Method for preparing high radioactive waste curing treatment base material

A high-radioactive, solidification treatment technology, which is applied in the preparation of substrates for solidification treatment of high-level radioactive waste, and in the field of solidification treatment of high-level radioactive waste, can solve the problems of expensive raw materials, low purity of target minerals, unfavorable engineering applications, etc., and achieve simplification Curing treatment process, low cost of curing treatment, beneficial to engineering application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

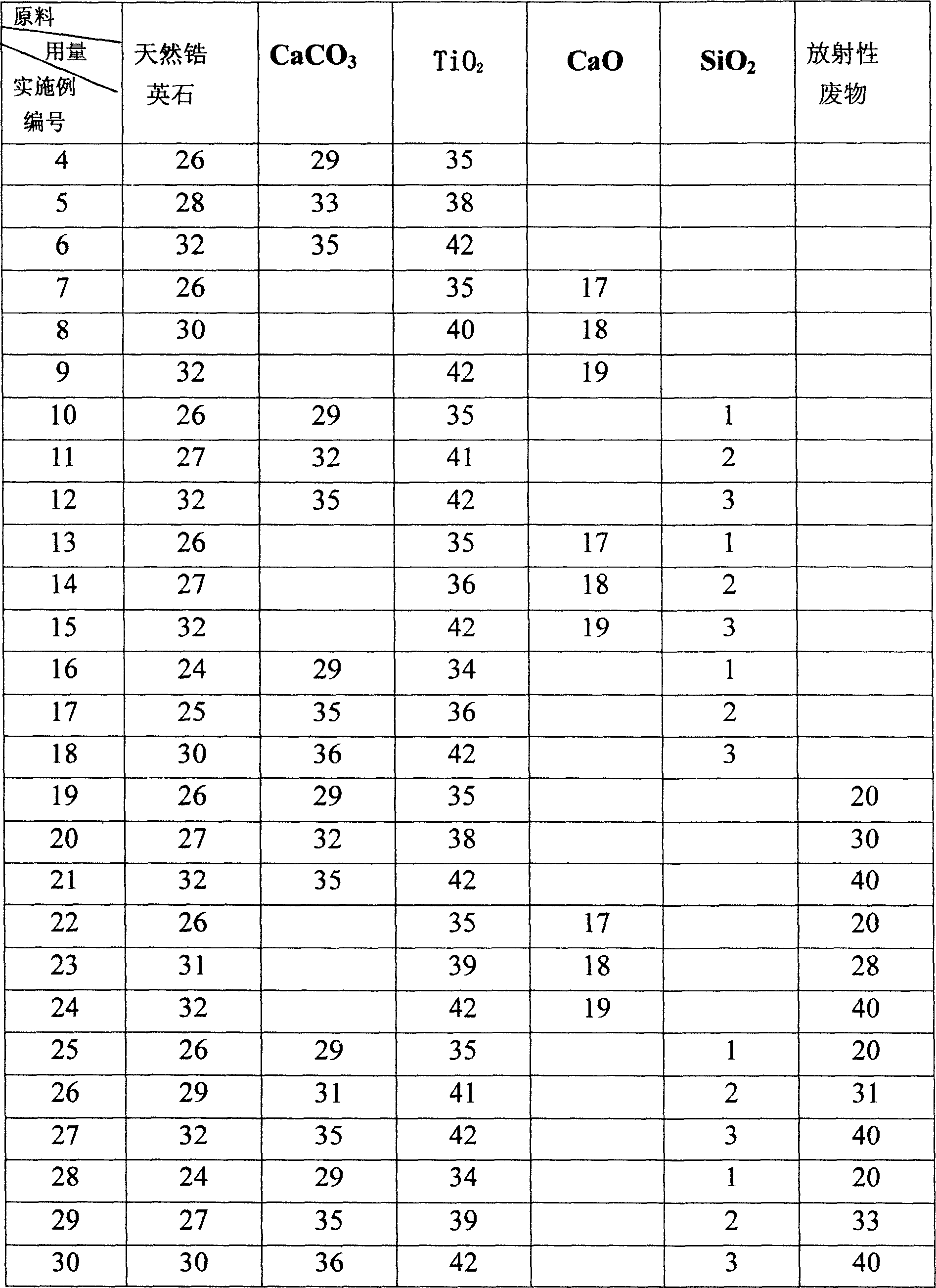

Examples

Embodiment 1

[0037] A method for preparing a base material for solidification treatment of high-level radioactive waste, comprising the following steps:

[0038] (1) Ingredients: natural zircon, CaCO 3 and TiO 2 As raw materials, according to natural zircon 28g, CaCO 3 33g, TiO 2 The ratio of 40g is taken from each raw material;

[0039] (2) Fine grinding: put each raw material into fine grinding equipment (for example: vibration mill), add grinding balls, vibrate and grind for 30-60 minutes to obtain powder with fine particle size and uniform composition;

[0040] (3) Calcination: calcining the material at a temperature of 1150°C to 1350°C (or 1260°C to 1320°C) for 20 to 60 minutes to obtain the product—high-purity perovskite zircon (CaZrTi 2 o 7 ) and titanite (CaTiSiO 5 ).

Embodiment 2

[0042] A method for preparing a base material for solidification treatment of high-level radioactive waste, comprising the following steps:

[0043] (1) Ingredients: natural zircon, CaCO 3 and TiO 2 As raw materials, according to natural zircon 30g, CaCO 3 31g, TiO 2 The ratio of 38g is taken from each raw material;

[0044] (2) Fine grinding: put each raw material into fine grinding equipment (for example: vibration mill), add grinding balls, and vibrate for 30-60 minutes;

[0045] (3) Powder granulation: adding the polyvinyl alcohol (polymerization degree 2000-8000, the same as the prior art) hydrosol of 10-20% concentration by weight in the powder after fine grinding is used as an adhesive, and the addition amount It is 5-8% of the weight of the finely ground powder, and it is ground and granulated;

[0046] (4) Compression forming: the powder material after granulation is packed in the steel mold, on the hydraulic press, adopt 30-60MPa pressure compression molding t...

Embodiment 3

[0049] A method for preparing a high-level radioactive waste solidified body, comprising the following steps:

[0050] (1) Ingredients: natural zircon, CaCO 3 and TiO 2 As raw materials, according to natural zircon 30g, CaCO 3 31g, TiO 2 Take each raw material at a ratio of 38g; and add 20g of radioactive waste;

[0051] Other steps and processing conditions are with embodiment 1 or embodiment 2, omit.

[0052] After calcining, the artificial rock solidified body in which high radioactive waste has been solidified in the lattice of perovskite zircon and sphene crystals is obtained, and the solidified body has good long-term safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com