A kind of preparation method of amorphous coating

An amorphous coating and amorphous technology, applied in coating, metal material coating process, fusion spraying, etc., to achieve the effect of solving the problem of secondary utilization, high stability, excellent mechanical properties and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

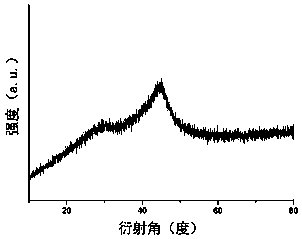

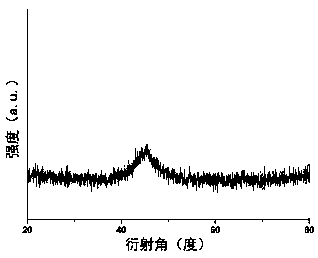

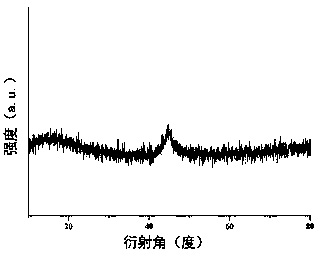

[0031] (1) Select Fe 78 Si 9 B 13 Amorphous ribbon waste, its XRD test results are shown in figure 1 , it can be seen that it is in a completely amorphous state. The strip is placed in a vacuum tube furnace, which is filled with argon and guaranteed to be an argon atmosphere. The temperature is raised from room temperature to 350 ° C, the heating rate is 20 ° C / min, and the holding time is 2 h. , after the heat preservation is over, the strip material is cooled with the furnace, and the Fe obtained after cooling 78 Si 9 B 13 Amorphous strip waste was detected by XRD figure 2 , indicating that the strip scrap has not crystallized.

[0032] (2) Place 150 g of heat-treated strips in a 2L ball milling jar with a ball-to-material ratio of 20 to 1. After the ball milling jar is sealed, vacuumize and feed argon to ensure that the ball milling jar is an argon atmosphere. Put the ball mill jar on a planetary ball mill for 10 hours, the rotation speed is 400r / min, and the revo...

Embodiment 2-5

[0037] Only heat treatment process parameter is different from embodiment 1 in this group of embodiment, Fe 78 Si 9 B 13 Amorphous ribbon replaced by Fe 83.3 Si 4 B 12 Cu 0.7 Amorphous ribbon

[0038] Other process and composition are identical with embodiment 1, and the average value after the friction coefficient of its concrete heat treatment parameter and gained coating is stabilized is shown in table 1

[0039] The concrete parameter of table 1 embodiment 2-5 heat treatment and gained coating coefficient of friction

[0040]

Embodiment 6-9

[0042] Only the ball milling process parameters of this group of examples are different from Example 1, Fe 78 Si 9 B 13 Amorphous ribbon replaced by Fe 84 Si 4 B12 Amorphous ribbon

[0043] , other process and composition are identical with embodiment 1, and the average value after the friction coefficient of its concrete ball milling parameter and gained coating stabilizes is shown in table 2

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com