Patents

Literature

712results about "Oxygen compounds purification/separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

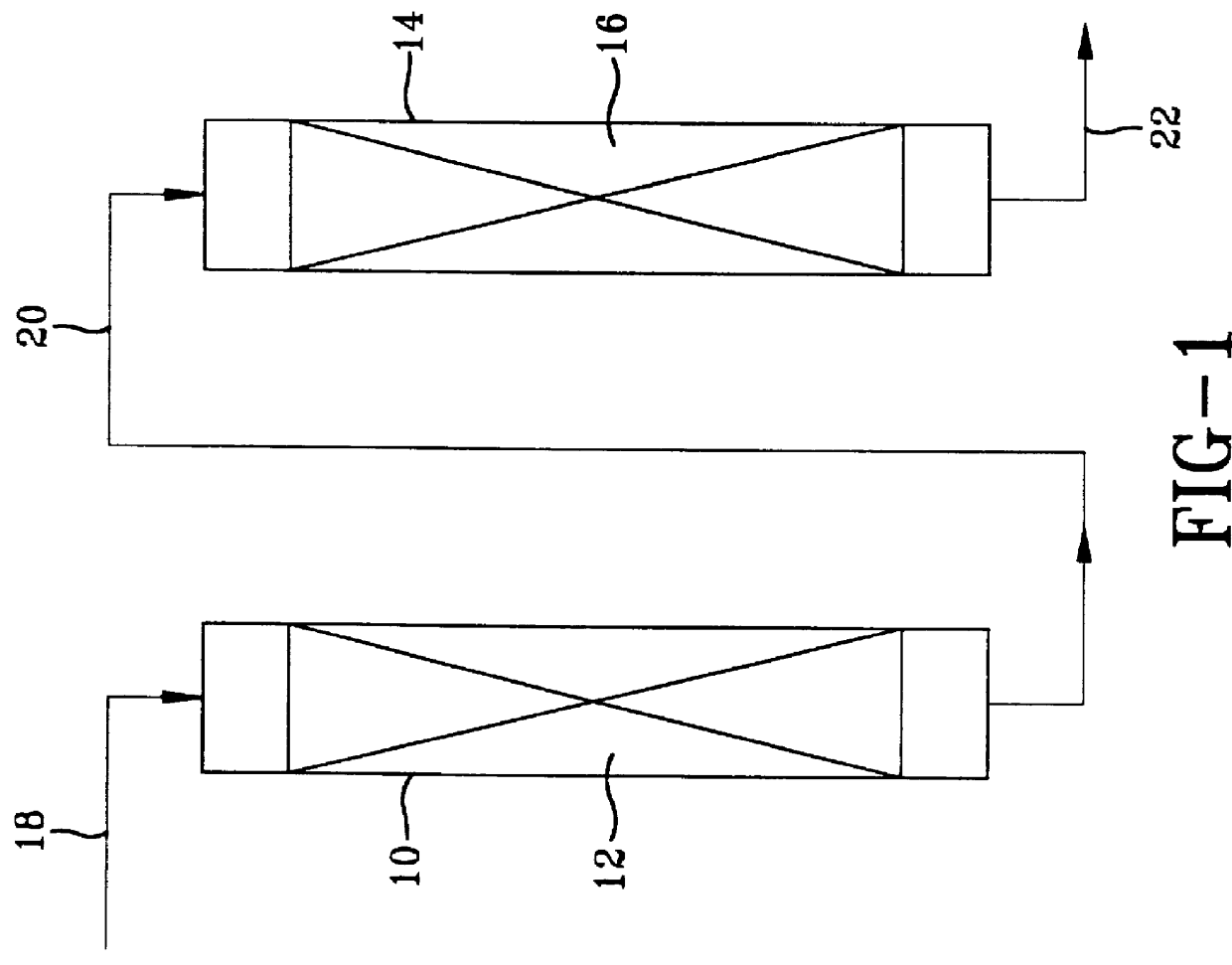

Purification of biologically-produced 1,3-propanediol

InactiveUS20050069997A1Reduce the amount of waterFermented solutions distillation/rectificationMembranesEscherichia coliDistillation

A process for purifying 1,3-propanediol from the fermentation broth of a cultured E. coli that has been bioengineered to synthesize 1,3-propanediol from sugar is provided. The basic process entails filtration, ion exchange and distillation of the fermentation broth product stream, preferably including chemical reduction of the product during the distillation procedure. Also provided are highly purified compositions of 1,3-propanediol.

Owner:DUPONT IND BIOSCIENCES USA LLC +1

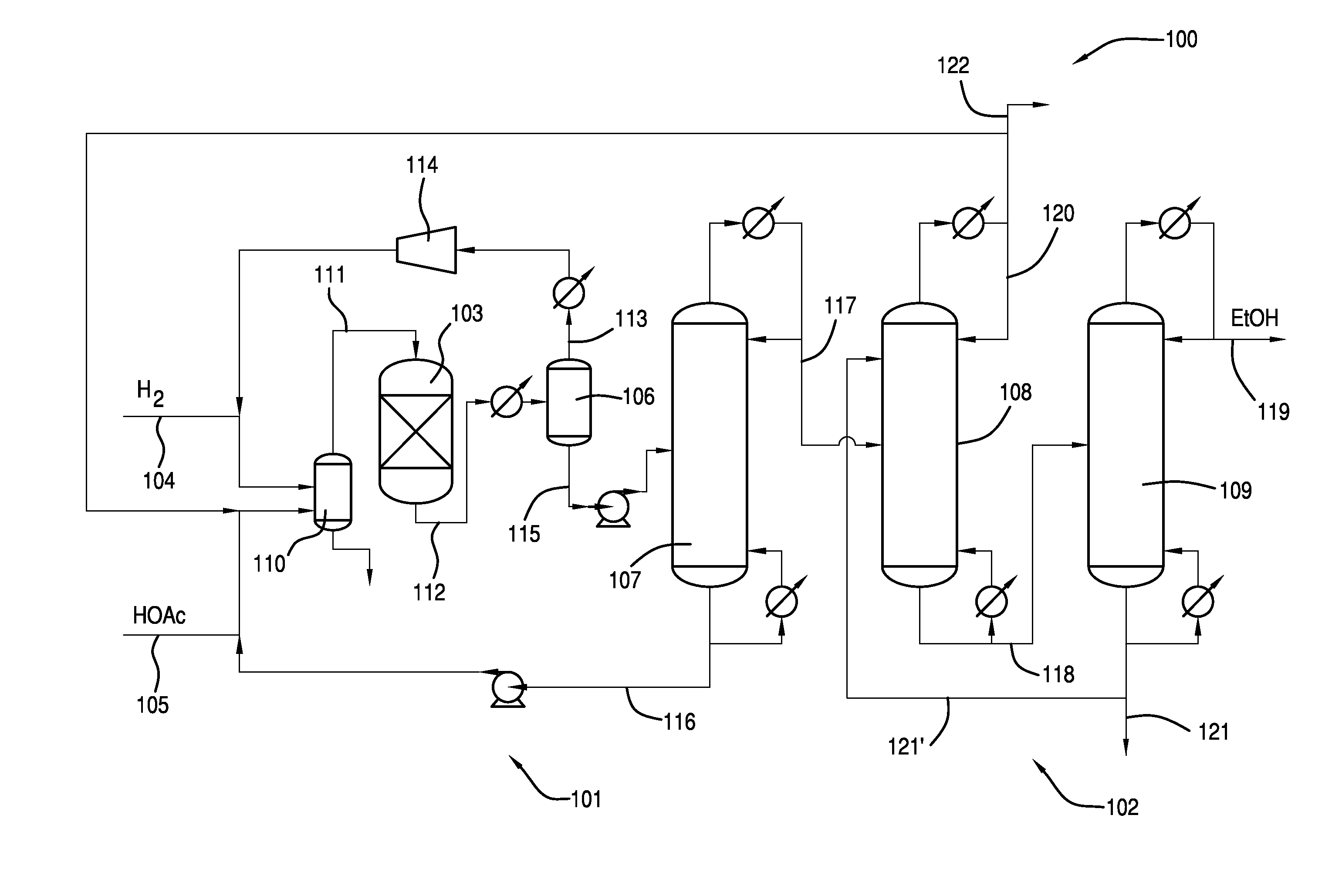

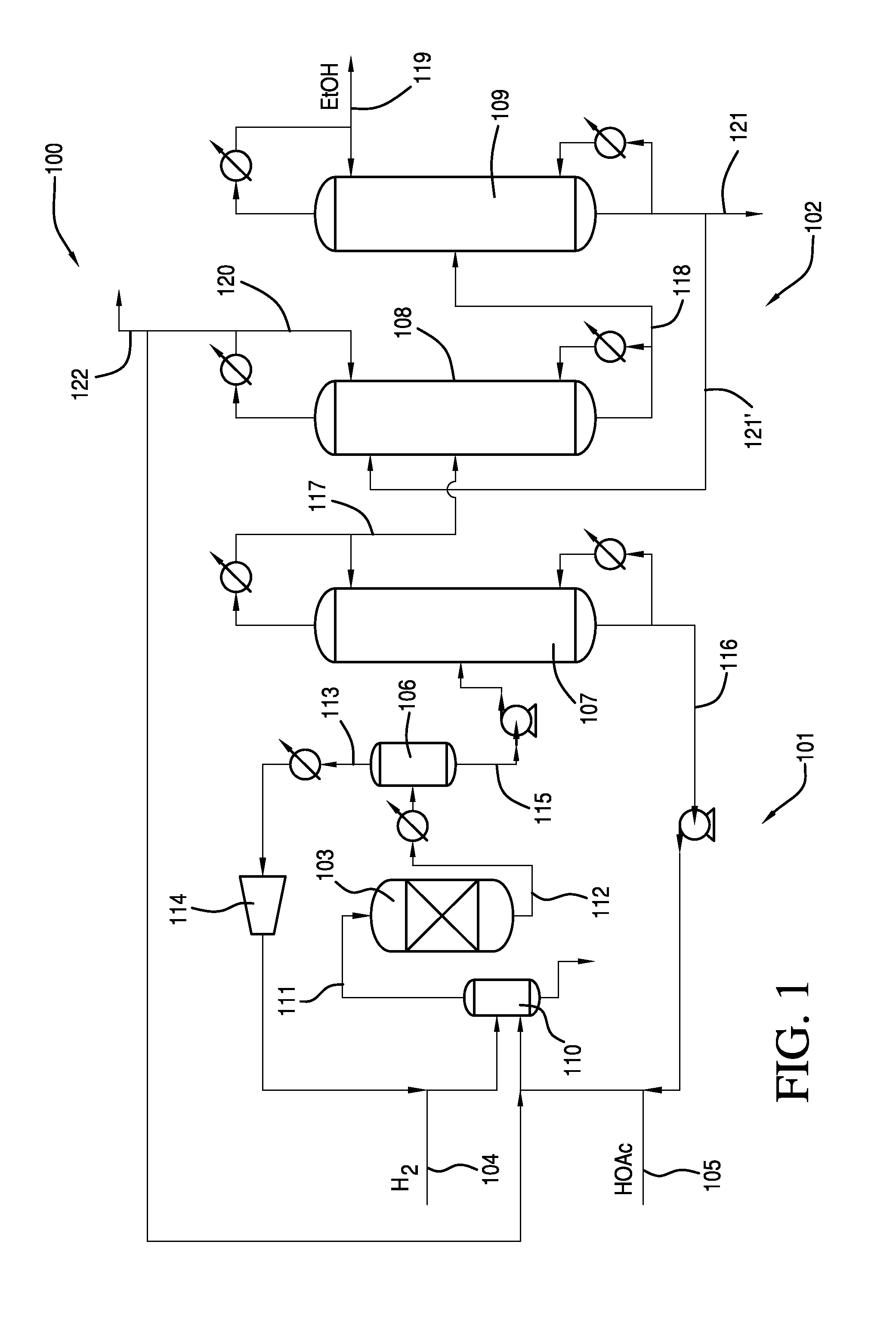

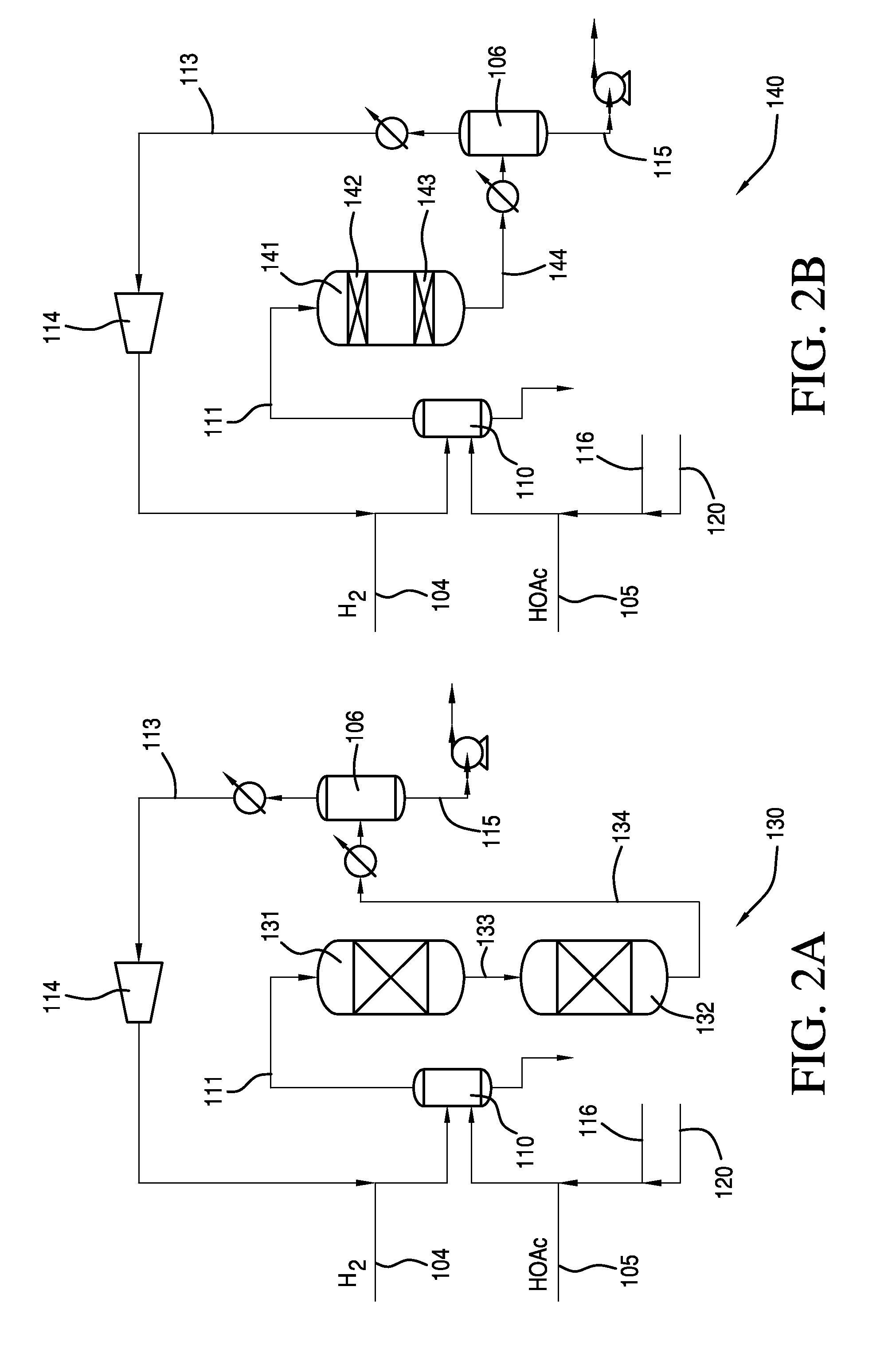

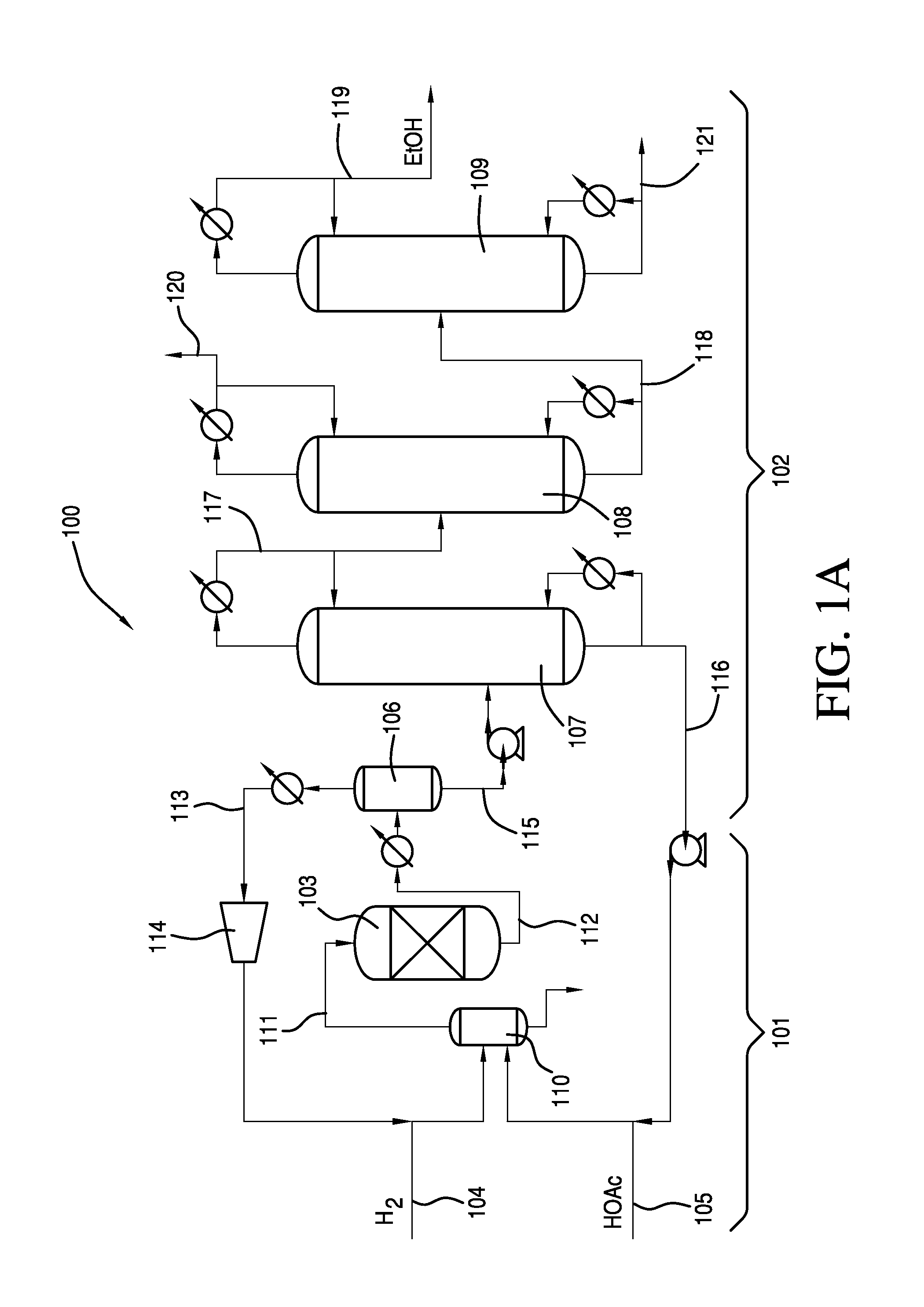

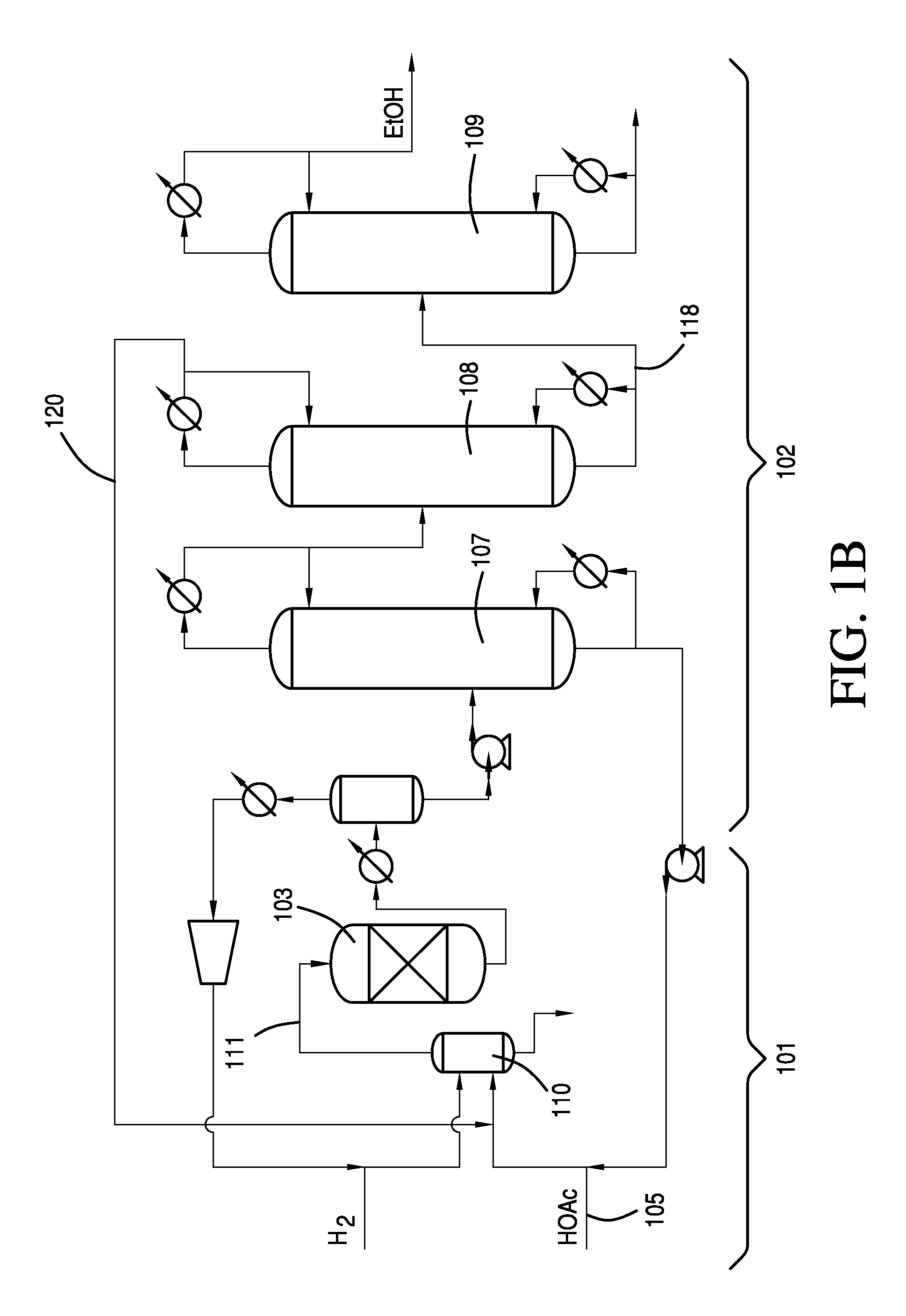

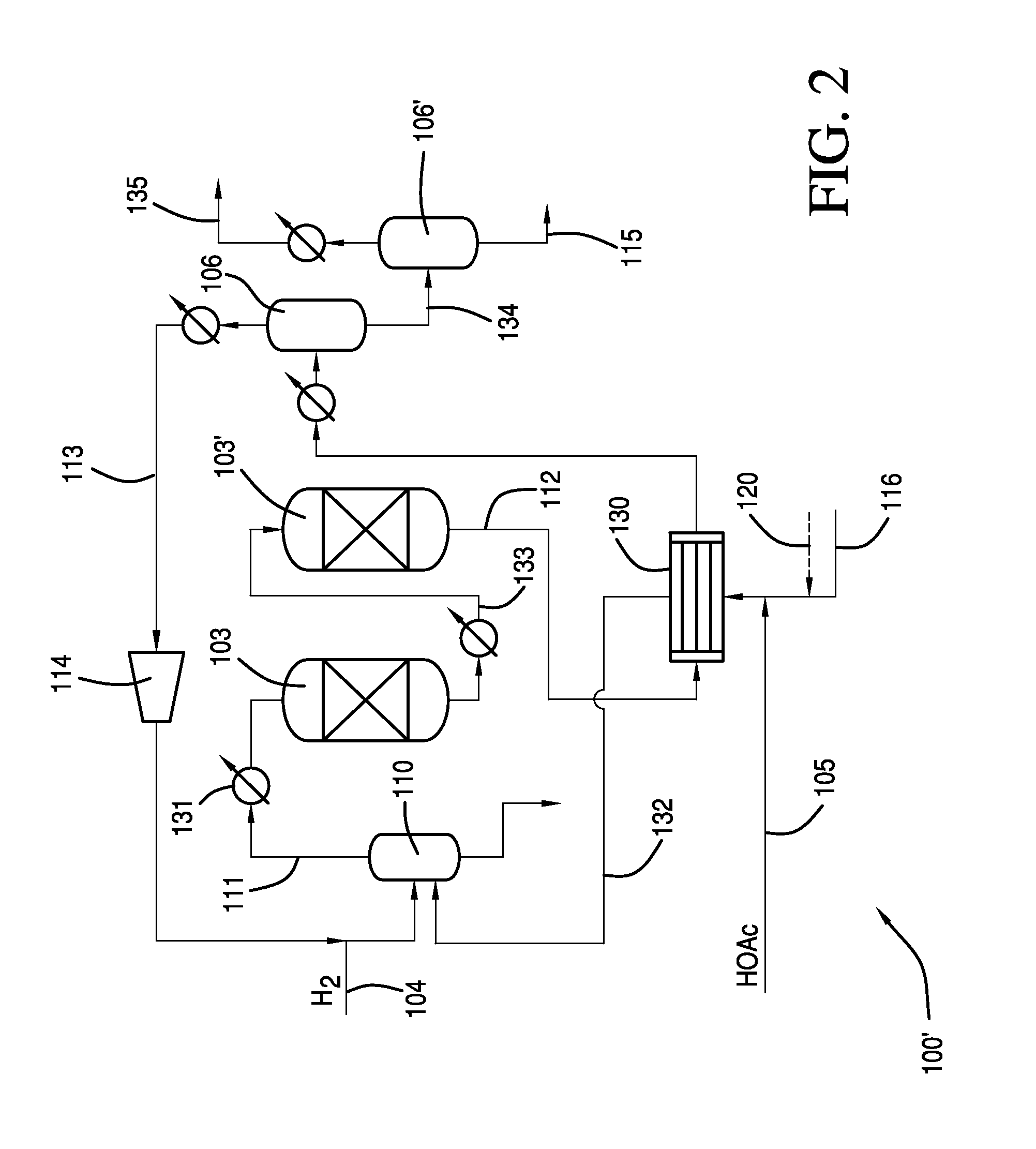

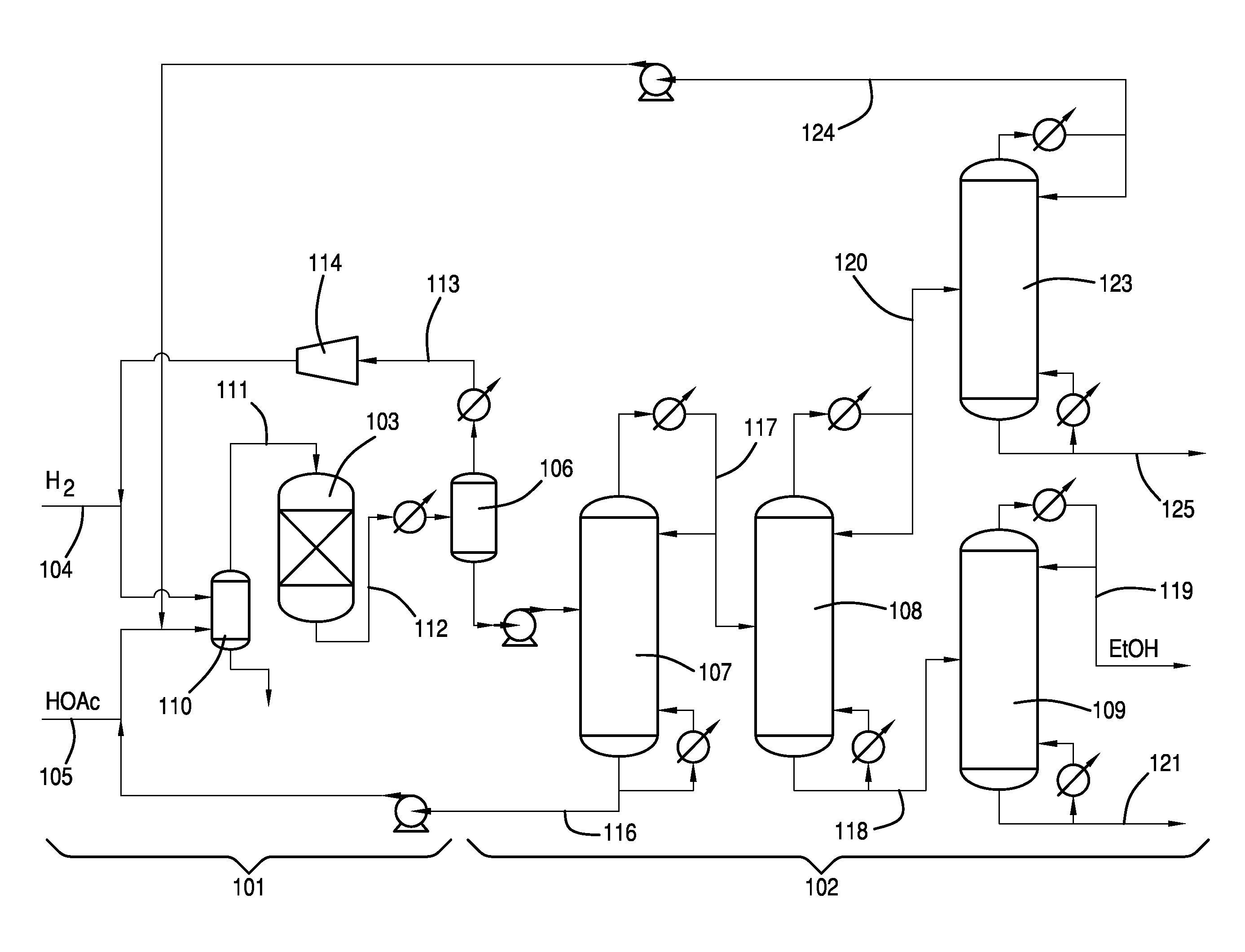

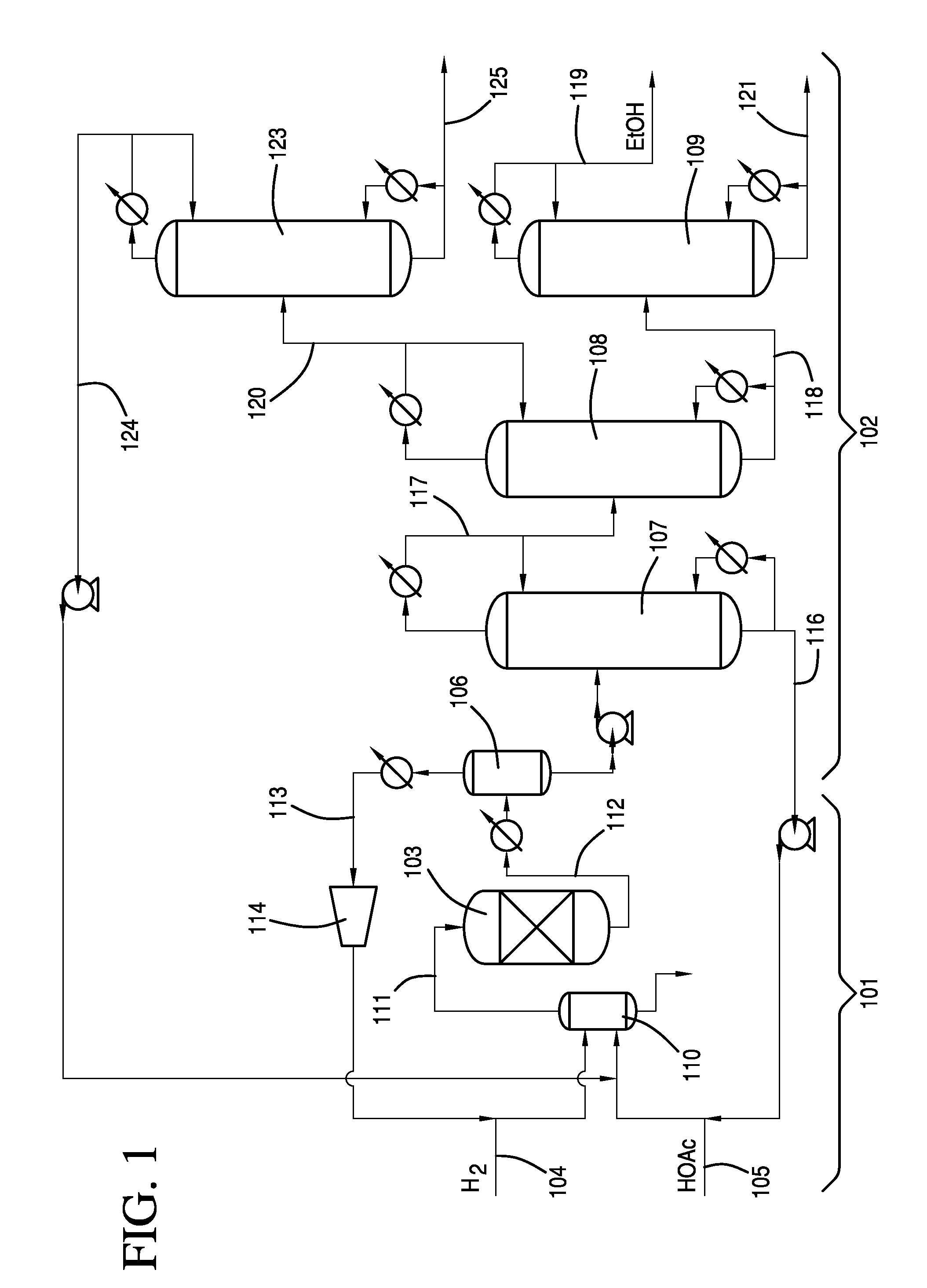

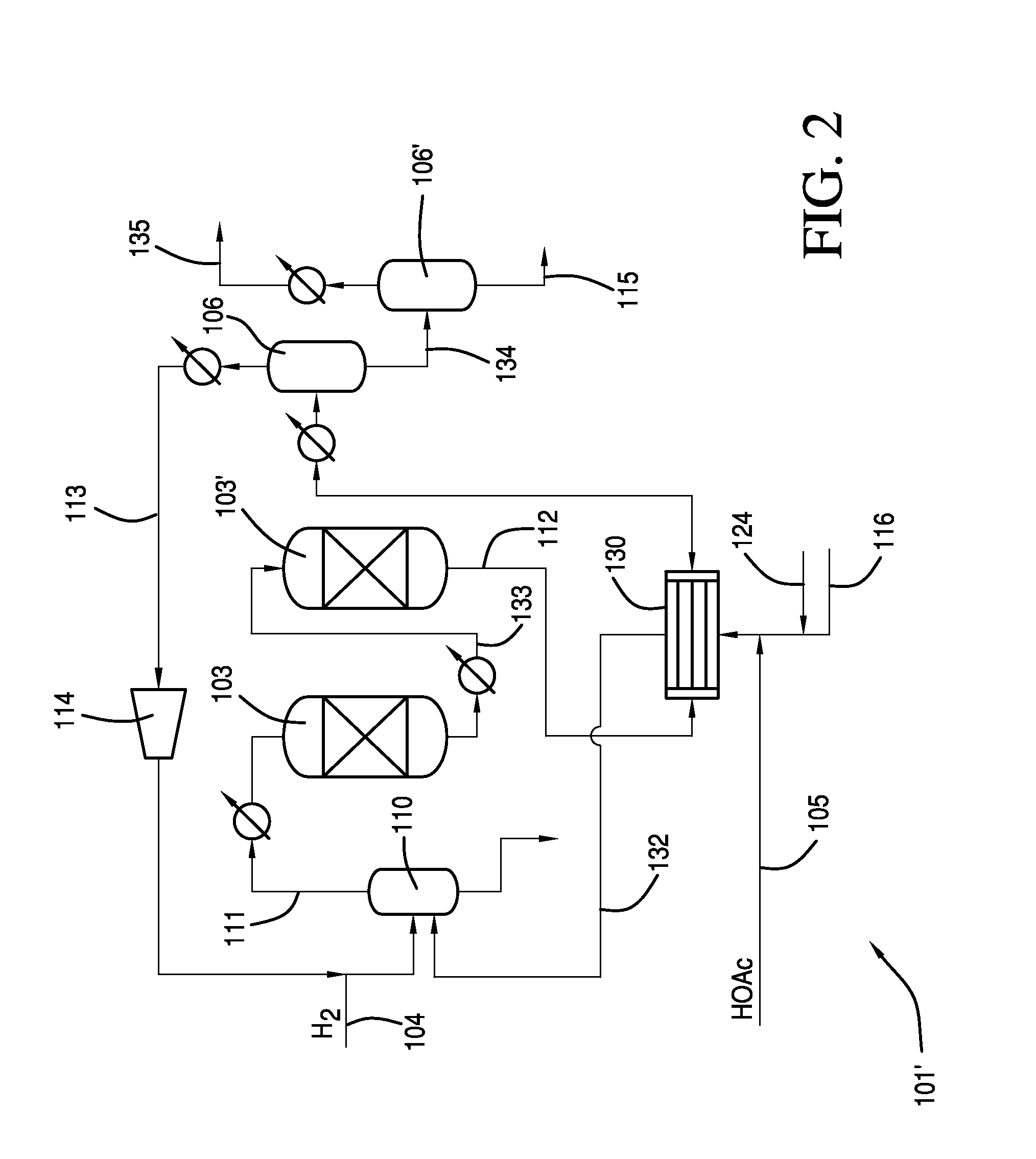

Process for Making Ethanol From Acetic Acid Using Acidic Catalysts

InactiveUS20110082322A1Organic compound preparationCarboxylic acid esters preparationAcetic acidMetal

A process for selective formation of ethanol from acetic acid by hydrogenating acetic acid in the presence of a catalyst comprises a first metal on an acidic support. The acidic support may comprise an acidic support material or may comprise an support having an acidic support modifier. The catalyst may be used alone to produced ethanol via hydrogenation or in combination with another catalyst. In addition, the crude ethanol product is separated to obtain ethanol.

Owner:CELANESE INT CORP

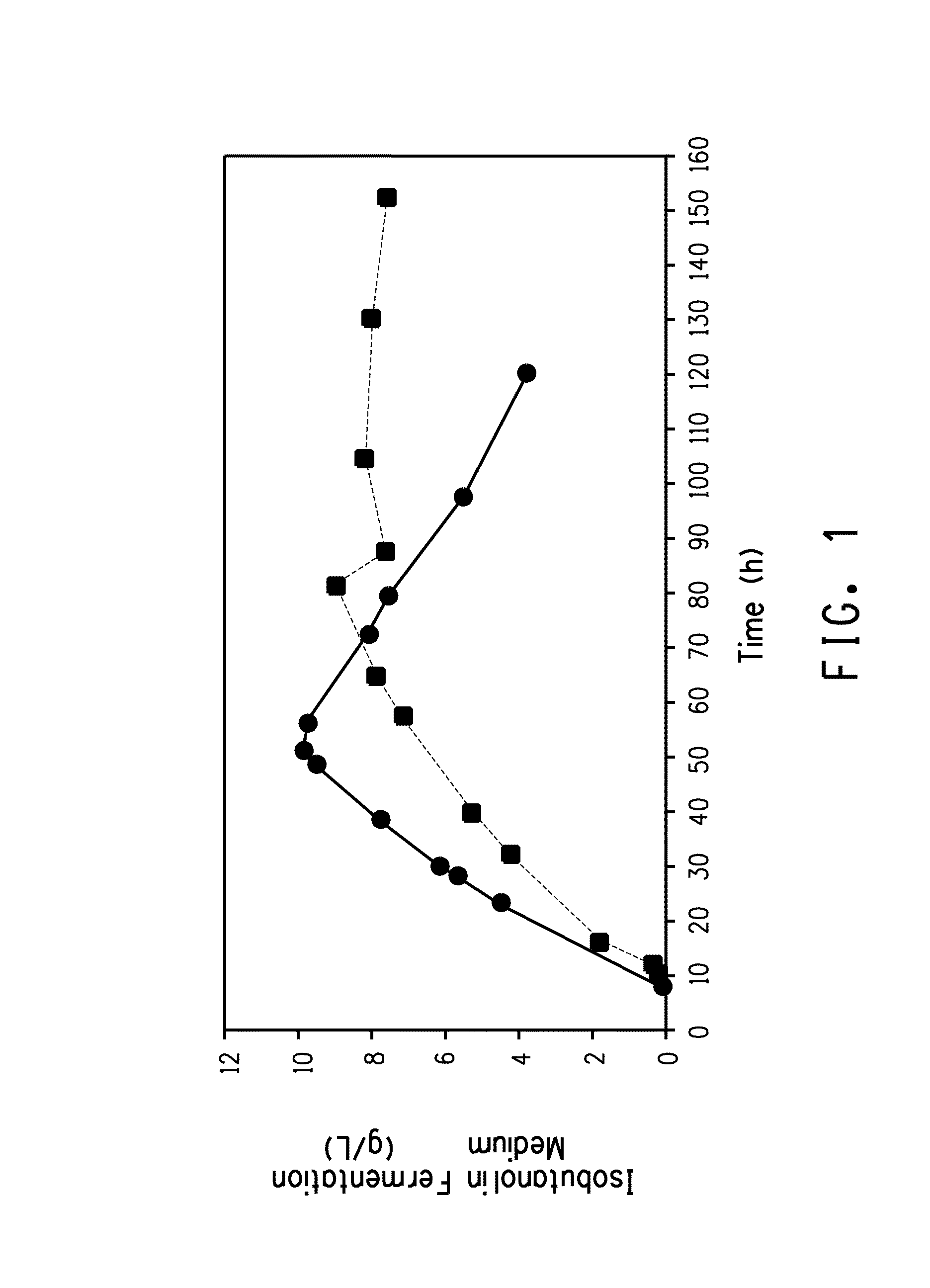

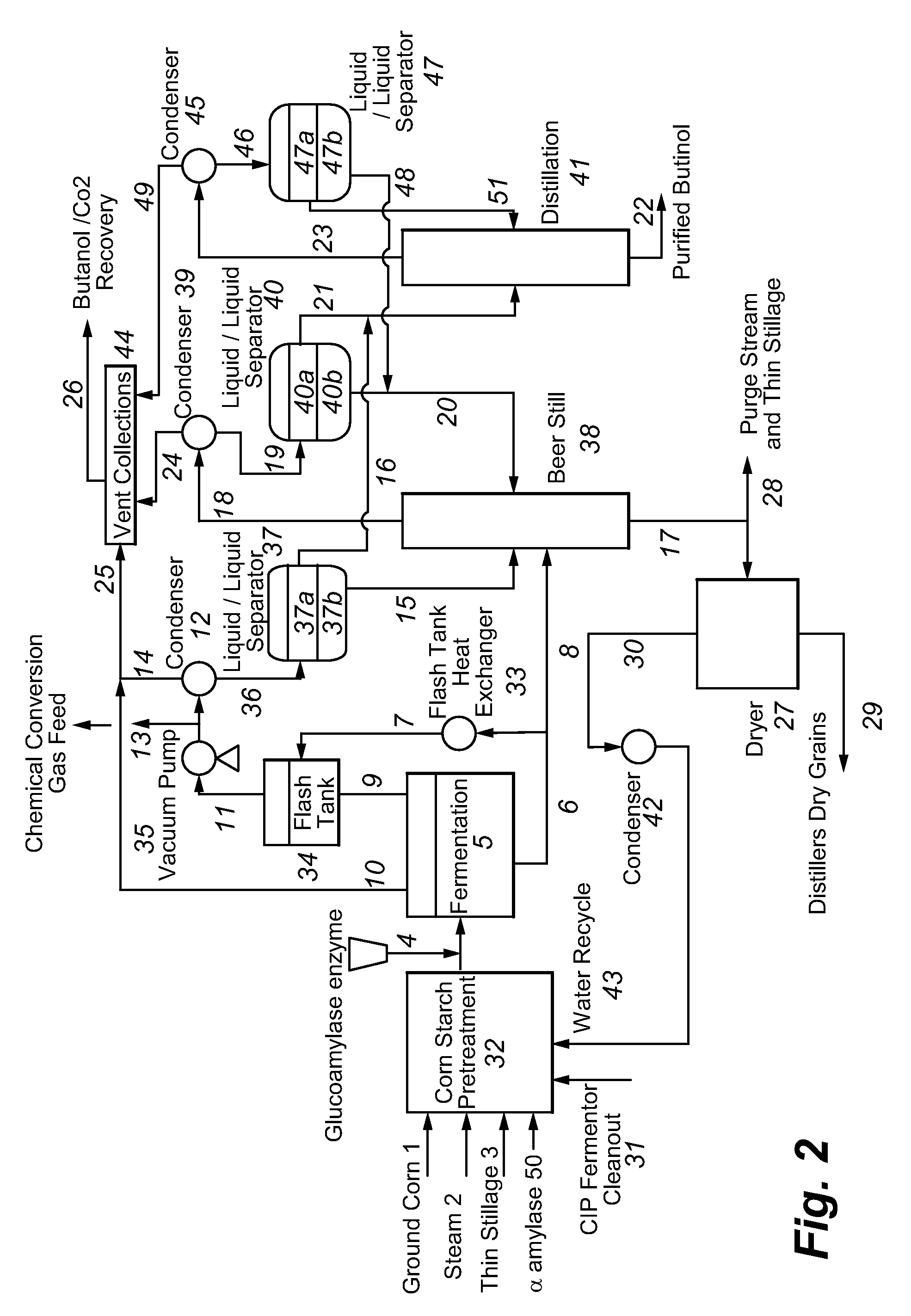

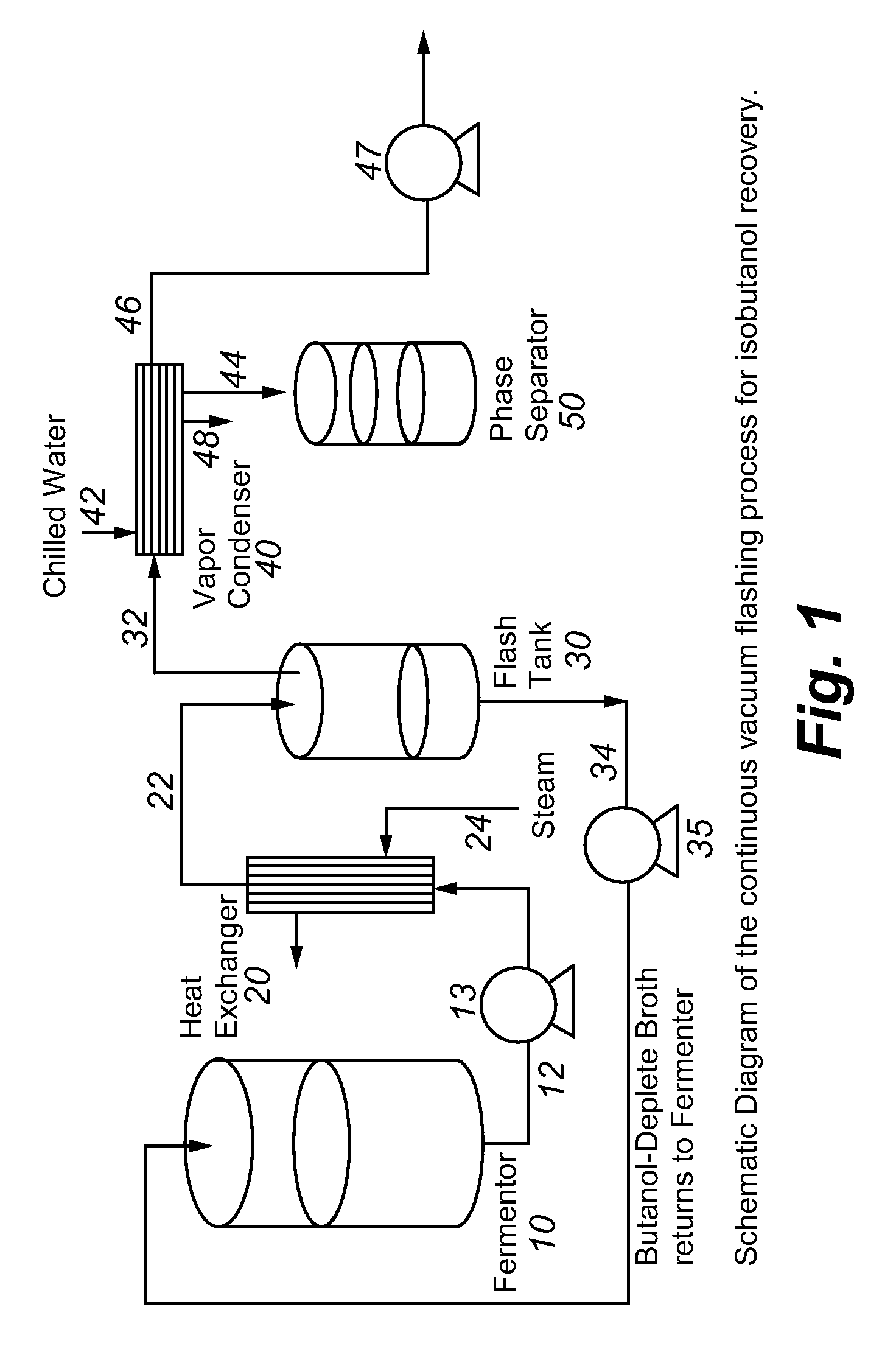

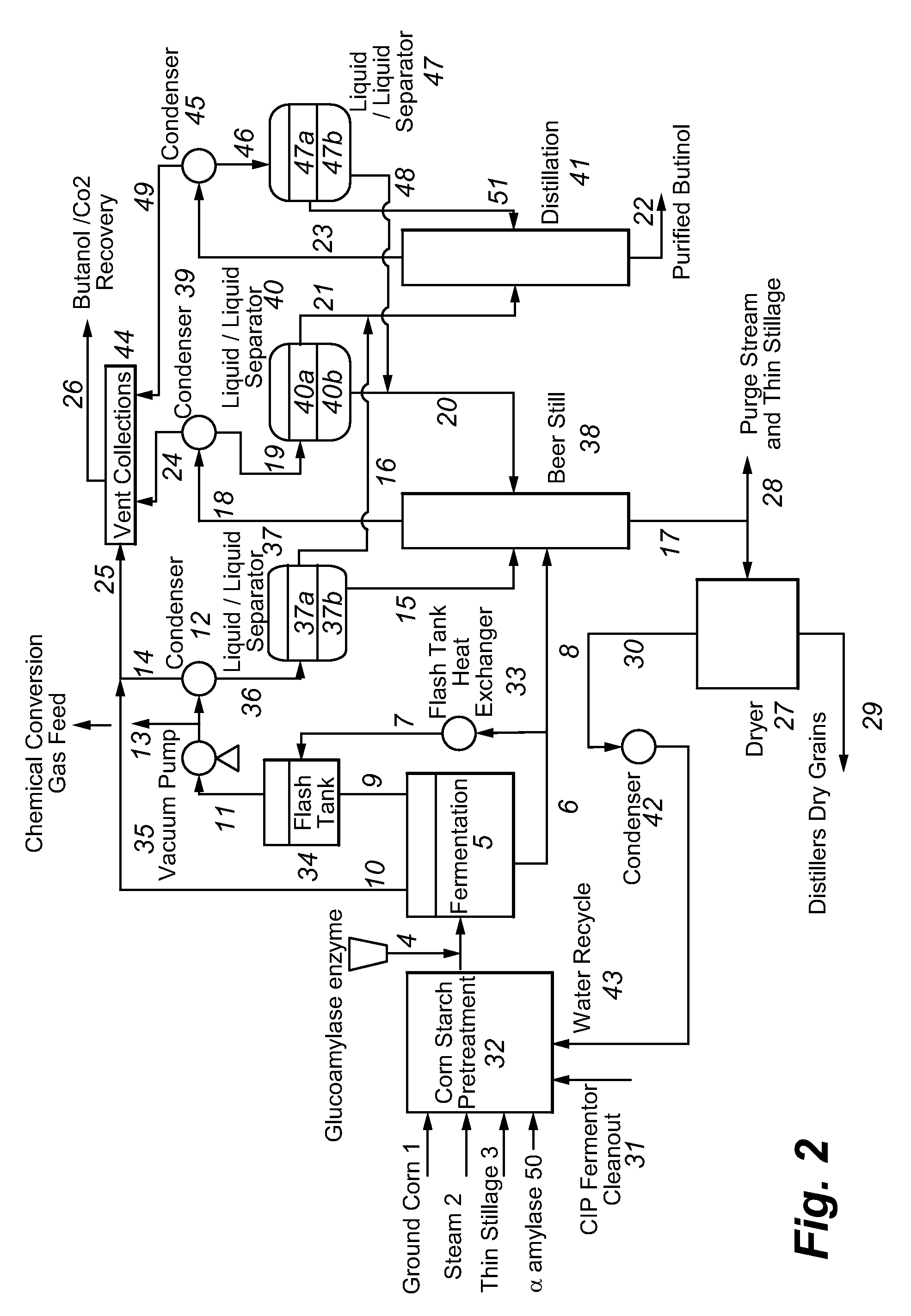

Method for producing butanol using two-phase extractive fermentation

InactiveUS20090305370A1Reformed easilyAvoid impactOrganic compound preparationBiofuelsMicroorganismMicrobiology

A method of making butanol from at least one fermentable carbon source that overcomes the issues of toxicity resulting in an increase in the effective titer, the effective rate, and the effective yield of butanol production by fermentation utilizing a recombinant microbial host wherein the butanol is extracted into specific organic extractants during fermentation

Owner:BUTAMAXTM ADVANCED BIOFUELS

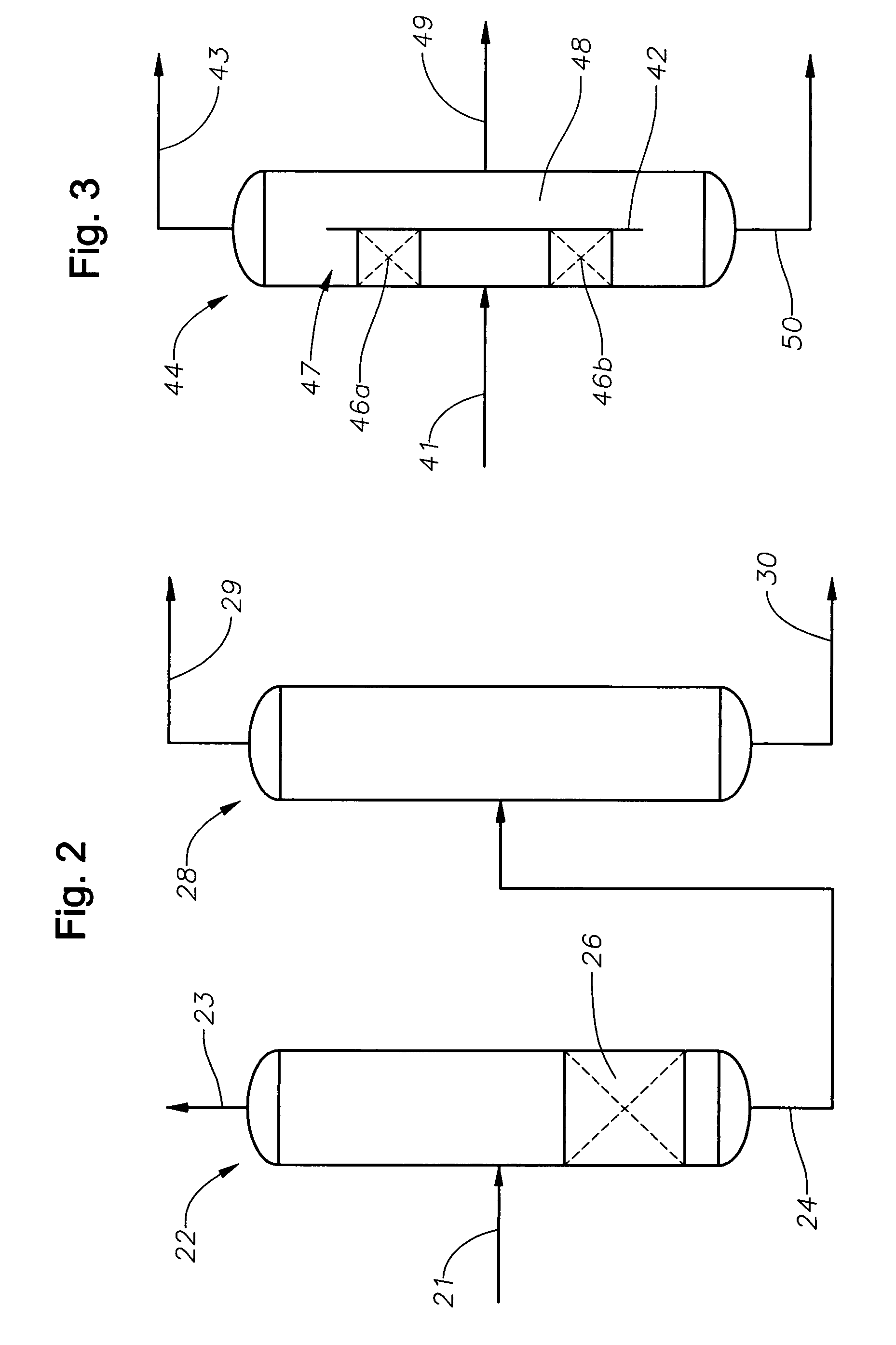

Process for the purification of 1,3-propanediol

InactiveUS6235948B1Organic compound preparationOxygen compounds purification/separation1,3-PropanediolPropanediol

Disclosed is a process for the removal of impurities, especially color forming impurities, from 1,3-propanediol.

Owner:EI DU PONT DE NEMOURS & CO

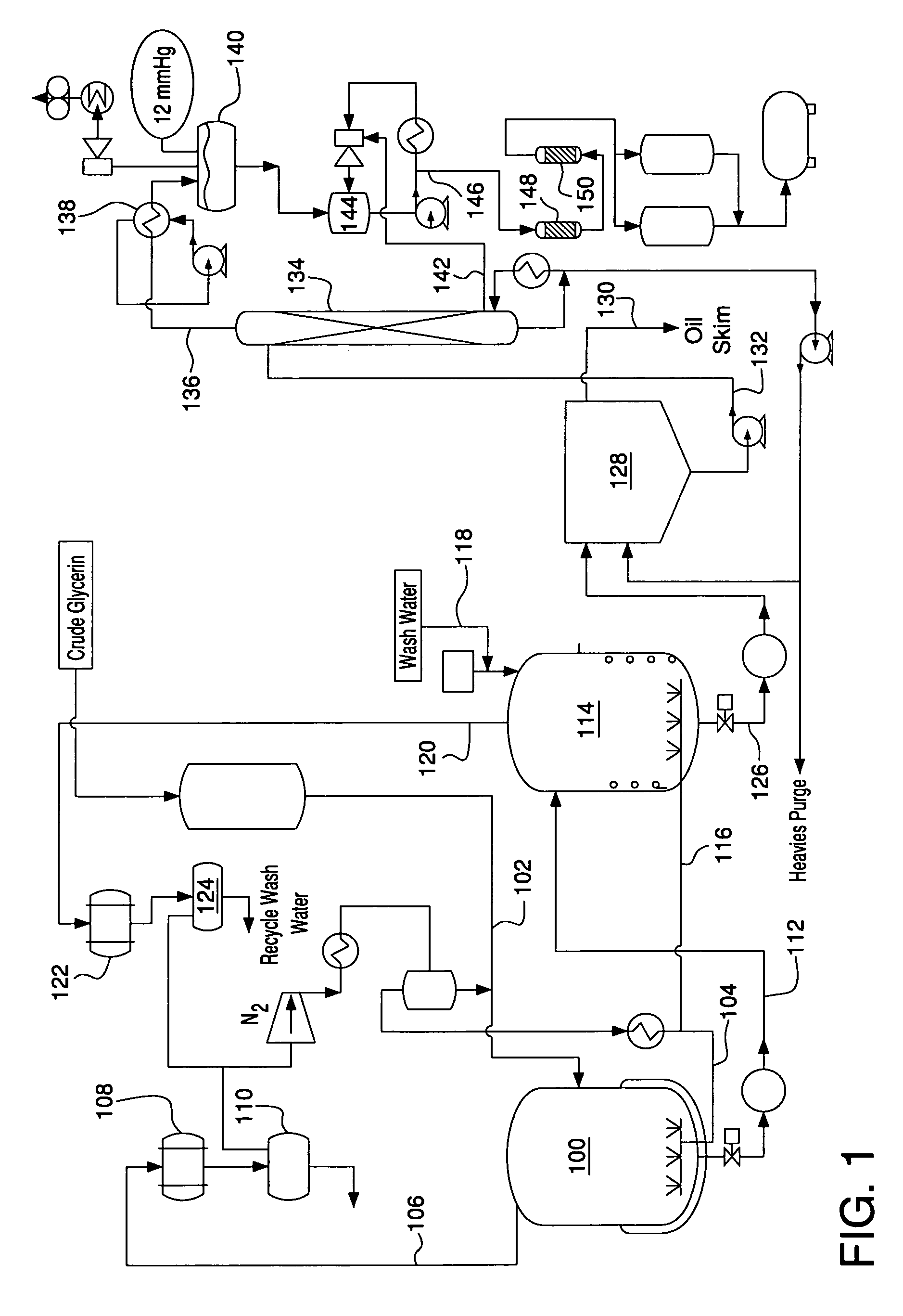

Purification of glycerin

InactiveUS7126032B1Low costEfficient recyclingOrganic compound preparationOxygen compounds purification/separationAlcoholWash water

A process for purifying glycerin recovered as a byproduct of biodiesel production comprises heating a glycerin effluent stream containing a low molecular weight alcohol, water and fatty acid esters of the low molecular weight alcohol to cause transesterification of the fatty acid esters to glycerides and additional low molecular weight alcohol. The reaction mixture is sparged with nitrogen to help remove water and low molecular weight alcohol, which drives the transesterification reaction towards glyceride formation. A wash water stream may also be added to the recovered glycerin stream from biodiesel production. Either before or following the transesterification reaction, an oil layer can be separated from the recovered glycerin stream by reducing the pH of the stream to below 7. Following separation of the oil layer and transesterification the glycerin stream is flash distilled to separate glycerin from water, salts, and glycerides.

Owner:SUNOCO INC (R&M)

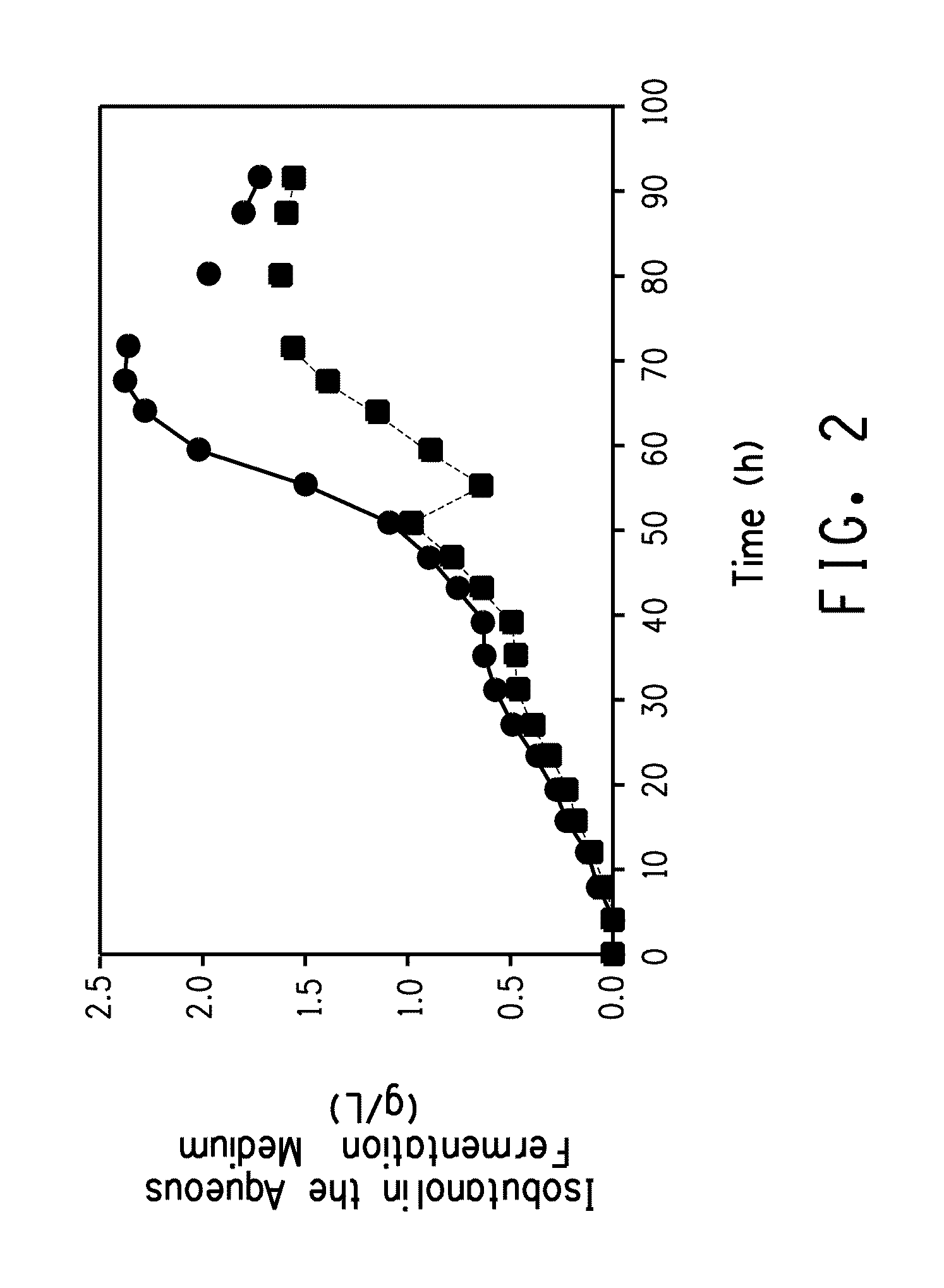

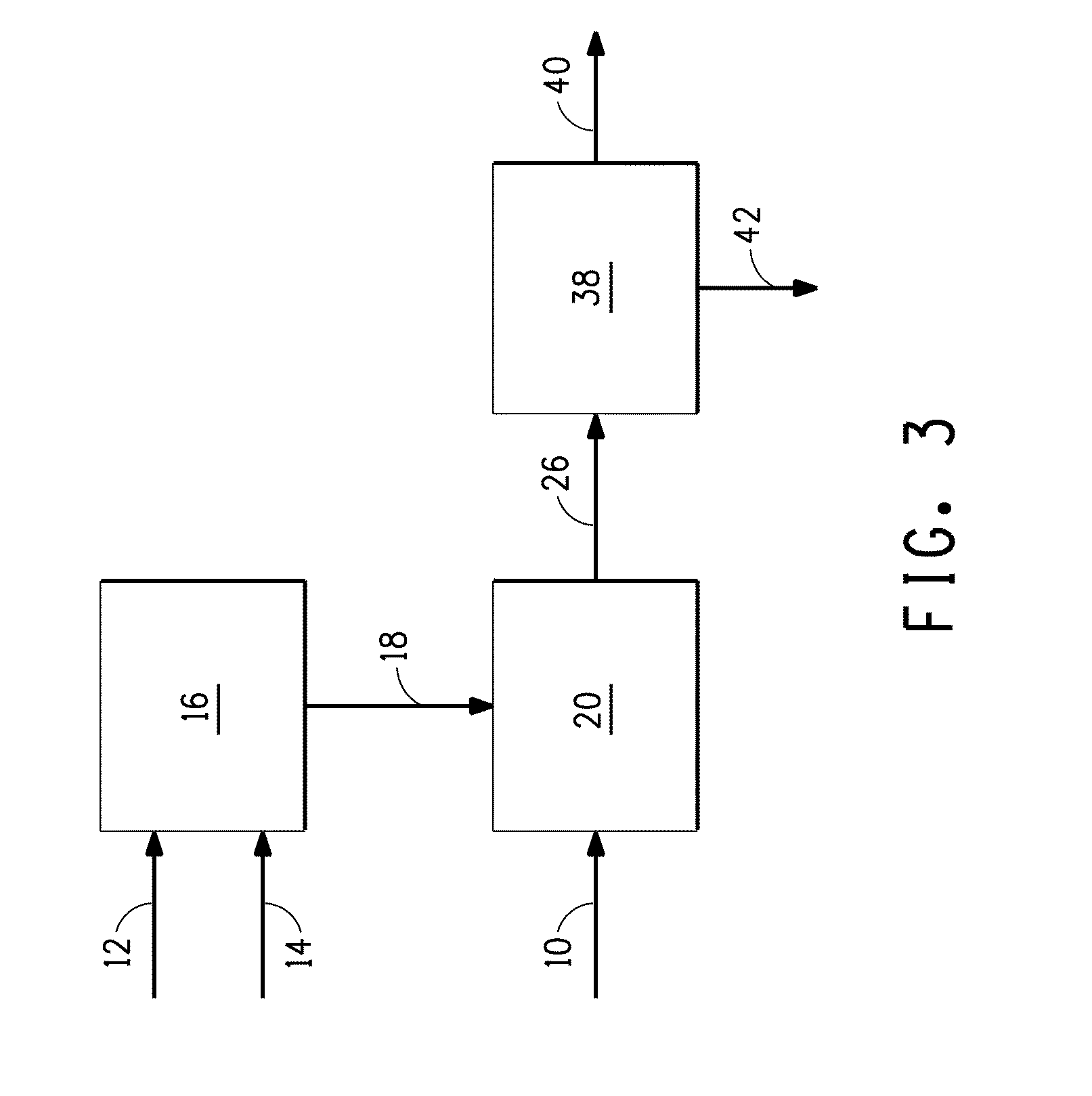

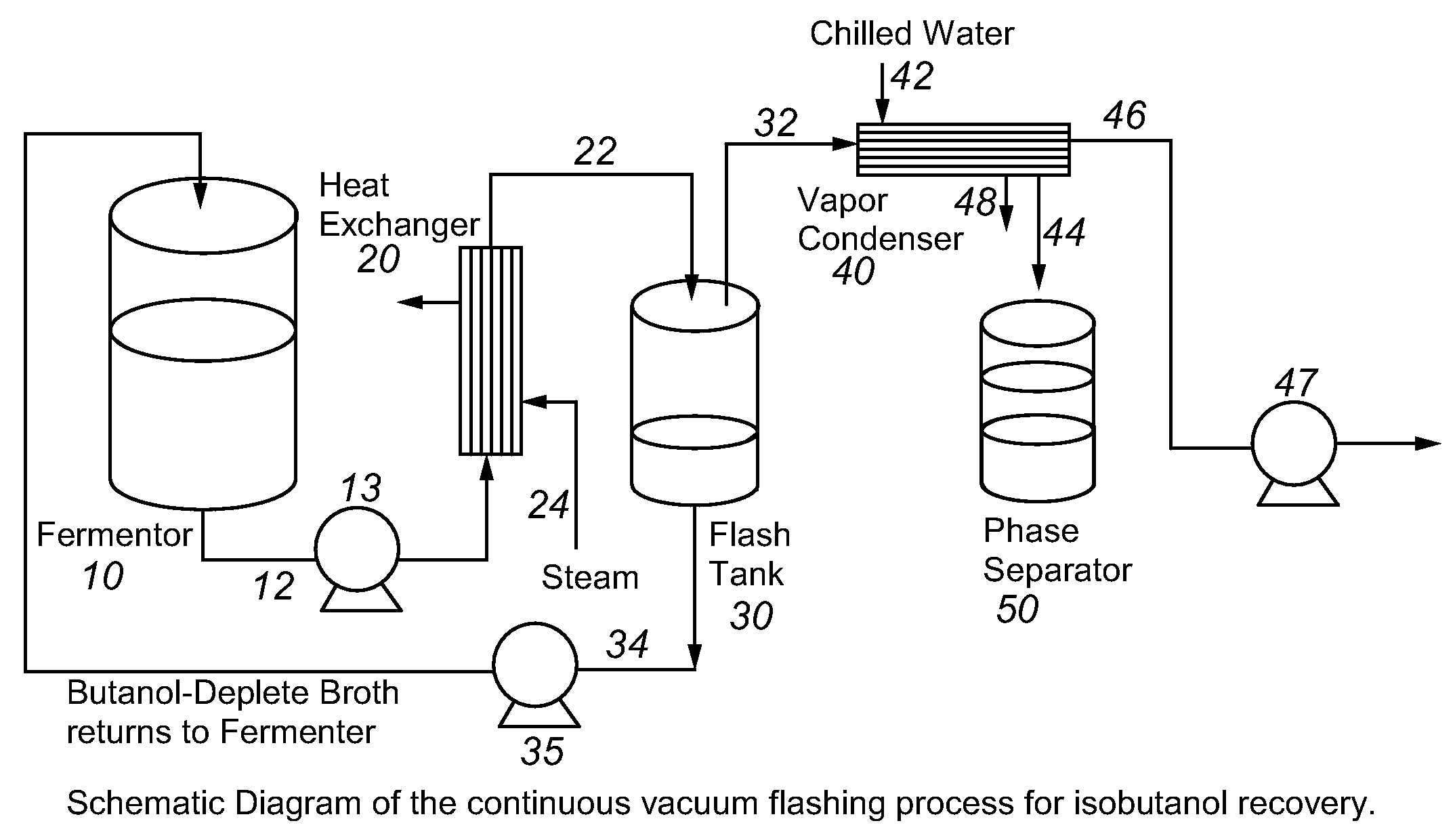

Recovery of higher alcohols from dilute aqueous solutions

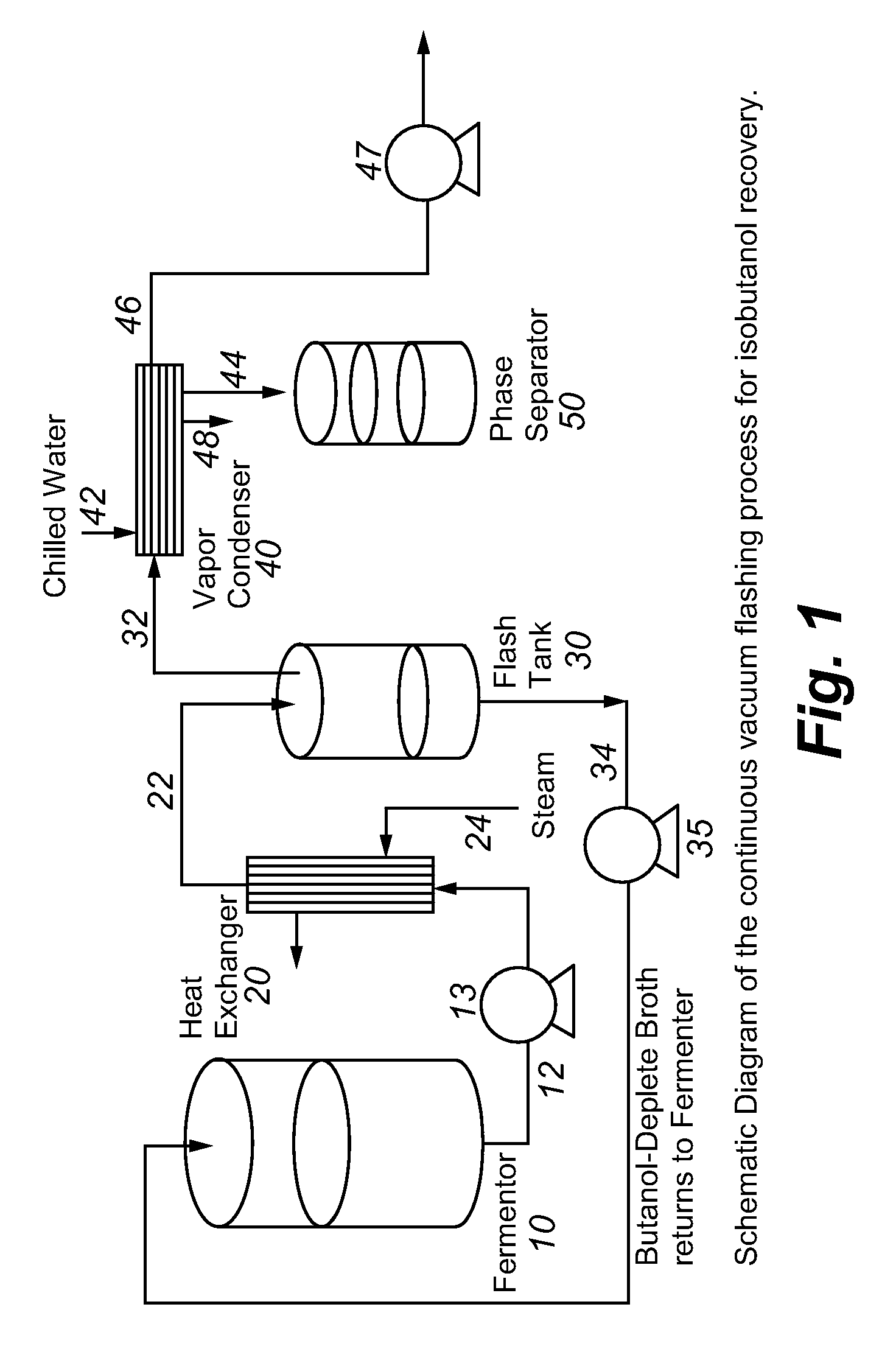

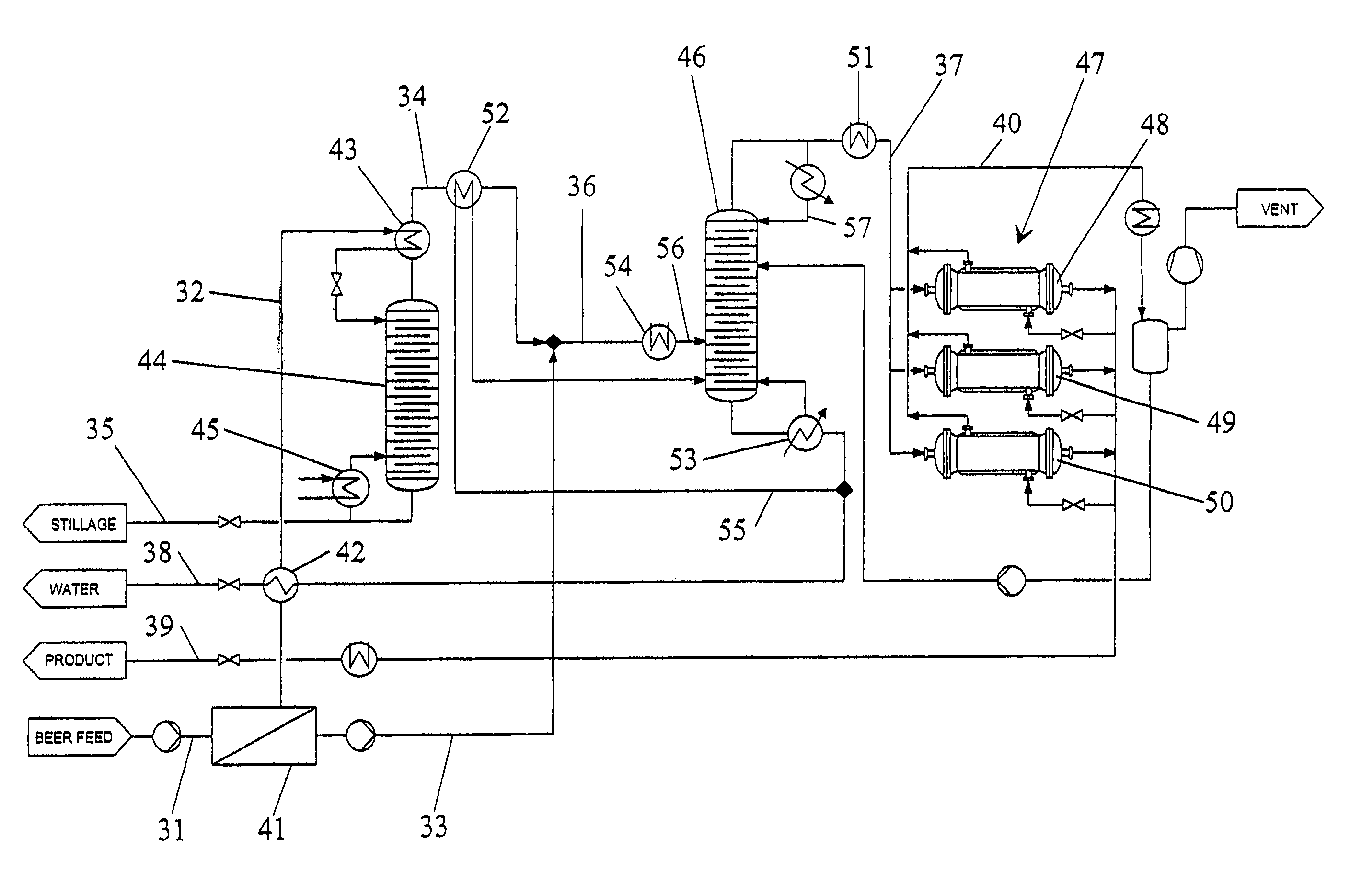

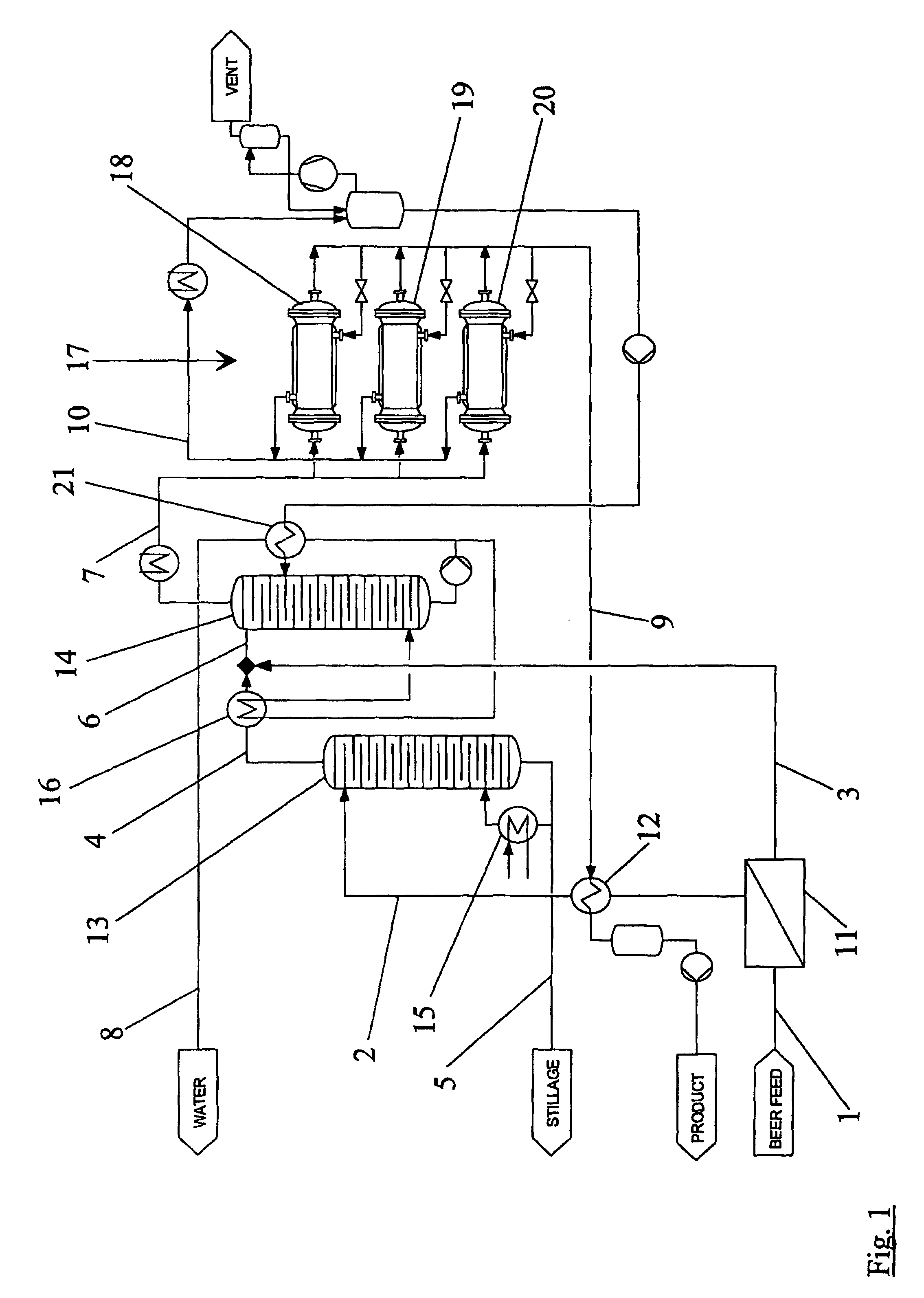

ActiveUS20090171129A1High activityBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateAqueous solution

This invention is directed to methods for recovery of C3-C6 alcohols from dilute aqueous solutions, such as fermentation broths. Such methods provide improved volumetric productivity for the fermentation and allows recovery of the alcohol. Such methods also allow for reduced energy use in the production and drying of spent fermentation broth due to increased effective concentration of the alcohol product by the simultaneous fermentation and recovery process which increases the quantity of alcohol produced and recovered per quantity of fermentation broth dried. Thus, the invention allows for production and recovery of C3-C6 alcohols at low capital and reduced operating costs.

Owner:GEVO INC

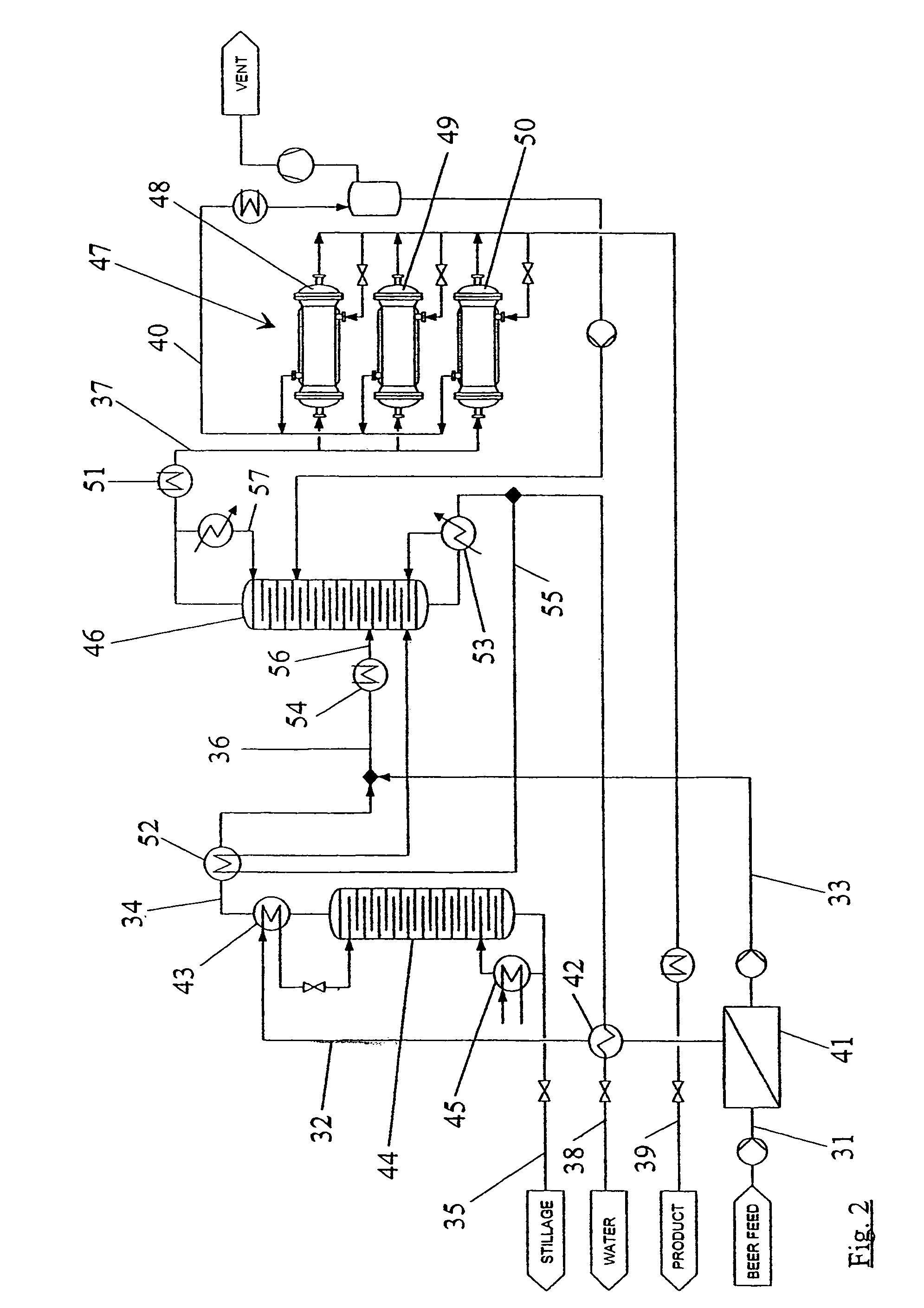

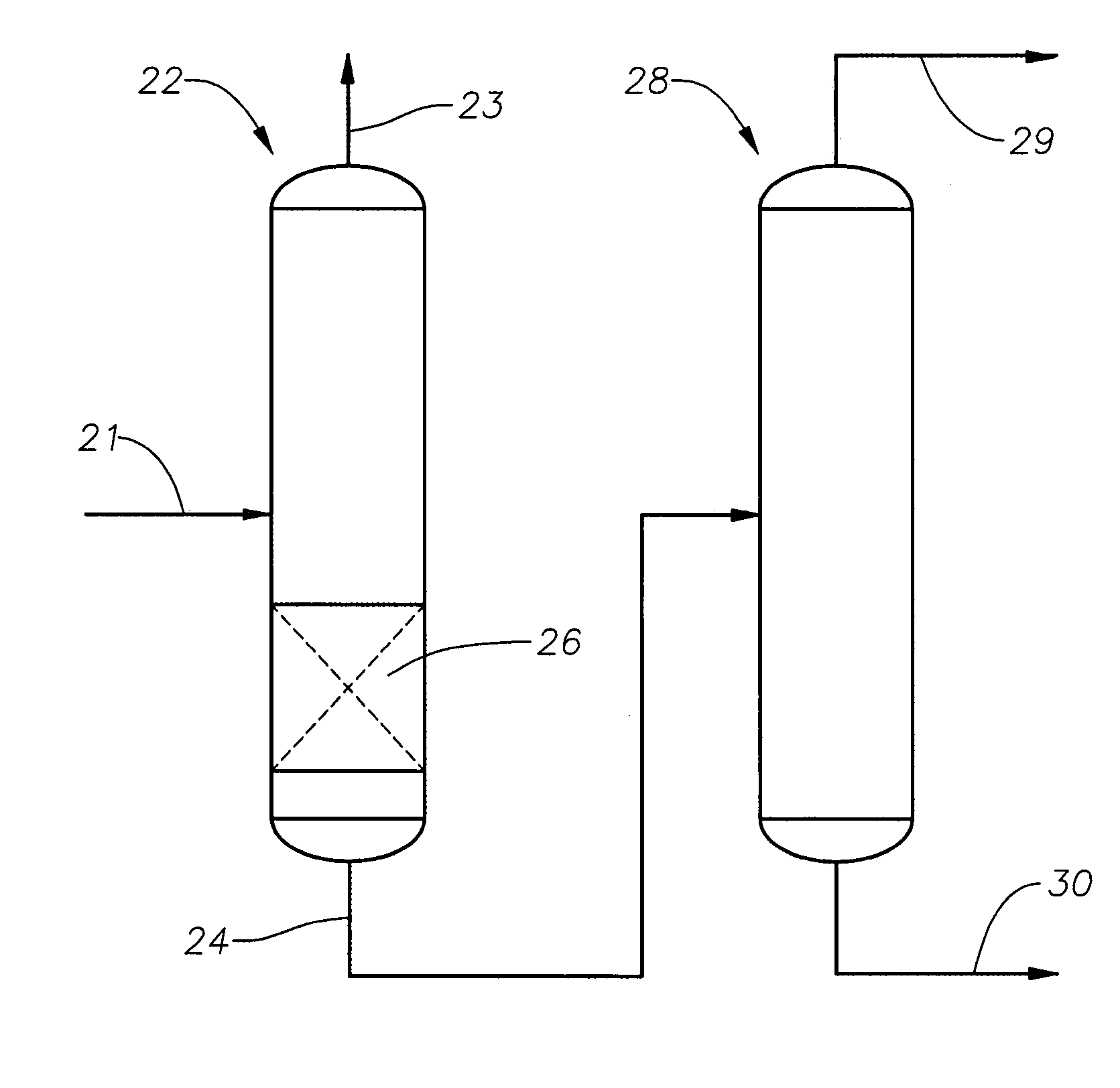

Distillation method

A method for distilling ethanol from a mash includes feeding a fluid to a first distillation column. The fluid and a distillate of the first distillation column are delivered to a second distillation column. The fed fluid and / or distillate of the second distillation column is / are purified in a first and / or last step of the method by a membrane separation process.

Owner:WHITE FOX TECH LTD

Purification of chemical 1,3-propanediol

InactiveUS7038092B2Organic compound preparationOxygen compounds purification/separationHydrogen1,3-Propanediol

Owner:EI DU PONT DE NEMOURS & CO

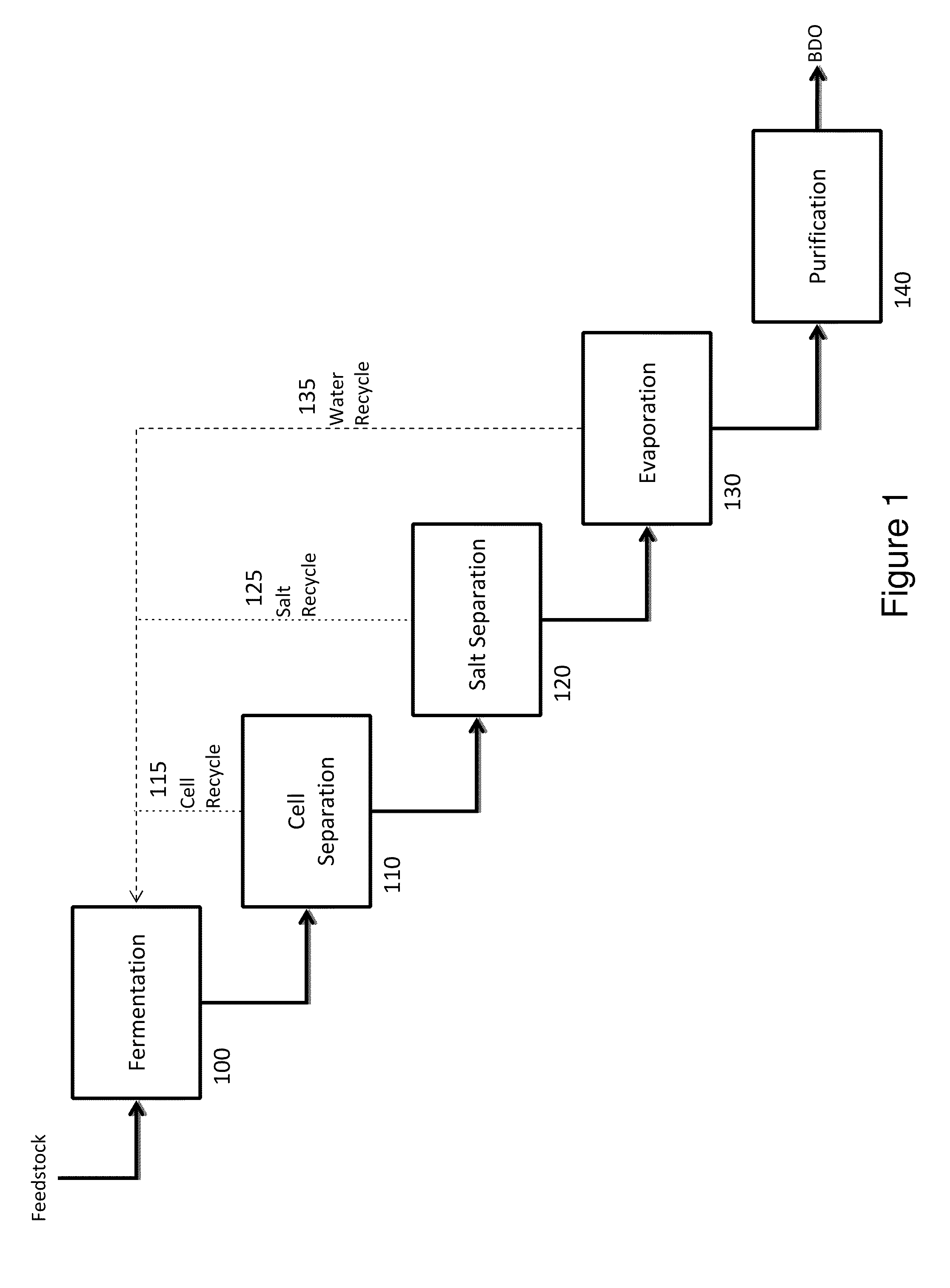

Process of separating components of a fermentation broth

ActiveUS20110003355A1Produce lotFermented solutions distillation/rectificationOrganic compound preparation1,4-ButanediolMicroorganism

A process of isolating 1,4-butanediol (1,4-BDO) from a fermentation broth includes separating a liquid fraction enriched in 1,4-BDO from a solid fraction comprising cells, removing water from said liquid fraction, removing salts from said liquid fraction, and purifying 1,4-BDO. A process for producing 1,4-BDO includes culturing a 1,4-BDO-producing microorganism in a fermentor for a sufficient period of time to produce 1,4-BDO. The 1,4-BDO-producing microorganism includes a microorganism having a 1,4-BDO pathway having one or more exogenous genes encoding a 1,4-BDO pathway enzyme and / or one or more gene disruptions. The process for producing 1,4-BDO further includes isolating 1,4-BDO.

Owner:GENOMATICA INC

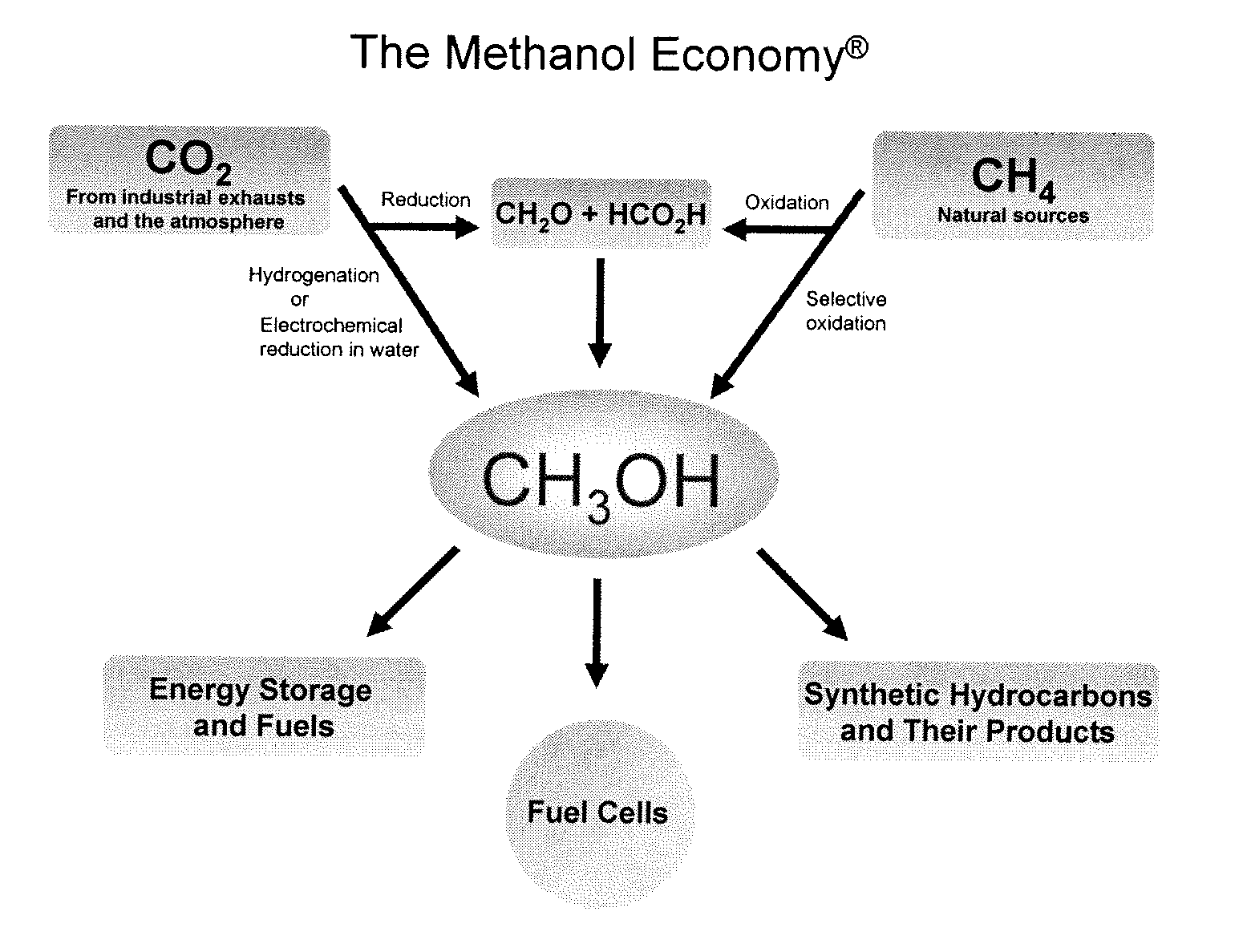

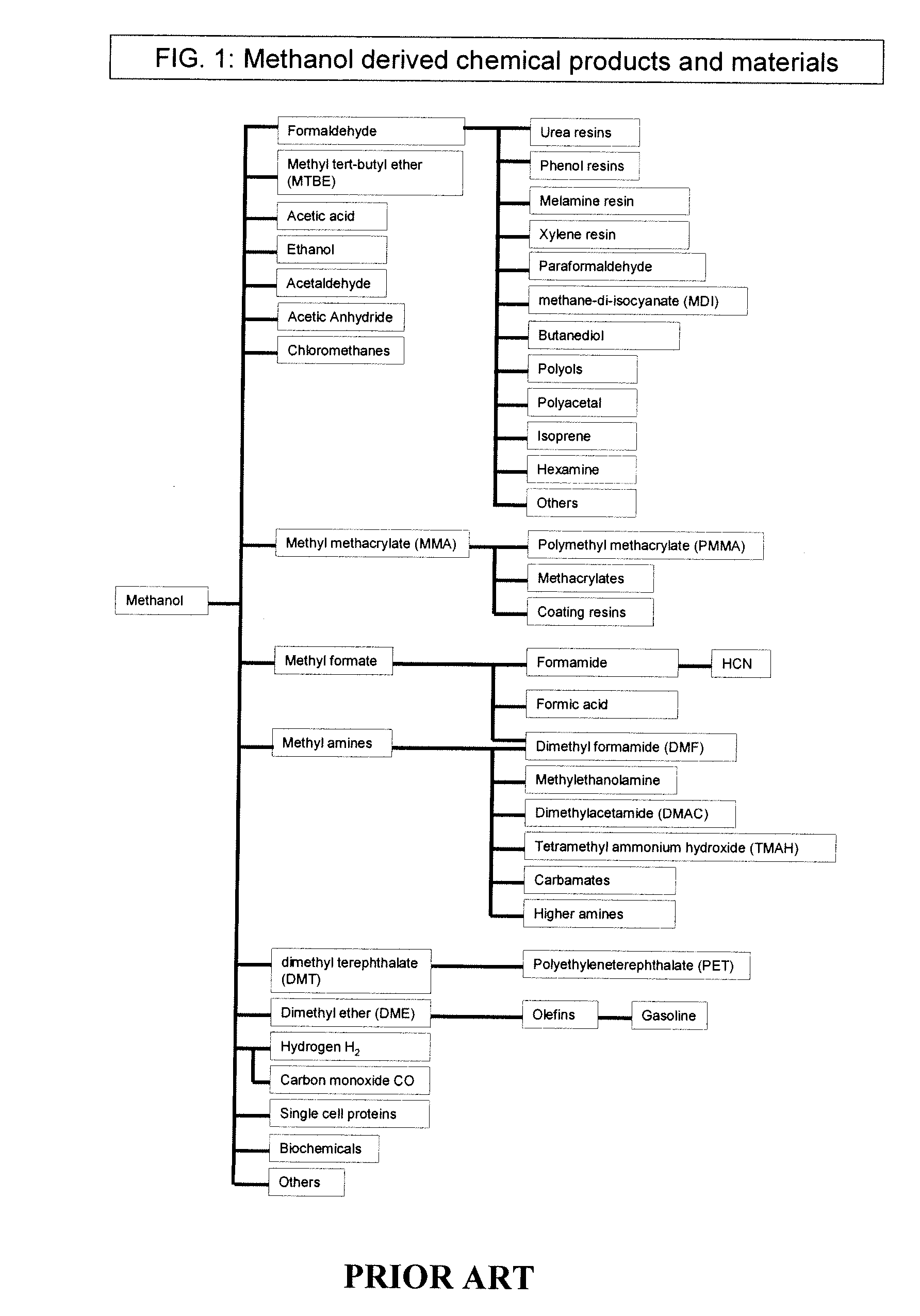

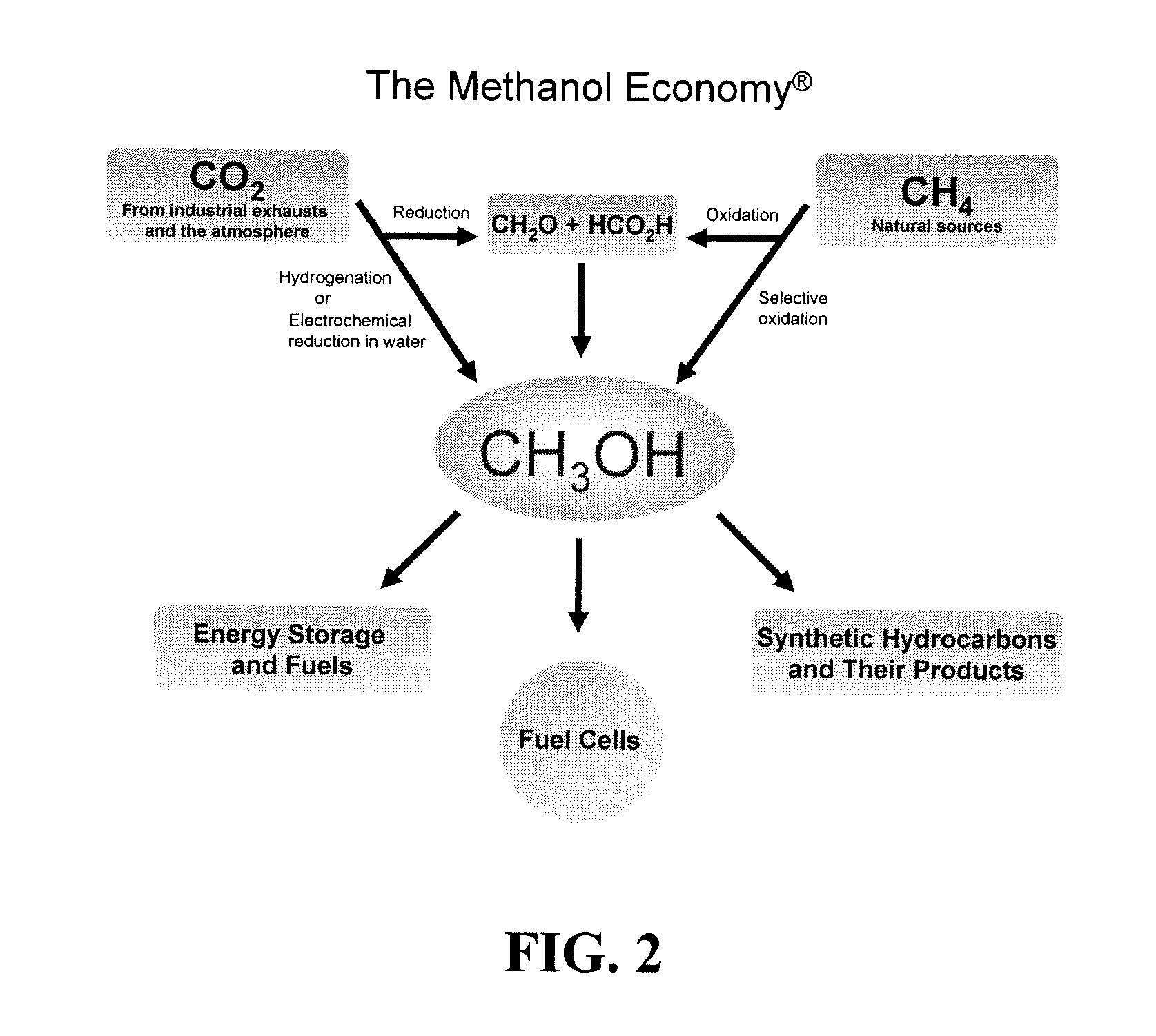

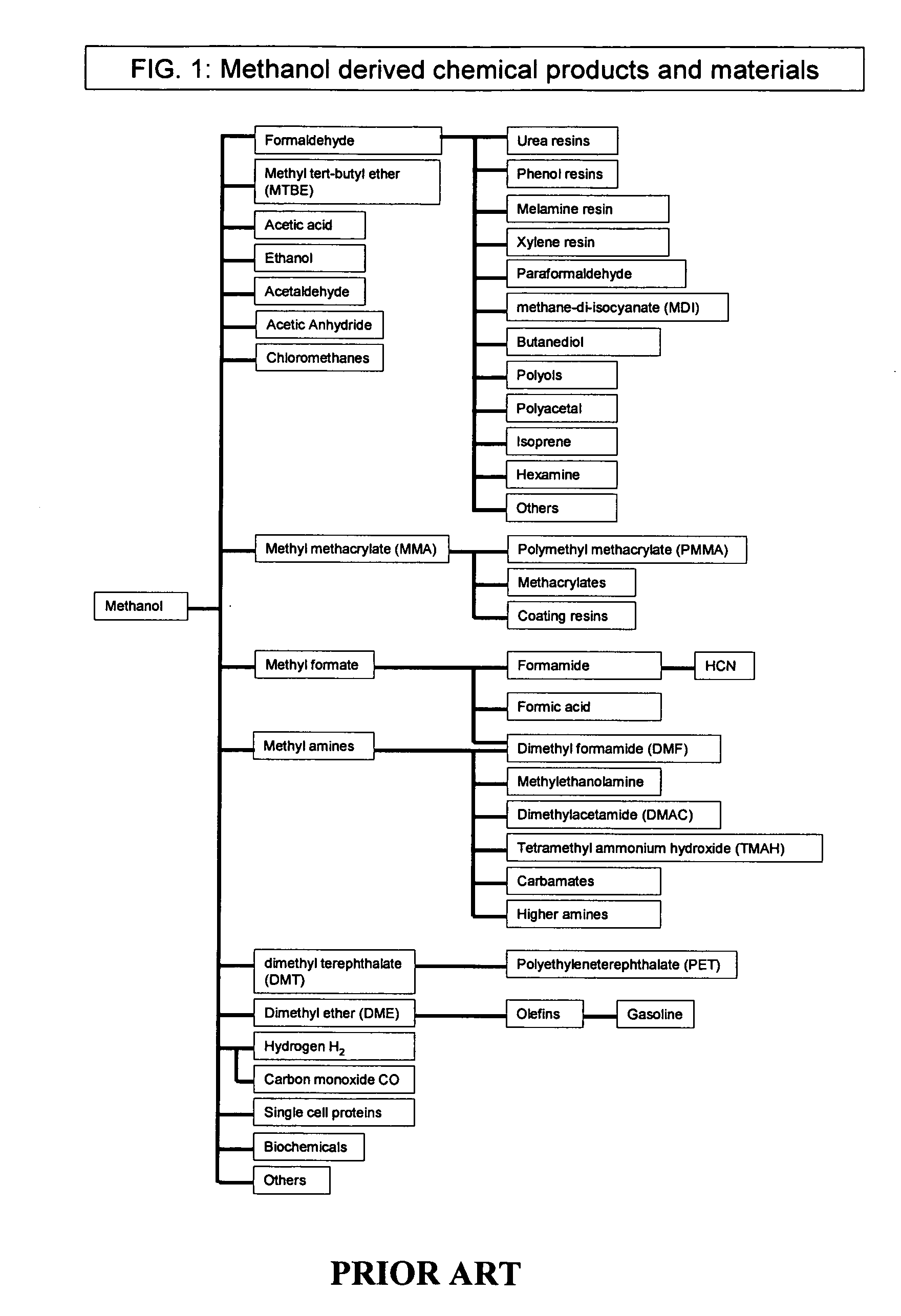

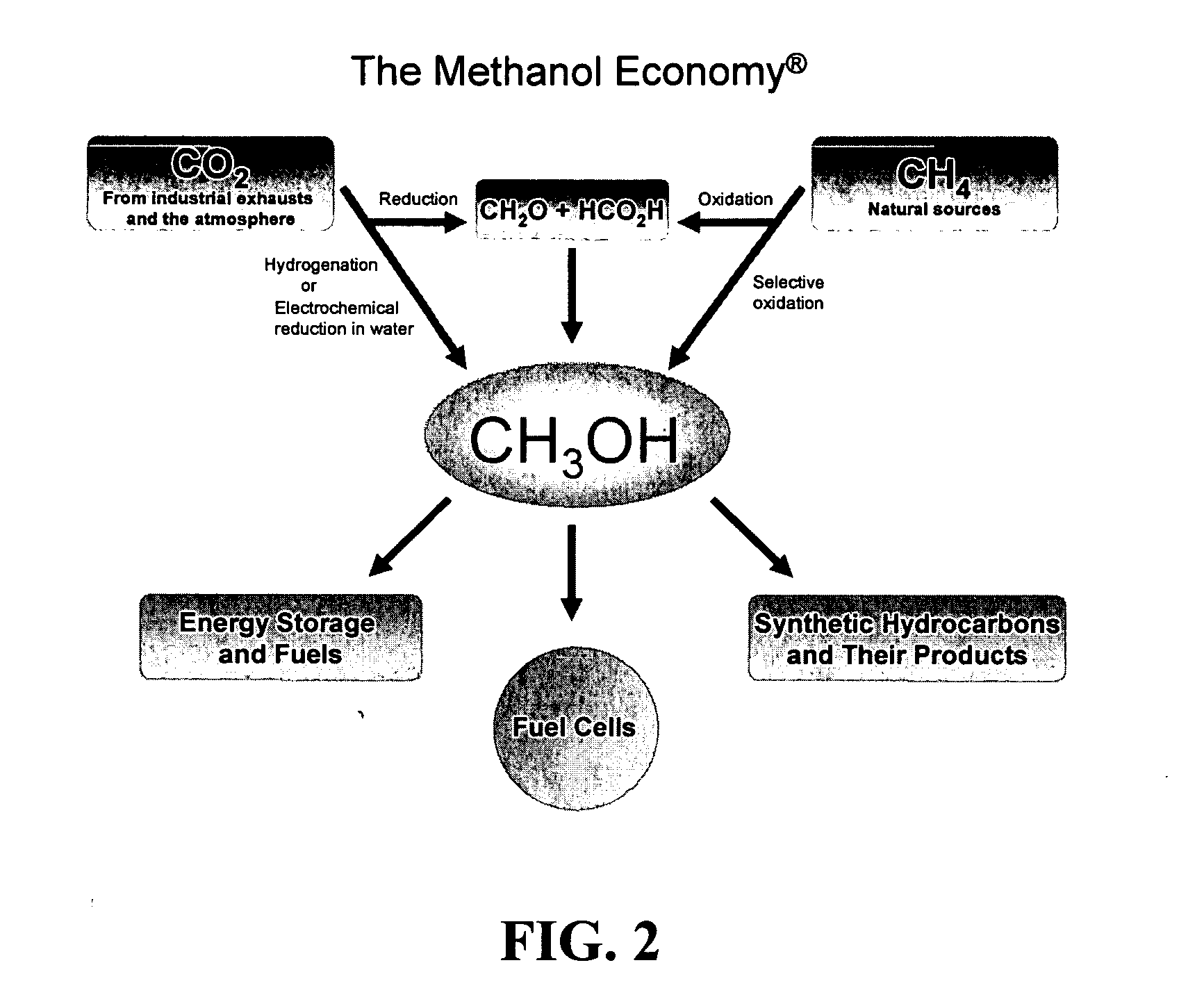

Efficient and selective chemical recycling of carbon dioxide to methanol, dimethyl ether and derived products

ActiveUS20070254969A1Avoid emissionsElectrolysis componentsOxygen compounds purification/separationElectrochemistryDimethyl ether

An efficient and environmentally beneficial method of recycling and producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning powerplants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by chemical or electrochemical reduction secondary treatment to produce essentially methanol, dimethyl ether and derived products.

Owner:UNIV OF SOUTHERN CALIFORNIA

Efficient and selective conversion of carbon dioxide to methanol, dimethyl ether and derived products

ActiveUS20060235091A1Minimize or eliminate the disadvantages or dangers inherentElectrolysis componentsCarbon compoundsHydrogenFlue gas

An environmentally beneficial method of producing methanol from varied sources of carbon dioxide including flue gases of fossil fuel burning powerplants, industrial exhaust gases or the atmosphere itself. Converting carbon dioxide by electrochemical reduction produces formic acid acid and some formaldehyde and methanol mixtures. The formic acid can be used as source of carbon as well as hydrogen to produce methanol, dimethyl ether and other products.

Owner:UNIV OF SOUTHERN CALIFORNIA

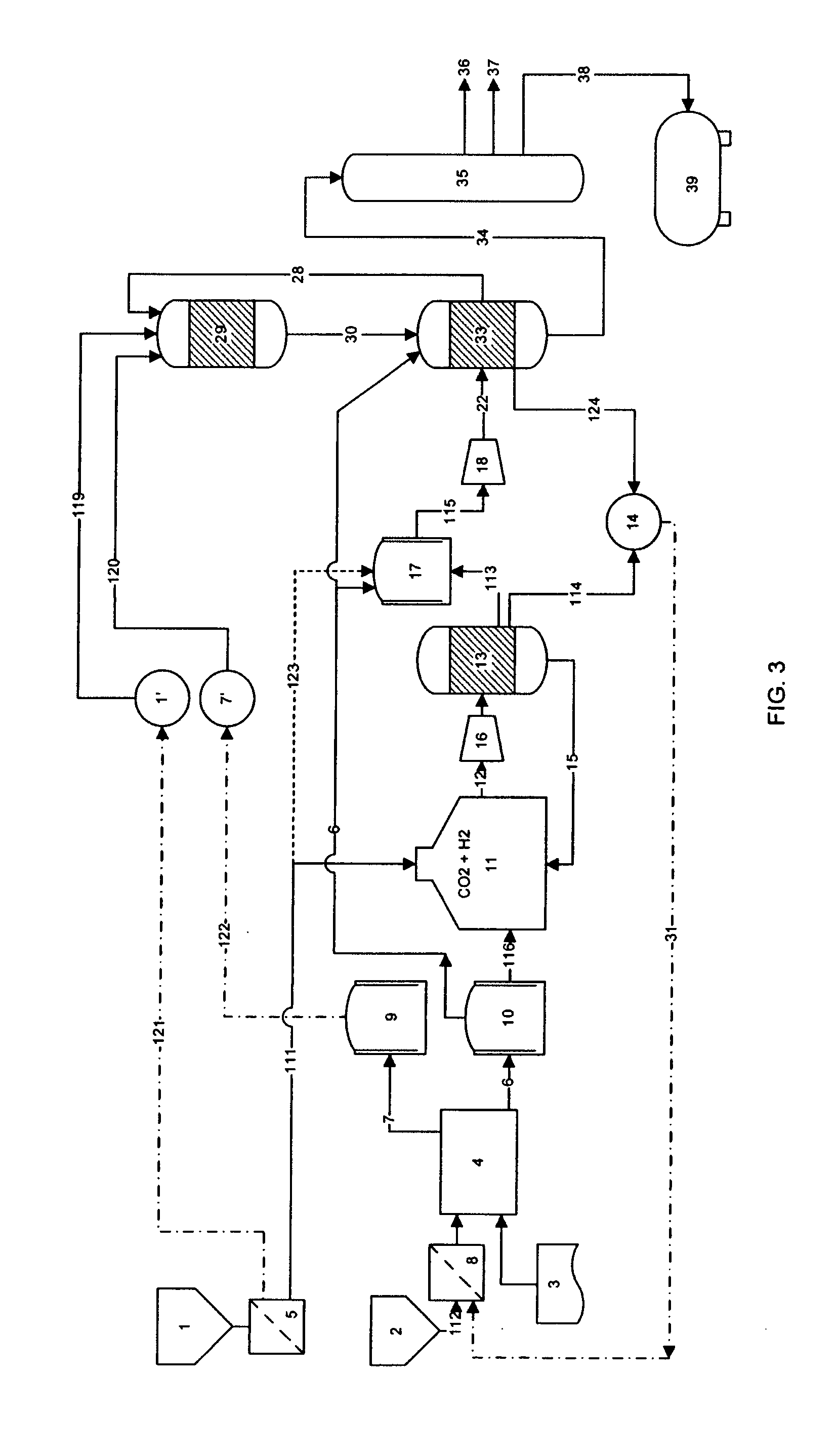

Process for producing liquid fuel from carbon dioxide and water

ActiveUS20070244208A1Combustible gas chemical modificationOrganic compounds purification/separation/stabilisationHydrocotyle bowlesioidesLiquid fuel

A process for producing high octane fuel from carbon dioxide and water is disclosed. The feedstock for the production line is industrial carbon dioxide and water, which may be of lower quality. The end product can be high octane gasoline, high cetane diesel or other liquid hydrocarbon mixtures suitable for driving conventional combustion engines or hydrocarbons suitable for further industrial processing or commercial use. Products, such as dimethyl ether or methanol may also be withdrawn from the production line. The process is emission free and reprocesses all hydrocarbons not suitable for liquid fuel to form high octane products. The heat generated by exothermic reactions in the process is fully utilizes as is the heat produced in the reprocessing of hydrocarbons not suitable for liquid fuel.

Owner:CRI EHF

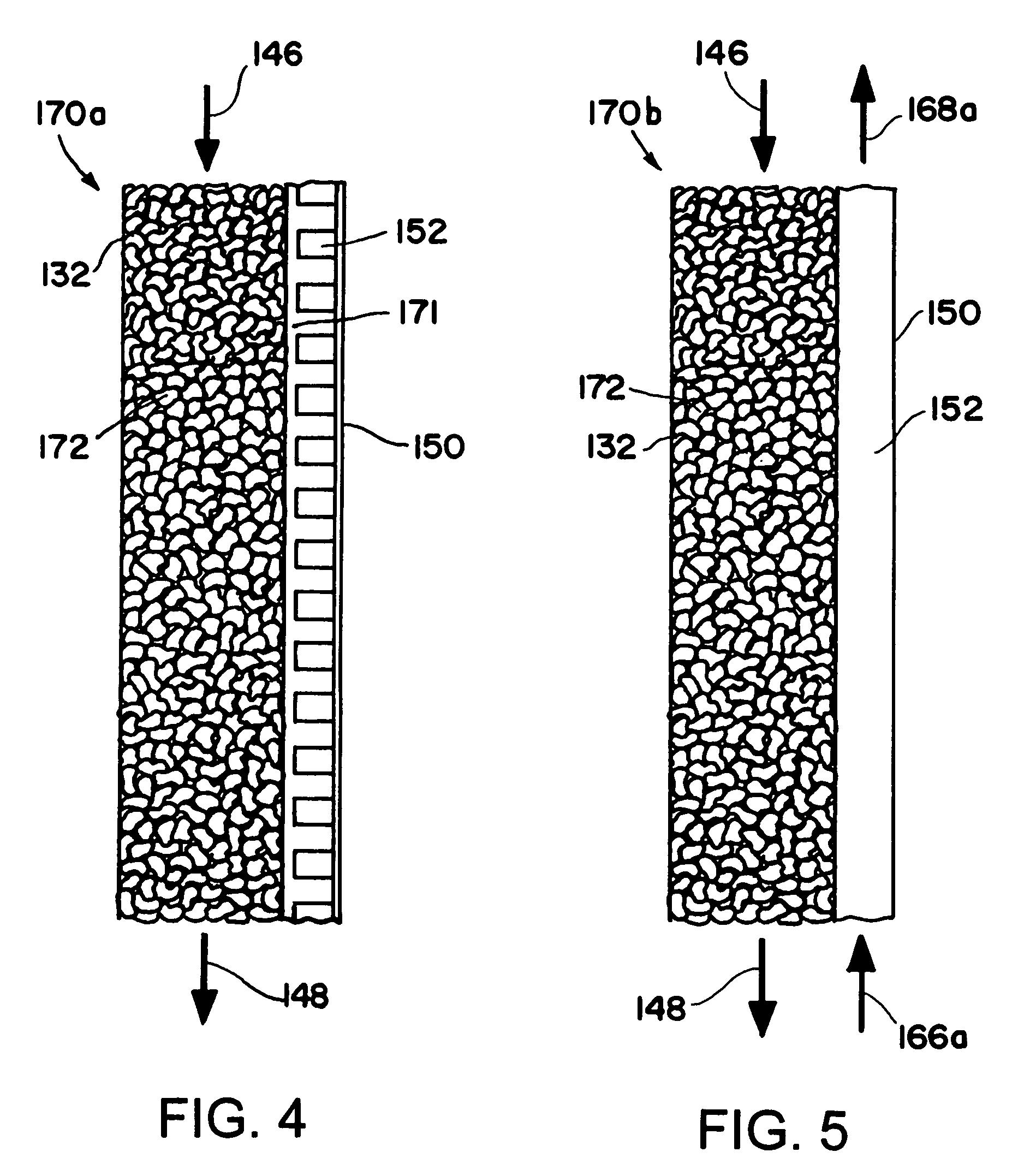

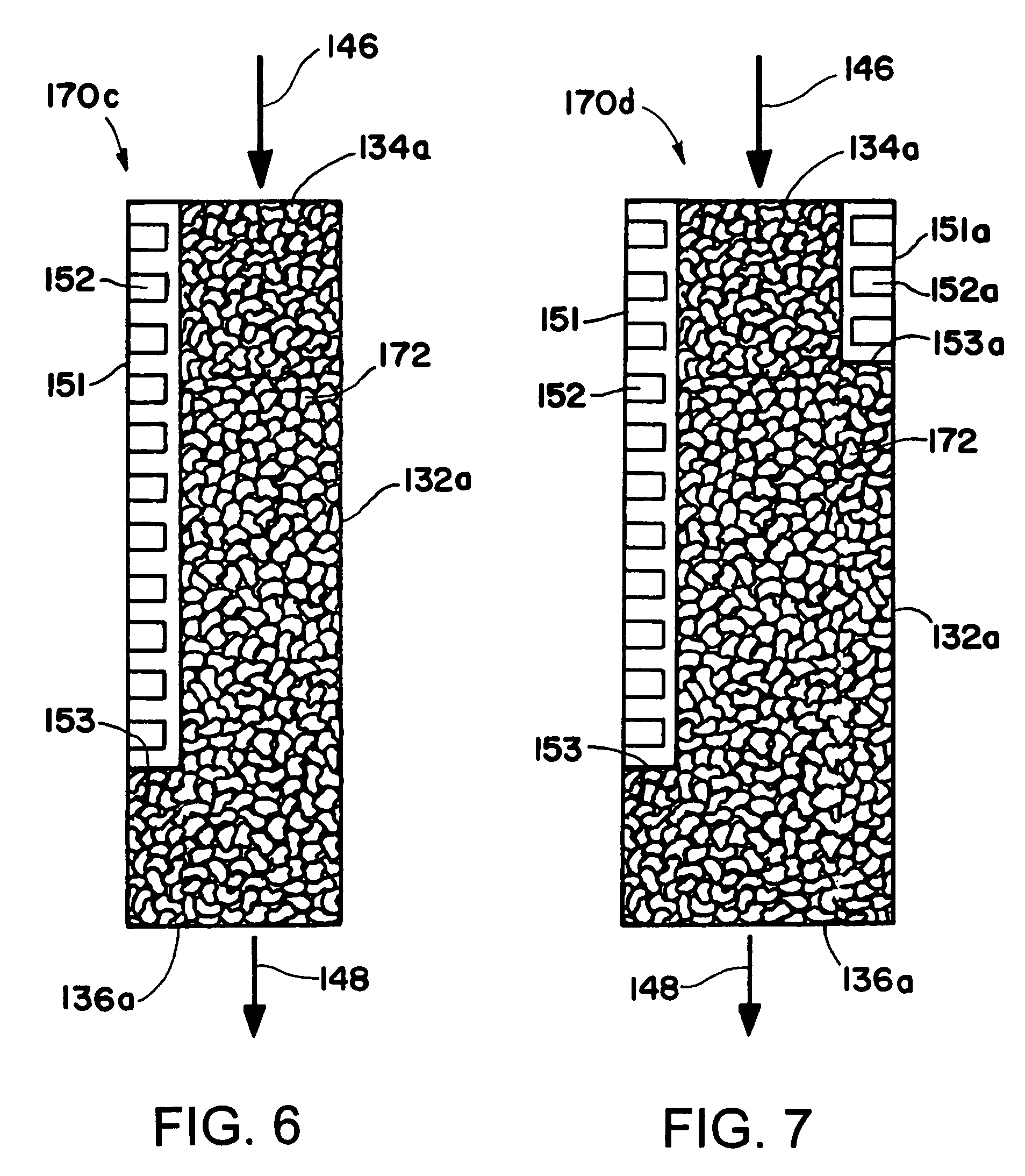

Fischer-tropsch synthesis using microchannel technology and novel catalyst and microchannel reactor

ActiveUS7084180B2Organic compounds purification/separation/stabilisationOrganic compound preparationGramAliphatic hydrocarbon

Owner:VELOCYS INC

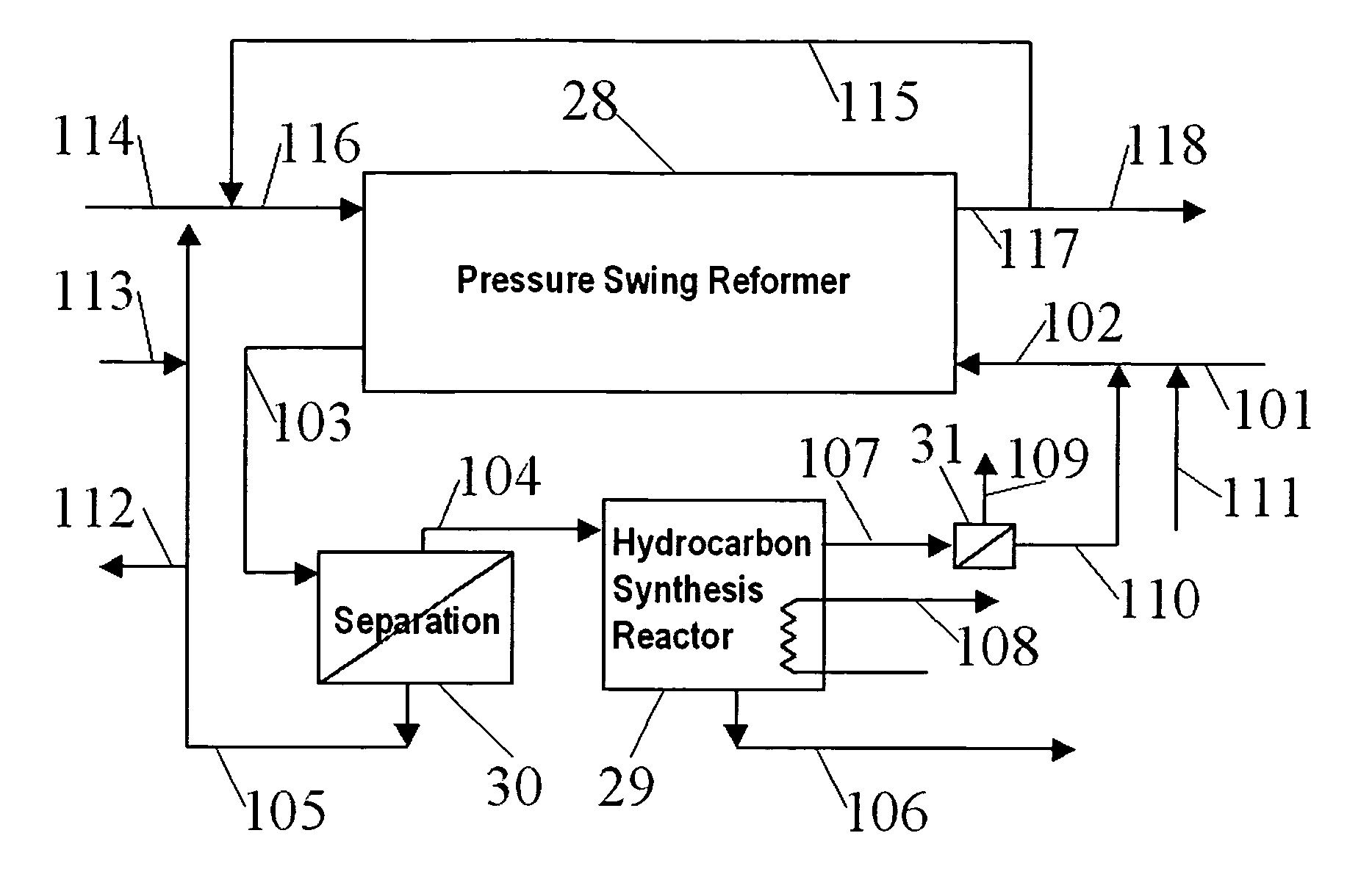

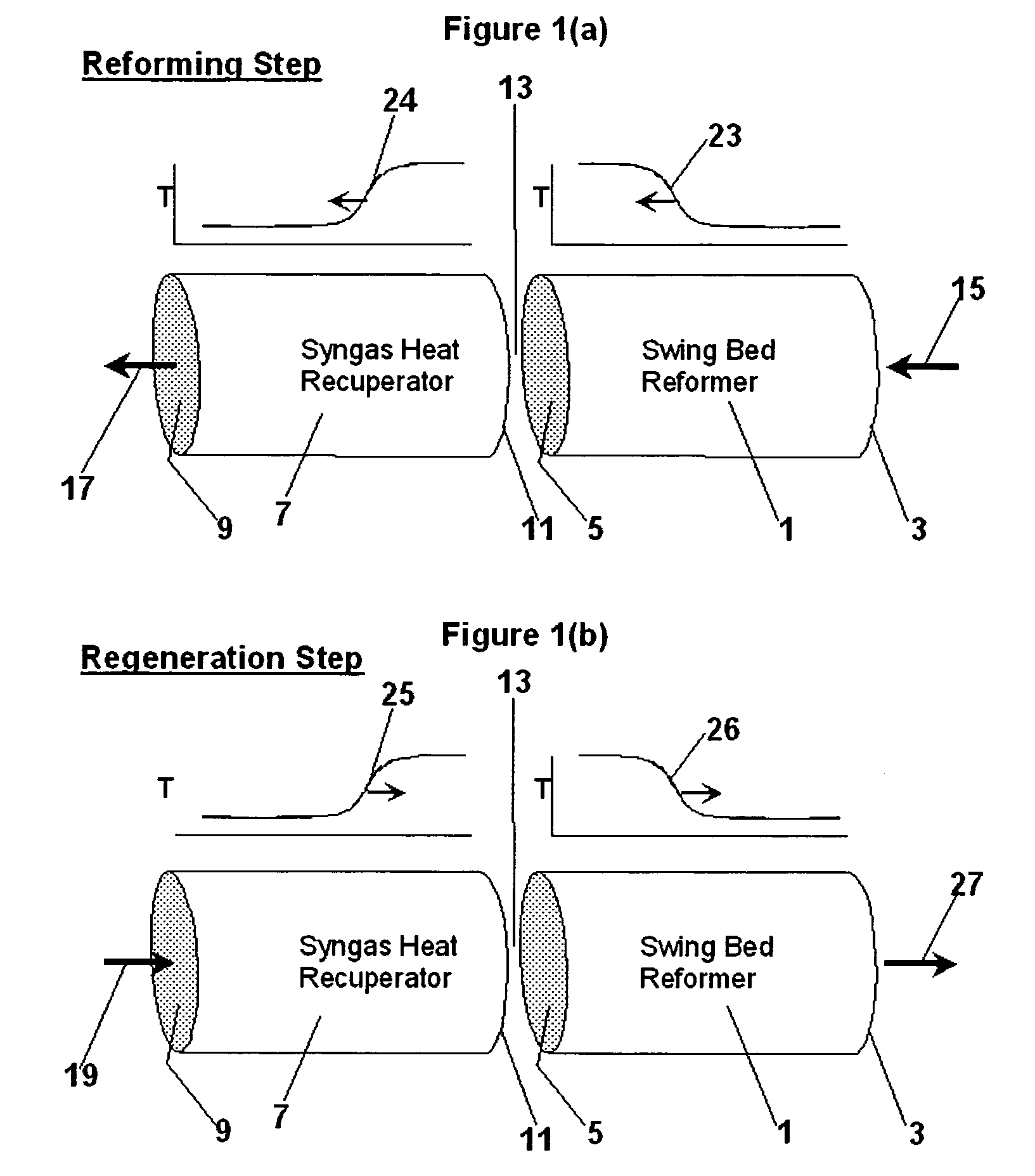

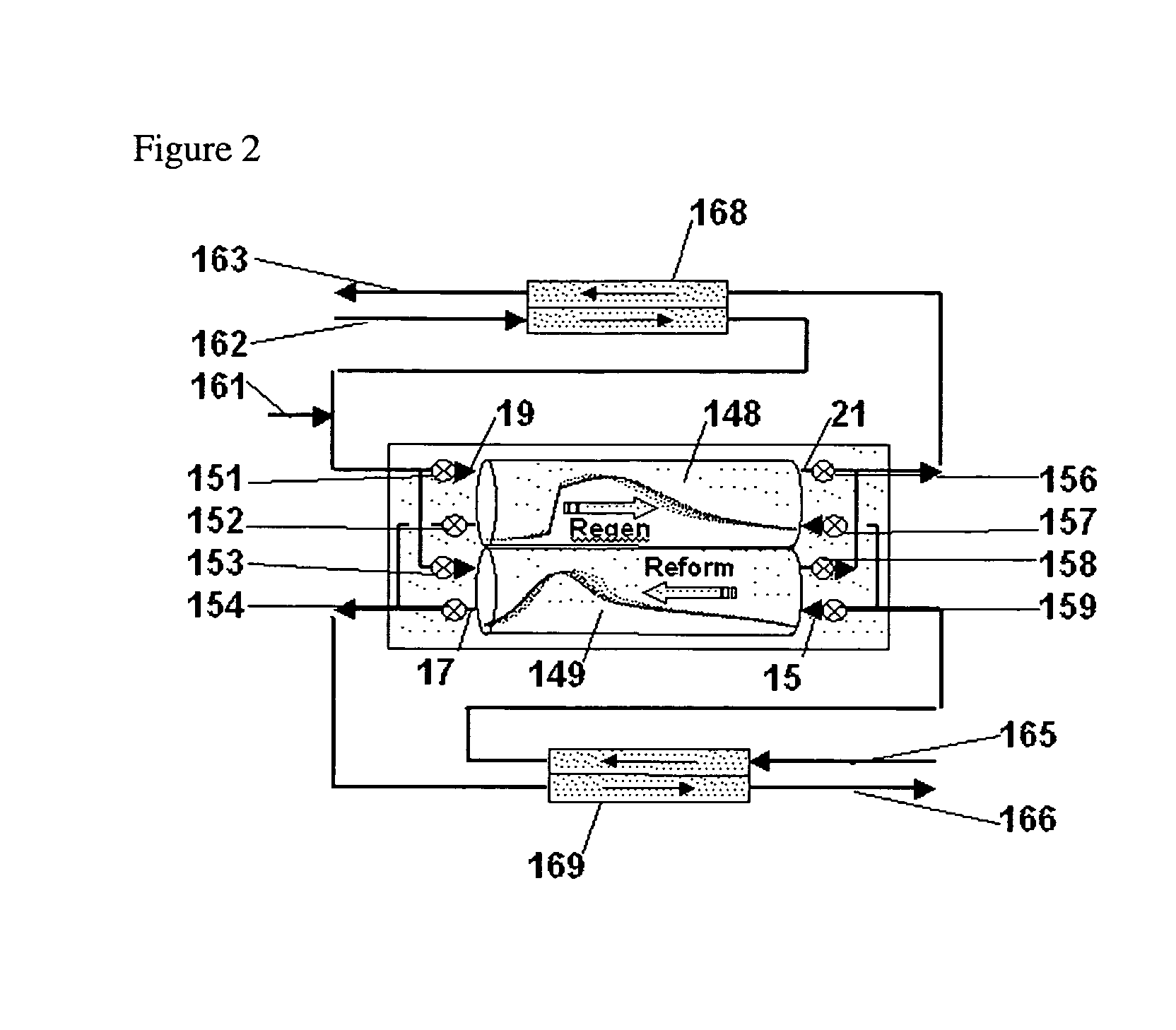

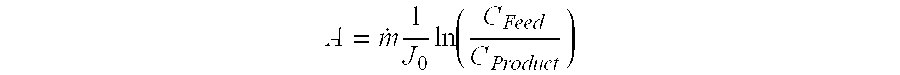

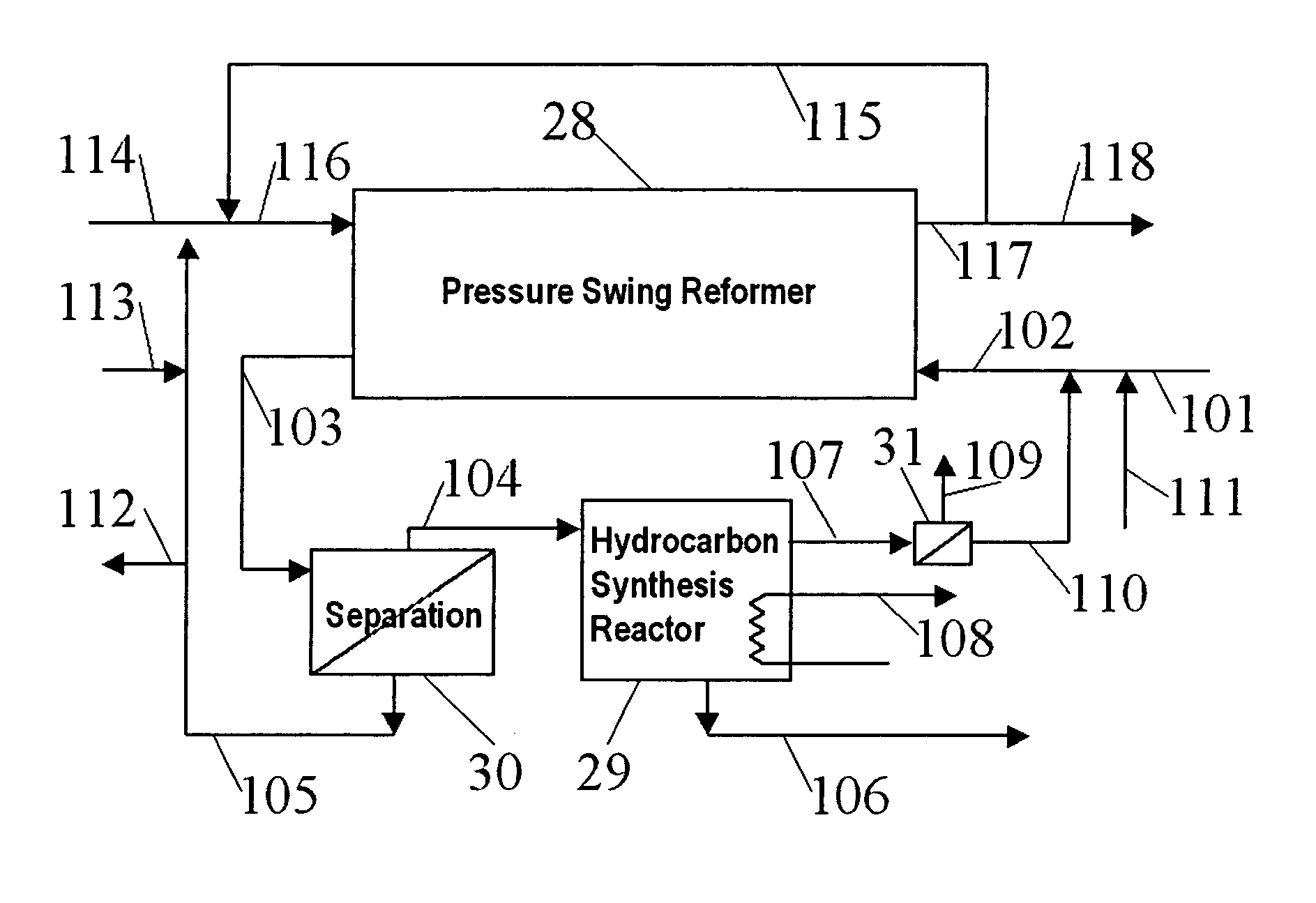

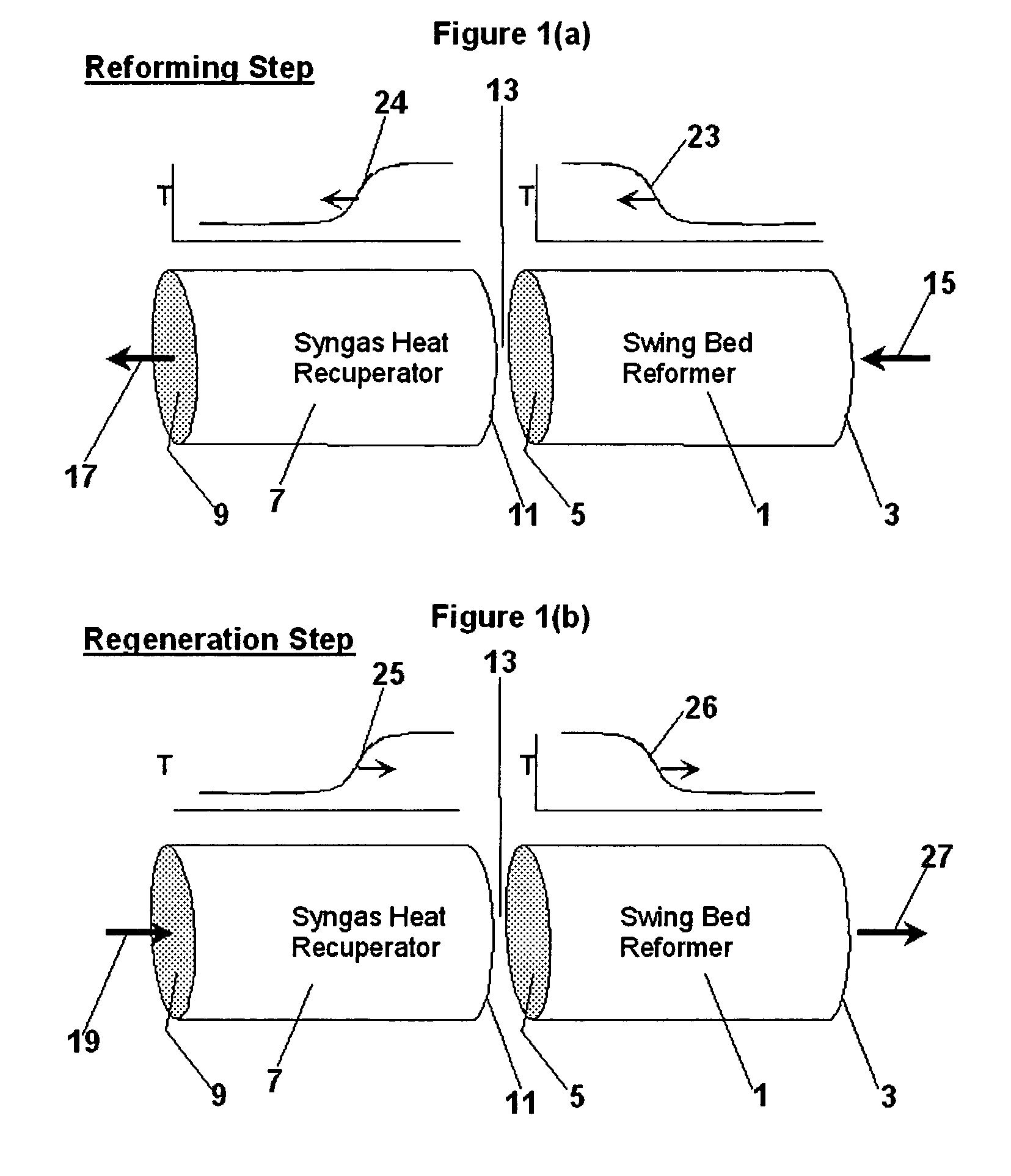

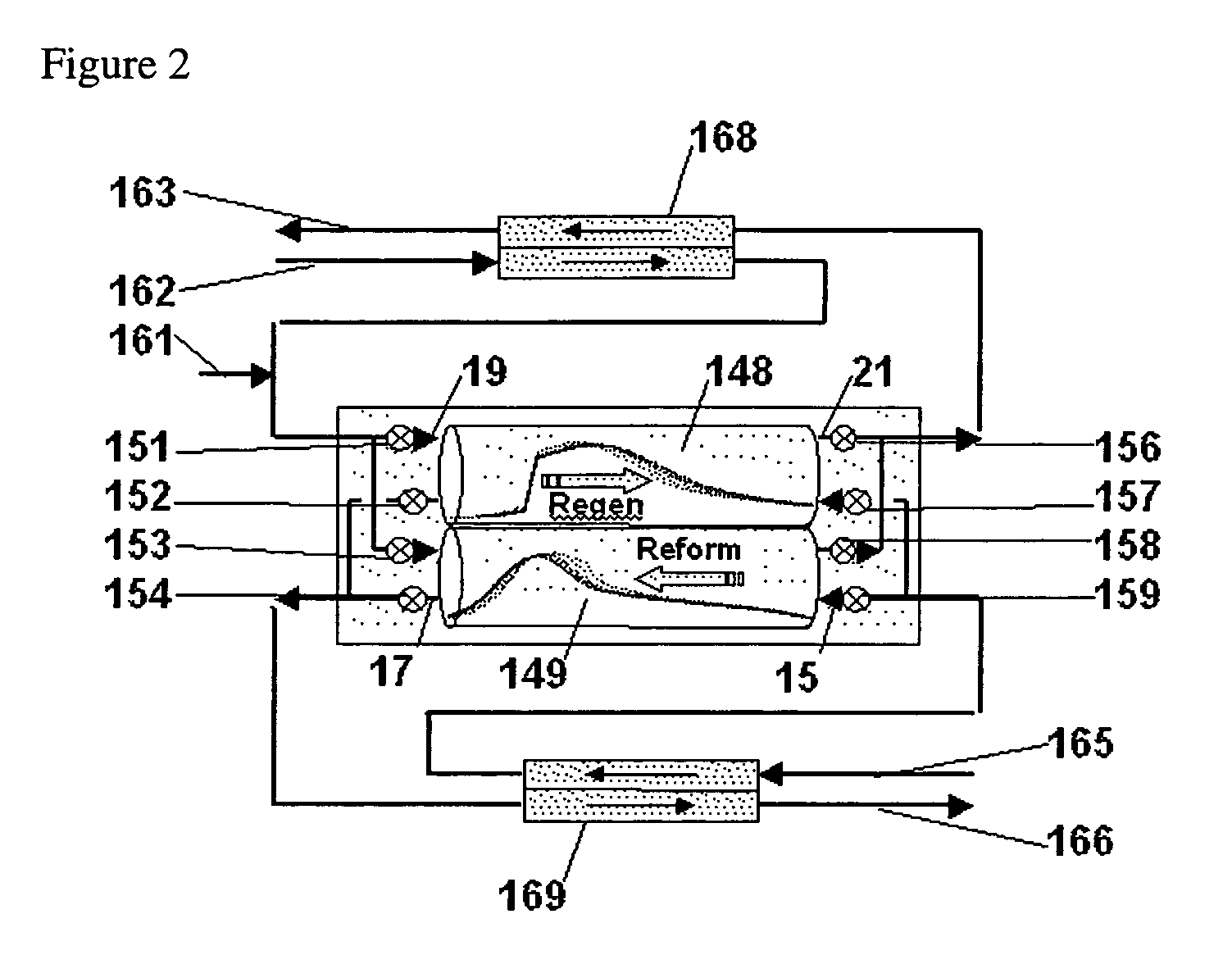

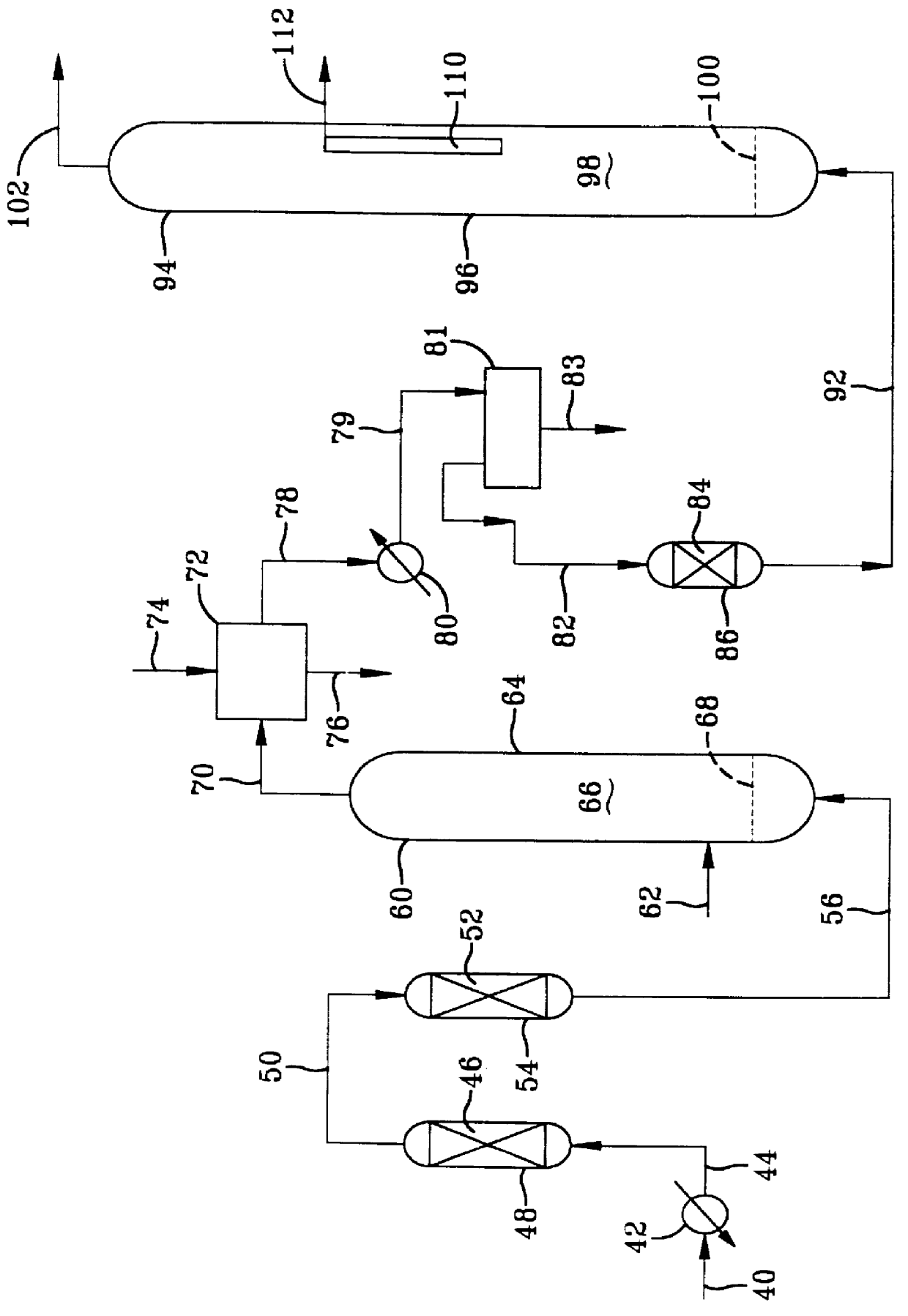

Hydrocarbon synthesis process using pressure swing reforming

ActiveUS7045553B2Material efficiencyAccelerates synthesis processOrganic compounds purification/separation/stabilisationHydrogenLiquid productSyngas

The invention provides a method for producing liquid hydrocarbons by first generating in a pressure swing reformer a synthesis gas stream having a mole ratio of H2:CO greater than 2:1. Then, a portion of the hydrogen is separated to produce a synthesis gas stream having a mole ratio of H2:CO of about 2:1 which steam is then introduced into a hydrocarbon synthesis reactor for conversion to liquid products.

Owner:EXXON RES & ENG CO

Hydrogenation of biochemical derived 1,3 -propanediol

InactiveUS7098368B2Organic compound preparationOxygen compounds purification/separationDownstream processingHydrogenation process

The invention discloses a hydrogenation process for removing impurities and controlling acid for use in downstream processing of biochemically-derived 1,3-propanediol. Preferably, the biochemically-derived 1,3-propanediol, before the contacting, has an initial color and, after the contracting, has a color that is lower than the initial color.

Owner:EI DU PONT DE NEMOURS & CO

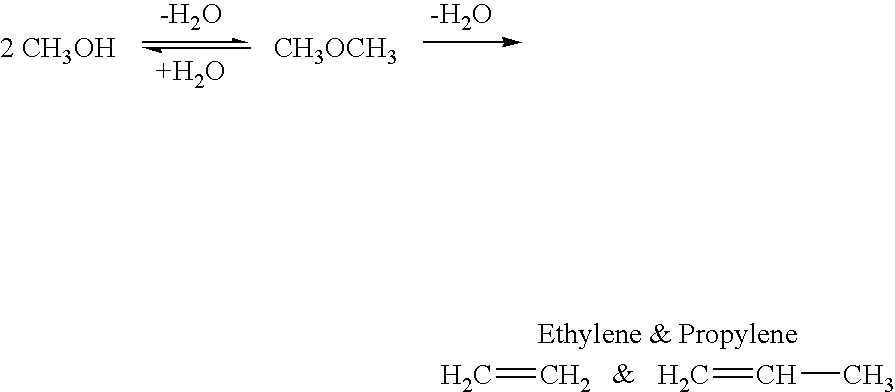

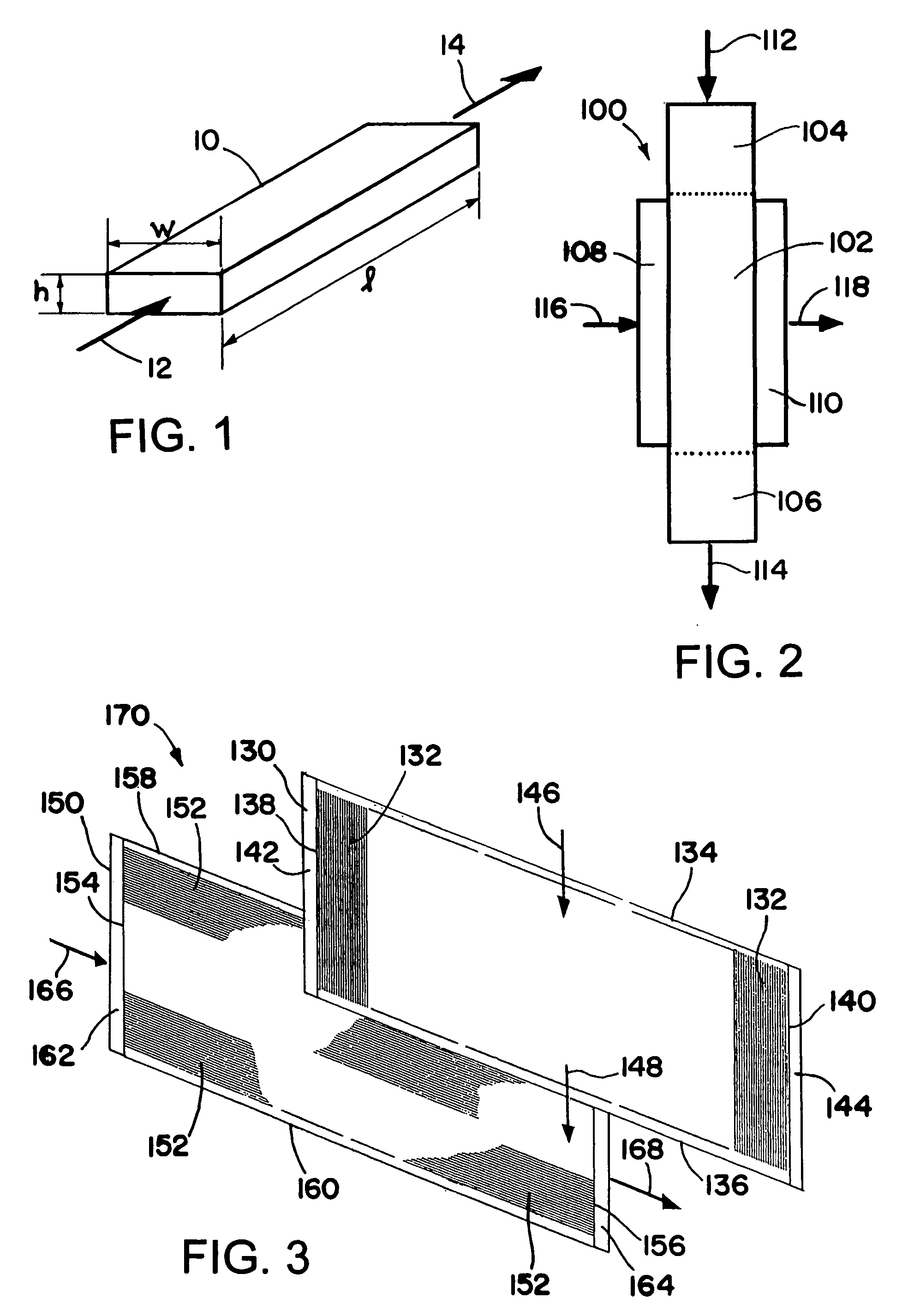

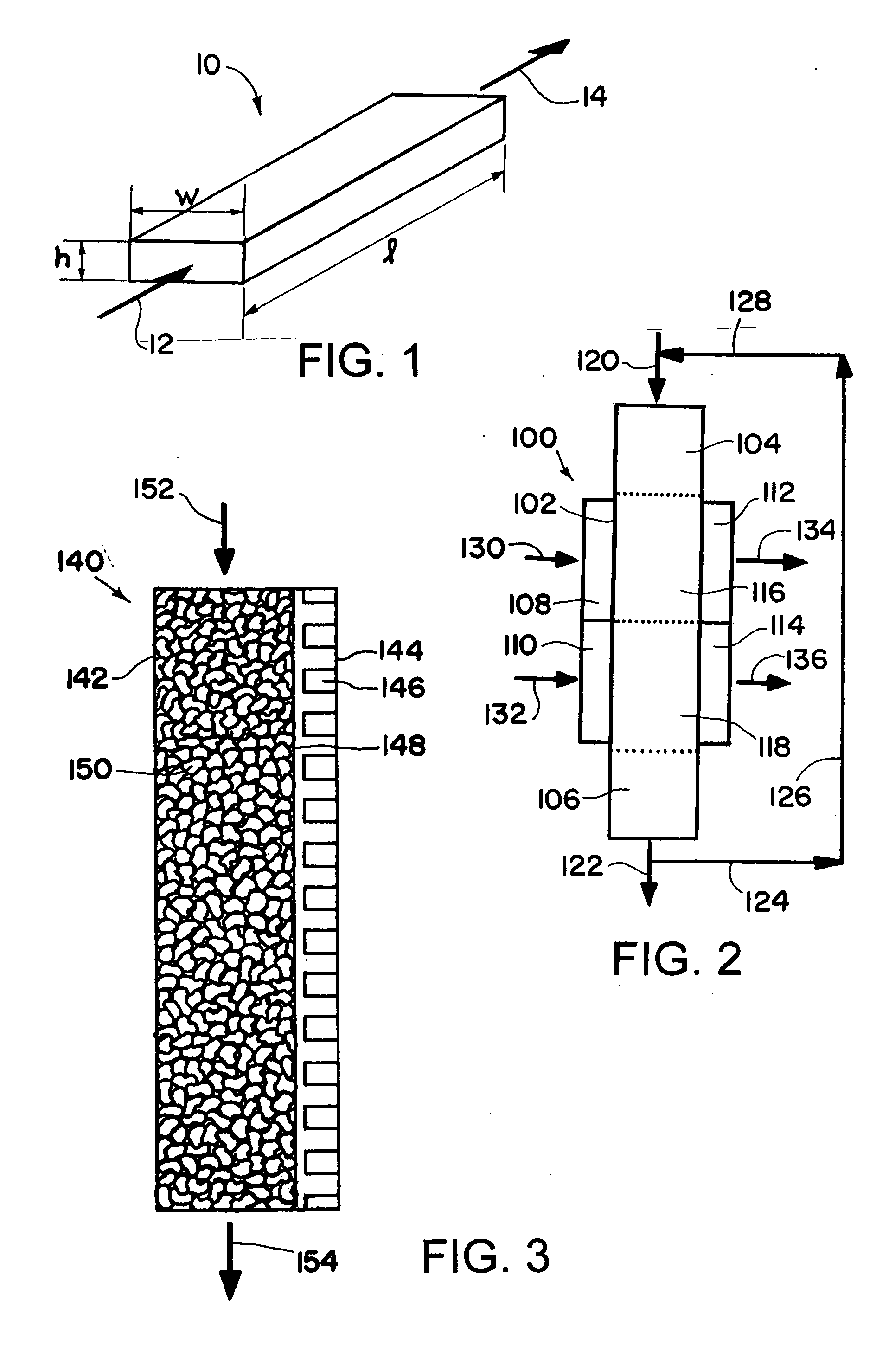

Process for conducting an equilibrium limited chemical reaction using microchannel technology

InactiveUS20050176832A1Large specific surface areaIncrease heatOrganic compounds purification/separation/stabilisationOrganic compound preparationChemical reactionDimethyl ether

The disclosed invention relates to a process for conducting an equilibrium limited chemical reaction in a microchannel reactor. The process involves the use of active heat exchange and is suitable for conducting exothermic and endothermic reactions. The process is particularly suitable for synthesizing methanol and dimethyl ether.

Owner:VELOCYS CORPORATION

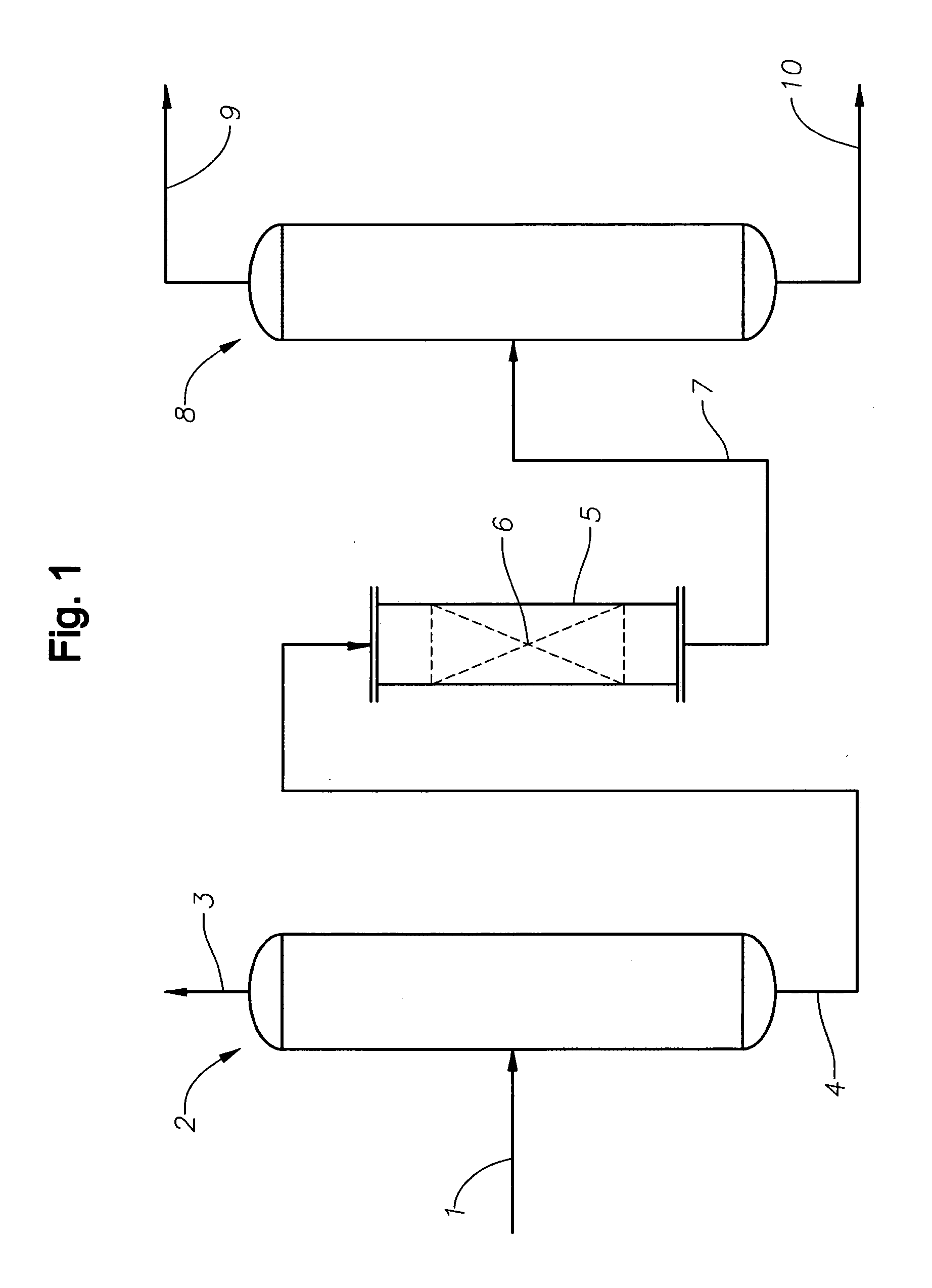

Process for dewatering ethanol

InactiveUS7399892B2Avoid disadvantagesSemi-permeable membranesMembranesEthyl tert-butyl etherWater content

A process for preparing low-water ethanol from at least two streams of relatively water-rich ethanol that have a different water content by dewatering at membranes. The low-water ethanol can be used to prepare ethyl tert-butyl ether (ETBE).

Owner:EVONIK OXENO GMBH (DE)

Hydrocarbon synthesis process using pressure swing reforming

ActiveUS7053128B2HydrogenOrganic compounds purification/separation/stabilisationLiquid productHydrogen

The invention provides a method for producing liquid hydrocarbons by first generating in a pressure swing reformer a synthesis gas stream having a mole ratio of H2:CO greater than 2:1. Then, a portion of the hydrogen is separated to produce a synthesis gas stream having a mole ratio of H2:CO of about 2:1 which steam is then introduced into a hydrocarbon synthesis reactor for conversion to liquid products.

Owner:EXXON RES & ENG CO

Fischer-Tropsch process in the presence of nitrogen contaminants

InactiveUS20050154069A1Organic compounds purification/separation/stabilisationHydrocarbon from carbon oxidesNitrogenPre conditioning

A Fischer-Tropsch process in the presence of nitrogen is provided wherein the Fischer-Tropsch catalyst retains at least 50% of its original activity and about the original C5+ selectivity. A process for pre-conditioning a Fischer-Tropsch catalyst such that no more than 50% of the original catalyst activity is lost while the resultant catalyst retains about its original C5+ selectivity.

Owner:SYNTROLEUM

Process and System for producing synthetic liquid hydrocarbon fuels

ActiveUS7420004B2High volumetric and gravimetric energy densityExcellent resistance to thermal oxidation processLiquid hydrocarbon mixture productionOxygen compounds purification/separationOcean thermal energy conversionElectric power

A process for producing synthetic hydrocarbons that reacts carbon dioxide, obtained from seawater of air, and hydrogen obtained from water, with a catalyst in a chemical process such as reverse water gas shift combined with Fischer Tropsch synthesis. The hydrogen is produced by nuclear reactor electricity, nuclear waste heat conversion, ocean thermal energy conversion, or any other source that is fossil fuel-free, such as wind or wave energy. The process can be either land based or sea based.

Owner:NAVY U S A AS REPRESENTED BY THE SEC OF THE THE

Process for recovering ethanol

InactiveUS20110190547A1Organic compound preparationOxygen compounds preparation by reductionAcetic acidPurification methods

Owner:CELANESE INT CORP

Recovery of higher alcohols from dilute aqueous solutions

ActiveUS8101808B2High activityBioreactor/fermenter combinationsBiological substance pretreatmentsAqueous solutionAlcohol products

This invention is directed to methods for recovery of C3-C6 alcohols from dilute aqueous solutions, such as fermentation broths. Such methods provide improved volumetric productivity for the fermentation and allows recovery of the alcohol. Such methods also allow for reduced energy use in the production and drying of spent fermentation broth due to increased effective concentration of the alcohol product by the simultaneous fermentation and recovery process which increases the quantity of alcohol produced and recovered per quantity of fermentation broth dried. Thus, the invention allows for production and recovery of C3-C6 alcohols at low capital and reduced operating costs.

Owner:GEVO INC

Process for purifying ethanol

InactiveUS20110190548A1Organic compound preparationOxygen compounds preparation by reductionAcetic acidAcetaldehyde

Purifying and / or recovery of ethanol from a crude ethanol product obtained from the hydrogenation of acetic acid. Separation and purification processes of crude ethanol mixture are employed to allow recovery of ethanol and remove impurities. In addition, the process involves returning acetaldehyde separated from the crude ethanol product to the reactor.

Owner:CELANESE INT CORP

Manufacture of alcohols

Owner:EXXONMOBIL CHEM PAT INC

Very low sulfur gas feeds for sulfur sensitive syngas and hydrocarbon synthesis processes

Very low sulfur content hydrocarbon gas is achieved by sequentially contacting the gas first with zinc oxide and then with nickel metal. This has reduced the total sulfur content of natural gas feed for a fluid bed syngas generator to less than 0.1 ppm and has resulted in greater syngas productivity. A zinc oxide guard bed downstream of the syngas generator reduces the total sulfur content of the syngas to less than 10 vppb and preferably less than 5 vppb. This very low sulfur content syngas is used for sulfur sensitive processes, such as hydrocarbon synthesis. The process is especially useful for natural gas which contains H2S, COS, mercaptans and other sulfur bearing compounds.

Owner:EXXON RES & ENG CO

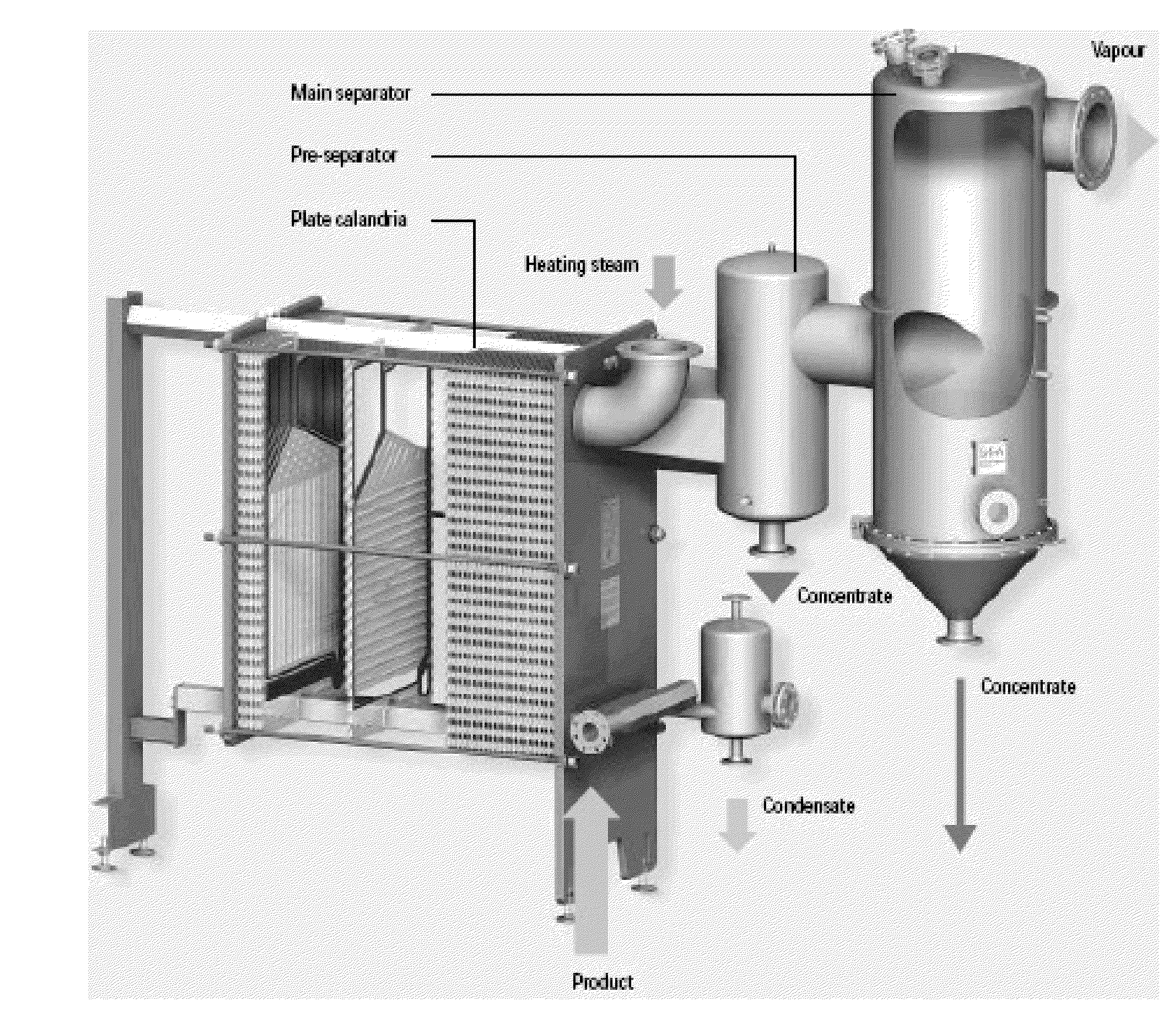

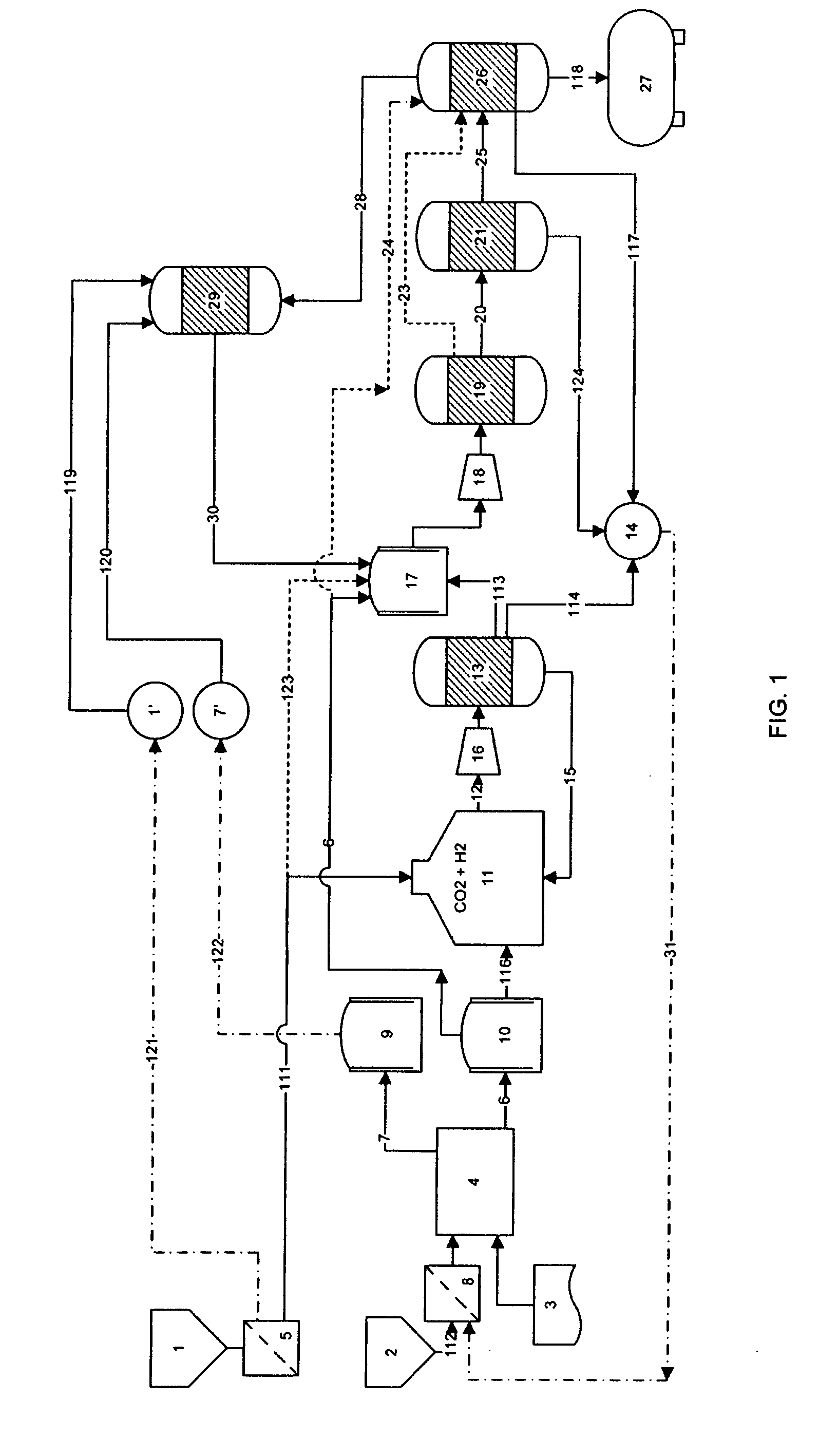

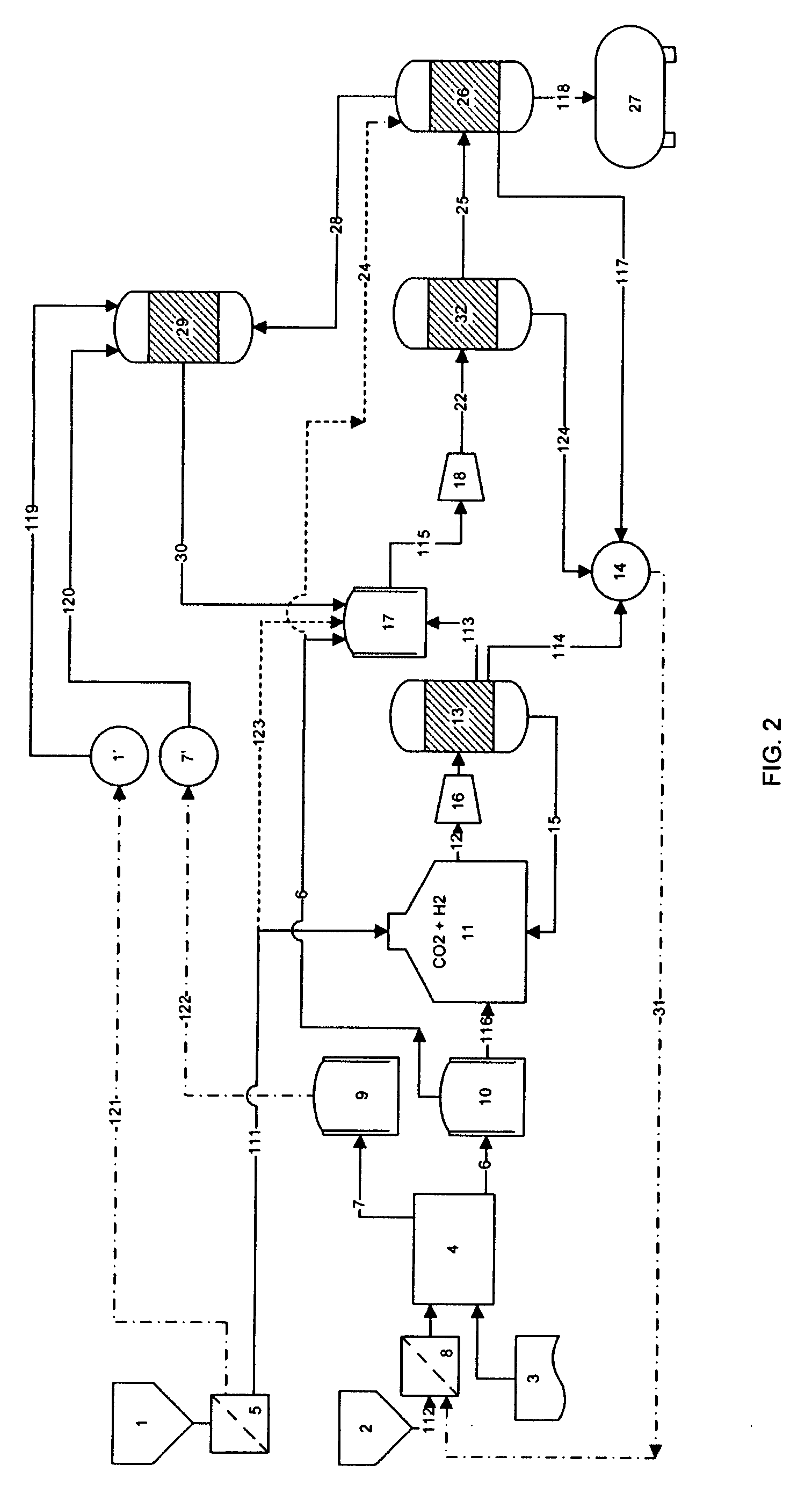

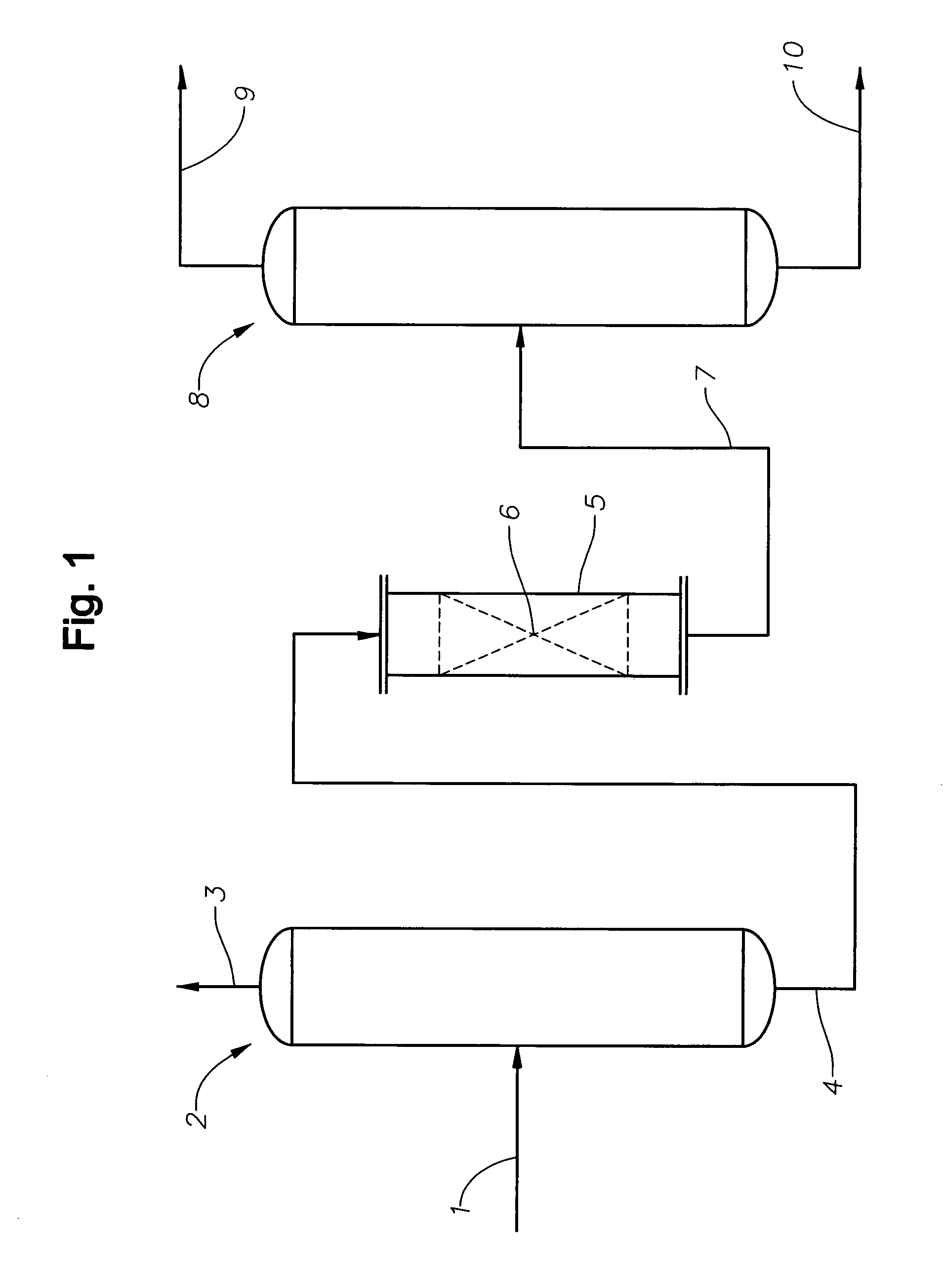

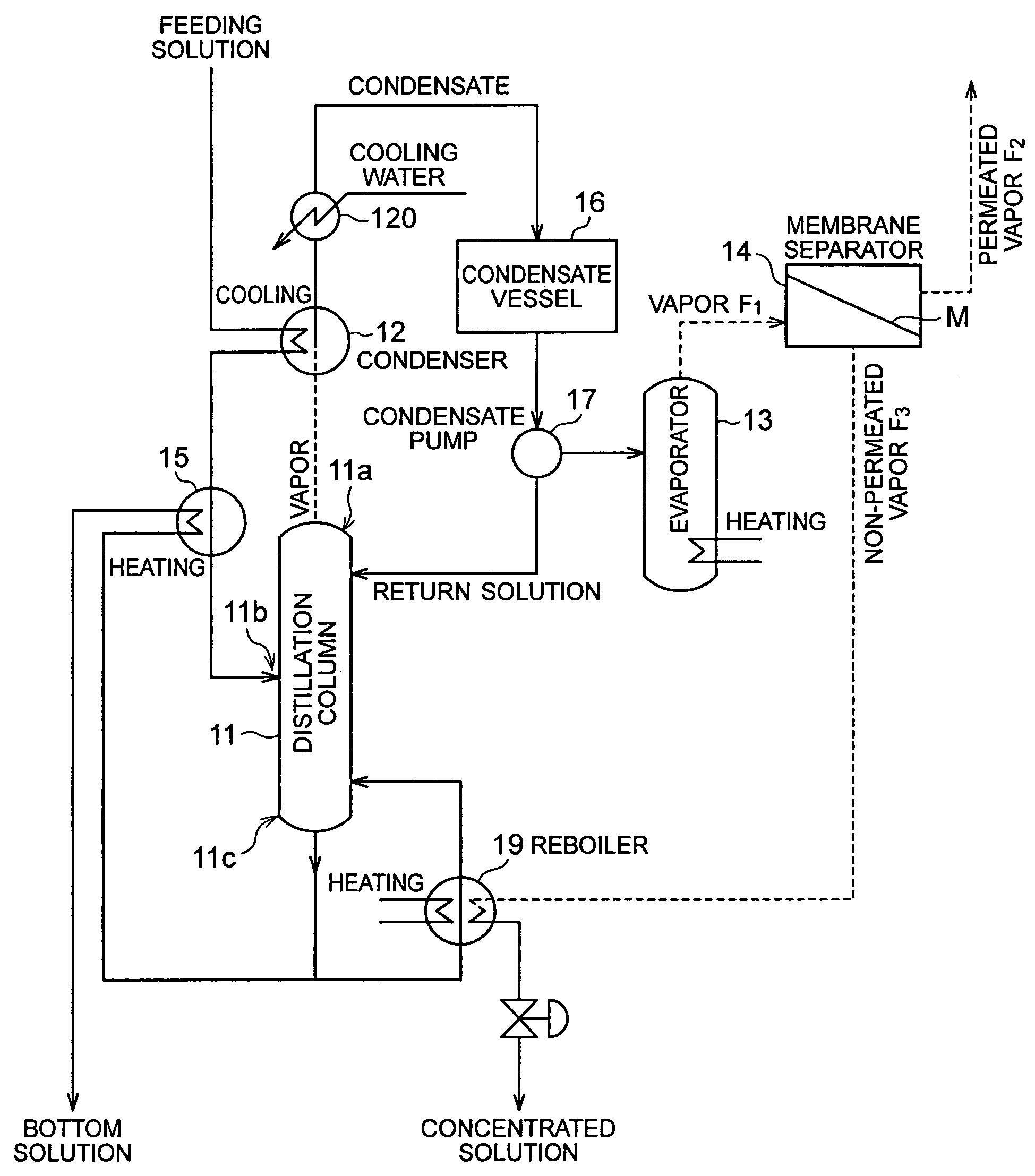

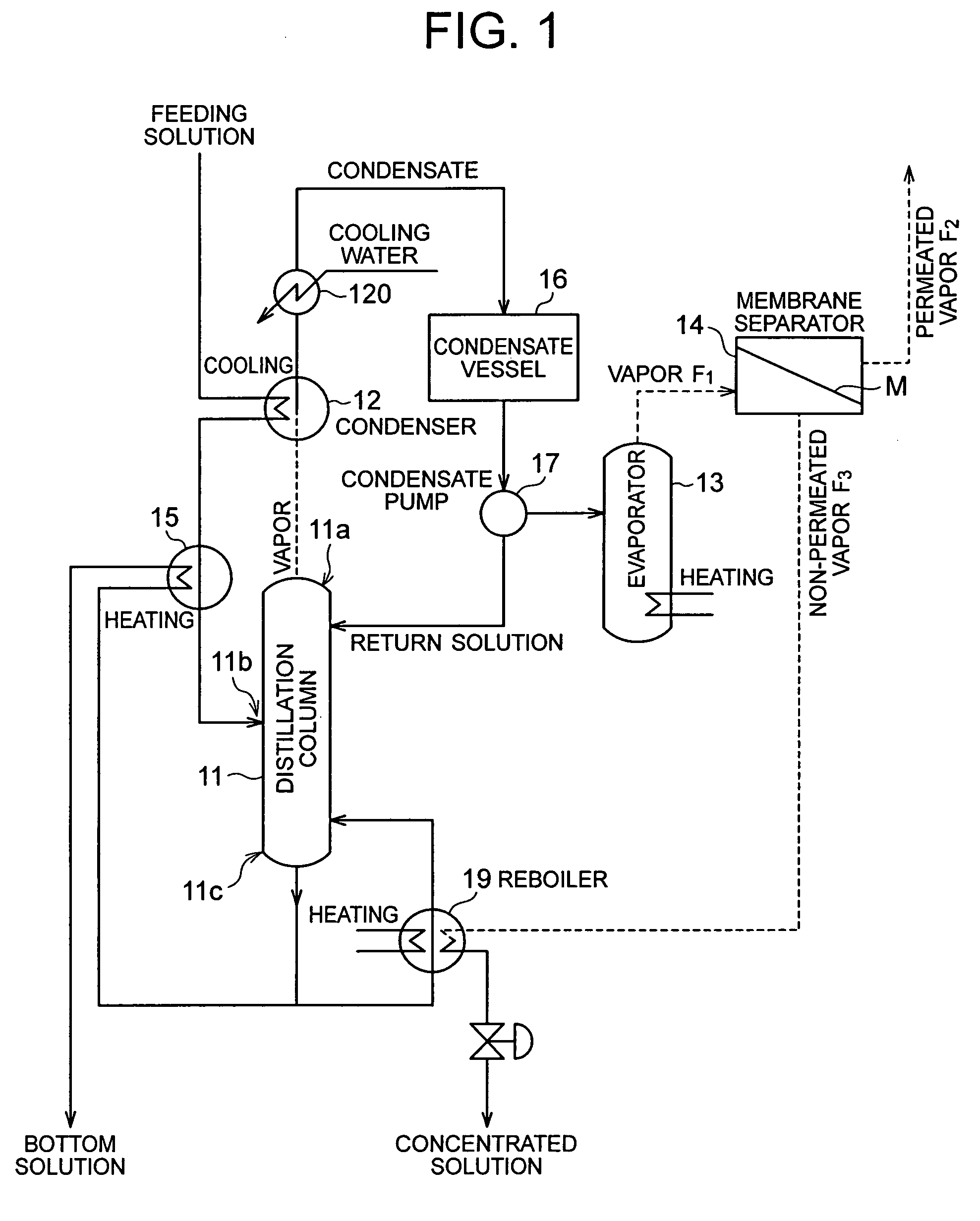

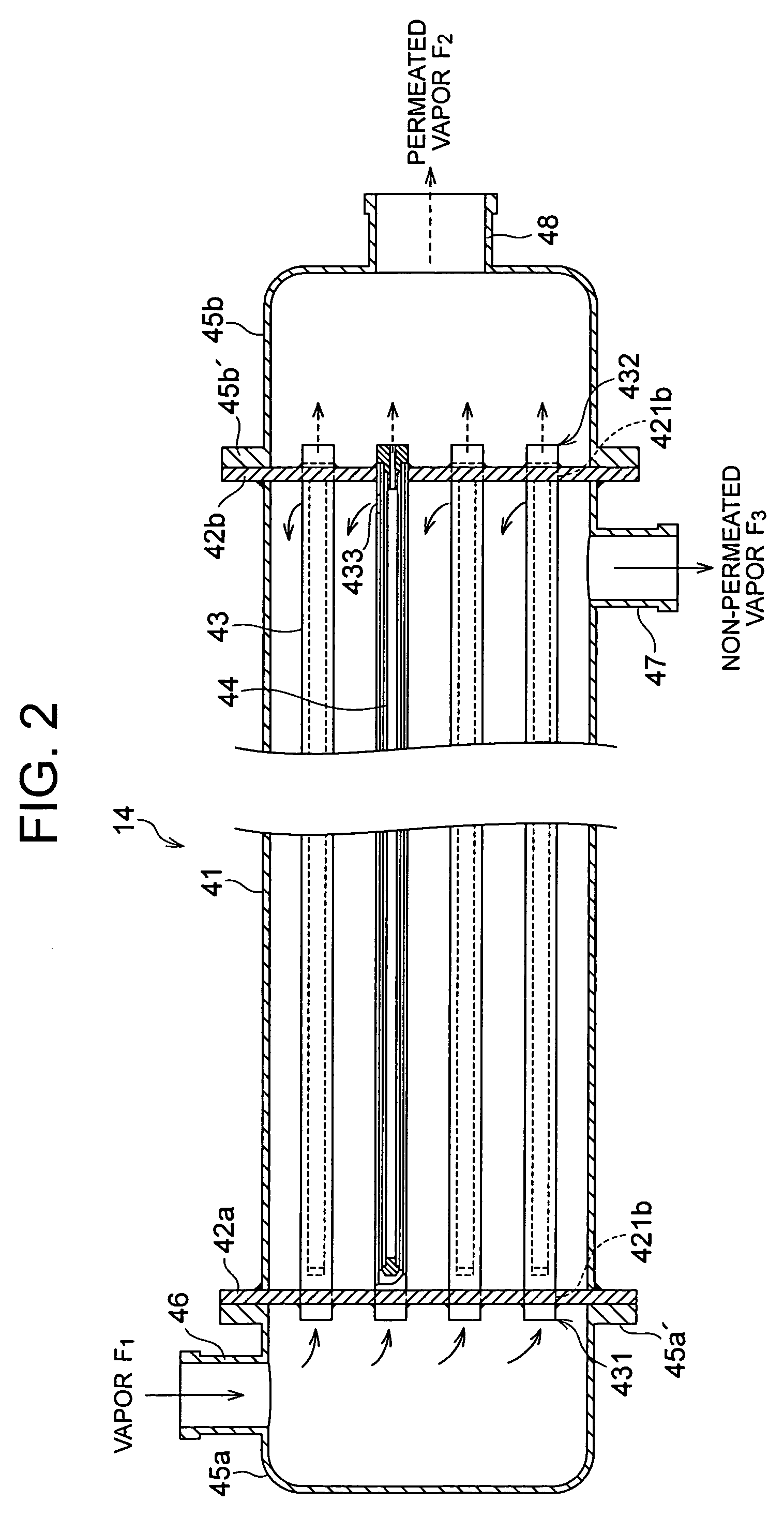

Method for concentrating water-soluble organic material

InactiveUS7594981B2Improve permeabilityIncrease operating pressureOrganic compound preparationDispersed particle separationDistillationWater soluble

A method for concentrating a water-soluble organic material wherein a mixture of the water-soluble organic material with water is distilled in a distillation column (11), and the fraction from the top (11a) of the distillation column (11) is separated by the use of a membrane separator (14) into a permeated vapor (F2) and a non-permeated vapor (F3), which comprises once condensing the fraction to form a condensate, heating the condensate in an evaporator (13) to generate a vapor (F1) having a pressure higher than the operation pressure for the distillation column (11), and introducing the vapor (F1) to the membrane separator (14), thereby separating water from the mixture.

Owner:MITSUBISHI CHEM CORP

Process for producing synthetic liquid hydrocarbon fuels

ActiveUS20050232833A1Meet high volumeIncreased gravimetric energy densityLiquid hydrocarbon mixture productionOxygen compounds purification/separationThermal energyOcean thermal energy conversion

A process for producing synthetic hydrocarbons that reacts carbon dioxide, obtained from seawater of air, and hydrogen obtained from water, with a catalyst in a chemical process such as reverse water gas shift combined with Fischer Tropsch snthesis. The hydrogen is produced by nuclear reactor electricity, nuclear waste heat conversion, ocean thermal energy conversion, or any other source that is fossil fuel-free, such as wind or wave energy. The process can be either land based or sea based.

Owner:NAVY U S A AS REPRESENTED BY THE SEC OF THE THE

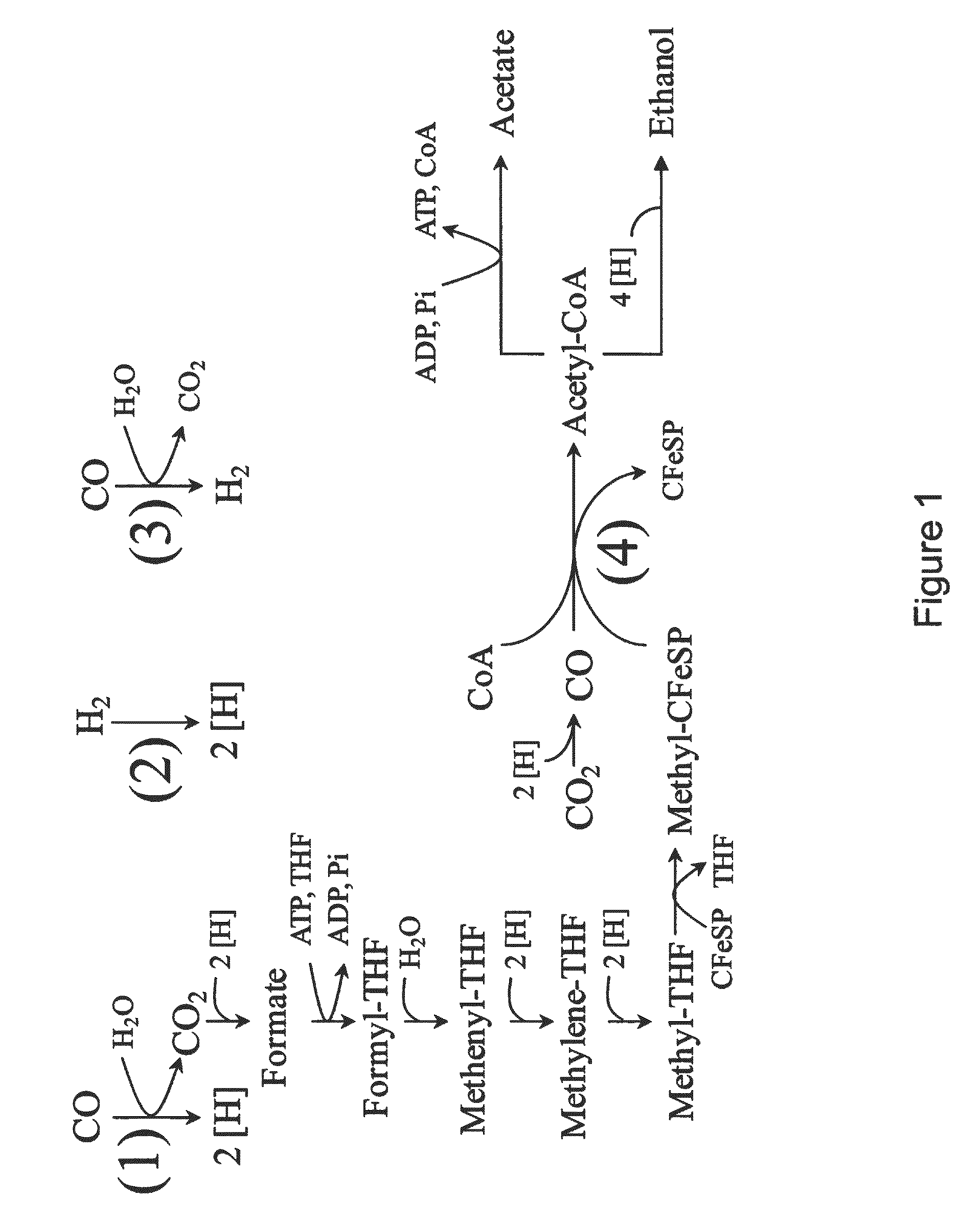

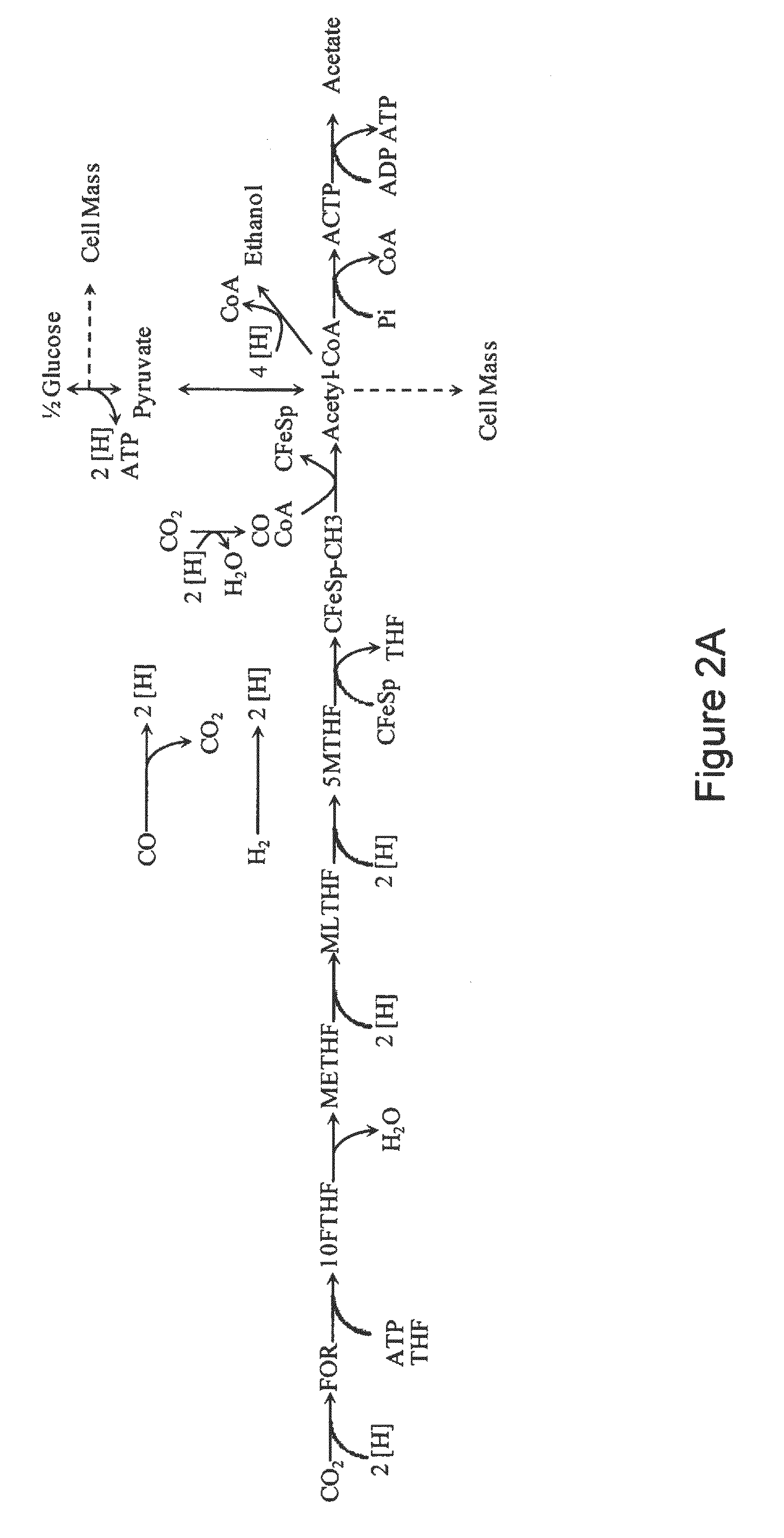

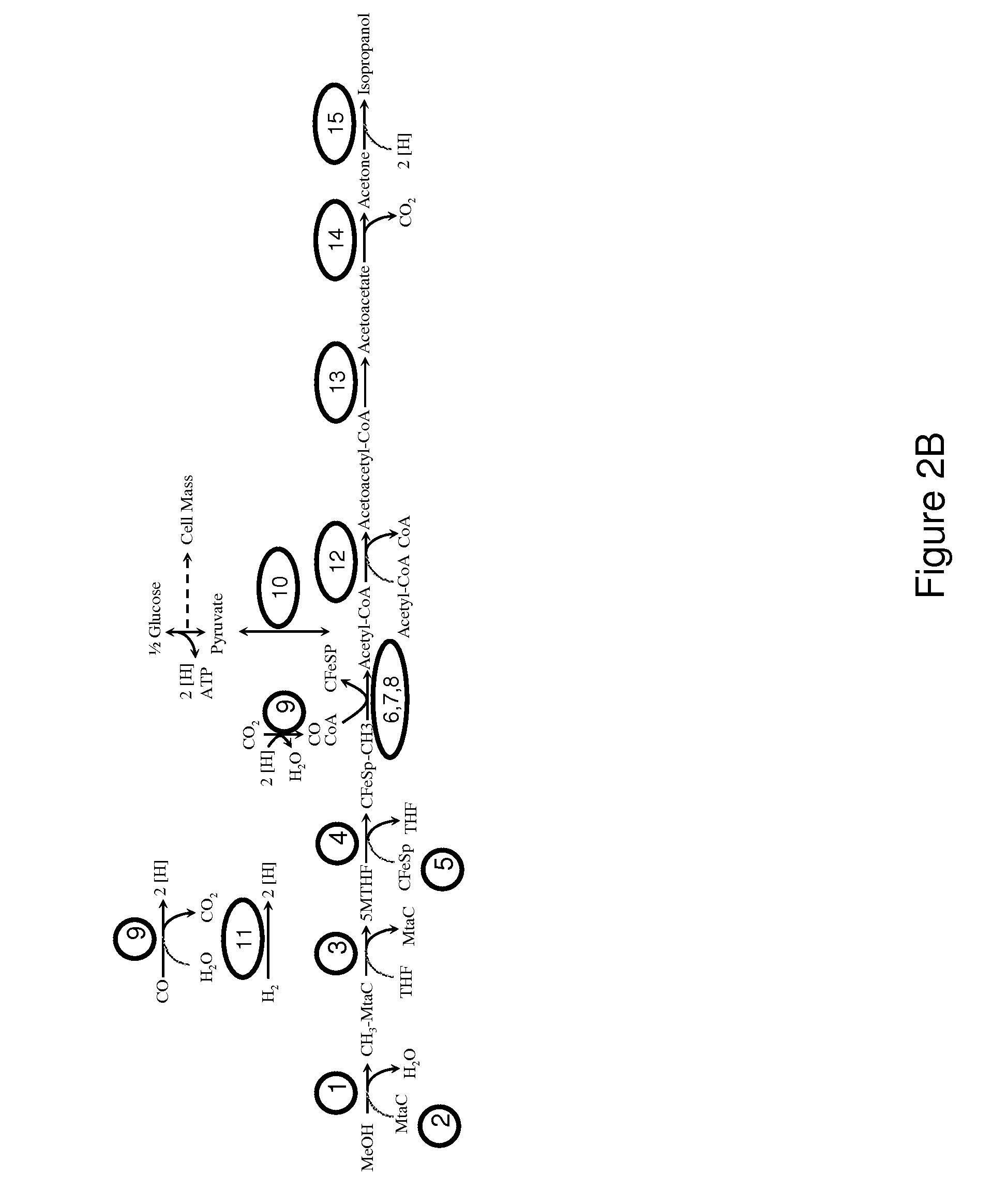

Microorganisms and methods for conversion of syngas and other carbon sources to useful products

A non-naturally occurring microbial organism having an isopropanol, 4-hydroxybutryate, or 1,4-butanediol pathway includes at least one exogenous nucleic acid encoding an isopropanol, 4-hydroxybutryate, or 1,4-butanediol pathway enzyme expressed in a sufficient amount to produce isopropanol, 4-hydroxybutryate, or 1,4-butanediol. The aforementioned organisms are cultured to produce isopropanol, 4-hydroxybutryate, or 1,4-butanediol.

Owner:GENOMATICA INC

Popular searches

Nanostructure manufacture Reverse osmosis Fermentation Hydroxy compound separation/purification Metal/metal-oxides/metal-hydroxide catalysts Beer fermentation Oxygen compounds preparation by hydrocarbon oxidation Preparation by hydrolysis Solid sorbent liquid separation Alcoholic beverage preparation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com