Fuel screening device for power plant

A technology for screening devices and power plants, applied in fuel supply, measurement devices, solid fuel pretreatment, etc., can solve problems such as inconvenience in use, single functionality, and inability to screen pulverized coal, so as to improve accuracy, ensure uniformity, The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

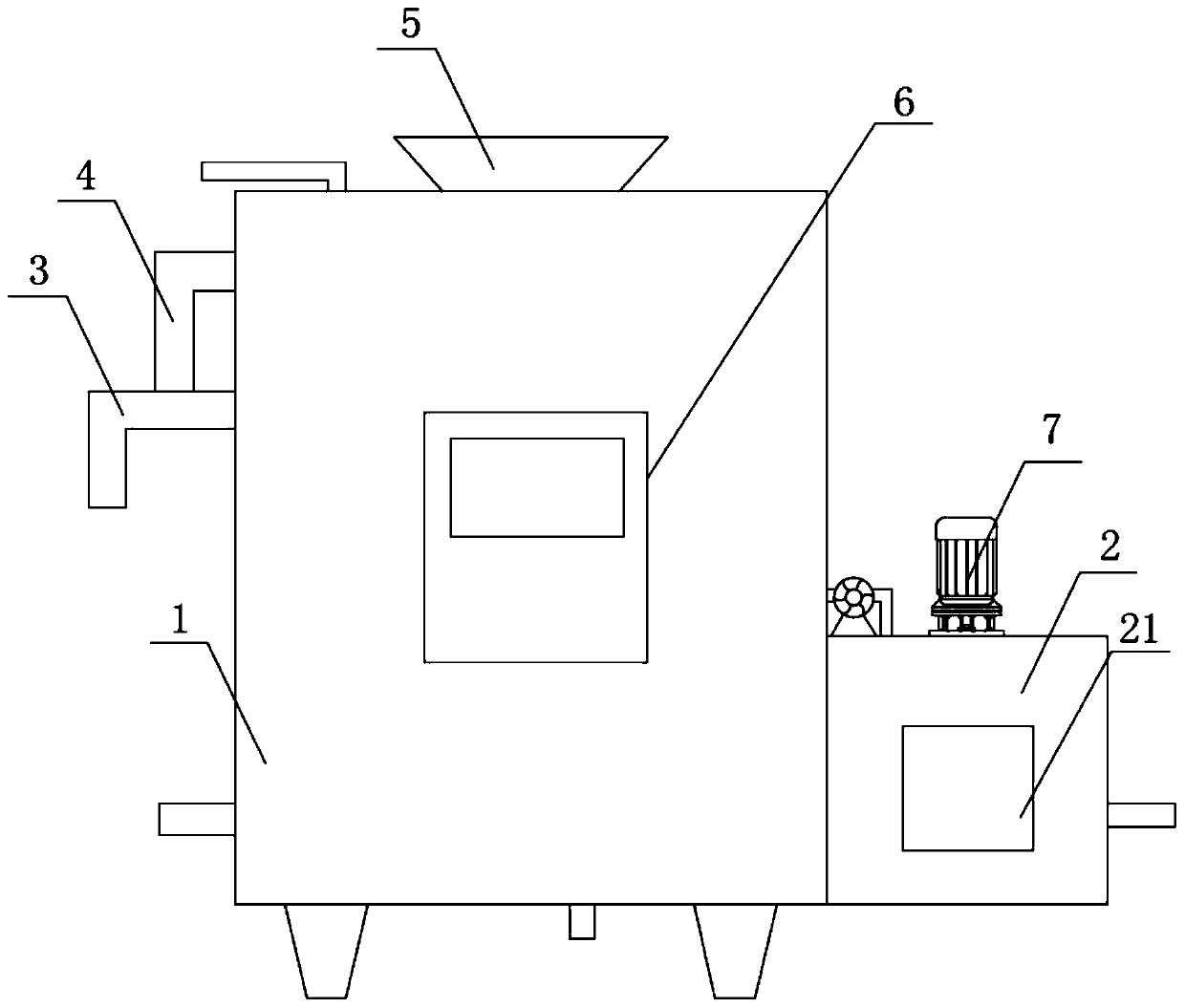

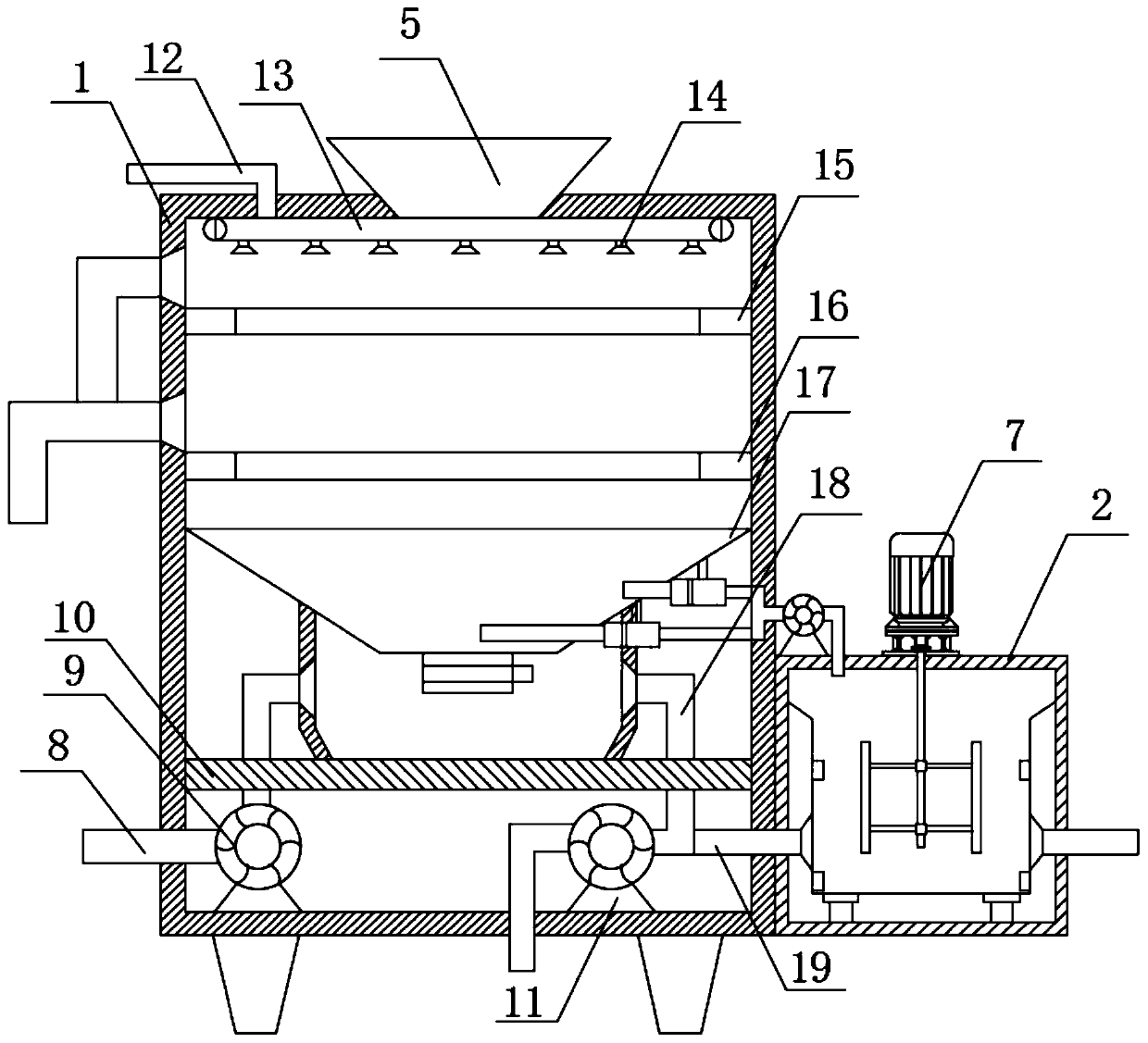

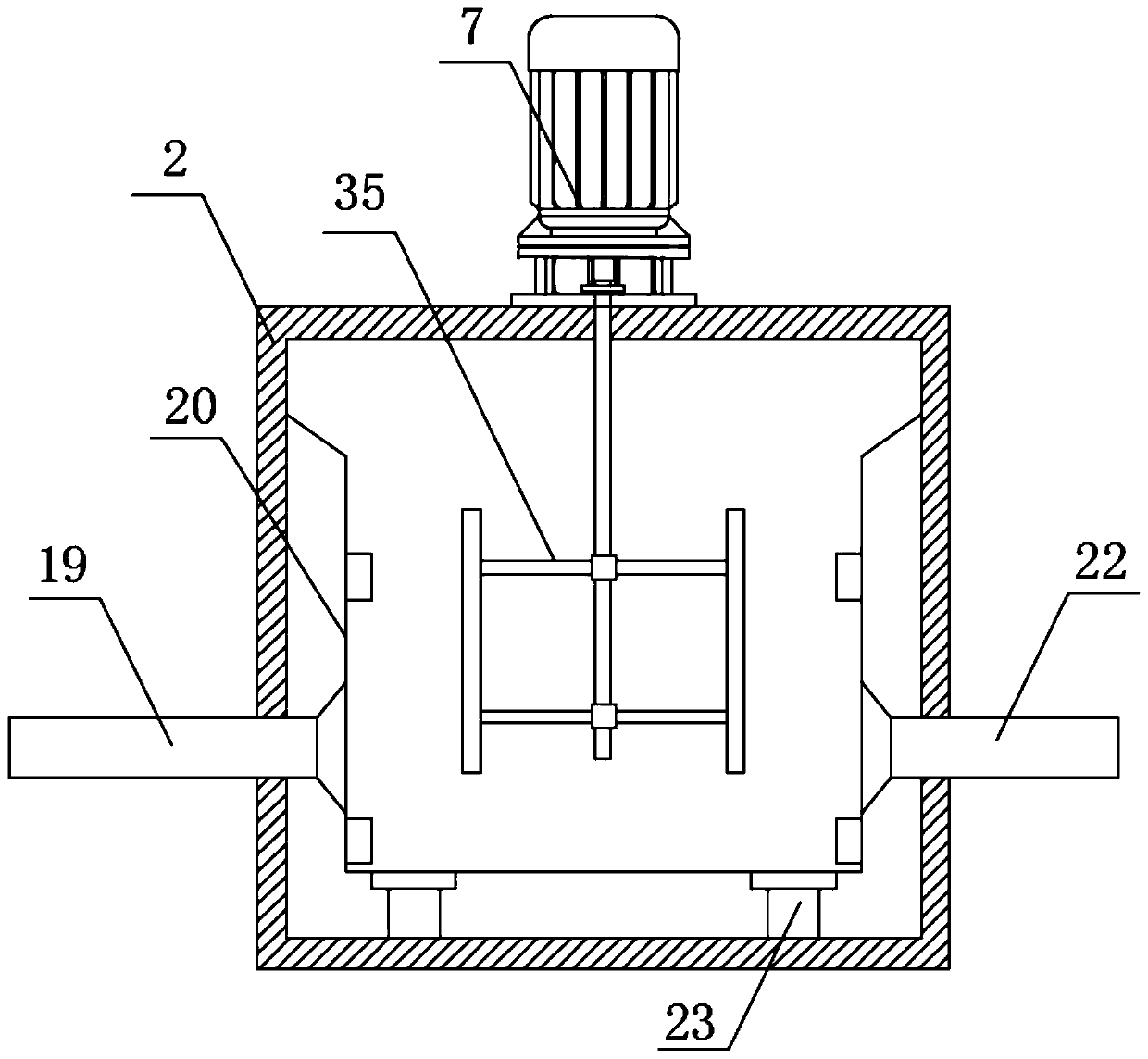

[0031] see Figure 1-7 , the present invention provides a technical solution: a power plant fuel screening device, including a box body 1, a feed hopper 5 is fixedly installed on the top of the box body 1, and a PLC controller is fixedly connected to one side of the outer wall of the box body 1 6. A detection box 2 is fixedly installed on one end of the outer wall of the box body 1, and an inner cylinder 20 is movable installed inside the detection box 2, and a load cell 23 is fixedly installed at the four corners of the bottom end of the inner tube 20, and the load cell 23 It is fixedly connected with the box body 1. A contact microwave moisture meter 21 is fixedly installed on one side of the outer wall of the detection box 2. The detection probe of the contact type microwave moisture meter 21 is fixedly installed on the inner wall surface of the inner cylinder 20. The box body 1 A bucket 17 to be detected is fixedly installed at the middle end of the inner wall, and a colle...

Embodiment 2

[0039] see Figure 1-7 , the present invention provides a technical solution: a power plant fuel screening device, including a box body 1, a feed hopper 5 is fixedly installed on the top of the box body 1, and a PLC controller is fixedly connected to one side of the outer wall of the box body 1 6. A detection box 2 is fixedly installed on one end of the outer wall of the box body 1, and an inner cylinder 20 is movable installed inside the detection box 2, and a load cell 23 is fixedly installed at the four corners of the bottom end of the inner tube 20, and the load cell 23 It is fixedly connected with the box body 1. A contact microwave moisture meter 21 is fixedly installed on one side of the outer wall of the detection box 2. The detection probe of the contact type microwave moisture meter 21 is fixedly installed on the inner wall surface of the inner cylinder 20. The box body 1 A bucket 17 to be detected is fixedly installed at the middle end of the inner wall, and a colle...

Embodiment 3

[0041] see figure 1 , figure 2 and Figure 4, the present invention provides a technical solution: a fuel screening device for a power plant, a blowing ring pipe 13 is fixedly installed on the top inside of the box body 1, and a nozzle 14 is fixedly connected to the bottom end of the blowing ring pipe 13, and the blowing ring The top of the pipe 13 is fixedly connected with the air supply pipe 12, and the end of the air supply pipe 12 away from the blowing ring pipe 13 runs through the box body 1 and is fixedly connected with the air outlet end of the air compressor, and one side of the outer wall of the collecting plate 24 is fixedly connected There is an unqualified discharge pipe 8. The other end of the unqualified discharge pipe 8 runs through the box body 1 and extends to the outside of the box body 1. The middle end of the unqualified discharge pipe 8 is fixedly connected to the first fan 9, and the second A fan 9 is fixedly installed on one side of the bottom end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com