Lithium battery self-discharge screening method

A screening method and self-discharge technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems that the voltage of the battery is difficult to reach the true value and the accuracy is low, and achieve a short detection period, convenient production and operation, and method easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

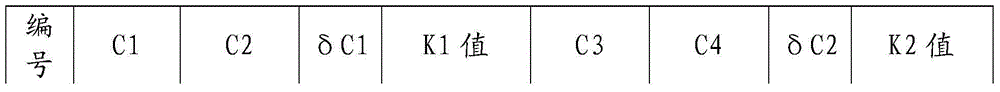

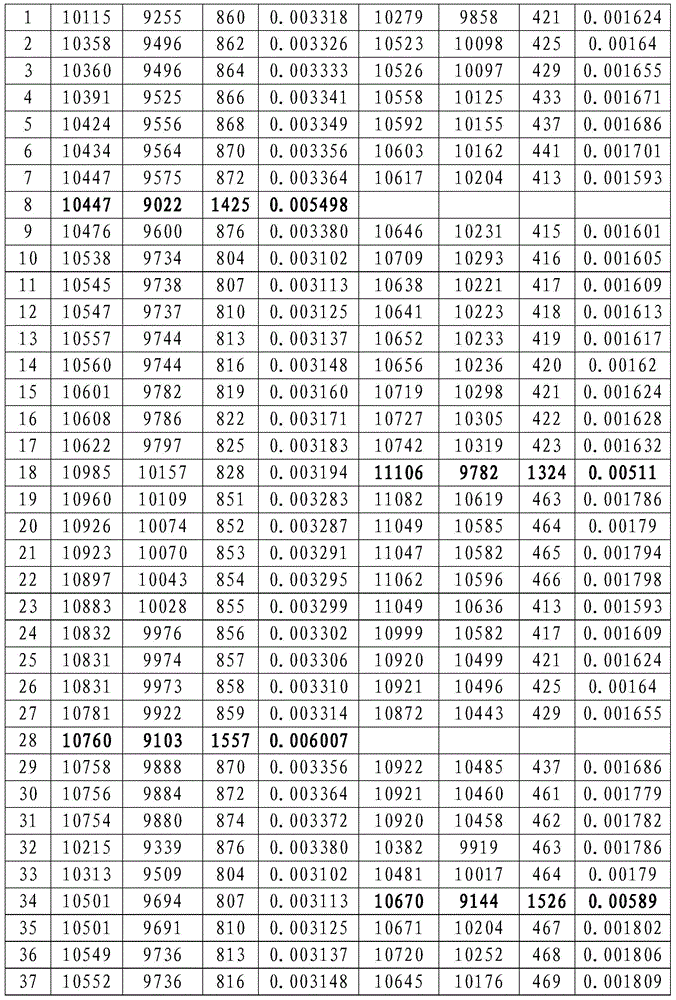

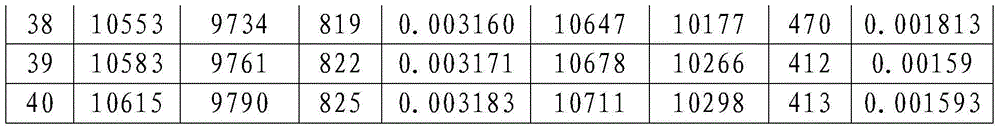

[0023] The embodiment of the present invention provides a lithium battery self-discharge screening method, which specifically includes the following steps:

[0024] (1) After the battery filled with electrolyte is left to stand for a certain period of time, the pre-charge formation is started, and the total battery capacity C1 after the pre-charge formation is recorded;

[0025] (2) Place the pre-charged battery in a constant temperature and normal pressure workshop at 48-52°C for aging, and the aging time T1 is 2-3 days;

[0026] (3) After the aging time is up, take the battery out and place it under normal temperature and pressure for a certain period of time to fully reduce the battery temperature to normal temperature;

[0027] (4) Under the normal temperature environment, the battery is discharged with a constant current until its voltage value is V1 and then stopped, then the battery is charged with the same constant current until the cut-off voltage is V2 and the cut-of...

Embodiment 2

[0035] (1) Take 30 10Ah lithium batteries to be converted into, charge the batteries at a constant current of 0.2A for 5 hours in an environment of normal temperature and pressure, and then charge them at a constant current of 2A for 3 hours, and record the charging capacity C1 of the batteries;

[0036] (2) Then, put the battery in a normal pressure environment at 50°C for 3 days;

[0037] (3) After the time is up, take out the battery, take out the battery and place it under normal temperature and pressure for 8-15 hours to fully reduce the battery temperature to normal temperature;

[0038] (4) When discharging the battery with a constant current of 10A to 2.5V in an environment of normal temperature and pressure, stop discharging, record the discharge capacity C2 of the battery, and then charge the battery with a constant current of 10A and constant voltage in an environment of normal temperature and pressure Stop charging when the cut-off voltage is 3.7V and the cut-off c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com