Patents

Literature

119results about How to "Easy to adjust the thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for transparent silver nanowire conducting electrode

ActiveCN104658700AGood application prospectGood light transmission and conductivityConductive layers on insulating-supportsFinal product manufactureTransmittanceNanometre

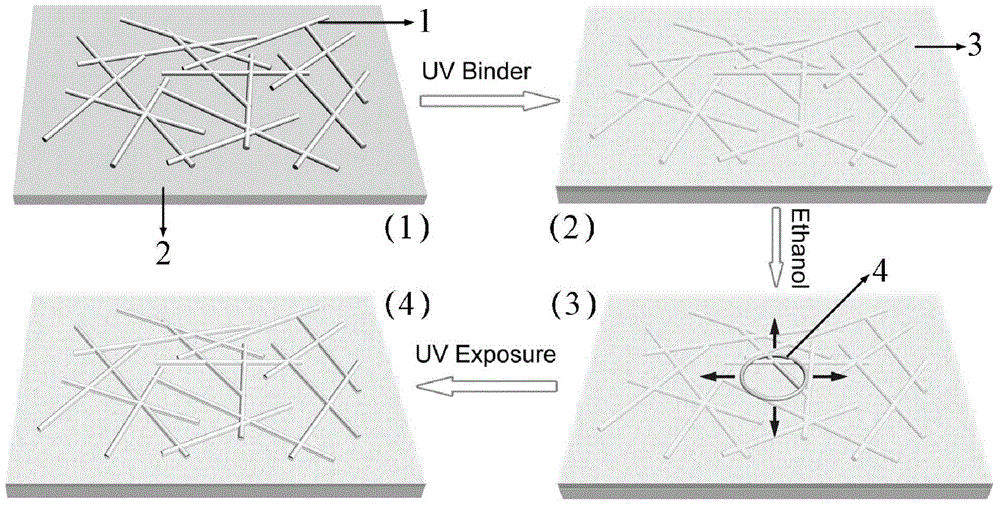

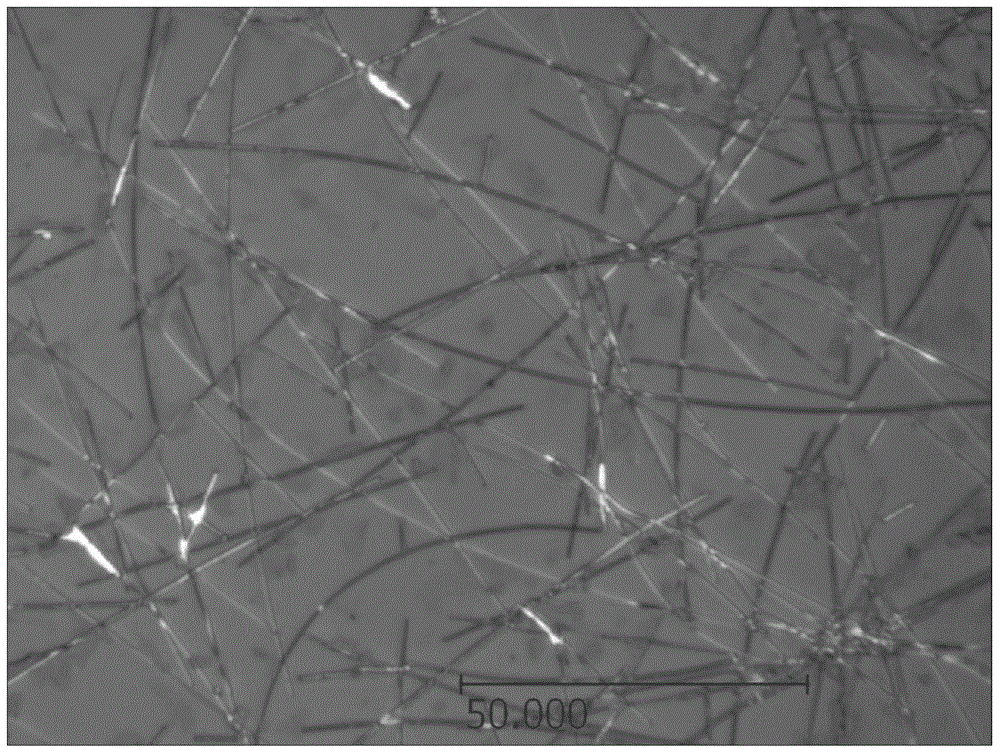

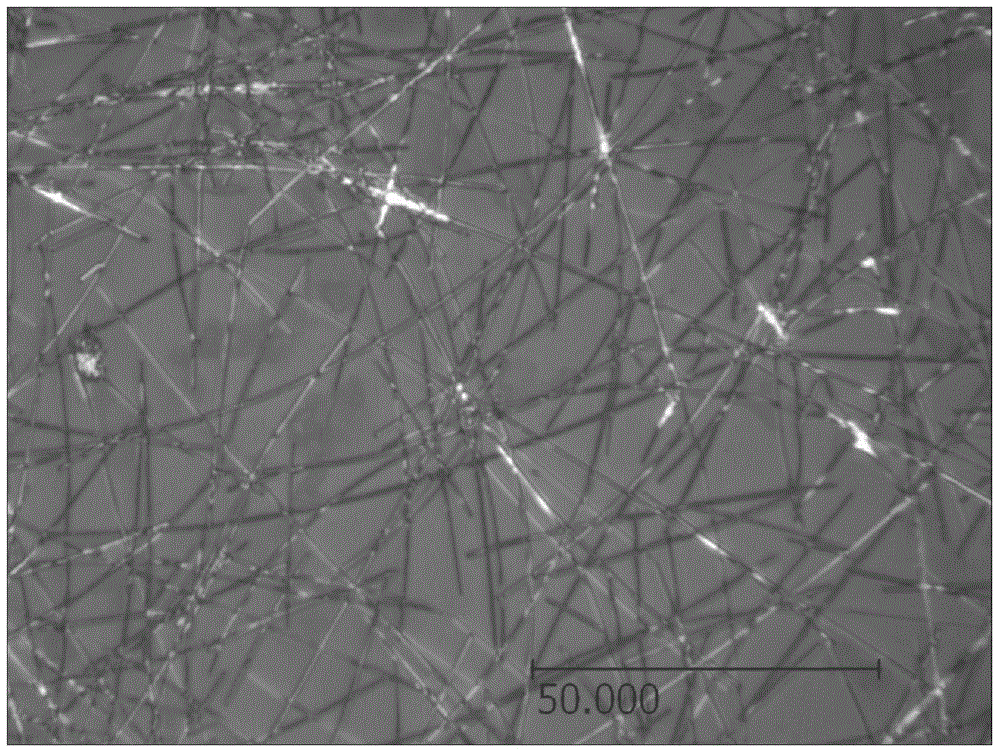

The invention discloses a preparation method for a transparent silver nanowire conducting electrode. The preparation method comprises the following steps: (1) preparing a high length-diameter ratio silver nanowire solution; (2) conducting hydrophilization on a substrate; (3) coating the prepared silver nanowire solution on the substrate, and carrying out drying to obtain a transparent silver nanowire conducting thin film on the substrate; (4) conducting adhesion treatment on the transparent silver nanowire conducting thin film and the substrate; (5) exposing the transparent silver nanowire conducting thin film treated with adhesion to ultraviolet light, so as to obtain the transparent silver nanowire conducting electrode, wherein the adhesive force between the transparent silver nanowire conducting electrode and the substrate is high. The transparent silver nanowire conducting electrode prepared according to the method is excellent in carrier collection efficiency and relatively high in light transmittance, can improve the conductibility of a front electrode of a solar battery, reduce reflectivity, and potentially improve battery efficiency and reduce production cost, and is high in mechanical and environmental stability, and suitable for large-area low-cost preparation.

Owner:SOUTH CHINA NORMAL UNIVERSITY

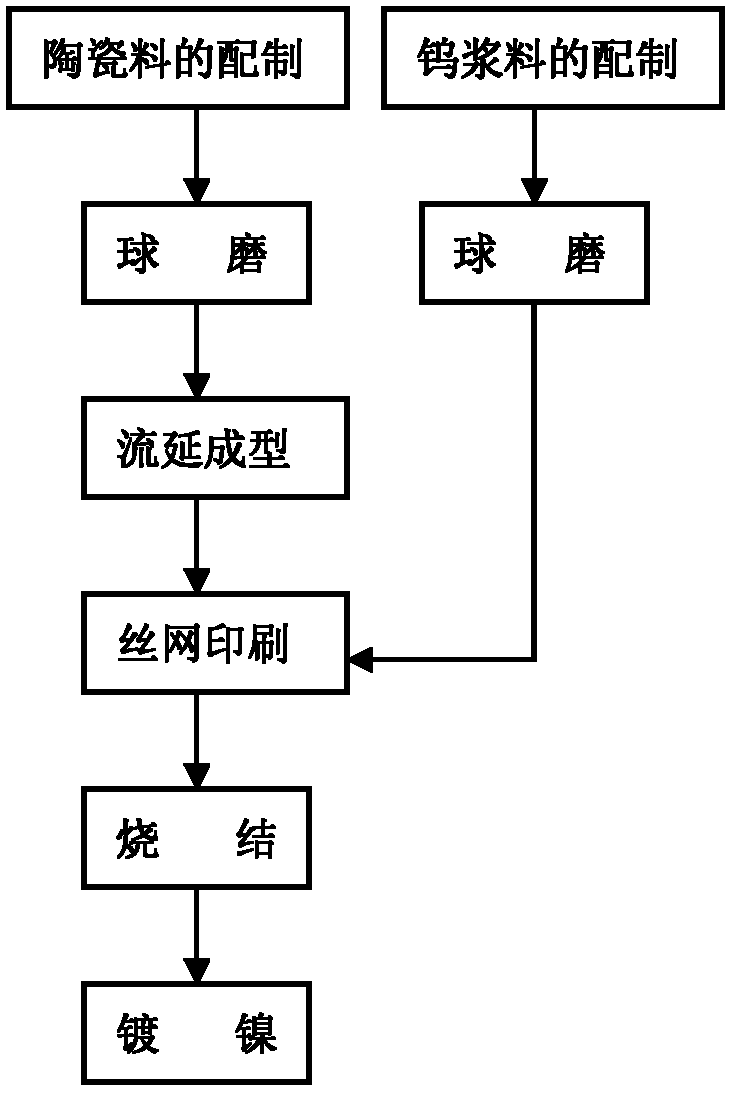

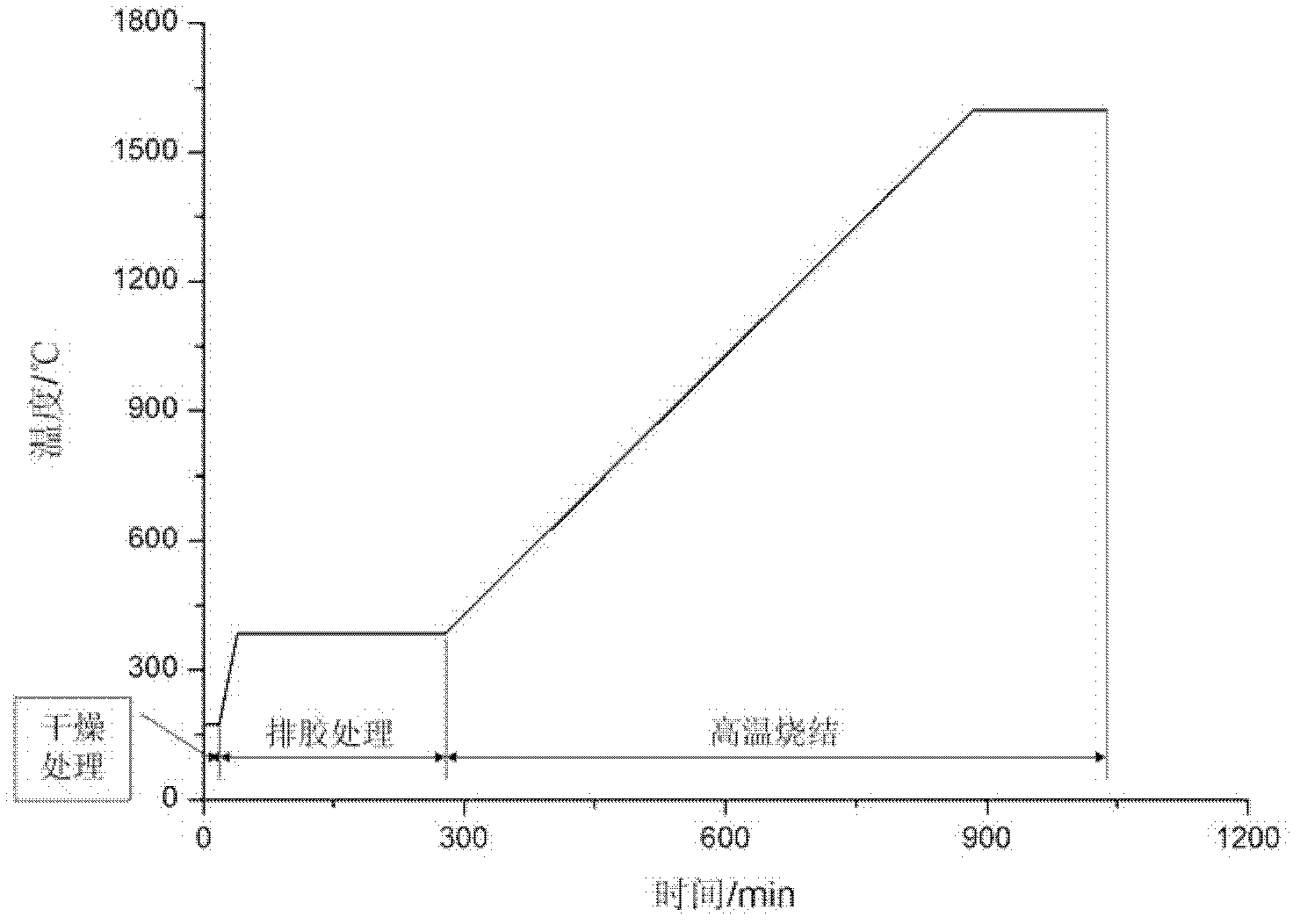

Method for preparing tungsten-containing alumina ceramic heating substrate

The invention provides a method for preparing a tungsten-containing alumina ceramic heating substrate, and relates to a method for preparing a ceramic heating element. The invention is capable of solving the problems of poor wettability on powder by a solvent (water), difficult defoaming on slurry, slow volatilization, long drying time, poor bonding force of ceramic and metal level after sintering during an aqueous tape-casting process. The method for preparing the tungsten-containing alumina ceramic heating substrate can substantially enhance the sintering qualification rate and production efficiency. The method comprises the following steps: preparing a premix compound and tungsten slurry, ball milling, tape-casting, screen printing, sintering and nickel plating.

Owner:XIAMEN UNIV

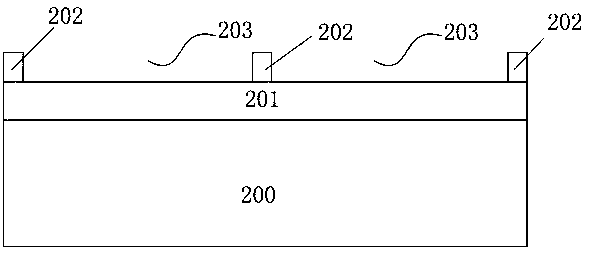

Integrated circuit element and forming method of bumping block structure

ActiveCN102237316APrevent oxidationExcellent adhesionSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorFilling materials

The invention provides an integrated circuit element and a forming method of a bumping block structure. The integrated circuit element comprises a semiconductor substrate, a bumping block metal layer disposed on the semiconductor substrate, a copper column which is disposed on the bumping block lower metal layer and has a side wall surface and an upper surface, and a protection layer which is disposed on the side wall surface and the upper surface of the copper column. The protection layer is a nickel-containing layer, including phosphor with content being less than 0.01 weight%. The invention provides a copper column bumping block, having a side wall protection layer formed by an electrolytic metal layer. The electrolytic metal layer is an electrolytic nickel layer, an electrolytic gold layer, an electrolytic copper layer or an electrolytic silver layer, preventing the copper column side wall from oxidation, and increasing the adhesion strength between the copper column side wall and the bottom filler materials formed afterwards. The bumping block can prevent stress to be concentrated on one point, resolving the problem that the bumping blocks are peeled off or delaminated from the copper column side wall.

Owner:TAIWAN SEMICON MFG CO LTD

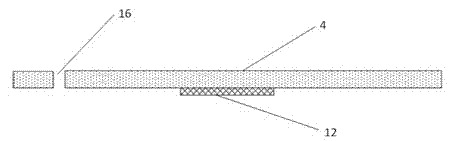

Passive wireless pressure sensor preparation method based on flexible substrate

InactiveCN103091003AMass productionSimple processForce measurementCapacitive pressure sensorEngineering

The invention discloses a passive wireless pressure sensor preparation method based on a flexible substrate. The preparation method comprises the following steps: 10) preparing an upper flexible substrate: electroplating an upper metal layer on the upper surface of the flexible substrate, forming a capacitance upper plate and a planar inductor coil on the upper metal layer in a photoetching mode, and drilling a hole to form an upper through hole, 20) preparing a middle flexible substrate: drilling holes in the flexible substrate to form a hollow cavity and a middle through hole, 30) preparing a lower flexible substrate: electroplating a lower metal layer on the lower surface of the flexible substrate, and drilling a hole to form a lower through hole, 40) manufacturing a capacitor: using a laminating technique to enable the upper flexible substrate, the middle flexible substrate and the lower flexible substrate to be connected fixedly to manufacture the capacitor of a pressure sensor and 50) manufacturing the pressure sensor: electroplating the upper through hole, the middle through hole and the lower through hole to form a guide line to manufacture the passive wireless pressure sensor. The passive wireless pressure sensor preparation method based on the flexible substrate can be used for the mass production of capacitive pressure sensors, and is simple in technology and high in consistency and reliability.

Owner:SOUTHEAST UNIV

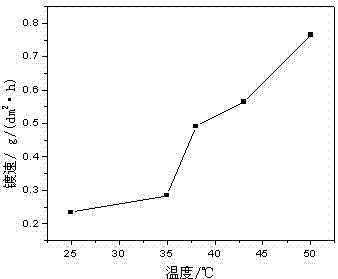

Preparation method of nickel electrode made of piezoelectric composite material

InactiveCN102337526ALow costReduce the temperatureLiquid/solution decomposition chemical coatingNickel saltChemical plating

The invention discloses a preparation method of a nickel electrode made of a piezoelectric composite material. The nickel electrode is prepared by using a chemical plating method. The preparation method comprises steps of roughening, sensitizing and activating the piezoelectric composite material, and putting the piezoelectric composite material in a nickel plating liquid to be plated with nickelto obtain the nickel electrode, wherein the activating solution used in the activation procedure is a palladium salt activating solution or nickel salt activating solution, the palladium salt activating solution is prepared by dissolving PdCl2 in certain hydrochloric acid, the PdCl2 content is 0.3-0.5 g / L and the content of the concentrated HCl is 9.9-11 ml / L; the nickel salt activating solution is prepared by dissolving nickel acetate and sodium borohydride in absolute methanol, the content of the nickel acetate is 64-68 g / L, and the content of the sodium borohydride is 64-68 g / L. The invention has the advantages of high nickel plating speed, easiness in regulating and controlling the thickness of a plating layer, uniform and dense thickness of the plating layer of a nickel plate, strongcombination force of the plating layer, good uniformity and wearing resistance, remarkable erosion resistance, excellent welding property and long service life, so that the application demand of the composite material is met.

Owner:UNIV OF JINAN

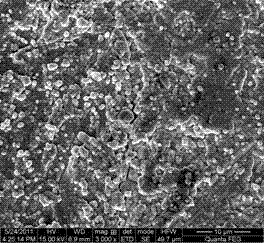

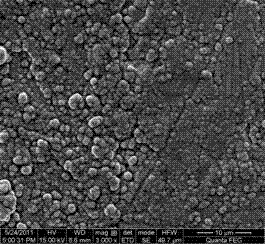

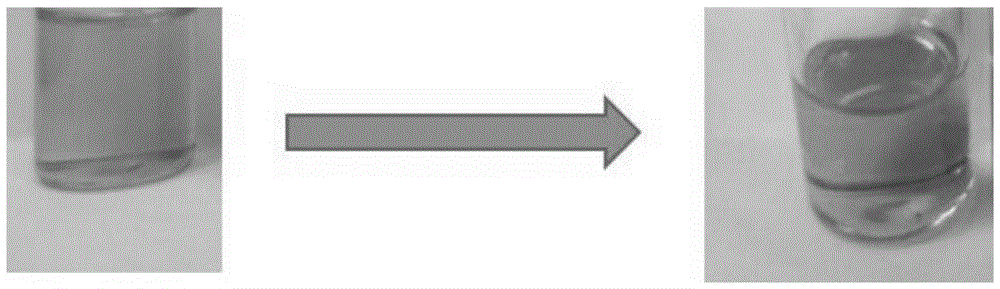

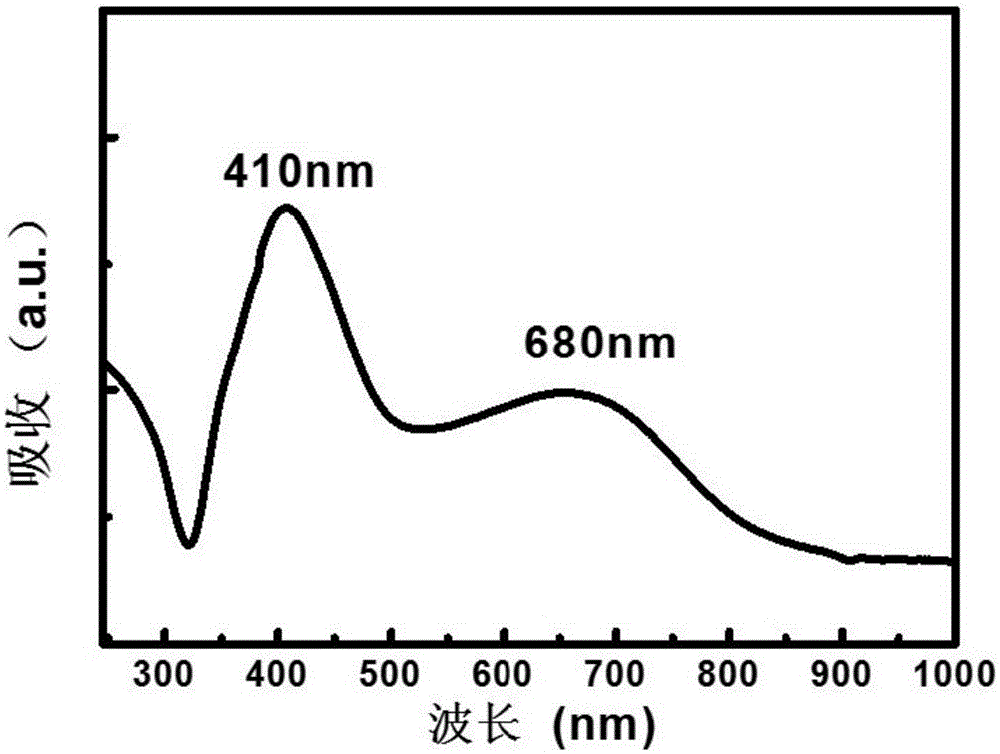

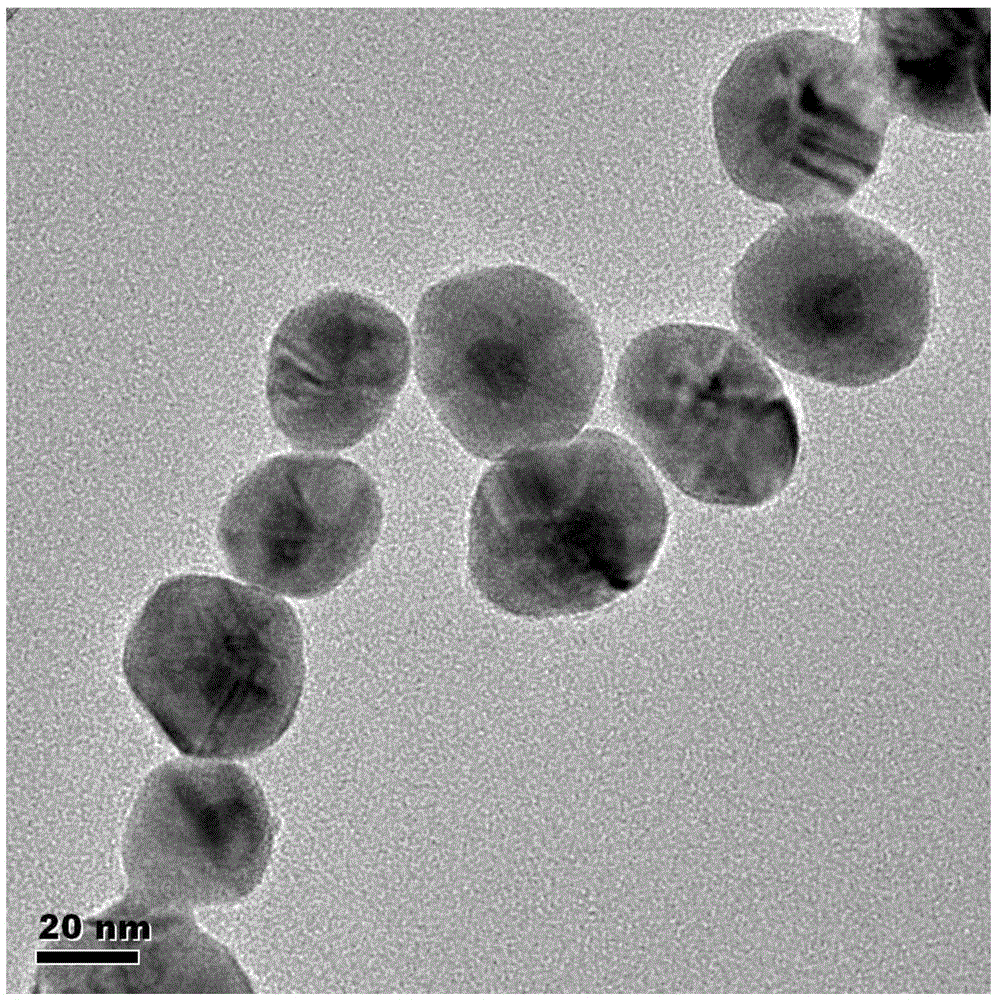

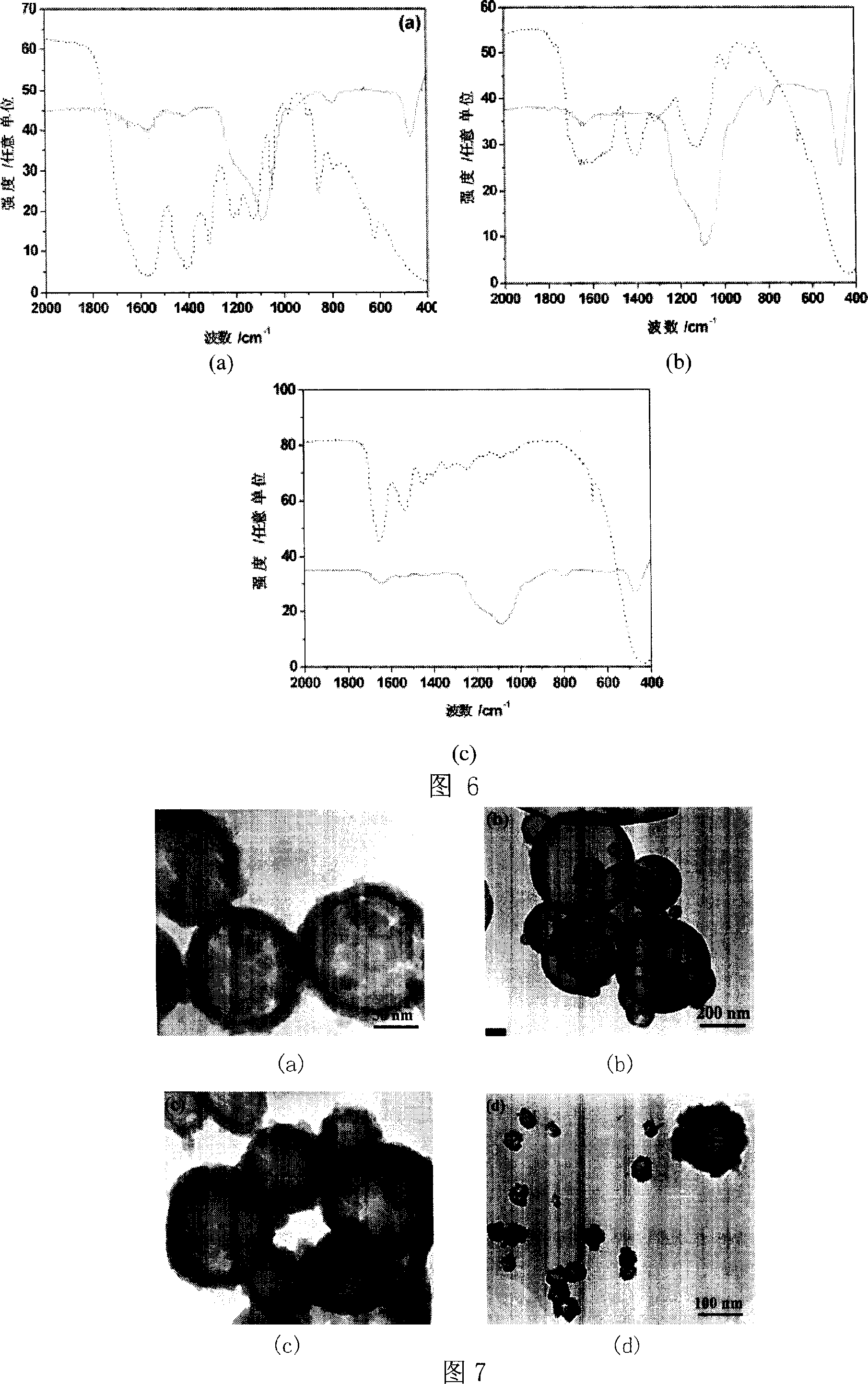

One-dimensional chainlike Au-Ag core-shell nanostructure, self-assembly preparing method and SERS application

ActiveCN105598442AImprove protectionLow costMaterial nanotechnologyTransportation and packagingSynthesis methodsSurface-active agents

The invention relates to a one-dimensional chainlike Au-Ag core-shell nanostructure, a self-assembly preparing method and SERS application. Nanoparticles of an Au core and Ag shell structure are synthesized through a liquid-phase synthesis method and a seed crystal growth method; the obtained nanoparticles of the core and shell structure are dispersed in a mixed solution of inorganic salt and ethyl alcohol; a certain quantity of alkaline solution is taken, and the mixed solution is added to be stirred and centrifuged to obtain the one-dimensional chainlike structure. By controlling the electrostatic mutual acting force between the core-shell nanoparticles, the one-dimensional nanometer structure of different Au core sizes and different Ag shell thicknesses is obtained through self-assembly; the method does not need the aid of any templates or surface active agents, the assembly process is simple, the Au core sizes and shell thicknesses are easy to regulate and control, products are easy to separate, the surface Raman enhancing effect of organic substance molecules is remarkable, a preparation system is green and environmentally friendly, no toxic or harmful solvent is added, prepared products are stable in performance, preparation cost is low, the application range is wide, repeatability is high, and large-scale preparation is easy.

Owner:TIANJIN POLYTECHNIC UNIV

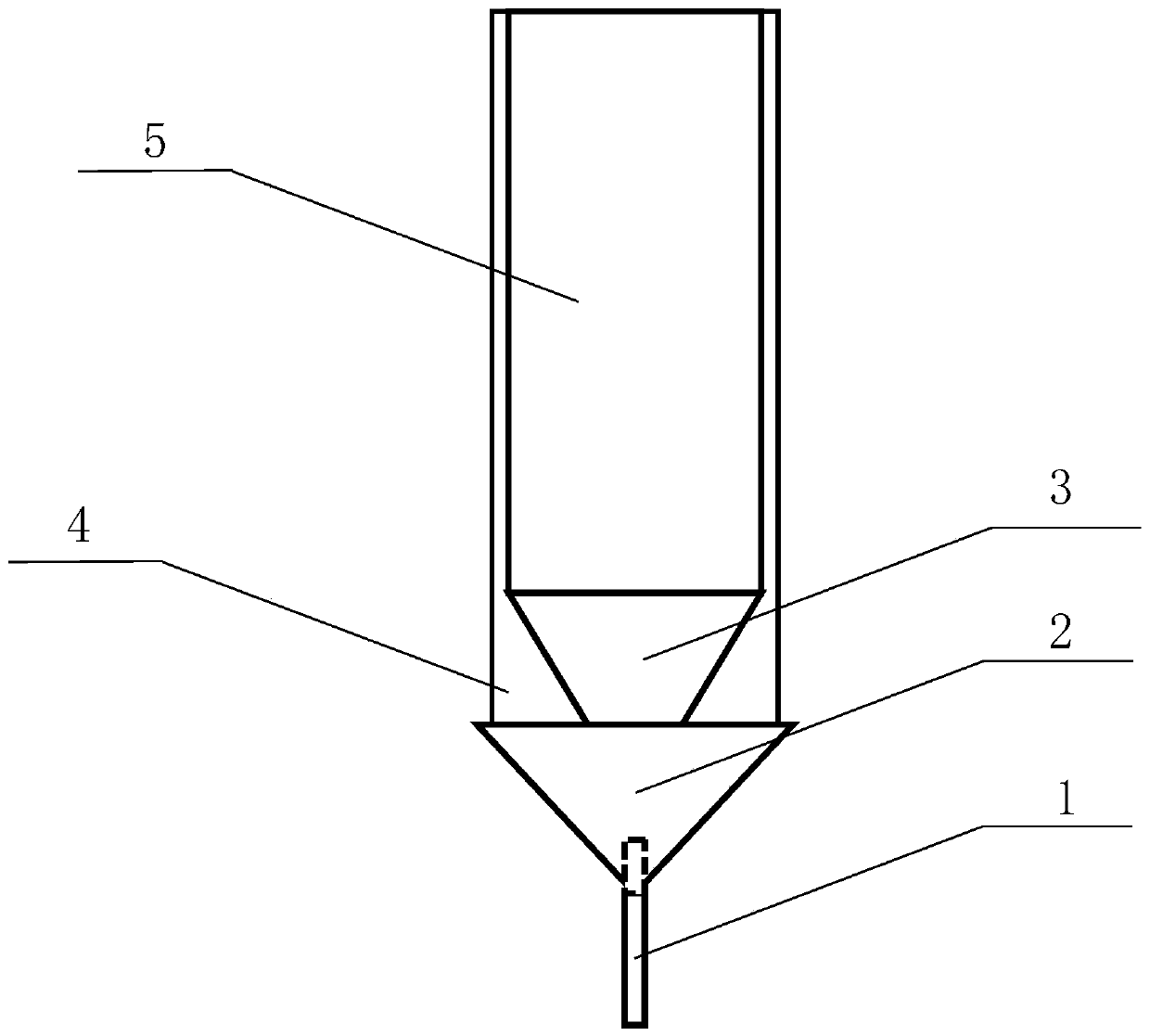

Single-crystal high-temperature alloy thin-wall casting based on secondary orientation control and preparation method thereof

ActiveCN111360234AEasy to adjust the thicknessEasy to adjust shapeFoundry mouldsFoundry coresSingle crystal superalloyCrystal orientation

The invention relates to the technical field of high-temperature alloys, in particular to a single-crystal high-temperature alloy thin-wall casting based on secondary orientation control and a preparation method thereof. By adopting the method, single-crystal high-temperature alloy thin-wall castings with different primary orientations and secondary orientations can be prepared, and meanwhile, mixed crystals can be prevented from being generated. The single-crystal high-temperature alloy thin-wall casting based on secondary orientation control is prepared, a three-dimensional crystal orientation material with the optimal performance is selected to prepare a single-crystal high-temperature alloy blade by researching the thin-wall effect of the alloy under secondary orientation, and great significance is achieved for prolonging the service life of the single-crystal high-temperature alloy blade.

Owner:成都航大新材料有限公司 +1

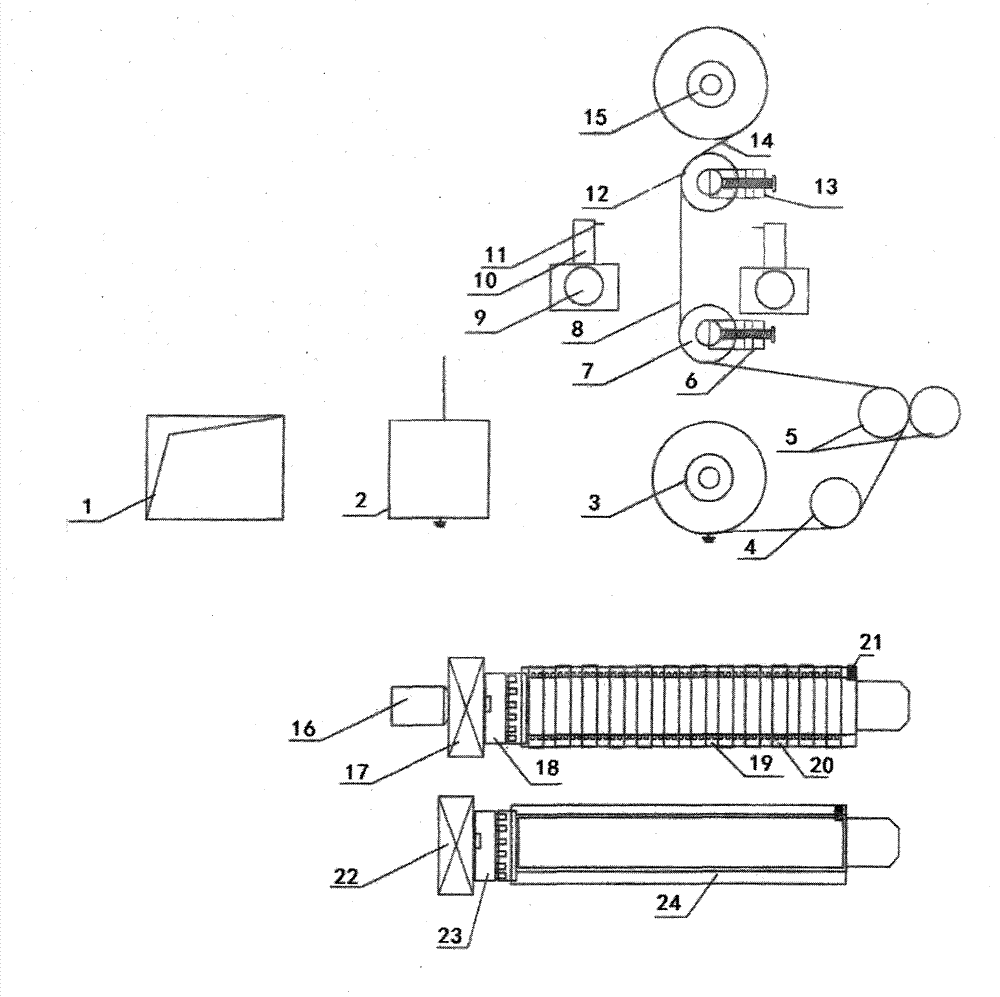

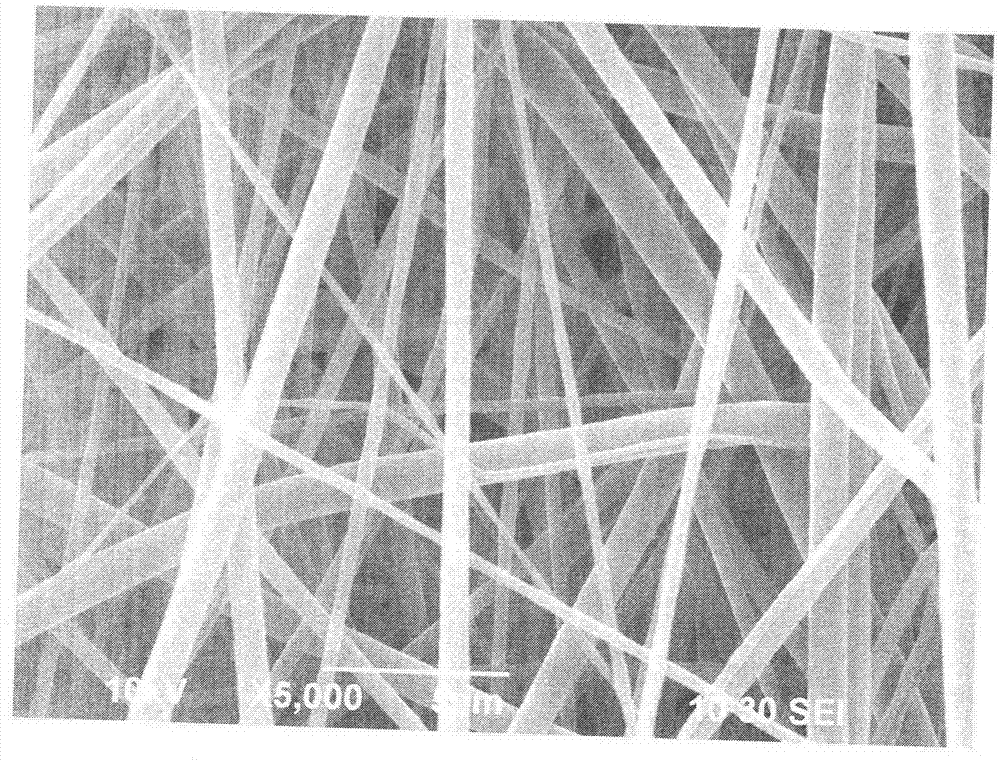

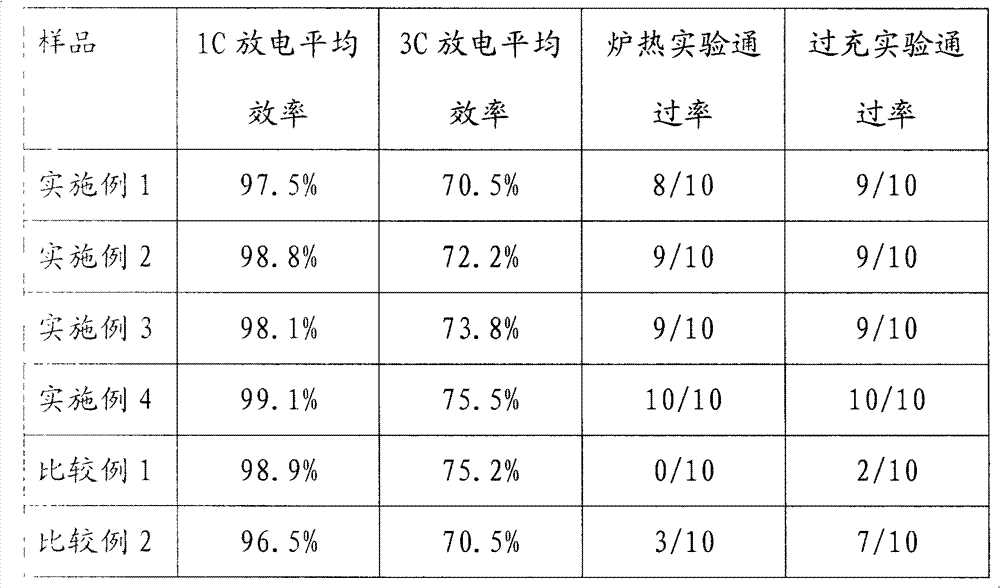

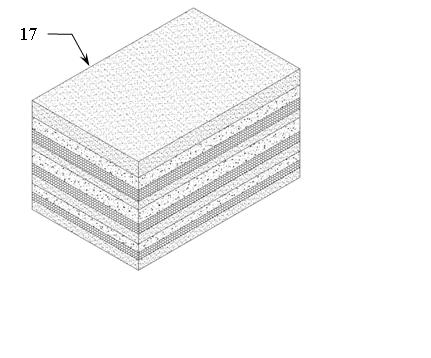

Lithium ion battery film in situ preparation method, lithium ion battery film, and lithium ion battery

The present invention relates to a lithium ion battery film in situ preparation method, which comprises the following steps: preparing a metal substrate, and coating a lithium ion positive electrode film material or a lithium ion negative electrode film material on the surface of the metal substrate; preparing a polymer solution raw material, adopting a direct current high voltage power supply to spray the polymer solution on the treated metal substrate surface in an electrostatic spinning device to form a nanometer fiber separation film; and carrying out a curing treatment on the treated metal substrate in a heat treatment device to obtain the lithium ion battery film prepared in an in situ manner. With the method, the separation film material can be prepared on the lithium ion battery substrate coated with the positive electrode film material or the negative electrode film material in the in situ manner, such that the technical problem of poor adhesion between the separation film and the positive electrode film material or the negative electrode film material is completely solved, the progression that the nanometer fiber film prepared by the electrostatic spinning method enters the lithium ion battery industry is accelerated, and charge and discharge performance and safety of the lithium ion battery are substantially increased.

Owner:河南曼博睿新材料科技有限公司

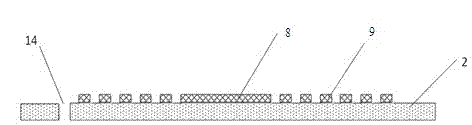

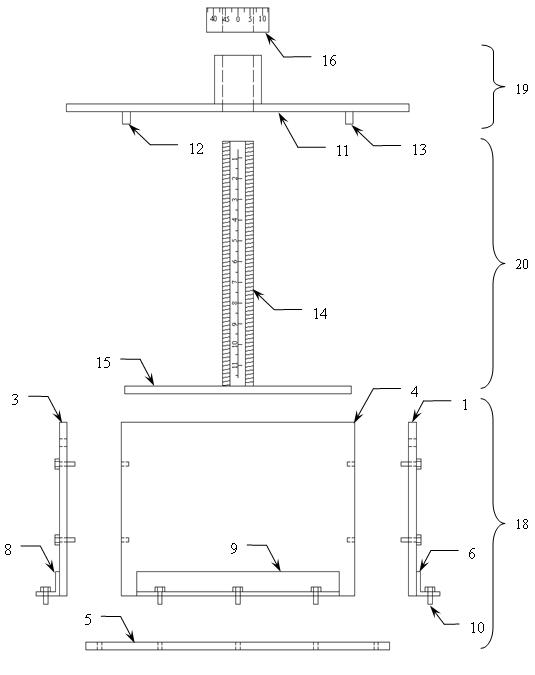

Device for preparing multi interbedding rock-soil modeling materials

InactiveCN101949790ASimple structureEasy to processPreparing sample for investigationSteel platesSheet steel

The invention discloses a device for preparing multi interbedding rock-soil modeling materials, which comprises a material box, a horizontal push pedal, a T-shaped frame, a regulating nut and fastening bolts, and is characterized in that the T-shaped frame is provided with the regulating nut after passing through a square hole on the horizontal push pedal; the horizontal push pedal is positioned at the top of the material box and is provided with an embossment which is internally provided with a square hole; the bottoms of the two sides of the horizontal push pedal are wielded with a strip steel respectively; the material box is composed of five steel plates, namely first, second, third and forth side plates as well as a base plate; the adjacent side plates are connected through the fastening blots; the base plate is drilled with a screw hole; the first, second, third and the forth side plates as well as the base plate are all wielded with angle iron; the opening of the angle iron corresponds to the screw hole on the base plate; the first, second, third and fourth side plates are respectively connected with the base plate through the fastening bolts; and the left and right side plates of the material box are respectively provided with two screw holes. The invention has simple structure, is easy to process, and has the advantages of simple operation and high work efficiency.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

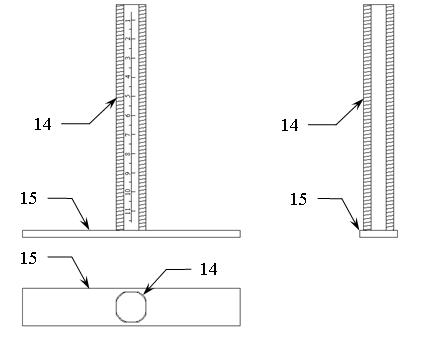

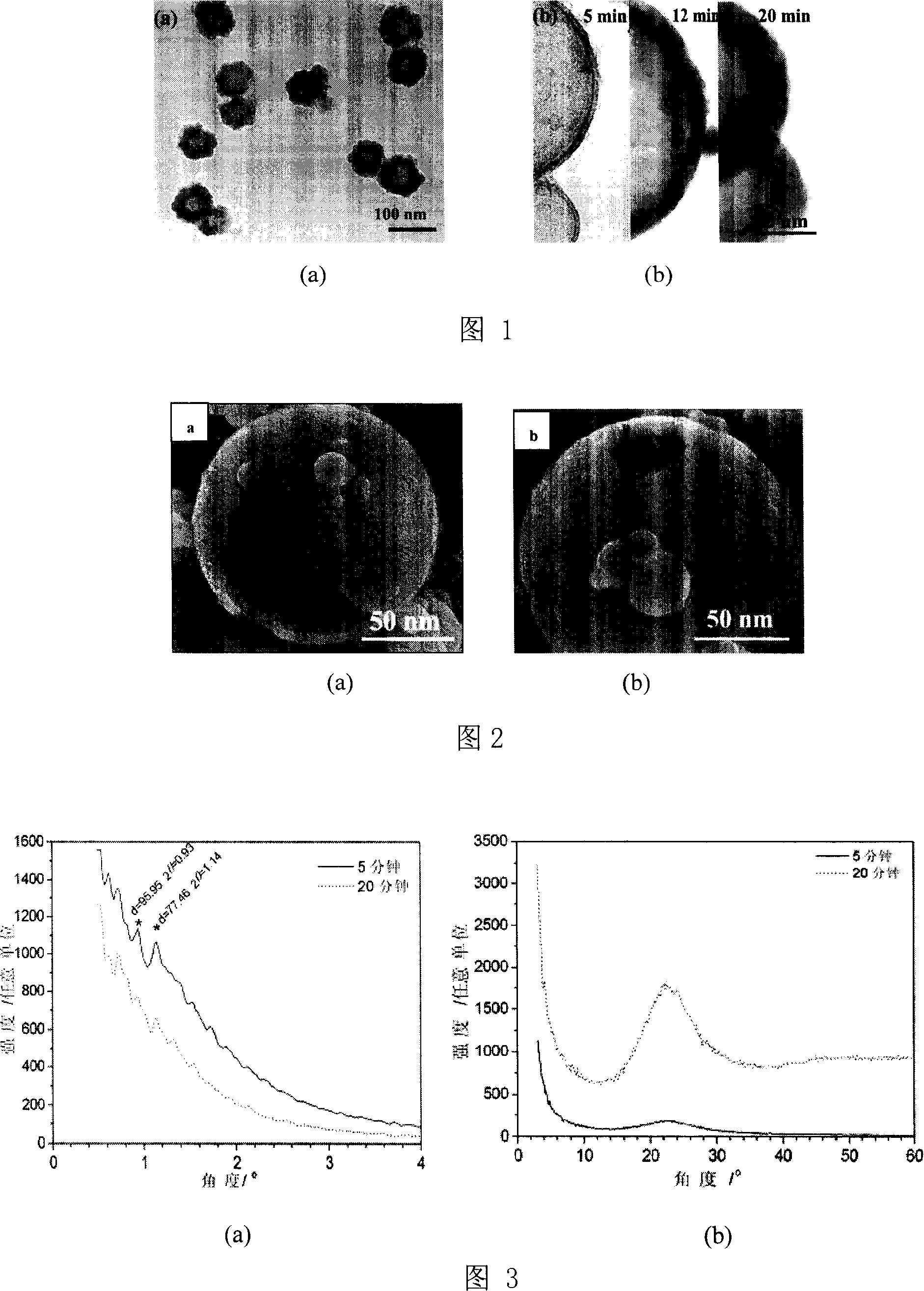

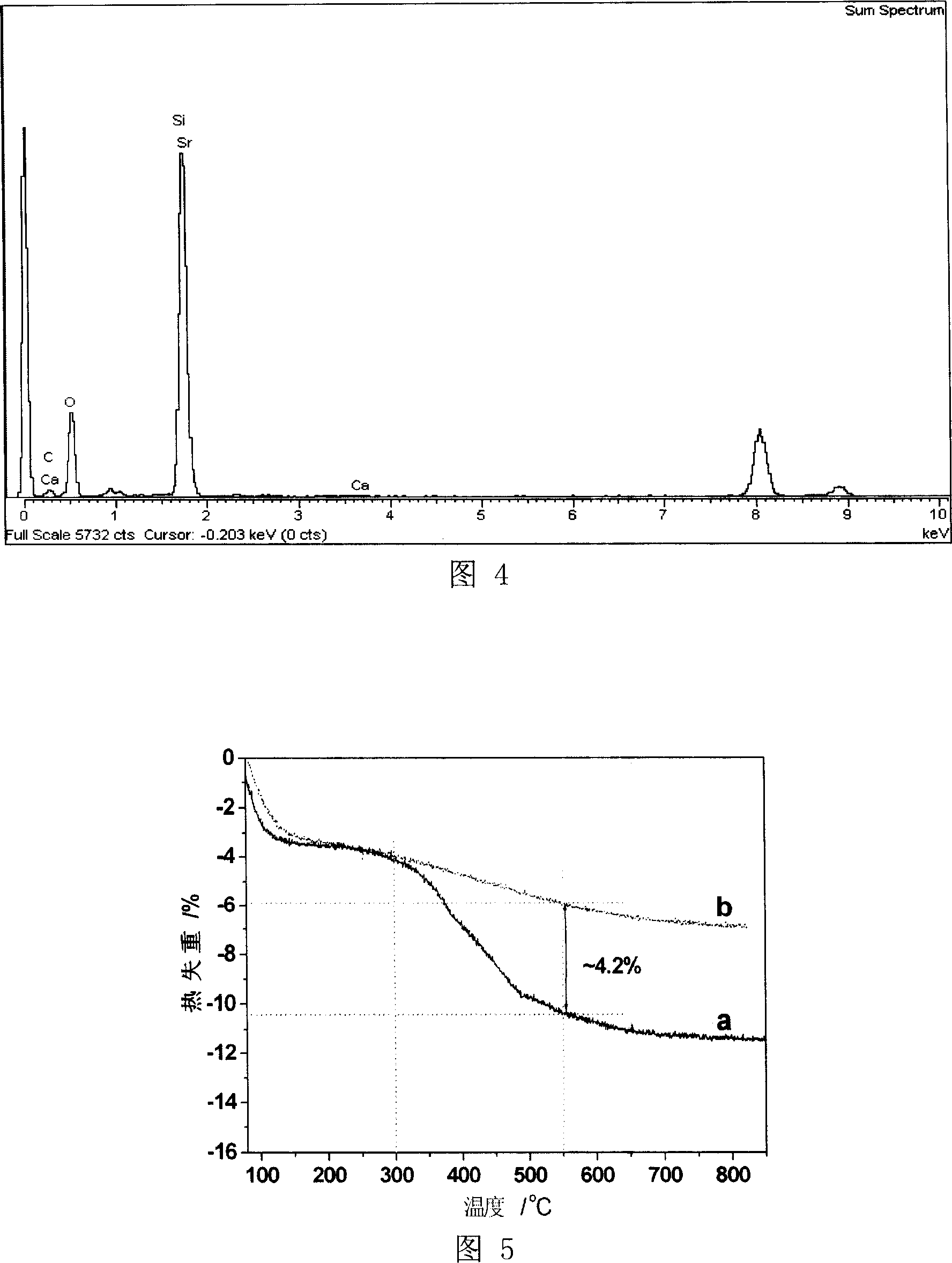

Hollow silicon gel nano powder material and its preparation method

The invention discloses a nanometer ball powder material of hollow silicon gel, which comprises the following steps: blending long-chained organic molecule, ammonia and inorganic salt with alkaline metal ion into deionized water; stirring to form clear solution; adding alcohol solution with silicon source; stirring; proceeding ultrasonic cavitation disposal; filtering; washing; drying; obtaining the product with through-out pore path on the case and inner wall surface of case decorated by organic molecule.

Owner:ZHEJIANG UNIV

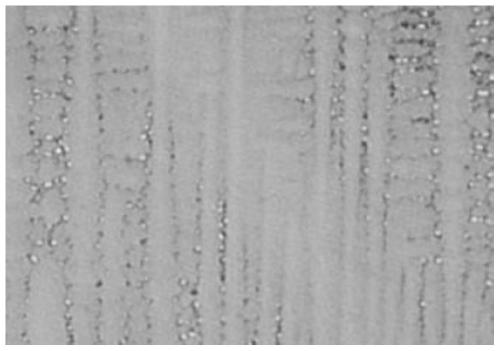

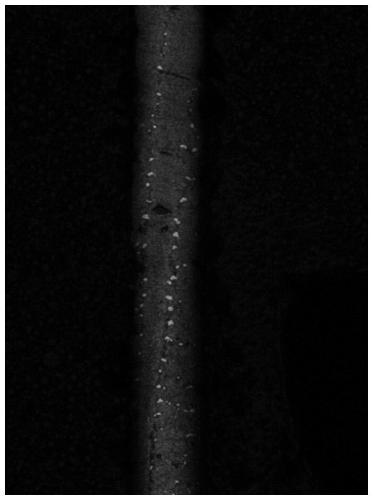

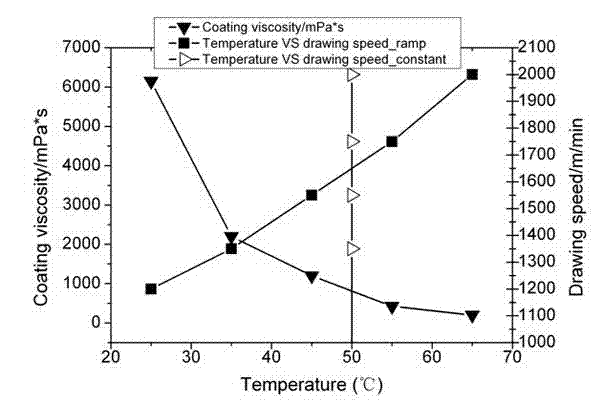

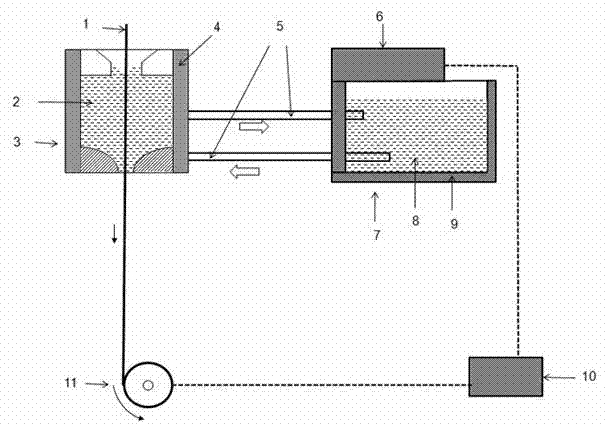

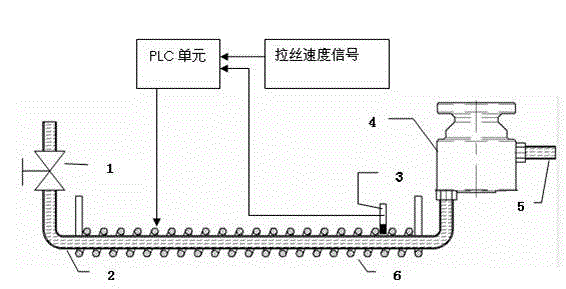

Automatic temperature control method and device for optical fiber coating

ActiveCN102759910AViscosity can be adjusted freelyReduce and avoid scrapLiquid surface applicatorsCoatingsTemperature controlAutomatic control

The invention relates to an automatic temperature control method and device for an optical fiber coating. The automatic temperature control device comprises an optical fiber coating device provided with a heating chamber, wherein the heating chamber of the optical fiber coating device is communicated with a circular heater through a circulating pipeline; liquid heat-conducting media are filled in the heating chamber, the circulating pipeline and the circular heater; and the circular heater is used for heating coating in the optical fiber coating device by circularly heating the liquid heat-conducting media. The automatic control method is characterized in that the automatic control method comprises the following steps of: arranging a processing control unit; controlling the heating process of the circular heater by acquiring a wire drawing speed sensing signal and a liquid heat-conducting medium temperature sensing signal and comparing the wire drawing speed sensing signal and the liquid heat-conducting medium temperature sensing signal with a preset parameter value through the processing control unit, thus realizing the automatic control and adjusting process of the temperature of the coating in the optical fiber coating device. According to the automatic temperature control method and device disclosed by the invention, the temperature of the coating can be automatically changed along with the wire drawing speed in the wire drawing process of optical fibers, and favorable matching between the temperature (viscosity) of the coating and the wire drawing speed is achieved, so that the quality of a coating layer on the surface of the optical fiber is ensured and the finished product rate of optical fiber processing is increased.

Owner:长飞光纤潜江有限公司

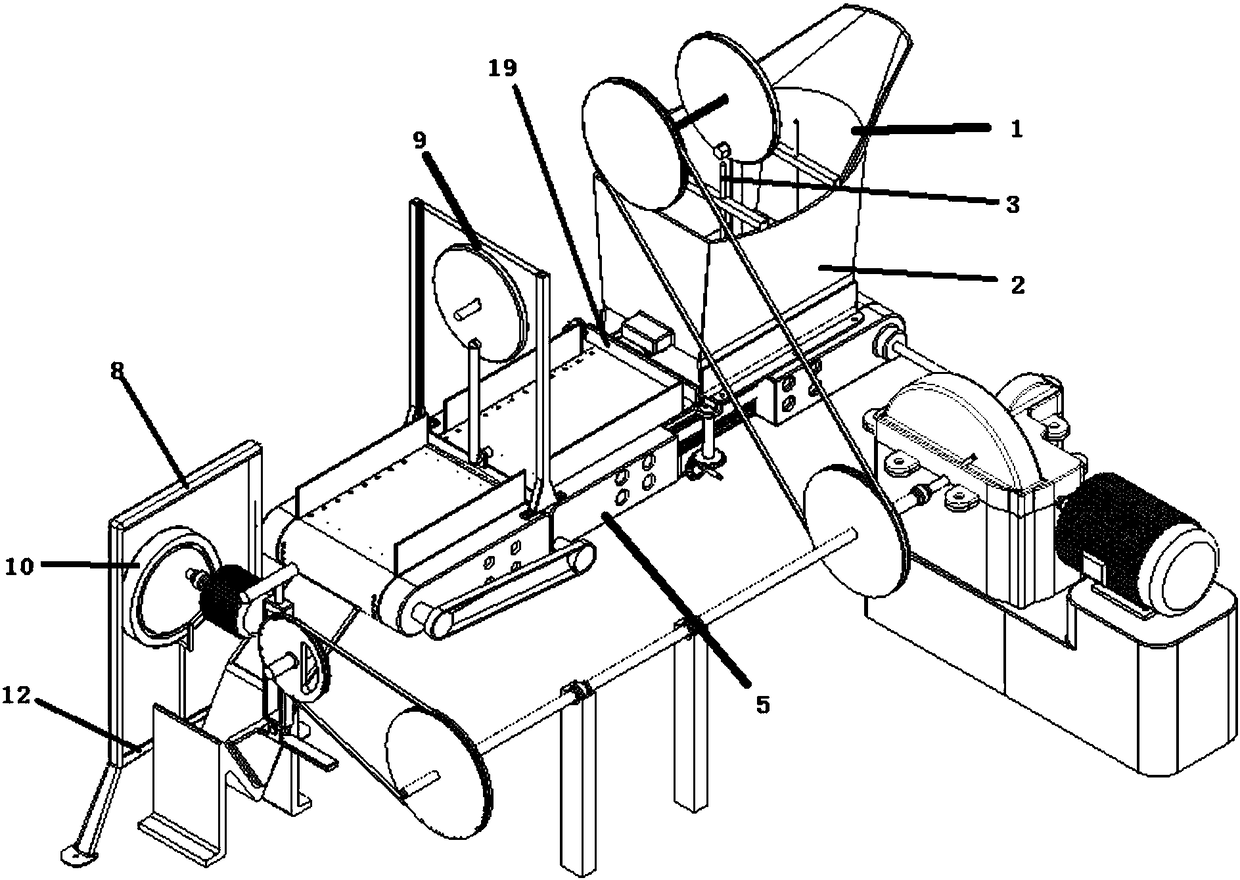

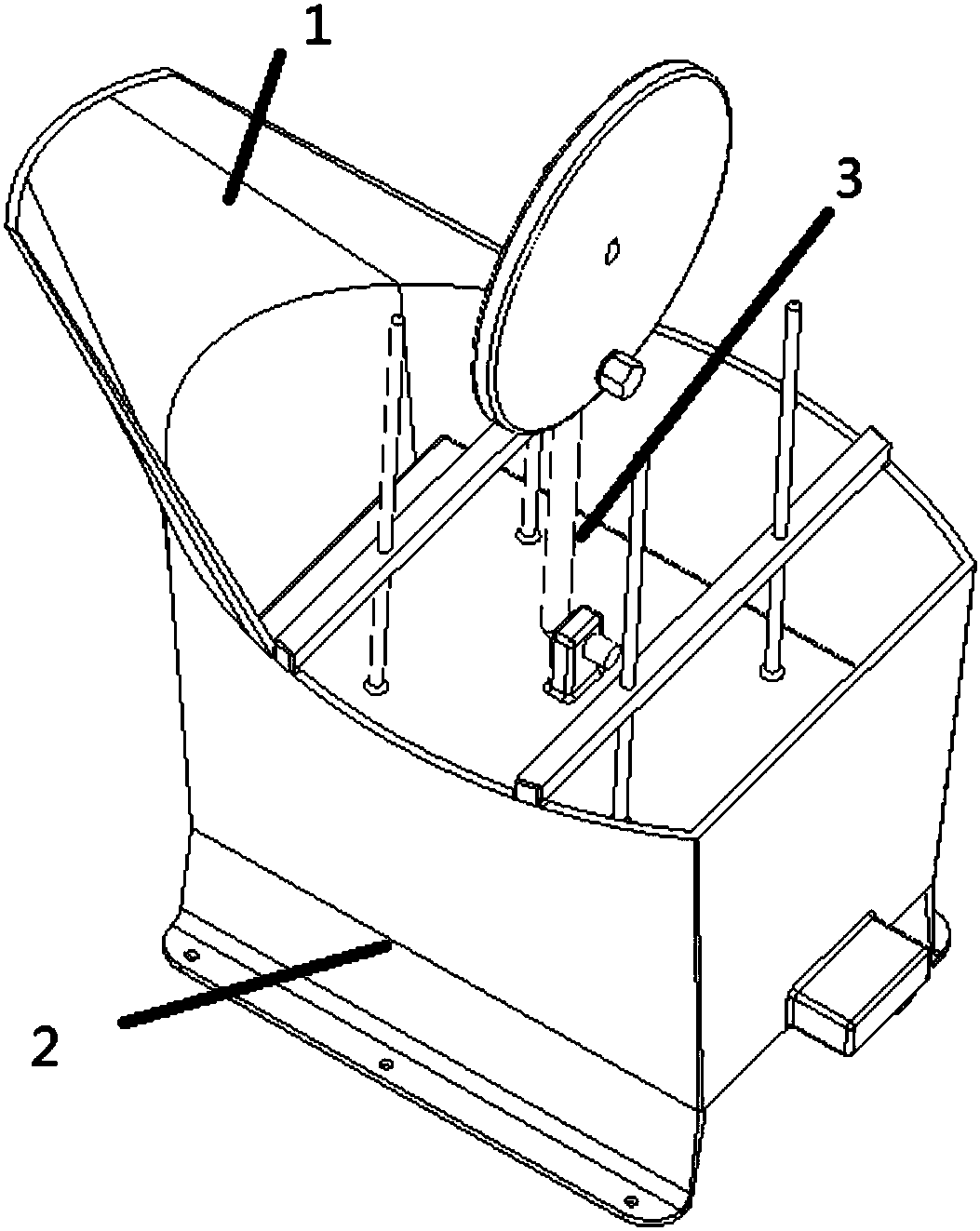

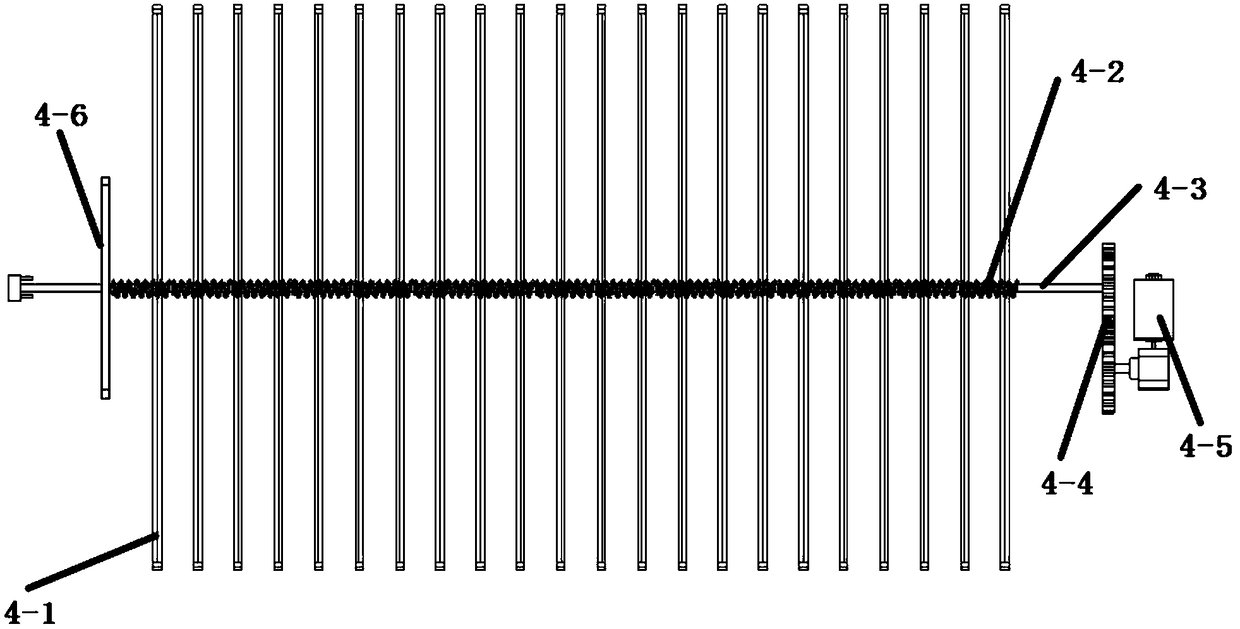

Multifunctional processing machine for diced food materials

InactiveCN108202359AEasy to disassemble and repairExtended service lifeMetal working apparatusFood materialMechanical engineering

The invention discloses a multifunctional processing machine for diced food materials. The multifunctional processing machine comprises a slicing device, a shredding device, a push groove device, a dicing device, a transmission device and conveying belts. The slicing device conveys sliced food materials to the shredding device by virtue of the conveying belts, the shredding device is arranged between the two conveying belts, the sliced food materials are cut into shredded food materials by virtue of the up-down reciprocating movement of a blade, the shredded food materials are transferred to the push groove device through the conveying belts, the push groove device drives the shredded food materials to carry out reciprocating movement to be pushed to the dicing device, the blade of the dicing device is mutually vertical to the shredded food materials, and cuts the shredded food materials into diced food materials; and the transmission device provides power for the slicing device, the shredding device, the push groove device, the dicing device and the conveying belts. The multifunctional diced food material processing machine disclosed by the invention is various in function, capable of carrying out batch treatment on the food materials, fully-automatic, high in efficiency and easy to maintain.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

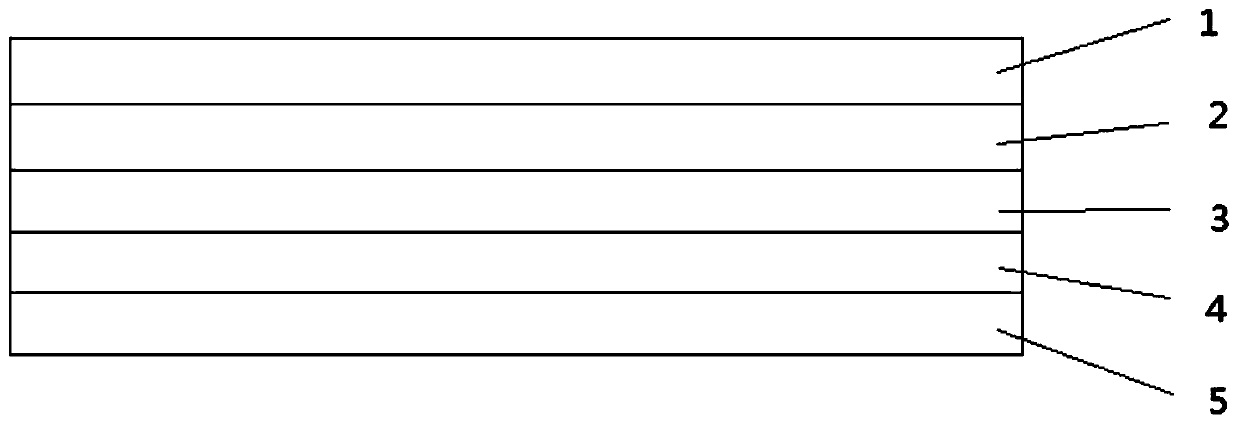

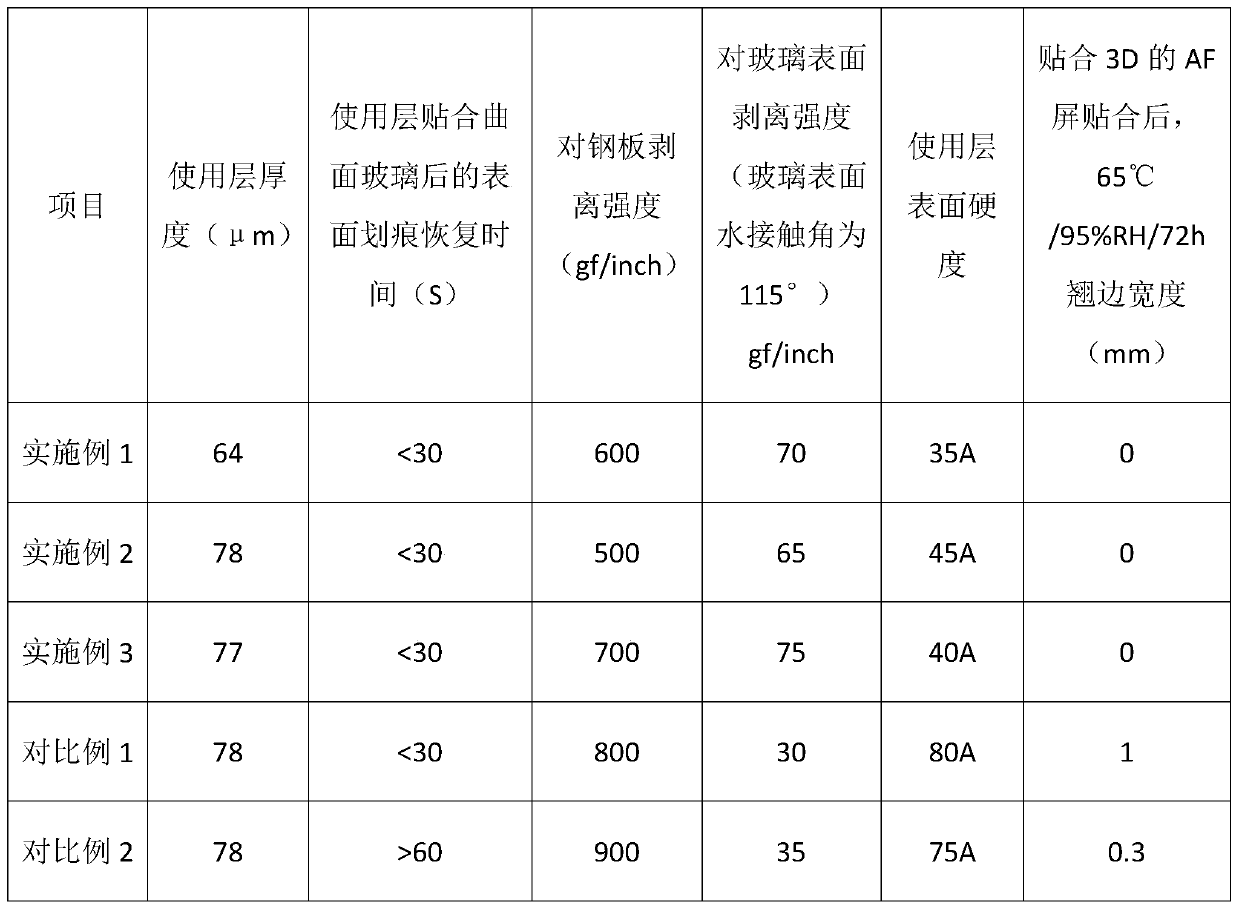

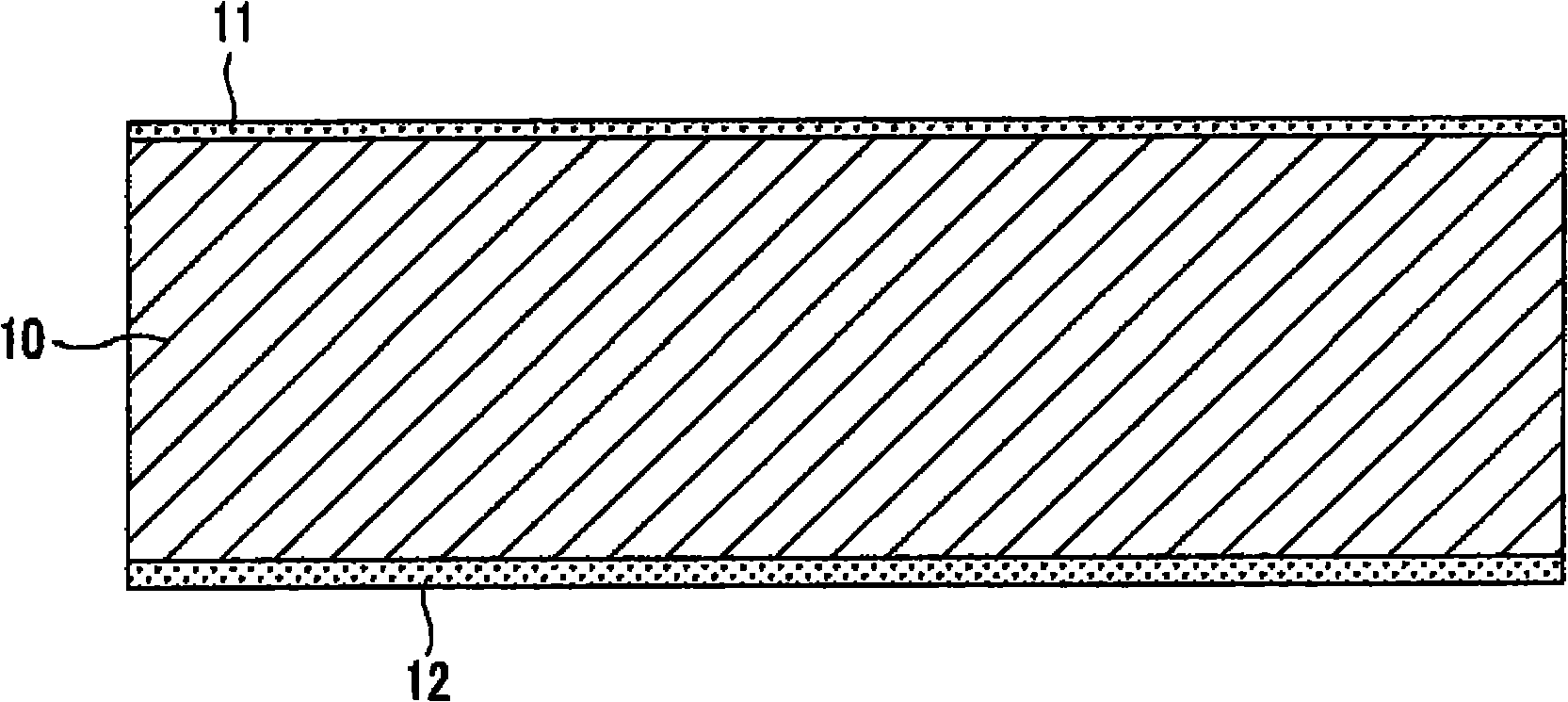

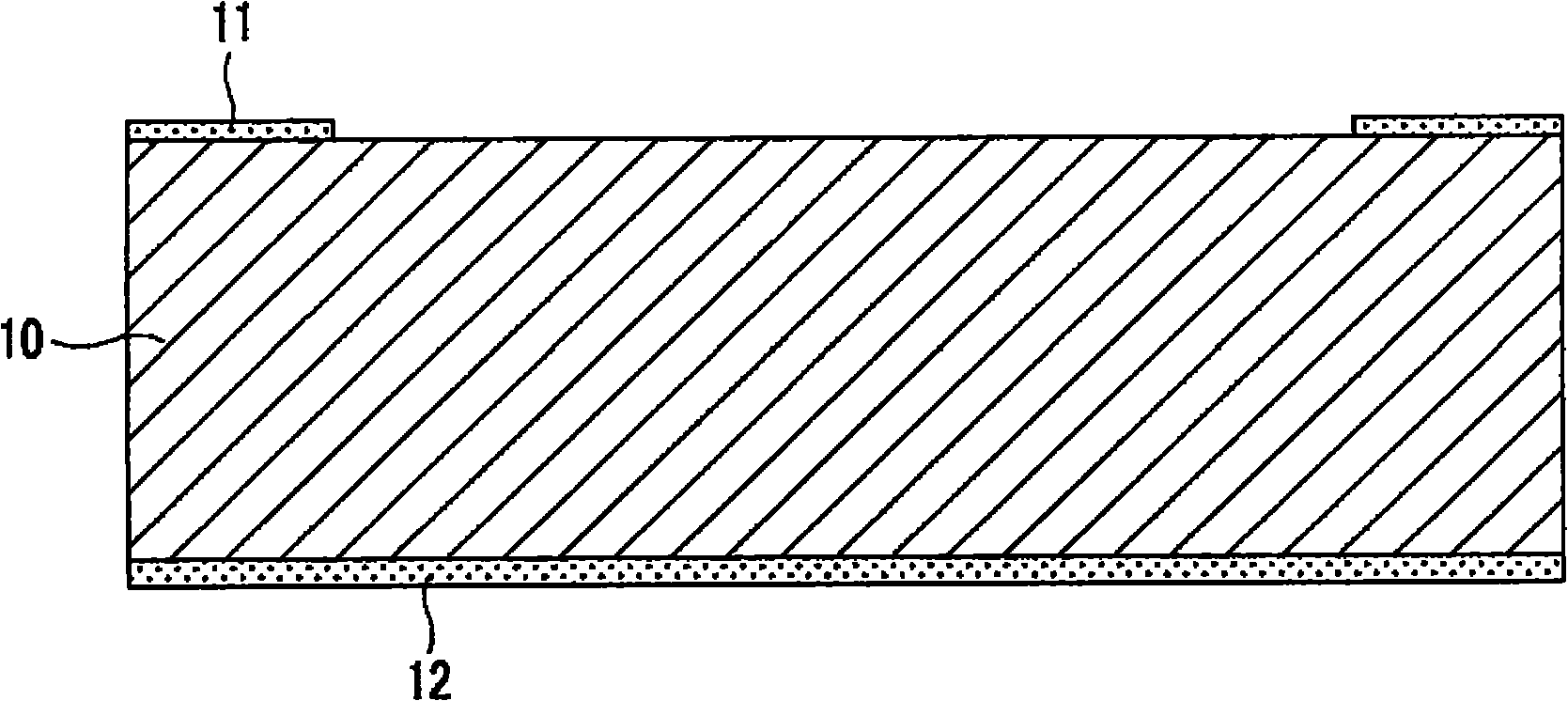

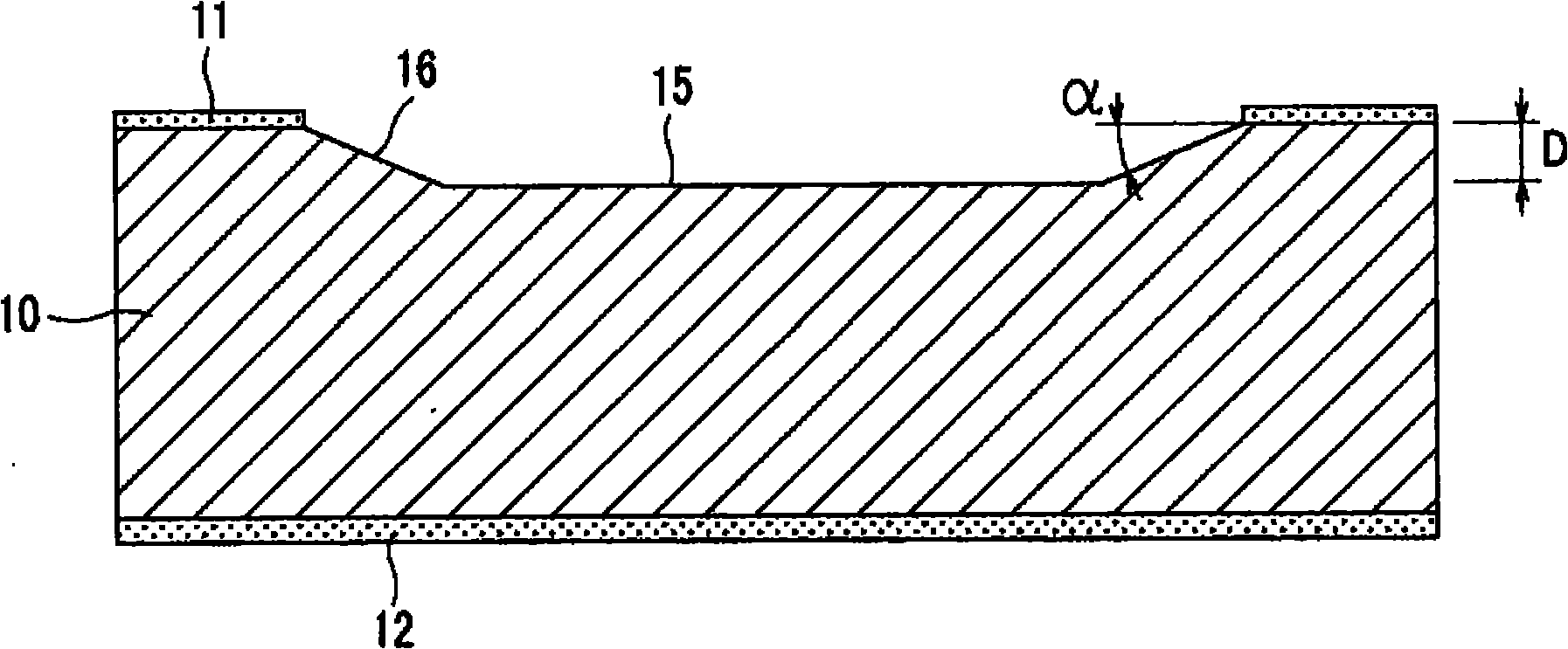

Flexible silica gel screen protection film and preparation method thereof

InactiveCN111440551AEasy to adjust softnessEasy to adjust the thicknessEster polymer adhesivesPolyurea/polyurethane coatingsColloidal silicaPolymer science

The invention discloses a flexible silica gel screen protection film, and belongs to the technical field of protection films. The flexible silica gel screen protection film mainly structurally comprises a PETrelease film, a hardened coating coated on the release surface of the PET release film, an organic silica gel layer coated on the hardened coating, an organic silicon pressure-sensitive adhesive layer coated on the organic silica gel layer, and a fluorine release film adhered on the organic silicon pressure-sensitive adhesive layer, wherein the hardened coating, the organic silica gel layer and the organic silicon pressure-sensitive adhesive layer are compounded into a use layer; the surface hardness of the use layer is HB-2H, the light transmittance is greater than or equal to 91%, the haze is less than or equal to 1%, and the softness is 25A-60A; and the thickness ratio of the hardened coating to the organic silica gel layer to the organic silicon pressure-sensitive adhesive layer in the use layer is (2-4): (40-50): (20-30). The flexible silica gel screen protection film has better flexibility and has more excellent fitting performance for curved edge amplitudes of an AF screen and a 2.5 D / 3D screen and is not degummed during die cutting and can be directly fit with a curved screen for use without hot-pressing preforming, and can play a better role in protecting existingcurved screen electronic equipment.

Owner:太仓斯迪克新材料科技有限公司

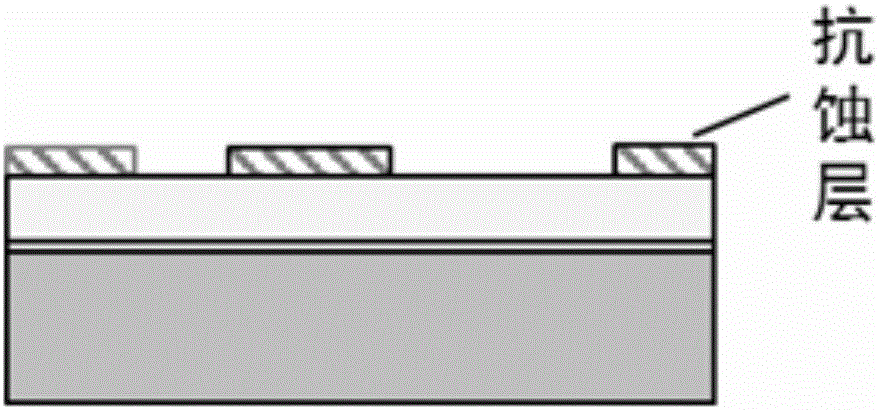

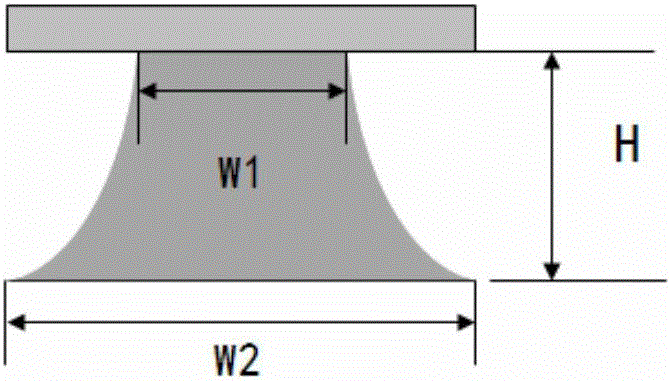

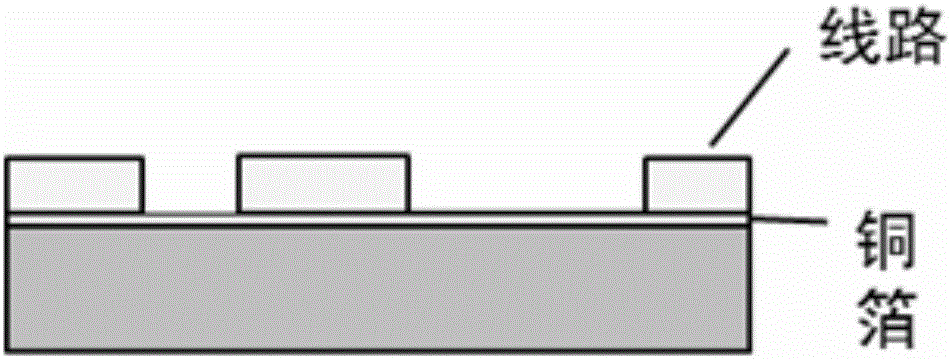

Manufacturing method of fine circuit board free of corrosion resistant layer

InactiveCN106852003AAvoid the impact of side erosionImprove manufacturing qualityConductive pattern formationCopper foilElectroplating

The invention discloses a manufacturing method of a fine circuit board free of a corrosion resistant layer. The method comprises the processes of laminating, base copper reduction, drilling, depositing copper preplating, pattern electroplating, stripping and flash rusting and subsequent processes. According to the manufacturing method, the fine circuit board is manufactured by combining a thin copper foil with a flash rusting technology; the manufacturing method can be used for manufacturing an ultrafine circuit; and the manufacturing accuracy of the circuit is improved.

Owner:YIXING SILICON VALLEY ELECTRONICS TECH

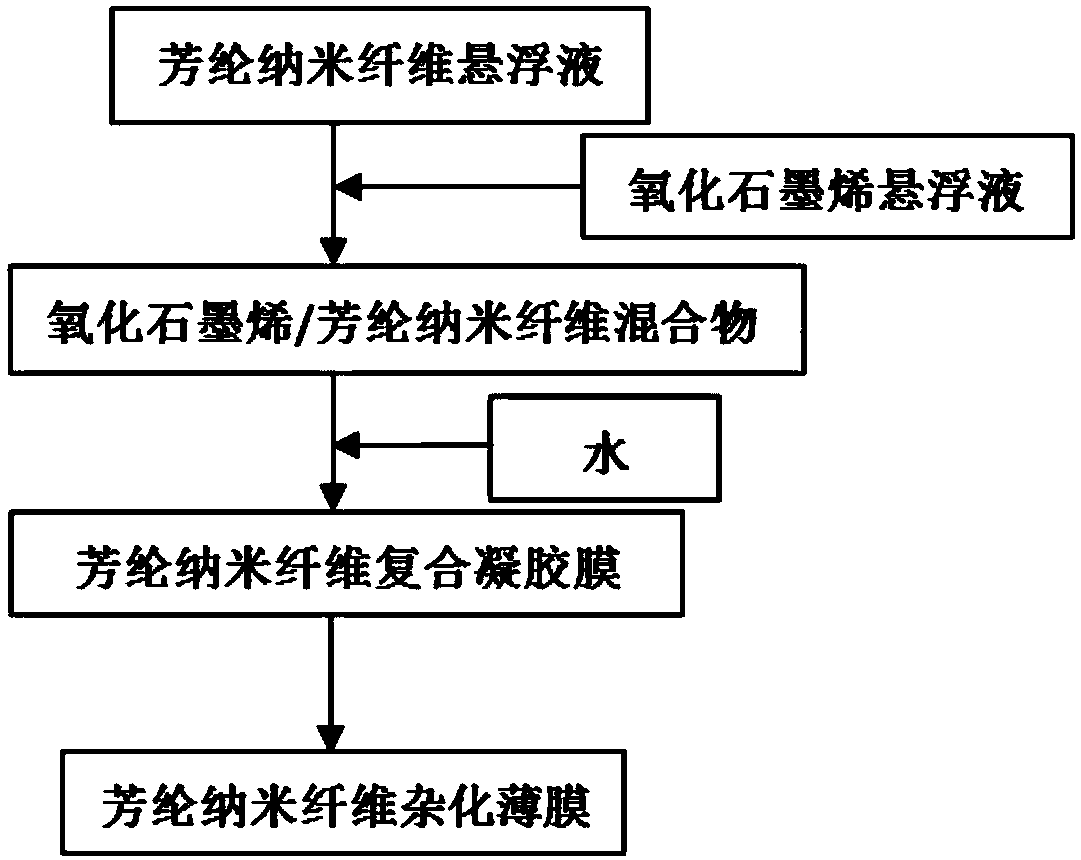

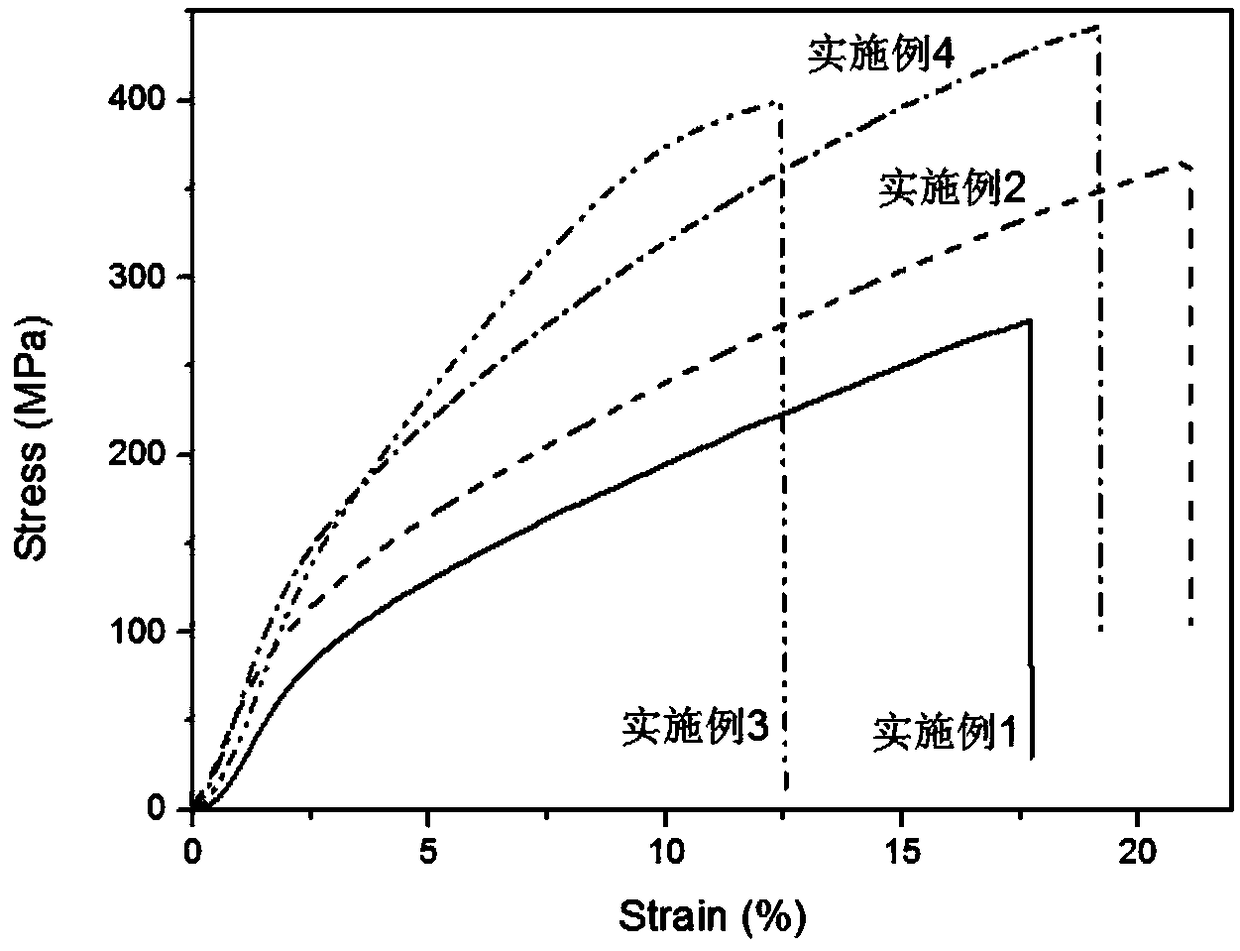

High-mechanical-strength aramid nanofiber hybrid thin film and preparation method thereof

ActiveCN108752611AFacilitate structural reorganizationImprove mechanical propertiesGraphite oxideNanofiber

The invention discloses a high-mechanical-strength aramid nanofiber hybrid thin film and a preparation method thereof. The thin film is prepared from the following components in parts by mass: 100 parts of an aramid nanofiber and 3 to 15 parts of graphene oxide. According to the high-mechanical-strength aramid nanofiber hybrid thin film disclosed by the invention, a hydration protonation effect isused for promoting structural recombination of the aramid nanofiber and also induce ordered gelation and self-assembling of the nanofiber, so as to conveniently regulate and control the thickness ofa thin film material; a one-dimensional nanofiber matrix is filled with a two-dimensional graphene oxide reinforcement phase to effectively exert the interface compatibility advantage between phase components, so that the mechanical property of an aramid fiber composite thin film is greatly improved.

Owner:NANJING UNIV OF SCI & TECH

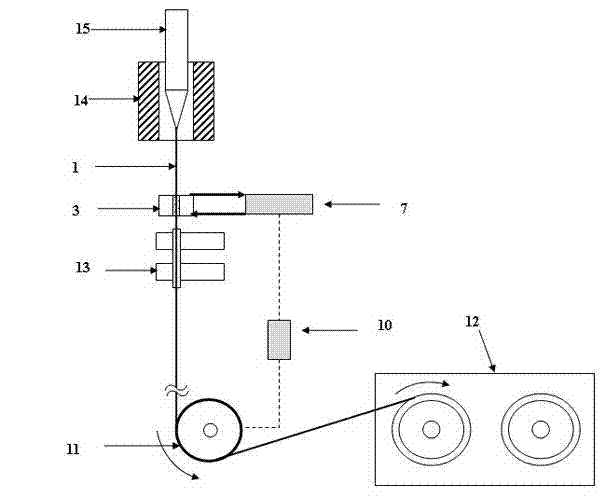

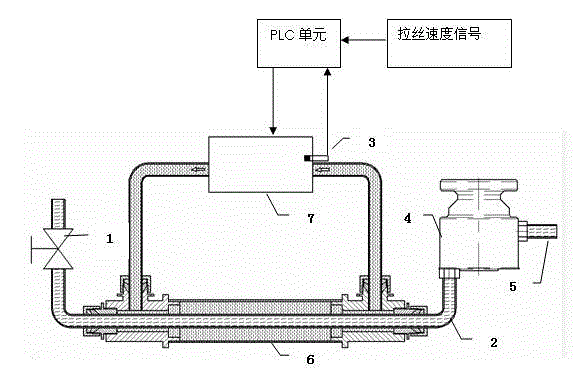

Method and device for automatically controlling temperature of optical fiber coatings in wiredrawing process

The invention relates to a method and a device for automatically controlling the temperature of optical fiber coatings in a wiredrawing process. The device comprises an optical fiber coating device, wherein a coating cavity of the optical fiber coating device is communicated with a charging bucket by a charging pipeline. The device is characterized in that the charging pipeline is externally provided with a controllable heater which is used for heating the coatings in the charging pipeline, the charging pipeline is externally provided with a processing control unit which is used for comparing an acquired wiredrawing speed sensing signal and charging pipeline temperature sensing signal with a preset parameter numerical value, so as to control the heating process of the controllable heater, so that the automatic controlling and adjusting process of the temperate of the coatings in the optical fiber coating device can be realized. According to the device and the method, the temperature of the coatings can be automatically changed along with the wiredrawing speed when the optical fiber is wiredrawn, so that the temperature (or the viscosity) of the coatings can be well matched with the wiredrawing speed, and therefore, the quality of a coating layer on the surface of the optical fiber can be guaranteed, and the machining yield of the optical fiber can be improved. The method and the device are simple in structure, and convenient to implement and popularize, so that the automatic level of optical fiber machining equipment can be improved.

Owner:SICHUAN LEFEI OPTOELECTRONICS TECH CO LTD

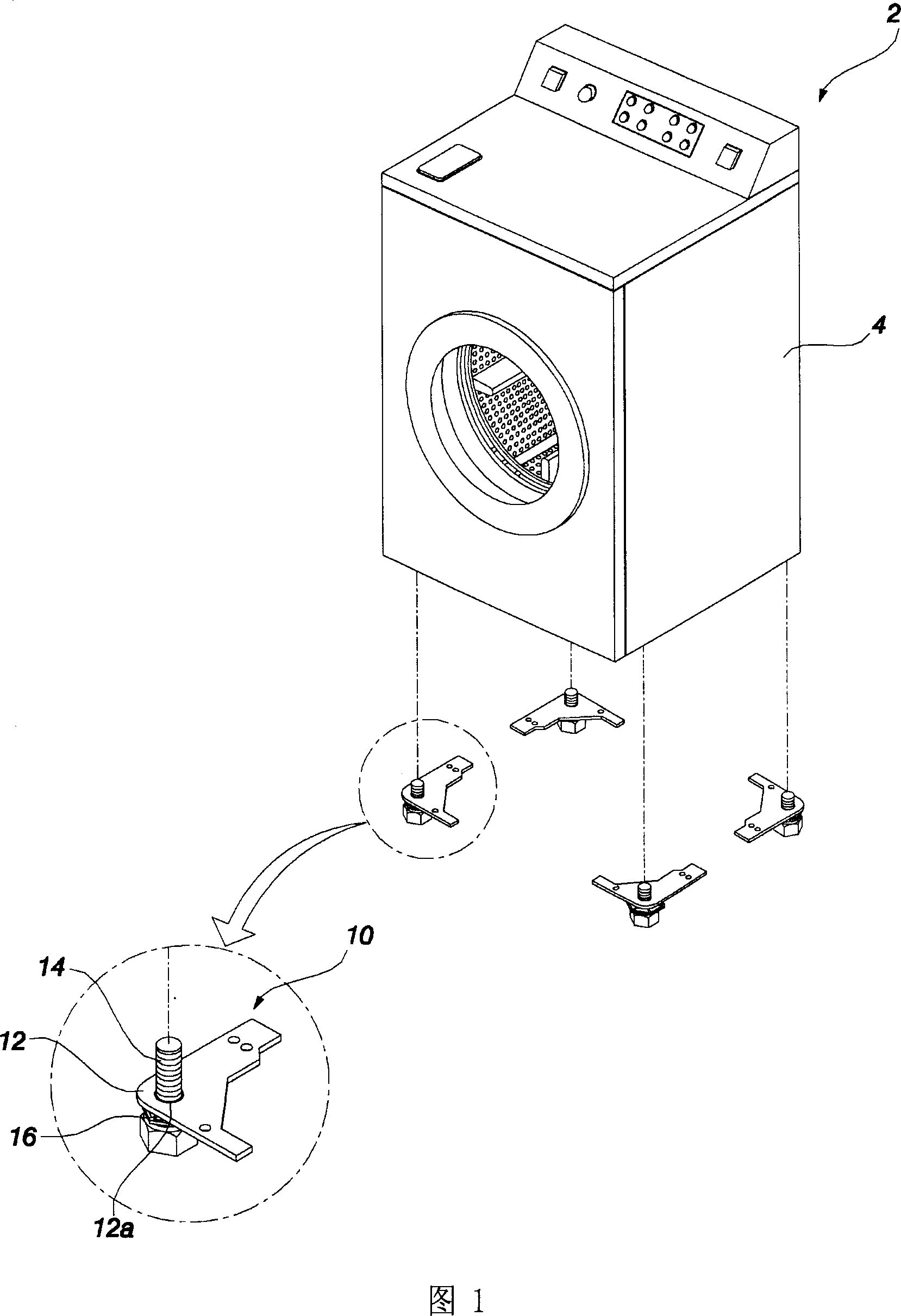

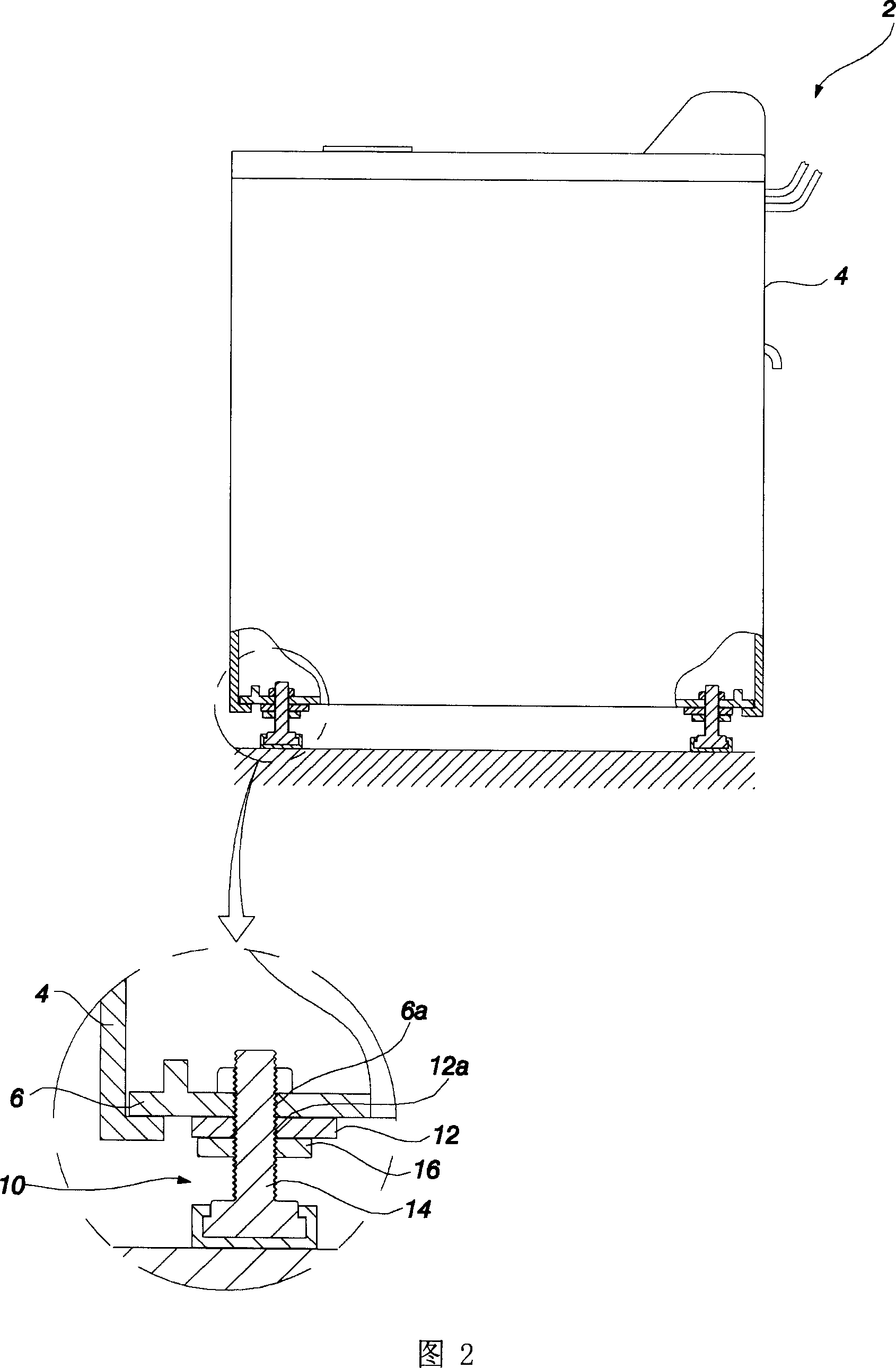

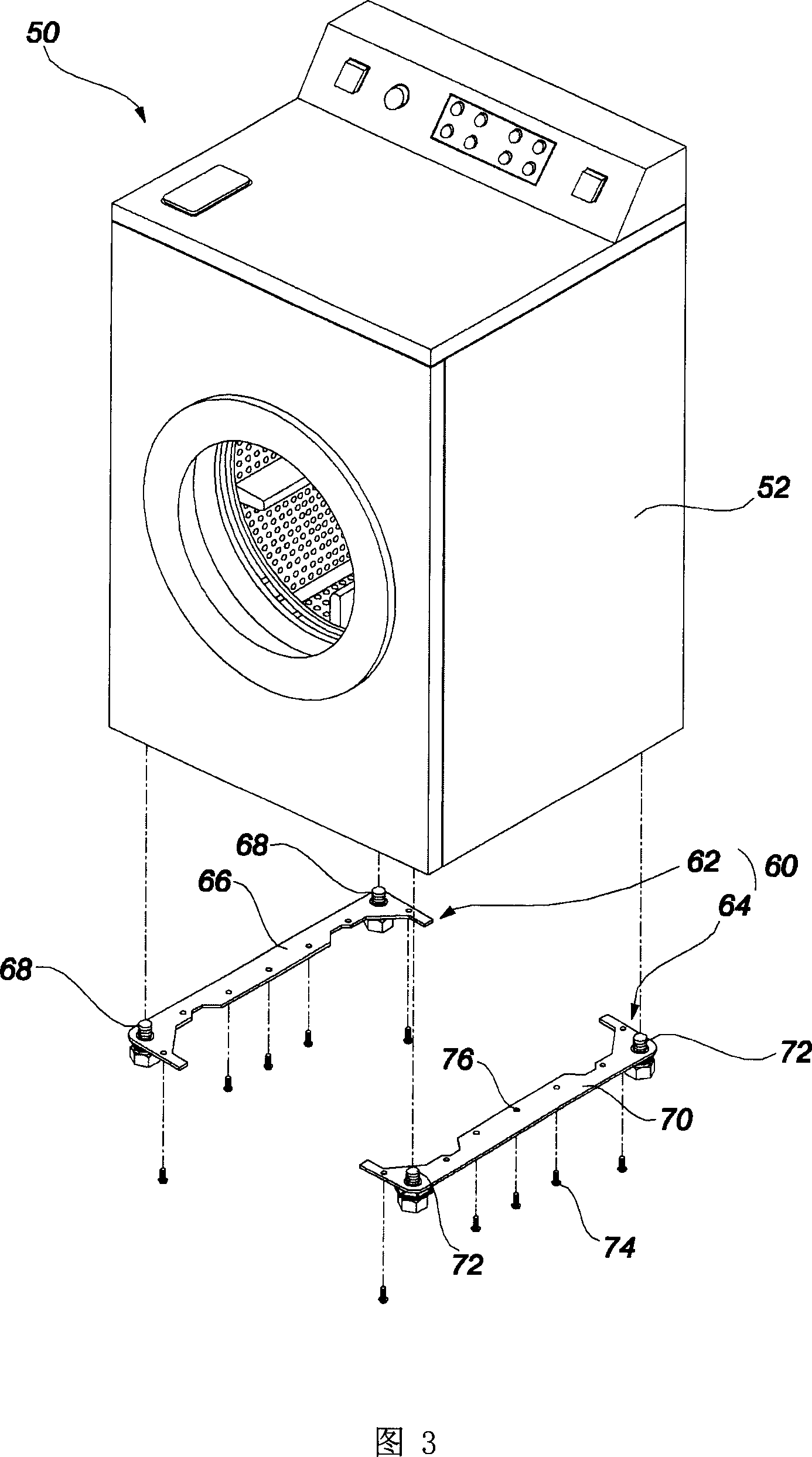

Mounting structure for bottom supports of washing machine

InactiveCN1966822AHigh strengthEasy to assembleOther washing machinesTextiles and paperResonanceMechanical engineering

The installation structure of the feet of the washing machine comprises a base under the housing, a bracket on the base, a feet assembly made of more than one foot on the bracket, and a step holding installation section for installing feet. It can also comprise housing, a bracket under the housing, the feet assembly made of more than one foot on the bracket. All of them join together at the bottom of the bracket to form the base of the bottom of the washing machine. It can improve the intensity of the bracket and reduce the resonance caused by the washing machine. It also improves assembly performance with stable support. At the bottom of the housing, sets a bracket with several feet, a base under the bracket. It adds the thickness of the installation sector, improves its intensity, and ensures the flexibility of the design with easily adjusted thickness of the bracket.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Preparation method for hollow microspheres

InactiveCN102319903ASimple preparation processEase of industrial productionMicrosphereSpherical shaped

The invention discloses a preparation method for hollow microspheres, and belongs to the fields of powder metallurgy and new material preparation. Micro spherical alloy powder with components of AxB(1-x) (x is more than or equal to 0.4 and less than 1) is used as a raw material in the method. The method comprises the following steps of: forming a layer of oxide micro film on the spherical wall ofthe alloy by pre-oxidation treatment, calcining the treated raw material to evaporate the component A and deposit the component B on the surface of the spherical wall, and thus forming the composite hollow microspheres containing a metal and a metal oxide. The oxide film on the surface of the composite hollow microspheres can be removed by a reduction or dissolution post-treatment process, and the metallic hollow microspheres can be obtained. The method for preparing the hollow microspheres has the characteristics of simplicity in process, controllability in product shape and applicability for large-scale industrial production.

Owner:BEIJING BGRIMM ZINC INDAL

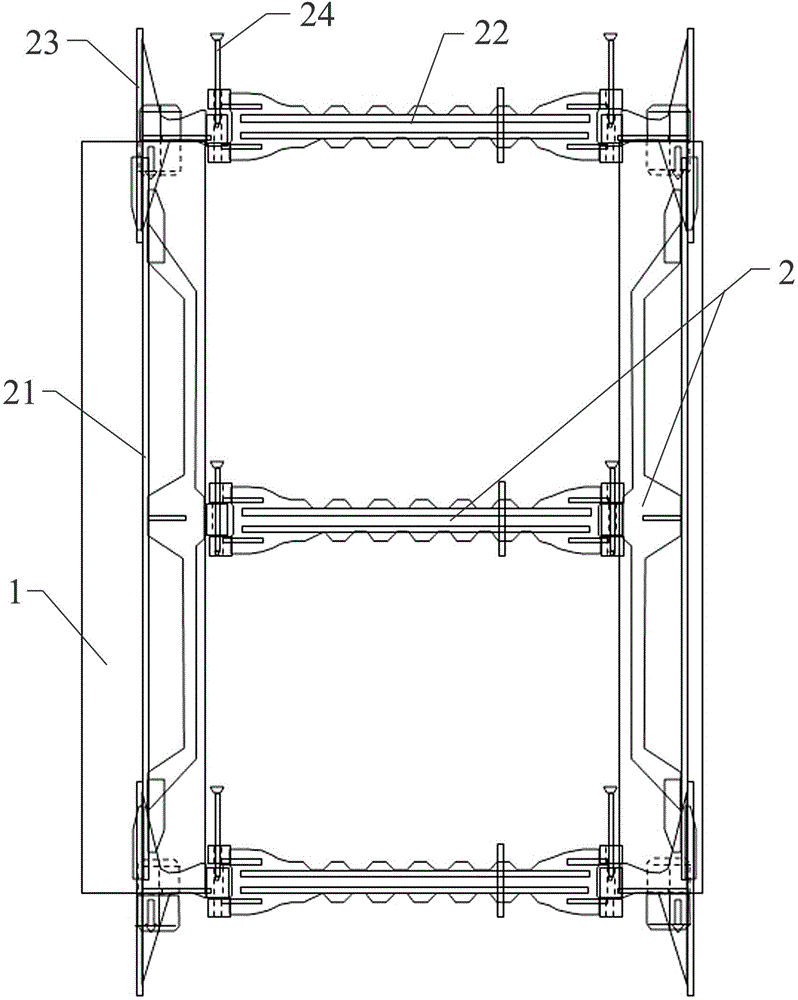

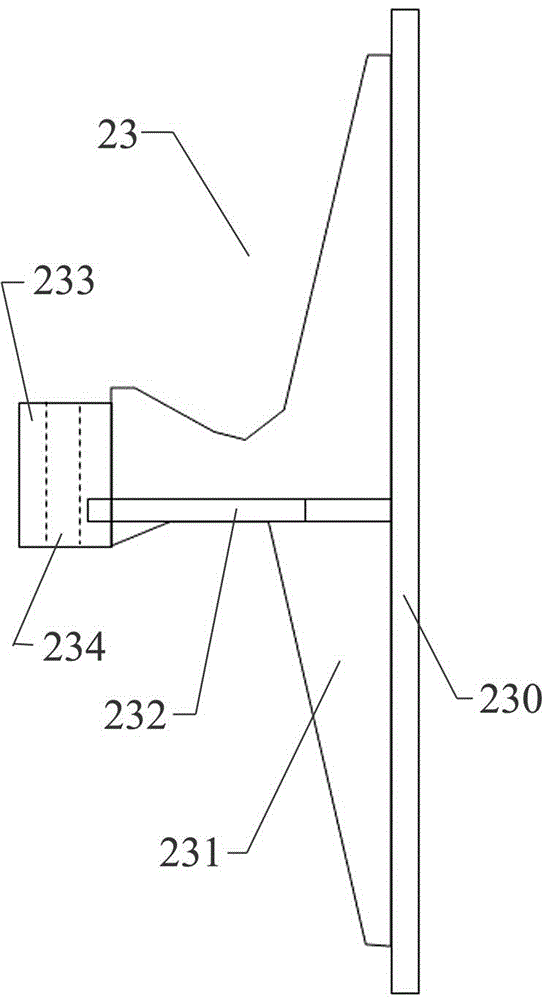

Non-dismantling heat preservation wall module unit

The invention relates to a non-dismantling heat preservation wall module unit. The non-dismantling heat preservation wall module unit comprises a pair of heat preservation boards and supporting connecting components arranged between the heat preservation boards. A high-strength EPS polystyrene board is adopted in each heat preservation board, the heat preservation boards have the advantages of being resistant to fire and water and good in heat preservation performance, the adjacent heat preservation boards are in seamless connection, operation is convenient, efficiency is high, and the construction period is short. A wall formed by cast-in-place concrete of the wall module unit is high in overall strength and seismic grade, and the probability of crushed collapse is completely eradicated. The wall is free of a cold bridge, the energy-saving effect is good, and saved energy can reach up to 80% compared with that of a common building. Grooves and rebar fixing boards are arranged on the supporting connecting components, rebars can be conveniently arranged and fixed, cross arrangement of the supporting connecting components is conveniently achieved, the supporting connecting components have multiple sizes, adaptability is high, and the thickness of the wall is conveniently adjusted. Split type design is adopted in the supporting connecting components, the occupied size is small in the transporting process, and transporting cost is greatly reduced.

Owner:潍坊领潮投资有限公司

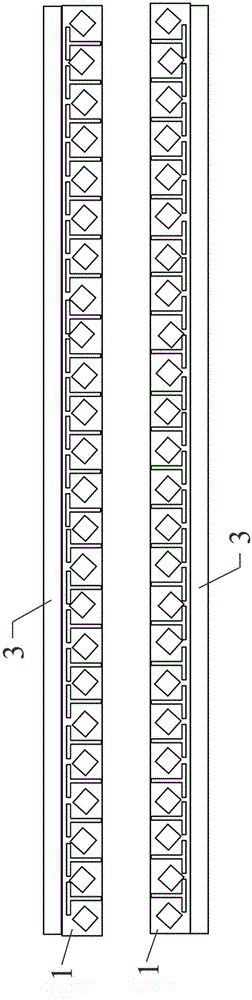

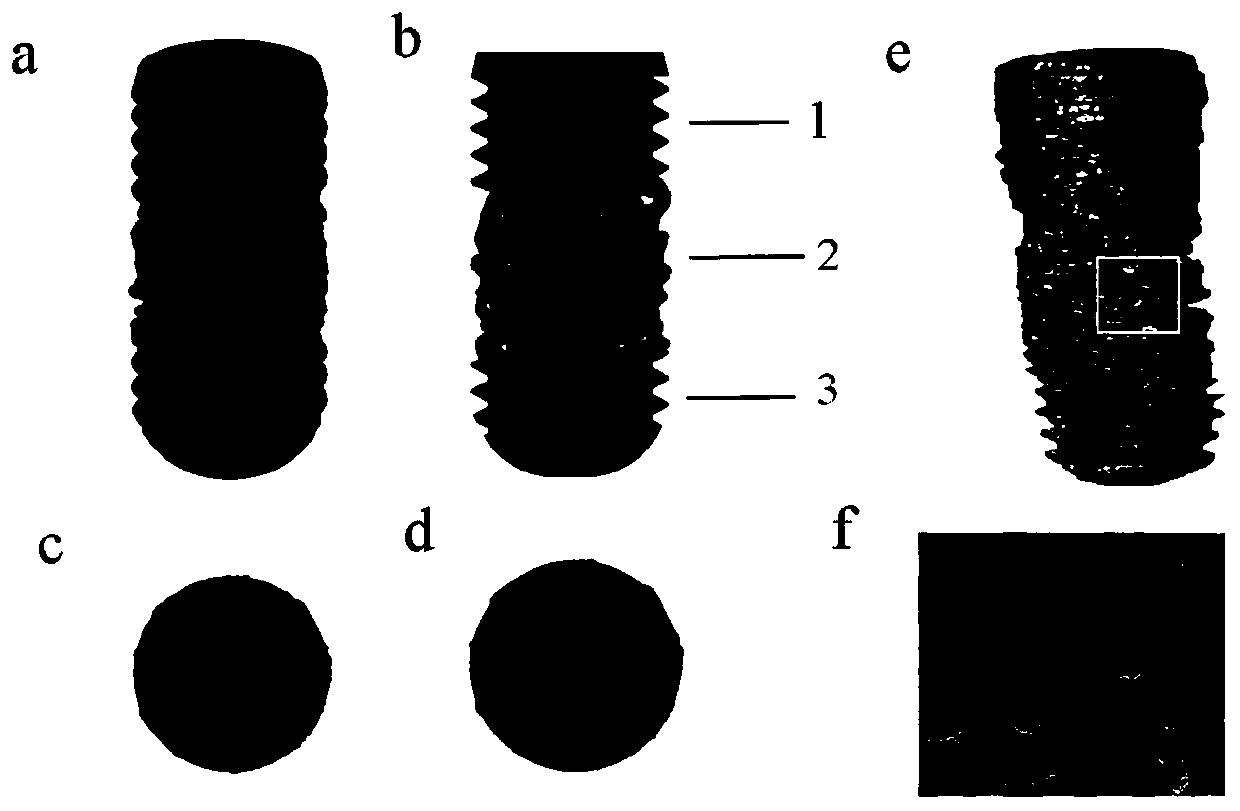

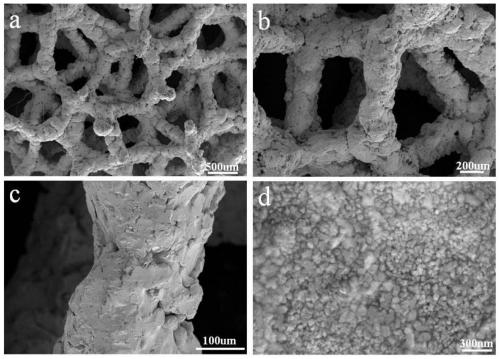

Bone trabecula porous tantalum dental implant and preparation method thereof

PendingCN111494035AHigh porosityHigh strengthDental implantsAdditive manufacturing apparatusPorous tantalumDentistry

The invention relates to the technical field of biomedical metal materials and oral implantation medical instruments, and provides a bone trabecula porous tantalum dental implant and a preparation method thereof. The bone trabecula porous tantalum dental implant provided by the invention has a cylindrical structure and sequentially comprises a top functional area, a middle functional area and a bottom functional area from top to bottom. The top functional area is of a compact structure, the middle functional area has a bionic bone trabecula porous structure, and the bottom functional area hasa compact structure. The bone trabecula porous tantalum dental implant is integrally prepared by taking pure tantalum or medical tantalum alloy powder as a raw material through an additive manufacturing technology. The bone trabecula porous tantalum dental implant provided by the invention is high in friction force, close to human bone in strength and modulus, excellent in bone ingrowth effect, high in implantation stability and long in service life, is of an integrated structure, and has no risk of delamination and separation during implantation.

Owner:深圳大洲医学科技有限公司

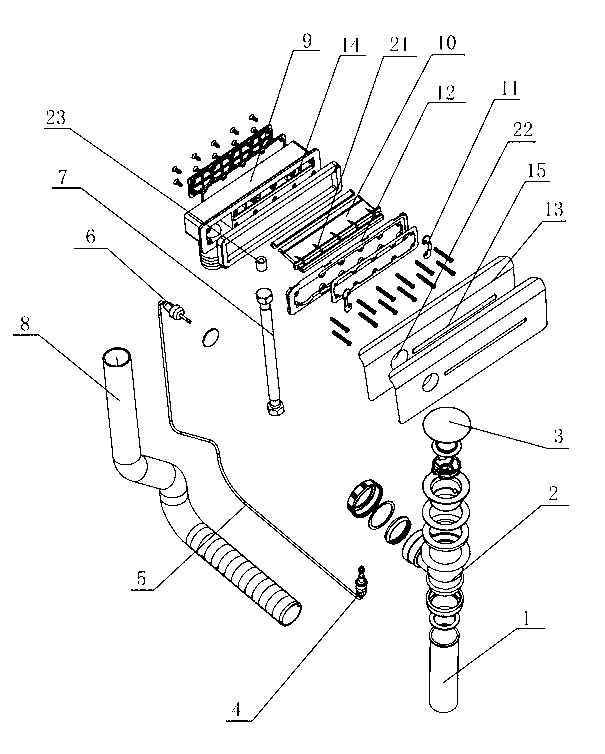

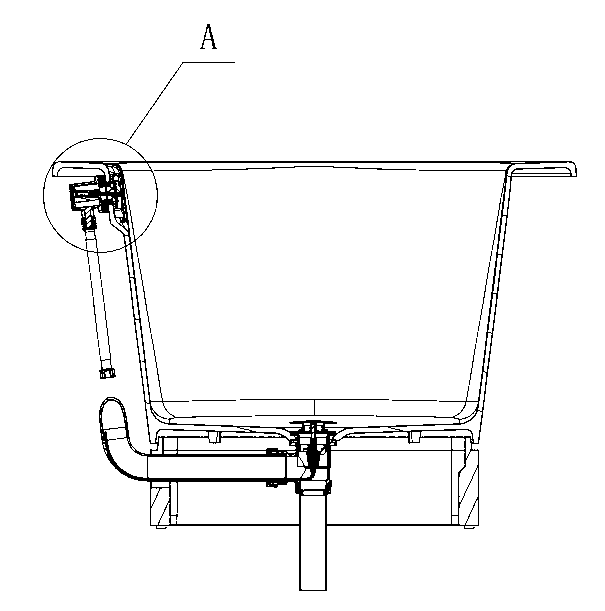

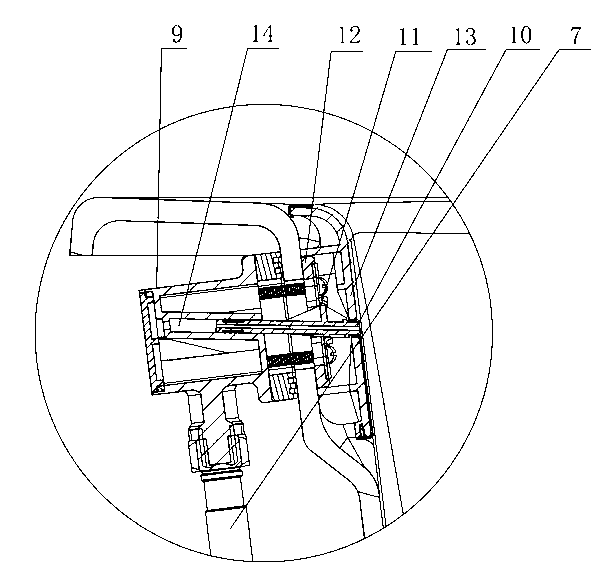

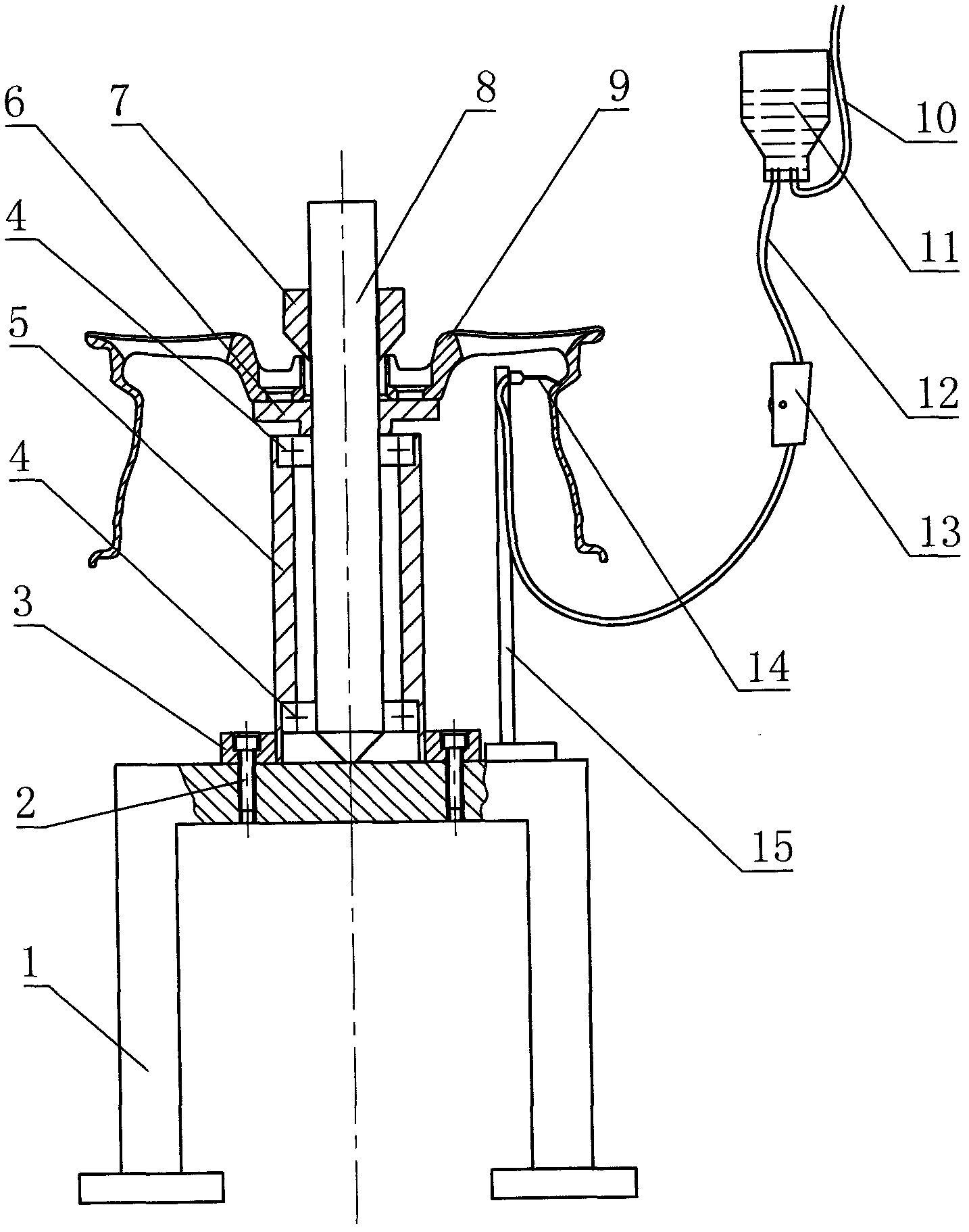

Bathtub water removing device integrating water feeding, water overflowing and water discharging

ActiveCN103255817AImprove protectionExtended service lifeDomestic plumbingWater dischargeDrive by wire

The invention relates to the technical field of bathroom equipment and particularly relates to a bathtub water removing device integrating water feeding, water overflowing and water discharging. The bathtub water removing device comprises a water discharging device and a water overflowing and water discharging device, wherein the water discharging device is arranged at the bottom of a bathtub and is provided with a drive-by-wire switch; the water overflowing and water discharging device arranged on the wall of the bathtub; the water discharging device comprises a water discharging seat (2) which is communicated with a sewer pipe (1), and a choke plug (3) which covers the water discharging seat (2); the drive-by-wire switch is connected with the choke plug (3); the water overflowing and water discharging device is in a retractable structure capable of being adjusted according to the thickness of the wall of the bathtub; and a protection device for protecting the drive-by-wire switch is arranged between the drive-by-wire switch and the choke plug (3). The bathtub water removing device disclosed by the invention can be applicable to the bathtubs with different thicknesses and has an anti-trampling function.

Owner:ZHEJIANG DELIFU TECH CO LTD

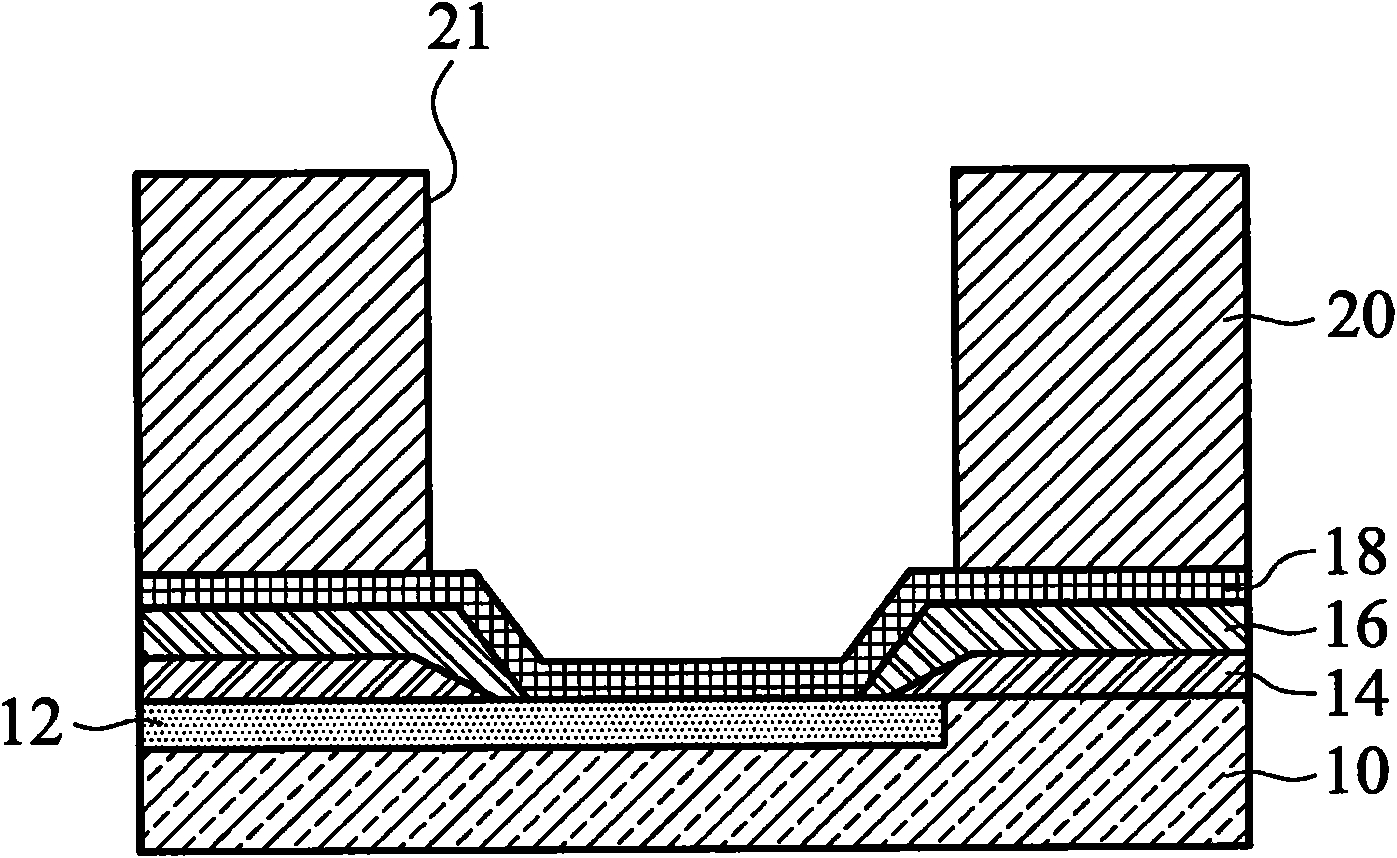

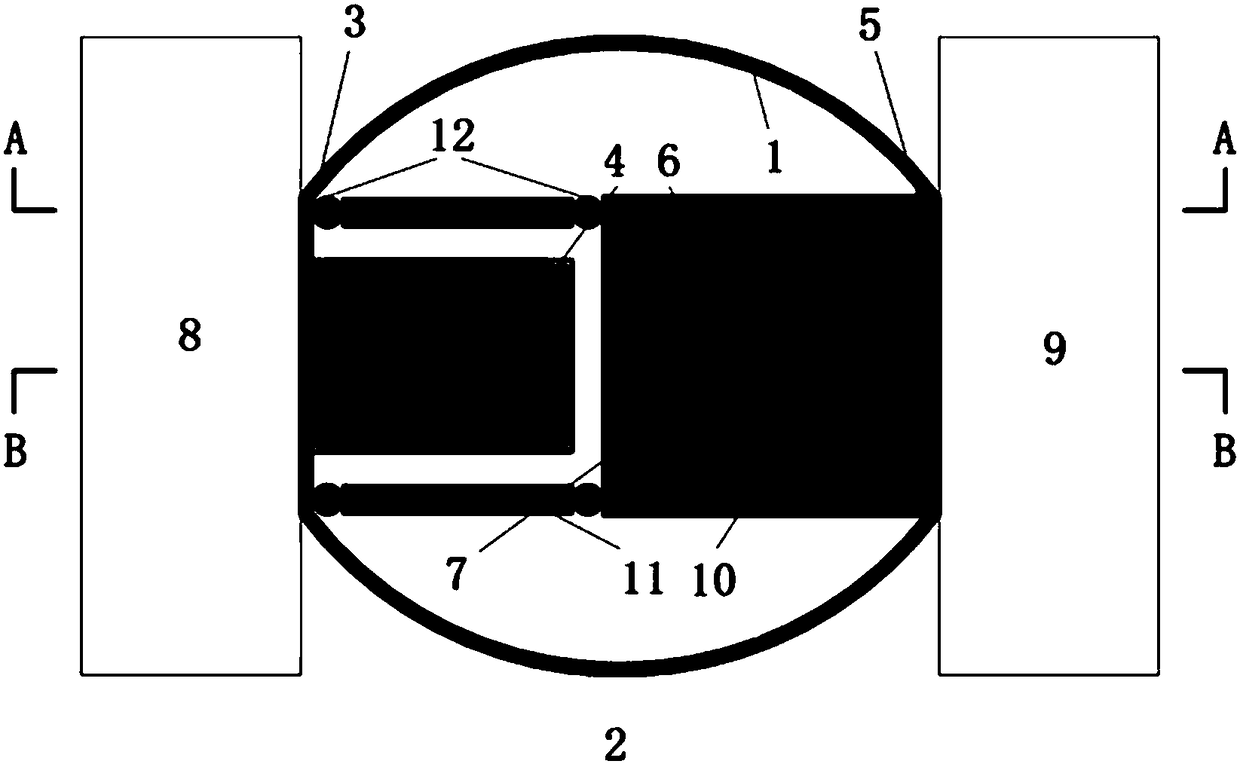

Mems microphone and method for manufacturing same

InactiveCN102111705AResidual Stress MinimizationAvoid breakingSemiconductor electrostatic transducersElectrostatic transducer microphonesMems microphoneSilicon

The present invention relates to a MEMS microphone having less residual stress at a contact portion between a silicon substrate and a membrane, and to a method for manufacturing the MEMS microphone. The MEMS microphone comprises: a silicon substrate in which a back chamber is formed; a back plate deposited on the silicon substrate and including a plurality of sound holes; a membrane deposited on the silicon substrate and spaced apart from the back plate to form an air gap; and a stress buffer deposited between the membrane and the silicon substrate.

Owner:BSE CO LTD

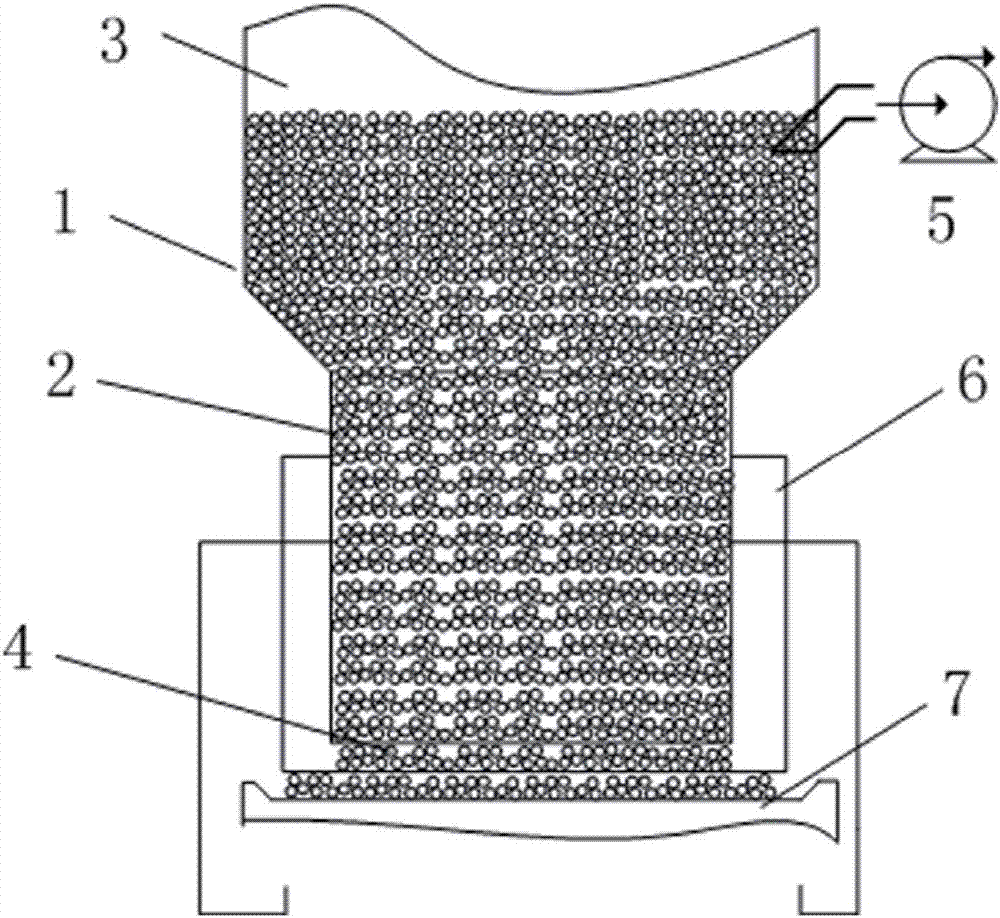

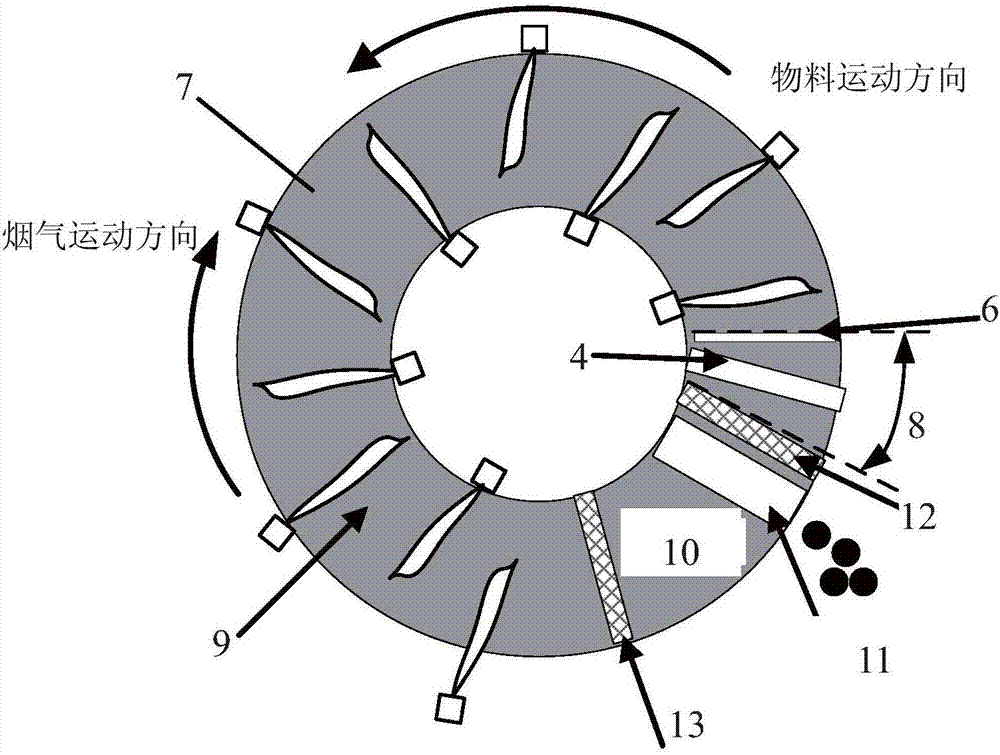

Rotary hearth furnace

The invention relates to a rotary hearth furnace. The rotary hearth furnace comprises an annular furnace body, an annular hearth, a heat power engineering system, a discharge mechanism, a distributionmechanism and a smoke discharge mechanism. The rotary hearth furnace effectively solves low CO utilization rate, and meanwhile, fully uses the smoke afterheat; more CO participates in indirect reduction; materials are preheated by the smoke afterheat; compared with a traditional rotary hearth furnace technology, the rotary hearth furnace can reduce adding of the material carbon dosage, effectively reduces the smelting energy consumption, and reduces the production cost; and the angle of a high-temperature reduction area is increased, so that the reduction time is prolonged, the reduction effect is improved, and meanwhile, the treatment capacity of the rotary hearth furnace is improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

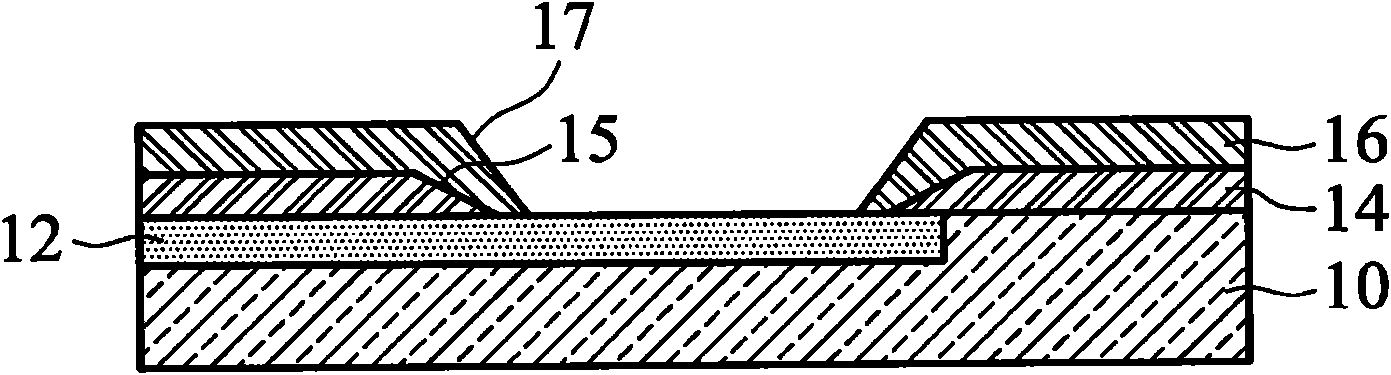

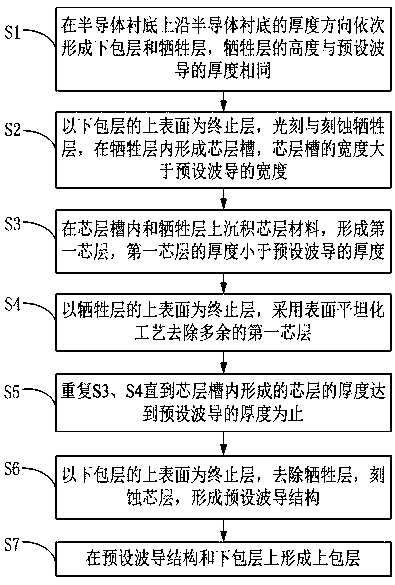

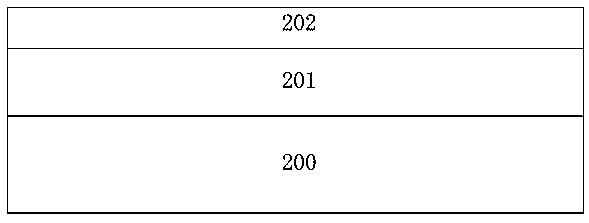

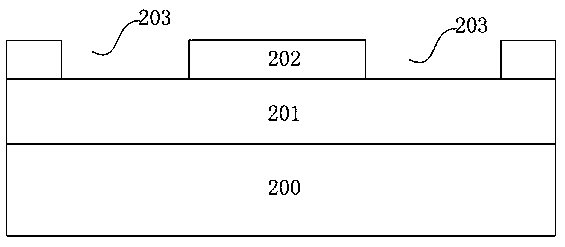

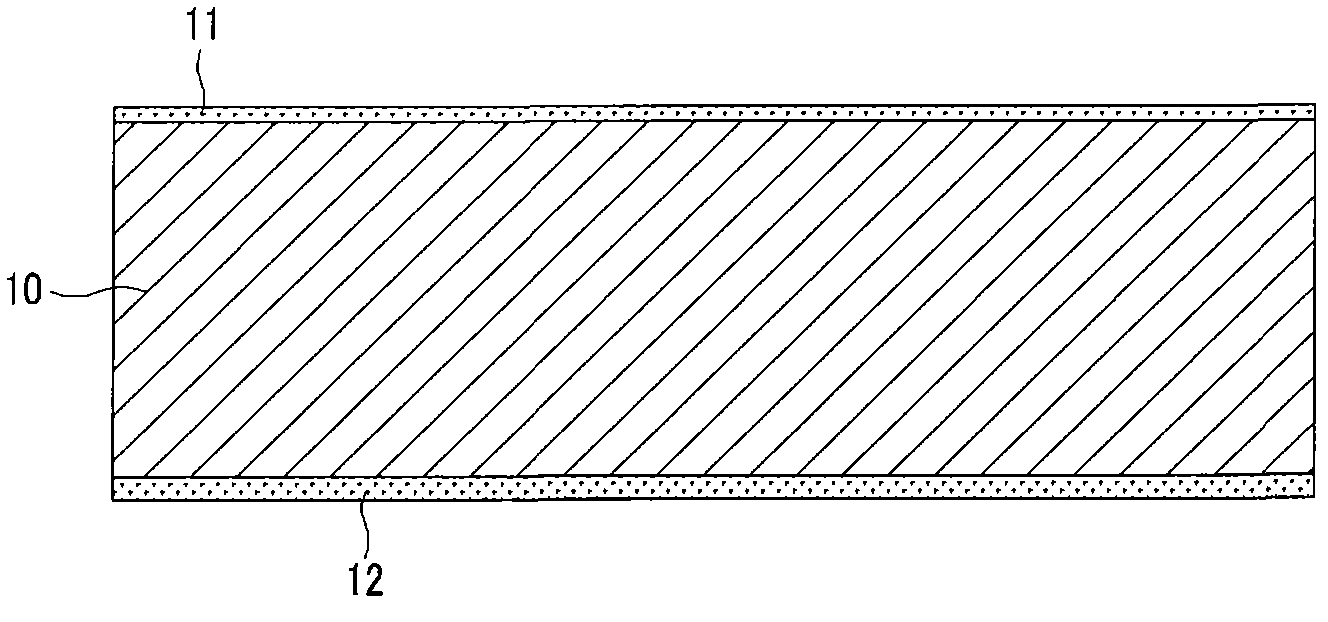

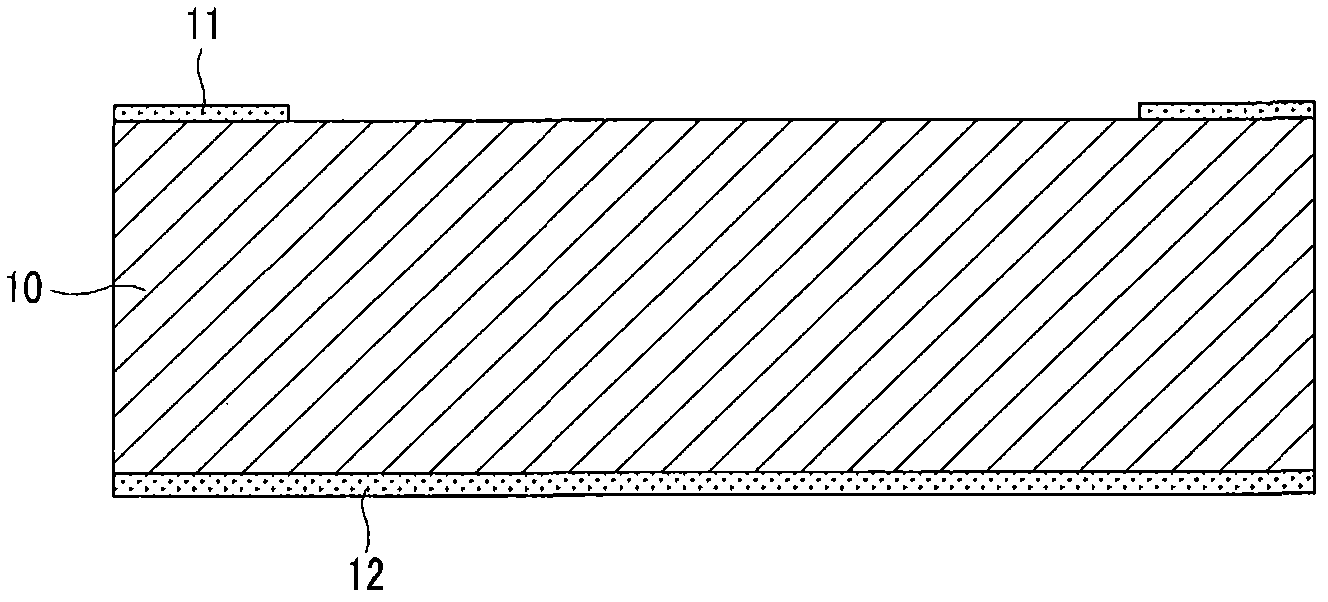

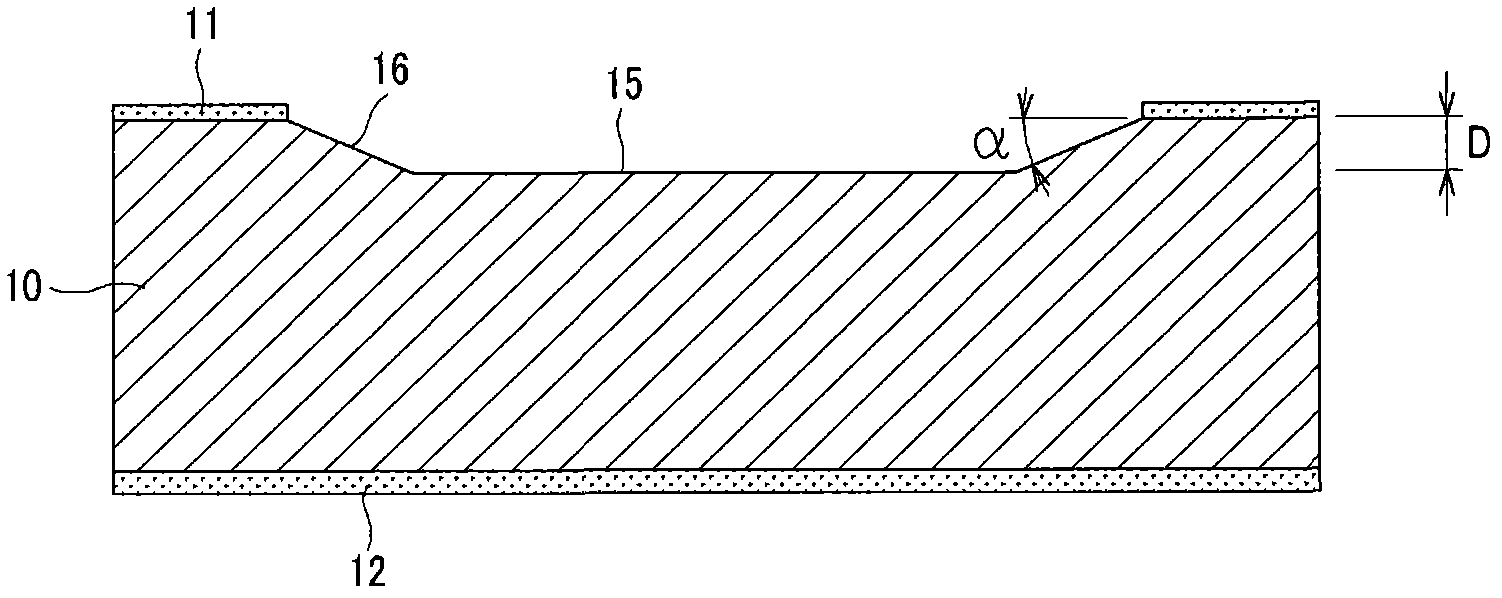

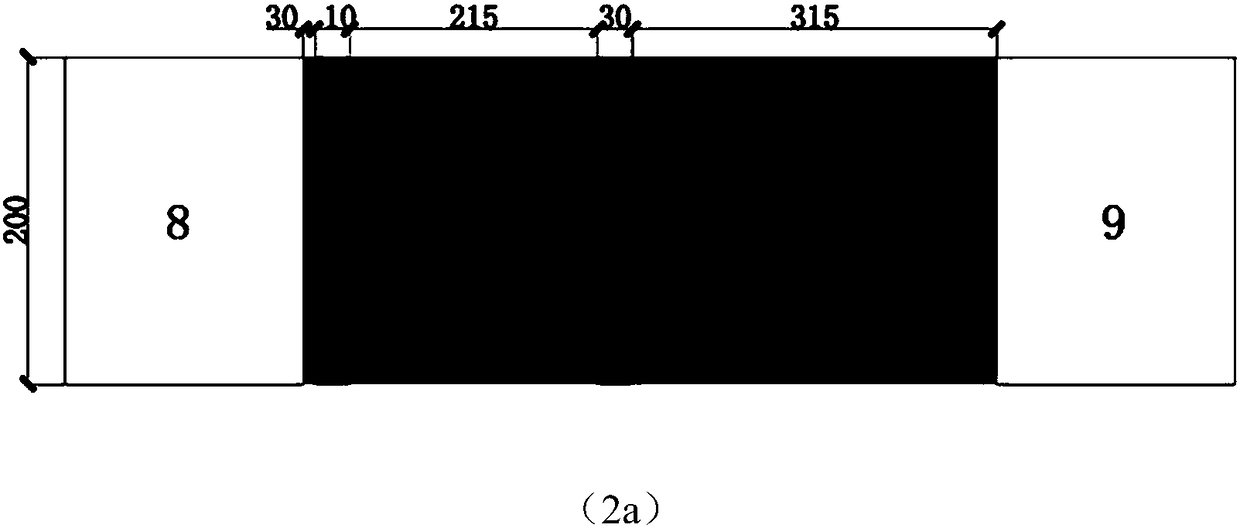

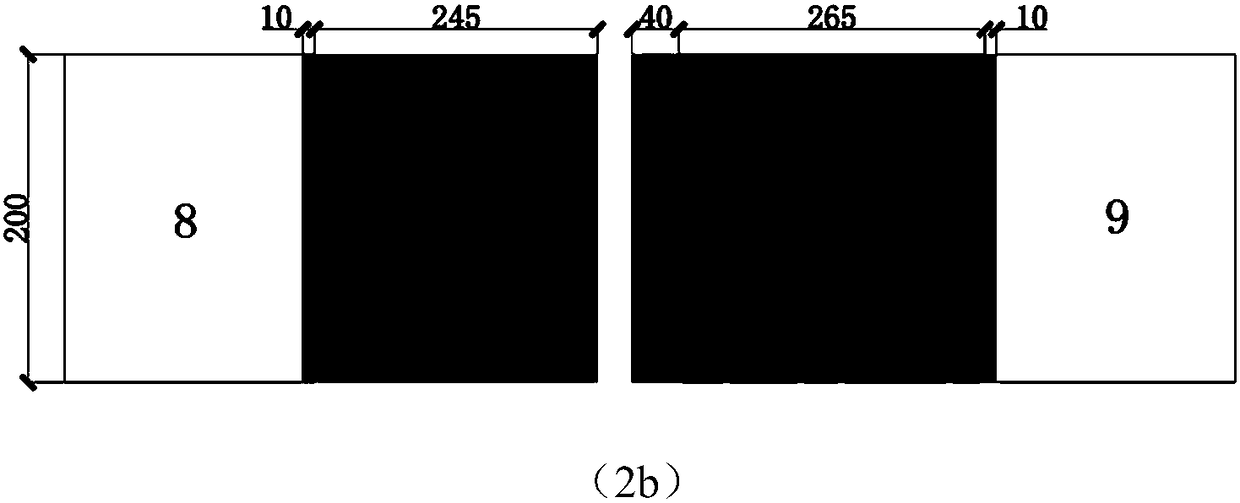

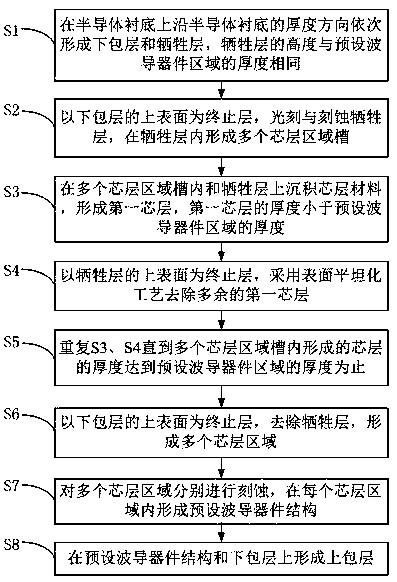

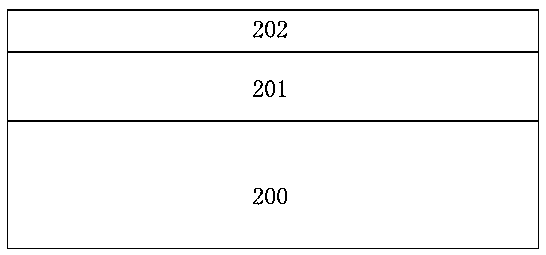

Method for preparing thick film silicon nitride waveguide

ActiveCN110456450AReduce lossEasy to adjust the thicknessOptical waveguide light guideSidewall roughnessHigh stress

The invention discloses a method for preparing a thick film silicon nitride waveguide, comprising the steps of: sequentially forming a lower cladding layer and a sacrificial layer on a semiconductor substrate, wherein the height of the sacrificial layer is the same as the thickness of a preset waveguide; photoetching and etching the sacrificial layer to form a core layer groove by using an upper surface of the lower cladding layer as a termination layer, wherein the width of the core layer groove is greater than the width of the preset waveguide; depositing a core layer material in the core layer groove and on the sacrificial layer to form a first core layer; removing the excess first core layer by using a surface planarization process and by using the upper surface of the sacrificial layer as the termination layer; repeating the above step until the thickness of the core layer formed in the core layer groove reaches the thickness of the preset waveguide; removing the sacrificial layerand etching the core layer to form a preset waveguide structure by using the upper surface of the lower cladding layer as the termination layer; and forming an upper cladding layer on the preset waveguide structure on the lower cladding layer. By adopting the scheme, the high stress problem caused by the excess thickness of the thin film is solved, and the shape of the waveguide is optimized to reduce the sidewall roughness.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Automobile wheel hub aluminum alloy rim stroke machine

InactiveCN102989628AReduce labor intensityEasy to adjust the thicknessLiquid surface applicatorsCoatingsAluminium alloyMaterials science

The invention relates to an automobile wheel hub aluminum alloy rim stroke machine. The automobile wheel hub aluminum alloy rim stroke machine comprises a frame (1), a connection board (3), a cylinder (5), a positioning cylinder (7), a shaft (8), a breather tube (10), a paint bottle (11), a liquid conveying tube (12), a flow adjustment valve (13), a steel needle tube (14) and a support (15). The automobile wheel hub aluminum alloy rim stroke machine is characterized in that a baseboard (3) is fixed on the frame (1) through screws (2); the baseboard is connected with the cylinder (5) through welding; inner apertures at two ends of the cylinder (5) are respectively provided with a bearing (4); and the lower end surface of a workbench (6) contacts with the inner ring of the bearing arranged in the upper-end inner aperture of the cylinder (5). The automobile wheel hub aluminum alloy rim stroke machine has the advantages of simple operation, adjustment convenience, uniform stroke, high product qualification rate, less maintenance frequency, and long service life.

Owner:KINGHWA TOPTRUE WHEEL

Mems microphone and method for manufacturing same

InactiveCN102056063AReduce production processMinimize residual stressDecorative surface effectsSolid-state devicesEngineeringMems microphone

Owner:BSE CO LTD

Electric-eddy-type coupling-beam damper

ActiveCN108590301AAdaptive energy consumption reachesImprove energy consumptionProtective buildings/sheltersShock proofingSnubberStructural coupling

The invention relates to an electric-eddy-type coupling-beam damper which is arranged between adjacent shear wall structural coupling beams. The electric-eddy-type coupling-beam damper is characterized in that the electric-eddy-type coupling-beam damper comprises a yield energy-consumption assembly and an electric-eddy energy-consumption assembly; the yield energy-consumption assembly comprises upper U-shaped soft steel and lower U-shaped soft steel which are arranged between the adjacent shear wall structural coupling beams correspondingly; and the electric-eddy energy-consumption assembly isarranged in a space formed by the upper U-shaped soft steel and the lower U-shaped soft steel. Compared with the prior art, the electric-eddy-type coupling-beam damper has the technical advantages that the self-adaption energy-consumption capacity is high, energy consumption is high, the sensitiveness is high, and design is easy, overcomes the choke point of a traditional damping technology, andis suitable for damping design of a fabricated shear wall structure in a high-seismic-intensity area.

Owner:TONGJI UNIV

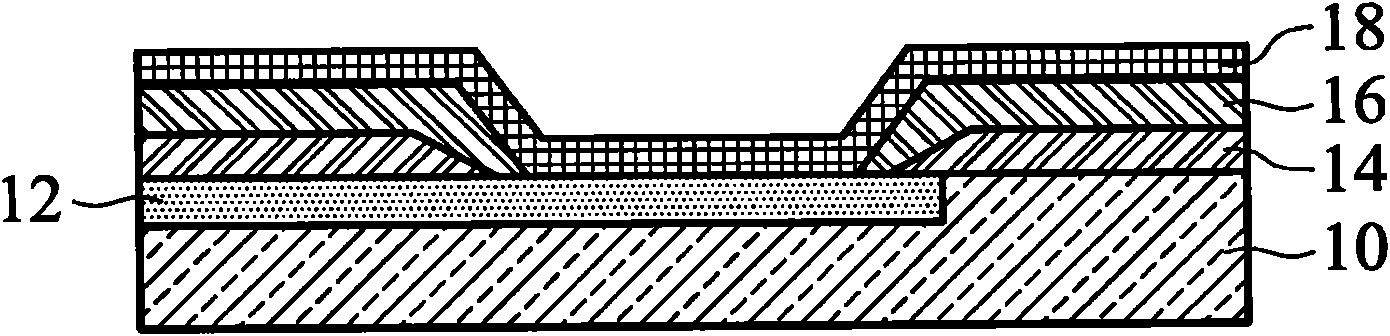

Preparation method of area thick film silicon nitride

ActiveCN110456451AConducive to high integrationEasy thicknessOptical waveguide light guideSilicon nitrideWaveguide

The invention provides a preparation method of area thick film silicon nitride, and the method comprises the following steps of sequentially forming a lower cladding layer and a sacrificial layer on asemiconductor substrate, wherein the height of the sacrificial layer is the same as the thickness of a preset waveguide device area; forming a plurality of core region grooves by taking the upper surface of the lower cladding layer as a stop layer; depositing a core layer material in the plurality of core region grooves and on the sacrificial layer to form a first core layer, wherein the thickness of the first core layer is smaller than that of the preset waveguide device area; removing the redundant first core layer by taking the upper surface of the sacrificial layer as the stop layer; repeating the above-mentioned steps until the thickness of the formed core layer reaches the thickness of the preset waveguide device area; removing the sacrificial layer to form a plurality of core regions by taking the upper surface of the lower cladding layer as the stop layer, and etching the core regions to form a preset waveguide device structure; and forming an upper cladding layer on the preset waveguide structure and the lower cladding layer. The preparation method of area thick film silicon nitride solves the problem of high stress caused by too thick film, is beneficial to realize highintegration of a chip, and simultaneously solves the problem that direct grooving is not beneficial to prepare a high-integration waveguide device.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

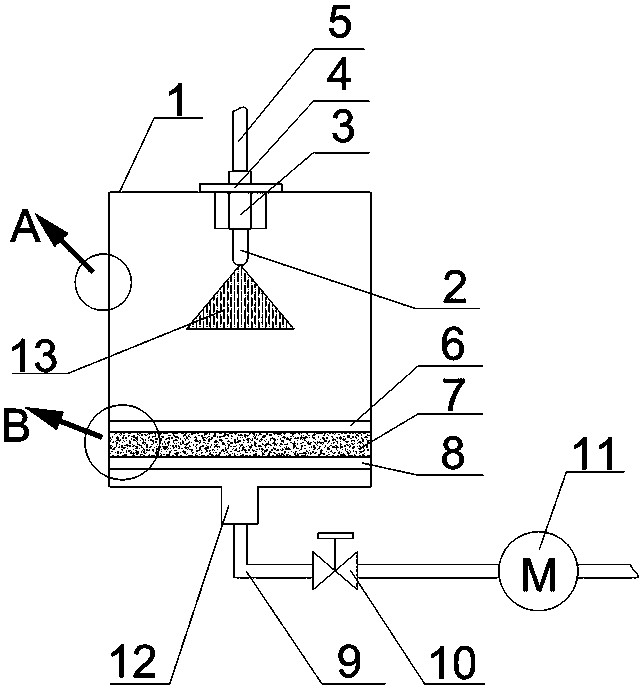

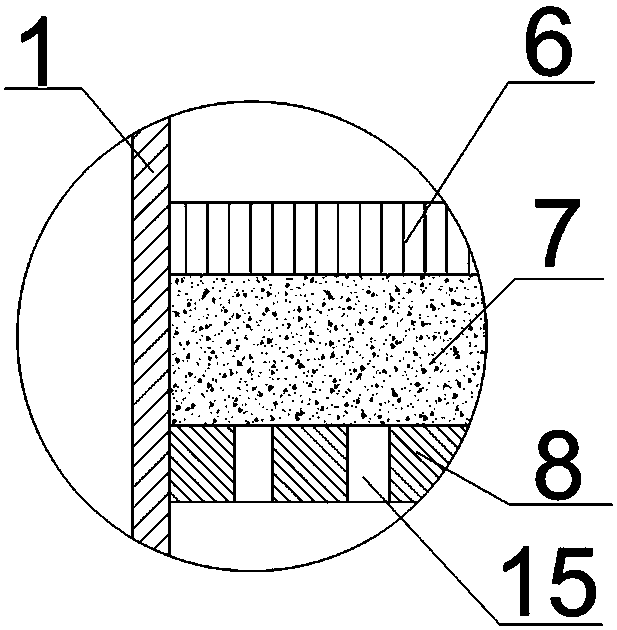

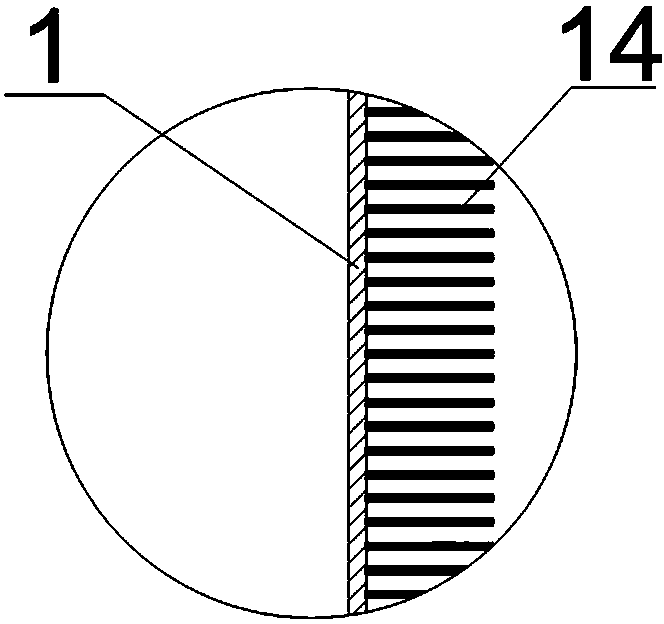

Anti-atomization device for fuel nozzle test bench

PendingCN109269783AReduce distractionsPrevent reboundMachine part testingEngine testingFuel oilEngineering

The invention discloses an anti-atomization device for a fuel nozzle test bench. The device comprises a test bench box body; a fuel oil nozzle is installed at the upper part of the interior of the test bench box body; a filamentous adsorption layer, a flow stabilization plate and an air suction port are arranged in the test bench box body; the filamentous adsorption layer is disposed below the fuel oil nozzle; the flow stabilization plate is disposed below the filamentous adsorption layer; and the air suction port is disposed below the flow stabilization plate. The anti-atomization device of the invention generates uniform negative pressure in the vicinity of the filamentous adsorption layer, and therefore, the interference of air suction on the atomization angle of the nozzle can be decreased; the filamentous adsorption layer can effectively prevent the rebound of atomized fuel oil particles and better adsorb suspended oil droplets; the inner surface of the test bench box body is provided with hairy objects, and oil mist is directly adsorbed on the hairy objects; a steel wire mesh can be adjusted so as to move up and down, so that the thickness and density of the filamentous adsorption layer can be adjusted; a flow rate regulating valve is used for adjusting the flow rate of the suction port, so that influence on the test area of the inner cavity of a test bench caused by a too large air suction flow rate can be prevented.

Owner:PLA NO 5719 FACTORY

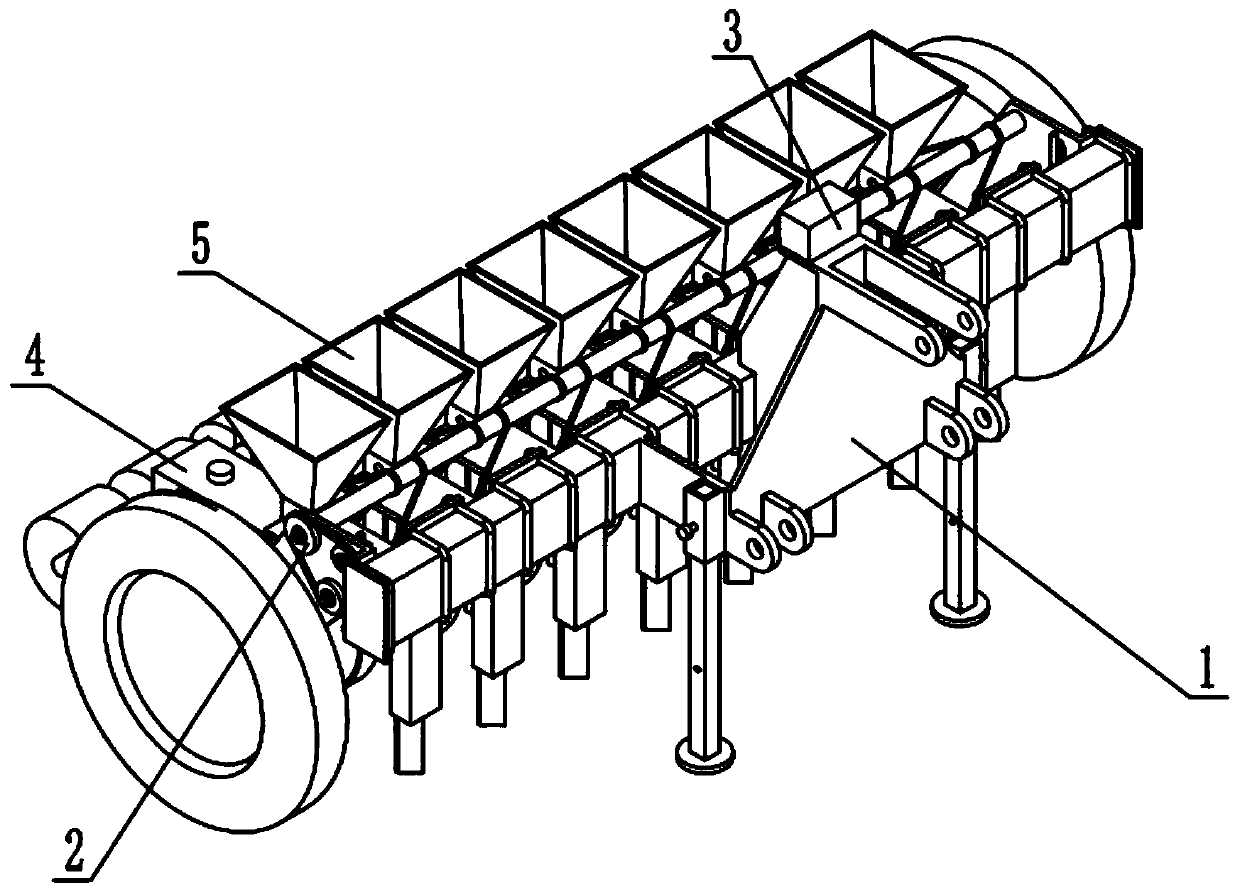

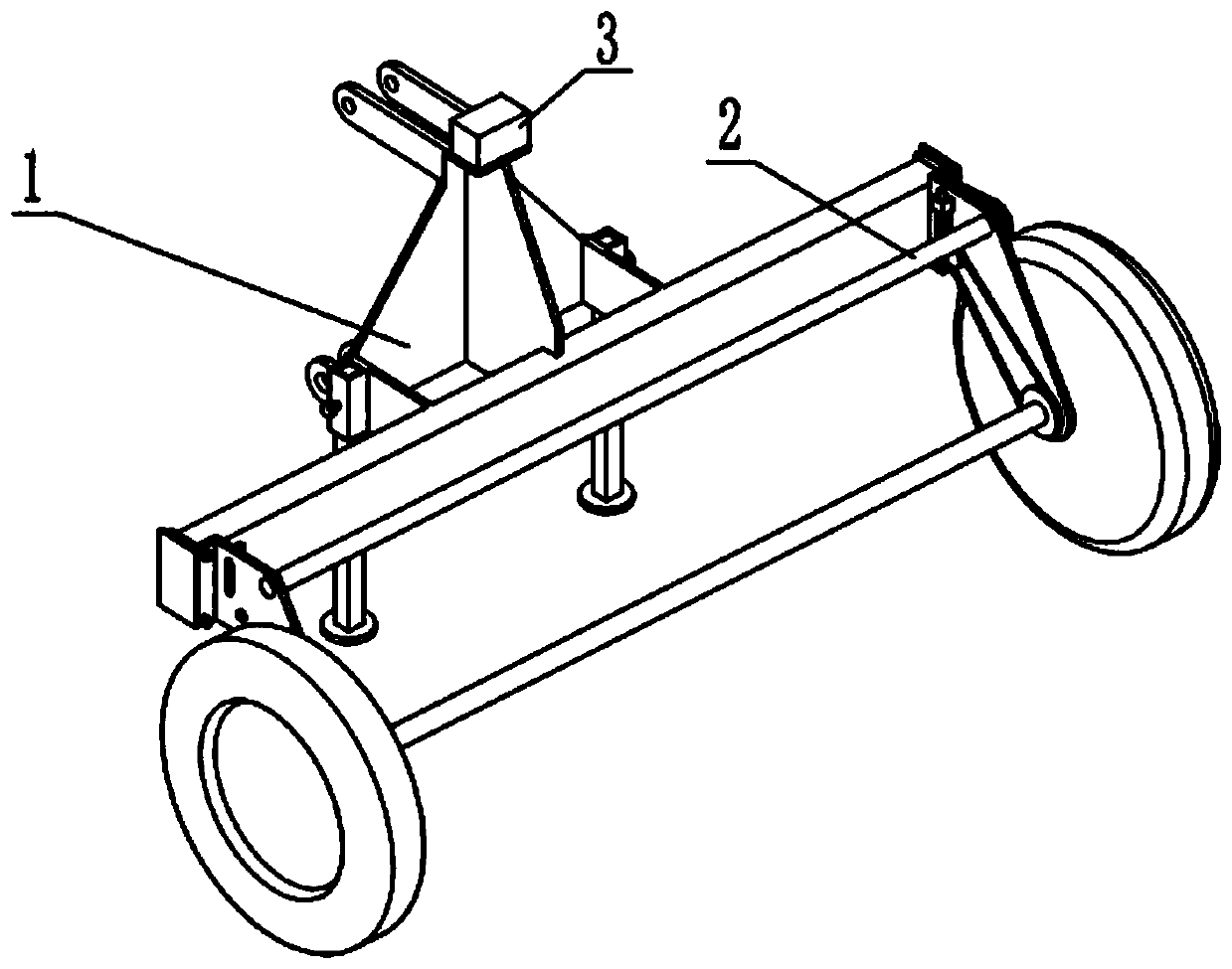

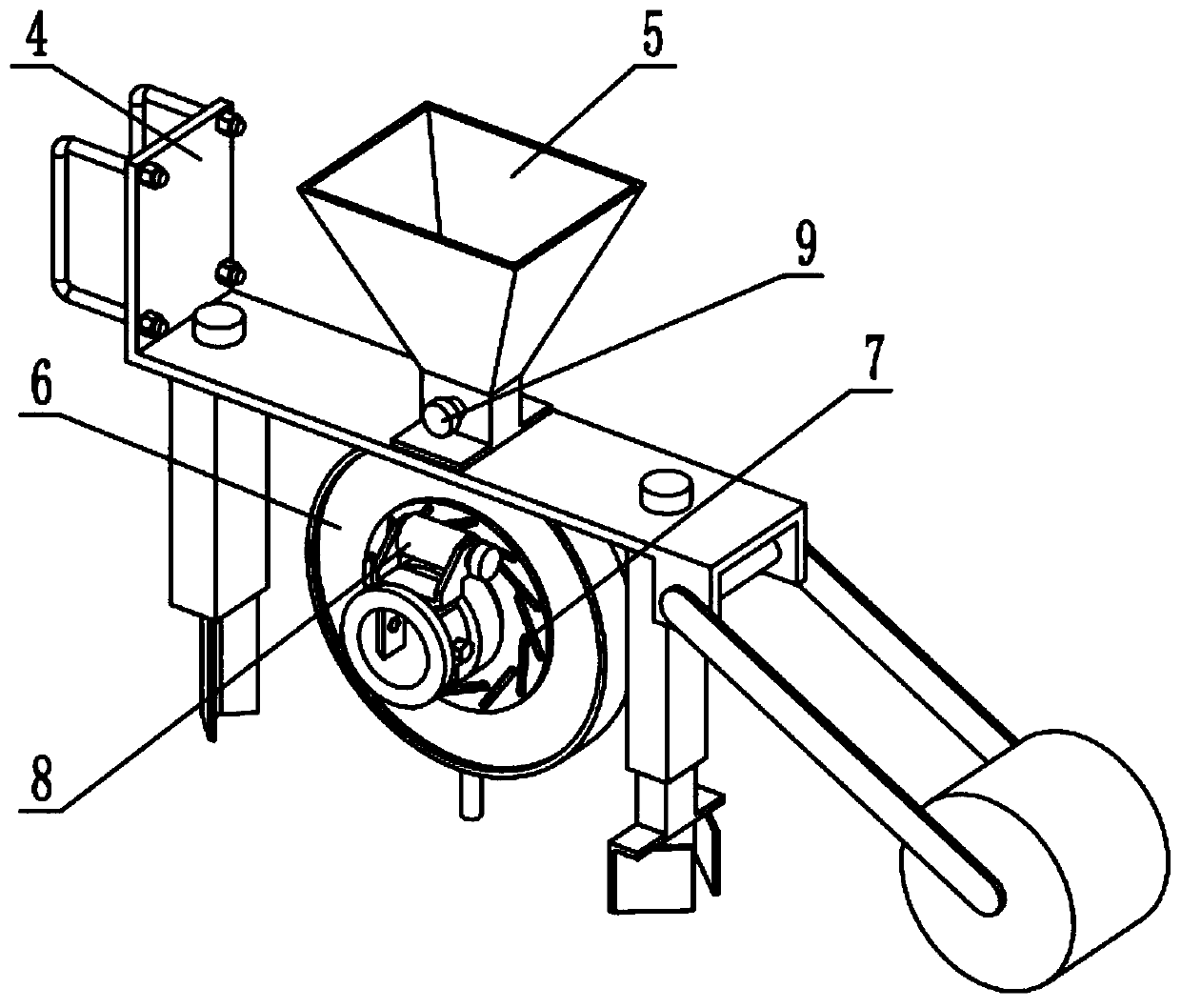

Organic vegetable planting device

ActiveCN111567191AAvoid Seed RollingPrevent rollingPlantingSeed depositing seeder partsAgricultural engineeringVegetable farming

The invention relates to the field of vegetable planting, in particular to an organic vegetable planting device. The organic vegetable planting device comprises a main frame mechanism, a transmissionmechanism, an air pump, a plurality of branch frame mechanisms, seed box mechanisms, sowing mechanisms, seed grain carrying mechanisms, seed grain adjusting mechanisms, stirring mechanisms and axis mechanisms. The multiple branch frame mechanisms are all fixedly connected with the main frame structure; the seed box mechanisms are fixedly connected to all the multiple branch frame mechanisms; the sowing mechanisms are rotationally connected into the multiple seed box mechanisms; the multiple seed grain carrying mechanisms are slidably connected into each sowing mechanism; the seed grain adjusting mechanisms are rotationally connected to the multiple sowing mechanisms, and each seed grain adjusting mechanism is slidably connected with the multiple seed grain carrying mechanisms; the stirringmechanisms are rotationally connected in the plurality of seed box mechanisms; and a plurality of axis mechanisms are arranged, and the plurality of axis mechanisms are rotationally connected in thesowing mechanism respectively, so that seeds can be greatly prevented from rolling after falling to the ground, and good growth of vegetables is facilitated.

Owner:建始县慧民农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com