Patents

Literature

32results about How to "Joint strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

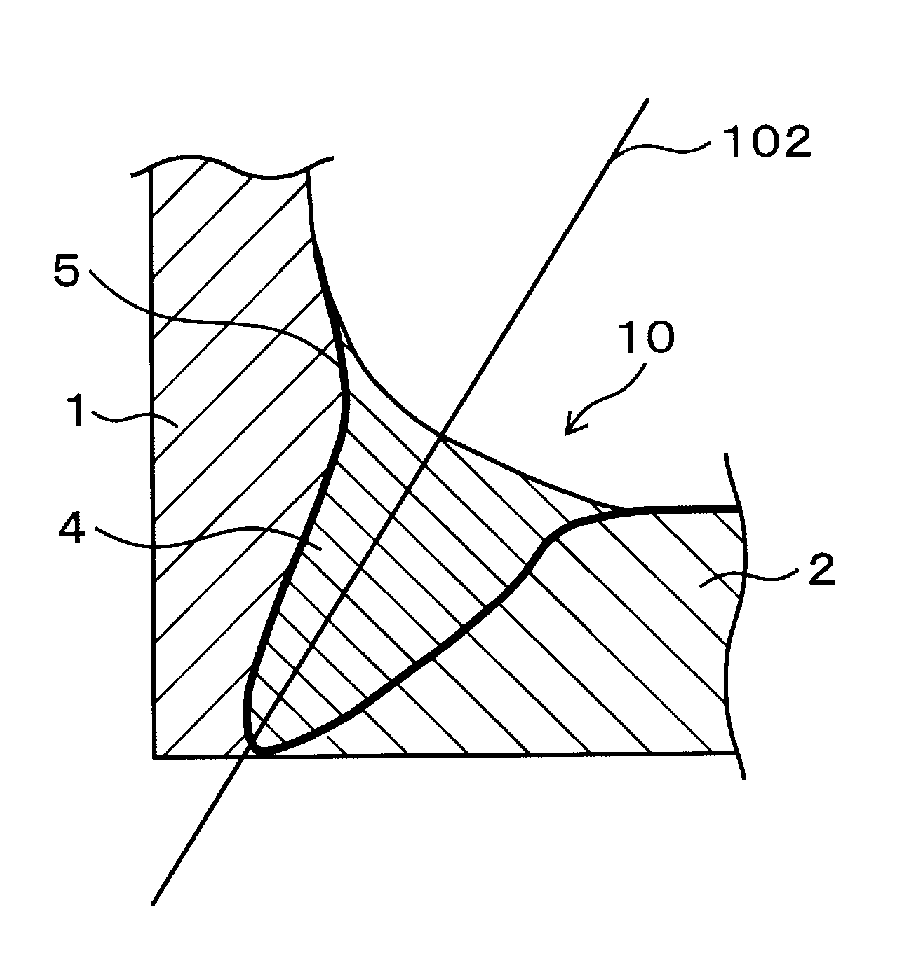

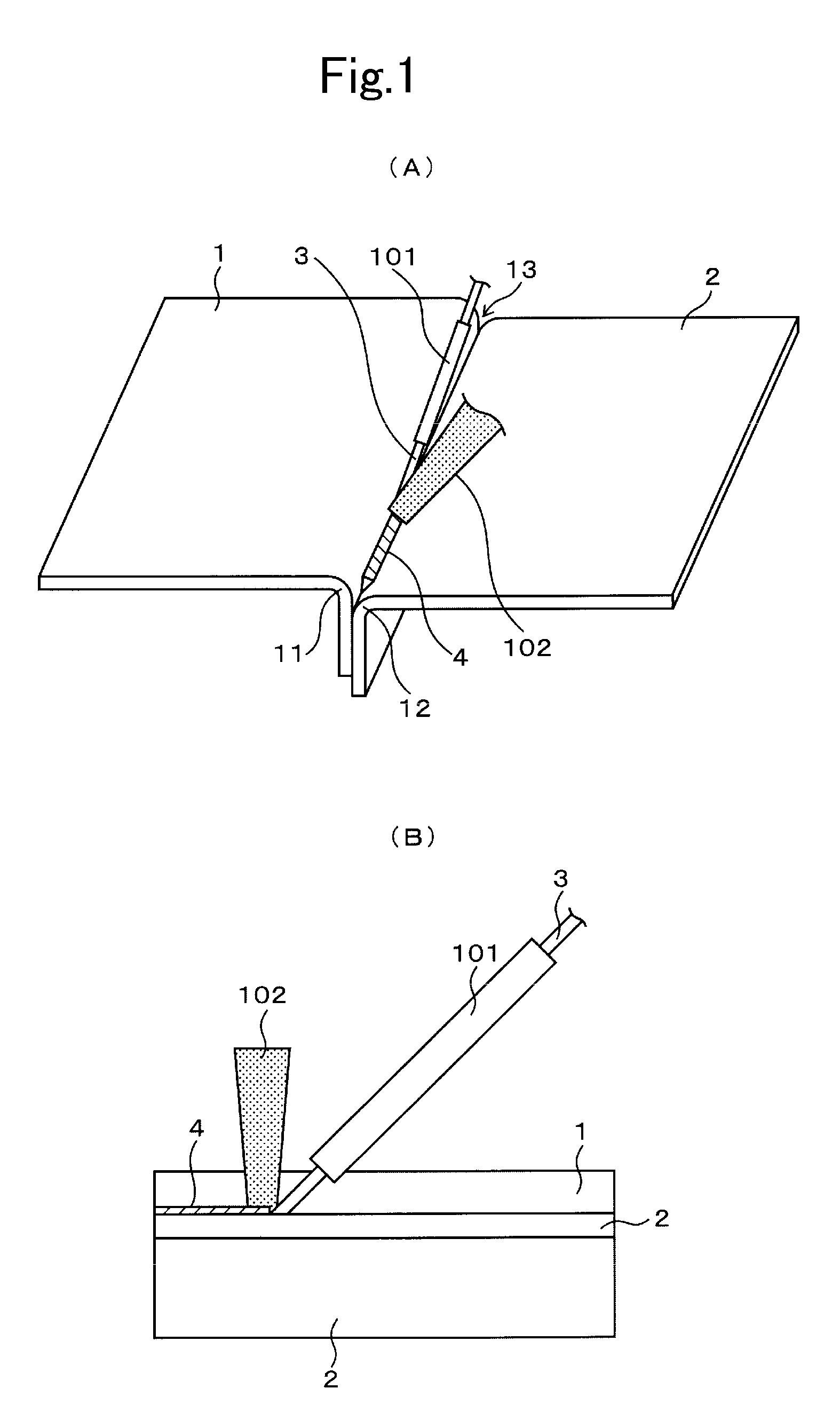

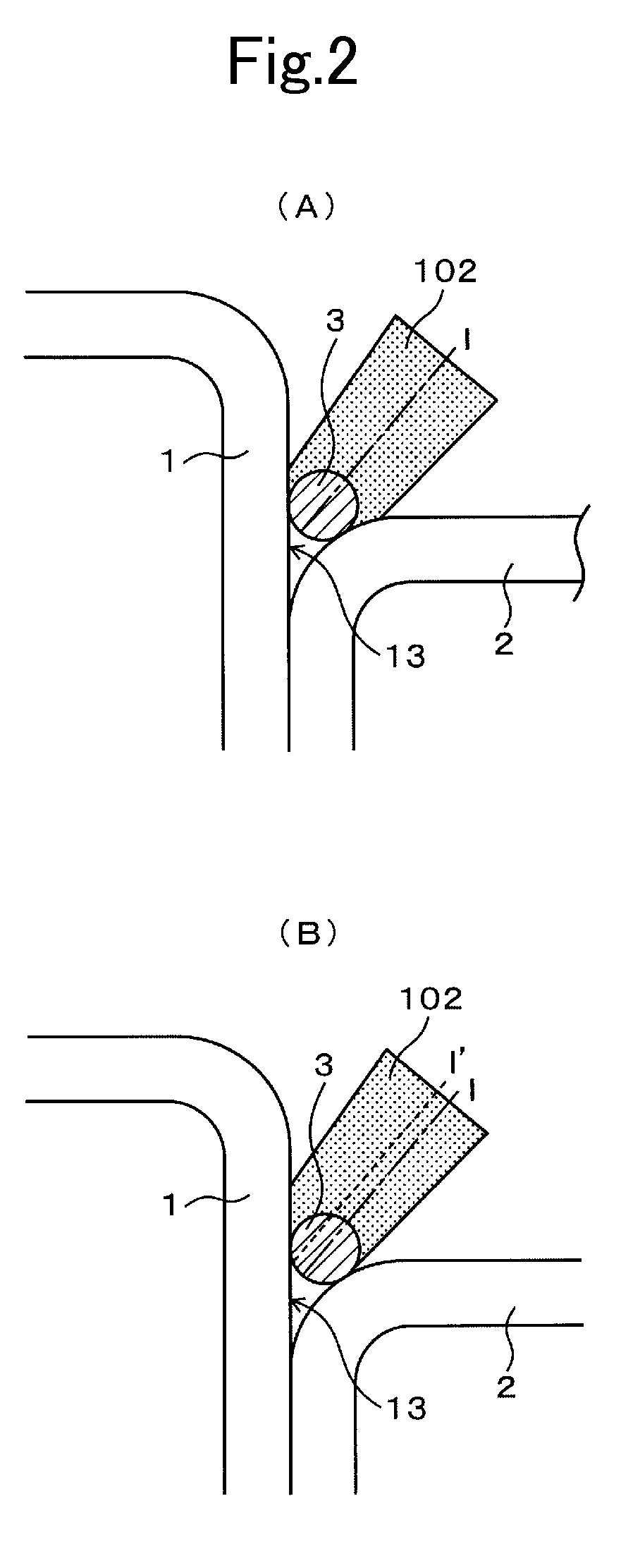

Method for joining metallic members, joint structure and brazing filler metal

InactiveUS20110020666A1Improve joint strengthJoint strengthWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalMetal

In joining an Fe-based metallic member comprising an Fe-based material and an Al-based metallic member comprising an Al-based material by a Zn-based brazing filler metal, a joined part of the Fe-based metallic member is heated at a temperature higher than a melting point of the Fe-based material.

Owner:HONDA MOTOR CO LTD

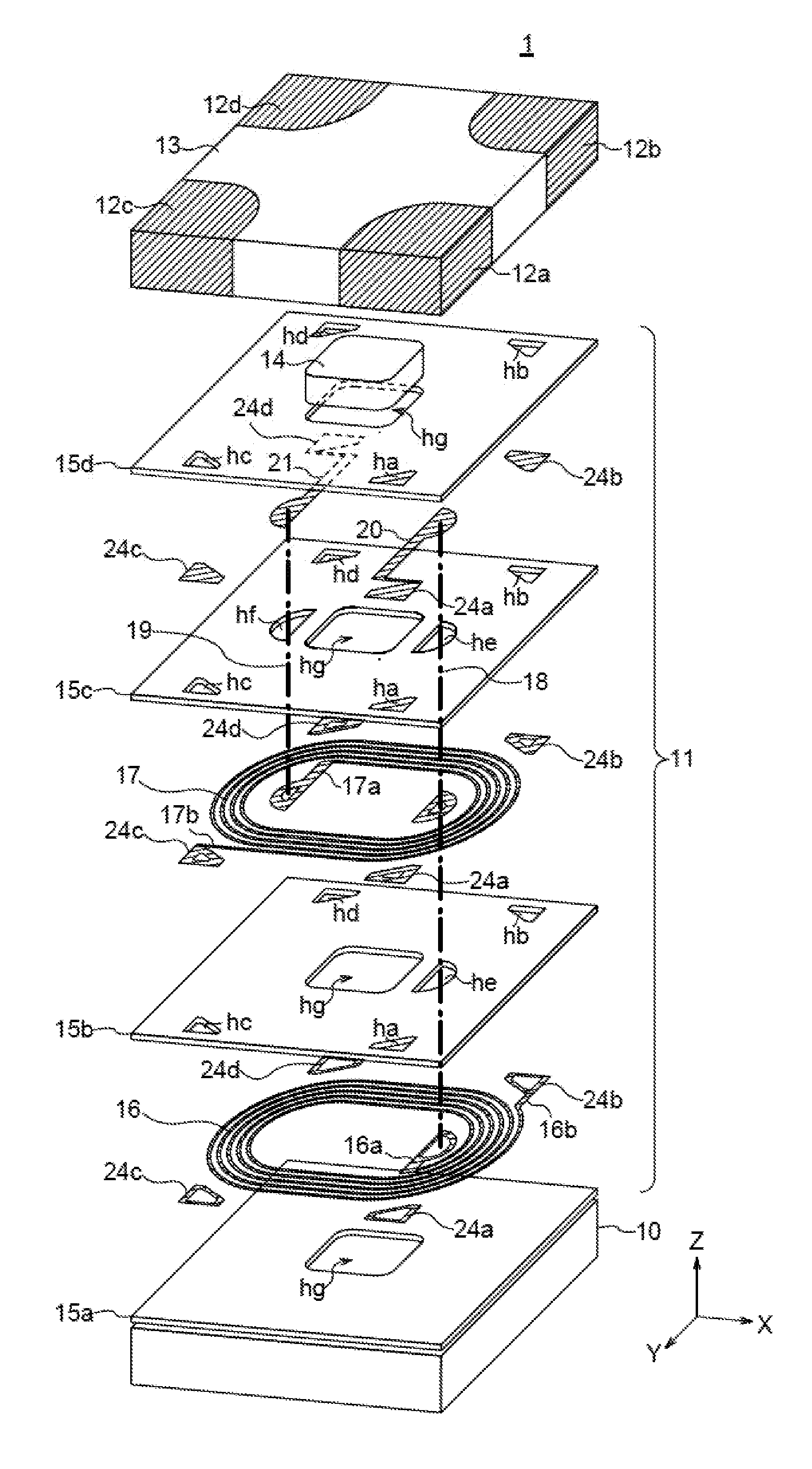

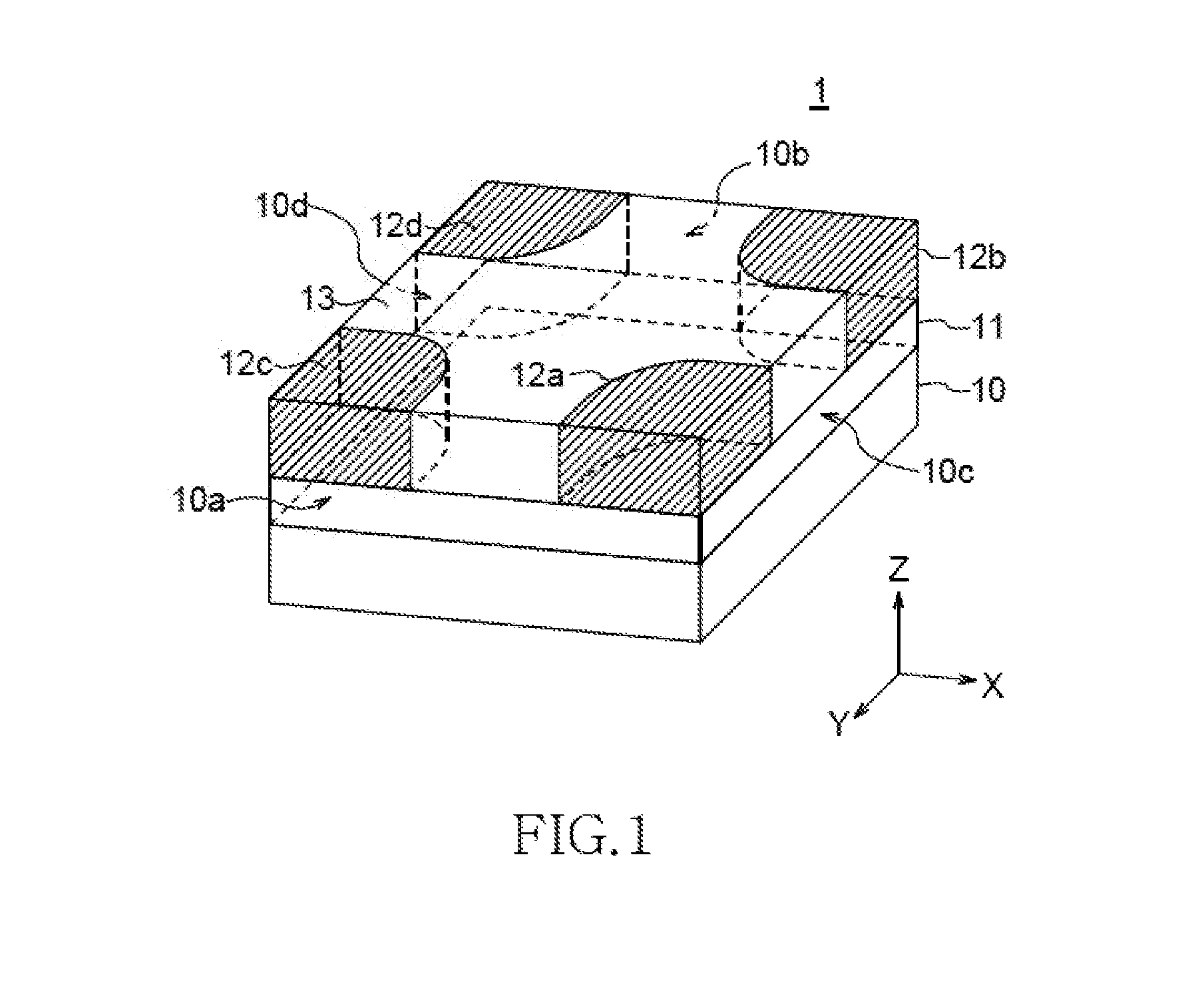

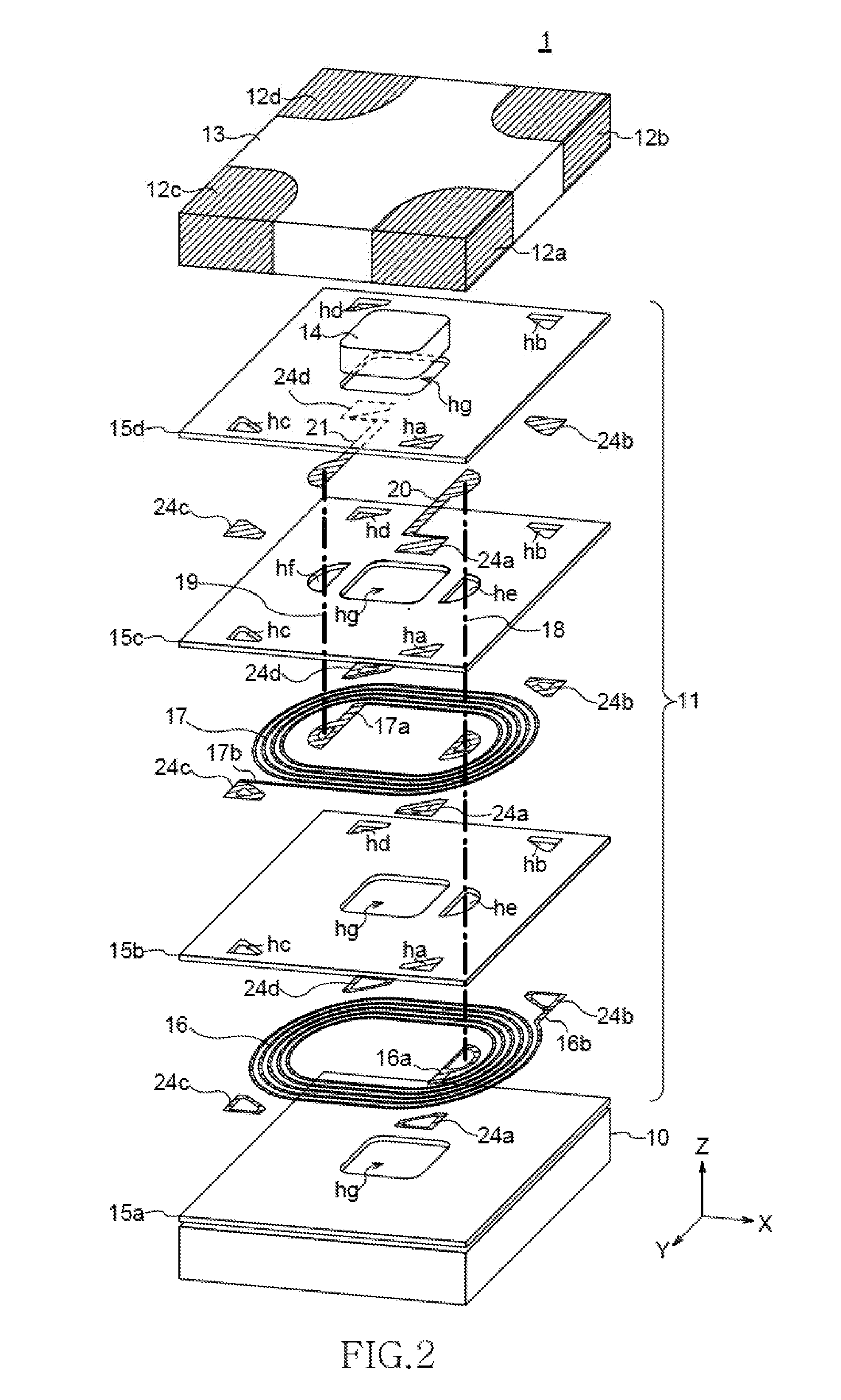

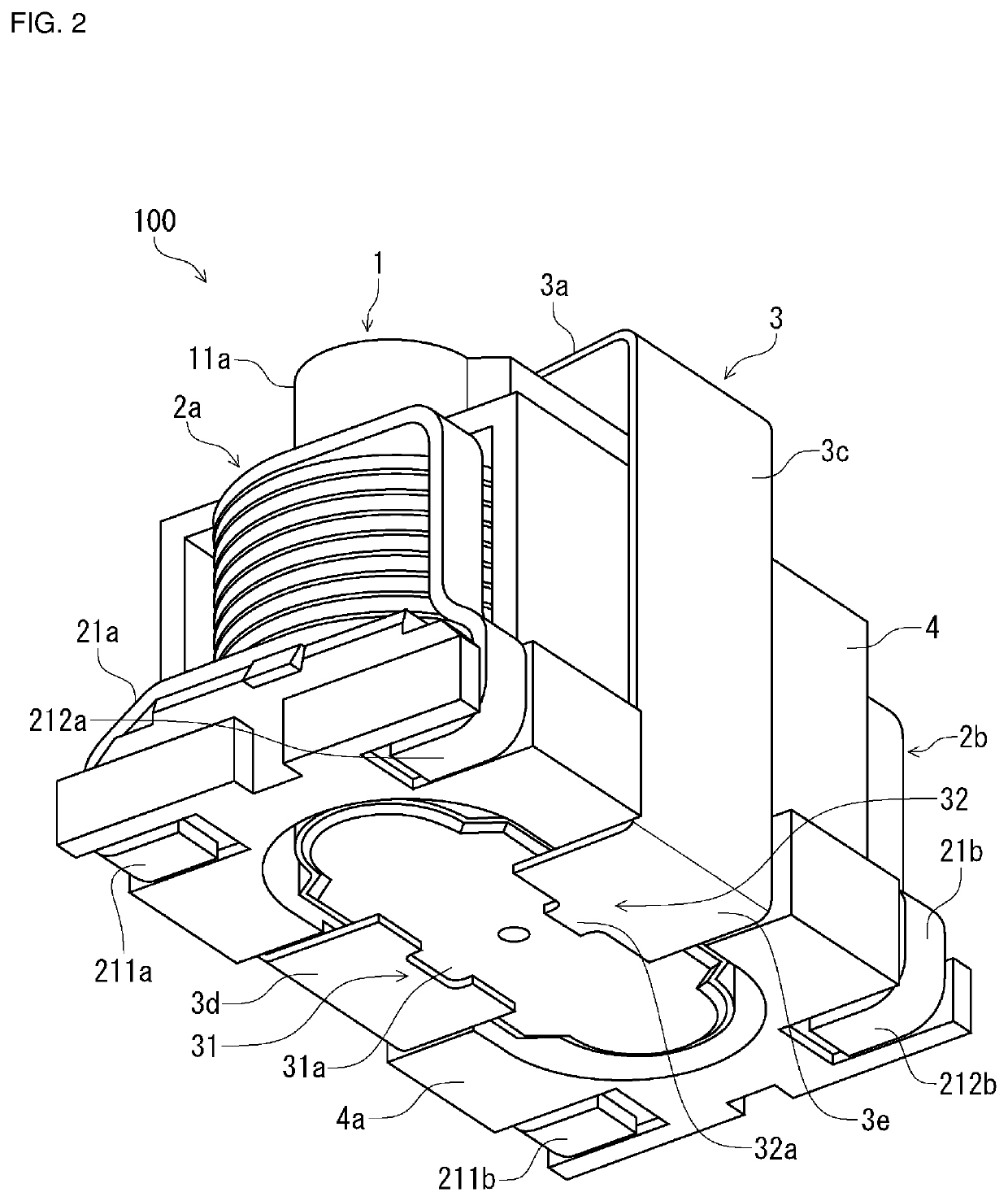

Electronic component and manufacturing method thereof

ActiveUS20140266547A1Joint strengthReduce DC resistanceTransformers/inductances coils/windings/connectionsCoils manufactureElectrical conductorElectronic component

An electronic component includes a first conductor layer including a first conductor pattern P1, a first insulating layer covering the first conductor layer, a first opening h1 passing through the first insulting layer to expose top and side surfaces of the first conductor pattern P1 therethrough, and a second conductor layer formed on the first insulating layer and including a second conductor pattern P2 connected to the first conductor pattern P1 through the first opening h1. A first opening region which is a planar region inside the first opening h1 includes a first region in which the first conductor pattern P1 is formed and a second region in which the first conductor pattern P1 is not formed. The second conductor pattern P2 is embedded in both the first and second regions of the first opening h1.

Owner:TDK CORPARATION

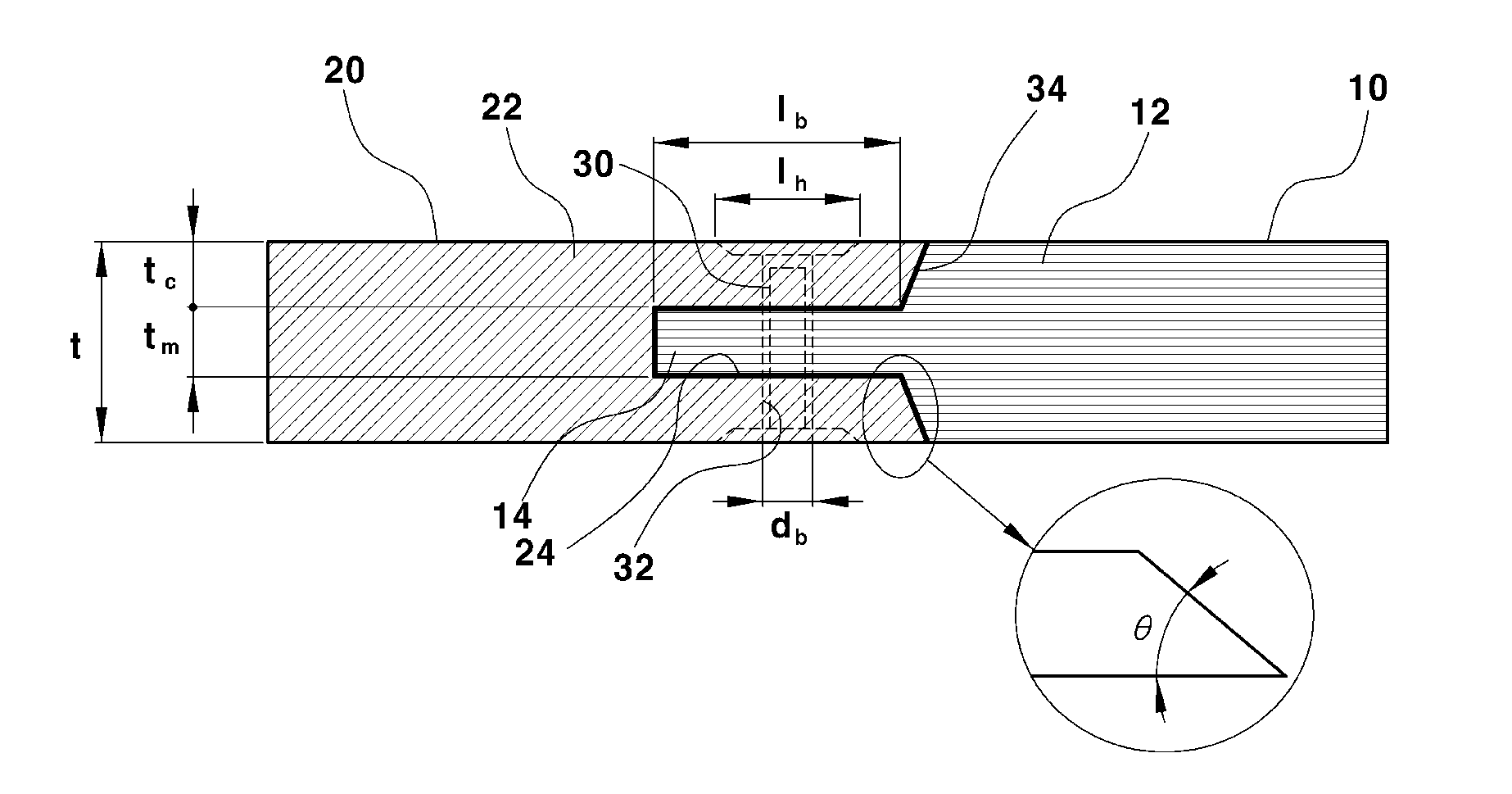

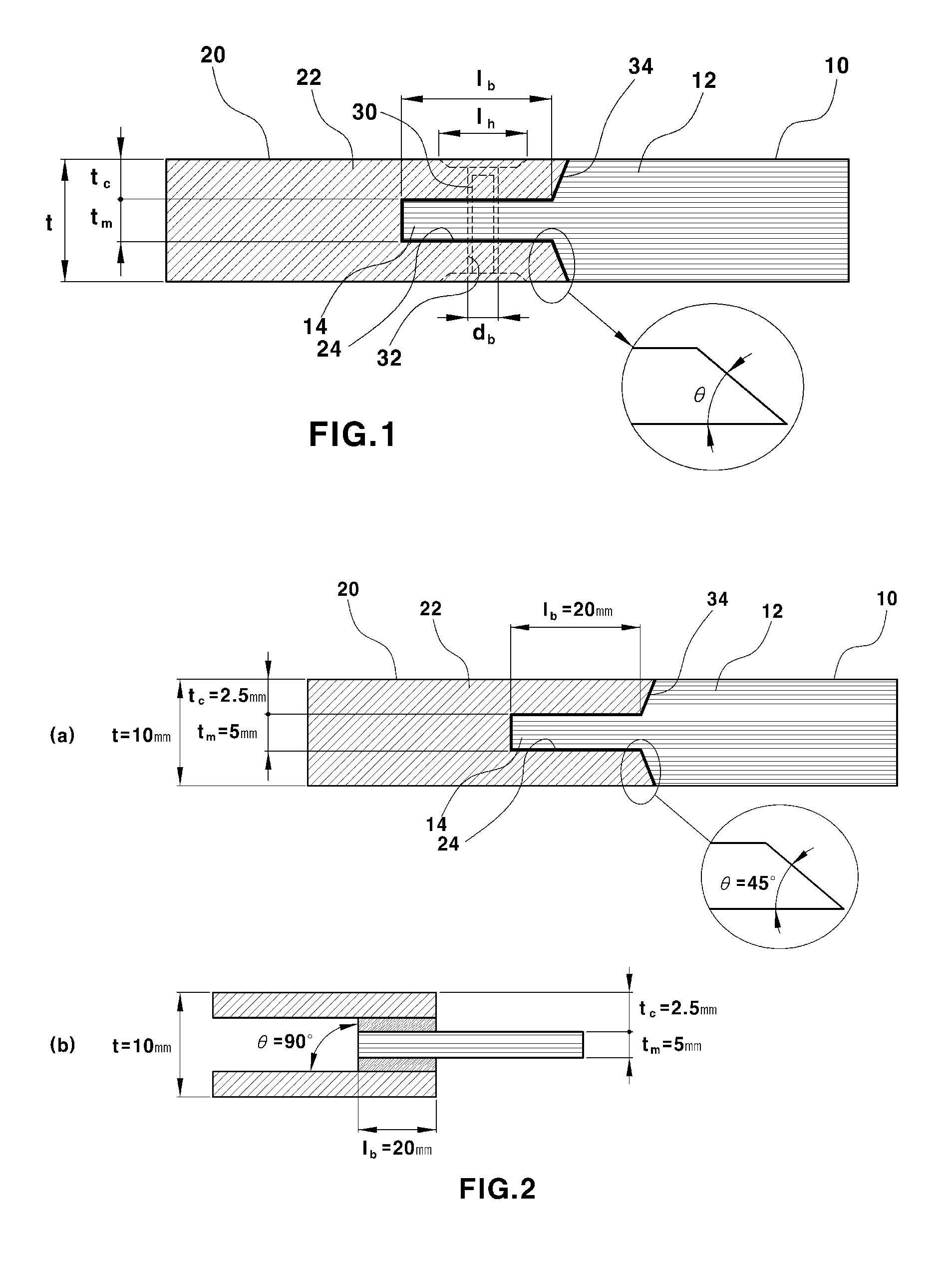

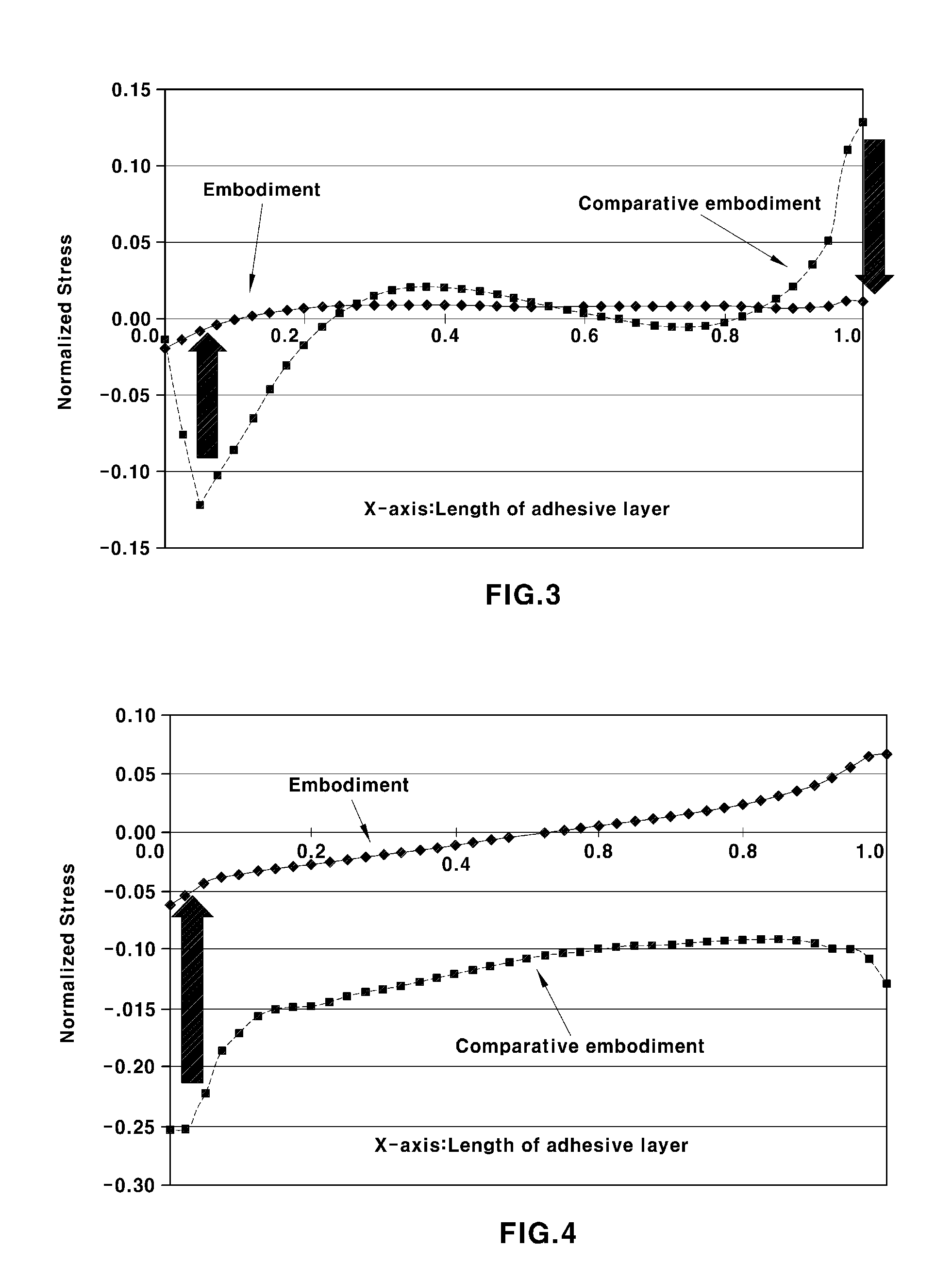

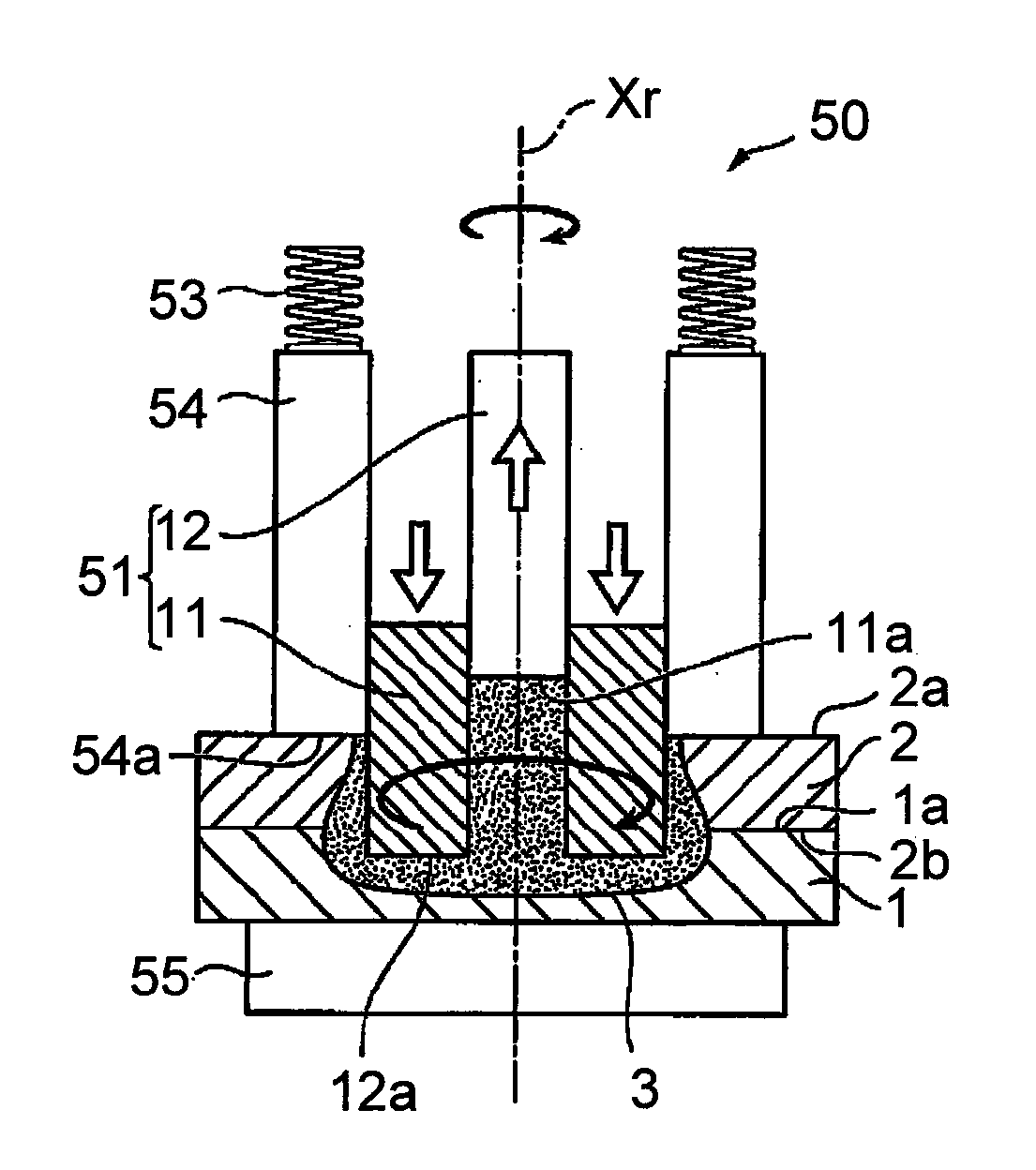

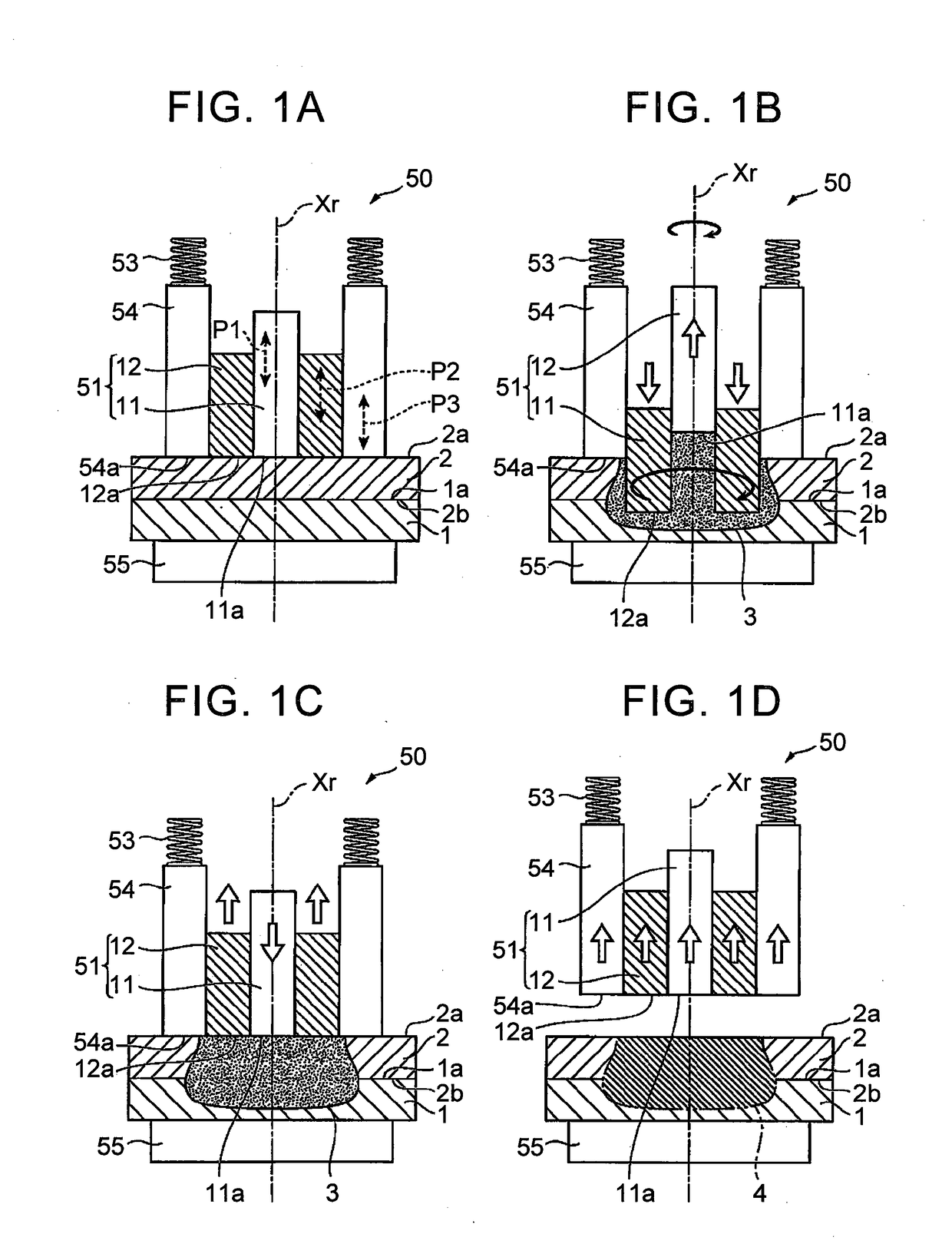

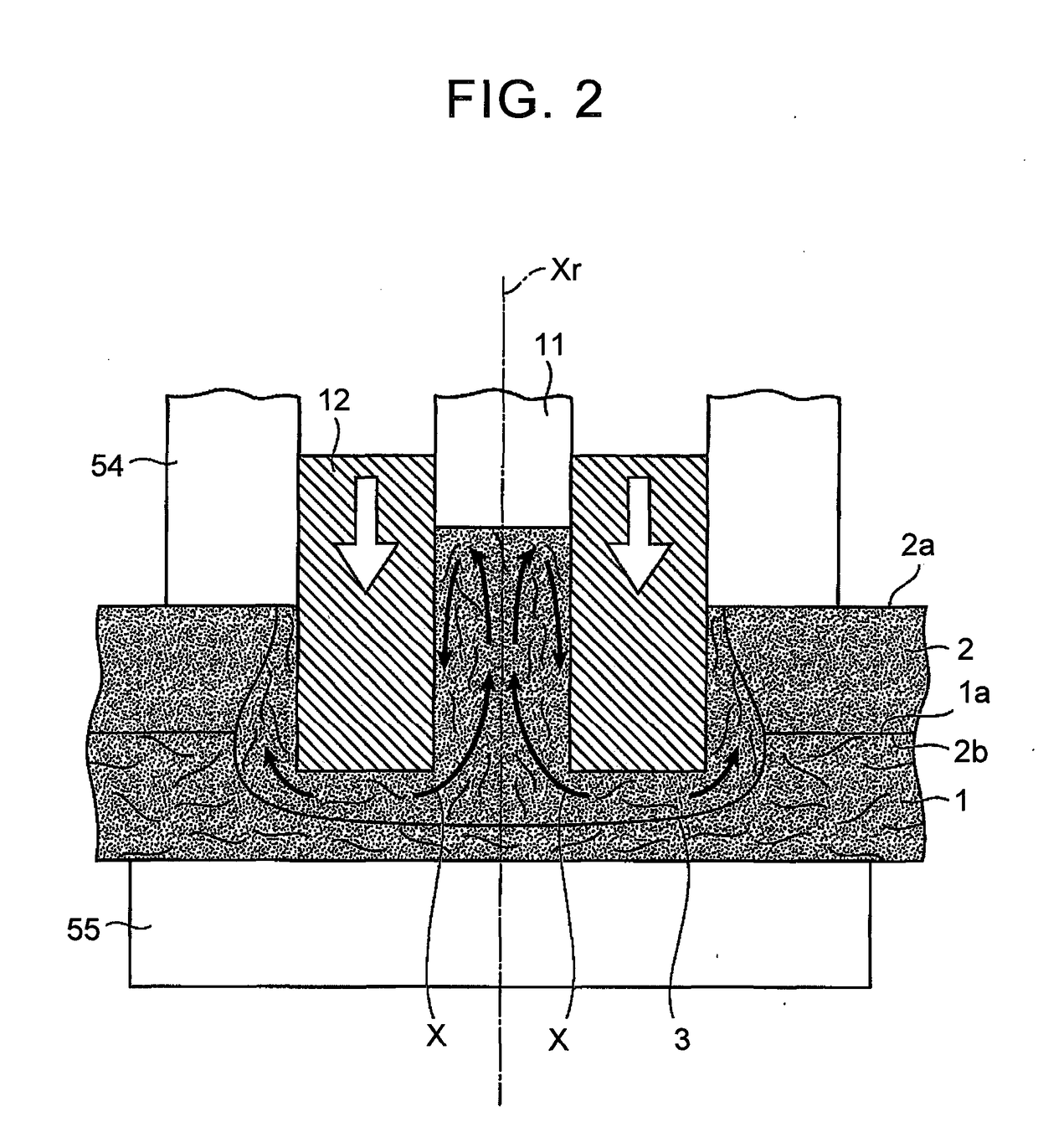

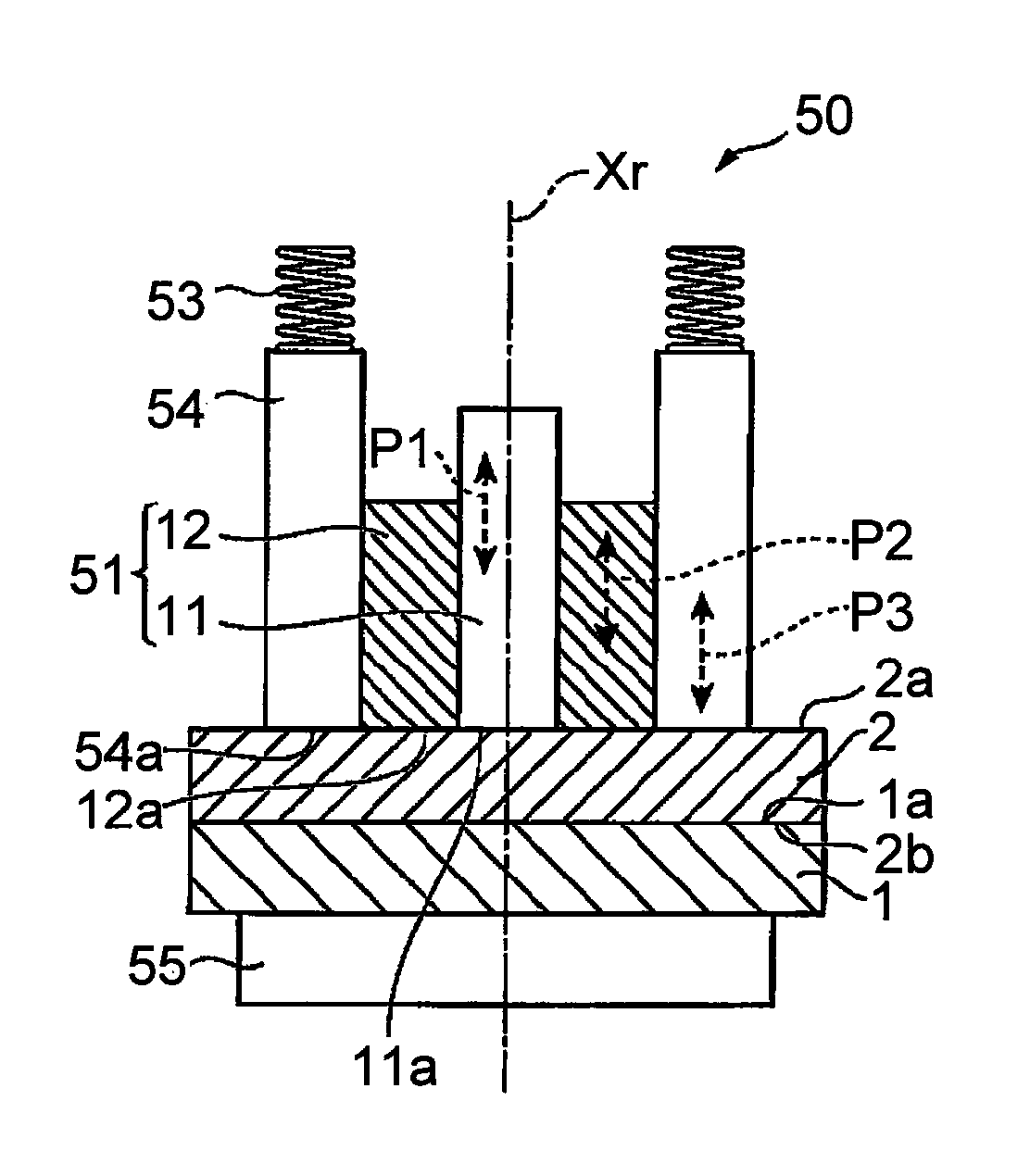

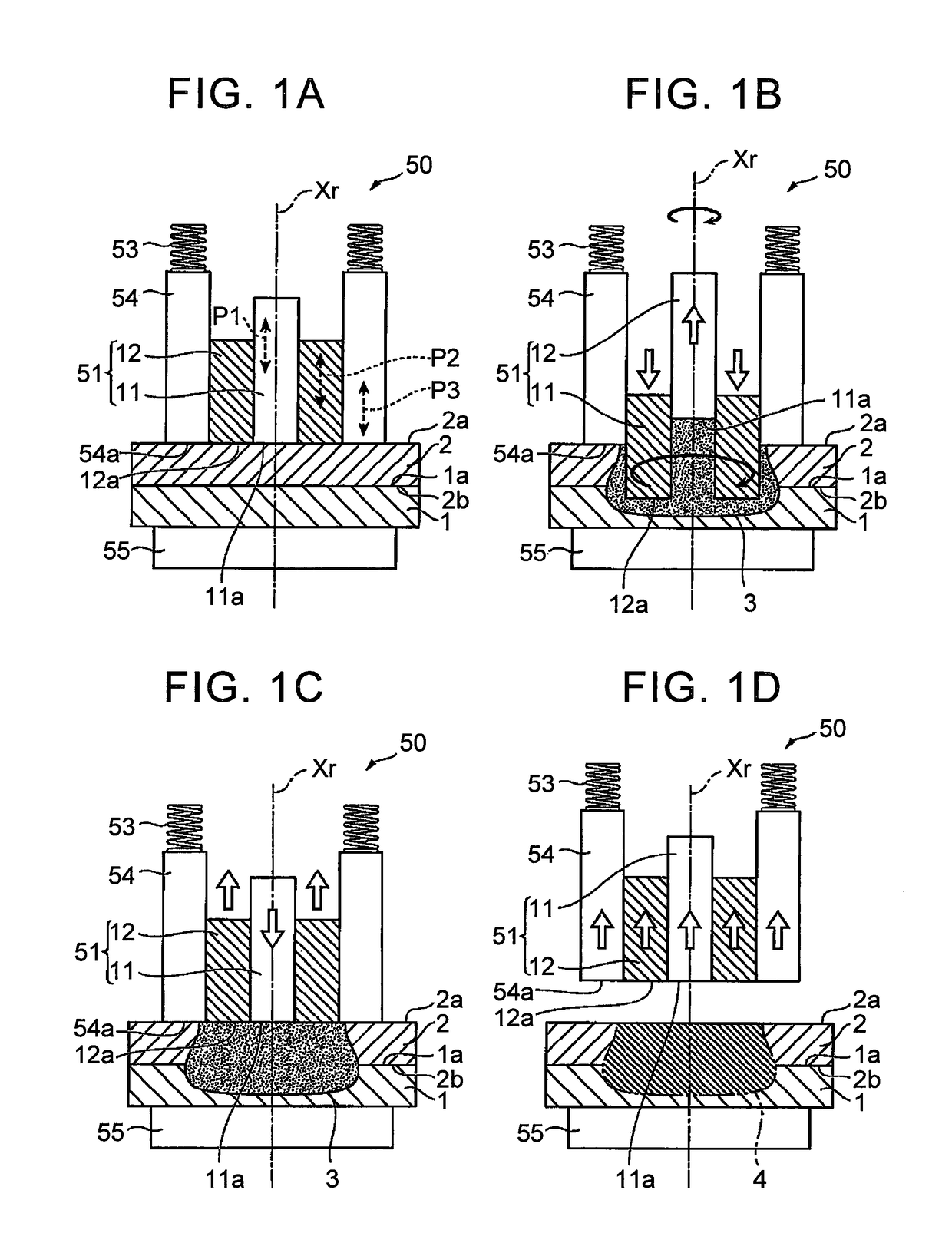

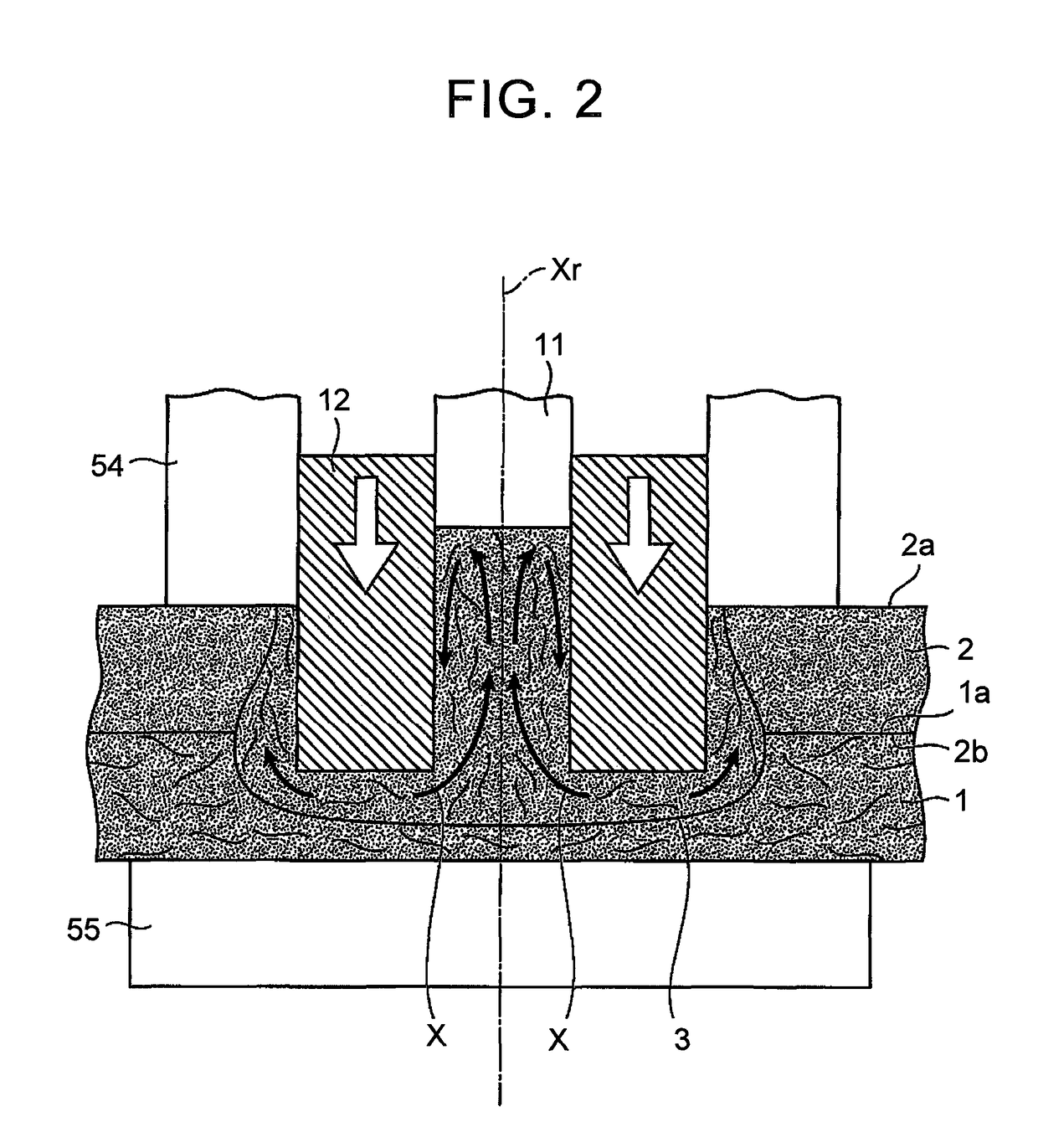

Device and method for joining a composite and metallic material

InactiveUS20130129409A1Joint strengthImprove joint strengthMaterial gluingLaminationEngineeringMetallic materials

Owner:HYUNDAI MOTOR CO LTD

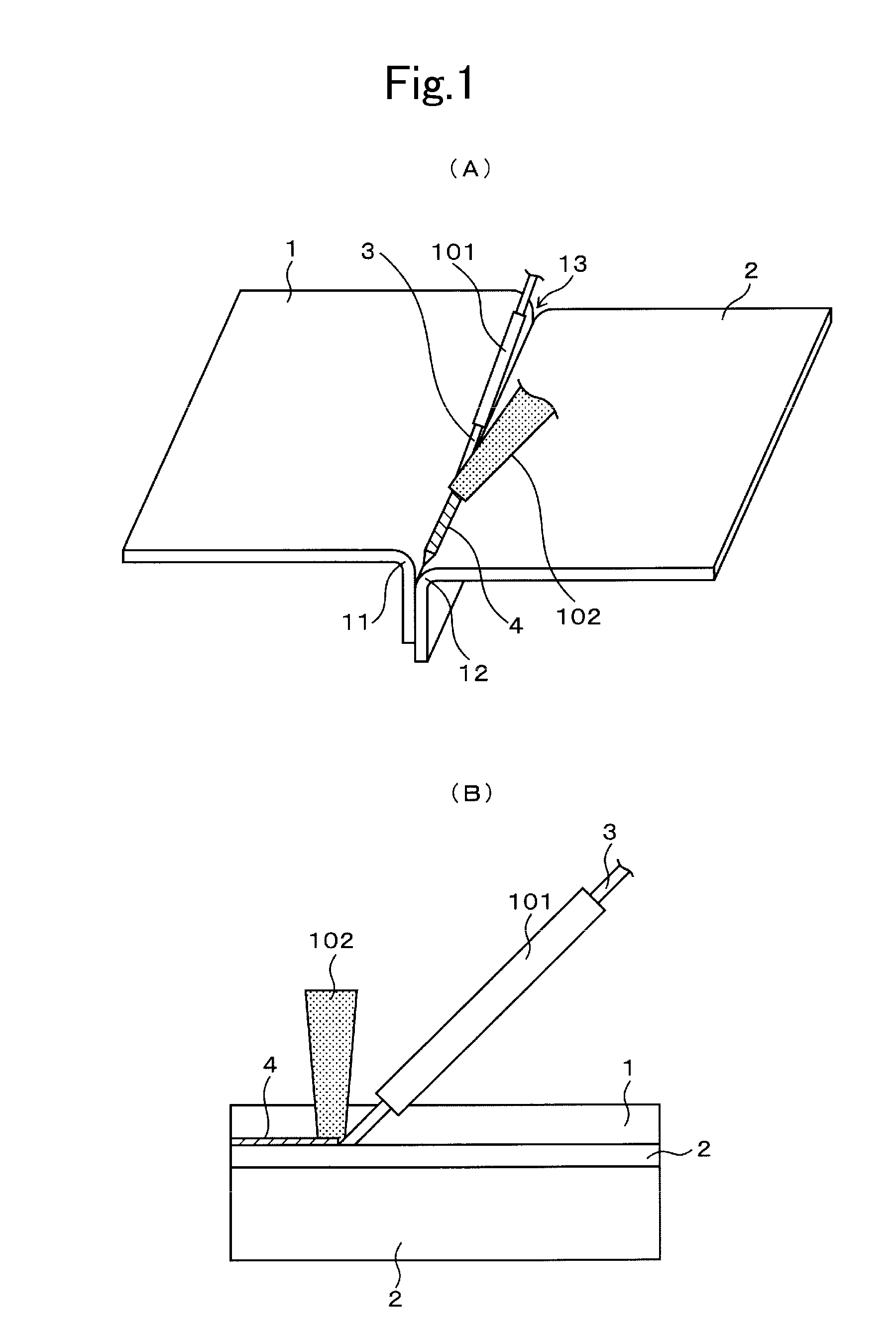

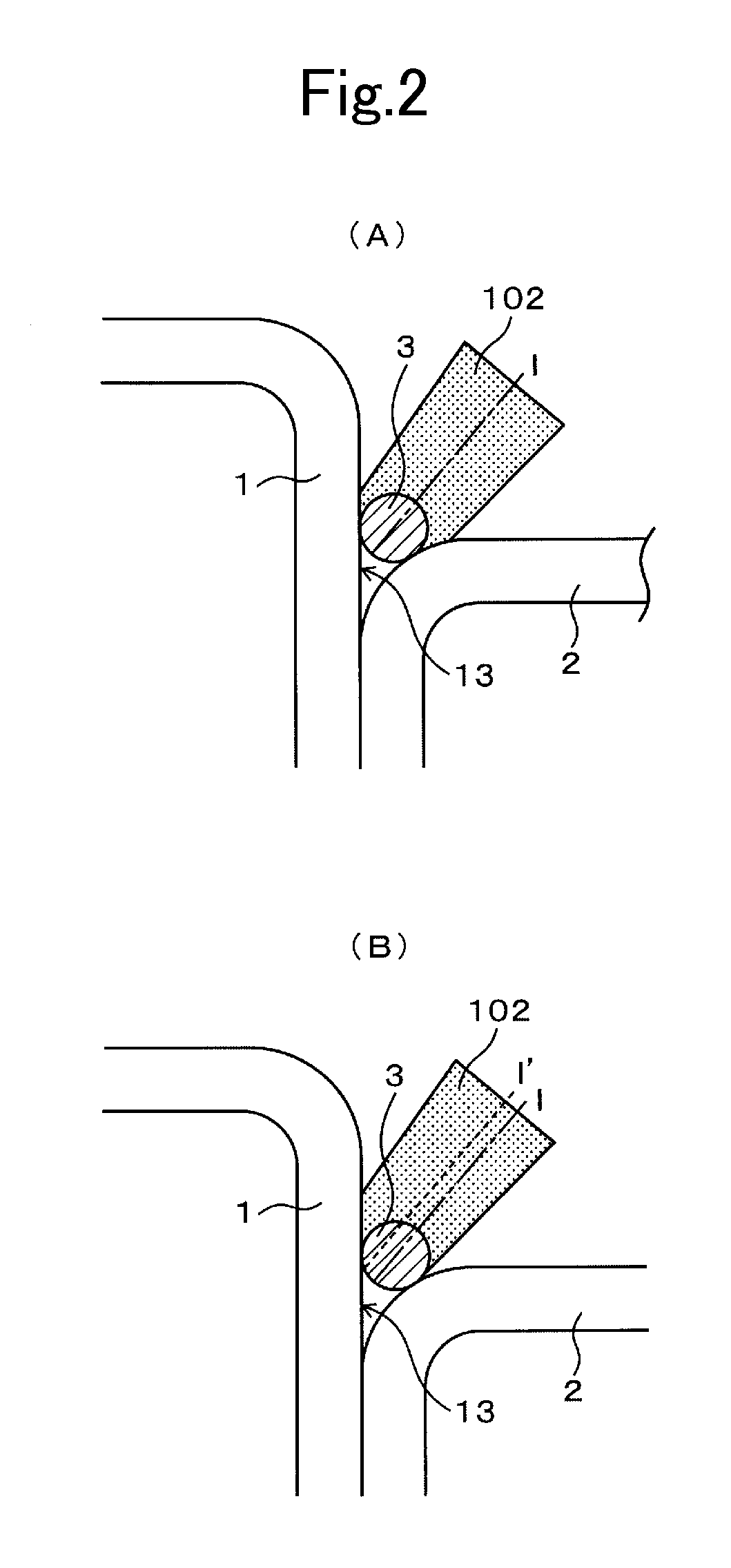

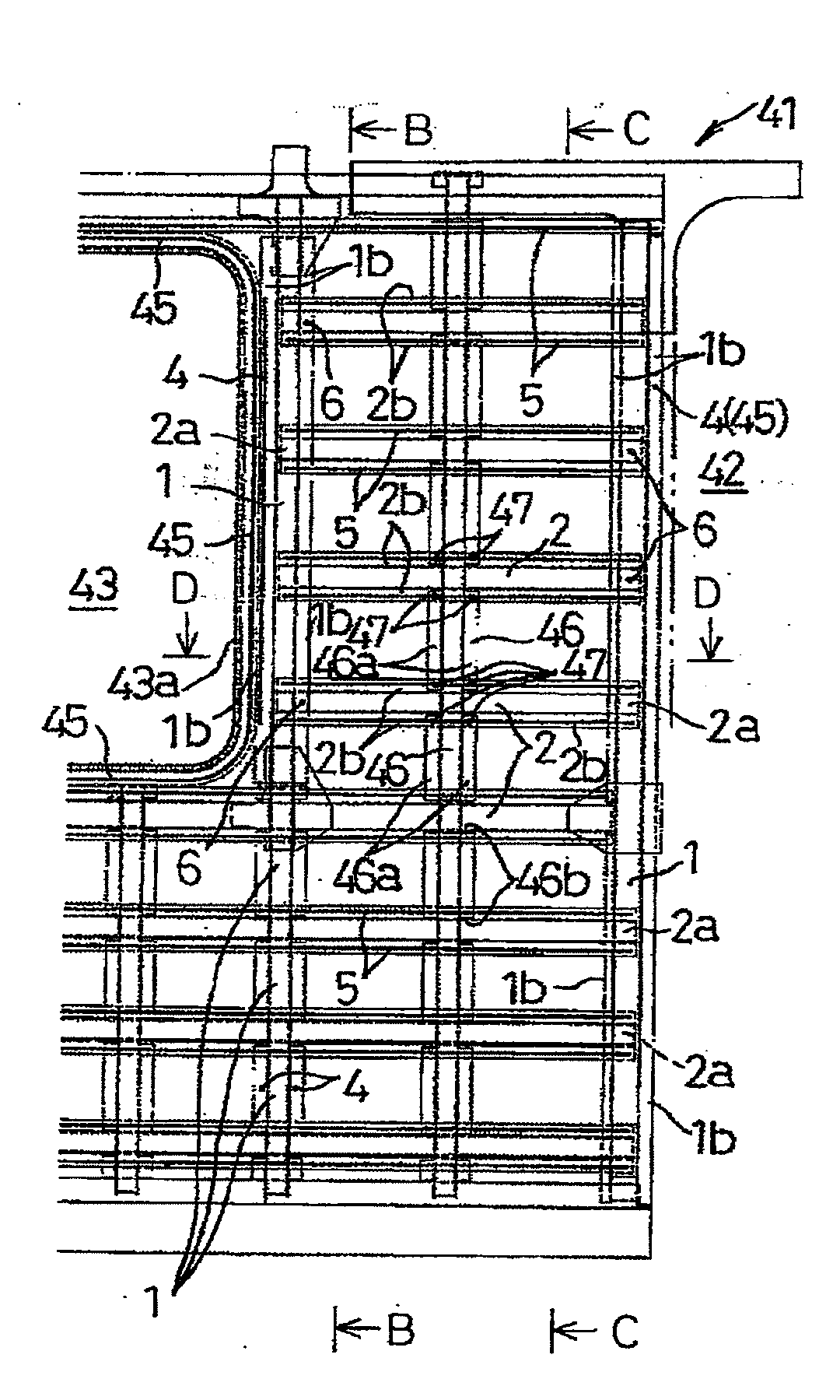

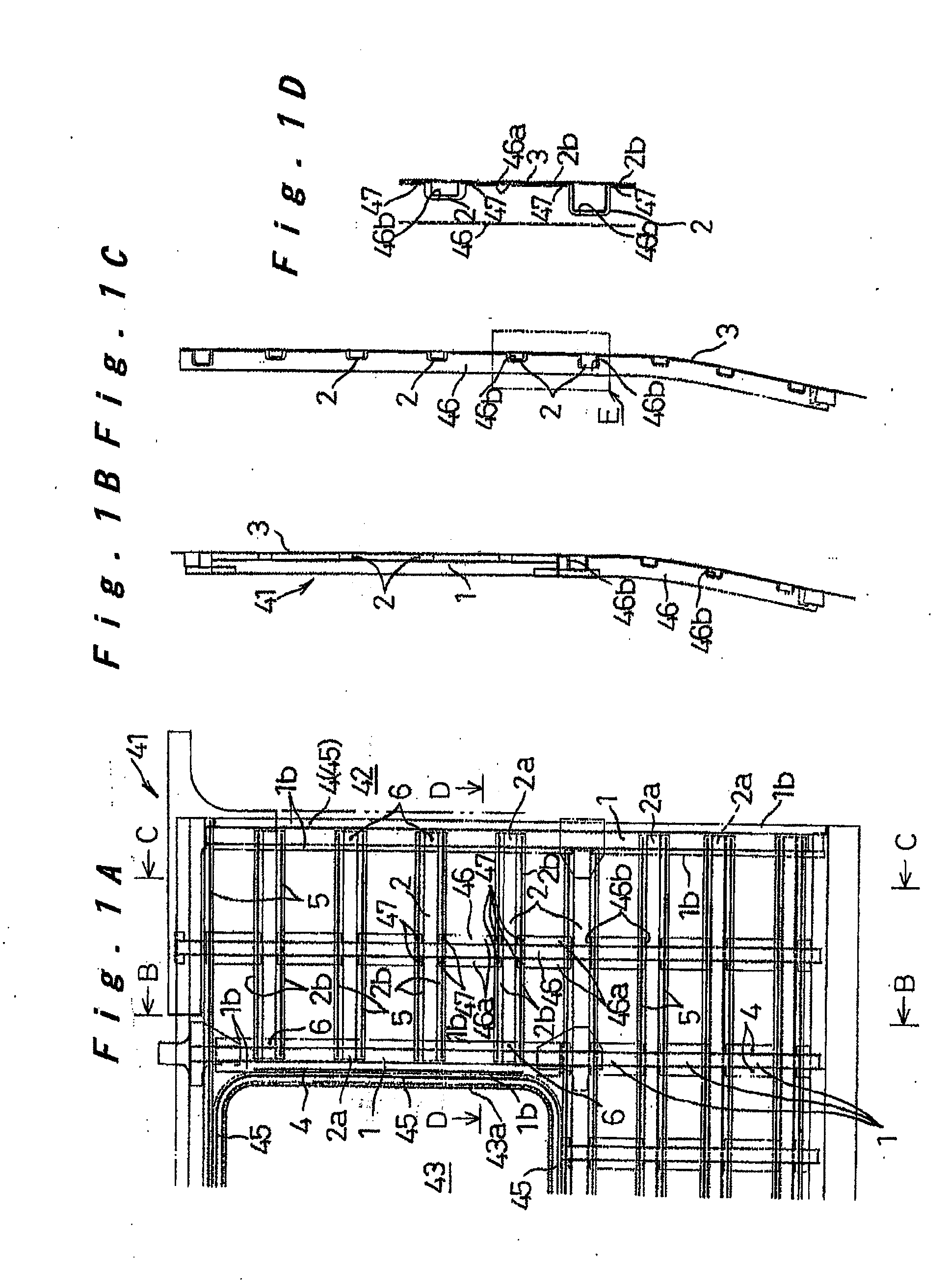

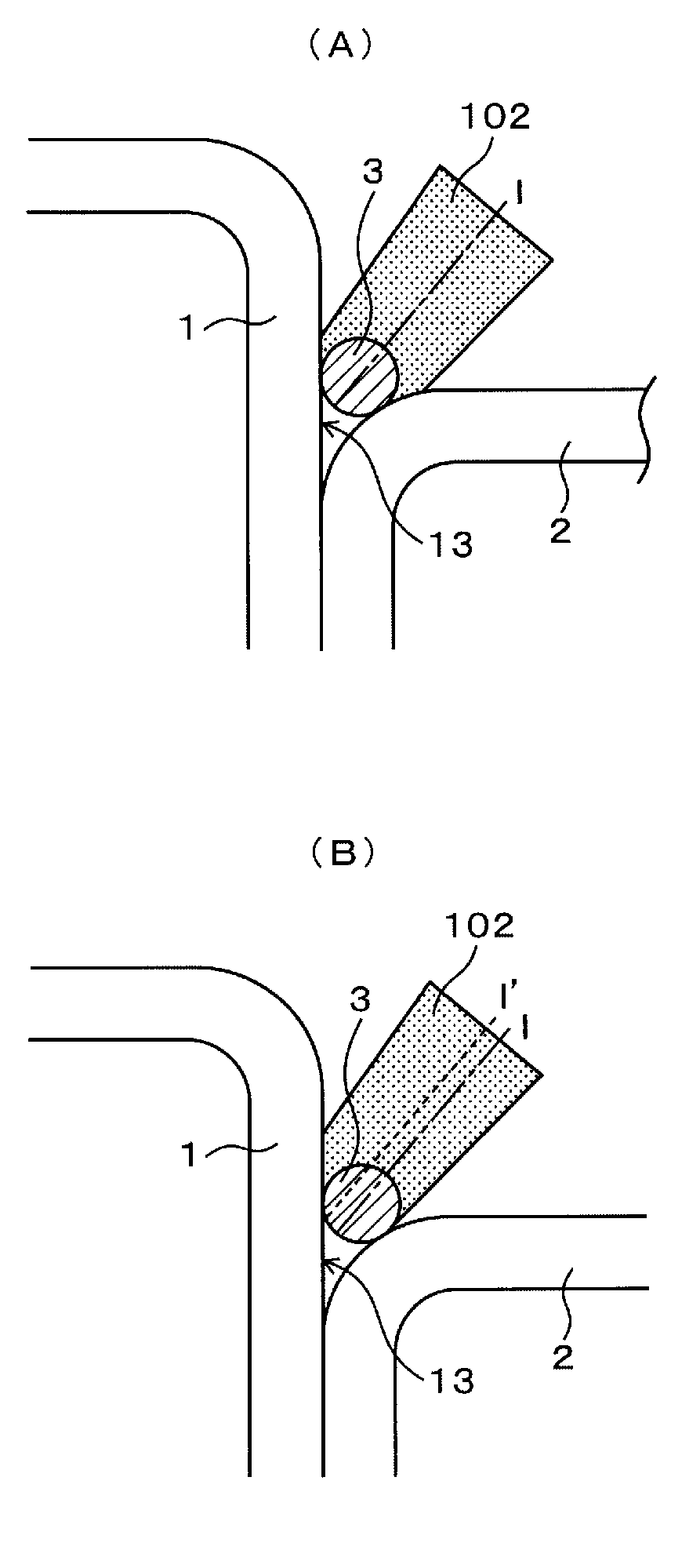

Method for weld-joining attachment to outer panel of railway vehicle and car body side structure produced by the same

ActiveUS20100077935A1Improve workabilityLow costAxle-box lubricationVehicle componentsMachinabilityLaser

A weld-joining structure between an outer panel and an attachment is achieved, which is advantageous in terms of appearance, workability, and cost. To weld-join the outer panel and the attachments including, such as frame members and opening frames and opening frame members, which is a reinforcement or an interior or exterior member for use in the outer panel, the outer panel and the attachment placed on the outer panel are weld-joined by laser welding at overlapping portions of the outer panel and the attachment. The laser welding is performed along a polishing mark formed in one direction on an externally exposed-side surface of the outer panel and the attachment.

Owner:KINKI SHARYO

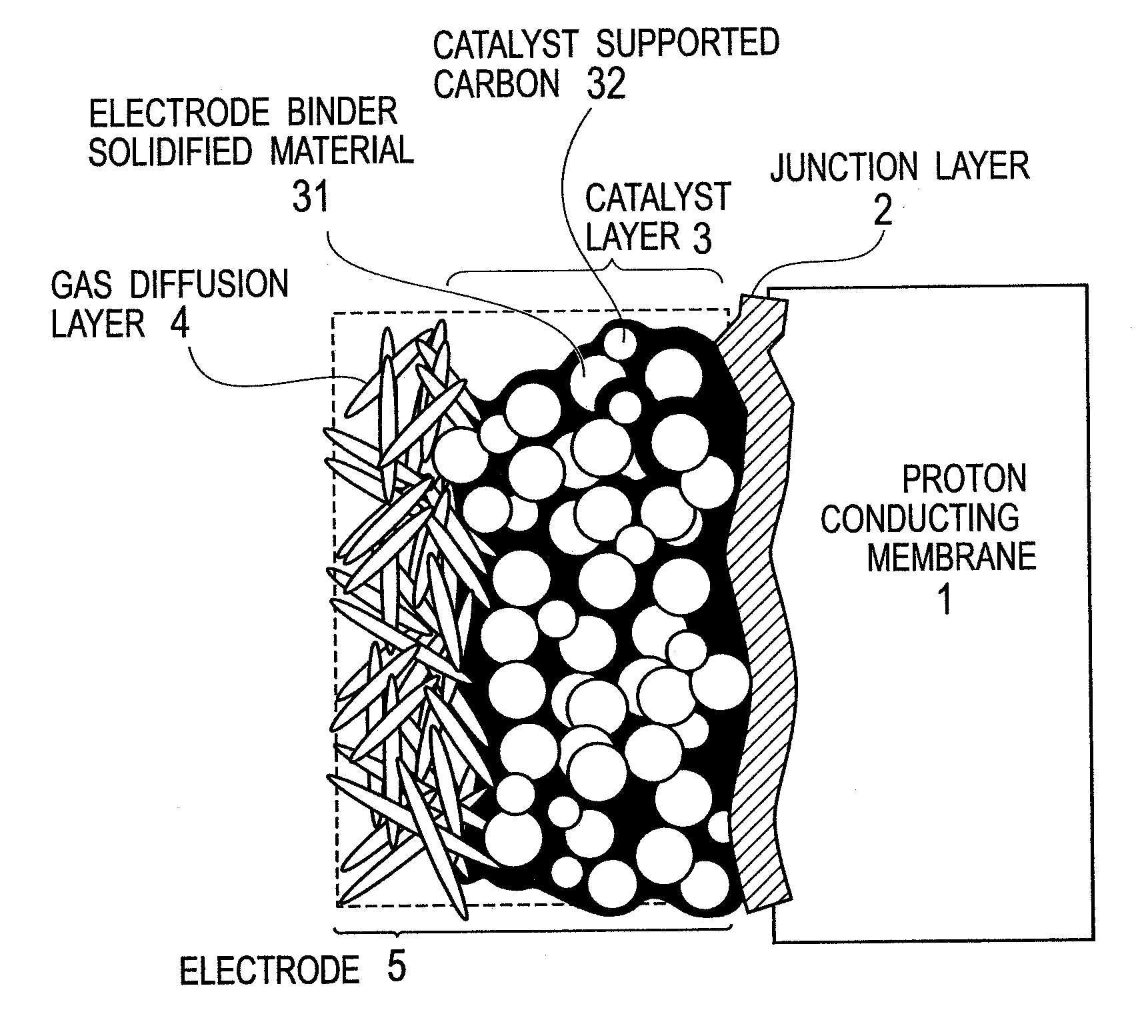

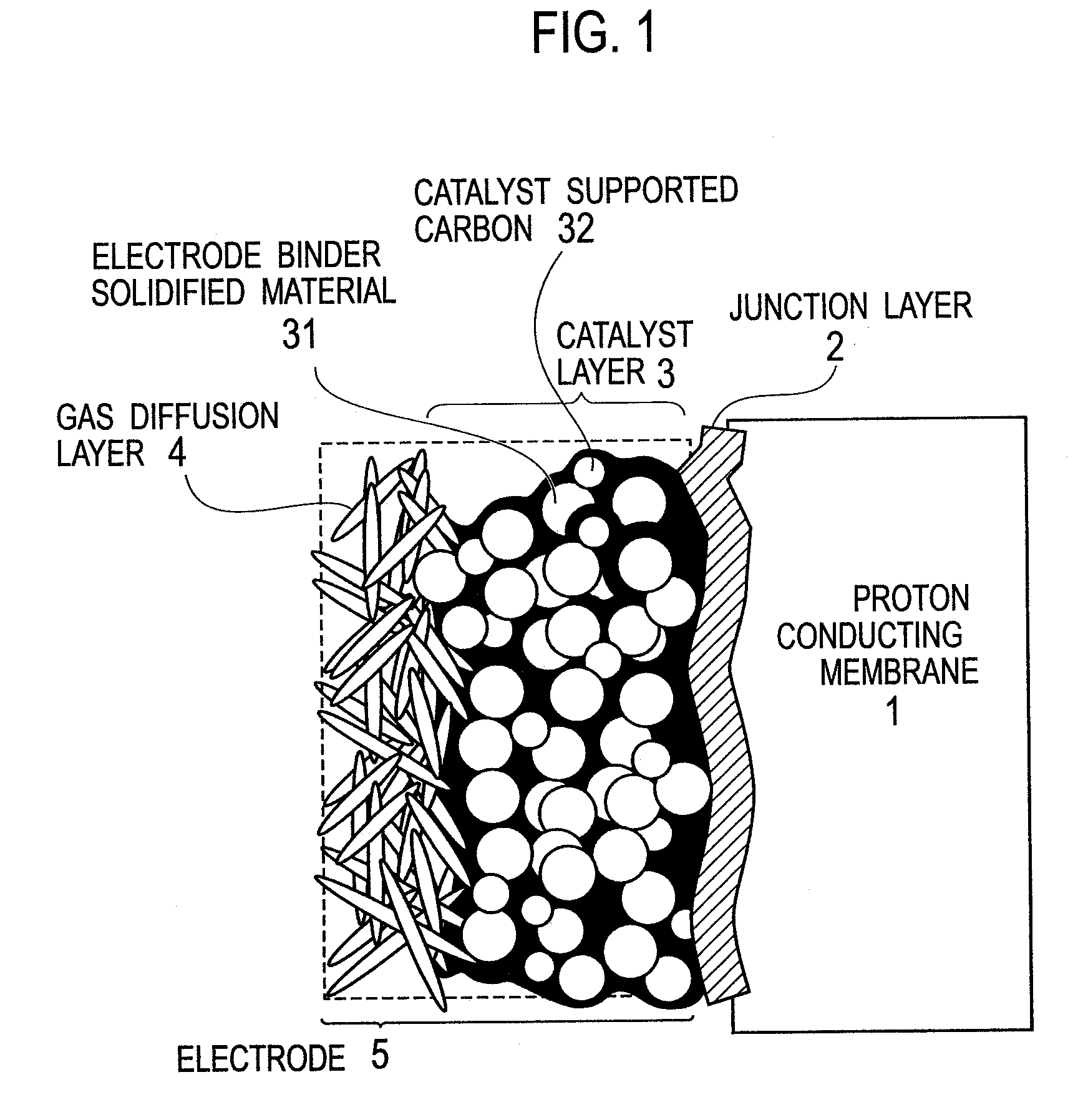

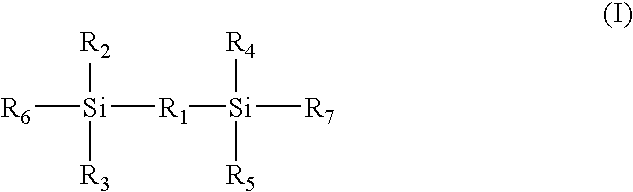

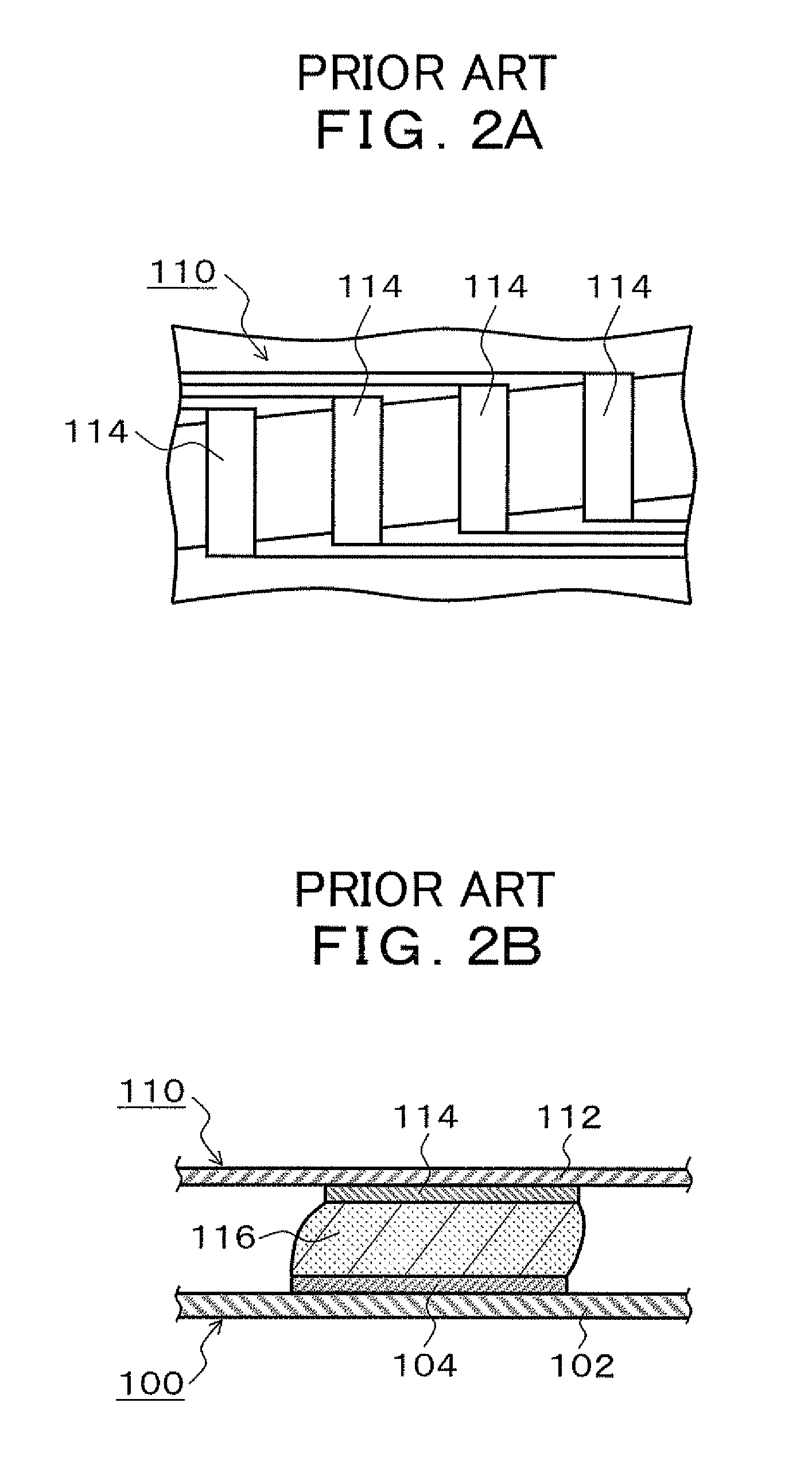

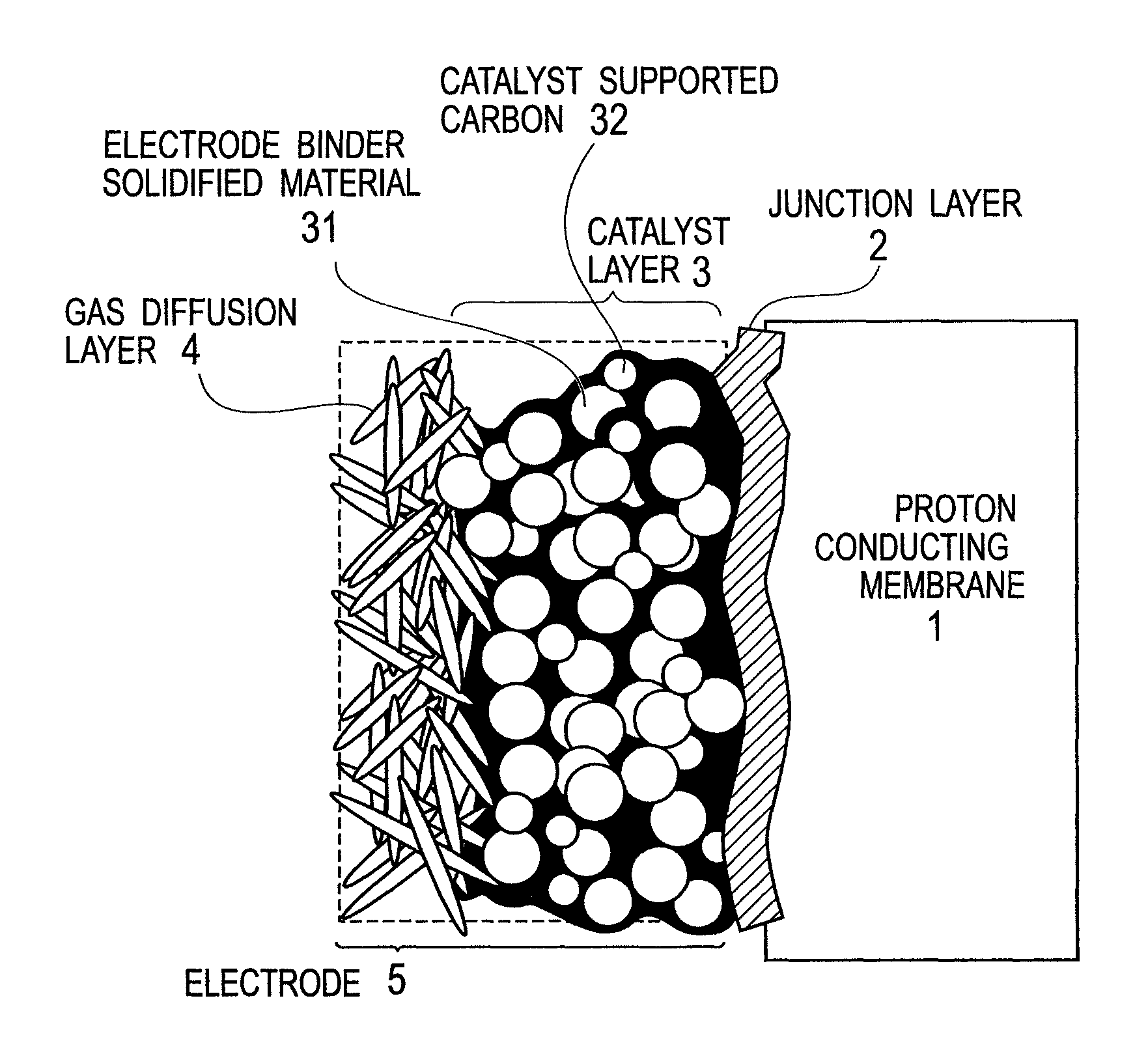

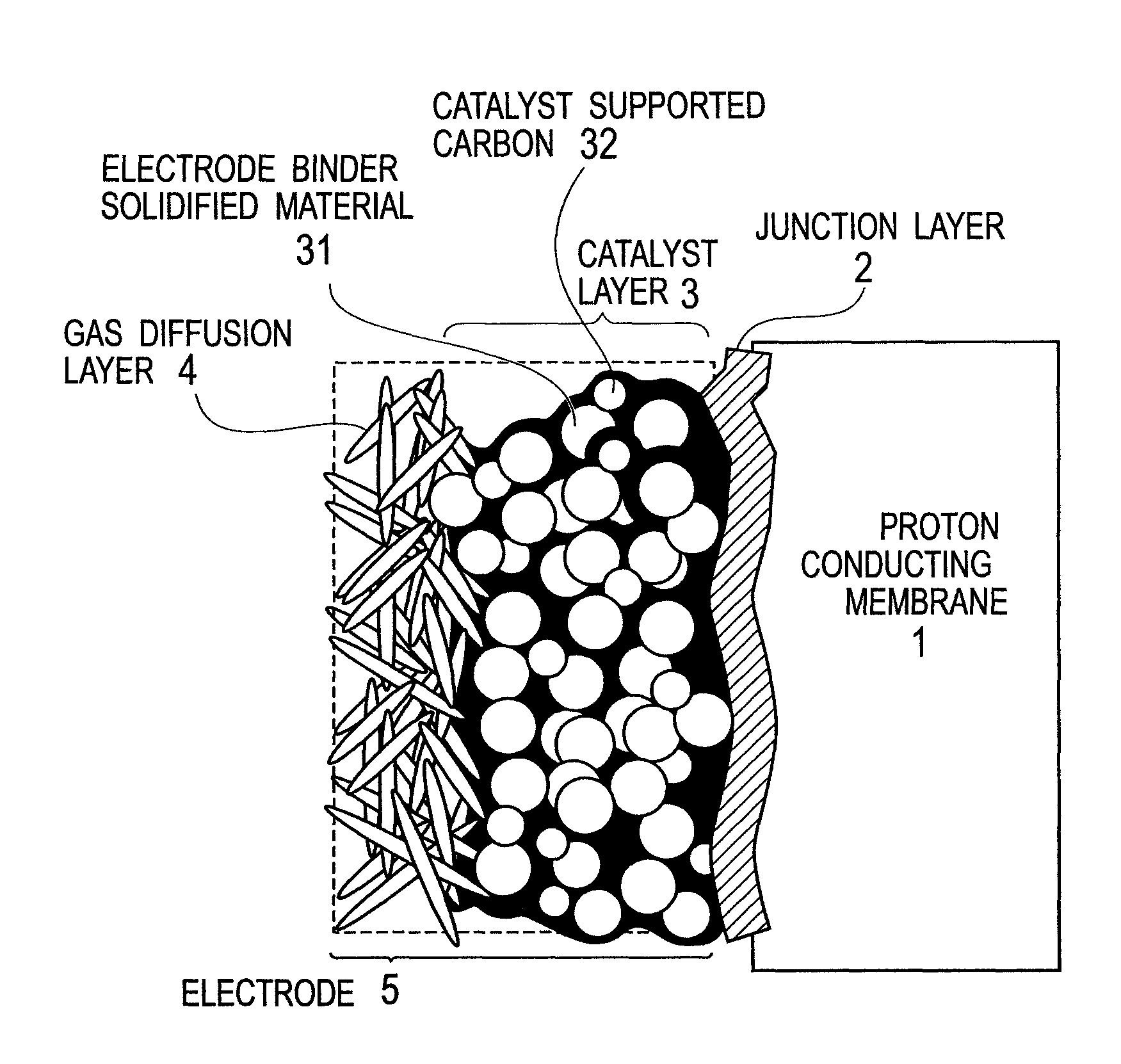

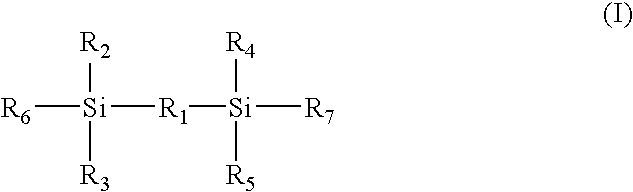

Membrane-electrode junction agent, proton conducting membrane having junction layer, membrane-electrode assembly, polymer electrolyte fuel cell, and manufacturing method of the membrane-electrode assembly

InactiveUS20100047659A1Improve joint strengthHigh fuel barrier propertyFinal product manufactureActive material electrodesCross-linkFuel cells

A membrane-electrode junction agent, a proton conducting membrane having a junction layer, a membrane-electrode assembly, a polymer electrolyte fuel cell, and a manufacturing method of the membrane-electrode assembly, which enhance the power generation performance, realize the high fuel barrier property, and are capable of enhancing the joint strength between the membrane and the electrodes, is provided. A membrane-electrode junction agent that joins a proton conducting membrane and electrodes arranged on both surfaces of the proton conducting membrane to each other, the membrane-electrode junction agent including: a cross-linked compound (X) having a silicon-oxygen bond; a polymer material (Y) containing an acid group; and a hydrophilic resin (Z) containing no acid group.

Owner:SEKISUI CHEM CO LTD

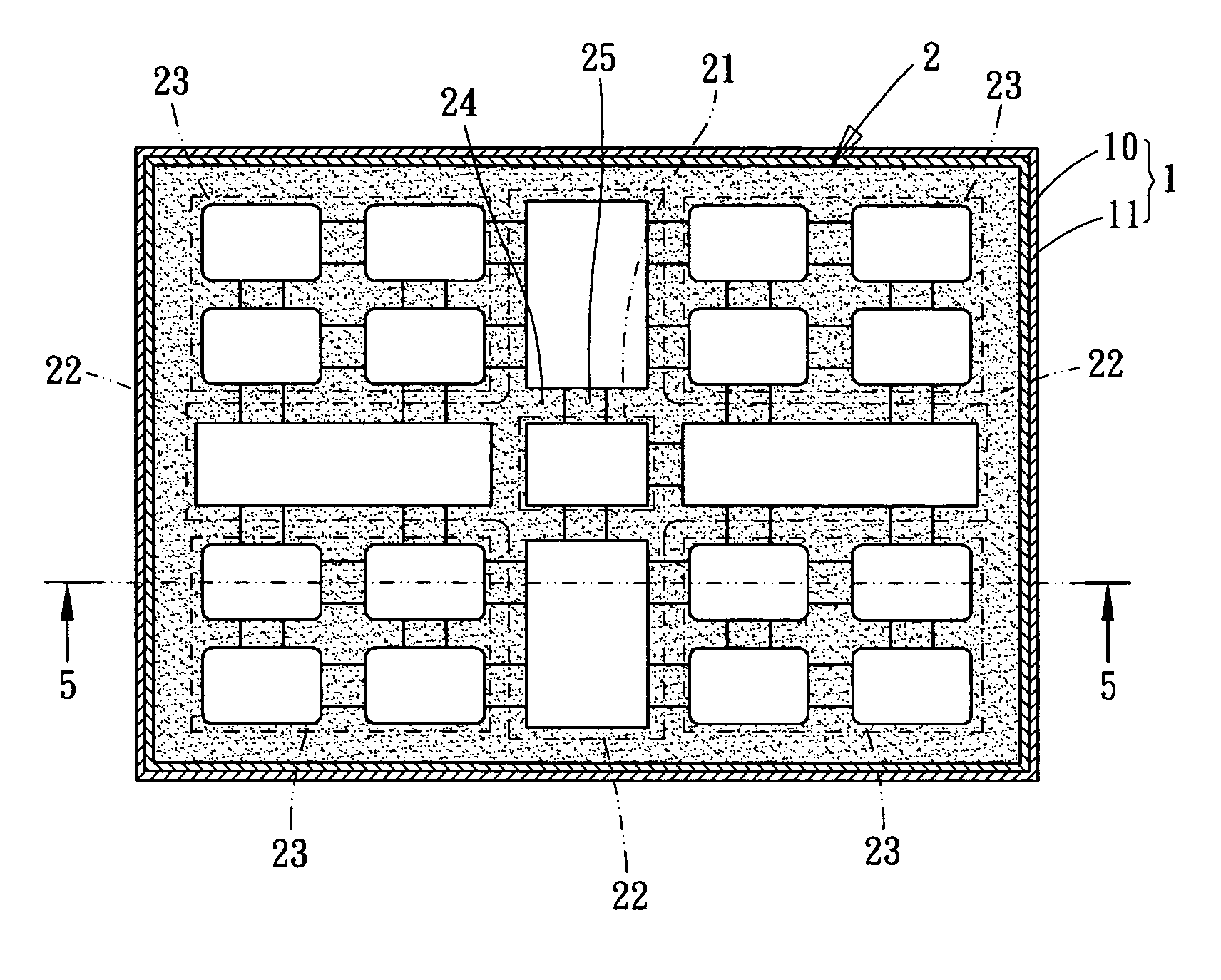

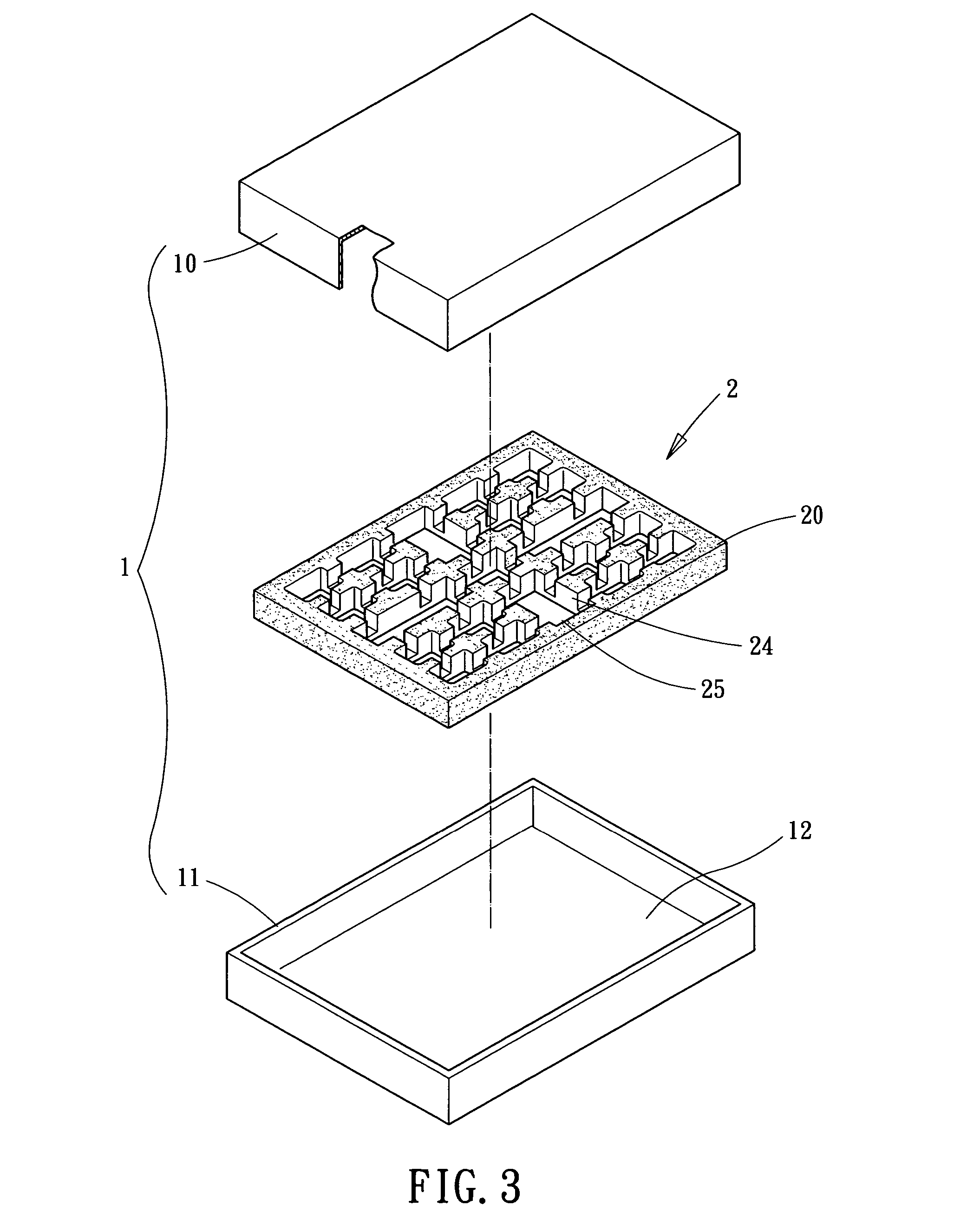

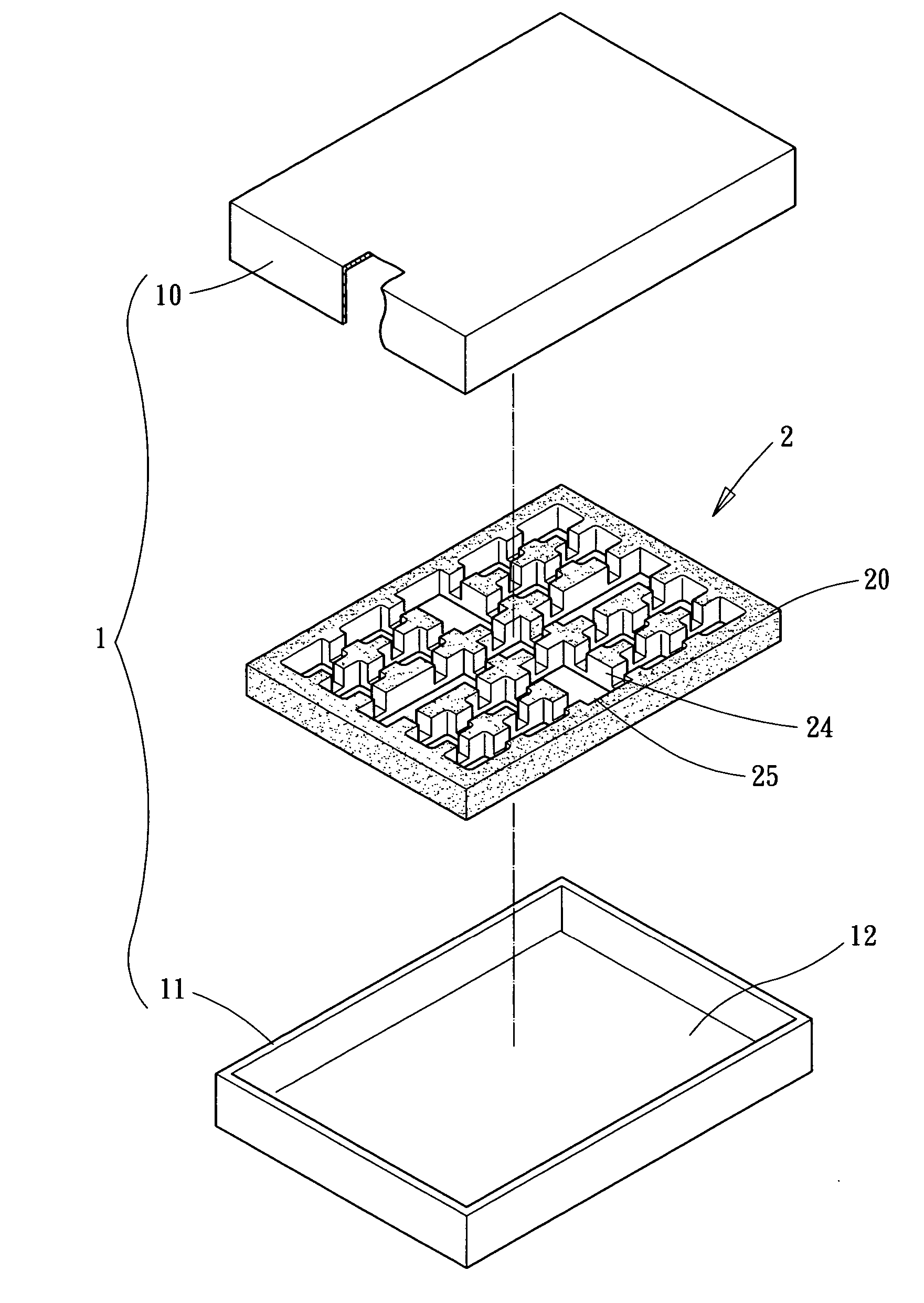

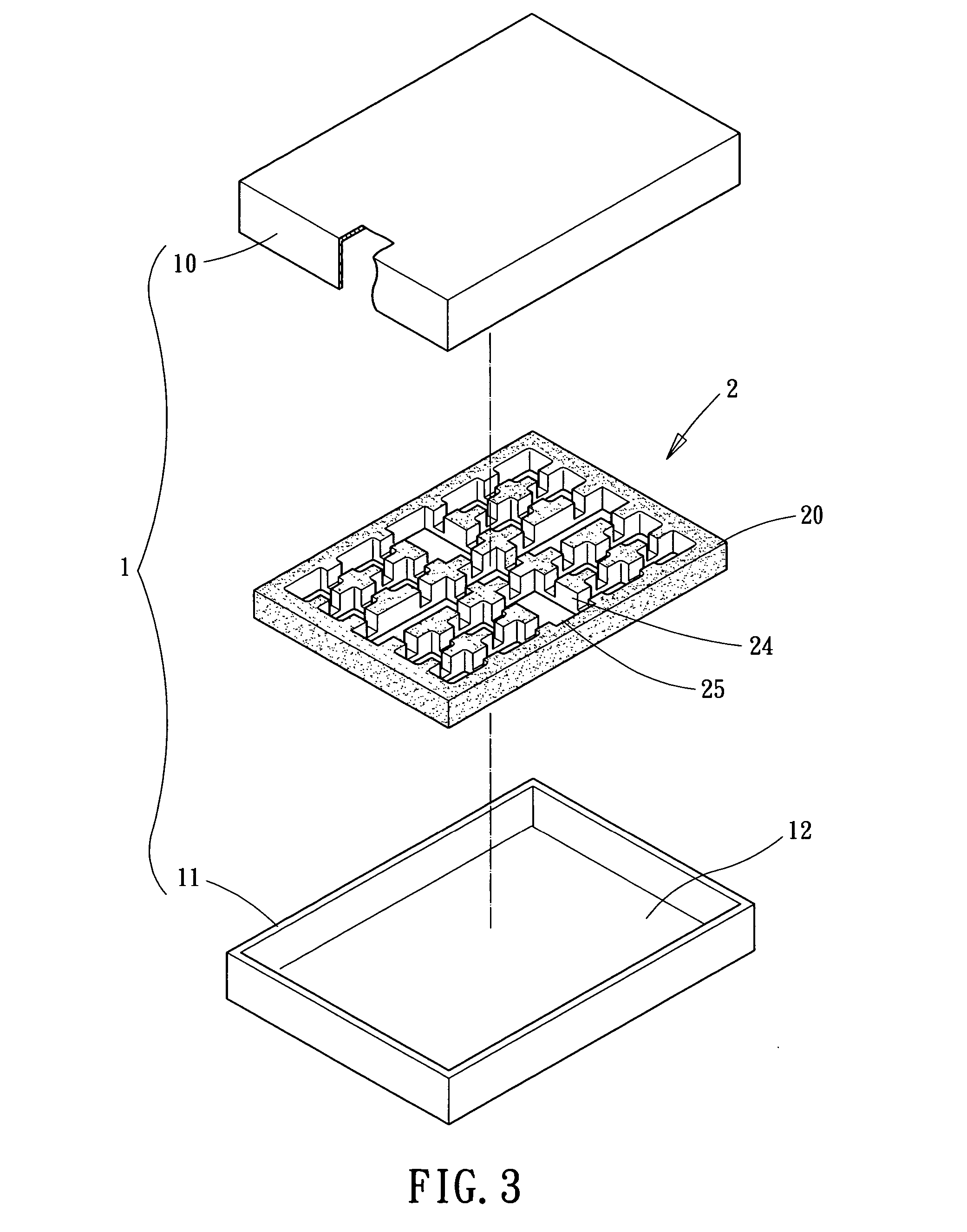

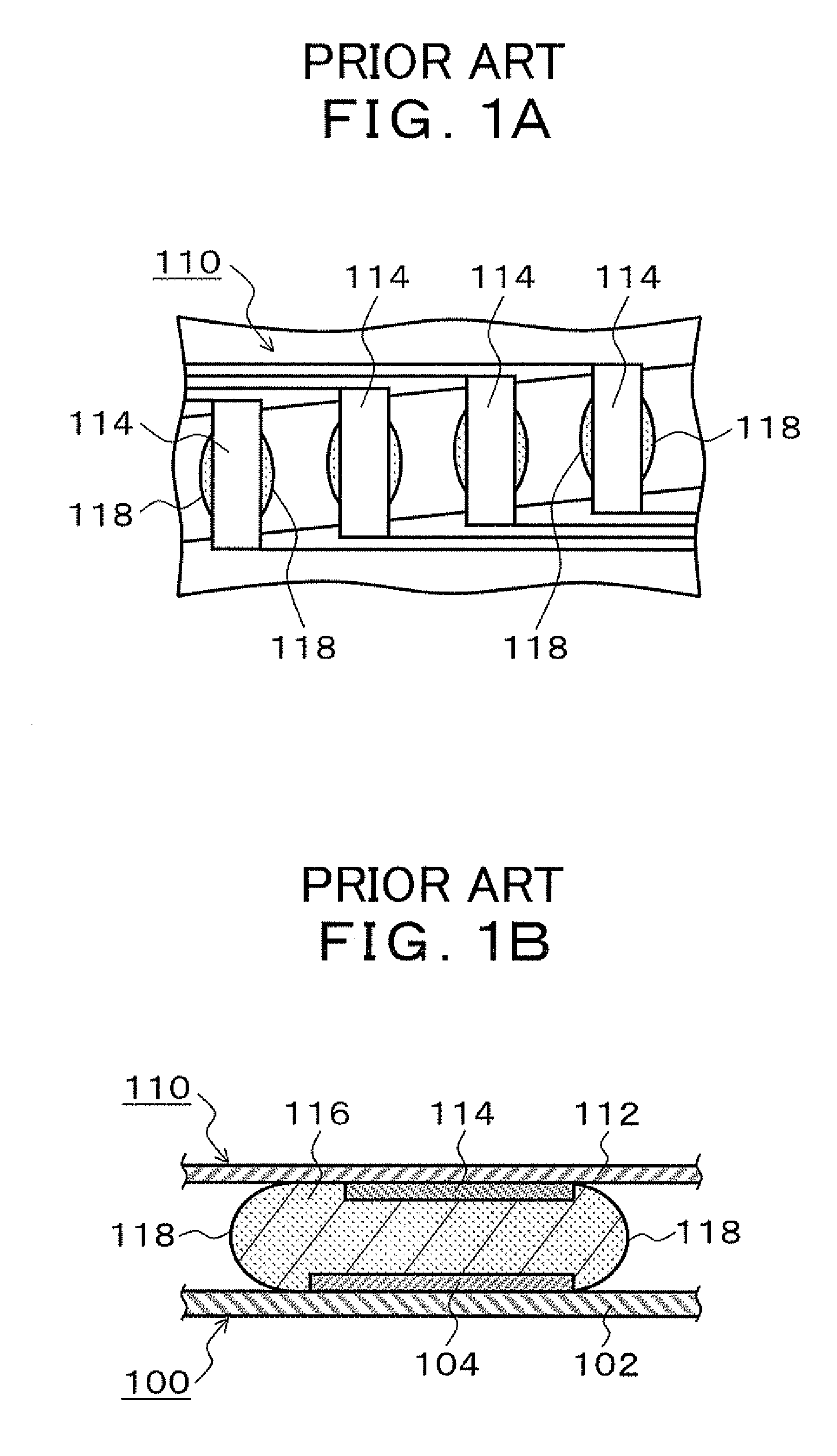

Supporting structure for planar heat pipe

InactiveUS7025124B2Add support structureImprove joint strengthReinforcing meansSemiconductor/solid-state device detailsWorking fluidHeat pipe

An improved supporting structure for a planar heat pipe, having a housing and a supporting member installed in the shell is disclosed. The housing has an upper lid and a lower lid engaged with each other to form a hollow chamber therein. The hollow chamber is filled with a working fluid. The supporting member is a planar member perforated with a plurality of holes. The supporting member is sintered with the upper and lower lids in the hollow chamber. Therefore, the housing and the supporting member are integrated together.

Owner:PYROSWIFT HOLDING CO LIMITED

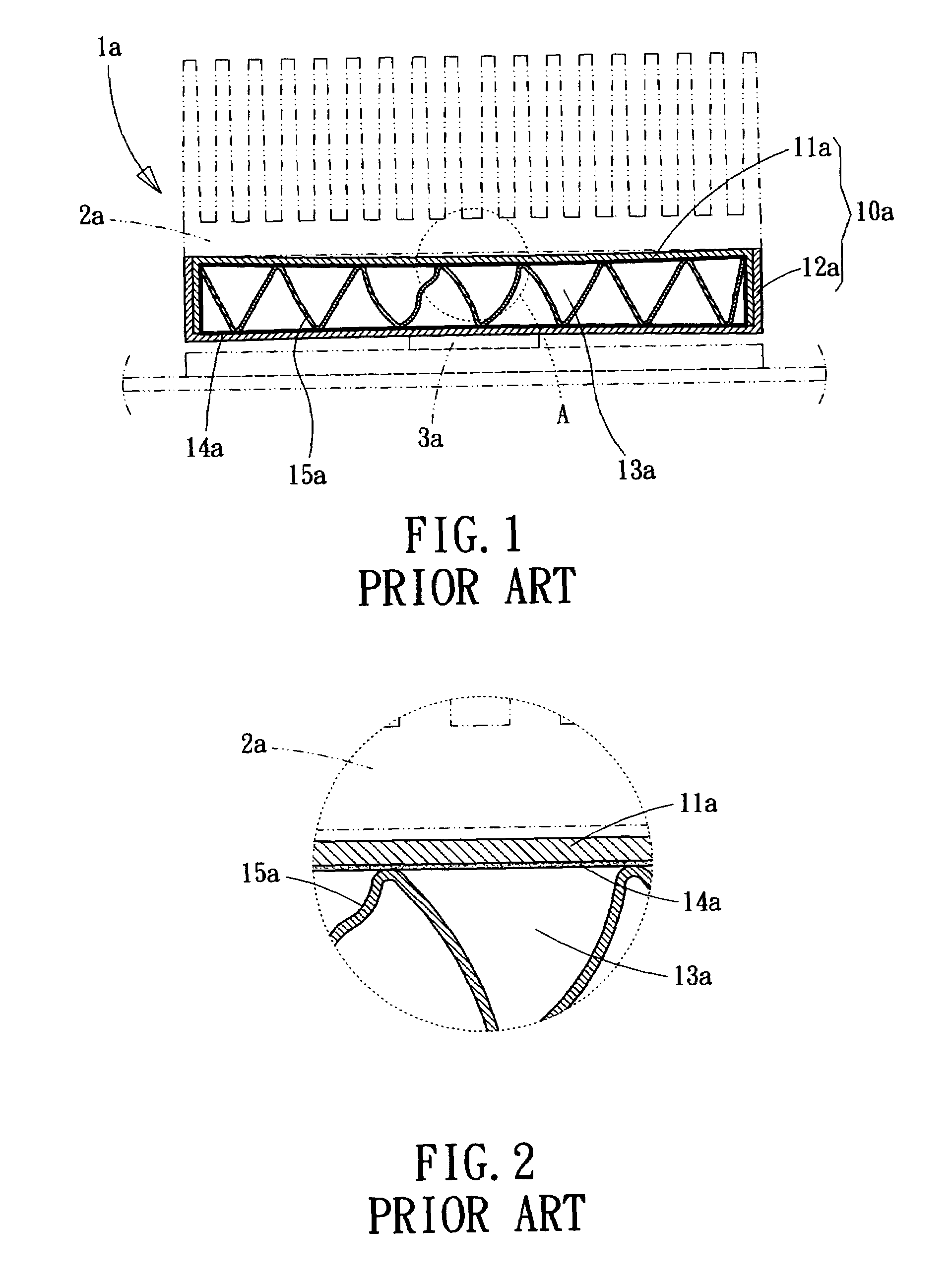

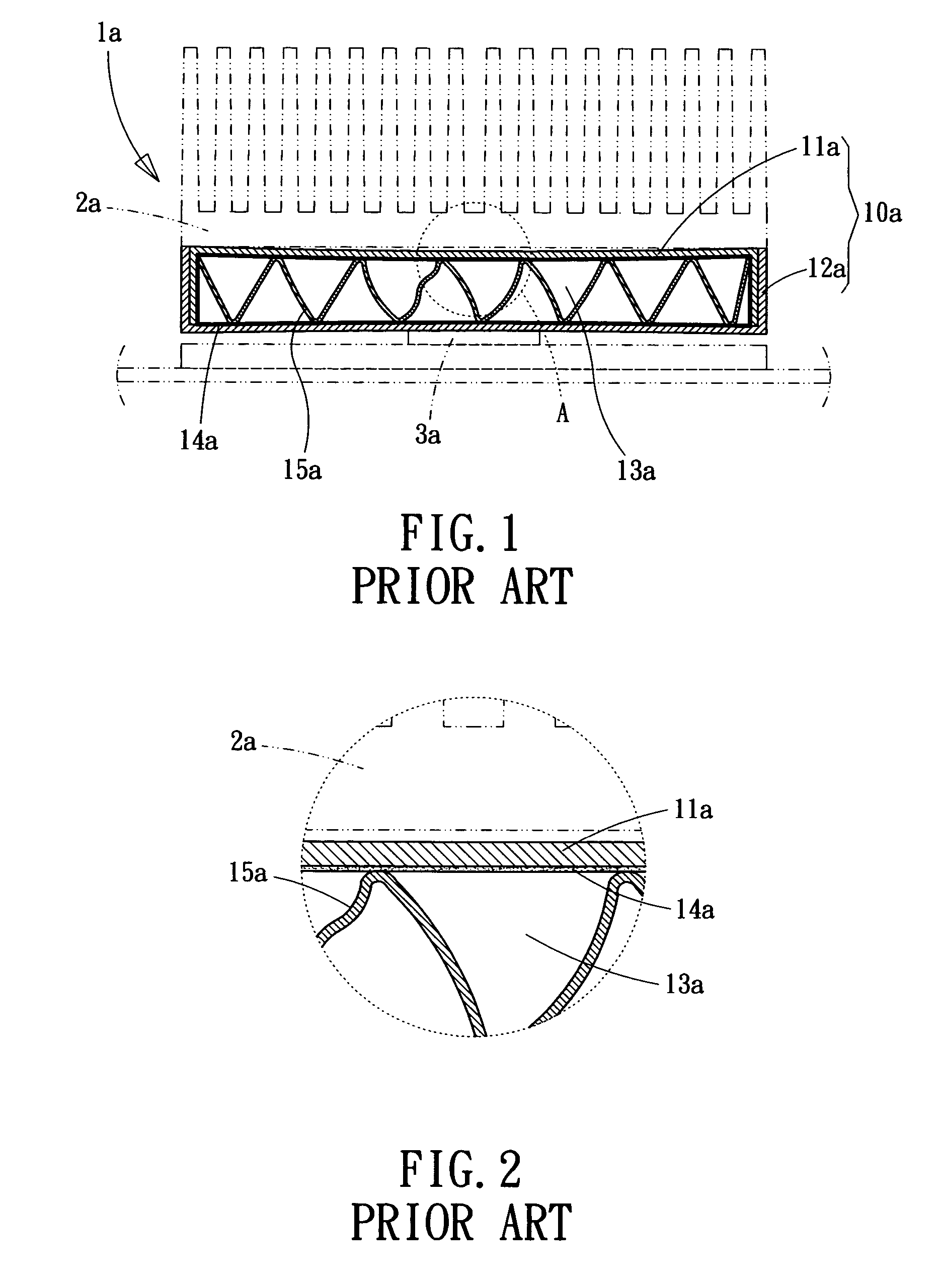

Supporting structure for planar heat pipe

InactiveUS20050087327A1Add support structureImprove joint strengthReinforcing meansSemiconductor/solid-state device detailsWorking fluidEngineering

An improved supporting structure for a planar heat pipe, having a housing and a supporting member installed in the shell is disclosed. The housing has an upper lid and a lower lid engaged with each other to form a hollow chamber therein. The hollow chamber is filled with a working fluid. The supporting member is a planar member perforated with a plurality of holes. The supporting member is sintered with the upper and lower lids in the hollow chamber. Therefore, the housing and the supporting member are integrated together.

Owner:PYROSWIFT HOLDING CO LIMITED

Varistor

InactiveUS20100117782A1Avoid crackingJoint strengthSemiconductor/solid-state device detailsCurrent responsive resistorsEngineeringLight emitting device

A varistor having a favorable heat-dissipating property is provided.In the varistor, a composite part having a favorable heat-dissipating property formed by a composite material composed of ZnO and Ag is arranged between main faces of a varistor matrix. Therefore, the heat transmitted from a semiconductor light-emitting device to a varistor part through an outer electrode can rapidly be transferred toward a main face on the opposite side through the composite part. In this varistor, side faces excluding inner side faces are exposed at side faces of the varistor matrix. Such a structure yields a favorable heat-dissipating property.

Owner:TDK CORPARATION

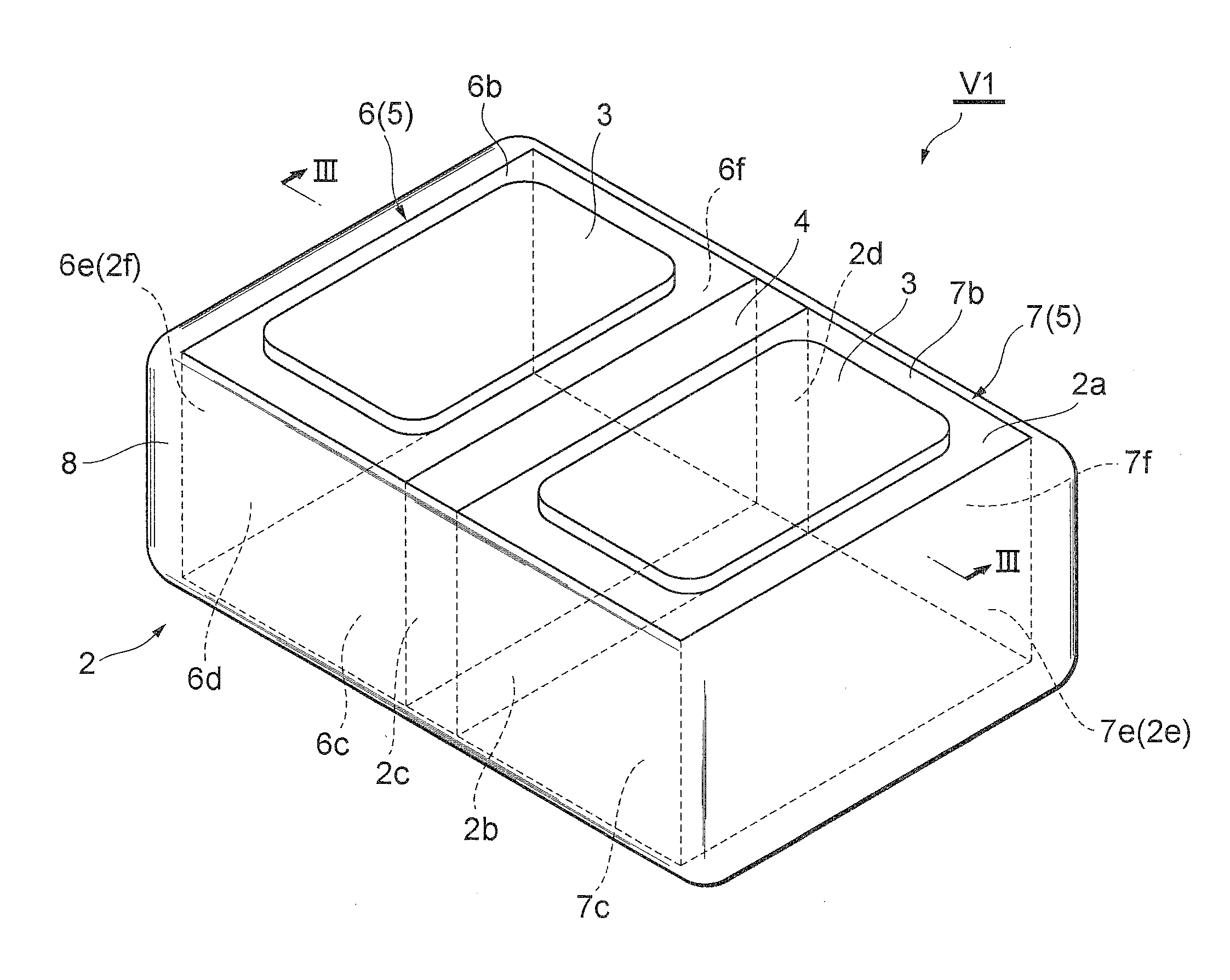

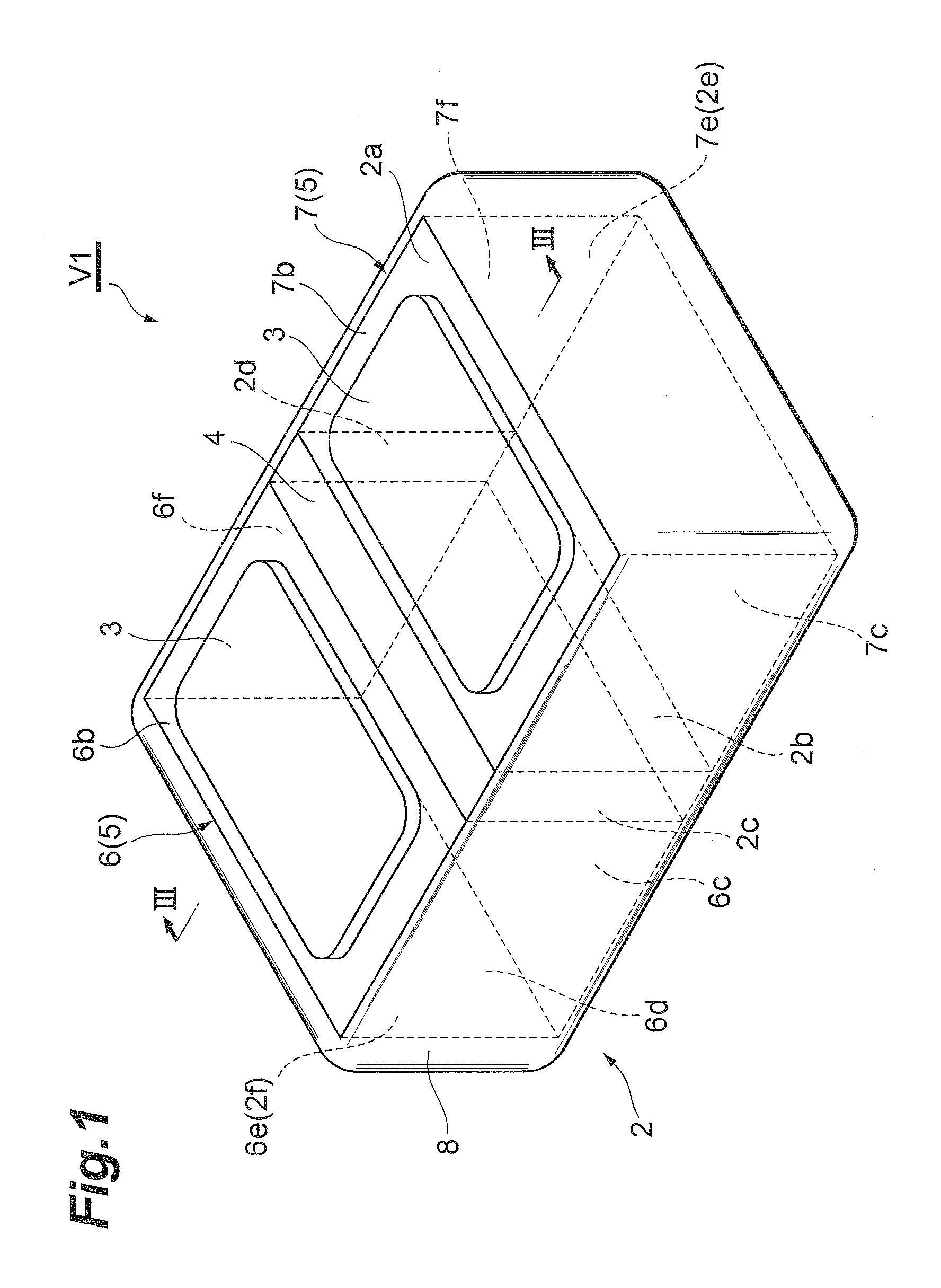

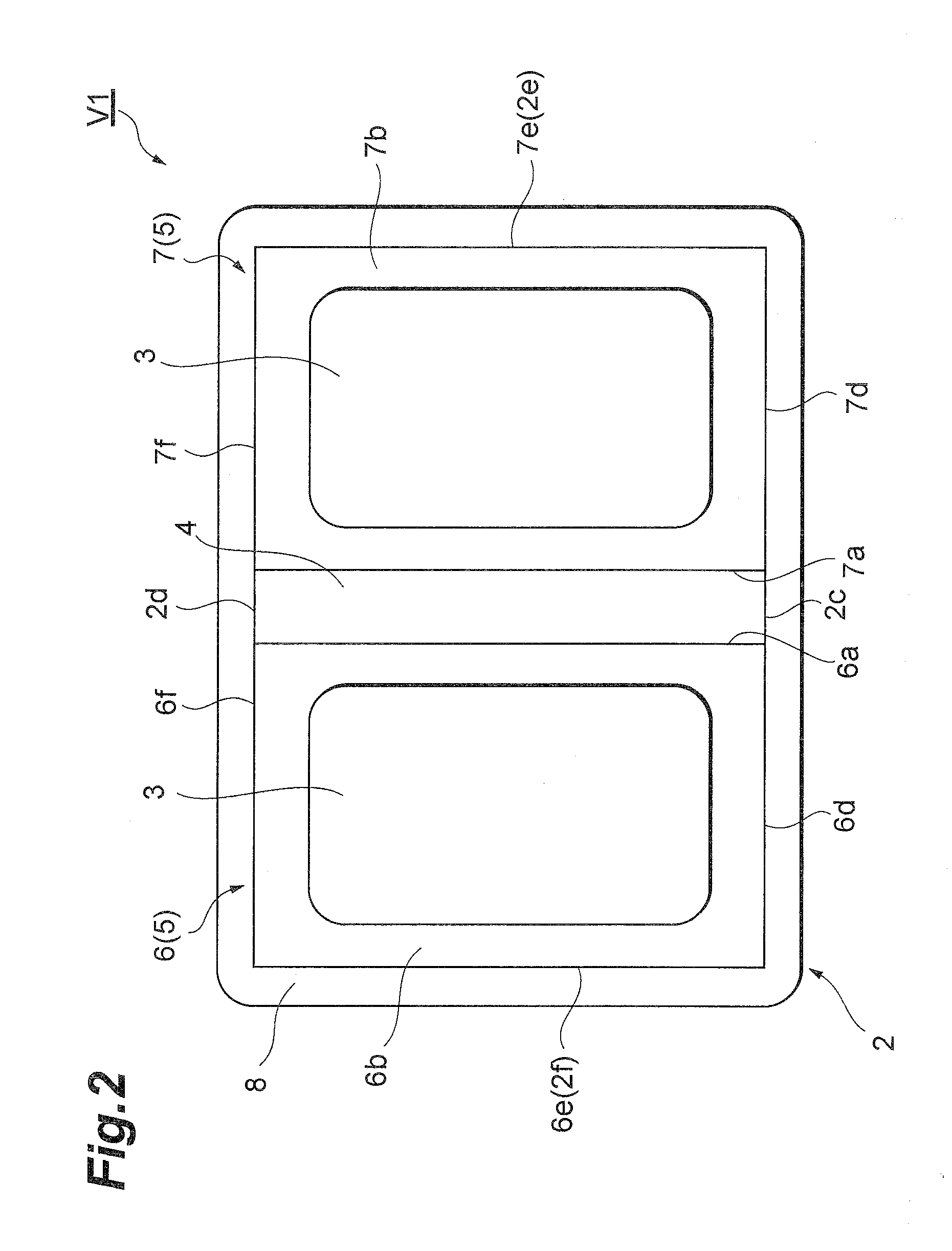

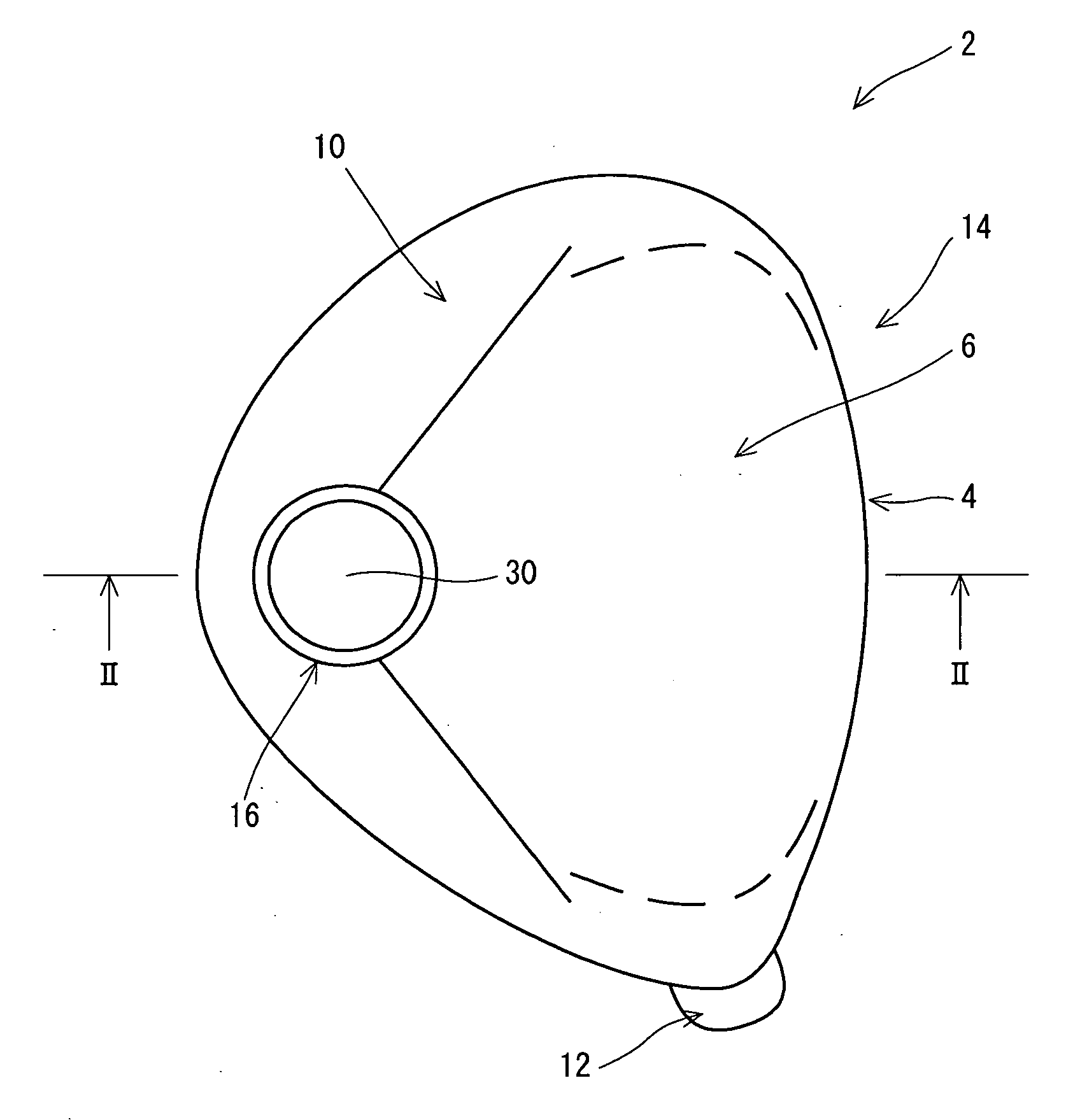

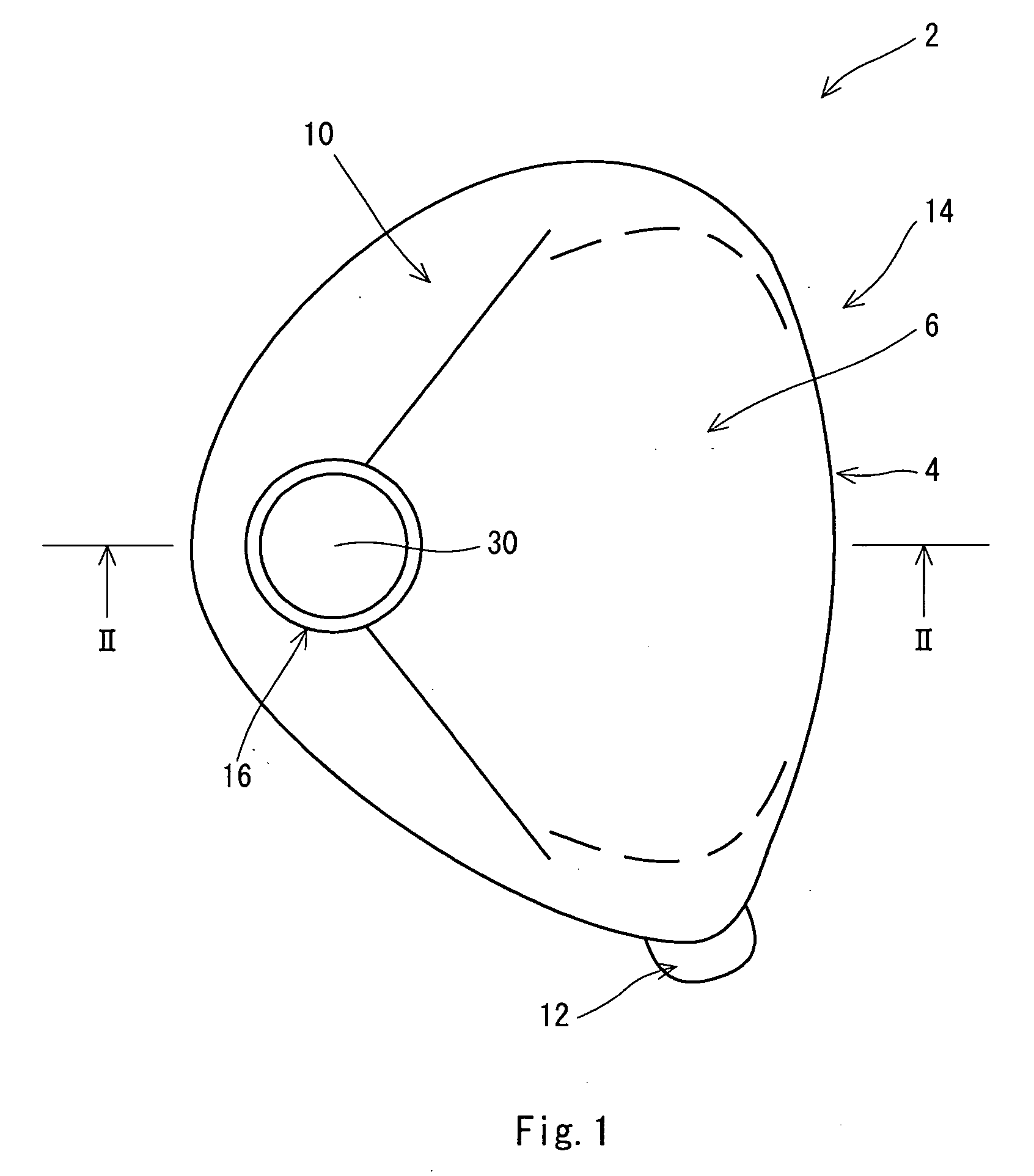

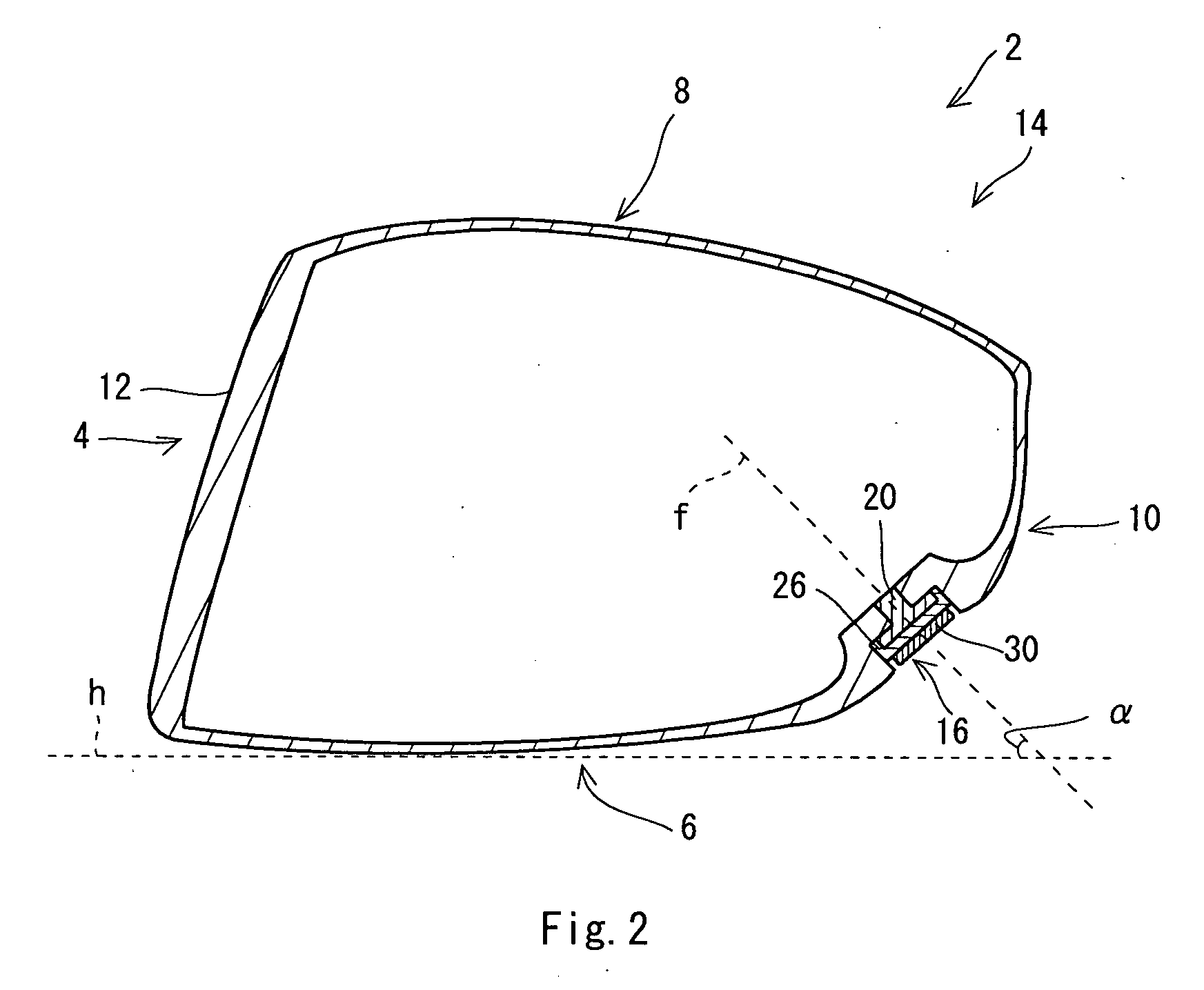

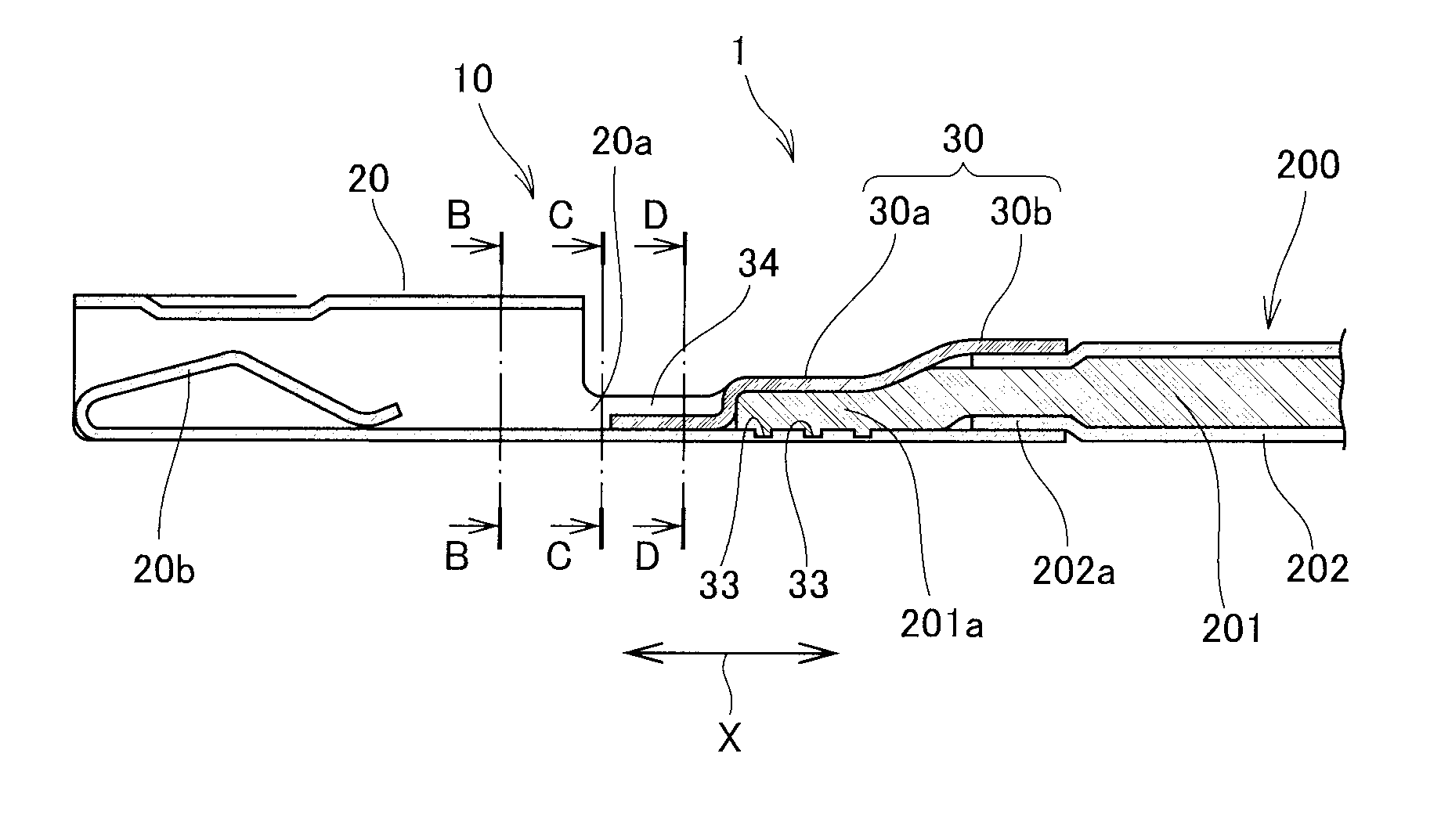

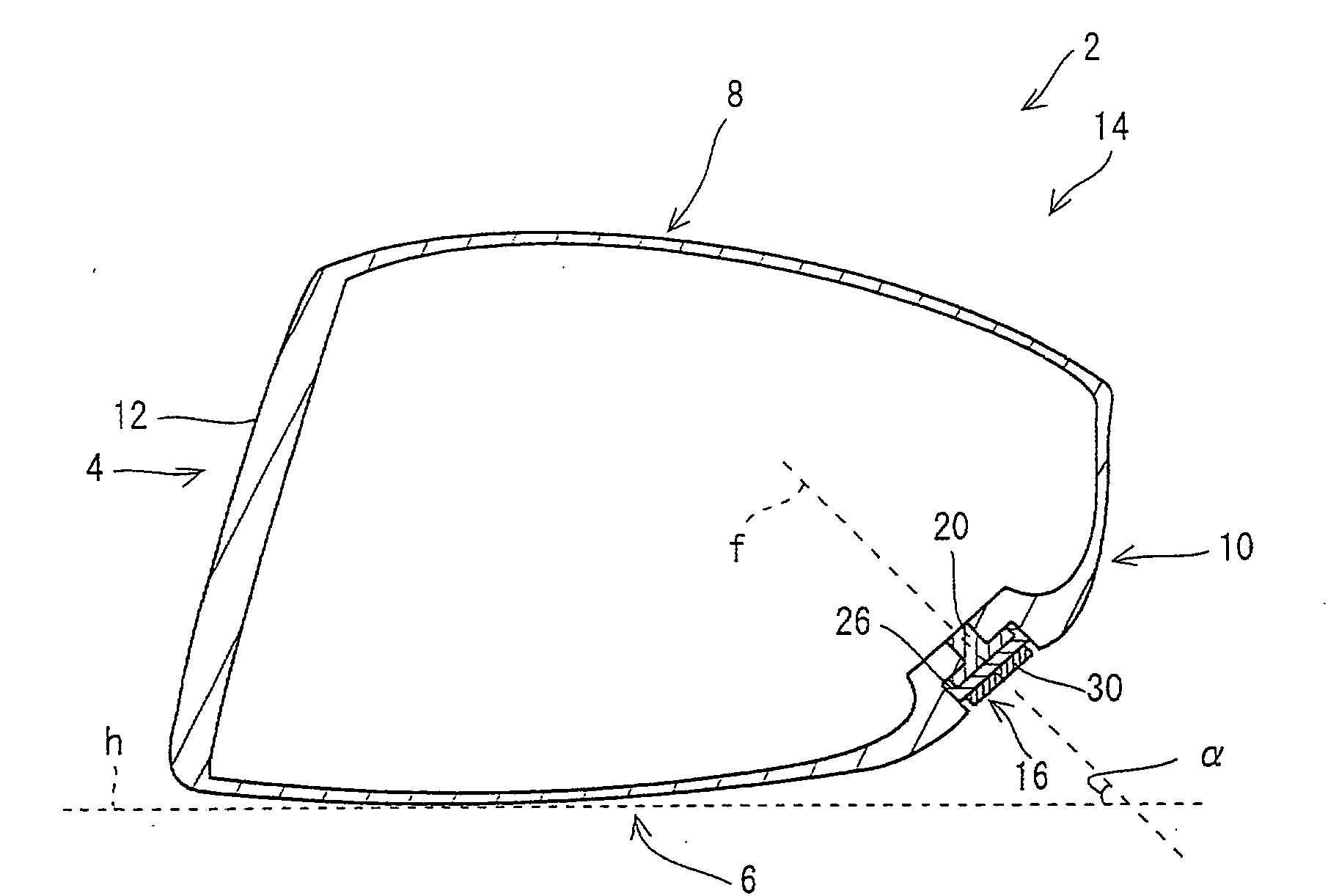

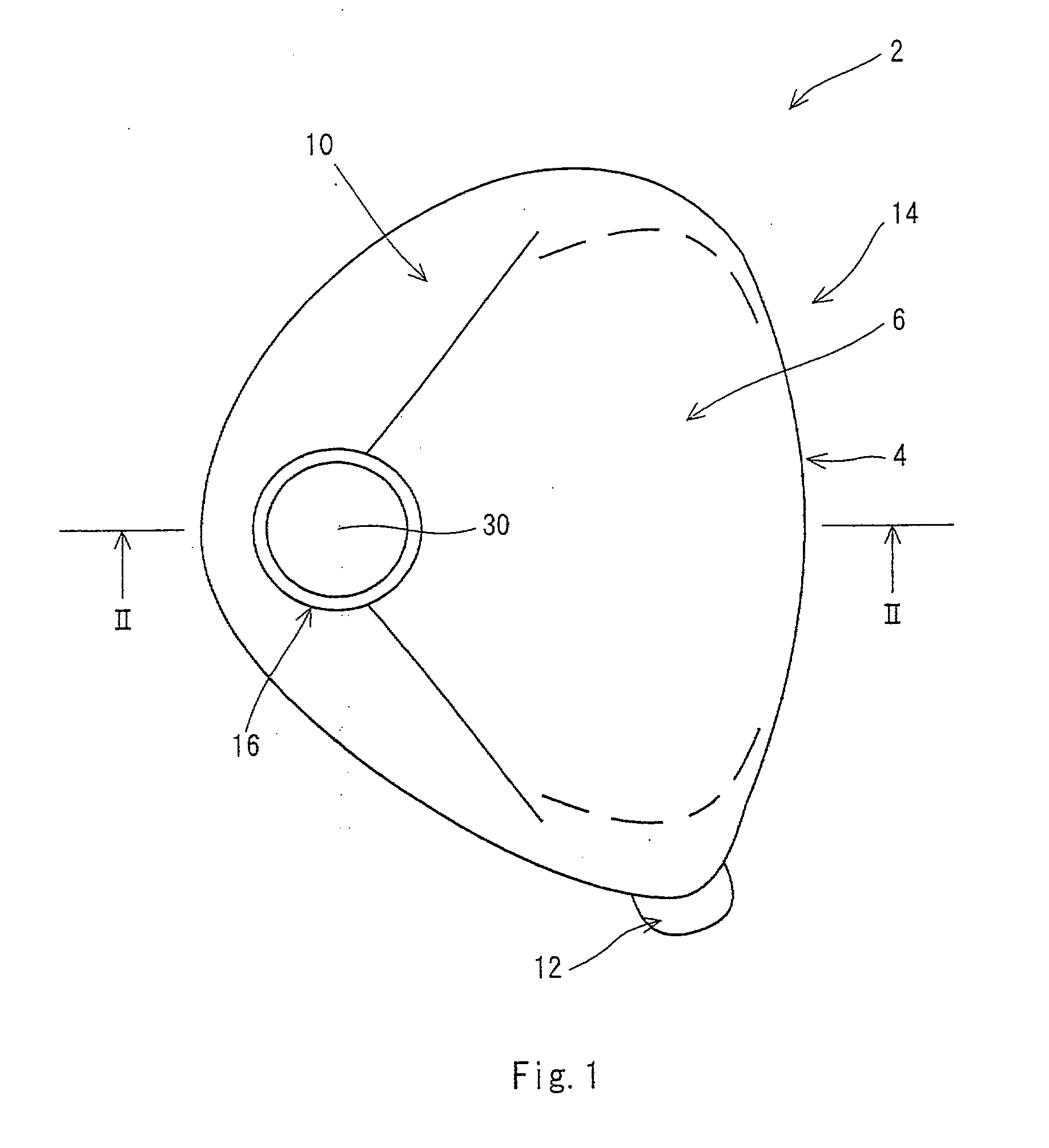

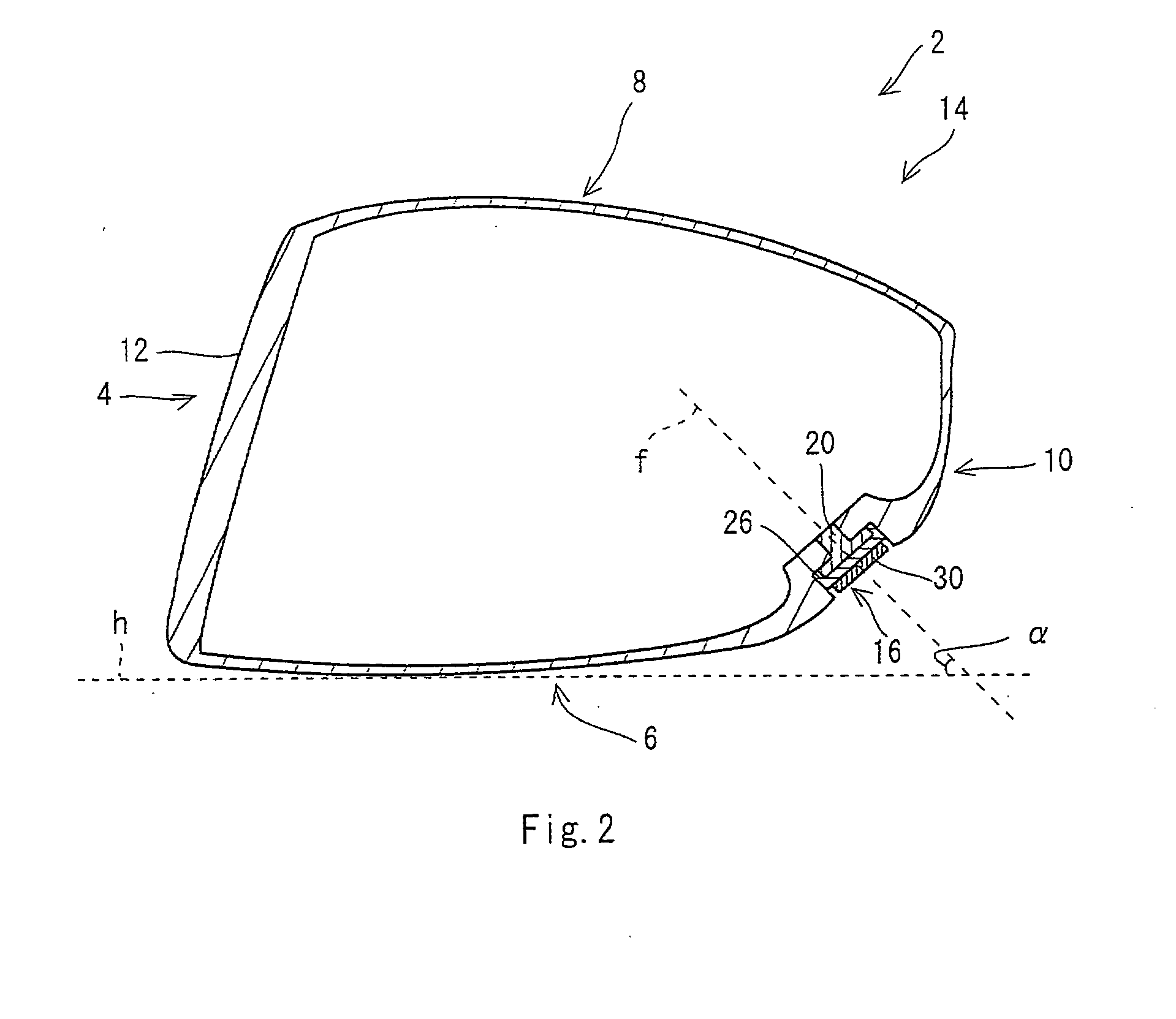

Golf club head and golf club

A golf club head 2 is provided which includes a recessed part 16 provided on the external surface of a head main body 14, and a weight member 20 which is mounted in this recessed part 16 and which is formed of a material having a specific gravity greater than that of the head main body 14. This golf club head 2 has a first addition member 26 mounted on the external side of the weight member 20 while abutting the external surface of the weight member 20. A base of this first addition member 26 is a resin or a rubber. Furthermore, the head 2 has a second addition member 30 mounted on the external side of the first addition member 26 while abutting the external surface of the first addition member 26. This second addition member 30 is formed of a metal. This metal has a specific gravity being greater than that of the first addition member and smaller than that of the weight member 20. According to the present invention, joint strength between the head main body and the weight member can be enhanced. The present invention can achieve improved good-looking appearance.

Owner:DUNLOP SPORTS CO LTD

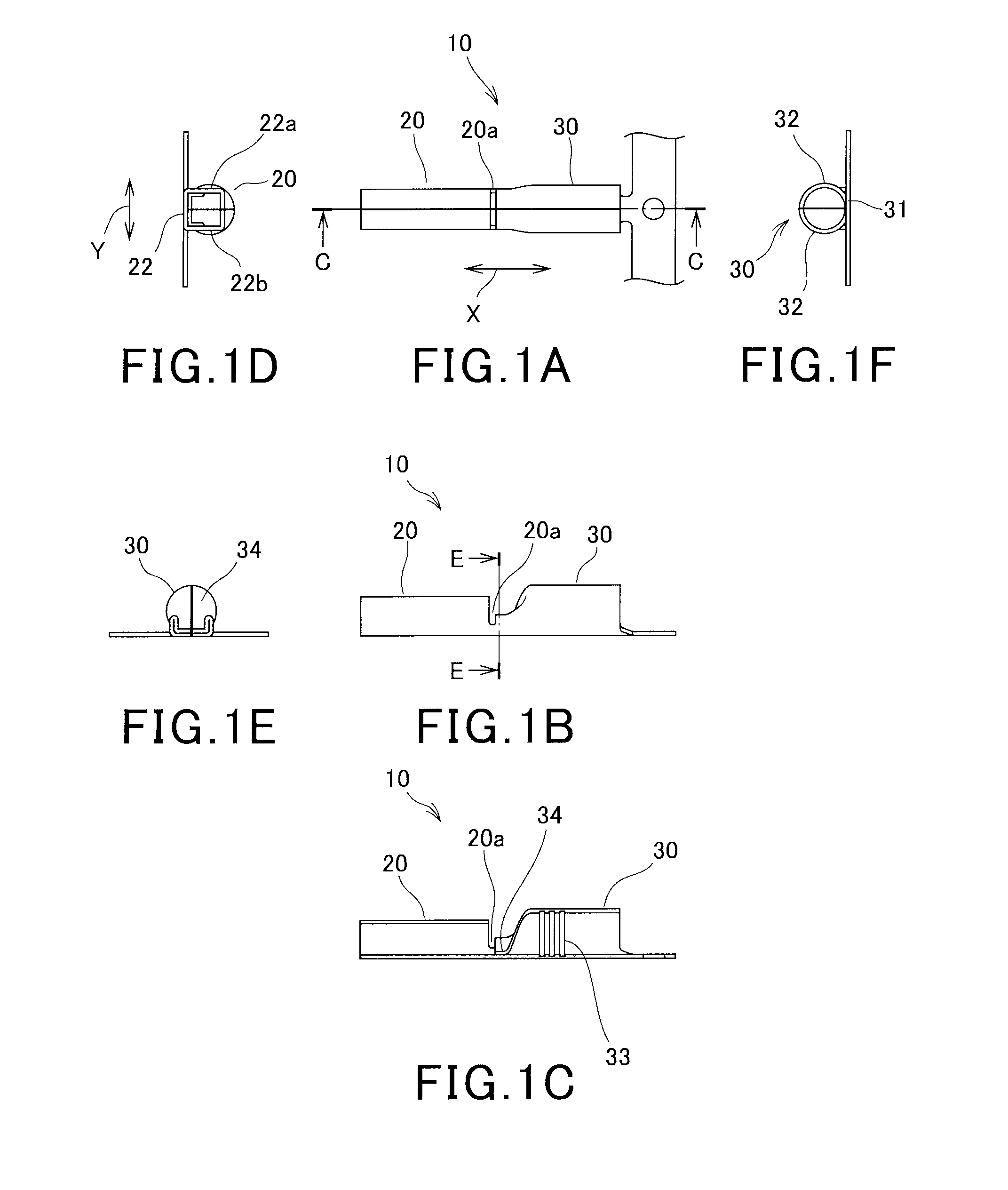

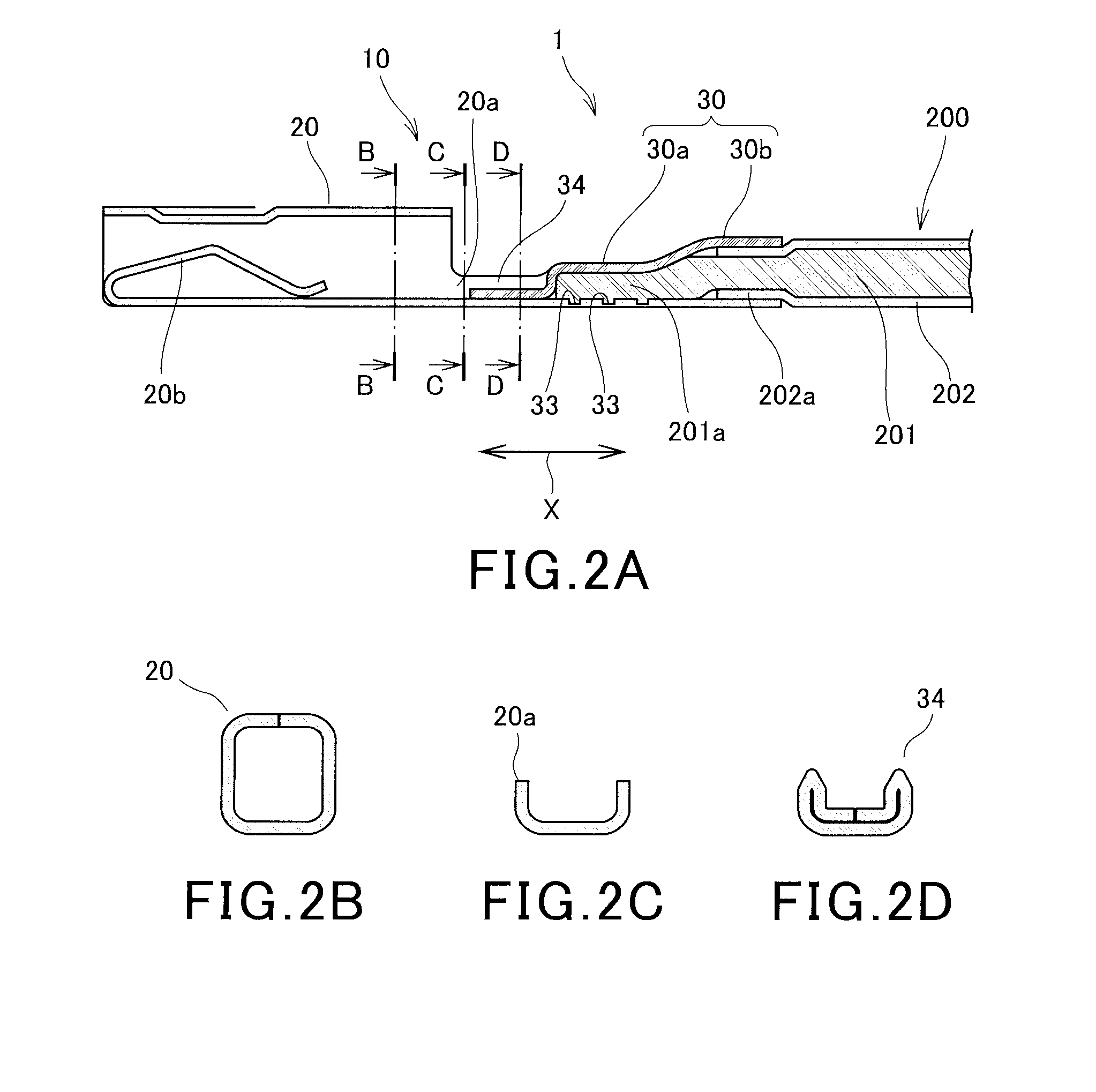

Crimp terminal, method of manufacturing crimp terminal, electrical wire connection structure, and method of manufacturing electrical wire connection structure

ActiveUS20150340772A1Good water stop effectJoint strengthConnections effected by permanent deformationConnection formation by deformationUltimate tensile strengthElectric wire

A crimp terminal that can maintain excellent water-stop performance over a long term and is enhanced in joint strength between a fitting portion and a covered electrical wire connection portion. The crimp terminal has a fitting portion at a tip thereof and an electrical wire connection portion at a rear end thereof, the electrical wire connection portion is configured in a tubular shape, a tip of the tube is crushed to be superimposed and closed, and a portion between the fitting portion and the electrical wire connection portion is formed by superimposing and bending two or more sheets of a plate material.

Owner:FURUKAWA ELECTRIC CO LTD +1

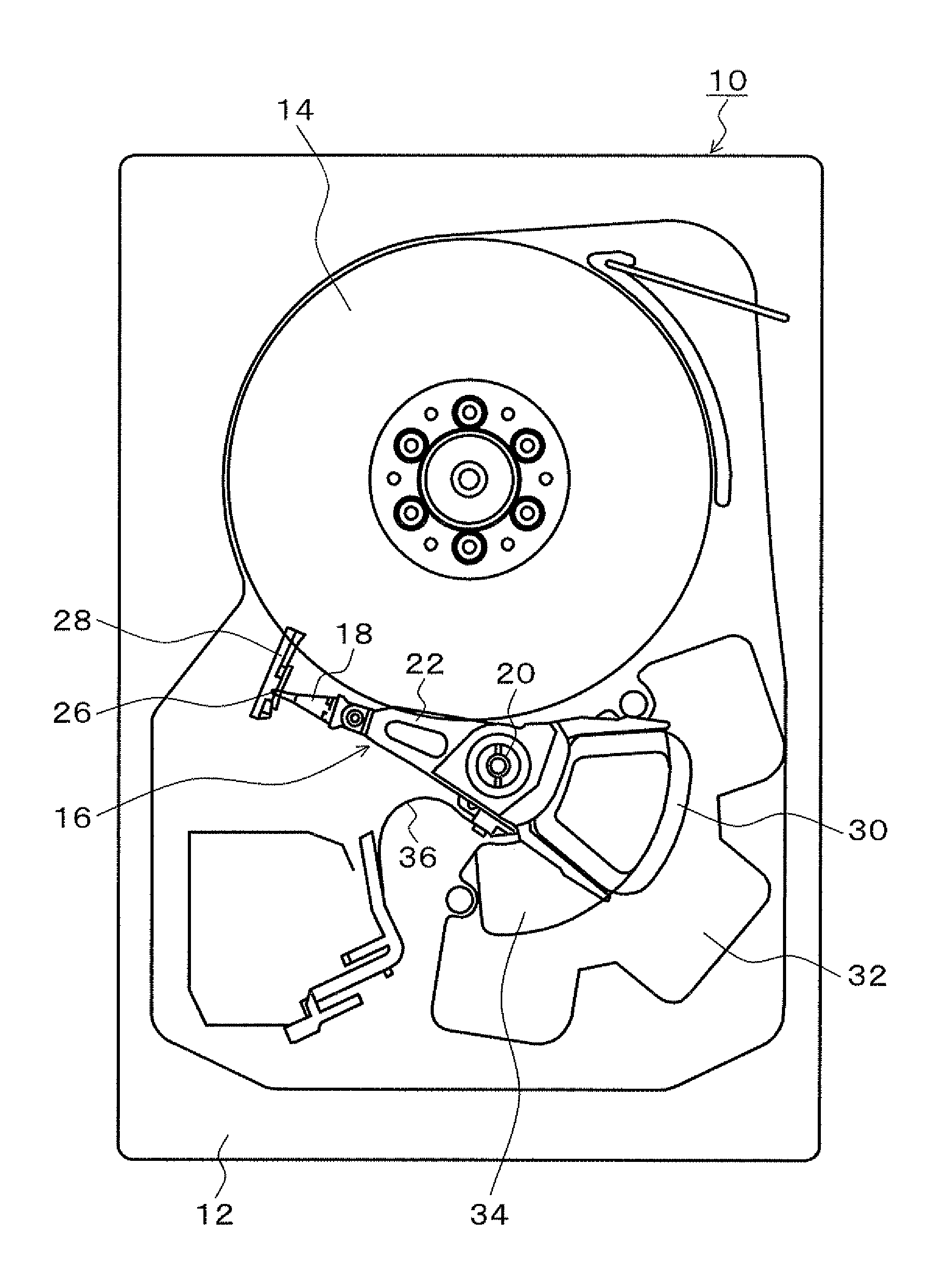

Electronic device and manufacturing method of electronic device

InactiveUS20080298218A1Correctly determineJoint strengthCarrier constructional parts dispositionDriving/moving recording headsEngineeringElectrical conductor

In the state in which a FPC terminal conductor precoated with a solder bump is opposed to a suspension terminal conductor having an Au plating layer, heating and melting is carried out while the suspension terminal conductor is pressed against the solder bump by a heater chip, thereby joining the FPC terminal conductor with the suspension terminal conductor by solder without using flux. In the suspension terminal conductor, a notch, a slit, or the like is formed as a solder joint observation window through which the solder joint state by the solder bump can be visually checked from outside via an insulating layer.

Owner:FUJITSU LTD

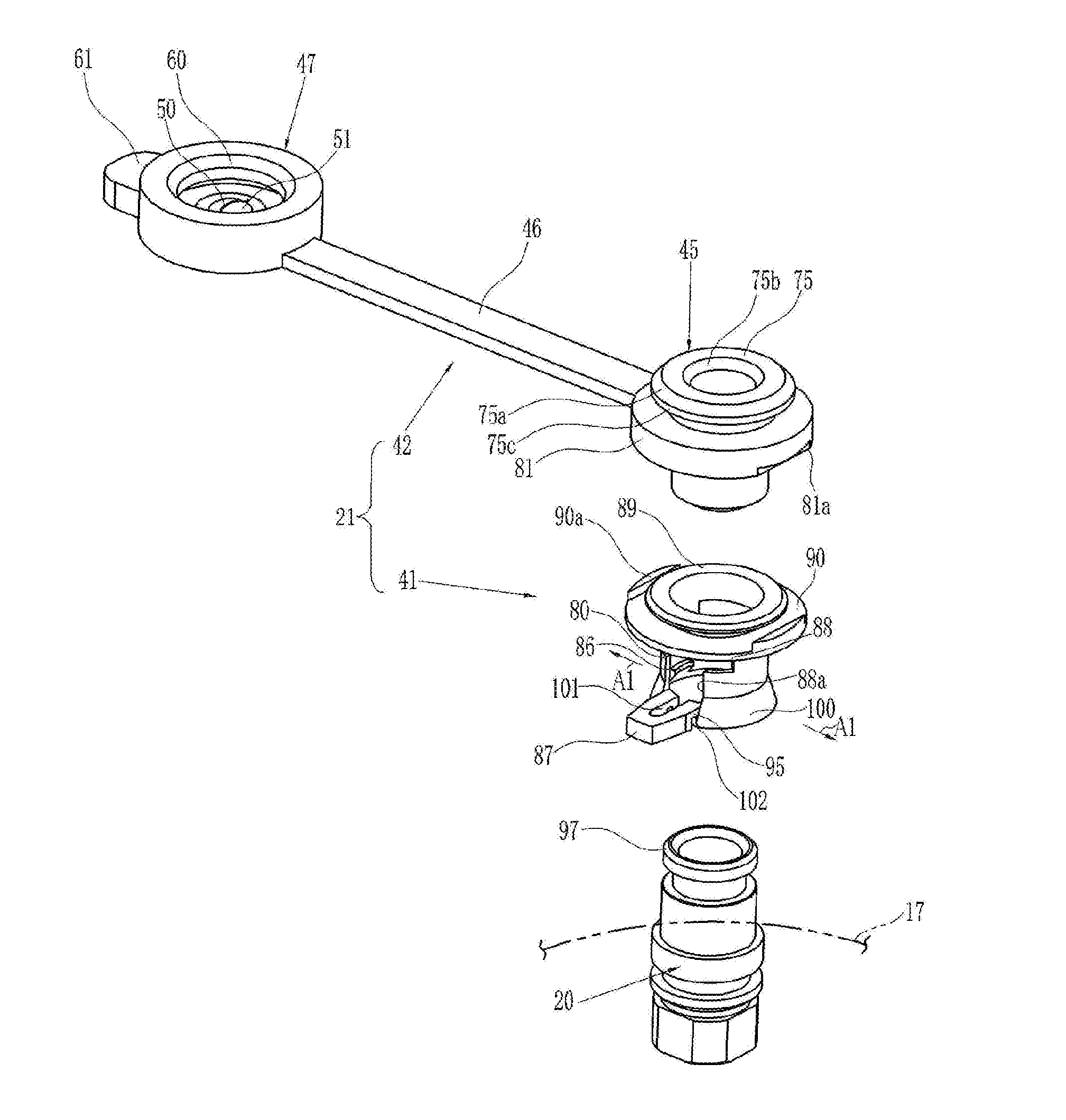

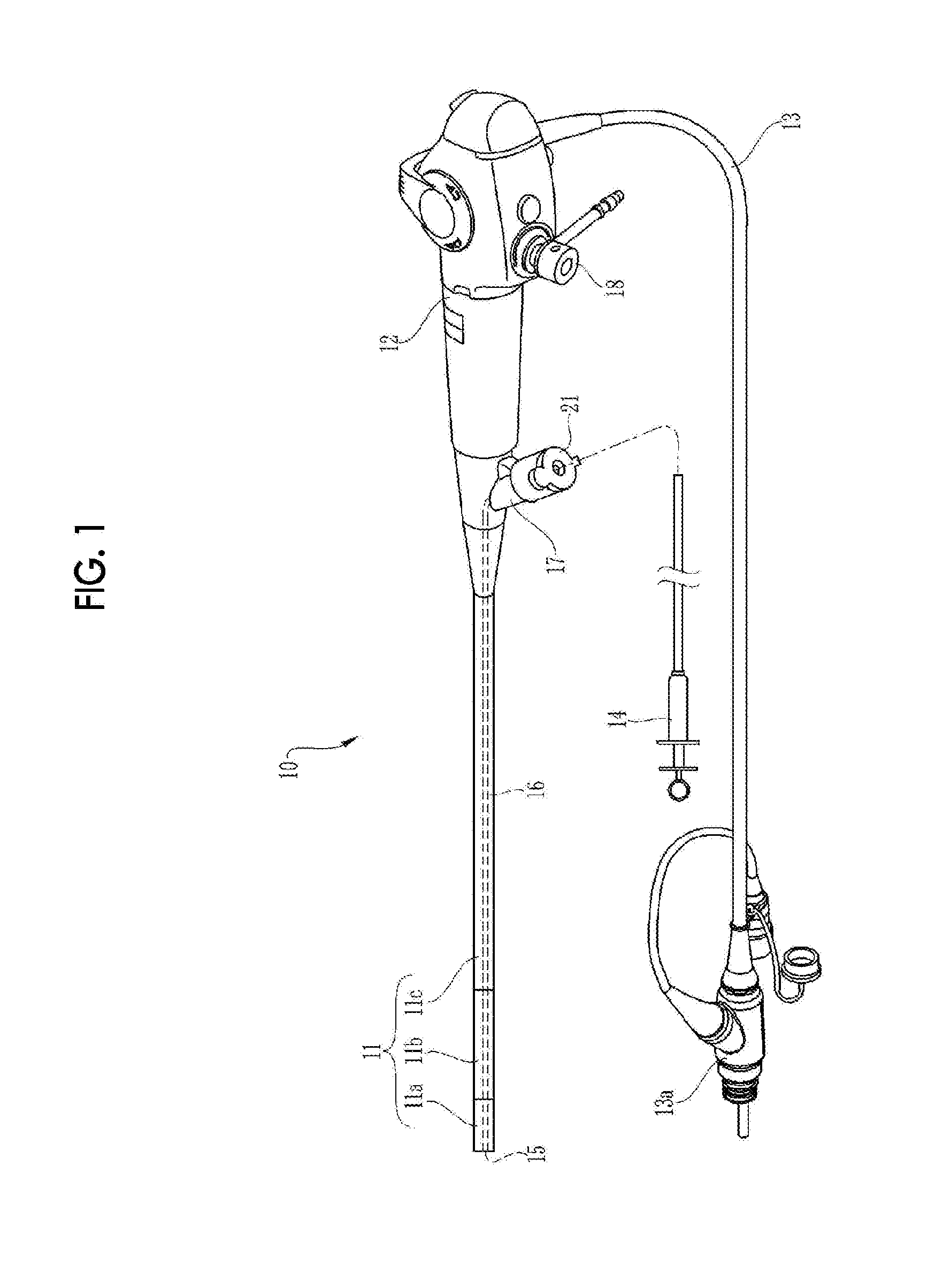

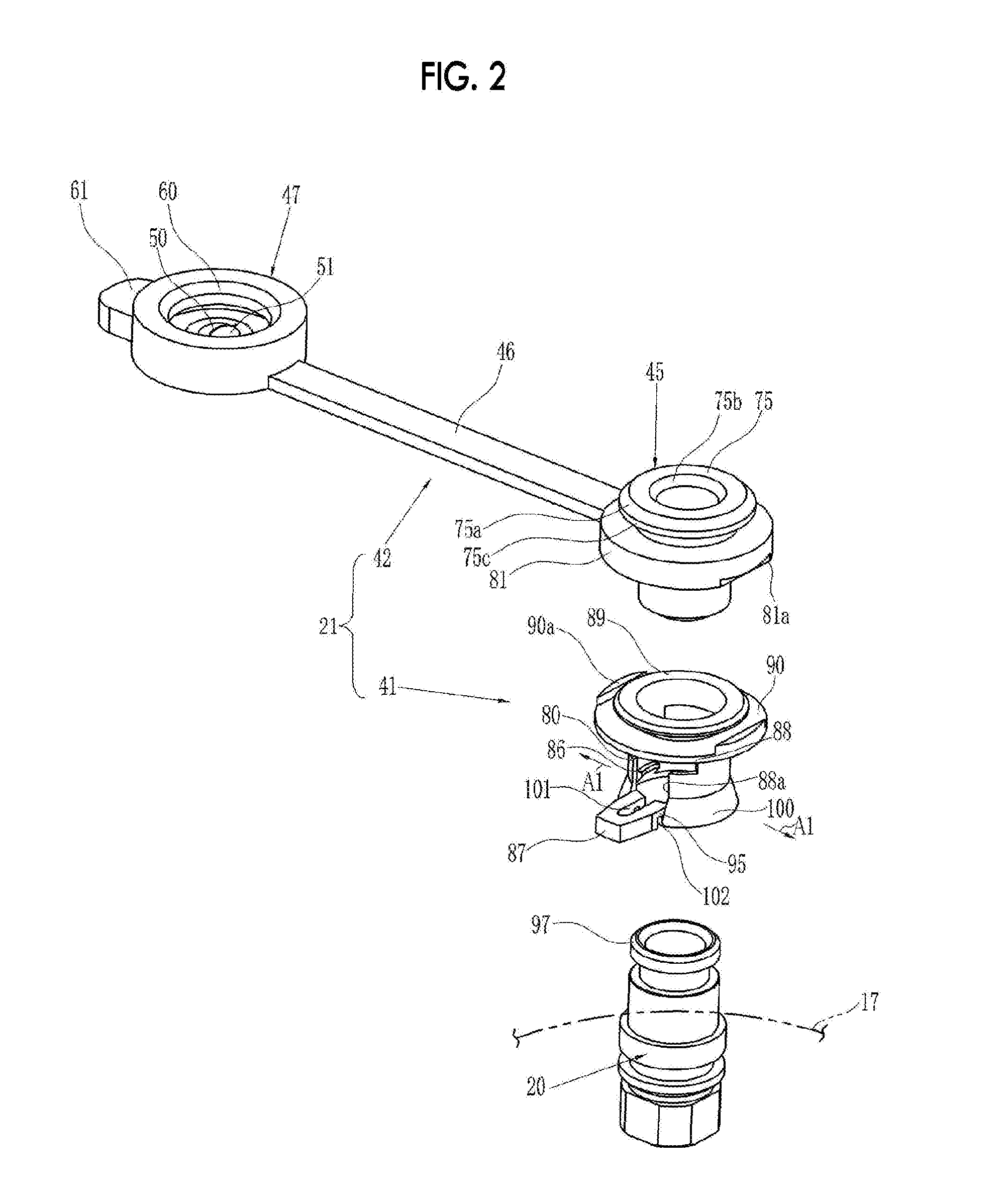

plug

The fixed valve and the attachable and detachable valve are connected to each other via a connecting band, and both are integrally made of elastomer. A frame body is constituted of a rigid body made of plastic. A flange and a receiving portion are formed on an upper portion of the frame body. A second flange is formed on a lower end of the fixed valve. The fixed valve is installed on the frame body by engaging the second flange with flange. The second flange is prevented from being separated from the flange of the second flange by interposing a part of the second flange between the flange and the receiving portion. The fixed valve is securely installed on the frame body, whereby the fixed valve is prevented from uncoupling when removing a treatment tool.

Owner:FUJIFILM CORP

Golf club head and golf club

InactiveUS20080293516A1Joint strengthGood lookingGolf clubsRacket sportsGolf BallUltimate tensile strength

A golf club head 2 is provided which includes a recessed part 16 provided on the external surface of a head main body 14, and a weight member 20 which is mounted in this recessed part 16 and which is formed of a material having a specific gravity greater than that of the head main body 14. This golf club head 2 has a first addition member 26 mounted on the external side of the weight member 20 while abutting the external surface of the weight member 20. A base of this first addition member 26 is a resin or a rubber. Furthermore, the head 2 has a second addition member 30 mounted on the external side of the first addition member 26 while abutting the external surface of the first addition member 26. This second addition member 30 is formed of a metal. This metal has a specific gravity being greater than that of the first addition member and smaller than that of the weight member 20. According to the present invention, joint strength between the head main body and the weight member can be enhanced. The present invention can achieve improved good-looking appearance.

Owner:SUMITOMO RUBBER IND LTD

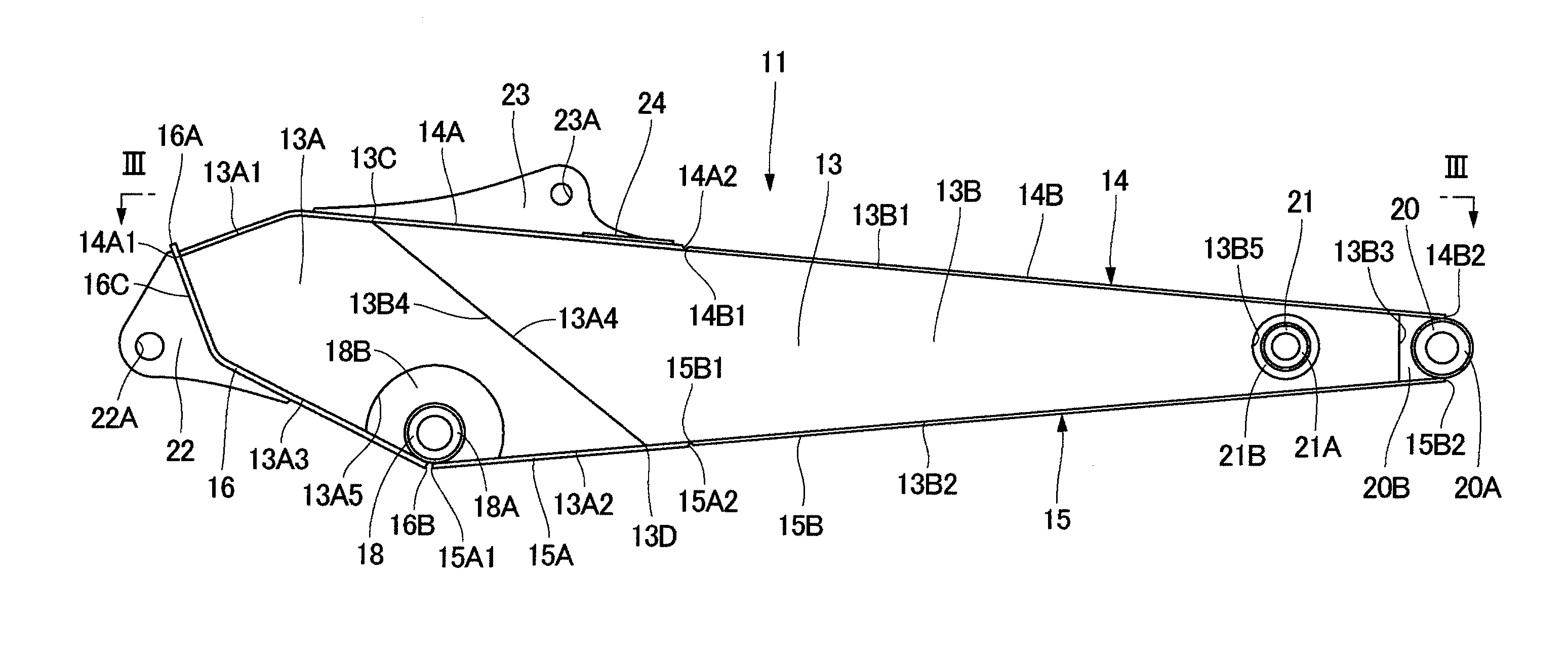

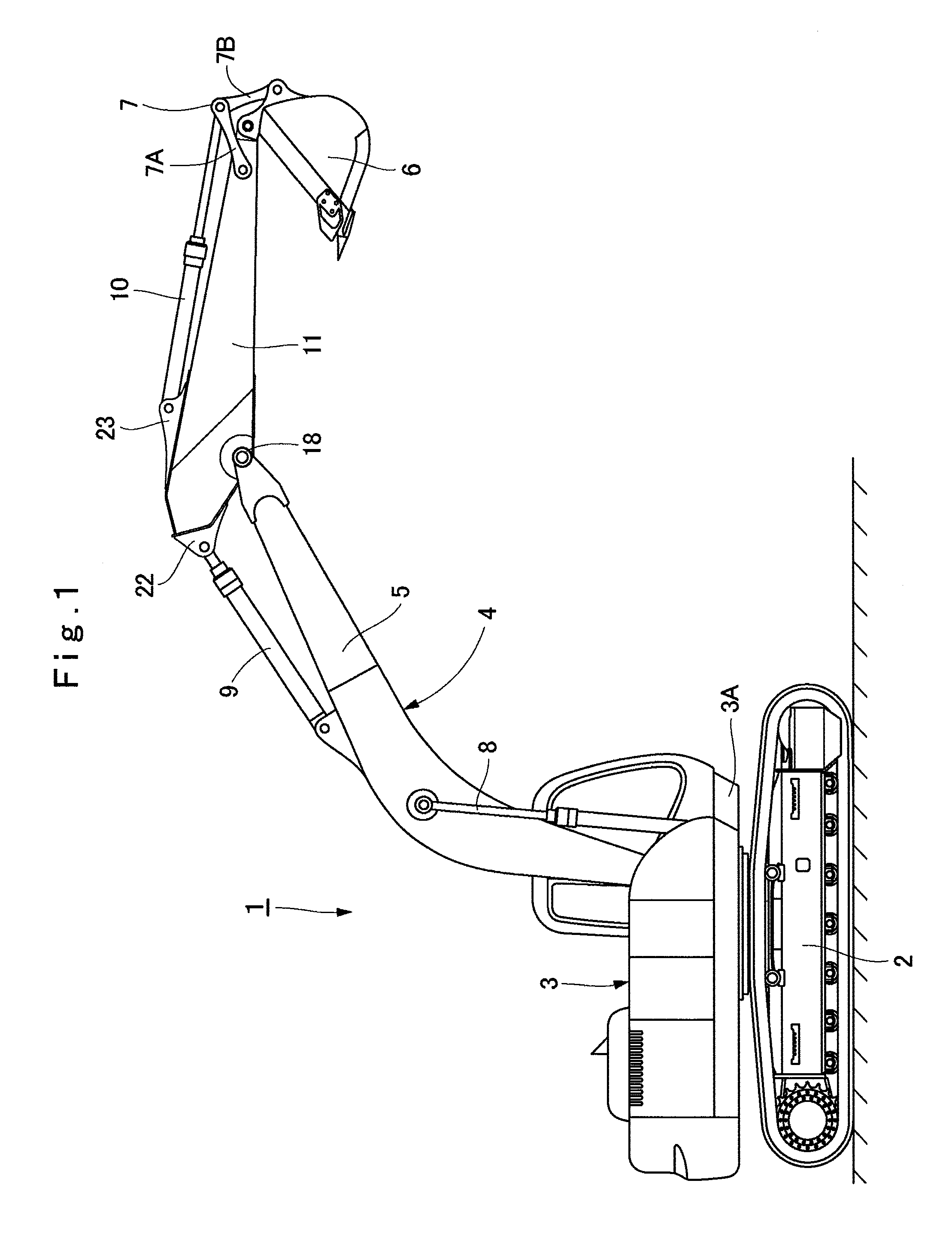

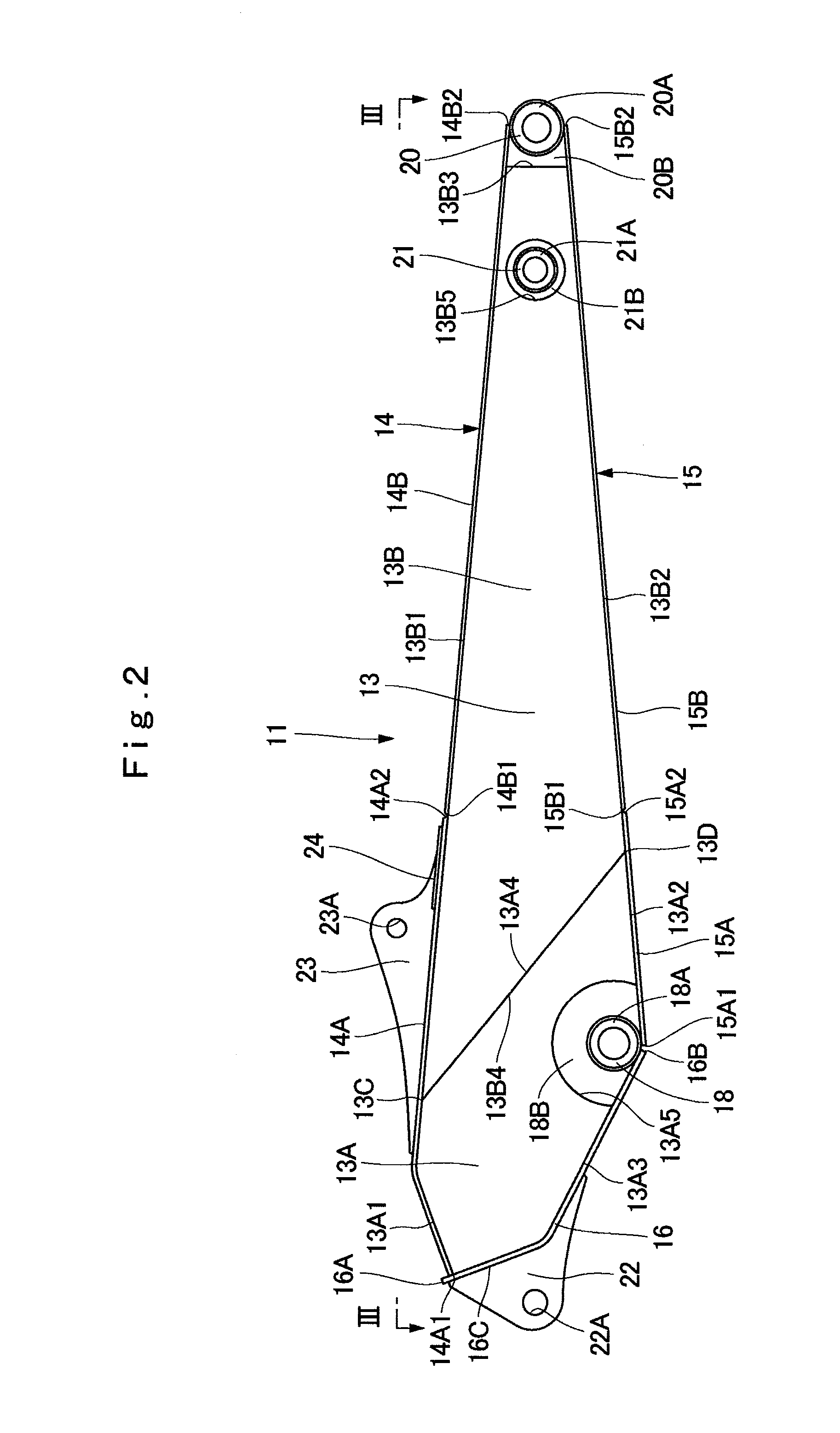

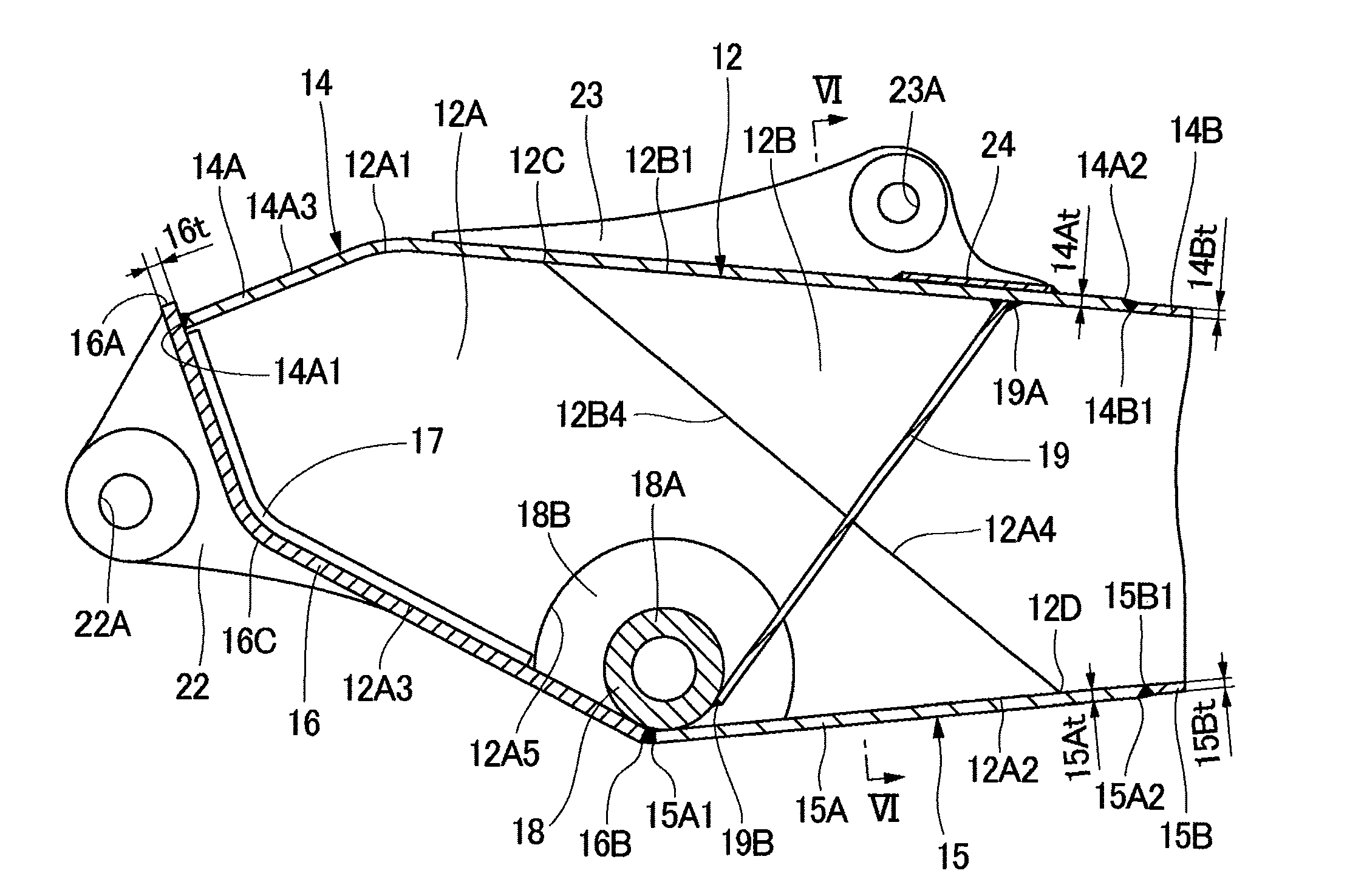

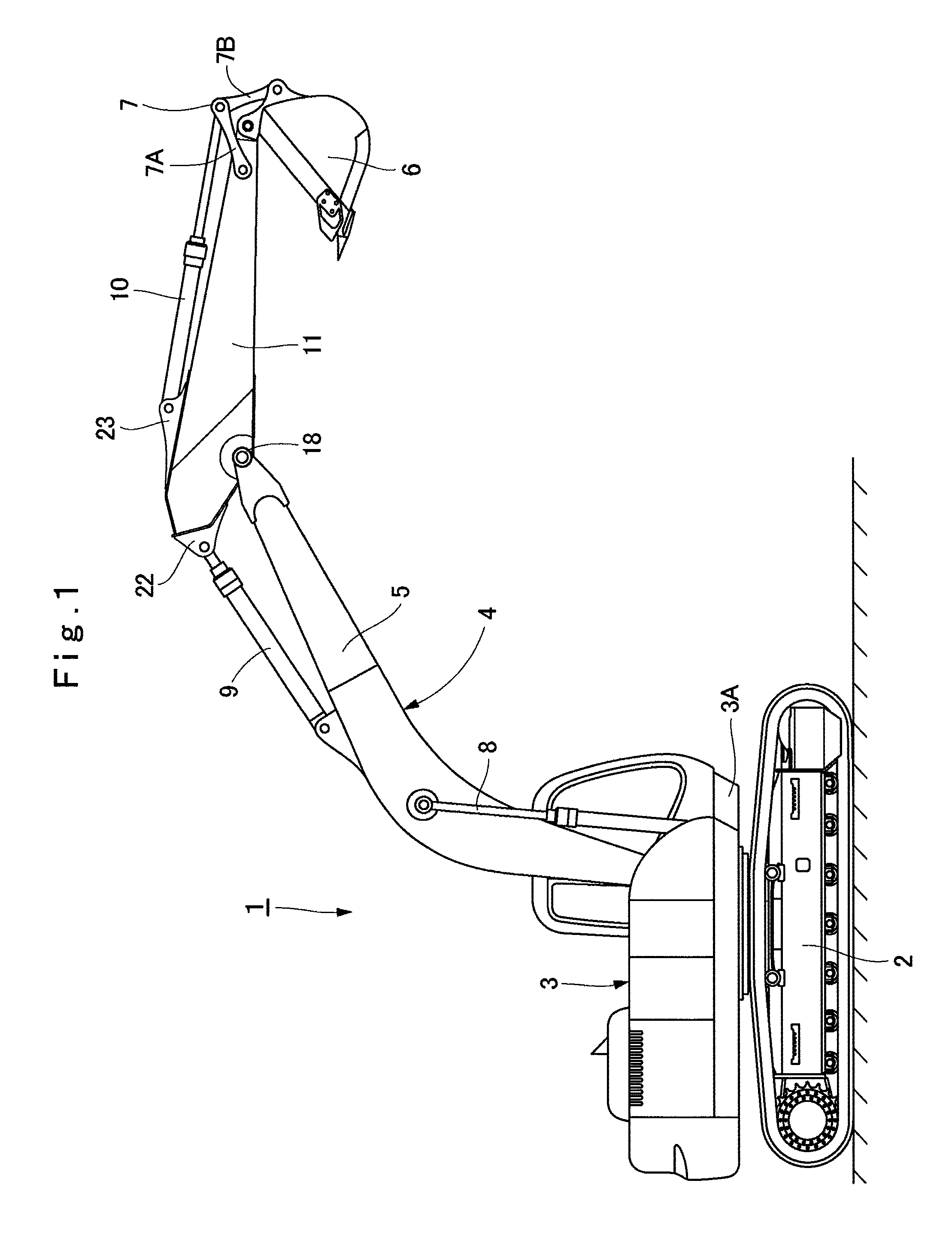

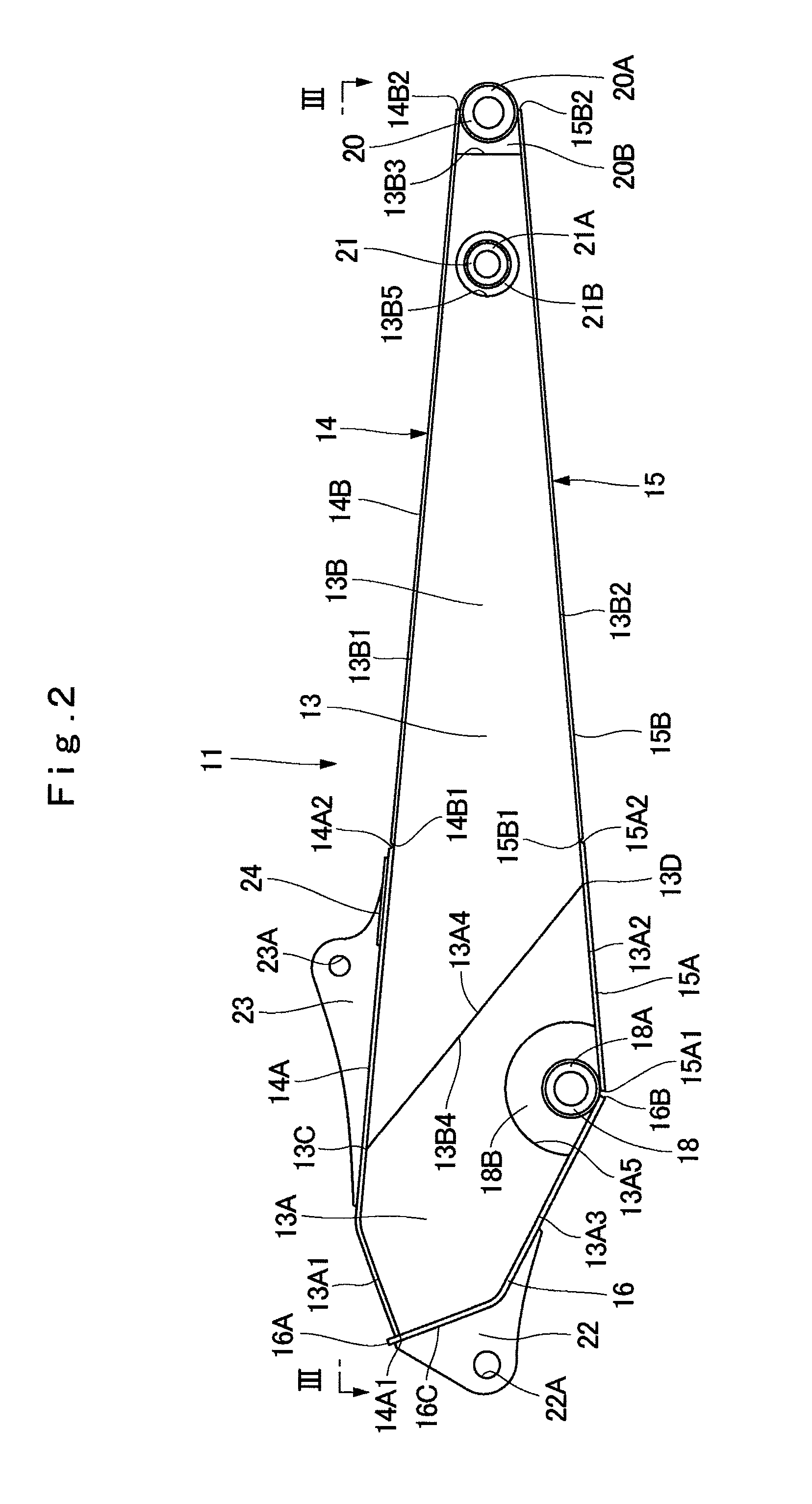

Arm for construction machine

ActiveUS20130343854A1Improved strengthJoint strengthMechanical machines/dredgersLifting devicesEngineeringExcavator

An arm (11) of a hydraulic excavator (1) is formed as a box-shaped structural body surrounded by left and right side plates (12, 13), an upper plate (14), a lower plate (15), and a thick rear plate (16). An upper end (16A) of the thick rear plate (16) is protruded upward from an outer surface (14A3) of the upper plate (14). Upper ends (22B) of a pair of arm cylinder brackets (22) joined to an outer surface (16C) of the thick rear plate (16) are arranged higher than the outer surface (14A3) of the rear thick upper plate (14A) and lower than the upper end (16A) of the thick rear plate (16). As a result, in each of the arm cylinder brackets (22), a joint area with the thick rear plate (16) can be ensured large, and joint strength can be improved.

Owner:HITACHI CONSTR MASCH CO LTD

Membrane-electrode junction agent, proton conducting membrane having junction layer, membrane-electrode assembly, polymer electrolyte fuel cell, and manufacturing method of the membrane-electrode assembly

InactiveUS8318377B2Improve joint strengthHigh fuel barrier propertyActive material electrodesSolid electrolyte fuel cellsCross-linkFuel cells

A membrane-electrode junction agent, a proton conducting membrane having a junction layer, a membrane-electrode assembly, a polymer electrolyte fuel cell, and a manufacturing method of the membrane-electrode assembly, which enhance the power generation performance, realize the high fuel barrier property, and are capable of enhancing the joint strength between the membrane and the electrodes, is provided. A membrane-electrode junction agent that joins a proton conducting membrane and electrodes arranged on both surfaces of the proton conducting membrane to each other, the membrane-electrode junction agent including: a cross-linked compound (X) having a silicon-oxygen bond; a polymer material (Y) containing an acid group; and a hydrophilic resin (Z) containing no acid group.

Owner:SEKISUI CHEM CO LTD

Joining method

A joining method for joining together a first member in which fiber material is mixed into a first resin, and a second member that includes at least a second resin, includes abutting the first member and the second member together, and softening or melting the first resin of the first member and the second resin of the second member that are adjacent to abutting surfaces of the first member and the second member; and stirring a joint forming portion formed by the softened or melted first resin of the first member and the softened or melted second resin of the second member, and the fiber material included in the softened or melted first resin of the first member, in a direction inclined with respect to the abutting surfaces, and hardening the joint forming portion.

Owner:TOYOTA JIDOSHA KK

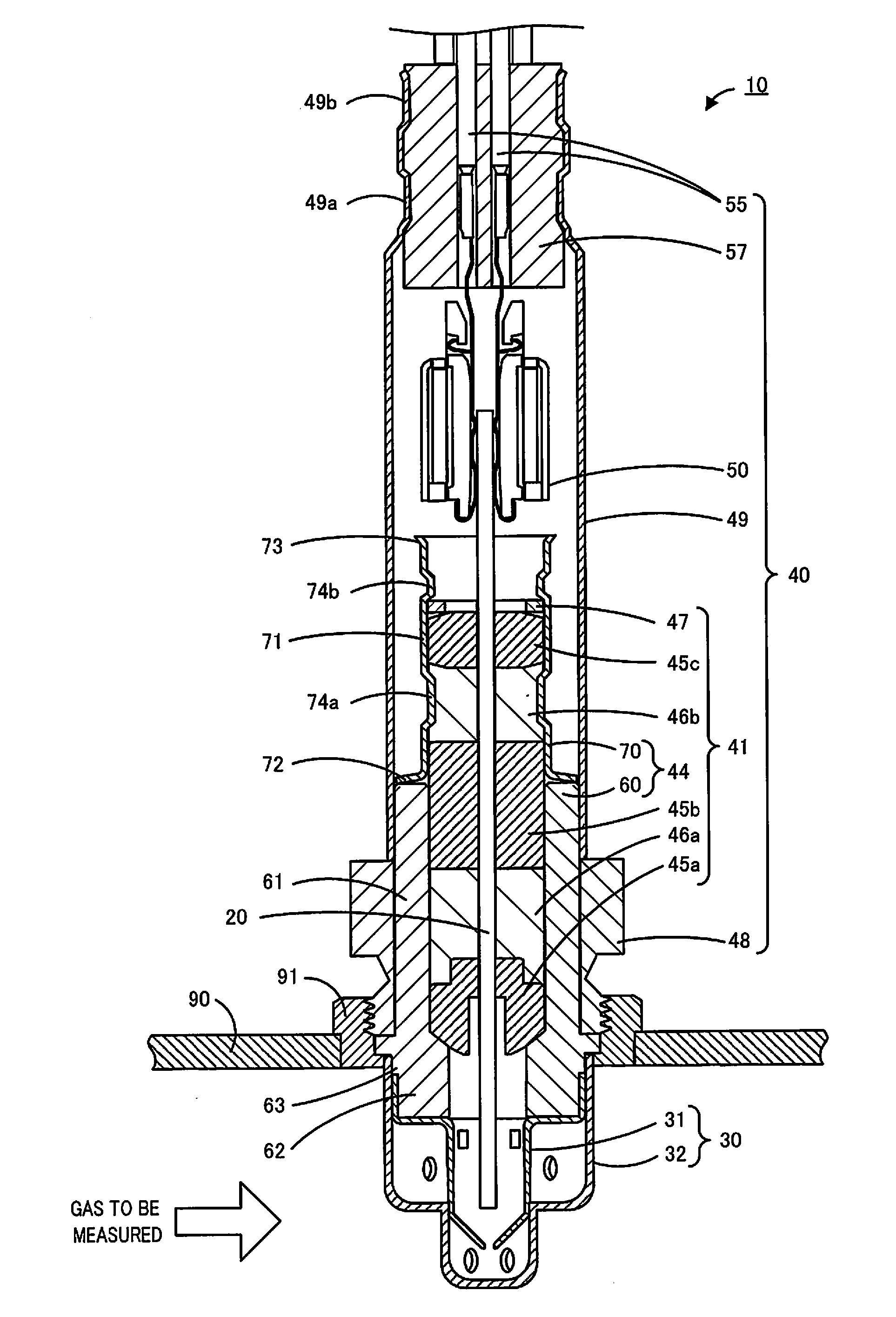

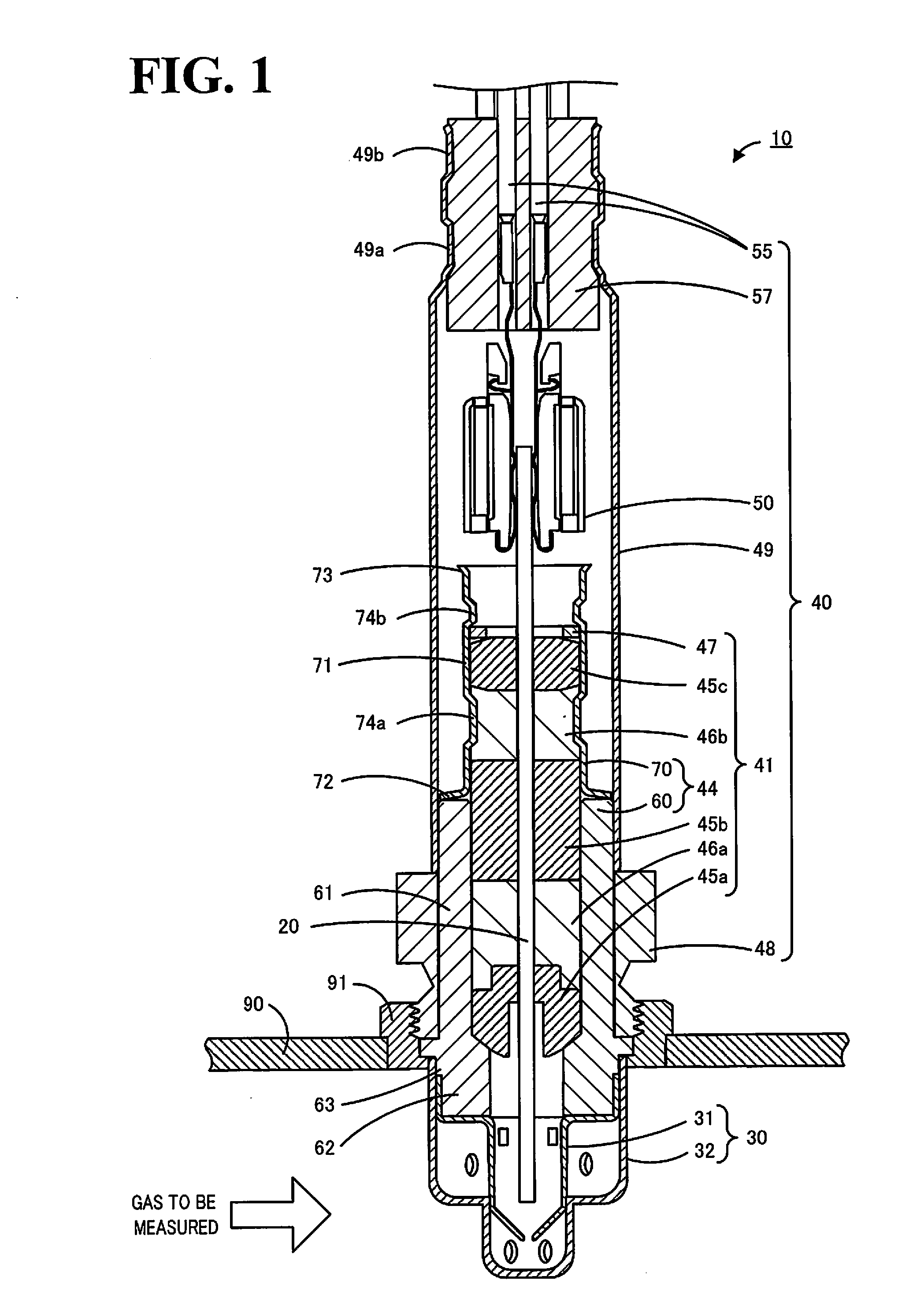

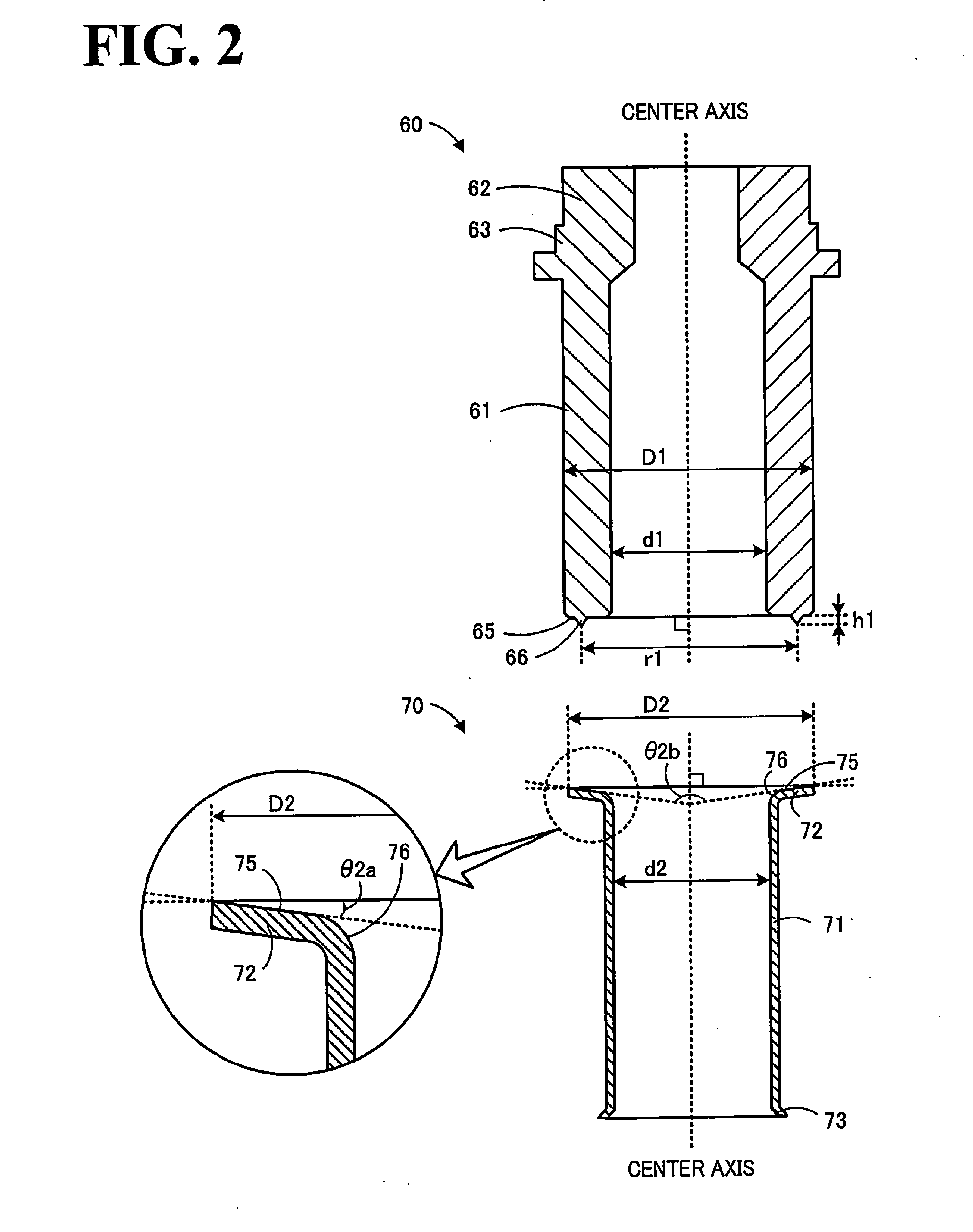

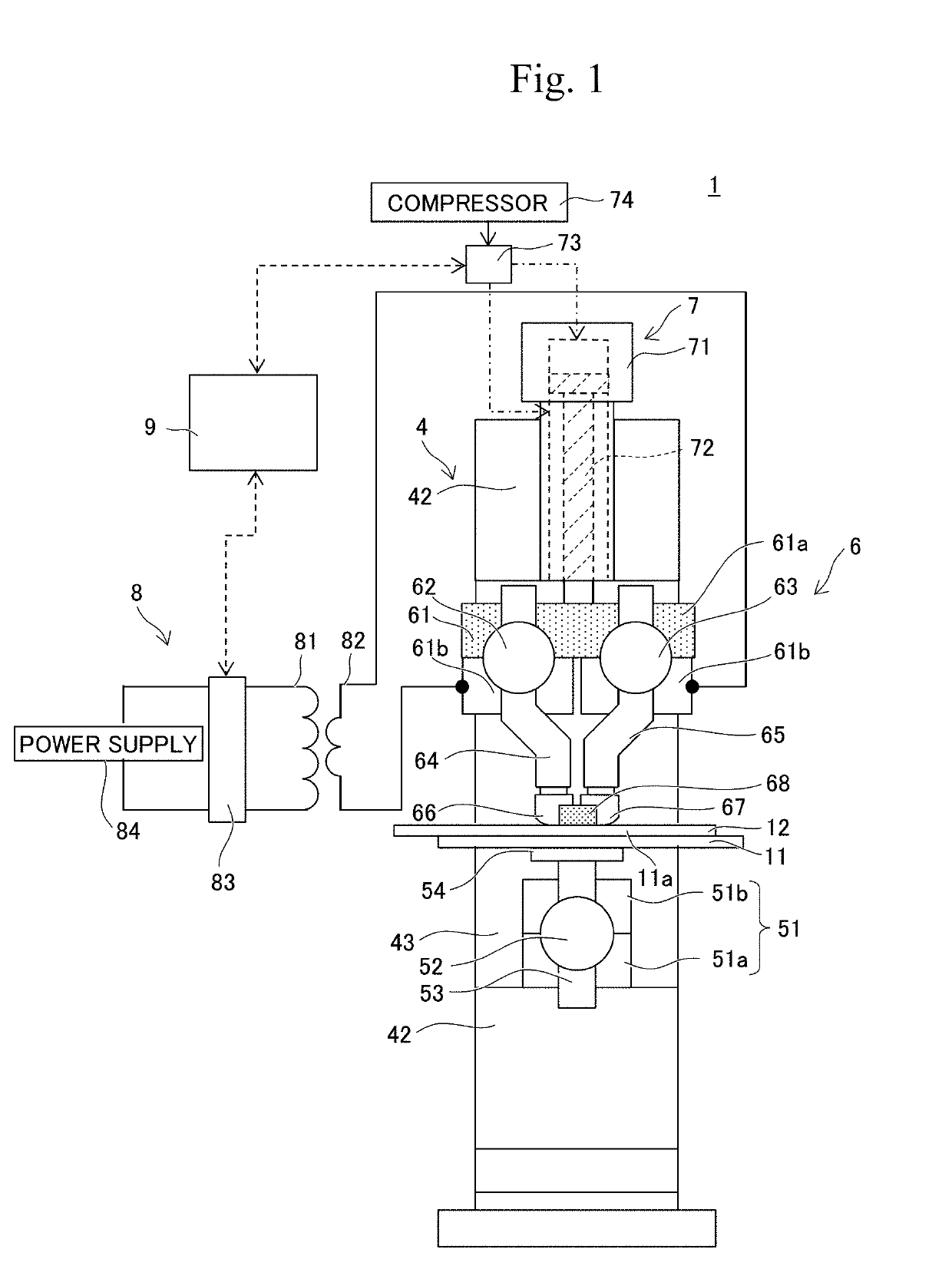

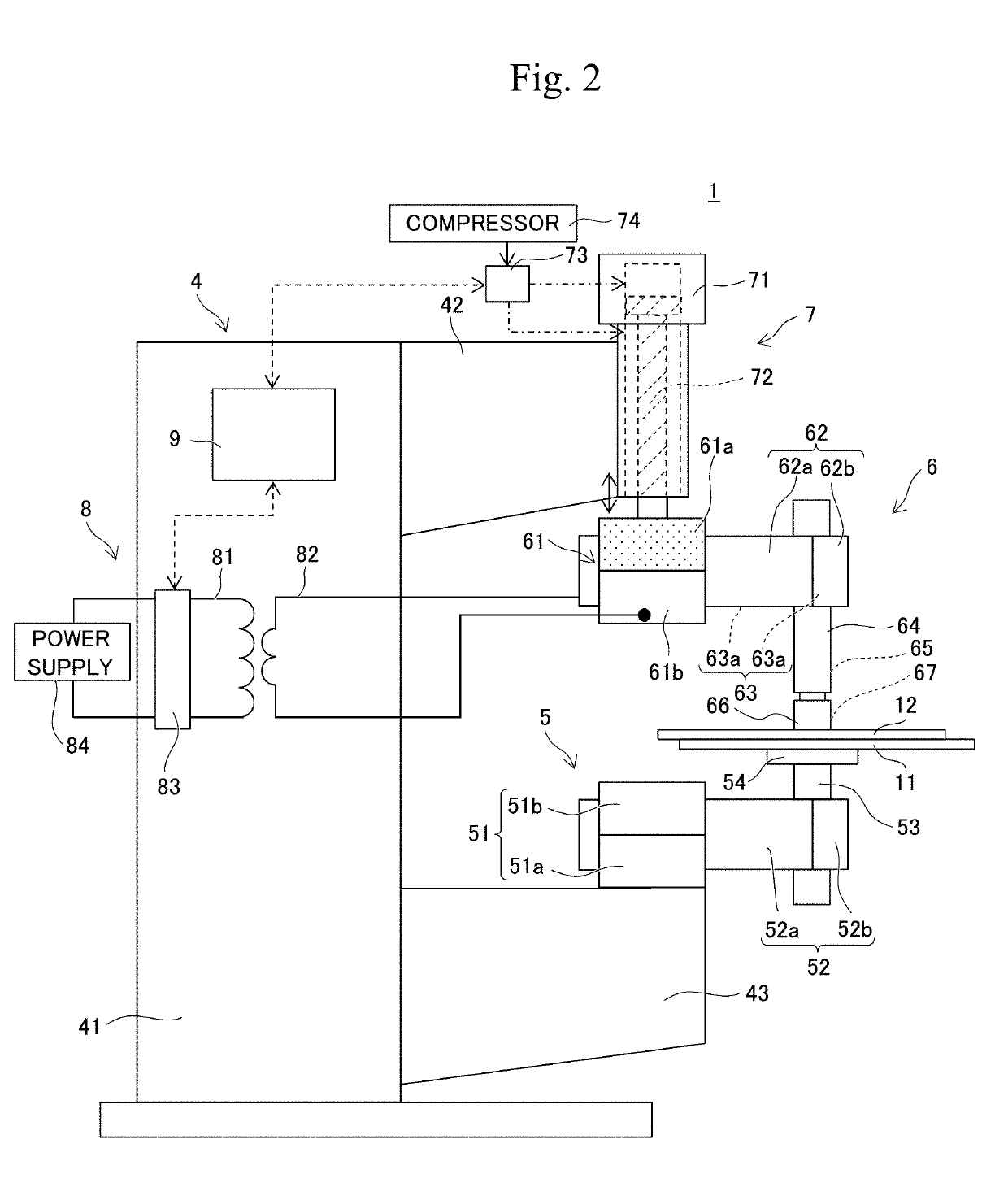

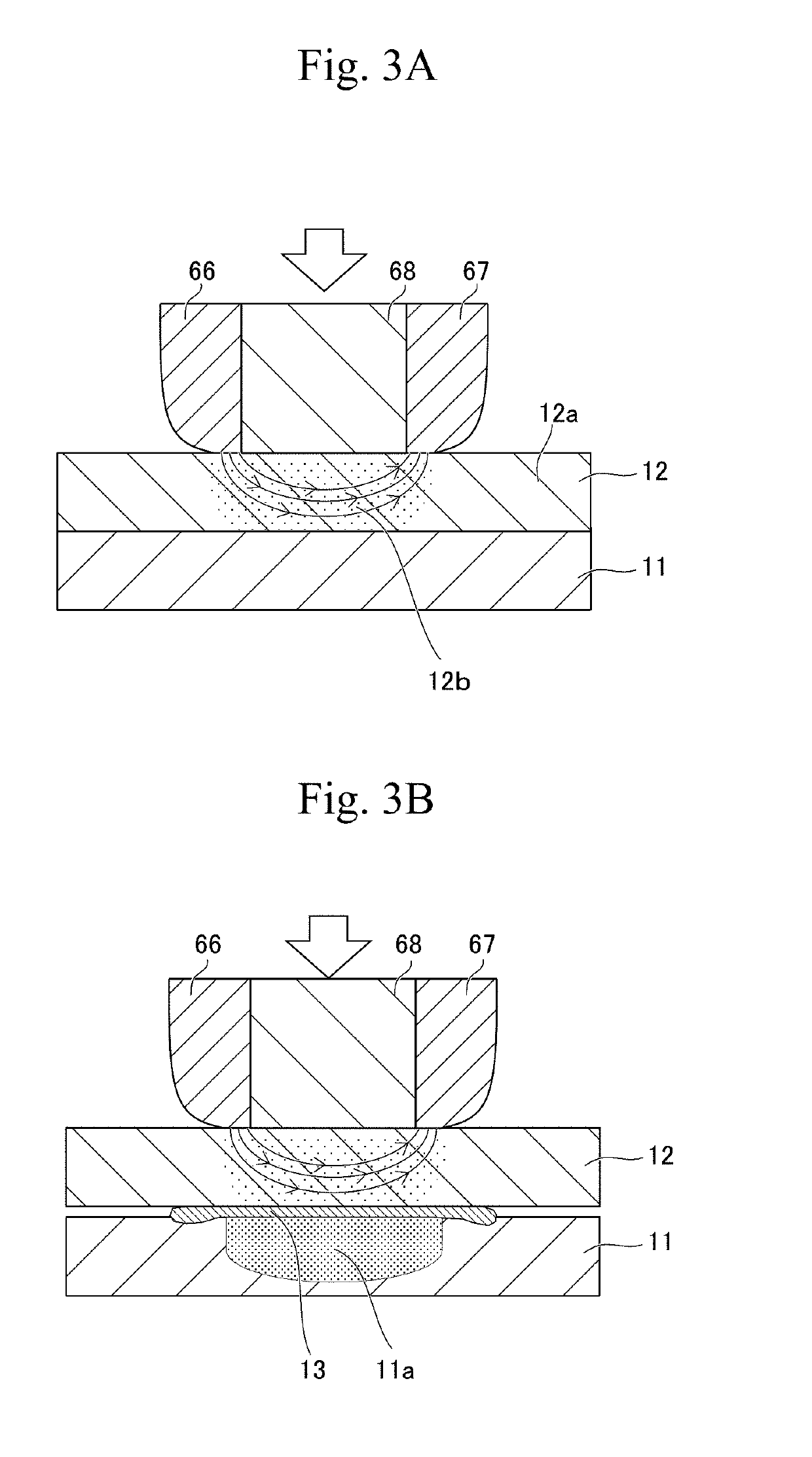

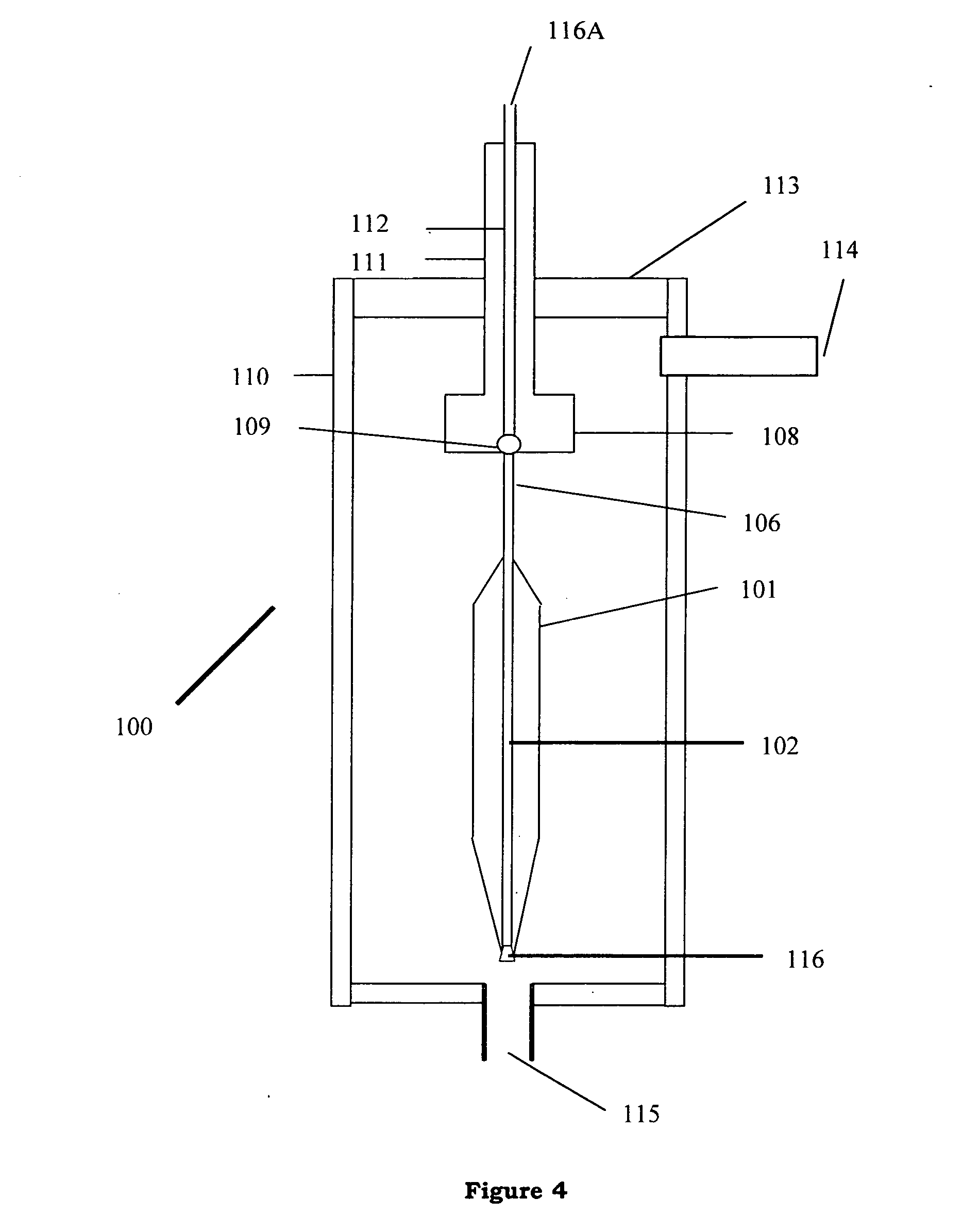

Production method for welded body and production method for gas sensor

ActiveUS20160114420A1Suppress formationSpeed up the flowResistance welding apparatusEngineeringMetal

In a main metal piece 60 and an inner cylinder 70 serving as cylindrical bodies before welding, a second end surface 75 is an inclined surface that inclines toward an end portion opposite from the second end surface 75 as the second end surface 75 extends toward the center axis, and an angle θ2a is 5° to 15°. Thus, the distance between a first end surface 65 and the second end surface 75 positioned in resistance welding increases toward the center axis, and an angle θc (=angle θ2a) between the first end surface 65 and the second end surface 75 is 5° to 15°.

Owner:NGK INSULATORS LTD

Laser welding Al and Fe members with Zn filler

InactiveUS8492675B2Improve joint strengthJoint strengthWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalMetal

Owner:HONDA MOTOR CO LTD

Arm for construction machine with upper ends of rear plate protruding upward

ActiveUS9315966B2Reduce weightHigh strengthMechanical machines/dredgersLifting devicesEngineeringExcavator

An arm of a hydraulic excavator is formed as a box-shaped structural body surrounded by left and right side plates, an upper plate, a lower plate, and a thick rear plate. An upper end of the thick rear plate is protruded upward from an outer surface of the upper plate. Upper ends of a pair of arm cylinder brackets joined to an outer surface of the thick rear plate are arranged higher than the outer surface of the rear thick upper plate and lower than the upper end of the thick rear plate. As a result, in each of the arm cylinder brackets, a joint area with the thick rear plate can be ensured large, and joint strength can be improved.

Owner:NIHON KENKI CO LTD

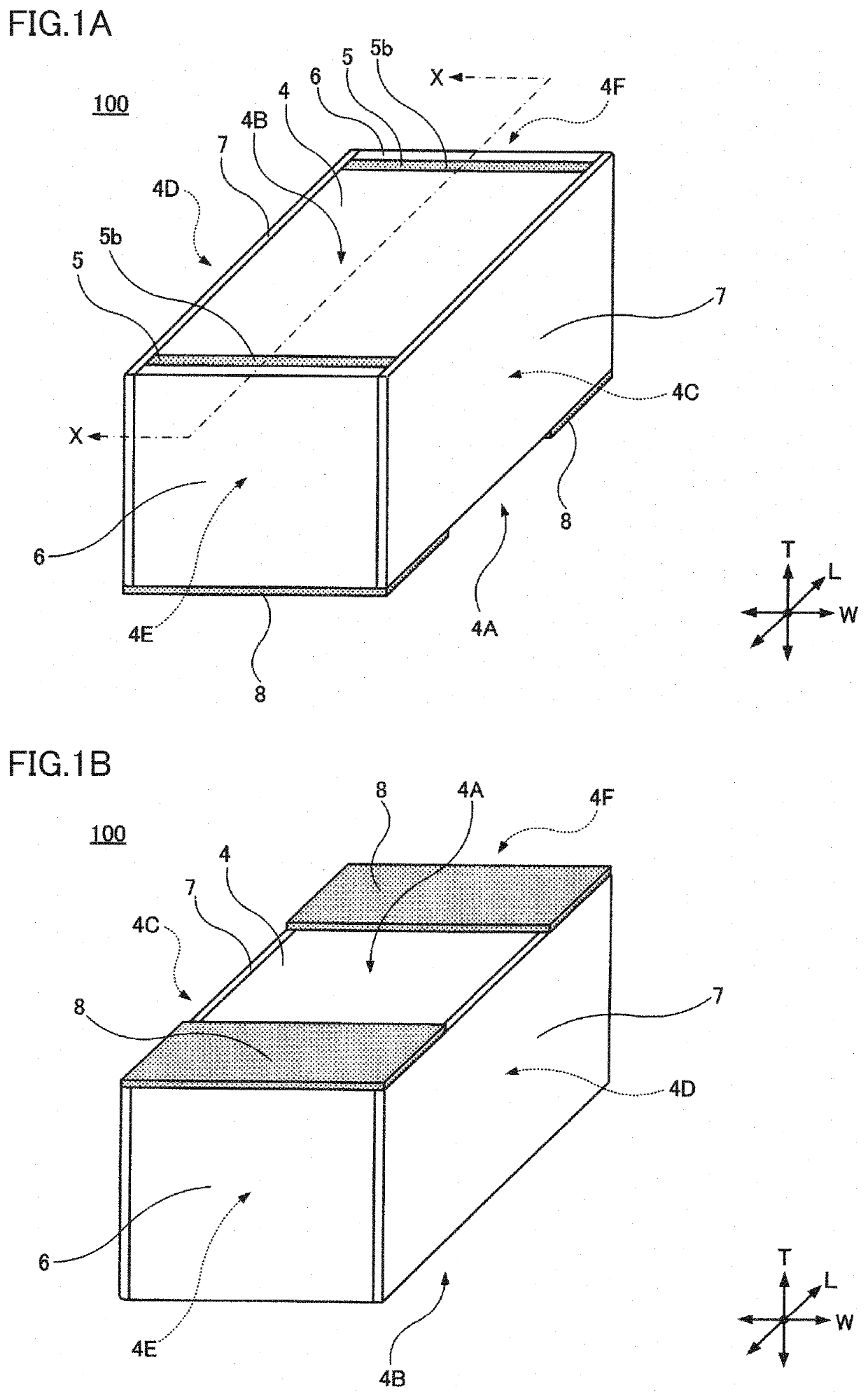

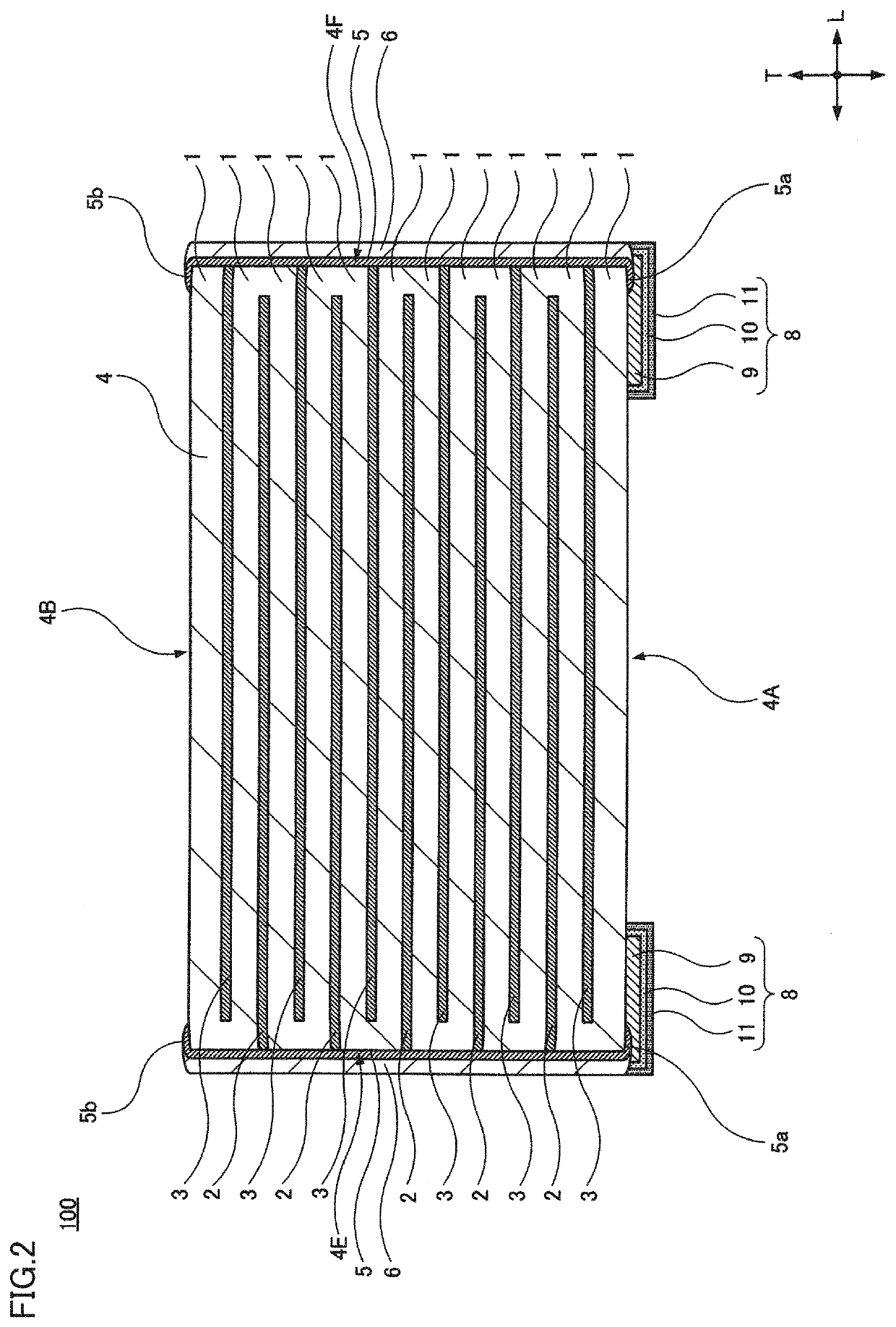

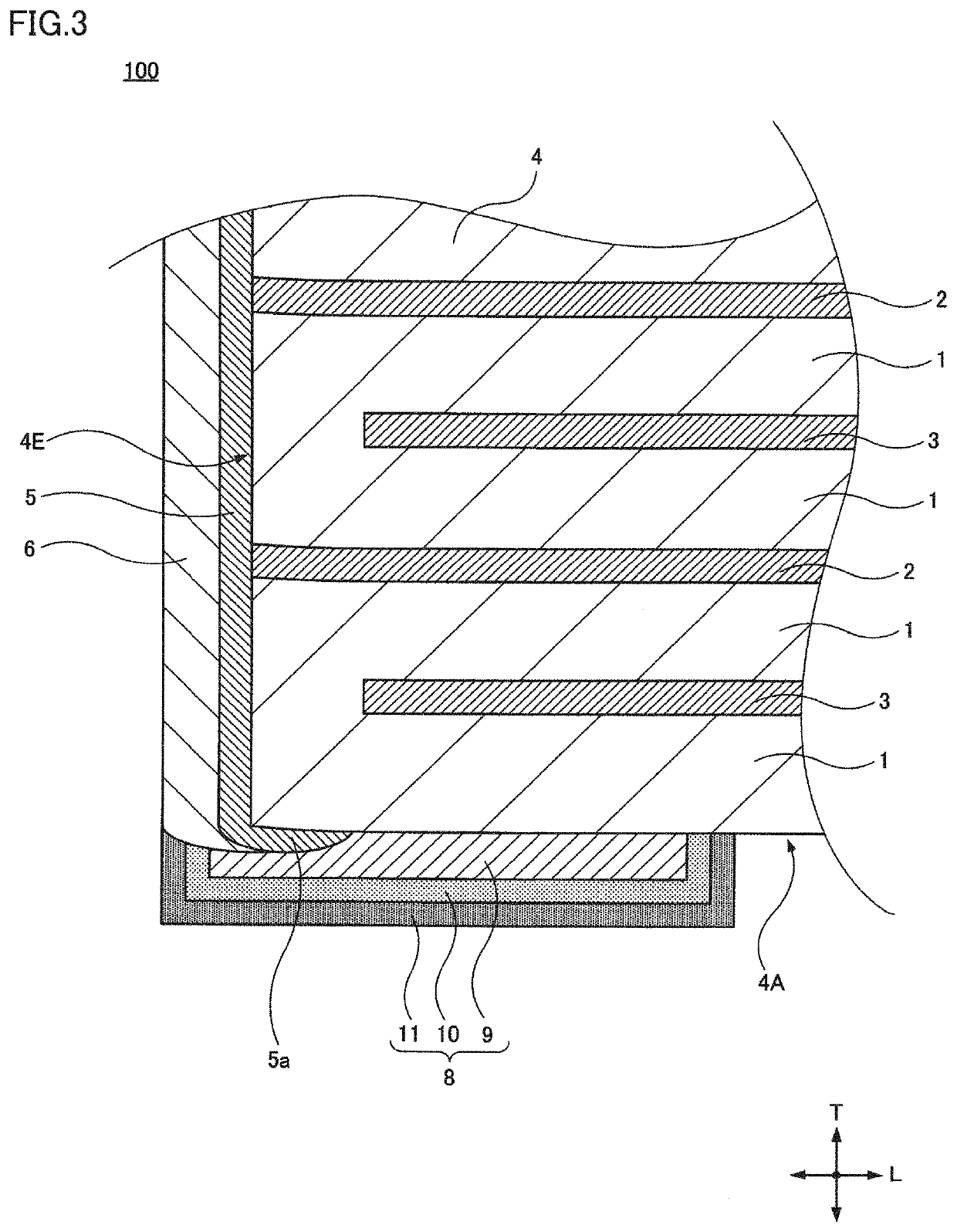

Multilayer ceramic capacitor

ActiveUS20210020377A1Improve joint strengthEnsure electrical connection reliabilityFixed capacitor electrodesFixed capacitor dielectricElectrical conductorCeramic capacitor

A multilayer ceramic capacitor includes a ceramic multilayer body including ceramic layers and internal electrodes that are layered, main surfaces, side surfaces, and end surfaces, a conductor layer covering each of the end surfaces of the ceramic multilayer body and electrically connected to the internal electrodes, an insulating layer covering the conductor layer, and an external electrode electrically connected to the conductor layer. The conductor layer includes a portion that extends to a portion of each of the main surfaces of the ceramic multilayer body.

Owner:MURATA MFG CO LTD

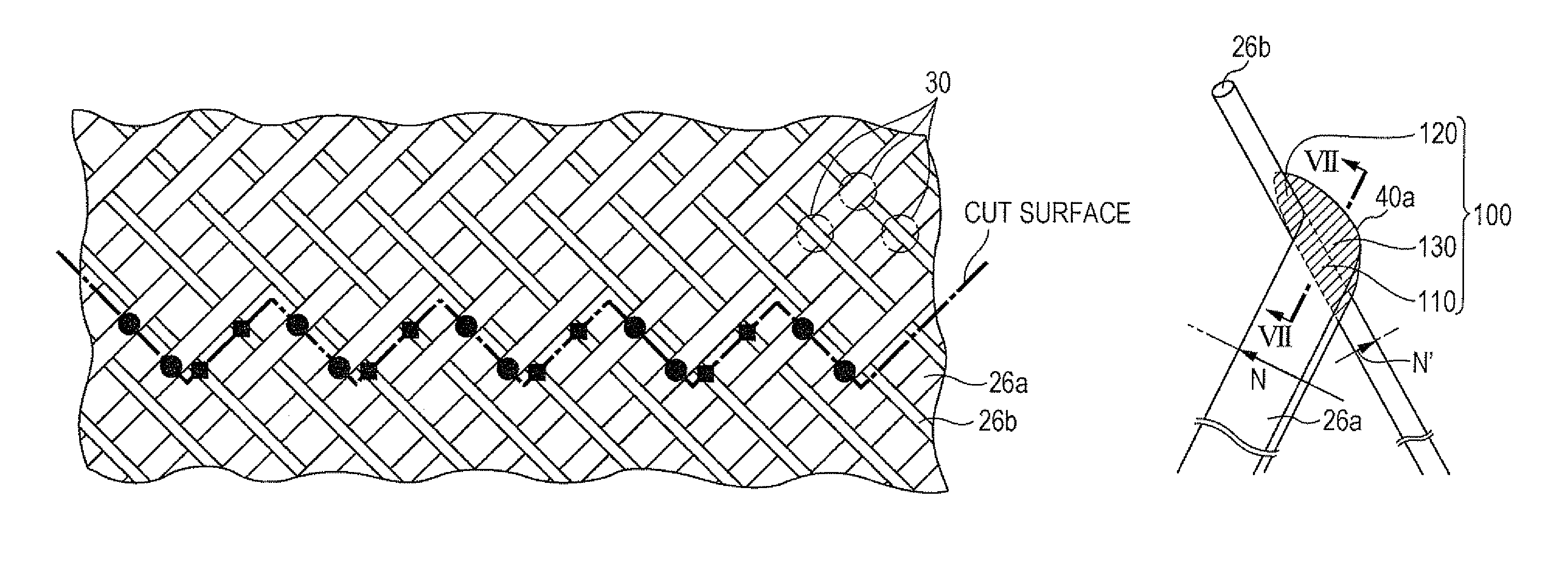

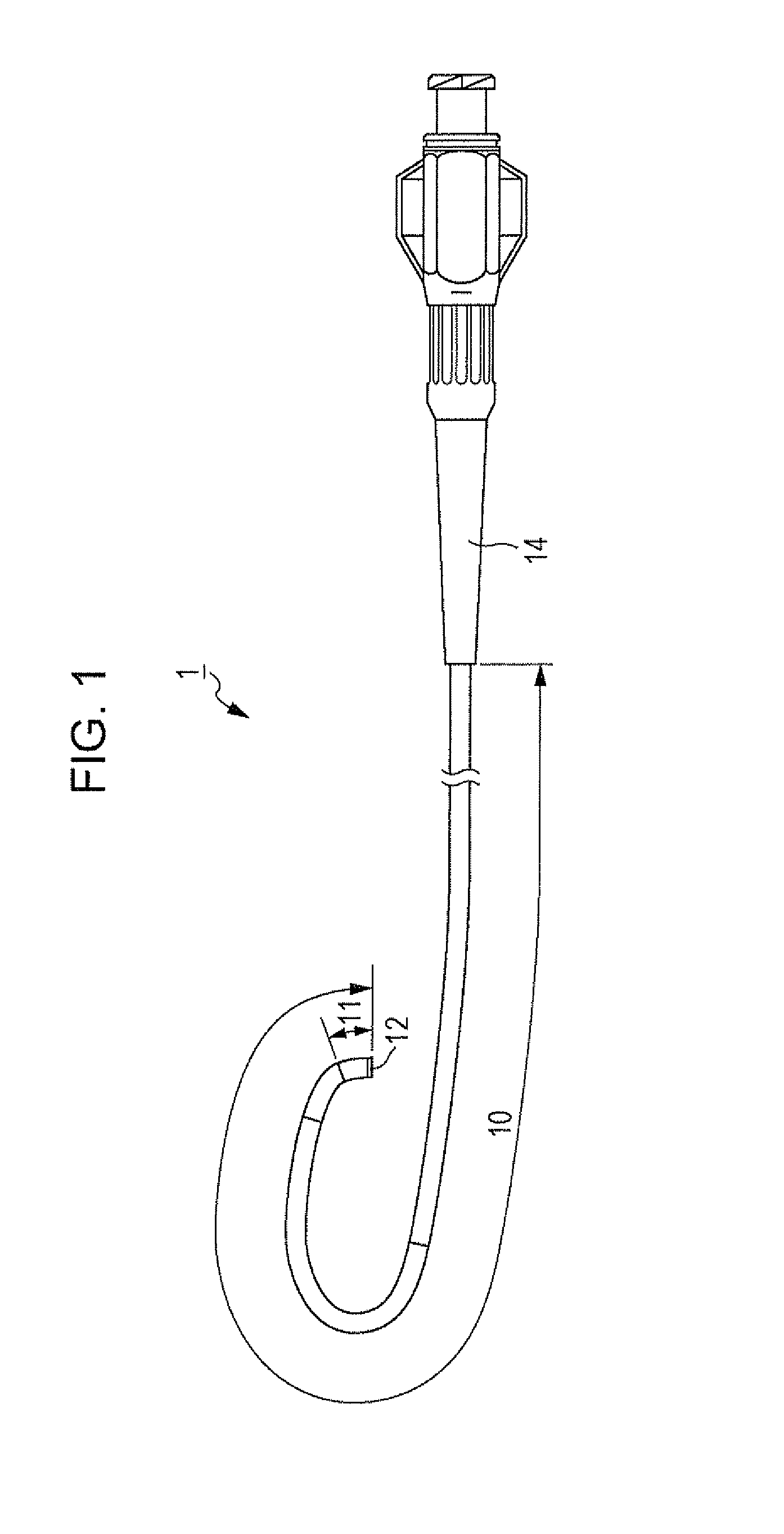

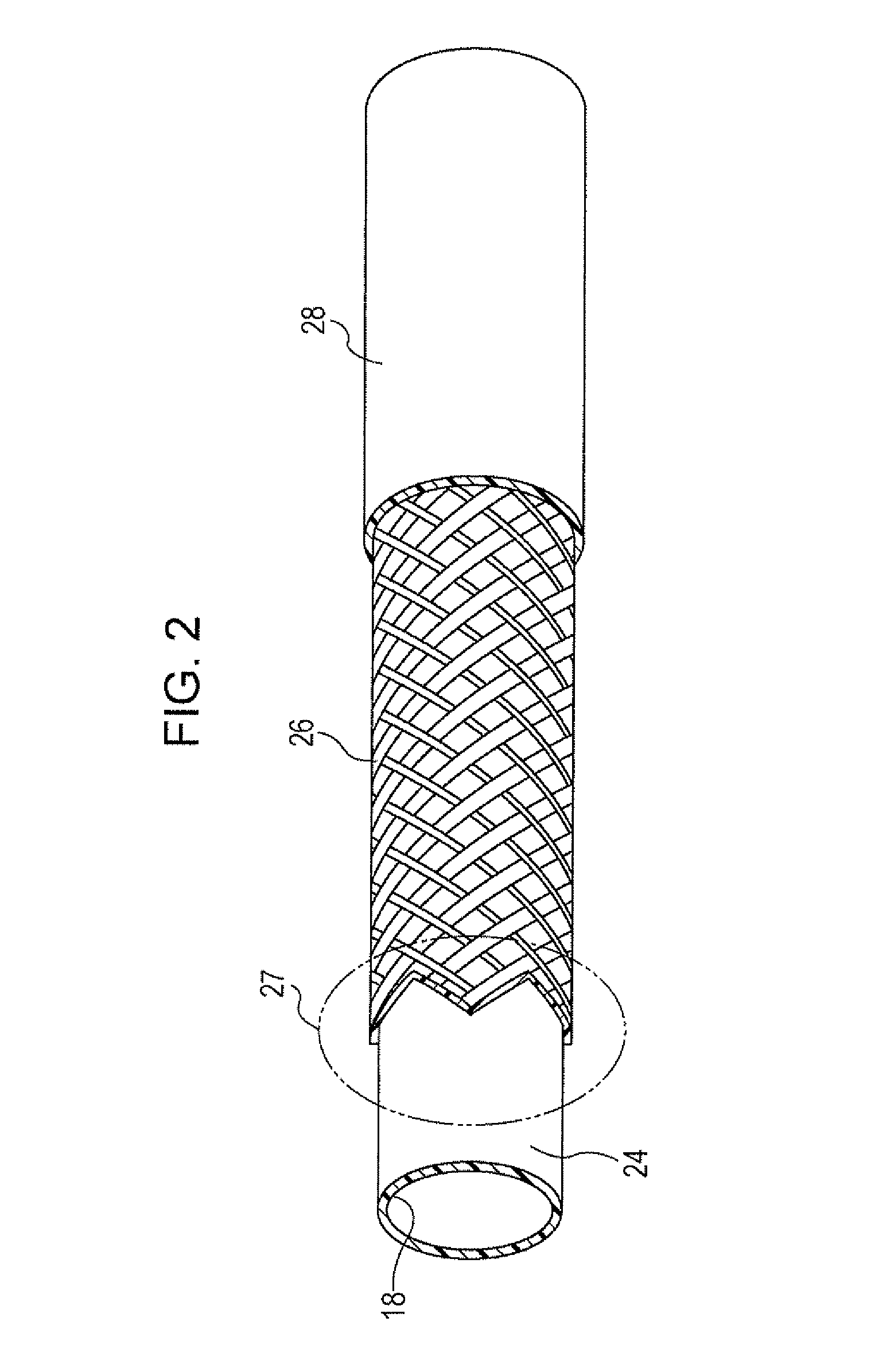

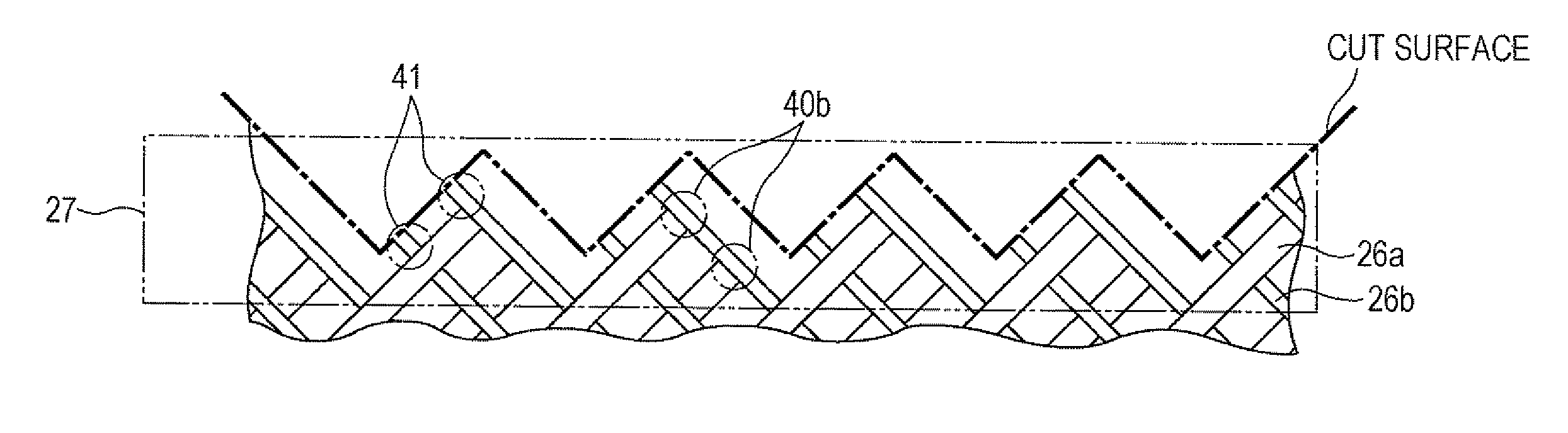

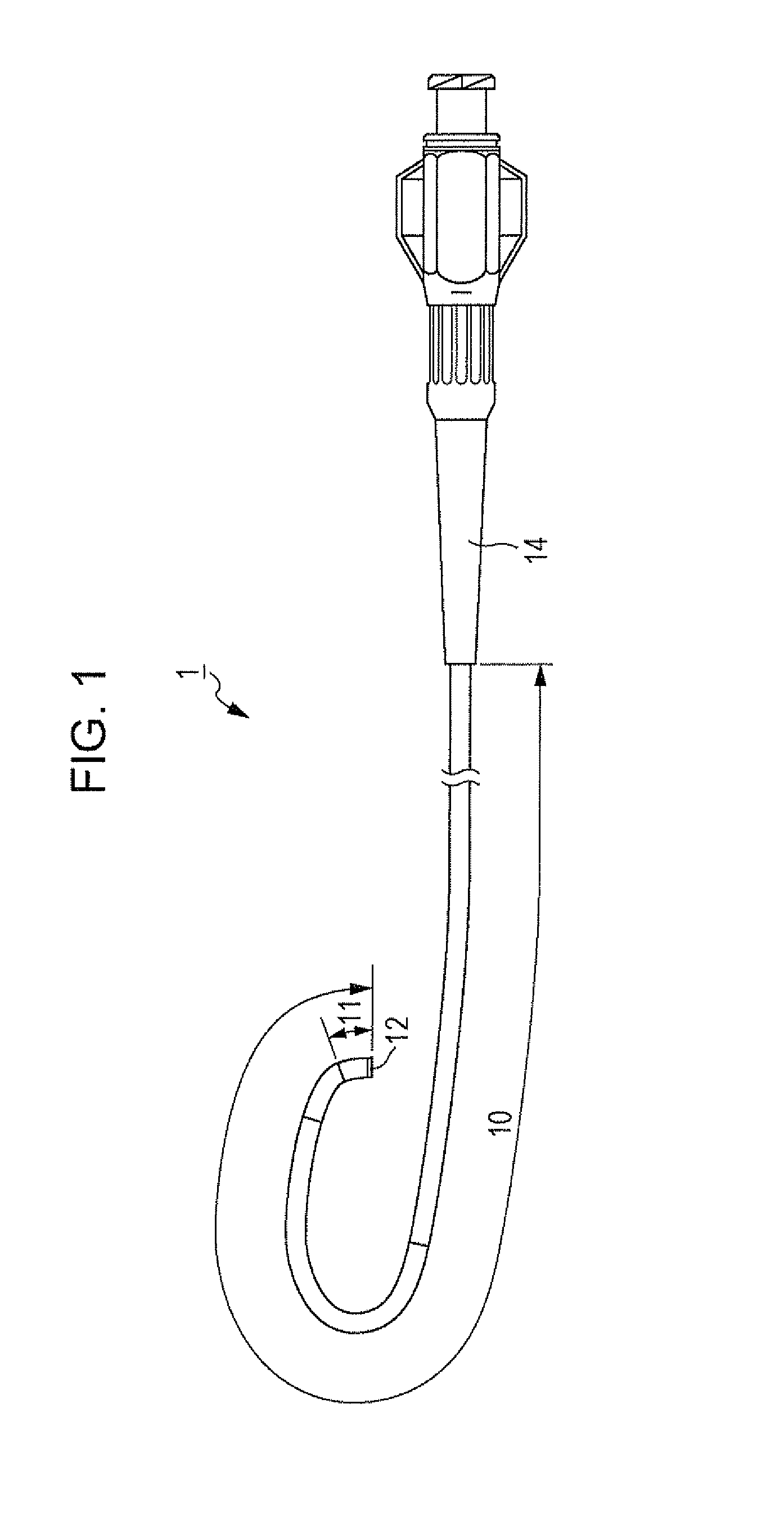

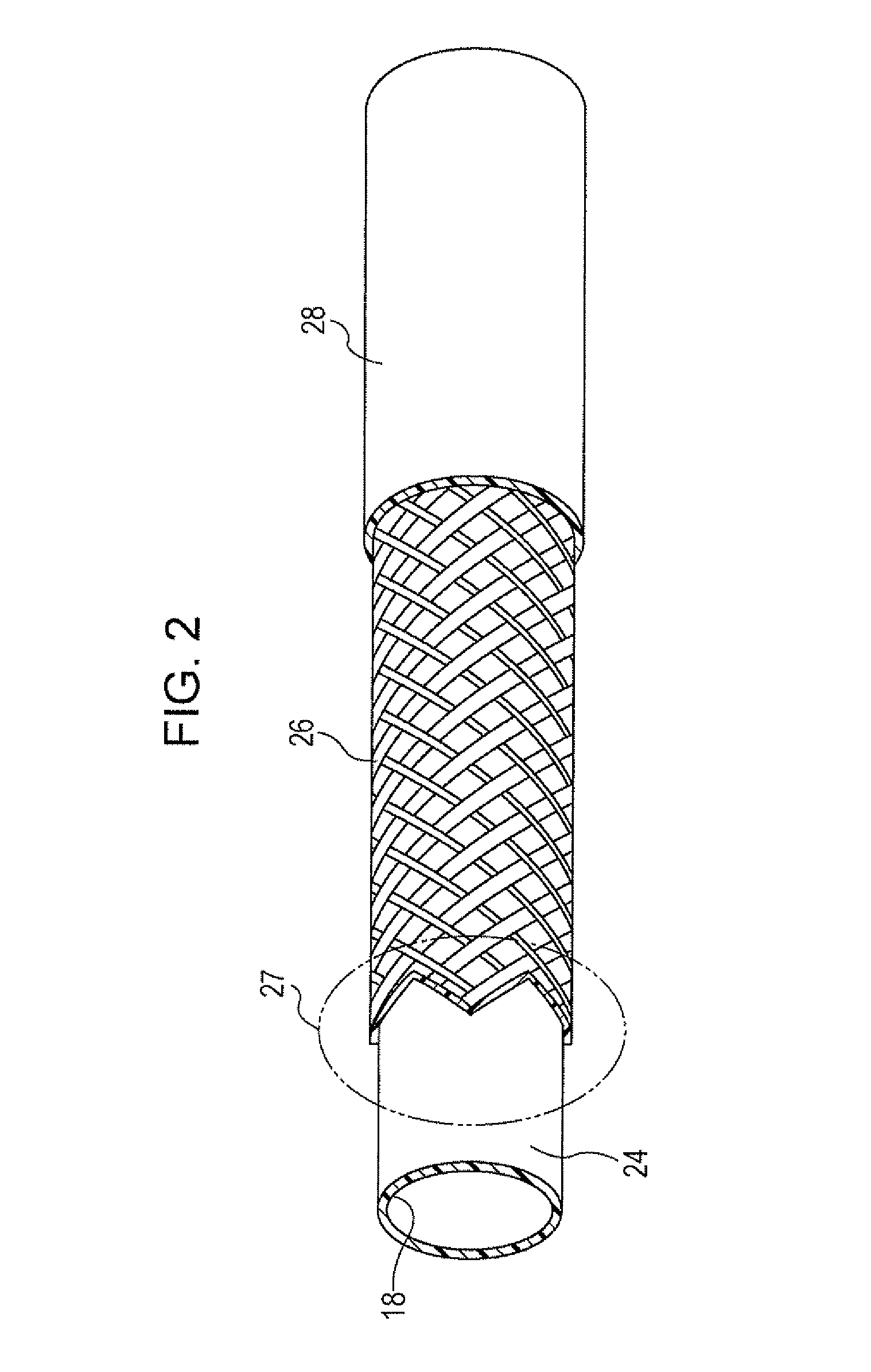

Catheter

A body of a catheter includes an inner layer, a braid, and an outer layer. The braid includes first and second wires. The first and second wires can be joined together such that the distal end portion of the first wire winds itself around a side surface of the second wire. A joint includes a first joint portion positioned at the intersection point, a second joint portion positioned beyond the first wire in a width direction of the first wire, and a third joint portion positioned beyond the second wire in a width direction of the second wire. Thus, even when the first and second wires have small thicknesses for size reduction of the braid, the first and second wires can be joined together with high joint strength by increasing the area of the second joint portion or the thickness of the third joint portion.

Owner:ASAHI INTECC CO LTD

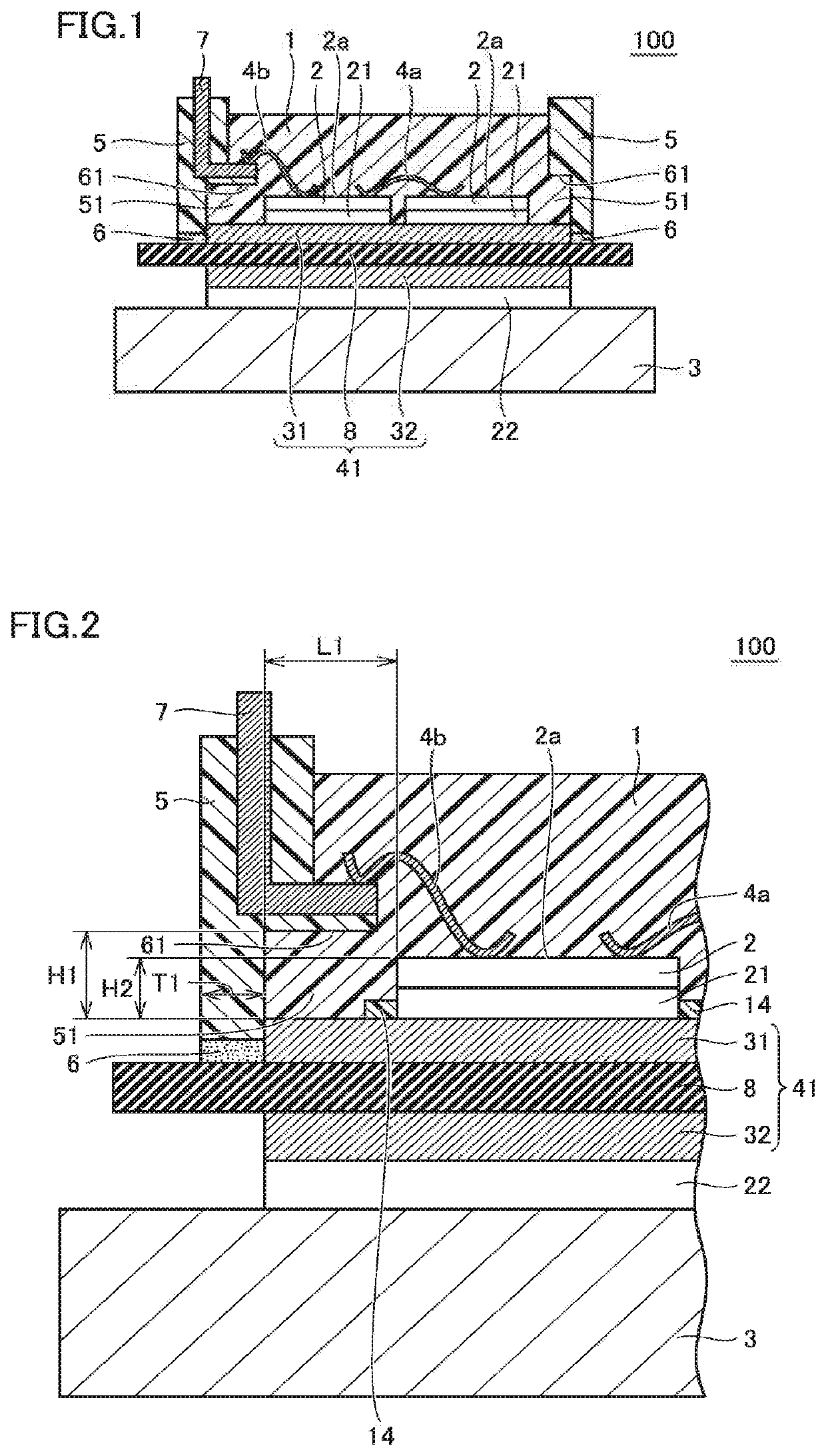

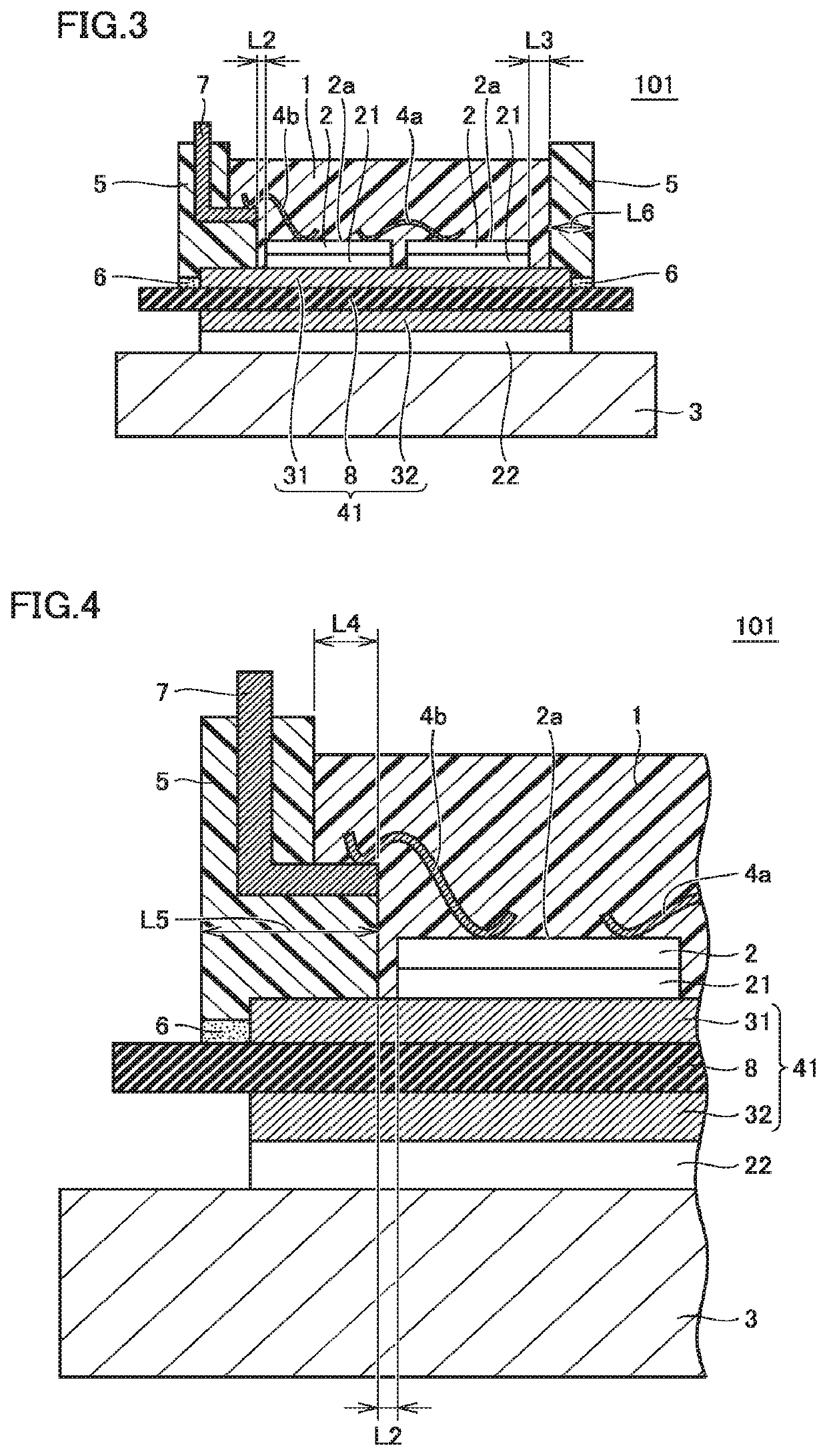

Method for joining dissimilar metal plates

ActiveUS20190247949A1Improve joint strengthJoint strengthPressure electrodesWelding/soldering/cutting articlesElectrical resistance and conductanceSupply current

A method for joining two dissimilar metal plates having different volume resistivity with enhanced joint strength. The method includes overlaying a first metal plate made of first metal and a second metal plate made of second metal with higher volume resistivity and higher melting point in comparison with the first metal, bringing a pair of electrodes into contact with the surface of a portion of the second metal plate overlapping the first metal plate, supplying current between the electrodes so as to resistance-heat the second metal present in a current-flowing region to a temperature lower than the melting point of the second metal and higher than the melting point of the first metal, thereby partially melting the first metal plate with the heat so that an intermetallic compound is generated between the first and second metal plates, and thus joining the first and second metal plates via the intermetallic compound.

Owner:TOYOTA JIDOSHA KK

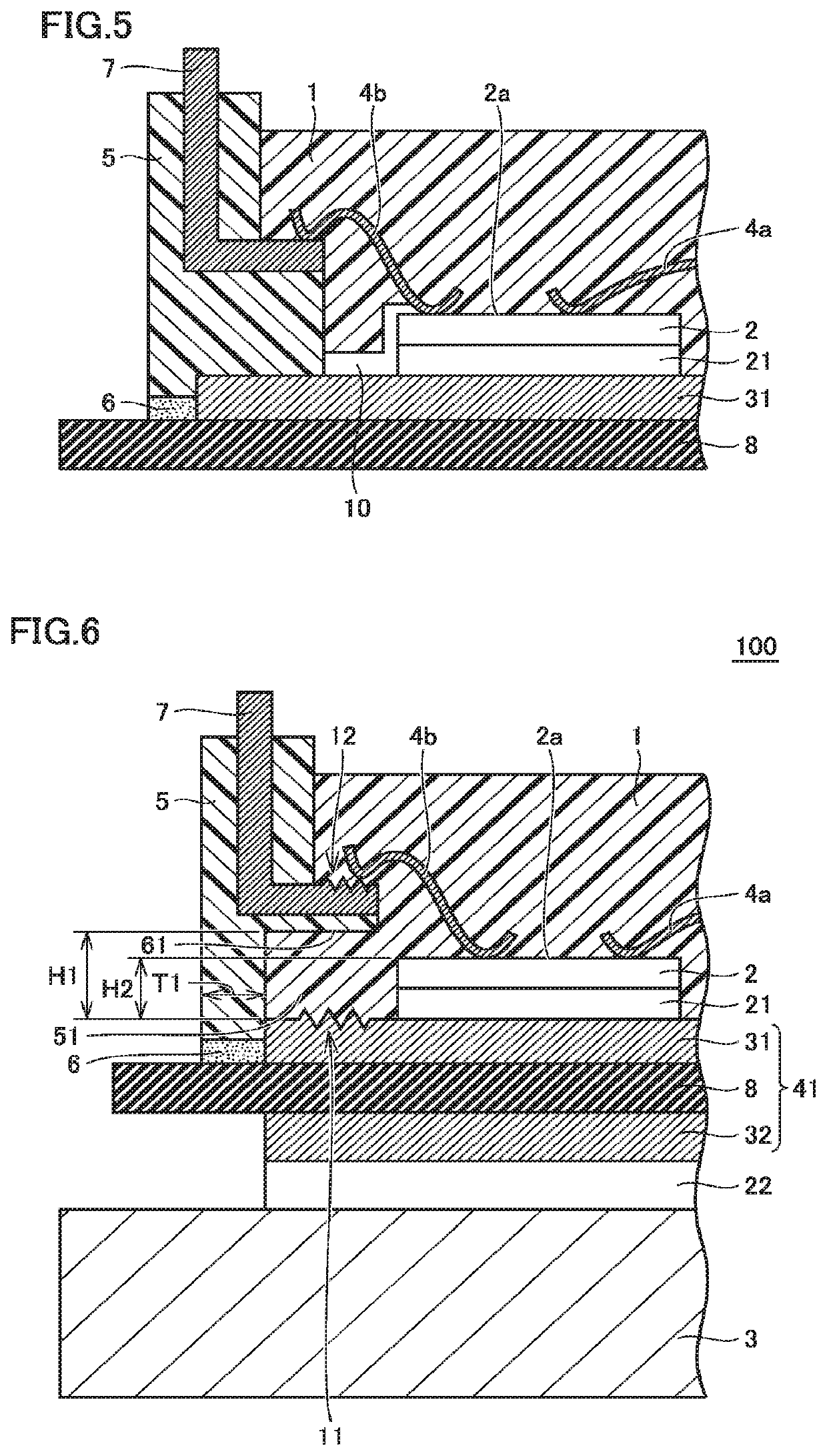

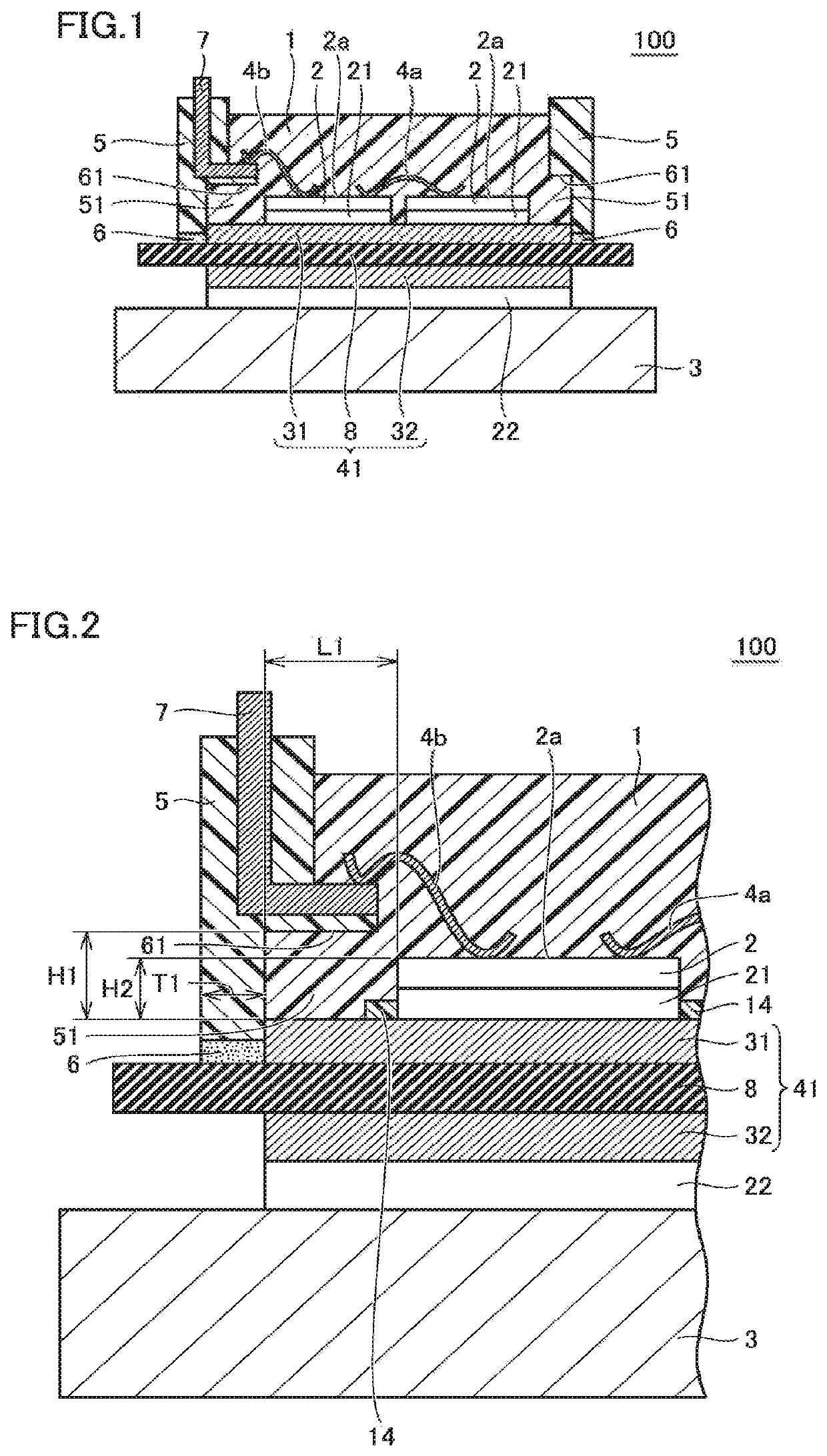

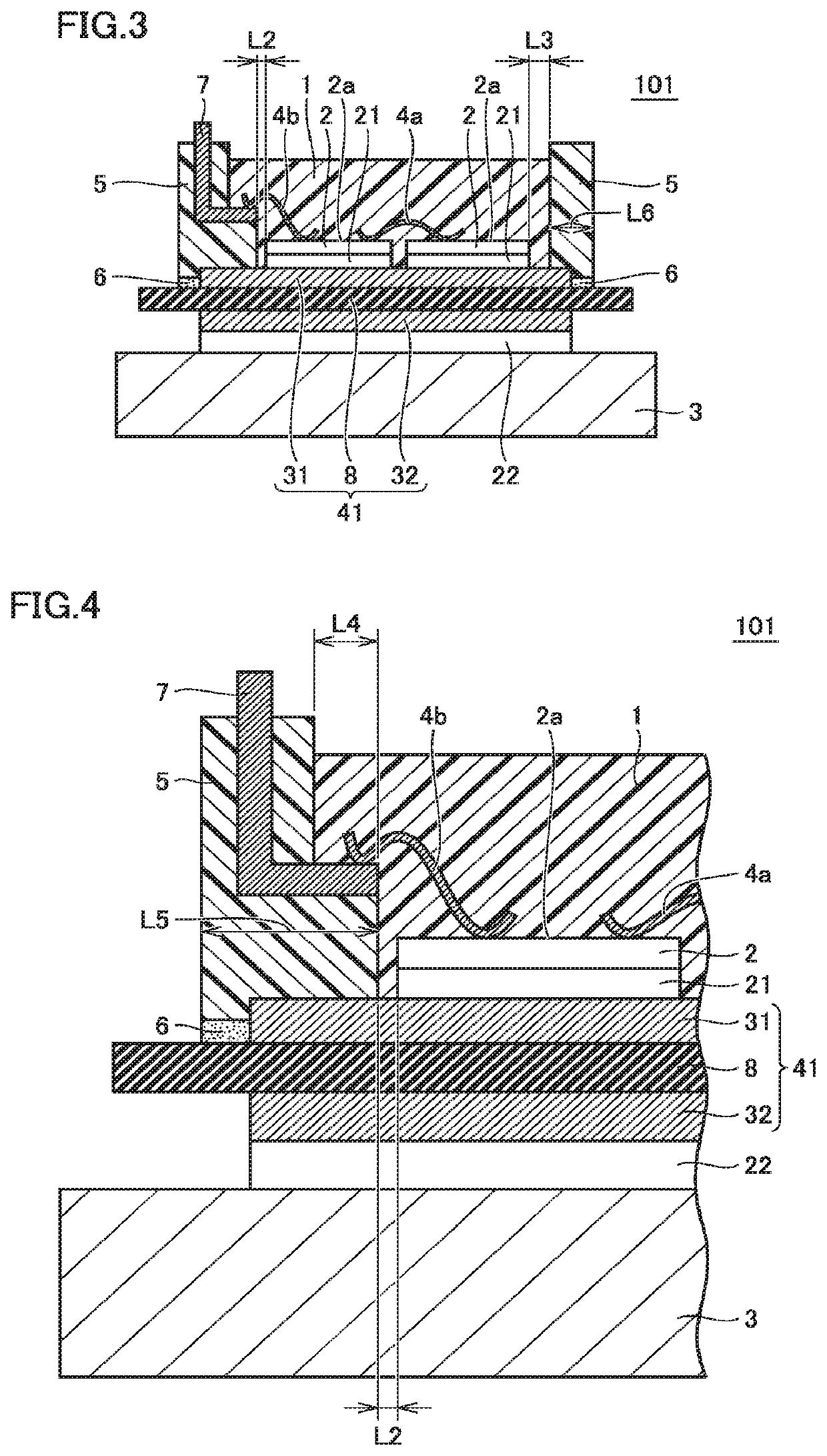

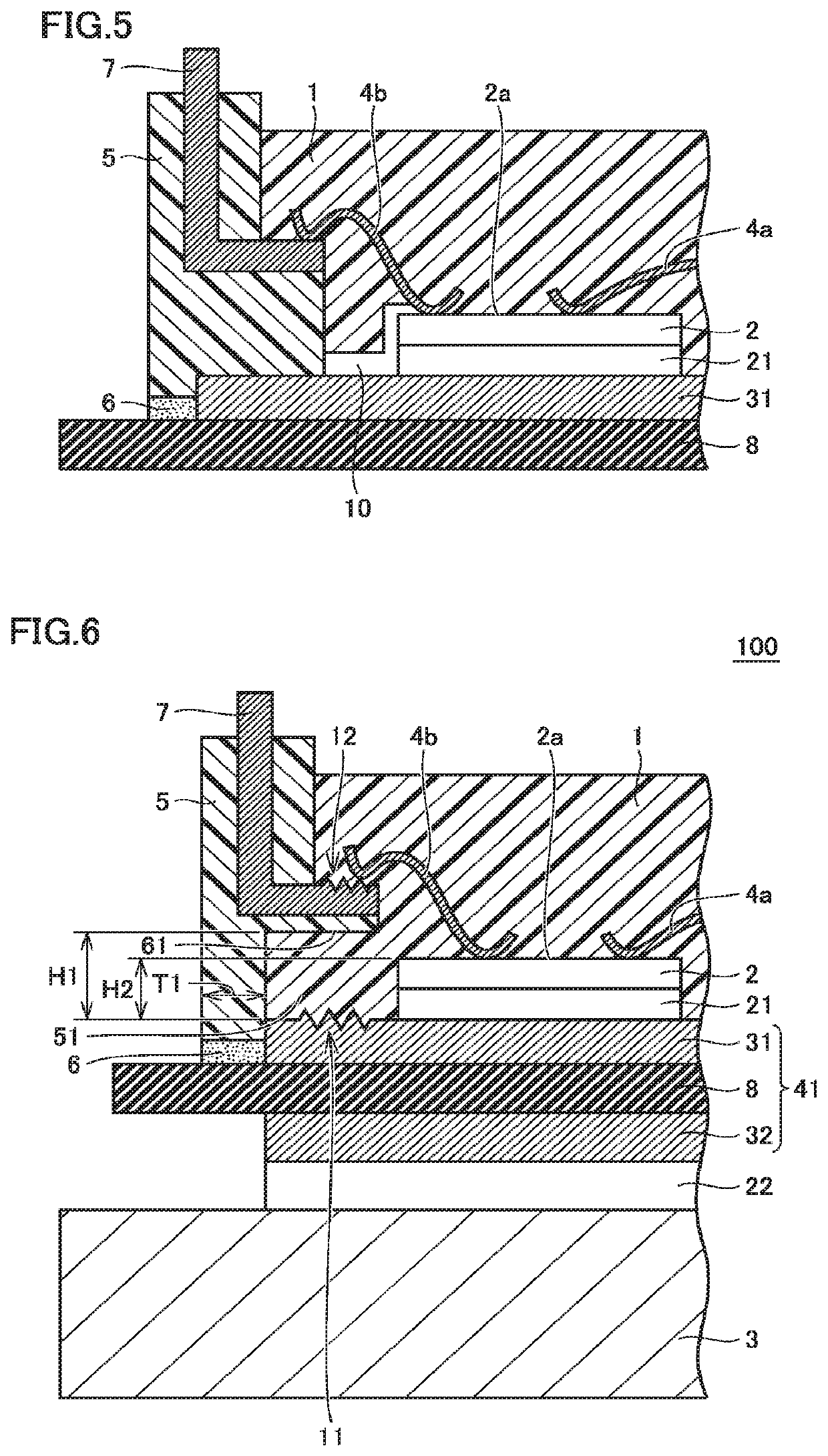

Semiconductor device

ActiveUS20200286840A1Small sizeHigh bulk densitySemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering physics

A semiconductor device includes an insulating substrate having a main surface, a semiconductor element, a case member, and a sealing resin as a sealing material. The case member includes a recess that is continuous with a connection portion of the case member connected to the insulating substrate, and that faces the internal region. The recess includes a facing surface as an inner wall portion facing the main surface of the insulating substrate. A distance from the main surface of the insulating substrate to the facing surface as the inner wall portion is greater than a distance from the main surface to an upper surface of the semiconductor element.

Owner:MITSUBISHI ELECTRIC CORP

catheter

ActiveUS20140046301A1High joint strengthJoint strengthCatheterDomestic articlesEngineeringSize reduction

A body of a catheter includes an inner layer, a braid, and an outer layer. The braid includes first and second wires. The first and second wires can be joined together such that the distal end portion of the first wire winds itself around a side surface of the second wire. A joint includes a first joint portion positioned at the intersection point, a second joint portion positioned beyond the first wire in a width direction of the first wire, and a third joint portion positioned beyond the second wire in a width direction of the second wire. Thus, even when the first and second wires have small thicknesses for size reduction of the braid, the first and second wires can be joined together with high joint strength by increasing the area of the second joint portion or the thickness of the third joint portion.

Owner:ASAHI INTECC CO LTD

Joining method

ActiveUS10065362B2Improve joint strengthJoint strengthLaminationLamination apparatusFiberEngineering

A joining method for joining together a first member in which fiber material is mixed into a first resin, and a second member that includes at least a second resin, includes abutting the first member and the second member together, and softening or melting the first resin of the first member and the second resin of the second member that are adjacent to abutting surfaces of the first member and the second member; and stirring a joint forming portion formed by the softened or melted first resin of the first member and the softened or melted second resin of the second member, and the fiber material included in the softened or melted first resin of the first member, in a direction inclined with respect to the abutting surfaces, and hardening the joint forming portion.

Owner:TOYOTA JIDOSHA KK

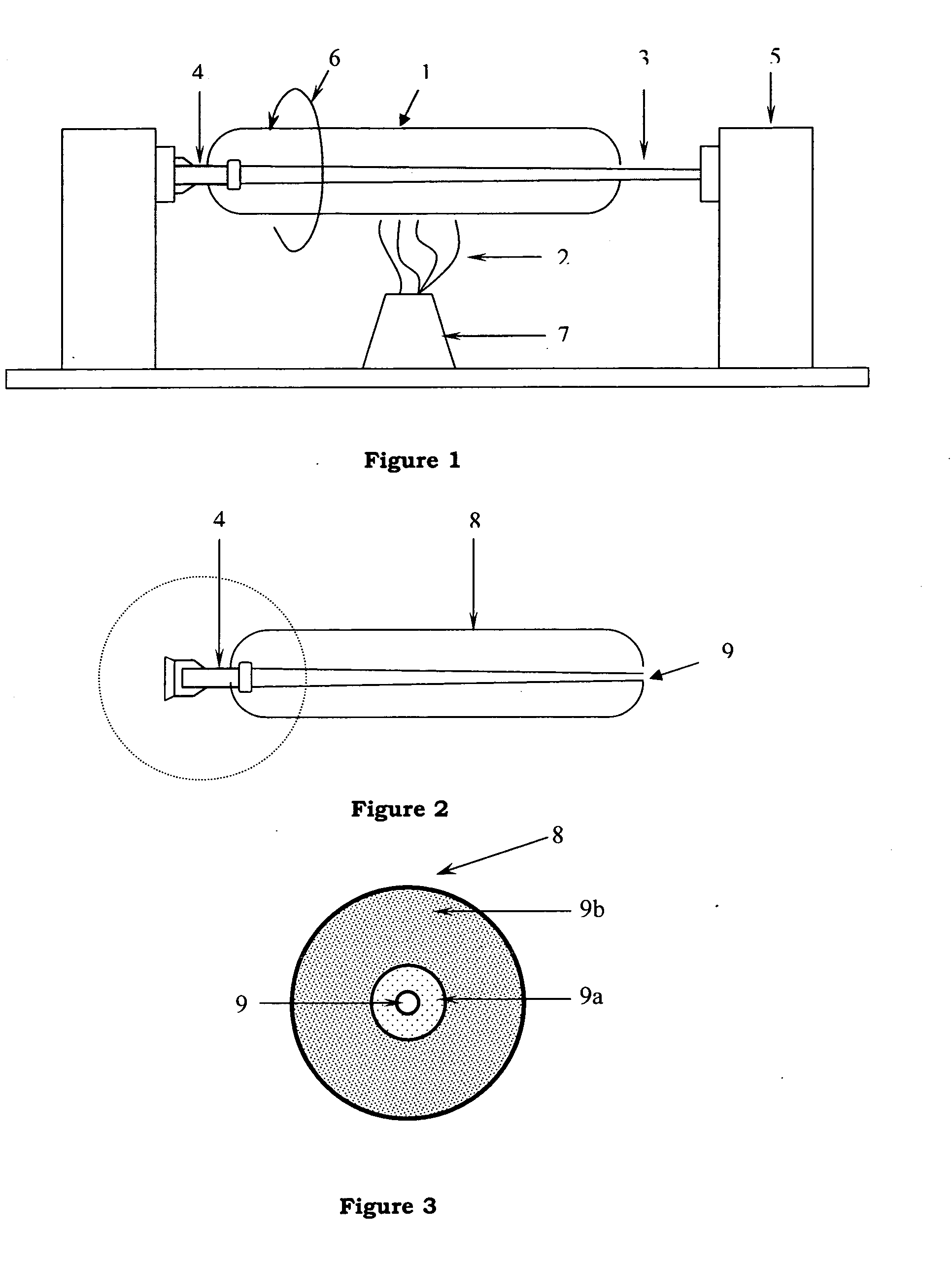

Method for preparation of core rod assembly for overcladding, and perform and fiber produced from such core rod assembly

InactiveUS20070065082A1Joint strengthSafe and convenientGlass making apparatusCladded optical fibreFiberControl manner

A method for preparation of core rod assembly suitable for overcladding comprising the steps of preparing core rod having reduced diameter, fixing glass rods at each of the opposite ends of the core rod having reduced diameter characterized in that the core rod with fixed glass rods at its opposite ends obtained is fire polished in a controlled manner and two step process to produce core rod assembly suitable for overcladding, wherein first step is hard fire polish and second step is soft fire polish is provided. A core rod assembly, and soot preform prepared from core rod assembly, and a daughter preform prepared from soot preform, and an optical fiber prepared from daughter preform are also provided.

Owner:STERLITE TECHNOLOGIES

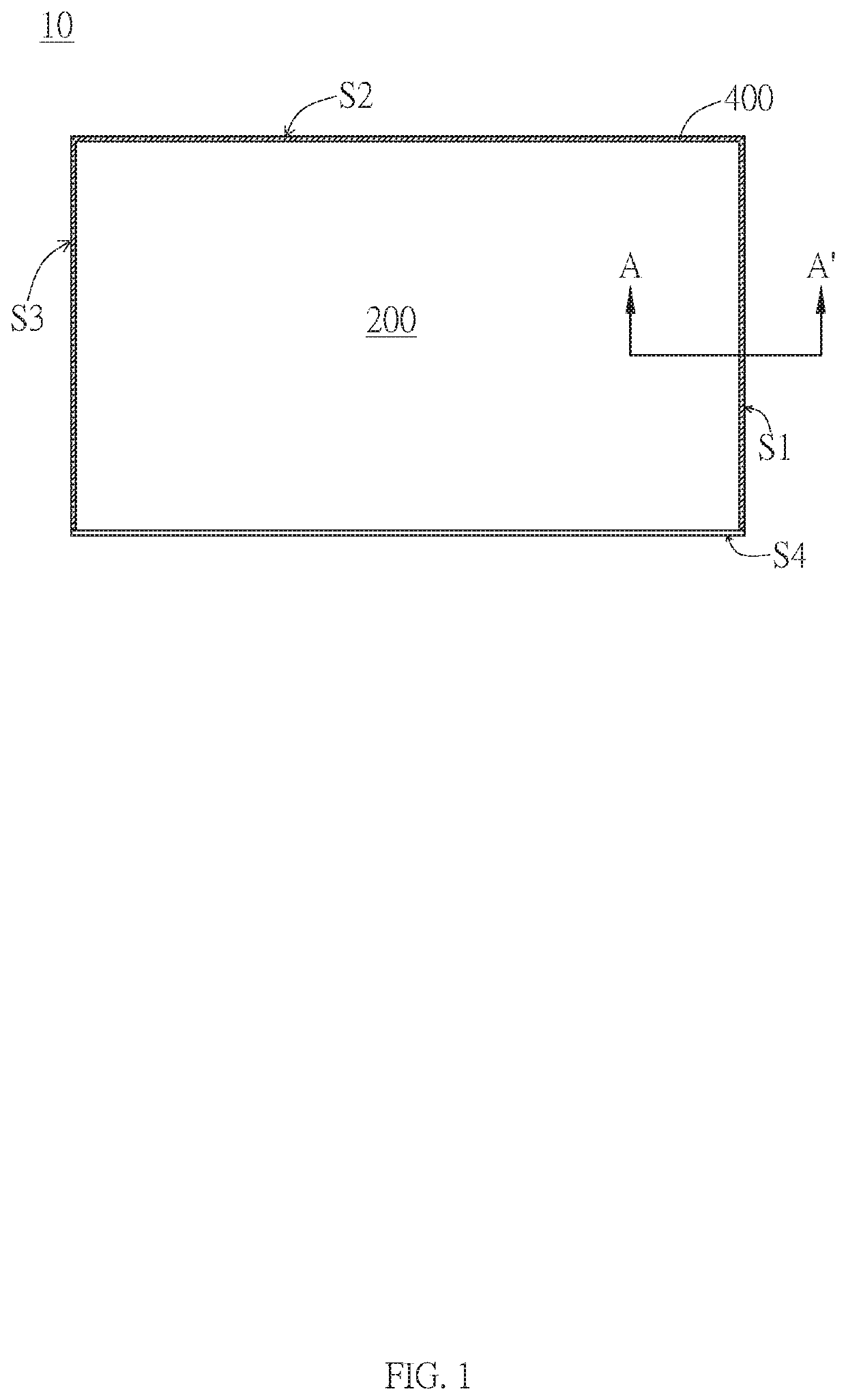

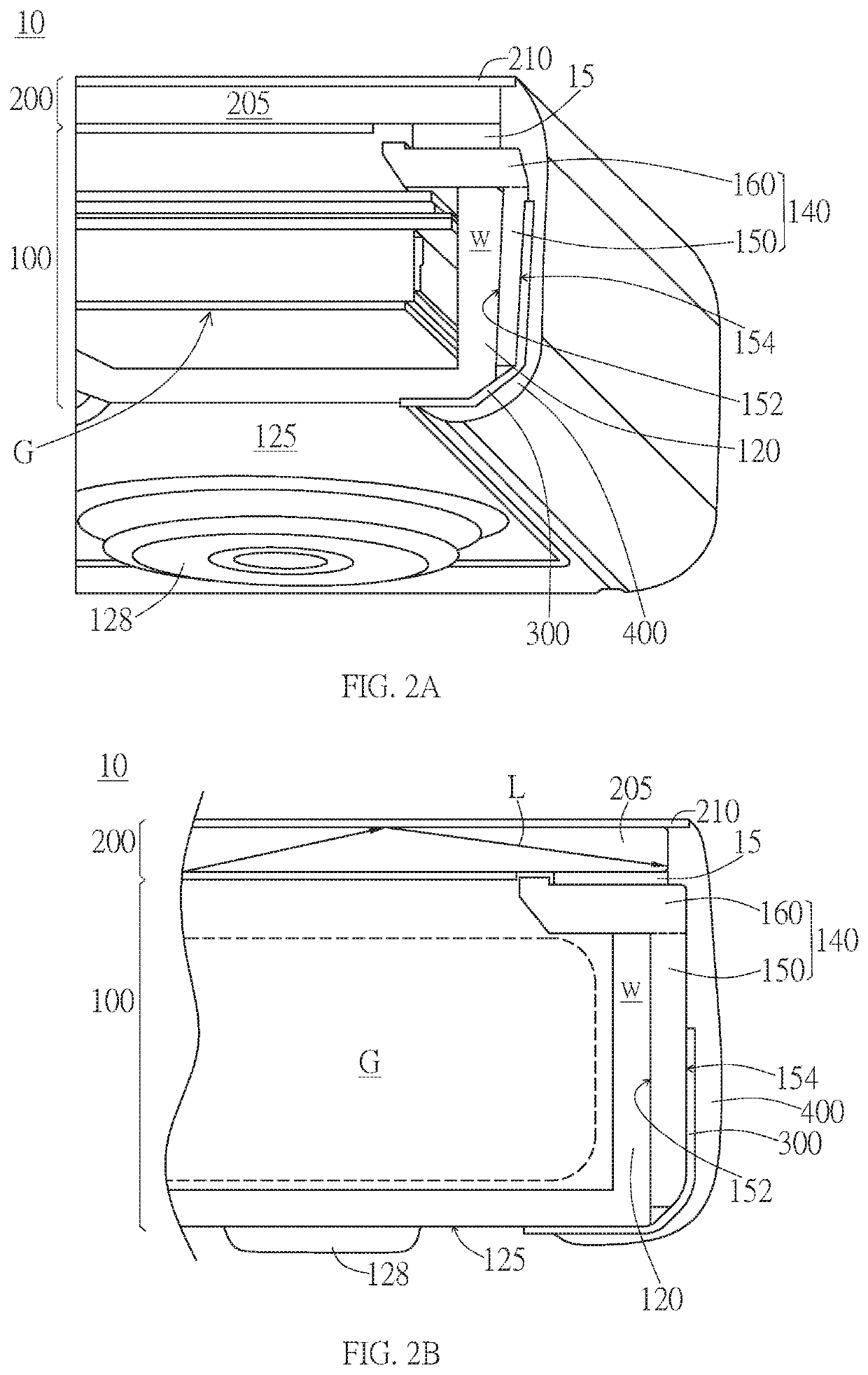

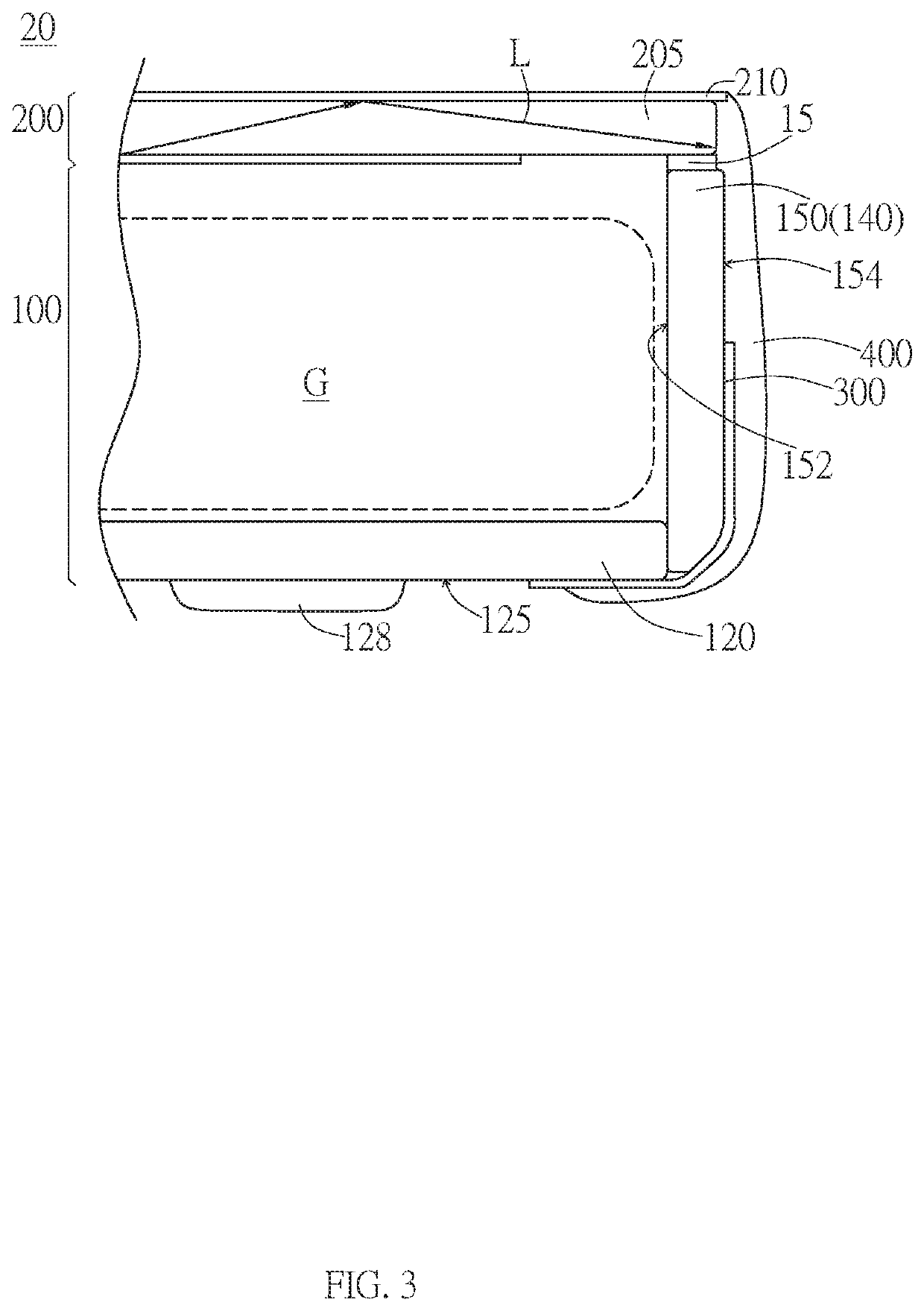

Display device

ActiveUS11106241B2Reduce thicknessJoint strengthDigital data processing detailsCasings with display/control unitsDisplay deviceMechanical engineering

The present invention provides a display device including: a backlight module, including a back bezel having a bottom surface, and a frame having a side wall portion, where the side wall portion has an inner side surface and an outer side surface, and the back bezel faces the inner side surface of the side wall portion; a display module, disposed on the backlight module and supported by the frame; a tape, attached to the outer side surface of the side wall portion of the frame and extending to the bottom surface of the back bezel; and a sealant, disposed and extending from an end edge of the display module to the bottom surface of the back bezel through an outer side of the outer side surface of the side wall portion of the frame, and at least partially covering the tape.

Owner:AU OPTRONICS CORP

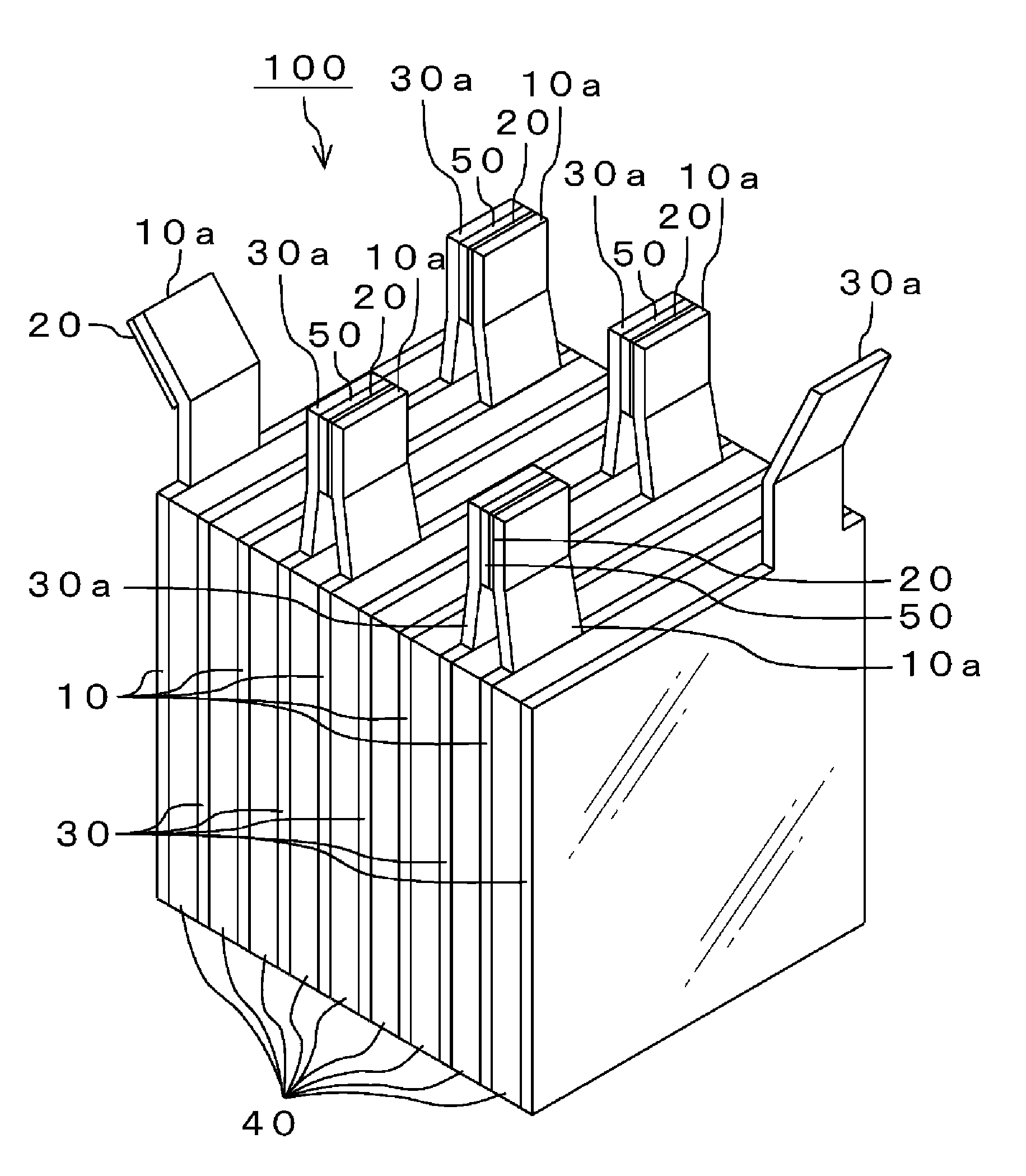

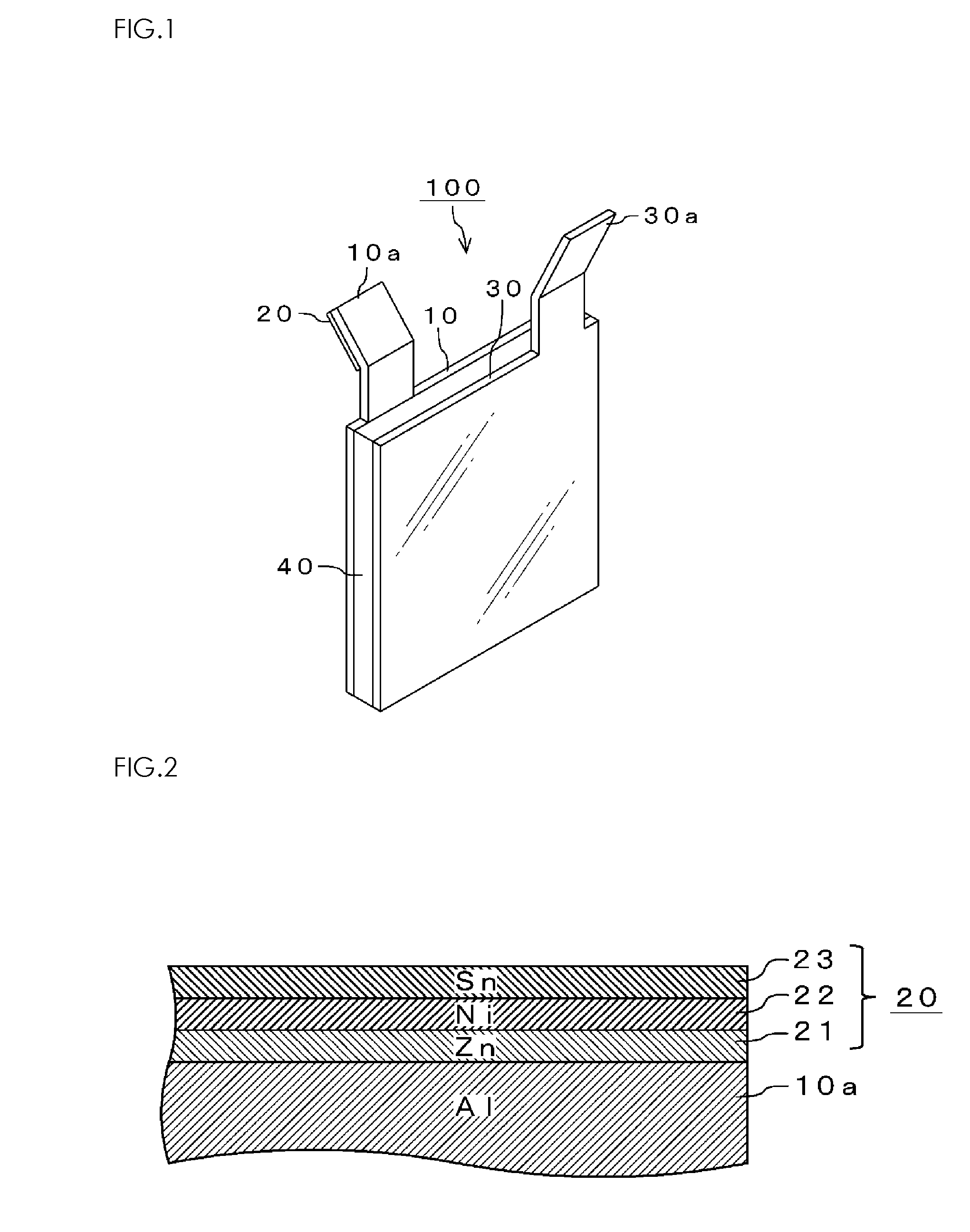

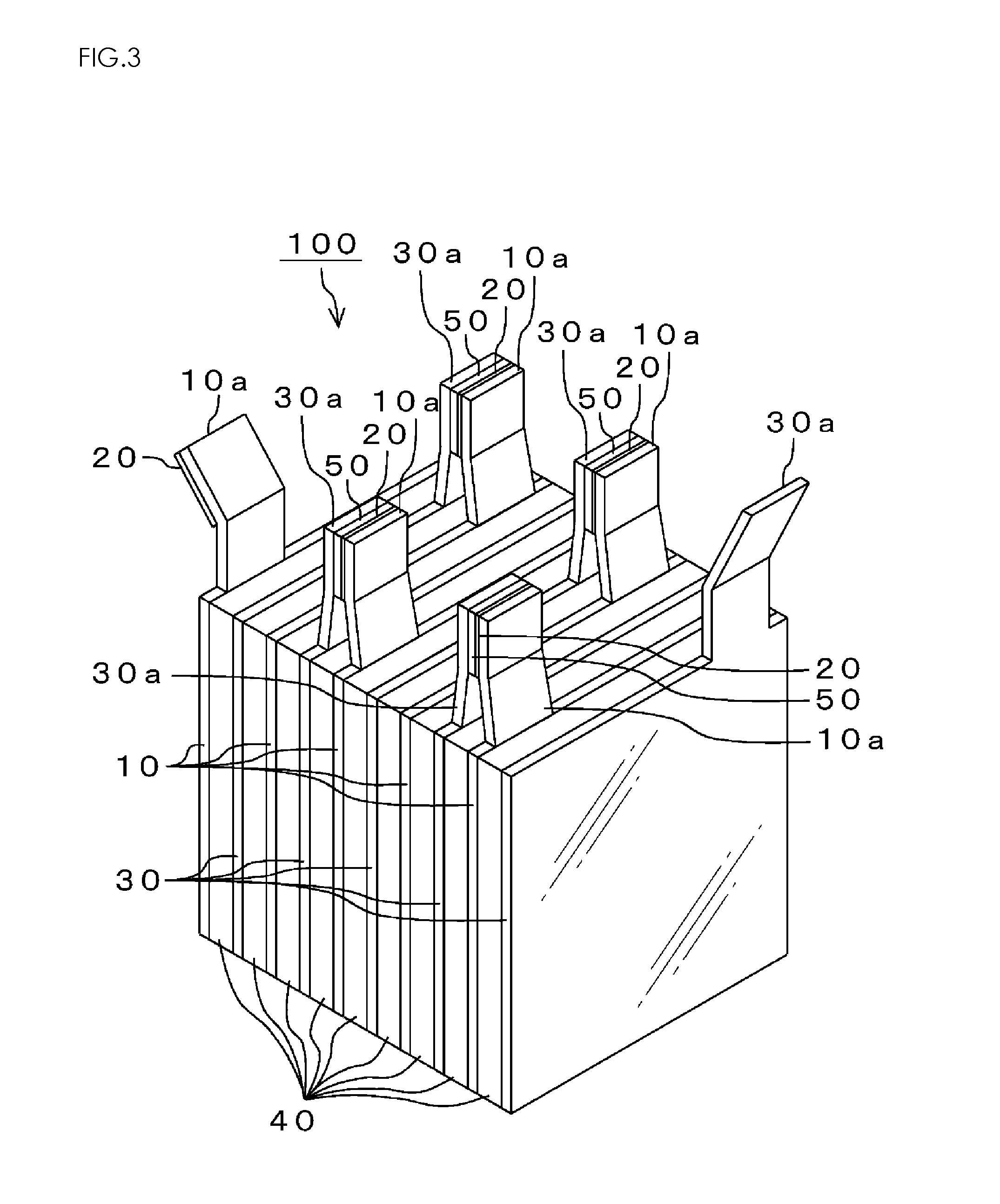

Method of manufacturing an electrode for an energy storage device

ActiveUS9368249B2Joint strengthContact areaContact member manufacturingDouble layer capacitorsVoltage dropOptoelectronics

Zn layer 21 or Zn alloy layer, Ni layer 22, and Sn layer 23 or Sn alloy layer are formed on a connecting terminal part 10a of a positive electrode composed of Al by plating. Accordingly, this can solder Cu negative electrode, which is composed of metal that is different species from Al, through Sn layer 23 or Sn alloy layer so that jointing strength of the Al positive electrode and the Cu negative electrode can be enhanced. Further, since the contacting area is increased in comparison with the conventional jointing by the spot-welding or the conventional fastening by a bolt so that the resistance value at the contacting point is reduced, the voltage drop of the energy storage device by contact resistance can be reduced.

Owner:SENJU METAL IND CO LTD

Semiconductor device

ActiveUS11031355B2Small sizeHigh bulk densitySemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering physics

Owner:MITSUBISHI ELECTRIC CORP

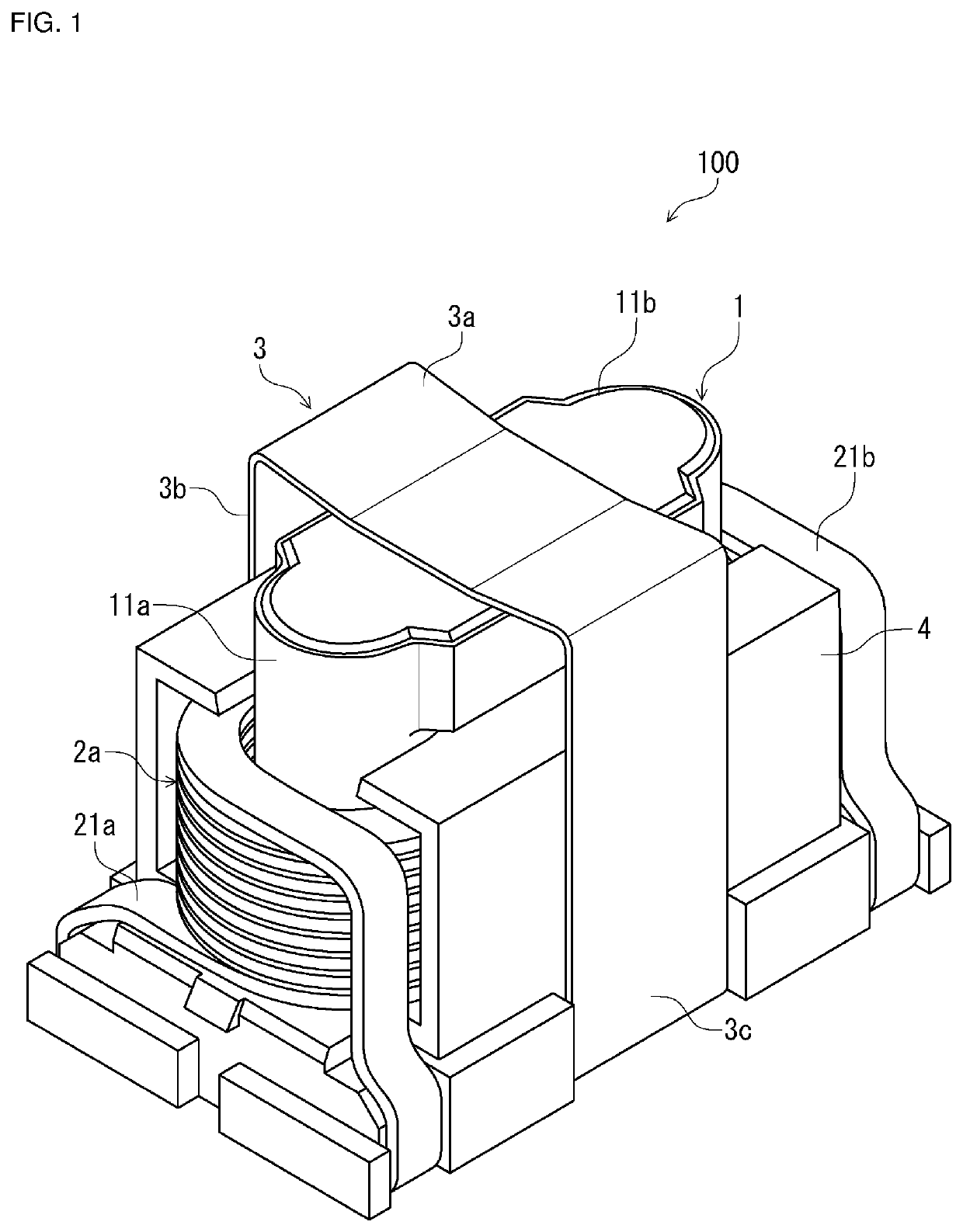

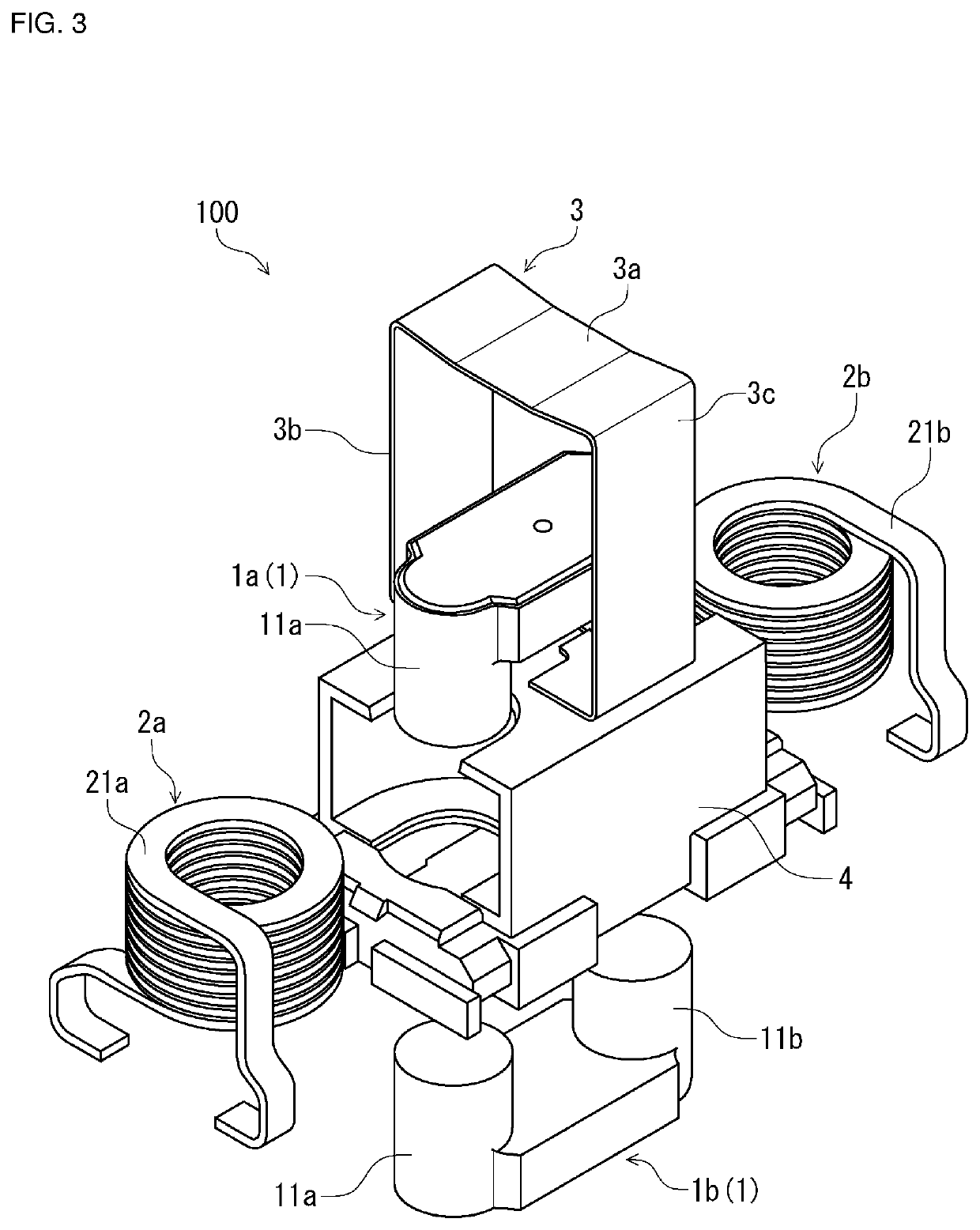

Coil component and electronic component

PendingUS20210375521A1Enhance mounting strengthImprove installation strengthTransformers/reacts mounting/support/suspensionTransformers/inductances coils/windings/connectionsPhysicsMagnetic core

A coil component includes a magnetic core that includes a pair of wind portions, a pair of coil conductors where respective conductive wires are wound around the wind portions, and a securing member that has spring properties, includes an upper surface portion, first and second side surface portions, and first and second bottom surface portions, and secures the core while surrounding the core. With the securing member removed from the core, angles formed by the upper surface portion and first side surface portion, the upper surface portion and second side surface portion, the first side surface portion and first bottom surface portion, and the second side surface portion and second bottom surface portion are acute angles. The first and second side surface portions are formed by curved surfaces. The first and second bottom surface portions serve as mounted portions when the coil component is mounted over a mounting board.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com