Patents

Literature

501 results about "Automatic train operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic train operation (ATO) is an operational safety enhancement device used to help automate operations of trains. This is achieved according to the Grade of Automation (GoA) present, up to GoA 4 level, where the train is automatically controlled without the presence of staff on board. Mainly, it is used on automated guideway transits and rapid transit systems which are easier to ensure safety of humans. Most systems elect to maintain a driver (train operator) to mitigate risks associated with failures or emergencies.

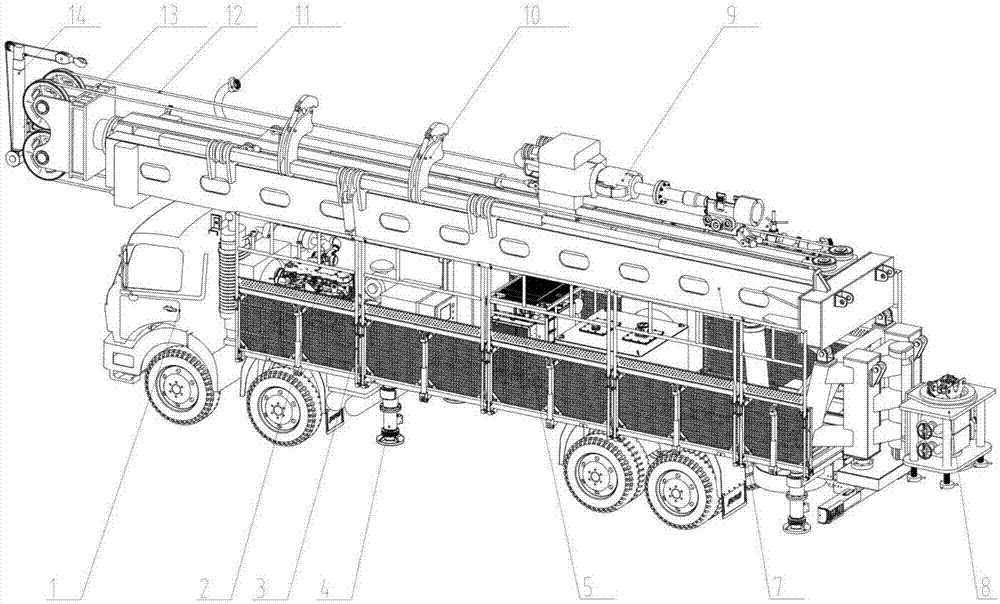

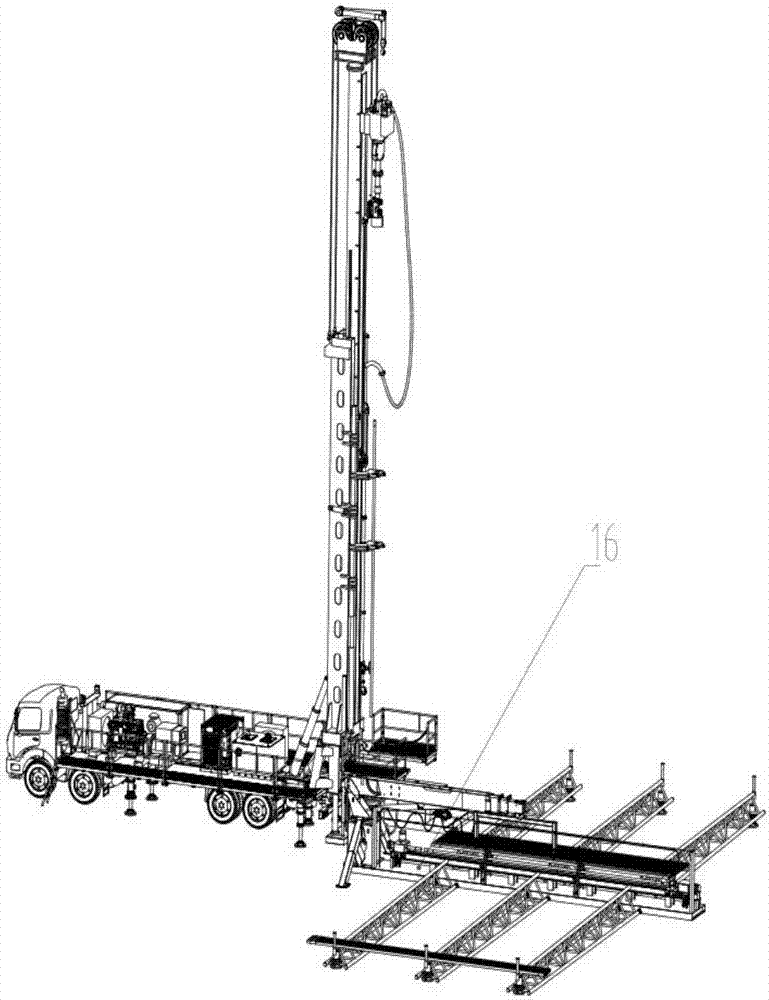

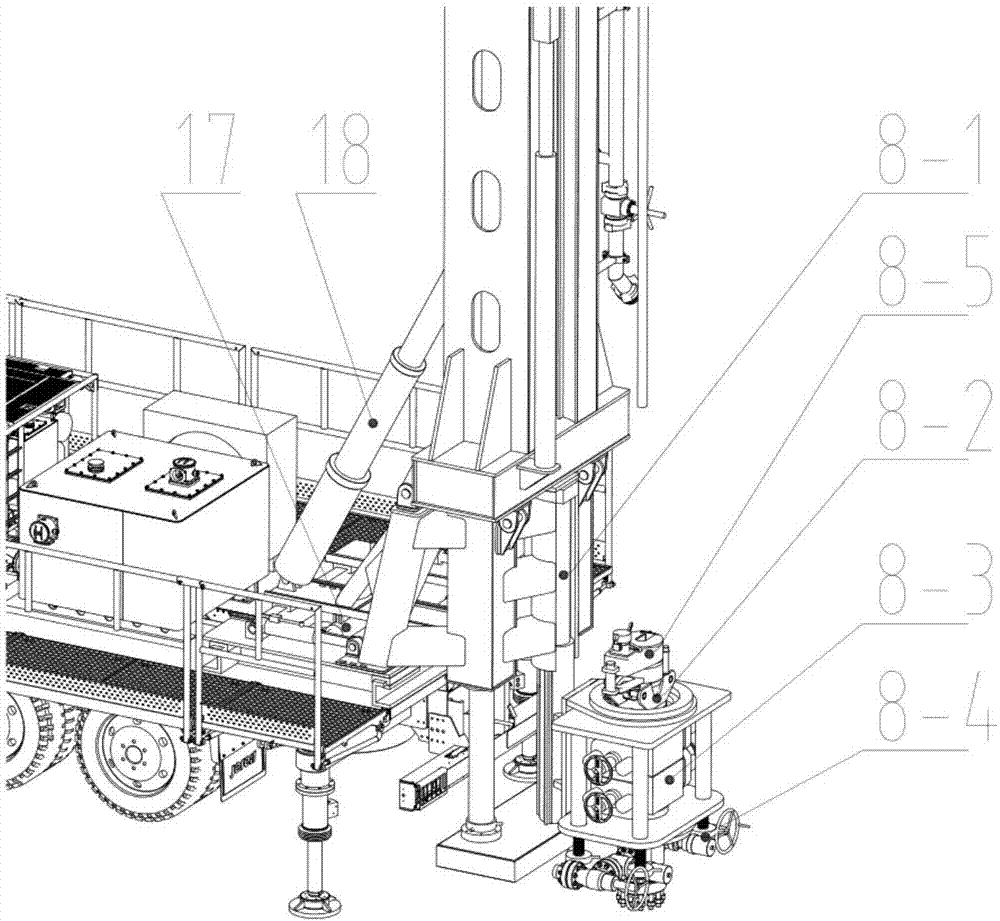

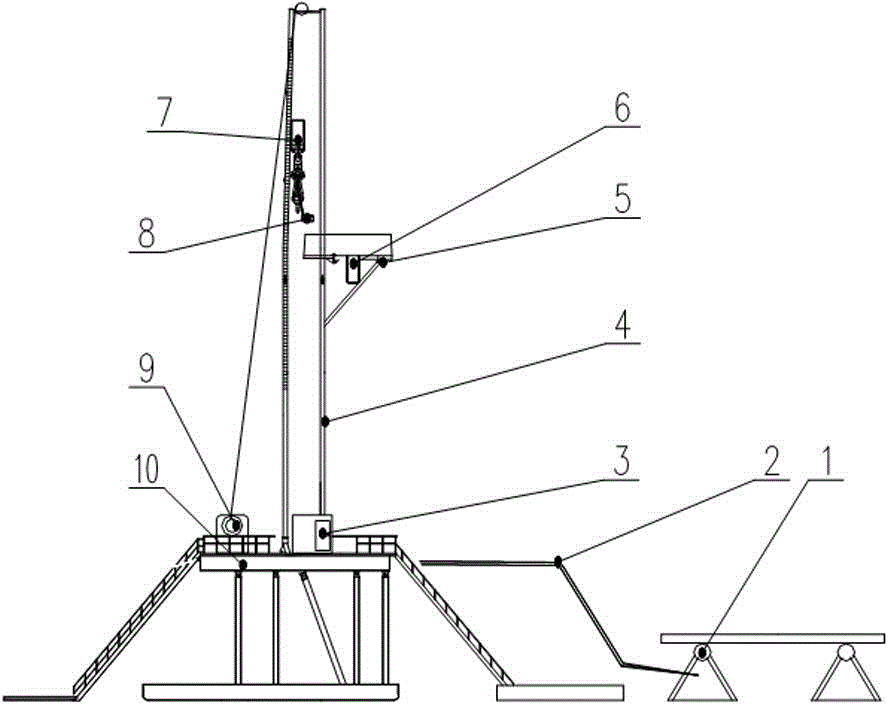

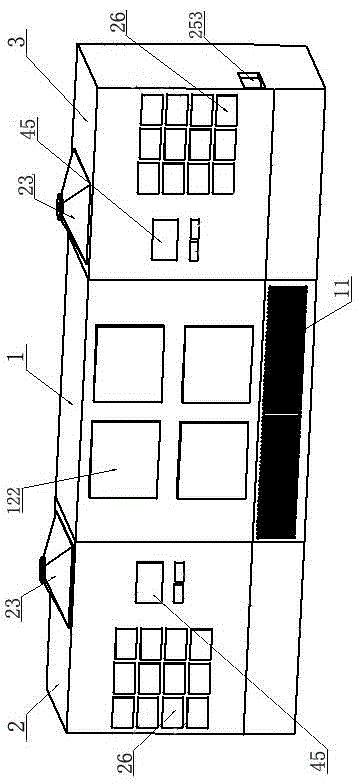

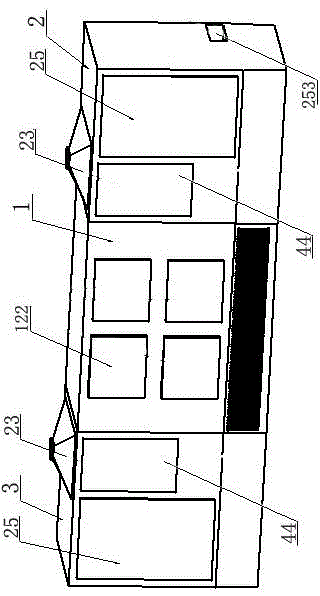

Fully hydraulic intelligent workover rig

InactiveCN107476769ARealize grabbingRealize pipe deliveryDrilling rodsDrilling casingsBlowout preventerTruck

The invention belongs to the field of oil equipment, and particularly relates to a fully hydraulic intelligent workover rig. The fully hydraulic intelligent workover rig is characterized in that an engine 2 and a hydraulic pressure station 5 are installed on a chassis truck 1, in the conveying state, a walkway is folded automatically and stored, a wellhead assembly is fixed to the tail of the chassis truck, after the hydraulic workover rig is moved to a well site, a wellhead is subjected to initial positioning through a reverse image in a cab and positioning and ranging, and then accurate positioning is conducted by moving a rapid positioning device through a derrick; by conducting height adjusting and supporting on a vehicle carrying chassis through hydraulic adjusting landing legs and conducting mechanical locking, rapid positioning and locking of the wellhead are achieved; the automatic folding walkway is designed, and convenient and labor-saving installation is achieved; increasing and decreasing of pressure of a string in a well and setting and control of bit pressure and drilling speed parameters can be achieved automatically, full automatic operations such as tubing string gripping and conveying, automatic fastening and unfastening, automatic discharging and automatic detection are achieved; integrated transport of a blowout preventer is achieved, and separate disassembly and transport are not needed.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

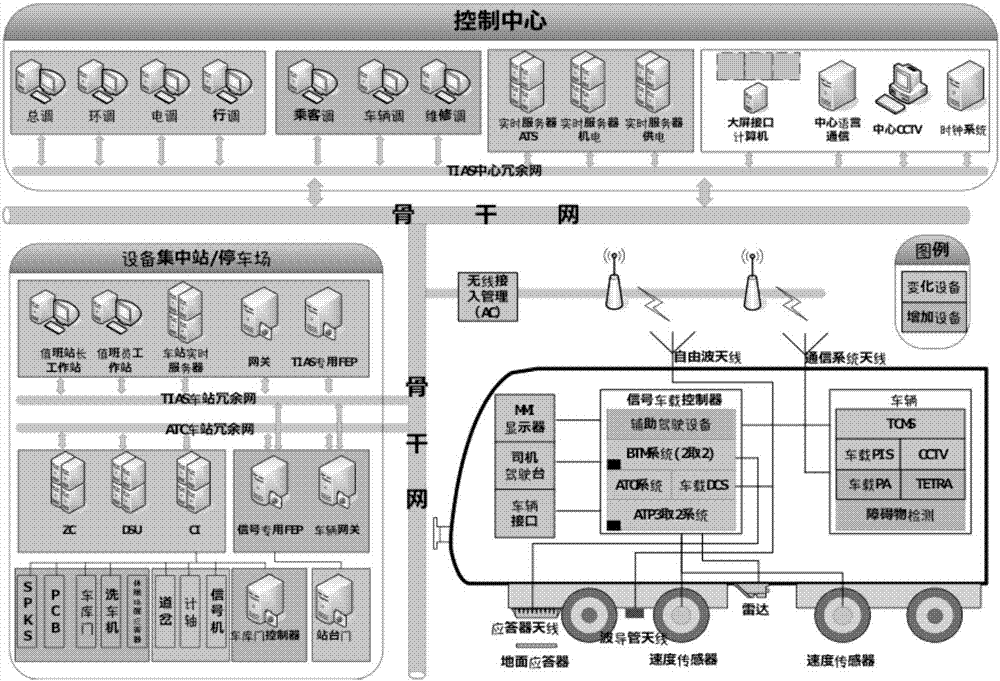

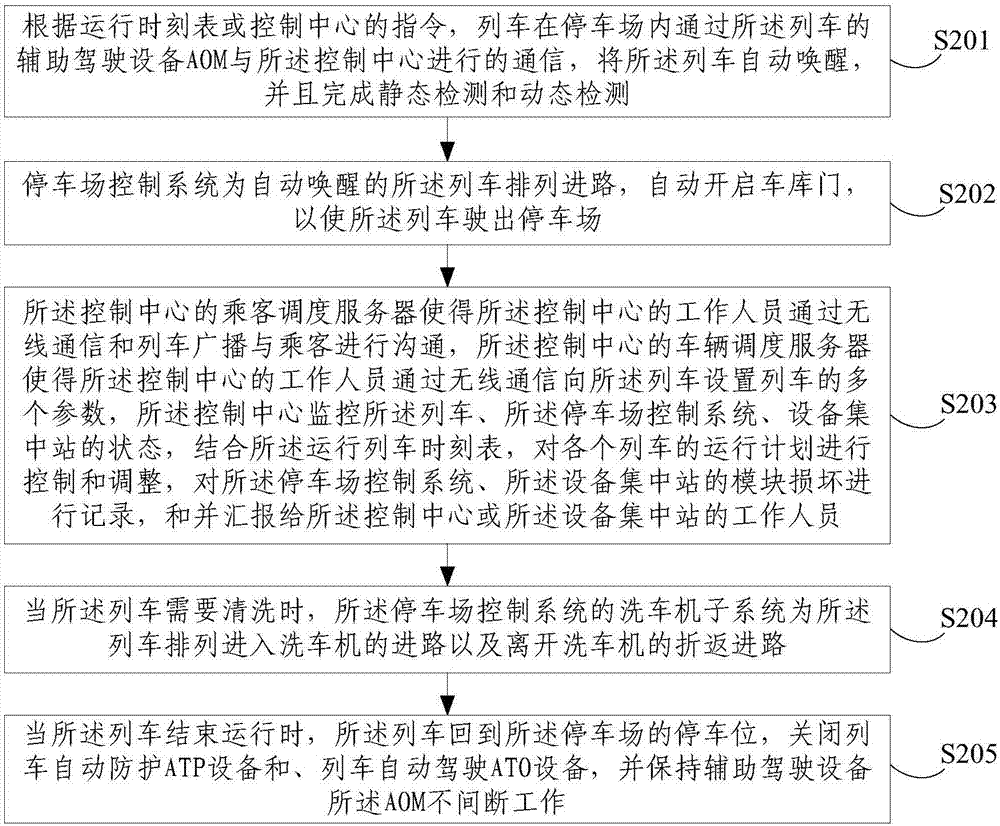

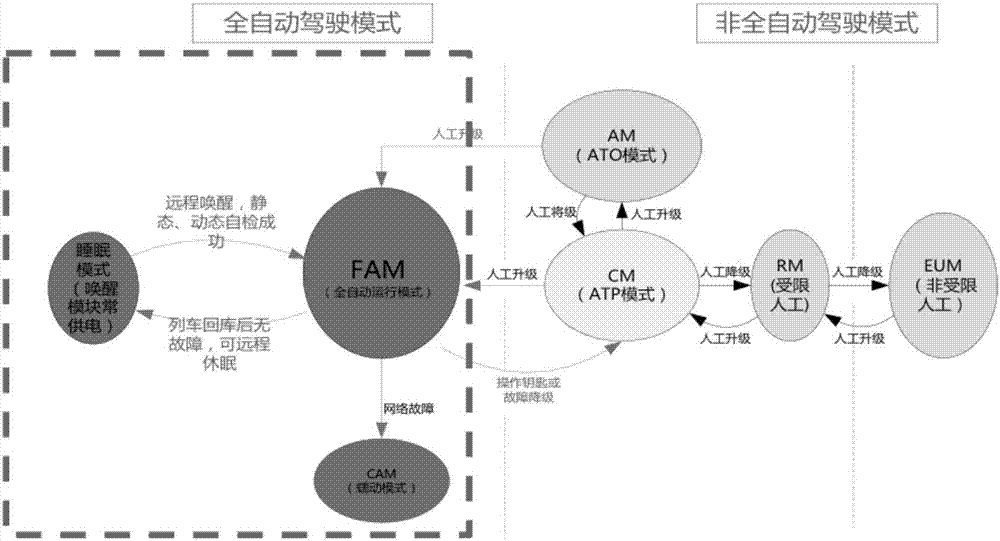

Train full-automatic running method and system

ActiveCN107226099ARealize fully automatic operationImprove reliabilityAutomatic systemsLocomotivesAutomatic train protectionProgram planning

The invention provides a train full-automatic running method and system. The train full-automatic running method comprises the following steps that according to a running schedule or a command of a control center, trains are automatically awakened, and static detection and dynamic detection are completed; a parking lot control system performs route arrangement on the trains which are automatically awakened; the control center monitors the condition of the trains, the condition of the parking lot control system and the condition of an equipment centralization station, and controls and adjusts the running plan of each train combining the running schedule; when the trains need cleaning, a train washing machine sub system of the parking lot control system arranges a route for the trains to enter the train washing machine and a reentrant route for the trains to leave from the train washing machine; and when the trains stop running, automatic train protection ATP equipment and automatic train operation ATO equipment are closed, and AOM is kept working continuously. Compared with a conventional CBTC system, the train full-automatic running method disclosed by the invention realizes full-automatic running, the reliability, the safety, the availability and the maintainability of the train full-automatic running system are further improved, the operating emergency handling level is improved, the automation level is improved, and the labor strength is reduced.

Owner:TRAFFIC CONTROL TECH CO LTD

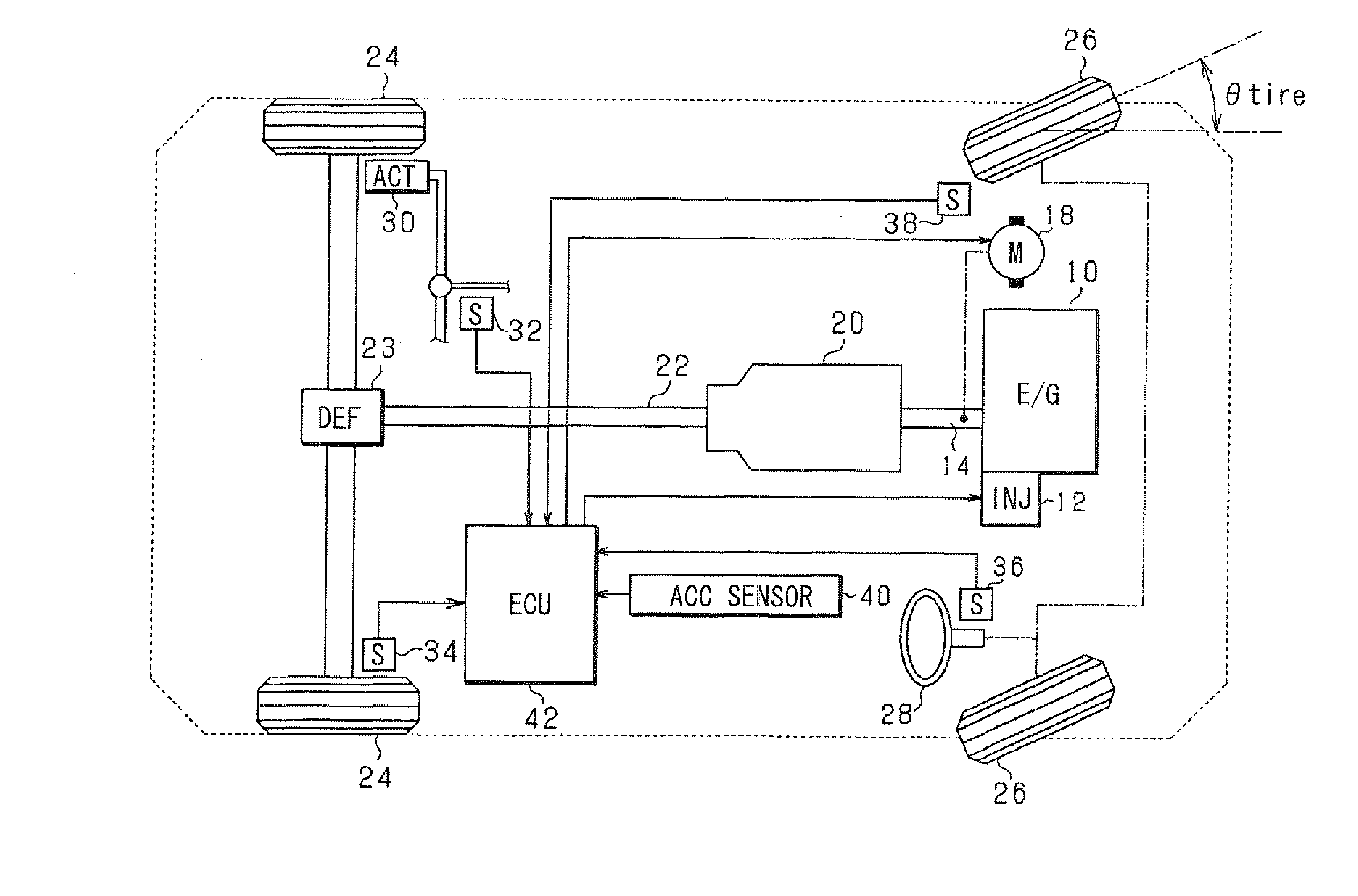

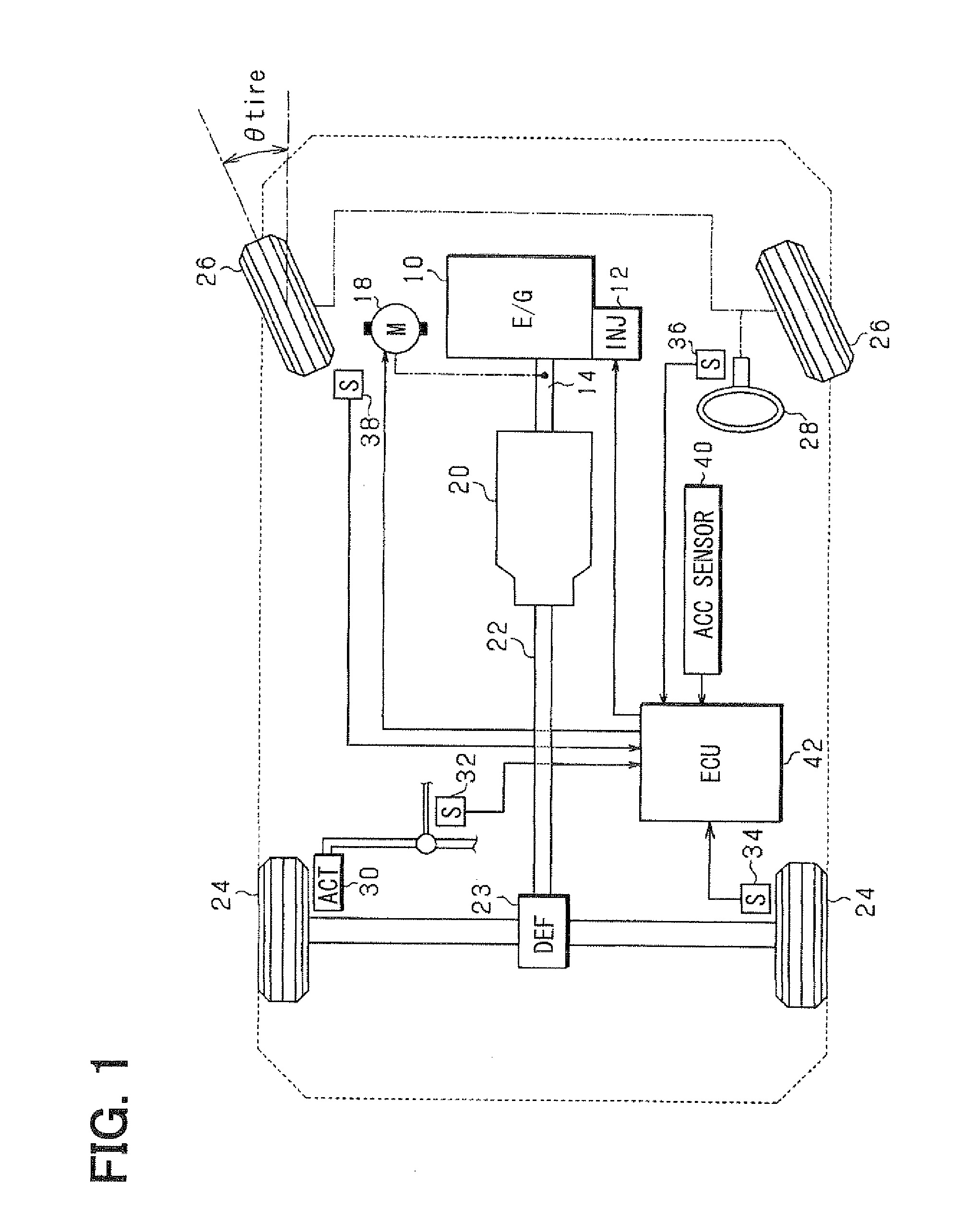

Control device for internal combustion engine and method for controlling internal combustion engine

InactiveUS20110112740A1Analogue computers for vehiclesAnalogue computers for trafficSteering wheelExternal combustion engine

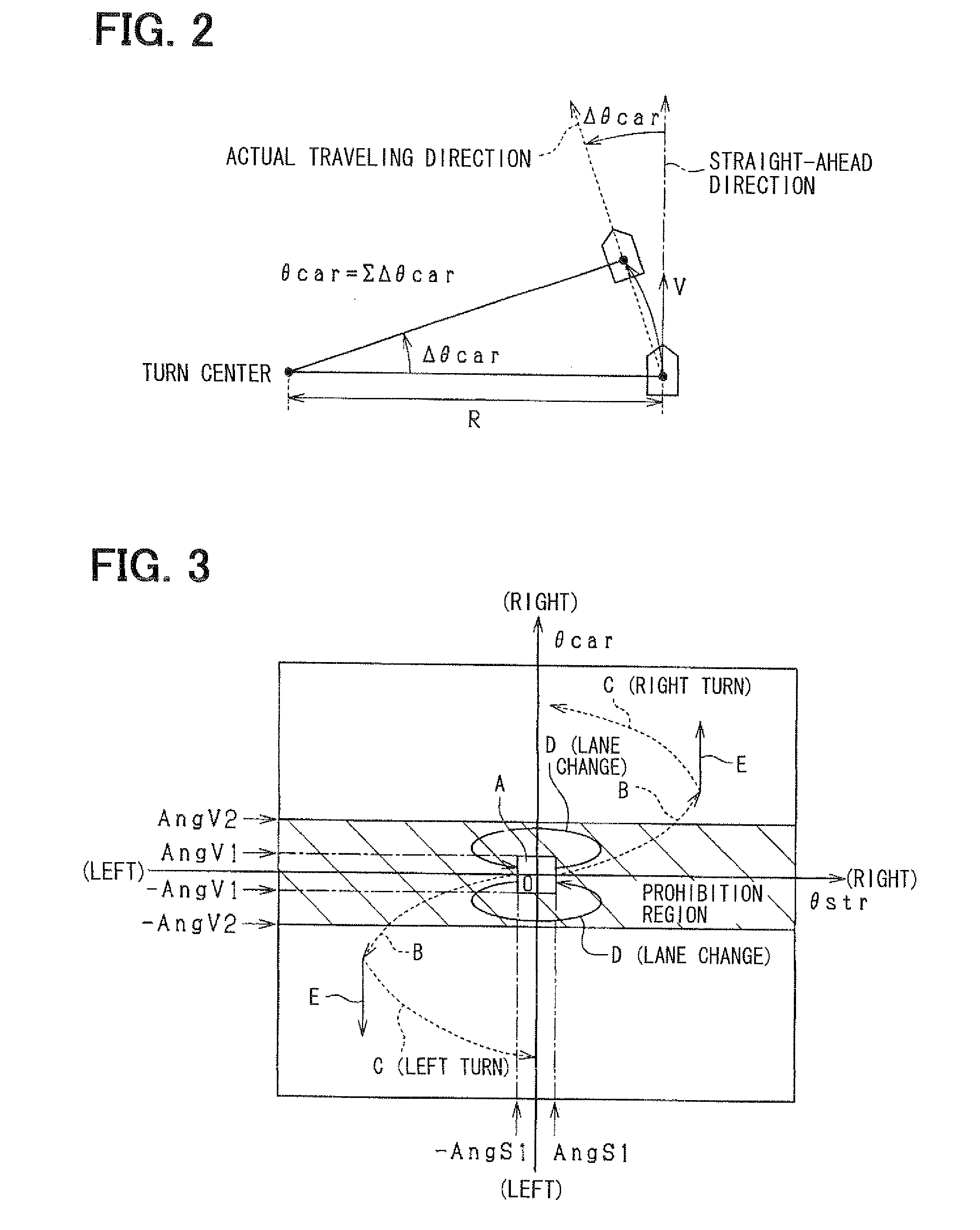

A control device performs an automatic stop operation and an automatic restart operation of an internal combustion engine of a vehicle having a steering device, which is manipulated by a driver to steer a steering wheel of the vehicle. A prohibition unit prohibits the automatic stop operation according to transition of a steering degree of the steering device when the vehicle travels.

Owner:DENSO CORP

Vehicle control apparatus and vehicle control method

ActiveUS20160033964A1Unusable conditionExternal condition input parametersDriver input parametersEmbedded systemControl equipment

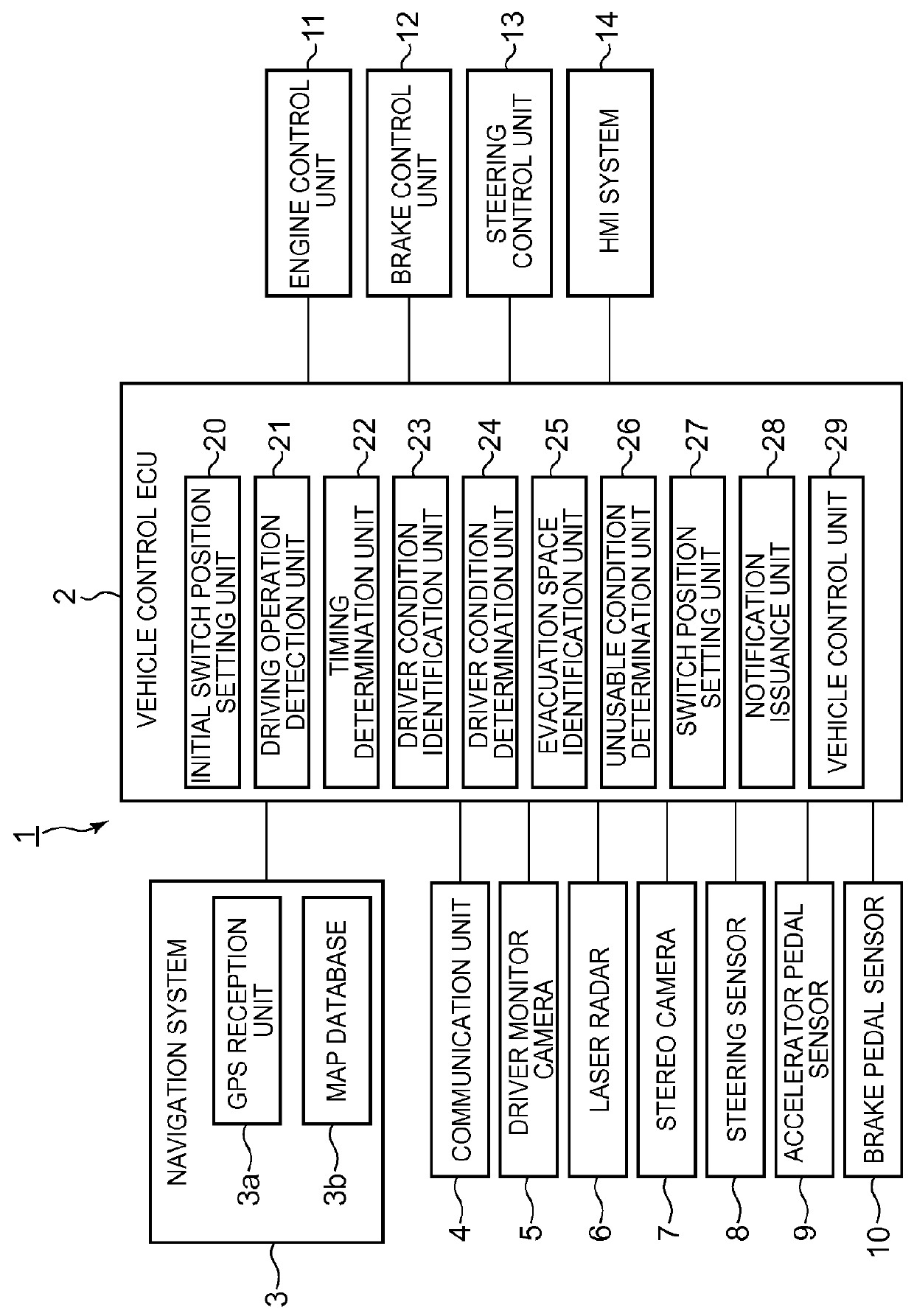

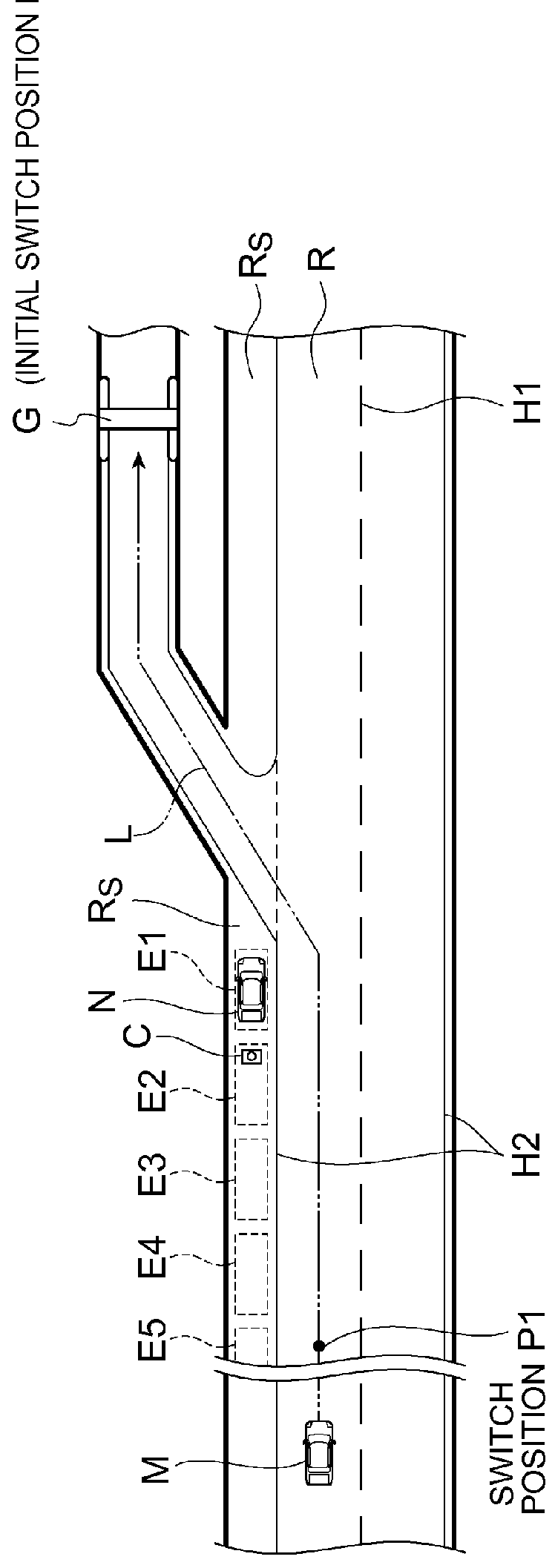

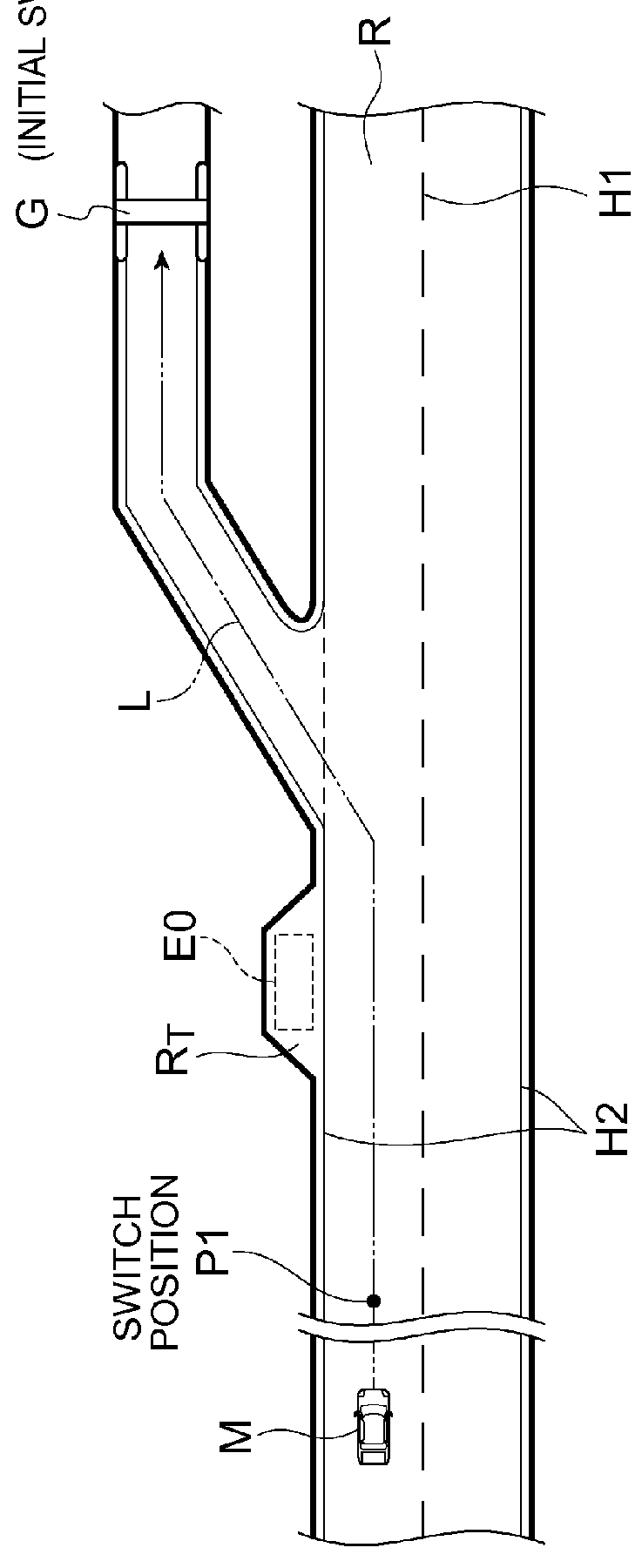

A vehicle control apparatus that switches an operating condition of a vehicle to a manual operation when the vehicle reaches a preset initial switch position while an automatic operation is underway includes: a driver condition determination unit configured to determine whether or not a driver is in a manual operation acceptance condition; an evacuation space identification unit configured to identify an evacuation space provided on a path of the vehicle before the initial switch position on the basis of map information; and a switch position setting unit configured to set a switch position in which the operating condition of the vehicle is to be switched from the automatic operation to the manual operation, in a position between the vehicle and the evacuation space when the driver is not in the manual operation acceptance condition.

Owner:TOYOTA JIDOSHA KK

Automatic operation system of drilling string

The invention discloses an automatic operation system of a drilling string. The automatic operation system mainly consists of an automatic catwalk machine, a drilling floor manipulator, a power clip, an iron driller, a power hanging clip, a monkey board pipe arrangement manipulator, a top drive, a winch, a driller integrating control system and the like. The automatic operation system has the advantages that after the automatic operation system is arranged on a petroleum drilling machine, the automatic drilling operations, such as lifting and lowering of the drilling string in the drilling floor, drilling, drill lifting, drill lowering, and stand discharging, are realized; the automation degree of the drilling machine is improved, and the problems of high labor intensity, high risk and low efficiency caused by overhead operation and multi-person matching operation in the existing drilling string operation method are solved; the defects of decreasing of local labor intensity, and failure of reducing of number of operators and improvement of operation efficiency caused by using of one or several automatic devices of the existing drilling machine are overcome.

Owner:CHINA PETROCHEMICAL CORP +1

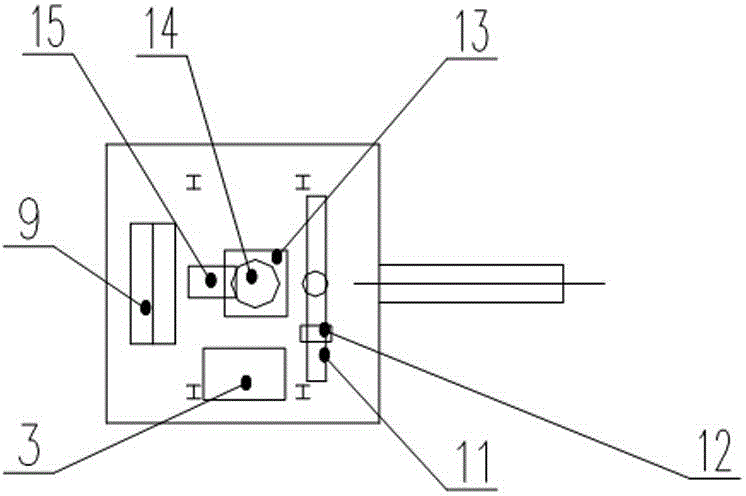

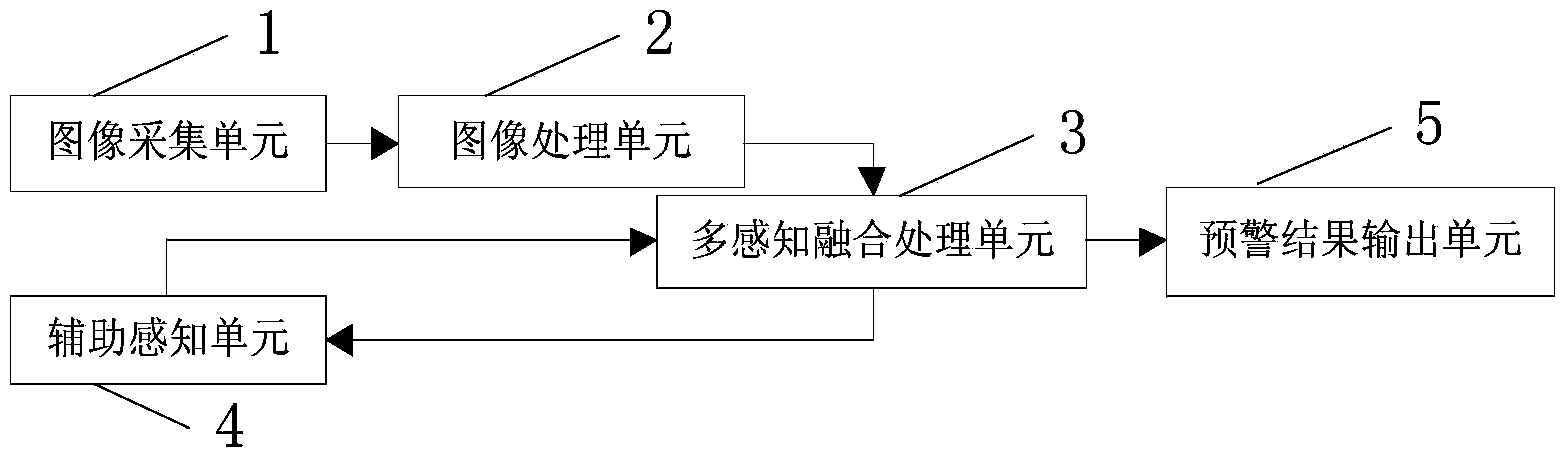

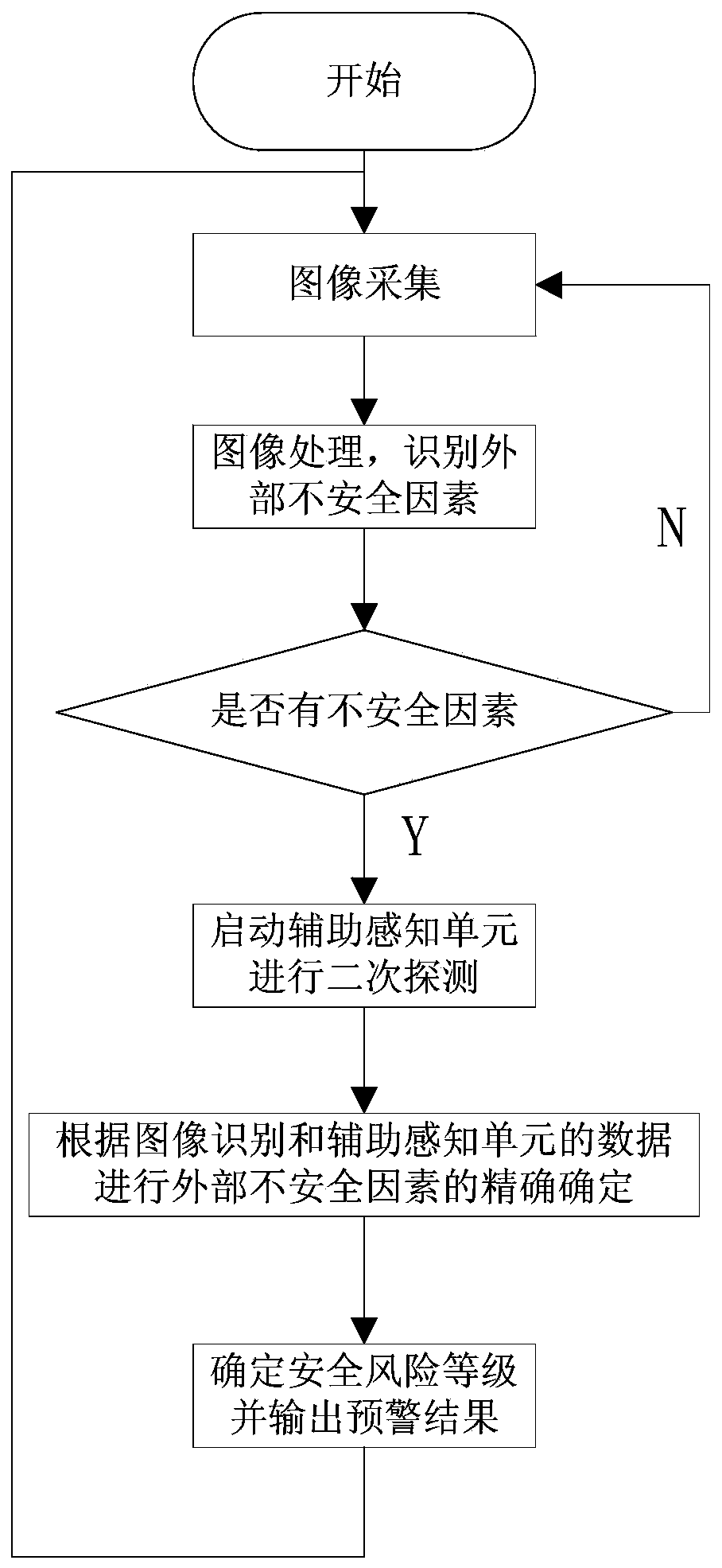

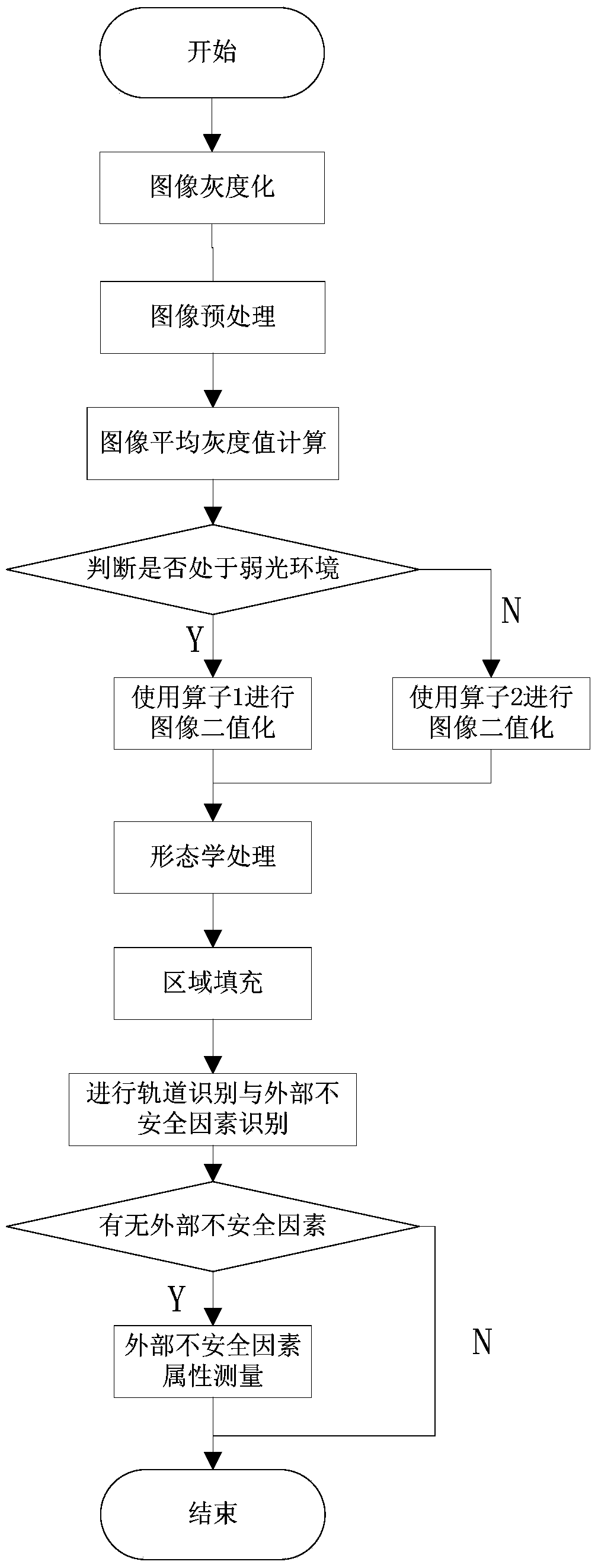

Automatic train protection system and method based on image identification and multi- perception fusion

ActiveCN104386092AAutomatically implement security protectionRealize automatic protectionCharacter and pattern recognitionRailway signalling and safetyImaging processingAutomatic train protection

The invention relates to an automatic train protection system and method based on image identification and multi-perception fusion. The automatic train protection system comprises an image collection unit (1), an image processing unit (2), a multi-perception fusion processing unit (3), an auxiliary perception unit (4) and an early warning result output unit (5), wherein the image collection unit (1), the image processing unit (2), the multi-perception fusion processing unit (3) and the early warning result output unit (5) are connected in sequence; the auxiliary perception unit (4) is connected with the multi-perception fusion processing unit (3). Compared with the prior art, the automatic train protection system and method based on image identification and multi-perception fusion can be adapted to complex conditions appearing in urban mass transit operation lines, the safe protection of a train is automatically realized according to the practical condition of a line, and the operation safety of urban mass transit is greatly improved.

Owner:CASCO SIGNAL

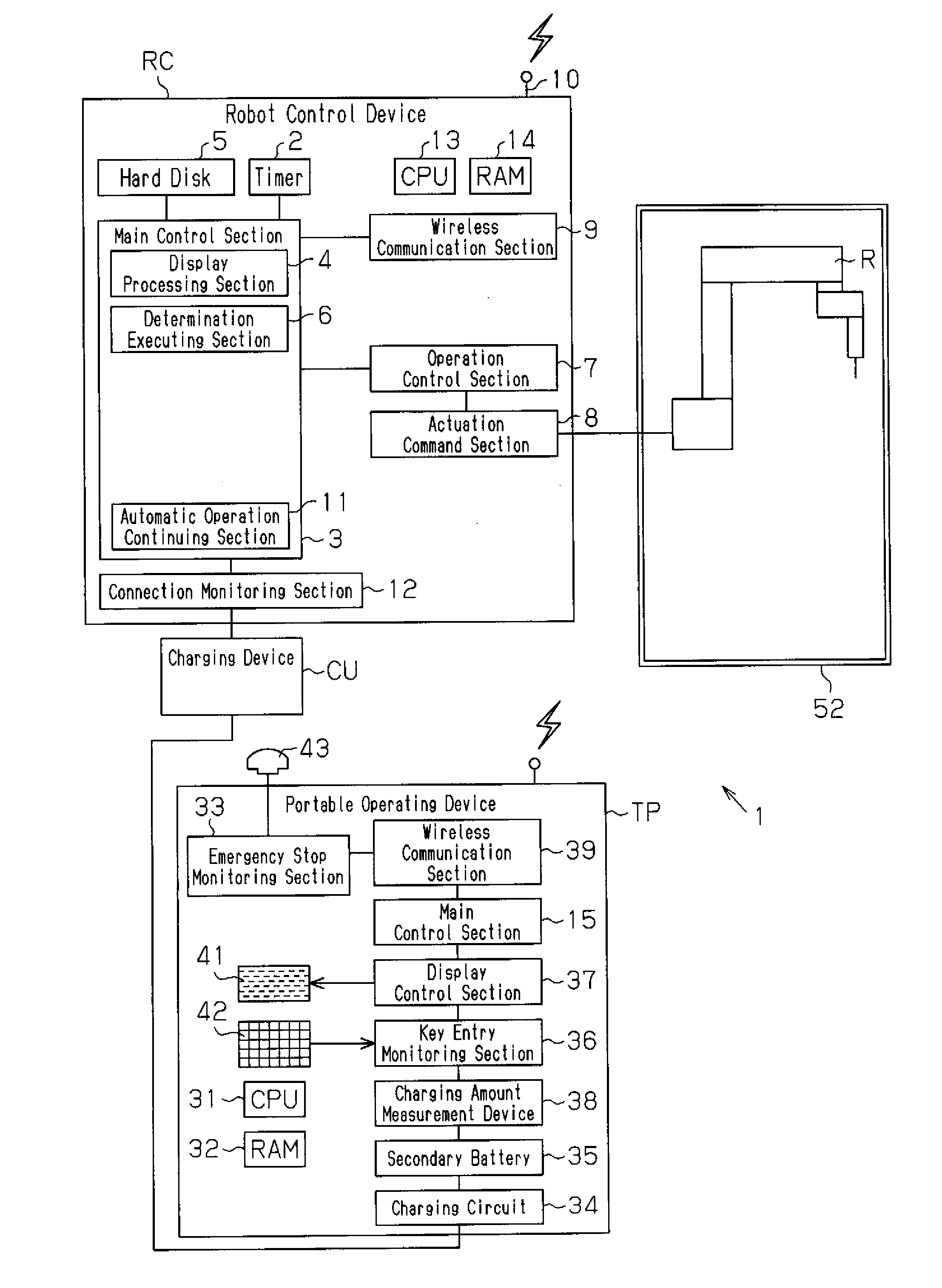

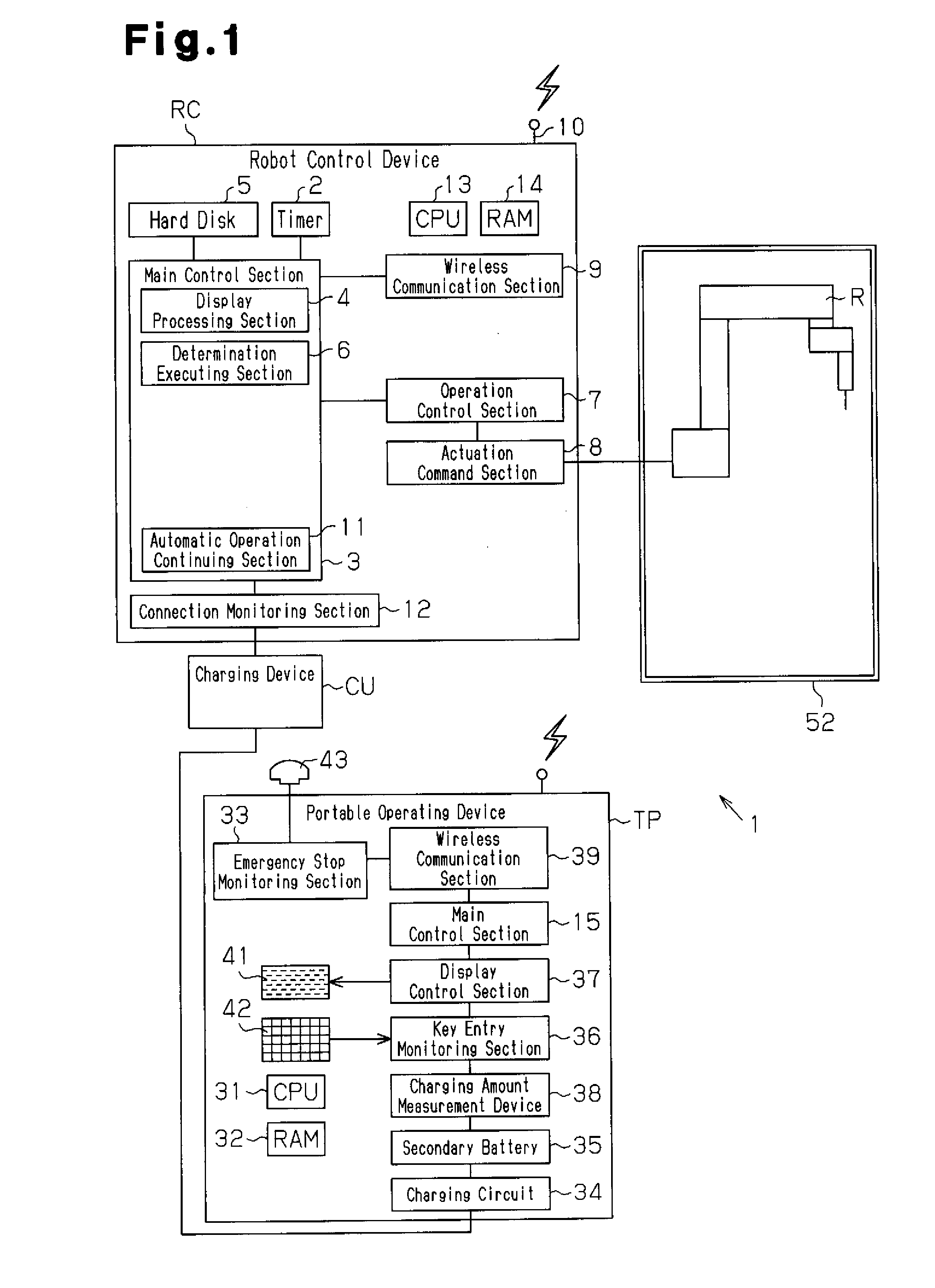

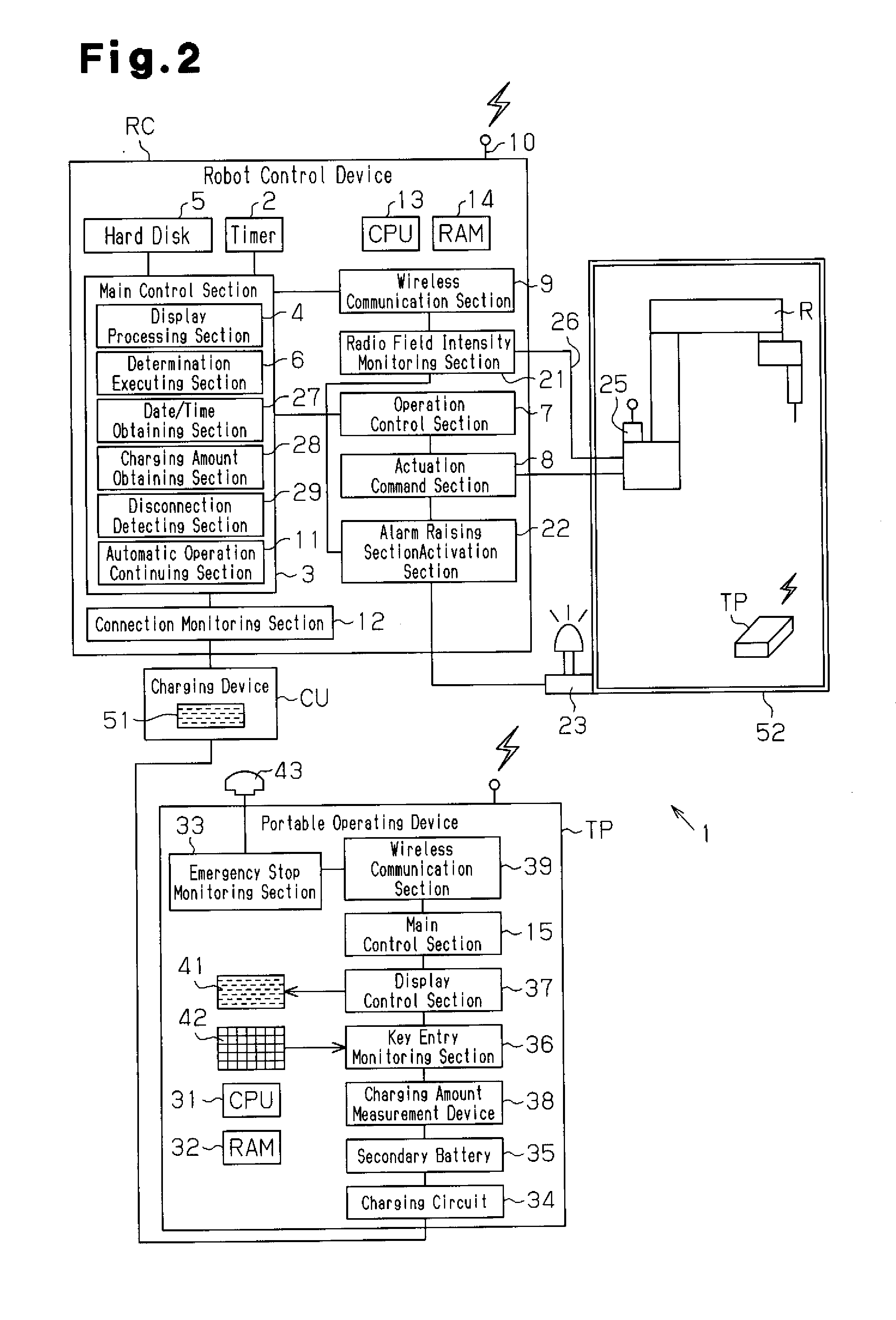

Robot control system

ActiveUS20110010006A1Improve work efficiencyProgramme-controlled manipulatorSpecial data processing applicationsElectricityControl system

A robot control system has a portable operating device TP and a robot control device RC. The portable operating device TP is actuated by a rechargeable secondary battery and used to operate a robot R. The robot control device RC is capable of wireless communication with the portable operating device TP and performs automatic operation of the robot R based on teaching data provided by the portable operating device TP. The robot control system causes an emergency stop of the robot R when the wireless communication between the portable operating device TP and the robot control device RC is interrupted. The robot control system further includes a charging device CU, a connection monitoring section 12, and an automatic operation continuing section 11. The charging device CU charges the secondary battery by electrically connecting the portable operating device TP to the robot control device RC. The connection monitoring section 12 monitors whether connection between the portable operating device TP and the robot control device RC through the charging means is established. Even if it is detected that the aforementioned connection is not established when the robot R is in automatic operation, the automatic operation continuing section 11 ends wireless communication without causing an emergency stop of the robot R and continues automatic operation of the robot R solely through the robot control system RC.

Owner:DAIHEN CORP +1

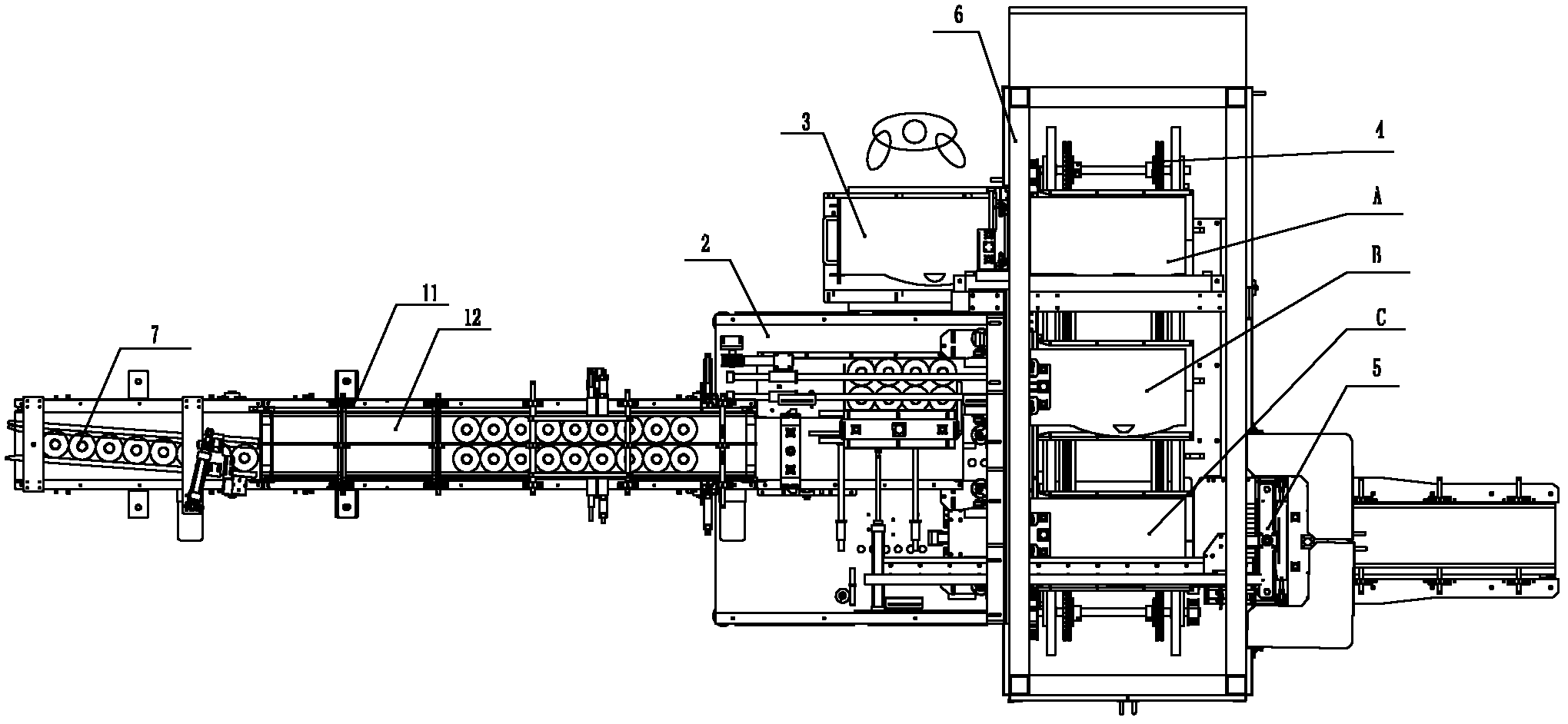

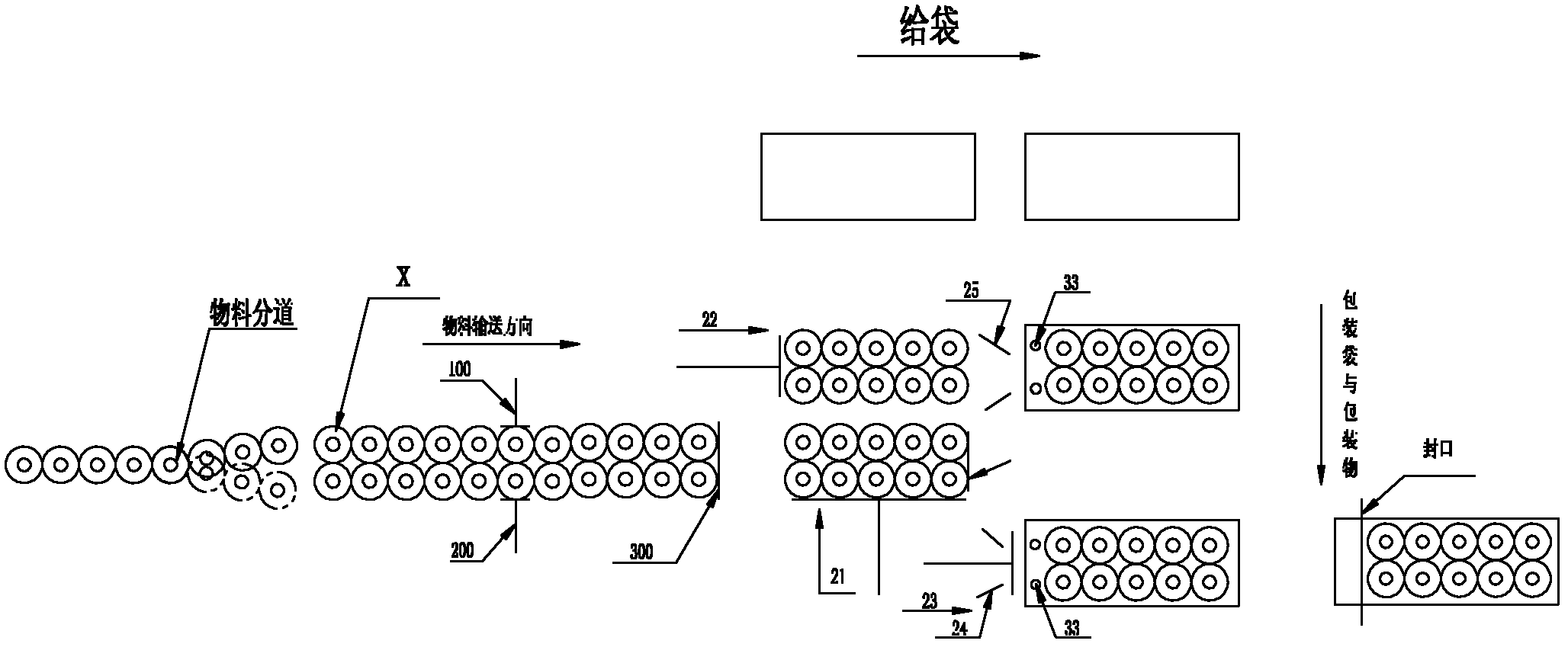

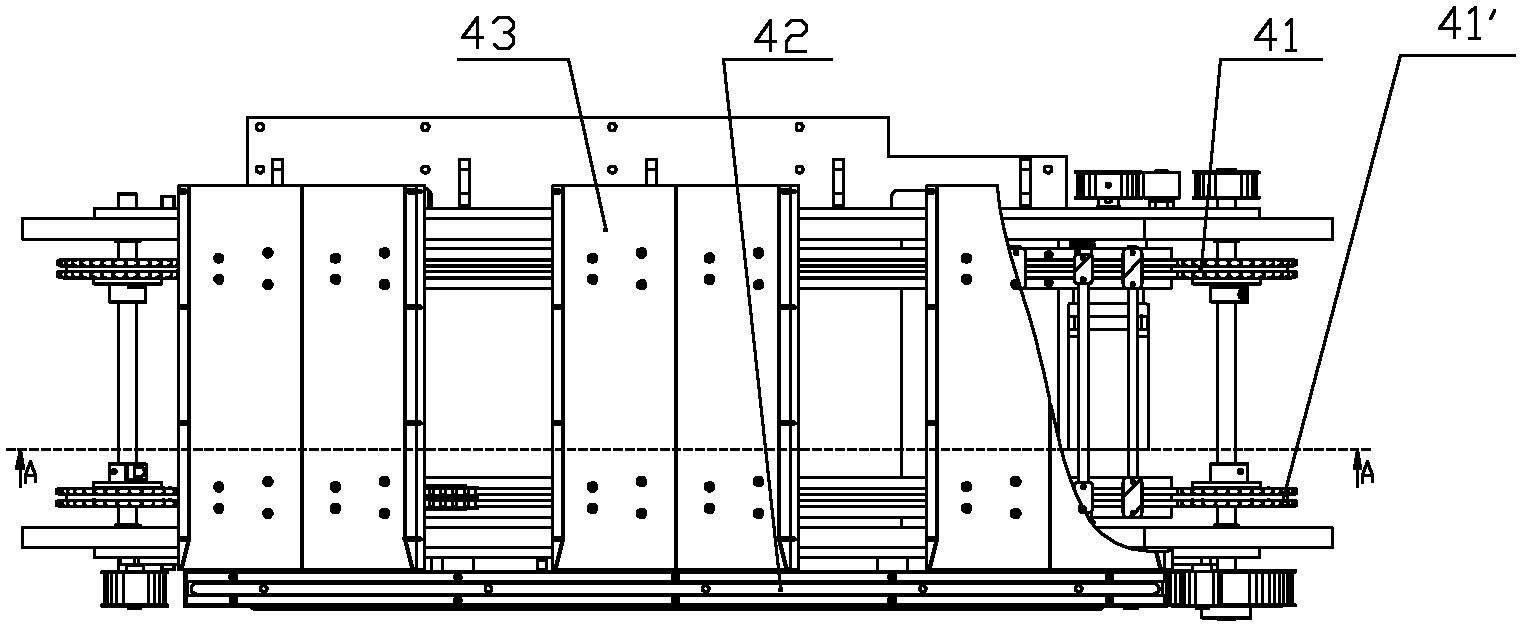

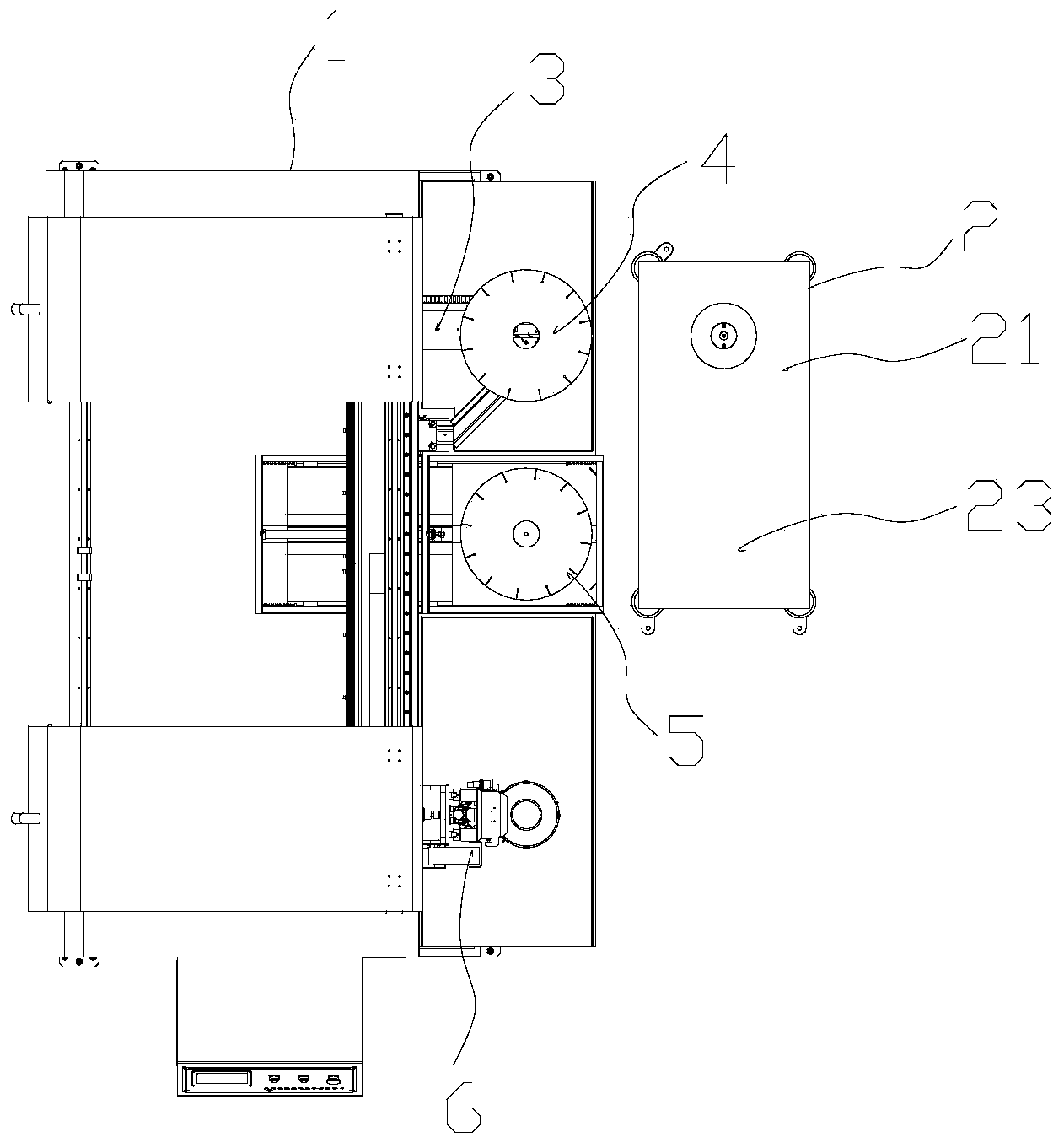

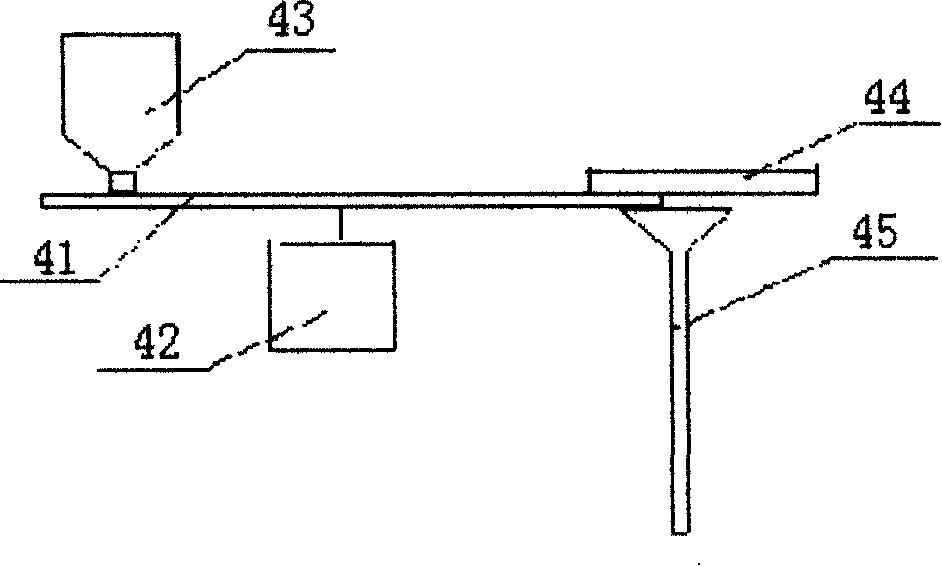

Roll paper packing machine

InactiveCN102556397AGuaranteed uniformityReduce labor costsPaper article packagingContinuous/uninterruptedRolling paper

The invention relates to a packing machine, in particular relates to a packing machine for packing roll paper. The roll paper packing machine is characterized by comprising a split conveying part, a feeding and managing conveying part, a bagging part, a packaging bag warehouse, a drag conveying part, a sealing output part and a frame part. The roll paper packing machine has the obvious advantages that: 1, the roll paper continuously enters the machine and forms the packaged finished products on sale finally, true whole assembly line operation is realized and true automatic operation is achieved; 2, labor cost is saved; and 3, a condition that the manual operation is influenced by different proficiency is avoided, and the automatic operation can fully ensure the unity of the final product quality.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP +2

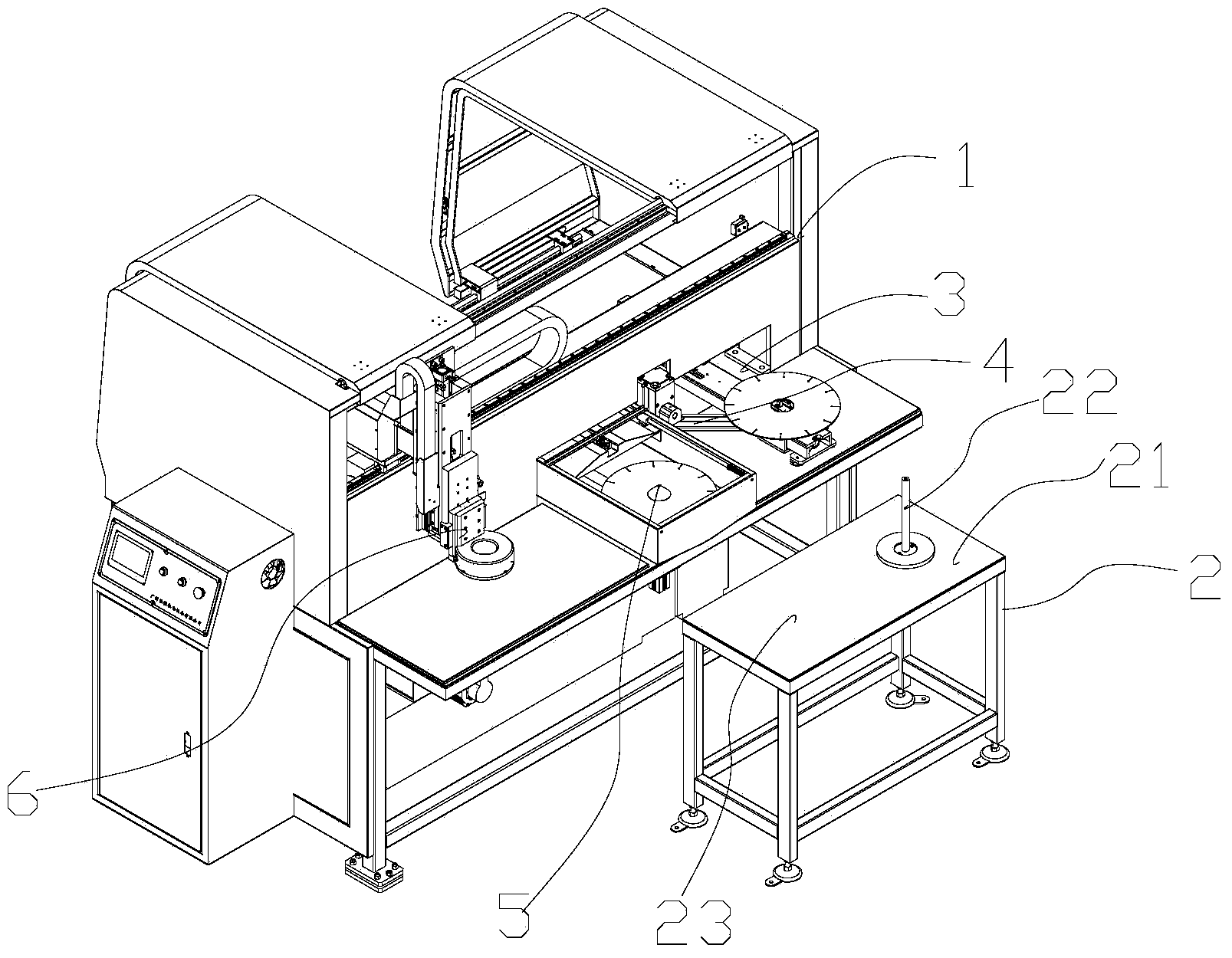

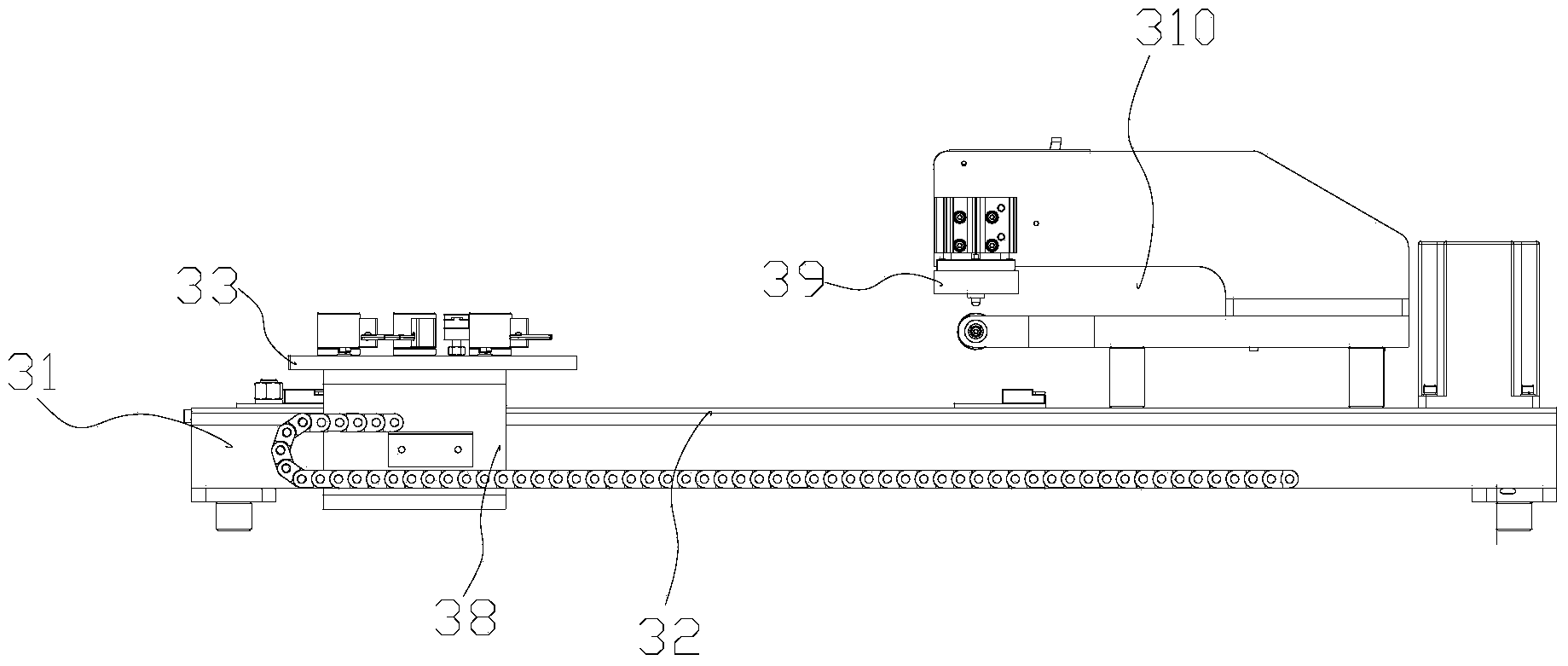

Full-automatic horizontal surface grinding machine mechanical arm

ActiveCN103831680AReduce labor costsImprove pass rateProgramme-controlled manipulatorGripping headsWork periodNumerical control

The invention discloses a full-automatic horizontal surface grinding machine mechanical arm which comprises a machine table and a product containing table. An automatic detection device, a turning device, a cleaning device and a grabbing mechanical arm body are arranged on the machine table. The product containing table and the machine table are arranged side by side. The automatic detection device, the turning device, the cleaning device and the grabbing mechanical arm body are all installed on the machine table, and an automatic grinding machine device is connected with the machine table. By means of the automatic detection device, the turning device, the cleaning device, the grabbing mechanical arm body and the automatic grinding machine device, saw blades are fed, discharged, detected, cleaned and ground in a full-automatic mode, full-automatic operation of the whole process is achieved, and labor cost of an enterprise is greatly reduced; by means of accurate numerical control operation, cost is reduced, the yield is improved, and the production loss rate is reduced; production efficiency is improved, and working time is shortened; by means of full-automatic production, guarantees can be provided for workers on the aspects of mechanical contusion, tiny dust and exhaust gas inhalation and metal dirty water corrosion to human bodies.

Owner:GUANGZHOU HENGWEI ELECTROMECHANICAL EQUIP CO LTD

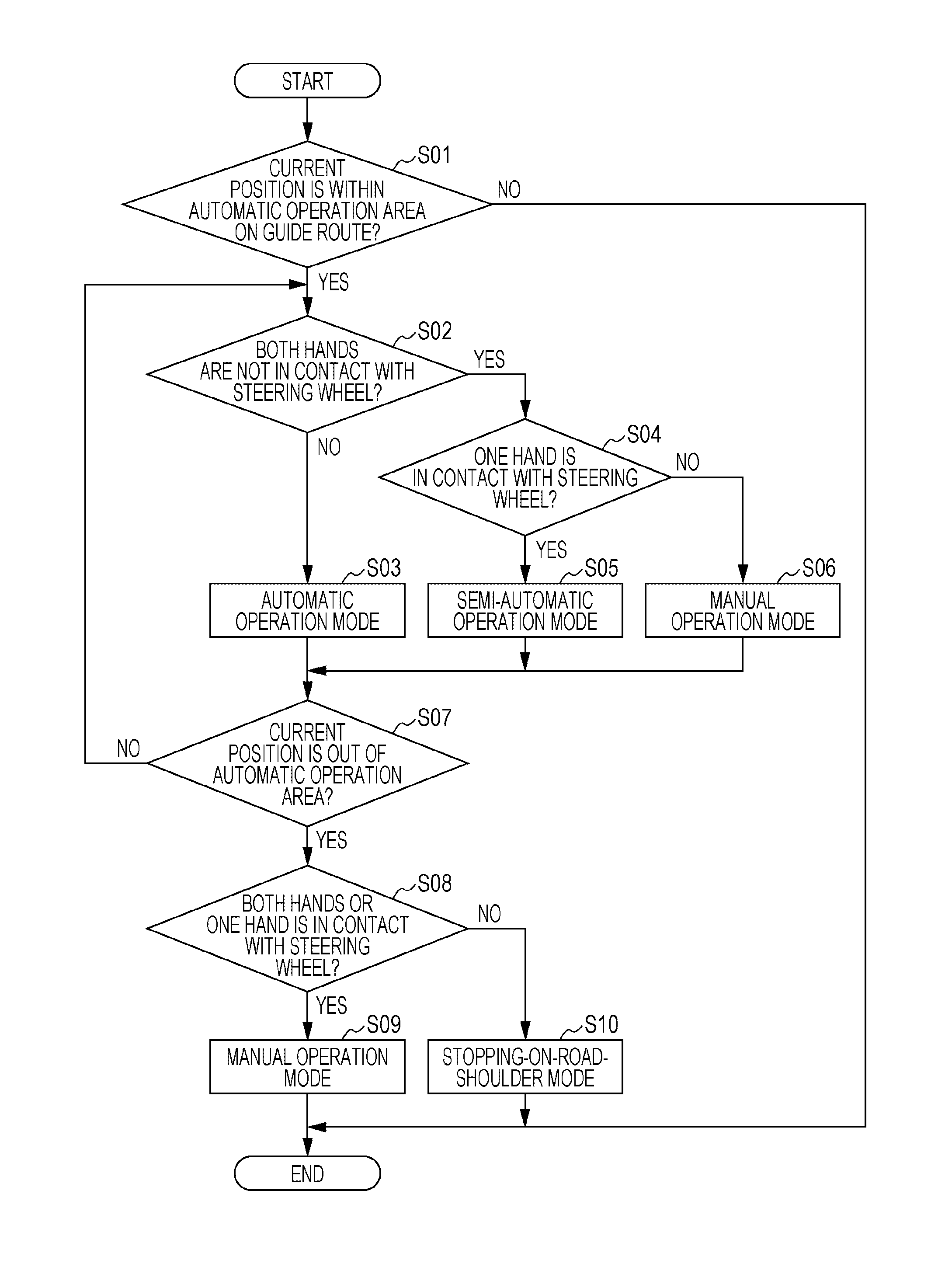

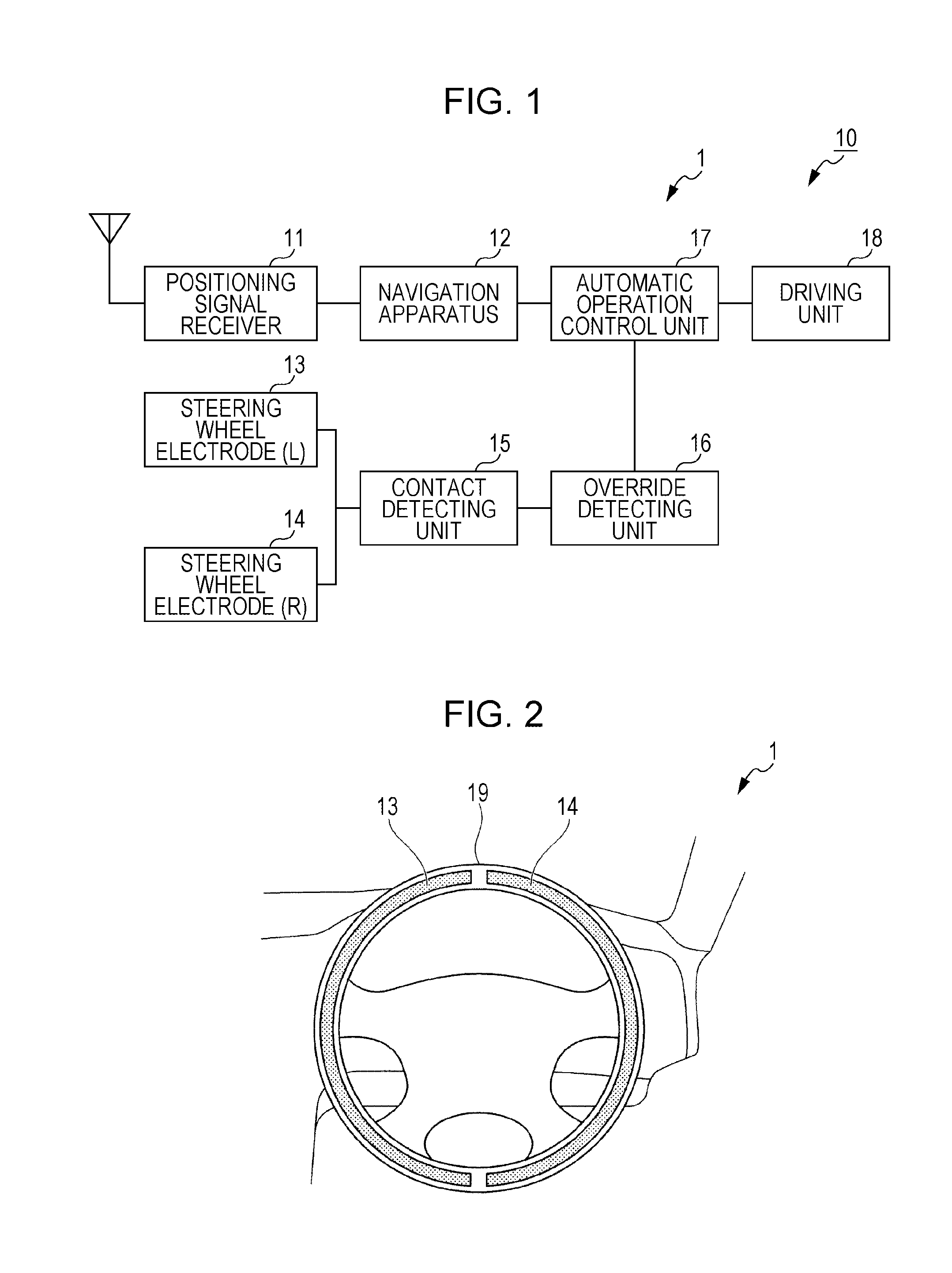

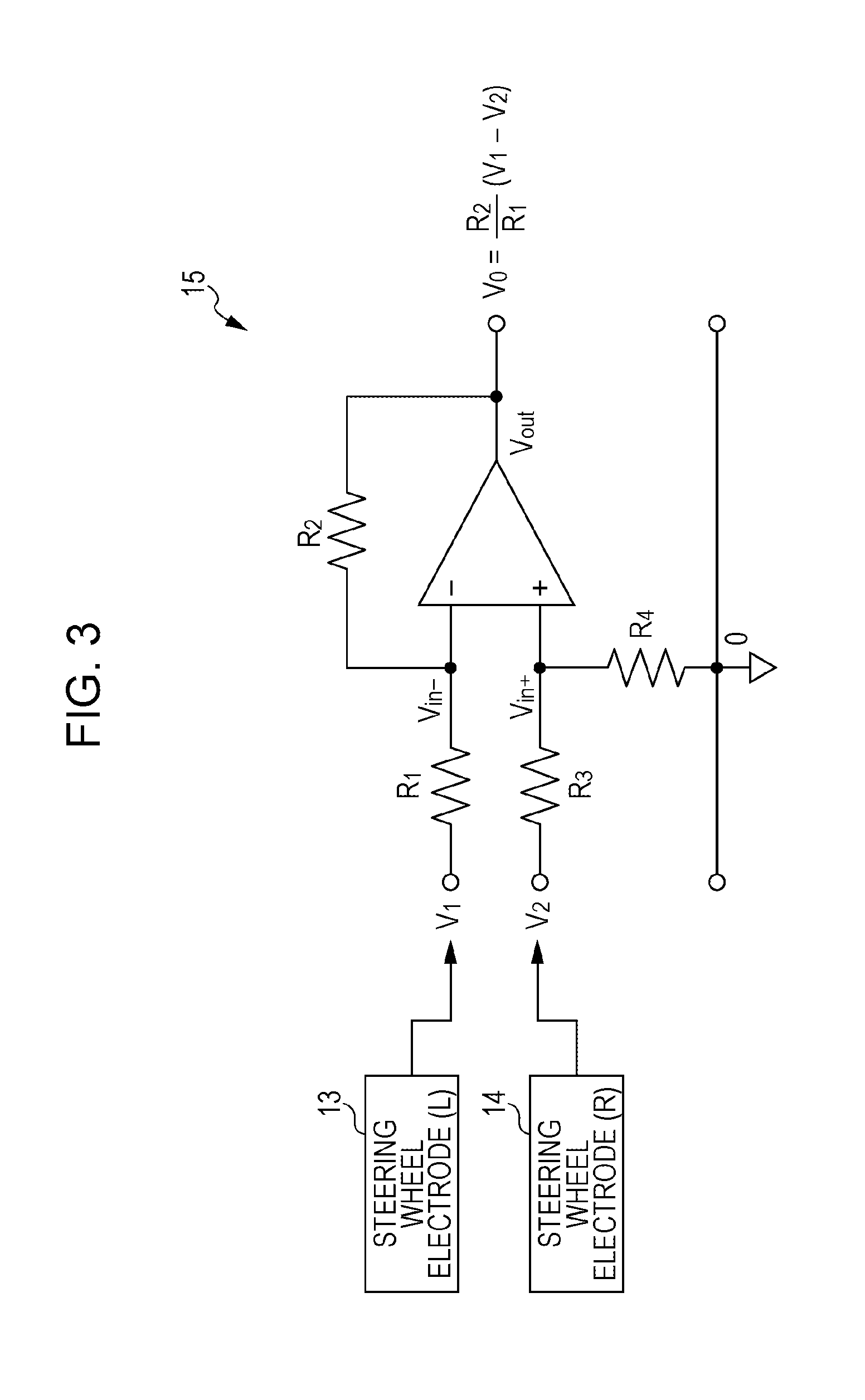

Automatic operation vehicle control apparatus

ActiveUS20160039428A1Low costIncrease the sense of designAutonomous decision making processExternal condition input parametersAutomatic Generation ControlDriver/operator

An automatic operation vehicle control apparatus includes a contact detecting unit, an override detecting unit, and an automatic operation control unit. The contact detecting unit detects the presence of contact of a hand or hands of a driver with a steering wheel of a vehicle. The override detecting unit detects the presence of override on the steering wheel by the driver on the basis of the result of the detection by the contact detecting unit. The automatic operation control unit switches the operation mode at least including the automatic operation and the manual operation of the vehicle on the basis of the result of the detection by the override detecting unit.

Owner:HONDA MOTOR CO LTD

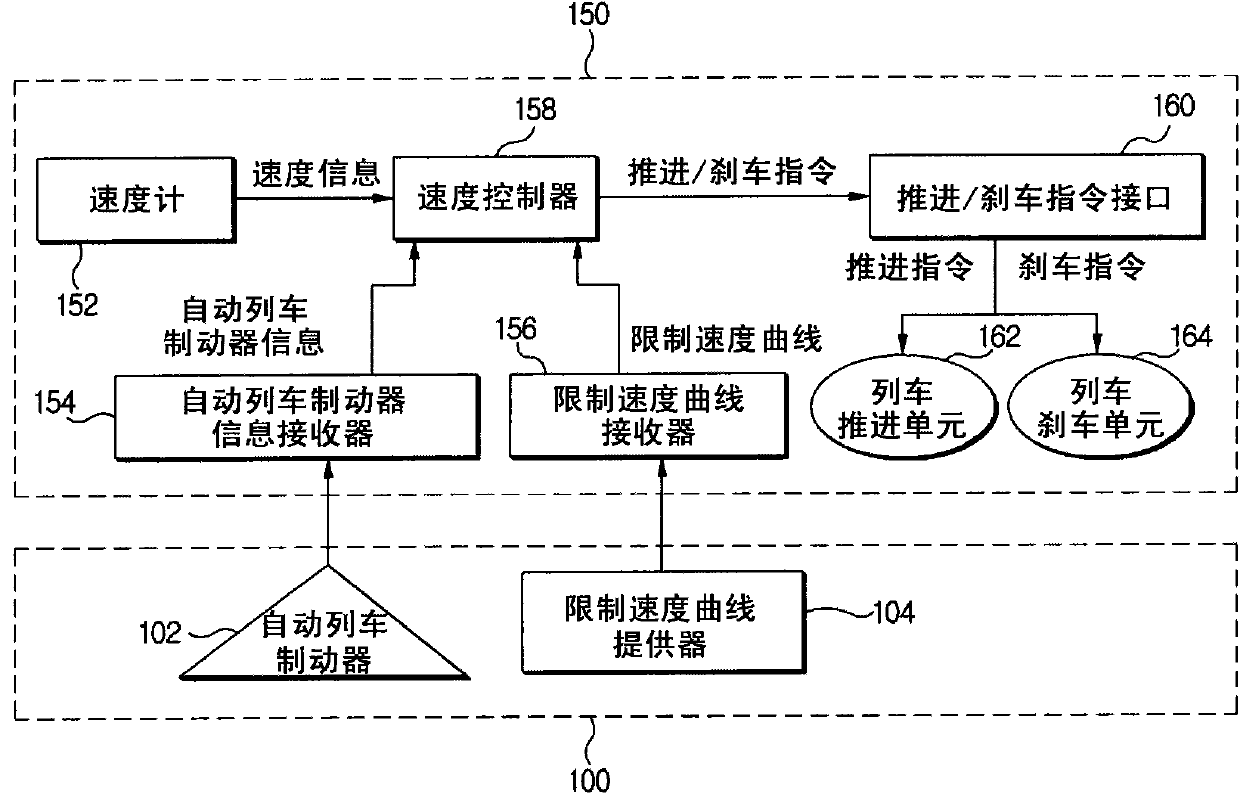

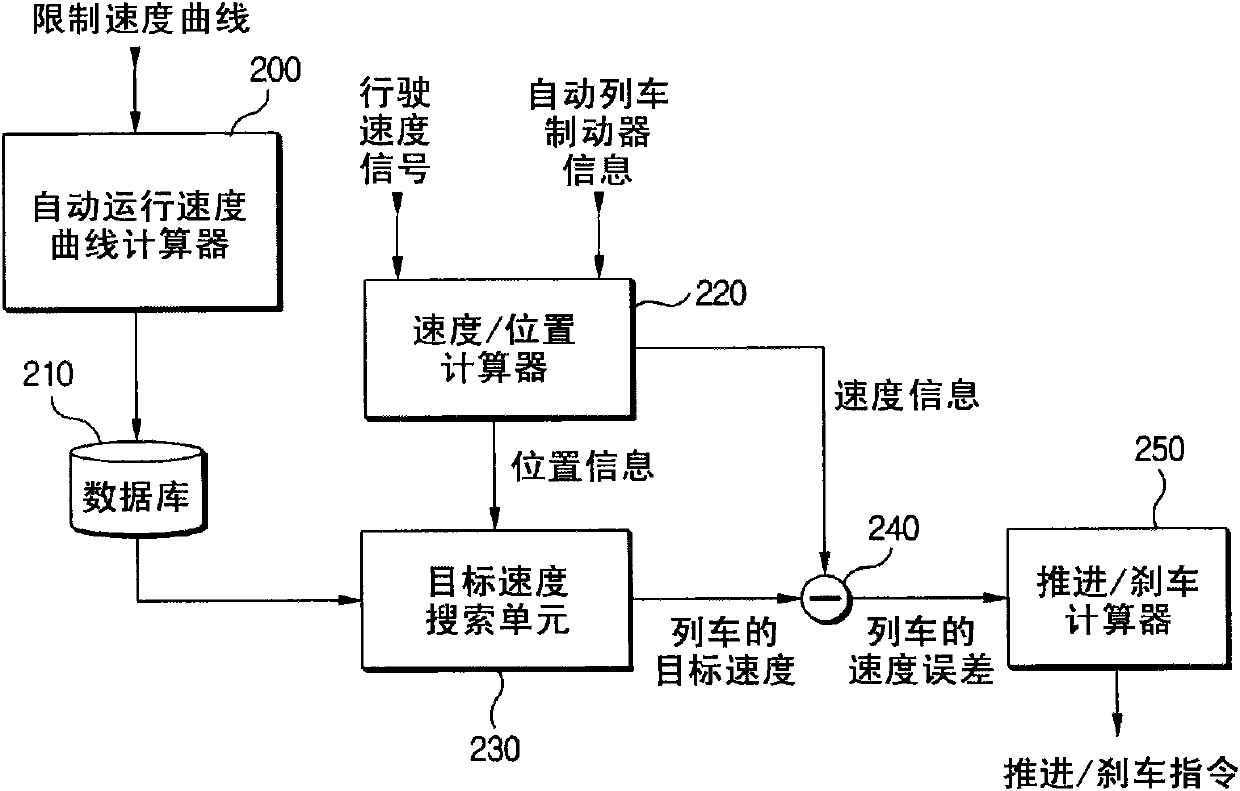

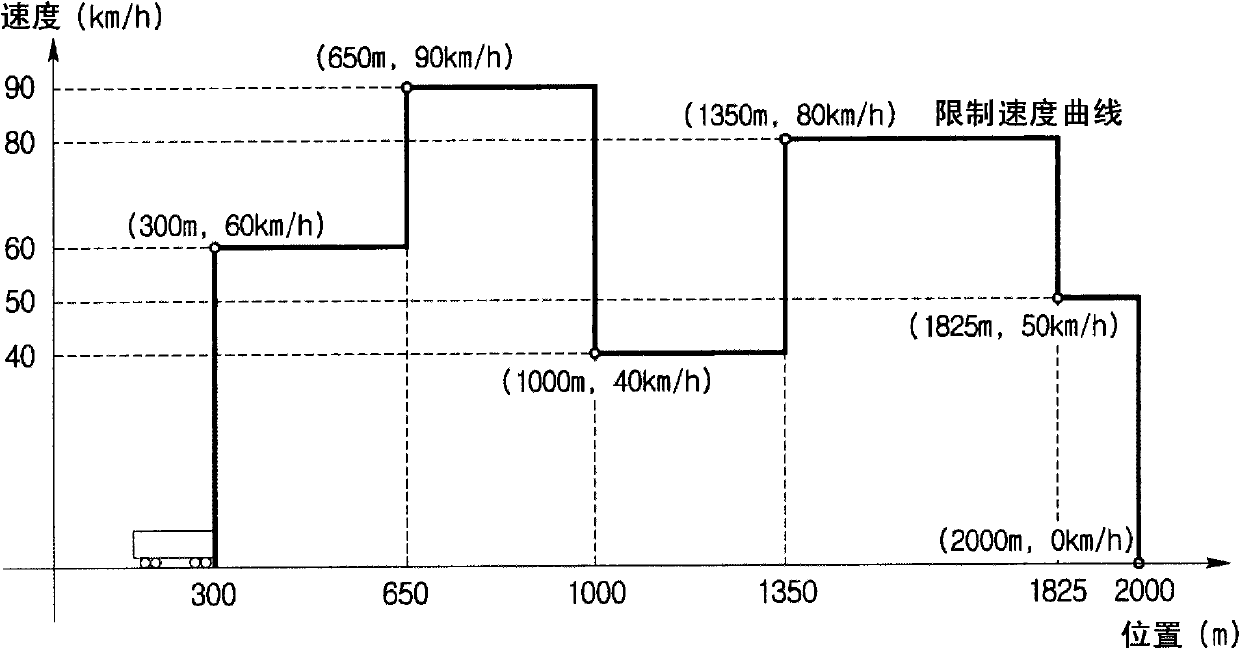

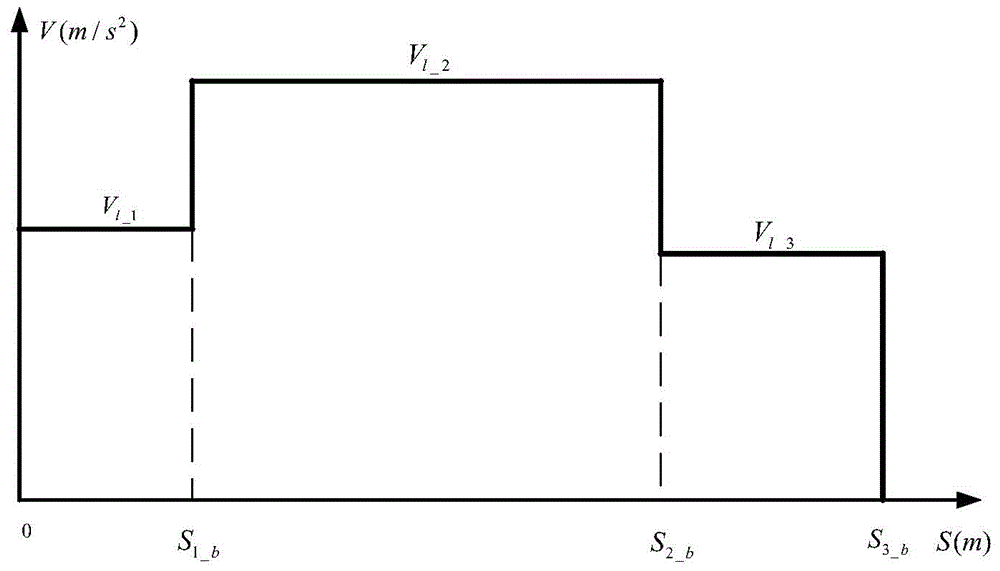

Apparatus and method for controlling speed in automatic train operation

ActiveCN101992795AAutomatic systemsRoute devices for controlling vehiclesAutomatic train operationAcceleration Unit

The present disclosure relates to an apparatus and method for controlling speed in an automatic train operation, capable of estimating and controlling a speed at which a train should run at each position where the train will run in order to satisfy a restrictive speed profile and to make passengers comfortable by observing acceleration limit and jerk limit in case of accelerating or decelerating the train.

Owner:LSIS CO LTD

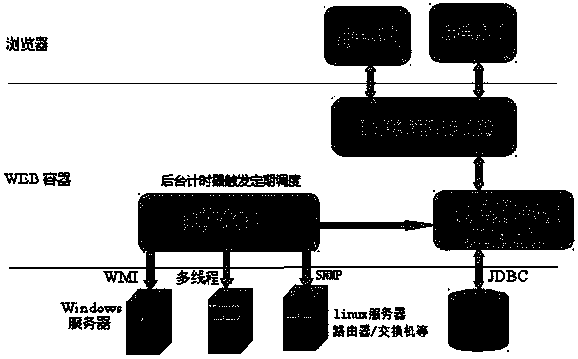

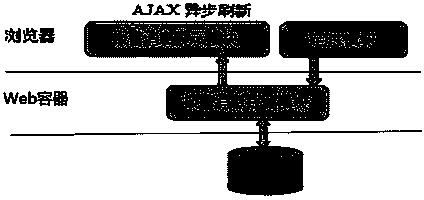

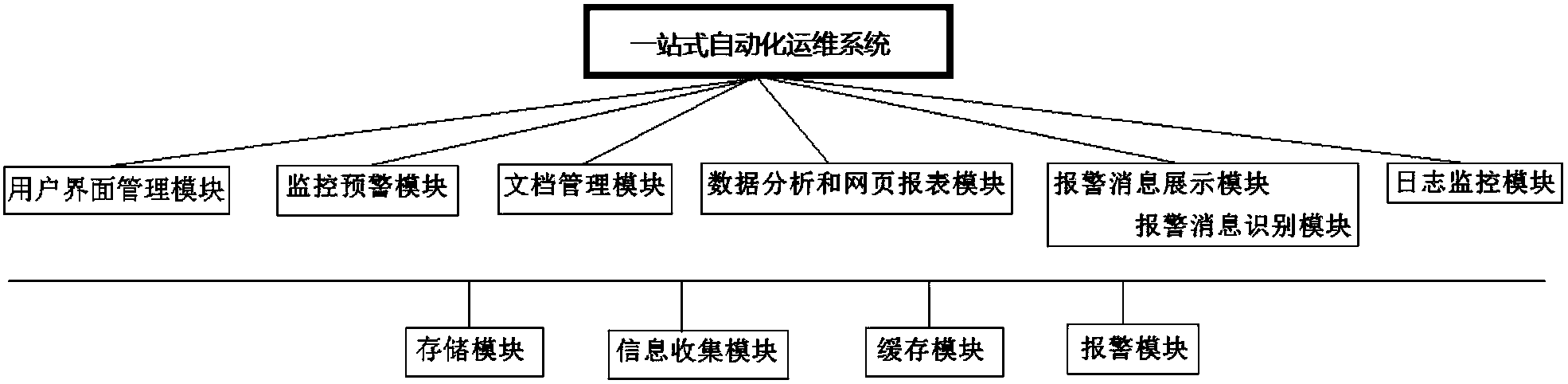

One-stop automatic operation and maintaining system

InactiveCN104022903AEasy to operateRealize one-clickData switching networksInformation processingData center

The invention provides a one-stop automatic operation and maintaining system which comprises an information collection module, a monitoring early warning module, an alarm information identification module, an alarm information processing, operation and storing module and a user interface management module. By means of the one-stop automatic operation and maintaining system, the functions of automatic fault diagnosis, document management, automatic monitoring early warning, automatic load / log collection, webpage statements, alarm information showing and classified identification are combined, operation loads of front-line operation and maintaining persons are relieved, and the management efficiency and the operation and maintaining level of a data center are greatly improved.

Owner:TRAVELSKY

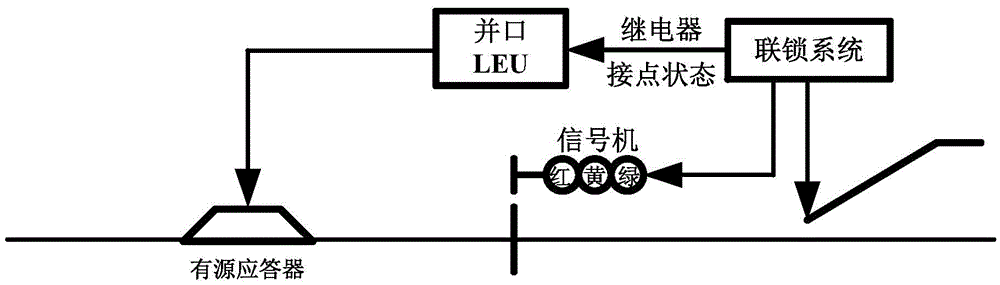

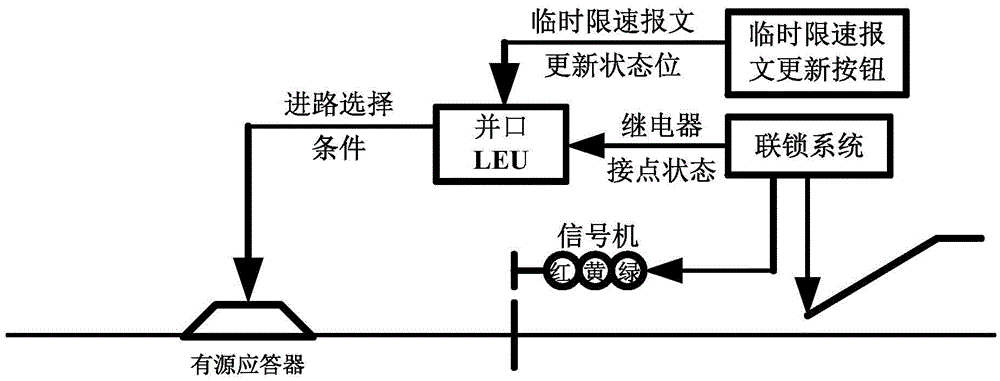

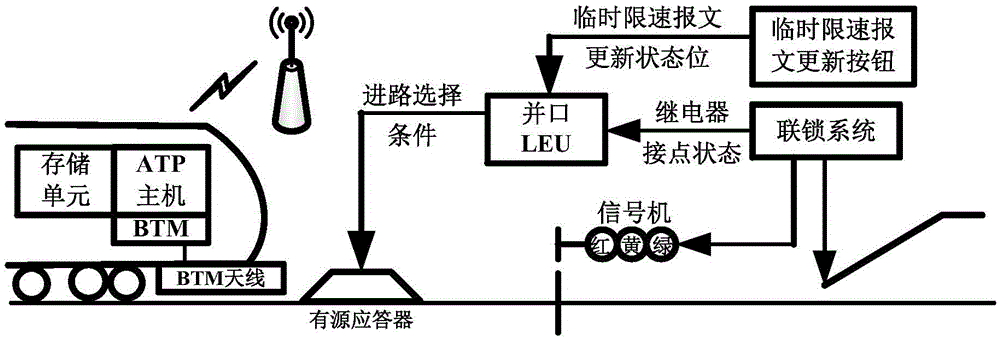

Train control system adapting to existing line reconstruction and train control method

The invention discloses a train control system adapting to existing line reconstruction. The train control system adapting to existing line reconstruction comprises ground equipment and on-board equipment. The ground equipment comprises an interlocking system, a parallel-port LEU and an active balise which are mounted in a station and connected sequentially, wherein the parallel-port LEU combines contact states of the interlocking system into access selection conditions and sends station messages to the corresponding active balise, and when a train passes through an acting range of the active balise, the active balise sends the corresponding station message to the on-board equipment of the train. The on-board equipment comprises a BTM (balise transmission module), a BTM antenna and an automatic train protection system, wherein when the train passes through the acting range of the active balise, the BTM receives the station messages sent by the active balise and sends the station messages to the automatic train protection system for subsequent processing. The train control system adapting to existing line reconstruction has the advantage that access information is sent to the on-board BTM through the station messages to enable a driver to acquire correct access information directly, so that the train pull-in risk that the driver selects wrong access information due to misoperation is avoided.

Owner:BEIJING JIAOTONG UNIV

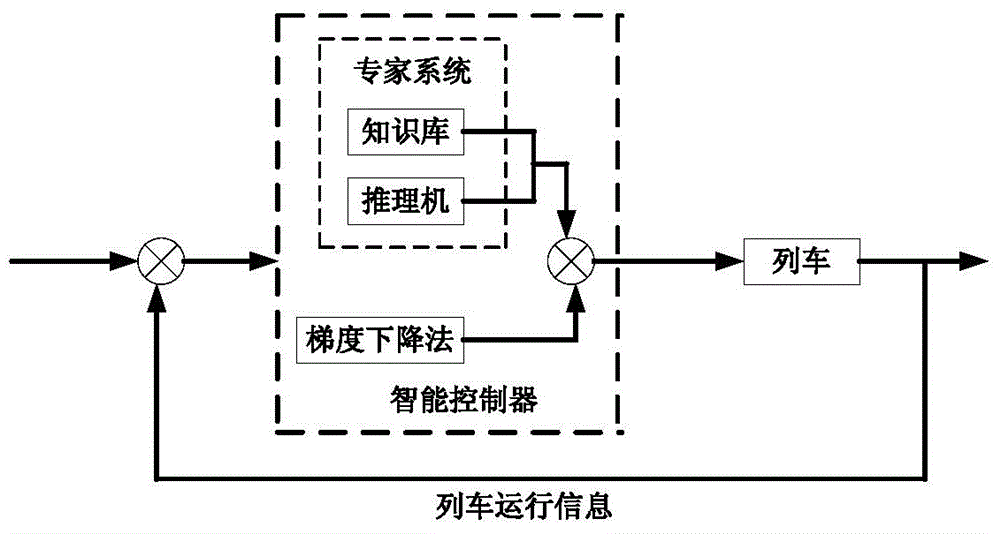

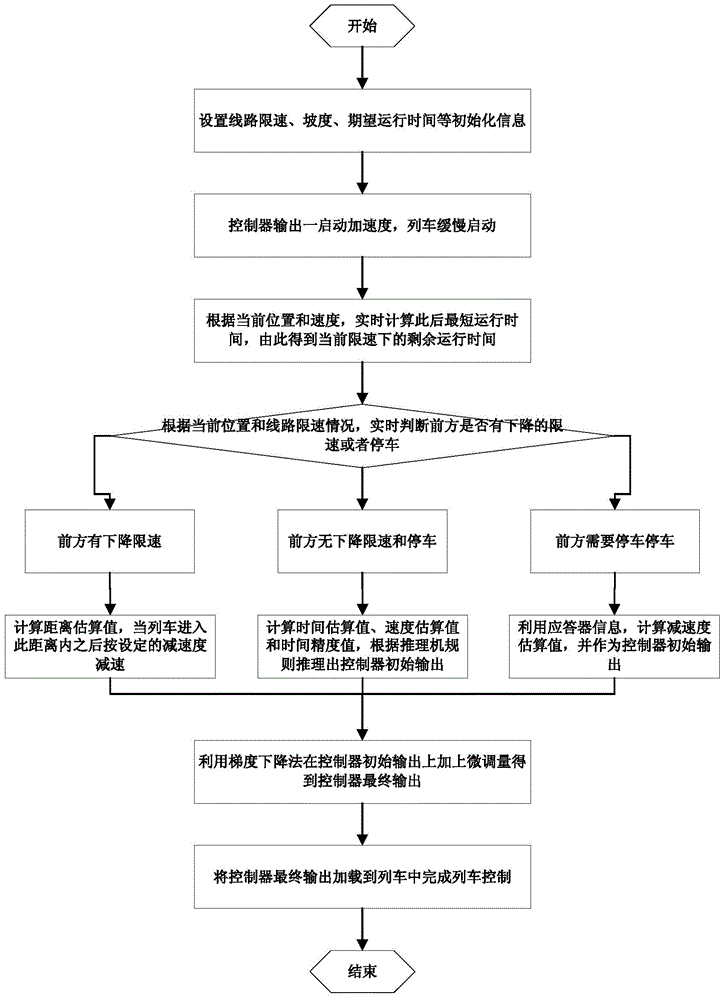

Urban rail train intelligent control method based on driving experience and online study

InactiveCN104134378AAvoid uncertaintyImprove ride comfort performanceCosmonautic condition simulationsSimulatorsTime informationOnline study

The invention discloses an urban-railway-system train intelligent control method based on driving experience and online study. The method obtains output of a controller through simulation of a driving strategy of an experienced driver, use of real-time data of train operation and reasoning and induction, and uses real-time information and speed-limit information of the trains to reasonably distribute the remaining time of train operation so that a time precision estimation value and a speed estimation value are obtained, and based on an MTDA algorithm of the real-time information, the method uses a train operation limit speed and current position, speed and time to deduct an expectation operation time and an expectation operation speed of train operation. Compared with a simulation result of automatic train operation (ATO) of a Yizhuang line of the Beijing city, the intelligent control method is capable of saving energy and improving on-time performance.

Owner:BEIJING JIAOTONG UNIV

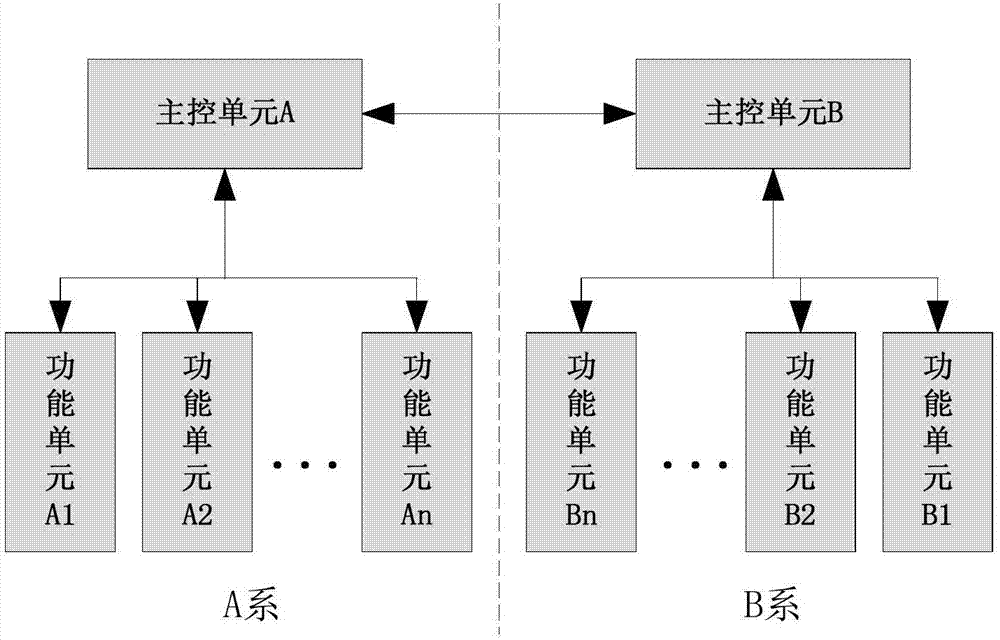

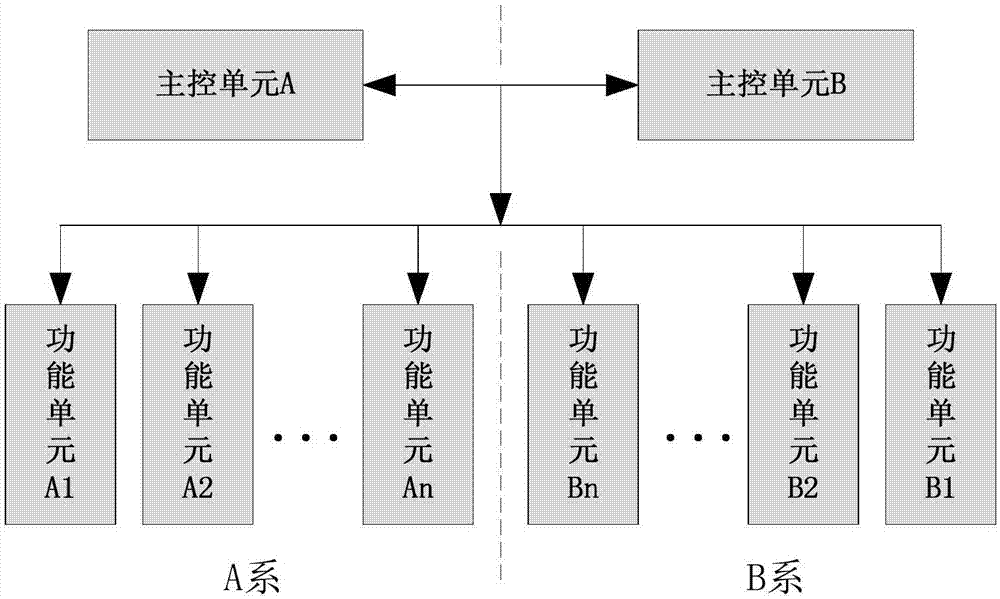

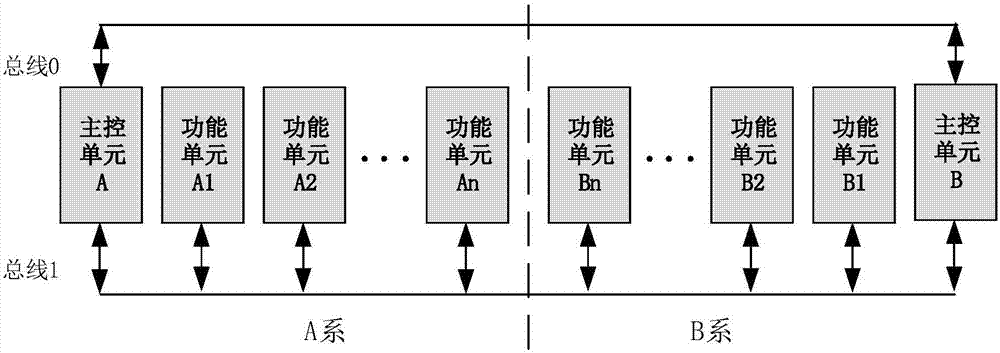

Cell-level hot standby redundancy ATO system architecture

ActiveCN107187465ARealize interconnectionImprove field availabilitySignalling indicators on vehicleStandby redundancyAutomatic train operation

The invention provides a cell-level hot standby redundancy ATO system architecture and a cell-level hot standby redundancy automatic train operation system. The system comprises a first sub-system running as a main system, and a second sub-system running as a standby system, wherein the first sub-system is provided with a first main control unit and a first group of functional units; the second sub-system is provided with a second main control unit and a second group of functional units corresponding to the functional units in the first group of functional units one to one; when one function unit in the first group of functional units of the first sub-system breaks down, the system activates the function unit, corresponding to the functional unit which breaks down, in the second group of functional units of the second sub-system, so that the functional units which do not break down in the first sub-system and the activated function unit in the second sub-system continue to work together.

Owner:HUNAN CRRC TIMES SIGNAL & COMM CO LTD

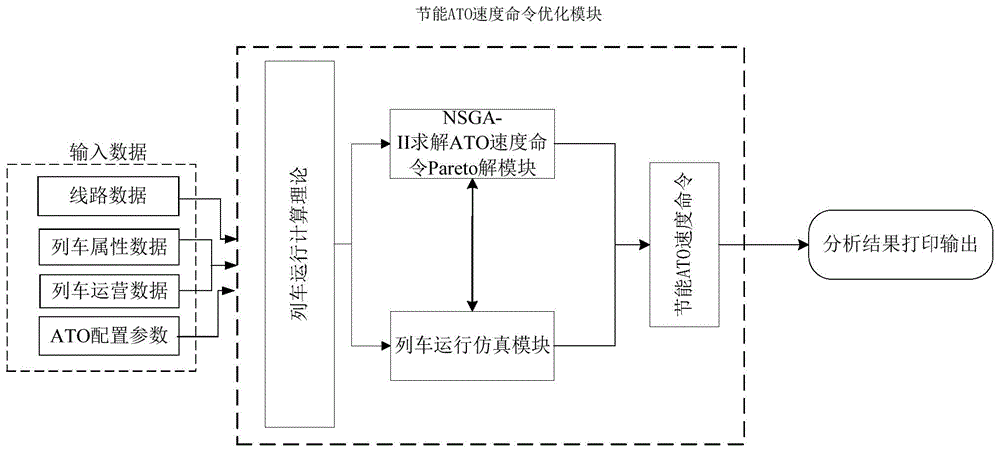

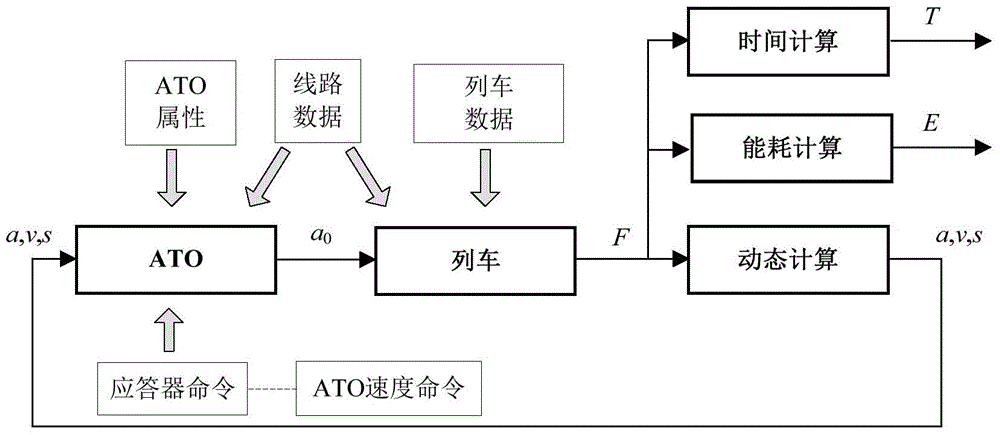

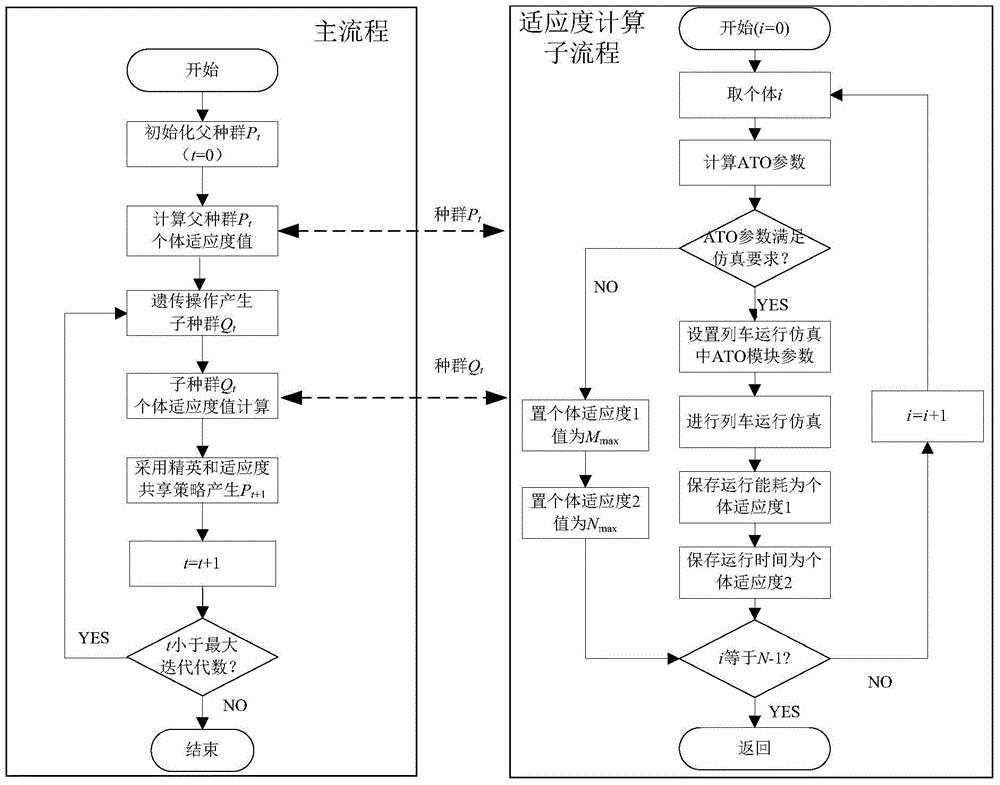

ATO (Automatic Train Operation) speed command optimization method of urban rail transit train

ActiveCN104881527AGuaranteed comfortWith energy saving effectSoftware simulation/interpretation/emulationSpecial data processing applicationsSimulationGenetic algorithm

The invention discloses an ATO (Automatic Train Operation) speed command optimization method of an urban rail transit train. The method comprises the following steps: establishing a data module for optimizing an ATO speed command; establishing an ATO speed command combination evaluation module to evaluate superiority-inferiority of a current ATO speed command combination; establishing a multi-objective genetic algorithm NSGA-II (Non-dominated Sorting Genetic Algorithm II)-based ATO speed command energy-saving optimization method to determine an energy-saving ATO speed command so as to finally obtain an interval energy-saving ATO speed command set. According to the method, the optimal ATO speed command set of all operation intervals of a metro line can be obtained, the optimization time is greatly shortened, off-line optimization can be performed, on-line optimization can also be performed, the metro traction power consumption is reduced, and a large amount of electric energy can be saved for the urban rail traffic system of China each year.

Owner:NANJING UNIV OF SCI & TECH

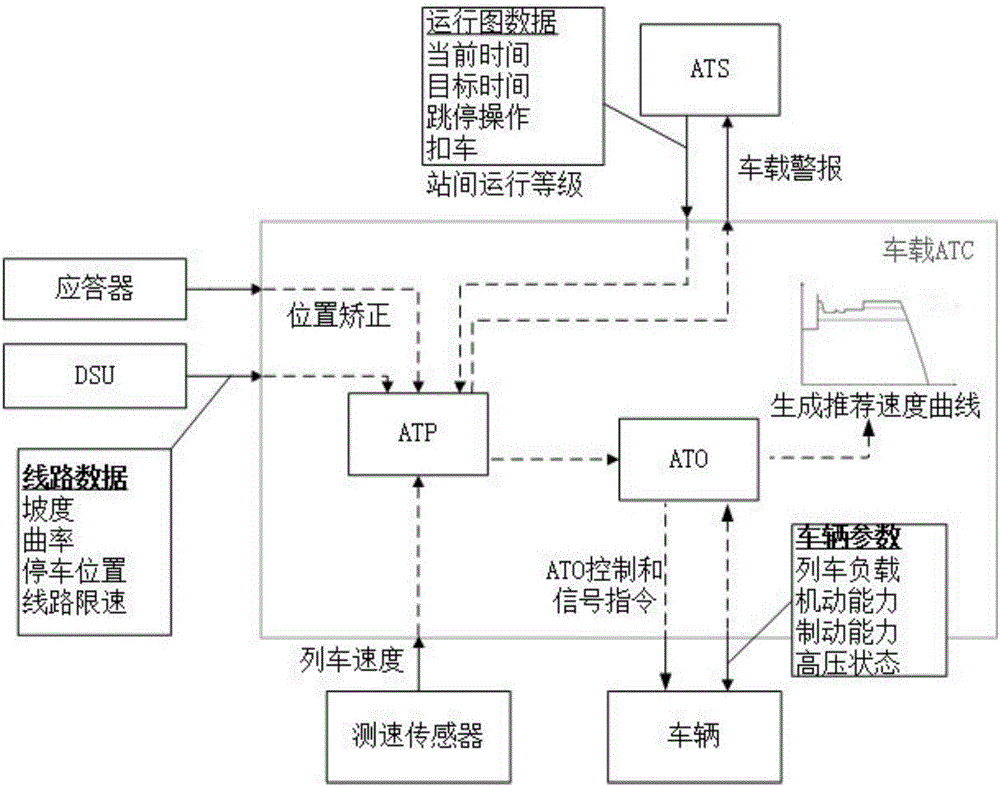

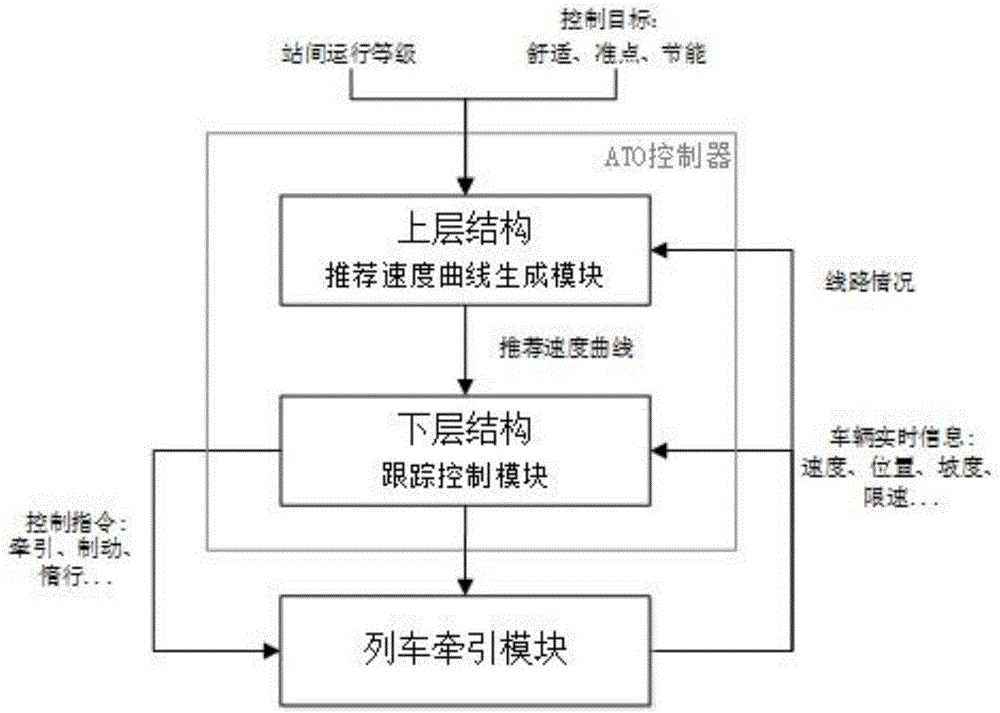

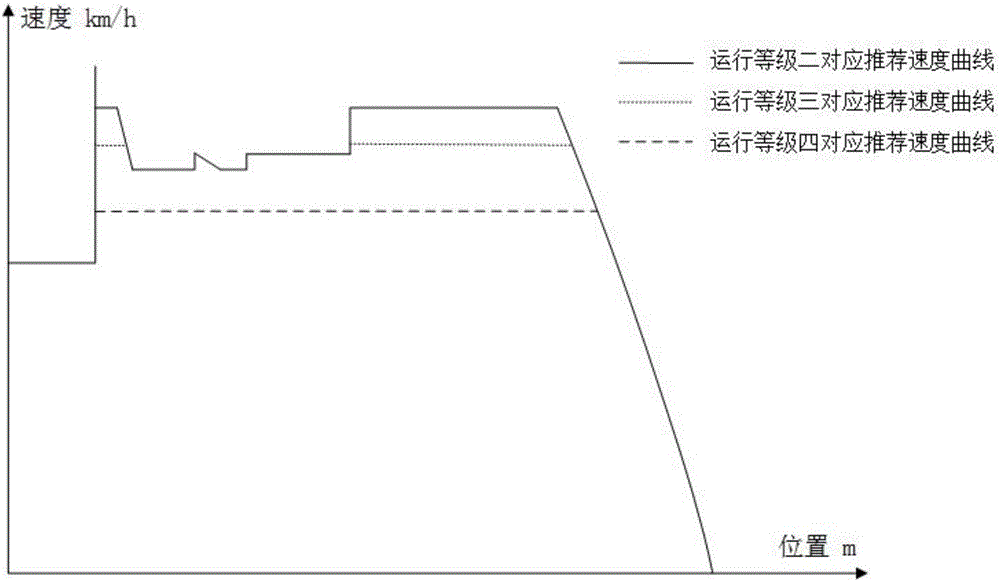

Method for controlling train operation on basis of train operation grades

ActiveCN106828540AGuaranteed punctualityMeet the requirements of control objectivesAutomatic systemsSignalling indicators on vehicleTime conditionTime information

The invention provides a method for controlling train operation on the basis of train operation grades. The method includes determining a plurality of operation grades by the aid of ATS (automatic train control) systems according to train operation plans and control targets when trains are operated between stations, generating recommended speed curves by the aid of ATO (automatic train operation) systems and storing the recommended speed curves in vehicular equipment; automatically selecting corresponding inter-station operation grades and the corresponding recommended speed curves by the aid of the ATO systems according to actual early departure time conditions of the trains, controlling train operation by the aid of the curves, determining train tracking recommended curve control strategies, transmitting control instructions to the trains according to train operation real-time information and operating train tracking recommended speed curves. The method has the advantages that the train operation grades, the corresponding recommended speed curves and the train tracking recommended curve control strategies can be automatically selected to transmit control commands to vehicles according to real-time conditions, real-time information feedback of the vehicles can be received, and accordingly the target control requirements can be met on the premise that the train operation punctuality is guaranteed.

Owner:BEIJING JIAOTONG UNIV

Large intelligent small-pot continuous automatic cooker equipment

ActiveCN104856556AProgrammaticFully automatedCooking vesselsTableware washing/rinsing machinesSide dishEngineering

The invention discloses large intelligent small-pot continuous automatic cooker equipment, and belongs to the technical field of intelligent robots for food and beverage service. The large intelligent small-pot continuous automatic cooker equipment achieves programming, automation and standardization of vegetable matching, cooking and cleaning of large quantities of food supply. According to the adopted technical scheme, the large intelligent small-pot continuous automatic cooker equipment comprises a vegetable storage cabinet, a left cooker, a right cooker and an intelligent control system, wherein the left cooker and the right cooker are symmetrically arranged and installed on the two sides of the vegetable storage cabinet, side dishes and seasonings in the vegetable storage cabinet are conveyed to the left cooker and the right cooker through belt conveyers to be stirred and fried fully automatically and mechanically, and the intelligent control system sets programs and carries out operation. The large intelligent small-pot continuous automatic cooker equipment is mainly used for places such as dining halls of enterprises, public institutions, schools and armies and fast food restaurants, where a lot of cooked food is required, full-automatic operation is achieved, the cooked food is delicious, and labor cost is reduced.

Owner:CHANGZHI LUAN HELI MACHINERY

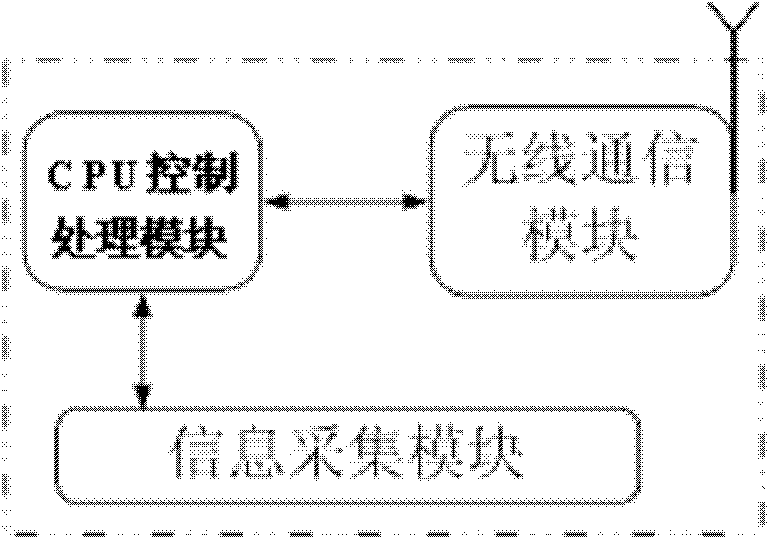

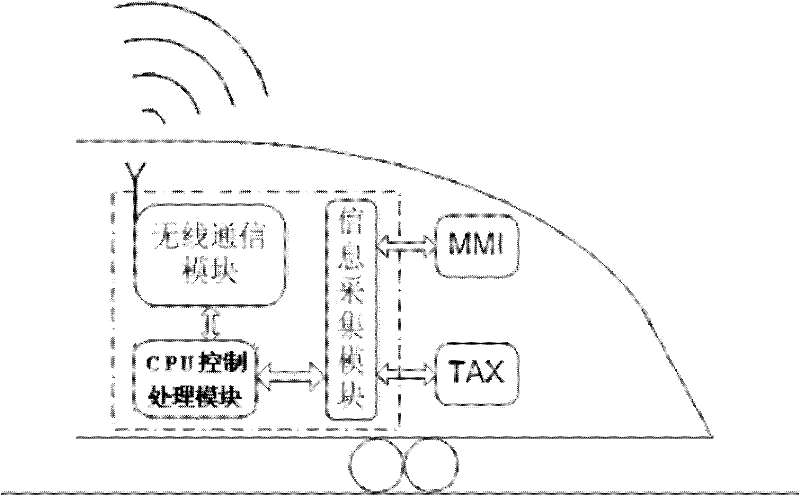

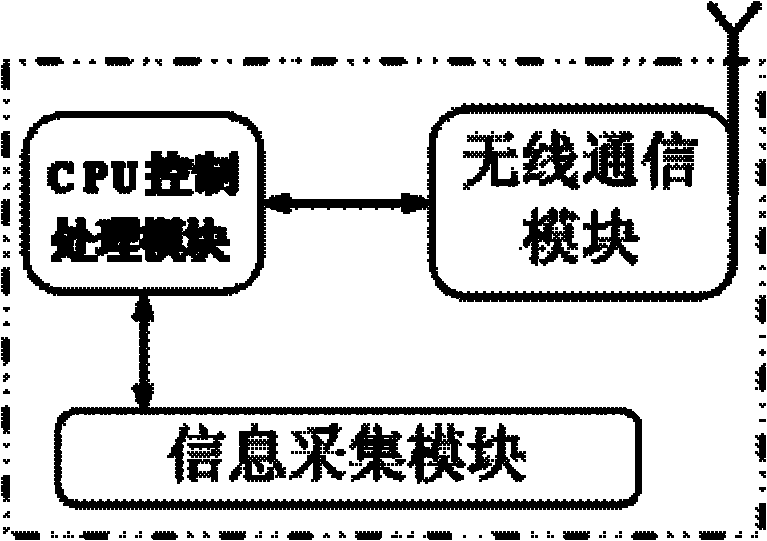

Train collision prevention warning system

InactiveCN102358334AKeep abreast of driving statusImprove securityRailway signalling and safetyEngineeringWireless broadcasting

The invention relates to a train collision prevention warning system. A train information collection module is used for collecting train status information, and the train status information comprises a train running line, a train location, a train speed, a safety level and the like; a wireless communication module is used for wirelessly broadcasting the train status information and wirelessly receiving the train status information broadcast by other trains; and a CPU (central processing unit) control processing module is used for receiving and processing the train status information of the train and other trains collected by the train information collection module and transmitted by the wireless communication module. The current train status information of the train can be broadcast wirelessly to other trains via the wireless communication module, the train status information wirelessly broadcast by other trains can be received by the wireless communication module, the running safety distance and speed can be judged by the CPU control processing module according to relationships between the train and other trains, and pre-warning signals can be sent to drivers and automatic train operation systems. The system has a simple and reliable structure and can be installed conveniently, the train drivers can promptly know running statuses of approaching trains, and the train running safety can be improved effectively.

Owner:BEIJING JIAOTONG UNIV

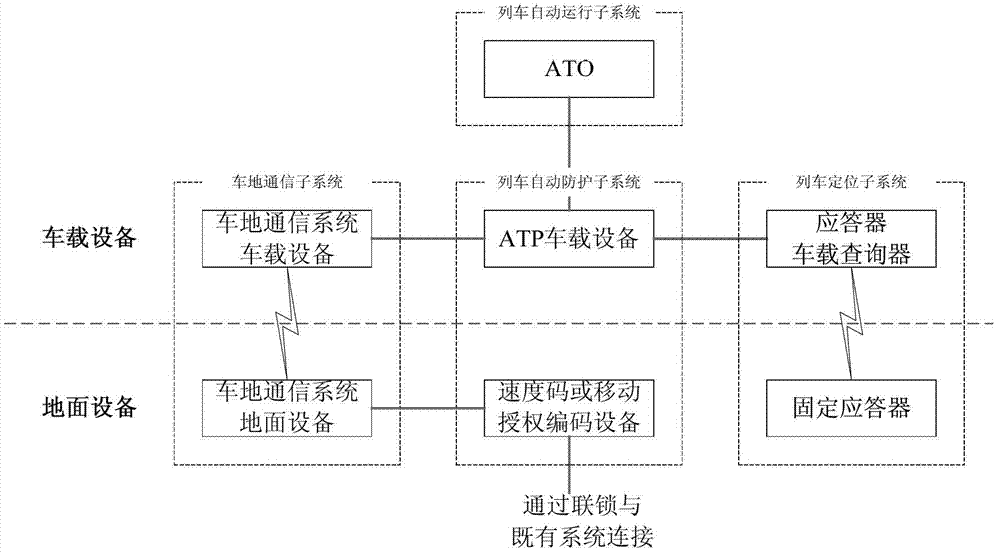

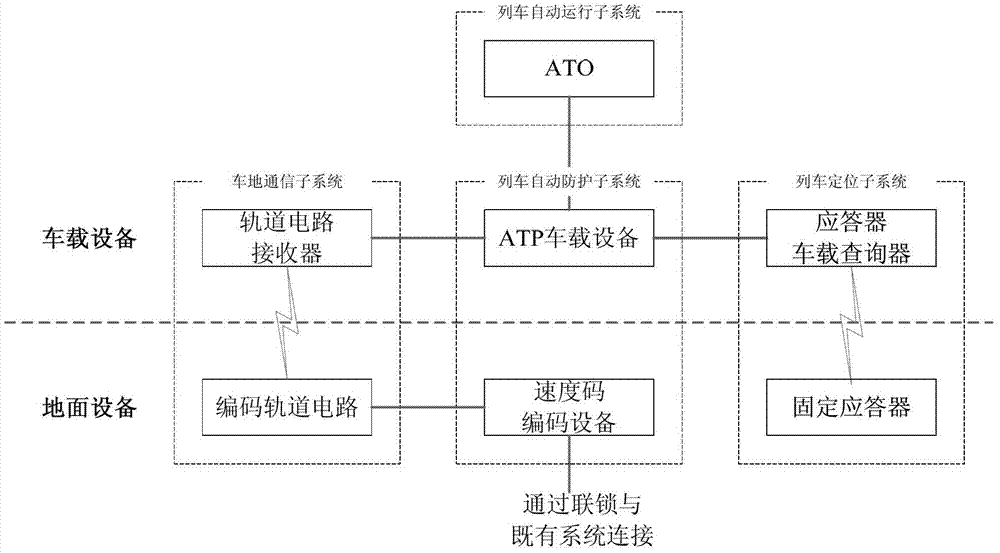

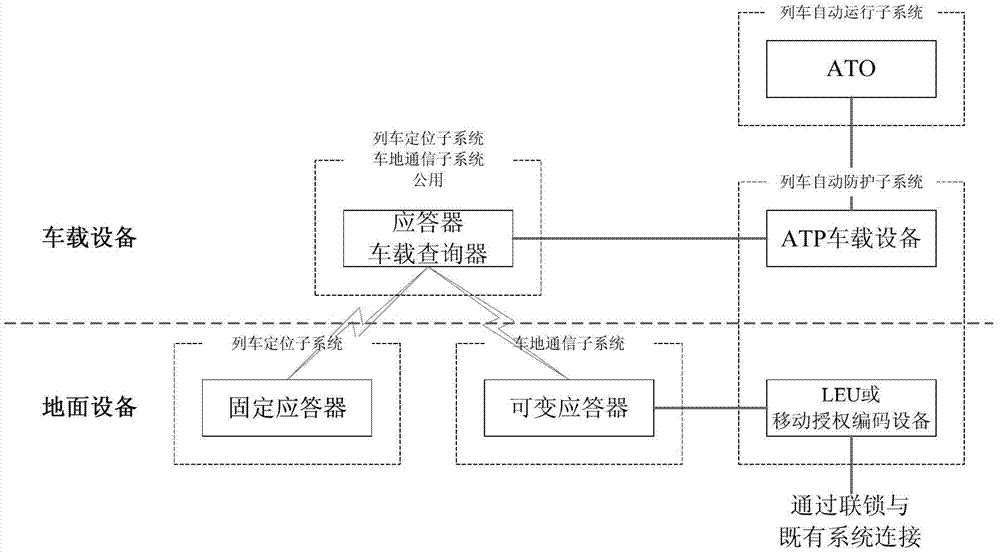

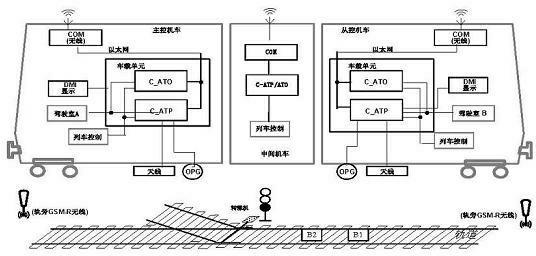

Full-automatic operation control system of rail transit car depot or parking lot

InactiveCN102897197AAvoid safety hazardsImprove securityAutomatic systemsAutomatic train controlAutomatic train protection

The invention discloses a full-automatic operation control system of a rail transit car depot or parking lot. The full-automatic operation control system comprises a train-ground communication subsystem, a train locating subsystem, an automatic train protection subsystem and a train automatic operation subsystem, wherein the train-ground communication subsystem is used for sending speed codes or movement authority information to the automatic train protection subsystem; the train locating subsystem is used for providing train position information and rectifying the distance measuring result of the automatic train protection subsystem; the automatic train protection subsystem is used for monitoring the running speed of a train; and the train automatic operation subsystem is used for realizing automatic operation of the train. The system can be used for improving the safety of traveling operation in the car deport and the parking lot, reducing the labor intensity of a driver and avoiding the influence of slow operation of a train inlet / outlet section on main track operation sequence; and meanwhile, the system is compatible with a main track and an existing system, can adapt to new construction and renovation projects, can be easily realized and does not need more investment.

Owner:TRAFFIC CONTROL TECH CO LTD

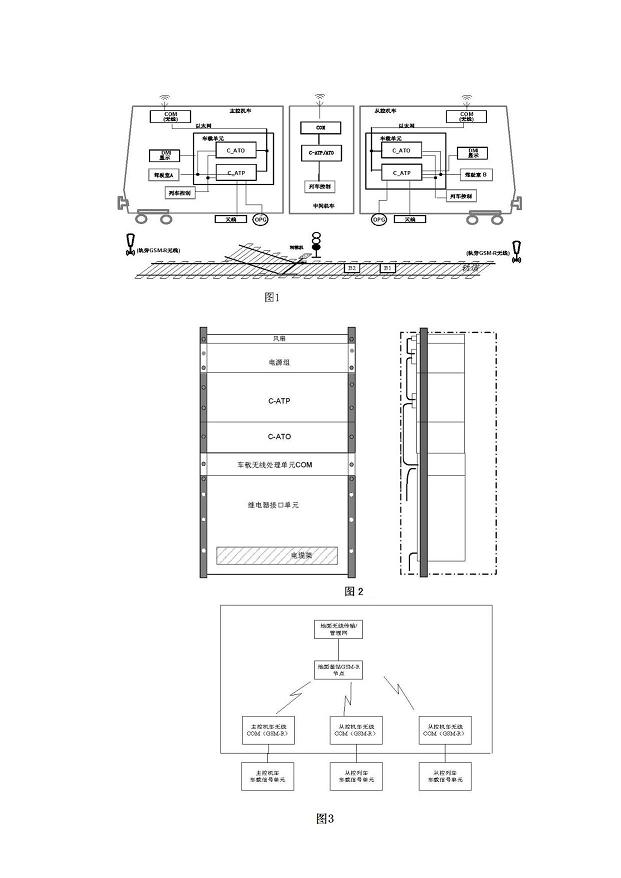

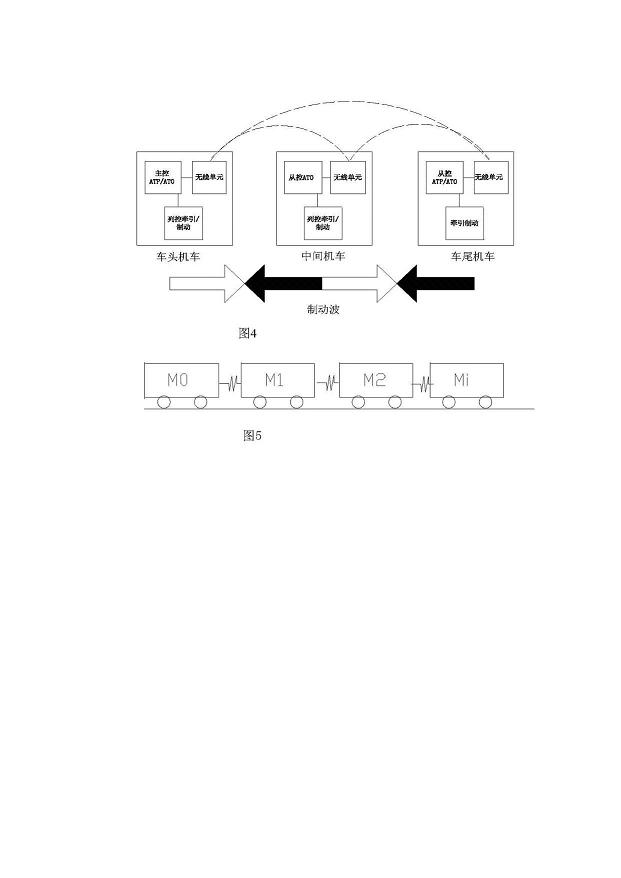

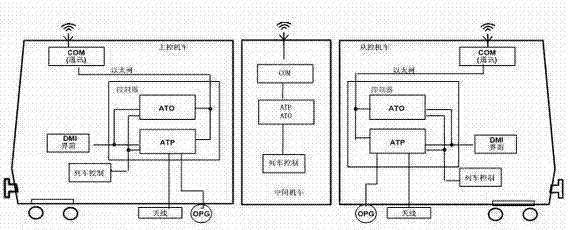

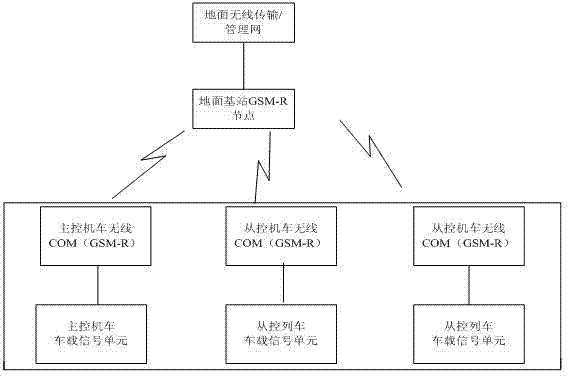

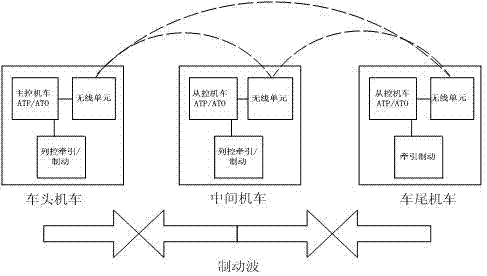

Synchronous control method for heavy-duty locomotive signal based on ATP/ATO (Automatic Train Protection/Automatic Train Operation) equipment

ActiveCN102616258AImprove securityImprove reliabilityRailway traffic control systemsAutomatic train protectionSynchronous control

The invention provides a synchronous control method for a heavy-duty locomotive signal based on ATP / ATO (Automatic Train Protection / Automatic Train Operation) equipment. The synchronous control method is characterized by comprising the following steps of: synchronously controlling the power distribution of a train, and synchronously transmitting wireless data, wherein each locomotive is provided with a set of identical ATP / ATO equipment for grouping; the locomotive at one end in running direction is used as the main control locomotive for the train and responsible for the communication with a train control dispatching center; meanwhile, the main control locomotive is used for calculating the power distribution according to the line conditions and the grouping conditions and transmitting a synchronous control command to a slave control locomotive; after receiving the command from the main control locomotive, the slave control locomotive can synchronously apply traction force or braking force; and a GSM-R (Global System for Mobile Communications for Railway) digital mobile communication network is adopted as a wireless communication synchronization link of the locomotive signal according to the control command between the main control locomotive and the slave control locomotive. By implementing the synchronous control method for the heavy-duty locomotive based on the ATP / ATO equipment, the safety and the reliability of the control system are greatly improved.

Owner:NANJING NRIET IND CORP

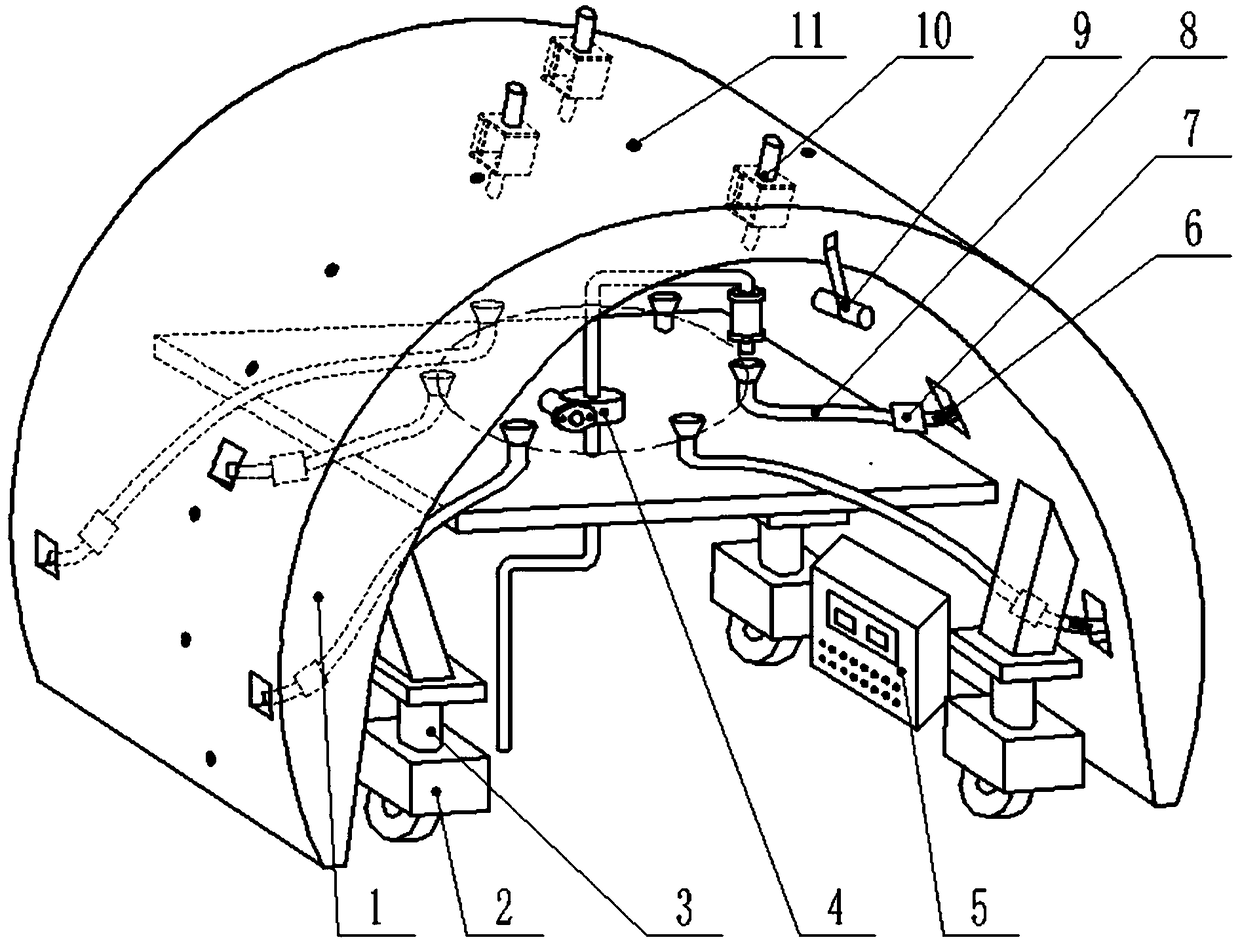

Automation control method for tunnel lining construction

ActiveCN108104838ARealize information collectionRealize automatic controlUnderground chambersTunnel liningAutomatic train controlAutomatic control

Disclosed is an automation control method for tunnel lining construction. A control system integrates all information collecting and control procedures of a traveling mechanism, a hydraulic system, aconcrete distribution device, a vibrating device, a temperature sensor, a flowmeter, a video monitor and a pressure sensor, is equipped with a GPRS wireless data transmission module, and can collect and upload information in the casting process of a tunnel lining to a project department monitoring room. The distribution device can be connected with a plurality of distribution pipes in series, thetemperature sensor is used for detecting the concrete casting temperature, and the flowmeter is used for collecting the concrete casting quantity and implementing automatic control over casting. The video monitor monitors real-time work picture information, and collects and transmits the real-time work picture information to the project department monitoring room. The vibrating device achieves vibrating automatic control operation for concrete. The pressure sensor detects and collects pressures of all points in the concrete casting process and displays the casted height of the concrete. The control system conducts concentration analysis on data collected in the casting process of the tunnel lining, gives out a control instruction, and uploads the detected data to the project department monitoring room.

Owner:中铁隧道勘察设计研究院有限公司

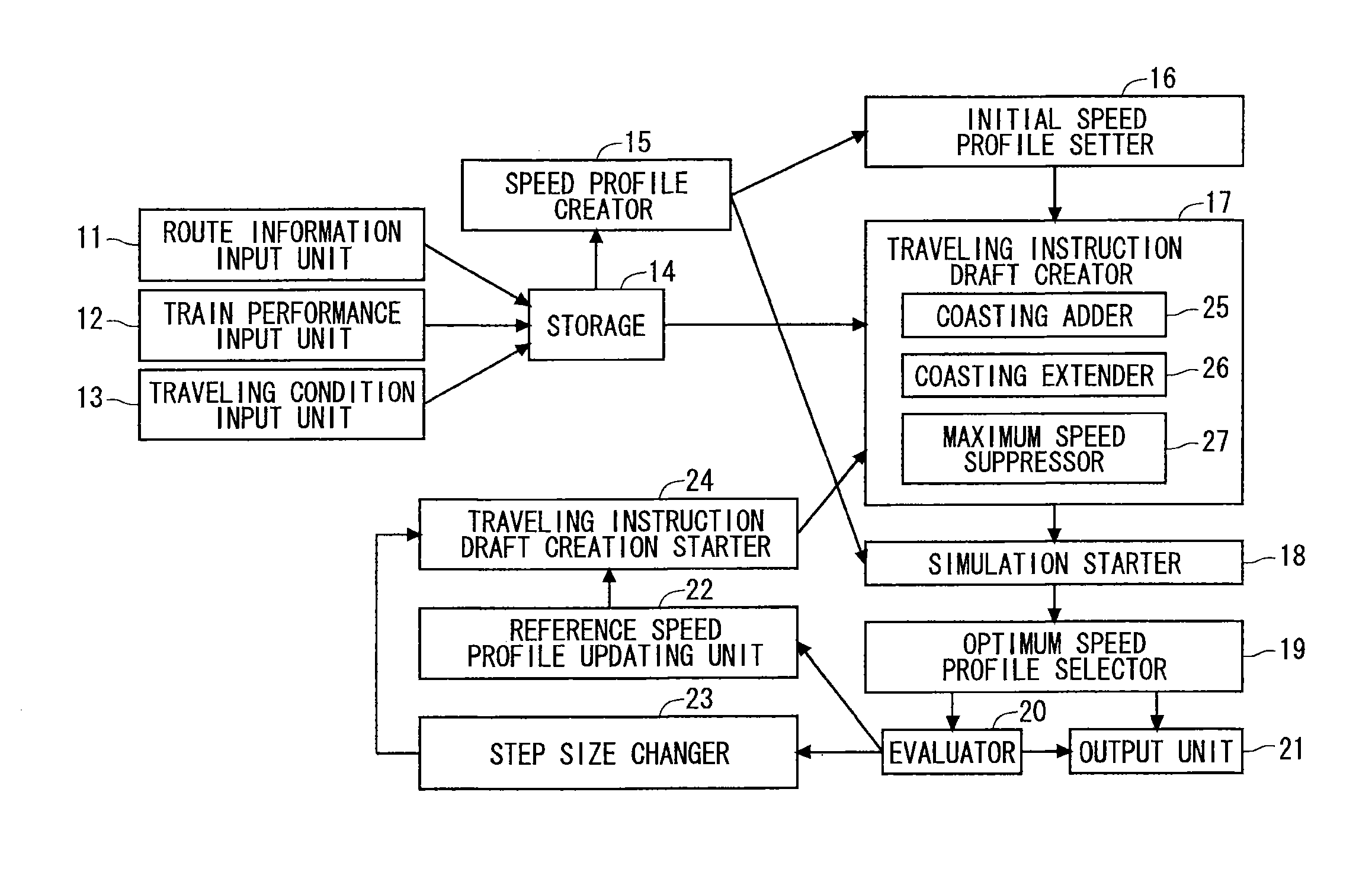

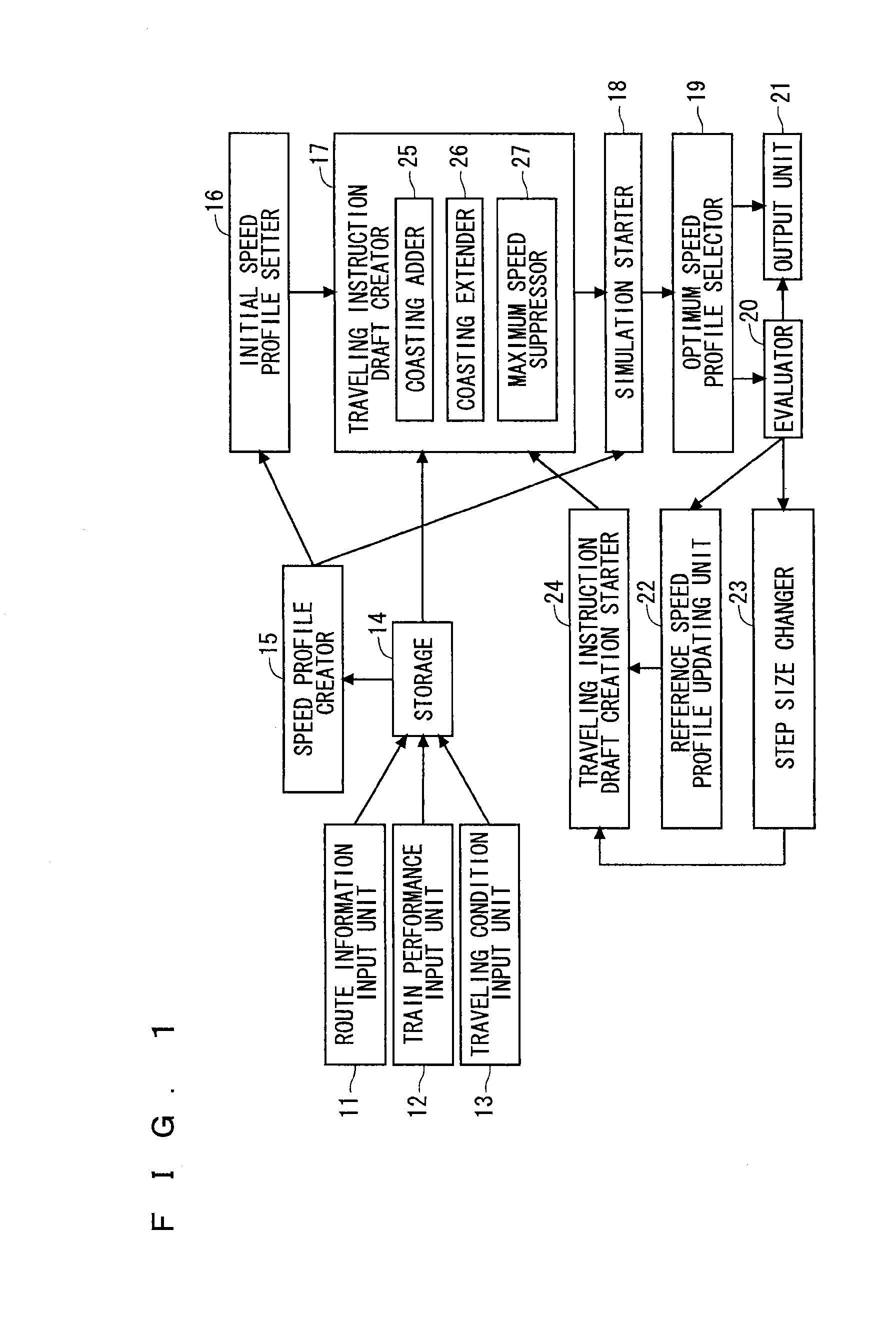

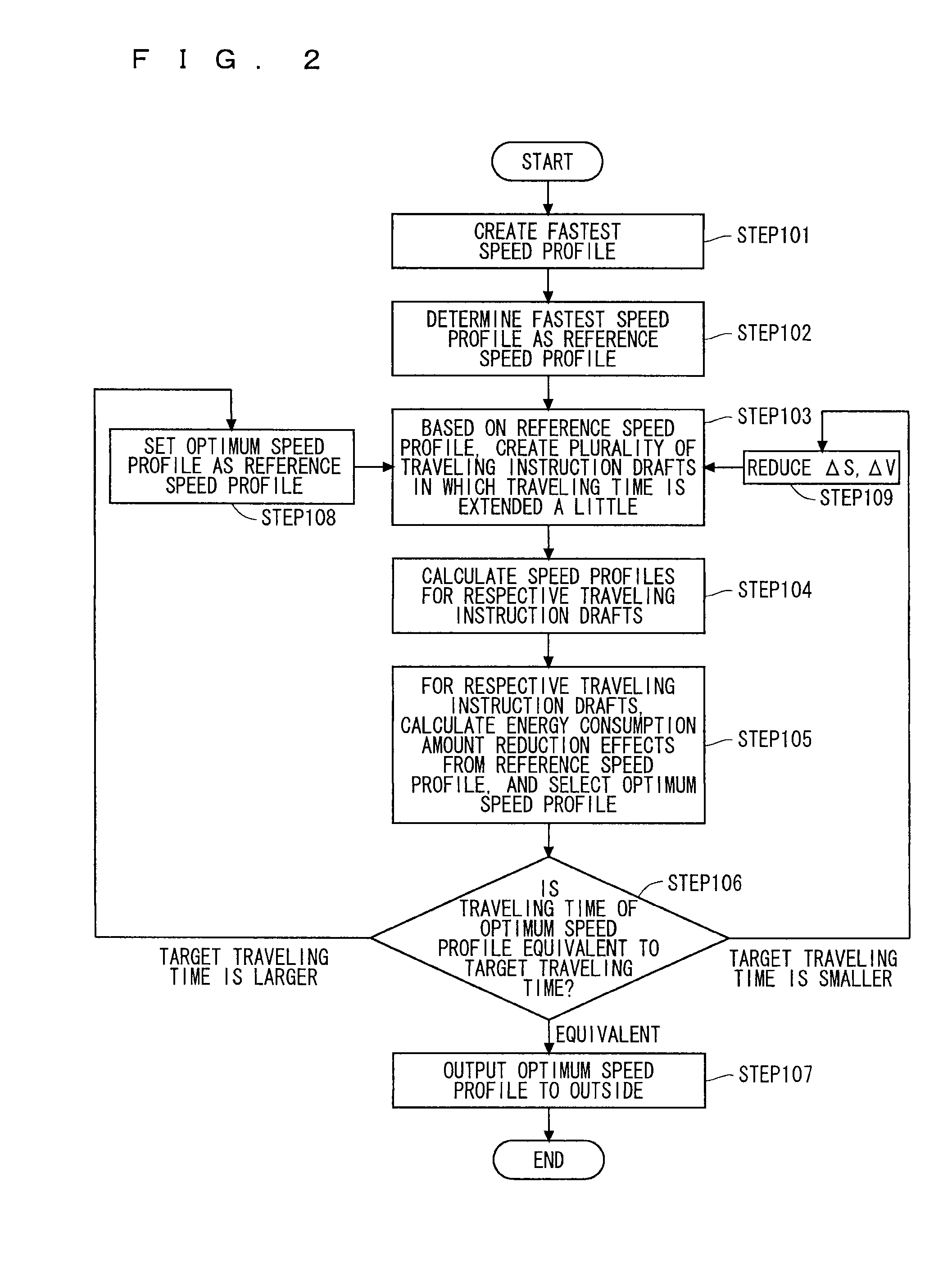

Speed profile creation device and automatic train operation apparatus

ActiveUS20140222259A1Energy consumption amount is smallReduce energy consumptionDigital data processing detailsTraffic regulationEngineeringEnergy expenditure

A speed profile creation device includes: a traveling simulator that creates, from a traveling instruction, a speed profile of allowing the train to travel through a traveling section together with a traveling time and energy consumption amount thereof by using a route condition, train performance, and a traveling condition; a traveling instruction draft creator that creates a plurality of traveling instruction drafts in which a reference speed profile is changed so that the energy consumption amount can decrease though the traveling time is lengthened a little; an optimum speed profile selector that selects an optimum speed profile in which an energy consumption amount reduction effect is maximum among the plurality of traveling instruction drafts; and a reference speed profile updating unit that updates the reference speed profile until the traveling time of the optimum speed profile becomes equivalent to the target traveling time.

Owner:MITSUBISHI ELECTRIC CORP

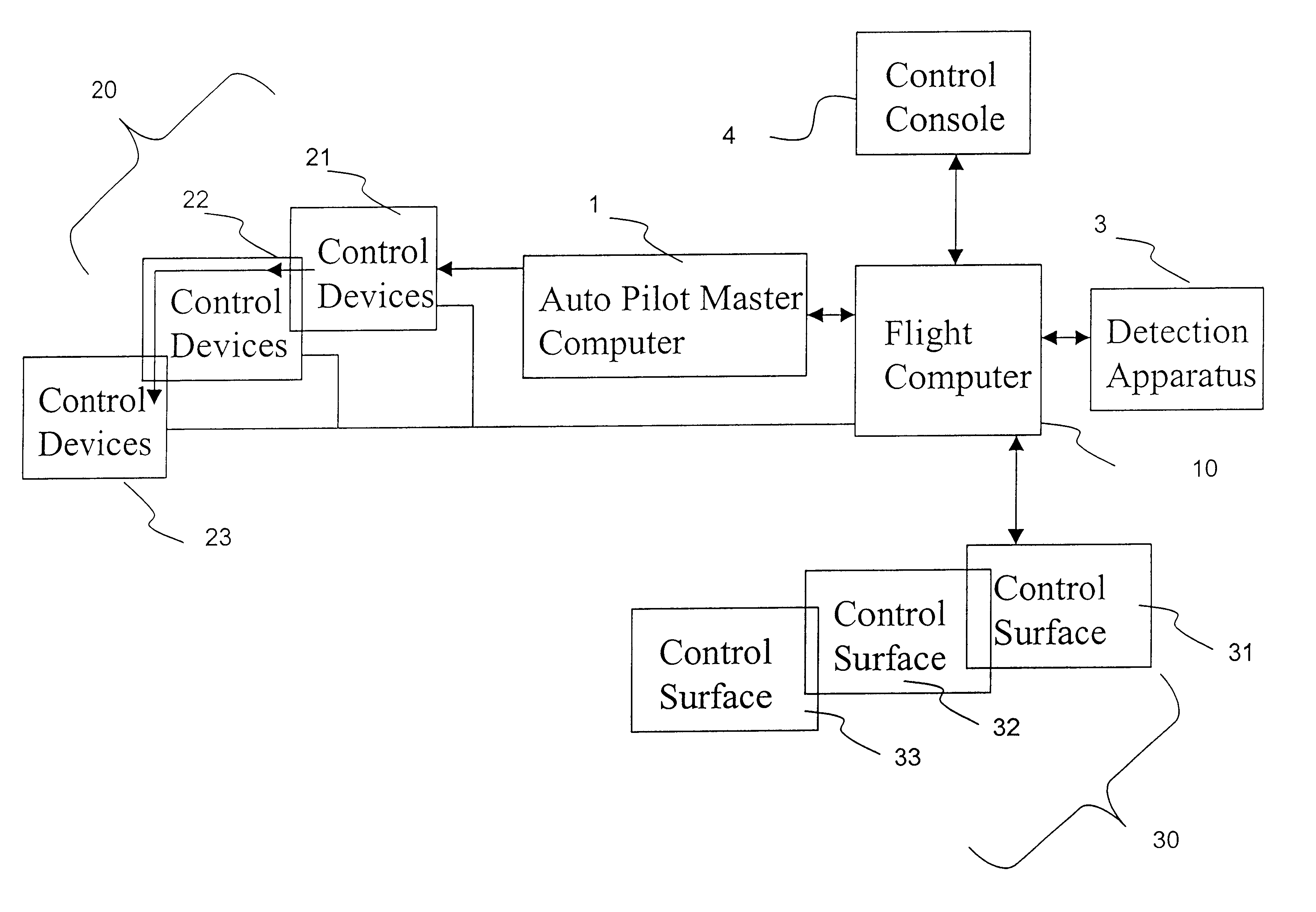

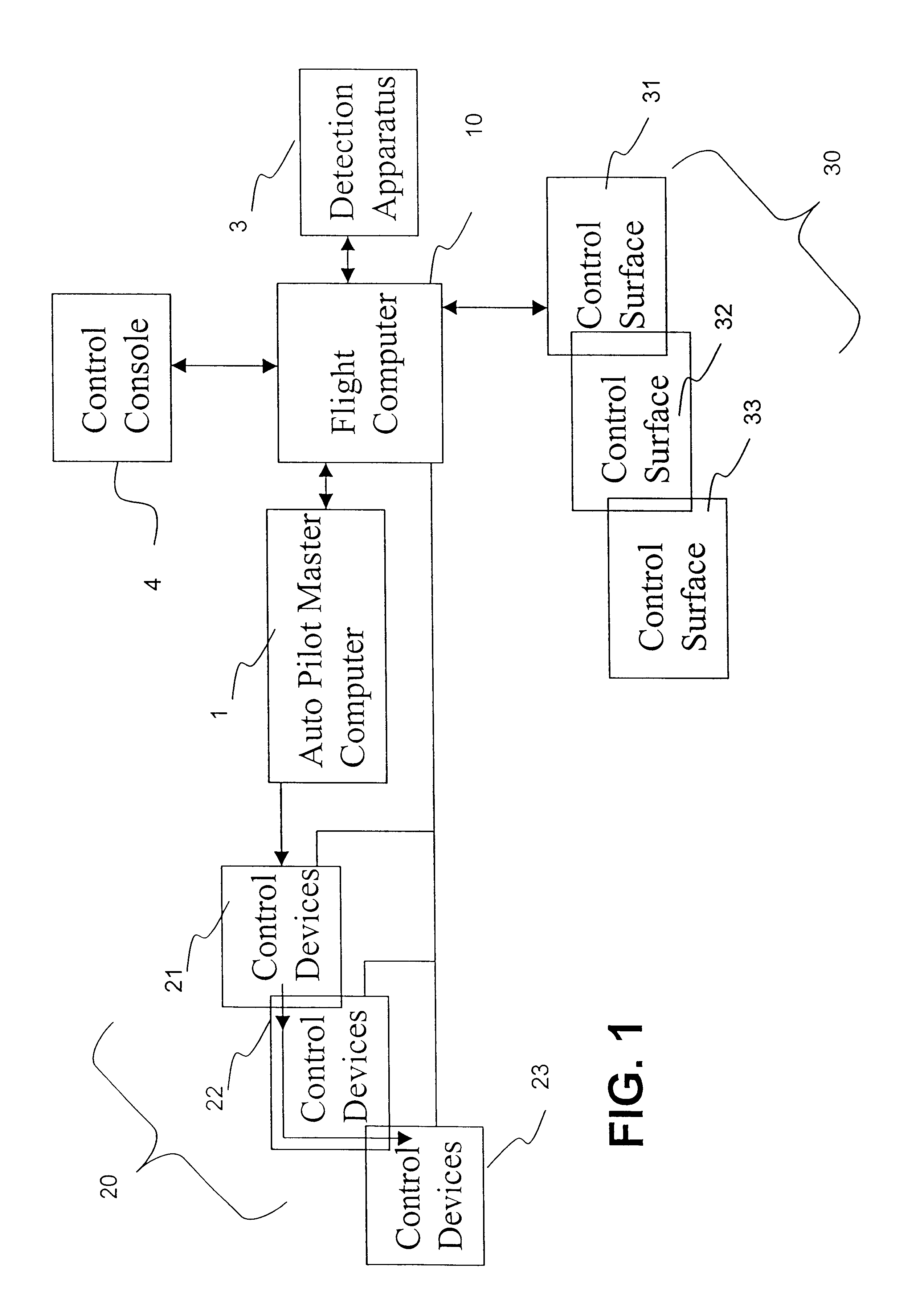

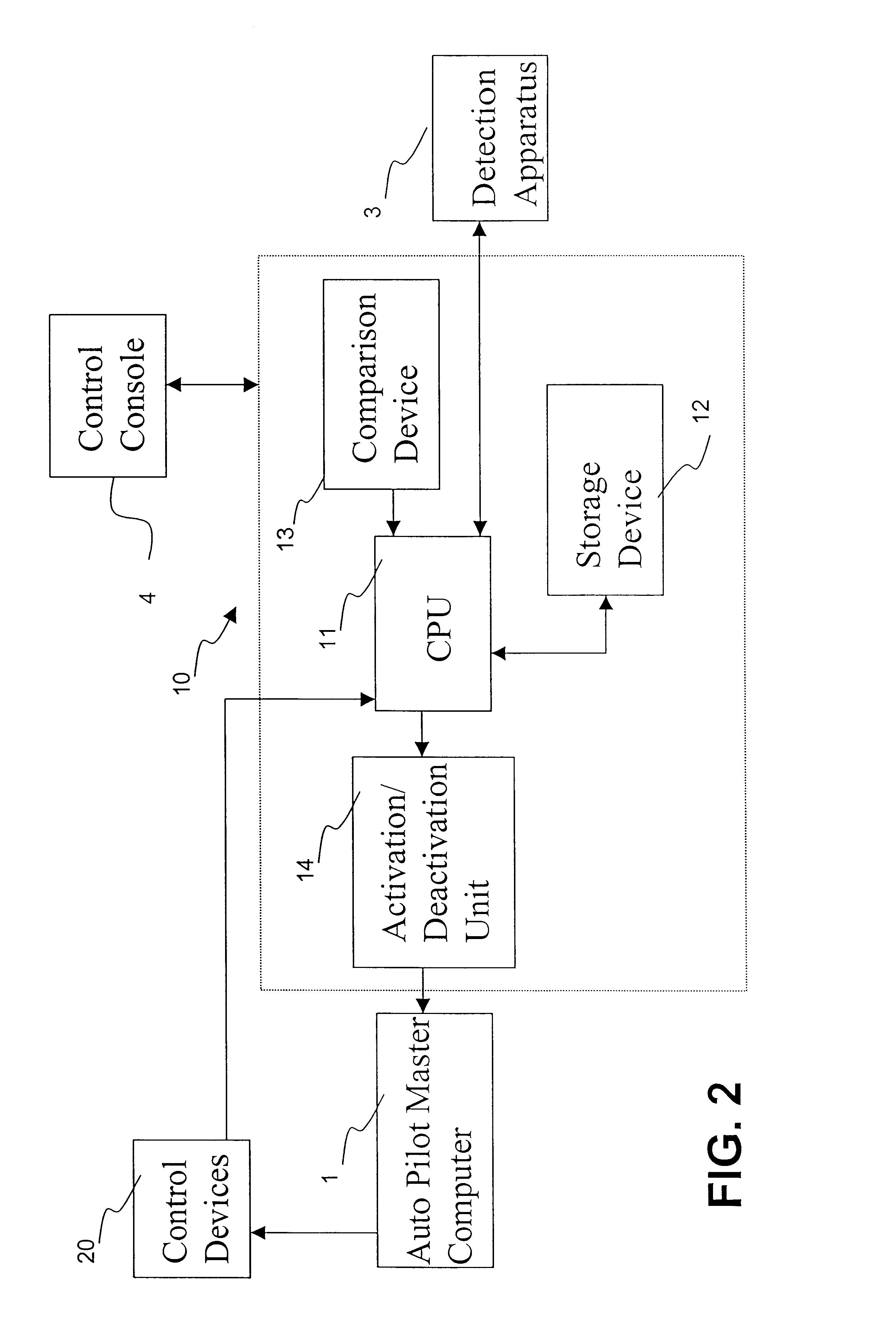

Aircraft security system to prevent manual flight operation by unauthorized individuals

InactiveUS6882288B2Electric signal transmission systemsImage analysisBiological activationSecurity system

A security system having a detector to detect specific physical characteristics, such as for example the weight of the pilot, is disclosed. The security system further includes a device to prevent activation of manual flight operation or to switch from manual to automatic flight operation or to deactivate manual flight operation, if the detected physical characteristics do not match predefined physical characteristics. By inputting a personal code into an inputting device the pilot may identify himself as an authorized operator at any time with regard to the security system.

Owner:WEIGL ADOLF

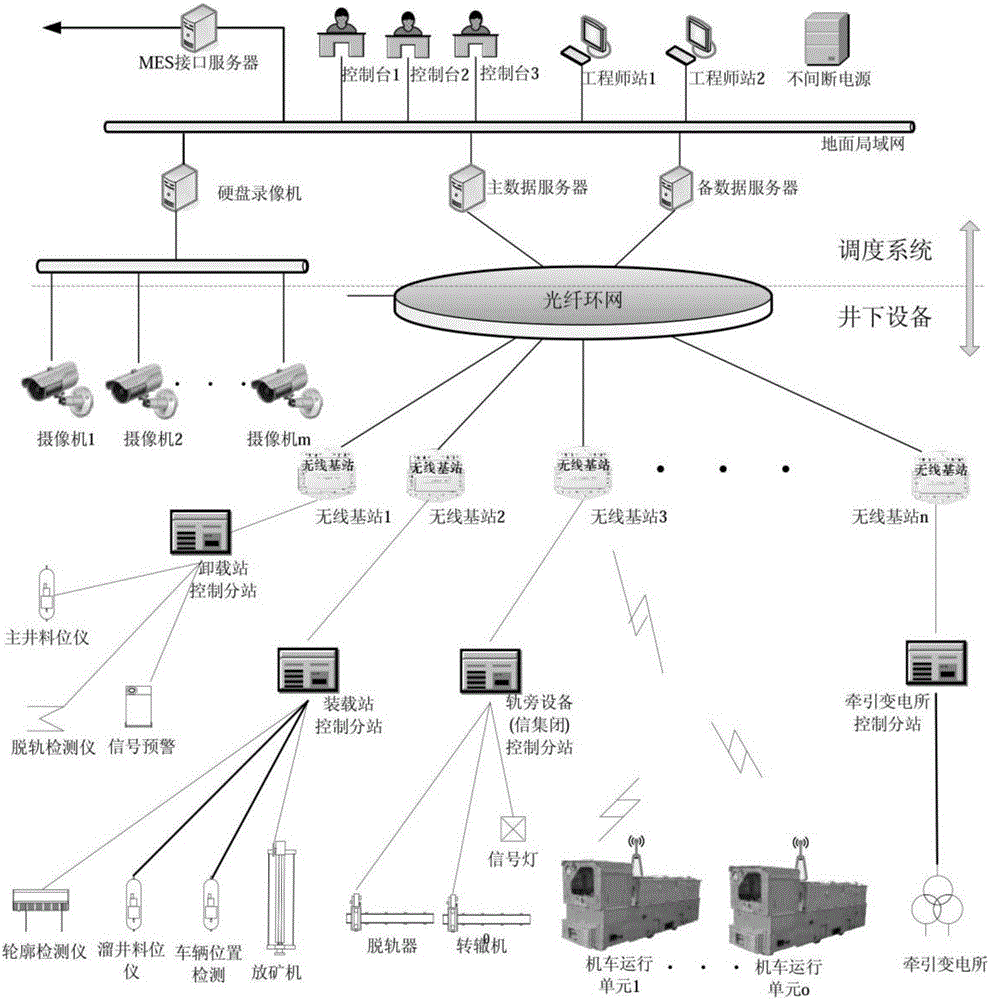

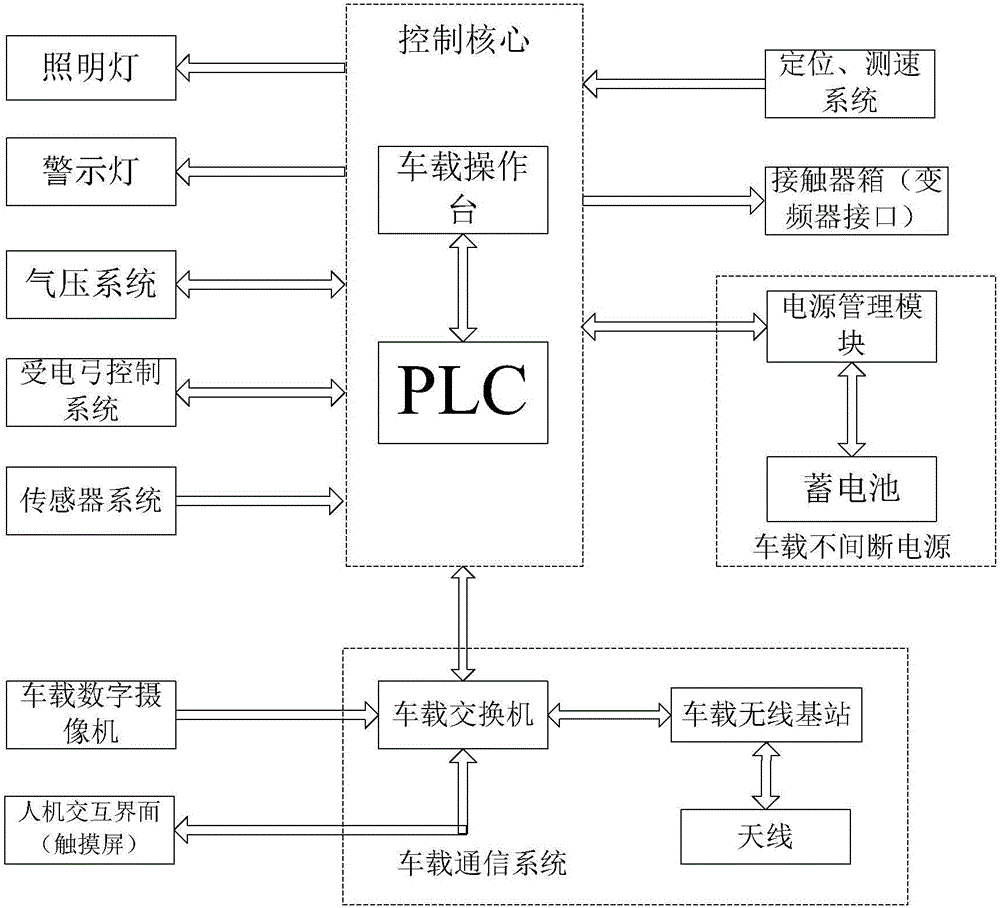

Unmanned transportation system of underground electric locomotive

ActiveCN105892397ARealize automatic liftingRealize automatic drivingProgramme control in sequence/logic controllersIntrinsic safetyCommunications system

The invention discloses an unmanned transportation system of an underground electric locomotive. The unmanned transportation system is characterized by comprising a dispatching system, a locomotive running unit, one or more loading station control units, one or more unloading station control units, a monitoring system, one or more trackside equipment control units, a communication system and a traction power supply monitoring system. The unmanned transportation system realizes the automatic operation of ore loading, transportation and unloading processes, ensures safe and efficient operation of the electric locomotive, simplifies the operation, improves the operation rate of the electric locomotive, and increases the ore yield. The unmanned transportation system integrates operations of underground electric locomotive drivers and ore drawing workers, ensures that the worker work position is transferred to the ground from the downhole, increases the safety, avoids the occurrence of occupational diseases, improves the intrinsic safety level, and improves the manual operation environment; and for a transport planning, the dispatching system automatically generates an order.

Owner:唐山威程科技有限公司

Synchronous control system and method for heavy-duty locomotive

InactiveCN102774389AImprove securityImprove reliabilityLocomotivesSynchronous controlAutomatic train protection

The invention discloses a synchronous control system and method for a heavy-duty locomotive. The synchronous control system is characterized in that an ATP (automatic train protection) plug-in box and an ATO (automatic train operation) plug-in box transfer a message to wireless COMs (component object model) by an Ethernet interface, transfer a message to a DMI (desktop management interface) by a 422 interface and are in hard wired connection with vehicle control. The synchronous control method comprises the following steps that: a ground management GSM-R (global system for mobile communications for railway) network sends an operation command to a master-control locomotive by a ground communication node; after the wireless COM of the master-control locomotive receives the command, the command is sent to the ATP / ATO equipment of the master-control locomotive; the ATP / ATO equipment calculates the traction force or the brake force of the master-control locomotive and a slave-control locomotive according to the line data and the current state of the locomotive, and outputs the command; the command is sent to the ground communication node by the wireless COM of the master-control locomotive; the communication node forwards the command to an intermediate locomotive and the slave-control locomotive according to an IP (internet protocol) address; after receiving the respective command, the wireless COM of the intermediate locomotive and the wireless COM of the slave-control locomotive forward the respective commands to the ATP / ATO equipment of the locomotive; after the synchronous control system receives the command, driving or brake control is carried out, and the locomotive marshaling control is guaranteed to be synchronous.

Owner:NANJING NRIET IND CORP

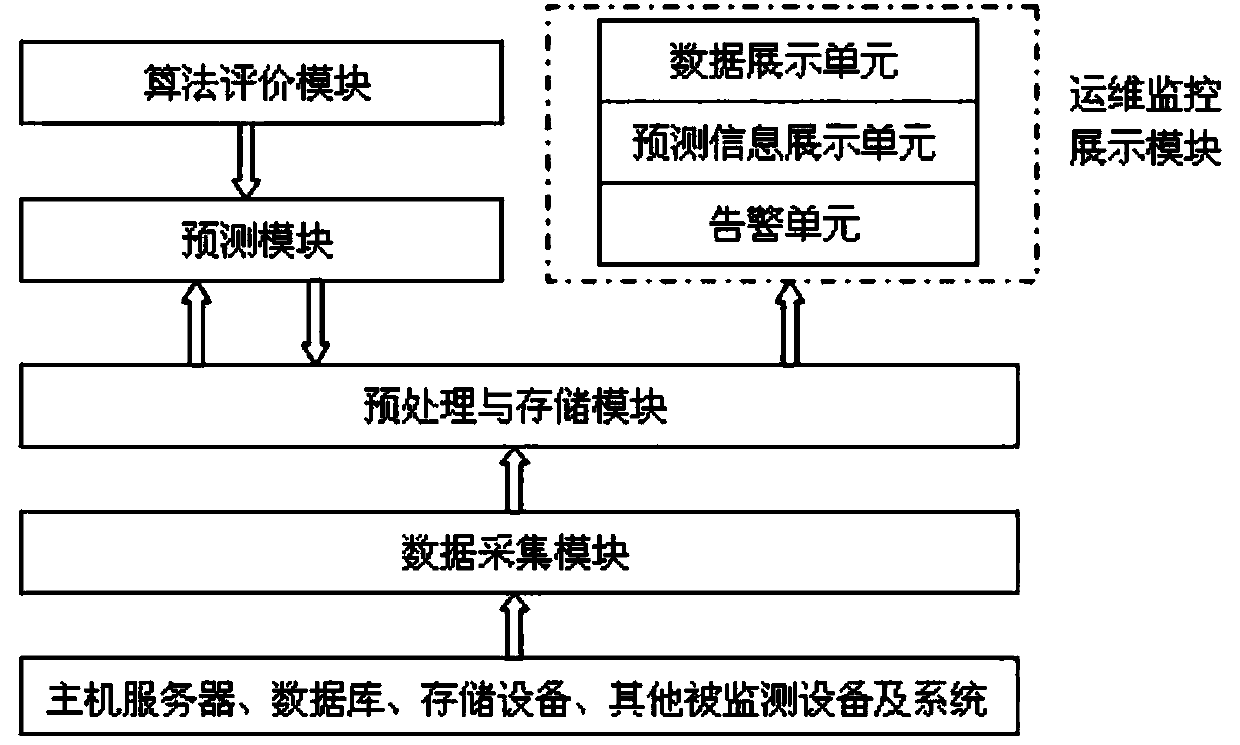

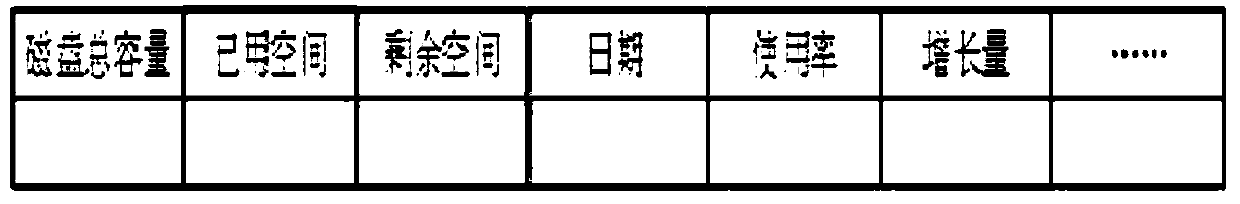

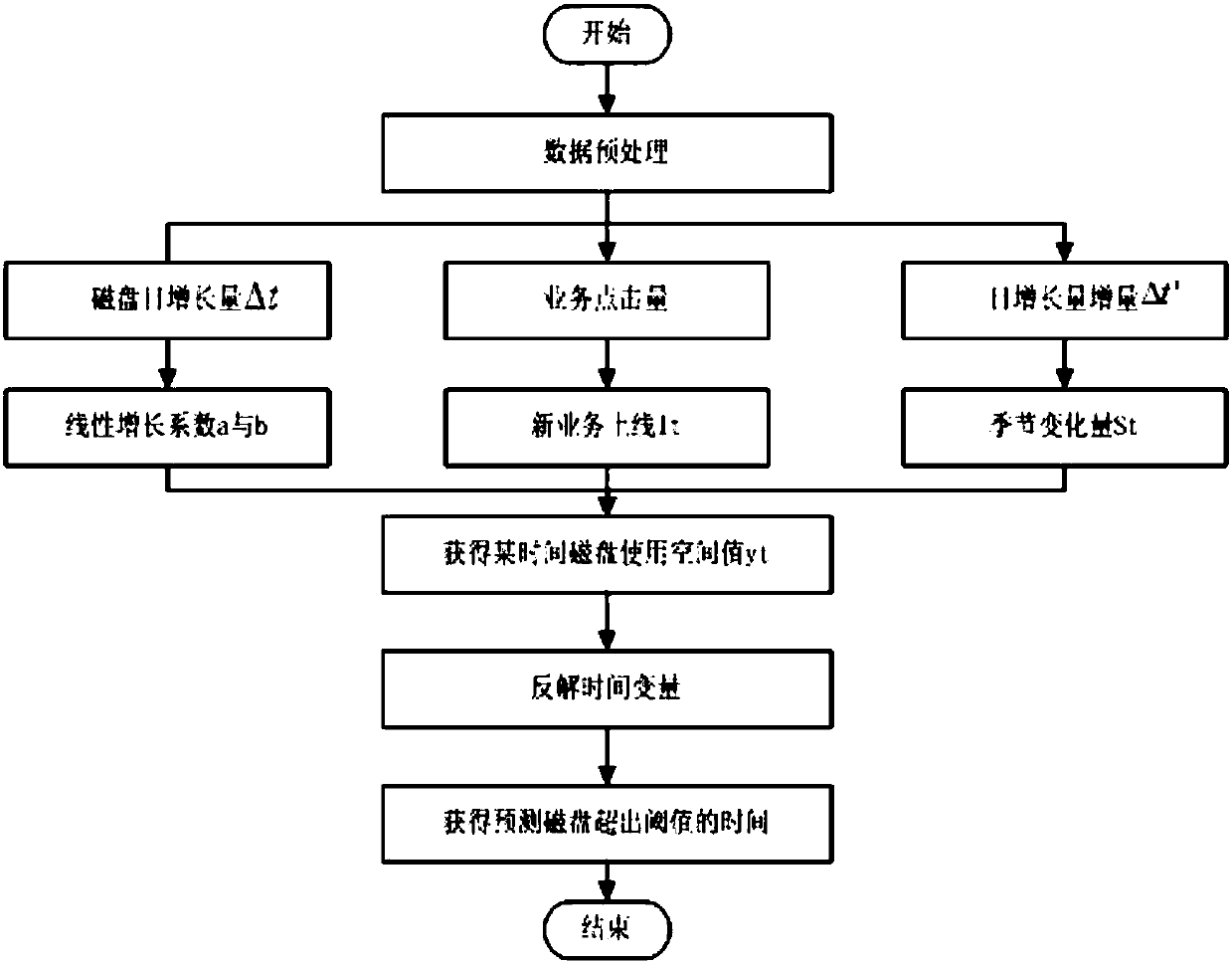

IT automatic operation and maintenance system and method

InactiveCN110278102AEasy to viewImprove the difficulty of operation and maintenanceHardware monitoringData switching networksPrediction algorithmsData acquisition

The invention discloses an IT automatic operation and maintenance system and method. The IT automatic operation and maintenance system comprises a data collection module used for obtaining key performance indexes and operation states of all monitored units in the operation and maintenance system through a network management protocol or a log file; a preprocessing and storage module, used for performing preprocessing work and classified storage on the data acquired by the data acquisition module; a prediction module, used for predicting according to the data processed by the preprocessing and storage module; an algorithm evaluation module, used for establishing an evaluation standard of the prediction algorithm of the prediction module; and an operation and maintenance monitoring and management module, responsible for interacting with operation and maintenance management personnel. The invention aims to provide an IT automatic operation and maintenance system and method. A unified operation and maintenance monitoring management and load prediction system is built, operation and monitoring state information of a CPU, a memory, a disk and a database table is managed, a storage and prediction model is designed, and storage resource prediction management and computing resource distribution management in the whole server operation and maintenance cluster are achieved.

Owner:勤智数码科技股份有限公司

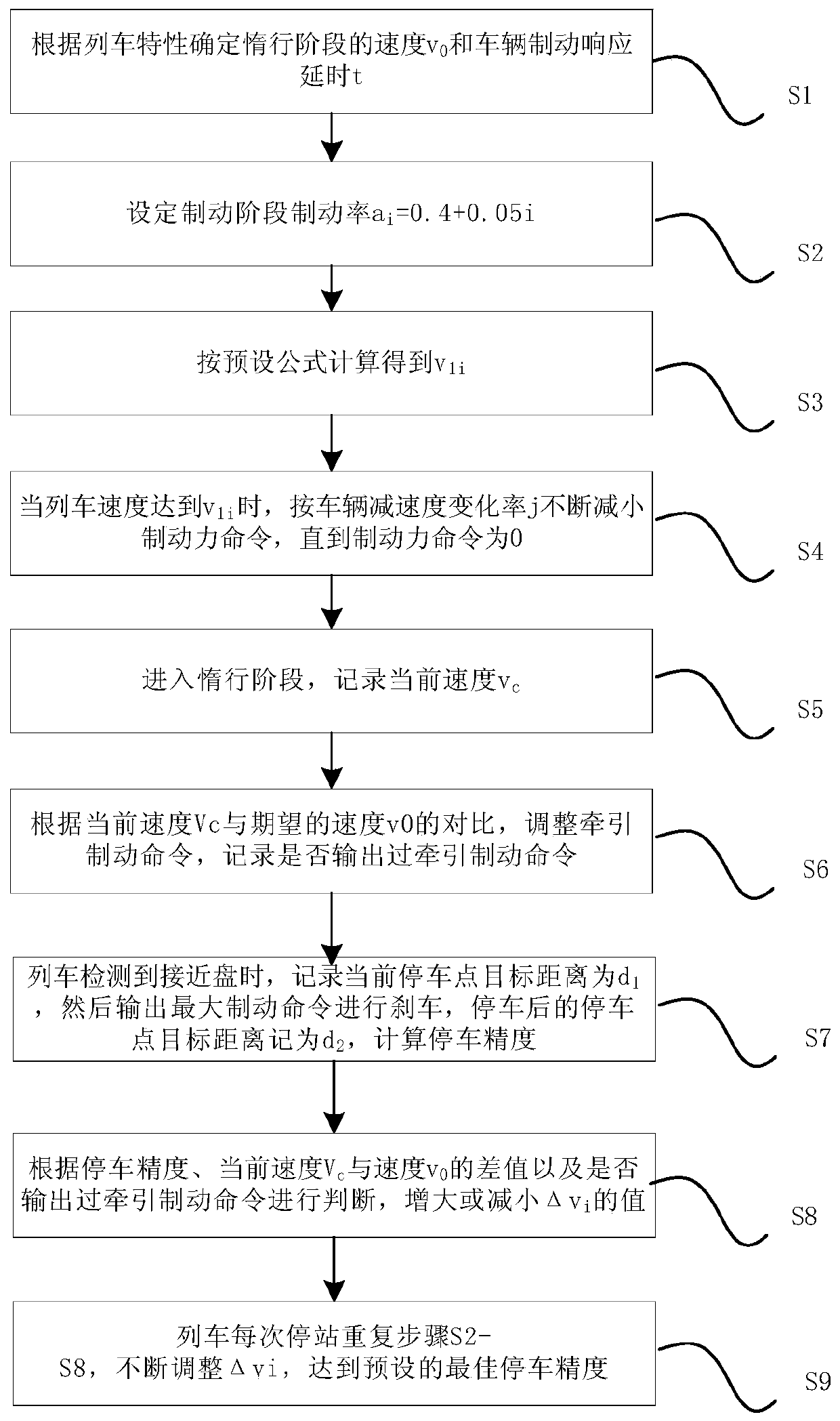

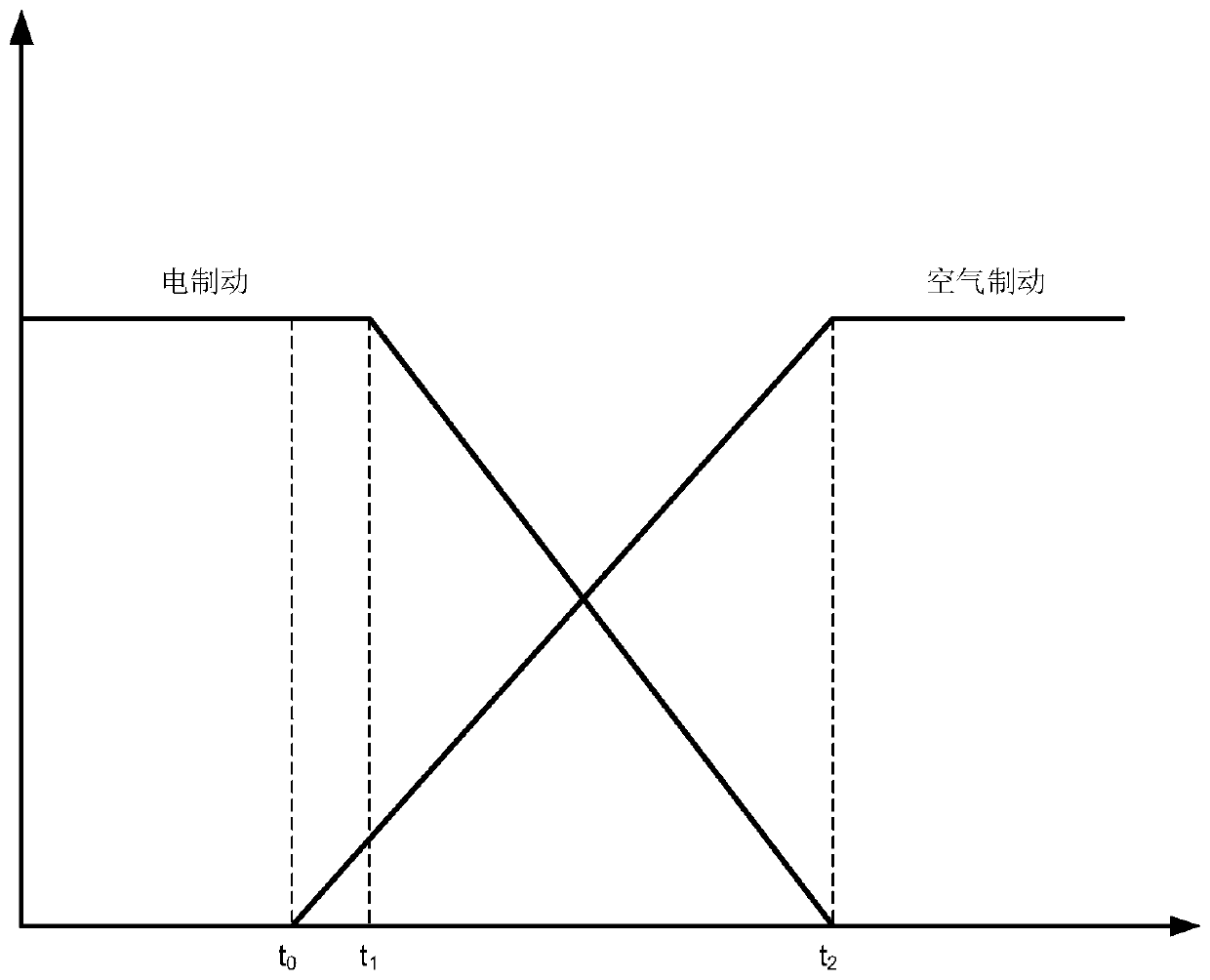

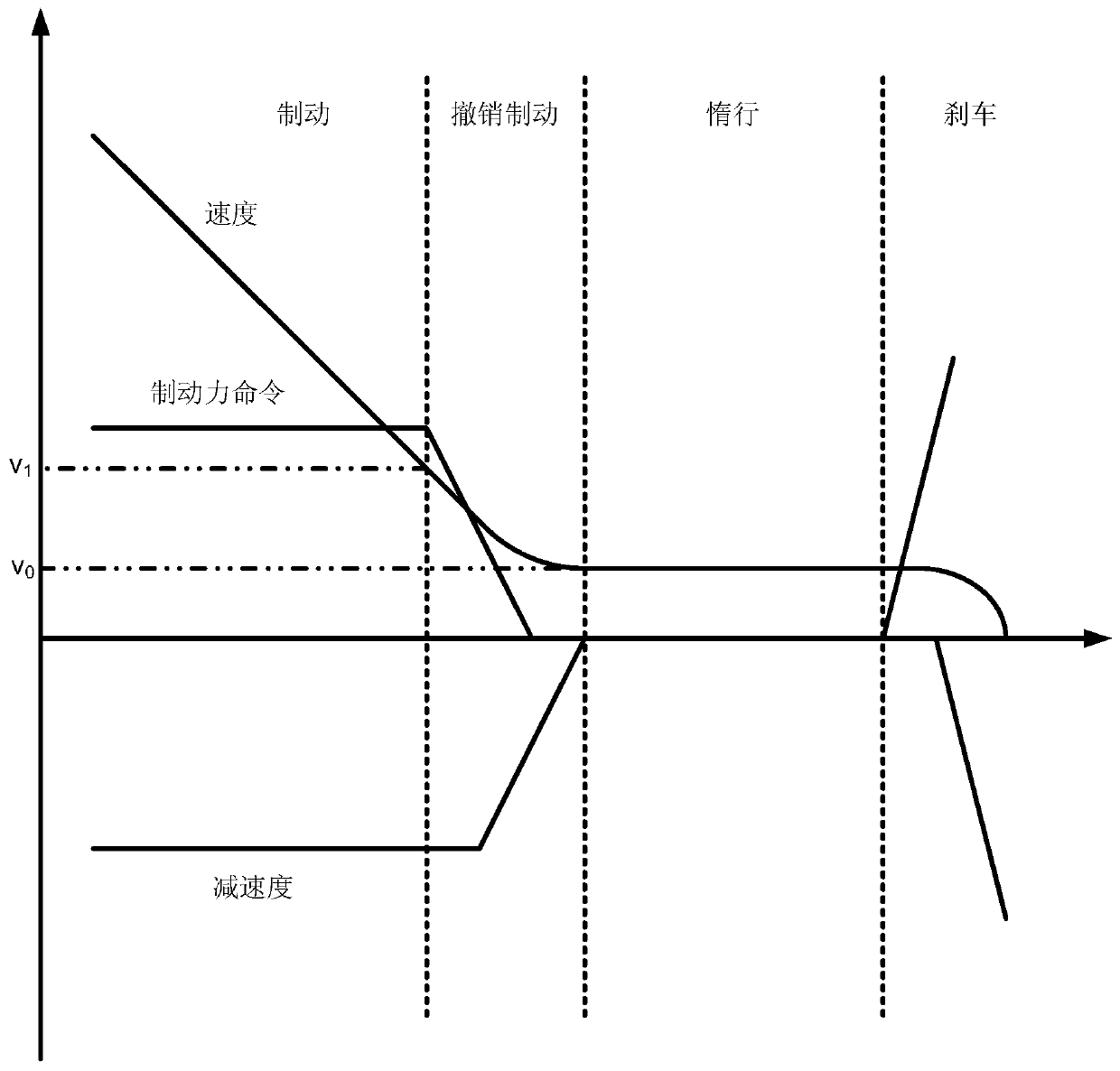

Method for automatically adjusting stopping accuracy of automatic train operation

ActiveCN110304113AExcellent parking accuracyTroubleshoot performance changesSignalling indicators on vehicleBraking systemsElectricityDelta-v

The invention discloses a method for automatically adjusting stopping accuracy of automatic train operation. According to the method, a parameter delta v is introduced into a speed correcting calculation formula, so that the influence of large differences between the performance of train electric-braking and the performance of air braking on the stopping precision of ATO is avoided; and meanwhile,through a method of combining historical station stopping accuracy data with a current control policy state, the correction value of the parameter delta v can be automatically adjusted, thus solvingthe problems that different trains have differences in braking performance and changes of performance occur to the same train during different periods of time.

Owner:SHANGHAI ELECTRIC THALES TRANSPORTATION AUTOMATION SYST CO LTD

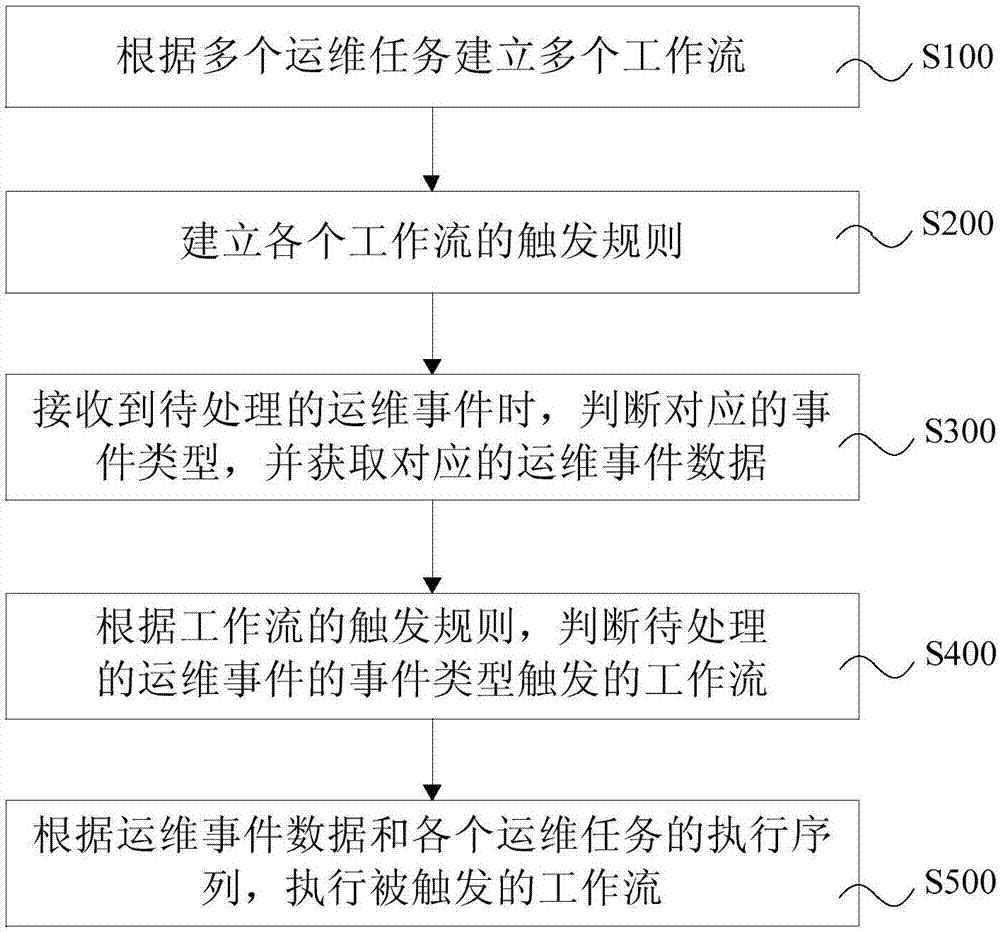

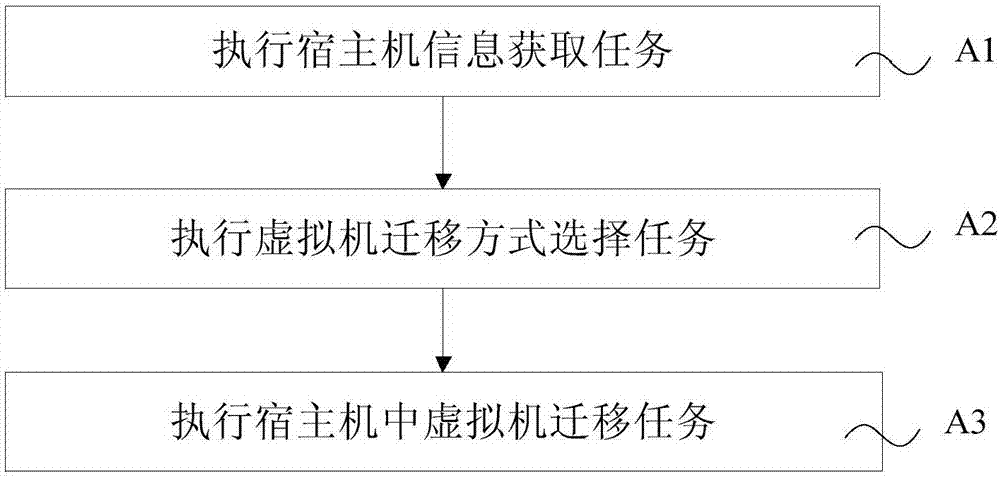

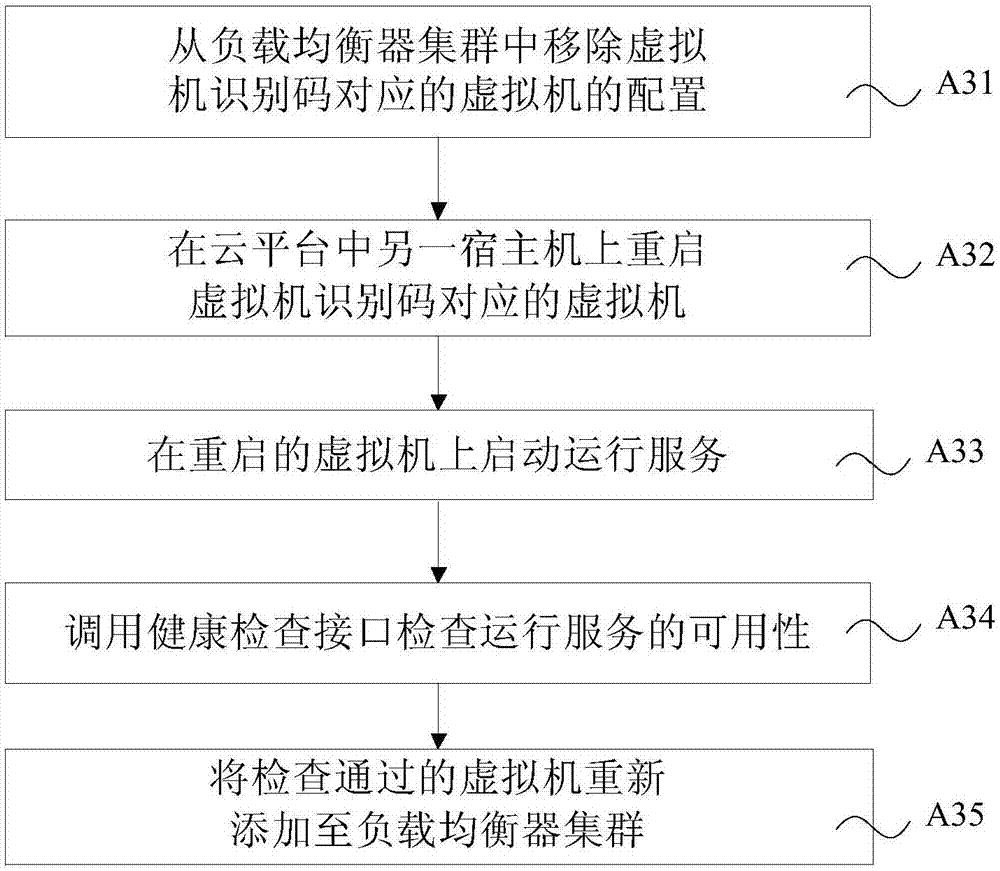

Automatic operation and maintenance method, system and equipment for cloud platform and storage medium

InactiveCN107368365ASolve operational problemsSolve the costProgram initiation/switchingSoftware simulation/interpretation/emulationEvent typeEvent data

The invention provides an automatic operation and maintenance method, system and equipment for a cloud platform and a storage medium. The method comprises the steps that multiple workflows are built according to multiple operation and maintenance tasks; trigger rules of the workflows are built; when to-be-processed operation and maintenance events are received, corresponding event types are judged, and corresponding operation and maintenance event data is obtained; according to the trigger rules of the workflows, workflows triggered by the event types of the to-be-processed operation and maintenance events are judged; according to the operation and maintenance event data and an execution sequence of all the operation and maintenance tasks in the triggered workflows, the triggered worklfows are executed. Accordingly, on the basis of an event capturing and workflow technology, an event driving operation and maintenance mechanism is achieved, the degree of automation of cloud platform operation and maintenance is improved, the operation and maintenance operation is driven by a tool, manual operation of an engineer is reduced, and the potential risk of the operation possibly caused by human factors is avoided; the communication cost is lowered on the basis of a rule engine technology, and the operation and maintenance efficiency is improved.

Owner:携程旅游信息技术(上海)有限公司

Boat diesel oil generator tank cover repair process method

InactiveCN101204766AImprove surface propertiesExtended service lifeMetallic material coating processesLaser beam welding apparatusSurface fatigueEngineering

The invention provides a technique for repairing an oil electric engine cylinder sleeve for ship, which is characterized in that the invention comprises the following working procedures: 1 detecting and cleaning the cylinder sleeve: carrying out a jump detection and a dimension detection on the cylinder sleeve on a lathe, confirming a hurt part, carrying out mechanical cleaning on the machine type of the hurt part and carrying out detection of removing a surface fatigue layer; 2 laser cladding repairing on the hurt part: the parameters during an operation process are: a laser power of 6200 to 8000W, a facula diameter of 2 to 6mm and a facula moving speed of 100 to 150mm / s; 3 machinery processing to resume the shape of the cylinder sleeve: carrying out machinery processing to resume the original designed dimension state on a boring lathe and a boring lathe. The technique for repairing an oil electric engine cylinder sleeve for ship provided by the invention has the advantages of high suitability, simple and convenient operation, small temperature distortion, uniform welding structure, realizing automatic operation with little residual stress; the invention requires no restoration heat treatment.

Owner:SHENYANG DALU LASER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com