Solidified body of cadmium-containing waste residue and preparation method thereof

A technology of solidified body and waste residue, which is applied in the field of cadmium-containing waste solidified body and its preparation, can solve the problem of high cost, achieve the effects of increasing solidification capacity, reducing cost, and reducing leaching concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: The cadmium-containing waste residue solidified body is composed of cadmium-containing waste residue, curing agent, cadmium residue treatment agent, stabilizer, aggregate and water, and each component is measured according to weight percentage: 100 parts of cadmium-containing waste residue, 50 parts of curing agent 20 parts, 20 parts of cadmium slag treatment agent, 200 parts of aggregate, 4 parts of stabilizer, 300 parts of water, wherein, the curing agent is a mixture of cement and loess, and the cadmium slag treatment agent is fly ash, limestone, kiln A mixture of ash and carbide slag, the aggregate is a mixture of quartz sand and metallurgical slag, and the stabilizer is a mixture of sodium humate, lignocellulose, mineral cellulose and synthetic cellulose.

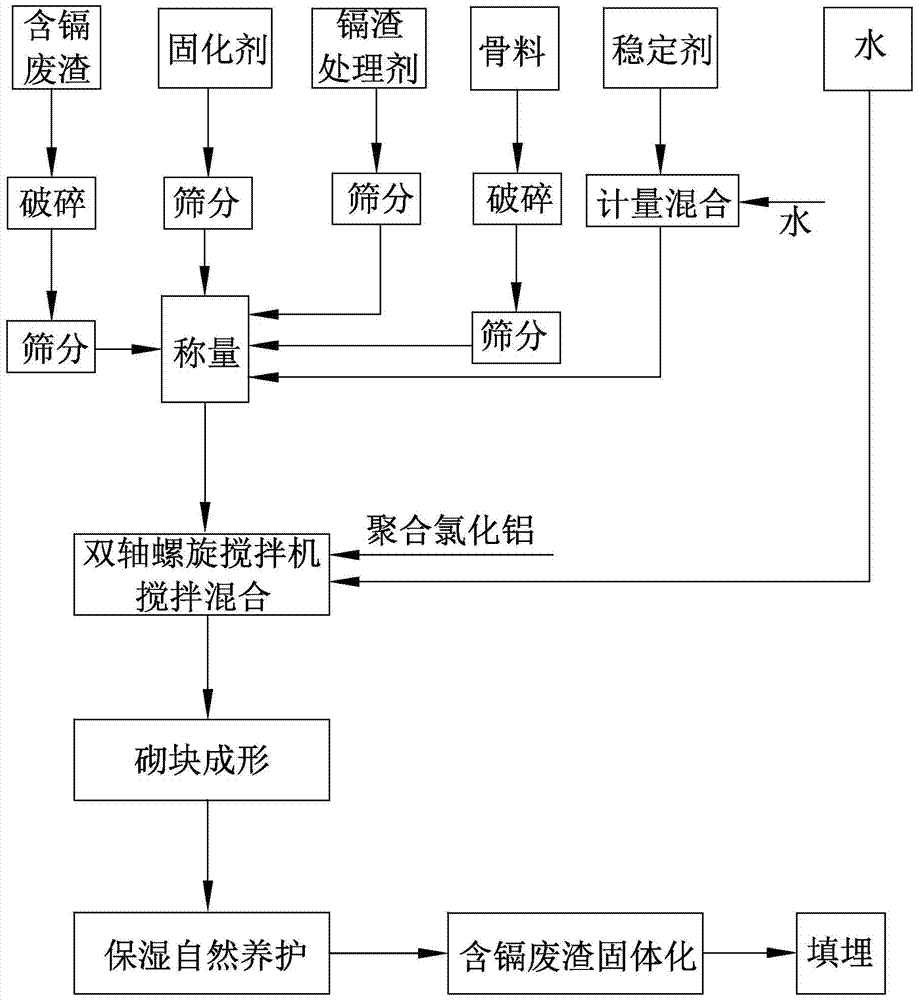

[0029] see figure 1 , is the process flow chart of the preparation method of the cadmium-containing waste residue solidified body provided by the present invention.

[0030] The preparation method...

Embodiment 2

[0047] Embodiment 2: The cadmium-containing waste residue solidified body is composed of cadmium-containing waste residue, curing agent, cadmium residue treatment agent, stabilizer, aggregate and water, and each component is measured according to weight percentage: 100 parts of cadmium-containing waste residue, 60 parts of curing agent parts, 10 parts of cadmium slag treatment agent, 300 parts of aggregate, 1.2 parts of stabilizer, 400 parts of water, wherein, the curing agent is a mixture of cement and loess, and the cadmium slag treatment agent is a mixture of fly ash and limestone , the aggregate is a mixture of quartz sand and metallurgical slag, and the stabilizer is a mixture of sodium humate, lignocellulose, mineral cellulose and synthetic cellulose.

[0048] see again figure 1 , is the process flow chart of the preparation method of the cadmium-containing waste residue solidified body provided by the present invention.

[0049] The preparation method of this cadmium-c...

Embodiment 3

[0066] Embodiment 3: The cadmium-containing waste residue solidified body is composed of cadmium-containing waste residue, curing agent, cadmium residue treatment agent, stabilizer, aggregate and water, and each component is measured according to weight percentage: 100 parts of cadmium-containing waste residue, 70 parts of curing agent parts, 15 parts of cadmium slag treatment agent, 500 parts of aggregate, 2.5 parts of stabilizer, 700 parts of water, wherein, the curing agent is a mixture of cement and loess, and the cadmium slag treatment agent is fly ash, limestone, kiln A mixture of ash and carbide slag, the aggregate is a mixture of quartz sand and metallurgical slag, and the stabilizer is a mixture of sodium humate, lignocellulose, mineral cellulose and synthetic cellulose.

[0067] see again figure 1 , is the process flow chart of the preparation method of the cadmium-containing waste residue solidified body provided by the present invention.

[0068] The preparation m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com