Production method of regenerated fibroin fiber

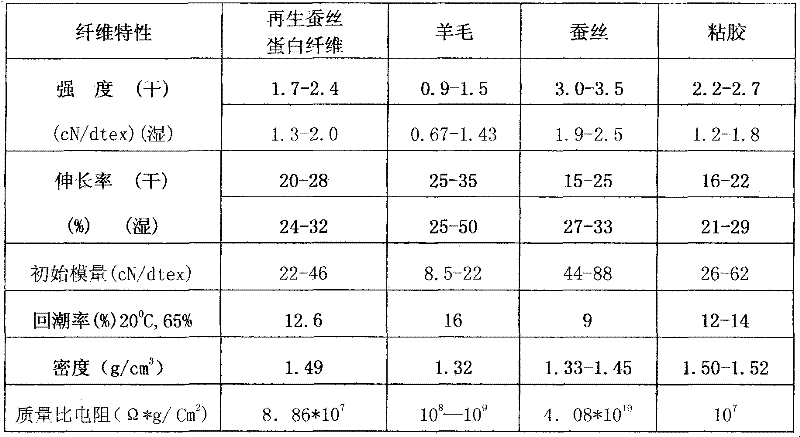

A technology for regenerated silk and protein fibers, applied in the direction of cellulose/protein conjugated artificial filaments, wet spinning, etc., can solve the problem of poor performance, unstable structure of regenerated silk protein fibers, and relatively high requirements for process steps and equipment. Advanced problems, to achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

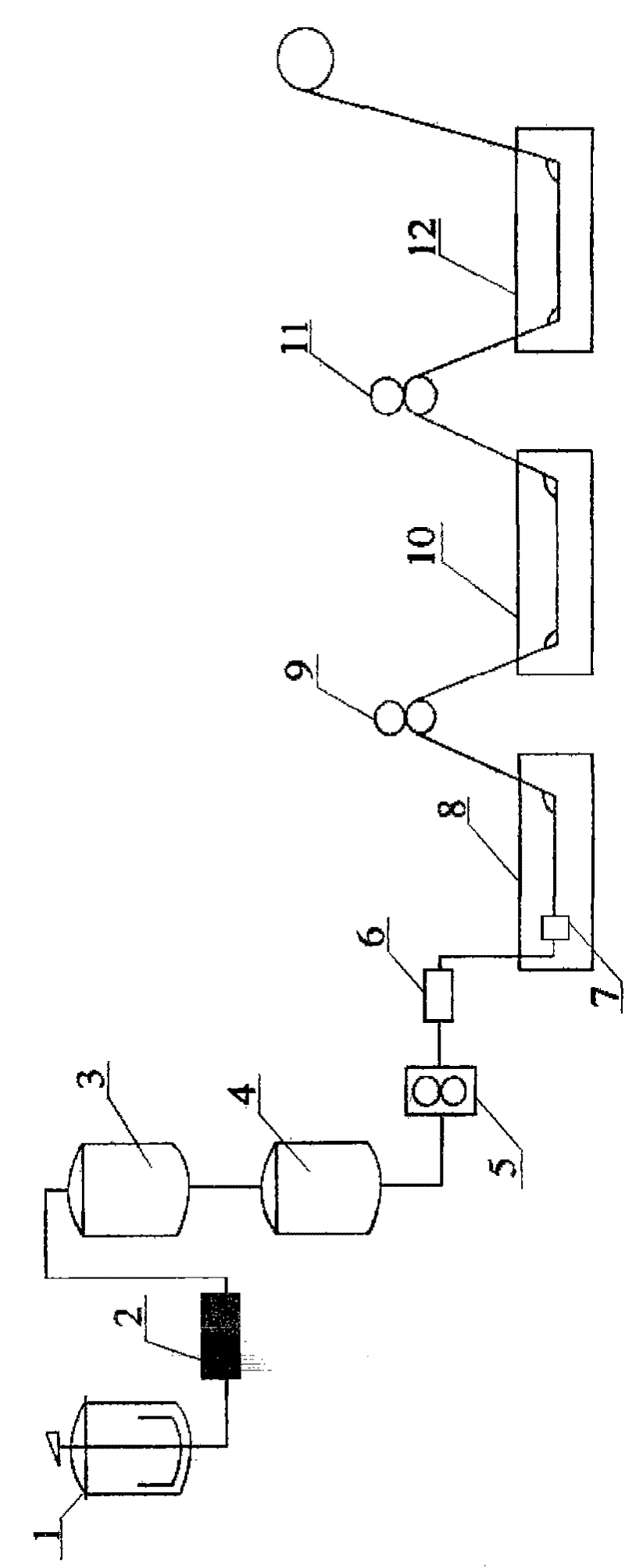

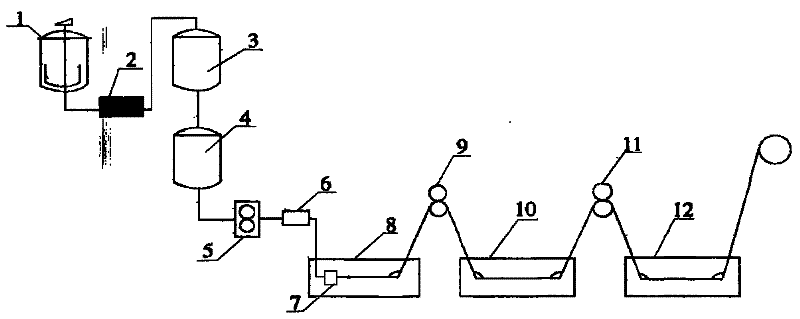

[0018] In conjunction with shown in Fig. 1, the production method of regenerated silk protein fiber of the present invention comprises the following steps:

[0019] 1. Raw material selection

[0020] Select non-spinnable protein materials such as silk waste, silk waste, waste spinning, and silk spinning waste.

[0021] 2. Preparation of regenerated silk protein powder

[0022] Wash the silk waste, silk waste, waste spinning, silk spinning waste, etc. with water, then dry and weigh at room temperature, and then put the above silk material into lye (NaOH) with a concentration of 3-5% (weight percentage) In the process, according to the ratio of silk material: lye (weight ratio) of 1:50, hydrolyze at 60-70°C for 3-5 hours, filter after hydrolysis, remove lye and impurities, and obtain the regenerated silk protein stock solution, which is subjected to 100°C Under drying, the regenerated silk protein powder is obtained.

[0023] 2.1. Effect of hydrolysis temperature on hydrolysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com