Patents

Literature

47results about How to "Reduce methane content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

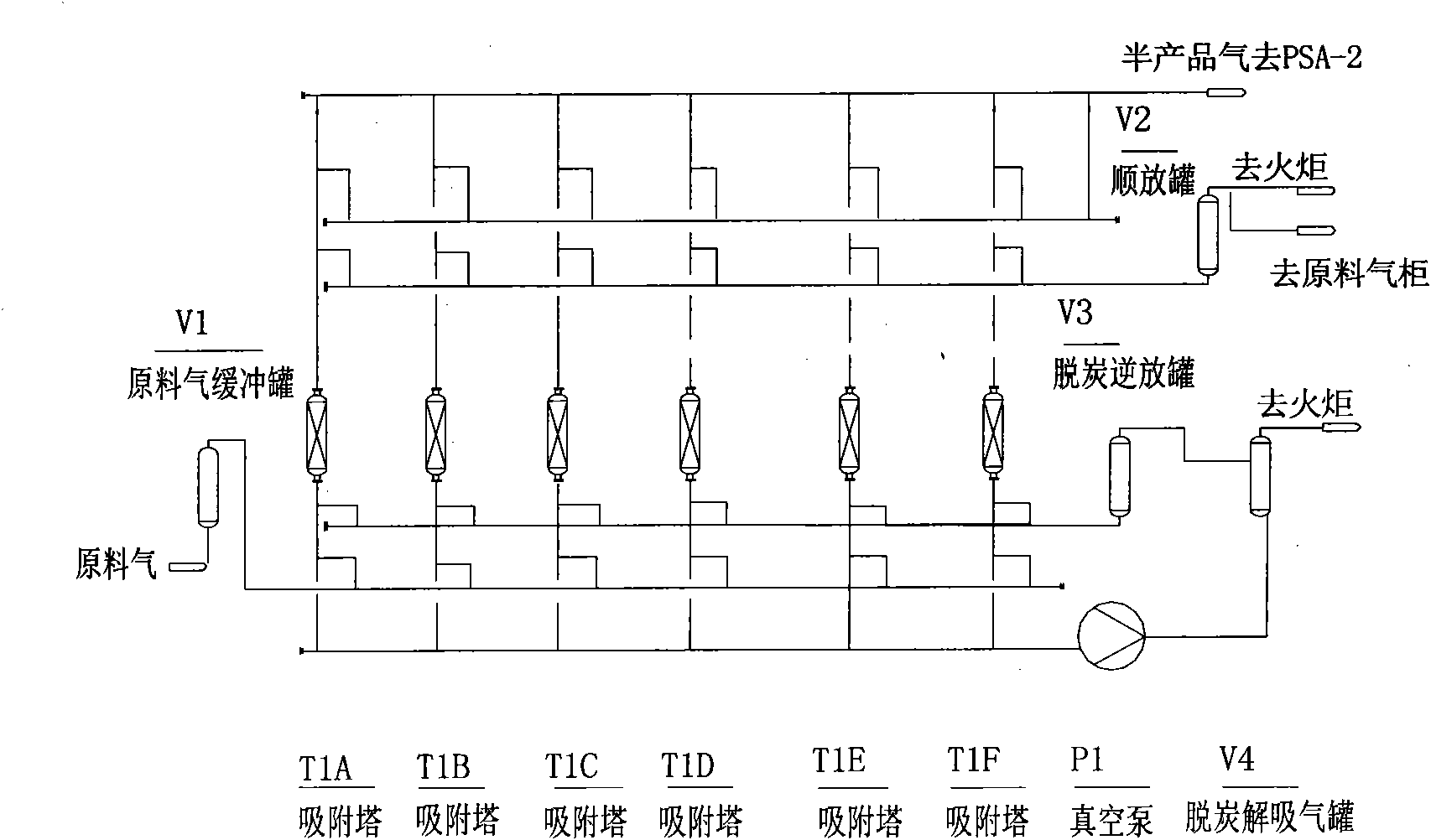

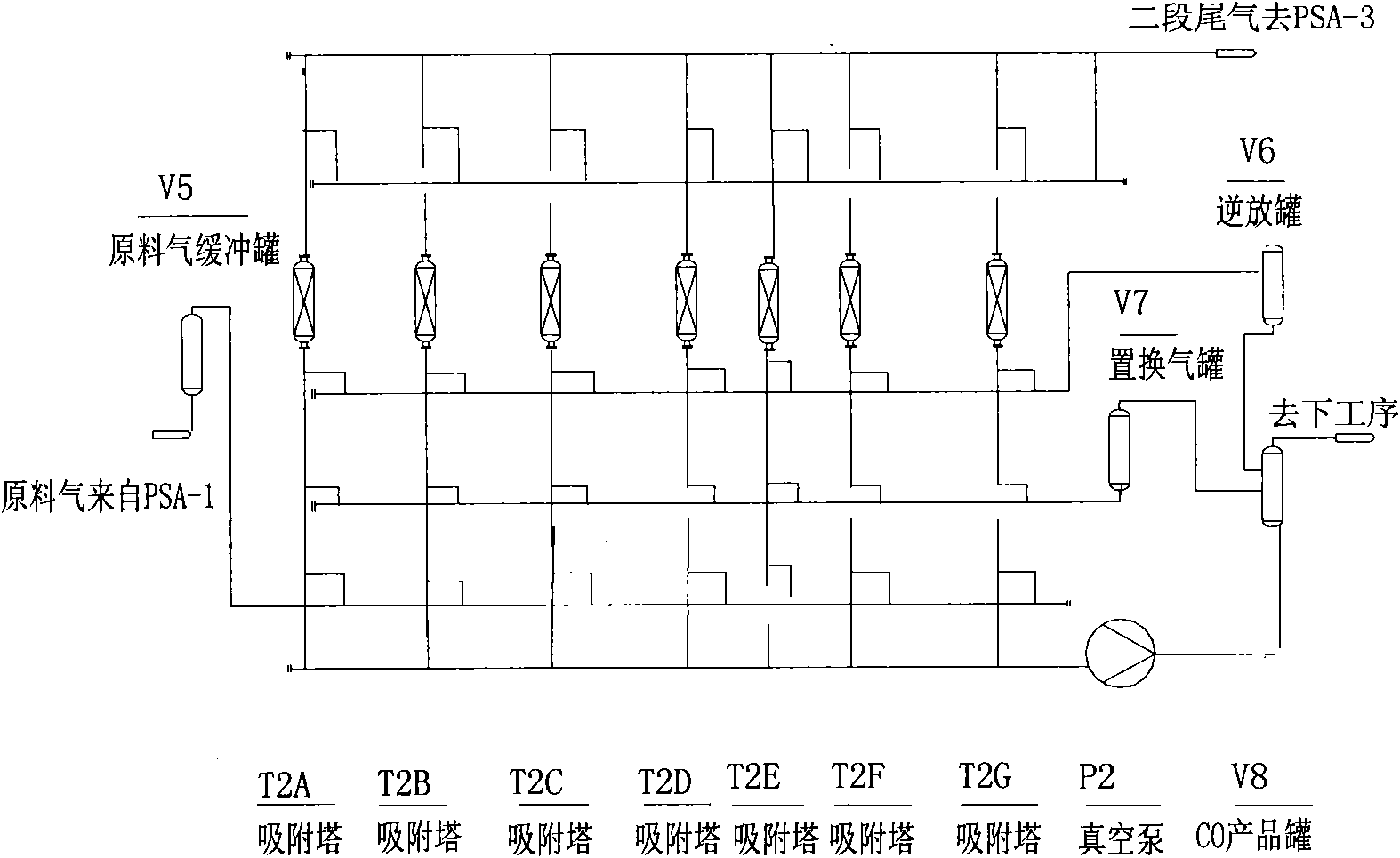

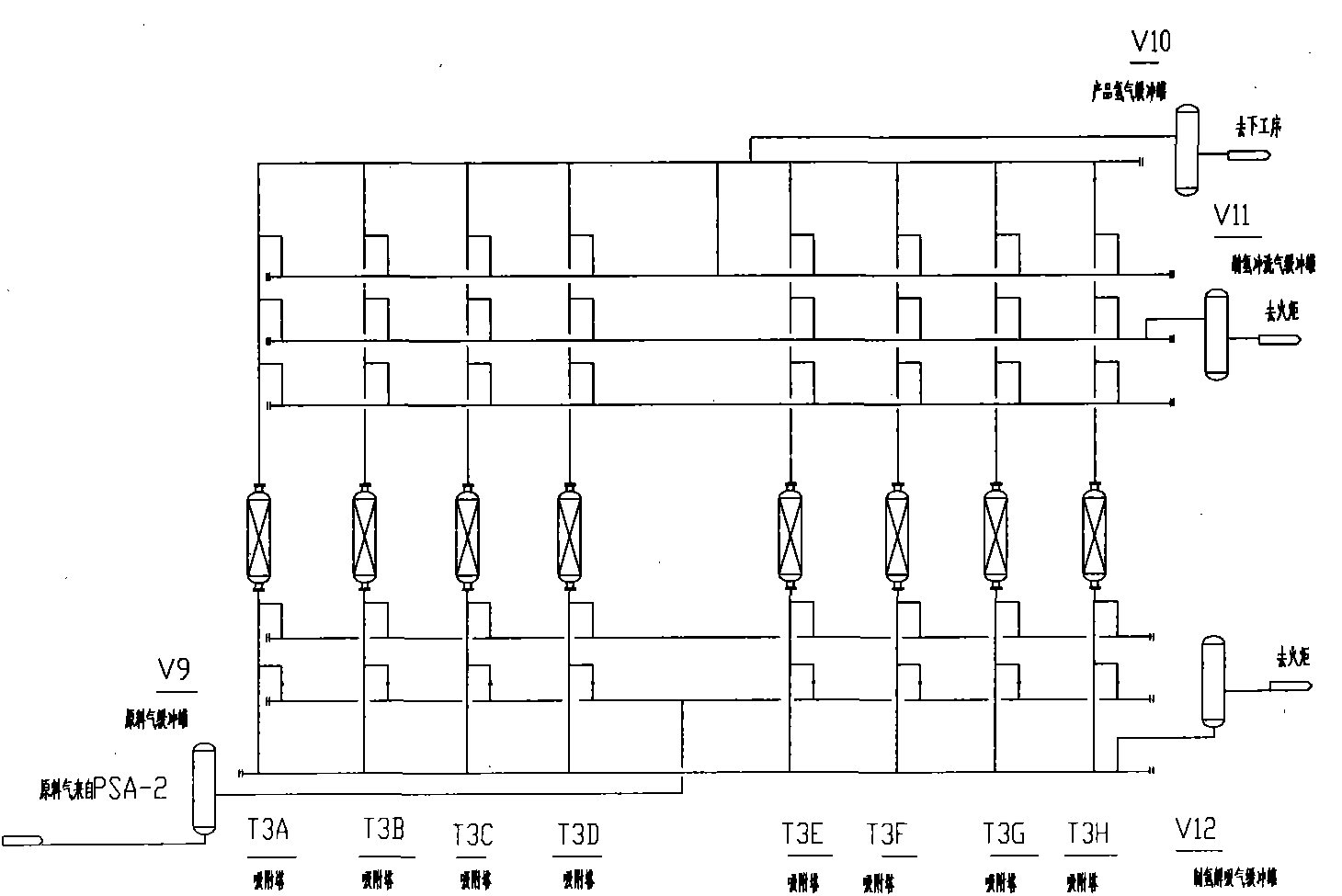

Method for separating and purifying hydrogen from water gas by pressure swing adsorption

InactiveCN102078740AImprove hydrogen yieldReduce the loss of effective componentsProductsReagentsGas compressorProduct gas

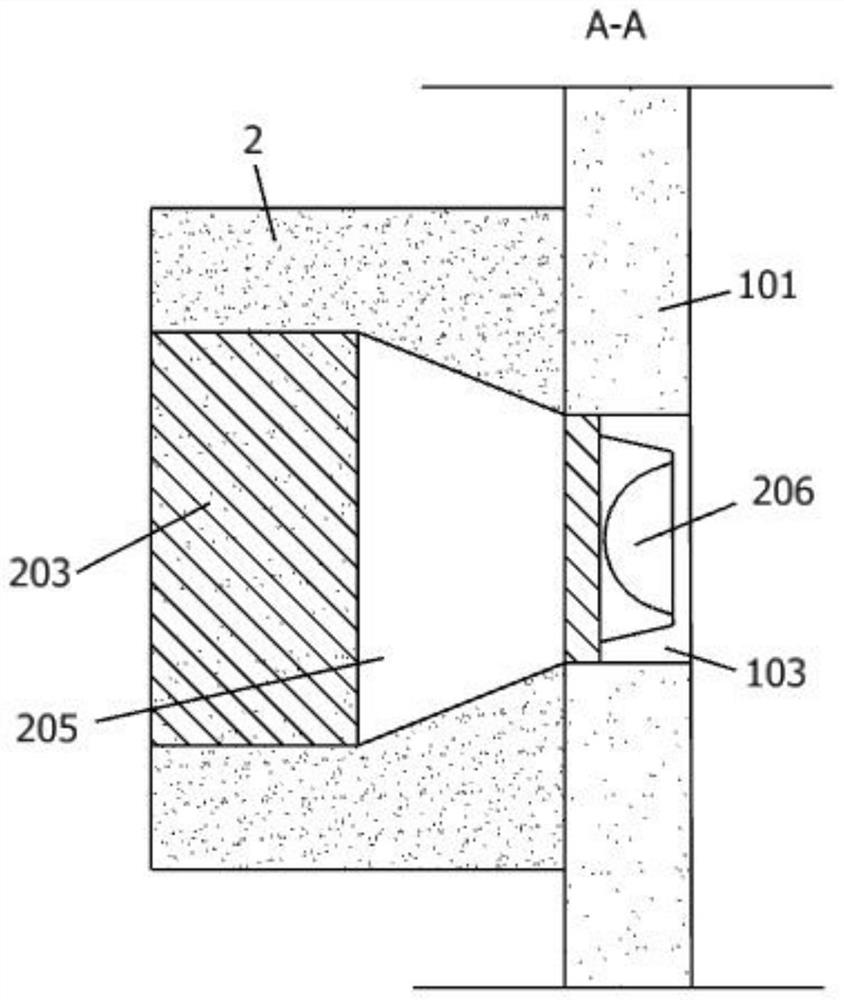

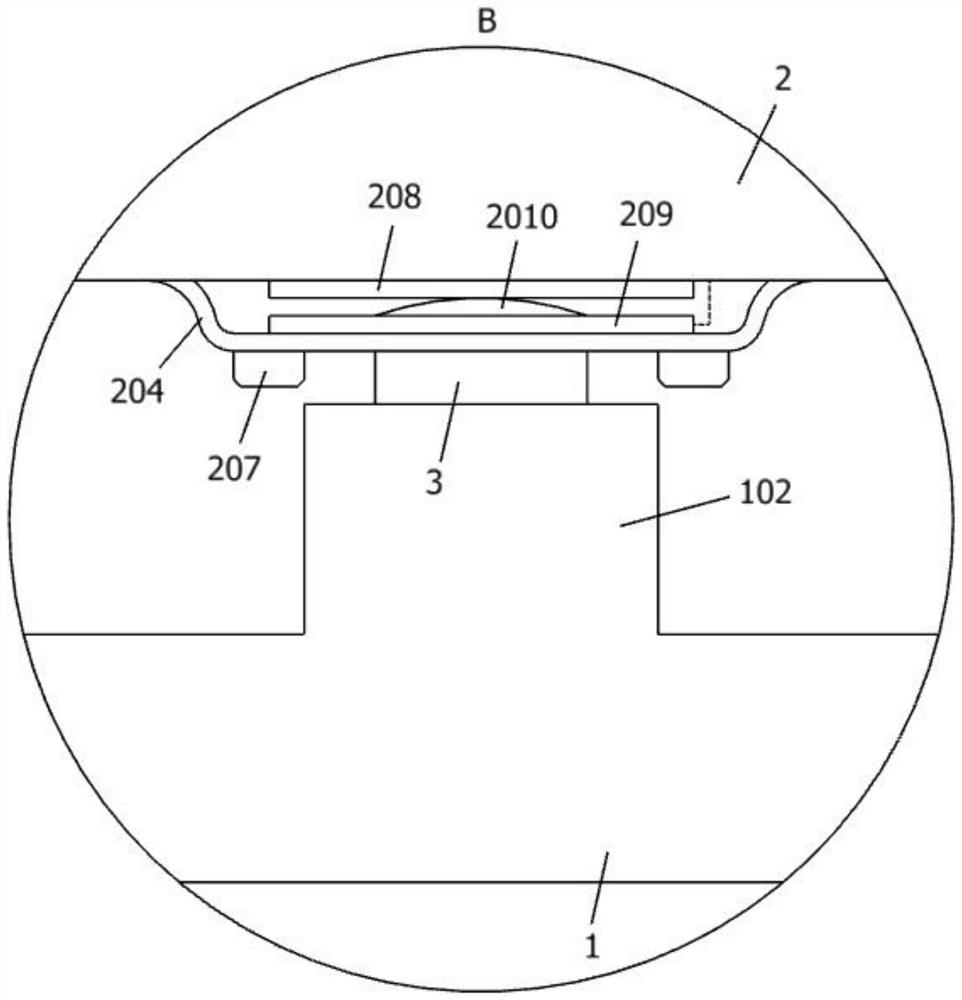

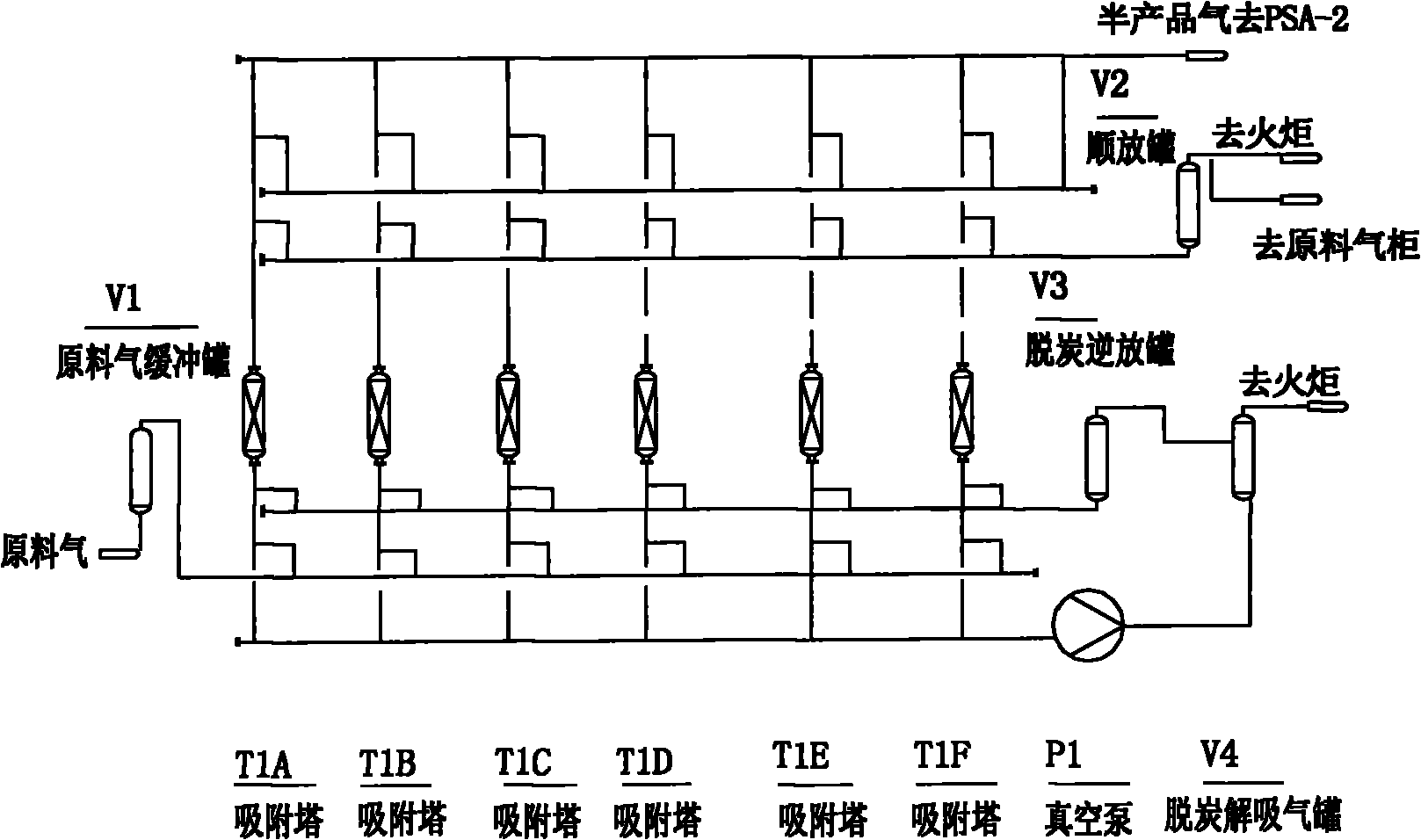

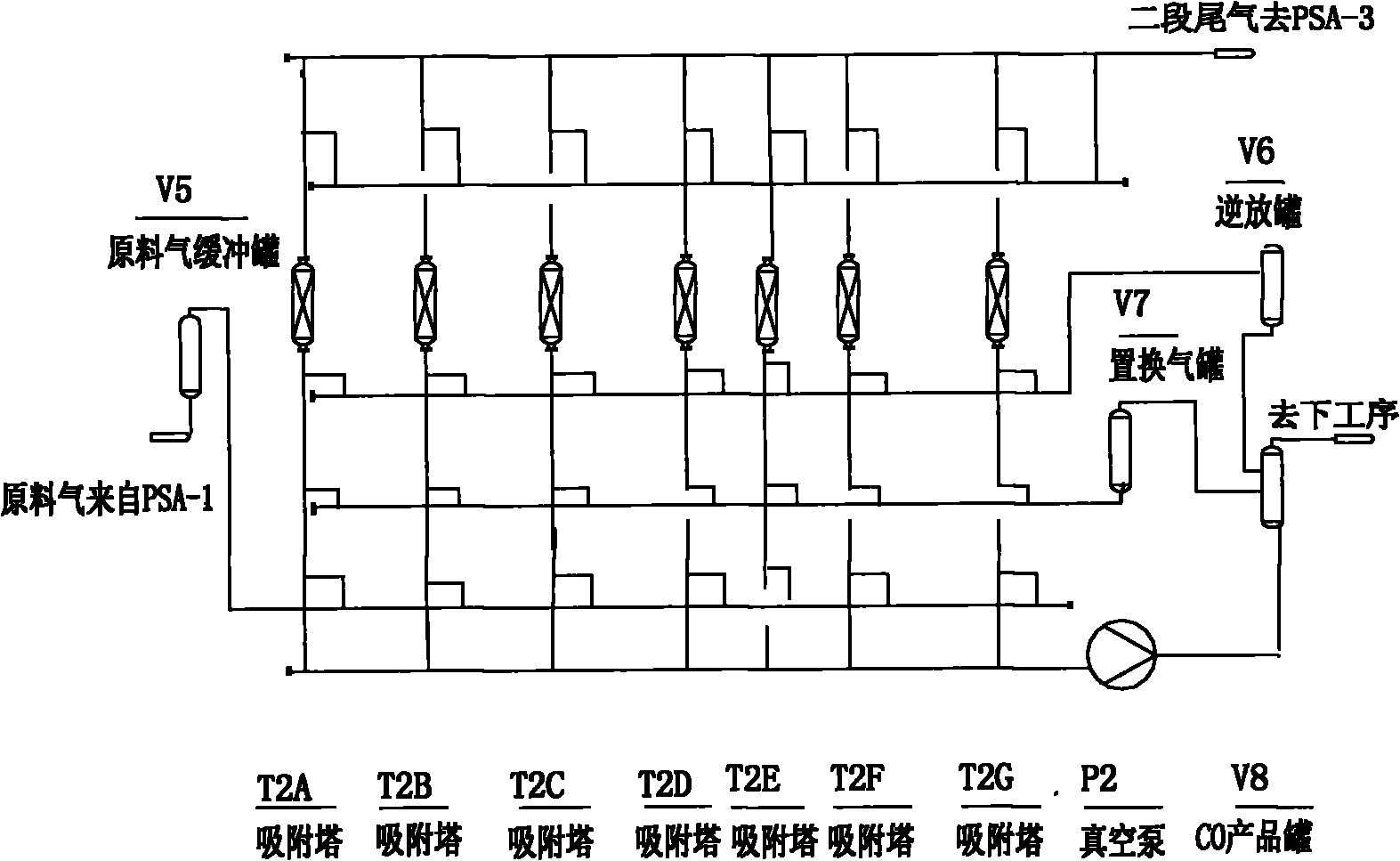

The invention relates to a method for separating and purifying hydrogen from water gas by pressure swing adsorption. Raw material gas is sequentially subjected to a PSA-1 (Pressure Swing Adsorption) decarburization working procedure, a PSA-2 CO purification working procedure and a PSA-3 H2 purification working procedure. Six adsorption beds ABCDEF of a primary adsorption tower T1, seven adsorption beds ABCDEFG of a secondary adsorption tower T2 and eight adsorption beds ABCDEFGH of a tertiary adsorption tower T3 are mainly provided. Backward discharge gas in the PSA-3 H2 purification working procedure is used as the outward blowing gas for the PSA-1 decarburization working procedure, thereby increasing the hydrogen yield by about 3%; forward discharge gas recovered by the six beds of PSA-1 is circularly purified at the inlet of a raw material gas compressor, thereby reducing the loss of effective components in the decarburization working procedure; the content of methane in the process product gas generated by the seven beds of PSA-2 is decreased to 0; and the yield of the product CO is improved to be above 80%.

Owner:甘肃银光聚银化工有限公司 +1

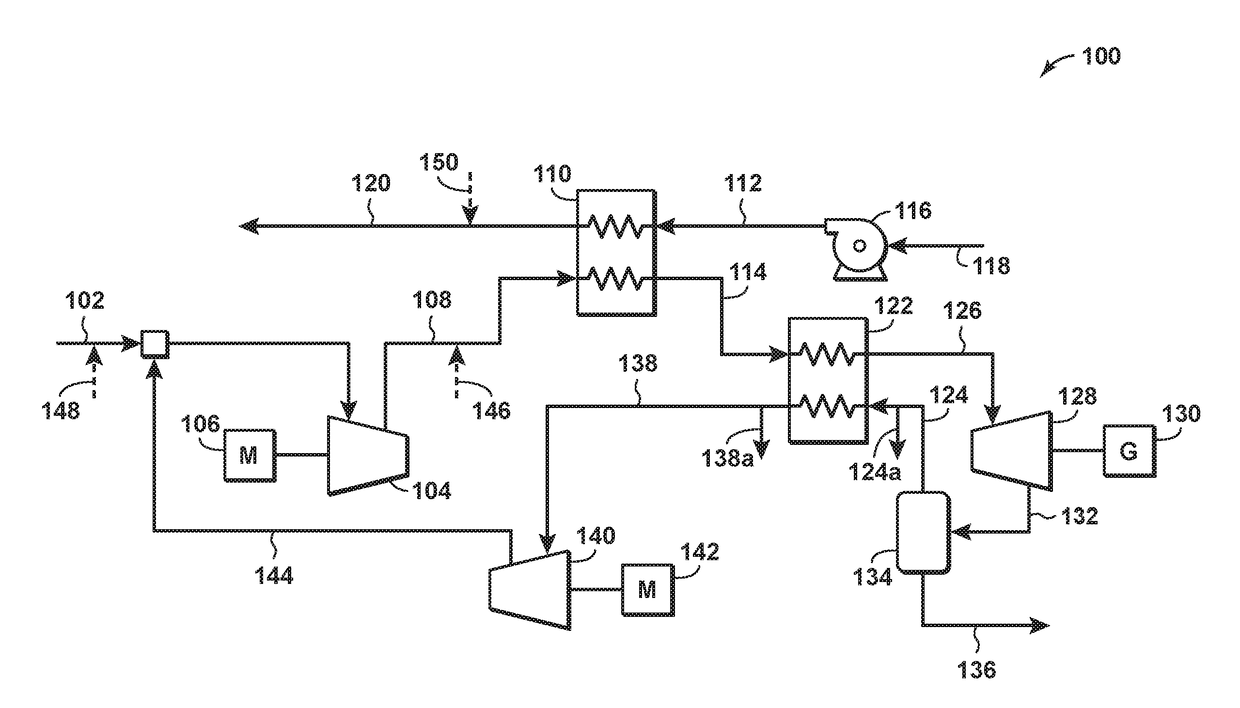

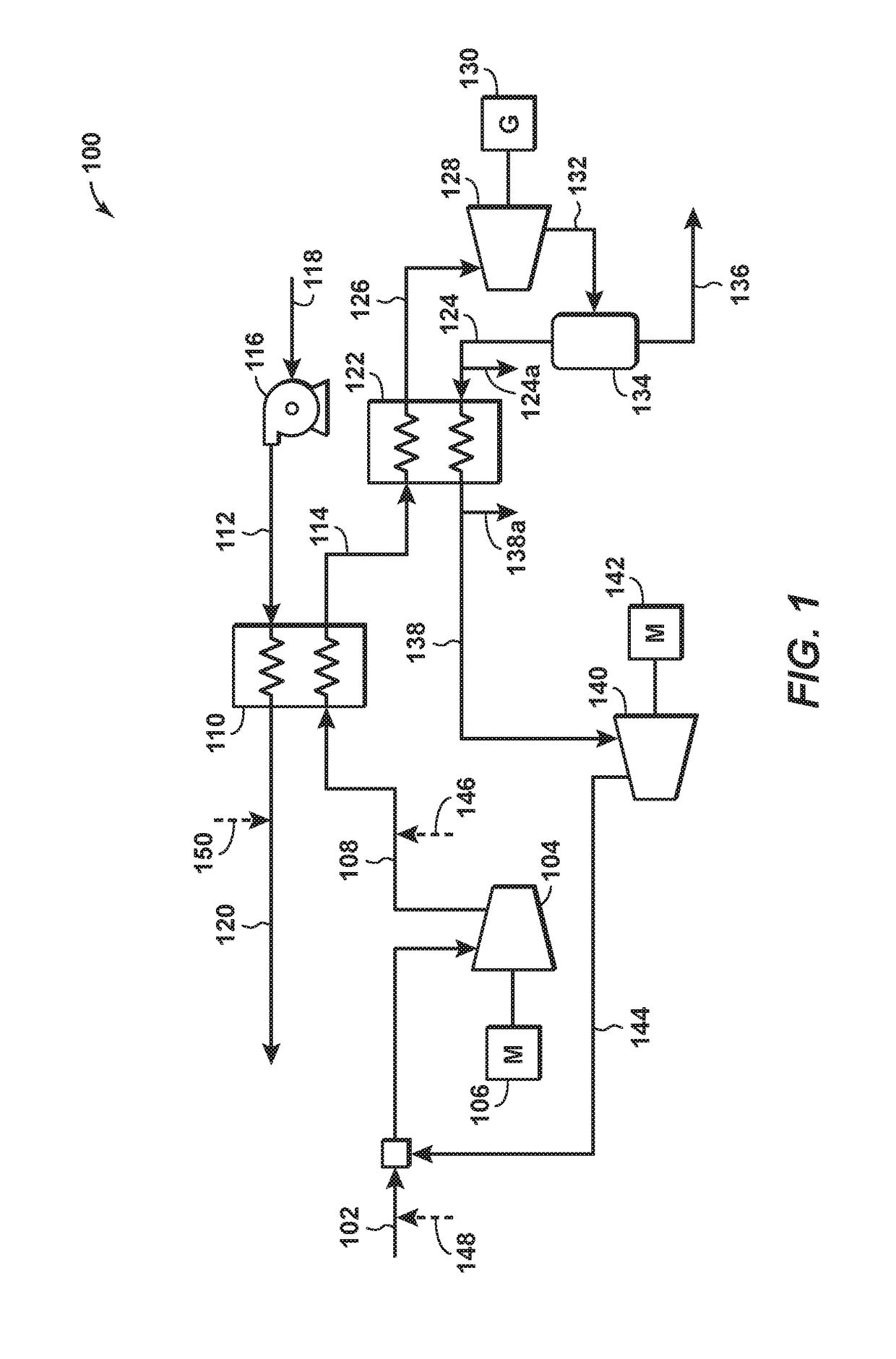

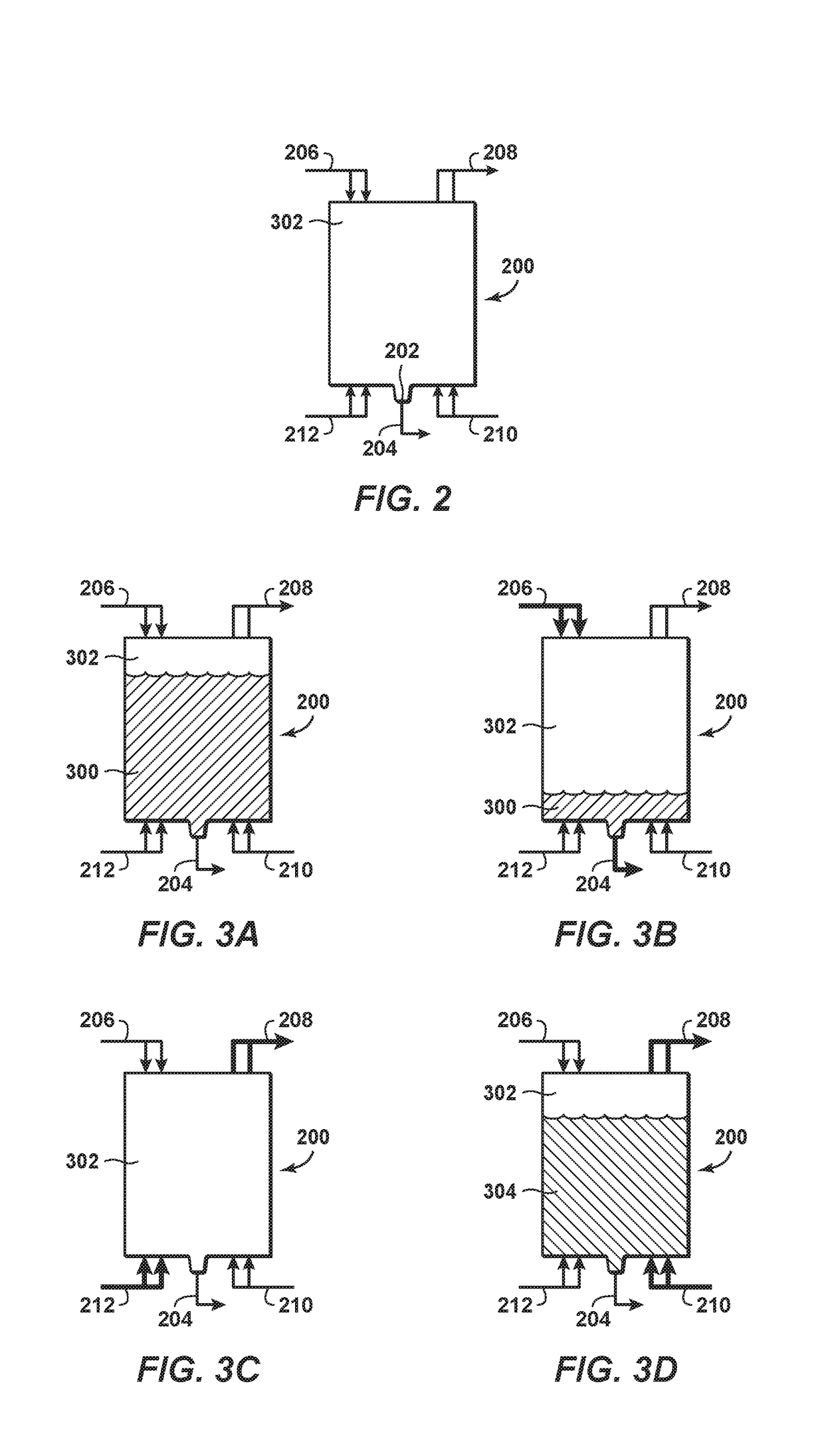

Method of Purging a Dual Purpose LNG/LIN Storage Tank

ActiveUS20180245740A1Reduce natural gas contentReduce methane contentGas handling applicationsGas handling/storage effectsChemistryAirflow

A method for loading liquefied nitrogen (LIN) into a cryogenic storage tank initially containing liquid natural gas (LNG) and a vapor space above the LNG. First and second nitrogen gas streams are provided. The first nitrogen stream has a lower temperature than the second nitrogen gas stream. While the LNG is offloaded from the storage tank, the first nitrogen gas stream is injected into the vapor space. The storage tank is then purged by injecting the second nitrogen gas stream into the storage tank to thereby reduce a natural gas content of the vapor space to less than 5 mol %. After purging the storage tank, the storage tank is loaded with LIN.

Owner:EXXONMOBIL UPSTREAM RES CO

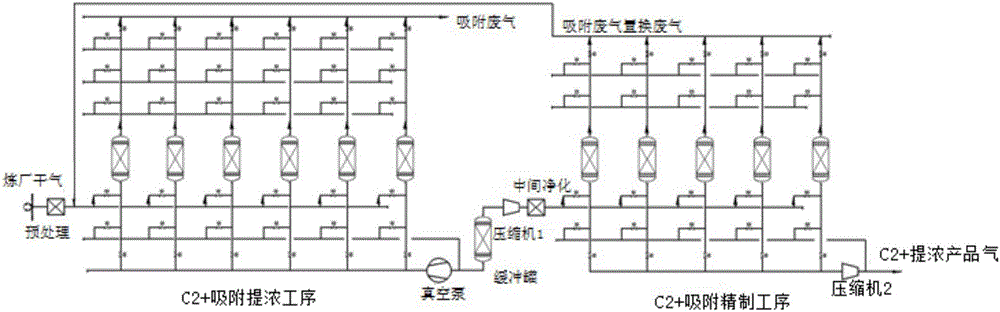

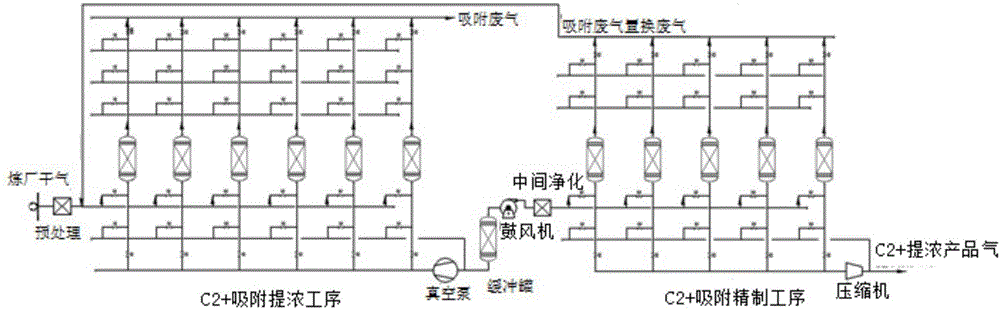

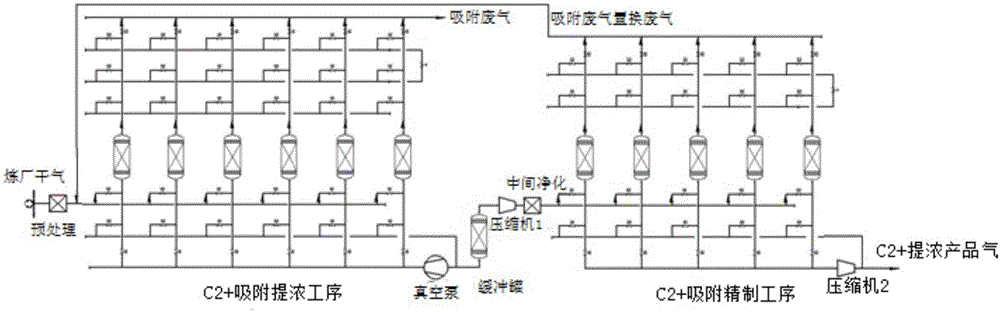

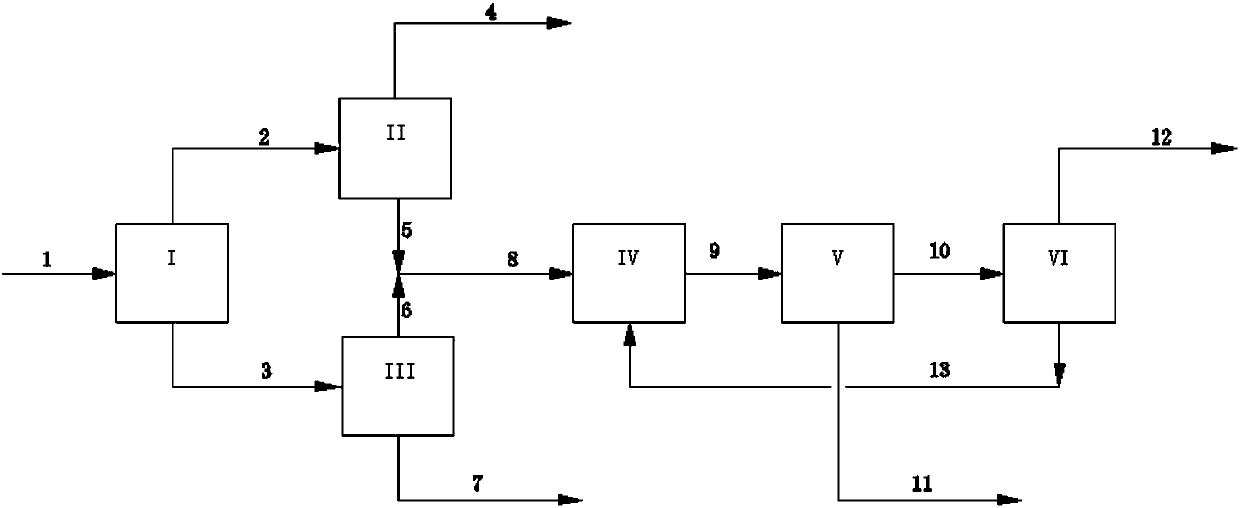

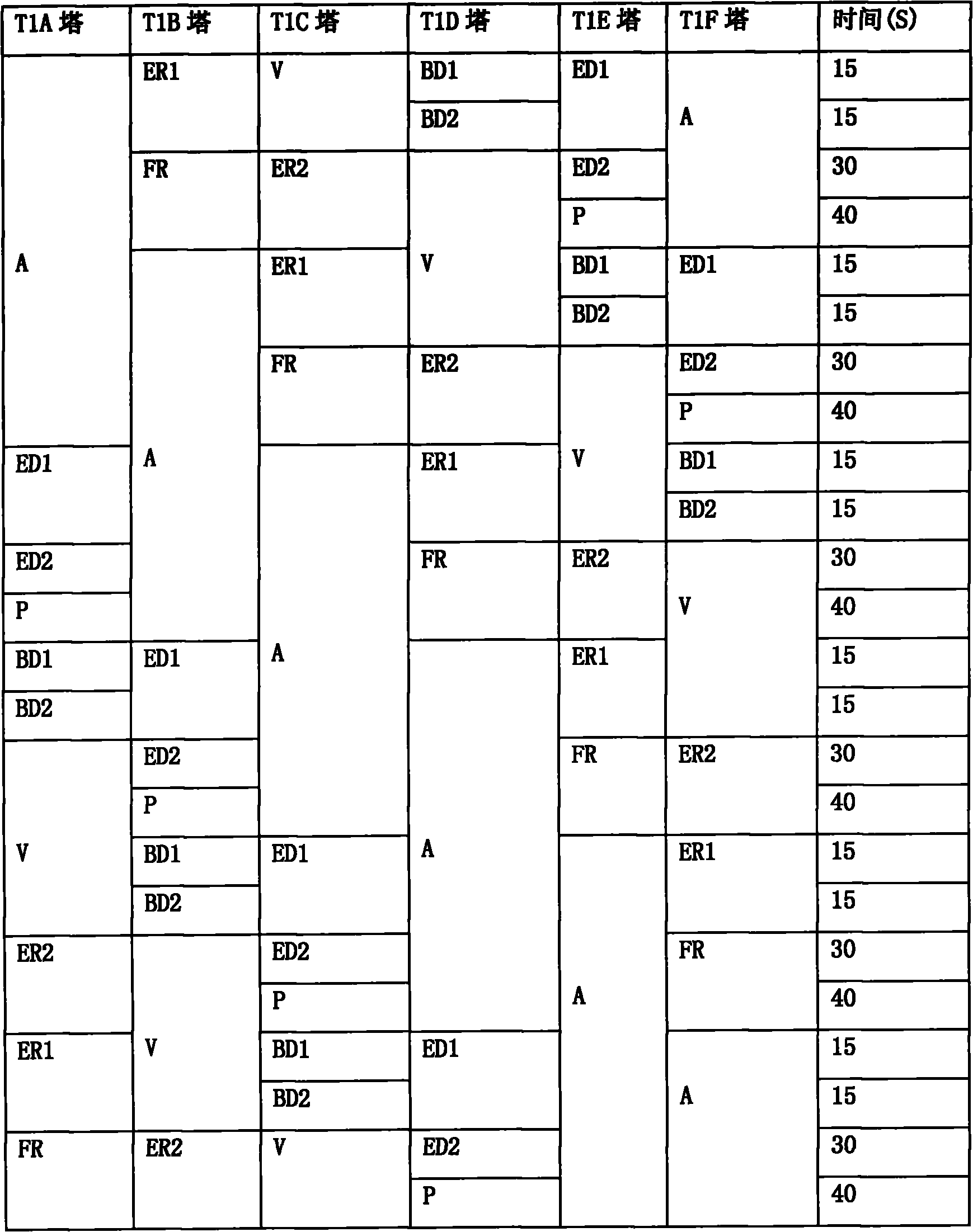

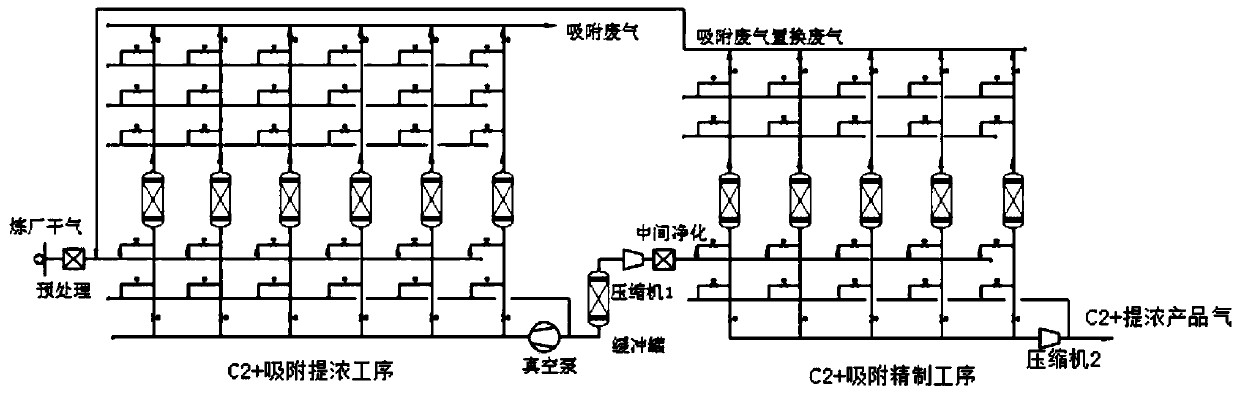

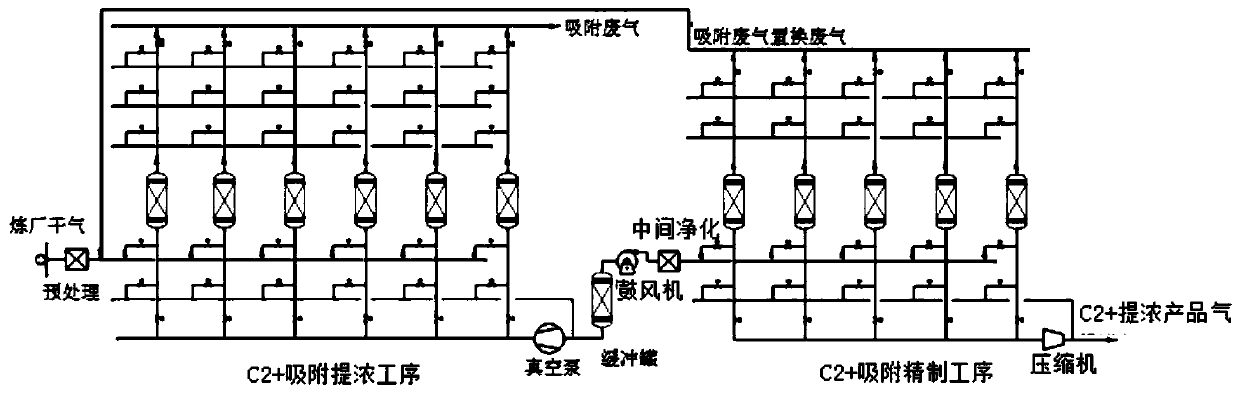

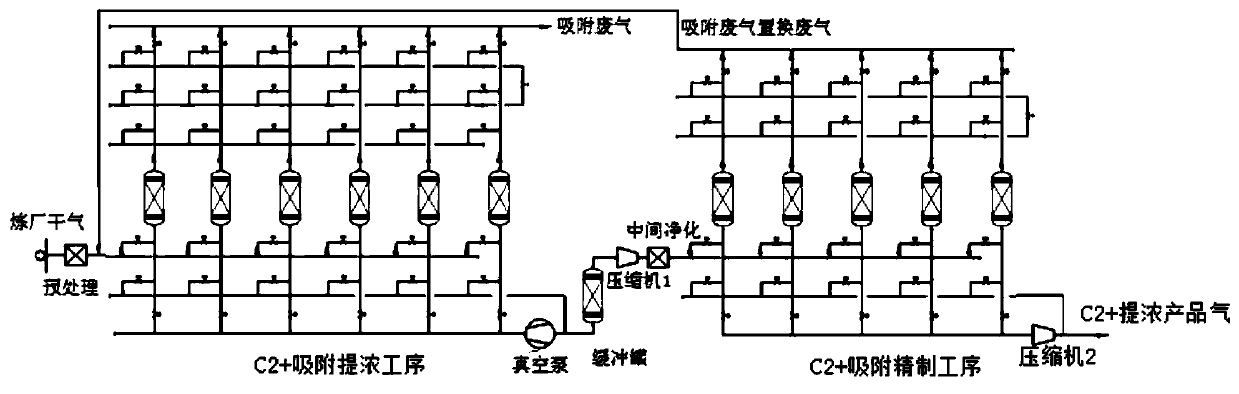

Two-stage PSA method for recovering C2+ from refinery dry gas according to concentration

ActiveCN107433107ABreak adsorption equilibriumReduce methane contentProductsGas treatmentHydrogenPetrochemical

The invention discloses a two-stage PSA method for recovering C2+ from refinery dry gas according to concentration, which relates to the technical field of separating and recovery of in valuable substances in petrochemical tail gas. The method comprises a pretreatment process, a C2+ adsorption concentration process, an intermediate purifying process, and a C2+ adsorption refining process, wherein, the pre-treated refinery mixed dry gas is introduced into the CO2+ adsorption concentration process, then flowed non-adsorption phase gas is the adsorption exhaust gas, or directly taken as hydrogen (H2) product gas, or taken as fuel gas, or taken as raw material gas for extraction of hydrogen for output; the flowed adsorption phase gas forms the intermediate gas through the intermediate purifying process, and then is introduced into the C2+ adsorption refining process for refining, the flowed non-adsorption phase gas is taken as the raw material gas for mixing with the refinery mixed dry gas, a mixture is returned to the C2+ adsorption concentration process; the flowed adsorption phase gas has the C2+ concentration being more than 90-95% (a volume ratio), wherein the methane impurity concentration is less than 4%, the flowed adsorption phase gas is taken as the C2+ concentrate product gas for output, and the yield of C2+ is more than 90-95%.

Owner:SICHUAN TECHAIRS

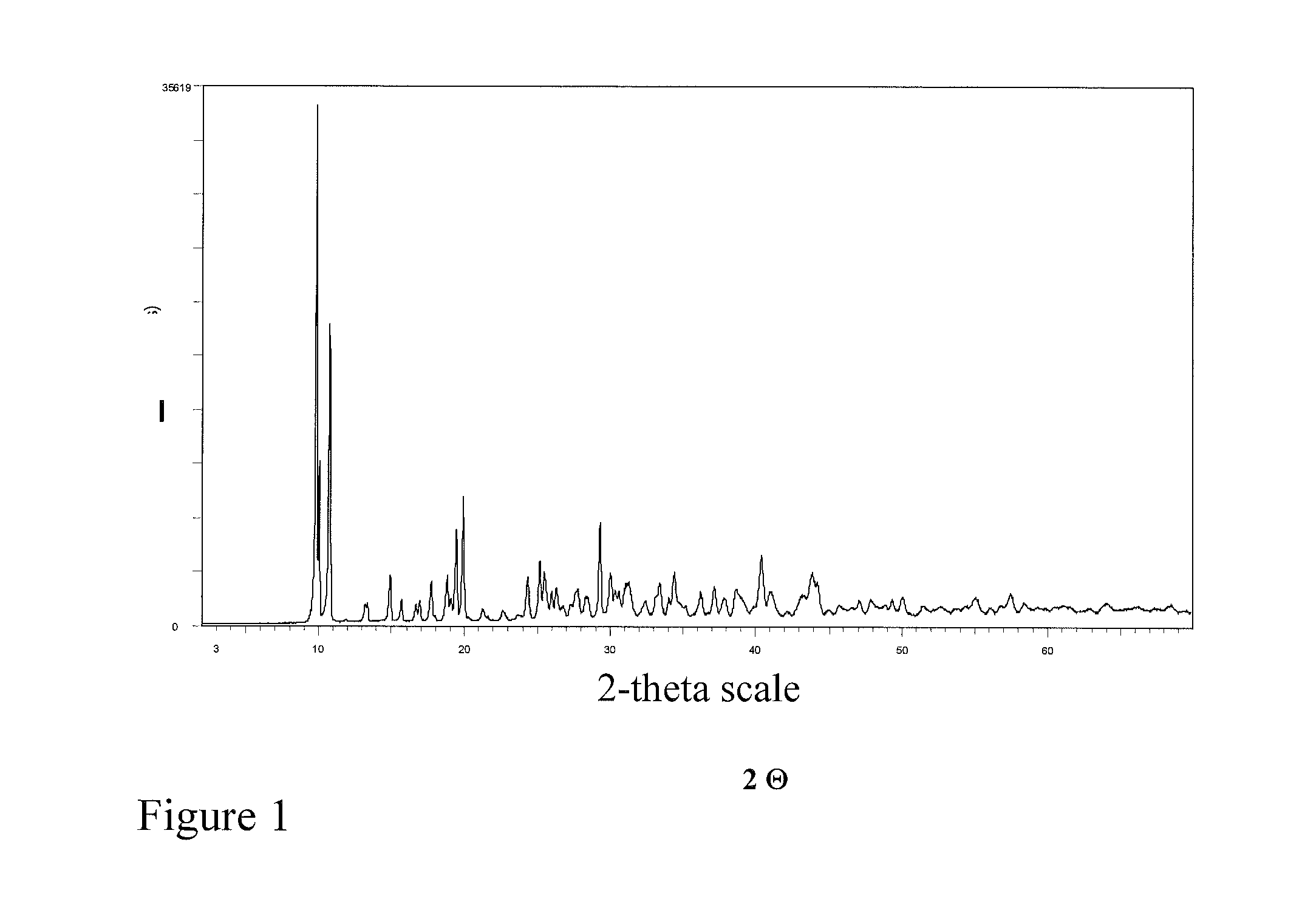

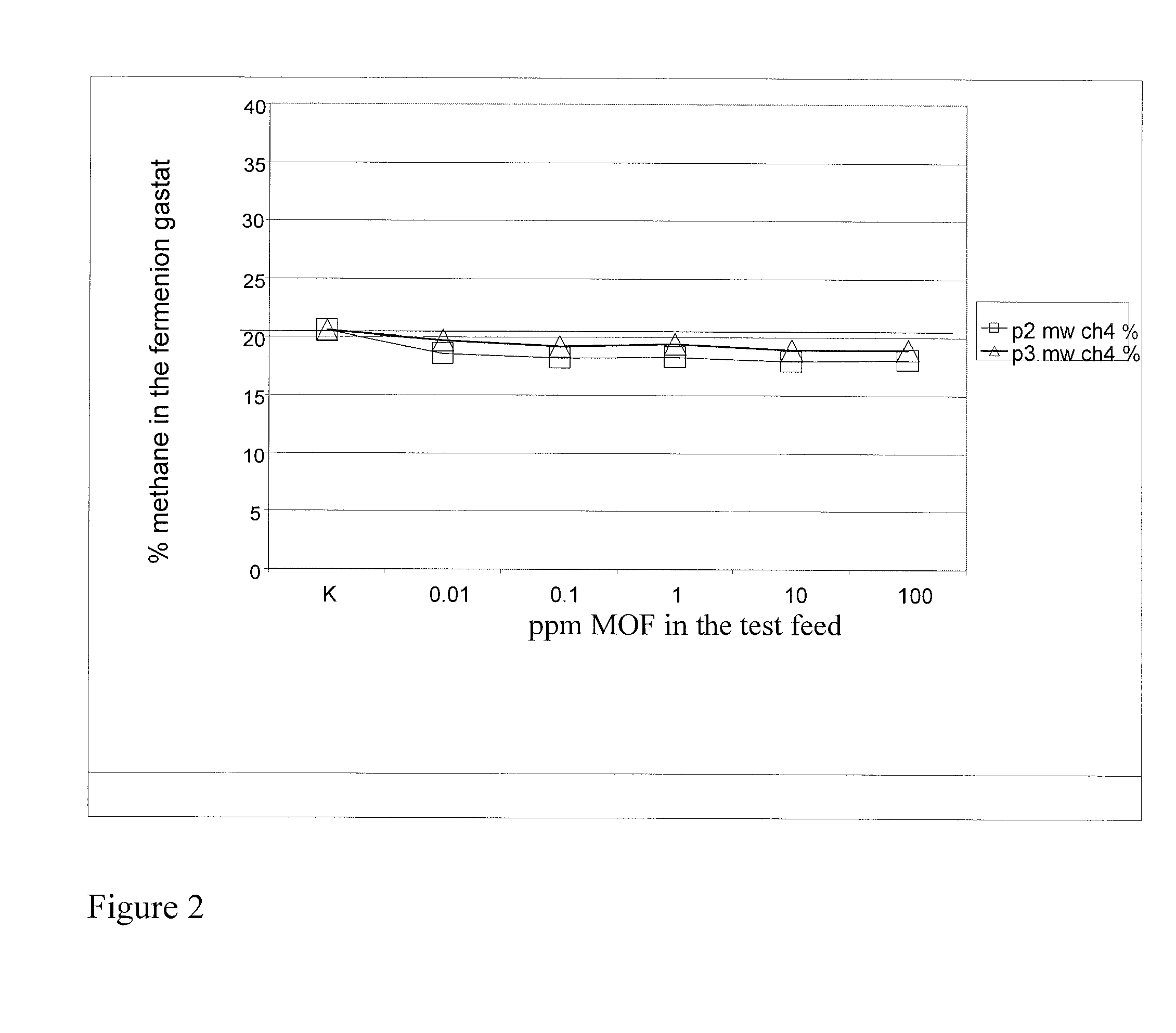

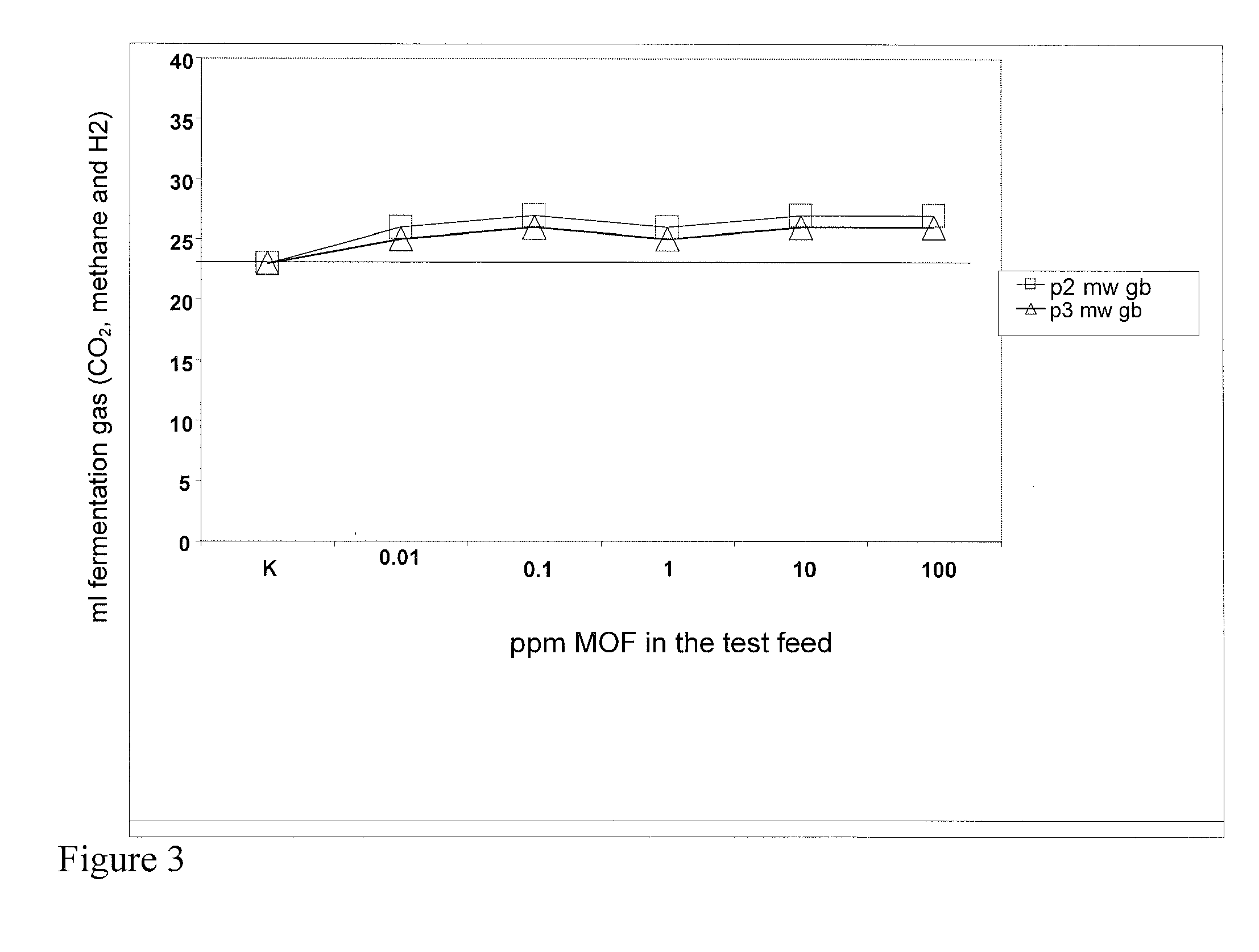

Method of reducing the methane gas level and of increasing the total gas yield in animal feed

InactiveUS20110152375A1Reduce energy lossIncrease energy yieldBiocideDigestive systemDigestionMethane gas

The present invention relates to the use of at least one porous metal-organic framework material (MOF) comprising at least one first and, if appropriate, one second organic compound, where at least the first organic compound binds coordinatively to at least one metal ion in an at least partly bidentate manner, where the at least one metal ion is Mg(II) and where the first organic compound is derived from formic acid and the second organic compound from acetic acid, for reducing the methane level in the total gas produced, and to the use for increasing the total gas formation during feed digestion in ruminants as well as a method for reducing the methane level in the total gas produced and a method for increasing the total gas formation during feed digestion in ruminants.

Owner:BASF AG

C4 fraction catalytic onversion method for yielding propylene

InactiveCN1978410AImprove conversion rateHigh yieldBulk chemical productionHydrocarbon by hydrocarbon crackingFluidized bedAlkene

A C4 fraction catalytic conversion method to increase the production of propylene is to infuse C4 fraction being rich in olefin into fluidized bed or lift pipe reactor in two or more stages, contact the zeolite catalyst with five-ring and pre-carbon-deposition capacity being 0.01 ~ 2.0w% to react, separate reaction products and catalyst to be produced. The catalyst to be produced is processed with stripping, regeneration, pre-carbon-deposition, and then returned to the reactor for recycling, and C4 fraction of the products can be taken back for refining. The method uses C4 fraction to activate the pre-carbon-deposition catalyst, to increase the conversion rate of C4 olefin and the yield of propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

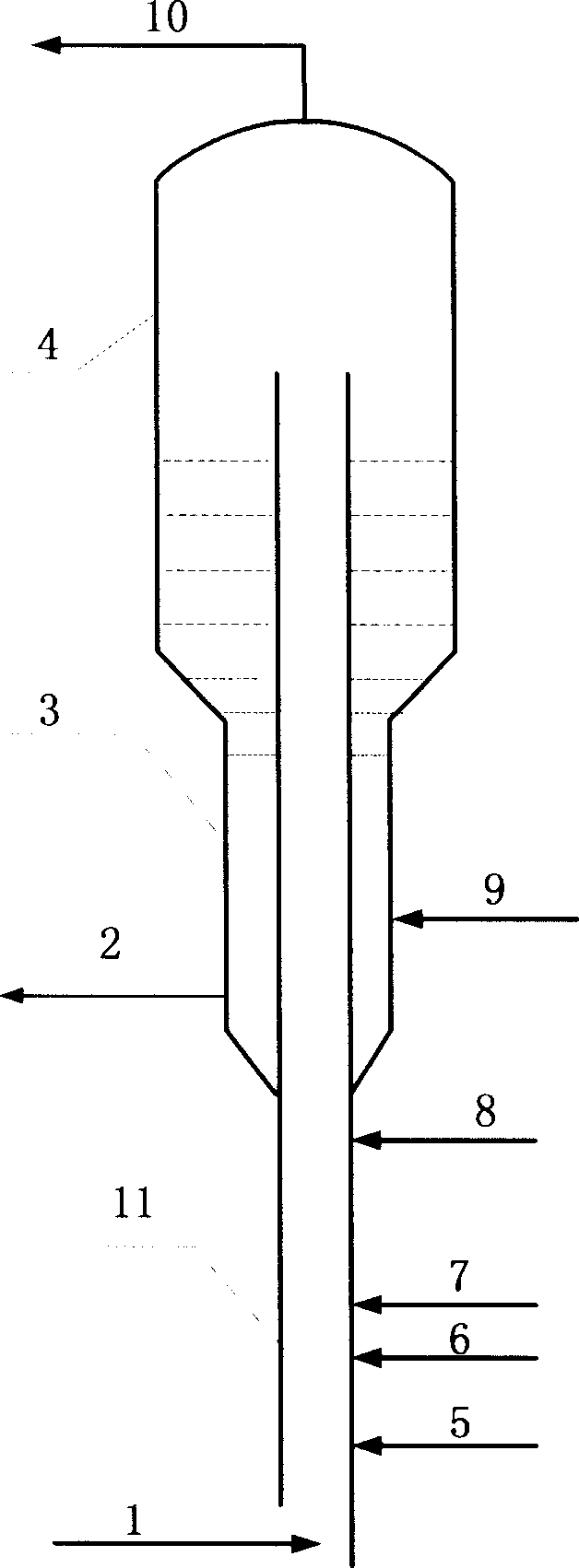

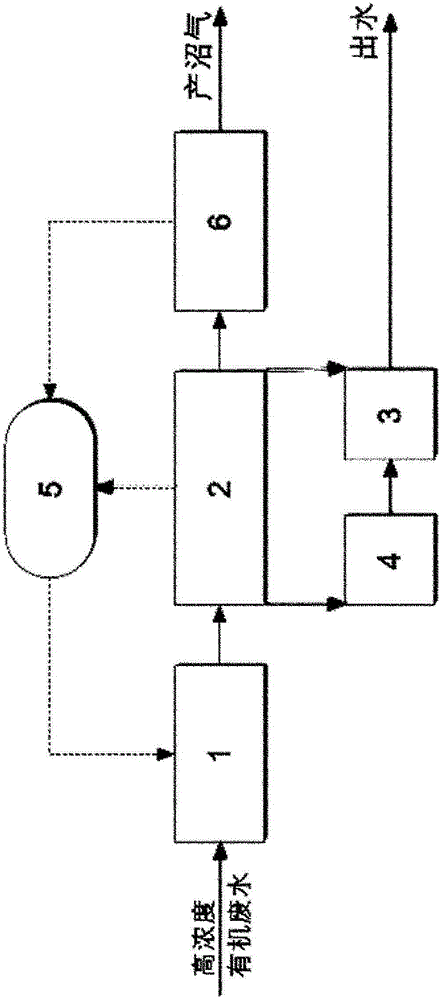

Method and device for treating organic wastewater with two-phase anaerobic tubular membrane bioreactor

ActiveCN104478172AEasy maintenanceShort processWater treatment parameter controlSpecific water treatment objectivesHigh concentrationGeneration rate

The invention discloses a method for treating organic wastewater with a two-phase anaerobic tubular membrane bioreactor. The method comprises the following steps of: adding anaerobic digested sludge into an up-flow complex acid-production reactor and a completely mixed methane-production reactor in an inoculating way; enabling organic wastewater to flow through all reaction chambers in the up-flow complex acid-production reactor in sequence and enter the completely mixed methane-production reactor, and adding wastewater into the completely mixed methane-production reactor by controlling the gas generation rate and the pH value; enabling a methane-phase mixed solution in the completely mixed methane-production reactor to scour the inner side of a tubular membrane component and flow back to the completely mixed methane-production reactor in a circulating way so as to be mixed hydraulically; separating the methane-phase mixed solution by using the membrane component to obtain effluent and methane gas; and collecting the methane gas at the methane gas outlet of the completely mixed methane-production reactor. The invention further discloses a device for implementing the method. The method and the device can be used for treating high-concentration organic wastewater so that the organic wastewater reaches the standard in a short process, and the method and the device can be also used for treating low-concentration organic wastewater so that the discharge of methane dissolved in effluent as a greenhouse gas can be reduced.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

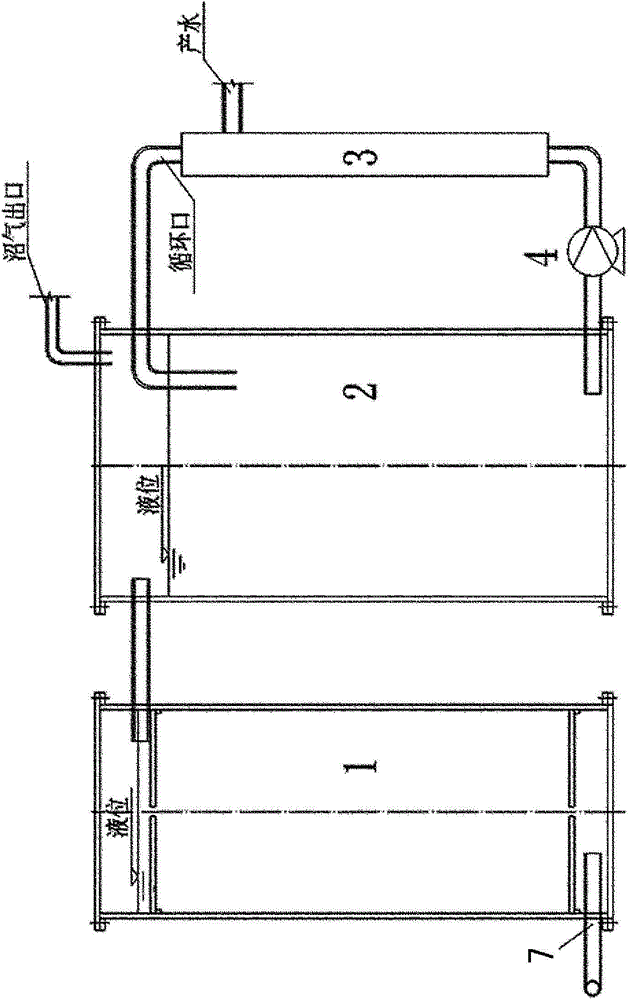

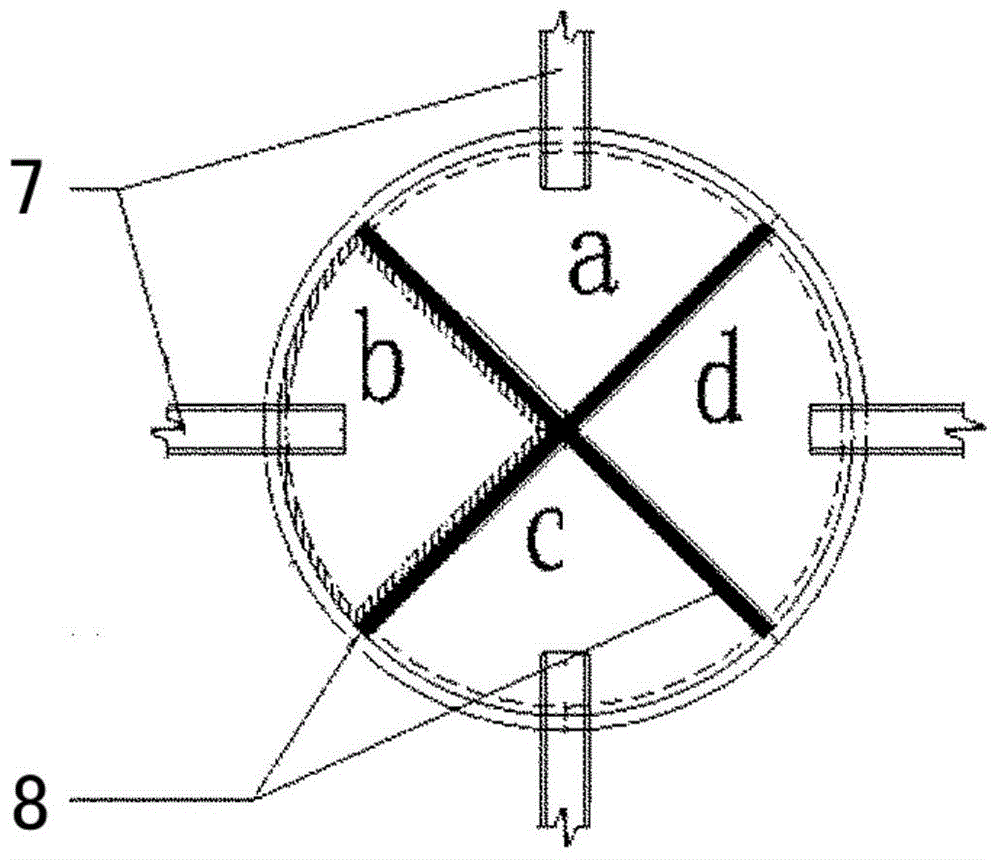

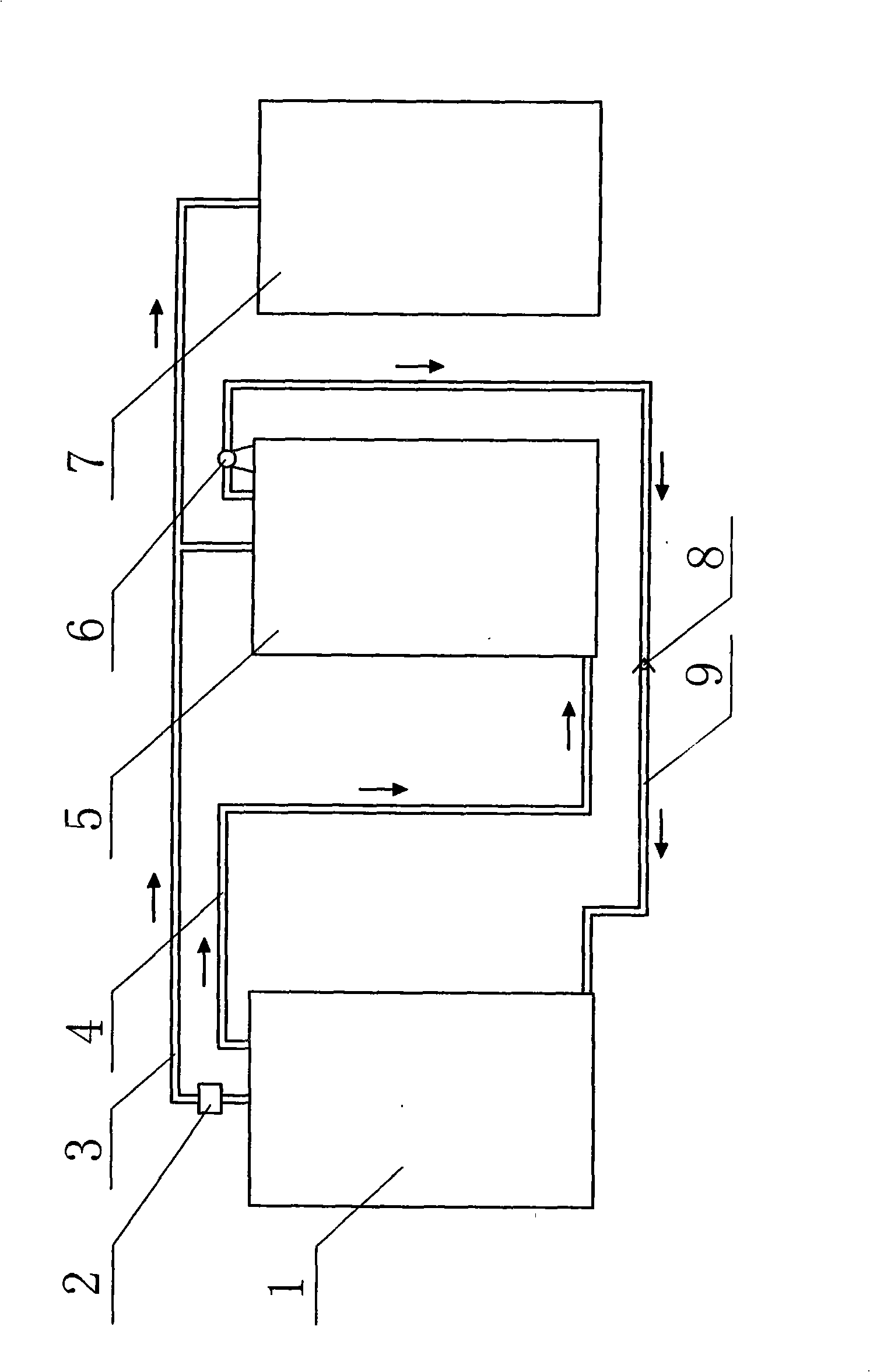

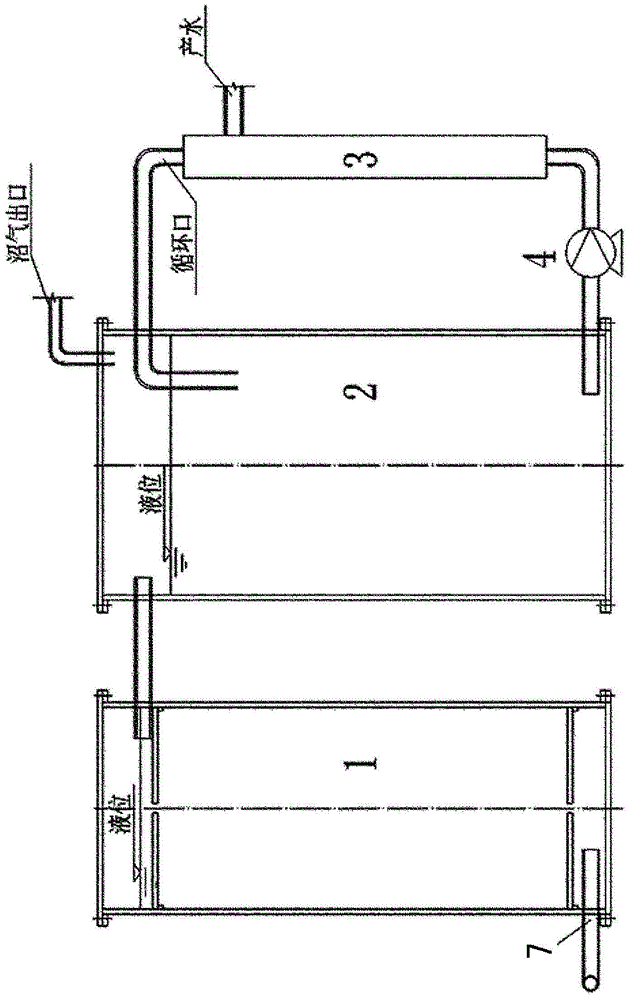

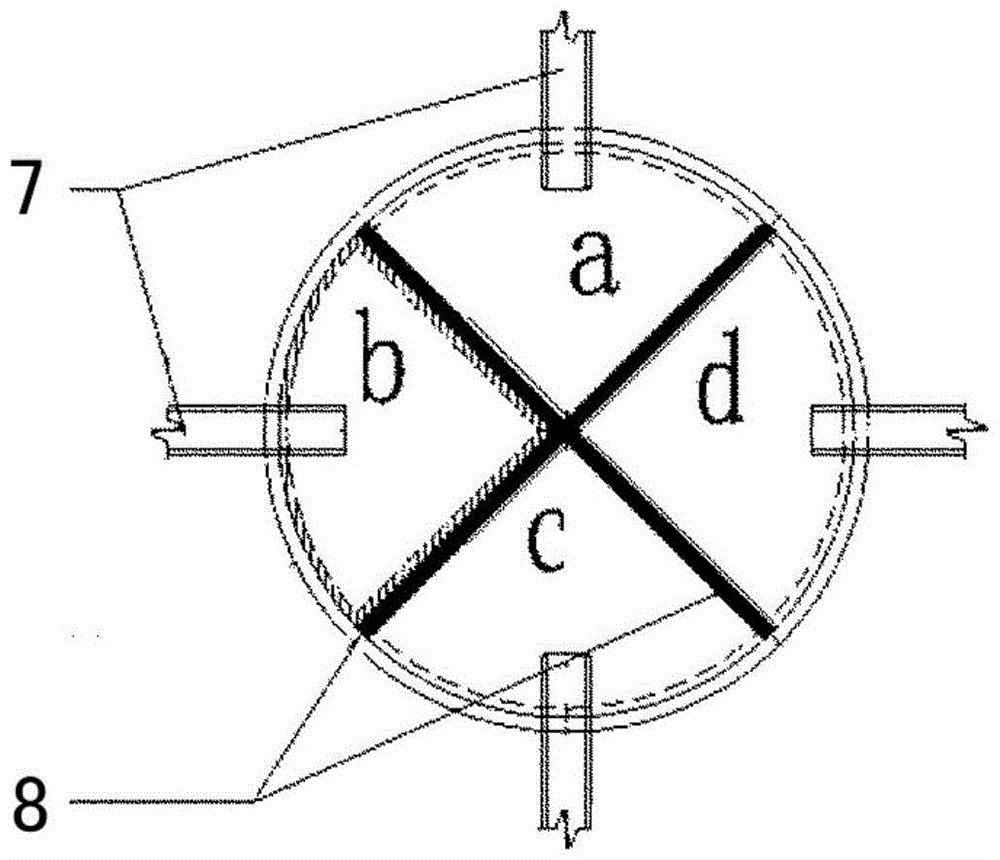

Firedamp biphasic anaerobic fermentation gas stirring system

InactiveCN101265447AReduce propionic acid contentAvoid accumulationBioreactor/fermenter combinationsBiological substance pretreatmentsProduction rateProcess engineering

The invention relates to a methane two-phase anaerobic fermentation gas mixing system, which belongs to a methane generator. A gas returning pipe and a gas inlet pipe are connected and installed between a hydrolytic acidification tank and a gas production tank, the both ends of the gas returning pipe are respectively connected with the upper part of the hydrolytic acidification tank and the lower part of the gas production tank, the both ends of the gas inlet pipe are respectively connected with the lower part of the hydrolytic acidification tank and the upper part of the gas production tank; an air pump and a one-way valve are arranged on the gas inlet pipe; and a normally open solenoid valve is installed on a gas collector, and is positioned at the gas collector position between the hydrolytic acidification tank and the gas production tank. The system has the advantages that the structure is simple, the operation is convenient, the running is stable, the gas production process is smooth, the gas production rate is high, and the quality is good.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

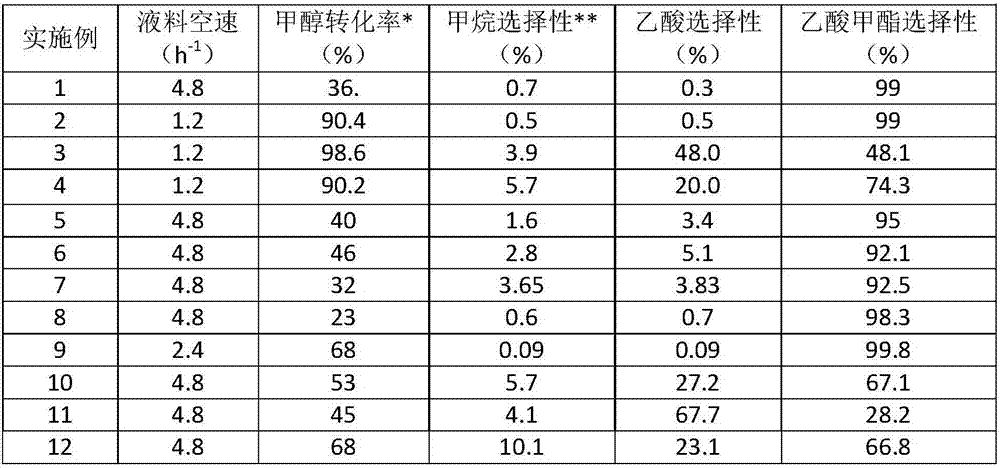

Iridium-based catalyst supported by acid-treated carbon carrier, and preparation method and application thereof

ActiveCN107486191AHigh selectivityLow selectivityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsIridiumHigh activity

The invention a catalyst supported by an acid-treated carbon carrier and used for preparation of methyl acetate from methanol through carbonylation, and a preparation method thereof. The catalyst is composed of main active components and a carrier, wherein the main active components are iridium and transition metal or an oxide aid thereof, and the contents of iridium and transition metal or the oxide aid thereof account for 0.01-5.0% and 0.1-30% of the weight of the catalyst, respectively; and the carrier is the acid-treated carbon carrier including acid-treated coconut shell carbon or apricot shell carbon and other acid-treated carbonized carriers. The purpose of acid treatment is to increase methyl acetate selectivity and reduce methane. According to the invention, the Ir-based catalyst is formed by loading metal on the acid-treated carrier through an impregnation method. In a fixed-bed reactor, high-activity high-selectivity conversion of CH3OH / CO into methyl acetate and reduction in methane selectivity can be realized at a certain temperature and pressure and under the action of the catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for coupling deethanization process and propane dehydrogenation process before hydrocarbon steam cracking

ActiveCN111747814AHarsh conditionsEasy to cokeHydrocarbon by hydrogenationHydrocarbon purification/separationPtru catalystDehydrogenation

The invention discloses a method for coupling a deethanization process and a propane dehydrogenation process before hydrocarbon steam cracking in the technical field of petrochemical engineering. Aiming at the characteristics of cracking gas of a hydrocarbon steam cracking device and reaction gas of a propane dehydrogenation device, through coupling of the two processes, the purposes of reducing equipment investment, reducing device energy consumption, reducing construction land and prolonging the service life of an alkyne hydrogenation catalyst are achieved, and long-period stable productionof a coupling device is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for coupling deethanization process and propane dehydrogenation process before hydrocarbon steam cracking

ActiveCN111807921AHarsh conditionsEasy to cokeDistillation purification/separationHydrocarbonsPtru catalystDehydrogenation

The invention discloses a method for coupling a deethanization process and a propane dehydrogenation process before hydrocarbon steam cracking in the technical field of petrochemical engineering. Aiming at the characteristics of cracking gas of a hydrocarbon steam cracking device and reaction gas of a propane dehydrogenation device, through coupling of the two processes, the purposes of reducing equipment investment, reducing device energy consumption, reducing construction land and prolonging the service life of an alkyne hydrogenation catalyst are achieved, and long-period stable productionof a coupling device is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +2

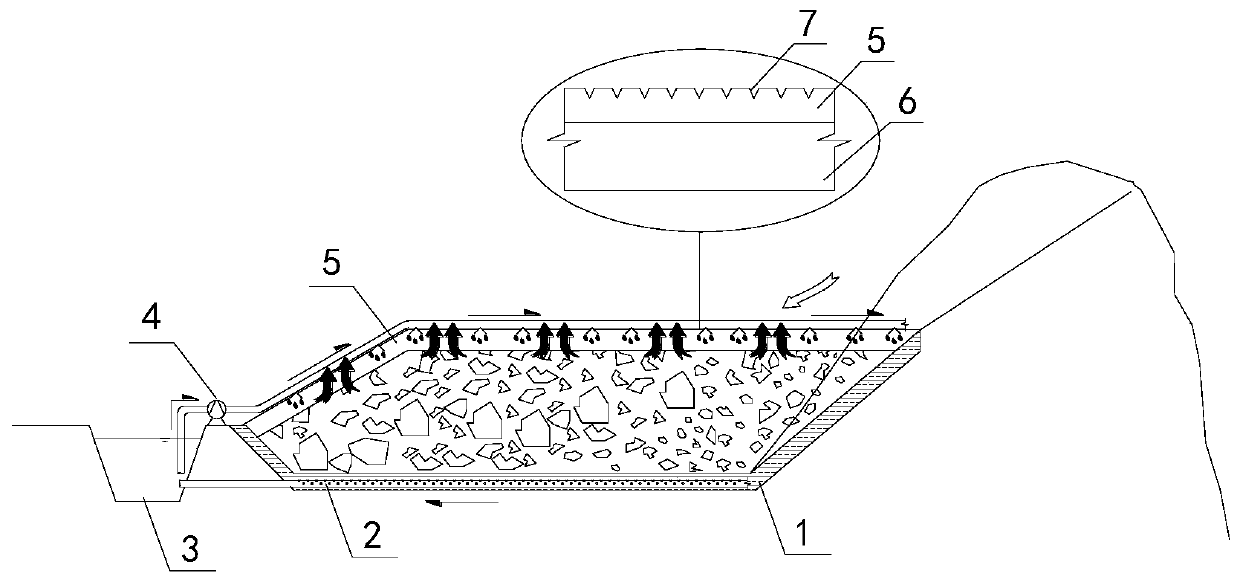

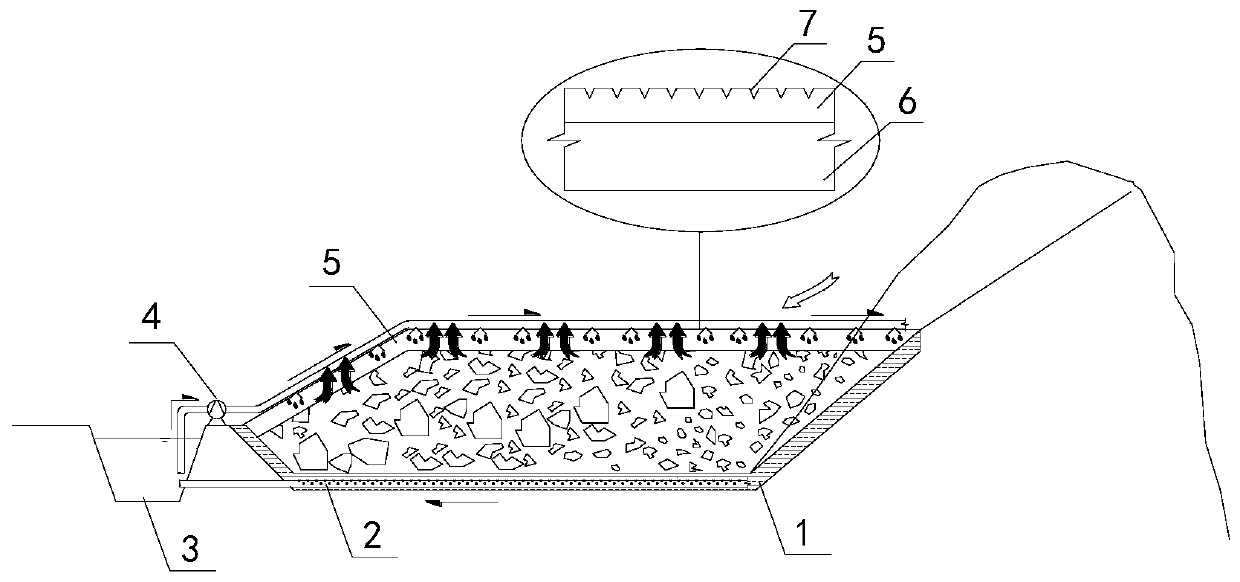

Household garbage sanitary landfill covering method for loess area

ActiveCN111112275AHigh organic contentIncreased hydraulic conductivityLandfill technologiesSolid waste disposalSoil scienceEnvironmental engineering

The invention discloses a household garbage sanitary landfill covering method for a loess area, and belongs to the technical field of garbage landfill. The method comprises the following steps that loess covers landfill garbage in a household garbage landfill to form a loess covering layer, a shallow trench is plowed out on the surface of the loess covering layer, and when the minimum temperatureof the area is not less than 5 DEG C, a landfill garbage leachate is irrigated to the surface of the loess covering layer in a sprinkling manner. The household garbage sanitary landfill covering method is simple and convenient to operate, not only can effectively utilize the loess and the landfill leachate with sufficient earthwork amount at the local area, saves land resources, reduces the treatment amount of the leachate, but also the method can effectively improve the covering layer strength and the content of organic matter, and can improve the water holding capacity of the loess coveringlayer and improve the anti-seepage capacity of the loess covering layer while avoiding the problems of raised dust and water and soil loss caused by loess covering; furthermore, landfill gas generatedby landfill garbage can also be subjected to biodegradation, and the degradation effect is good.

Owner:TONGJI UNIV

Hydrocarbon steam cracking sequential separation process and propane dehydrogenation process coupling method

InactiveCN111875467AHarsh conditionsEasy to cokeHydrocarbon by hydrogenationHydrocarbon purification/separationPtru catalystDehydrogenation

The invention discloses a method for coupling a hydrocarbon steam cracking sequential separation process and a propane dehydrogenation process in the technical field of petrochemical engineering, andaims at the characteristics of cracking gas of a hydrocarbon steam cracking device and reaction gas of a propane dehydrogenation device, By coupling the two processes, the purposes of reducing equipment investment, reducing device energy consumption, reducing construction land and prolonging the service life of the alkyne hydrogenation catalyst are achieved, and long-period stable production of the coupling device is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for coupling hydrocarbon steam cracking sequential separation process and propane dehydrogenation process

ActiveCN111747813AHarsh conditionsEasy to cokeHydrocarbon by hydrogenationHydrocarbon purification/separationPtru catalystDehydrogenation

The invention discloses a method for coupling a hydrocarbon steam cracking sequential separation process and a propane dehydrogenation process in the technical field of petrochemical engineering. Aiming at the characteristics of cracking gas of a hydrocarbon steam cracking device and reaction gas of a propane dehydrogenation device, through coupling of the two processes, the purposes of reducing equipment investment, reducing device energy consumption, reducing construction land and prolonging the service life of an alkyne hydrogenation catalyst are achieved, and long-period stable productionof a coupling device is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for coupling depropanization process before hydrocarbon steam cracking and propane dehydrogenation process

ActiveCN111848327AHarsh conditionsEasy to cokeHydrocarbon by hydrogenationDistillation purification/separationPtru catalystDehydrogenation

The invention discloses a method for coupling a depropanization process before hydrocarbon steam cracking and a propane dehydrogenation process in the technical field of petrochemical engineering. According to the characteristics of cracking gas of a hydrocarbon steam cracking device and reaction gas of a propane dehydrogenation device, through coupling of the two processes, the purposes of reducing equipment investment, reducing device energy consumption, reducing construction land and prolonging the service life of an alkyne hydrogenation catalyst are achieved, and long-period stable production of a coupling device is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method for preparing biogas through mixed anaerobic fermentation of cow dung and corn straw

InactiveCN110029132AExtended fermentation cycleStraw decomposition rate is lowWaste based fuelFermentationBiogasCorn stover

The invention provides a method for preparing biogas through mixed anaerobic fermentation of cow dung and corn straw. The method comprises the steps of with the corn straw and the cow dung as raw materials, firstly pretreating the corn straw in a manner of mechanical crushing and basic hydrolysis, then mixing the pretreated corn straw with the cow dung in the mass ratio being (1.5-2) to 1, addingFe2+ according to the quantity being 1.0mg.L<-1>-1.5mg.L<-1>, adjusting the total solid content of a mixture to be 6%-10%, with anaerobic sludge as a fermentation initiator, controlling the anaerobicfermentation temperature to be 20-30 DEG C, and in the fermentation process, performing noncontinuous stirring. The biogas is prepared by the method, fermentation starting is quick, the fermentation period is shortened, the decomposition rate of raw materials is increased, the biogas yield is promoted, the content of methane in gas is increased, and the stability of the fermentation process is increased.

Owner:CHONGQING UNIV OF ARTS & SCI

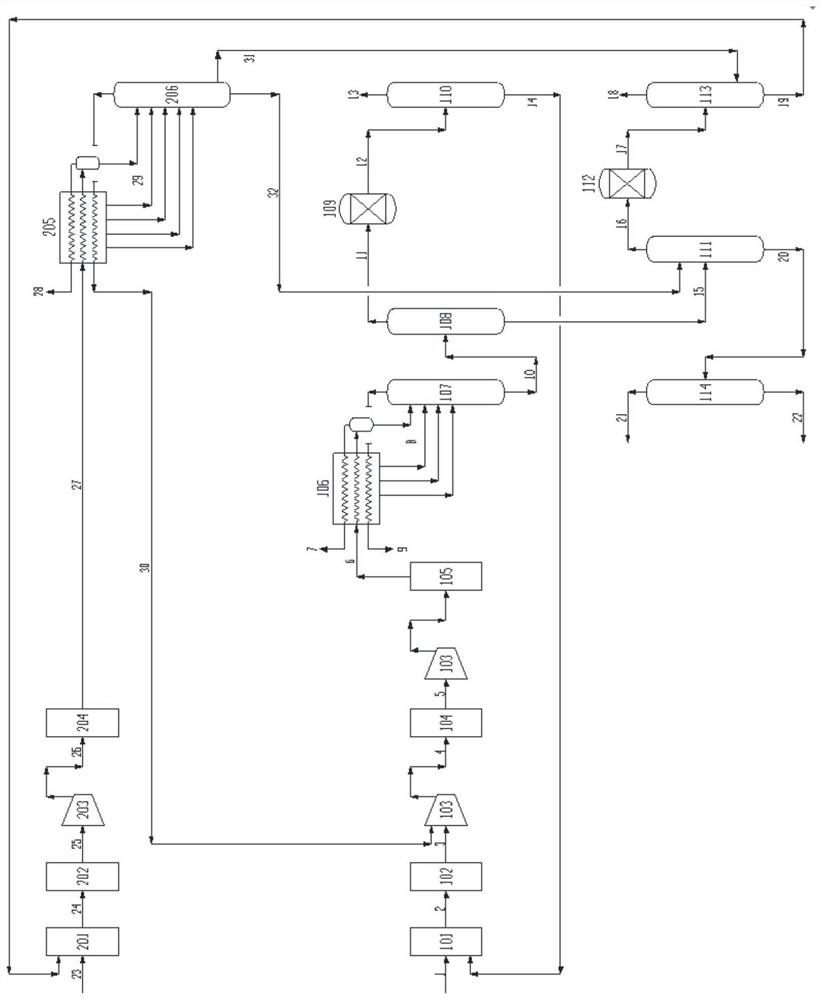

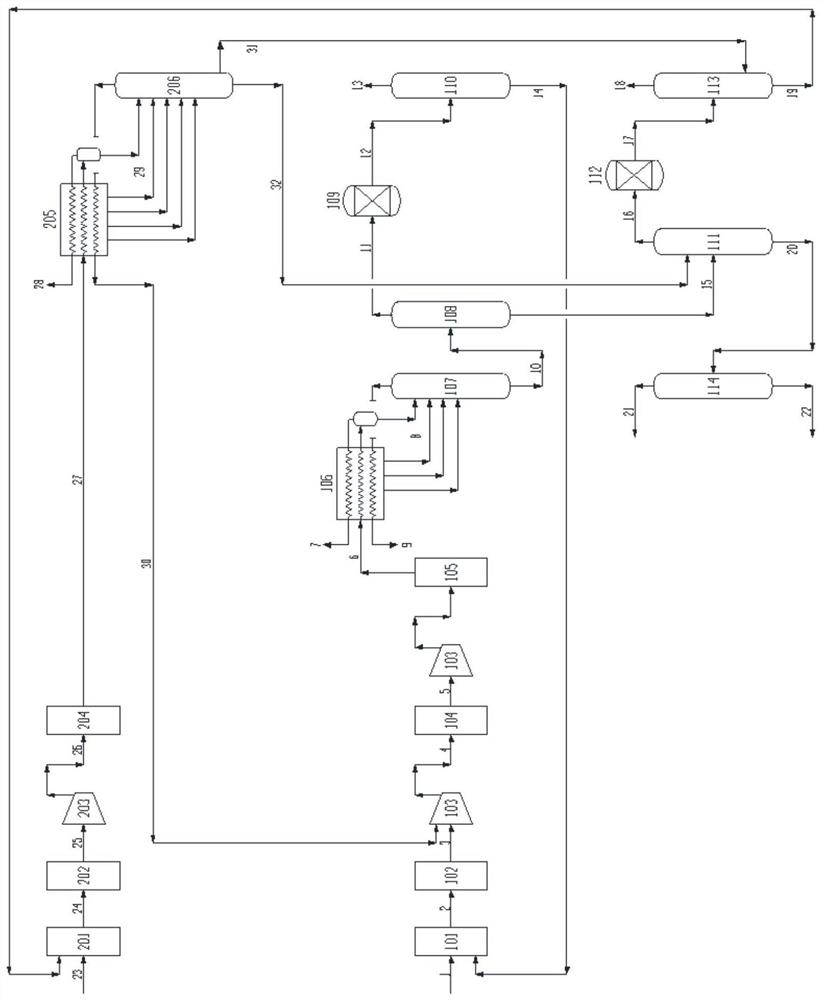

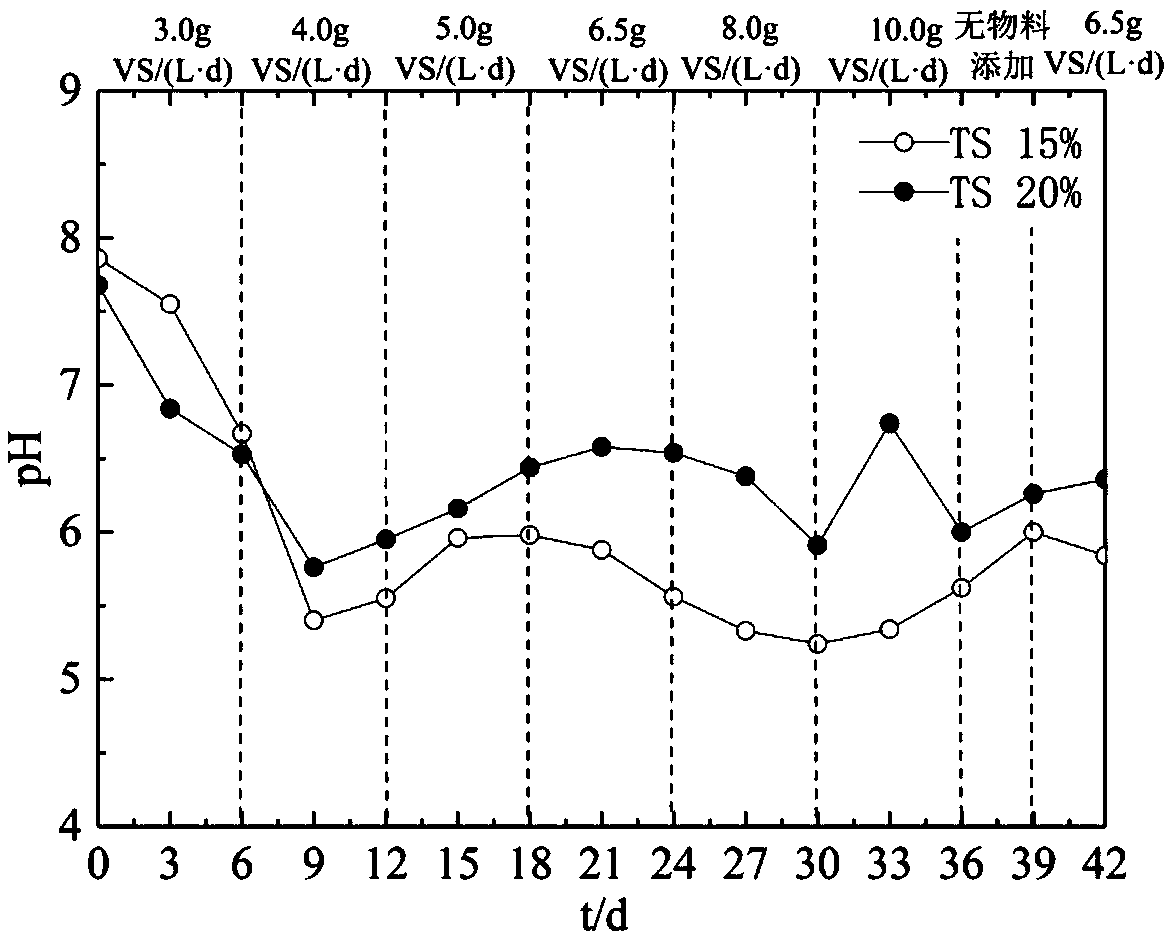

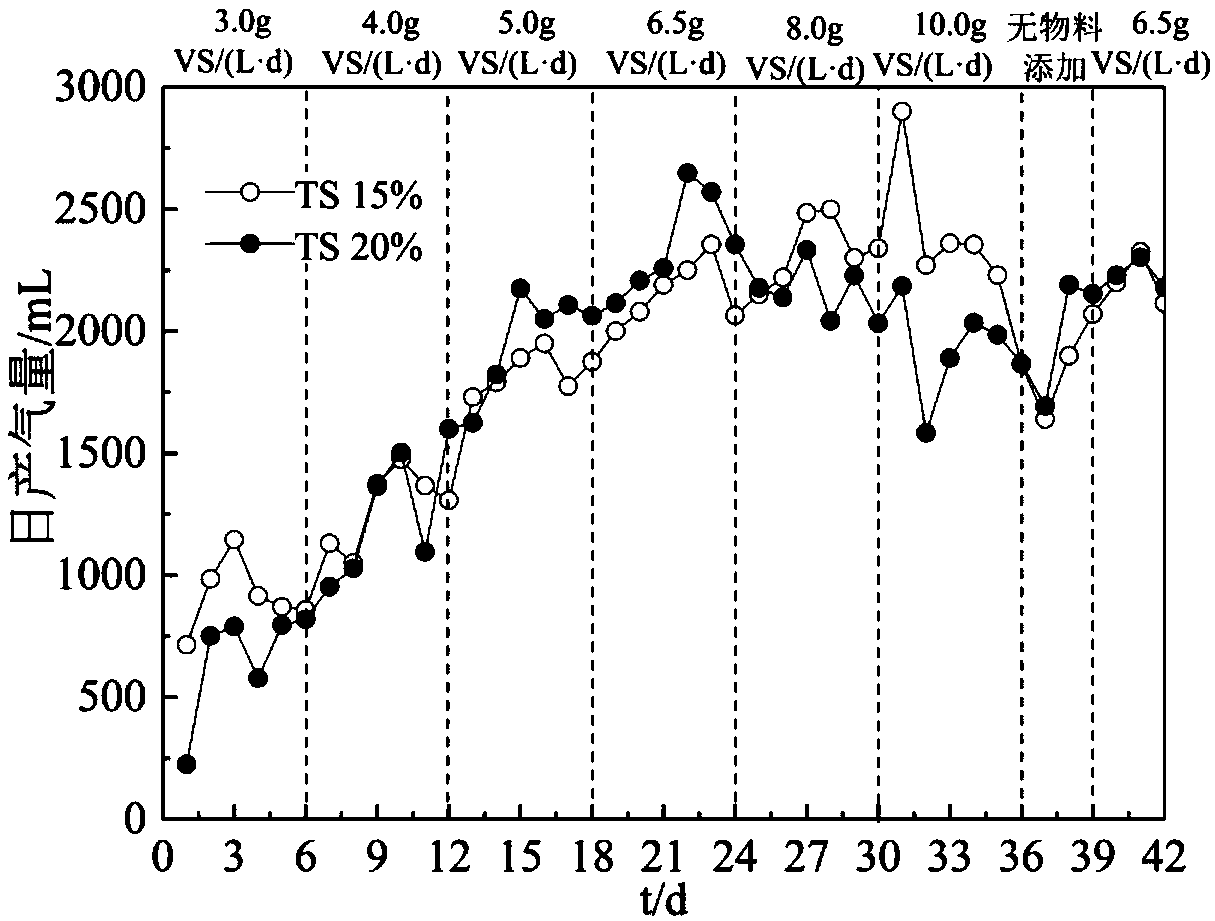

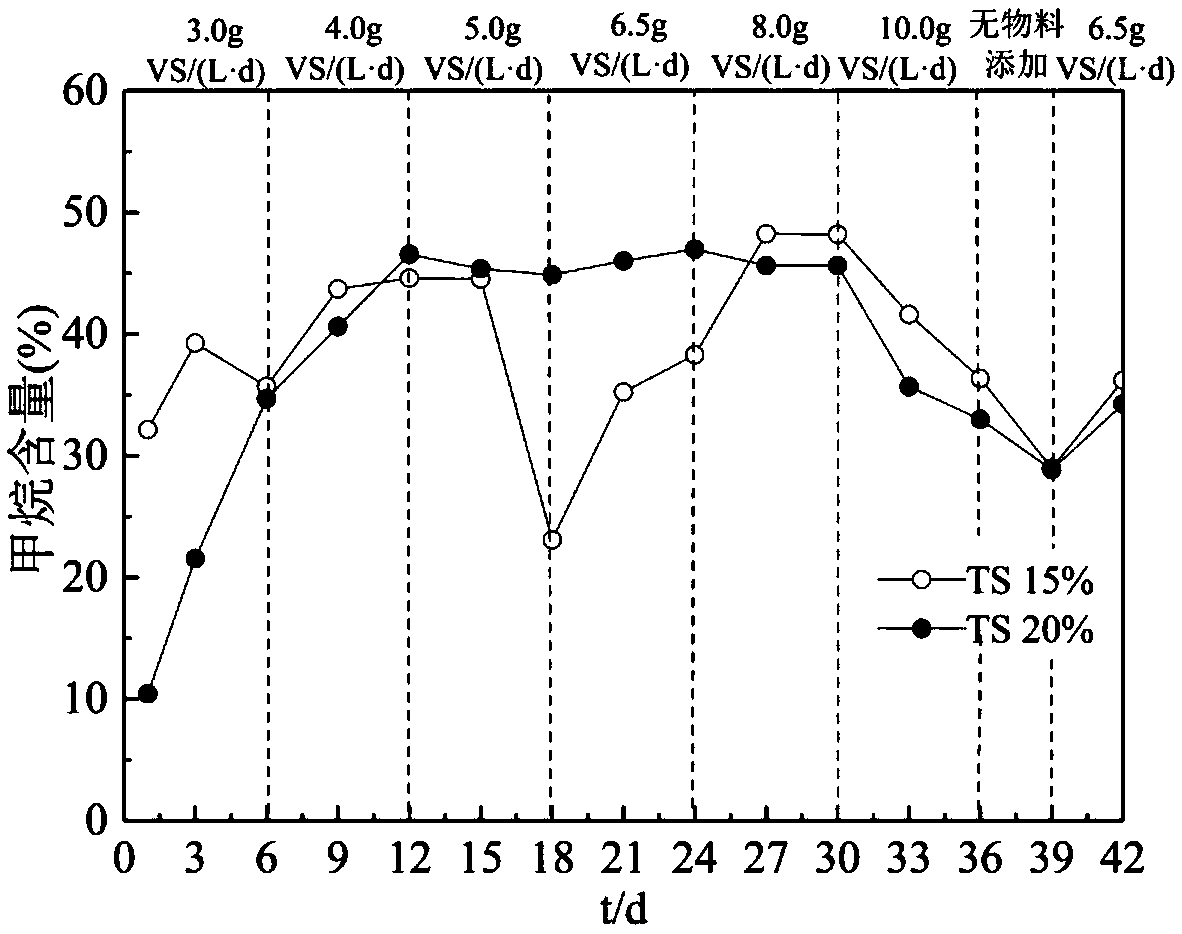

Method for producing biogas through semi-continuous dry anaerobic fermentation of cassava residues

The invention discloses a method for producing biogas through semi-continuous dry anaerobic fermentation of cassava residues. The method comprises the following concrete steps: (1) pretreatment and mixing of materials: subjecting the cassava residues to drying and sieving, refrigerating the obtained product at 4 DEG C for subsequent usage, mixing the product with biogas residues, and allowing a solid content to reach 15% to 25%; (2) starting of a reactor: starting the reactor at a load of 3.0 gVS / (L.d), increasing 20%-30 % of load each time until the load of the reactor is 10.0 gVS / (L.d); and(3) adding a mixture into a fermenter, starting anaerobic fermentation at 32-37 DEG C in stages for 30-45 d, adding a fixed amount of the cassava residues and taking out an equal amount of the mixtureeach day, and carrying out stirring regularly. Compared with traditional semi-continuous wet anaerobic fermentation of cassava residues with high solid content, the method provided by the invention has the following advantages: high specific biogas yield can be still obtained under the conditions of higher solid content and organic load, and optimal effect can be improved by 55%; the specific yield of methane is decreased, but the specific methane yield still reaches 80% or more of the specific methane yield of traditional semi-continuous wet anaerobic fermentation; and the content of methaneis slightly decreased by about 18% to 30%.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

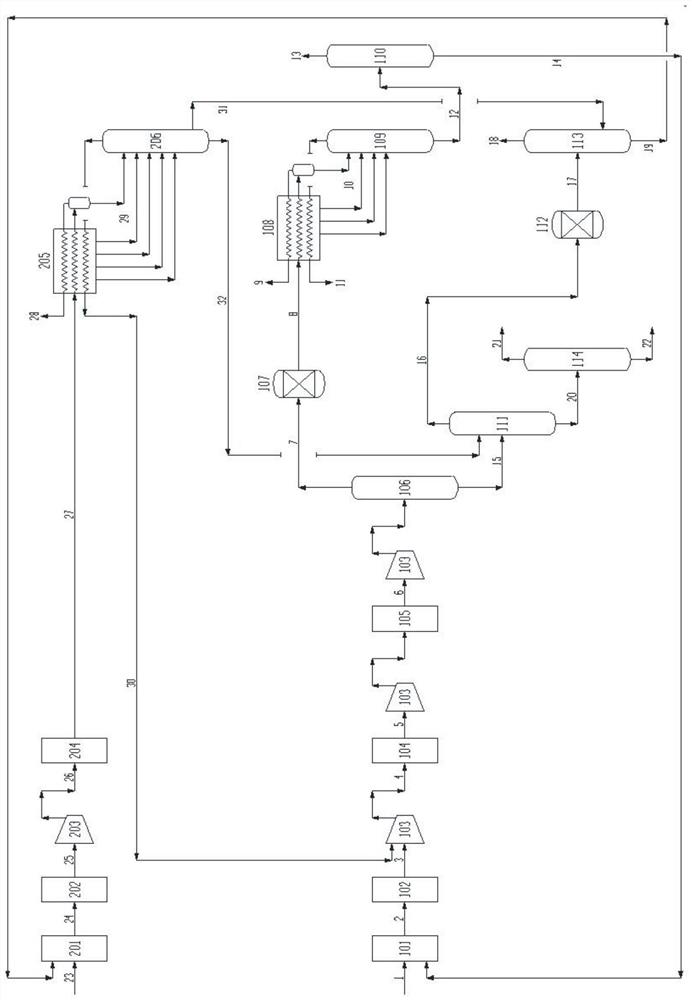

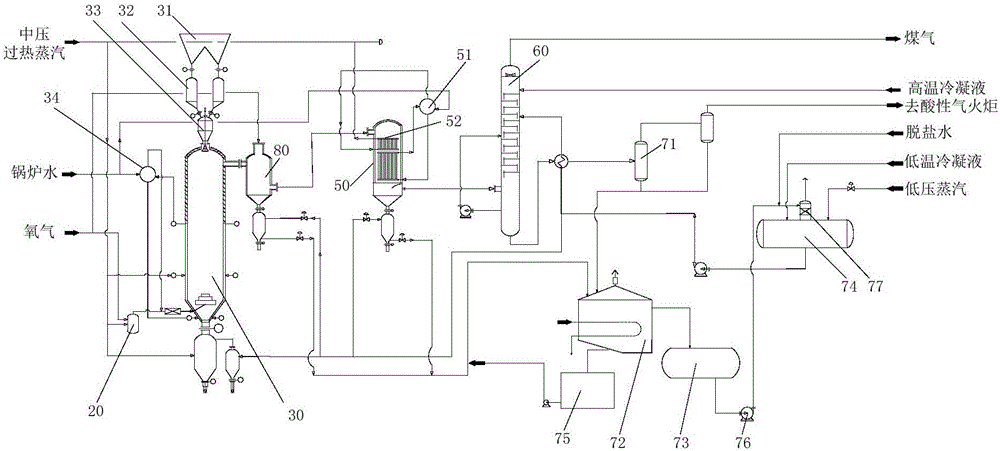

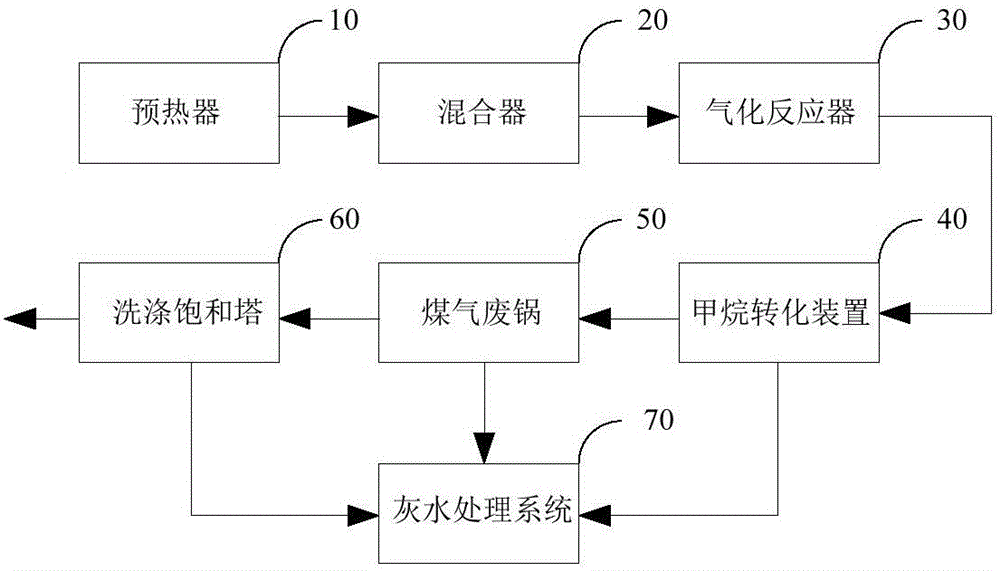

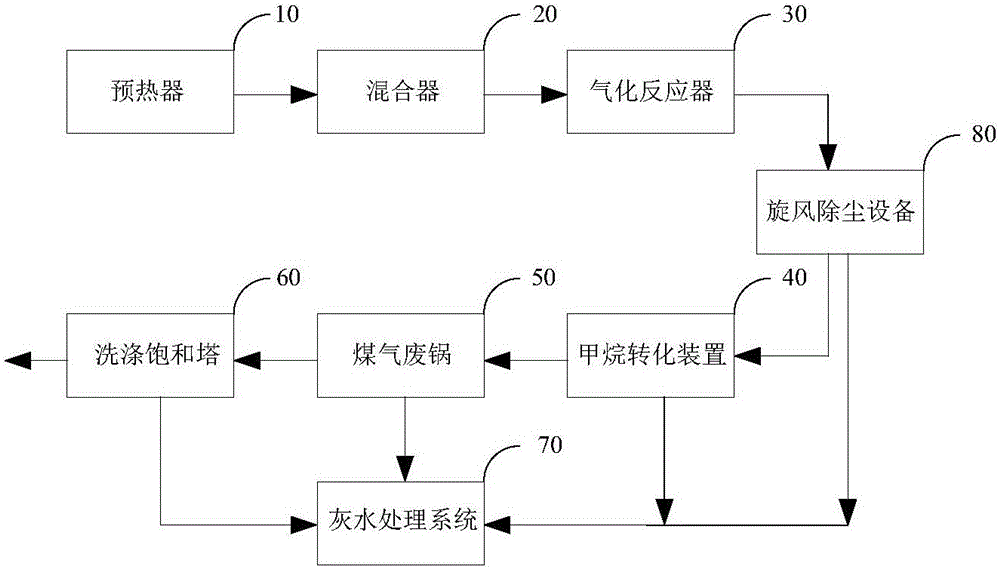

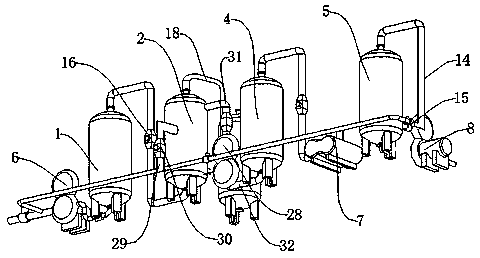

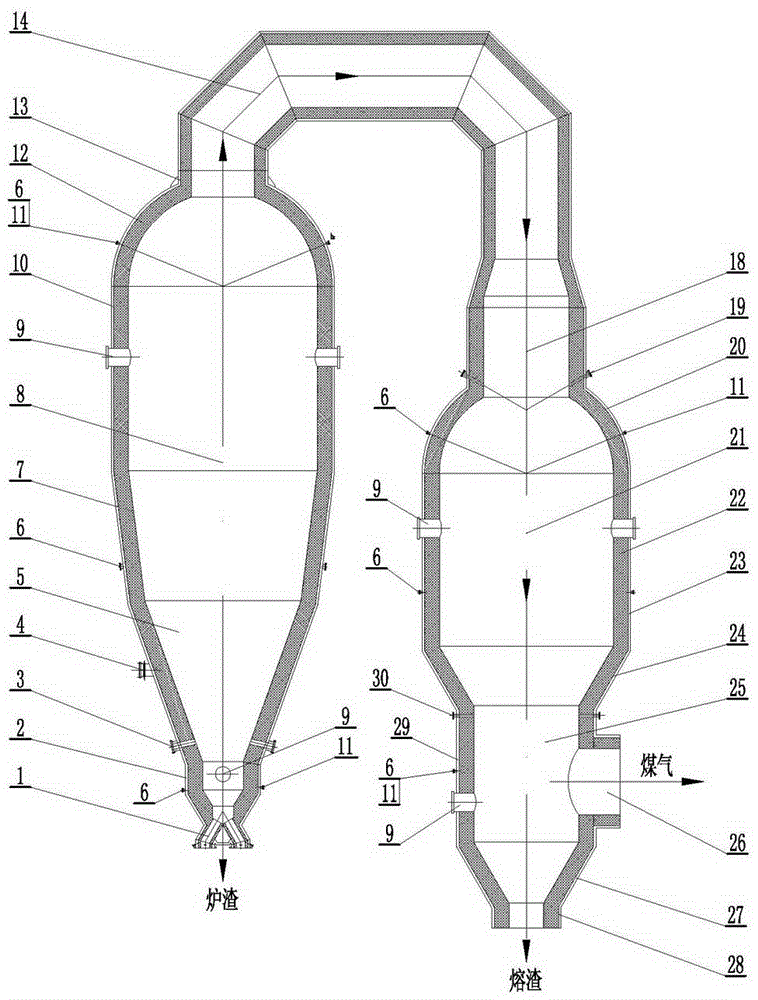

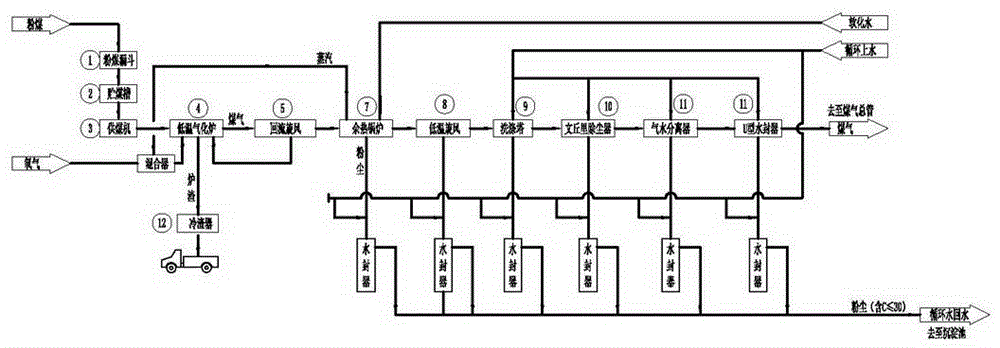

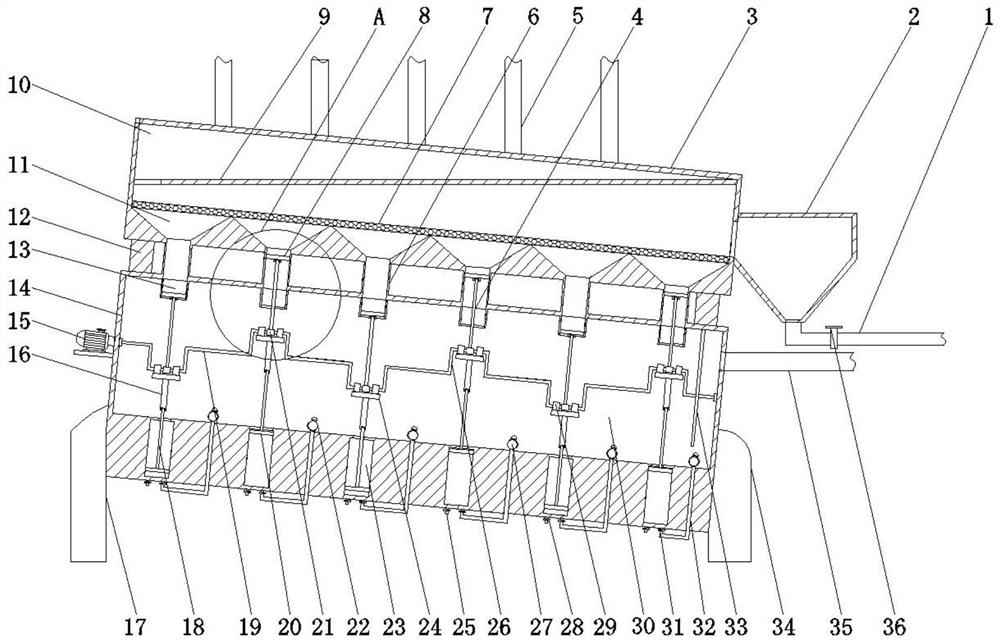

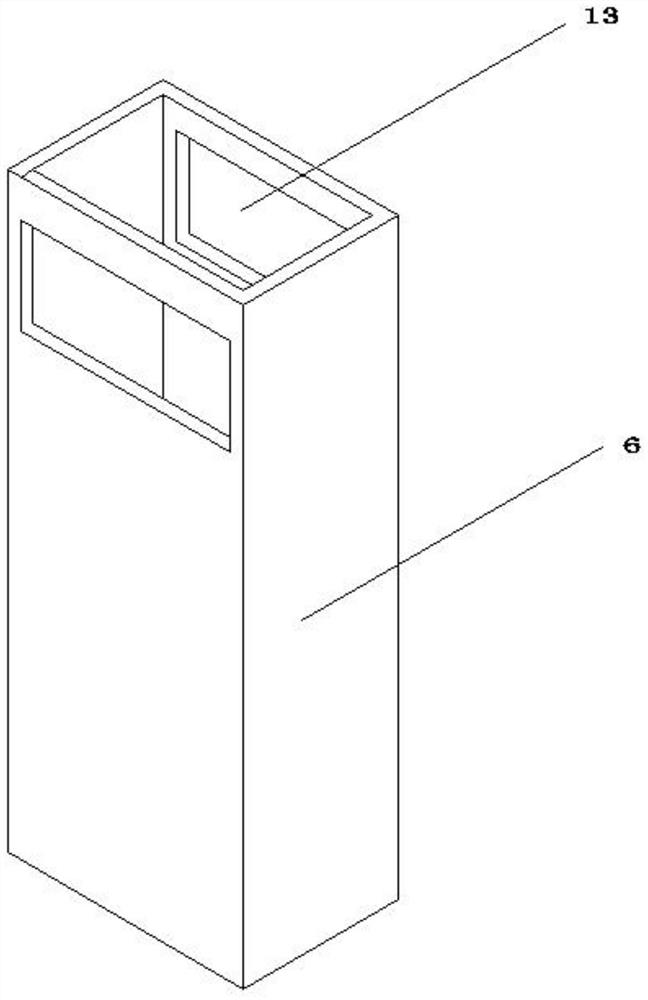

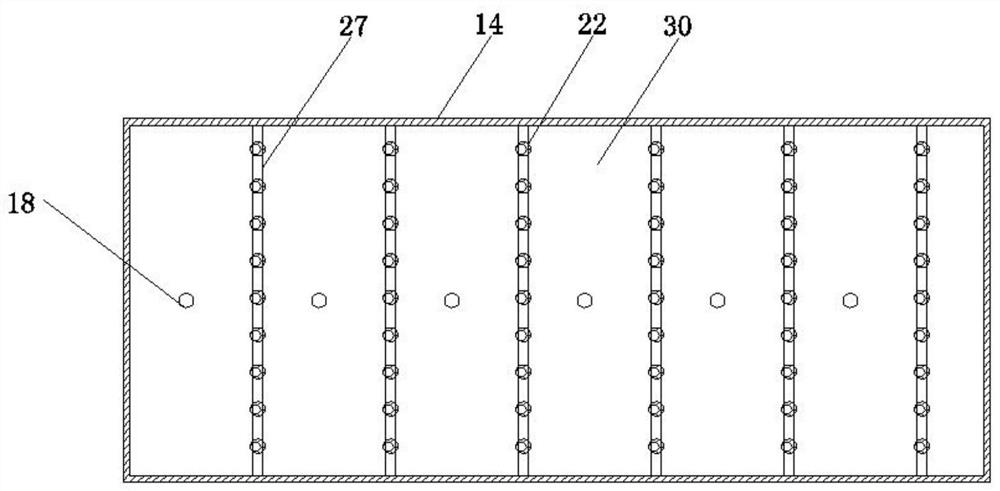

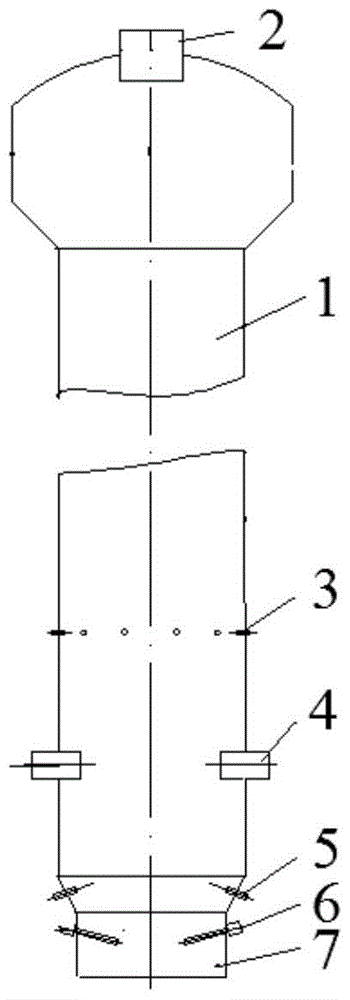

Fixed bed pressurized gasification system

InactiveCN106544058AReduce methane contentImprove conversion rateGasification processes detailsMultistage water/sewage treatmentWater treatment systemTar

The invention provides a fixed bed pressurized gasification system and relates to the technical field of gasification processes, aiming at solving the problems that the content of methane in produced coal gas is high and influences on a production capacity of the system are relatively great. The fixed bed pressurized gasification system comprises a gasification reactor, a methane conversion device, a coal gas waste boiler, a washing saturation tower and an ash water treatment system, wherein a gas inlet of the methane conversion device is communicated with a gas outlet of the gasification reactor; a gasification agent inlet is arranged in the top of the methane conversion device; a gasification agent which enters the methane conversion device from the gasification agent inlet comprises oxygen; the coal gas waste boiler is communicated with a gas outlet of the methane conversion device; the washing saturation tower is communicated with the coal gas waste boiler; the ash water treatment system is communicated with the gasification reactor, the coal gas waste boiler and the washing saturation tower respectively. By adopting the fixed bed pressurized gasification system provided by the invention, the disadvantages that the content of methane in the produced coal gas is high, the coal gas carries organic matters including coke tar and the like can be effectively overcome.

Owner:北京金泰瑞和工程科技有限公司

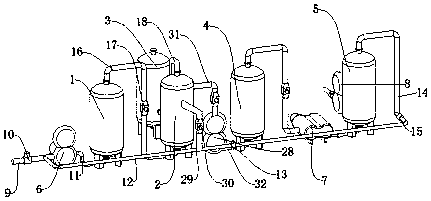

Two-stage series pressure swing adsorption biogas purification system capable of improving methane recovery rate

PendingCN110643404AReduce construction costsNot affected by methane contentGaseous fuelsBuffer tankMethane yield

The invention discloses a two-stage series pressure swing adsorption biogas purification system capable of improving the methane recovery rate. The system comprises a biogas buffer tank, a first-stagePSA adsorption tank, a product gas buffer tank and a desorption gas buffer tank, a biogas compressor is arranged at one end of the biogas buffer tank, a gas inlet pipe is arranged at one end of the biogas compressor, the gas inlet pipe is provided with a first electric control valve, a return pipe is arranged at the front end of the gas inlet pipe, the return pipe is provided with a second electric control valve, the first-stage PSA adsorption tank is arranged on the other side of the biogas buffer tank, and the desorption gas buffer tank is arranged on one side of the first-stage PSA adsorption tank. The system has a low cost, and allows the methane yield to be easier to control than that of an original two-stage PSA technology, the methane yield is controlled to control the methane emptying amount of a PSA decarburization device, and the higher the yield is, the less the methane is emptied, so the system contributes to the national environmental protection control of carbon emission.

Owner:山东红枫环境能源有限公司

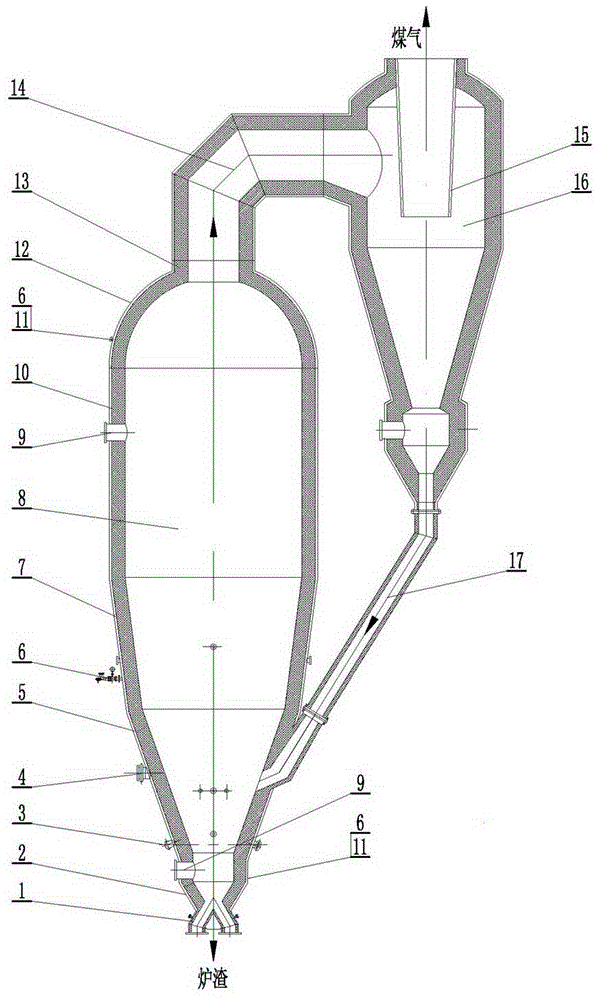

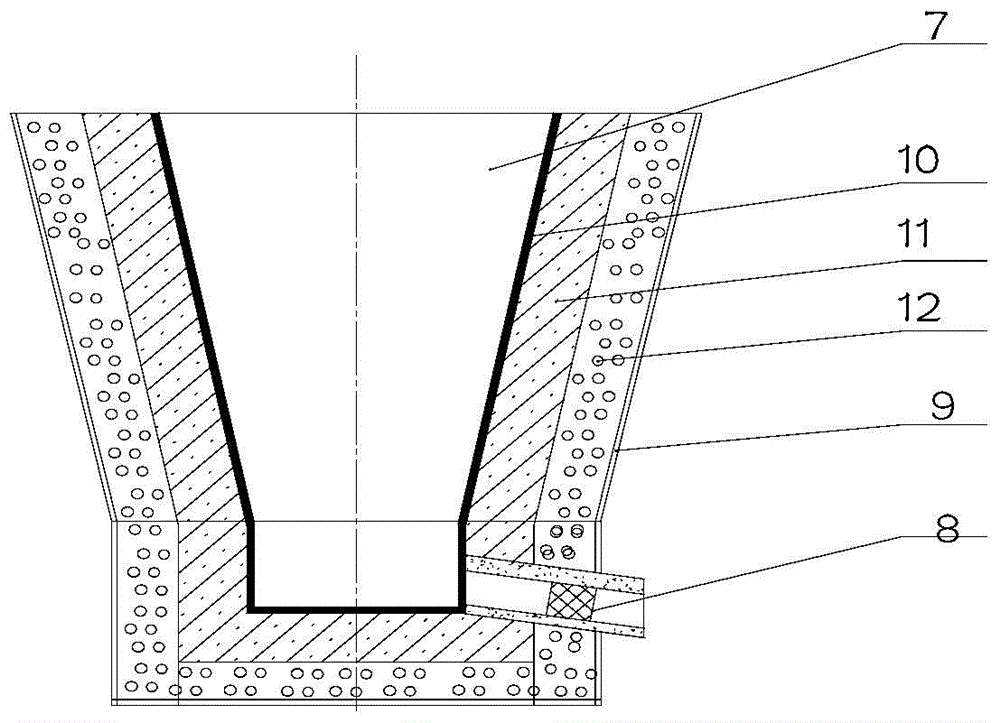

Low-high temperature combined normal-pressure powder coal gasification furnace and gasification technological method

InactiveCN104893760AReduce methane contentImprove carbon utilizationProductsReagentsSlagEconomic benefits

The invention discloses a low-high temperature combined normal-pressure powder coal gasification furnace and a gasification technological method. The low-high temperature combined normal-pressure powder coal gasification furnace adopts the structure that a high-temperature gasification furnace is communicated to the one end of a gas pipe of which the other end is communicated with a low-temperature gasification furnace; the high-temperature gasification furnace has a vertical cylindrical furnace body; a gas outlet pipe is arranged at the lower part of the cylindrical furnace body. As the low-temperature gasification furnace and the high-temperature gasification furnace are combined together, powder coal, which does not reacts at the moment and is carried by gas from the low-temperature gasification furnace, reacts with a gasifying agent again in the high-temperature gasification furnace, organic materials in coal gas are decomposed completely, and the vast majority of carbon dioxide in feed gas is converted into carbon monoxide, dust in the coal gas is dissolved completely, carbon in the dust is recovered almost completely. The content of effective gas in outlet coal gas of the high-temperature gasification furnace can reach 78 to 85 percent, the carbon content of slag is about 0.5 percent, the carbon use ratio is larger than or equal to 99 percent. The low-high temperature combined normal-pressure powder coal gasification furnace and the gasification technological method have the advantages that the coal gas cost is reduced greatly; the economic benefit is considerable; the environmental problem of dust pollution is solved thoroughly.

Owner:LIAONING ENDE ENG & CONSTR

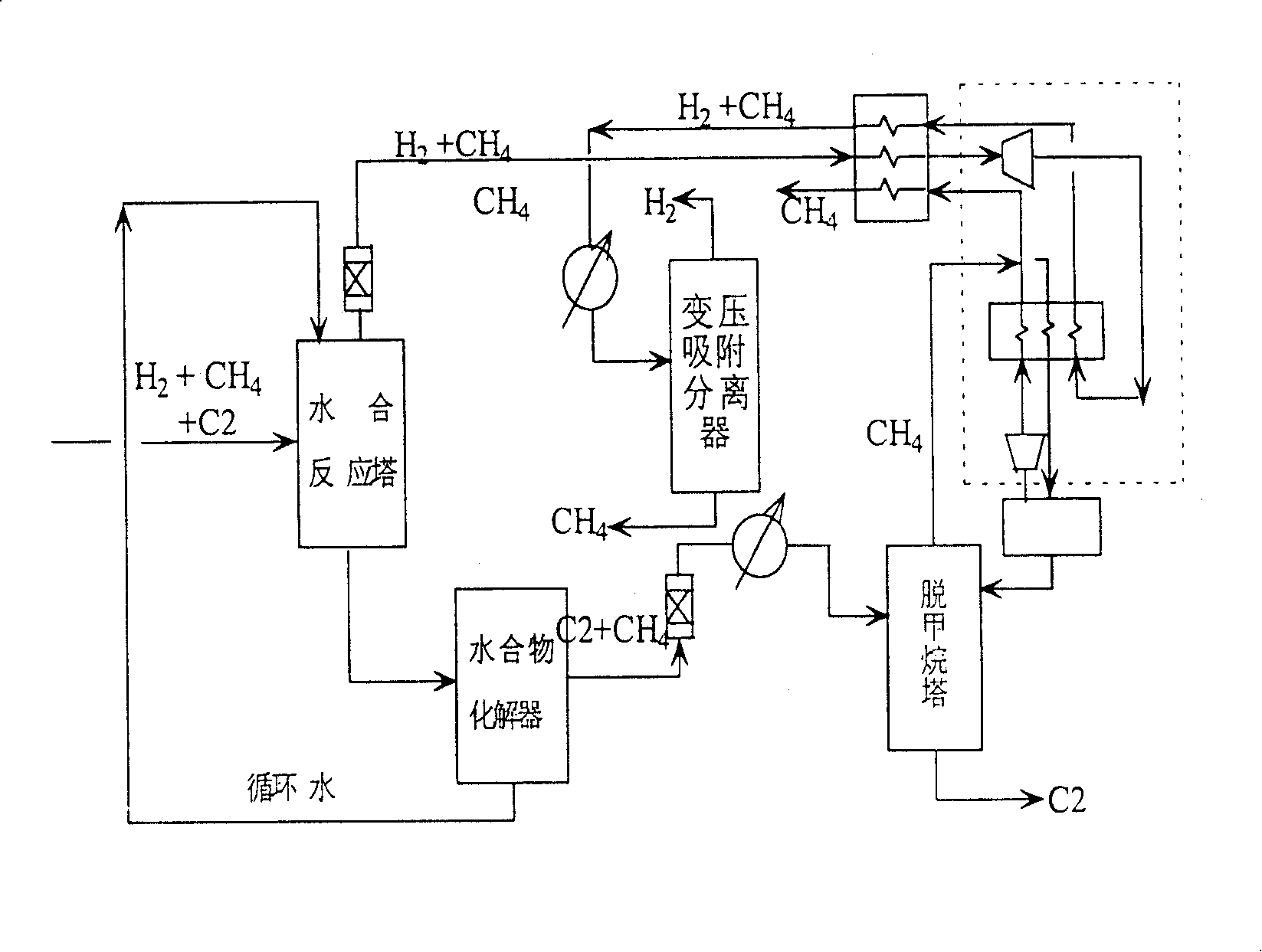

Hydration, pressure swing adsorption and deep cooling combined process for separating ethene cracking gas

InactiveCN100404483CReduce top cooling loadReduce energy costsHydrocarbon purification/separationHydrocarbonsChemistrySeparation process

The present invention proposes one method of separating ethylene cracking gas, is one combined separation process including hydrating separation, cryogenic separation and PSA separation, and aims at applying new hydrating separation process in the separation of ethylene cracking gas. First, reaction condition is controlled for the C2 component in the cracked gas to form hydrate prior and to be separated. Then, the cold produced by the expanding methane and hydrogen flow is used as the cold source for the methane eliminating tower, and PSA separation is combined to realize the separation of hydrogen, methane and C2 component ultimately. The present invention has no stage-by-stage condensation steps and cold casing and thus lowered cold load of the methane eliminating tower.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for preparing aromatic hydrocarbon from mixed light hydrocarbon

ActiveCN108017494AReduce contentReduce methane contentLiquid hydrocarbon mixtures productionHydrocarbon by hydrocarbon condensationHydrogenGas phase

The invention relates to a method for preparing an aromatic hydrocarbon from a mixed light hydrocarbon. In the prior art, the energy consumption for recycling ethylene in the mixed light hydrocarbon raw material is high. A purpose of the present invention is mainly to solve the problem in the prior art. The technical scheme of the present invention comprises that 1) a light hydrocarbon raw material is subjected to cooling separation to obtain hydrogen-rich gas and a hydrogen-depleted liquid; 2) the hydrogen-rich gas is separated by a methane removing unit to obtain methane-hydrogen mixing gasand a methane removing stream; 3) the hydrogen-depleted liquid is subjected to rectification separation to obtain a heavy removing stream and a first aromatic hydrocarbon stream; 4) the methane removing stream and the heavy removing stream are converged, and the converged stream is fed into a light hydrocarbon aromatization reactor, and is converted into an aromatization product; 5) the aromatization product is subjected to cooing separation to obtain a gas phase product and a second aromatic hydrocarbon stream; 6) the gas phase product is compressed, and the compressed product is fed into anethane removing tower to obtain ethane gas and a circulation stream; and 7) the circulation stream returns the light hydrocarbon aromatization reactor. With the technical scheme, the problem in the prior art is well solved. The method of the present invention can be used in the industrial production of light hydrocarbon aromatization.

Owner:CHINA PETROLEUM & CHEM CORP +1

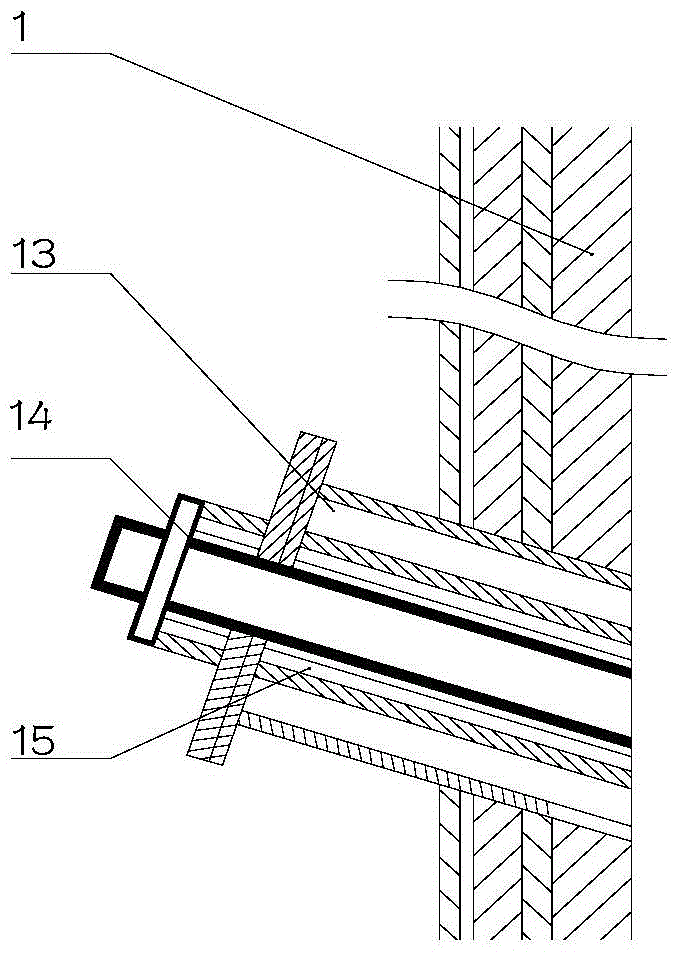

A sewage treatment and purification integrated device for municipal sewage pipe network

ActiveCN111995165BReduce filter timeLarge water flowTreatment using aerobic processesSpecific water treatment objectivesEngineeringMunicipal sewage

The invention discloses a sewage treatment and purification integrated device for a municipal sewage pipe network, which comprises a main body component, a sewage filter component, a drive component, a pressurization component and an aeration component. 2. Outlet pipe, connecting column, filter box and rectangular piston pipe, and the reaction box is arranged obliquely. In the present invention, since the adjacent "several" characters on the rotating rod are opposed to each other, that is, the movement track of the piston inside the adjacent rectangular piston pipe is one up and one down, and the sewage discharged from the municipal sewage branch conduit can be introduced into the sewage due to the setting of the guide plate. The filter cavity on the side away from the sludge storage box, the sewage enters the funnel-shaped groove through the filter screen one by one, and the sludge on the filter screen is in the process of the piston plate moving up and down and under the action of gravity, so that the sludge is collected towards the sludge The tank moves on one side, and finally discharged into the sludge storage tank and then discharged through the sewage pipe, reducing the sludge production and subsequent treatment costs.

Owner:ANHUI POLYTECHNIC UNIV

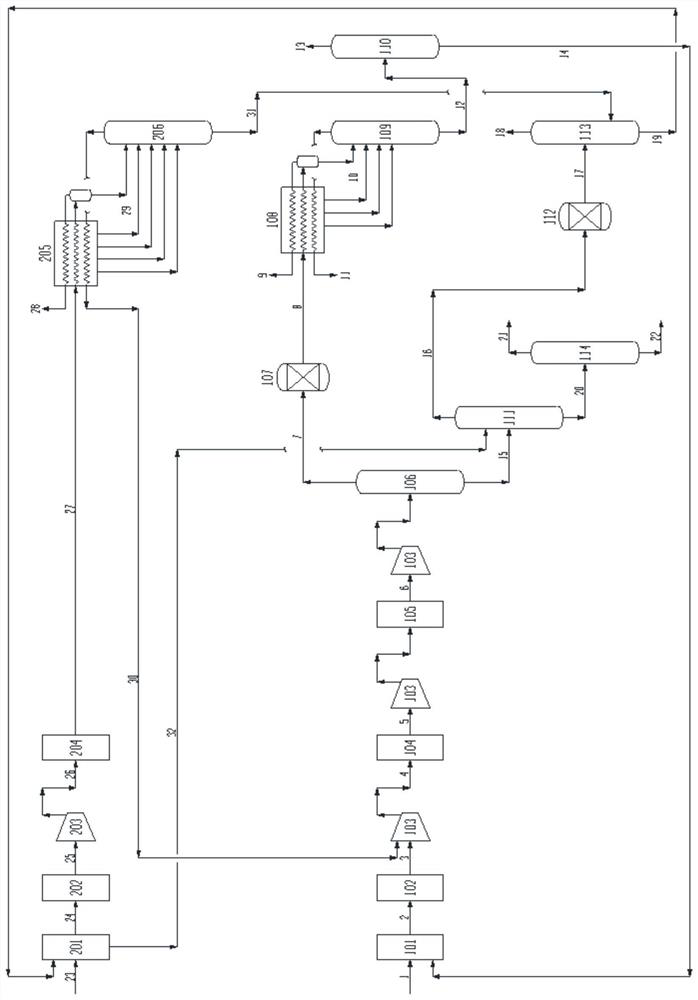

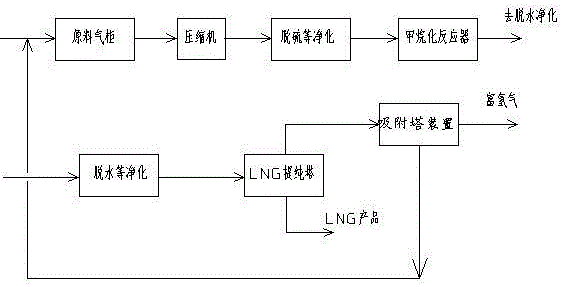

A method of improving the recovery rate of liquefied natural gas

ActiveCN104357118BHigh recovery rateReduce methane contentGaseous fuelsDispersed particle separationRecovery methodTower

The invention relates to the field of liquefied natural gases, and in particular to a method for recycling methane from an uncondensed gas of a liquefied natural gas purifying column by using a pressure swing adsorption method so as to increase the recycling rate of methane in the liquefied natural gas. According to the method, a raw material gas conveying pipe, the liquefied natural gas purifying column, the uncondensed gas discharged from the liquefied natural gas purifying column, and an adsorption tower are included. The method is characterized by comprising the following steps: adsorbing, vacuuming and increasing the pressure of the uncondensed gas, thereby obtaining a methane-rich gas, feeding back the methane-rich gas to the raw material gas conveying pipe or the liquefied natural gas purifying column to be recycled, adjusting the adsorption time so as to control the content of methane in a waste gas adsorbed by a pressure swing adsorption device, and achieving the purpose of increasing the recycling rate of methane of the liquefied natural gas purifying column. The method is simple to operate, the cost is reduced, the energy consumption is reduced, and the recycling rate of the liquefied natural gas is greater than 99.8%.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

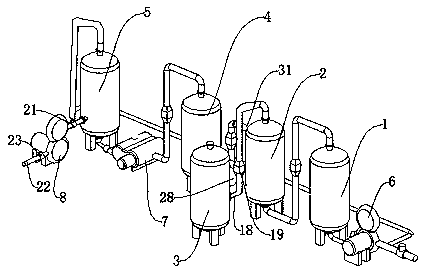

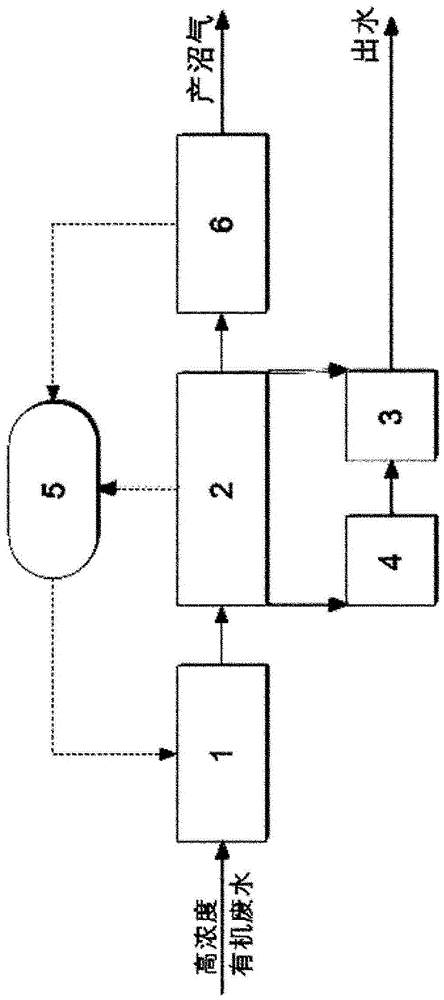

Two-phase anaerobic tubular membrane bioreactor treatment method and device for organic wastewater

ActiveCN104478172BEasy maintenanceShort processWater treatment parameter controlSpecific water treatment objectivesHigh concentrationGeneration rate

The invention discloses a method for treating organic wastewater with a two-phase anaerobic tubular membrane bioreactor. The method comprises the following steps of: adding anaerobic digested sludge into an up-flow complex acid-production reactor and a completely mixed methane-production reactor in an inoculating way; enabling organic wastewater to flow through all reaction chambers in the up-flow complex acid-production reactor in sequence and enter the completely mixed methane-production reactor, and adding wastewater into the completely mixed methane-production reactor by controlling the gas generation rate and the pH value; enabling a methane-phase mixed solution in the completely mixed methane-production reactor to scour the inner side of a tubular membrane component and flow back to the completely mixed methane-production reactor in a circulating way so as to be mixed hydraulically; separating the methane-phase mixed solution by using the membrane component to obtain effluent and methane gas; and collecting the methane gas at the methane gas outlet of the completely mixed methane-production reactor. The invention further discloses a device for implementing the method. The method and the device can be used for treating high-concentration organic wastewater so that the organic wastewater reaches the standard in a short process, and the method and the device can be also used for treating low-concentration organic wastewater so that the discharge of methane dissolved in effluent as a greenhouse gas can be reduced.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Fluidized bed gasifier and its application

ActiveCN104629810BWide adaptability of coal typesGuaranteed uptimeGasification processes detailsGasification apparatus detailsFluidized bed gasifierFluidized bed

Owner:南京科立科盈科技有限公司

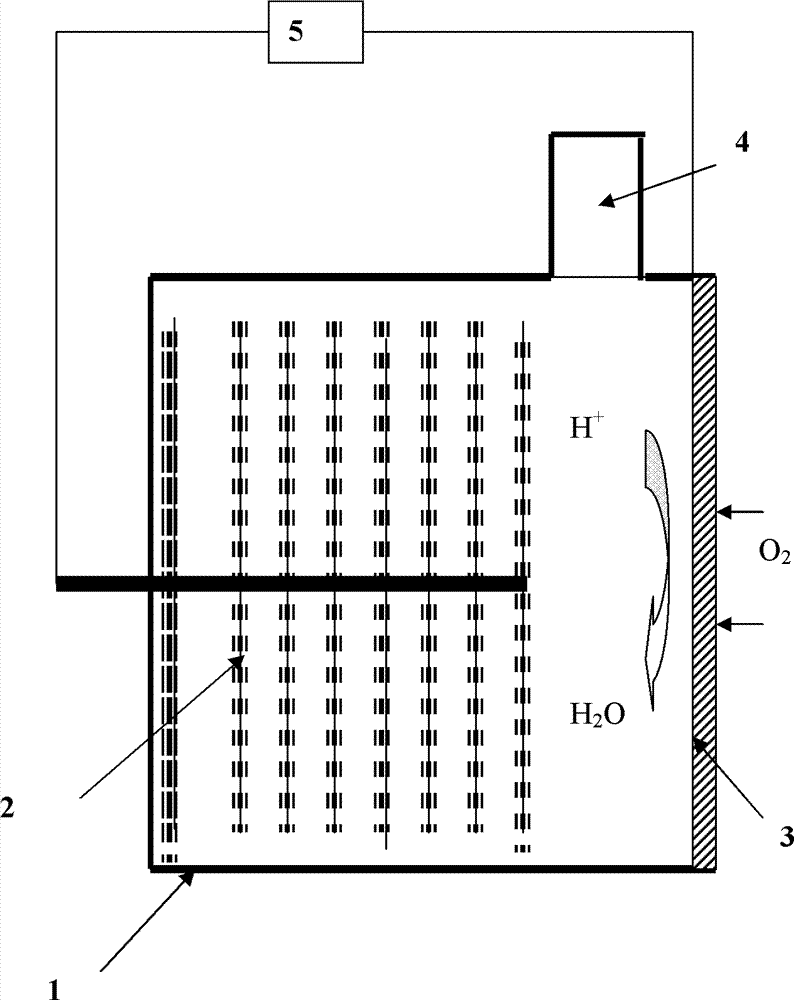

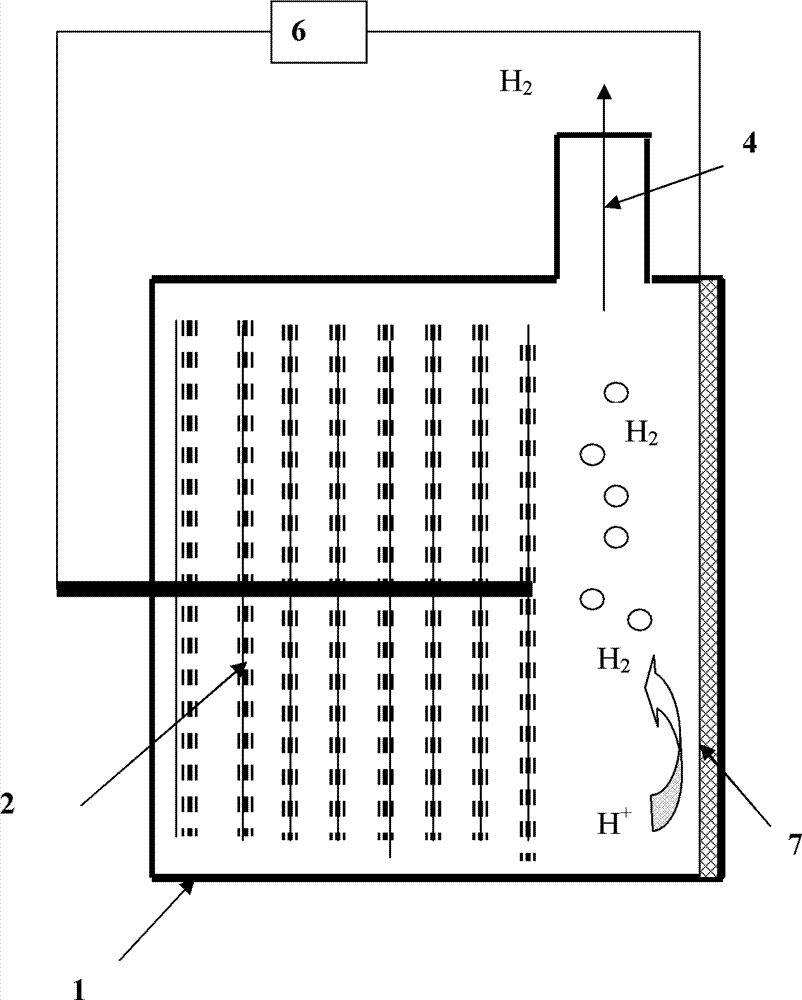

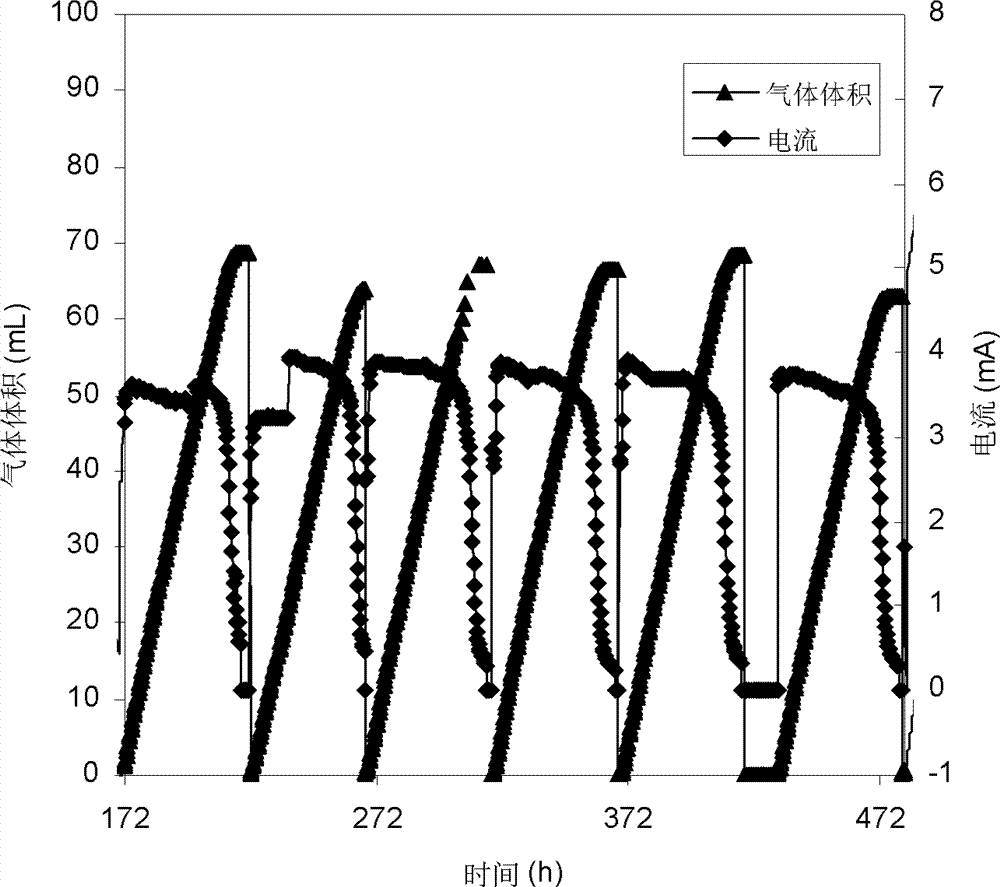

Method for producing hydrogen by alkalescent microbe electrolysis

InactiveCN102400169BInhibitionReduce methane contentWater/sewage treatmentEnergy based wastewater treatmentGeneration rateBatch operation

The invention belongs to the technical field of microbe electrochemistry and aims to provide a method for producing hydrogen by alkalescent microbe electrolysis. The method comprises steps of: (1) starting an electrolytic bath under a microbiological fuel cell mode: accessing a resistor in a closed-loop of a system and replacing a solution in the electrolytic bath when a voltage is low; continuing to replace until voltages at two ends of the resistor are higher than 500mV to finish anode starting; (2) producing hydrogen under a microbe electrolytic bath mode: replacing a cathode in the started electrolytic bath with stainless steel net or foamed nickel, keeping solution in the whole electrolytic bath in a anaerobic state and applying 0.4-0.8 V voltage at two ends of the cathode and the anode by using direct-current power supply and realizing hydrogen production of the electrolytic bath at 20-35 DEG C. The invention can effectively inhibit generation of methane, realize long time continuous operation or multiple batch operation and generate gas with low methane content; the method has a low cost and can obtain high hydrogen generation rate; utilization rate of organic matter under an alkalescent environment is increased, and hydrogen generation stability of the system is increased.

Owner:ZHEJIANG UNIV

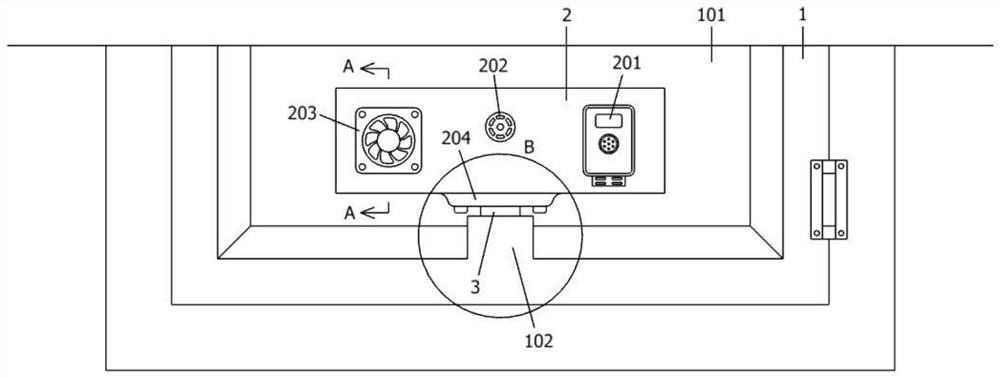

Intelligent door and window based on intelligent research and development and capable of being automatically sensed by environment

PendingCN114320128AAvoid wastingReduce methane contentVentilation arrangementPump controlControl engineeringComputer science

The invention provides an intelligent door and window based on intelligent research and development and capable of being automatically sensed by the environment, relates to the technical field of intelligent doors and windows, and solves the problems that an existing intelligent door and window is only capable of monitoring the methane content singly, and if the door and window are in an open state, the methane content must be lower than a set limit value; when the environment automatic induction function is in a starting state or a closing state, the environment automatic induction function is not influenced, and at the moment, the environment automatic induction function is always in the starting state, a large amount of electric power resources are consumed, and excessive waste is caused. An intelligent door and window capable of being automatically sensed by the environment based on intelligent research and development comprises an intelligent sensing shell, the intelligent sensing shell is of a rectangular block structure, and the intelligent sensing shell is fixedly installed on transparent glass. When the door and window body is not closed, the environment automatic induction mode is not started, and waste of electric power resources is avoided.

Owner:徐州泰和门窗有限公司

Method for separating and purifying CO from water gas by pressure swing adsorption

InactiveCN102080000BReduce the loss of effective componentsReduce methane contentDispersed particle separationGas purification with selectively adsorptive solidsGas compressorProduct gas

Owner:甘肃银光聚银化工有限公司 +1

A Two-Stage Concentration PSA Method for Recovering C2+ from Refinery Dry Gas

ActiveCN107433107BBreak adsorption equilibriumReduce methane contentProductsGas treatmentPhysical chemistryExhaust fumes

The invention discloses a two-stage PSA method for recovering C2+ from refinery dry gas according to concentration, which relates to the technical field of separating and recovery of in valuable substances in petrochemical tail gas. The method comprises a pretreatment process, a C2+ adsorption concentration process, an intermediate purifying process, and a C2+ adsorption refining process, wherein, the pre-treated refinery mixed dry gas is introduced into the CO2+ adsorption concentration process, then flowed non-adsorption phase gas is the adsorption exhaust gas, or directly taken as hydrogen (H2) product gas, or taken as fuel gas, or taken as raw material gas for extraction of hydrogen for output; the flowed adsorption phase gas forms the intermediate gas through the intermediate purifying process, and then is introduced into the C2+ adsorption refining process for refining, the flowed non-adsorption phase gas is taken as the raw material gas for mixing with the refinery mixed dry gas, a mixture is returned to the C2+ adsorption concentration process; the flowed adsorption phase gas has the C2+ concentration being more than 90-95% (a volume ratio), wherein the methane impurity concentration is less than 4%, the flowed adsorption phase gas is taken as the C2+ concentrate product gas for output, and the yield of C2+ is more than 90-95%.

Owner:SICHUAN TECHAIRS

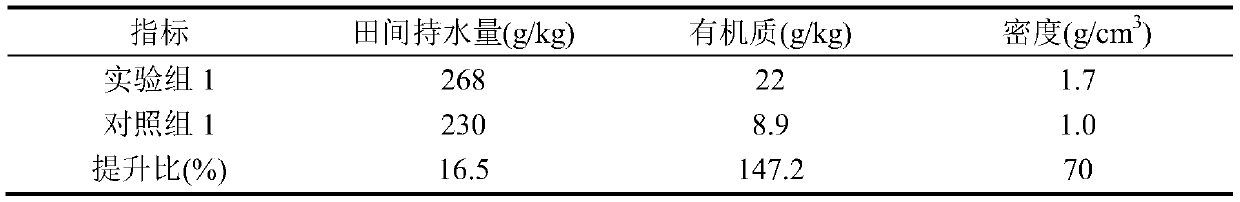

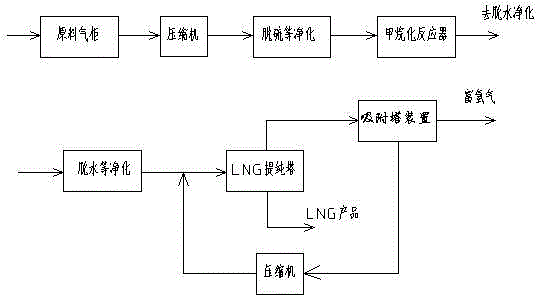

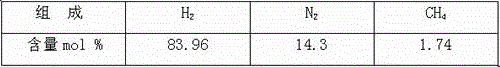

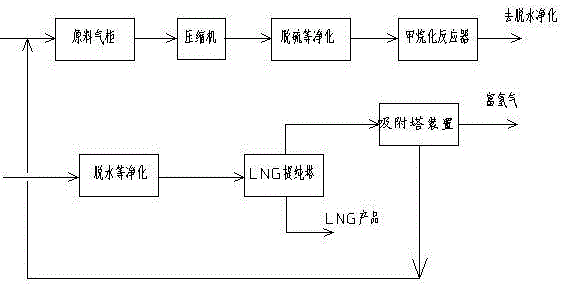

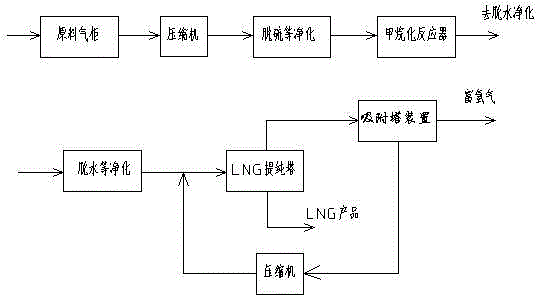

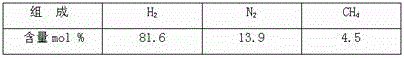

A system for improving the recovery rate of liquefied natural gas

The invention discloses a system for improving liquefied natural gas recovery rate and relates to the field of liquefied natural gas production. The system comprises a raw material gas conveying pipe, a compressor, a methanation reactor, a liquefied natural gas purification tower and pipelines, and the system is characterized by being further provided with a pressure swing adsorption device which is provided with a pressure swing adsorption tower, wherein the raw material gas conveying pipe is connected with the compressor, the compressor is connected with the methanation reactor, the methanation reactor is connected with the liquefied natural gas purification tower which is connected with the pressure swing adsorption tower, the pressure swing adsorption tower is connected with the raw material gas conveying pipe or the liquefied natural gas purification tower, and the devices are communicated by virtue of corresponding pipelines. The system disclosed by the invention is simple to operate and cost-saving, the energy consumption is reduced, and the recovery rate of the liquefied natural gas can reach over 99.8%.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com