Multifunctional raw gas purifying agent, preparation method and application method thereof

A raw gas, multi-functional technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of no conversion removal, less research on conversion removal, catalyst poisoning or corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

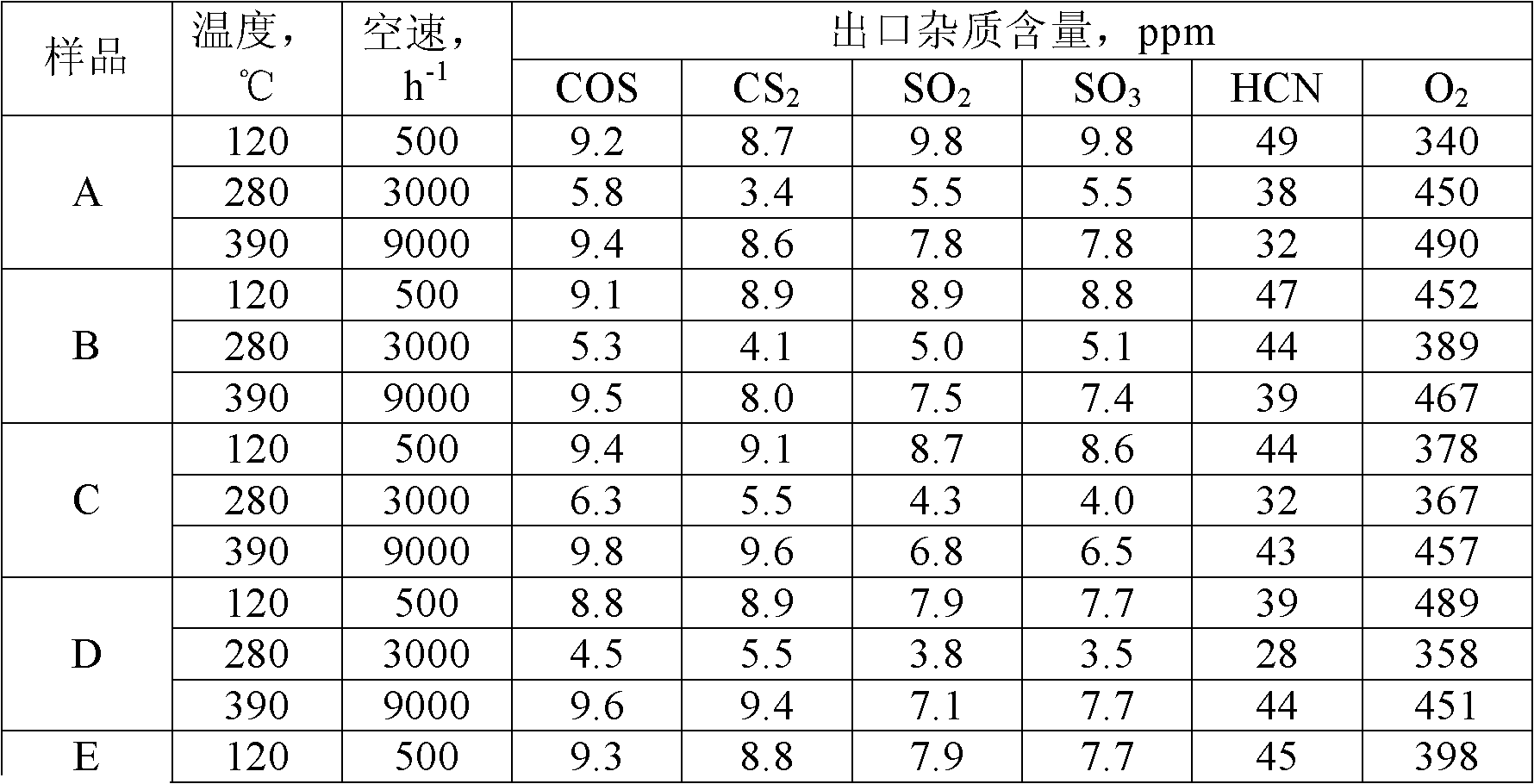

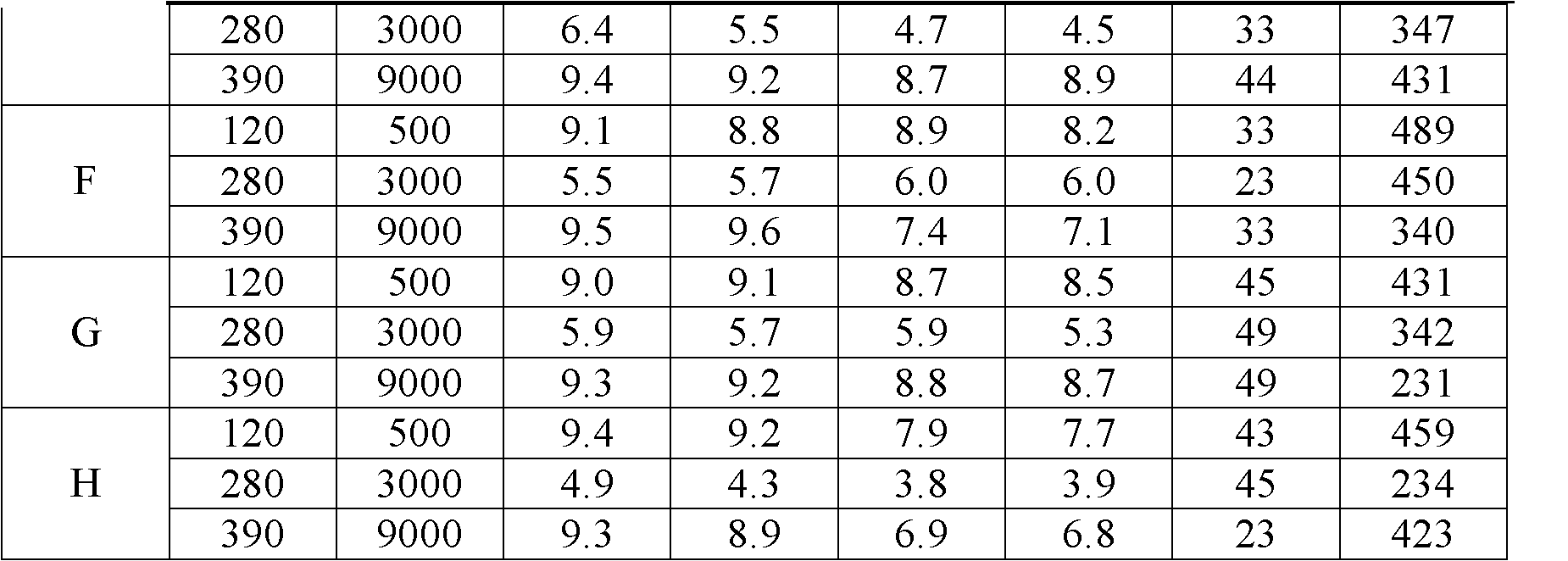

Embodiment 1

[0024] Weigh 5 grams of ammonium molybdate, 7 grams of copper acetate, and 7 grams of magnesium chloride, mix them into 52 grams of water, add 10% ammonia solution to adjust the pH value to 9-12, heat and stir to prepare the active component impregnation solution, and the impregnation solution Pour into a beaker with 100 grams of active alumina carrier and soak for 4 hours, take it out and dry it at 120°C for 3 hours, then bake it at 300°C for 5 hours to obtain the multifunctional raw material gas purifier, coded as A.

Embodiment 2

[0026] Weigh 7 grams of ammonium molybdate, 9 grams of lead acetate, and 15 grams of potassium carbonate, mix them into 52 grams of water, add 10% ammonia solution to adjust the pH value to 9-12, heat and stir to prepare the active component impregnation solution, and the impregnation solution Pour into a beaker containing 100 grams of activated alumina carrier and soak for 4 hours, take it out and dry it at 120°C for 4 hours, then bake it at 280°C for 4 hours to obtain the multifunctional raw material gas purifier, coded as B.

Embodiment 3

[0028] Weigh 10 grams of ammonium molybdate, 5 grams of nickel oxalate, and 5 grams of sodium carbonate, mix them into 52 grams of water, add 10% ammonia solution to adjust the pH value to 9-12, heat and stir to prepare the active component impregnation solution, and impregnate Pour the liquid into a beaker with 100 grams of activated alumina carrier and soak for 4 hours, take it out, dry it at 120°C for 2 hours, and then roast it at 340°C for 6 hours to obtain the multifunctional raw material gas purifier, coded as C .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com