Method for preparing tungsten-containing alumina ceramic heating substrate

A ceramic heating and tungsten alumina technology, which is applied in the preparation of tungsten-containing alumina ceramic heating substrates and the preparation of ceramic heating elements, can solve the problem of poor bonding force between ceramics and metal layers, poor wettability of powders, and difficulty in defoaming of slurry. and other problems, to achieve the effect of improving the sintering qualification rate, good air tightness and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

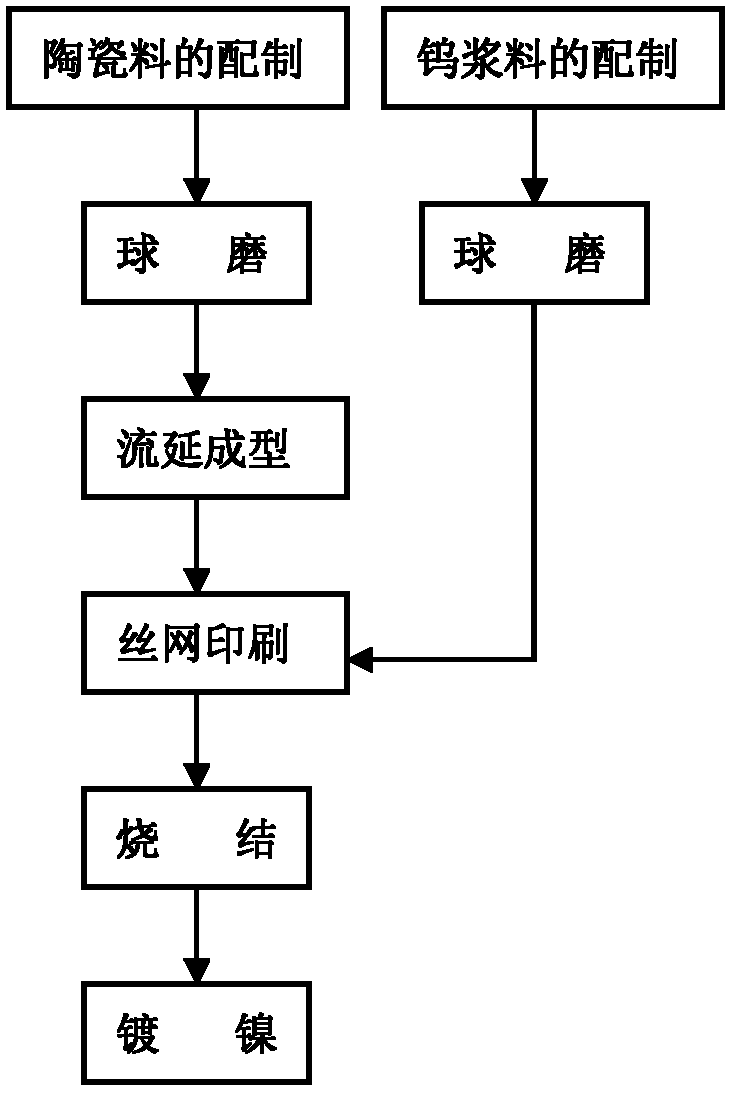

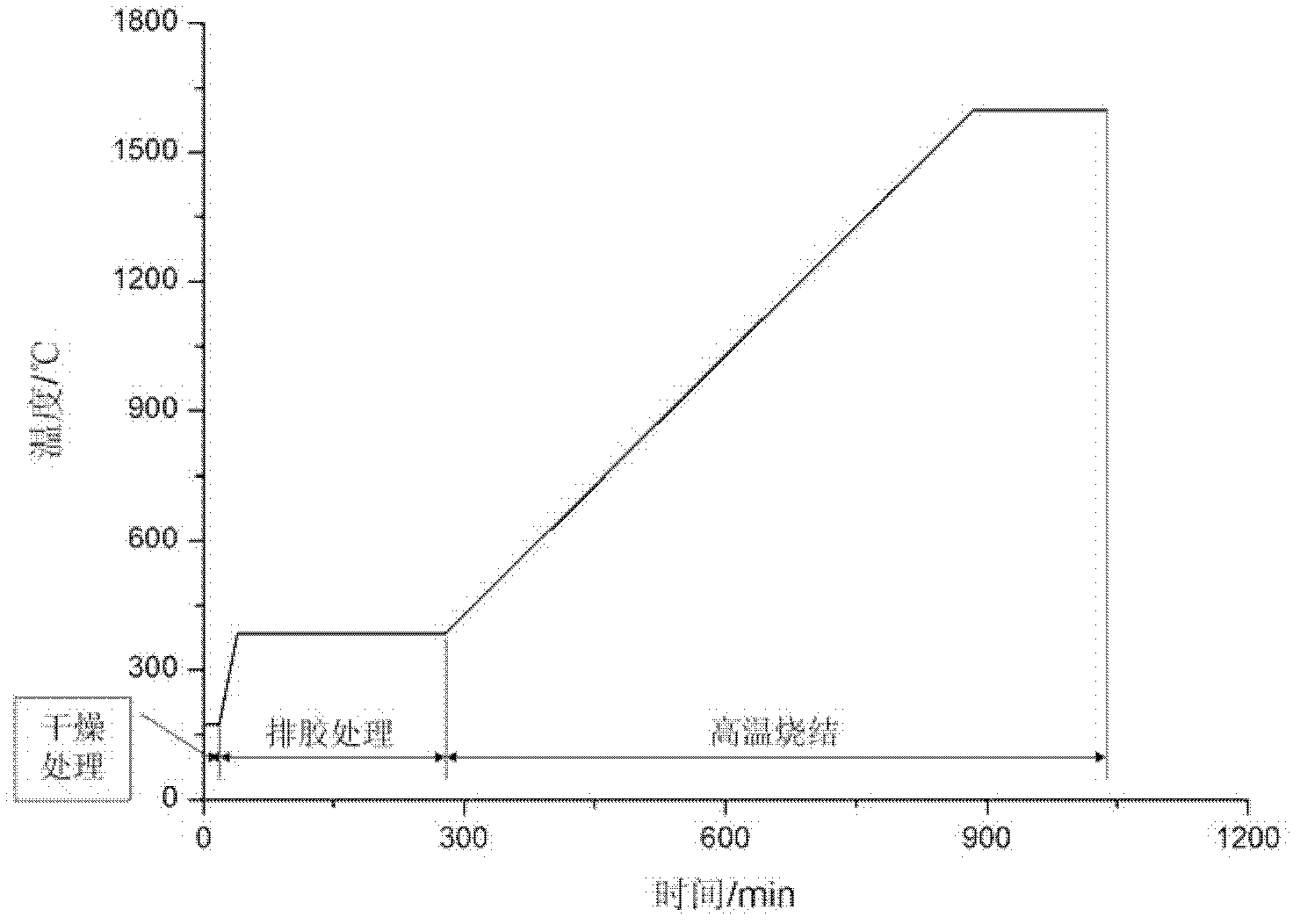

Method used

Image

Examples

Embodiment 1

[0043] ① Preparation of ceramic premix

[0044] Mix distilled water, magnesium oxide, titanium oxide, dispersant and plasticizer, stir with an ultrasonic mixer for 15 minutes, then add 96% alumina powder and adjust the pH value of the system to 11 with ammonia water to prepare a ceramic premix. The amounts of distilled water, magnesium oxide, titanium oxide, dispersant and plasticizer are respectively 101%, 1.8%, 0.7%, 1.6% and 10.7% of the mass of the alumina powder.

[0045] ② Preparation of tungsten slurry

[0046] The composition of the tungsten slurry is as follows: 70% tungsten powder, 20% binder phase, and 10% organic vehicle; the tungsten powder, binder phase, and organic vehicle are mixed and then put into a vibrating ball mill for mixing to make the tungsten slurry evenly The particle size is less than 0.8μm. Wherein the composition of the binder phase is: 5% of manganese oxide, 20% of magnesium oxide, and 75% of silicon dioxide; the composition of the organic carr...

Embodiment 2

[0054] The preparation method is the same as in Example 1, the difference is that the addition of distilled water, magnesium oxide, titanium oxide, dispersant and plasticizer to the ceramic premix described in ① of step 1) is respectively 103% of the quality of the alumina powder. %, 1.4%, 0.9%, 1.8%, 10.6%. The pH value is 10. The addition of the antifoaming agent in step 2) is 0.7% of the quality of the alumina powder, the addition of the binder is 11% of the quality of the alumina powder, and the composition of the binder is by mass percentage: Polyvinyl alcohol 55%, polyethylene glycol 45%.

[0055] The obtained tungsten-containing alumina ceramic heating substrate was tested, and the test results are shown in Table 1.

Embodiment 3

[0057] The preparation method is the same as in Example 1, the difference is that the amounts of distilled water, magnesium oxide, titanium oxide, dispersant and plasticizer in the ceramic premix formula are respectively 99%, 1.5%, and 1.0% of the mass of the alumina powder , 2.0%, 10%, the pH value is 10.5. The addition of defoamer is 1.0% of the mass of the alumina powder, the addition of the binder is 10% of the mass of the alumina powder, and the composition of the binder is: polyvinyl alcohol 50%, Polyethylene glycol 50%.

[0058] The obtained ceramic heating substrate was tested, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com