Patents

Literature

163results about How to "Small cutting resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slurry for slicing silicon ingot and method for slicing silicon ingot using same

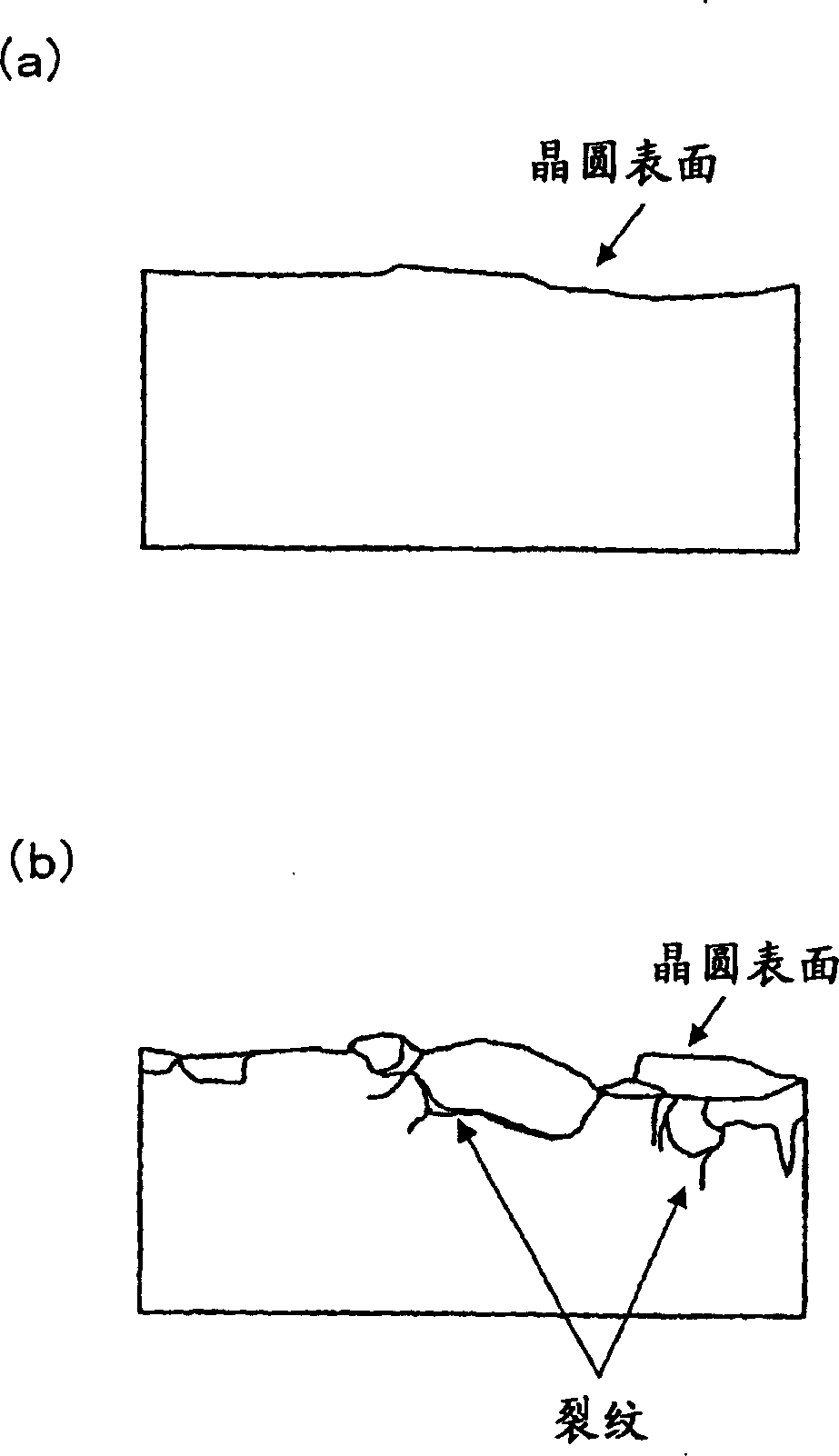

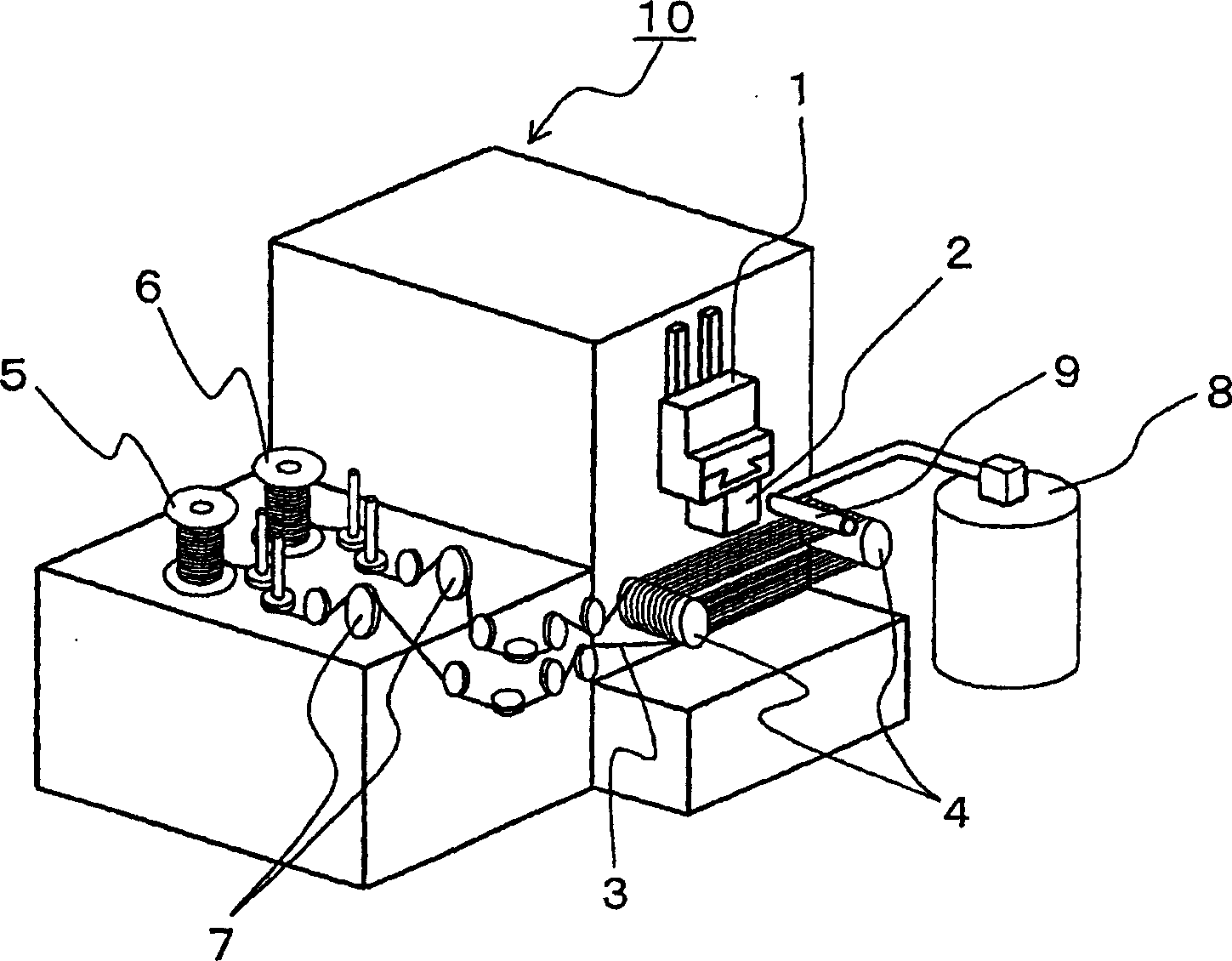

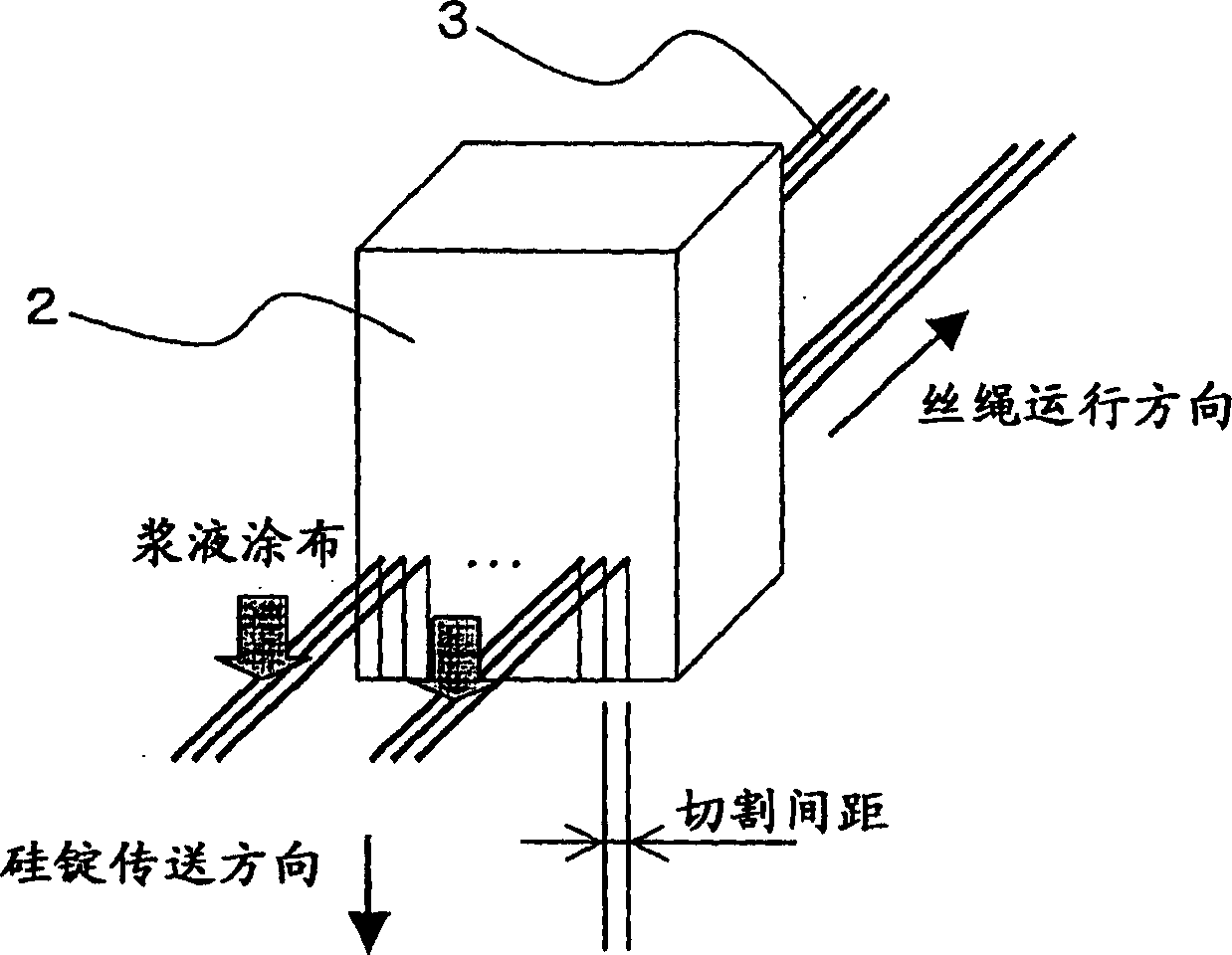

InactiveCN1780901ASmall cutting resistanceImprove qualityOther chemical processesSemiconductor/solid-state device manufacturingMetallurgyWafer

In the slurry for silicon ingot cutting according to the present invention, the content of the alkaline substance is at least 3.5% by mass relative to the entire mass of the liquid component of the slurry; amines, and the pH of the slurry is above 12. Moreover, in the silicon ingot cutting method of this invention, the said slurry for silicon ingot cutting is used at 65 degreeC - 95 degreeC. As a result, the cutting resistance at the time of silicon ingot dicing is reduced, and high-quality wafers can be efficiently obtained.

Owner:MITSUBISHI ELECTRIC CORP

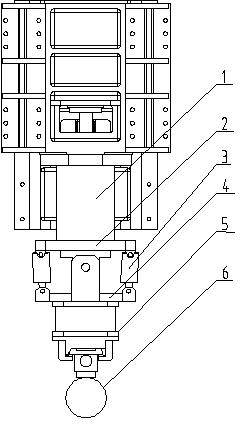

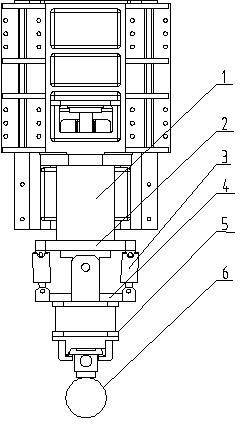

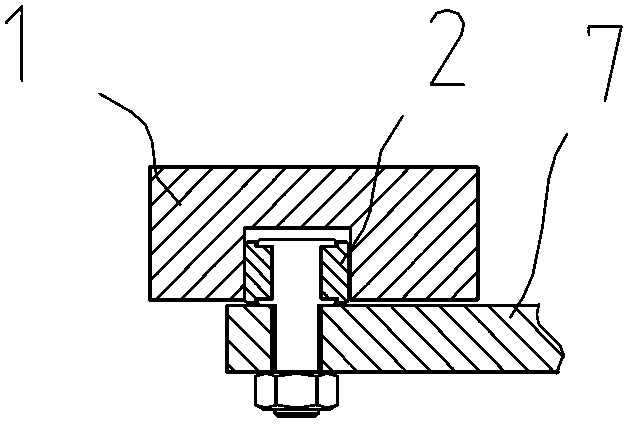

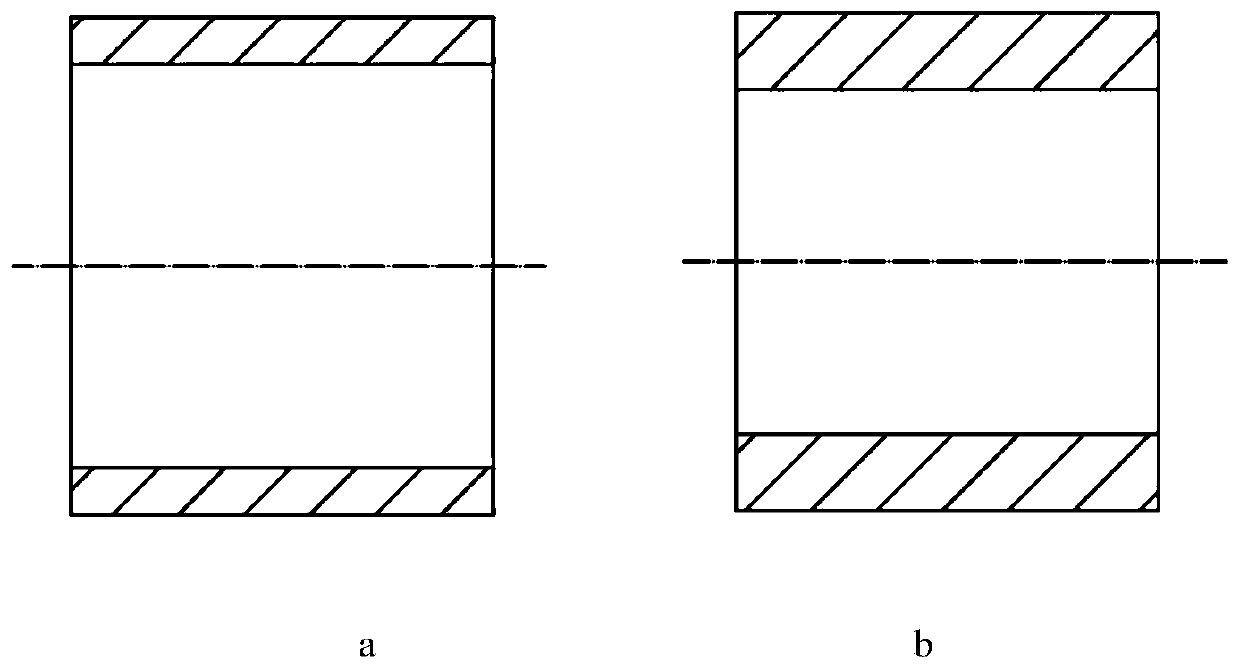

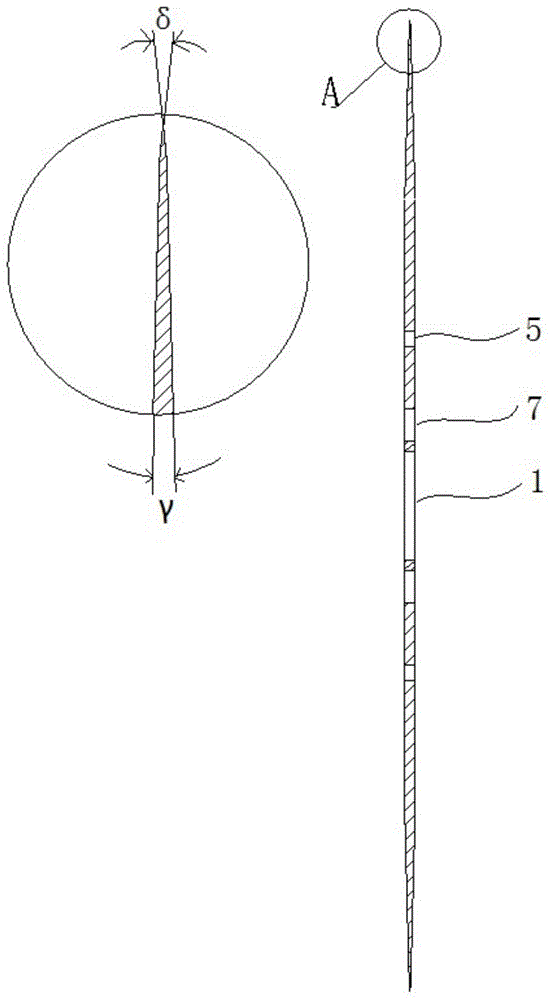

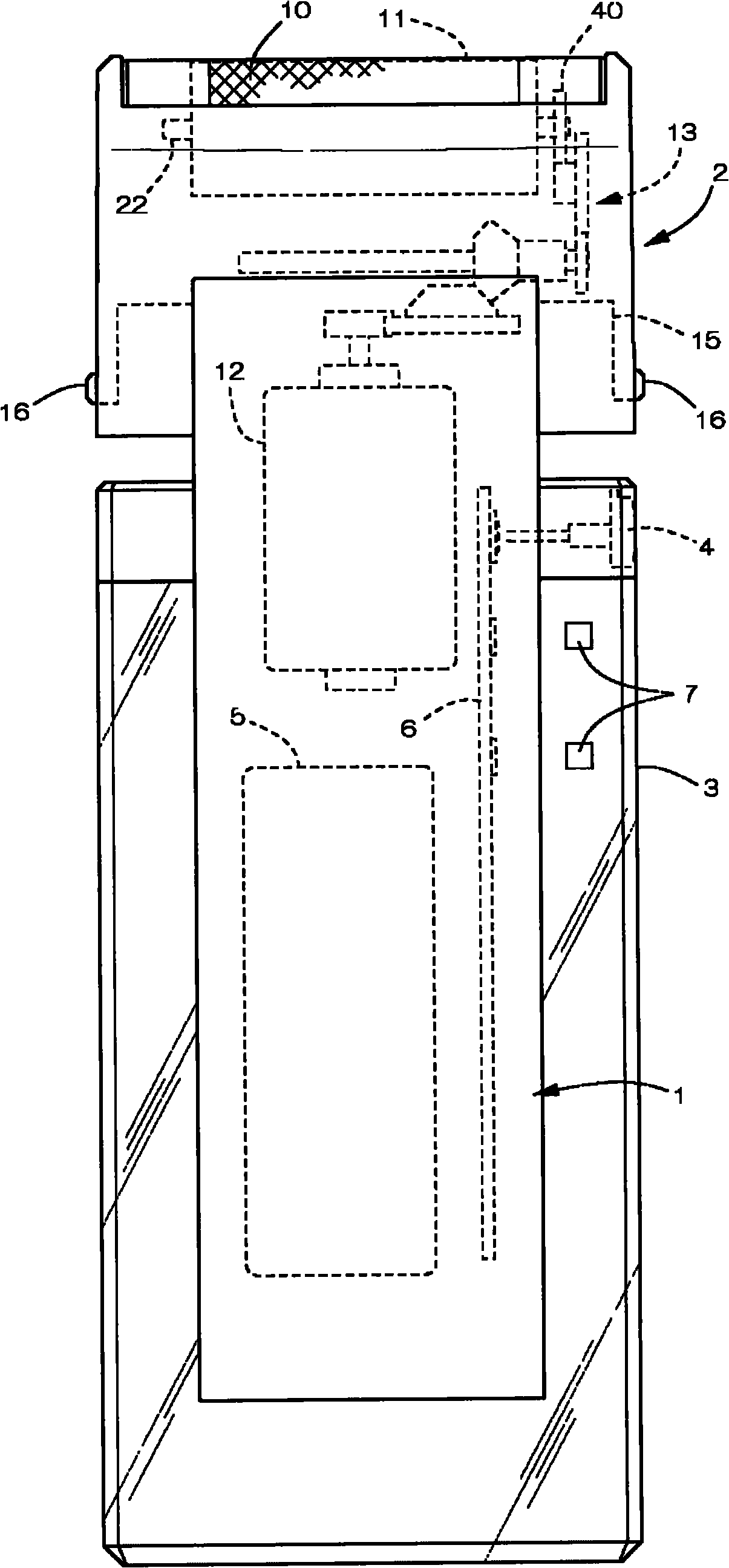

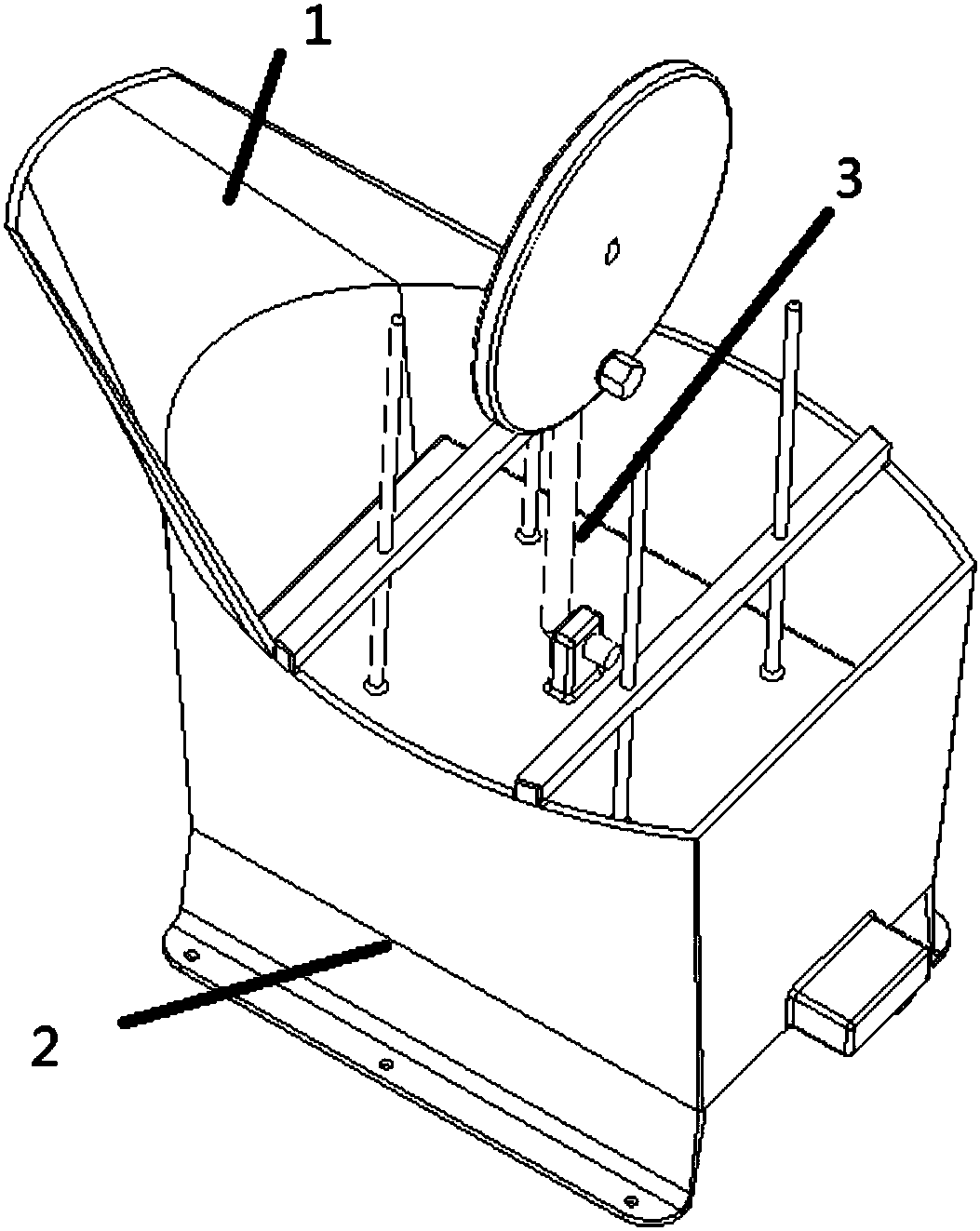

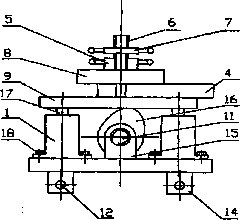

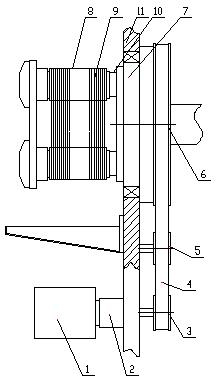

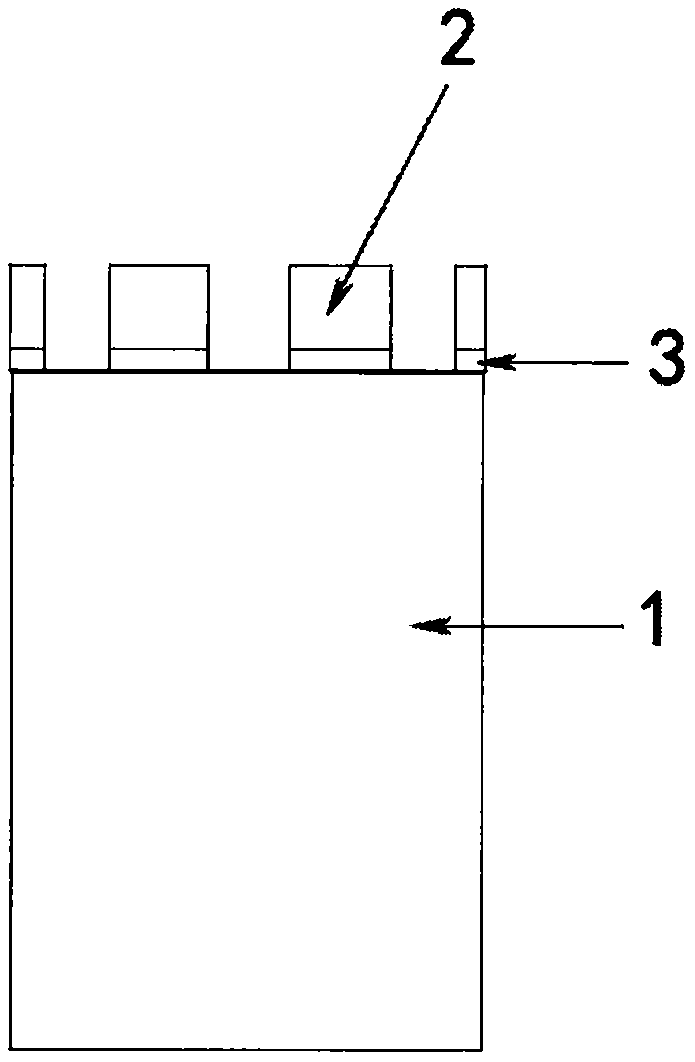

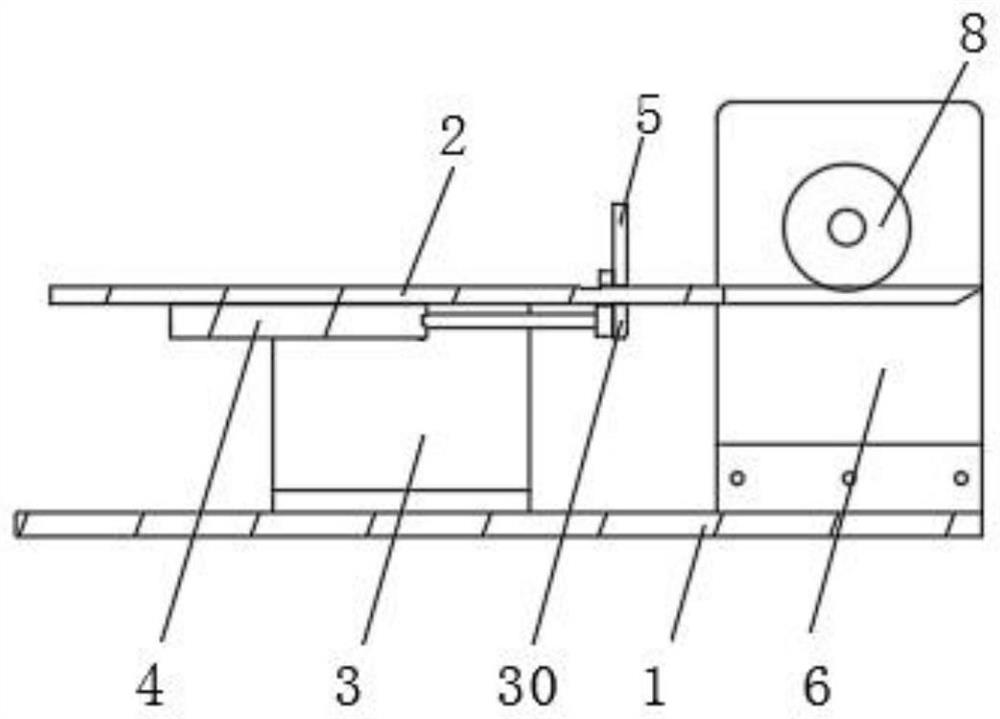

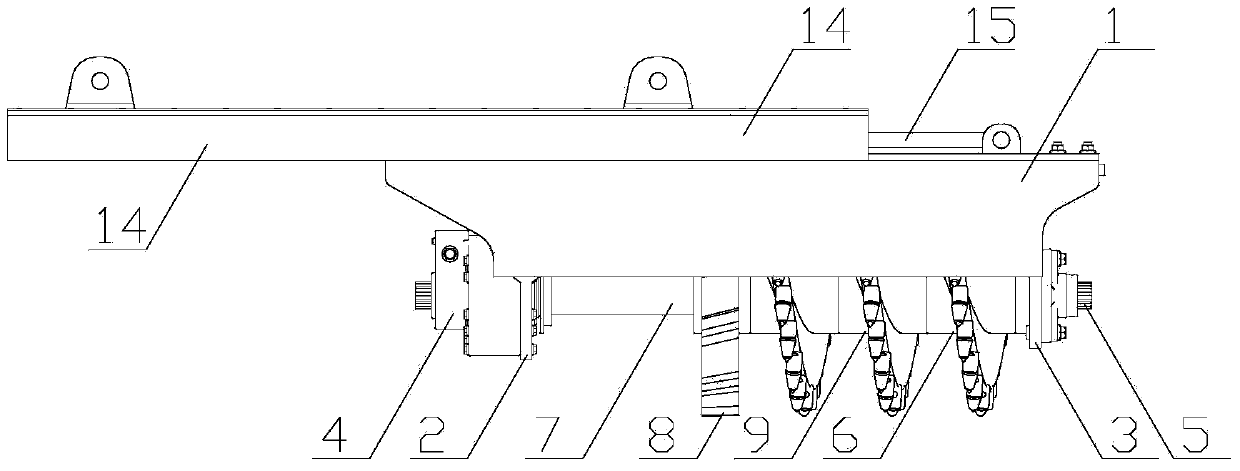

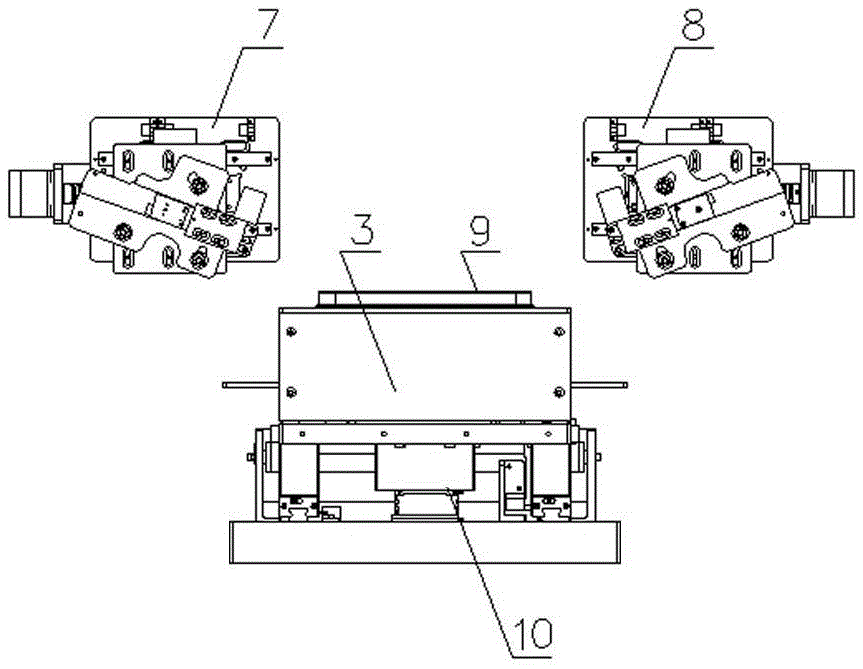

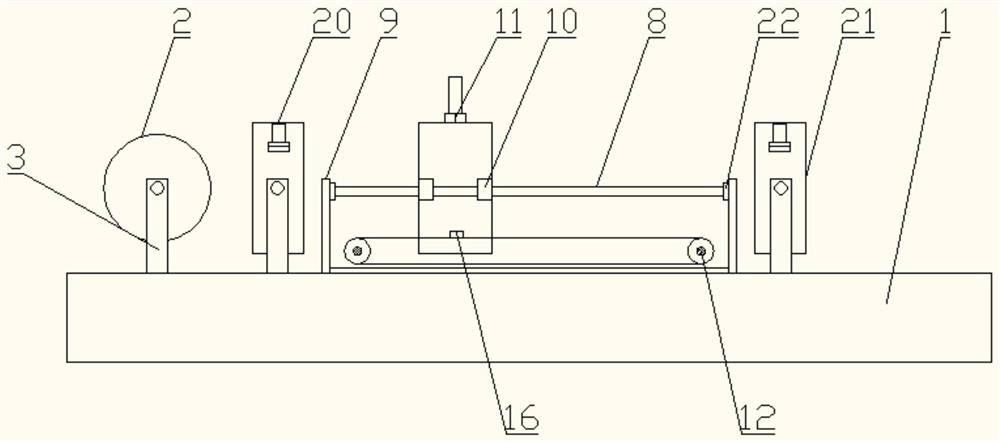

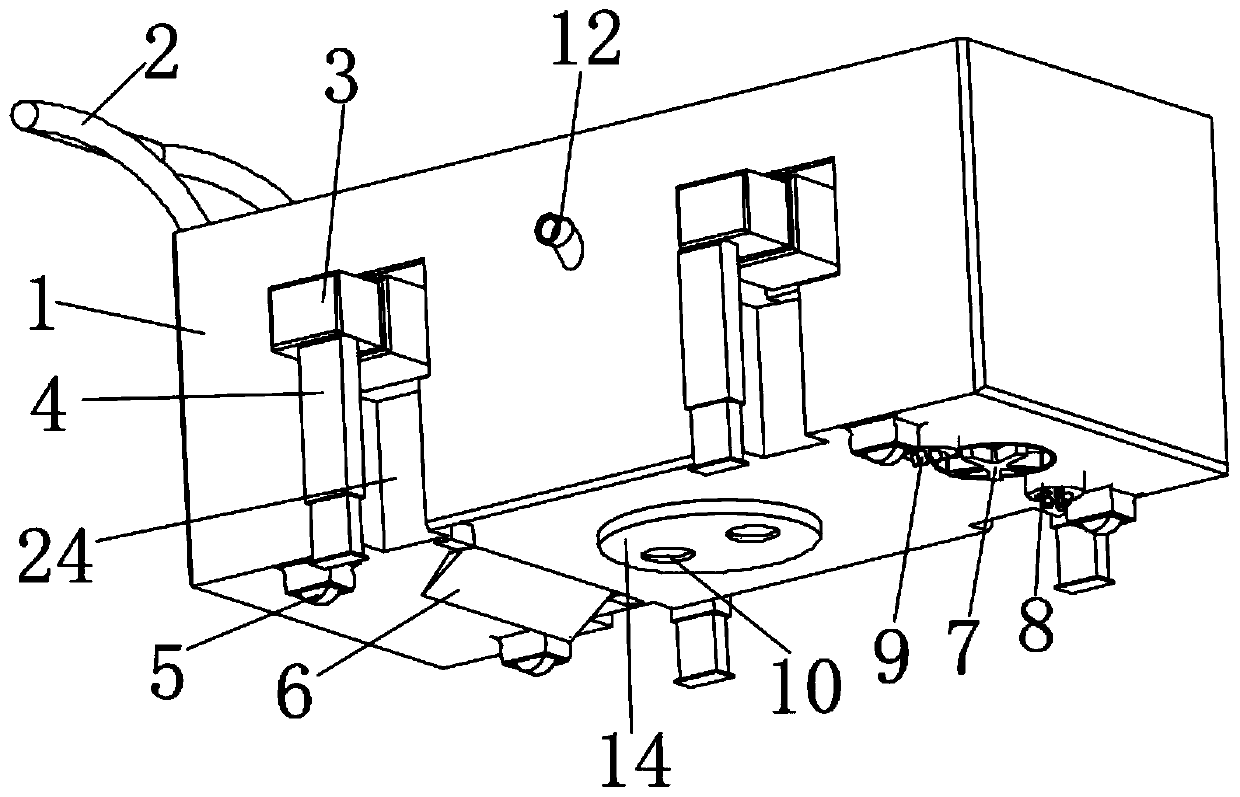

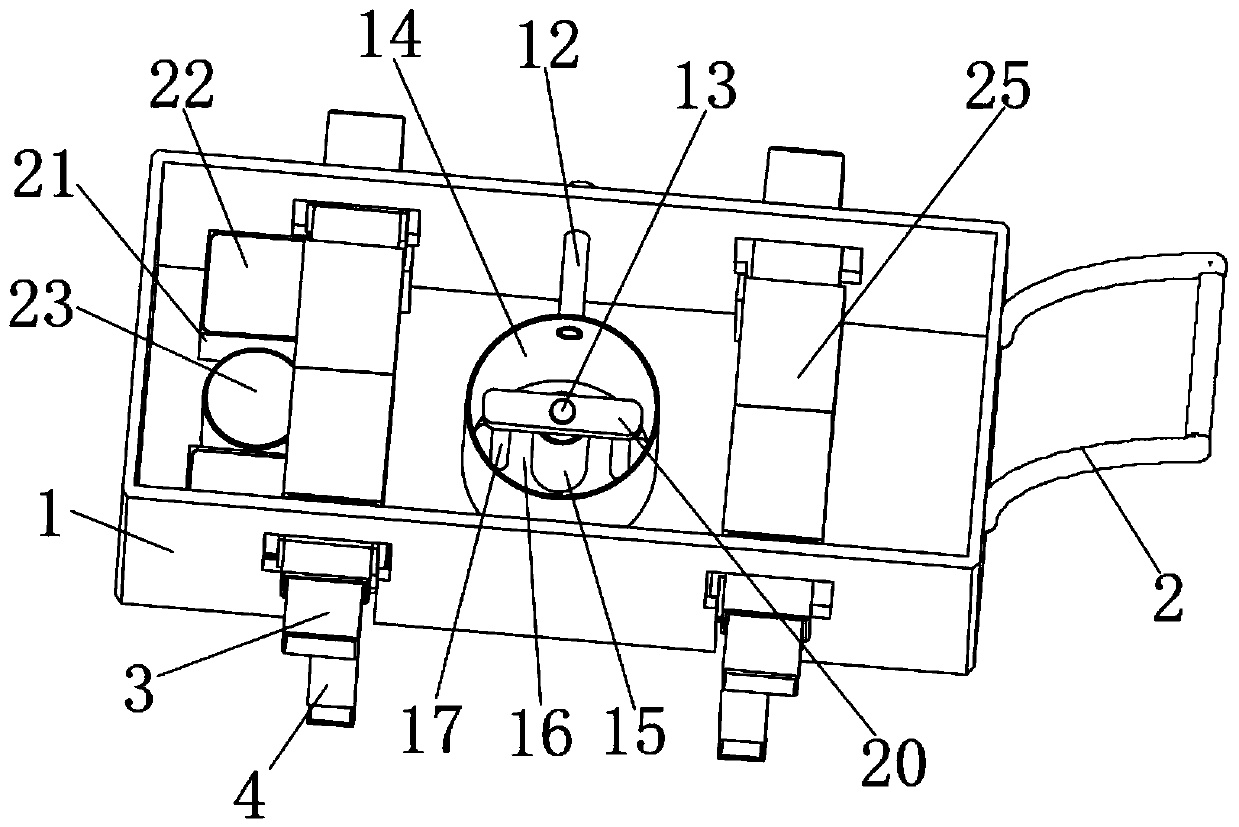

Working platform of multi-wire cutting machine

InactiveCN102049820AEasy accessReduce wearWorking accessoriesFine working devicesWire cuttingEngineering

The invention discloses a working platform of a multi-wire cutting machine, which adopts the scheme that that a metal wire is in point-contact with a workpiece during cutting. The working platform comprises a cutting sleeve (1) mounted on a working platform feeding device, and a working platform (5) equipped with a workpiece (6). The working platform is characterized in that a swinging device capable of enabling the working platform (5) to swing along the cutting center of the working platform (5) is arranged between the cutting sleeve (1) and the working platform (5). The working platform of the multi-wire cutting machine has simple structure, since the working platform capable of swinging in a reciprocating manner is adopted, and the workpiece is in point-contact with the metal wire array to be cut, the length of the contact surface of the metal wire to be cut and the workpiece is reduced greatly, namely the cutting resistance is dissolved, the abrasion of the metal wire to be cut is reduced, and the service life of the metal wire to be cut is prolonged, and at the same time, during the swinging process of the working platform, the grinding material can be enabled to better enter the incision, so that the cutting capacity and the cutting precision are improved.

Owner:HUNAN YUJING MACHINE

Chip-free cutting apparatus used for plastic section bar

ActiveCN102729272APrevent chippingSmall cutting resistanceMetal working apparatusEngineeringKnife holder

The invention relates to a chip-free cutting apparatus used for a plastic section bar. The apparatus comprises a worktable, a support, a driving cylinder, a cutting knife and a knife rest. The driving cylinder is fixed on the support, and the cutting knife is fixed at the bottom of the knife rest. The knife rest can horizontally and slidably fixed on bottom end of the driving cylinder along a cutting edge direction of the cutting knife. A guide groove is arranged on the support, wherein the guide groove inclines or bends to one side of the cutting knife from top to bottom. A follower cooperated with the guide groove is fixed on one end of the knife rest. According to the invention, simple upper and lower cutting motion is converted into a cutting motion of cutting while sliding, such that cutting resistance is buffered and tipping of the cutting knife is prevented so as to prolong a service life of the cutting knife, and improve safety performance of the equipment.

Owner:ANHUI NAIKE EXTRUSION SCI & TECH

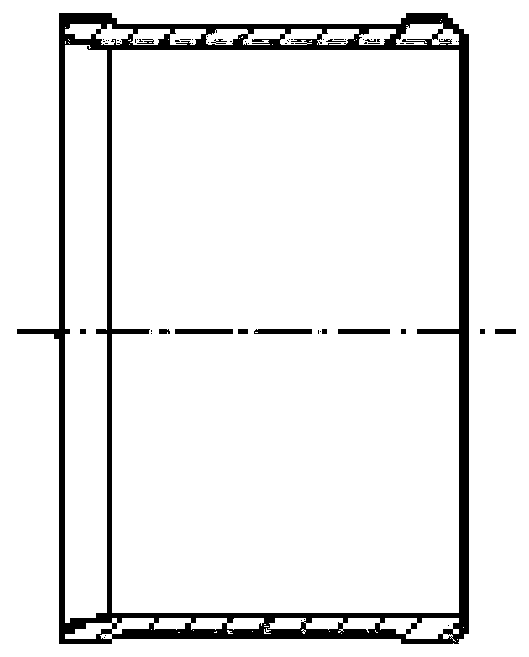

Thin-wall sleeve part processing method

The invention discloses a thin-wall sleeve part processing method which comprises the steps of firstly roughly turning an excircle and drilling and boring an inner hole; after roughly turning the excircle and roughly boring the inner hole to the reserved processing allowance, semi-extractive turning an excircle of a thin-wall sleeve part, obtaining a semi-finished product of the thin-wall sleeve part, and cutting off from a bar material; loading the semi-finished product on a digital controlled lathe, precisely turning an incircle and an excircle of the semi-finished product to the set processing allowance, half cutting-off, reserving the set thickness during half cutting-off after chamfering an excircle of a part at the cut-off end, and semi-extractive turning the excircle to the design dimension again; and thoroughly cutting off the processed thin-wall sleeve part from the semi-finished product. The process method provided by the invention is simple and feasible, no working procedureis increased, the deformation in the part processing process is greatly reduced, the excircle dimension tolerance can be ensured to meet the technical requirement of the process design, the product qualification rate is remarkably improved, the method can be completed by adopting a cutting manner, the production period is short, and no auxiliary fixture with high cost is required to be configured.

Owner:AECC AVIATION POWER CO LTD

Flat and round cutter and manufacturing method thereof

ActiveCN104942879AIncrease sharpnessImprove securityFurnace typesMetal working apparatusEngineeringAlloy

The invention discloses a flat and round cutter and a manufacturing method thereof and belongs to the field of machining of cutters. The flat and round cutter comprises a center hole, a cutter head and a blade, wherein the center hole is located in the center of the cutter head, the blade is located on the outer ring of the cutter head, a cutting edge is arranged on the outer ring of the blade, the cutting edge angle delta of the cutting edge is in a range of 13-18 degrees, and threaded holes and mounting holes are formed in the cutter head. The flat and round cutter is manufactured from an alloy material comprising special elements under strictly controlled technological conditions through steps such as blank forging, isothermal spheroidizing, preliminary processing, heat treatment, rough grinding, leveling, tempering, deep processing and the like, the cutter has very high abrasion resistance while meeting the requirement for the sharpness, the service life is long, and the cutting edge is low in abrasion loss and free of cracking after long-term usage.

Owner:安徽华天机械股份有限公司

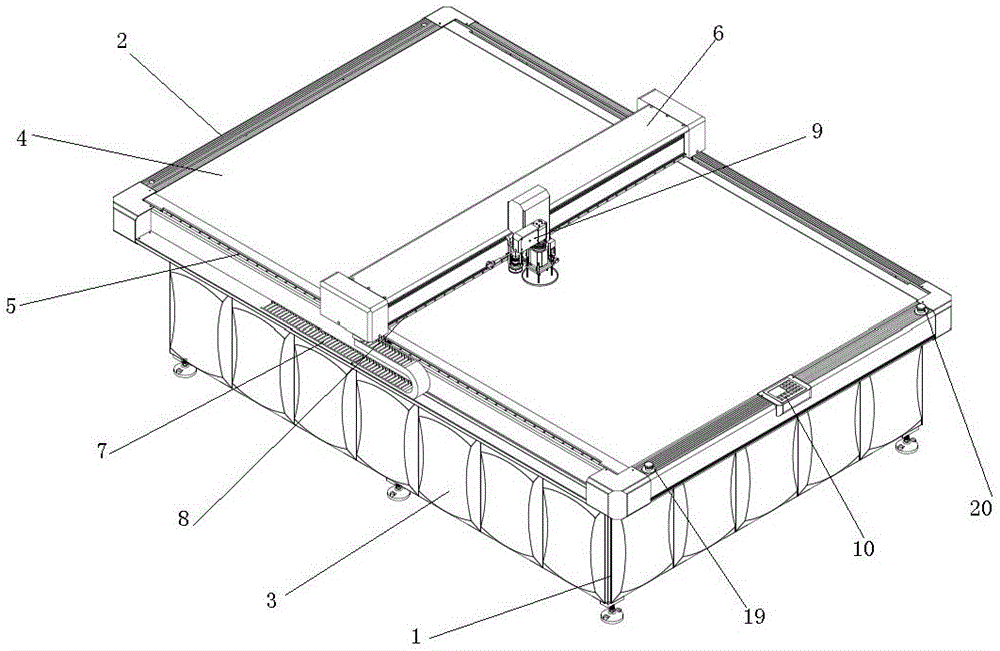

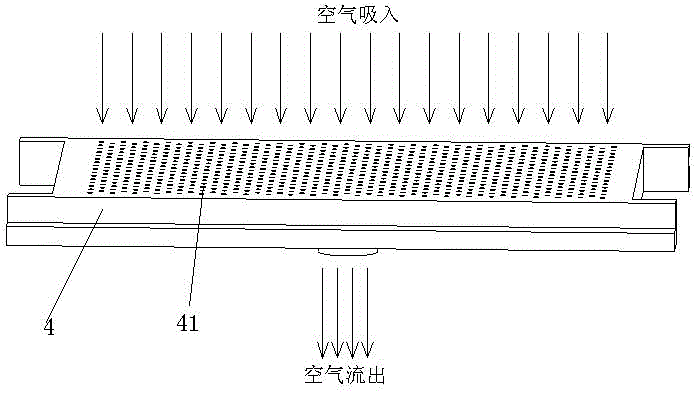

Intelligent hot-knife cutting device

InactiveCN105082241ASmall cutting resistanceImprove automationMetal working apparatusIntelligent lightingEngineering

The invention discloses an intelligent hot-knife cutting device which comprises a lower rack and an upper rack, wherein the upper is mounted on the lower rack; a plurality of lower rack baffles are arranged at intervals on four edges of the lower rack; a cutting table is arranged on the upper plane surface of the upper rack; an X-axis guide rail is arranged on the left side and the right side of the cutting table respectively; a sliding block I is mounted on each of the two X-axis guide rails; a support is mounted on each of the sliding blocks I; the two supports are connected via a Y-axis cross beam; one end of the Y-axis cross beam is connected with an X-axis drag chain; two mutually parallel Y-axis guide rails are arranged on one side of the Y-axis cross beam; sliding blocks II are arranged on both of the Y-axis guide rails; a thermal cutting machine head is mounted on the sliding blocks II; and a main control panel for controlling the thermal cutting machine head to perform X-axis, Y-axis, Z-axis and W-axis motion to cut a product is arranged on the front side of the upper rack. The intelligent hot-knife cutting device is simple in structure, high in cutting efficiency and convenient to control, and can be used for batch production of low-melting-point materials such as pearl wool, sponge and foam.

Owner:GUANGDONG HUAYI TECH CO LTD

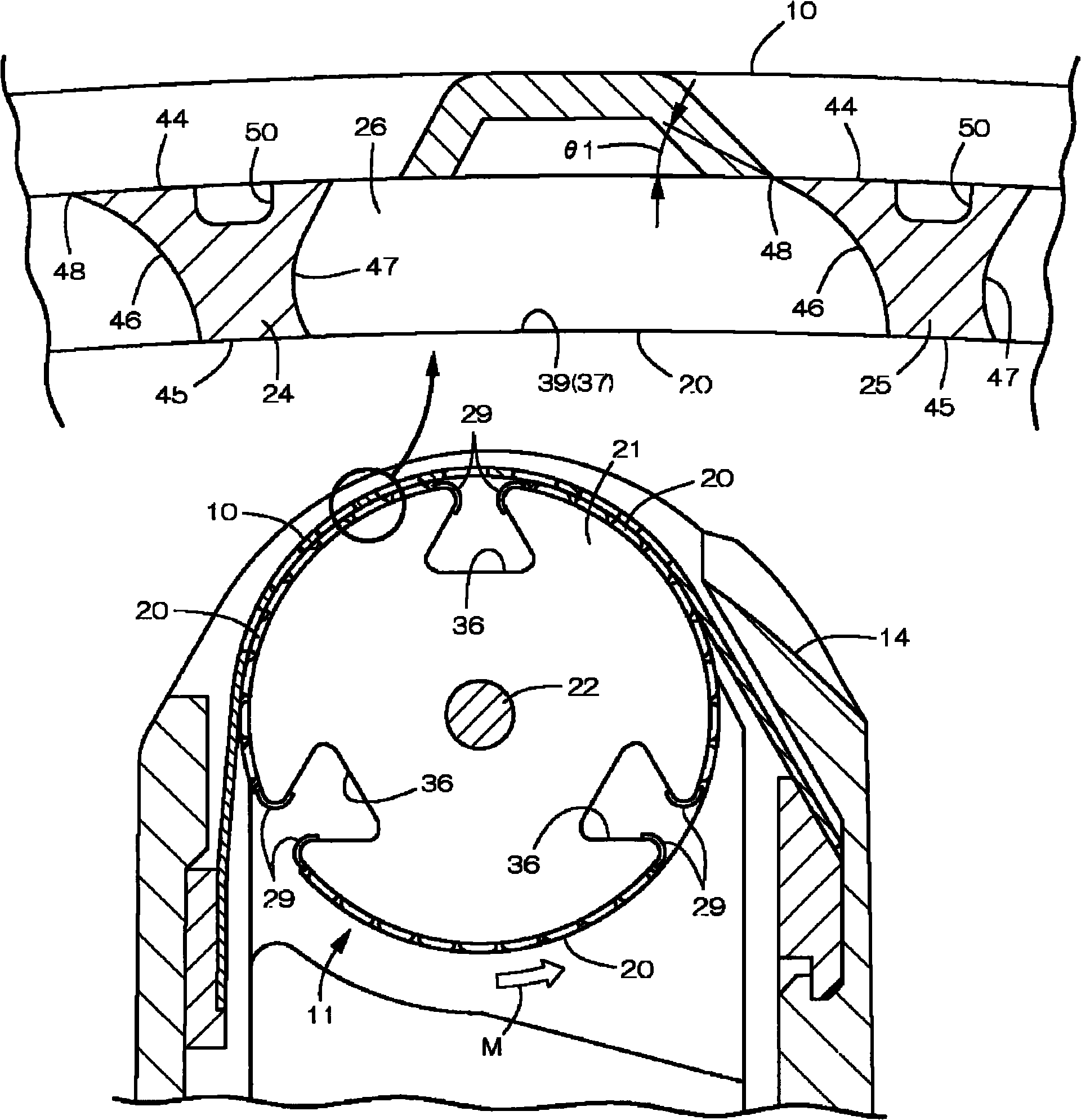

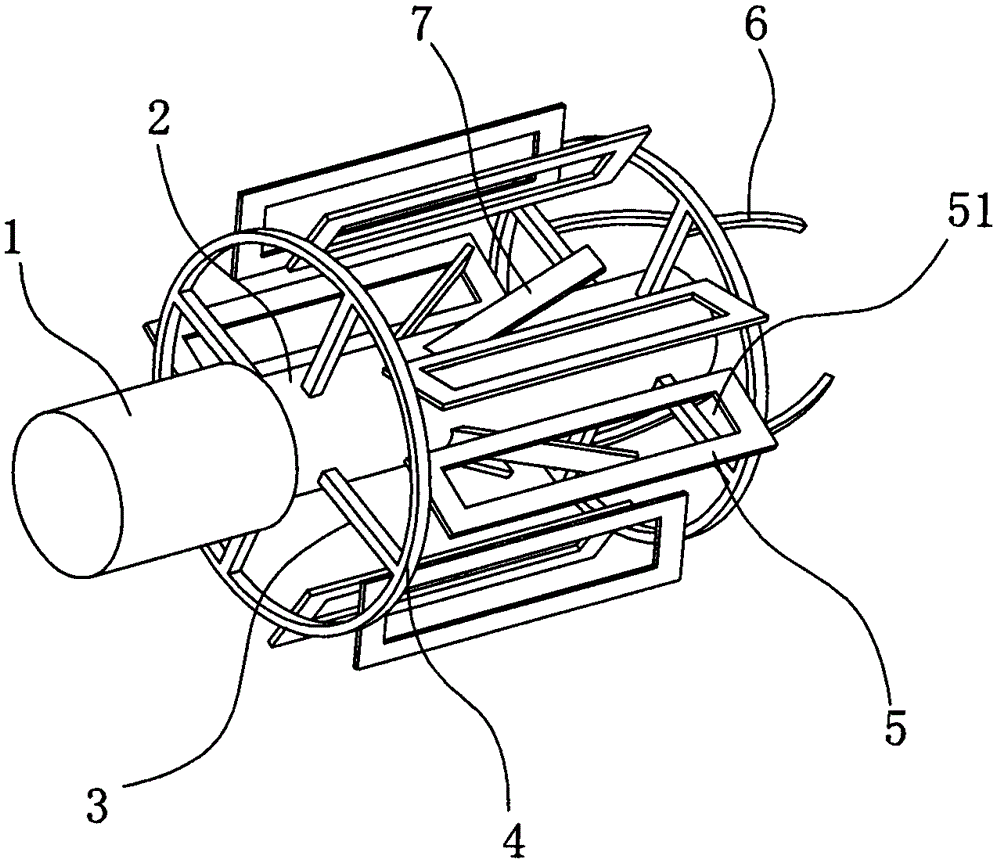

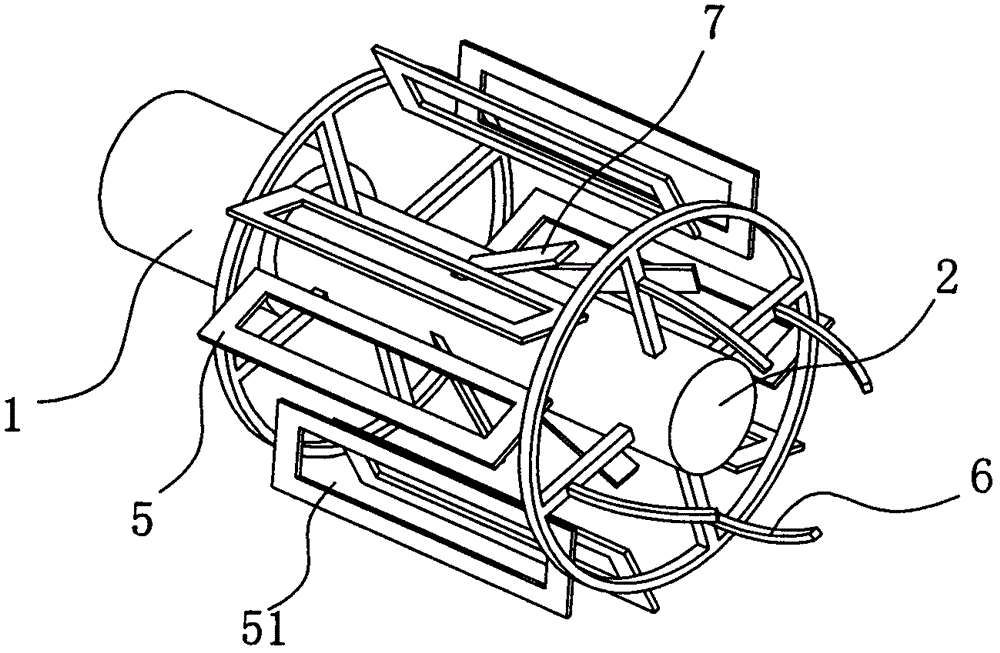

Rotator blade and small electric instrument having rotator blade

ActiveCN102039604ACutting sharpEffectively cut offMetal working apparatusEngineeringElectrical equipment

The present invention provides a rotary blade and a small electric instrument having the rotator blade, wherein the rotator blade which can effectively introduce and efficiently cut off the beard and has easy cleaning of flock is provided. The rotator blade which comprises a blade body and a blade bracket that supports the blade body is composed. Etching treatment is performed for stainless steel plate thereby forming a group of rib-shaped small cutting edge and a group of cutting blade holes in the blade body. A plurality of blade bodies are fixed on a circumferential surface of the blade bracket and the rotator blade is composed to a cylinder shape. Each small cutting edge is provided with the following components: a cutting surface of an external surface; a non-cutting surface of an inner surface; a side edge part for connecting the cutting surface with the non-cutting surface; a cutting edge which is formed at an upstream side in a rotation direction of the cutting surface; and a back clearance surface edge which is formed at the downstream side in the rotation direction of the cutting surface. A width center of the non-cutting surface deviates from a width center of the cutting surface to the downstream side of the rotation direction. A cutting edge angle of the cutting edge, which is smaller than an edge angle of the back clearance surface edge, is formed.

Owner:MAXELL HLDG LTD

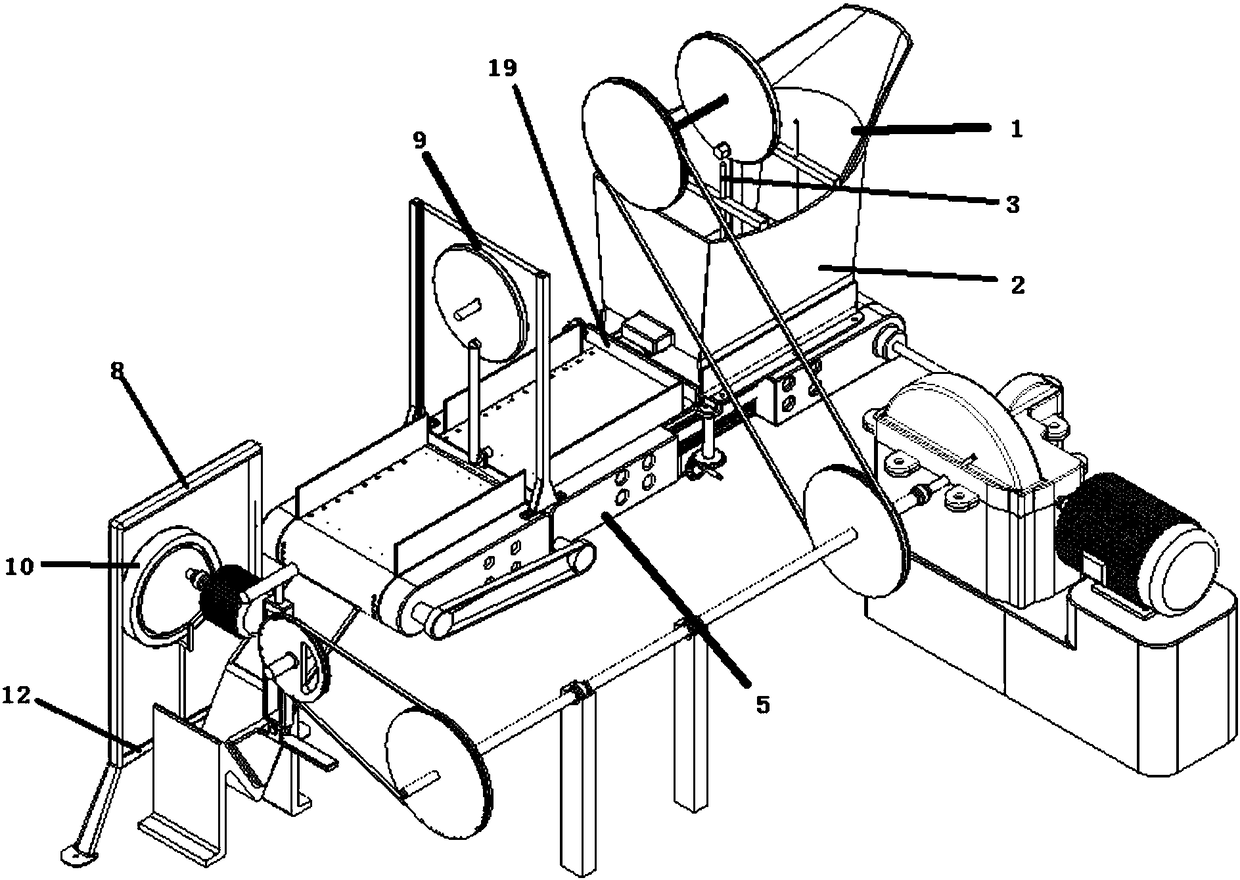

Multifunctional processing machine for diced food materials

InactiveCN108202359AEasy to disassemble and repairExtended service lifeMetal working apparatusFood materialMechanical engineering

The invention discloses a multifunctional processing machine for diced food materials. The multifunctional processing machine comprises a slicing device, a shredding device, a push groove device, a dicing device, a transmission device and conveying belts. The slicing device conveys sliced food materials to the shredding device by virtue of the conveying belts, the shredding device is arranged between the two conveying belts, the sliced food materials are cut into shredded food materials by virtue of the up-down reciprocating movement of a blade, the shredded food materials are transferred to the push groove device through the conveying belts, the push groove device drives the shredded food materials to carry out reciprocating movement to be pushed to the dicing device, the blade of the dicing device is mutually vertical to the shredded food materials, and cuts the shredded food materials into diced food materials; and the transmission device provides power for the slicing device, the shredding device, the push groove device, the dicing device and the conveying belts. The multifunctional diced food material processing machine disclosed by the invention is various in function, capable of carrying out batch treatment on the food materials, fully-automatic, high in efficiency and easy to maintain.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

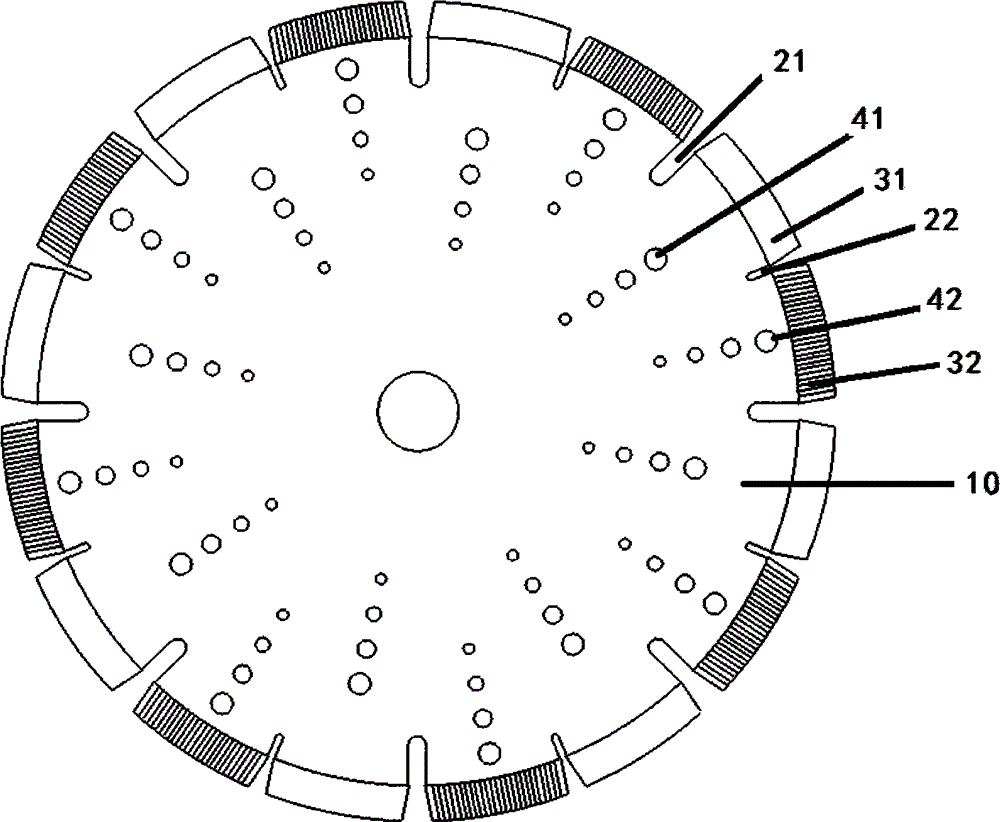

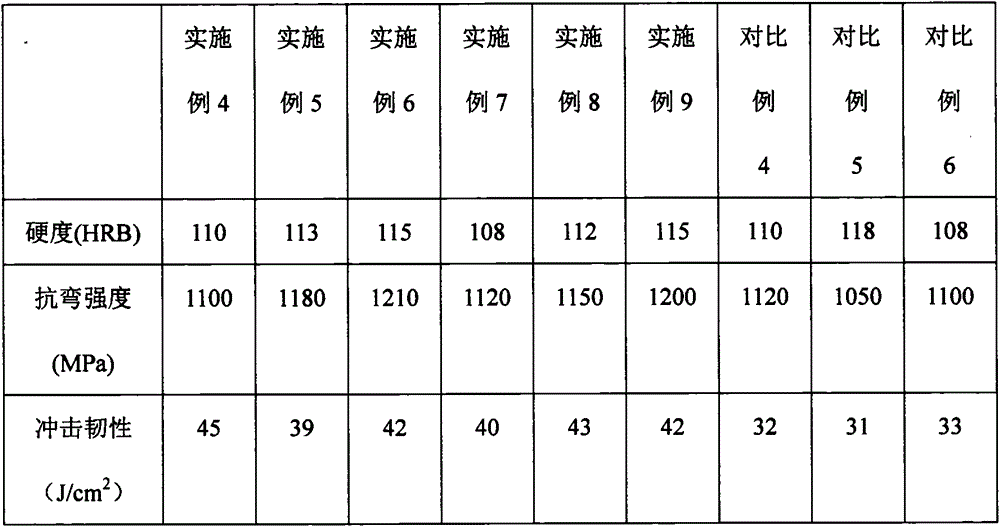

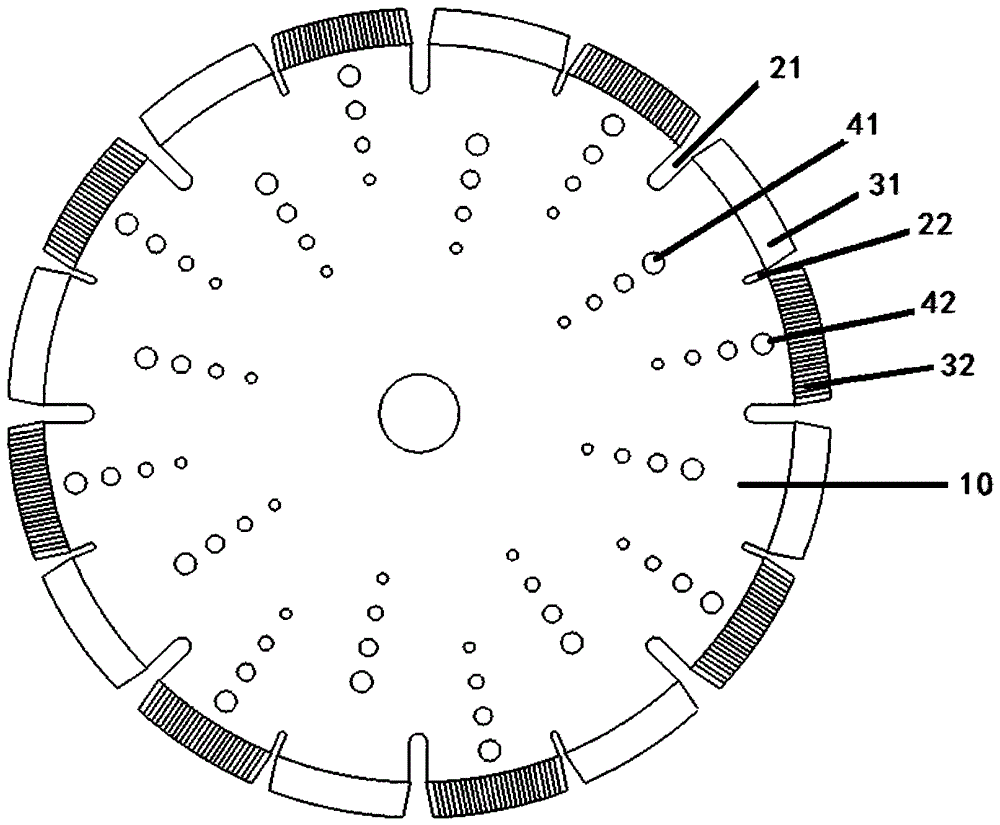

Manufacture method for dry and wet dual-purpose diamond saw blade

ActiveCN104874863AImprove cutting efficiencyImprove cutting effectMetal sawing tool makingDual purposeMaterials science

The invention relates to a manufacture method for a dry and wet dual-purpose diamond saw blade, and belongs to the technical field of diamond processing tools. The method includes the following steps of providing a circular base body, wherein the circular base body comprises a side circumferential surface located on the edge of the base body; machining a plurality of chip removal grooves which are formed at intervals inwards in the radial direction in the side circumferential surface of the base body, wherein the chip removal grooves include the first chip removal grooves and the second chip removal grooves, and the first chip removal grooves and the second chip removal grooves are formed at intervals; arranging diamond tool bits between the chip removal grooves of the base body, wherein the diamond tool bits include the first diamond tool bits and the second diamond tool bits, the first diamond tool bits and the second diamond tool bits are arranged at intervals, the surfaces of the first diamond tool bits are planes, a plurality of protruding strips are arranged on the surfaces of the second diamond tool bits, and grooves are formed between the protruding strips. The diamond saw blade can well conduct chip removal and heat dissipation in the cutting process, the good cutting performance can be kept under the condition of no cooling water grinding, and the purpose of conducting processing under extreme conditions is achieved for users.

Owner:JIANGSU FENGTAI TOOLS

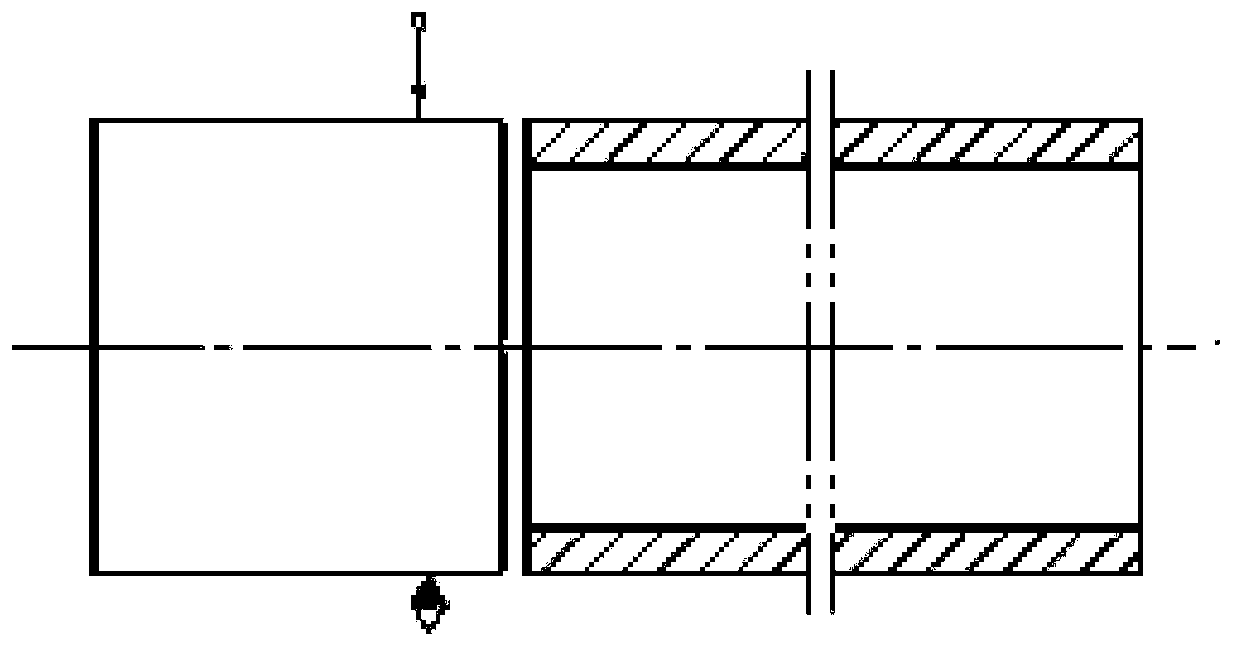

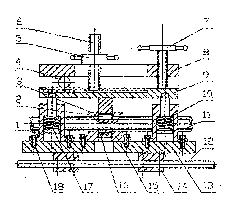

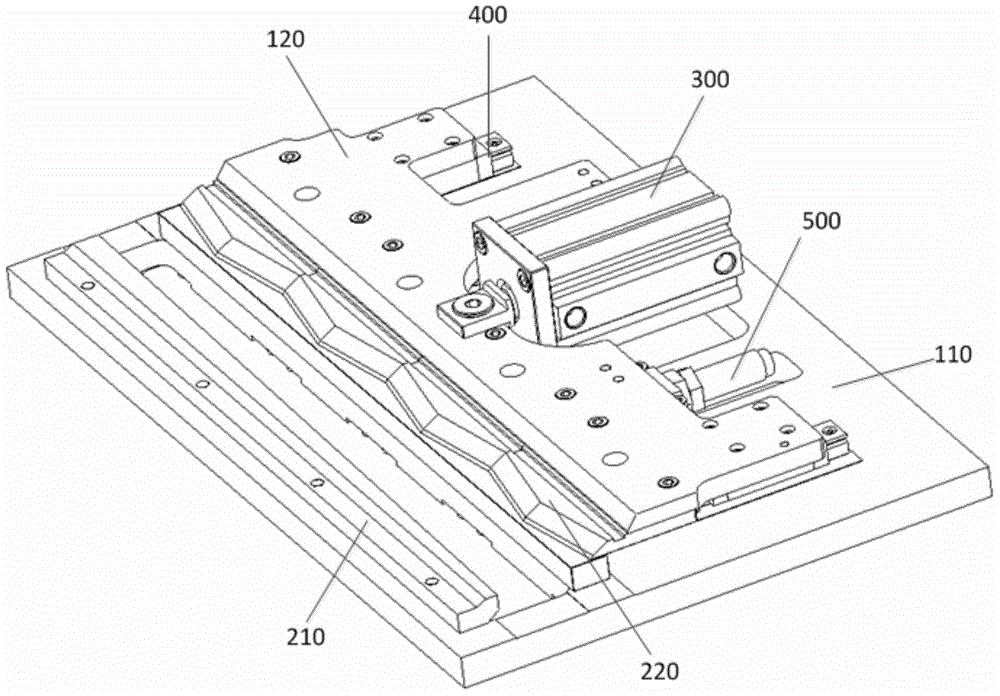

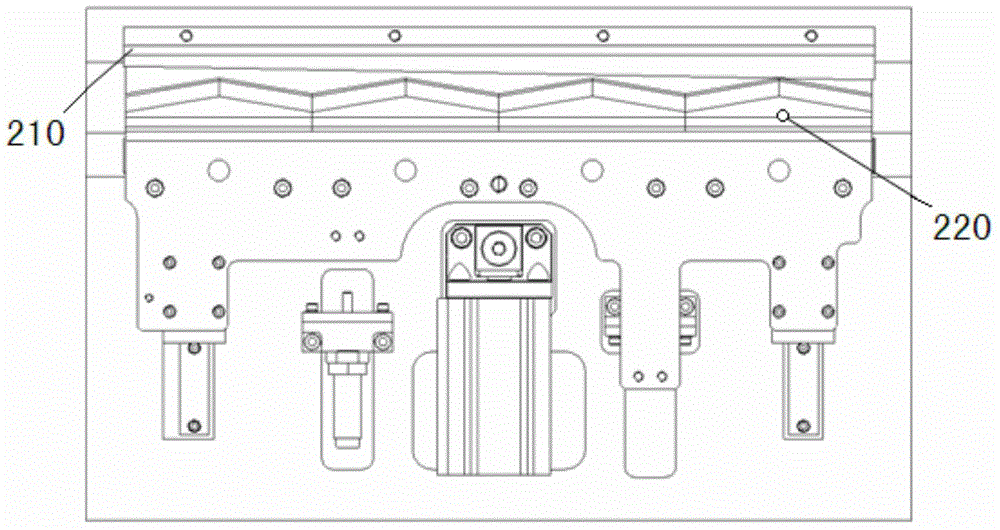

Workpiece combined clamp for abrasive wheel cutting machine

InactiveCN101797711AEasy dischargeEasy clampingGrinding machine componentsGrinding machinesReciprocating motionEngineering

The invention discloses a workpiece combined clamp for an abrasive wheel cutting machine, which comprises a clamping mechanism and an elastic movement mechanism, wherein the clamping mechanism comprises a press plate for holding a workpiece and a bottom plate, and a compacting screw and an adjusting bolt are arranged between the press plate and the bottom plate; the elastic movement mechanism is arranged below the clamping mechanism and comprises a screw rod, the middle part of the screw rod is provided with a cam, and a screw rod nut is fastened to a work table; a guide sleeve is arranged on the work table, a guide post is arranged in the guide sleeve, a spring is arranged on the guide post, and the top of the guide post is positioned in a groove in a panel on the lower side of the bottom plate and forms a clearance fit with the groove; and the lower side of the work table forms a slide fit with a guide rail through a fixed slide block. The combined clamp can conveniently and quickly clamp the workpiece. In the cutting process, the workpiece can make a back-and-forth up-and-down aggregate reciprocating motion, thereby being beneficial to reducing cutting resistance, facilitating the discharge of cuttings, avoiding binding, preventing an abrasive wheel from damage, enhancing the work efficiency of the abrasive wheel cutting machine and enabling the cutting process to be safer.

Owner:HEBEI AGRICULTURAL UNIV.

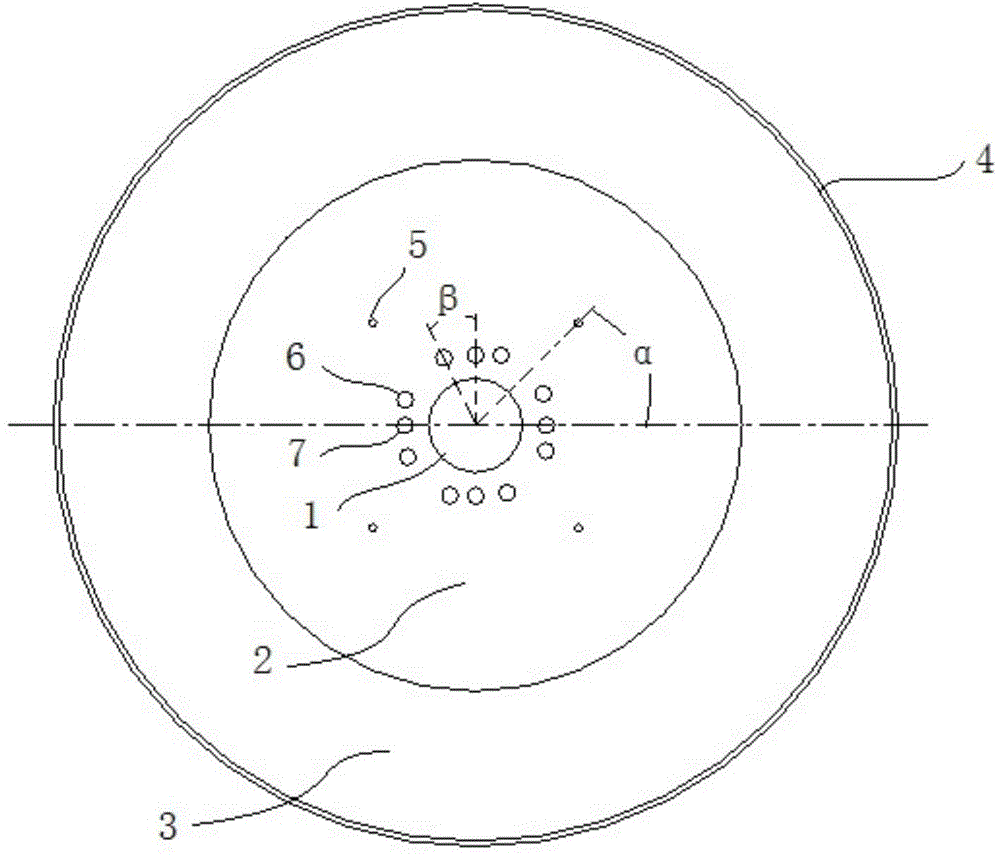

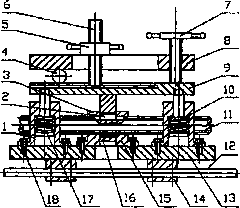

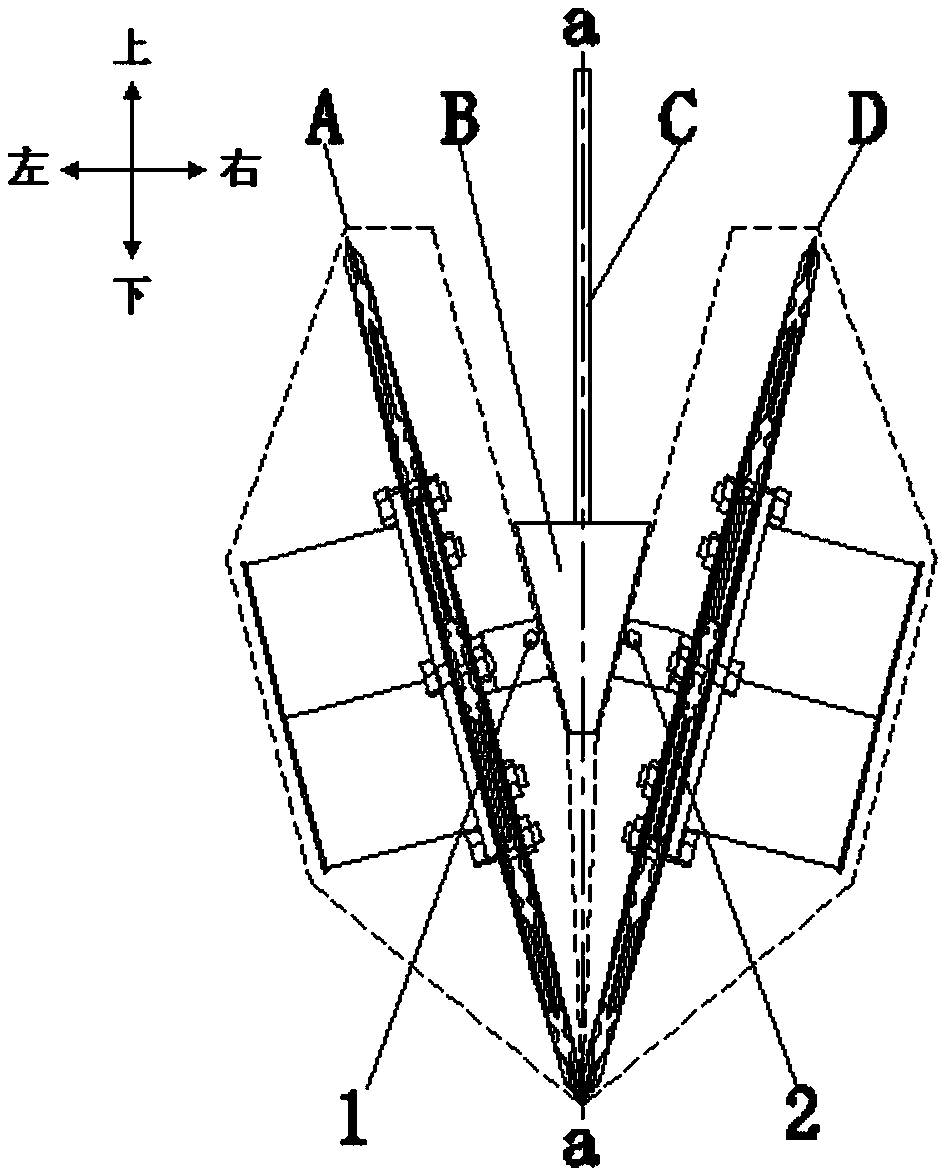

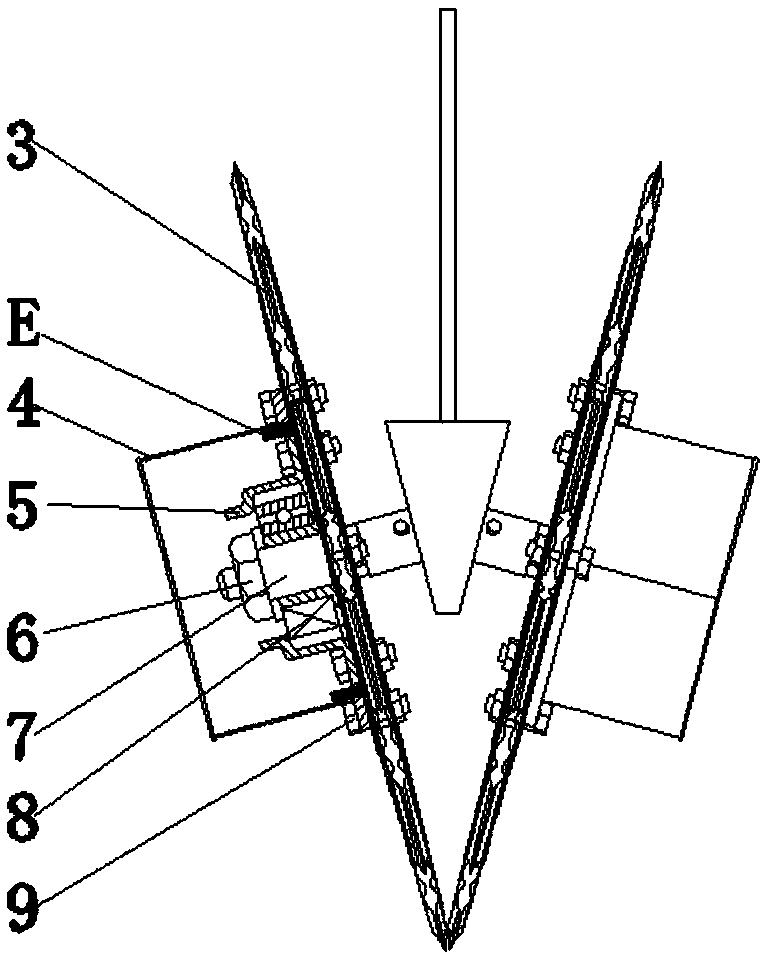

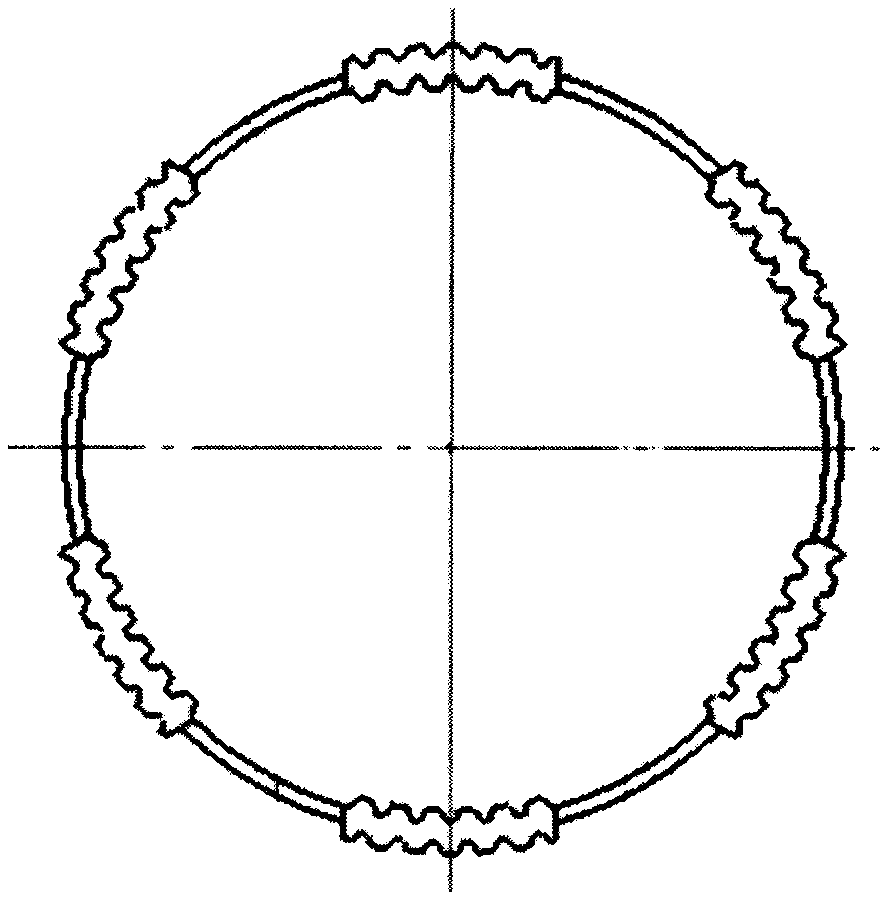

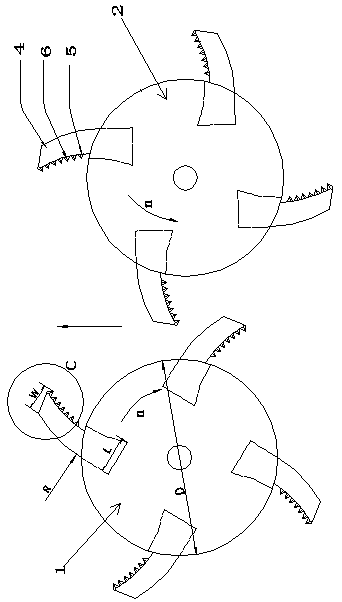

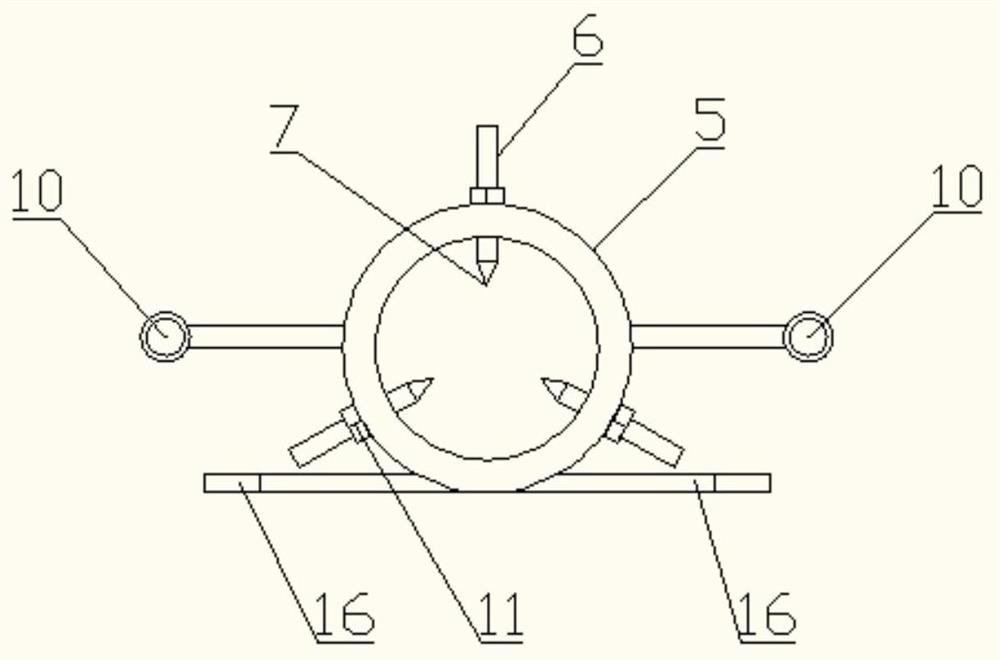

Real-time adjustable and controllable type double-layer bionic notch circular-disc furrow opener

ActiveCN108848775AStructure real-time regulationImprove efficiencyPlantingAgriculture gas emission reductionCircular discMicro structure

The invention provides a real-time adjustable and controllable type double-layer bionic notch circular-disc furrow opener and belongs to the technical field of agricultural machinery. According to thereal-time adjustable and controllable type double-layer bionic notch circular-disc furrow opener, a notch circular-disc assembly I and a notch circular-disc assembly II are symmetrically arranged relative to an a-a central longitudinal axis; a furrow opening handle is fixedly connected to a top center of a base in a connection part; the right end of a connection shaft in the notch circular-disc assembly I is fixedly connected with a shaft sleeve I of a connection part through a screw I; the left end of the connection shaft in the notch circular-disc assembly II is fixedly connected with a shaft sleeve II of the connection part through a screw II; a circular-disc disc body soil-entering furrow opening section is provided with a corrugated bionic curve surface; a circular-disc notch soil cutting blade is obtained by symmetrically cutting a disc body curve surface through a bionic curve; a circular disc stubble-breaking and soil-entering tool has two forms including a circular arc edge and a bionic tooth-shaped edge; a cutting edge of the circular arc edge has a bionic included angle; the bionic tooth-shaped edge is a tooth-shaped micro-structure with a bionic coupling design. The real-time adjustable and controllable type double-layer bionic notch circular-disc furrow opener has the advantages of strong wear resistance, excellent soil-entering performance, good soil crushing andstubble breaking performance, high working efficiency and long service life, is applicable to different working environments can be used for initiatively replacing the edge.

Owner:JILIN UNIV

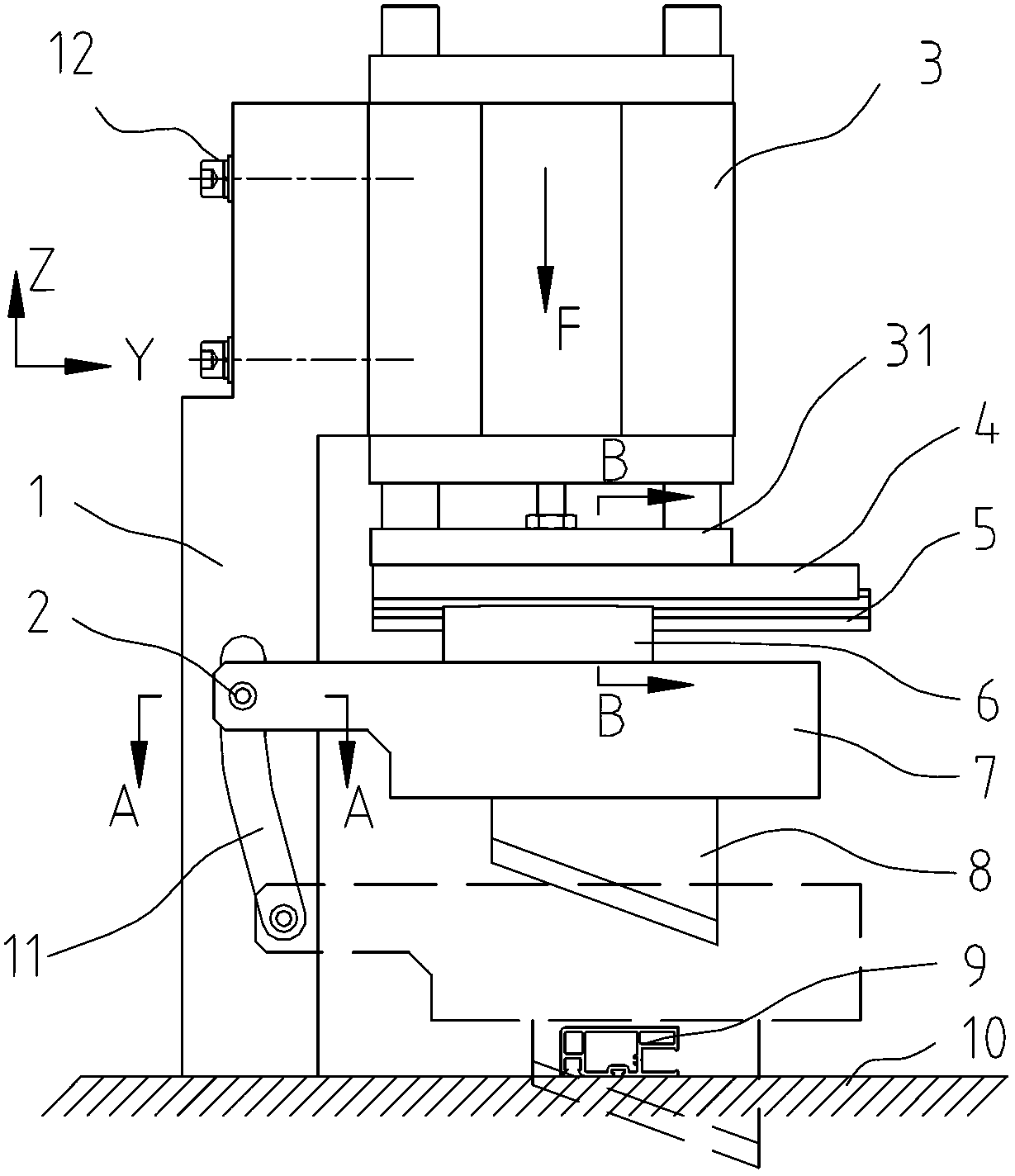

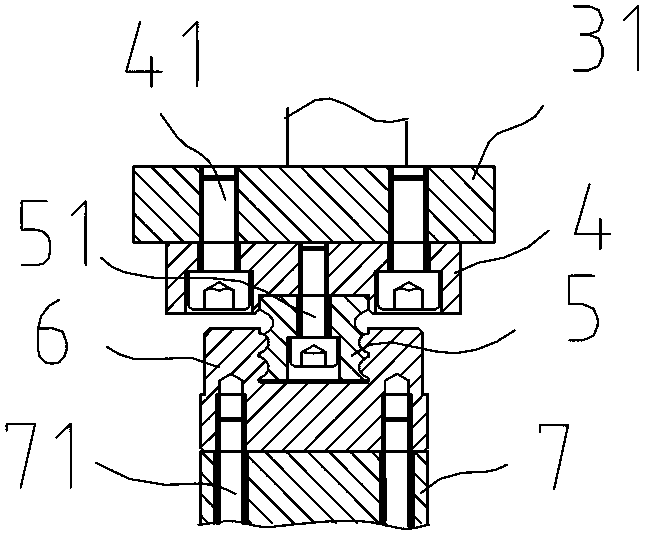

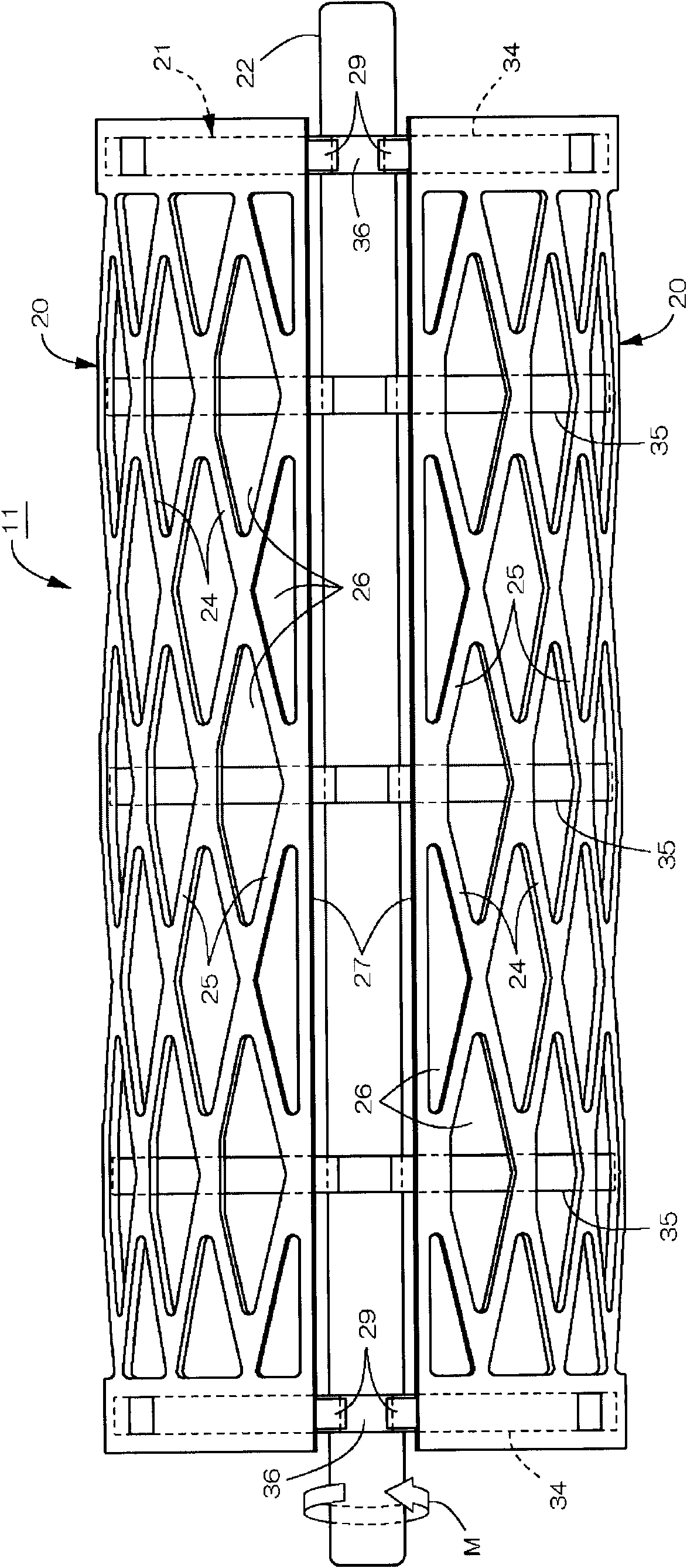

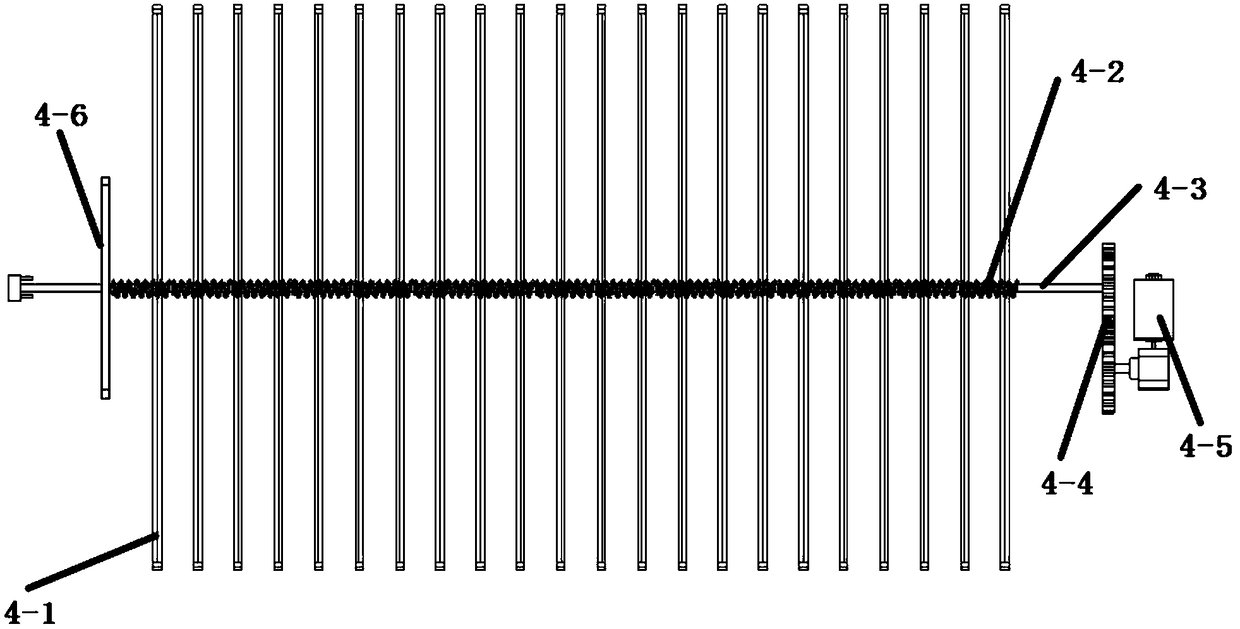

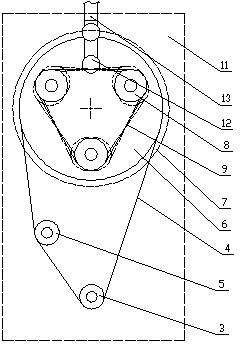

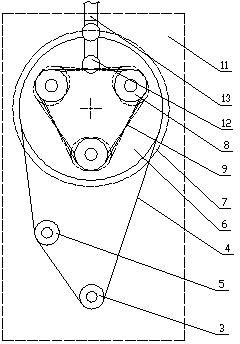

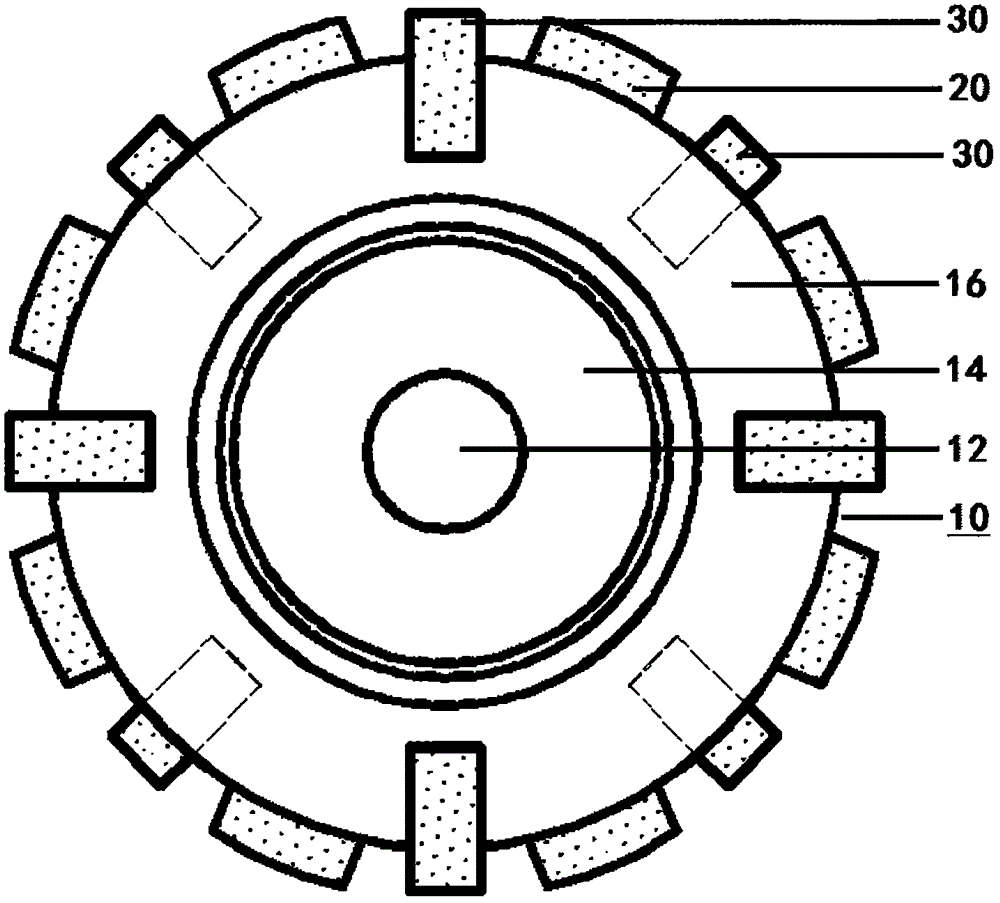

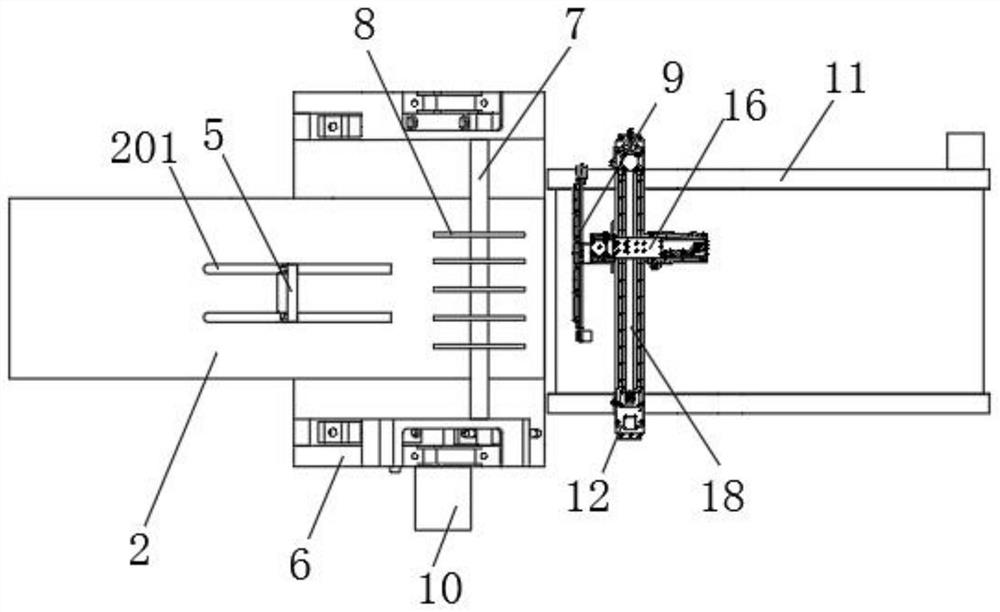

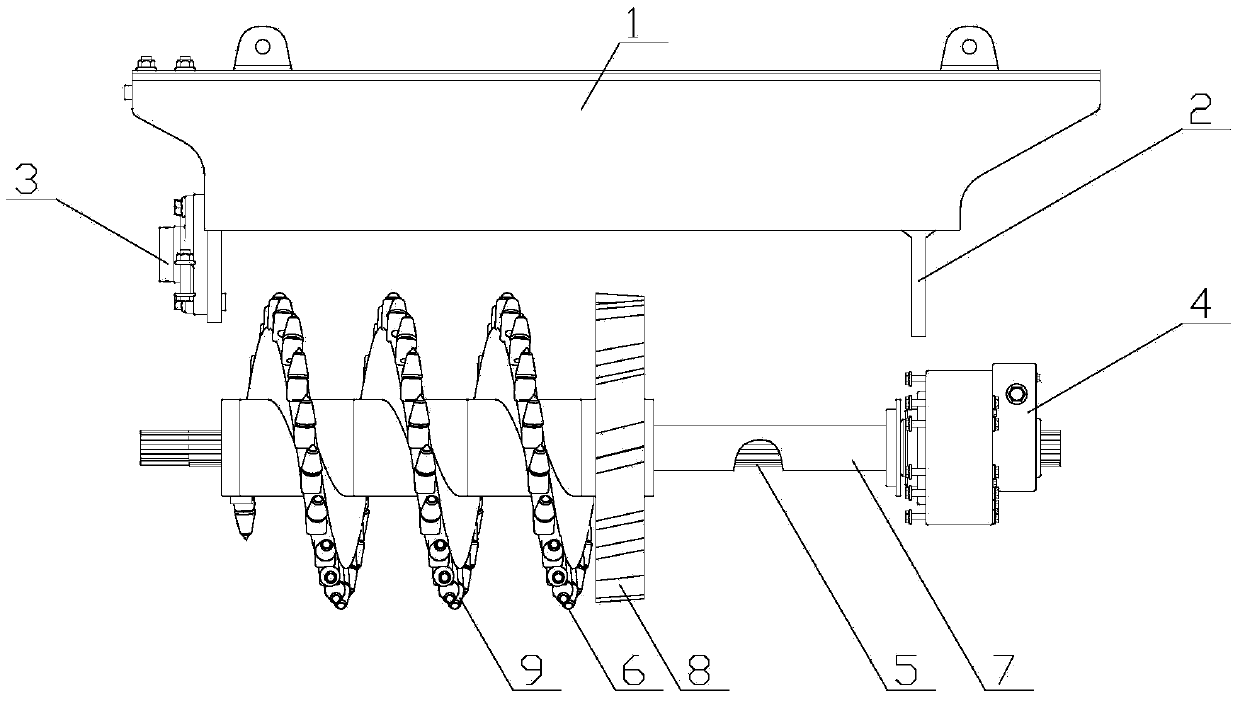

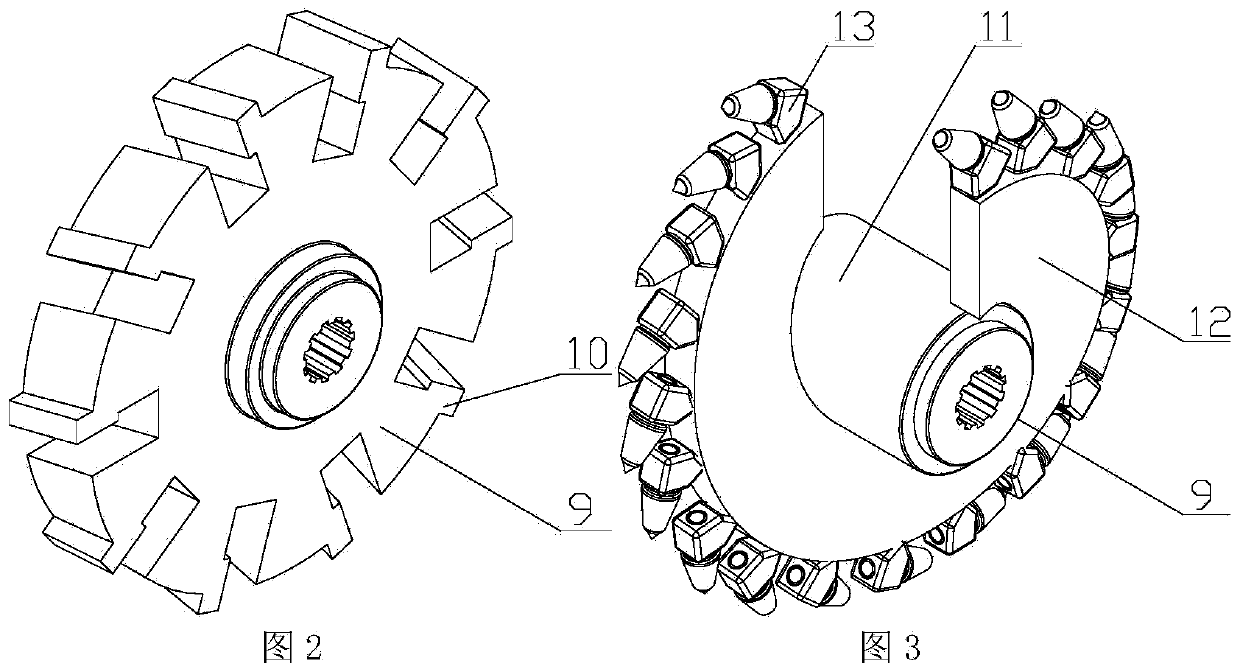

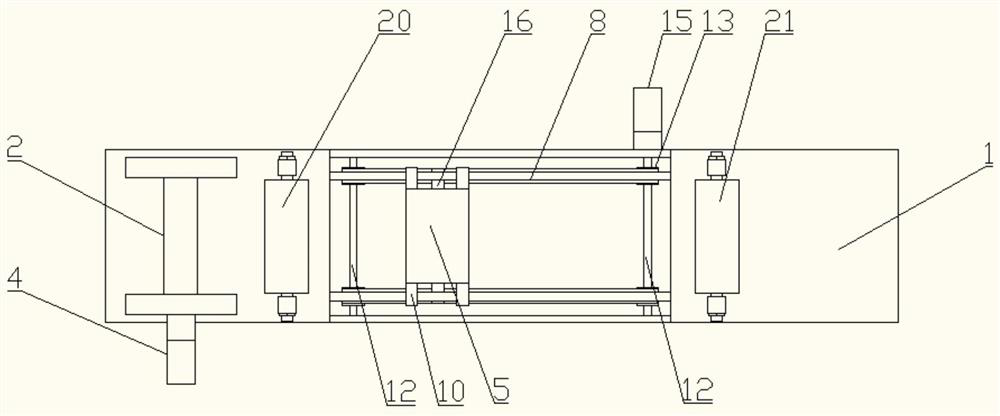

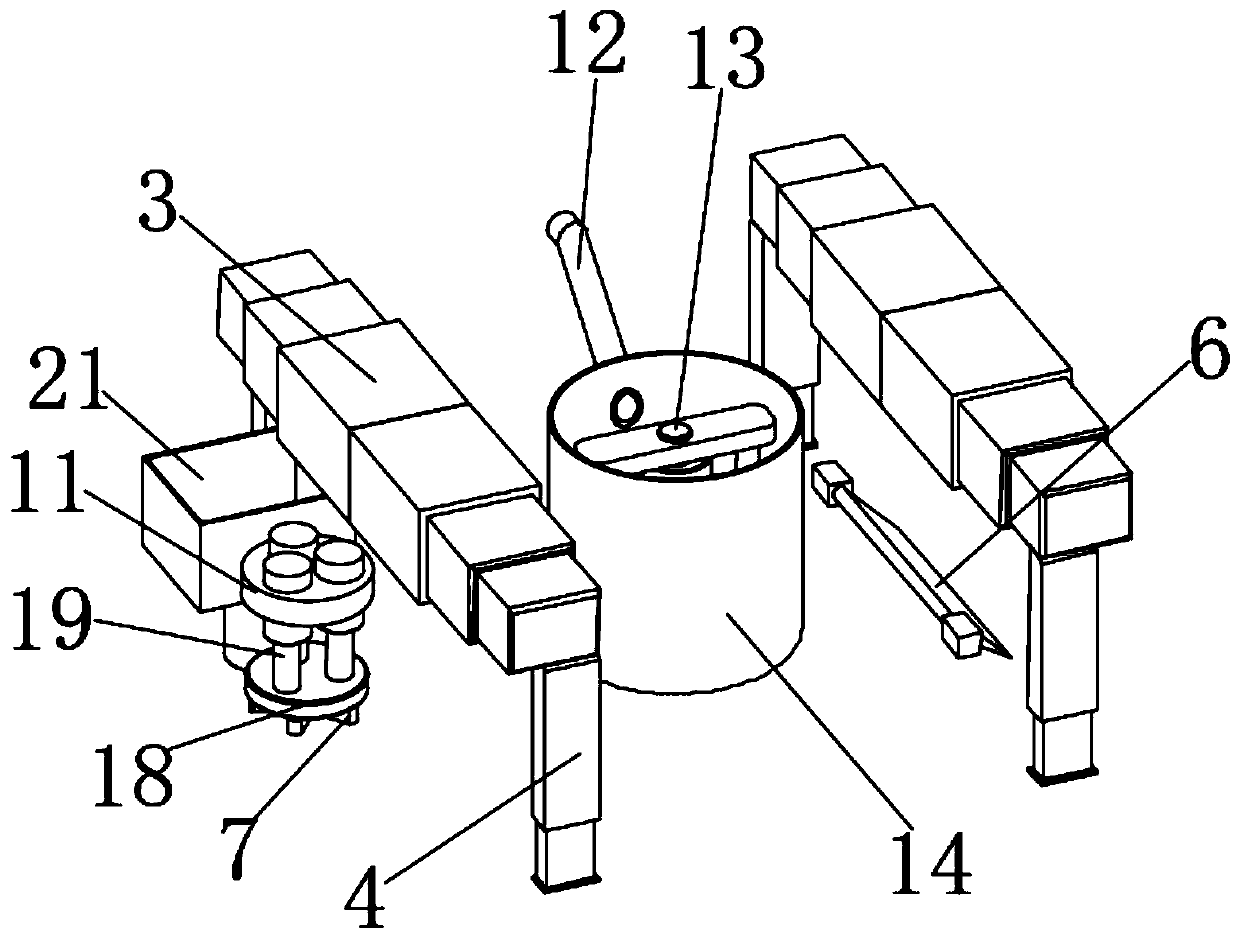

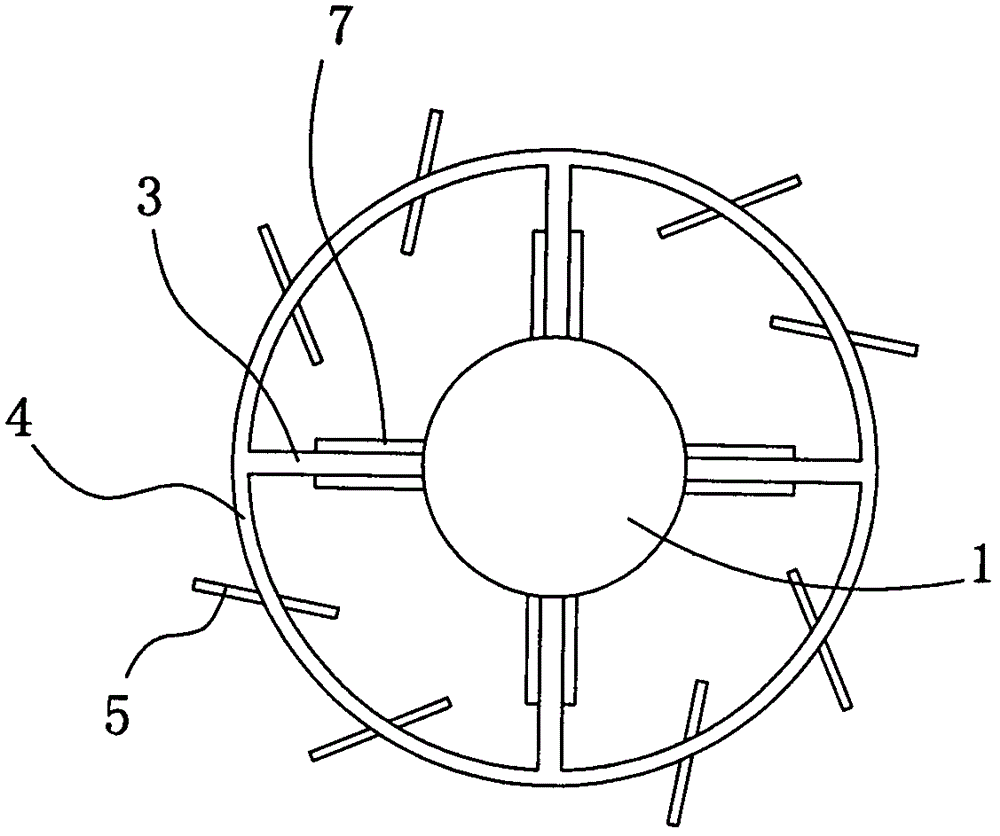

Cutting rollers of multi-wire cutting machine

The invention discloses cutting rollers of a multi-wire cutting machine for point contact of a metal wire and a workpiece during cutting. The multi-wire cutting machine comprises a rack (11), and is characterized in that: the rack (11) is provided with a rocker panel (7) driven by power, and a cutting roller set consisting of the cutting rollers (8) is arranged on the rocker panel (7) through a support seat (10). The cutting roller has a simple structure; the reciprocating swing cutting roller is adopted, and the workpiece is in point contact with a cutting wire array, so the contact face length of the cutting metal wire and the workpiece is greatly reduced, the cutting resistance is weakened, the abrasion of the cutting metal wire is also reduced, and the service life of the cutting metal wire is prolonged; and meanwhile, the abrasive better enters a shear mark in the swing process of the cutting roller, so the cutting capability is improved, and the cutting precision is also improved.

Owner:HUNAN YUJING MACHINE

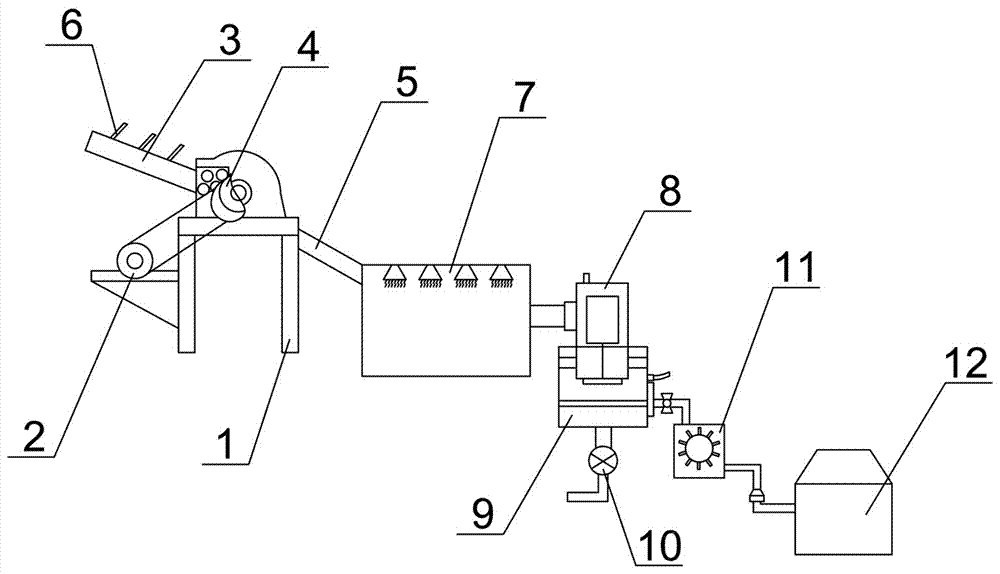

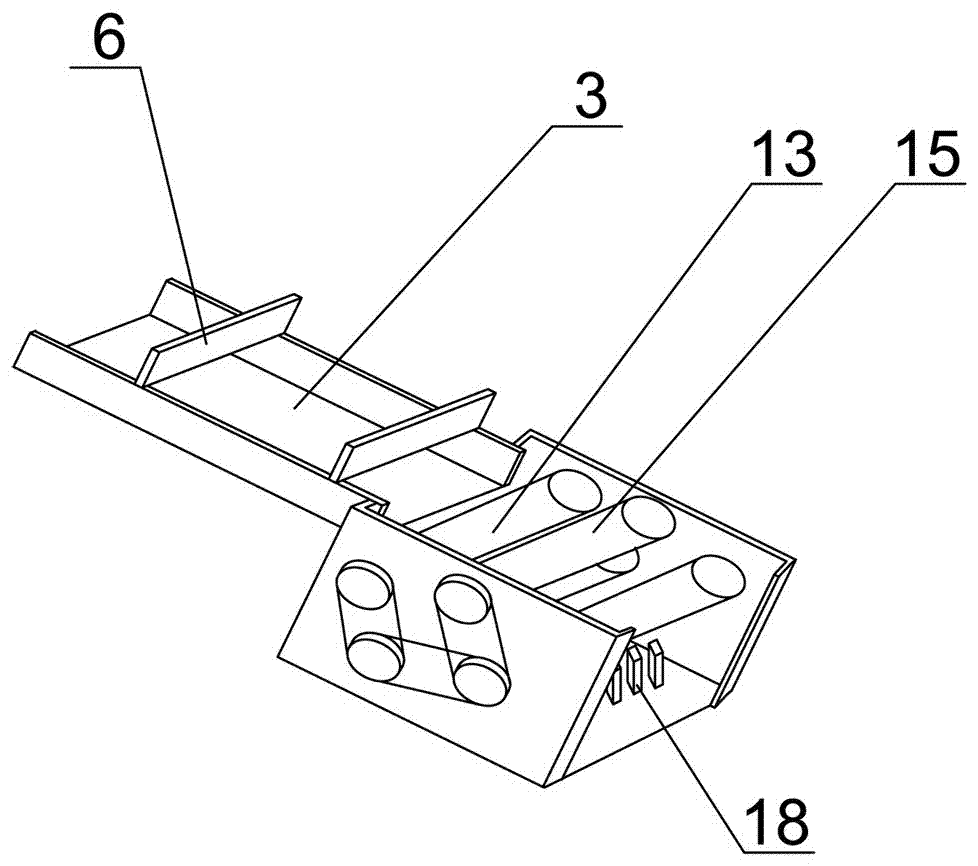

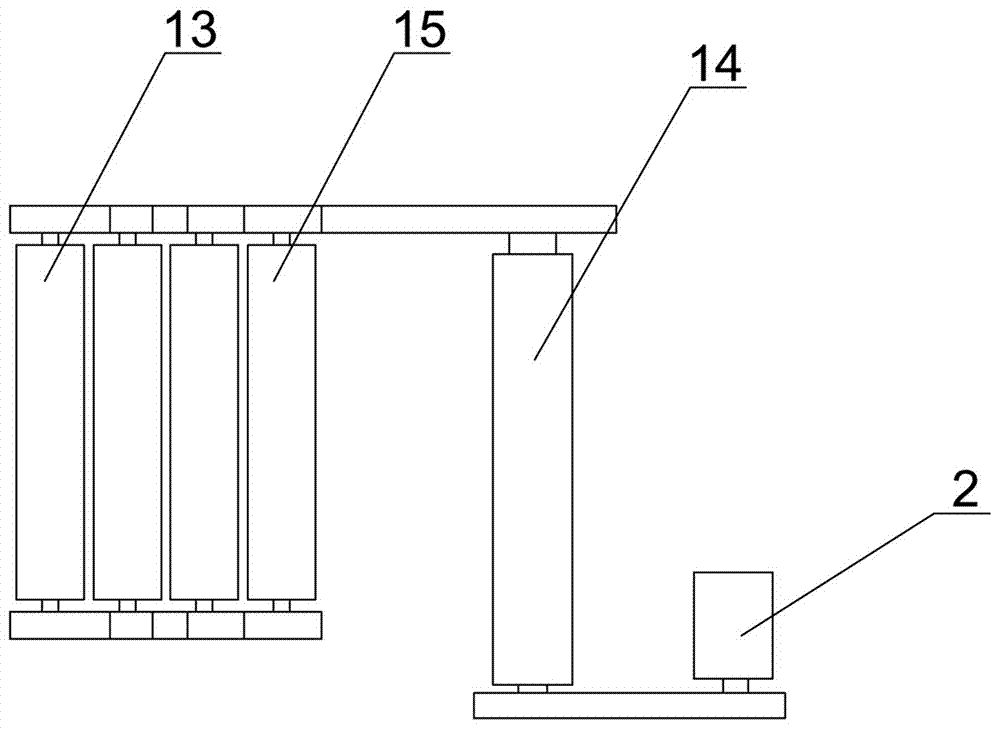

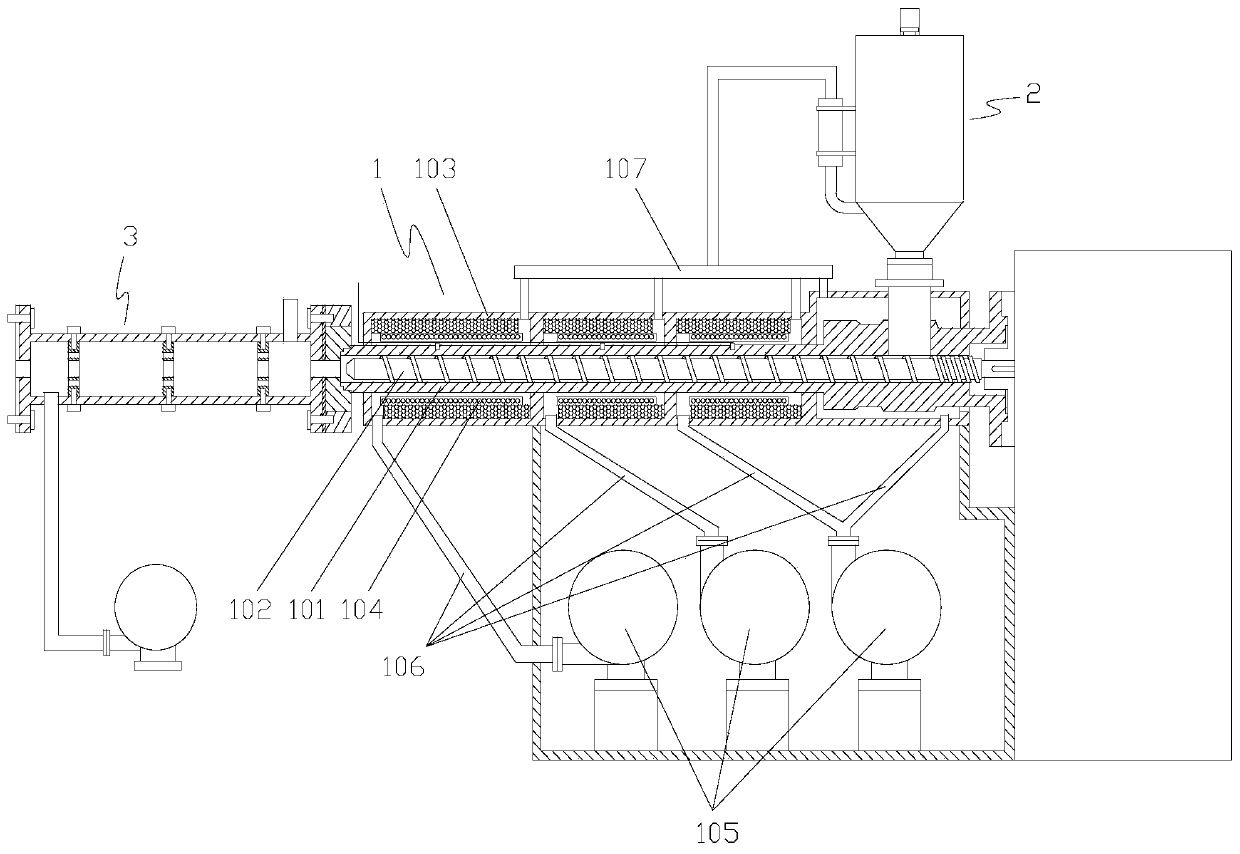

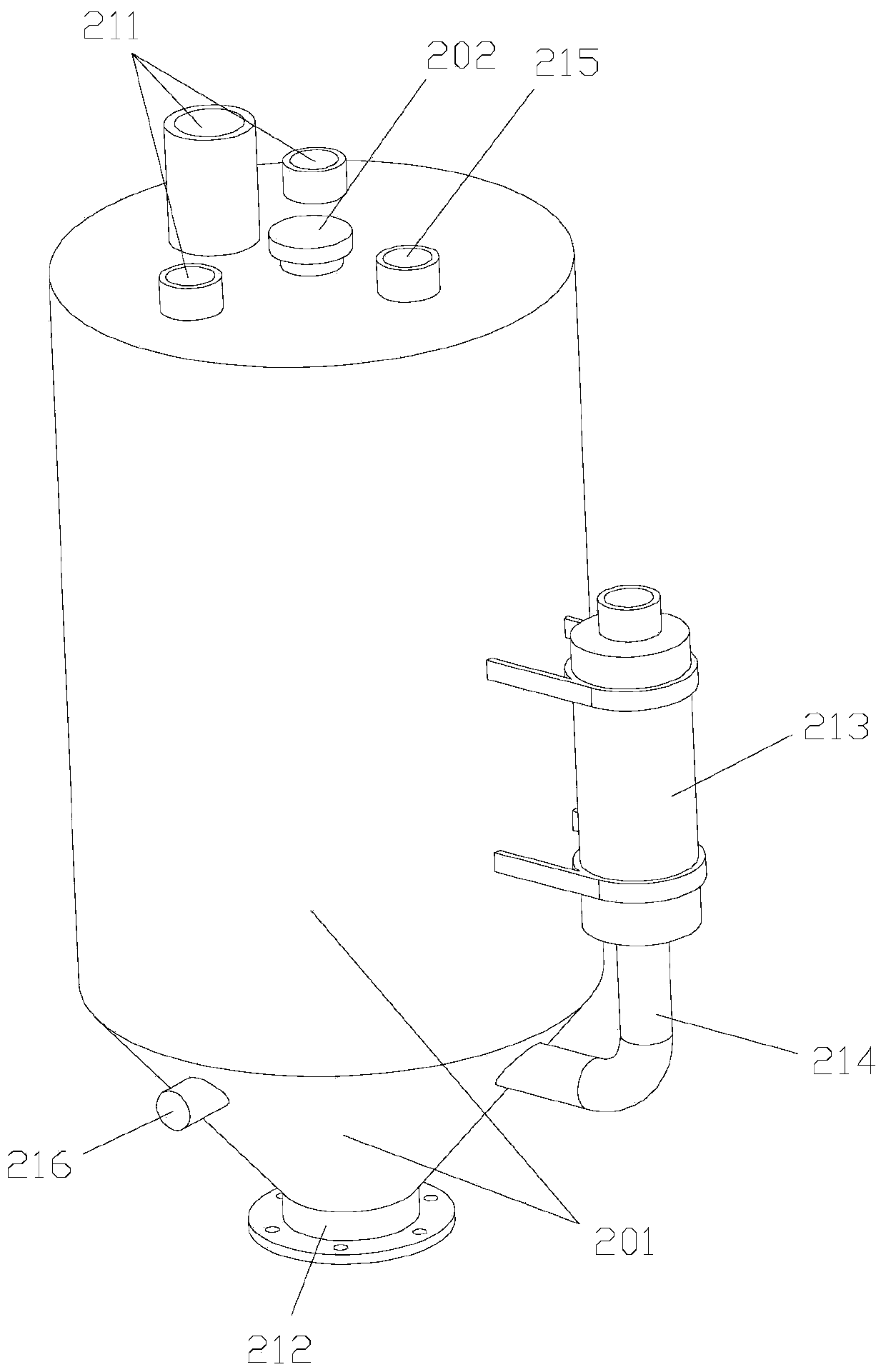

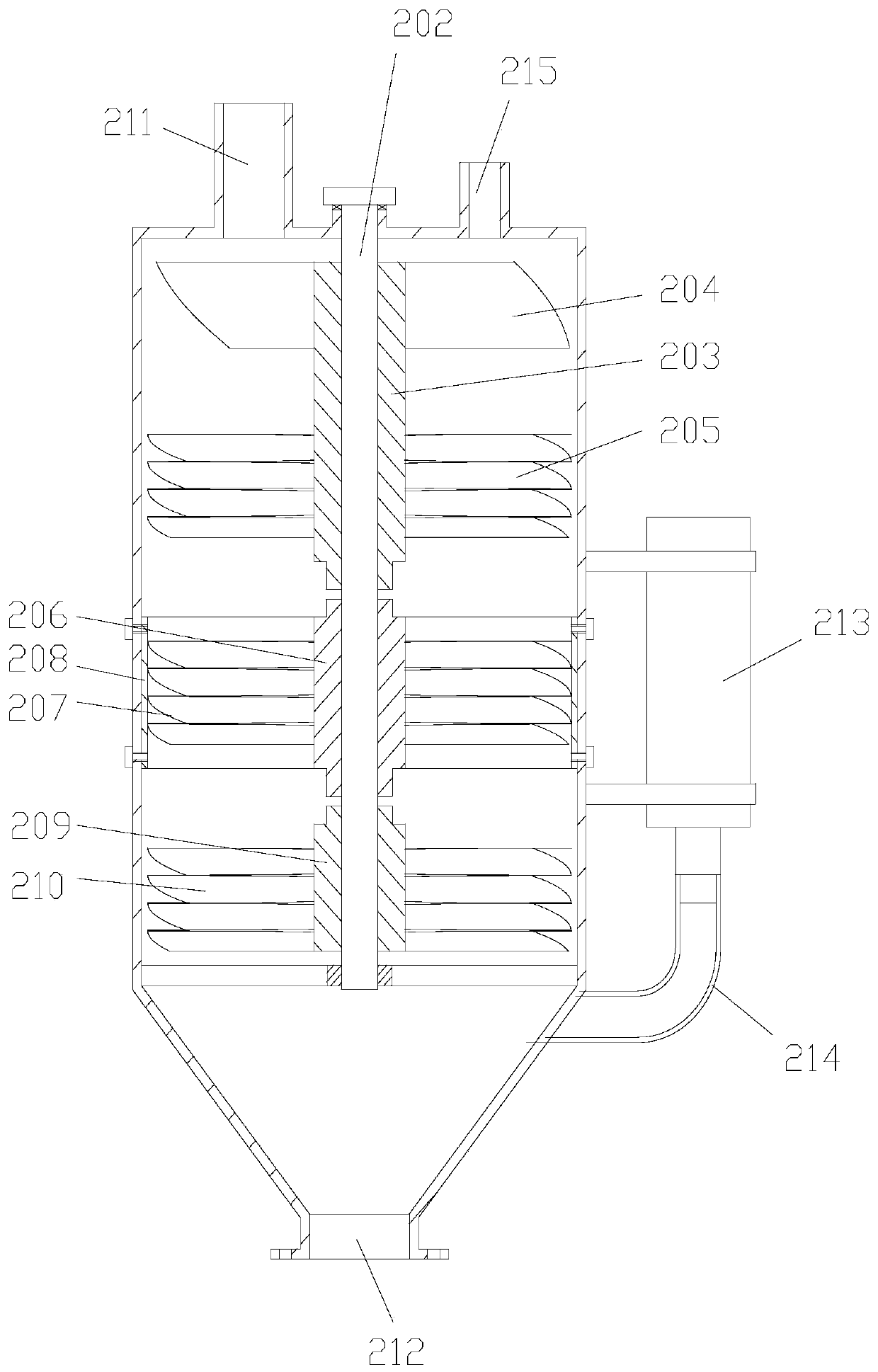

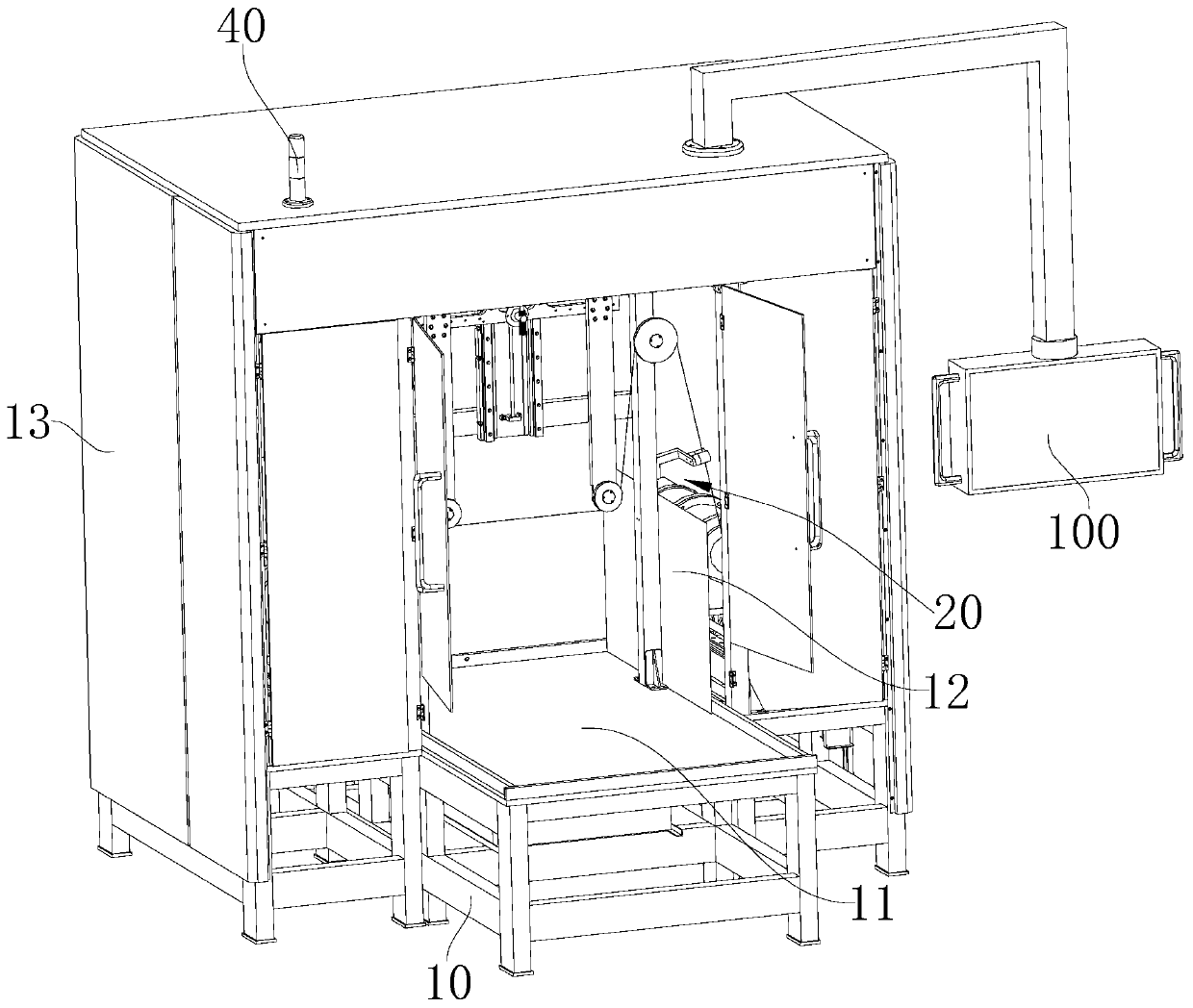

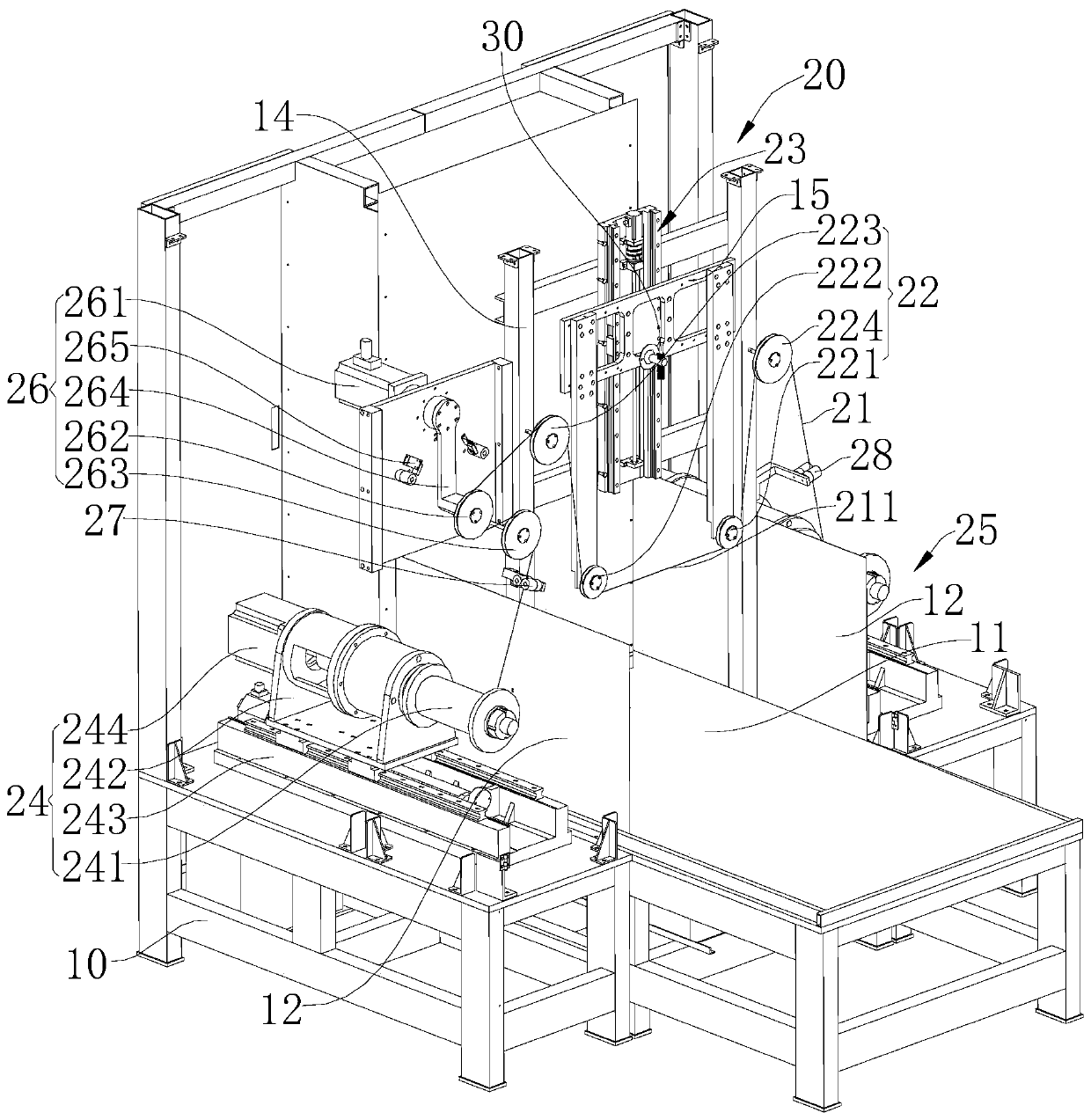

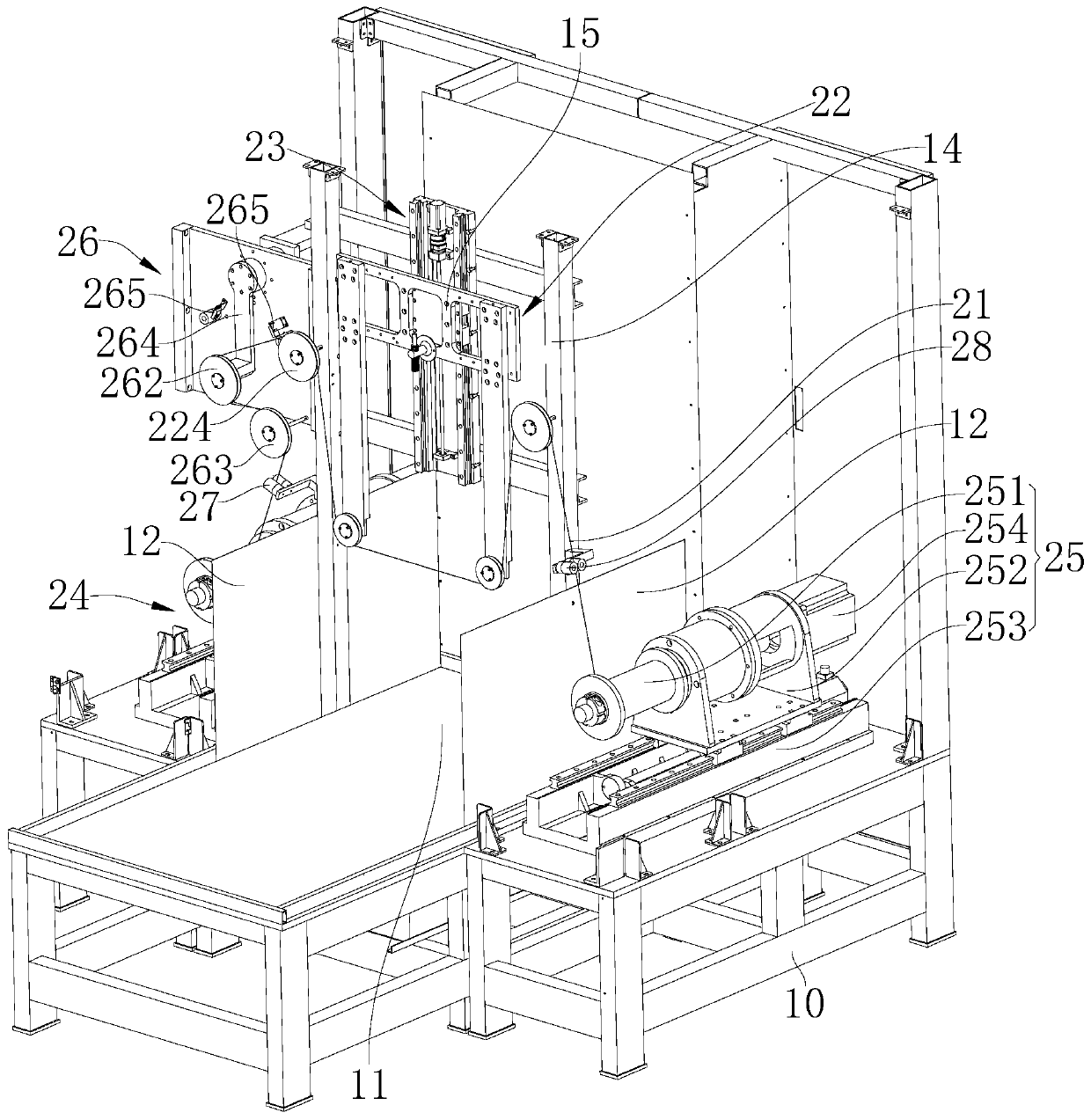

Pretreatment method of crop straw and device thereof

ActiveCN107142764AHigh extraction rateReduce contentPretreatment with water/steamWood working apparatusBiotechnologyPretreatment method

The invention relates to a pretreatment method of crop straw, which includes the following steps: A. cutting the crop straw to be treated by using a cutting device for crop straw; B. processing the cut crop straw in the step A with infiltration; C. processing the infiltration processed crop straw in the step B with steam explosion in a steam explosion tank and washing the infiltration processed crop straw in the step B; D. naturally drying the washed steam explosion straw in the step C in a hurricane dryer at a room temperature, grinding the naturally dried steam explosion straw in a mill, and storing the straw in a storage tank after being filtered in a 30-40 mesh sieve. The invention further relates to a device of crop straw pretreatment, and the device has the advantages that the crop straw can be easily ground, the phenomenon of mess of incinerated straw and air pollution caused by incinerating straw is effectively avoided, and renewable resources in the world is effectively developed.

Owner:南京普渃斯派生态环境研究院有限公司

Diamond coring bit and a laser welding preparation process thereof

InactiveCN109736713AImprove coring efficiencyFast deliveryDrill bitsConstructionsTool bitSpecial design

The invention discloses a diamond coring bit and a laser welding preparation process thereof, and belongs to the technical field of diamond coring bits. The diamond coring bit is formed by connectinga metal base body and diamond tool bits, and the tool bits are evenly distributed on the end face of the metal base body. A transition layer is arranged between the metal base body and the diamond tool bit, a plurality of strip-shaped grooves are evenly formed in the side surface of the diamond tool bit, and the side surface of the wavy tooth structure is formed. And the metal base body and the tool bit are connected into a whole through a laser welding process. Through the special design of the shape of the tool bit, the high-speed coring drill bit can play a very good water cooling role during large-depth drilling, and meanwhile, the continuous wave tooth structure on the inner wall of the tool bit is more beneficial to timely discharging of smashed silt, so that very good cutting performance is kept. By optimizing the components of the tool bits and the transition layer and optimizing technological parameters such as laser power and welding speed, a welding seam with excellent performance is obtained.

Owner:江苏友美工具有限公司

Door/window frame plastic steel profile extrusion production line

The invention discloses a door / window frame plastic steel profile extrusion production line. The door / window frame plastic steel profile extrusion production line comprises a plastic extruding machine, a hopper connected with a feeding inlet of the plastic extruding machine, a water cooling device connected with the machine head of the plastic extruding machine, a splitting device arranged on thedownstream portion of the water cooling device, and a discharging device arranged on the downstream portion of the splitting device; the hopper comprises a spiral mixer, and the spiral mixer comprisesa middle shaft which is arranged at the center part of a hopper shell and is in rotary fit with the hopper shell, and further comprises an upper spiral material uniformizing assembly, a middle spiralmaterial uniformizing assembly and a lower spiral material uniformizing assembly which are sequentially arranged on the middle shaft from top to bottom; and the splitting device comprises a supporting table, a synchronous translation mechanism and a cutting-off mechanism, and a cutting edge of a cutter is in an M shape. Through the door / window frame plastic steel profile extrusion production line, the problems that an existing production line needs additional equipment, and raw materials are mixed and dried through manpower are solved, and in addition, the problem that an existing splitting device can cause cutting is solved.

Owner:重庆海塑建材有限公司

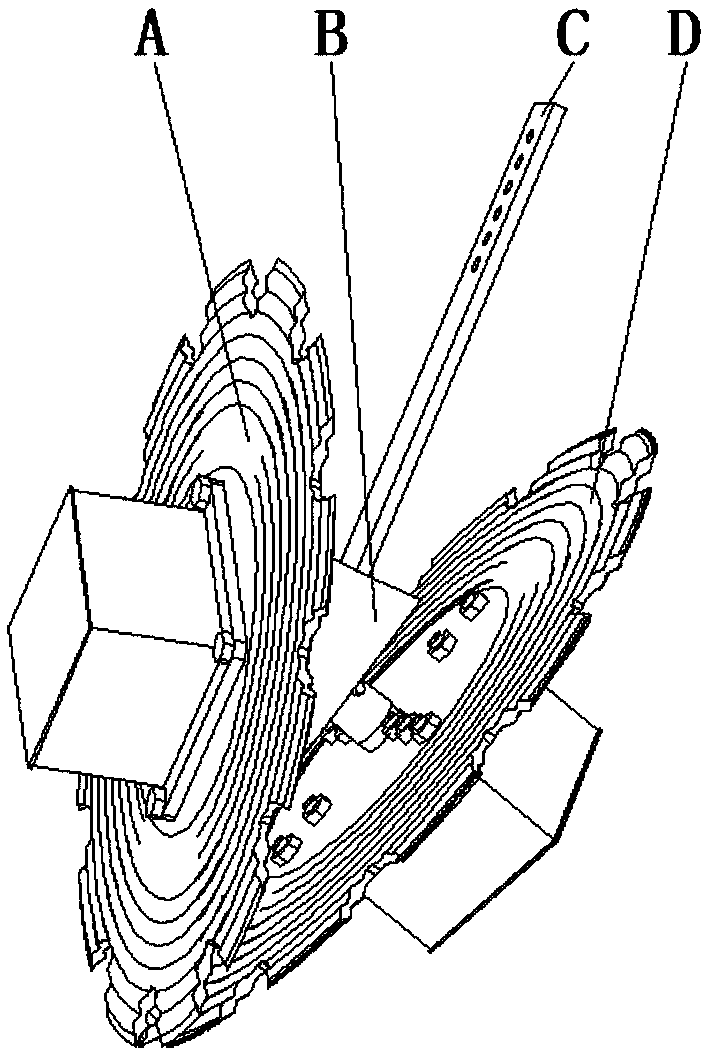

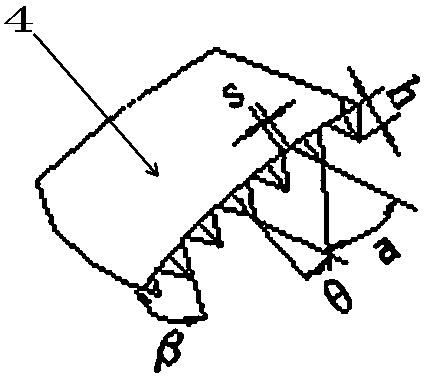

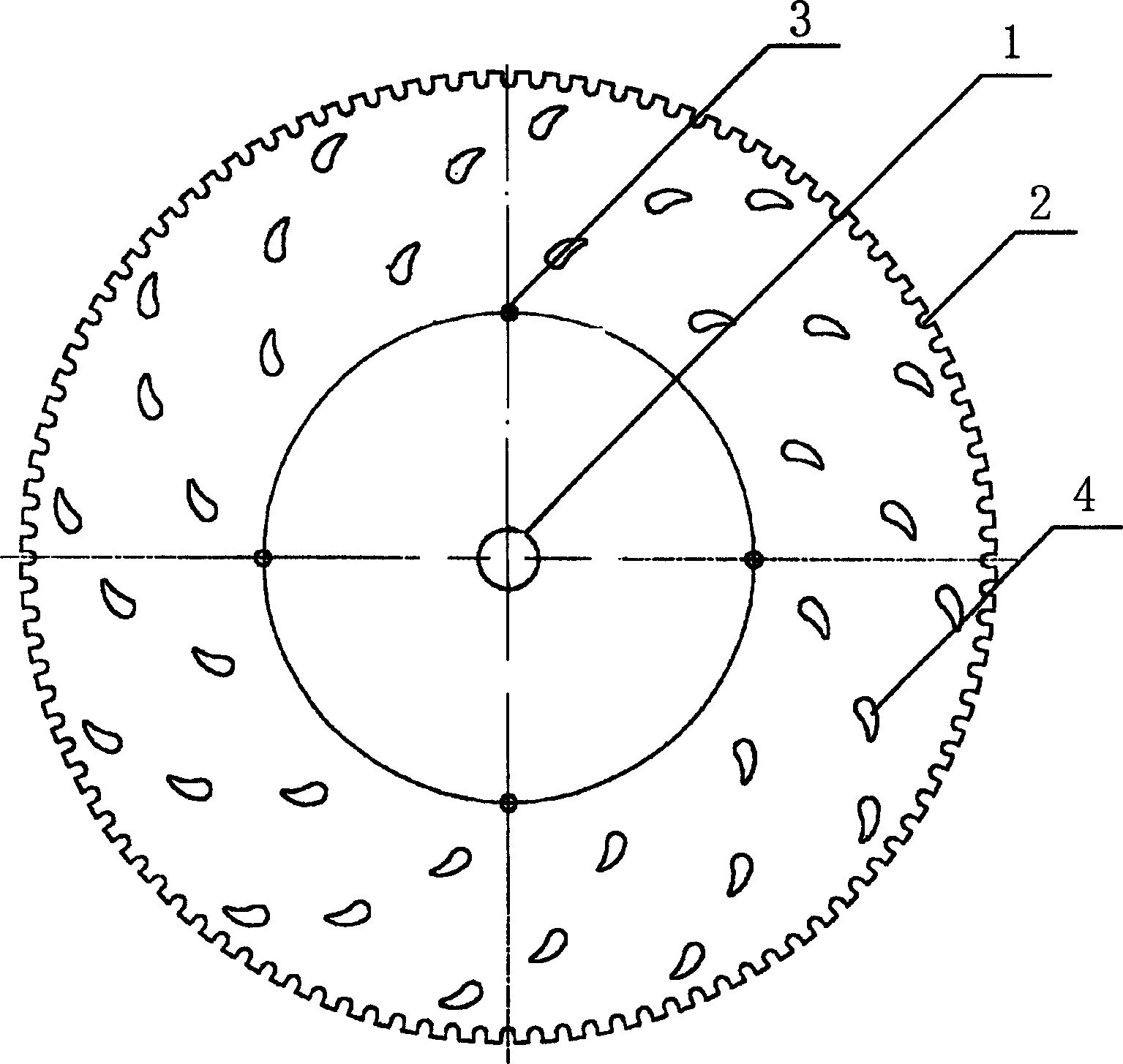

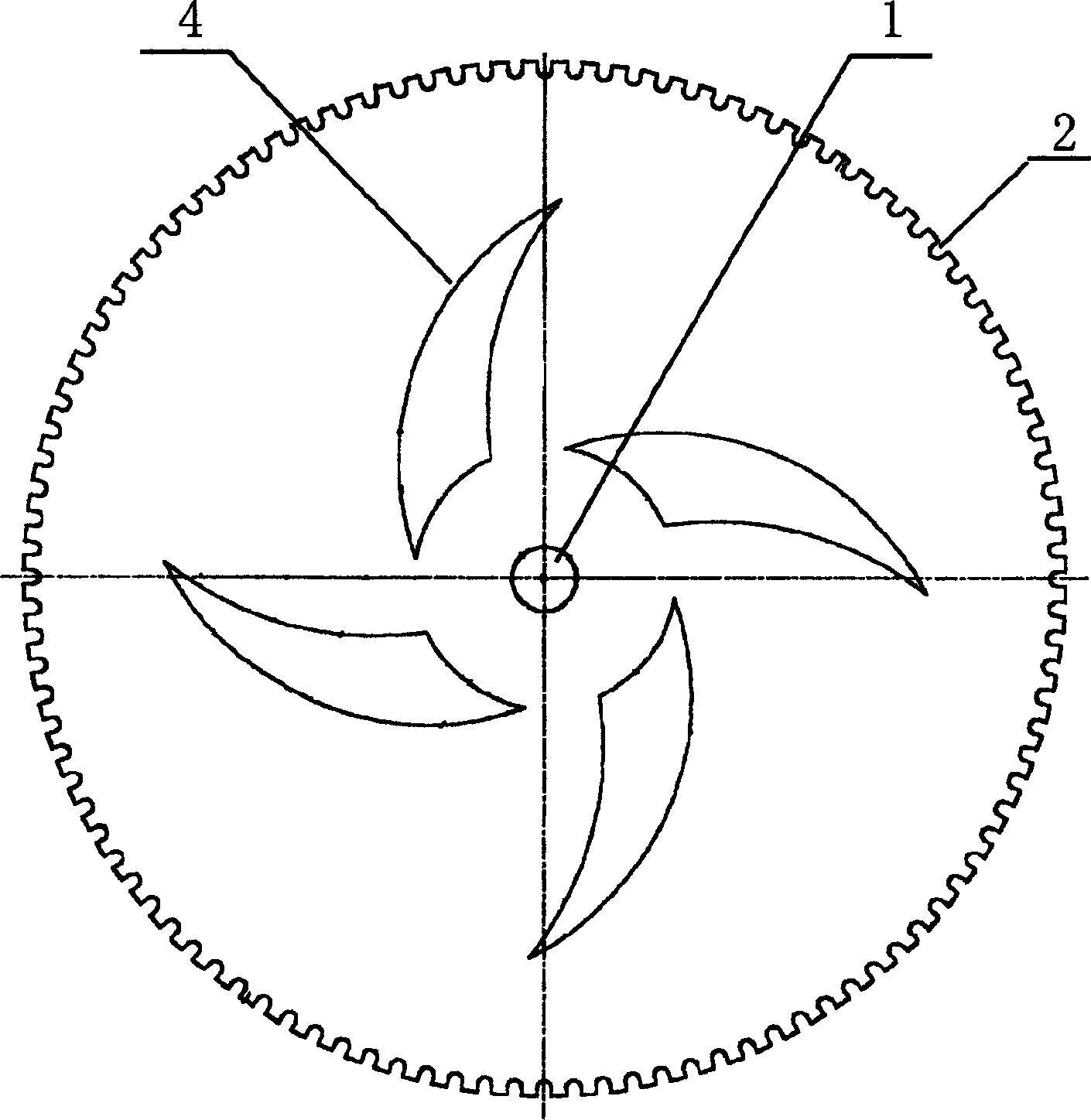

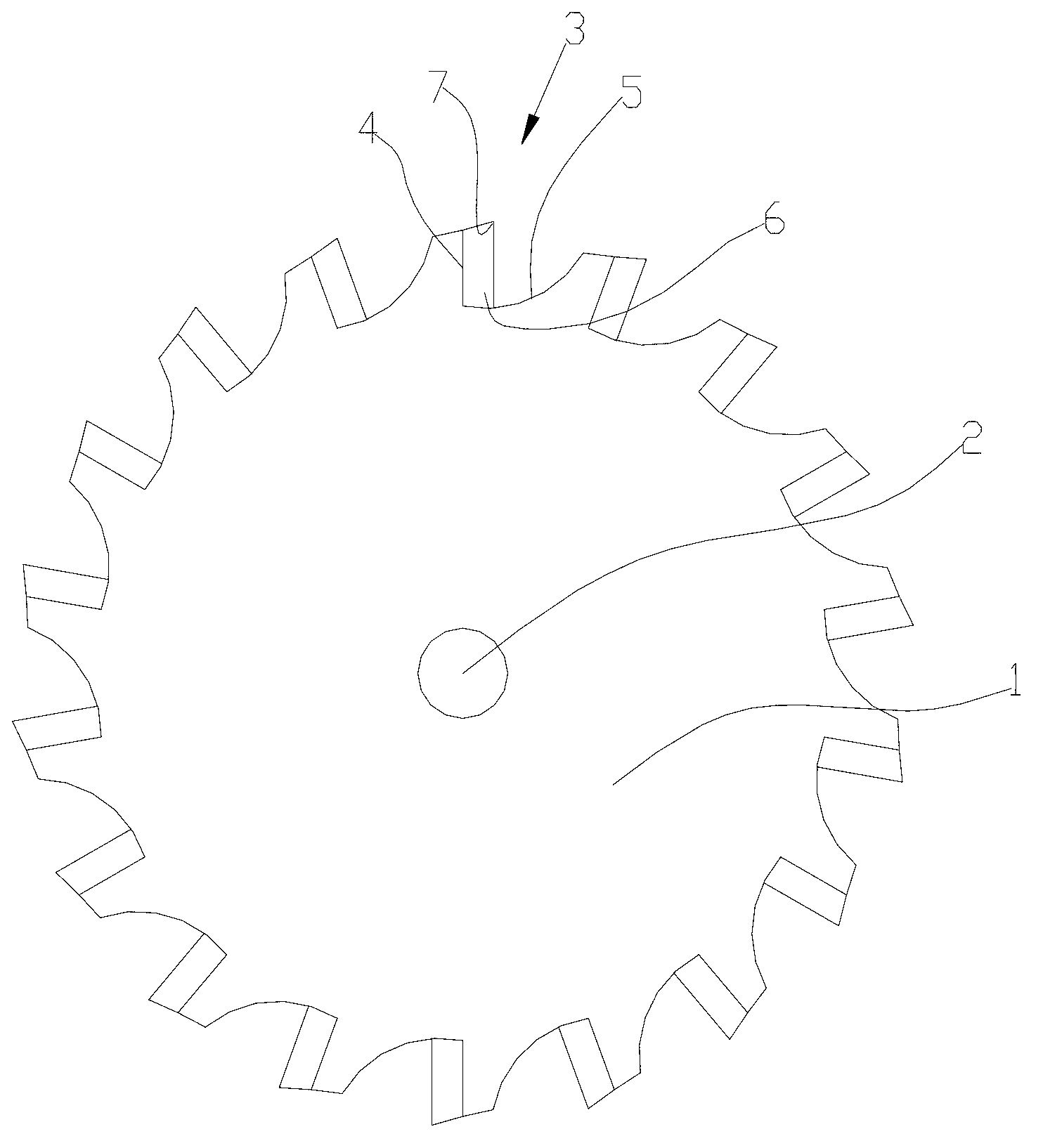

Bionic disc tool for cutting crop stalks

InactiveCN108406895ASmall cutting resistanceReduce job power consumptionHarvestersMetal working apparatusTibiaEdge structure

The invention discloses a bionic disc tool for cutting crop stalks, and belongs to the field of agricultural machines. The bionic disc tool comprises a first tool disc and a second tool disc which oppositely rotate. Each of the first tool disc and the second tool disc is composed of a rotation disc and cutting blades. The shapes of the cutting blades are of an arc curve structure. A plurality of toothed structures are continuously arranged on a curve of a cutting edge of each cutting blade. According to the bionic disc tool, the arc outline of the propodeum tibia of the mantis and the outer edge armature geometric structure and the arrangement form of the mantis serve as a bionic archetype, and the cutting face shape and the bionic toothed cutting edge structure of the cutting blades in the disc tool are designed; and compared with a traditional disc tool, by means of the bionic disc tool for cutting the crop stalks, the power consumption of cutting work can be reduced by about 10%.

Owner:JILIN UNIV

Preparation method of flying saucer welding slotted piece

ActiveCN106626087ARapid positioningReduce contact areaStone-like material working toolsMaterials scienceRaw material

The invention relates to a preparation method of a flying saucer welding slotted piece, and belongs to the technical field of preparation of cutting tools. The preparation method comprises the following steps: a steel basal body is selected, and is machined to form an internal area and a peripheral annular area; diamond raw material powder is selected, and is uniformly mixed for cold press molding and hot press sintering to form a diamond tool bit; the diamond tool bit includes diamond main tooth tool bits and diamond protective tooth tool bits; the diamond protective tooth tool bits are welded on the frontal and reverse surfaces of the peripheral annular area at intervals, and extend out of the peripheral annular area; and the diamond main tooth tool bits are welded on the end wall in the peripheral annular area between the adjacent diamond protective tooth tool bits. The prepared flying saucer welding slotted piece can position a cutting point more quickly during high-speed cutting; and the diamond protective tooth tool bits are welded on the side surface of the basal body to reduce the contact area with machined materials, so that the cutting resistance is largely reduced, the noise is lowered, and the cutting efficiency is improved.

Owner:JIANGSU FENGTAI TOOLS

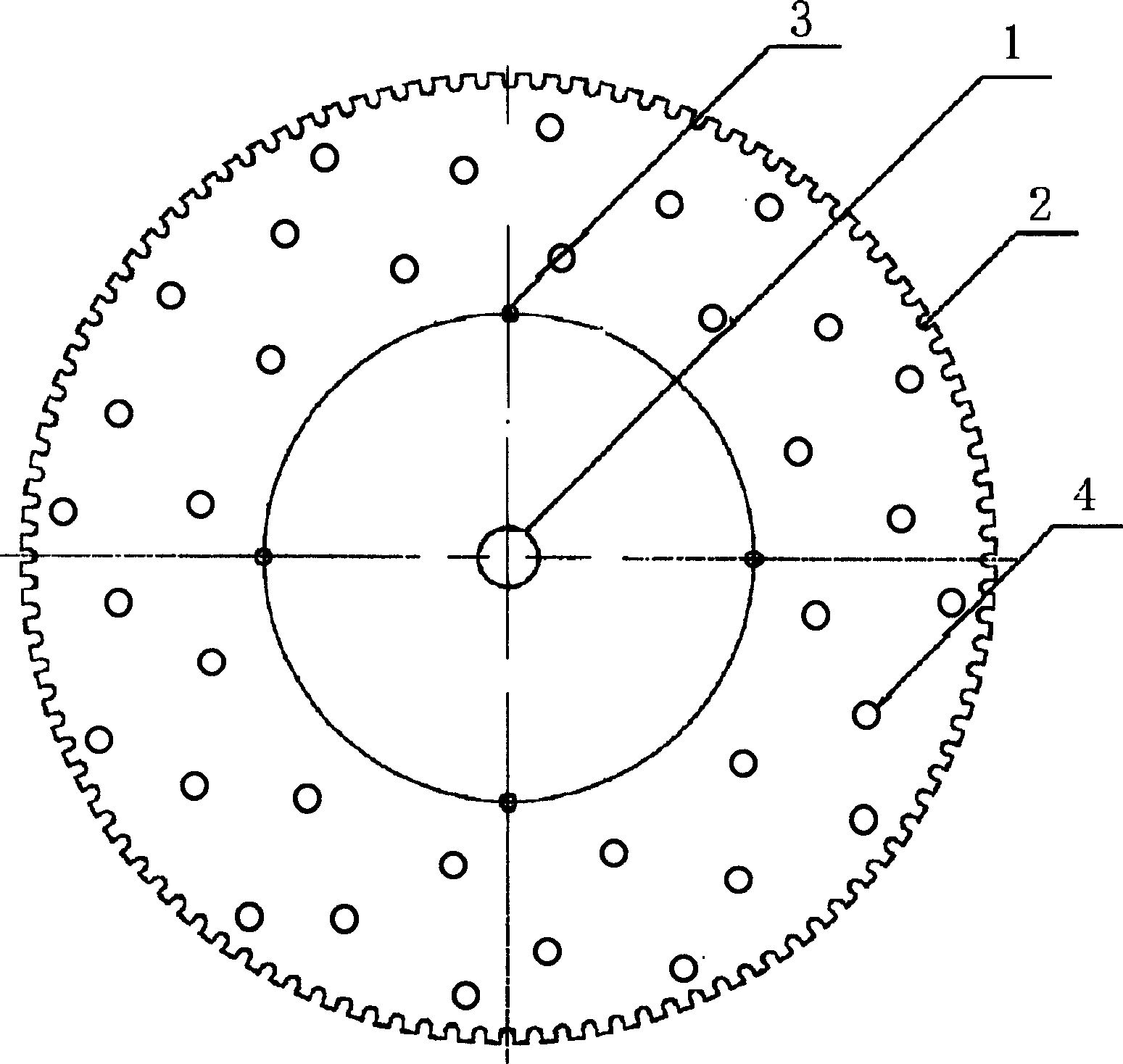

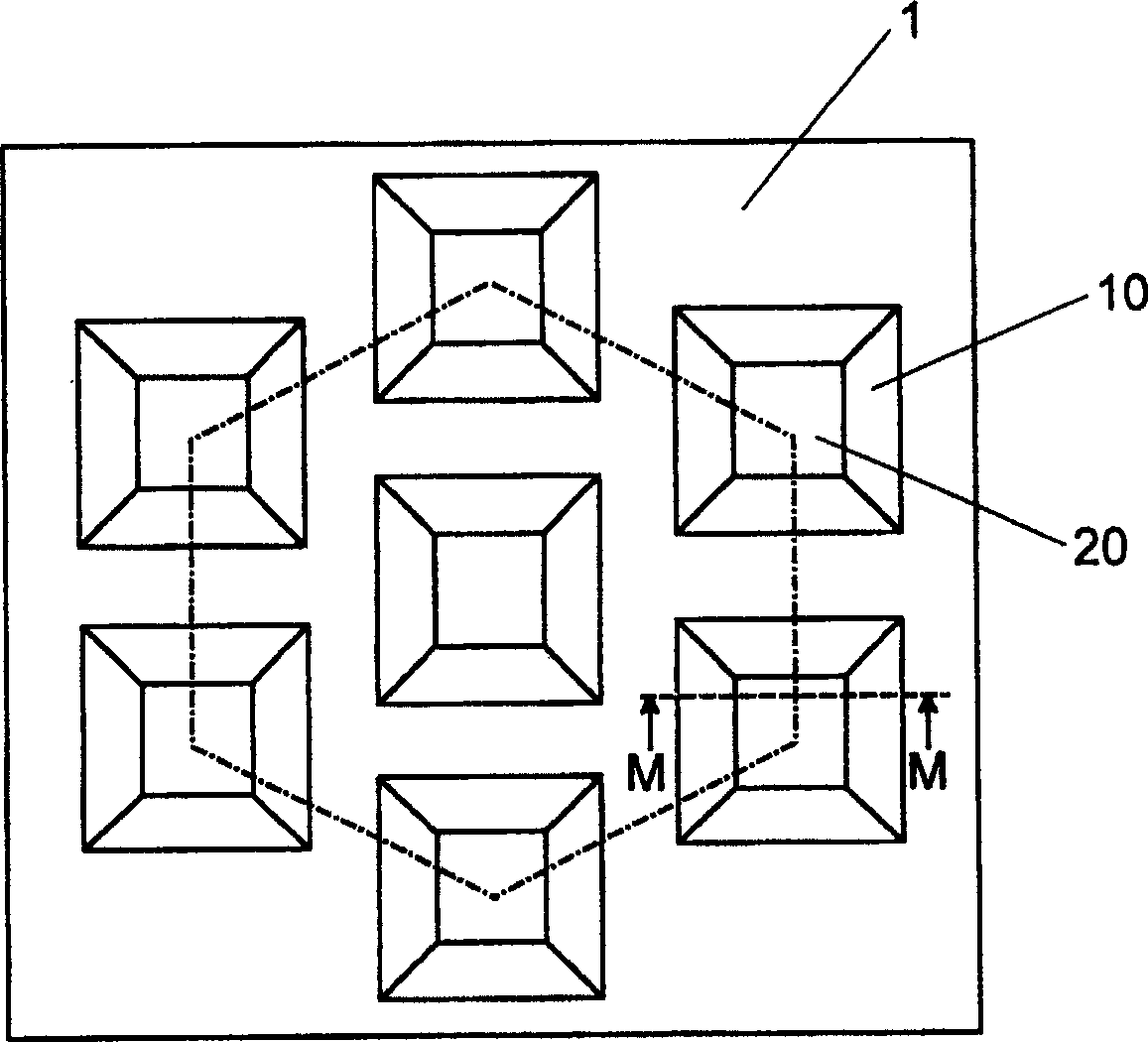

Saw web base body with hollowed holes

ActiveCN1544229AReduce frictionSmall cutting resistanceCircular sawsStone-like material working toolsEngineeringRadiation

The invention discloses a through hole saw blade basal body, there are central installation hole and processing locating hole, the outer edge of the basal body is made with water channel, and the through holes are uniformly distributed on the basal body. It reduces contact surface area, has small cutting resistance, effectively reduces noise, enhances heat radiation and cooling, and has simple process and lower fabrication cost.

Owner:HEIXUANFENG SAW IND

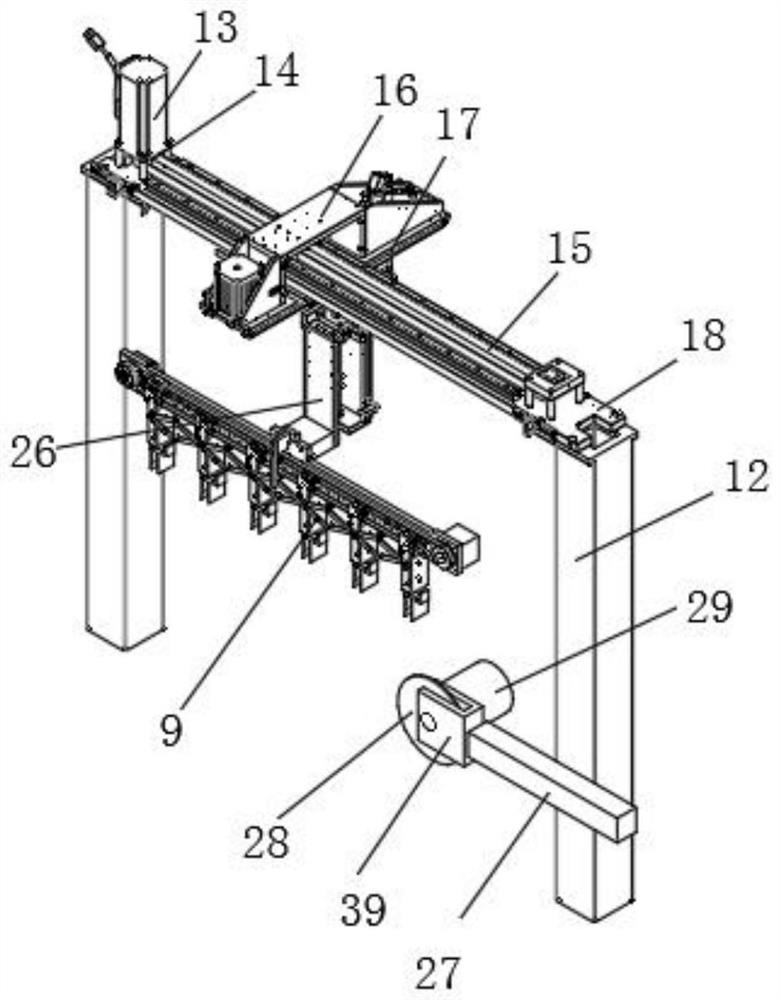

Furniture wood cutting forming integrated machine and work method thereof

InactiveCN111775222ASmall cutting resistanceSolve labor-intensive technical problemsProfiling/shaping machinesStructural engineeringMachining process

The invention discloses a furniture wood cutting forming integrated machine and a work method thereof. The integrated machine comprises a supporting bottom plate. A containing plate is horizontally arranged above the supporting bottom plate. A cutting tool shaft is transversely arranged between installing vertical plates and fixedly provided with a plurality of first cutting blades. A belt conveyor is arranged on one side of the containing plate. A supporting beam is fixedly arranged at the top ends of two supporting columns and movably provided with a first connecting plate. An installing frame is movably arranged on the bottom face of a second connecting plate and movably provided with an installing arm in the vertical direction. A material grabbing mechanism is fixedly arranged at the bottom end of the installing arm. The first cutting blades and second cutting blades are adopted in the furniture wood cutting forming integrated machine for wood cutting, wood can be rapidly cut and formed, the work efficiency is high, the service life of the second cutting blades is guaranteed, automatic transportation is adopted in the machining process, manual carrying is not needed, and the labor intensity is low.

Owner:安徽纬奥特工艺品有限公司

Waste material strip cutting device of electronic component assembling machine

InactiveCN104985246AEasy to replaceCompact structureShearing machinesShearing toolsElectronic componentWaste material

The invention discloses a waste material strip cutting device of an electronic component assembling machine. The device comprises a fixed rack and a movable rack. One end of the fixed rack is provided with a stationary cutter. The middle position of the other end of fixed rack is provided with a drive device. The fixed rack on two sides of the drive device is provided with guiding devices. A limiting device is arranged between the drive device and one of the guiding devices. The movable rack is connected with the drive device. The movable rack is provided with a movable cutter. The movable cutter and the stationary cutter are cooperated. The integrated width of the movable cutter is corresponding to the integrated width of the stationary cutter. The device is compact in structure, good in adaptability, convenient in operation and maintenance, and low in use and maintenance cost. The movable cutter is in a spliced structure, and a strip cutting device can conveniently change blades whose cutting edges are worn, so as to prolong life of the device.

Owner:SHANDONG RIFA TEXTILE MACHINERY

Pavement milling apparatus

A disclosed pavement milling apparatus comprises a milling-apparatus main support; one side of the bottom of the main support is provided with a motor fixing plate, and the other side of the bottom of the main support is flexible provided with a cutter adjusting clamping plate; a driving motor is arranged on the motor fixing plate; the output shaft of the driving motor is coaxially fixedly provided with a spline shaft; the top of the spline shaft penetrates the cutter adjusting clamping plate; and the spline shaft is sleeved by milling cutter wheels and a limit casing pipe. The pavement milling apparatus has the advantages that milling apparatuses with different width can be obtained through combination according to user demands, cutter wheels are easy and convenient to replace, the dumping direction and the direction for cutting edges of a reference layer are selectable, cut reference-layer edges are tidy, and because two employed cutter wheels have different structures and are used to specifically process pavement, the cutting resistance is reduced and milling and ditching operations are steady.

Owner:SHANDONG VANSE MECHANICAL TECH CO LTD

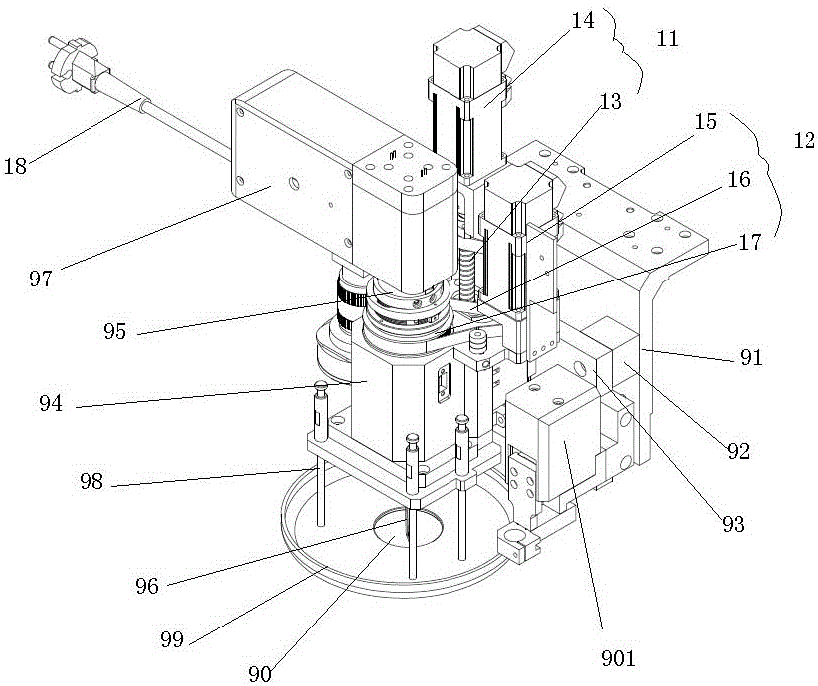

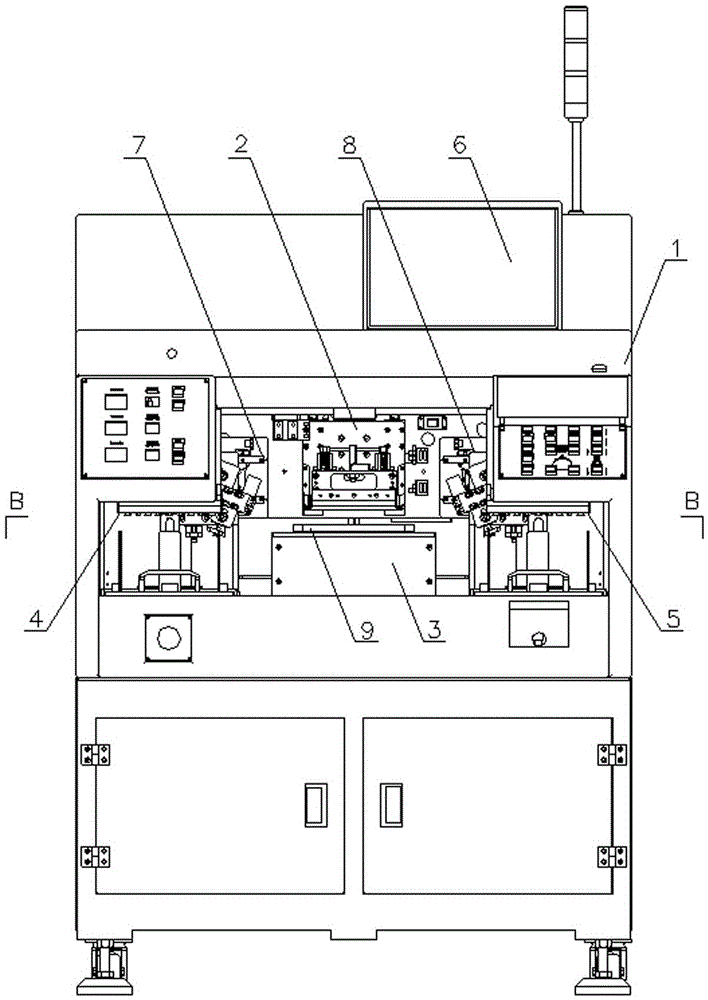

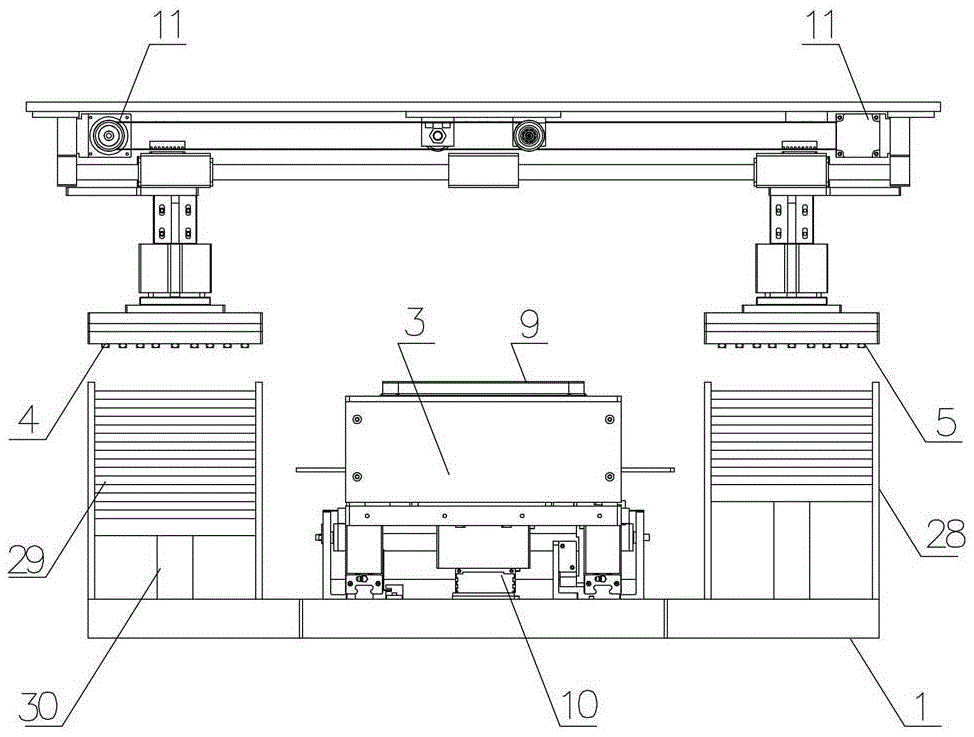

Laser cutting device for flexible display

InactiveCN106825939AHigh positioning accuracyHigh speedLaser beam welding apparatusControl systemLaser cutting

The invention relates to a laser cutting device for flexible display in the field of electronic component manufacturing equipment, including a body structure, a carrier, a detection and positioning mechanism, a laser cutting mechanism and a control system; The feeding mechanism and the receiving mechanism of the silo are equipped with an electric ejector rod at the bottom of the silo; the lower part of the carrier is connected to the worktable, and at the connection between the carrier and the worktable, there is a servo that allows the carrier to rotate relative to the worktable Rotation mechanism, under the workbench, there is a servo motor that can make the workbench move forward and backward in a straight line; the detection and positioning mechanism is a CCD detector, which is equipped with a motor that can drive the CCD to move, search for marking points and automatically focus; set up an automatic feeding and receiving mechanism , replace manual operation, improve production quality, CCD detector and linear drive servo motor realize automatic alignment detection; equipped with laser cutting mechanism, realize high-speed precision cutting, accurate detection, intelligent identification, high cutting precision, and can cut products of various sizes .

Owner:肇庆市宏华电子科技有限公司

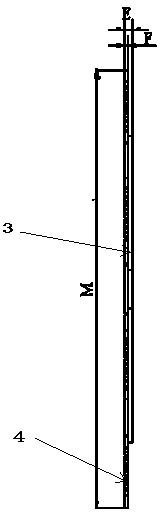

Wire cutting device and material cutting equipment

PendingCN111267237AEase wasteReduce generationWorking accessoriesStone-like material working toolsWire cuttingStructural engineering

The invention belongs to the technical field of material cutting and particularly relates to a wire cutting device and material cutting equipment. The wire cutting device comprises a mounting rack anda wire cutting mechanism. The mounting rack is provided with a material placement table, and the wire cutting mechanism comprises a cutting wire, a paying-off assembly, a take-up assembly and a cutting driving assembly. The paying-off assembly and the take-up assembly are arranged on the two sides of the material placement table respectively and connected with the two ends of the cutting wire respectively, a wire cutting segment is formed on the portion, between the paying-off assembly and the take-up assembly, of the cutting wire, the cutting driving assembly is in driving connection with the wire cutting segment, and when the cutting driving assembly drives the wire cutting segment to move until the wire cutting segment abuts against a material, the paying-off assembly and the take-up assembly execute paying-off and take-up actions, so that the wire cutting segment rubs and cuts the material. The contact area between the cutting wire and the material is smaller when the cutting wirecuts the material, the cutting resistance is smaller, the cutting efficiency is higher, in addition, a cutting edge of the cutting wire is relatively small, less waste is generated during cutting, material waste can be effectively reduced, and the production cost is lowered.

Owner:深圳市威雄精机有限公司

Circular saw blade

The invention discloses a circular saw blade comprising a saw blade base body. A center hole is formed at the center of the saw blade base body, a plurality of toothed grooves are evenly formed along the periphery of the saw blade base body, and each toothed groove is formed by connection of a right-angle side and a concave circular arc edge; each right-angle side is provided with a saw tooth; each saw tooth is thicker than the saw blade base body; a cutting edge angle of each saw tooth is an acute angle. According to the technical scheme, the toothed grooves are adopted to reduce vibration of the saw blade during cutting, so that low-noise cutting effect is achieved; the concave circular arc edges of the toothed grooves can increase ventilation quantity to have the saw blade cooled rapidly, high temperature is less prone to generation, cutting resistance is small, cutting efficiency is high and service life of the saw blade is prolonged at the same time.

Owner:朱兴生

Stripping device for cable and using method

PendingCN112530642AAvoid displacementPrevent rotationBasic electric elementsElectronic waste recyclingTool bitProcess engineering

The invention provides a stripping device for a cable and an application method. The stripping device comprises a workbench, wherein the workbench is provided with a conveying mechanism, a fixing mechanism and a stripping mechanism, the workbench is provided with a reciprocating translation driving mechanism, and the reciprocating translation driving mechanism drives the stripping mechanism to reciprocate along the length direction of the workbench. According to the stripping device, the cable sheath is automatically cut, the rotation of the cable is avoided, the engagement of the cutter headis small, the cutting resistance is small, the cutting efficiency is high, the clamping range and the engagement can be adjusted, the cables in various sizes can be peeled, the peeling method providedby the invention is convenient to operate, and working efficiency is improved.

Owner:YANGXIN POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

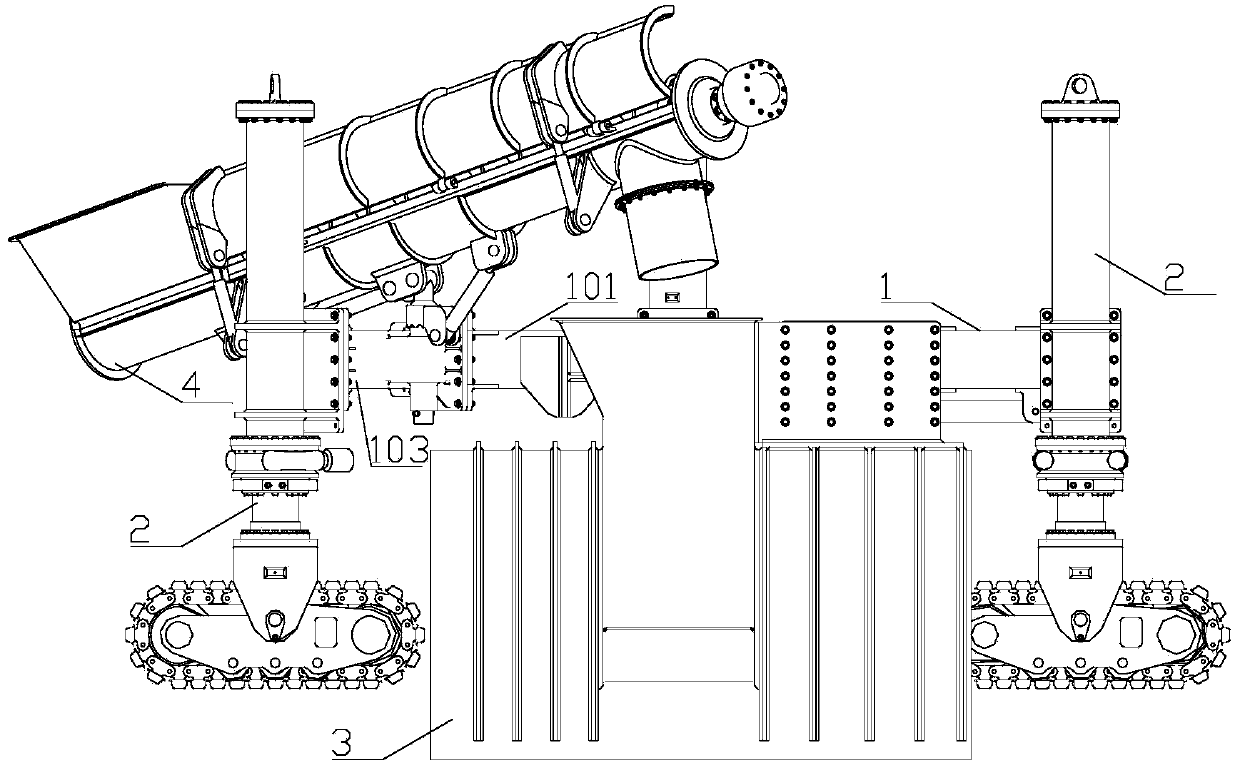

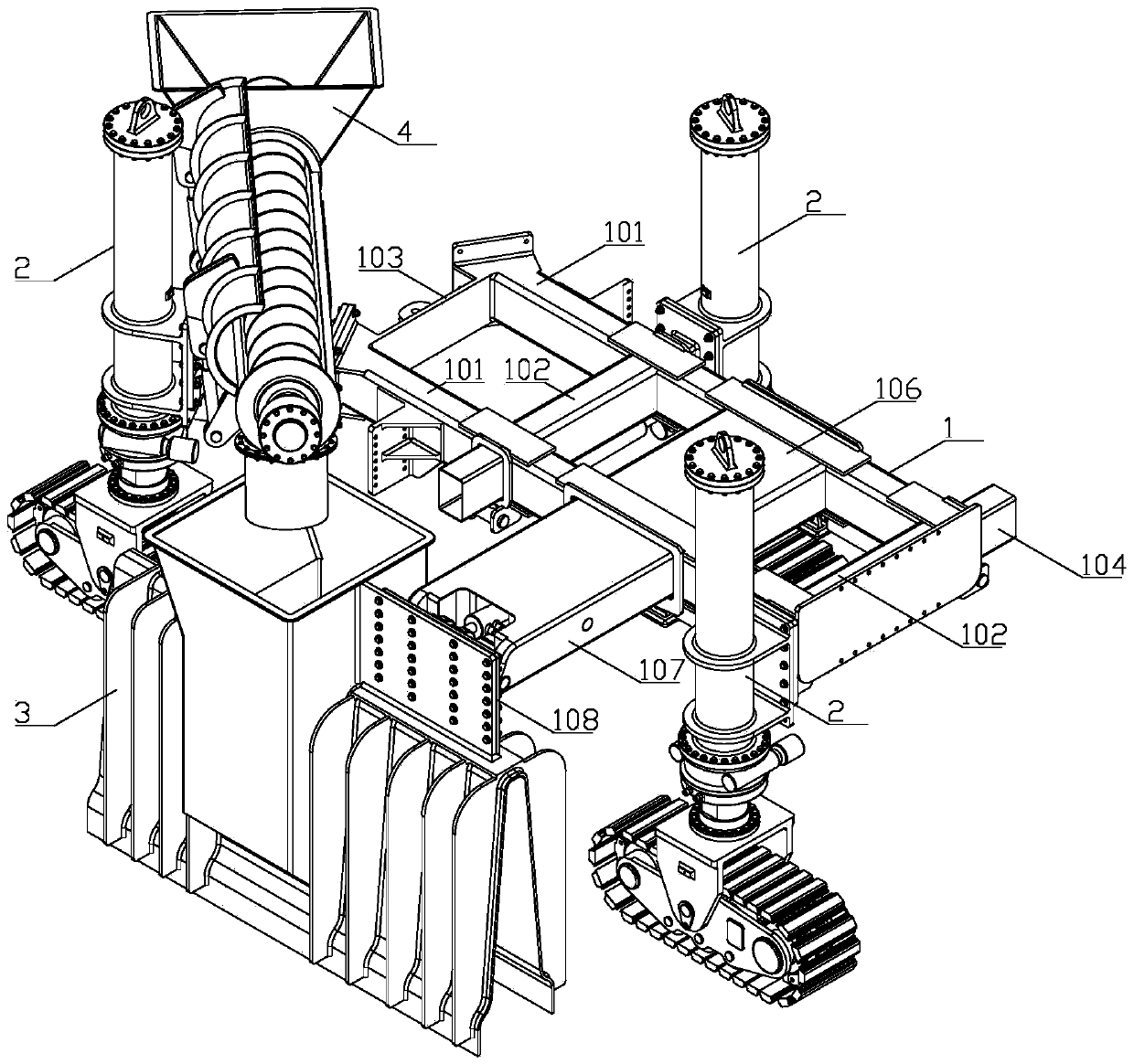

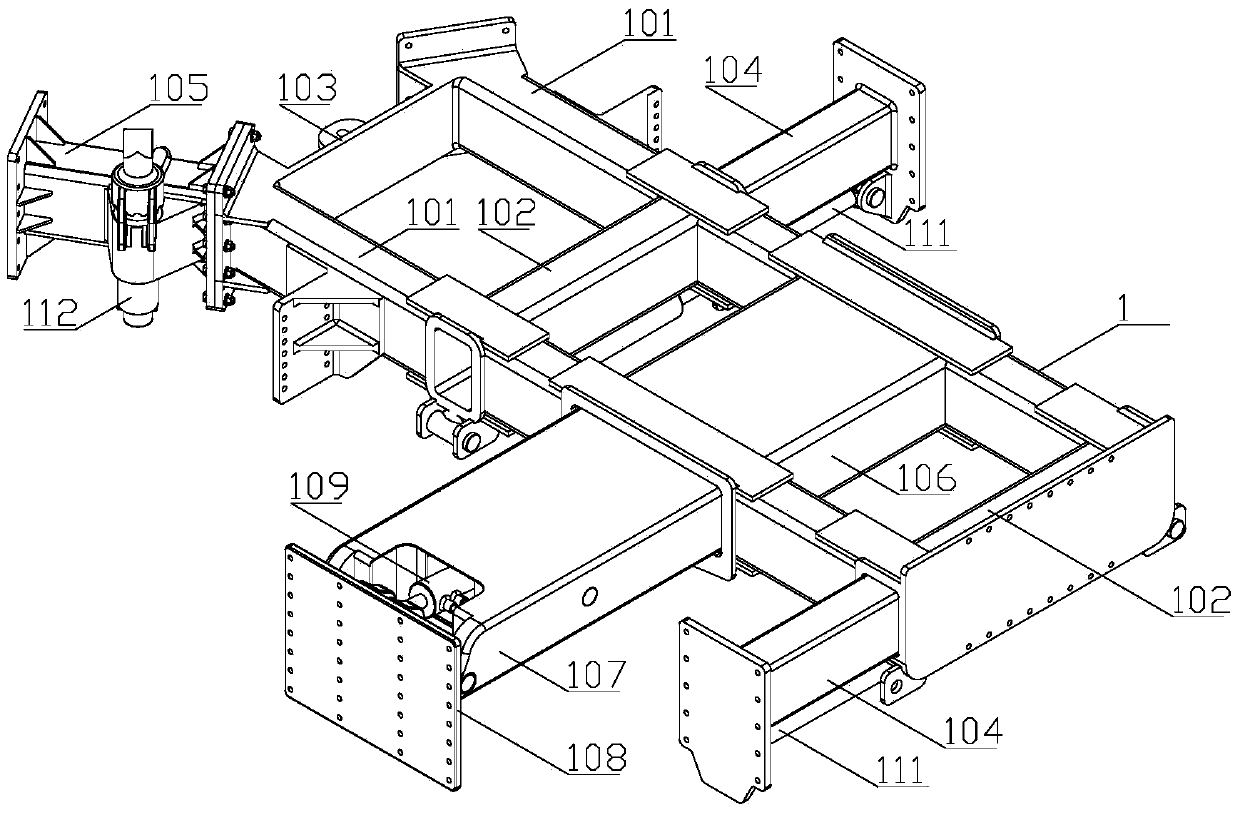

T-shaped three-crawler-belt slipform paver

ActiveCN103993542AEasy to install and maintainEasy to replaceRoads maintainenceSupport pointPiston rod

A disclosed T-shaped three-crawler-belt slipform paver comprises a T-shaped telescopic chassis and crawler-type elevating turning apparatuses; the T-shaped telescopic chassis comprises two longitudinal main beams, two transverse main beams, two telescopic beams and a connection beam; one transverse main beam is arranged between the ends of the two longitudinal main beams, and the other transverse main beam is arranged at the middle of the two longitudinal main beams; each transverse main beam is inside provided with one telescopic beam; the bottom of each transverse main beam is provided with a telescopic-beam oil cylinder; the cylinder body of the telescopic-beam oil cylinder is fixedly disposed on the transverse main beam, and the piston rod of the telescopic-beam oil cylinder is connected with the telescopic beam; one end of the connection beam is fixedly disposed at the front end of one longitudinal main beam; and the top end of each telescopic beam and the outer end of the connection beam are provided with the crawler-type elevating turning apparatuses. The T-shaped three-crawler-belt slipform paver has the advantages that the T-shaped telescopic chassis is designed by employing a modularization structure, and left / right-side slipform paving can be optionally combined according to construction demands; and the positions of support points of three crawler belts do not need adjusting when small-arc side paving is performed.

Owner:山东万顺机械制造有限公司

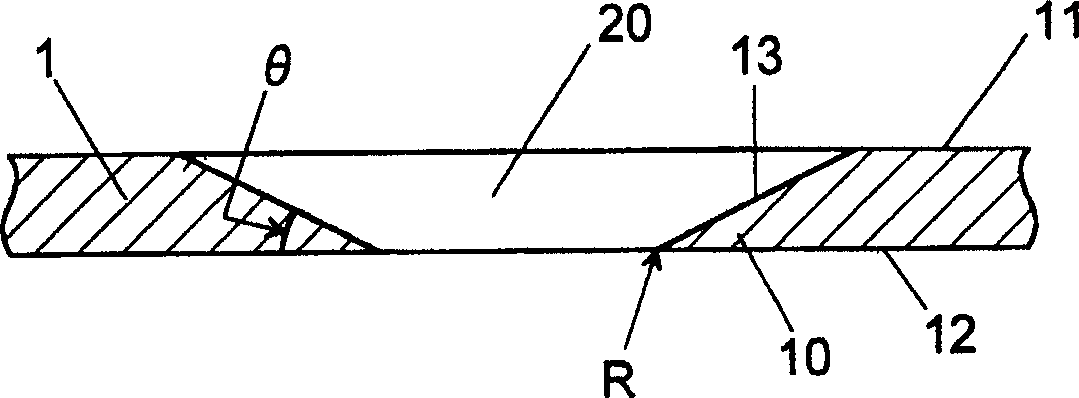

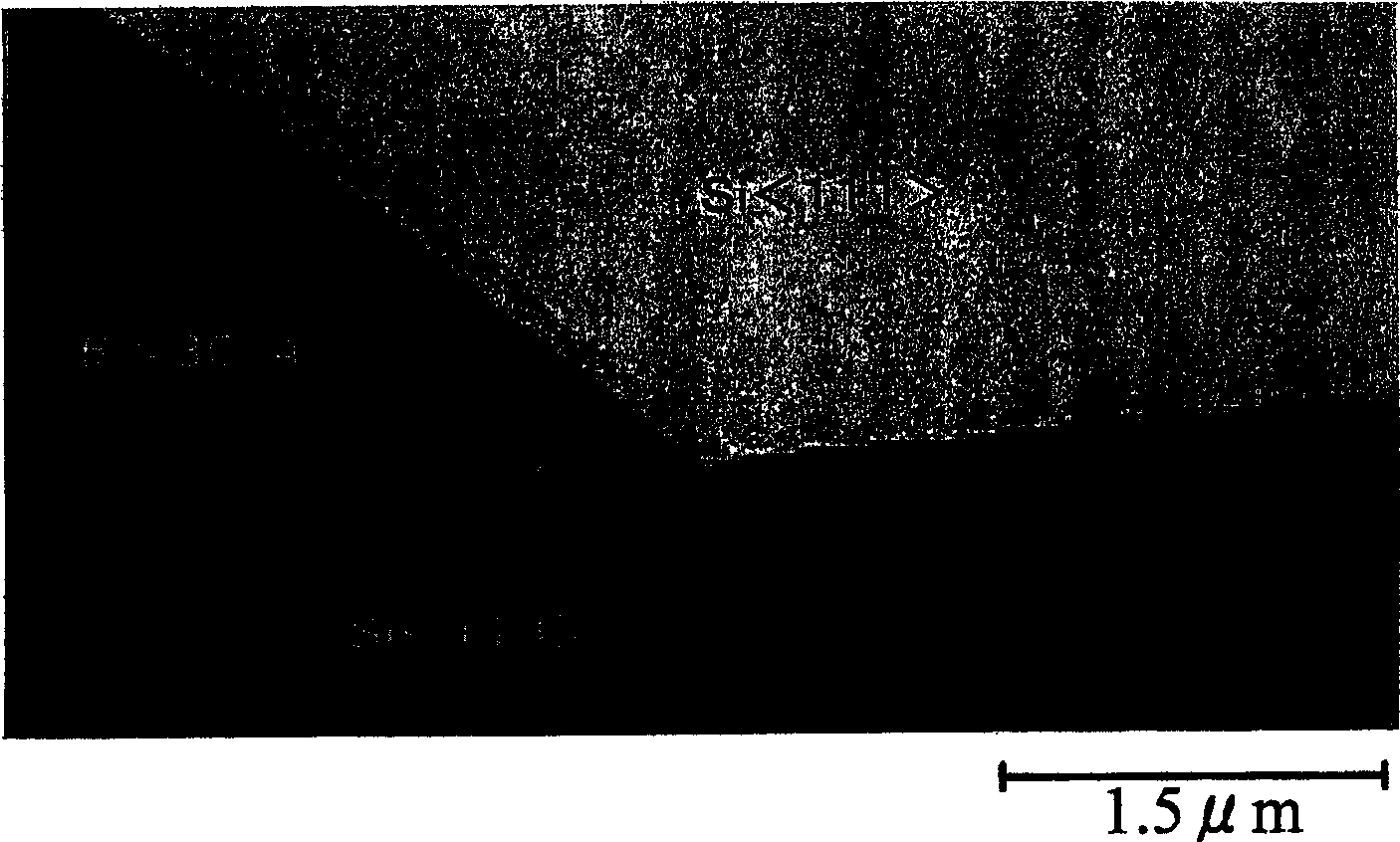

Razor blade

InactiveCN1511080AImprove the safety of useSmall cutting resistanceMetal working apparatusEtchingSingle crystal

A razor blade which is smaller in cutting resistance to objects of cutting such as hair and beard than conventional blades, and is improved in safety when in use. This razor blade is obtained by using as a silicon thin sheet a single crystal Si material such as an Si wafer or a polycrystalline Si material containing comparatively large Si crystal particles, forming at least one opening in this silicon thin sheet by chemical etching, and then, without depending on machining, using ion beam etching to form an Si single crystal blade point projecting into the opening so that a nose radius is 0.5 [mu]m or smaller, preferably 0.1 [mu]m or smaller.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Preparation method of wet and dry dual-purpose diamond saw blade

ActiveCN104874863BImprove cutting efficiencyImprove cutting effectMetal sawing tool makingDual purposeMaterials science

The invention relates to a manufacture method for a dry and wet dual-purpose diamond saw blade, and belongs to the technical field of diamond processing tools. The method includes the following steps of providing a circular base body, wherein the circular base body comprises a side circumferential surface located on the edge of the base body; machining a plurality of chip removal grooves which are formed at intervals inwards in the radial direction in the side circumferential surface of the base body, wherein the chip removal grooves include the first chip removal grooves and the second chip removal grooves, and the first chip removal grooves and the second chip removal grooves are formed at intervals; arranging diamond tool bits between the chip removal grooves of the base body, wherein the diamond tool bits include the first diamond tool bits and the second diamond tool bits, the first diamond tool bits and the second diamond tool bits are arranged at intervals, the surfaces of the first diamond tool bits are planes, a plurality of protruding strips are arranged on the surfaces of the second diamond tool bits, and grooves are formed between the protruding strips. The diamond saw blade can well conduct chip removal and heat dissipation in the cutting process, the good cutting performance can be kept under the condition of no cooling water grinding, and the purpose of conducting processing under extreme conditions is achieved for users.

Owner:JIANGSU FENGTAI TOOLS

Road depression rapid repairing device

ActiveCN111270595APromote repairRepair firmRoads maintainenceElectric machineryStructural engineering

The invention discloses a road depression rapid repairing device, and relates to the technical field of road maintenance. The road depression rapid repairing device comprises a vehicle body, a hydraulic rod cylinder is arranged on one side in the vehicle body, a first hydraulic rod with a downward output end and extending to the lower portion of the vehicle body is arranged in the hydraulic rod cylinder, the output end of the first hydraulic rod is connected with a second motor, and the output end of the second motor is connected with a brush. The brush driven by the second motor is arranged at the front end of the bottom of the vehicle body, water pipes and water spraying heads are arranged on the two sides, the concave to-be-repaired part of the road can be cleaned and wetted, and this is more conducive to road repair; and the two hydraulic sets are arranged at the two ends of the vehicle body correspondingly, the supporting legs are arranged at the bottoms of the tail ends of the hydraulic sets correspondingly, the ground can be fixed through the hydraulic devices, the repairing process is more stable, the scraping plate is arranged at the bottom of the vehicle body and can scrape the vehicle body flat, and repairing operation is convenient.

Owner:郑州市公路工程公司

High-efficiency cutting knife structure of grass cutter

The invention relates to a high-efficiency cutting knife structure of a grass cutter. The high-efficiency cutting knife structure comprises a drive shaft, wherein a knife shaft is mounted at one end of the drive shaft, cutting blades are mounted on the knife shaft, a supporting ring is mounted on the outer wall of each of the two ends of the knife shaft by means of supporting rods, the cutting blades are fixedly connected between the two supporting rings and are symmetrically arranged opposite to a center shaft of the knife shaft, and a cutting groove is formed in each of the cutting blade; inner reamers are symmetrically mounted on the outer walls of the two ends of the knife shaft, and an end reamer positioned on the outer end side of the knife shaft is mounted on each of the supporting rods. When the high-efficiency cutting knife structure works, an engine drives the knife shaft to rotate at a high speed; when in rolling, the cutting blades perform continuous cutting on weeds, so that the effect is good, and the efficiency is high; as the cutting blades provided with the cutting grooves are arranged, the cutting efficiency is improved; as the cutting blades are obliquely arranged opposite to the knife shaft, the one-time contact areas between the cutting blades and the weeds are smaller, so that the cutting resistance is reduced, and the cutting speed is improved; as the inner reamers and the end reamers are arranged on the knife shaft, the grass cutting resistance is reduced, and the cutting efficiency is improved.

Owner:WUXI HUSHAN PLANT PROTECTION MACHINERY FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com