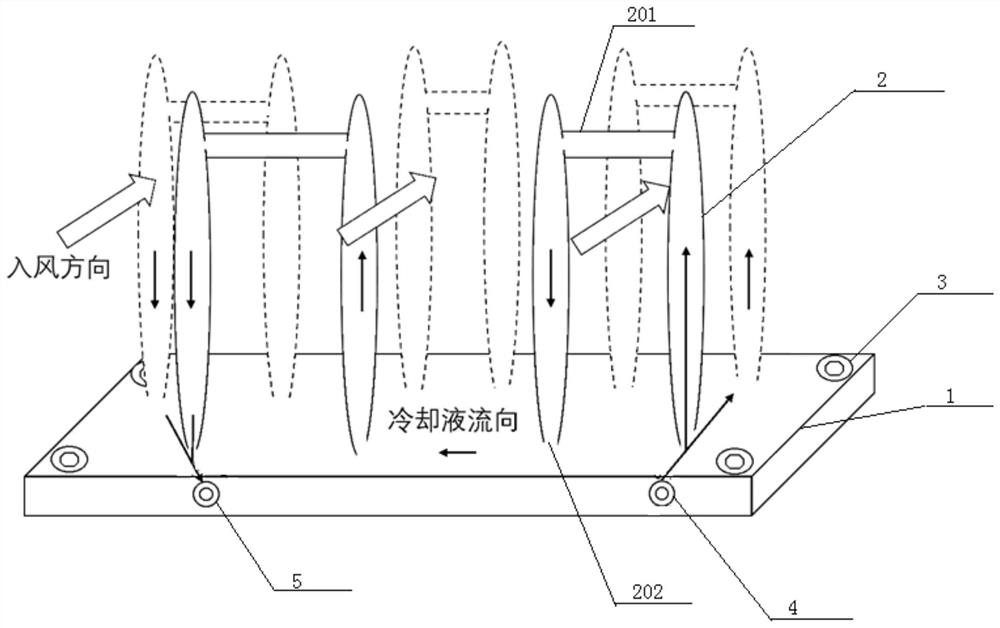

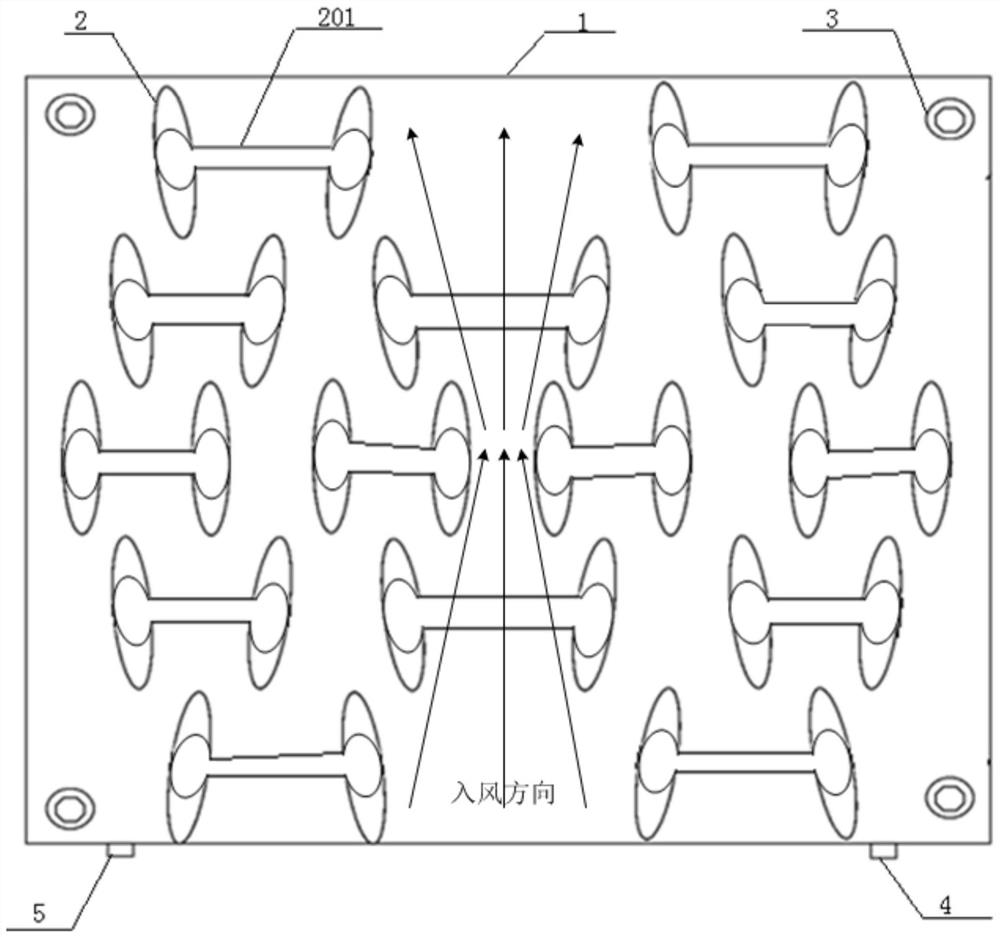

Liquid-cooled radiator, novel server radiating system and regulation and control method

ActiveCN111966191ASolve the hysteresisAvoid wastingDigital data processing detailsHardware monitoringAir cooling systemCooling fluid

The invention provides a liquid-cooled heat radiator, a novel server heat dissipation system and a regulation and control method. The liquid-cooled heat radiator comprises a heat dissipation base anda plurality of heat dissipation fin groups arranged on the heat dissipation base, wherein each heat dissipation fin group comprises a hollow pipe and two heat dissipation fins, the heat dissipation fins are of hollow structures, ends, away from the heat dissipation base, of the first heat dissipation fins and the second heat dissipation fins are connected through the hollow pipes, the first heat dissipation fins, the second heat dissipation fins and the hollow pipe form a communicated cavity, two ends of each of a plurality of radiating fin groups are respectively communicated with a water inlet and a water outlet after a plurality of radiating fin groups are communicated in series or in parallel or in series-parallel combination, the heat dissipation base is fixed to a heat generation element through fixing holes. When a liquid-cooled radiator works, a communicated cavity formed by the first radiating fins, the second radiating fins and the hollow pipe is filled with cooling liquid, heat dissipation efficiency of an air cooling system is improved, and the effect of saving energy can be achieved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

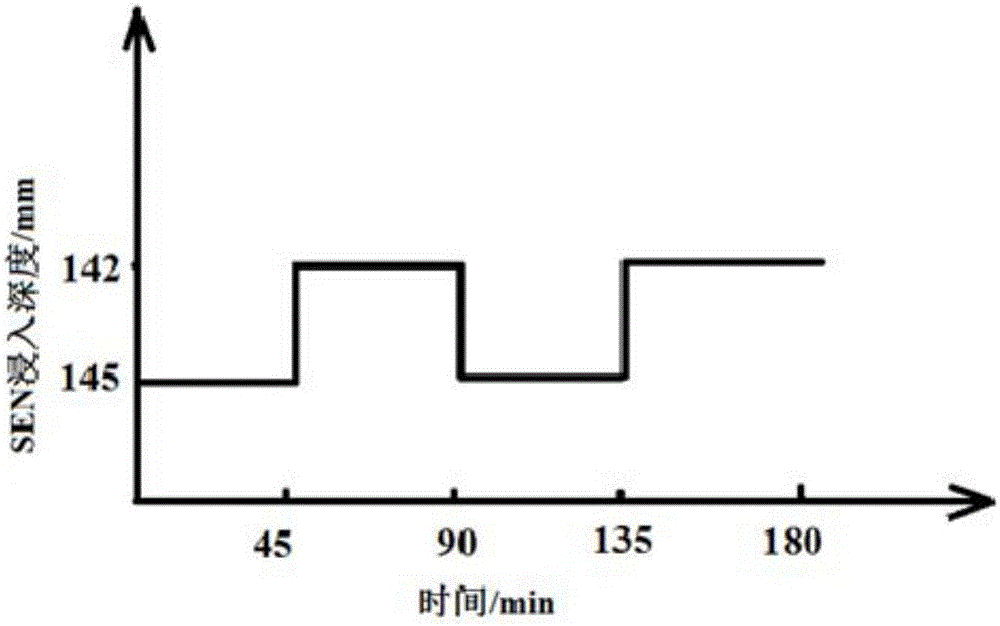

Method for controlling fluctuation of liquid level of crystallizer

InactiveCN105945252AAvoid wild swingsOffset local fluctuationsMaterials scienceContinuous casting mold

The invention belongs to the technical field of metallurgy and discloses a method for controlling fluctuation of the liquid level of a crystallizer. The method comprises the steps that a tundish supporting oil cylinder acts, and a submersed nozzle executes initial immersion at the initial immersion depth; and 45 minutes are considered as a cycle, and the immersion depth of the submersed nozzle is adjusted, wherein the adjustment range of the immersion depth of the submersed nozzle is 3 mm at the maximum. The step of adjusting the immersion depth of the submersed nozzle comprises the sub-steps that the tundish supporting oil cylinder acts, and the immersion depth of the submersed nozzle is increased or decreased at the constant speed. By means of the method, the effect of stabilizing the liquid level of the existing crystallizer for continuous casting is achieved.

Owner:SHOUGANG CORPORATION

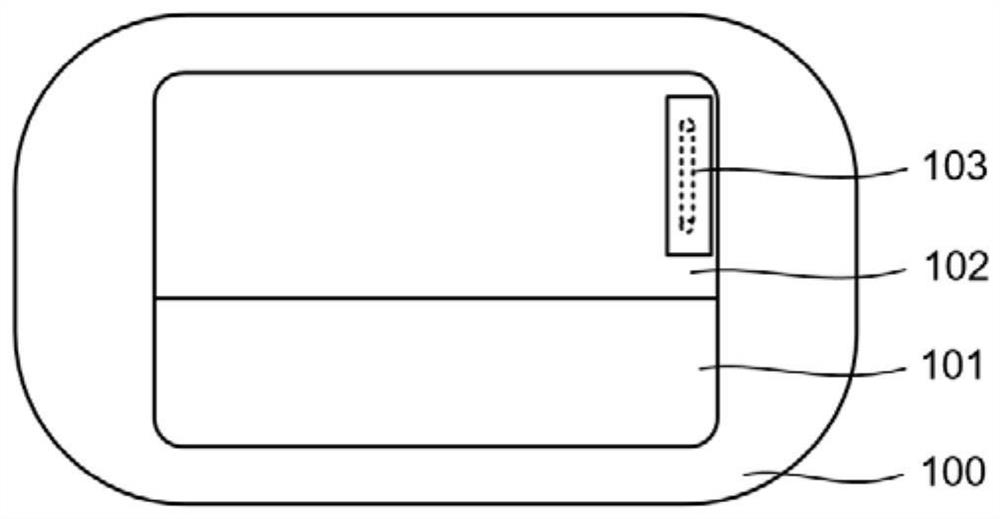

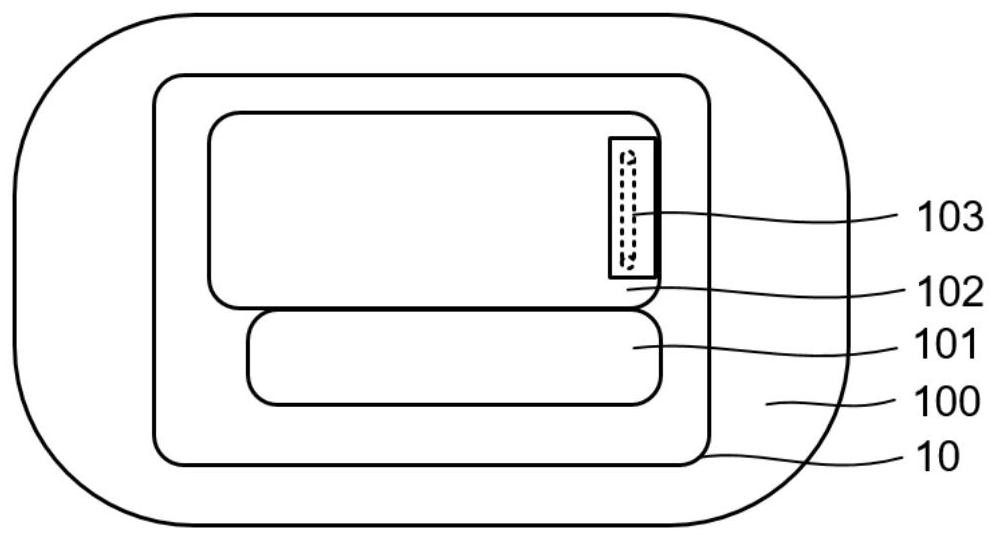

Liquid material storage device

The invention relates to a liquid material storage device, comprising a material storage tank, the upper part and the lower part of the material storage tank are respectively provided with a liquid material inlet and a liquid material outlet; a buffer component is arranged in the material storage tank; the buffer The assembly includes a buffer plate and a buffer guide rail, the buffer guide rail is vertically arranged on the inner wall of the storage tank, the buffer plate is slidably arranged on the buffer guide rail, and a plurality of air holes are arranged on the buffer plate. The liquid material storage device of the present invention is provided with a buffer component, and utilizes the characteristic that the buffer plate freely floats up and down with the liquid level, so as to prevent the liquid level of the storage tank from fluctuating violently, and the air holes provided on the buffer plate can displace the liquid material in the liquid material. The air bubbles are filtered and discharged, and the gas and liquid phases are separated as much as possible.

Owner:台山市兰宝磨具有限公司

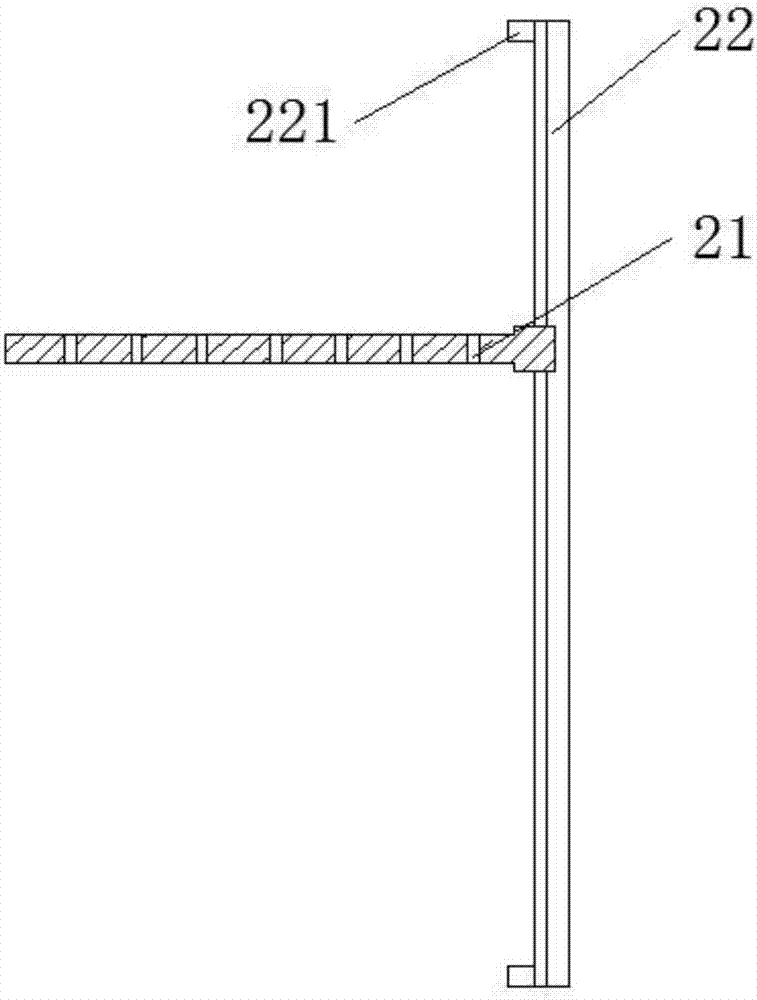

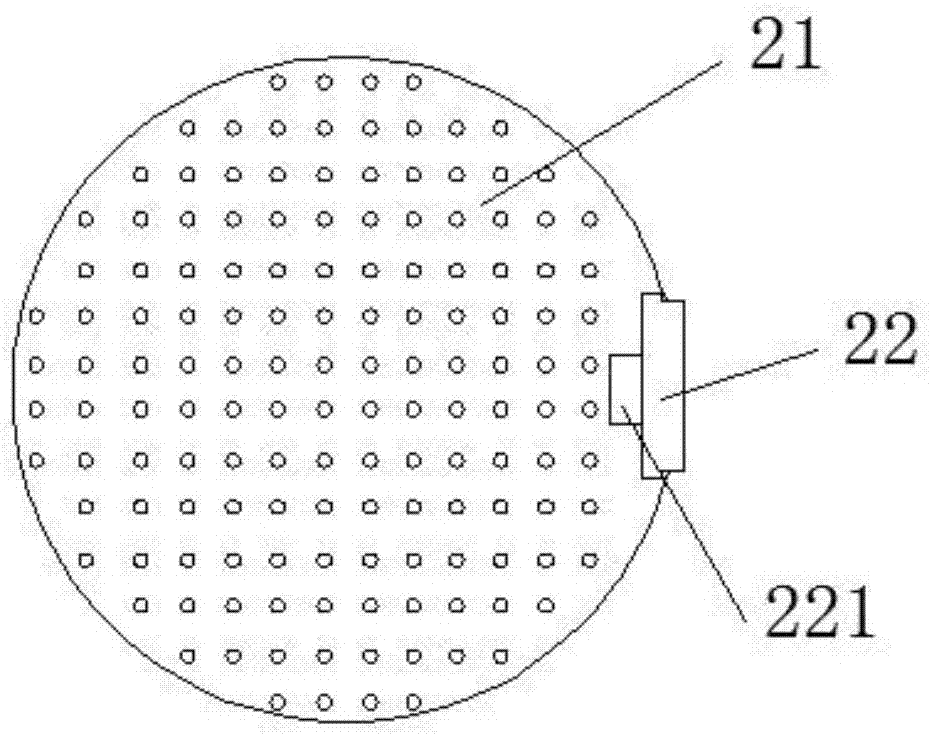

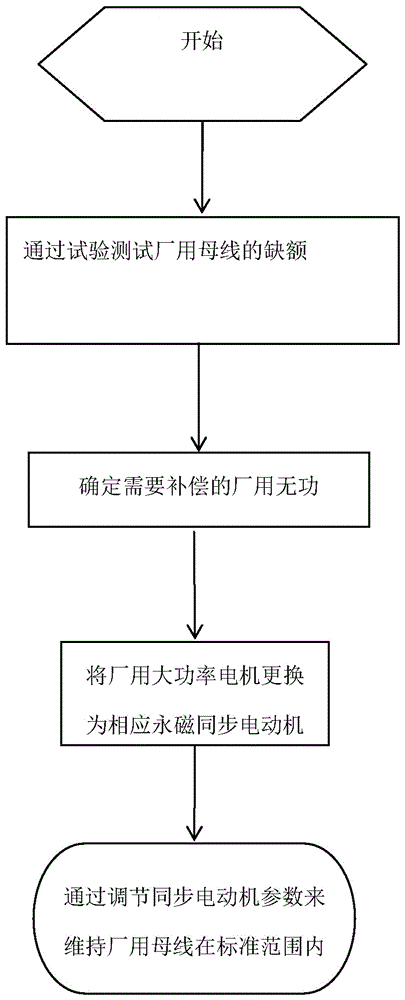

Method of adjusting voltage of station service working bus of power plant through synchronous motor

ActiveCN106410814AEasy to determineGood energy saving effectEnergy industrySingle network parallel feeding arrangementsSynchronous motorTransformer

The invention aims to solve the problem that the set safety performance is reduced as the voltage fluctuation range of voltage of the station service working bus of a power plant is large in the operation process of the conventional synchronous generator, and provides a method of adjusting voltage of a station service working bus of a power plant through a synchronous motor. The method is characterized in that by a test fitting mode, a relation curve between the voltage of the station service working bus of the power plant and stator voltage and high voltage side reactive power of a station service transformer is obtained, the maximal station service system capacitive reactive power vacancy value is obtained, and the synchronous motor is adopted as a station service working motor, so that adjustment of the voltage of the station service working bus is achieved. The invention provides a testing method which combines testing and curve fitting, the reactive power vacancy value of the power plant is effectively measured, station service working motor parameter information can be conveniently determined, voltage of the set station service bus can be maintained in a reasonable range, violent fluctuation of the voltage of the station service bus is avoided, the set energy saving effect is improved, and the high economic efficiency and the utility value are achieved.

Owner:CHINA DATANG CORP SCI & TECH RES INST CO LTD EAST CHINA BRANCH +1

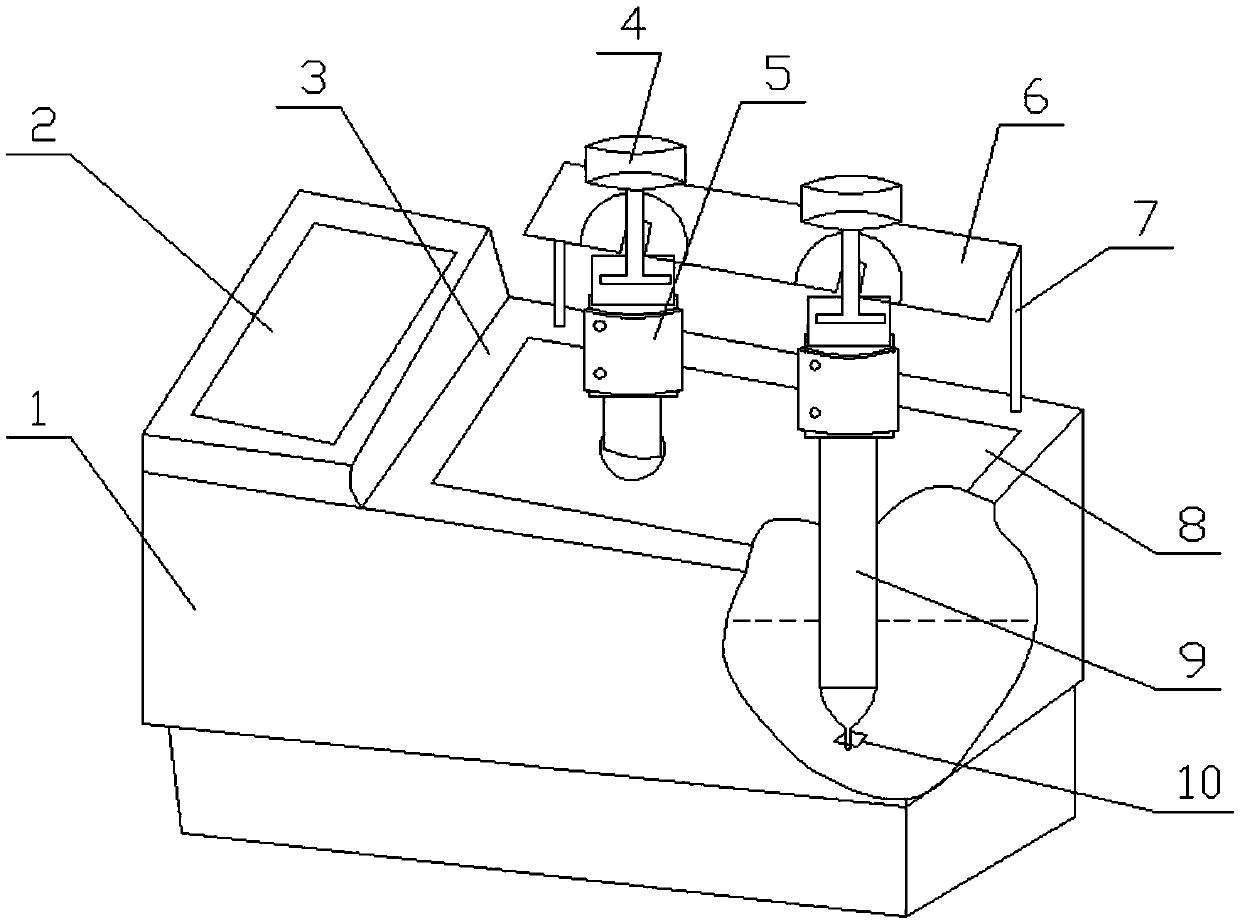

Concentrator

ActiveCN105363225ASpeed up evaporationAccelerate evaporationEvaporator accessoriesPreparing sample for investigationImpellerElectric heating

The invention discloses a concentrator, including a box body, a water bath, a support, an airflow generator, a jacketed condenser and a liquid level detection module. The box body is provided inside with a groove; the water bath is arranged in the groove; the water bath and an electric heating plate are fixedly connected; the water bath is provided with a water inlet and a water outlet; the bottom of the support is fixedly connected with the box body; the airflow generator is fixed on the support in a hanging way; the airflow generator includes an electric motor, an impeller and a drainage cover; the jacketed condenser and the open end of the drainage cover are fixed in abut joint; the jacketed condenser includes a condenser tube, a jacketed pipe, a waste liquid collection tank and a drainage pipe; the liquid level detection module includes a photoelectric sensor, a data acquisition card and a data acquisition controller; a photoelectric sensor is arranged in the box body horizontally; and the light emission port of the photoelectric sensor and a terminal liquid level line are at the same height. The concentrator is compact in structure and easy to operate, significantly shortens the concentration process, and can accurately detect the terminal liquid level of a concentration sample.

Owner:湖北鼎泰高科有限公司

Instant food capable of preventing and lowering hyperglycemia, hyperlipidemia and hypertension

InactiveCN110521918AImprove efficacyPrevent and reduce high blood sugarVitamin food ingredientsNatural extract food ingredientsAcute hyperglycaemiaSide effect

The invention relates to the field of nutritional functional foods and provides an instant food capable of preventing and lowering hyperglycemia, hyperlipidemia and hypertension, and specifically relates to an instant food capable of preventing and reducing the hyperglycemia, the hyperlipidemia and the hypertension. The instant food is prepared by mixing oats, barley, wheat, buckwheat, rye, tartary buckwheat, inulin, L-arabinose, polydextrose, xylooligosaccharide, a fructus momordicae charantiae extract, a fructus lycii extract, a hawthorn extract, a radix puerariae extract, a grosvenor momordica fruit extract, a mulberry leaf extract, a ginkgo extract, rhizoma dioscoreae powder, pumpkin powder, barley seedling powder, rivier giantarum rhizome powder and a compound nutrient. The instant food is rich in nutrition, can regulate blood sugar, blood fat and blood pressure, can well promote metabolism of a human body, is beneficial to intestinal health, is matched according to the traditional Chinese medicine principle and a dietary nutrition rule, does not have the hypersensitivity and toxic or side effects and is safe and reliable after being eaten.

Owner:广西景红健康产业有限公司

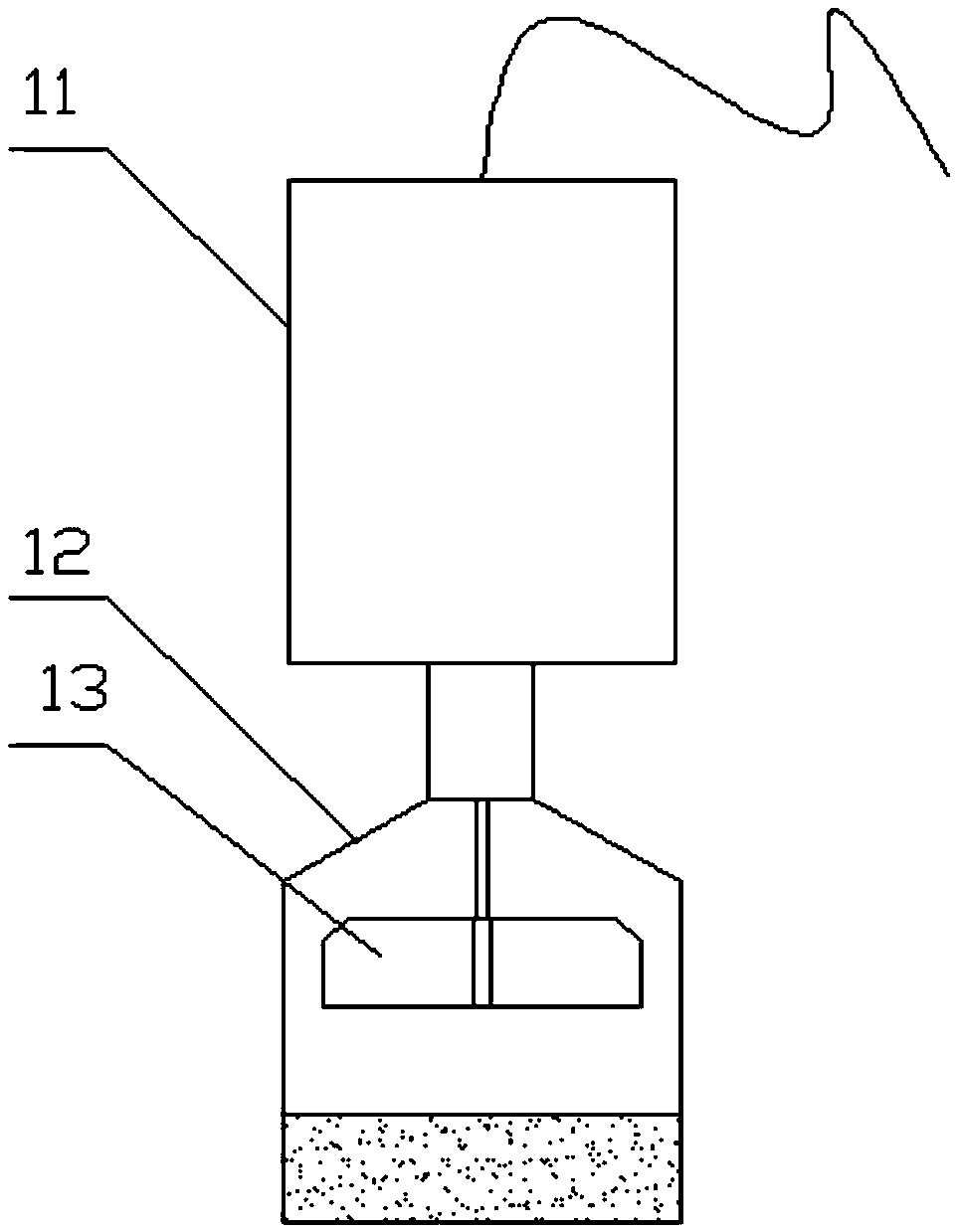

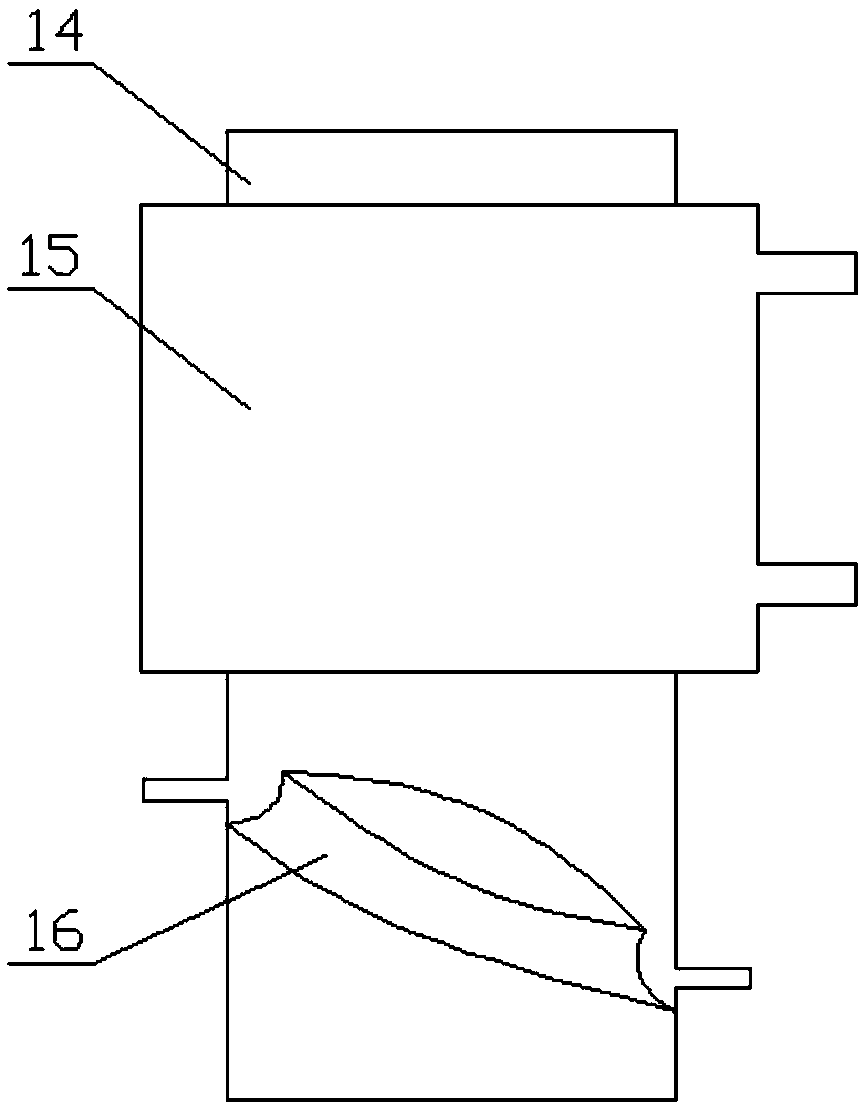

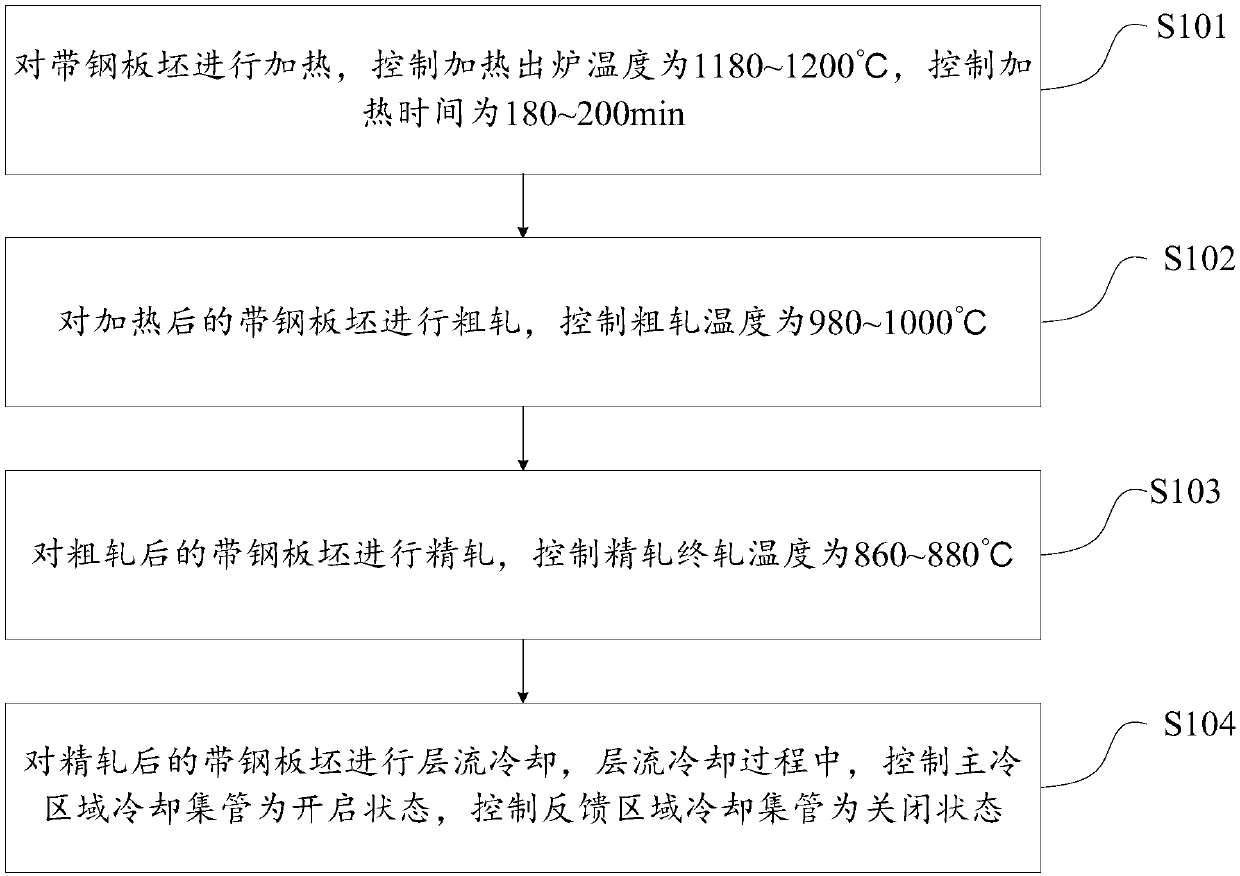

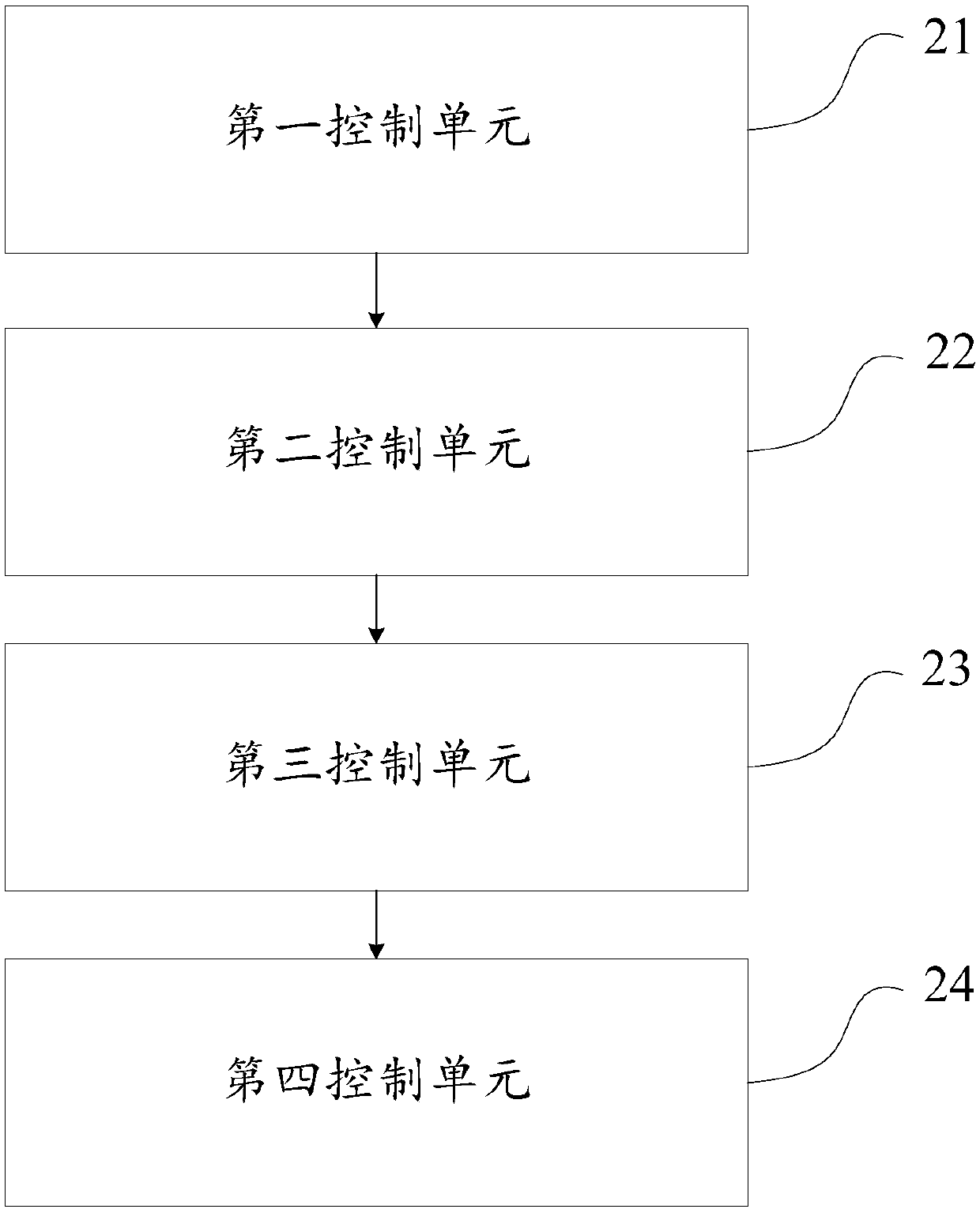

Method and device for manufacturing cold-rolled high-strength steel

ActiveCN107828951AHigh control precisionGuaranteed stabilityTemperature control deviceHeating timeStrip steel

The embodiment of the invention provides a method and a device for manufacturing cold-rolled high-strength steel. The method comprises the following steps: heating a strip steel slab, controlling theheating and tapping temperature to be 1,180-1,200 DEG C, and controlling the heating time to be 180-200 min; performing rough rolling on the heated strip steel slab, and controlling the rough rollingtemperature to be 980-1,000 DEG C; performing finish rolling on the strip steel slab subjected to rough rolling, and controlling the final finish rolling temperature to be 860-880 DEG C; and performing laminar cooling on the strip steel slab subjected to finish rolling, in the laminar cooling process, controlling a cooling manifold in a main cooling area to be in an open state and controlling a cooling manifold in a feedback area to be in a closed state. Therefore, in the laminar cooling process, the cooling manifold in the main cooling area is controlled to be in an open state, and the cooling manifold in the feedback area is controlled to be in a closed state, so that abnormal feedback adjustment caused by temperature fluctuation can be avoided, the precision in controlling the strip steel winding temperature is improved, the winding temperature is prevented from severe fluctuation, and the cold rolling stability of follow-up procedures is ensured.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

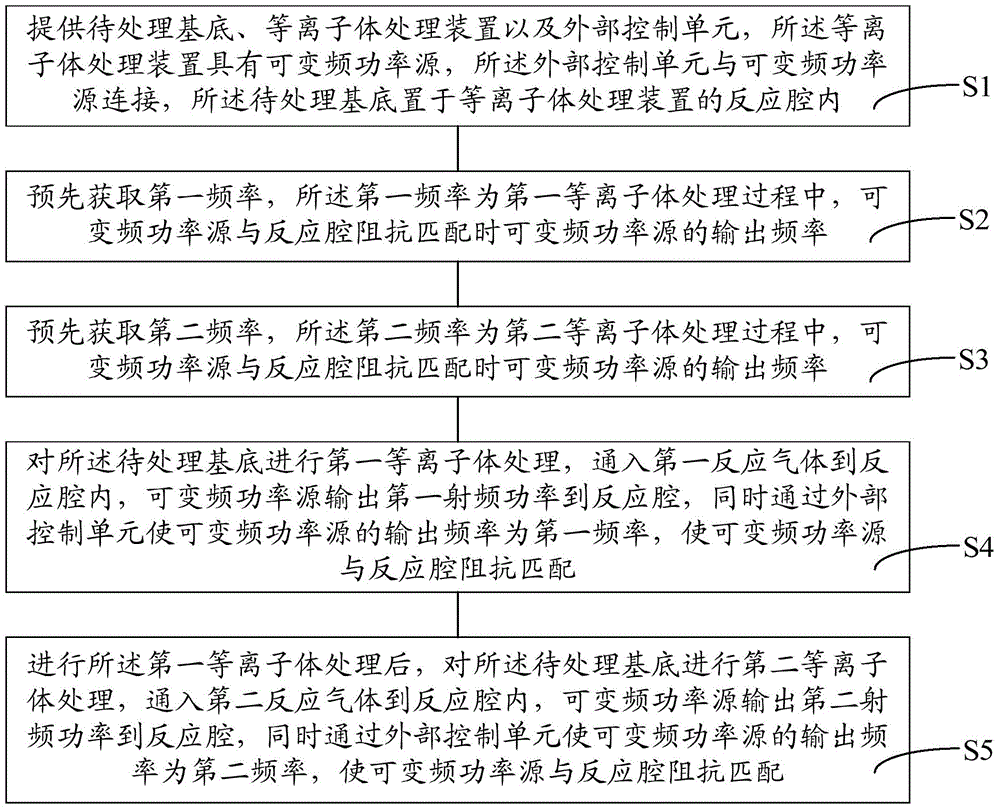

Plasma processing method

ActiveCN104900472AAvoid going outGuaranteed continuous ignitionElectric discharge tubesSemiconductor/solid-state device manufacturingImpedance matchingPlasma processing

The invention provides a plasma processing method. The plasma processing method comprises that a first frequency is obtained in advance, and the first frequency is the output frequency of a frequency-variable power source when the frequency-variable power source matches the impedance of a reaction chamber in the first plasma processing process; a second frequency is obtained in advance, and the second frequency is the output frequency of the frequency-variable power source when the frequency-variable power source matches the impedance of the reaction chamber in the second plasma processing process; first plasma processing is carried out on a substrate to be processed, and at the same time, an external control unit sets the output frequency of the frequency-variable power source as the first frequency so that the frequency-variable power source matches the impedance of the reaction chamber; and second plasma processing is carried out on the substrate to be processed, and at the same time, the external control unit sets the output frequency of the frequency-variable power source as the second frequency so that the frequency-variable power source matches the impedance of the reaction chamber. The plasma processing method can keep plasma stable and avoid plasma from quenching.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Feedwater treatment and disinfection process by converting multipoint free chlorine into chloramine

ActiveCN102659266BPrevent nitrificationImprove stabilityMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processChloramine BChemical oxygen demand

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

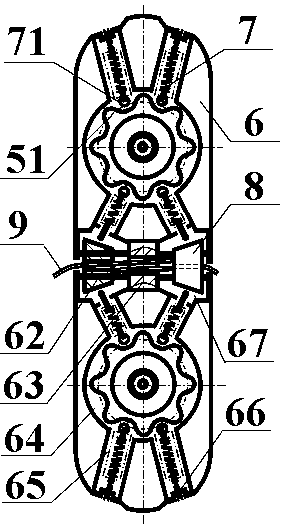

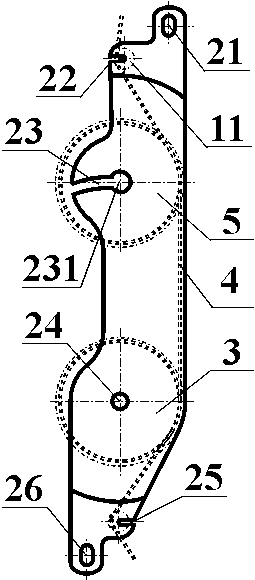

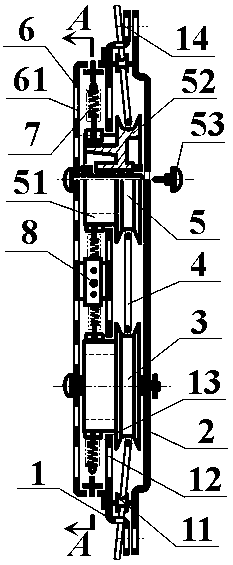

Descending machine for absorbing energy through damping element

ActiveCN110115809AExtended service lifeControlled descent speedBuilding rescueForeign matterEnergy absorption

The invention relates to a descending machine for absorbing energy through a damping element, and belongs to the technical field of firefighting and motion equipment. A lower rope wheel (3) and an upper rope wheel (5) butt against rubber springs (7) through grooves, so that the rubber springs (7) extend and absorb kinetic energy of personal descending. The rubber springs (7) butt against the lowerrope wheel (3) and the upper rope wheel (5) through rollers (71), and relatively roll to prevent the sliding friction with ropes (4), so that the service life of the ropes (4) is prolonged. The rubber springs (7) are wrapped by rubber layers, and are clamped with a secondary plate heat dissipating gap (61) and a main plate heat dissipating gap (12) through the rubber layers to prevent invasion and blockage of foreign matters, so that the safety and the reliability can be guaranteed; and the heat dissipating parts leave away from the lower ropes (4) for full heat dissipation. The damping energy absorption effect of the rubber springs (7) is adjusted through adjusting screws (66) and control ropes (9) to prevent acute fluctuation of the descending speed and to prevent the panic.

Owner:SHANDONG INST OF BUSINESS & TECH

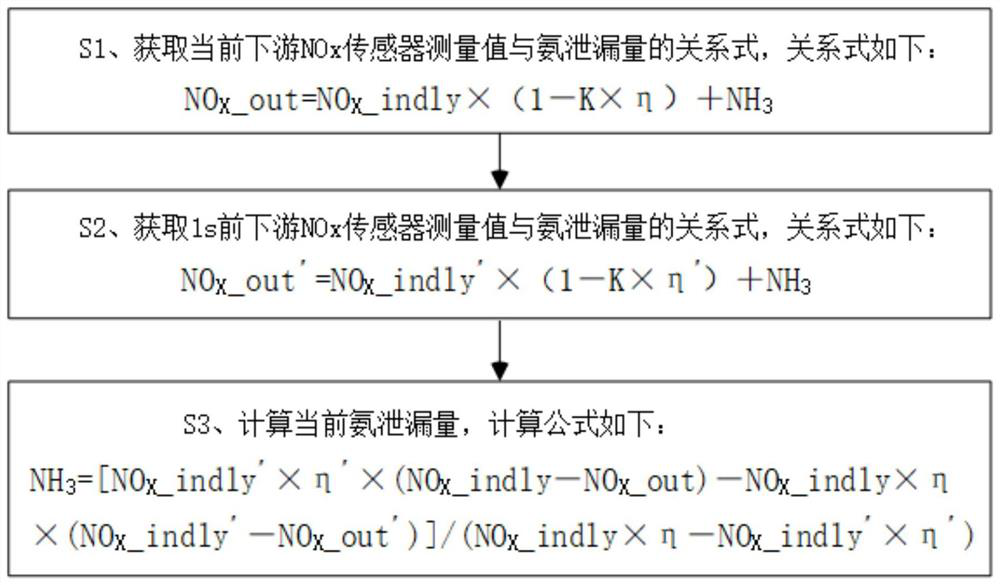

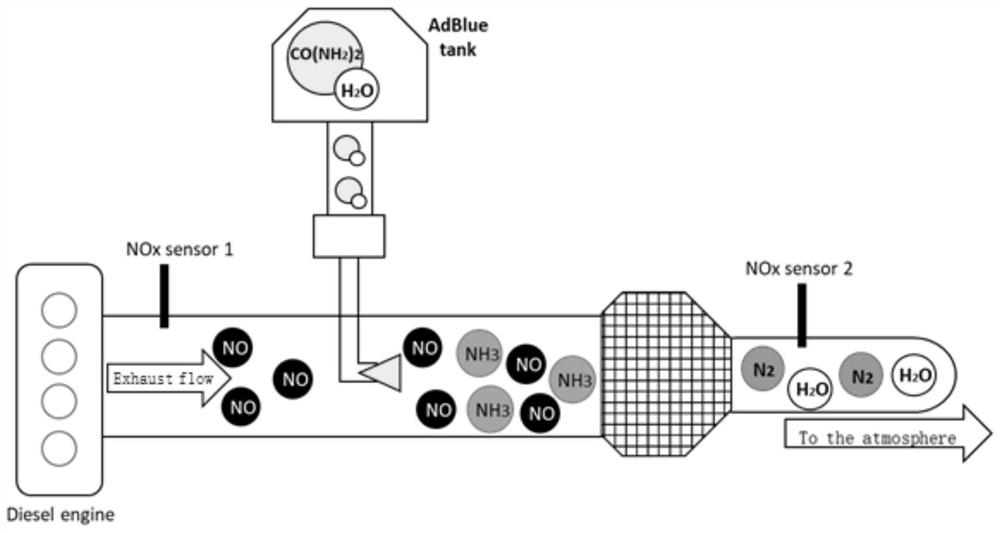

Method for calculating ammonia leakage amount of SCR post-processing system

ActiveCN113202605AGuaranteed accuracyPrecise control of injection volumeInternal combustion piston enginesExhaust apparatusEnvironmental engineeringAmmonia

The invention discloses a method for calculating the ammonia leakage rate of an SCR post-processing system. The method comprises the following steps that S1, a relational expression between a current downstream NOx sensor measurement value and the ammonia leakage rate is obtained; S2, a relational expression between a downstream NOx sensor measurement value before 1s and the ammonia leakage amount is obtained; S3, the current ammonia leakage amount is calculated; a calculated value of the ammonia leakage amount is processed through low-pass filtering; the calculated value of the ammonia leakage amount is corrected according to the change trend of the calculated value of the ammonia leakage amount and an ammonia leakage amount actual value; and when the NOx conversion efficiency obtained through an upstream NOx sensor measurement value and the downstream NOx sensor measurement value is larger than a threshold value, the ammonia leakage amount calculation value is set to be 0. According to the design, the precision of SCR closed-loop control is improved, and the calculation accuracy of the ammonia leakage rate is high.

Owner:DONGFENG AUTOMOBILE COMPANY

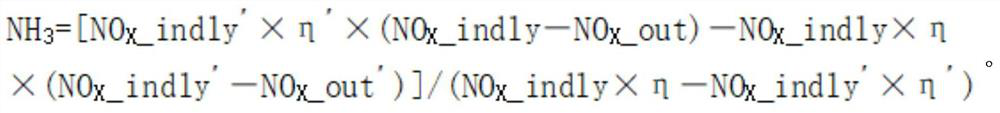

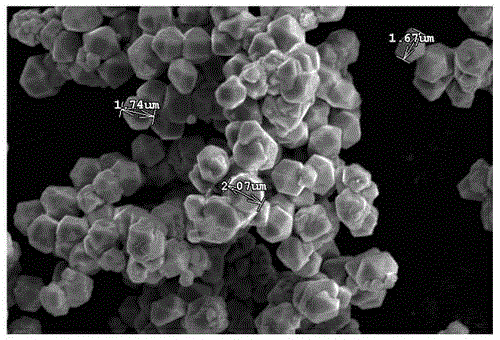

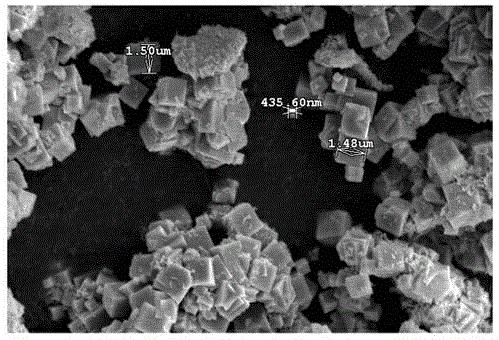

Preparation method of cubic micro/nano cuprous oxide powder

ActiveCN104591257AFlat surfaceSuperficially easyNanotechnologyCopper oxides/halidesSulfite saltSodium sulfite

The invention provides a preparation method of cubic micro / nano cuprous oxide powder suitable for ship antifouling paints, which comprises the following steps: preparing a copper solution with certain concentration and pH value, preheating to 40-50 DEG C while stirring, adding a composite dispersing agent, quickly adding a sodium sulfite solution with certain concentration, slowly and dropwisely adding a sodium carbonate solution to control the pH value of the reaction solution, continuing heating to 60-100 while stirring, reacting for 1-5 hours, and carrying out solid-liquid separation, washing and drying on the collected reaction end product to obtain the cubic micro / nano cuprous oxide powder, wherein the composite dispersing agent is prepared from gelatin and sodium dodecyl benzene sulfonate in a mass ratio of 1:1. The preparation method is simple to operate and controllable in technique. The cuprous oxide powder prepared by the method is cubic, has the particle size of 0.4-3.0 mu m, has the advantages of small specific area, slow release of copper ions, low bulk density, favorable suspensibility and low oil absorption, and is especially suitable to be used in ship antifouling paints.

Owner:GUANGDONG GUANGHUA SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com