Anti-corrosion glass fiber bush and preparation method thereof

A technology for corroding glass and fiber sleeves, applied in sheet pile walls, buildings, bridges, etc., can solve the problems of using requirements and not meeting the requirements of glass fiber sleeves, etc., achieve corrosion resistance, improve stability, be easy to control, and improve impact resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

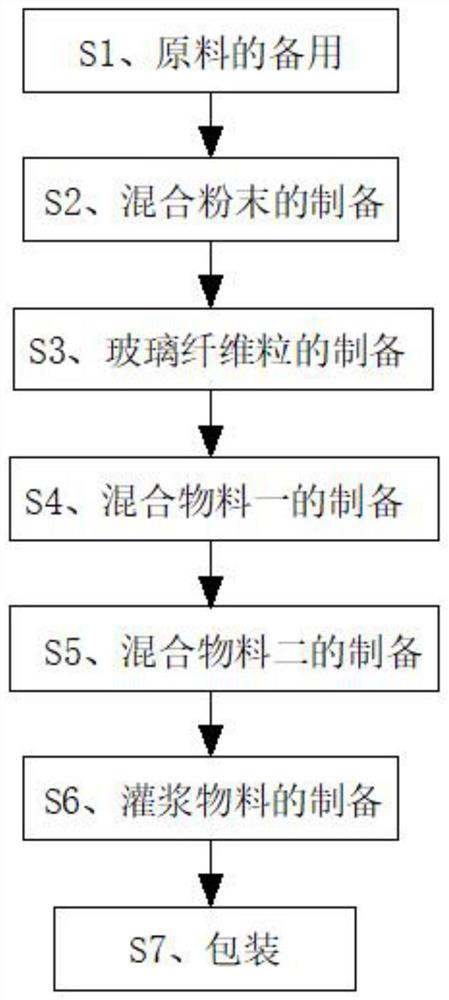

[0025] Example 1: Please refer to figure 1 , a kind of anti-corrosion fiberglass sleeve, comprising the following parts by weight: 30 parts of polyhexamethylene terephthalamide resin, 40 parts of quartz sand, 20 parts of fly ash, 25 parts of barium sulfate powder, antioxidant 10 parts, 8 parts of toughening agent, 15 parts of weather resistance agent, 10 parts of glass fiber, 10 parts of glycerol tri(1,2-epoxy) propyl ether, 8 parts of defoamer and 30 parts of glass fiber sleeve.

[0026] A kind of preparation method that is beneficial to anti-corrosion glass fiber sleeve, comprises the following steps:

[0027] S1, raw materials for standby: weigh polyhexamethylene terephthalamide resin, quartz sand, fly ash, barium sulfate powder, antioxidant, toughening agent, weather-resistant agent, glass fiber, glycerin in order by weight Three (1,2-epoxy) propyl ether and defoamer, spare;

[0028] S2, preparation of mixed powder: put the quartz sand weighed in step S1 into a pulverize...

Embodiment 2

[0034] Example 2: Please refer to figure 1 , a kind of anti-corrosion glass fiber sleeve, including the following parts by weight: polyhexamethylene terephthalamide resin 40 parts, quartz sand 45 parts, fly ash 30 parts, barium sulfate powder 30 parts, antioxidant 15 parts, 9 parts of toughening agent, 18 parts of weather resistance agent, 20 parts of glass fiber, 12 parts of tri(1,2-epoxy) propyl ether, 9 parts of defoamer and 35 parts of glass fiber sleeve.

[0035] A kind of preparation method that is beneficial to anti-corrosion glass fiber sleeve, comprises the following steps:

[0036] S1, the spare of raw material: weigh polyhexamethylene terephthalamide resin, quartz sand, fly ash, barium sulfate powder, antioxidant, toughening agent, weathering agent, glass fiber, glycerin successively by weight parts Three (1,2-epoxy) propyl ether and defoamer, spare;

[0037] S2, preparation of mixed powder: put the quartz sand weighed in step S1 into a pulverizer for pulverizatio...

Embodiment 3

[0043] Example 3: Please refer to figure 1 , an anti-corrosion fiberglass sleeve, comprising the following parts by weight: 50 parts of polyhexamethylene terephthalamide resin, 50 parts of quartz sand, 40 parts of fly ash, 35 parts of barium sulfate powder, antioxidant 20 parts, 10 parts of toughening agent, 20 parts of weather resistance agent, 30 parts of glass fiber, 15 parts of glycerol tri(1,2-epoxy) propyl ether, 10 parts of defoamer and 40 parts of glass fiber sleeve.

[0044] A kind of preparation method that is beneficial to anti-corrosion glass fiber sleeve, comprises the following steps:

[0045] S1, the spare of raw material: take polyhexamethylene terephthalamide resin, quartz sand, fly ash, barium sulfate powder, antioxidant, toughening agent, weathering agent, glass fiber, glycerin successively by weight Three (1,2-epoxy) propyl ether and defoamer, standby;

[0046] S2, preparation of mixed powder: put the quartz sand weighed in step S1 into a pulverizer for p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com