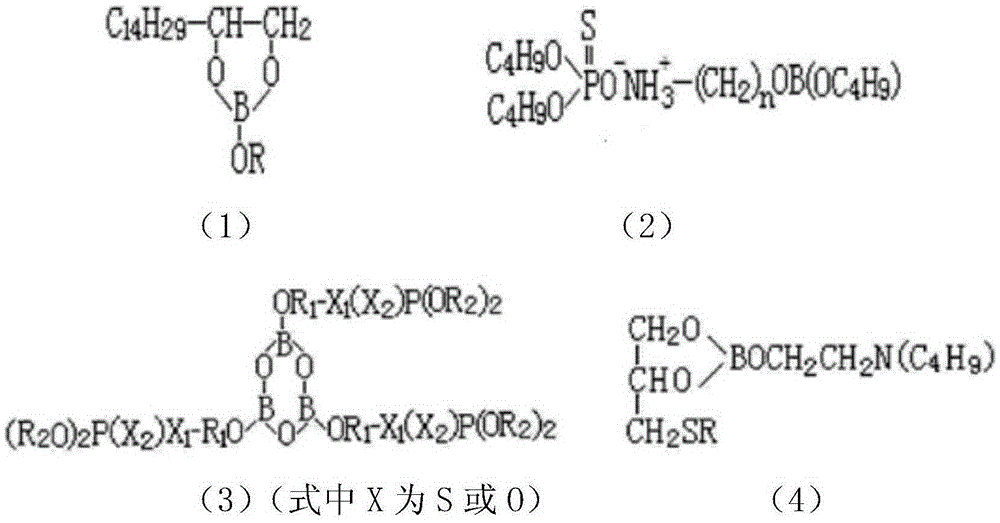

Milt-functional metal surface treatment additive containing boride diethanolamine phosphates and preparation method

A technology of ethanolamine phosphate and metal surface treatment, which is applied in additives, phosphorus organic compounds, petroleum industry, etc., can solve the problems of friction reduction, anti-wear performance reduction, poor hydrolysis resistance, and easy hydrolysis, etc., to improve extreme pressure Enhanced performance and service life, improved lubricity and rust resistance, strong hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

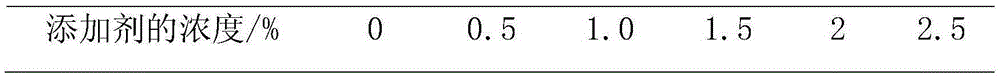

Examples

Embodiment 1

[0017] Add diethanolamine (21g, 0.2mol) into the reaction kettle, under stirring at room temperature, add the mixed solution of benzene and phosphorus pentoxide dropwise in batches (0.3mol phosphorus pentoxide is dissolved in 36ml of benzene), at 80°C React for 4 hours. After the reaction is over, add 3ml of water, hydrolyze at 80°C for 3 hours, distill off the solvent mixture of benzene and water under reduced pressure to obtain a brown-red viscous liquid. Add 50ml of water-carrying agent toluene to the brownish-red viscous liquid obtained above, add boric acid (12.4g, 0.2mol) under stirring, stir and react at about 110°C for 3h, toluene and the water generated by the reaction form an azeotropic liquid and pass through the water separator. Finally, the toluene is distilled off to obtain a multifunctional metal surface treatment additive containing borated diethanolamine phosphate. In the additive, the borated diethanolamine phosphate accounts for 53.2% of the total weight of ...

Embodiment 2

[0019] Add 30ml of decane solvent and 85% phosphoric acid (23.0g, 0.2mol) into the reaction kettle, under stirring at room temperature, add diethanolamine (10.5g, 0.1mol) dropwise in batches, after the addition is complete, heat up to 120°C and keep it warm for reaction After 5 hours of reaction, 4ml of water was added, hydrolyzed at 120°C for 1 hour, and the mixture of solvent and water was distilled off under reduced pressure to obtain a brown-red viscous liquid. Add 60ml of water-carrying agent xylene to the brown-red viscous liquid obtained above, add boric acid (10.5g, 0.1mol) under stirring, stir and react at about 130°C for 2h, xylene and the water generated by the reaction form an azeotropic liquid through water separation Finally, the xylene is distilled off to obtain the multifunctional metal surface treatment additive containing borated diethanolamine phosphate. In the additive, the borated diethanolamine phosphate accounts for 41.2% of the total weight of the addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com