Curing method for storage battery

A curing method and battery technology, applied in the direction of lead-acid battery, lead-acid battery electrode, lead-acid battery construction, etc., can solve problems such as battery scrap and damage, and achieve the effect of preventing surface peeling, easy operation, and increasing bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0029] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

[0030] 1. Inspection of equipment and tools

[0031] ⑴ Check whether the heating, humidifying and exhausting devices of the curing room are normal, and report for repair immediately if they are not normal.

[0032] (2) Check whether the water level of the water tank in the curing room meets the requirements; check whether the use of the small gauze on the temperature and humidity sensor meets the requirements;

[0033] (3) Check whether there is rust on the surface of the curing rack, if there is rust, stop using it, and use it after painting.

[0034] 2. Material inspection

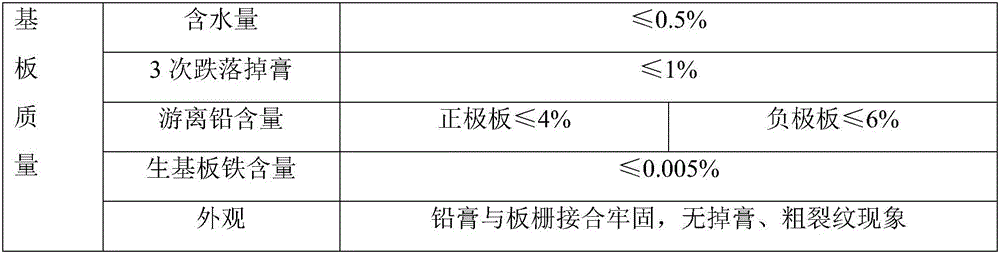

[0035] Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com