Roll paper packing machine

A roll paper and charter technology, which is used in the packaging, packaging, transportation and packaging of paper products to ensure uniformity and save labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

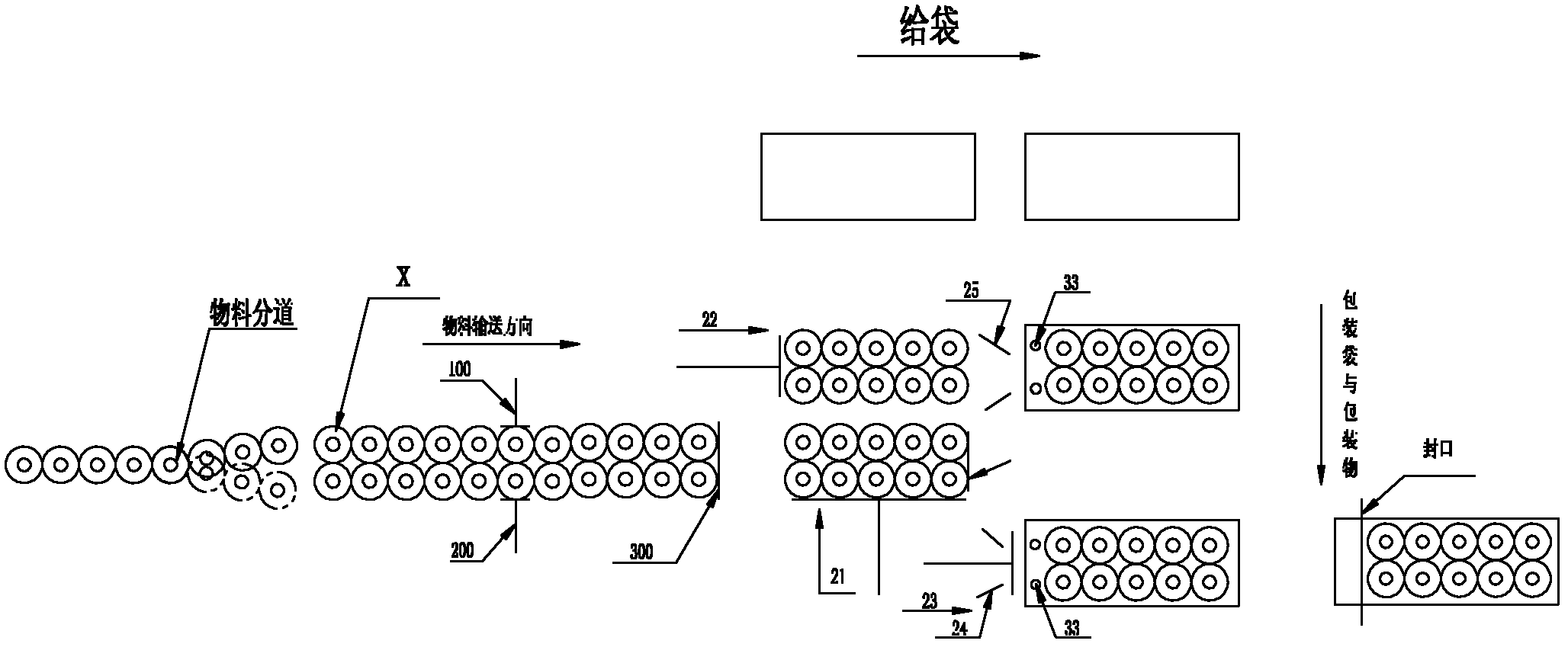

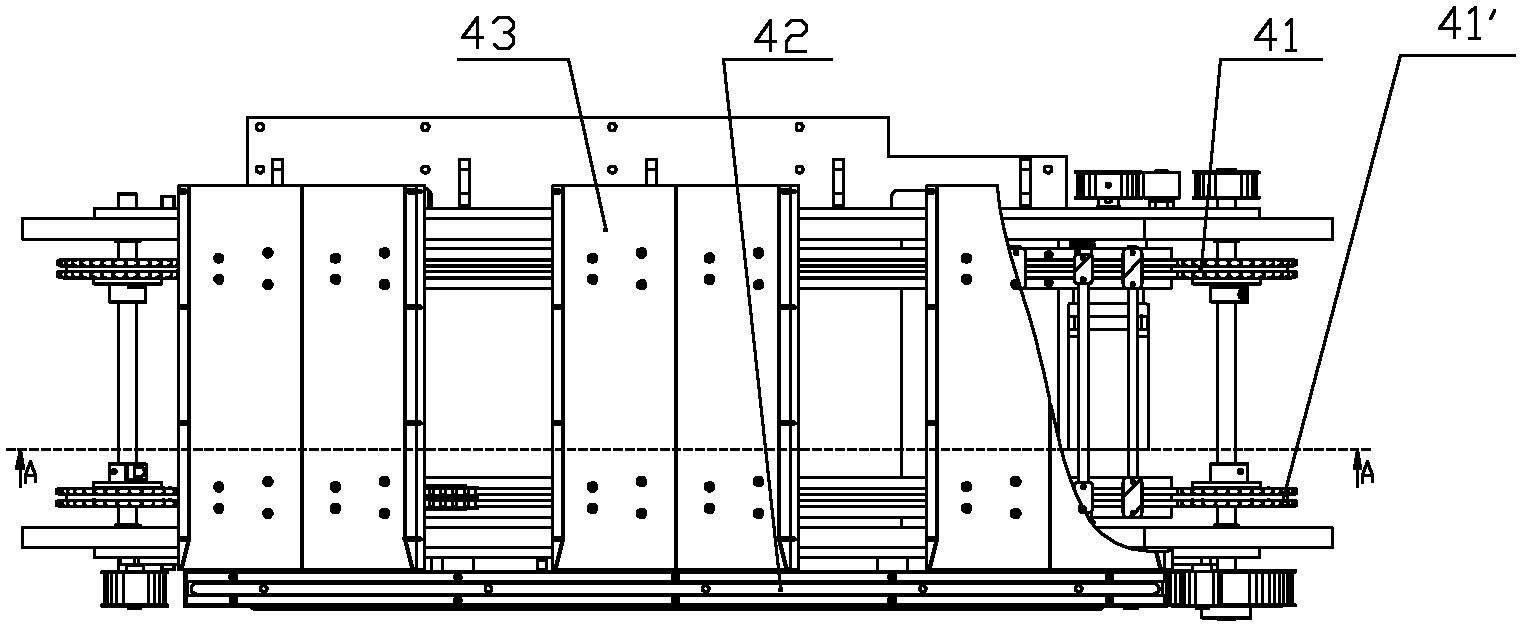

[0062] The present invention will be further described below according to the accompanying drawings.

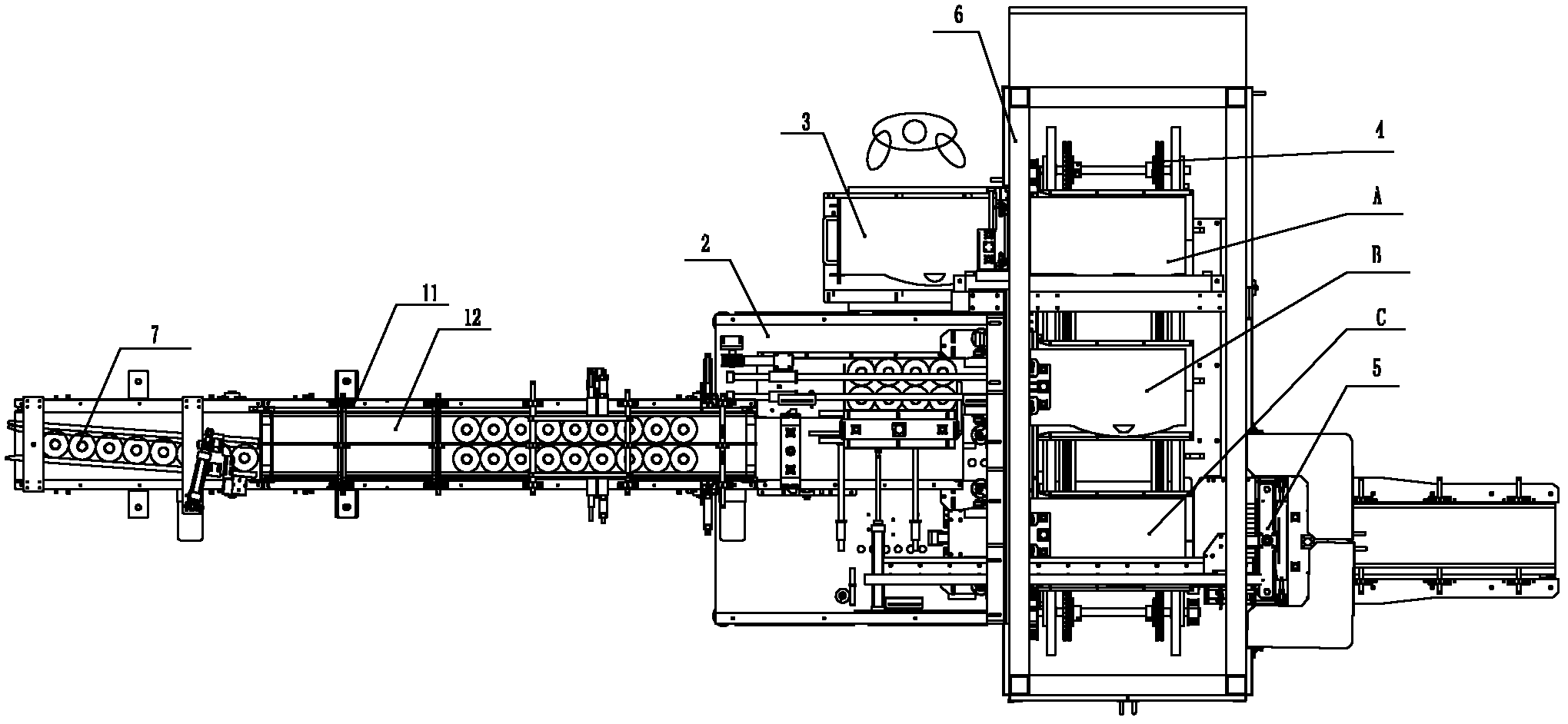

[0063] Such as Figure 1 to Figure 9 As shown, a roll paper bagging machine, including

[0064]A lane-dividing conveying part 7 is arranged on the feeding side of the roll paper tucking machine, including a rib 72, another rib 78, a conveyor belt 79, a guide plate 73, a guide bearing 74, a lane-dividing cylinder 76, and a motor 77 One side of the lane-dividing conveying part 7 is provided with a motor 77, and is connected with the conveying belt 79 on the lane-dividing conveying part 7, and both sides on the conveying belt 79 are respectively provided with a rib 72 and another rib 78, and the rib 72 And another rib 78 adopts connecting plate 75 to connect, and the upper right side of conveying part 7 connects guide plate 73, connects the tail end of lane-dividing cylinder 76 on the guide plate 73 rear side, and the telescoping rod of lane-dividing cylinder 76 connects guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com