Patents

Literature

2500 results about "Nickel plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

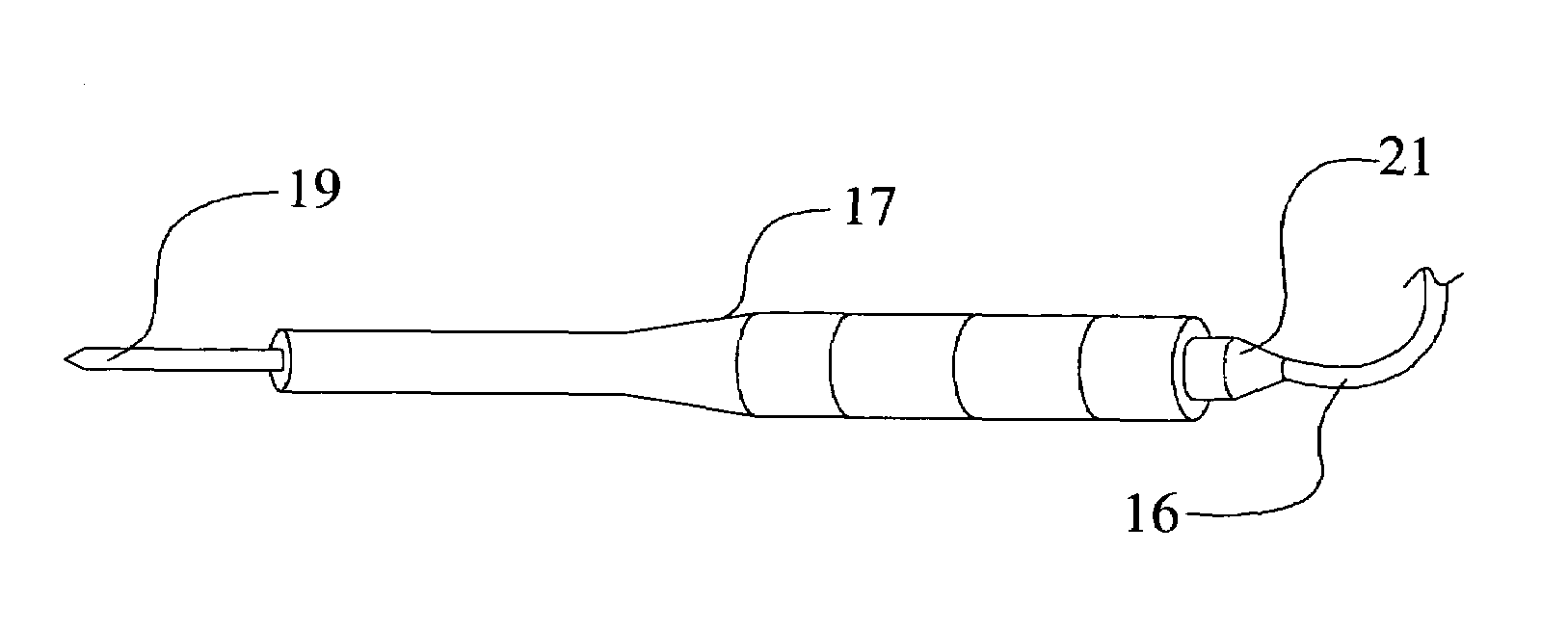

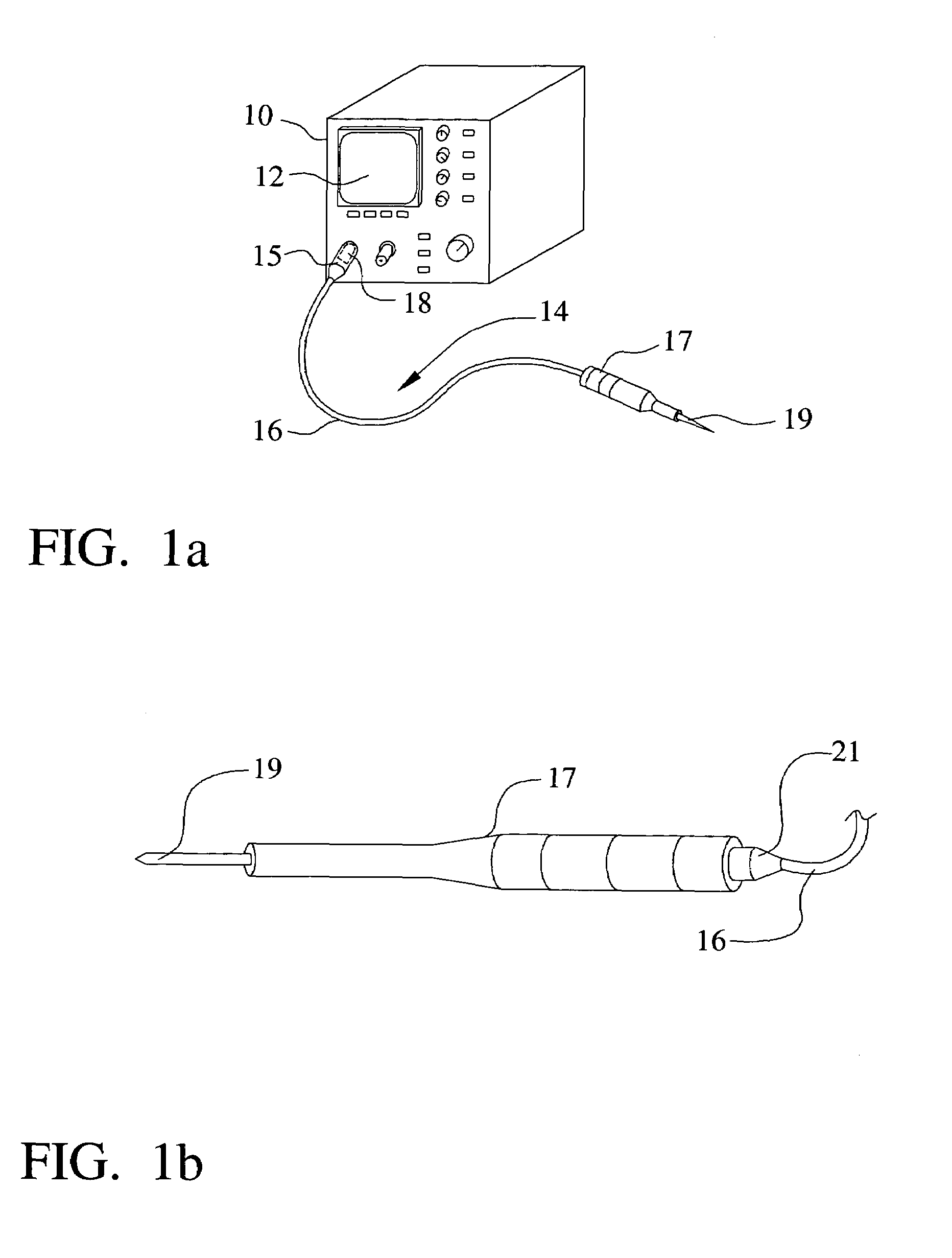

Low cost electronic probe devices manufactured from conductive loaded resin-based materials

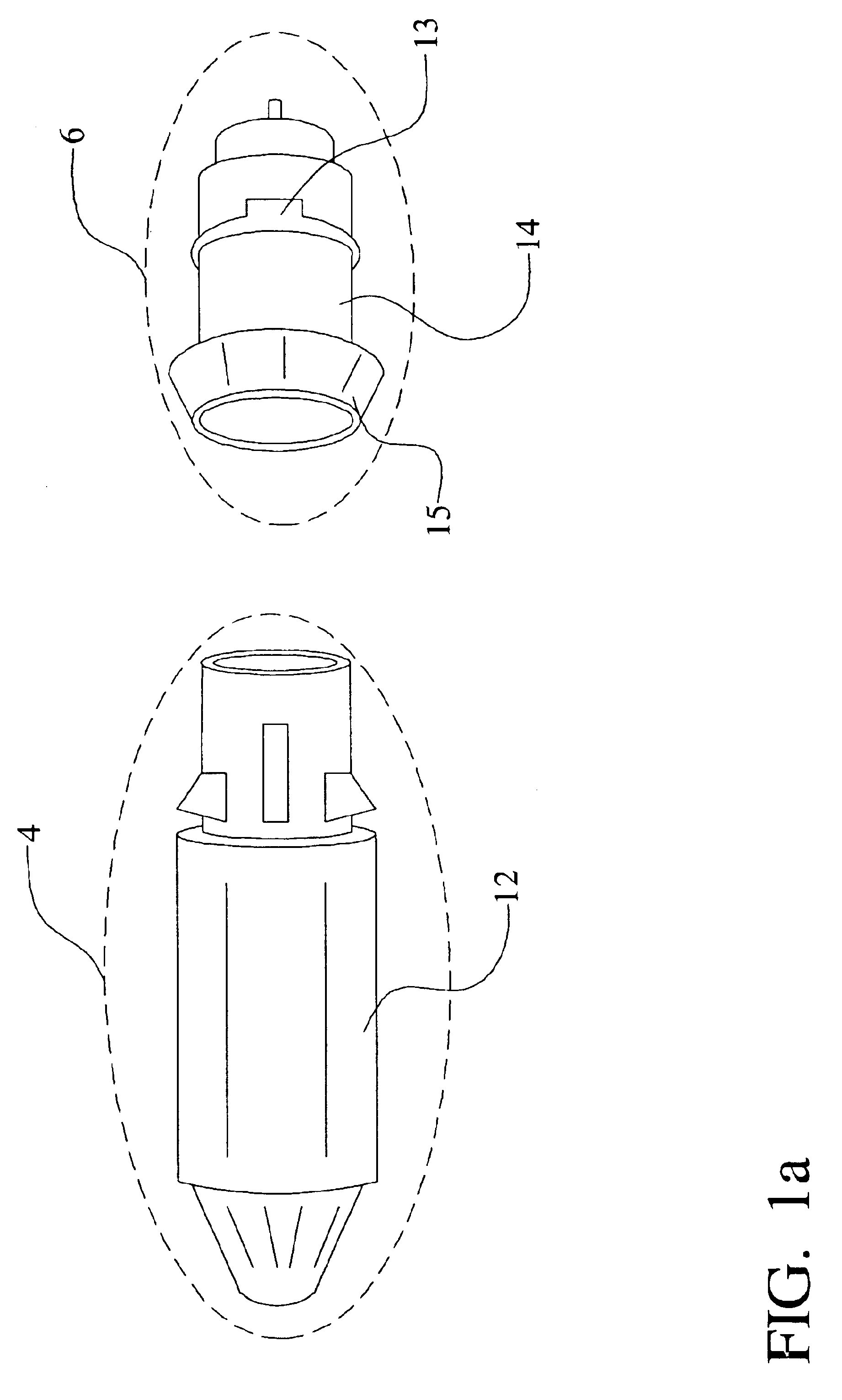

InactiveUS7006046B2EffectiveImprove Noise CancellationElectrical measurement instrument detailsAntenna supports/mountingsOptoelectronicsNickel plate

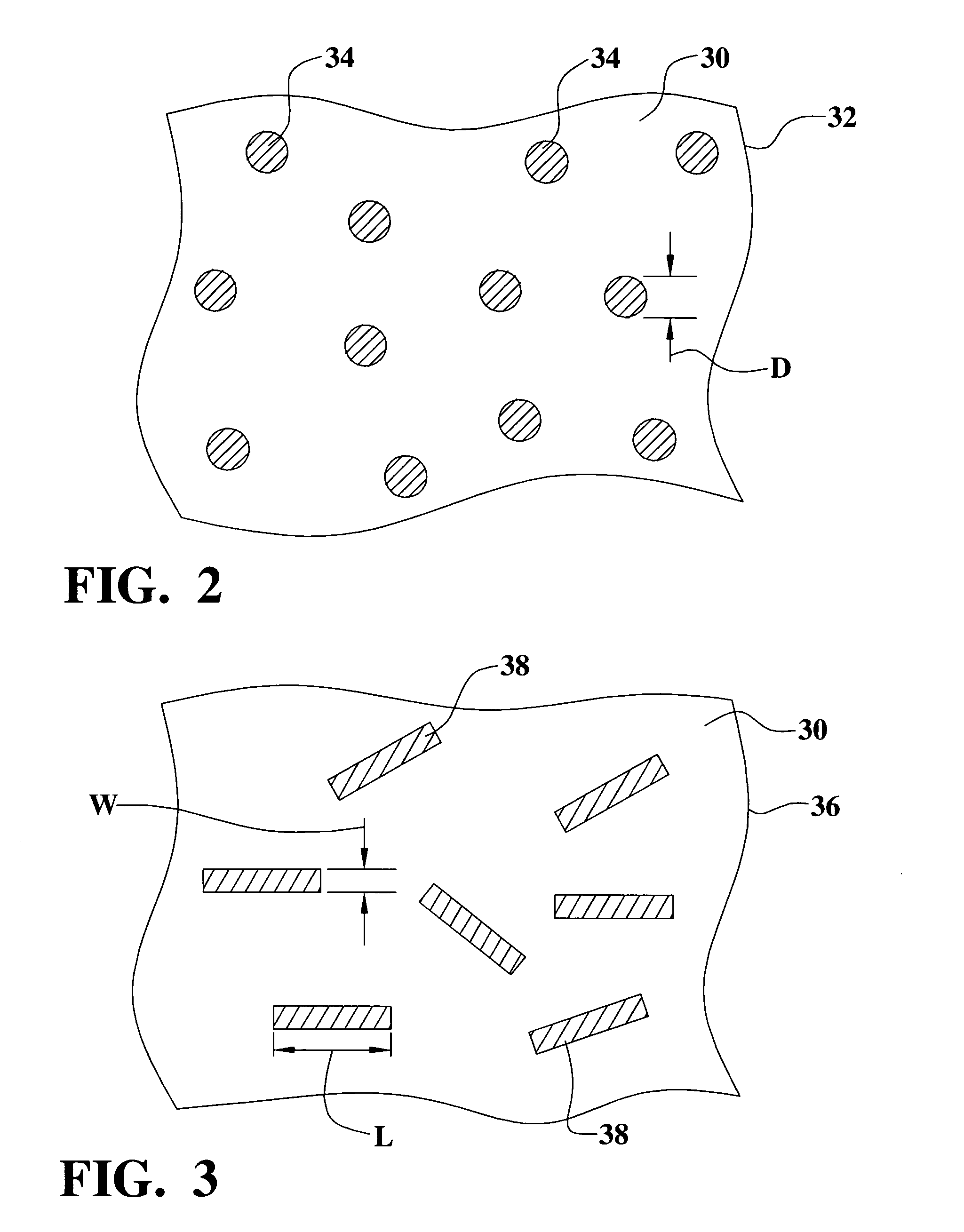

Electronic probe devices are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The ratio of the weight of the conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers to the weight of the base resin host is between about 0.20 and 0.40. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

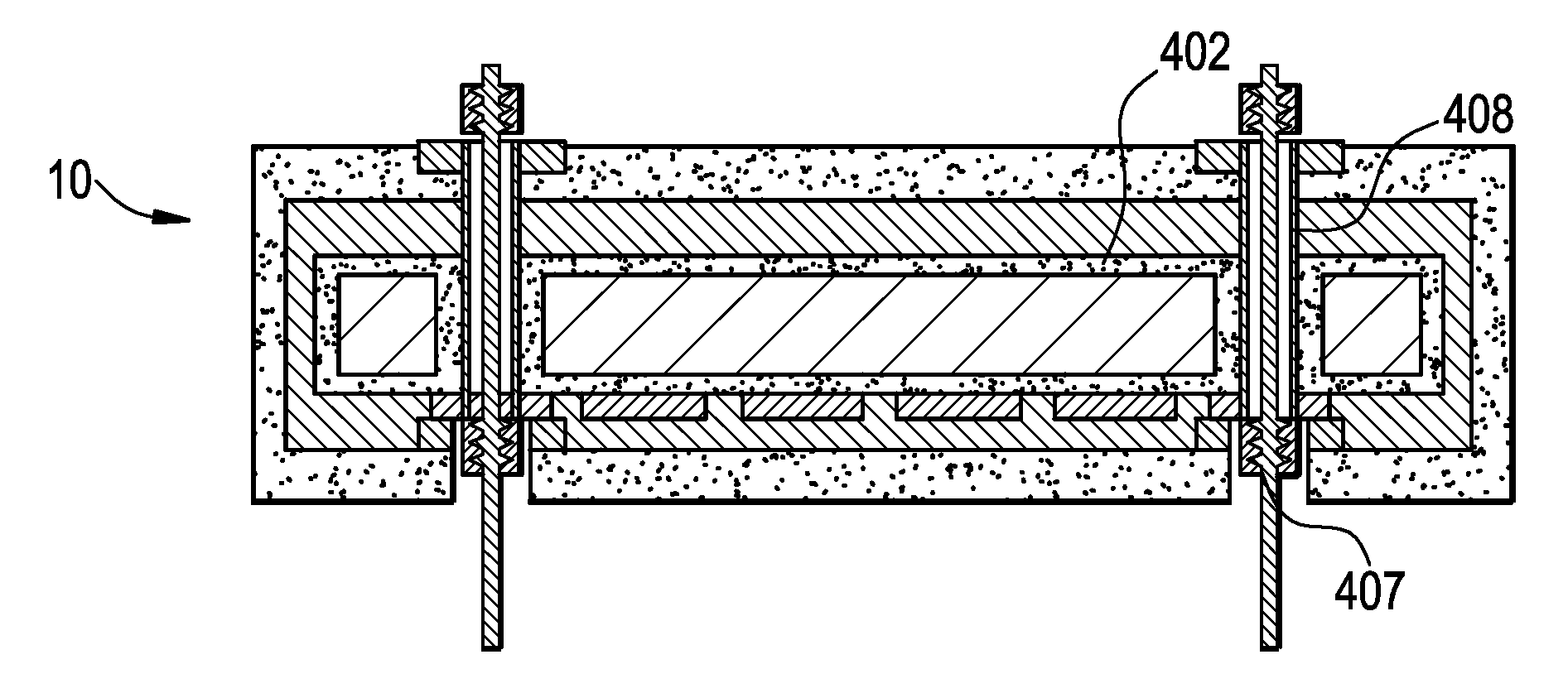

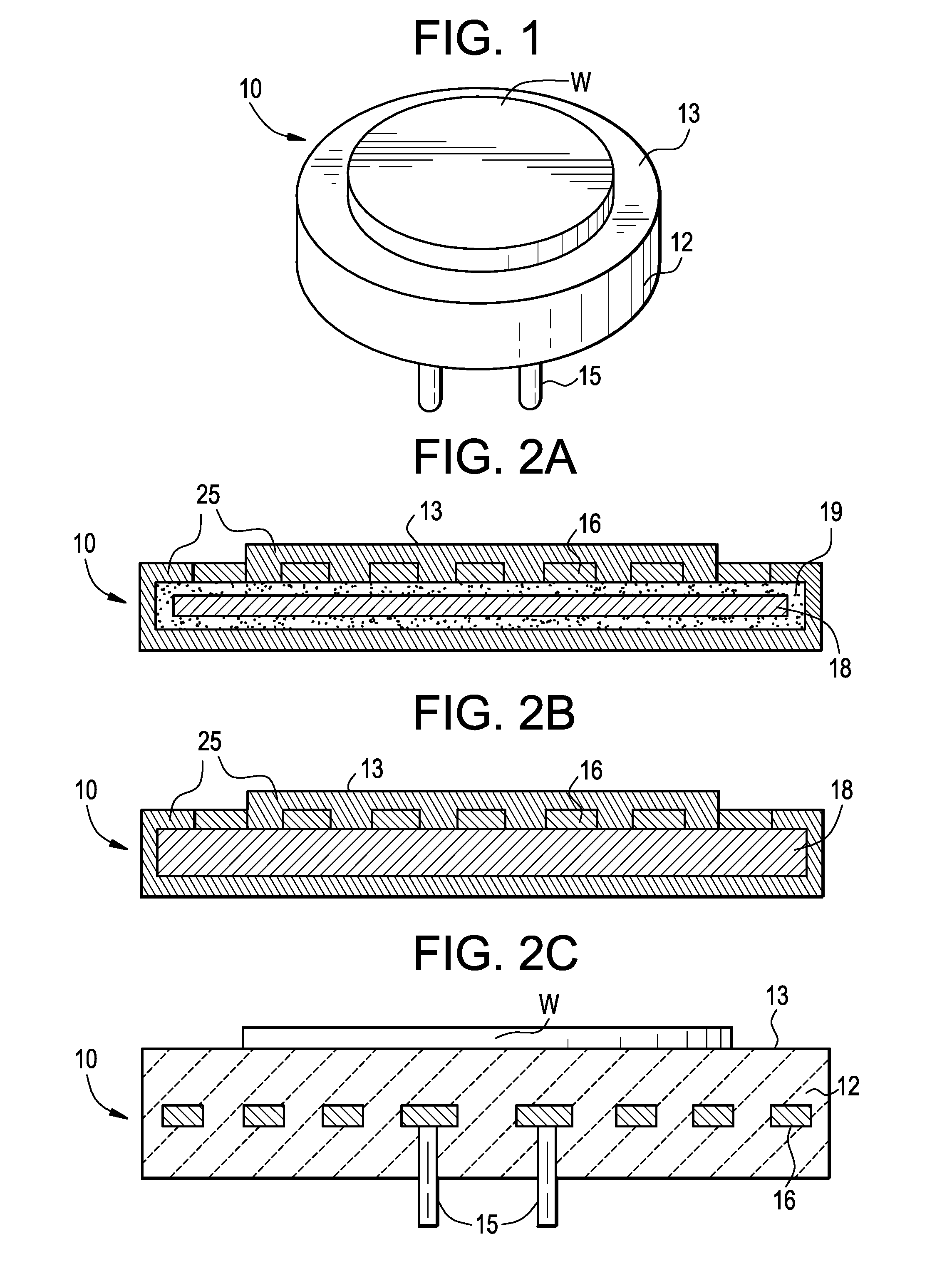

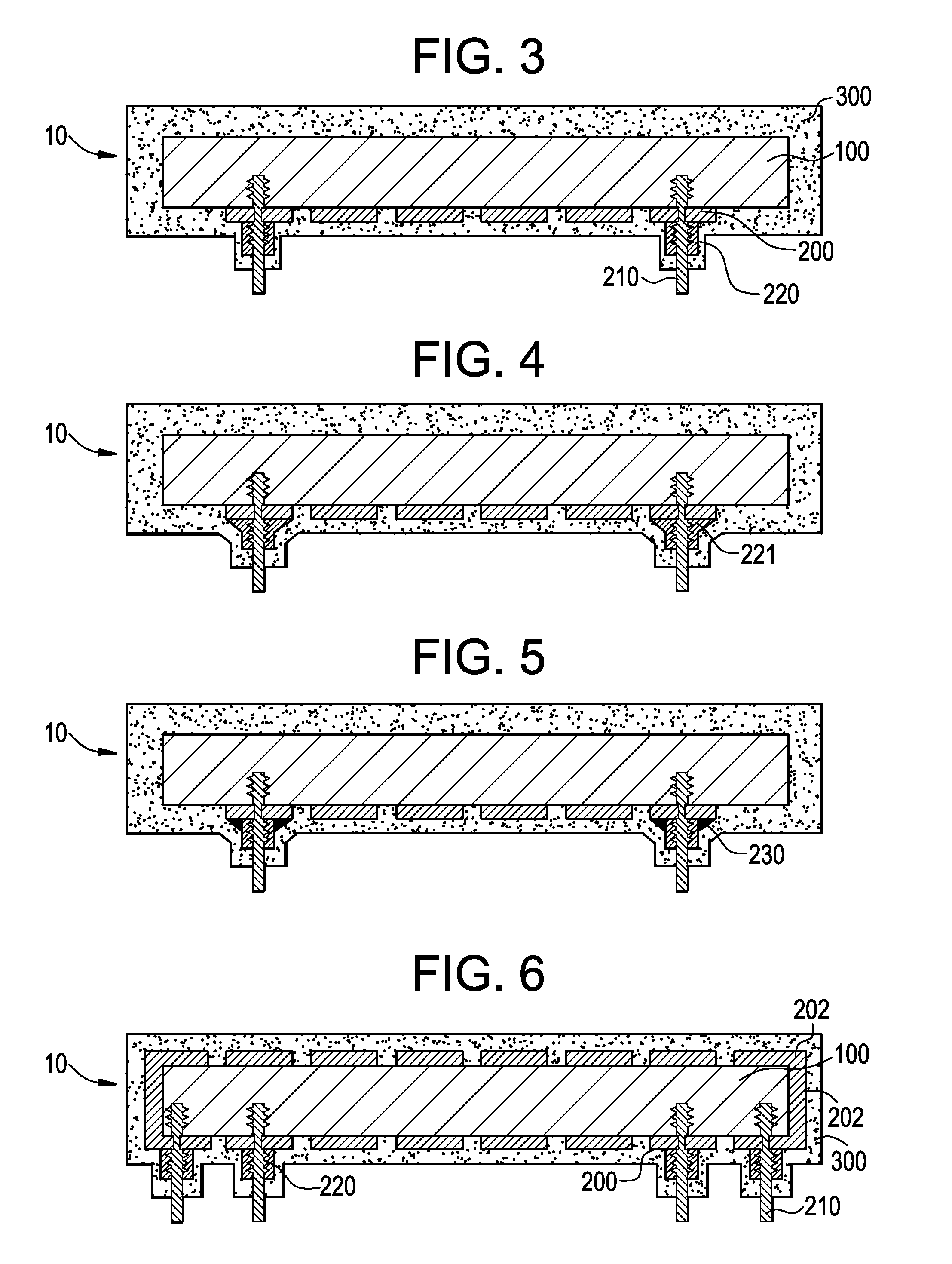

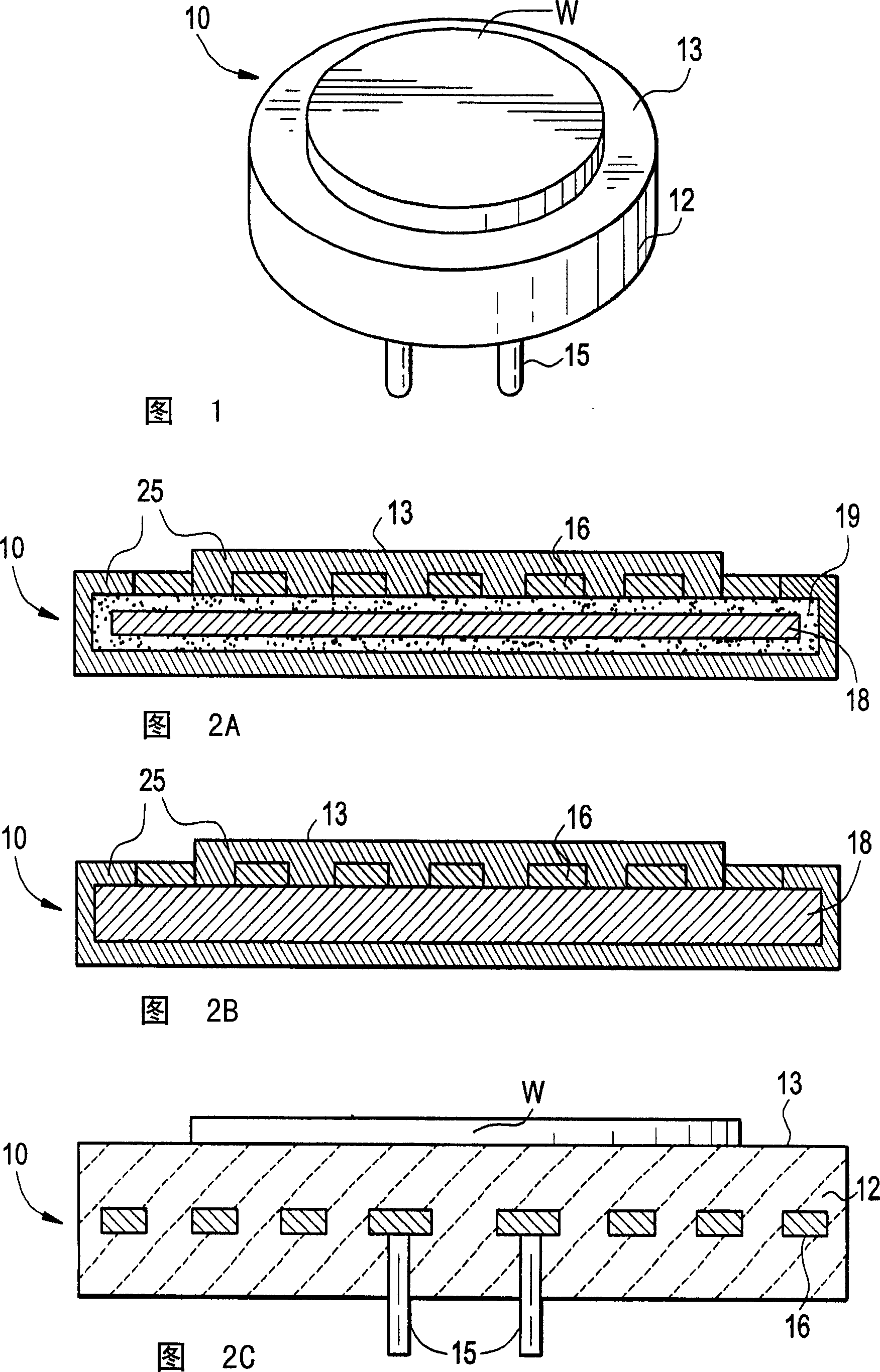

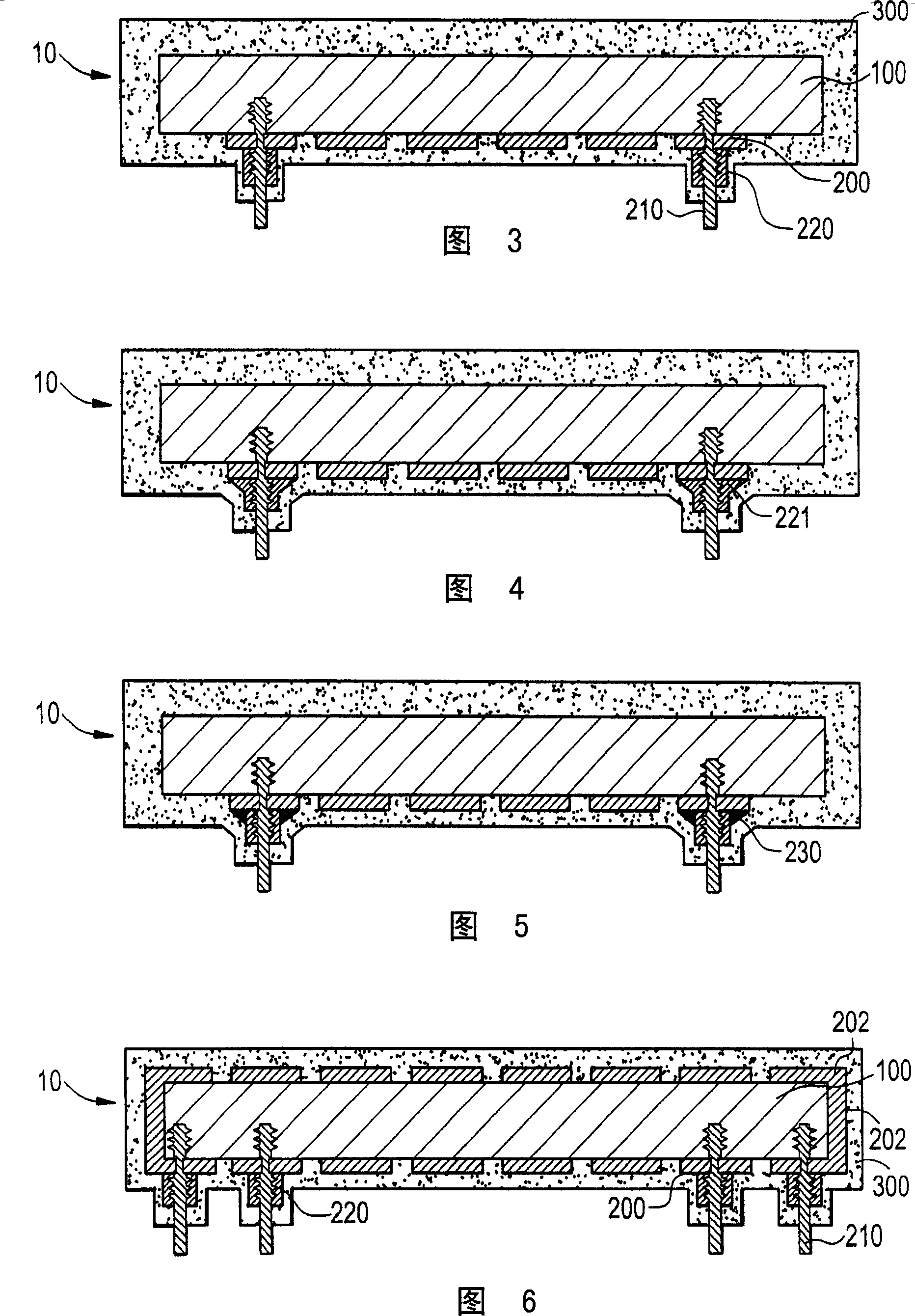

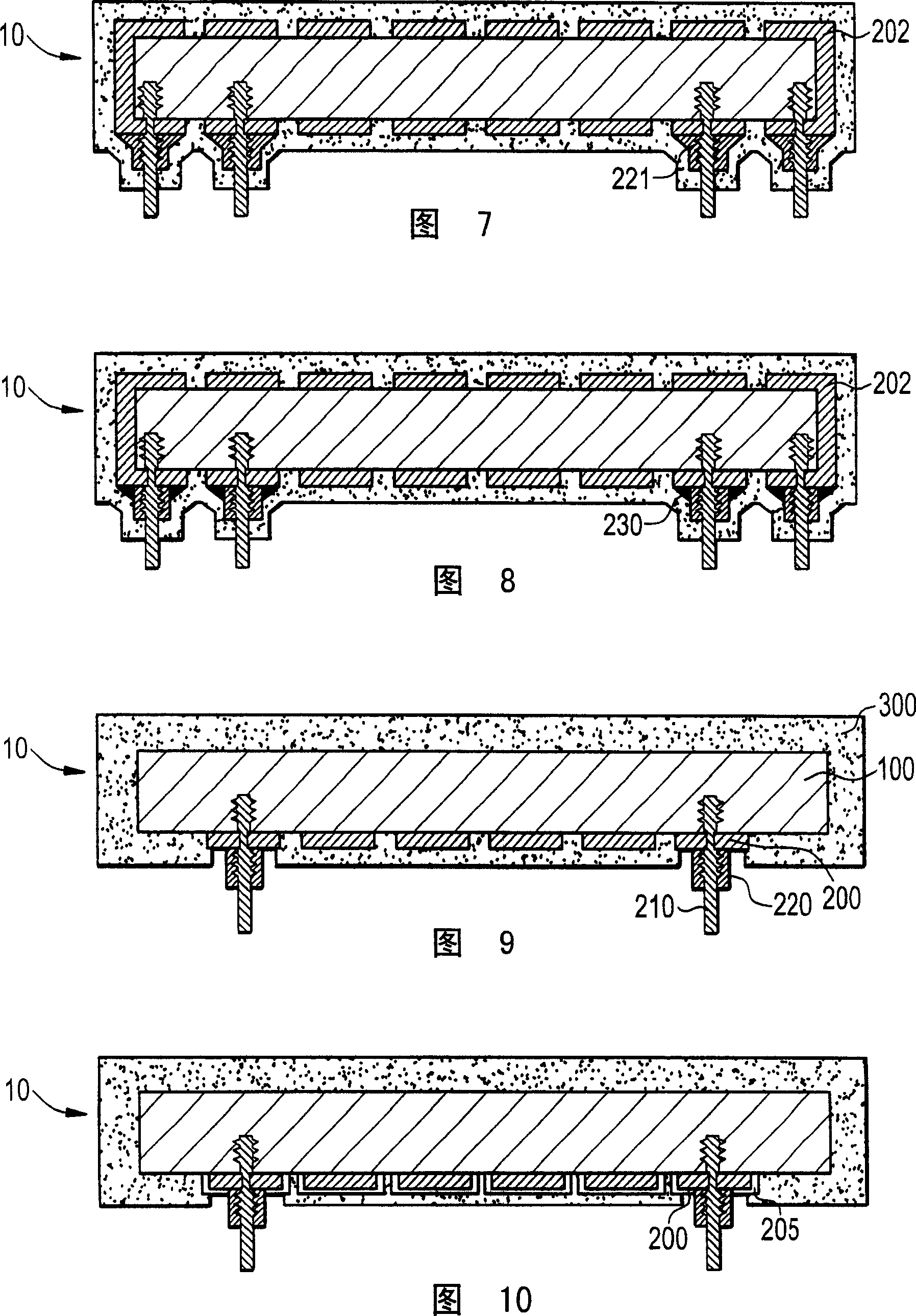

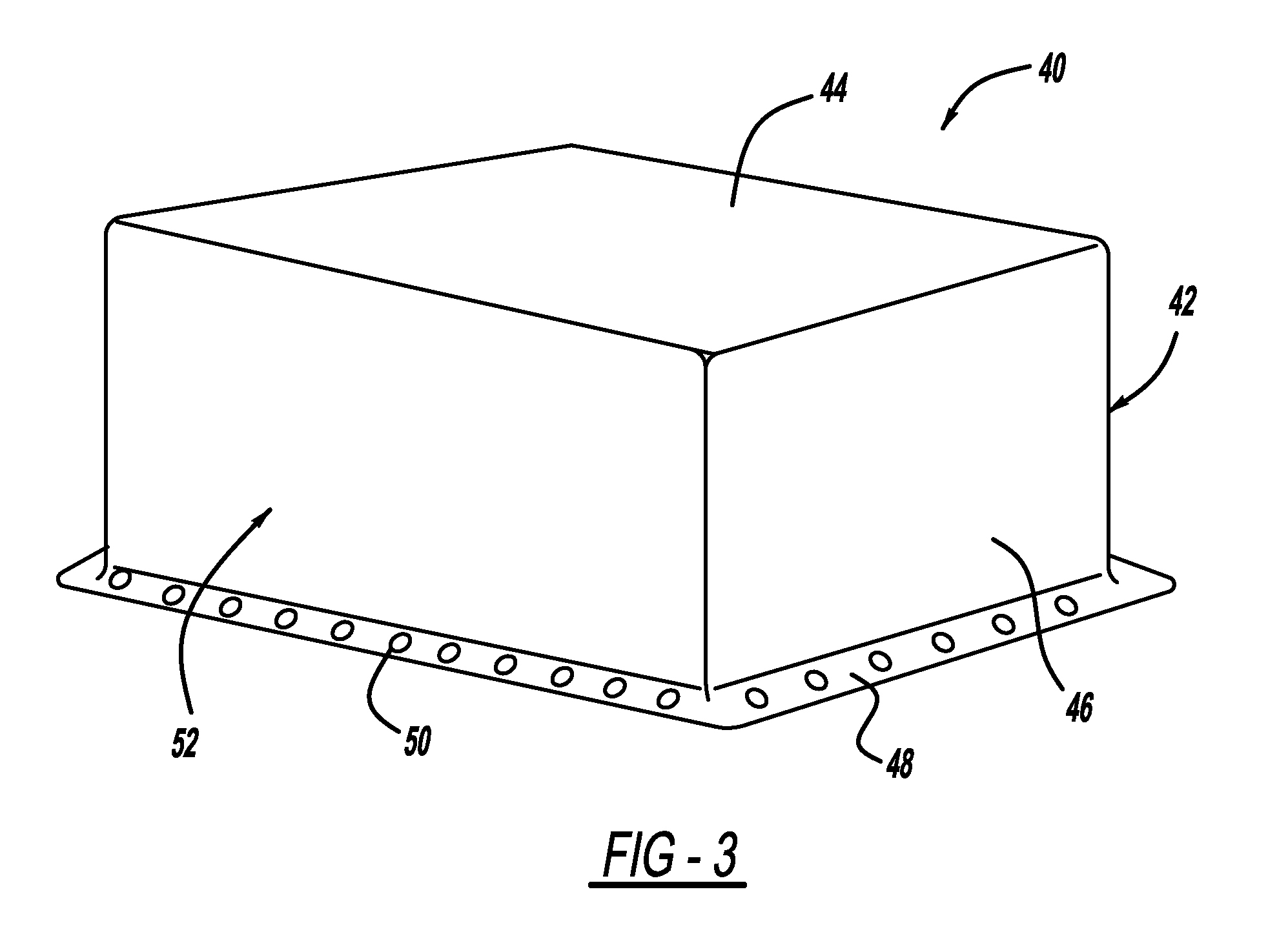

Corrosion resistant wafer processing apparatus and method for making thereof

InactiveUS20080016684A1Line/current collector detailsSemiconductor/solid-state device manufacturingElectrical connectionWadding

A wafer processing apparatus characterized by having corrosion resistant connections for its electrical connections, gas feed-through channels, recessed areas, raised areas, MESA, through-holes such as lift-pin holes, threaded bolt holes, blind holes, and the like, with the special configurations employing connectors and fillers having excellent chemical resistant properties and optimized CTEs, i.e., having a coefficient of thermal expansion (CTE) that closely matches the CTE of the base substrate layer, the electrode(s), as well as the CTE of coating layer. In one embodiment, a nickel plated molybdenum insert is employed.

Owner:GENERAL ELECTRIC CO

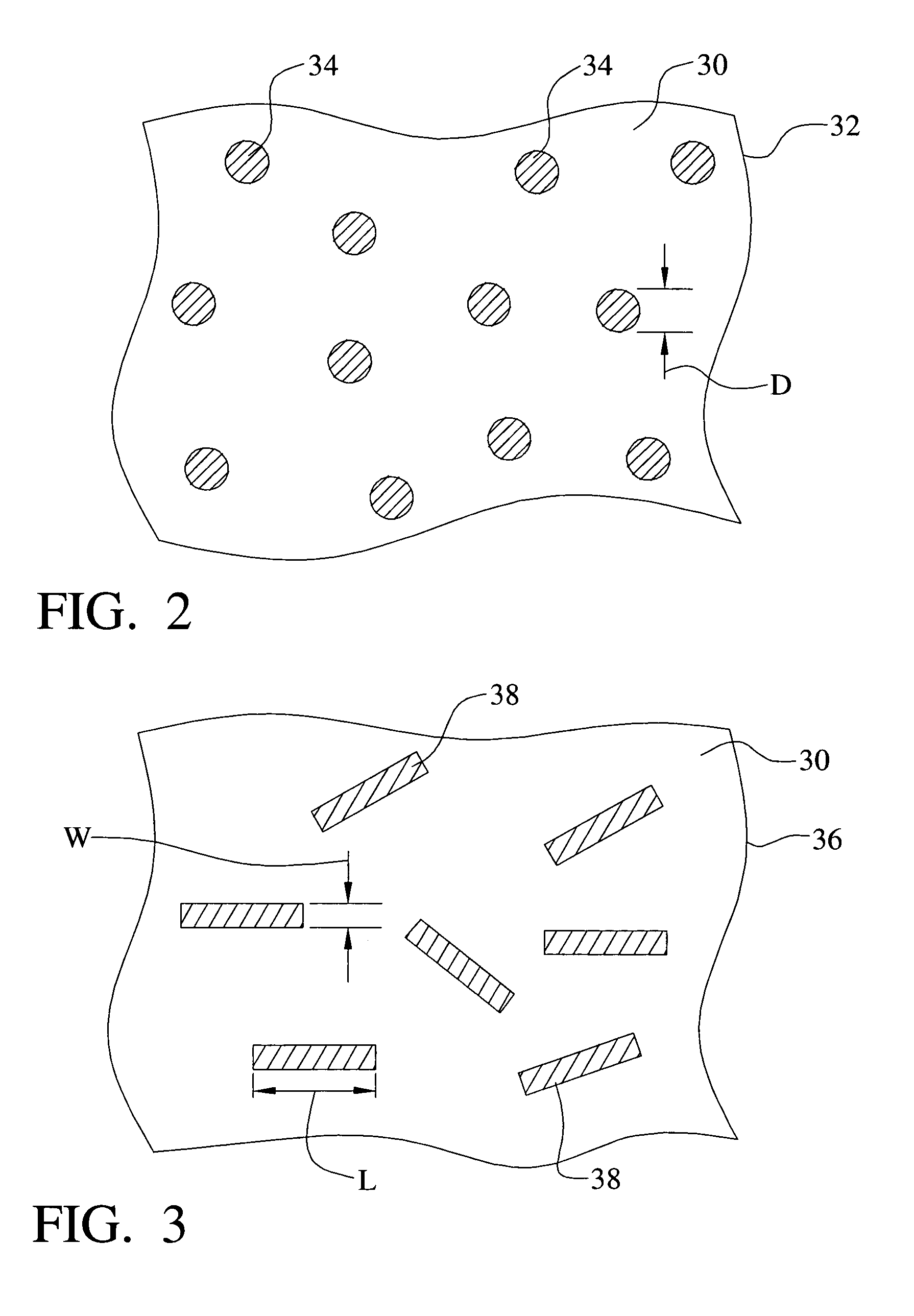

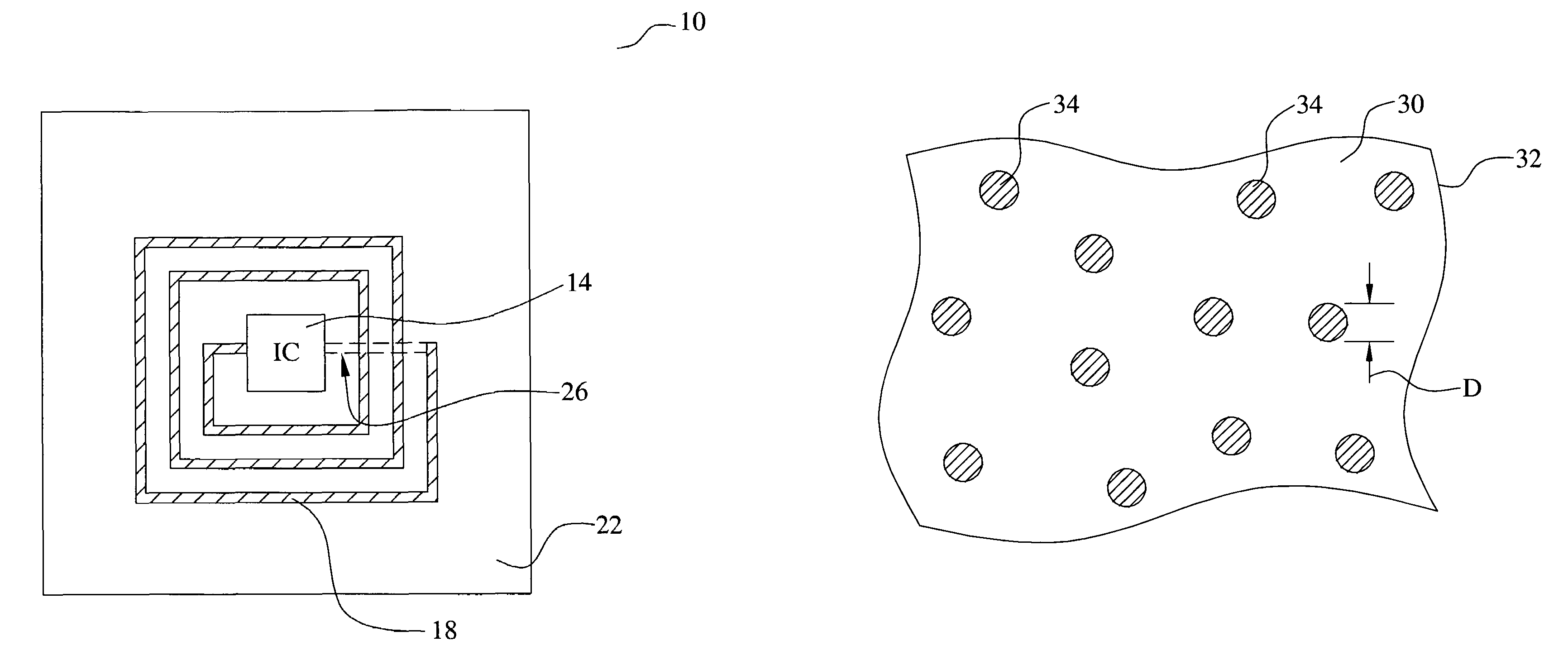

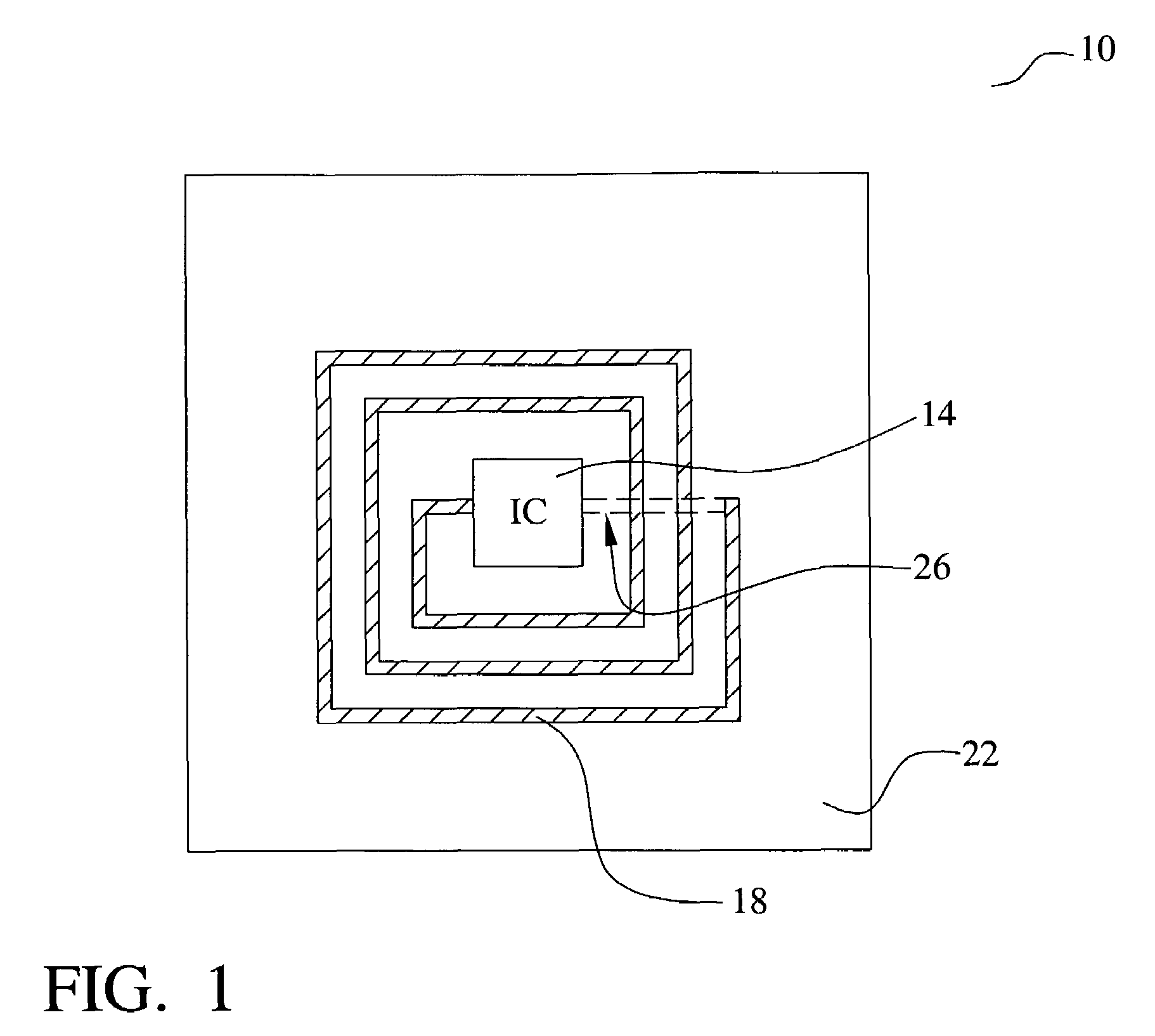

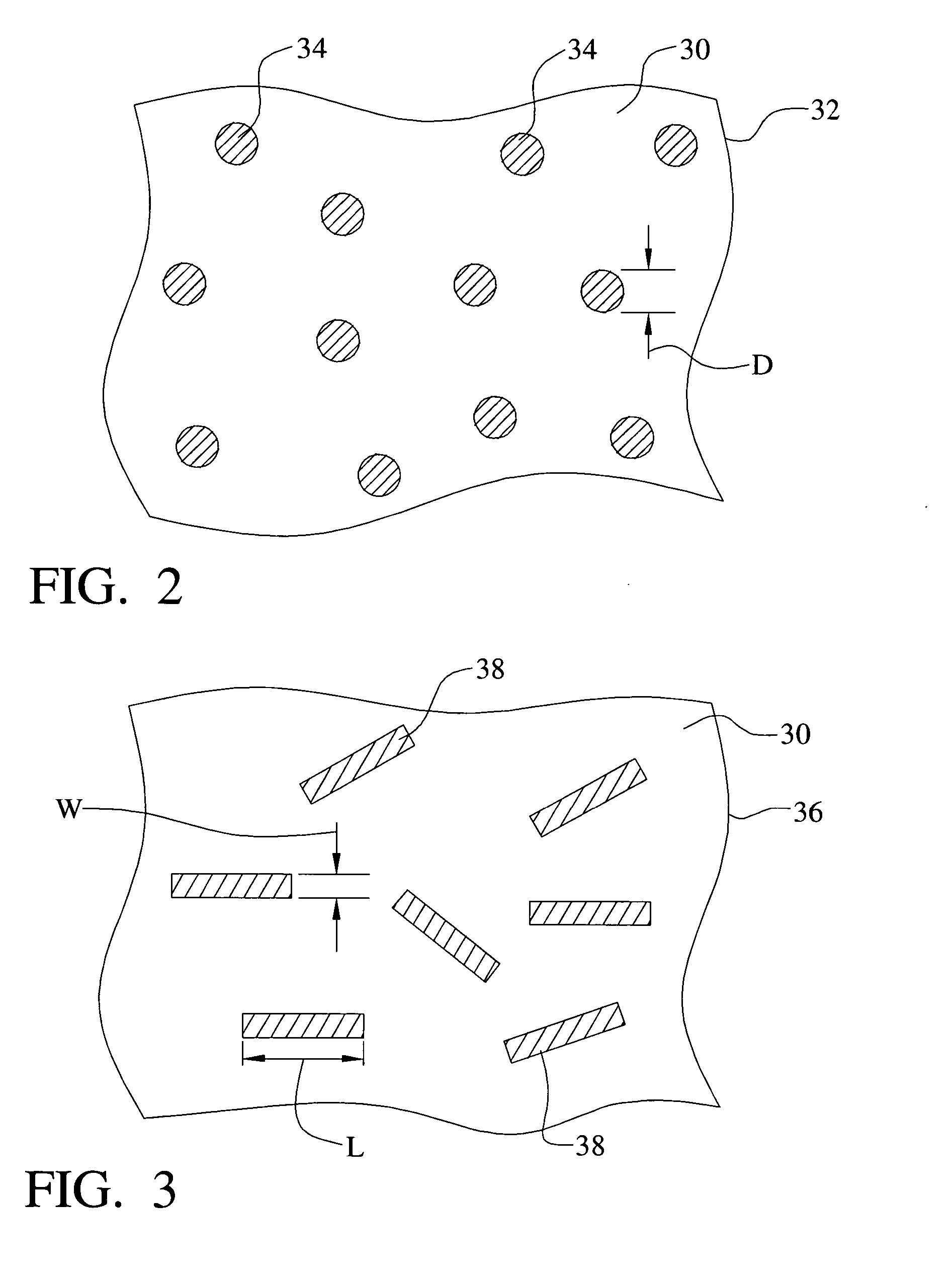

Low cost RFID antenna manufactured from conductive loaded resin-based materials

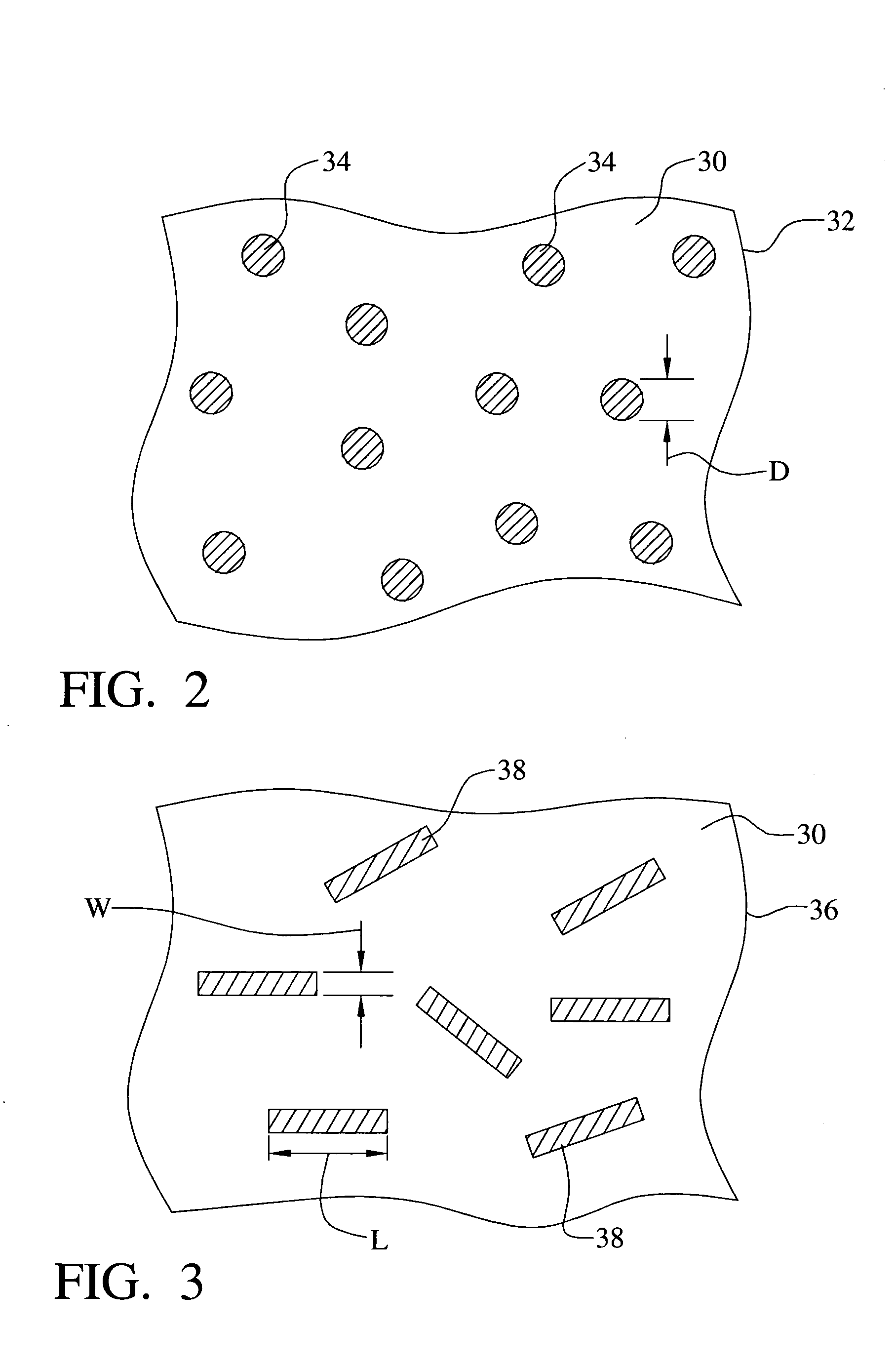

RFID antennas are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

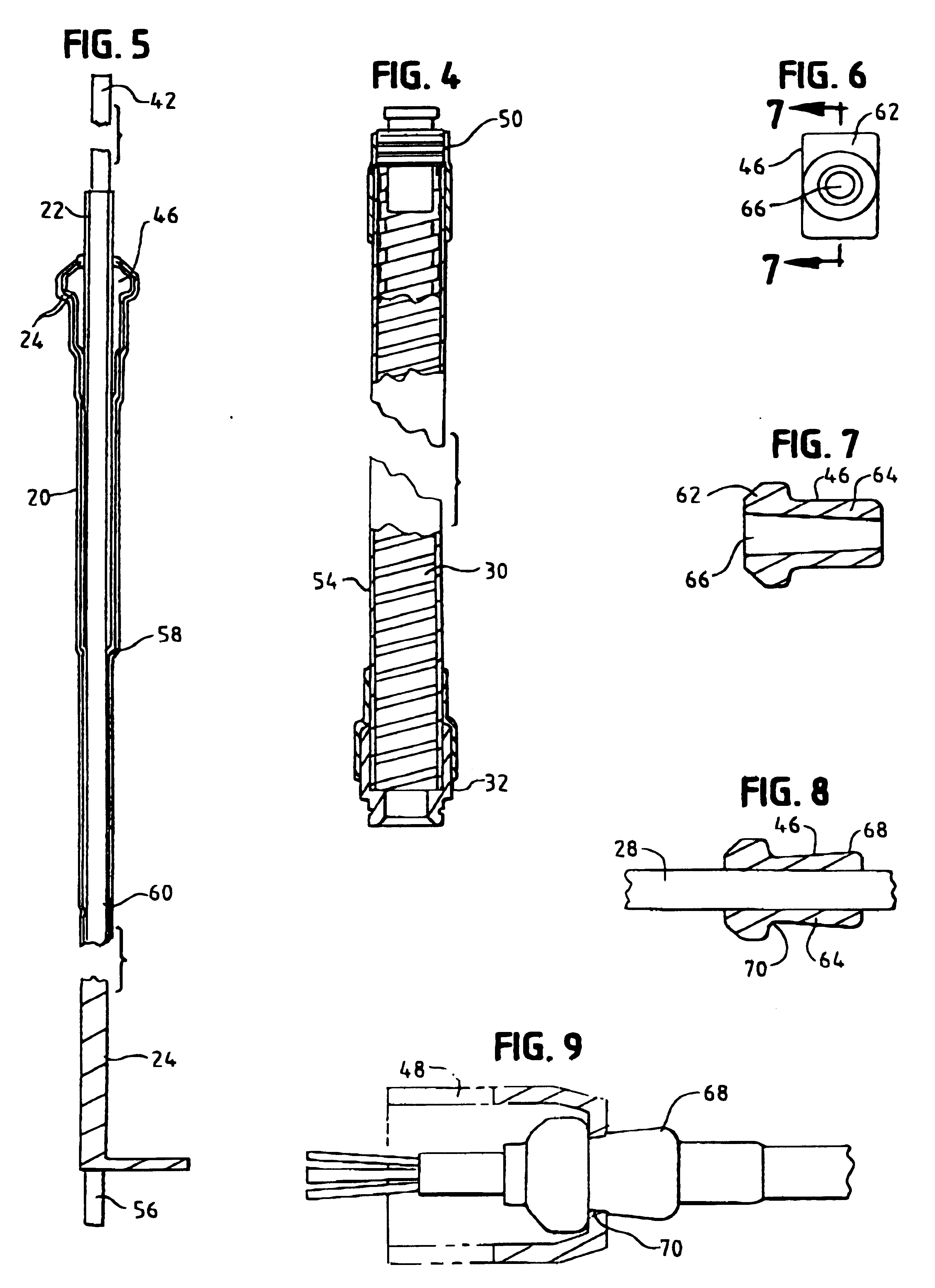

Low cost electrical cable connector housings and cable heads manufactured from conductive loaded resin-based materials

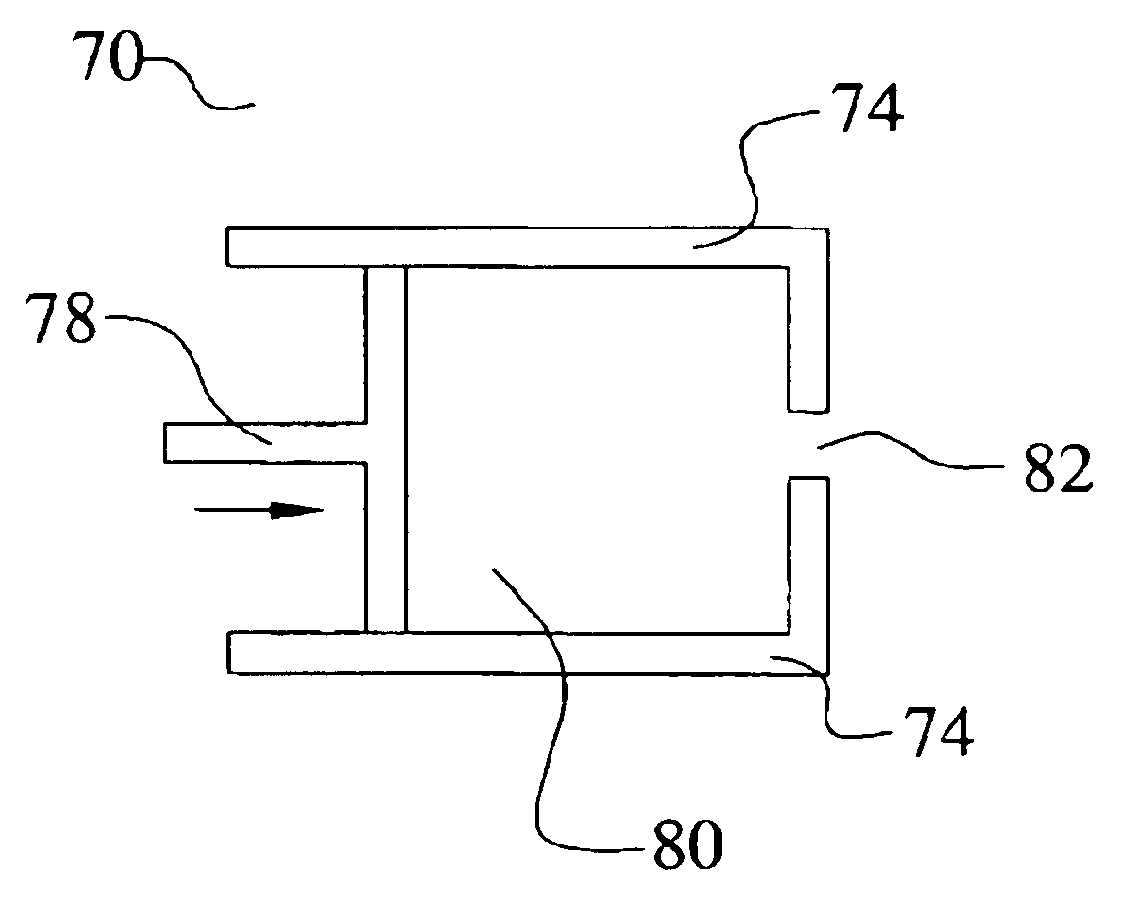

InactiveUS6947012B2Soldered/welded conductive connectionsAntennas earthing switches associationElectrical conductorEngineering

Electrical connector housings are formed of a conductive loaded resin-based material which provides superior protection from EMI and RFI by absorbing such interfering signals. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination thereof, in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 40% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

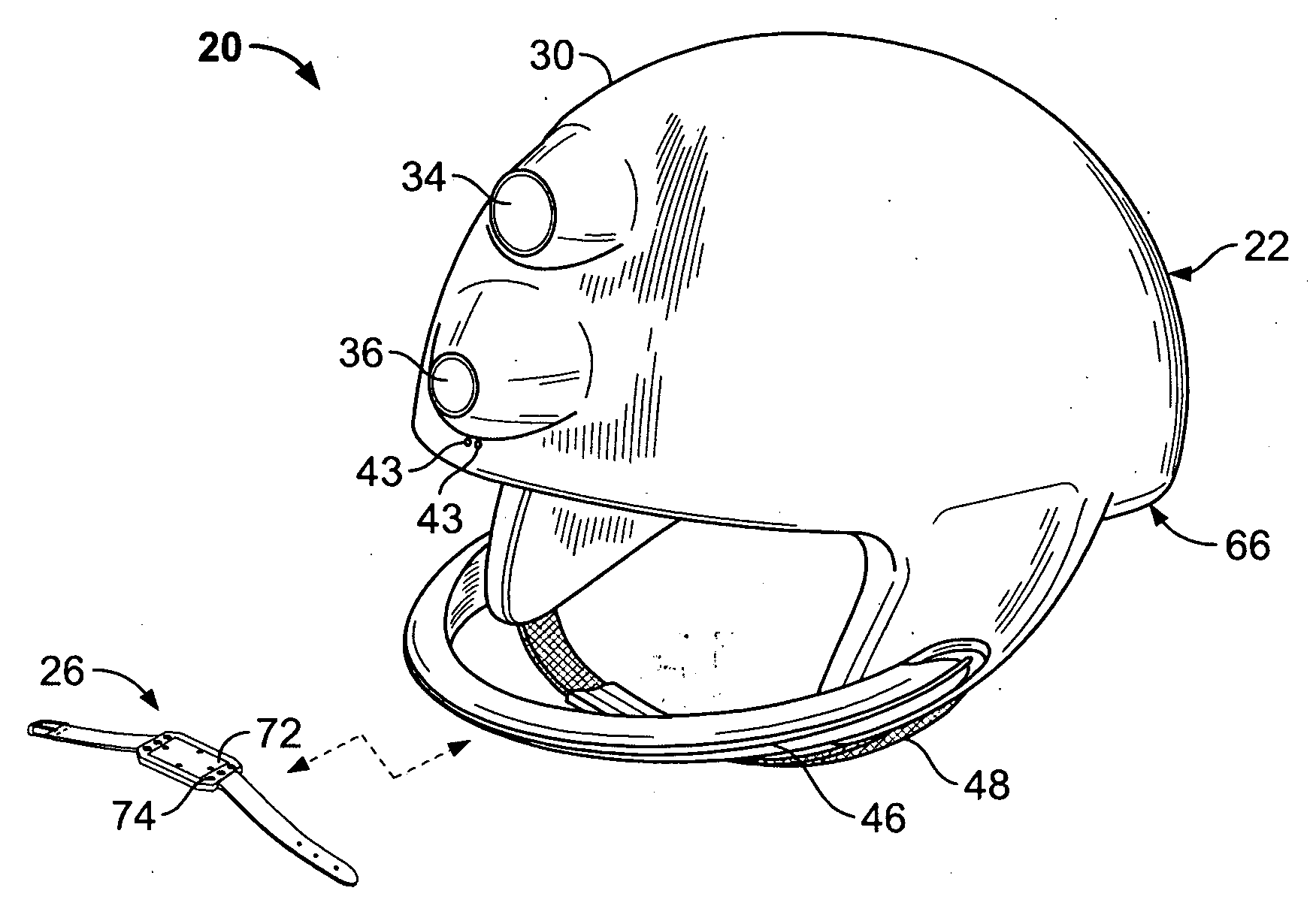

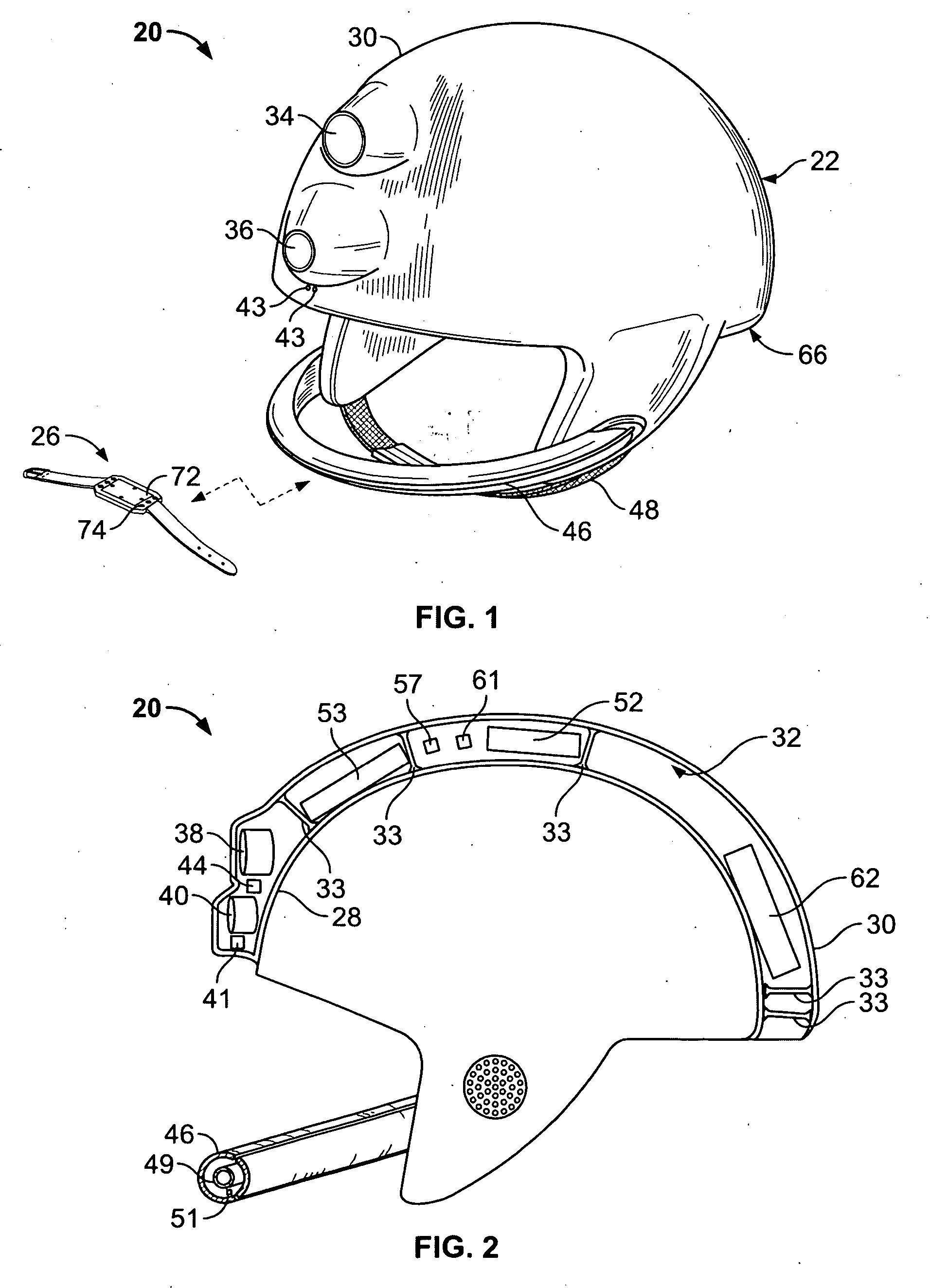

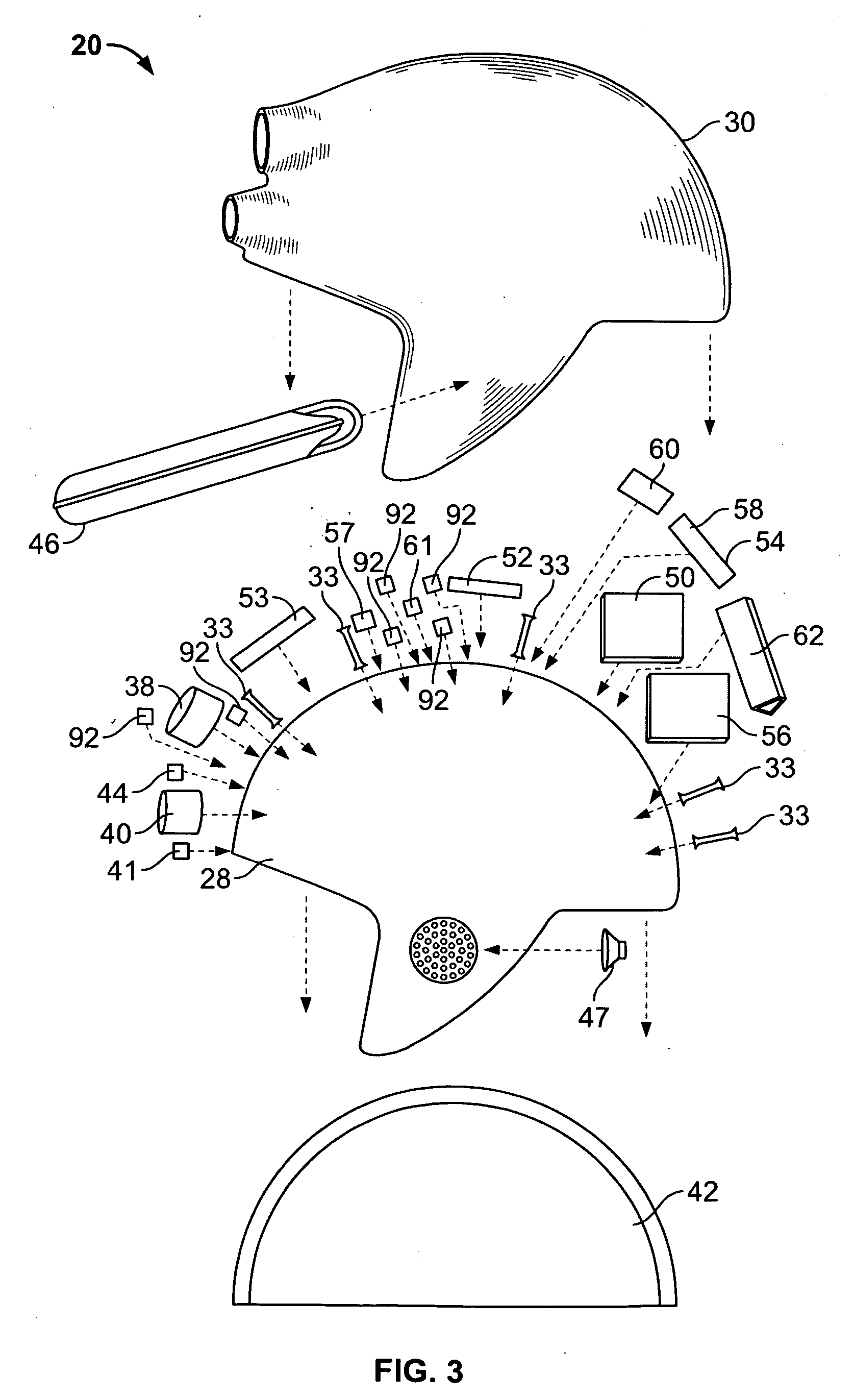

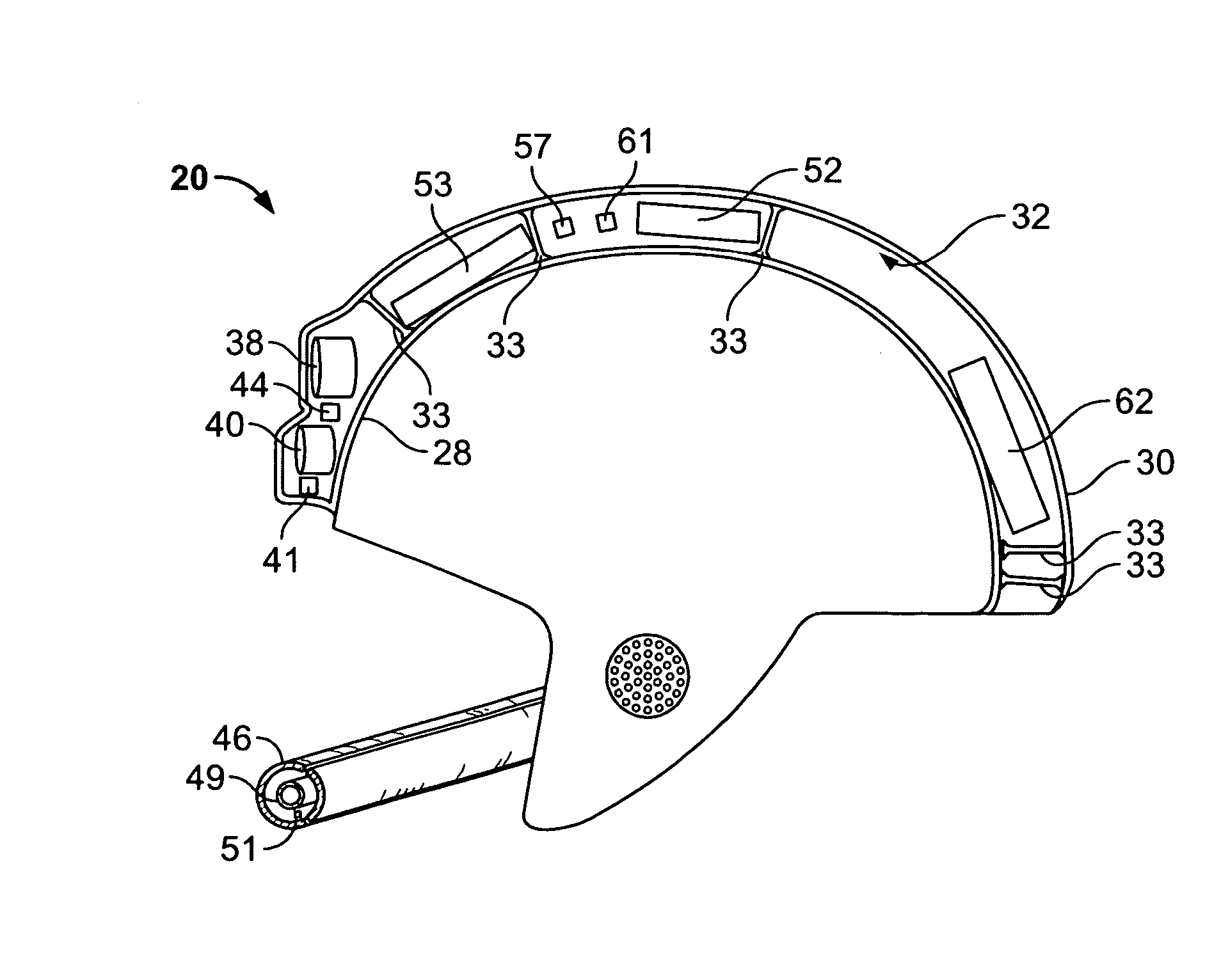

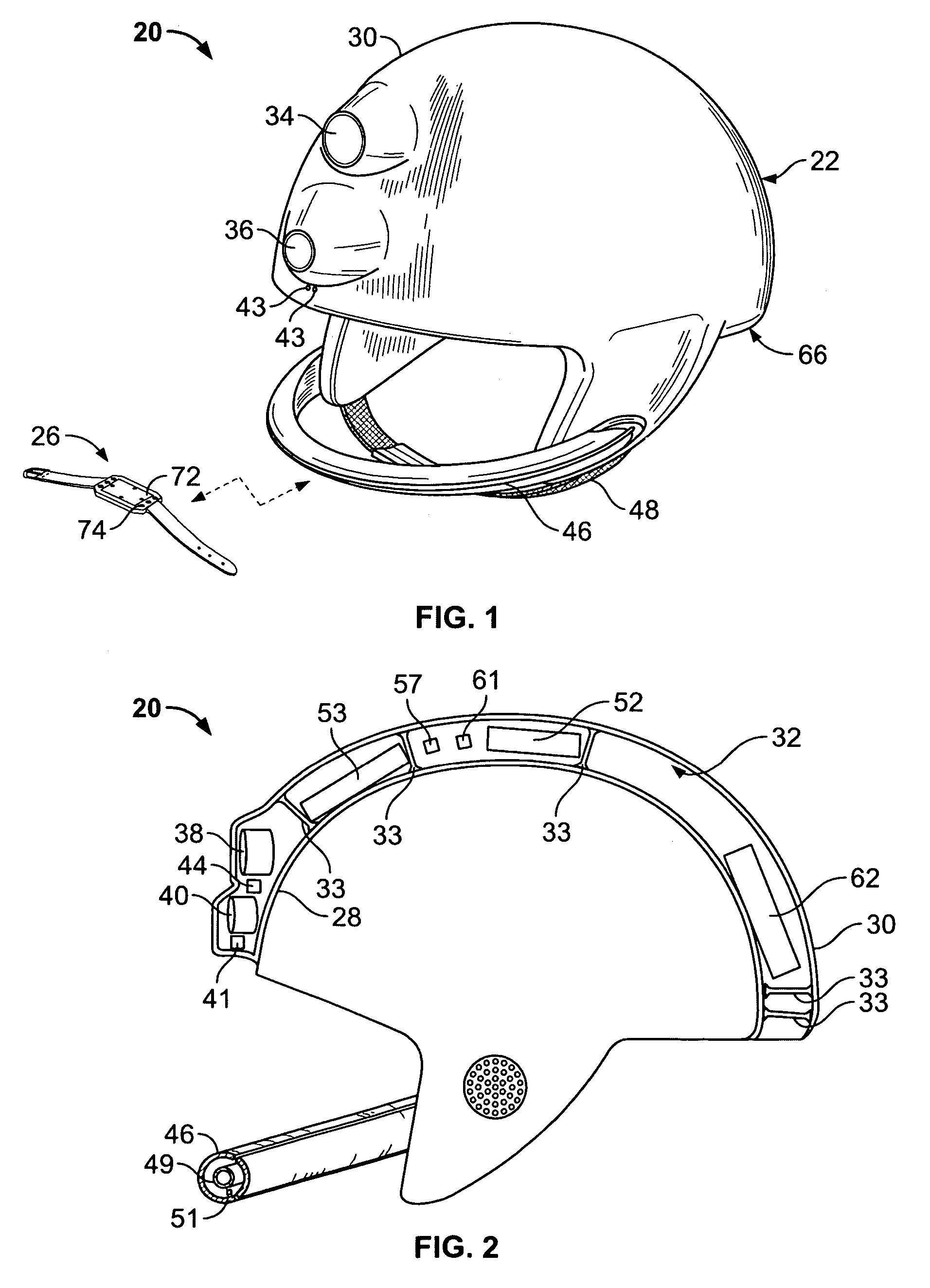

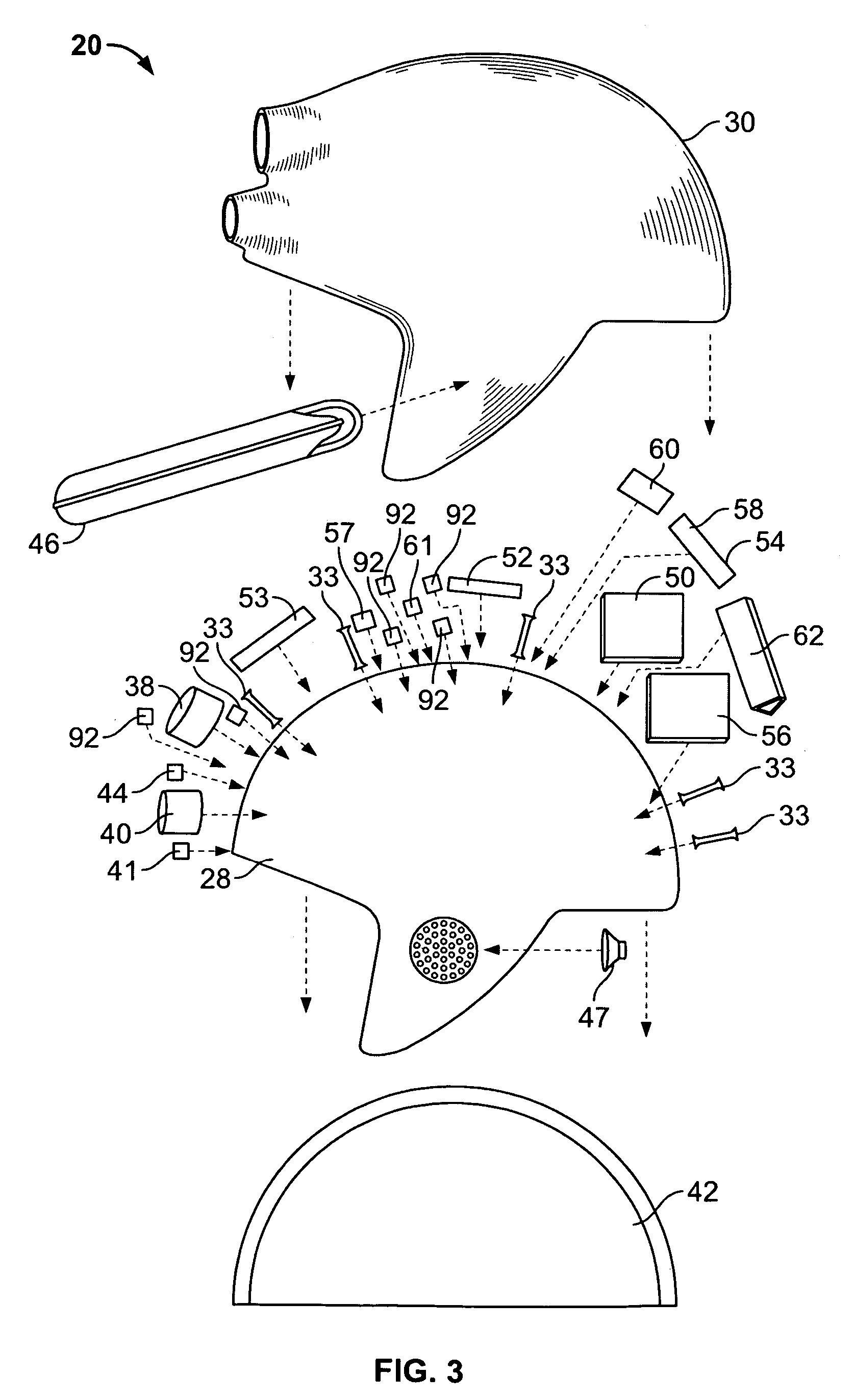

Electronic helmet

An electronic helmet is provided that includes a helmet body and an integrated electronic system disposed in the helmet body. In an exemplary embodiment, the electronic system provides the user with a number of convenient functions and is operable from a wireless remote control. The components of the electronic system are sufficiently small and rugged for use in the helmet, ensuring that the helmet is lightweight and durable. Moreover, the components are spaced about the helmet to provide even weight distribution to promote overall balance and safety. In an exemplary embodiment of the invention, the helmet body has a hard outer shell and a hard inner shell mounted to the outer shell such that a cavity is defined between the outer and the inner shells. The inner shell includes suitable material to provide the user effective RF shielding from the electronic system. For example, the inner shell can include nickel-plated carbon fiber to provide RF shielding. The helmet body further includes a shock-absorbent structure disposed between the inner shell and the head of a user, when the helmet is worn.

Owner:OXYSTRAP INTL INC

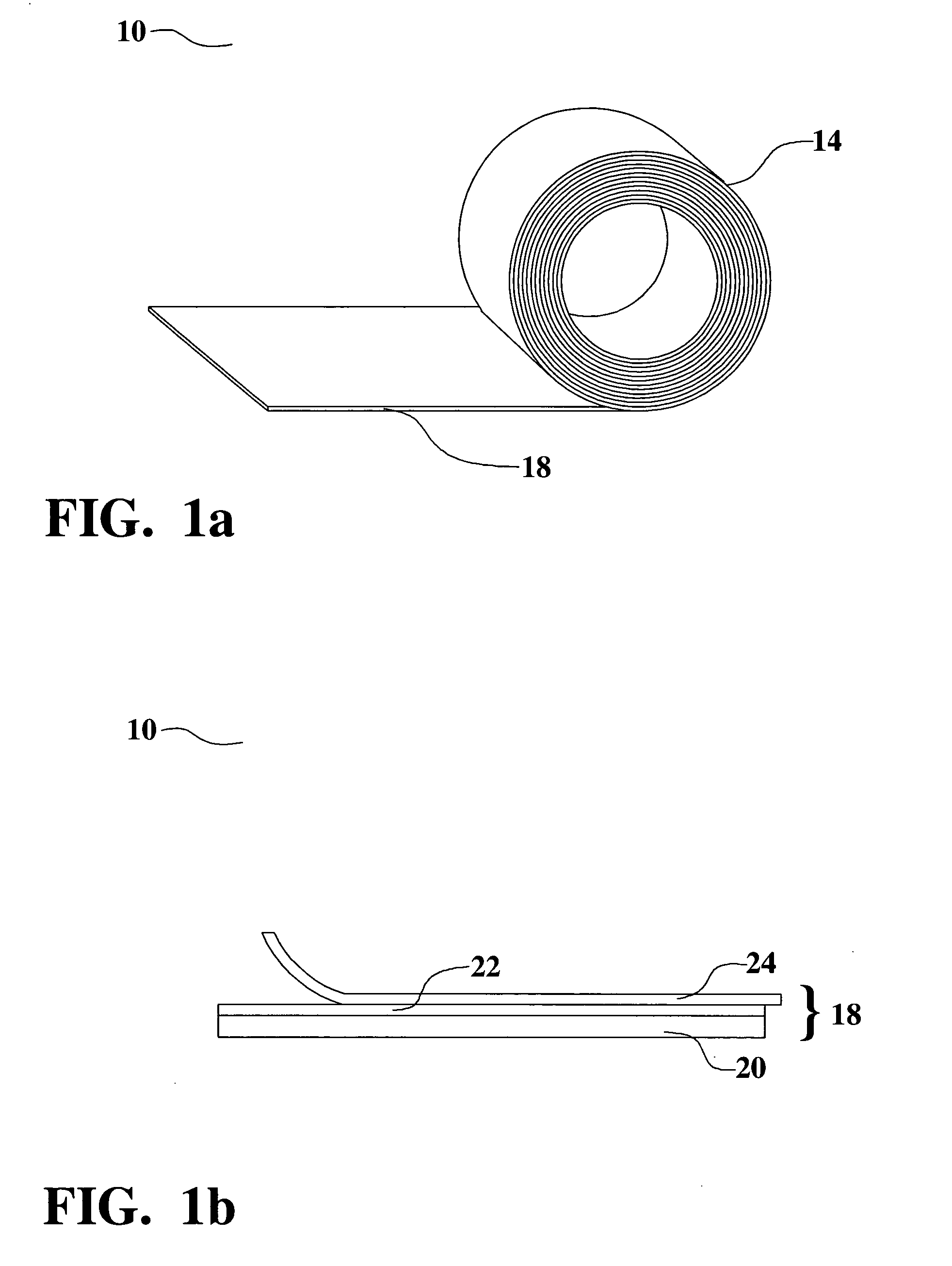

Low cost electrically conductive tapes and films manufactured from conductive loaded resin-based materials

Electrically conductive tapes and films are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, aluminum fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

Retractable cord assembly

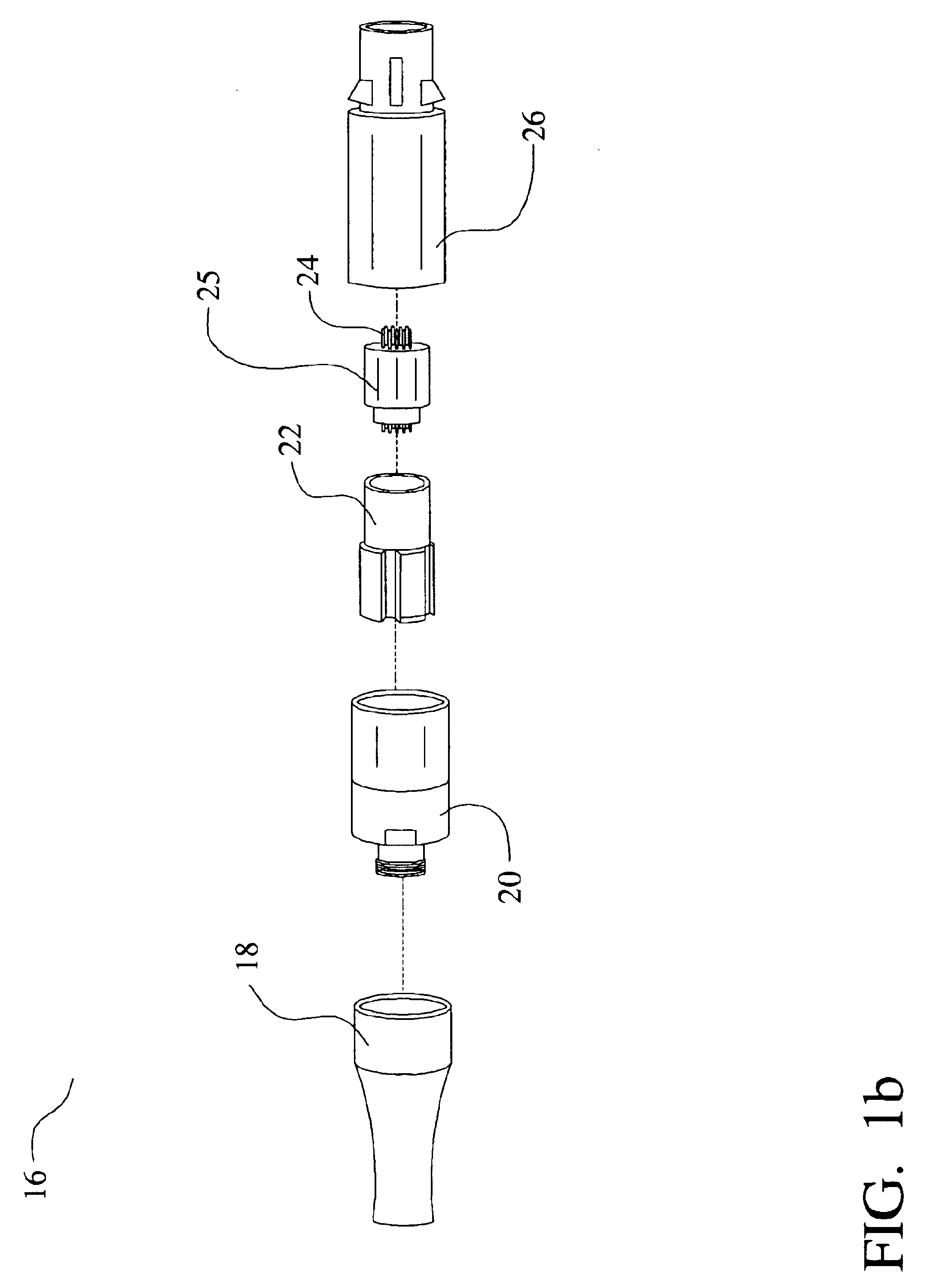

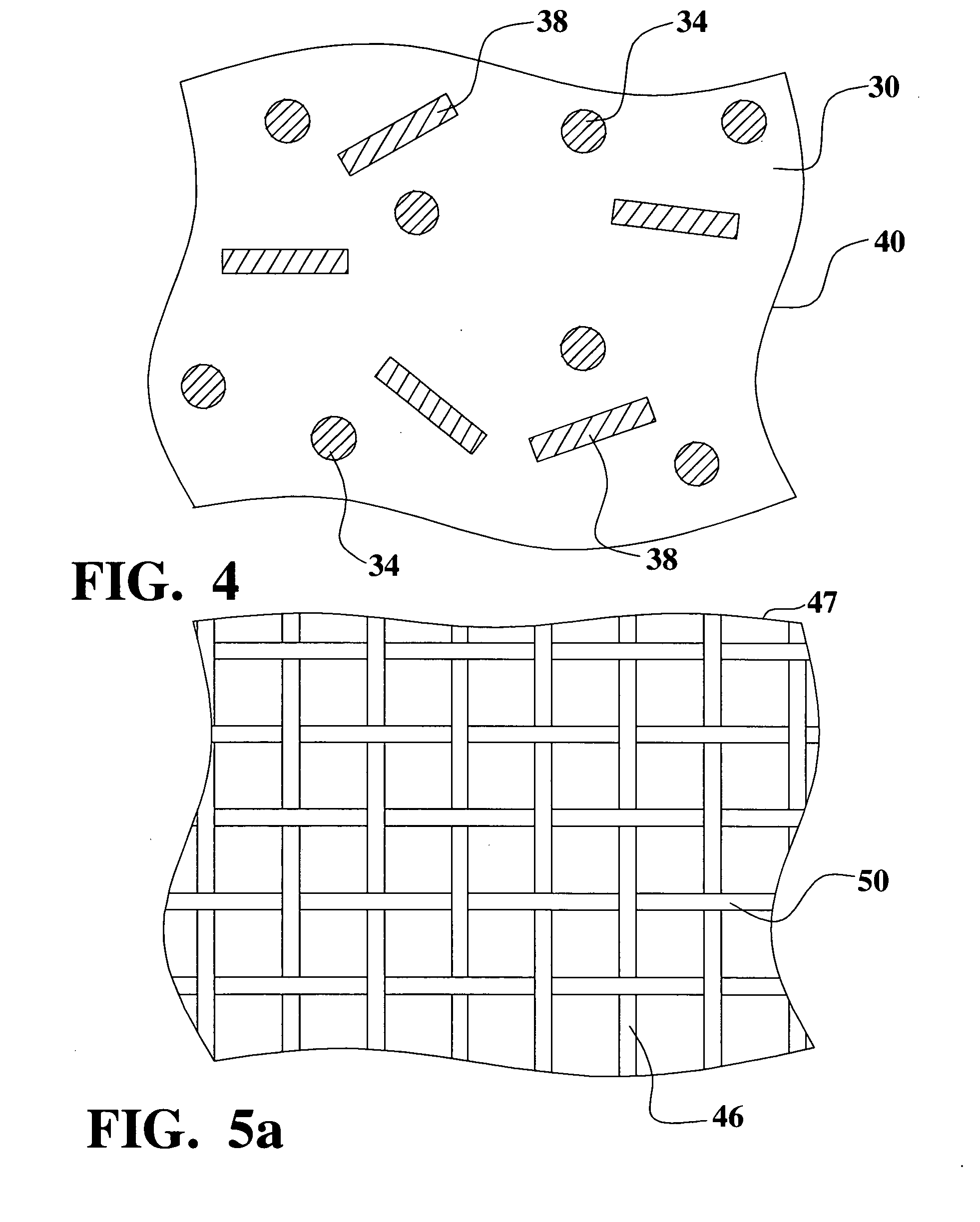

InactiveUS6495756B1Improved resistance to failureExtended service lifeArrangements using take-up reel/drumExtensible conductorsElectrical conductorCatheter

The retractable cord assembly (26) comprises a cable (28) having a central carrier and plural conductors helically wrapped about the central carrier. The assembly further includes a grommet for connecting the cable (28) to a device, the grommet having a head and stem, with a passage throught he head and stem for receiving the cable (28). The passgae is tapered to provide an enlarged proximal end when installed. The assembly further includes a flexible metal conduit (30) through which the cable slides. The cable outer surface is nylon braid and the conduit inner surface is a nickel plated to minimize friction therebetween.

Owner:ASTRONICS CONNECTIVITY SYST & CERTIFICATION CORP

Anti-rust treating agent for nickel-plated battery steel shell and using method thereof

ActiveCN102002698AFast film formationReduce processing timeMetallic material coating processesPolyvinyl alcoholPhytic acid

Owner:XIANGTAN UNIV

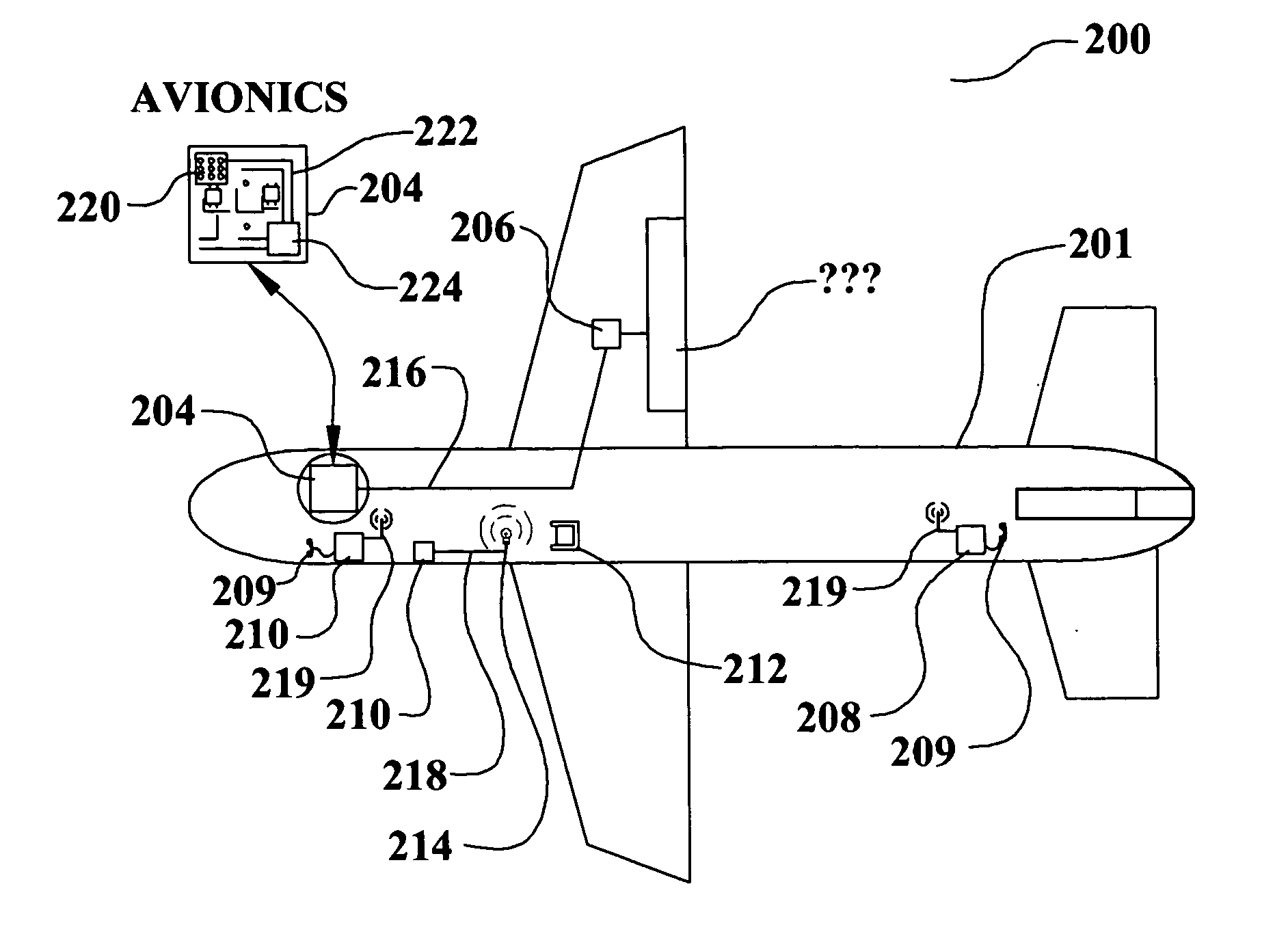

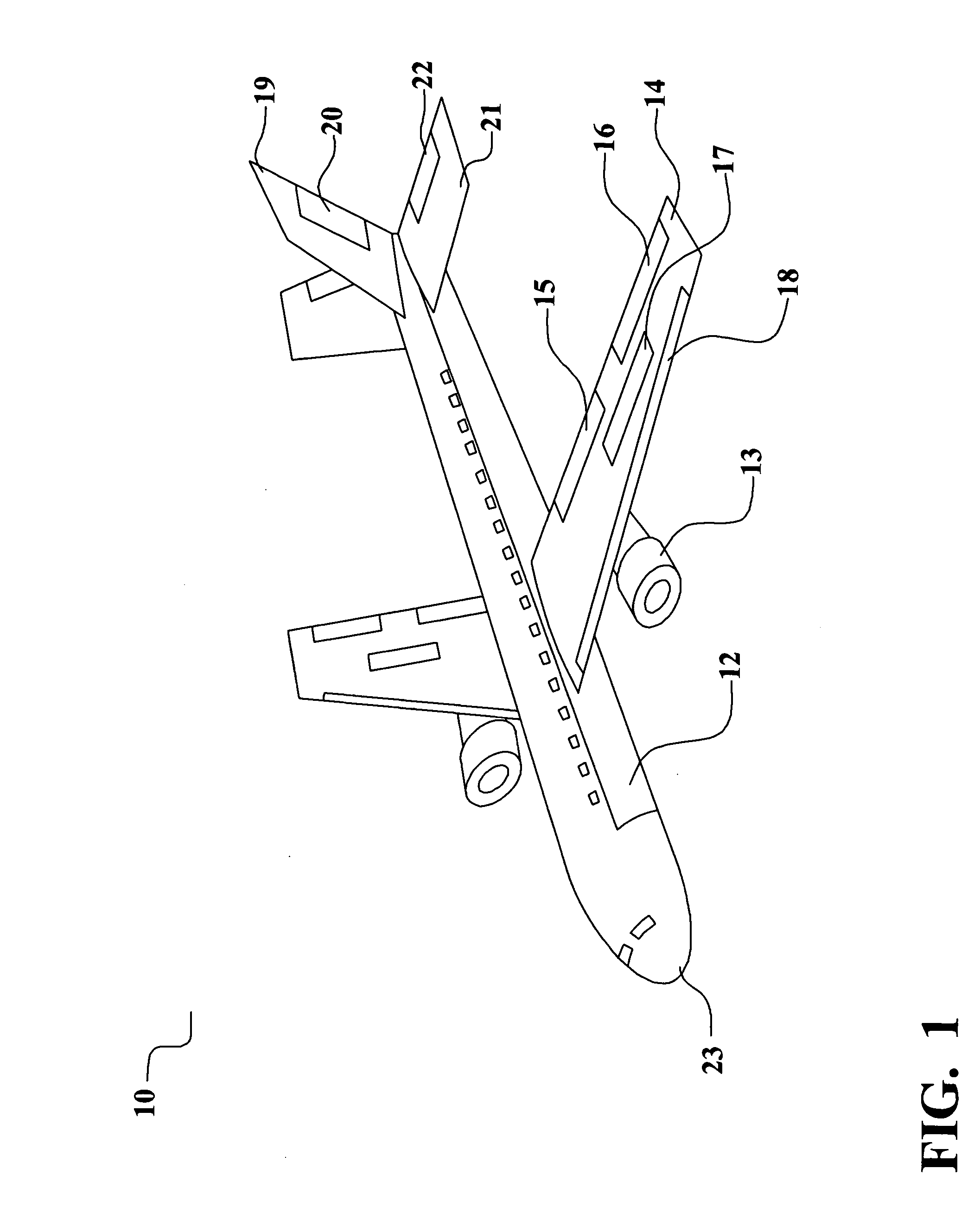

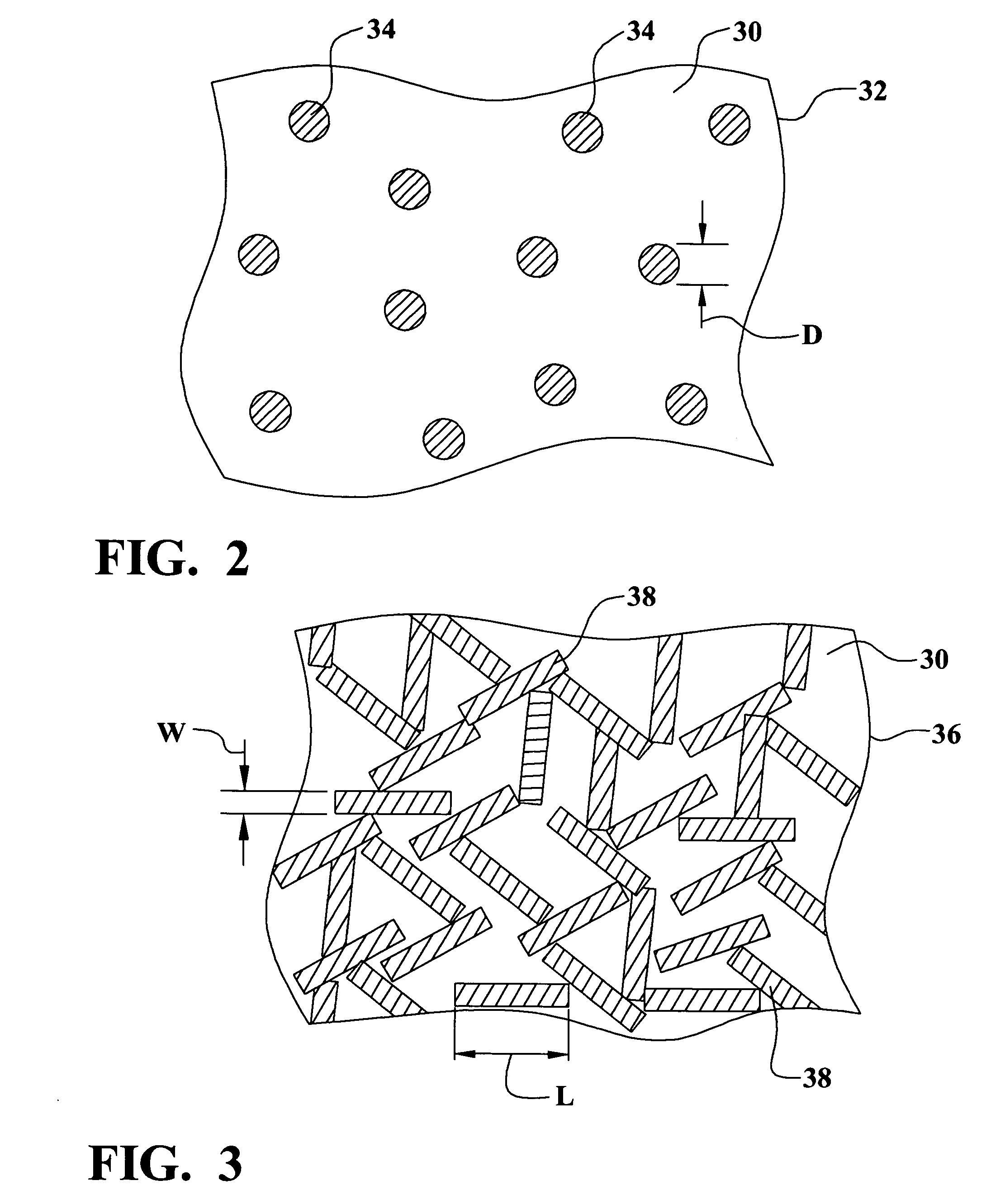

Low cost aircraft structures and avionics manufactured from conductive loaded resin-based materials

InactiveUS20060060690A1Reduce weightImprove performanceNon-insulated conductorsDe-icing equipmentsAviationCarbon fibers

Aircraft structures and avionics are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, aluminum fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

Nickel-base high-temperature alloy with low density and high melting point and preparation process thereof

The invention relates to high-temperature alloy technology, and in particular provides an isometrical cast nickel-base high-temperature alloy with low density, high incipient melting temperature and good casting property and a preparation process thereof, which can be used for floating tile materials of a combustion chamber. The alloy comprises the following compositions by mass percentage: 0.03 to 0.06 percent of C, 5 to 12 percent of Cr, 5.5 to 6.5 percent of Al, 3 to 8 percent of Co, 3 to 7 percent of W, 2 to 4 percent of Mo, 1.6 to 3.2 percent of Nb, 0.01 to 0.03 percent of B, 0.008 to 0.025 percent of Y and the balance of Ni. A vacuum induction furnace is adopted to smelt a master alloy, and a smelting crucible is a CaO crucible or a MgO crucible; and the operation process comprises the following steps: putting alloying elements such as carbon, chromium, cobalt, tungsten, molybdenum and niobium in proportion and a nickel plate into the crucible; melting the alloy when the vacuum degree reaches between 50 and 0.1 Pa; and after completion of the melting, refining for 30 to 300 seconds at a temperature of between 1,550 and 1,600 DEG C, cutting off electricity, forming a film, breaking the film to add Al and Al-Y and Ni-B interalloy for uniform stirring, and casting a master alloy pig at a temperature of between 1,450 and 1,500 DEG C. The invention solves the problems of low incipient melting temperature, poor plasticity and inoxidability and the like of the nickel-base high-temperature alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

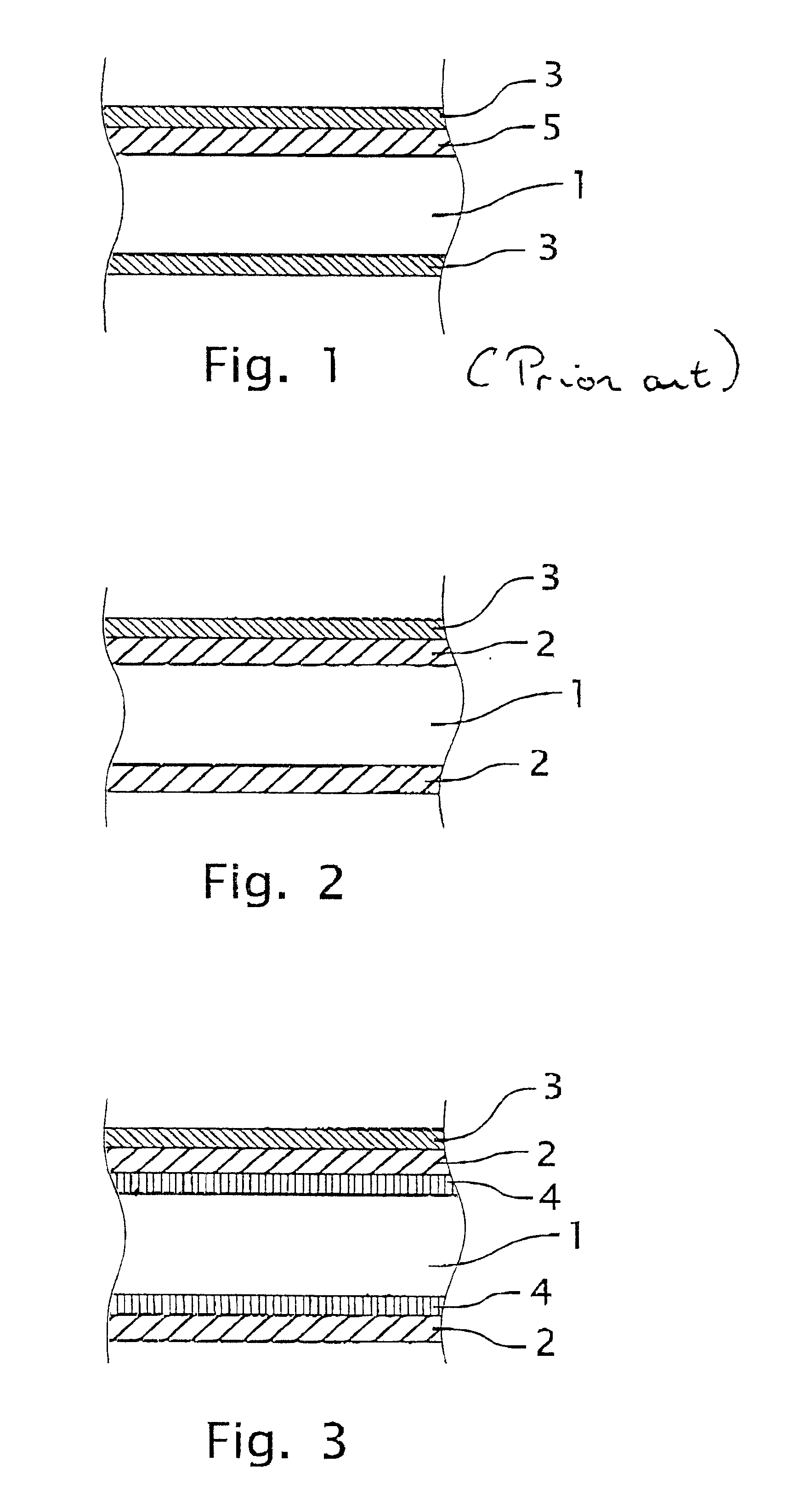

Nickel-plated brazing sheet product

InactiveUS6568584B2Improve corrosion resistanceReduce the temperatureWelding/cutting media/materialsWelding/soldering/cutting articlesZincImpurity

The invention relates to a brazing sheet product comprising a core sheet made of an aluminum alloy, an aluminum clad layer cladding at least one of the surfaces of said core sheet, and a layer comprising nickel on the outersurface of one or both said clad layer or layers, and wherein the brazing sheet product is devoid of a layer comprising zinc or tin as a bonding layer between said outersurface of said aluminum clad layer or layers and said layer comprising nickel, and wherein the aluminum clad alloy layer comprises, in weight percent: Si 2 to 18, Mg up to 8.0, Zn up to 5.0, Cu up to 5.0, Mn up to 0.30, In up to 0.30, Fe up to 0.80, Sr up to 0.20, at least one element selected from the group consisting of: (Bi 0.01 to 1.0, Pb 0.01 to 1.0, Li 0.01 to 1.0, Sb 0.01 to 1.0), impurities each up to 0.05, total up to 0.20, balance aluminum.

Owner:DANA CANADA CORP

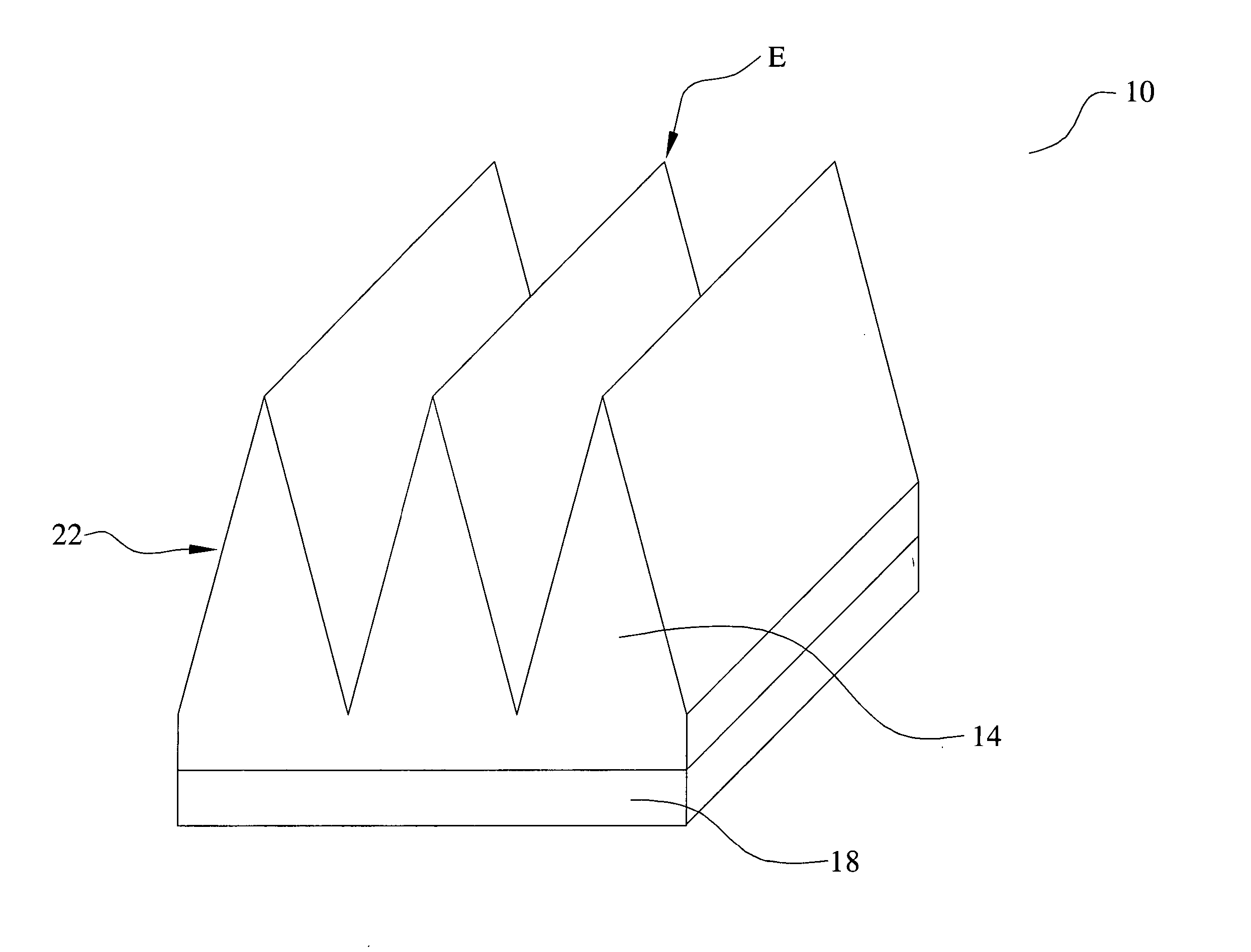

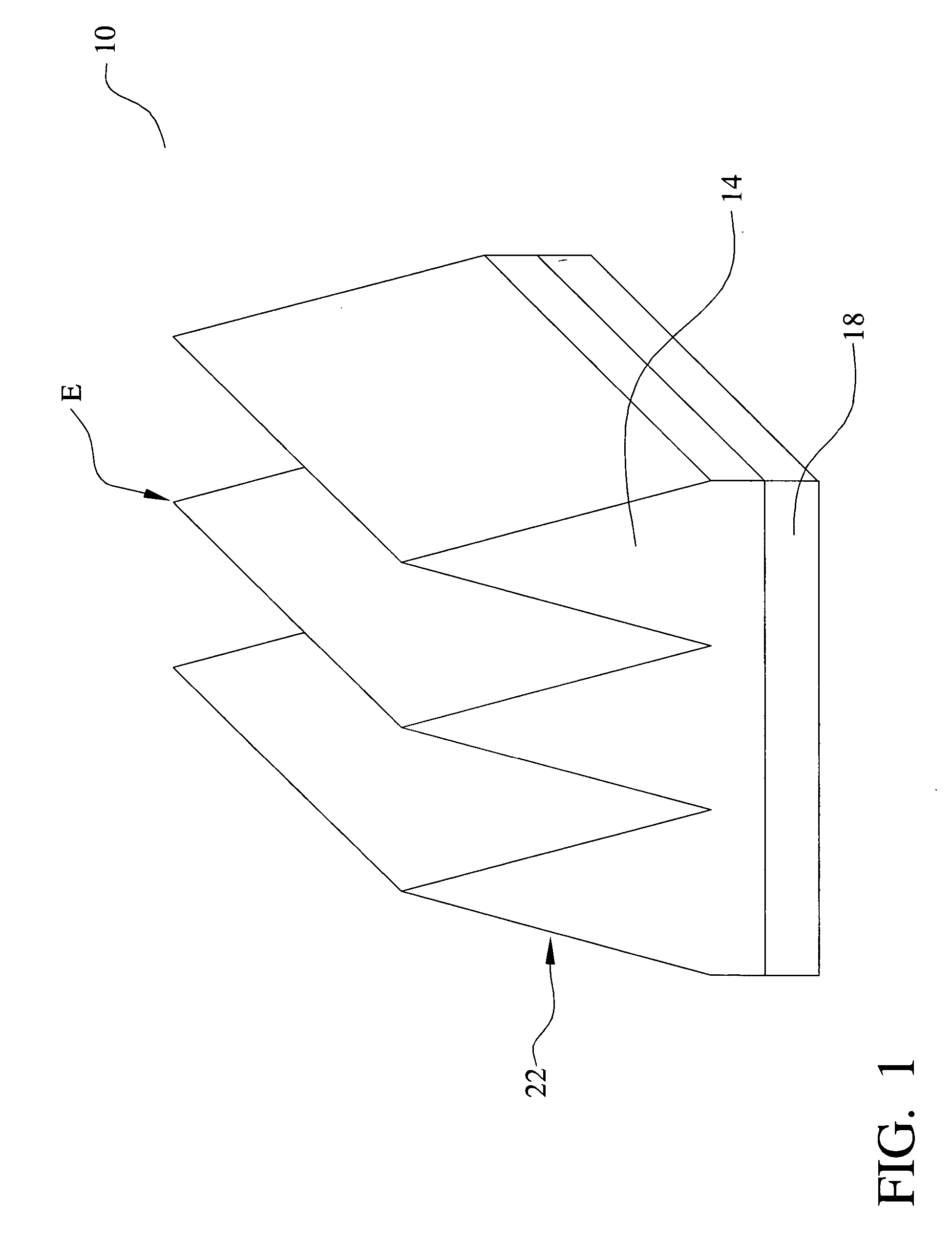

Low cost electromagnetic energy absorbers manufactured from conductive loaded resin-based materials

Electromagnetic energy absorbing devices are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The ratio of the weight of the conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers to the weight of the base resin host is between about 0.20 and 0.40. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

Electronic helmet

An electronic helmet is provided that includes a helmet body and an integrated electronic system disposed in the helmet body, providing a number of convenient functions. The helmet body has a hard outer shell and a hard inner shell mounted to the outer shell such that a cavity is defined between the outer and the inner shells. The inner shell can include suitable material to provide the wearer effective RF shielding from the electronic system, such as, nickel-plated carbon fiber to provide RF shielding. The helmet body further includes a shock-absorbent structure disposed between the inner shell and the head of a wearer.

Owner:OXYSTRAP INTL INC

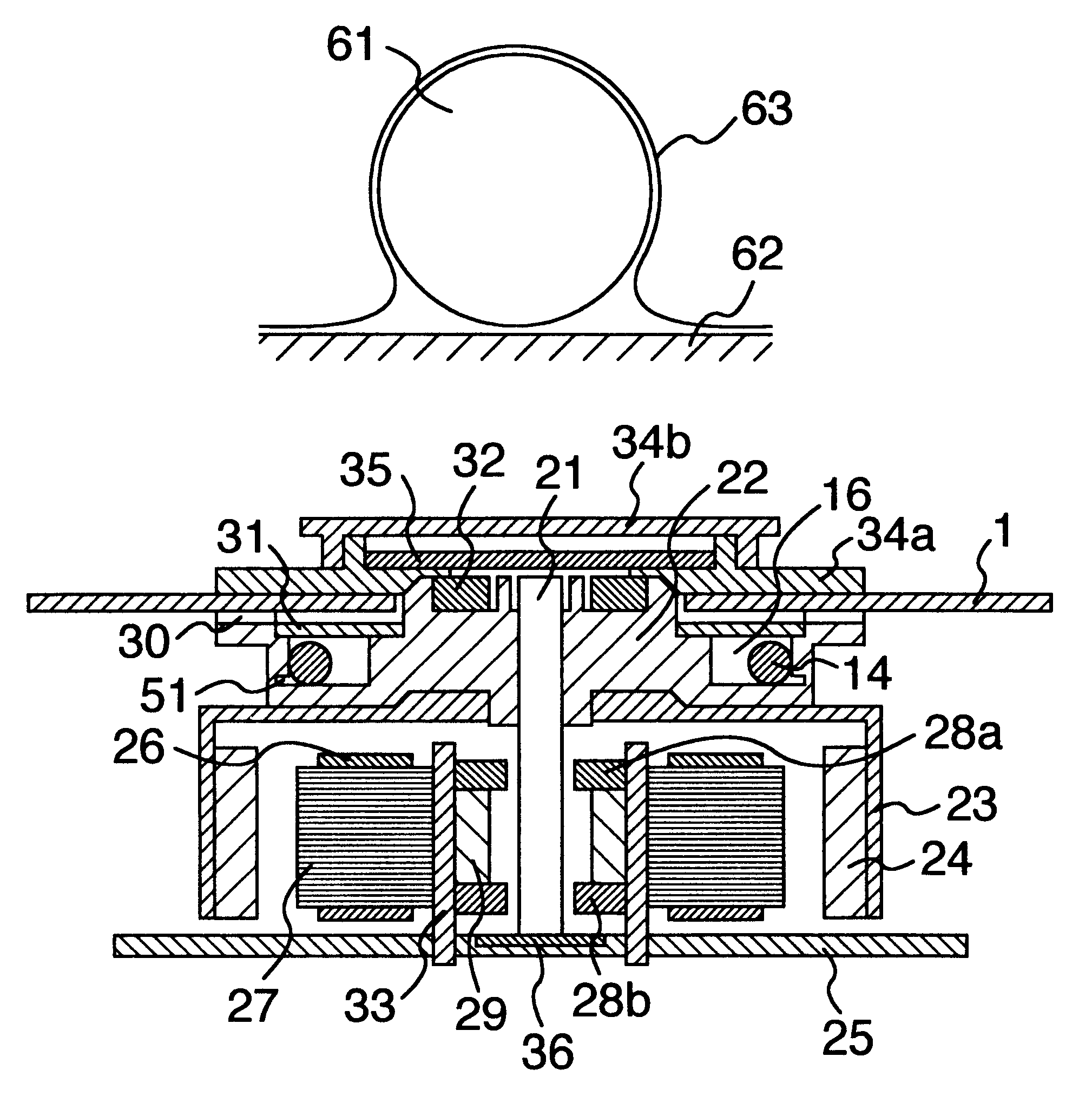

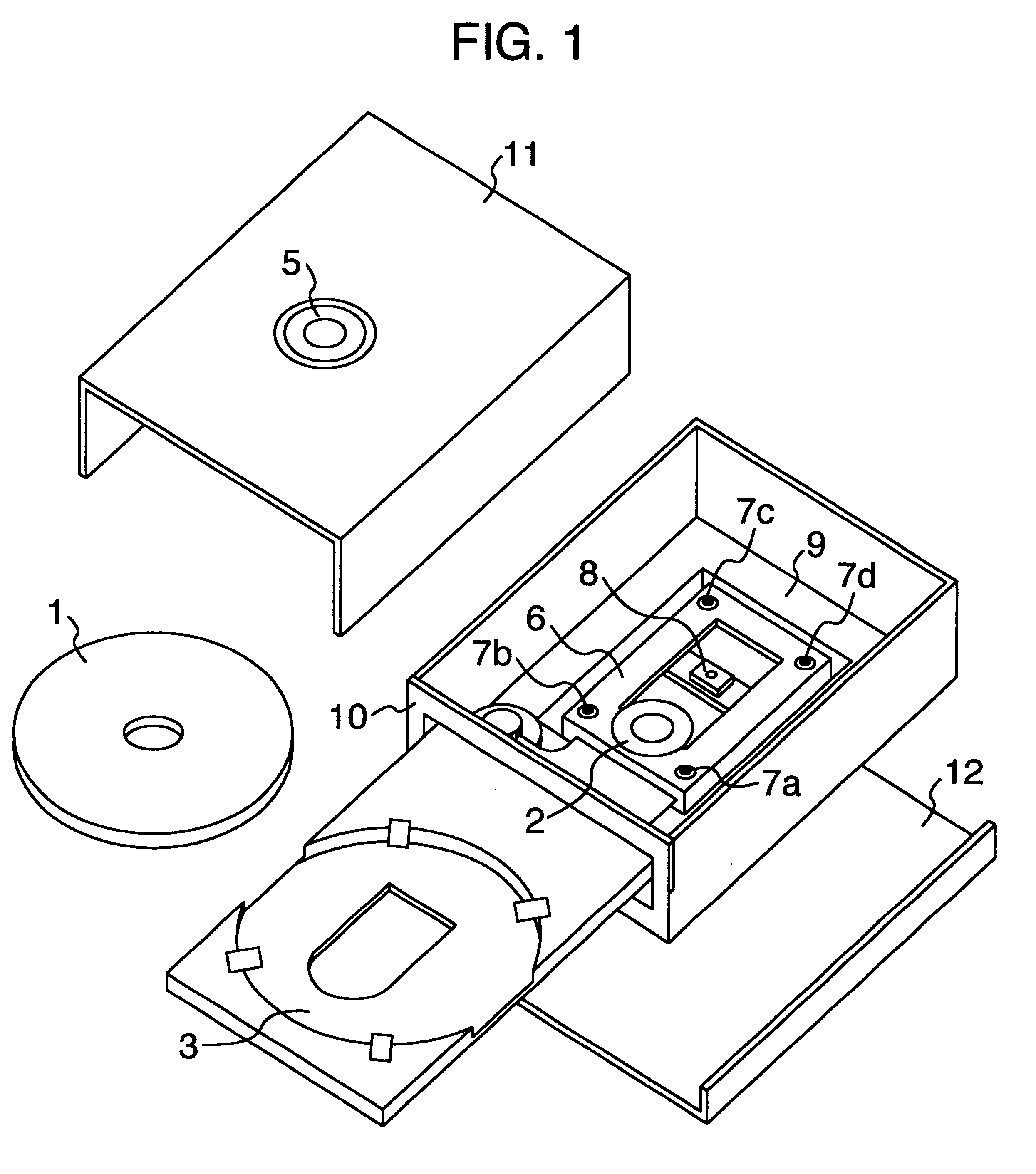

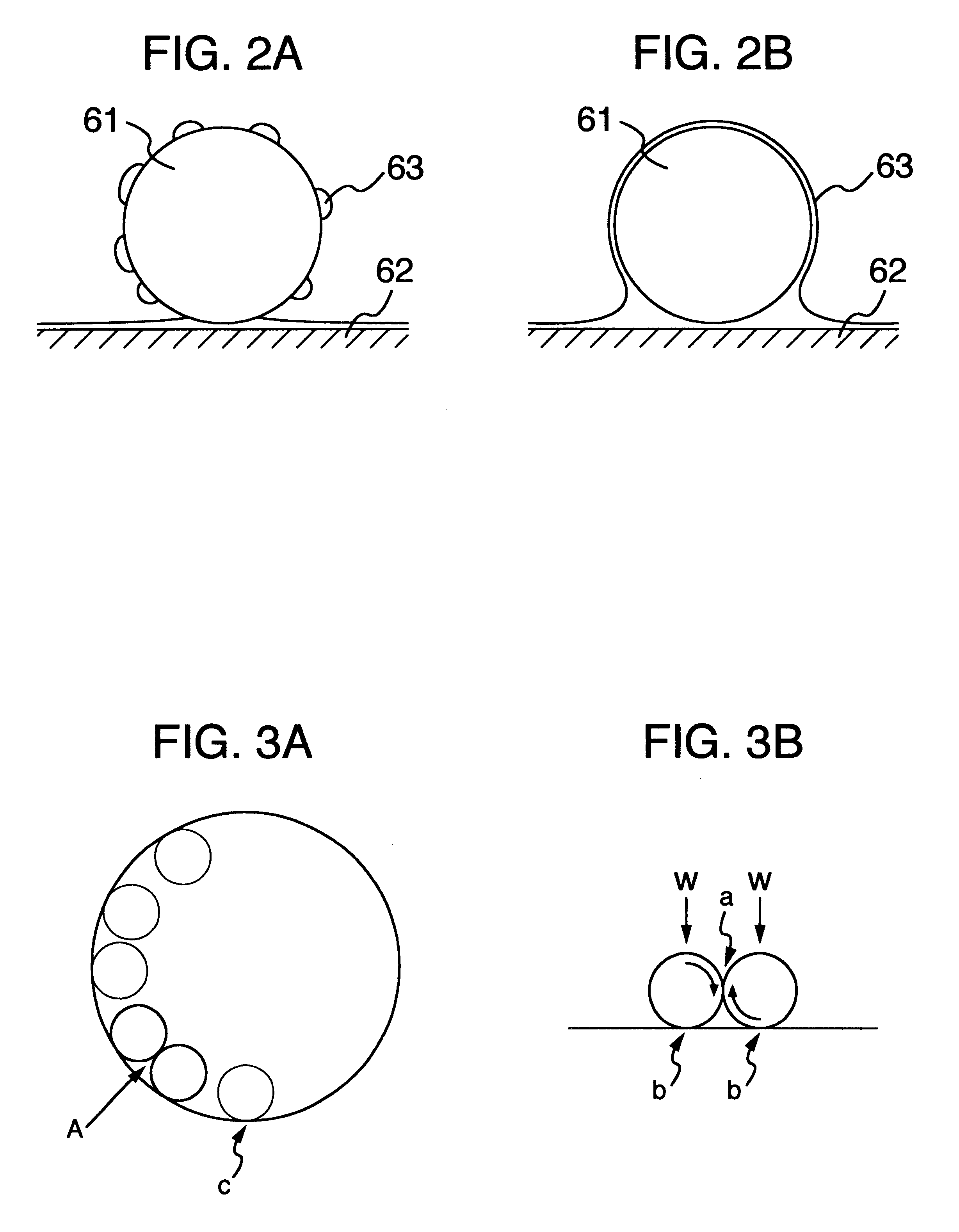

Disk drive with unbalance correcting mechanism

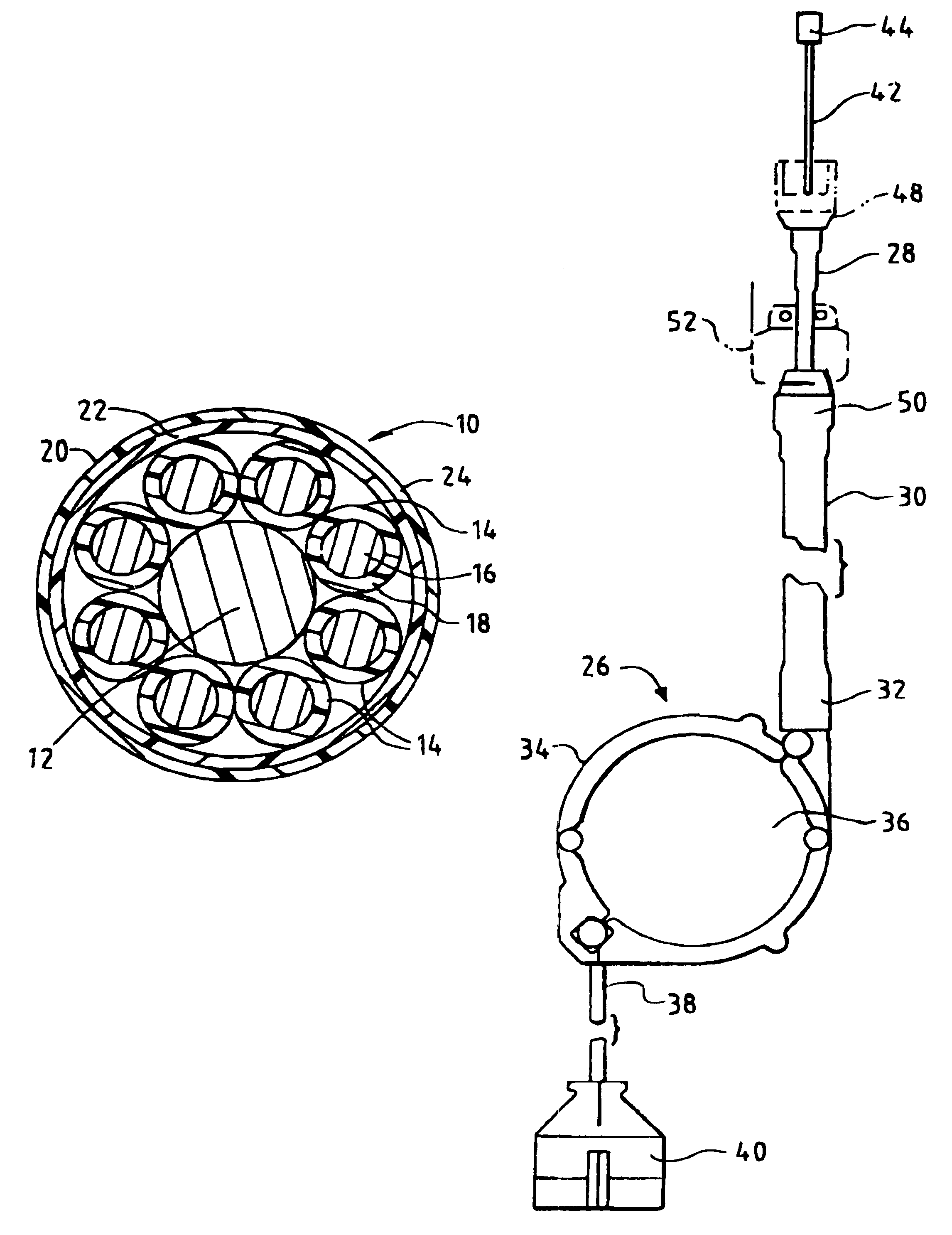

InactiveUS6477133B1Shorten the timeLow costUndesired vibrations/sounds insulation/absorptionRotating bodies balancingEngineeringBoron

A disk drive is realized, which omits running-in for stabilizing a change in a correcting function produced by sliding between balls and a rolling groove in an unbalance correcting mechanism, and prevents immobility and straying of balls, and which comprises a unit mechanism assembled by using 12 balls subjected to surface treatment with heptadecafluorodecyltrimethoxysilane and a turntable plated with a chemical nickel plating containing phosphorus and boron to have a thickness of 5 mum and by injecting 1 microliter of ester oil into the rolling groove, and further comprises a recess formed in a sidewall of the rolling groove of the unbalance correcting mechanism to prolong the service life of the correcting function.

Owner:HITACHI LTD

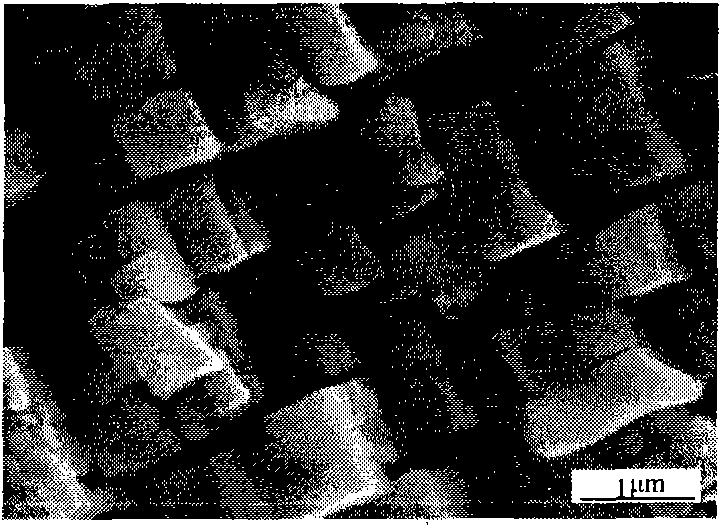

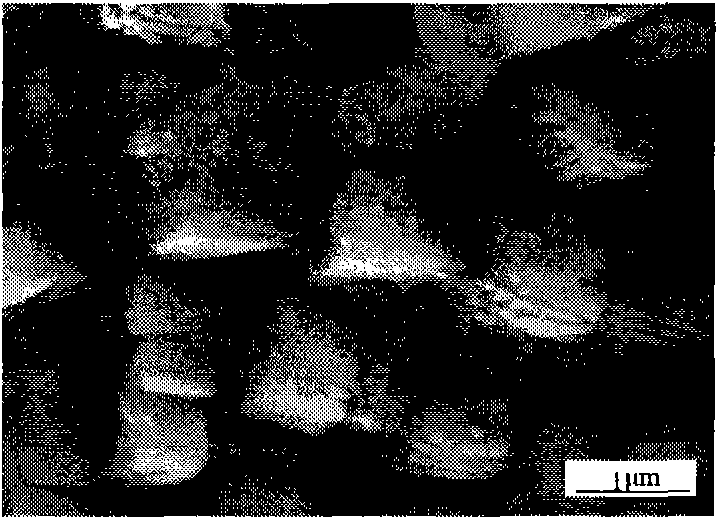

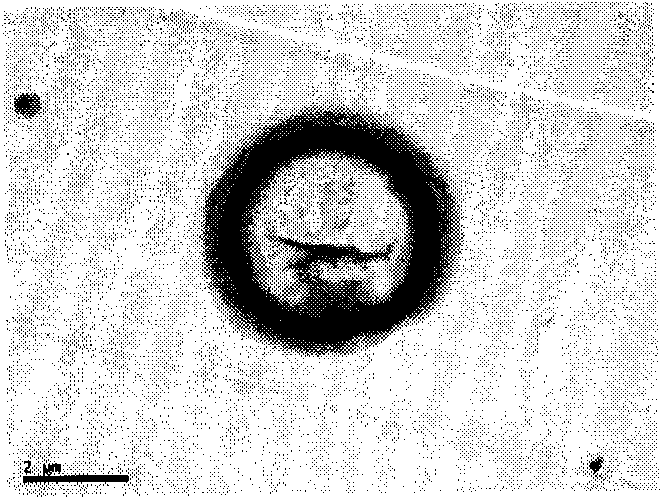

Preparation method of nickel-plated and silver-plated aromatic polyamide conductive fibers

The invention relates to a preparation method of nickel-plated and silver-plated aromatic polyamide conductive fibers, which comprises the following concrete steps of: a. washing and oil removal; b. coarsening: increasing the surface roughness and the surface wettability of fibers; c. sensitizing: soaking the fibers by adopting an aqueous solution formed by stannous chloride and hydrochloric acid; d. activation: soaking the fibers by adopting an aqueous solution formed by palladium chloride and hydrochloric acid; e. chemical nickel plating; f. sensitizing; g. activation; h. chemical silver plating; and i. coating protection. The prepared high performance nickel-plated and silver-plated aromatic polyamide conductive fibers have good electric conductivity, characteristics of heat resistance, flame retardance, light weight and high strength and functions of eliminating static electricity, conducting electricity and transmitting electrical signals. Therefore, the prepared nickel-plated and silver-plated aromatic polyamide conductive fibers can be widely applied to special departments of aviation, space flight, war industry, communication and the like and can also satisfy the clothing and equipment requirements of staffs engaging radars, television relaying and the like.

Owner:SHANGHAI UNIV

Preparation method for preparing Co3O4@CoP composite electrode based on MOF template

InactiveCN105977467AImprove performanceEasy to mass manufactureCell electrodesDecompositionNew energy

The invention provides a preparation method for preparing a Co3O4@CoP composite electrode based on an MOF template and belongs to the technical field of energy conversion. The preparation method comprises the following steps: uniformly growing Co(CO3)0.5OH 0.11H2O on a nickel plate substrate by virtue of simple hydrothermal reaction, and further growing favorable-appearance ZIF-67 in situ on the surface of Co(CO3)0.5OH 0.11H2O, thereby obtaining a Co(CO3)0.5OH 0.11H2O@ZIF-67 composite material; and furthermore, performing bonderizing so as to obtain Co3O4@CoP derivates. Compared with a single Co(CO3)0.5OH 0.11H2O electrode, the derivate electrode material has relatively low oxygen evolution potential and relatively high corresponding current density under same electric potential, and can be applied to the fields of hydrogen production based on electrocatalysis and decomposition of water and conversion of new energy resources such as fuel cells.

Owner:BEIJING UNIV OF TECH

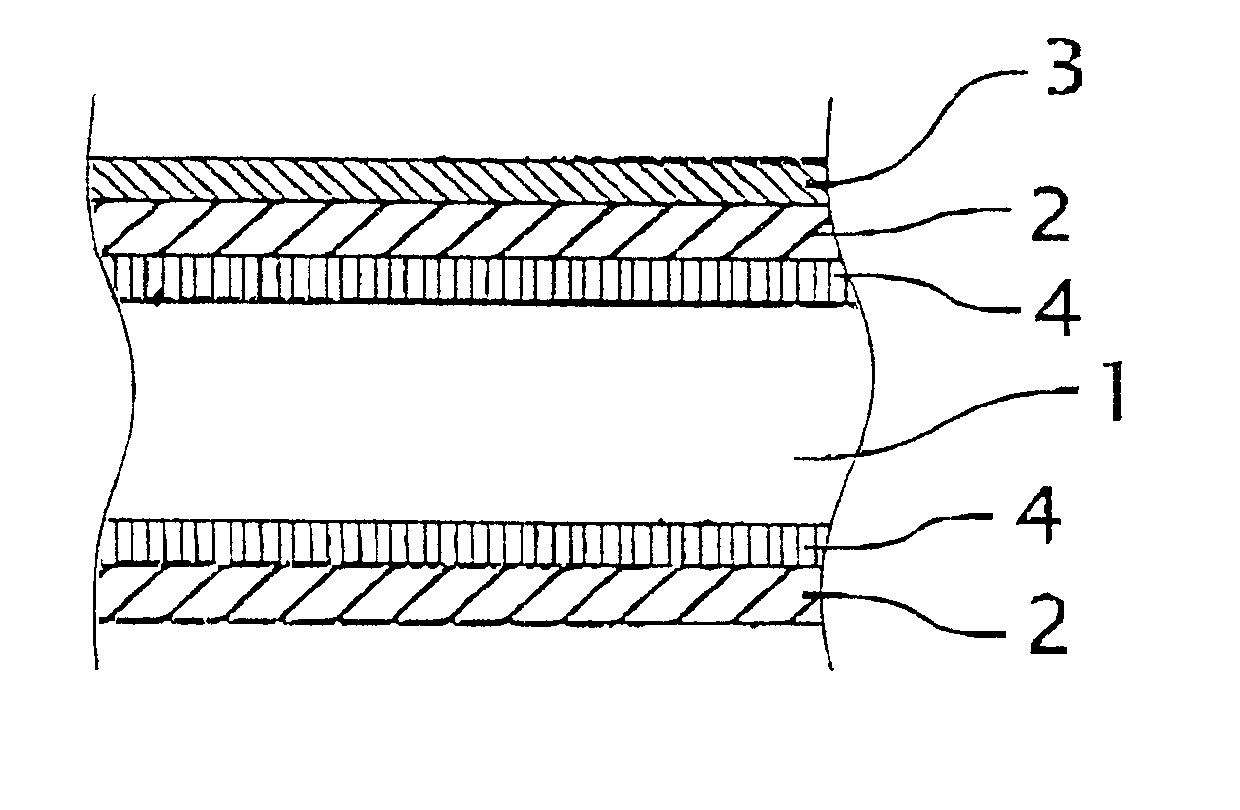

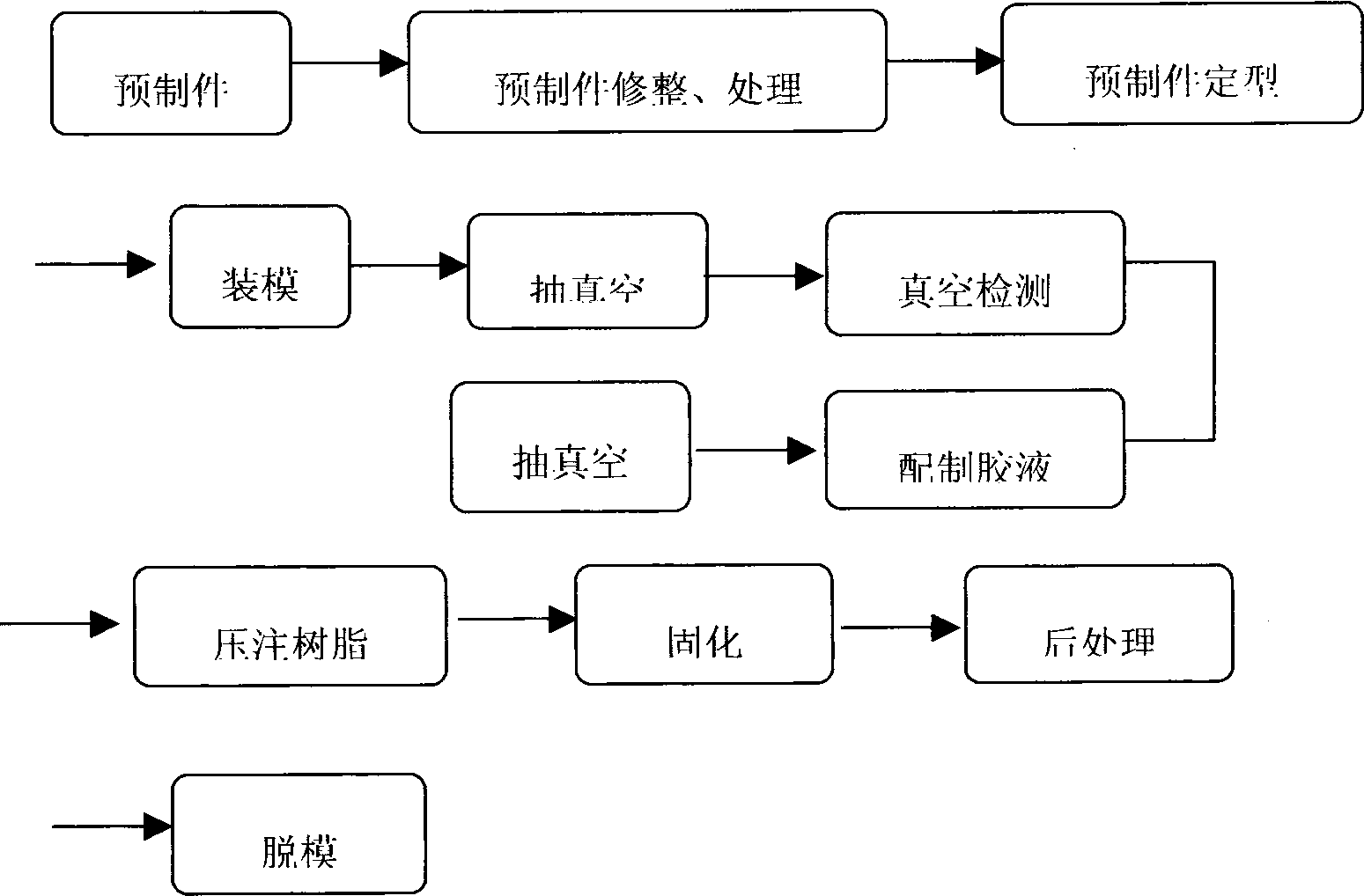

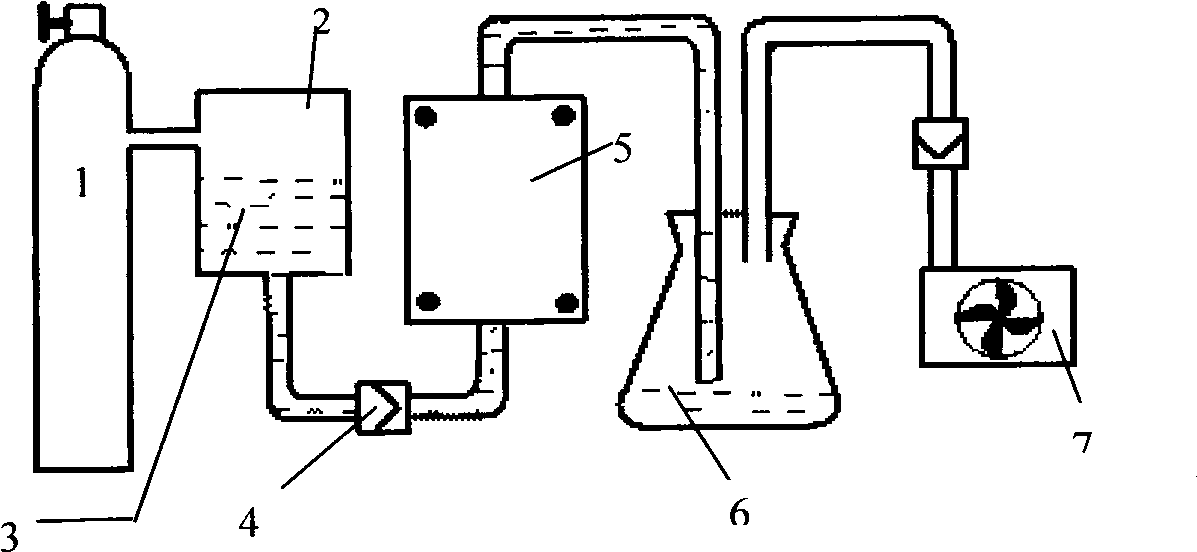

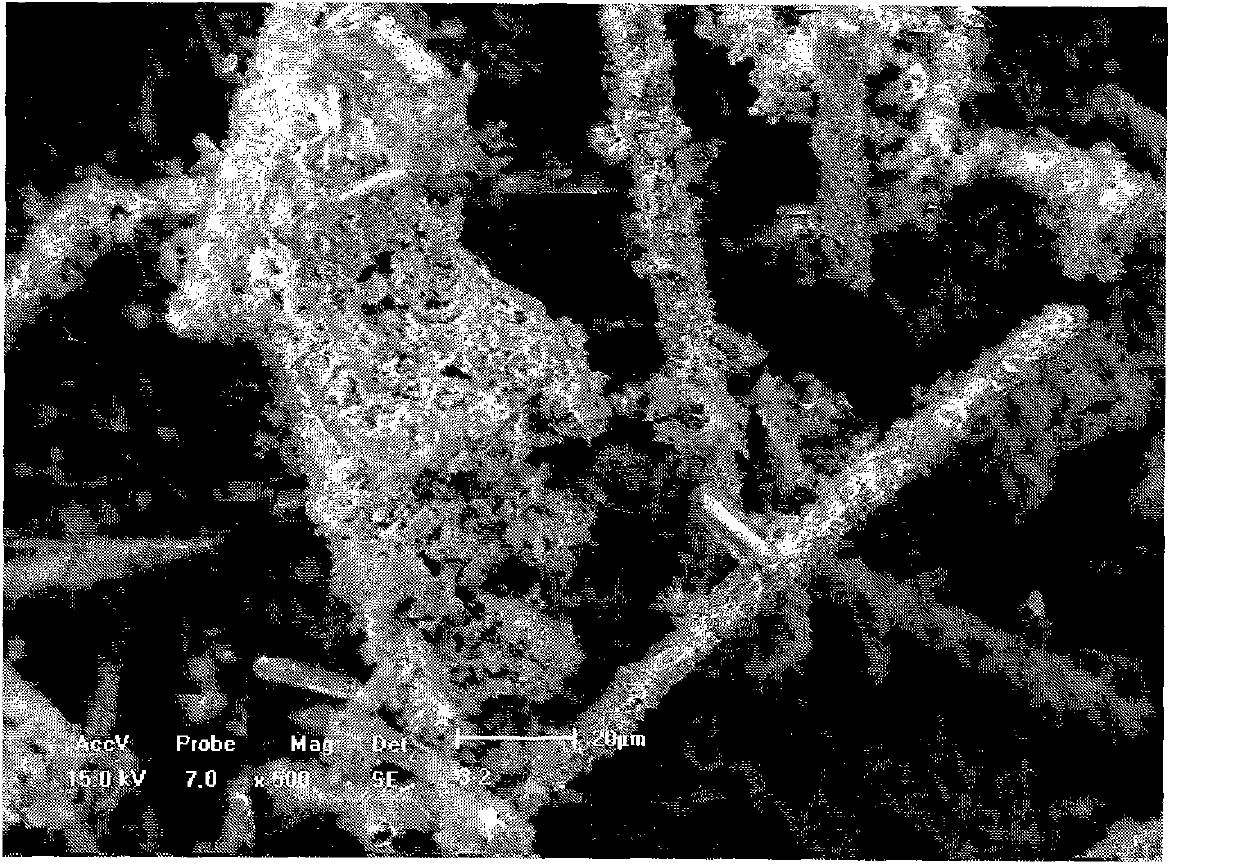

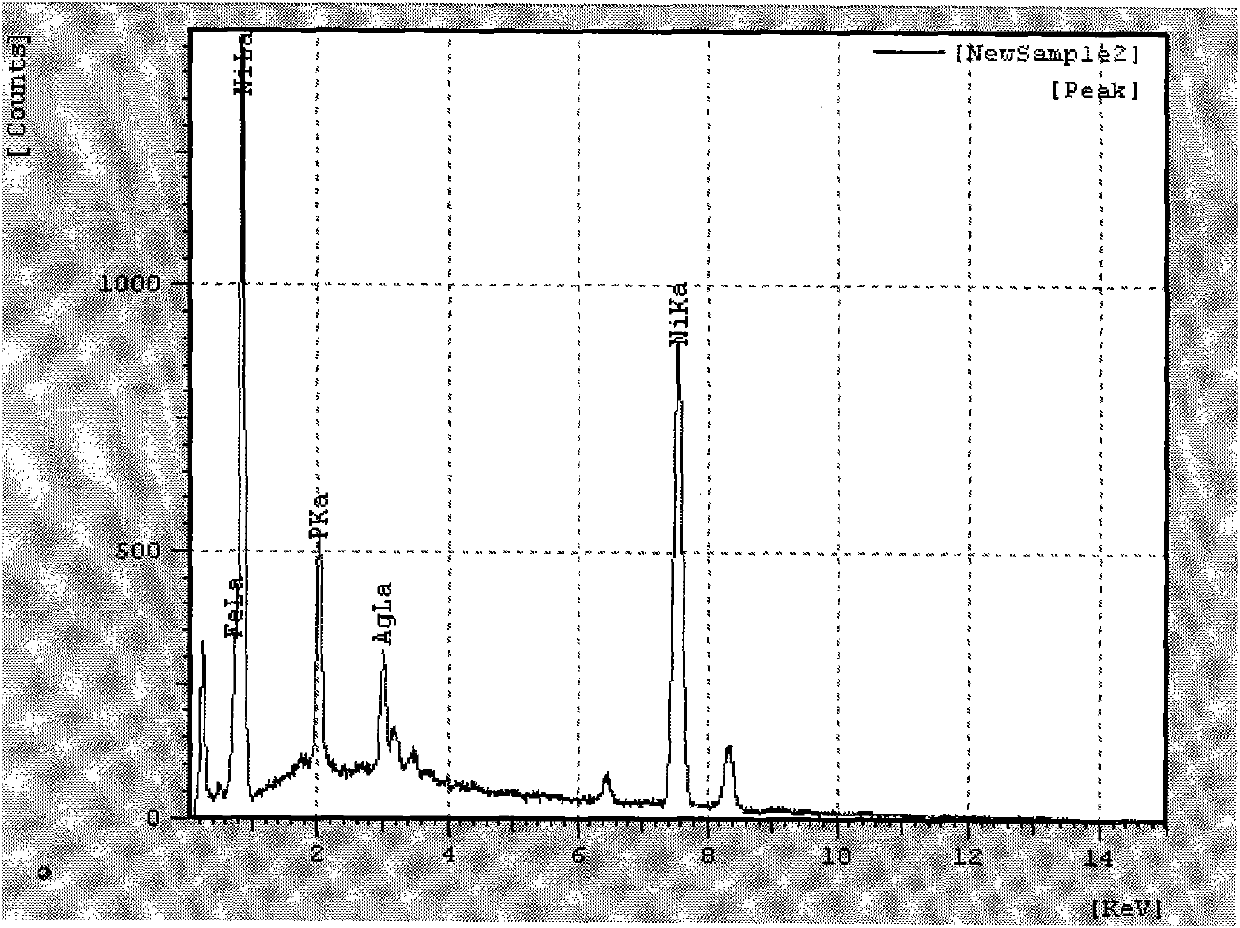

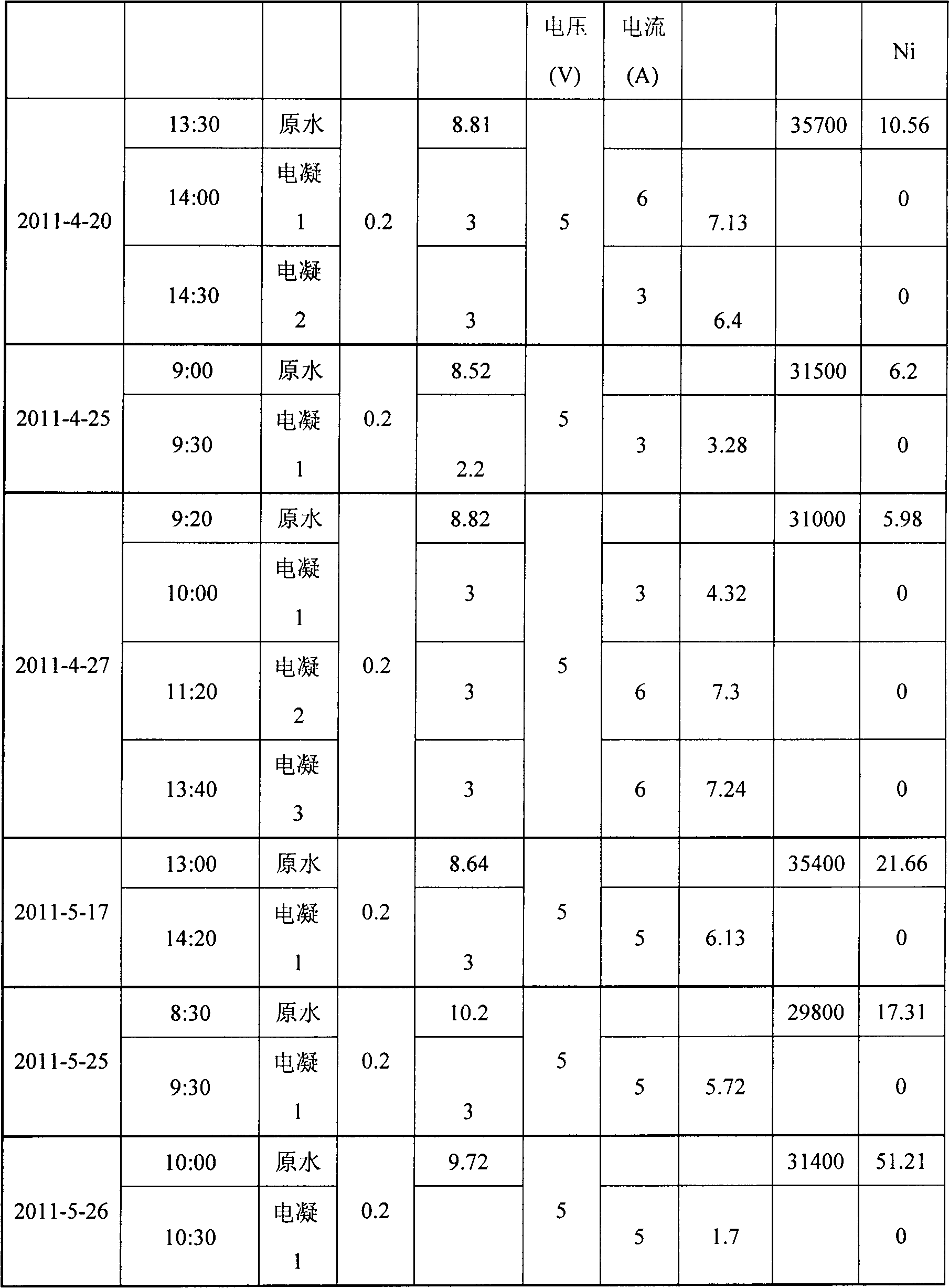

Electromagnetic shielding compound material made from three-dimensional braided nickel-plated carbon fiber and epoxy resin and method for preparing same

InactiveCN101531804AImprove performanceGood electromagnetic shieldingOther chemical processesFiberEpoxy

The invention relates to an electromagnetic shielding compound material made from three-dimensional braided nickel-plated carbon fiber and epoxy resin and a method for preparing same. The method comprises the following steps: carbon fiber surface treatment, carbon fiber nickel-electroplating, nickel-plated carbon fiber three-dimensional braiding, and compound material preparation on the basis of RTM (resin transfer molding) method and electromagnetic shielding effectiveness test. In the invention, the nickel-plated carbon fiber / epoxy resin braided compound material is prepared through the following steps: plating the carbon fiber with nickel, the metal; carrying out three-dimensional four-directional braiding; and then, compounding the nickel-plated carbon fiber braid and the epoxy resin. Owing to the good conductivity of the carbon fiber braid and the nickel-plated layer and the ferromagnetism of the nickel-plated layer, the braided compound material has good electromagnetic shielding performance. According to the test results based on the flange co-axial method, the electromagnetic shielding level of the braided compound material reaches 70dB to 80dB.

Owner:TIANJIN UNIV

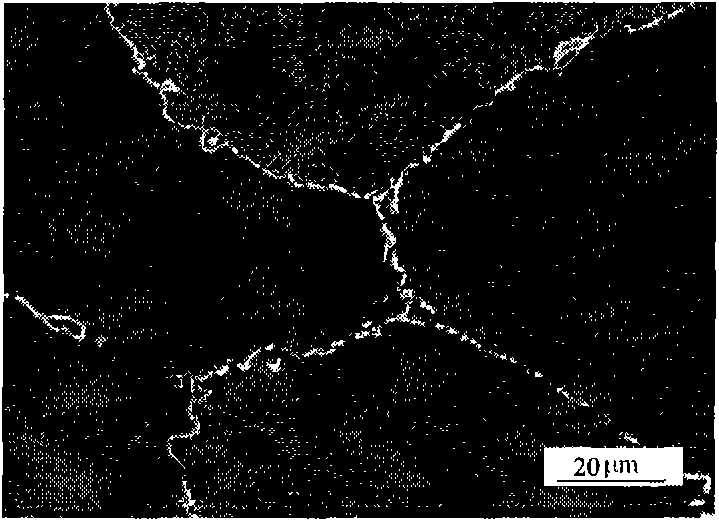

Chemical nickel-plating method for carbon fiber

InactiveCN102086517ALow costEasy to operateLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention discloses a chemical nickel-plating method for carbon fiber, which is designed for overcoming the disadvantages of high cost, a large number of process steps and poor operability existing in the prior art. In the method, a chemical plating process is adopted; and a pre-treatment is performed on a raw material and chemical plating solution is prepared before the chemical plating. The pre-treatment process comprises the steps of: calcining by using a muffle furnace to remove glue; soaking in solution of absolute ethanol to remove oil; performing surface roughening and activating treatment by using solution of sodium hydroxide and solution of silver ammonia; sensitizing by using a sensitizer, namely stannous chloride; and performing surface reduction by using solution of sodium hypophosphite. The chemical plating solution consists of nickel sulfate hexahydrate, sodium hypophosphite, sodium pyrophosphate and sodium citrate. The chemical nickel-plating on the carbon fiber is finished by placing a pre-treatment product of the chemical plating into the chemical plating solution, and reacting, standing, filtering and drying under a chemical plating condition. The method has the characteristics that: the product has a uniform surface, a compact plating layer and uniform particles.

Owner:沈阳临德陶瓷研发有限公司

Corrosion resistant wafer processing apparatus and method for making thereof

InactiveCN101101887ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingThermal dilatationWafering

A wafer processing apparatus characterized by having corrosion resistant connections for its electrical connections, gas feed-through channels, recessed areas, raised areas, MESA, through-holes such as lift-pin holes, threaded bolt holes, blind holes, and the like, with the special configurations employing connectors and fillers having excellent chemical resistant properties and optimized CTEs, i.e., having a coefficient of thermal expansion (CTE) that closely matches the CTE of the base substrate layer, the electrode(s), as well as the CTE of coating layer. In one embodiment, a nickel plated molybdenum insert is employed.

Owner:GENERAL ELECTRIC CO

Preparation method of electromagnetic shielding conductive fabric

InactiveCN101876140ALess investmentSmall plating resistancePhysical treatmentSuperimposed coating processPolyesterCopper plating

The invention discloses a preparation method of an electromagnetic shielding conductive fabric. In the preparation method, the electromagnetic shielding conductive fabric is prepared by sequentially carrying out pretreating, vacuum nickel plating, copper electroplating and nickel electroplating on a full polyester fabric, and then the obtained electromagnetic shielding conductive fabric is cured, wherein plasma glow discharge treatment is carried out in the pretreating step, a magnetron sputtering technology is adopted in the vacuum nickel plating step, and a vertical placement mode is adopted among conductive rods in the processes of copper electroplating and nickel electroplating. By adopting the technology combining the vacuum nickel plating with the copper electroplating and the nickel electroplating, the defects of high cost and difficult treatment of electroplating wastewater, caused by the adoption of an electroless copper and nickel plating technology in the traditional preparation method of the electromagnetic shielding conductive fabric, are avoided; and compared with the traditional preparation method of the electromagnetic shielding conductive fabric, which adopts a full vacuum copper and nickel plating technology, the method of the invention which adopts the technology combining the vacuum nickel plating with the copper electroplating and the nickel electroplating has smaller equipment investment and plating resistance, is more suitable for large-scale production, and can better adapt to market demands.

Owner:昆山市同福电子材料厂

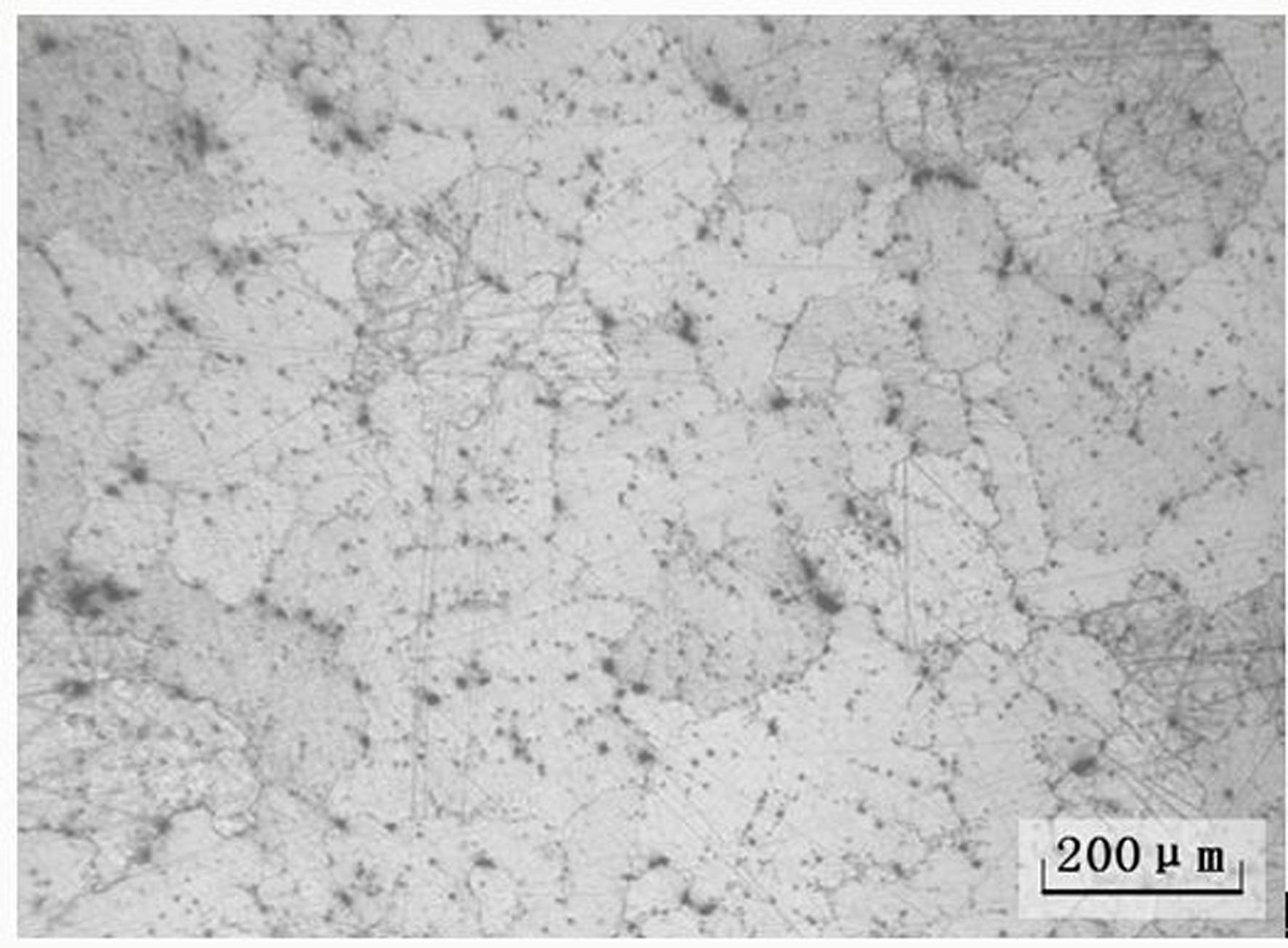

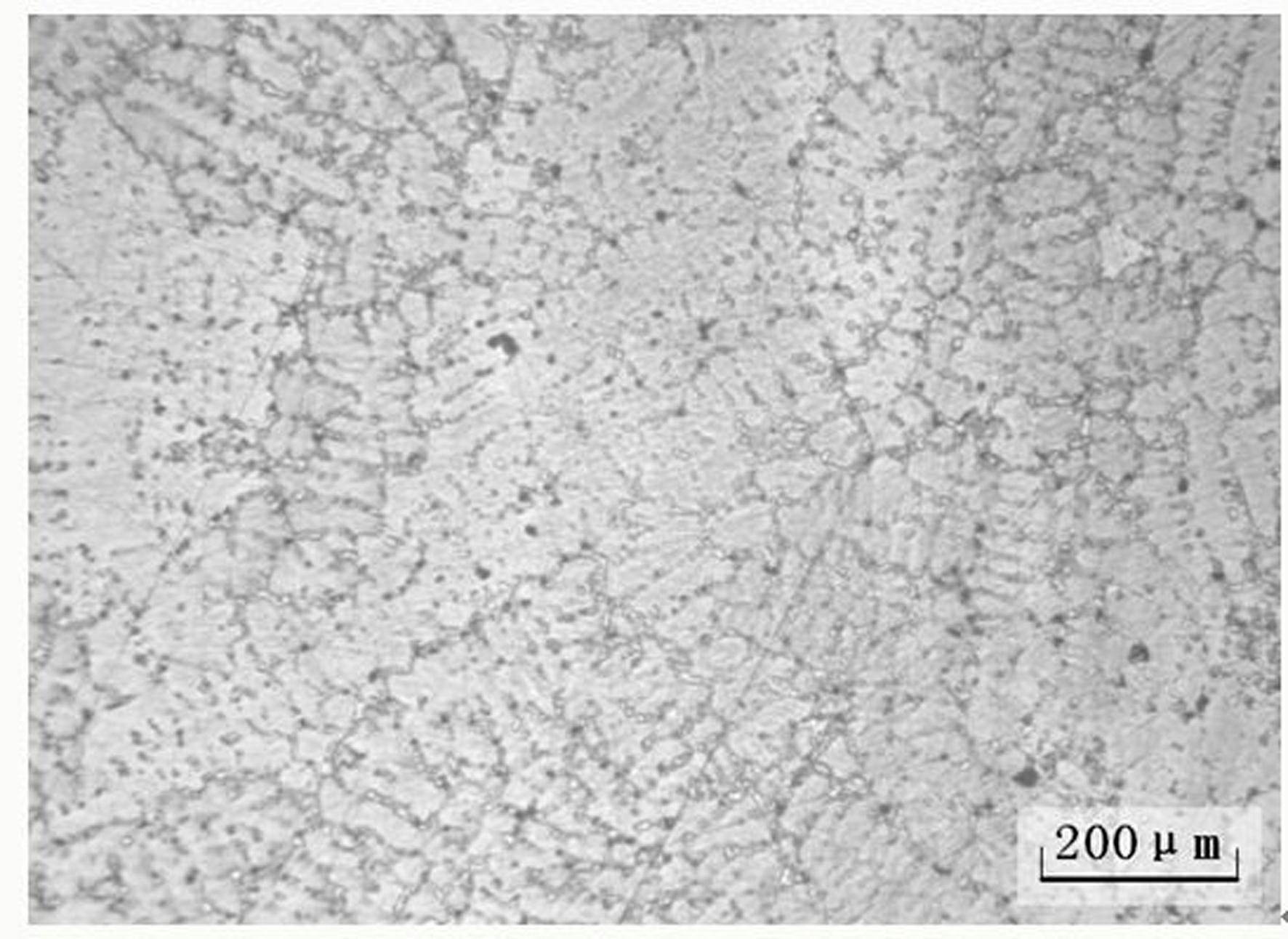

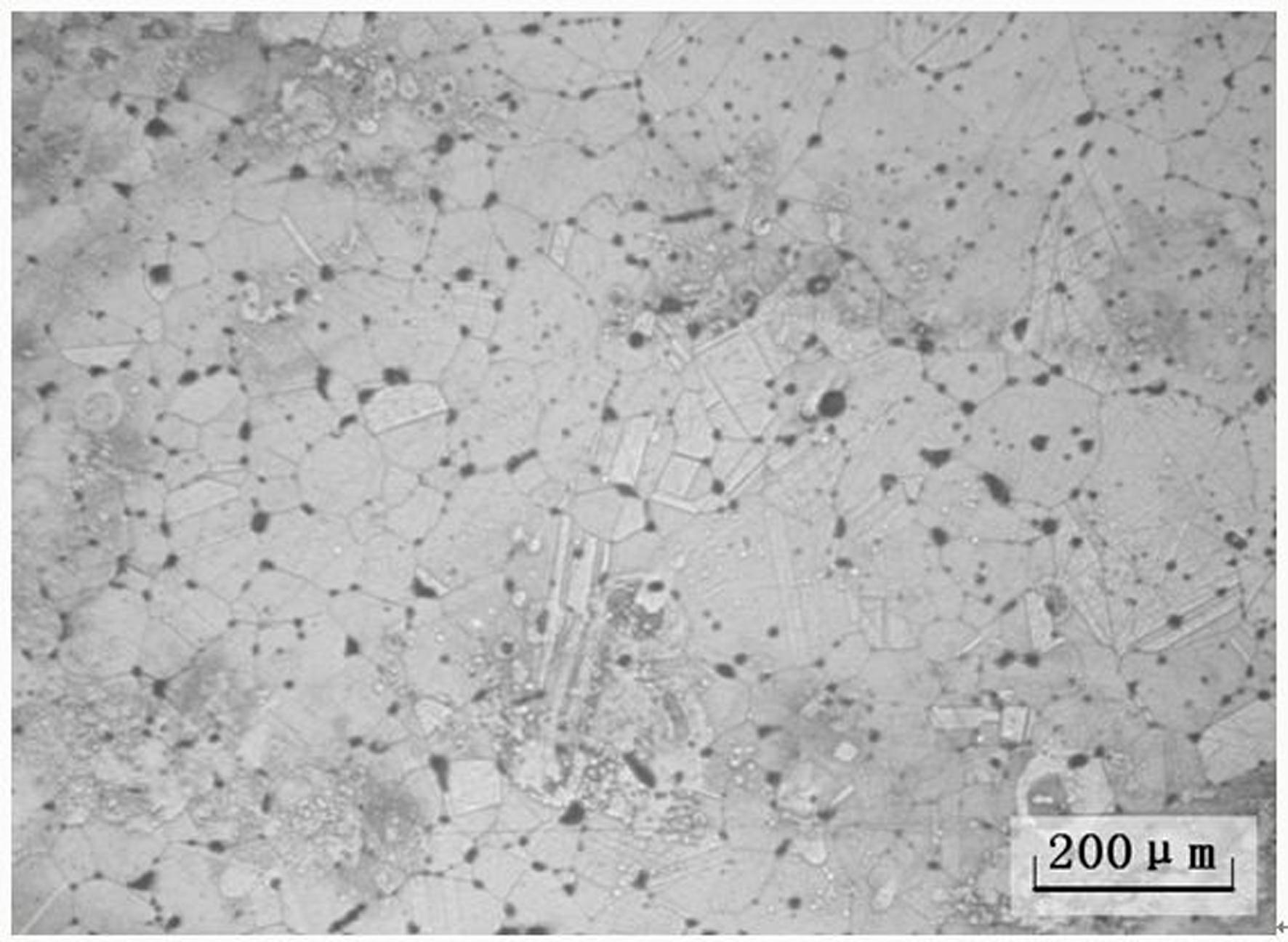

Cast wear-resistant tin bronze alloy and preparation method thereof

The invention discloses a cast wear-resistant tin bronze alloy and a preparation method thereof. The cast wear-resistant tin bronze alloy comprises the following components in percentage by weight: 10 to 14 percent of Sn, 2 to 5 percent of Pb, 1 to 4 percent of Ni, less than or equal to 0.25 percent of Fe, Sb, Al, Zn, P, Si and Bi which serve as impurities and the balance of Cu. The preparation method comprises the following steps of: smelting an electrolytic copper plate, a pure nickel plate, a pure tin ingot and a pure lead ingot which serve as raw materials sequentially; adding a refining agent into melting liquid, pouring, cooling, and thus obtaining a cast wear-resistant tin bronze alloy ingot; and homogenizing and annealing the alloy ingot to obtain a cast wear-resistant tin bronze alloy product. The prepared cast wear-resistant tin bronze alloy has uniform ingredients, dendritic segregation is improved obviously, a small number of cast state defects occur, the hardness of the alloy is more than or equal to 100HB, the tensile strength is more than or equal to 300MPa, the elongation is more than or equal to 10 percent, and the cast wear-resistant tin bronze alloy is particularly suitable for wear-resistant heavy load key parts in a traffic power industry.

Owner:HENAN UNIV OF SCI & TECH +1

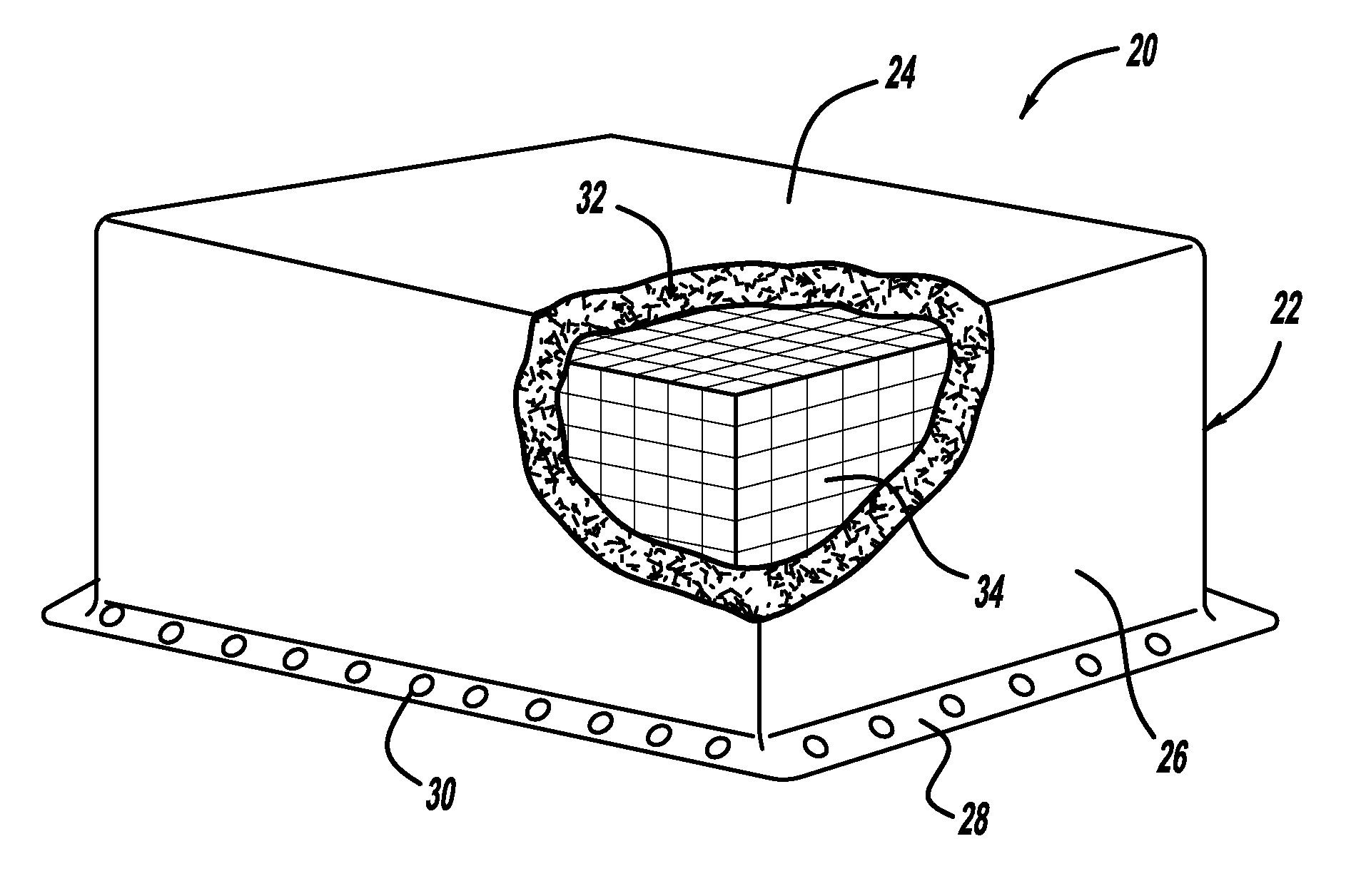

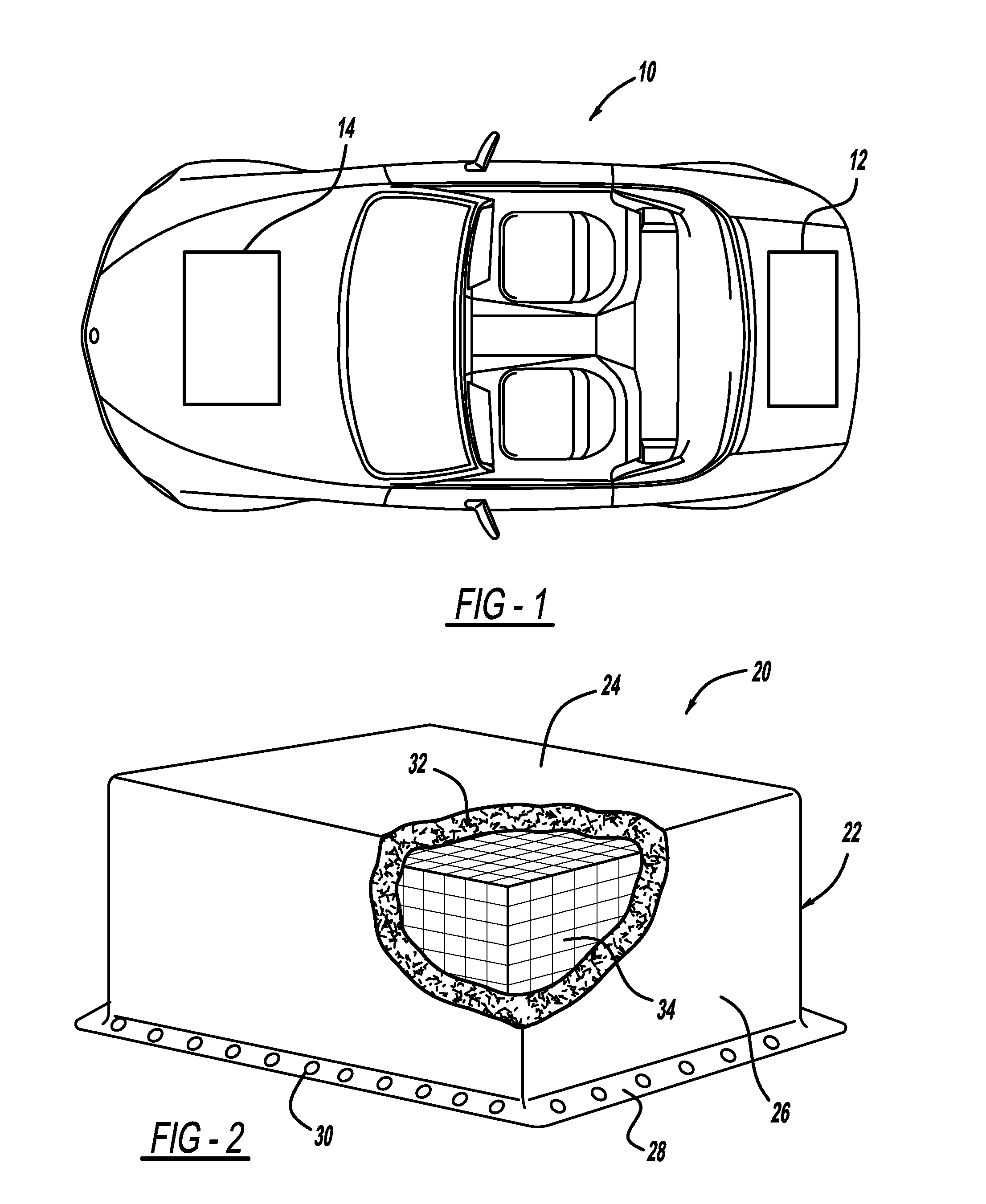

Encapsulated emi/rfi shielding for a non-conductive thermosetting plastic composite phev battery cover

A cover for a high voltage vehicle battery is disclosed that is made of a light weight, non-conductive thermoset plastic composite, such as a polyester resin matrix, and includes an EMI / RFI shield. In one embodiment, the EMI / RFI shield is a Faraday cage including a ferrous mesh that is molded into the thermoset plastic composite so that it is completely encapsulated therein. In another embodiment, the EMI / RFI shield is an acrylic polymer coating including nickel plated copper flakes formed on an outside surface of the thermoset plastic composite.

Owner:GM GLOBAL TECH OPERATIONS LLC

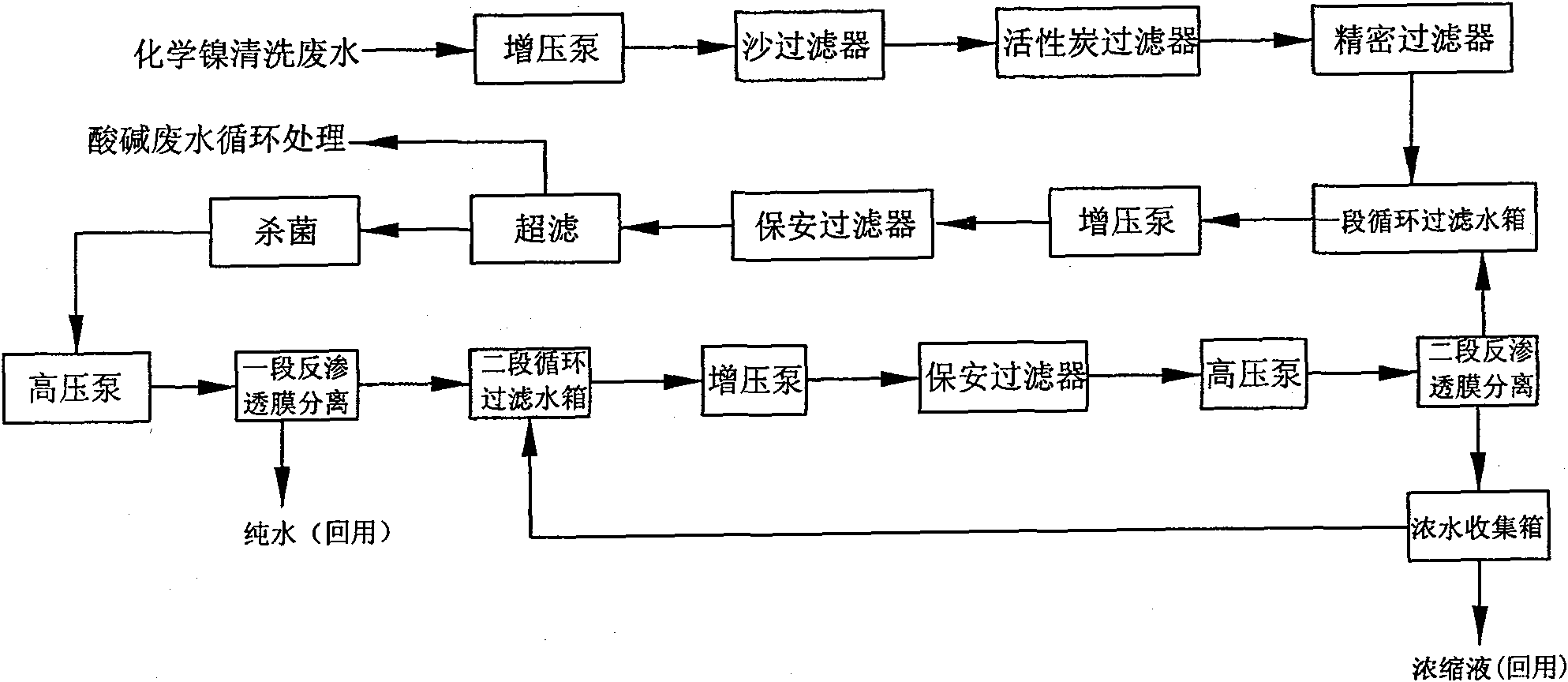

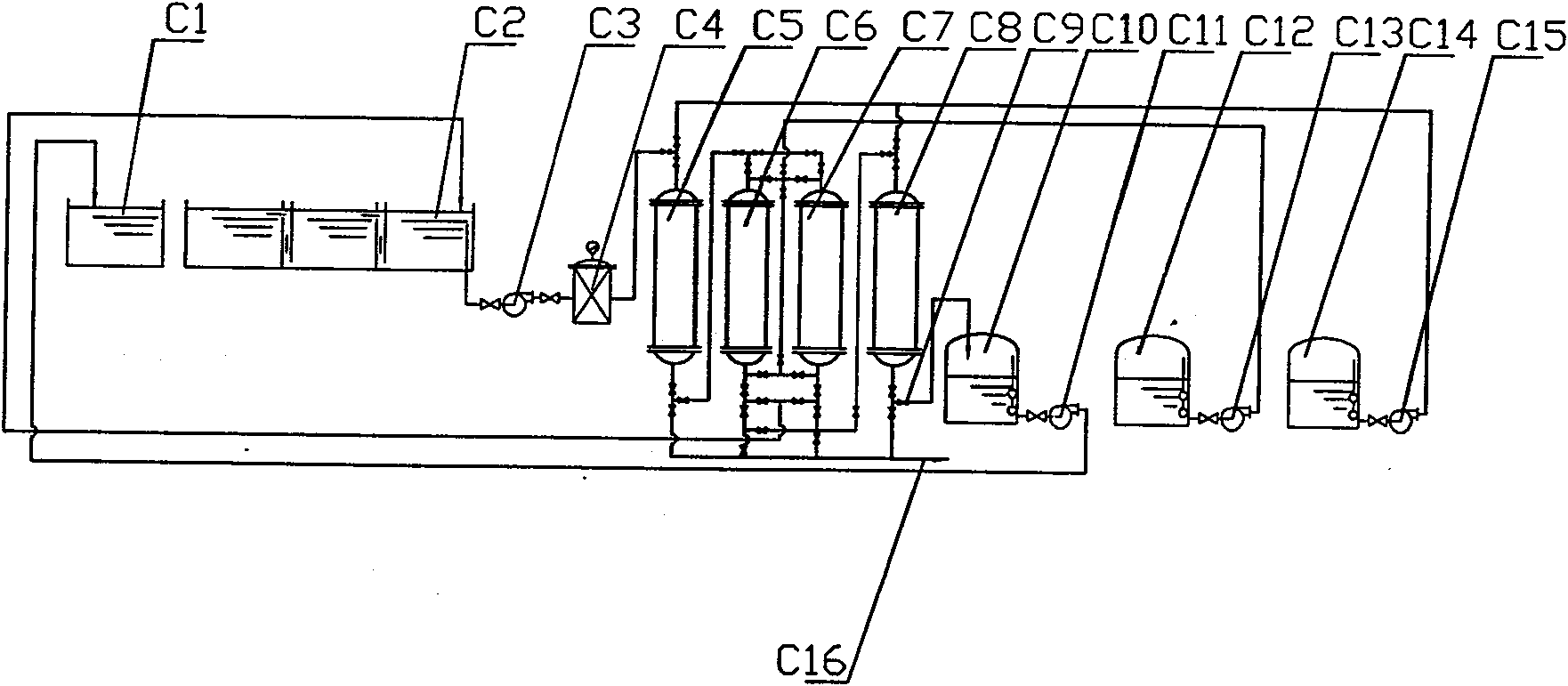

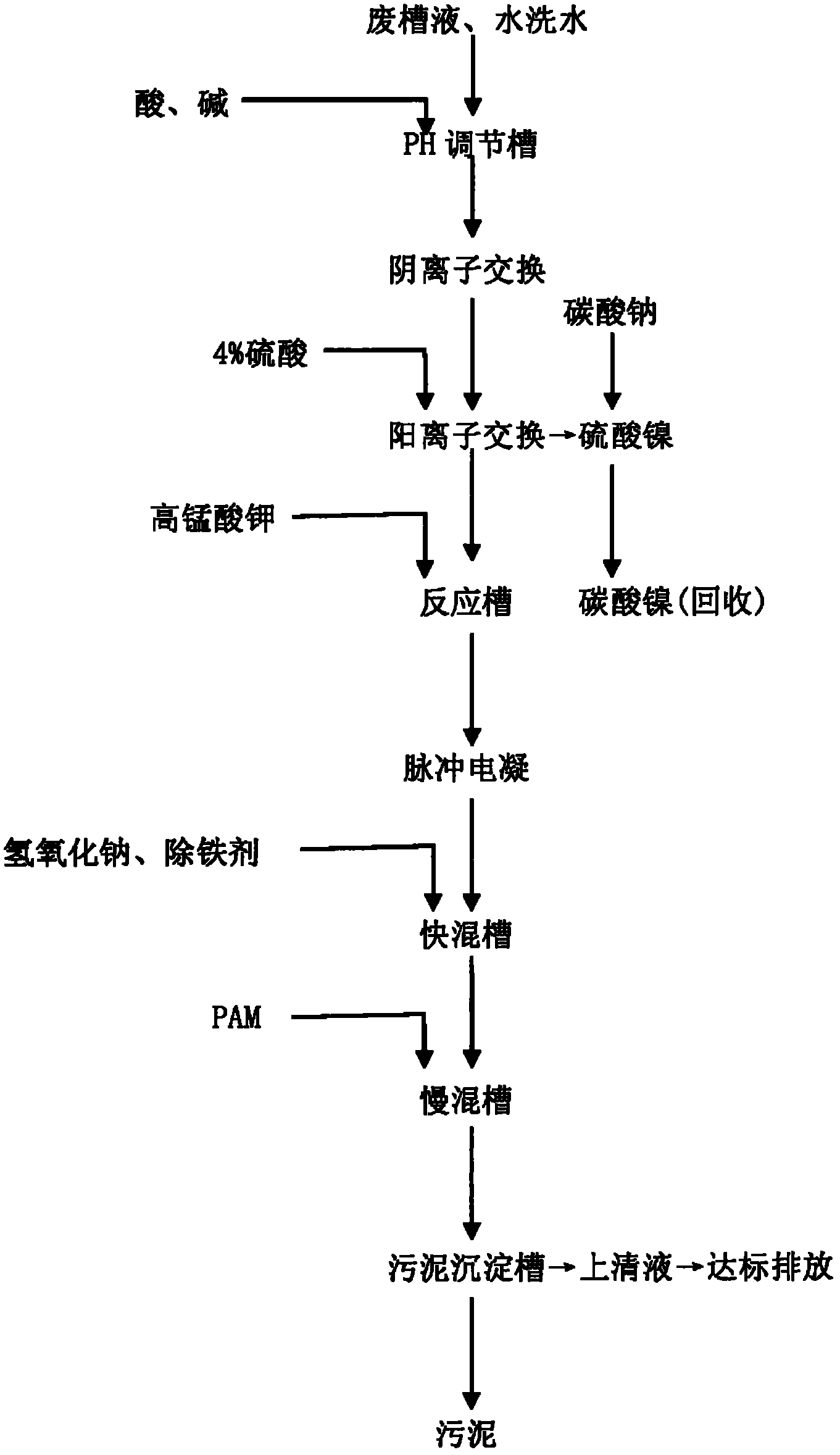

Method for classifying, treating and recycling plating washing water on line

ActiveCN101891323AAvoid cross contaminationStrong targetingWater contaminantsWater/sewage treatment by ion-exchangeCopper platingWater cycling

The invention discloses a method for classifying, treating and recycling plating washing water on line, which comprises the following steps of: removing oil, coarsening, reducing, activating, peptizing, chemically plating nickel, preplating nickel, plating copper, plating nickel and plating chromium in a plating process; and treating water and washing water during production and cleaning. The method specifically comprises the following steps of: preparing pure plating water, circularly processing acid and alkaline waste water, coarsening, circularly treating chromium-plating washing water, circularly treating chemically nickel-plating washing water, circularly treating copper-plating washing water and circularly treating nickel-plating washing water. Waste water in each procedure is directly used beside a tank edge in a closed cycle by an economical and effective means after being treated, no wastewater is discharged, and the cross contamination of different water qualities among the procedures is avoided. The method is a technological innovation for realizing zero emission of plating waste water and plating cleaner production.

Owner:NANJING YUANQUAN TECH CO LTD

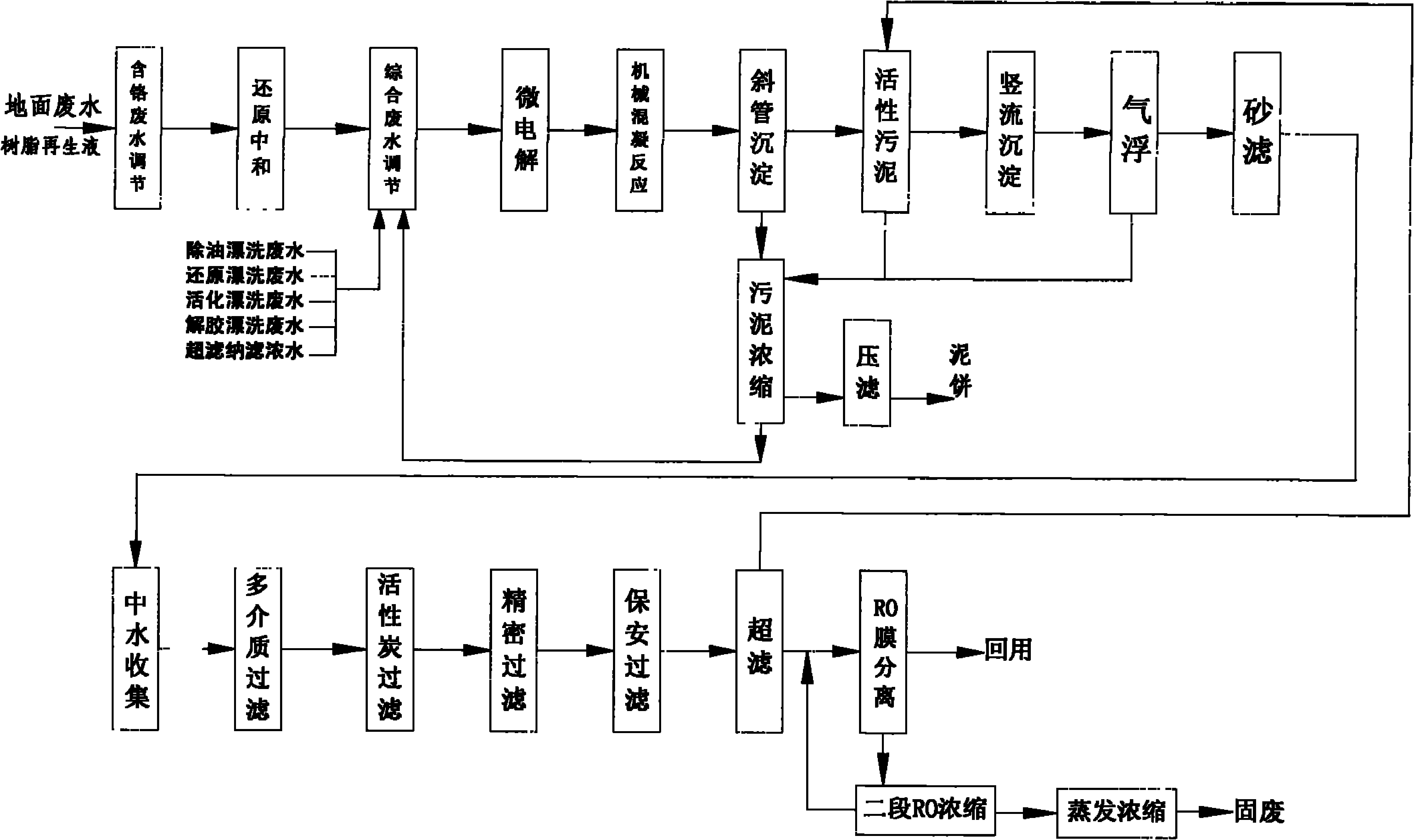

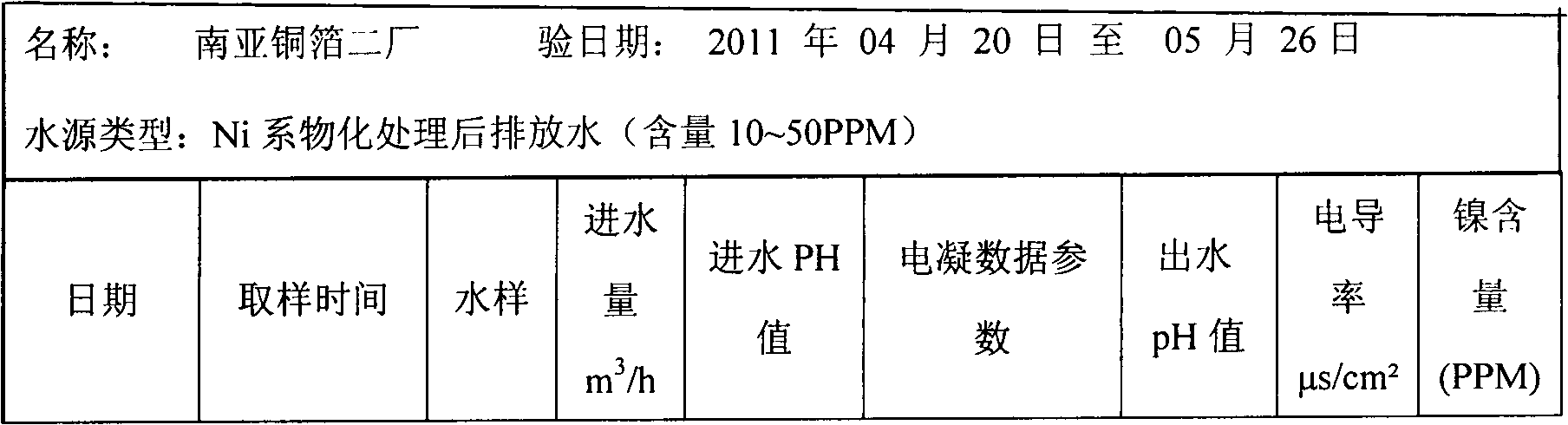

Treatment method of chemical nickel-plating wastewater

ActiveCN102329030AImprove processing economicsAchieve recyclingWaste water treatment from metallurgical processWater/sewage treatment by ion-exchangePhosphateIon-exchange resin

The invention discloses a treatment method of chemical nickel-plating wastewater. The method comprises the following steps: (1) treating nickel-plating wastewater with strongly basic anion-exchange resin so as to destabilize nickel complex; (2) adsorbing nickel ions contained in the nickel-plating wastewater with strongly acidic cation-exchange resin; (3) adding a strong oxidant in the nickel-plating wastewater so that hypophosphite, phosphite and macromolecular organic acid complexing agent which are contained in the wastewater are oxidized so as to form phosphate and organic micromolecules;(4) carrying out pulse electrocoagulation on the nickel-plating wastewater so that the phosphate forms iron phosphate to be precipitated and residual nickel ions are oxidized to form oxidized scale precipitate at the same time; and (5) regulating the wastewater to alkalinity so that iron ions in the wastewater are precipitated, successively adding a deironing agent and a flocculant to remove ferrous ions and suspended matters in the wastewater, and directly discharging supernate. According to the invention, the content of the nickel ions in the wastewater treated by the process is far less than 0.1ppm and meets a national primary standard, the recycle of nickel resources can be realized, and the economic benefits of wastewater treatment are improved.

Owner:中新联科环境科技(安徽)有限公司

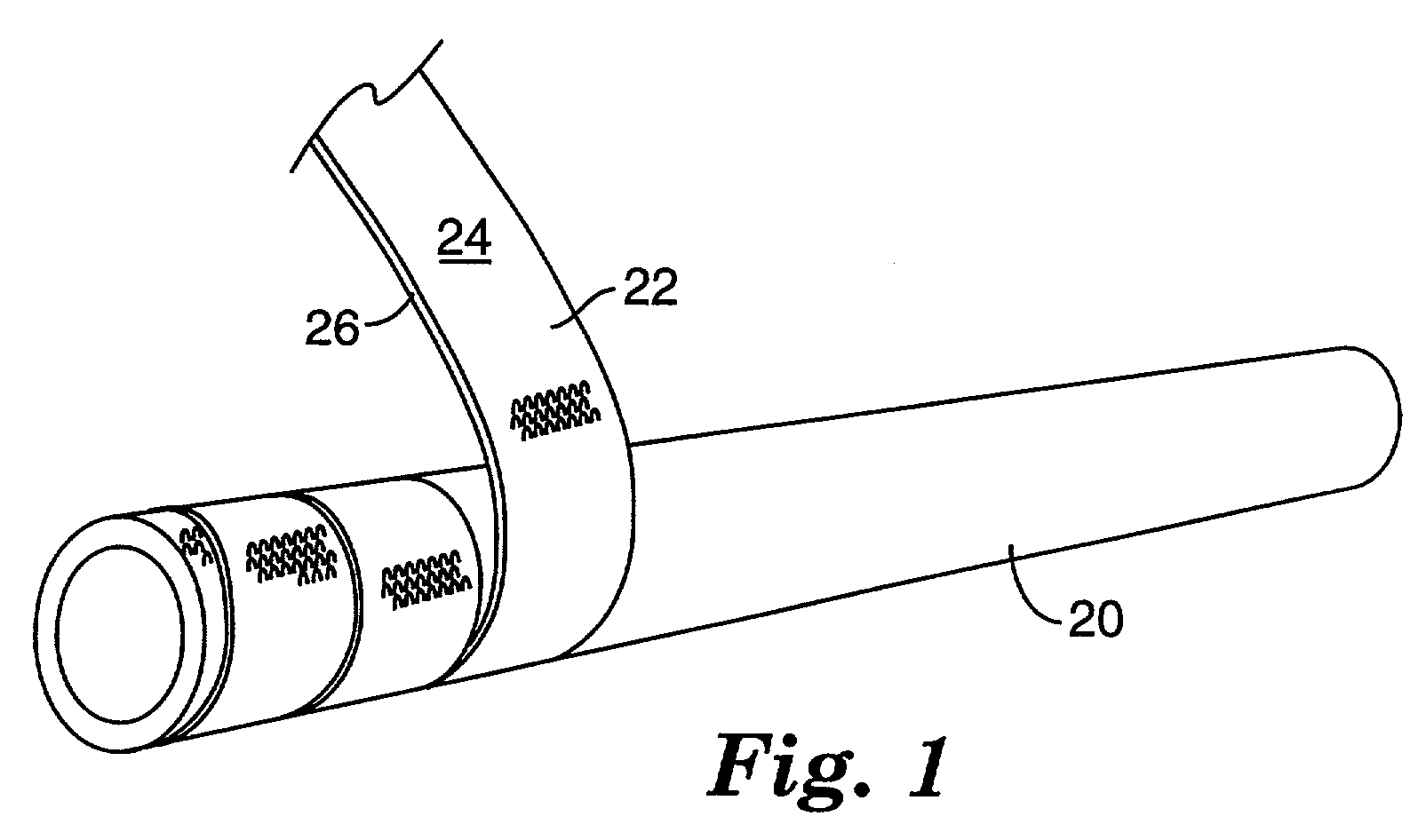

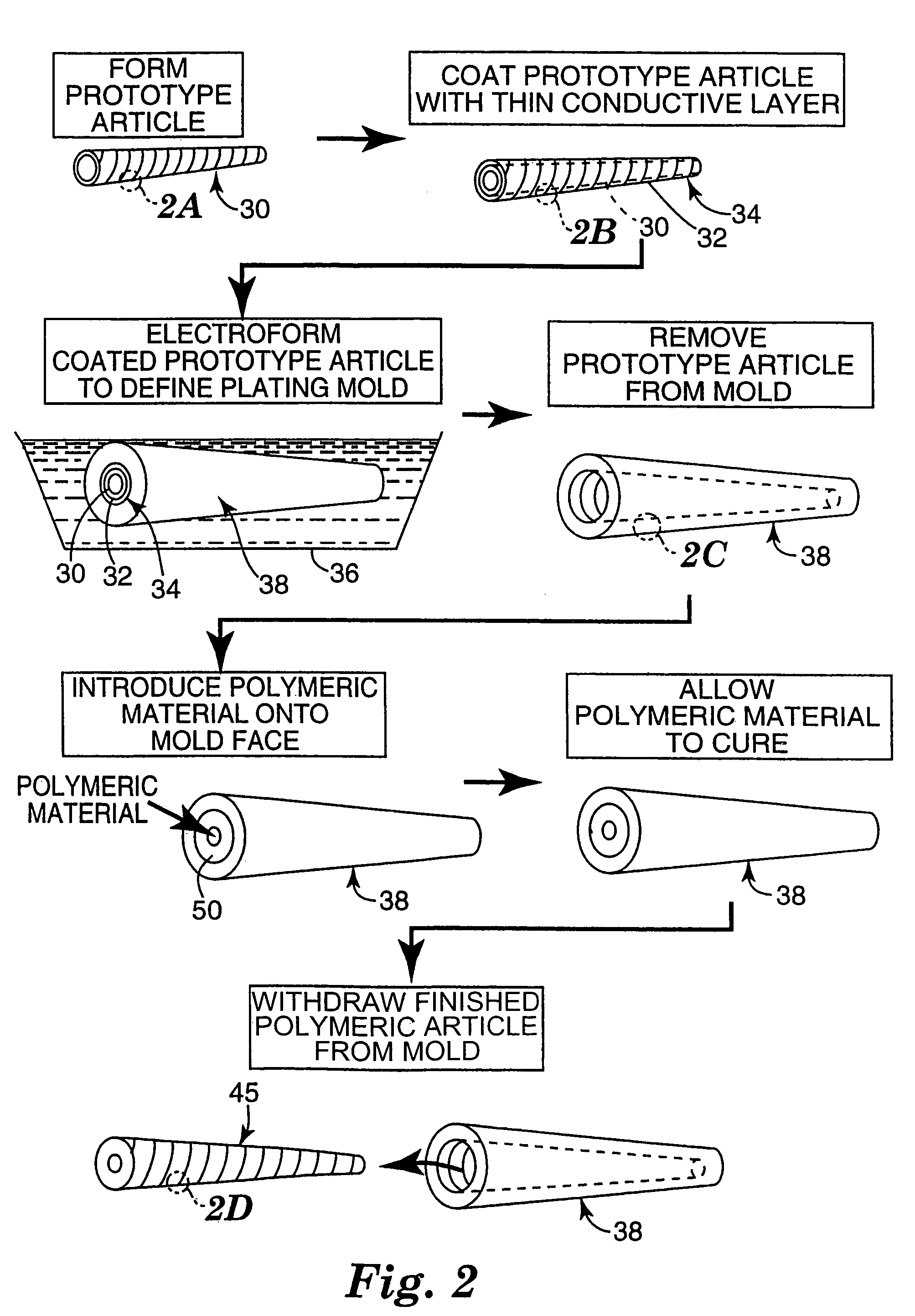

Microreplicated surface

InactiveUS7703179B2Increase heightImprove toleranceTravelling carriersHoldersPolymer scienceSurface structure

This disclosure relates to a method for making a polymeric article mold, a method for making a polymeric article with that mold, and improved surface topography features for a polymeric article. A prototype article is formed and then coated with a thin conductive layer. The coated prototype article is then electroformed until nickel plated to a sufficient depth to define a nickel plating tool. After the prototype article has been removed from the mold face of the nickel tool, the tool can be used as a mold for forming finished polymeric articles which replicate the original prototype article. The use of fine topography features such as a dense upstanding stem array on the surface of the prototype article facilitates accurate and complete electroforming by increased surface area presentation. The disclosure also presents improvements to microreplicated surface structures such as stem arrays. The improvements include the formation on a stem array having separate zones of stems of differing heights, and the formation of directional microreplicated features (e.g., stems) which are oriented and shaped to promote or restrict frictional interaction in one or more particular directions.

Owner:3M INNOVATIVE PROPERTIES CO

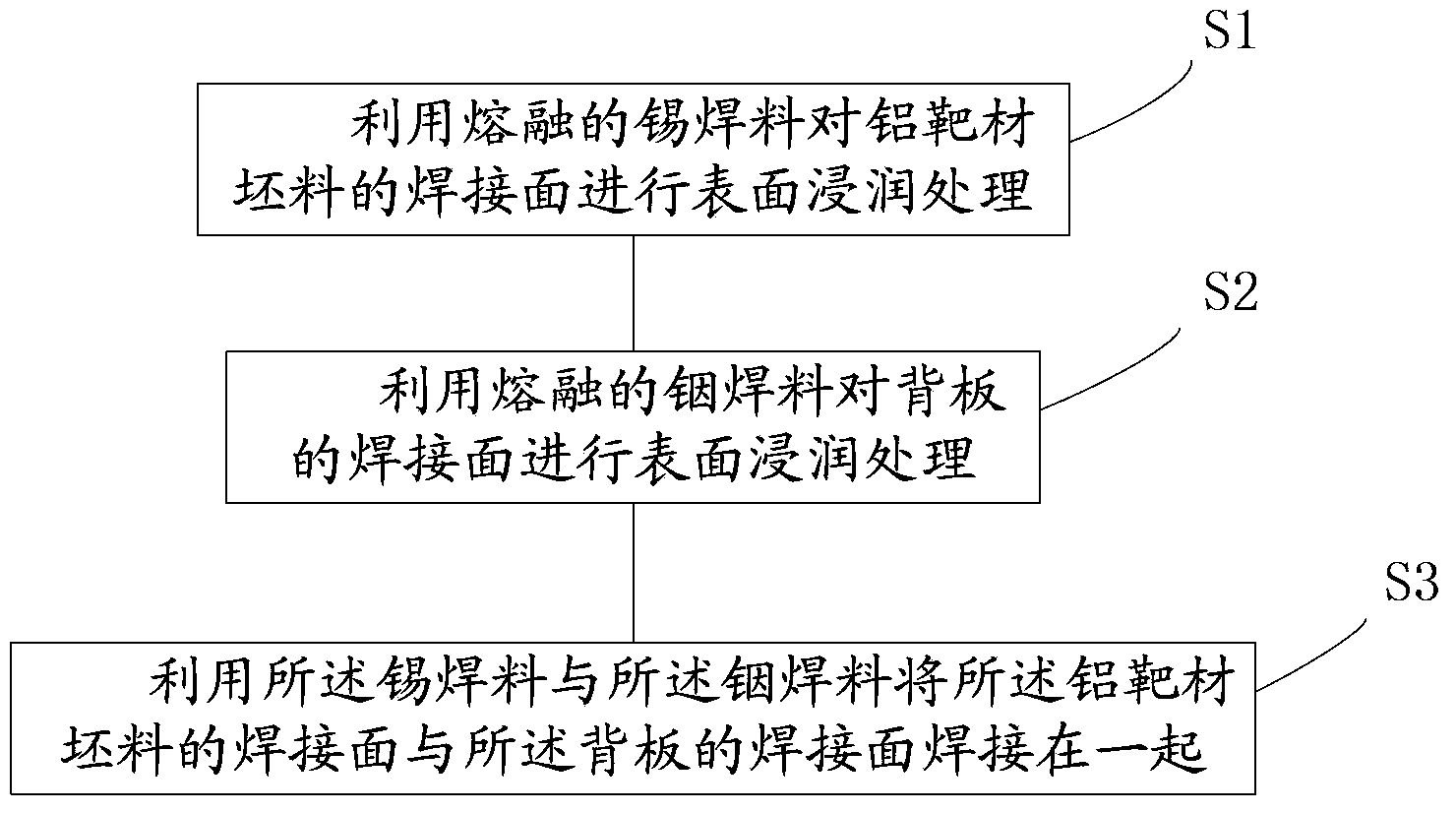

Method for welding aluminum target assemblies

ActiveCN103567583AAdvantages of welding methodReduce energy consumptionSoldering apparatusWelding/soldering/cutting articlesIndiumEnergy consumption

The invention provides a method for welding aluminum target assemblies. The method includes wetting welded surfaces of aluminum target blanks by molten tin solder; wetting welded surfaces of back plates by molten indium solder; welding the welded surfaces of the aluminum target blanks with the welded surfaces of the back plates by the tin solder and the indium solder. The method for welding the aluminum target assemblies has the advantages that nickel plating on the welded surfaces of the aluminum target blanks can be omitted, accordingly, energy consumption can be reduced, the cost can be saved, and pollution can be decreased.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Chemical palladium plating solution

InactiveCN101709462AReduce utilizationIncrease profitLiquid/solution decomposition chemical coatingPrinted circuit boardStabilizing Agents

The invention relates to a chemical palladium plating solution, in particular to a chemical palladium plating solution which can directly form a palladium film with good adhesive force on a chemical nickel plating film formed on a printed circuit board (PCB) and does not affect the chemical nickel plating film serving as a base film. The chemical palladium plating solution contains a soluble palladium salt, a first complexing agent, a second complexing agent and a stabilizing agent, wherein the first complexing agent is one out of ammonia and diamine compounds, and the second complexing agent is one or more out of alcohol amine compounds with 2-7 carbon atoms, amine compounds with less than 7 carbon atoms and aminocarboxylic acid compounds. The palladium plating solution has stable pH, stable deposition rate, long bath service life and excellent bath stability, does not generate cracks, and can obtain the palladium plating film with very low phosphorus content and excellent corrosion resistance, solder connectivity and lead weldability.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

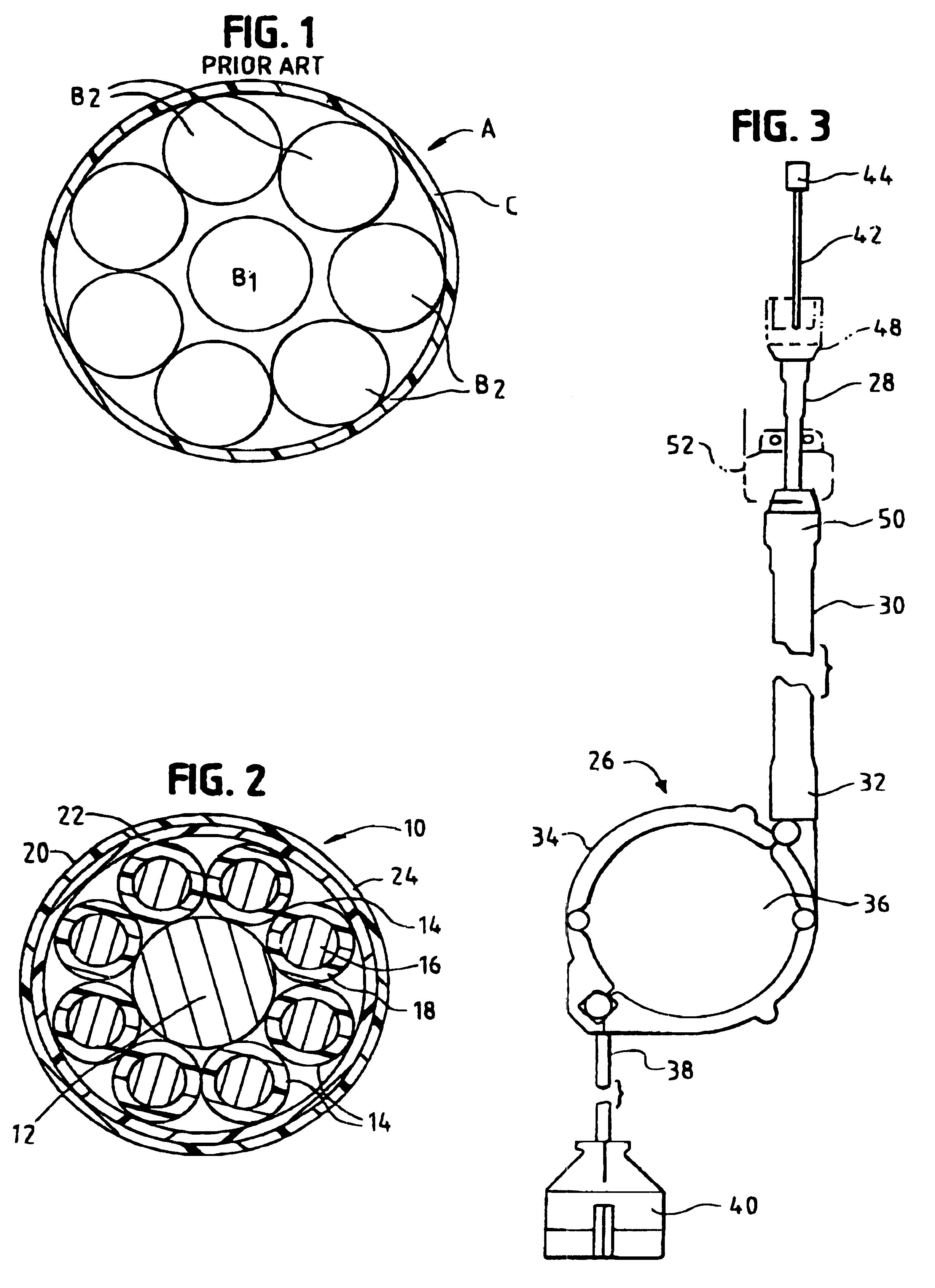

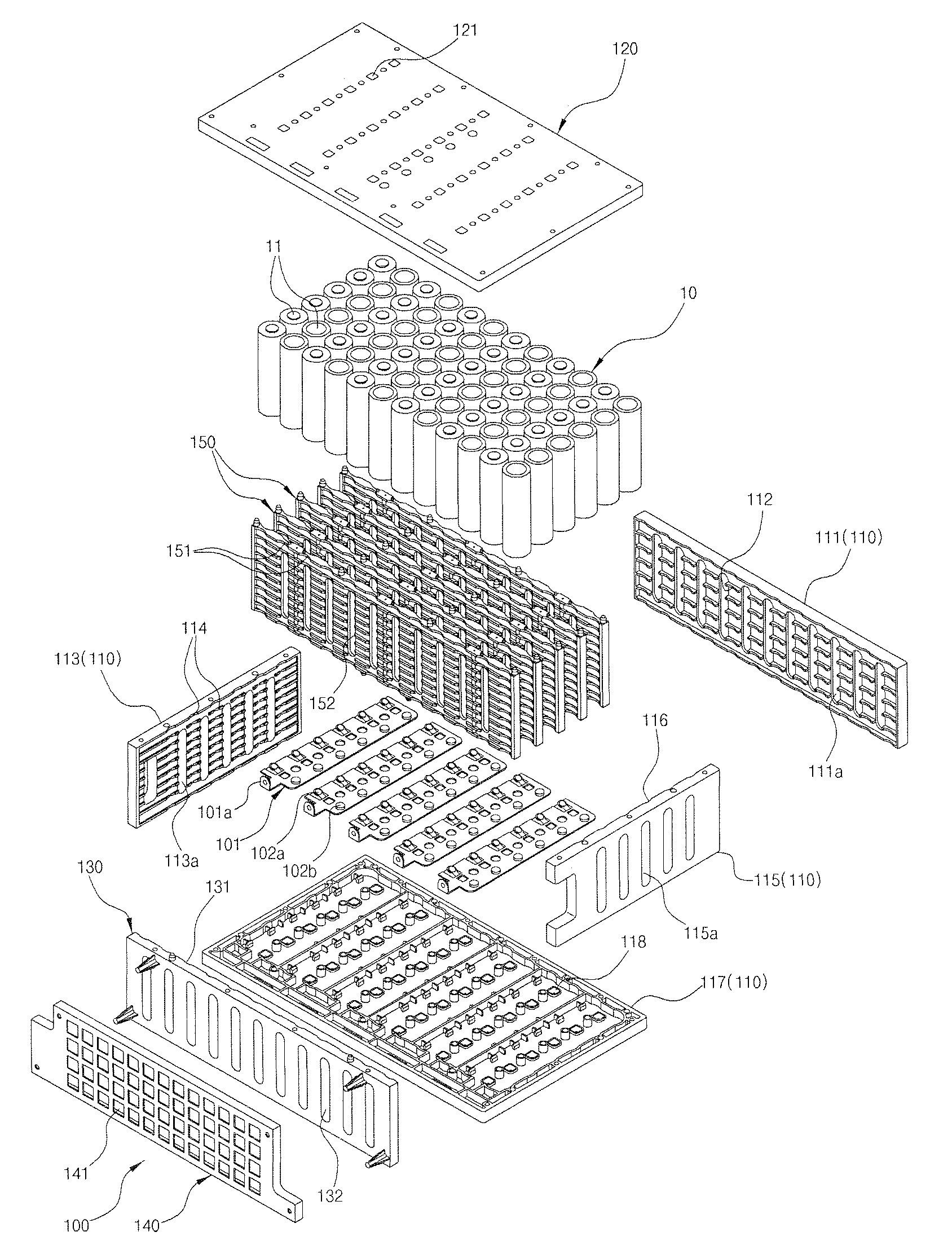

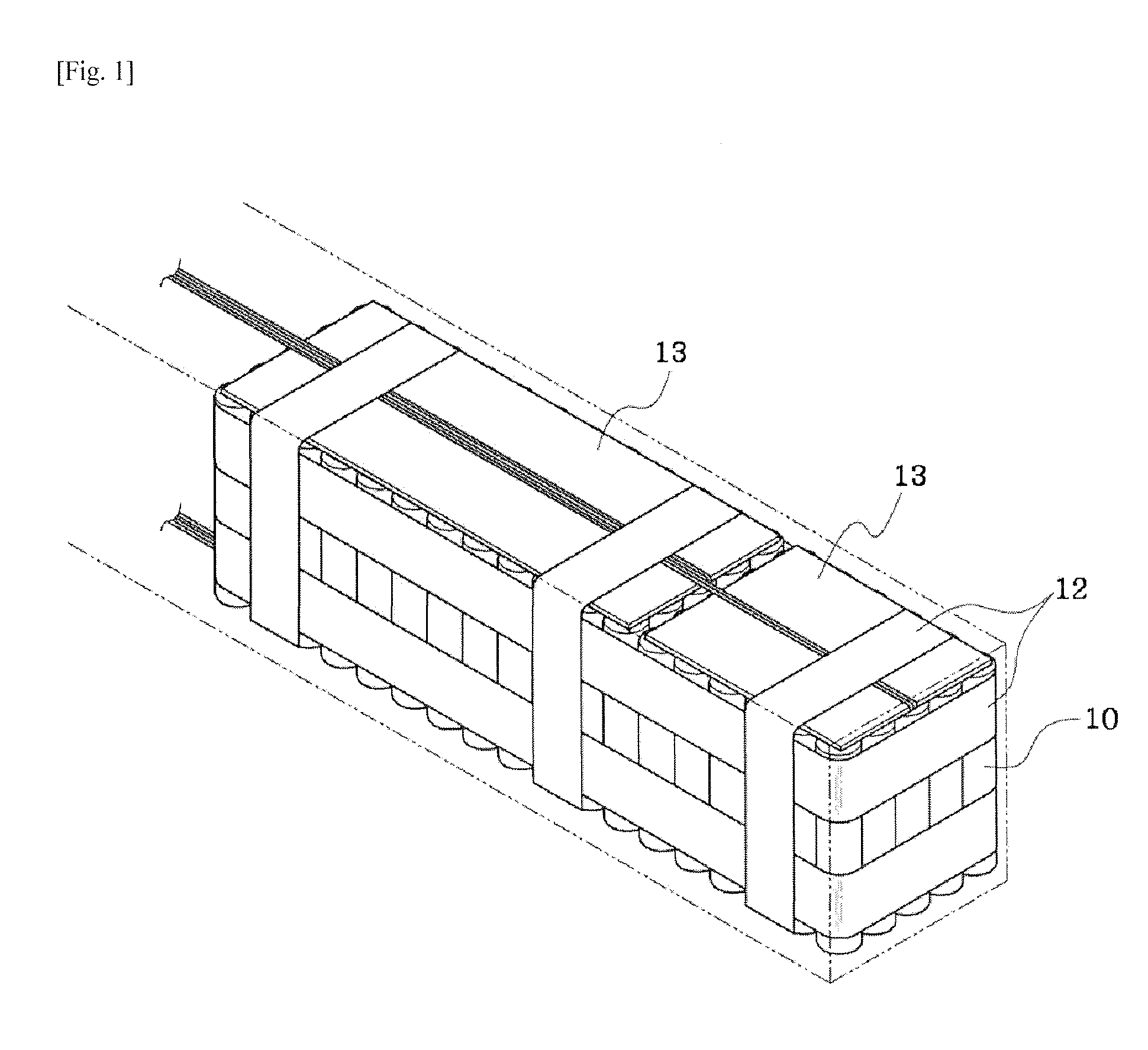

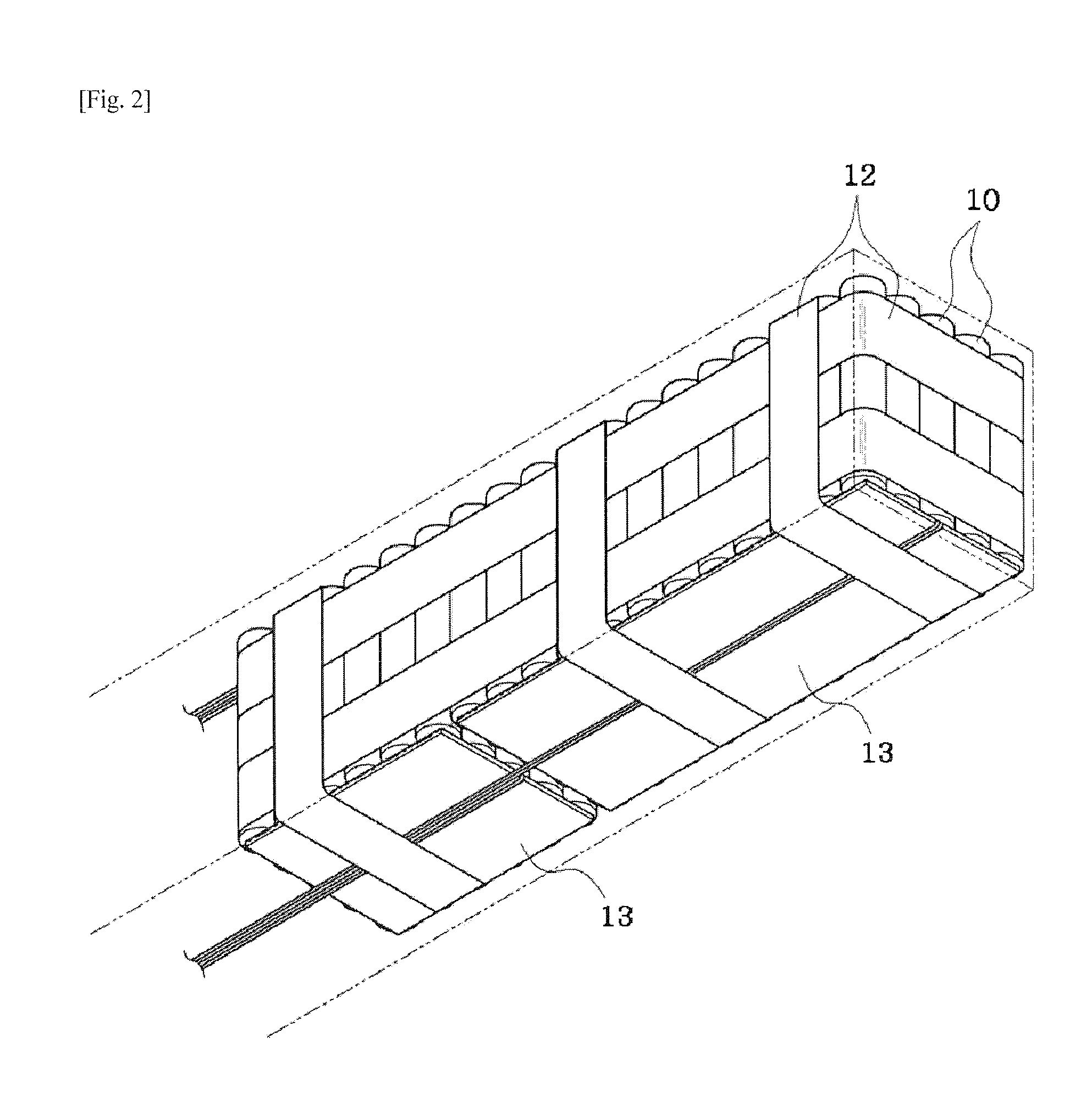

Cell Cartridge with a Composite Intercell Connecting Net Structure

InactiveUS20110287287A1Improve accuracyShorten the timePrimary cell to battery groupingSecondary cellsElectrical resistance and conductanceProduction rate

The present invention provides a cell cartridge with a composite cell interconnection network, in which plural unit cells are assembled and modularized in a case in a composite series-parallel connection manner. An object of the present invention is to provide a cell cartridge with a composite cell interconnection network, in which a plurality of unit cells can be simply assembled, as opposed to conventional methods of binding the unit cells with glass tape, for example, to shorten the time required for assembly, improve assemblability and productivity, and increase the accuracy of manufacturing standards. Moreover, another object of the present invention is to provide a cell cartridge with a composite cell interconnection network, in which a plurality of unit cells are spaced at regular intervals to prevent problems caused by direct contact between the cells and by heat generated thereby, prevent problems such as cell performance degradation and reduced battery lifespan caused by the direct contact and the generated heat, and enable mass production of standardized and modularized battery packs. Furthermore, still another object of the present invention is to provide a cell cartridge with a composite cell interconnection network, in which the structure of external terminals connected to cell terminals is modified to prevent a contact failure or excessive contact resistance between the cell terminals and the external terminals, and which can solve many other problems, caused by the welding of a nickel plate in conventional methods, such as welding defects, inconvenience of welding process, excessive assembly time due to the welding, degradation of assemblability and productivity, etc. To this end, a cell cartridge with a composite cell interconnection network is disclosed, the cell cartridge comprising: a plurality of unit cells; a case which accommodates the unit cells and is then assembled; a plurality of spacing members, each disposed between the unit cells accommodated in the case to space the unit cells a predetermined distance from each other; and a plurality of connection plates fixedly mounted on an inner side of the case and each including terminals connected to electrodes of the respective unit cells to connect the electrodes of adjacently arranged cells to each other, wherein the unit cells are connected to each other by the connection plates connected to the respective electrodes in a composite series-parallel connection manner.

Owner:ICEL SYST KOREA +1

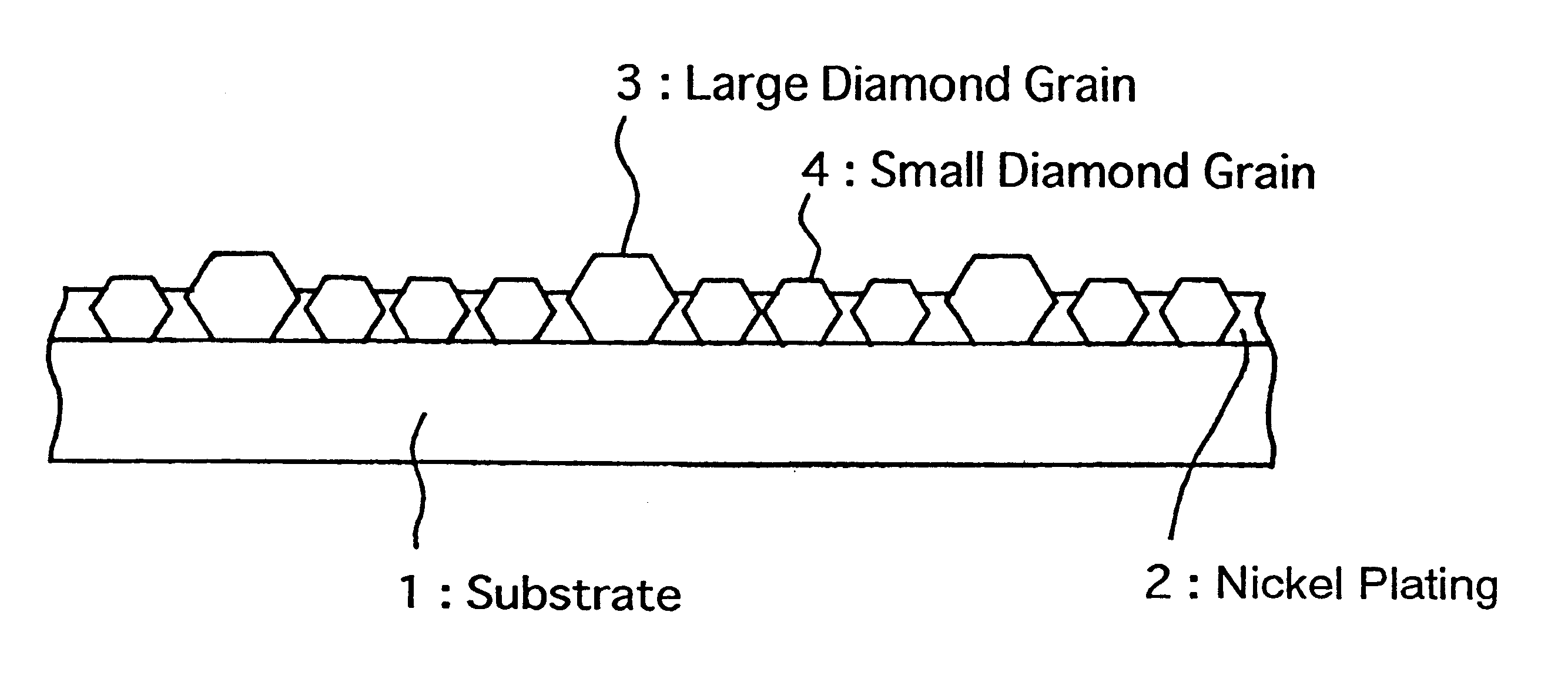

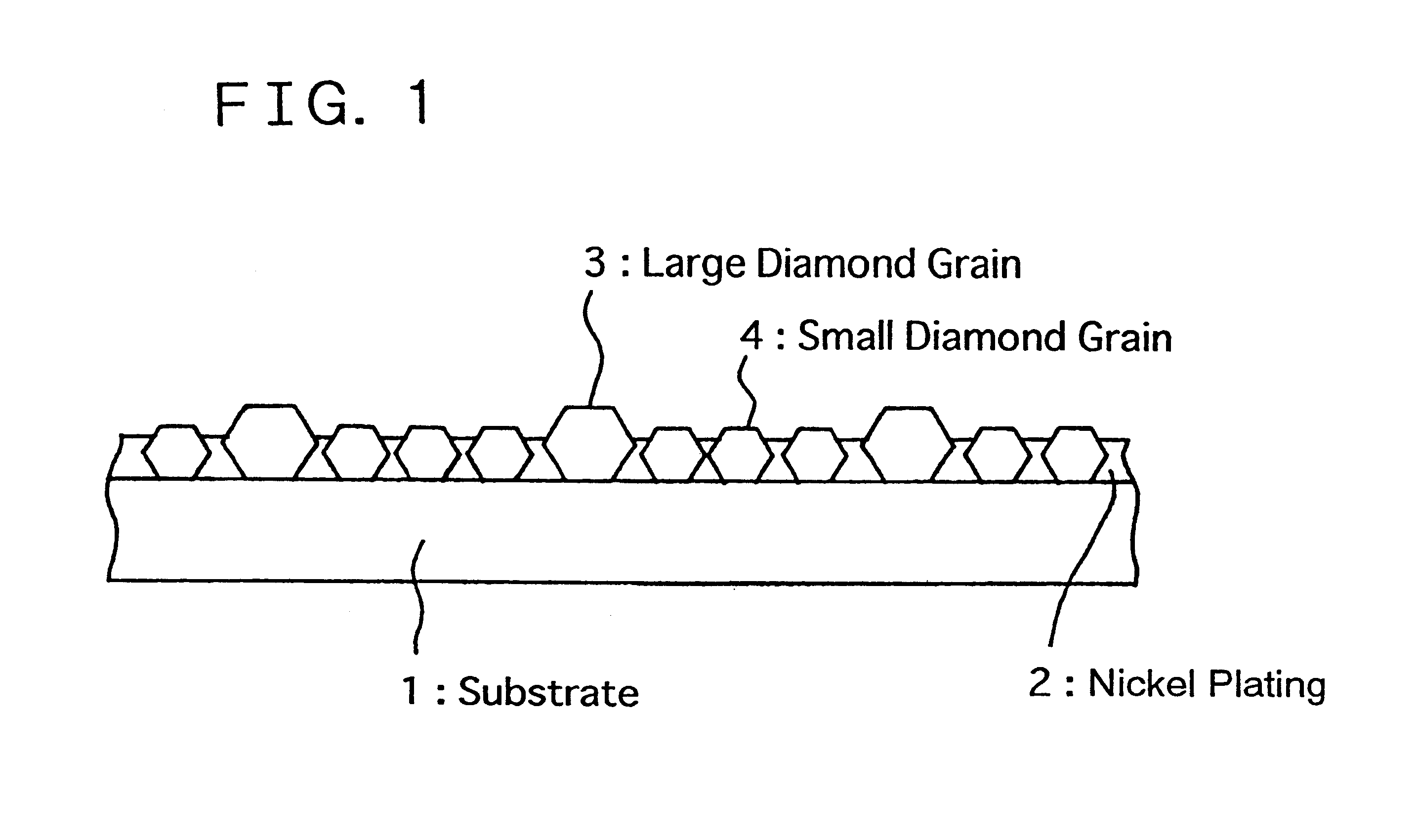

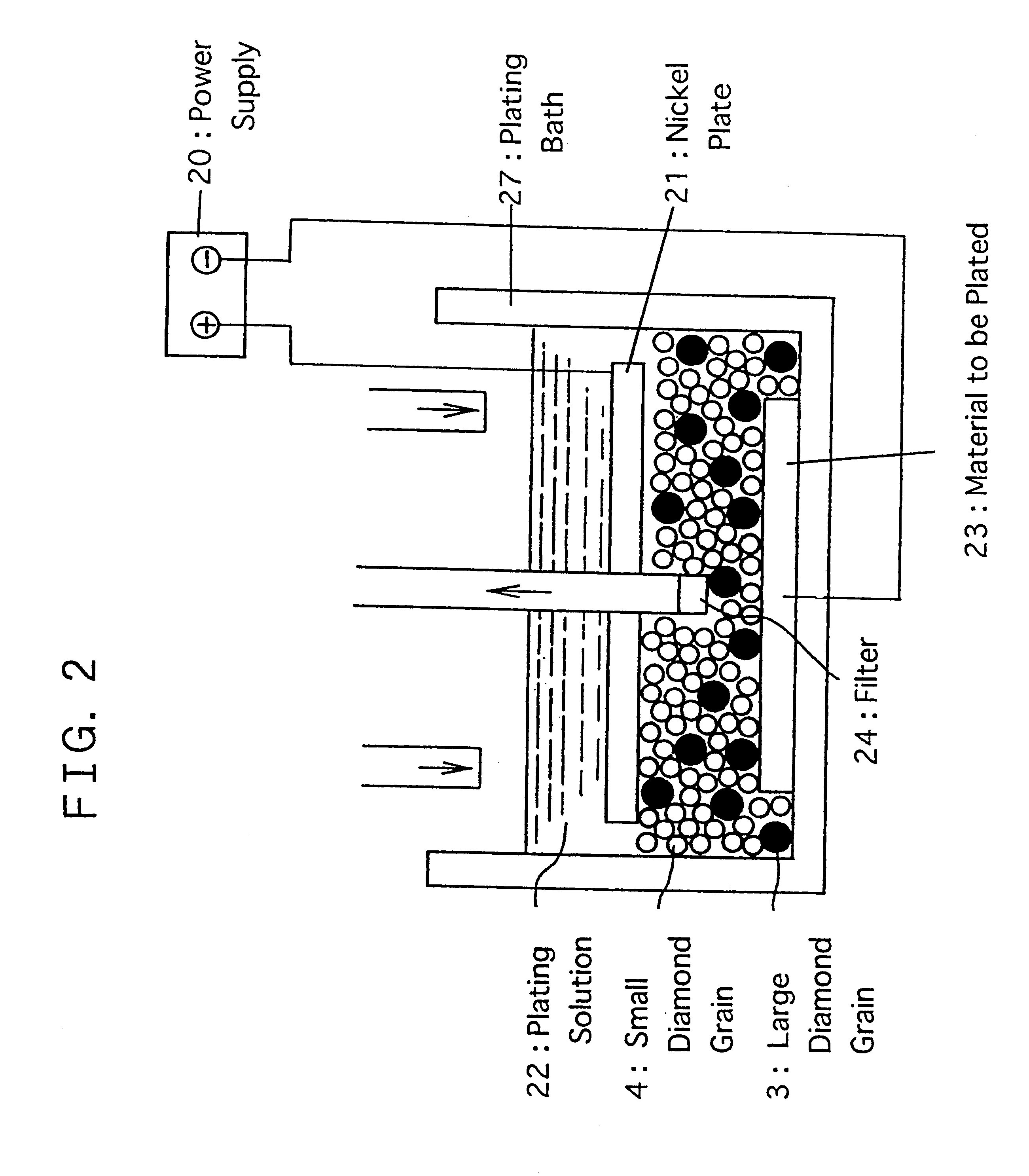

Dressing tool for the surface of an abrasive cloth and its production process

InactiveUS6306025B1Short lifeSimple processElectrolytic coatingsGrinding drivesForeign matterForeign substance

Onto the surface of a dressing tool for removing the clogging of an abrasive cloth, diamond grains of plural groups each having a different average particle diameter are subjected to be mixed and then fixed. In this state, the upper end of small diamond grains 4 is projected over nickel plating 2. Thereby foreign substances aggregated in the concave of the abrasive cloth are effectively removed and at the same time wearing the surface of the nickel plating 2 is prevented. Achieved are the stabilization of a polishing speed in polishing and the inhibition of dropping out diamond grains and wearing nickel plating in dressing.

Owner:NEC ELECTRONICS CORP

Secondary aluminum battery and preparation method thereof

InactiveCN101764253AReduce manufacturing costSimple processFinal product manufactureCell electrodesElectrolysisSlurry

The invention discloses a secondary aluminum battery and a preparation method thereof. The material of the positive electrode of the battery is organic polysulfide, the material of the negative electrode is aluminum or aluminum alloy, and the electrolyte is halogen aluminic acid ionic liquid; and the organic polysulfide is polysulfide carbine, thereby solving the problems that the elementary active substance is bad in conductivity and the frame is collapsed due to the dissolving of the reducing product. The electrolyte used is non-aqueous ionic liquid so that no oxide film, corrosive product or colloidal secondary product can be produced on the surface of the aluminum negative electrode so as to reduce the capacity loss of the negative electrode; the oxidation reduction reaction of the aluminum electrode in the electrolyte is reversible; and the battery is rechargeable. The preparation method for the secondary aluminum battery comprises the following steps: (1) preparing positive active material paste; (2) coating the positive active material paste on a foam nickel base, baking the paste and rolling the base into a positive plate; (3) rolling the positive plate, glass fiber non-woven membrane and the negative electrode made by taking any one of aluminum powder, aluminum foil and aluminum alloy as the negative active material into a battery core and arranging the battery core in a nickel-plated steel shell; then adding organic electrolyte in the steel shell; and sealing the steel shell to make the AA-type cylindrical secondary aluminum battery. The invention further discloses a preparation method for the positive material polysulfide carbyne of the battery.

Owner:无锡欧力达新能源电力科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com