Multifunctional processing machine for diced food materials

A processing machine and multi-functional technology, applied in the direction of metal processing, etc., can solve the problems of easy occurrence of danger, time-consuming and labor-intensive, single function, etc., to achieve the effect of preventing deviation and slipping, improving mechanical efficiency, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

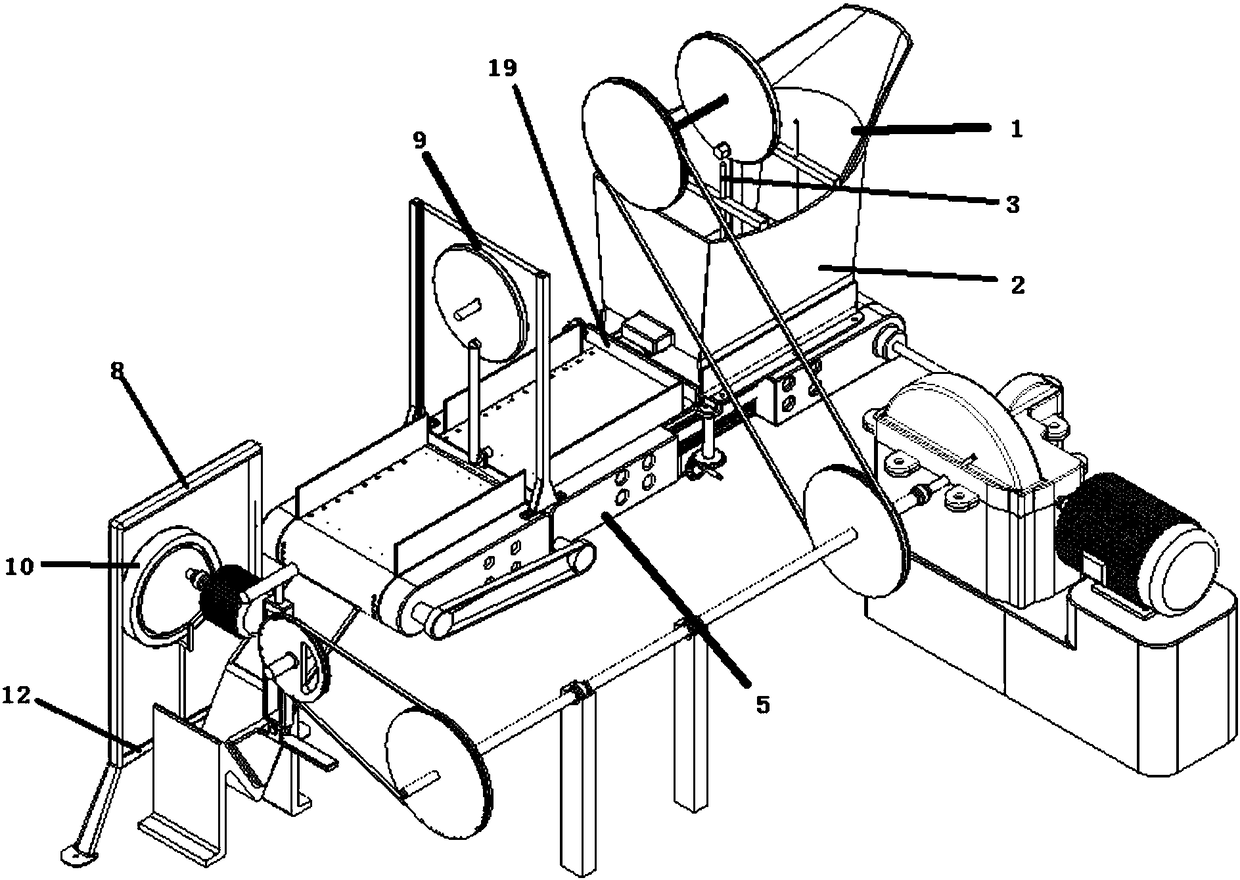

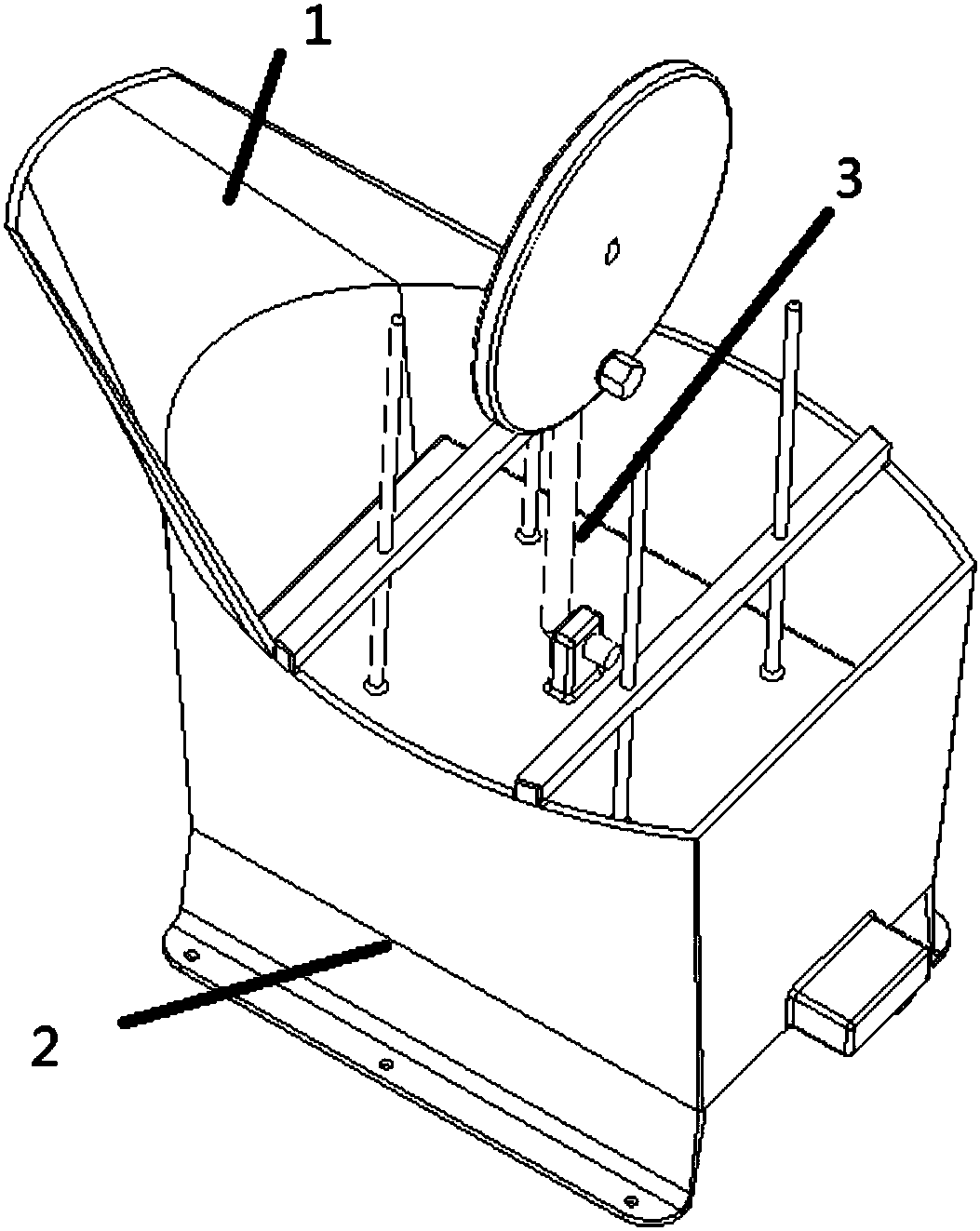

[0035] The invention provides a multifunctional block food processing machine, such as figure 1 As shown, it includes a slicing device, a shredding device, a slotting device, a cutting device, a transmission device and a conveyor belt.

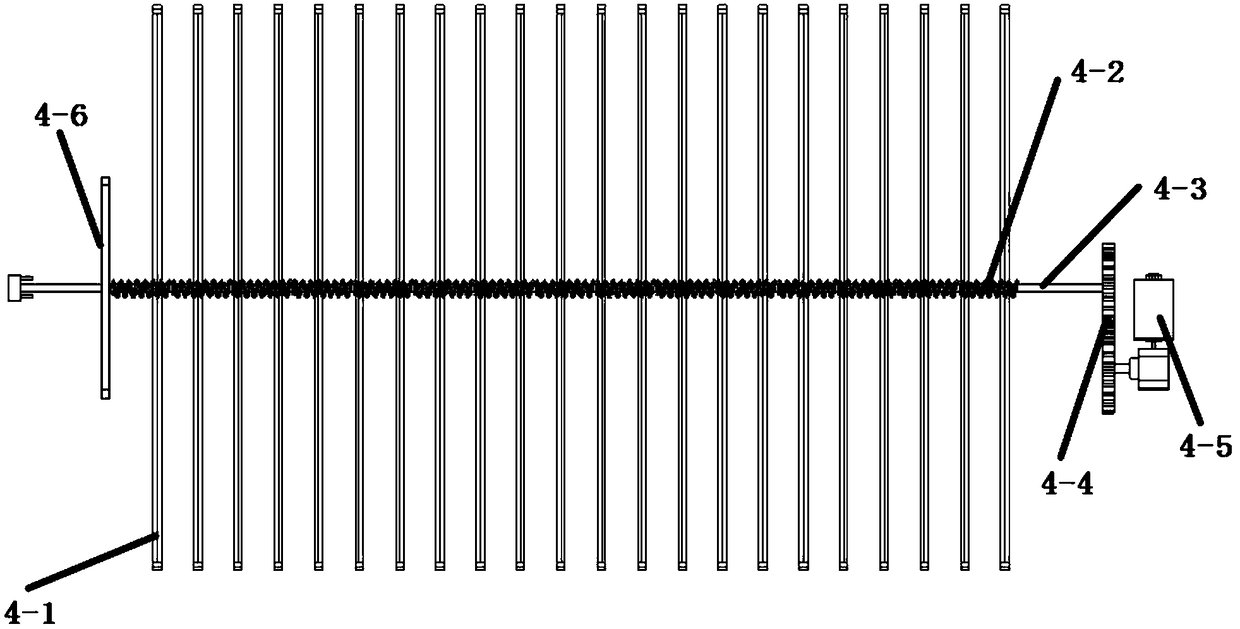

[0036] The slicing device uses the conveyor belt to transmit the sliced food to the shredded device. The shredded device is installed between the two conveyor belts. The sliced food is cut into silky food by the blade reciprocating up and down, and the silky food is passed to the push groove device through the conveyor belt. , the push groove device drives the reciprocating movement of the filamentary ingredients to the cutting device, the blade of the cutting device is perpendicular to the filamentary ingredients, and cuts the filamentary ingredients into blocks; the transmission device uses the form of connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com