A method of improving the recovery rate of liquefied natural gas

A technology for liquefied natural gas and recovery rate, applied in chemical instruments and methods, separation methods, gas fuels, etc., can solve the problem of failing to improve the methane recovery rate of LNG, reduce the methane recovery rate of liquefied natural gas plants, and reduce the methane recovery rate. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

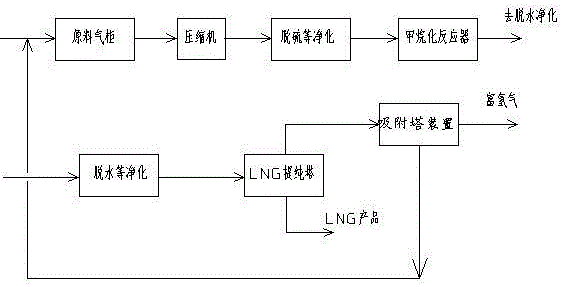

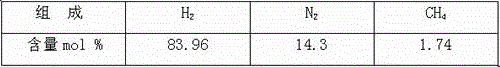

Embodiment 1

[0032] This embodiment is a device for producing liquefied natural gas by using coke oven gas as raw material through methanation, and the output of liquefied natural gas is 100,000 tons / year. In the embodiment, the coke oven gas enters the methanation conversion reactor after being desulfurized and purified. In the methanation reactor, carbon monoxide, carbon dioxide and hydrogen react to form methane, and the gas after the methanation reaction is purified to remove water, trace carbon dioxide and Mercury and other impurities enter the low-temperature purification tower of liquefied natural gas. The low-temperature purification tower adopts MRC refrigerant cycle refrigeration and liquid nitrogen refrigerant dual refrigerant cycle refrigeration to reduce the temperature at the top of the purification tower and increase the methane recovery rate. In this case, methane recovery The rate is 98.5%, the hydrogen-rich gas pressure at the top of the tower is 1.3Mpa, the methane conten...

Embodiment 2

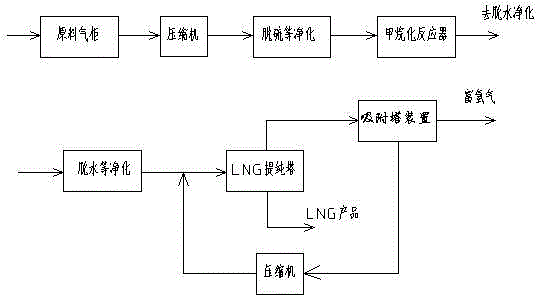

[0065] This embodiment is a device for producing liquefied natural gas (liquefied natural gas) by using coke oven gas as raw material through methanation, and the output of liquefied natural gas is 80,000 tons / year. In the embodiment, the coke oven gas enters the methanation conversion reactor after being desulfurized and purified. In the methanation reactor, carbon monoxide, carbon dioxide and hydrogen react to form methane, and the gas after the methanation reaction is purified to remove water, trace carbon dioxide and Mercury and other impurities enter the liquefied natural gas low-temperature purification tower. The low-temperature purification tower adopts MRC refrigerant cycle refrigeration, the methane recovery rate is 96%, the hydrogen-rich gas pressure at the top of the tower is 1.3Mpa, and the methane content is 4.5%. The hydrogen-rich gas discharged from the top of the low-temperature purification tower of liquefied natural gas is introduced into the pressure swing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com