Preparation method of Hastelloy surface coating

A technology of Hastelloy and coating, applied in the field of preparation of Hastelloy surface coating, can solve the problems of decreased mechanical properties and corrosion resistance, limited application range, poor wear resistance, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of preparation method of Hastelloy surface coating provided by the present invention, it comprises the following steps:

[0035] Step 1. Hastelloy surface pretreatment

[0036] First, a Hastelloy alloy is provided. The type of Hastelloy is not limited, and Hastelloy C22 is used in this embodiment. The shape of the hastelloy is not limited, and it has a surface. The surface can be flat or curved. In this embodiment, the Hastelloy is a Hastelloy plate. The method for surface treatment of the Hastelloy alloy comprises the following steps:

[0037] ①Ultrasonic cleaning

[0038] First, use acetone, petroleum ether or soda ash as cleaning agents to clean the Hastelloy alloy with an ultrasonic cleaner for 10 to 30 minutes at a cleaning temperature of 15 to 35°C; then use ethanol or deionized water as cleaning agents to clean the Hastelloy alloy with Clean with an ultrasonic cleaner for 10-30 minutes at a cleaning temperature of 15-35°C.

[0039] ②Surface polishin...

Embodiment 1

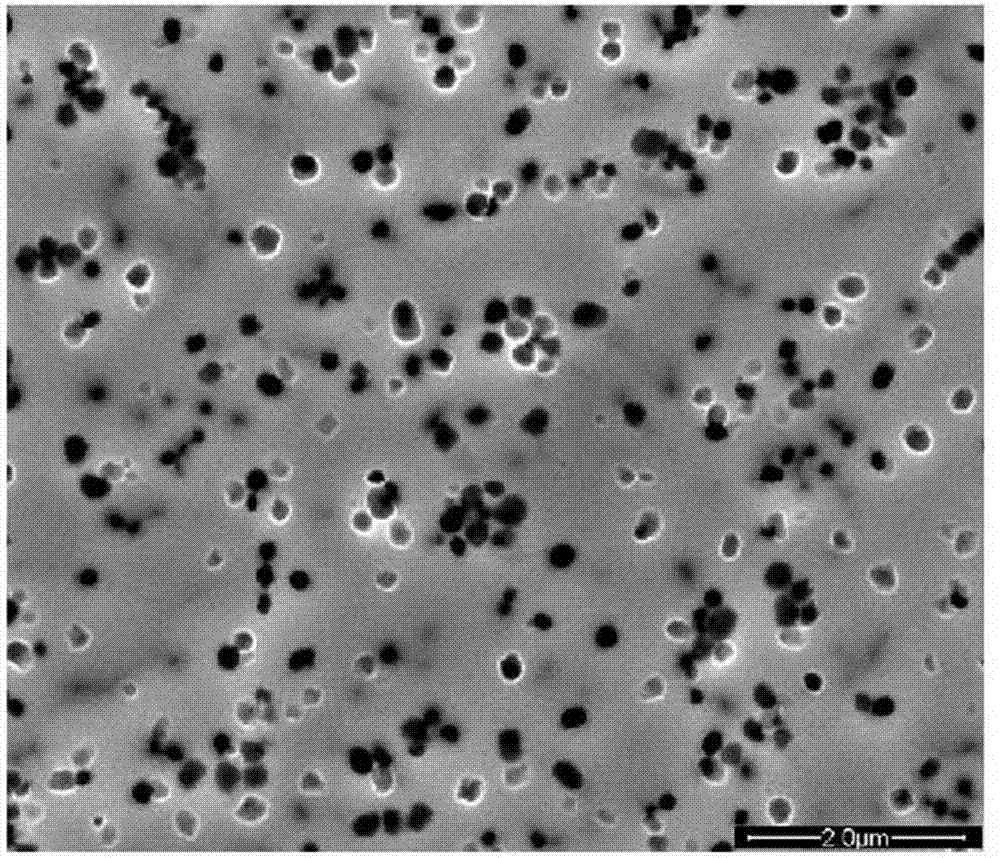

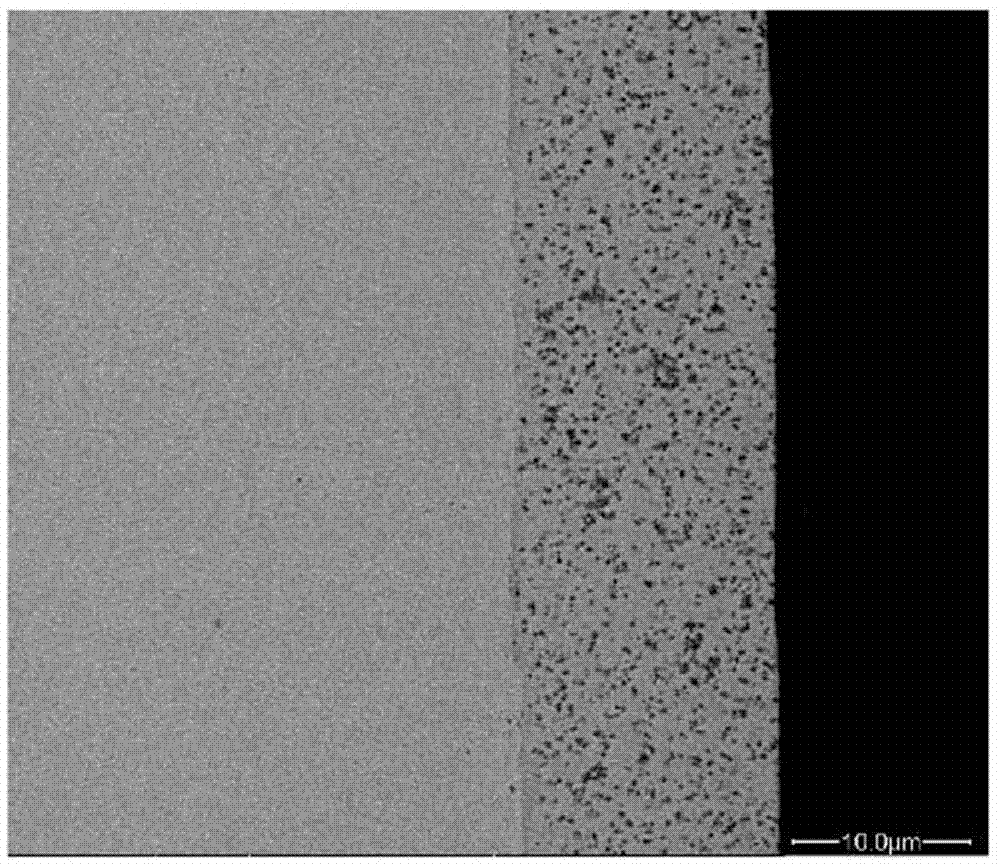

[0055] This embodiment provides a preparation method of Hastelloy surface coating, which mainly adopts "two-step method" - "pre-plating pure nickel layer by electroplating method + chemical composite plating Ni-P-nanoPTFE" to obtain resistance on Hastelloy surface. Abrading the corrosion-resistant hydrophobic composite coating, comprising the following steps:

[0056] Step 1. Pretreatment of Hastelloy surface

[0057] The method for carrying out pretreatment to Hastelloy surface comprises the following steps:

[0058] ①Ultrasonic cleaning

[0059] First use acetone as a cleaning agent to clean the Hastelloy alloy with an ultrasonic cleaner for 20 minutes at a temperature of 25°C; then use deionized water as a cleaning agent to clean the Hastelloy alloy with an ultrasonic cleaner for 20 minutes at a temperature of 25°C. ℃.

[0060] ②Surface polishing

[0061] Polish the Hastelloy surface after ultrasonic cleaning, inlay the Hastelloy in the resin, cure for 12 hours, and use...

Embodiment 2

[0075] Use the "two-step method" - "electroplating pure nickel layer + chemical composite plating Ni-P-nanoPTFE" to obtain a wear-resistant, corrosion-resistant and hydrophobic composite coating on the surface of Hastelloy. The steps are as follows:

[0076] Step 1. Hastelloy surface pretreatment

[0077] The method for surface pretreatment of the Hastelloy alloy comprises the following steps:

[0078] ①Ultrasonic cleaning

[0079] First use acetone as a cleaning agent to clean the Hastelloy alloy with an ultrasonic cleaner for 30 minutes at a temperature of 20°C; then use deionized water as a cleaning agent to clean the Hastelloy alloy with an ultrasonic cleaner for 30 minutes at a temperature of 20°C. ℃.

[0080] ②Surface polishing

[0081]Polish the Hastelloy surface after ultrasonic cleaning, inlay the Hastelloy in the resin, cure for 12 hours, and use a polishing machine to polish the Hastelloy until the surface is rough The degree is Ra0.6~0.3μm, the polishing time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com