Method for classifying, treating and recycling plating washing water on line

A technology for treating circulating and cleaning water, applied in water/sewage treatment, metallurgical wastewater treatment, adsorbed water/sewage treatment, etc., to avoid cross-contamination, concise and practical promotion, and targeted effects

Active Publication Date: 2010-11-24

NANJING YUANQUAN TECH CO LTD

View PDF5 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this method only completes the recycling of cleaning water for a single type of plating, and the recycling of cleaning water for the entire electroplating line still needs to be solved urgently.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

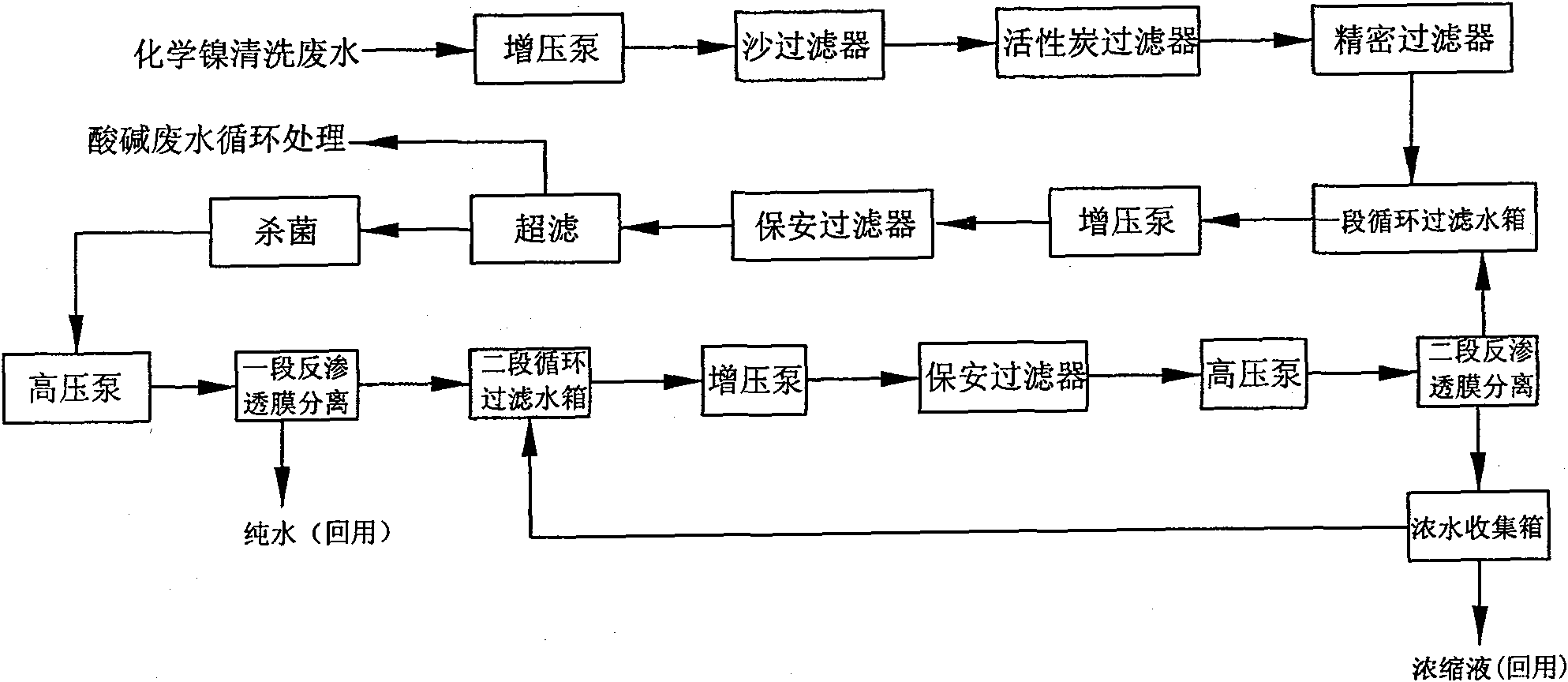

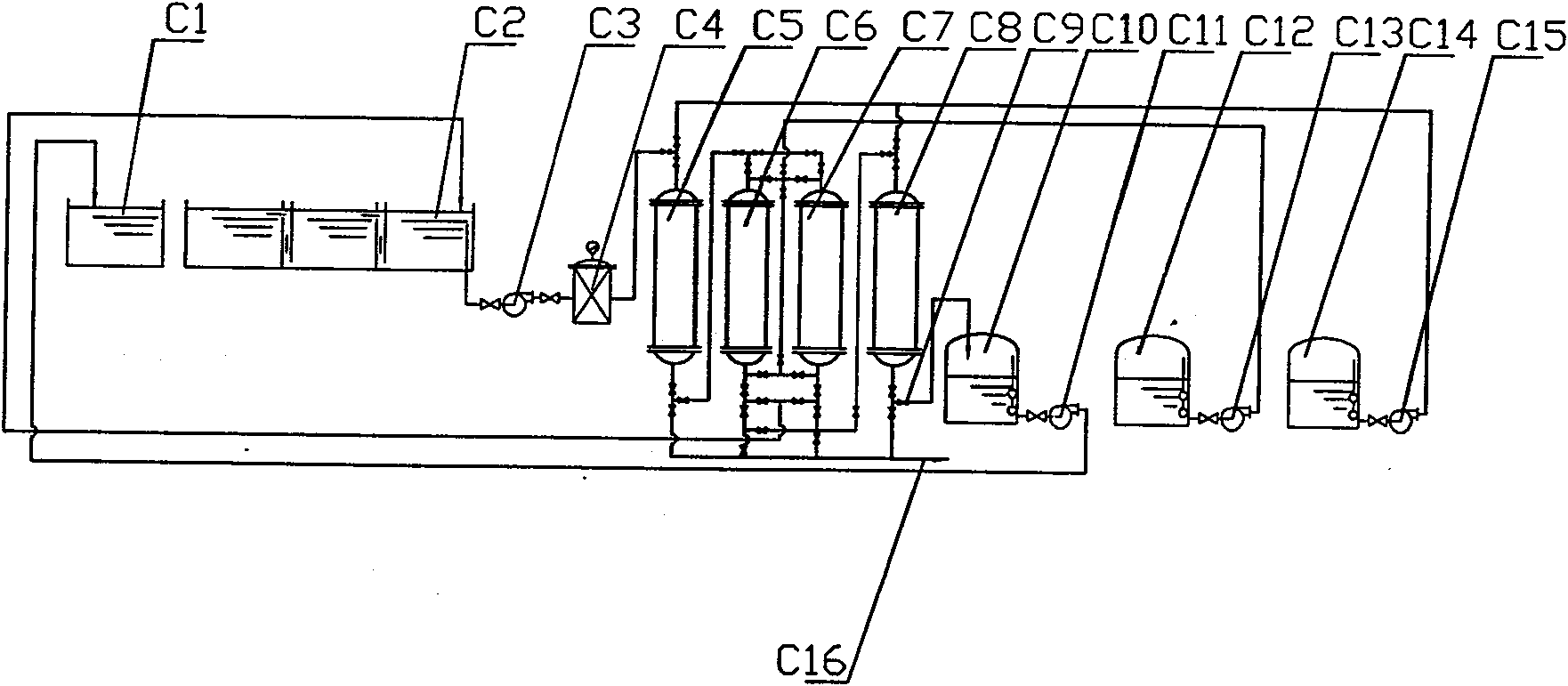

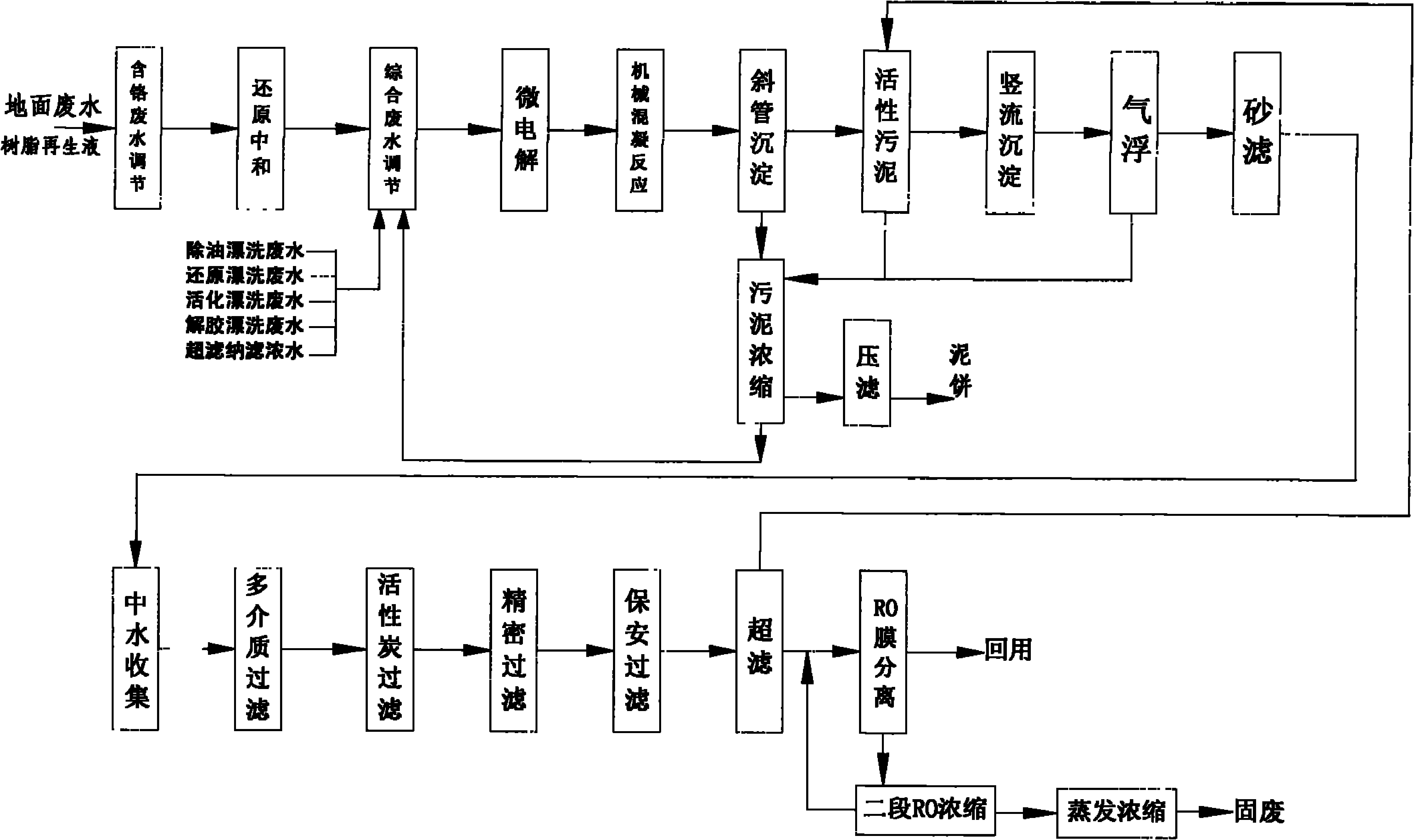

The invention discloses a method for classifying, treating and recycling plating washing water on line, which comprises the following steps of: removing oil, coarsening, reducing, activating, peptizing, chemically plating nickel, preplating nickel, plating copper, plating nickel and plating chromium in a plating process; and treating water and washing water during production and cleaning. The method specifically comprises the following steps of: preparing pure plating water, circularly processing acid and alkaline waste water, coarsening, circularly treating chromium-plating washing water, circularly treating chemically nickel-plating washing water, circularly treating copper-plating washing water and circularly treating nickel-plating washing water. Waste water in each procedure is directly used beside a tank edge in a closed cycle by an economical and effective means after being treated, no wastewater is discharged, and the cross contamination of different water qualities among the procedures is avoided. The method is a technological innovation for realizing zero emission of plating waste water and plating cleaner production.

Description

Method for on-line classification, treatment and recycling of electroplating cleaning water technical field The invention belongs to the technical field of industrial wastewater treatment, and in particular relates to a treatment technology of electroplating wastewater. Background technique The pollution of electroplating wastewater to the environment has been a major problem that has restricted the development of electroplating enterprises for a long time. Since electroplating wastewater contains heavy metals that are difficult to completely remove, after discharge, it will cause great harm to water bodies, nature and human beings. The most fundamental way to solve the environmental pollution of electroplating wastewater is to realize the full recycling of electroplating wastewater and achieve zero discharge. Although there have been many research results on the reuse of electroplating wastewater in order to achieve zero discharge for a long time, there are not many compl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F9/06C02F1/28C02F1/44C02F1/66C02F1/461C02F1/52C02F1/42C02F103/16C02F101/12C02F101/10C02F101/20

Inventor 沈德华吕建来范正芳余素耘

Owner NANJING YUANQUAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com