Patents

Literature

1063 results about "After discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

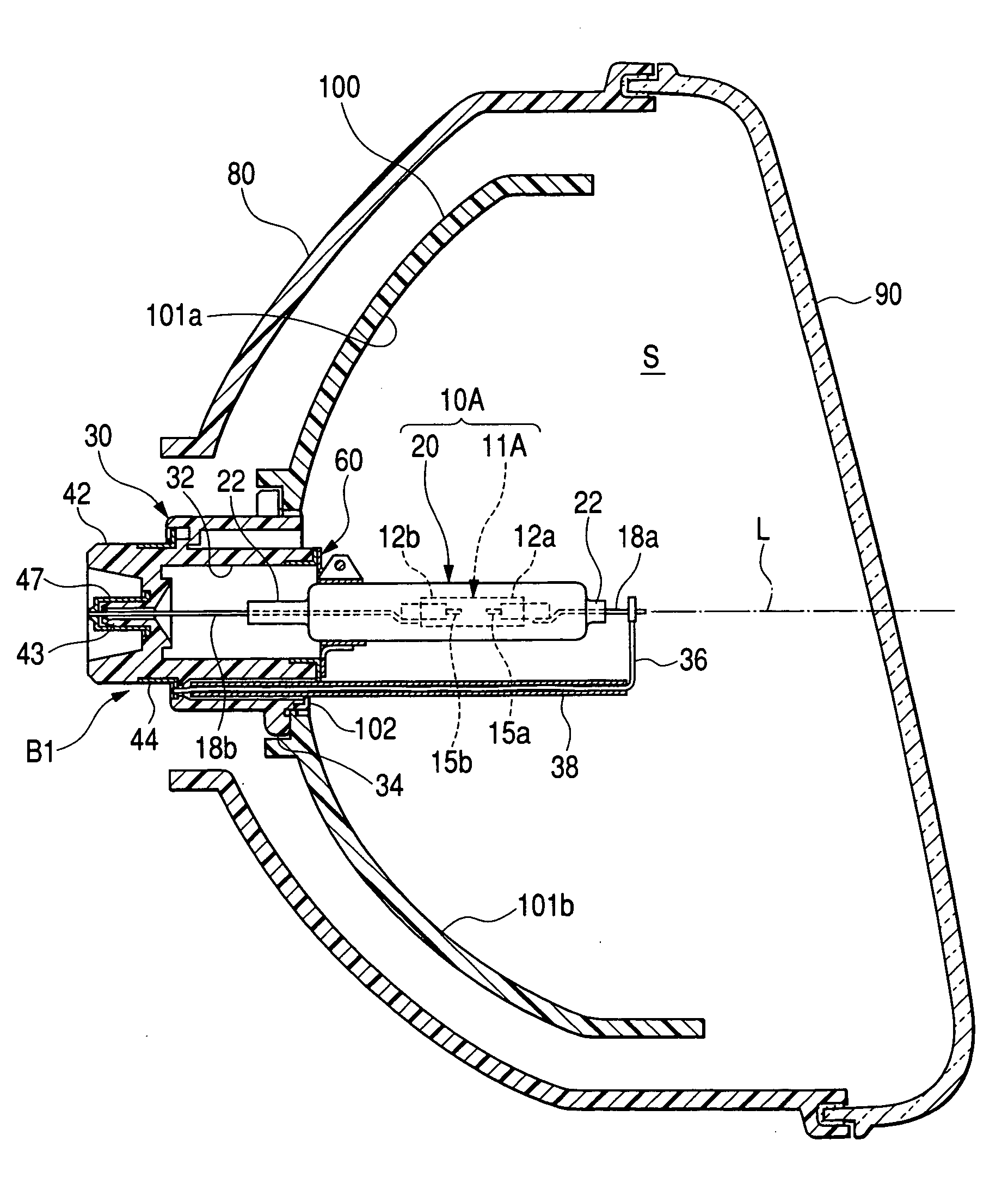

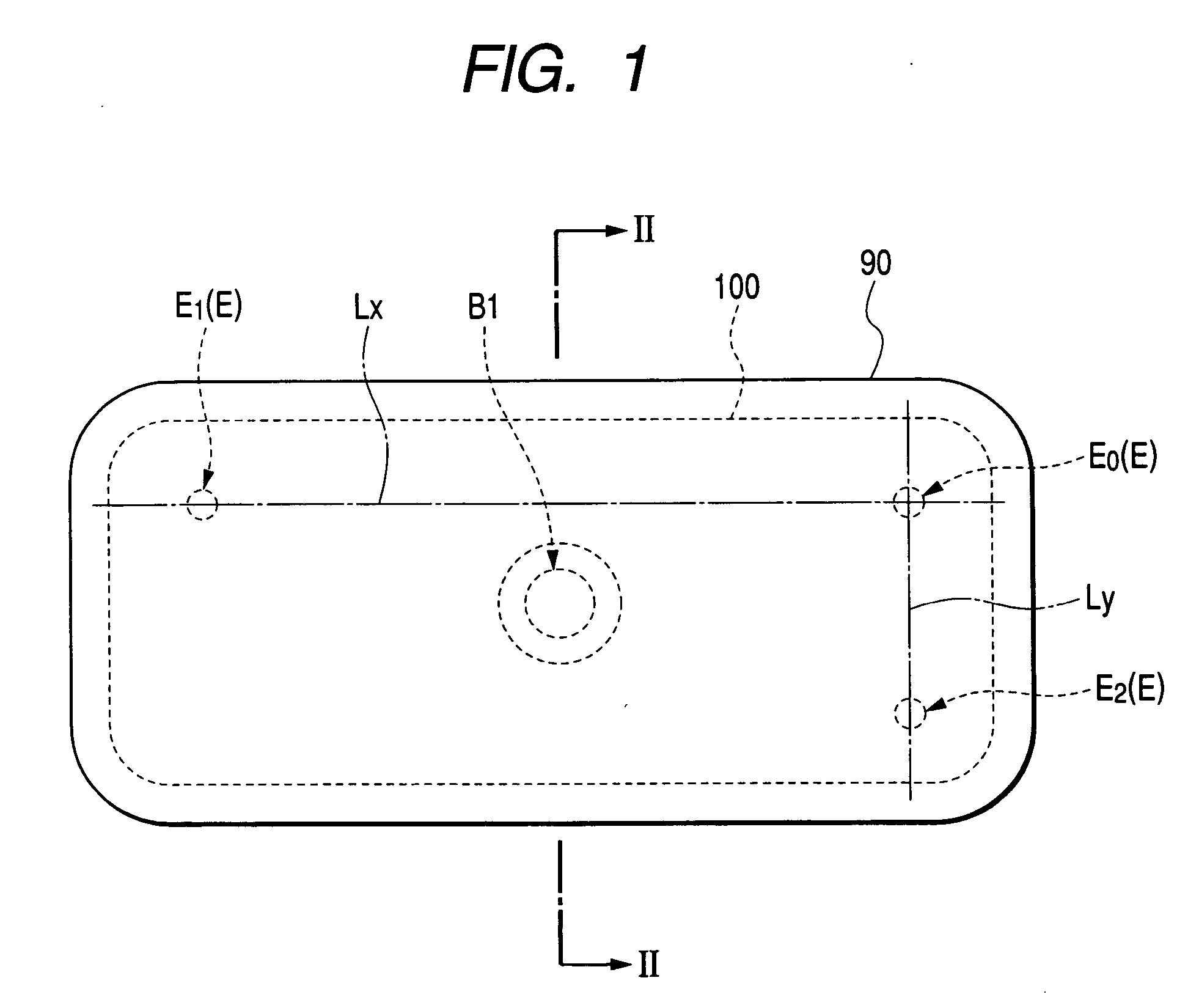

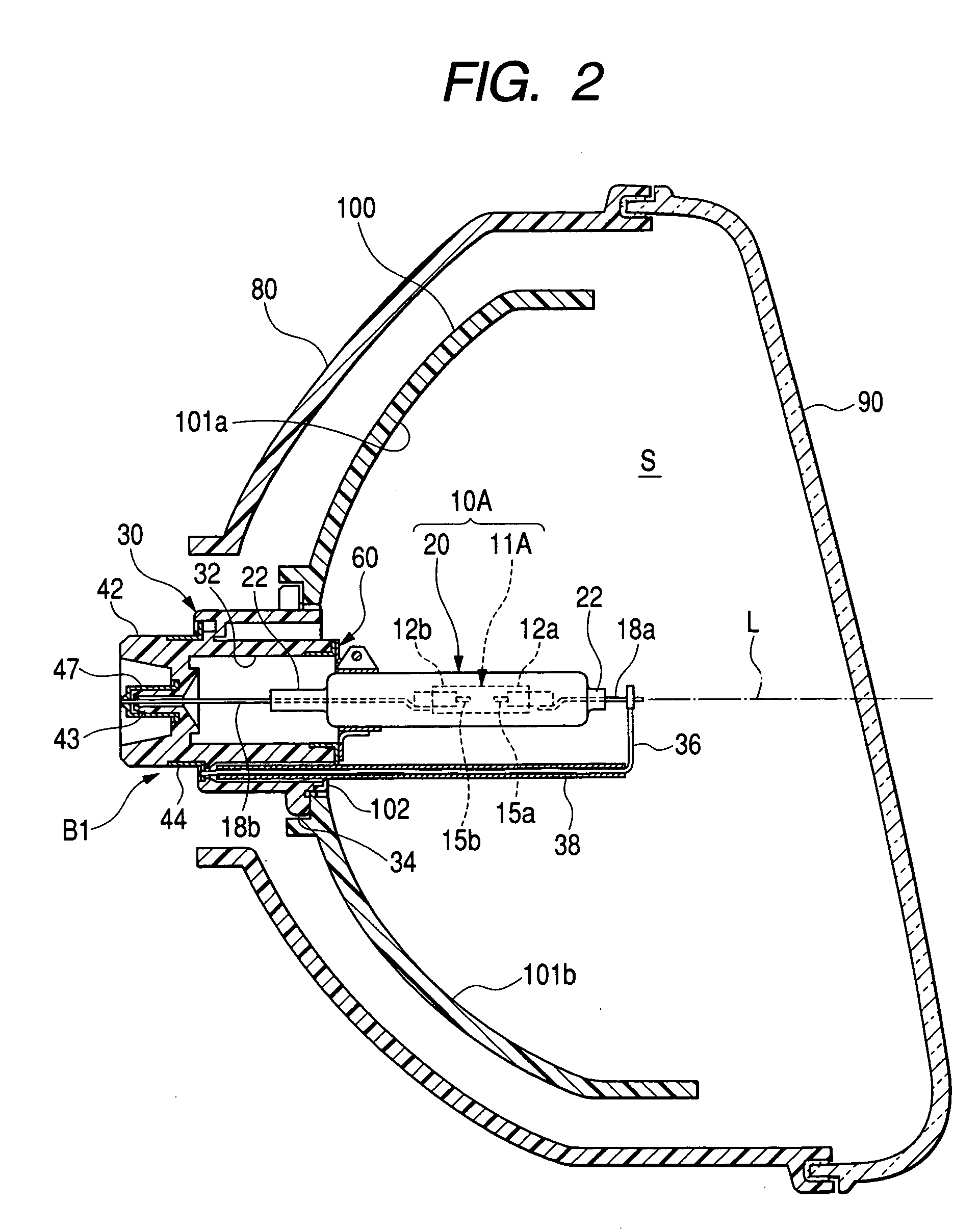

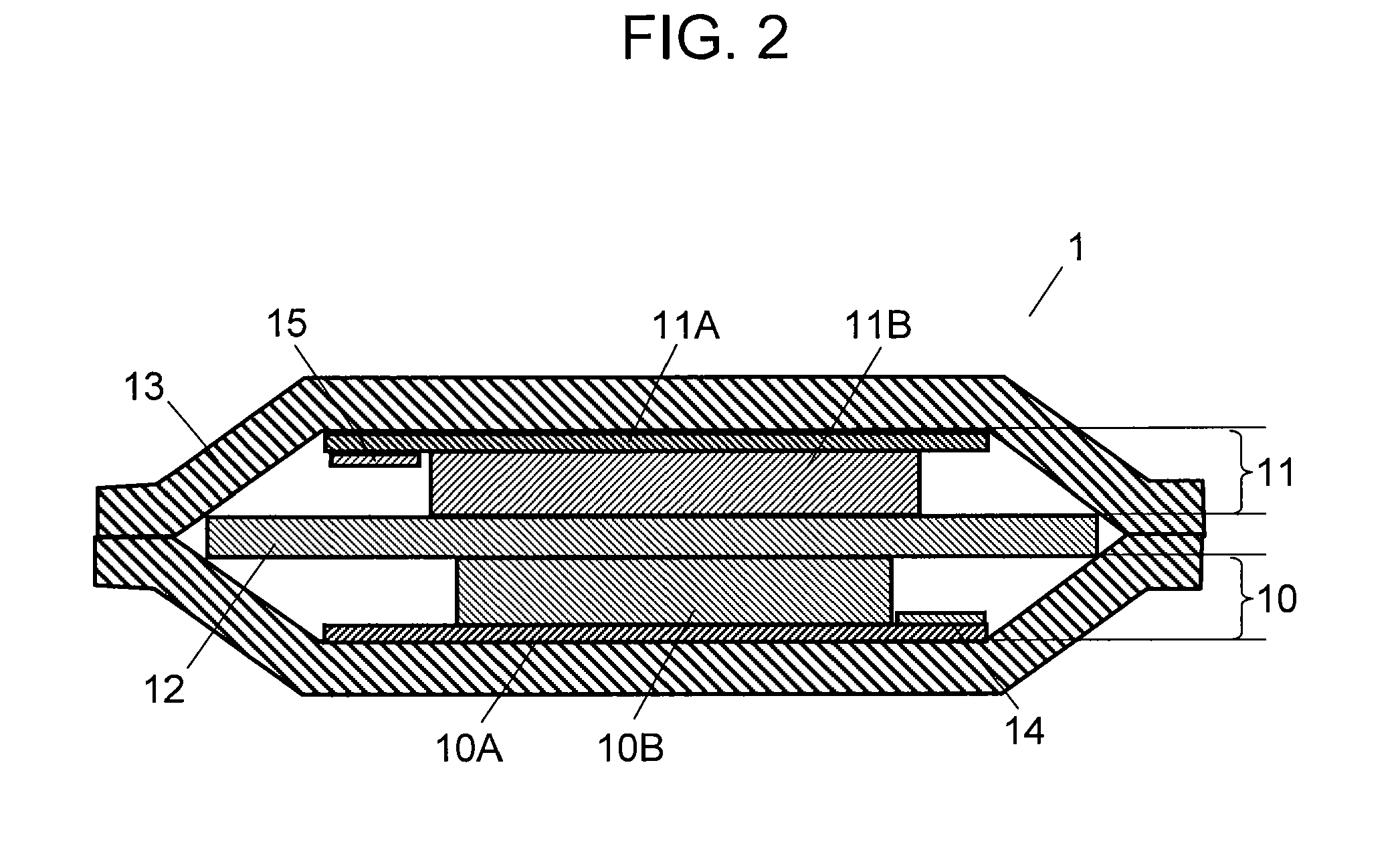

Automotive discharge bulb and automotive headlamp

InactiveUS20050007020A1Wasteful consumption can be reducedReduce the ratioDischarge tube luminescnet screensPoint-like light sourceNoble gasLuminous flux

An automotive discharge bulb having a light emitting tube includes a ceramic tube with paired electrodes oppositely placed, and contains a light emitting material and starting rare gas. A transversal section of the ceramic tube is longitudinally elongated. Because the capacity of an enclosed space of the ceramic tube is small, after discharging begins, the enclosed space temperature increases. Consequently, the ceramic tube has a good luminous flux rising characteristic. Because of the small surface area of the ceramic tube, the load imposed on the wall surface increases. Consequently, the ceramic tube has good luminous efficiency. In the ceramic tube having a longitudinally elongated transversal section, an arc generated into an upwardly convex shape and the tube wall do not make contact. Thermal shock resistance required of the ceramic tube is alleviated, durability is enhanced, and the ceramic tube is made of a ceramic material hitherto unusable.

Owner:KOITO MFG CO LTD

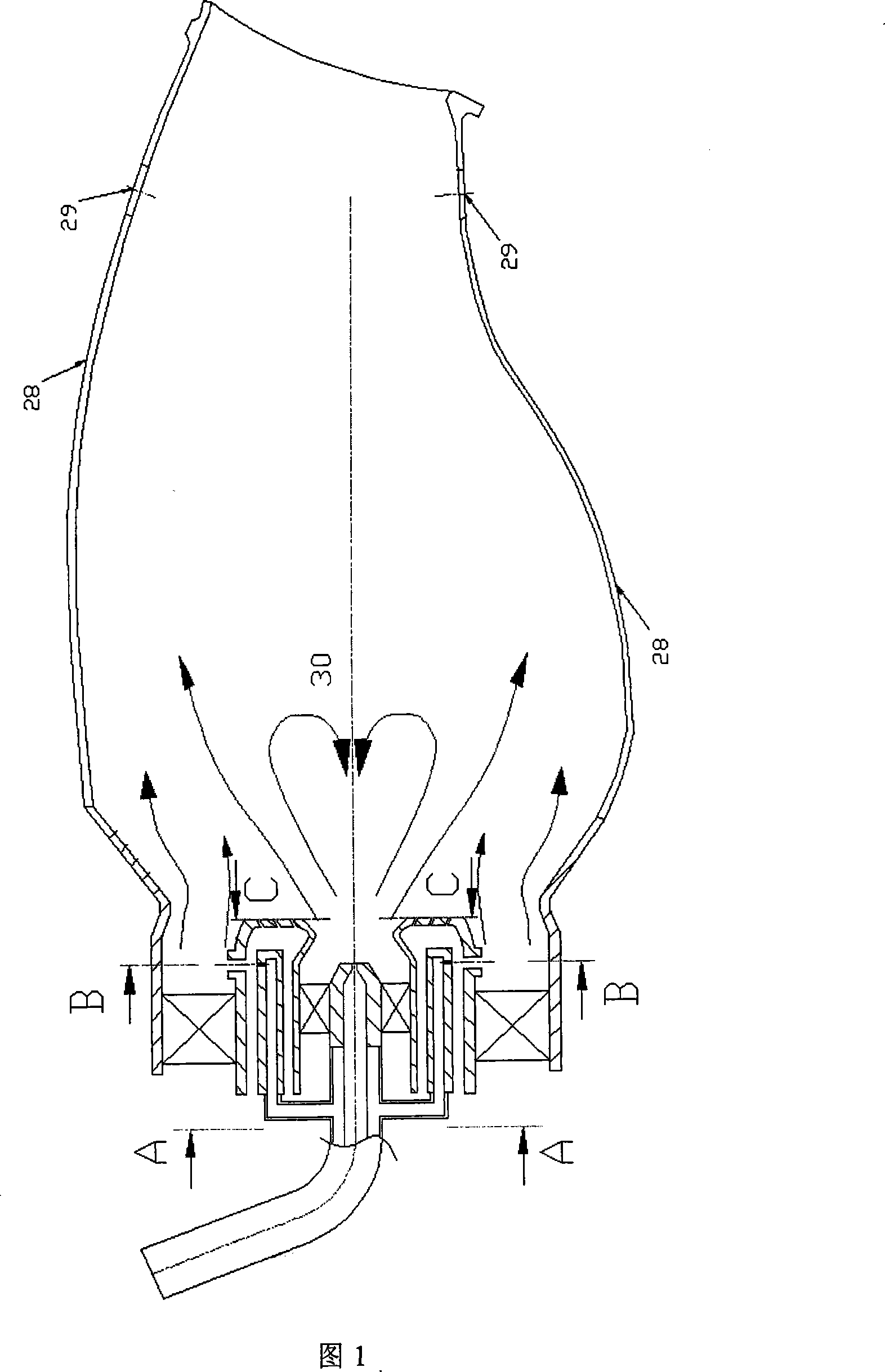

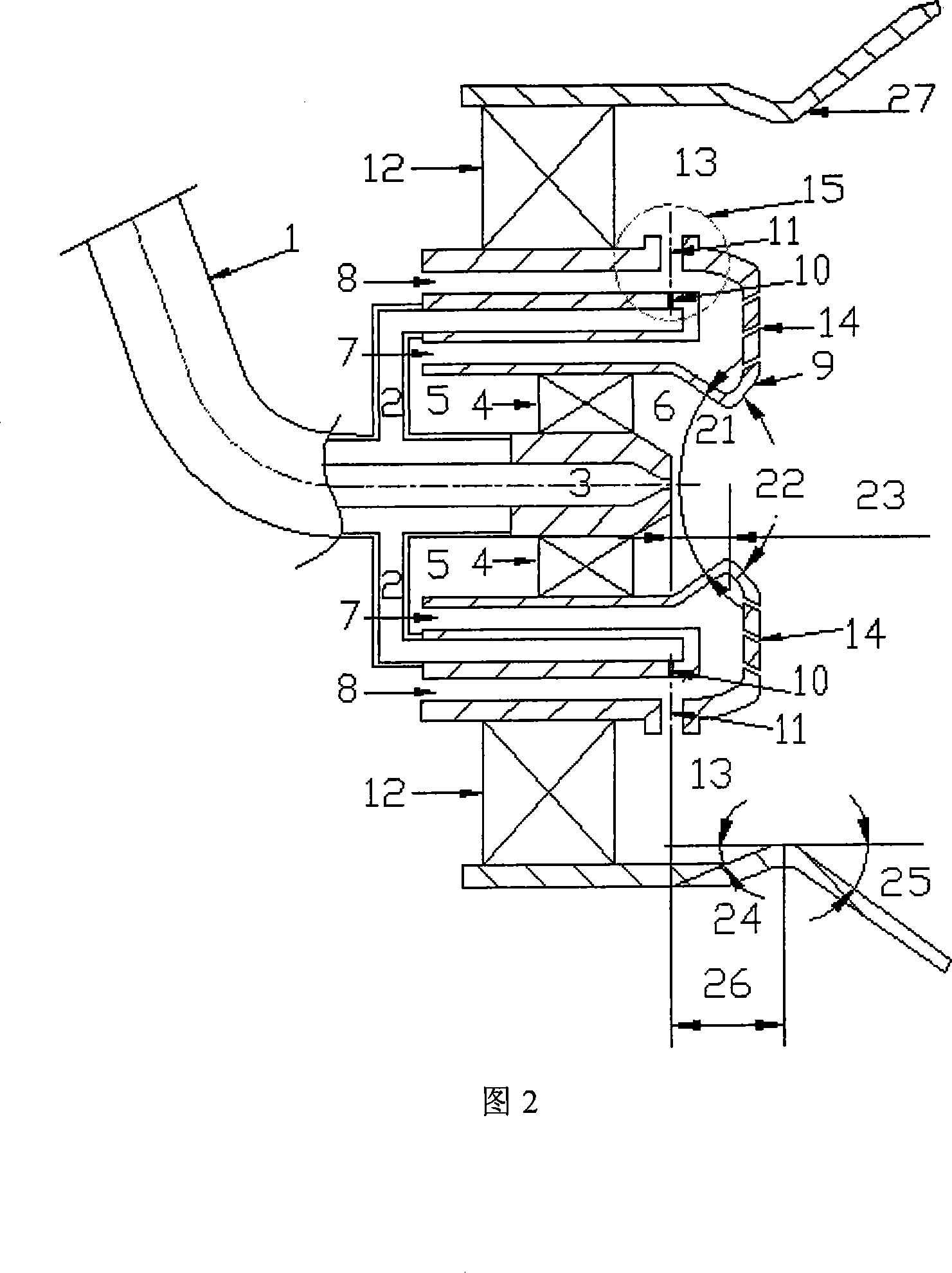

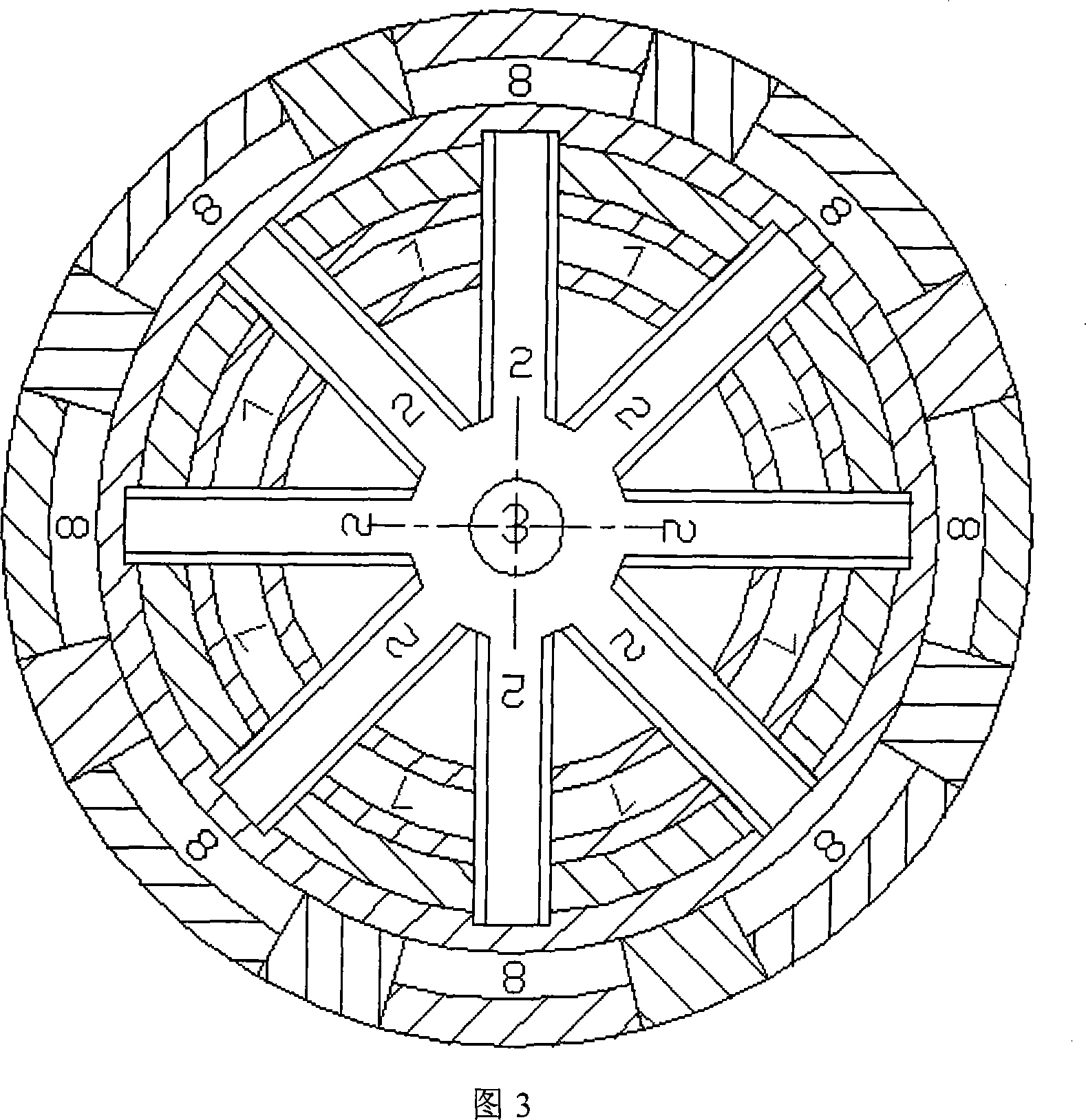

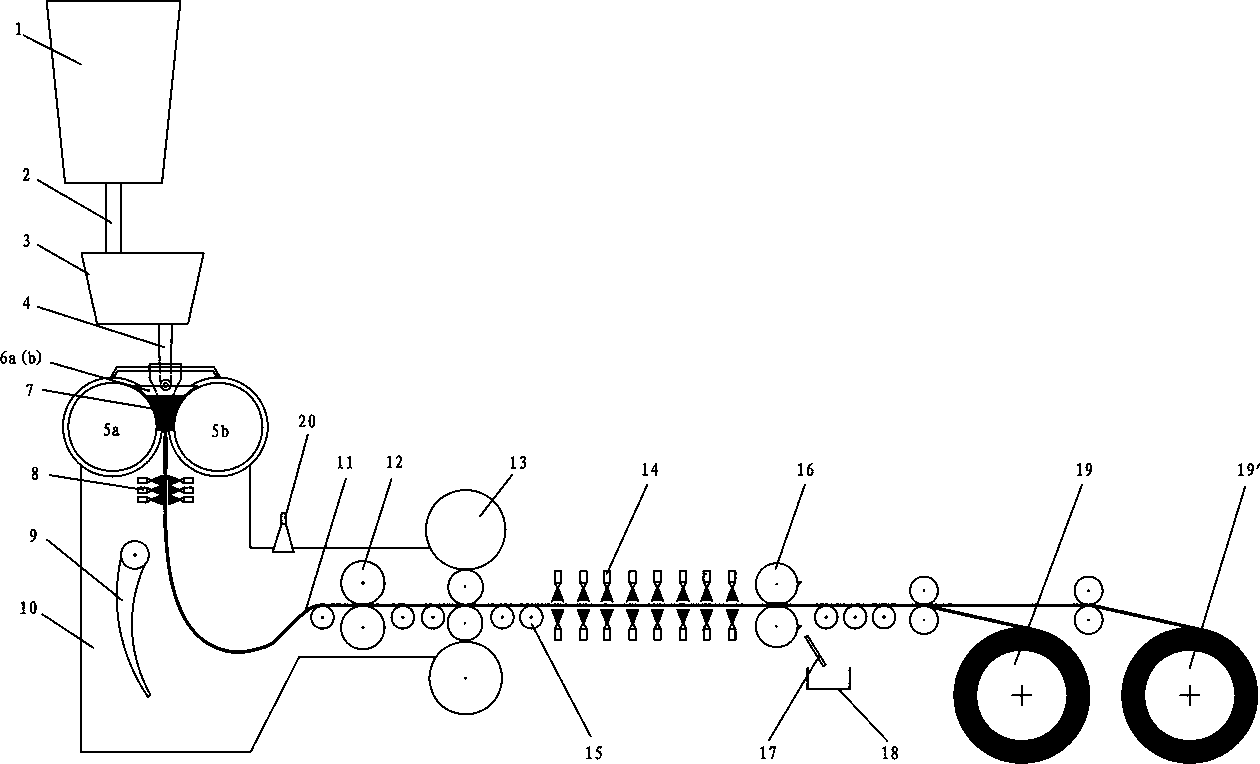

Aerial engine lean premixed preevaporated low contamination combustion chamber

An aero-engine lean-oil premixed pre-evaporation low-pollution combustor consists of a head and a flame tube, the combustion gas is all supplied from the head of the combustor, and the cooling gas and mixed gas enter from the flame tube; the head is The double-ring cavity structure is divided into two stages, the pre-combustion stage and the main combustion stage. The pre-combustion stage is included, and the main combustion stage surrounds the pre-combustion stage. The pre-combustion stage includes a centrifugal nozzle and a swirler surrounding the centrifugal nozzle. After being sprayed out from the centrifugal nozzle, the fuel is sheared and broken by the air swirl from the swirler, mixed in the mixing chamber area of the pre-combustion stage and then enters the combustion area Diffusion combustion is formed inside; the main combustion stage includes a direct air atomizing nozzle, a main swirler and a premixing ring chamber, the main swirler is located upstream of the nozzle, and the premixing ring chamber is located downstream of the nozzle, and the fuel goes first in the nozzle It is mixed and atomized with air, and then tangentially injected into the premixed ring cavity for premixed pre-evaporation, and enters the combustion area to form premixed combustion; in the downstream of the pre-combustion stage combustion and main combustion stage fuel outlets, contraction and expansion ports are used to prevent backflow fire and carbon buildup. The invention has a simple structure and can effectively reduce the pollution discharge of the aero-engine under the condition of ensuring the working state.

Owner:BEIHANG UNIV

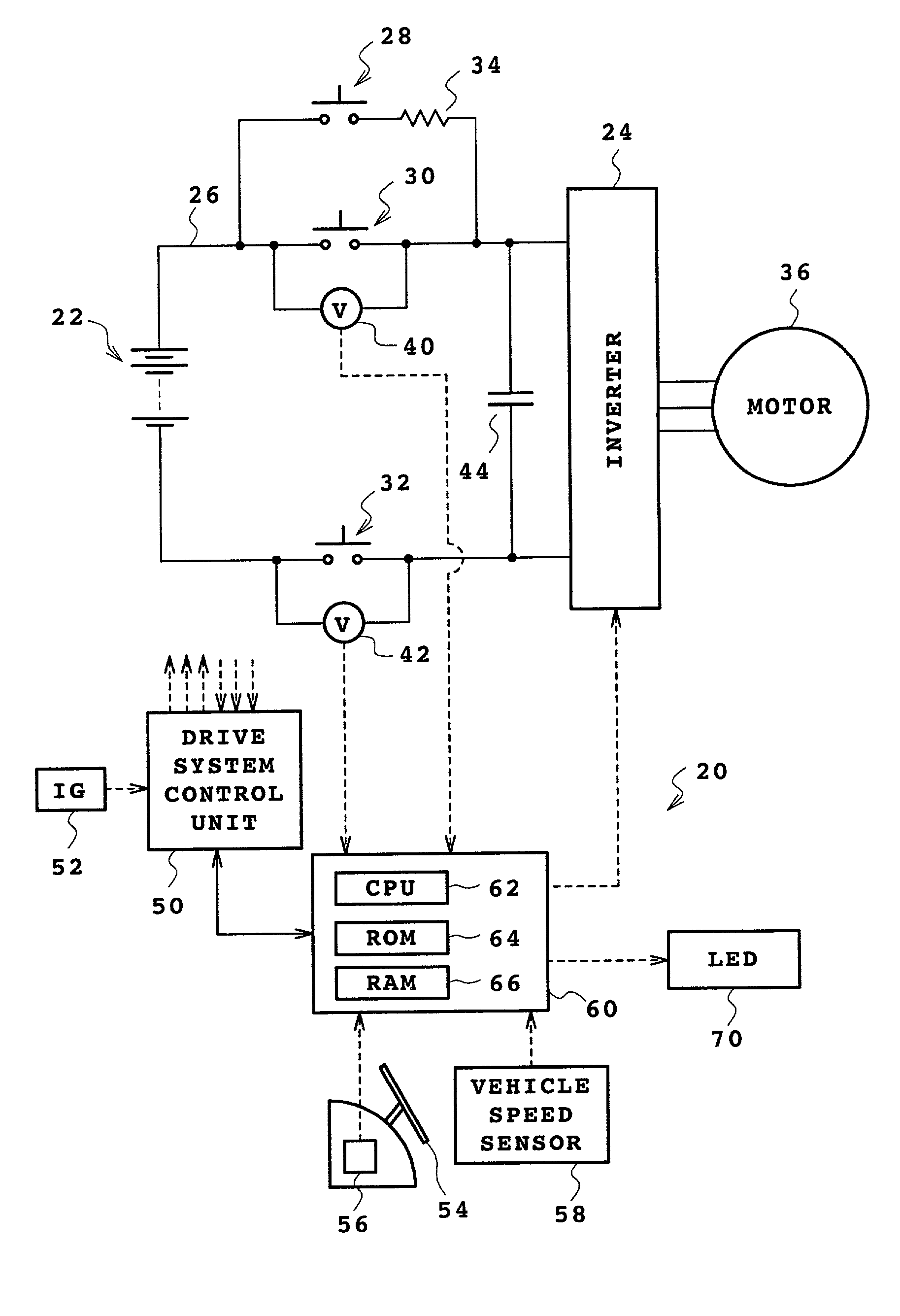

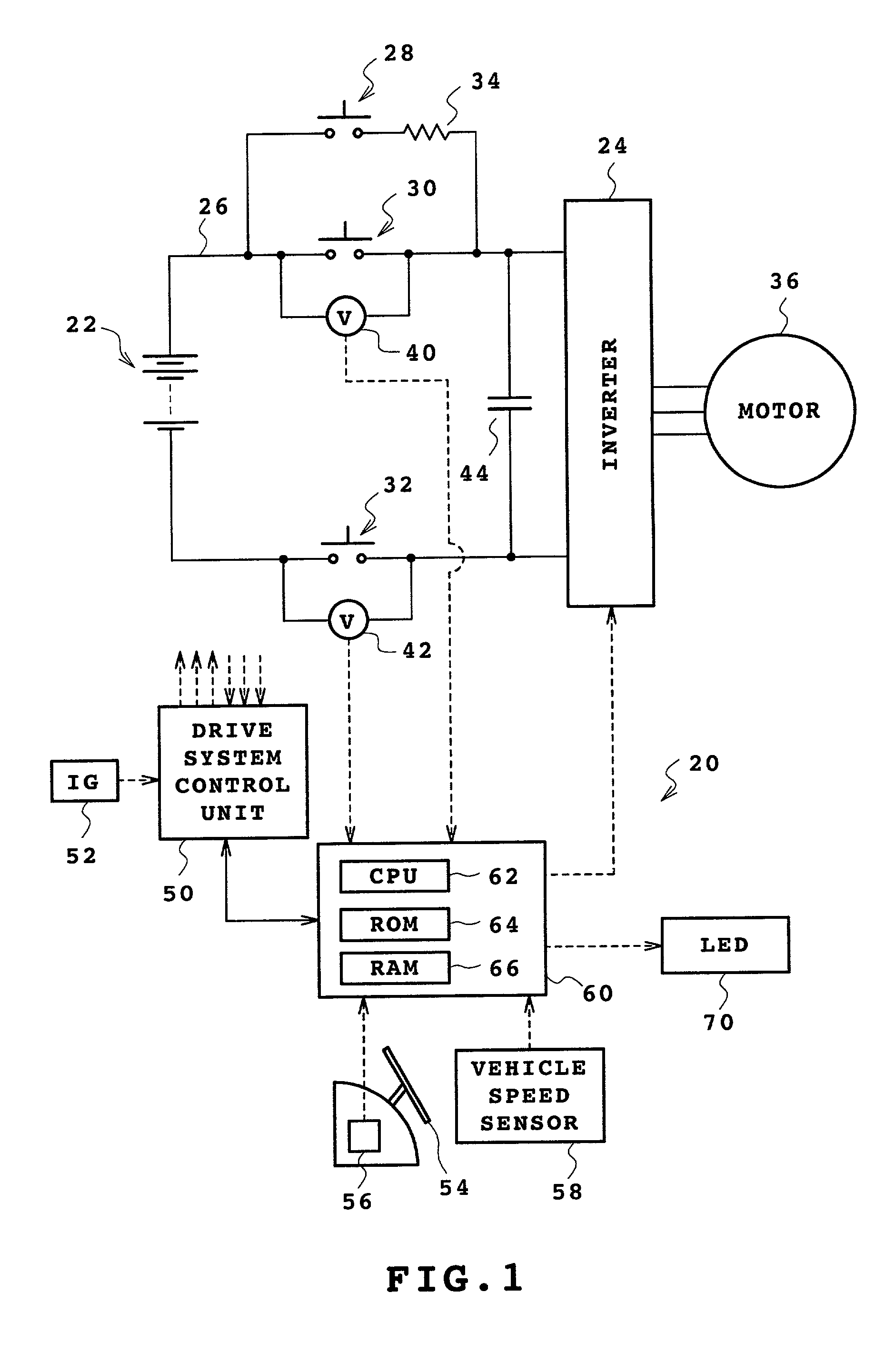

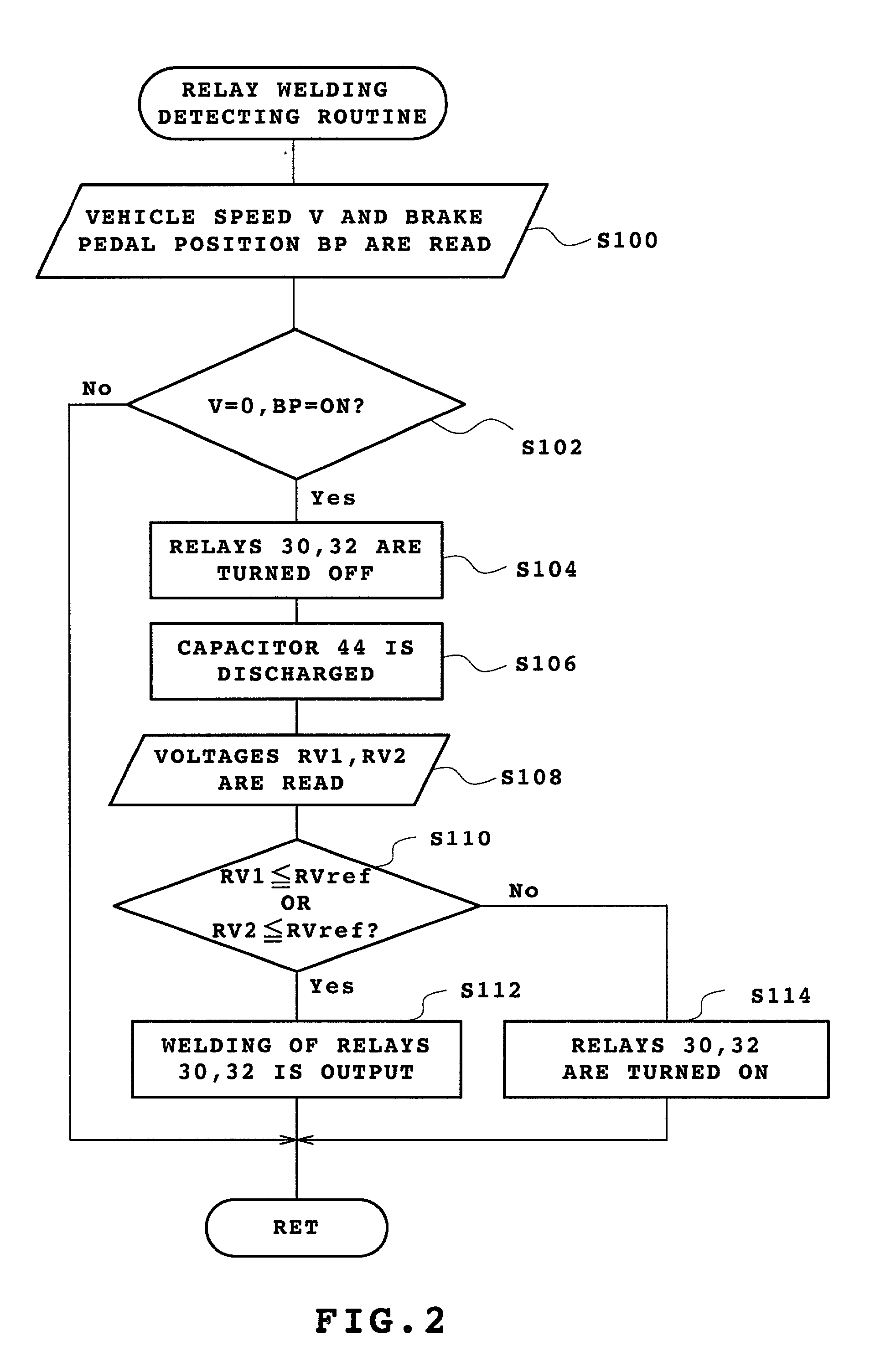

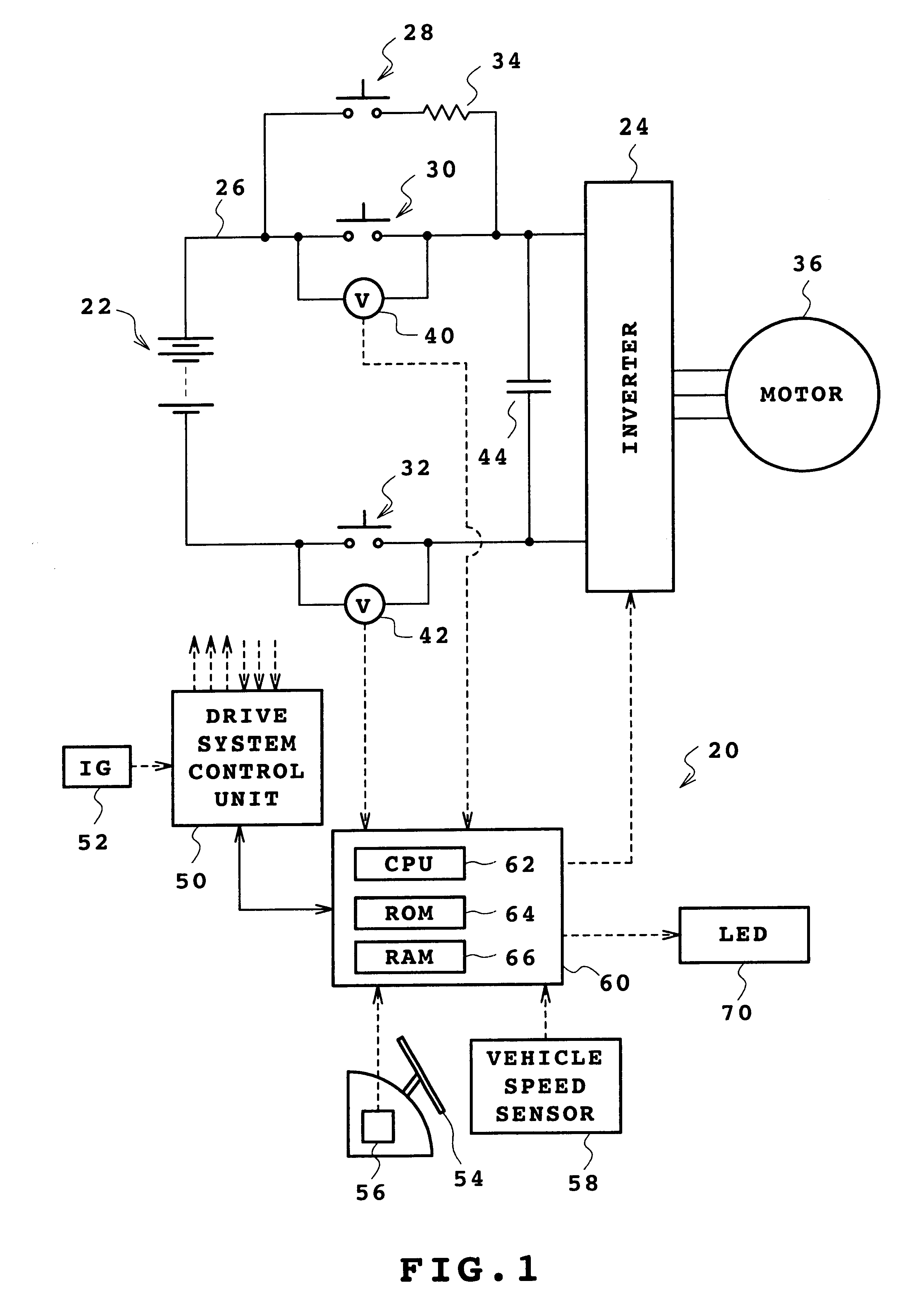

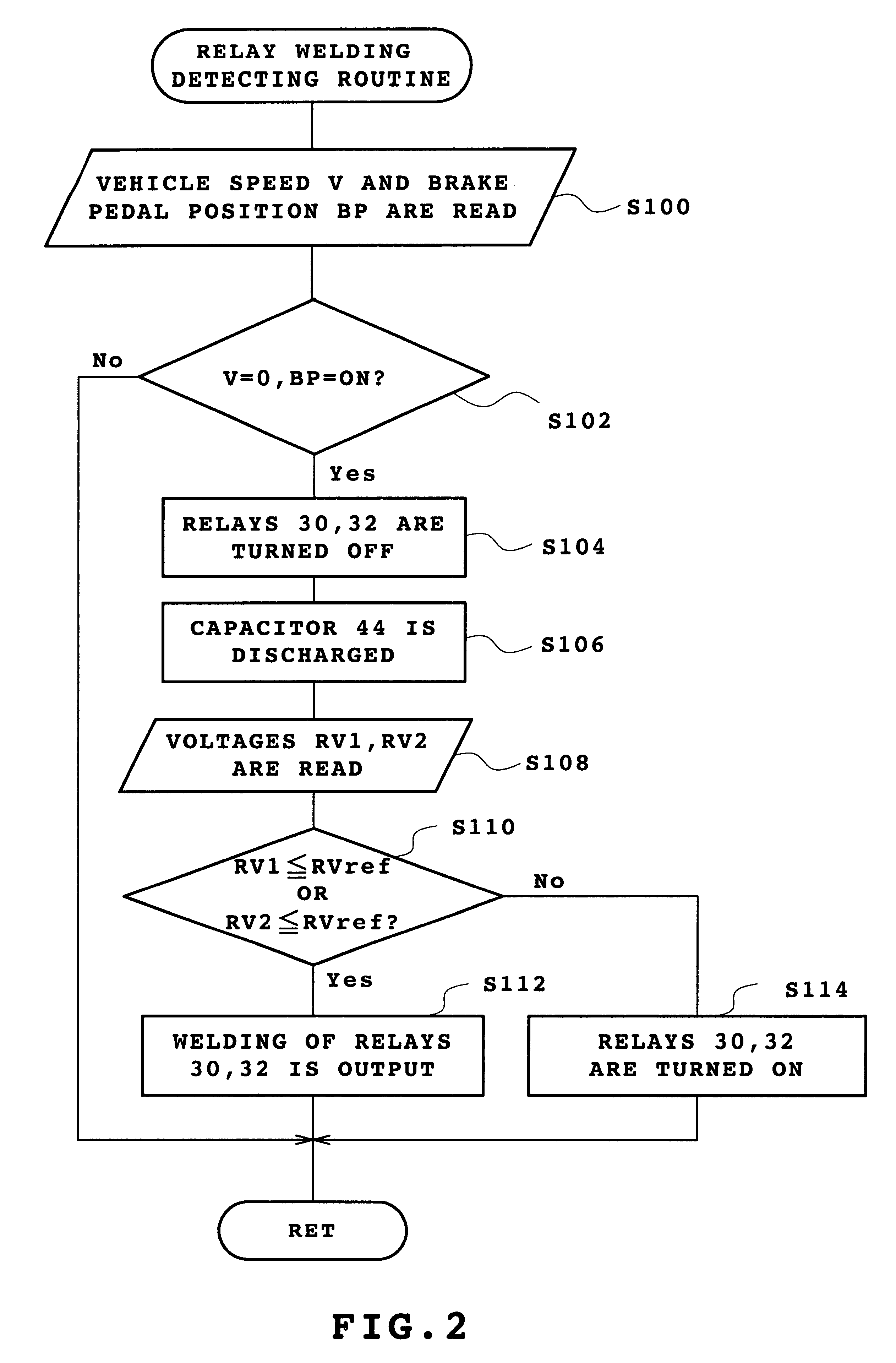

Relay welding detector and detecting method

InactiveUS20020070608A1Frequently performedReduce voltageAC motor controlElectric devicesVoltmeterEngineering

Frequency of judgment of welding of relays is increased to increase likelihood of early detection of welding. It is determined that a battery 22 is not being recharged or discharged when a vehicle speed V of an electric vehicle is approximately 0 and a brake pedal 54 is pressed, and a switching element of an inverter 24 is controlled to be switched to discharge electric charges which are stored in a capacitor 44. After discharging, relays 30, 32 are turned off, and voltages RV1, RV2 between the terminals of the relays 30, 32 are detected by voltmeters 40, 42 to judge whether either of the voltages RV1, RV2 has a threshold value RVref (approximate value 0) or less. When it is so determined, it is judged that the relays 30, 32 are welded, and an LED 70 is illuminated.

Owner:TOYOTA JIDOSHA KK

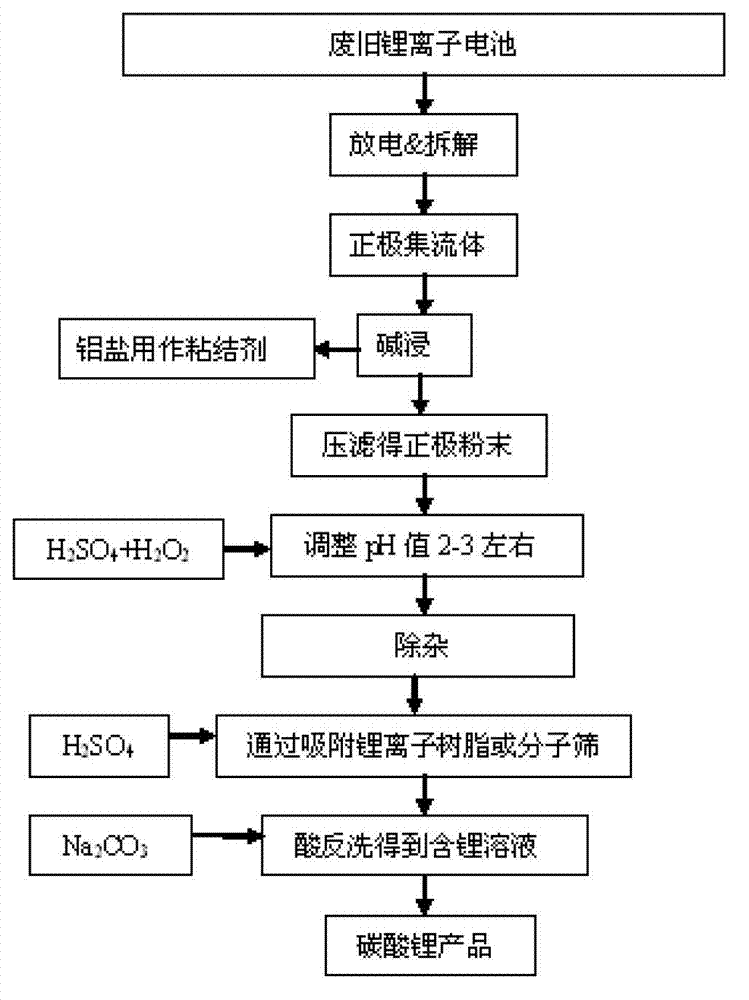

Method for separating and recovering lithium from waste lithium ion battery

ActiveCN103035977AEasy to recycleHigh purityWaste accumulators reclaimingBattery recyclingRecovery methodPhysical chemistry

The invention discloses a method for separating and recovering lithium from a waste lithium ion battery. The method comprises the following steps: dismounting after discharging the waste lithium ion battery, and removing a battery case; crashing a battery cell; leaching and filtering the crushed battery cell with inorganic acid and oxidant to obtain a filter liquor; regulating the pH of the filter liquor to be more than or equal to 8, then filtering to remove impurities and sediment to obtain a recovery liquor containing lithium ions; adsorbing the lithium ions in the recovery liquor through resin; and desorbing the resin to obtain the separated and recovered lithium salt. The recovery method provided by the invention is simple and efficient, has high purity of lithium and brings no pollution.

Owner:深圳市泰力废旧电池回收技术有限公司

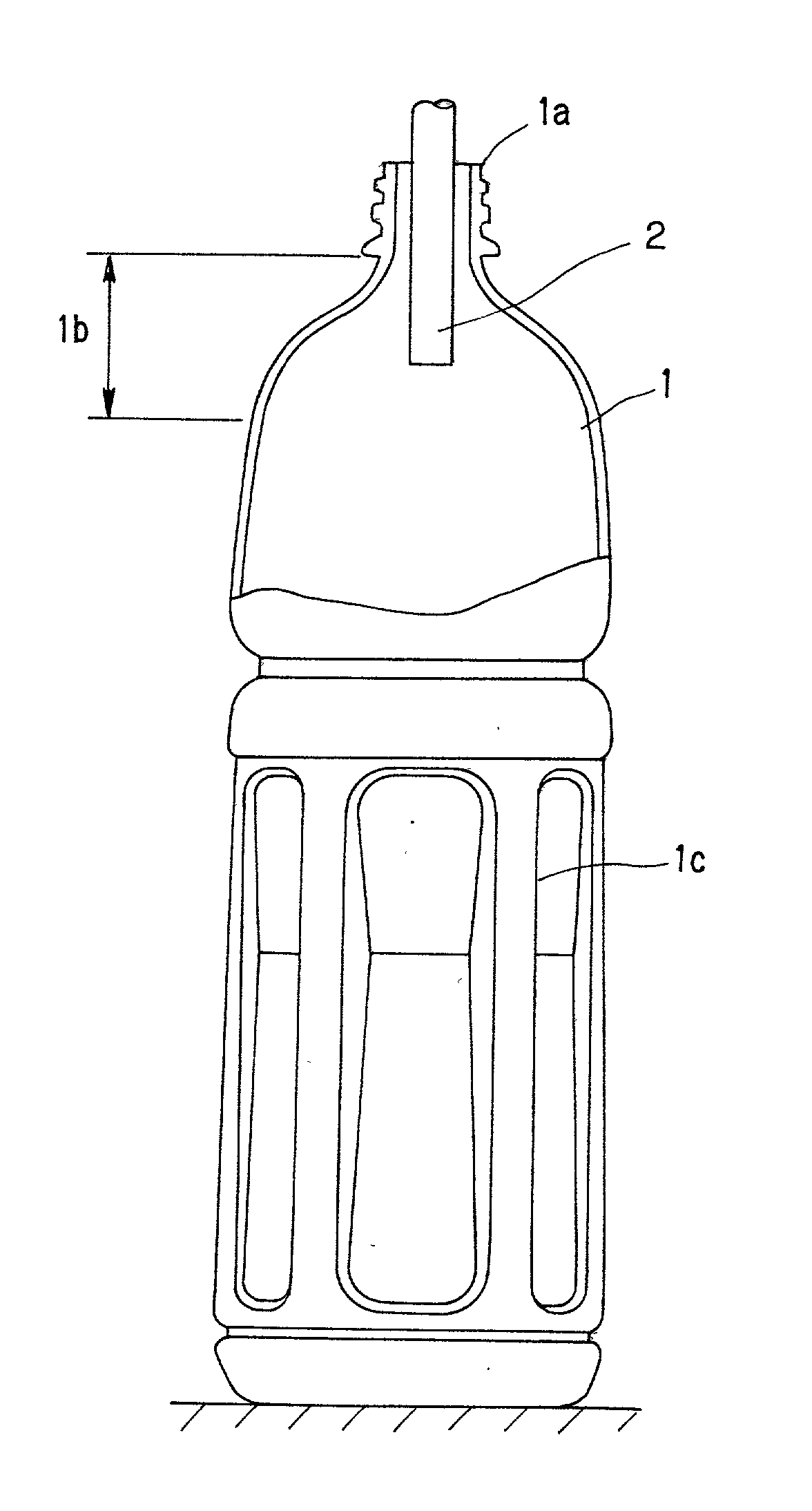

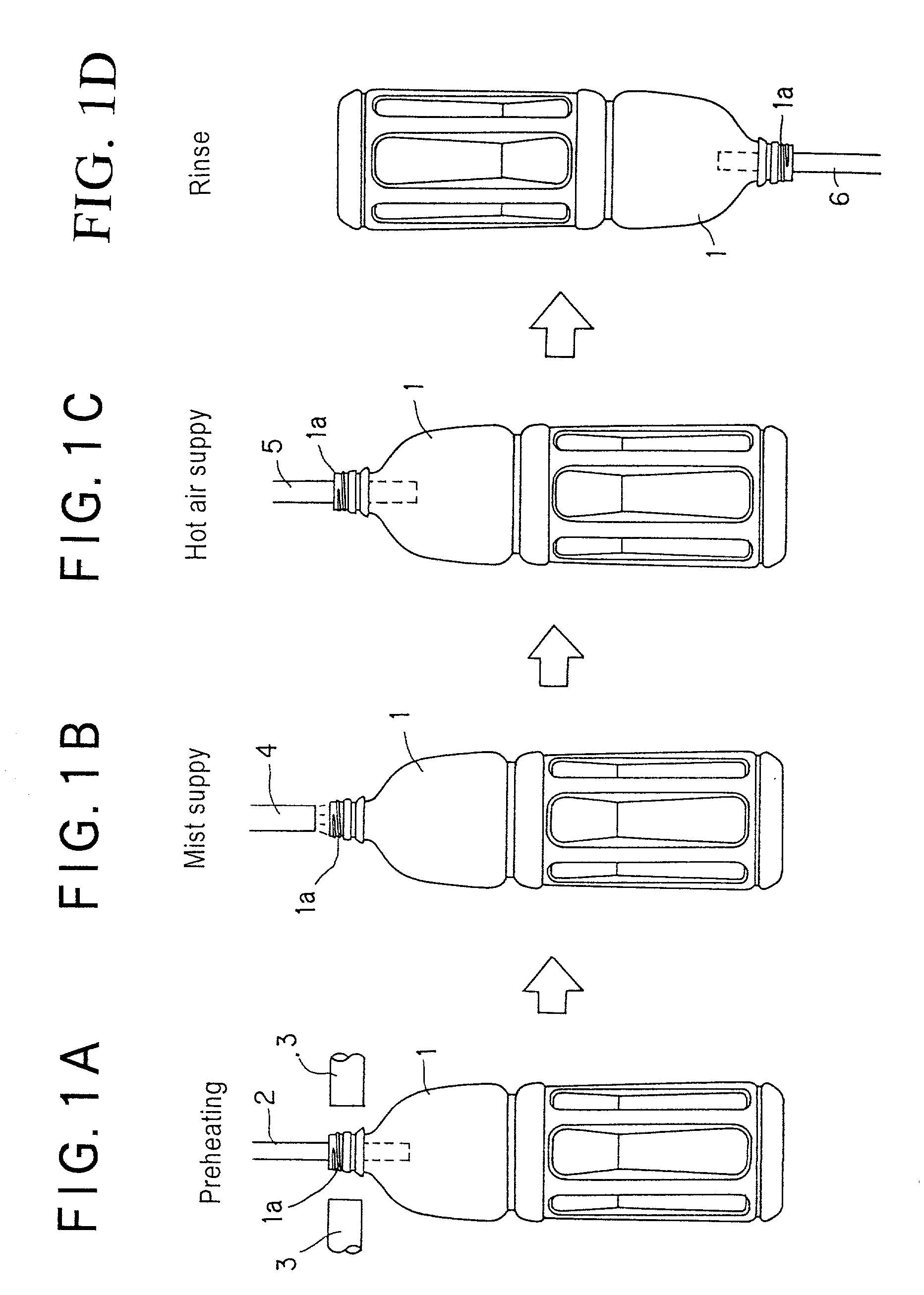

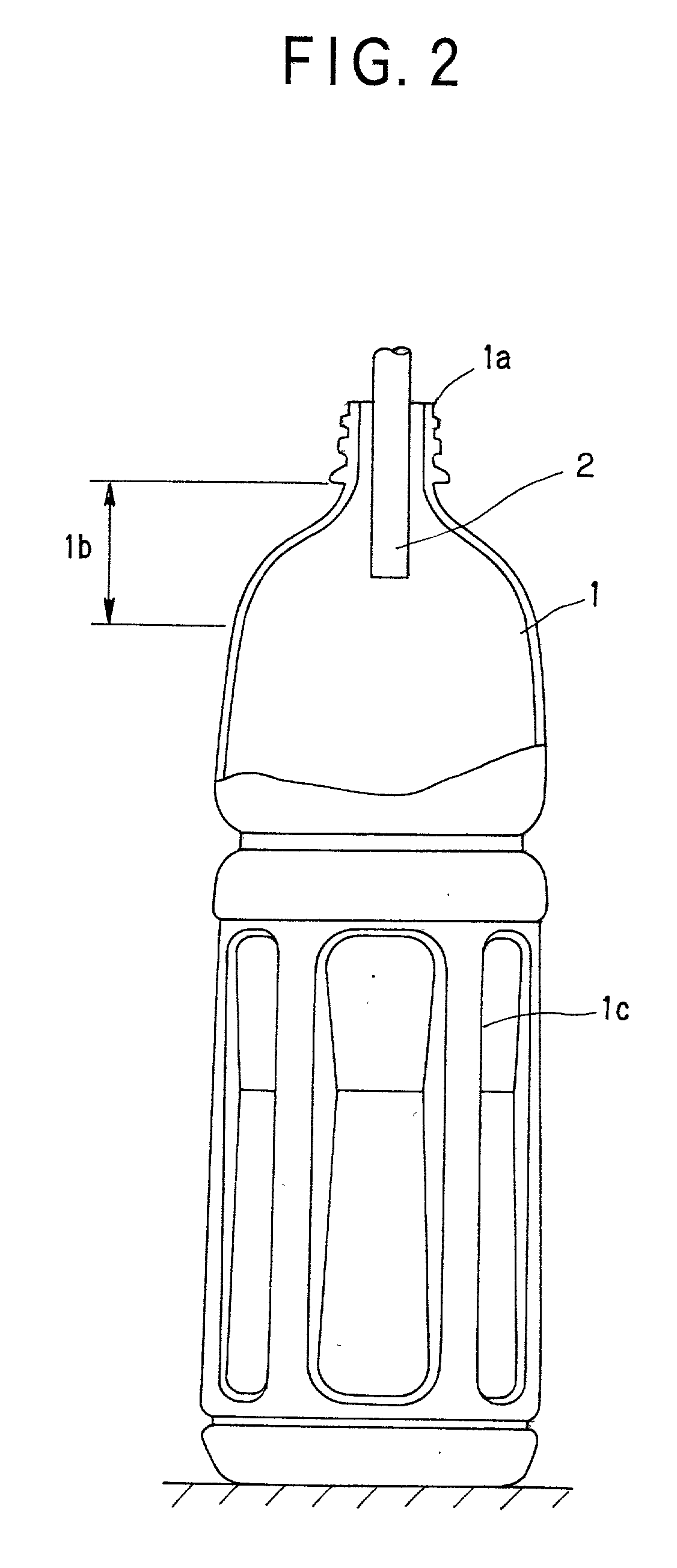

Method of sterilzation for container, apparatus using therefor and heat treatment for container

Sterilization method for at high speed and surely sterilizing the container, such as a beverage bottle is offered. An apparatus comprises the step of supplying a disinfectant mist into a container 1, the step of heating the container 1 into which the mist has been supplied, the step of while discharging the mist from the container 1, and the step of rinsing an inside of the container 1 after discharge of the mist therefrom. The apparatus may comprise a further step of preheating the container 1 in advance of supply of the mist. The step of preheating the container, a lip portion 1a of the container may be heated separately.

Owner:DAI NIPPON PRINTING CO LTD

Refuelable metal air electrochemical cell and refuelabel anode structure for electrochemical cells

InactiveUS20020142203A1Fuel and primary cellsFuel and secondary cellsMetal–air electrochemical cellMetal particle

A refuelable anode structure containing anode paste for a metal air electrochemical cell is provided. The anode paste comprises metal particles, a gelling agent, and a base. The spent anode structure may be removed after discharging. The anode structure may thereafter be electrically recharged to convert oxidized metal into consumable metal fuel, or mechanically emptied and refilled with fresh metal fuel paste.

Owner:EVIONYX INC

Method for recycling electrolyte of waste lithium ion battery

ActiveCN102496752AEasy to handleSimple processWaste accumulators reclaimingBattery recyclingSocial benefitsHydrogen fluoride

The invention discloses a method for recycling the electrolyte of a waste lithium ion battery. The method mainly comprises the following steps of: collecting and cleaning the lithium ion battery; after discharge, putting the lithium ion battery in a drying room or a glove box under protection of inert gas; opening the battery, carefully taking out the electrolyte and placing in a material tank; performing high-vacuum decompressed rectification and separation to obtain the organic solvent contained in the electrolyte; performing rectification and purification for recycling; putting a rough product of lithium hexafluorophate into a dissolution kettle, and adding a hydrogen fluoride solution for dissolving the recycled lithium hexafluorophate; filtering the solution and then putting into a crystallization kettle for crystallization and purification; and screening, drying, packaging and recycling to obtain the product lithium hexafluorophate. The method has simple technology, is practical, efficient, clean and environment-friendly and easy to control, and realizes close integration of economic benefits and environmental social benefits.

Owner:CHINA NAT OFFSHORE OIL CORP +1

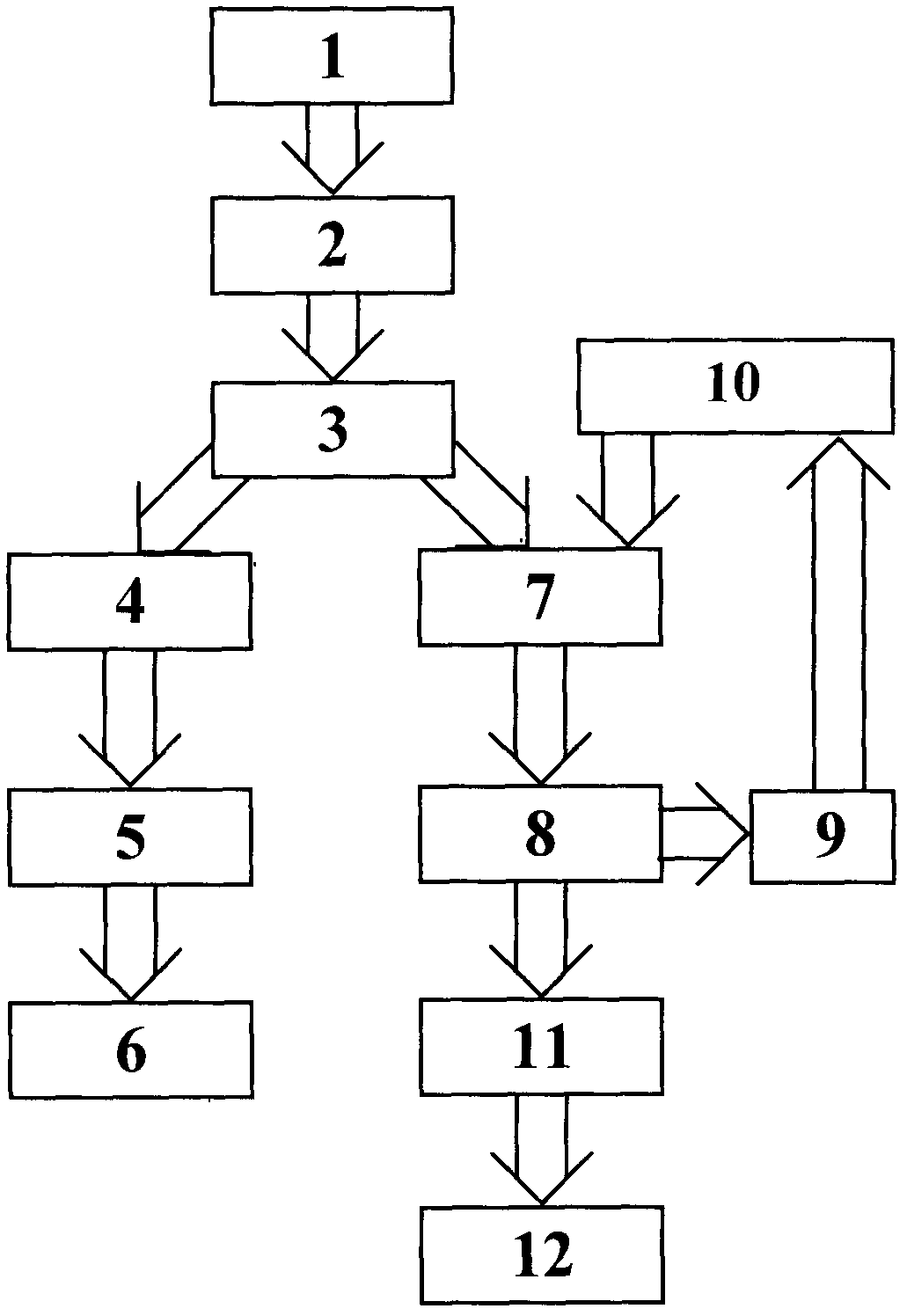

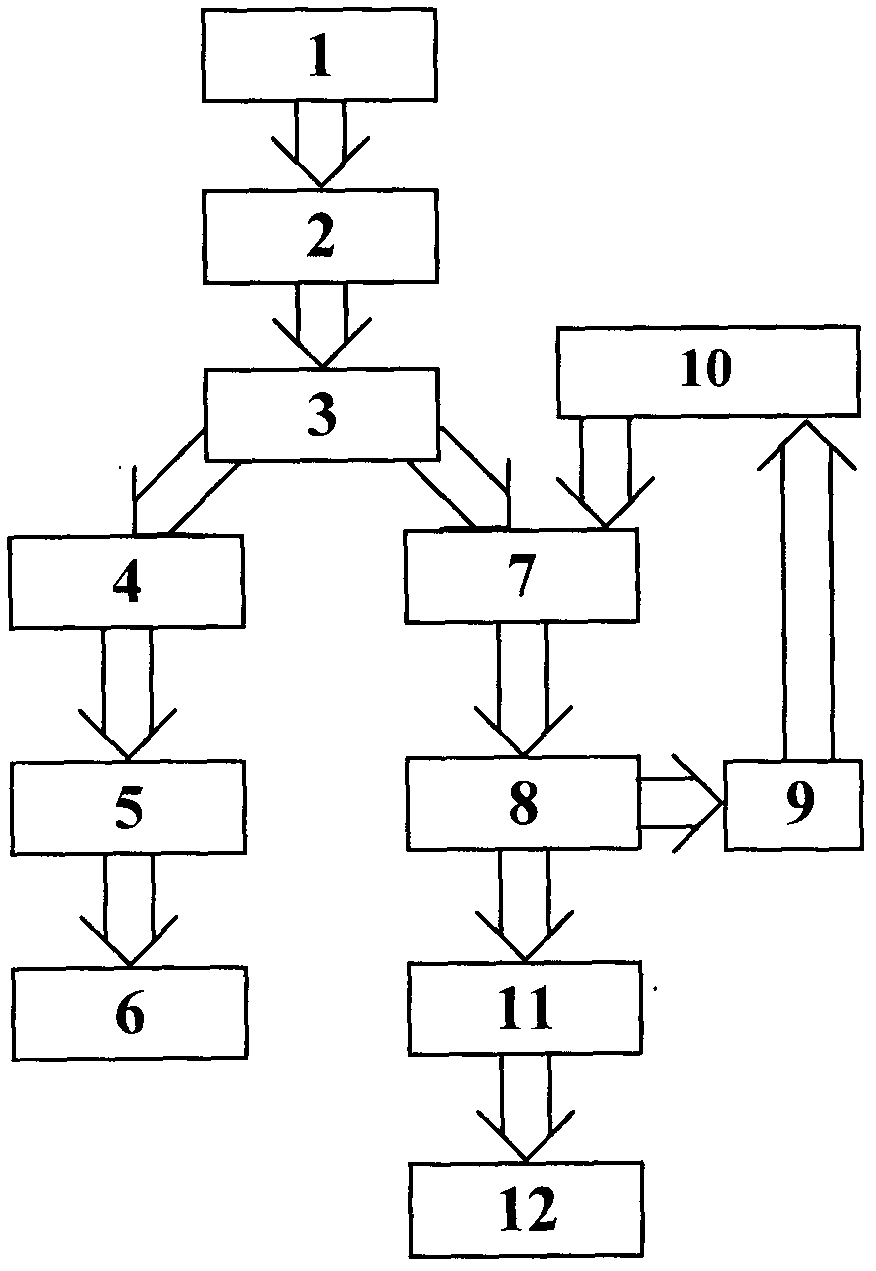

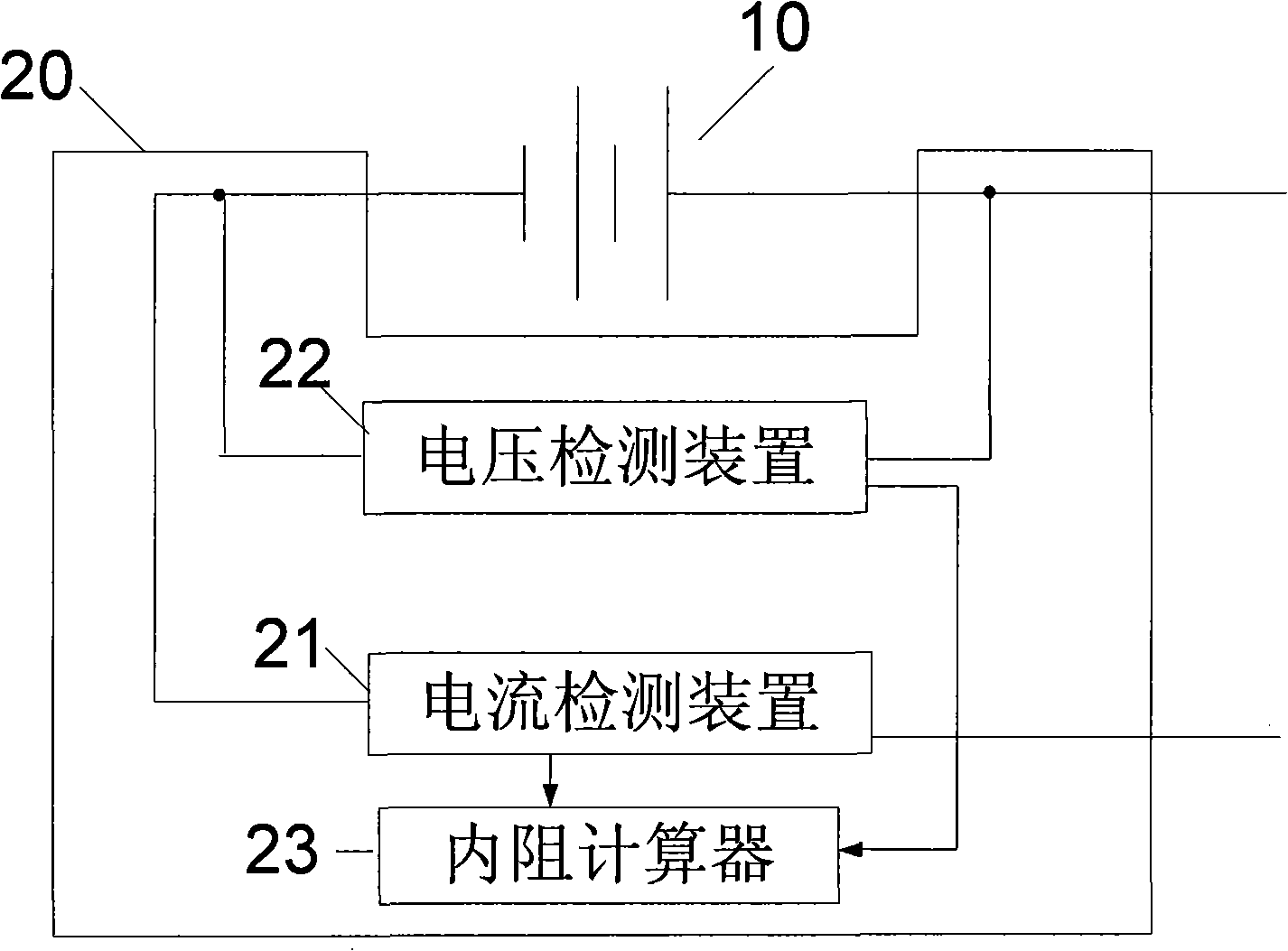

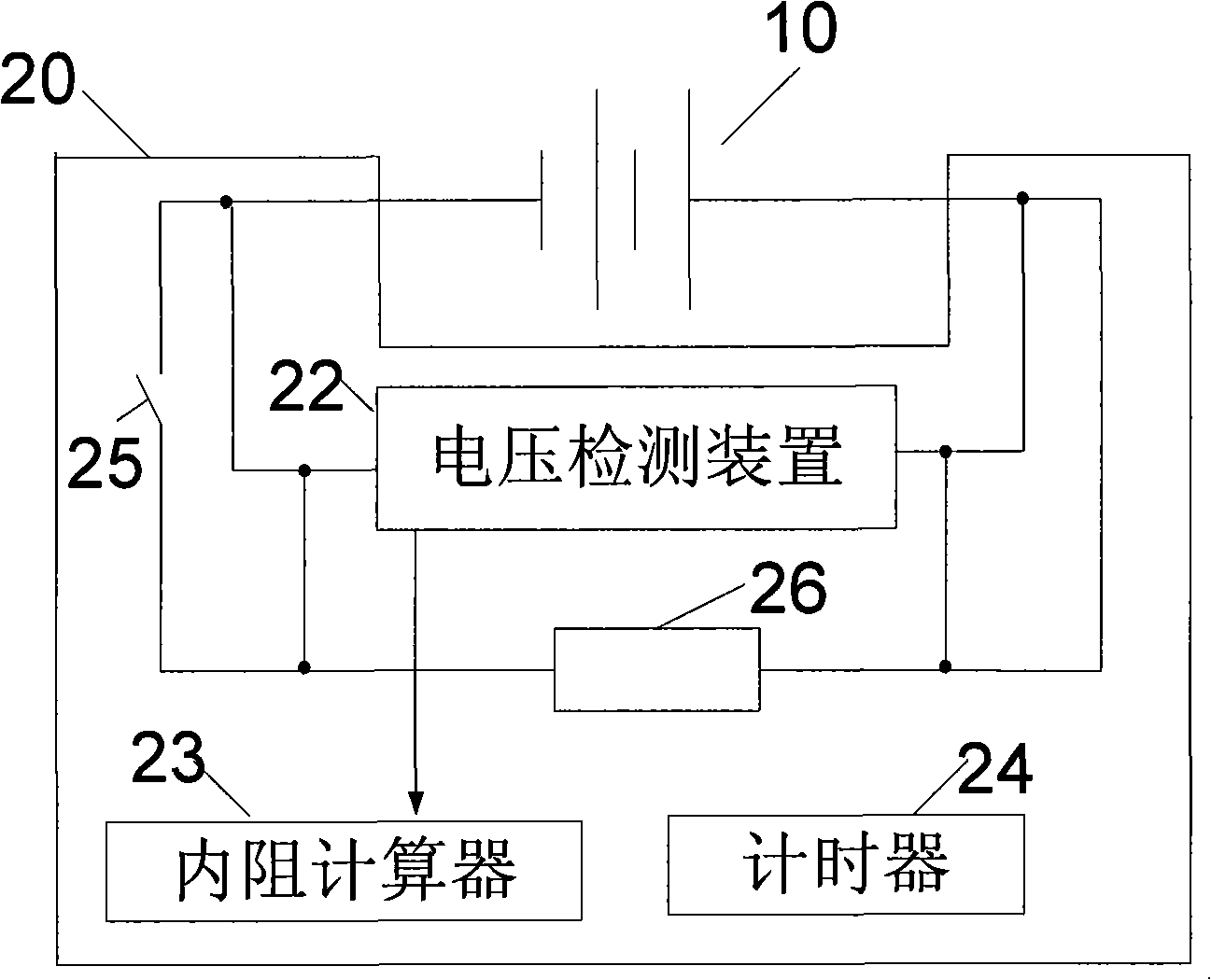

Method and apparatus for measuring battery internal resistance

InactiveCN101359035ADoes not affect lifespanDoes not affect capacityElectrical testingCharge currentInternal resistance

The invention provides a method and a device for measuring the battery internal resistance; the method and the device detect a discharge current or charge current I, as well as a discharge or charge voltage U1 of the battery under detection, and then detect a voltage U2 after discharge or charge of the battery under detection so as to calculate an internal resistance r of the battery under detection; and the internal resistance r is equal to (U2-U1) / I. The method and the device are easy to implement and are low in cost, which can be widely used in battery chargers, back-up power supplies and other mobile power supplies.

Owner:BYD CO LTD

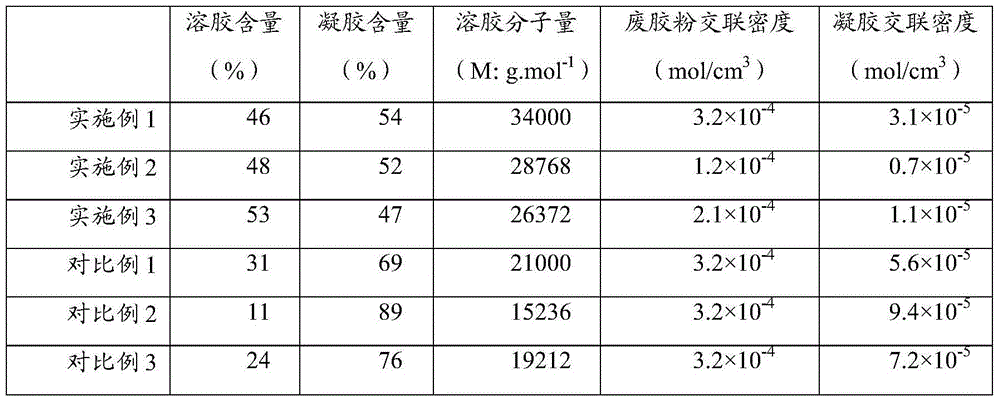

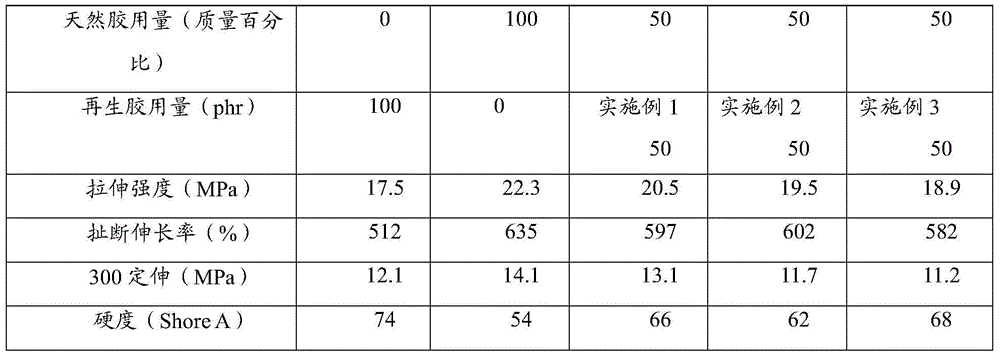

Environment-friendly method for regenerating waste rubber

ActiveCN104387611AImprove performanceFully qualitative regenerationPlastic recyclingBulk chemical productionCross-linkMicrowave

The invention discloses an environment-friendly method for regenerating waste rubber. The method comprises the following steps: 1) uniformly mixing waste rubber and an environment-friendly desulfurizing agent according to a mass ratio of 100:0.2-2; 2) guiding the mixed waste rubber into a first reaction chamber and then fully filling the first reaction chamber with supercritical CO2 fluid; 3) starting a microwave heating device of a second reaction chamber so as to desulfurize waste rubber powder; and 4) after the desulfurization is completed, cooling the waste rubber powder to be below 80 DEG C and refining into pieces after discharging. According to the method, supercritical CO2 fluid which has excellent swelling and permeating characteristics can be used for replacing a rubber softening agent so that a regenerant can permeate and disperse inside the waste rubber powder in a short time and the waste rubber can reach swelling balance; then, microwaves are utilized to selectively damage S-S and C-S cross-linked bonds of the rubber and the desulfurizing agent completely so that a main chain is protected from being damaged to the greatest extent.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

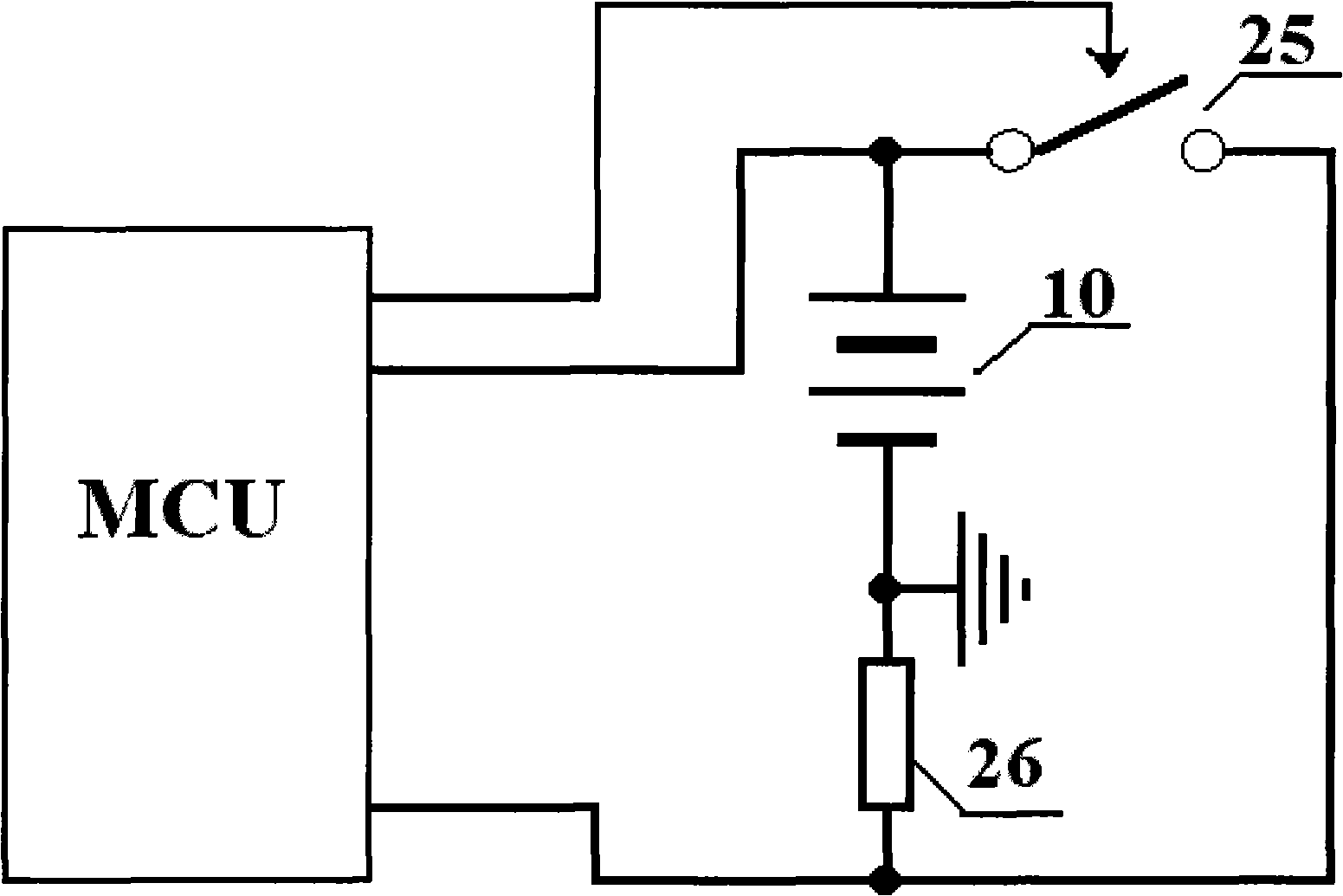

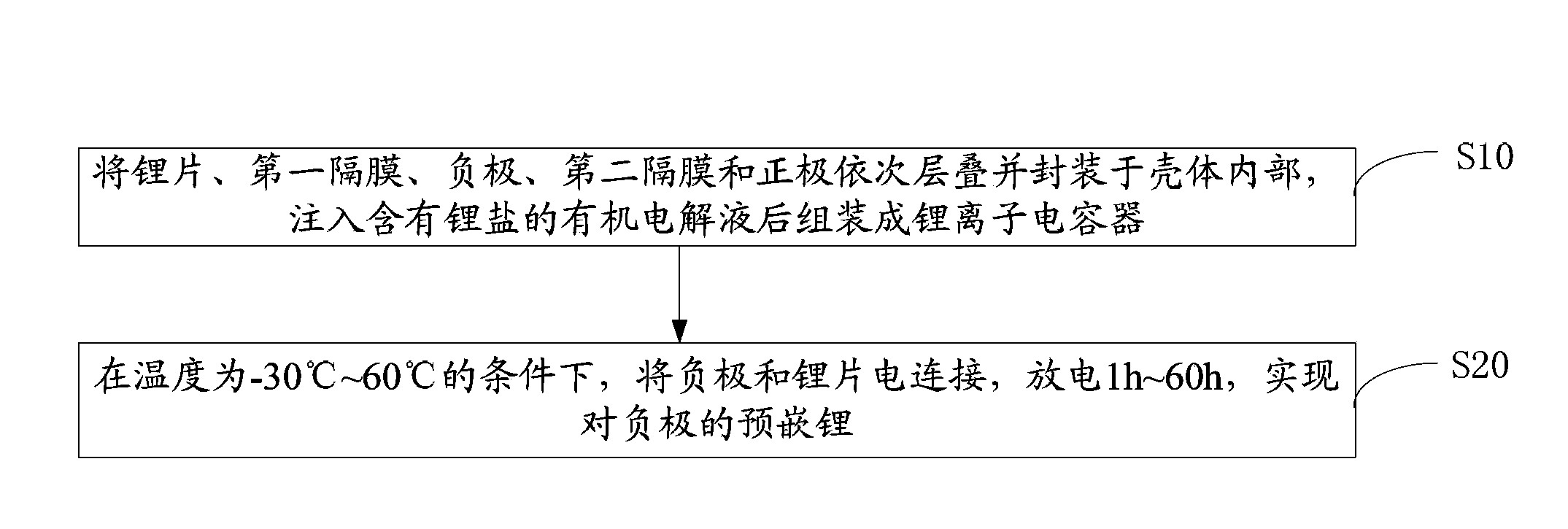

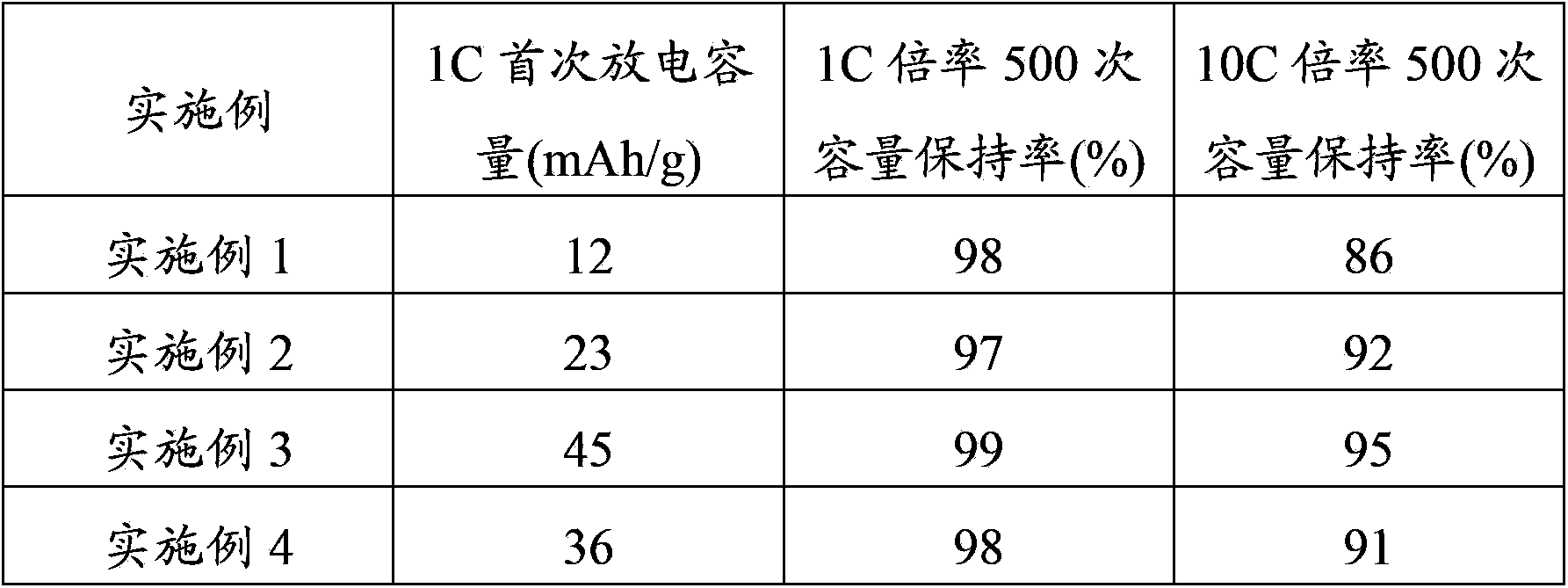

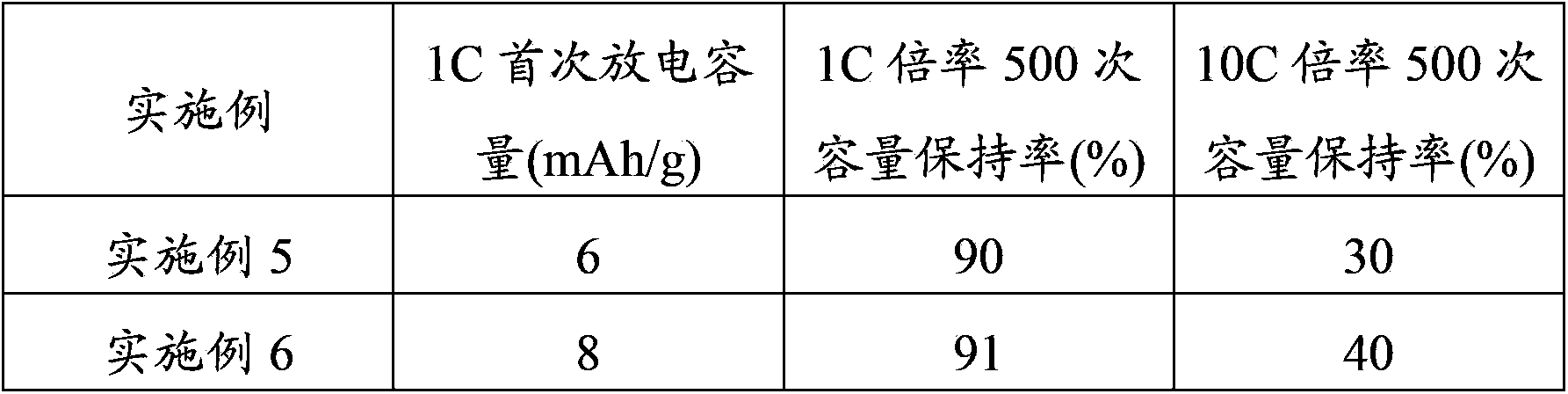

Method for lithium pre-embedment of negative electrode of lithium ion capacitor

ActiveCN103915262AIncrease capacityPre-embedded lithium implementationHybrid/EDL manufactureLarge capacityAfter discharge

The invention discloses a method for lithium pre-embedment of a negative electrode of a lithium ion capacitor. The method comprises the following steps that a lithium sheet, a first diaphragm, the negative electrode, a second diaphragm and a positive electrode are sequentially stacked and packaged in a shell and after an organic electrolyte with lithium salt is injected, the lithium ion capacitor is assembled; on the condition that the temperature ranges from -30 DEG C to 60 DEG C, the negative electrode is electrically connected with the lithium sheet, discharging is conducted for one hour to sixty hours, and lithium pre-embodiment of the negative electrode is achieved. According to the method for lithium pre-embedment of the negative electrode of the lithium ion capacitor, the negative electrode is electrically connected with the lithium sheet at the appropriate temperature, after discharging is conducted for one hour to sixty hours, the lithium sheet in the lithium ion capacitor can be slowly dissolved into the electrolyte to form lithium ions, so that the lithium ions are embedded in the negative electrode, lithium pre-embedment of the negative electrode is achieved, and the capacity of the obtained lithium ion capacitor is high. According to the method for lithium pre-embedment of the negative electrode of the lithium ion capacitor, it is only required that the electric connection mode of the negative electrode and the lithium sheet is controlled and the appropriate time and temperature are obtained, the lithium ion capacitor with the high capacity can be obtained, and the method has the advantages of being simple in operation process and the like.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

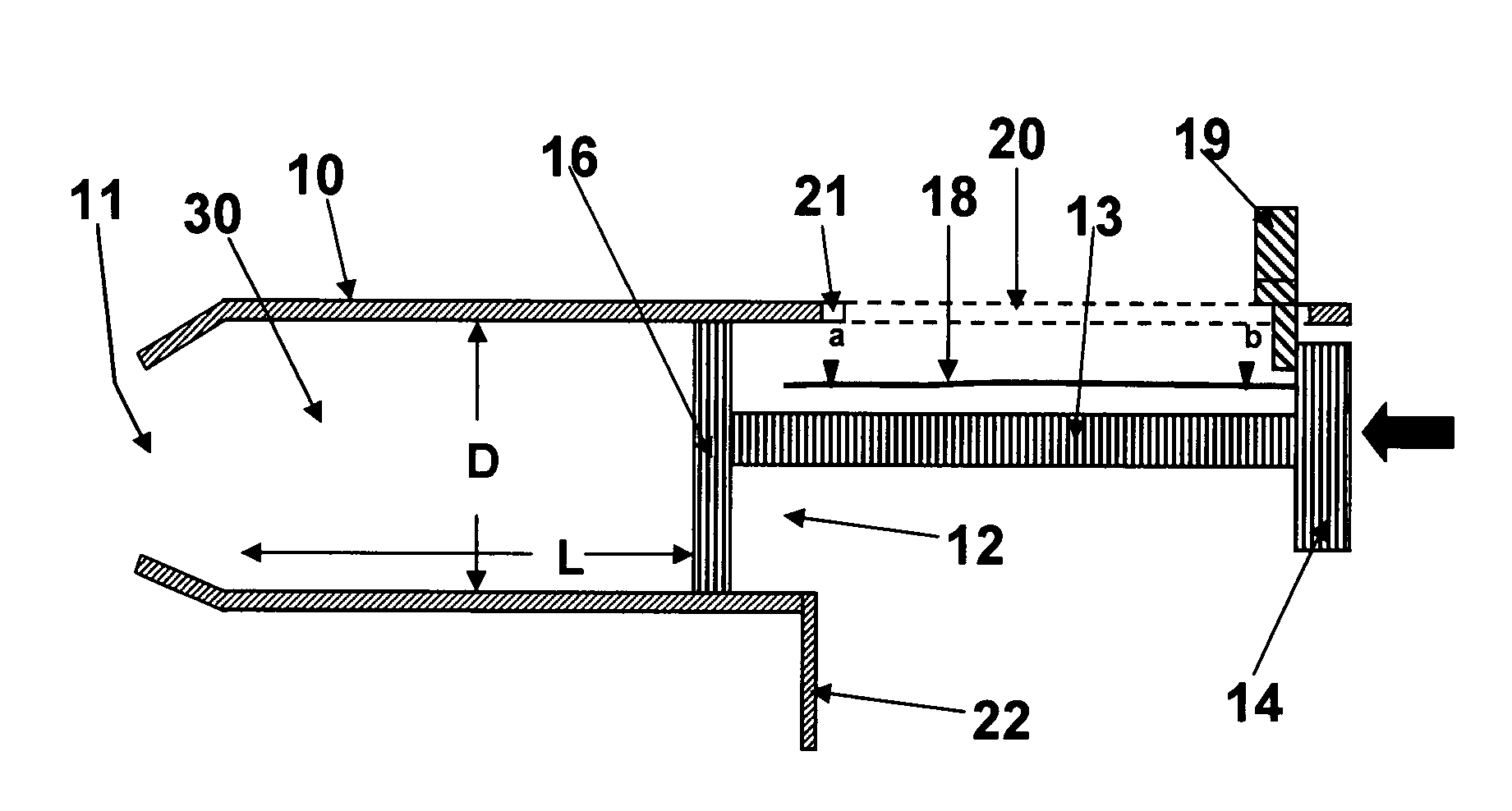

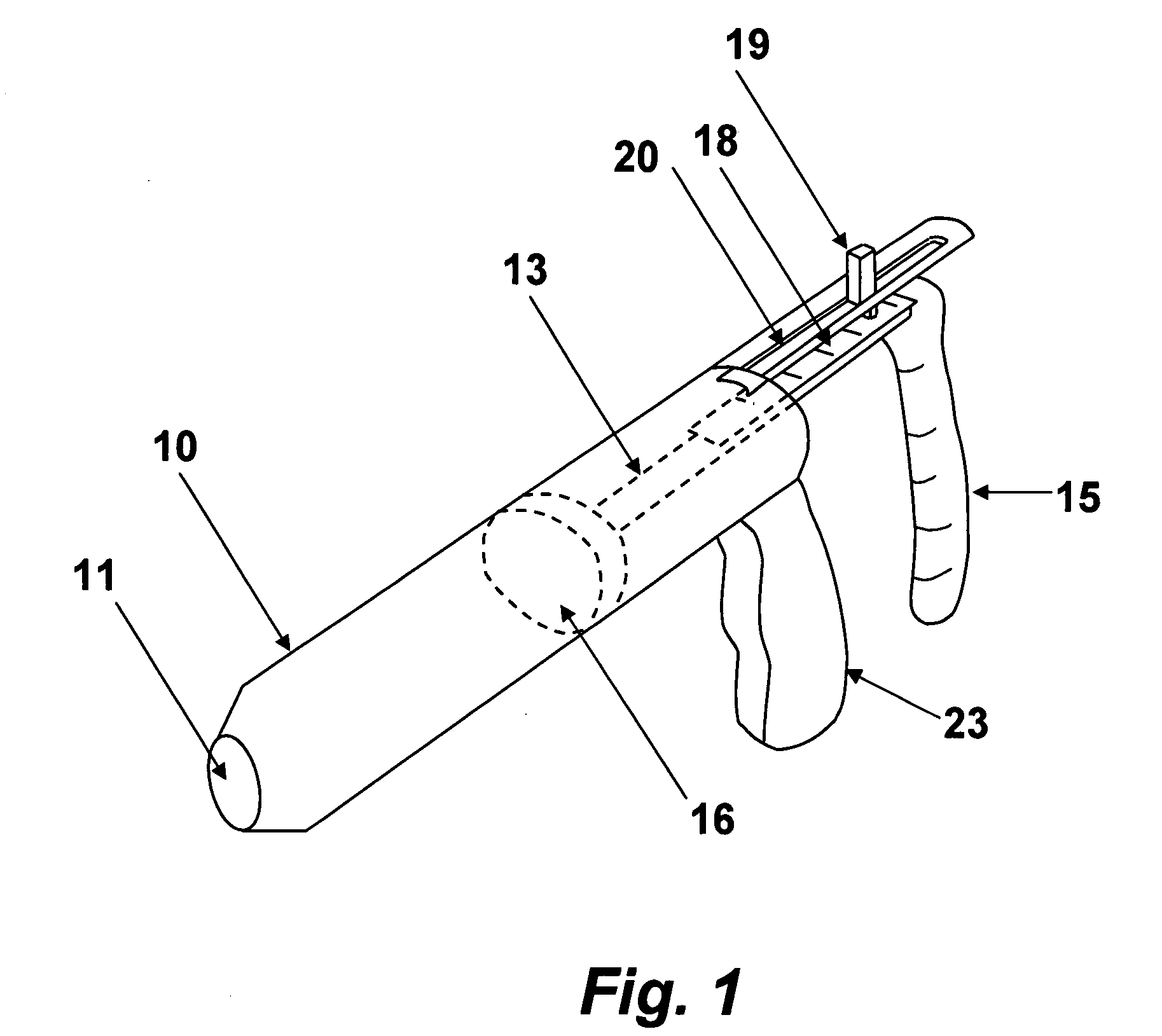

Adjustable dosage syringe

The present invention is directed to determining, without repeated calculation by an operator, the volume of a non-solid composition remaining in the barrel of a syringe after discharge of a dose of the composition. The present invention provides a syringe barrel, and a plunger having a dose volume scale disposed along the longitudinal axis and orientated such that the numeric values increase in the direction from the proximal end of the plunger towards the discharge end. The dosage syringe also comprises an adjustable dose selector that may be moved to a volume mark of the scale corresponding to a desired dose to be delivered. The dose syringe barrel further comprises an indicator means that may be an opening in the barrel directly above the dose volume scale such that, when the plunger is in a fully retracted position, the window shows the volume of the full capacity of the syringe barrel and when the plunger is depressed, will show the remaining volume in the syringe.

Owner:MERIAL SAS

Mineral separation process of magnetic iron ore

ActiveCN101480632AReduce energy consumptionFine Concentrate SizeSievingScreeningMagnetiteMaterials science

The invention discloses a beneficiation method for a pure magnetic iron ore. A crude ore is sequentially treated according to the steps such as first crushing, first-stage dry-type magnetic dressing, medium crushing, second-stage dry-type magnetic dressing, fine crushing and third-stage dry-type magnetic dressing, fine ore is obtained after a great amount of gangues are thrown by the third-stage dry-type magnetic dressing and sent to a grinding head sieve to be griddled and separated, granules griddled by the grinding head sieve are treated in a first-section magnetic dressing process, rough ore griddled by the grinding head sieve is treated in a first-section ball grinding and then enters the first-section magnetic dressing process; ore aggregates obtained from the first-section magnetic dressing process are treated in a second-section ball grinding after discharging gangue sands till the granularity of ore powder is -200meshes being more than or equal to 60 percent, ore powder generated from the second-section ball grinder are treated in second-section magnetic dressing, ore aggregates generated from the second-section magnetic dressing are treated in a high-frequency sieve after discharging gangue sands, products positioned on the high-frequency sieve are filtered to obtain ore concentrate, and products positioned below the high-frequency sieve are treated with desliming and then treated with floatation. The invention adopts two sections of grinding ore open-way processes and distinguishes the ore aggregates during the ore dressing process, thereby greatly reducing the energy consumption of a system, lowering the production cost and enhancing the utility ratio of equipment.

Owner:安徽大昌矿业集团有限公司

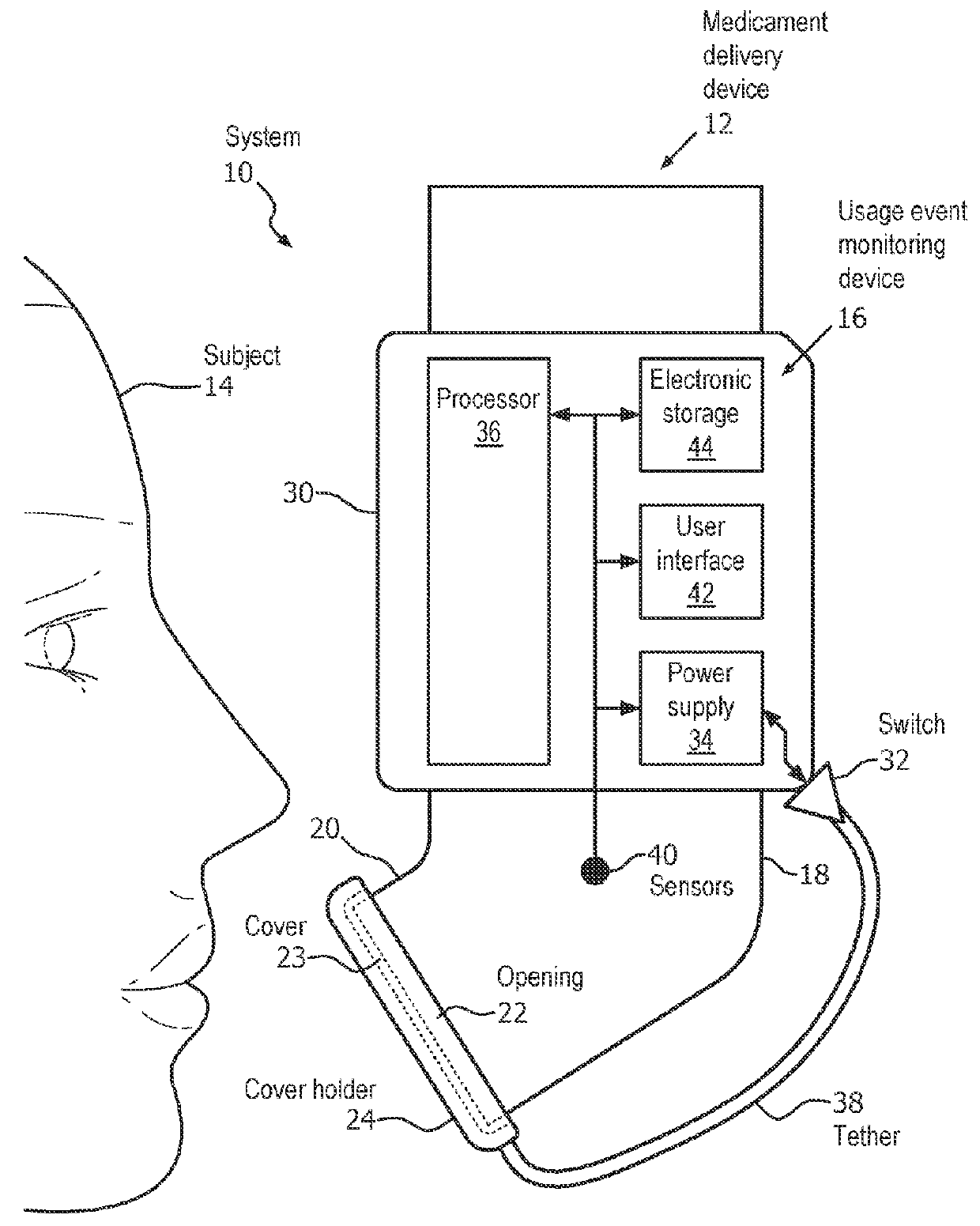

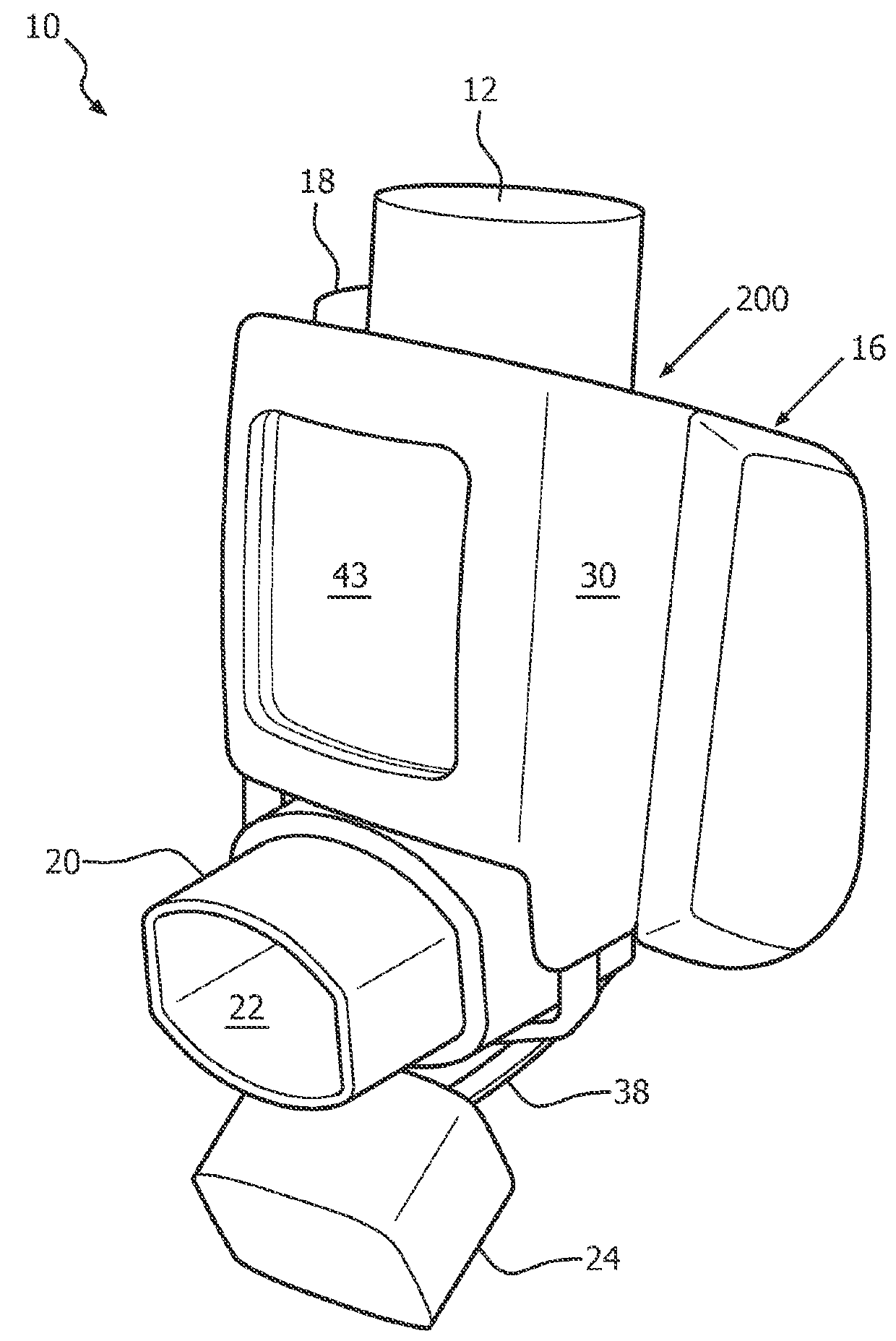

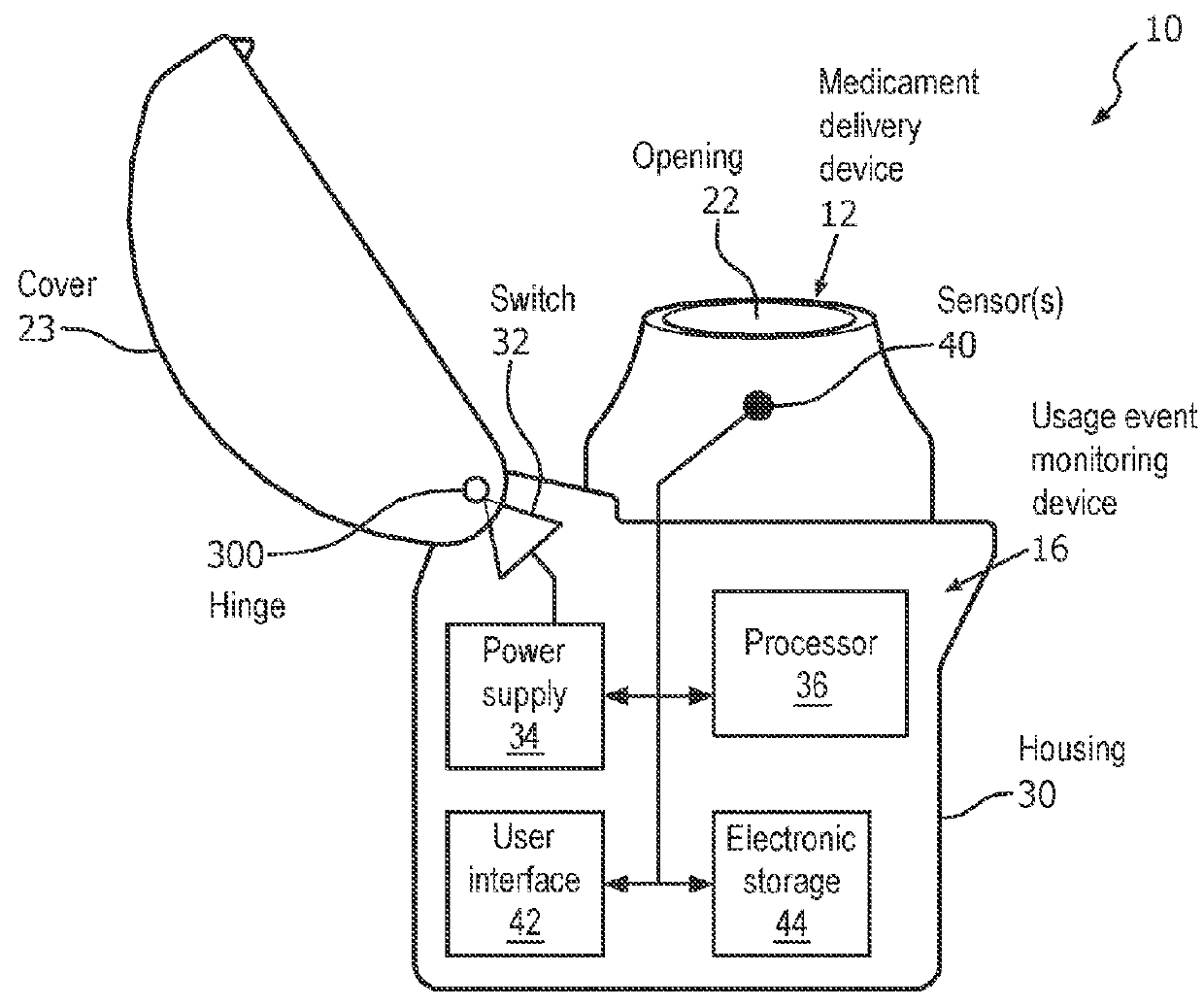

System and method for monitoring usage of a respiratory medication delivery device

The present disclosure pertains to a system and method for monitoring usage of a respiratory medicament delivery device. Regular use of a respiratory medicament delivery device at intervals prescribed by a doctor may be critical to a subject's health. The system described herein is configured to monitor usage of a respiratory medicament delivery device such that manual tracking of a patient's adherence to a dosage plan by a doctor, for example, is not required. Monitoring usage of the medicament device delivery device may allow the doctor to judge the adherence of the subject to the dosage plan and encourage increased adherence. Improved adherence by the subject may result in improvement in the condition of the subject and economic benefits including reducing costs associated with re-hospitalization after discharge. In some embodiments, the system comprises a medicament delivery device and a usage event monitoring device.

Owner:KONINKLJIJKE PHILIPS NV

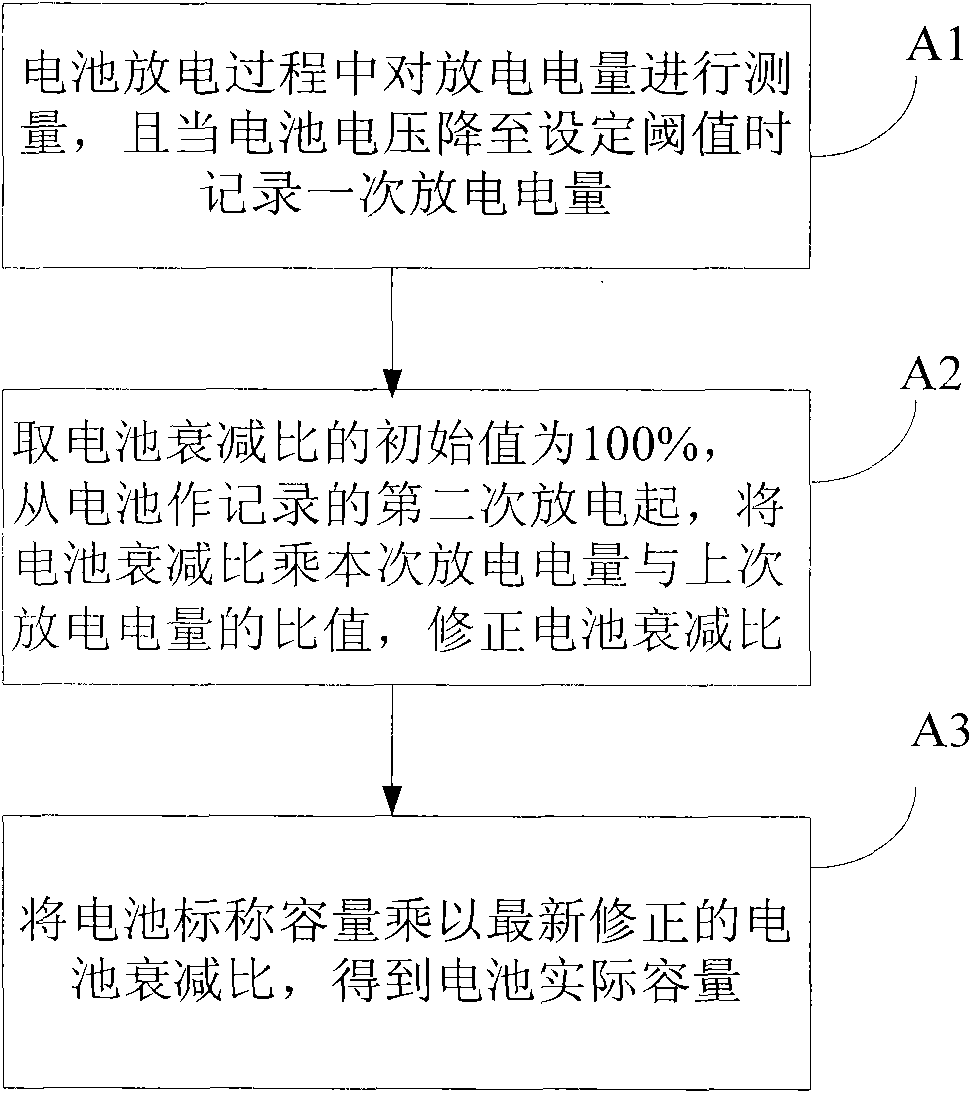

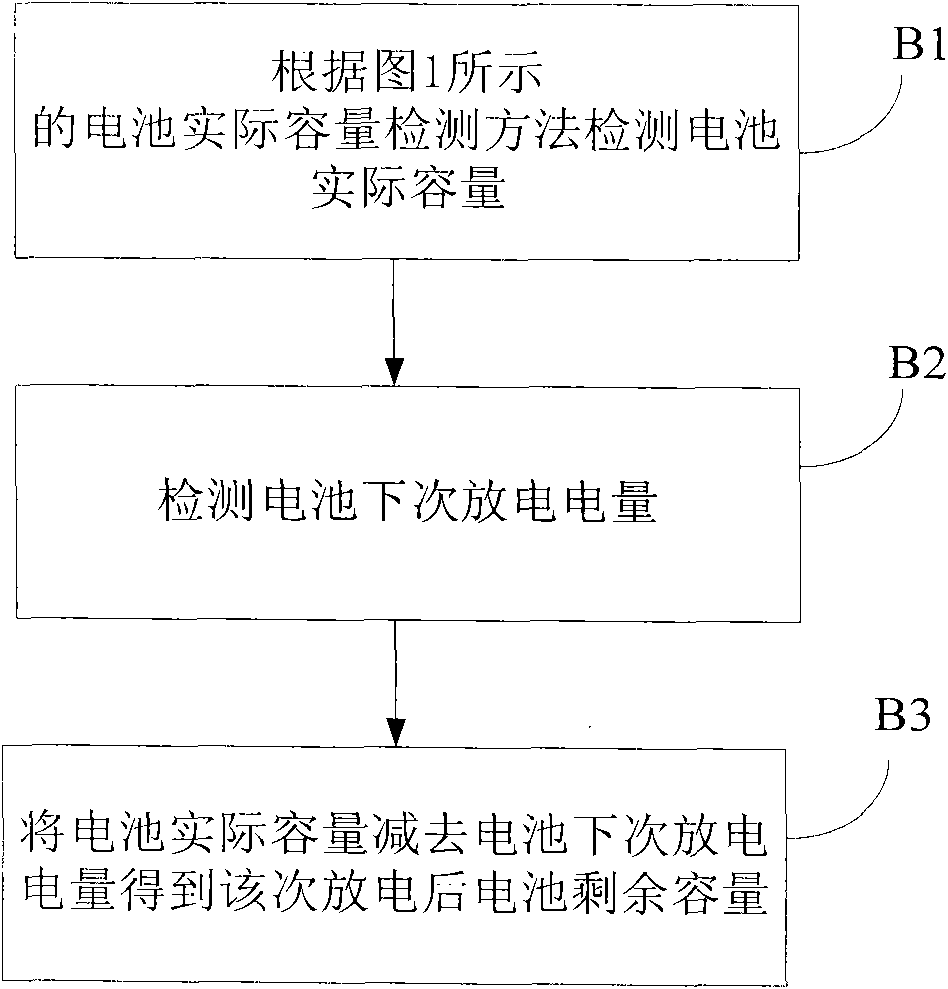

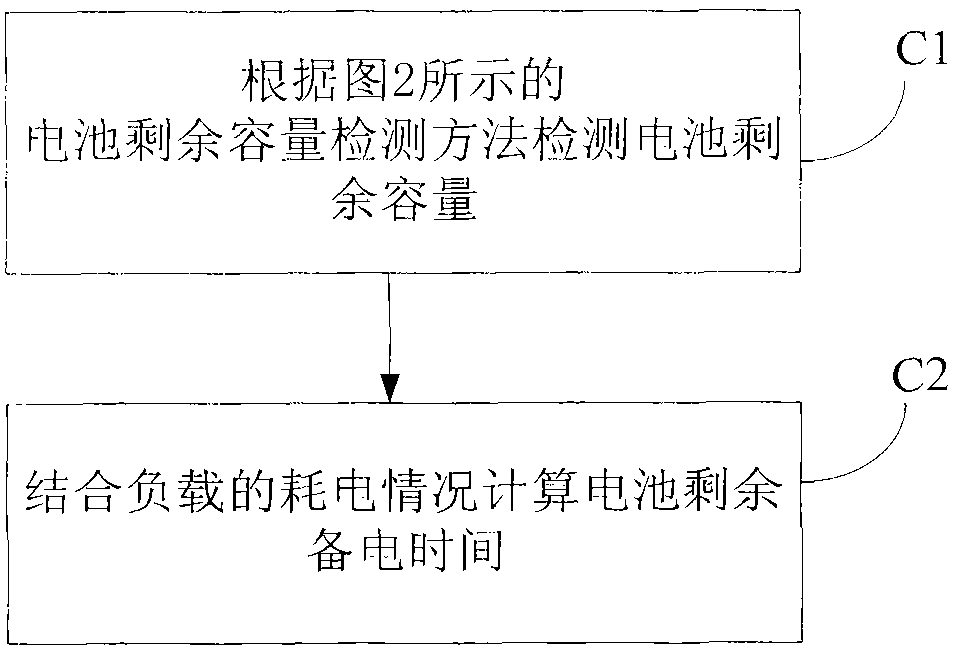

Methods for detecting actual capacity, residual capacity, standby time and health condition of battery

ActiveCN102073016AIn line with the real situationInsufficient improvementCurrent/voltage measurementElectrical testingElectricityState of health

The invention discloses a method for detecting the actual capacity of a battery, which comprises the following steps: (A1) measuring discharge quantity in the battery discharge process, and recording the discharge quantity when the battery voltage is reduced to a set threshold; (A2) setting the initial value of battery attenuation ratio as 100%, and multiplying the battery attenuation ratio by the ratio of the discharge quality this time to the discharge quantity last time after discharge from the recorded second discharge, thus obtaining the corrected battery attenuation ratio; and (A3) multiplying the nominal capacity of the battery by the newly corrected battery attenuation ratio, thus obtaining the actual capacity of the battery. The invention also discloses methods for detecting the residual capacity, the residual standby time and the health condition of a battery based on the method for detecting the actual capacity of a battery. By using the methods disclosed by the invention, the service condition and health state of the battery can be accurately obtained.

Owner:VERTIV CORP

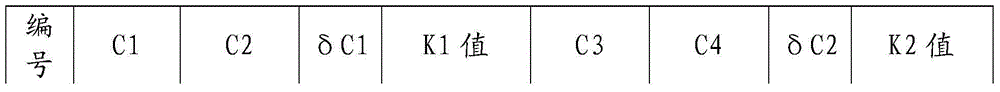

Lithium battery self-discharge screening method

ActiveCN104090241AImprove the accuracy of judgmentSimple methodElectrical testingPower flowScreening method

A lithium battery self-discharge screening method includes the steps that lithium batteries are charged in advance, the total capacity C1 of the batteries is recorded, constant-temperature aging is carried out on the batteries, the aged batteries are discharged through constant current under the environment with normal temperature, the batteries are charged through the same constant current, the capacity C2 obtained after constant current discharging is carried out and the capacity C3 obtained after charging are recorded respectively, C1 minus C2 is the capacity difference delta1, and then K1 is calculated by dividing delta1 by T1; batteries of which K1 is within the qualified range are directly transferred to the next process; constant-temperature aging is carried out on the batteries which are transferred normally; the aged batteries are discharged through the constant current under the normal temperature and normal voltage, and the capacity C4 obtained after discharging is finished is recorded; C4 minus C3 is delta2, K2 is calculated by dividing delta2 by T2, and batteries of which K2 is within the qualified process range are batteries small in self discharge. Through changes of battery capacities within a certain period, lithium batteries high in self discharge are effectively selected out through two times of screening, the method is simple and easy to implement, and production and operation are convenient.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

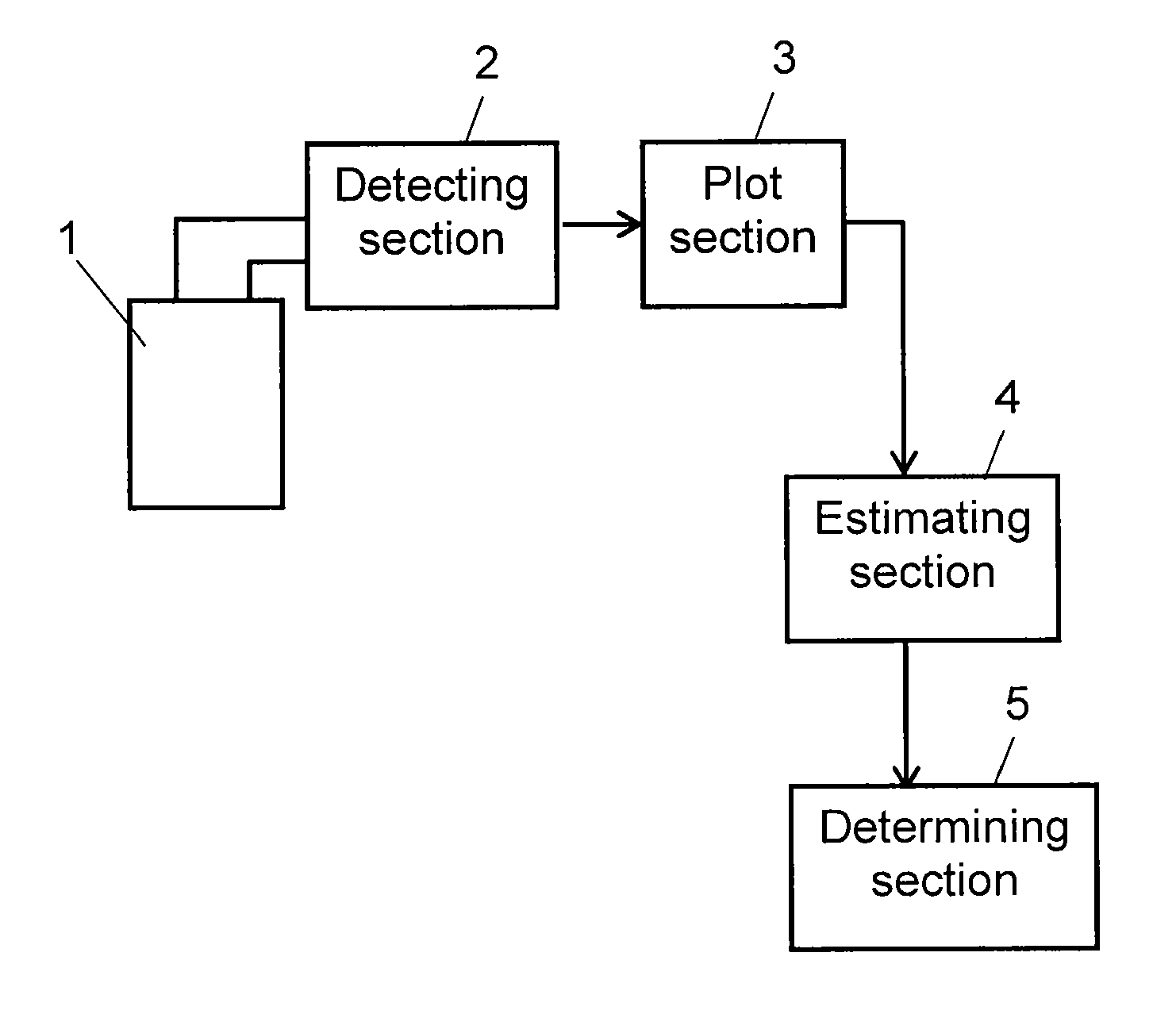

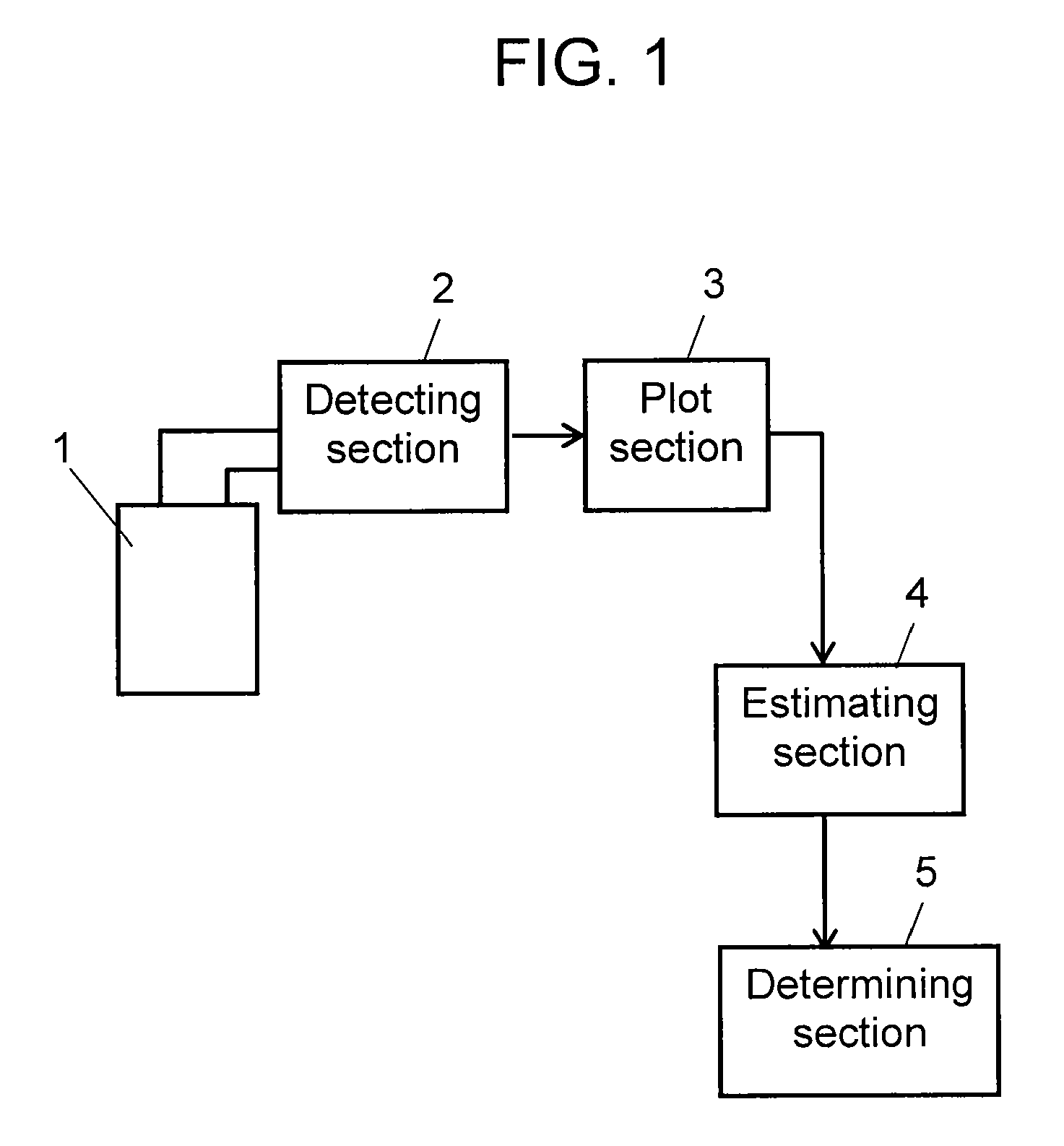

Lifetime estimating method and deterioration suppressing method for rechargeable lithium battery, lifetime estimating apparatus, deterioration suppressor, and battery pack and charger using the same

InactiveUS20100264929A1Lifetime be accurately estimatedCapacity reduction can be suppressedBatteries circuit arrangementsCell electrodesSuppressorEngineering

In a lifetime estimating method for a rechargeable lithium battery, the open circuit voltages of the rechargeable lithium battery after discharging for at least two different charge / discharge cycle numbers are detected while charge / discharge cycles go on. Next, at least the two of the voltage values are plotted for respective cycle numbers, and a circular arc passing the plotted points is drawn. Furthermore, the lifetime of the rechargeable lithium battery is estimated based on a size of the circular arc. The progression of deterioration can be suppressed by controlling the charge and discharge of the rechargeable lithium battery based on the lifetime estimation.

Owner:PANASONIC CORP

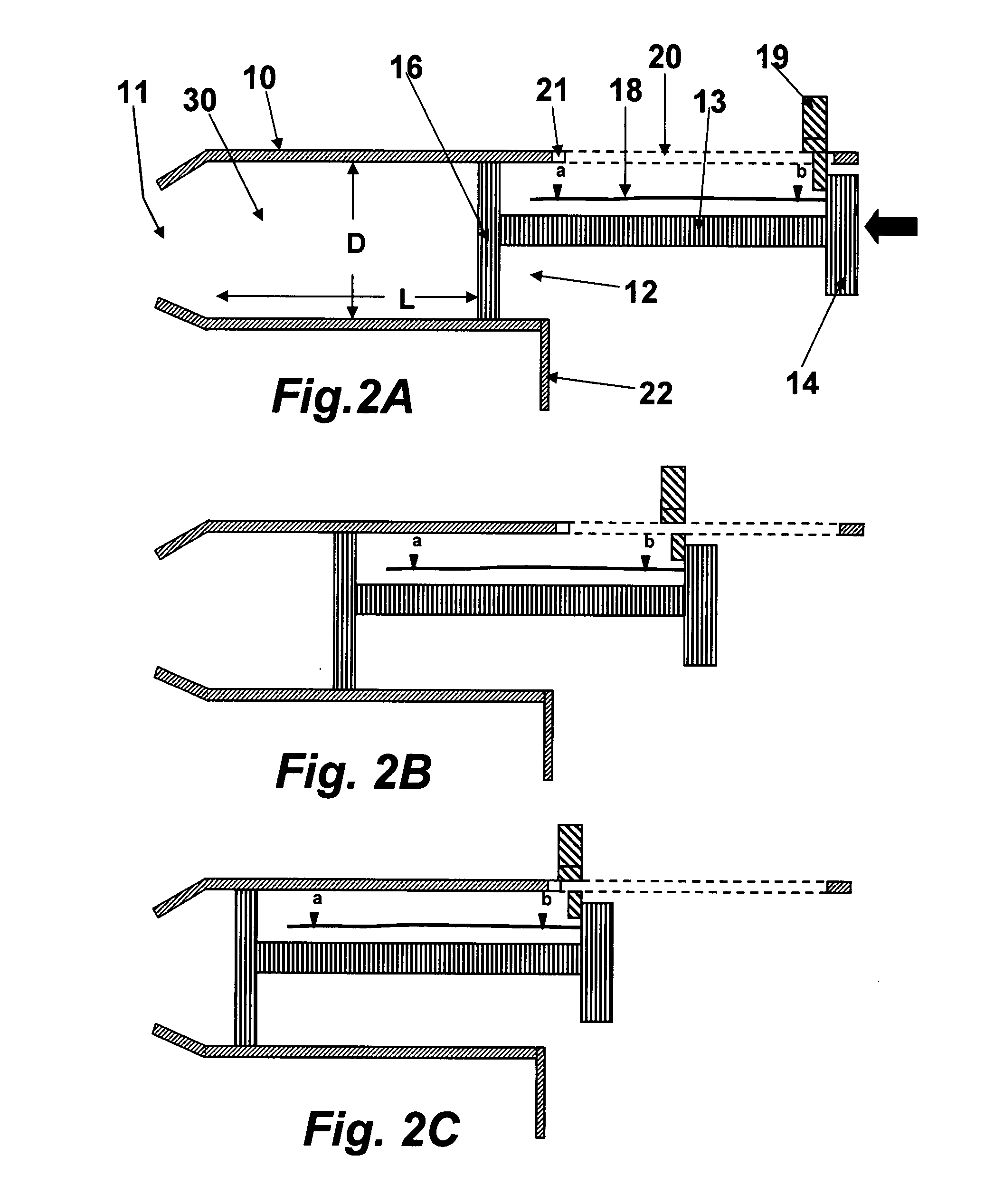

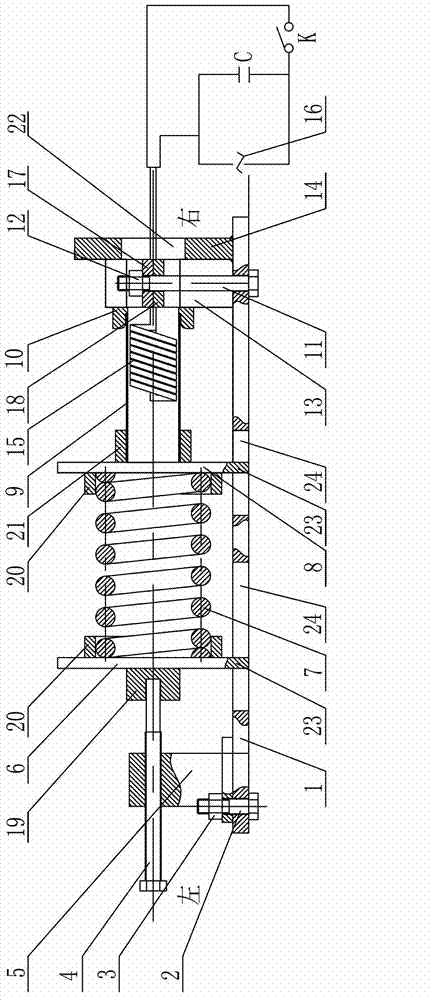

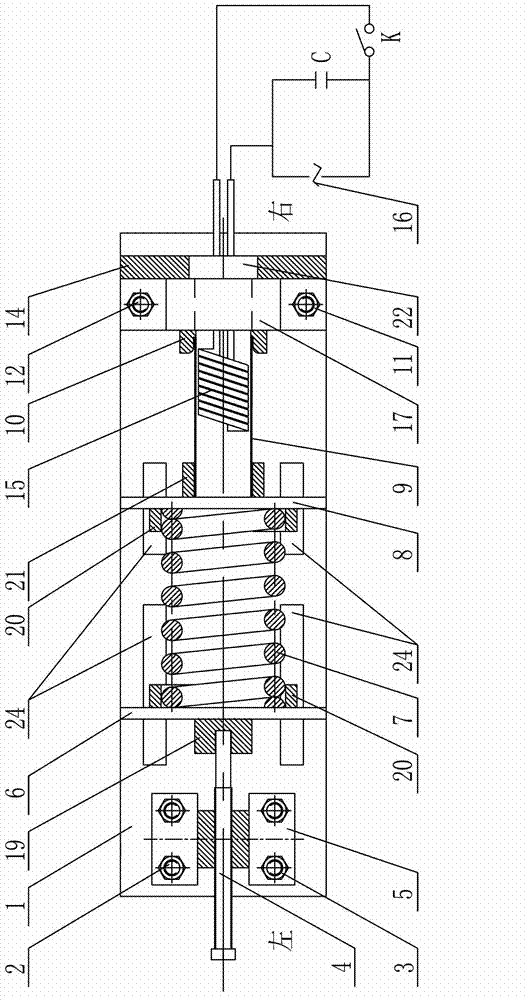

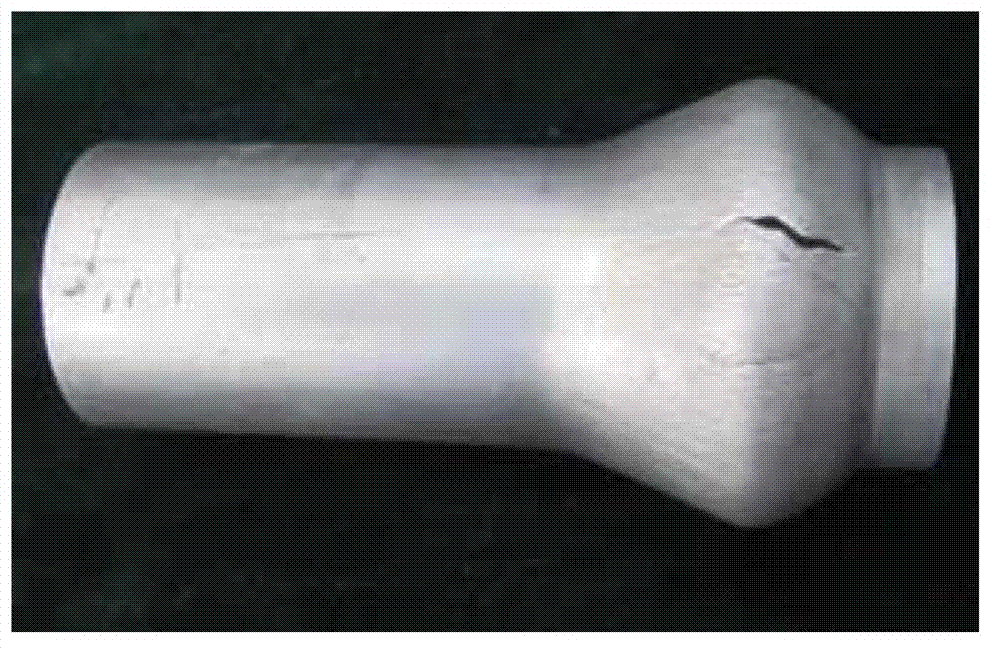

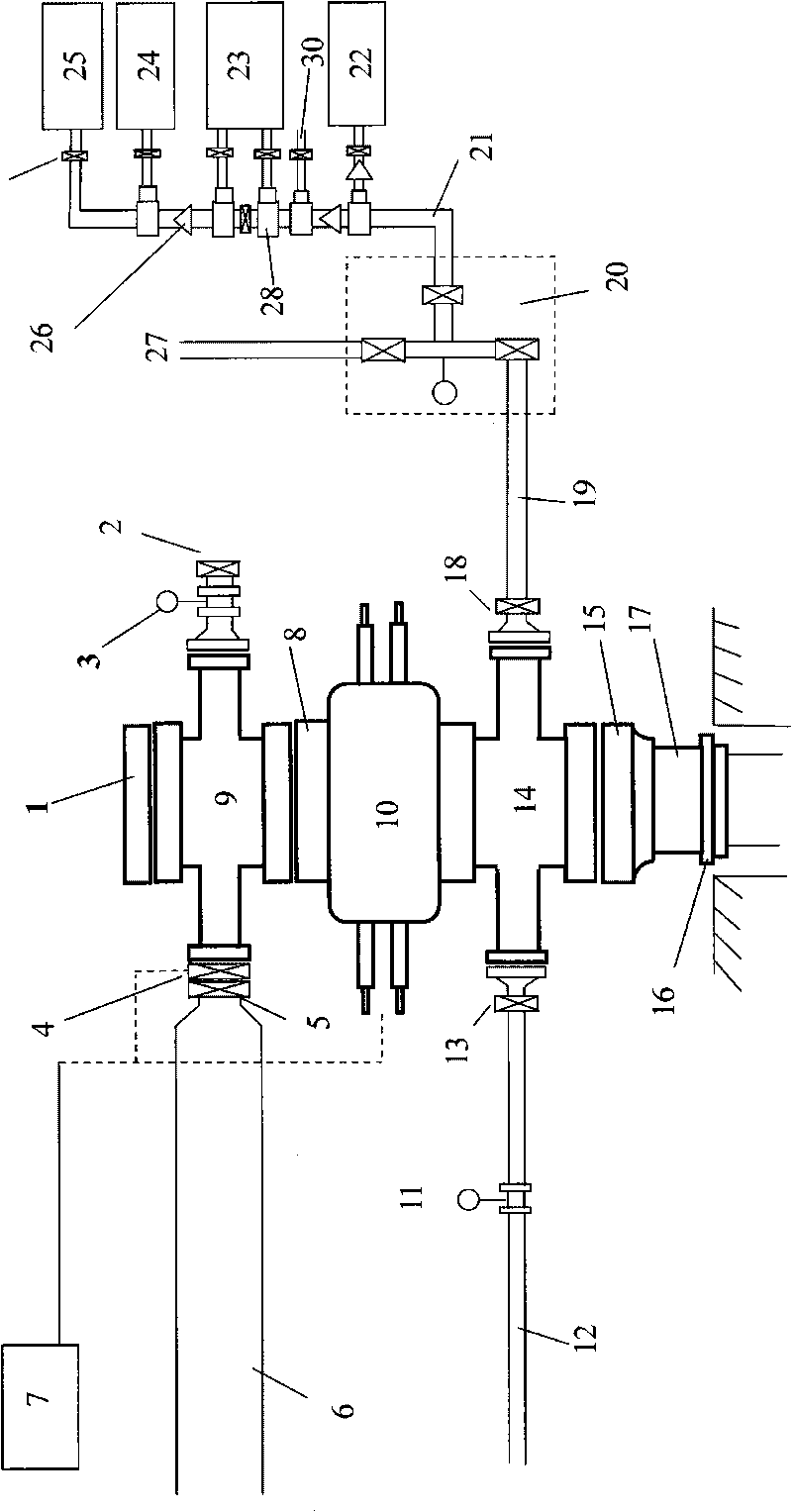

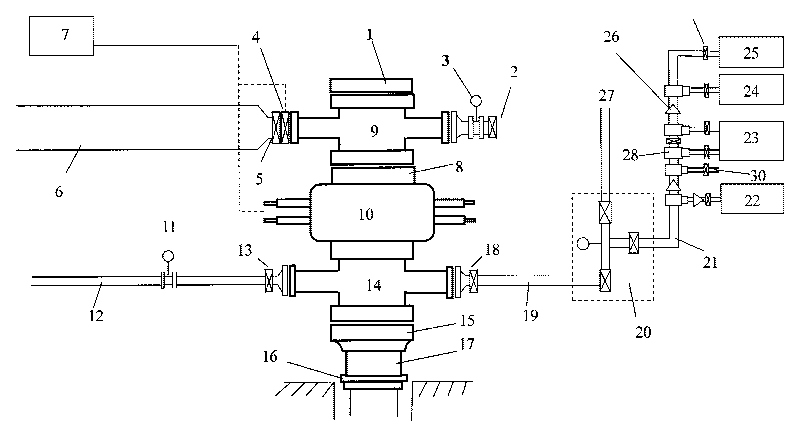

Device and method for axial loading to assist bulging of magnetic pulse pipe

The invention discloses a device and a method for axial loading to assist bulging of a magnetic pulse pipe, relates to a device and a method for bulging of a magnetic pulse pipe, and aims to solve the problem of breakage due to the fact that when a pipe fitting is locally bulged by existing magnetic pulse forming technology, deformation of a pipe wall is uneven and the pipe wall is excessively thinned. A lead guiding block is connected with a rectangular bottom plate, an upper clamp block and a lower clamp block are connected with the rectangular bottom plate, a lead screw is connected with the lead screw guiding block in a threaded manner, bumps on two push plates are slidably arranged in guide grooves of the rectangular bottom plate, the right end of the lead screw is arranged in a lead screw limiting sleeve fixedly connected with the left push plate, a spring is arranged in spring limiting sleeves fixedly connected with the two push plates, a coil is arranged between the right push plate and a fixture, two lead wire sections of the coil are serially connected onto a discharge control switch, and a capacitor bank is serially connected with a power source. The method includes sleeving a pipe fitting on the coil; exerting axial pre-tightening force; and taking out the formed pipe fitting after discharge forming. The device and the method are used for bulging and machining pipe fittings difficult to form.

Owner:HARBIN INST OF TECH

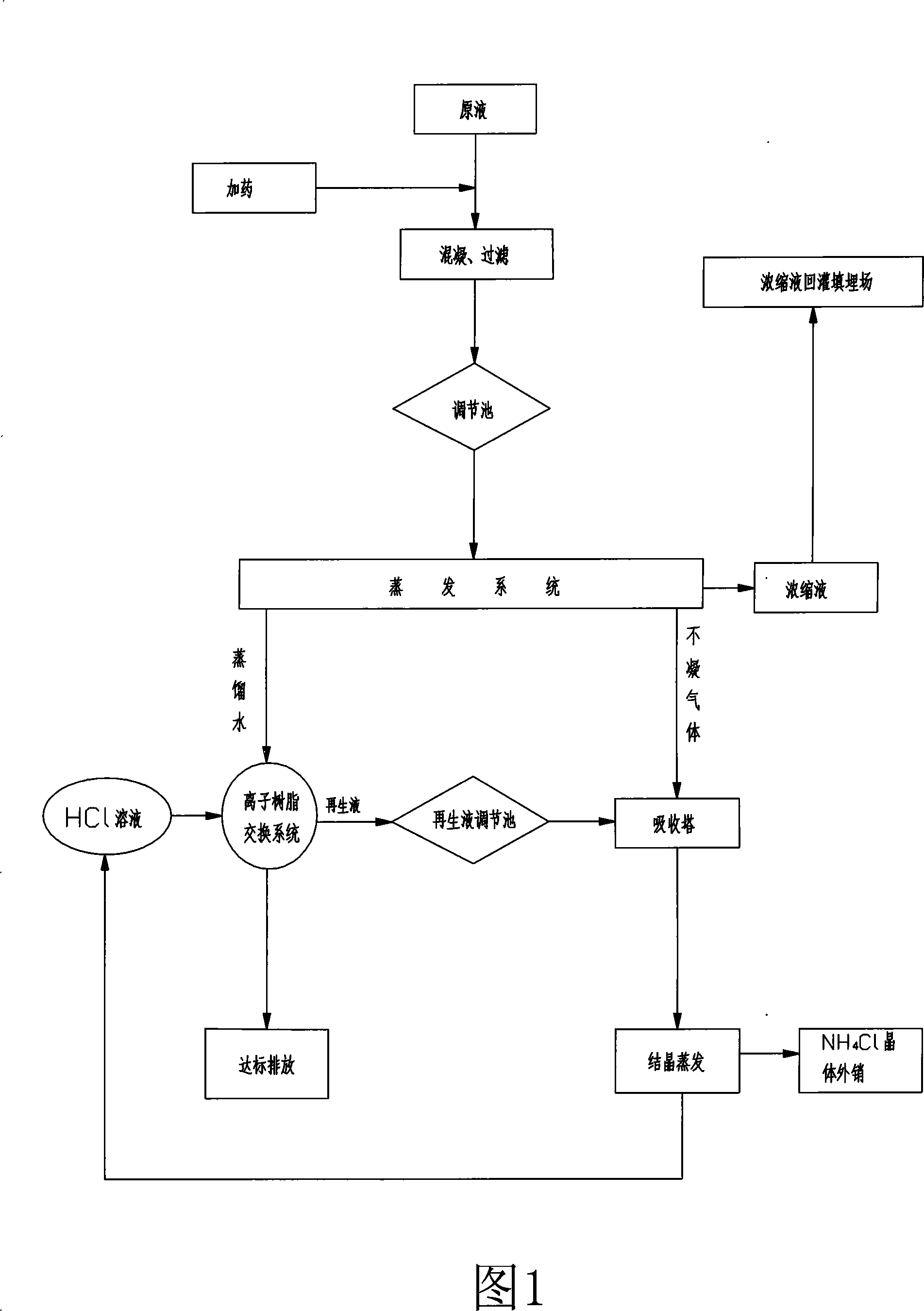

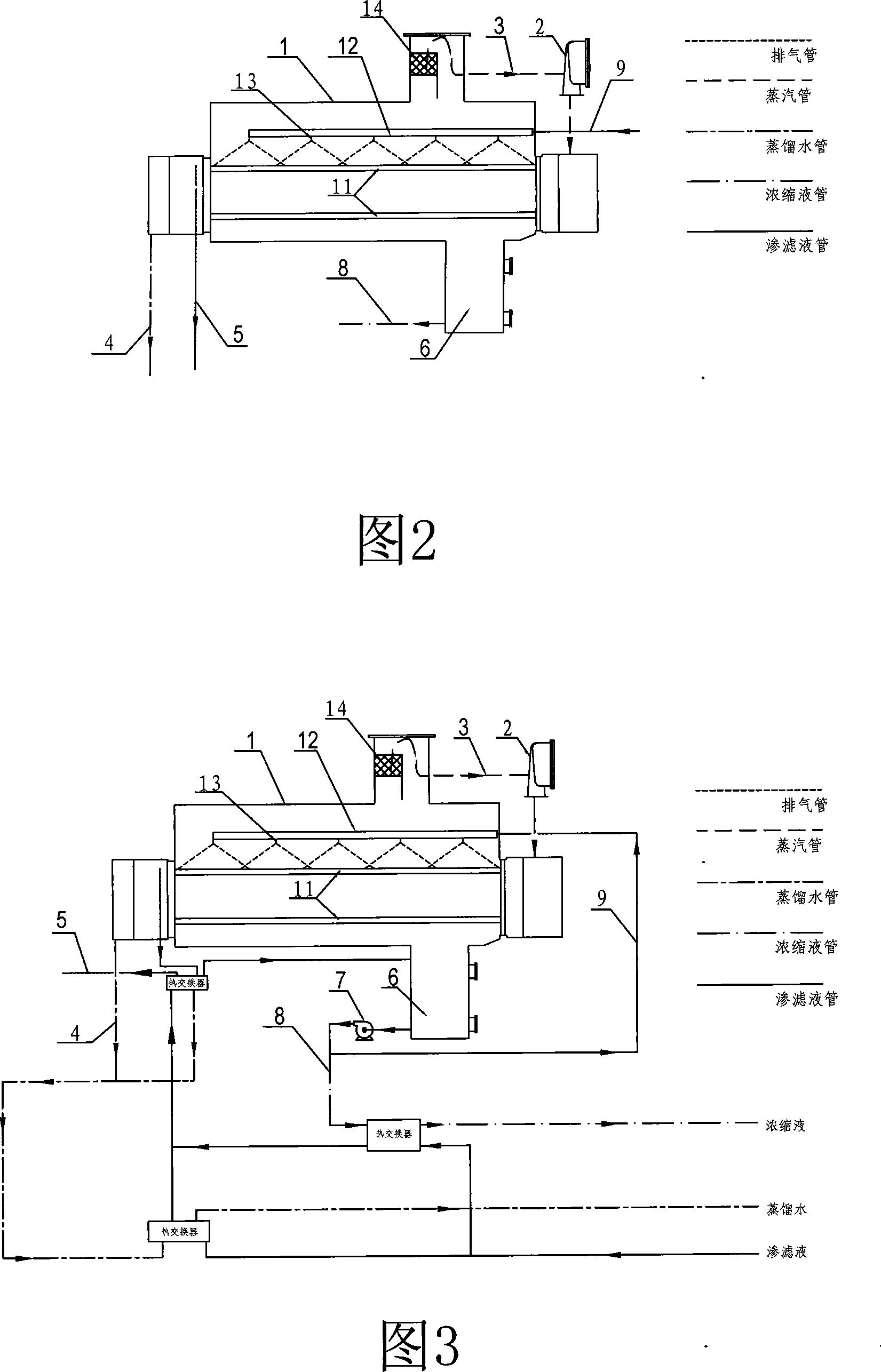

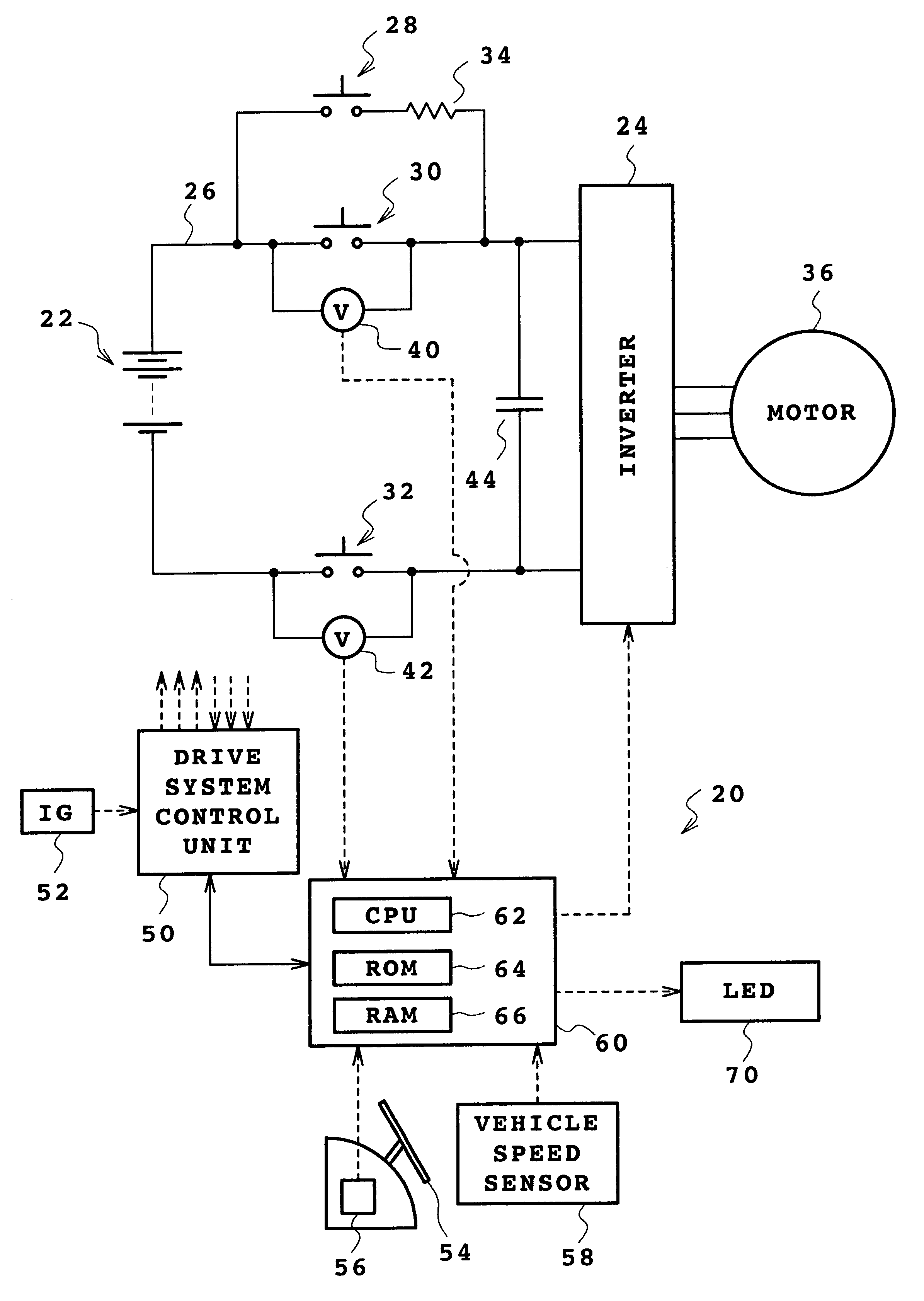

Treatment technique of garbage filter liquor

InactiveCN101182083ALess investmentLow running costWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentFiberComing out

A treatment process for landfill leachate, specifically comprising the following steps: (1) first adding a coagulant to the landfill leachate, coagulating and filtering to remove tiny fibers in the leachate; (2) filtering the leachate Enter the adjustment tank; (3) The leachate from the adjustment tank enters the evaporation system, and after evaporation, water and ammonia boil out of the leachate into steam, which becomes distilled water after condensation and is discharged, and then enters the ion resin exchange system, and the distilled water passes through the resin When the ion exchange reaction occurs, the ammonium is removed, and the ammonia nitrogen index of the distilled water is discharged after reaching the standard; the non-condensable gas and a small amount of non-condensable steam in the steam are discharged from the evaporation system and enter the absorption tower; (4) The leachate from the regulating tank enters the Evaporation system, the remaining part of the leachate after evaporation is pollutants that cannot be turned into gas and escape the evaporation system. After being concentrated into a concentrated liquid, it is discharged from the evaporation system and can be recharged to the landfill. The process is thorough and the operating cost is low.

Owner:陈伟雄 +1

Relay welding detector and detecting method

InactiveUS6657833B2Frequently performedReduce voltageAC motor controlElectric devicesVoltmeterElectric vehicle

Frequency of judgment of welding of relays is increased to increase likelihood of early detection of welding. It is determined that a battery 22 is not being recharged or discharged when a vehicle speed V of an electric vehicle is approximately 0 and a brake pedal 54 is pressed, and a switching element of an inverter 24 is controlled to be switched to discharge electric charges which are stored in a capacitor 44. After discharging, relays 30, 32 are turned off, and voltages RV1, RV2 between the terminals of the relays 30, 32 are detected by voltmeters 40, 42 to judge whether either of the voltages RV1, RV2 has a threshold value RVref (approximate value 0) or less. When it is so determined, it is judged that the relays 30, 32 are welded, and an LED 70 is illuminated.

Owner:TOYOTA JIDOSHA KK

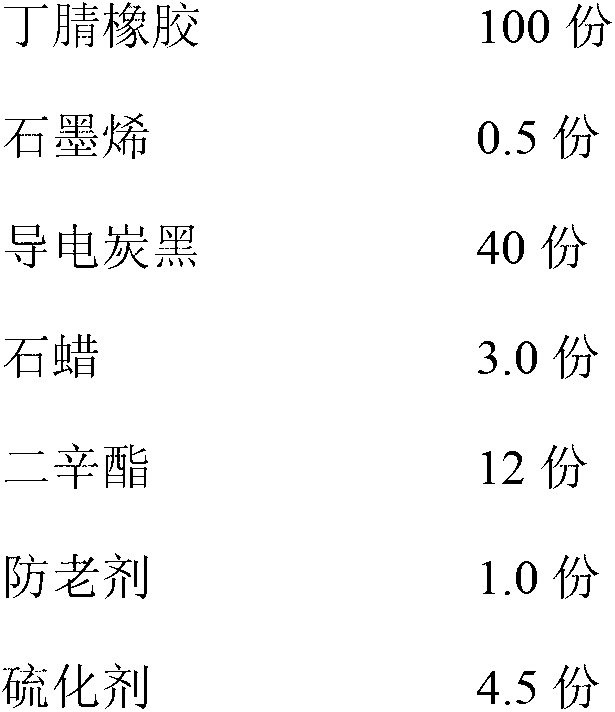

Strippable semiconductive shielding rubber for rubber insulation and preparation method thereof

ActiveCN103122085AHighly cleanAvoid performance biasPower cables with screens/conductive layersPlasticizerResidual carbon

The invention relates to a strippable semiconductive shielding rubber for rubber insulation and a preparation method thereof. The strippable semiconductive shielding rubber comprises the following components in parts by weight: 100 parts of nitrile-butadiene rubber, 0.5-8 parts of graphene, 10-40 parts of conductive carbon black, 7-15 parts of plasticizer, 1-2 parts of anti-aging agent and 2.5-4.5 parts of vulcanizing agent, wherein the nitrile-butadiene rubber is a solar one; the minimum surface-diameter ratio of the graphene is 1000; the plasticizer is one or a mixture of paraffin, dioctyl ester, stearic acid and the like; and the vulcanizing agent is a peroxide vulcanizing system. The preparation method comprises the following steps: plasticating the nitrile-butadiene rubber twice (10 minutes for each time), and standing at normal temperature for 12 hours; adding the graphene into the plasticated nitrile-butadiene rubber, evenly mixing, and adding 1 / 2 of the conductive carbon black or acetylene carbon black; 3 minutes later, adding the residual carbon black and the plasticizer, and compounding for 2 minutes; sequentially adding various assistants, finally adding the vulcanizing agent, compounding for 1 minute, and then discharging, wherein the compounding temperature is not higher than 120 DEG C; and after discharging, tabletting semiconductive shielding gum on a tabletting machine to prepare the semiconductive shielding rubber. The semiconductive shielding rubber provided by the invention is easy to process and strip and high in conductivity.

Owner:SHANGHAI LEVSON ENTERPRISE GRP

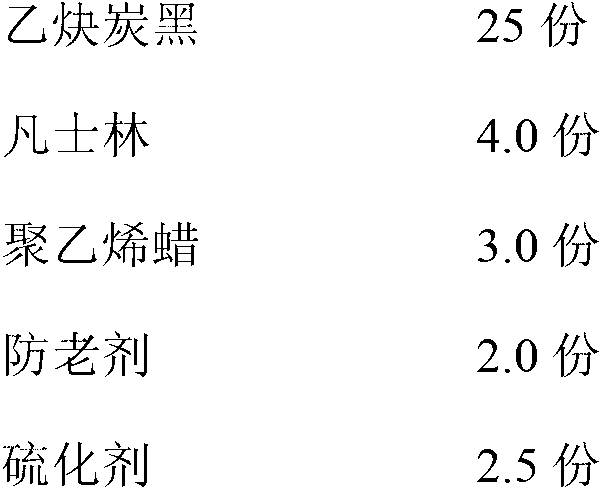

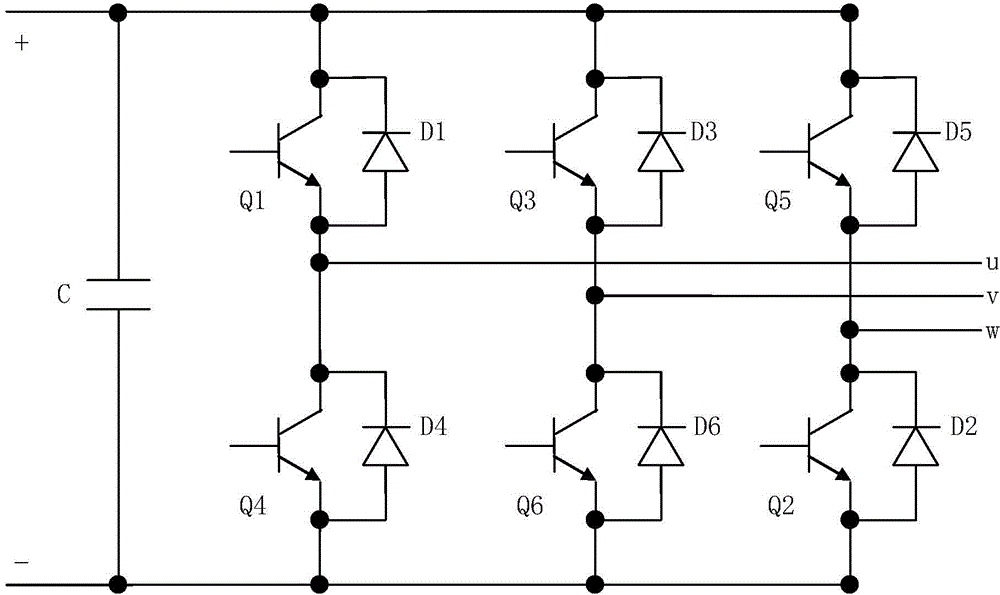

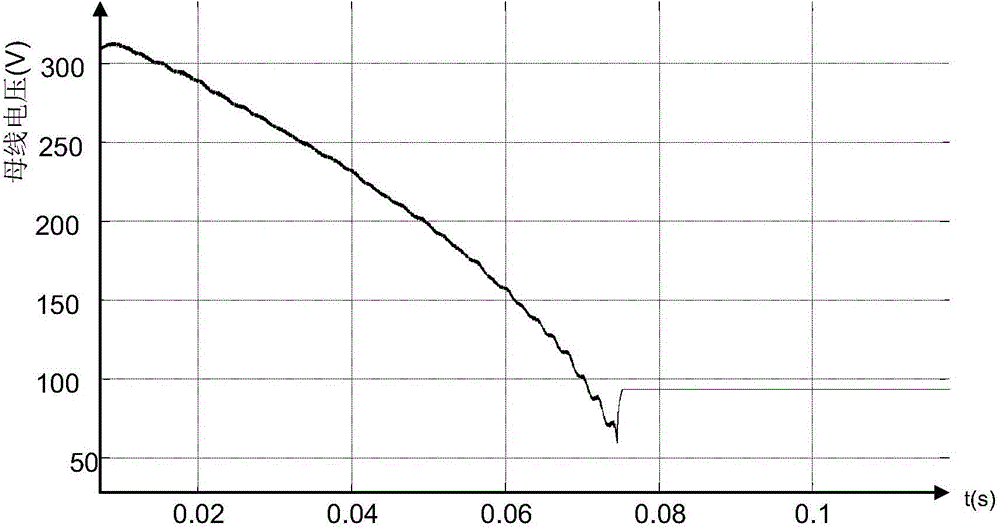

Discharging method of new energy automobile for bus high voltage

ActiveCN105270182ANo speed limit requiredExtend discharge timeBatteries circuit arrangementsElectric devicesCapacitanceNew energy

The invention discloses a discharging method of a new energy automobile for bus high voltage. The discharging method comprises the following steps that firstly, when a hybrid control unit(HCU) sends out a discharging instruction, a battery management system enables a high-voltage battery and an inverter to be disconnected; secondly, a motor controller controls six power switching devices in the inverter, so that the direct-axis current of a permanent magnet synchronous motor is reduced along with reduction of the bus voltage, the quadrature-axis current is zero all the time, and thus the energy of a bus capacitor is consumed inside the permanent magnet synchronous motor; and thirdly, when the bus voltage value is lowered to be within a safe voltage range within given time, the motor controller enables three phases of the permanent magnet synchronous motor to be initiatively shortly circuited, or the direct-axis current and the quadrature-axis current of the permanent magnet synchronous motor are made to be both zero, and otherwise, the motor controller enables the three phases of the permanent magnet synchronous motor to be initiatively shortly circuited and feeds back a discharging overtime fault to the HCU. By means of the discharging method, the discharging time is short, safety and reliability are achieved, and the bus voltage cannot rise again after discharging is completed.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

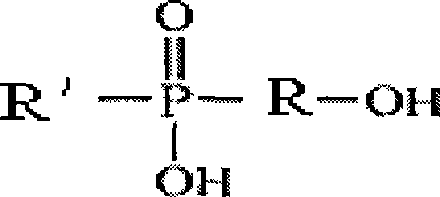

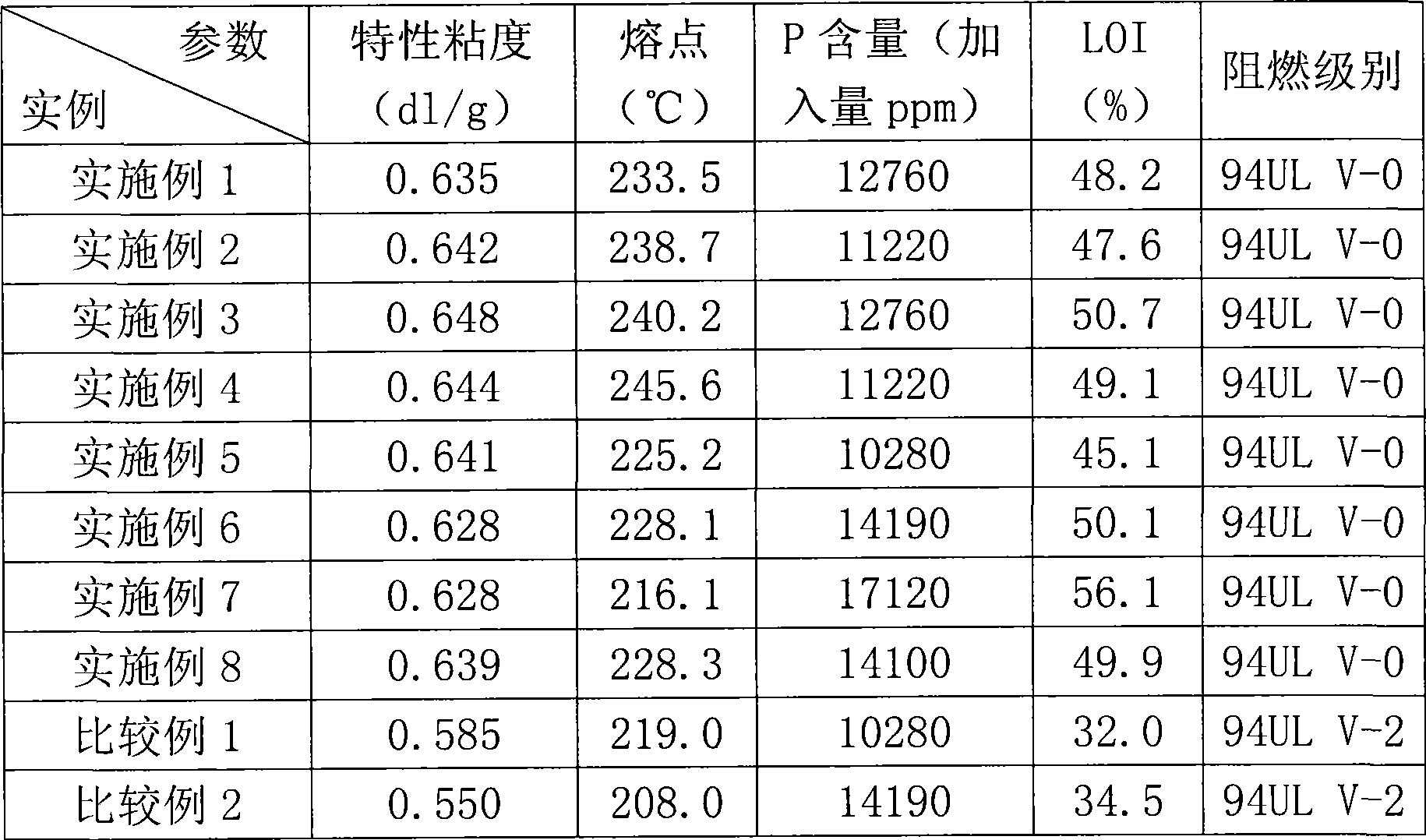

Method for preparing phosphor system halogen-free flame-proof copolymerization polyester

ActiveCN101508770AImprove responseIncrease the amount of effective additionFiberDimethyl terephthalate

The invention relates to a method for preparing phosphorus halogen-free flame retardant copolyester. The method is characterized in that halogen-free phosphoric copolymerized flame retardant and glycol are mixed to carry out esterification reaction for 4 to 6 hours under the temperature of 140-210 DEG C and the pressure of 40-70Kpa and then are filtered; flame-retardant esterified product solution is prepared from the filtrate; dimethyl terephthalate, the glycol and promoter are mixed to carry out ester exchange reaction for 2 to 4 hours under the temperature of 160-240 DEG C; after the reaction, the flame-retardant esterified product solution is added, and catalyst and stabilizing agent are added to carry out polyreaction for 2.5 to 4 hours under the temperature of 240-290 DEG C and the pressure of 100Pa; and the phosphorus halogen-free flame retardant copolyester is prepared after discharging the material. Polyester slice can be used as raw material for producing film with flame retardance of grade 94UL V-O or grade VTM-O (collectively called grade VO), flame retardant fibre with flame retardance of grade I or above and grade VO flame retardant plastic product, and the polyester slice has excellent flame retardance.

Owner:四川东方绝缘材料股份有限公司

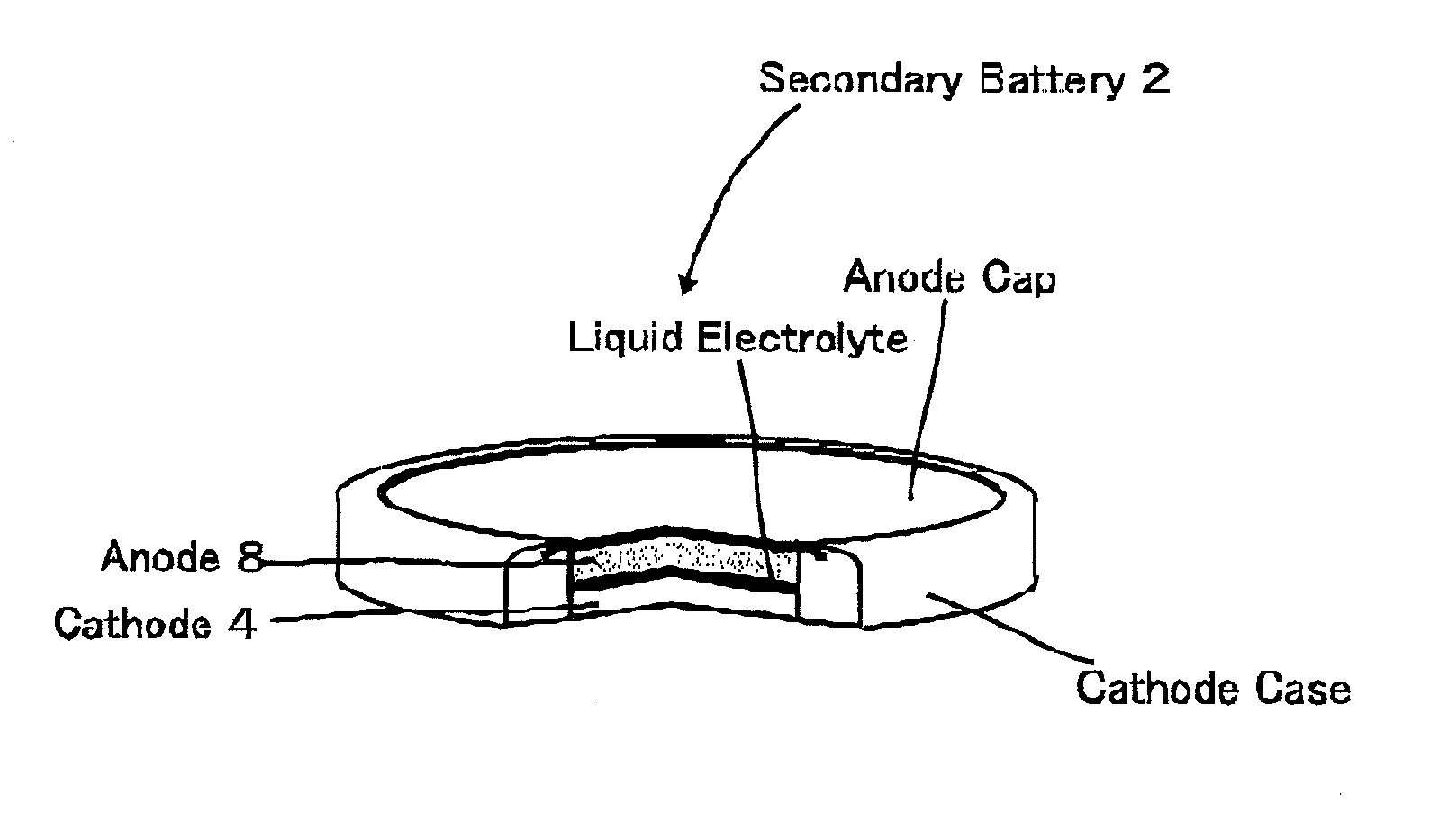

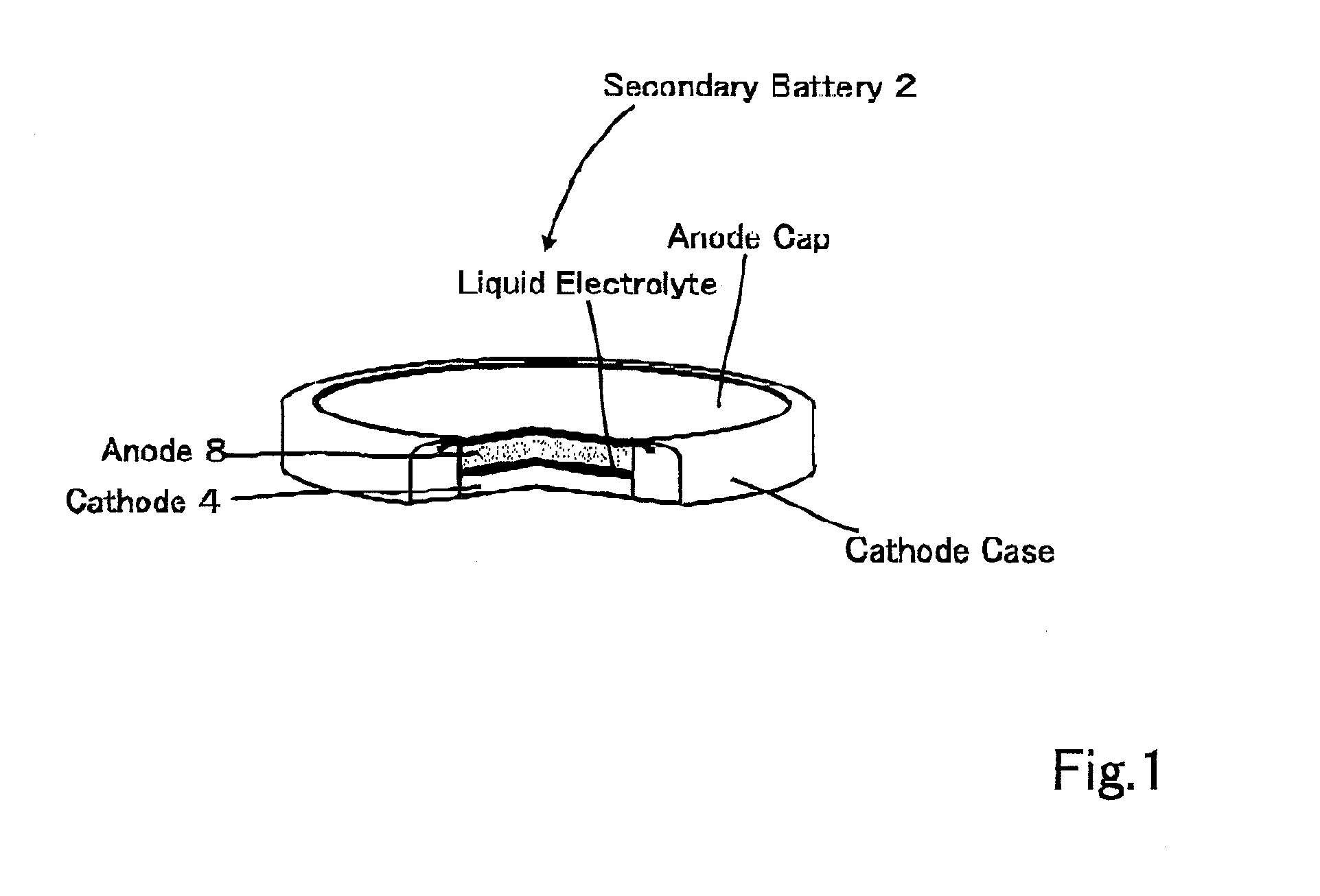

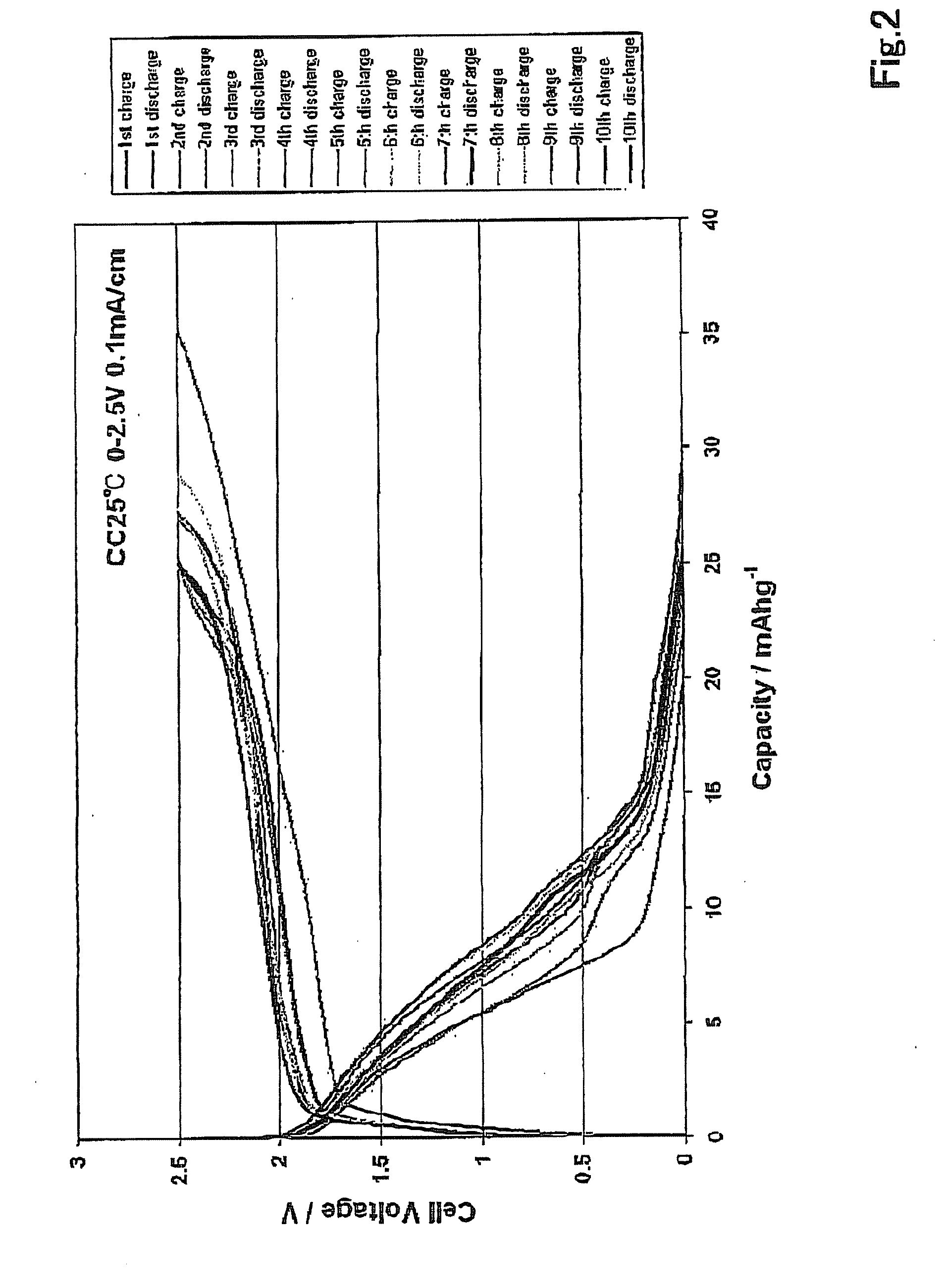

Secondary battery

InactiveUS20080213674A1Reduced characteristicsPromote degradationFinal product manufactureElectrode carriers/collectorsEngineeringFluid electrolytes

The present invention provides a secondary battery using a liquid electrolyte excellent in storage characteristics. The secondary battery includes a cathode, an anode, and a liquid electrolyte, where the cathode and the anode contain at least one mutual active material. This symmetrical electrode configuration, that the at least one active material for the cathode and the anode is mutual, enables equalization of an electrode electric potential difference before charge or after discharge; and thus electrolyte degradation is efficiently restrained to improve storage characteristics.

Owner:KYUSHU UNIV +1

Concrete recovery method and system

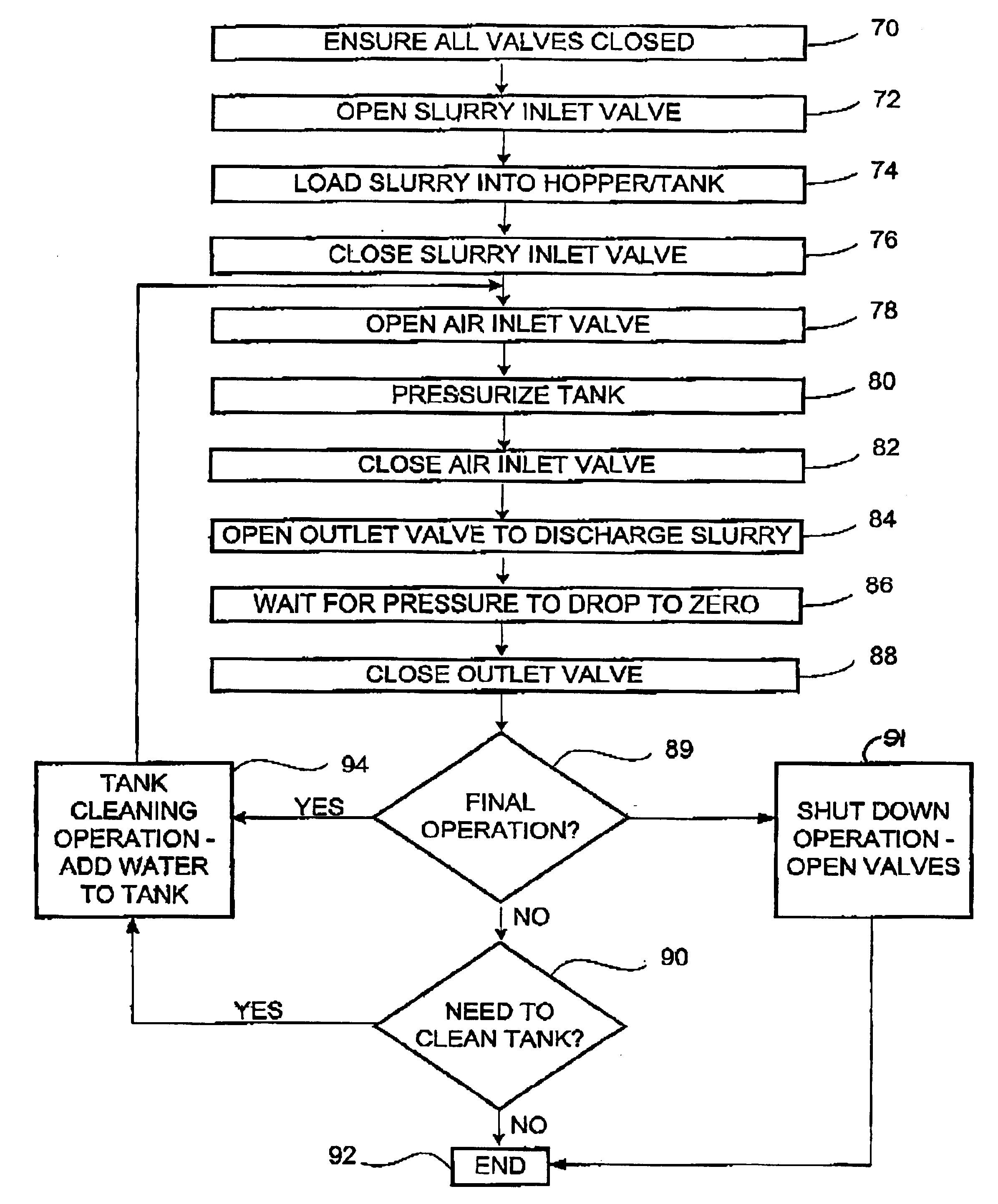

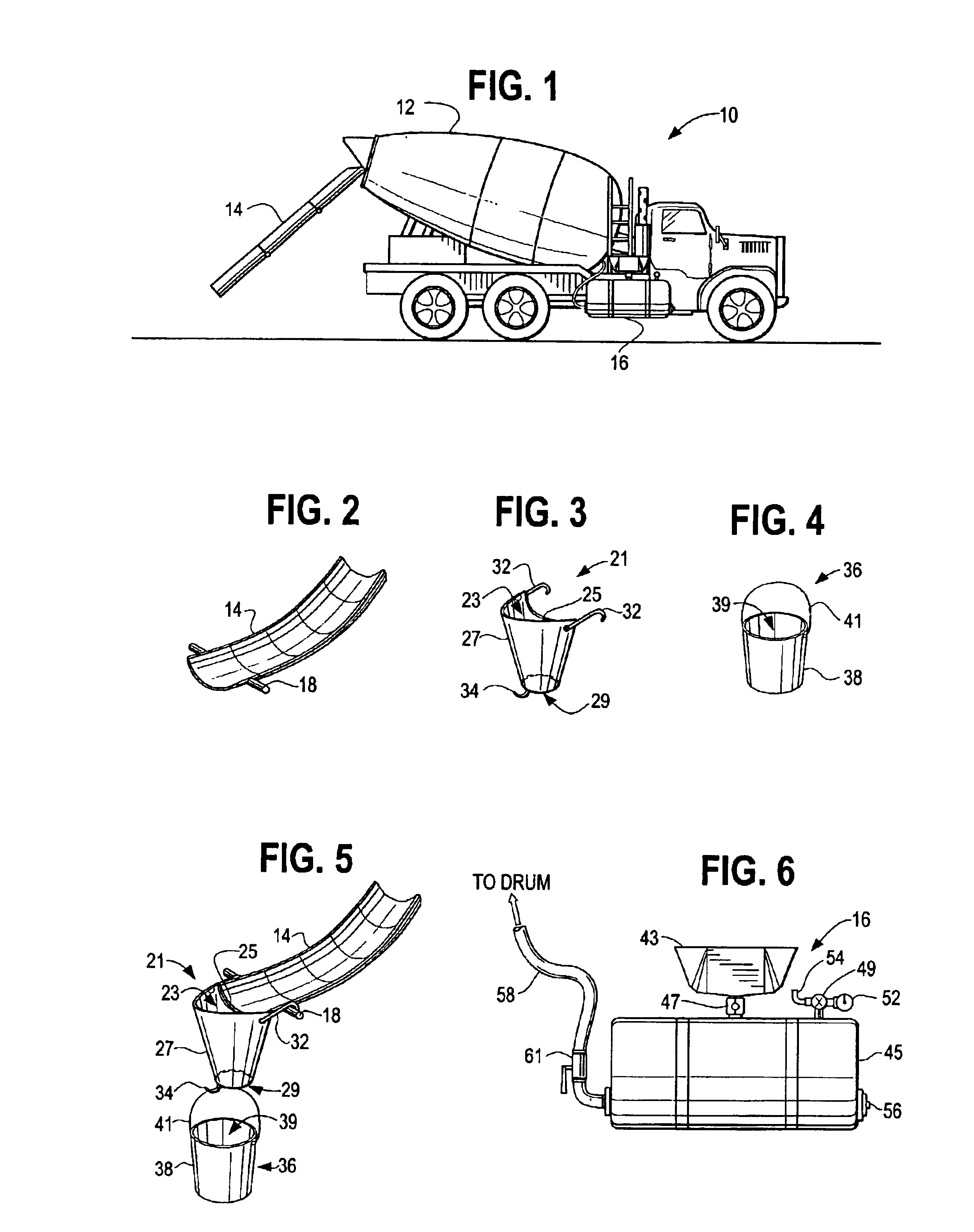

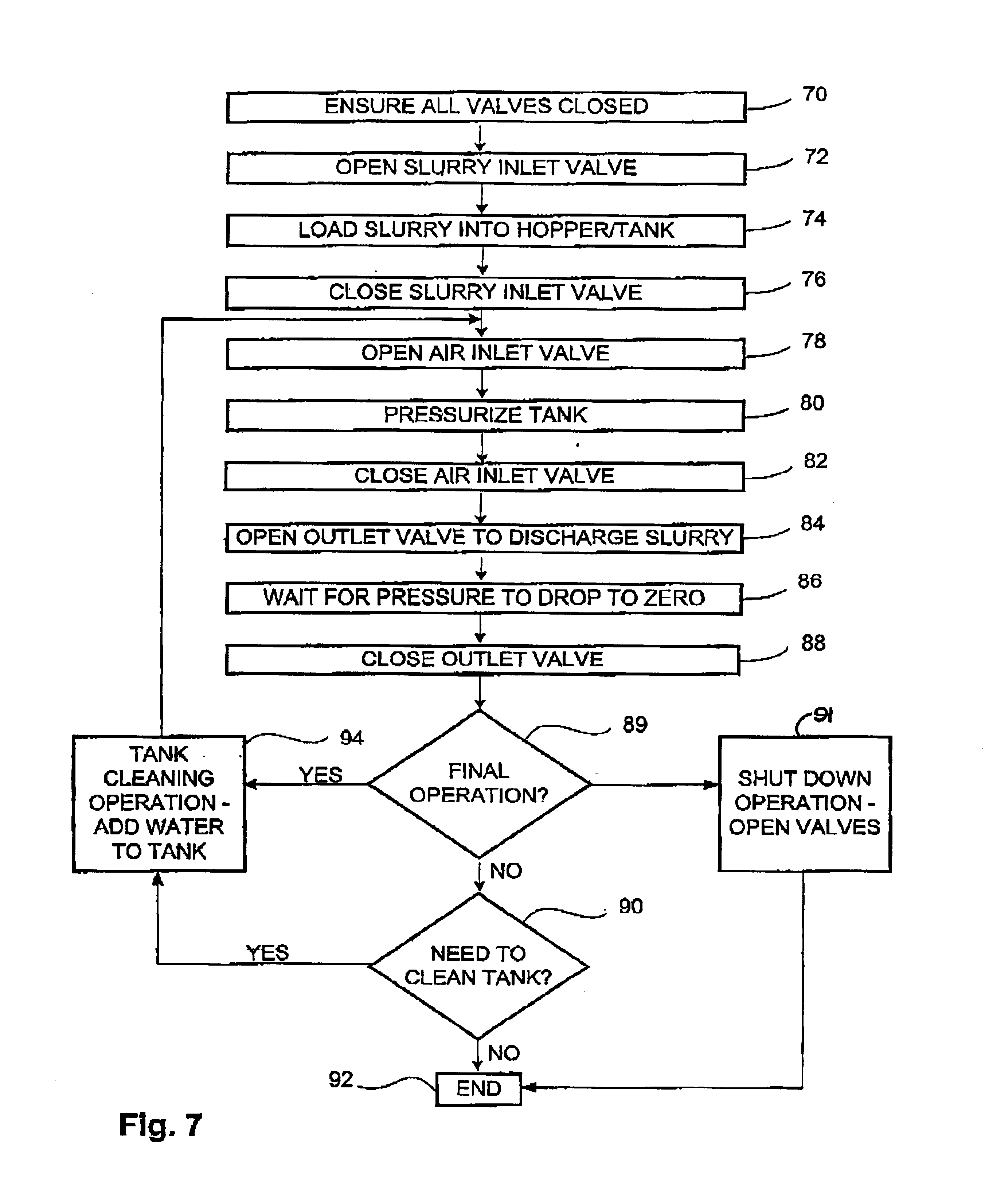

According to certain embodiments of the present invention, there is disclosed herein a method and system of recovering concrete which includes admitting a concrete slurry to a tank, pressurizing the tank with a fluid under pressure, discharging through a discharge line the pressurized fluid-slurry from the tank, cleaning the tank by admitting a cleaning liquid into the tank after discharging fluid-slurry therefrom, and discharging the cleaning liquid from the tank through the discharge line for cleaning purposes.

Owner:FE HLDG LLC

High-strength thin band steel for cold forming and manufacturing method thereof

The invention relates to high-strength thin band steel for cold forming and a manufacturing method thereof. The method comprises the following steps: after discharging a cast band from a crystal roll, cooling the cast band forcibly and uniformly in a mode of spraying dry ice under high pressure; quickly cooling the cast band to be below 1,280 DEG C at the cooling speed of 200-300 DEG C / s; performing austenite on-line recrystallization rolling, wherein the rolling temperature is 1,050 to 1,200 DEG C and the rolling reduction is 20 to 50 percent; and quickly cooling the band steel subjected to hot rolling in an anti-oxidation mode, wherein the anti-oxidation quick cooling speed is 80 to 200 DEG C / s and the reeling temperature is 500 to 600 DEG C. By the method, the high-strength thin band steel for automobile cold forming and with low yield strength and excellent stamping performance can be obtained, can be directly used in a mode of substituting heat for cold, cancels the cold rolling procedure and greatly reduces the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

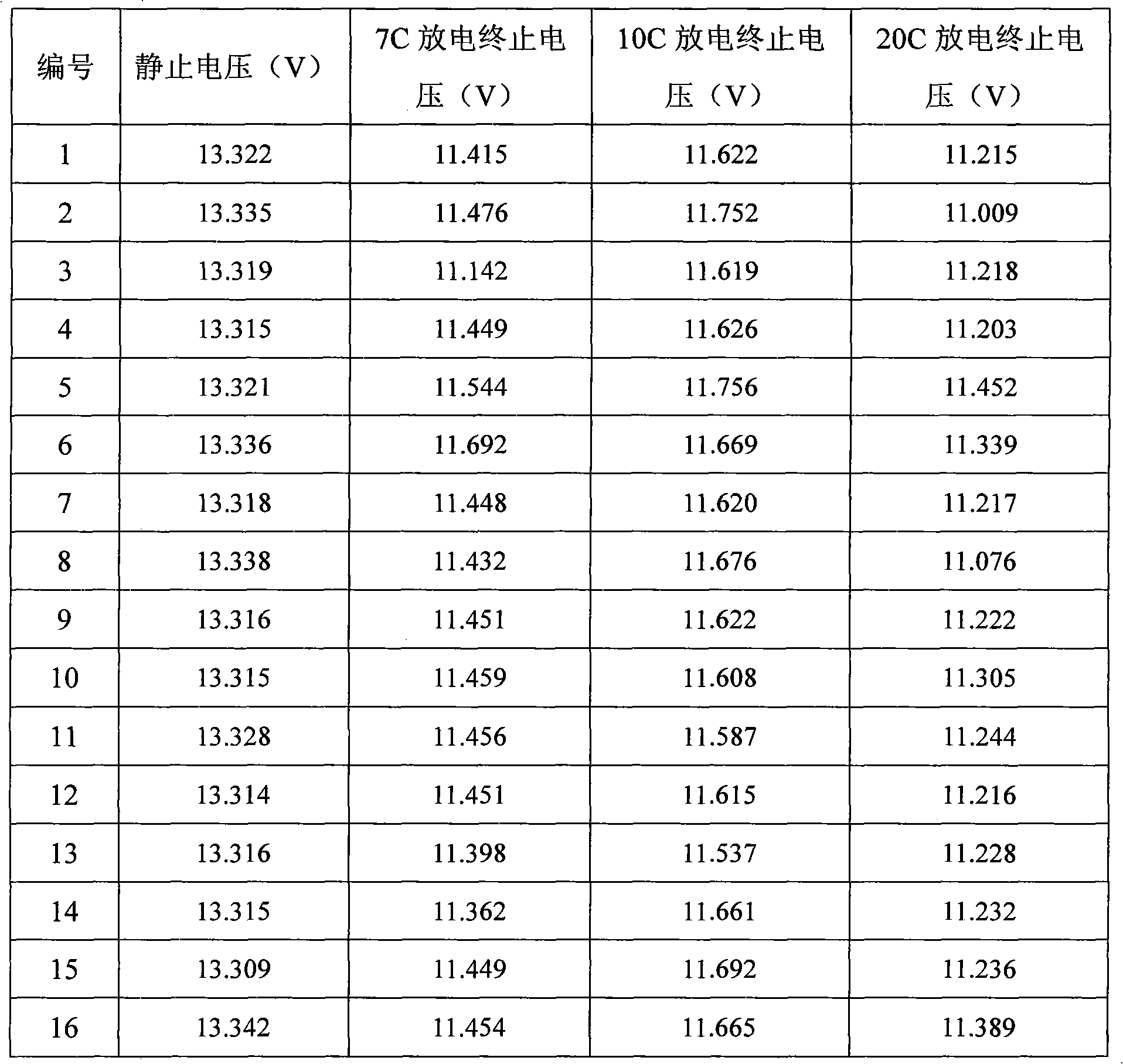

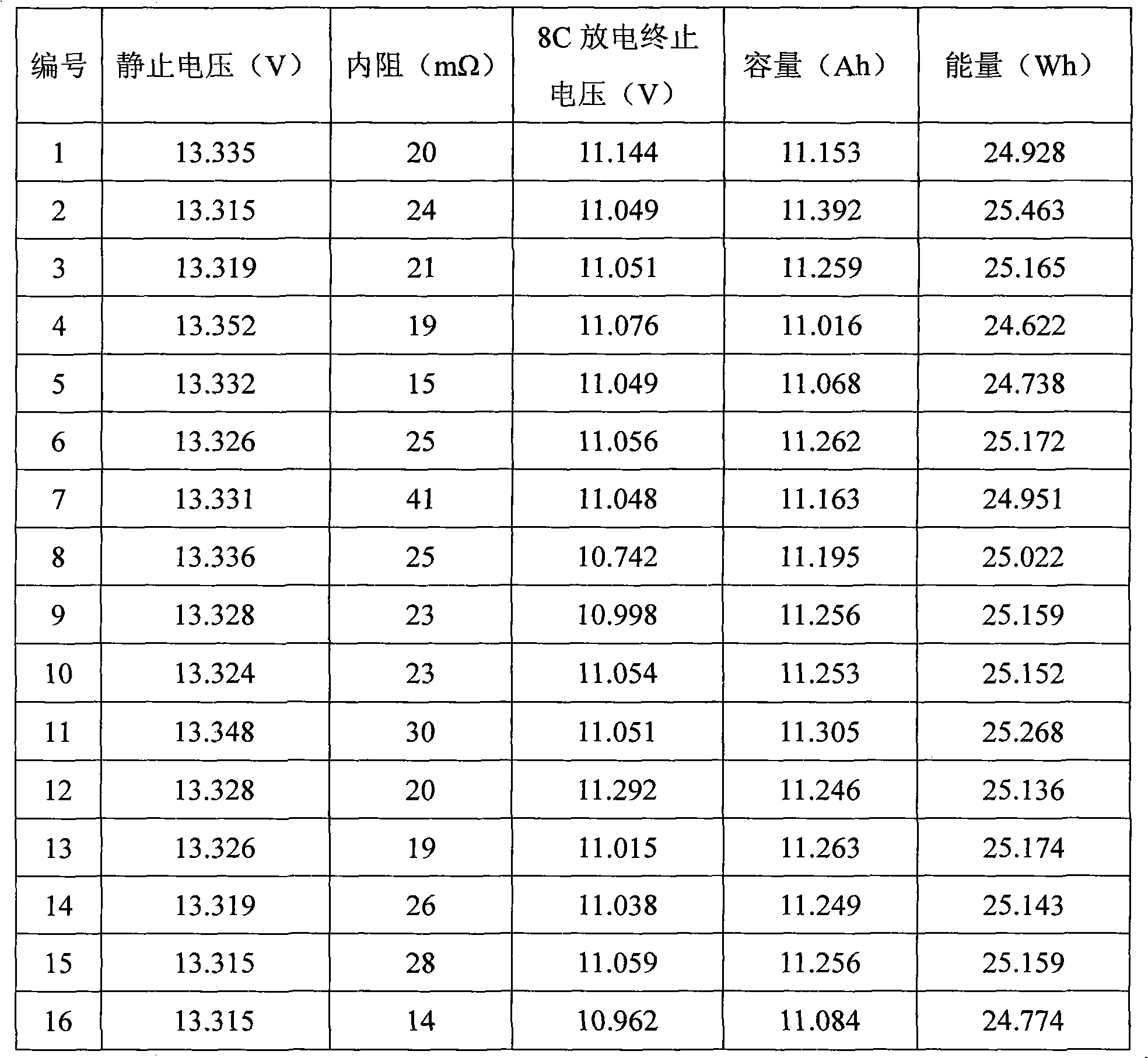

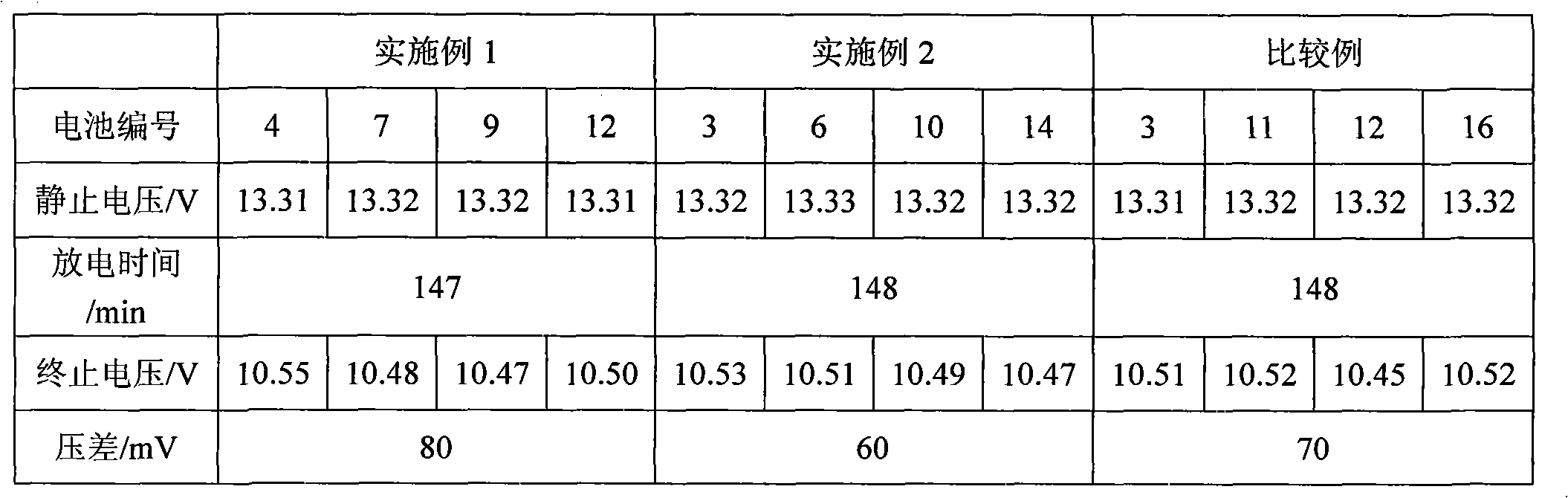

Lead-acid cell grouping method

InactiveCN101924257APerformance is not affectedConsistent performanceLead-acid accumulatorsElectrical testingInternal resistanceTerminal voltage

The invention discloses a lead-acid cell grouping method, comprising the following steps: detecting and recording static the voltage of a cell; detecting and recording the internal resistance of the cell; carrying out transient pulse discharging for one or more times on the lead-acid cell at different currents and discharging times; recording one or more data of discharging terminal voltage, discharging volume and discharging energy each time; after discharging detection, grouping the cell according to the difference range of one or more parameters of static voltage, internal resistance, discharging terminal voltage, discharging volume and discharging energy. The grouped cell group has high uniformity and long service life; the method is simple; and the required test device is easily realized and has strong operability.

Owner:JIANGSU SHUANGDENG GROUP

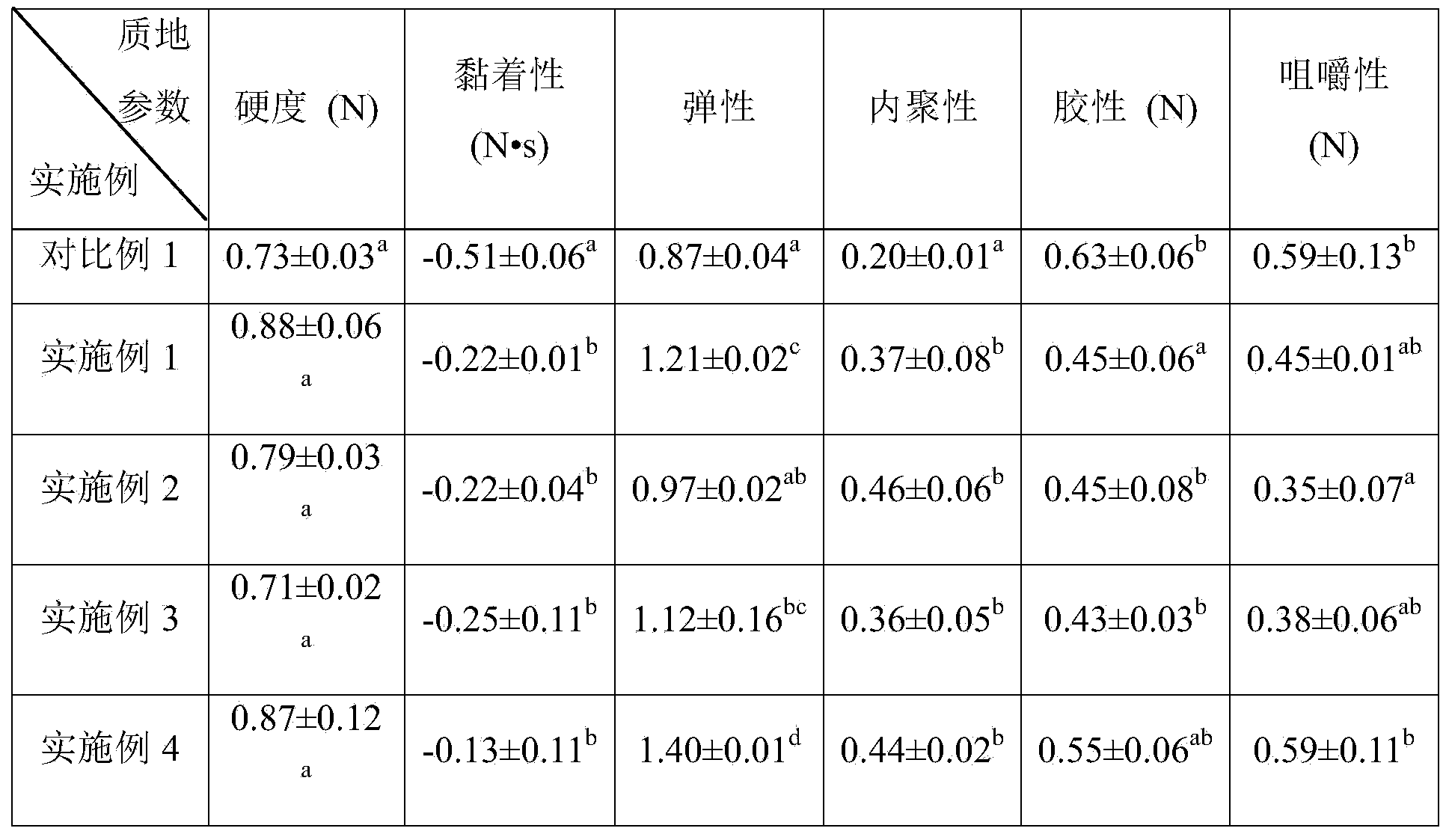

Preparation method of monascus sp. cheese and product thereof

ActiveCN103444878ABreakthrough understandingImprove immunityCheese manufactureNutritive valuesFlavor

The invention discloses a preparation method of monascus sp. cheese and a product of the monascus sp. cheese. The preparation method comprises the following steps: (1), sterilizing raw milk and then cooling to obtain treated milk, inoculating a lactic acid bacteria starter in the treated milk, adding chymosin when fermenting until pH is 6.0-6.5, curdling for 30-40min to obtain curd; (2), cutting the curd into blocks, stirring and discharging whey, adding salt in the curd after discharging the curd, and feeding into a mould after uniformly stirring; (3), carrying out or not carrying out pressing after feeding in the mould, overturning for 5-10 times at a frequency of 15-30min / times, and standing to ensure that the whey is discharged; and (4), cutting the curd into curd blocks, uniformly spraying a monascus fermentation liquor on the surface of the curd blocks, loading in a container, and curing to obtain the monascus sp. cheese. The monascus sp. cheese disclosed by the invention belongs to natural mould aged cheese; the quality and the flavor of the cheese are effectively improved by using the monascus sp., and the nutritional value of the cheese is increased; the preparation method is simple, convenient and easy to popularize and apply.

Owner:BRIGHT DAIRY & FOOD

Reverse circulation aerodynamic cavitation method for coalbed methane well and equipment

The invention discloses a reverse circulation aerodynamic cavitation method for a coalbed methane well and equipment. The reverse circulation aerodynamic cavitation method comprises the following steps of: arranging wellhead equipment on a wellhead and sinking a working pipe to a bottom hole; clearly eliminating rock coal dust and water inside the well by using an air compressor in a circulating way; then lifting the working pipe upwards and injecting air / foam by using the air compressor and a supercharger, wherein the air injecting pressure is 3-15 MPa; meanwhile continuously injecting atomized water into the well with the water injecting amount of 3.0-5.0 m<3> each time; opening a hydraulic flat plate gate valve for discharging; after discharging, sinking the working pipe to a coalbed part; injecting the air simultaneously by the air compressor and the supercharger; meanwhile injecting water / foam with the amount of 3.0-10.0 m<3> by using an injection pump for washing the well to thebottom hole; after completing one cycle of discharging and well washing, detecting initial data; closing the air compressor, the supercharger, the injection pump and the hydraulic flat plate gate valve to enable gas inside the well to return freely; measuring the change of gas output of coalbed gas in one hour by using a flow meter; and placing a torch at a discharge port to ignite the gas. The invention improves the construction safety, improves the yield of single well coalbed gas, and saves the construction cost.

Owner:河南省资源环境调查二院

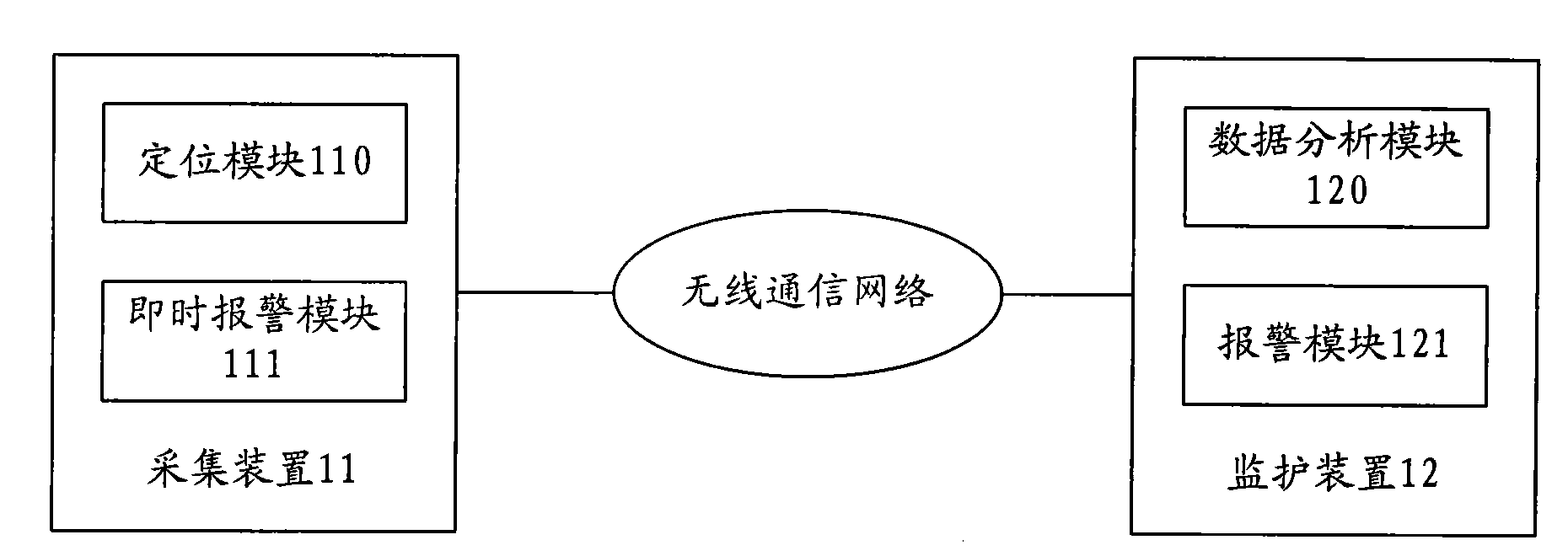

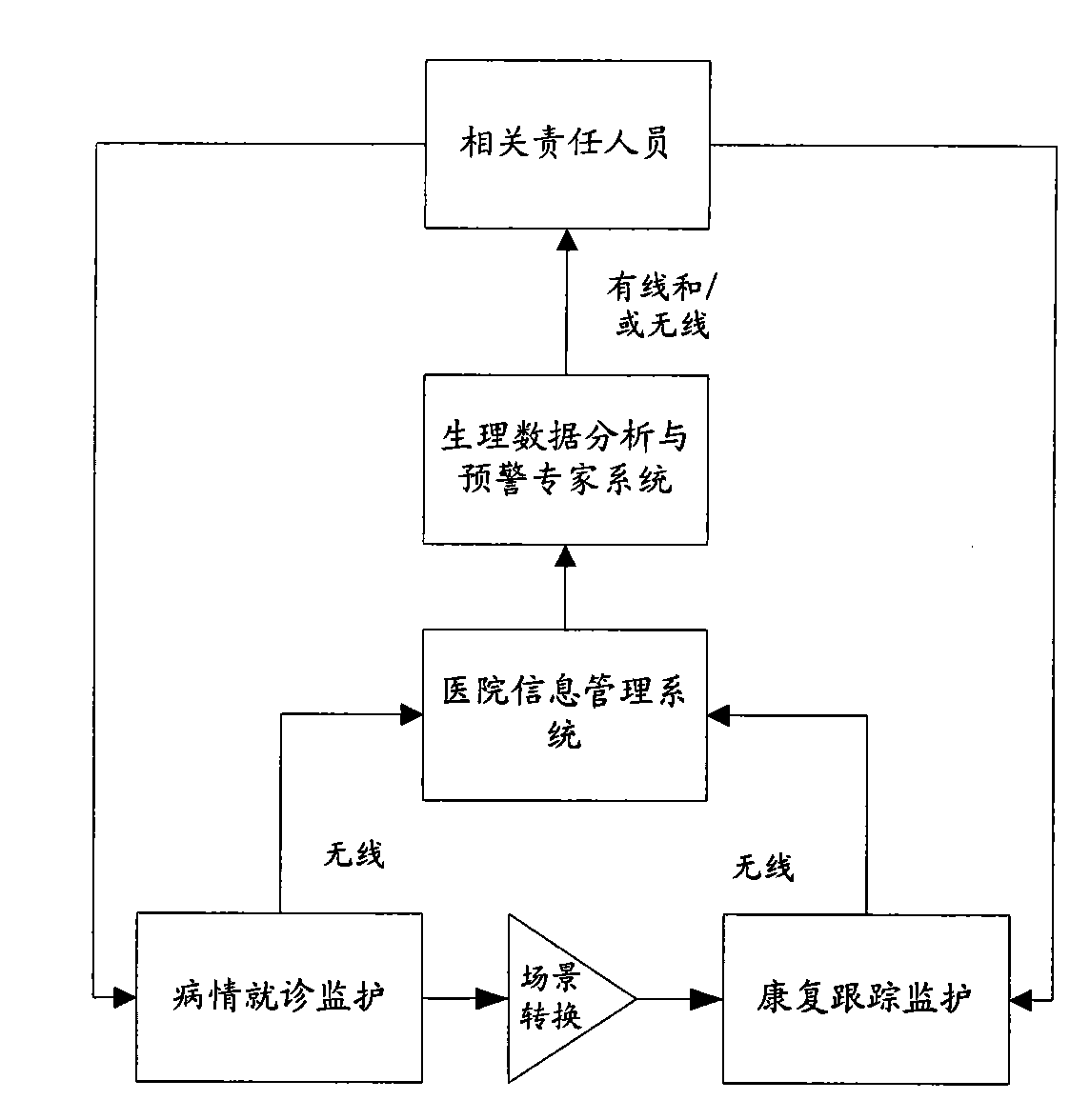

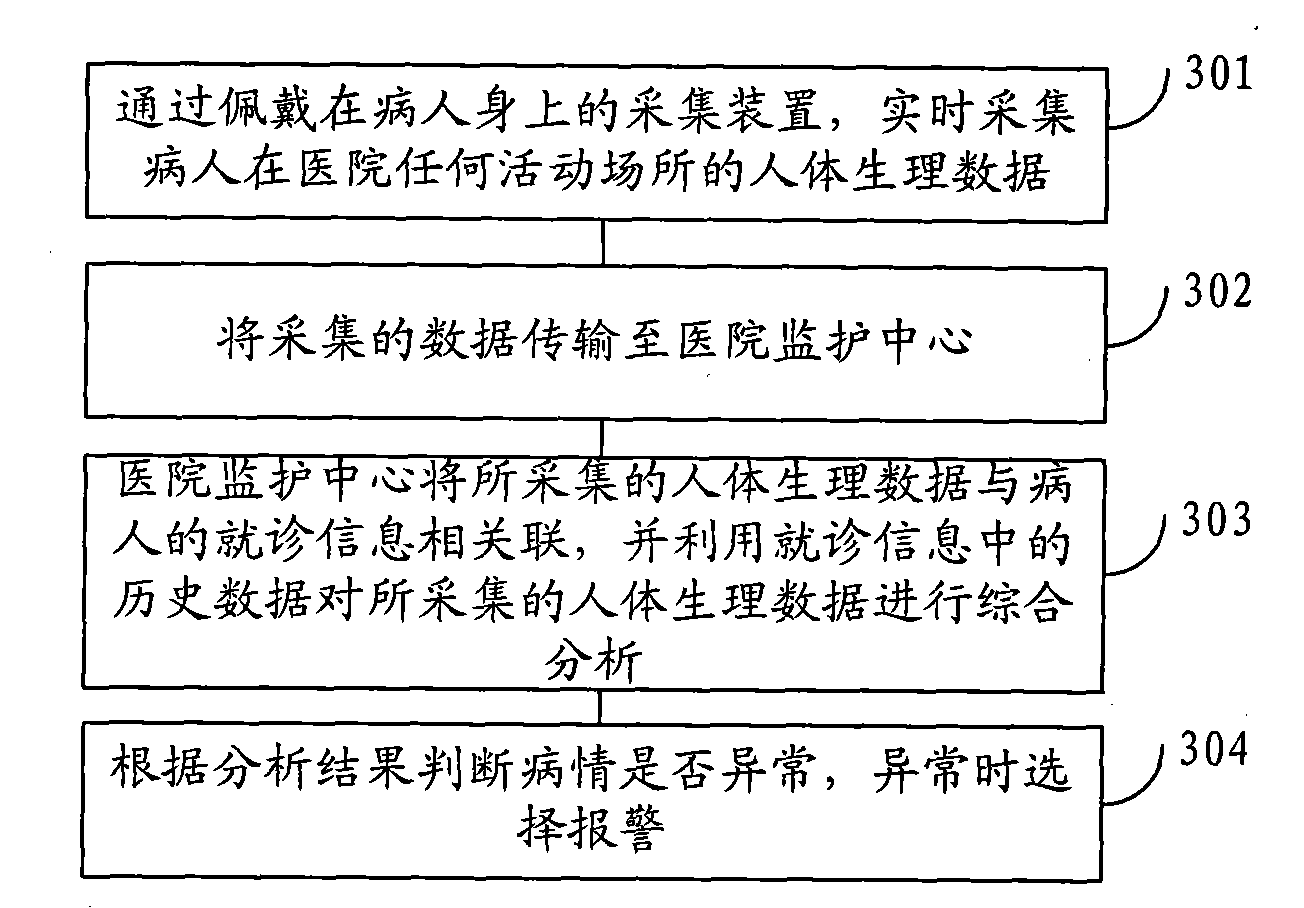

Method and system of wireless medical monitoring

InactiveCN102038548AEasy to moveAvoid accidentsSurgeryDiagnostic recording/measuringHuman bodyAcquisition apparatus

The invention provides a method and system of wireless medical monitoring which can be used anytime and anywhere to carry out wireless monitoring to patients in hospital and revisiting after discharge. The method comprises: acquiring human body physiology data of patients at any place in hospital in real time through an acquisition apparatus adorned on patients and transmitting the data to a monitoring center of the hospital; associating by the hospital monitoring center the acquired human body physiology data with medical information of patients, carrying out an integrate analysis of the acquired human body physiology data by utilizing historical data of medical information; determining whether condition is abnormal in dependence on analysis results and alarming when in abnormity. The method and system raise free degree of monitoring and change the situation that in traditional monitoring mode patients are constrained in ward beds, besides, they can carry out a whole course tracking and monitoring to patients after discharge and realize integration of wireless monitoring in hospital and rehabilitation tracking after discharge, thereby easily solving the problem of revisiting hard for patients after discharge at present.

Owner:PEKING UNIV

Trivalent chromic rainbow color passivating agent for galvanizing and its production

ActiveCN1584117ANo pollutionLarge operating rangeMetallic material coating processesRainbowNitrogen dioxide

A trivalent chromic ion iridescent passivating agent for galvanizing and its preparing method are disclosed. It consists of trivalent chromic salt, chelating agent, oxidant, the mol ration is 1:1:2.5-1:2:5.5, the trivalent chromic ion concentration in passivating groove liquid is 2.5-25g / L. It is prepared by adding the components into reactor, heating, mixing and chelating reacting, boiling and back-flowing to remove nitrogen dioxide after reacting, adding water and adjusting to obtain passivating agent concentrate with Cr3+ ionic concentration 30-80g / l after discharging. It achieves no pollution and wide range.

Owner:江西伟邦化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com