Patents

Literature

400 results about "Alcohol products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

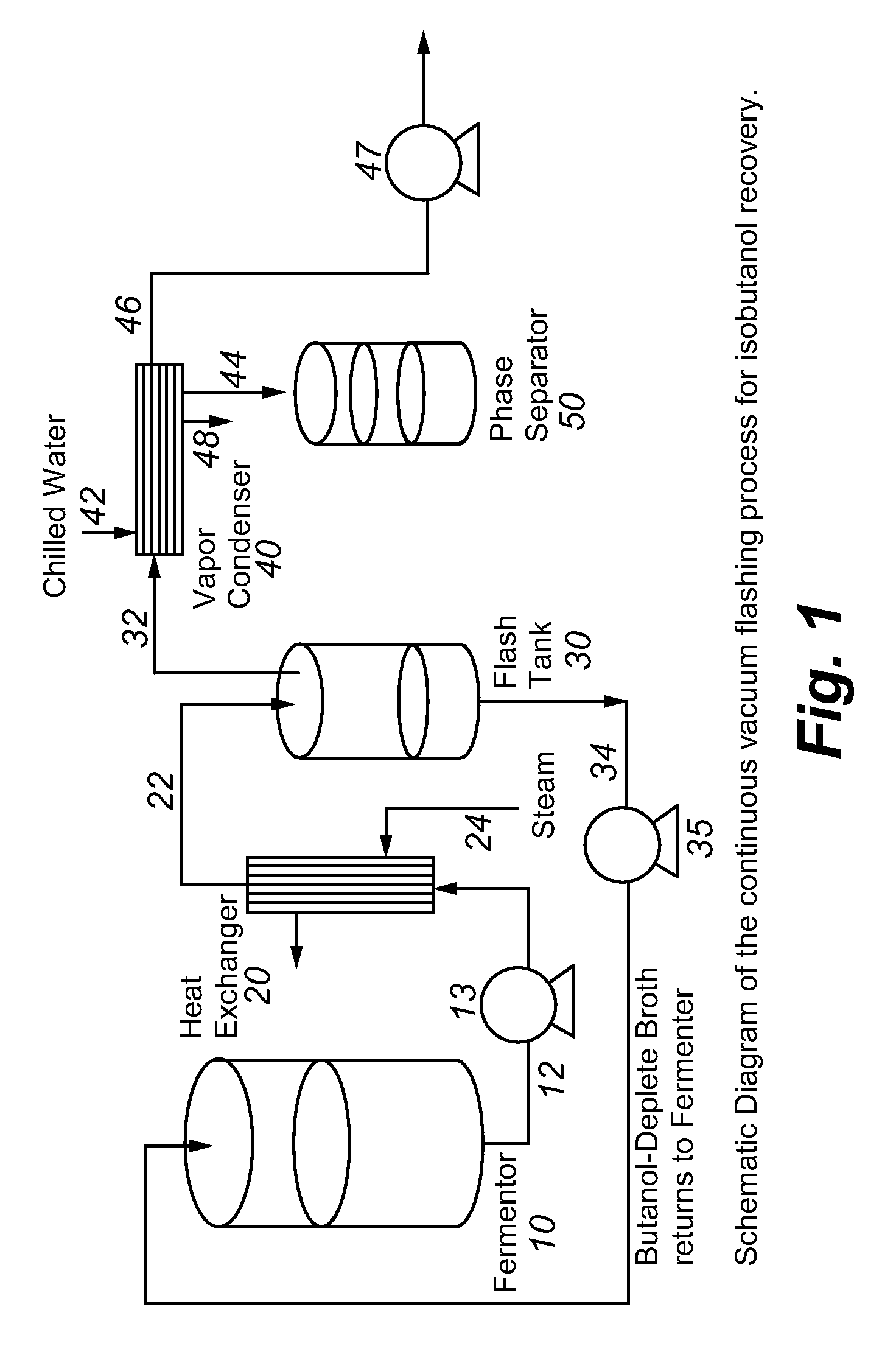

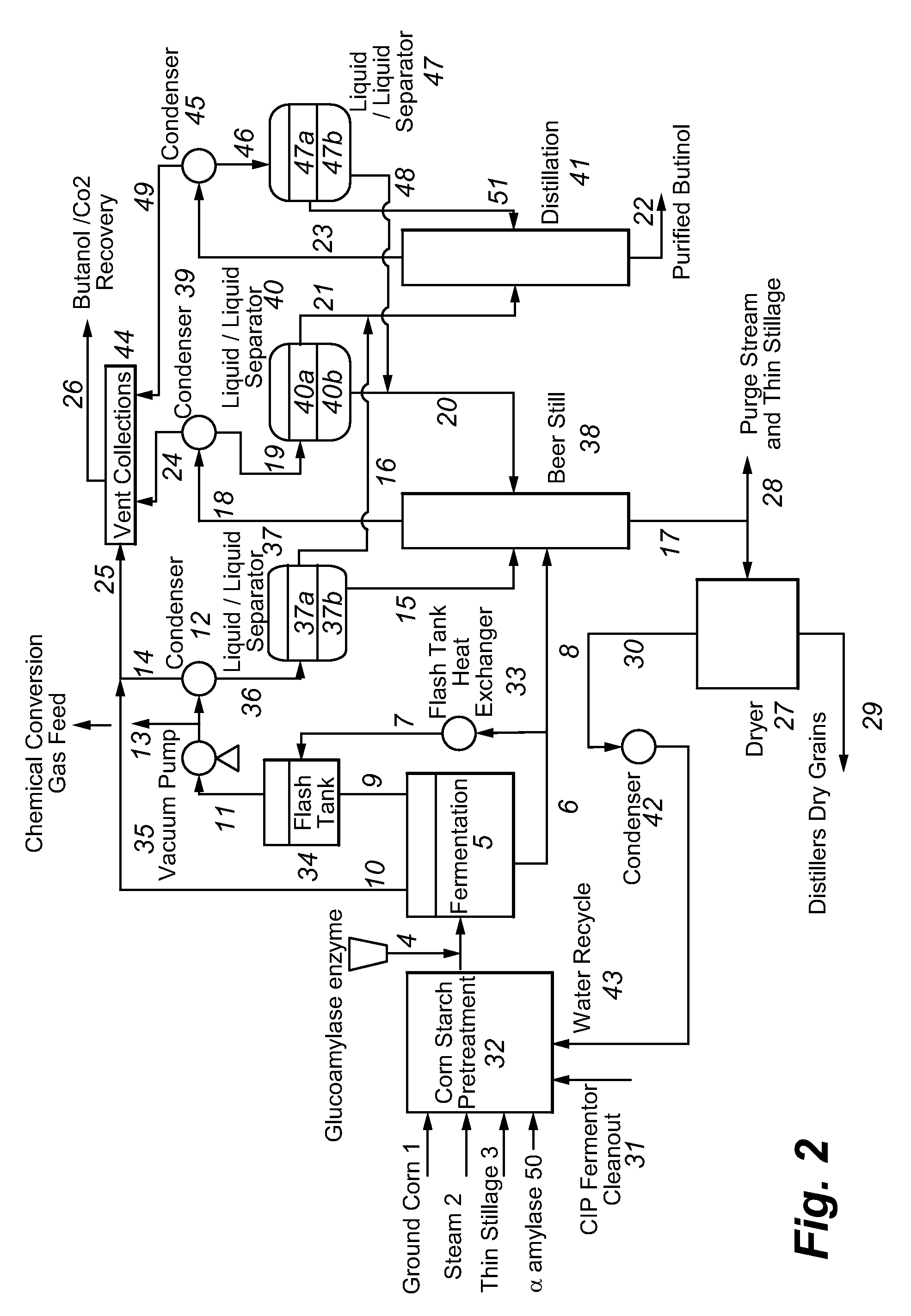

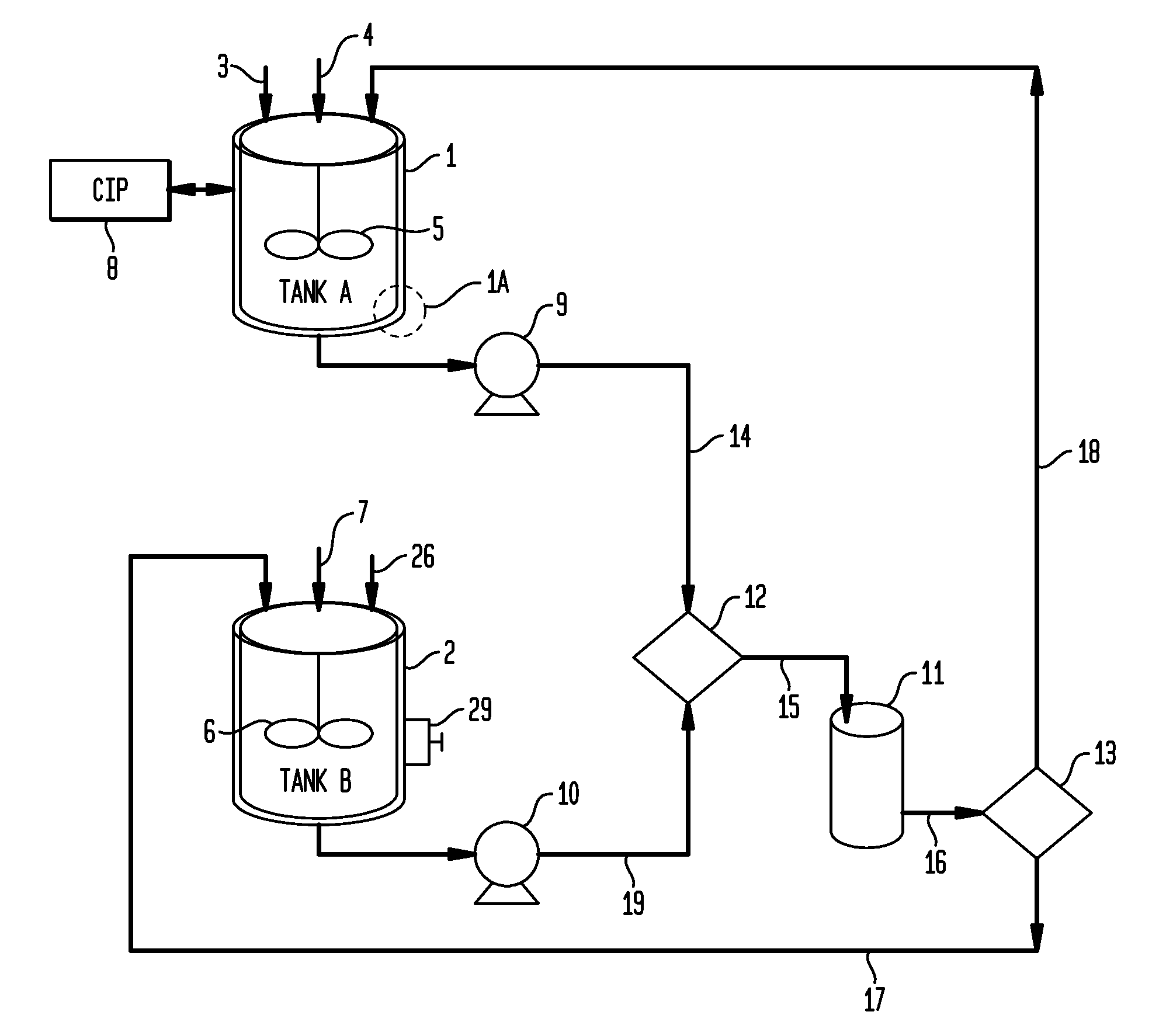

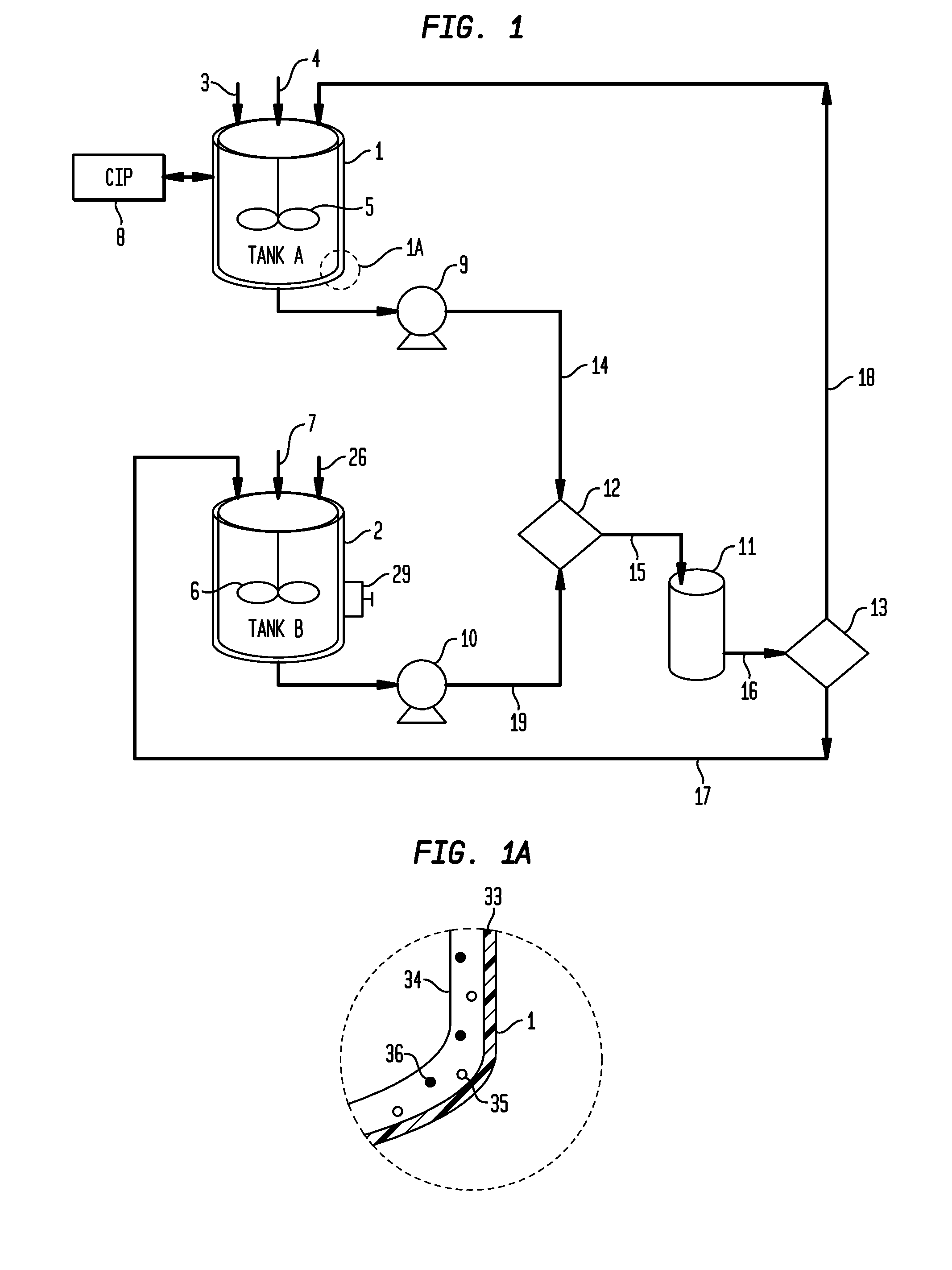

Recovery of higher alcohols from dilute aqueous solutions

ActiveUS20090171129A1High activityBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateAqueous solution

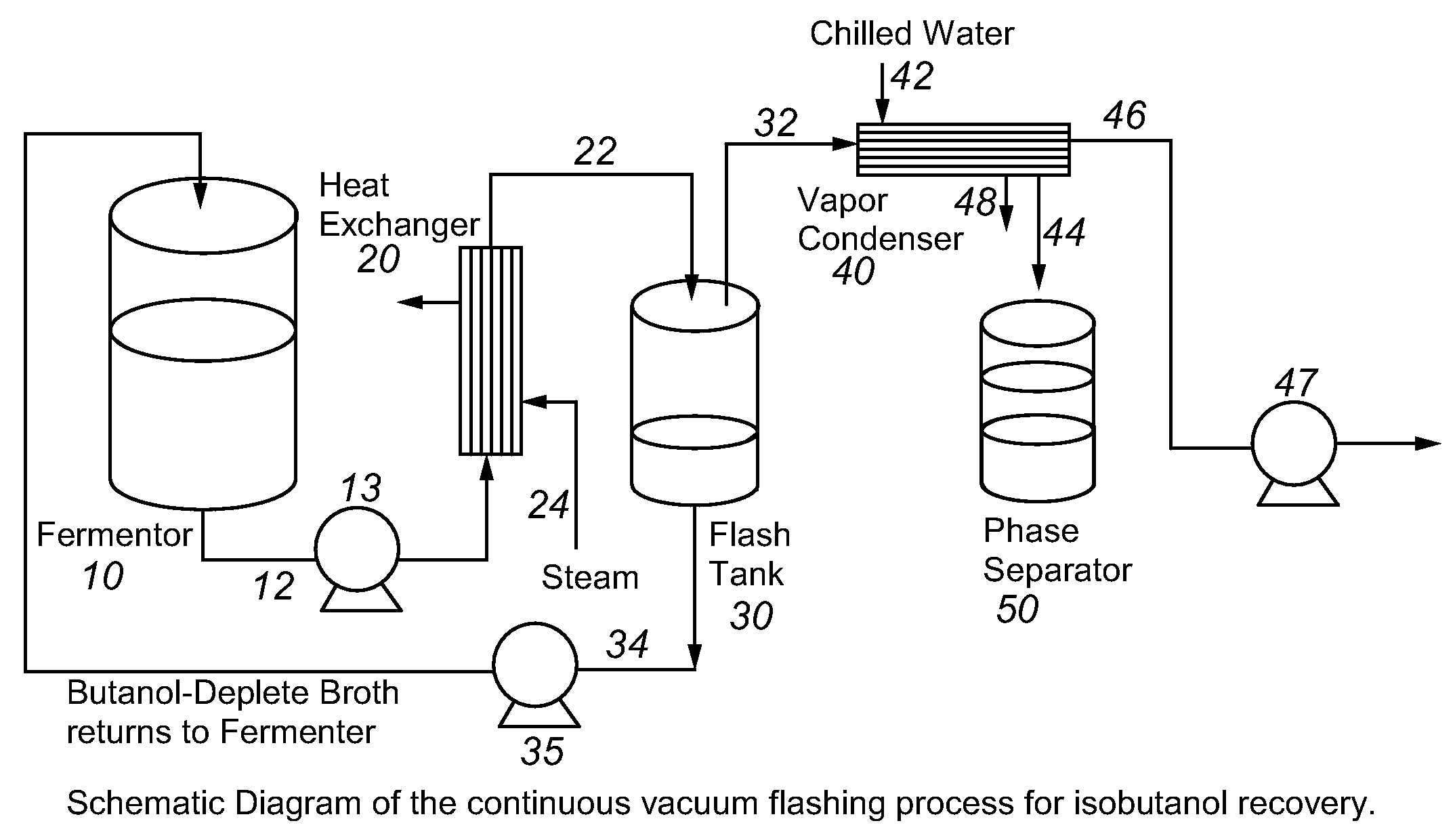

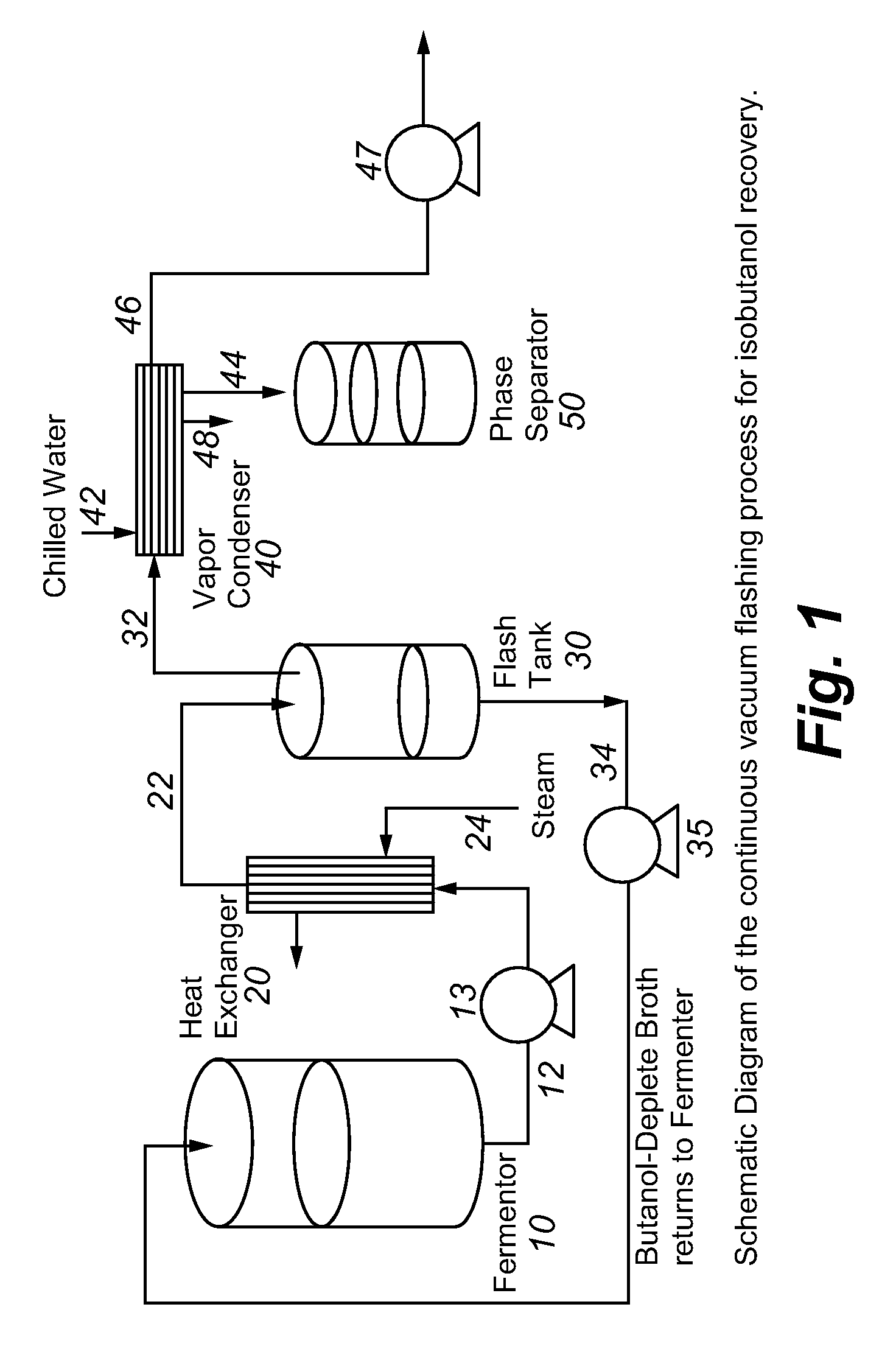

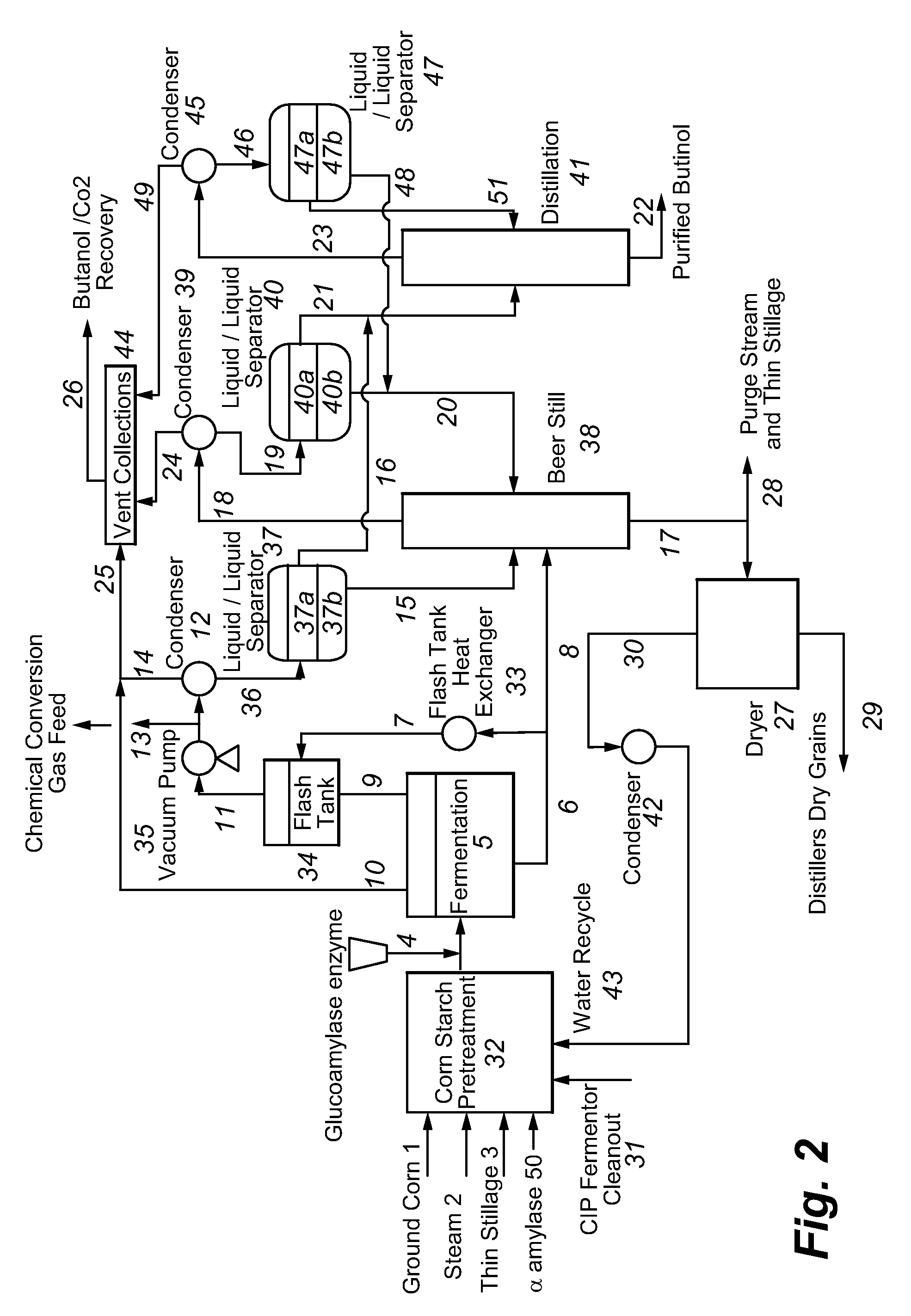

This invention is directed to methods for recovery of C3-C6 alcohols from dilute aqueous solutions, such as fermentation broths. Such methods provide improved volumetric productivity for the fermentation and allows recovery of the alcohol. Such methods also allow for reduced energy use in the production and drying of spent fermentation broth due to increased effective concentration of the alcohol product by the simultaneous fermentation and recovery process which increases the quantity of alcohol produced and recovered per quantity of fermentation broth dried. Thus, the invention allows for production and recovery of C3-C6 alcohols at low capital and reduced operating costs.

Owner:GEVO INC

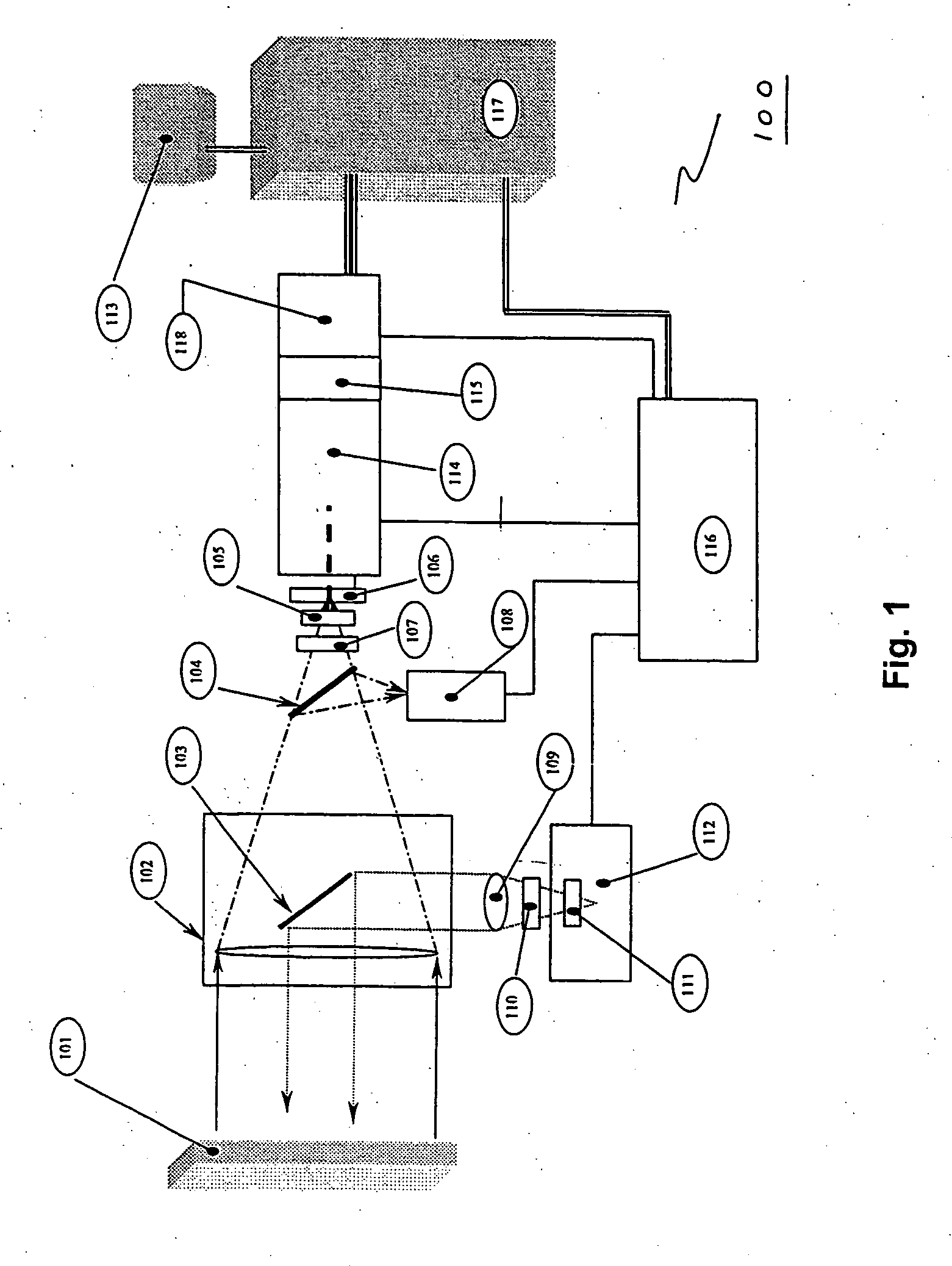

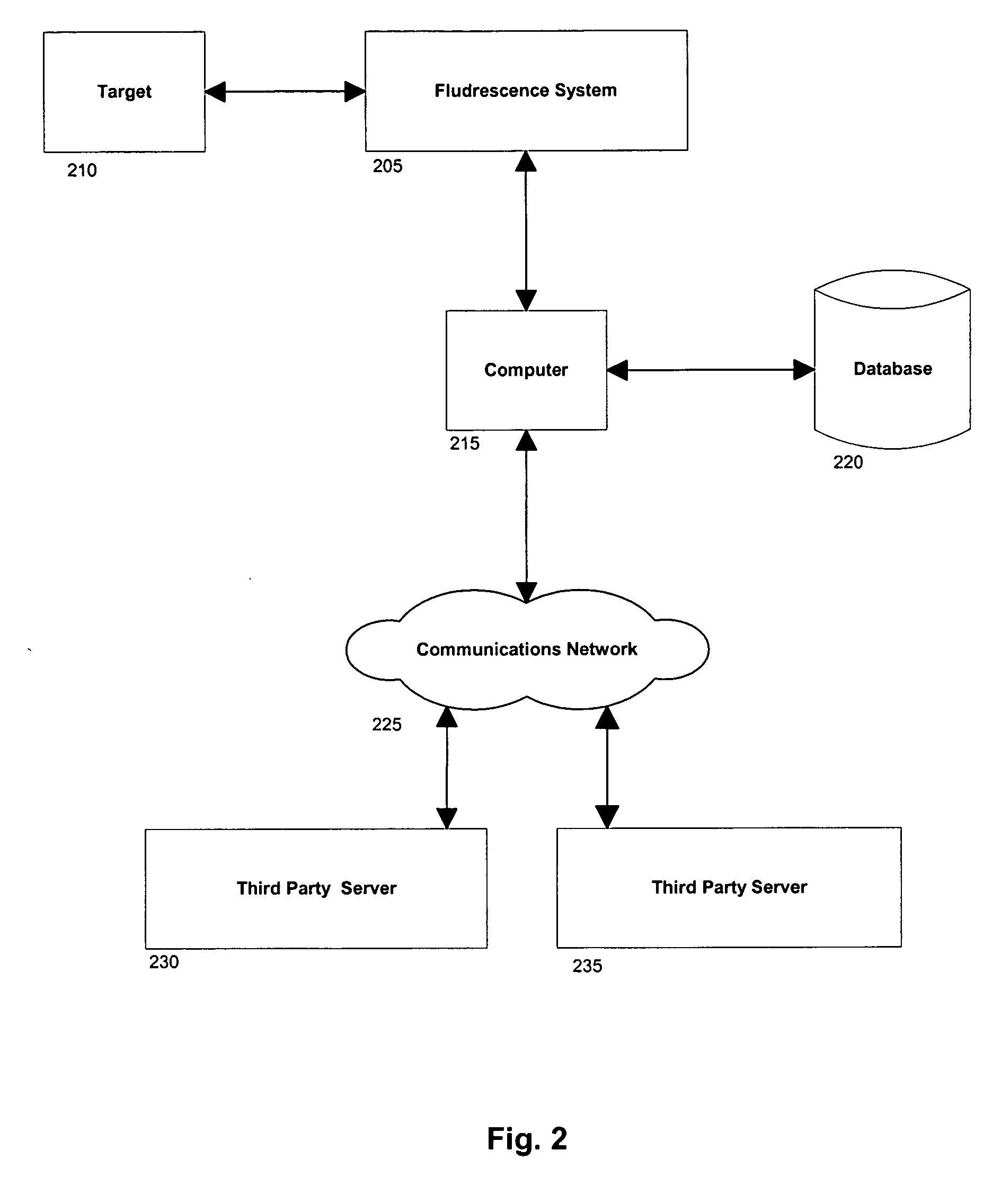

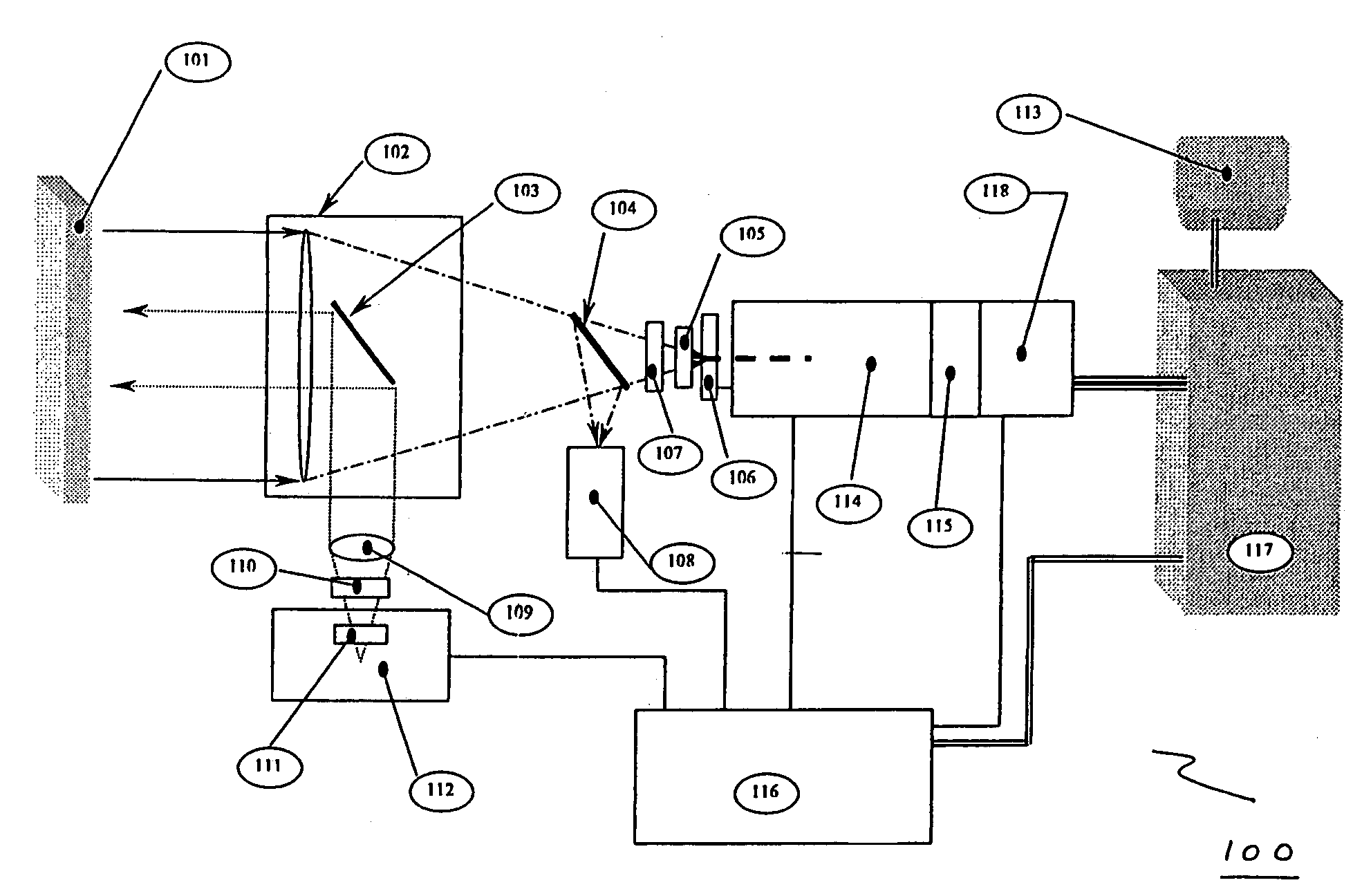

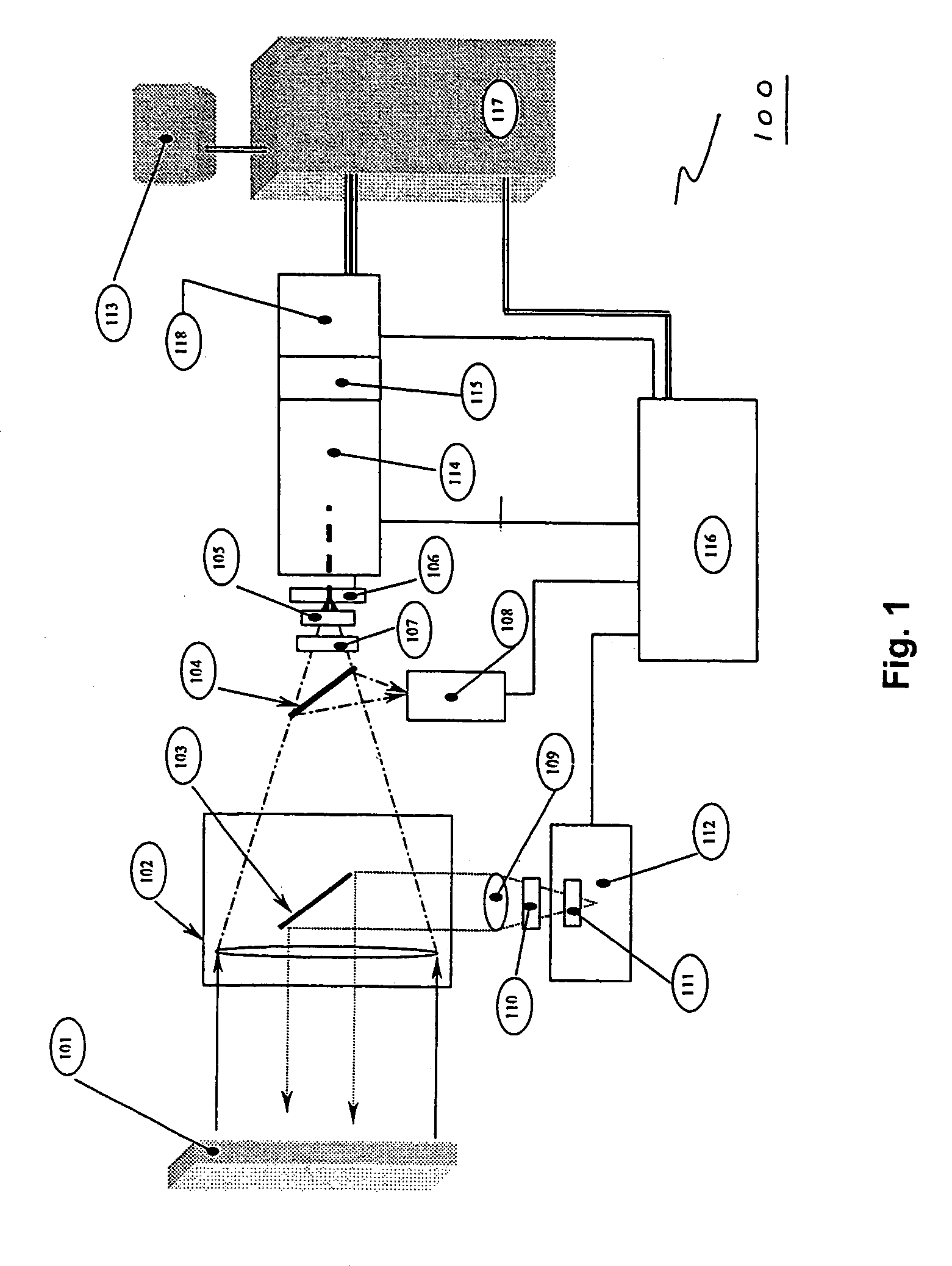

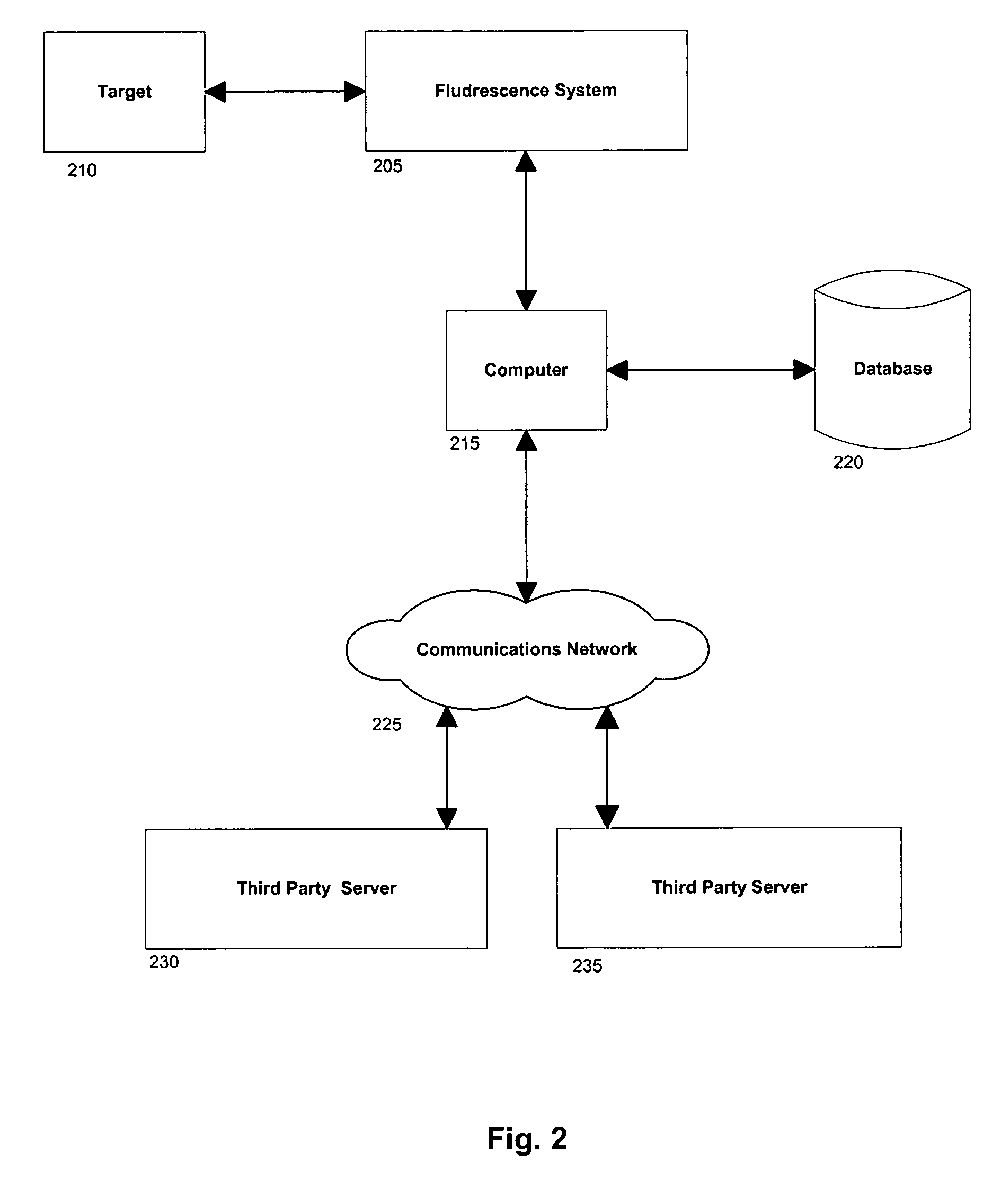

System and methods for detection and identification of chemical substances

InactiveUS20050077476A1MinimizesHigh sensitivityRadiation pyrometrySpectrum investigationAnesthetic AgentSpectrograph

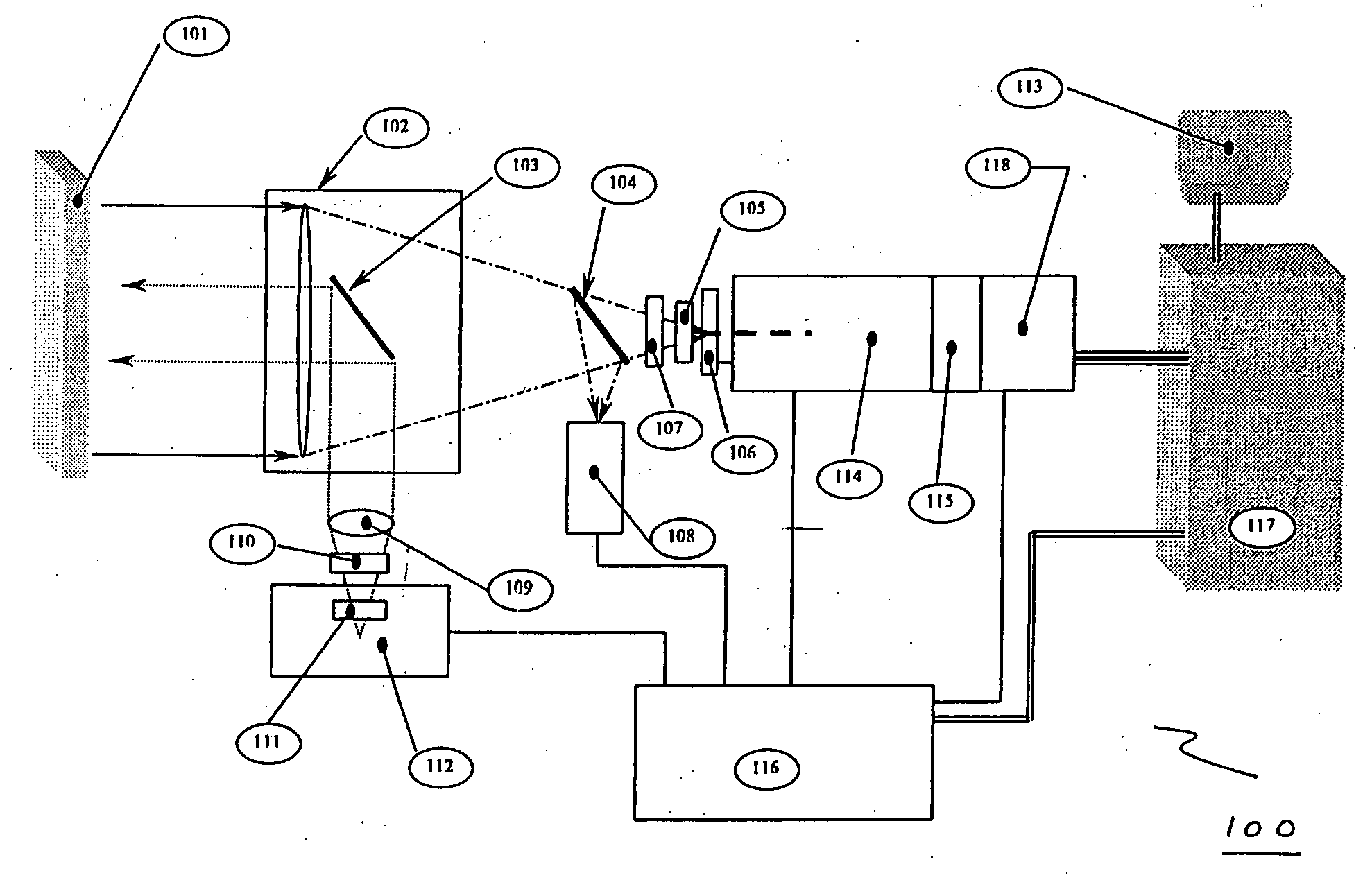

The invention provides a system and method utilizing, among other things, fluorescence spectroscopy in the ultraviolet portion of the electromagnetic spectrum to determine chemical species and concentrations. The basic measuring system includes optics, a spectrograph, a detector, and an energy source (“head” components), along with a computer and control electronics and power source capable of generating and detecting unique fluorescence signatures for individual and unique mixtures of chemical substances including, for example, prescribed and / or compounded medications, alcohol products, food types, synthetic drugs, narcotics, perfumes, liquids, and the like.

Owner:CDEX

Recovery of higher alcohols from dilute aqueous solutions

ActiveUS8101808B2High activityBioreactor/fermenter combinationsBiological substance pretreatmentsAqueous solutionAlcohol products

This invention is directed to methods for recovery of C3-C6 alcohols from dilute aqueous solutions, such as fermentation broths. Such methods provide improved volumetric productivity for the fermentation and allows recovery of the alcohol. Such methods also allow for reduced energy use in the production and drying of spent fermentation broth due to increased effective concentration of the alcohol product by the simultaneous fermentation and recovery process which increases the quantity of alcohol produced and recovered per quantity of fermentation broth dried. Thus, the invention allows for production and recovery of C3-C6 alcohols at low capital and reduced operating costs.

Owner:GEVO INC

System and methods for detection and identification of chemical substances

InactiveUS7154102B2Lower potentialMinimize distribution and sale and useRadiation pyrometrySpectrum investigationSpectrographAlcohol products

The invention provides a system and method utilizing, among other things, fluorescence spectroscopy in the ultraviolet portion of the electromagnetic spectrum to determine chemical species and concentrations. The basic measuring system includes optics, a spectrograph, a detector, and an energy source (“head” components), along with a computer and control electronics and power source capable of generating and detecting unique fluorescence signatures for individual and unique mixtures of chemical substances including, for example, prescribed and / or compounded medications, alcohol products, food types, synthetic drugs, narcotics, perfumes, liquids, and the like.

Owner:CDEX

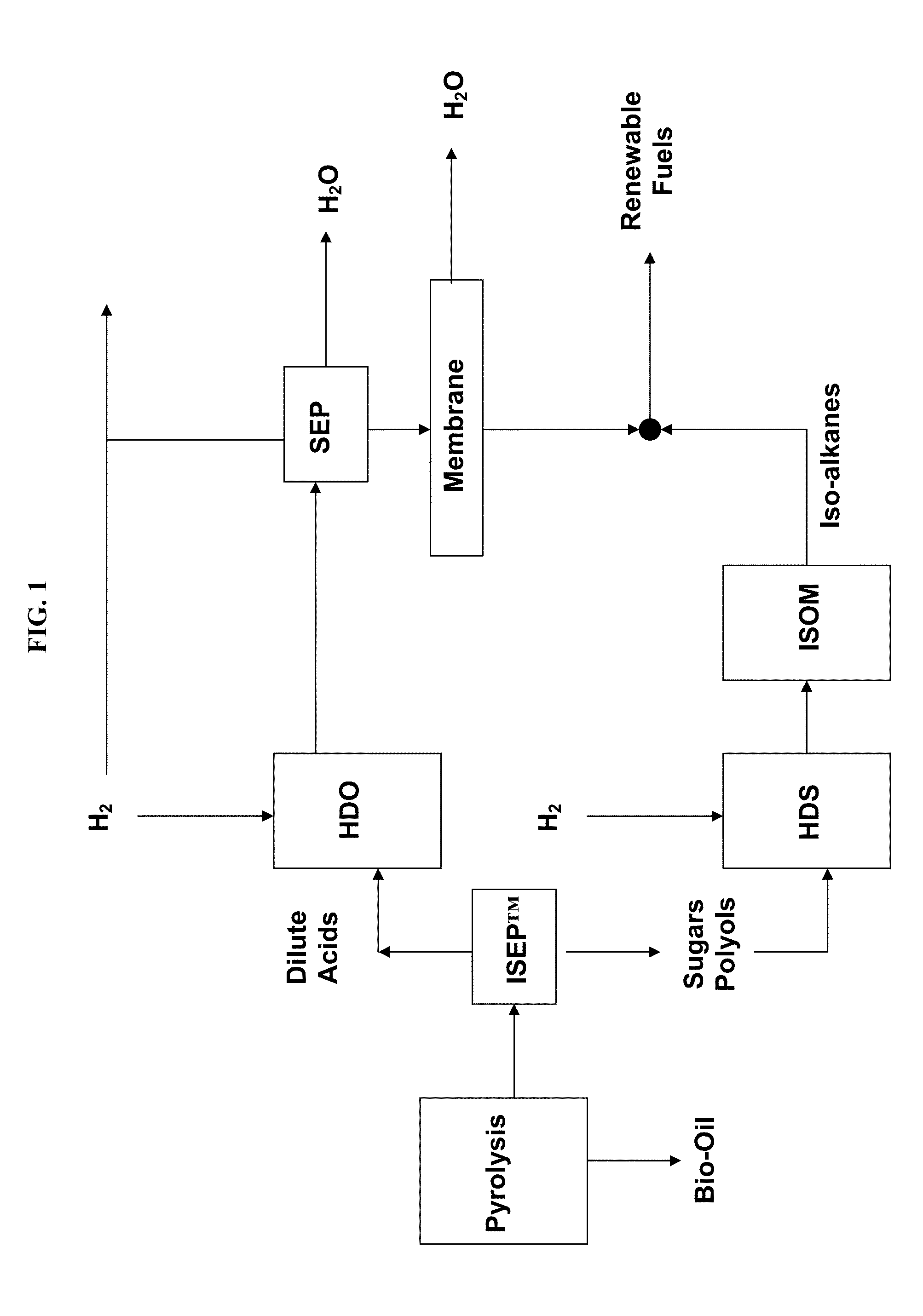

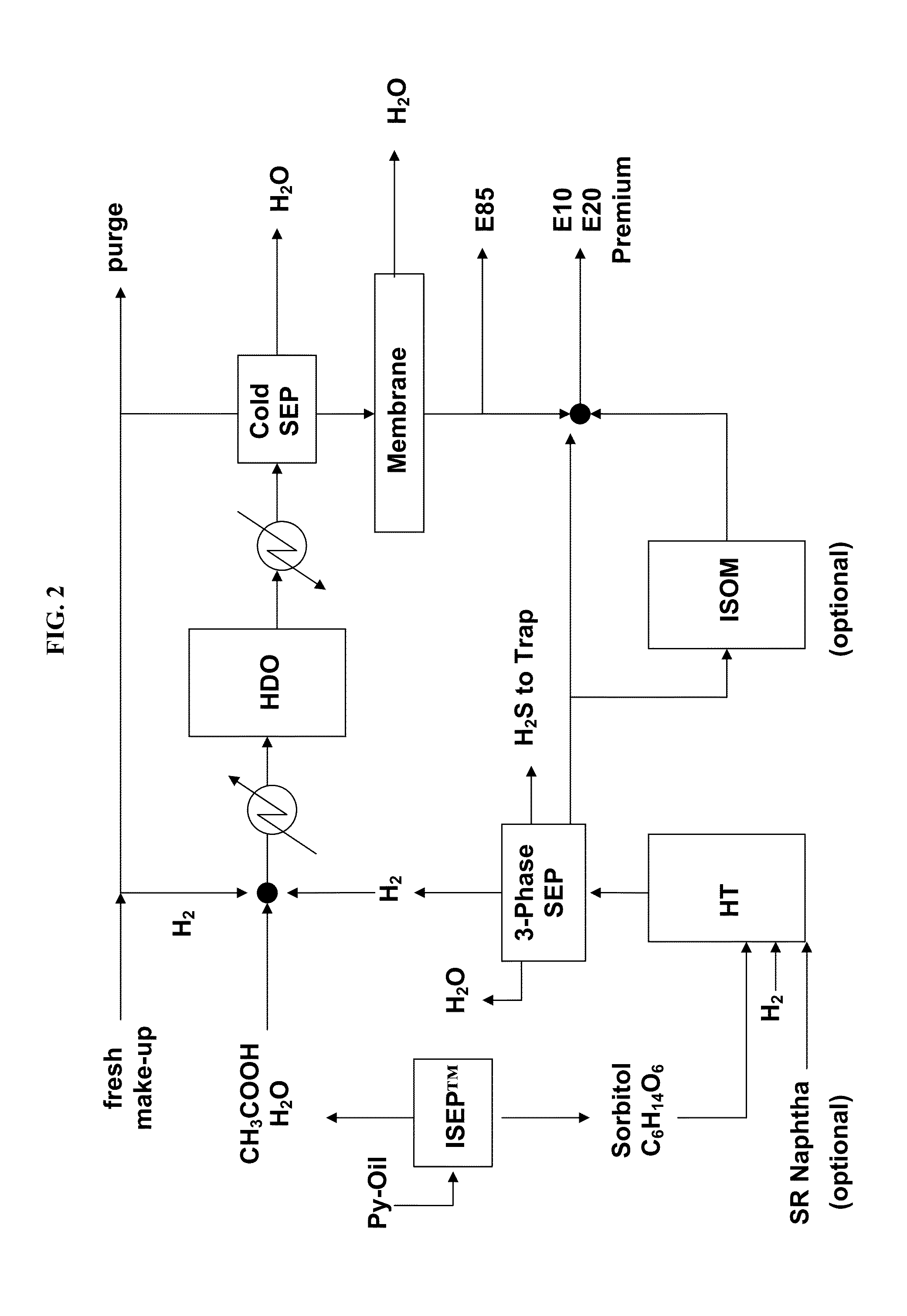

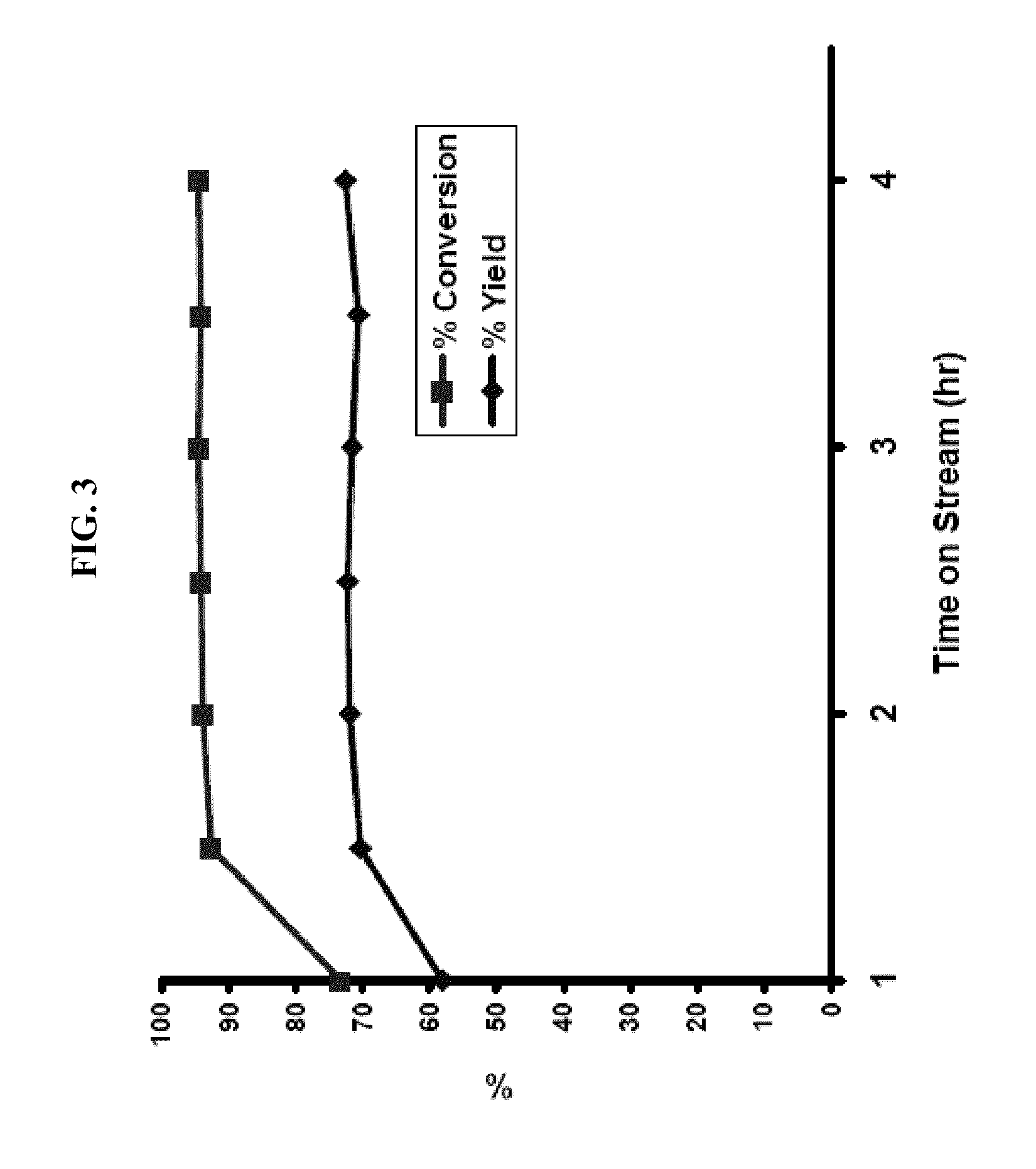

Advanced cellulosic renewable fuels

ActiveUS20130067803A1Refining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsOrganic acidCellulose

The invention relates to a process to manufacture advanced cellulosic gasolines. Dilute organic acids derived from pyrolized biomass are converted to their corresponding alcohols in a stand-alone hydrodeoxygenation unit followed by membrane pervaporation step to remove water. The alcohol product is blended directly into a neat hydrocarbon fuel basestock to make unadditized gasoline.

Owner:PHILLIPS 66 CO

Desulfurization process

InactiveUS7144499B2Refining with oxygen compoundsTreatment with plural serial refining stagesSulfurSorbent

Owner:LYONDELL CHEM TECH LP

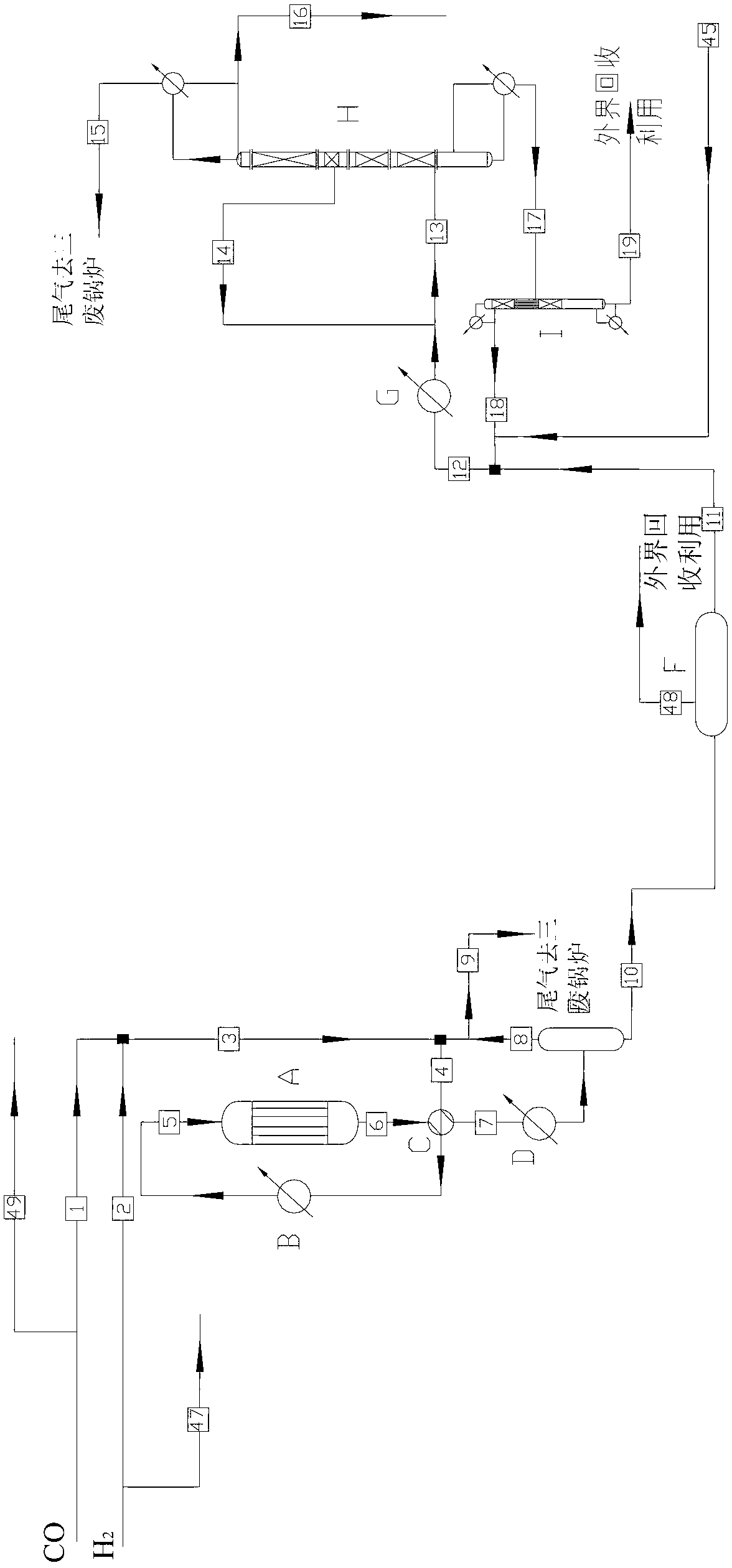

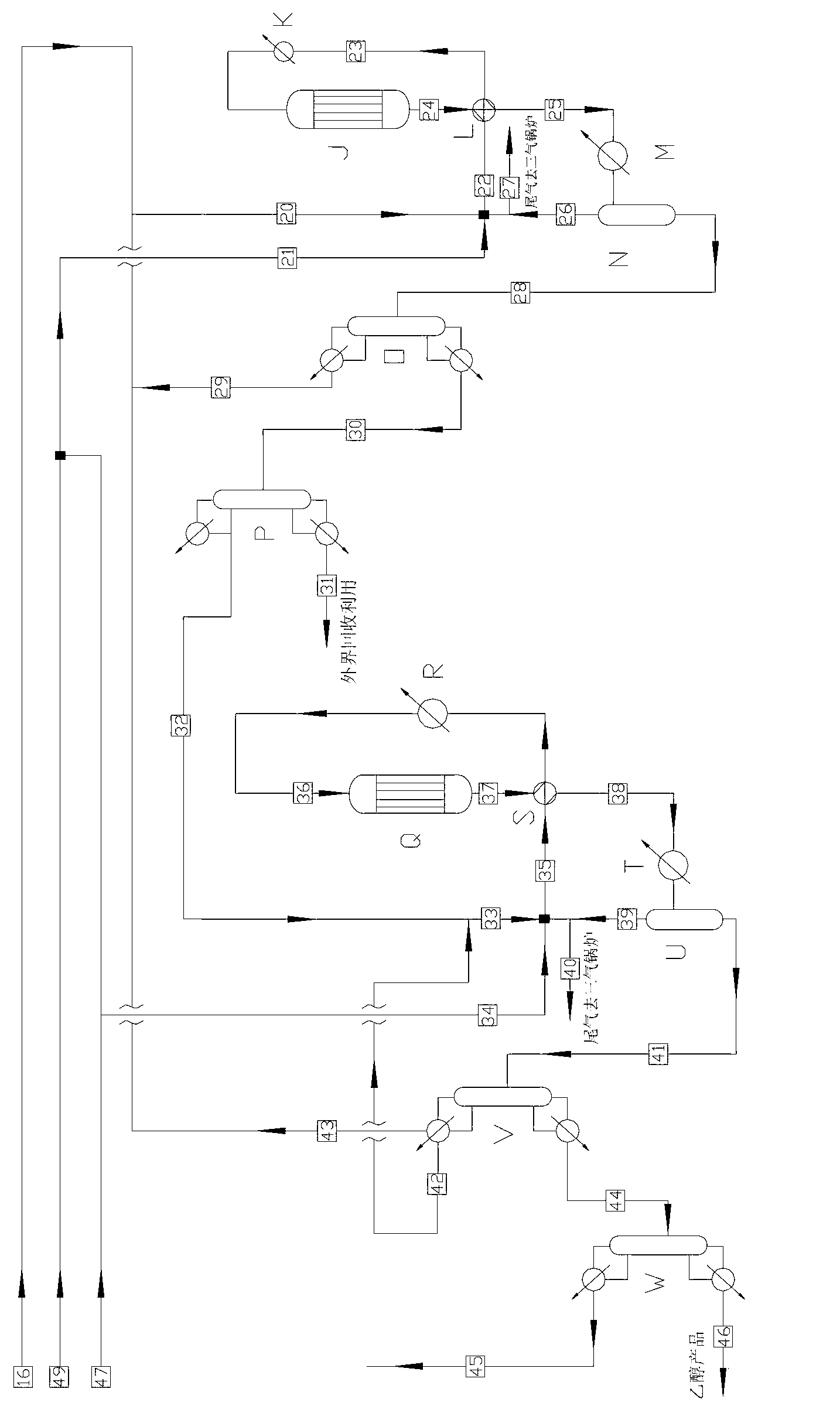

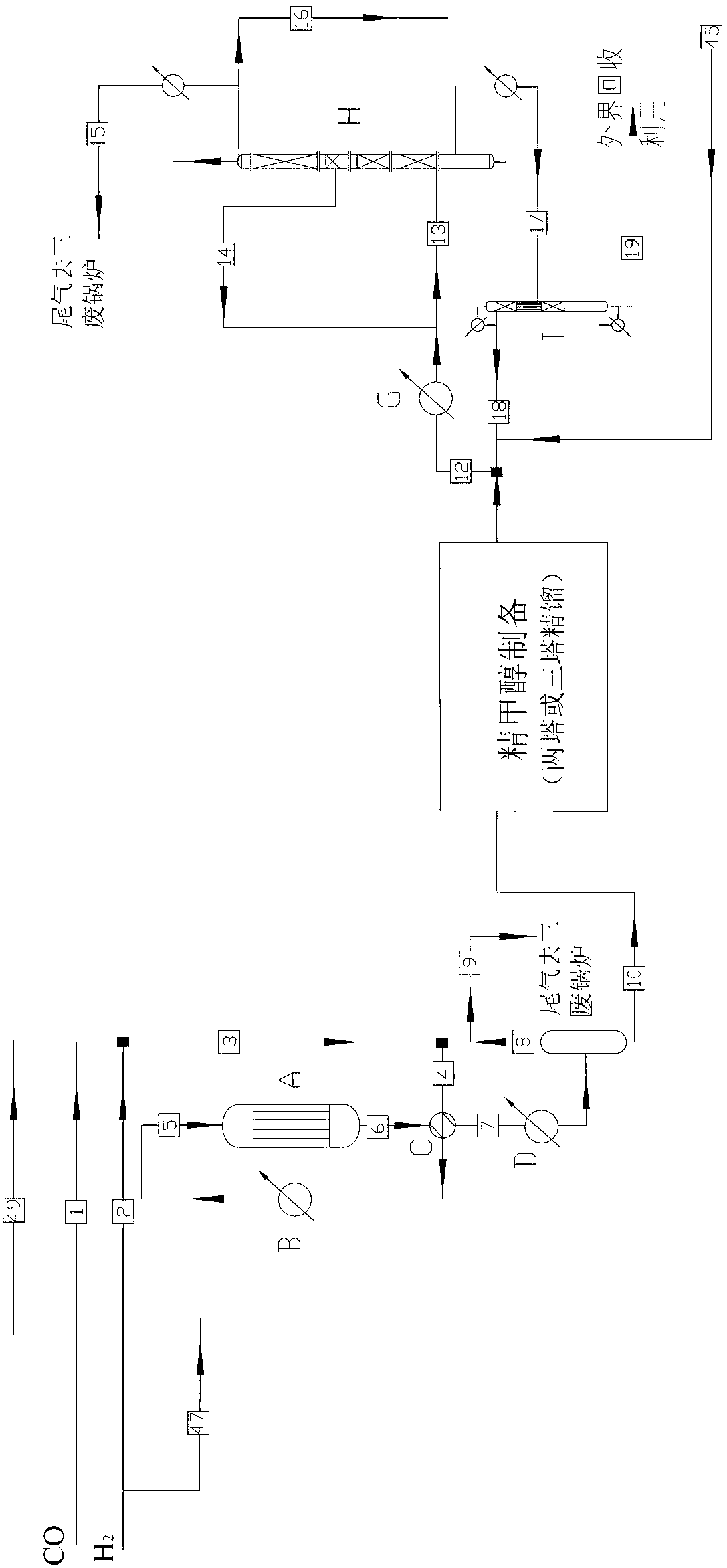

Process for indirectly producing alcohol with synthetic gas and application of process

ActiveCN103012062AReduce energy consumptionMild reaction conditionsOrganic compound preparationHydroxy compound preparationHydrogenMethyl acetate

The invention relates to a process for indirectly producing alcohol with synthetic gas. The process comprises the steps that the synthetic gas formed by mixing industrial carbon monoxide with hydrogen is taken as a raw material to synthesize methanol; methanol is dehydrated to prepare dimethyl ether; dimethyl ether, carbon monoxide and hydrogen are mixed for carbonylation reaction to prepare methyl acetate; methyl acetate is purified and hydrogenated; a hydrogenated product is purified; and an alcohol product is obtained. An adopted catalyst, the process and a device have the characteristics of high conversion per pass and high effective utilization rate of reaction heat; the load of separating a crude product is reduced greatly; the production flow is shortened; and the production energy consumption is reduced greatly.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

Dietary nutritional supplements for persons consuming alcohol products

A dietary nutritional supplement is designed specifically to address the needs of moderate to heavy alcohol product consumers. The nutritional supplement contains effective amounts of essential components vitamin B2, vitamin B6, vitamin B12 (Cobalamin), vitamin B3 (Niacin), vitamin B1 (Thiamin), Calcium, magnesium, vitamin A, vitamin C (ascorbic acid), folic acid, L-cysteine, L-methionine, Milk Thistle, selenium, dandelion, and Molybdenum.

Owner:LAK ZAHRAMEHRAN SALARI

Distiller yeast, preparation process of distiller yeast and process for preparing health care liquor by utilizing distiller yeast

ActiveCN103421646AHarmonizeQuality improvementAlcoholic beverage preparationHordeum vulgareChinese liquor

The invention relates to alcohol products, in particular to distiller yeast for manufacturing liquor and a process for preparing the distiller yeast, and further relates to a process for preparing health care liquor by utilizing the distiller yeast. A mixture of wheat, barley and peas is used as a raw materials formula, and the wheat, the barley and the peas are mixed, wherein the weight ratio of the wheat to the barley to the peas is 4:5:1. The raw material formula further comprises bighead atractylodes rhizome which, by weight, accounts for 0.5% of the mixture of the wheat, the barley and the peas, pericarpium citri reticulatae which, by weight, accounts for 0.3% of the mixture of the wheat, the barley and the peas, red jujube which, by weight, accounts for 0.2% of the mixture of the wheat, the barley and the peas, liquorice which, by weight, accounts for 0.3% of the mixture of the wheat, the barley and the peas and folium mori which, by weight, accounts for 0.3% of the mixture of the wheat, the barley and the peas. According to the distiller yeast and the process for preparing the distiller yeast, beneficial microorganisms in the yeast for making hard liquor are fully bred, the quality of the distiller yeast is improved, and a role in restraining infectious microbes is played by adding Chinese herbal medicine. The invention further provides the process for preparing the health care liquor, according to the process, the style characteristics of traditional Chinese liquor are kept, and the health care liquor has the effects of body building, fitness and disease treatment.

Owner:河南尧香酒业有限公司

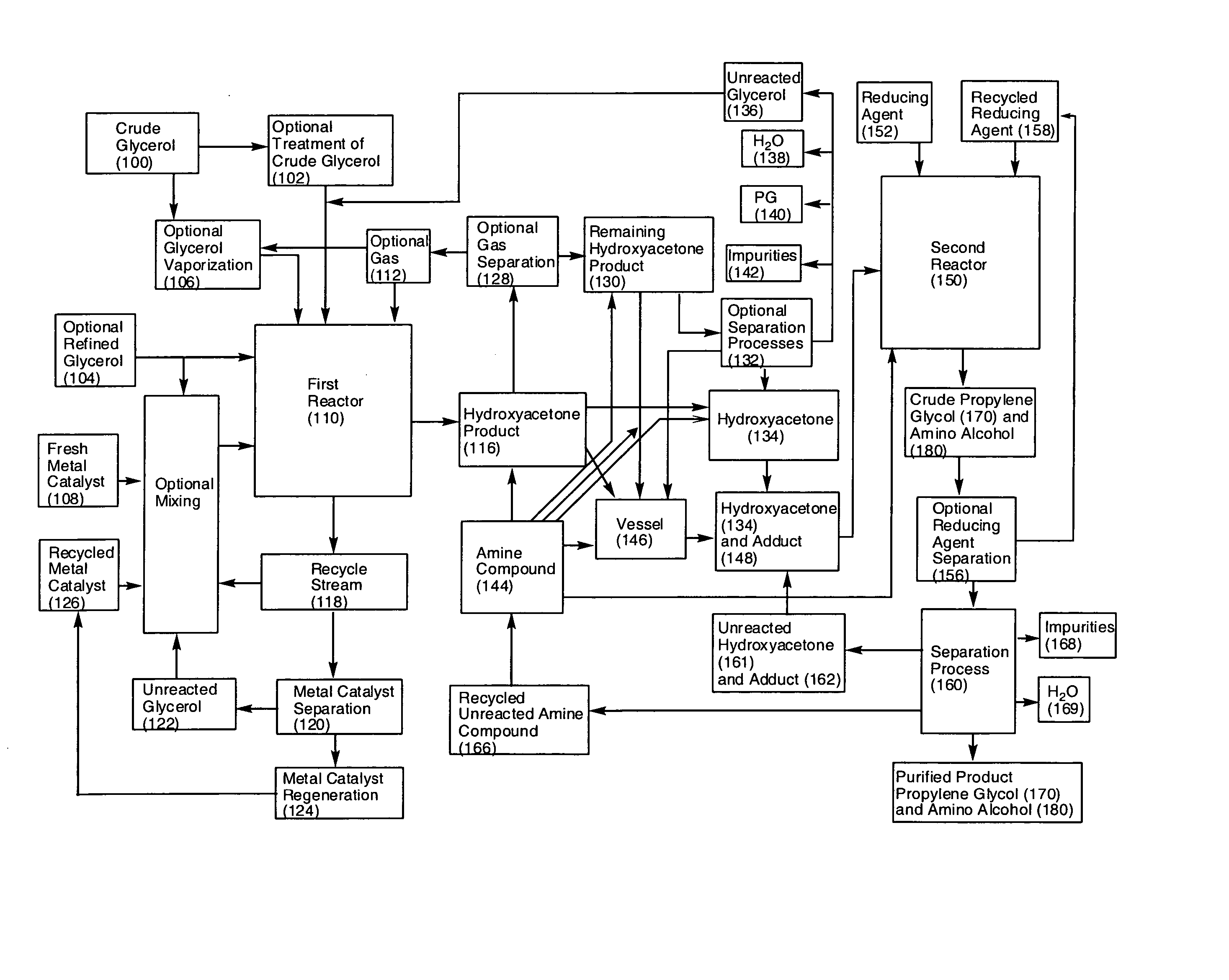

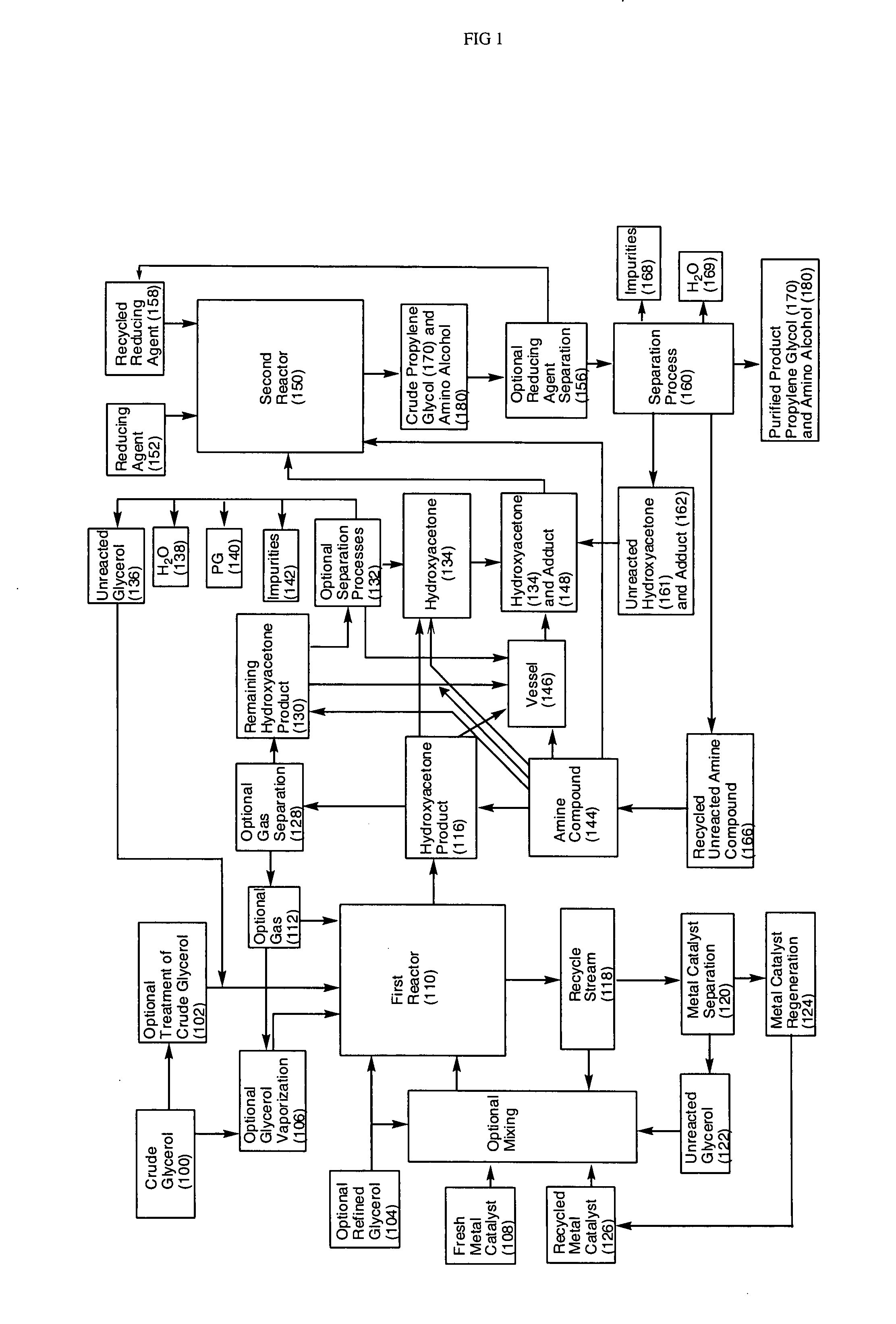

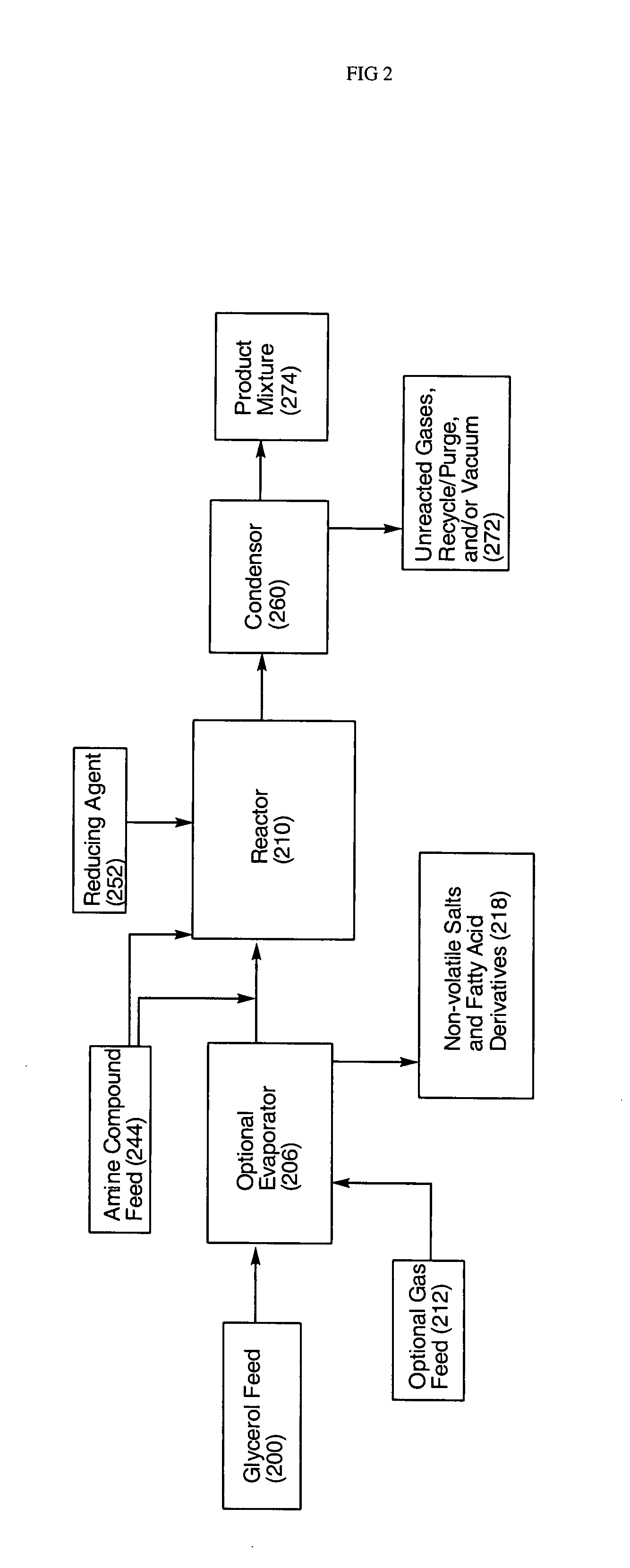

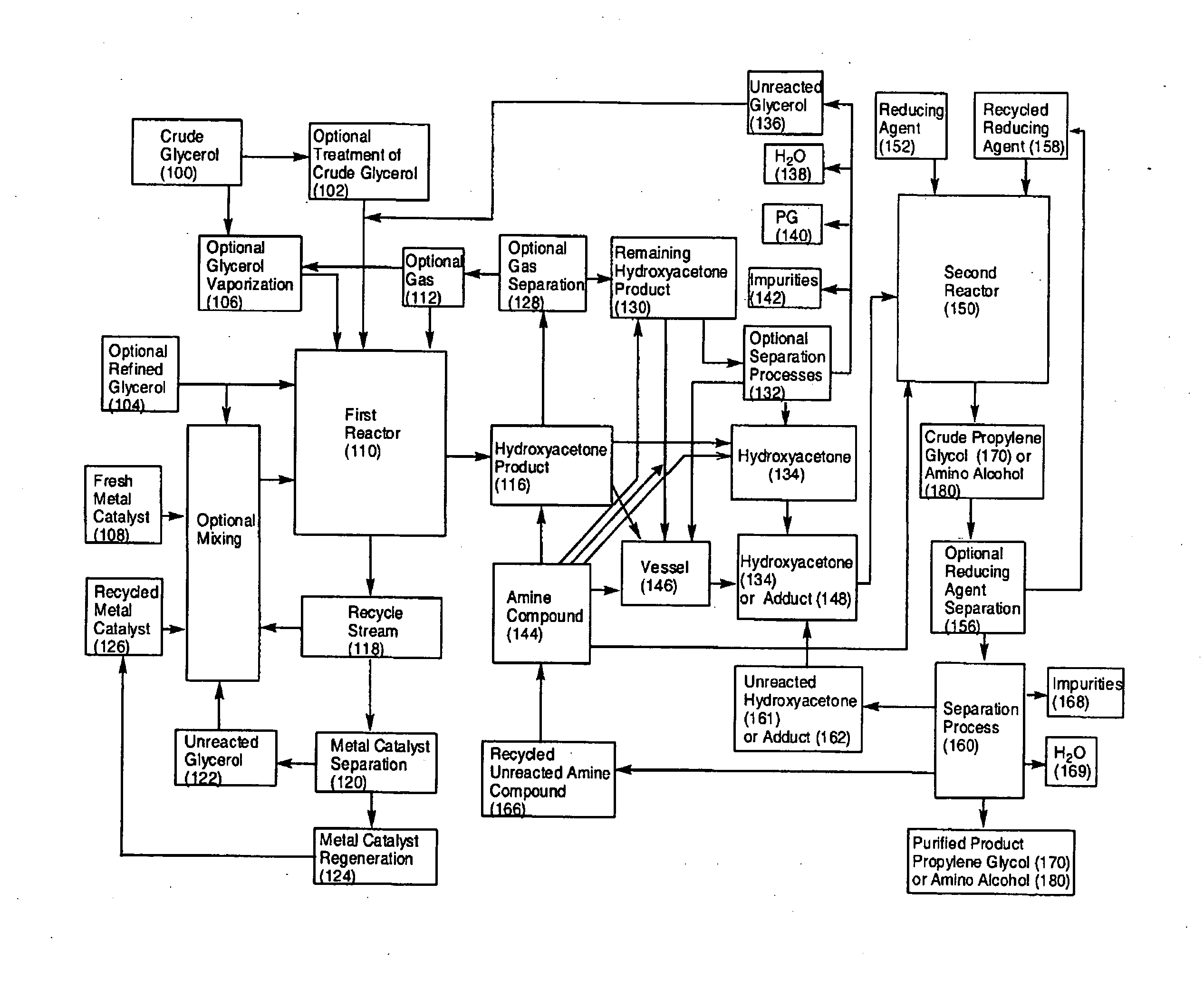

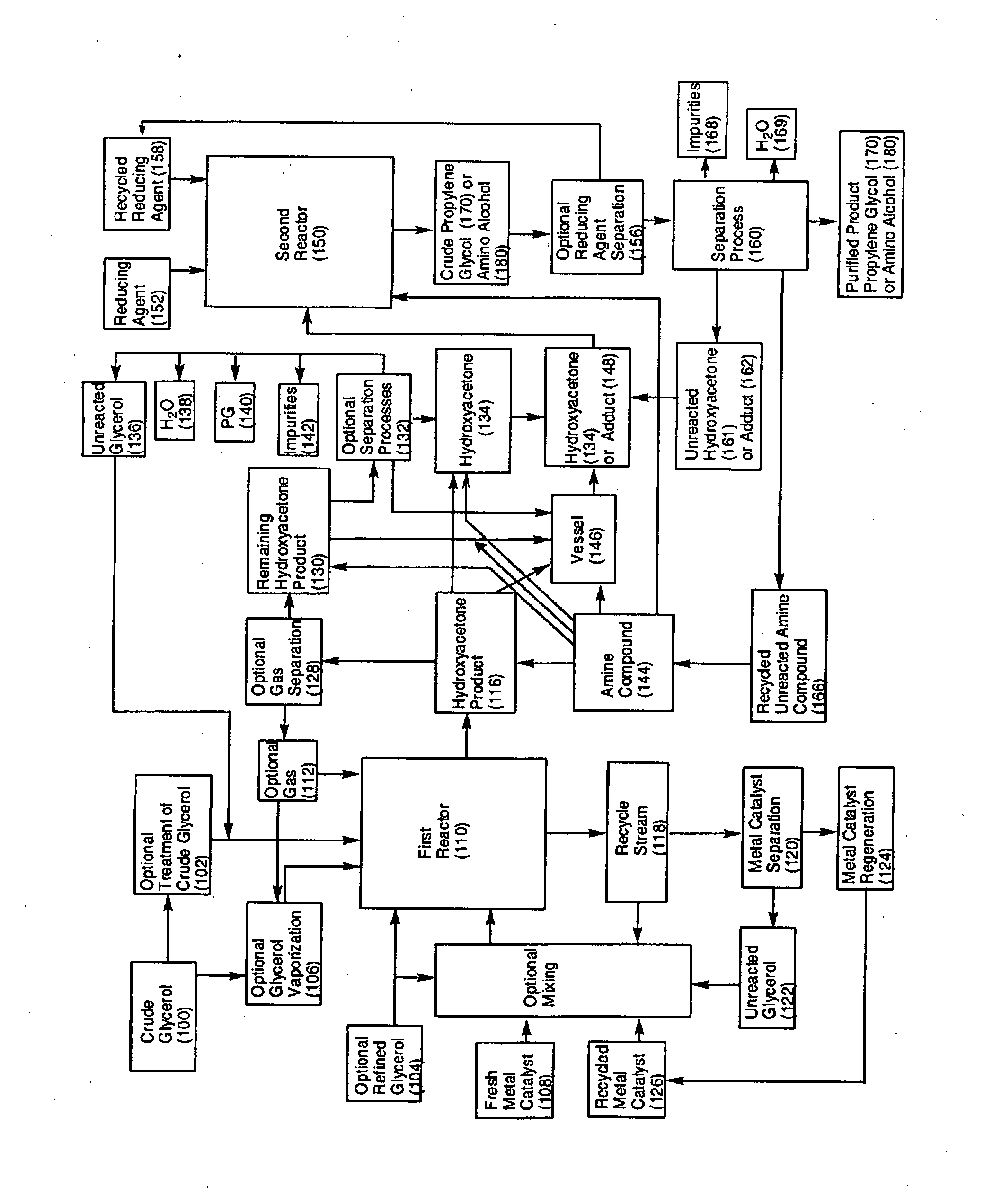

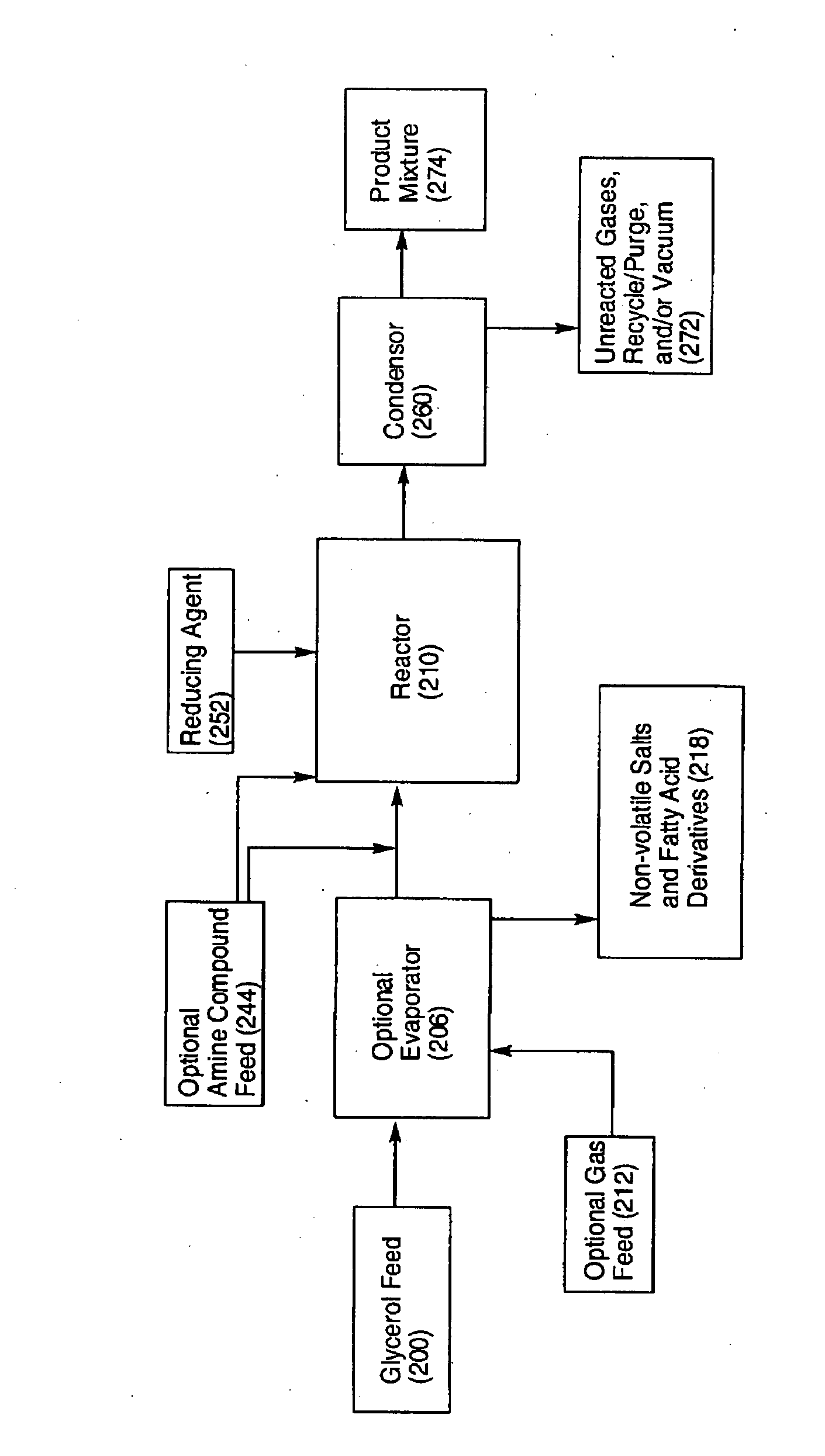

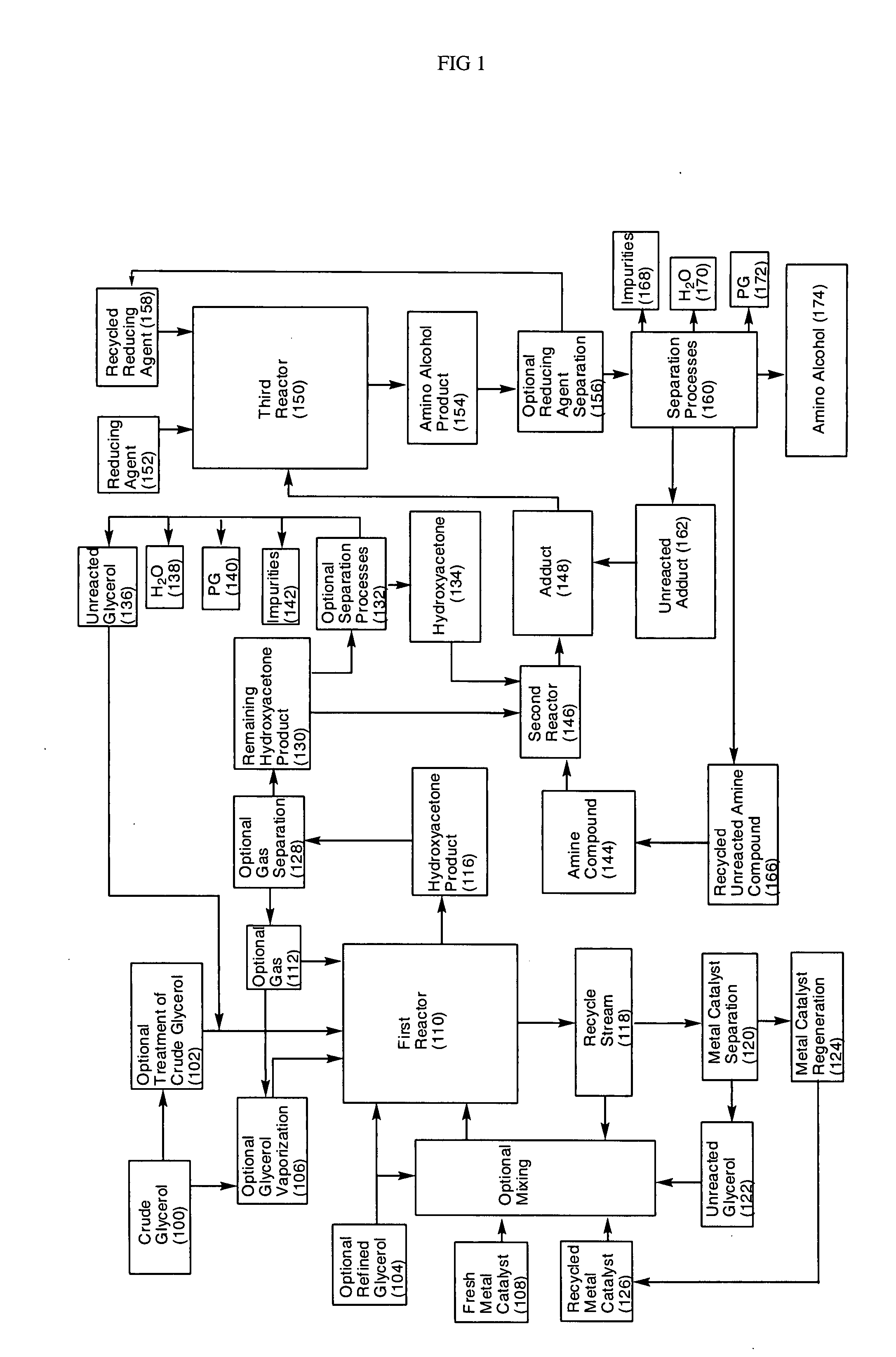

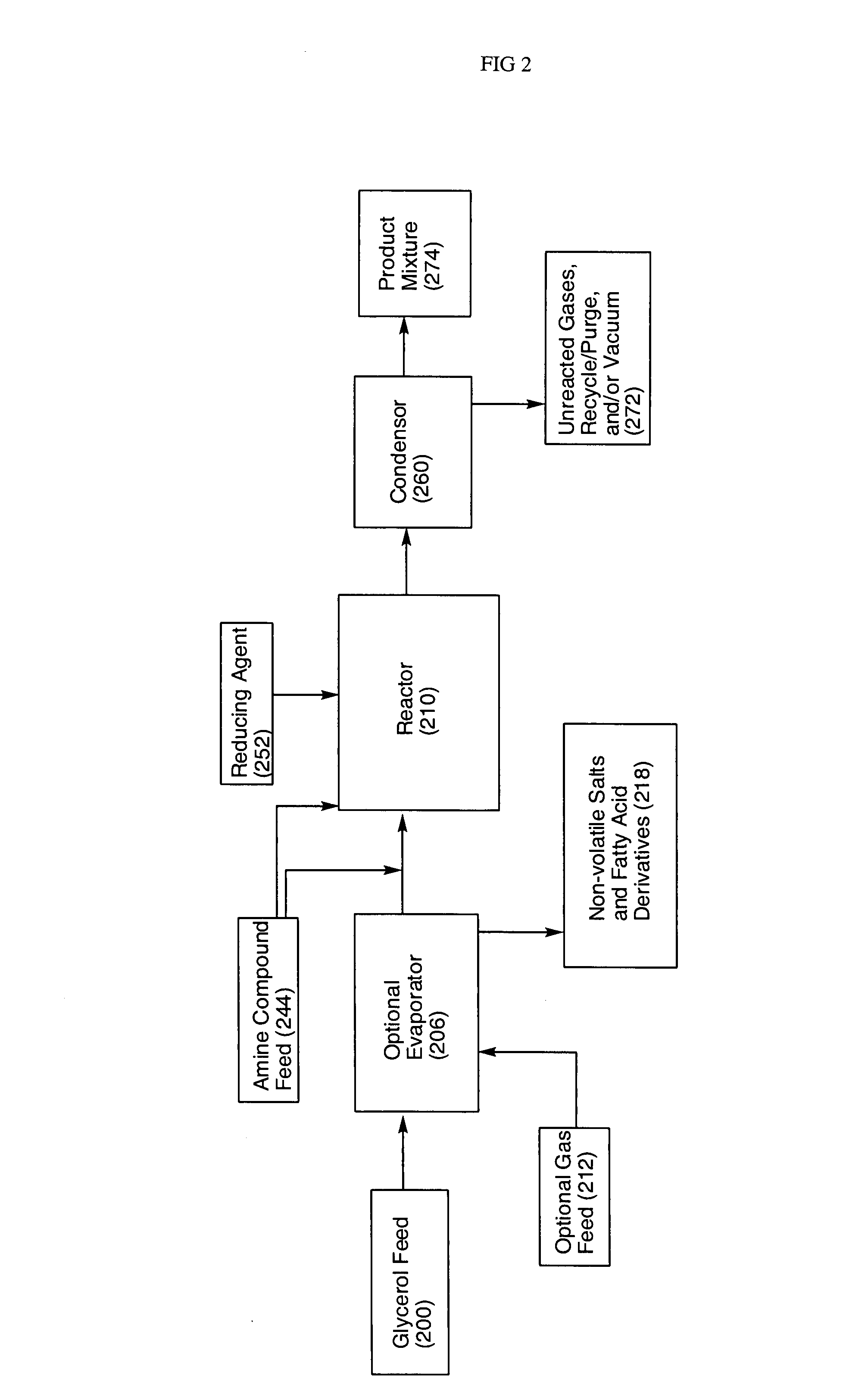

Process for the conversion of glycerol to propylene glycol and amino alcohols

ActiveUS20070287865A1Oxygen-containing compound preparationOrganic compound preparationGlycerolAlcohol products

Processes for the conversion of glycerol to a product mixture of an amino alcohol product and propylene glycol are disclosed. Glycerol is converted to hydroxyacetone and the hydroxyacetone is reduced with a reducing agent or reacted with an amine compound to give an adduct which is reduced using the reducing agent to obtain a product mixture of propylene glycol and an amino alcohol product.

Owner:THE PROCTER & GAMBLE COMPANY

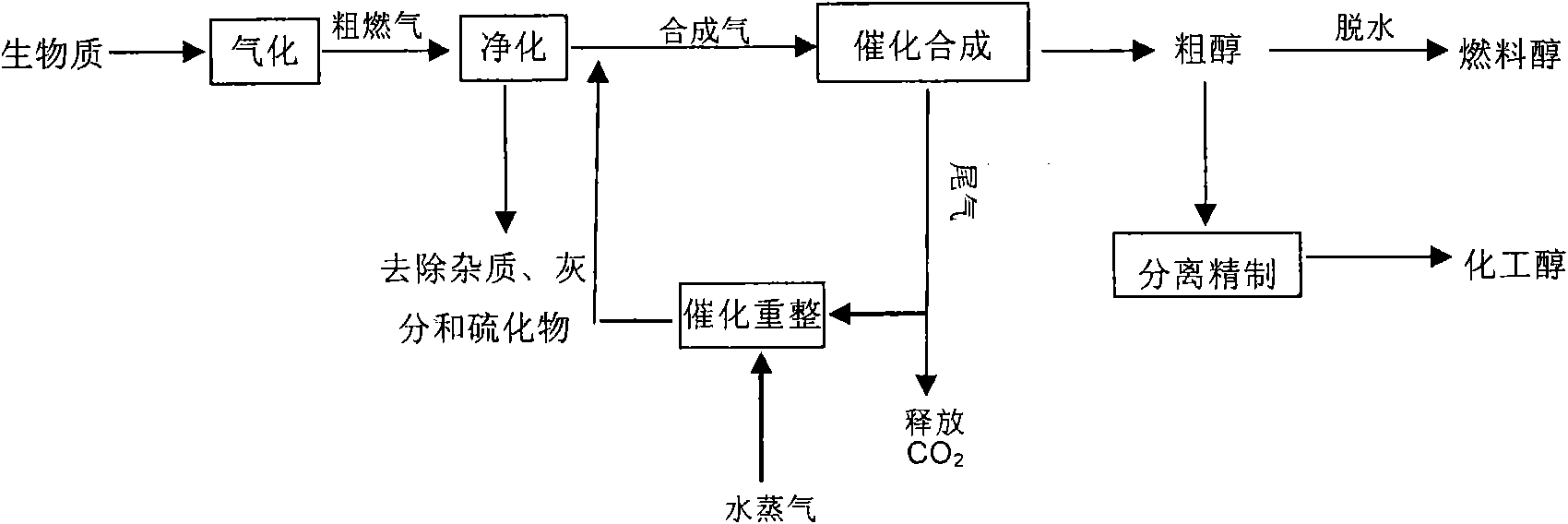

Process and method thereof for preparing lower alcohol by biomass

InactiveCN101654395AOutstanding advantagesHighlight positive effectsOrganic compound preparationBiofuelsCatalytic reformingDesorption

The invention provides a method for preparing lower alcohol by biomass, which uses straws, branches and other agriculture and forestry solid waste as raw materials. The method comprises the steps of biomass gasification, gas purification, catalytic synthesis, catalytic reforming, dehydration, separation, rectification and the like. The process has simple process, has requirement on H2 / CO / CO2 in synthesis gas lower than requirement without water gas transforming adjustment or CO2 pre-desorption, is particularly suitable for biomass based synthesis gas with lower H2 / CO and rich in CO2; after catalytic synthesis, tail gas rich in CO2, methanol and other light hydrocarbons is reformed with water vapor, and enters a catalytic synthesis unit to further synthesize a target product lower alcohol so as to sufficiently utilize carbon and hydrogen resources of the biomass; and the obtained crude alcohol product can be directly used as substitute fluid fuel or clean gasoline additive, and can be prepared into chemical single methanol by further separation and rectification.

Owner:青岛生物能源与过程研究所

Alcohol product processes

Owner:NOVOZYMES AS

Process for the alternating conversion of glycerol to propylene glycol or amino alcohols

InactiveUS20080045749A1Reducing hydroxyacetoneOrganic compound preparationOxygen compounds preparation by reductionGlycerolAlcohol products

Industrial processes for the alternating conversion of glycerol to either an amino alcohol product or propylene glycol are disclosed. Glycerol is converted to hydroxyacetone which may then be directly reduced to obtain propylene glycol or optionally reacted with an amine compound to produce an adduct that may be reduced to obtain an amino alcohol product.

Owner:THE PROCTER & GAMBLE COMPANY

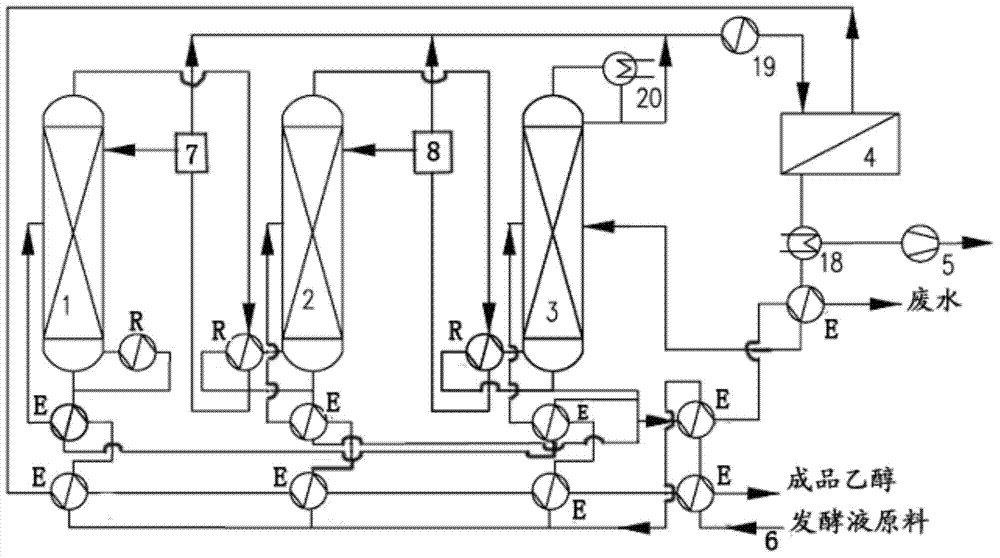

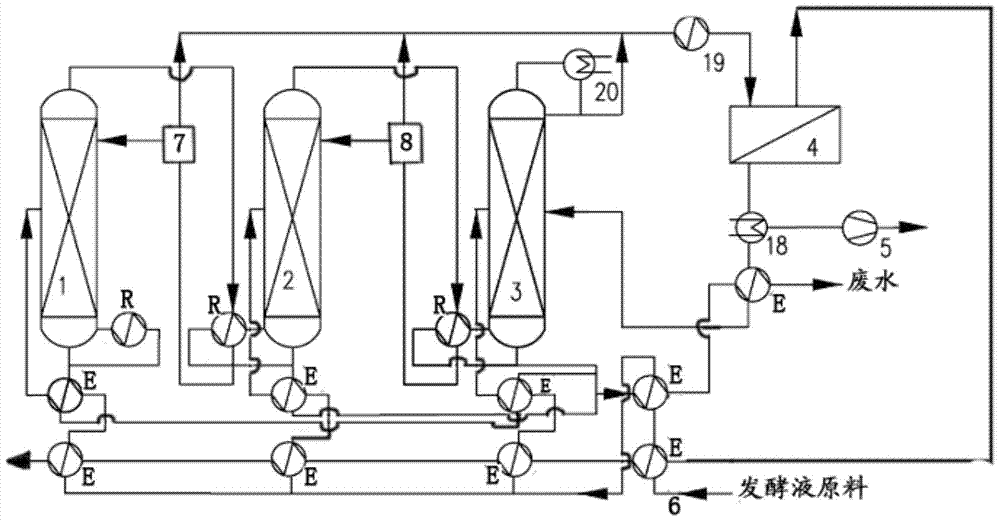

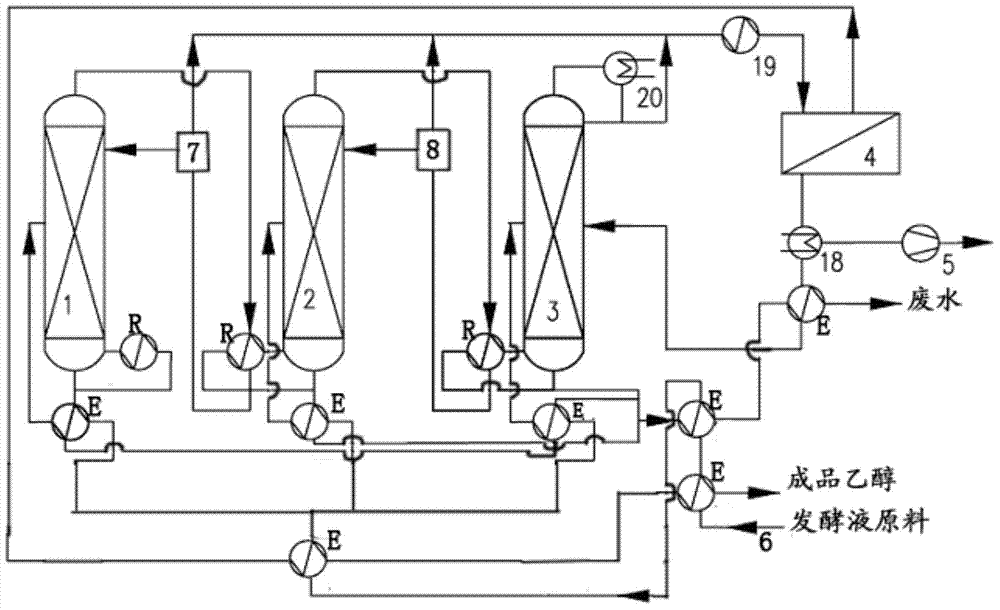

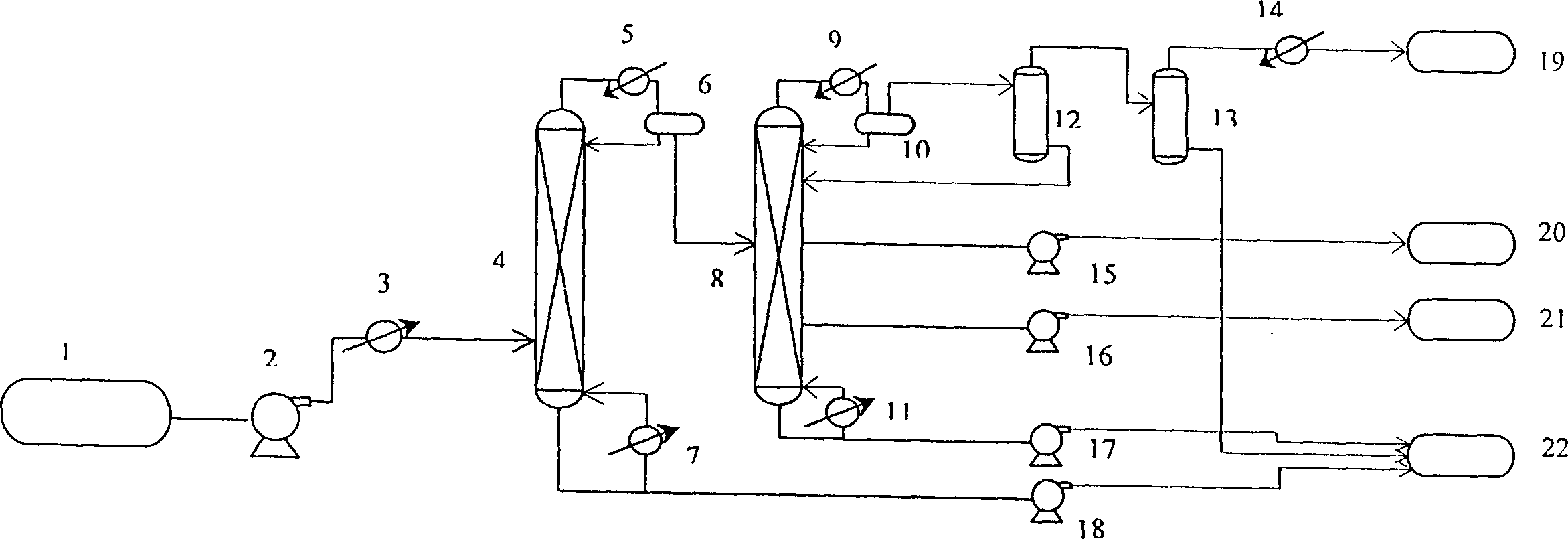

Method and device for producing biomass absolute ethyl alcohol

ActiveCN104262090AAvoid pollutionEmission reductionOrganic compound preparationBiofuelsOrganosolvProcess engineering

The invention relates to a method and a device for producing biomass absolute ethyl alcohol, and belongs to the technical field of organic solvent dehydration. The equipment used by the production method comprises a pressurized rectifying tower, an atmospheric rectifying tower, a vacuum distillation tower and a pervaporation membrane dehydration device, wherein the equipment is connected through a pipeline and a valve; reboiling heat at the bottom of the pressurized rectifying tower is provided by primary steam; the reboiling heat at the bottom of the atmospheric rectifying tower is provided by an overhead product of a high-pressure tower; and the reboiling heat at the bottom of the vacuum distillation tower is provided by the overhead product of an atmospheric tower. A feed solution enters the rectifying tower after being preheated by an absolute ethyl alcohol product and kettle raffinate; and the overhead product of the rectifying tower is further evaporated after being mixed, and then enters the pervaporation membrane dehydration device to dehydrate. According to the production method, optimal configuration of all levels of energy in the system is considered, thus the target of the system for saving energy is achieved, and the steam consumption of the overall system can be saved by over 30%-50% in comparison with a traditional technology.

Owner:JIANGSU NINE HEAVEN HIGH TECH

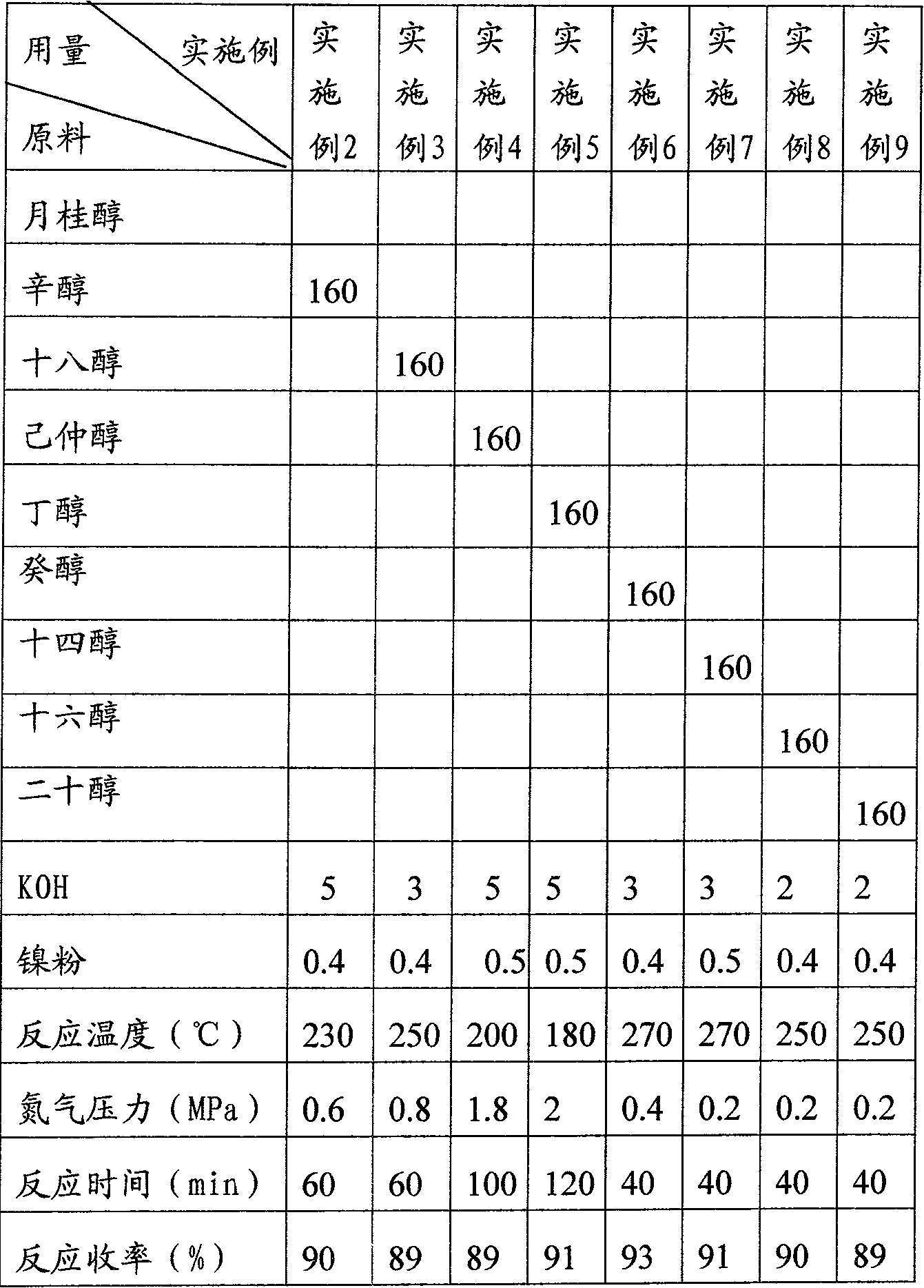

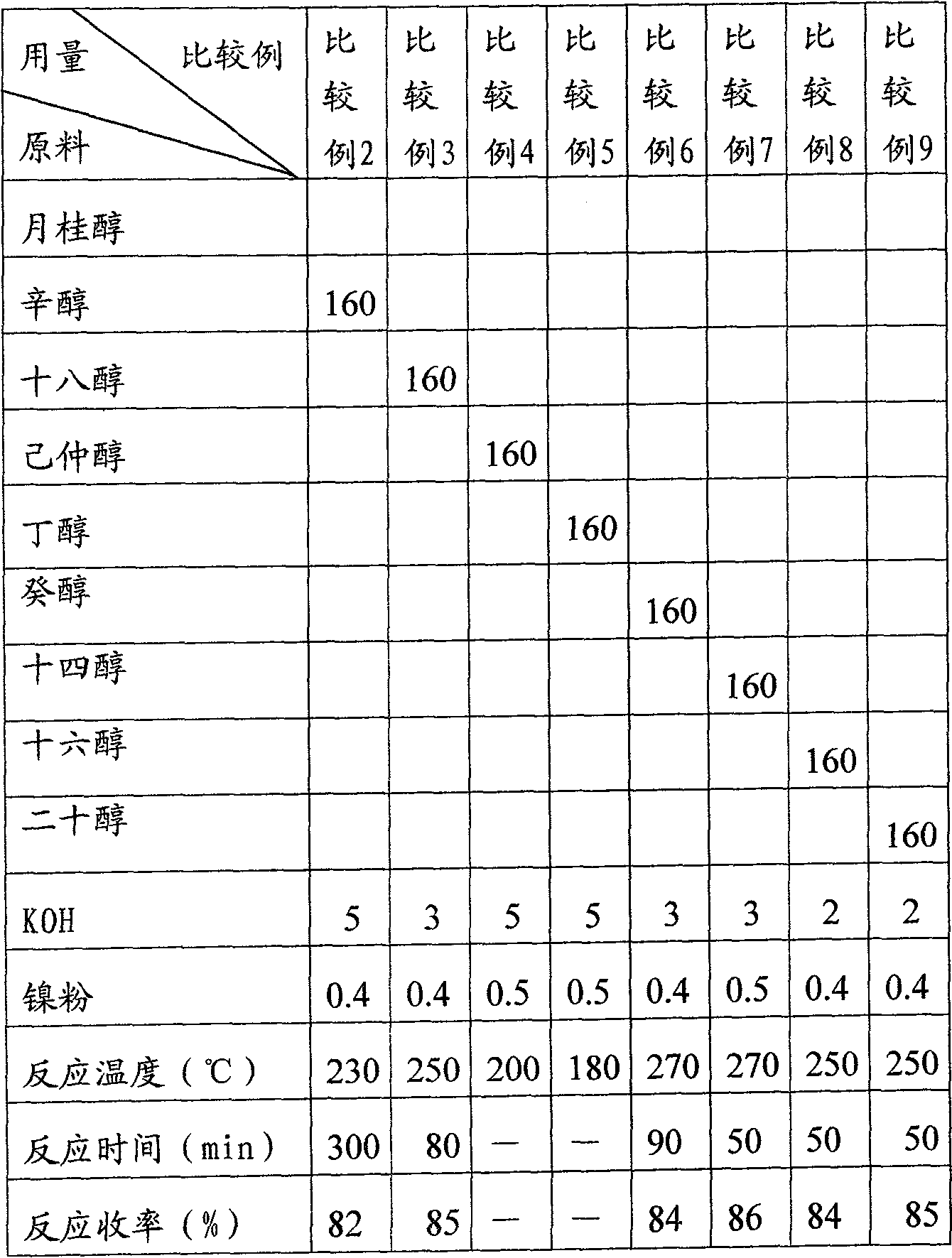

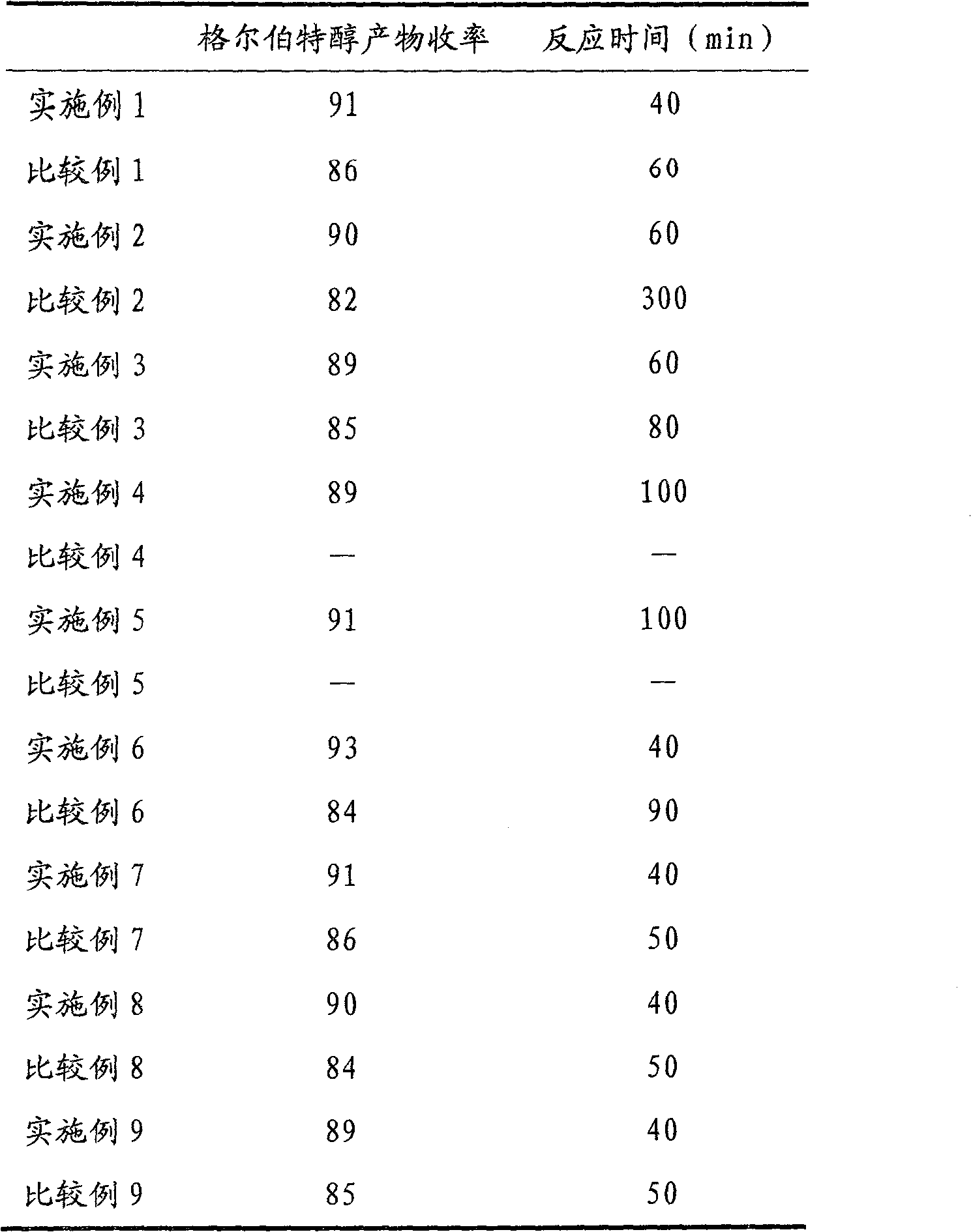

Method for preparing Guerbet alcohol

InactiveCN101659597AAvoid it happening againAvoid consumptionOrganic compound preparationHydroxy compound preparationHigh pressureNitrogen gas

The invention discloses a method for preparing Guerbet alcohol, which comprises the steps of mixing aliphatic primary alcohol or secondary alcohol, KOH and nickel powder according to the ratio by parts by weight of 160: 2-5: 0.4-0.6, then adding into a reactor, carrying out condensation reaction at the temperature of 100-270 DEG C under the stirring state and the nitrogen protection of 0.2MPa-2MPa, terminating the reaction when no water is produced by detection, then cooling a reaction product to room temperature, after that, filtering and concentrating, thereby obtaining a Guerbet alcohol product. As the condensation reaction is carried out in the high-pressure reactor under the condition of nitrogen protection, the method excludes the influences of oxygen on the reaction, effectively avoids the side reactions of oxidation, the production of acid, aldehyde and other byproducts of oxidation and the consumption of the raw material alcohol, the product alcohol and a catalyst, improves the reaction yield and improves the conversion rate by more than 5%. Meanwhile, as the reaction with pressure is carried out, the boiling point of the raw material alcohol is increased, and the long-time reflux reaction is unnecessary, thereby shortening the reaction time by more than 50%, reducing the annual energy consumption which accounts for 500 tons of standard coal and having great popularization and utilization prospects.

Owner:石家庄联合石化有限公司 +1

Processes for converting glycerol to amino alcohols

ActiveUS20070287868A1Reducing adductOrganic compound preparationAmino compound preparationMetal catalystGlycerol

Processes for converting glycerol to an amino alcohol product involving reacting glycerol with a metal catalyst to obtain hydroxyacetone, and reacting the hydroxyacetone with an amine compound to obtain an adduct that is then reduced using a reducing agent to obtain an amino alcohol product are described.

Owner:THE PROCTER & GAMBLE COMPANY

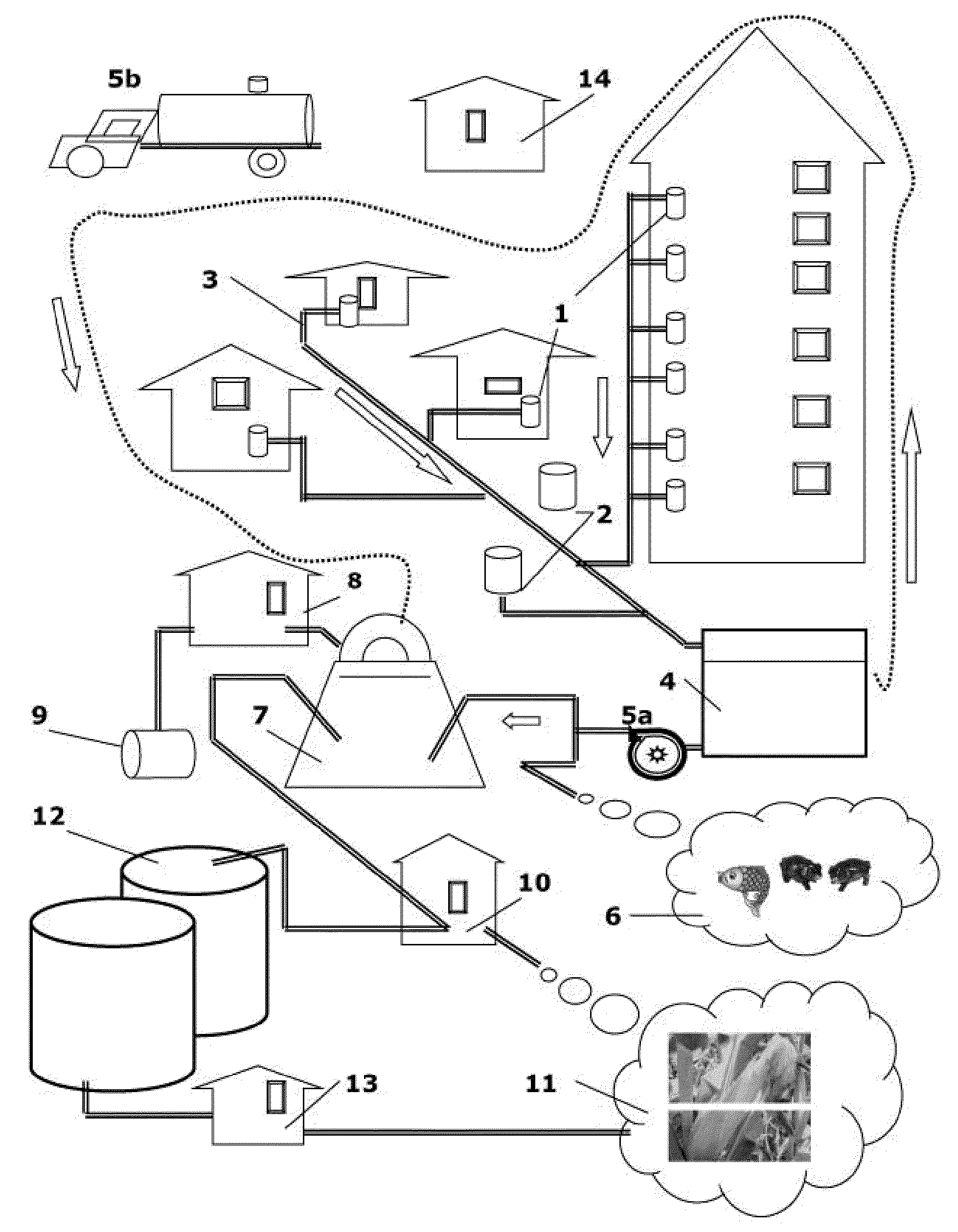

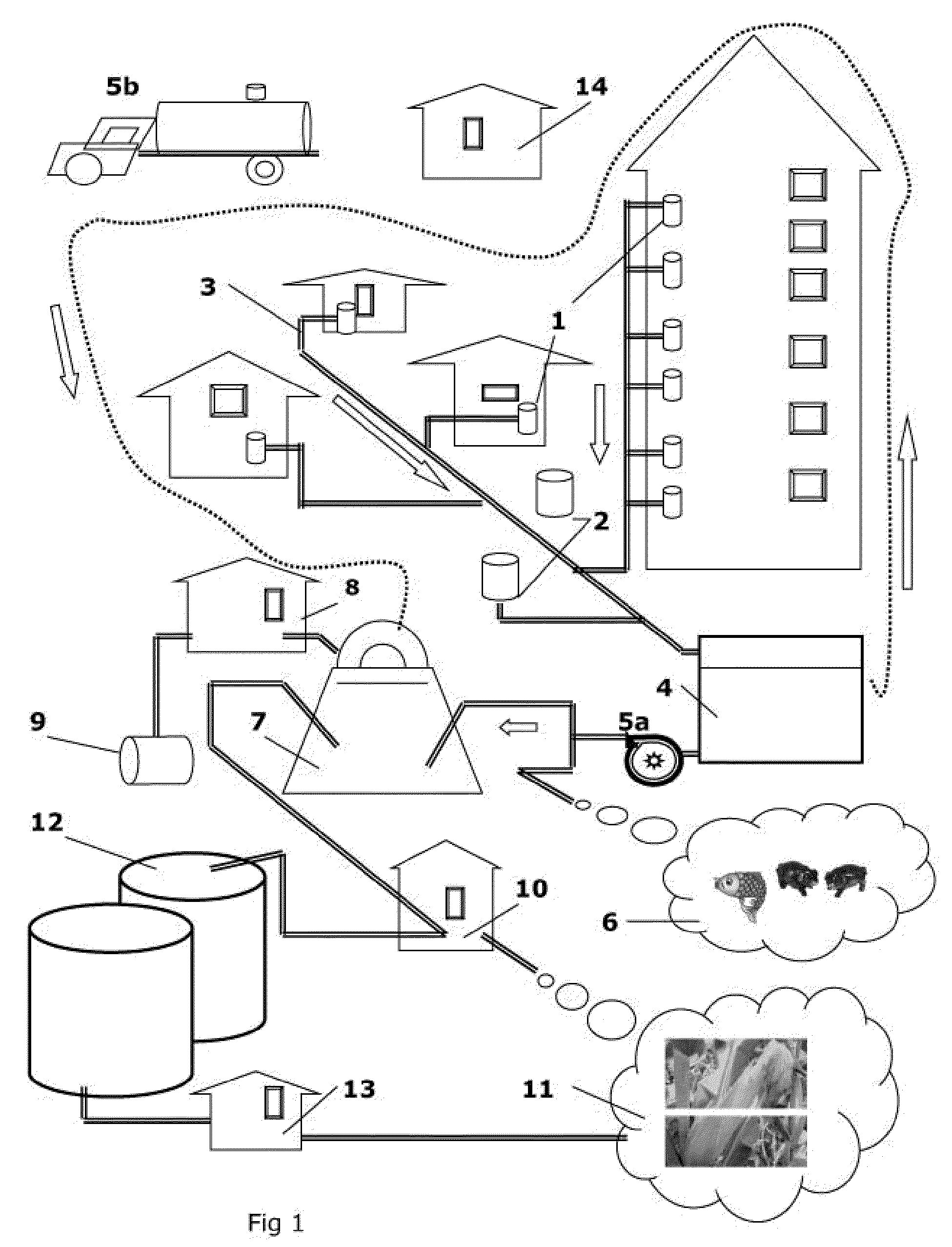

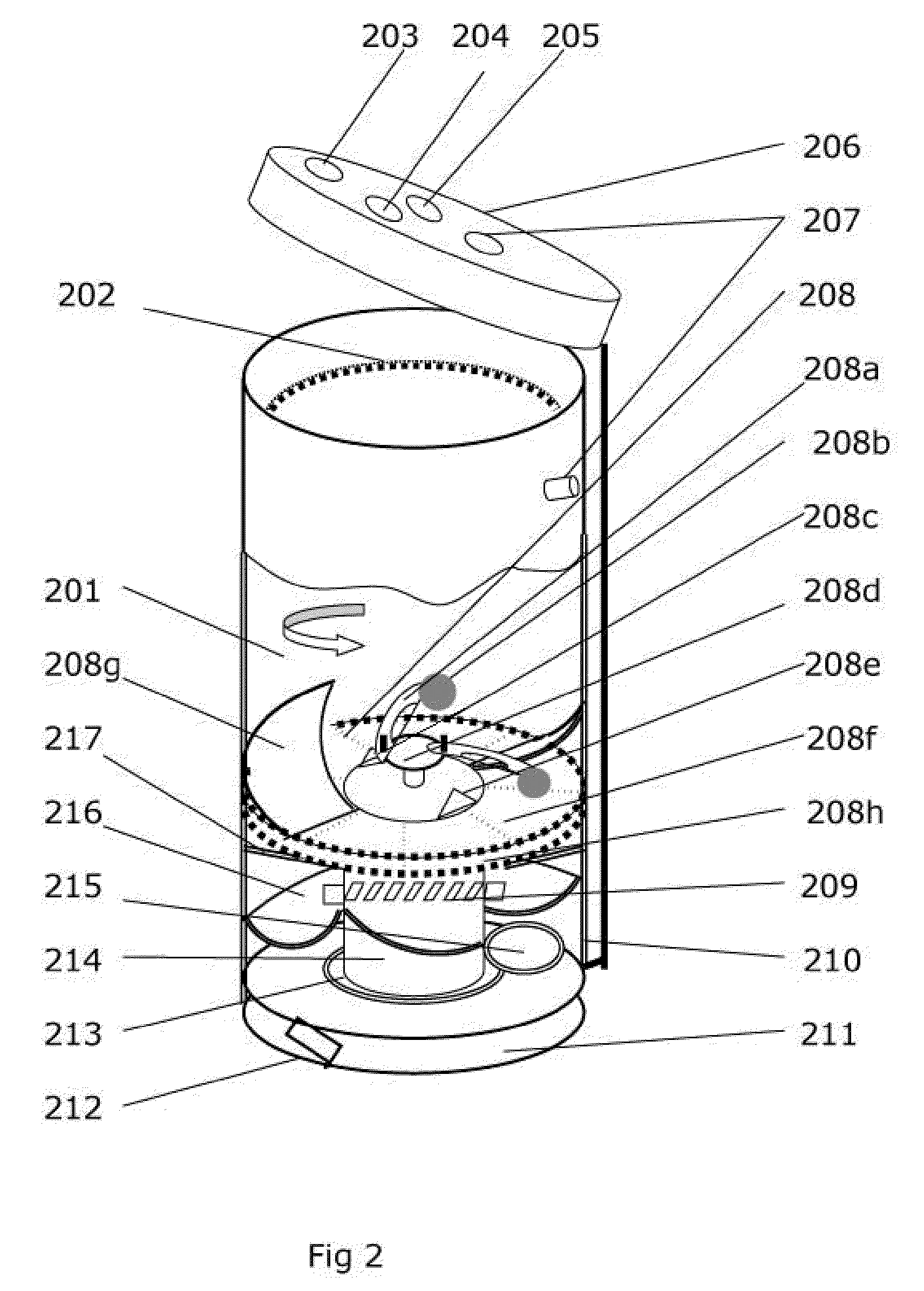

Method and Apparatus of Solid Wastes Automatic Collection Ductwork Evacuation and Comprehensive Utilization

ActiveUS20100243559A1Save wasteIncrease wasteBio-organic fraction processingLiquid degasificationLiquid mediumSystem capacity

The method and apparatus of solid wastes automatic collection ductwork evacuation and comprehensive utilization contemplated to reach a facilitative dropping, quietly, effectively and automatically collecting, evacuating, transporting of all kinds of biodegradable solid waste, getting poly package-less uniform waste particle and jam for recycle that largely reduce the emission of greenhouse gas, pollution of poly package materials, contamination of putrefactive solid waste, generate resource from waste and benefit dwellers, industrials, business units. The disclosed method, procedure and apparatus comprise setting multiple waste grinding collectors indoor and outdoor; cutting, shredding and grinding all kinds of biodegradable solid waste with gaseous and liquid medium into both dry fluidized particle for gaseous medium transportation and wet fluidized jam for liquid medium transportation by the invention multiple waste grinding collectors with multiple functions of automatic information exchange, water proportion, waste cut, shred & grind to satisfy duct pipe evacuation and transportation; Through ductwork pipes, which connect all the waste grinding collectors, pumps with liquid medium, and air pump, suction with gaseous medium, respectively evacuate and transport the fluidized particle and jam into regional collect tanks; By sorting, vehicles, pumps and vacuum aspirators via duct pipeline transport the fluidized particle and jam respectively going to feedstuff plants, bio-purifications, methane generating pools and alcohol generating pools; Methane and alcohol products purified for fuel; Dreg and sludge after disinfecting and sterilization, is respectively transported to farm for irrigation, and transported to dewater chamber to produce organic fertilizer, and further carbonized for fuel; Wastewater purified by filter and activated carbon for recycle and discharged; The regional manage house manages the regional disposal system capacity and to share living regional municipal drainage ductwork and facilities by timer, automatic information exchange assembly and the switch set at the end of the regional municipal drainage pipeline.

Owner:QIU ZEGUO

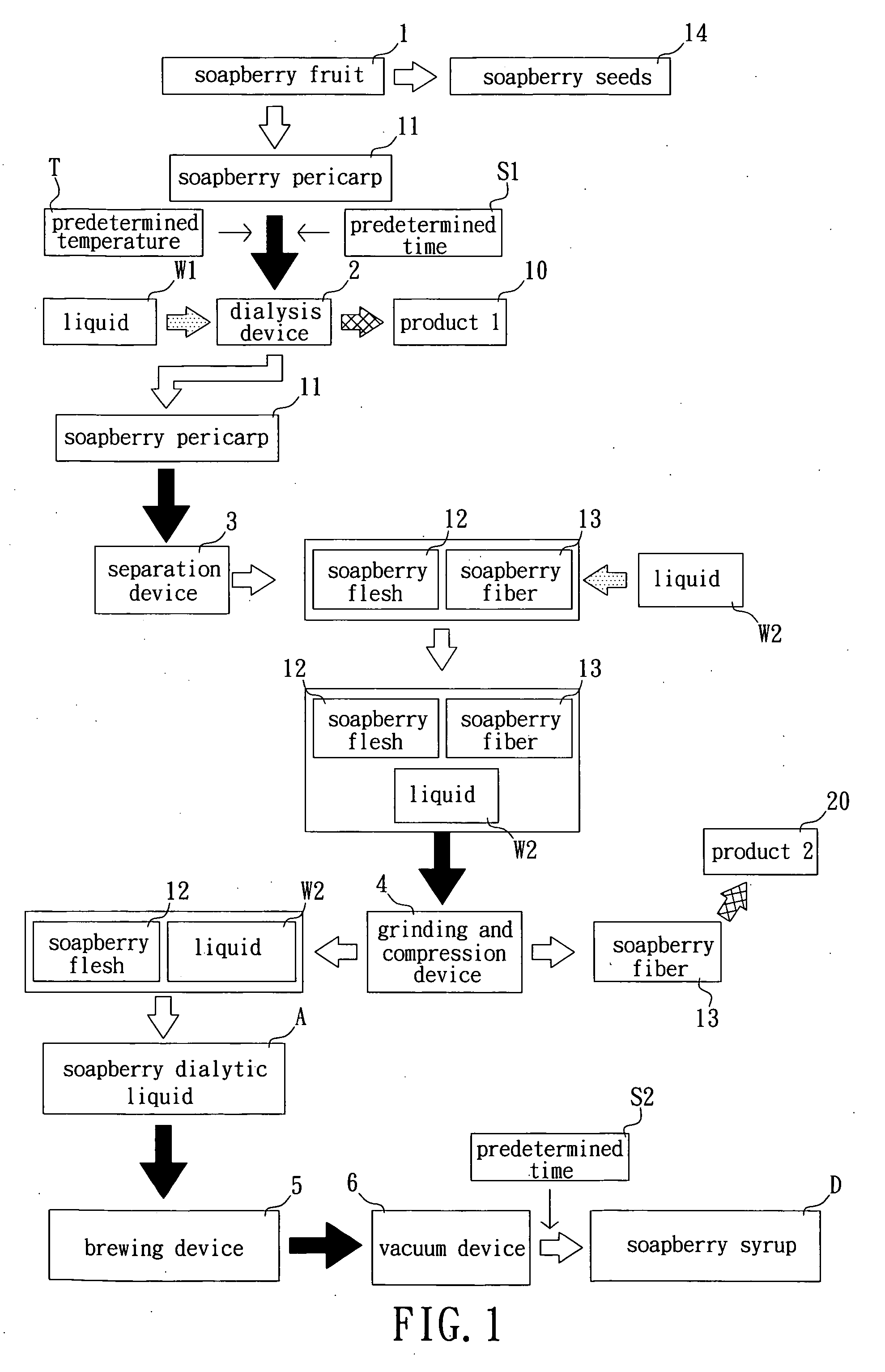

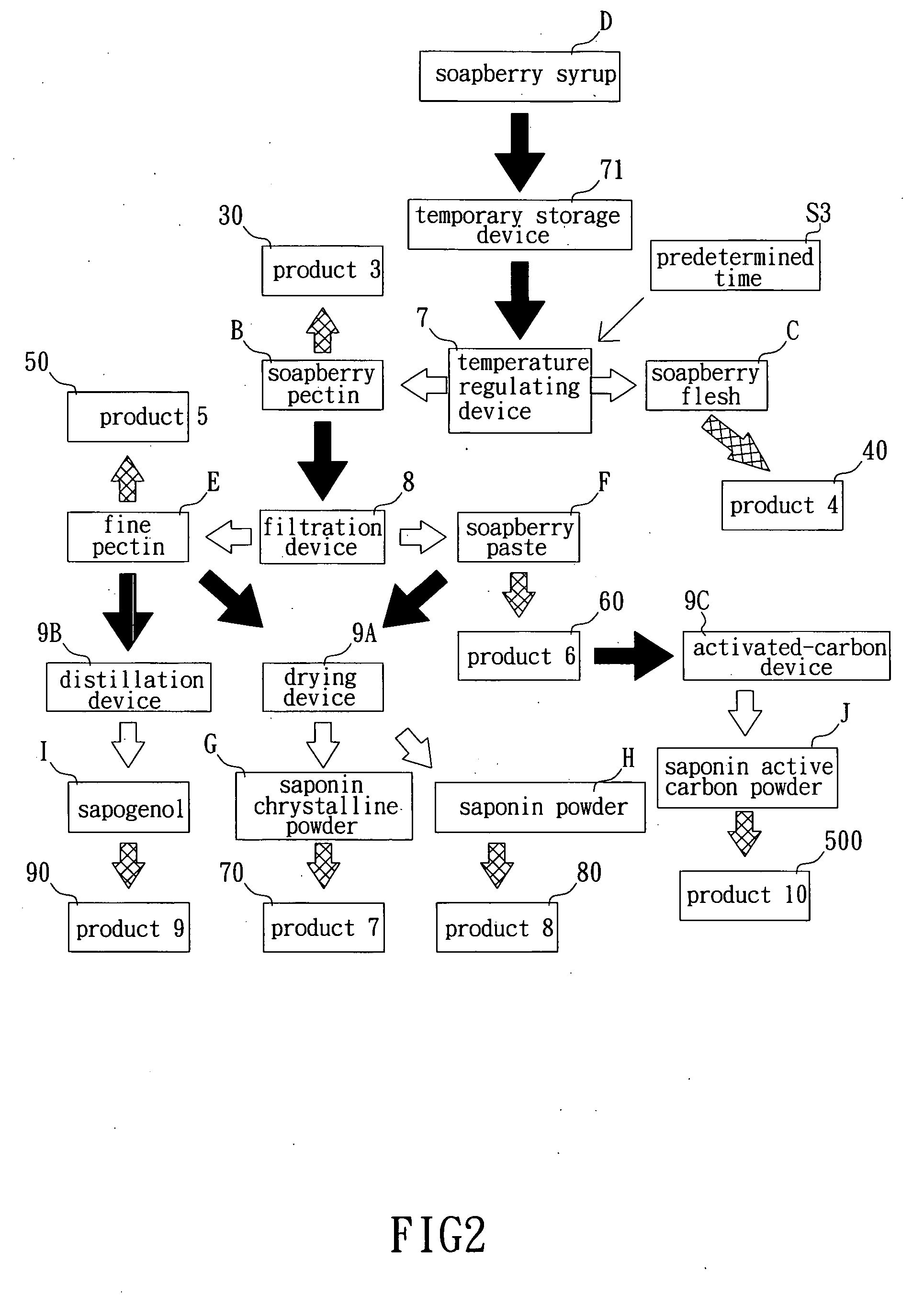

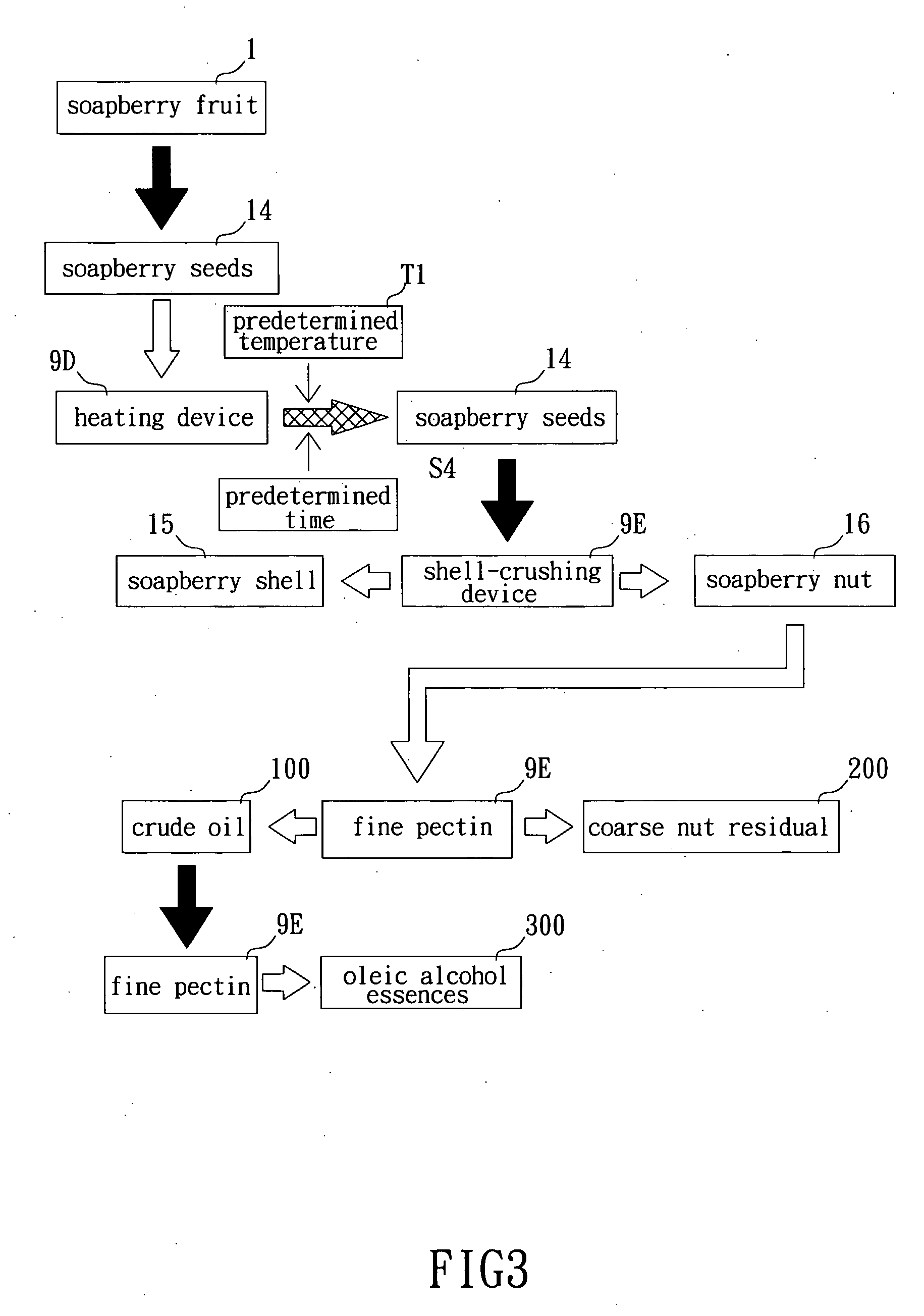

Method for extracing substances from soapberry fruit and seed and products made therefrom

InactiveUS20100316752A1No additional benefitLow costCosmetic preparationsBiocideBiotechnologyOleyl alcohol

An exclusive manufacturing technique for extracting active interface saponin and organic substances from soapberry; organic elements and oleic alcohol products from soapberry seeds through the process of fermentation and end products made therefrom, wherein the manufacturing process includes: 1. Pre-ferment soapberry fruit (1). 2. Processing said fruit (1) by a dialysis device (2). 3. Separating the soapberry flesh (12) and fiber (13) by a separation device (3). 4. Extracting soapberry dialytic liquid (A) through a grinding and compression device (4) and separating the fiber (13). 5. Eliminating bacteria inside the dialytic liquid (A) by a huge stewing device (5). 6. A second fermenting process by a vacuum device (6) and generating a soapberry syrup (D). Said method is healthy, toxin free and biologically safe, produce no wastage, zero carbon emissions, zero pollution, low energy production and is ecologically friendly. End products produced by said method are variables with excellent economic viability.

Owner:HSU HENG JUI

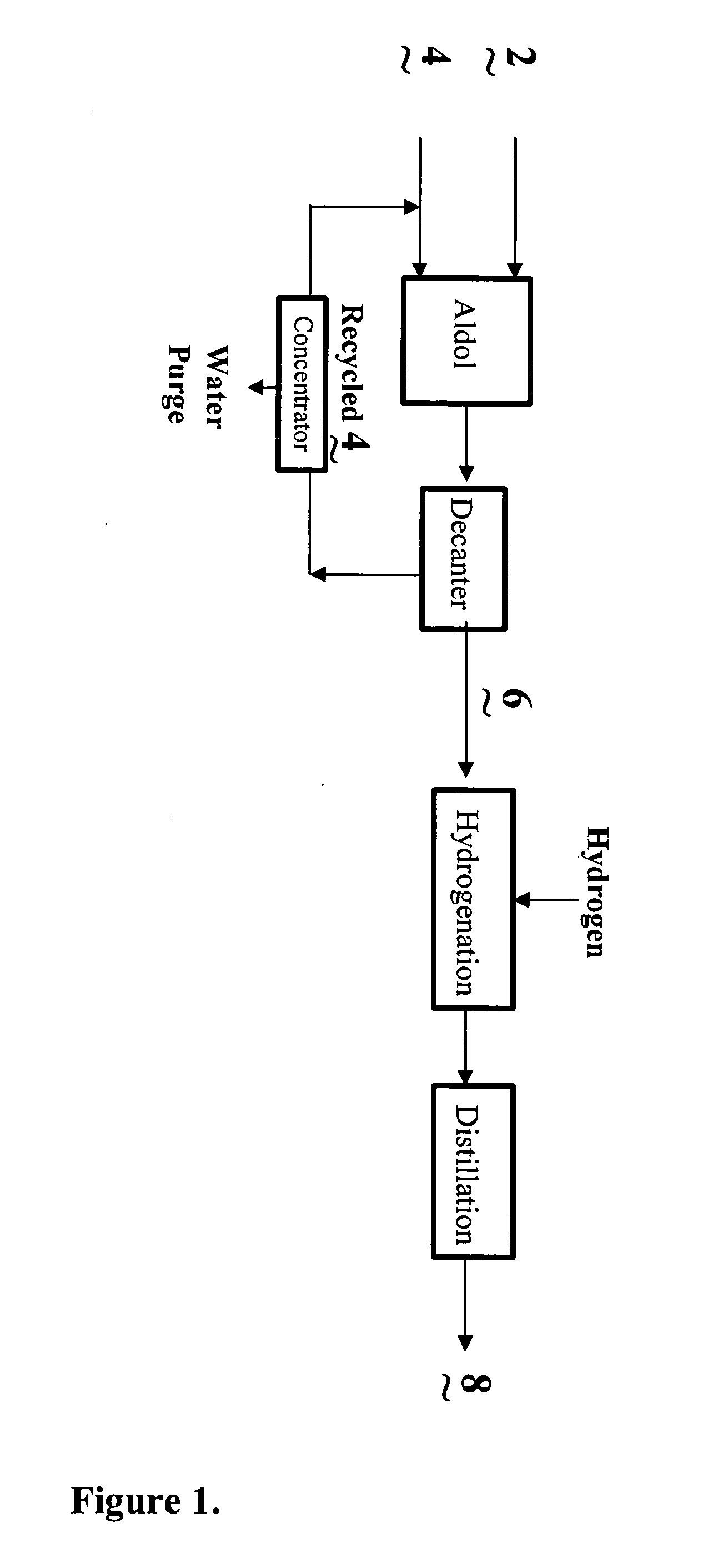

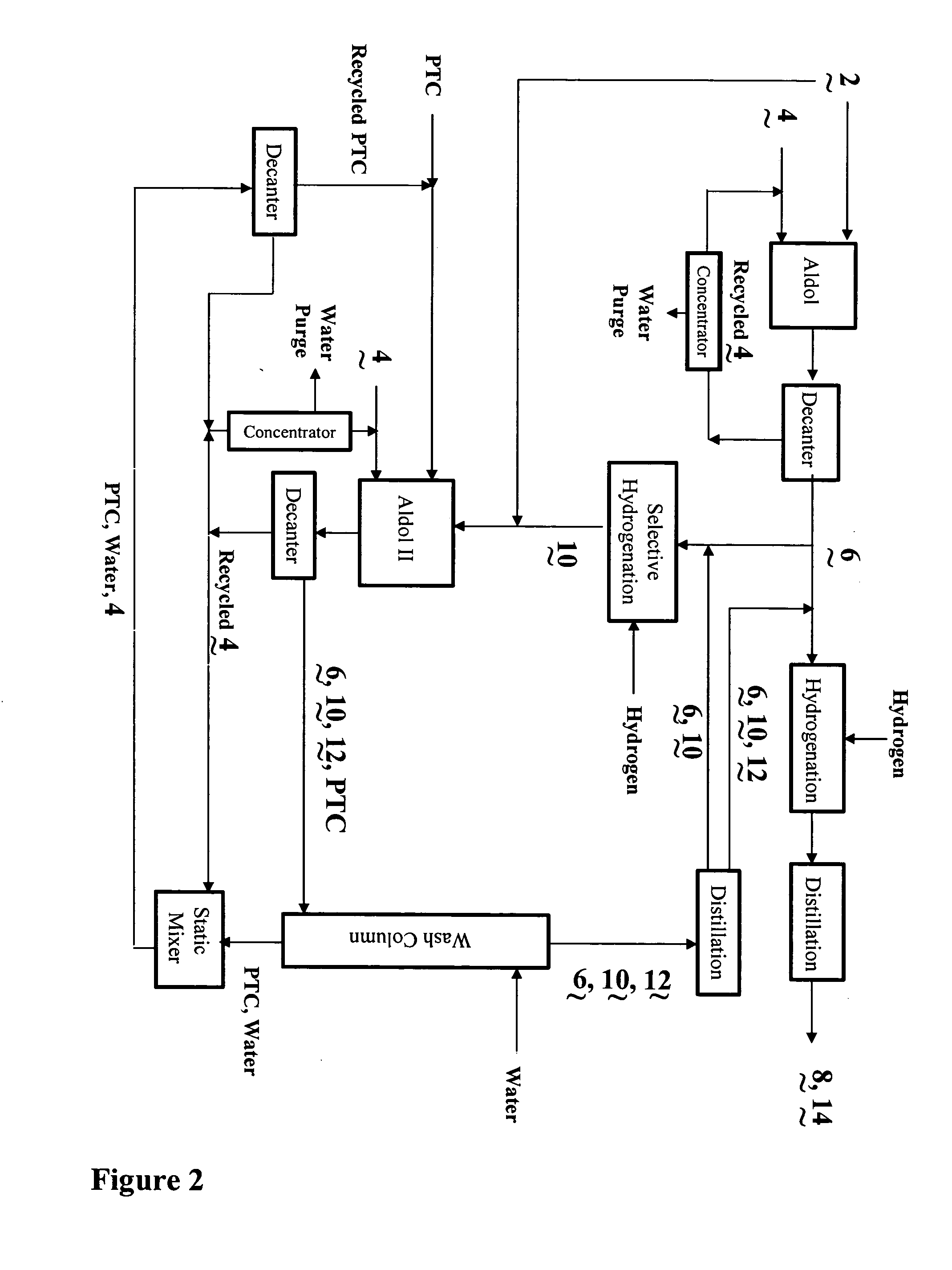

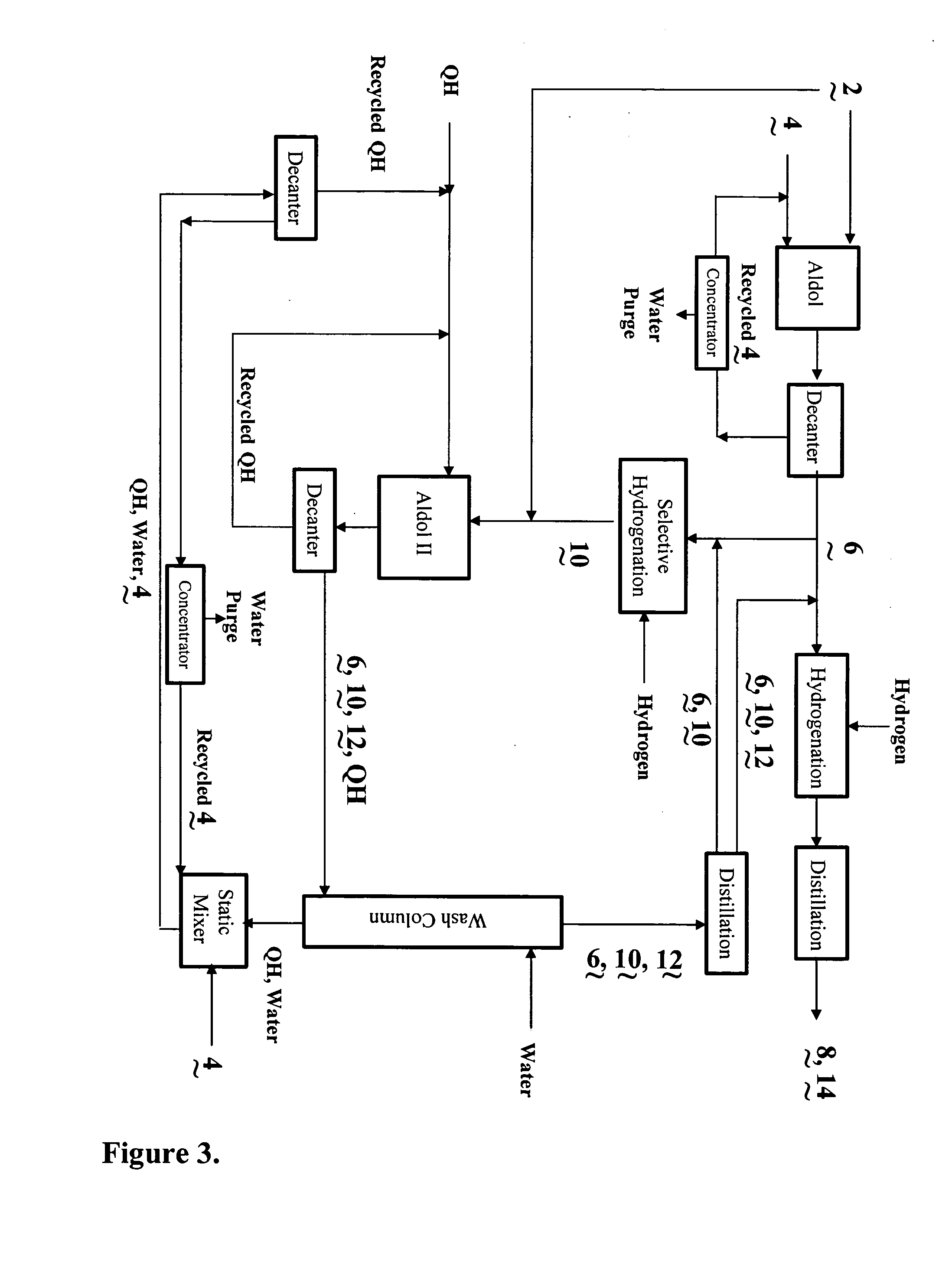

Process for the co-production of alcohols

InactiveUS20040138510A1Efficient processingPromote formationOrganic compound preparationPreparation by hydrogenationSalting outWater soluble

The present invention relates to the co-production of unsaturated aldehydes via a crossed-aldol condensation reaction catalyzed by recyclable water-soluble phase-transfer catalysts or the hydroxides thereof. The aldehydes are then hydrogenated to the desired alcohol products or saturated aldehyde feed stocks. Specifically, methods in which 2,4-diethyloctanol is co-produced with 2-ethylhexanol in batch and continuous processes are described. Recovery of the phase-transfer catalyst through water washing followed by "salting out" from the washings is also demonstrated.

Owner:BASF CORP

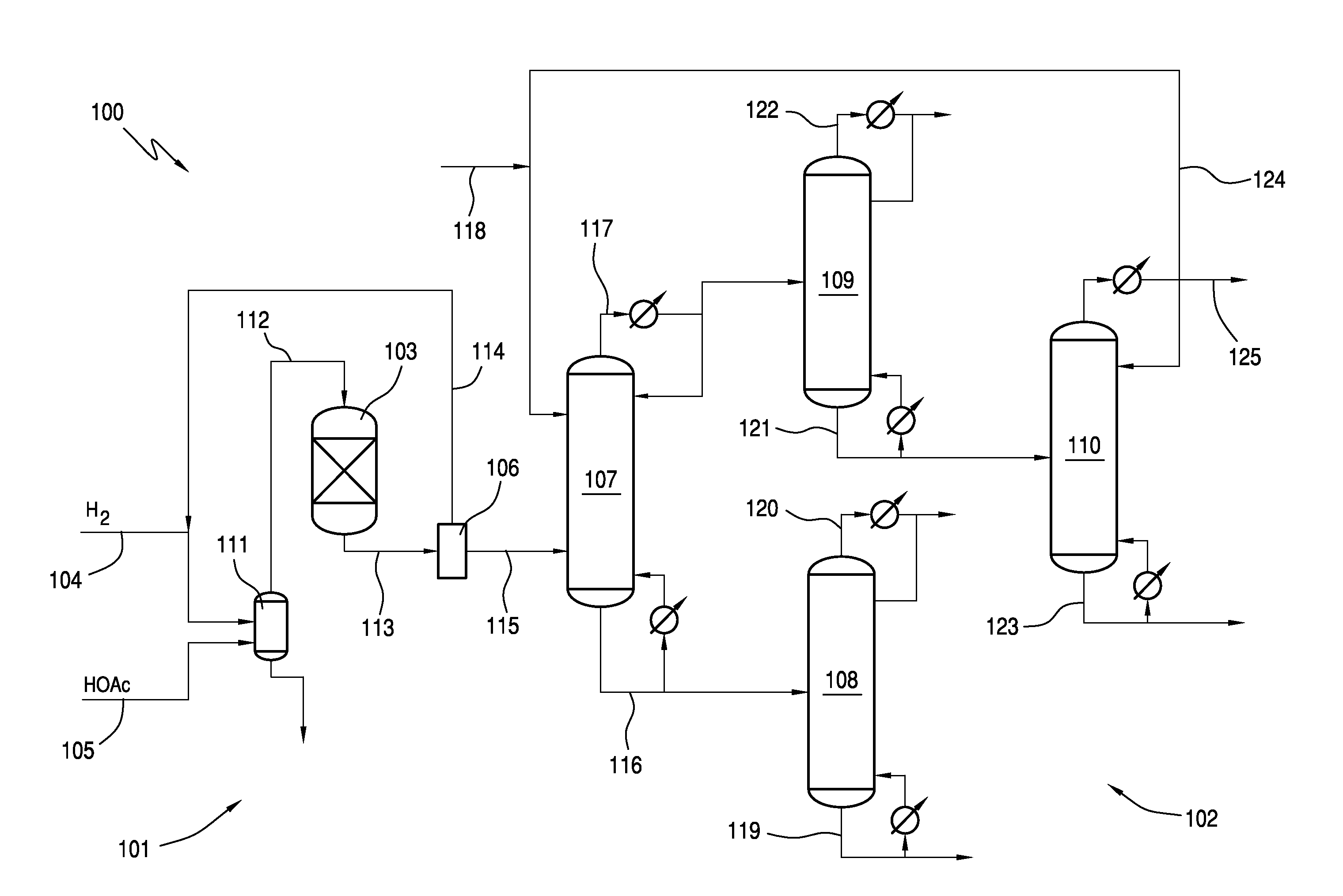

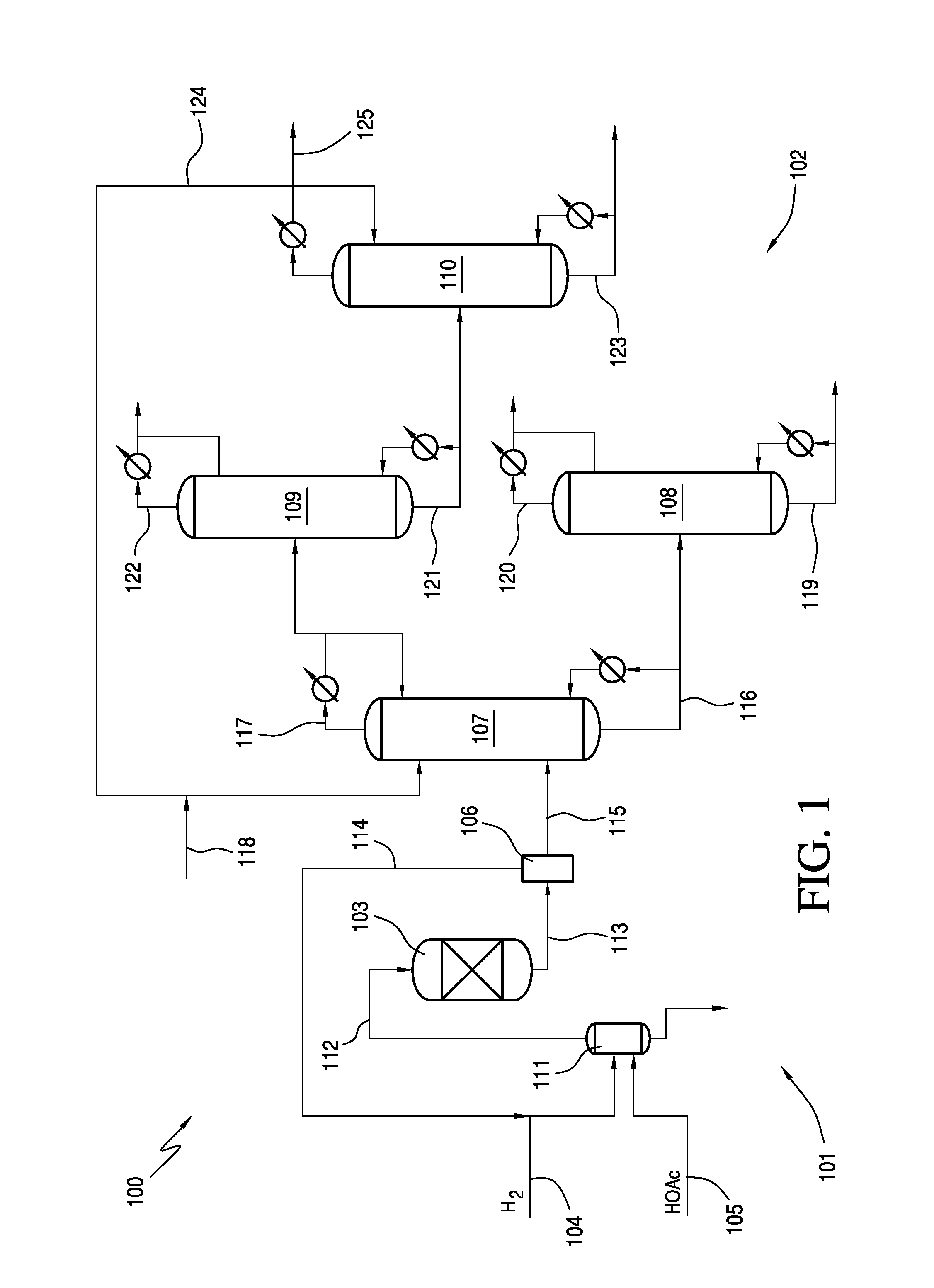

Distillation of Crude Alcohol Product Using Entrainer

InactiveUS20120323049A1Organic compound preparationOxygen compounds preparation by reductionAcetic acidDistillation

Recovery of ethanol from a crude ethanol product obtained from the hydrogenation of acetic acid using a low energy process and an entrainer. The crude ethanol product is separated in an distillation column to produce a distillate stream comprising the entrainer. The ethanol product is recovered from the residue stream.

Owner:CELANESE INT CORP

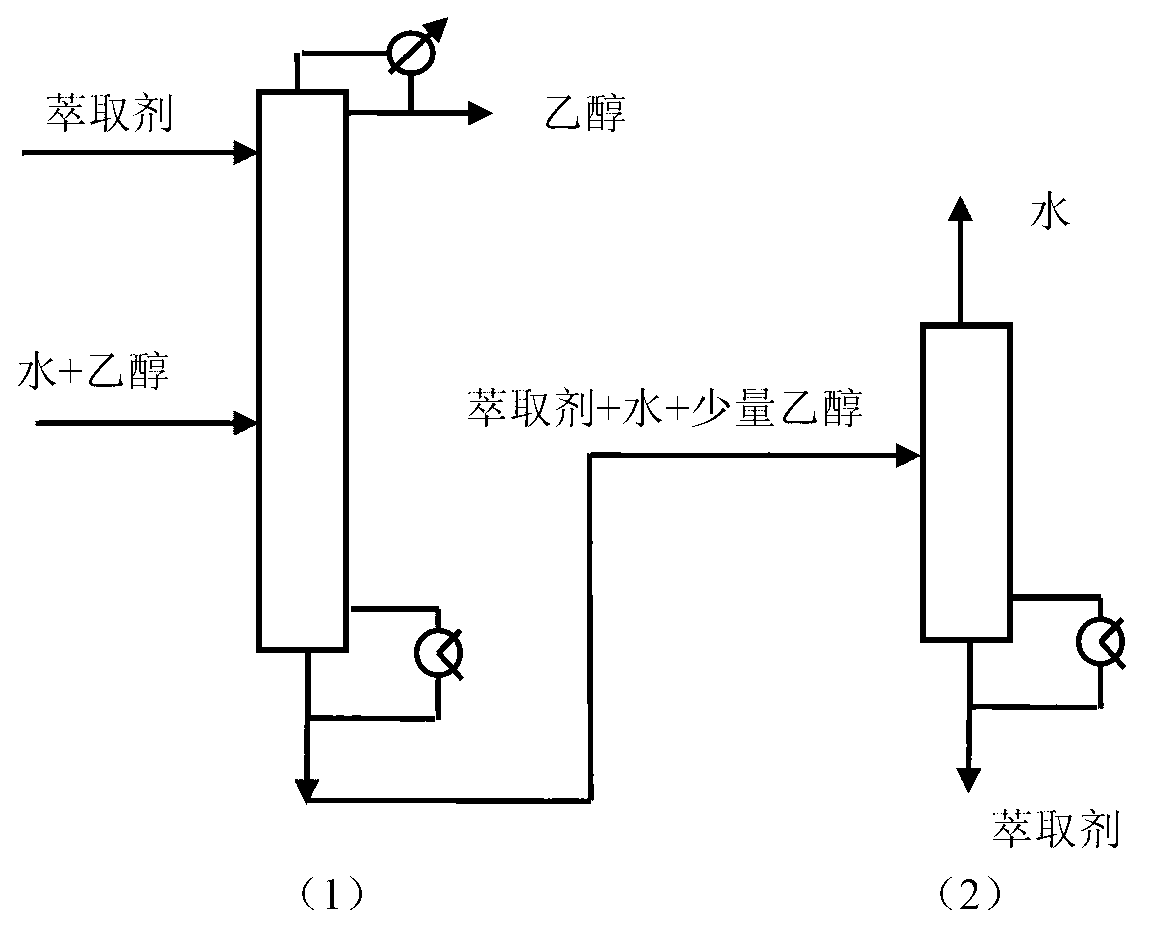

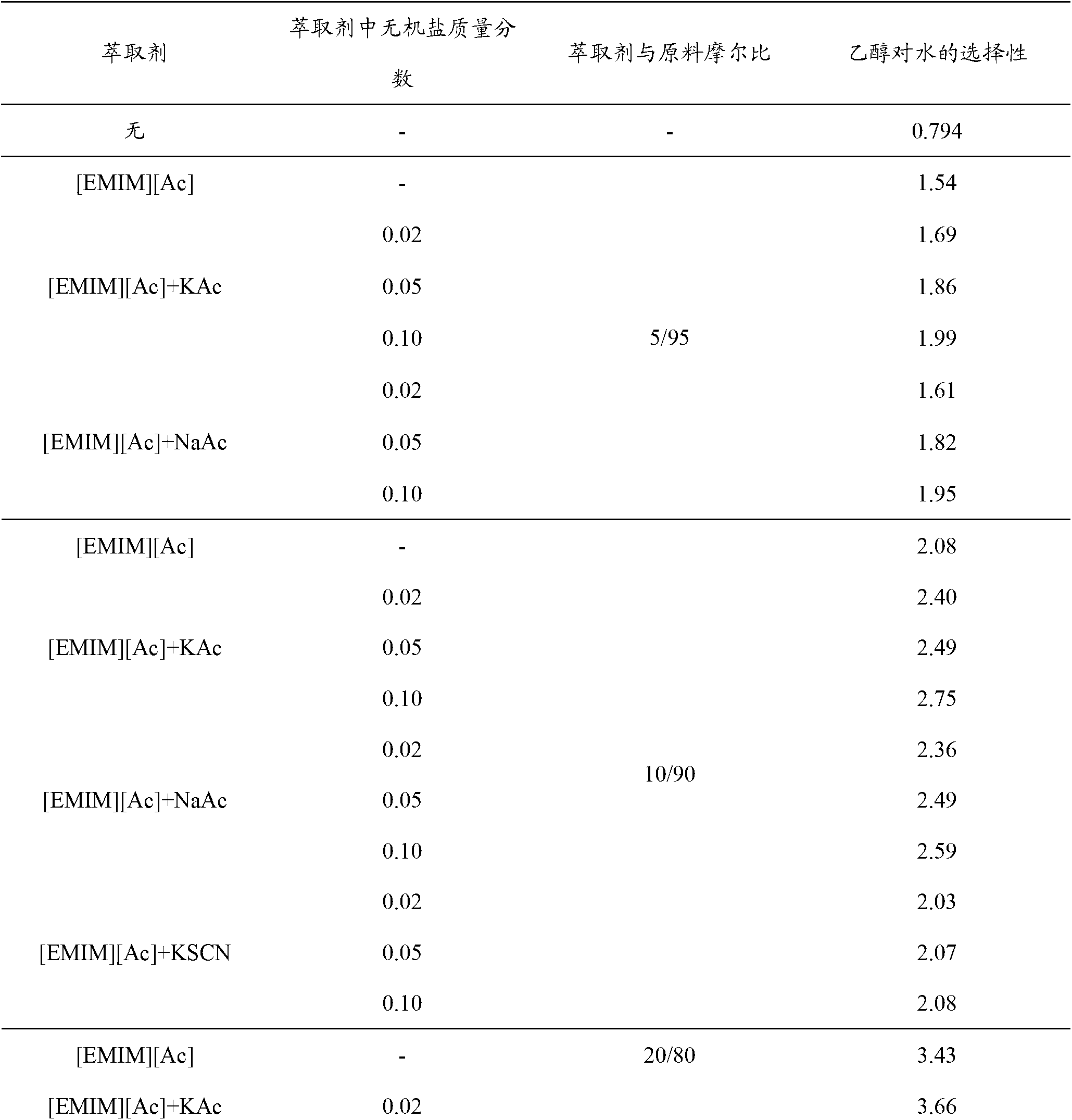

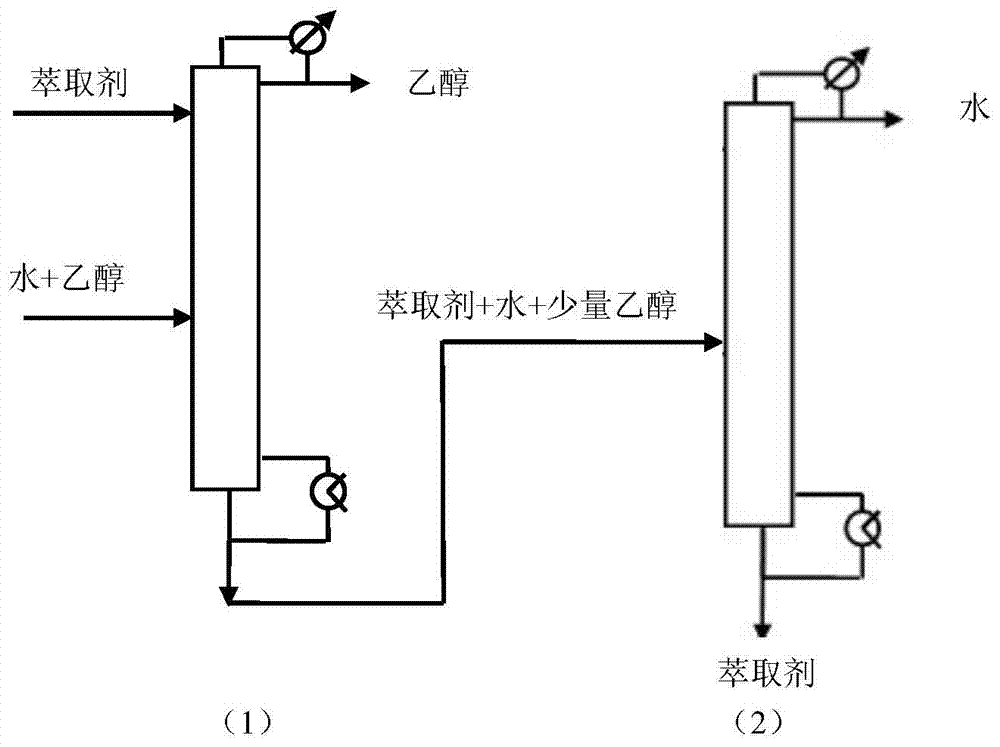

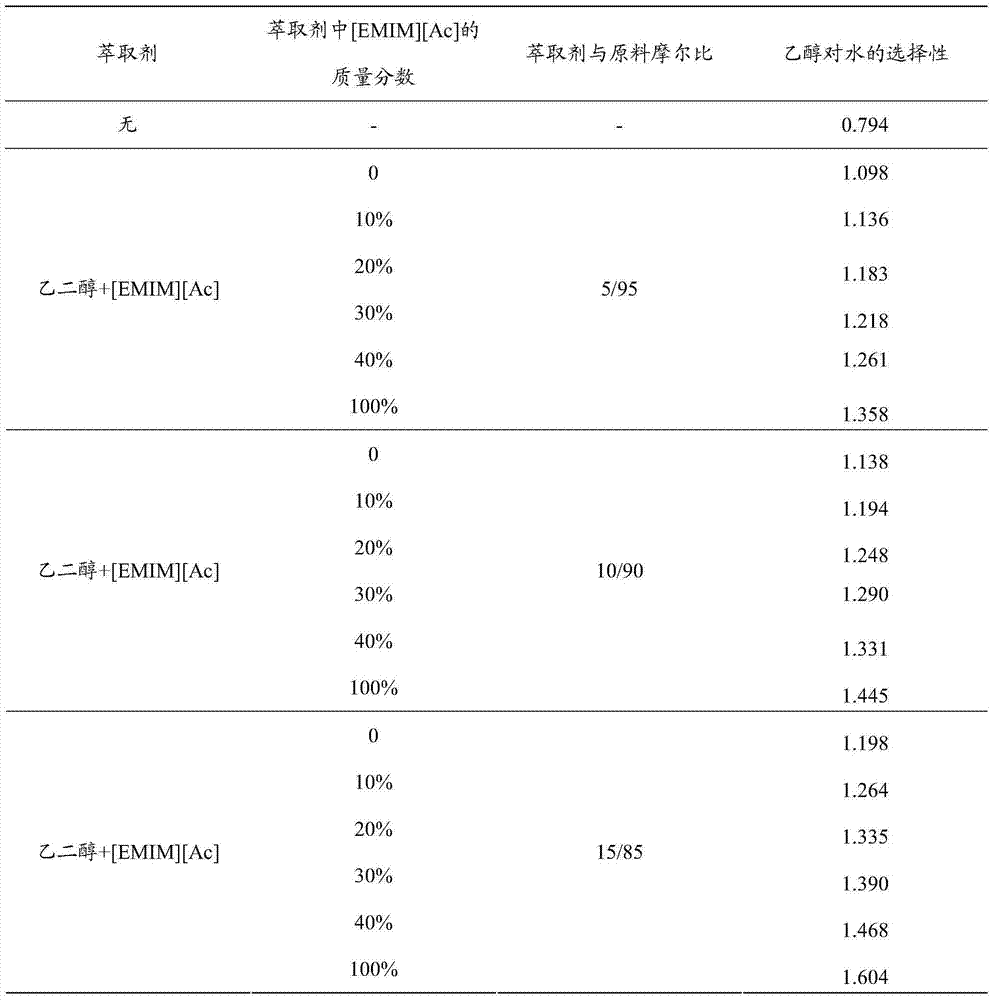

Method for separating alcohol from water through ion liquid extraction and rectification

InactiveCN103073388AHigh purityBreaking the azeotropeOrganic compound preparationHydroxy compound preparationRefluxInorganic salts

The invention belongs to the technical field of rectification separation, and relates to a method for separating alcohol from water through ion liquid extraction and rectification, in particular to a method for separating alcohol from the water through extraction and rectification with an ion liquid and a compound solvent of the ion liquid. The method comprises the steps that an ion liquid [EMIM][Ac] and inorganic salt serve as extraction agents for separating alcohol from the water, wherein a mass fraction of inorganic salt is 0-20%; a high-purity alcohol product formed by crossing azeotrope can be obtained from the top of an extraction and rectification tower on the conditions that the extraction and rectification tower is at atmospheric pressure, a mass flow ratio of the extraction agents to a raw material is 0.5-6.0, and a reflux ratio is 1.0-5.0; a solvent recovery flash tank operates on the conditions that reduction pressure is 0.05-0.5atm and a temperature is 120-200 DEG C; and an extraction agent obtained from a tower kettle is recycled. With the method, the selectivity is improved significantly, and azeotropy of alcohol and the water is broken, so that a concentration of alcohol can be formed by the crossing azeotrope.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing corn straw polyatomic alcohol

InactiveCN101186559AIncrease contentReduce dependencePreparation by hydrolysisOrganic solventPerformance index

The invention relates to a preparation method of maize straw polyhydric alcohol, which comprises the steps: (1) materials of the following mass portions are taken: 100 portions of organic solvent, 30 to 120 portions of maize straw and 1 to 8 portions of catalyst; the organic solvent and the catalyst are mixed evenly; (2) the mixed liquid is kept at the temperature of 90 to 200 DEG C; the maize straw is added by a plurality of steps and reacts for 60 to 180min after the addition and the maize straw polyhydric alcohol is obtained after cooling. The method of the invention can increase the content of maize straw catabolite in polyhydric alcohol products, fully utilizing wasted maize straw. The content of the maize straw catabolite in the polyhydric alcohol is 20 to 65 percent with 150 to 780 mg KOH / g hydroxyl value. Maize straw catabolites of different contents and polyhydric alcohol of different performance indexes can be obtained by adjusting the production process and the portions of the raw materials. The obtained maize straw polyhydric alcohol can be directly used for synthesizing polyurethane foam plastics.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

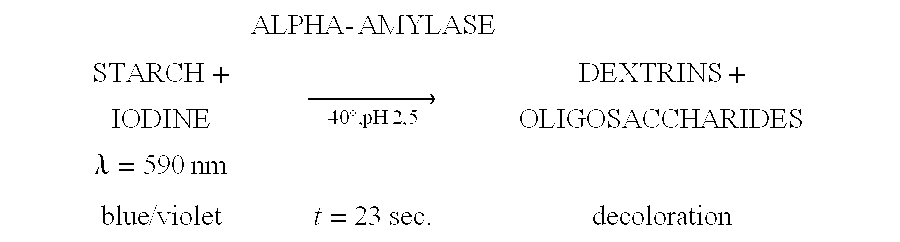

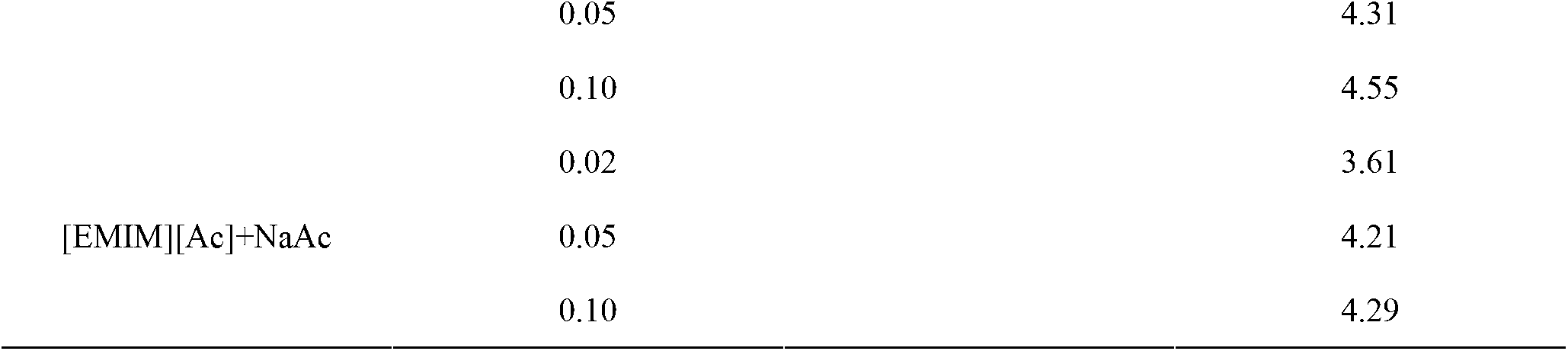

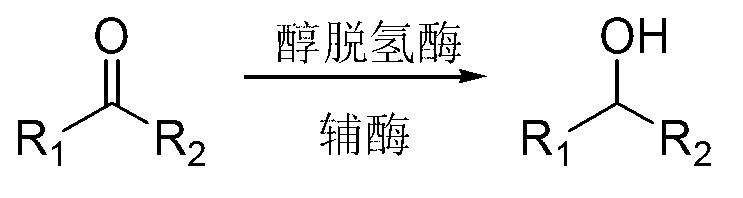

Method for reducing ketone compound by using two alcohol dehydrogenases

The invention discloses a method for reducing a ketone compound by using two alcohol dehydrogenases. Commercial materials in market or easy-to-obtain ketone compound are selected as initial raw materials, wherein R1 and R2 are respectively C1-C8 straight-chain alkyl, C5-C10 cycloalkyl, C5-C10 aryl or pyridyl group. The aryl or pyridyl group is not substituted or is substituted by one or more following groups: halogen, alkoxy or C1-C5 straight-chain alkyl. The reaction steps comprise feeding, dehydrogenase adding, reaction, and post-treatment. Especially, with the method, high-optical-purity chiral alcohol products can be obtained, and subsequent treatment purification operation is simple and safe. The method has the advantages of stable process condition, simple operation, and suitability for large-scale productions. Novel idea and method are provided for preparing chiral alcohol compounds.

Owner:ASYMCHEM LAB TIANJIN +5

Epoxy-terminated waterborne polyurethane resin and preparation method thereof

ActiveCN105218778AFlexibleFlexible with the rigidity of epoxyPolyurea/polyurethane coatingsEpoxyPolymer science

The invention discloses epoxy-terminated waterborne polyurethane resin and a preparation method thereof. The resin is prepared in the following steps that vegetable oil polyhydric alcohols, small molecular polyhydric alcohols, diisocyanate and a hydrophilic chain-extending agent are contained in organic solvent, and an isocyanate-terminated polyurethane prepolymer is obtained through an addition reaction under the action of a catalyst; a hydroxyl-terminated epoxy compound is added for reacting, and epoxy-terminated polyurethane is obtained; then amine is added for neutralizing, water is dripped for conducting phase reversal, heat preservation is performed, the organic solvent is removed through reduced pressure distillation, and accordingly the epoxy-terminated waterborne polyurethane resin is obtained. The resin is water-based paint, no volatile organic pollutants exist, and environmental friendliness is achieved. The epoxy-terminated waterborne polyurethane resin is prepared from combining the polyurethane and the epoxy resin through a chemical method, and the resin not only has the flexibility of the polyurethane but also has the advantages of rigidity and cohesiveness of the epoxy resin. The vegetable oil polyhydric alcohols are adopted as the raw materials, and the method has advantages of being low in price, environmentally friendly, capable of regenerating raw materials and the like compared with a traditional mode that a petrochemical engineering dihydric alcohol product is used as the raw material.

Owner:中山大桥化工集团有限公司

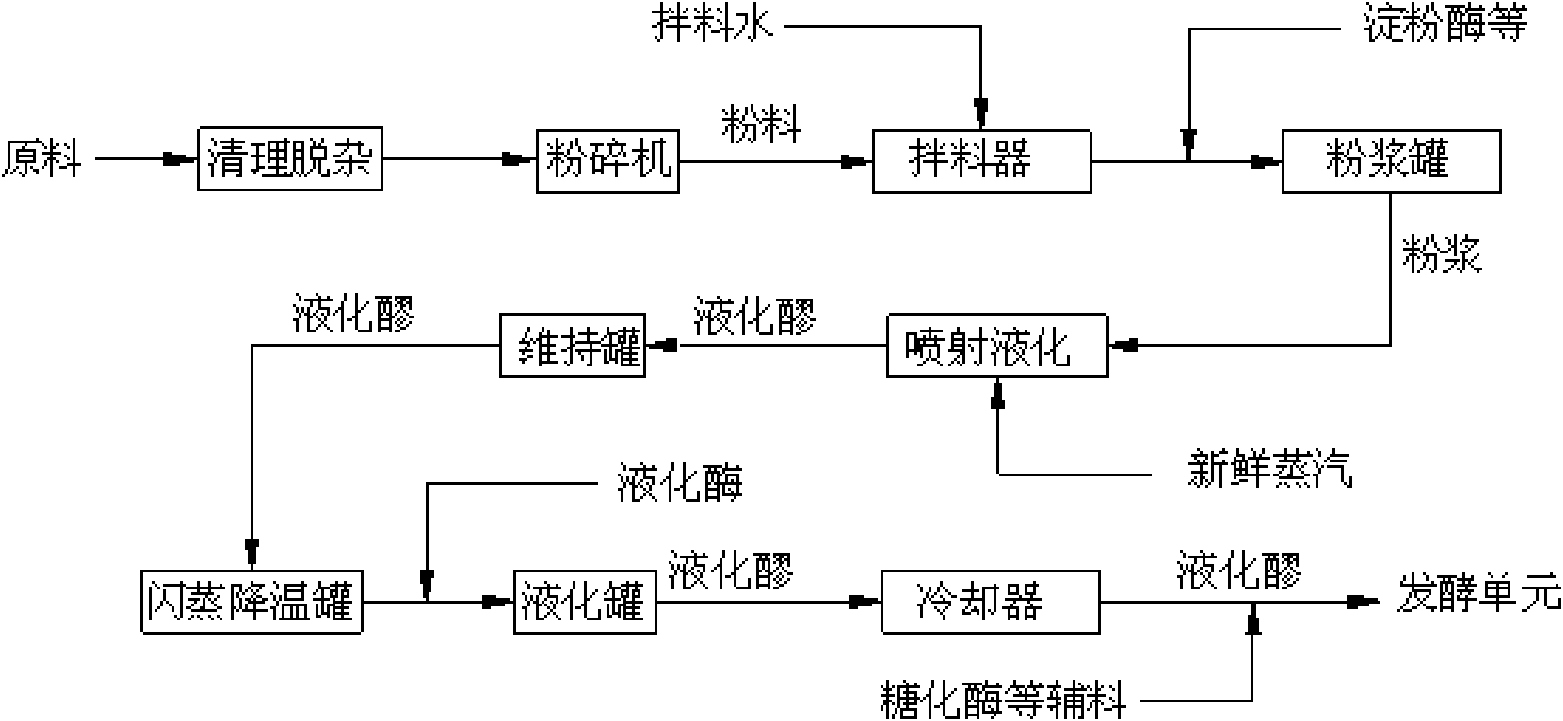

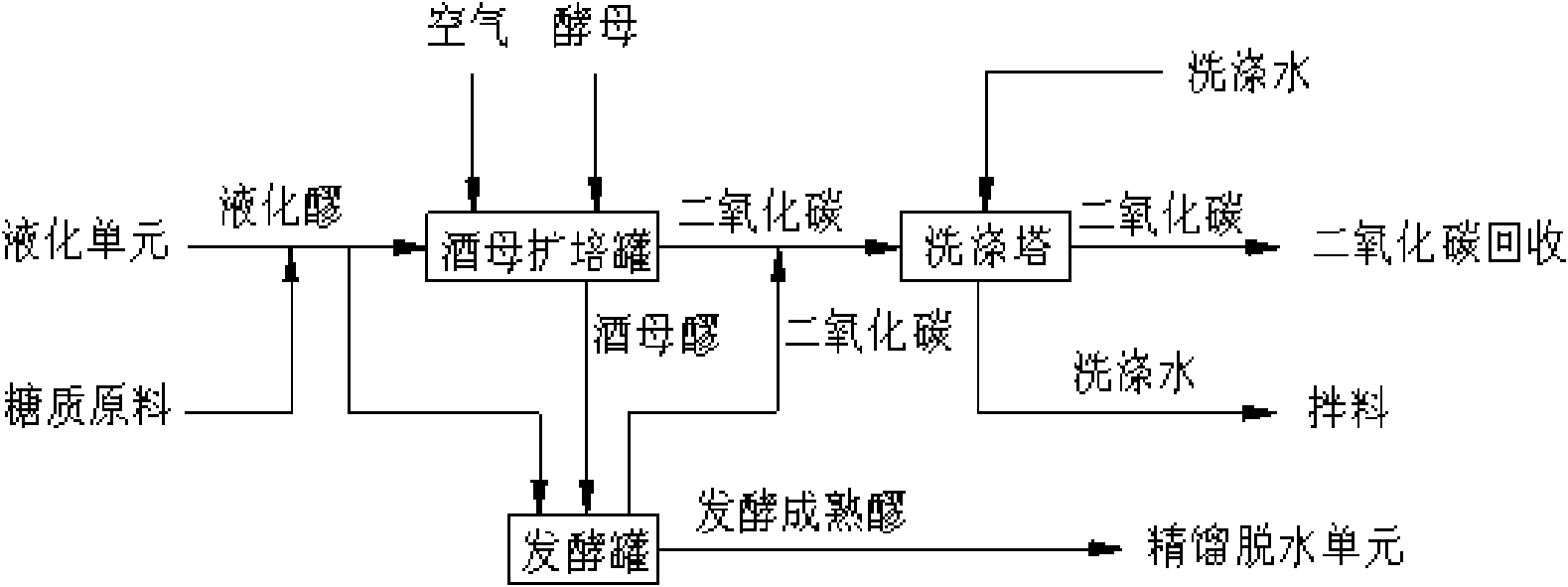

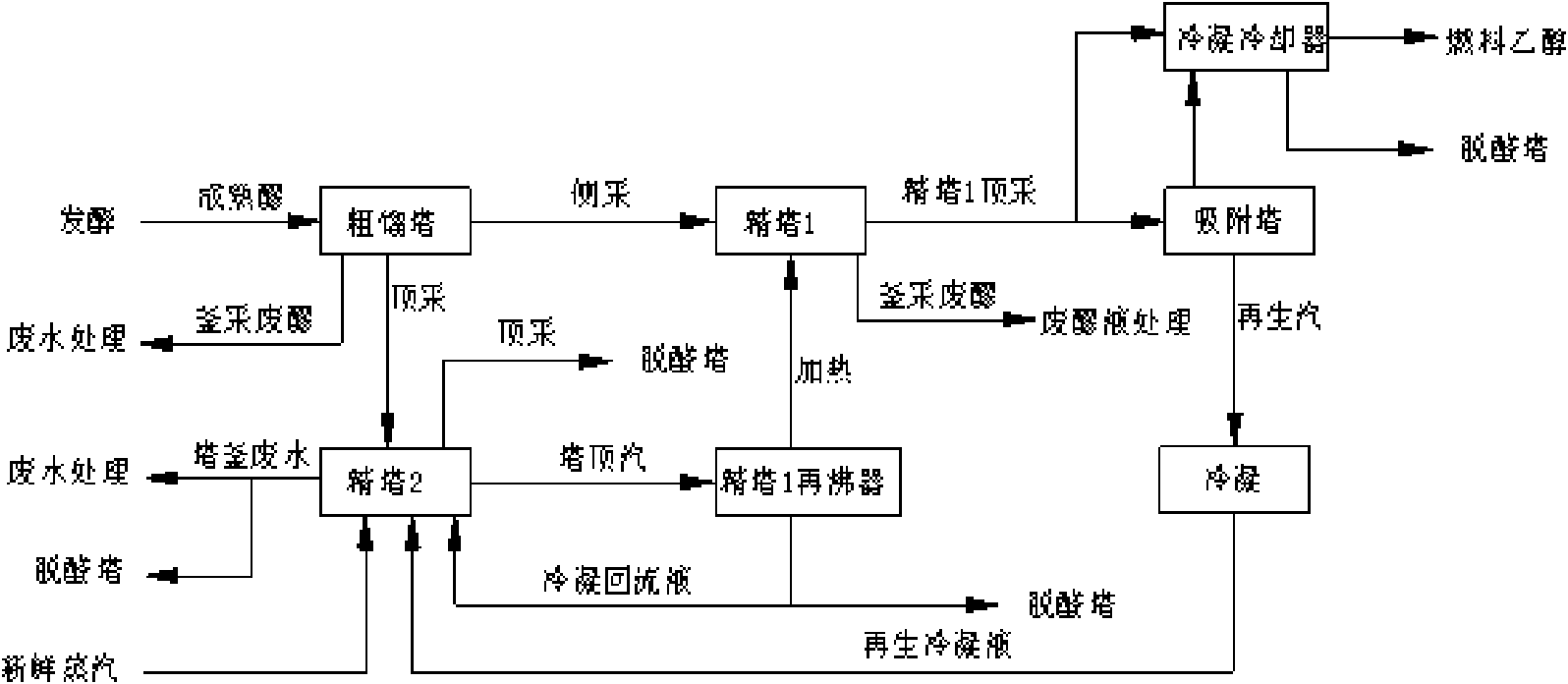

Composite process of fuel alcohol and edible alcohol

ActiveCN101648847AReduce material consumptionReduce energy consumptionOrganic compound preparationBiofuelsMolecular sieveDistillation

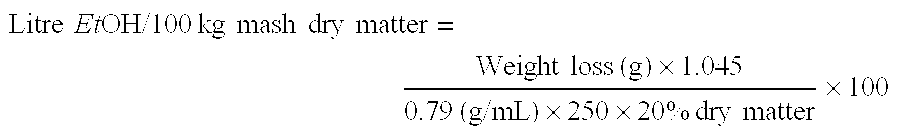

The invention relates to a composite process of fuel alcohol and edible alcohol. In the production process of alcohol products, fermented mash mature in a self-fermentation unit enters a rough distillation column, crude alcohol distilled from the top of the rough distillation column is fed into a rectification column (2), liquid alcohol distilled from the side of the rough distillation column column is fed into a feed inlet of a rectification column (1), vapor phase objects distilled from the top of the rectification column (1) are fed into a molecular sieve absorption column, and thus, fuel alcohol is obtained. In the production process of edible alcohol products, objects distilled from the top of the rough distillation column and the top of the rectification column (1) and partial objects distilled from the boiler of the rectification column (2) are all fed into an aldehyde disengagement column, liquid alcohol distilled from the boiler of the aldehyde disengagement column is fed into the rectification column, and then, the liquid alcohol is distilled from the top of the column and fed into a reclaiming column as feed; the liquid alcohol is distilled from the side of the upper part of the rectification column (2) and fed into the feed inlet of a rectification column (3) , and qualified edible alcohol is distilled from the boiler of the rectification column (3). The invention realizes multiple varieties of alcohol products on the same device, effectively decreases consumption in materials and energy in the production process of fuel alcohol and edible alcohol, reduces the investment on device, and improves the market competitiveness of the fuel alcohol and the edible alcohol.

Owner:TIANJIN UNIV

Method for making low-alcohol or alcohol-less raw juice fermented alcohol drink by low-temperature two-tower rectification method

InactiveCN1814739AAvoid Heat Sensitive DeteriorationAlcoholic beverage preparationFood scienceAlcohol drinkDistillation

This invention relates to a method for producing low mellow or mellowless flumet fermented liquor with the low temperature double tower rectify method, which carries out super-short time contact-low temperature decompression distillation to the raw spirit in a first tower, in which, the bottom gets the de-mellow solution, the top gets the mixture of water, alcohol and perfume contents, the top distilled part enters into the middle of the second tower at low temperature, which applies decompression fractionation, the top distilled part is the perfume contents with the constant pressure boiling point lower than alcohol, which are collected directly in the way of controlling temperature of the segregator and controlling refluence ratio and the methyl alcohol in them is removed, alcohol product is collected from the middle of the tower, perfume contents with the boiliong point higher than the alcohol are collected from the lower part of the tower, the residue liquid at the bottom is the perfume compoment with the highest boiling point, the de-mellow liquid at the bottom of the first, the perfume components at the top of the second tower and the the perfume components at the bottom of the second tower are mixed and added with suitable distilled water to get low-mellow or mellowless raw fermented liquor.

Owner:NANJING UNIV

Method for extracting, distilling and separating alcohol-water solution through ethylene glycol and ionic liquid

ActiveCN103613485AHigh purityBreaking the azeotropeOrganic compound preparationHydroxy compound preparationExtractive distillationLower grade

The invention relates to a method for extracting, distilling and separating alcohol-water solution through ethylene glycol and ionic liquid and belongs to the technical field of distillation separation. The method is characterized in that the ethylene glycol and ionic liquid are used as extraction agents to carry out the extraction distillation operation, the operation condition of an extraction distillation tower is normal pressure, an alcohol-water mixture raw material is fed through bubble points, the mass flow-rate ratio of the extraction agent and the alcohol-water mixture raw material is 0.5 to 6.0, the backflow ratio is 0.5 to 5.0, an alcohol product crossing azeotrope is obtained on the top of the tower, and the extraction distillation tower bottom is provided with a mixture of extraction agent, water and trace alcohol. By adopting the method, the phenomenon that the alcohol and the water are simultaneously boiled can be broken through, the selectivity is remarkably improved, and the high-purity low-grade alcohol solvent is obtained.

Owner:BEIJING UNIV OF CHEM TECH

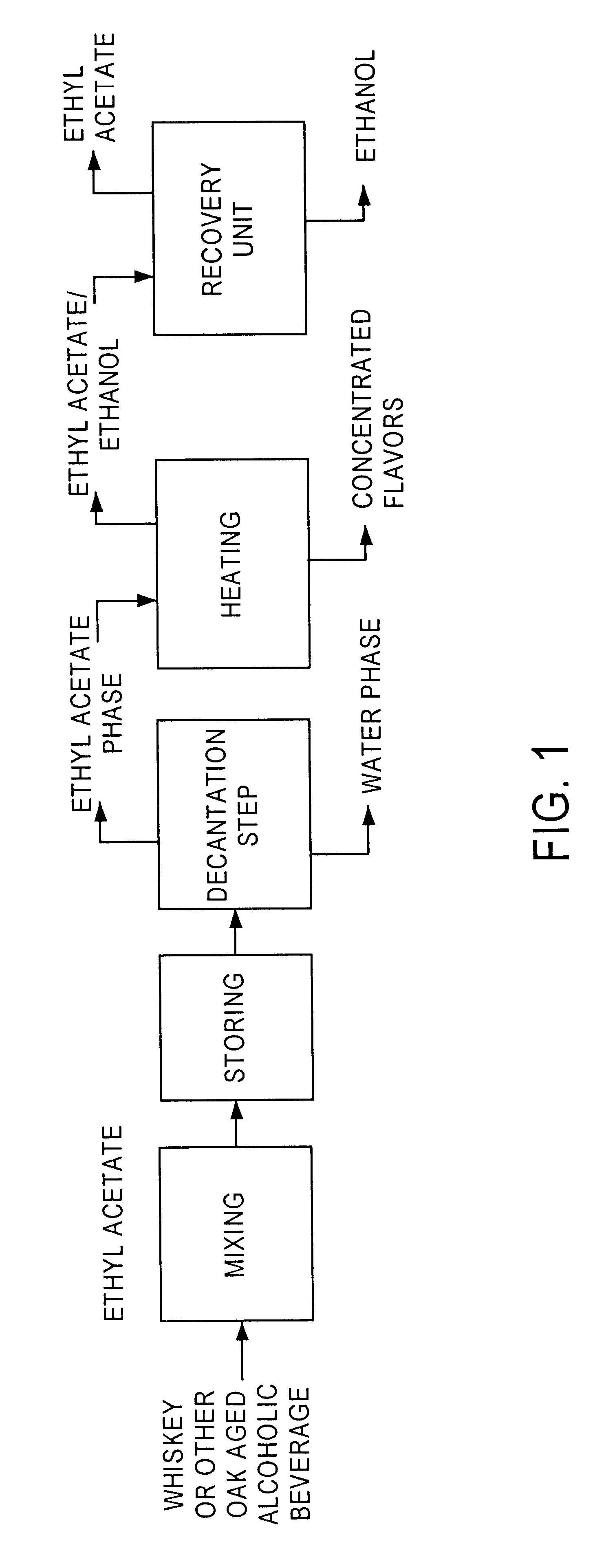

Process for producing an extract of an accelerated oak aged alcoholic concentrate

InactiveUS6344226B1Less costlySame characteristicsProtein composition from eggsTea substituesAlcoholFood grade

An extract of an oak aged alcoholic product is produced by adding a food grade solvent, such as ethyl acetate, to the oak aged alcoholic product and mixing the two liquids. The resulting mixture is allowed to separate into two layers, a first layer and a second layer. The first layer, including the food grade solvent, flavors, color, alcohol (i.e., ethanol) and water, is separated from the second layer. The solvent is then removed from the first layer to produce the extract. The extract can be added to a less costly alcoholic beverage, such as grain neutral spirits, or sugar beet spirits, to produce a beverage having the taste of a mature oak aged alcoholic beverage. Also disclosed is an accelerated whisky maturation method, including combining an alcoholic distillate with toasted oak chips, heating and aerating and / or oxygenating the resulting mixture to produce an accelerated oak aged alcoholic product. The toasted oak chips are then removed.

Owner:BROWN-FORMAN

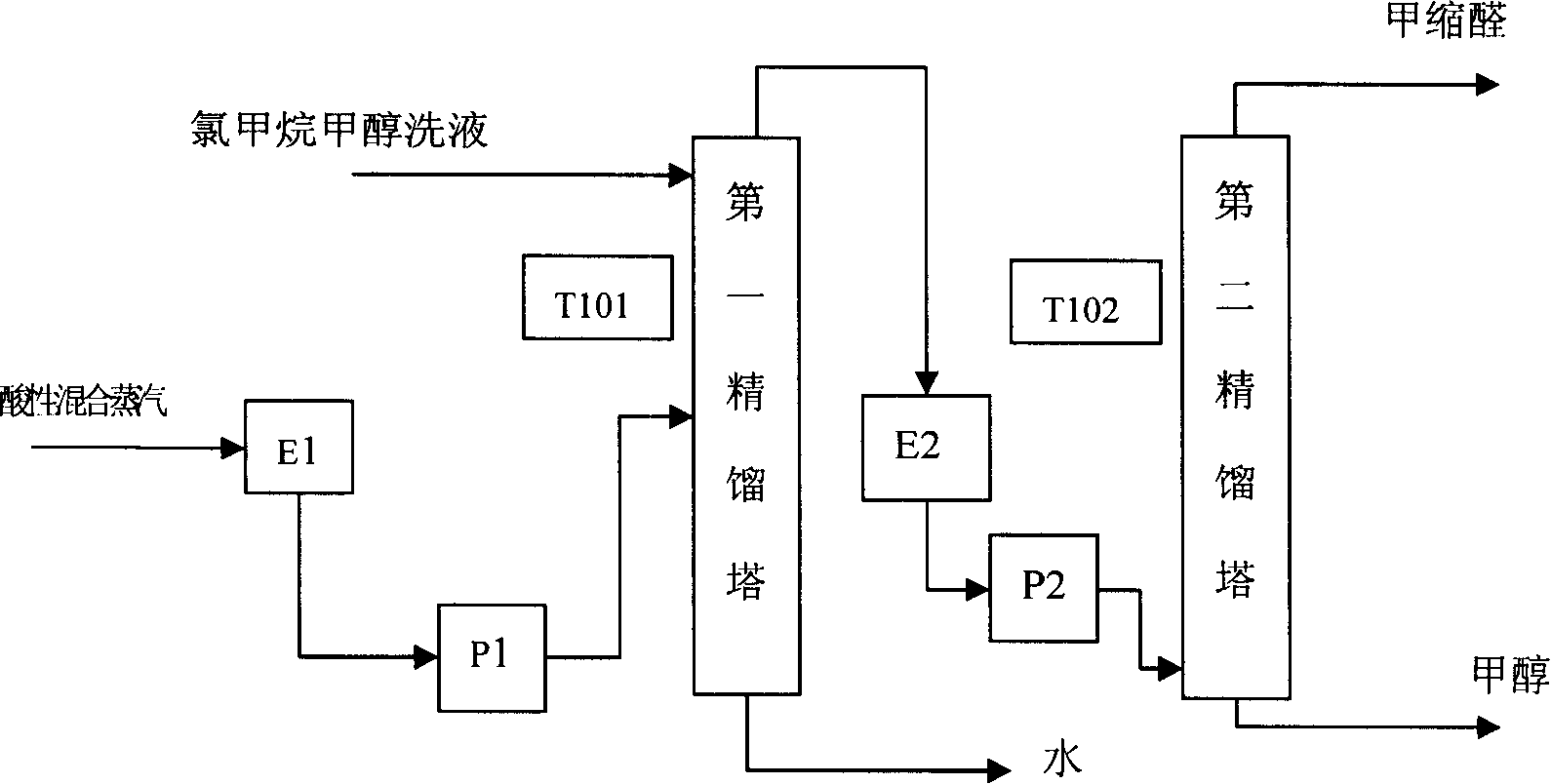

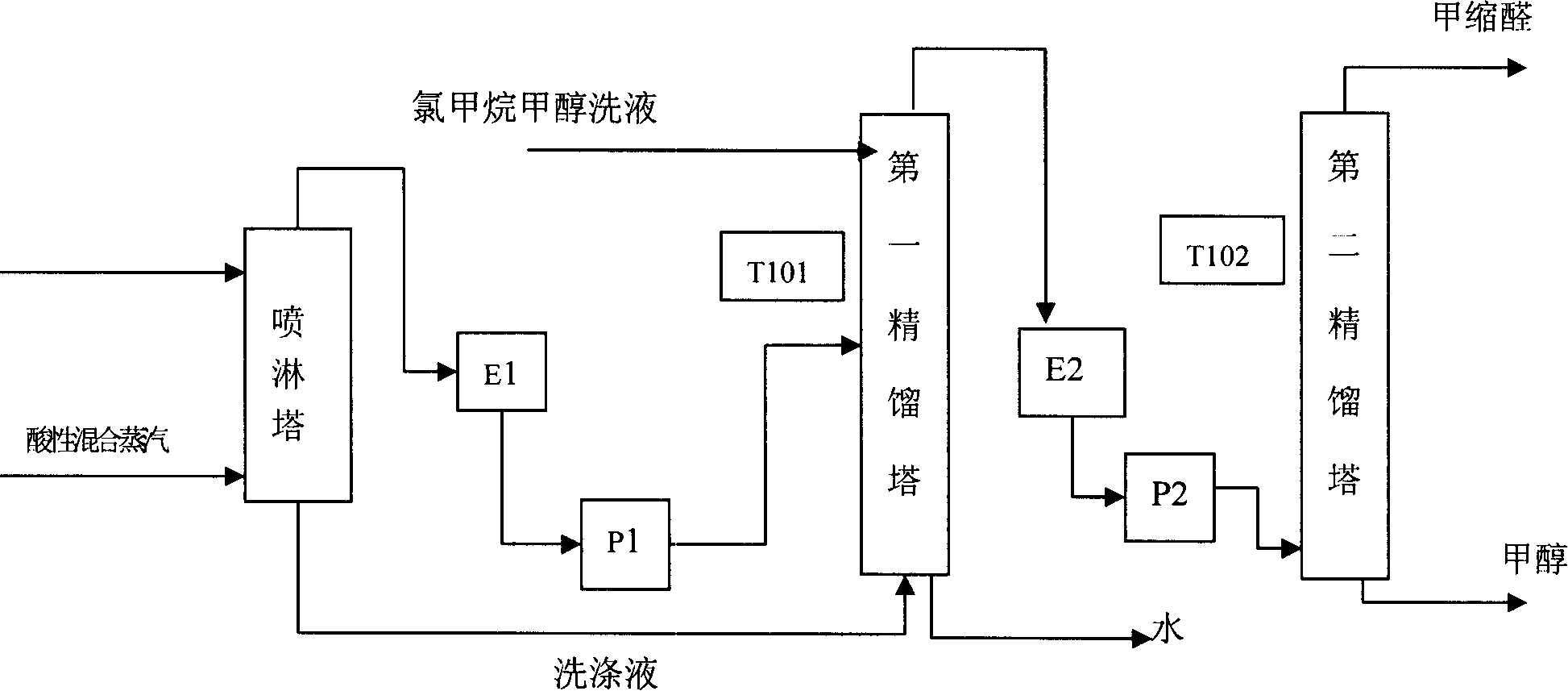

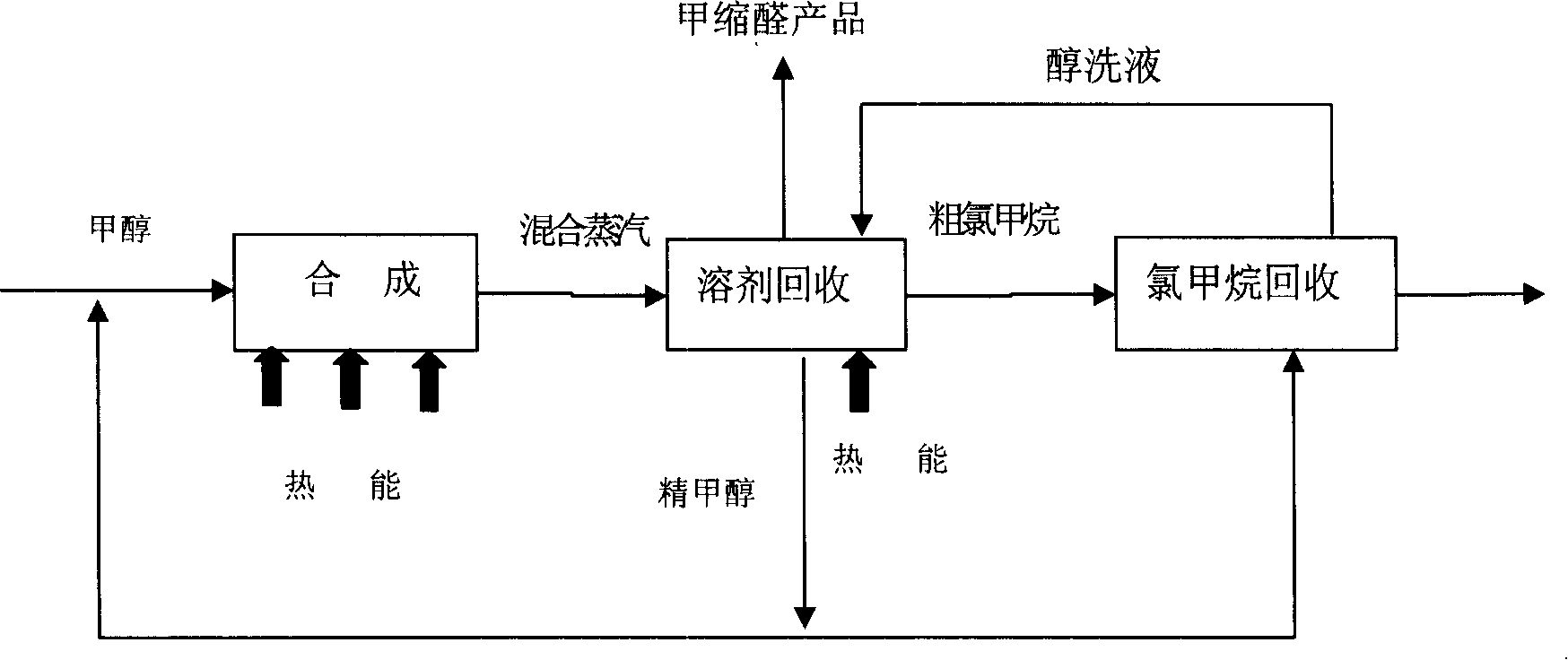

Method for utilizing thermal energy during continuous synthesis of glyphosate

ActiveCN101225030ASave recycling consumptionAlleviate shortagesOrganic compound preparationGroup 5/15 element organic compoundsThermal energyGas phase

The invention provides a reasonable utilization method for heat energy in the synthesis of glyphosate. The process is as follows: adding the steady saturated steam into the tower after preheating for the neutralization inside the tower or gas phase neutralization outside the tower. After the dehydration, the top of the tower steams out the vapor to overheating state after re-preheating, then sent into the second rectifying tower for separation, gaining qualified methylal and methyl alcohol products.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com