Method for preparing BiVO4 film with photocatalysis performance by using sol-gel method

A technology of photocatalysis and gel method, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve environmental friendliness, uniform components, and high purity of products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Step (1): According to the molar ratio of Bi:CA=1:1, 0.012mol Bi(NO 3 ) 3 ·5H 2 O and 0.012mol of citric acid were dissolved in 10ml of deionized water, stirred evenly, and the pH was adjusted with ethanolamine until the solution was clear to obtain precursor solution A; wherein CA was the abbreviation of citric acid;

[0018] Step (2) according to the molar proportion of V:CA=1:1.8 will 0.012mol NH 4 VO 3 and 0.0216mol citric acid were dissolved in 10ml boiling water to prepare precursor solution B;

[0019] Step (3) According to the ratio of Bi:V=1:1, slowly add the precursor solution A to the precursor solution B and mix, stir at constant temperature for 5 hours to obtain dark blue BiVO 4 Sol C;

[0020] Step (4): Spin-coat dark blue BiVO on the surface of the pre-treated FTO substrate at a speed of 4000 rpm with a spin coating method 4 Sol C, pre-annealed the film on the surface of the spin-coated FTO substrate at 200 ° C for 6 min, and the pre-treatment proce...

Embodiment 2

[0024] Step (1): According to the molar ratio of Bi:CA=1:1.5, 0.01mol Bi(NO 3 ) 3 ·5H 2 O and 0.015mol citric acid were dissolved in 10ml of deionized water, stirred evenly, and the pH was adjusted with ethanolamine until the solution was clear to obtain the precursor solution A;

[0025] Step (2) according to the molar proportion of V:CA=1:1.5 will 0.012mol NH 4 VO 3 and 0.018mol citric acid were dissolved in 10ml boiling water to prepare precursor solution B;

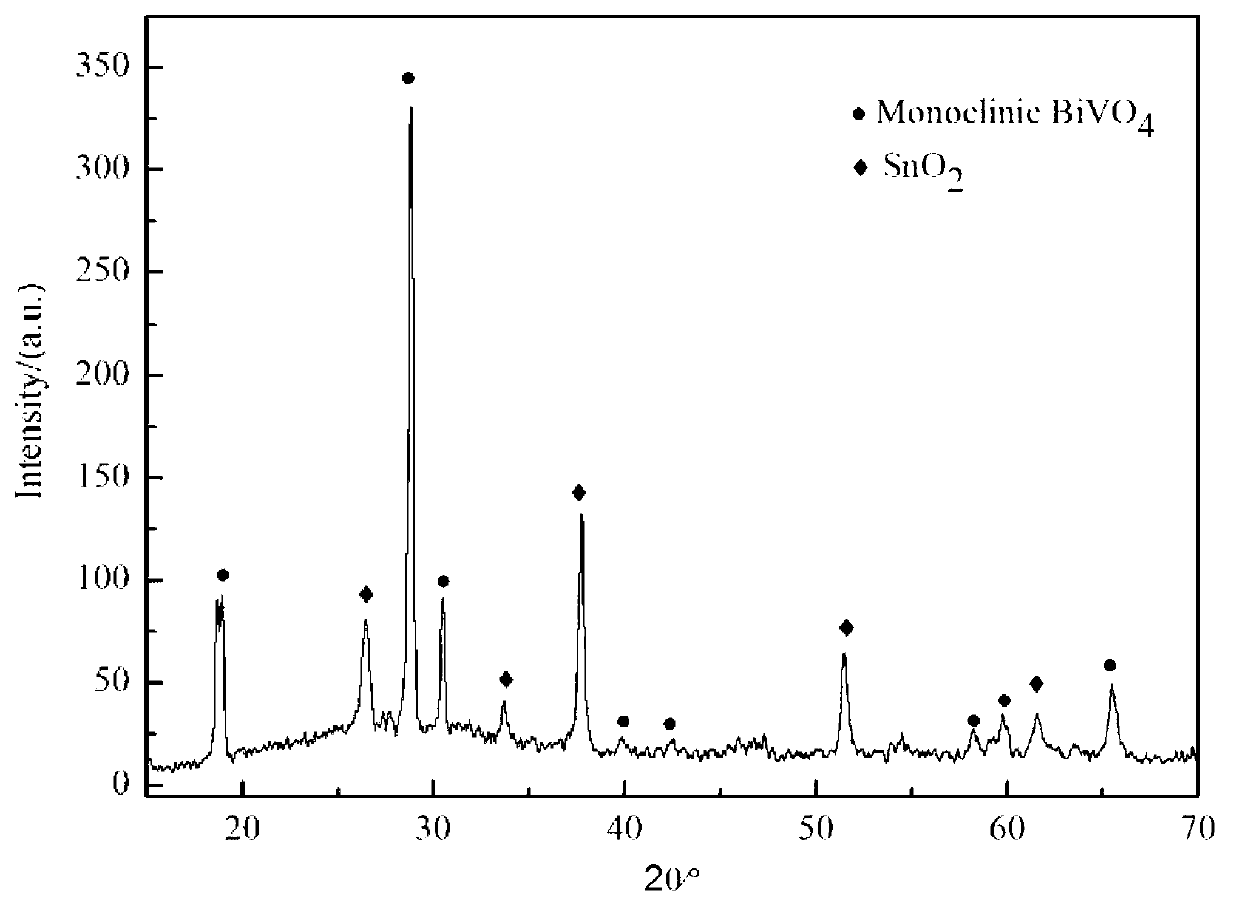

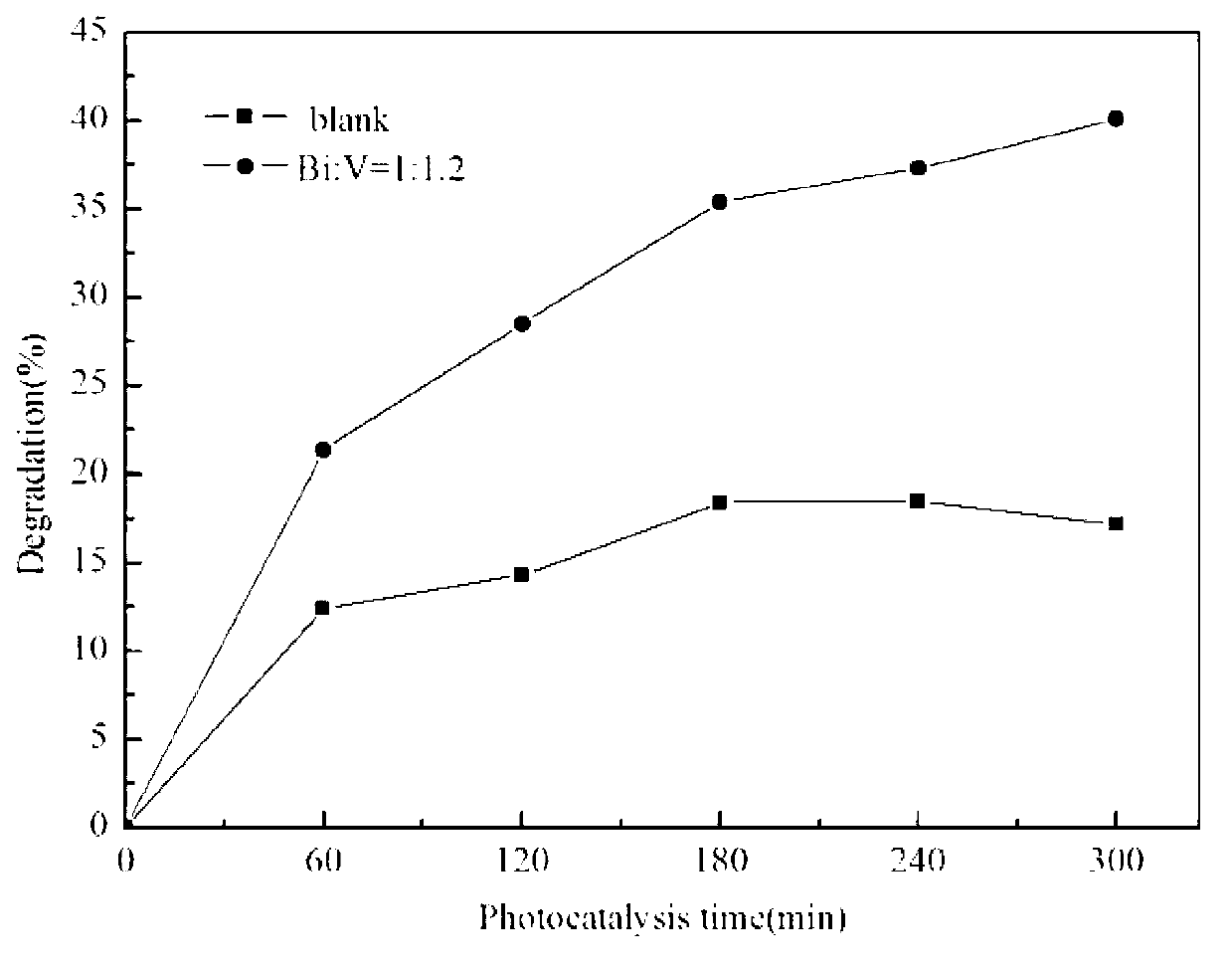

[0026] Step (3) According to the ratio of Bi:V=1:1.2, the precursor solution A was slowly added dropwise to the precursor solution B for mixing, and stirred at constant temperature for 5 hours to obtain dark blue BiVO 4 Sol C;

[0027] Step (4): Spin-coat dark blue BiVO on the surface of the pre-treated FTO substrate at a speed of 4500 rpm with a spin coating method 4 Sol C, pre-annealed the film on the surface of the spin-coated FTO substrate at 200 ° C for 3 min, and the pre-treatment process of the FTO glass ...

Embodiment 3

[0033] Step (1): According to the molar ratio of Bi:CA=1:0.8, 0.008mol Bi(NO 3 ) 3 ·5H 2 O and 0.0064mol citric acid were dissolved in 10ml deionized water, stirred evenly, and the pH was adjusted with ethanolamine until the solution was clear to obtain the precursor solution A;

[0034] Step (2) according to the molar proportion of V:CA=1:0.8 will 0.008mol NH 4 VO 3 and 0.0064mol citric acid were dissolved in 10ml boiling water to prepare precursor B;

[0035] Step (3) According to the ratio of Bi:V=1:1, slowly add the precursor solution A to the precursor solution B and mix, stir at constant temperature for 5 hours to obtain dark blue BiVO 4 Sol C;

[0036] Step (4): Spin-coat dark blue BiVO on the surface of the pre-treated FTO substrate at a speed of 3500rpm with a spin coater 4 Sol C, pre-annealed the film on the surface of the spin-coated FTO substrate at 250 ° C for 4 min, and the pre-treatment process of the FTO glass substrate was ultrasonic cleaning with aceton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com