Method and device for automatically controlling plate discharge at outlet of drying machine

A dryer and controller technology, applied in the direction of program control, drying of solid materials, electrical program control, etc., can solve the problems of difficult cleaning, labor-intensive, long maintenance time, etc., and achieve the effect of improving operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

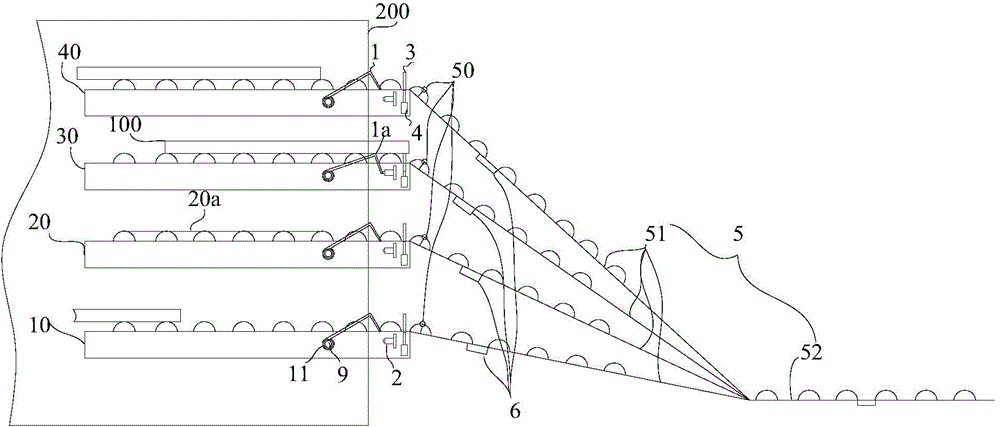

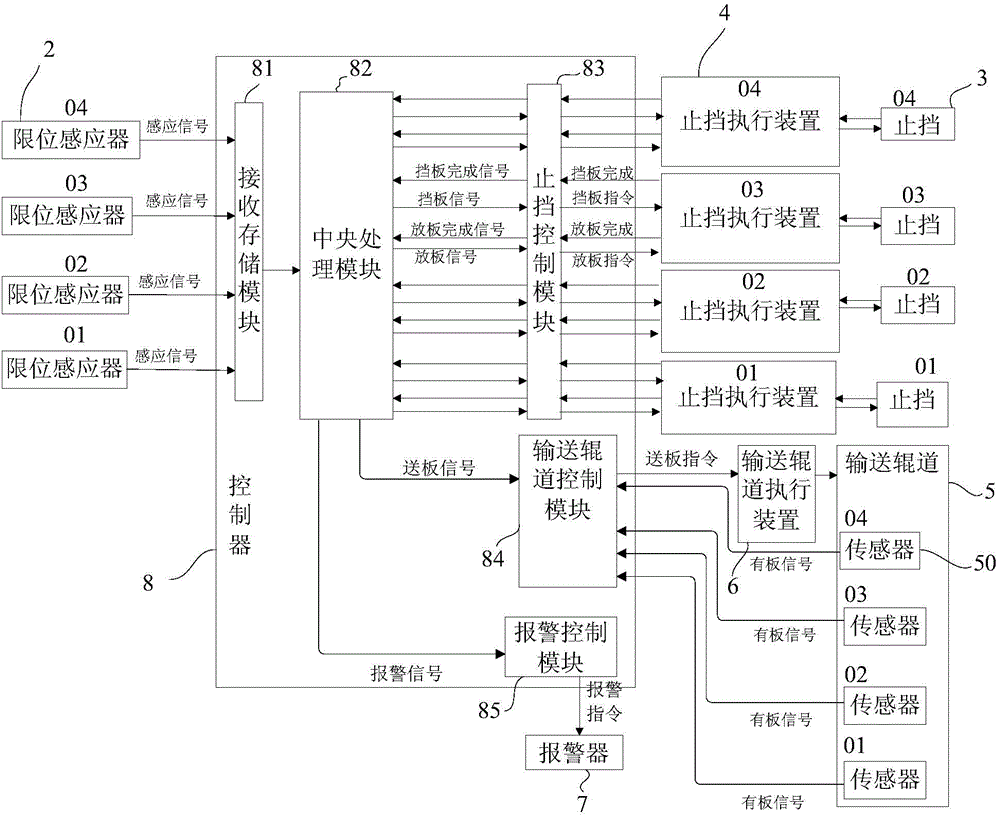

[0051] Such as figure 1 , figure 2 As shown, the embodiment of the present invention provides an automatic control method for releasing plates at the outlet of the dryer, including the following steps:

[0052] Step 1, when the gypsum board 100 runs to the outlet 200 of the dryer roller table on one layer, press down on the shrapnel 1 arranged at the outlet 200 of the dryer roller table, and the shrapnel 1 produces elastic deformation to trigger the limit sensor arranged below it 2. The limit sensor 2 sends an induction signal to the controller 8;

[0053] Such as figure 1 As shown, there are four layers of roller tables inside the dryer, which are the first layer, the second layer, the third layer and the fourth layer from bottom to top. In this embodiment, it is located on the third layer of dryer roller table 30 The gypsum board 100 first runs to the outlet 200 of the roller table of the dryer, and the gypsum board 100 will press down the shrapnel 1 that is higher than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com