Patents

Literature

2229 results about "Coke oven gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coke-oven gas is a fuel gas having a medium calorific value that is produced during the manufacture of metallurgical coke by heating bituminous coal to temperatures of 900°C to 1000°C in a chamber from which air is excluded. The main constituents are, by volume, about 50% hydrogen, 30% methane and 3% higher hydrocarbons, 7% carbon monoxide, 3% carbon dioxide and 7% nitrogen.

Method for preparing hydrogen and LNG from coke oven gas

InactiveCN108179046ALow investment costLow running costHydrogenGaseous fuelsHigh concentrationSeparation technology

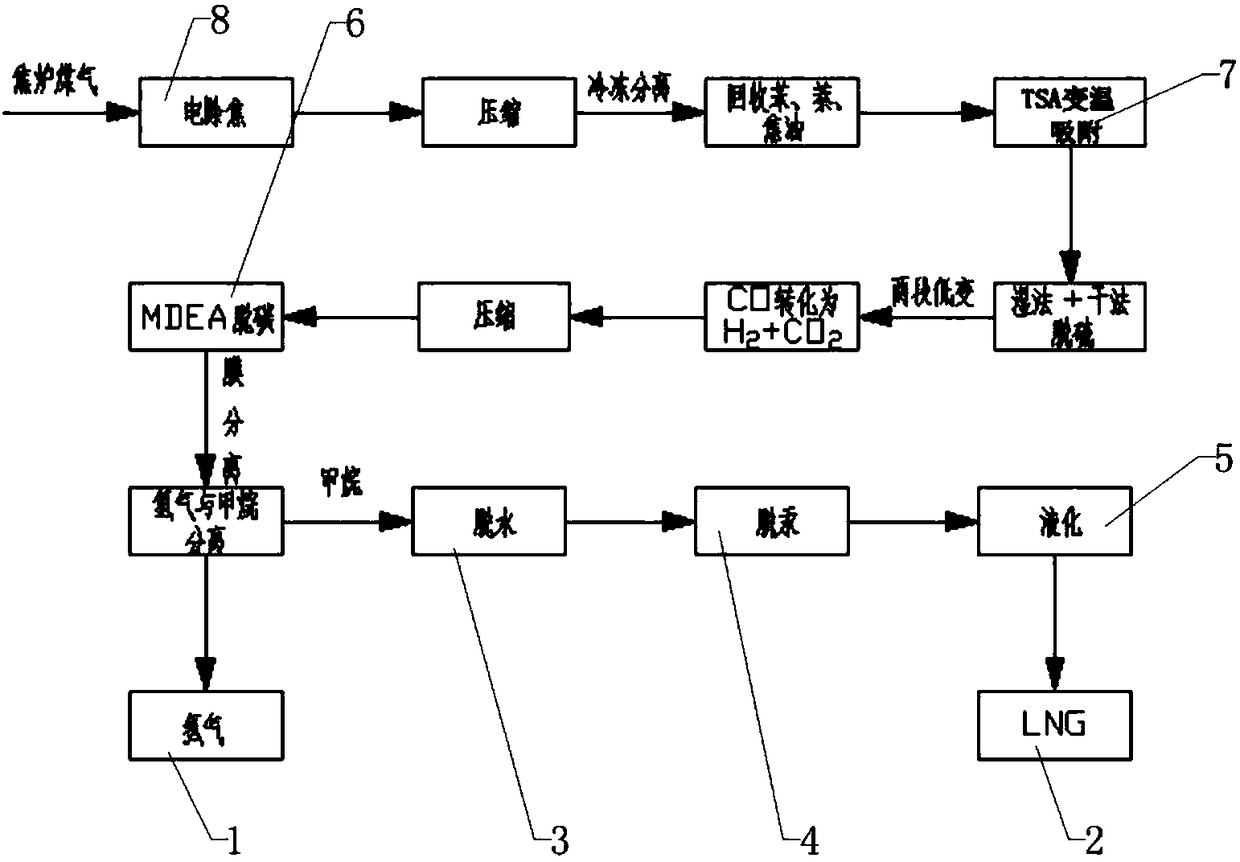

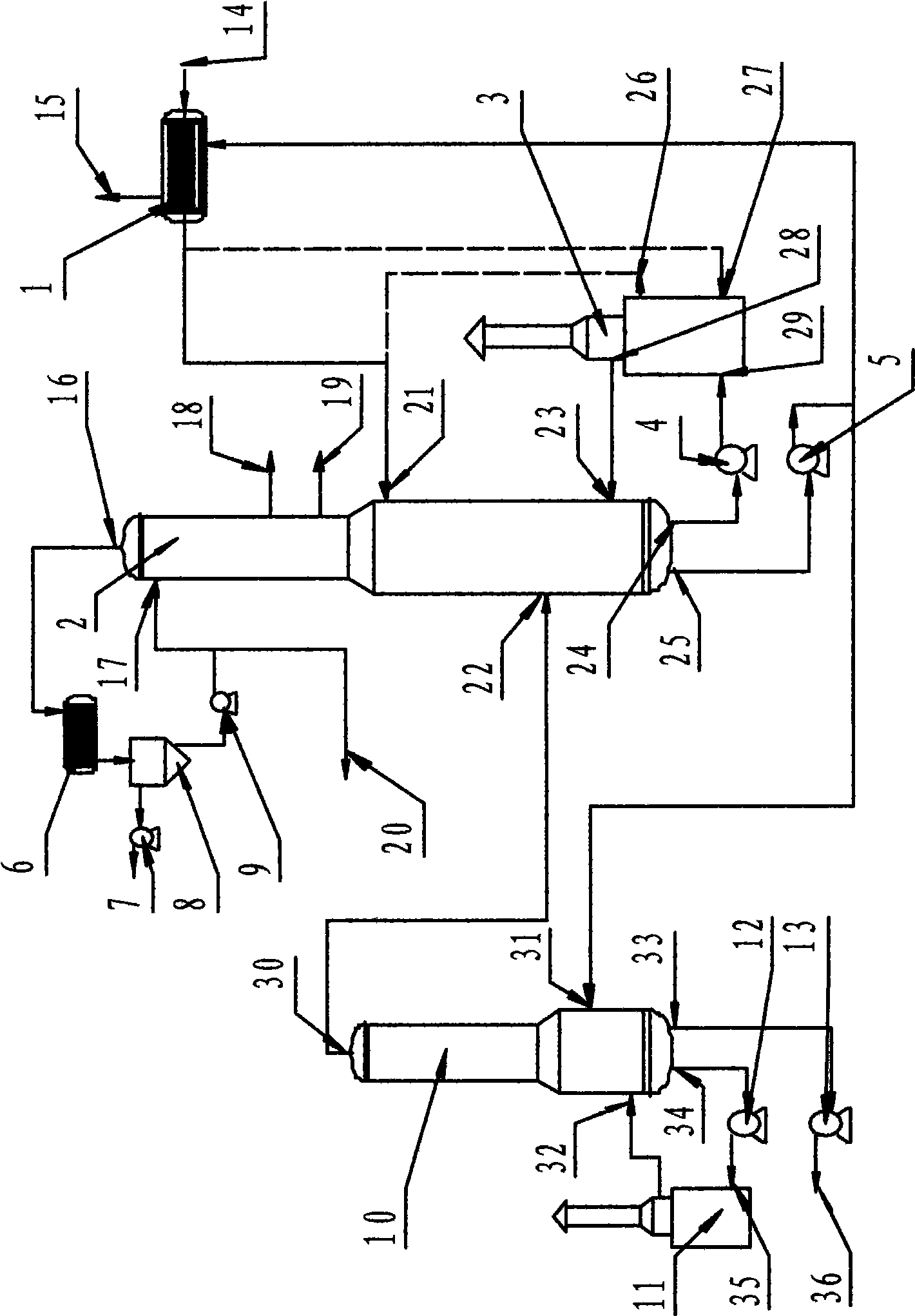

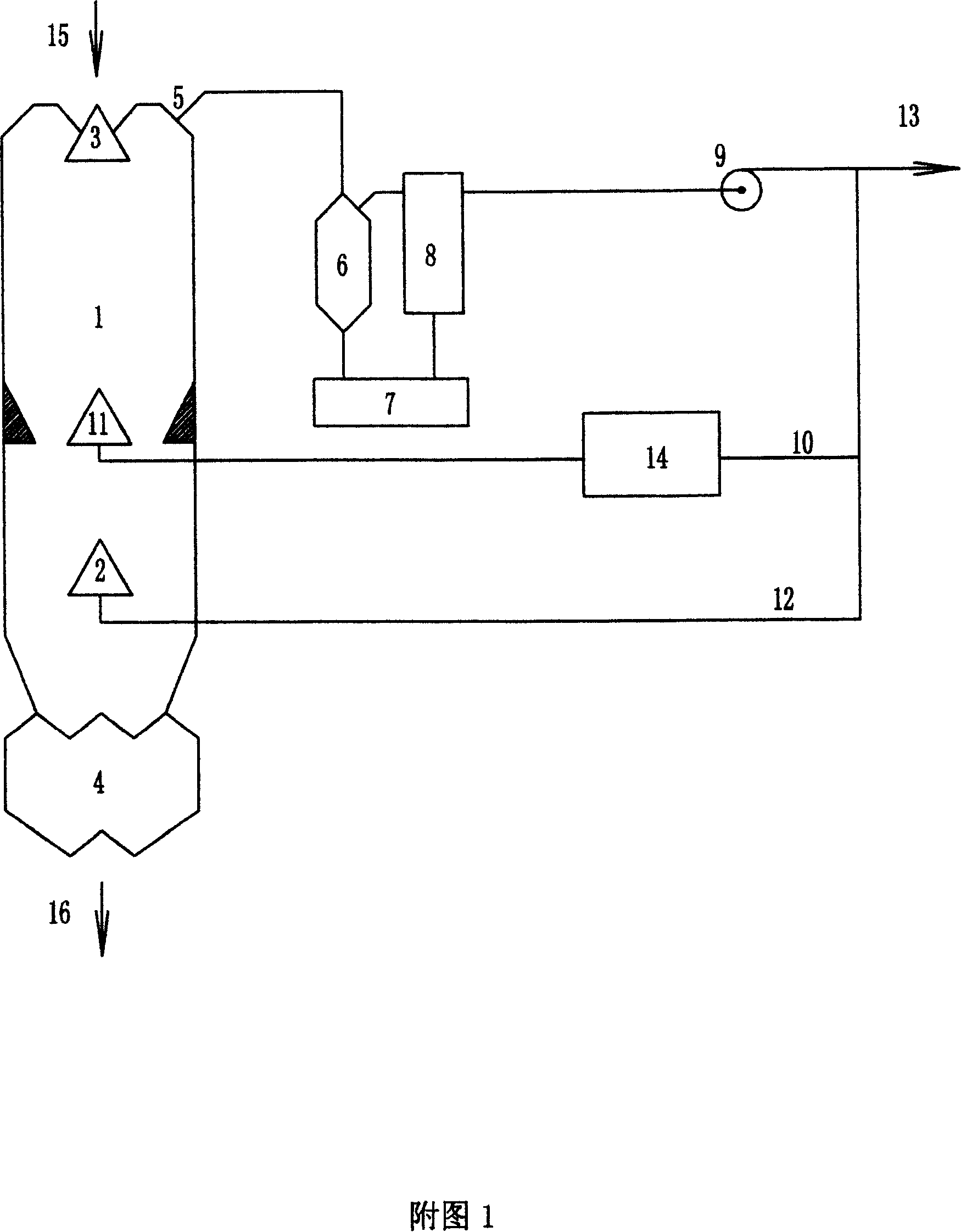

The invention provides a method for preparing hydrogen and LNG from coke oven gas. The method comprises the following steps: electric decoking; boosting of the coke oven gas by a compression system; cooling of the raw gas coke oven gas by using the BOG gas (the BOG gas is a gas formed after the passive heating gasification of LNG) of LNG in order to further remove tar, benzene, naphthalene and like substances in the coke oven gas; and pretreatment using a TSA process to finely remove macromolecular impurities, such as tar, benzene, naphthalene and the like; wet and dry two-stage desulfurization for removing sulfides in the coke oven gas; two-stage low pressure shifting for a reaction of CO and water vapor to form CO2 and hydrogen; and pressurization using a compressor, an MDEA solution process for removing carbon dioxide, a membrane separation technology for separating hydrogen and methane, separation, concentration and purification of the hydrogen and methane, and dehydration, demercuration and liquefaction of the separated high-concentration methane to obtain the LNG. The coke oven gas is finally converted into the hydrogen and the LNG which have high values, so the energy of thecoke oven gas is fully used, and the environment is protected.

Owner:SICHUAN HENGRI GAS ENG CO LTD

Coke-oven gas methanation catalyst and preparation method thereof

ActiveCN101391218AHigh activityImprove carbon resistanceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMethanationActive component

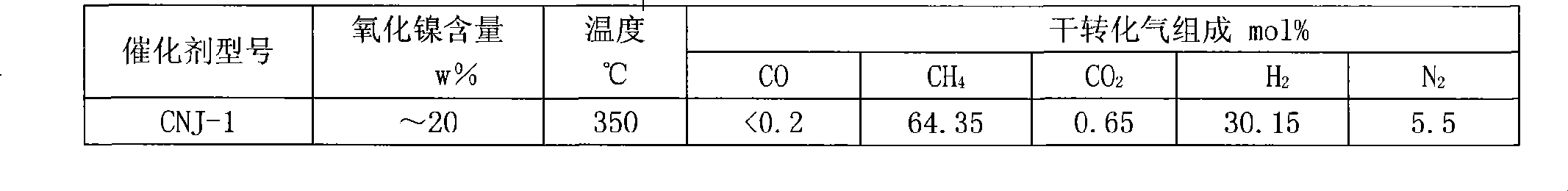

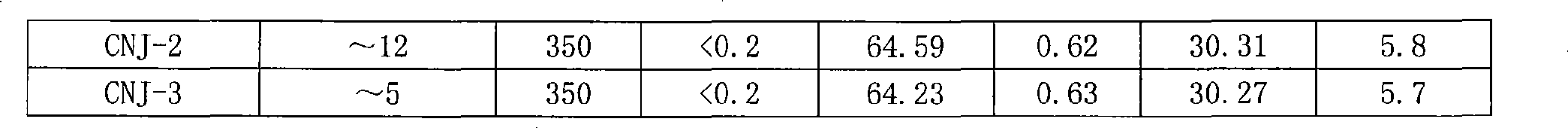

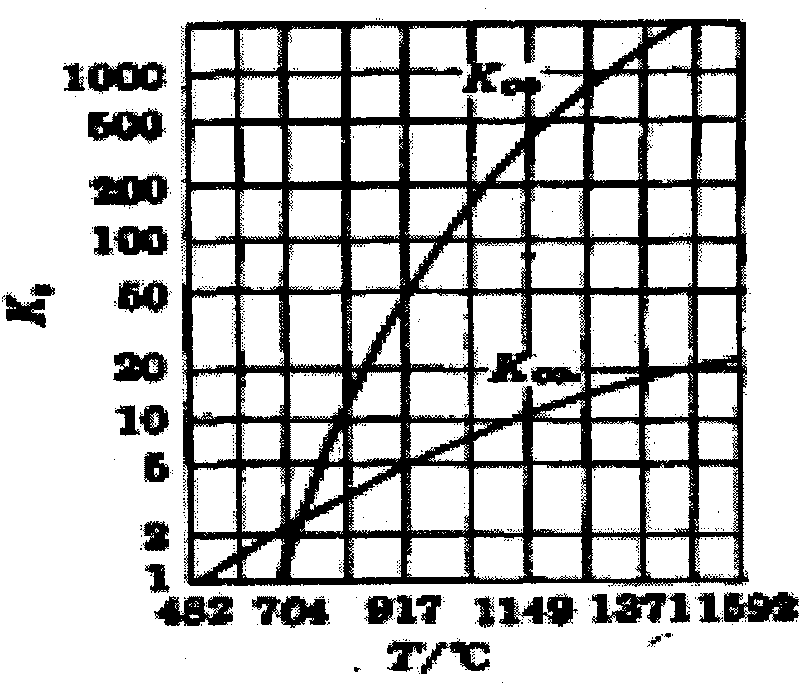

The invention discloses a coke oven gas methanation catalyst, which takes Al2O3 as a carrier, nickel as a main active component, and MgO as an auxiliary agent; wherein: the active component nickel exists in the catalyst in the form of NiO, and the carrier Al2O3 and the auxiliary agent MgO form a carrier structure of magnesia-alumina spinel; the main components respectively include, by weight percentage: 5 percent to 20 percent of NiO, 30 percent to 80 percent of Al2O3, and 1 percent to 50 percent of MgO. The catalyst has the advantages of high strength, good activity, good thermal stability, excellent anti-coking performance and good low temperature activity, and also has the properties of transforming high hydrocarbon and good anti-oxidation. The invention also discloses a preparation method of the coke oven gas methanation catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

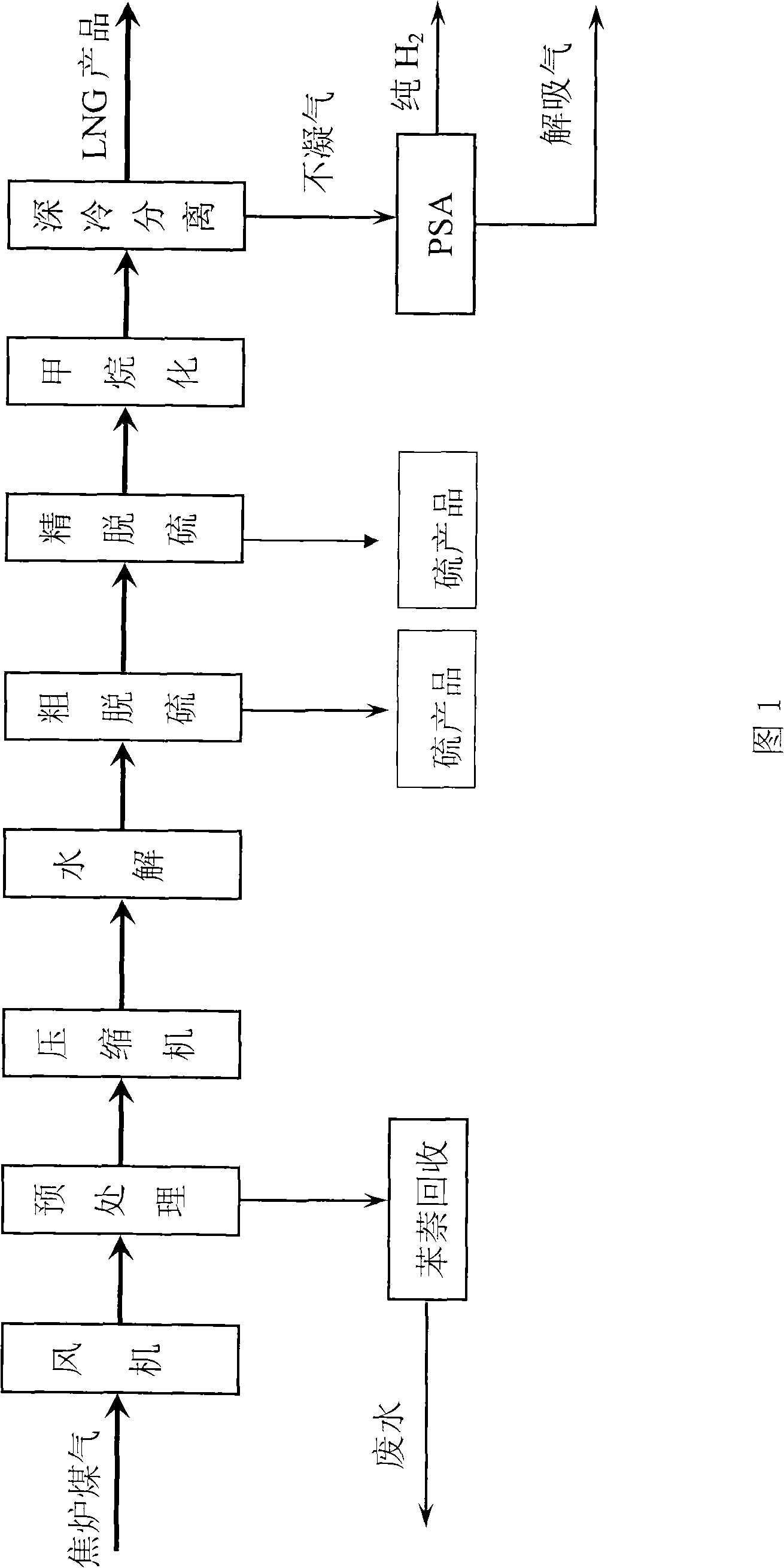

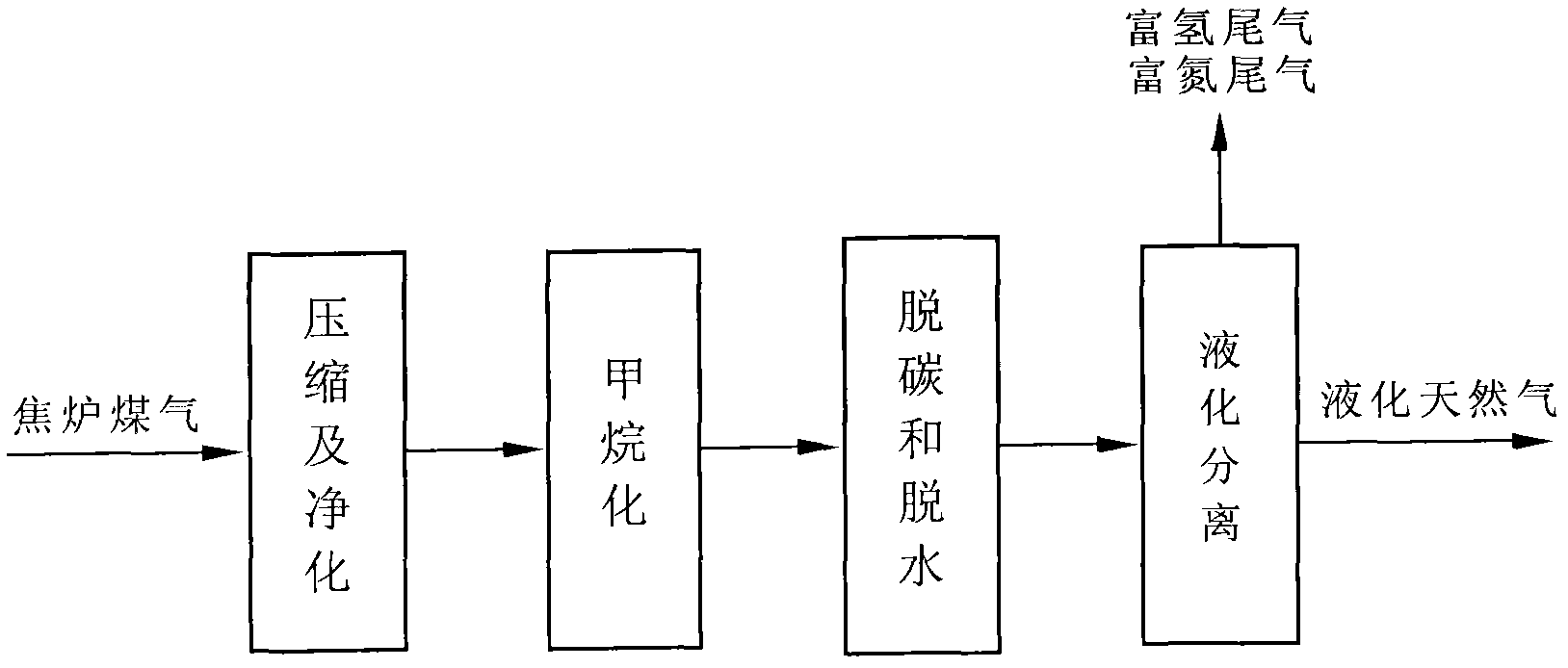

Method for preparing liquefied natural gas from coke oven gas

InactiveCN101280235ATo achieve coordinated developmentReasonable process combinationCombustible gas chemical modificationChemical industryMethanationImpurity

Disclosed is a method which uses coke-oven gas as the raw material to produce liquefied natural gas; the method includes that the coke-oven gas is pretreated firstly to enable the tar, naphthalene and benzene impurities contained in the coke-oven gas to be purified deeply; and the purified coke-oven gas is processed with methanation reaction after compression and desulfurization; the liquefied natural gas product which contains CH4 with the content of more than 85% through the cryogenic separation process; the residual non-condensable gas is prepared to obtain the hydrogen with the purity of 99% through the PSA separation technique; the residual desorbed gas can be used as manufactured gas. The method which uses the coke-oven gas as the raw material to produce liquefied natural gas has the advantages of making full use of the compositions, saving energy, water and the investment, simple process and realizing the trinity coordinated development of economy, environment and energy sources.

Owner:SHENGHE RESOURCES HLDG CO LTD

Method and device for synthesizing natural gas by using coke oven gas

A method for synthesizing and producing natural gas by hydrogen of coal gas and its synthesizer are disclosed. The process is carried out by purifying tar, crude removing sulfur, ammonia, benzene and naphthalene, compressing to 0.5-5.0 MPa, removing sulfur impurities, supplementing carbon 5-20 wt%, and methanation reacting to obtain final product. It saves energy resources and has no environmental pollution.

Owner:张文慧 +1

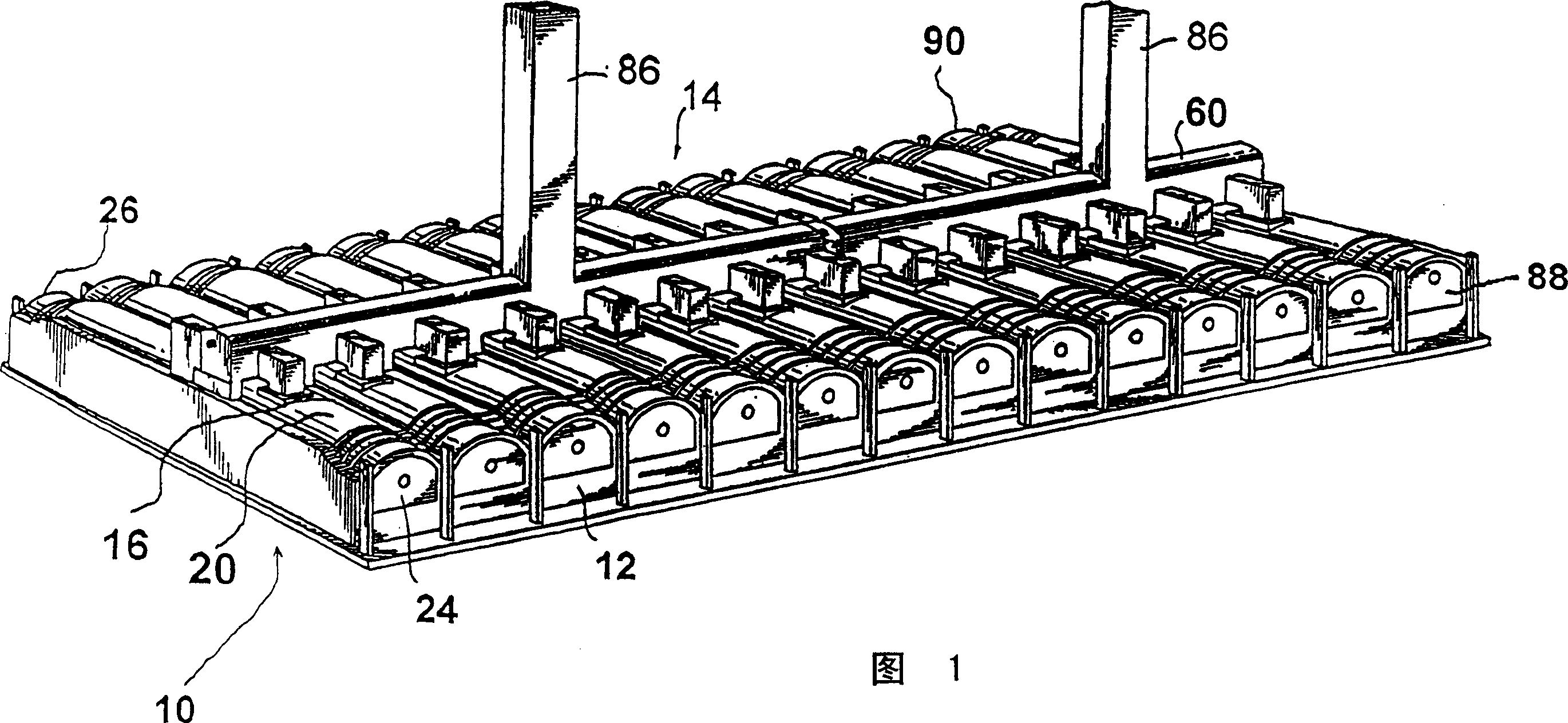

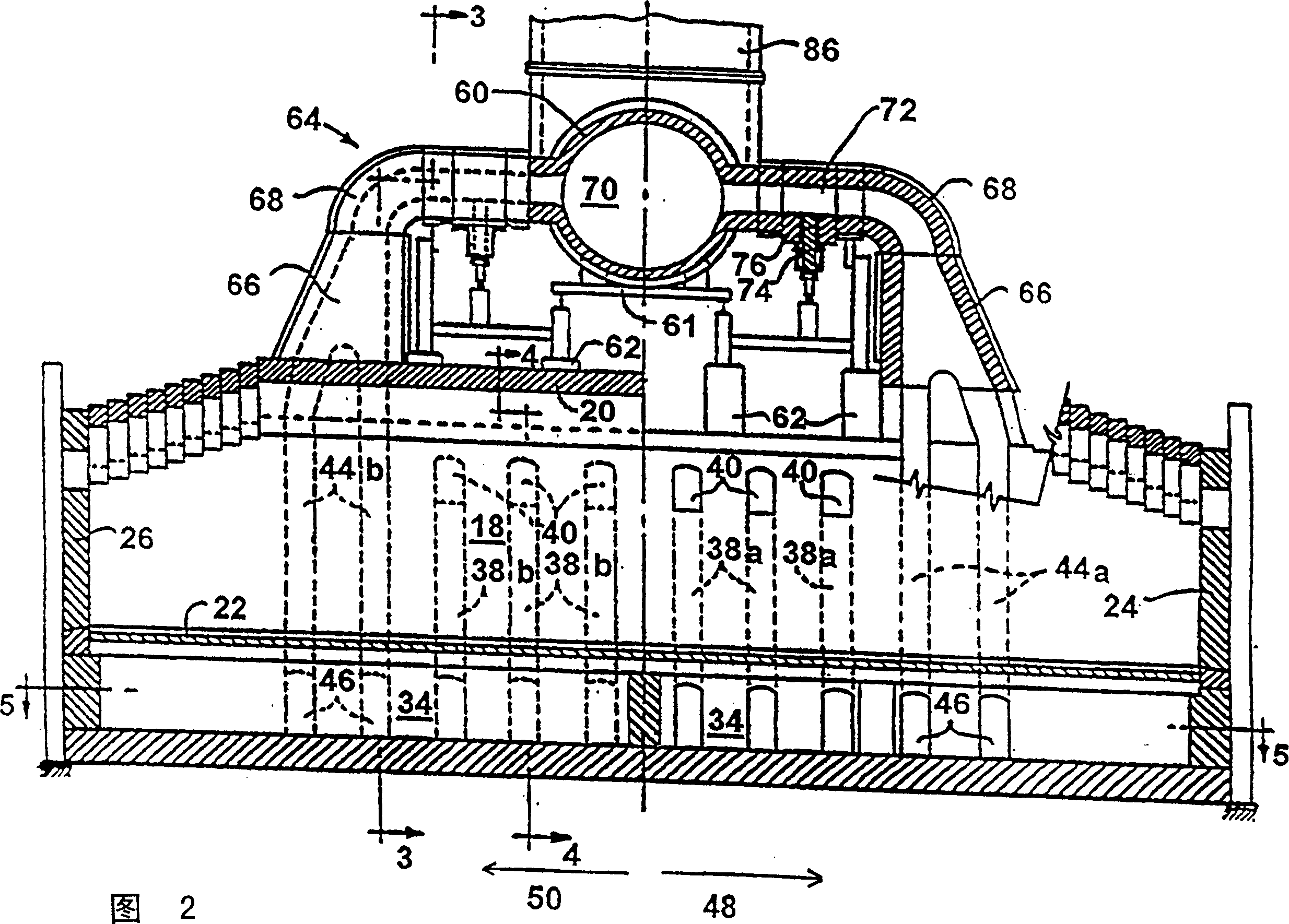

Coke oven flue gas sharing

InactiveCN1527872AExtend your lifeReduce the gas flow rateCombustible gas coke oven heatingBeehive ovensFlue gasProduct gas

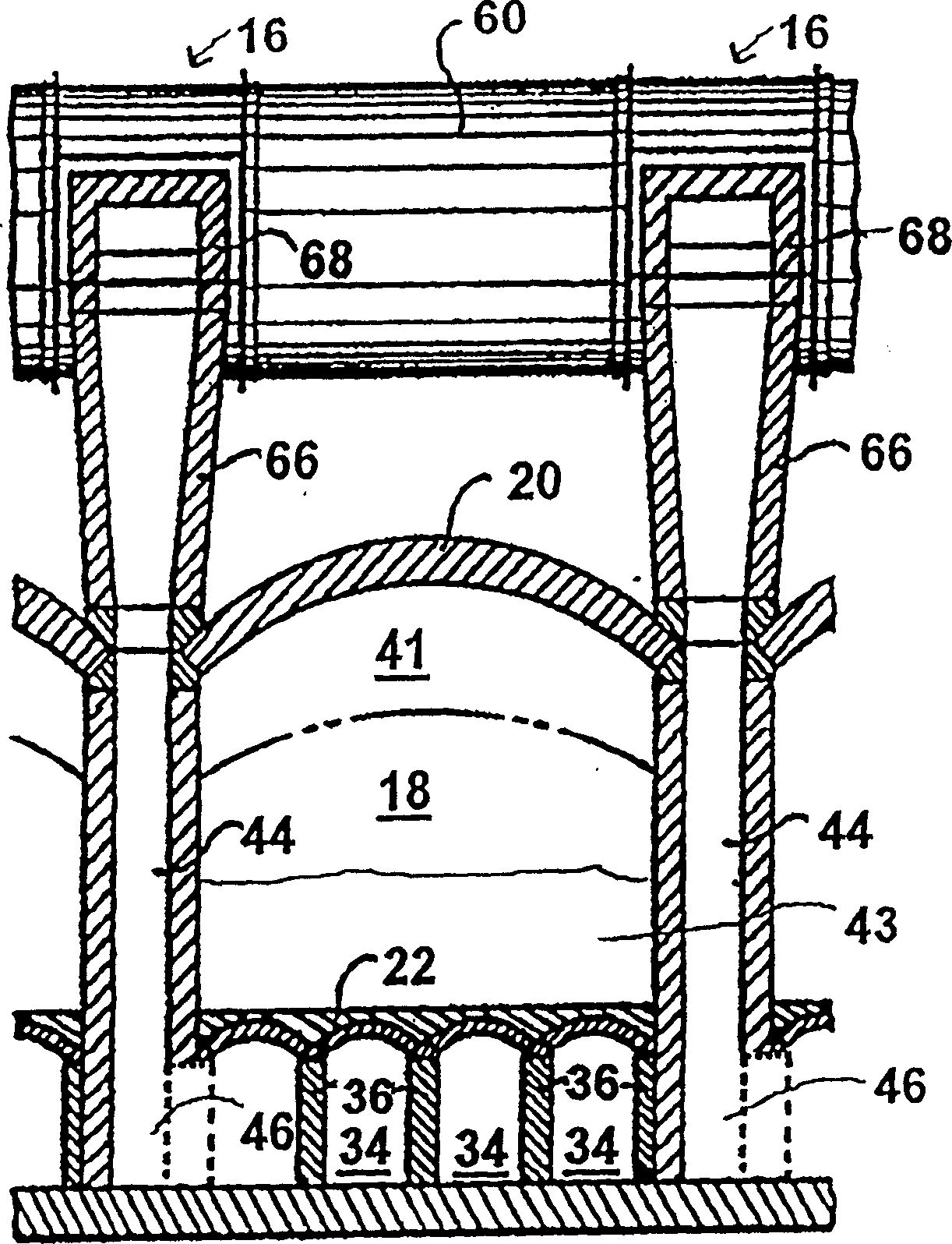

The invention provide a method and apparatus for decreasing gas flow rates in a sole flue gas system for a coke oven during at least an initial coking operation after charging a coking oven with coal (43). The method includes providing a duct system (96, 98) between a first coke oven having a first coking chamber (18) and a second coke oven having a second coking chamber (18) to direct at least a portion of gas from a gas space (41) in first coking chamber (18) to the second coke oven thereby reducing a gas flow rate in the first sole flue gas system of the first coke oven. Reduction in sole flue gas flow rates has a beneficial effect on product throughput, the life of the coke oven and environmental control of volatile emissions from coke ovens.

Owner:SUNCOKE TECH & DEV LLC

Method and apparatus for producing clean reducing gases from coke oven gas

InactiveUS20060027043A1Avoiding complex and expensiveOxygen/ozone/oxide/hydroxideHydrogen separationProcess engineeringCoke oven

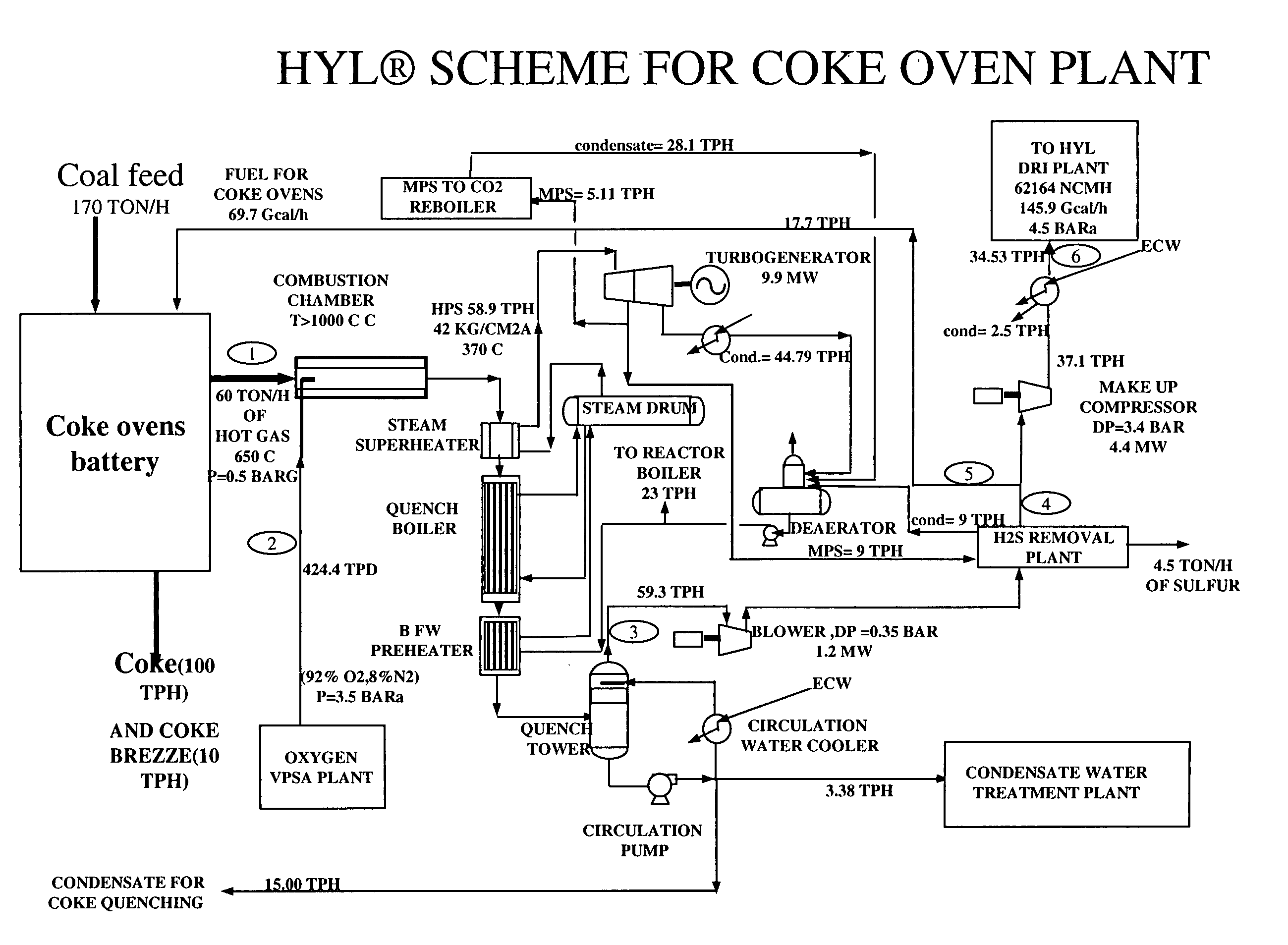

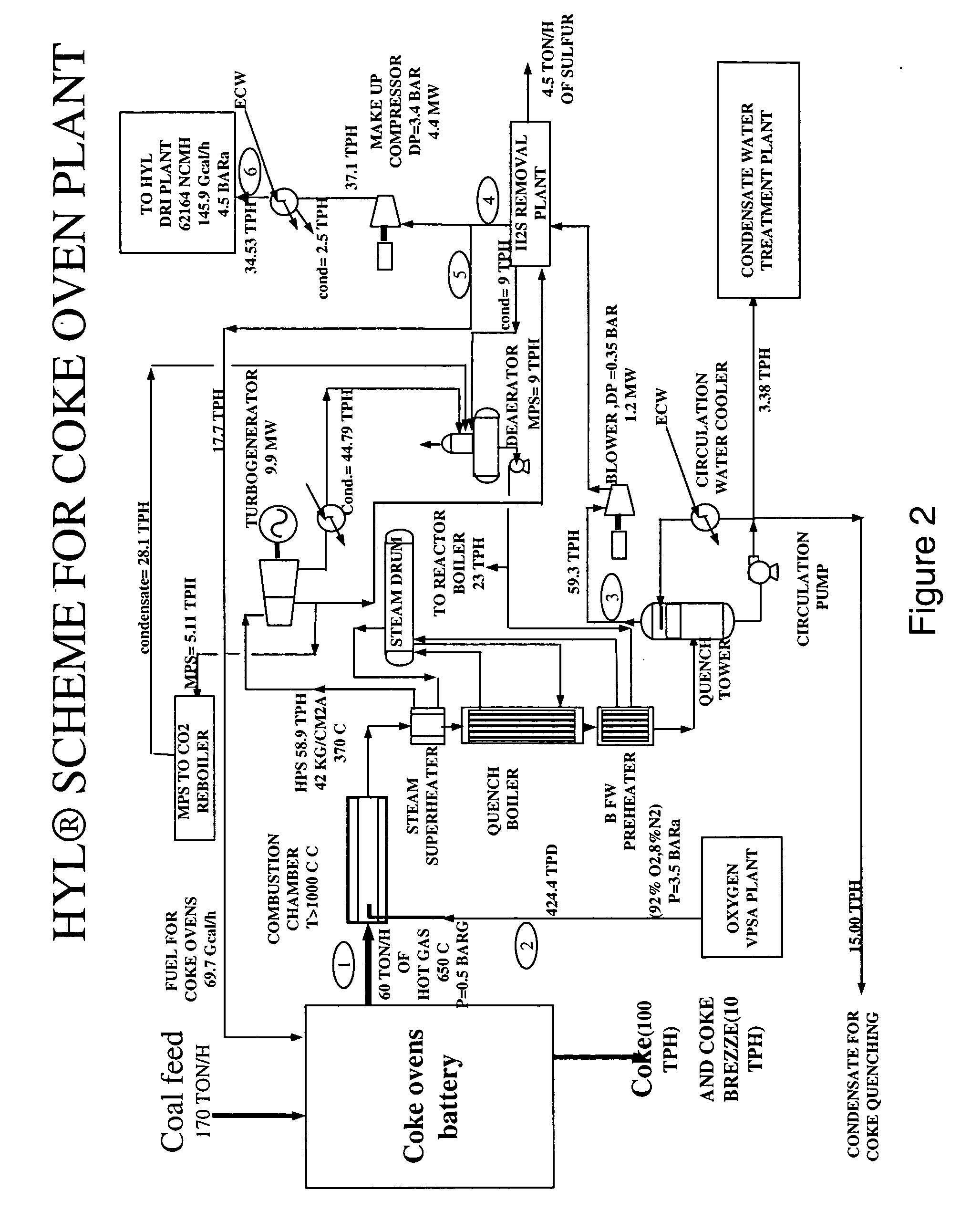

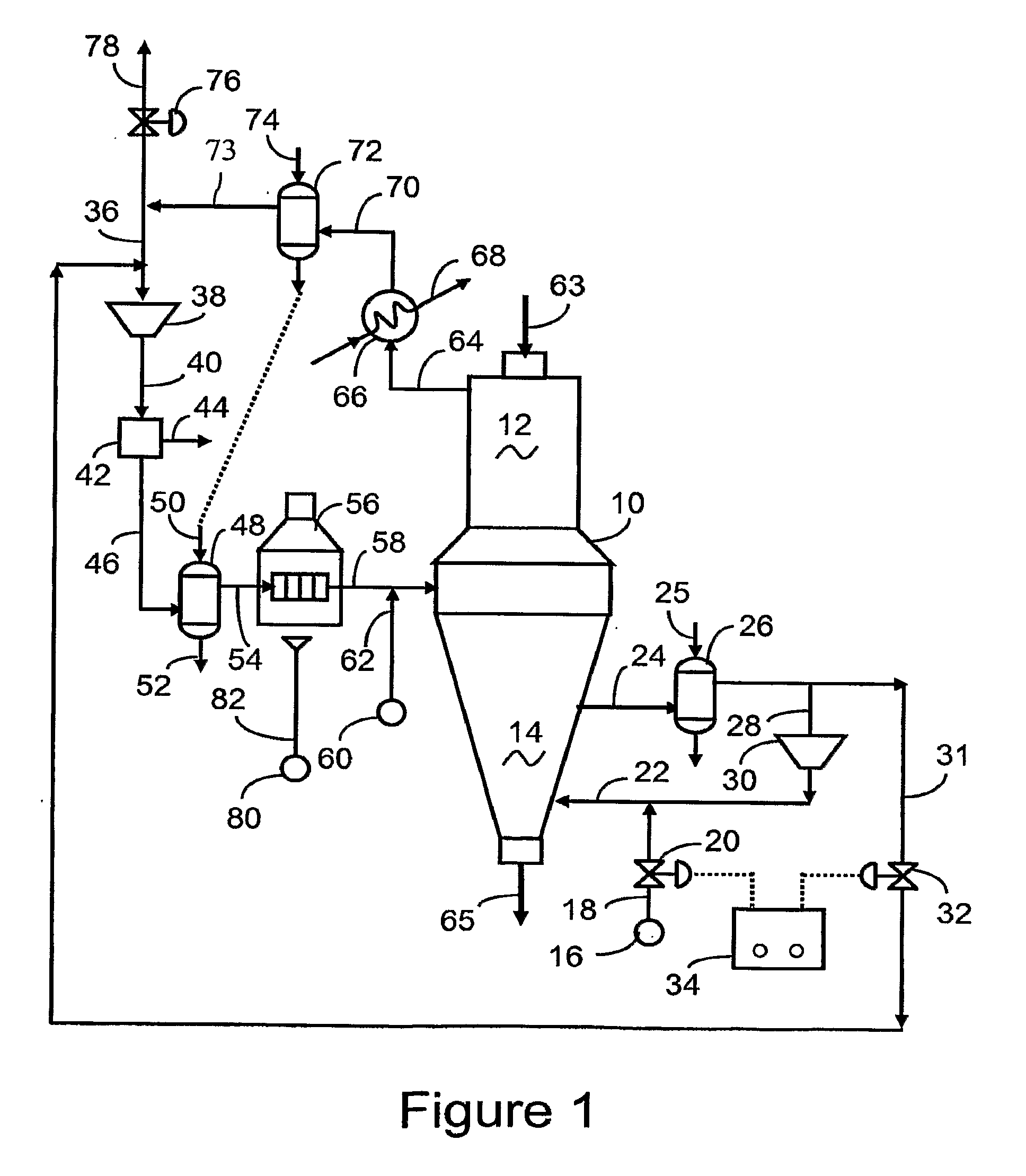

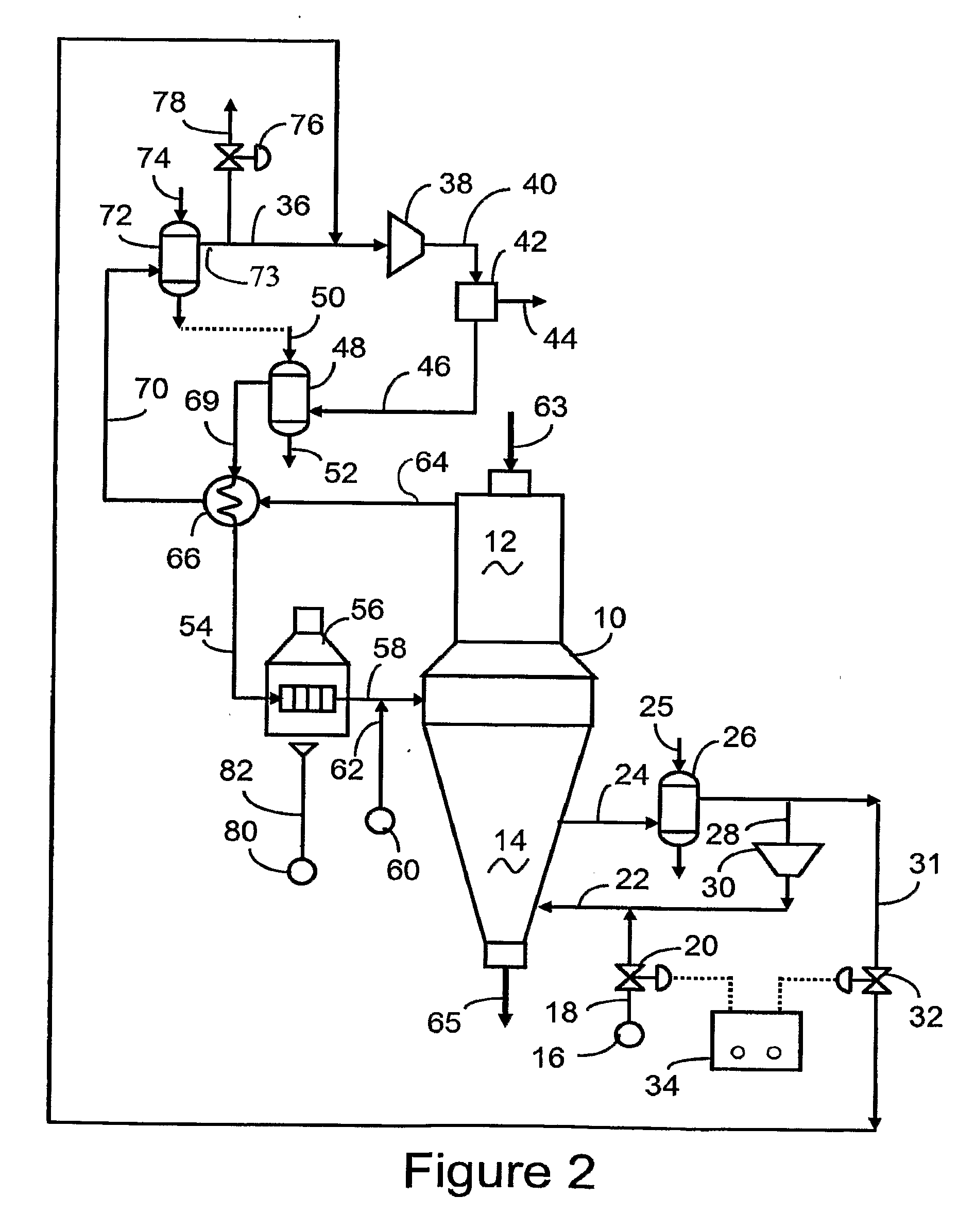

A process and system for producing reducing gases are disclosed, wherein volatile components derived from coal are transformed into reducing gases suitable for utilization as synthesis gas, as a reducing agent for the direct reduction of iron ores and / or as a clean fuel.

Owner:HYLSA SA DE CV

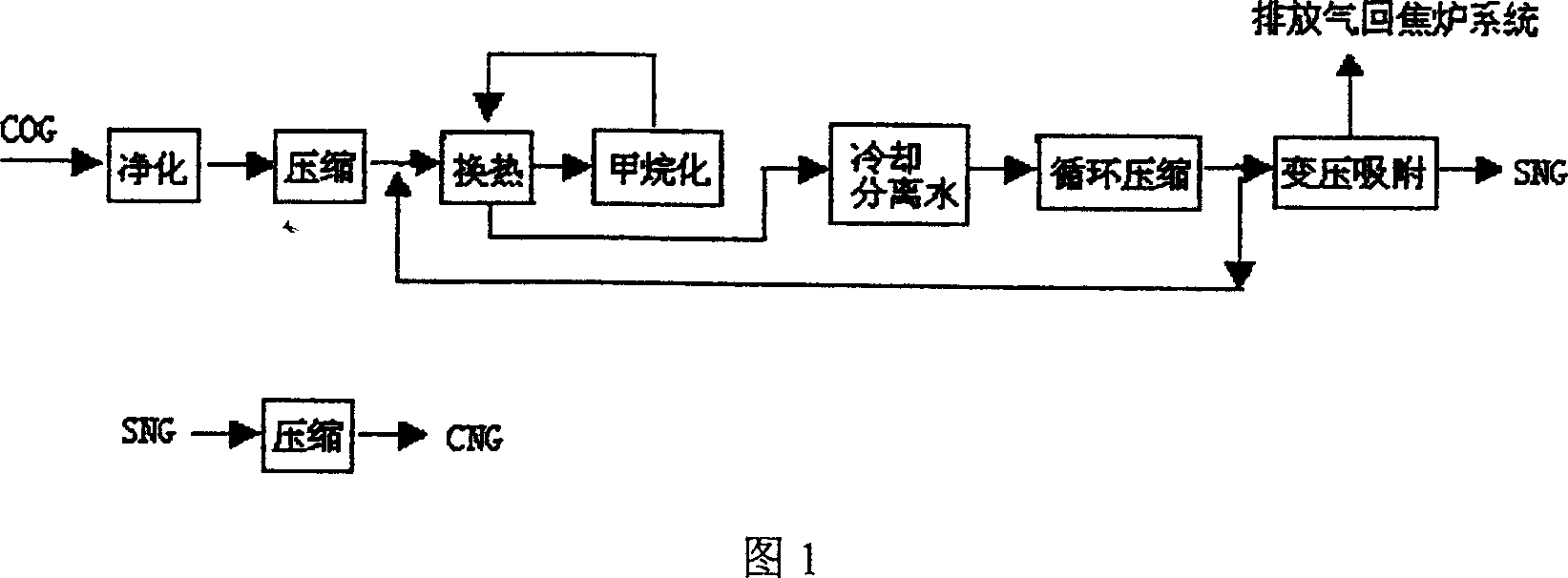

Method of preparing synthetic natural gas by coke oven gas

ActiveCN1919985AHigh calorific valueLow impurity contentGaseous fuelsCompressed natural gasMethanation

The invention discloses the method for producing natural gas with coking gas, comprising the following steps: purifying coking gas and removing benzene, naphthalene, hydrocarbon and sulphide, compressing, heat transferring, carrying out methanation reaction with catalyst, hydrogen in COG reacting with carbonic oxide and carbon dioxide to get methane; putting the mixture gas into pressure swing adsorbing device, and getting natural gas whose concentration is 90%. The natural gas has high caloric value, low impurity content.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

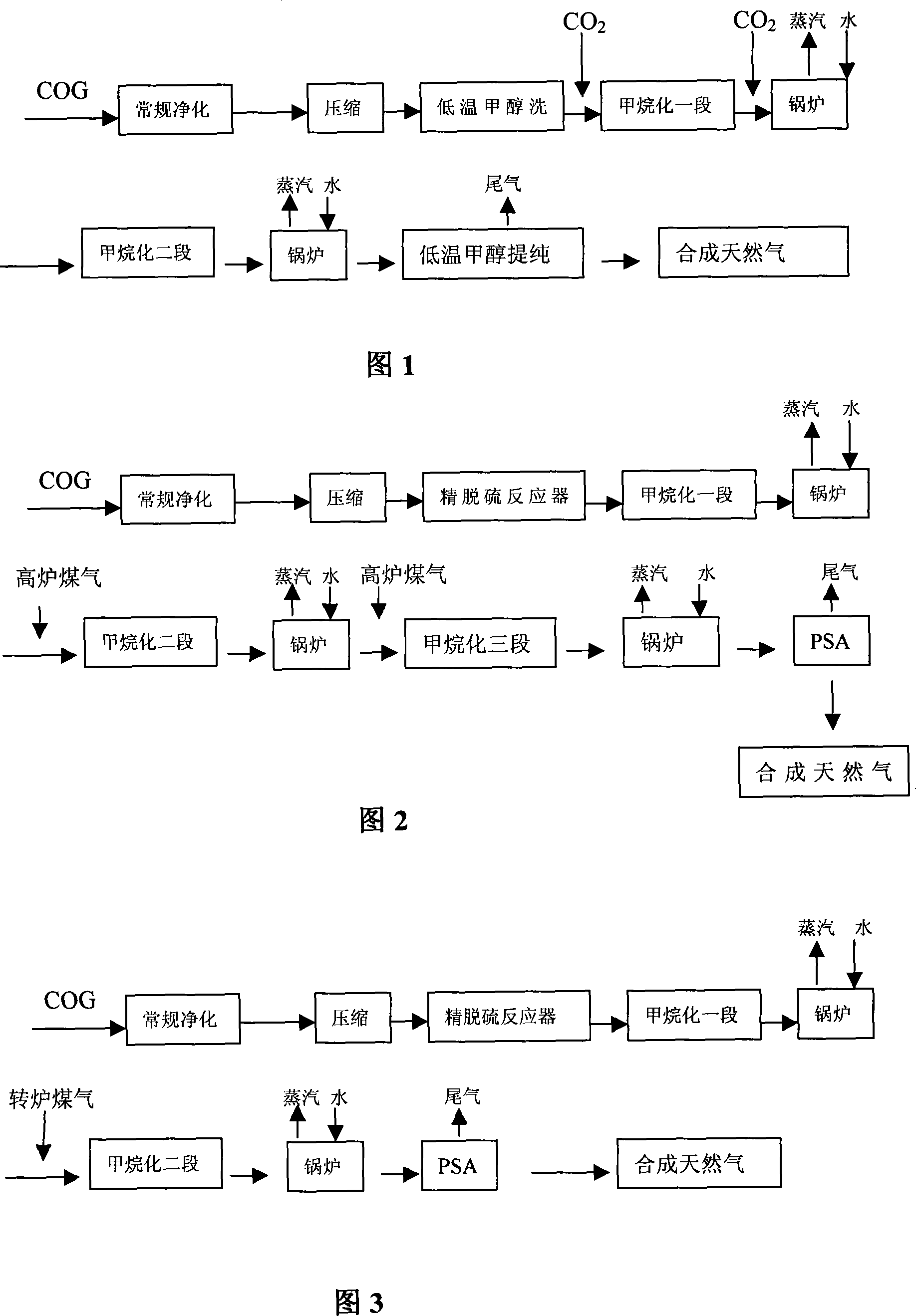

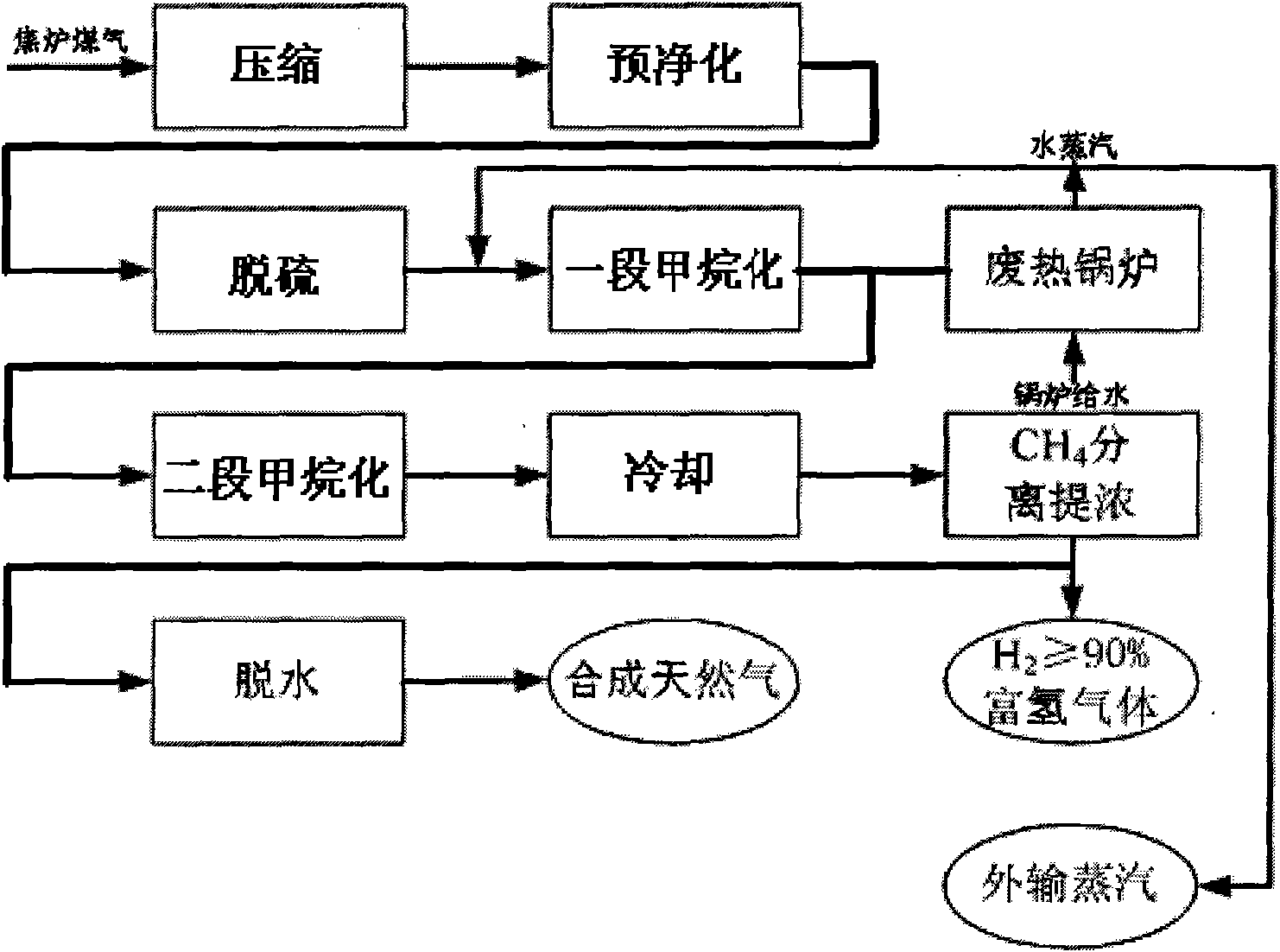

Synthesis process of natural gas employing methanation of coke oven gas

The invention relates to a comprehensive utilization synthesis process of natural gas employing methanation of coke oven gas, belonging to the technical field of new energy utilization. The process comprises the following steps: compressing coke oven gas, preliminary cleaning, removing sulfur, performing first section methanation, performing second section methanation and separating natural gas toprepare natural gas which reaches the grade A technological requirements of natural gas national standard (GB17820-1999). The synthesis process of natural gas employing methanation of coke oven gas reaches the aim of high effective comprehensive utilization of natural gas and provides a new way of preparing and synthesizing natural gas.

Owner:SHANDONG TIEXIONG METALLURGICAL TECH CO LTD +2

Amido-containing ionic liquid used for absorbing acidic gases and preparation method and application thereof

ActiveCN101993378ASynthetic raw materials are cheap and easy to obtainLow costDispersed particle separationSulfonic acids salts preparationPressure reductionIonic liquid

The invention provides an amido-containing ionic liquid used for absorbing acidic gases and a preparation method and application thereof and in particular relates to a method for absorbing acidic gases of CO2, H2S, SO2 and the like by using an amido-containing ionic liquid. The amido-containing ionic liquid comprises one or more of primary amine, secondary amine and tertiary amine, wherein positive ions of the ionic liquid are derived from organic polyamines, negative ions of the ionic liquid are derived from inorganic acid or organic acid, and the ionic liquid is prepared by mixing the organic polyamines with the inorganic acid or organic acid and then carrying out neutralization reaction through acid and alkali. The ionic liquid has the advantages of low cost, simple preparation method,strong absorbing capability and short balance time, can be used for the enriching of acidic gases, the deacidification refining of acid-containing gases of natural gas, refinery gas, methane, coal gas, synthesis gas, coke-oven gas, pyrolysis gas, smoke, motor vehicle tail gas and the like and the purification of gases under a proper space and an operating environment; meanwhile, the ionic liquid absorbing the acidic gases can release the acidic gases through pressure reduction and temperature raise, thus the absorbing capability of the ionic liquid is restored and the multiple absorption property of the ionic liquid is better.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

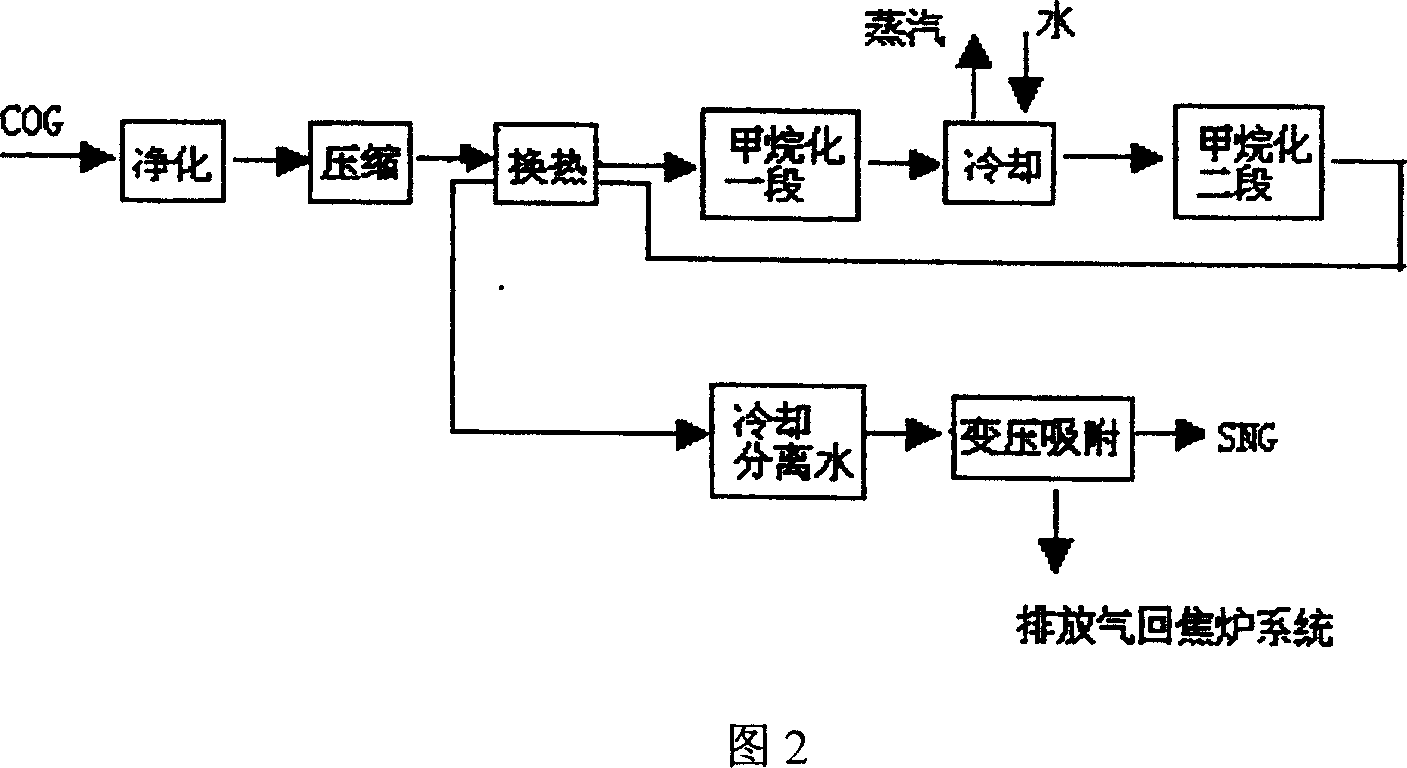

Method for synthesizing methane by using coke-oven gas

ActiveCN101391935AHigh methane contentHigh calorific valueHydrocarbon from carbon oxidesChemical industryWater vaporMethanation

The invention discloses a method for synthesizing methane by utilizing oven gas. Product gas with methane concentration of more than 90 percent is obtained through the main steps of purifying to remove impurities, compressing to exchange heat, adding water vapor, first stage of methanation reaction, second stage of methanation reaction, third stage of methanation reaction, PSA methane separation and the like. By adopting the method and utilizing the oven gas as raw materials, synthetic natural gas with high content of methane, low content of impurities and high heating value can be obtained, which is favorable to protecting the environment, saving energy and developing new energy; in addition, in the method, the addition of appropriate water vapor in the raw materials of oven gas before the fist sage of reaction properly inhibits the depth of the methanation reaction, reduces the heat amount released in the whole reaction process, conduces the cooling of the gas after the reaction and prevents the occurrence of carbon deposition reaction to devitalize the activity of a catalyst, thus being beneficial to the continuous normal operation of the whole synthesizing process.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

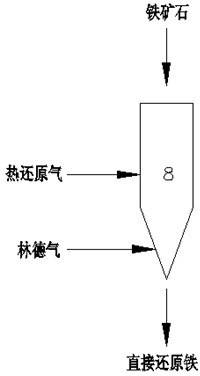

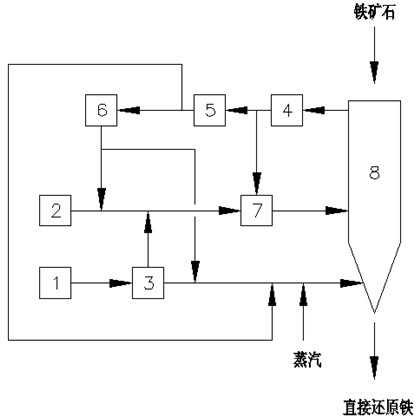

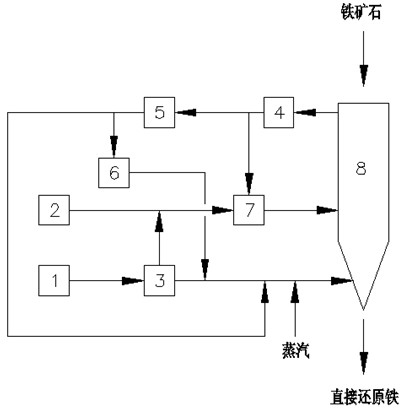

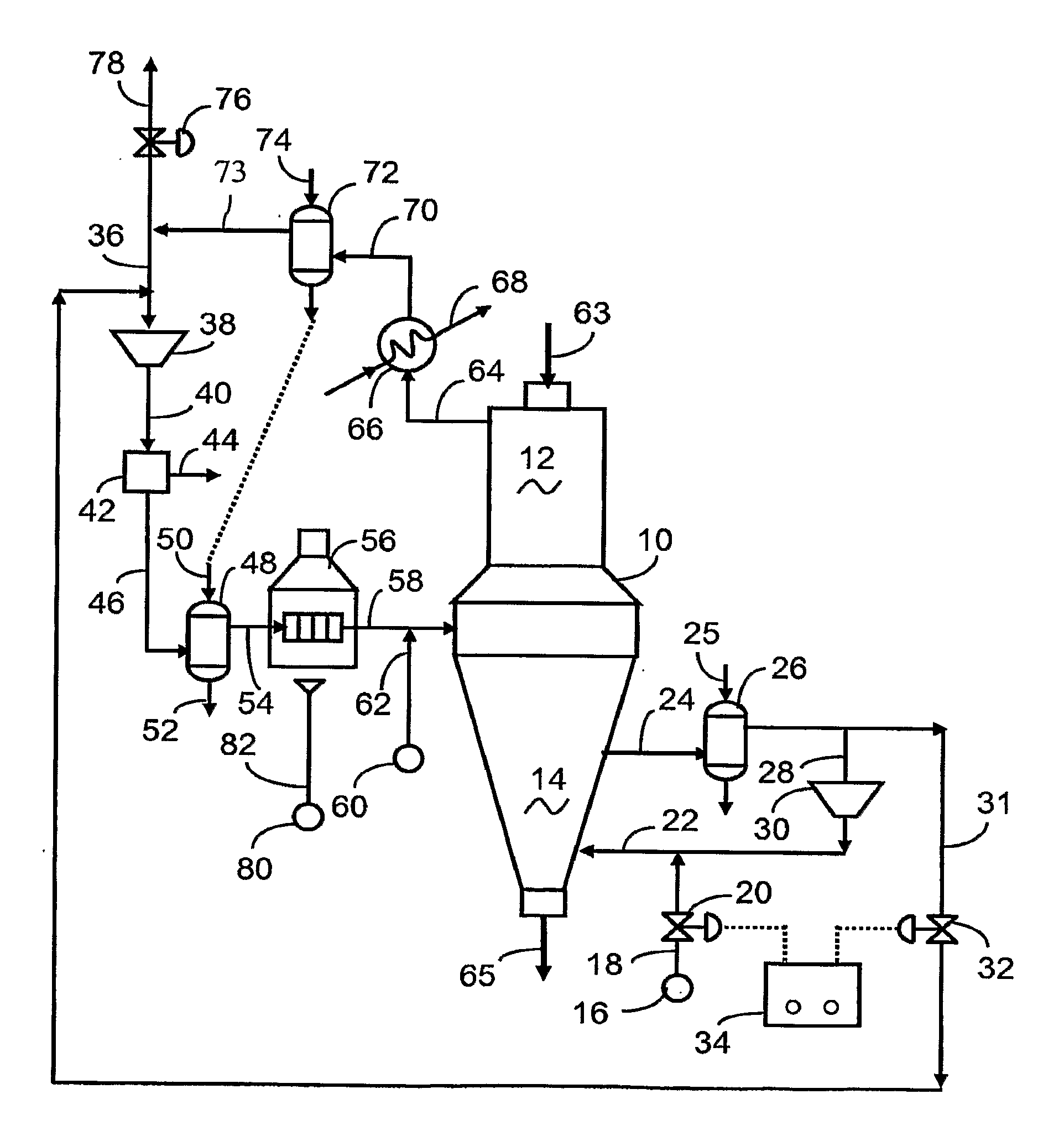

Method and device for producing direct reduced iron by using gas-based reduction shaft furnace

The invention discloses a method and device for producing direct reduced iron by using a gas-based reduction shaft furnace. Coal reducing gas and coke oven gas are mixed and supplied to a shaft furnace so as to produce direct reduced iron. The method comprises the following steps: separating the coke oven gas into hydrogen gas and linde gas, mixing the hydrogen gas with the coal reducing gas and using as reducing gas to reduce iron ores, and using the linde gas as cooling gas to cool direct reduced iron. The device for realizing the method comprises a shaft furnace, a coke oven gas source, a coal gasification device, a coke oven gas hydrogen-extracting device and a gas heating device. In the invention, coal gasification devices of different sizes can be flexibly used with a coke oven gas supply device, thereby reducing the size of the coal gasification device and effectively using the coke oven gas. Meanwhile, the invention cancels the minor cycle of a cooling section of a common shaft furnace, saves the equipment and investment, and brings the heat of direct reduced iron to a reducing section, thereby saving the heating load of the system reducing gas.

Owner:CISDI SHANGHAI ENG CO LTD +1

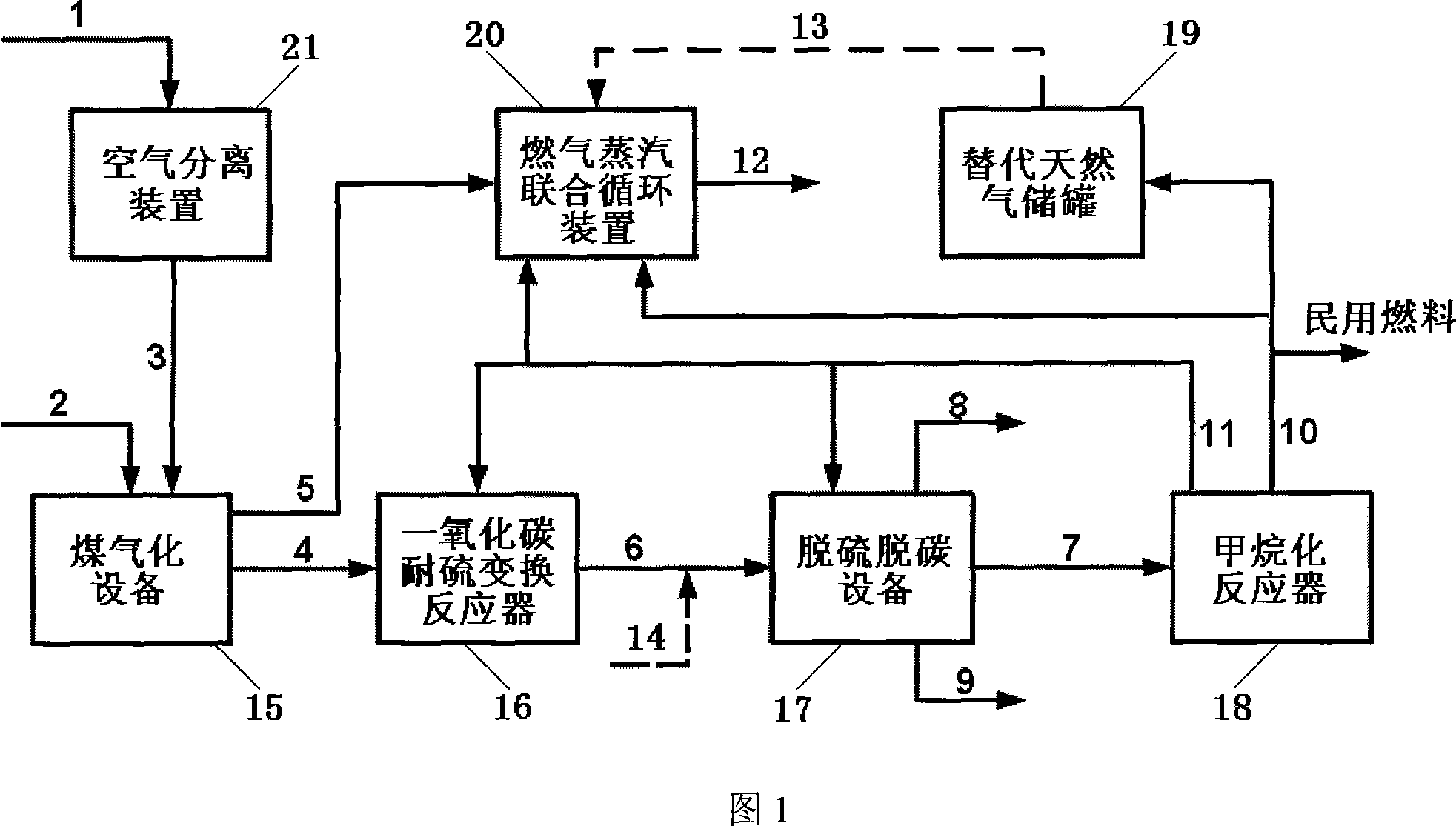

Combined system and process for producing electric-substituted natural gas based on coal gasification and methanation

ActiveCN101074397AEfficient and clean utilizationEfficient use ofCombustible gas chemical modificationCombustible gas purificationMethanationSlurry

An electric-substituting natural gas combined system and process based on coal gasification and methanation are disclosed. The process is carried out by delivering oxygen, powdered coal or water-gas slurry into gasified apparatus, recovering for crude gasified gas by wet heat, delivering into sulfur-resisting carbon monoxide carbon reactor, adjusting hydrogen-carbon ratio, entering into desulfurizing decarbonizer, recovering elementary sulfur while enriching carbon dioxide, delivering synthetic gas into methane reactor to generate substituted natural gas as domestic gas partially, entering into gas and steam combined circulator partially, and entering into substituted natural gas storage tank partially. It integrates coal gasified, methanation and gas steam combined circulation together, it's efficient and clean, has better utilizing rate, no CO2 discharge and need for changing gas turbine or load.

Owner:TSINGHUA UNIV

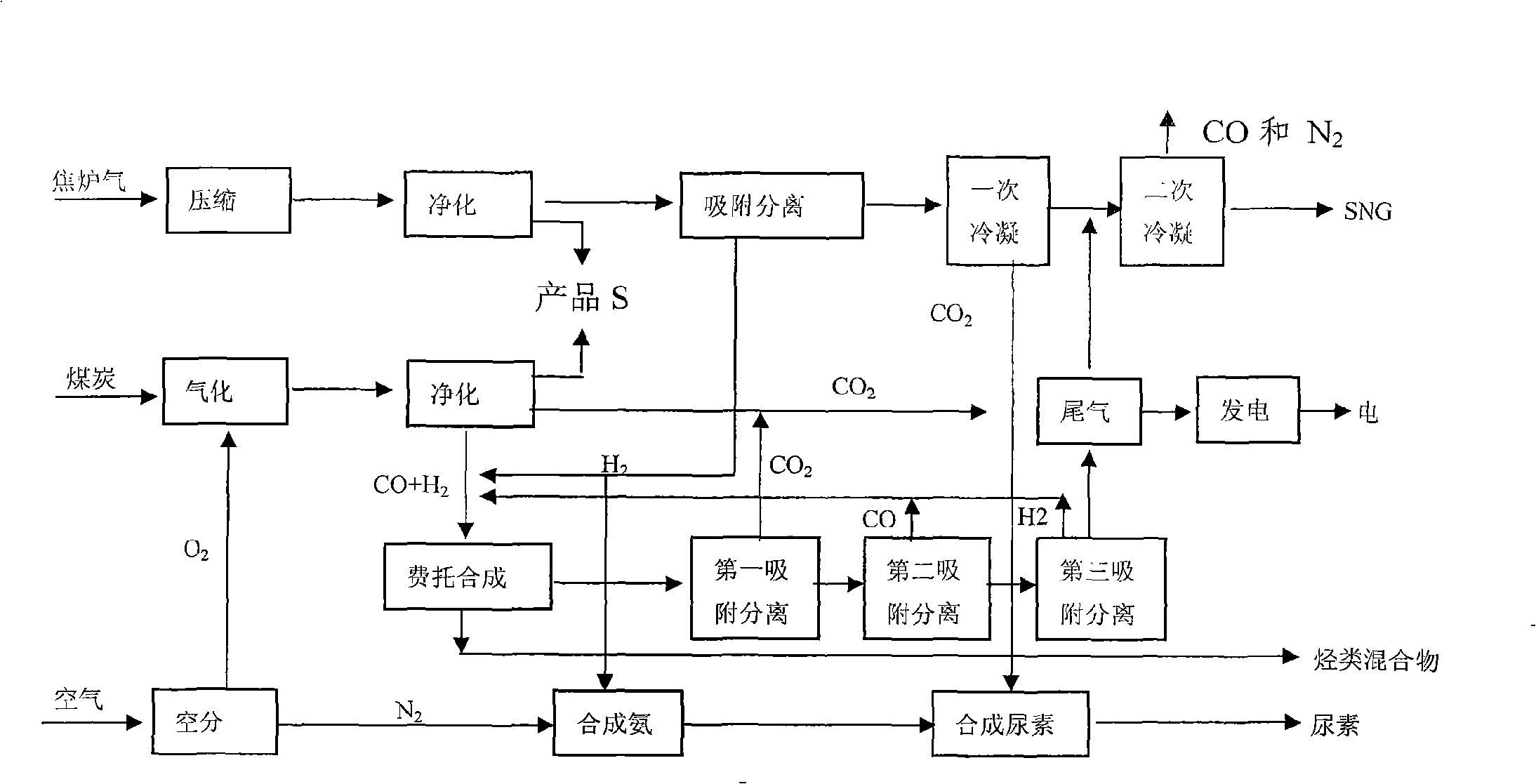

Poly-generation technique for using coal gas and coke oven gas as raw materials

ActiveCN101538483ANo conversionNo transform operationUrea derivatives preparationOrganic compound preparationHydrocarbon mixturesDesorption

The invention relates to a poly-generation technique for using coal gas and coke oven gas as raw materials. The poly-generation technique comprises the following steps of: carrying out mixing on part of H2 prepared by purified water gas and coke oven gas through pressure swing adsorption and tail gas obtained by Fischer-Tropsch synthesis, carrying out Fischer-Tropsch synthesis and obtaining hydrocarbon mixture and tail gas. The CO2 separated from tail gas separate by first pressure swing adsorption enters a urea synthesis unit for reaction, the CO and the hydrogen respectively obtained by separation of second pressure swing adsorption and third pressure swing adsorption of the residual tail gas are circulated back to a Fischer-Tropsch synthesis unit for reaction; and the residual gases can be used for generating power or obtaining SNG by secondary condensation. The coke oven gas enters pressure swing adsorption after being purified and desulphurized so as to separate H2; wherein one part of H2 is used as supplementation of H2 needed by Fischer-Tropsch synthesis and the other part of H2 is mixed with N2 for ammonia synthesis so as to obtain synthetic ammonia; and the synthetic ammonia is mixed with CO2 obtained by the first condensation and CO2 separated from the Fischer-Tropsch synthesis for urea synthesis so as to obtain urea. The CO2 separated from the first condensation of desorption gas by pressure swing adsorption of the coke oven gas is used for urea synthesis; and the residual gases is treated by the second condensation to obtain SNG and mixed gas of CO and N2. The invention has no emission of greenhouse gases, uses richness in carbon and deficiency in hydrogen of the coal gas and the richness in hydrogen and deficiency in carbon of the coke oven gas to carry out complementation, realizes modulation of product structure by Fischer-Tropsch synthesis and improves the economical efficiency of the process of Fischer-Tropsch synthesis.

Owner:中科潞安能源技术有限公司

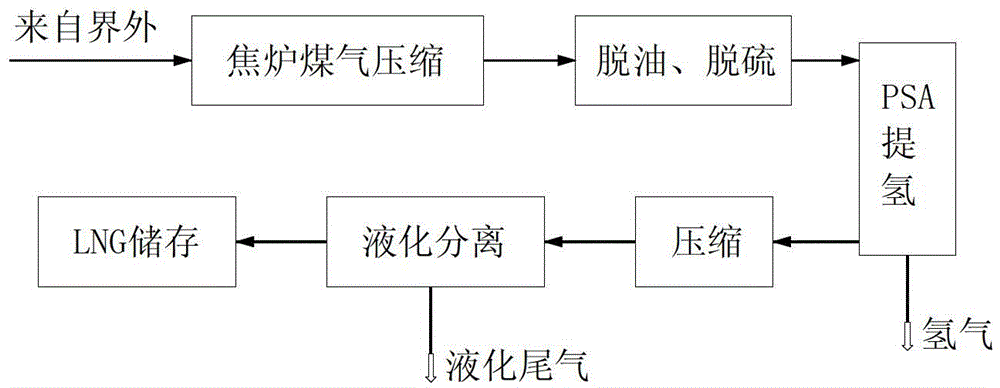

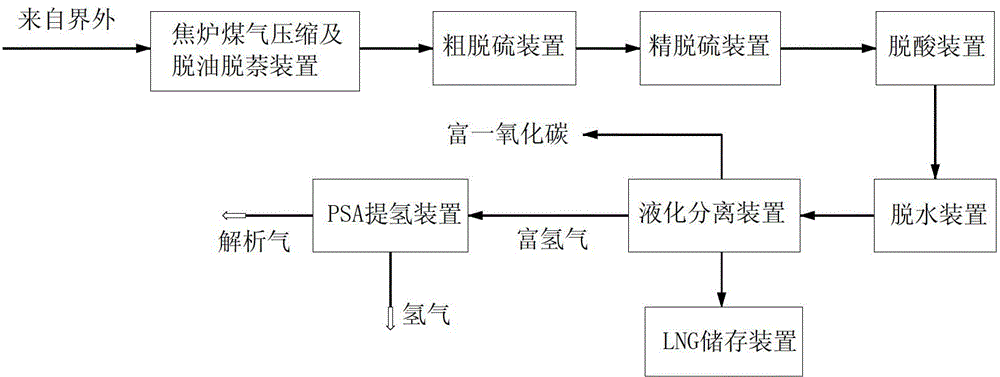

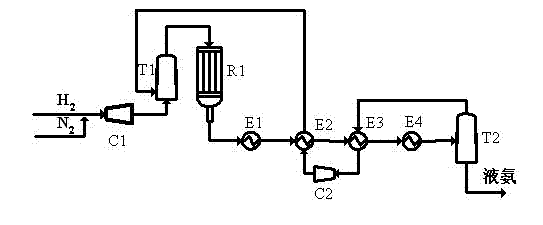

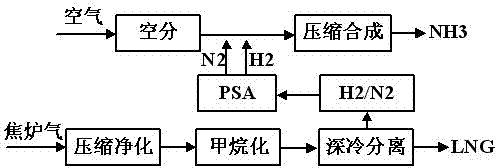

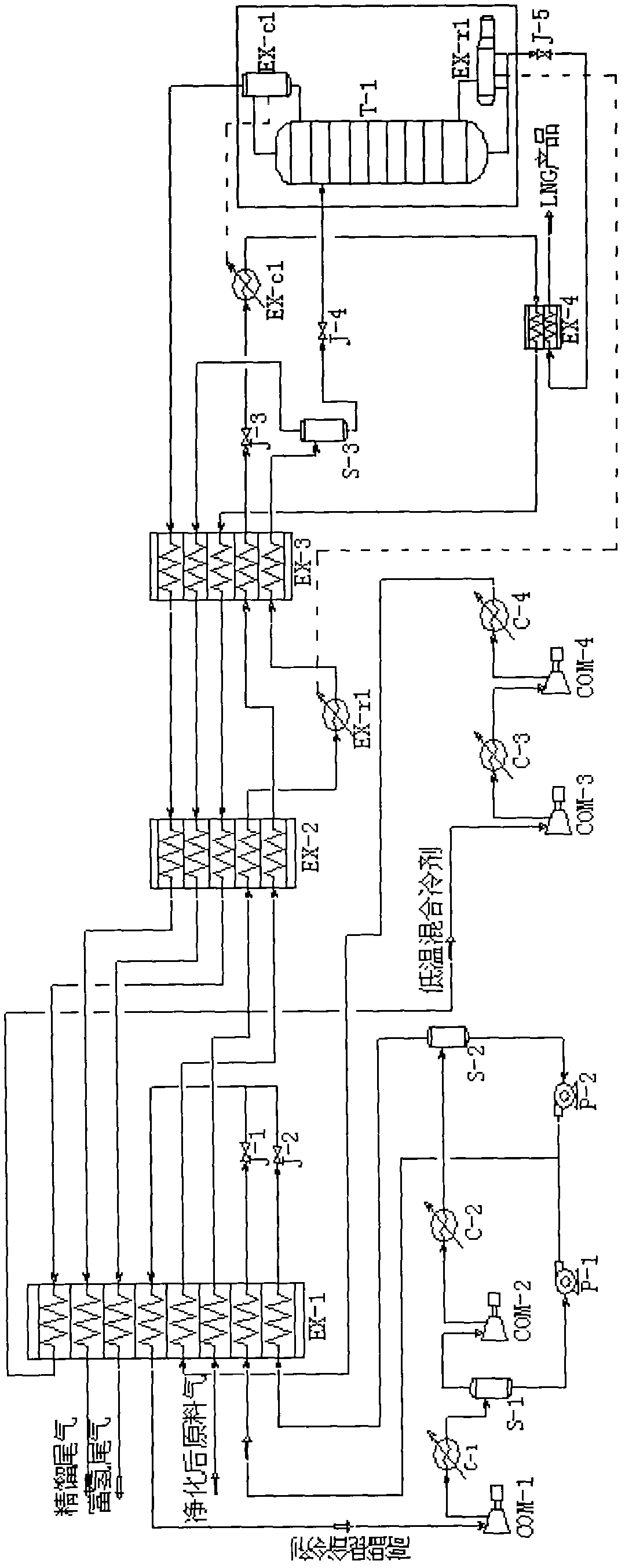

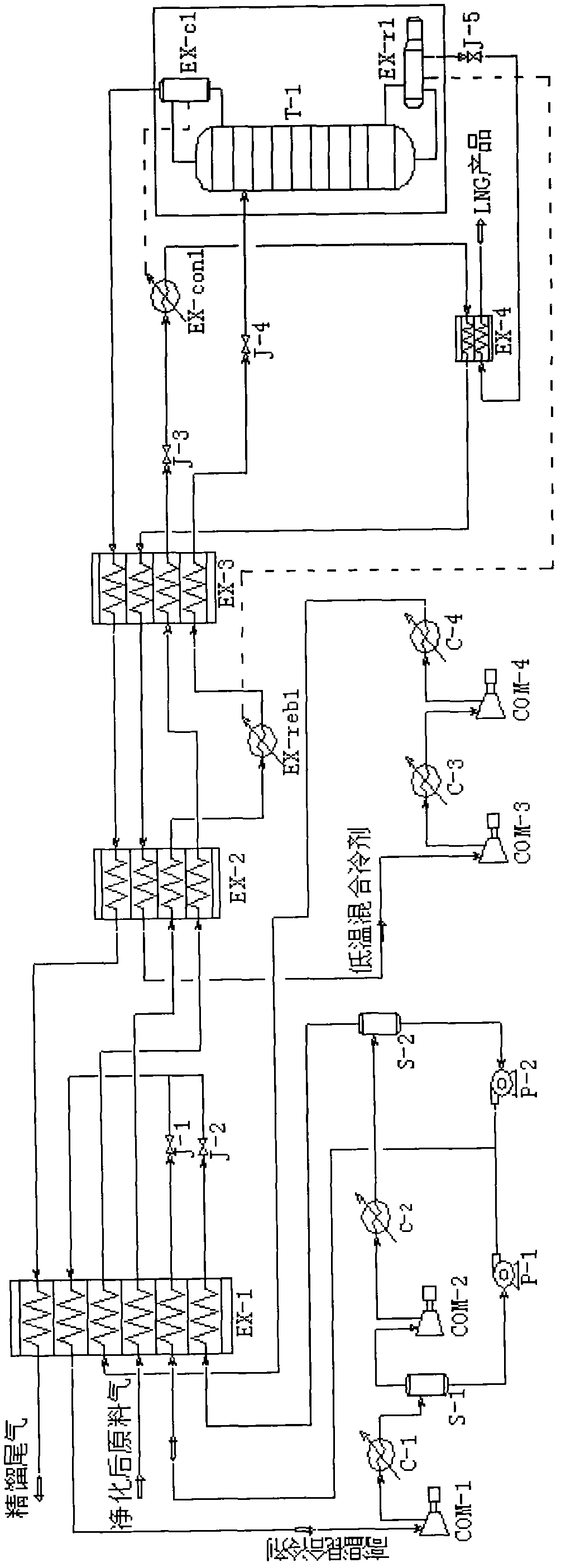

Process for preparing liquefied natural gas (LNG) and hydrogen from coke oven gas

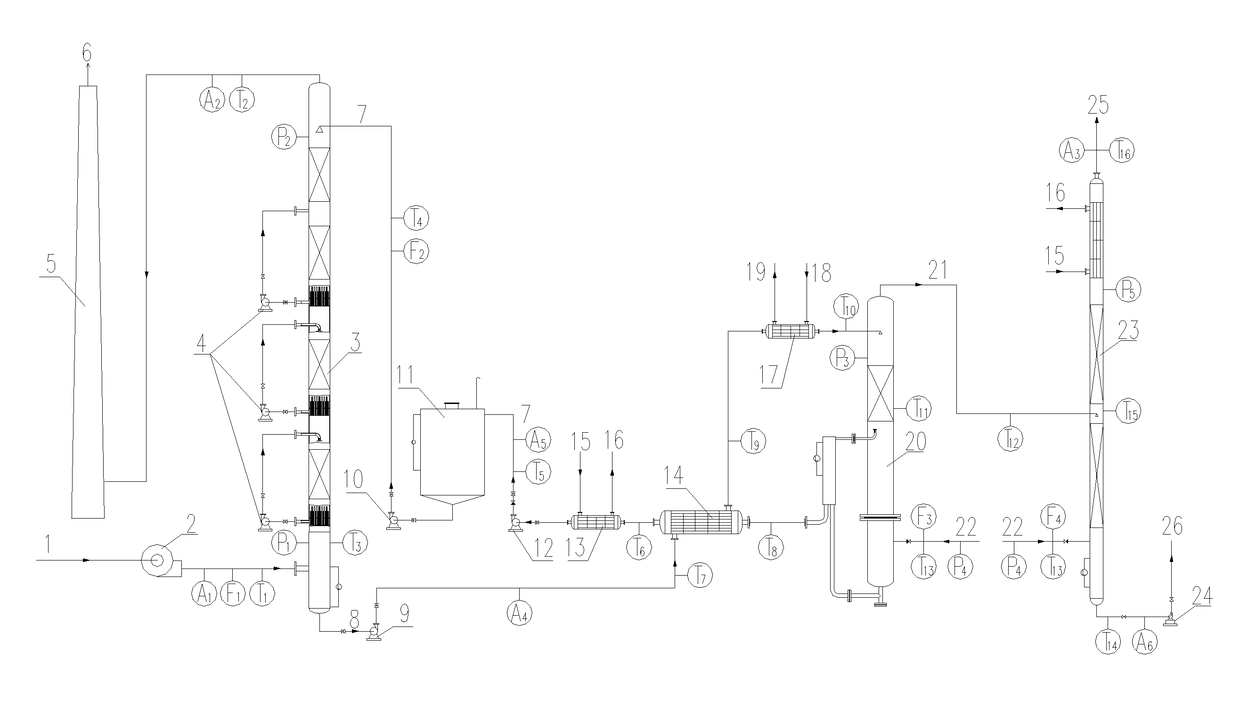

ActiveCN102719289AAvoid vacuum desorptionEliminate secondary compression systemSolidificationLiquefactionNitrogenCoke oven

The invention relates to a process for preparing liquefied natural gas (LNG) and hydrogen from coke oven gas. A process device for the process comprises a compressing device, an oil and naphthalene removing device, a coarse desulphurizing device, a fine desulphurizing device, a deacidifying device, a dehydrating device, a cryogenic liquefying and separating device, a pressure swing adsorption (PSA) hydrogen enriching and extracting device, and the like. The coke oven gas pressurized by the compressing device sequentially passes through each purifying, liquefying and separating device according to pressure difference to finally obtain an LNG product and a high-purity hydrogen, wherein the content of the hydrogen, nitrogen and carbon monoxide in the LNG is less than or equal to 2,000 ppm, less than or equal to 4% and less than or equal to 6% respectively; and the purity of the hydrogen product can reach 99.99%. The process of the invention overcomes the defects of the conventional process and consumes less energy than the conventional process.

Owner:XINDI ENERGY ENG TECH

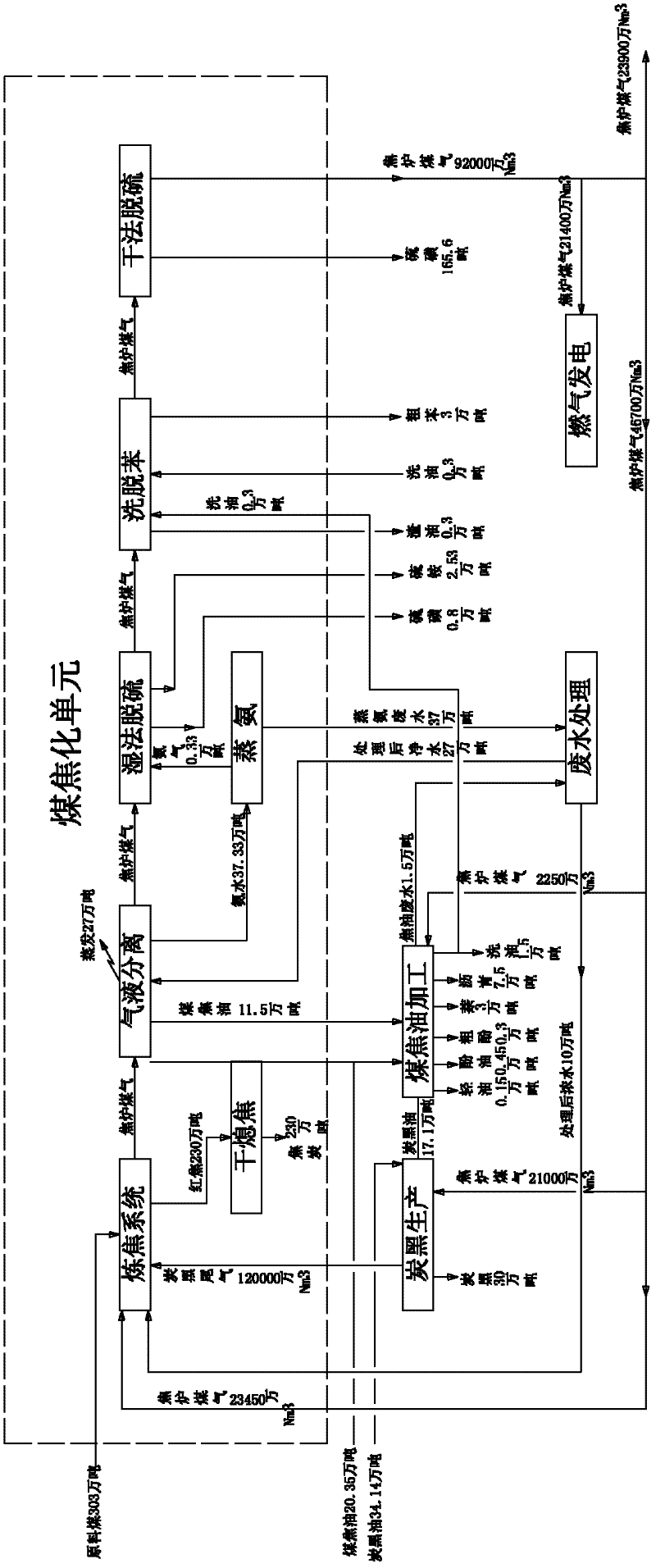

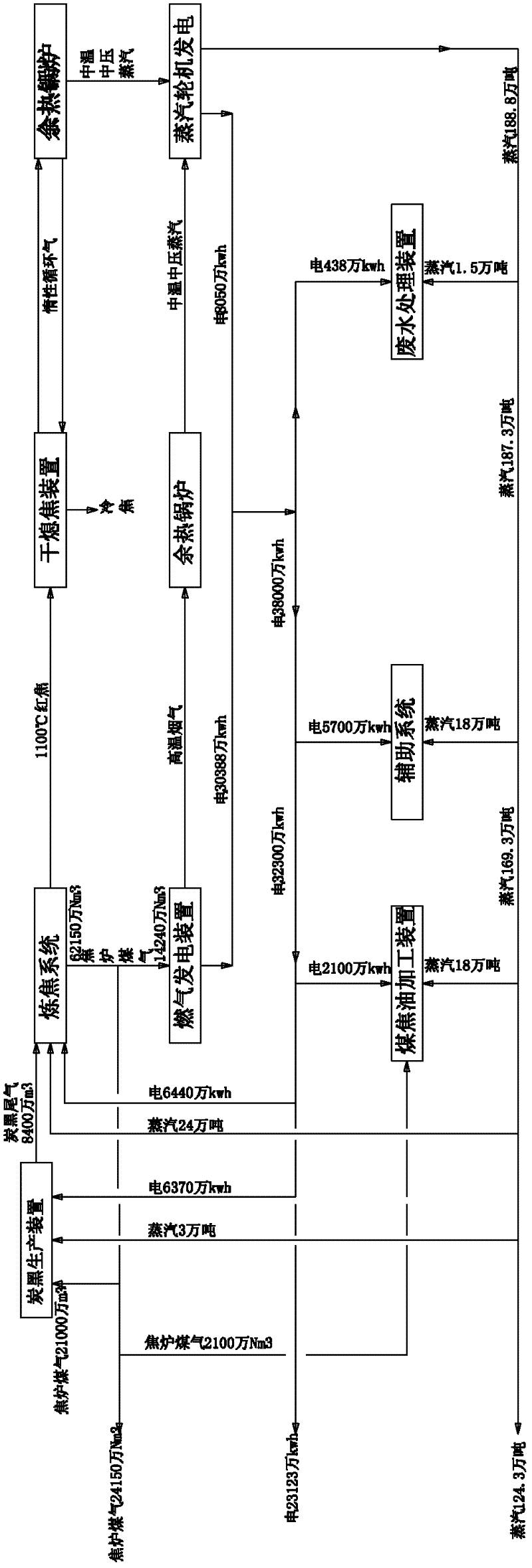

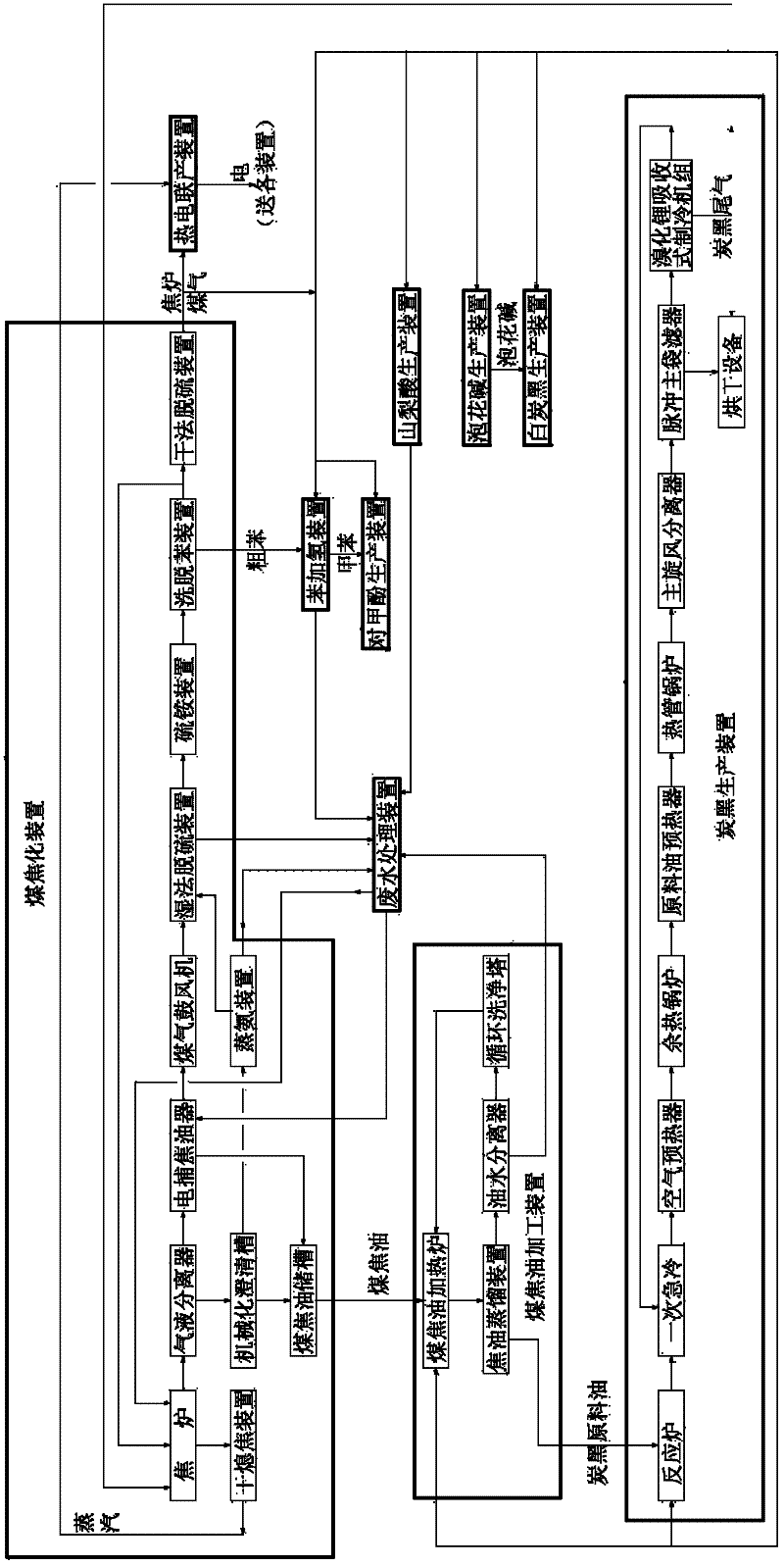

Green circular economy technology with coal coking as the main part

ActiveCN102229806AHigh aromatic contentQuality improvementPigmenting treatmentCoke quenchingCogenerationEngineering

The invention provides a green circular economy technology with coal coking as the main part. The technical scheme of the technology is as follows: a coal coking part, a coal tar processing part, a carbon black part and a part of combined power and thermoelectricity generation by coke oven gas are organically combined to form the relationship of industrial metabolism, symbiosis and coupling; suchmeasures as differentially utilizing tail gas of carbon black, recovering energy of coke drying quenching, reducing, recycling and changing the three wastes into resources, etc., enable resources to be saved, production cost to be reduced and pollution to be lessened; therefore, economic benefits of coal coking enterprises are maximized and the green circular economy technology is realized indeed. The invention also provides an apparatus for realizing the green circular economy technology with coal coking as the main part.

Owner:JINNENG SCI & TECH

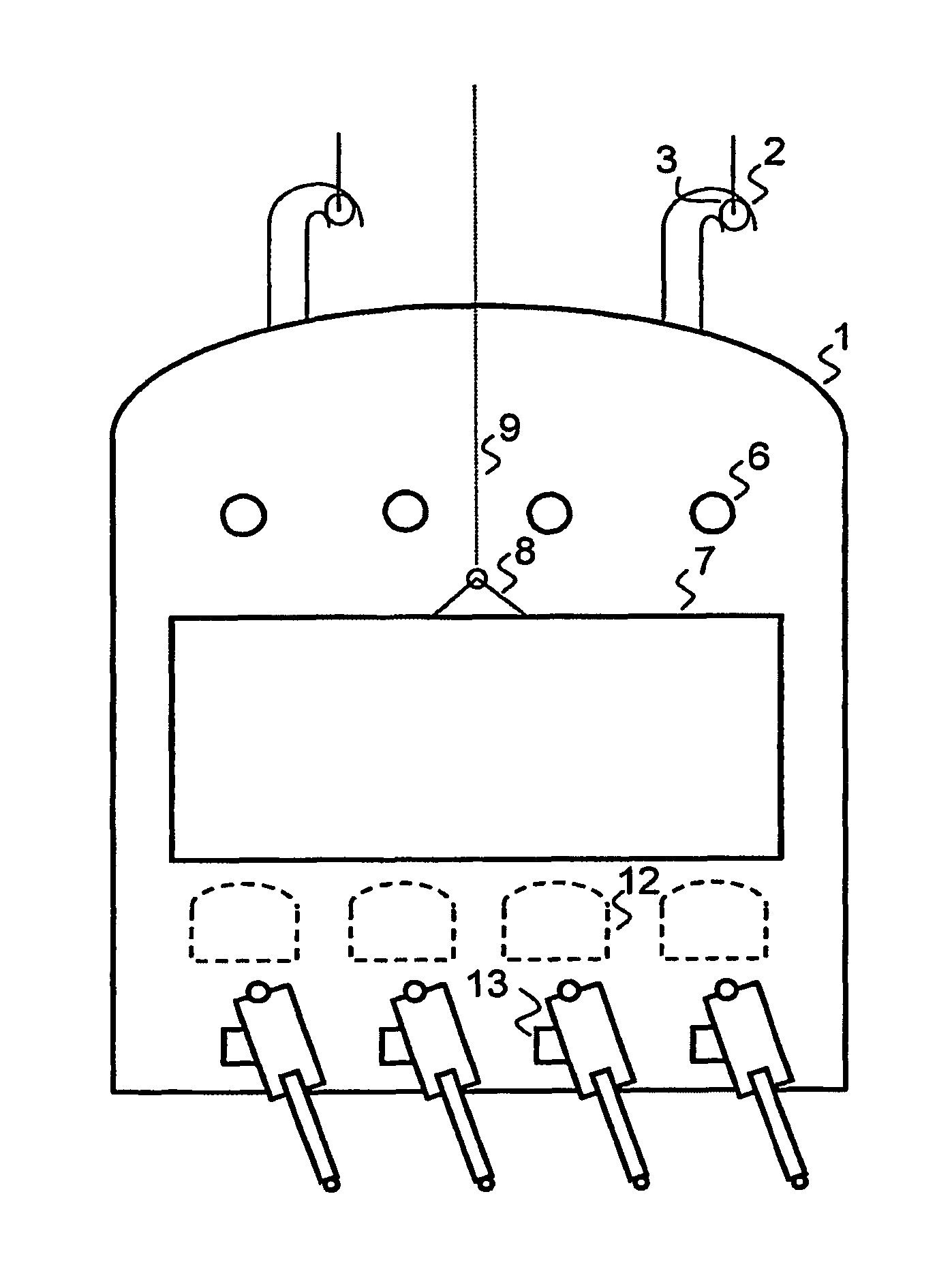

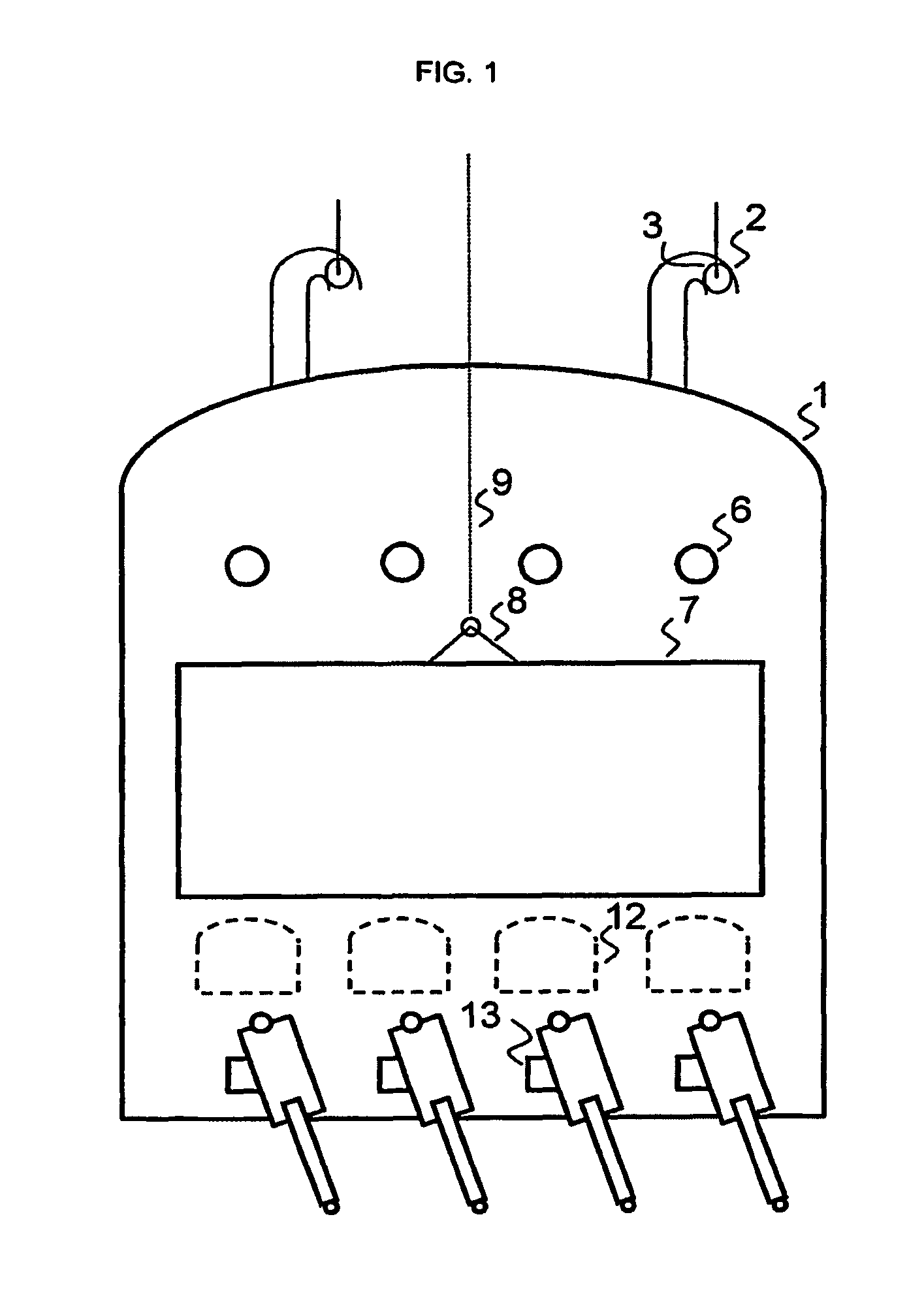

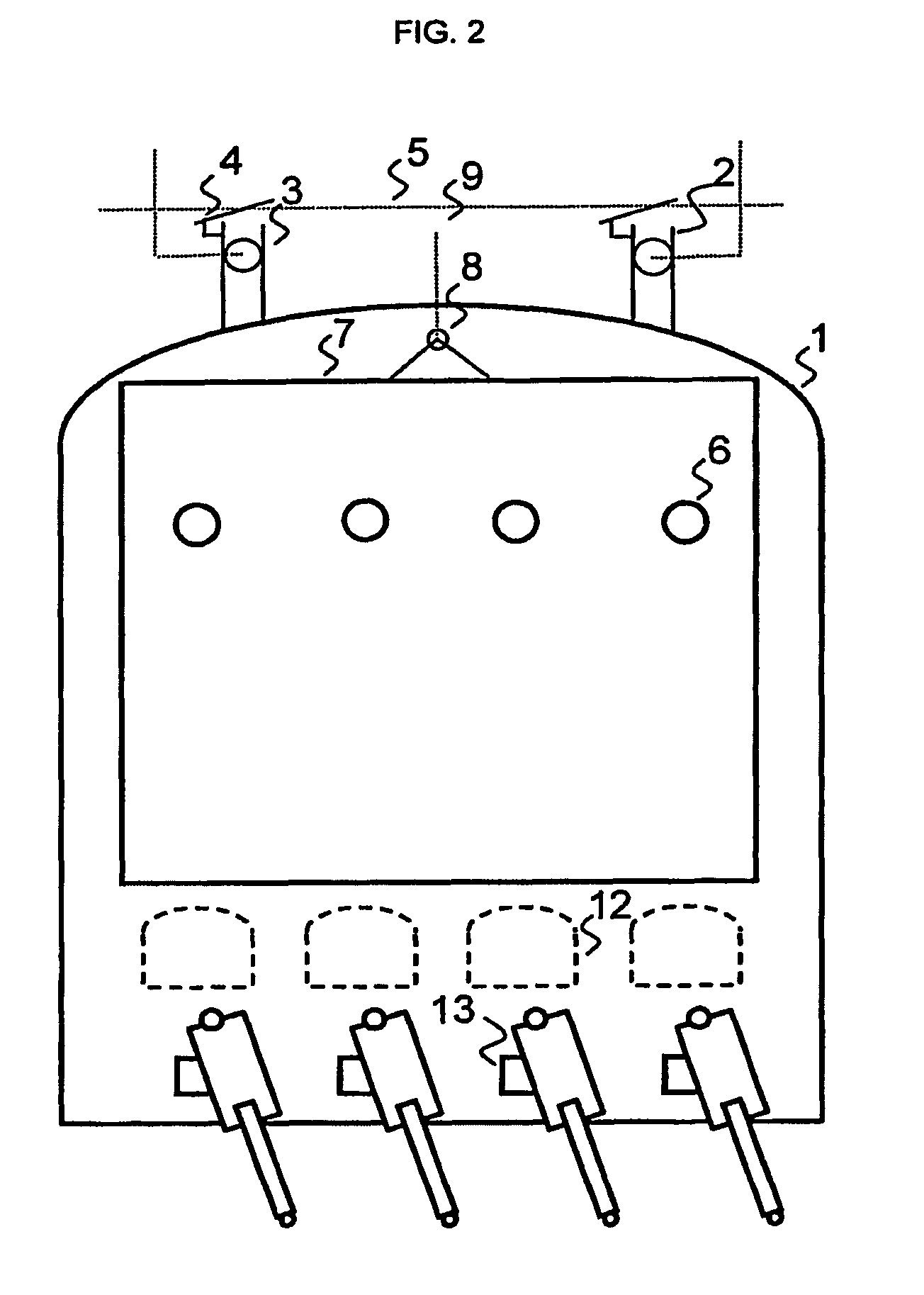

Device for feeding combustion air or gas influencing coal carbonization into the upper area of coke ovens

ActiveUS8647476B2Cause additional costCombustible gas coke oven heatingDirect heating destructive distillationFlueCoke oven gas

Disclosed is a device and a method for feeding primary combustion air for the combustion of coke oven gas into a coking chamber of a coke oven of the non-recovery or heat recovery type, the coke oven is provided with openings in the oven chamber through which the oven chamber can be charged with primary air, and heating flues in the oven chamber sole with openings through which the heating flues can be charged with secondary air, and downcomer-channels which allow for guiding partially burned gas for combustion with secondary air from the oven chamber into the heating flues, wherein in the oven wall above the door or in the upper door area there are one or more non-controlled openings comprised of a heat-proof material through which part of the primary air can be guided, and in the top area of the oven there are further controllable air feeder ducts conducting primary air through the oven top.

Owner:UHDE GMBH

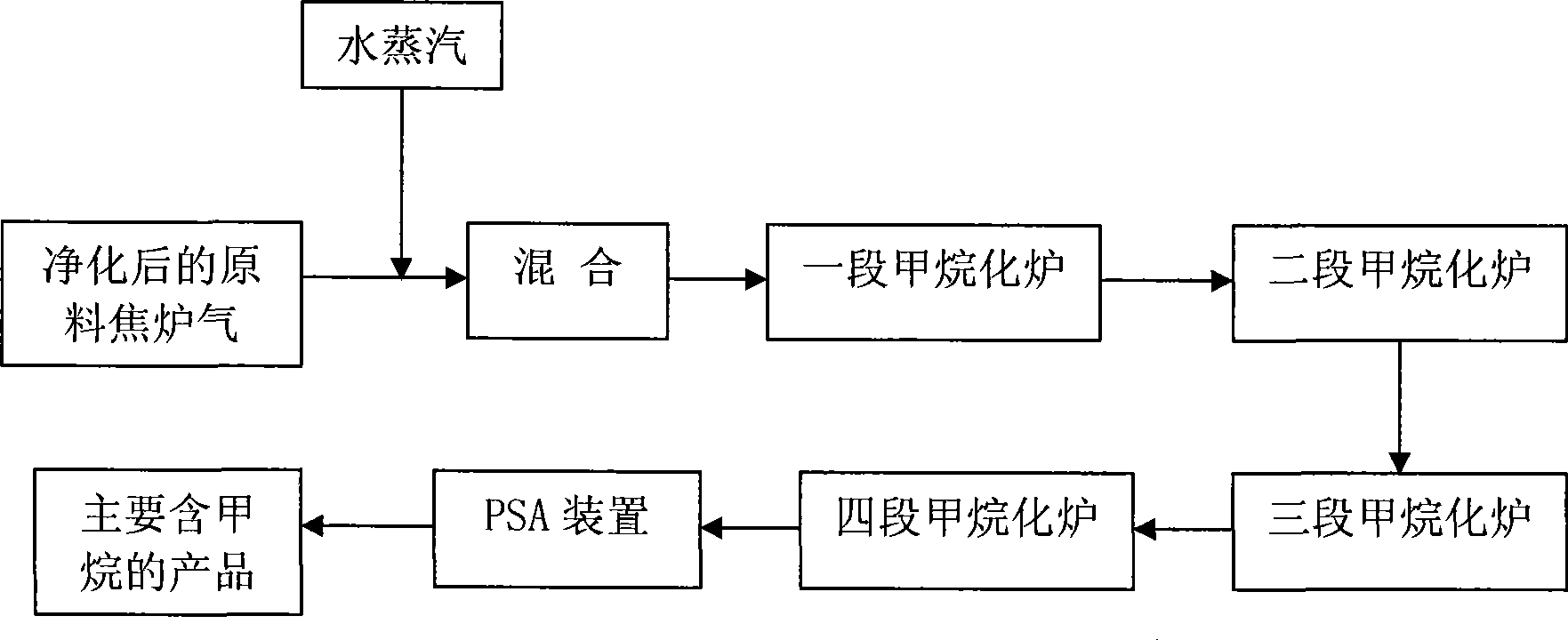

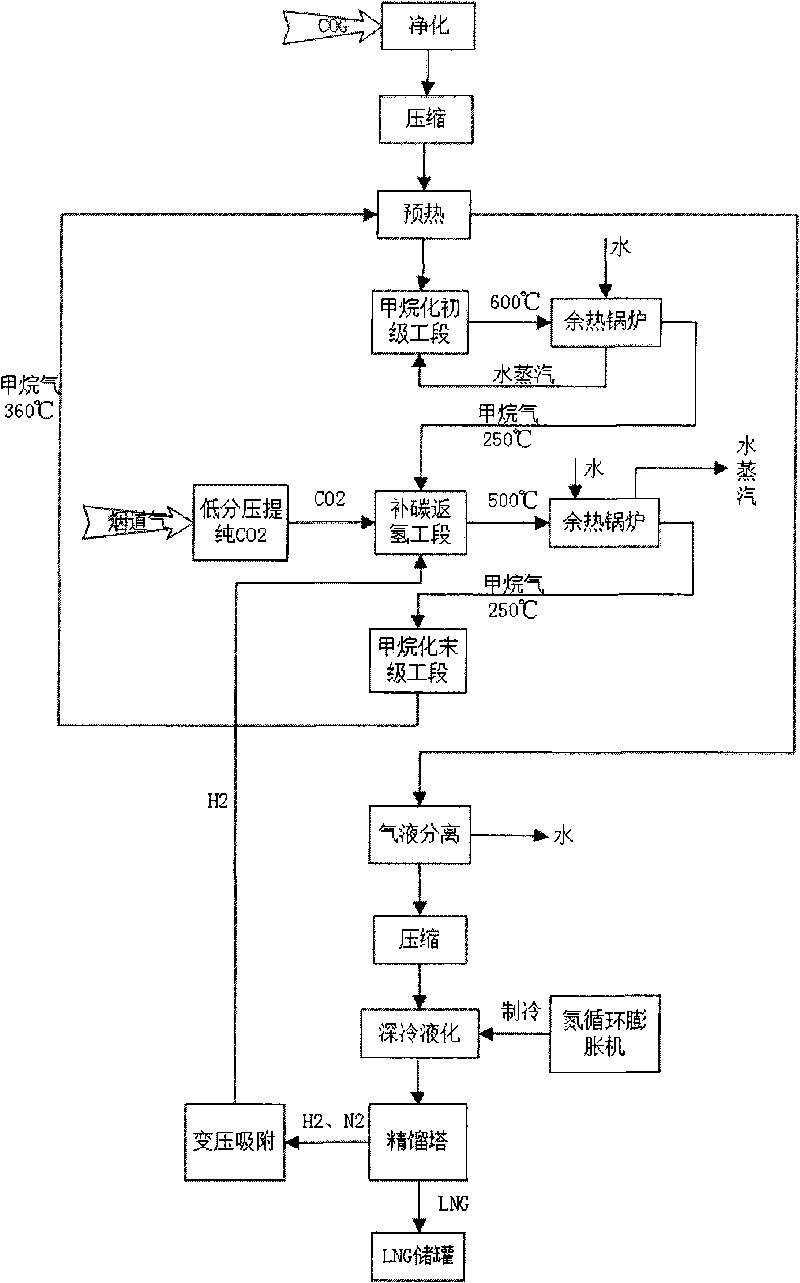

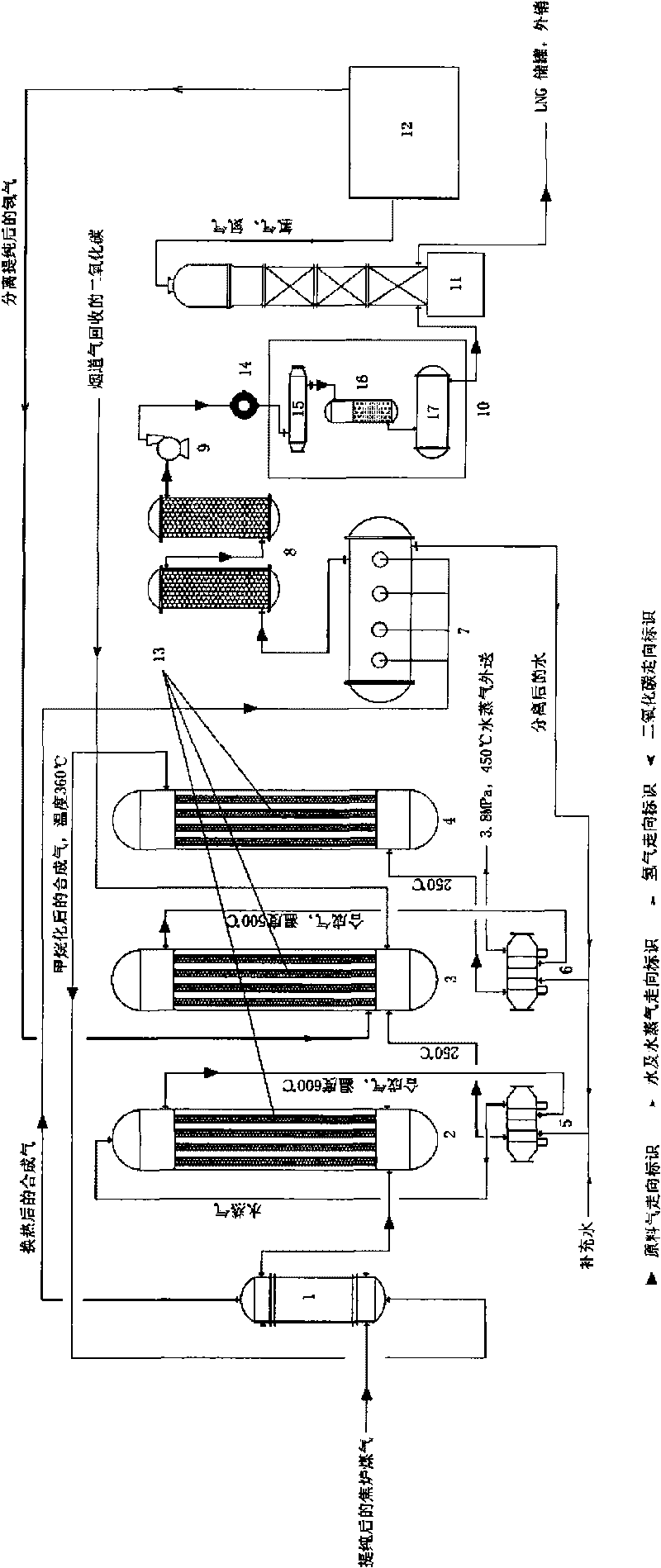

Method for realizing methanation of coke oven gas through carbon-replenishing hydrogen-returning process for synthetic natural gas

InactiveCN101712897AReduce unit energy consumptionIncrease productionGaseous fuelsMethanationSynthesis methods

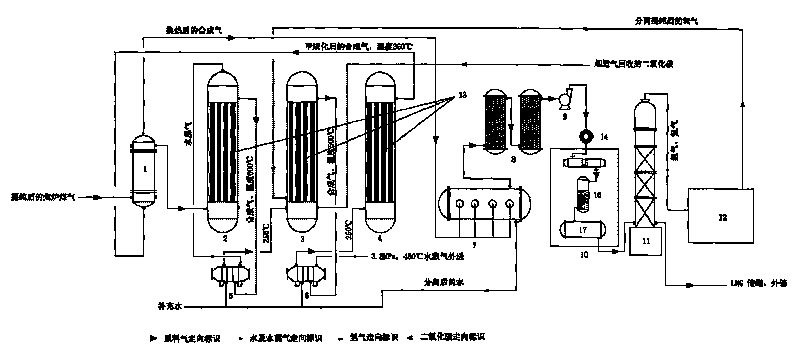

The invention relates to the field of coal coking production, in particular to a method for realizing methanation of coke oven gas through carbon-replenishing hydrogen-returning process for synthetic natural gas. The method comprises: pressurizing purified coke oven gas to 1 MPa; raising temperature to 250 DEG C for heat exchange; under the action of catalysts, performing three-stage methanation reaction of CO2 recycled by a low-partial-pressure system added with flue gas and H2 obtained through the separation of a membrane separation device after methanation to obtain synthetic gas of which the concentration of methane is over 94 percent. The method adopts a low-pressure non-cyclic methanation process, and the reaction temperature of the method is as follows: a primary stage is at 600 DEG C; a carbon-replenishing hydrogen-returning stage is at about 500 DEG C; a final stage is at 360 DEG C; and the temperature before every stage of methanation reaction is controlled at 250 DEG C through balancing control. Through a heat-insulating reactor and a waste-heat boiler heat exchange system, the method not only controls reaction temperature, but also produces steam serving as a byproduct at 3.8 MPa and 450 DEG C. Compared with other synthesis methods, waste heat energy produced during the methanation reaction is utilized more fully, so that the aims of saving energy, reducing emission and causing no environmental pollution are achieved while capacity is expanded.

Owner:SHANGHAI EUROFO ENTERPRISE GROUP

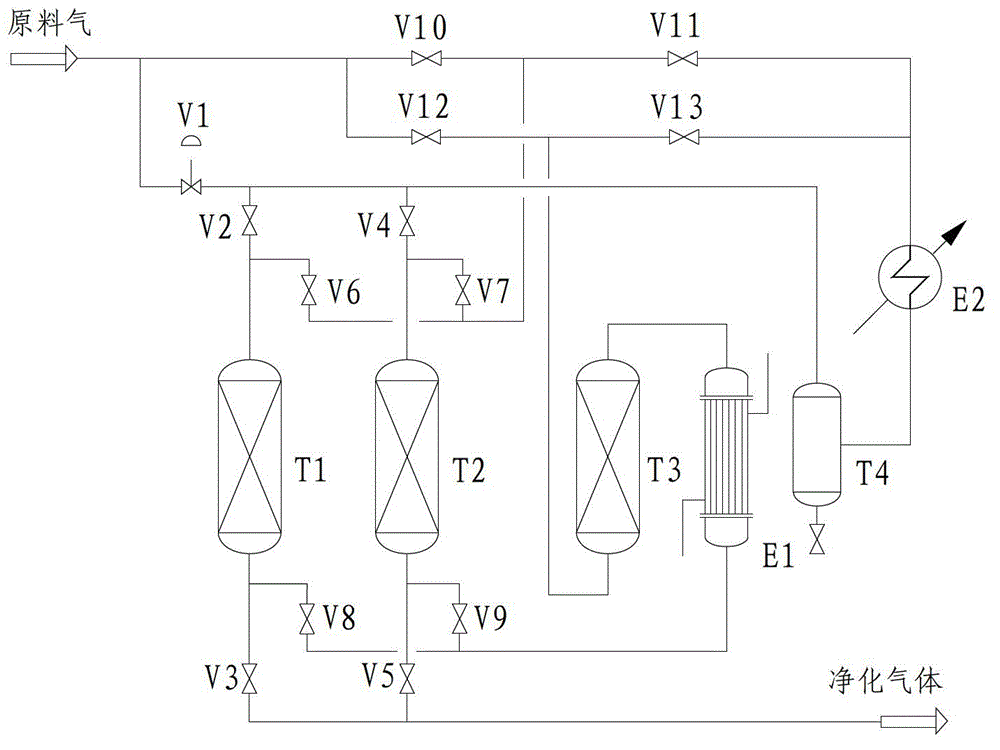

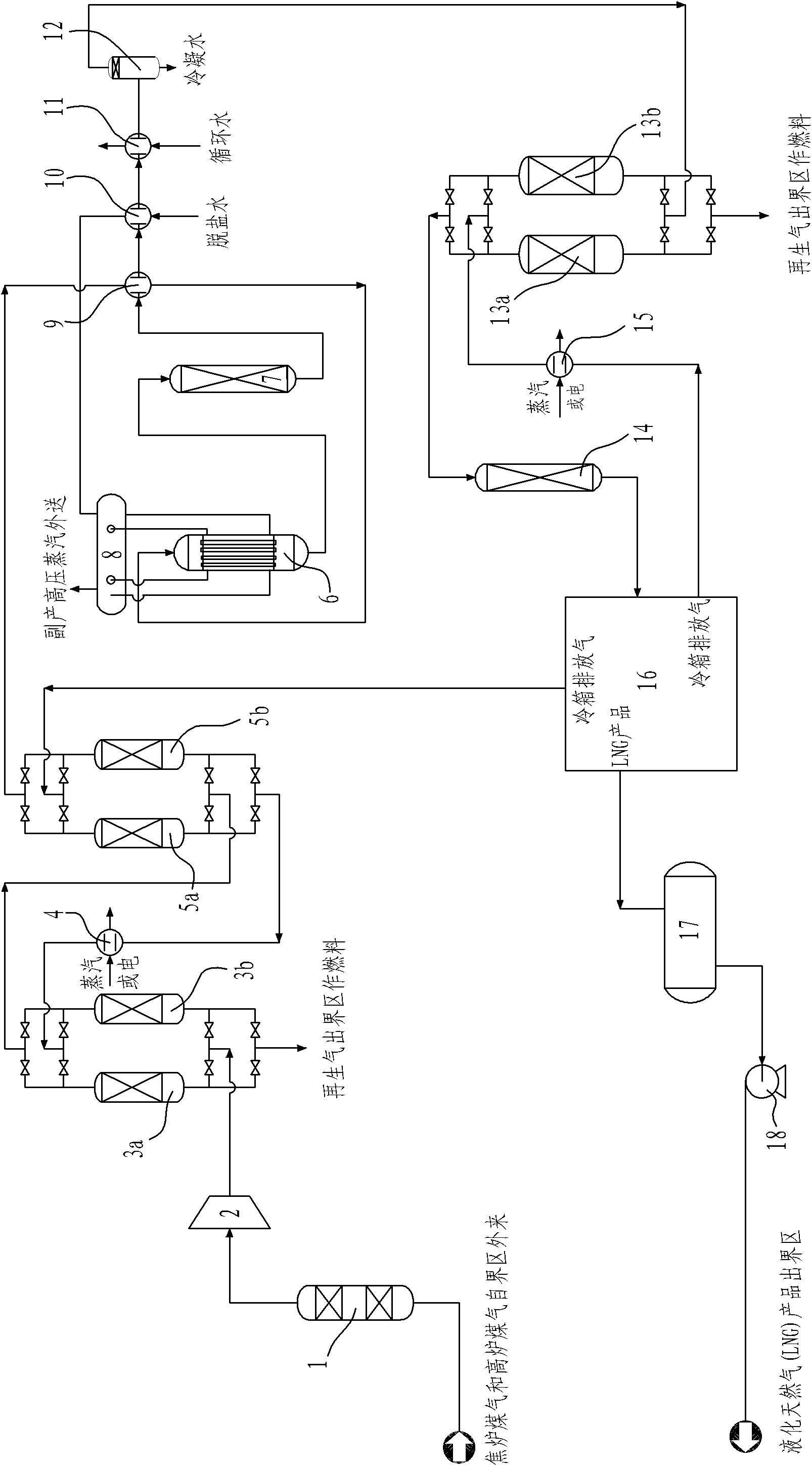

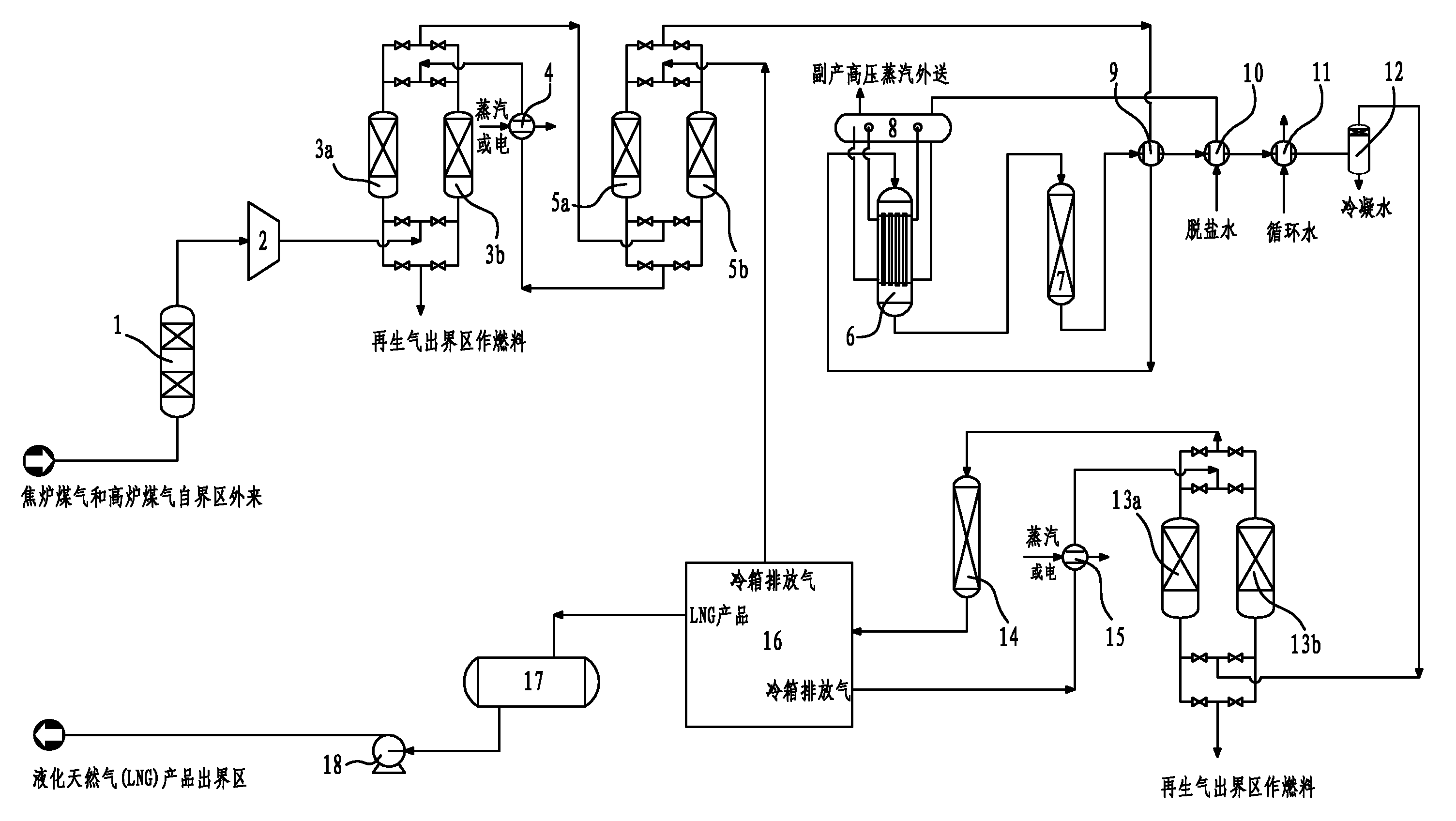

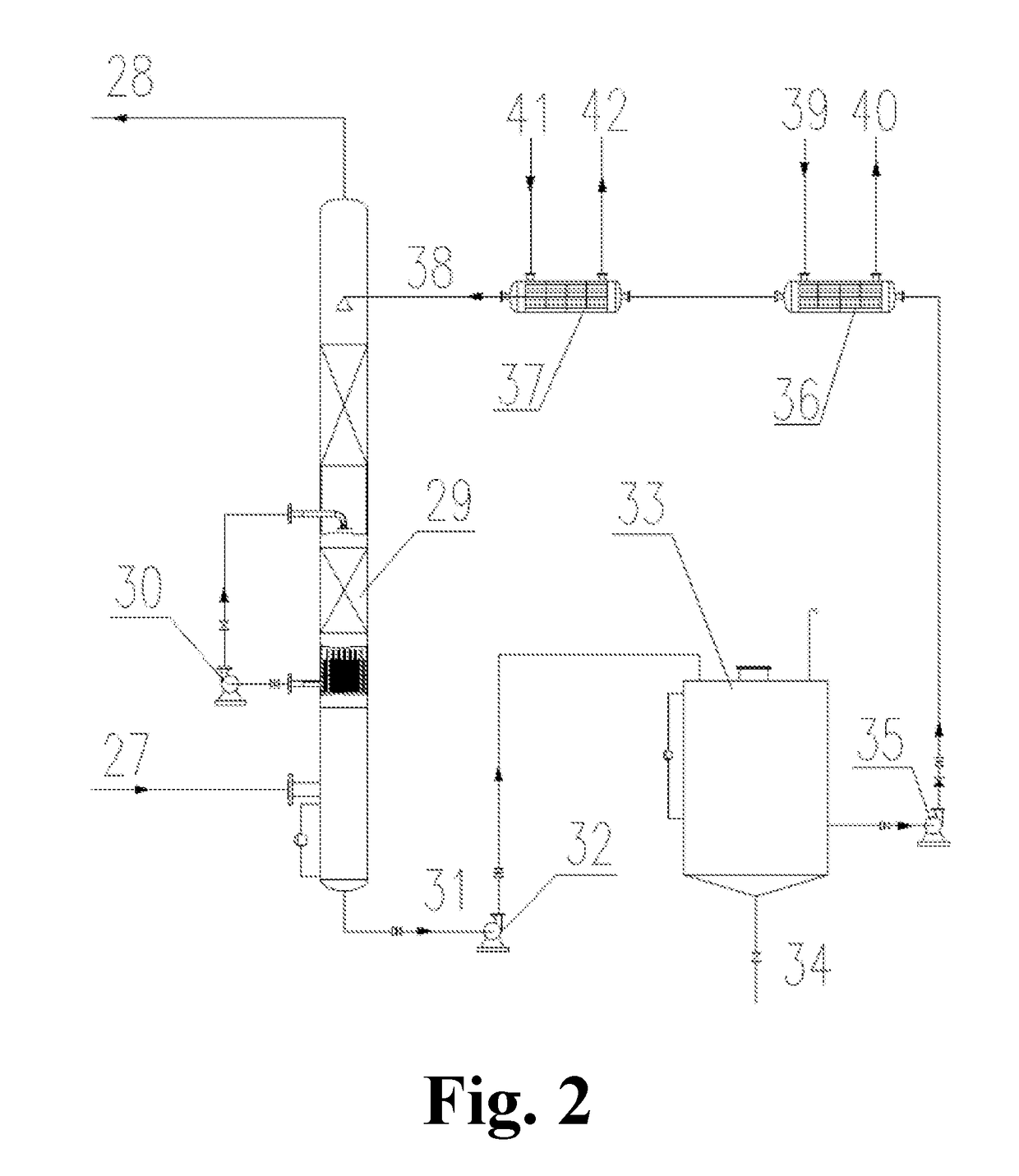

Method for preparing liquefied natural gas by converting raw materials of coke oven gas and blast furnace gas

InactiveCN102250658AEasy to operateSimple processGaseous fuelsGas purification with selectively adsorptive solidsMethanationImpurity

The invention discloses a method for preparing liquefied natural gas by converting raw materials of coke oven gas and blast furnace gas. In the technology, the coke oven gas and the blast furnace gas are taken as the raw materials, the raw materials are subjected to normal-temperature normal-pressure dry desulfurization, gas compression, gas adsorption purification, gas isothermal-adiabatic serial methanation, gas adsorption drying and demetalization, freezing liquefication separation and other technical processes, and high-quality liquefied natural gas with the purity of over 99 percent is produced. By the technology, harmful impurities such as sulfur, naphthalene, tar, benzene, mercury and the like in the gas can be efficiently and easily removed fully at low cost, and components with low value, such as H2, CO, CO2 and the like are completely converted into required CH4 component with high value, so the method has the characteristics of low requirement on quality of feed gas, high yield of liquefied natural gas product, high product purity, low production energy consumption, no environmental pollution, reliable flow, low investment, simple operation and good economic benefit.

Owner:SHANGHAI HANXING ENERGY TECH

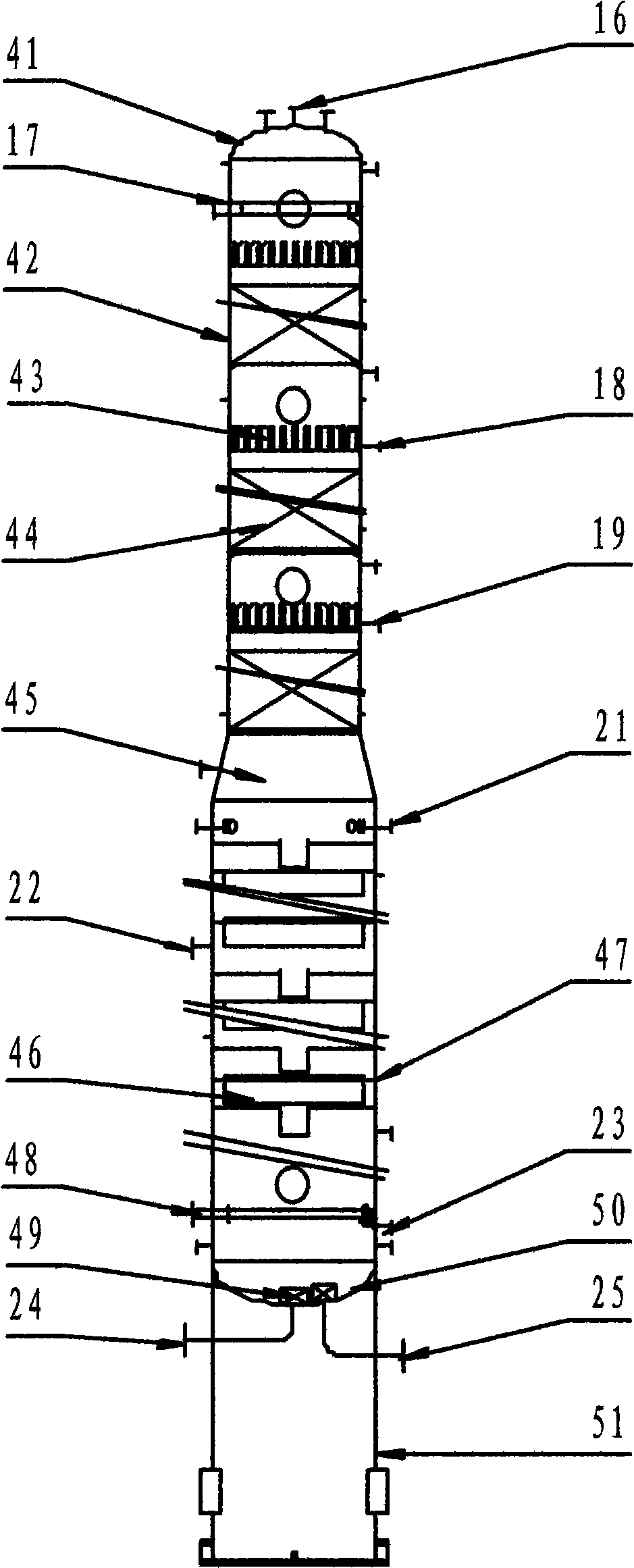

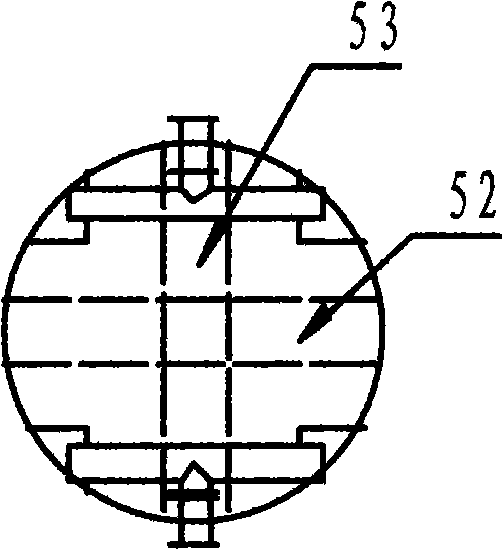

Process and equipment for negative pressure benzene removal

ActiveCN101544913ALow boiling pointReduce partial pressureCombustible gas purificationBenzeneThermodynamics

The invention discloses a process and equipment for negative pressure benzene removal , belonging to technology and equipment for recovering resultant in the coking industry, in particular to technology and equipment for removing and recovering benzene contained in coke gas. To solve the problems existing in the prior art, the invention develops the process for non-steam and non-distillation debenzolization under the negative pressure operation condition is developed and designs a novel debenzolization tower thus the disadvantages of equipment and process for benzene removal by adopting tubefurnace for heating rich oil under normal pressure can be overcome. The invention mainly has the advantages that firstly, as benzene is removed by the negative pressure process, the boiling point of the benzene and the partial pressure of the benzene in gaseous phase are lowered, and the benzene can be removed without using direct steam for steaming and blowing, thus waste water generated by the steam is reduced and the environment can not be polluted; secondly, the productive rate of dry coal due to benzene removal is increased to be more than 1.35 percent from the original 1 percent, and the recovery ratio of the benzene is increased to be more than 35 percent; and thirdly, compared with the existing benzene removal process, the process reduces the energy consumption by more than 20 percent.

Owner:JINAN METALLURGICAL CHEM EQUIP CO LTD

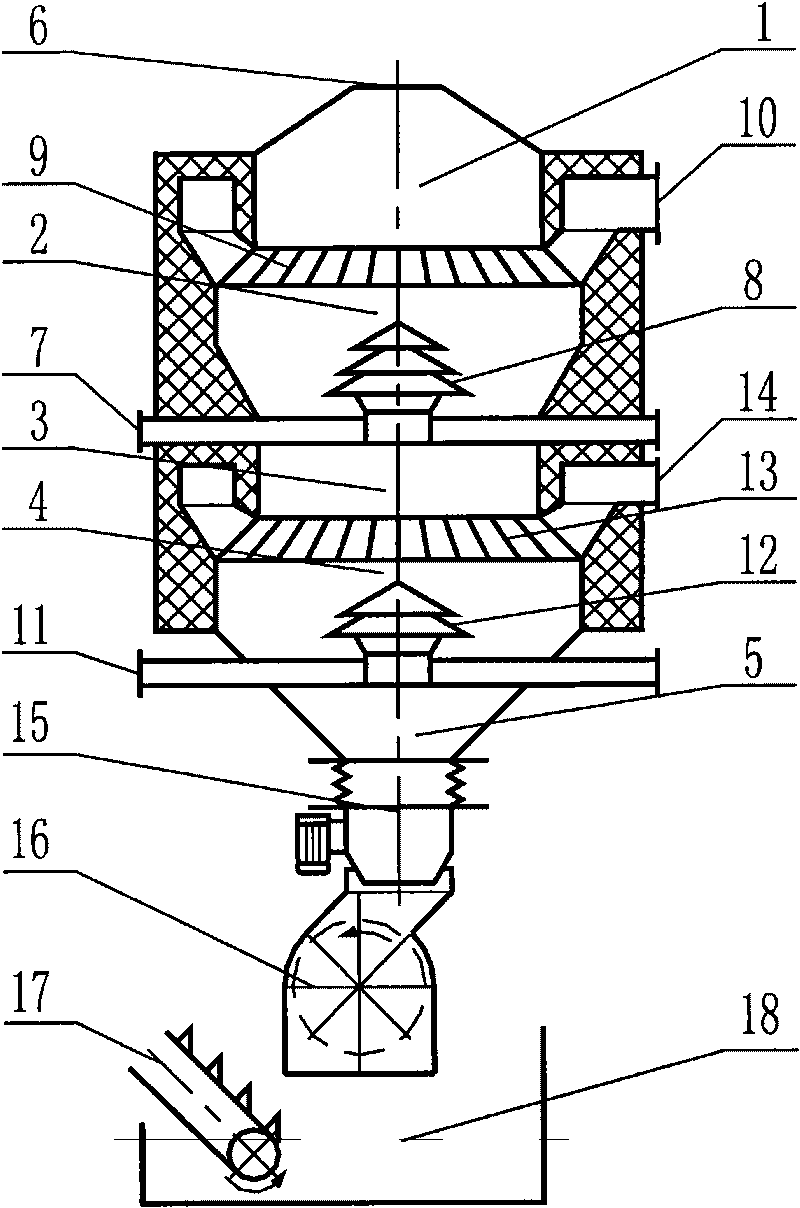

Device and method for cooling coke

InactiveCN101705101AQuality improvementIncrease productionCoke quenchingCombustible gas productionWater vaporEngineering

The invention discloses a device and a method for cooling coke. The device consists of a prestorage section, a vapor cooling section, a transitional section, a physically cooling section and a discharge section, wherein the upper prestorage section and the vapor cooling section are communicated by a vaporization gas collection channel; the middle transitional section and the physically cooling section are communicated by high-temperature coolant collection channel; a rotary discharge valve of the discharge second is immersed in liquid-sealed coke quenching tank; and a coke conveying device is arranged in the liquid-sealed coke quenching tank or a belt conveyor is arranged at the outlet of the discharge valve to convey the coke to the outside. The method for cooling the coke by vapor and coke oven gases comprises: introducing the vapor into the vapor cooling section; performing vaporization and generating synthesis gases; and introducing the coke oven gases into the physically cooling section to allow the coke oven gases to absorb the sensible heat of the coke and perform physical heat exchange with the coke. The device and the method have the advantages of reducing circulating gas volume, recovering the sensible heat of high-temperature coke, generating water gas and fully utilizing resources.

Owner:TAIYUAN UNIV OF TECH

Iron-base desulfurizer for catalyzing, translating and absorbing carbonyl sulfur at middle-low temperature and preparation thereof

InactiveCN101054538AHigh breakthrough sulfur capacityHigh precisionCombustible gas purificationSyngasSecondary component

The invention relates to a preparation of catalyzing and transforming-absorbing Fe-desulphurizer by high accuracy carbonyl sulfur at medium and low temperature, which has a good hydrogenation effect to the carbonyl sulfur and absorbs the produced carbonyl sulfur. The invention can be used to accurately remove the carbonyl sulfur in the ammonia material gas, coke oven gas, natural gas and composed gas. The desulphurizer is provided with primary active components Fe2O3, CeO2, MnO2, Ni2O3, and secondary components CuO, ZnO, MgO, K2O and etc, and the carriers are Al2O3, ZrO2, and residual binding agent and expanding drilling agent, and water. The process has a reacting temperature of 150-350 DEG C, an airspeed of 500-2000h-1, a carbonyl sulfur concentration in the gas from minim to 5000ppm. The inventive desulphurizer has a high catalytic transforming capacity with a carbonyl sulfur converting ratio more than 99%.

Owner:EAST CHINA UNIV OF SCI & TECH

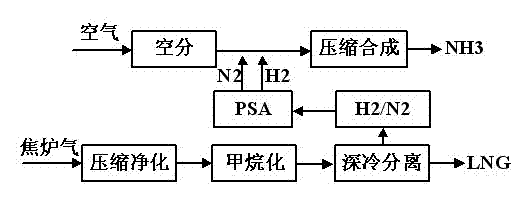

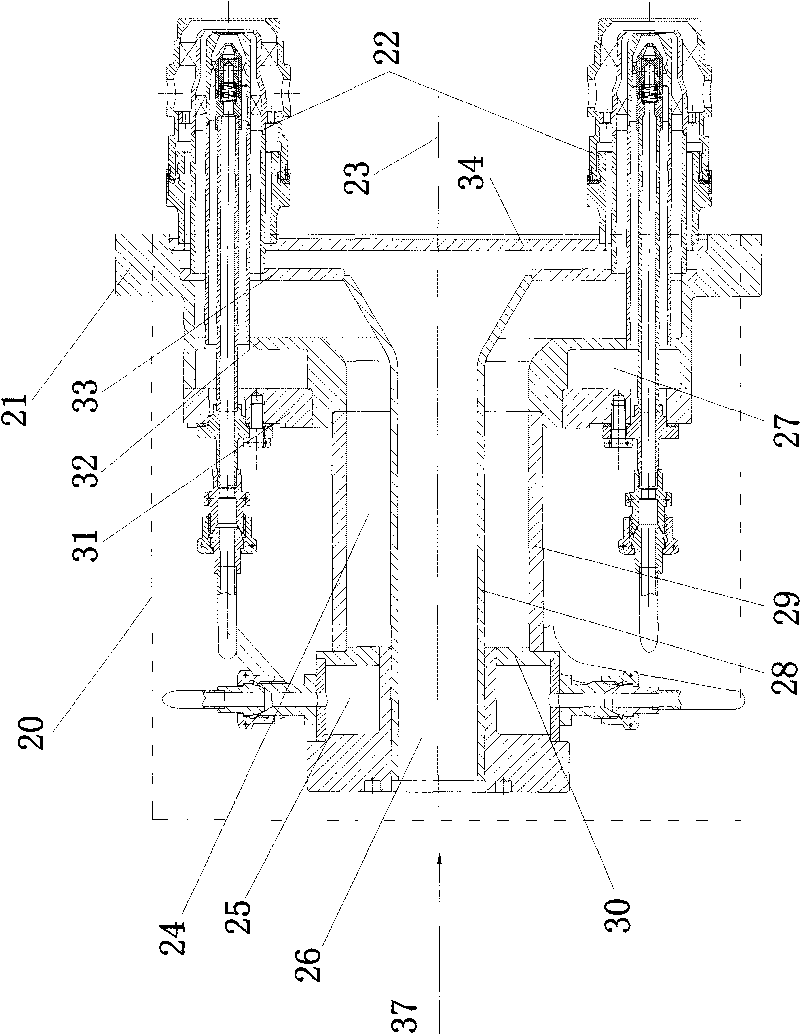

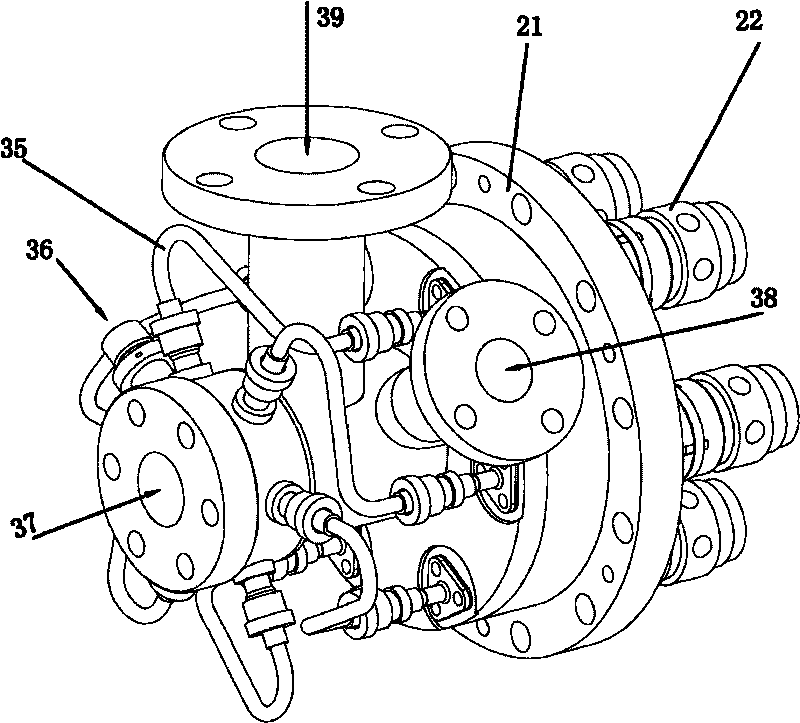

Technology for preparing liquefied natural gas and liquid ammonia by using coke oven gas

InactiveCN102517108AIncrease added valueReduce in quantityGaseous fuelsBulk chemical productionMethanationCoke oven

The invention discloses a technology for preparing liquefied natural gas and liquid ammonia by using coke oven gas. The coke oven gas is subjected to the steps of compression, purification, methanation, cryogenic separation and liquefaction of synthetic natural gas, variable pressure adsorptive separation and liquid ammonia preparation with hydrogen rich gas, so that the liquefied natural gas (LNG) of which methane purity is more than 99 percent and the liquid ammonia reaching national first level standard are obtained. By the technology, the hydrogen byproduct of the coke oven gas for preparing the LNG is fully utilized; effective ingredients of the coke oven gas such as H2, N2, CH4, CO and CO2 are furthest utilized; the CO and the CO2 are methanated, so that the yield of the CH4 is improved by about 1 / 3; the liquefied CH4 is used as the LNG and sold; and the rest nitrogen-containing hydrogen-rich gas is used as a raw material for synthesizing ammonia, so that the additional value of the coke oven gas is improved, and reliable raw material guarantee is provided for developing downstream products with high additional values and prolonging the product chain.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

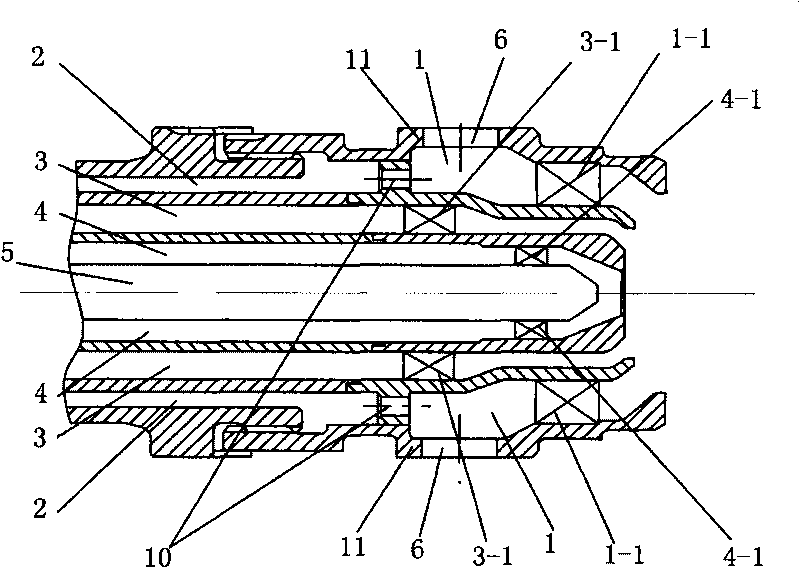

Low-pollution combustor for various fuels

InactiveCN101713546AEmission controlAvoid flashback of premixed combustionContinuous combustion chamberCombustion chamberAir cleaning

The invention discloses a low-pollution combustor for various fuels, which comprises a shunt system, a mounting edge and a plurality of double fuel nozzles, wherein the shunt system is connected with the plurality of double fuel nozzles through the mounting edge into a whole; the shunt system comprises a gas fuel subchannel, a liquid fuel subchannel, a diluent subchannel and an atomized air subchannel; and the double fuel nozzles are arranged circumferentially along the central line of the combustor. The low-pollution combustor for various fuels provided by the invention reduces the dischargeof pollutants such as NOX, solves the problems such as backfire and unstable combustion of premixing combustion of synthetic gases, simplifies an air cleaning and blowing protective system of a combustion chamber, avoids increasing the discharge of carbon monoxide, and can work with low and medium thermal value gas fuel such as coke oven gas, chemical tail gases and synthetic tail gases from IGCCpower plants and high thermal value gas fuel such as diesel oil and natural gas.

Owner:SHENYANG ENGINE DESIGN RES INST CHINA AVIATION IND CORP I

Carbonization process of high-volatilize content coal

InactiveCN101113340AGuaranteed not to oxidizeGuaranteed to burnDirect heating destructive distillationHeat carrierVolatiles

The invention relates to a carbonization process of high volatile coal, a direct heating process that heats and distills high volatile coal by using high temperature cycle gas in a shaft furnace as a carrier. Lump coal that moves up and down in the shaft furnace is heated by rising hot gas and the discharged volatiles form char; the char is cooled by cold gas that is introduced by the furnace bottom from the lower part of a furnace and then discharged outside the furnace; the rising gas is introduced outside finally by the furnace top, washed, purified and cooled; one part is taken as a cycle cooling medium, one part is taken as a cycle heat carrier after being per-heated and the rest is taken as a gas external supply and the calorific value is equal to that of a coke oven gas.

Owner:万天骥

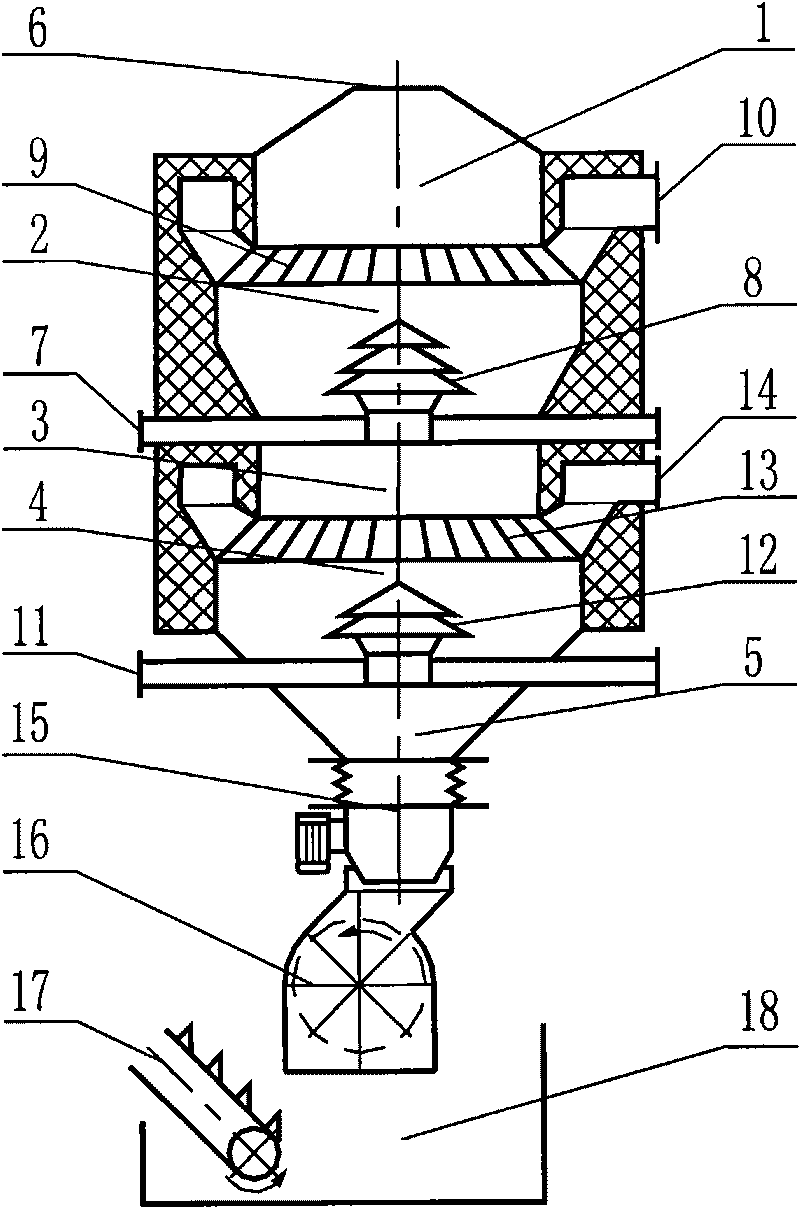

Process and device for desulphurization and denitration of flue gas

ActiveUS20170197180A1Promote circulationIncrease volumeGas treatmentNitrogen compoundsFiberSulfur dioxide

The invention discloses a process and device for desulfurization-denitration of a flue gas. A desulfurization-denitration solution is used in an absorption tower to absorb sulfur dioxide and / or nitrogen oxides from the flue gas or various combustion tail (waste) gases. The desulfurization-denitration solution with absorbed sulfur dioxide and / or nitrogen oxides releases the sulfur dioxide and / or nitrogen oxides by heating and / or gas stripping and / or vacuum regeneration in a regeneration tower. The released sulfur dioxide and / or nitrogen oxides are further concentrated into a sulfur dioxide and / or nitrogen oxide product with a higher purity in a concentration tower. The regenerated desulfurization-denitration solution is recycled for use. The process and device have a wide range of industrial applications, and can be used for desulfurization and / or denitration of flue gases, incineration gases, coke-oven gases, synthetic waste gases from dyestuff plants, pollutant gases discharged from chemical fiber plants and other industrial raw material gases or waste gases containing SOx.

Owner:WEI XIONGHUI +1

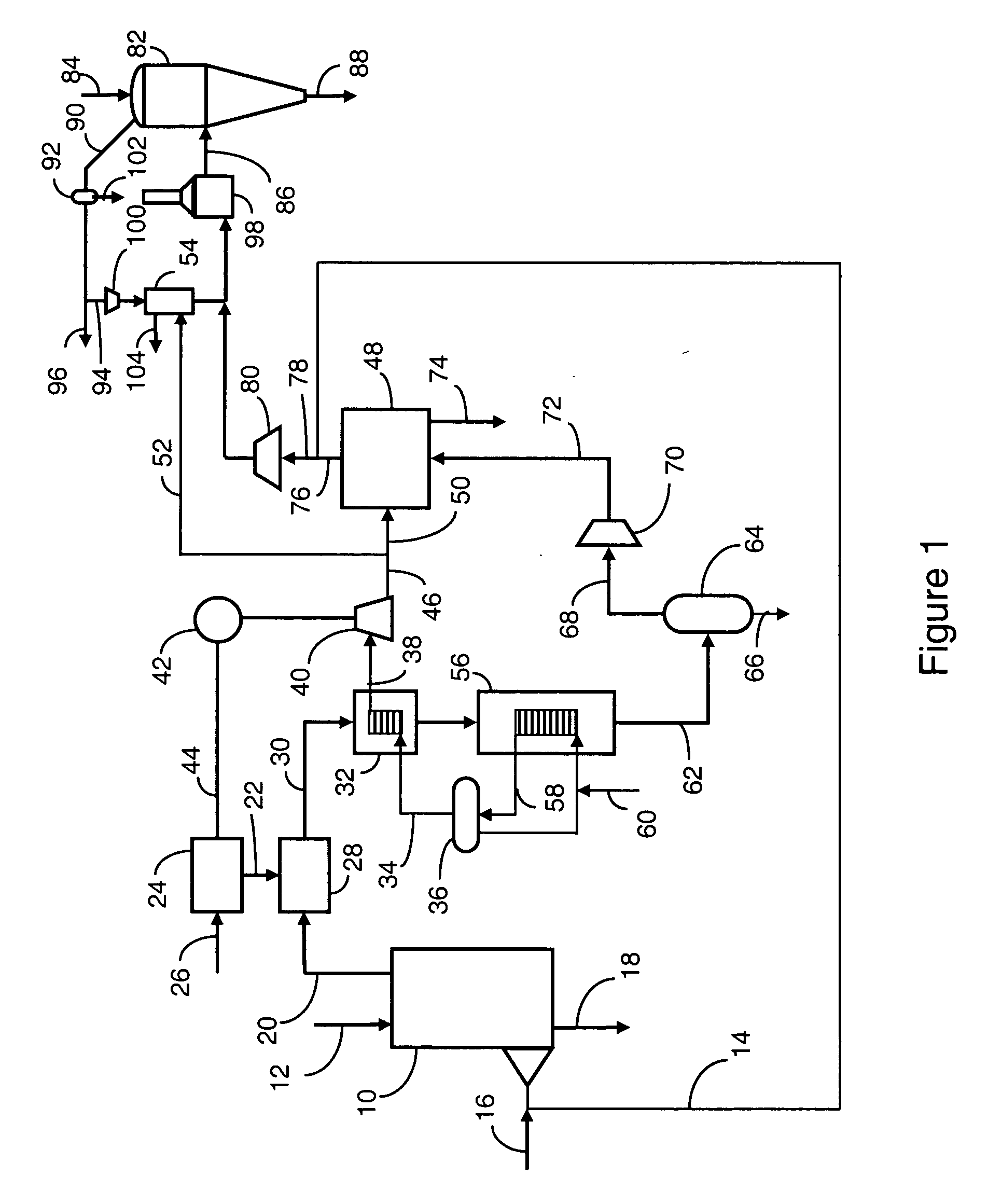

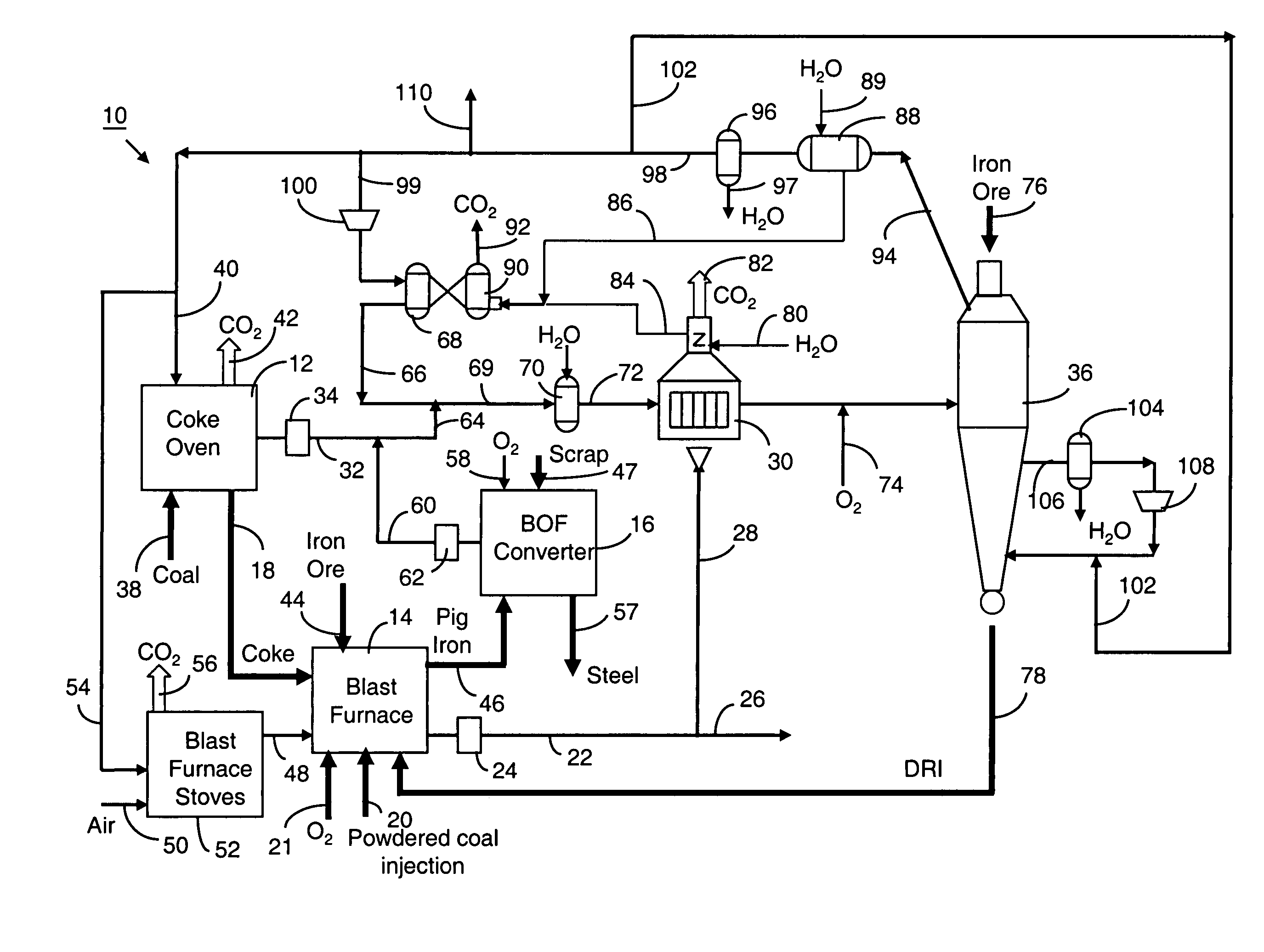

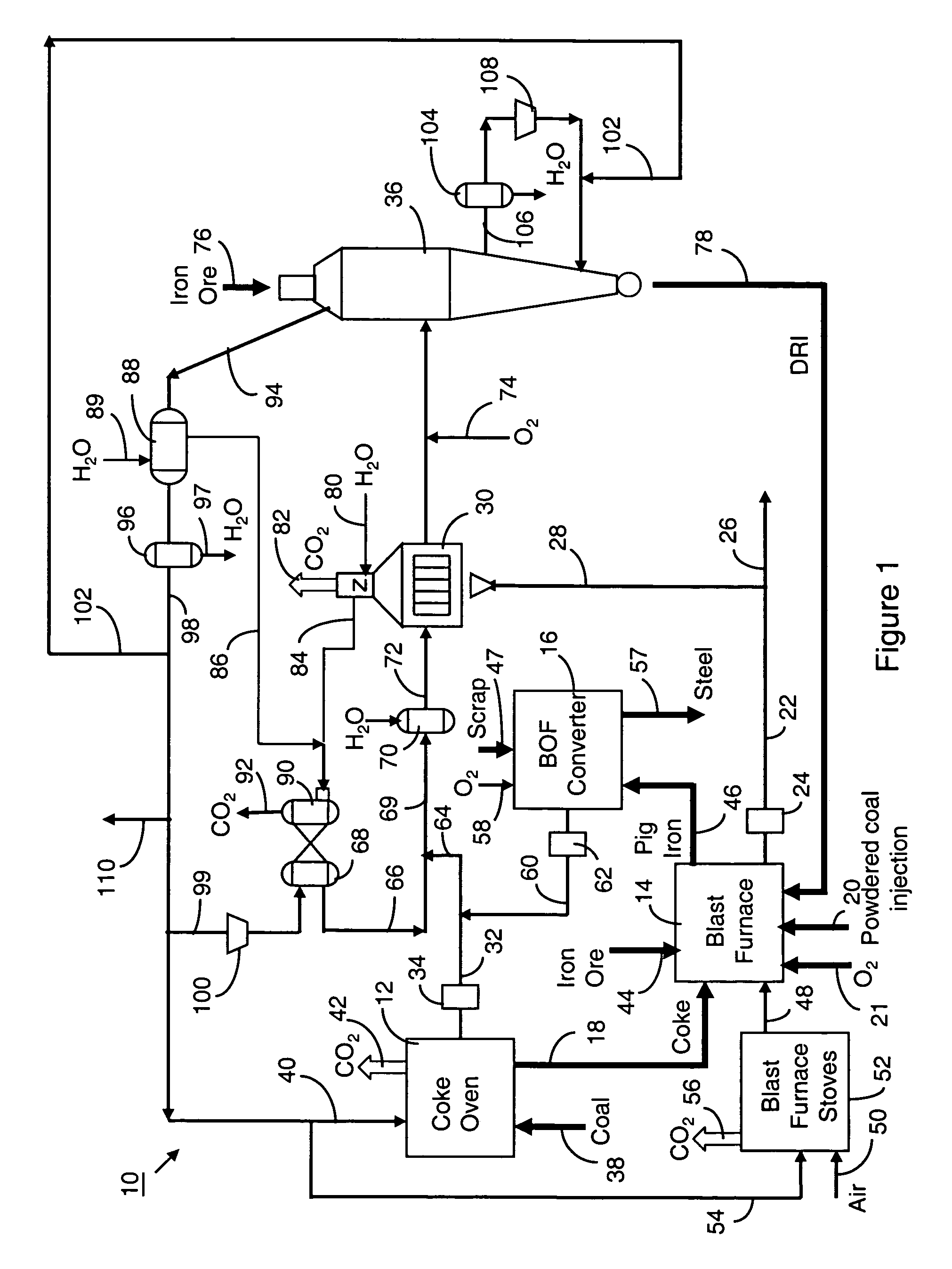

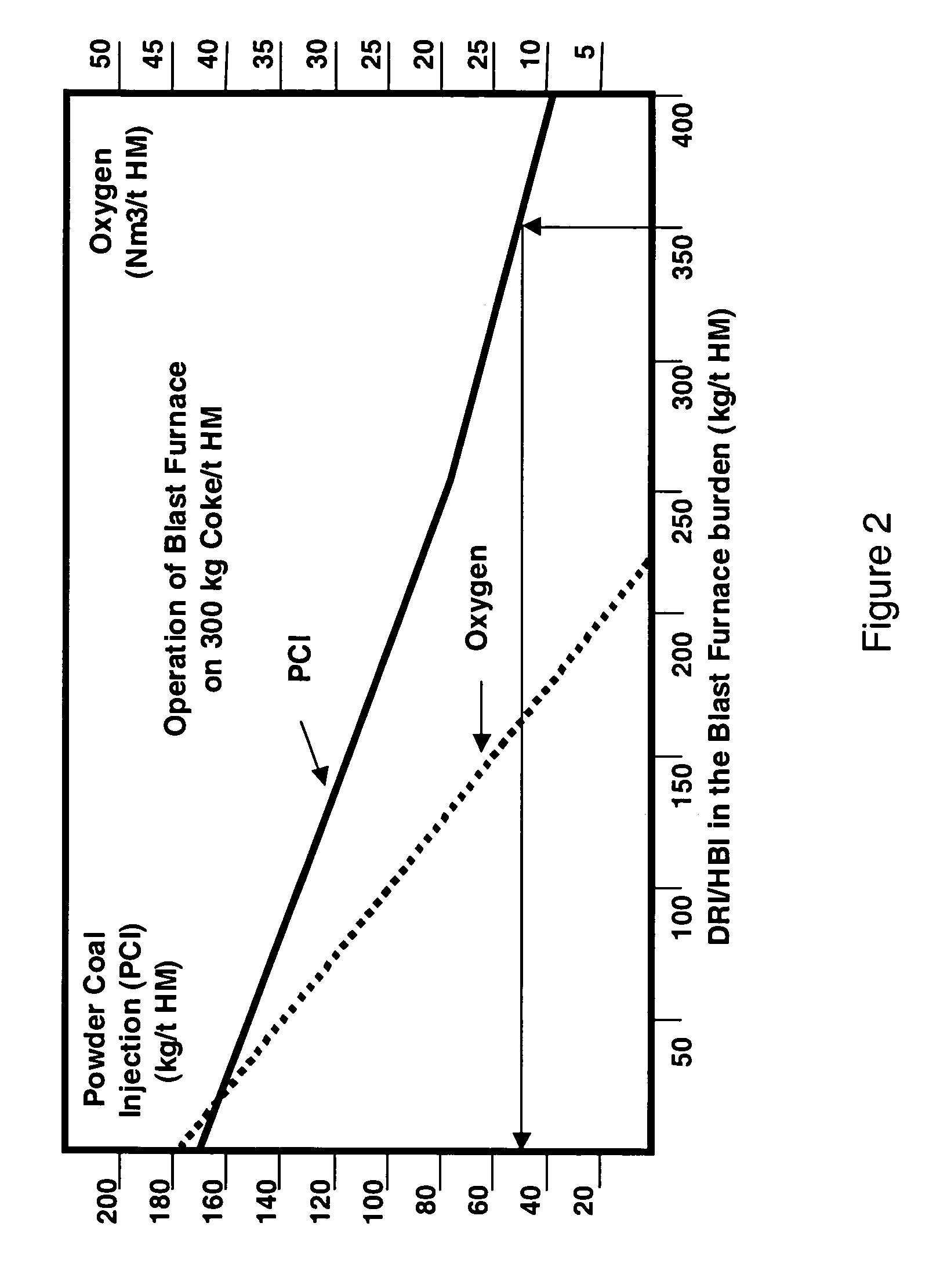

Method and apparatus for improved use of primary energy sources in integrated steel plants

ActiveUS6986800B2Increase productionReduction of fossil fuel specific consumptionBlast furnace detailsManufacturing convertersChemical agentFossil fuel

A method and an integrated steel plant wherein, instead of using coke oven gases, converter gases and blast furnace top gases available as fuel for power generation or other heating purposes, these gases are more efficiently utilized as chemical agents for direct reduction of iron ores producing DRI.DRI is charged to blast furnaces increasing production of crude steel without increasing the capacities of the coke oven plant and blast furnaces and without changes in the quality of the crude steel, or, if production rate is maintained, the fossil fuels specific consumption is significantly reduced.Utilisation of primary fossil energy according to the invention also reduces the specific CO2 emissions per ton of crude steel. The specific CO2 emission in conventional integrated mills is about 1.6 tons of CO2 per ton of crude steel.

Owner:HYLSA SA DE CV

Method for the direct reduction of iron oxides to metallic iron utilizing coke oven gas or the like

A process for reducing iron ore particles in a moving bed reduction reactor comprising an upper reduction zone and a lower discharge zone, wherein the coke oven gas, preferably forming all the make-up for the reducing gas circulating through and reacting in said reduction zone, is first fed to said discharge (cooling) zone and thereafter said coke oven gas, conditioned by the DRI in the lower zone, is withdrawn from the reactor and fed preferably into the recycled reducing gas for injection into the reduction zone of the reactor. Heavy hydrocarbons and other components of coke oven gas which may otherwise cause fouling, corrosion, or deposits in the direct reduction plant are removed from coke oven gas by catalytic and / or adsorptive action of the DRI present in said lower zone, before being externally transferred to the reduction zone of the reduction reactor.

Owner:HYL TECH

Multifunctional raw gas purifying agent, preparation method and application method thereof

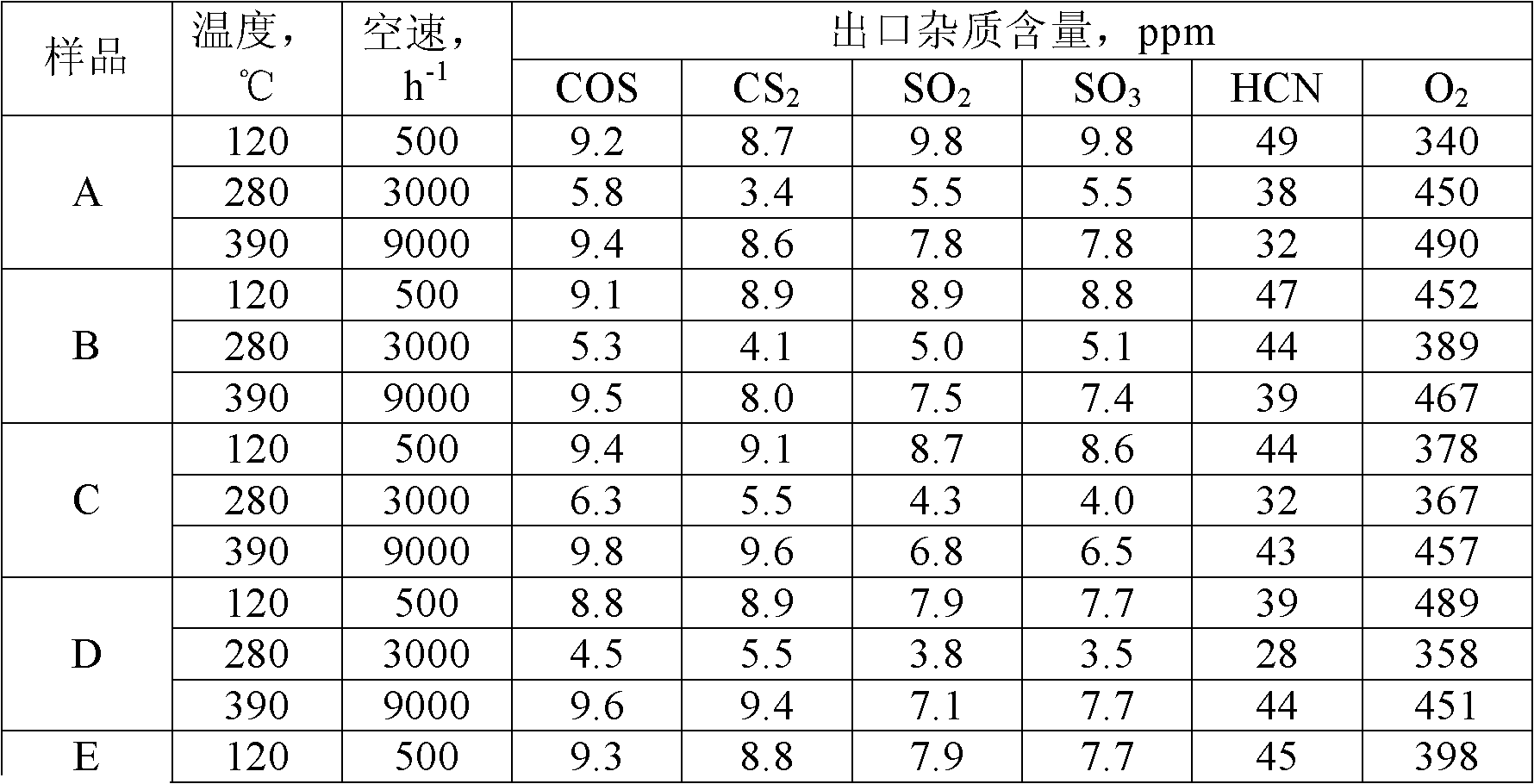

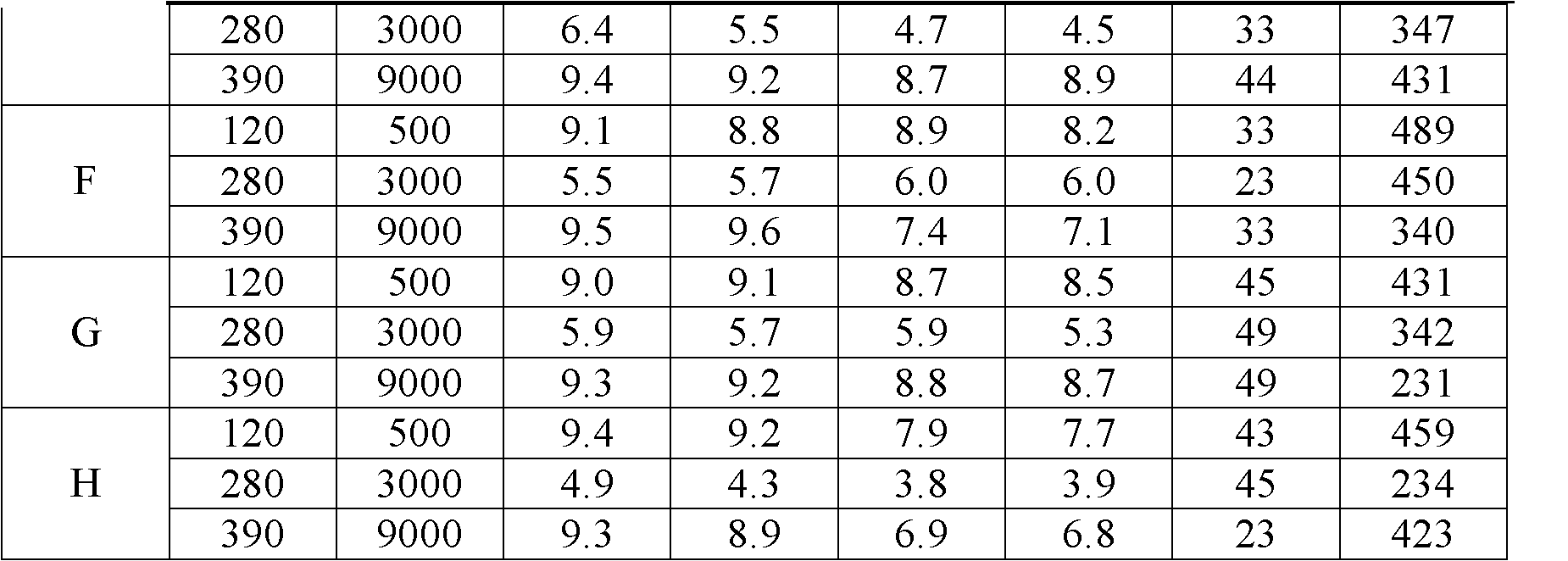

The invention relates to a multifunctional raw gas purifying agent, a preparation method and an application method thereof. According to the present invention, active alumina is adopted as a carrier, and the carrier loads ammonium molybdate, one or two materials selected from copper acetate, zinc acetate, lead acetate, nickel oxalate and ammonium metavanadate, and one material selected from magnesium chloride, potassium carbonate and sodium carbonate to prepare the multifunctional raw gas purifying agent, wherein the mass of the loaded ammonium molybdate is 1-10% of the mass of the carrier, the total mass of the other two or three loaded metal compounds is 10-25% of the mass of the carrier. The preparation method for the multifunctional raw gas purifying agent comprises: impregnating the carrier for 2-6 hours by the metal compound solution; drying for 2-4 hours at a temperature of 120 DEG C; carrying out baking for 4-6 hours at the temperature of 280-350 DEG C to prepare the multifunctional raw gas purifying agent. The multifunctional raw gas purifying agent of the present invention is adopted in the raw gases of water gas, semi-water gas, coke oven gas or IGCC power generation fuel gas to purify COS, CS2, HCN, SO2, SO3 O2 and other impurities, wherein the conversion rates of the COS, the CS2, the HCN, the SO2 and the SO3 are more than or equal to 90%, and the O2 removal rate is more than or equal to 95%.

Owner:HAISO TECH

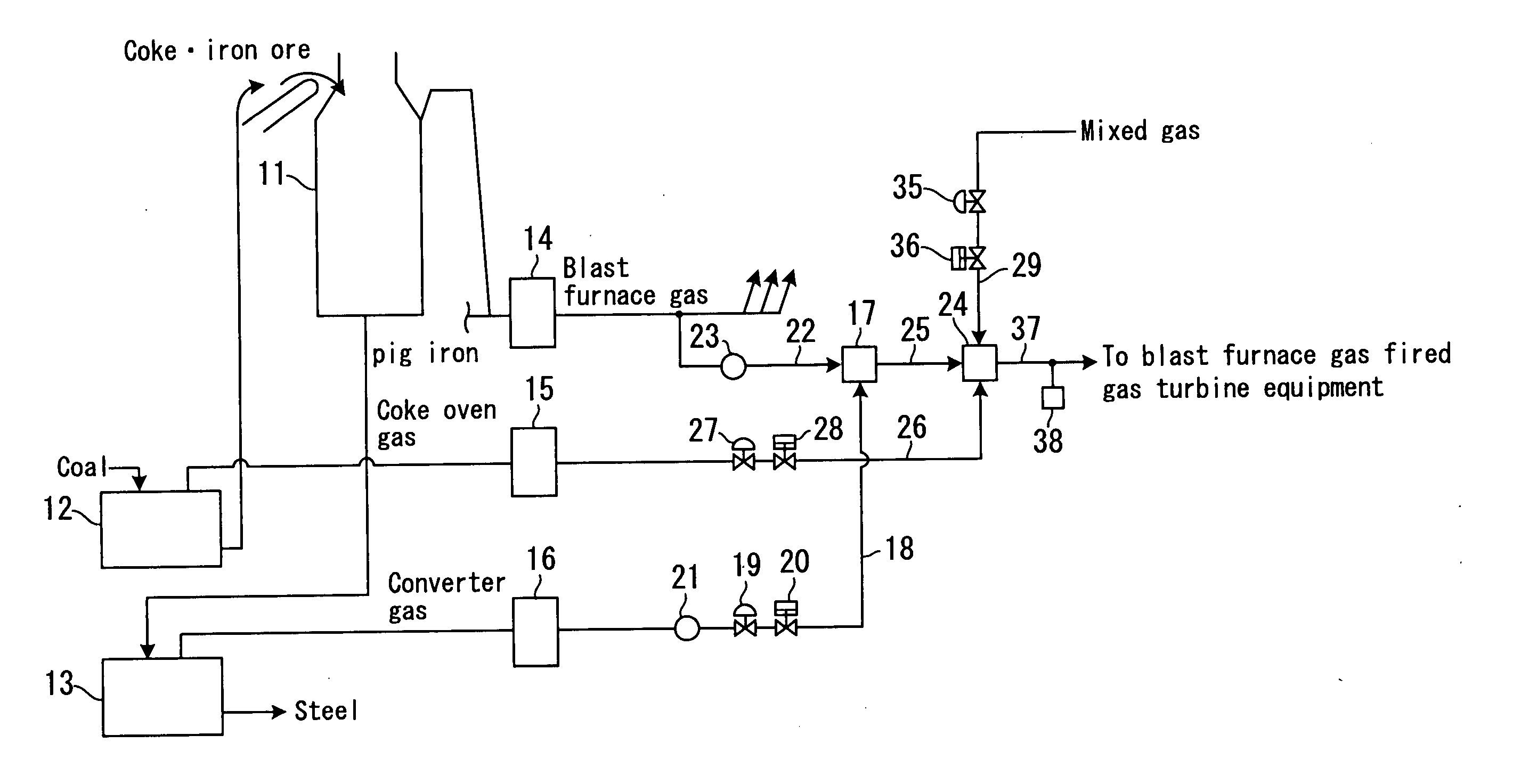

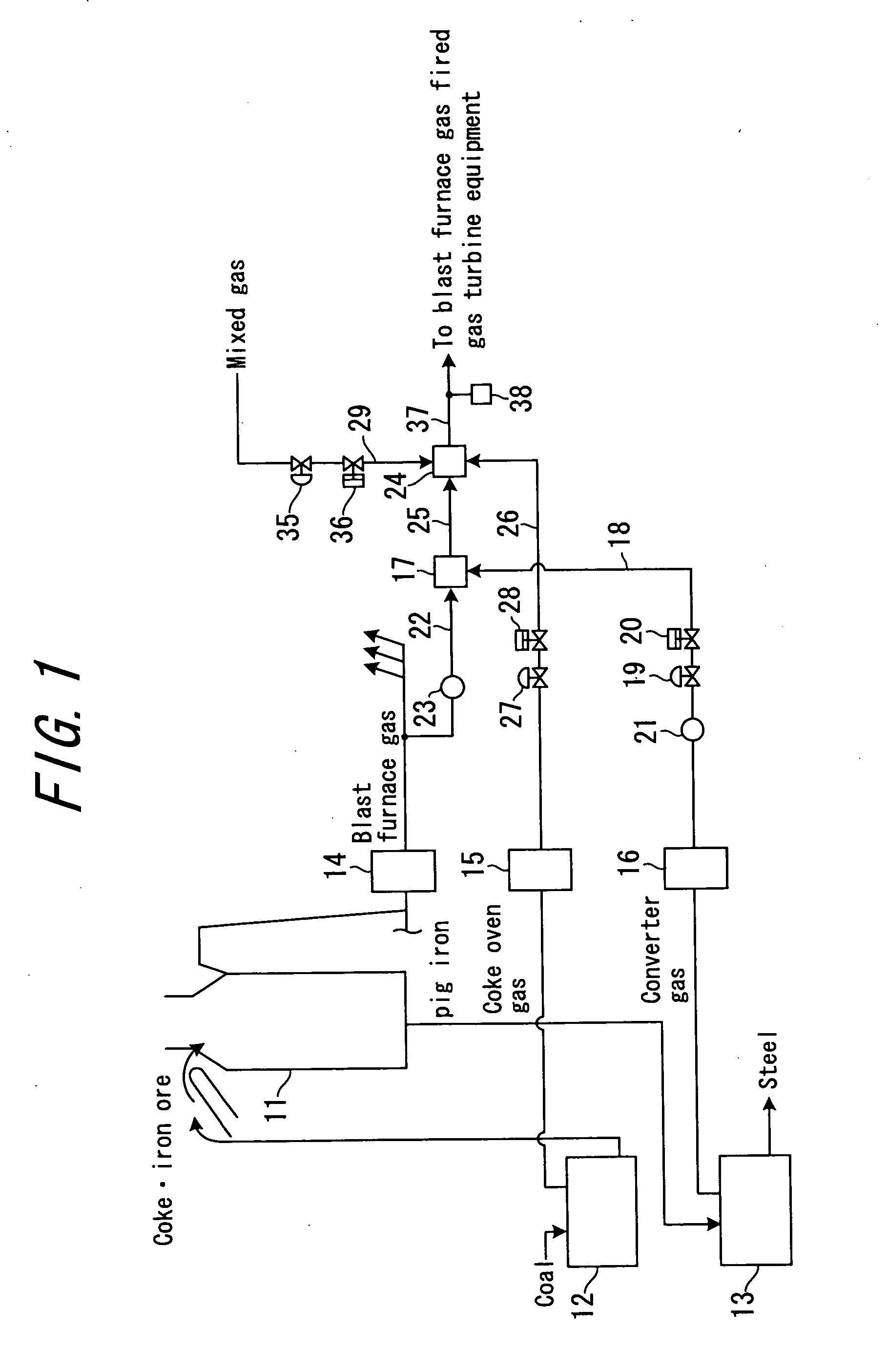

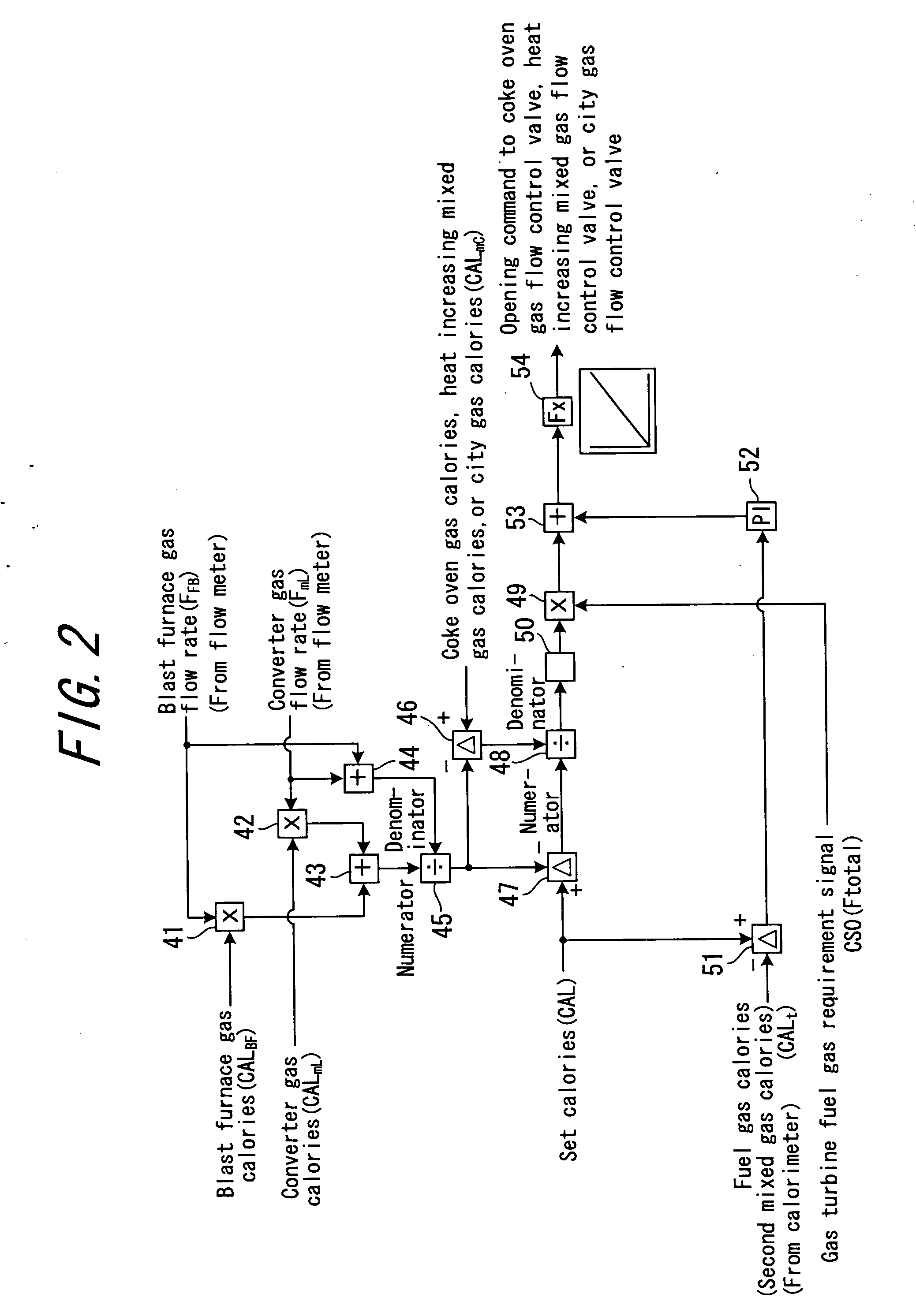

Fuel gas calorie control method and device

ActiveUS20060234171A1Excessive mixingEasy to controlBurnersGas modification by gas mixingMixed flowEngineering

Calories of a first mixed gas are predicted by calculations based on the mixed flow rate of a blast furnace gas and the mixed flow rate of a converter gas measured by flow meters, and preset blast furnace gas calories and converter gas calories; the flow rate ratio of the mixed flow rate of a coke oven gas to a gas turbine consumed fuel gas flow rate is calculated based on the predicted calories, set calories, and preset coke oven gas calories; the mixed flow rate required value of the coke oven gas is calculated based on the flow rate ratio and a gas turbine fuel gas requirement signal corresponding to the gas turbine consumed fuel gas flow rate; and the opening of a coke oven gas flow control valve provided in a fuel gas production system is controlled, based on the mixed flow rate required value, to control the mixed flow rate of the coke oven gas.

Owner:MITSUBISHI POWER LTD

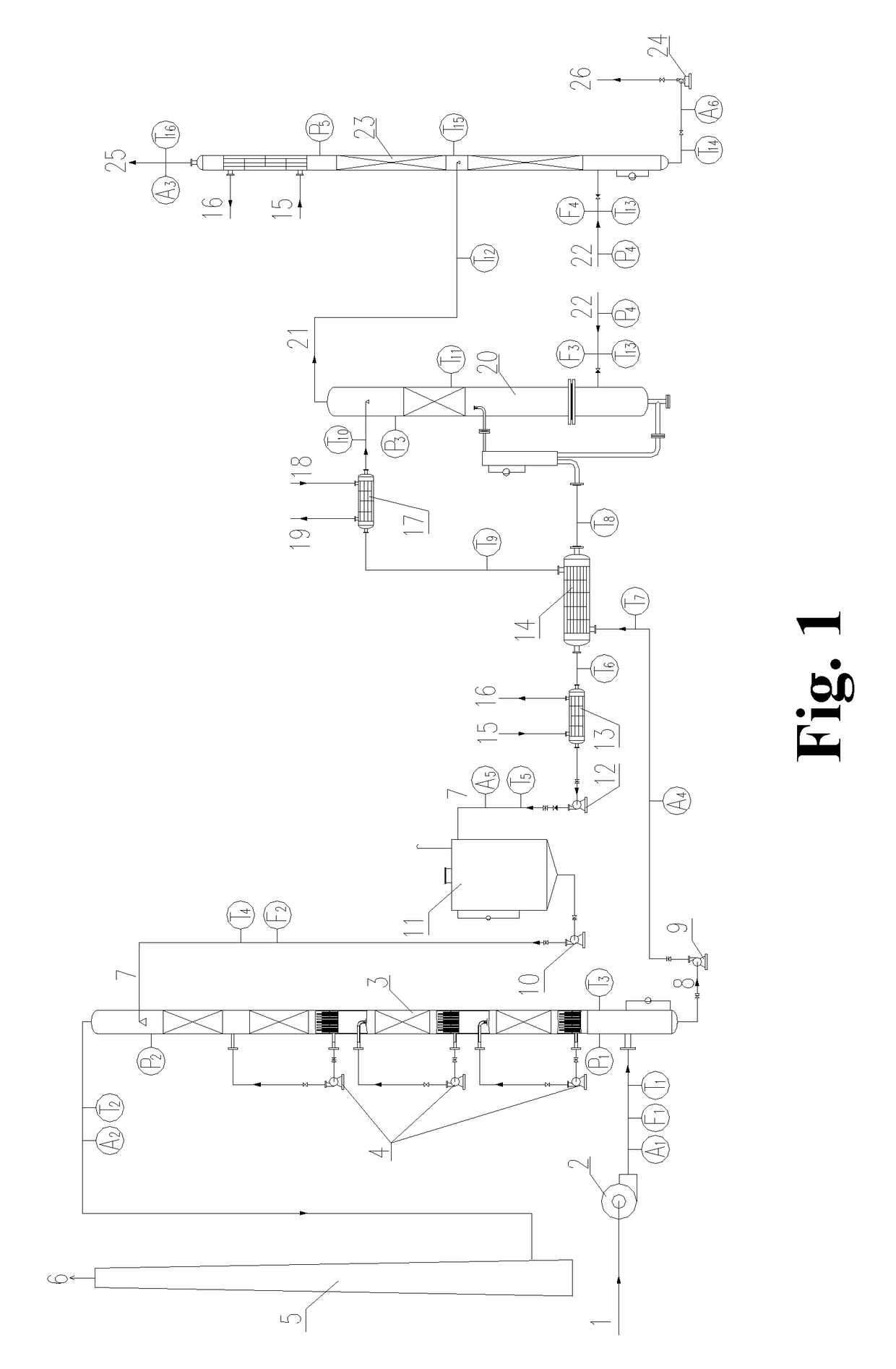

Method for producing liquefied natural gas by using coke oven gas

The invention provides a method for producing liquefied natural gas by using coke oven gas. The method comprises the following steps: (1) the coke oven gas is pretreated to remove benzene, naphthalene, tar and HCN (hydrogen cyanide); (2) sulfur is removed; (3) carbon is removed and the coke oven gas is dried; (4) the coke oven gas is led to a first heat exchanger and pre-cooled; (5) the pre-cooled coke oven gas passes through a second heat exchanger, a reboiler at the bottom of a low-temperature rectifying tower and a third heat exchanger in sequence, so that the temperature is lowered step by step; (6) gaseous liquid coming out of the third heat exchanger is led to a gas-liquid separator for gas-liquid separation, then the liquid coming out of the gas-liquid separator enters the low-temperature rectifying tower, and a liquefied natural gas product is acquired at the bottom of the low-temperature rectifying tower; and otherwise, the gaseous liquid coming out of the third heat exchanger is directly led to the low-temperature rectifying tower, and the liquefied natural gas product is acquired at the bottom of the low-temperature rectifying tower. The method for producing the liquefied natural gas by using the coke oven gas as raw material has the advantages of high output as well as low energy consumption and cost, and is easy to operate.

Owner:BEIJING ZHONGKE RUIAO ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com