Process and method thereof for preparing lower alcohol by biomass

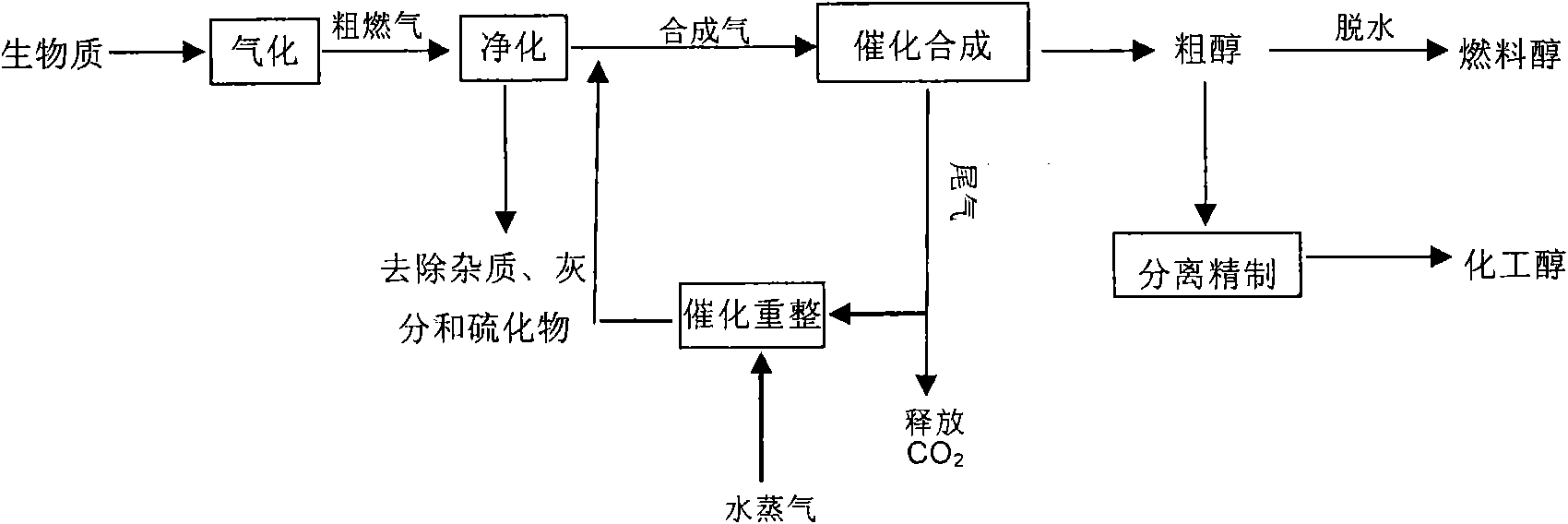

A biomass and low-carbon alcohol technology, applied in the fields of biofuels, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of reasonable matching and the overall economy needs to be further improved, and achieve obvious social and environmental benefits. , reduce the tar content and methane content, the effect of efficient conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Taking corn cob as raw material below, the specific content of the present invention is described in further detail.

[0051] (1) Biomass gasification:

[0052] Biomass corncobs are fed into the gasifier from a quantitative feeder at a rate of 50kg / h, and gasified by a two-stage directional gasification method. The temperature of the pyrolyzer during gasification is 500°C, and the high temperature The zone temperature is controlled at 1000°C, and the H in the resulting syngas 2 / CO=1.02, the tar content is less than 8mg / Nm 3 , methane content 5%, biomass gasification efficiency = 80%, carbon conversion rate = 98%.

[0053] (2) Gas purification:

[0054] Syngas from the gasifier is dry-filtered at 240°C to remove impurities such as ash and carbon black, and finely desulfurized by industrial technology to remove sulfide impurities in the gas. The ash in the gas is 0.09%, and the moisture = 2.0%, sulfur content = 0.1mg / Nm 3 .

[0055] (3) Catalytic synthesis

[0056...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com