Coking wastewater advanced treatment system and process

A coking wastewater and advanced treatment technology, applied in the direction of oxidized water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as insufficient matching, reverse osmosis membrane fouling, clogging, etc., and achieve It is not easy to clog and has a long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

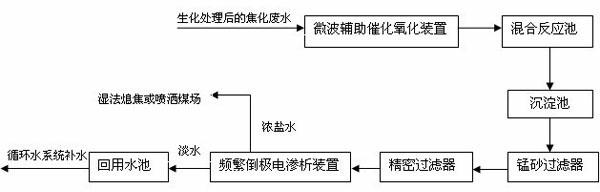

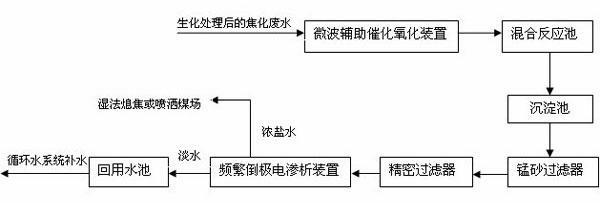

[0049] The coking wastewater advanced treatment system described in this embodiment is as follows: figure 1 shown, including:

[0050] A microwave-assisted catalytic oxidation device, the microwave-assisted catalytic oxidation device performs catalytic oxidation treatment on coking wastewater after A / O biochemical treatment;

[0051] A mixing reaction tank connected to the microwave-assisted catalytic oxidation device, and a sedimentation tank connected to the mixing reaction tank;

[0052] A manganese sand filter connected with the sedimentation tank, and a precision filter connected with the manganese sand filter;

[0053] The coking wastewater advanced treatment system also includes a frequent electrode reversal electrodialysis device connected to the precision filter.

[0054] The treatment process based on the coking wastewater advanced treatment system described in this embodiment is:

[0055] (1) Coking wastewater after A / O biochemical treatment, with a volume of 120...

Embodiment 2

[0066] The coking wastewater advanced treatment system described in this embodiment is the same as that in Embodiment 1.

[0067] The treatment process based on the coking wastewater advanced treatment system described in this embodiment is:

[0068] (1) Coking wastewater after A / O biochemical treatment, with a volume of 4800m 3 The water intake of / d enters the microwave-assisted catalytic oxidation device, and acid is added to the coking wastewater in the microwave-assisted catalytic oxidation device to adjust the pH value of the coking wastewater to 5.0, and then ferrous iron is added to the coking wastewater Salt and hydrogen peroxide are mixed evenly, and coking wastewater is catalytically oxidized under the action of microwave field;

[0069] The added concentration of ferrous salt described in this embodiment is Fe 2+ Calculated as 91.5 mg / L, which is 0.3 times of the COD concentration; 2 o 2 Calculated as 646.6 mg / L, which is 2.12 times of the COD concentration of...

Embodiment 3

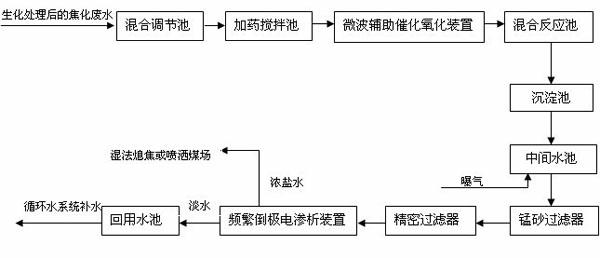

[0078] The coking wastewater advanced treatment system described in this embodiment is as follows: figure 2 shown, including:

[0079] A mixing regulating tank, a dosing stirring tank connected to the mixing regulating tank, and a microwave-assisted catalytic oxidation device connected to the dosing and stirring tank, the microwave-assisted catalytic oxidation device is used for A / O biochemically treated Catalytic oxidation treatment of coking wastewater;

[0080] A mixing reaction tank connected to the microwave-assisted catalytic oxidation device, and a sedimentation tank connected to the mixing reaction tank, and an intermediate water tank connected to the sedimentation tank, and the intermediate water tank is provided with an aerator;

[0081] A manganese sand filter connected to the intermediate pool, and a precision filter connected to the manganese sand filter;

[0082] The coking wastewater advanced treatment system also includes a frequent pole-reversing electrodia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com