Patents

Literature

141results about How to "Guaranteed response time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

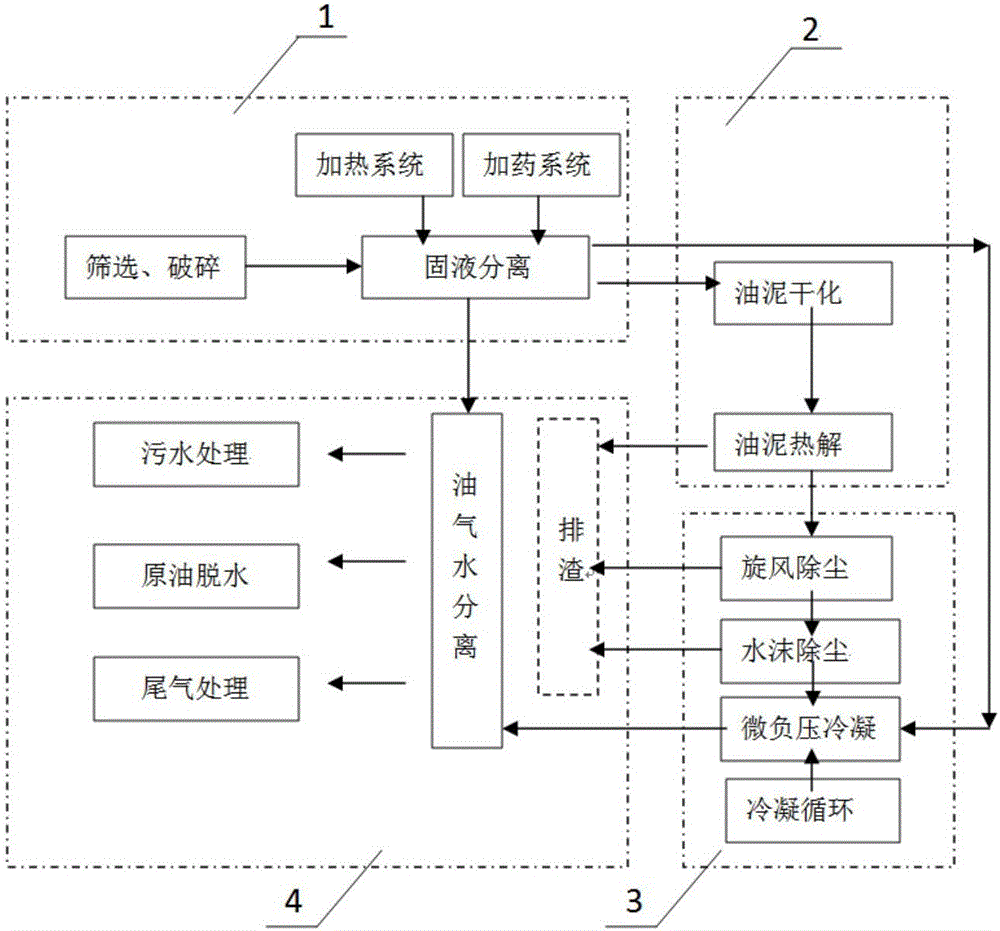

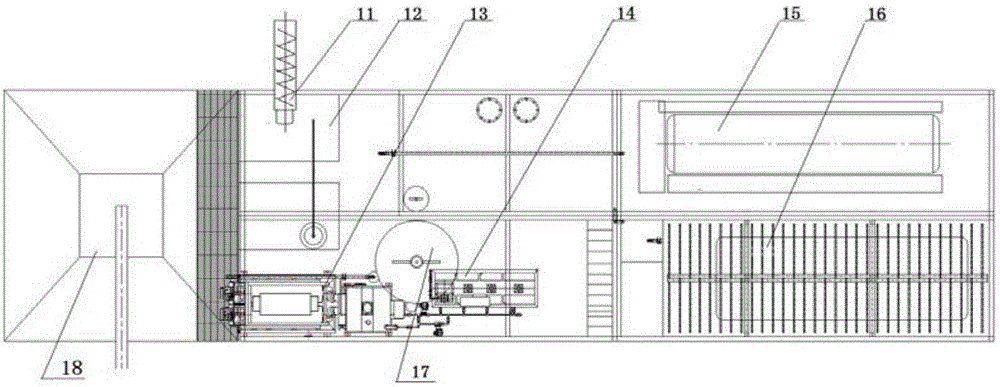

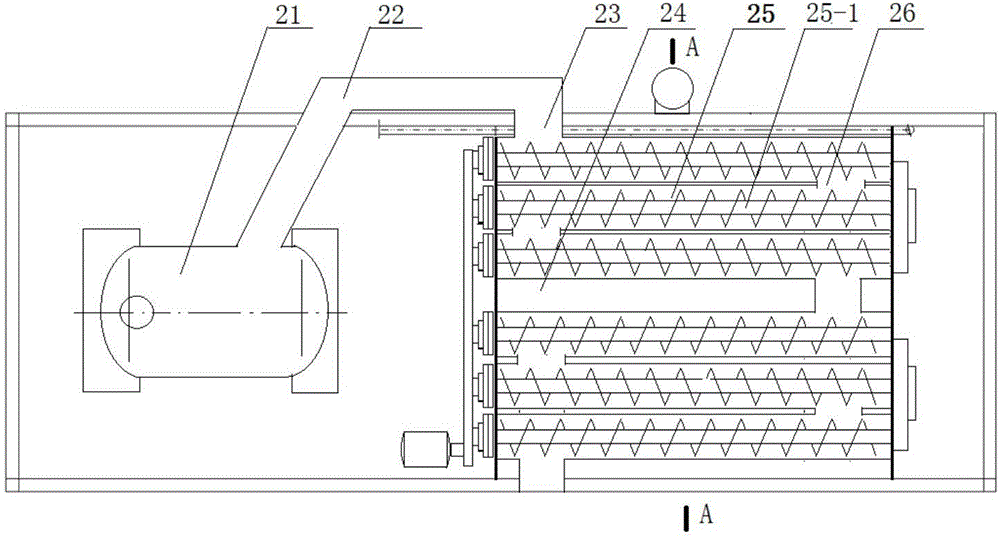

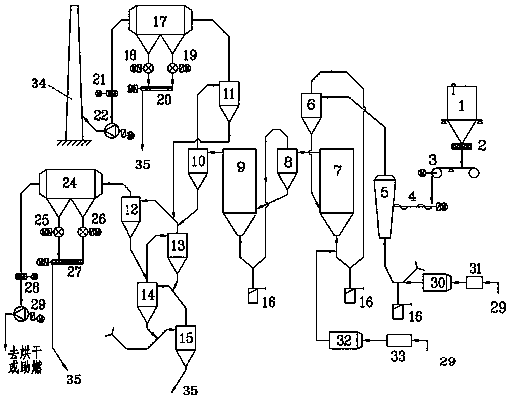

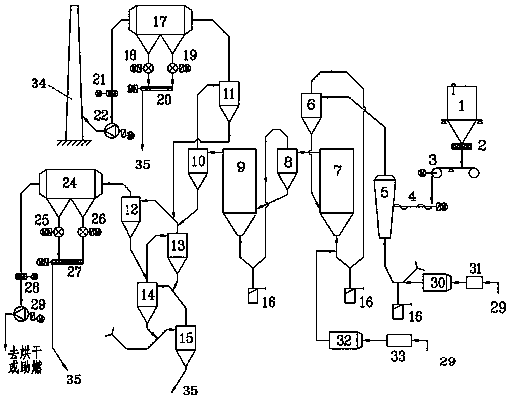

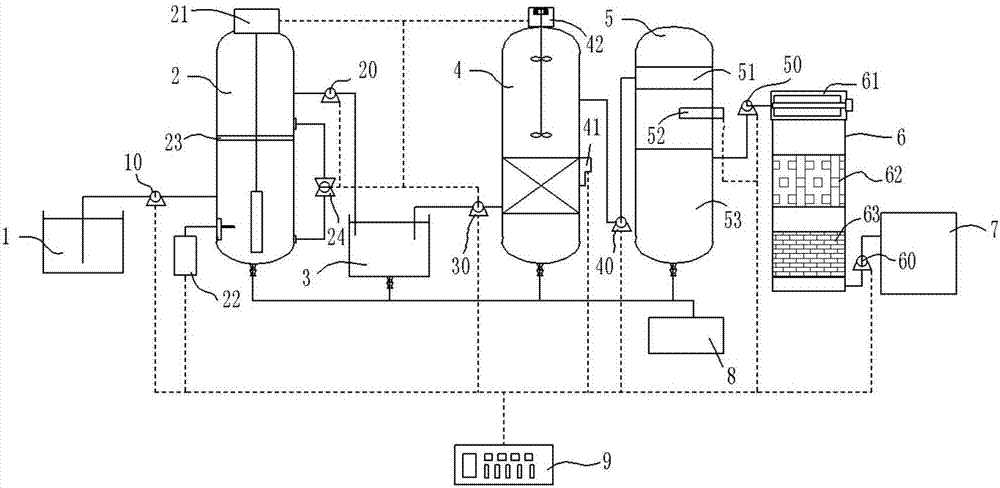

Industrialization scale pyrolysis treatment system and method for oily sludge

InactiveCN106746419ALarge amount of processingEasy to operateCombination devicesSludge treatment by de-watering/drying/thickeningPetroleumPyrolysis

The invention belongs to the field of waste disposal in petroleum industry, and relates to an industrialization scale pyrolysis treatment system for oily sludge. The industrialization scale pyrolysis treatment system comprises a feeding pre-separation unit for performing secondary screening and solid-liquid separation on the oily sludge, a drying pyrolysis unit for performing drying and pyrolysis reaction on the oily sludge, a dust removal and condensation unit for performing dust removal and condensation on a pyrolysis gas mixture generated by the drying pyrolysis unit, and a discharge treatment unit which receives and treats separated substances of the other units respectively. Solid or solid-liquid mixed waste such as the oily sludge can be finally treated to achieve reduction, stabilization, harmlessness and recycling.

Owner:PANJIN NINGTAI ENERGY TECH

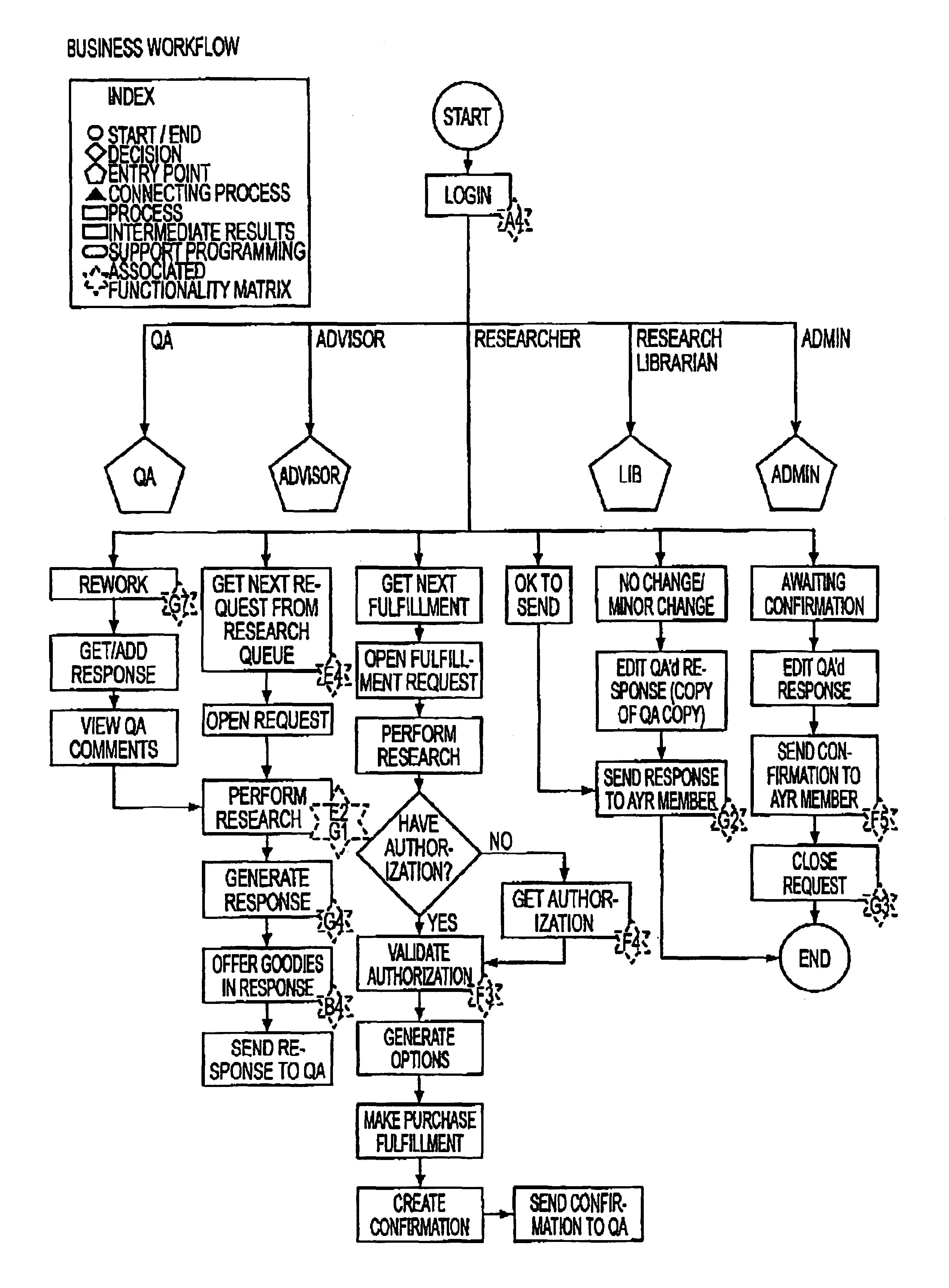

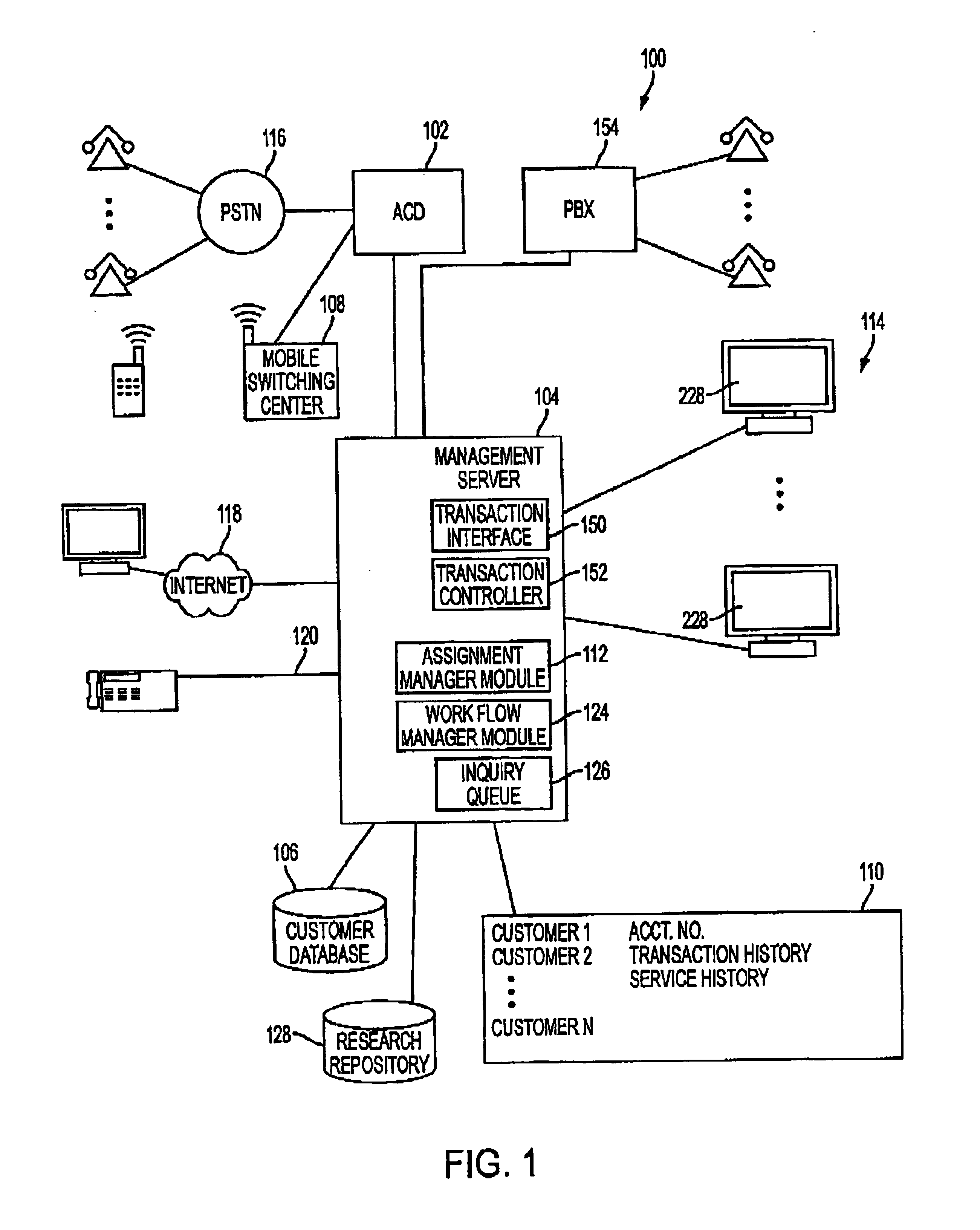

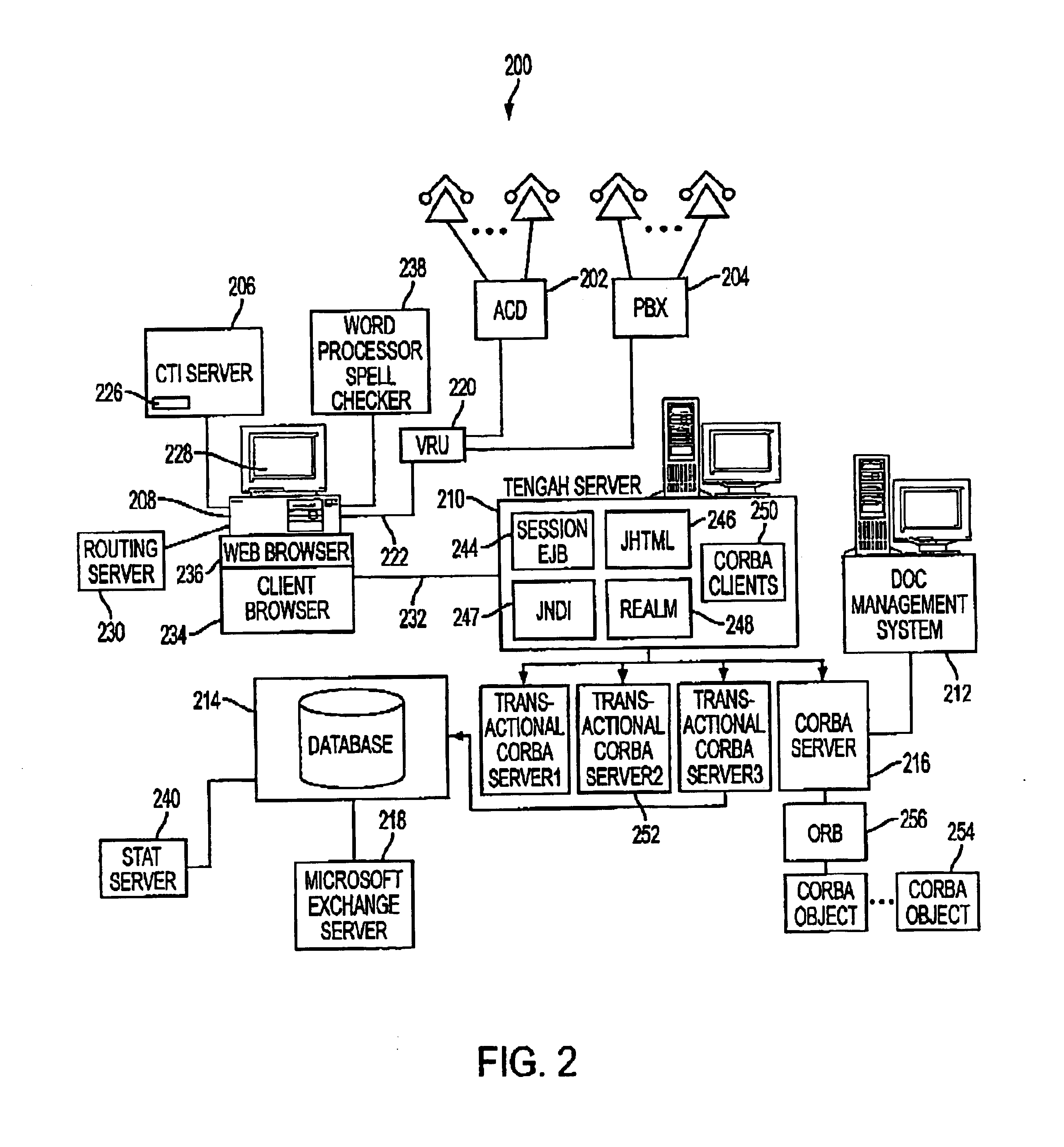

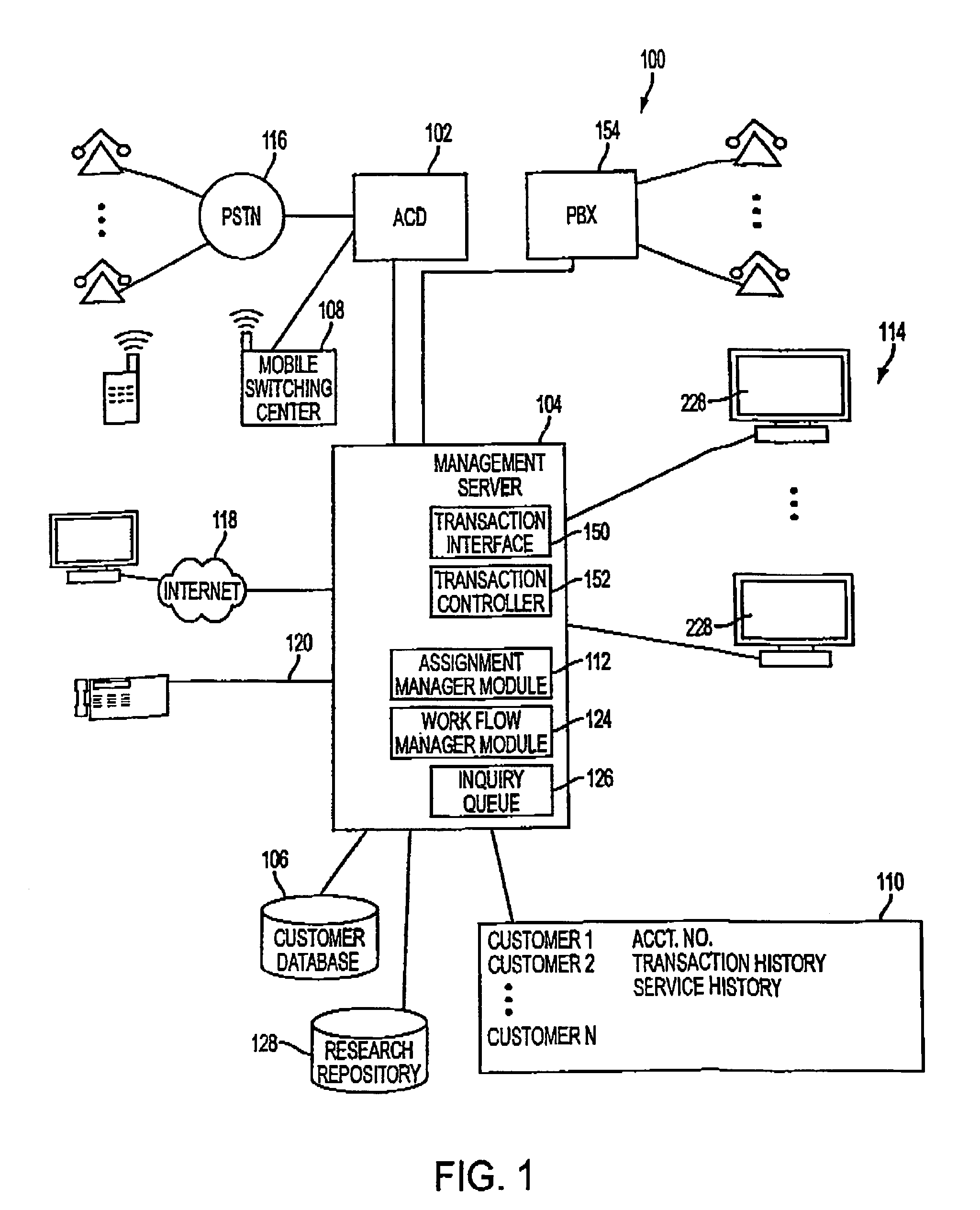

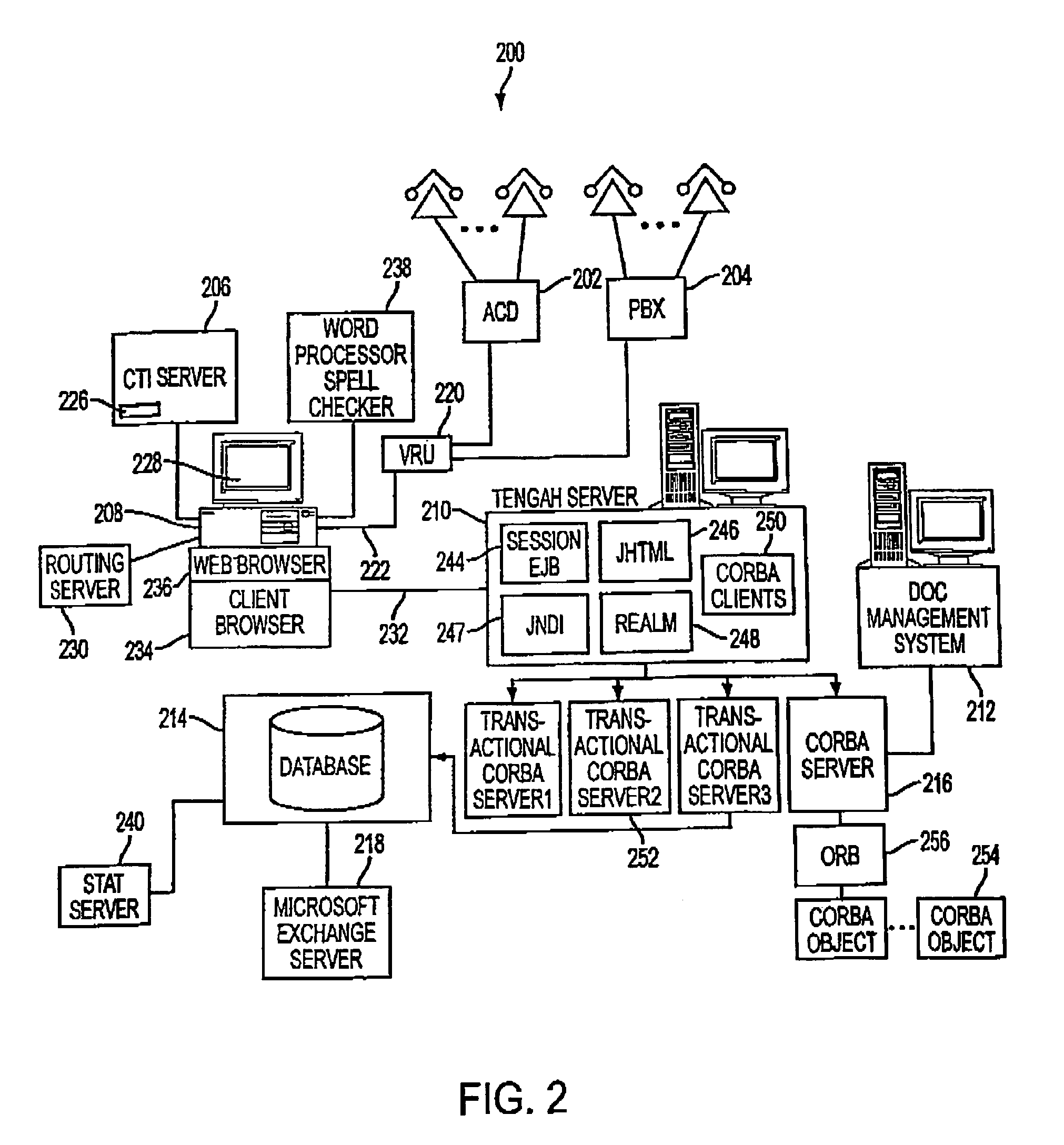

System and method for integrated customer management

InactiveUS6965865B2Reduce per service member costIncrease incomeInterconnection arrangementsDiscounts/incentivesCustomer engagementDatabase

An automated system and method for customer management deploys customer databases to profile customer service requests for distribution to appropriately assigned agent representatives. The representatives adopt particular roles according to customer care volume, inquiry type, time of day and other customer management needs. Consumer profiles may be accessed in real time to combine customer care events with cross-selling and other promotions related to the consumer's transaction history and other factors.

Owner:JPMORGAN CHASE BANK NA

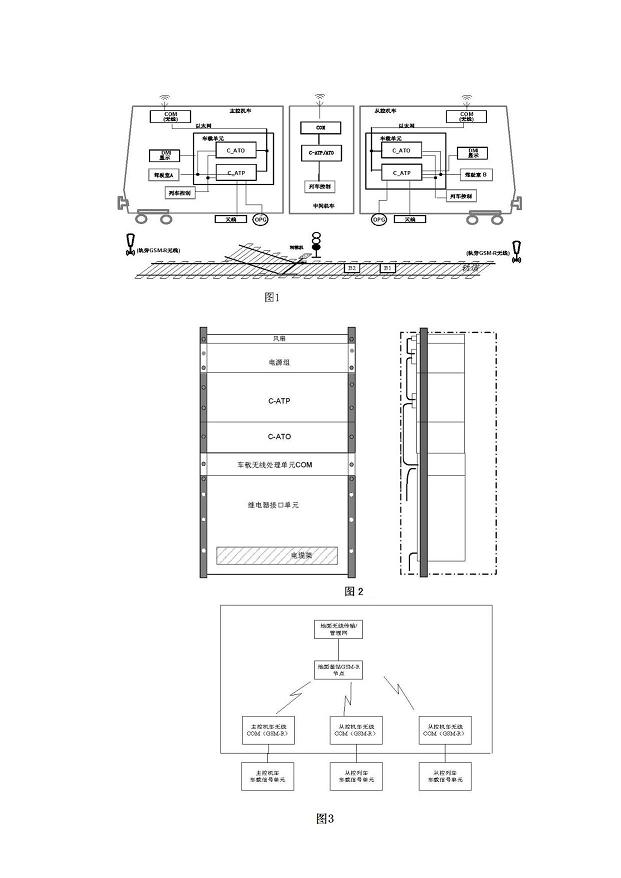

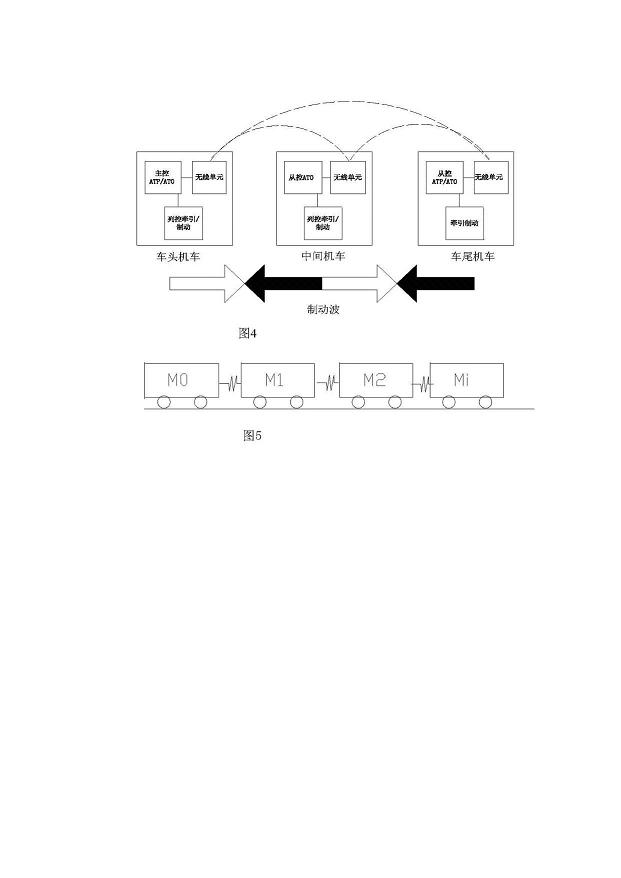

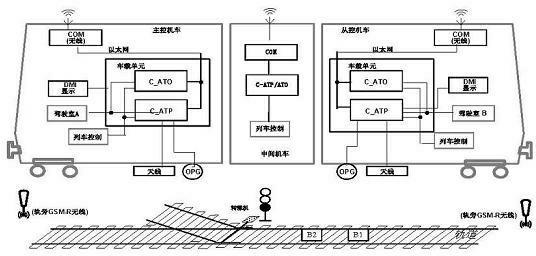

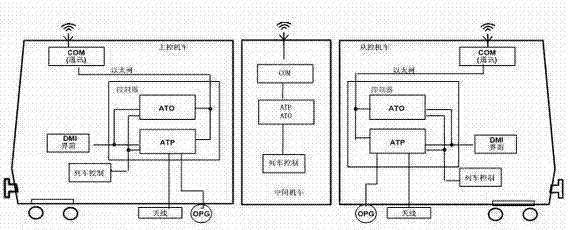

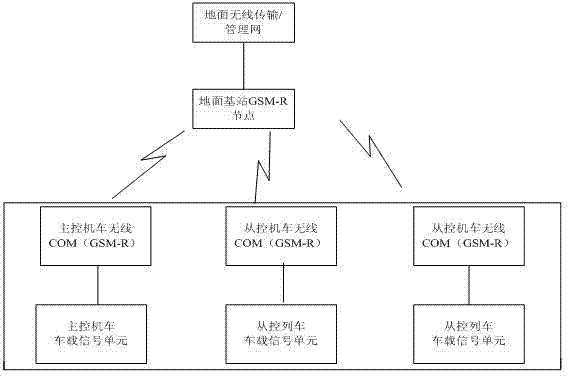

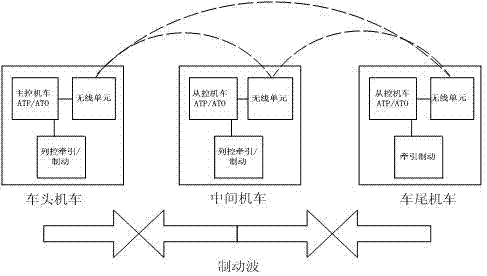

Synchronous control method for heavy-duty locomotive signal based on ATP/ATO (Automatic Train Protection/Automatic Train Operation) equipment

ActiveCN102616258AImprove securityImprove reliabilityRailway traffic control systemsAutomatic train protectionSynchronous control

The invention provides a synchronous control method for a heavy-duty locomotive signal based on ATP / ATO (Automatic Train Protection / Automatic Train Operation) equipment. The synchronous control method is characterized by comprising the following steps of: synchronously controlling the power distribution of a train, and synchronously transmitting wireless data, wherein each locomotive is provided with a set of identical ATP / ATO equipment for grouping; the locomotive at one end in running direction is used as the main control locomotive for the train and responsible for the communication with a train control dispatching center; meanwhile, the main control locomotive is used for calculating the power distribution according to the line conditions and the grouping conditions and transmitting a synchronous control command to a slave control locomotive; after receiving the command from the main control locomotive, the slave control locomotive can synchronously apply traction force or braking force; and a GSM-R (Global System for Mobile Communications for Railway) digital mobile communication network is adopted as a wireless communication synchronization link of the locomotive signal according to the control command between the main control locomotive and the slave control locomotive. By implementing the synchronous control method for the heavy-duty locomotive based on the ATP / ATO equipment, the safety and the reliability of the control system are greatly improved.

Owner:NANJING NRIET IND CORP

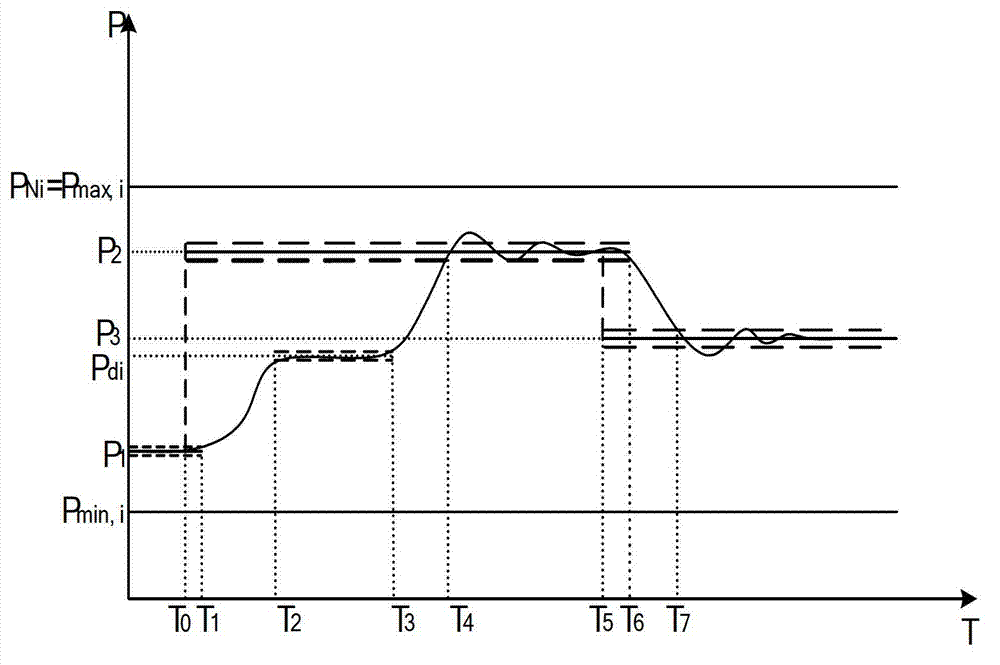

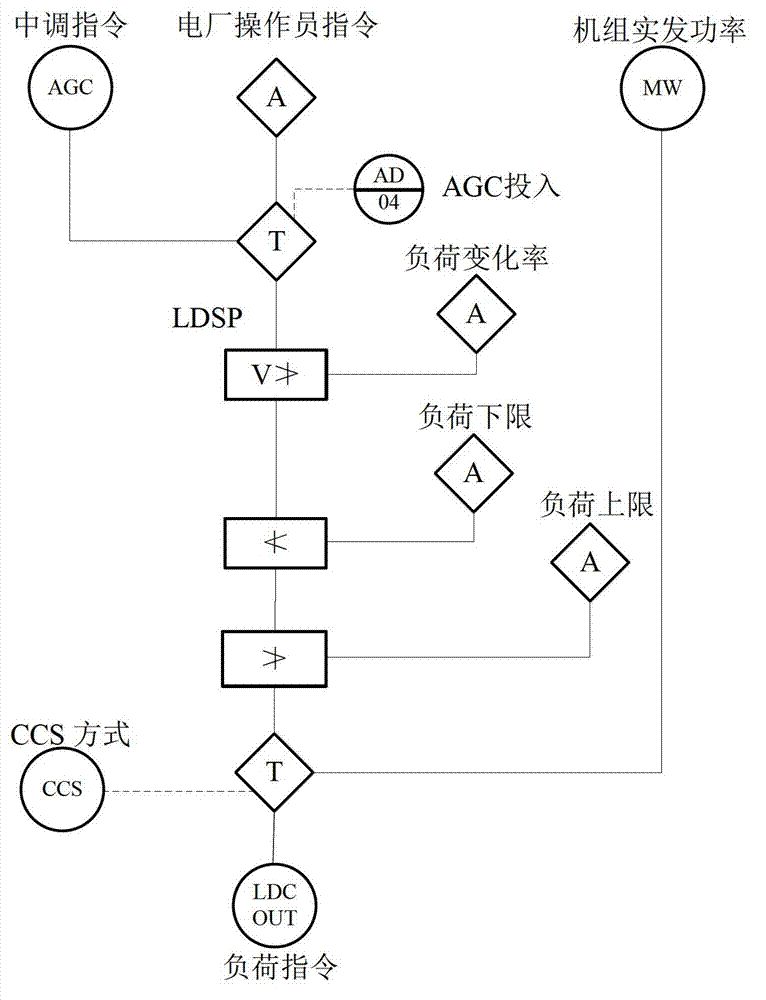

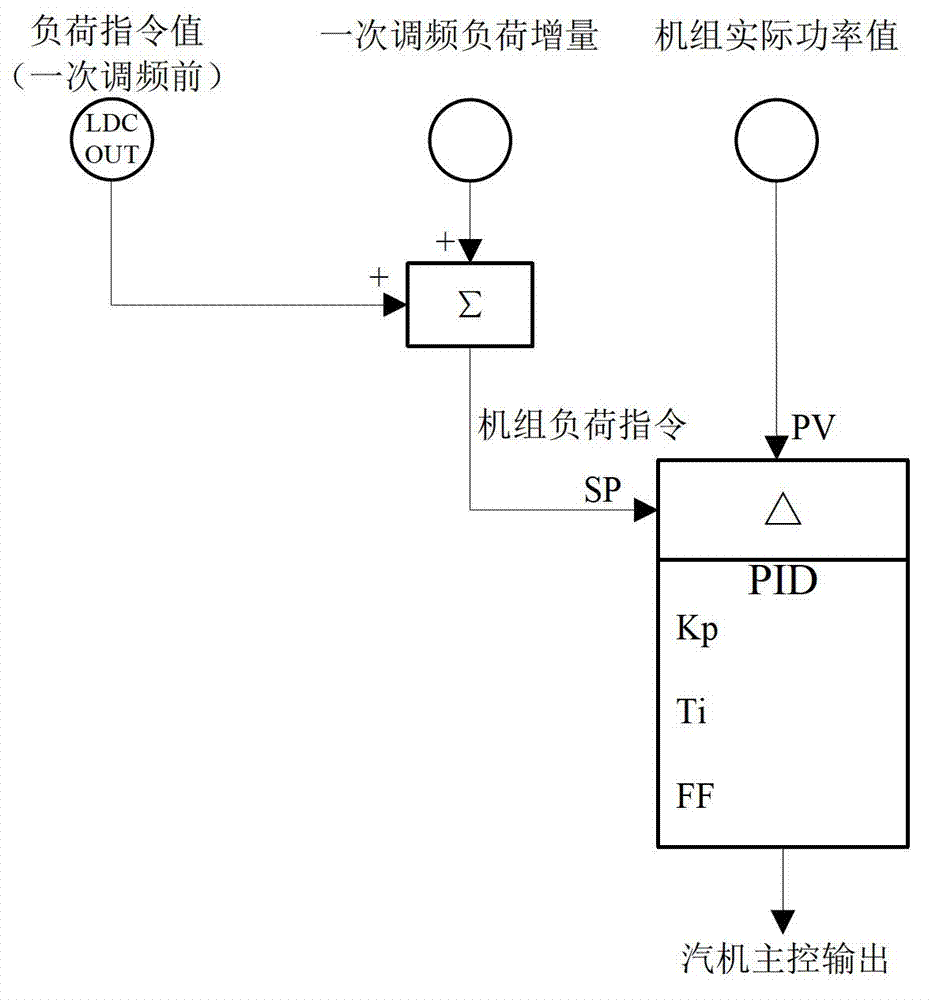

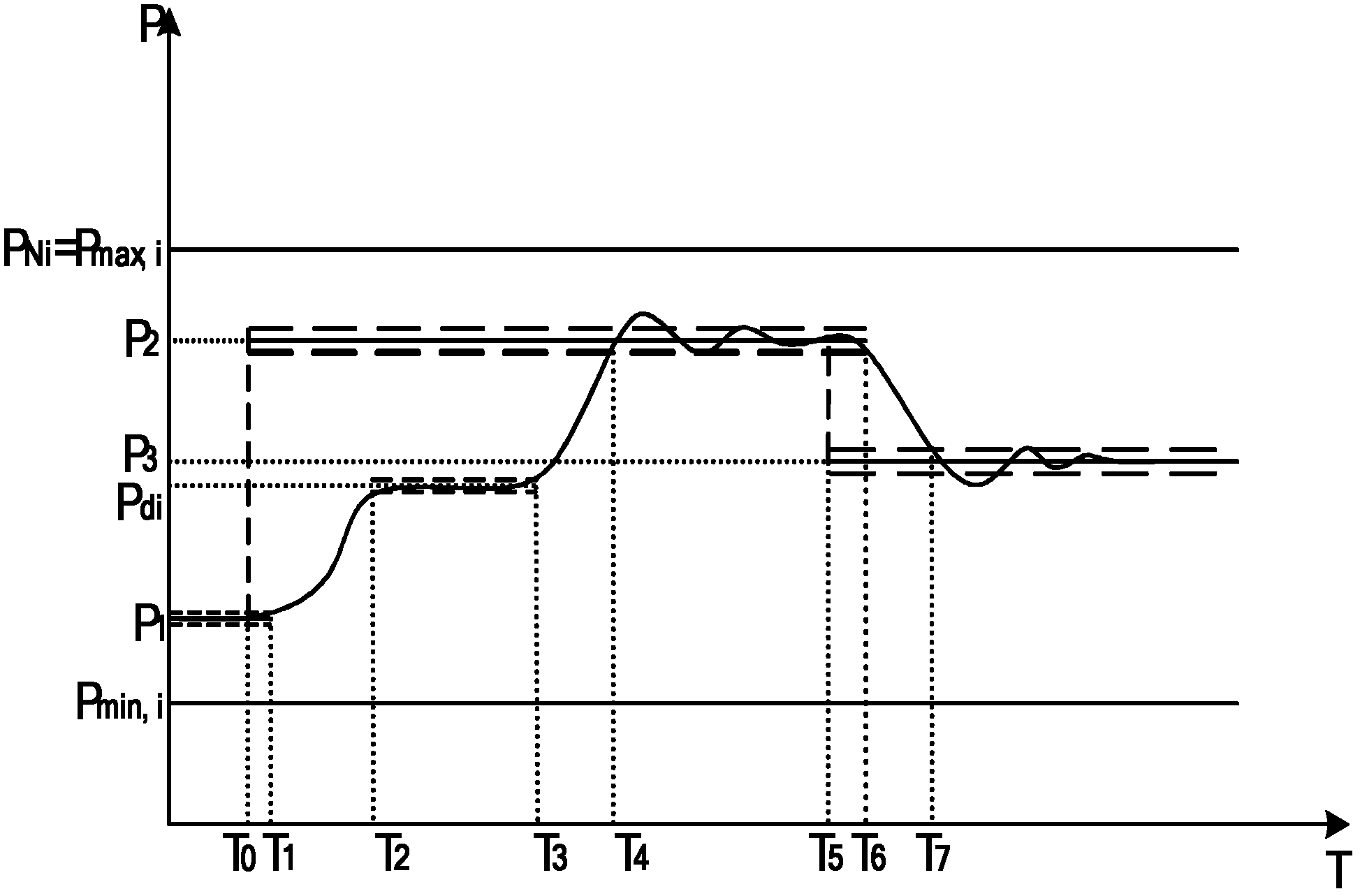

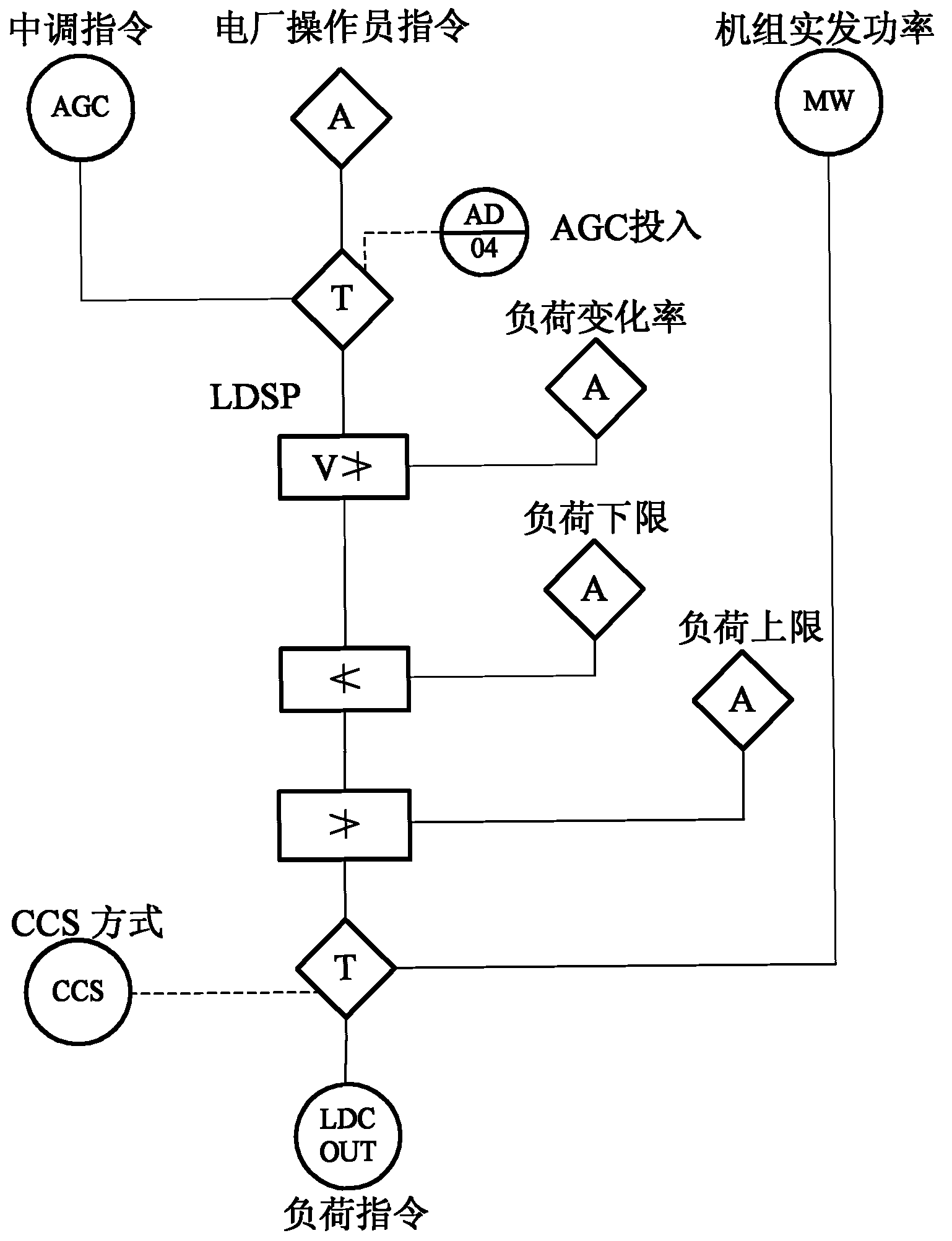

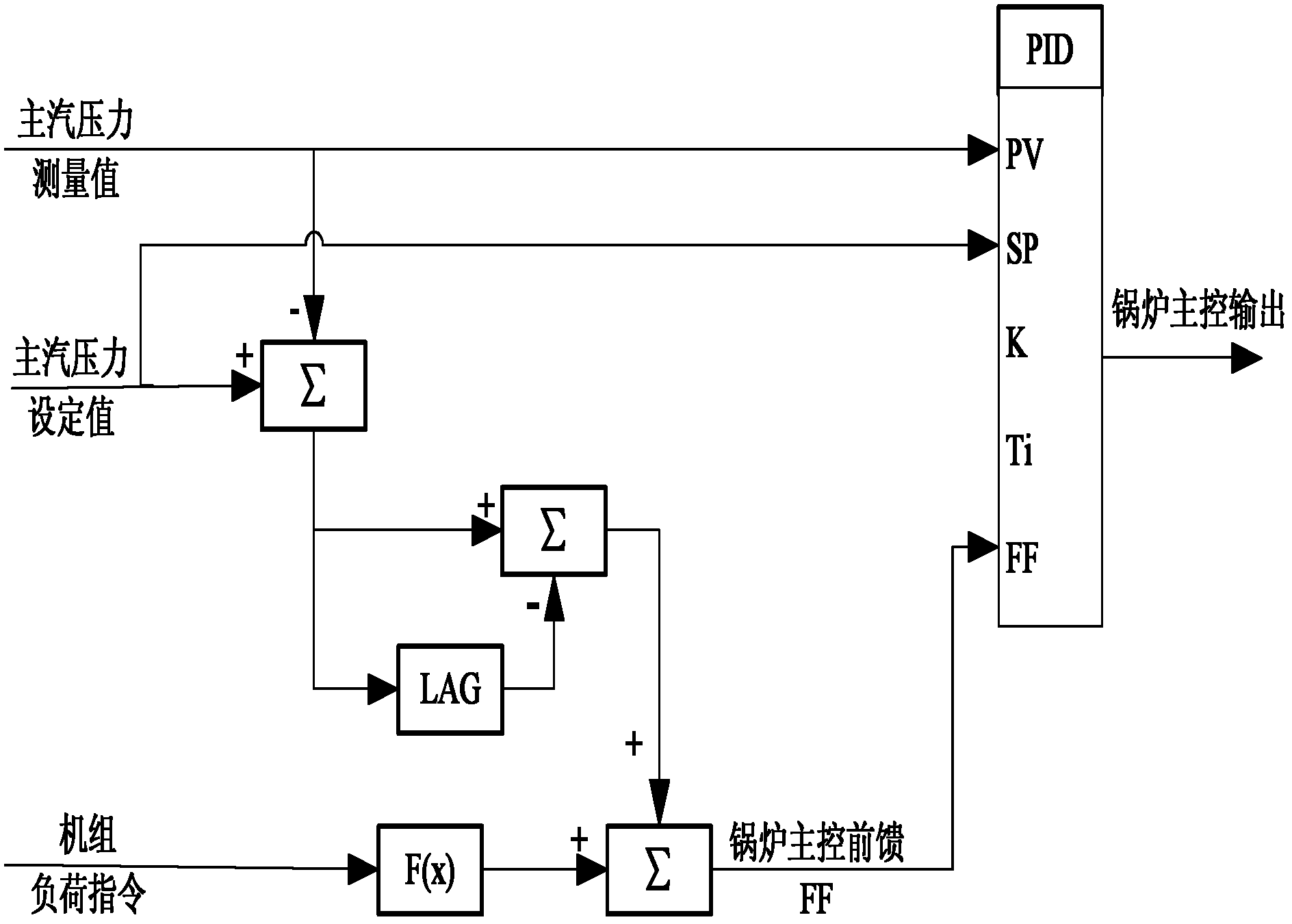

Parameter-varying load optimization control method of thermal power generating unit

ActiveCN103174471ALogical structure optimizationEliminate dead zone and inertiaMachines/enginesEngine startersControl measureParameter control

The invention discloses a parameter-varying load optimization control method of a thermal power generating unit. The method comprises the following specific steps: step 1, generating a judging numerical value through a differentiation element according to a change of a load instruction value; step 2, generating judging conditions of a parameter varying changing-over logic by a high-low amplitude judging module according to the judging numerical value generated by the differentiation element; and step 3, switching a switcher by using a steam engine main controller according to an output command of the high-low amplitude judging module. According to method provided by the invention, a logical structure of the steam engine main controller is optimized and a parameter varying control measure is adopted according to the change condition of load, thereby effectively eliminating the dead zone and inertance of a turbine door regulating executing mechanism, improving the control accuracy and dynamic quality of a system, ensuring a regulating speed, a regulating accuracy and a responsive time of a thermal power generating unit load, and improving the control quality and assessment index of a AGG (automatic gain control) of the thermal power generating unit.

Owner:STATE GRID CORP OF CHINA +1

Synchronous control system and method for heavy-duty locomotive

InactiveCN102774389AImprove securityImprove reliabilityLocomotivesSynchronous controlAutomatic train protection

The invention discloses a synchronous control system and method for a heavy-duty locomotive. The synchronous control system is characterized in that an ATP (automatic train protection) plug-in box and an ATO (automatic train operation) plug-in box transfer a message to wireless COMs (component object model) by an Ethernet interface, transfer a message to a DMI (desktop management interface) by a 422 interface and are in hard wired connection with vehicle control. The synchronous control method comprises the following steps that: a ground management GSM-R (global system for mobile communications for railway) network sends an operation command to a master-control locomotive by a ground communication node; after the wireless COM of the master-control locomotive receives the command, the command is sent to the ATP / ATO equipment of the master-control locomotive; the ATP / ATO equipment calculates the traction force or the brake force of the master-control locomotive and a slave-control locomotive according to the line data and the current state of the locomotive, and outputs the command; the command is sent to the ground communication node by the wireless COM of the master-control locomotive; the communication node forwards the command to an intermediate locomotive and the slave-control locomotive according to an IP (internet protocol) address; after receiving the respective command, the wireless COM of the intermediate locomotive and the wireless COM of the slave-control locomotive forward the respective commands to the ATP / ATO equipment of the locomotive; after the synchronous control system receives the command, driving or brake control is carried out, and the locomotive marshaling control is guaranteed to be synchronous.

Owner:NANJING NRIET IND CORP

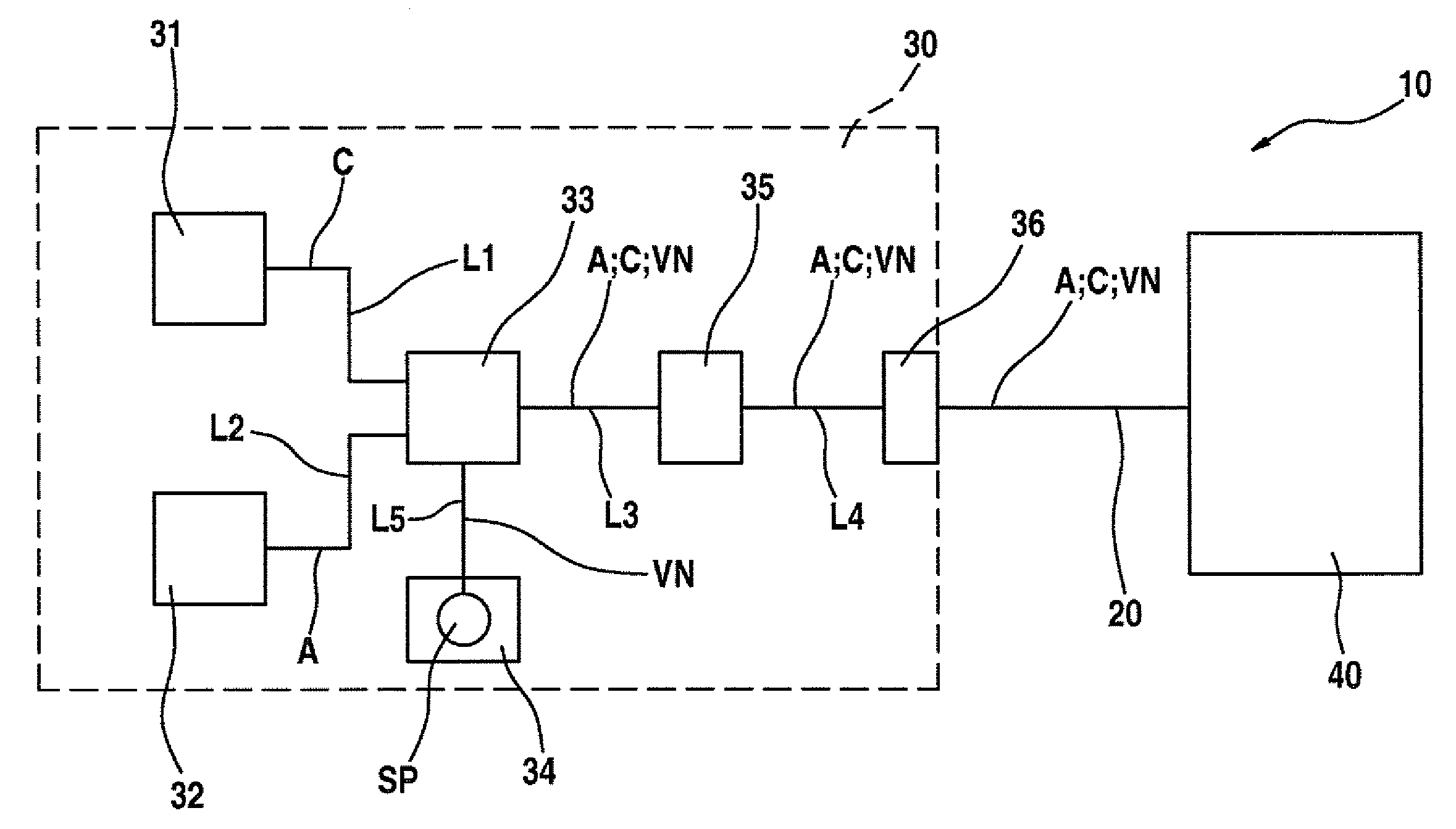

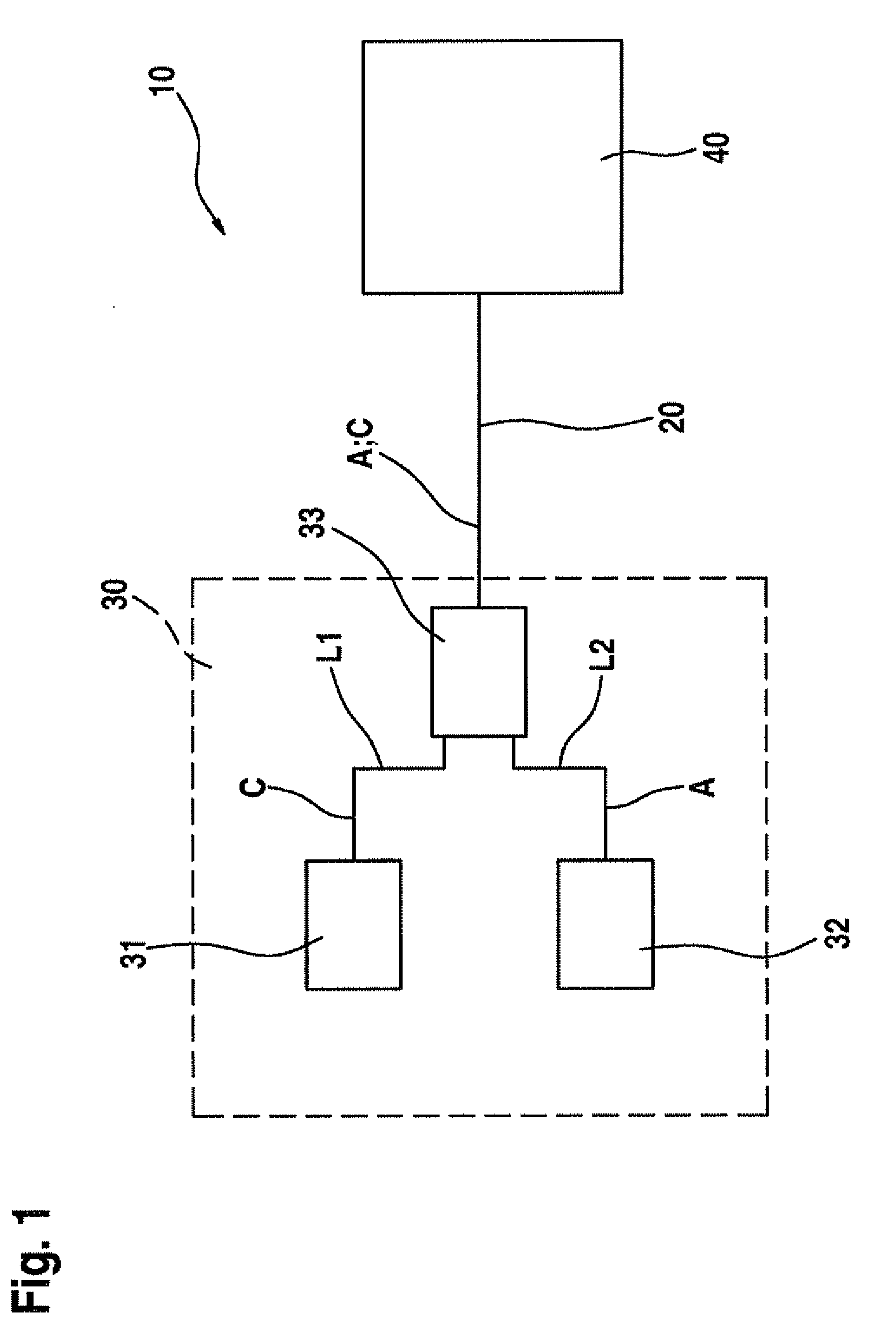

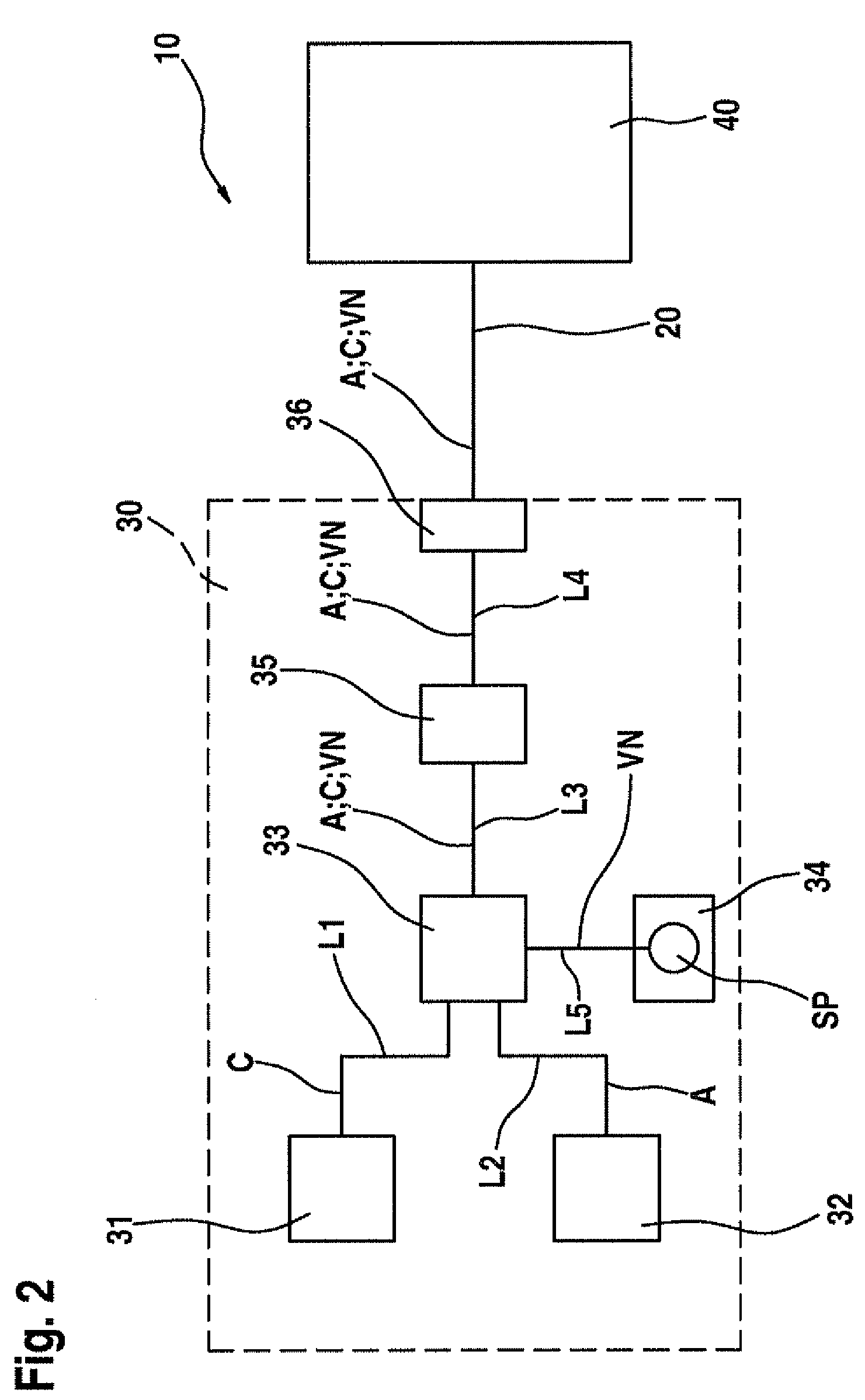

Communication system having a can bus and a method for operating such a communication system

ActiveUS20110125940A1Parts are smallPart can be usedData switching networksElectric digital data processingCommunications systemAsynchronous serial communication

A communication system and a method for operating a communication system, the communication system having a CAN bus and at least two devices connected with the aid of the CAN bus. Such a device has a CAN control unit, an asynchronous, serial communication (ASC) interface unit, and a switch. The CAN control unit is suitable for transmitting, in a first transmission mode, CAN data frames over the CAN bus with the aid of a first physical protocol. The asynchronous, serial communication interface unit or ASC interface unit is suitable for transmitting, in a second transmission mode, ASC data frames over the CAN bus with the aid of a second physical protocol. The switch is designed for switching over between the first transmission mode and the second transmission mode as a function of at least one agreement effective between the device and at least one other device.

Owner:ROBERT BOSCH GMBH

Automatic gain control (AGC) optimizing control method of supercritical unit under coal quality changes

ActiveCN102541028AEnsure regulation rateGuaranteed adjustment accuracyTotal factory controlProgramme total factory controlAutomatic controlBritish thermal unit

The invention discloses an automatic gain control (AGC) optimizing control method of a supercritical unit under coal quality changes, which comprises (1) correcting differential feed-forward of main vapor pressure deviation according to a coal quality correction coefficient British thermal unit (BTU), (2) correcting proportion feed-forward of unit load instructions according to the coal quality correction coefficient BTU, and (3) correcting proportion coefficient K of boiler master control according to the coal quality correction coefficient BTU, overlying the corrected differential feed-forward of the main vapor pressure deviation in the step (1) and the corrected proportion feed-forward of the unit load instructions in the step (2) to serve as new master control feed-forward of the unit boiler, enabling the corrected proportion coefficient K of the boiler master control in the step (3) to serve as an input quantity in a follow-up proportion integration differentiation (PID) step, and achieving output control of the unit boiler master control. The AGC optimizing control method of the supercritical unit under the coal quality changes has the advantages that by optimizing a logic structure of a unit boiler master controller, measures of sectional parameter varying are adopted specific to different coal quality, stability of main vapor pressure of the unit is effectively ensured, and control quality and key performance indexes of the AGC of the supercritical unit are improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

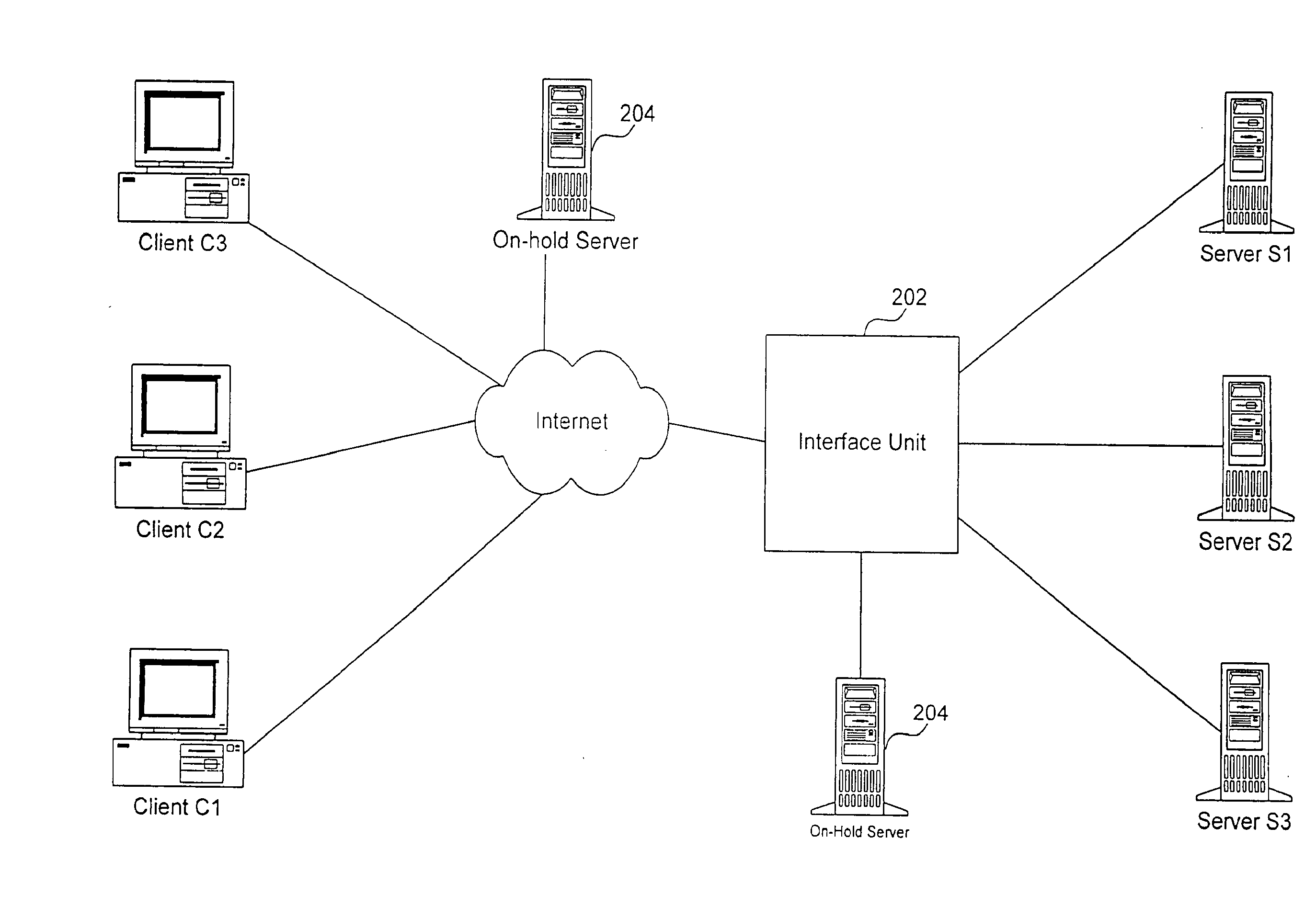

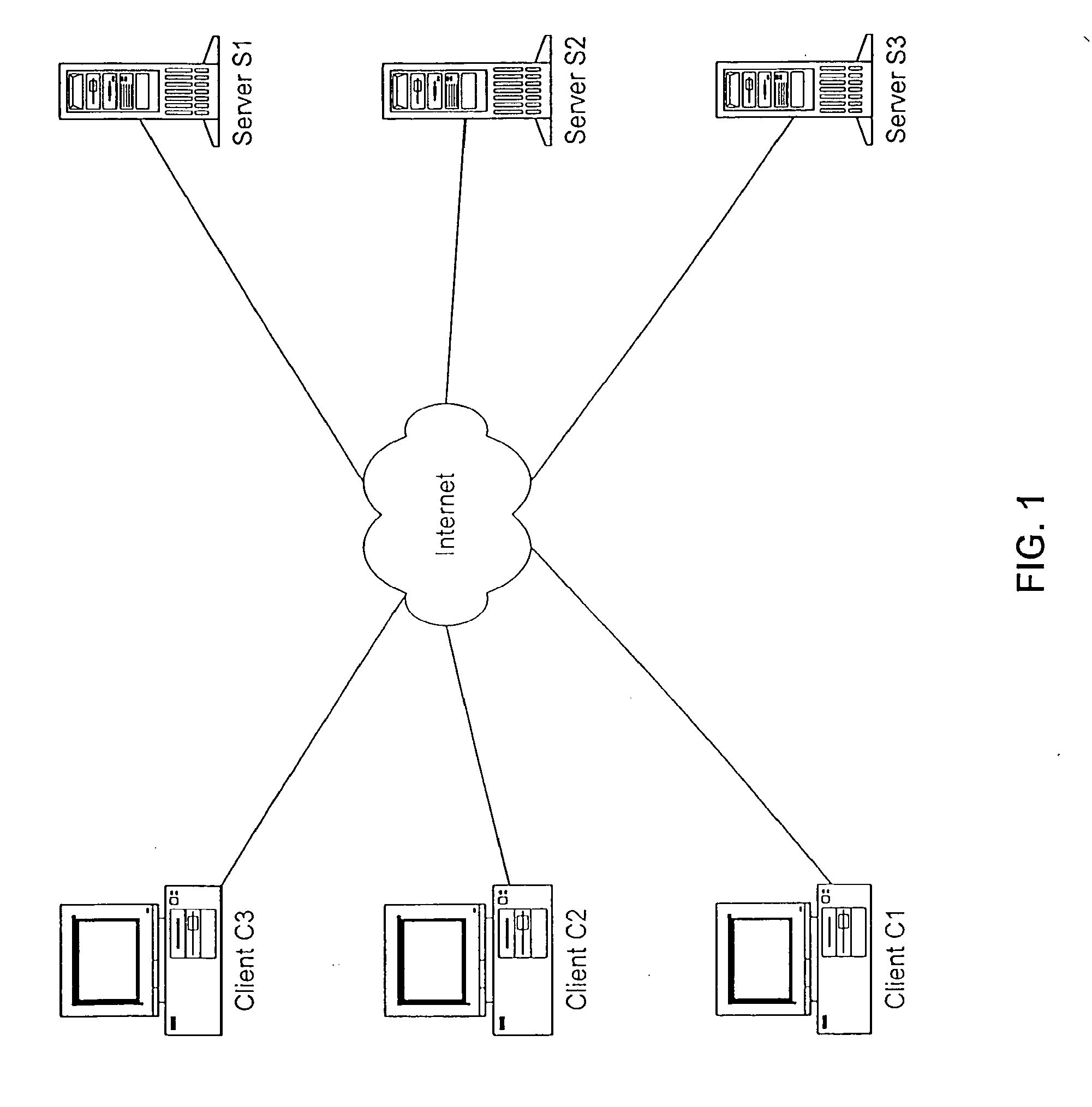

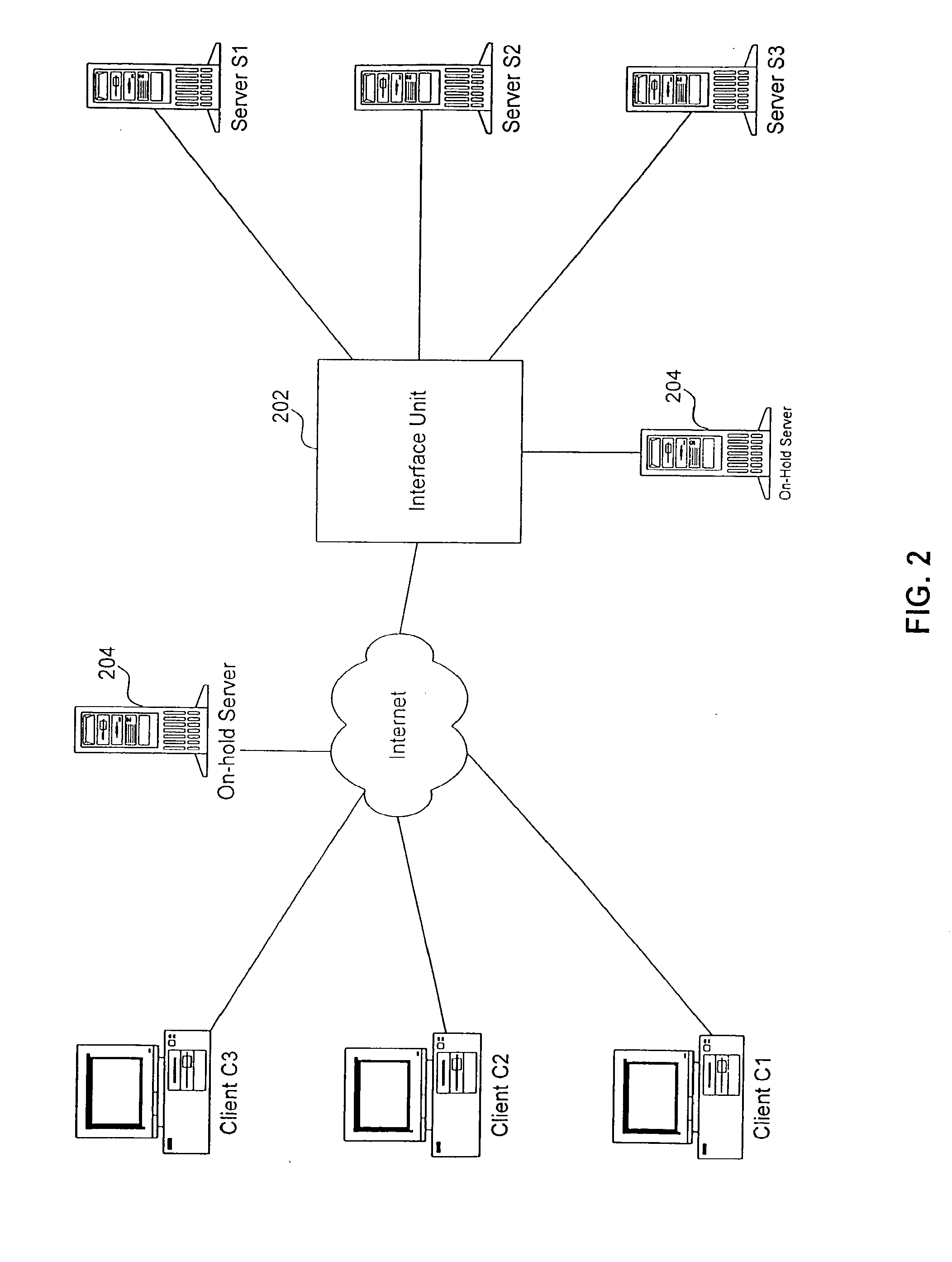

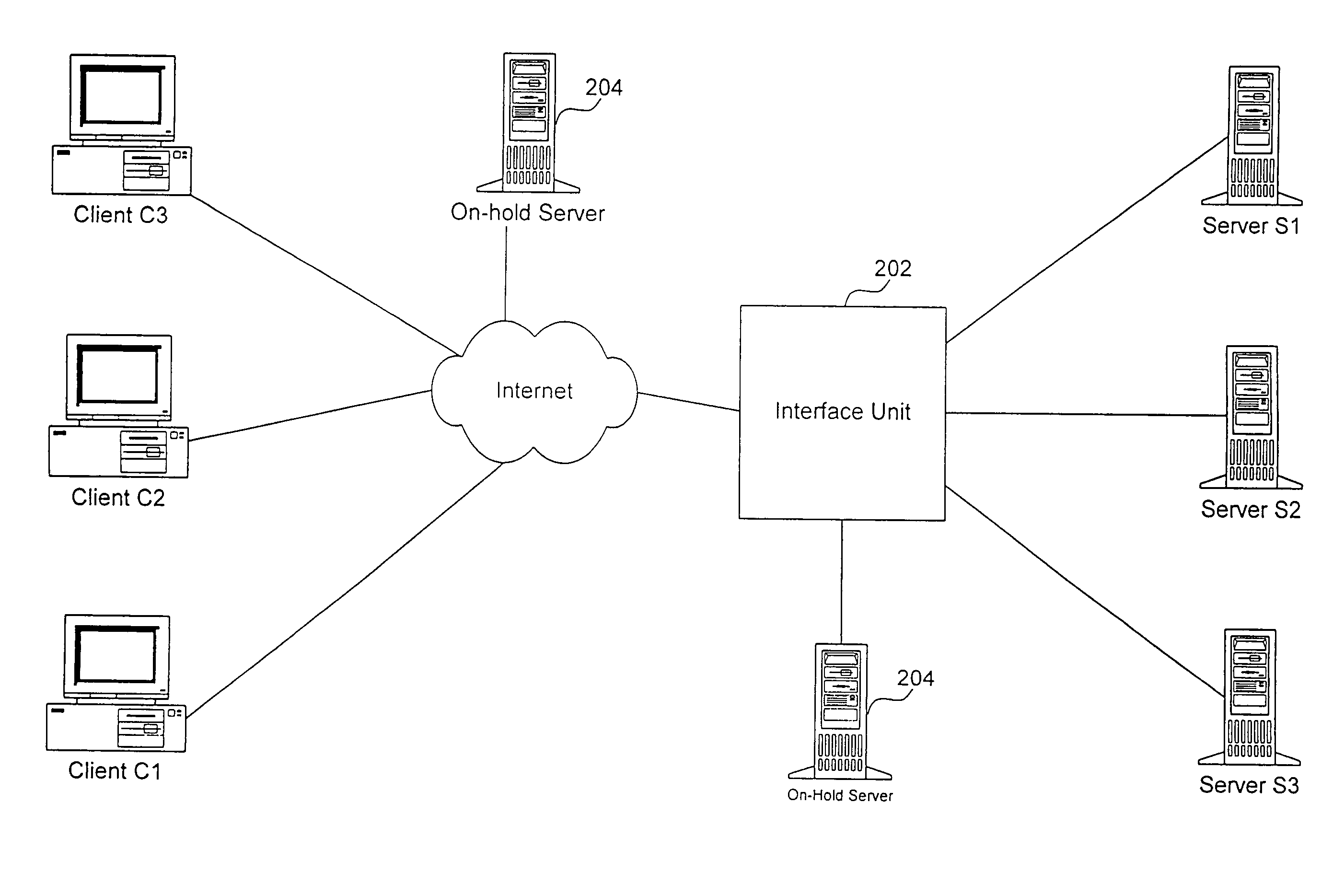

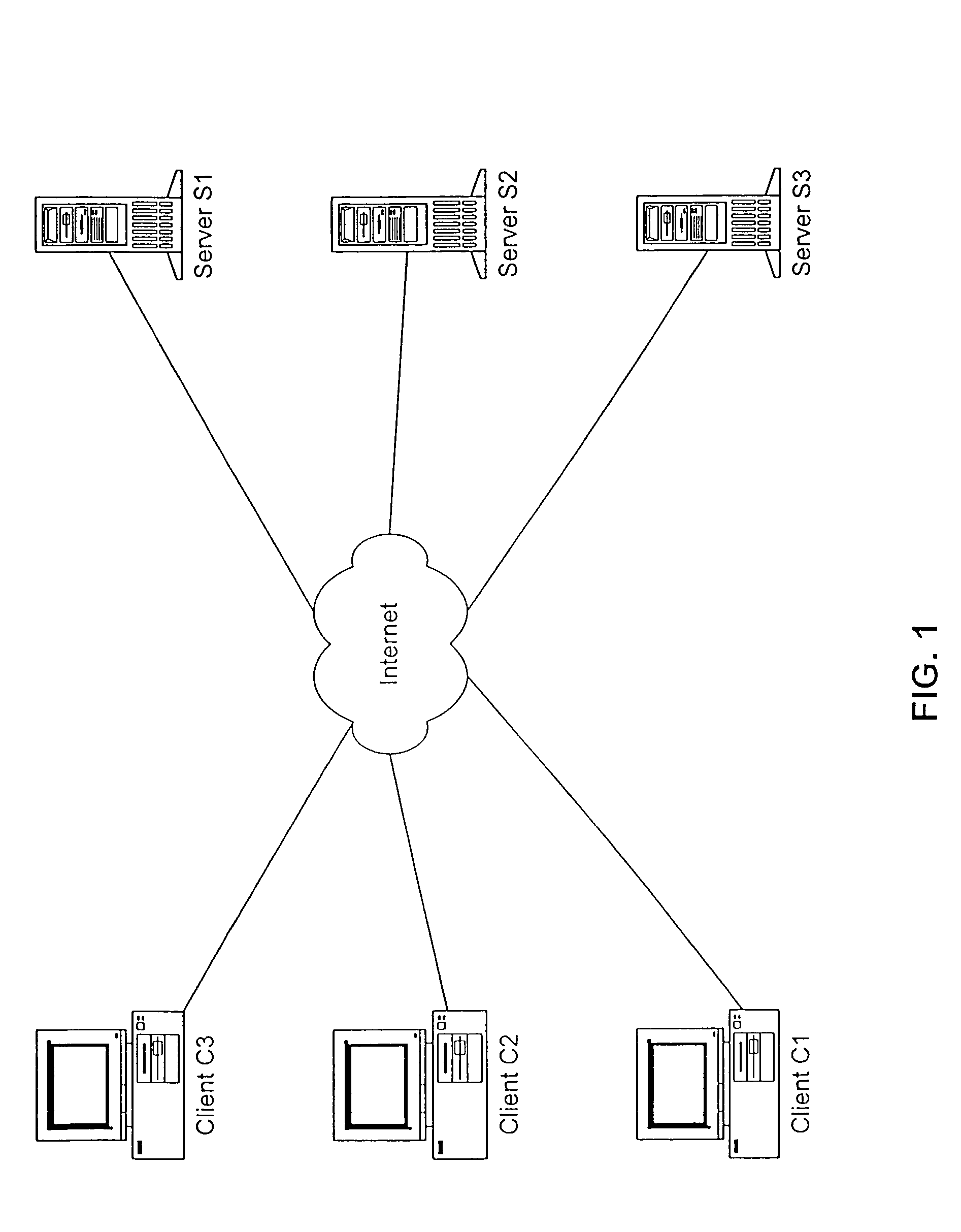

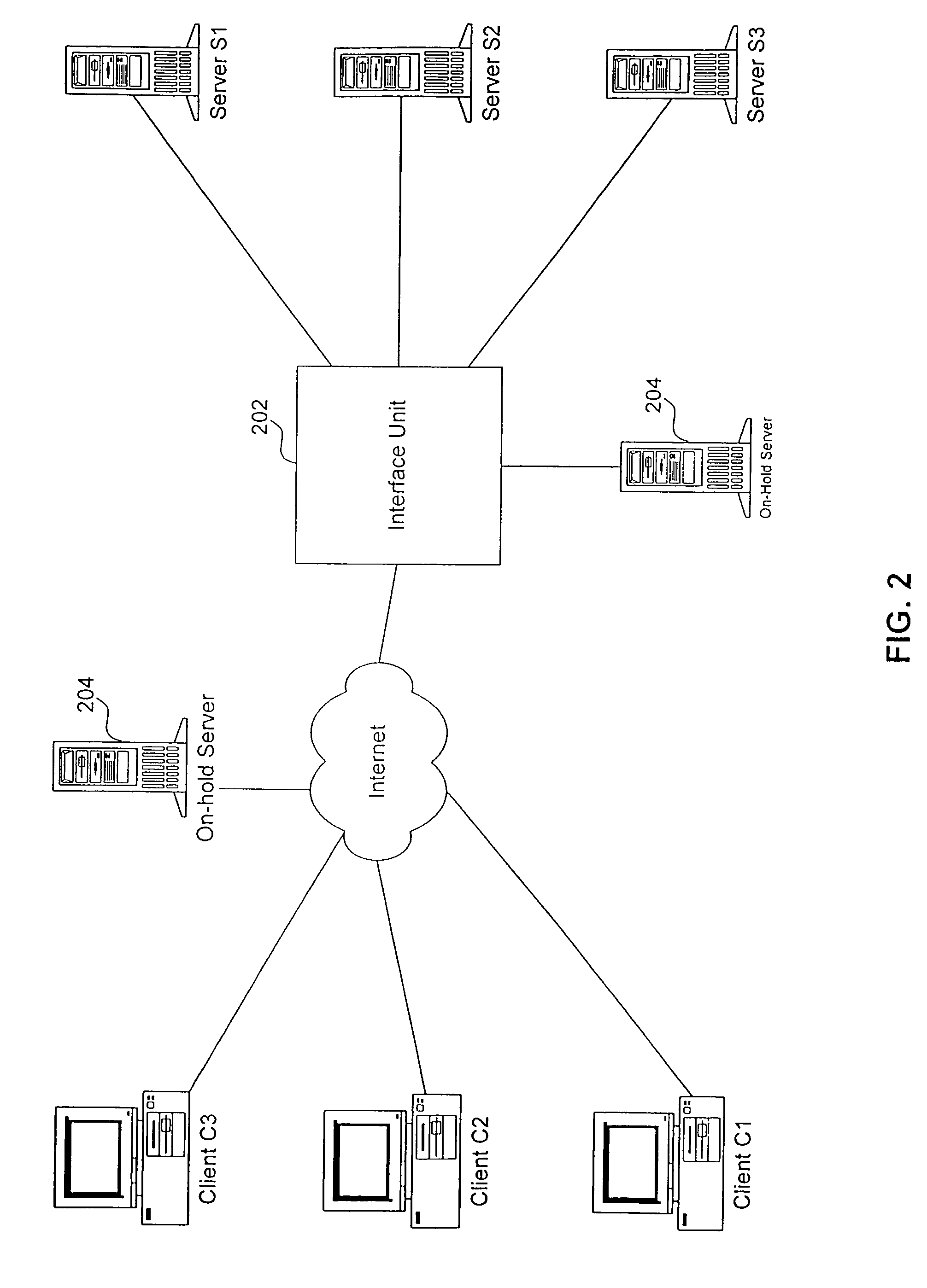

Apparatus, method and computer program product for guaranteed content delivery incorporating putting a client on-hold based on response time

InactiveUS20110060840A1Guaranteed response timeMultiple digital computer combinationsData switching networksThe InternetClient-side

An apparatus, method and computer program product for guaranteeing network client-server response time while providing a way of putting the client on-hold when the response time temporarily prohibits access to the requested server. The apparatus is implemented within an interface unit connecting a plurality of servers and an on-hold server to the Internet, which is connected to a plurality of clients. According to one aspect of the invention, the method includes the steps of opening a connection between a client and the interface unit; determining which server the client desires a page from; determining the current response time of the requested server; if the response time is acceptable then opening a connection between the interface unit and the requested server if no free connection is open between the interface unit and the requested server; allowing the client to access information on the requested server-via the connections; and closing the connection between the client and the interface unit while keeping open the connection between the interface unit and the requested server. Alternatively, if the response time is not acceptable, then putting the client on-hold by redirecting the client to an on-hold server until the response time of the requested server becomes acceptable. According to a “on-hold distribution” aspect of the invention, the interface unit determines the on-hold preference of the client and selects the server hosting that on-hold preference. According to another aspect of the invention, instead of utilizing the interface unit, each server has the intelligence to put the client on-hold when applicable.

Owner:CITRIX SYST INC

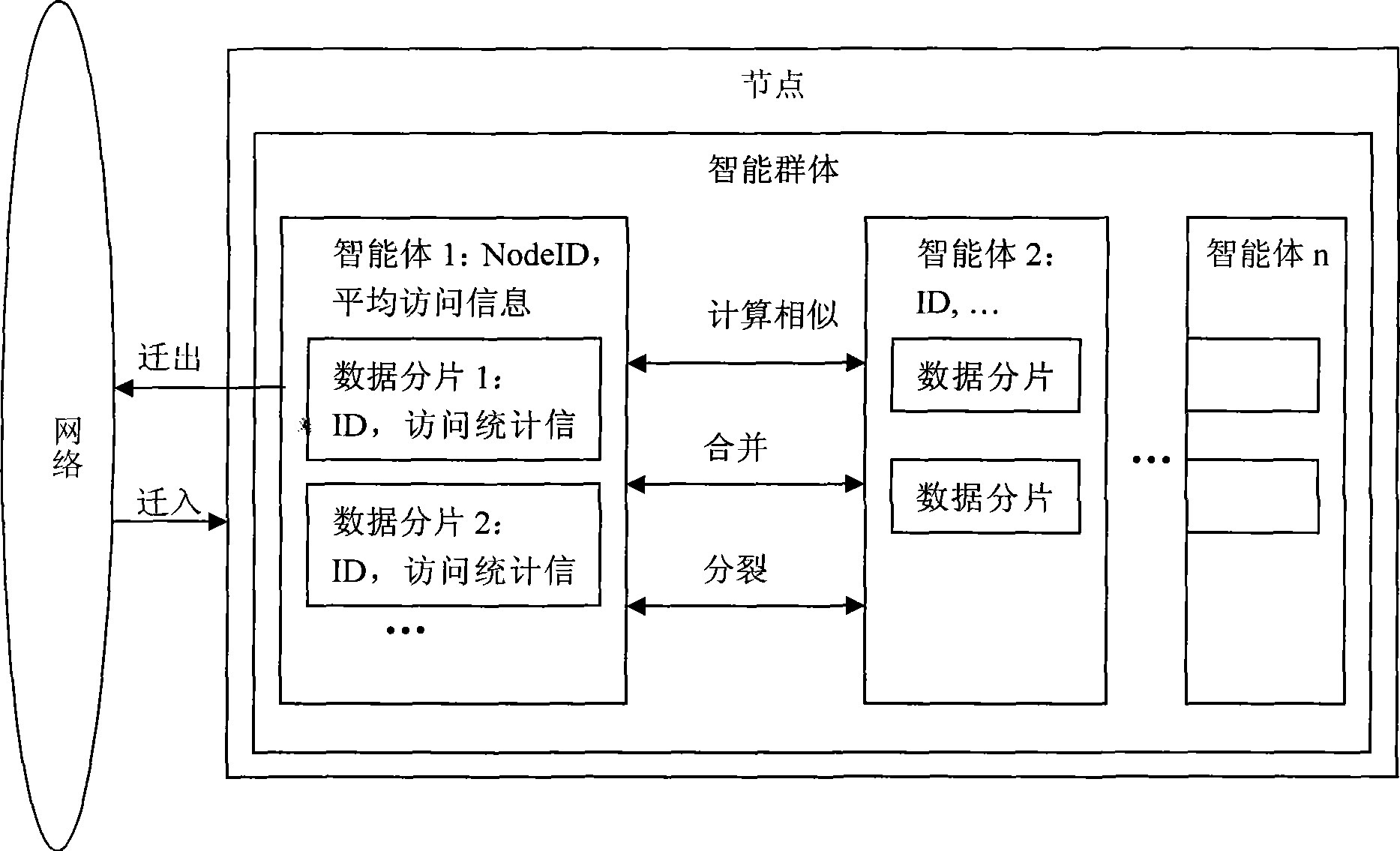

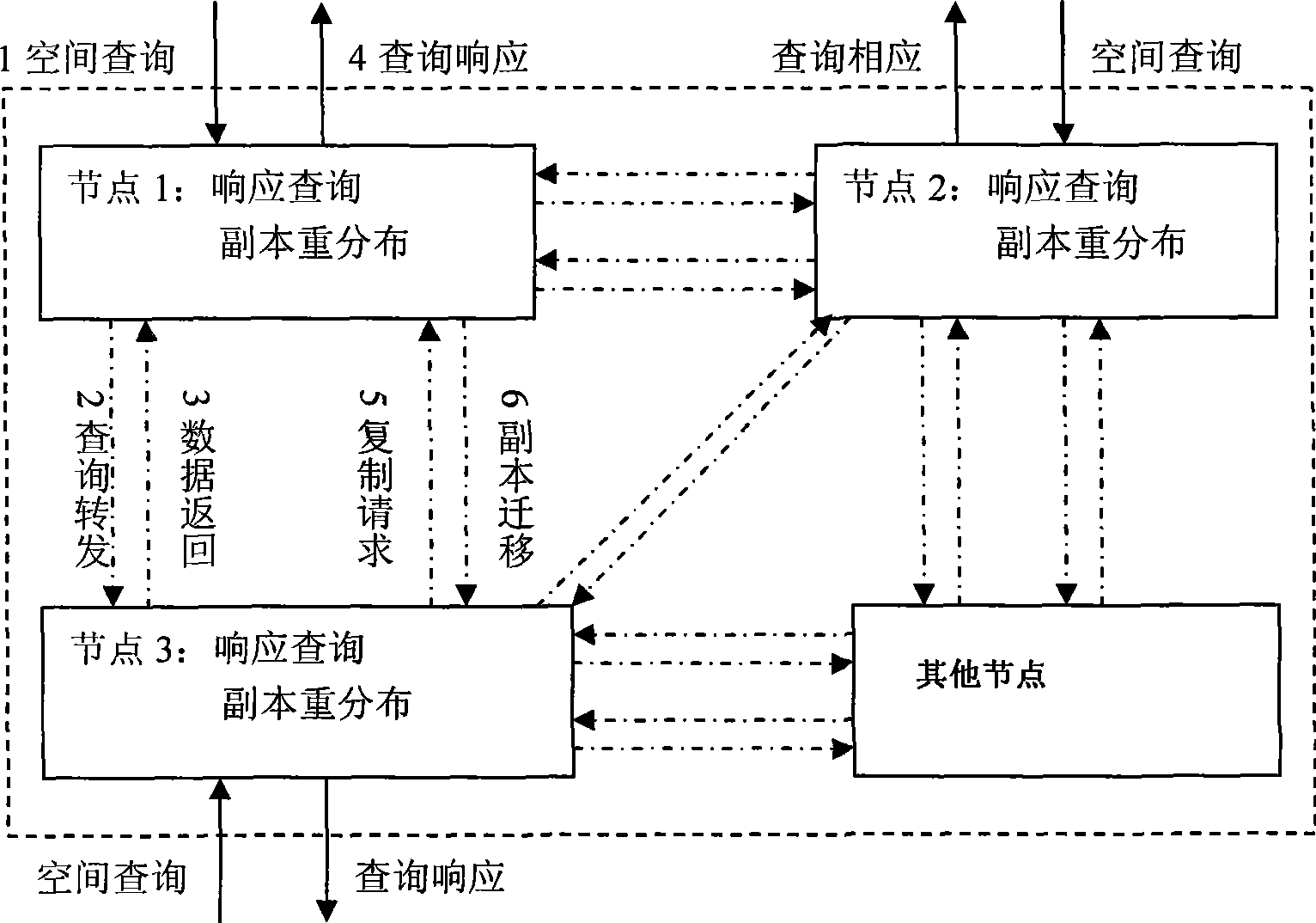

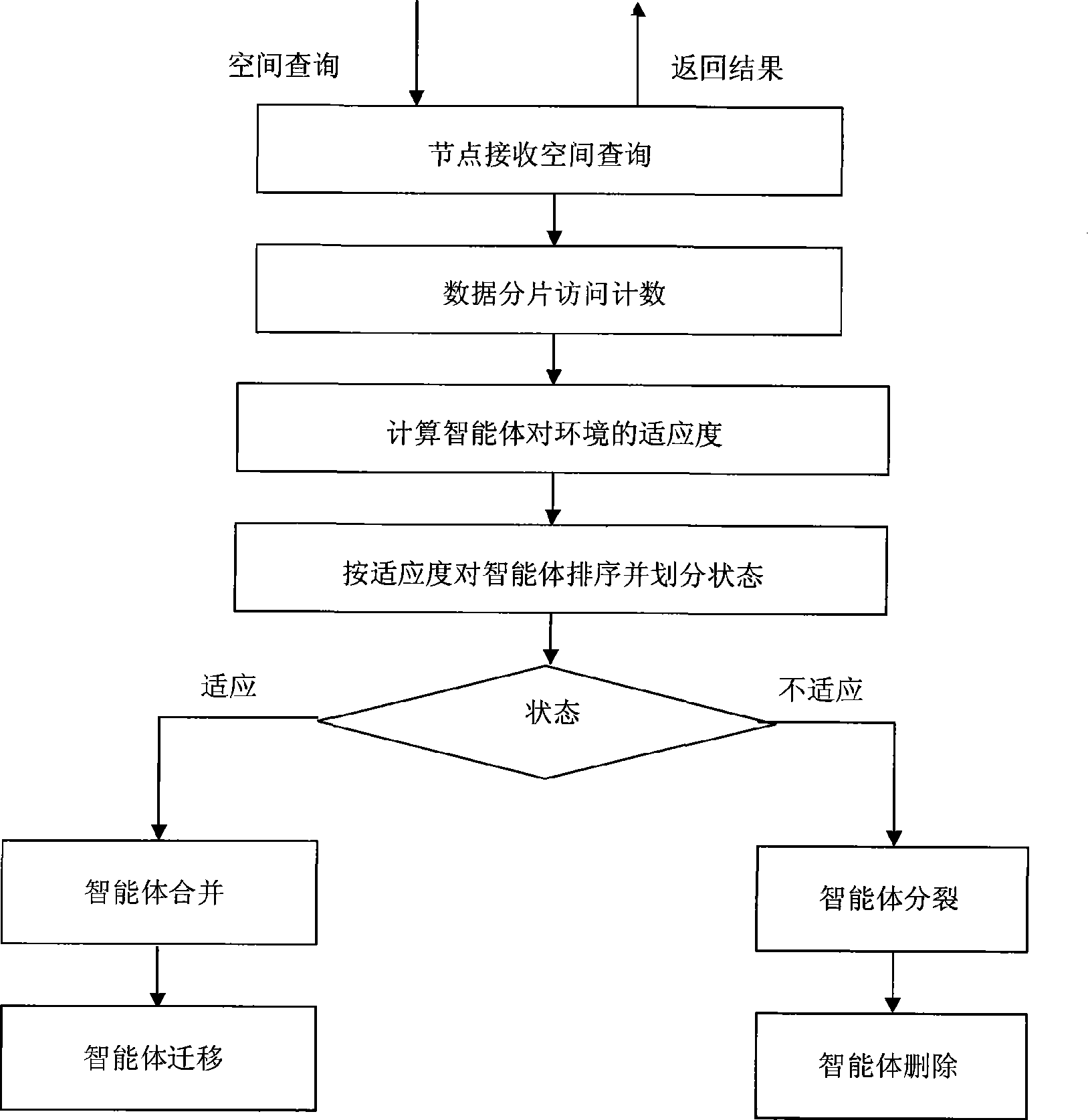

Swarm intelligence based spatial data copy self-adapting distribution method

InactiveCN101504663AGood scalability and robustnessGuaranteed response timeTransmissionSpecial data processing applicationsGeographic information systemRobustification

The invention belongs to the technical field of grid computing and geographic information systems, and in particular relates to a self-adapting distribution method for spatial data copies on the basis of swarm intelligence, wherein each node consists of a plurality of intelligent agents; each intelligent agent maintains access information of a plurality of data fragments; intelligent agents in various grid nodes form an intelligent mass society; and the self-adapting distribution of the spatial data copies in the whole grid system is realized through merging, splitting, deletion and transferring of the swarm intelligence. The method is event-driven, and various nodes adjust the redistribution of respective data copies in the mode of asynchronous copy by self-adapting according to the variation of self spatial inquiry events. The method is completely distributed, has no global control center, and is bottom-up. Moreover, the method is simple and easy to realize, has strong self-adaptability, is favorable for the spatial grid system to obtain higher response capability of data access with smaller system maintenance cost, and improves the robustness and the flexibility of the spatial grid system.

Owner:PEKING UNIV

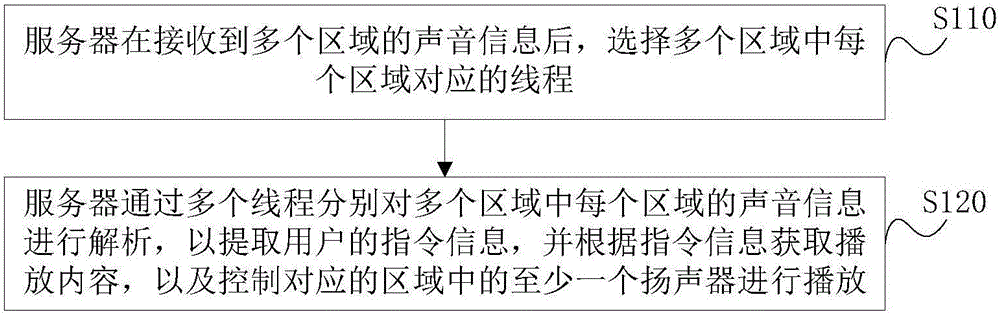

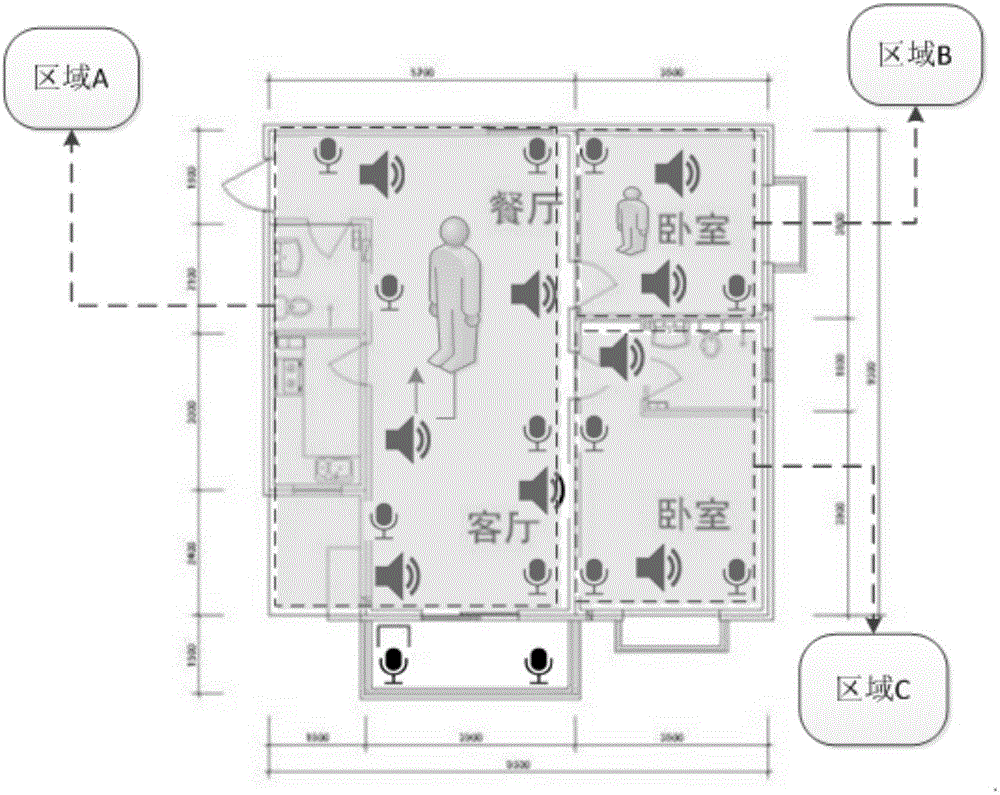

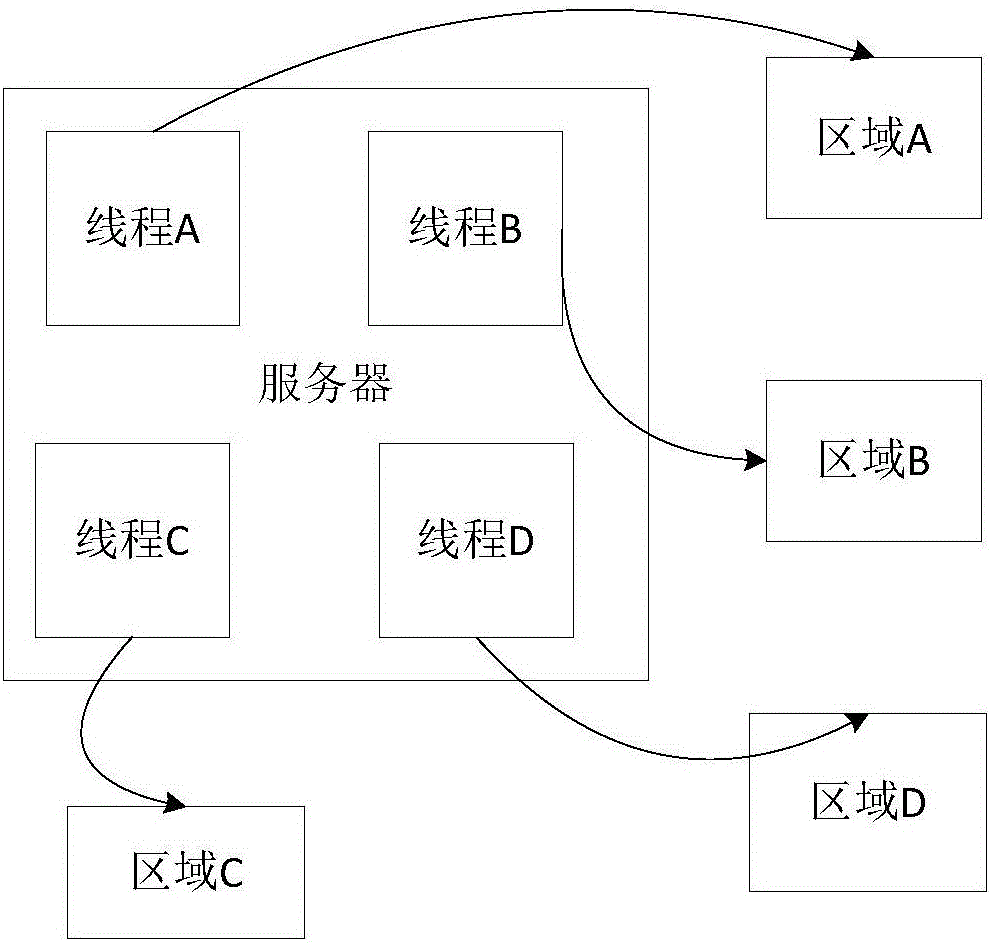

Method and system for carrying out voice control in multiple regions simultaneously, server and microphone

ActiveCN105957519AImprove experienceGuaranteed response timeNon-electrical signal transmission systemsSpeech recognitionInteraction controlLoudspeaker

The invention discloses a method and a system for carrying out voice control in multiple regions simultaneously, as well as a server and a microphone. The method comprises the steps that: the server selects a thread corresponding to each region of the multiple regions after receiving voice information of the plurality of regions, wherein the server stores the plurality of threads, and each thread corresponding to one region; and the server analyzes the voice information of each region of the multiple regions separately by means of the plurality of threads, so as to extract instruction information of a user, obtain playing content according to the instruction information, and control at least one loudspeaker in the corresponding region to play. Therefore, the voice information in the corresponding region is processed through the independent thread, the interaction control in a manner that multiple users in different regions use voice instructions simultaneously is achieved, the response time is ensured, and user experience is enhanced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Distributed type cloud computing data migration method

The invention provides a distributed type cloud computing data migration method. Different data migration methods can be adopted according to different network states. Under the condition that the network state is good, the data migration method based on network transmission is adopted, under the condition that the network state is poor, the data migration method based on pre-storage is adopted, and when the network state constantly changes along with external factors, the data migration method based on the network state is adopted. Due to the fact that the data migration modes are changed according to the network state, the method can effectively shorten response time, reduce dependency on the storage resources, reduce dependency on the network resources, effectively improve working efficiency, enhance working reliability and be suitable for popularization and use.

Owner:XIDIAN UNIV

Apparatus, method and computer program product for guaranteed content delivery incorporating putting a client on-hold based on response time

ActiveUS7836191B2Guaranteed response timeEasy maintenanceMultiple digital computer combinationsData switching networksSoftware engineeringThe Internet

An apparatus, method and computer program product for guaranteeing network client-server response time while providing a way of putting the client on-hold when the response time temporarily prohibits access to the requested server. The apparatus is implemented within an interface unit connecting a plurality of servers and an on-hold server to the Internet, which is connected to a plurality of clients. According to one aspect of the invention, the method includes the steps of opening a connection between a client and the interface unit; determining which server the client desires a page from; determining the current response time of the requested server; if the response time is acceptable then opening a connection between the interface unit and the requested server if no free connection is open between the interface unit and the requested server; allowing the client to access information on the requested server via the connections; and closing the connection between the client and the interface unit while keeping open the connection between the interface unit and the requested server. Alternatively, if the response time is not acceptable, then putting the client on-hold by redirecting the client to an on-hold server until the response time of the requested server becomes acceptable. According to a “on-hold distribution” aspect of the invention, the interface unit determines the on-hold preference of the client and selects the server hosting that on-hold preference. According to another aspect of the invention, instead of utilizing the interface unit, each server has the intelligence to put the client on-hold when applicable.

Owner:CITRIX SYST INC

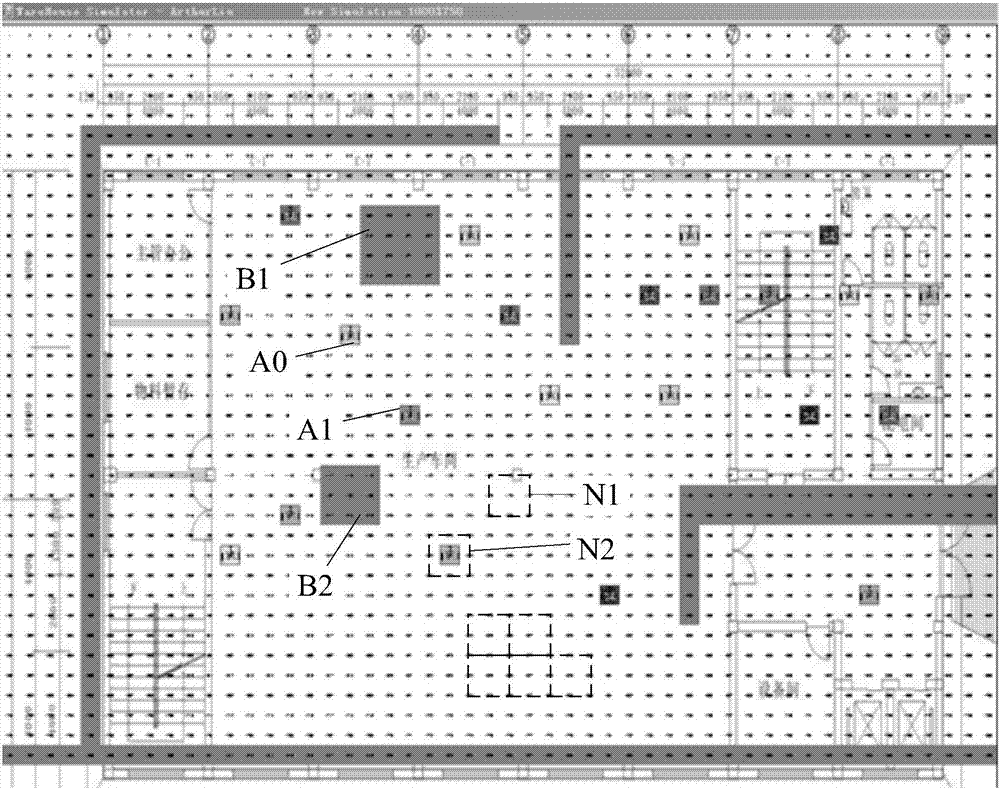

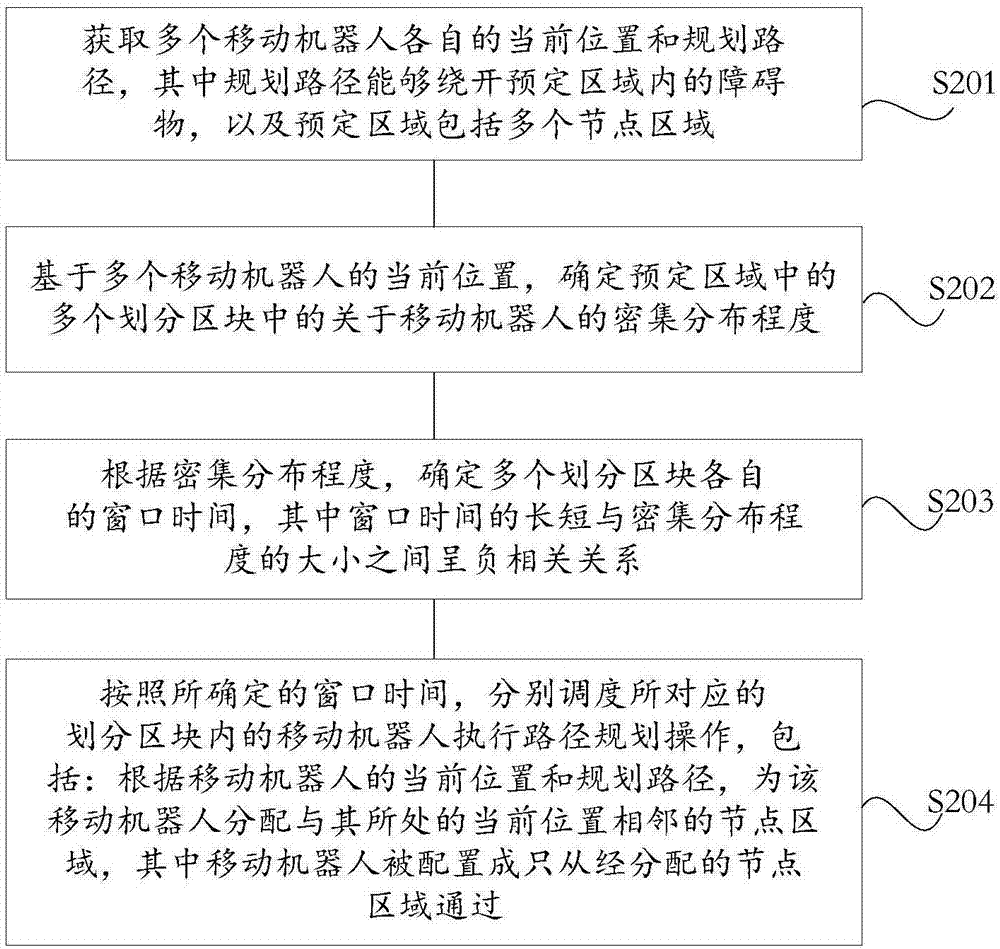

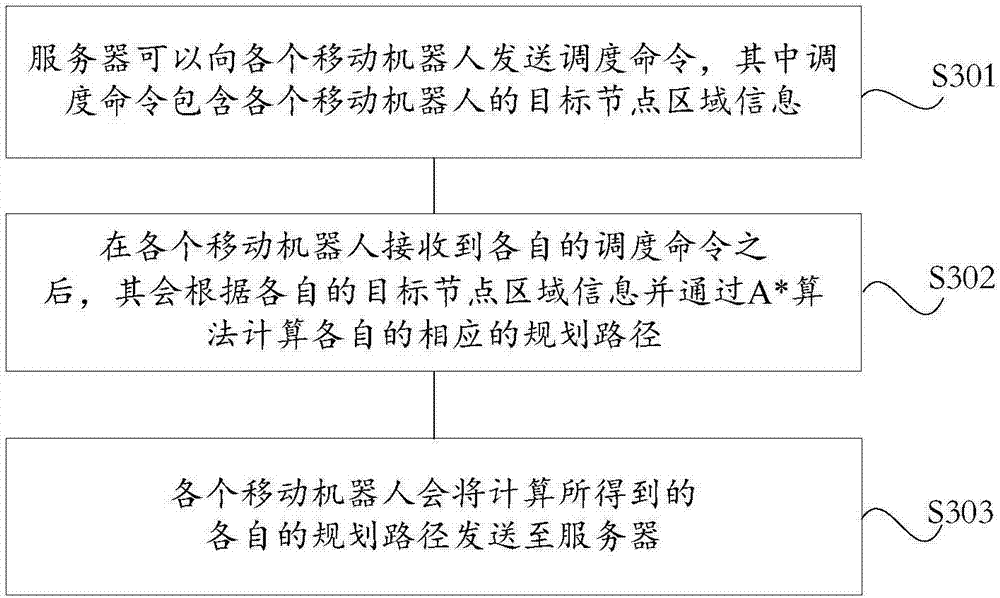

Route planning method and system of multiple moving robots

ActiveCN107992060AGuaranteed response timeReduce consumptionPosition/course control in two dimensionsVehiclesPlanning approachEngineering

The embodiment of the invention provides a route planning method and system of multiple moving robots, and belongs to the technical field of robots. The route planning method of the multiple moving robots comprises the following steps of obtaining the respective current positions and planning paths of each moving robot among the a plurality of moving robots; on the basis of the current position ofthe plurality of moving robots, determining the dense distribution degree relevant to the moving robots in a plurality of division blocks in current position determined preset region; according to the dense distribution degree, determining the respective window time of the plurality of division blocks; according to the determined window time, respectively dispatching the moving robots in the division blocks to execute the path planning operation including the operations of allocating the node region adjacent to the current position to the moving robots according to the current positions and the planning path of the moving robots, so that the moving robots are configured to only pass through the allocated node regions. Therefore the balance is found between the space resource and the conflict avoidance; the conflict occurrence probability of jamming blocks can be reduced. The practicability is higher.

Owner:KUKA ROBOTICS GUANGDONG CO LTD

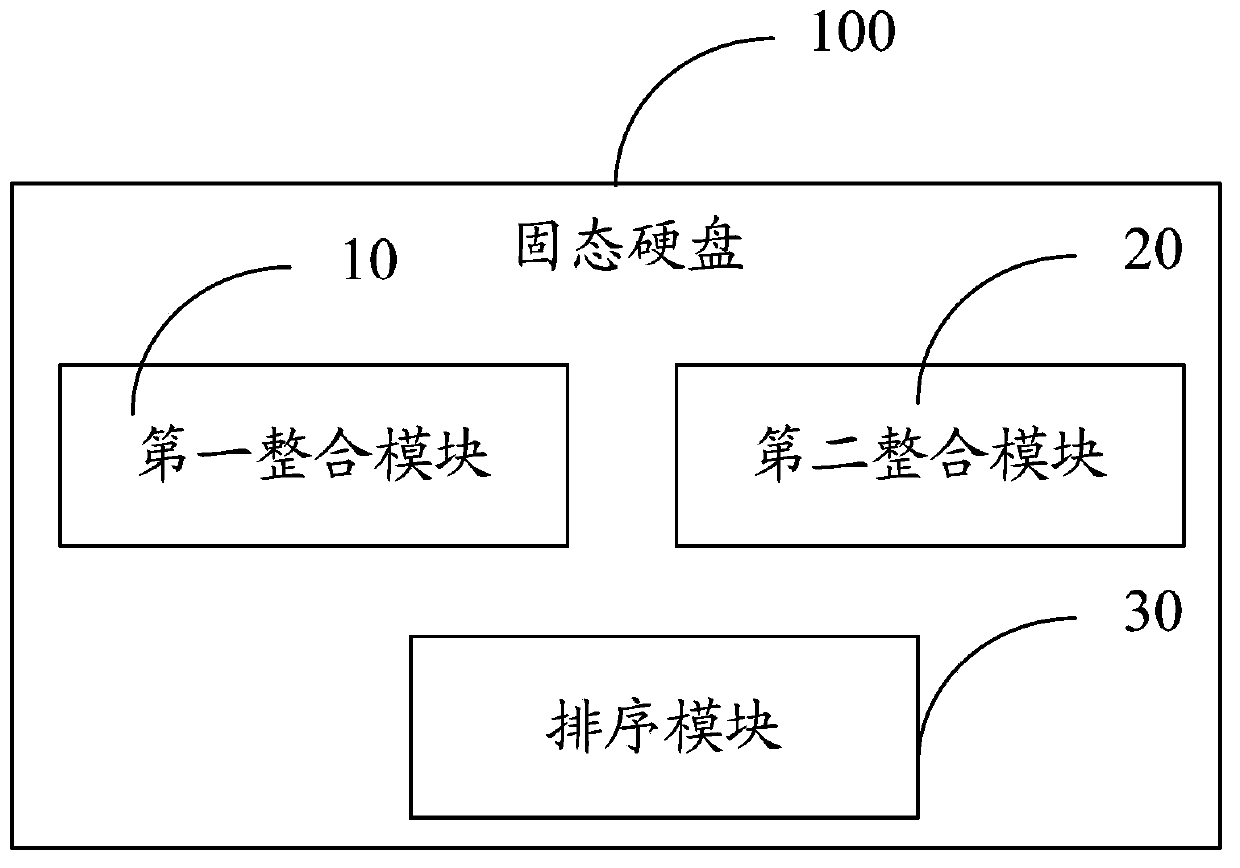

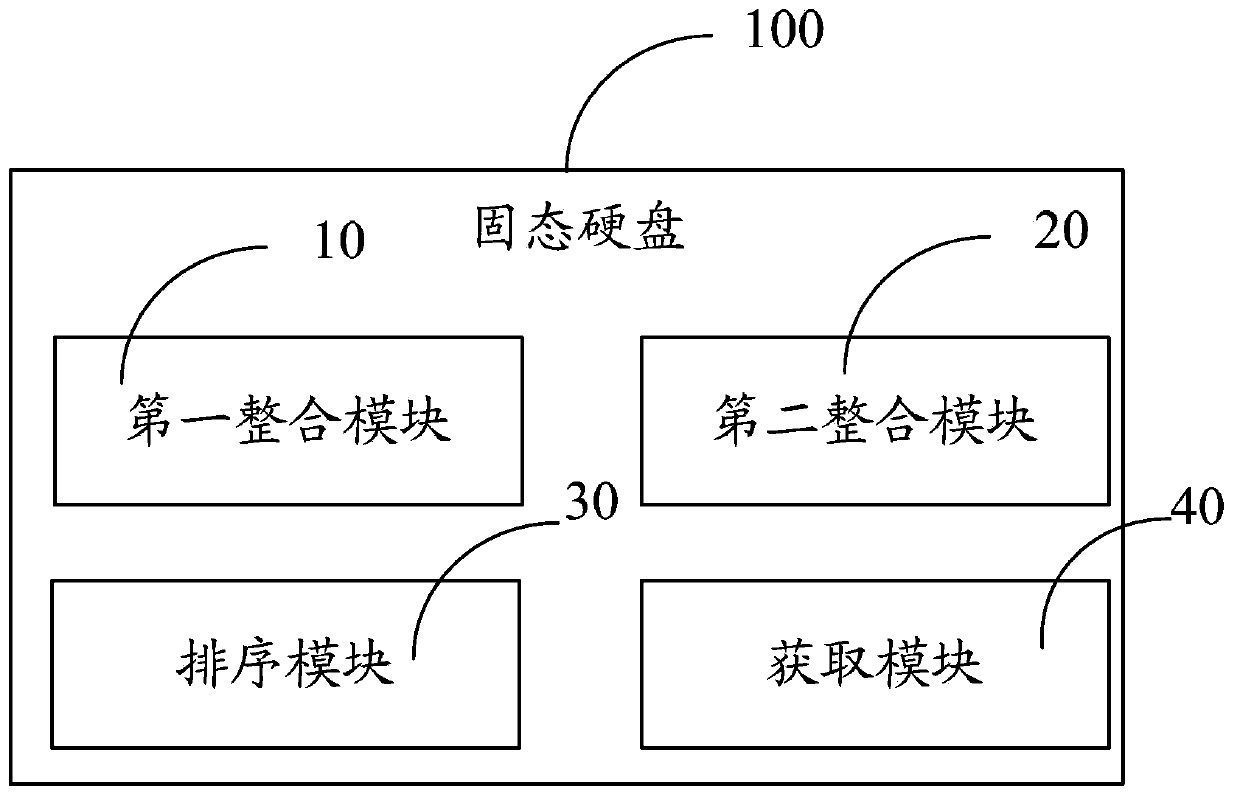

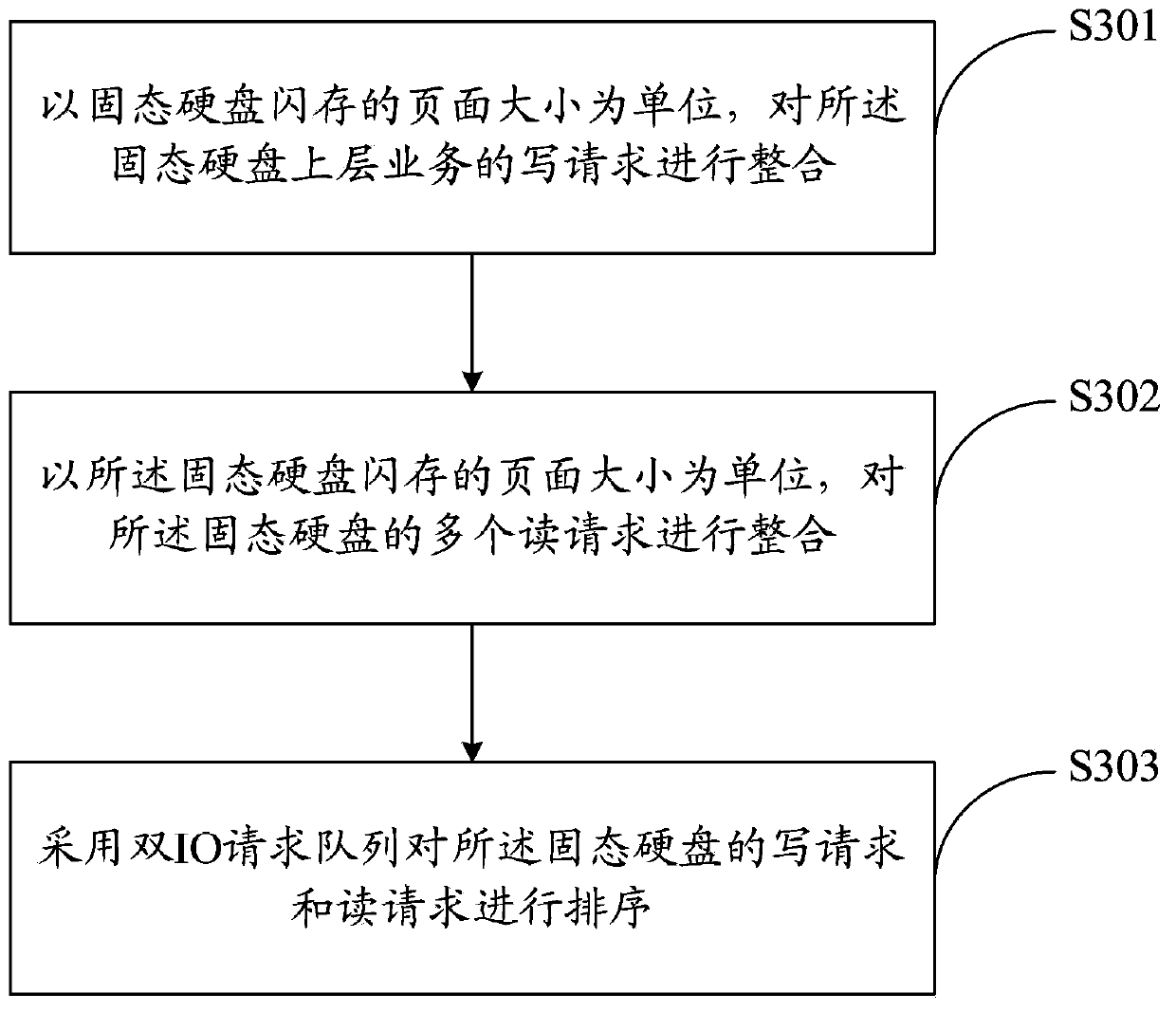

Method for reading and writing solid-state disk and solid-state disk thereof

InactiveCN103425439AExtended service lifeImprove experienceInput/output to record carriersThe InternetSolid-state drive

The invention belongs to the technical field of solid-state disks, and provides a method for reading and writing a solid-state disk and the solid-state disk of the method. In order to achieve the aims, the invention provides the method for reading and writing the solid-state disk. The method comprises the following steps: A, using the page size of flash memory of the solid-state disk to integrate write requests of an upper-layer service on the solid-state disk, B, using the page size of the flash memory of the solid-state disk to integrate a plurality of read requests of the solid-state disk, and C, adopting an IO request queue to rank the write requests and the read requests of the solid-state disk. Therefore, according to the method for reading and writing the solid-state disk and the solid-state disk of the method, the application of the solid-state disk in the Internet is optimized, and the use efficiency of the solid-state disk is improved.

Owner:RAMAXEL TECH SHENZHEN

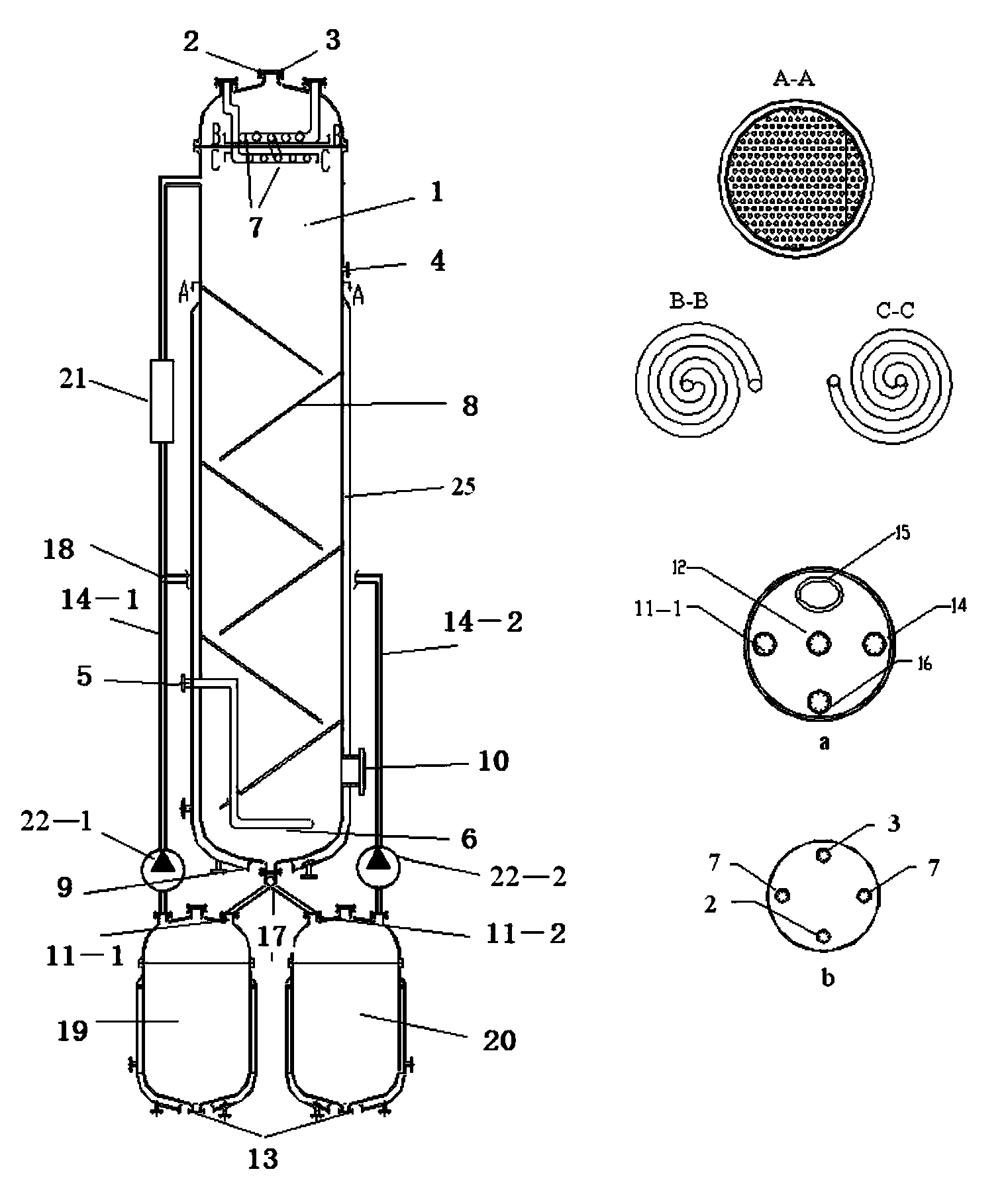

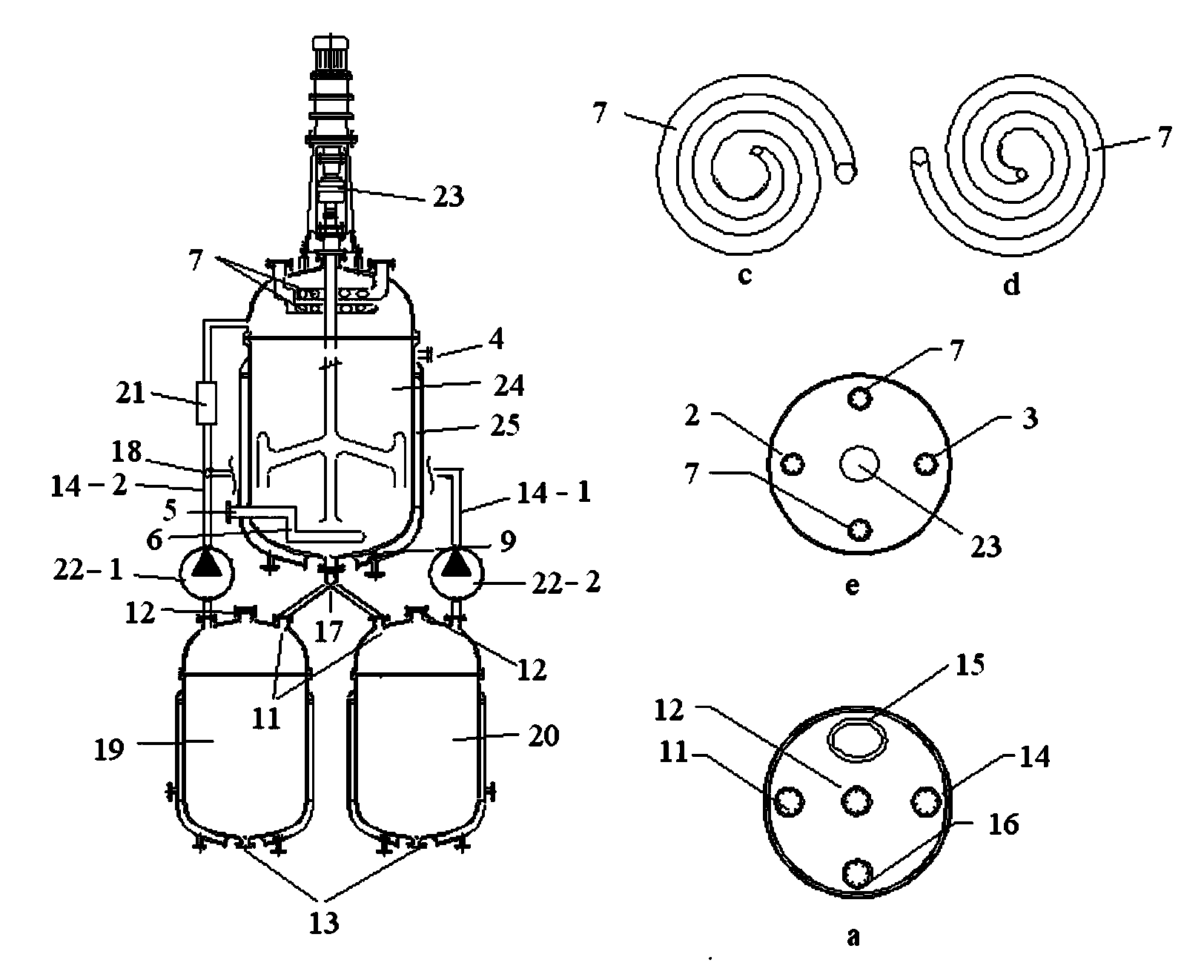

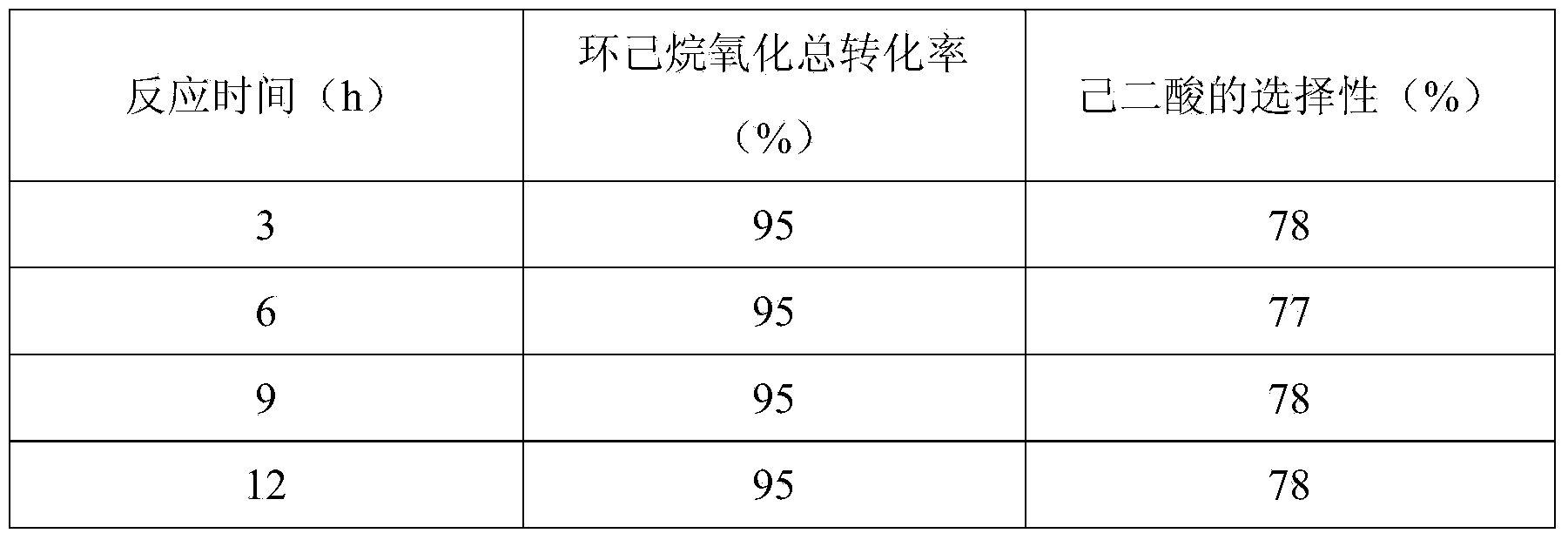

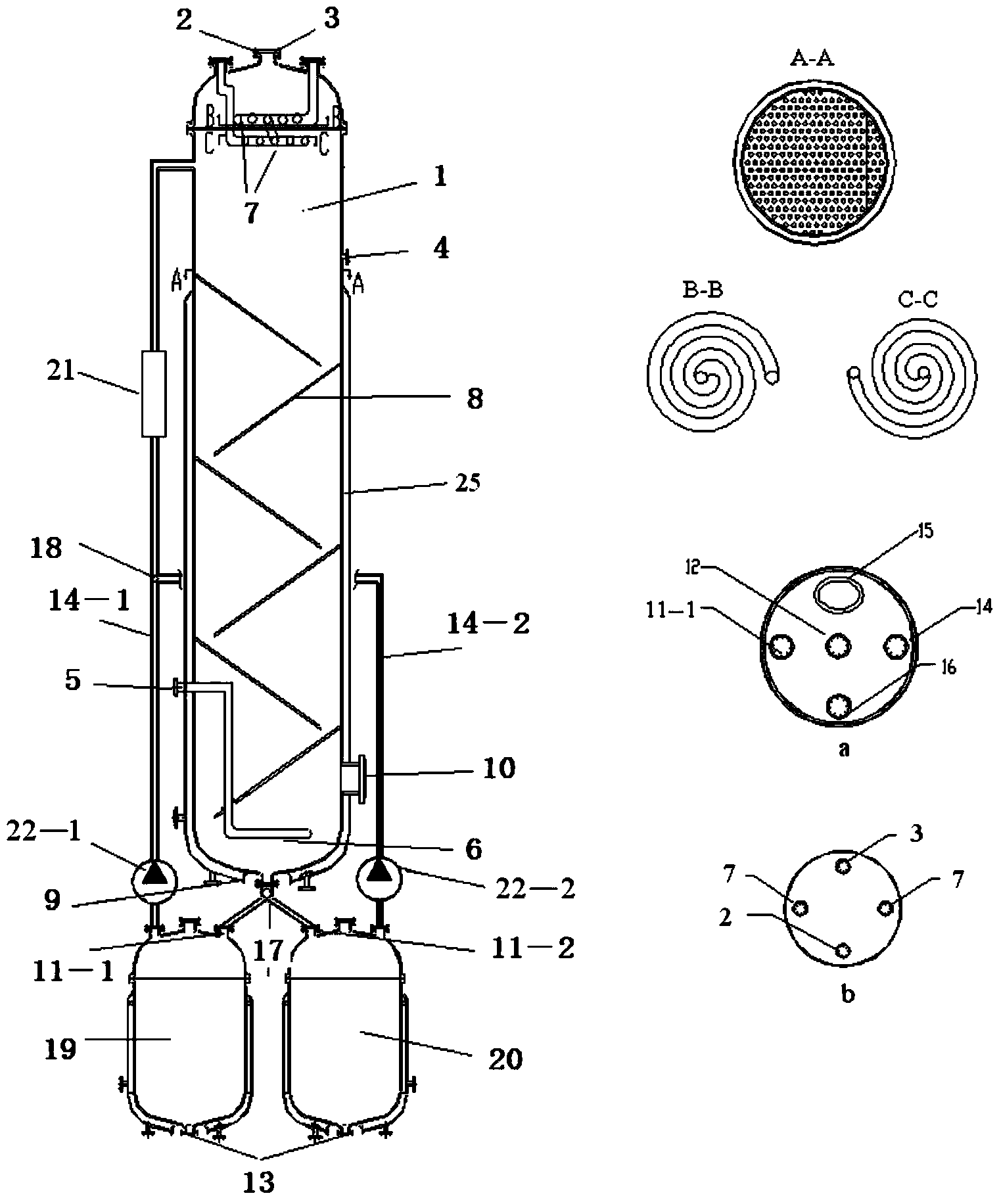

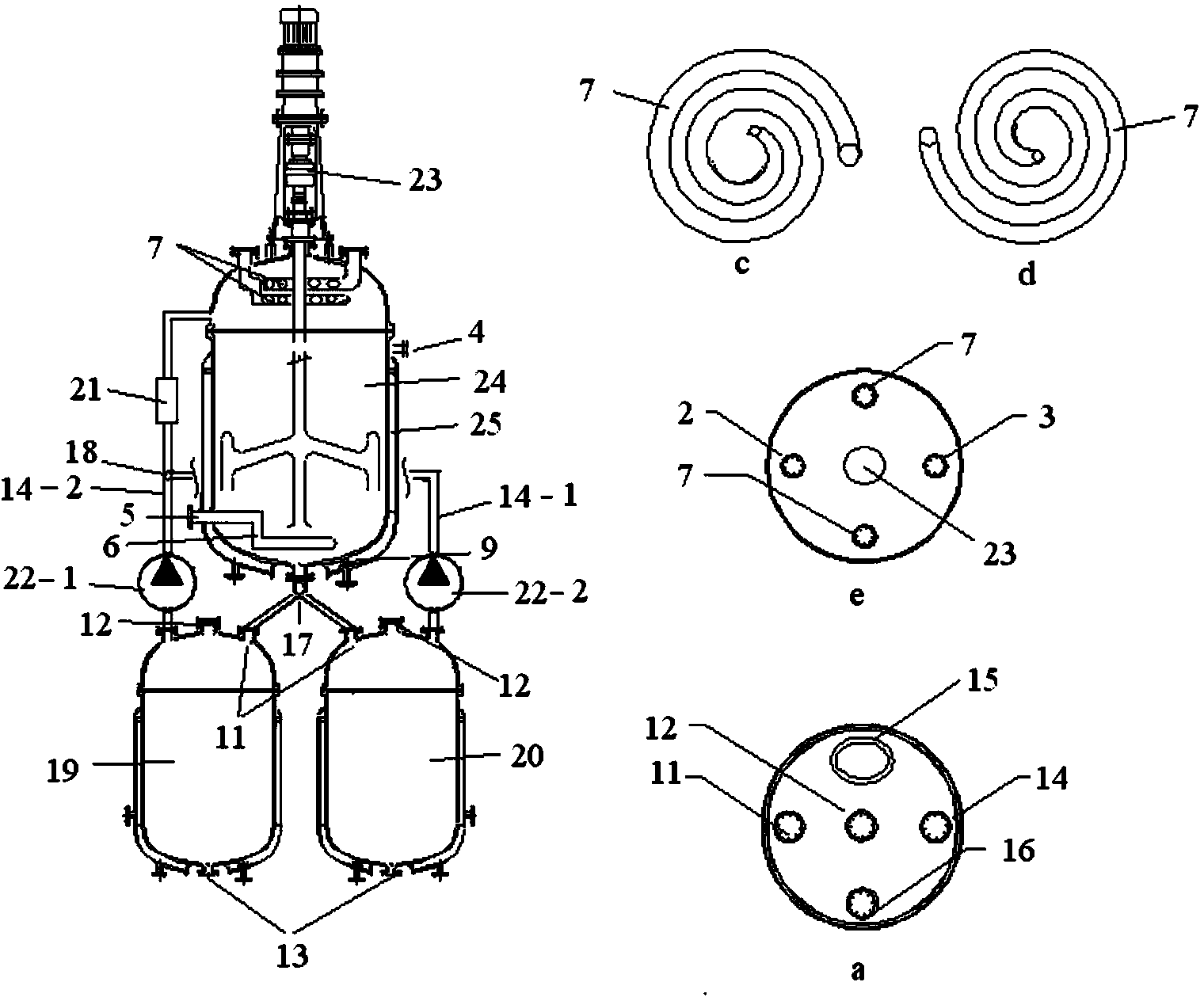

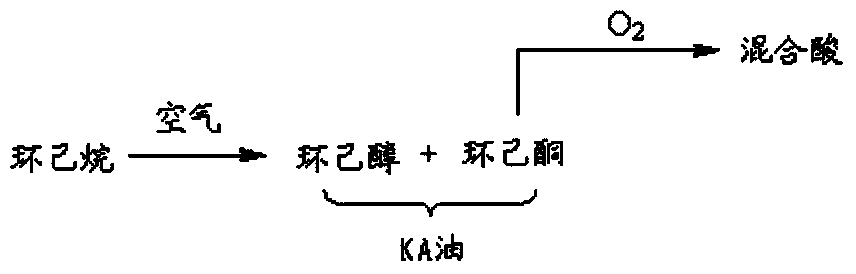

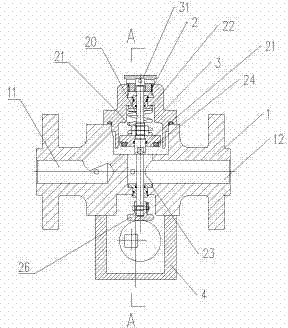

Method for producing adipic acid by oxidizing cyclohexane by utilizing air based on gas-liquid-solid multiphase reaction and separation synchronization reactor

ActiveCN103755543AHigh yieldImprove conversion rateOrganic compound preparationCarboxylic preparation by oxidationGas phaseAdipic acid

The invention discloses a method for producing adipic acid by oxidizing cyclohexane by utilizing air based on a gas-liquid-solid multiphase reaction and separation synchronization reactor. The method is characterized by adding cyclohexane to the gas-liquid-solid multiphase reaction and separation synchronization reactor, wherein the reactor comprises a reaction tower and at least two constant temperature settling towers communicated with the bottom of the reaction tower, and the reaction tower is internally provided with a gas phase zone, an oxidation zone and a gas outlet; during reaction, filling the oxidation zone and constant temperature settling towers with cyclohexane, continuously pumping air from the bottom of the oxidation zone to come into contact with cyclohexane to carry out oxidation reaction, simultaneously enabling generated adipic acid solid to enter the constant temperature settling towers through settling, at the moment, enabling cyclohexane in the constant temperature settling towers to enter the oxidation zone via an external circulation system so that reaction is continuously carried out, enabling adipic acid to continuously settle in the constant temperature settling towers until the constant temperature settling towers are filled with the adipic acid phase, and switching a reaction tower to be communicated with the other constant temperature settling tower filled with cyclohexane, thus alternating the steps to carry out continuous production. The method can be used for continuously producing adipic acid with high conversion rate and high yield, and has the effects of improving the production efficiency and reducing the production cost.

Owner:蚌埠启邦科技信息咨询有限公司

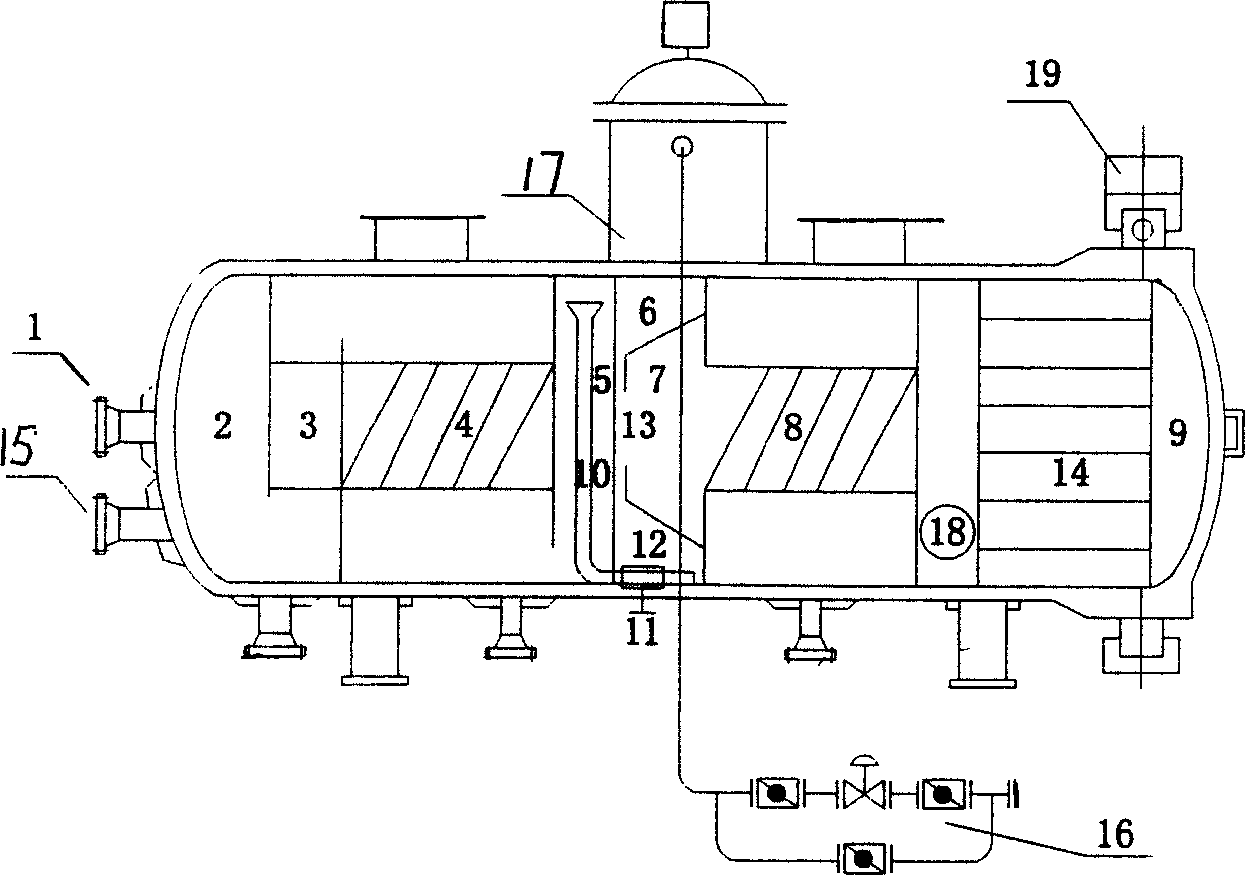

Multifunctional oil-contained waste water treatment device

InactiveCN101139122AExtend the flow lineGuaranteed response timeFatty/oily/floating substances removal devicesLiquid separationProduced waterMultiple function

A multifunctional oily waste disposal plant relates to a waste disposal plant. A horizontal container is designed to comprise a coarse-graining chamber, a first-level inclined plate / pipe oil eliminating chamber, a flocculation reaction chamber and a second-level inclined plate / pipe oil eliminating setting pocket which are communicated with the water according to the treatment order. The flocculation reaction chamber is composed of a cone-shaped second-level reaction chamber and a first-level reaction chamber arranged at the external circumference and a diffusion port of the first-level reaction chamber is communicated with the second-level reaction chamber. A water outlet of the second-level reaction chamber is connected with the second-level inclined plate / pipe oil eliminating setting pocket and a water inlet pipe of the first-level reaction chamber is arranged at the bottom of the cone-shaped second-level reaction chamber in the direction of interior contact; a mixing reactor is arranged on the water inlet pipe. The equipment with a integral structure can be arranged simply, has reasonably arranged structure, has good effect of separating the oil from the water, has long service life and has low running cost, in particular after filtration, the utility model delivers high effluent precision, completely meets the requirement of the produced water reinjection or exhaust and is suitable for the treatment of the oilfield produced water and oily sewage in other industries.

Owner:宜兴市官林锦生泰环保设备有限公司

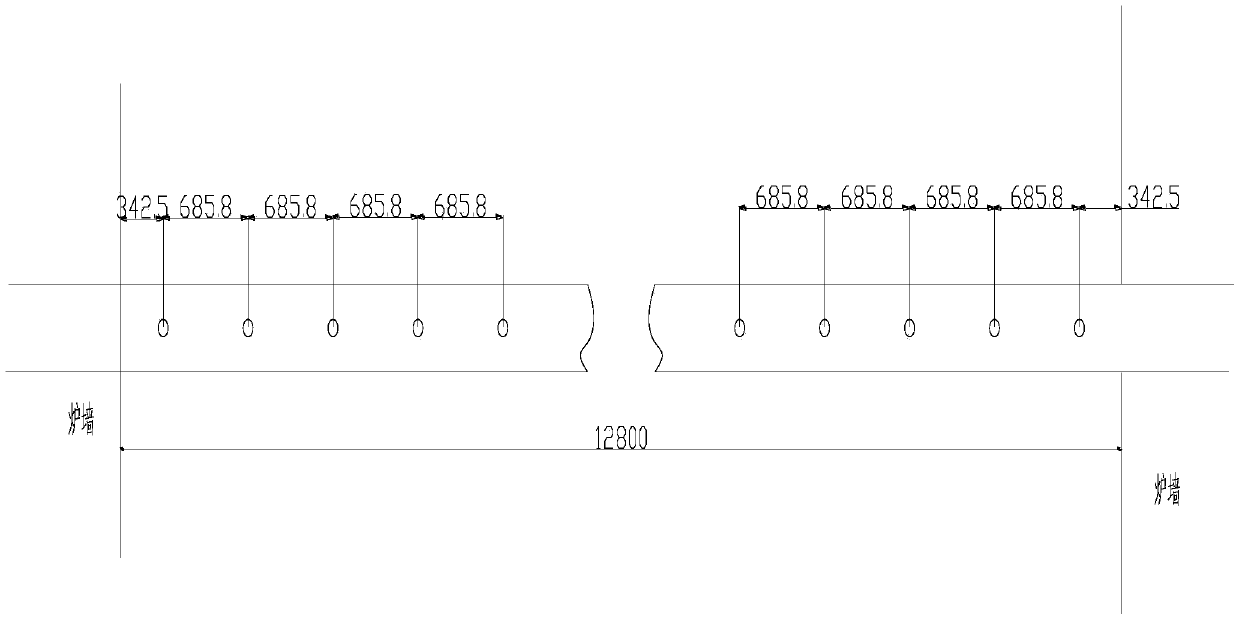

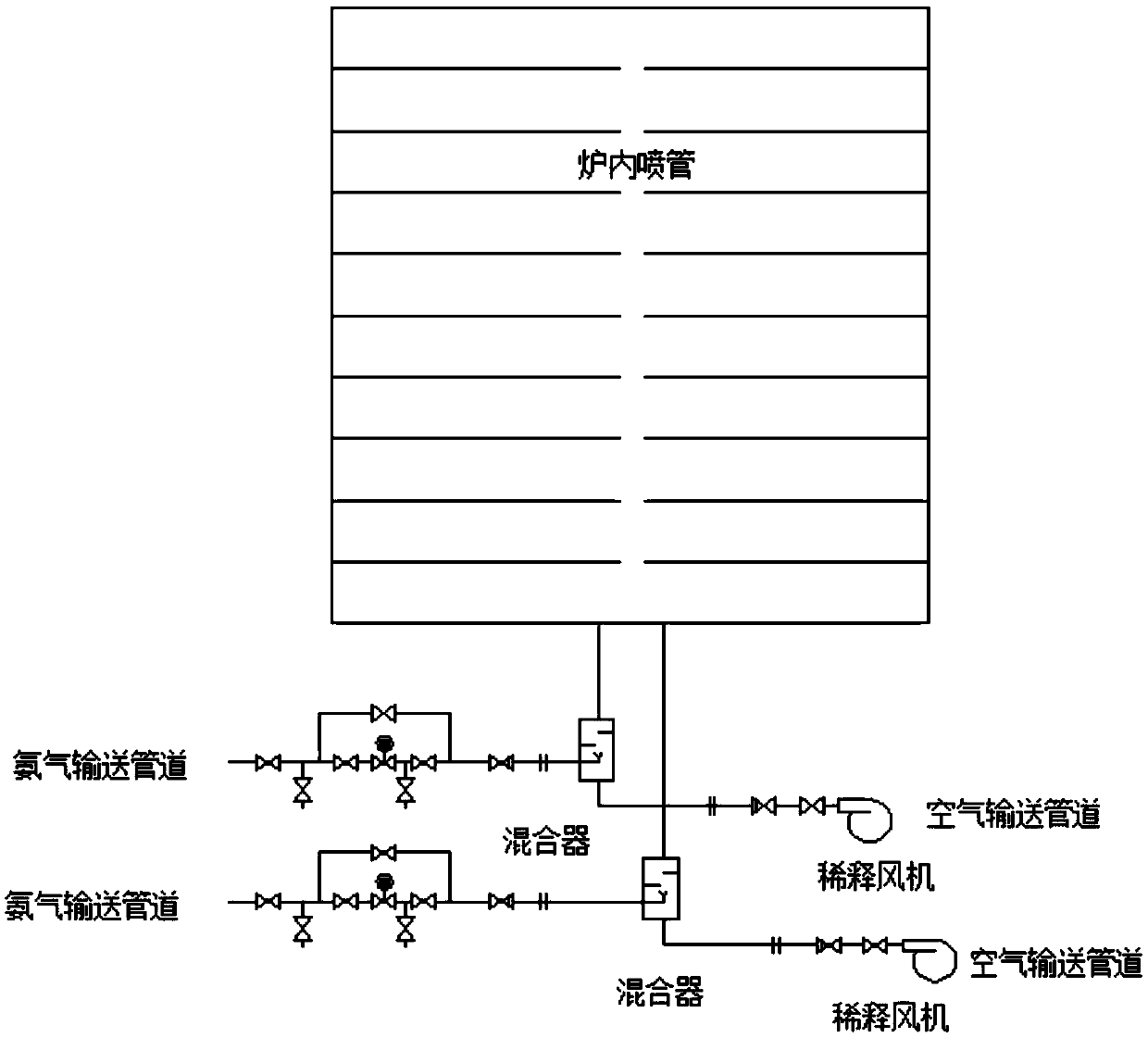

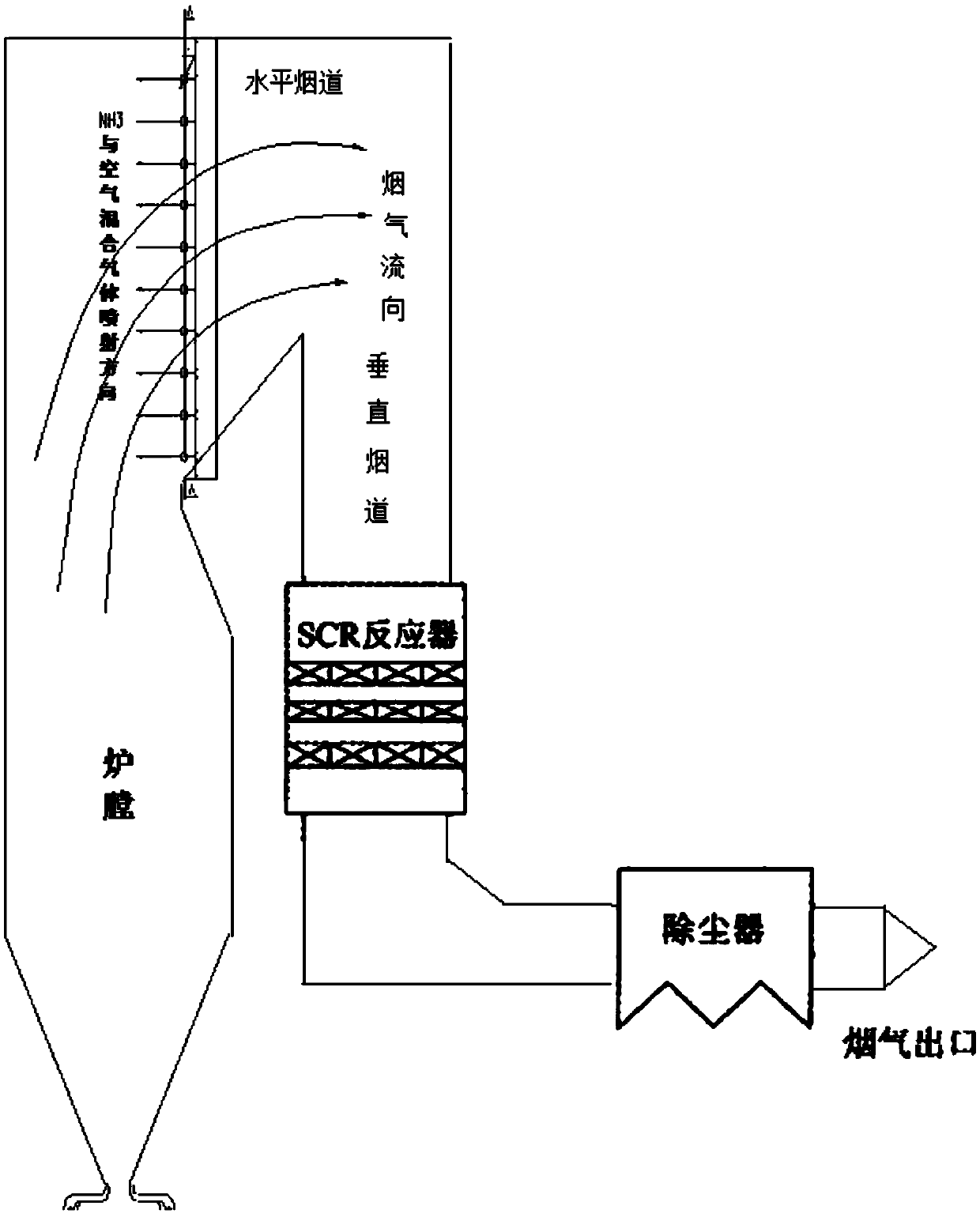

System and process for denitration by spraying ammonia gas in large-sized boiler high-temperature flue gas area

ActiveCN105509081AGuarantee the effect of denitrification onceGuaranteed denitrification effectGas treatmentEmission preventionFlue gasEngineering

The invention belongs to the technical field of flue gas denitration and relates to a system for denitration by spraying ammonia gas in a large-sized boiler high-temperature flue gas area. A boiler comprises a horizontal flue and a vertical flue. The system comprises an SNCR (selective non-catalytic reduction) system provided with a reducing agent injector, the reducing agent injector is a spray pipe disposed on the transverse section of the horizontal flue, an input end of the spray pipe is connected with a reducing agent conveyer, the other end of the spray pipe is closed, and the wall of the spray pipe opposite to flue gas is provided with a spray hole. The invention also discloses a denitration process for denitration treatment using the system, the denitration treatment with the system gives high denitration rate and low ammonia escape quantity as well as full flue gas purification, this product is applicable to present coal-consuming boilers for thermal power generation, iron and steel, chemicals, cements and the like, and satisfactory NOx emission index of these boilers can be ensured.

Owner:杜梦凡

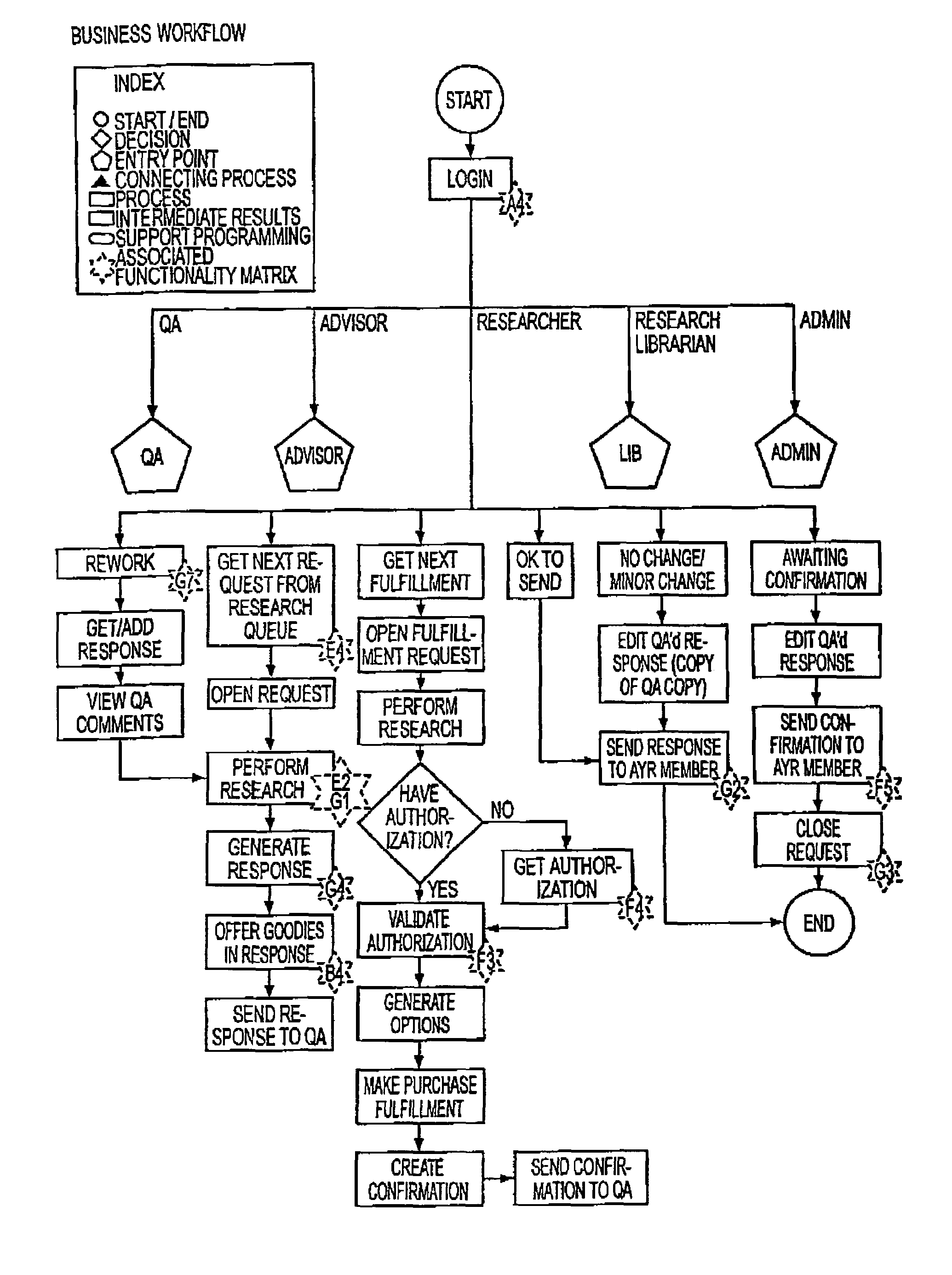

System and method for integrated customer management

InactiveUS7269567B1Low costImprove retentionInterconnection arrangementsDiscounts/incentivesCustomer engagementDatabase

An automated system and method for customer management deploys customer databases to profile customer service requests for distribution to appropriately assigned agent representatives. The representatives adopt particular roles according to customer care volume, inquiry type, time of day and other customer management needs. Consumer profiles may be accessed in real time to combine customer care events with cross-selling and other promotions related to the consumer's transaction history and other factors.

Owner:JPMORGAN CHASE BANK NA

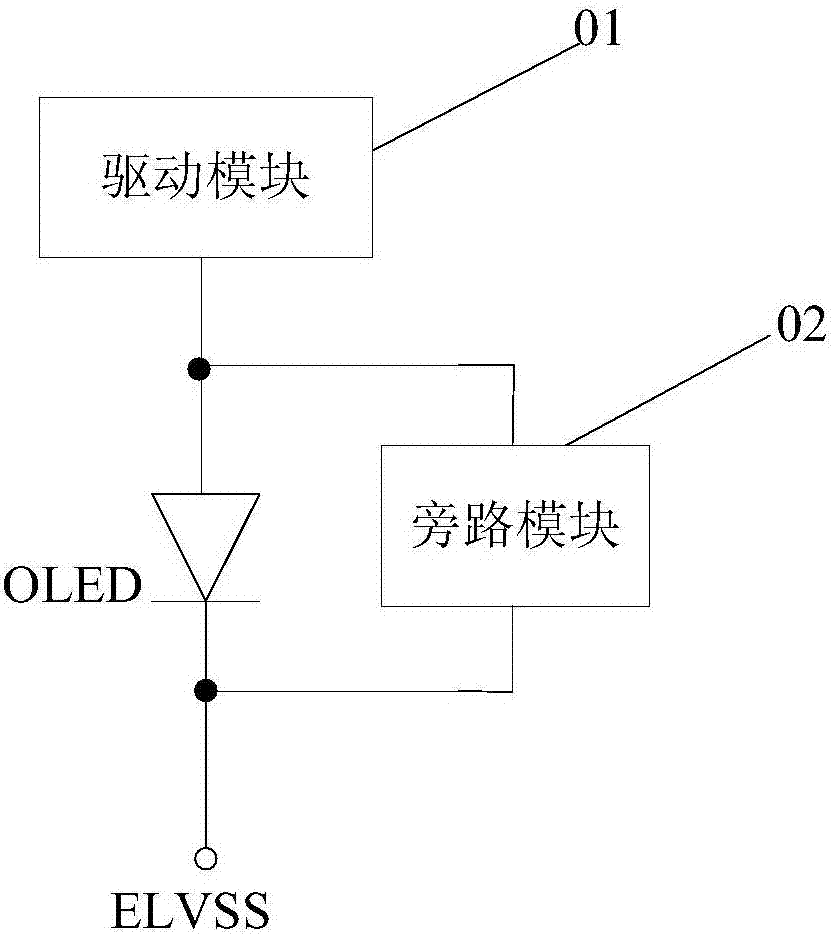

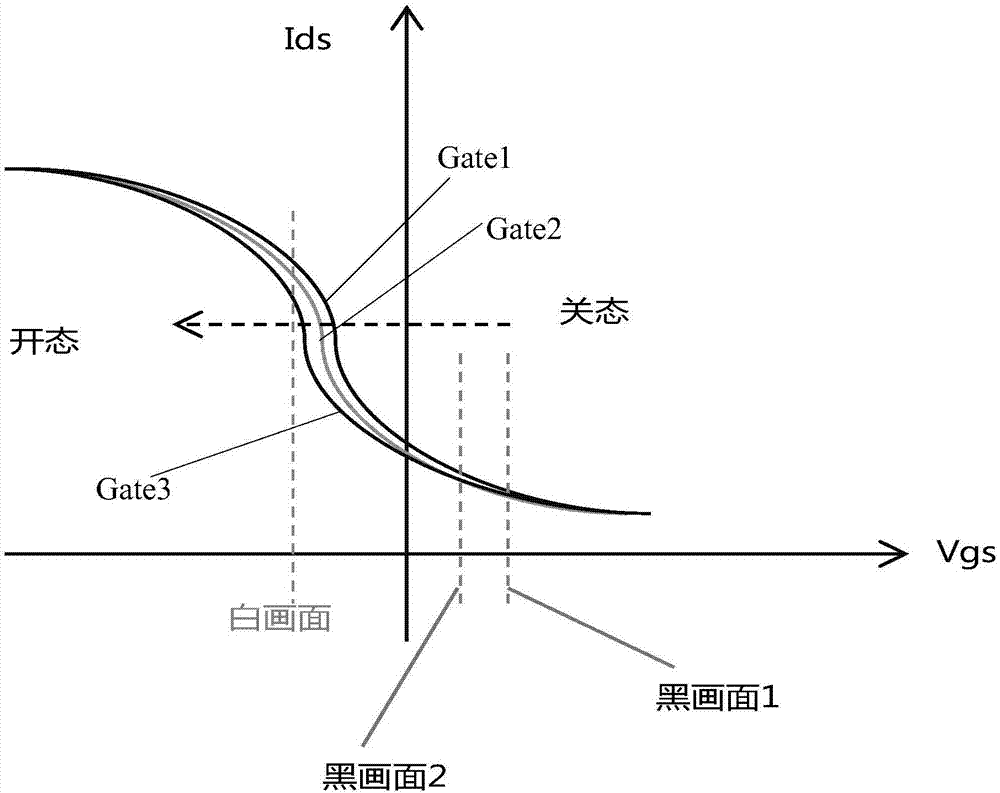

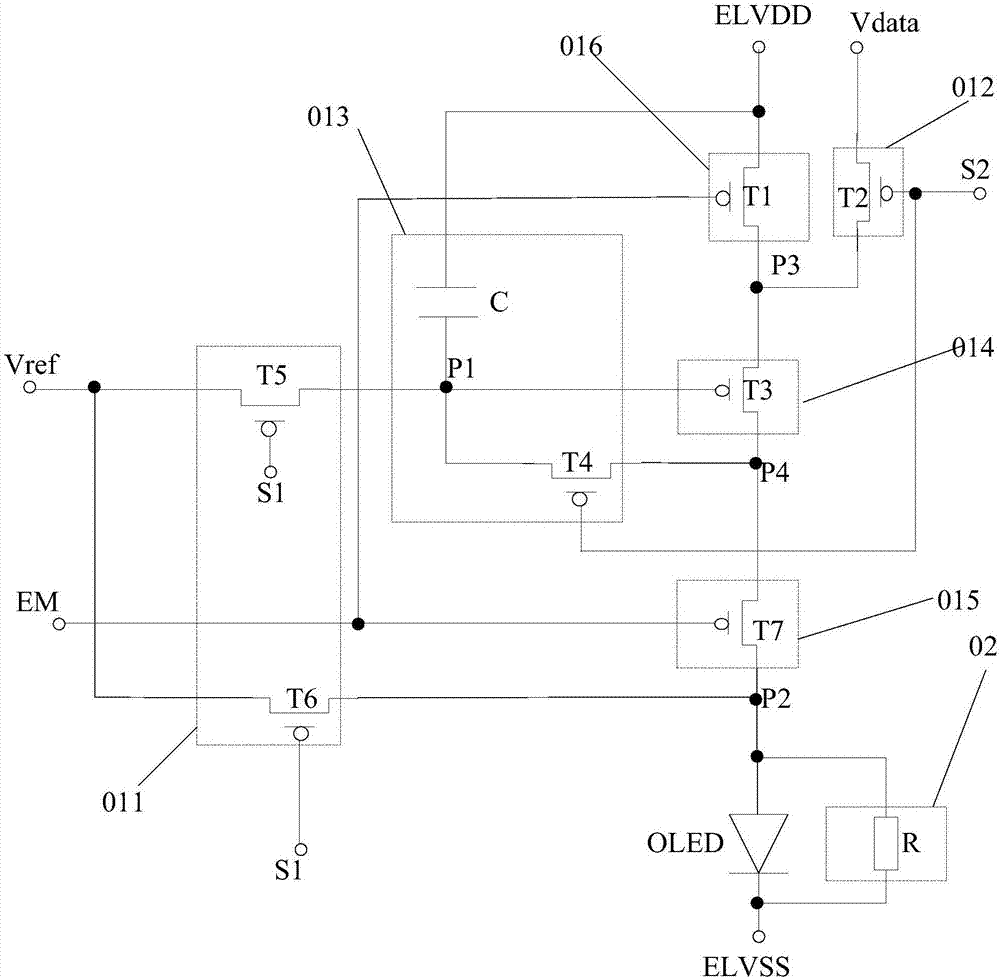

Pixel circuit and display panel

InactiveCN107170409AEnsure dark state display brightnessReduce brightnessStatic indicating devicesDriving currentPower flow

The invention discloses a pixel circuit and a display panel. The pixel circuit comprises a driving module, a bypass module and a light emitting device. The driving module is used to input driving current to the input end of the light emitting device to drive the light emitting device to emit light. The bypass module is connected between the input end and the output end of the light emitting device, and is used to shunt the driving current input by the driving module to the light emitting device. The off-state voltage of the driving module can be set to be smaller, so that the driving module in a dark state can output trace current to protect response time, improve response speed and improve a hysteresis effect. The bypass module is connected between the input end and the output end of the light emitting device, and then the current through the light emitting device is small through the shunt of the bypass module. The brightness of the light emitting device in a dark state is dark enough to ensure that the dark state display brightness of the display panel.

Owner:BOE TECH GRP CO LTD +1

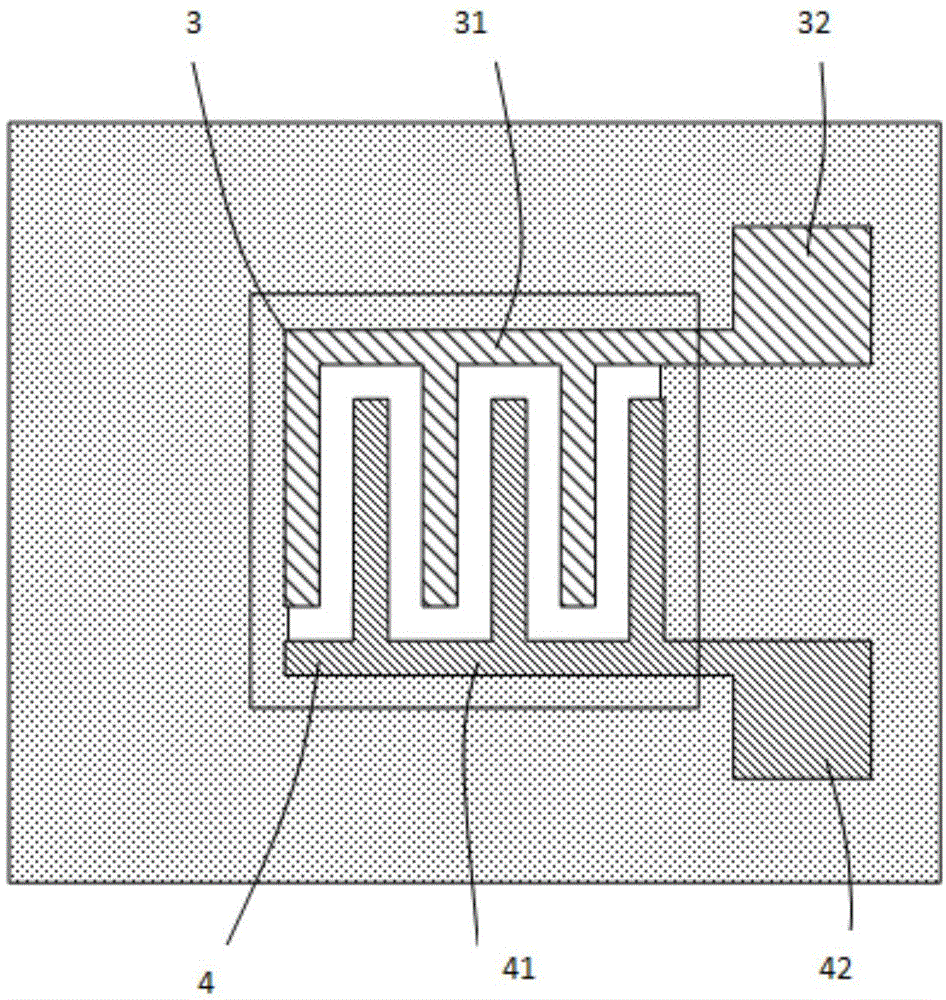

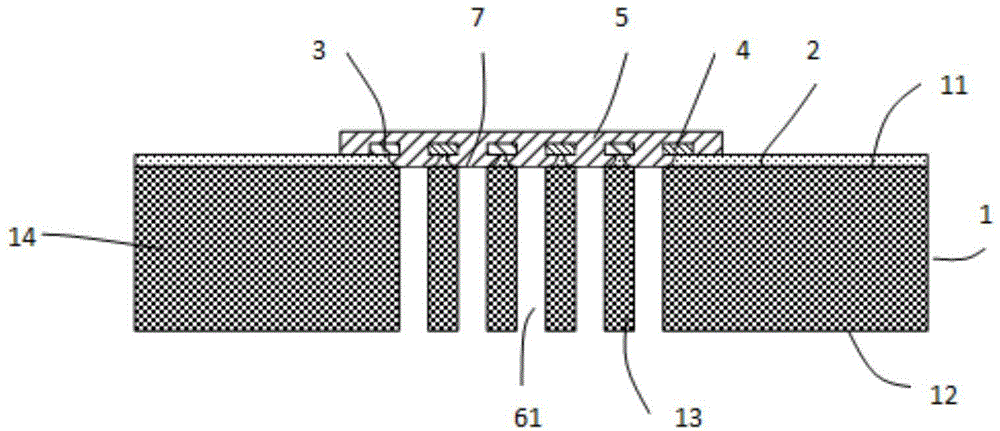

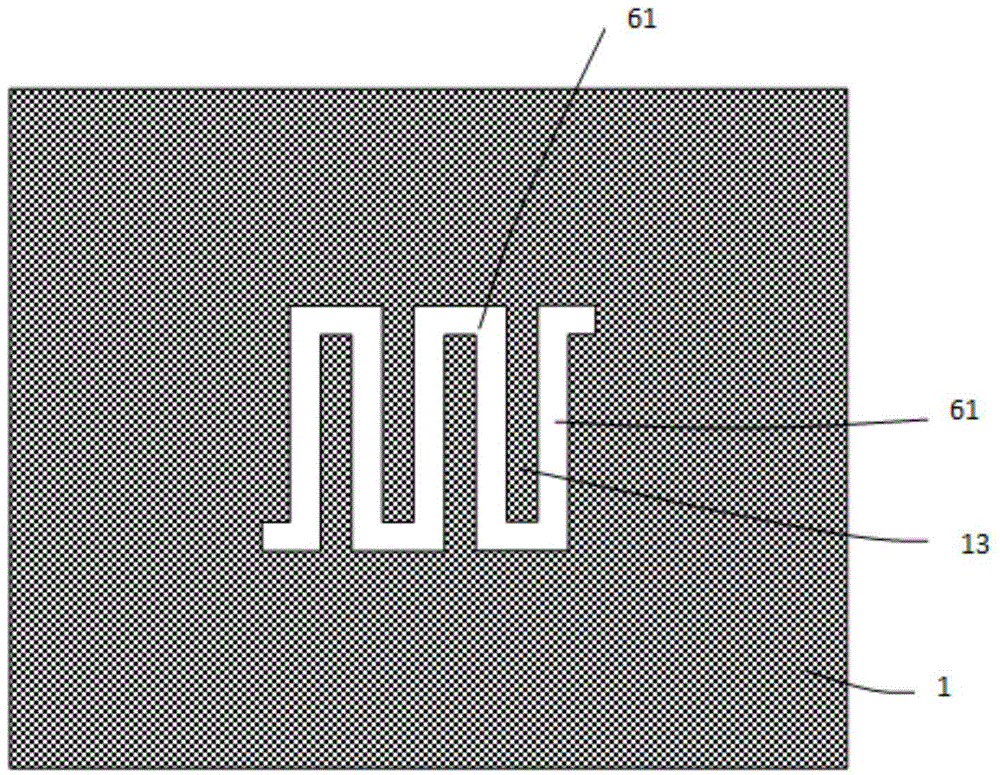

CMOS MEMS capacitance-type humidity sensor and preparation method thereof

The invention relates to a CMOS MEMS capacitance-type humidity sensor and a preparation method thereof, and belongs to the technology of a semiconductor chip. A plurality of air subchannels are formed on a substrate in orthographic projection of a humidity sensing medium layer, the sensitivity of the sensor can be improved and the response time can be shortened by virtue of the air subchannels; moreover, a supporting column is formed between two adjacent air subchannels, so that the strength of a sensitive device area can be improved by virtue of the supporting column, the cracking of the humidity sensor in real application can be prevented, and under the situation that the sensitivity and the response time of the humidity sensor are guaranteed, the structural strength of the humidity sensor is improved; the CMOS MEMS capacitance-type humidity sensor formed by adopting the method is provided with the air subchannels and the supporting column, so that the structural strength of the capacitance-type humidity sensor can be improved under the situation that the sensitivity and the response time of the capacitance-type humidity sensor are guaranteed.

Owner:苏州工业园区纳米产业技术研究院有限公司

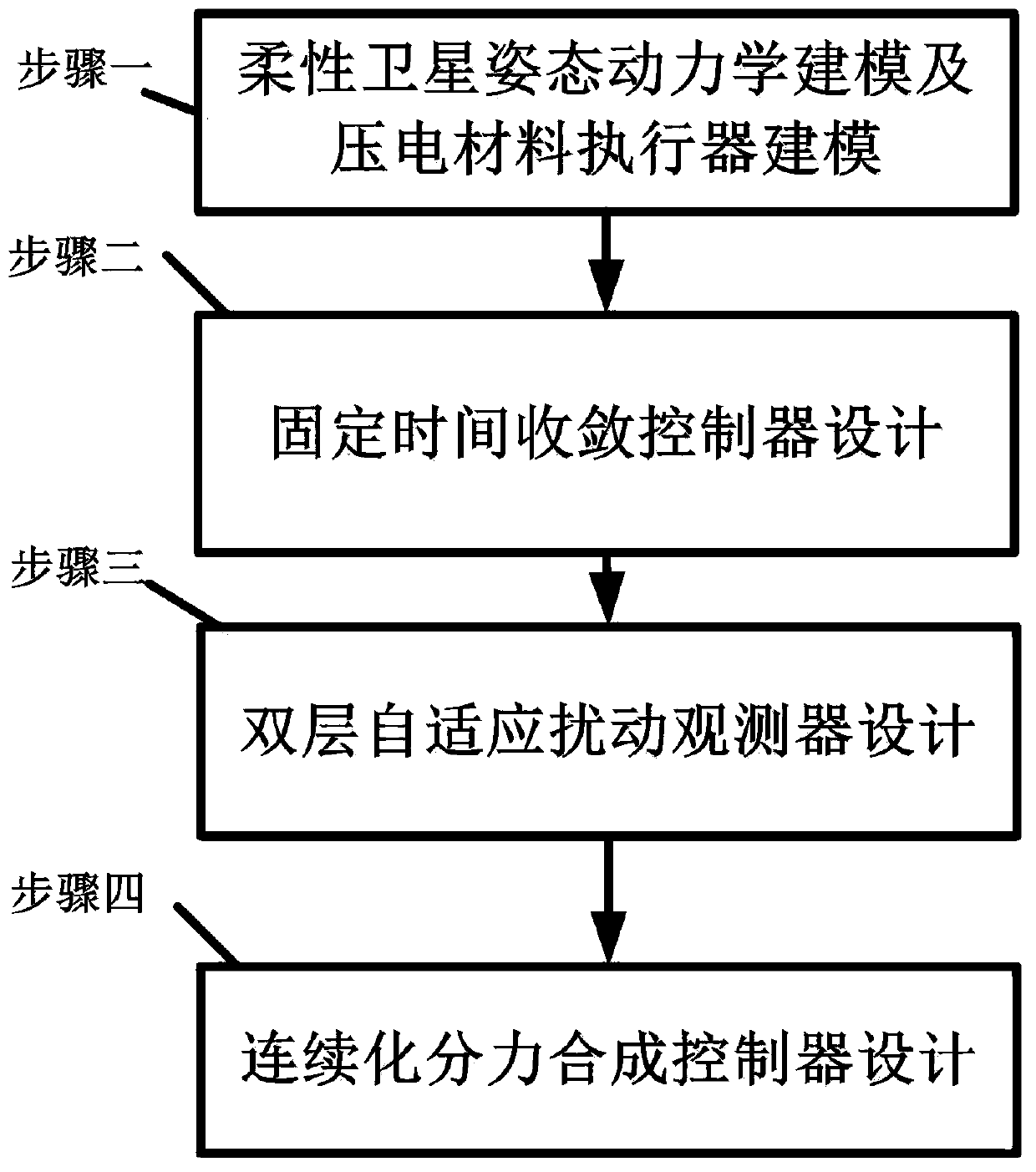

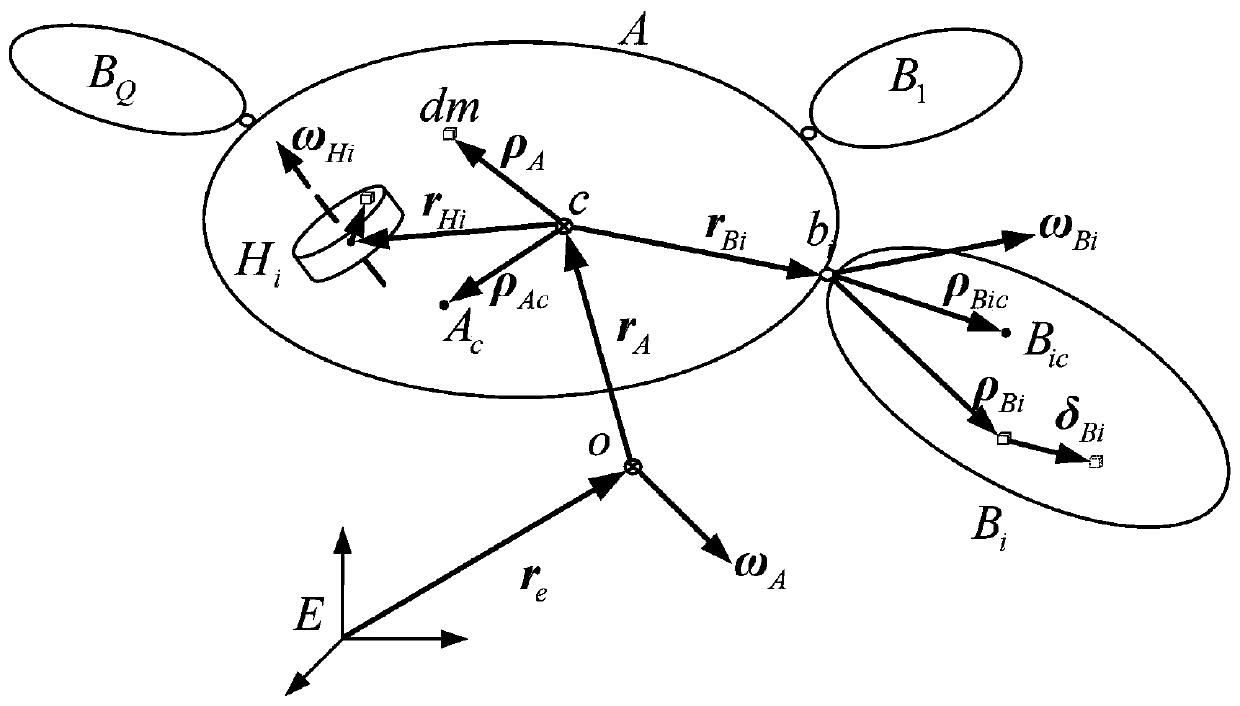

Flexible satellite active vibration suppression method based on component force synthesis and fixed time convergence

ActiveCN110733668ASuppression of elastic vibrationsImprove attitude control accuracyCosmonautic vehiclesSustainable transportationLoop controlDynamic models

The invention discloses a flexible satellite active vibration suppression method based on component force synthesis and fixed time convergence. The flexible satellite active vibration suppression method comprises the following steps of step 1, establishing a flexible satellite attitude dynamics model with two pairs of large solar panels, and simultaneously establishing a dynamic model of a piezoelectric intelligent material actuator; step 2, designing a fixed time convergence sliding mold controller; step 3, designing a disturbance observer for ensuring a double-layer self-adaptive law with fixed time convergence characteristics; and step 4, outputting a dynamic model of the piezoelectric intelligent material actuator, implementing processing by adopting a continuous component force synthesis control idea, generating a new control torque command to be applied to a flexible accessory to counteract the influence of elastic vibration, and ensuring the attitude stability of a satellite body. The flexible satellite active vibration suppression method has the advantages of high attitude control precision and strong robustness. Meanwhile, a continuous component force synthesis method is introduced into a closed-loop control process through a piezoelectric sheet attached to the flexible accessory, vibration is inhibited, and the system interference is reduced.

Owner:SUN YAT SEN UNIV

Method for producing KA oil through oxidizing cyclohexane by using air on basis of gas-liquid-solid heterogeneous reaction separation synchronization reactor

ActiveCN103755521AHigh yieldReduce the effect of settling velocityPreparation by oxidation reactionsOrganic compound preparationGas phaseOil phase

The invention discloses a method for producing KA oil through oxidizing cyclohexane by using air on the basis of a gas-liquid-solid heterogeneous reaction separation synchronization reactor, wherein the water-containing cyclohexane is added into the reactor, the reactor comprises a reaction tower and at least two constant temperature settlement towers communicated with the bottom of the reaction tower, and the reaction tower is internally provided with a gas phase area, an oxidization area and a gas outlet; the oxidization area and the constant temperature settlement towers are filled with the cyclohexane in the reaction, the air is introduced continuously from the bottom of the oxidization area and is in contact with the cyclohexane to carry out the oxidization reaction, meanwhile, the produced KA oil is blended with water to form a KA oil phase, the KA oil phase is settled into the constant temperature settlement tower, the cyclohexane in the constant temperature settlement tower at the moment enters the oxidization area through an external circulation system, so that the reaction is conducted continuously, the KA oil phase continues to settle in the constant temperature settlement tower until the constant temperature settlement tower is fully filled the KA oil phase, then the reaction tower is switched to be communicated with the other constant temperature settlement tower filled with the cyclohexane, the operation is conducted on the constant temperature settlement towers alternatively to continuously produce the KA oil. The method is used to continuously produce the KA oil with high percent of conversion and high selectivity, the production efficiency is improved, and the production cost is lowered.

Owner:新疆普禾粟新型环保材料有限公司

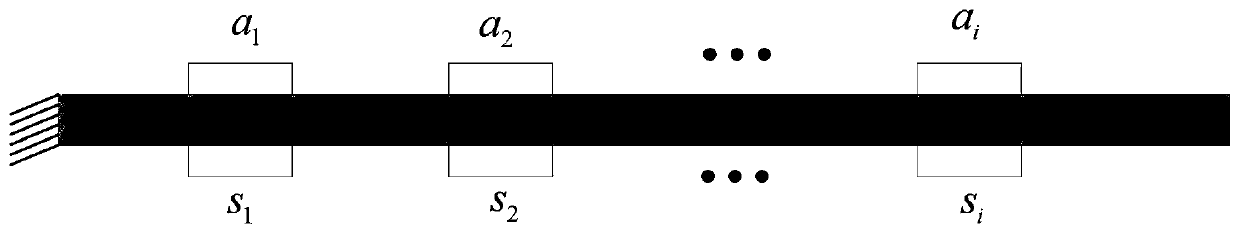

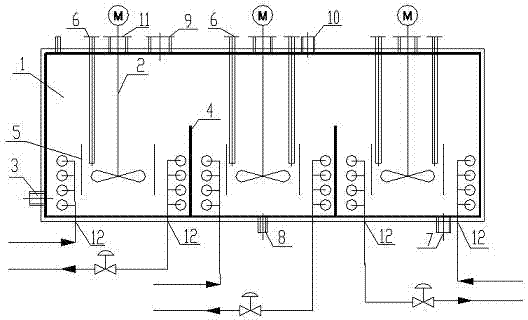

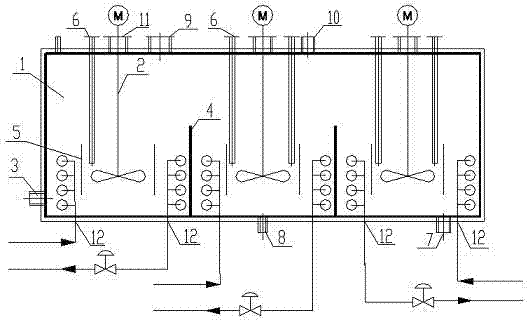

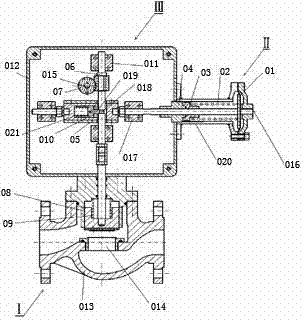

Second esterification reactor in continuous production device of poly (trimethylene terephthalate)

InactiveCN102311541AGuaranteed response timeGuaranteed sequential flowPolyethylene terephthalateRetention time

The invention provides a second esterification reactor in a continuous production device of poly (trimethylene terephthalate) (PTT), comprising a reactor autoclave body, wherein, the reactor autoclave body is horizontal and provided with one or more separator plates inside, the separator plates separate the inner space of the reactor autoclave body into at least two cavities, each cavity has same or different length with other cavity, the bottom of the separator plate is provided with a through hole or a gap for the circulation of the materials, the upper edge of the separator plate is apart from the inner wall of the upper portion of the reactor autoclave body with a spacing, partial or all cavities are correspondingly provided with additive conduits and stirrers, and the reactor autoclave body is provided with a jacket and / or a heating coil. According to the invention, the retention time of the esters in different cavity is controllable, so that the esterification degree is controlled, and by adding various additives in the esters with different esterification degree in different cavity, the product quality is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

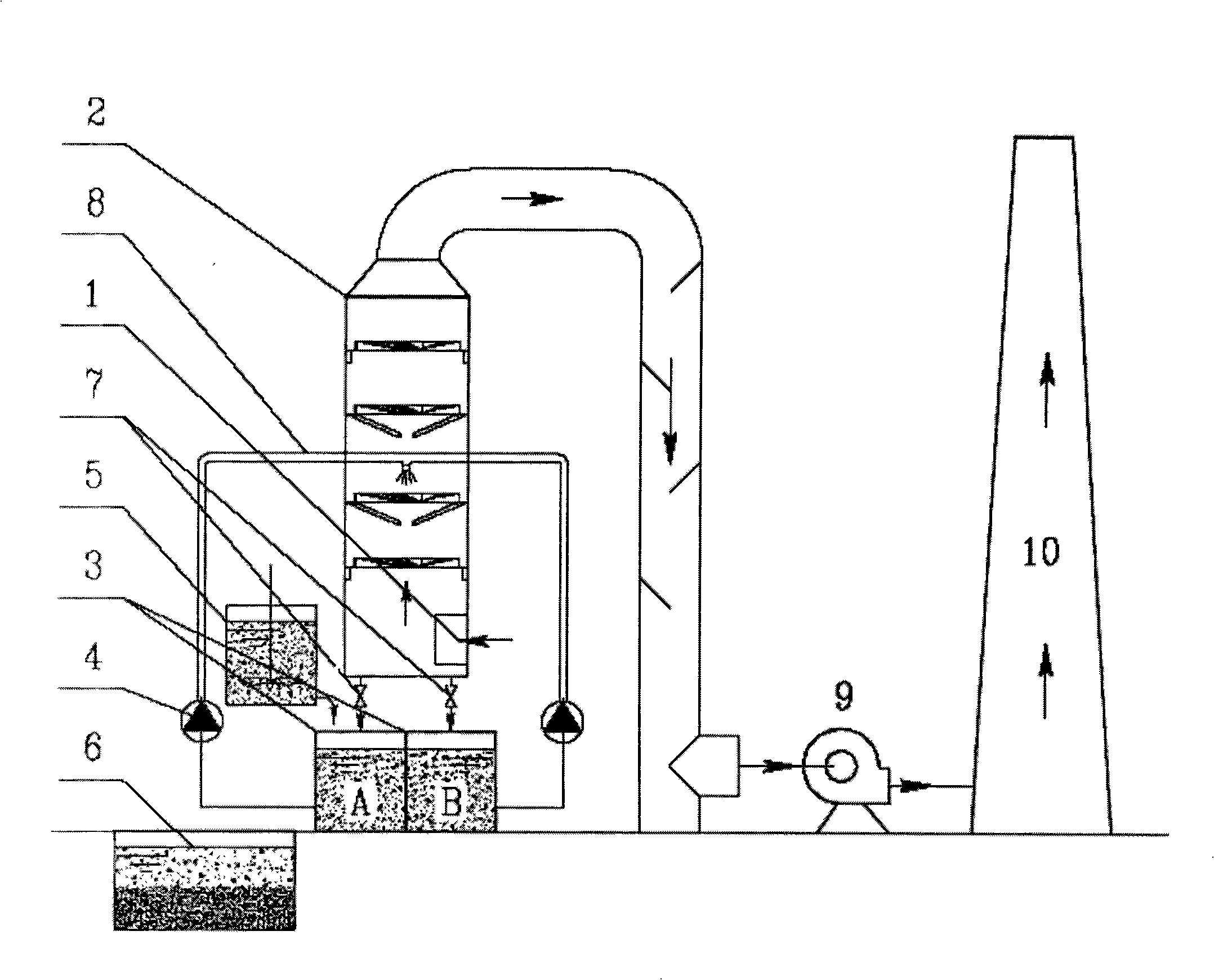

Sequencing batch limestone slurry wet desulfurization technique

InactiveCN101327395ASimple crafting systemLow by-product disposal requirementsDispersed particle separationSlagPH decrease

The present invention provides an order-batch-mode limestone mortar wet desulphurization process, in particular relates to a high-efficient limestone desulphurization process that adopts the limestone mortar as the desulphurization agent, and adopts the order-batch alternative absorption reaction, and adopts the high-efficient desulphurization tower as the desulphurization device, and adopts lower pH value, lower liquid-gas ratio and economical desulphurization rate, and adopts the desulphurization waste slag as the byproduct. Smoke enters into the high-efficient desulphurization device, and a group of limestone mortar is adopted as absorption agent for the smoke to be desulphurized, until the pH value is decreased to a pre-determined value, and the smoke is temporarily withdrawn and the absorption is stopped; the absorption solution is continued to be reacted with the tiny particle of CaCO3, until the pH value is returned to the original value, and then another group of limestone mortar is filled to be desulphurized until the pH decreases to the pre-determined value; the mortar is filled at one group by another group for alternative absorption and after the mortar is reacted with the CaCO3, a new group of limestone mortar is replaced; the waste mortar is discharged after being processed; the waste slag is processed after being dehydrated. The order-batch-mode limestone mortar wet desulphurization process saves the investment, and has low operation expense, and is simple to be operated and managed, and has wide application, and resolves the scale formation problem of the tower and pool.

Owner:贡有成

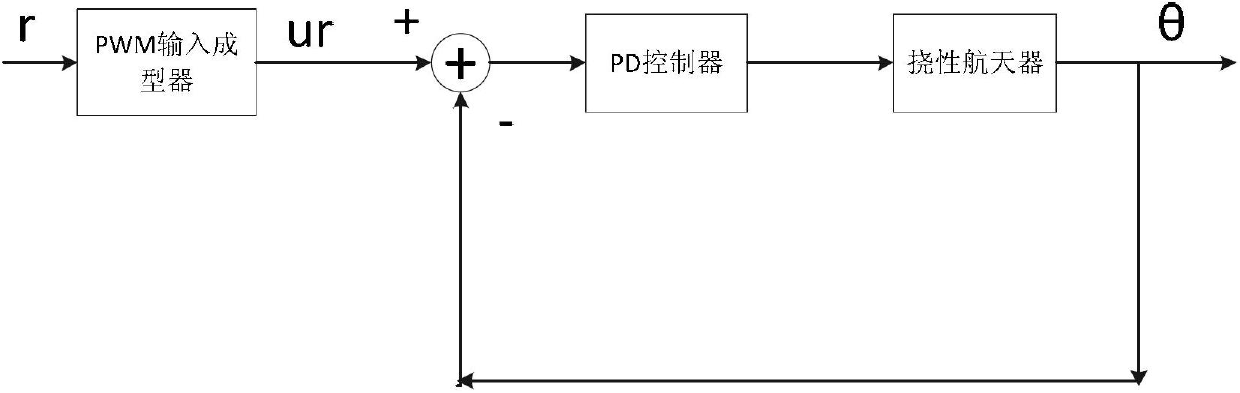

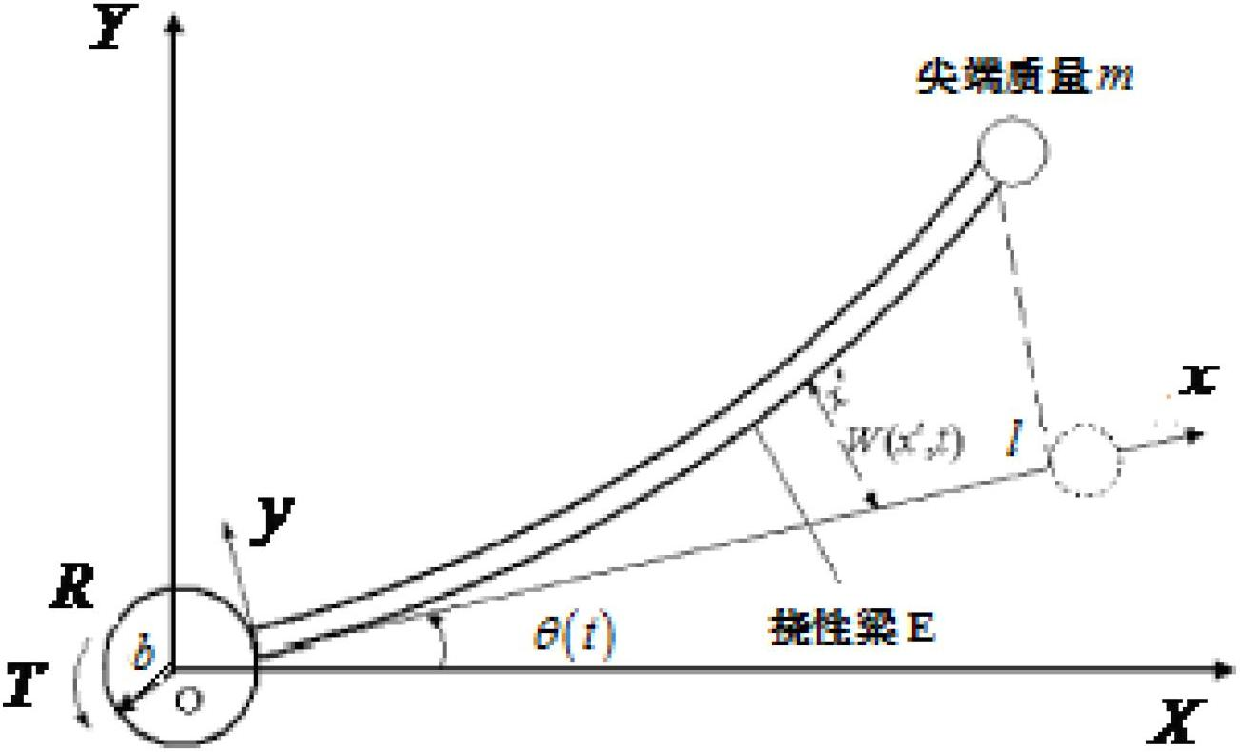

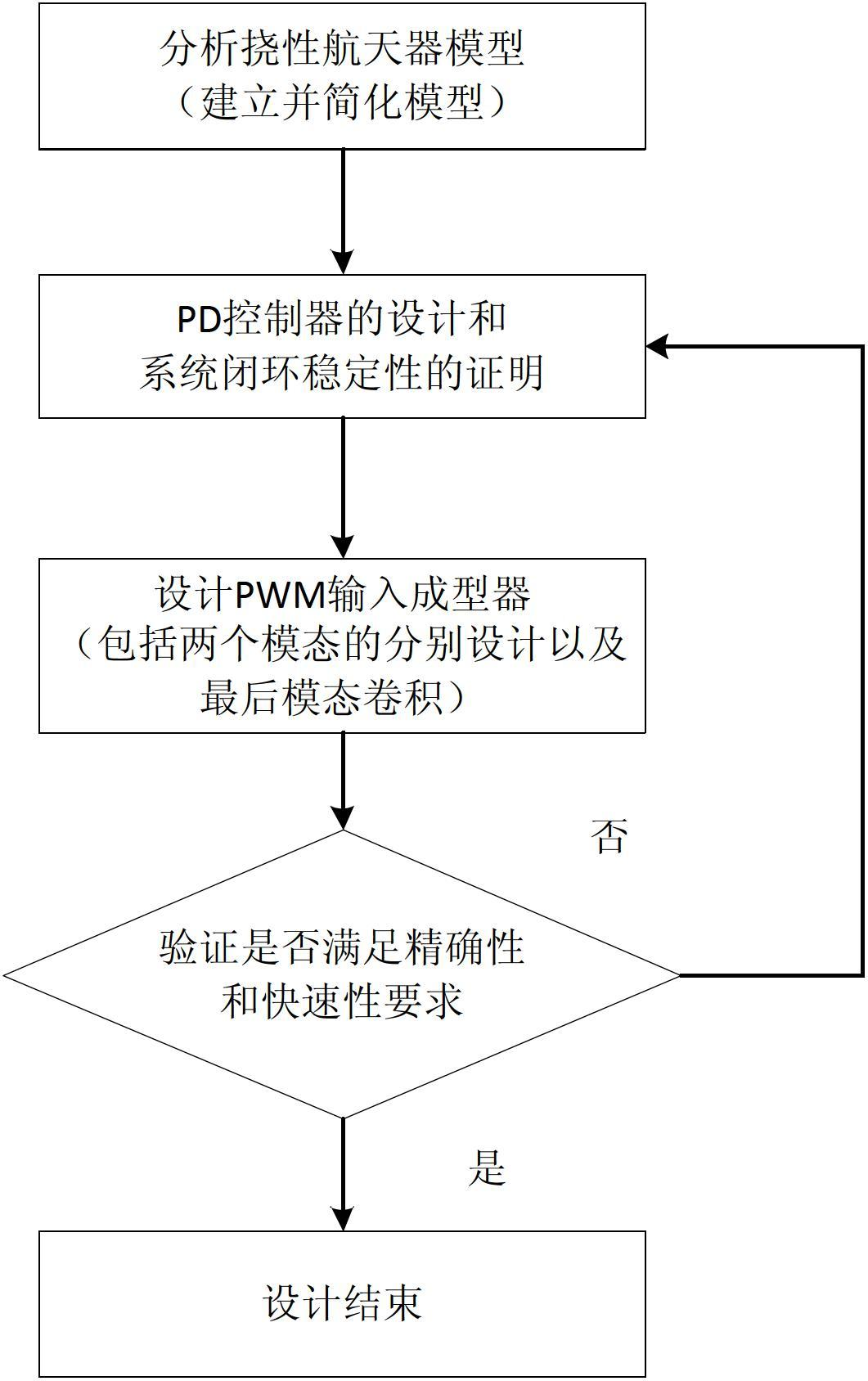

Method for controlling flexible spacecraft based on ZVDD and PWM (pulse-width modulation) mixing input former

InactiveCN102654773AReduce flex vibrationAccurate trackingAttitude controlAdaptive controlAutomatic controlSpace vehicle control

The invention relates to a method for controlling a flexible spacecraft based on a ZVDD and PWM (pulse-width modulation) mixing input former. The method comprises the following five steps of: step 1, analyzing and constructing the flexible spacecraft system model; step 2, designing a PD controller of the flexible spacecraft and analyzing the stability of the PD controller of the flexible spacecraft; step 3, designing a ZVDD and PWM mixing input former; step 4, verifying tracking performance; and step 5, finishing the design. According to the method for controlling the flexible spacecraft based on the ZVDD and PWM mixing input former, disclosed by the invention, a posture angle of the spacecraft is used for being controlled by aiming at a large flexible spacecraft system; and the method for controlling the flexible spacecraft based on the ZVDD and PWM mixing input former, disclosed by the invention, has better practical value and a wide application prospect in an aerospace automatic control technical field.

Owner:BEIHANG UNIV

Concurrent high-sulfur bauxite desulfurization roasting process and device

PendingCN111170346AIncrease contact timeGuaranteed dynamic propertiesAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationFlue gasProcess engineering

The invention discloses a concurrent high-sulfur bauxite desulfurization roasting process and device. The process comprises the steps of grinding, weighing and feeding, drying, primary suspension desulfurization roasting, secondary suspension desulfurization roasting, desulfurization roasting dust collection, cyclone cooling, cooling and dust removal and the like. According to the invention, a flue gas and material concurrent manner is adopted in the desulfurization roasting section, the contact time of the material and high-temperature flue gas in a proper reaction temperature interval rangeis prolonged, the dynamic characteristic of the high-sulfur bauxite desulfurization reaction is ensured, no return material is generated in the technological process, and the method has the characteristics of good desulfurization effect, low production cost, stable product quality and high production efficiency.

Owner:贵州正道实业有限公司

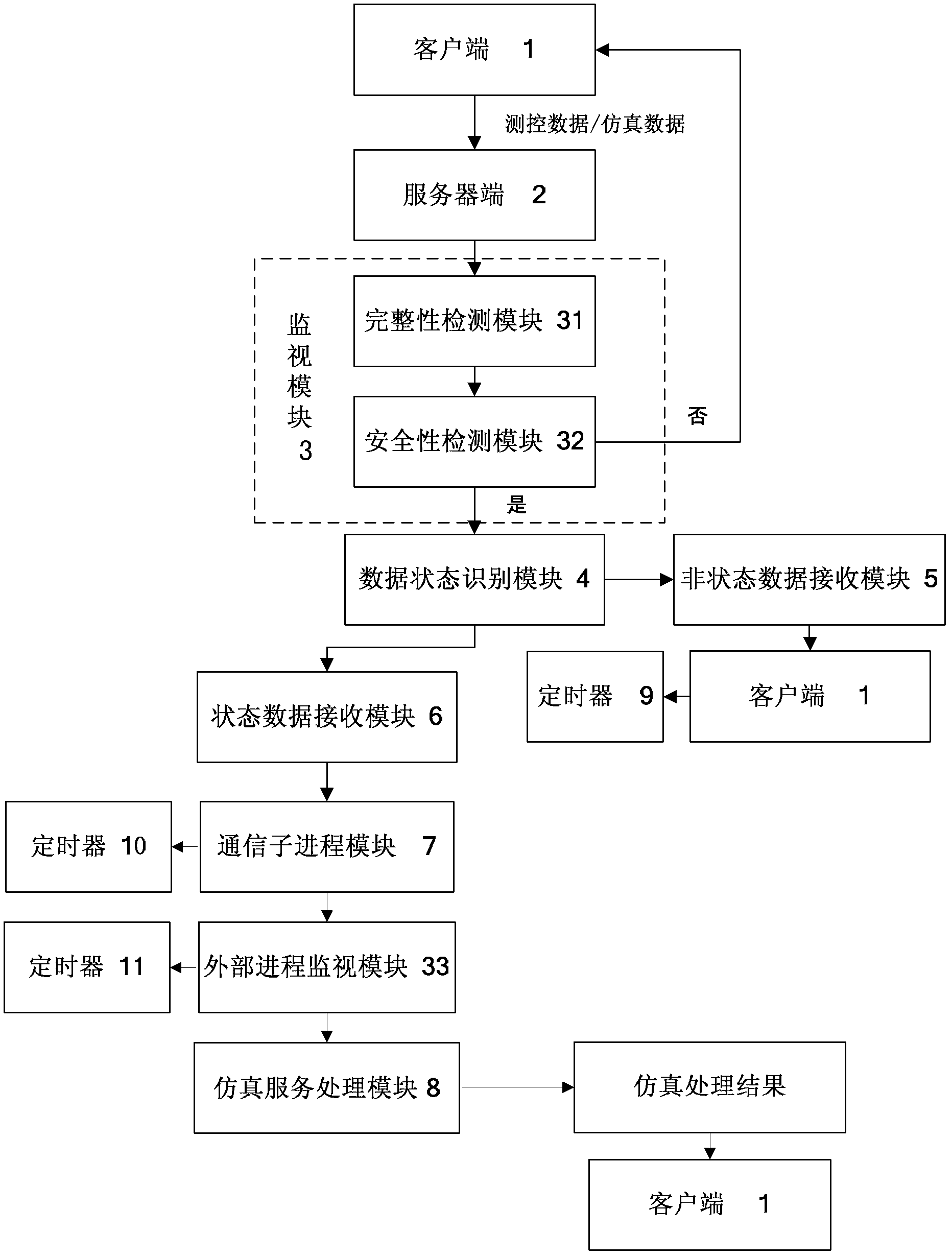

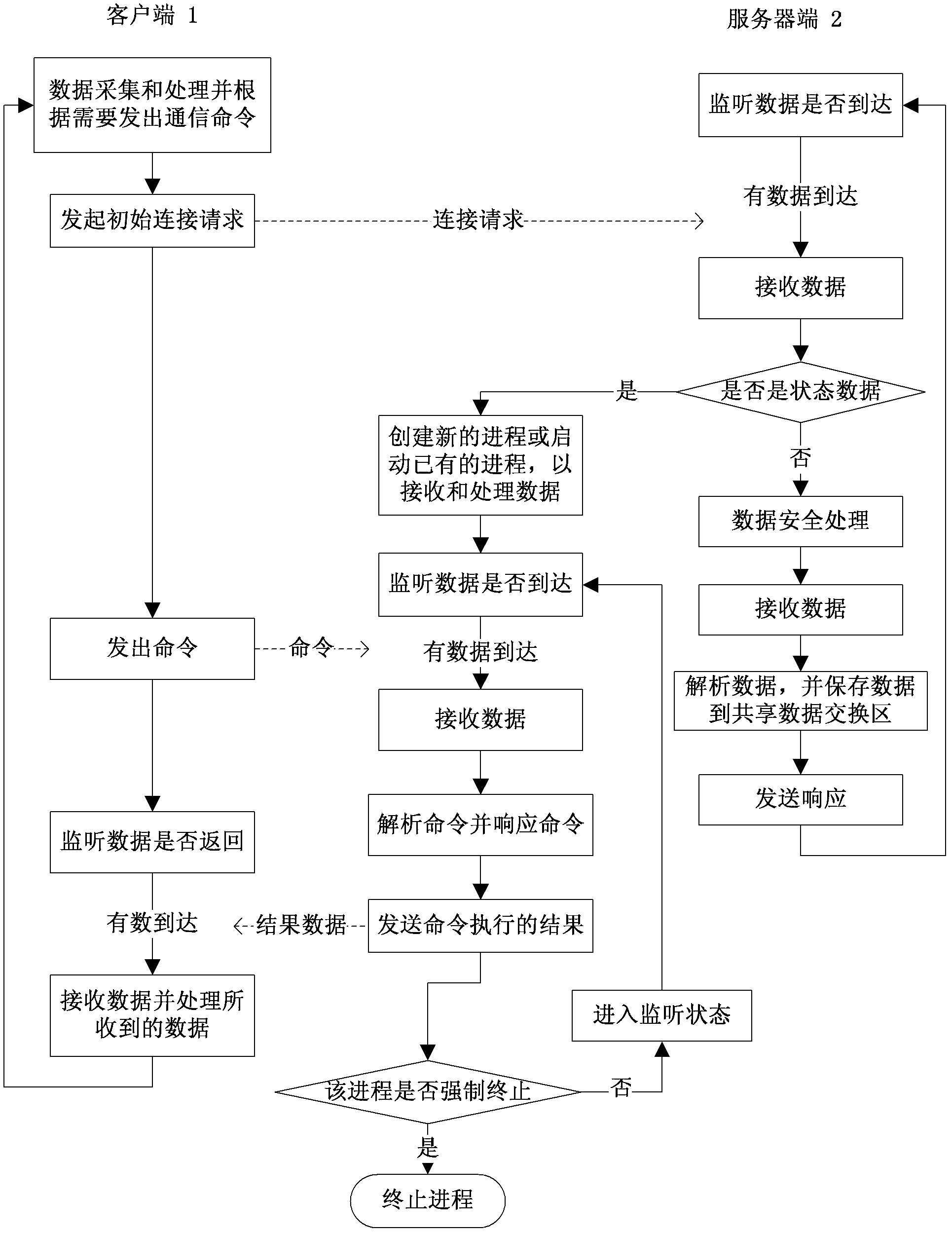

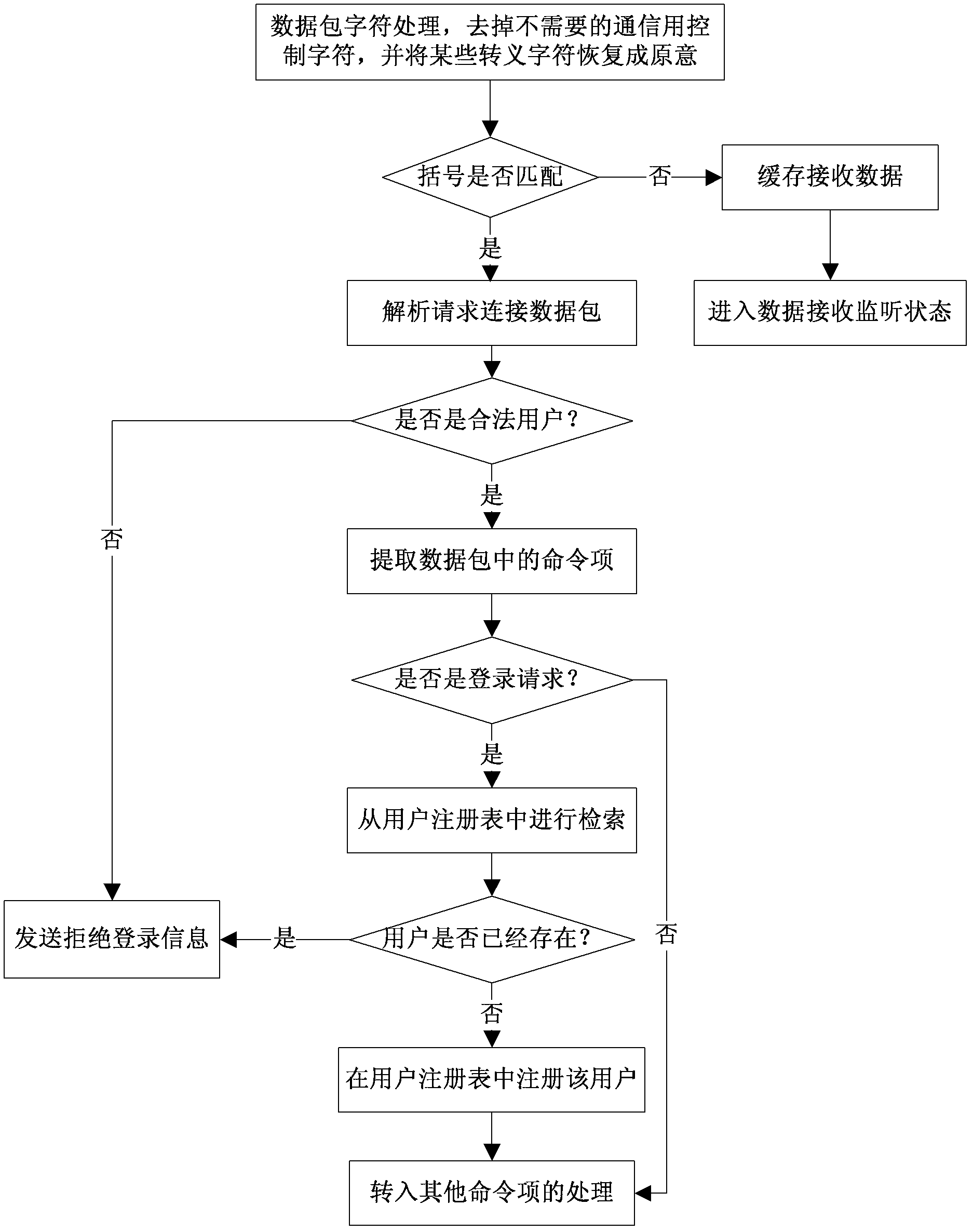

Communication system for transmitting simulation data

InactiveCN102325156ASolve the problem of infinite waitingQuality assuranceTransmissionCommunications systemProcess module

The invention relates to a communication system for transmitting simulation data, which comprises a plurality of clients and a server. The server comprises a monitoring module, a data state recognition module, a non-state-data receiving module, a sate data receiving module, a communication sub-process module and a simulation service processing module. The clients transmit data to the server, the server transmits the received data to the monitoring module and the monitoring module detects the data; if the clients are valid clients, the data are transmitted to the data state recognition module;otherwise, the data are returned back to the clients; the data state recognition module analyzes the data, if the data are non-state-data, the data are transmitted to a shared data exchange area through the non-state-data receiving module; and if the data are state data, the communication sub-process module is enabled through the state data receiving module, the data are processed in the simulation service processing module, a processing result is transmitted to the shared data exchange area and a simulation result is transmitted to the clients through a communication sub-process. The communication system for transmitting the simulation data can be widely used in the communication system for simulation data transmission in the test control field.

Owner:BEIJING UNION UNIVERSITY

Equipment and method for degrading industrial organic wastewater by coupling ultrasonic ozone-microelectrolysis

InactiveCN108002650AReduce surface tensionImprove permeabilityWater treatment parameter controlSpecific water treatment objectivesEngineeringTower

The invention discloses equipment and a method for degrading industrial organic wastewater by coupling ultrasonic ozone-microelectrolysis. The equipment mainly comprises an ultrasonic ozone treatmenttank, a pH regulating tank, a microelectrolysis treatment tank, a biodegradation tank, an adsorption filtering tower, a wastewater treatment device and a PLC automatic controller, wherein the ultrasonic ozone treatment tank is connected with the pH regulating tank; the pH regulating tank is connected with the microelectrolysis treatment tank; the microelectrolysis treatment tank is connected withthe biodegradation tank; the biodegradation tank is connected with the adsorption filtering tower; the wastewater treatment device is connected with drainage valves of the ultrasonic ozone treatment tank, the pH regulating tank, the microelectrolysis treatment tank and the biodegradation tank; the PLC automatic controller is connected with the electrical installations of the equipment through wires. The method comprises the following steps: ultrasonic ozone treatment, iron-carbon microelectrolysis treatment, biodegradation treatment and wastewater purifying treatment; the treatment process provided by the invention has the characteristic of high efficiency.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

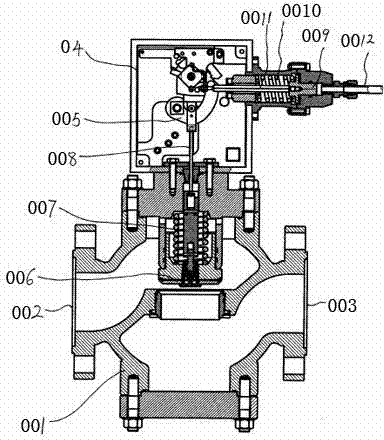

Safety shut-off valve

InactiveCN104763827AImprove securityImprove organizational structureOperating means/releasing devices for valvesEqualizing valvesEngineeringShock resistance

The invention discloses a safety shut-off valve. The safety shut-off valve comprises a valve body, an upper valve body and a shut-off mechanism. The valve body is provided with a first channel and a second channel, the upper valve body is connected with the upper end of the valve body through a screw and used for sealing the valve body, and the shut-off mechanism is arranged in the middle of the valve body and used for connecting or disconnecting the first channel and the second channel. The safety shut-off valve is characterized in that the shut-off mechanism comprises a shut-off part and a cam connecting device which are separated from each other; the valve body is integrally formed by forged steel in a turn milling mode. The independent cam connecting device is adopted, so that separated repair is facilitated, and the situation that the shut-off valve cannot work normally due to maintenance assembly errors is avoided; the internal structure of the valve body is simple, the forged steel integration valve body is adopted, the internal organizational structure of the valve body is improved, grains are refined, the mechanical properties, such as shock resistance, plasticity and toughness, of the forged steel integration valve body are superior to those of a cast steel valve body, and the safety performance of the valve is improved.

Owner:北京润凡电子制造有限公司

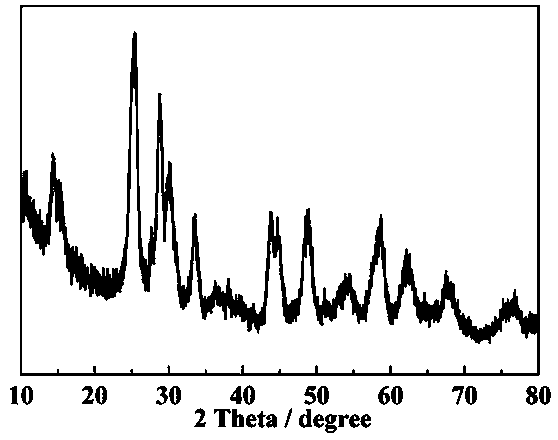

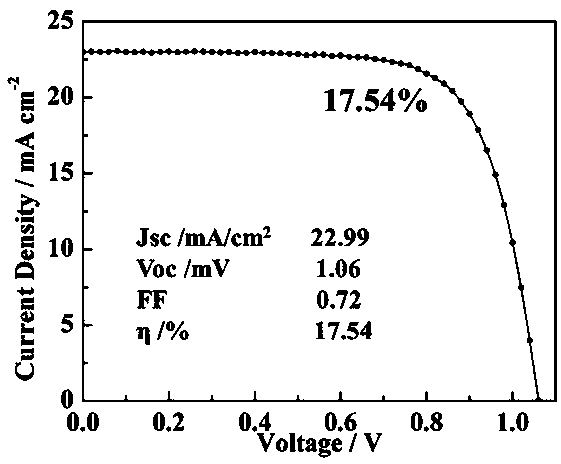

An application of a rapidly synthesized B-phase titanium dioxide in a perovskite solar cell

ActiveCN109216559AExcellent electrochemical performanceImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingIonPerovskite solar cell

The invention discloses an application of a rapidly synthesized B-phase titanium dioxide in a perovskite solar cell, wherein the rapidly synthesized B-phase titanium dioxide is applied to a perovskitesolar cell for the first time. The method relates to a rapid hydrothermal synthesis method, glycolic acid, urea is dissolved in deionized water, After adding tetrabutyl titanate and concentrated sulfuric acid, the precursor of B-phase titanium dioxide was obtained by reacting in a high temperature reactor for more than 2 hours. The precursor was coated on FTO conductive glass and calcined to prepare B-phase titanium dioxide electron transport layer. The layer was applied to the assembly of perovskite solar cells, and the high efficiency of 17.54% was obtained. The synthesis method is simple and reproducible, which provides a new idea for the preparation of high efficiency perovskite solar cells in the future.

Owner:FUZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com