Patents

Literature

70 results about "Discharge instructions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Most patient-specific discharge instructions still contain only free text. How to provide visual aid to these discharge instructions is a research question that we are trying to answer. As a first step, we conducted a pilot study to develop pictographs for discharge instructions and test their efficacy in improving patient comprehension and recall.

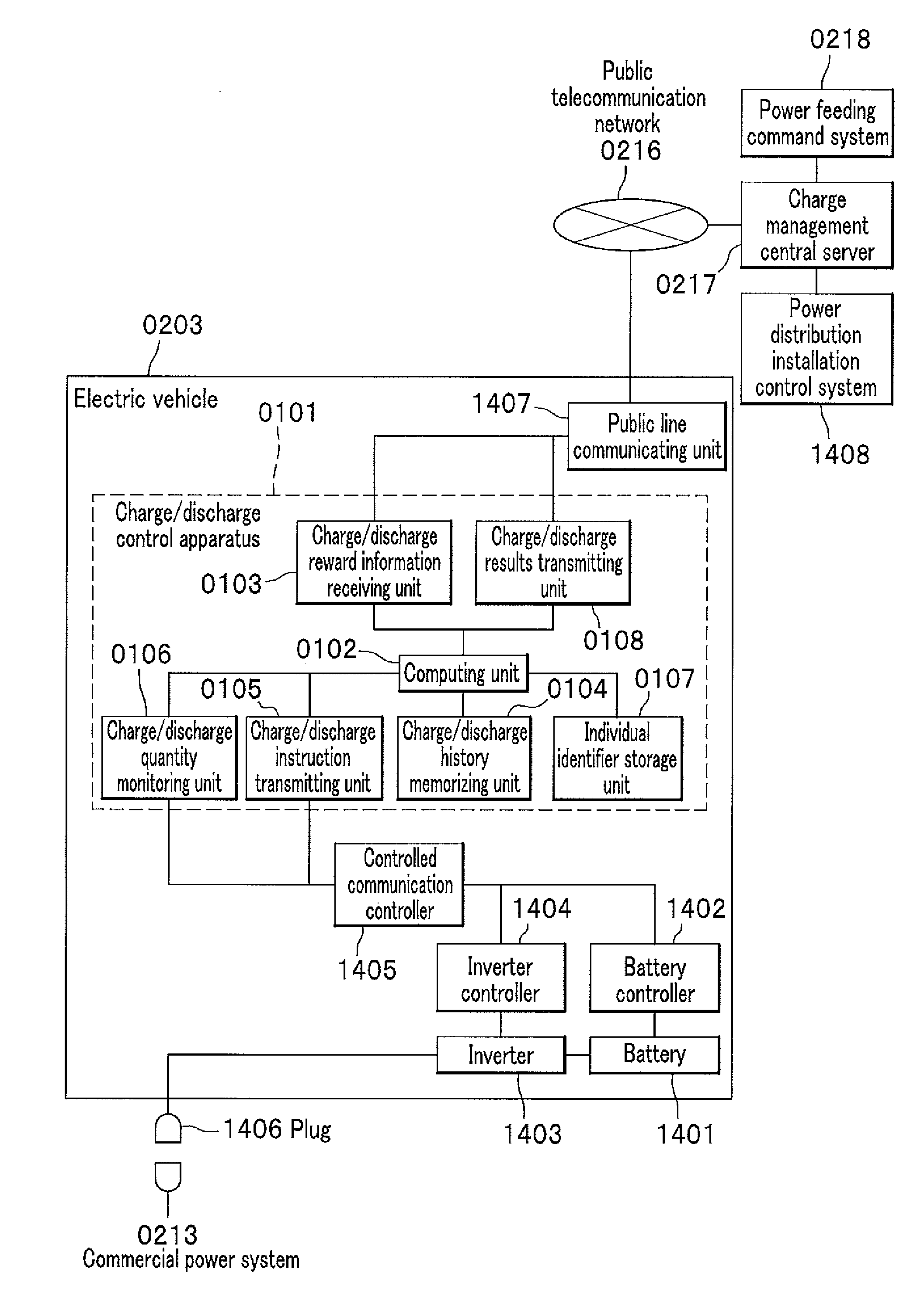

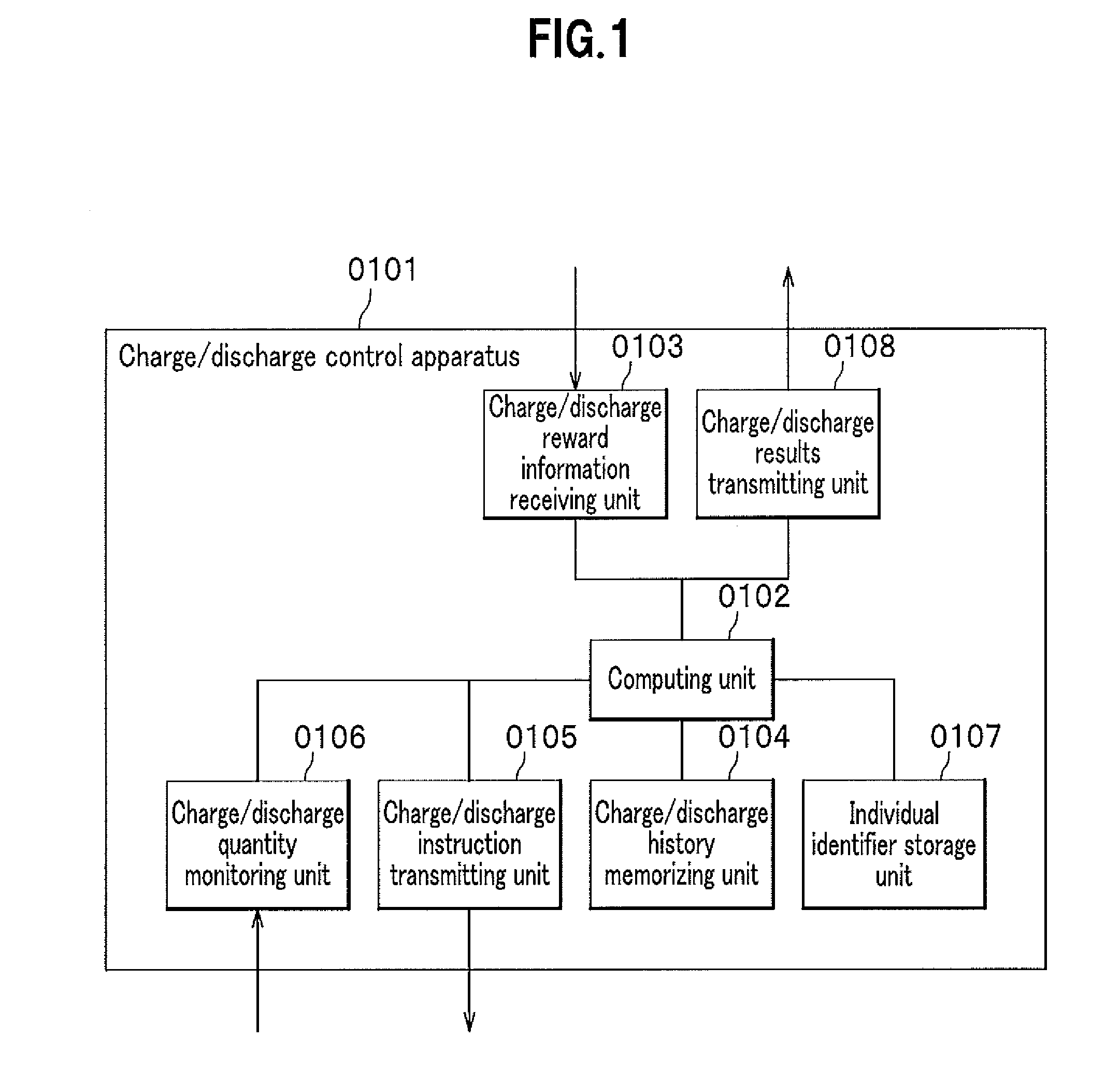

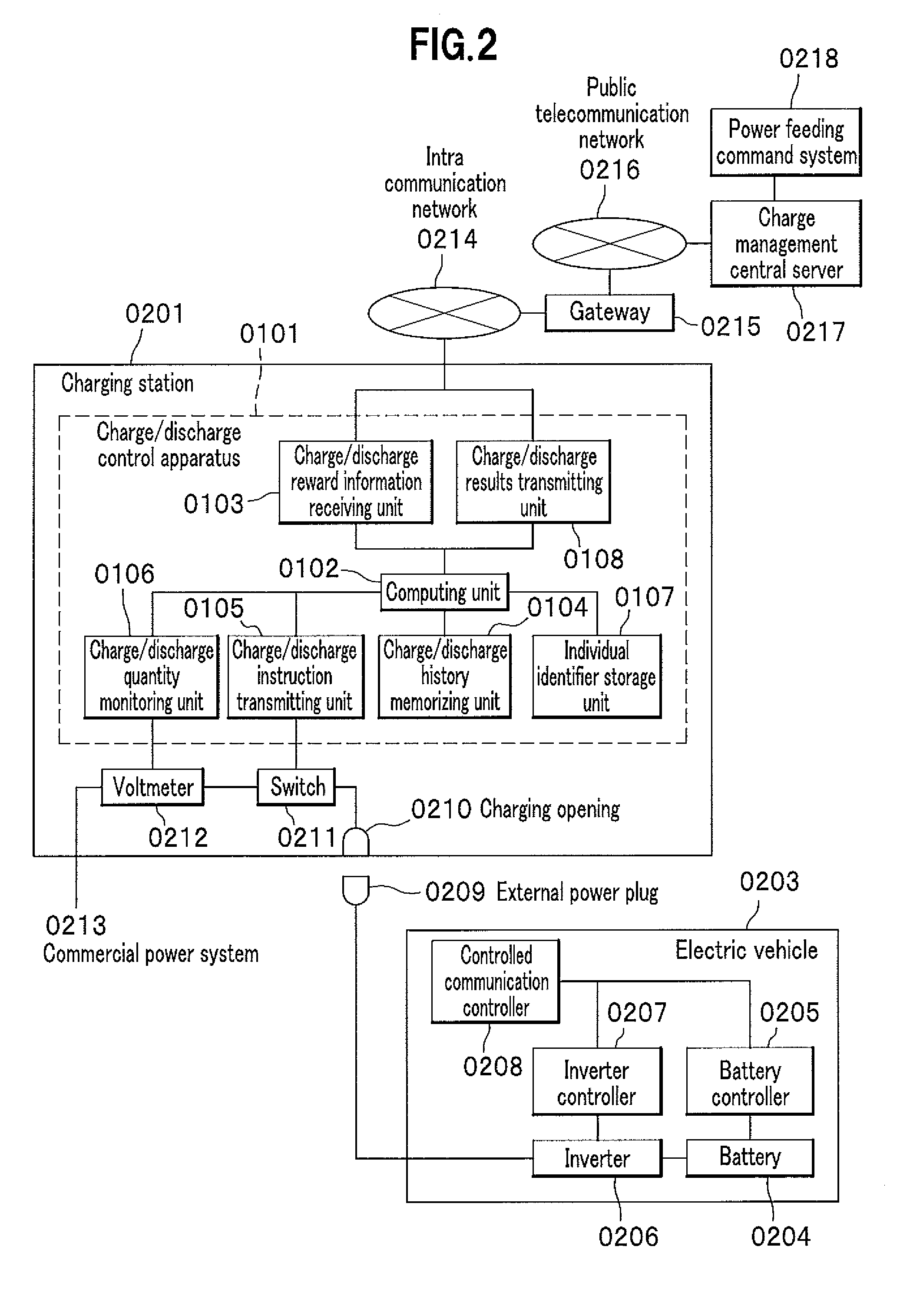

Charge/discharge control apparatus

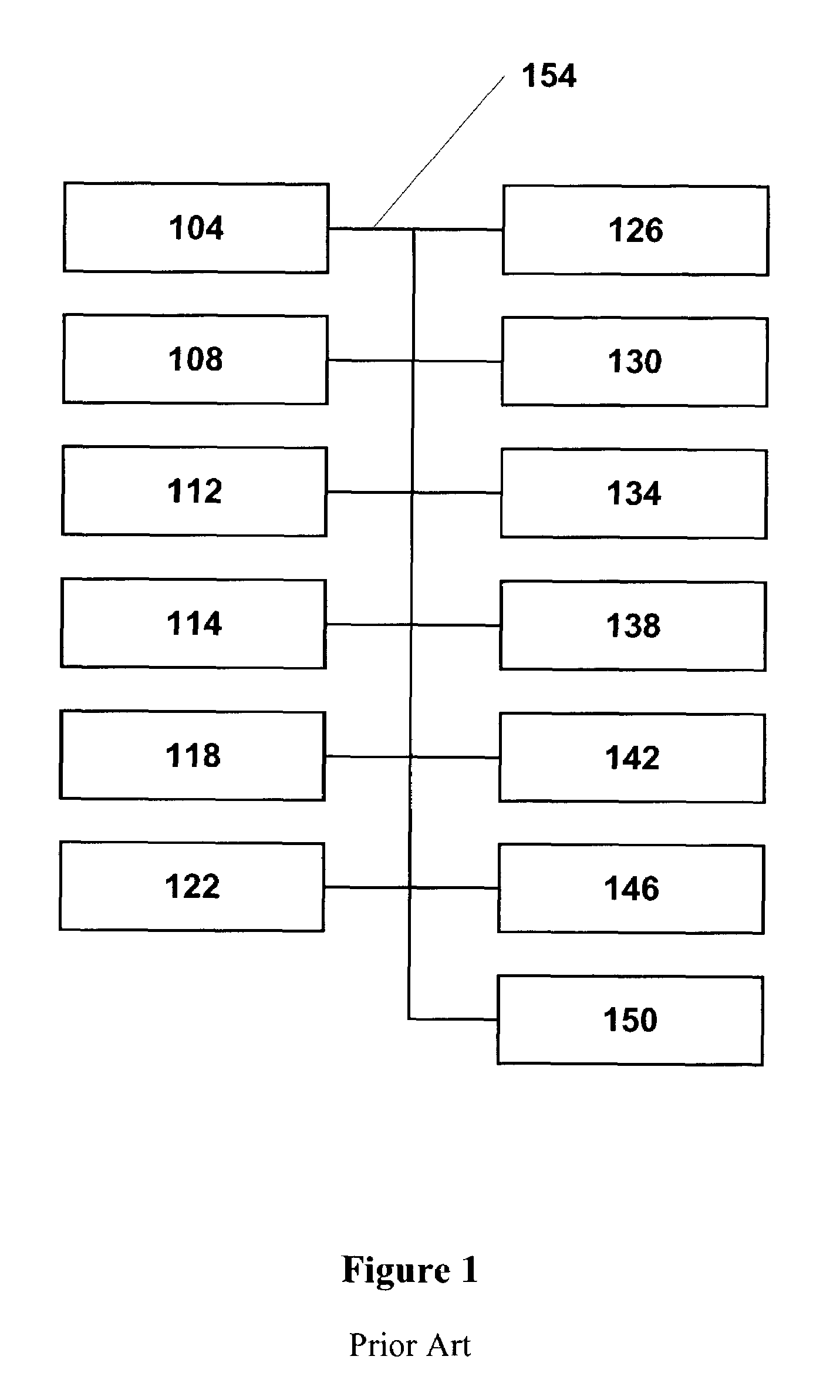

ActiveUS20100076825A1Reduce flat electric power rateReduced power ratingHybrid vehiclesBatteries circuit arrangementsStart timeDischarge plans

A charge / discharge control apparatus includes: a charge / discharge reward information receiving unit for receiving charge / discharge reward information representing a reward given to a charge / discharge action of a customer and a restriction in conducting a charging / discharging from a charge management central server; a computing unit for creating a charge / discharge plan including a total charging quantity in a time zone and an estimated use start time of an electric vehicle such that a reward is maximized, based on the charge / discharge reward information; a charge / discharge instruction transmitting unit for instructing the electric vehicle to start or finish a charging / discharging according to the charge / discharge plan; a charge / discharge quantity monitoring unit for monitoring the charging / discharging; and a charge / discharge results transmitting unit for transmitting results of monitored charging / discharging including contents of the conducted charging / discharging and individual identification information for identifying itself, to a charge management central server.

Owner:HITACHI LTD

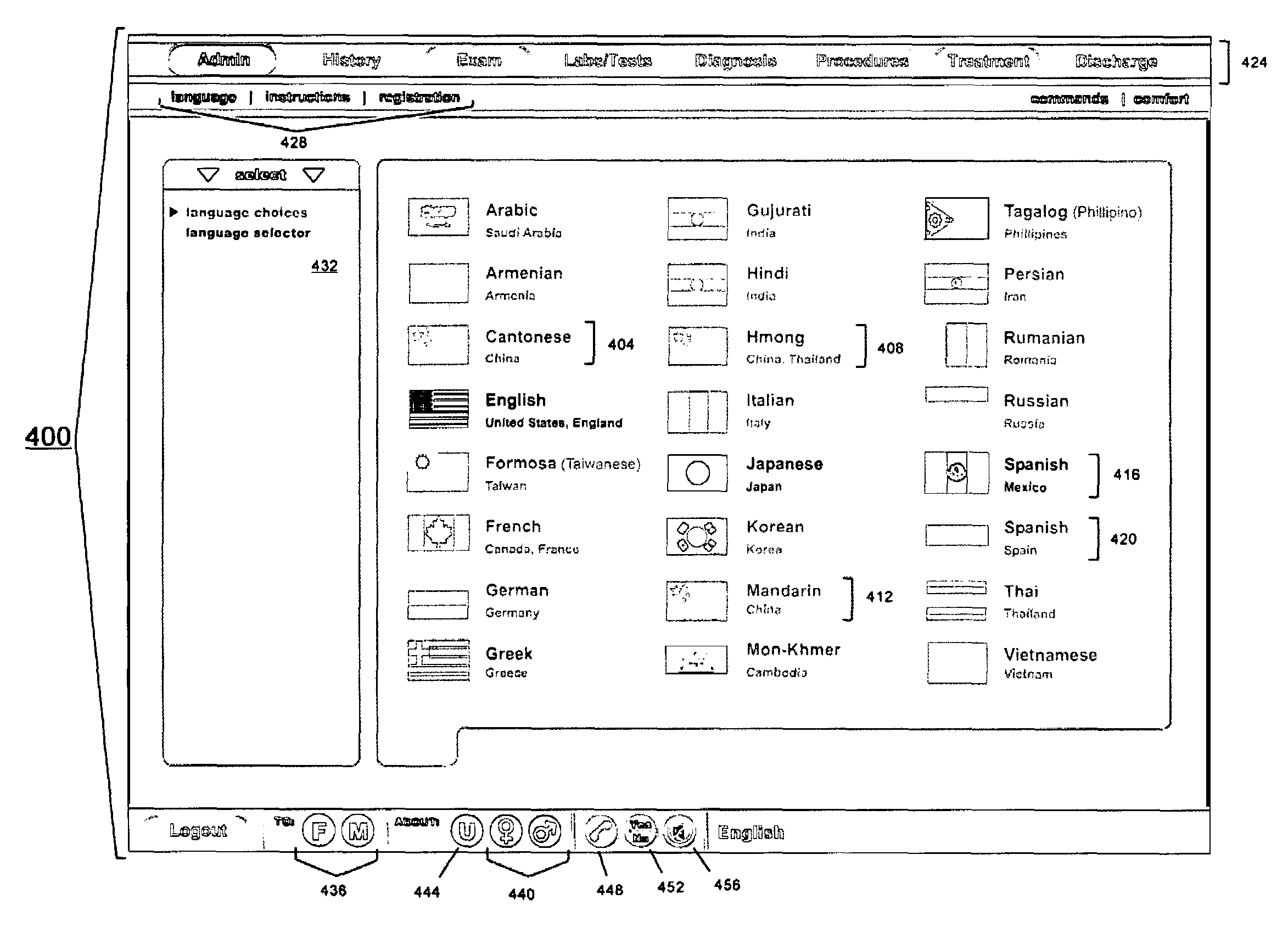

Inter-language translation device

ActiveUS7359861B2Facilitate communicationMinimization requirementsNatural language translationSpeech analysisComputerized systemContext sensitivity

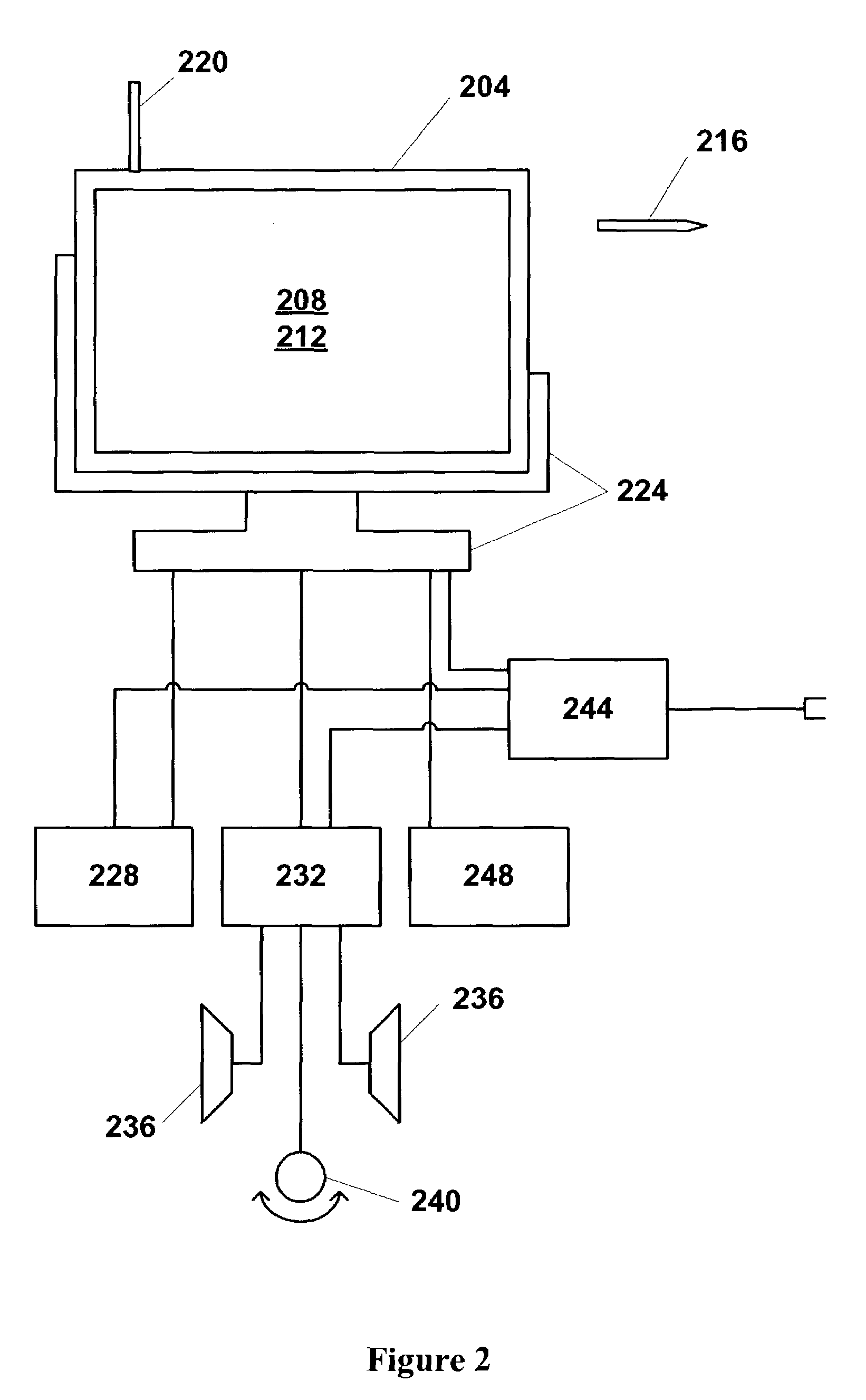

A computer system with an appropriate set of instructions to allow the computer system to serve as a translation device for use in a structured interview between an interviewer using a first language and an interviewee in a second language in order to minimize or eliminate that need for a human translator during the acquisition of routine information. Problems addressed include: determination of the appropriate language for use as the second language, the use of a single display screen through the use of a toggle function to toggle from the first language to the second language, delivery of context sensitive audio files while controlling the number of screens to be created and presented to the interviewer, and the creation of a set of discharge instructions. A preferred set of hardware and a mobile cart is discussed.

Owner:POLYGLOT SYST

Discharging method of new energy automobile for bus high voltage

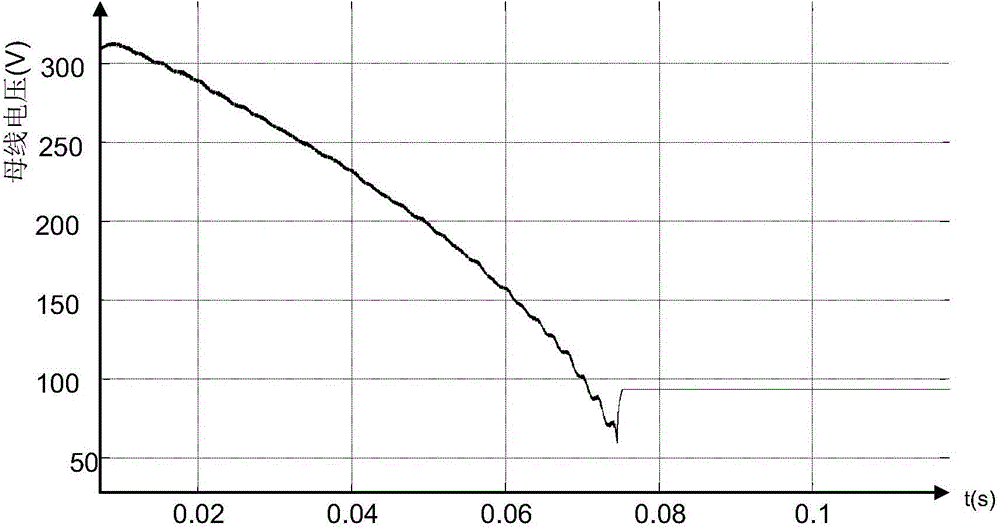

ActiveCN105270182ANo speed limit requiredExtend discharge timeBatteries circuit arrangementsElectric devicesCapacitanceNew energy

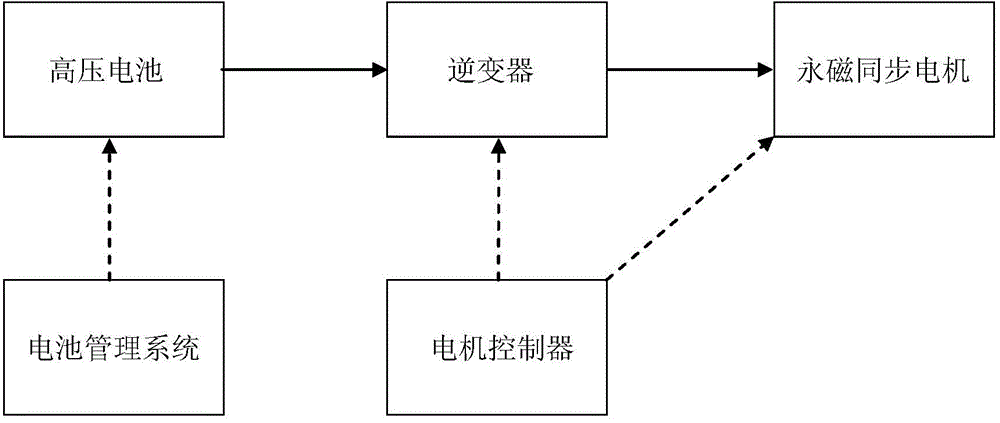

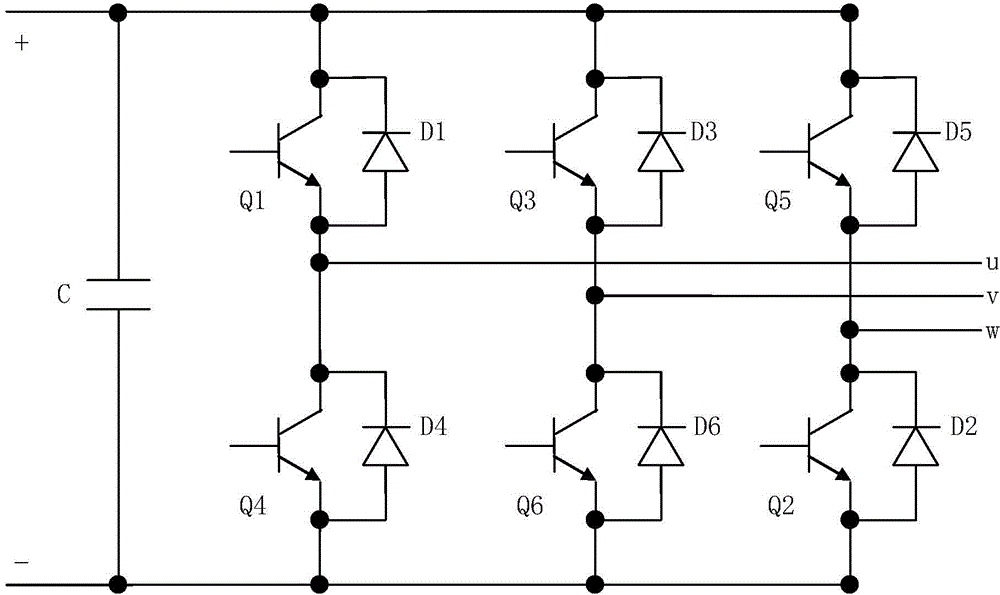

The invention discloses a discharging method of a new energy automobile for bus high voltage. The discharging method comprises the following steps that firstly, when a hybrid control unit(HCU) sends out a discharging instruction, a battery management system enables a high-voltage battery and an inverter to be disconnected; secondly, a motor controller controls six power switching devices in the inverter, so that the direct-axis current of a permanent magnet synchronous motor is reduced along with reduction of the bus voltage, the quadrature-axis current is zero all the time, and thus the energy of a bus capacitor is consumed inside the permanent magnet synchronous motor; and thirdly, when the bus voltage value is lowered to be within a safe voltage range within given time, the motor controller enables three phases of the permanent magnet synchronous motor to be initiatively shortly circuited, or the direct-axis current and the quadrature-axis current of the permanent magnet synchronous motor are made to be both zero, and otherwise, the motor controller enables the three phases of the permanent magnet synchronous motor to be initiatively shortly circuited and feeds back a discharging overtime fault to the HCU. By means of the discharging method, the discharging time is short, safety and reliability are achieved, and the bus voltage cannot rise again after discharging is completed.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

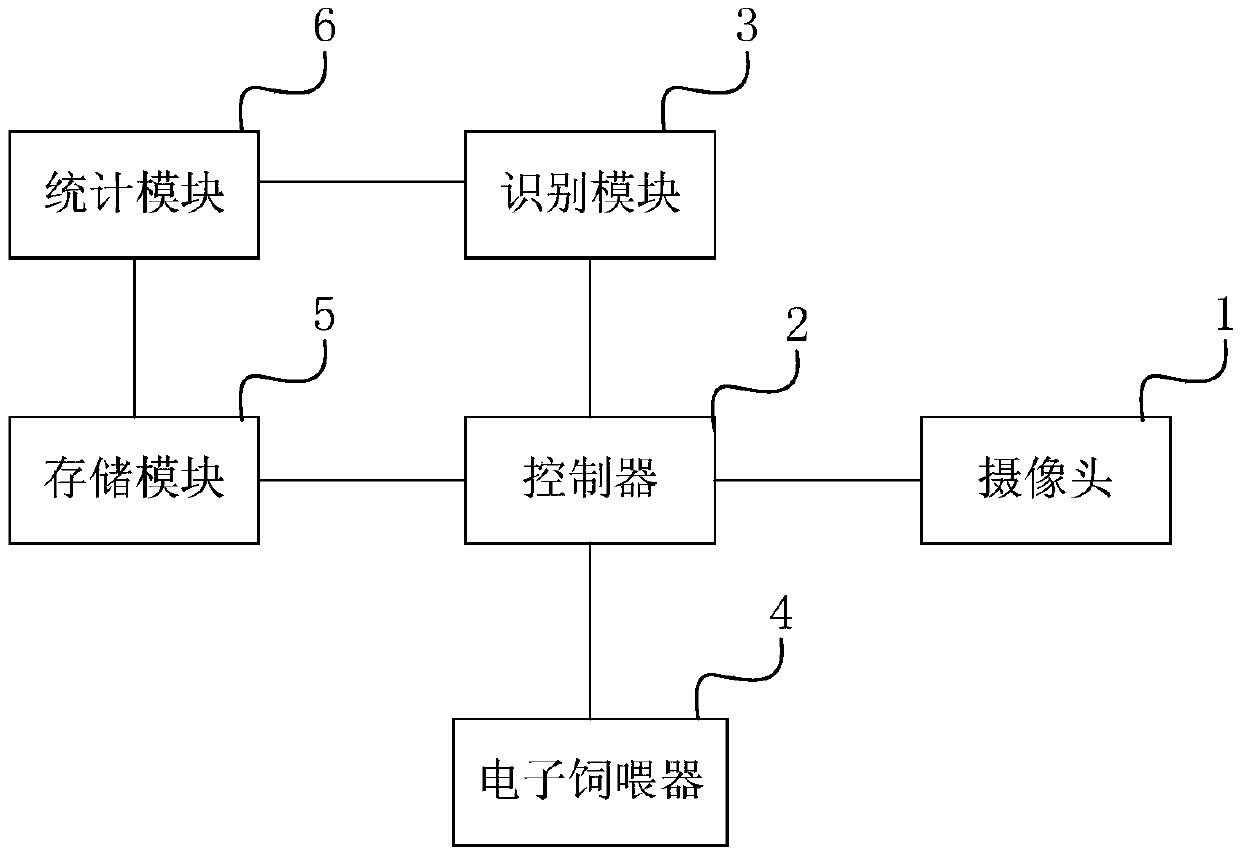

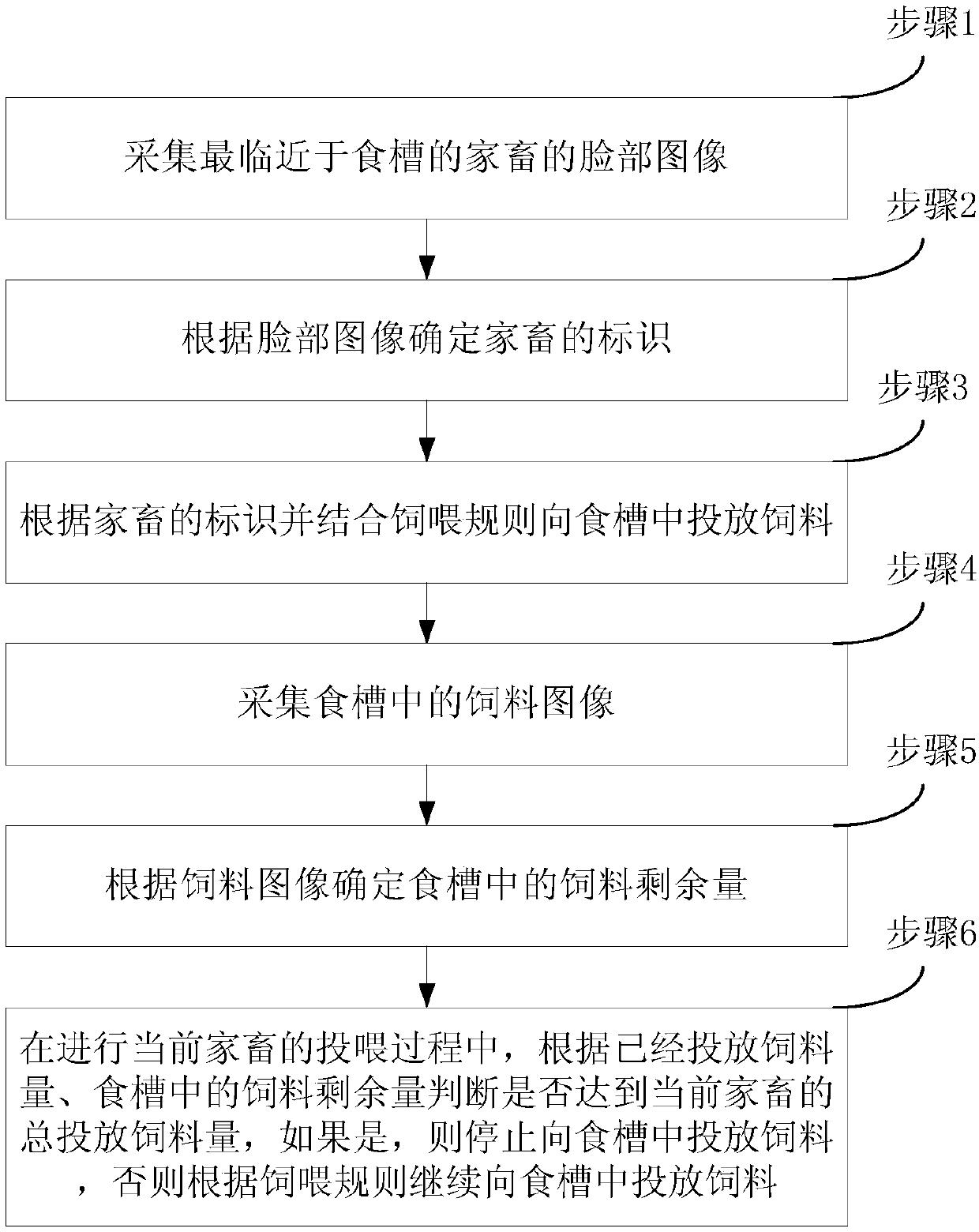

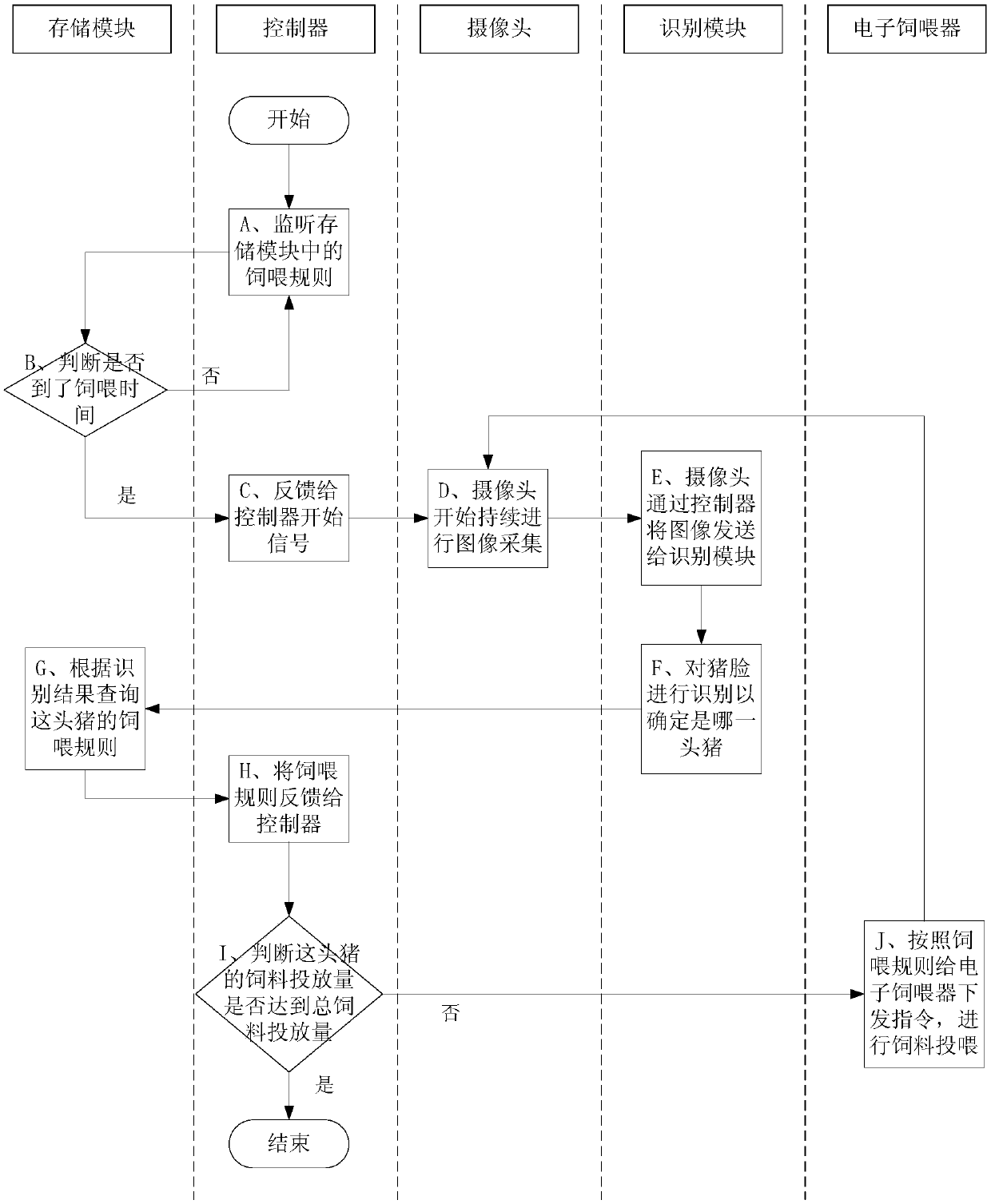

Intelligent feeding system and method for livestock

ActiveCN109618961AEasy to formulateEasy to adjustData processing applicationsAnimal feeding devicesComputer moduleComputer science

The invention discloses an intelligent feeding system and method for livestock. The system comprises a storage module, a camera, an identification module, an electronic feeder and a controller. The storage module is used for storing a feeding rule of livestock; the camera is installed above a trough and collects a face image of the livestock which are closest to the trough when a shooting instruction is received; the identification module is used for determining an identifier of the livestock according to the face image; the electronic feeder is installed on the trough and adds feed to the trough according to a received discharging instruction; the controller is used for sending the shooting instruction to the camera according to the feeding rule of the storage module, receiving the face image and a feed image from the camera, transmitting the face image and the feed image to the identification module, receiving the identifier of the livestock and the feed surplus amount of the troughfrom the identification module and sending the discharging instruction to the electronic feeder according to the identifier of the livestock in combination with the feeding rule. According to the intelligent feeding system, all the livestock are distinguished through a face identification technology of artificial intelligence, the livestock individuals are remotely and precisely fed and controlled, and the feeding rule is conveniently made and adjusted.

Owner:JINGDONG TECH HLDG CO LTD

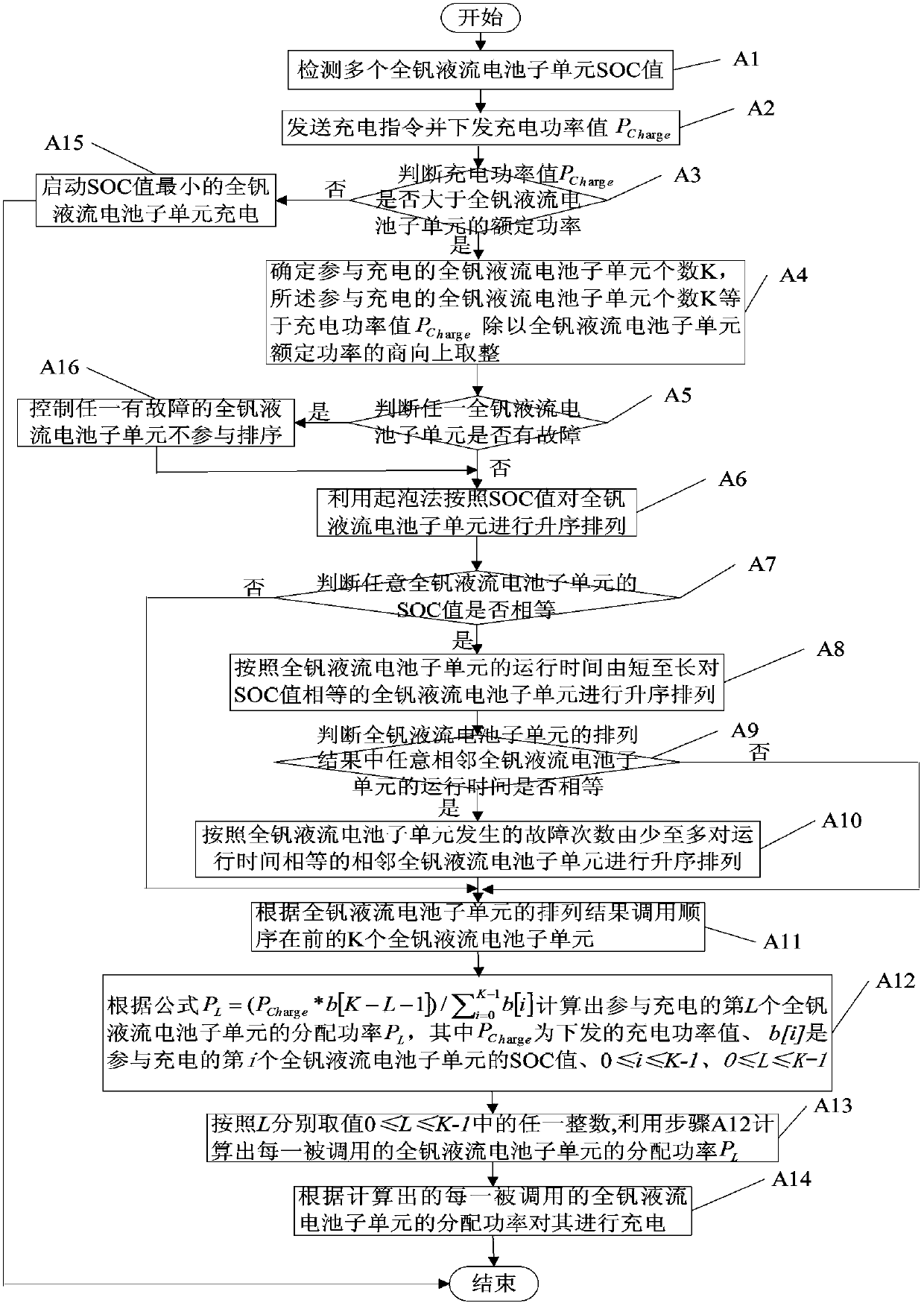

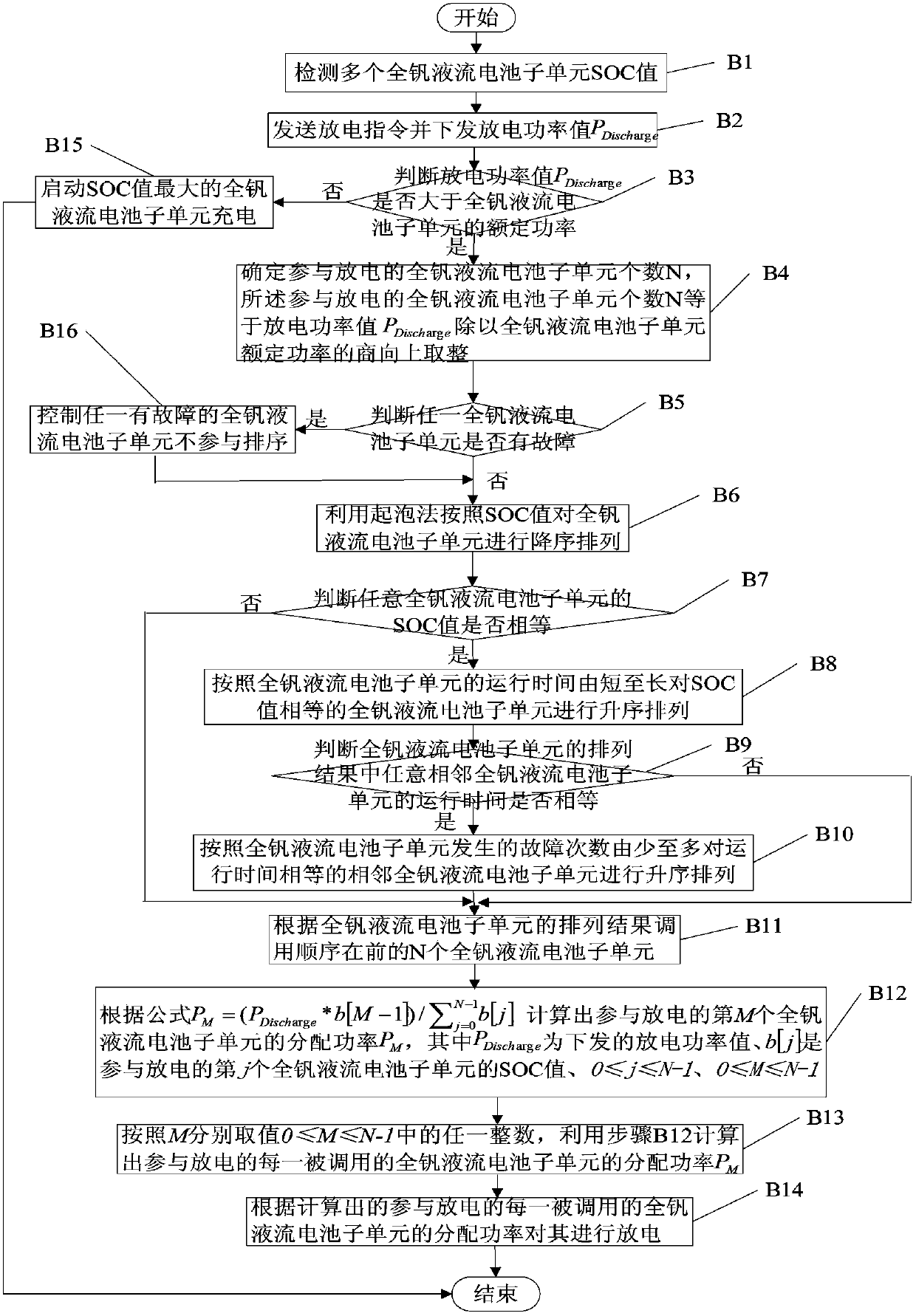

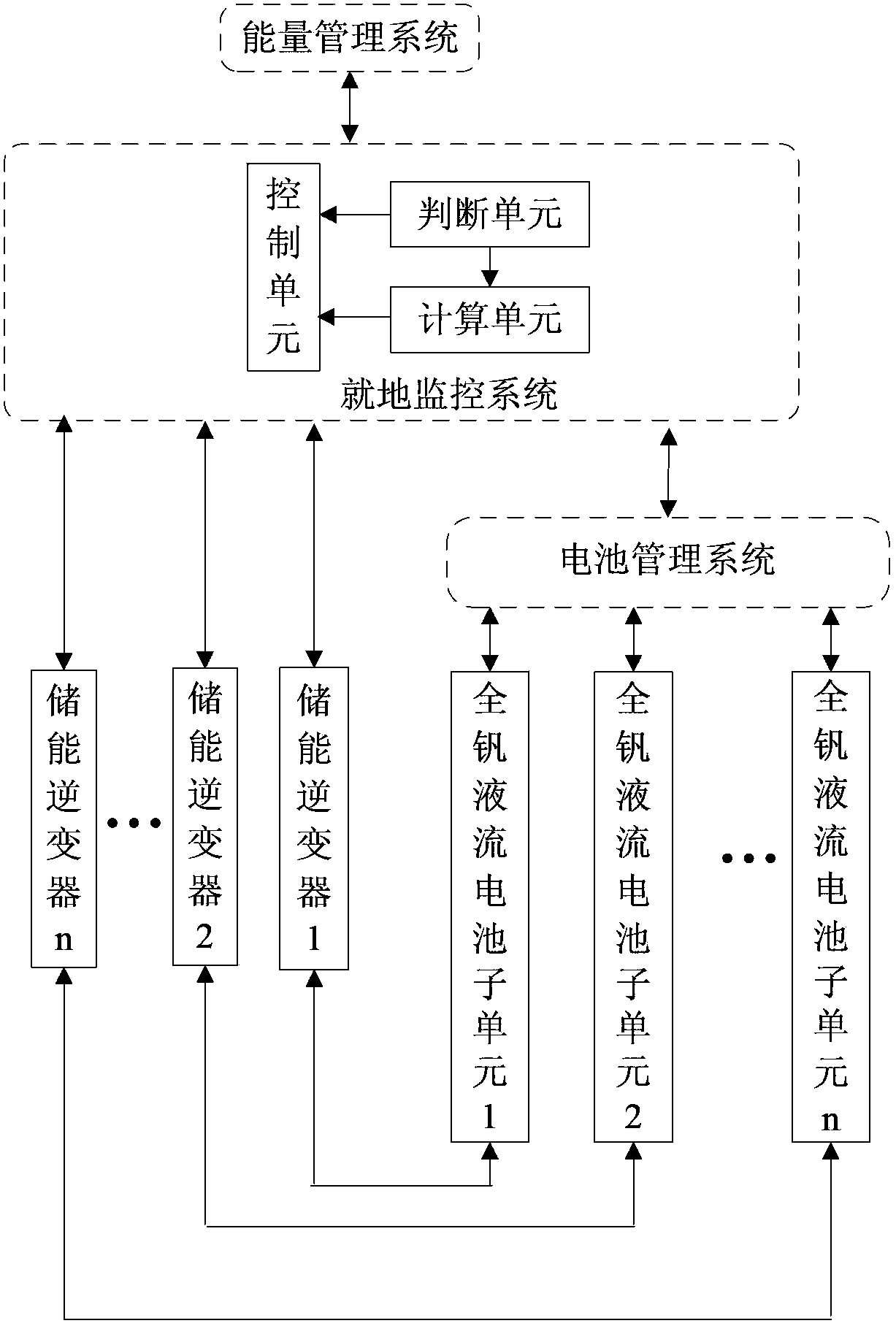

All vanadium redox flow battery management method and system applied to scale energy storage

ActiveCN103390920AEfficient managementImprove performanceBatteries circuit arrangementsElectric powerElectrical batteryDischarge instructions

The invention discloses an all vanadium redox flow battery management method and a system which are applied to scale energy storage. The system comprises an energy management system used for sending a charge instruction, issuing a charge power value PCharge, sending a discharge instruction and issuing a discharge power value PDischarge, a plurality of all vanadium redox flow battery subunits, a battery management system connected with the all vanadium redox flow battery subunits and used for detecting working states of the all vanadium redox flow battery subunits, a plurality of energy storage inverters connected with the all vanadium redox flow battery subunits respectively, and an in-situ monitoring system connected with the energy management system, the energy storage inverters and the battery management system respectively and comprising a judgment unit, a computing unit and a control unit. According to the method and the system, the service life of an all vanadium redox flow battery is prolonged, and charge states, the use frequency and the running time of the all vanadium redox flow battery subunits can be kept consistent conveniently.

Owner:DALIAN RONGKE POWER

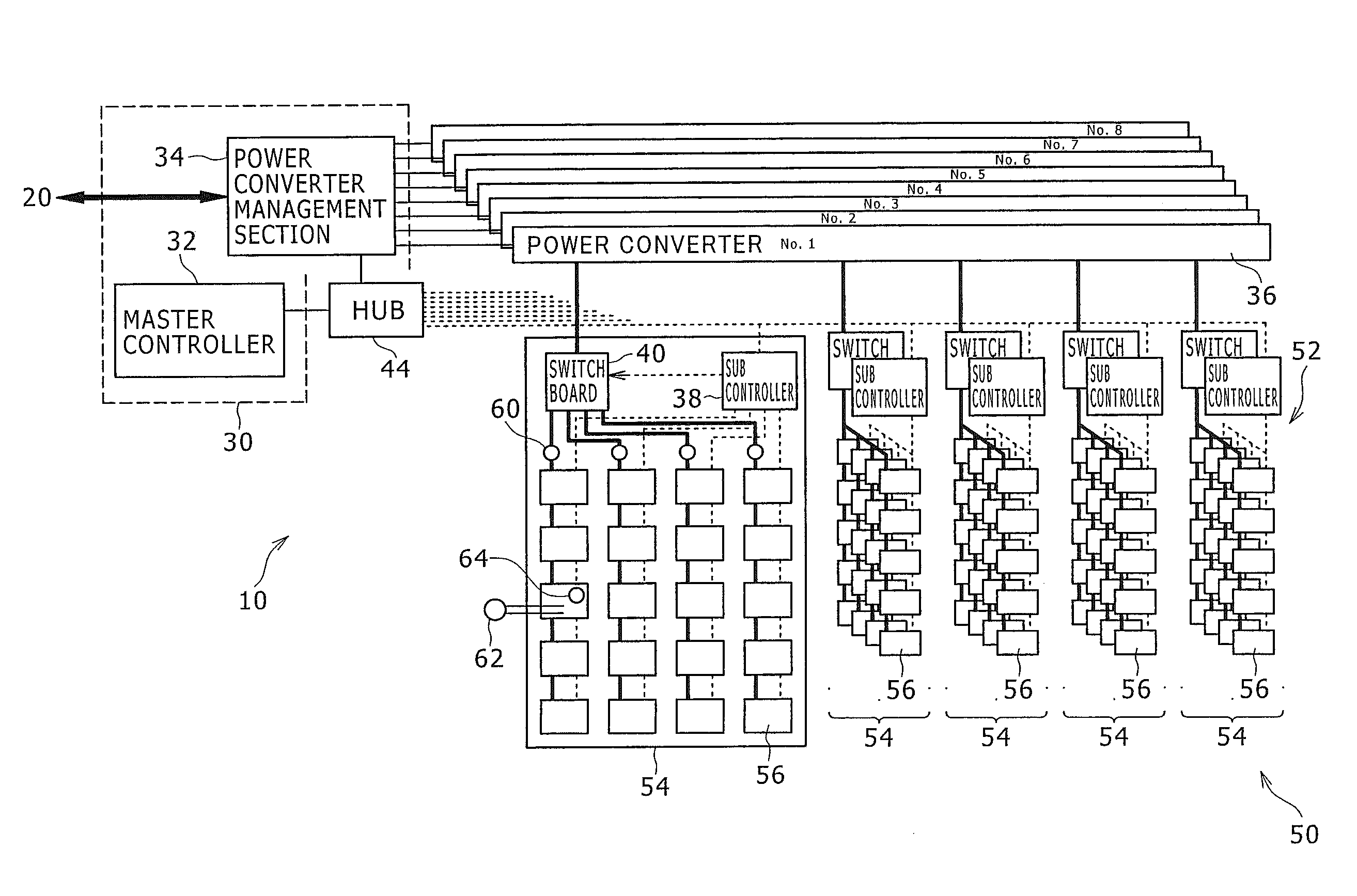

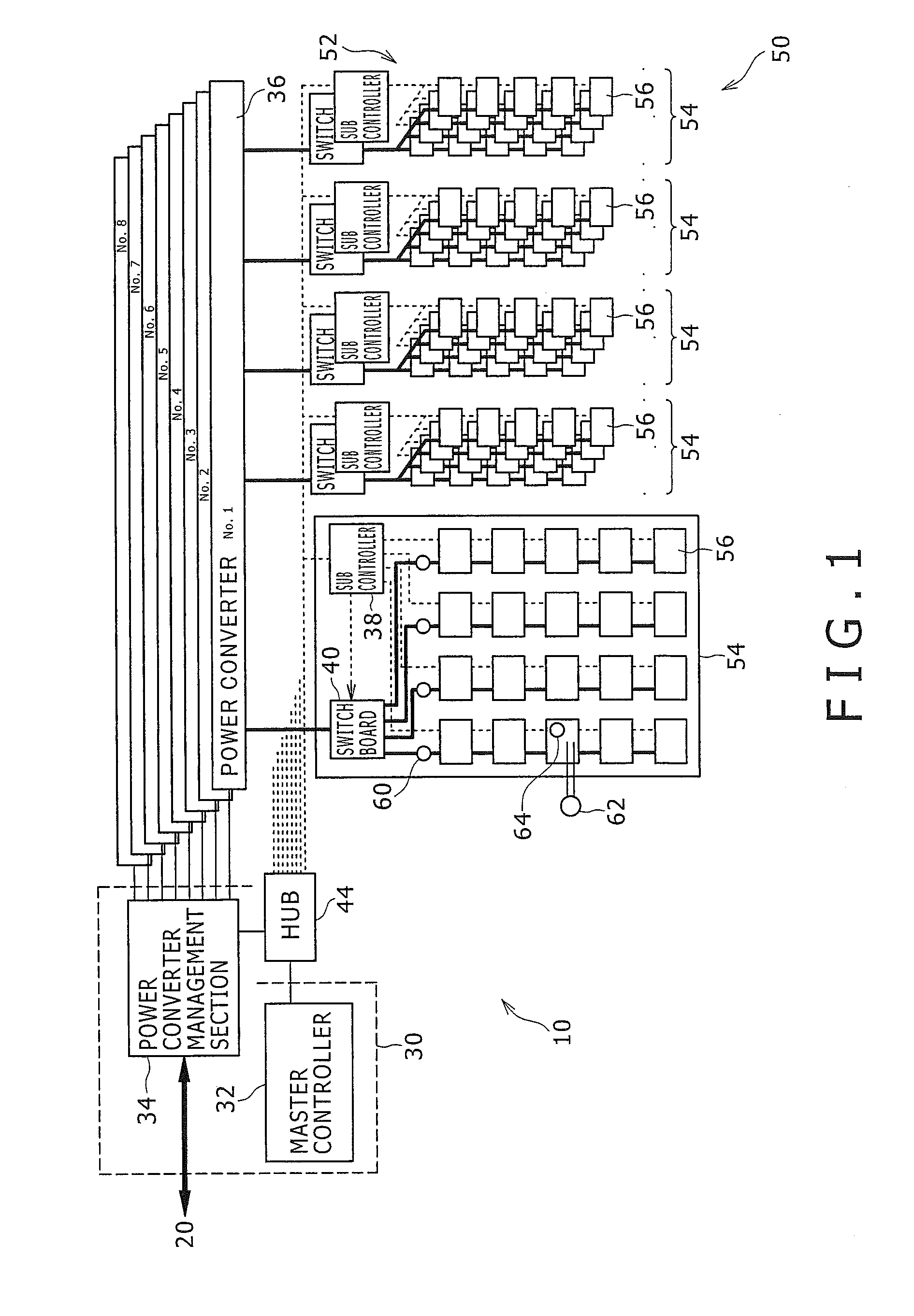

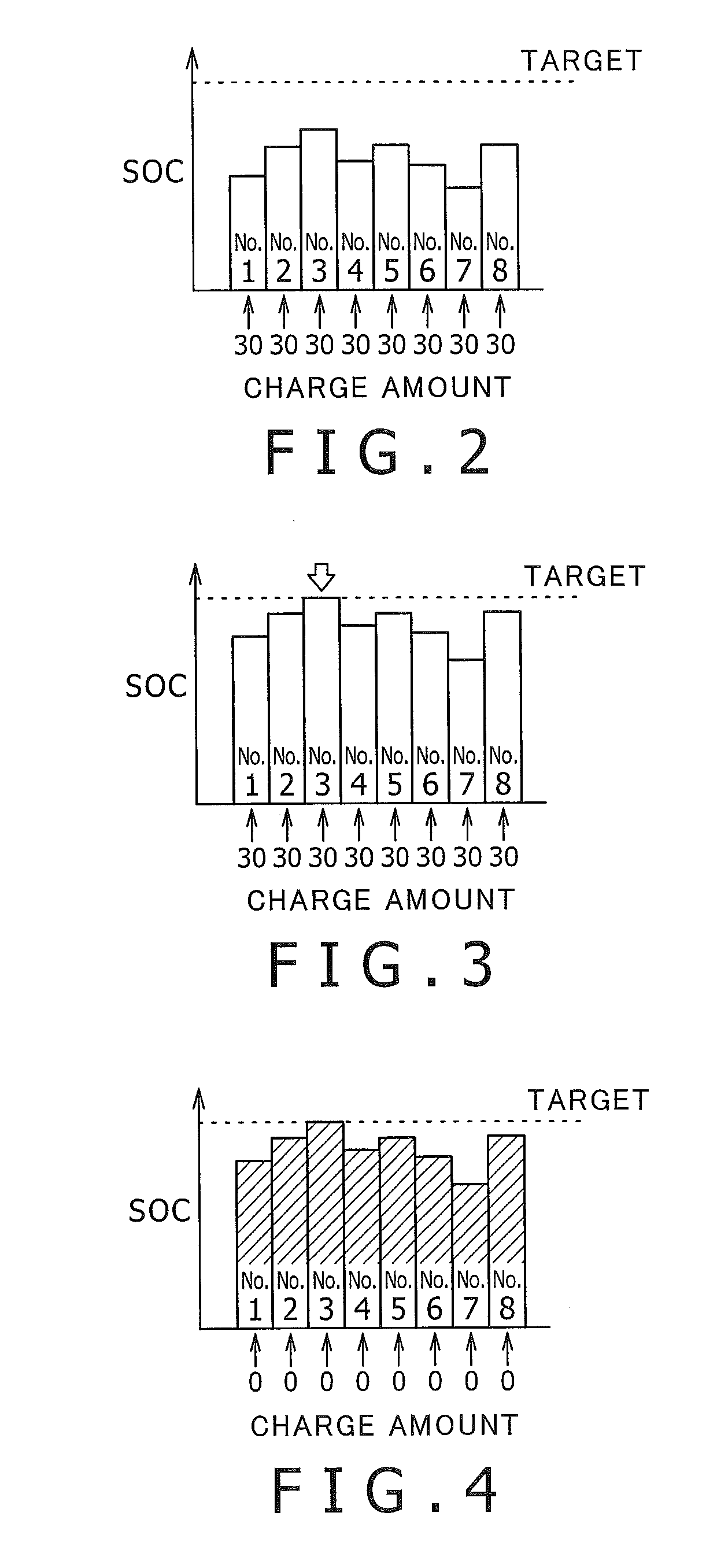

Battery charge and discharge control apparatus and method for controlling battery charge and discharge

A master controller of a battery charge and discharge control apparatus is a device performing charge and discharge control on a group of a predetermined number of battery arrays, the battery arrays being connected together in parallel. The master controller acquires an entire charge or discharge instruction intended for the entire battery array group, starts charging or discharging each of the battery arrays at a uniform charge or discharge power value, acquires a charge or discharge status of each of the battery arrays after the beginning of the charge or discharge and compares the charge or discharge status with a predetermined charge or discharge set value for the entire battery array group, and changes the charge or discharge power value of each of the battery arrays based on a result of the comparison.

Owner:SANYO ELECTRIC CO LTD

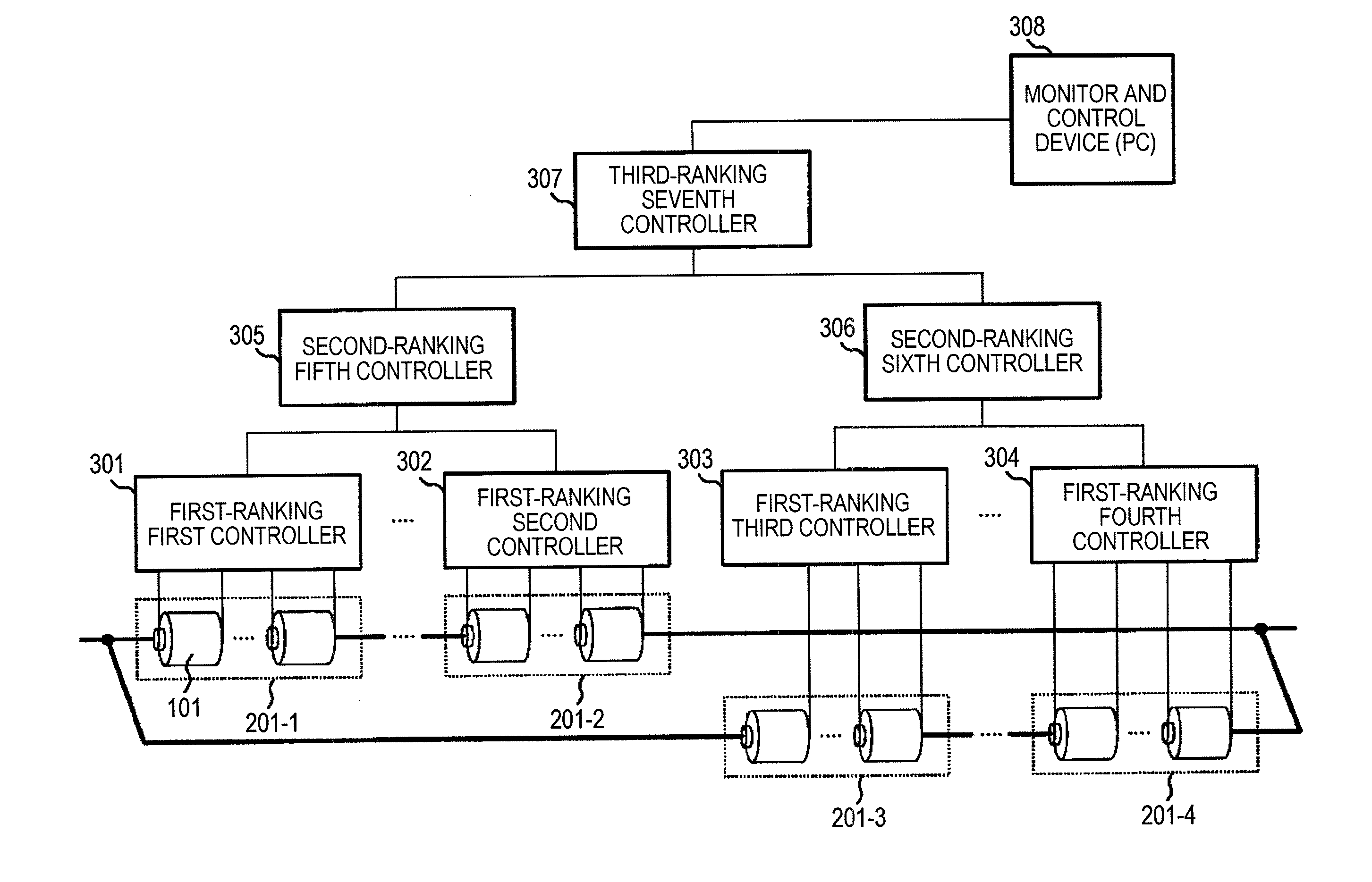

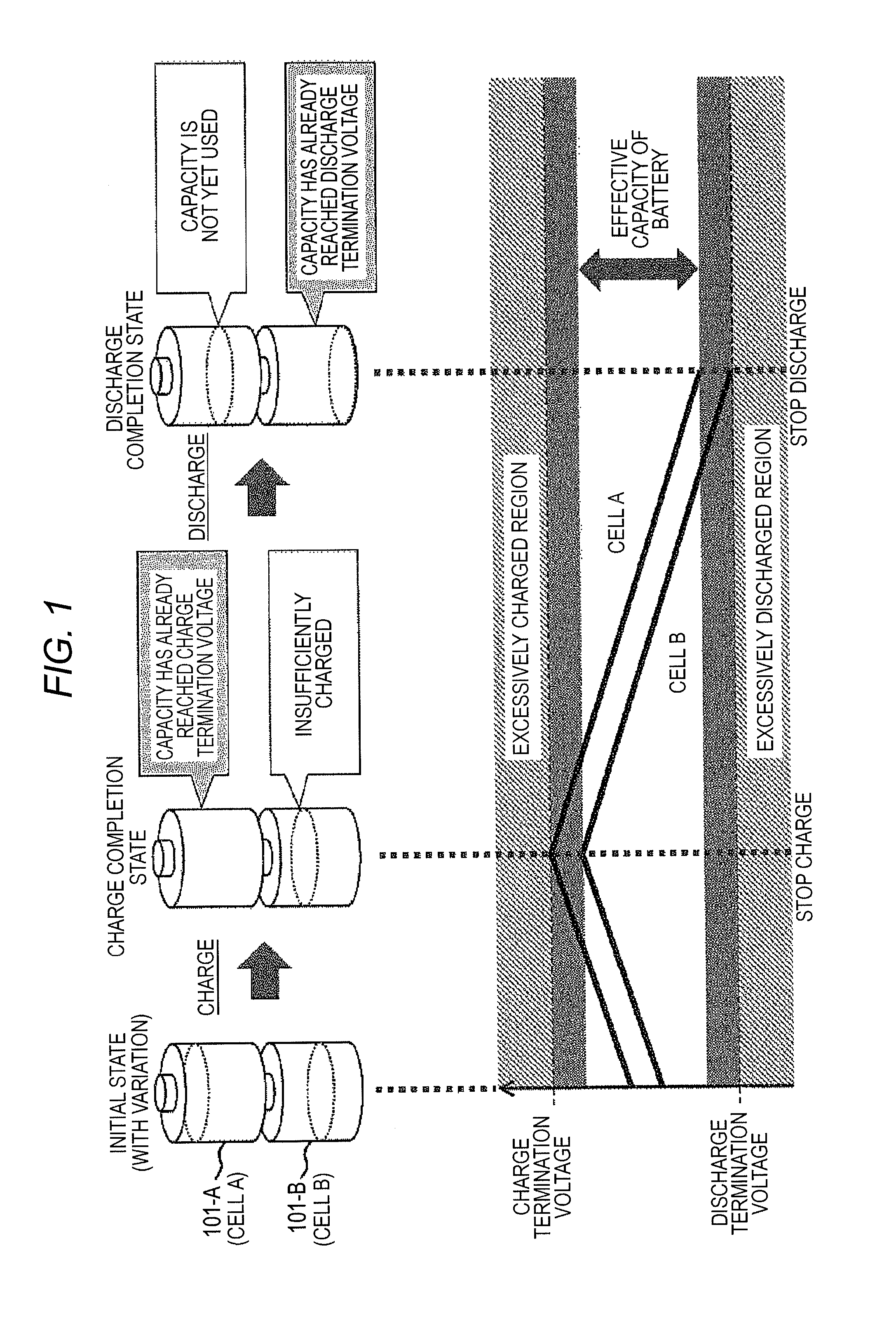

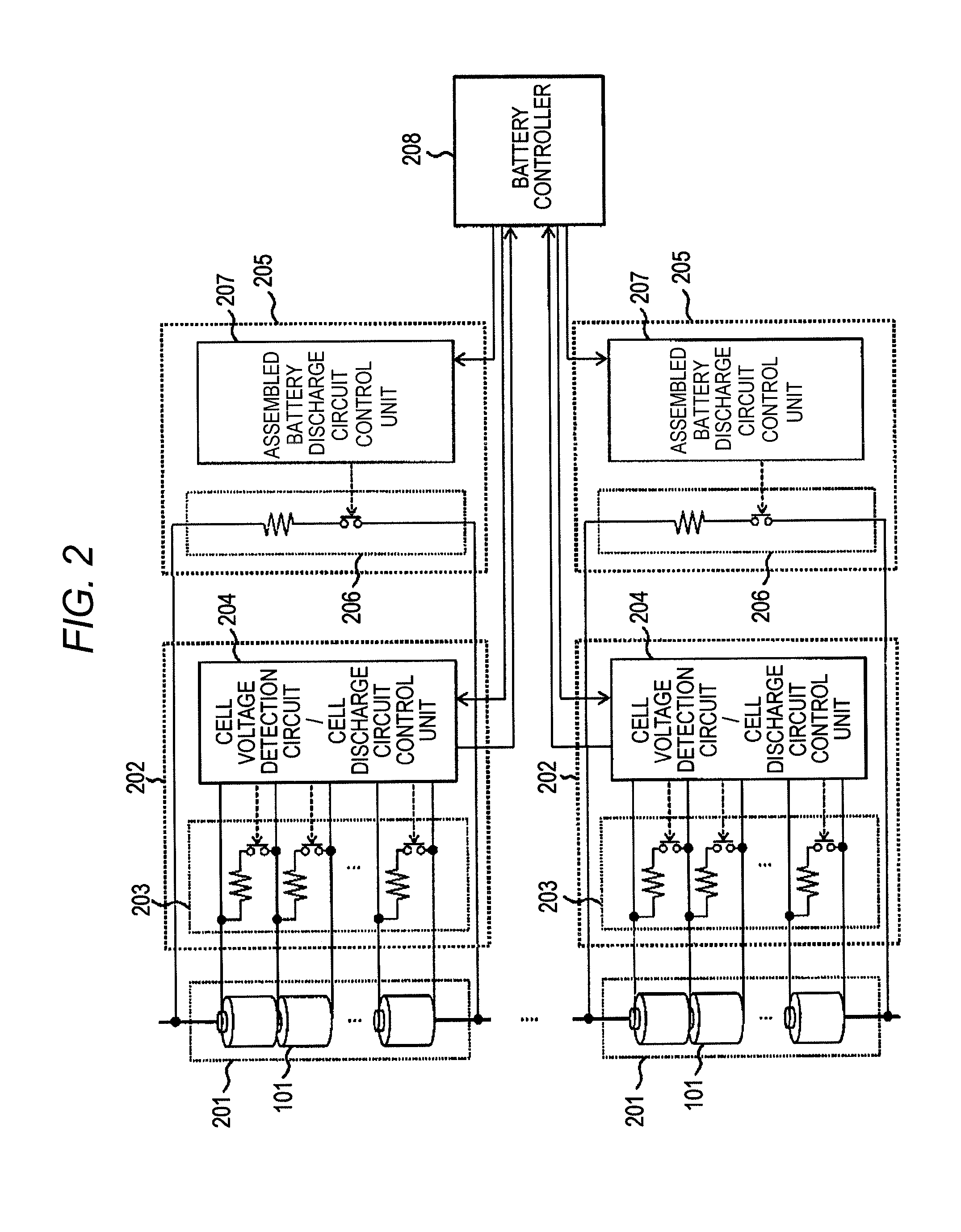

Battery System Control Method

InactiveUS20140079963A1Reduce the amount requiredLarge capacityCharge equalisation circuitCells structural combinationVoltage variationControl theory

The entire voltage of batteries is transmitted to a higher-ranking controller as information. The higher-ranking controller gives a discharge instruction or the like to a lower-ranking controller having a voltage higher than those of the other controllers. Thus, voltage variation of the respective batteries is balanced.

Owner:HITACHI LTD

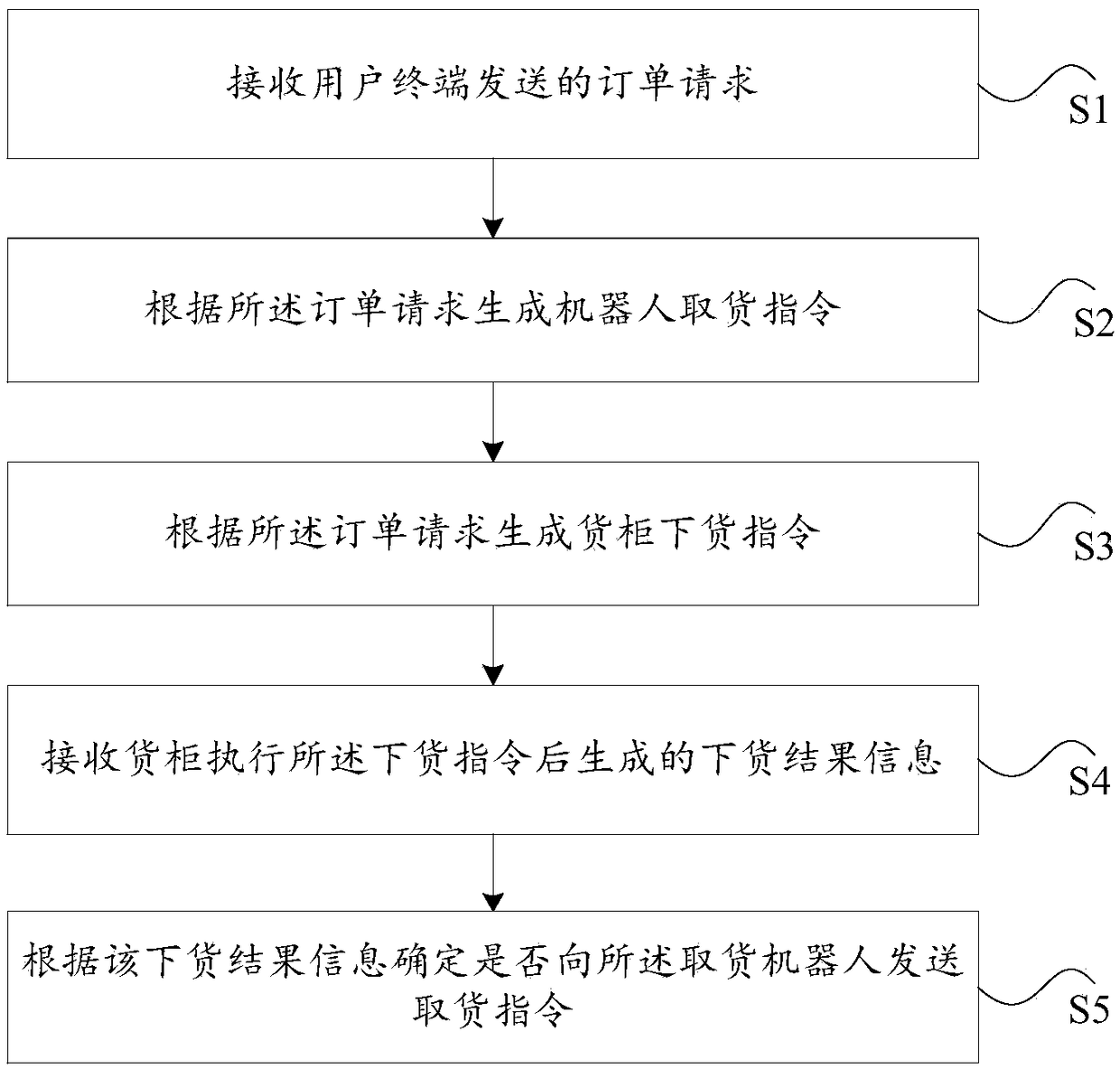

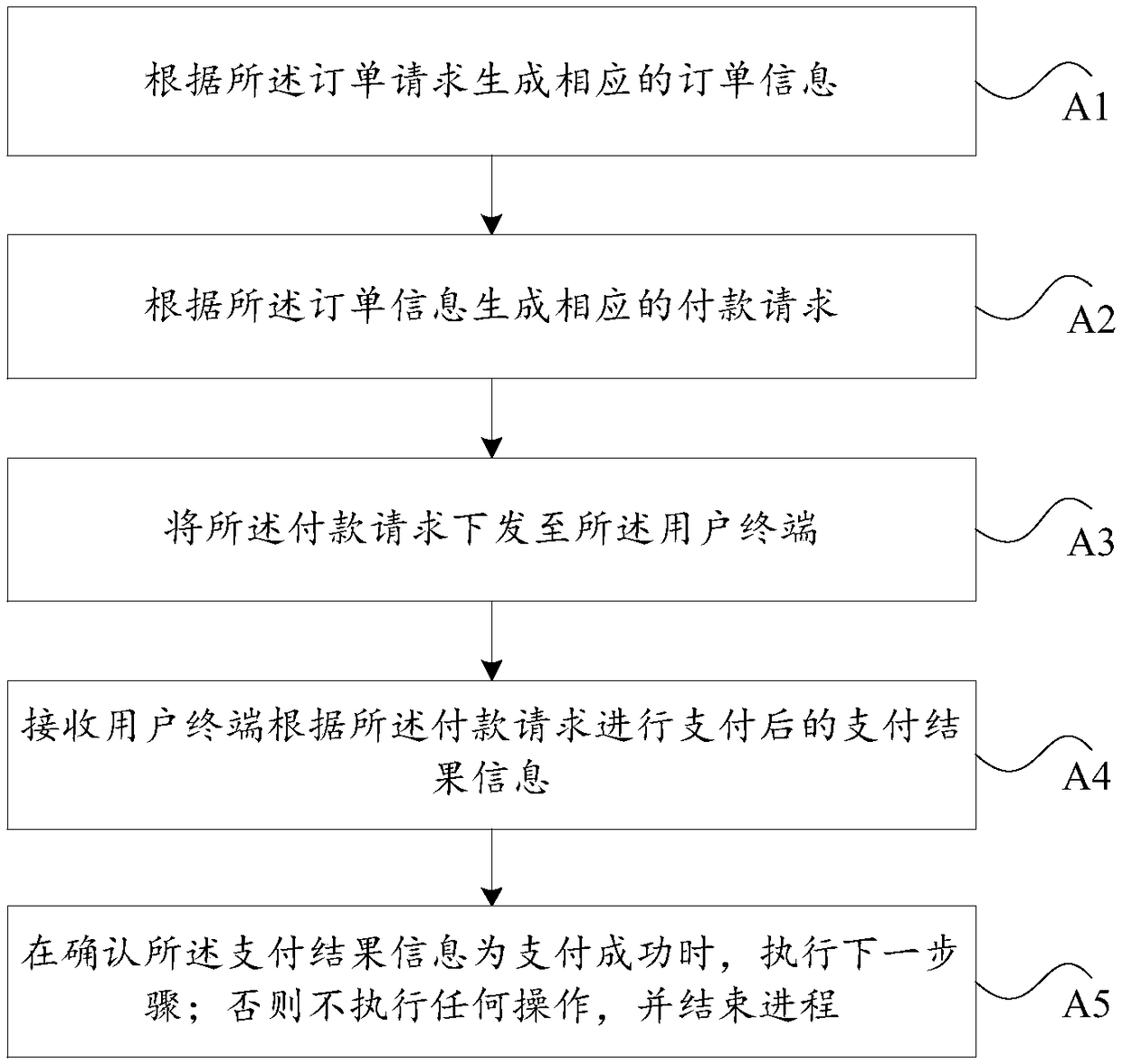

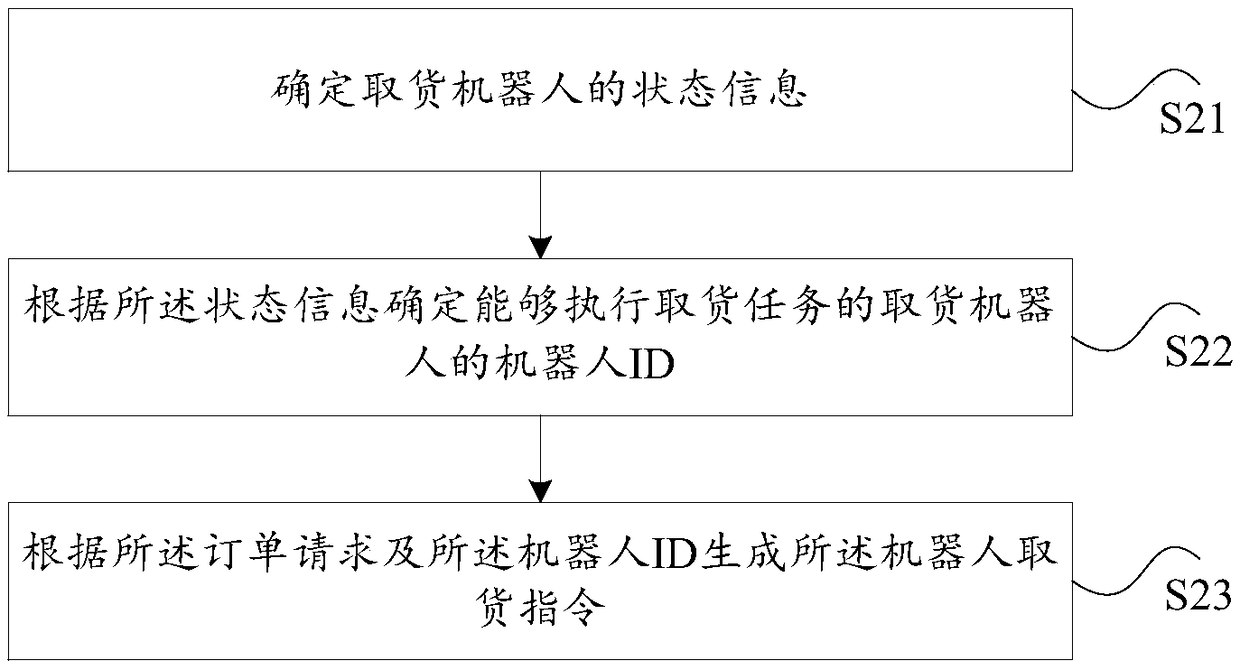

Intelligent container control method and system

InactiveCN109081033AEfficient, convenient and intelligent servicesCo-operative working arrangementsStorage devicesControl engineeringComputer science

The application discloses an intelligent container control method and system. The intelligent container control method comprises the following steps that an order request sent by a user terminal is received; a robot goods-picking instruction is generated according to the order request, wherein the robot goods-picking instruction is used for dispatching a goods-picking robot to a corresponding container for goods-picking; a container goods-discharging instruction is generated according to the order request; goods-discharging result information generated after the container executes the goods-discharging instruction is received, wherein the goods-discharging result information is used for representing whether the container is successfully in goods-discharging result information or not; and whether the goods-picking instruction is sent to the goods-picking robot or not is judged according to the goods-discharging result information, the goods-picking robot is enabled to pick up goods at the picking point, and the goods are sent to the position designated by a user after the goods are picked. By arranging the container and the goods-picking robot in hotels, supermarkets or shopping malls, the container and the goods-picking robot can provide efficient, convenient and automatic intelligent services for the user by executing the intelligent container control method.

Owner:北京云迹科技股份有限公司

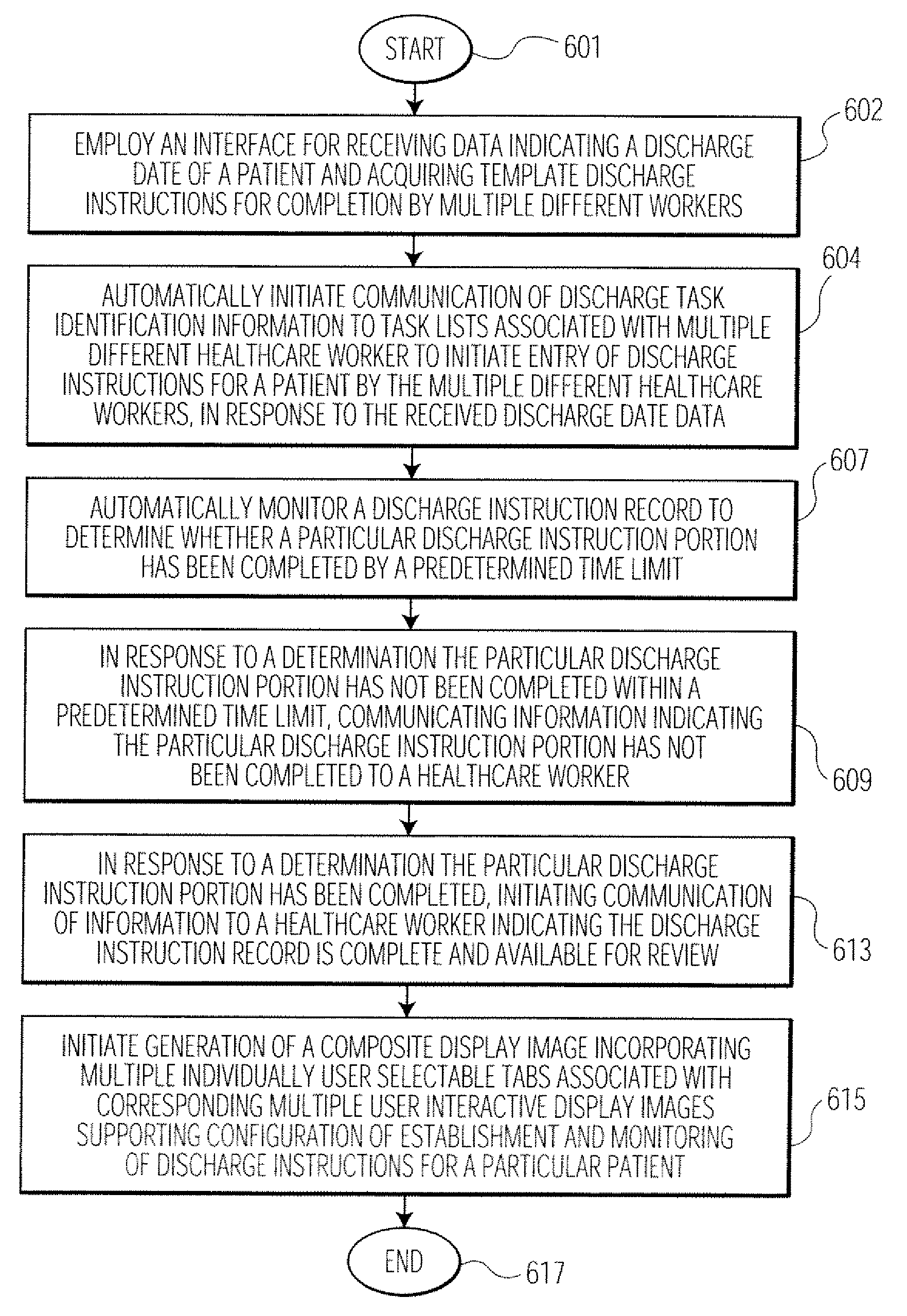

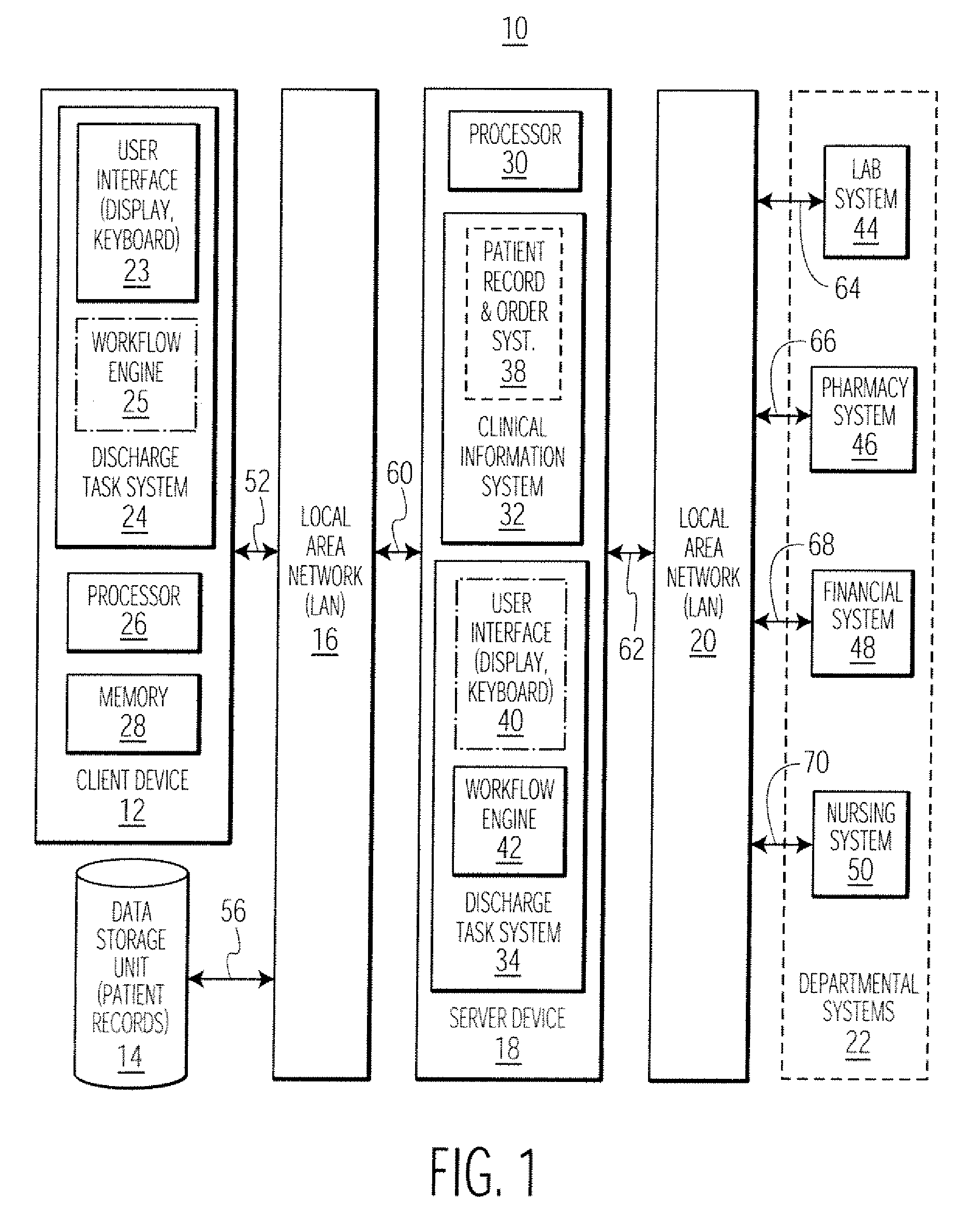

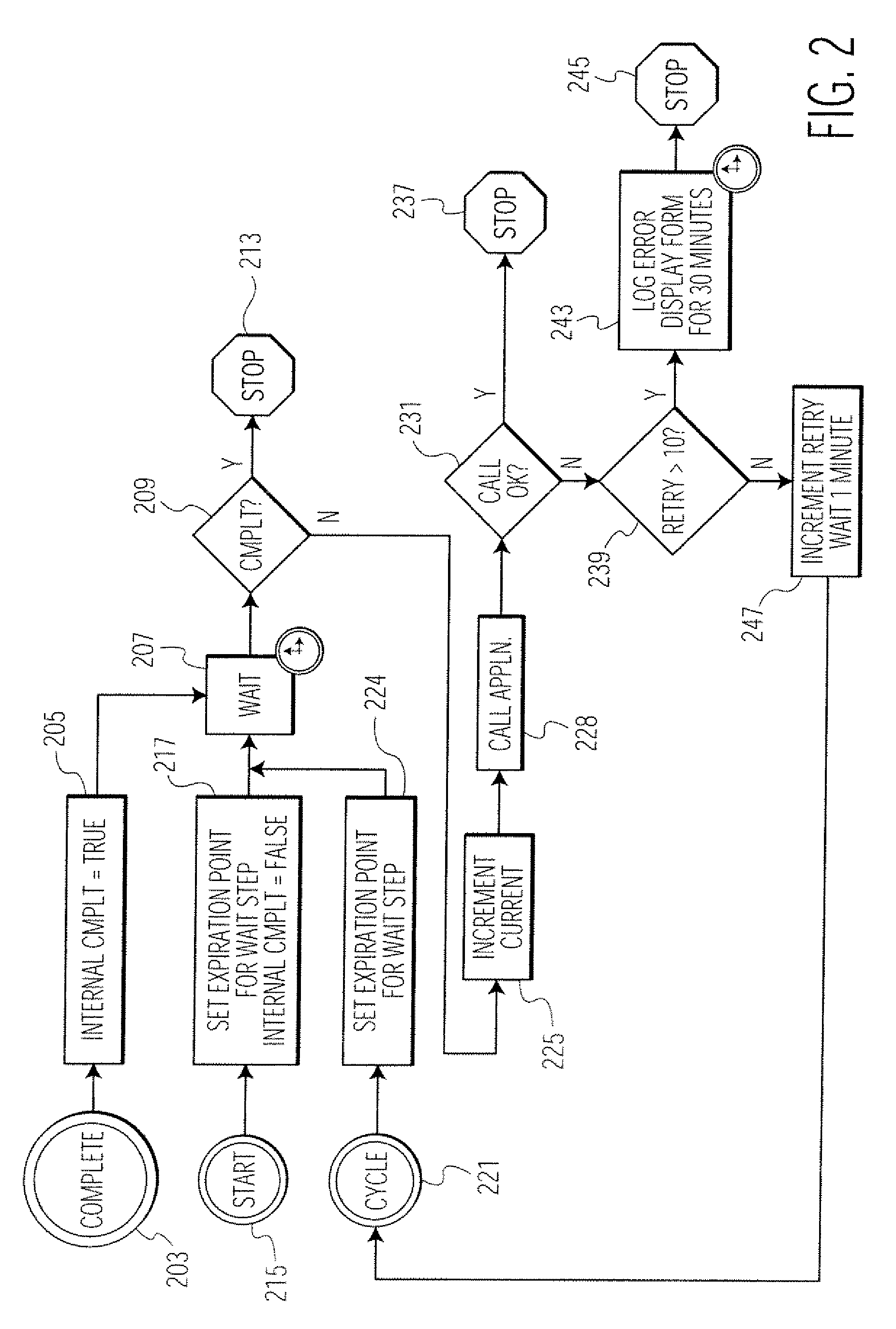

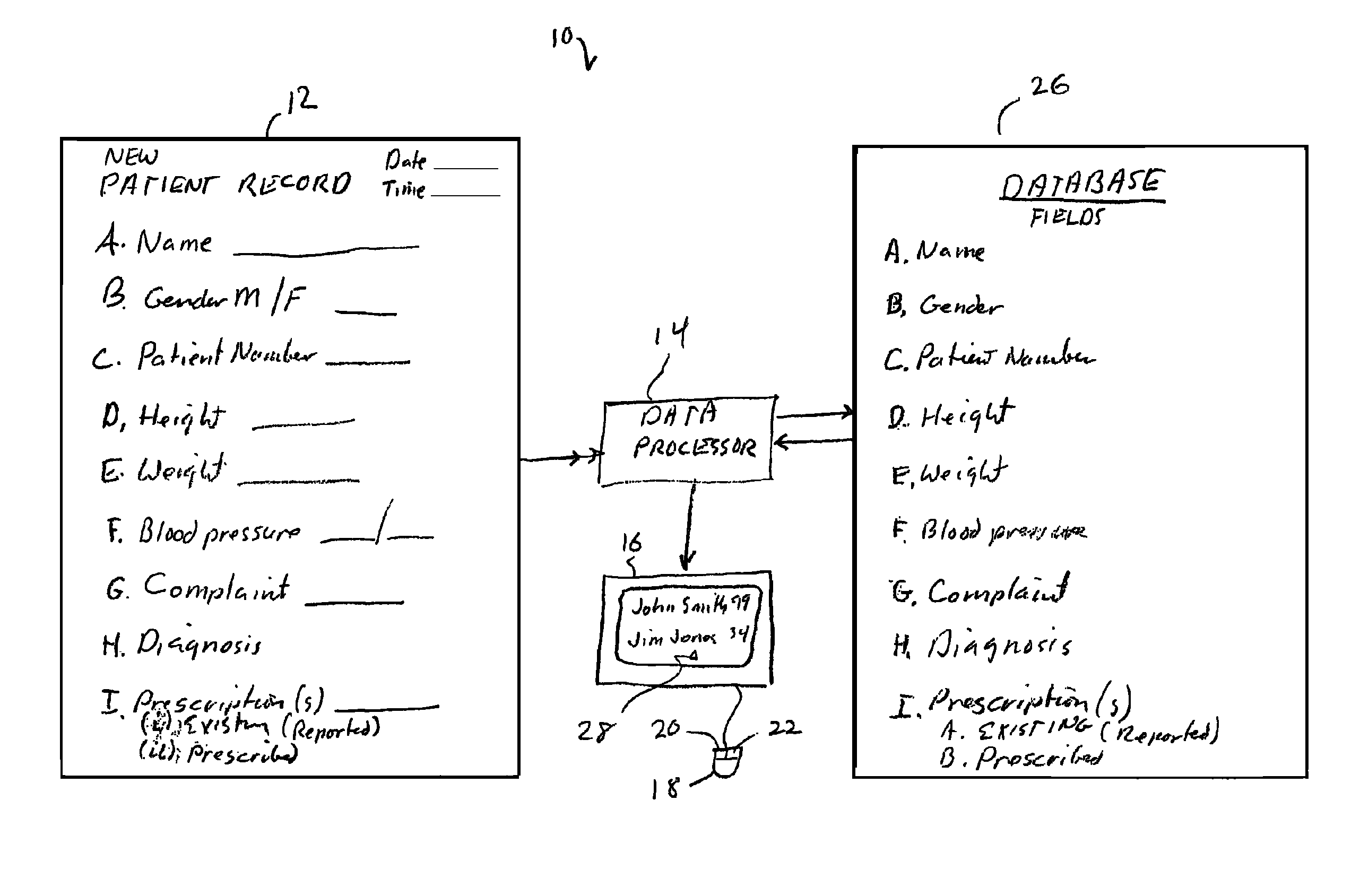

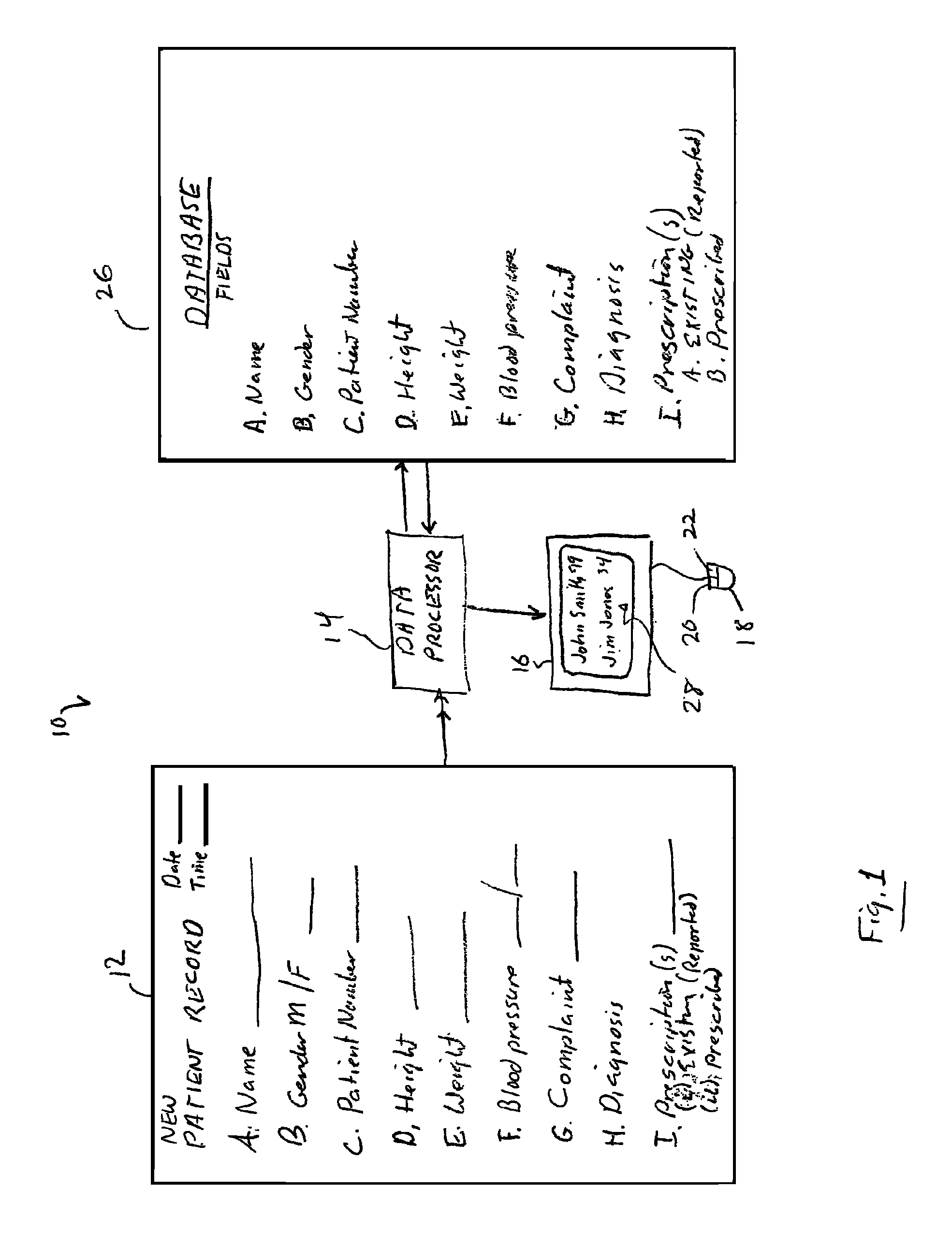

Patient Discharge Data Processing System

InactiveUS20070143143A1Easy to collectMultiprogramming arrangementsOffice automationData processing systemTime limit

A system for managing patient discharge instruction preparation includes an interface for receiving data indicating a discharge date of a patient and a workflow processor. The workflow processor automatically, initiates communication of discharge task identification information to task lists associated with multiple different healthcare workers to initiate performance of discharge tasks by the workers, in response to the received discharge date data. The workflow processor automatically monitors a discharge instruction record to determine whether a particular discharge task has been completed by a predetermined time limit. Also in response to a determination the particular discharge task has not been completed within a predetermined time limit, the workflow processor automatically escalates notification indicating the particular discharge task remains to be performed by communication of information identifying the particular discharge task to a healthcare worker in response to a predetermined escalation hierarchy. In response to a determination the particular discharge tasks have been completed, the workflow processor automatically initiates communication of information to a healthcare worker indicating the discharge instruction record is complete and available for review.

Owner:CERNER INNOVATION

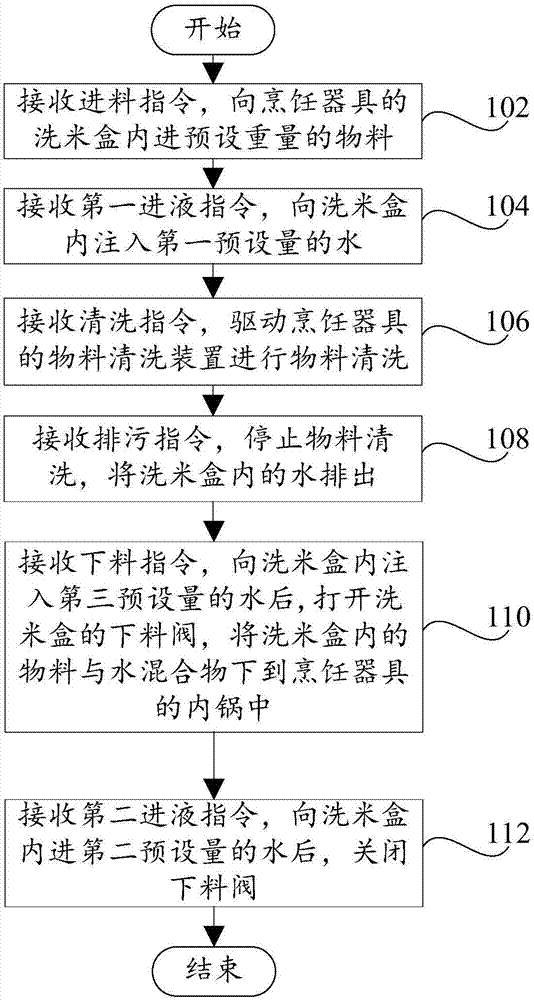

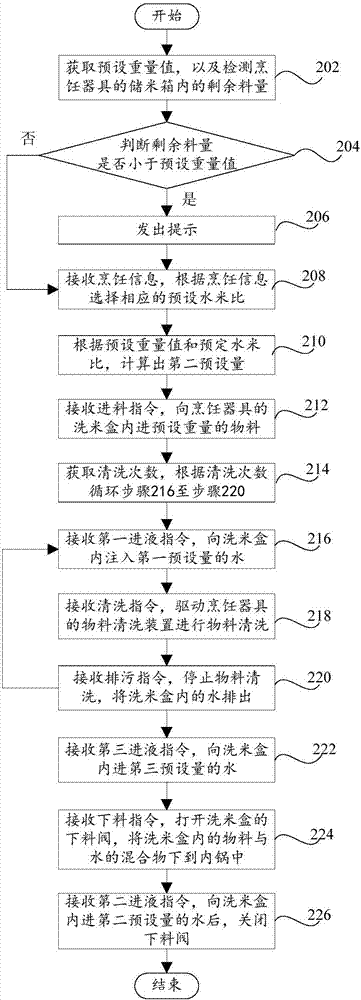

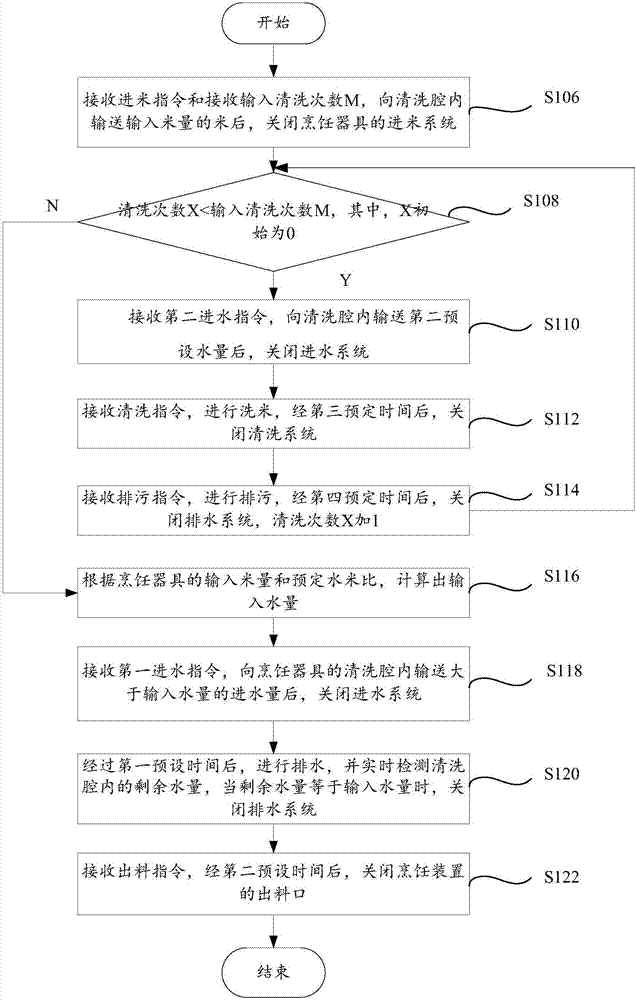

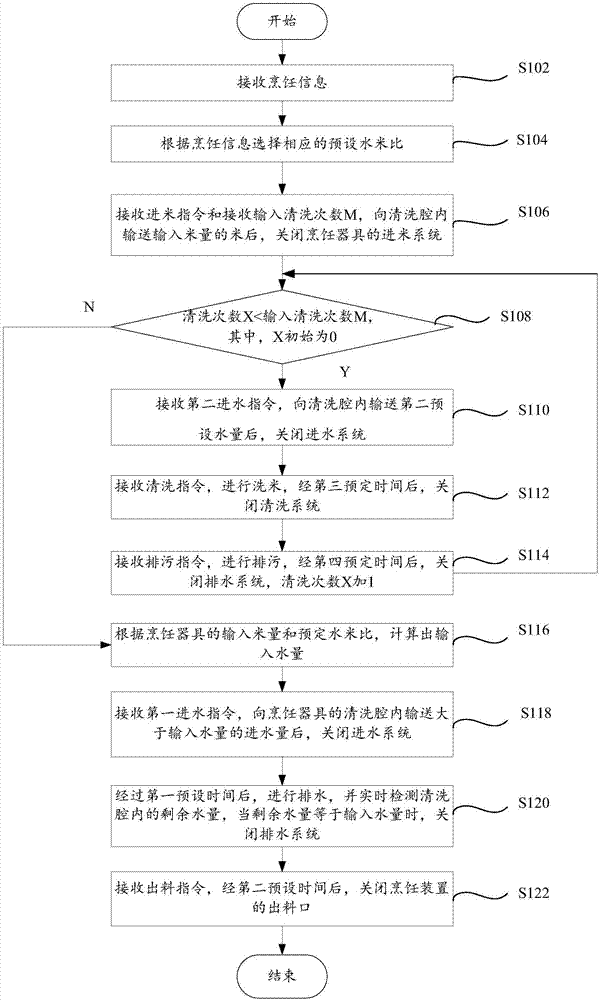

Control method and control system of cooking device

The invention provides a control method and a control system of a cooking device. The control method comprises the steps that step 102, a material feed instruction is received, and materials with preset weights are put into a rice washing box of the cooking device; step 104, a first liquid feed instruction is received, and a first preset amount of water is injected into the rice washing box; step 106, a cleaning instruction is received, a material cleaning device of the cooking device is driven to carry out material cleaning; step 108, a sewage discharge instruction is received, the material cleaning is stopped, and water in the rice washing box is discharged; step 110, a material discharging instruction is received, a ball valve of the rice washing box is switched on, the materials in the rice washing box are discharged into an inner pot of the cooking device; step 112, a second liquid feed instruction is received, the ball valve is switched off after a second preset amount of water is put into the rice washing box. According to the control method, the process of automatic cleaning and discharging of the materials is achieved, the operation steps are simplified, the automation degree of the cooking device is increased, and the cleanliness of the material and the safety of food are improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

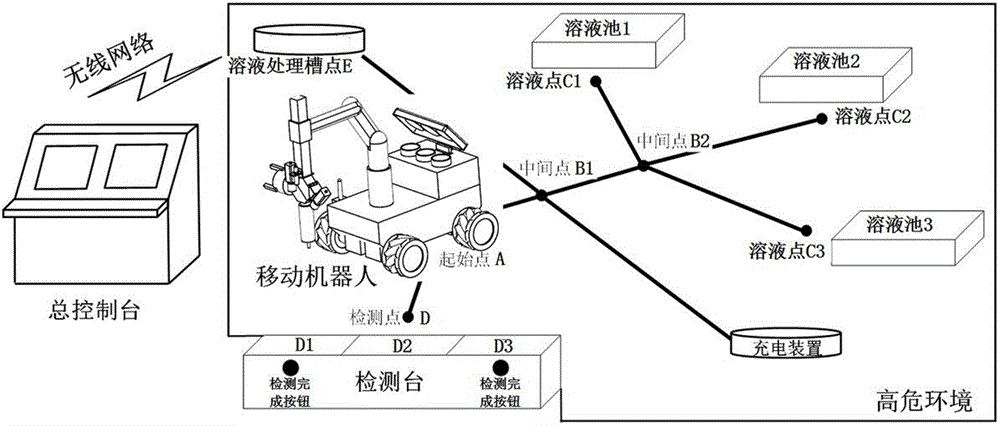

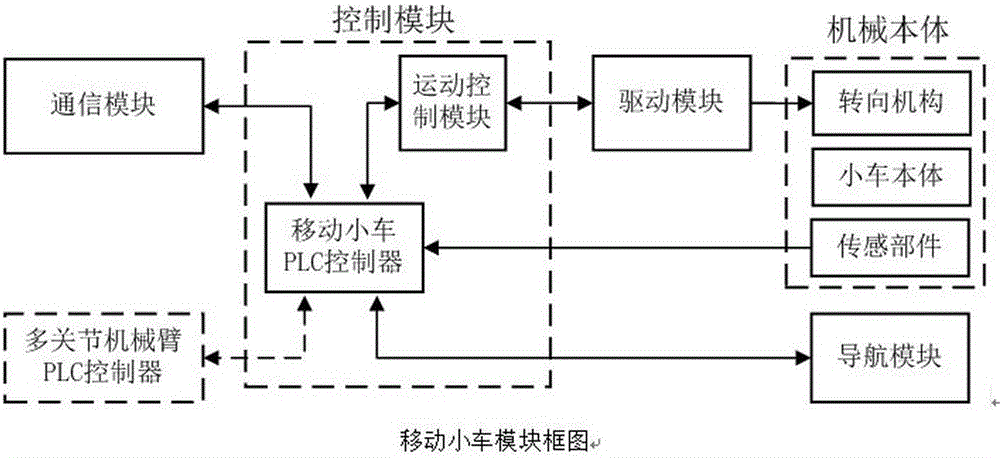

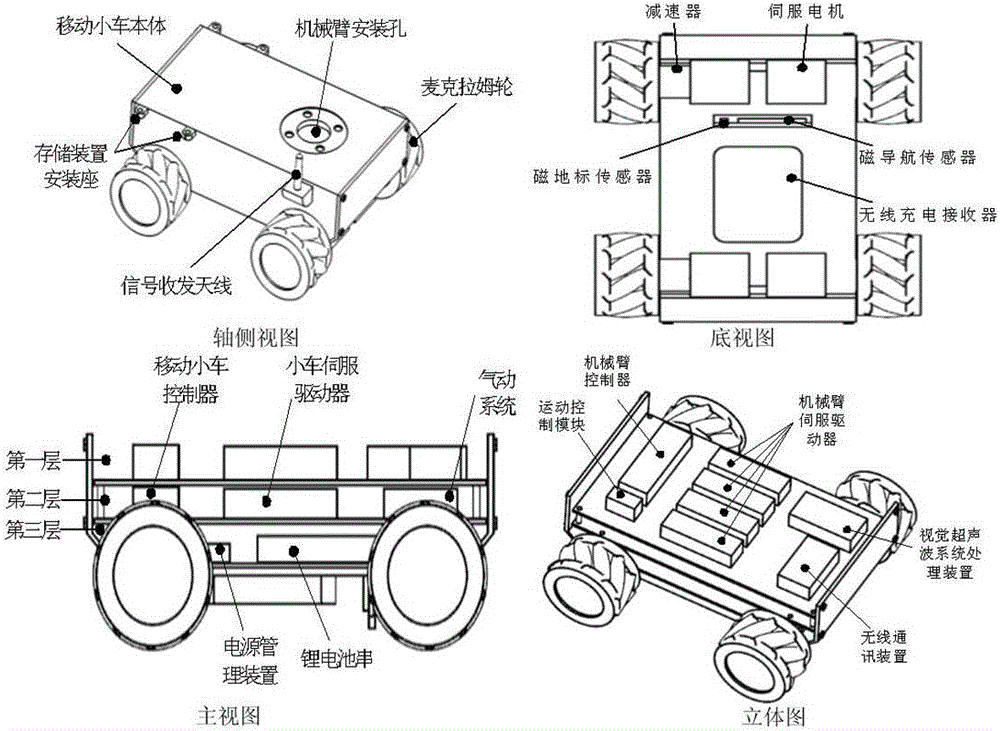

Dangerous chemical liquid safe storage and transportation and fixed-point placement method based on mobile robot

ActiveCN106799737ARigorous control logicData transfer is smoothProgramme-controlled manipulatorChemical solutionEngineering

The invention relates to a dangerous chemical liquid safe storage and transportation and fixed-point placement method based on a mobile robot. The dangerous chemical liquid safe storage and transportation and fixed-point placement method based on the mobile robot comprises the steps that a moving trolley system moves from the designated position of the dangerous chemical solution to a designated detection point according to a planned route; a dangerous chemical solution storage system is started; a multi-joint mechanical arm system receives a solution discharging instruction and moves to the position above the dangerous chemical solution storage system; and the multi-joint mechanical arm system controls a clamp system to place the dangerous chemical solution to the designated detection point. The dangerous chemical liquid safe storage and transportation and fixed-point placement method based on the mobile robot is suitable for the high-risk dangerous chemical solution sampling and detecting stage, a dangerous chemical solution extraction system based on the mobile robot is introduced, so that a fixed type dangerous chemical solution extracting device used in a high-risk environment is replaced by a mobile robot dangerous chemical solution extracting device resistant to radiation and corrosion, and therefore efficient, quantitative and visual extracting operation of the dangerous chemical solution is achieved.

Owner:中国东方电气集团有限公司

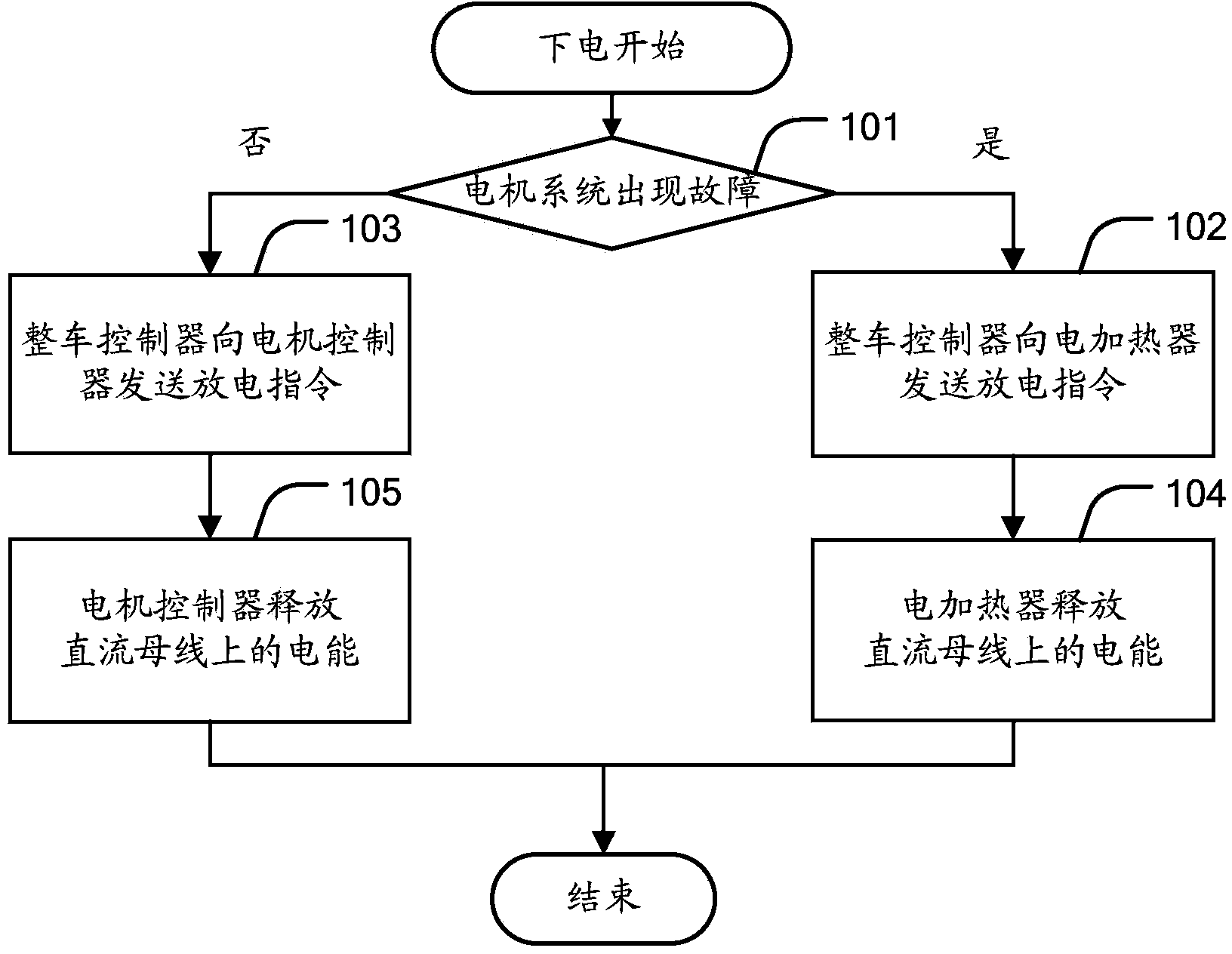

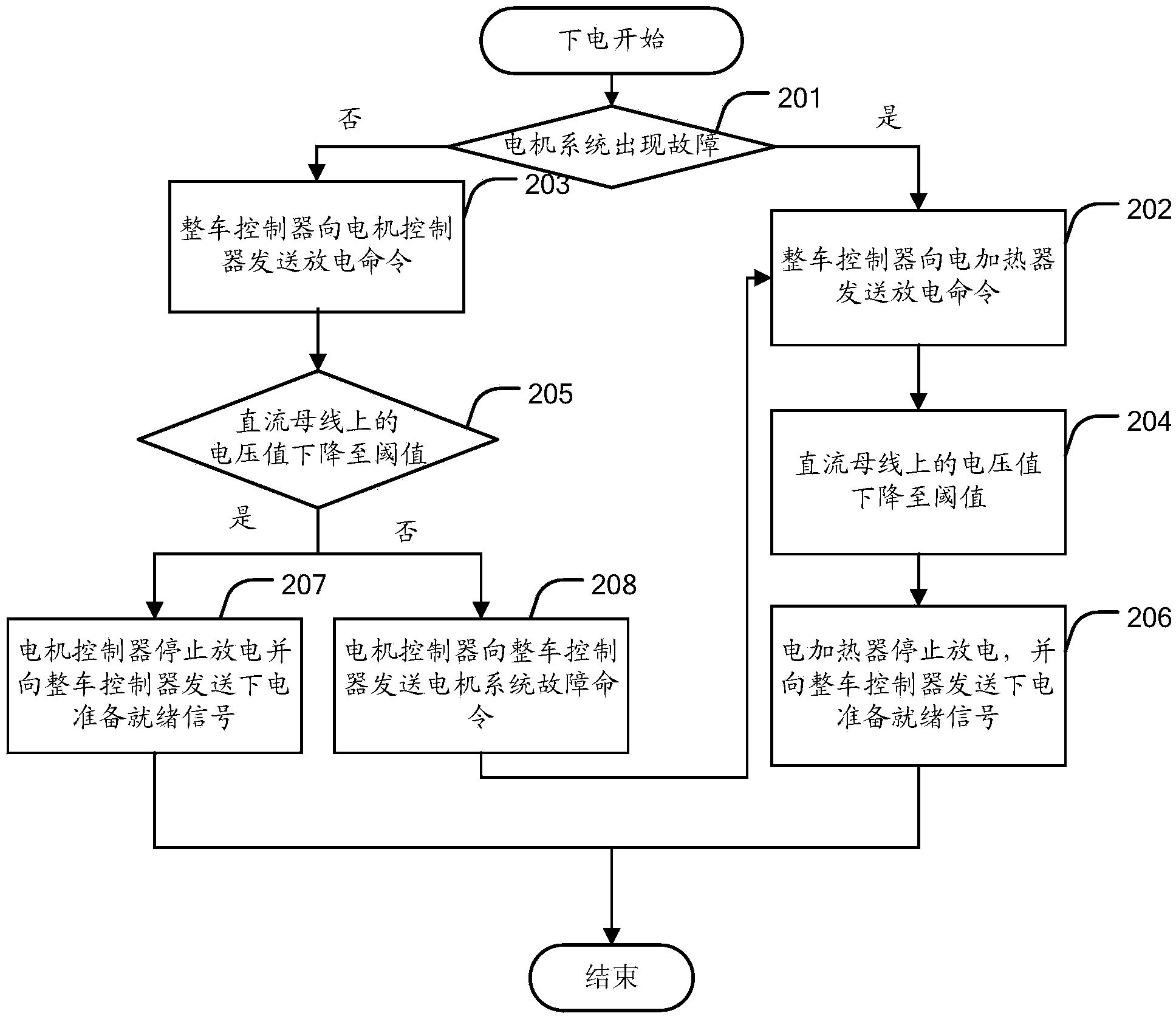

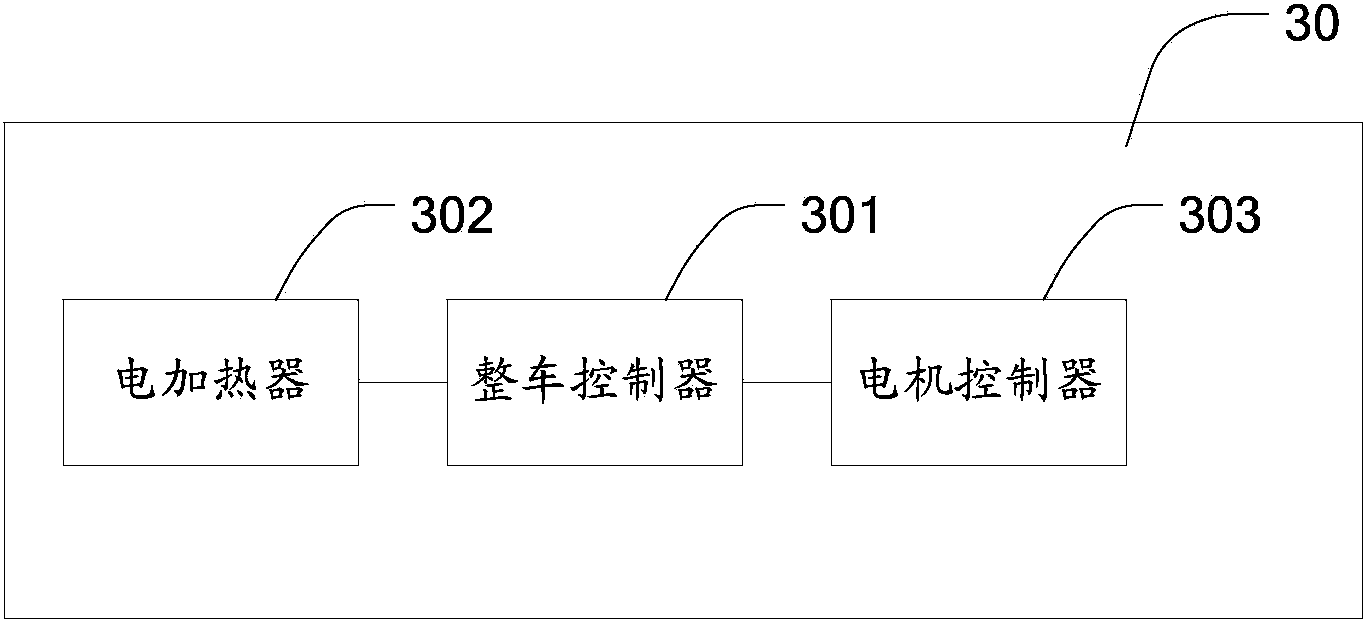

Discharging method and system for new energy vehicle

InactiveCN104354655AImprove securityReduce energy consumptionElectric devicesElectric/fluid circuitElectrical resistance and conductanceElectricity

The invention discloses a discharging method and system for a new energy vehicle. When the whole vehicle needs powering down, a whole vehicle controller is adopted to determine whether a motor system of the new energy vehicle breaks down or not; when the motor system breaks down, the whole vehicle controller sends a discharging instruction to an electric heater of the new energy vehicle, so that the electric heater releases electric energy on a DC bus through its own heating resistor according to the discharging instruction. Therefore, compared with the conventional discharging method by increasing a power resistor, the discharging method, which adopts the electric heater to release the electric energy on the DC bus when the motor system breaks down, reduces energy consumption of the whole vehicle; since the resistance value of the heating resistor is quite large, the release of the electric energy on the DC bus can be quickly realized, and the safety performance of the whole vehicle is improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

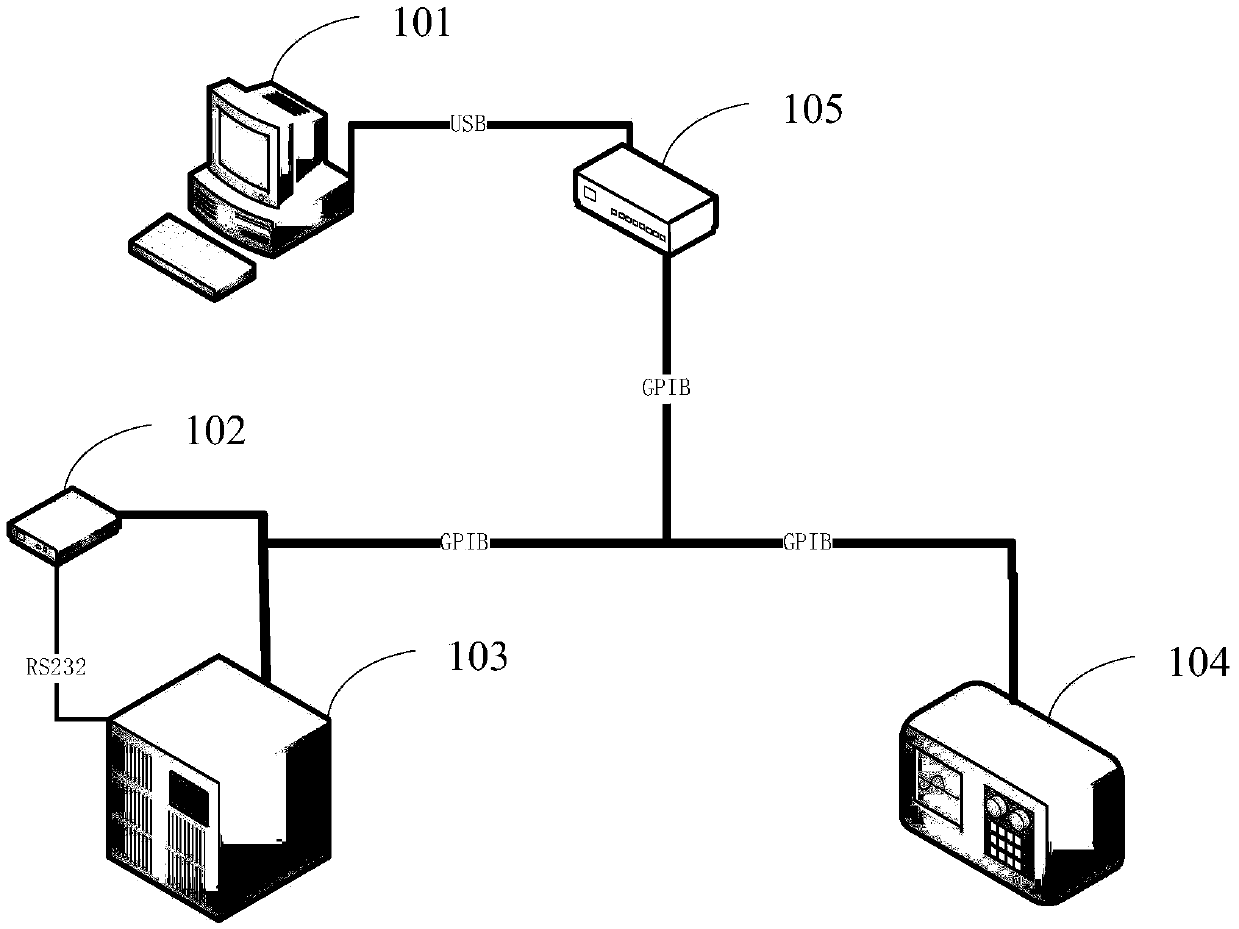

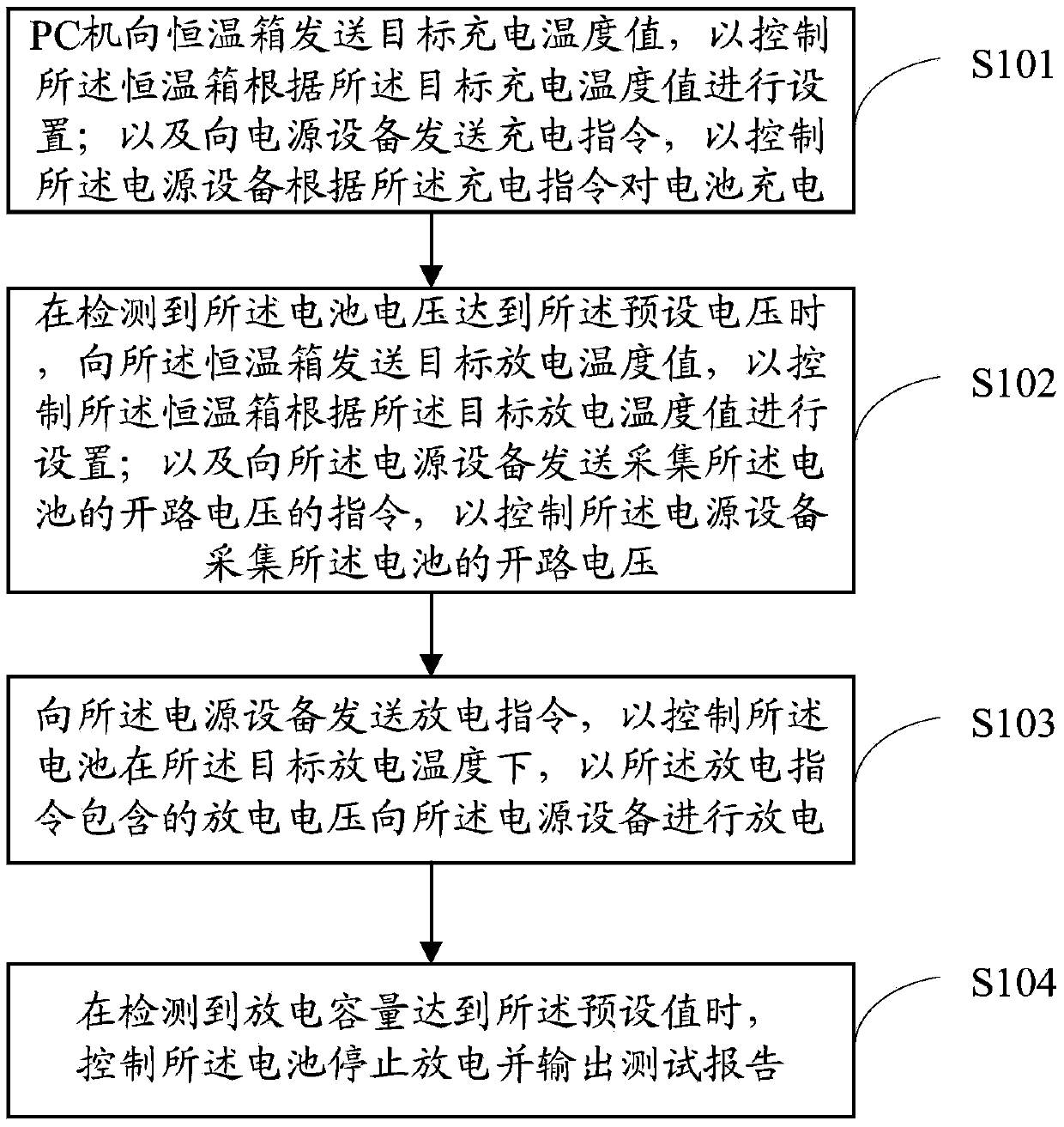

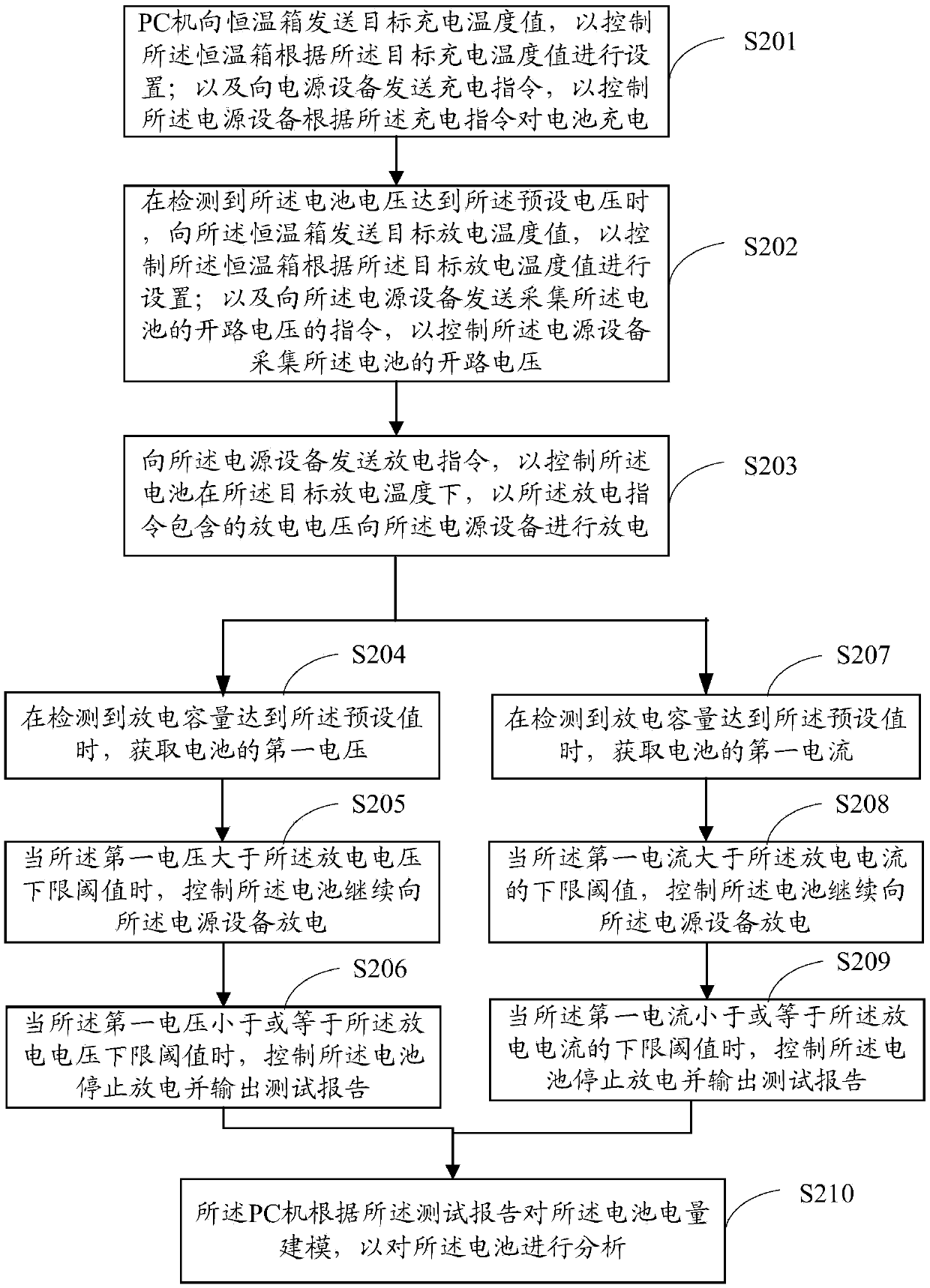

Battery testing method and system

The invention discloses a battery testing method and system. The battery testing method comprises that a PC transmits a target charging temperature value to a thermotank to set the thermotank according to the target charging temperature value; a charging instruction is sent to a power supply device so that the power supply device charges a battery according to the charging instruction; when it is detected that the battery voltage reaches a preset voltage, a target discharging temperature value is sent to the thermotank to set the thermotank according to the target discharging temperature value; instruction to collect the open circuit voltage of the battery is transmitted to the power supply device, so that the power supply device collects the open circuit voltage of the battery; a discharging instruction is sent to the power supply device, so that the battery discharges to the power supply device in the discharging voltage included in the discharging instruction at the target discharging temperature; and when it is detected that the discharging capacity reaches a preset value, the battery stops charging and outputs a test report. Thus, the battery can be tested without electronic loads, and the test cost is reduced.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

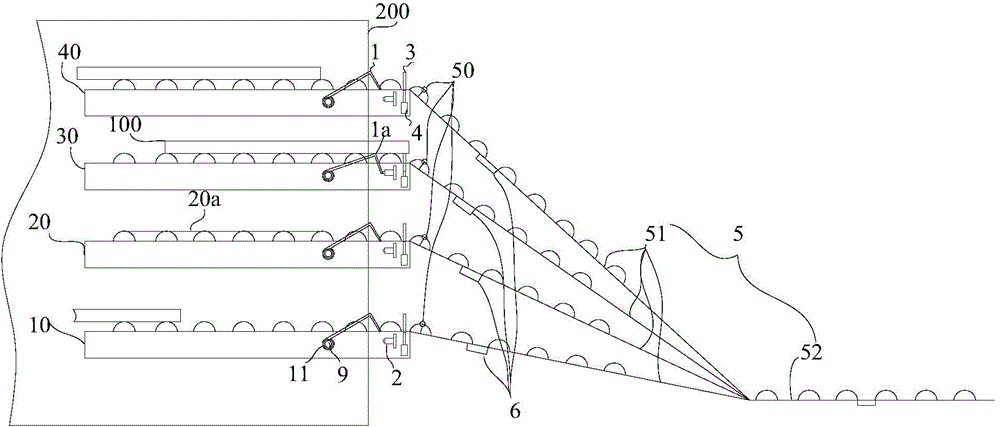

Method and device for automatically controlling plate discharge at outlet of drying machine

ActiveCN104317239ACause blockageAvoid cloggingDrying solid materialsProgramme control in sequence/logic controllersAutomatic controlEngineering

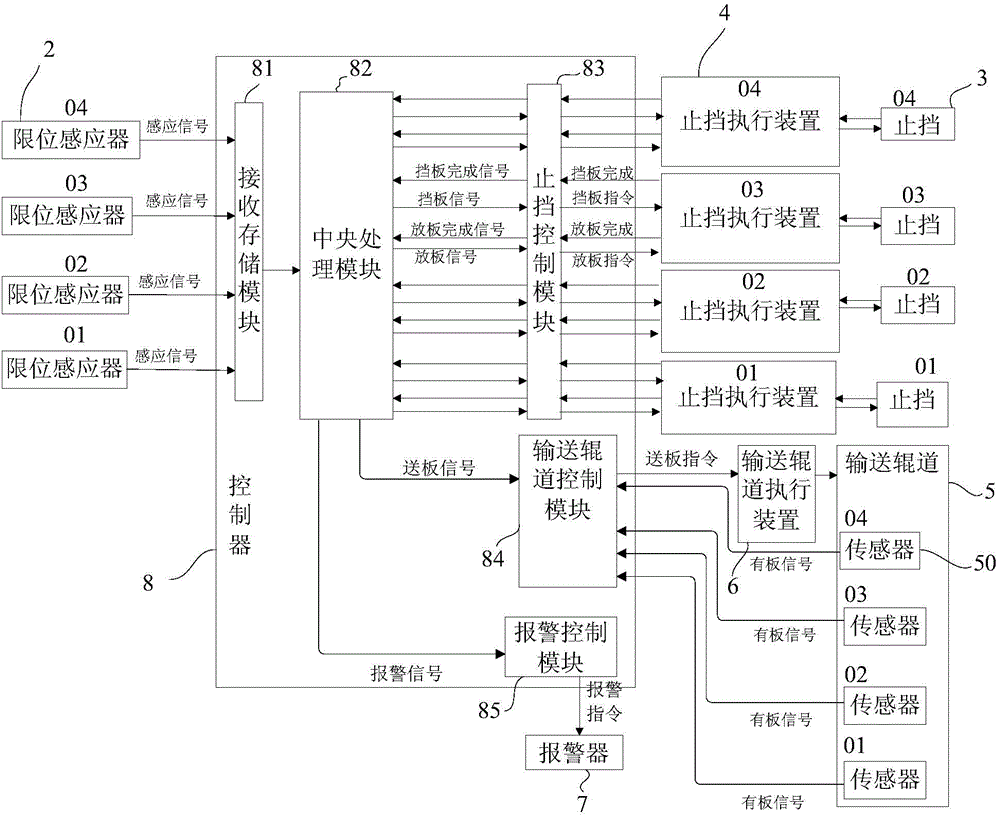

The invention provides a method and a device for automatically controlling plate discharge at the outlet of a drying machine. The method comprises the following steps: limiting sensors send sensing signals to a controller; the controller selects a current layer according to the order of the received sensing signal, sends a plate discharge instruction to a stopper actuating device and begins timing, and the stopper moves downwards; the time is delayed by t seconds after the sensing signal sent out by the limiting sensor of the current layer disappears and the controller sends a plate stopping instruction to the stopper actuating device; the stopper moves upwards and a plate stopping completion signal is fed back to the controller; the next layer is selected and plate discharge is repeated; when the time that the limiting sensor of the current layer continuously sends out the sensing signals reaches T, if the controller does not receives a plate stopping completion signal, the other layers are selected to repeat plate discharge; when the time that the limiting sensor of the current layer continuously sends out the sensing signals reaches T1, if the controller does not receives the plate stopping completion signal, an alarm device gives an alarm, wherein T1 is greater than T. if one layer is out of order, the other layers are automatically controlled to perform normal plate discharge; the operation efficiency of the drying machine is improved and the blockage of the drying machine is avoided; as a result, the drying machine is convenient to maintain and clear.

Owner:HUAINAN BEIXIN BUILDING MATERIAL +1

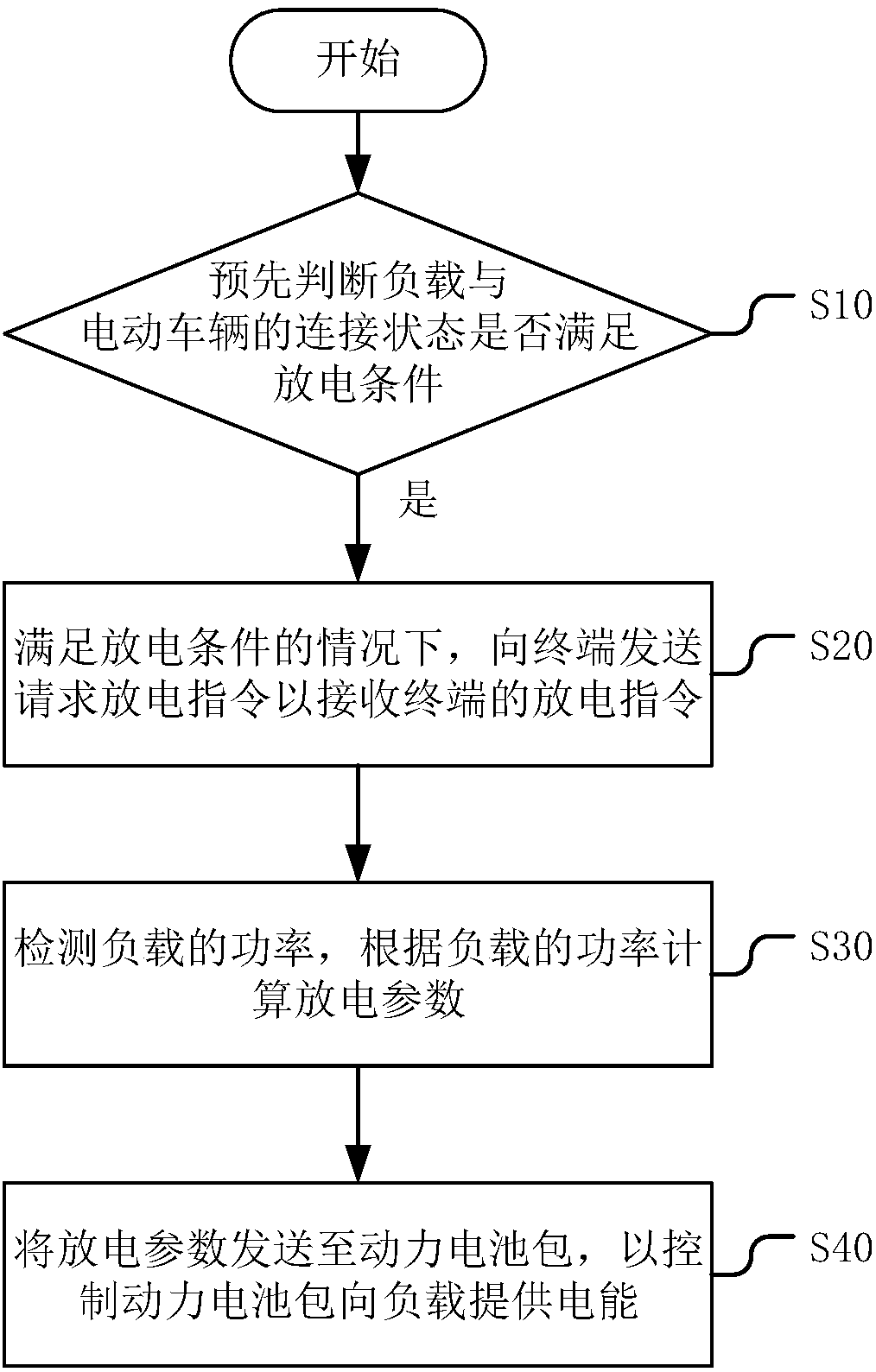

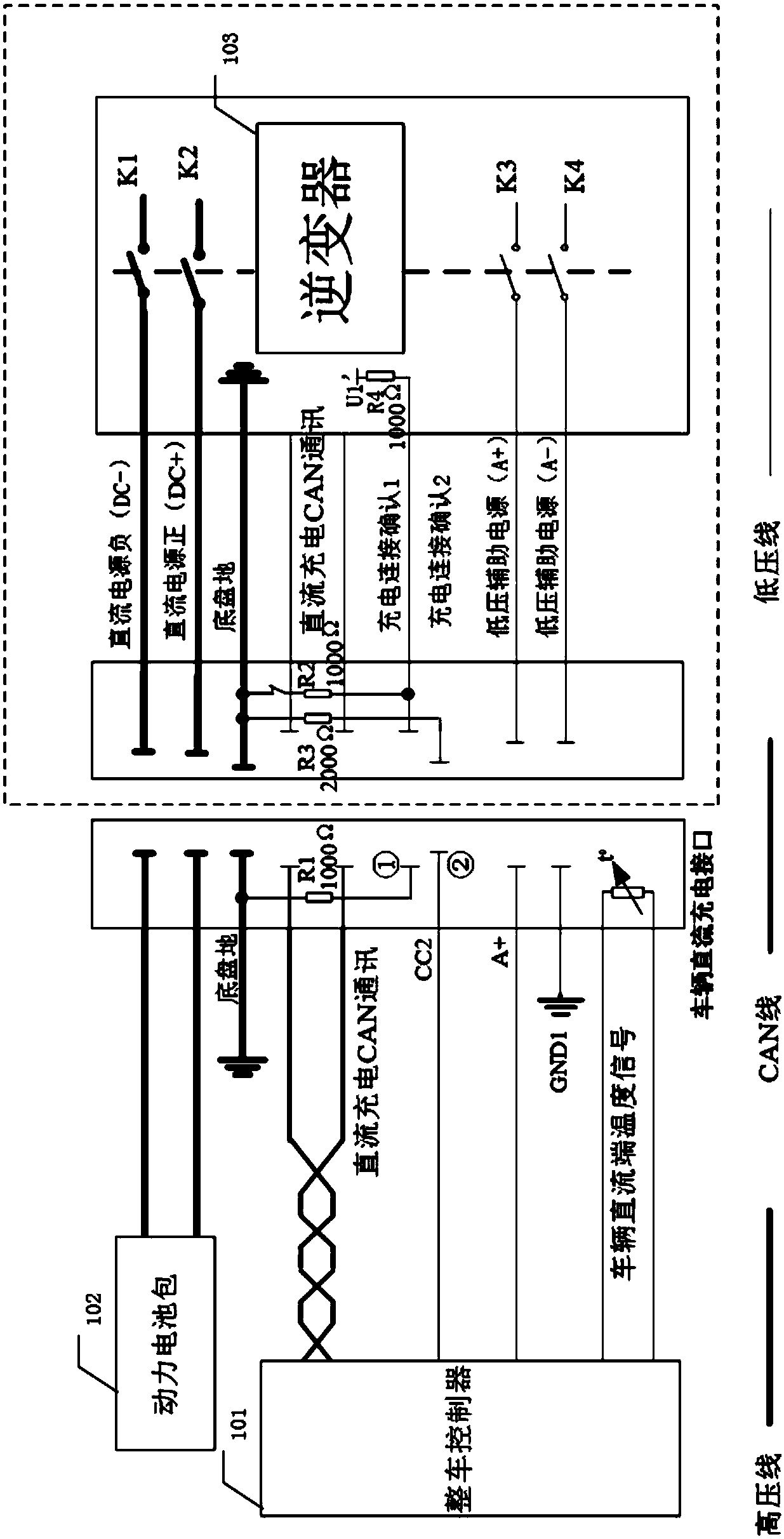

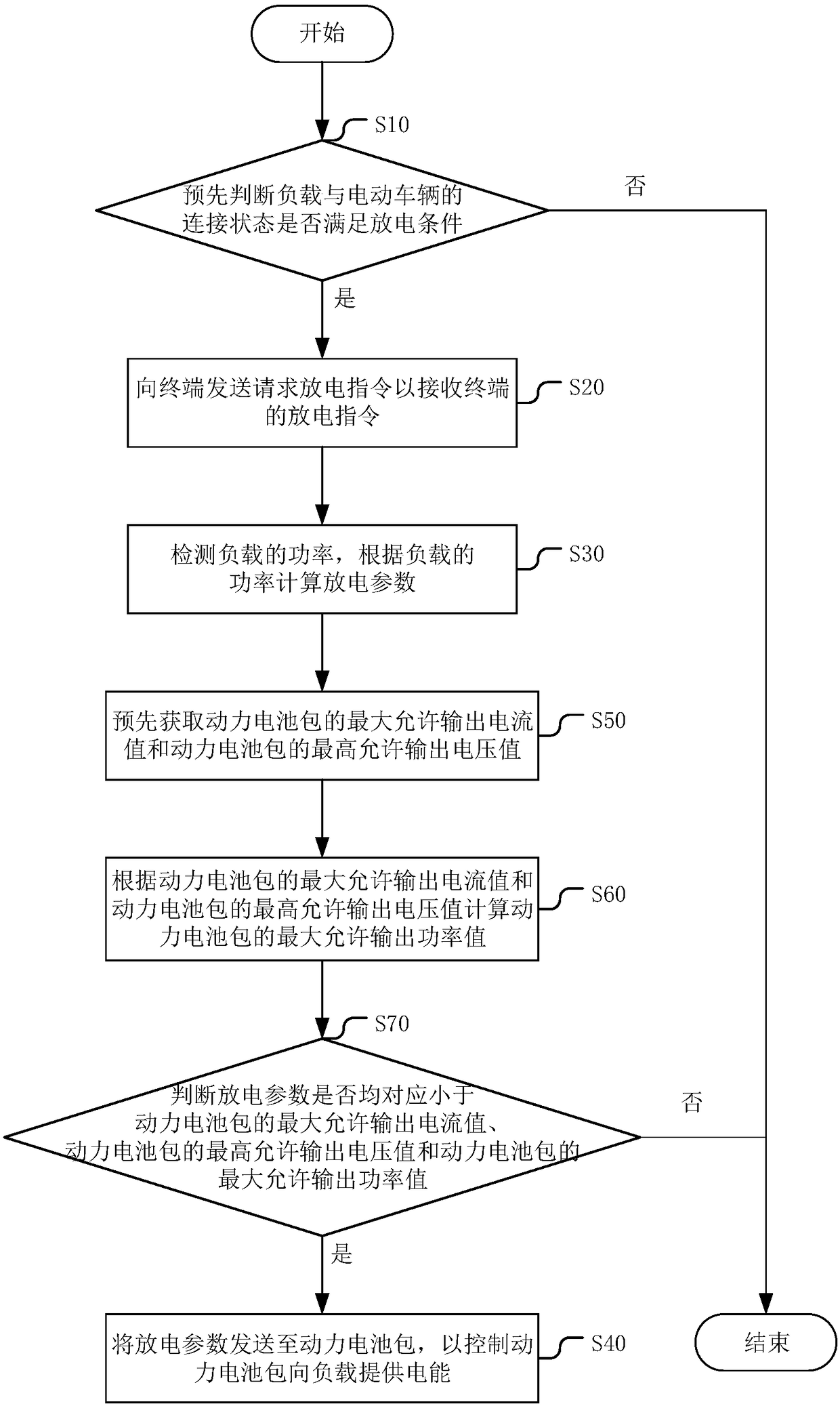

Control method and device for discharging electric vehicle and whole vehicle controller

The invention discloses a control method for discharging an electric vehicle. The control method comprises the steps of prejudging whether connecting state of the load and the electric vehicle satisfydischarging conditions or not; on the condition that the discharging conditions are satisfied, sending a discharging requesting instruction to a terminal to receive the discharging instruction of theterminal; detecting the power of the load, and according to the power of the load, calculating discharging parameters; sending the discharging parameters to a power battery pack to control the powerbattery pack to provide electric energy for the load. According to electric energy conditions actually needed by the load, the discharging parameters are set so that different loads can be subjected to power transmission, and the utilization rate of the electric energy of the electric vehicle is increased. The invention further discloses a control device for discharging the electric vehicle and awhole vehicle controller, and both the control device for discharging the electric vehicle and the whole vehicle controller have the advantages.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +2

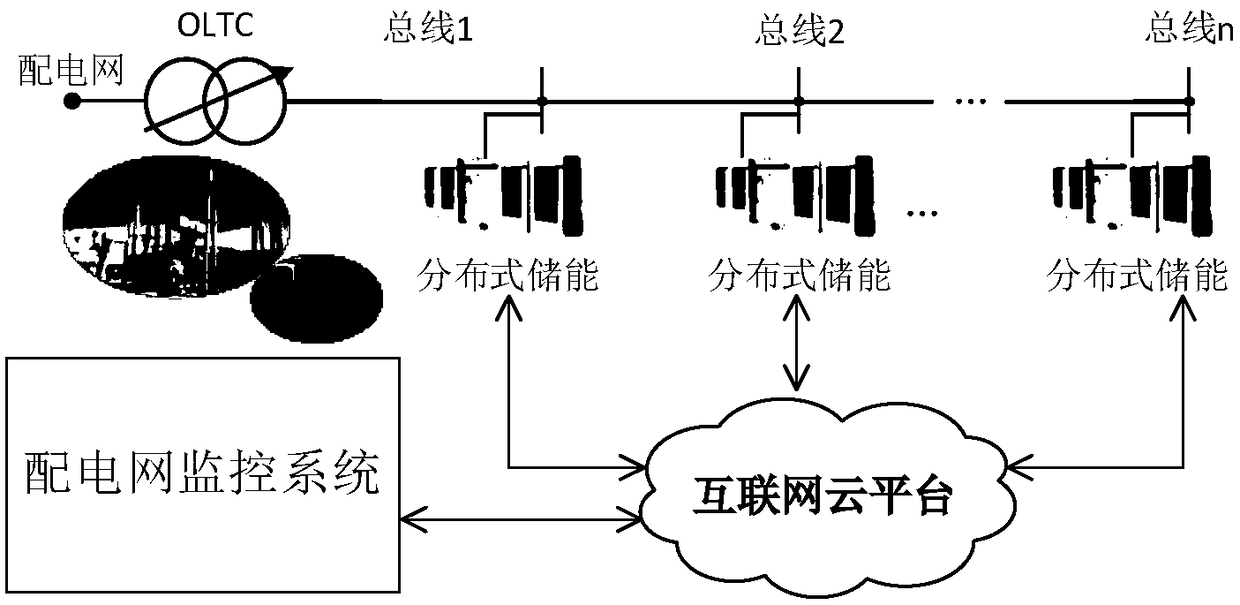

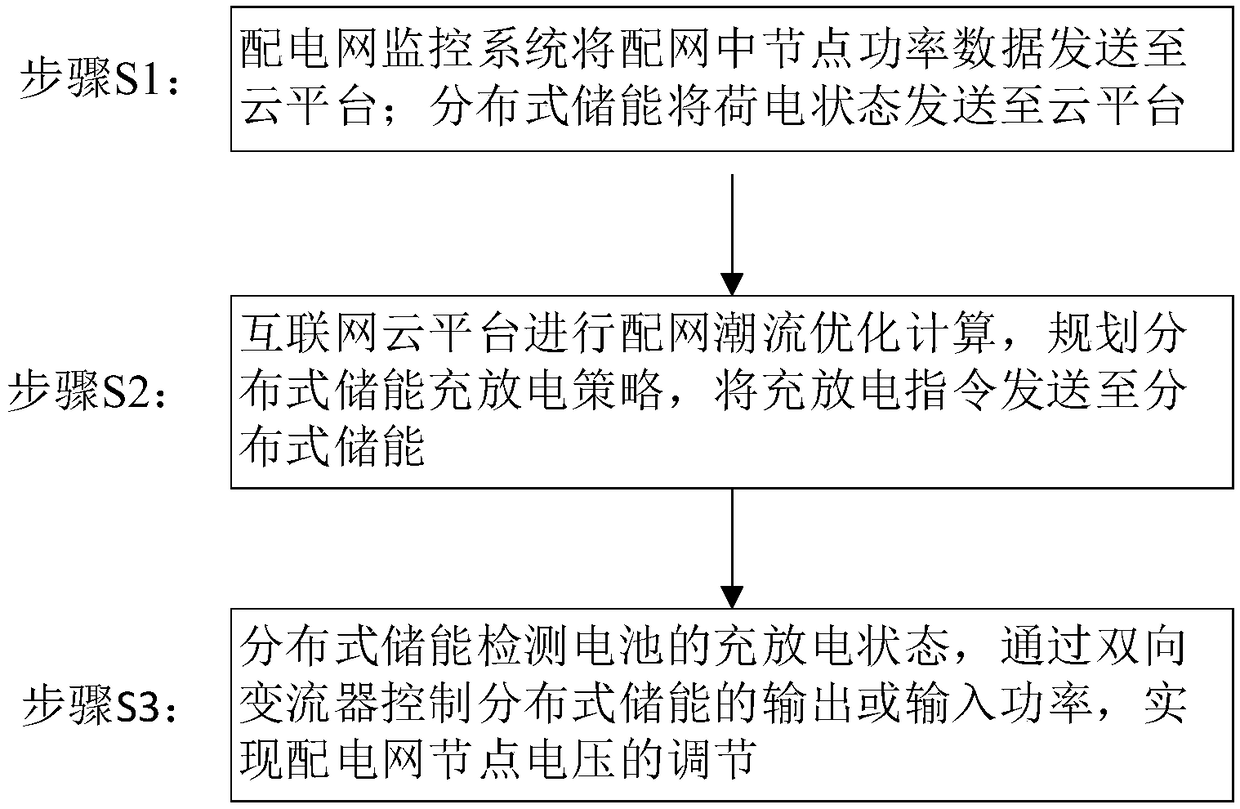

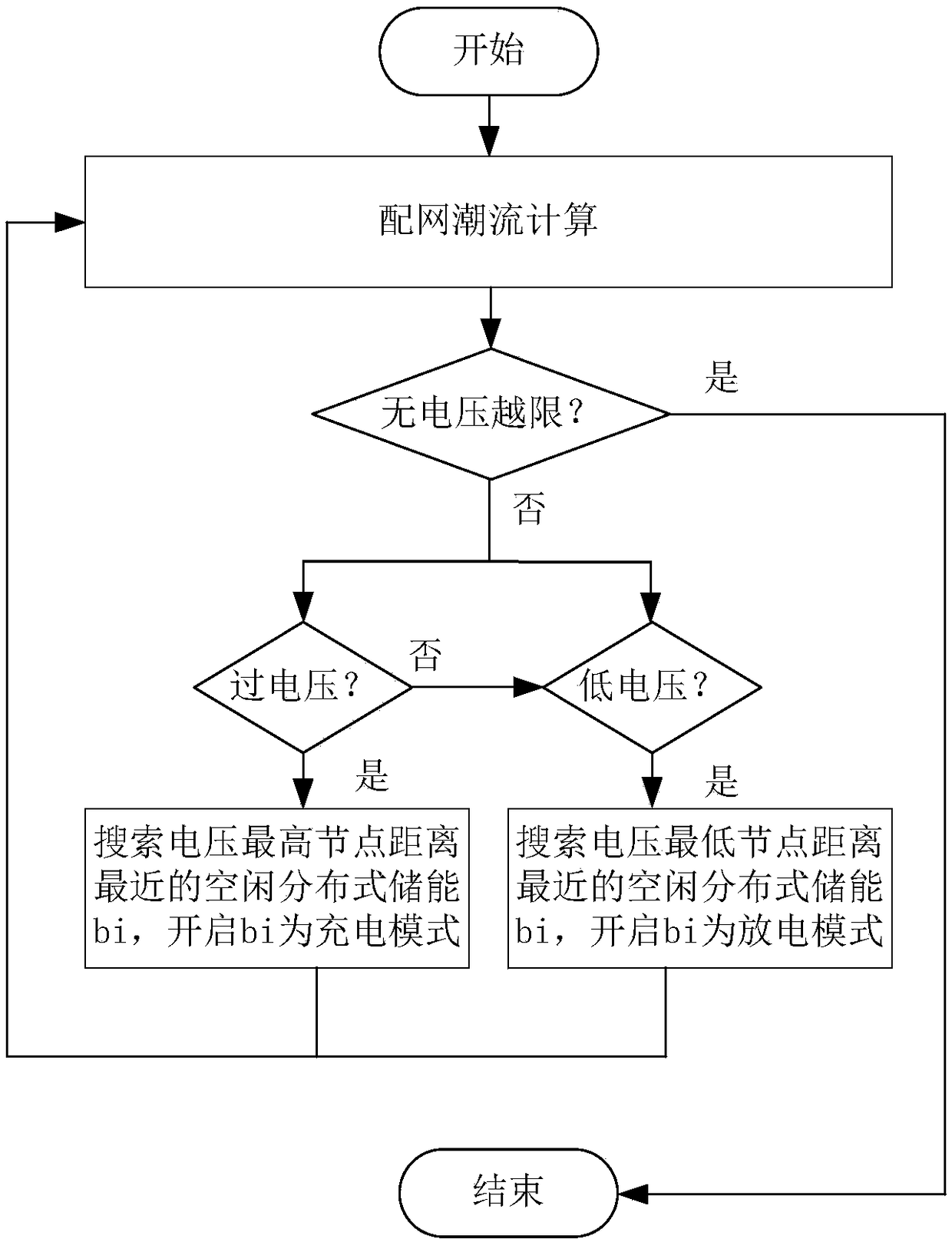

Power distribution network voltage regulation method based on internet platform and distributed energy storage

ActiveCN108599215AQuality improvementMeet power needsAc network load balancingAc networks with different sources same frequencyThe InternetPeak value

The invention discloses a power distribution network voltage regulation method based on an internet cloud platform and distributed energy storage. The distributed energy storage accesses to the cloudplatform through the internet, and sends an energy storage state and other data to the cloud platform; the cloud platform monitors power distribution network flow in real time, when a voltage peak ofa node in the power distribution network deviates from the normal range, the internet platform performs optimal computation on the power flow through a voltage sorting search method, determines the optimal distributed energy storage charging / discharging policy, and then sends the charging / discharging instruction to the distributed energy storage unit. The voltage is regulated to the normal range by using the charging / discharging of the distributed energy storage, and the safe and stable running of the power distribution network is maintained.

Owner:江苏芯卓物联网科技有限公司

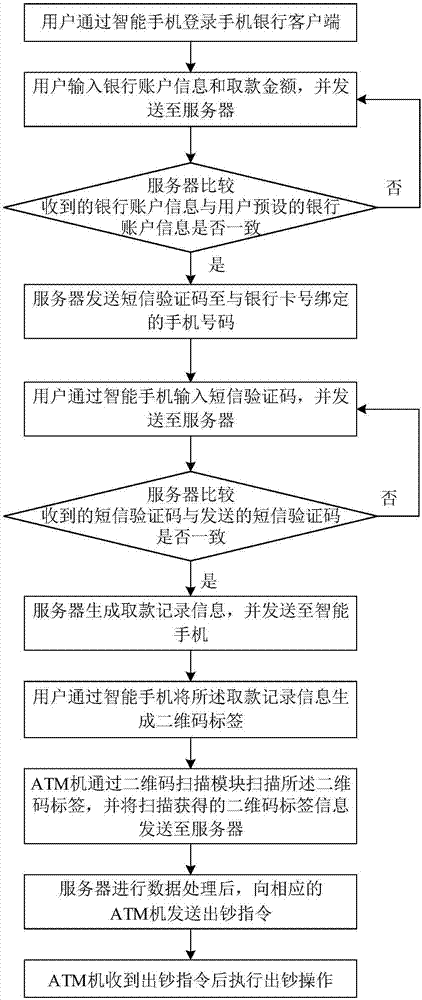

Method for card-free withdrawal

InactiveCN107393213AEasy to operateRealize cardless withdrawalComplete banking machinesATM softwaresComputer hardwareBank account

The invention relates to a method for card-free withdrawal, based on a smart phone and an ATM with a QR code scanning module. The method comprises the steps that (S1) a mobile phone bank client side is logged-in by the smart phone; (S2) bank account information and a withdrawal amount are input; (S3) a server compares the received bank account information with bank account information preset by a user; (S4) a short message verification code is sent by the server; (S5) the short message verification code is input by the smart phone; (S6) the server compares the received short message verification code and the sent short message verification code; (S7) withdrawal record information is generated by the server; (S8) by the smart phone, a QR code label is generated according to the withdrawal record information; (S9) the QR code label is scanned by the QR code scanning module of the ATM; (S10) the server carries out data processing and then sends a cash discharge instruction to the corresponding ATM; and (S11) the ATM executes a cash discharge operation after receiving the cash discharge instruction. By the method disclosed by the invention, card-free withdrawal can be achieved; operations are convenient; and safety is enhanced.

Owner:台山市金讯互联网络科技有限公司

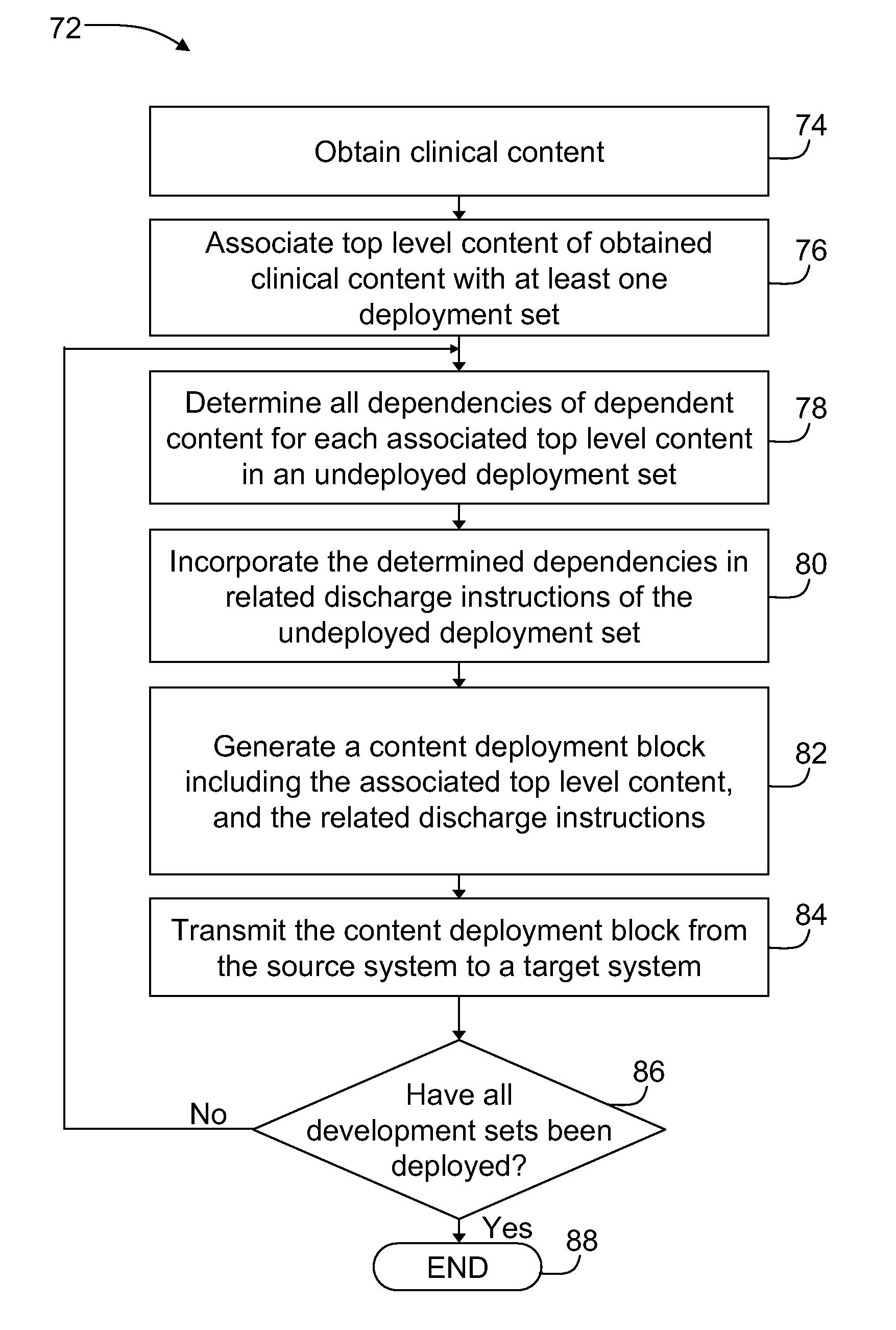

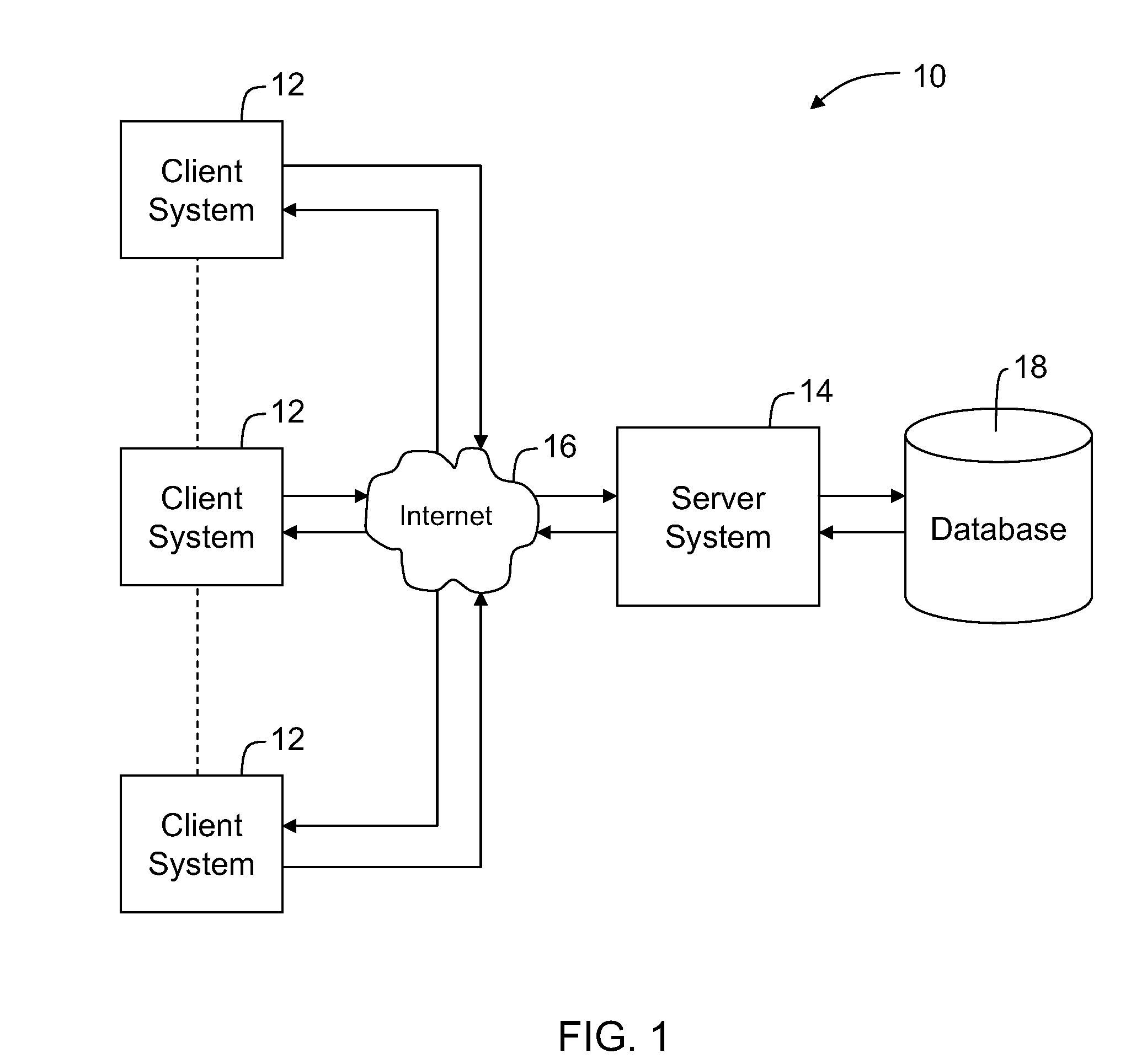

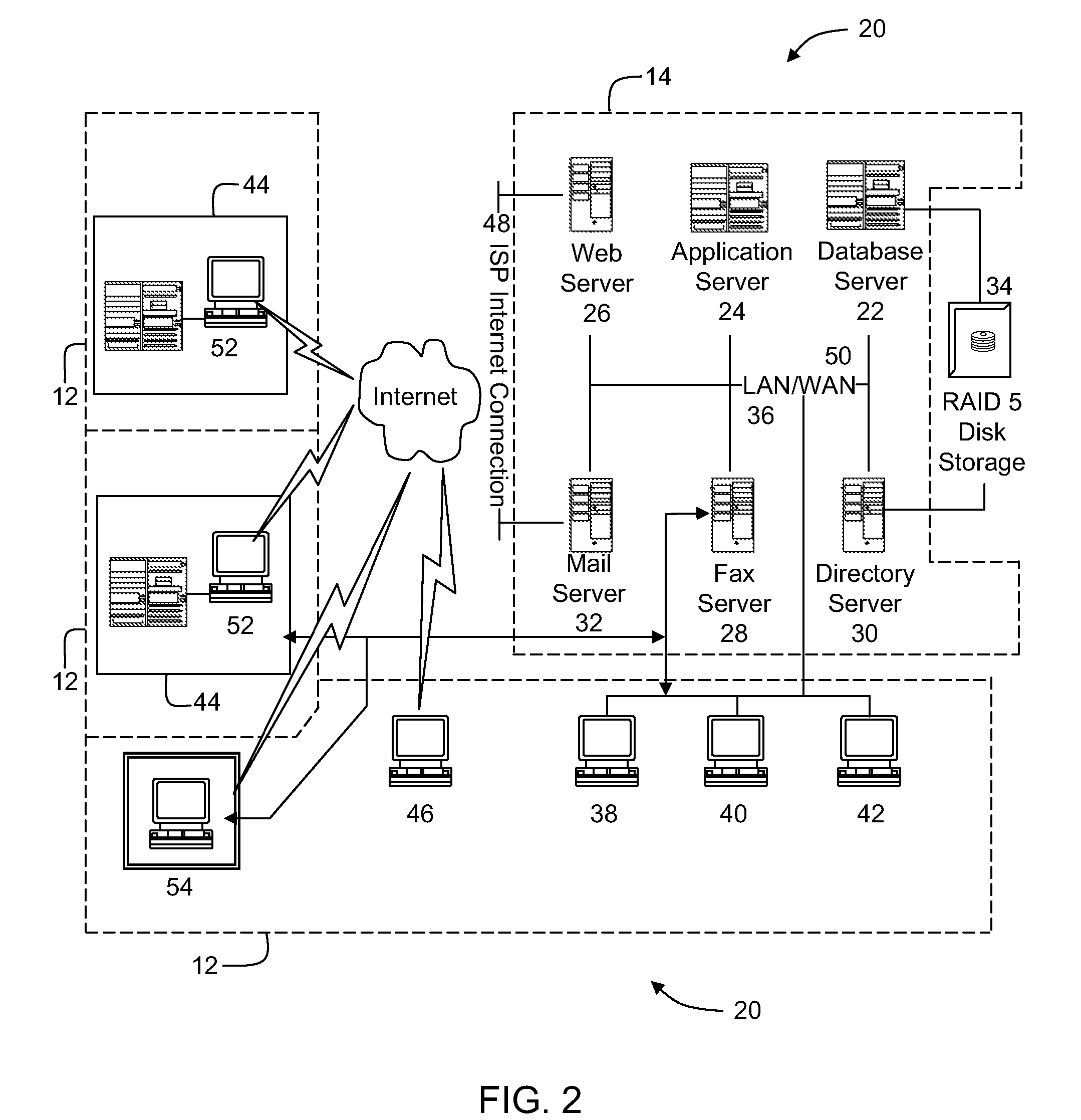

Methods and systems for managing content dependency deployment

InactiveUS7958485B2Hospital data managementProgram loading/initiatingDischarge instructionsElectronic content

A method for managing electronic content includes obtaining the content and associating top level contents of the obtained content with a deployment set. The top level content includes content that is specified by a user for deployment. The method also includes determining all dependencies of dependent content for each of the associated top level contents in the deployment set, incorporating the determined dependencies into discharge instructions for the deployment set, and generating a content deployment block including the associated top level contents, the dependent content, and the discharge instructions for the deployment set. The discharge instructions include dependency ordered deployment commands.

Owner:IHC HEALTH SERVICES +1

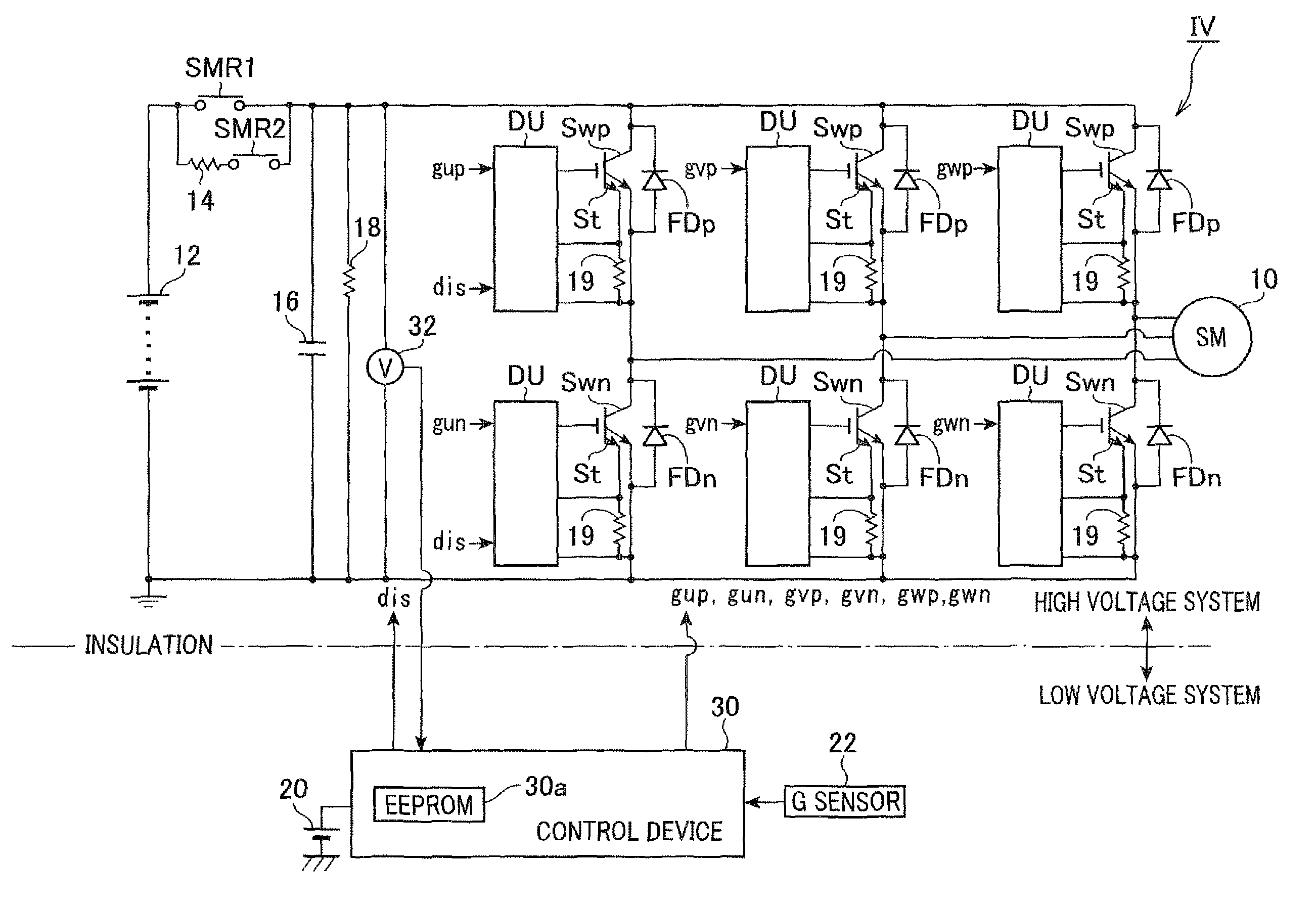

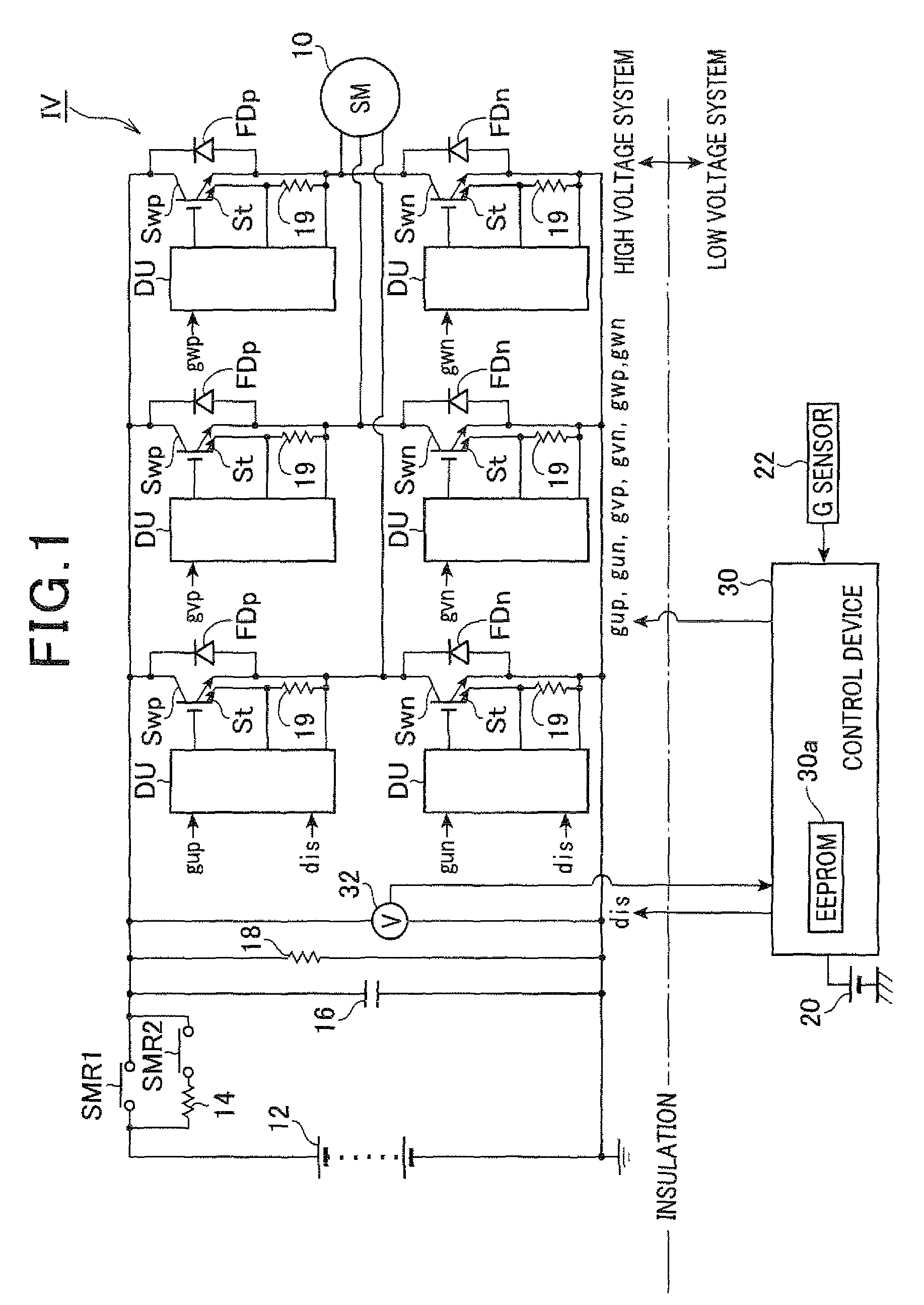

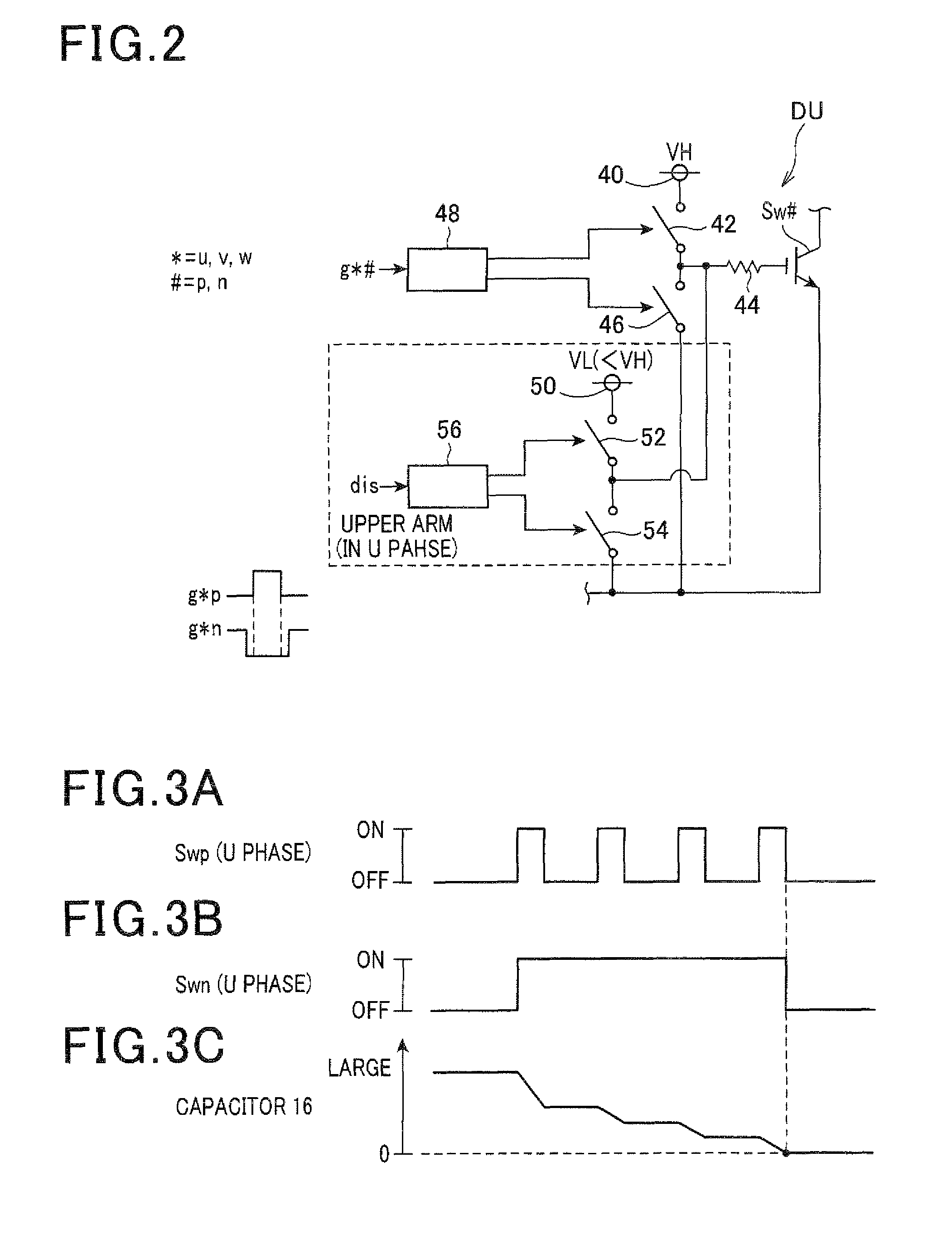

Discharging control device for electric power conversion system

ActiveUS8362754B2Reduce heatIncrease heatAc-dc conversionApparatus without intermediate ac conversionElectric power systemCapacitor voltage

A discharge control device in an electric power conversion system mounted to a motor vehicle turns off a relay in order to instruct an electric power conversion circuit to supply a reactive current into a motor generator, and thereby to decrease a capacitor voltage to a diagnostic voltage. After this process, the discharge control device outputs an emergency discharging instruction signal dis in order to turn on both power switching elements at high voltage side and a low voltage side in the electric power conversion circuit. This makes a short circuit between the electrodes of the capacitor in order to discharge the capacitor, and executes a discharging control to detect whether or not an emergency discharging control is correctly executed and completed. The discharge control device detects whether or not the electric power stored in the capacitor is discharged on the basis of the voltage of a voltage sensor.

Owner:DENSO CORP

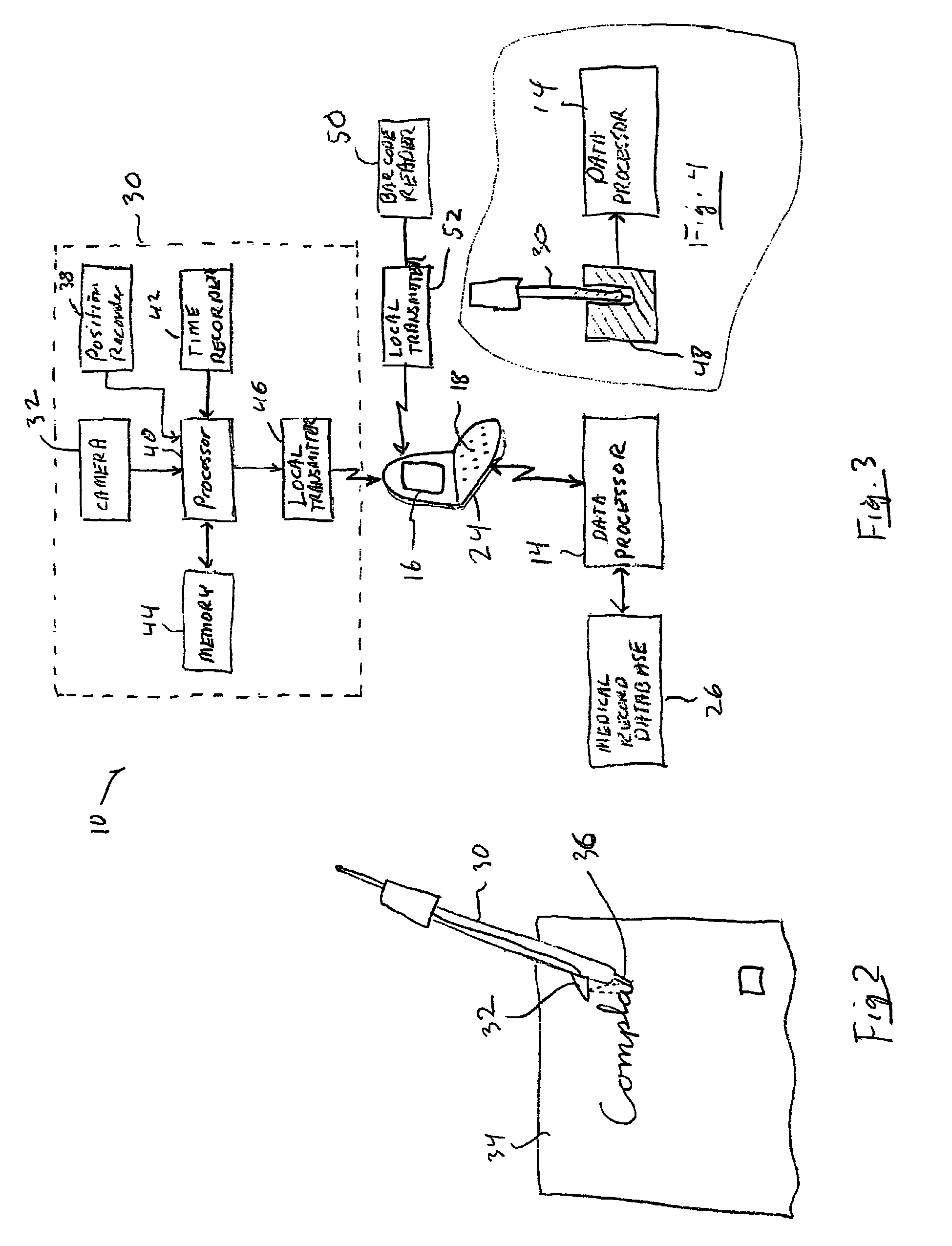

System and method of administrating instructions to a recipient of medical treatment

InactiveUS20110229867A1Educational modelsElectrical appliancesComputer scienceDischarge instructions

A system and method of administrating instructions to a recipient of medical treatment are provided herein. For the method, a computer and an interface connected thereto are provided. Instructions are communicated to the recipient after medical treatment. At least one question is communicated to the recipient after communicating the instructions. An answer to the at least one question is inputted into the computer through the interface. The answer is compared to an acceptable answer stored in the computer. Feedback is provided to the recipient from the computer after comparing the answer to acceptable answer. The system includes the computer and interface connected thereto. The computer is programmed to perform the method steps. The system and method provided herein address the shortcomings of current practices regarding administration of instructions to recipients of medical treatment and may assist in minimizing readmittance due to failure of such recipients to follow discharge instructions.

Owner:GOUGH JOSEPH WILLIAM +2

Association of data entries with patient records, customized hospital discharge instructions, and charting by exception for a computerized medical record system

InactiveUS8392216B2Reduce and eliminate ambiguityEasy inputMedical data miningData processing applicationsMedical recordDocumentation procedure

Owner:PICIS

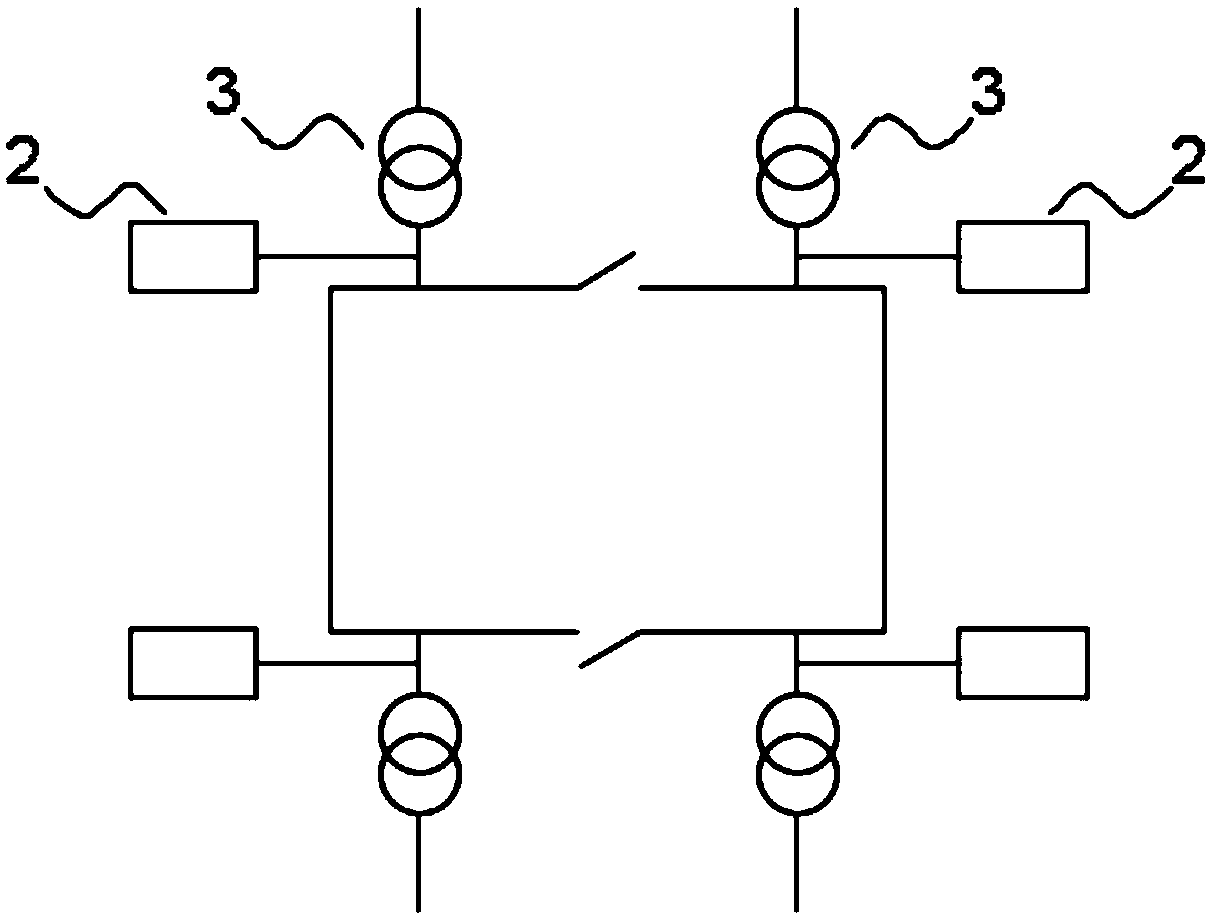

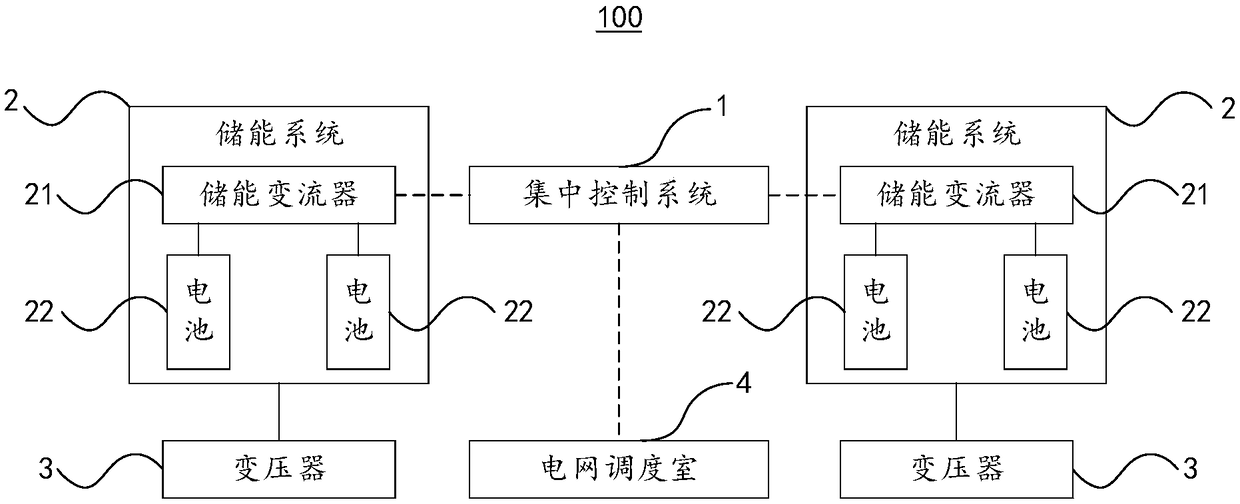

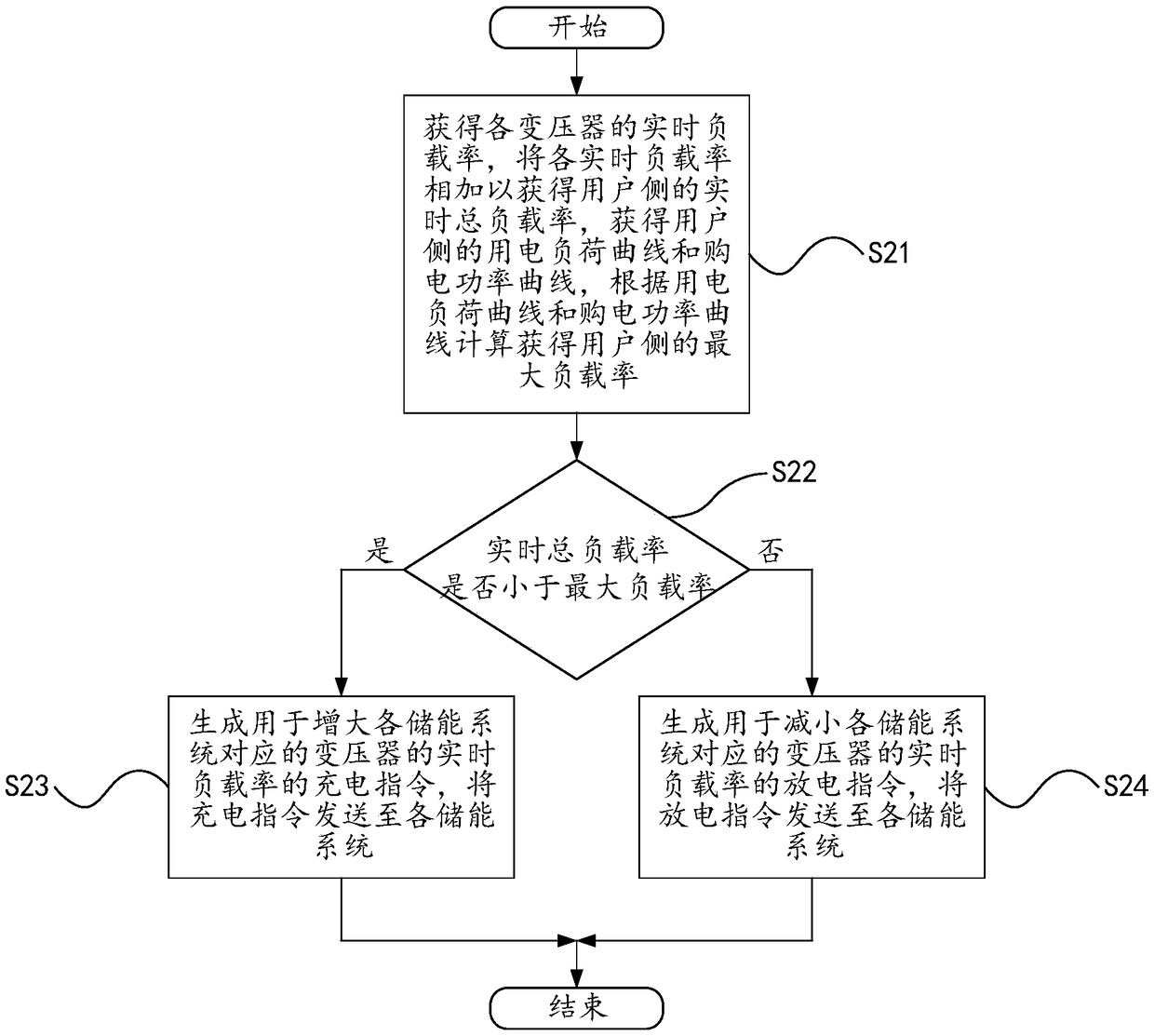

Transformer load rate control apparatus and method

InactiveCN109038690ALoad rate adjustmentSingle network parallel feeding arrangementsResourcesElectric power systemTransformer

Embodiments of the present invention relate to the technical field of power systems, in particular to a transformer load rate control apparatus and method. The apparatus includes a centralized controlsystem and a plurality of energy storage systems, each energy storage system is installed on the low-voltage outlet side of the corresponding transformer, each energy storage system is communicatively connected with a centralized control system, the centralized control system is used for obtaining the real-time total load rate and the maximum load rate of the user side, A real-time total load rate and a maximum load rate are compared to obtain a comparison result, A charge / discharge instruction is generated according to the comparison result and sent to each energy storage system, each energystorage system is configured to receive a charge / discharge instruction, charge and discharge according to the charge and discharge instruction, so as to realize the adjustment of the real-time load rate of the transformers corresponding to each energy storage system, the centralized control system is used for obtaining the real-time remaining power of each energy storage system, and the corresponding energy storage system is controlled to stop charging and discharging according to the change of the real-time remaining power, so as to realize the efficient control of the load rate of the transformers.

Owner:SICHUAN ENERGY INTERNET RES INST TSINGHUA UNIV +2

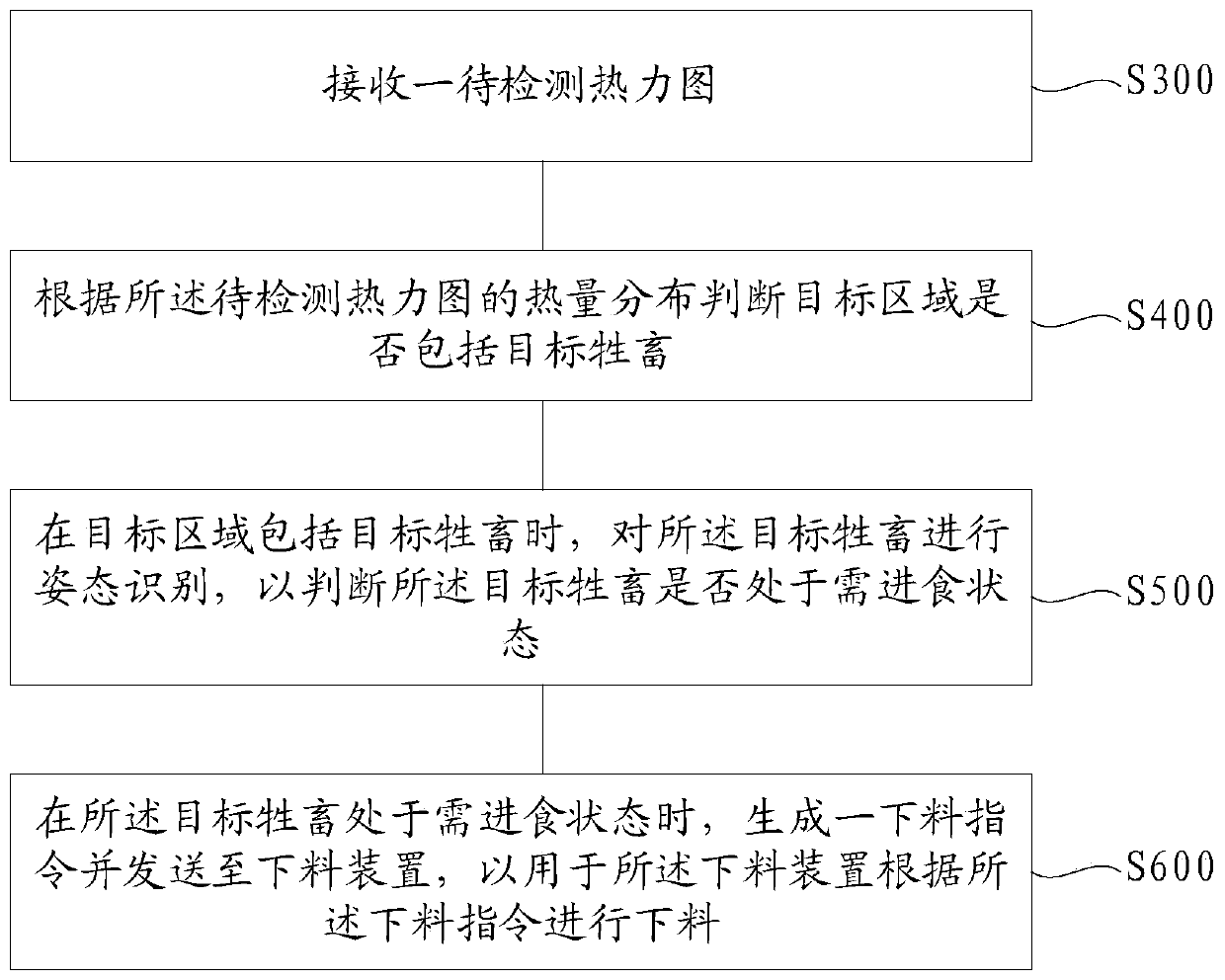

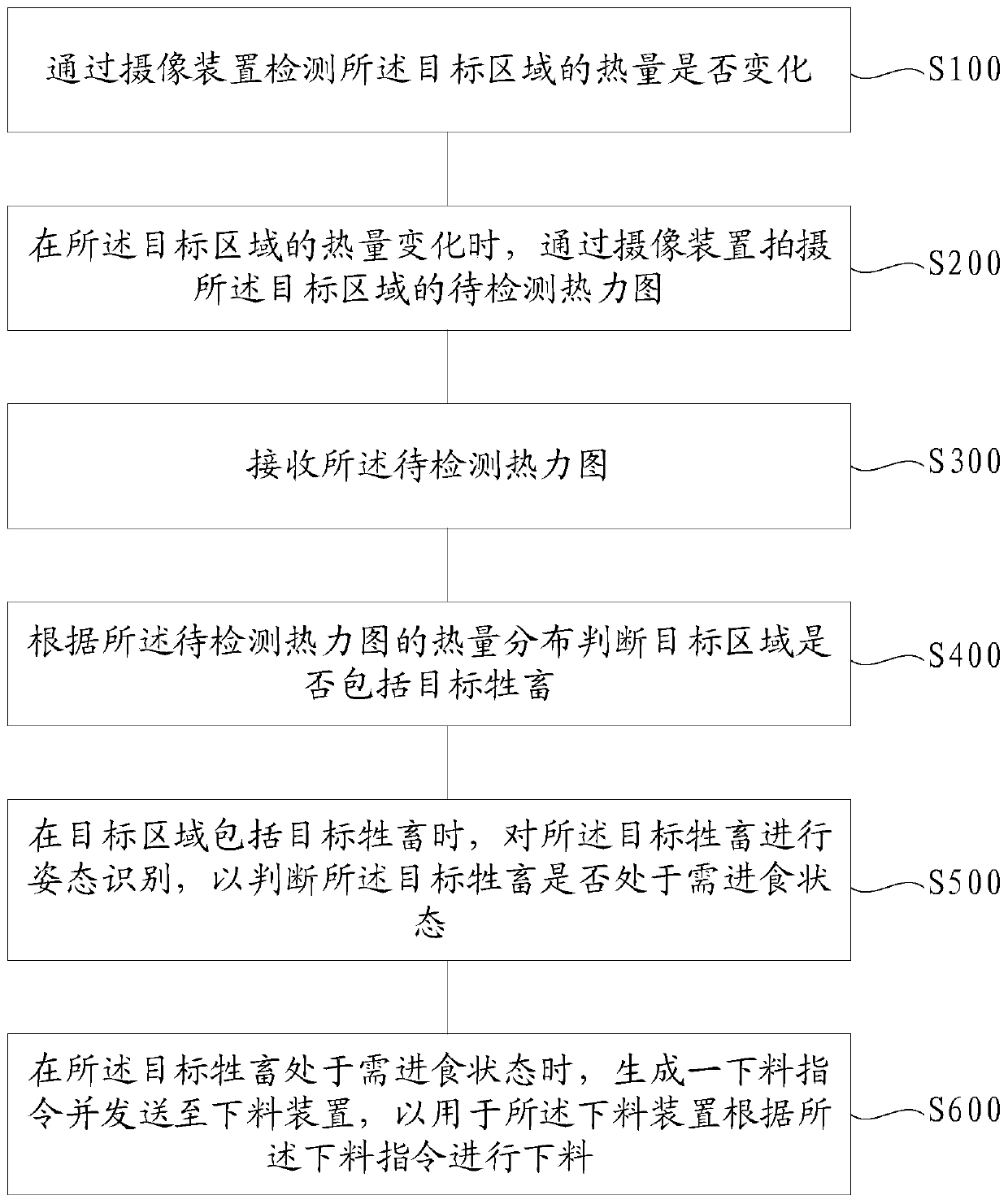

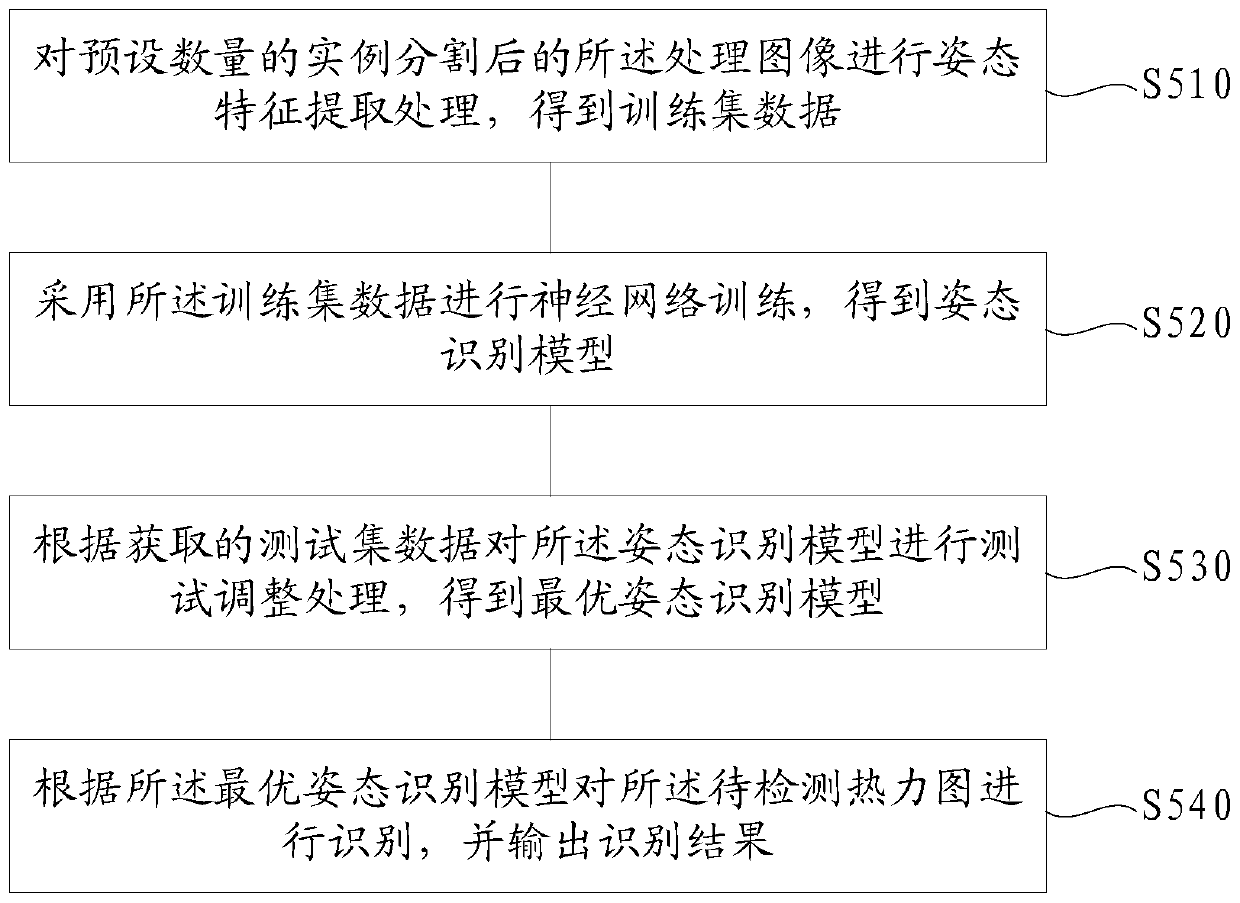

Feed supply method and system, computer system and storage medium

ActiveCN110547210AAchieve feedingGuaranteed reliabilityAnimal feeding devicesBiometric pattern recognitionComputerized systemLivestock

The invention relates to the technical field of feed supply, and relates to a feed supply method and system, a computer system and a storage medium. The feed supply method comprises the steps that a to-be-detected thermodynamic diagram is received; according to the heat distribution of the to-be-detected thermodynamic diagram, whether or not a target area contains target livestock is judged; if yes, posture recognition is performed on the target livestock to judge whether or not the target livestock needs feeding; if yes, a discharging instruction is generated and sent to a discharging device,and the discharging device accordingly performs discharging according to the discharging instruction. The provided feed supply method has high reliability, low labor cost and high feeding process flexibility.

Owner:JD DIGITS HAIYI INFORMATION TECHNOLOGY CO LTD

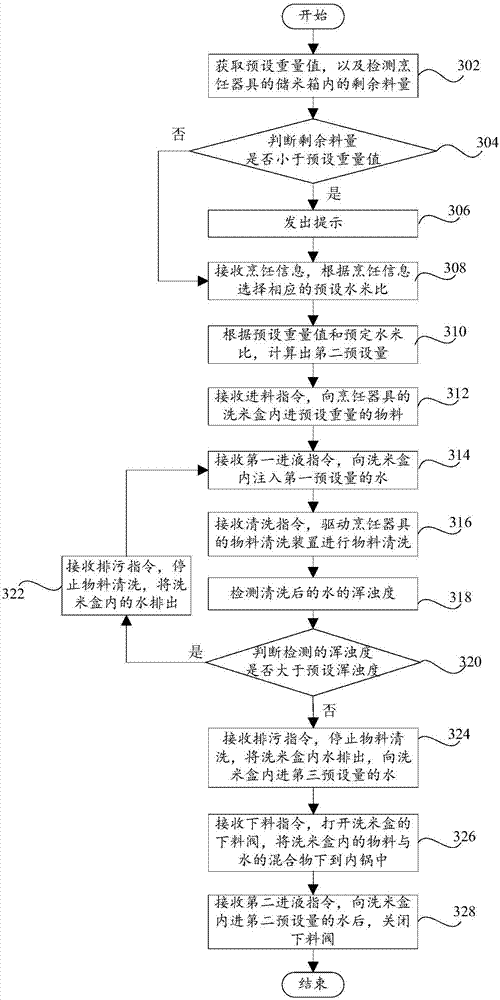

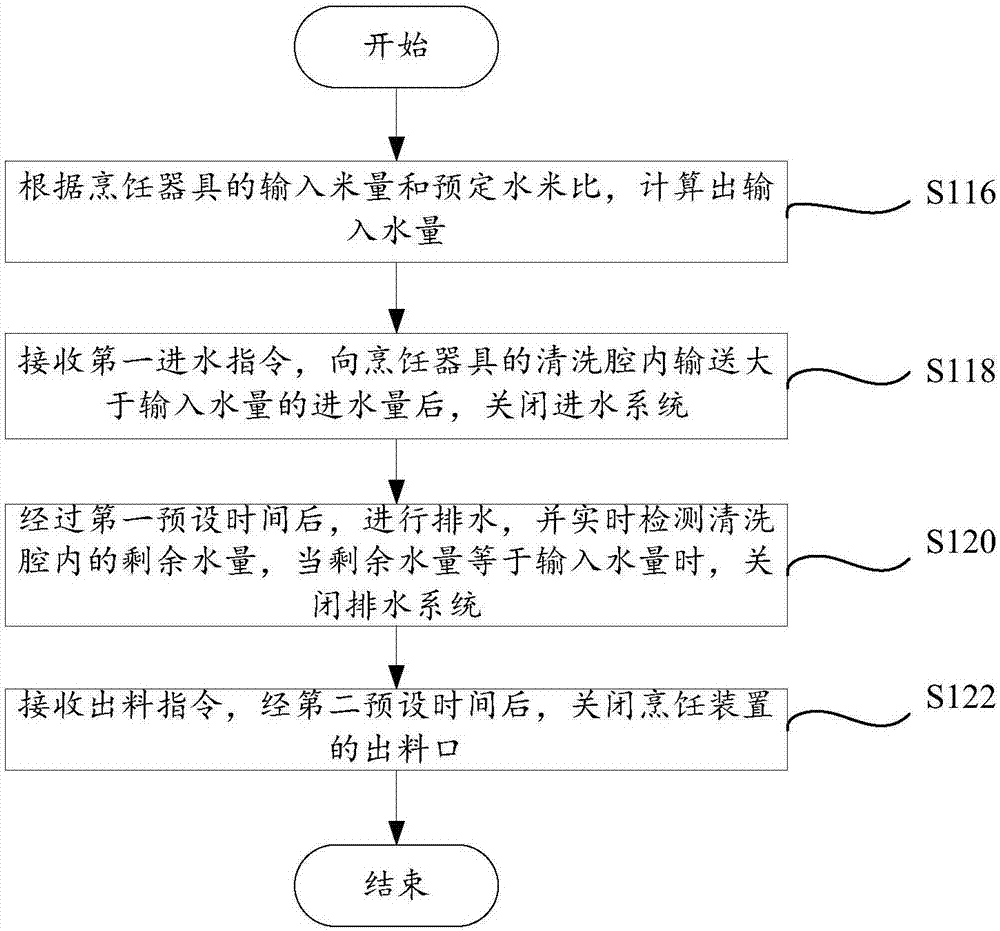

Rice feeding control method and system and cooking appliance

ActiveCN107296539AImprove experienceSolve the problem that the rice attached to the inner wall of the cleaning chamber cannot be dischargedCooking vesselsControl systemEngineering

The invention provides a rice feeding control method used for a cooking appliance. The method includes the steps that 116, according to the imported rice amount and the preset ratio of water to rice of the cooking appliance, the imported water amount is calculated; 118, a first water import instruction is received, and after the imported water with an amount larger than the imported water amount is conveyed into a washing cavity of the cooking appliance, a water import system is shut down; 120, after a first preset time, drainage is conducted while the surplus water amount in the washing cavity is detected in real time, and when the surplus water amount is equal to the imported water amount, a drainage system is shut down; 122, a discharging instruction is received, and after a second preset time, a discharging port of the cooking appliance is closed. According to the rice feeding control method and system and the cooking appliance, through addition of the water with the amount higher than the ratio of water to rice into the washing cavity, all the rice attaching to the inner wall of the washing cavity can sink to the bottom, then the redundant water is drained, and rice discharging is conducted, which is clean and thorough.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

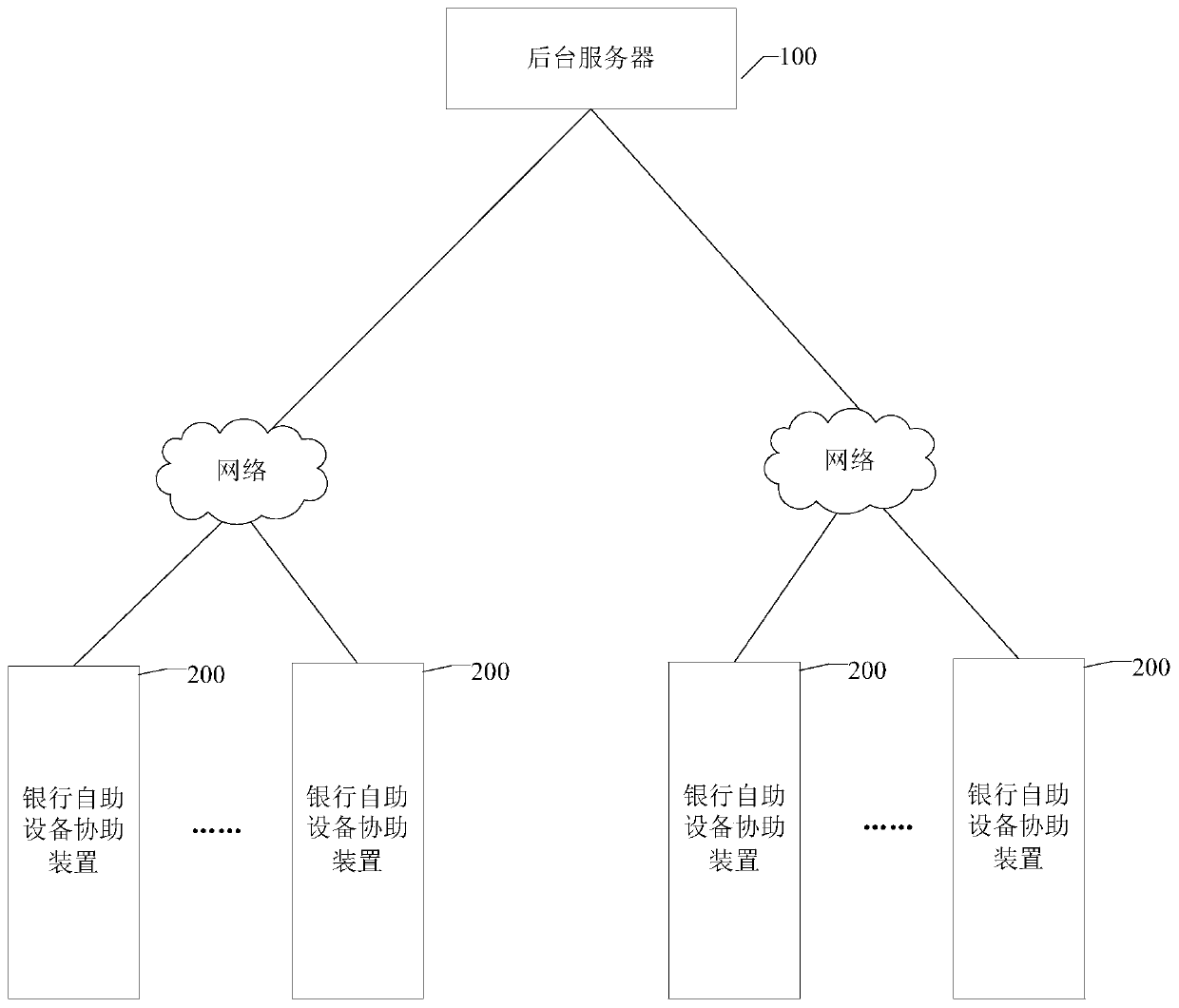

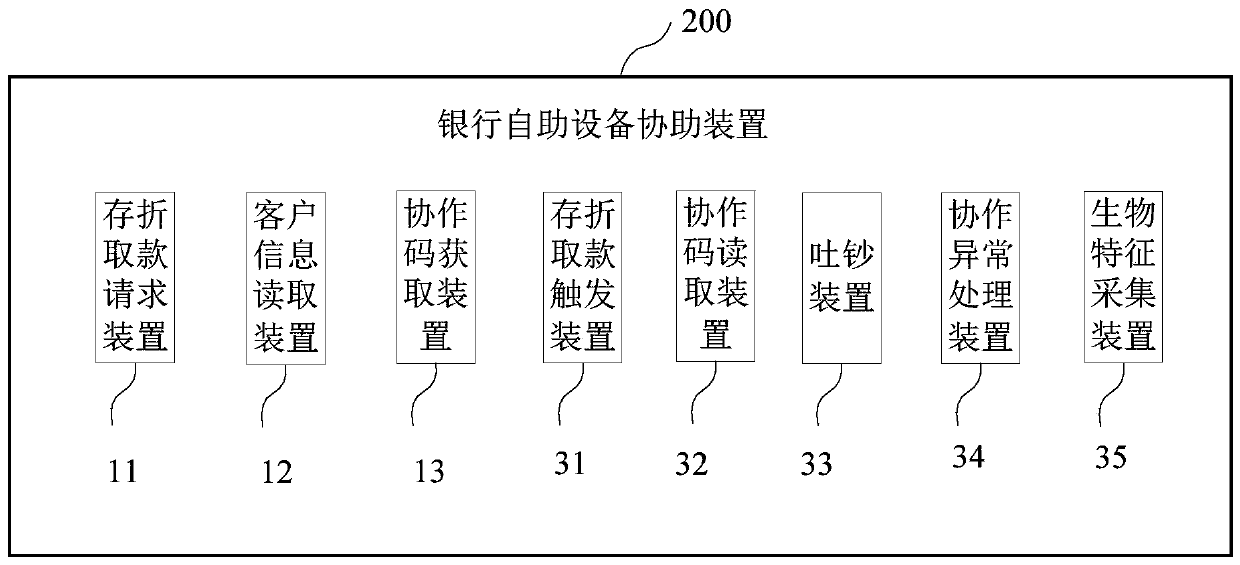

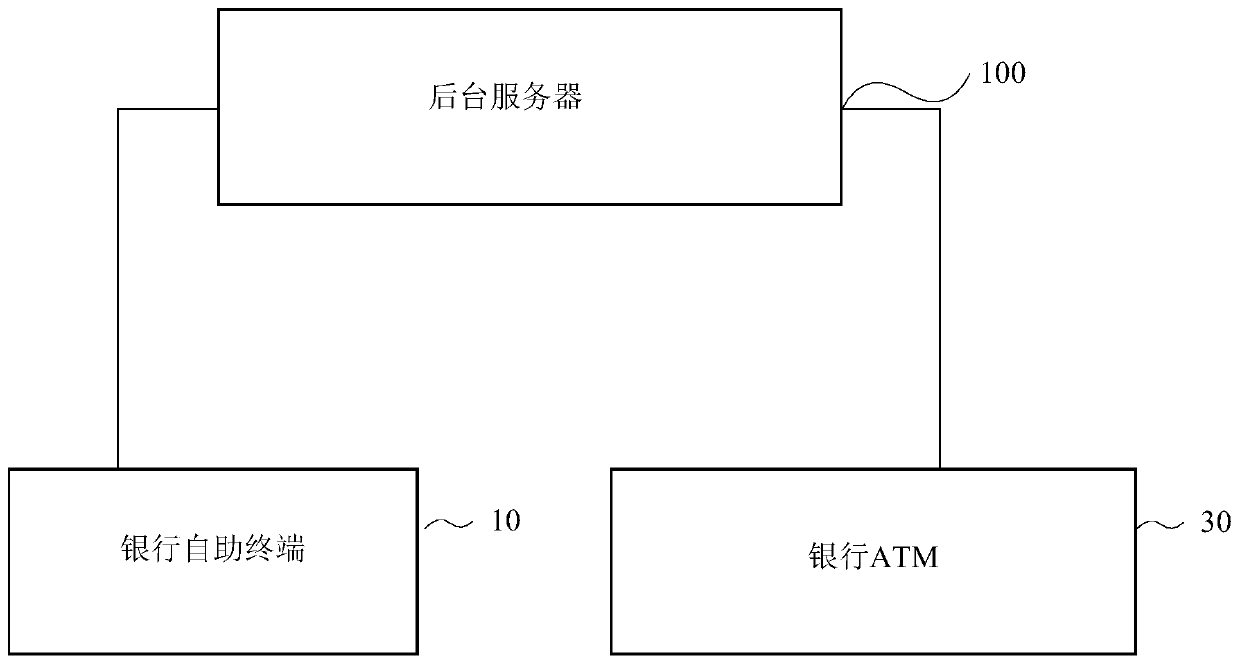

Bank self-service equipment assisting device, bank self-service cooperation system and method

ActiveCN110060433AAlleviate the business pressure of passenger flowComplete banking machinesATM softwaresPasswordPassbook

The invention provides a bank self-service cooperation method, a bank self-service equipment assisting device, a bank self-service cooperation system, computer equipment and a computer readable storage medium, and relates to the technical field of financial equipment. The method comprises the following steps that the bank self-service equipment assisting device receives a withdrawal request sent by a client through a passbook and reads client information; a background server generates a cooperation code and effective time of the cooperation code according to the client information; the bank self-service equipment assisting device receives an cooperation code, acquires the withdrawal information input by the client according to the cooperation code, and sends the cooperation code and the withdrawal information to the background server; the background server verifies the cooperation code and the passbook password, and outputs a bill spitting instruction when the verification is successful; and the bank self-service equipment assisting device is used for discharging the bank note according to a bank note discharging instruction. The bank self-service cooperation method, the bank self-service equipment assisting device, the bank self-service cooperation system, the computer equipment and the computer readable storage medium solve the problem that the passbook client cannot withdrawcash from the ATM in the bank outlets at present, and can relieve the pressure of the counter passenger flow business without extra hardware investment of a bank enterprise.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

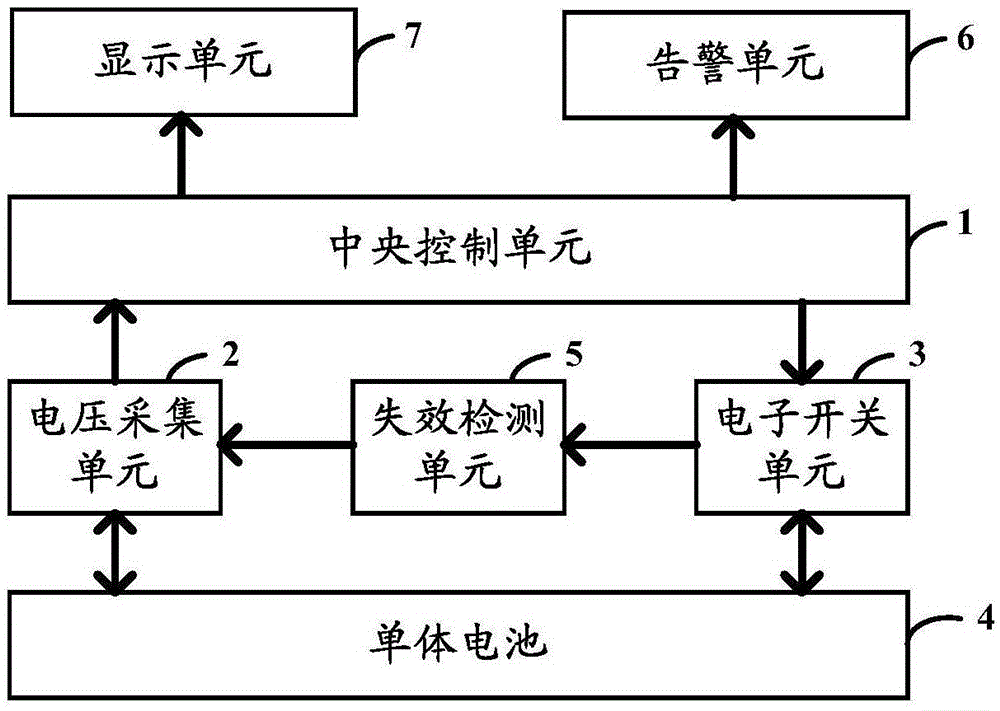

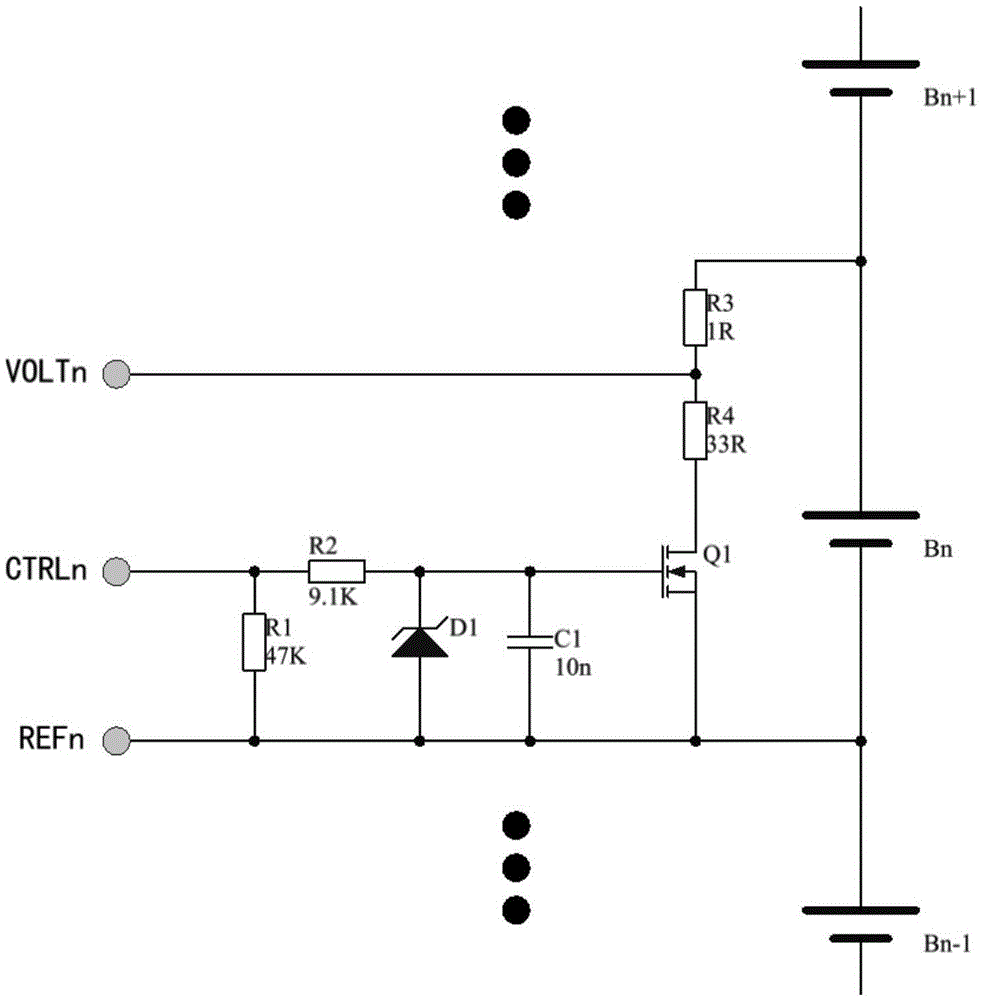

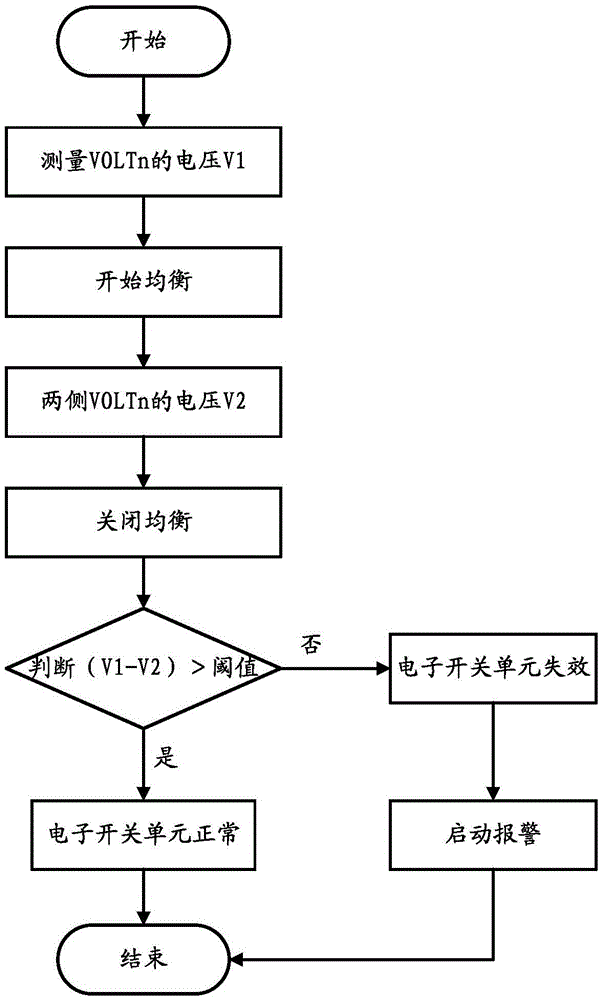

Passive equalization circuit for battery management system

InactiveCN105633491AReal-time monitoring of voltage informationAvoid over-discharge damageCells structural combinationElectrical batteryElectronic switch

The invention is applicable to battery management, and provides a passive equalization circuit for a battery management system. The passive equalization circuit comprises a central control unit, multiple voltage collection units and multiple electronic switch units, wherein the voltage collection units are used for collecting voltage information of single batteries and transmitting the voltage information to the central control unit; the central control unit analyzes according to the voltage information, and generates a discharge instruction to control the electronic switch units to discharge to the single batteries when the voltage of a certain single battery is higher than that of other single batteries, and stops the discharging process when the voltage of the certain single battery is consistent with that of other single batteries. By adoption of the passive equalization circuit, the voltage information of single batteries can be monitored in real time; discharging processing can be performed when a certain single battery is abnormal so as to enable the voltages of all the single batteries to be consistent; and furthermore, the real-time monitoring diagnostic function of the electronic switches is utilized, so that damaged switching devices can be found in time to send out an alarm so as to avoid overdischarge damage of batteries.

Owner:深圳市清友能源技术有限公司

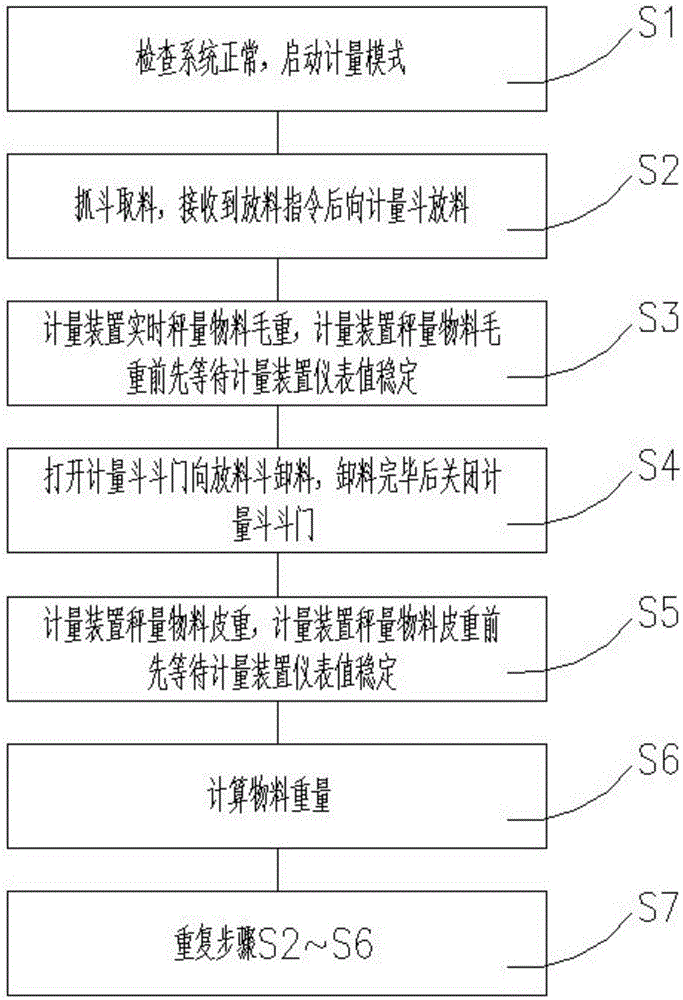

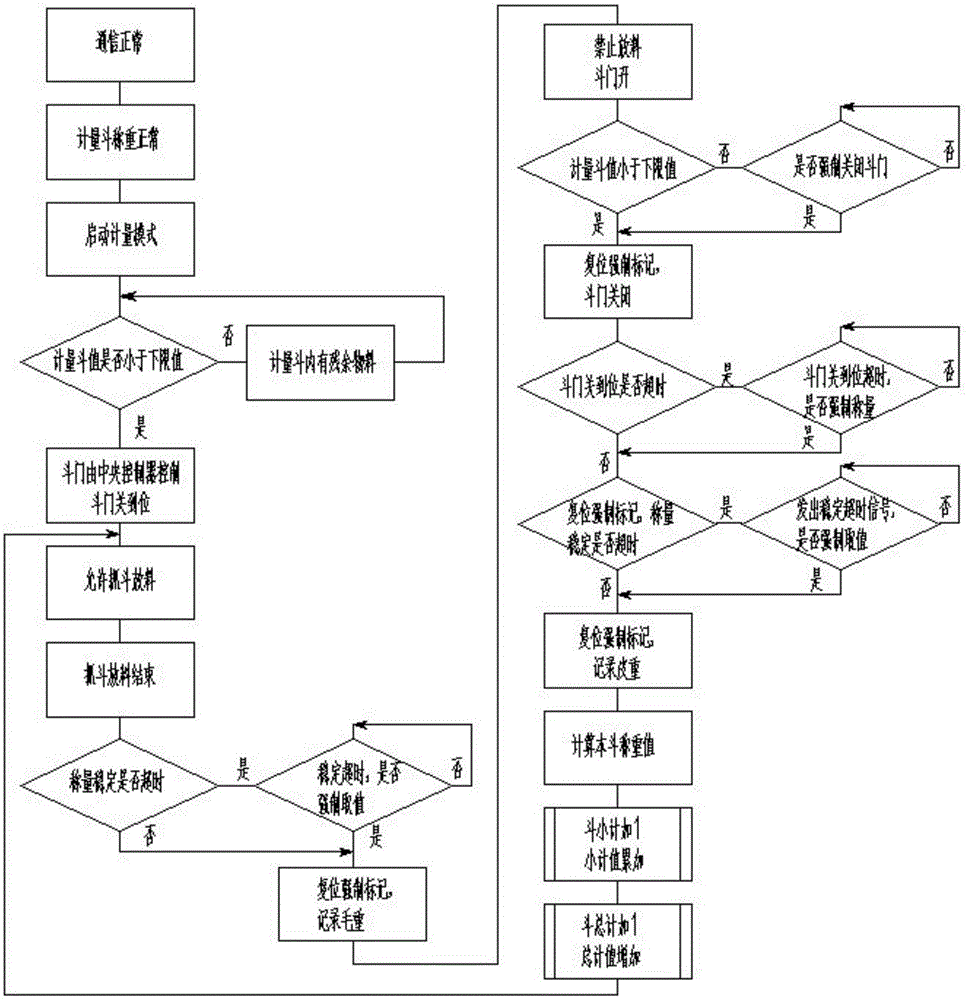

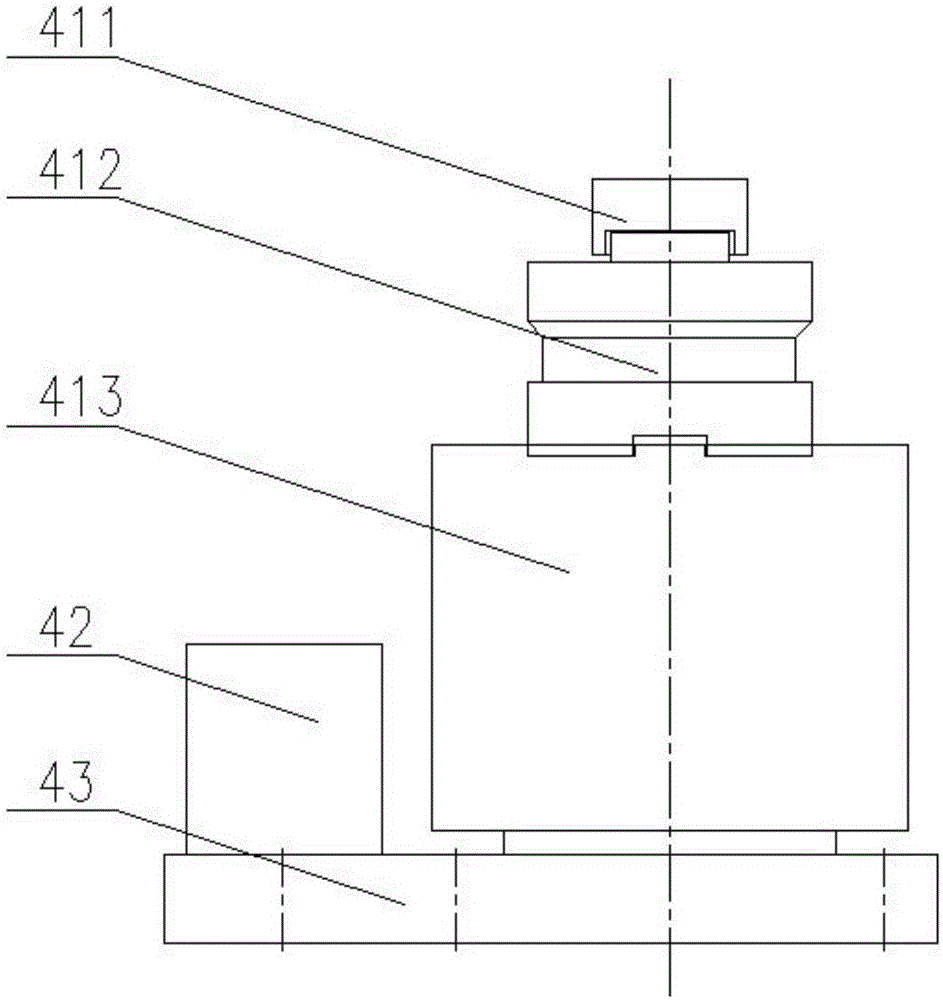

Ship unloader metering mode control method

ActiveCN105021263AEasy to manageGuaranteed accuracySpecial purpose weighing apparatusDischarge efficiencyMode control

The invention relates to a ship unloader metering mode control method. The method comprises the following steps: S1) detecting whether a system is normal and starting a metering mode; S2) carrying out grab hopper material taking, and after receiving a material discharging instruction, discharging material to a measuring hopper; S3) weighing rough weight of the material in real time through a metering device, wherein the metering device carries out material rough weight weighing after the instrument value of the metering device is stable; S4) opening a gate of the measuring hopper and discharging the material to a discharge hopper, and after discharging is finished, closing the gate of the measuring hopper; S5) weighing tare weight of the material through the metering device, wherein the metering device carries out material tare weight weighing after the instrument value of the metering device is stable; S6) calculating the weight of the material; and S7) repeating the steps S2)-S6). The reasonable and high-efficiency ship unloader metering mode control method guarantees metering precision of a ship unloader and improves discharging efficiency of the ship unloader, and guarantees transaction fairness and enterprise production operation efficiency.

Owner:HANGZHOU HUAXIN MECHANICAL & ELECTRICAL ENGINEERING CO LTD +1

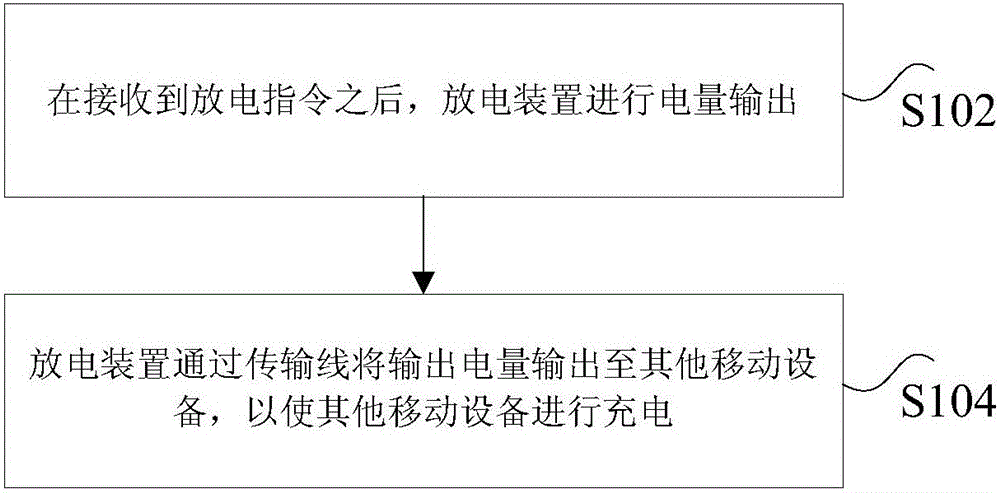

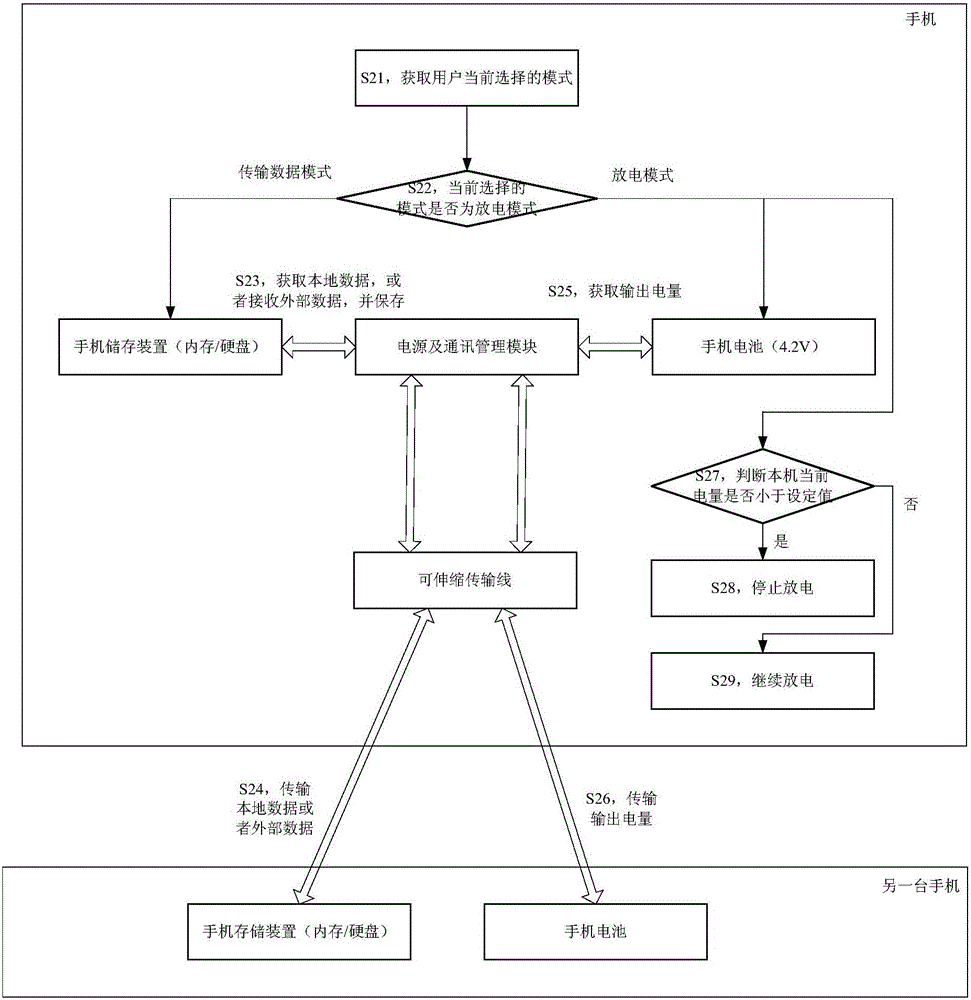

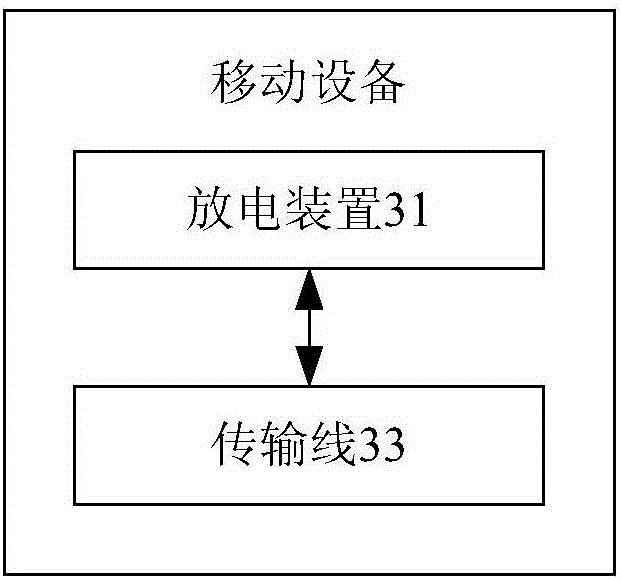

Mobile device power processing method, system and mobile device

ActiveCN106300505ARealize mutual deliveryFlexible chargingElectric powerBattery load switchingPower processingMobile device

The invention discloses a mobile device power processing method, a mobile device power processing system and a mobile device. The mobile device comprises a discharging device and a transmission line, wherein the transmission line is built in the mobile device. The method includes the following steps that: after receiving a discharging instruction, the discharging device outputs power; and the discharging device transmits the outputted power to the other mobile device through the transmission line, so that the other mobile device can be charged. With the method and system of the invention adopted, the technical problem that power in one mobile device cannot be transmitted to the other mobile device can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

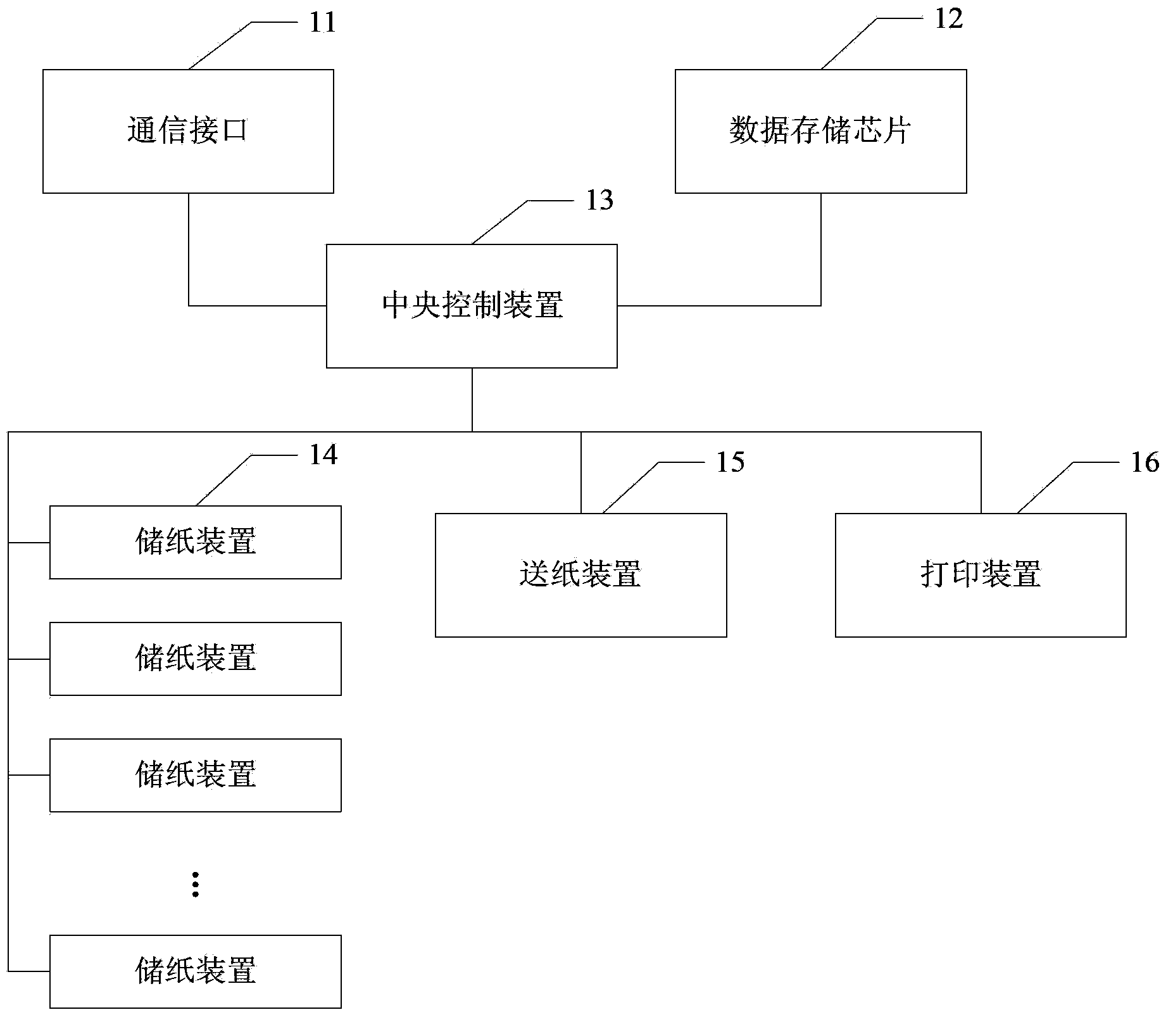

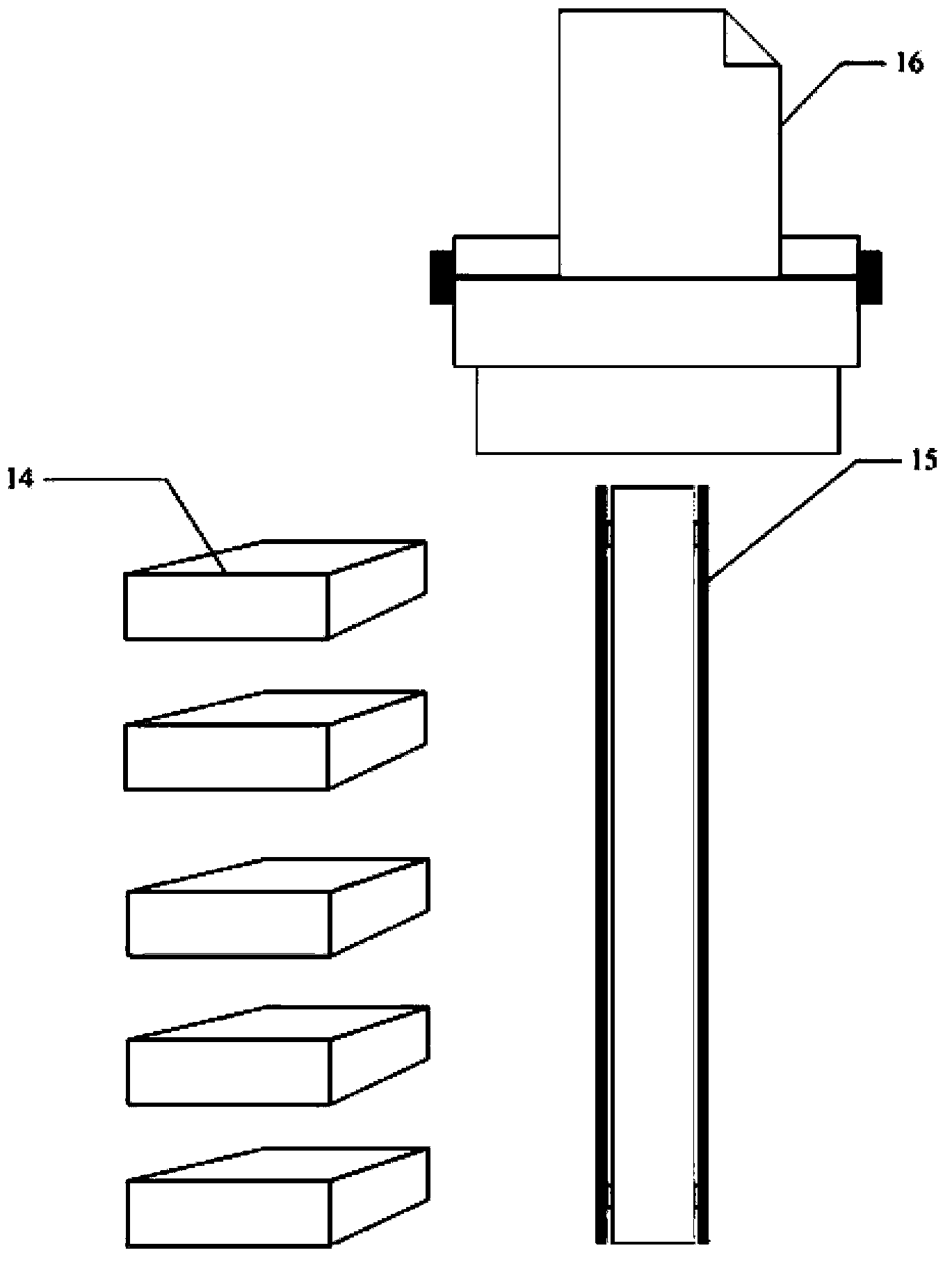

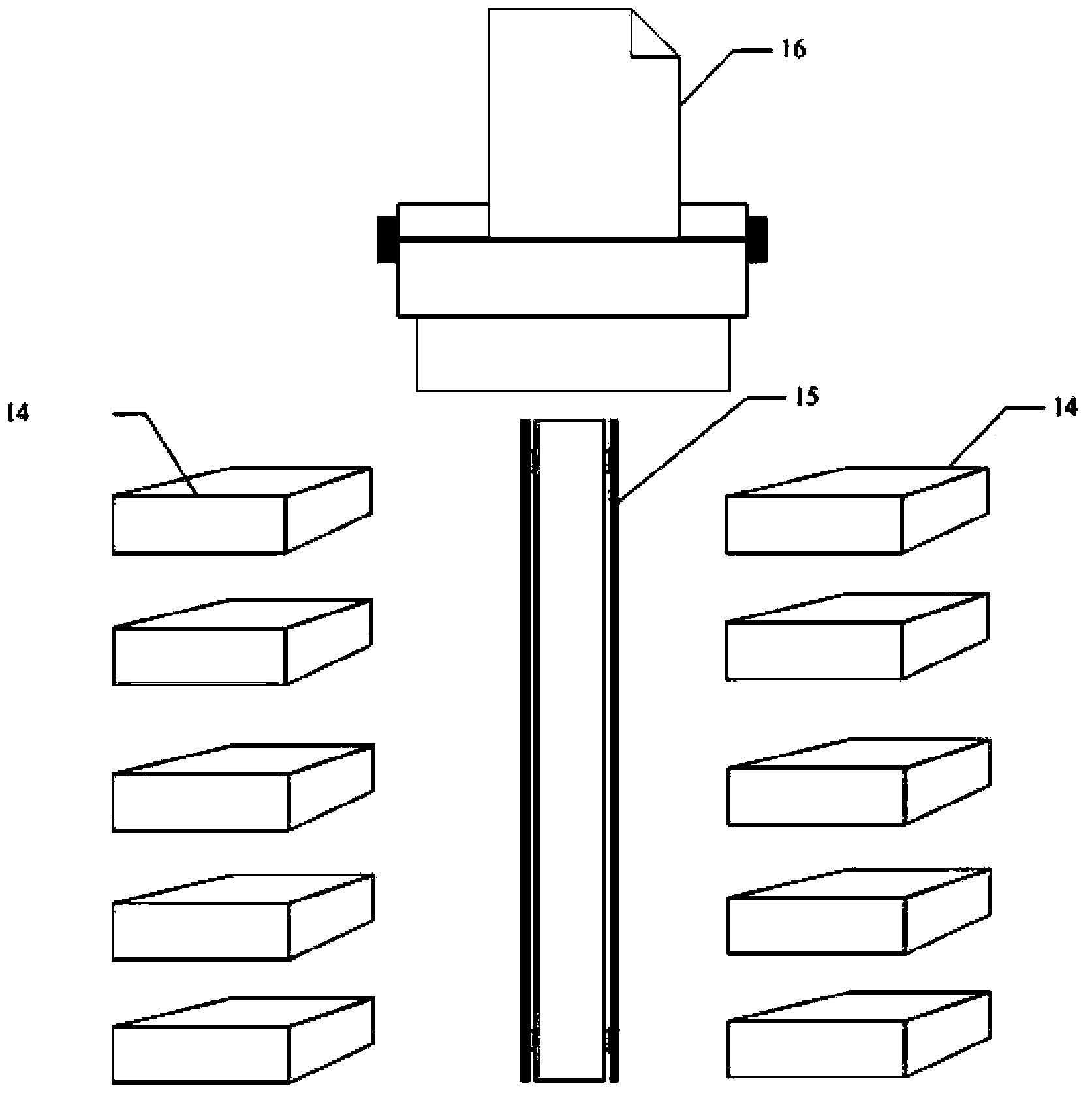

Multi-standard printing equipment

ActiveCN103434276ARealize automatic paper feedingHigh degree of automationOther printing apparatusCommunication interfacePulp and paper industry

The invention provides a set of multi-standard printing equipment. The multi-standard printing equipment comprises a communication interface, a data storage chip, a central control device, paper storage devices, a paper feeding device and a printing device. The communication interface is used for receiving a printing instruction of a user and transmitting the instruction to the central control device. The data storage chip is used for storing the corresponding relation between each paper storage device and each printing paper standard. The central control device is used for determining the target paper storage device according to the printing paper standards contained in the printing instruction of the user and the corresponding relation between each paper storage device and each printing paper standard, sending a paper discharging instruction to the target paper storage device, sending a paper feeding instruction to the paper feeding device and sending printing information contained in the printing instruction of the user to the printing device. Each paper storage device is used for storing printing paper with a set standard and outputting the printing paper to the paper feeding device when receiving the paper discharging instruction. The paper feeding device is used for receiving the printing paper from the target paper storage device when receiving the paper feeding instruction and conveying the paper to the printing device. The printing device is used for receiving the printing information and printing the printing information onto the printing paper conveyed by the paper feeding device. The multi-standard printing equipment can automatically feed the paper and support printing of vouchers or receipts with multiple standards and has the advantages of being high in automation degree and working efficiency, low in error rate and the like.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

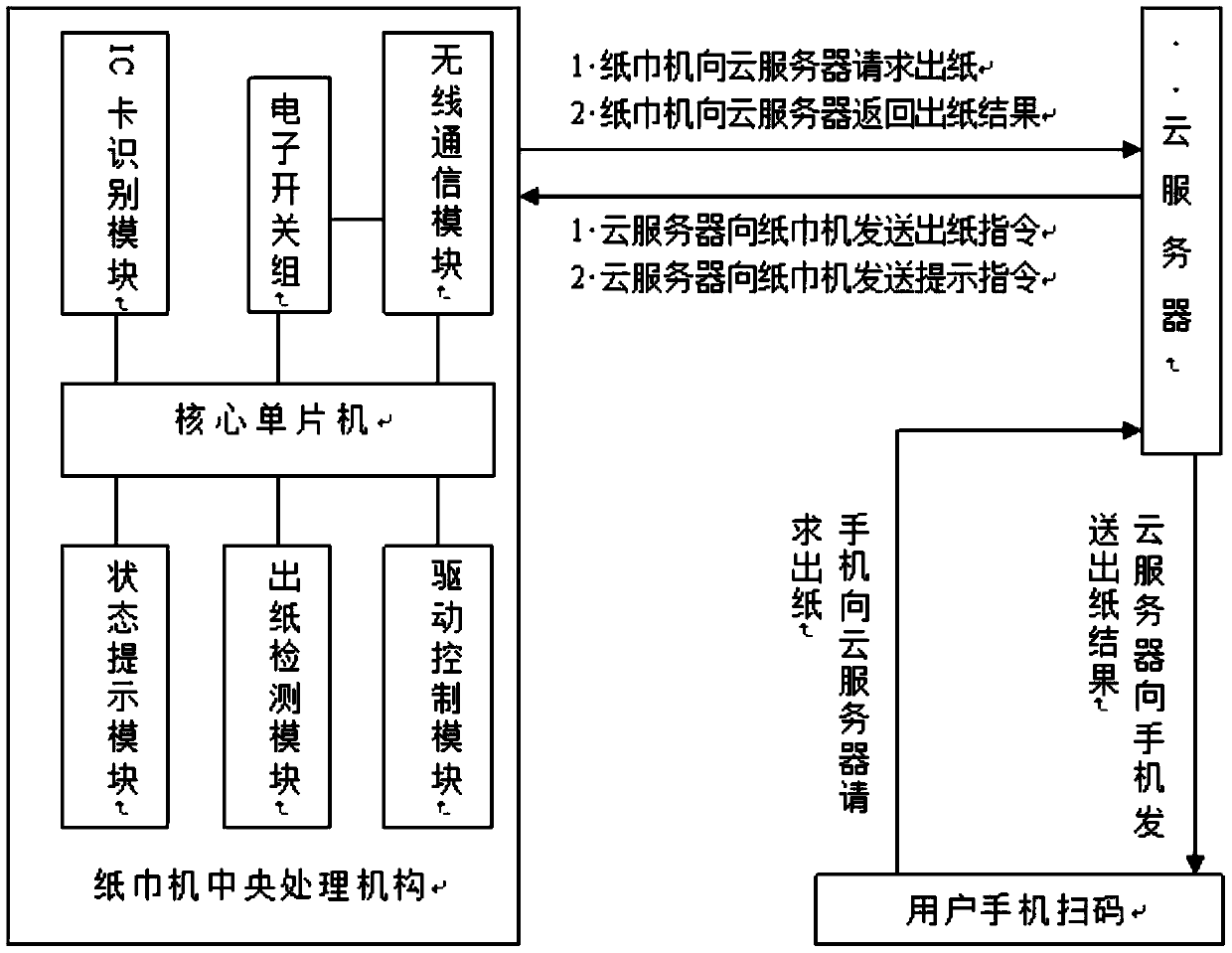

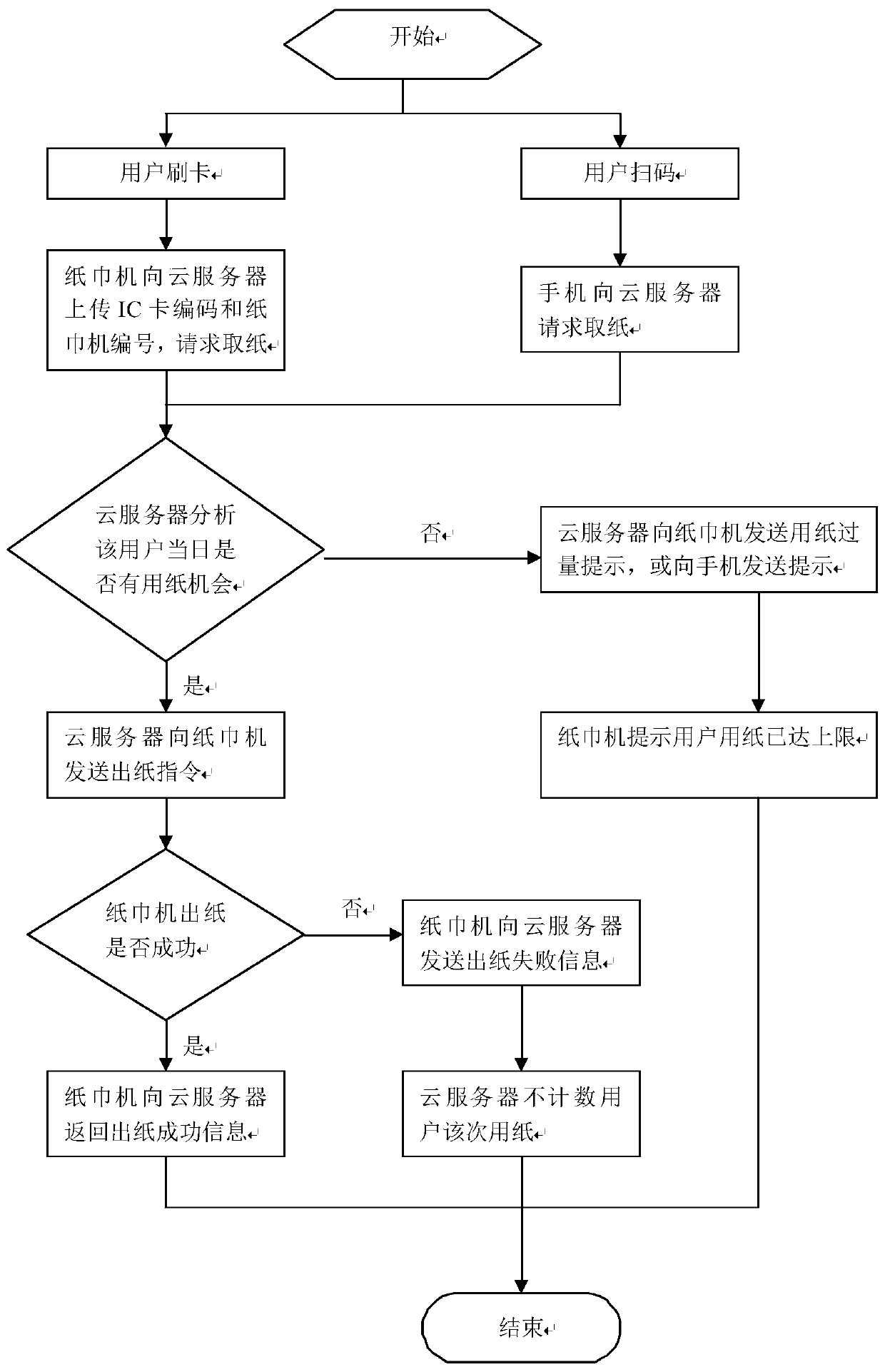

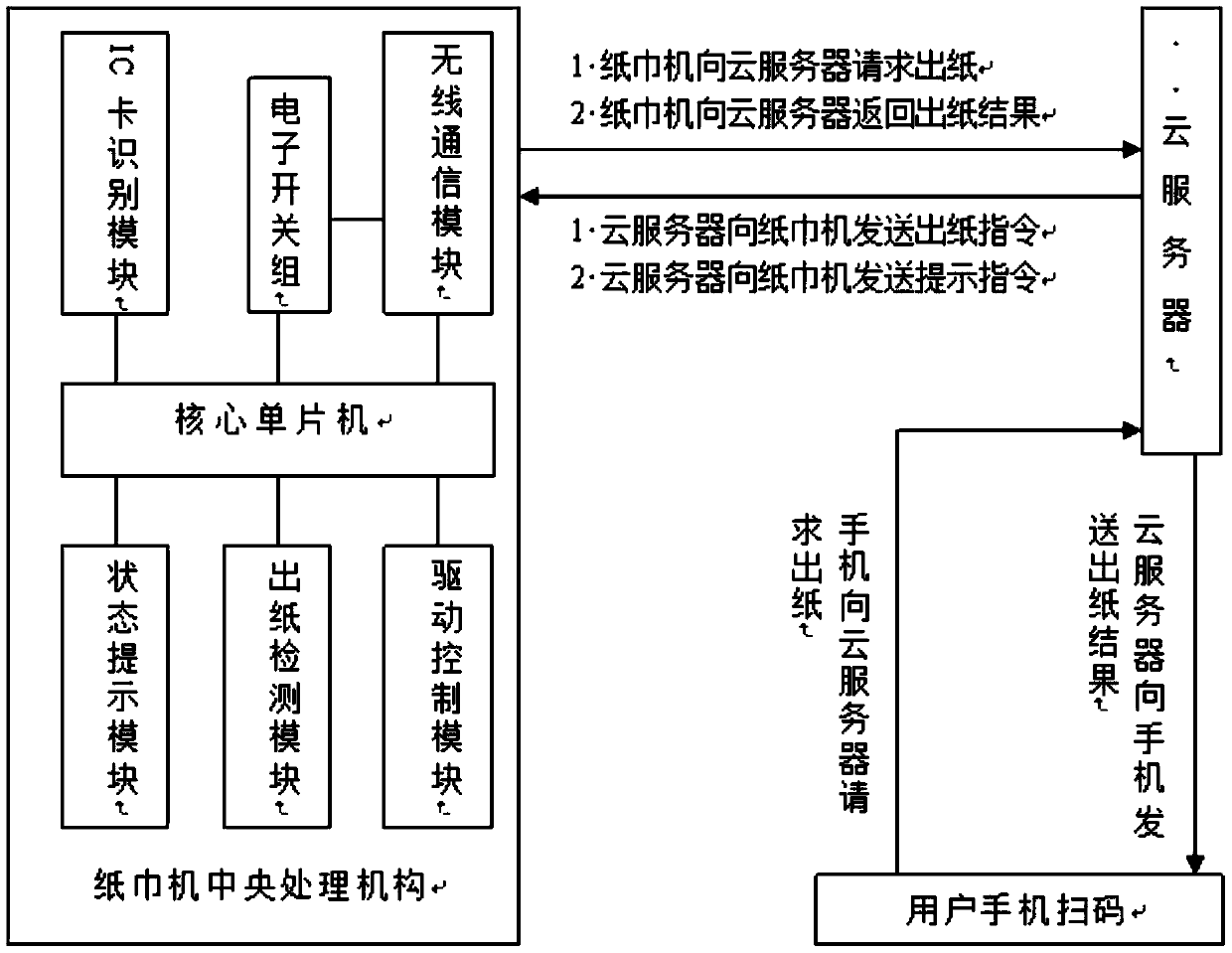

Networked card swiping-type public toilet paper supply system

ActiveCN109920137ACoin-freed apparatus detailsApparatus for dispensing discrete articlesLimit valueMobile phone

The embodiment of the invention discloses a networked card swiping-type public toilet paper supply system, which relates to a public toilet paper supply technology so as to solve the problem of wasteof the existing public toilet paper. A paper machine identifies the information of an IC card; or, a user scans the two-dimensional code of the paper machine by WeChat, the IC card information and thepaper machine management code are transmitted to a cloud server through the paper machine or the mobile phone, the cloud server counts the paper taking times on the paper machine corresponding to themanagement code by the IC card or the WeChat account on the day; and when the paper taking times do not exceed a preset upper limit value, a paper discharge instruction is sent to the paper machine,the paper machine receives the paper discharge instruction sent by the cloud server, and paper discharge operation is executed. The system is mainly used for public toilet paper supply.

Owner:吴大鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com