Synchronous control method for heavy-duty locomotive signal based on ATP/ATO (Automatic Train Protection/Automatic Train Operation) equipment

A technology for synchronous control and heavy-duty locomotives, which is applied in the direction of railway signal and safety, transportation center control system, railway car body parts, etc., can solve the problems of difficult synchronization of power and control signals, and achieve easy promotion, easy implementation, and improved Effects on Safety and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] Such as Figure 1-5 shown.

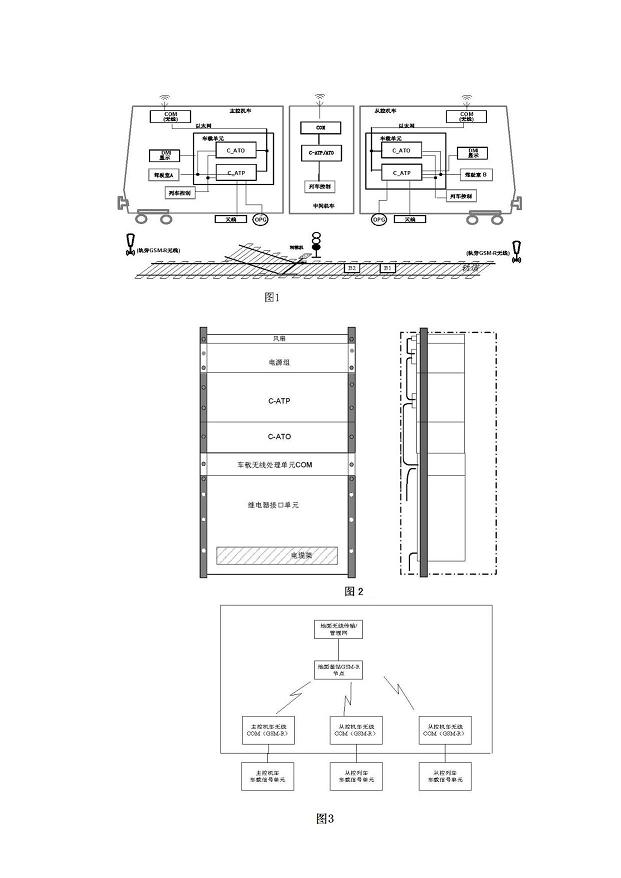

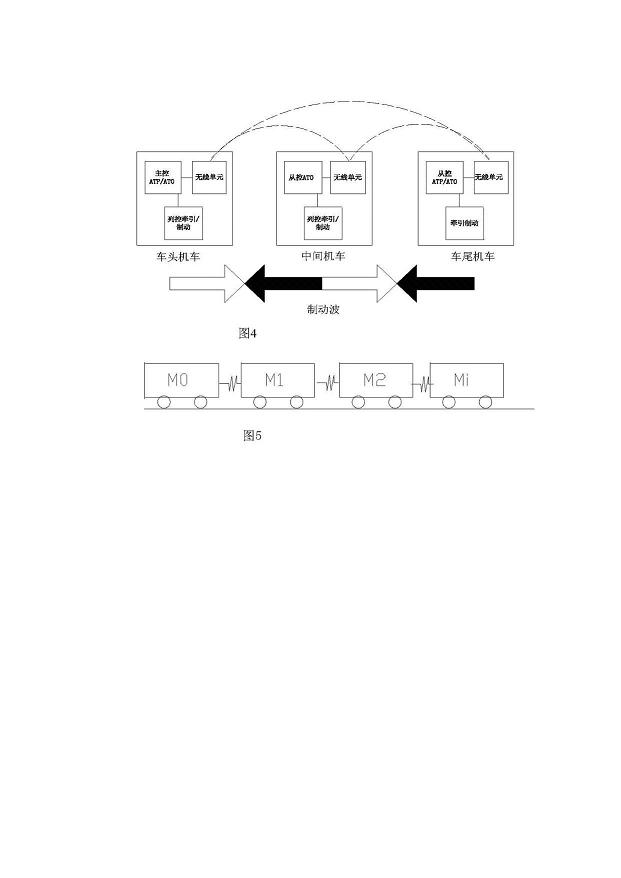

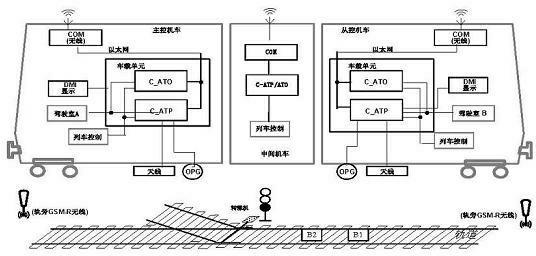

[0024] A synchronous control method for heavy-duty locomotive signals based on ATP / ATO equipment, which is an important part of the electrification equipment of the on-board signaling system of heavy-duty freight trains. For the equipment composition of the entire system, see figure 1 ; The whole control method includes synchronous control of train power distribution and synchronous transmission of wireless data, and the specific steps are as follows:

[0025] First, install a set of exactly the same ATP / ATO equipment for each locomotive to facilitate marshalling;

[0026] Secondly, the locomotive at one end along the running direction is used as the master locomotive of the train, which is responsible for communicating with the train control dispatching center. At the same time, the master locomotive calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com