Patents

Literature

103results about How to "Simple curing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

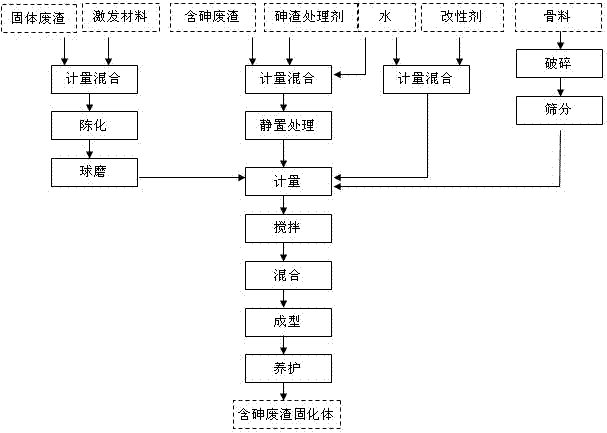

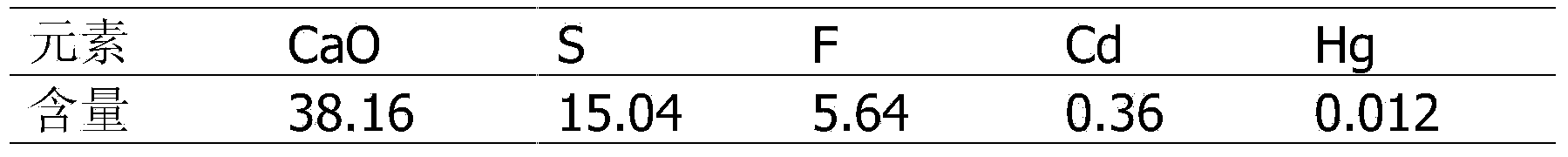

Arsenic-containing waste slag solidified body and preparation method thereof

InactiveCN102249609ASimple curing processLow costSolid waste managementSolid waste disposalArsenic pollutionSlag

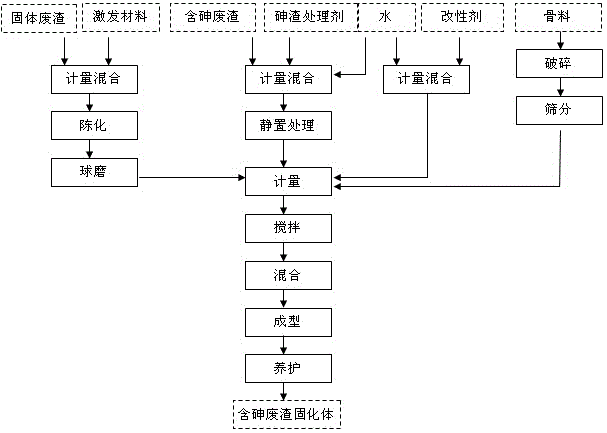

The invention relates to an arsenic-containing waste slag solidified body and a preparation method thereof, and belongs to the technical field of environmental protection. The preparation method comprises the following steps of: treating arsenic-containing waste slag, mixing the treated arsenic-containing waste slag and a curing agent prepared from industrial waste slag and a mineral activated material, a modifying agent, aggregates, water and the like, and stirring, forming and curing the mixed materials to obtain the solidified body with high strength and low arsenic leaching rate. Comparedwith the prior art, the solidification process is simple, low in cost, safe and reliable, and solves the problem of arsenic pollution of the arsenic-containing waste slag.

Owner:KUNMING UNIV OF SCI & TECH +1

Phenolic resin/phosphate hybrid adhesive and preparation method thereof

InactiveCN101875830AEasy to prepareImprove thermal stabilityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPhosphateWorking temperature

The invention provides a phenolic resin / phosphate hybrid adhesive and a preparation method thereof, relating to an adhesive and a preparation method thereof. The invention solves the problems of low working temperature, rigorous curing process and low adhesion strength of the conventional high-temperature resisting phenolic resin adhesive. The adhesive is prepared from phenolic resin, heat-resistant reinforced resin, a coupling agent, a toughening agent, phosphate, a curing agent, a framework material, fillers and a dispersing agent. The preparation method comprises the following steps of: mixing the phenolic resin, the heat-resistant reinforced resin, the coupling agent and the toughening agent and then evenly stirring to obtain a phenolic resin component; then mixing the phosphate, the curing agent, the framework material and the fillers and then evenly stirring to obtain a phosphate component; and then adding the phosphate component and the dispersing agent into the phenolic resin component and evenly stirring. The adhesive can be applied in aerospace, military and machining industries with the working temperature above 800 DEG C.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Water-soluble insulating varnish and preparation method thereof

InactiveCN101270256AGood transparency and stabilityLong application periodPolyurea/polyurethane coatingsEmulsion paintsWater basedDiluent

The invention relates to water-soluble insulating varnish and a preparation method thereof. The water-soluble insulating varnish of the invention consists of water-soluble resin, water-borne curing agent, water-base defoamer, water-base flow agent, water-base catalyst and water; the proportion of the components is as below: 30 percent to 50 percent of water-soluble resin; 10 percent to 30 percent of water-base curing agent, 1 percent to 1.0 percent of water-base catalyst, 0 percent to 0.5 percent of water-base defoamer, 0 percent to 0.5 percent of water-base flow agent and 20 percent to 60 percent of water; the water-soluble insulating varnish has the advantages of environmental protection and safety; no harmful solvent released to the atmosphere; no inflammability and explosion, no corrosion; no transparent or translucent paint liquid, good stability, long application service life under normal temperature; simple solidifying process, good insulating performance of the paint film after solidification, high strength and strong toughness; technical indexes meeting or exceeding the technical indexes of the prior solvent-type insulating varnish; the most important is that the insulating varnish takes water as solvent or diluent, which does not bring pollution and reduces the cost.

Owner:SHANGHAI BAOQING TONGYONG ELECTRICAL

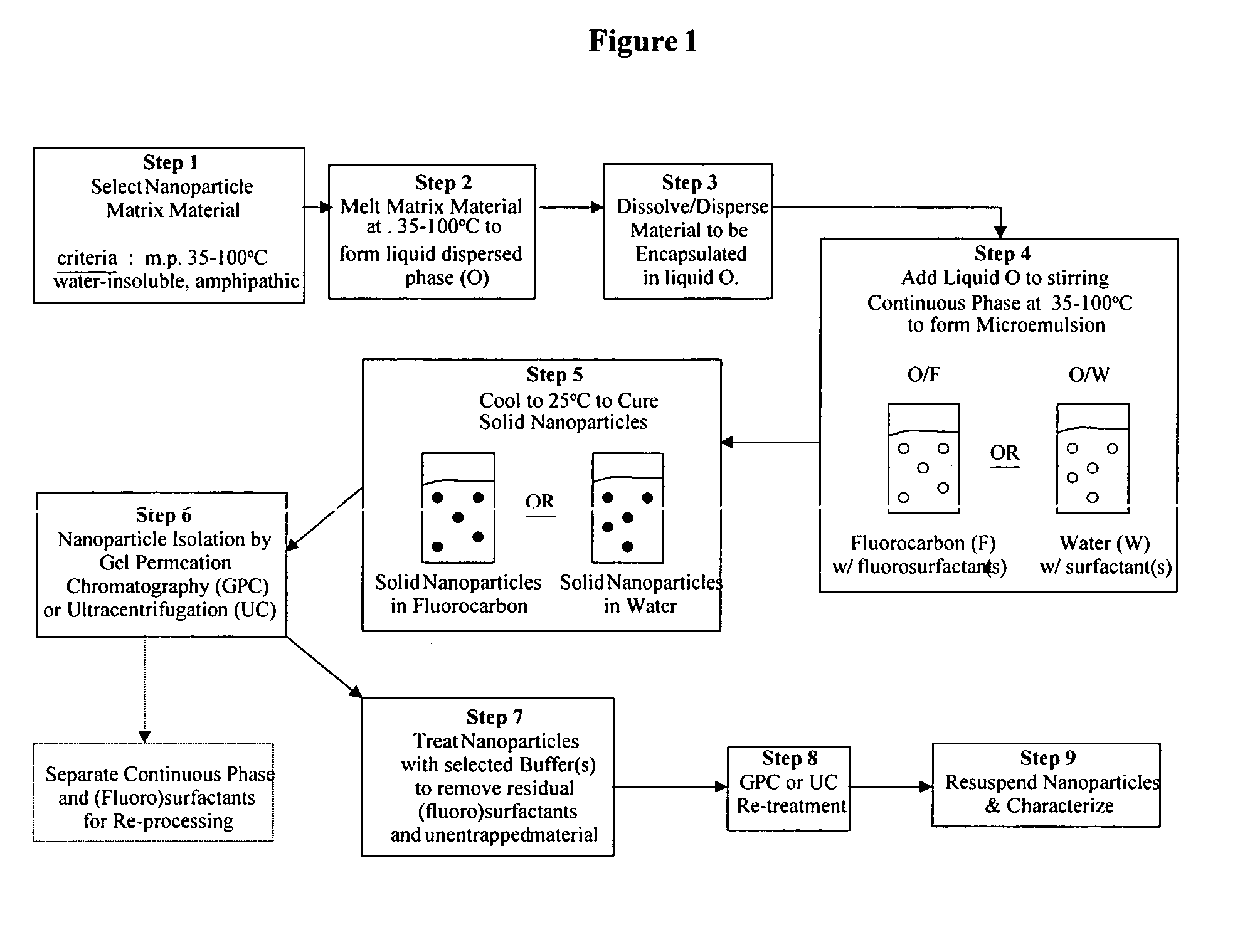

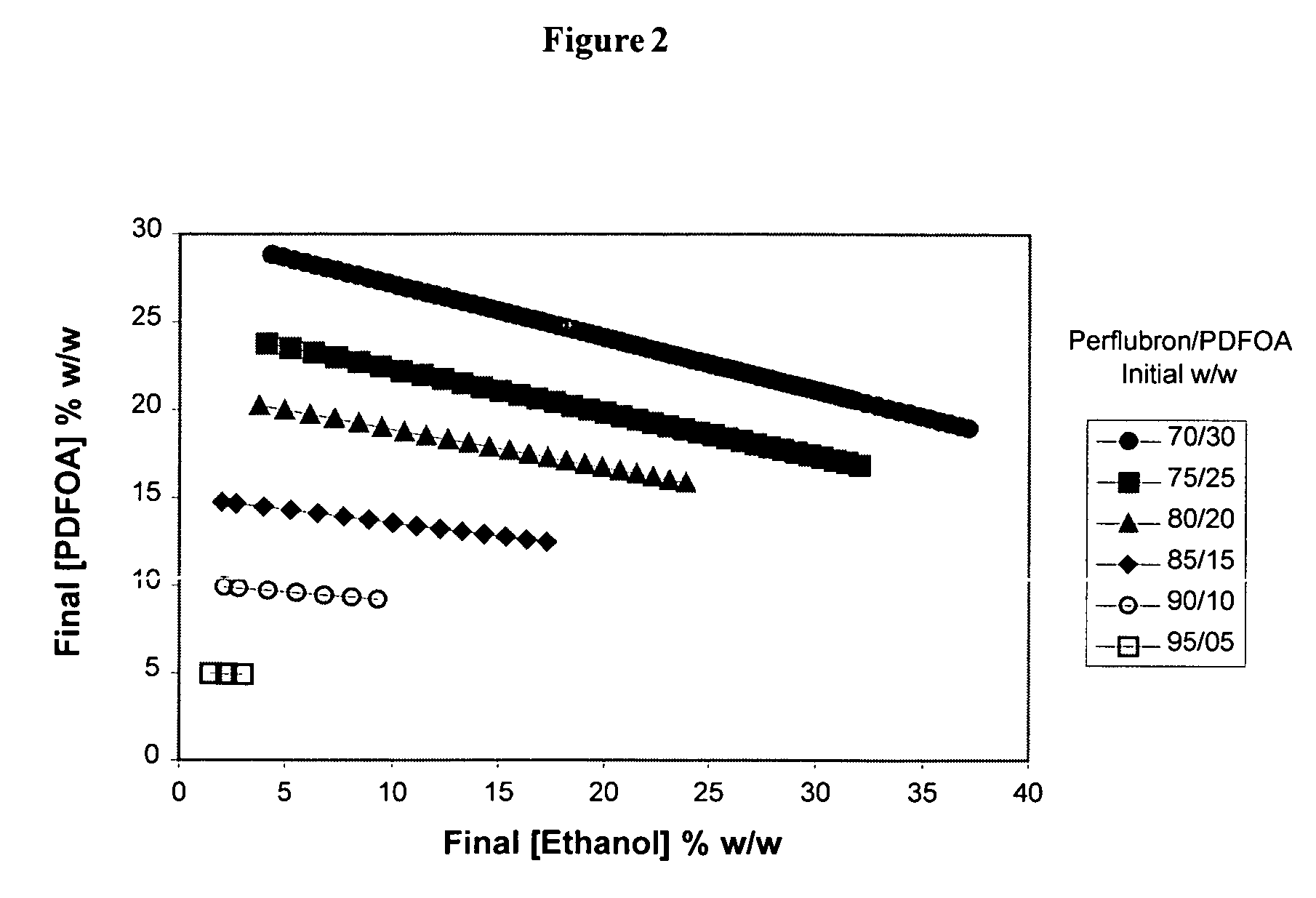

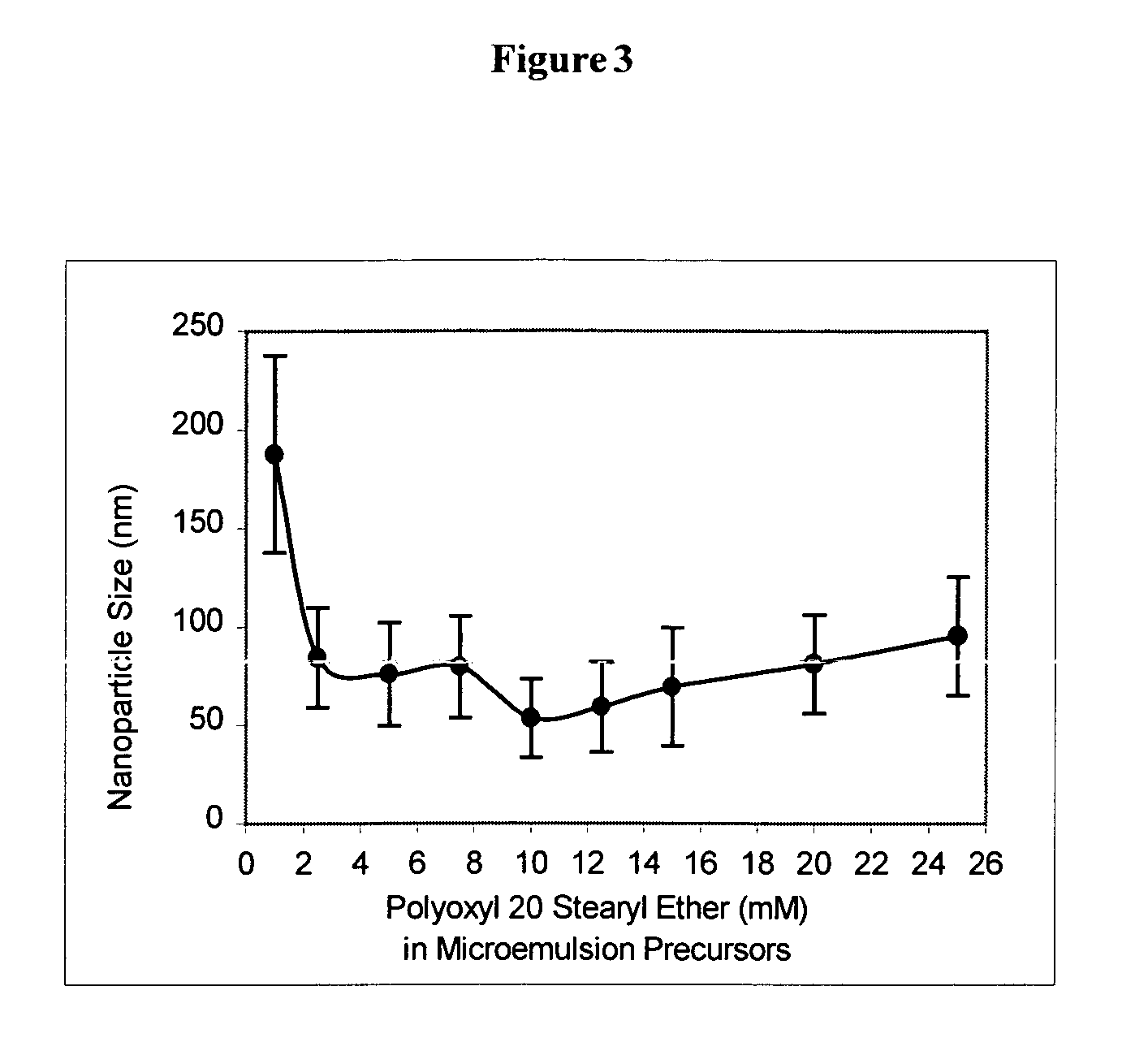

Microemulsions as precursors to solid nanoparticles

InactiveUS7153525B1Robust immune responseSimple curing processBiocideOrganic active ingredientsDrugNanometre

The preparation of novel microemulsions to be used as precursors for solid nanoparticles is described. The microemulsion precursors consist of either alcohol-in-fluorocarbon microemulsions, liquid hydrocarbon-in-fluorocarbon microemulsions, or liquid hydrocarbon-in-water microemulsions. The formed solid nanoparticles have diameters below 200 nanometers and can be made to entrap various materials including drugs, magnets, and sensors. The solid nanoparticles can be made to target different cells in the body by the inclusion of a cell-specific targeting ligand. Methods of preparing the novel microemulsion precursors and methods to cure solid nanoparticles are provided.

Owner:PARTICLE SCI

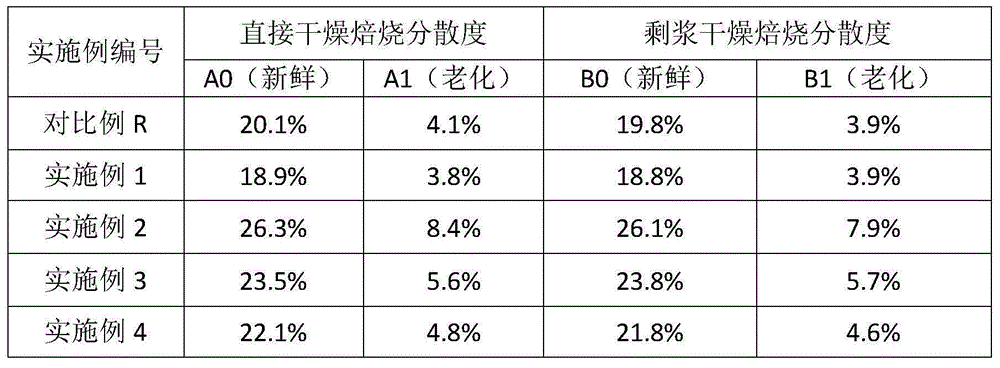

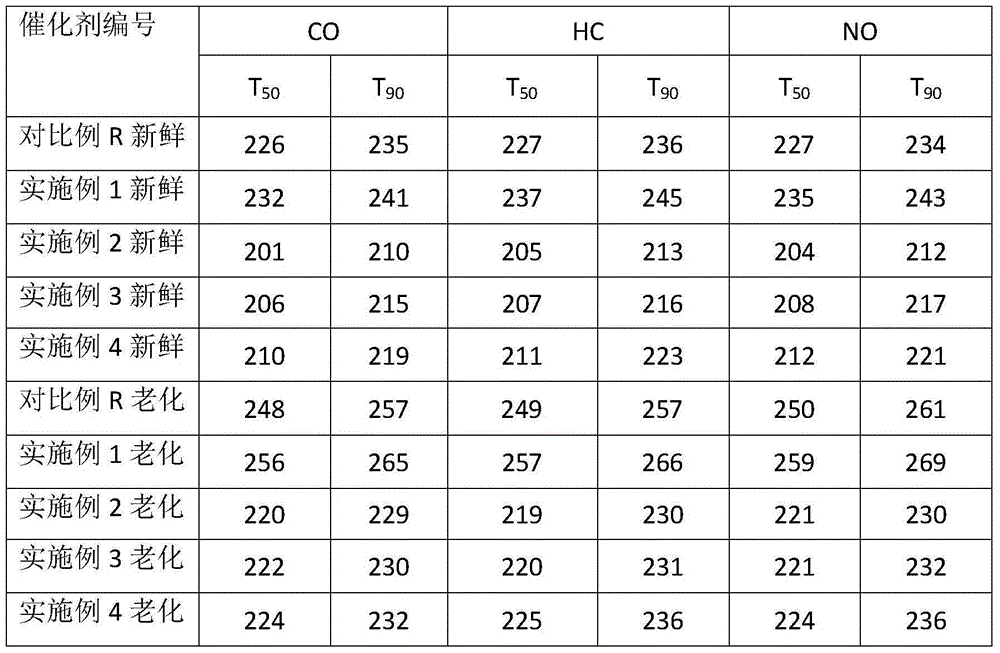

Preparation method and application of supported noble metal catalyst

ActiveCN105148908AIncrease productivitySmall dispersionExhaust apparatusDispersed particle separationDispersitySlurry

The invention discloses a preparation method of a supported noble metal catalyst. According to the method, a precursor solution is prepared from noble metal used as an active ingredient and evenly mixed with supporters; a liquid reducer is added, noble metal ions which are adsorbed or ionized on surfaces or in holes of the supporters are reduced, the noble metal is applied to the supporters in the reduced state, and mixed slurry is obtained; a cordierite matrix or a metal matrix is coated with the mixed slurry, and the supported noble metal catalyst is obtained through calcination; the noble metal is one or more of Pt, Pd, Rh, Au, Ag and Ru and serves as a raw material in forms of nitrate, chloride and an organic complex. Compared with the prior art, the method has the advantages that the noble metal is already reduced and solidified in the supporting process, and conditions that the dispersity of the noble metal is reduced and the activity is reduced due to the fact that the noble metal is gathered on the surfaces of the supporters due to migration caused by water migration in the drying process can be avoided. Besides, the dispersity of the noble metal on the supporters is good, and the sintering probability of the noble metal in the high-temperature ageing process is decreased.

Owner:SINOCAT ENVIRONMENTAL TECH

Special structure film for mirror seat of rear-view mirror in automobile and preparation method thereof

ActiveCN102516894AGood film formingSave materialNon-macromolecular adhesive additivesFilm/foil adhesivesPolysulfide rubberAdhesive

The invention relates to a special structure film for a mirror seat of a rear-view mirror in an automobile. The structure film is prepared from the following raw materials in parts by weight: 20-100 parts of acrylonitrile-butadiene rubber, 0-70 parts of polysulfide rubber which is not cured fully, 5-40 parts of bisphenol A type epoxy resin, 10-60 parts of modified epoxy resin, 0.1-2.5 parts of cross-linking agent, 0.2-2.5 parts of softening agent, 3-20 parts of curing agent, 1-10 parts of accelerant, 20-100 parts of inorganic filler and 0.1-3.0 parts of silane coupling agent. The structure film disclosed by the invention has the advantages of good film-forming performance, good aging resistance, simple curing process, high strength of structural adhesive after curing, good toughness, excellent heat resistance and cold resistance and the like.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

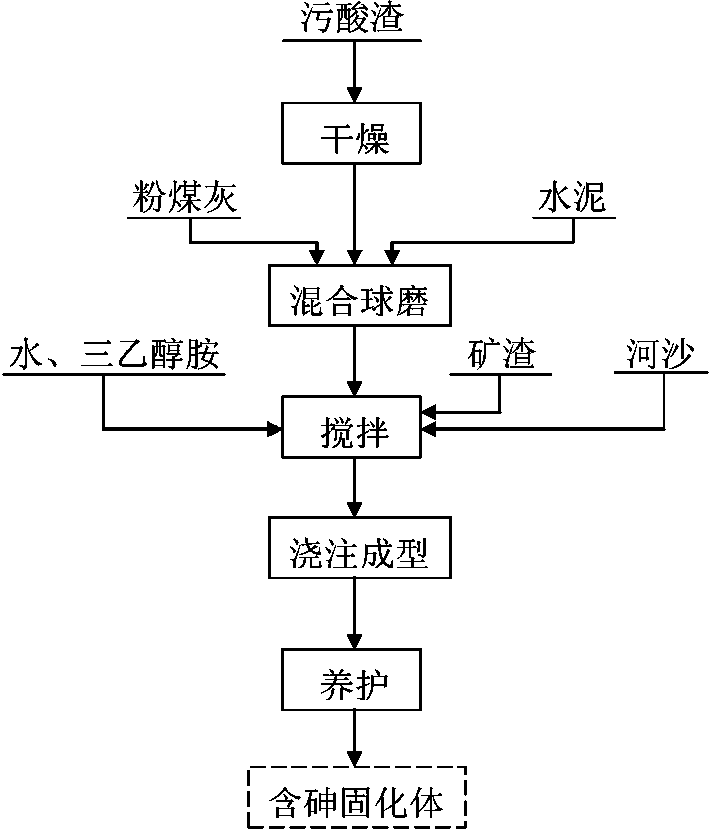

Pollutional acid sludge harmless treatment method

ActiveCN103449790ASimple curing processExtend your lifeSolid waste managementCement productionPortland cementSlag

The invention relates to a pollutional acid sludge harmless treatment method, and belongs to the technical field of environmental protection. Dried pollutional acid sludge and a solidification material composed of common Portland cement, coal ash, slag and river sand are subjected to mixed ball-milling, stirring, casting molding and maintenance in cooperation of additives and water to form a cement solidified body which is good in gelatinization state and low in arsenic leaching concentration. The pollutional acid sludge harmless treatment method has the advantages of being simple in process, low in production cost, safe and effective; industrial waste residue is used as the solidification material to achieve the purpose of treating waste with waste, and therefore the pollutional acid sludge harmless treatment method has obvious economic benefit and environmental benefit.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Hybridization liquid precursor, preparing method and method for preparing ZrC-SiC superhigh temperature ceramics and composite materials of ZrC-SiC superhigh temperature ceramics through hybridization liquid precursor

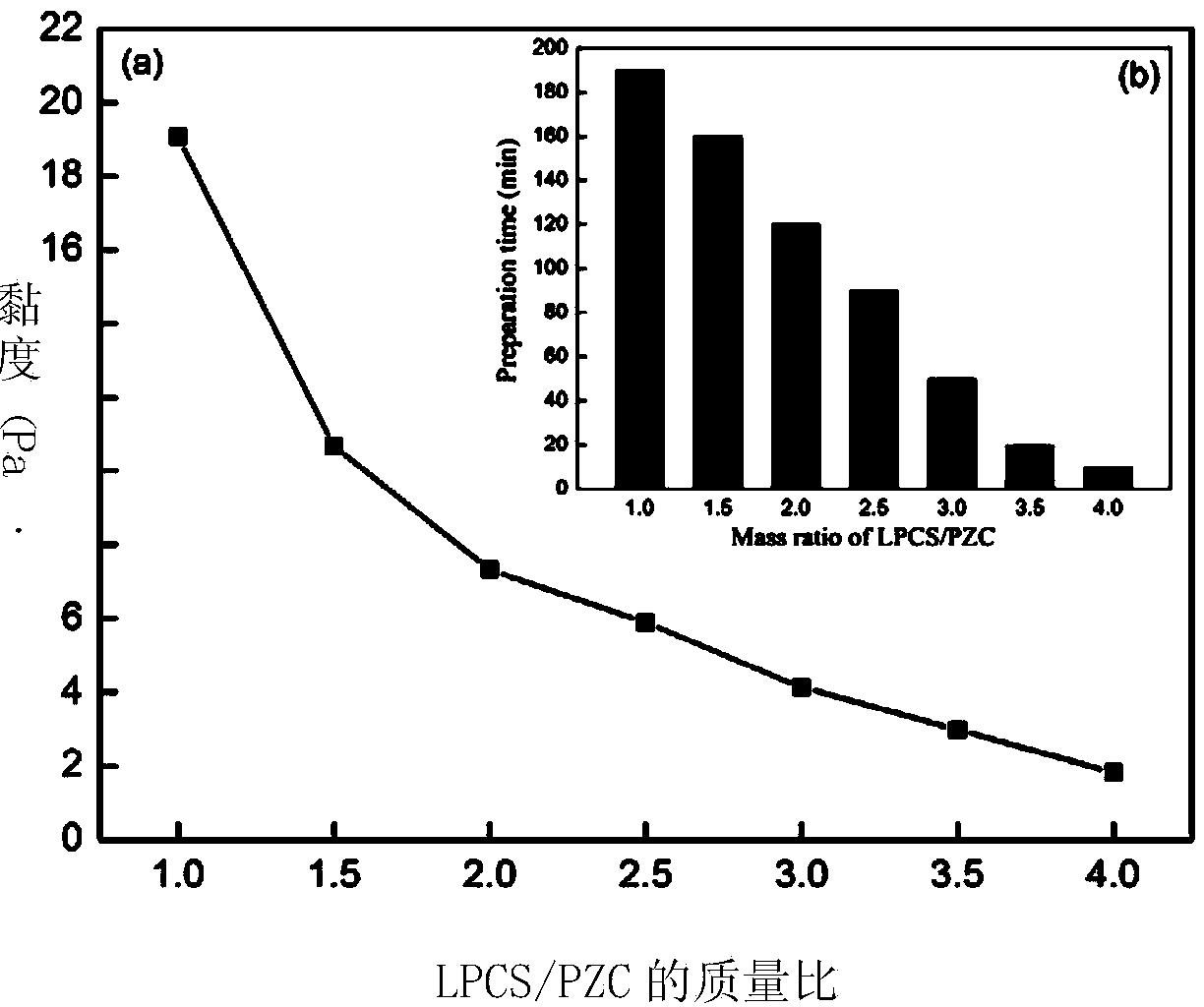

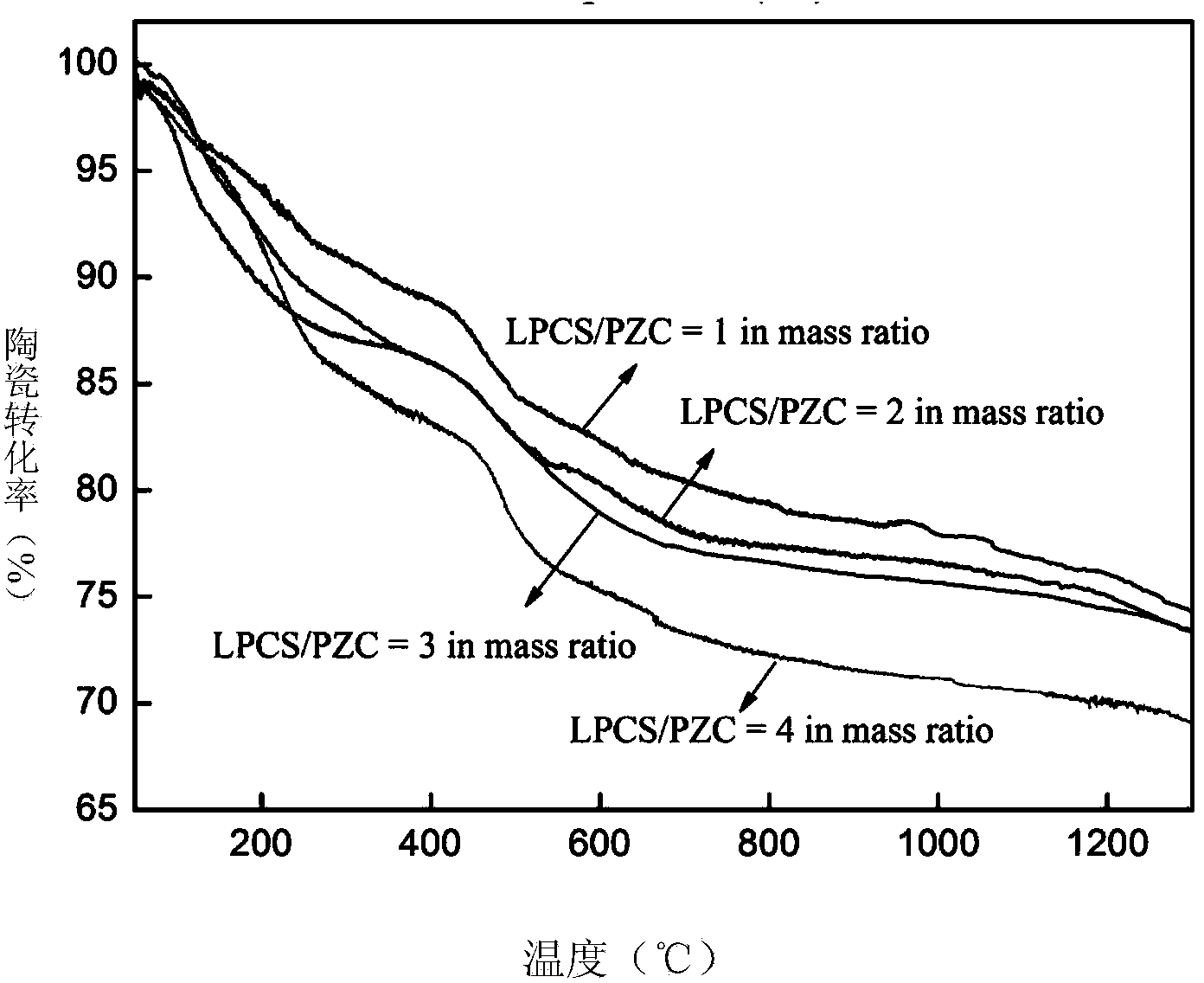

The invention relates to hybridization liquid precursor, a preparing method and a method for preparing ZrC-SiC superhigh temperature ceramics and composite materials of the ZrC-SiC superhigh temperature ceramics through the hybridization liquid precursor. Solid PZC precursor and carbon-rich vinyl adopted to replace liquid polycarbosilane (LPCS) precursor serve as raw materials for the first time and are processed in a hybridization mode to synthesize the brand new hybridization liquid precursor which is low in viscosity, adjustable in component, low in solidifying temperature, good in dipping performance, free of toxicity, harmless and high in productivity, organic solvent does not need to be added to the hybridization liquid precursor, the hybridization liquid precursor can be used for preparing the ZrC-SiC superhigh temperature ceramics and the composite materials of the ZrC-SiC superhigh temperature ceramics, and according to the thermogravimetric analysis, the ceramic productivity of the hybridization liquid LPCS-PZC ceramic precursor is more than 69 percent. The percent conversion of the ZrC-SiC superhigh temperature ceramics or the percent conversion of the fiber-reinforced ZrC-SiC superhigh temperature ceramic composite material ceramic is high, the technology is simple, and the high-temperature oxidation resistance of the obtained materials is good.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

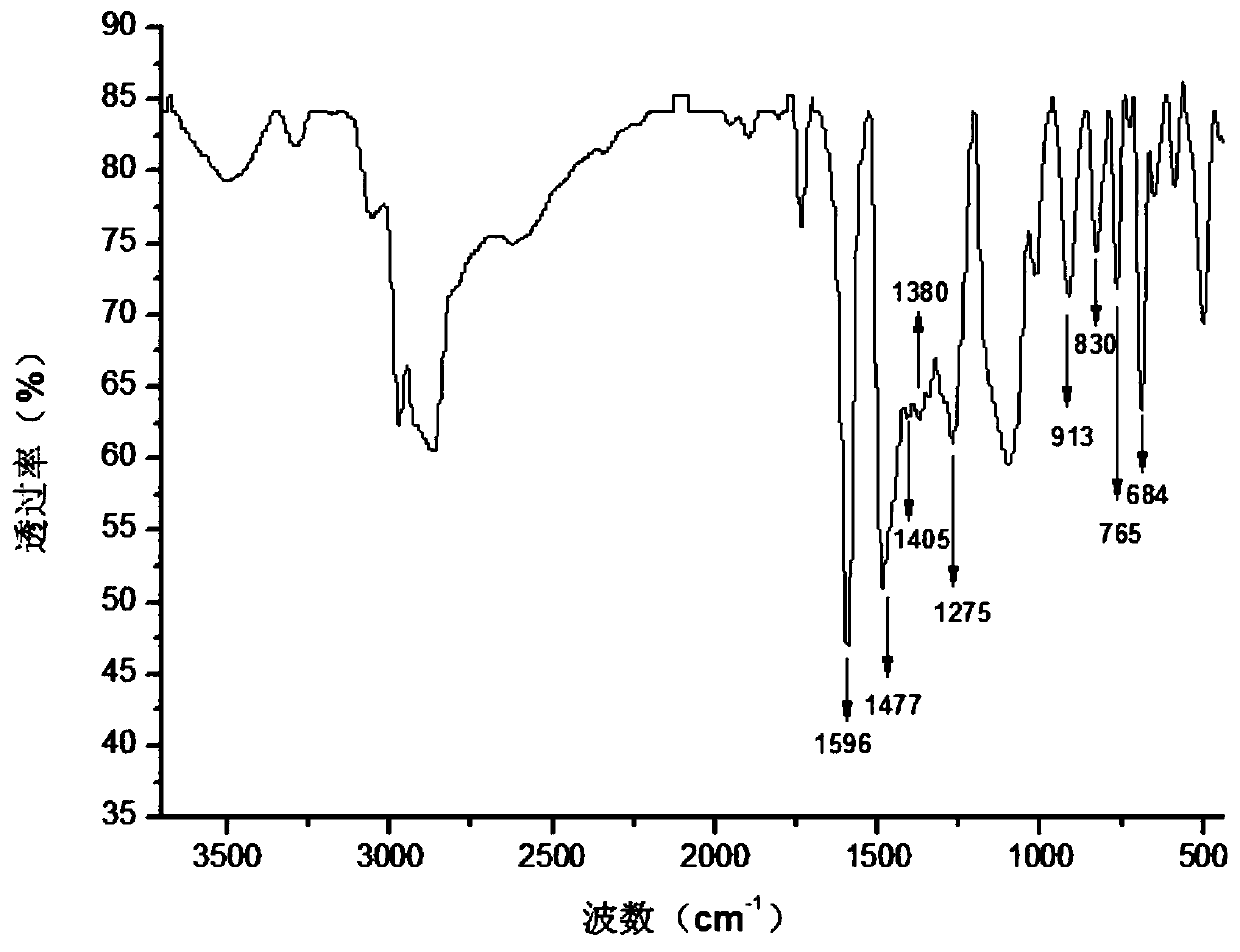

Triazine-containing benzoxazine, triazine-containing benzoxazine polymer, and preparation method thereof

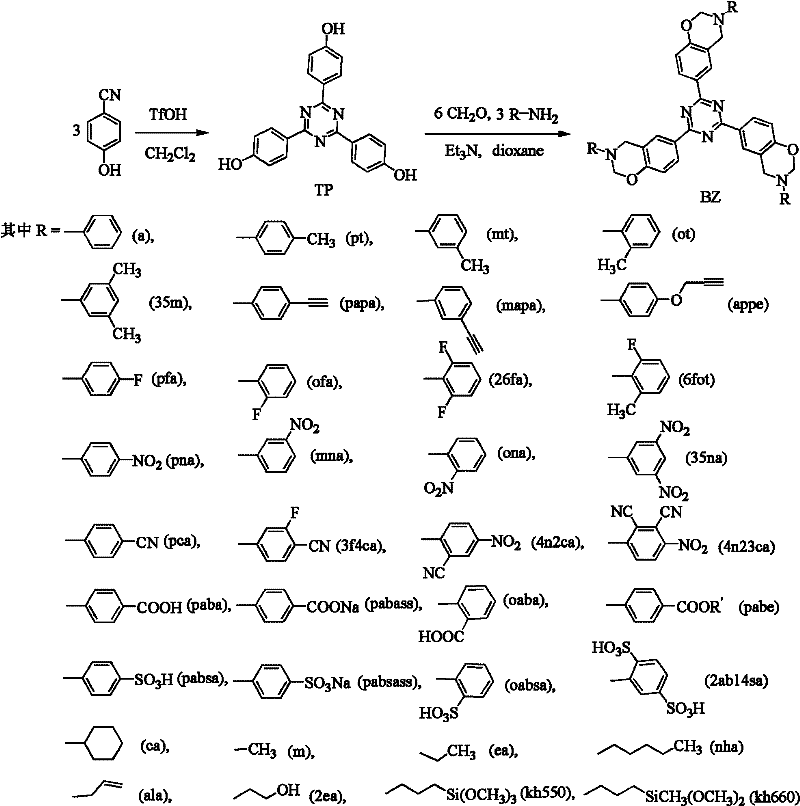

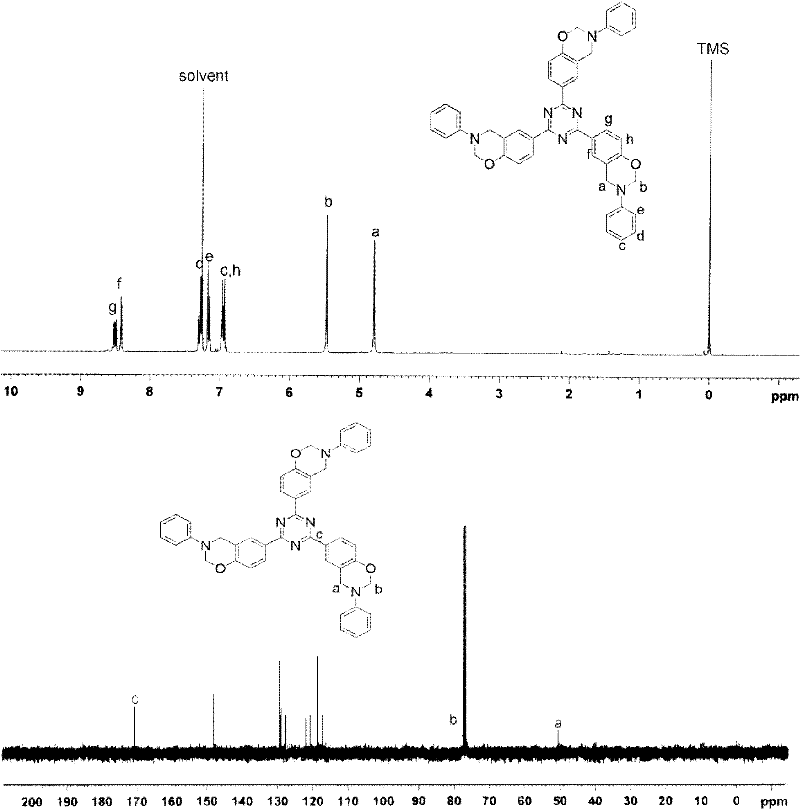

ActiveCN102219785AIncrease contentImprove heat resistanceOrganic chemistryTriflic acidStructural formula

The invention relates to triazine-containing benzoxazine, a triazine-containing benzoxazine polymer, and a preparation method thereof. The preparation method is characterized by: adopting cyanophenol as a raw material; adopting trifluoromethanesulfonic acid or trifluoroacetic acid as a catalyst; synthesizing triazine-containing trihydric phenol (TP for short) in dichloromethane or chloroform or acetone at a common temperature; adopting the synthesized TP, formaldehyde and aminated compounds as reaction raw materials; adopting a alkali as the catalyst, and carrying out a reaction in a alcohol solvent or a ether solvent to synthesize a series of triazine-containing polycyclic benzoxazine monomers (BZ for short) which have not been reported; heating the BZ to carry out a ring-opening polymerization to form polybenzoxazine (PBZ for short). A structural formula of the monomer BZ is shown as follow, substituents R are shown in the specification. The synthesized novel monomer provided by the present invention contains a triazine ring structure, such that the triazine content in the PBZ resin can be substantially raised so as to notably improve heat resistance, residual carbon rate, fire resistance property and wave transmission property of the PBZ.

Owner:SHANDONG UNIV

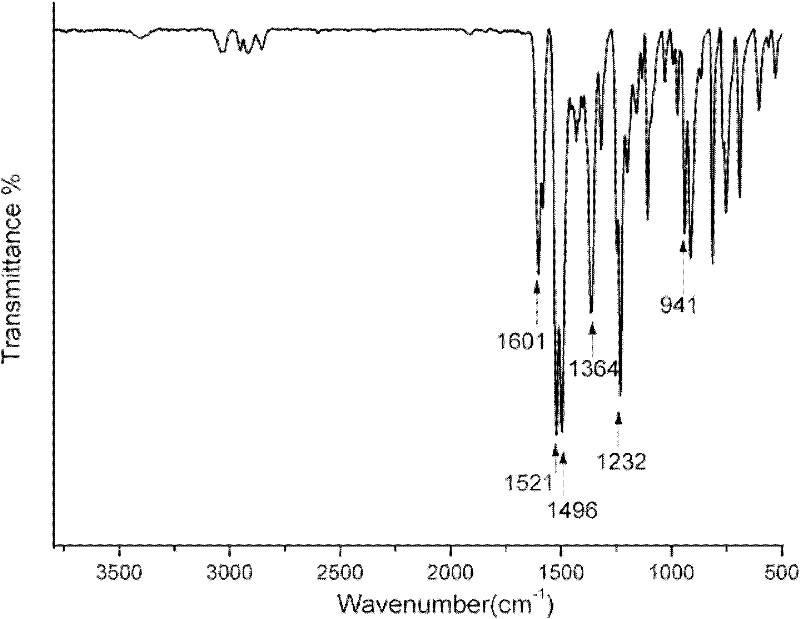

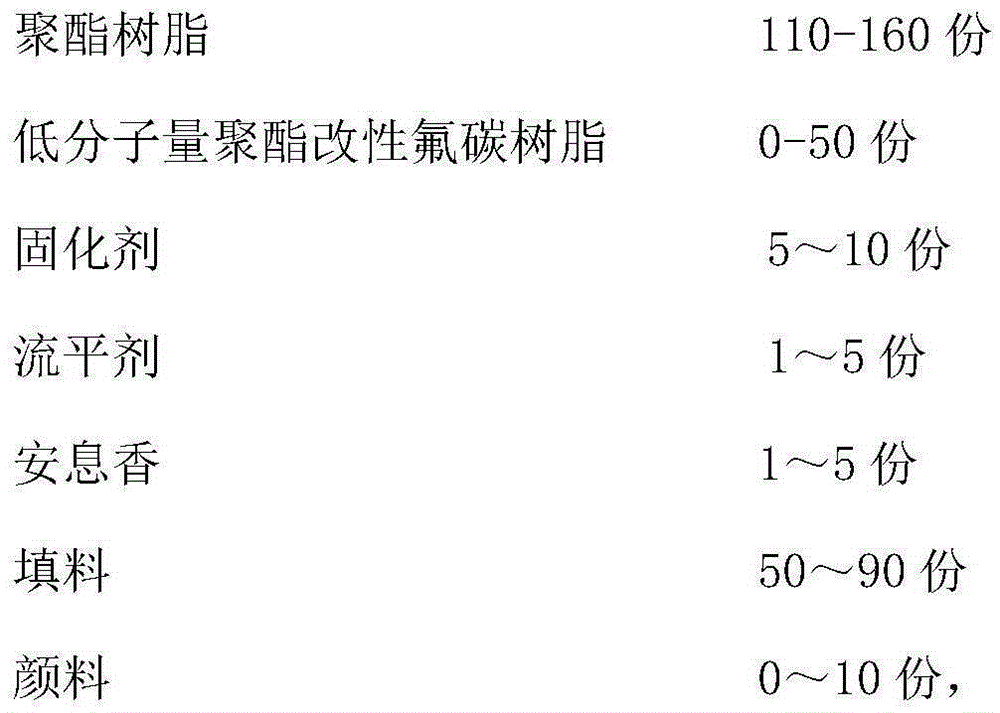

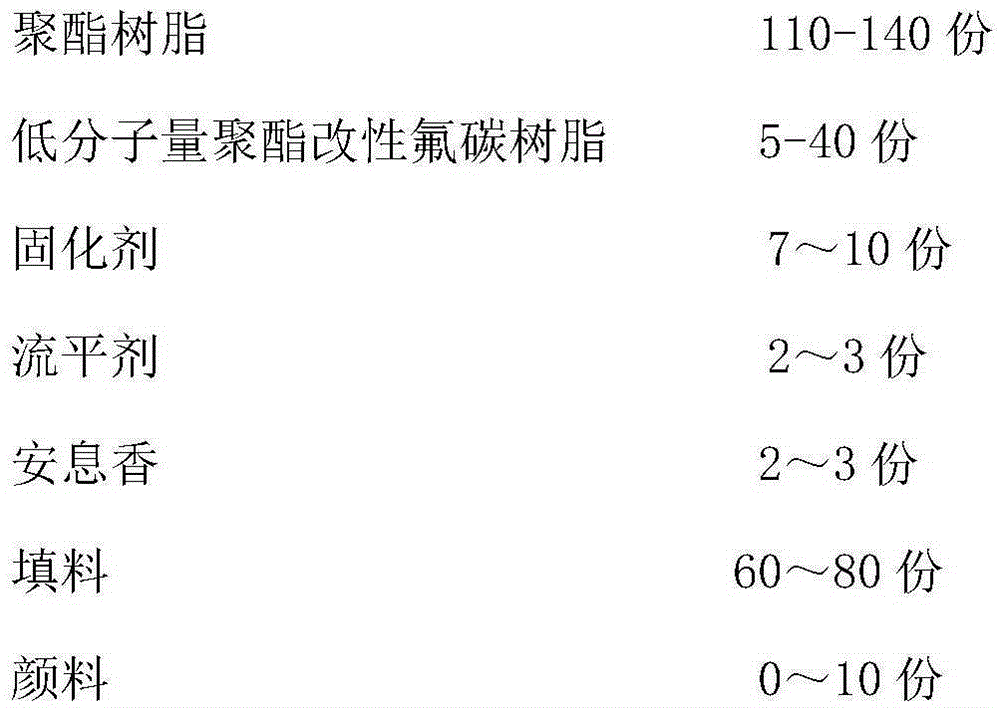

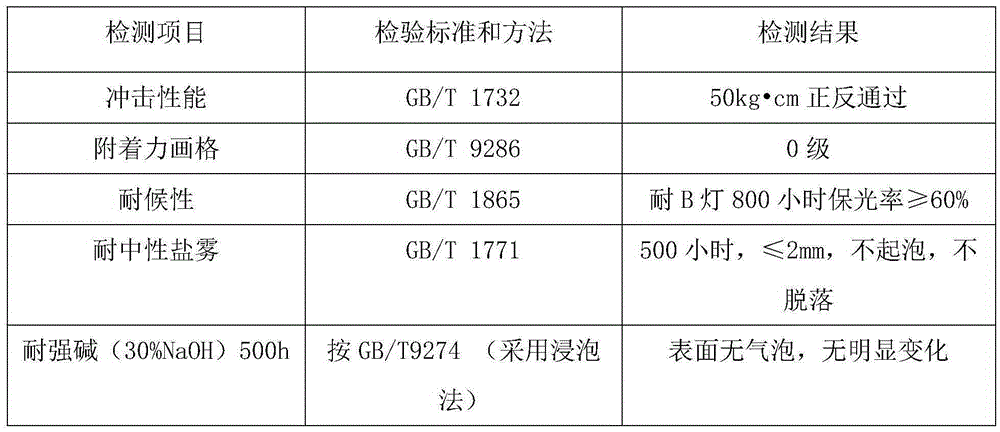

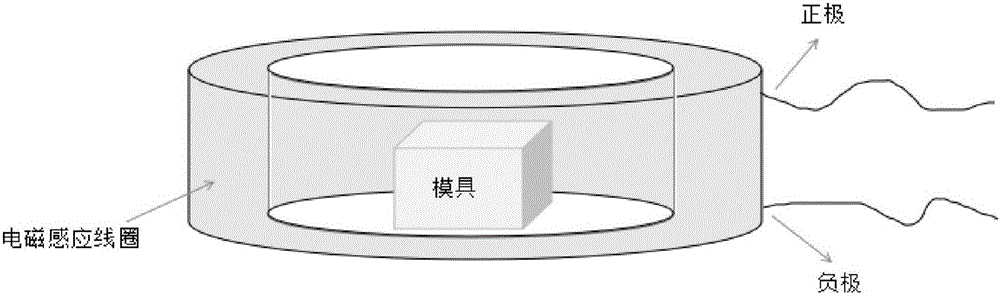

High-infrared rapid-curing powder paint for coil steel and preparation method thereof

ActiveCN105273581AGood compatibilityImprove the disadvantage of poor compatibilityPowdery paintsPolyester coatingsEnergy conservationCoating adhesion

The invention discloses high-infrared rapid-curing powder paint for coil steel. The high-infrared rapid-curing powder paint for the coil steel is prepared from, by weight, polyester resin, polyester-modified fluorocarbon resin with low molecular weight, a curing agent, a flatting agent, benzoin, packing and pigments. According to the powder paint, by adopting the polyester resin with the moderate viscosity and acid value to be compounded with the polyester-modified fluorocarbon resin with the low molecular weight, the coating surface condition and performance requirements are improved; curing can be achieved by performing high-infrared heating for 15-30 s, a cured powder coating is good in adhesive force and has the excellent weather resistance and alkali resistance. The powder paint has the advantages of being short in curing time, excellent in comprehensive performance and the like and can achieve energy conservation and environment protection.

Owner:GUANGZHOU KINTE IND

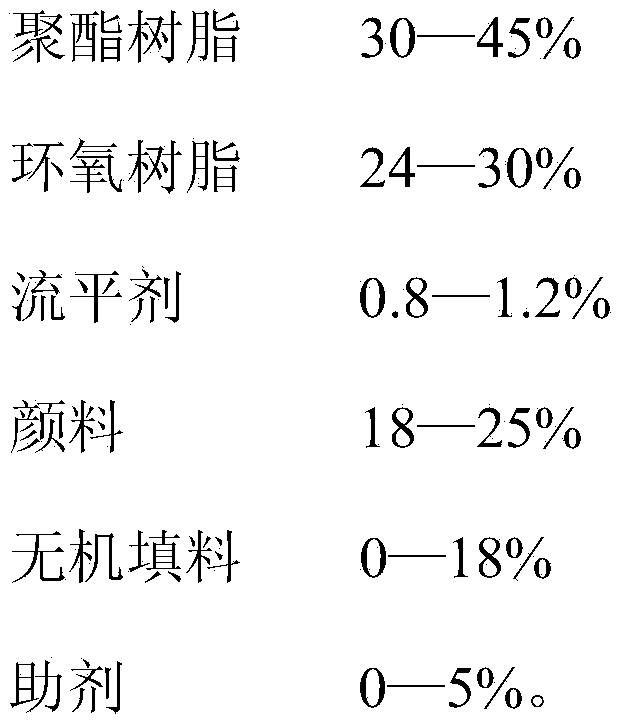

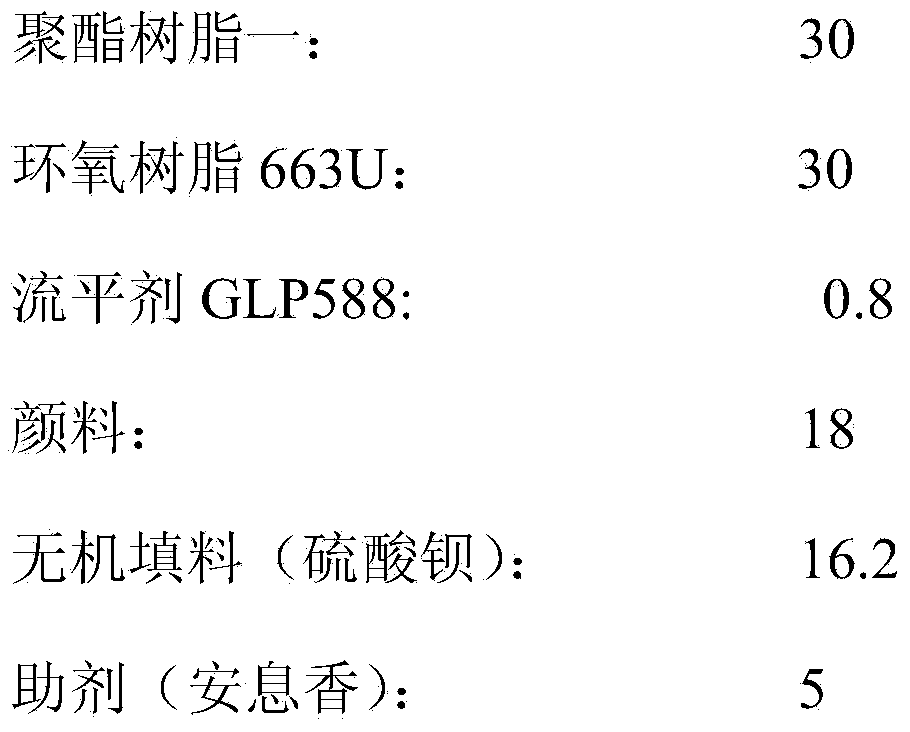

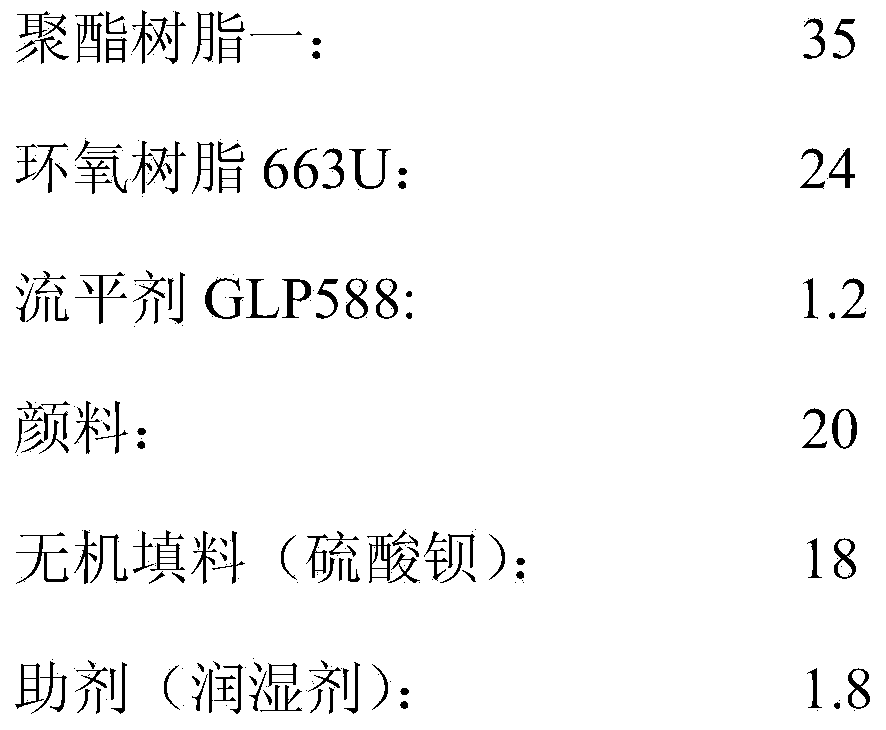

Powder paint applied to medium-density fiberboard, and preparation method and application thereof

The invention discloses powder paint applied to a medium-density fiberboard. The paint comprises the following components by weight percent: 30 to 45 percent of polyester resin, 24 to 30 percent of epoxy resin, 0.8 to 1.2 percent of flatting agent, 18 to 25 percent of pigment, 0 to 18 percent of inorganic filler and 0 to 5 percent of accessory ingredient. The invention also discloses a preparation method of the powder paint as well as an application of the powder paint in the medium-density fiberboard. The powder paint is solidified by adopting the conventional hot roasting method, so that the medium-density fiberboard is not damaged; moreover, the powder paint can be sufficiently fused and flatted and can be adequately completely solidified. When the powder paint is applied to the medium-density fiberboard, the glossiness is high, and the coating solvent-resisting property, the moisture resistance, the hardness and the adhesive force are excellent.

Owner:ANHUI SHENJIAN NEW MATERIALS

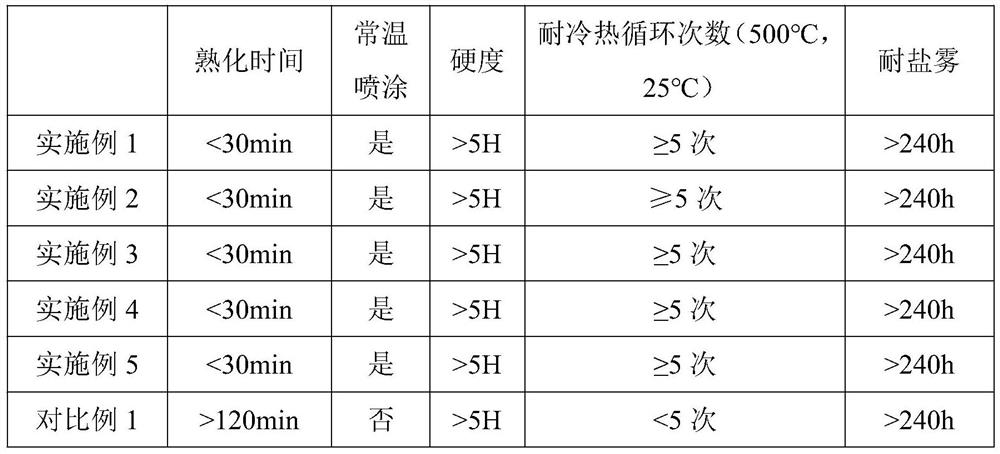

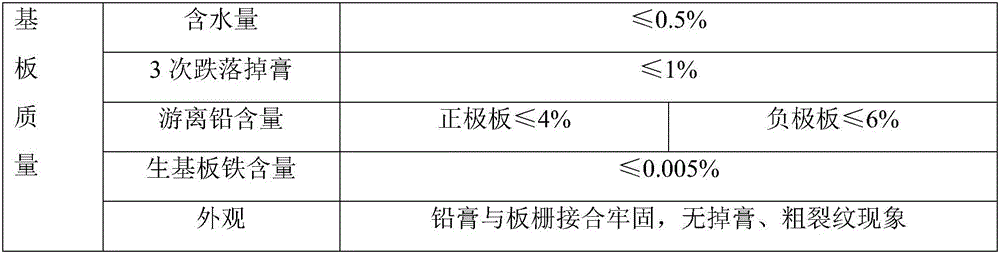

Curing and drying method for lead battery plates

ActiveCN110474022ASimple curing processLower requirementLead-acid accumulator electrodesEngineeringOxygen

The invention discloses a curing and drying method for lead battery plates. The method includes the following steps: temperature in a curing chamber being 40-45 DEG C and relative humidity being 95-99%, opening atomization humidification, and placing a pole plate into the curing chamber; the curing chamber being enclosed, closing atomization humidification, heating the negative plate curing chamber to 50-55 DEG C, and heating the positive plate curing chamber to 60-75 DEG C; the curing chamber being enclosed, adopting steam heating, maintaining the negative plate curing chamber at 50-55 DEG Cfor 6-8 h, and maintaining the positive plate at 60-75 DEG C for 6-8 h; closing steam heating, opening the curing chamber to perform heat dissipation, cooling the pole plate to 30-40 DEG C, then closing the curing chamber, setting the temperature in the curing chamber to be 40 DEG C and the relative humidity to be 80-90%, and opening an oxygen supplement air door and a humidity elimination air door to perform oxygen supplement and humidity elimination to maintain for 6-8 h; and adopting electric heating to heat to 75 DEG C, opening the humidity elimination air door to perform humidity elimination, arranging a drying device in an air intake channel so that the relative humidity of entered air is less than 70%, and performing maintaining for 6-8 h.

Owner:TIANNENG BATTERY GROUP

Epoxy-resin-based conductive adhesive and preparation method thereof

ActiveCN106047242AImprove conductivityEffective alignmentNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAdhesive

The invention discloses an epoxy-resin-based conductive adhesive and a preparation method thereof. The epoxy-resin-based conductive adhesive is composed of, by mass, 10-20 parts of epoxy resin, 0.5-5 parts of magnetic filler, 1-2 parts of solidifying agent, 0.1-0.3 part of promoter, 0.5-2 parts of flexibilizer and 0.5-5 parts of coupling agent. The epoxy-resin-based conductive adhesive has high conductive performance; magnetic field regulation is adopted to enable the magnetic filler to be in oriented distribution in an epoxy resin matrix, so that conductive performance of the epoxy-resin-based conductive adhesive is remarkably improved than that of conventional epoxy-resin-based conductive adhesive modified by filling. The e epoxy-resin-based conductive adhesive has the advantages of simple and convenient process and low filler consumption, meets requirements of high polymer conductive materials and is suitable for being used to prepare composite materials like conductive paint and conductive adhesives.

Owner:ANHUI UNIVERSITY

Lubricating paint

The invention discloses a machine oil resistant, high temperature resistant, and grinding resistant lubricating coating material. It is made up of binding agent, solid lubricant, mix solvent, and assistant agent. The binding agent adopts poly-phenylene thioether resin; solid lubricant adopts polytetrafluoroethylene, mix solvent is the mixture of distilled water and ethanol; assistant agent adopts cyanuric ammonia and cyanuric acid ester complex, antimony trioxide, and rare earth fluoride. It has the advantages of super high bearing capacity, good adaptability to hydraulic pressure and lubricant medium, high temperature resistant, long useful life, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

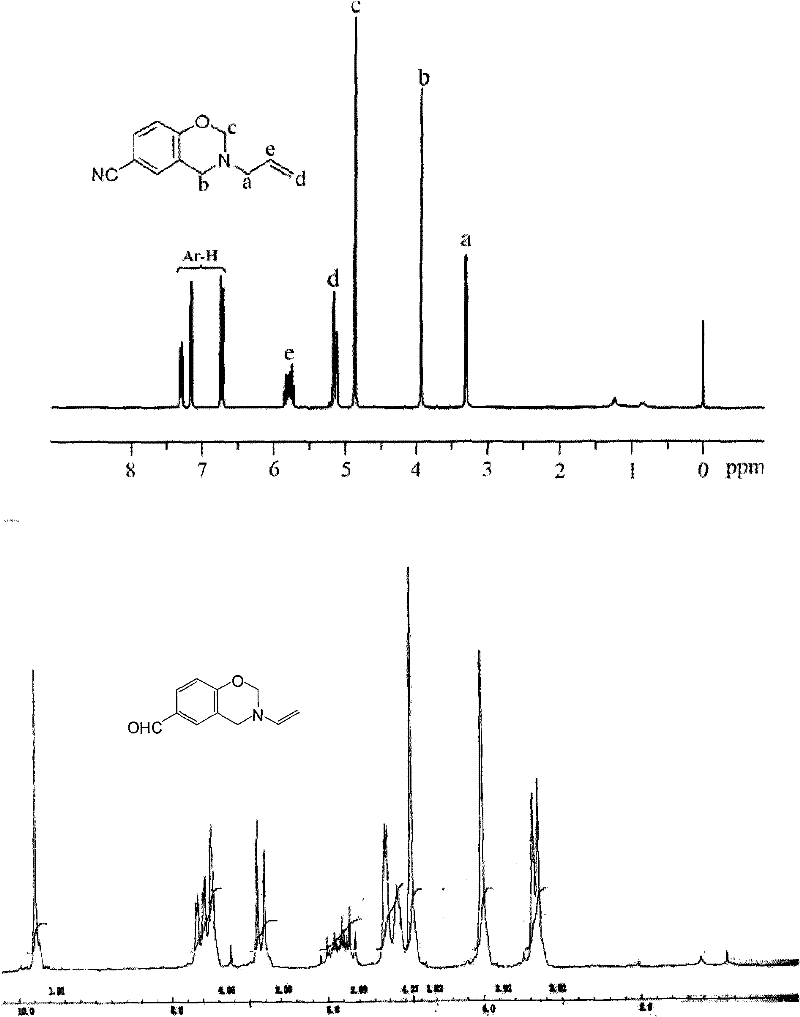

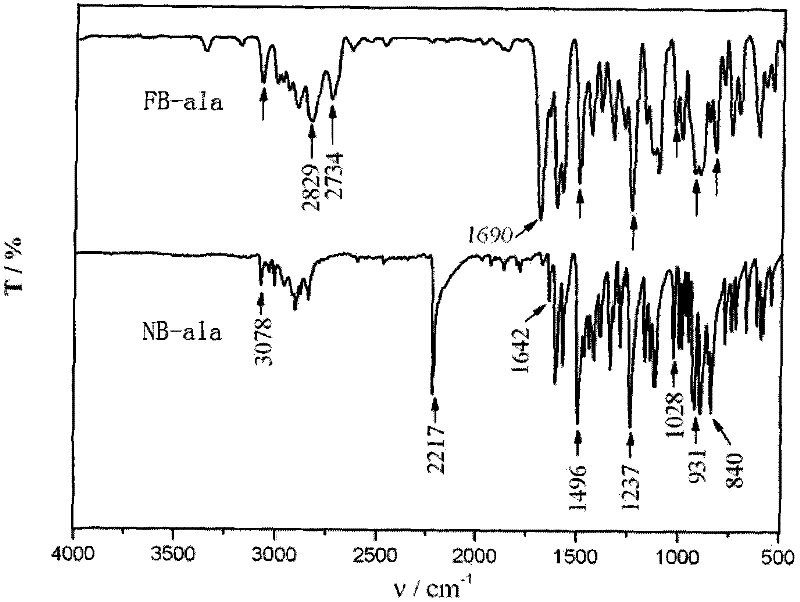

Monocyclic benzoxazine intermediate with low viscosity and a plurality of functional groups and synthesis method thereof

InactiveCN101747288ALow viscosityThe temperature of the ring-opening polymerization is loweredOrganic chemistryVitrificationCross-link

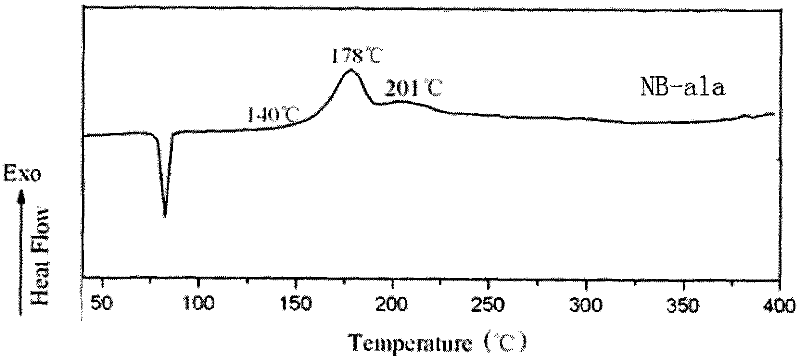

The invention discloses a monocyclic benzoxazine intermediate with low viscosity and a plurality of functional groups, a preparation method thereof and application thereof in the preparation of high-temperature resistant resin. The process method is simple, practicable, and suitable for industrial production in most of factories; a cross-linked polymer prepared by the benzoxazine intermediate has very high vitrification conversion temperature (Tg is larger than 250 DEG C), is available to high-temperature resistant materials used in the temperature more than 250 DEG C, and has higher carbon residue rate (800 DEG C, N2, PNB-ala: 57%; 800 DEG C, N2, FB-ala: 61%) and a certain application prospect in terms of the preparation of carbon materials and ablation resistant materials.

Owner:SHANDONG UNIV

Heat insulation composite board and preparation method thereof

ActiveCN111823681ASimple molding processEasy to operateClimate change adaptationSynthetic resin layered productsCalcium silicateInsulation layer

The invention belongs to the technical field of heat insulation, and discloses a heat insulation composite board and a preparation method thereof. The heat insulation composite board comprises a firstpanel layer and a heat insulation layer, and the heat insulation layer and the first panel layer are integrally formed; the first panel layer is a fiber reinforced resin-based composite sheet, a metal plate, a cement plate, a calcium silicate plate or a gypsum plate, and the heat insulation layer is a fiber reinforced aerogel felt. The preparation method comprises the following steps of: (1) flatly laying a fiber-reinforced aerogel felt; (2) paving the first panel layer on the upper surface of the fiber reinforced aerogel felt; and (3) carrying out hot press molding treatment to obtain the heat insulation composite board. The heat insulation composite board provided by the invention can implement a thermal insulation scheme on scenes like pipes, walls and box bodies, and has the advantages of convenient operation, simplicity, feasibility and the like.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Constant temperature curing high-bearing and anti-adhering wear resistant lubricating paint

InactiveCN1552783ASimple curing processImprove wear lifePolyurea/polyurethane coatingsPliabilityHardness

An antisticking, antiwear and lubricating paint solidified at ordinary temp and with high load-bearing power is prepared from tetrafluorowax, polyurethane resin, Sb2O3, and melamine-tripolycyanate complex. Its advantages are high hardness, high adhesion, and wide temp range (-50-200 deg.C).

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ultraviolet curing adhesive as well as preparation method and application thereof

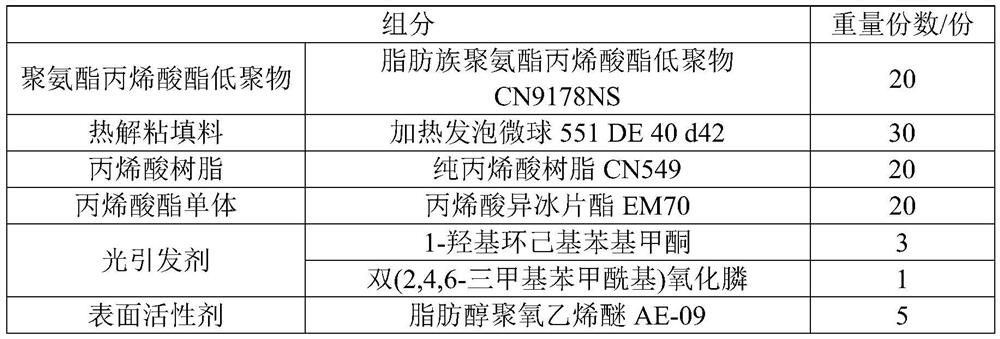

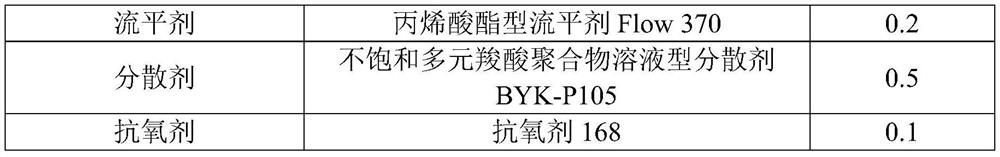

ActiveCN111748313AGood release effectEasy dispensingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceOligomer

The invention provides an ultraviolet curing adhesive as well as a preparation method and application thereof. The ultraviolet curing adhesive is prepared from the following components, by weight: 10to 60 parts of urethane acrylate oligomer, 10 to 50 parts of thermal debonding filler, 10 to 40 parts of acrylic resin, 20 to 40 parts of an acrylate monomer, 1 to 5 parts of a photoinitiator and 3 to10 parts of a surfactant. The ultraviolet curing adhesive has the advantages of being good in bonding strength, high in curing speed, capable of being automatically stripped and disengaged after being heated, high in disengagement speed, free of disengagement residues, good in reliability and the like.

Owner:上海仁速新材料有限公司

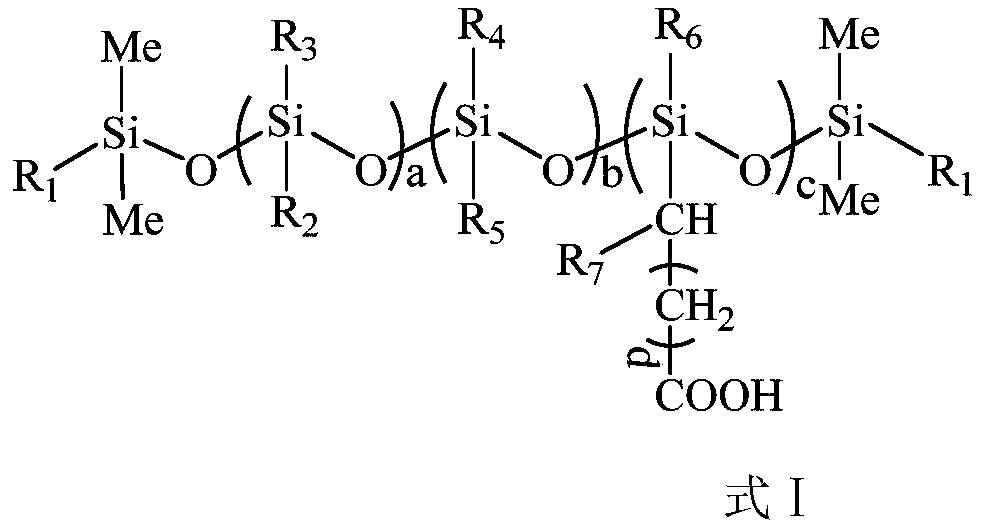

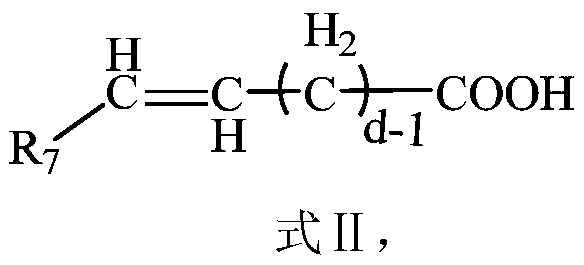

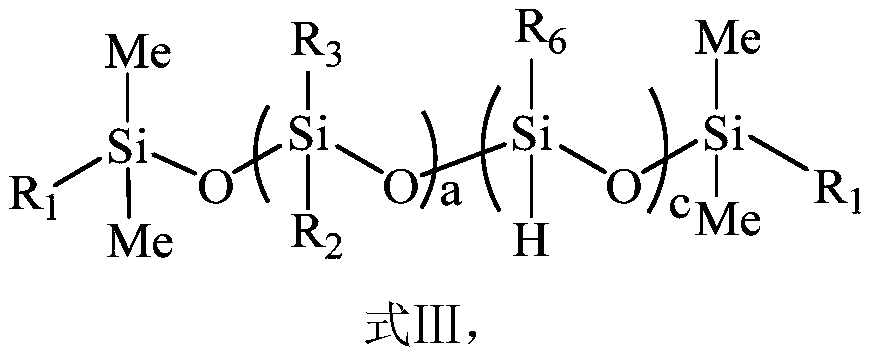

Ultraviolet-curable carboxyl alkyl substituted silicone as well as preparation method and application thereof

The invention discloses ultraviolet-curable carboxyl alkyl substituted silicone as well as a preparation method and an application thereof. The carboxyl alkyl substituted silicone is a modified organic silicon material taking Si-O-Si as a backbone and carboxyl groups and photocuring groups as branches. The ultraviolet-curable carboxyl alkyl substituted silicone contains ultraviolet-curable activegroups, can be rapidly cured under ultraviolet irradiation, is green, energy-saving and environmentally friendly, also has the characteristics of traditional carboxyl alkyl substituted silicone due tointroduction of the carboxyl groups, has thermal stability, corrosion resistance, oxidation stability and the like and is nontoxic, odorless and good in biocompatibility; the existing thermal curingprocess is changed, and the curing process is simple; the silicone oil has excellent storage stability, and storage stability time is about 400 days, the ultraviolet-curable carboxyl alkyl substitutedsilicone with stable performance is prepared with a two-step one-pot method, raw materials are easily available, the preparation method is simple and convenient, reaction conditions are mild, the yield is high, odor is small, and requirements of industrial production are met.

Owner:GUANGDONG UNIV OF TECH

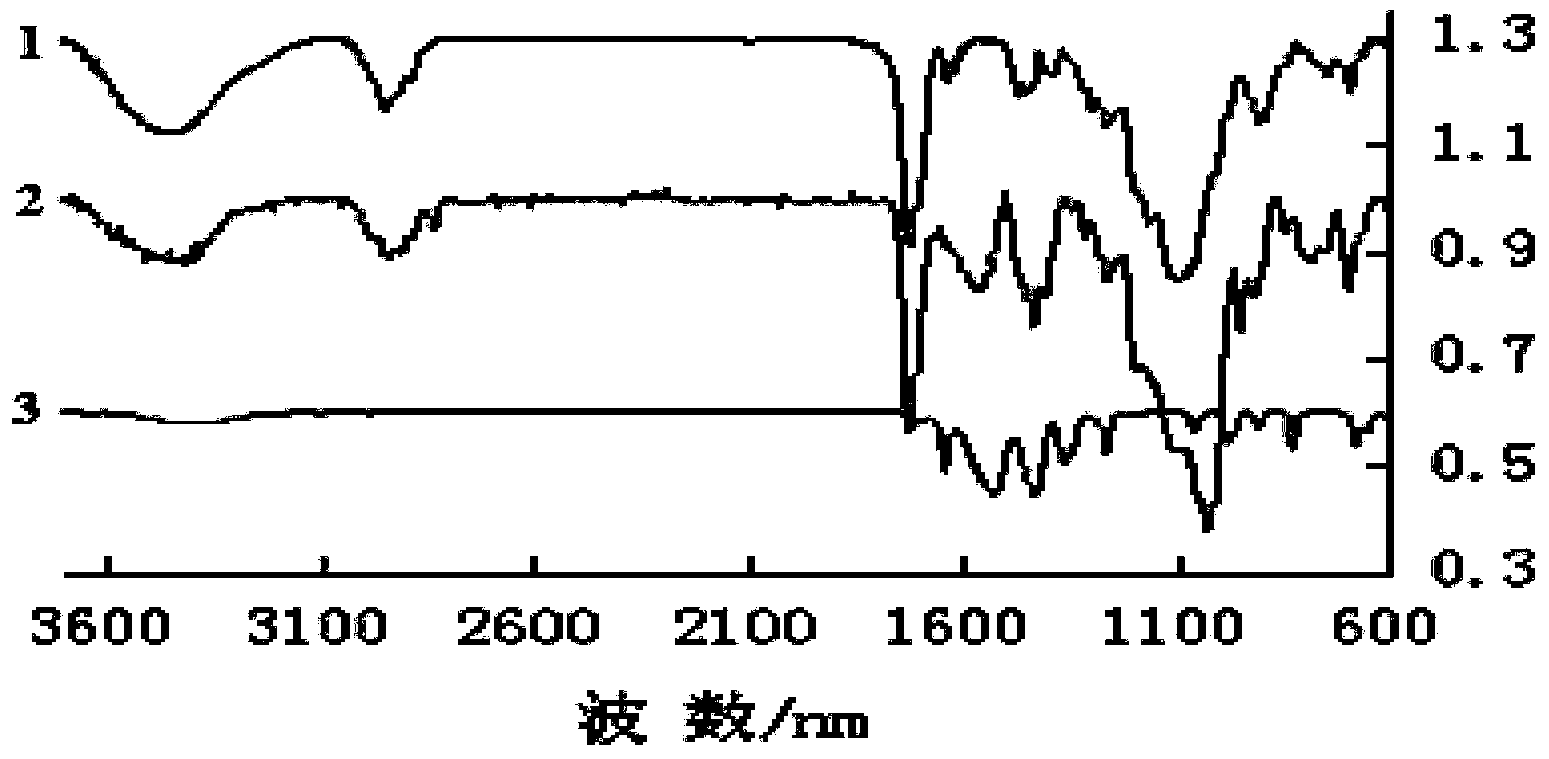

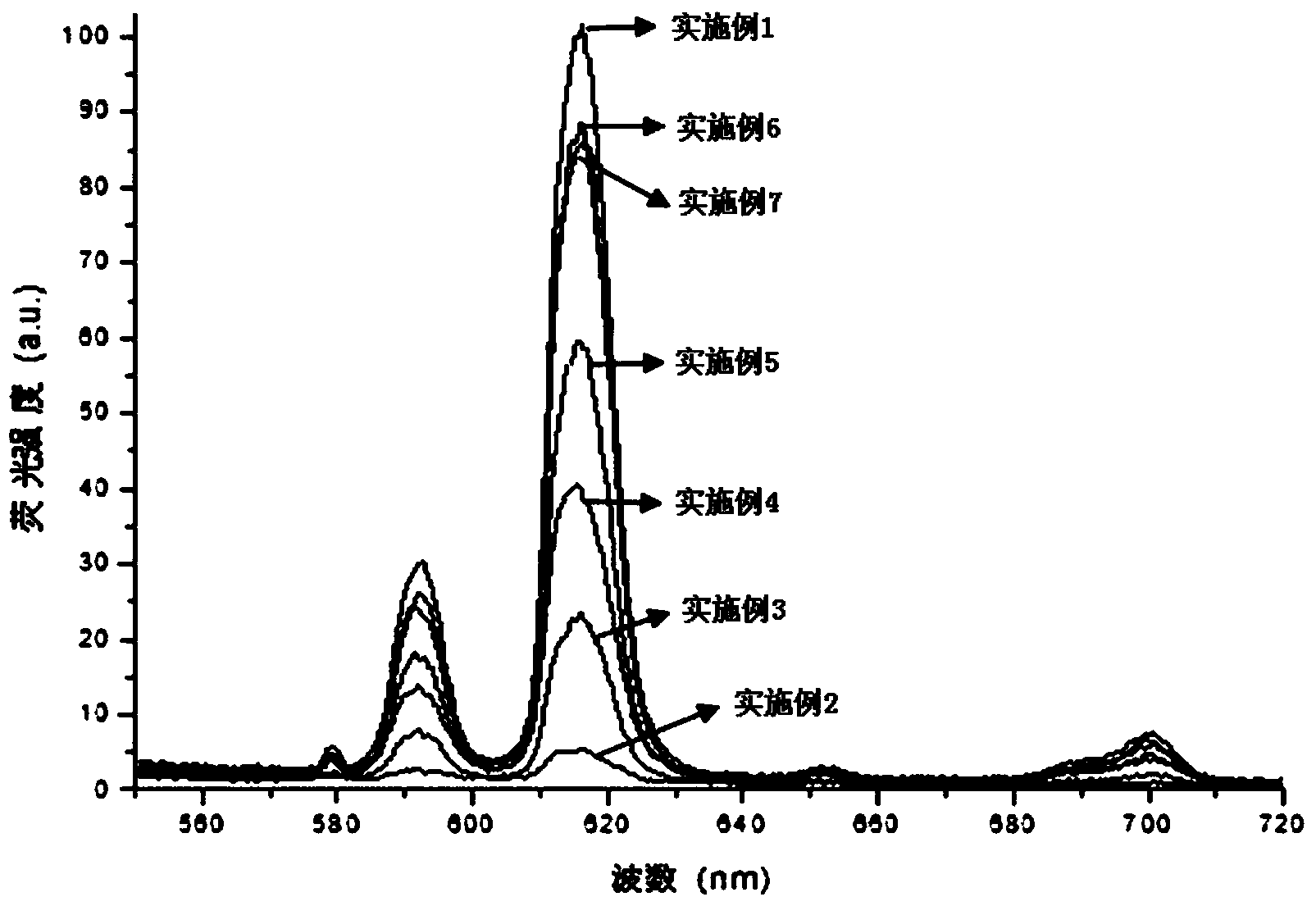

Light-curing preparation method of rare earth bonded fluorescent gel glass

InactiveCN103881005AHigh Rare Earth Doping ConcentrationHigh fluorescence intensityLuminescent compositionsFluorescenceRare earth

The invention discloses a light-curing preparation method of rare earth bonded fluorescent gel glass. According to the method, organosiloxane containing dual functional groups is used as a sol-gel precursor, and a rare-earth complex is bonded to a gel glass matrix in an ultraviolet light curing manner, thus the rare earth bonded fluorescent gel glass is prepared. Compared with the traditional thermal polymerization methods, the method disclosed by the invention has the advantages of simplicity and easiness in operation, short reaction time and environmental friendliness, and the prepared rare earth bonded gel glass is uniform and transparent, has good thermal stability, is prone to machine-shaping, is suitable for industrial production and has a broad application prospect in the field of photovoltaic cells or lighting.

Owner:SHAANXI NORMAL UNIV

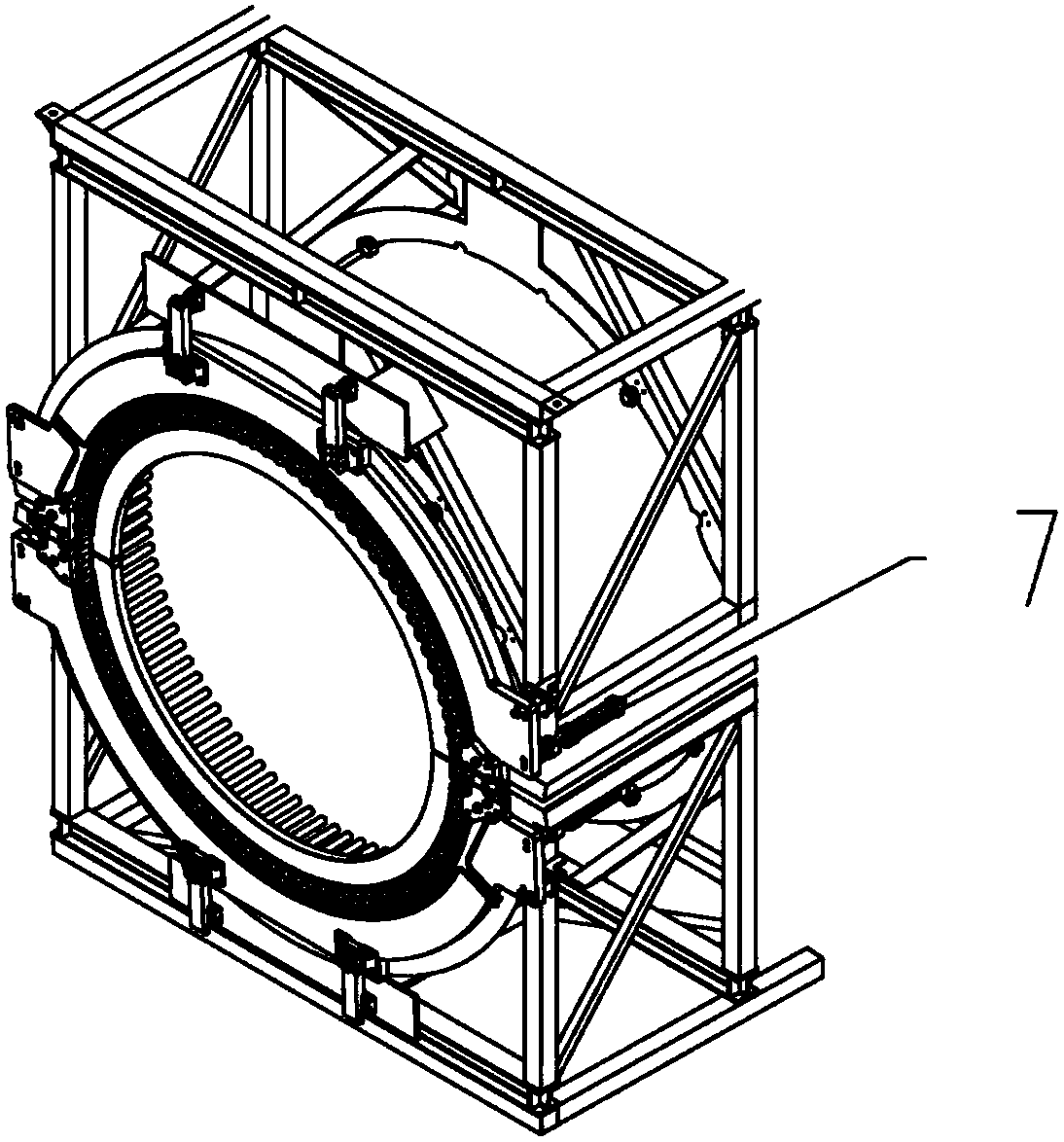

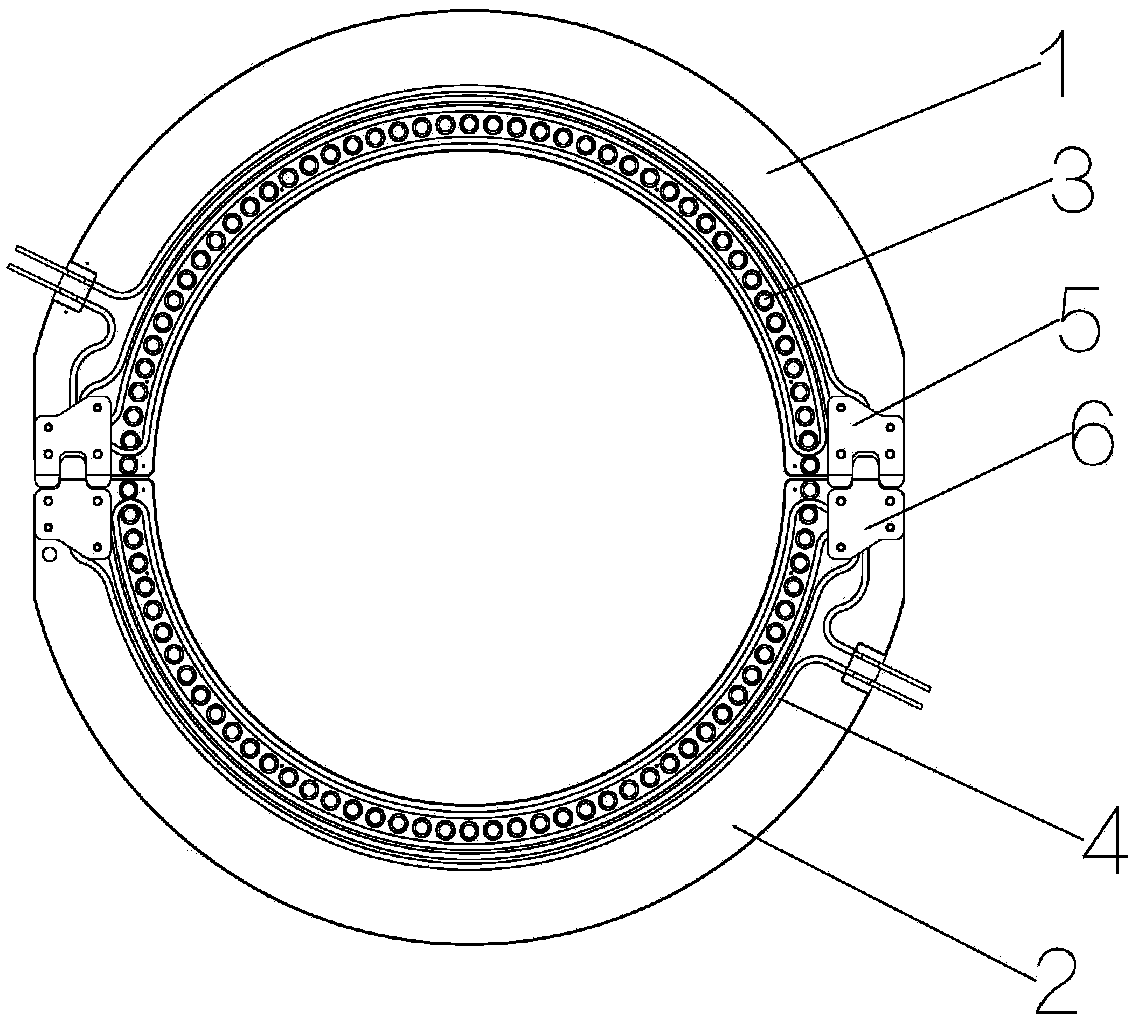

Manufacturing mold of wind power blade and flange of manufacturing mold

The invention discloses a manufacturing mold of a wind power blade and a flange of the manufacturing mold. The manufacturing mold of the wind power blade comprises an upper mold body and a lower moldbody which are arranged to be opposite mutually; the upper mold body and the lower mold body comprise an upper metal steel frame, a lower metal steel frame and an upper blade mold body and a lower blade mold body which are arranged on the upper and the lower metal steel frames respectively; the manufacturing mold of the wind power blade is characterized by further comprising the flange; the flangecomprises a semi-circular upper flange body and a semi-circular lower flange body which are used for being connected with the upper blade mold body and the lower blade mold body, heating modules arearranged on the upper flange body and the lower flange body respectively, and each heating module comprises a heat conduction part being at least partially pre-buried in the upper flange body and thelower flange body; a plurality of bolt holes are formed in each of the upper flange body and the lower flange body, pre-buried bolt sleeves are arranged on the upper blade mold body and the lower blade mold body respectively, and after the upper mold body and the lower mold body are assembled, the bolt holes of the upper flange body and the lower flange body are fixed with the pre-buried bolt sleeves arranged on the upper blade mold body and the lower blade mold body in an one-by-one corresponding mode; and the flange heats the upper blade mold body and the lower blade mold body through the heat conduction parts. The blade root curing process operation is outstandingly simplified, and the curing efficiency is improved.

Owner:苏州天顺复合材料科技有限公司

Water-based polysiloxane ceramic simulating coating

InactiveCN111909616AShort maturation timeSimple curing processAnti-corrosive paintsPtru catalystMetallic substrate

The invention relates to the technical field of coatings, in particular to a water-based polysiloxane ceramic simulating coating. The water-based polysiloxane ceramic simulating coating is composed ofa component A, a component B and a component C, wherein the component A is composed of water-based nano sol, filler, pigment, an anti-sagging agent, a leveling agent and a dispersing agent, the component B is a catalyst, the component C is a silane coupling agent, and the mass ratio of the component A to the component B to the component C is 10: (1-10): (0.1-5). The water-based polysiloxane ceramic simulating coating has the advantages of being good in stability before curing, simple in curing process, short in curing time, capable of being sprayed at normal temperature, long in shelf life after curing, resistant to hot and cold circulation, high in hardness, resistant to corrosion and the like, and can meet the requirement for long-term use of various metal base materials in complex andchangeable environments.

Owner:无锡米克新材料有限公司

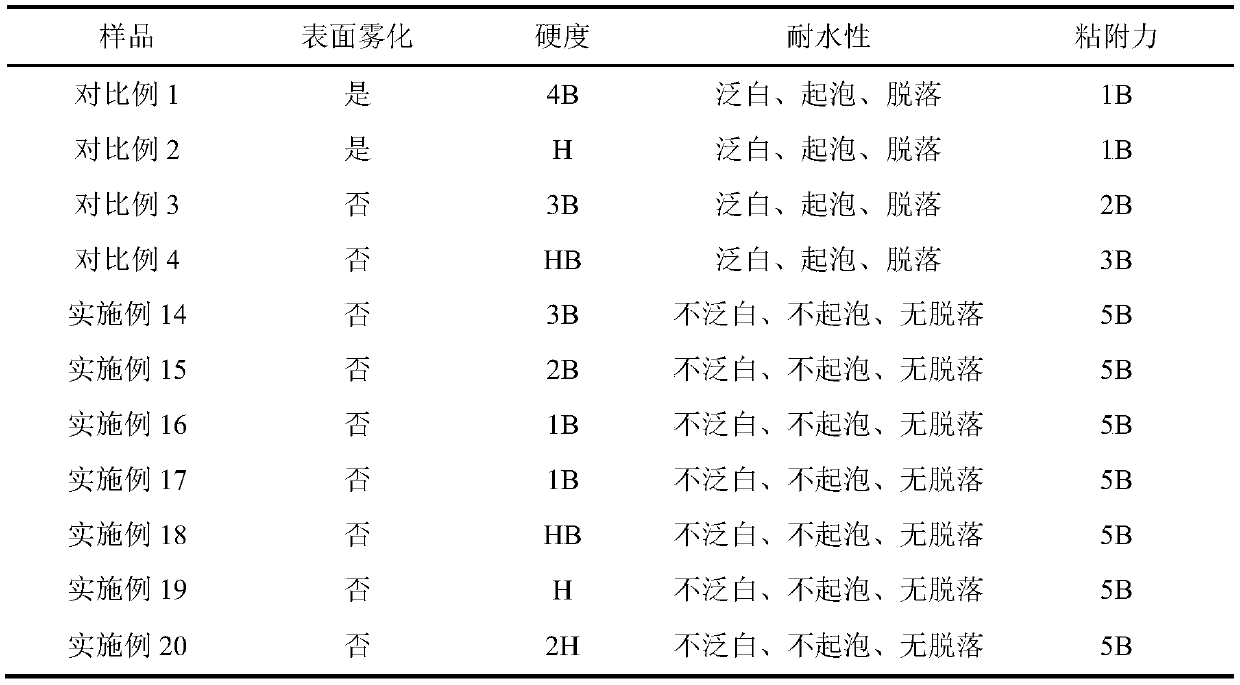

Photo-cured polyurethane anti-fog film with controllable soft/hard structure and preparation method thereof

The invention provides a photo-cured polyurethane anti-fog film with a controllable soft / hard structure and a preparation method thereof, and belongs to the technical field of polymer materials. The anti-fog film comprises a polyurethane prepolymer with a soft structure, a polyurethane prepolymer with a hard structure, and a crosslinking agent containing a carbon-carbon double bond according to aweight ratio of 100:(5-100):(0.5-5). The provided anti-fog film has a long lasting anti-fog effect, the surface is scratch resistant, the waterproof performance is excellent, the basic material adhesion force is high, the performance and structure can be controlled and adjusted, the cost is low, the technique is matured, and the preparation method is suitable for production.

Owner:JIANGNAN UNIV +1

Curing method for storage battery

InactiveCN106058160AImprove joint strengthInhibit sheddingFinal product manufactureLead-acid accumulator electrodesThree stageMaterials science

The invention discloses a curing method for a storage battery. The curing method is characterized by comprising the following steps: putting a positive plate and a negative plate after full-filling on a curing frame in a curing chamber, and carrying out three stages of steam curing, heating curing and drying curing, wherein in the stage of steam curing, under the relative humidity of 99%, the positive plate and the negative plate are cured at the temperatures of 35 DEG C, 55 DEG C, 60 DEG C, 65 DEG C, 70 DEG C and 75 DEG C respectively; in the stage of heating curing, at the temperature of 50 DEG C, the relative humidity is 65% and the curing time is 4 h, and at the temperature of 55 DEG C, the relative humidity is 45% and the curing time is 4 h; and in the stage of drying curing, under the relative humidity of 0%, the positive plate and the negative plate are cured at the temperatures of 60 DEG C, 70 DEG C and 30 DEG C respectively. The curing method disclosed by the invention is simple in curing process and easy to operate; and moreover, a pole plate after being cured by the curing method disclosed by the invention is long in service life.

Owner:JIANGSU KENENG POWER

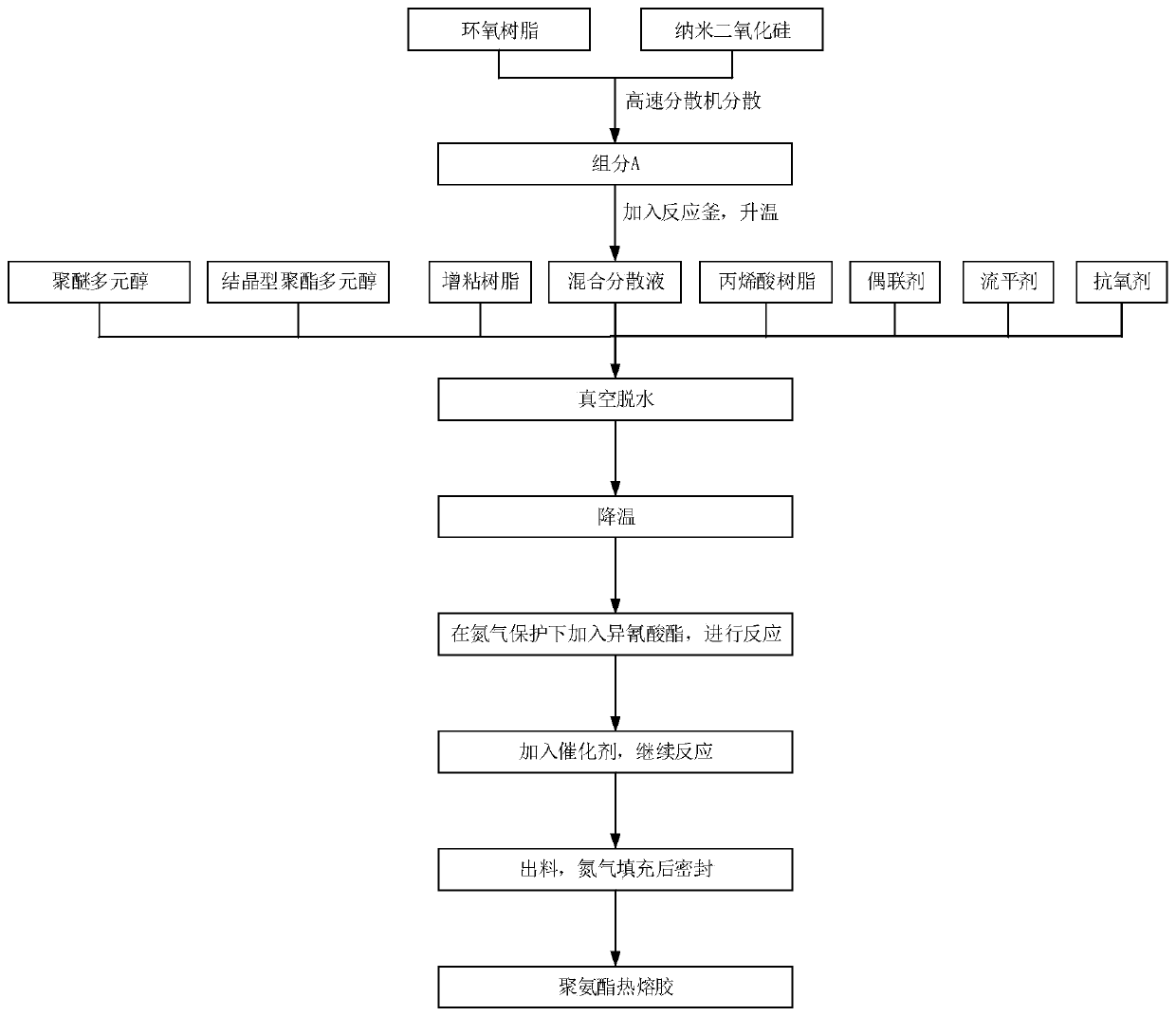

Moisture-curable polyurethane hot melt adhesive, preparation method and application thereof, and steel member

InactiveCN111303824ANo releaseNo pollution in the processAdhesive processesNon-macromolecular adhesive additivesPolymer scienceAdhesive glue

The invention belongs to the technical field of polyurethane hot melt adhesives, and particularly relates to a moisture-curable polyurethane hot melt adhesive, a preparation method and application thereof, and a steel member. The single-component moisture-curable polyurethane hot melt adhesive is prepared from the following raw materials: a hot melt adhesive main body, a coupling agent and an auxiliary agent, wherein all the components are suitable for forming the polyurethane hot melt adhesive with the solid content of 100%. In the using process, no small molecules are released, safety, environment friendliness and no pollution are achieved, the moisture-curable polyurethane hot melt adhesive has the advantages of being environmentally friendly, long in service life, high in bonding strength, safe, reliable and the like, no particle or bubbling phenomenon exists after gluing, an adhesive film is flexible and elastic after the adhesive is cured, high-temperature resistance and low-temperature resistance are good, and the moisture-curable polyurethane hot melt adhesive can be widely applied to composite bonding of steel structure veneering materials.

Owner:常州威斯敦粘合材料有限责任公司

Arsenic-containing waste slag solidified body and preparation method thereof

InactiveCN102249609BSimple curing processLow costSolid waste managementSolid waste disposalArsenic pollutionSlag

The invention relates to a solidified body of arsenic-containing waste residue and a preparation method thereof, belonging to the technical field of environmental protection. After the arsenic-containing waste residue is processed, it is mixed with a curing agent, modifier, aggregate, water, etc. prepared from industrial waste residue and mineral stimulating materials. After mixing, molding, and curing of the mixture, it becomes a solidified body with high strength and low arsenic leaching rate. Compared with the prior art, the invention has the advantages of simple solidification process, low cost, safety and reliability, and solves the problem of arsenic pollution of arsenic-containing waste residue.

Owner:KUNMING UNIV OF SCI & TECH +1

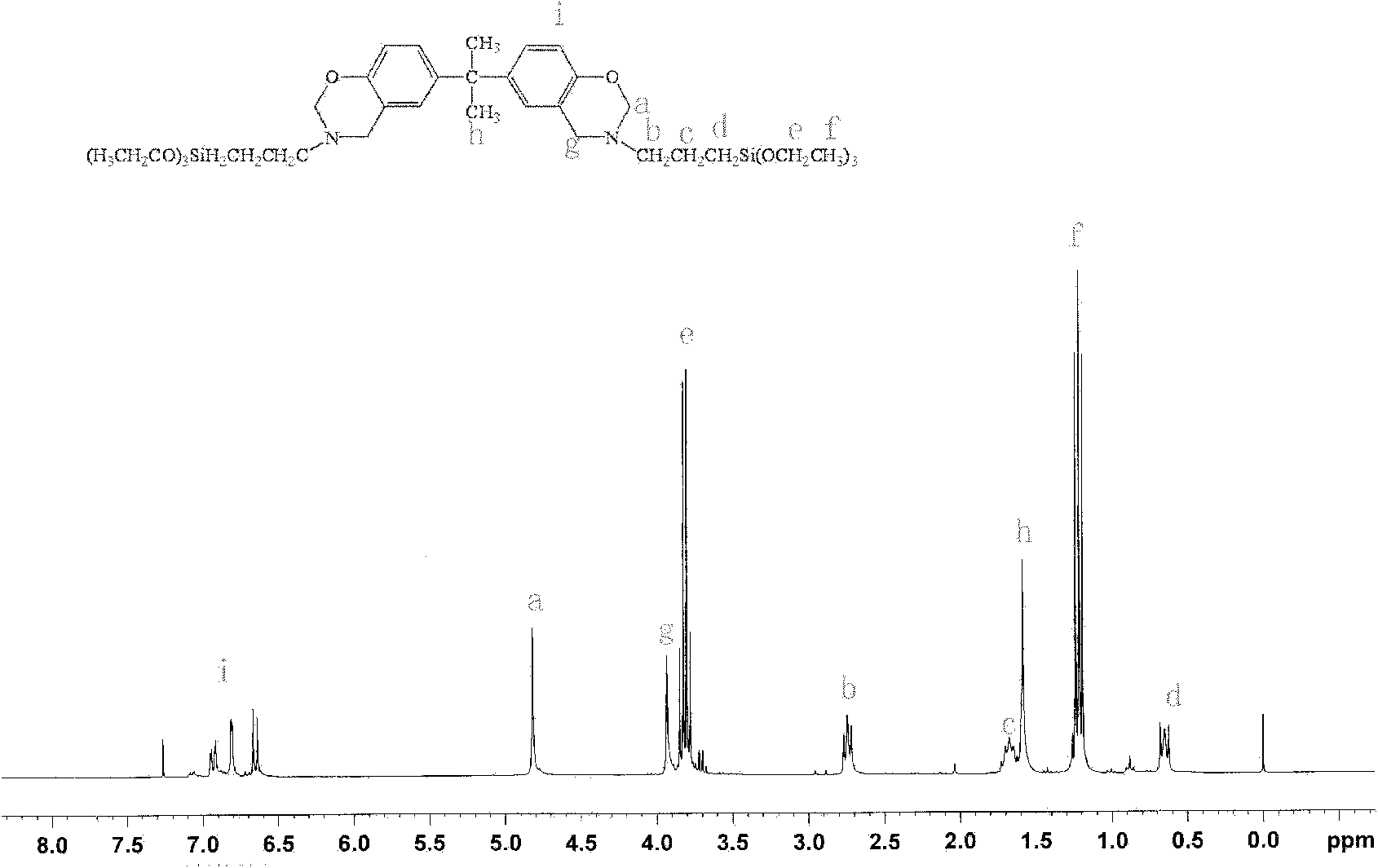

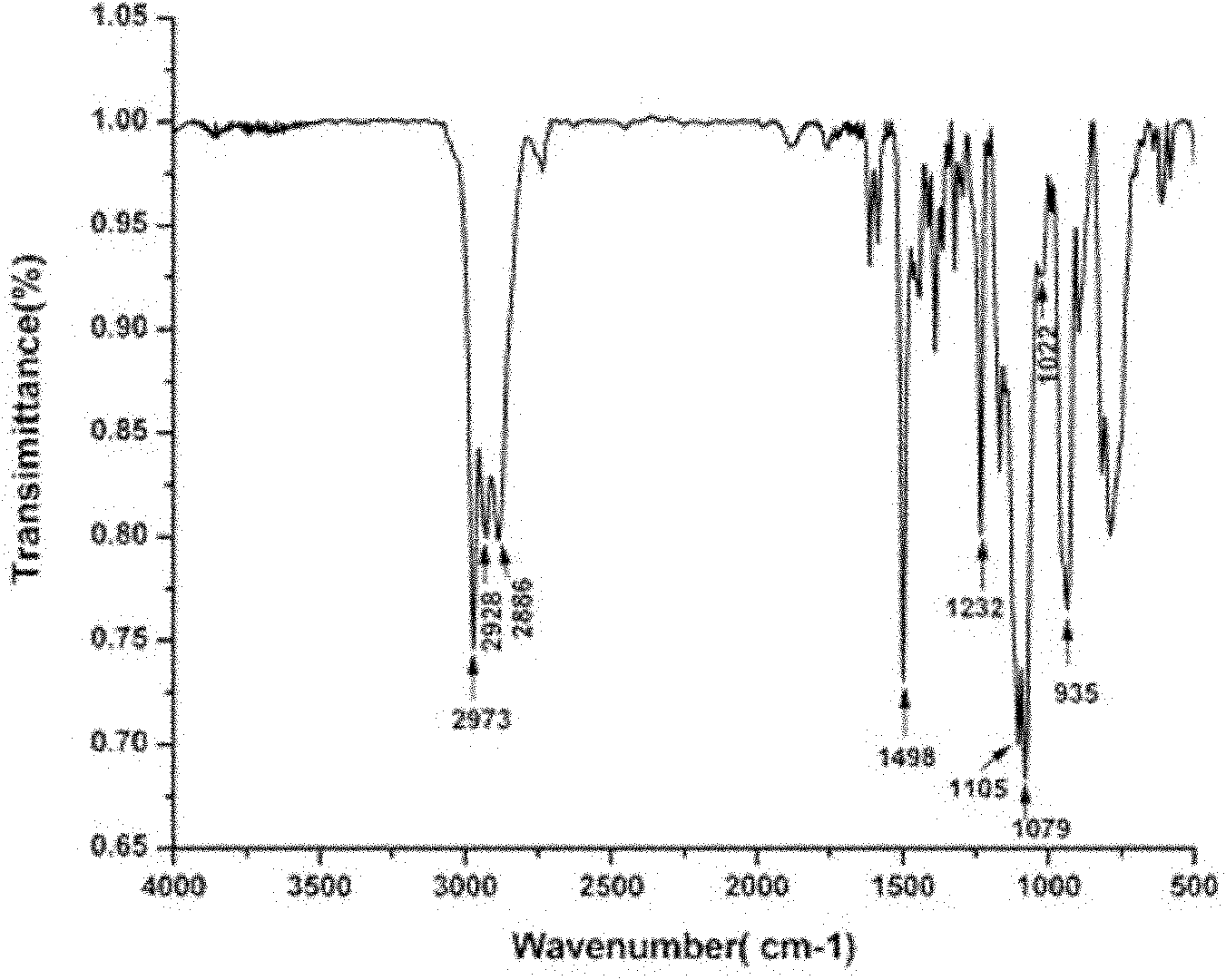

Silicon-containing benzoxazine resin as well as preparation method and application thereof

ActiveCN102134254BInhibition of macroscopic phase separationGood dispersionGroup 4/14 element organic compoundsCoatingsPolymer scienceMannich reaction

The invention discloses a silicon-containing benzoxazine resin. A monomer of the silicon-containing benzoxazine resin is synthesized through Mannich reaction according to theoretical mole ratio by taking phenols compounds, formaldehyde and amine compounds as reactive raw materials; and a polymer of the silicon-containing benzoxazine resin is obtained by carrying out hydrolytic condensation and heating ring-opening polymerization reaction on the monomer. Silicon-containing benzoxazine has higher carbon residual rate, glass transition temperature and silicon content and lower surface energy, thereby having potential application prospect in preparing ablation resisting materials, heat resisting material, flame-retardant materials and waterproof materials; and in addition, the invention has the advantages of simplicity, convenience and easy operation of a synthesis method of a benzoxazine monomer and a solidification process of poly-benzoxazine without specific equipment requirements and can carry out industrial production in a general plant.

Owner:SHANDONG UNIV

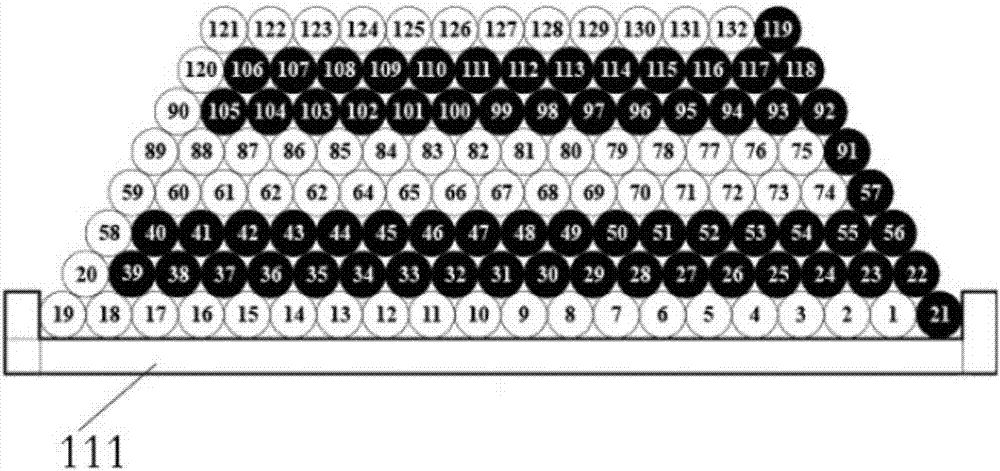

Winding method for high-stability fiber loop with trapezoidal cross section

ActiveCN106959107ASimple structureSimple processing technologySagnac effect gyrometersEngineeringClockwise

The invention discloses a winding method for a high-stability fiber loop with a trapezoidal cross section. The winding method comprises the following steps: S1) by taking a central point of an optical fiber as a starting point, clockwise winding N turns of first-layer optical fibers on a winding assembly at one end X of the optical fiber; S2) anticlockwise winding N-1 turns of second-layer optical fibers at the other end Y of the optical fiber, wherein the second-layer optical fibers are located on the middle positions of the two optical fibers on the lower layer; S3) anticlockwise winding N-2 turns of third-layer optical fibers at the other end Y; S4) clockwise winding N-3 turns of fourth-layer optical fibers at the end X; and S5) analogizing successively, thereby forming the fiber loop with the trapezoidal cross section. The invention has the beneficial effects that the cross section of the fiber loop is of trapezoidal shape, the overall stability is increased and the winding assembly structure and the fiber loop curing process are simple.

Owner:JIUJIANG SIYUAN TECH CO LTD

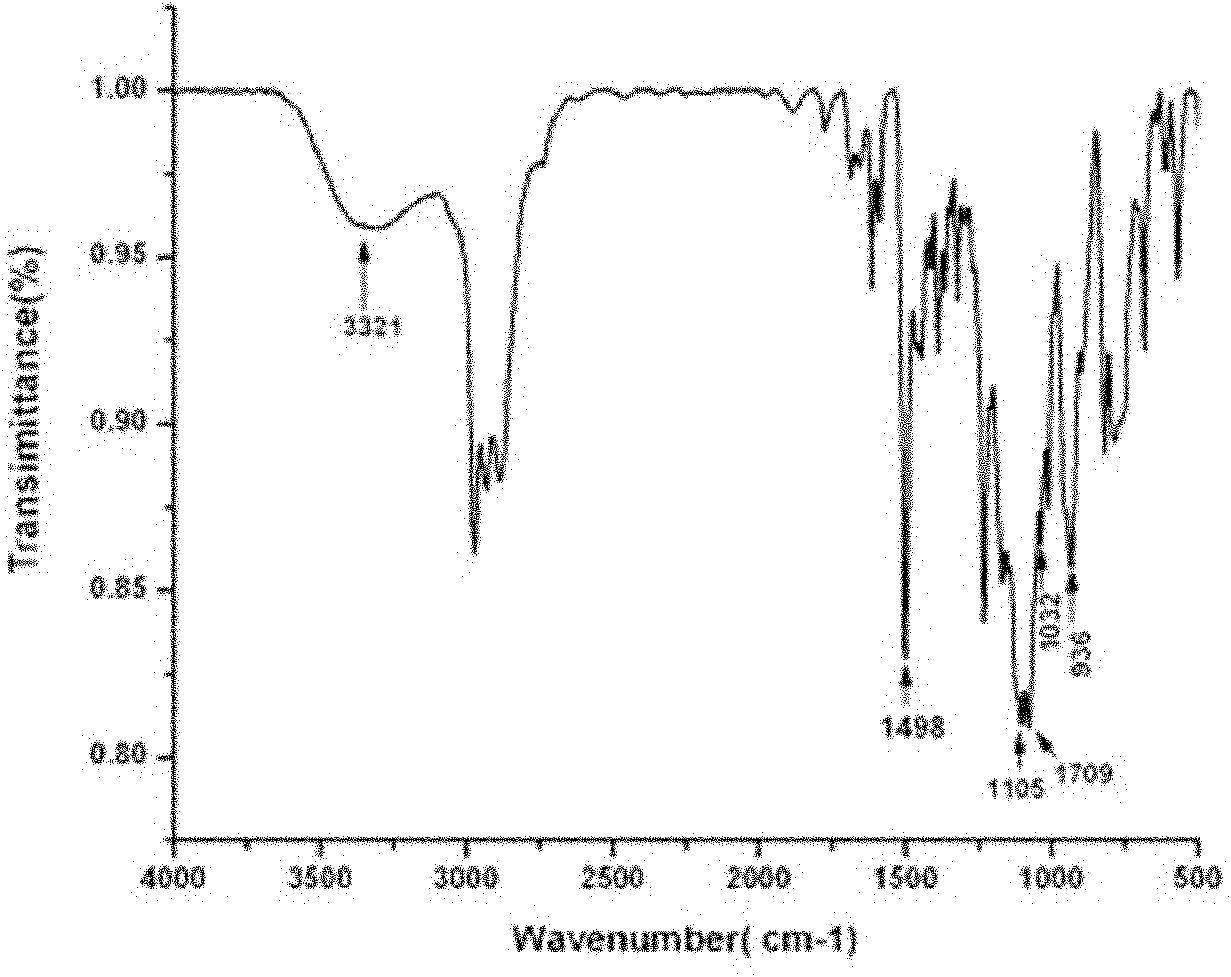

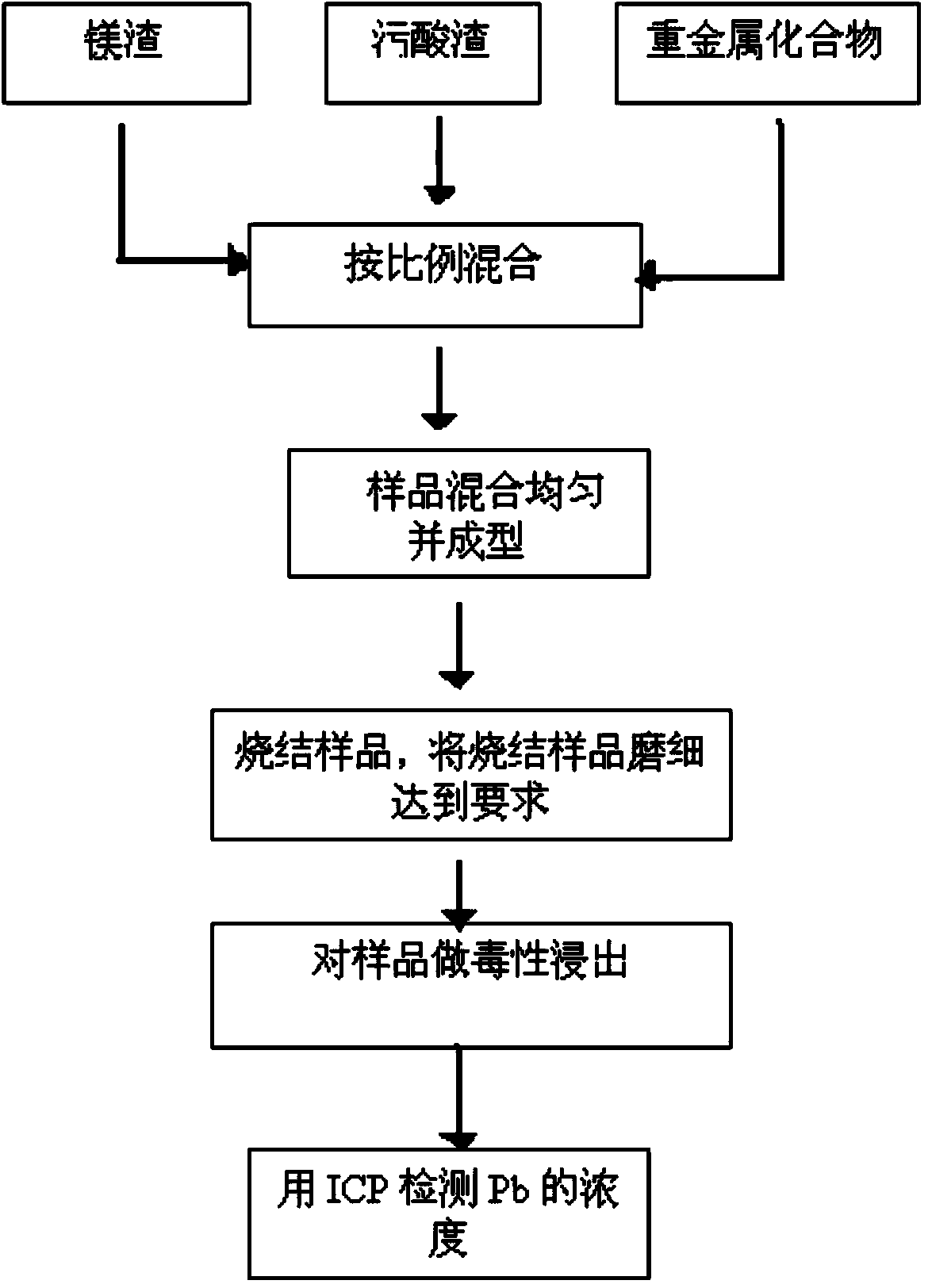

Method for curing lead in fouling acid slag

The method relates to a method for curing lead in fouling acid slag. The method is characterized by comprising the following steps that modified magnesium metal slag is added to the fouling acid slag after drying and grinding first, the modified magnesium metal slag and the fouling acid slag are mixed uniformly and then briquetted, and the obtained briquettes are placed in a sintering furnace for heat preservation under the temperature of 500-900 DEG C for 0.5-6 hours and are cooled and taken out. The method is a clean environmental protection treatment method for curing heavy metal Pb in the fouling acid slag, the modified magnesium slag of curing agents is magnesium metal smelting reducing slag, the purpose of waste control by waste is achieved, and therefore cost is low. The curing process for the fouling acid slag is simple, expensive materials are not used, and a project is easy to implement, so that industrialized operation is achieved; secondary waste slag, waste water and waste gas are not generated in the curing process, and the method can be implemented under safe and environment-friendly conditions.

Owner:BEIFANG UNIV OF NATITIES

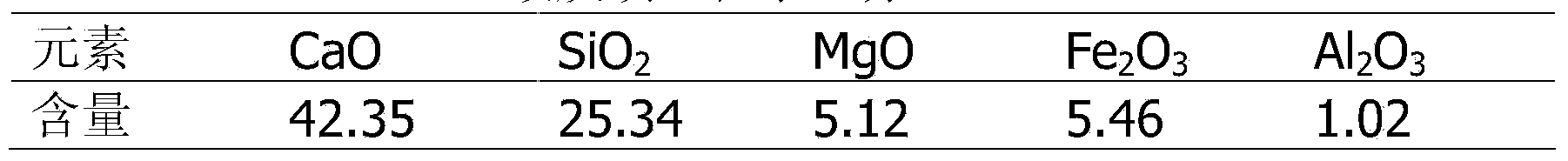

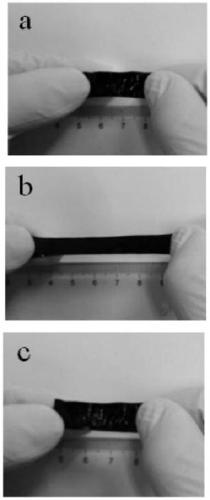

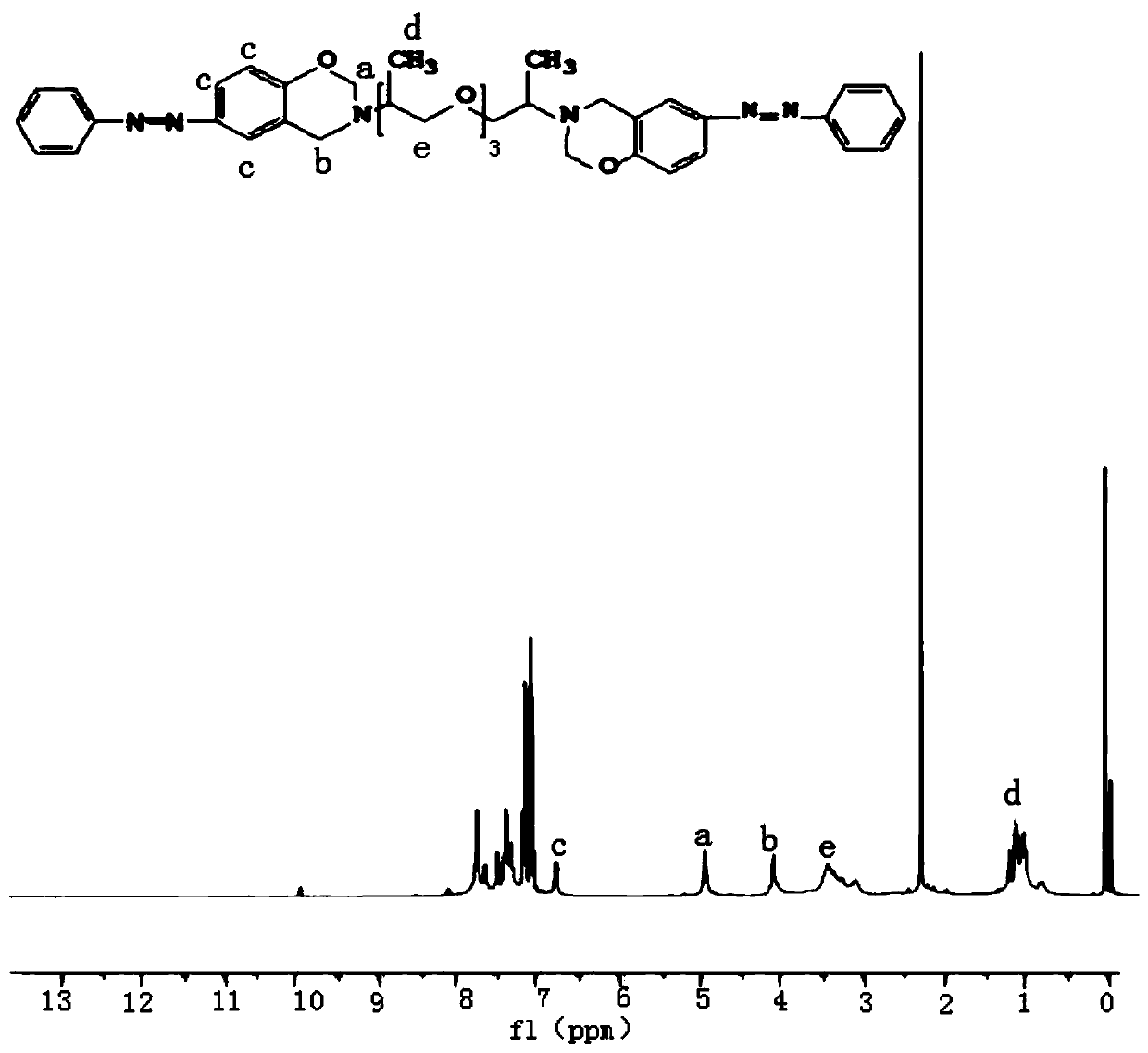

Photoactivity benzoxazine elastomer and preparation method thereof

The invention discloses a photoactivity benzoxazine elastomer. The elastomer is prepared from a benzoxazine monomer containing the azo structure and flexible chain segments through a ring opening polymerization reaction; the benzoxazine monomer is prepared from paraformaldehyde, phenol containing the azo structure and primary amine containing the flexible chain segments. A preparation method of the elastomer comprises the steps that (1) paraformaldehyde, the phenol containing the azo structure and a dispersion medium are added into a reaction kettle and stirred for 10-30 minutes at 25-60 DEG C, and then the primary amine containing the flexible chain segments is added slowly; (2) the system is heated to 100-125 DEG C, a reflux reaction is conducted for 4-10 hours, and through separation, the benzoxazine monomer is obtained; (3) firstly, the benzoxazine monomer is subjected to a reaction for 1-5 hours at 160-200 DEG C and then subjected to a reaction for 2-4 hours at 200-260 DEG C, andthe photoactivity benzoxazine elastomer is obtained. The photoactivity benzoxazine elastomer has photoactivity of an azoic compound and flexibility brought by a flexible group compound, keeps the application characteristic of polybenzoxazine and has a wide application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com