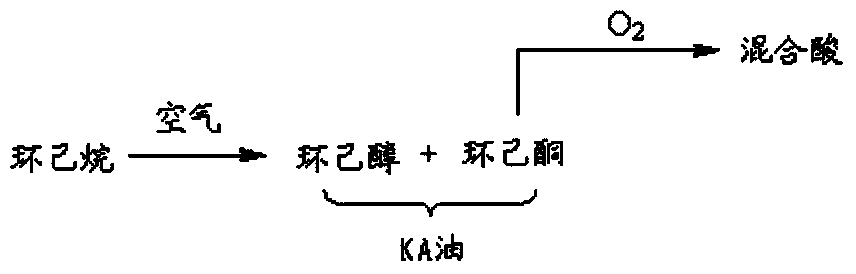

Method for producing KA oil through oxidizing cyclohexane by using air on basis of gas-liquid-solid heterogeneous reaction separation synchronization reactor

A heterogeneous reaction and air oxidation technology, applied in the separation/purification of hydroxyl compounds, separation/purification of carbonyl compounds, chemical instruments and methods, etc. Reduce product selectivity and yield, increase the residence time of reaction products, etc., to achieve the effect of expanding the operable range, avoiding oxidation or decomposition, and solving the complex structure of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

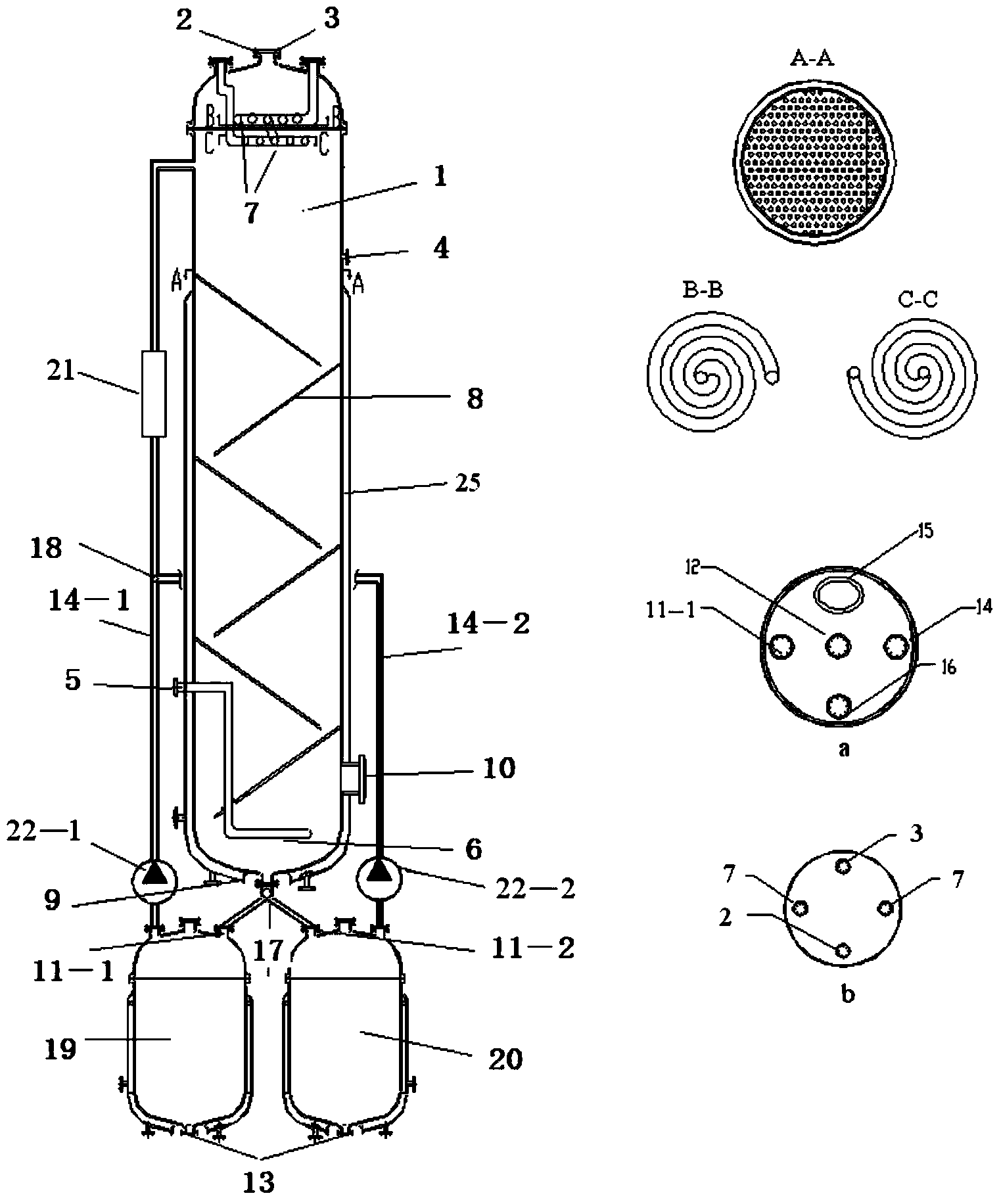

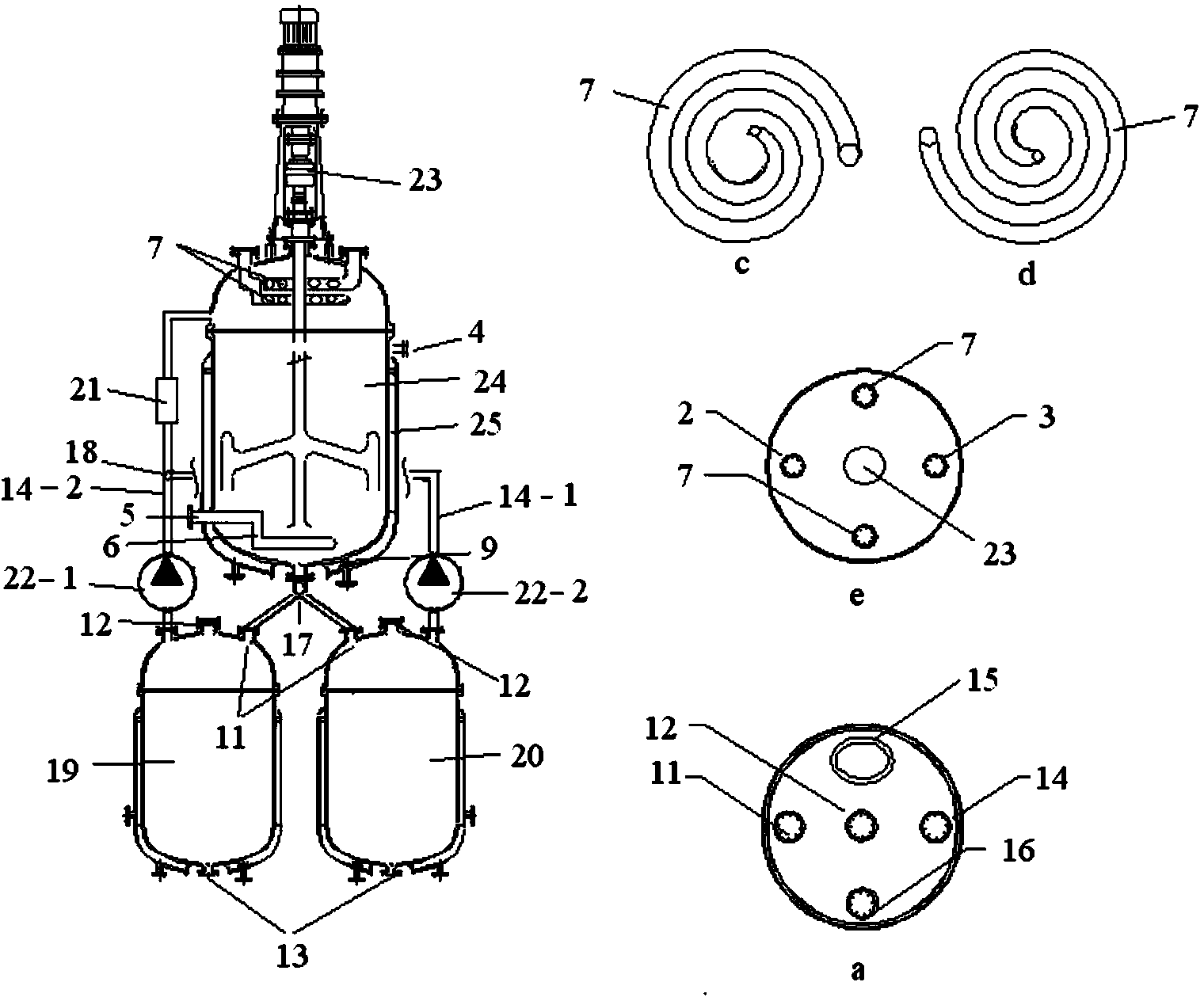

[0040] use figure 1 The shown gas-liquid-solid multiphase reaction separation synchronous reactor carries out the air oxidation of cyclohexane and prepares KA oil product; Wherein, the diameter-to-height ratio of the bubbling gravity reaction tower is 1:20; The length of the gravity settling plate and the tower diameter ratio are 1: 0.8; the included angle of the gravity settling plate along the tower axis is 75°; there are two constant temperature settling towers, the constant temperature settling tower I and the constant temperature settling tower II; the outlet of the reaction liquid is 2 / 5 of the height of the tower body from the top of the reaction tower.

[0041] The cyclohexane raw material with a water content of 0.5wt% enters the constant temperature settling tower I and the bubbling gravity reaction tower from the upper reaction material inlet of the constant temperature settling tower I, and fills the oxidation zone of the constant temperature settling tower I and th...

Embodiment 2

[0045] Attached figure 1 The shown gas-liquid-solid multiphase reaction separation synchronous reactor carries out the air oxidation of cyclohexane to prepare KA oil product; wherein, the ratio of diameter to height of the bubbling gravity reaction tower is 1:40; the length of the gravity settling plate and the diameter ratio of the tower are 1: 1.2; The included angle of the gravity settling plate along the tower axis is 45°; there are two constant temperature settling towers, I and II; the outlet of the reaction liquid is 3 / 7 of the height of the tower body from the top of the reaction tower.

[0046] The cyclohexane raw material with a water content of 0.7wt% enters the constant temperature settling tower I and the bubbling gravity reaction tower from the upper reaction material inlet of the constant temperature settling tower I, and fills the oxidation zone of the constant temperature settling tower I and the bubbling gravity reaction tower, and circulates The tee on the p...

Embodiment 3

[0050] Attached figure 1 The shown gas-liquid-solid multiphase reaction separation synchronous reactor carries out the air oxidation of cyclohexane to prepare KA oil product; wherein, the ratio of diameter to height of the bubbling gravity reaction tower is 1:35; the length of the gravity settling plate and the diameter ratio of the tower are 1: 1.2; The included angle of the gravity settling plate along the tower axis is 55°; there are two constant-temperature settling towers, the constant-temperature settling tower I and the constant-temperature settling tower II; the outlet of the reaction liquid is 3 / 7 of the height of the tower body from the top of the reaction tower.

[0051] The cyclohexane raw material with a water content of 0.8wt% is added with cobalt naphthenate (concentration: 10ppm) as a catalyst, and the mixed solution enters the constant temperature settling tower I and the bubbling gravity reaction tower from the upper reaction material inlet of the constant tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com