Patents

Literature

38results about How to "Strong resistance to hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Underground gel-forming blocking agent suitable for medium-high temperature high-salt low-permeability reservoirs and preparation method therefor

ActiveCN104974724AStrong ability to delay polycondensation and solidificationEffective blockingDrilling compositionChromatographic separationConcentration ratio

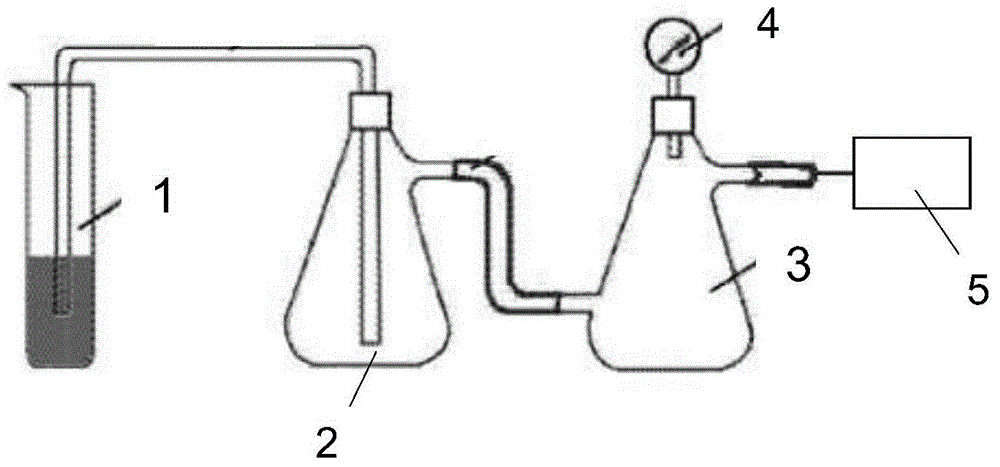

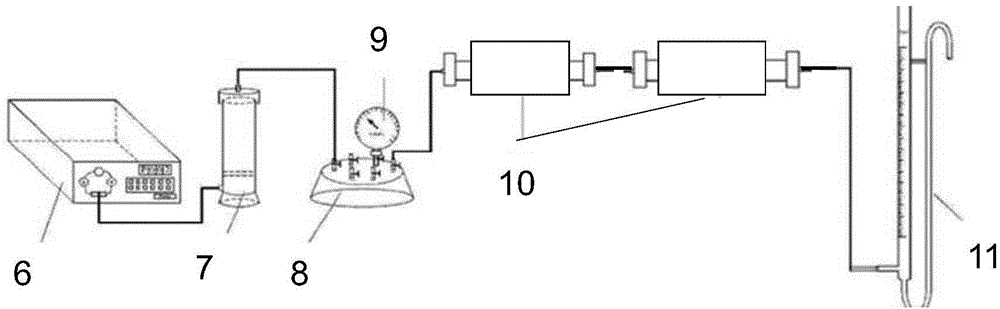

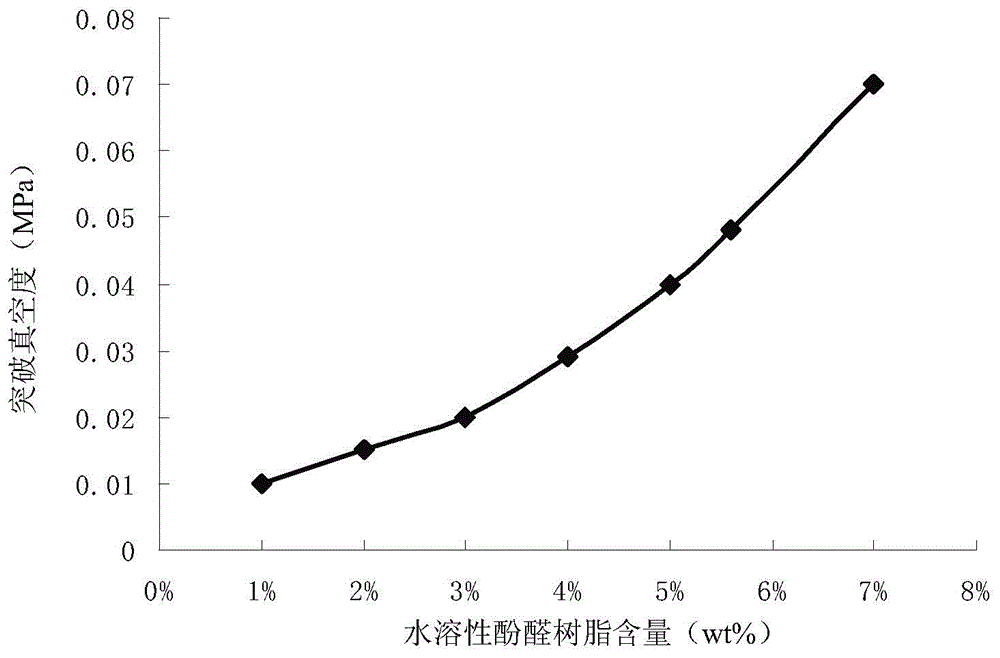

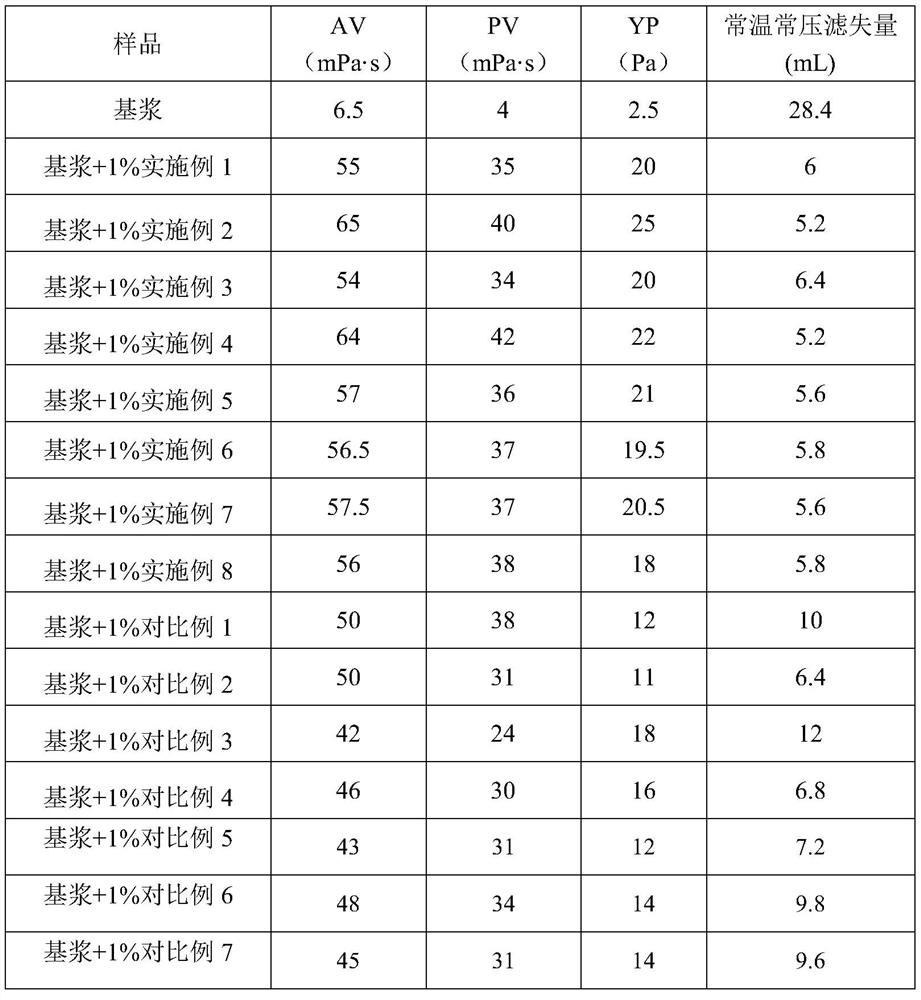

The invention provides an underground gel-forming blocking agent suitable for medium-high temperature high-salt low-permeability reservoirs and a preparation method therefor. By taking the total weight of the blocking agent as reference, the blocking agent comprises the following raw materials: 1% to 4% of water-soluble phenol-formaldehyde resin, 0.5% to 2% of stabilizer, 0 to 10% of flexibilizer and the balance of water. The preparation method of the blocking agent comprises the following steps: selecting the raw materials in proportion, and uniformly mixing so as to obtain the underground gel-forming blocking agent suitable for the medium-high temperature high-salt low-permeability reservoirs. The blocking agent provided by the invention is a homogeneous-phase, transparent and low-viscosity water solution before gel forming; the blocking agent can be selectively injected in a deep stratum water flow preferential migration passage, the shearing, adsorption and chromatographic separation of a stratum for the blocking agent can be ignored, and deep placement does not influence the concentration ratio of the blocking agent; and the polycondensation is delayed at the high temperature in the deep stratum, so that the formed gel has the advantages of high blocking rate, high blocking strength, water flow impact resistance, high temperature resistance and high hydrolysis resistance.

Owner:PETROCHINA CO LTD

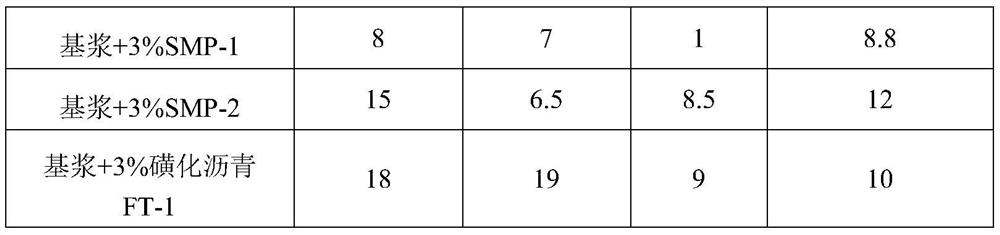

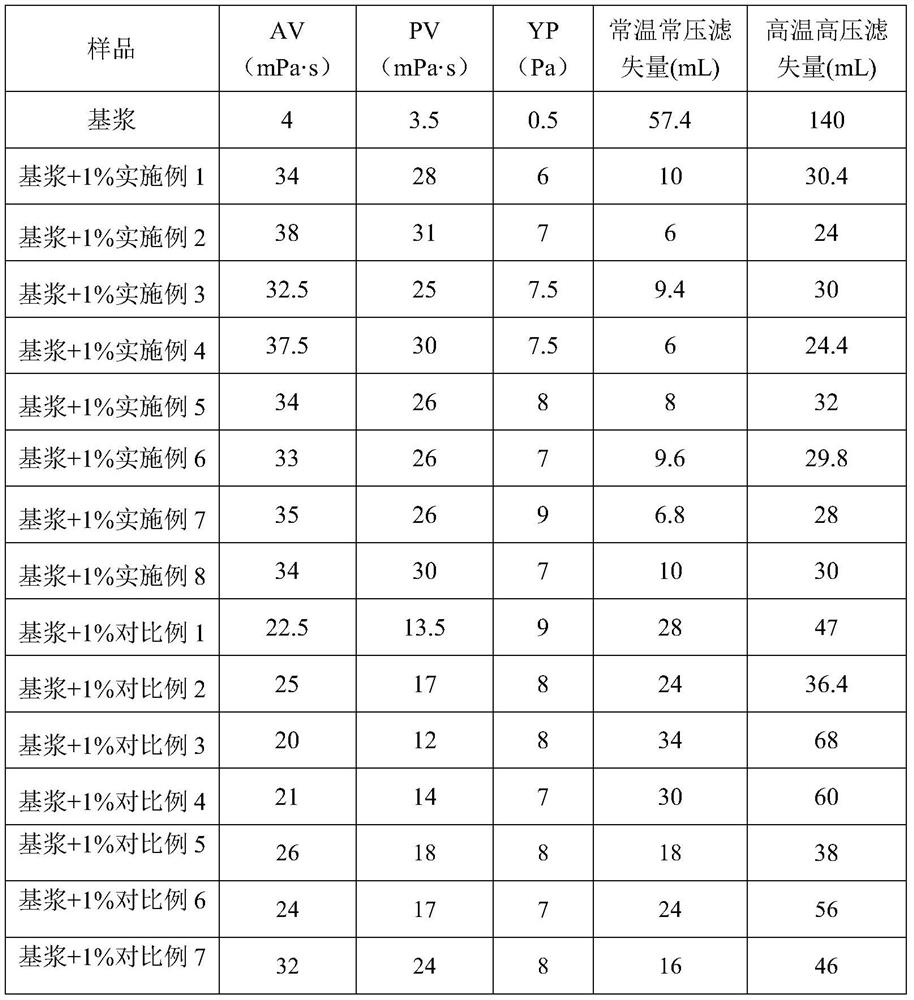

Preparation method of environment-friendly ultrahigh-temperature-resistant filtrate reducer for water-based drilling fluid

ActiveCN111875758AImprove temperature resistanceImprove hydrolysis resistanceDrilling compositionPhysical chemistryCross linker

The invention provides a preparation method of an environment-friendly ultrahigh-temperature-resistant filtrate reducer for a water-based drilling fluid, which comprises the following steps: reactingnano hectorite with a silane coupling agent to obtain a nano cross-linking agent; and in the presence of a nano cross-linking agent and an initiator, carrying out polymerization reaction on an amide monomer, a high-temperature-resistant monomer, a cationic monomer and a polyene monomer by using an inverse emulsion polymerization method to obtain the environment-friendly ultrahigh-temperature-resistant filtrate reducer. The filtrate reducer prepared by the preparation method disclosed by the invention can resist high temperature and has an excellent filtrate reduction effect and good environmental protection performance. The filtrate reducer disclosed by the invention is not only suitable for deep and ultra-deep oil and gas drilling, but also suitable for drilling of geothermal wells and environment-sensitive areas.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of plant straw plate

InactiveCN104802276AReduce releaseStrong resistance to hydrolysisPolyureas/polyurethane adhesivesWood working apparatusAdhesivePlant stalk

The invention provides a preparation method of a plant straw plate. The preparation method takes full components of dried corn straws, rice straws, wheat straws, sunflower straws, rapeseed straws and cotton straws as raw materials and utilizes a special adhesive of polyether polyol and a prepolymer of isocyanate, so that the water-resisting capability is strong, and the inner bonding intensity of a product is improved; the related indexes of the produced plant straw plate are equal to or better than quality standards of national standards (GB / T4897-92) of a wood artificial plate. The indexes including the inner bonding intensity, the static bending strength, the formaldehyde releasing amount, the water absorption thickness expansion rate and the like. The production process is simplified and the production cost is reduced.

Owner:CHANGCHUN YINGLONG MATERIAL TECH CO LTD

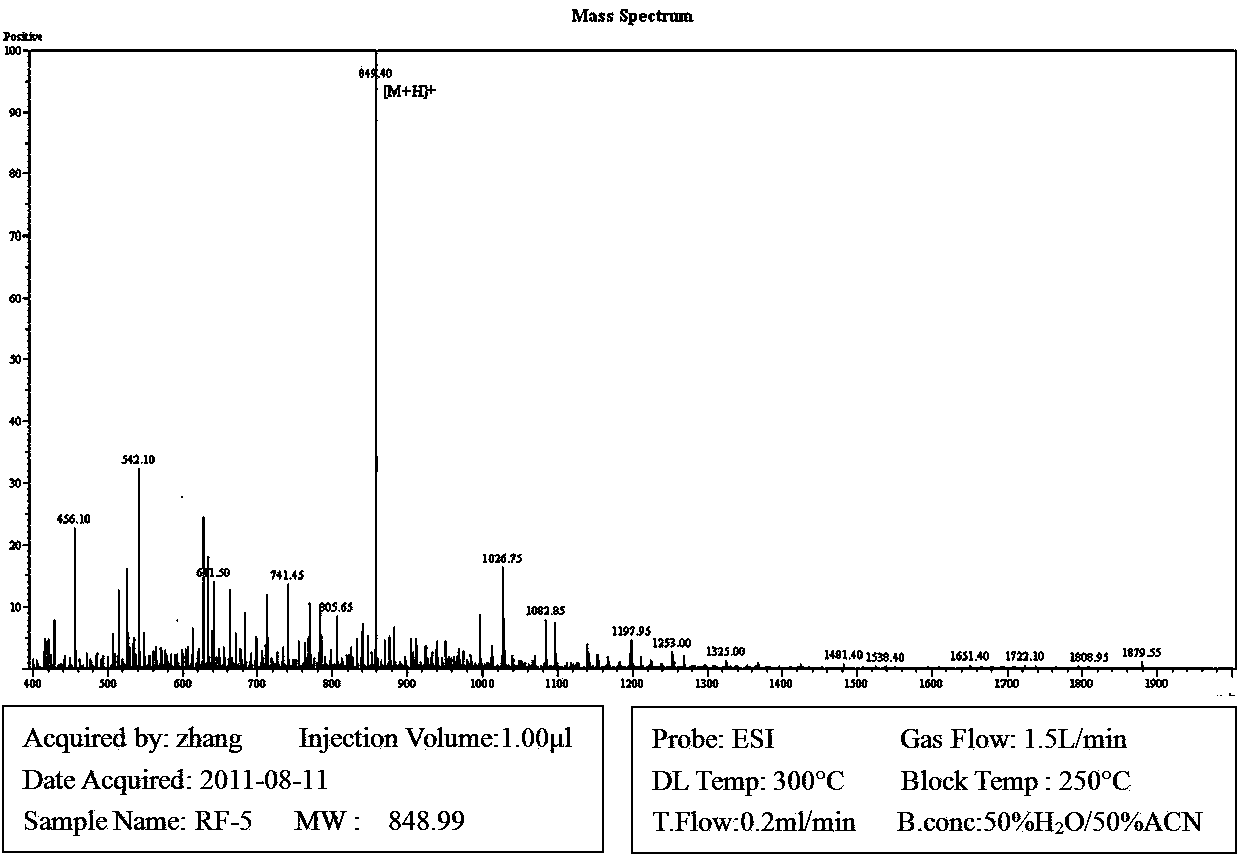

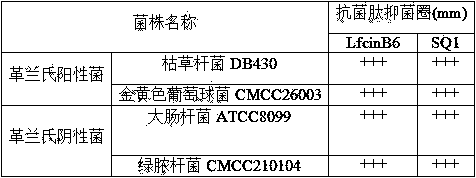

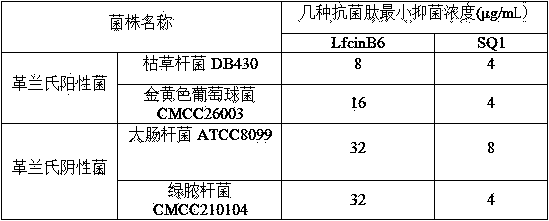

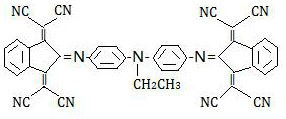

Micromolecule synthesized anti-microbial peptide, as well as preparation method and application thereof

InactiveCN104292301ASimple structureReduce manufacturing costAntibacterial agentsPeptide/protein ingredientsChemical synthesisAntibiosis

The invention discloses a micromolecule synthesized anti-microbial peptide, as well as a preparation method and application thereof. The sequence of a cationic anti-microbial peptide is SQ1: R-W-W-R-F-NH2 (Arg-Arg-Trp-Trp-Arg-NH2), and the preparation method is the solid-phase chemosynthesis method. The micromolecule synthesized anti-microbial peptide has broad-spectrum cytotoxicity to gram-positive bacteria and gram-negative bacteria, has stronger bactericidal activity than a natural anti-microbial peptide, is simple in structure, convenient for artificial synthesis without any modification and connection, has the advantages of small hemolytic toxicity and no poison effects on animal and plant cells, and has an important value in development and application of antimicrobial agents.

Owner:SOUTHWEST UNIVERSITY

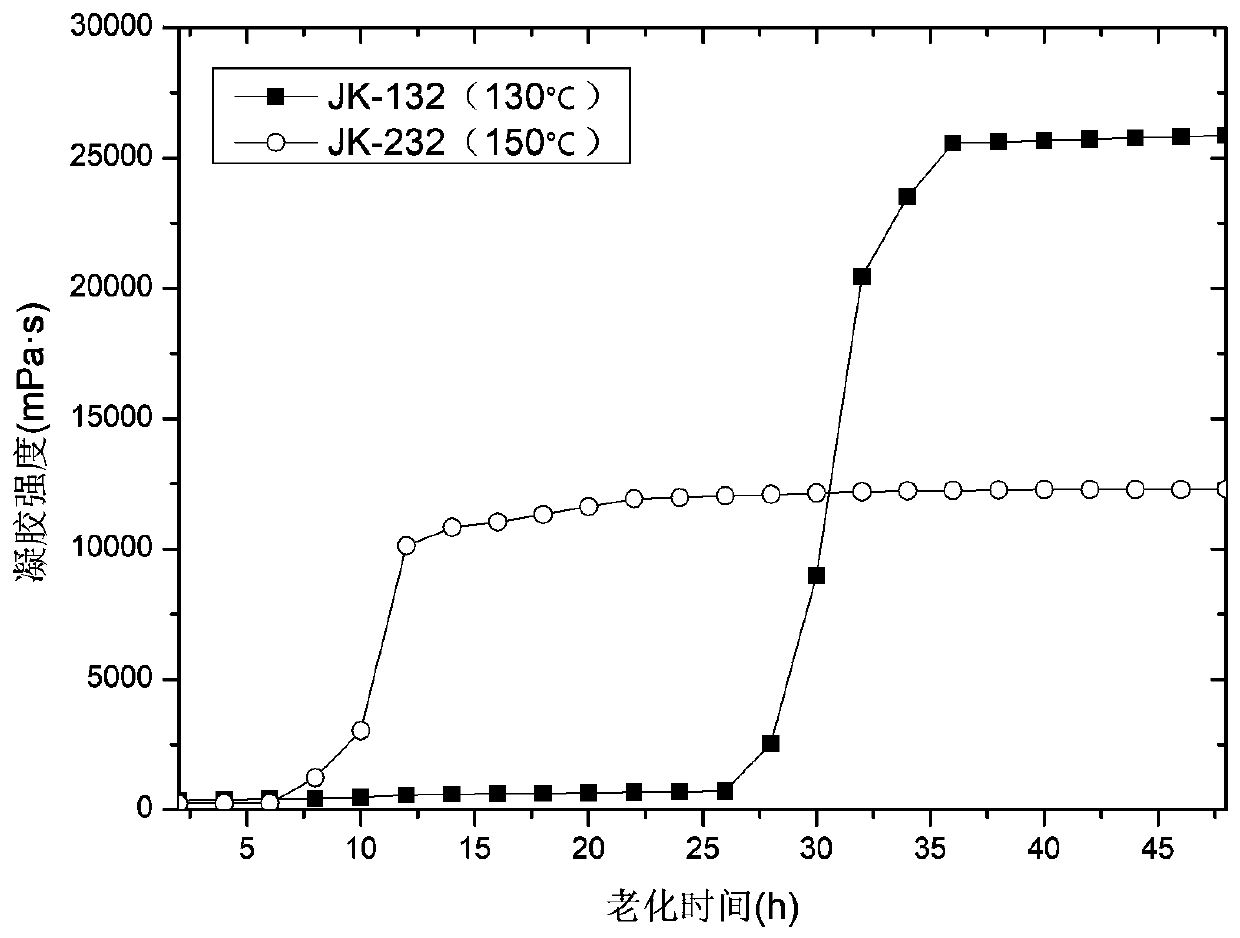

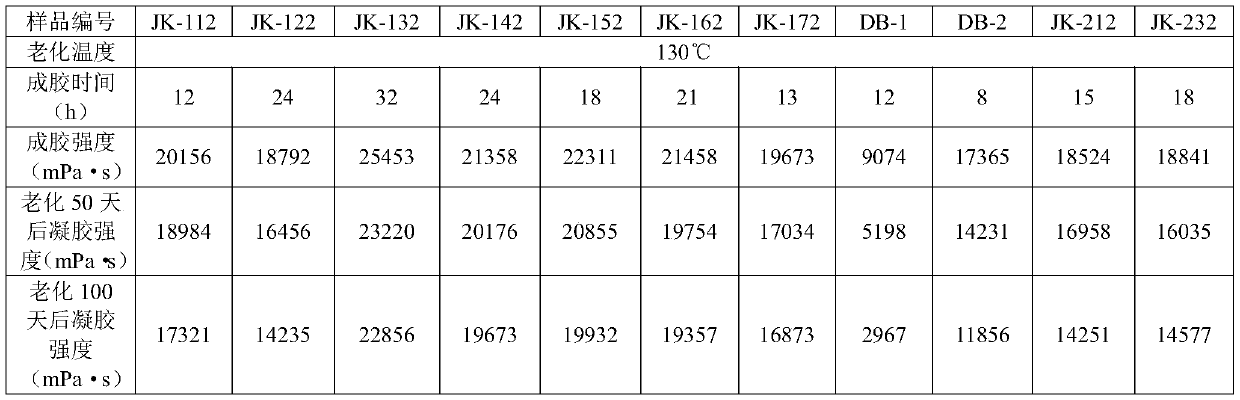

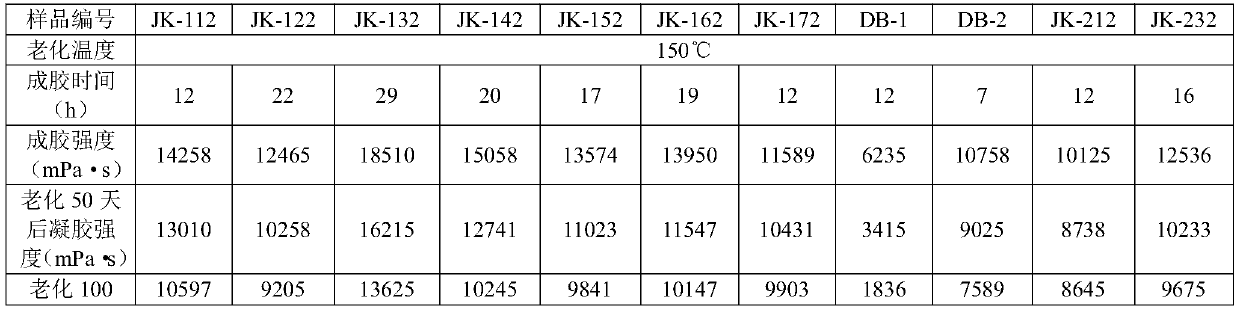

Nano composite polymer and temperature-resistant and salt-resistant profile control agent containing nano composite polymer

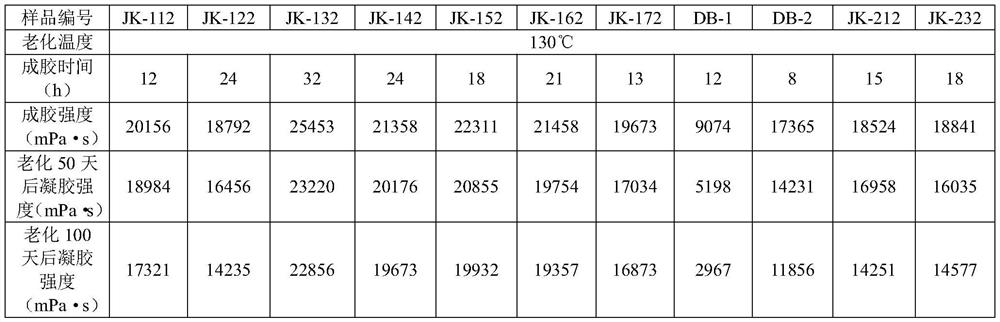

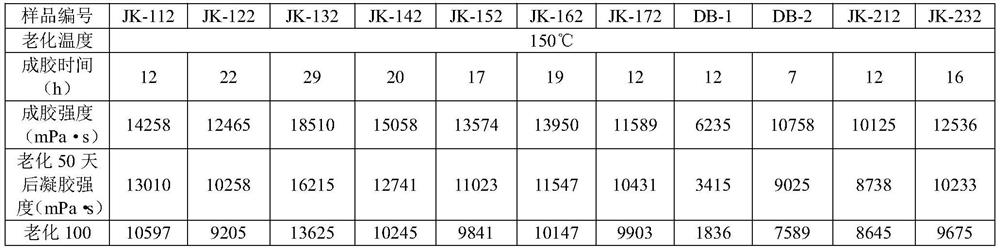

ActiveCN111499793AStrong resistance to hydrolysisImprove stabilityDrilling compositionPolymer sciencePolymer chemistry

The invention discloses a nano-composite polymer and a temperature-resistant and salt-resistant profile control agent containing the nano-composite polymer, the nano-composite polymer is mainly formedby inorganic nano sol and a temperature-resistant and salt-resistant polymerization monomer through polymerization, and the components of the temperature-resistant and salt-resistant profile controlagent comprise the nano-composite polymer. According to the profile control agent disclosed by the invention, a functional polymer formed by polymerizing a temperature-resistant and salt-resistant polymerization monomer and inorganic nano sol is introduced; the profile control agent has high stability, temperature resistance and salt resistance, the anti-aging time reaches 100 days or above underthe conditions that the temperature is 150 DEG C or above and the salt concentration is 300,000 mg / L, and the strength of the profile control agent is improved through inorganic matter nano sol.

Owner:北京九恒质信能源技术有限公司

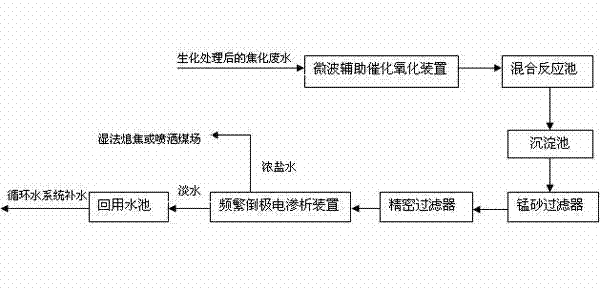

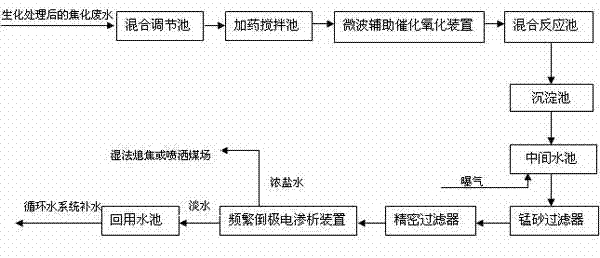

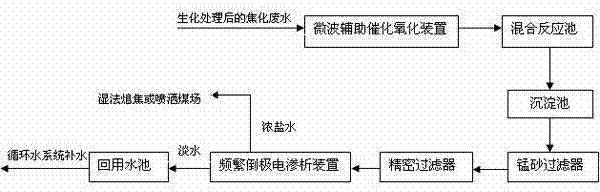

Coking wastewater advanced treatment system and process

InactiveCN102120663BStrong resistance to hydrolysisAvoid easy cloggingDispersed particle separationMultistage water/sewage treatmentCatalytic oxidationProcess engineering

The invention relates to a coking wastewater advanced treatment system, comprising a microwave-assisted catalytic oxidation device, a mixing reaction pool, a sedimentation pool, a manganese sand filter, a precision filter and a frequent electrode reverse electrodialysis device, wherein the microwave-assisted catalytic oxidation device is used for carrying out catalytic oxidation treatment on coking wastewater subjected to A / O (Anoxic / Oxic) biochemical treatment; the mixing reaction pool is connected with the microwave-assisted catalytic oxidation device and the sedimentation pool; the manganese sand filter is connected with the sedimentation pool and the precision filter; and the frequent electrode reverse electrodialysis device is connected with the precision filter. The advanced treatment process provided by the invention can be used for coking wastewater advanced treatment and simultaneously has a high-efficiency pretreatment and economic and proper type desalting system.

Owner:中电恒德环保投资有限公司

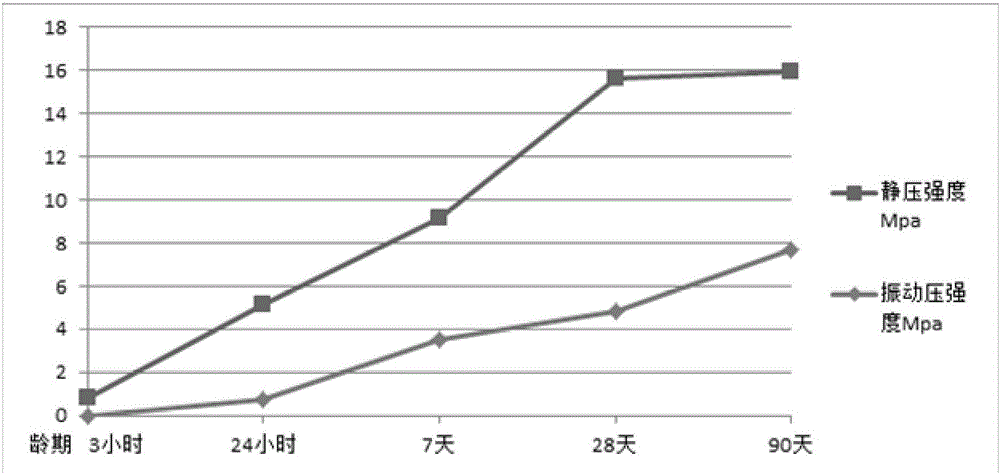

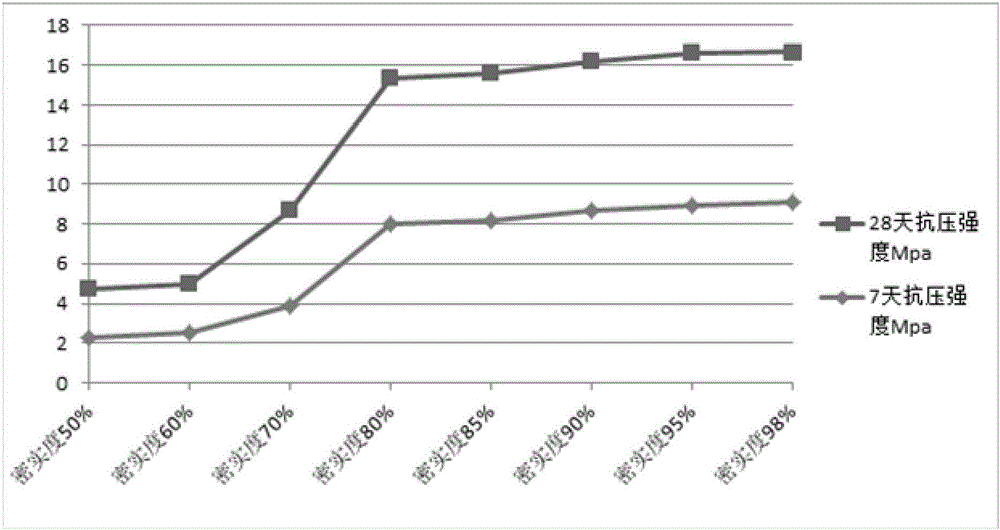

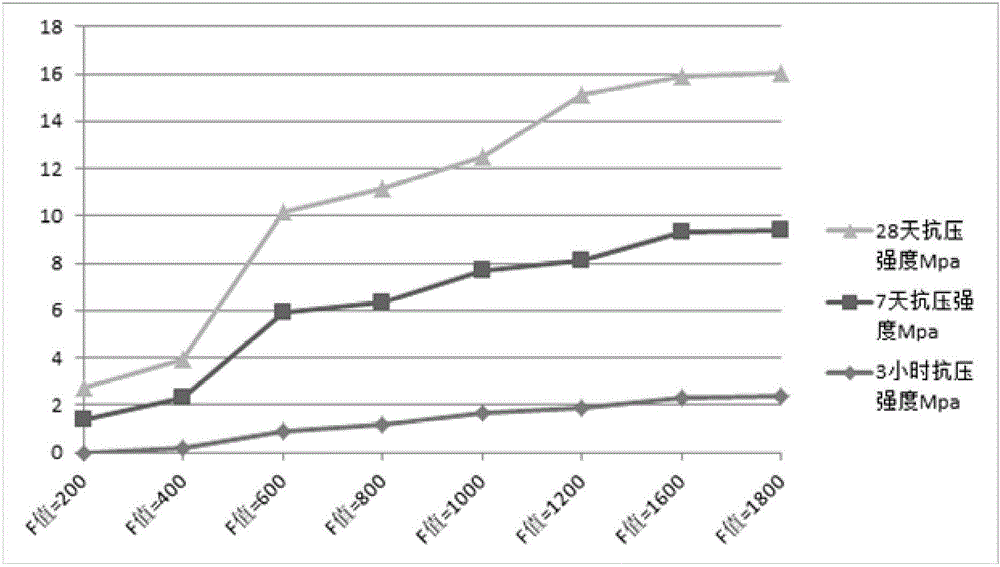

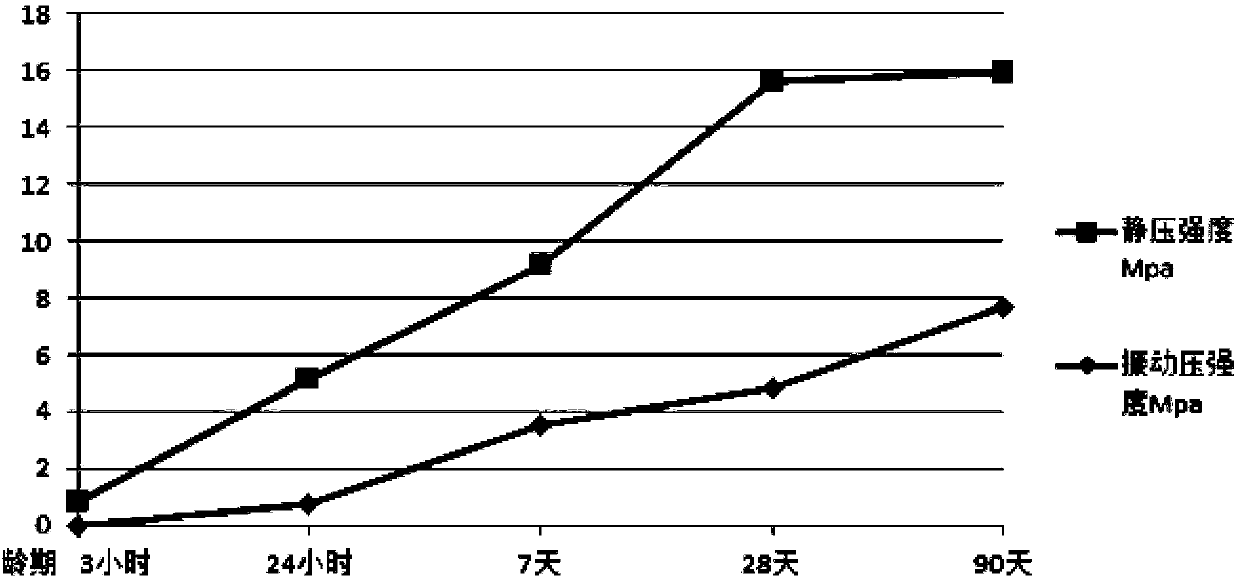

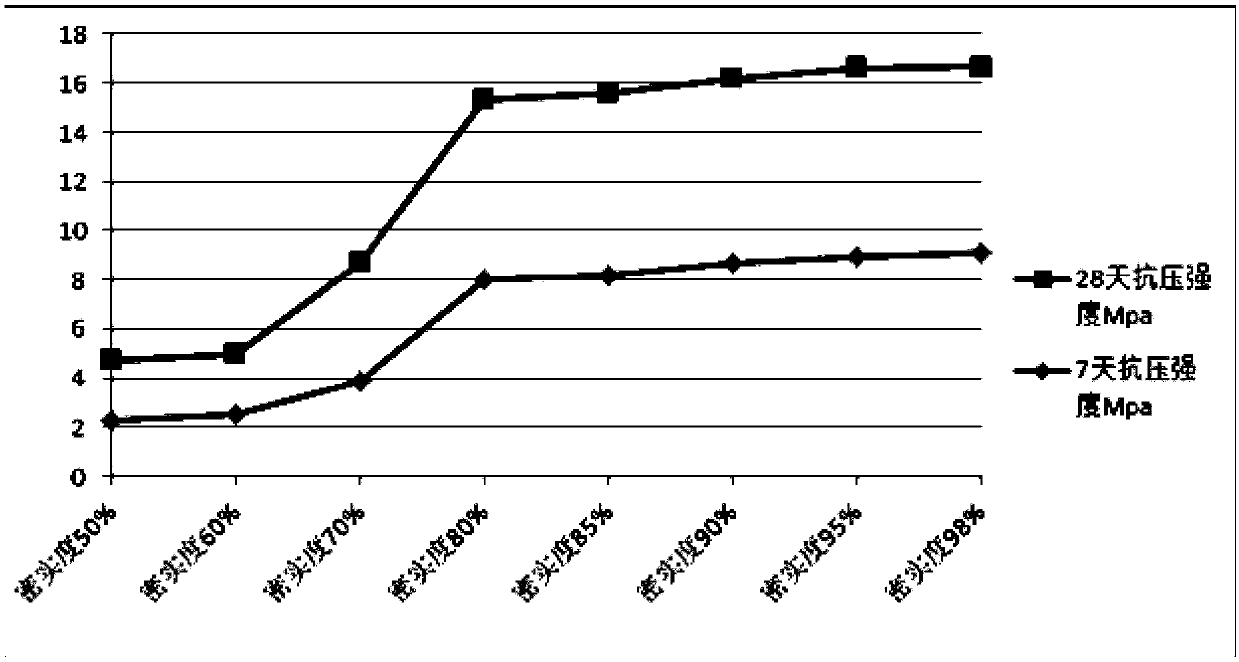

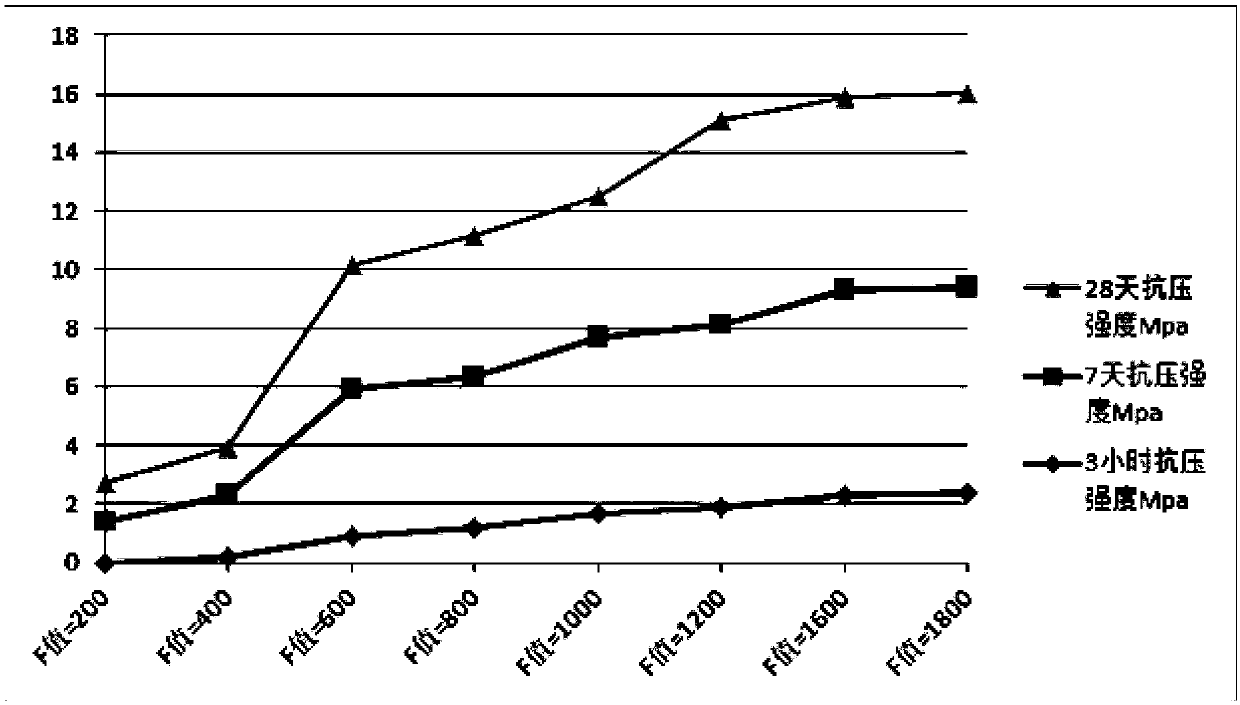

Well drilling waste brick making method

ActiveCN106587786AHarmlessAchieving processing powerWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningBrickFreezing thawing

The invention discloses a well drilling waste brick making method. The well drilling waste brick making method comprises the following steps that dirt elimination and desiccation treatment is conducted on well drilling waste to be treated with a dirt elimination and desiccation agent; a construction binding material and a construction aggregate are added to the well drilling waste, to be treated, obtained after dirt elimination and desiccation treatment, even mixing is conducted, and then a brick making mixture is obtained; the brick making mixture is solidified and pressed to be green bricks with the density not smaller than 80% by means of a static pressure type brick making machine; strength maintenance is conducted on the green bricks; the green bricks obtained after strength maintenance is completed are sprinkled or coated with waterborne waterproof coating or dipped in the waterborne waterproof coating, so that an environment-friendly blocking layer with the thickness being 1-10 mm is formed on the surfaces of the green bricks obtained after strength maintenance is completed, and then the finished bricks are made. By the adoption of the well drilling waste brick making method, the well drilling waste can be processed into the brick making raw material which is loose and dry and meets relative environment-friendly standard at a low cost, the brick making raw material can be finally made into the finished bricks which are ideal in compressive strength, ageing resistance, hydrolysis resistance, freezing-thawing resistance, corrosion resistance and environmental protection stability, and therefore harmless and resourceful treatment of the well drilling waste is achieved.

Owner:北京泾渭智能环保有限公司

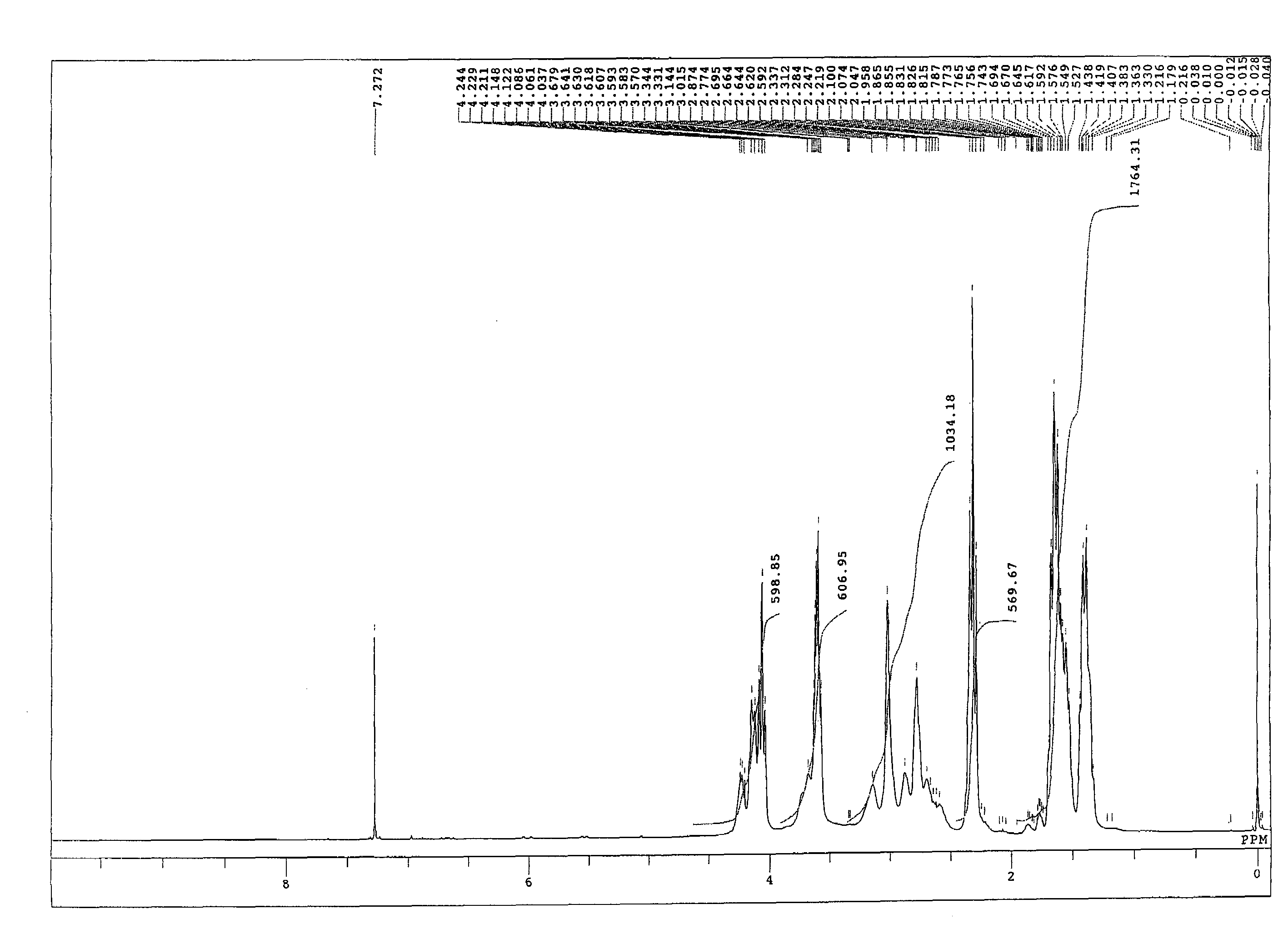

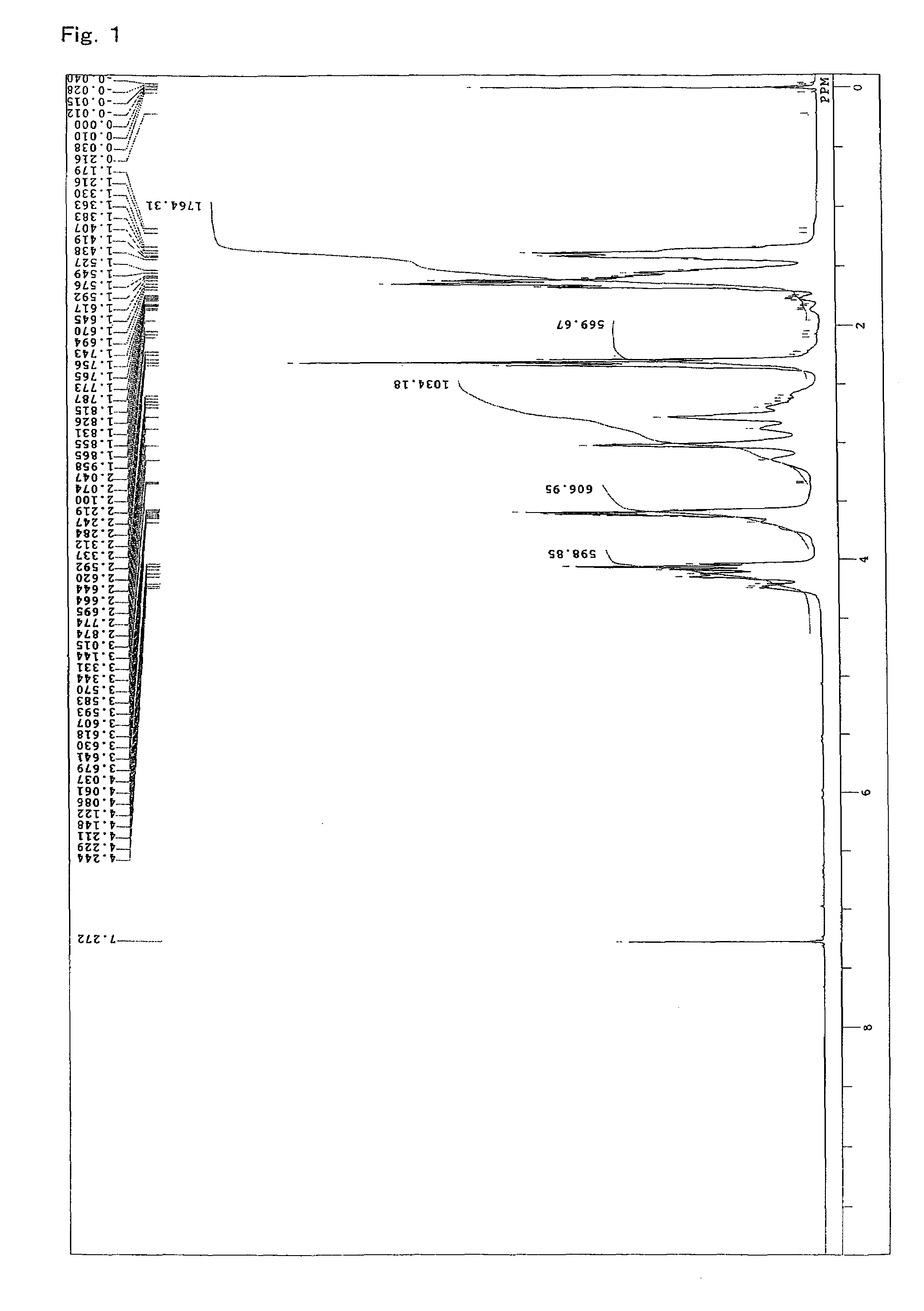

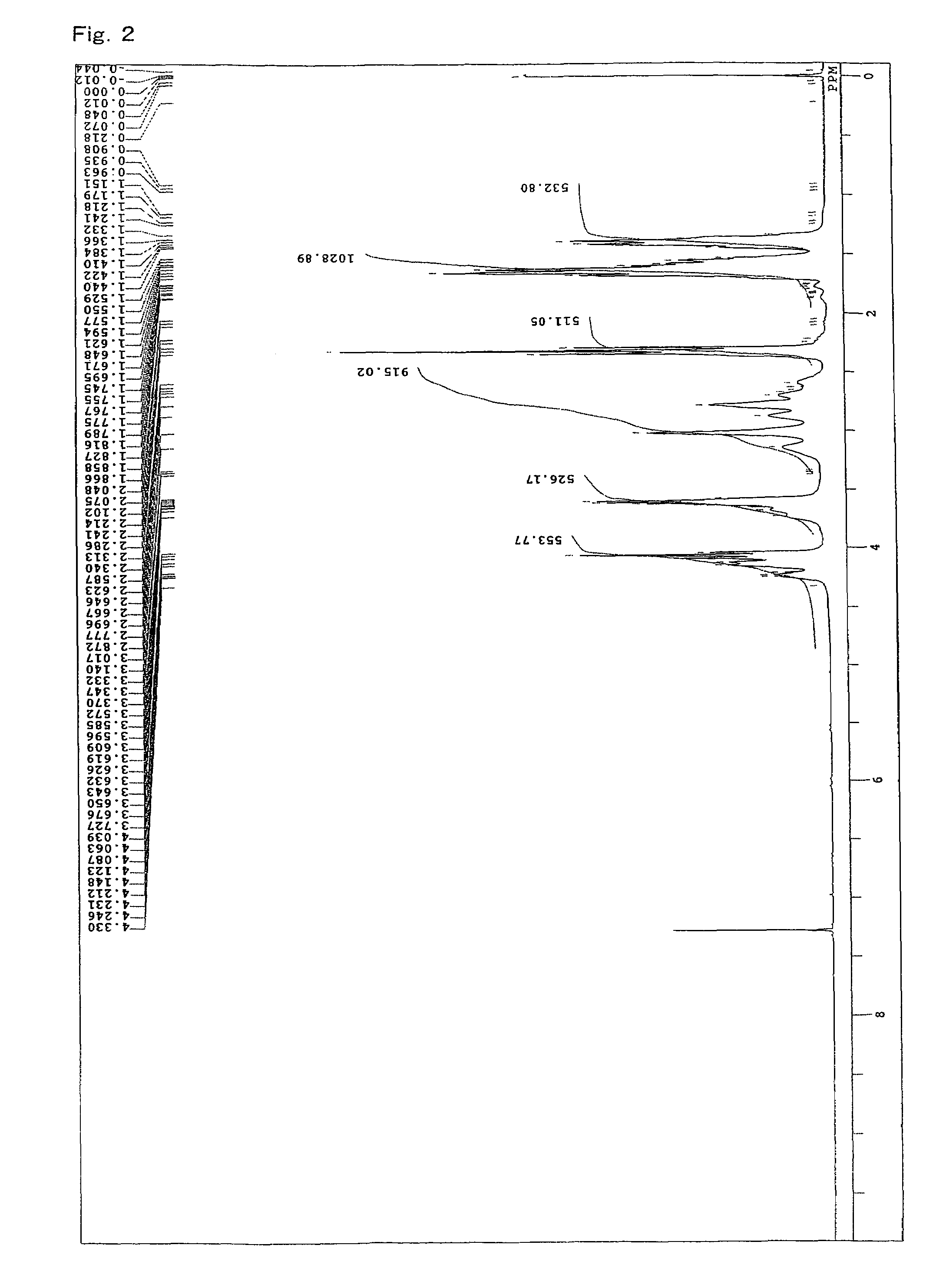

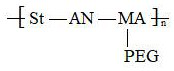

Temperature-resistant and salt-resistant copolymer and preparation method thereof

ActiveCN103772602AEnhance chain rigidityImprove hydrolytic stabilityDrilling compositionTO-18Hydrolysis

The invention relates to a temperature-resistant and salt-resistant copolymer and a preparation method thereof, and mainly solves a problem that polyacrylamide has high possibility of hydrolysis under the conditions of high temperature and high mineralization degree in a conventional technology for improving the recovery efficiency by tertiary oil recovery. According to the technical scheme, the temperature-resistant and salt-resistant copolymer NWKY-PAN has a general formula shown in the specification, wherein p is the number of -CH2- , and is 1 to 3; x, y and m are the structural unit mole numbers of acrylamide, hydrolyzed acrylamide and lactam monomers respectively, x is 95 to 15, y is 4 to 40, and m is 1 to 45; the molecular weight of the copolymer NWKY-PAN is 12,000,000 to 18,000,000; the problem in the prior art is better solved; the temperature-resistant and salt-resistant copolymer can be used for the industrial production of an oil displacement agent for oil recovery in an oilfield.

Owner:CHINA PETROLEUM & CHEM CORP +1

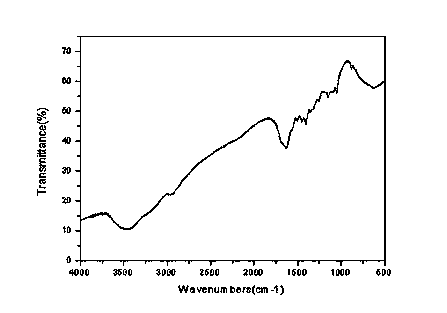

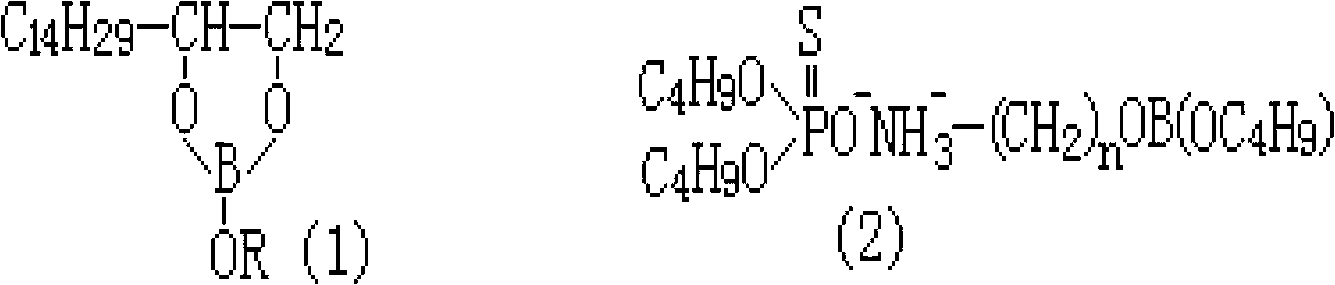

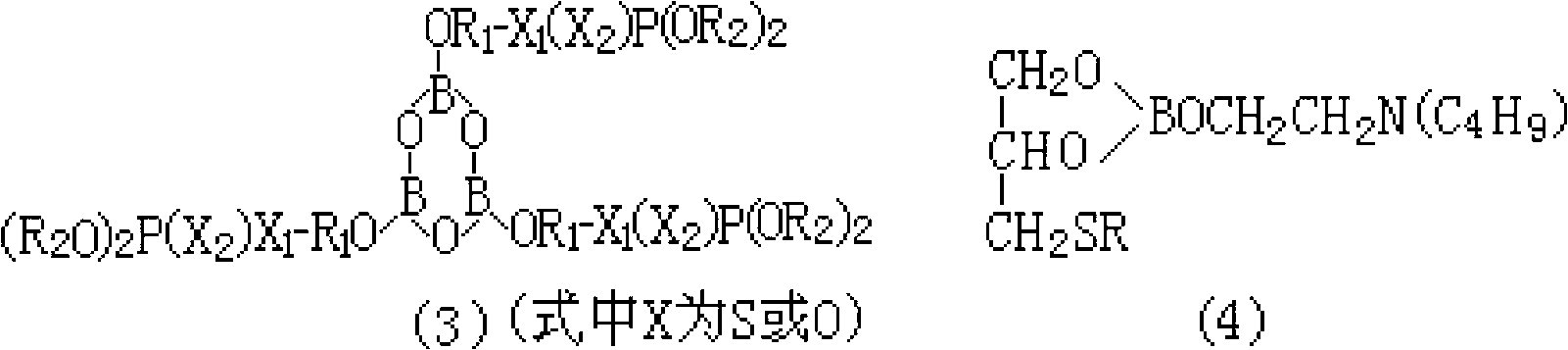

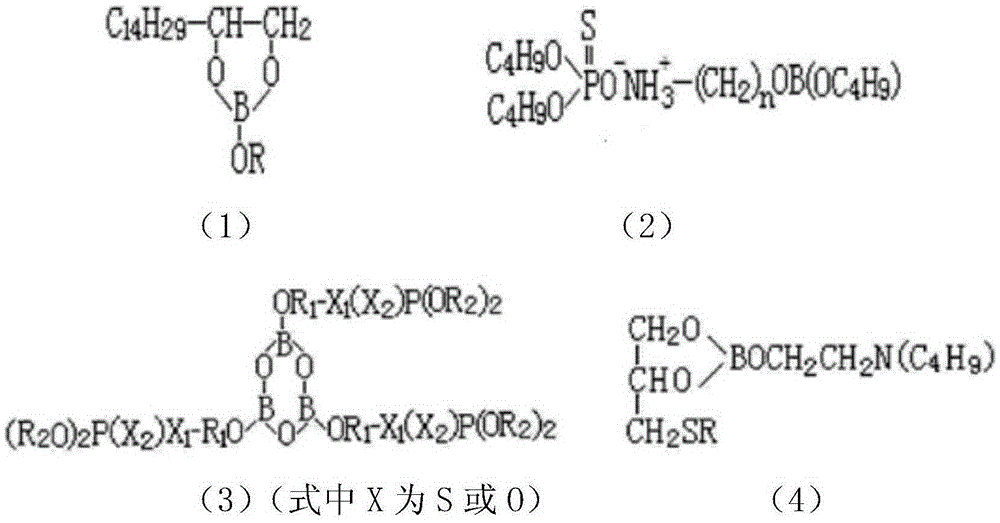

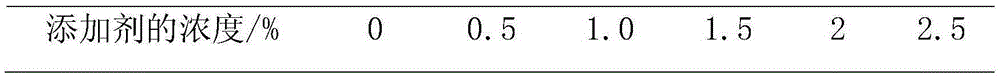

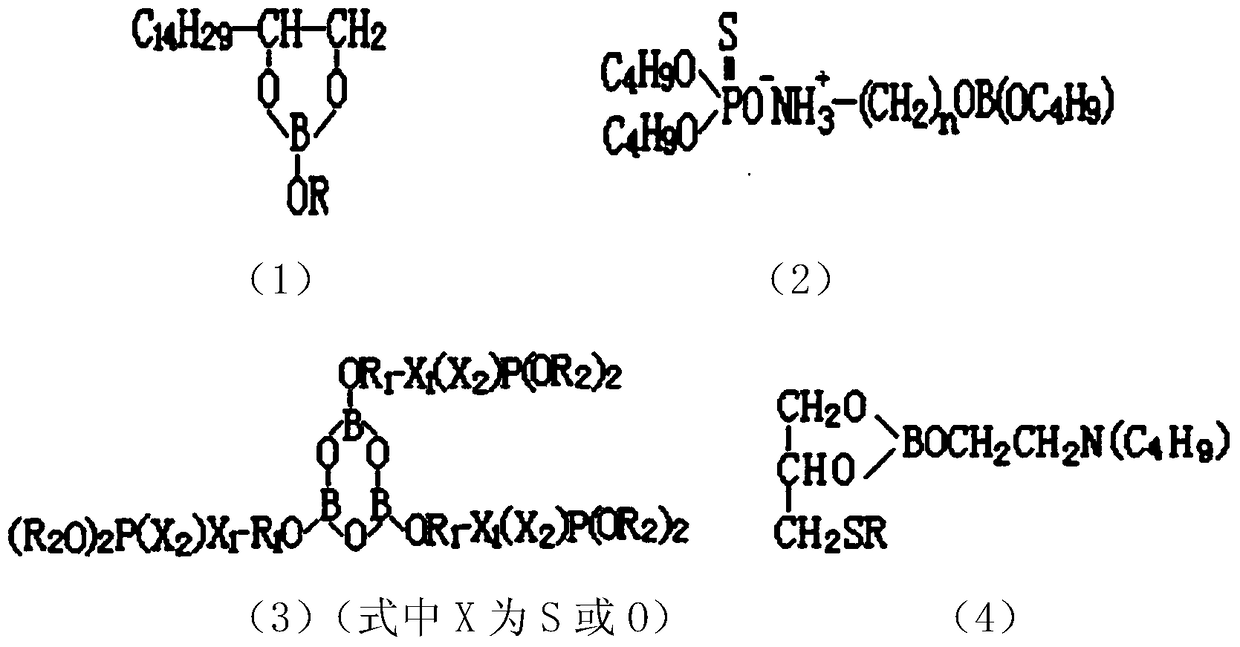

Amido boron phosphate and preparation method of amido boron phosphate

InactiveCN102850396AStrong resistance to hydrolysisImprove the lubrication effectGroup 5/15 element organic compoundsAdditivesWater basedRoom temperature

The invention relates to amido boron phosphate, which comprises the following ingredients: organic amine, dibutyl phosphite, formaldehyde and bononizing agents according to a ratio being 1:(2-3):(2-3):1. A preparation method of the amido boron phosphate comprises the following steps that a, the dibutyl phosphite and the formaldehyde are added into a reaction kettle, then, the organic amine is completely dripped into the reaction kettle under a stirring condition, the temperature in the reaction kettle is controlled to be smaller than or equal to 30 DEG C, and the stirring is continuously carried out for 1 to 2 hours when the temperature in the kettle is not raised; b, the bononizing agents are added into the reaction kettle, a water distribution device is started, temperature is raised to 110 to 130 DEG C through heating, the backflow reaction is carried out for 3 to 5 hours, the reaction is completed when the liquid surface of water in the water distribution device is not increased, cooling is carried out to the room temperature, and a target product is obtained. The synthetized amido boron phosphate belongs to a B-N-P type multifunctional Y lubricating oil additive, when the amido boron phosphate is added into water-base metal processing liquid, the anti-corrosion performance and the anti-rust performance of the processing liquid can be improved, and the lubricating performance of the water-base metal processing liquid can also be improved.

Owner:SHENYANG POLYTECHNIC UNIV

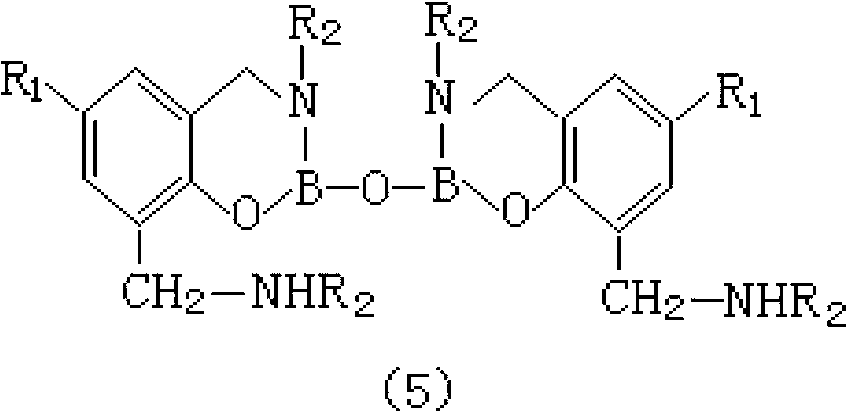

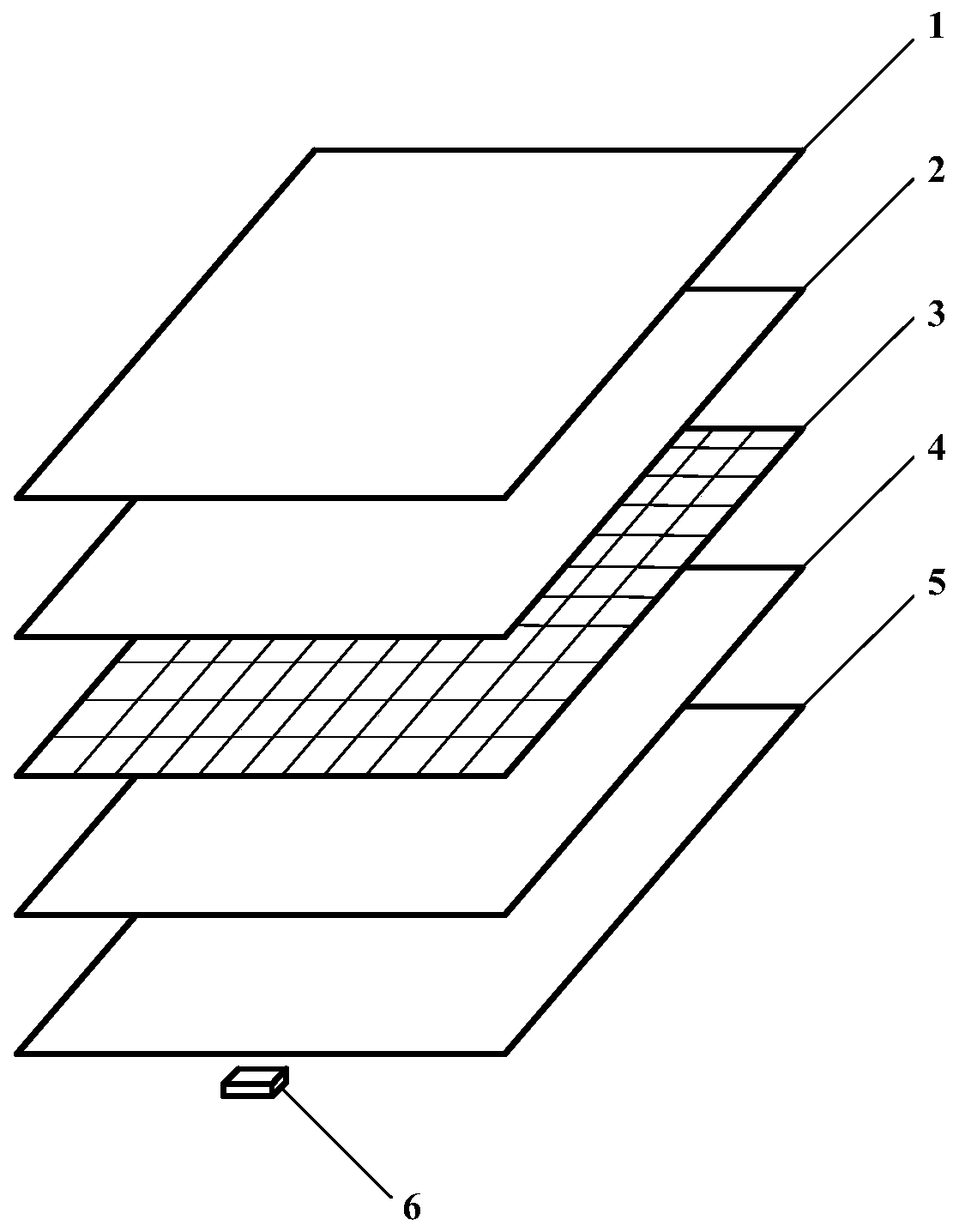

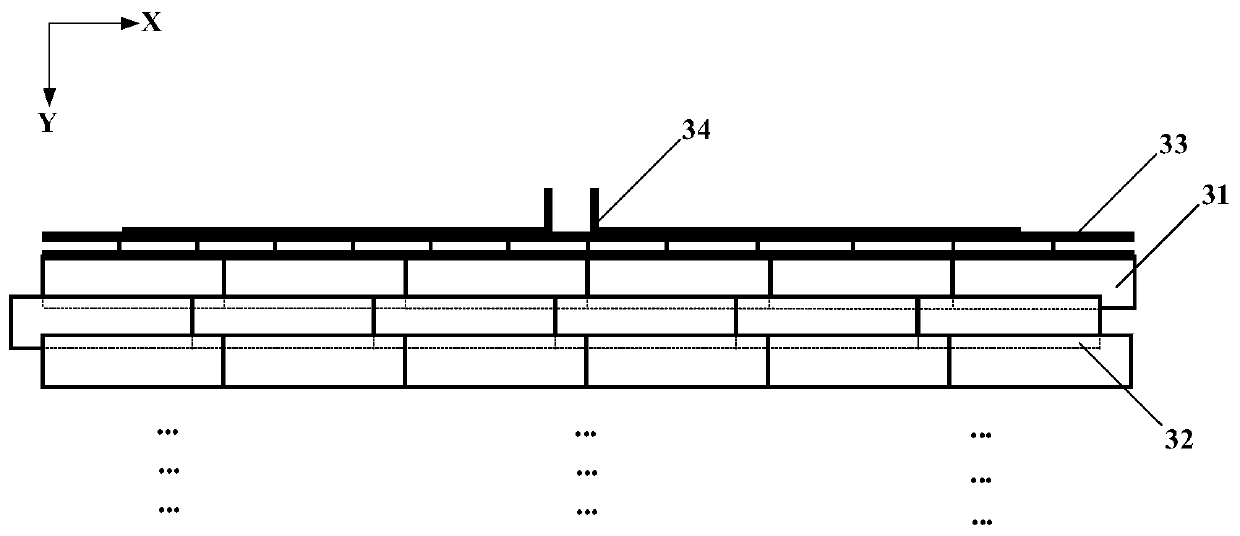

Flexible series-parallel imbricated photovoltaic module and manufacturing method thereof

PendingCN111477709AIncrease powerIncrease elasticityFinal product manufacturePhotovoltaic energy generationMechanical engineeringBattery cell

The invention discloses a flexible series-parallel imbricated photovoltaic module and a manufacturing method thereof, and belongs to the technical field of photovoltaic power generation. The photovoltaic module comprises a front plate, a front adhesive film, an imbricated battery piece group, a rear adhesive film and a back plate, wherein the imbricated battery piece group is packaged between thefront plate and the back plate, the front adhesive film is arranged between the front plate and the imbricated battery piece group, the back adhesive film is arranged between the imbricated battery piece group and the back plate, the front surface and the back surface of each battery piece in the imbricated battery piece group are respectively provided with an electrode, and the front plate and the back plate are flexible plates. The front plate and the rear plate are made of flexible materials, and the conductive adhesive is a silicon-based conductive silver adhesive; after being packaged, the conductive adhesive has excellent elasticity after being cured; the series-parallel imbricated photovoltaic module has the advantages that the partial stress of the series-parallel battery pieces isreduced, the problem of subfissure of the battery pieces can be well solved, the foundation settlement resistance is high, the combination with a building is good, the high-power advantage of the series-parallel imbricated photovoltaic module can be exerted in various occasions, and the application range of the series-parallel imbricated photovoltaic module is expanded.

Owner:CHINA HUANENG GRP CO LTD +1

Polyester polyol and polyurethane resin

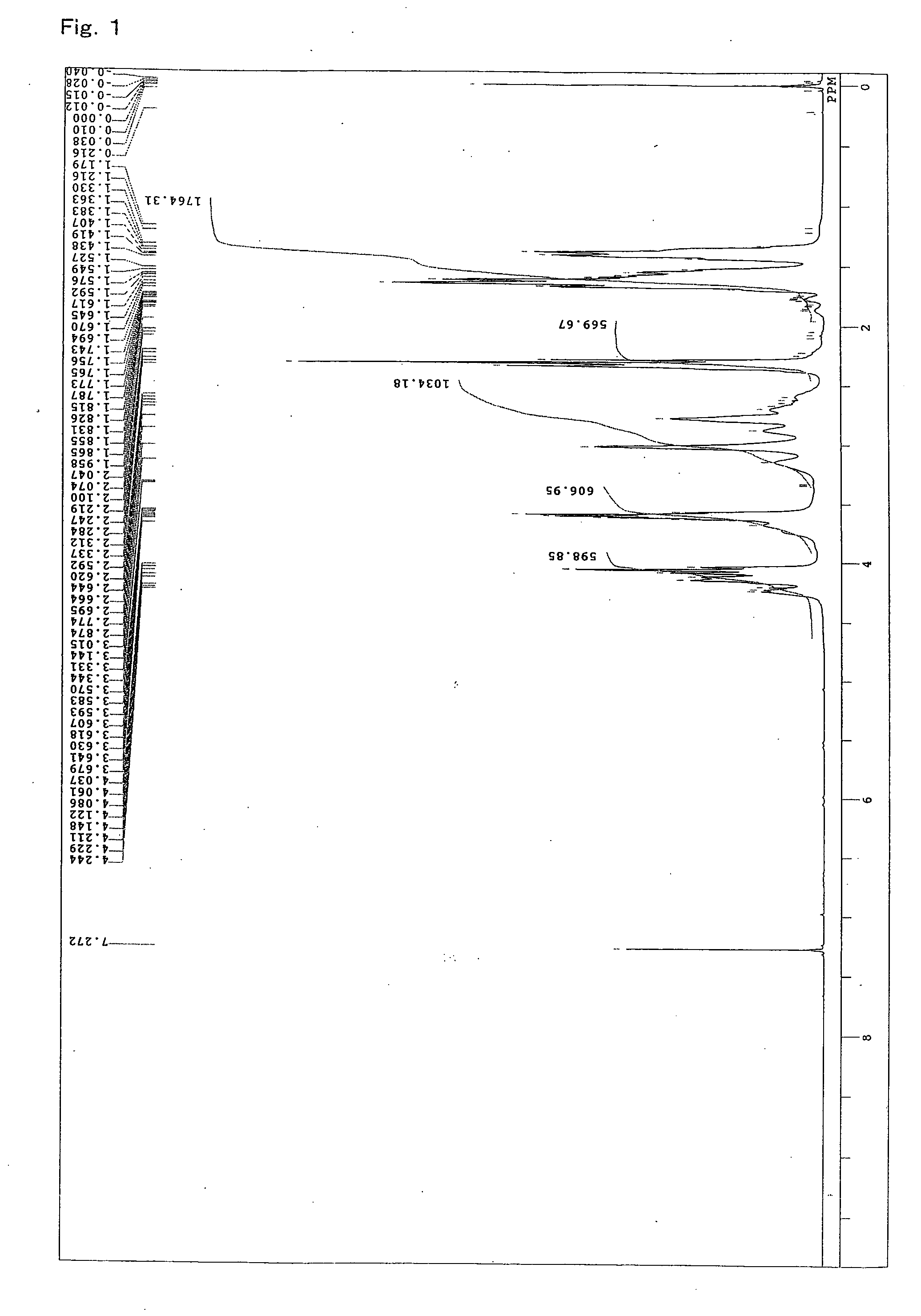

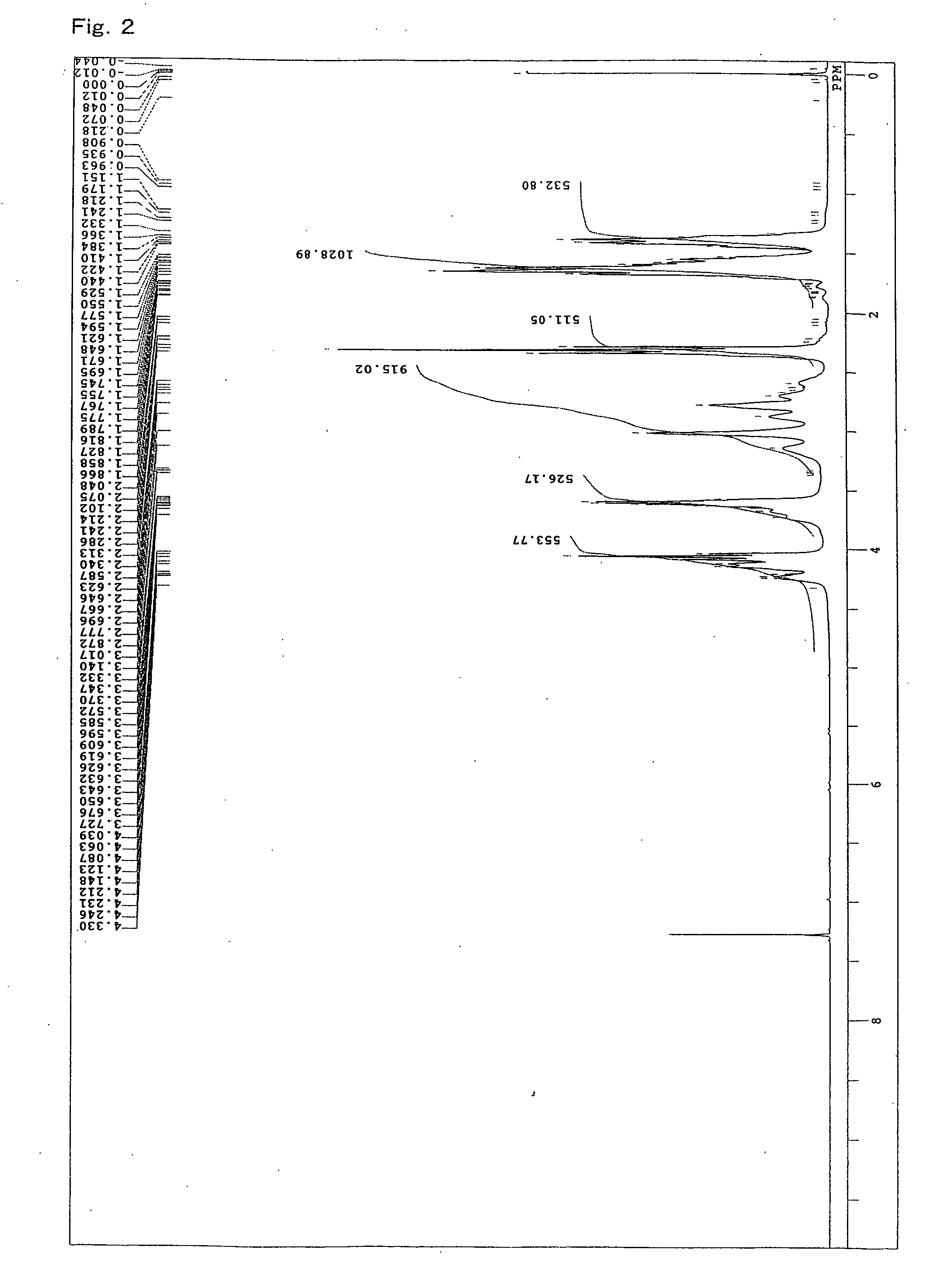

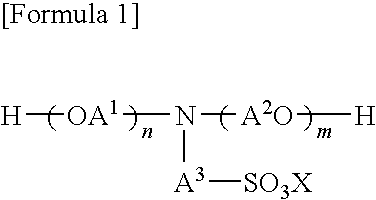

InactiveUS20090247674A1Easy to produceStrong resistance against hydrolysisOrganic chemistryMagnetic materials for record carriersSolubilityPolyester

To prepare a polyester polyol in which a lactone is ring-opening addition polymerized with the compound represented by formula (I).(wherein each of A1 and A2 represents an alkylene group having not less than 2 carbon atoms, A3 represents an alkylene group, X represents a cationic component, and each of n and m represents an integer of not less than 1.)The polyester polyol has a high hydrophilic group and high solubility in a solvent (particularly, a low-boiling organic solvent used in the production of a polyurethane) and can design an aqueous polyurethane desirably and produce the aqueous polyurethane.

Owner:DAICEL CHEM IND LTD

Milt-functional metal surface treatment additive containing boride diethanolamine phosphates and preparation method

ActiveCN105238499AImprove the lubrication effectImprove rust resistanceAdditivesPhosphorus organic compoundsWater basedViscous liquid

The invention relates to a method for preparing a milt-functional metal surface treatment additive containing boride diethanolamine phosphates, which comprises steps: diethanolamine and phosphate esterification agents are added into a reaction kettle to react, are hydrolysed and concentrated to obtain a viscous liquid, a water-carrying agent is added into the viscous liquid, a boriding agent is added to react by stirring, and the water-carrying agent is boiled up by decompressing to obtain a target product. The milt-functional metal surface treatment additive which is prepared through the method comprises 30-60% boride diethanolamine phosphates and 20-60% diethanolamine double phosphate esters. The method for preparing the milt-functional metal surface treatment additive containing the boride diethanolamine phosphates has the beneficial effects that the milt-functional metal surface treatment additive containing the boride diethanolamine phosphates has excellent antifriction, antioxidant, rust-proof and lubrication performance and the like because phosphates which are used as main components in the milt-functional metal surface treatment additive containing the boride diethanolamine phosphates contain active elements such as N, P and B and the like, is strong in anti-hydrolytic property, can improve lubricity and anti-rust property of a water-base metal working fluid by being added into the water-base metal working fluid, also can improve extreme pressure property and prolongs service life of the water-base metal working fluid simultaneously, and is an excellent multi-functional water-soluble additive.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

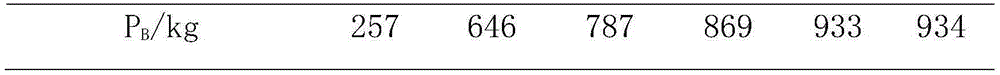

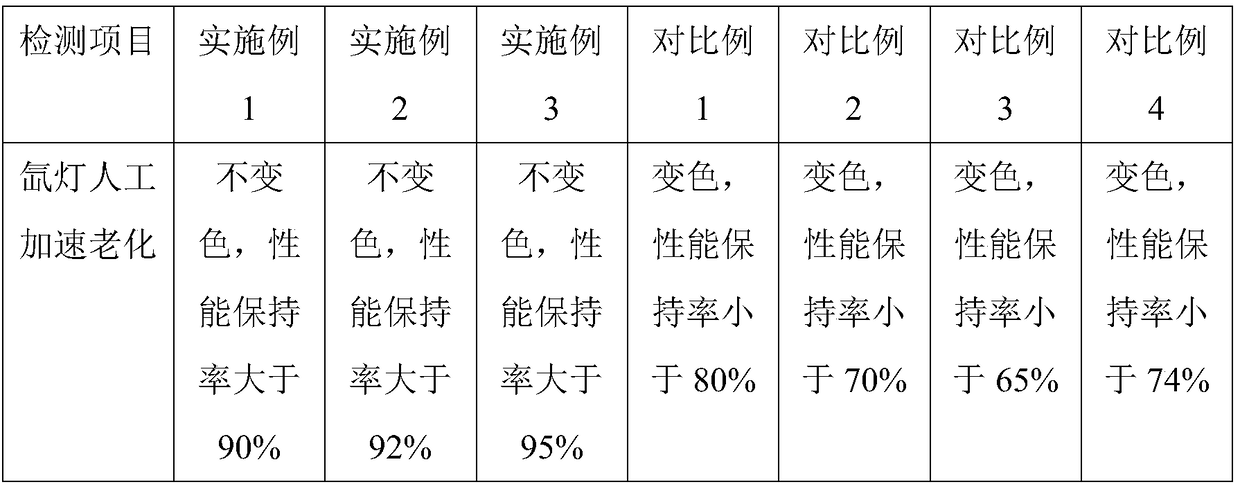

Weatherproof glass fiber reinforced PA66 high-speed rail sleeve material and preparation method thereof

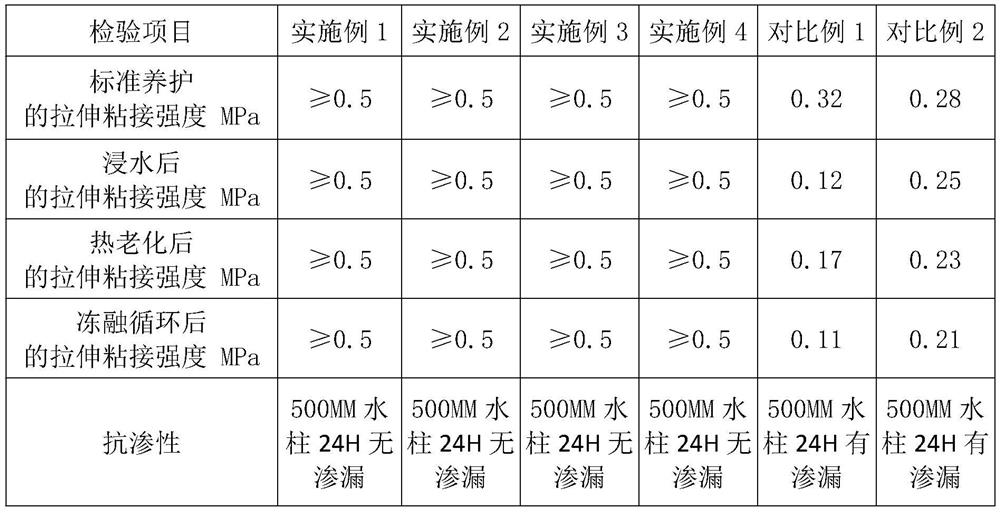

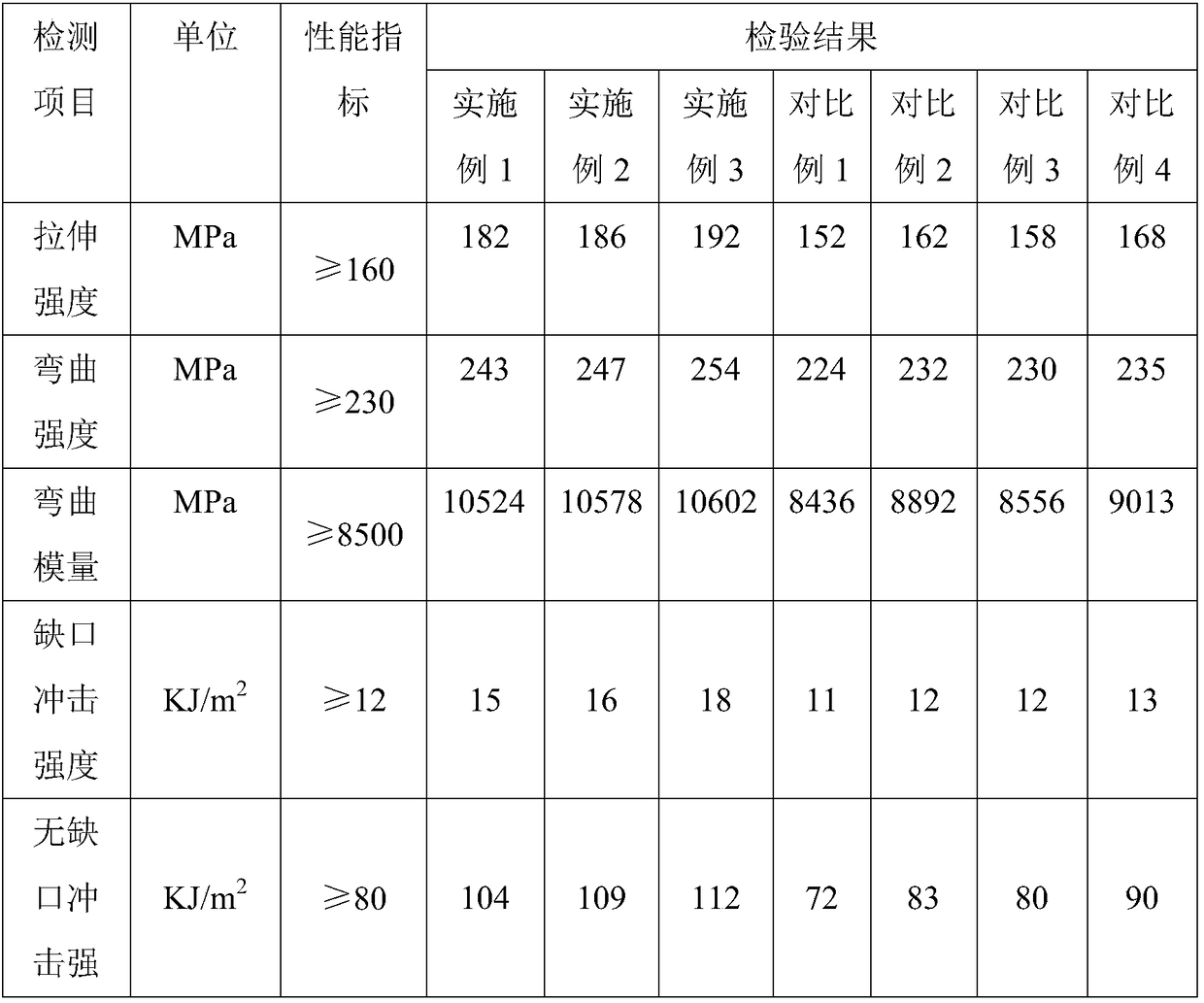

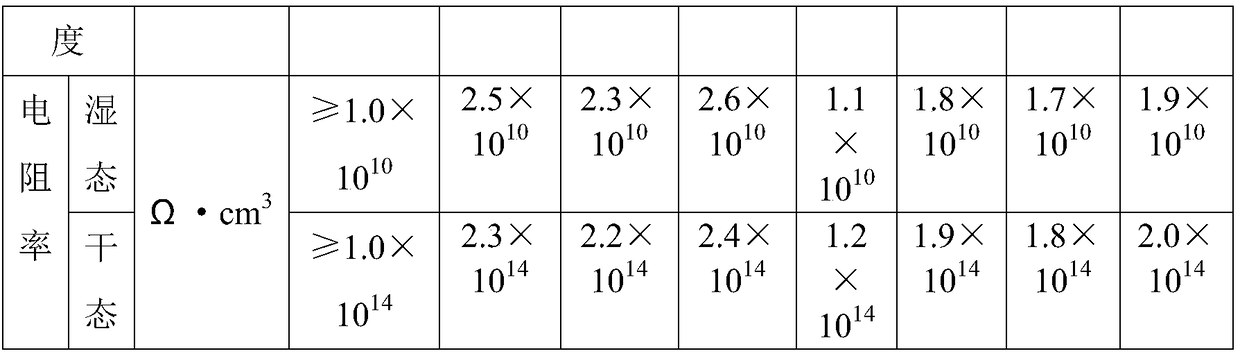

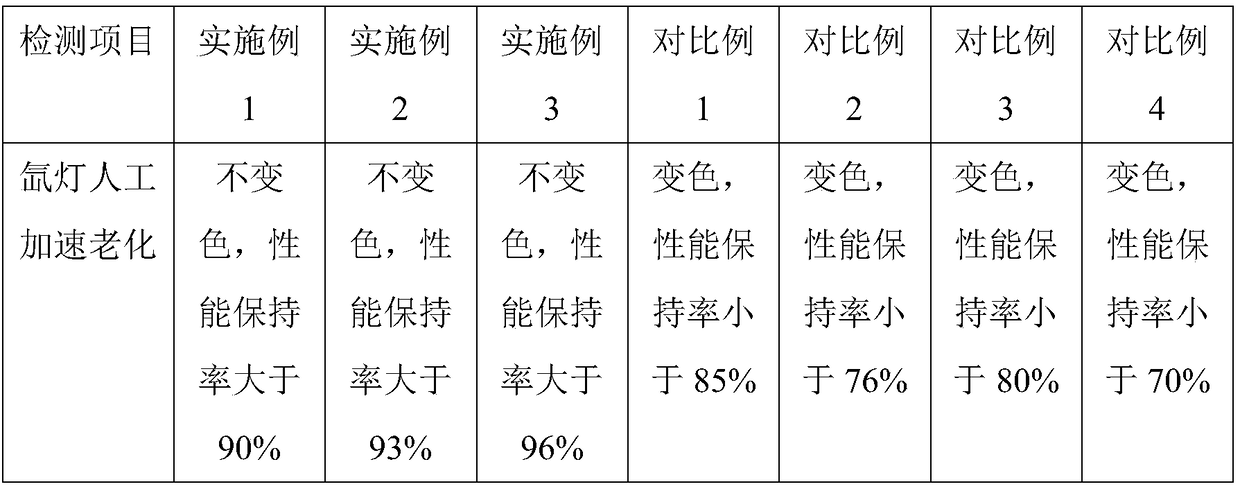

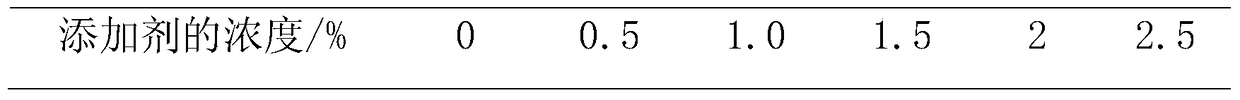

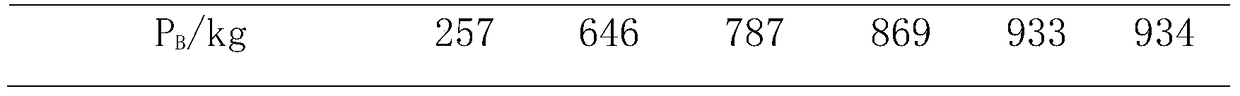

The invention belongs to the technical field of polymer materials, and particularly relates to a weatherproof glass fiber reinforced PA66 high-speed rail sleeve material and a preparation method thereof. The material comprises, by weight, the following components: 44.0-58.3% of PA66 resin, 5.0-10.0% of PA6T resin, 0.3-0.5% of antioxidant 1000, 0.3-0.5% of antioxidant 1098, 0.3-0.5% of lubricant, 5.0-10.0% of inorganic filler, 0.5-1% of toughening agent and 0.3-0.5% of weatherproof agent, 30-33% of glass fiber. The material has the advantages of low cost, high strength, strong toughness, fatigue resistance, stable size, good aging resistance, good weatherproof performance and the like, and can meet the high standard requirement of a high-speed rail sleeve.

Owner:GUANGDONG SHUNDE SHUNYAN NEW MATERIALS

Polyester polyol and polyurethane resin

InactiveUS7674930B2High hydrophilic groupEasy to produceOrganic chemistryMagnetic materials for record carriersPolyesterSolubility

To prepare a polyester polyol in which a lactone is ring-opening addition polymerized with the compound represented by formula (I).(wherein each of A1 and A2 represents an alkylene group having not less than 2 carbon atoms, A3 represents an alkylene group, X represents a cationic component, and each of n and m represents an integer of not less than 1.)The polyester polyol has a high hydrophilic group and high solubility in a solvent (particularly, a low-boiling organic solvent used in the production of a polyurethane) and can design an aqueous polyurethane desirably and produce the aqueous polyurethane.

Owner:DAICEL CHEM IND LTD

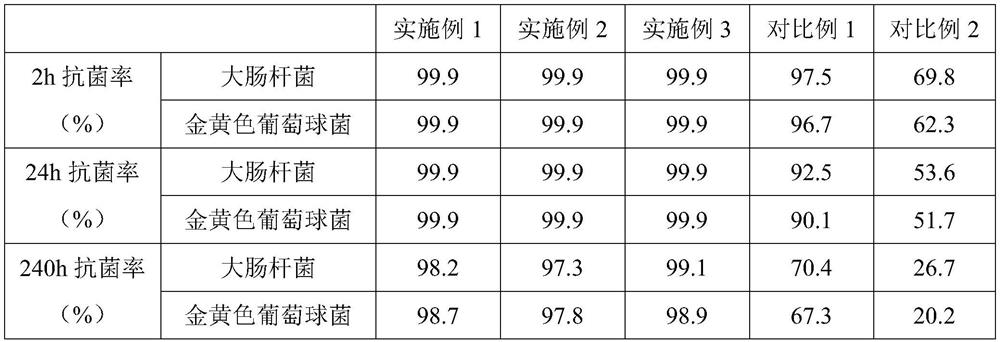

Long-acting antibacterial material, dental diaphragm and long-acting invisible appliance

ActiveCN112998884ALong-acting antibacterialEnhance physical fitnessOthrodonticsCalcium carbidePolymer sciencePolyethylene terephthalate glycol

The invention discloses a long-acting antibacterial material, a dental diaphragm and a long-acting invisible appliance. The long-acting antibacterial material comprises PETG (polyethylene terephthalate glycol) resin and modified tourmaline, wherein the mass ratio of the PETG resin to the modified tourmaline is (10-50):1. The preparation method of the modified tourmaline comprises the following steps: S1, treating nano tourmaline with concentrated sulfuric acid to obtain porous nano tourmaline; S2, treating the porous nano tourmaline with glycerin to obtain hydroxylated porous nano tourmaline; and S3, grafting the hydroxylated porous nano tourmaline with limonin to obtain the modified tourmaline. According to the antibacterial material and the preparation method thereof, the PETG resin and the modified tourmaline are combined to prepare the antibacterial material which is safe and non-toxic, has a strong antibacterial effect and can resist bacteria for a long time, and the antibacterial material is also applied to dental diaphragms and invisible orthodontic appliances.

Owner:JILIN UNIV

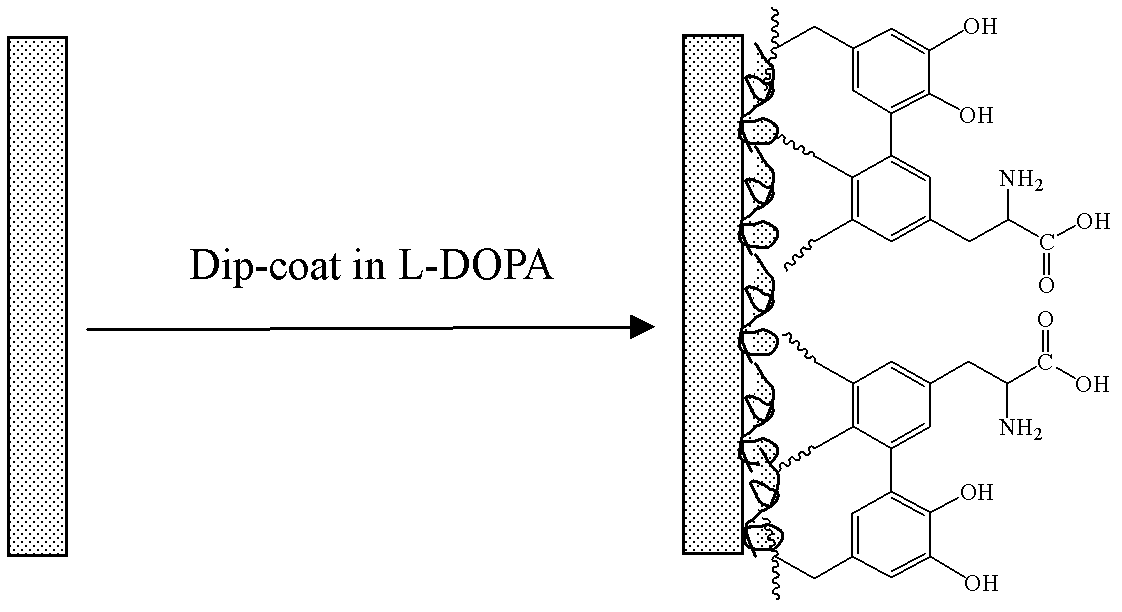

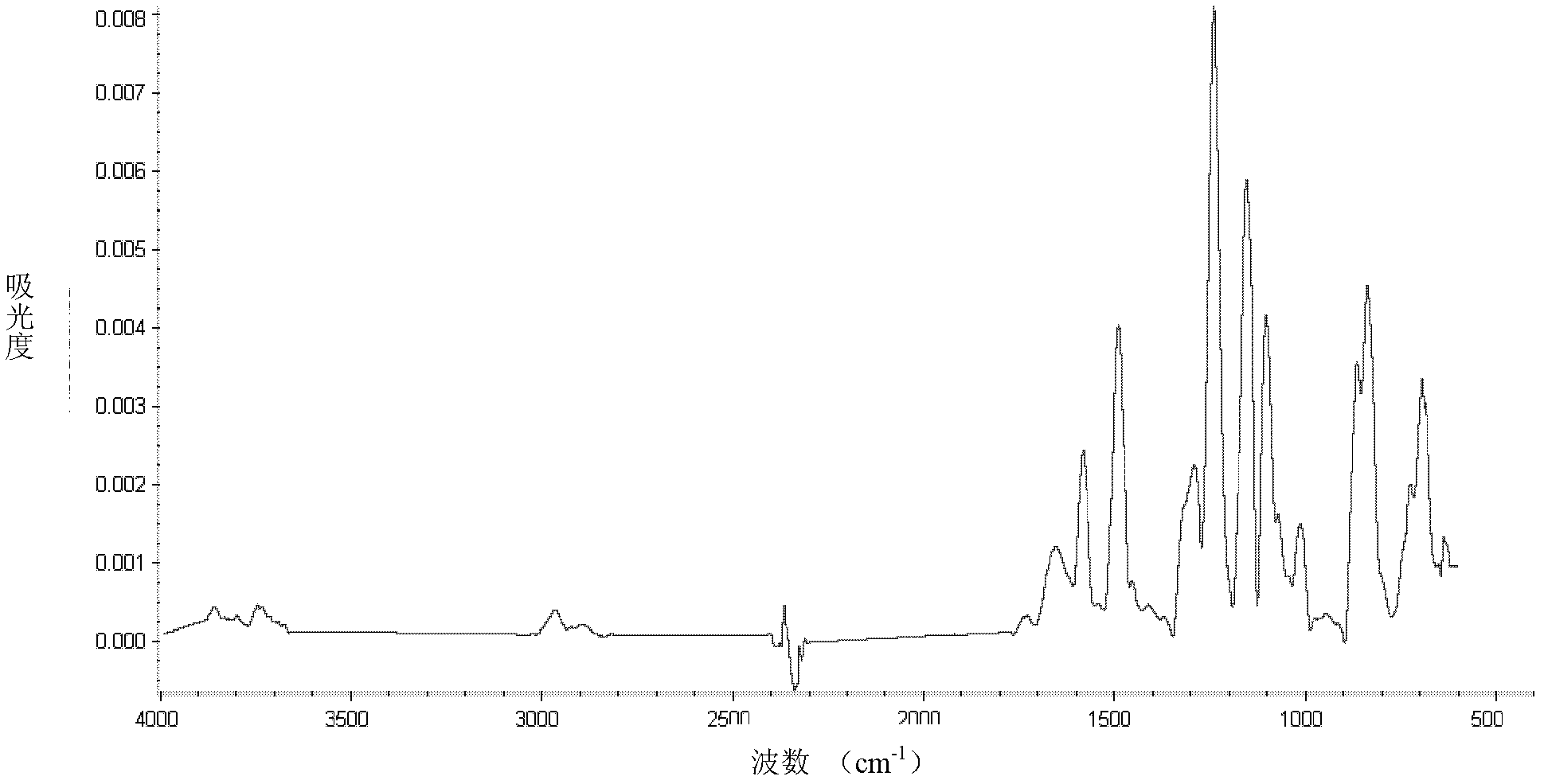

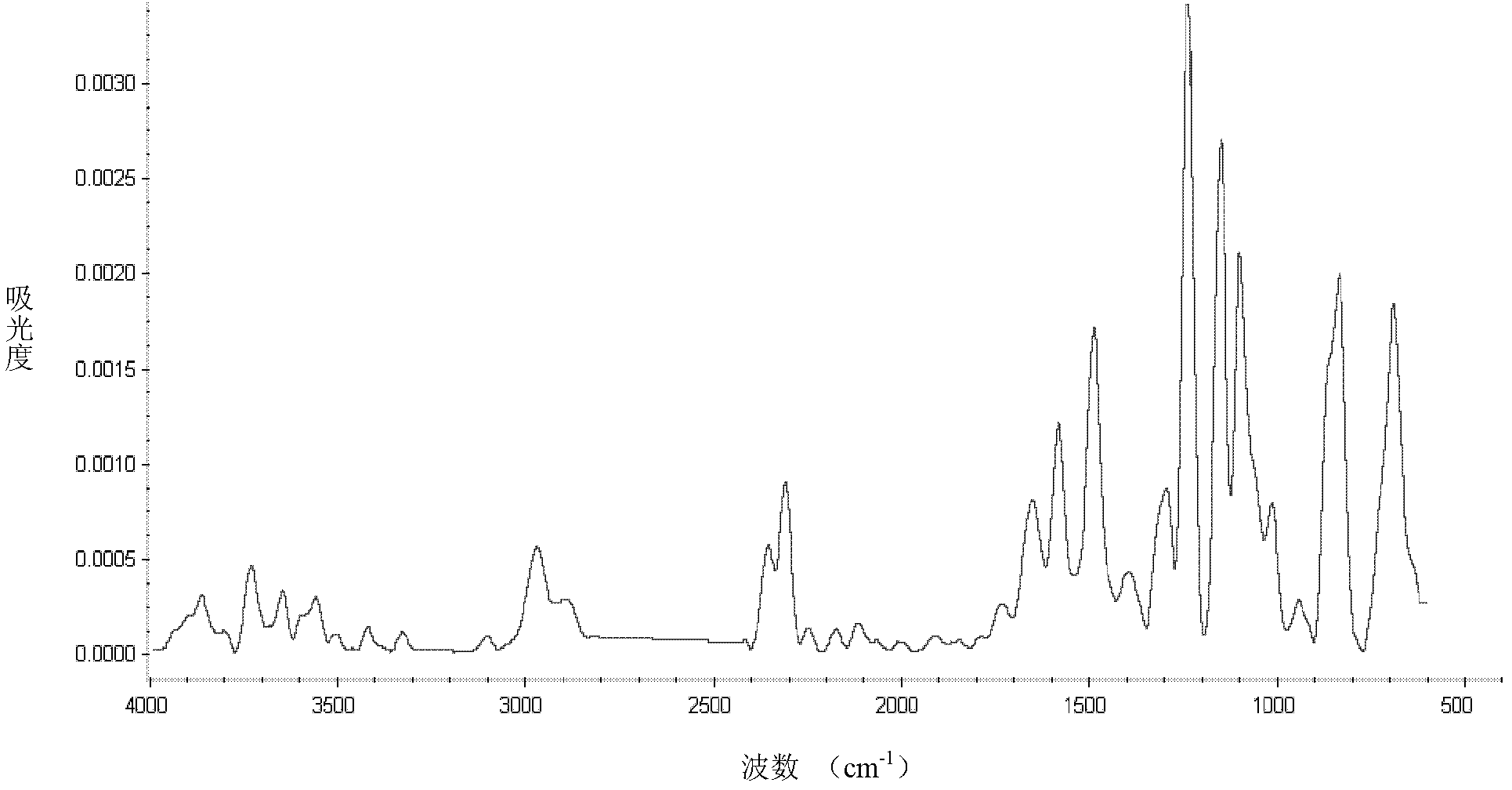

Nanofiltration separation membrane and preparation method thereof

ActiveCN102614789BWon't breakUnlimited sizeSemi-permeable membranesLayer thicknessBiological adhesion

The invention relates to a nanofiltration separation membrane which is prepared by dopa and / or dopamine through stem grafting and crosslinking after being stably auto-polymerized on the surface of a basement membrane. A poly-dopa or poly-dopamine composite layer which can be firmly combined with the basement membrane is obtained based on the principle of biological adhesion, and the composite layer is directly reacted with amino or sulfydryl in a long-chain molecule for crosslinking so as to prepare a series of nanofiltration separation membranes with different surface roughnesses, modified layer thicknesses, membrane pore diameters and hydrophilias. The nanofiltration separation membrane has the following advantages: (1) the composite strength between the composite layer and the basement membrane is large; (2) the seawater erosion resistant and hydrolytic resistance performances are strong so that the service life of the membrane is greatly prolonged; (3) the surface is smooth and uniform; (4) the surface hydrophilia is strong so that the permeability performance of the membrane can be improved; (5) the antibiosis is strong so that the pollution of the microbial membrane can be restrained; (6) the water flux is large and the separation efficiency of divalent ions is high; and (7) the process is simple, the condition is mild, and the realization is easy.

Owner:OCEAN UNIV OF CHINA

A long-lasting antibacterial material, a dental film and a long-lasting clear aligner

ActiveCN112998884BLong-acting antibacterialEnhance physical fitnessOthrodonticsCalcium carbidePolymer scienceGlycerol

Owner:JILIN UNIV

Water-resistant acrylate emulsion adhesive and preparation method thereof

PendingCN113698875ALow evaporation pointGood weather resistanceOrganic non-macromolecular adhesiveActive agentSurface-active agents

The invention relates to the technical field of coatings, in particular to a water-resistant acrylate emulsion adhesive and a preparation method thereof. The preparation method of the water-resistant acrylate emulsion adhesive comprises the following steps: mixing polystyrene methyl methacrylate, methyl acrylate, hydroxyethyl acrylate, hydroxyethyl methylacrylate, hexyl acrylate, 2-ethylhexyl acrylate and methyl methacrylate, stirring and dissolving for 60-80 minutes at the temperature of 45-50 DEG C; adding a defoaming agent, a thickening agent and a surfactant for continuous reaction, wherein the reaction temperature is 50-55 DEG C, and the reaction time is 25-35 minutes; and adding an emulsifying agent and deionized water for emulsifying at the emulsifying temperature of 55-60 DEG C for 25-35 minutes, and stopping heating to obtain the water-resistant acrylate emulsion adhesive. According to the preparation method, the reaction temperature and the reaction time in the preparation process can be effectively reduced, so that the energy consumption is effectively reduced, the production efficiency is improved, and the problems of high energy consumption and low production efficiency in the preparation process of the existing adhesive are solved.

Owner:佛山市鹏达家居有限公司

Weatherproof glass fiber reinforced PA66 common railway track gauge block material and preparation method thereof

Belonging to the technical field of macromolecular materials, the invention in particular relates to a weatherproof glass fiber reinforced PA66 common railway track gauge block material and a preparation method thereof. The weatherproof glass fiber reinforced PA66 common railway track gauge block material provided by the invention includes the following components by weight percentage: 39.0-52.8%of PA66 resin, 5.0-10.0% of PA6T resin, 0.6-1.0% of an antioxidant, 0.3-0.5% of a lubricant, 5.0-10.0% of inorganic filler, 1.0-2.0% of a toughening agent, 0.3-0.5% of a weathering agent, and 35-37% of glass fiber. The weatherproof glass fiber reinforced PA66 common railway track gauge block material provided by the invention has the characteristics of low cost and excellent comprehensive performance, and meets the high standard requirements of track gauge blocks. The weatherproof glass fiber reinforced PA66 common railway track gauge block material provided by the invention has low water absorption, good water resistance and excellent dimensional stability, and improves the product lifetime.

Owner:GUANGDONG SHUNDE SHUNYAN NEW MATERIALS

Preparation method of flame-retardant composite over-rust antirust paint

InactiveCN105949979ASimple preparation stepsUniform density and good fluidityFireproof paintsAnti-corrosive paintsPolymer scienceLacquer

The invention discloses a preparation method of a flame-retardant composite over-rust antirust paint, belonging to the technical field of antirust paint preparation. The preparation method comprises the following steps: drying and pulverizing tung seeds and Maofeng, mixing with lime water to regulate the pH value, standing, filtering, airing the filter residue, adding distilled water, grinding into slurry, heating to keep the temperature under ultrasonic actions, mixing with n-hexane, filtering to obtain the filtrate while keeping the temperature, stirring and mixing with hectorite, talcum powder and the like, adding zinc oxide, keeping the temperature, respectively adding polyurethane, iron oxide and barium sulfate, stirring and mixing, and keeping the pressure, thereby obtaining the flame-retardant composite over-rust antirust paint. The method has the advantage of simple preparation steps. The obtained product has the advantages of favorable adhesive force, favorable uniformity and compactness, favorable flowability, high shock strength (greater than 50kg.cm) and high hydrolysis resistance. After being immersed in water for 140-145 hours, the paint film does not shed or discolor, and does not generate the bubble phenomenon; the water resistance, alkali resistance, rust resistance and flame retardancy are effectively enhanced; and the paint film can resist the high temperature of 130 DEG C for 6080-7100 hours.

Owner:张静

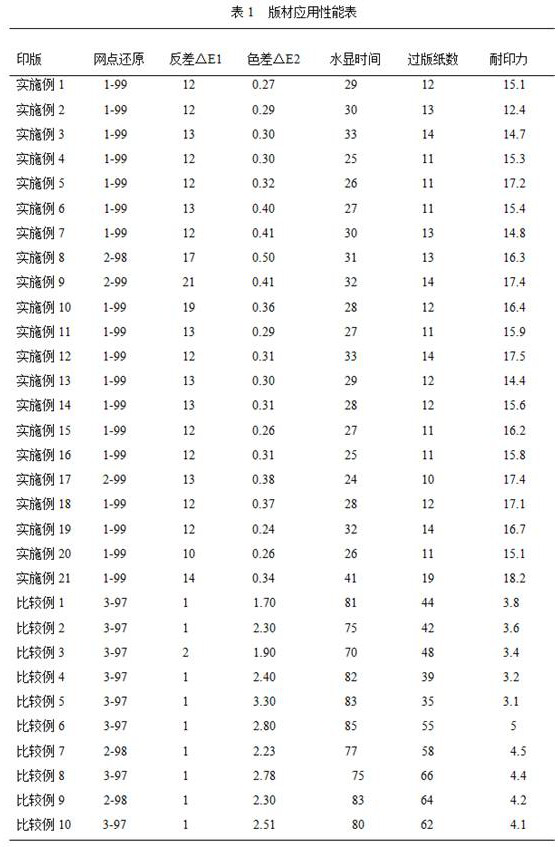

Cross-linking agent as well as preparation method and application thereof

PendingCN113831329AHigh activityStrong resistance to hydrolysisOrganic chemistryNon-macromolecular adhesive additivesPolymer scienceCross linker

The invention provides a cross-linking agent and a preparation method and application thereof, the cross-linking agent contains a urethane bond structure, and a coating polymer after a cross-linking reaction has wear resistance of polyurethane resin; the cross-linking agent has an epoxy bond with a four-membered ring structure, and is high in activity and high in hydrolysis resistance; the cross-linking agent contains a caprolactam group, and the caprolactam group endows the cross-linking agent with certain hydrophilicity, so that a coating which is not thermally cross-linked is easier to be removed by water, and green and environment-friendly development is realized; and the cross-linking agent has the characteristic of releasing active isocyanate groups after being heated, and can be subjected to a cross-linking reaction with active hydrogen in the polymer, such as hydrogen in hydroxyl.

Owner:LUCKY HUAGUANG GRAPHICS

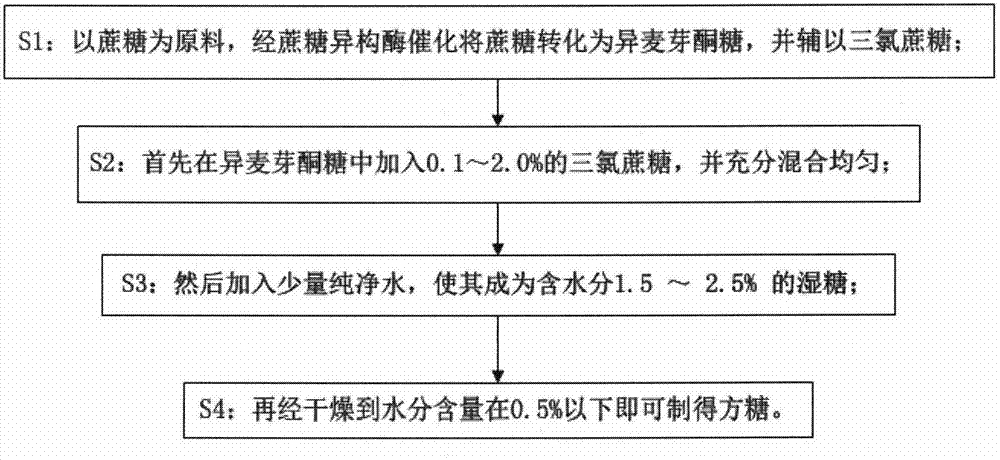

Production method of cube sugar

The invention discloses a production method of cube sugar. The method is characterized by comprising the following steps: with sucrose as a raw material, transforming the sucrose into isomaltulose under catalysis of sucrose isomerase, and assisting with sucralose; firstly, adding 0.1%-2.0% of sucralose to the isomaltulose, and fully mixing evenly; adding a little of purified water to form wet sugar with the moisture content of 1.5%-2.5%; drying until the moisture content is less than 0.5%, so as to prepare the cube sugar. The production method of the cube sugar disclosed by the invention does not cause increase of blood glucose and insulin, has low GI value and II value, has high tolerance, is free of any peculiar smell, and pure and natural in sweetness, has a good peculiar smell shielding effect, is very stable in structure, high in hydrolysis resistance and relatively high in chemical inertness, has non-hygroscopicity and a special brain strengthening function, and is an excellent bifidobacterium multiplication factor.

Owner:ZHENJIANG XINLONG BIOTECH

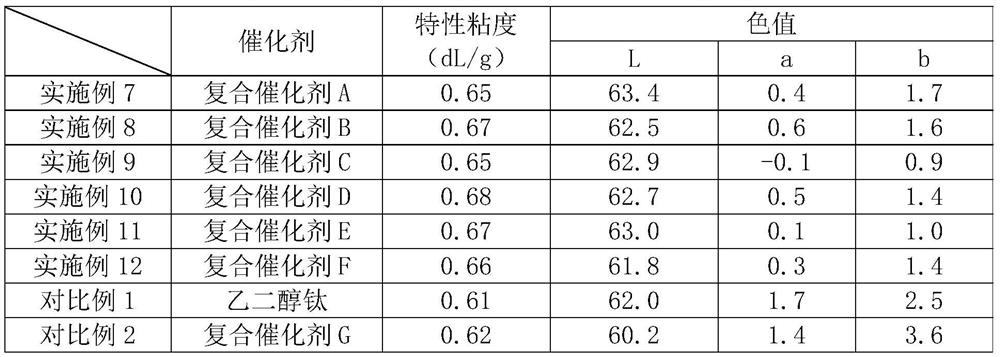

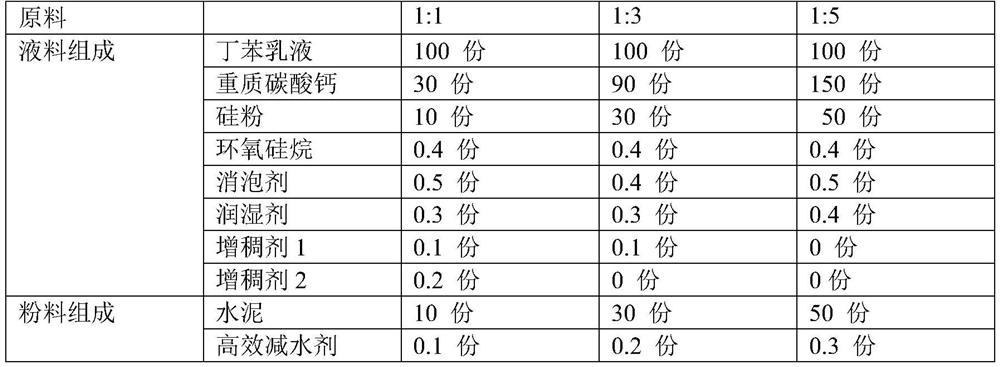

A kind of nano-loaded titanium series composite catalyst and its preparation method and application in polyester synthesis

The invention discloses a method for preparing a nano-loaded titanium-based composite catalyst. The titanium-based compound, tetraethyl orthosilicate and a hydrolyzing agent are dissolved in absolute ethanol, and stirred and reacted at room temperature for a certain period of time to obtain a mixed solution; Add one or more metal salts selected from chlorides, acetates or phosphates of Mg, Al, Mn, Co, Zn to the mixed solution, continue stirring, and heat up to volatilize excess solvent to obtain a gel; The gel is subjected to supercritical drying in the presence of a supercritical medium to obtain the final nano-loaded titanium-based composite catalyst. The catalyst prepared by the invention has strong hydrolysis resistance, can be stored for a long time, and has stable activity; has high catalytic activity and good stability, can effectively improve the efficiency of esterification and polycondensation reactions, has stable performance during the reaction process, and has stable product indicators; the catalyst is not Contains heavy metals, reducing the harm to the environment and human beings; the polyester prepared by using this catalyst has good hue, low yellow index and stable performance.

Owner:CHINA RESOURCES PACKAGING MATERIALS CO LTD

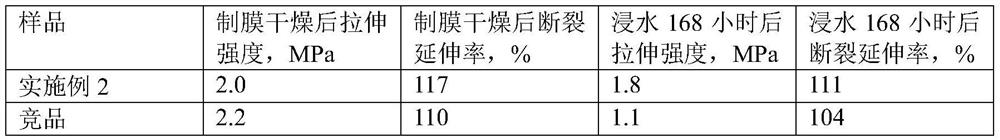

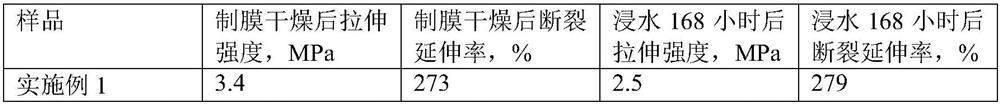

Special polymer cement coating containing inorganic powder in liquid material

InactiveCN113355000APrevent subsidenceAdjust curing timeConjugated diene hydrocarbon coatingsCarboxyl rubber coatingsInorganic materialsPolymer emulsion

The invention discloses a polymer cement coating containing inorganic powder in a liquid material. The coating is prepared from a liquid material component A and a powder material component B. The liquid material component A contains polymer emulsion, inorganic powder with chemical activity on the surface, silane or siloxane, and can contain or do not contain other inorganic filler. The powder material component B contains cement and other components. The mass ratio of the polymer solid to the inorganic material in the coating obtained by uniformly mixing and stirring the liquid material component A and the powder material component B according to a certain proportion is 1:1-1:5.

Owner:NANKAI UNIV

A kind of anti-icing pavement sealing layer material and preparation method thereof

ActiveCN110643282BImprove photocatalysisImprove stain resistanceAnti-corrosive paintsBituminous coatingsBitumen emulsionEthylic acid

The invention provides an anti-icing pavement sealing material and a preparation method thereof, which is made of the following raw materials: emulsified asphalt, filler, mixed solution and organic silicon polyacrylic resin; the filler is made of the following raw materials: zinc oxide, Zirconium and ferric chloride; the mixture is made from: acetylacetone, butyl acetate, cyclohexane. The present invention has undergone a large number of researches and tests, and the results show that applying the anti-icing emulsified asphalt seal material produced by the present invention to the laying of asphalt pavement can achieve the effect of melting snow and deicing, and can significantly improve the anti-icing performance and anti-icing performance of the road surface. slippery performance. In addition, this material can also form a dense waterproof layer on the asphalt pavement, which can effectively prevent water damage on the pavement, and can also play a role in sealing the cracks in the pavement, which has the effect of preventive maintenance.

Owner:CHANGAN UNIV

Nanocomposite polymer and temperature-resistant and salt-resistant profile control agent containing the same

ActiveCN111499793BStrong resistance to hydrolysisImprove stabilityDrilling compositionPolymer sciencePolymer chemistry

The present application discloses a nano-composite polymer and a temperature-resistant and salt-resistant profile control agent containing the nano-composite polymer, wherein the nano-composite polymer is mainly composed of an inorganic nanosol and a temperature-resistant and salt-resistant polymerized monomer. The composition of the temperature-resistant and salt-resistant profile control agent includes the nanocomposite polymer. The profile control agent of the present application has strong stability and temperature resistance and salt resistance by introducing a functional polymer formed by polymerizing a temperature-resistant and salt-resistant polymer monomer with an inorganic nanosol, so that the profile control agent has strong temperature resistance and salt resistance, and the temperature is above 150°C , and the anti-aging time reaches more than 100 days under the condition of salt concentration of 300,000 mg / L, and the strength of the profile control agent is improved by the inorganic nano-sol.

Owner:北京九恒质信能源技术有限公司

A method for making bricks from drilling waste

ActiveCN106587786BAvoid hidden dangersPrevent precipitationWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningBrickFreezing thawing

The invention discloses a well drilling waste brick making method. The well drilling waste brick making method comprises the following steps that dirt elimination and desiccation treatment is conducted on well drilling waste to be treated with a dirt elimination and desiccation agent; a construction binding material and a construction aggregate are added to the well drilling waste, to be treated, obtained after dirt elimination and desiccation treatment, even mixing is conducted, and then a brick making mixture is obtained; the brick making mixture is solidified and pressed to be green bricks with the density not smaller than 80% by means of a static pressure type brick making machine; strength maintenance is conducted on the green bricks; the green bricks obtained after strength maintenance is completed are sprinkled or coated with waterborne waterproof coating or dipped in the waterborne waterproof coating, so that an environment-friendly blocking layer with the thickness being 1-10 mm is formed on the surfaces of the green bricks obtained after strength maintenance is completed, and then the finished bricks are made. By the adoption of the well drilling waste brick making method, the well drilling waste can be processed into the brick making raw material which is loose and dry and meets relative environment-friendly standard at a low cost, the brick making raw material can be finally made into the finished bricks which are ideal in compressive strength, ageing resistance, hydrolysis resistance, freezing-thawing resistance, corrosion resistance and environmental protection stability, and therefore harmless and resourceful treatment of the well drilling waste is achieved.

Owner:北京泾渭智能环保有限公司

A kind of multifunctional metal surface treatment additive containing boride diethanolamine phosphate and preparation method thereof

ActiveCN105238499BImprove the lubrication effectImprove rust resistanceAdditivesPhosphorus organic compoundsWater basedViscous liquid

Owner:CHANGZHOU VOCATIONAL INST OF ENG

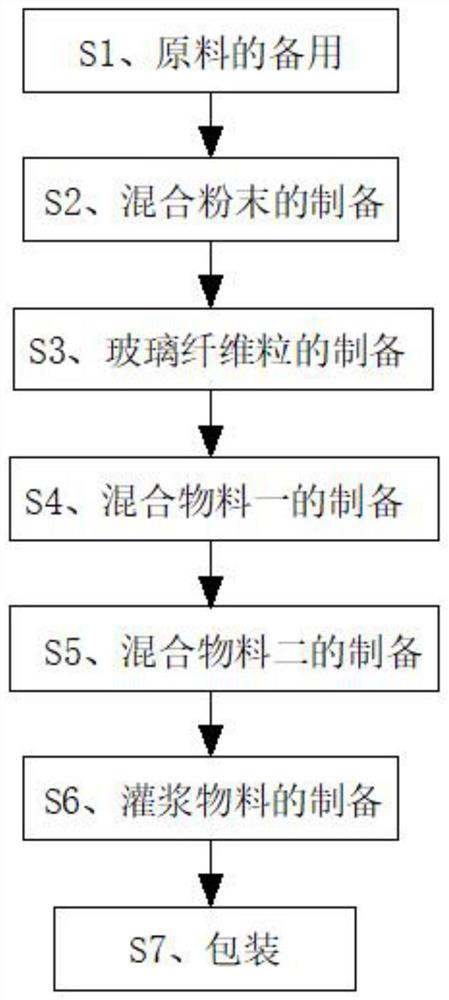

Anti-corrosion glass fiber bush and preparation method thereof

InactiveCN111943568AImprove performanceImprove toughnessBridge structural detailsBridge erection/assemblyEpoxyGlass fiber

The invention discloses an anti-corrosion glass fiber bush and a preparation method thereof, and relates to the technical field of glass fiber bushes. The anti-corrosion glass fiber bush comprises thefollowing components in parts by weight: 30-50 parts of polyhexamethylene terephthalamide resin, 40-50 parts of quartz sand, 20-40 parts of fly ash, 25-35 parts of barium sulfate powder, 10-20 partsof antioxidant, 8-10 parts of flexibilizer, 15-20 parts of weather-proof agent, 10-30 parts of glass fiber, 10-15 parts of glycerol tri(1,2- epoxy) propyl ether, 8-10 parts of defoaming agent and 30-40 parts of glass fiber bush. According to the glass fiber bush beneficial to corrosion prevention and the preparation method of the glass fiber bush, glass fibers with a certain particle size are added into a prepared grouting material, so that the prepared grouting material has excellent impact resistance; and by adding a polyhexamethylene terephthalamide resin, quartz sand, fly ash and barium sulfate powder, the prepared grouting material has good processability and mechanical strength, strong hydrolysis resistance and excellent comprehensive performance, so that when the grouting material is used on a glass fiber bush, the corrosion resistance and the stability of the grouting material are remarkably improved.

Owner:ZHENGZHOU SINO SINA BUILDING MATERIALS CO LTD

A kind of preparation method of bis(2,4-dicumylphenyl) pentaerythritol diphosphite

ActiveCN109232652BHigh selectivityReduce volatile lossGroup 5/15 element organic compoundsPhosphite esterPentaerithrityl

The embodiment of the invention discloses a preparation method of bis(2,4-dicumylphenyl)pentaerythritol diphosphite. Add phosphorus trichloride dropwise to pentaerythritol, amine hydrochloride catalyst, and aromatic hydrocarbon solvent at a reaction temperature of 5-10°C and slightly reduced pressure, then raise the temperature to 85-90°C in stages, and react under reduced pressure for 1 hour After stopping the decompression, fill with nitrogen protection to obtain the dichloropentaerythritol diphosphite reaction solution; add the above reaction solution dropwise to the aromatic hydrocarbon solvent of 2,4-dicumylphenol heated to 90-100°C, and depressurize Reflux reaction for 4 hours, feed nitrogen, add mixed amine to adjust the reaction system to be alkaline, cool down to room temperature, and filter to obtain bis(2,4-dicumylphenyl)pentaerythritol diphosphite. The invention finally obtains a high-performance product with high yield, narrow melting range, low acid value and excellent hydrolysis resistance through strict control of reaction conditions, such as temperature, pressure, time, catalyst, feeding sequence and post-treatment.

Owner:锦州英诺威科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com