Discharging method of new energy automobile for bus high voltage

A new energy vehicle, bus voltage technology, applied in electric vehicles, current collectors, electrical devices, etc., can solve the problems of bus voltage rise, high voltage risk, etc., and achieve the effect of rapid discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

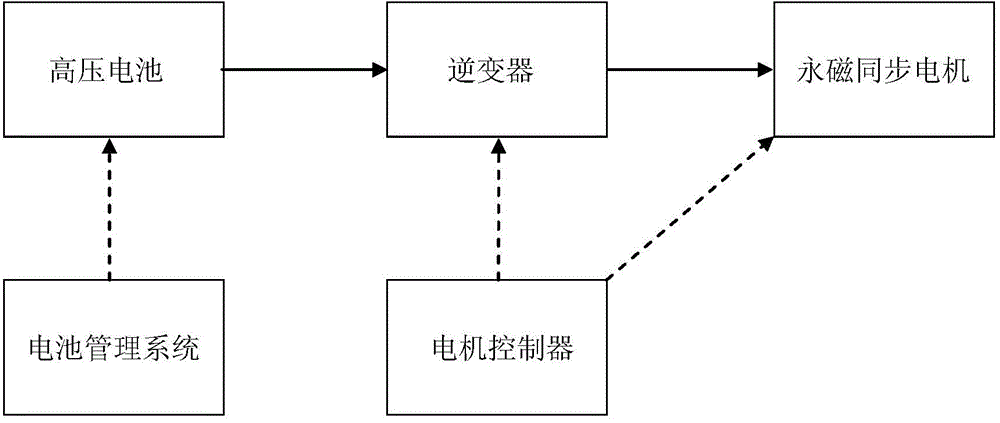

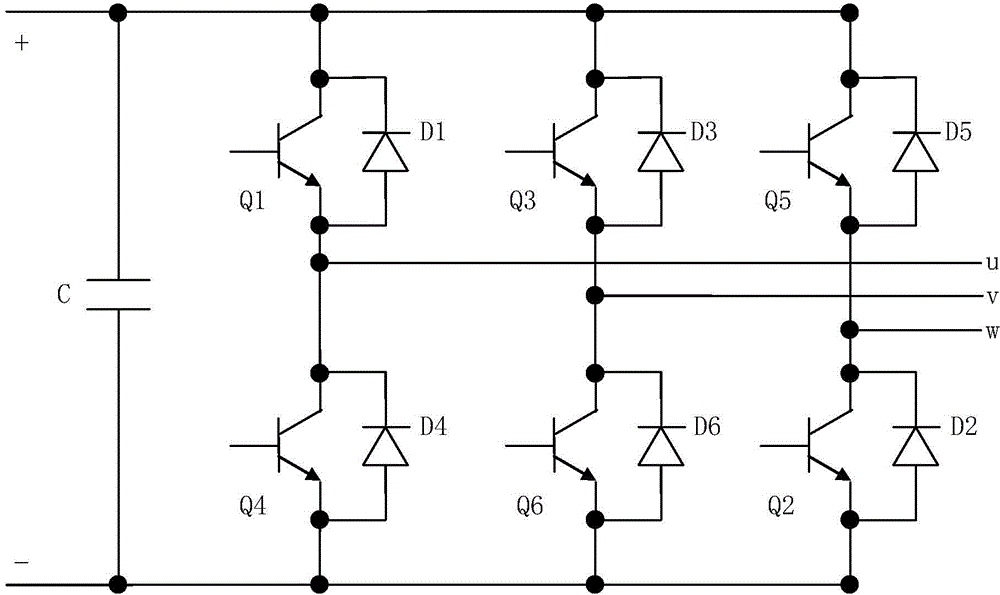

[0025] see figure 1 , The busbar high-voltage discharge system of the new energy vehicle of the present application is a high-voltage battery, a battery management system, an inverter, a motor controller, and a permanent magnet synchronous motor commonly used in new energy vehicles. On this basis, there is no need to add additional hardware structures such as discharge resistors and DC-DC converters, thereby achieving the lowest cost.

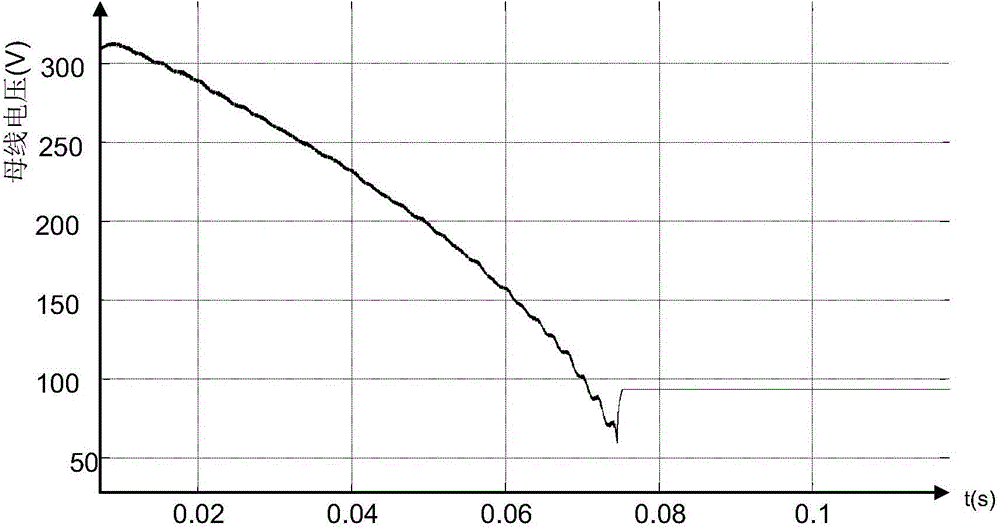

[0026] see Figure 4 , the method for discharging the high voltage of the busbar by the new energy vehicle of the present application comprises the following steps:

[0027] In the first step, when the ignition switch is turned off or the vehicle collides and other severe working conditions occur, the vehicle controller sends a command to discharge the high voltage of the bus to other node units. After receiving the discharge instruction, the battery management system disconnects the connection between the high-voltage battery and the input t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com