Patents

Literature

47results about How to "Improve friction reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil-based liquid-state fracturing fluid thickening agent, and preparation method thereof

ActiveCN103911136ADoes not affect outputDoes not affect structureDrilling compositionLiquid stateFracturing fluid

The invention discloses an oil-based liquid-state fracturing fluid thickening agent, and preparation method thereof. Density of the oil-based liquid-state fracturing fluid thickening agent ranges from 0.9 to 1.2g / cm<3>; gelling time is 20s or less; and viscosity of 1.2% of the oil-based liquid-state fracturing fluid thickening agent after dissolving is 30mPa.s or more. The invention also discloses a preparation method of the oil-based liquid-state fracturing fluid thickening agent.

Owner:北京爱普聚合科技有限公司

Water-based lubricating nanometer metal antifriction and wear resistant intensifying agent

InactiveCN1552833AThe nature of the system is stableStrengthen anti-friction and anti-wear effectLubricant compositionDispersed mediaNanometre

A water based lubricating wearproof nanometer metal strengthening agent is metal nanometer granular sol, consisting of nanometer metal particles, dispersing medium, and assistants. The sol system is stable, no limitation to dilute and soluble into water and water-base lubricant. As additive for water-base lubricating, it forms nanometer metal transfering film with antifriction and antiwear functions on friction pair surface to improve performance of water-base lubricant. It achieves low cost, non-toxic and non-corrosive for mass production.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Whisker reinforced resin-base composite friction material and its prepn process

The present invention relates to whisker reinforced resin-base composite friction material and its preparation process. The whisker reinforced resin-base composite friction material is prepared with calcium carbonate whisker in 5-30 weight portions and polyether ether ketone in 70-95 weight portions; and the preparation process includes the following steps: drying calcium carbonate whisker and polyether ether ketone at 130-150 deg.c for 3-5 hr, mixing through high speed stirring in a stirrer for 8-10 min, melting the mixture in a hot die at 380-390 deg.c, pressurizing at 20 MPa to form, maintaining for 8-10 min, cooling inside the die to 100 deg.c, demolding, cooling to room temperature, and maintaining at 250 deg.c of 1 hr to obtain the product. The calcium carbonate whisker reinforced polyether ether ketone composite friction material has low friction coefficient, low wear rate, high bearing capacity, low cost and other advantages.

Owner:FUZHOU UNIVERSITY

System having DLC contacting faces, method for lubricating the system and lubricating oil for the system

ActiveCN1863895ASuperior Friction Torque Reduction RateGood friction torqueGear lubrication/coolingMachines/enginesBase oilComponents of crude oil

Owner:NIPPON OIL CO LTD +1

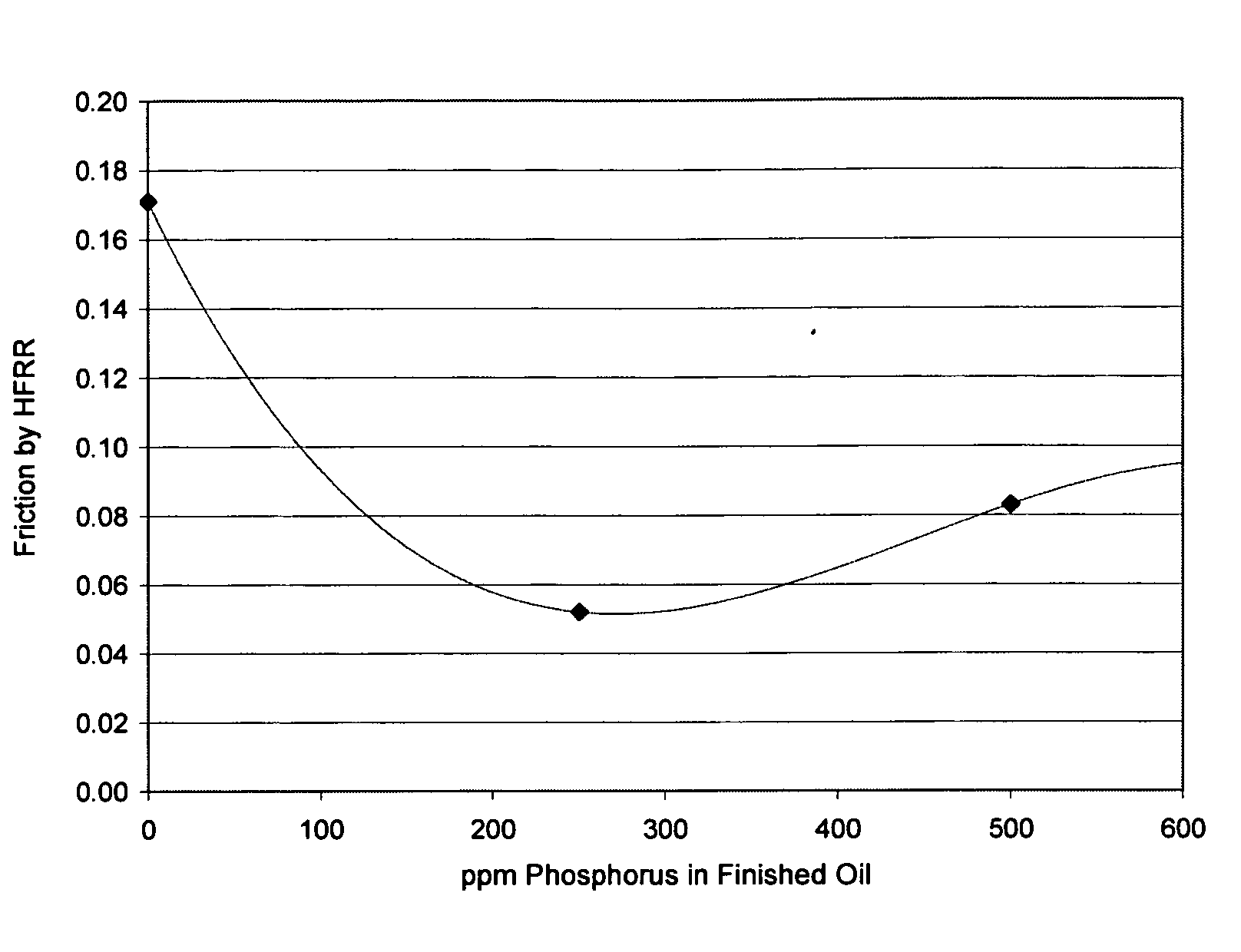

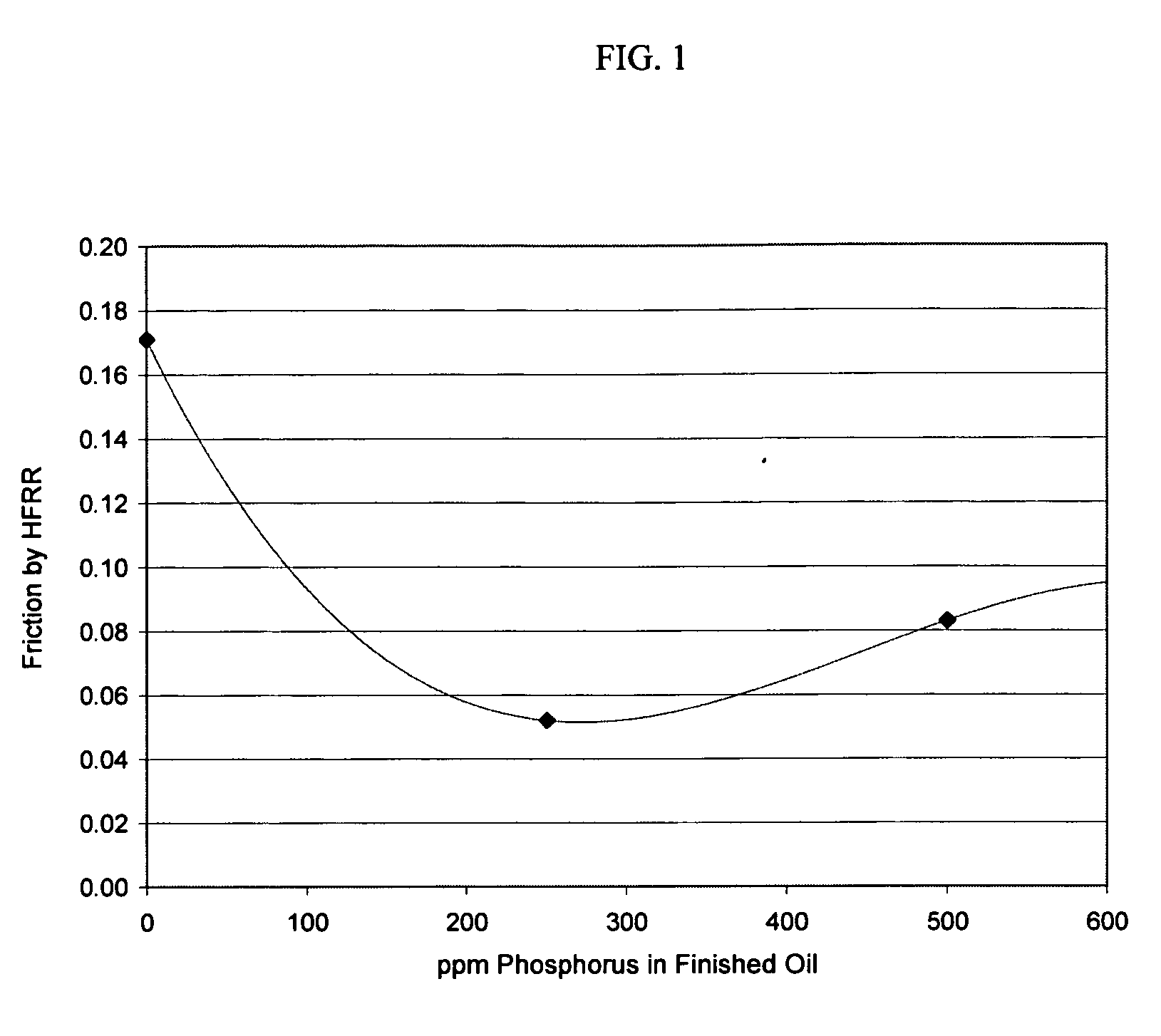

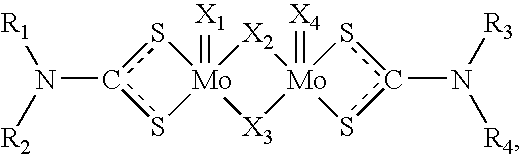

Lubricating oil compositions comprising a molybdenum compound and a zinc dialkyldithiophosphate

Provided herein are lubricating oil compositions comprising a major amount of a base oil, at least one oil-soluble molybdenum compound and a zinc dialkyldithiophosphate compound, wherein the molybdenum content derived from the molybdenum compound is at least 10 ppm based on the total weight of the lubricating oil composition and the phosphorus content derived from the zinc dialkyldithiophosphate compound is about 200 to 500 ppm based on the total weight of the lubricating oil composition. The lubricating oil composition can further comprise at least one additive. Methods of making and using the lubricating oil compositions are also described.

Owner:BOFFA ALEXANDER B +1

Preparation method of cast nylon composite material with high friction-reducing and anti-wear surface layer

InactiveCN103450469AHigh mechanical strengthIncreased mechanical toughnessHexamethylphosphoramideSurface layer

The invention discloses a preparation method of a cast nylon composite material with a high friction-reducing and anti-wear surface layer. The preparation method comprises the following steps of: preparing dispersive suspensoid by hexamethylphosphoramide, ultra-fine kaolin and toluene diisocynate in proportion; adding dispersive suspensoid and teflon micro powder to a caprolactam melt; initiating caprolactam anionic ring-opening polymerization through a sodium hydroxide-toluene diisocynate catalytic activating system; casting a reaction mass into a preheated and heat-preserved centrifugal rotating die under normal pressure; after the reacting and casting liquid is polymerized, solidified and formed, gradually cooling and demoulding, thus obtaining the cast nylon composite material with the high friction-reducing and anti-wear surface layer. The prepared cast nylon composite material has the characteristics that an inner matrix and an outer surface layer are different in structure and performance, so that the requirements on manufacturing and using various pulleys, idler wheels, rope wheels and guide wheels for a transportation mechanism, a hoisting device and mine equipment can be met.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

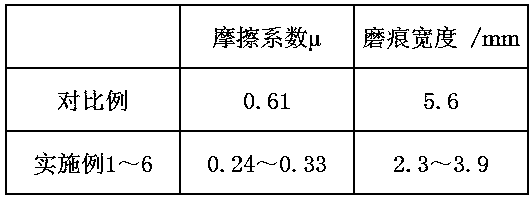

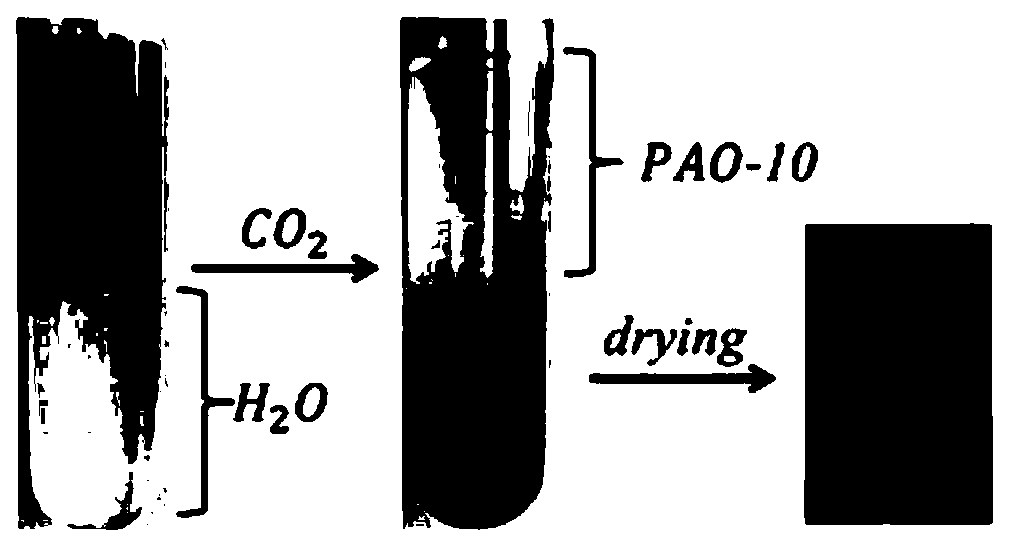

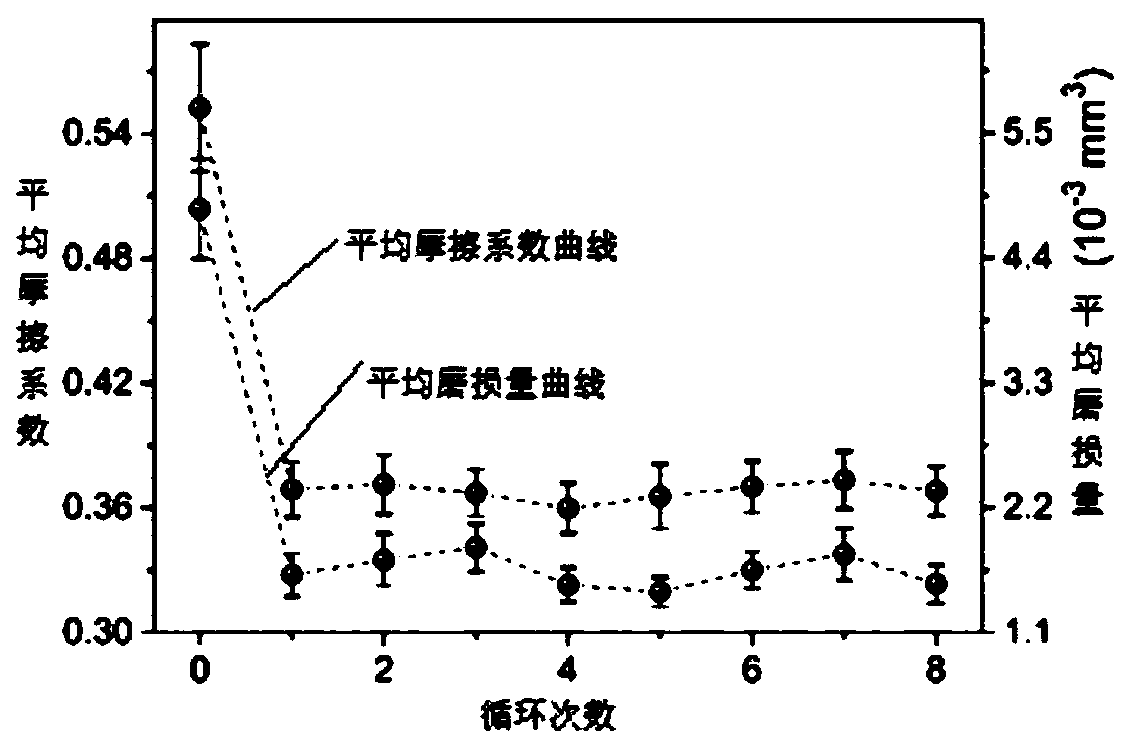

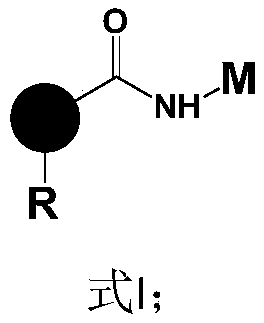

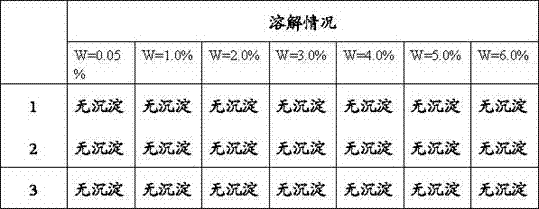

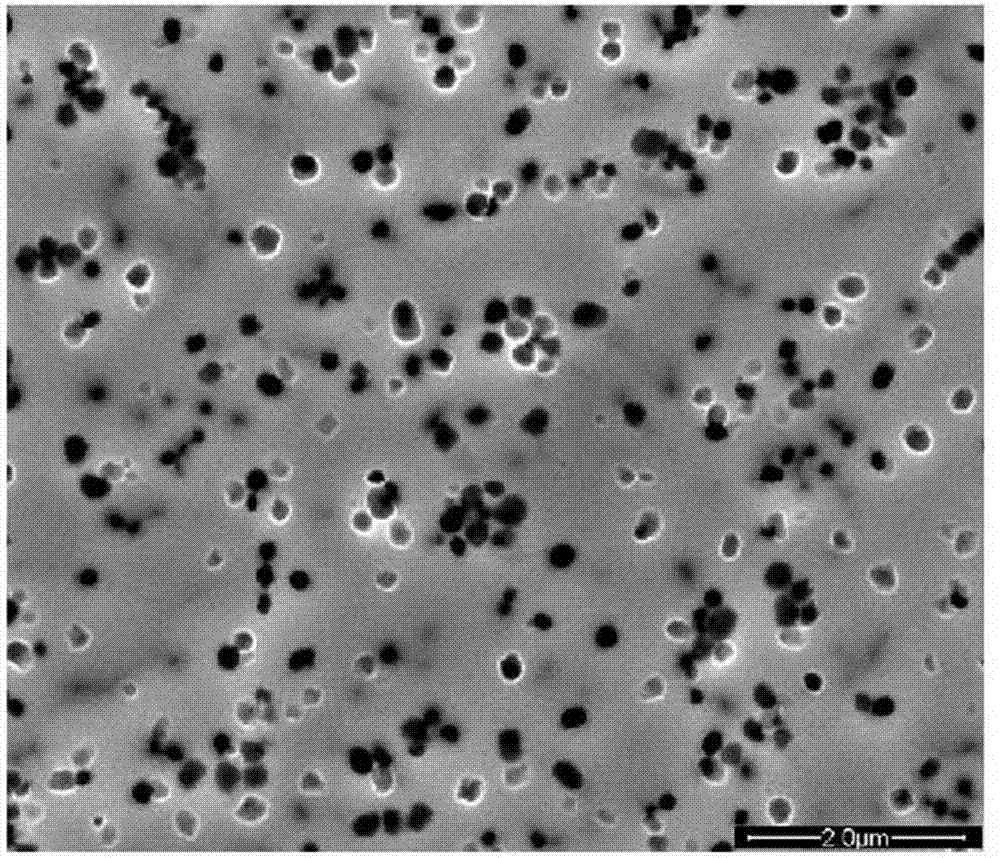

Recyclable carbon quantum dot nano lubricating oil additive and preparation method thereof

ActiveCN111471507ASmall particle sizeUniform size distributionAdditivesChemical recyclingOil additiveCarbon chain

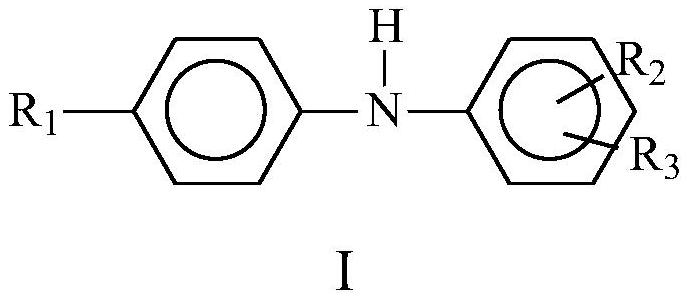

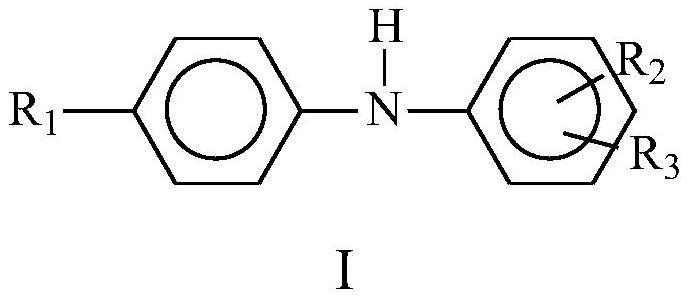

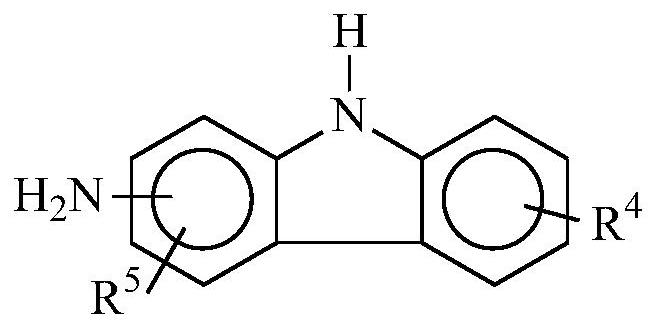

The invention relates to a recyclable carbon quantum dot nano lubricating oil additive and a preparation method thereof, and belongs to the technical field of lubricating materials. The structure of the recyclable carbon quantum dot nano lubricating oil additive is shown as a formula I, wherein a big black spot is used for representing carbon quantum dots, R is an oxygen-containing group, and M isan amino-containing carbon chain. The carbon quantum dot nano lubricating oil additive has unique CO2 responsiveness, and by means of the CO2 responsiveness, recycling and cyclic utilization of the carbon quantum dot nano lubricating oil additive in used PAO lubricating oil can be achieved. After multiple times of recycling, the tribological properties are not obviously weakened, so that the additive has a good application prospect. The preparation and functionalization are completed in one step, the prepared carbon quantum dots with CO2 responsiveness are small in particle size and uniform in size distribution, and the preparation process is simple, easy to operate and beneficial to large-scale production.

Owner:PANZHIHUA UNIV

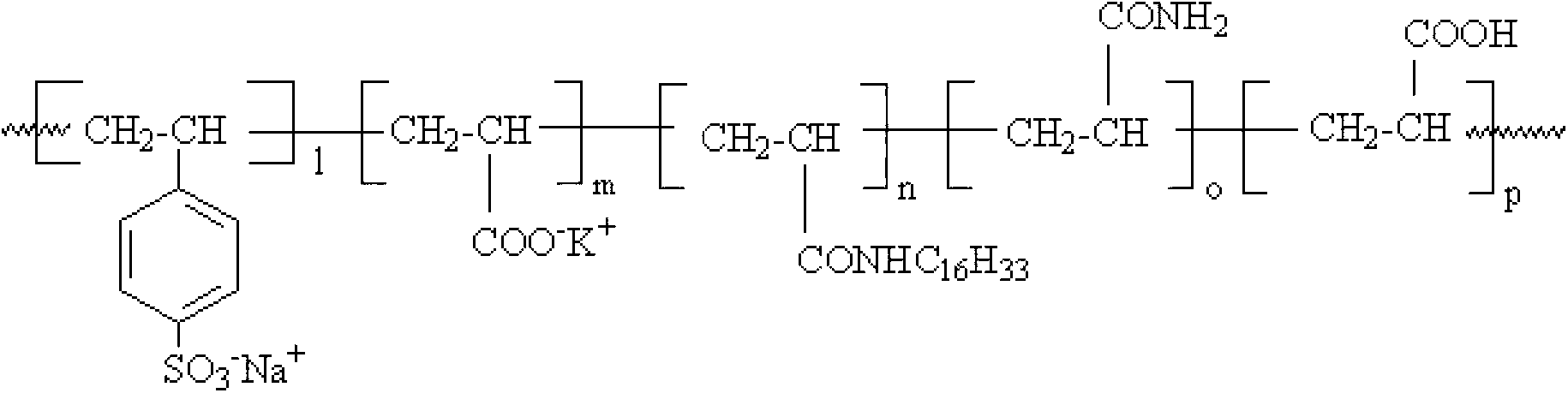

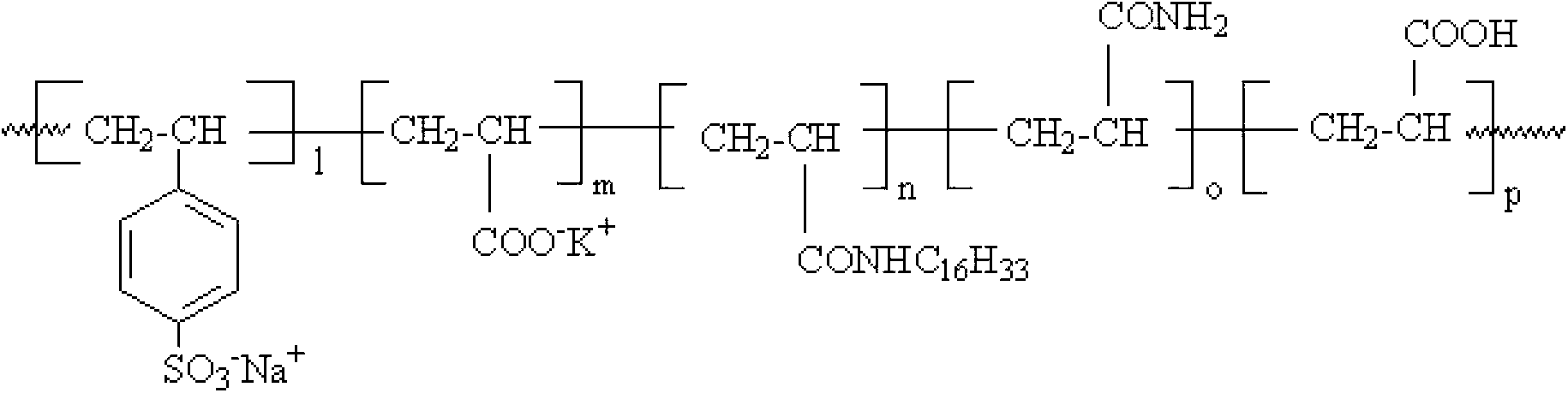

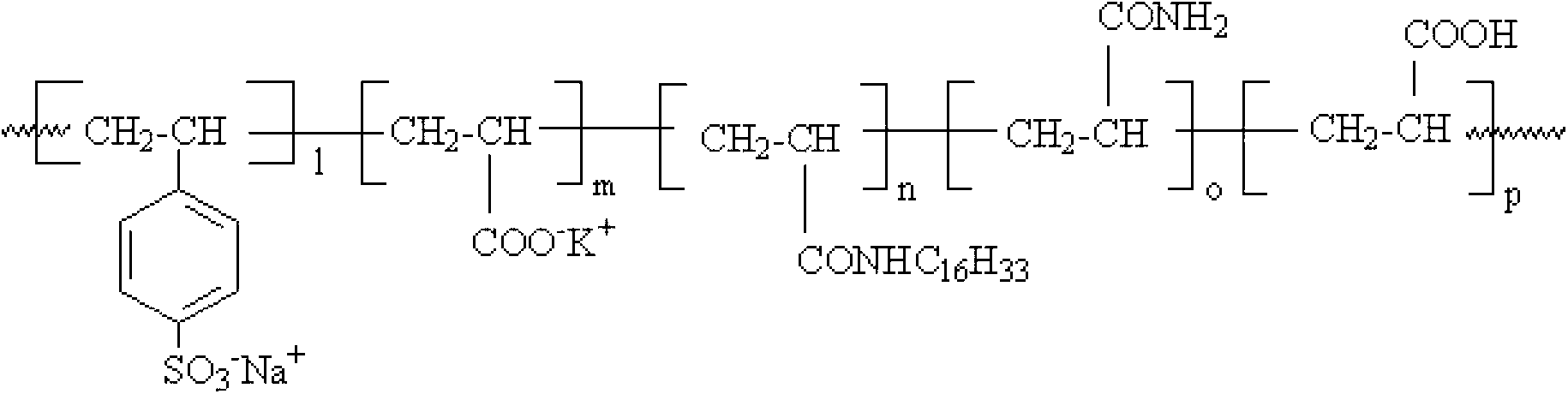

Liquefied polymer fracturing liquid thickener and preparation method thereof

ActiveCN103224778AImprove performanceExcellent and stable performanceDrilling compositionPolymer scienceFracturing fluid

The invention discloses a liquefied polymer fracturing liquid thickener, which has the following evaluation indexes: the density is 1.0-1.3g / cm<3>; the gelling time is less than or equal to 15s; and the viscosity of 1.0% the dissolved liquefied polymer fracturing liquid thickener is greater than or equal to 30mPa.s. The invention also discloses a method for preparing the liquefied polymer fracturing liquid thickener.

Owner:北京爱普聚合科技有限公司

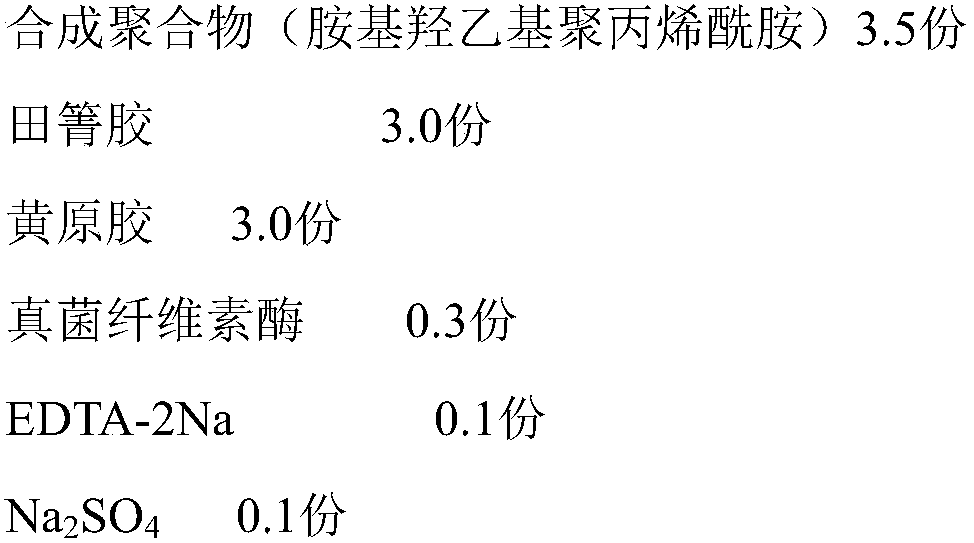

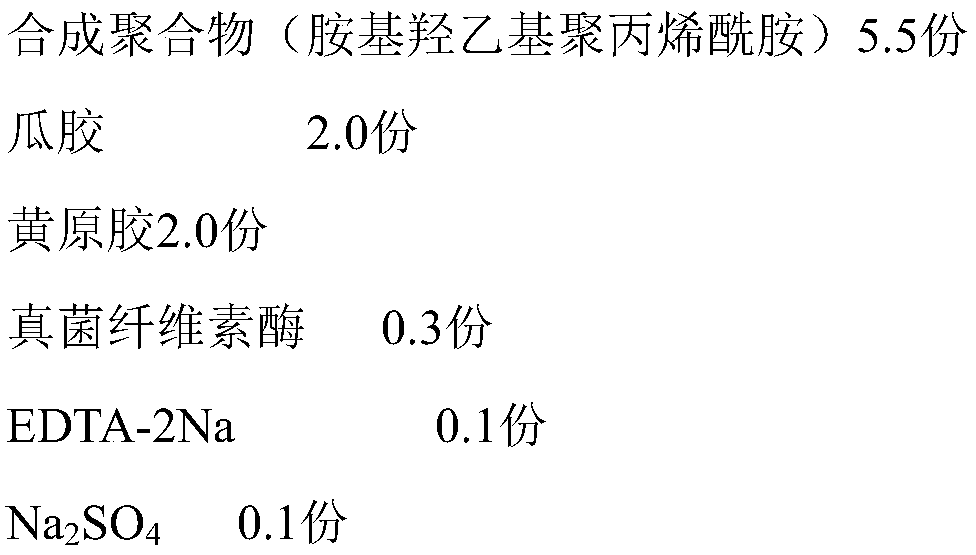

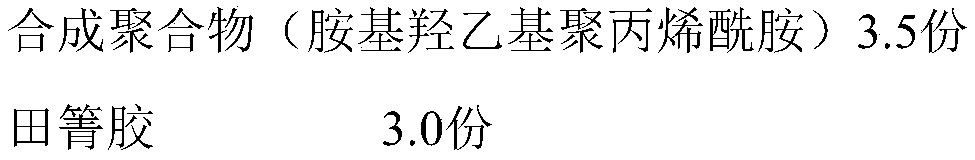

Clean and environment-friendly type compound thickening agent for fracturing fluid and preparation method

InactiveCN108641701AStrong thickeningHigh temperature resistanceOther chemical processesDrilling compositionCelluloseAdditive ingredient

The invention provides a clean and environment-friendly type compound thickening agent for fracturing fluid and a preparation method. The compound thickening agent is prepared from amido hydroxyethylpolyacrylamide, vegetable gelatin, xanthan gum, fungus cellulose enzyme, ethylene diamine tetraacetic acid disodium and sodium sulfate. The clean and environment-friendly type compound thickening agent for the fracturing fluid prepared in the invention has relatively strong thickening, temperature-resistant and anti-shear ability, is good in suspended sand-carrying ability and friction-reducing performance, easy for gel breaking and flowback, high in fracturing success rate and easier to degrade after flowing back to the ground, and does not cause pollution to the environment; meanwhile, the compound thickening agent is fewer in system ingredients and configuration links and easy for controlling quality, and can be compounded when needing to be used, the prepared compound thickening agentfor the fracturing fluid is stable in performance, can maintain a liquid state with a certain viscosity for a long time, and does not generate stratification or sediment; therefore, the application fields of the compound thickening agent are expanded, and the compound thickening agent has a good industrialized application prospect and practical application value.

Owner:禹王投资控股集团有限公司 +1

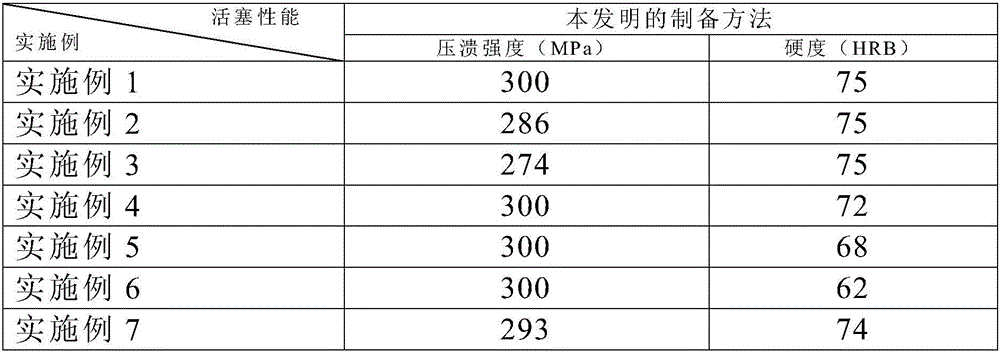

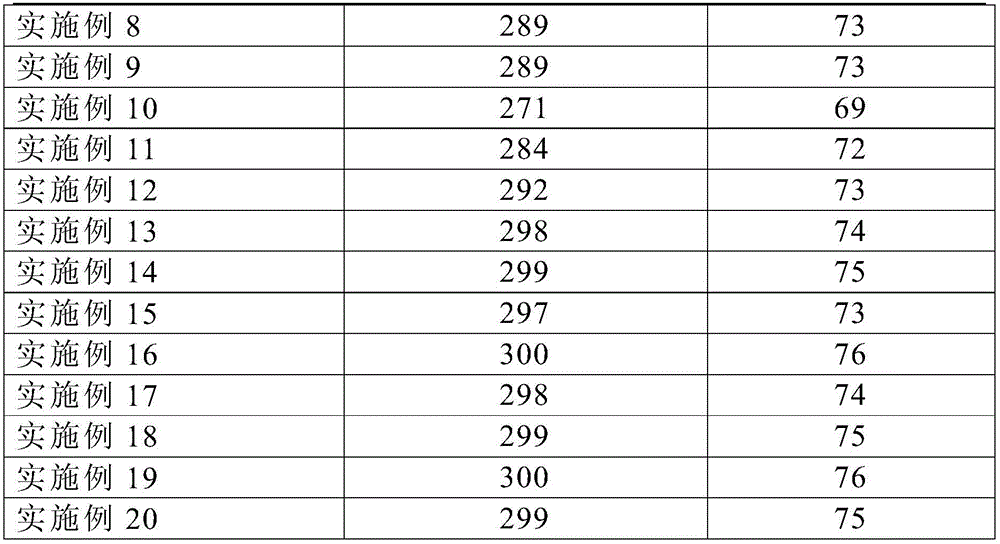

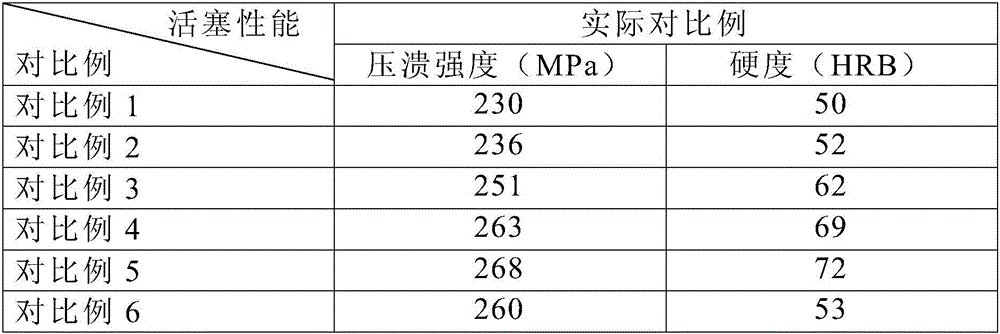

Damper piston and manufacturing process thereof

InactiveCN107520451AIncrease coefficient of frictionIncreased crush strengthSpringsShock absorbersBoron carbideCarbon dust

The invention discloses a damper piston and a manufacturing process thereof, and belongs to the technical field of powder metallurgy. The damper piston comprises raw materials including, by percentage composition, 36%-45% of tin bronze powder, 0.5%-1.3% of carbon dust, 0.5%-1.0% of manganese sulfide, 0.2%-0.3% of ceric oxide, 3%-6% of boron carbide and the balance iron powder. According to the raw material ratio, the proportion of the tin bronze powder to the proportion of the carbon dust approximates 1:1, iron-copper-base powder metallurgy is achieved, and the beneficial effects of iron-base powder metallurgy and copper-base powder metallurgy are achieved; and meanwhile, boron carbide is added, the product friction coefficient is increased, ceric oxide refined grains are added, the conquassation strength, hardness, antifriction performance and abrasive resistance of the materials are improved. Finally, a finished product is obtained through one-time sinter molding and surface treatment.

Owner:NINGBO RUIFENG AUTO PARTS

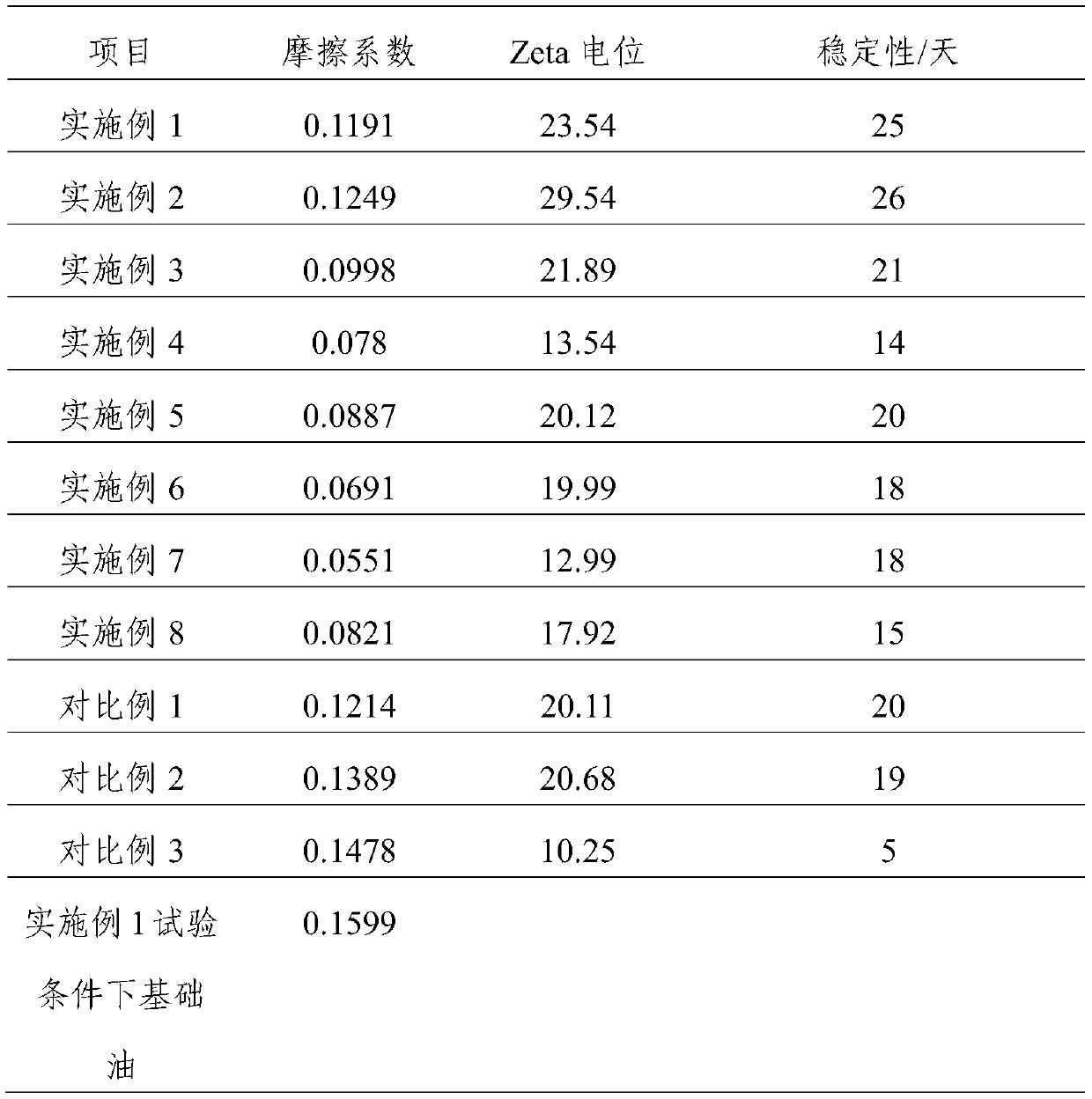

Graphene lubricating oil and preparation method thereof

The embodiments of the invention disclose graphene lubricating oil. The graphene lubricating oil is formed by mixing an ionic liquid, graphene and base oil, wherein a mass ratio of the ionic liquid tothe base oil is 0.0001%-1%; and a mass ratio of the graphene to the base oil is 0.001%-1%. According to the lubricating oil provided by the embodiments of the invention, after the graphene and the ionic liquid are added, the graphene is uniformly and firmly adhered to the surface of a metal to form a film having excellent lubrication and protective properties, and the graphene has very strong adsorption effects on the ionic liquid, so that the antifriction and anti-wear performance of the lubricating oil can be significantly improved, and the bearing capacity of lubricating oil can be improved.

Owner:SHENYANG JIANZHU UNIVERSITY

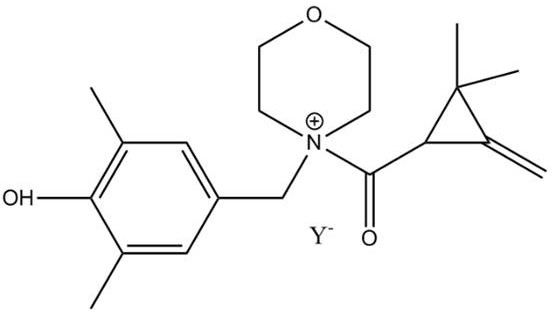

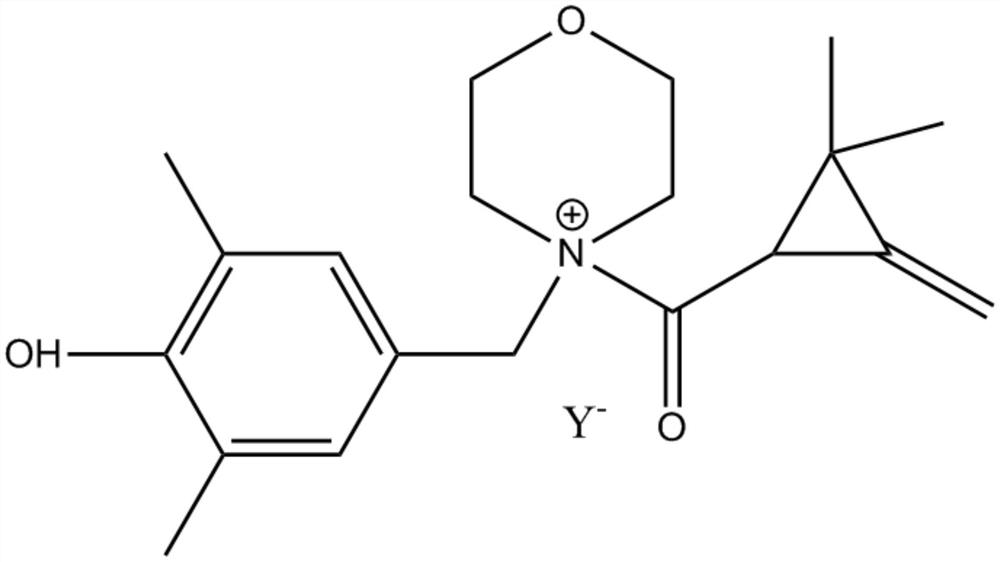

Multifunctional lubricating oil additive and application thereof

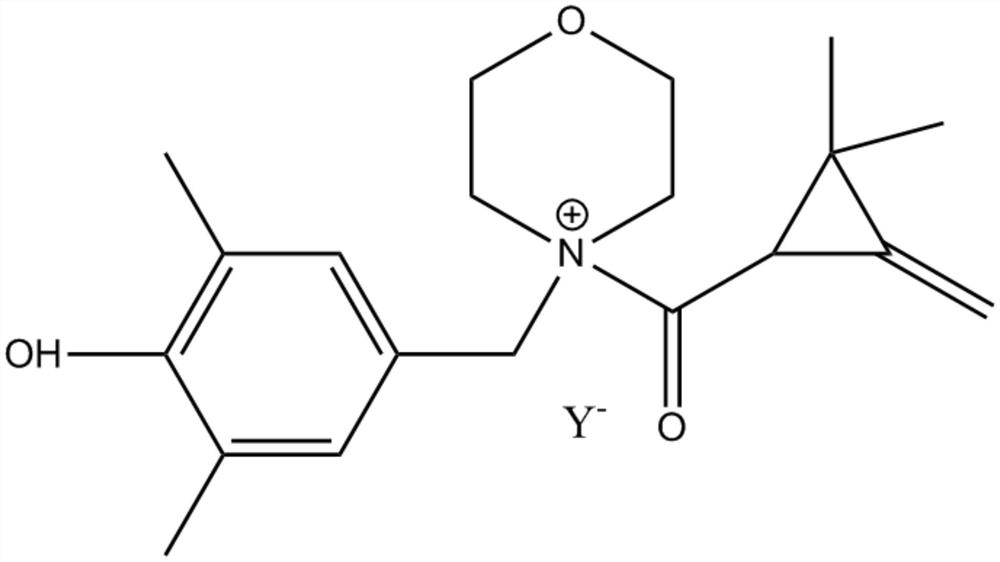

ActiveCN110423639AImprove anti-wear performanceIntermolecular tightnessOrganic chemistryAdditivesMorpholineOil additive

The invention discloses a multifunctional lubricating oil additive. The multifunctional lubricating oil additive is prepared from the following raw materials in part by weight: 50-100 parts of morpholine ionic liquid, 0.8-7.5 parts of a clearing agent, 1.2-2.6 parts of an antirust agent, 7-16 parts of an antioxidant and 0.2-3.8 parts of a foam inhibitor. The multifunctional lubricating oil additive is applied to a steel / steel or steel / aluminum friction pair, thus the antifriction and abrasion-resistant performance of the lubricating oil additive in the friction pair is significantly improved,meanwhile, the extreme pressure bearing performance of the lubricating oil additive is improved, and the friction pair is small in loss and long in service life.

Owner:广东顺德菲尔特润滑科技有限公司

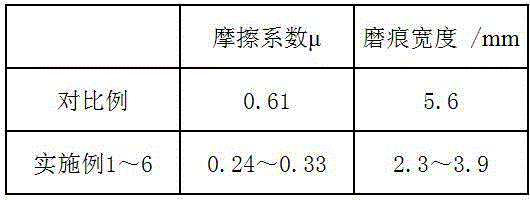

Milt-functional metal surface treatment additive containing boride diethanolamine phosphates and preparation method

ActiveCN105238499AImprove the lubrication effectImprove rust resistanceAdditivesPhosphorus organic compoundsWater basedViscous liquid

The invention relates to a method for preparing a milt-functional metal surface treatment additive containing boride diethanolamine phosphates, which comprises steps: diethanolamine and phosphate esterification agents are added into a reaction kettle to react, are hydrolysed and concentrated to obtain a viscous liquid, a water-carrying agent is added into the viscous liquid, a boriding agent is added to react by stirring, and the water-carrying agent is boiled up by decompressing to obtain a target product. The milt-functional metal surface treatment additive which is prepared through the method comprises 30-60% boride diethanolamine phosphates and 20-60% diethanolamine double phosphate esters. The method for preparing the milt-functional metal surface treatment additive containing the boride diethanolamine phosphates has the beneficial effects that the milt-functional metal surface treatment additive containing the boride diethanolamine phosphates has excellent antifriction, antioxidant, rust-proof and lubrication performance and the like because phosphates which are used as main components in the milt-functional metal surface treatment additive containing the boride diethanolamine phosphates contain active elements such as N, P and B and the like, is strong in anti-hydrolytic property, can improve lubricity and anti-rust property of a water-base metal working fluid by being added into the water-base metal working fluid, also can improve extreme pressure property and prolongs service life of the water-base metal working fluid simultaneously, and is an excellent multi-functional water-soluble additive.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Preparation method of lubricating oil nano detergent

The invention discloses a preparation method of a lubricating oil nano detergent and belongs to the technical field of preparation of lubricating oil additives. The preparation method comprises the following steps: putting nano copper powder into a fluidized bed reactor; after introducing nitrogen gas loaded with trimethyl aluminum, introducing water-containing nitrogen gas; discharging and drying to obtain cladded nano copper powder; mixing the cladded nano copper powder with a dopamine solution; then introducing air and filtering to obtain modified cladded nano copper powder; adding calcium oxide, an accelerant A, magnesium oxide, an accelerant B, a sodium silicate solution and the like and stirring at constant temperature to react; after keeping heat, naturally cooling to room temperature; discharging to obtain a mixture; mixing the mixture with petroleum ether and diluting; centrifuging and removing residues; carrying out reduced pressure distillation to obtain the lubricating oil nano detergent. The preparation method of the lubricating oil nano detergent, disclosed by the invention, has the beneficial effects that the lubricating oil nano detergent disclosed by the invention has a relatively good dispersion performance and an extreme-pressure anti-wearing performance; in a utilization process, corrosion, caused by acidic substances in a lubricating oil system, on mechanical parts can be effectively avoided.

Owner:常州蓝旗亚纺织品有限公司

Low-density environment-friendly drilling fluid capable of being repeatedly used for many times

The invention relates to a low-density environment-friendly drilling fluid capable of being repeatedly used for many times, and the low-density environment-friendly drilling fluid separately used foran upper well section and a lower well section according to the well vertical depth. The low-density environment-friendly drilling fluid is characterized by comprising a part used for the upper well section and a part used for the lower well section, wherein the part used for the upper well section is prepared from the following components by mass percent: 0.3-0.6% of a high-polymer mud shale inhibitor, 0.2-0.5% of a flocculating agent, 2-8% of a micromolecule mud shale inhibitor, 0.2-0.5% of a filtrate reducer and the balance of clear water. The part used for the lower well section is prepared from the following components by mass percent: 8-20% of a micromolecule mud shale inhibitor, 0.5-2% of filtrate reducer, 1-3% of a mud shale blocking agent, 0.1-0.3% of an adhesive improver, 0.1% ofNaOH and the balance of clear water. Through the proportion, pollution resistance of the drilling fluid is relatively strong, so that the drilling fluid has relatively good environment-friendliness,is easy to degrade, has low viscosity and high shear, reduces equipment power loss under the same viscosity, improves sand carrying ability, is good in reducing friction resistance, is low in density,and weakens mechanical anti-collapse needs by strengthening chemical anti-collapse ability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

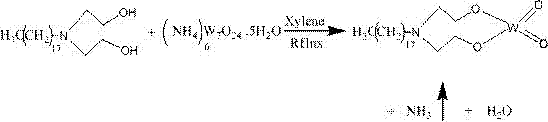

Environment-friendly antifriction and antioxidant non-sulfur phosphorus organic tungsten additive and lubricating oil containing same

InactiveCN107384513AGood oil solubilityGood dispersionAdditivesGroup 6/16 organic compounds without C-metal linkagesLinear alkylbenzeneSuccinimide

The invention belongs to the field of diesel engines, and particularly relates to an environment-friendly antifriction and antioxidant non-sulfur phosphorus organic tungsten additive and lubricating oil containing the same. The lubricating oil is prepared by dropwise adding an aqueous ammonium tungstate pentahydrate solution into a methylbenzene solution of dihydroxy octadecylamine, heating to 90-100 DEG C, reacting for two hours, performing reduced pressure distillation, drying to obtain N-octadecyliminodiethanol tungstic diester, adding the N-octadecyliminodiethanol tungstic diester into mineral base oil and alkyl naphthalene base oil, and mixing with polymethacrylate, a non-dispersive ethylene-propylene copolymer, synthetic low-chlorine long-chain linear alkylbenzene magnesium sulfonate, overbased sulfurized calcium alkylphenol, high-molecular weight polyisobutenyl succinimide and zinc bioctyl alkyl thiophosphate; the lubricating oil is free of sulfur and phosphorus, and has environment-friendly, energy-saving, antifriction, antioxidant and precipitate-free excellent performance.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

Preparation method of high-strength and high-conductivity anti-friction copper contact wire

ActiveCN110331313ASimple processShort processTransportation and packagingConductive materialPowder metallurgyManganese sulfide

The invention discloses a preparation method of high-strength and high-conductivity anti-friction copper contact wire, and belongs to the technical field of powder metallurgy copper-based materials. According to the preparation method, copper-manganese alloy powder is used as a raw material, vulcanization treatment is performed in a medium containing a sulfur source, in-situ generation of manganese sulfide nano particles is achieved inside the copper-manganese alloy powder through high-temperature diffusion, and the manganese sulfide dispersion strengthened copper contact wire is obtained through cold isostatic pressing and sintering-hot pressing combining densification processes. The preparation method has the advantages that the preparation technology is simple, the process is short, theenergy consumption is low, the raw material is rich and easy to obtain, the cost is low, and large-scale production is easy to achieve; and the prepared contact wire has the room temperature tensilestrength greater than 450 MPa, the conductivity greater than 75% IACS and the friction coefficient less than 0.2.

Owner:UNIV OF SCI & TECH BEIJING

Composite electroplating solution capable of prolonging service life of scaffolds

InactiveCN106048694AImprove wear resistanceImprove dispersionElectrolytic coatingsCitrate sodiumAmmonium sulfate

The invention discloses a composite electroplating solution capable of prolonging the service life of scaffolds. The composite electroplating solution is composed of, by weight, 1-3 parts of N-methyl pyrrolidone, 6.8-9 parts of aniline, 0.8-1 part of sodium citrate, 0.1-0.2 part of ammonium persulfate, 50-60 parts of boric acid, 220-250 parts of nickel sulfate, 40-50 parts of nickel chloride, 0.2-0.3 part of lauryl sodium sulfate, 50-60 parts of polytetrafluoroethylene emulsion, 3-4 parts of cationic surface active agents FC134, 2.6-3 parts of cerium oxide, 3-4 parts of nano-scaled calcium fluoride, 0.1-0.2 part of rare earth coupling agents, 2.2-2.8 parts of bentonite, an appropriate amount of ethyl alcohol and an appropriate amount of deionized water. The electroplating solution can be recycled many times, waste of the electroplating solution, environmental pollution and treatment cost are reduced, and the electroplating layers are good in mechanical property, high in hardness, long in service life and high in firmness. Thus, the composite electroplating solution is worthy of popularization.

Owner:王世群

Preparation method of Hastelloy surface coating

ActiveCN102787314AImprove the disadvantages that it is not easy to direct chemical composite platingImprove bindingSpecial surfacesSuperimposed coating processPre treatmentElectroplating

The present invention relates to a preparation method of a Hastelloy surface coating. The method comprises the following steps: providing a piece of Hastelloy, and carrying out surface pretreatment on the piece of Hastelloy; providing a first plating solution and a nickel plate, using the piece of Hastelloy as a cathode and the nickel plate as an anode, placing the piece of Hastelloy and the nickel plate in the first plating solution for electroplating for a while, so as to form a pure nickel layer on the surface of the piece of Hastelloy; providing a composite plating solution containing a nickel phosphor plating solution and nano PTFE particles; and placing the piece of Hastelloy with pure nickel layer on the surface, heating to 85-91 DEG C, and taking out the piece of Hastelloy after a period of time. The method provided by the invention is applicable to surface treatment of Hastelloy of a variety of shapes and models, and has wide application scope.

Owner:TSINGHUA UNIV

Ceramic bearing

InactiveCN102943808AImprove friction reductionImprove heat resistanceBearing componentsSliding contact bearingsHeat resistanceNeutral line

A ceramic bearing comprises an outer ring and an inner ring. The inner ring is nested in the outer ring; an inner hole of the outer ring is an adverse spherical surface; an outer side of the inner ring is a conical surface with a dip angle of 5-10 DEG; and a central line of the inner hole of the outer ring contacts with and the neutral line of the outer side of the inner ring. The invention provides a ceramic bearing with good friction reducing property, good heat resistance and reduced cost.

Owner:CIXI NEW MEIPEILIN PRECISION BEARING

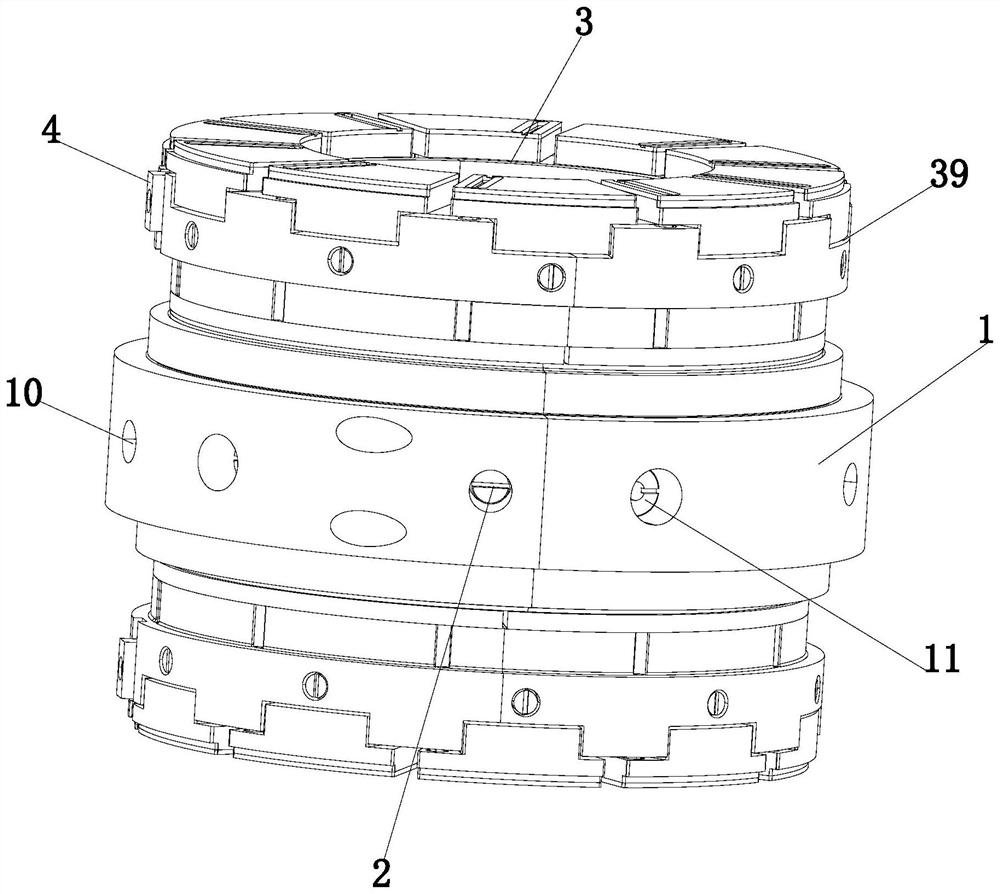

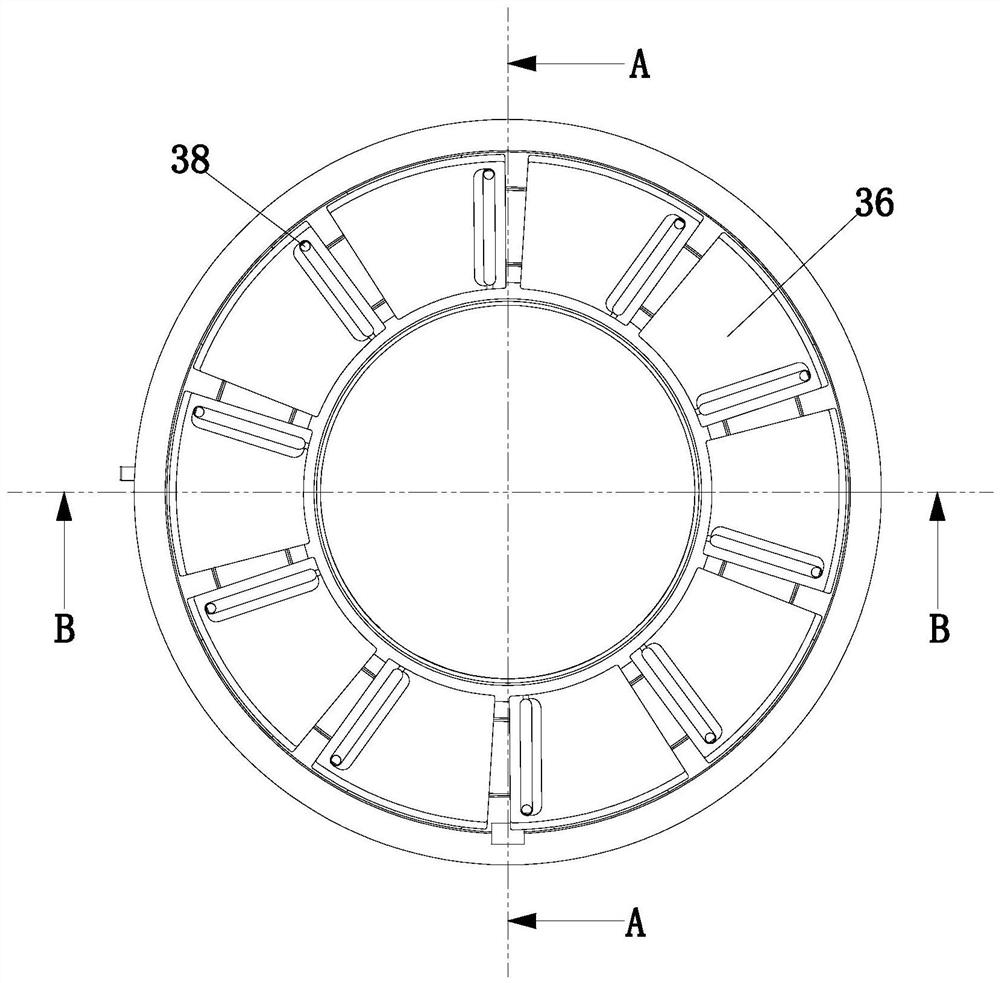

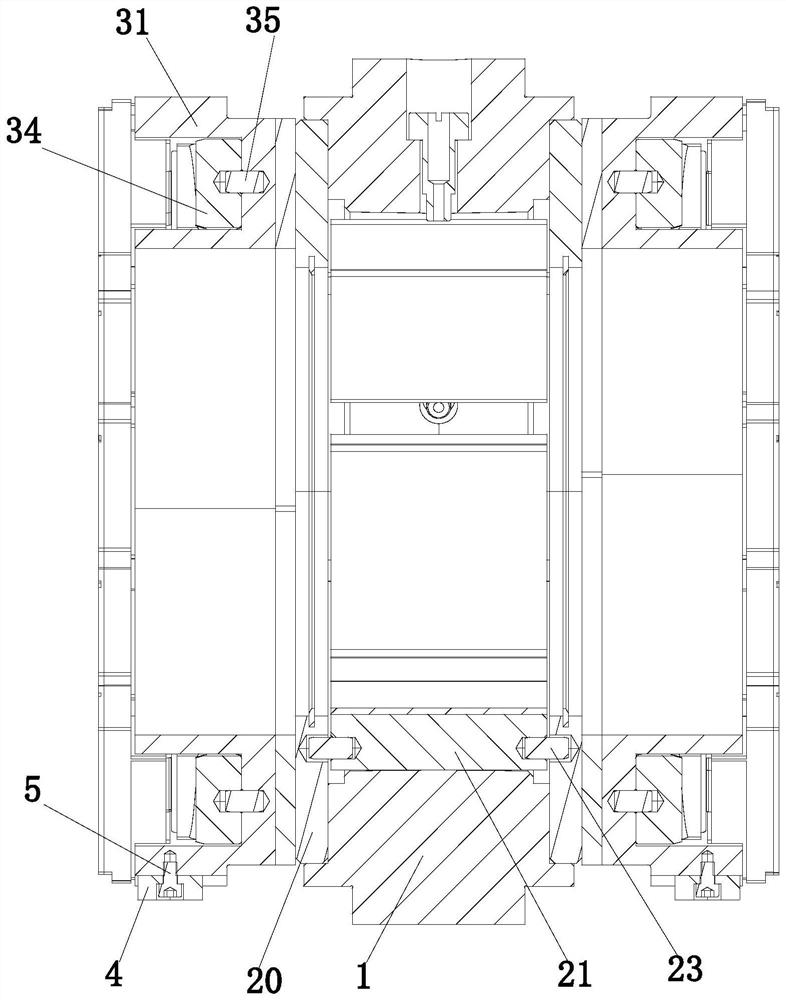

Water-lubricated tilting pad thrust bearing

PendingCN112360871AReduce temperature riseHigh strengthShaftsBearing componentsThrust bearingEngineering

The invention relates to the technical field of thrust bearings, in particular to a water-lubricated tilting-pad thrust bearing. The water-lubricated tilting-pad thrust bearing comprises a bearing body, a radial assembly and thrust assemblies. The bearing body is arranged in a circular ring shape, multiple circular holes are formed in the outer wall of the bearing body along the circumference, andthe radial assembly is arranged in the bearing body, and the top and the bottom of the radial assembly are attached to the top and the bottom of the bearing body correspondingly. The number of the thrust assemblies is two sets, and the two sets of thrust assemblies are the same in structure and are symmetrically installed at the two ends of the radial assembly. The bearing overcomes the radial and thrust combined compensation function, radial and thrust pad blocks are of point supporting movable structures, self-adaptive transient adjustment is conducted according to the working conditions, the working condition requirements are met, radial and thrust pads are of oil spraying lubrication structures, temperature rise of the bearing is reduced through elastic metal plastic, and the strengthof the bearing is improved; and meanwhile, a lubricating medium can adopt water lubrication, the use cost is reduced, the oil mixing state is reduced, cold oil directly enters the lubricating surface, and temperature rise and power consumption are reduced.

Owner:宜兴市环宇轴瓦制造有限公司

A preparation method of high-strength and high-conductivity anti-friction copper contact wire

ActiveCN110331313BSimple processShort processTransportation and packagingConductive materialManganese sulfideNanoparticle

The invention discloses a method for preparing a high-strength and high-conductivity anti-friction copper contact wire, which belongs to the technical field of powder metallurgy copper-based materials. The present invention uses copper-manganese alloy powder as raw material, performs vulcanization treatment in a medium containing a sulfur source, generates manganese sulfide nanoparticles in situ inside the copper-manganese alloy powder through high-temperature diffusion, and undergoes cold isostatic pressing and sintering-hot extrusion Manganese sulfide dispersion-strengthened copper contact wires were obtained by combination of pressure and densification process. The invention has simple preparation process, short process, low energy consumption, rich and easy-to-obtain raw materials, low cost, and is suitable for large-scale production; the prepared contact wire has room temperature tensile strength greater than 450 MPa, electrical conductivity greater than 75% IACS, and friction coefficient less than 0.2.

Owner:UNIV OF SCI & TECH BEIJING

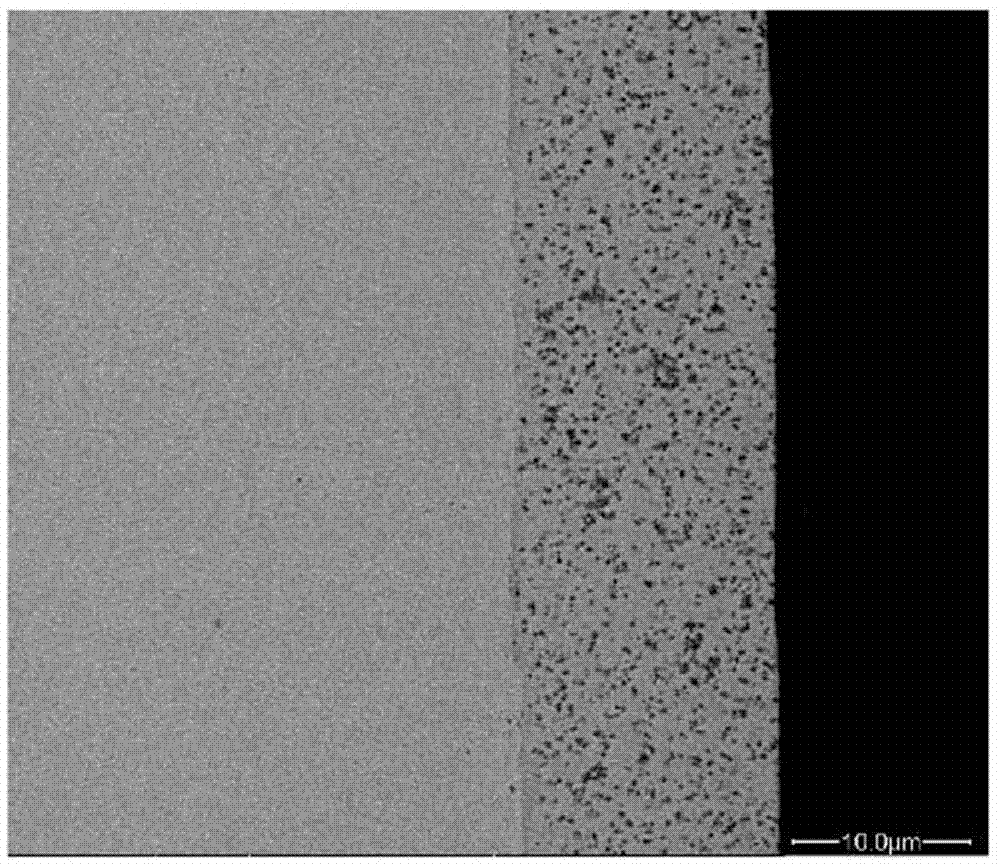

Preparation method of cast nylon composite material with high anti-friction and anti-wear surface layer

InactiveCN103450469BHigh mechanical strengthIncreased mechanical toughnessHexamethylphosphoramideSurface layer

The invention discloses a preparation method of a cast nylon composite material with a high friction-reducing and anti-wear surface layer. The preparation method comprises the following steps of: preparing dispersive suspensoid by hexamethylphosphoramide, ultra-fine kaolin and toluene diisocynate in proportion; adding dispersive suspensoid and teflon micro powder to a caprolactam melt; initiating caprolactam anionic ring-opening polymerization through a sodium hydroxide-toluene diisocynate catalytic activating system; casting a reaction mass into a preheated and heat-preserved centrifugal rotating die under normal pressure; after the reacting and casting liquid is polymerized, solidified and formed, gradually cooling and demoulding, thus obtaining the cast nylon composite material with the high friction-reducing and anti-wear surface layer. The prepared cast nylon composite material has the characteristics that an inner matrix and an outer surface layer are different in structure and performance, so that the requirements on manufacturing and using various pulleys, idler wheels, rope wheels and guide wheels for a transportation mechanism, a hoisting device and mine equipment can be met.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

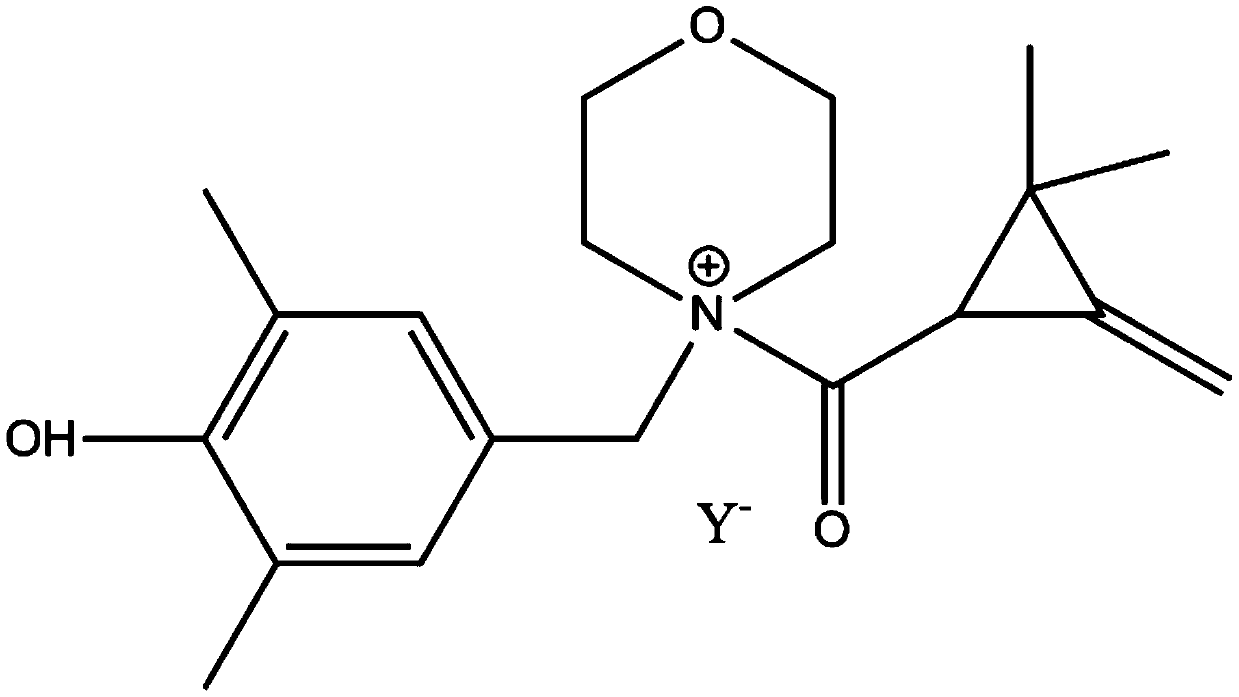

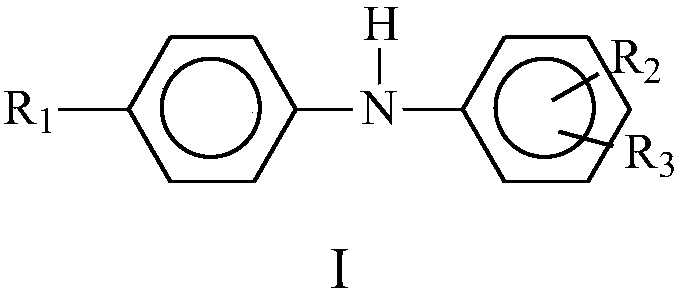

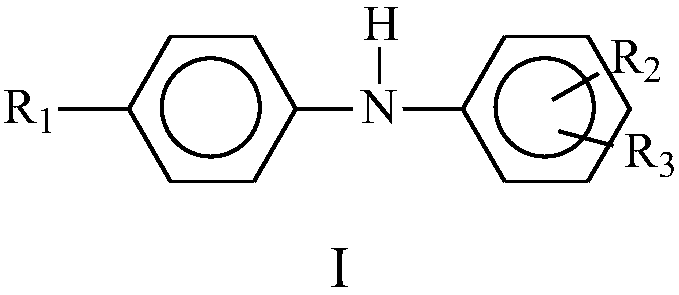

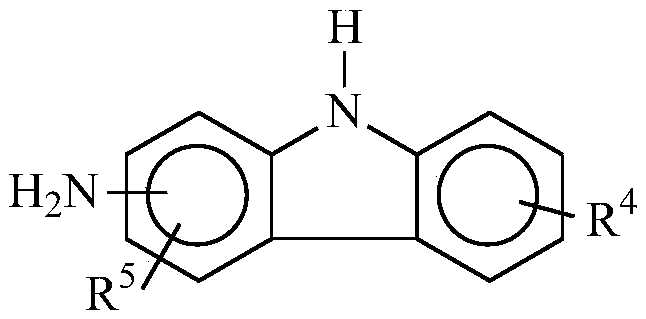

A functionalized polymer-coated ionic liquid lubricating oil additive and its preparation method and application

ActiveCN110655967BImprove anti-wear performanceImprove extreme pressure performanceAdditivesBulk chemical productionSulfonatePolymer science

The present invention discloses a functional polymer covering liquid liquid lubricant additive, which is a polymer polymer layer on the surface of the ionic liquid on the surface of the ionic liquid, and through the polymer polymer on the polymer polymerThe surface modifier of the layer modifies the carbon -carbon dual -bond sirrius coupling agent is composed of the modified sulfonate layer of the surface of the polymer polymer layer by the cross -linked branches.The functional polymers of the present invention cover the ionic liquid liquid lubricating oil additive in the steel / steel friction vice, which significantly improves the decrease and abrasion resistance of lubricant additives in the friction sideline.Small friction and side loss and long service life.The present invention also disclosed the preparation method and application of functional polymer to cover the ionic liquid lubricant additive.

Owner:圣保路石油化工(天津)股份有限公司

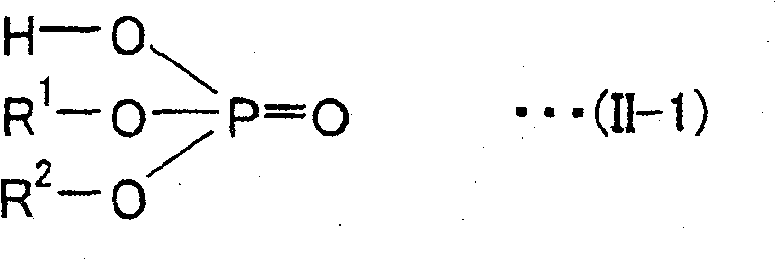

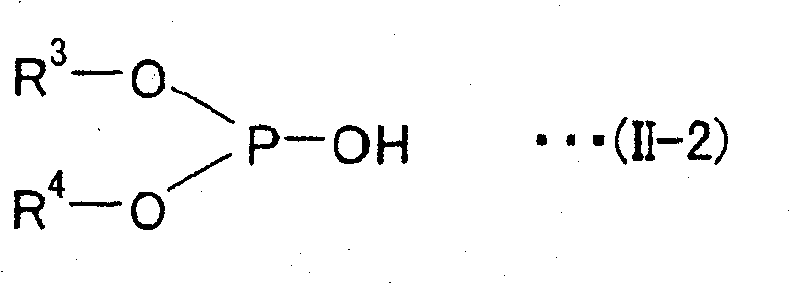

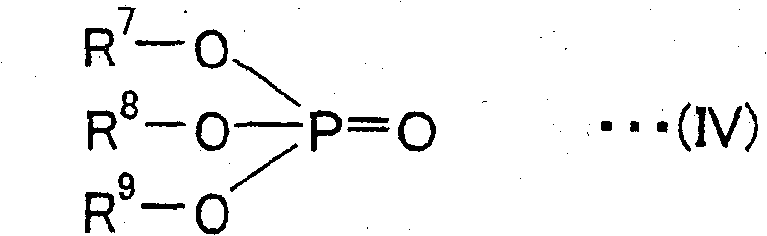

Hydraulic oil composition

ActiveCN101517054BImprove energy savingImprove thermal stabilityThickenersAdditivesFriction reductionAlcohol

A hydraulic oil composition obtained by blending a base oil having a sulfur content of less than 0.03% by mass, a content of saturates of 90% by mass or above, a viscosity index of 80 or above and an absolute viscosity at 40 DEG C of 1 to 1000mPa s with (A) 1 to 20% by mass of a polymethacrylate-type viscosity index improver having a weight-average molecular weight of 10,000 to 50,000, (B) 0.005 to 5% by mass of an acid amide, (C) 0.005 to 5% by mass of (c-1) a specific hydrogenphosphate ester and / or (c-2) a specific hydrogenphosphite ester and (D) 0.005 to 5% by mass of at least one member selected from among polyhydric alcohol esters, alkanolamines, olefin sulfides, and thiocarbamates. The hydraulic oil composition exerts satisfactory and well-balanced properties essential to hydraulic oil which include energy saving, heat stability (sludge resistance), prevention of wear and scuffing, water shedding, and friction reduction in sliding parts.

Owner:IDEMITSU KOSAN CO LTD

A kind of multifunctional lubricating oil additive and its application

ActiveCN110423639BImprove anti-wear performanceIntermolecular tightnessOrganic chemistryAdditivesMetallurgyMorpholine

The invention discloses a multifunctional lubricating oil additive. The additive is composed of the following raw materials in parts by weight: 50-100 parts of morpholine ionic liquid; 0.8-7.5 parts of detergent; 1.2-2.6 parts of antirust agent; 7 to 16 parts of agent; and 0.2 to 3.8 parts of foam inhibitor. The multifunctional lubricating oil additive of the present invention is applied in steel / steel or steel / aluminum friction pairs, which significantly improves the friction reduction and anti-wear performance of the lubricating oil additive in the friction pair, and at the same time improves its extreme pressure bearing performance, and the friction pair Small loss and long service life.

Owner:广东顺德菲尔特润滑科技有限公司

Antirust composite additive for lubricating oil and preparation method

The invention relates to the field of lubricating oil additives, and discloses an antirust composite additive for lubricating oil and a preparation method thereof. The preparation method comprises thefollowing steps: (1) adding a polyether carboxylic acid derivative and magnesium-aluminum hydrotalcite into alkali liquor, and carrying out heating, stirring, ageing, filtering and washing to obtainpolyether carboxylic acid derivative intercalated hydrotalcite; (2) adding the polyether carboxylic acid derivative intercalated hydrotalcite, 2,4-toluene diisocynate and an amine chain extender into4,4'-diaminodiphenyl ether, and carrying out heating and kneading to obtain a polyurea dispersion material; and (3) uniformly grinding and dispersing the polyurea dispersion material, barium alkyl benzene sulfonate, calcium alkyl benzene sulfonate, ammonium borate, zinc dialkyl dithiophosphate, nanometer polytetrafluoroethylene and base oil 150BS to obtain the antirust composite additive for lubricating oil . The polyether carboxylic acid derivative intercalated hydrotalcite is dispersed in a polyurea system to prepare the antirust composite additive, so when being used for lubricating oil, the antirust composite additive has better antifriction and antiwear properties and can form a stable antirust protective film to realize long-term rust prevention.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Dispersant viscosity index improvers to enhance wear protection in engine oils

ActiveCN109705956AGood dispersionImprove cleanlinessAdditivesLubrication indication devicesEngineeringPolyamine

An engine oil composition including greater than 50 wt.% of a base oil of lubricating viscosity selected from a Group III, a Group IV or a Group V base oil, and mixtures thereof, 0.1-10 wt.% of a dispersant viscosity index improver that a reaction product of an olefin copolymer, an acylating agent and a polyamine, one or more calcium-containing detergents that provide from about 900 ppmw to about2500 ppmw of calcium to the engine oil composition, and one or more molybdenum-containing compounds. The engine oil composition has an SAE viscosity grade of OW-X or 5W-X, wherein X = 16, 20, 30, or 40; from about 500 ppmw to about 1000 ppmw of phosphorus; and a total sulfated ash content of no greater than 1.2 wt.%, as measured by ASTM D874. Methods of using the engine oil composition to lubricate or operate an engine are also described.

Owner:AFTON CHEMICAL

Dispersant viscosity index improver for enhanced wear protection of engine oils

ActiveCN109705956BGood dispersionImprove cleanlinessAdditivesLubrication indication devicesViscosity gradeMolybdenum compounds

An engine oil composition comprising: greater than 50 wt % of a base oil of lubricating viscosity selected from Group III, IV or V base oils and mixtures thereof; 0.1 wt % - 10 wt % of a dispersant viscosity index improver, The viscosity index improver is the reaction product of an olefin copolymer, an acylating agent, and a polyamine; one or more calcium-containing detergents that provide from about 900 ppmw to about 2500 ppmw to the engine oil composition calcium; and one or more molybdenum-containing compounds. The SAE viscosity grade of the engine oil composition is 0W-X or 5W-X, where X = 16, 20, 30, or 40; phosphorus is from about 500 ppmw to about 1000 ppmw; and a total sulfated ash content as measured by ASTM D874 Not more than 1.2wt%. Methods of lubricating or operating the engine using the engine oil composition are also described.

Owner:AFTON CHEMICAL

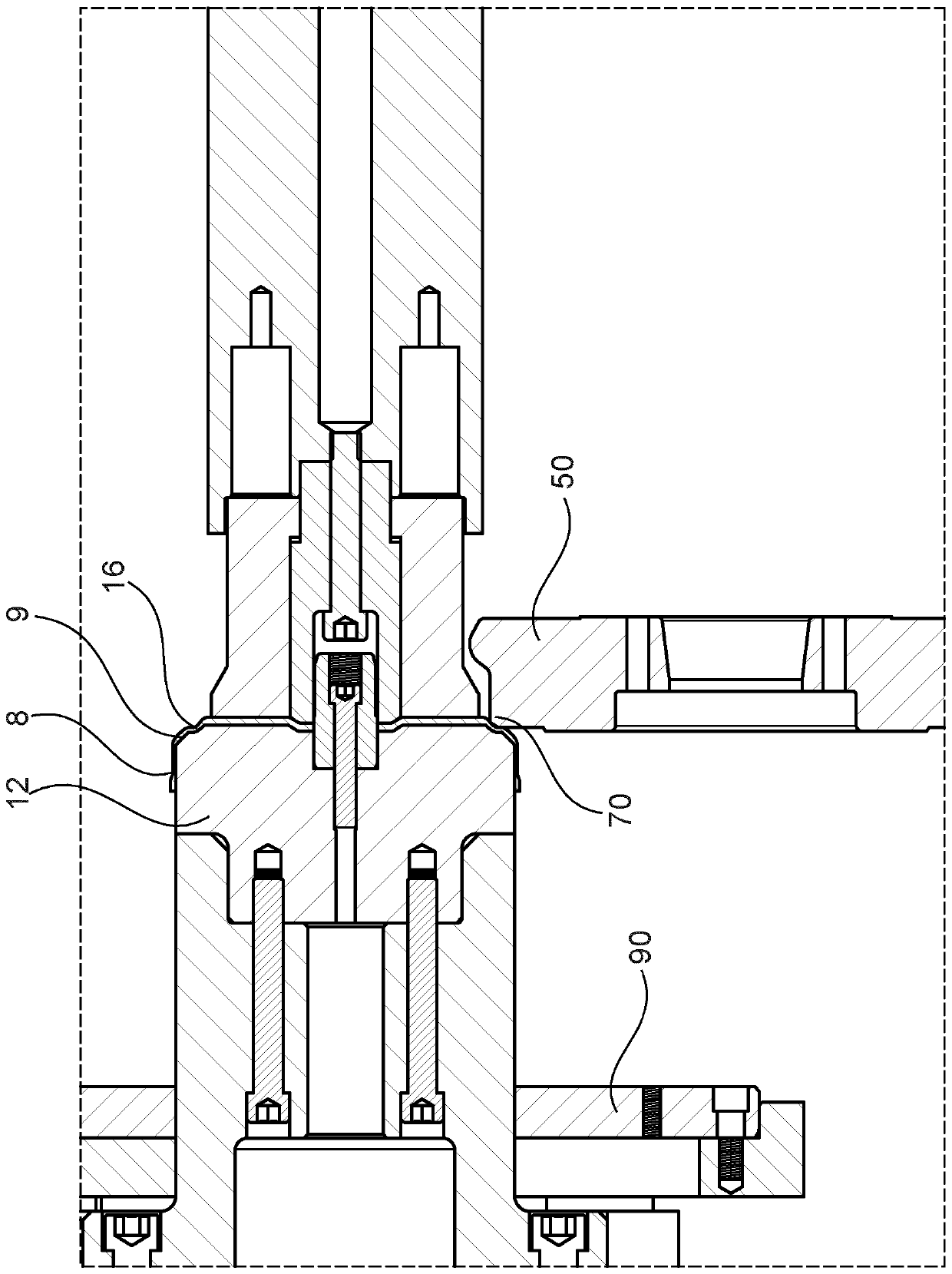

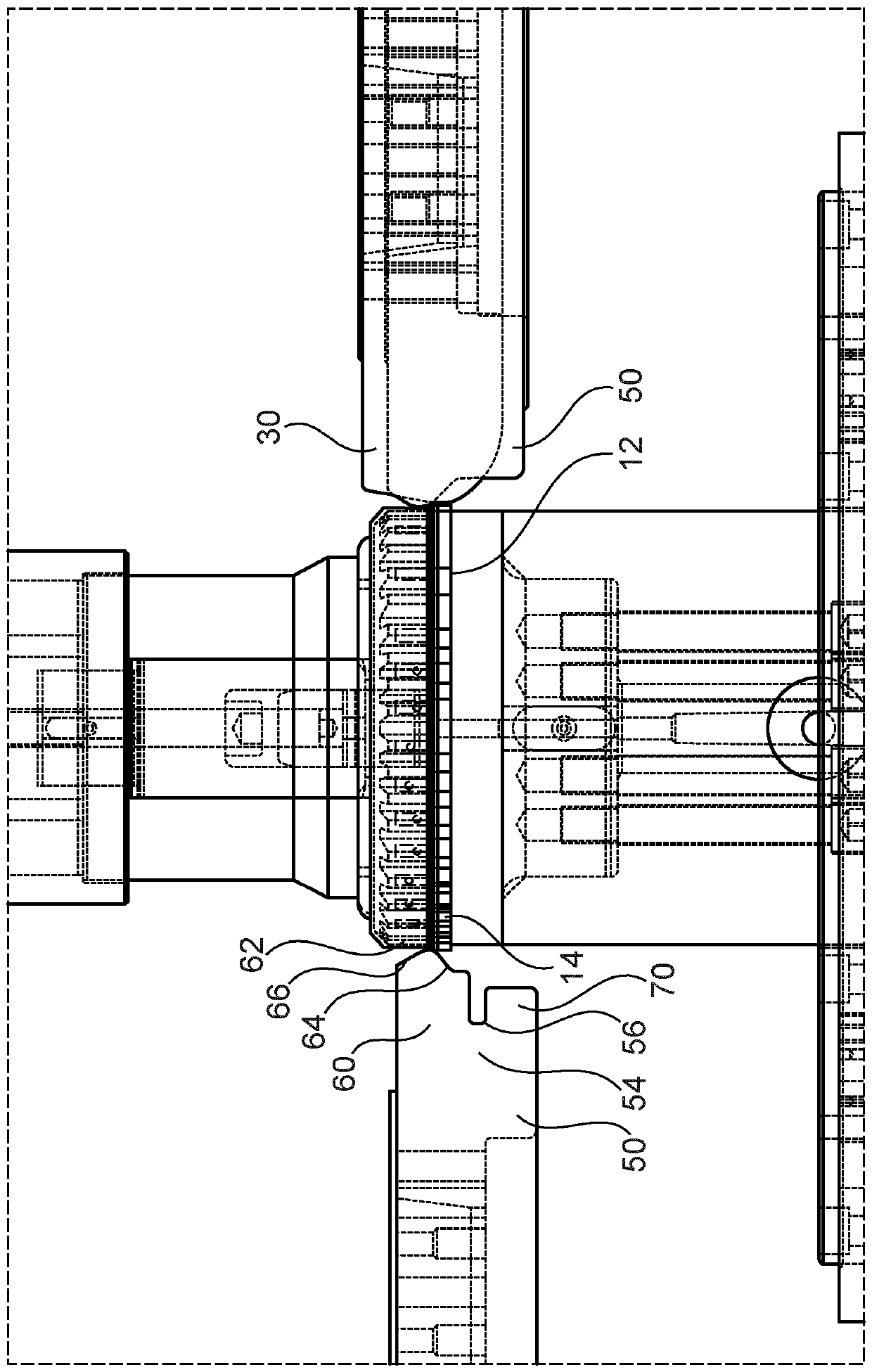

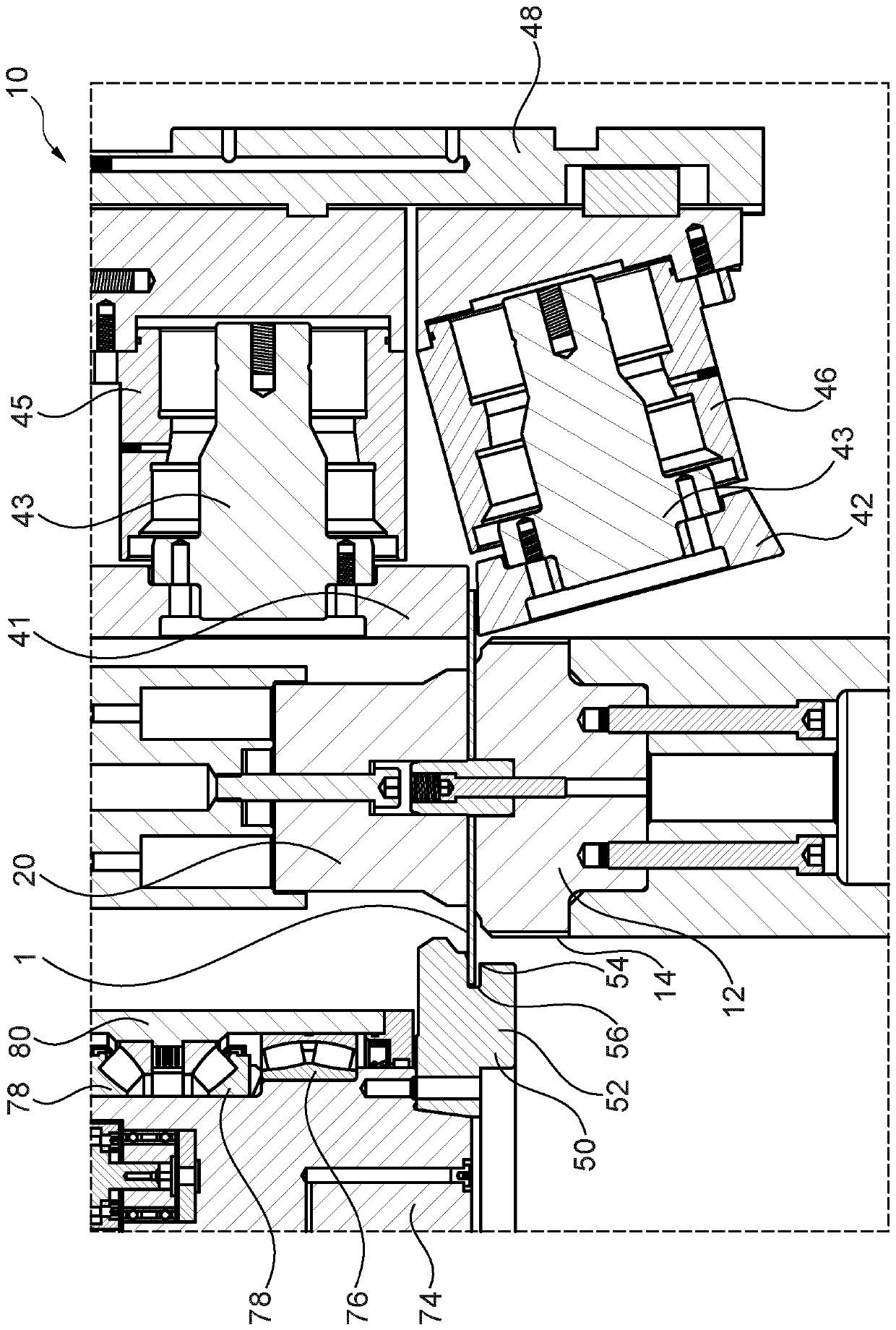

Method and device for producing deformable parts

ActiveCN109475913BReduce loadReduce friction lossGear wheelsDisc wheelsEngineeringRadial compression

Owner:LEIFELD METAL SPINNING AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com