Patents

Literature

96results about How to "Contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

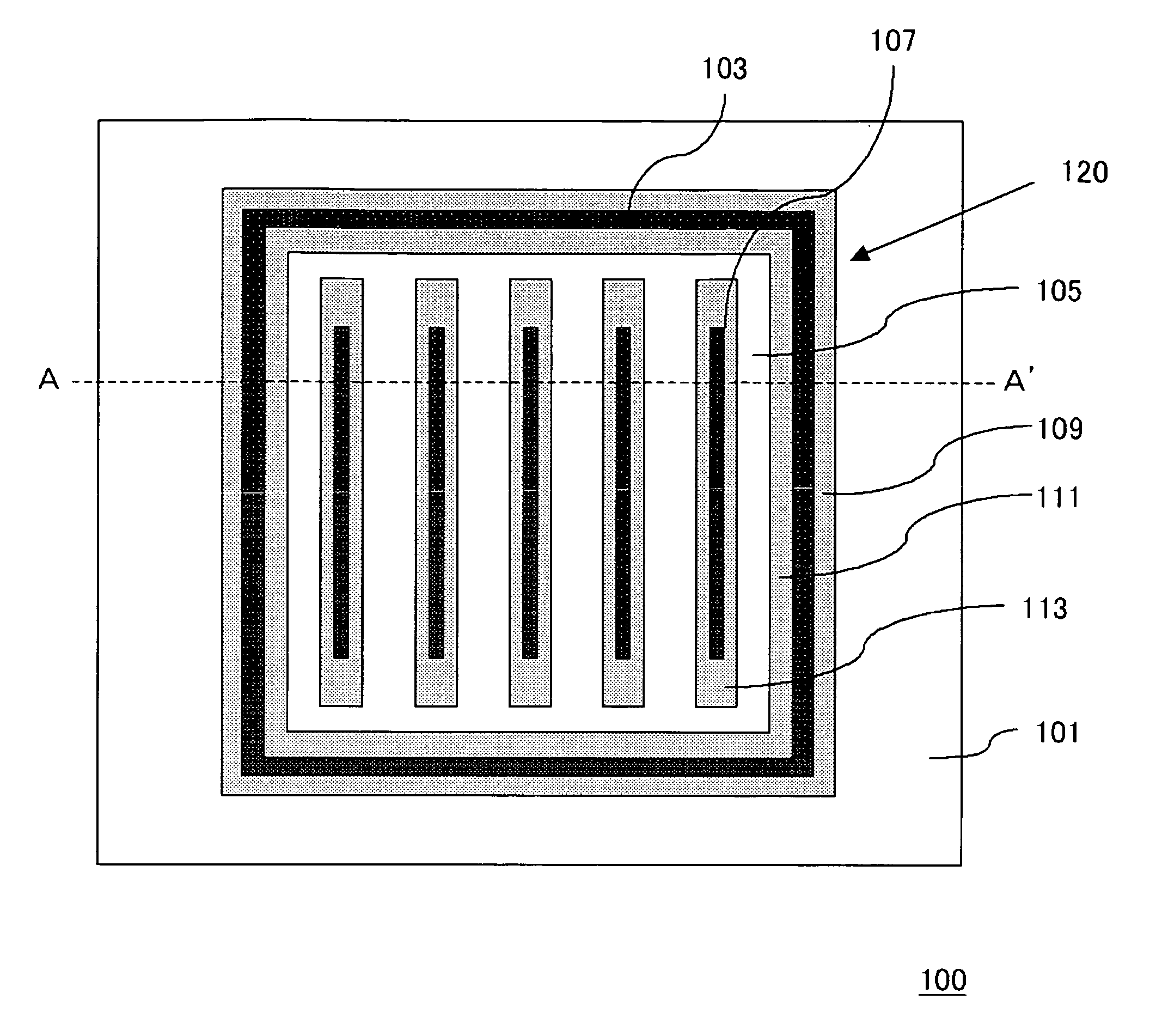

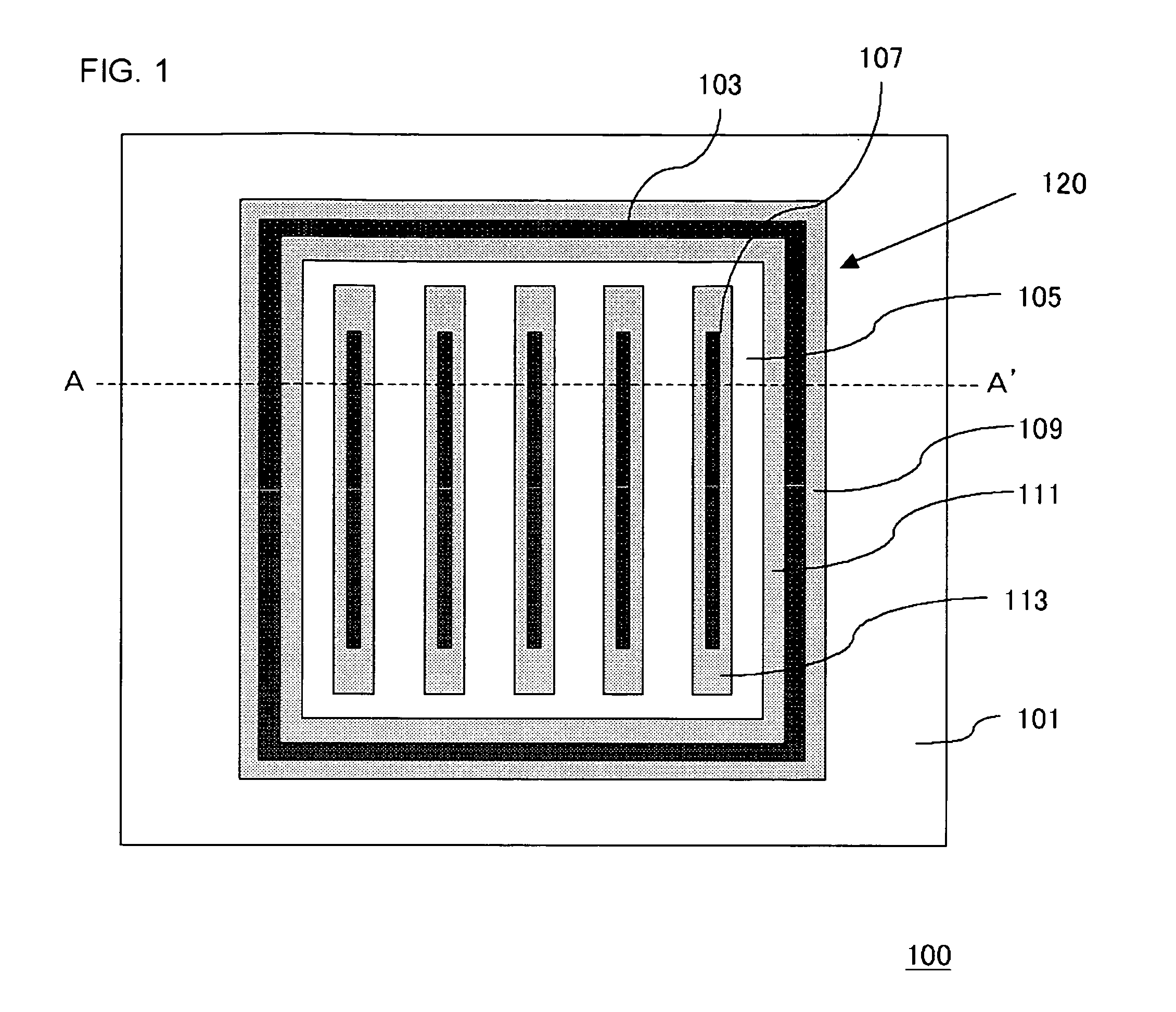

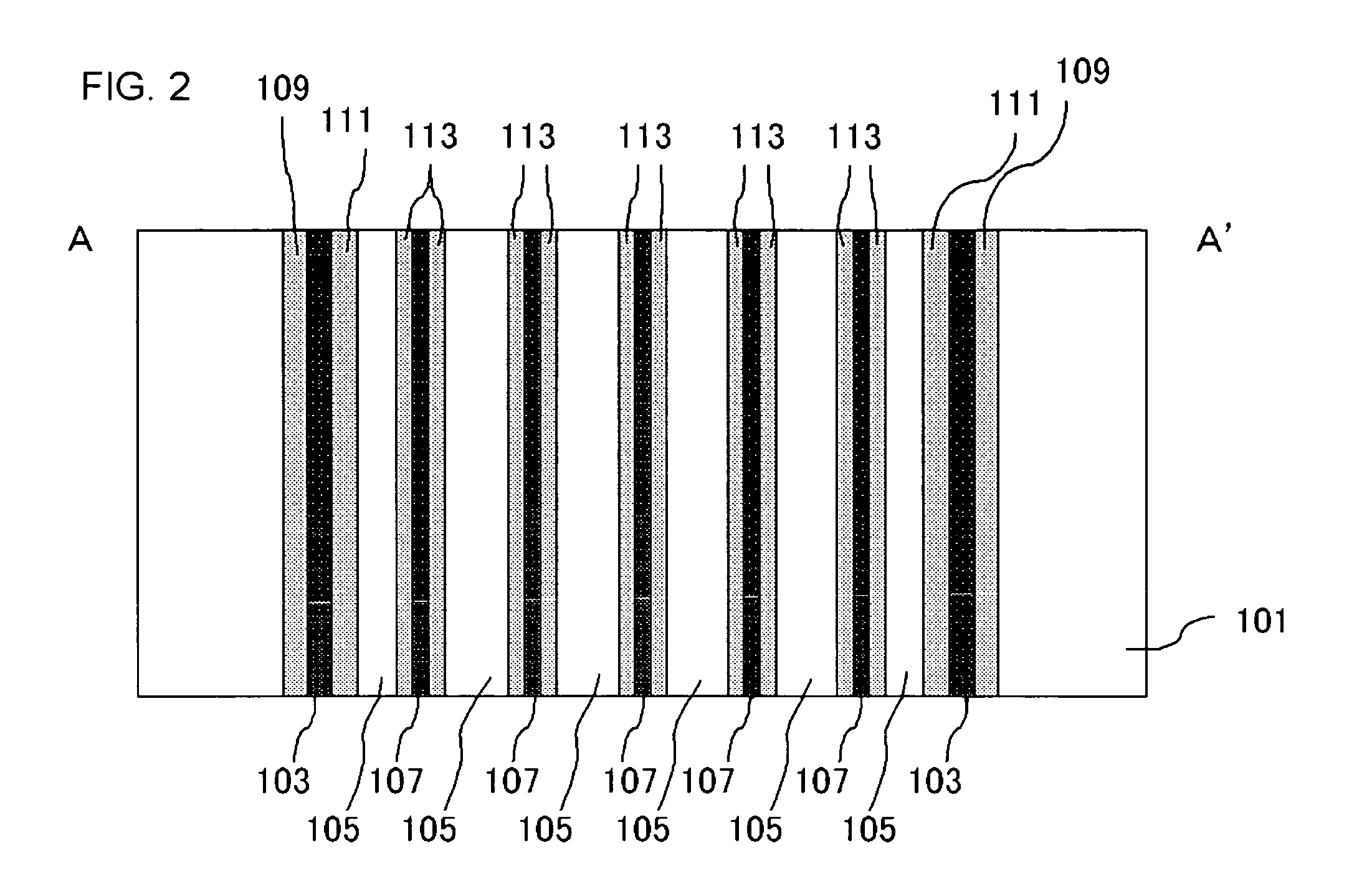

Semiconductor device and semiconductor module employing thereof

ActiveUS20060006539A1High densityReduce areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A semiconductor device 100 is provided with a silicon substrate 101 and a structure 120 filled in a through hole that has a rectangular cross section and extends through the silicon substrate 101. The structure 120 comprises a pipe-shaped through electrode 103, stripe-shaped through electrodes 107, silicons 105, a first insulating film 109, a second insulating film 111 and a third insulating film 113. The pipe-shaped through electrode 103 is utilized as a pipe-shaped electric conductor that extends through the silicon substrate 101. In addition, the stripe-shaped through electrodes 107 are provided in the interior of the pipe-shaped through electrode 103 so that the stripe-shaped through electrodes 107 extend through the silicon substrate 101 and is spaced away from the pipe-shaped through electrode 103. A plurality of through electrodes 107 are provided in substantially parallel within the inner region of the pipe-shaped through electrode 103.

Owner:TESSERA ADVANCED TECH

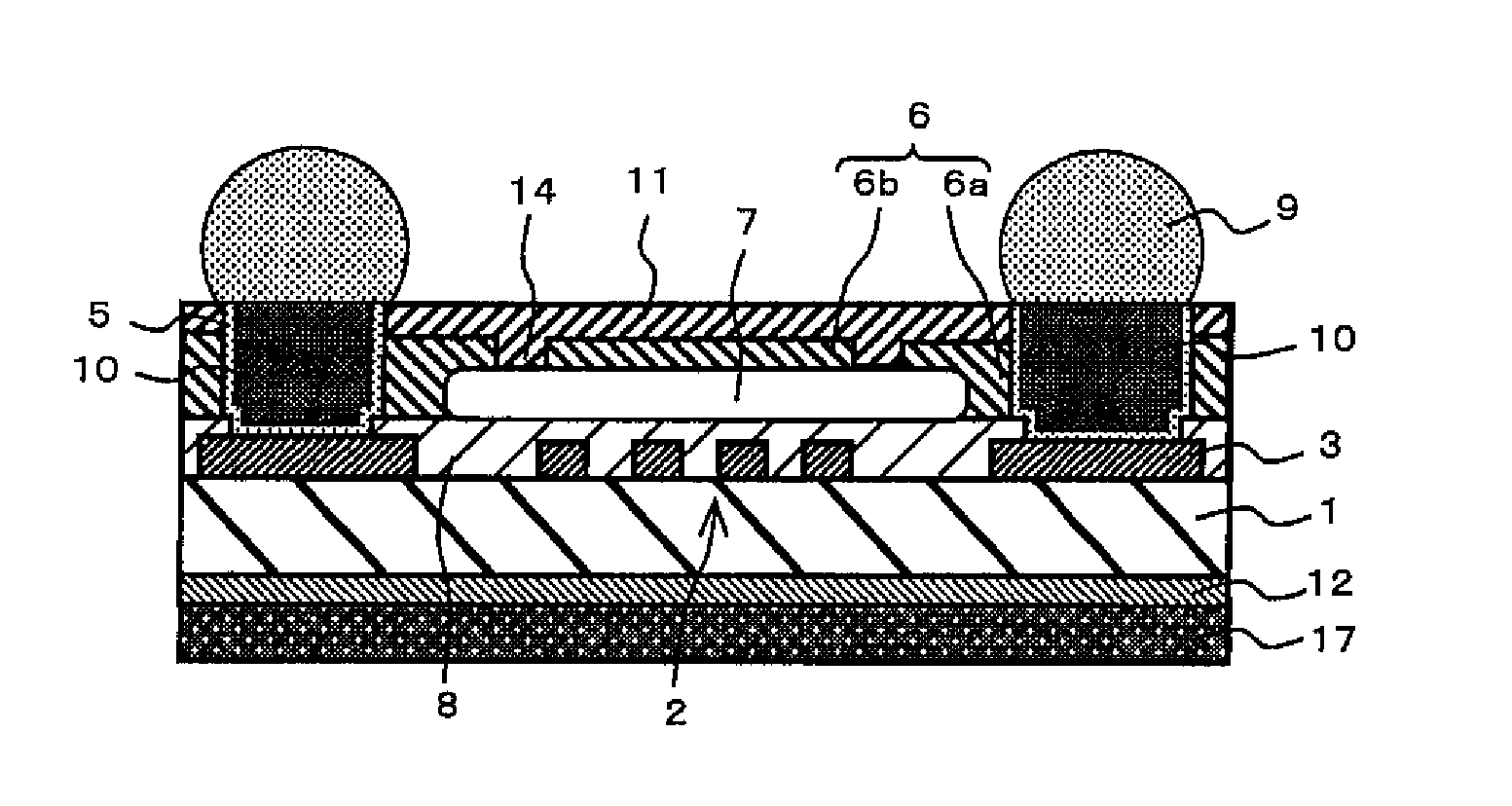

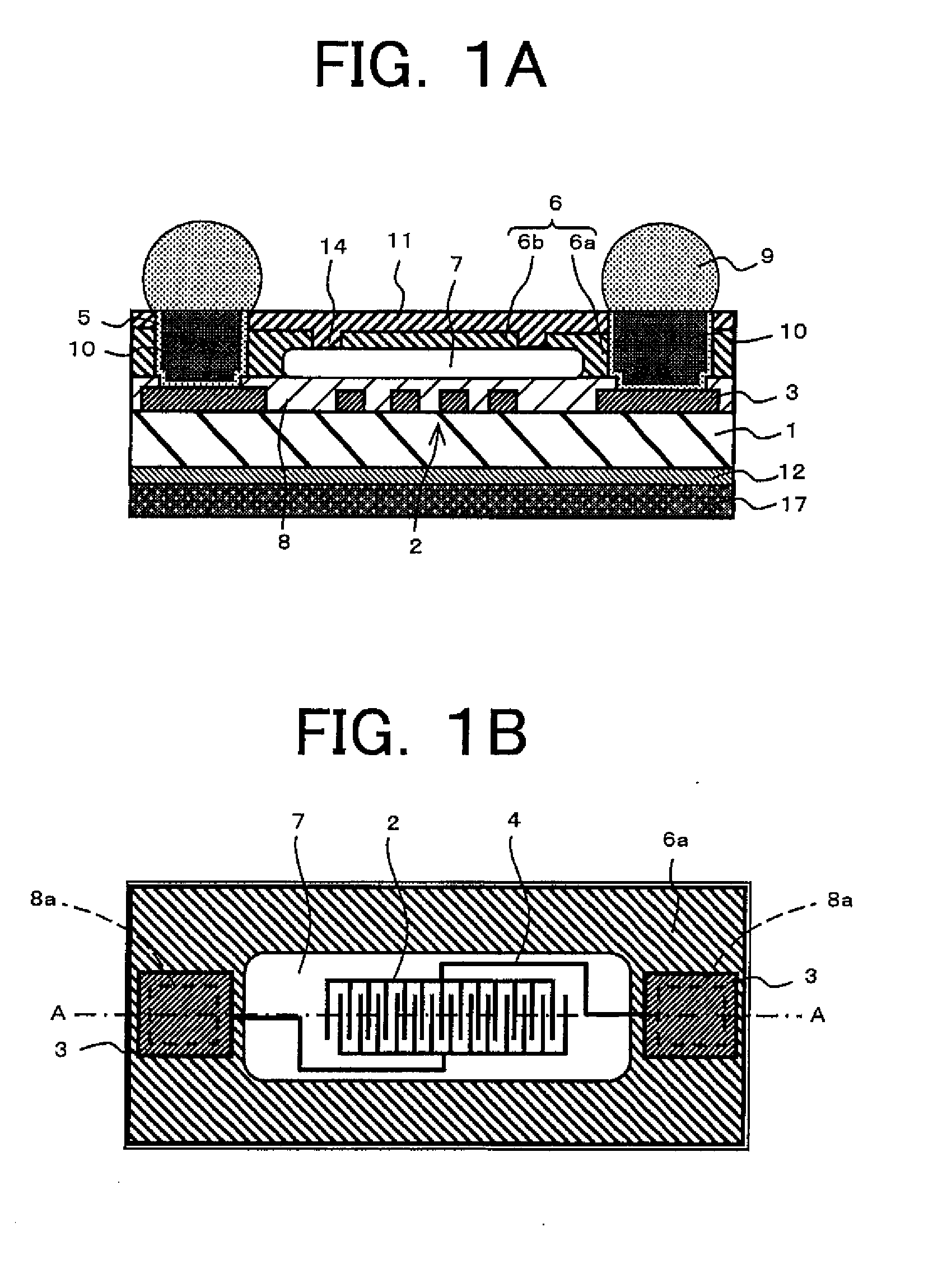

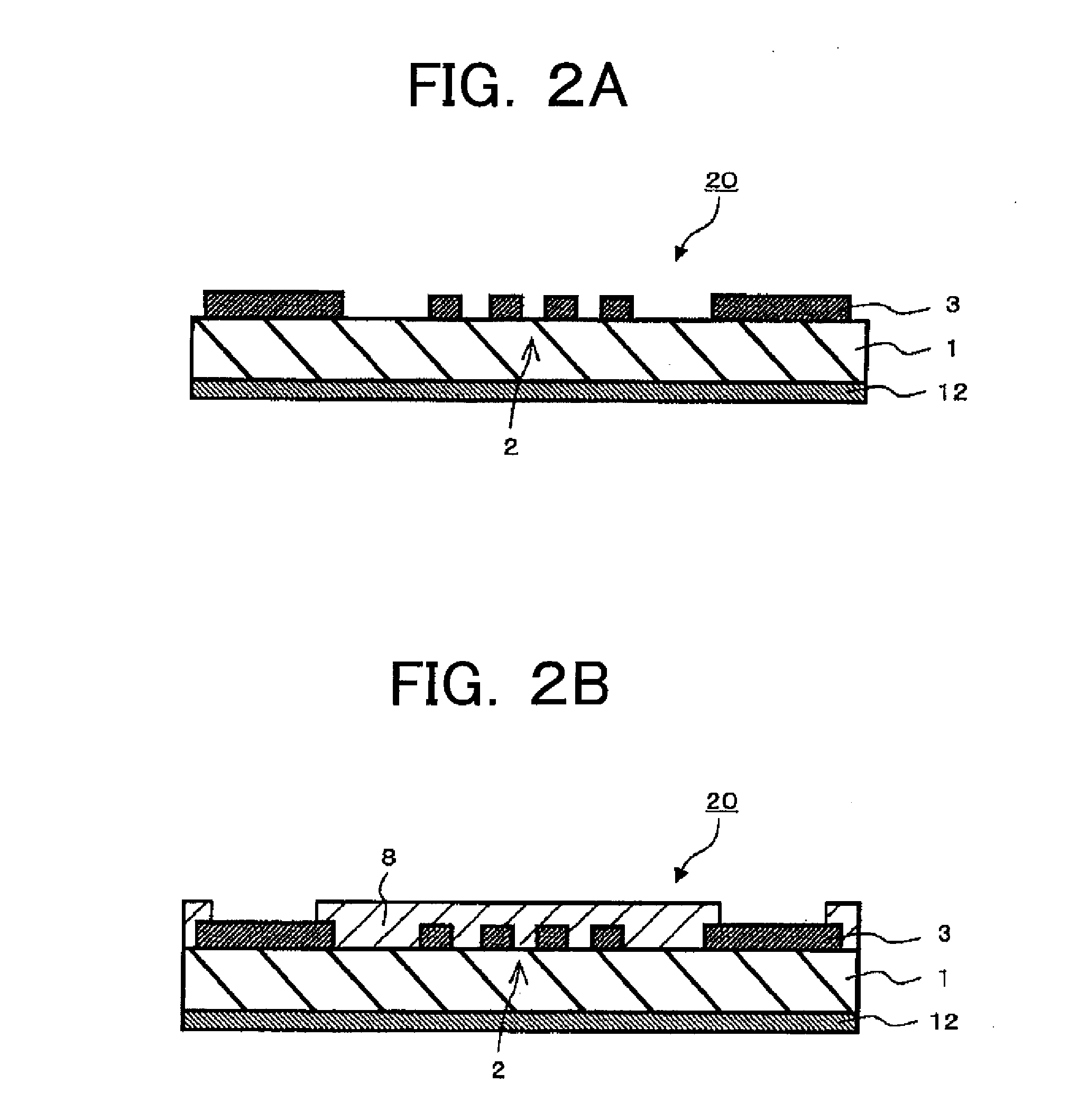

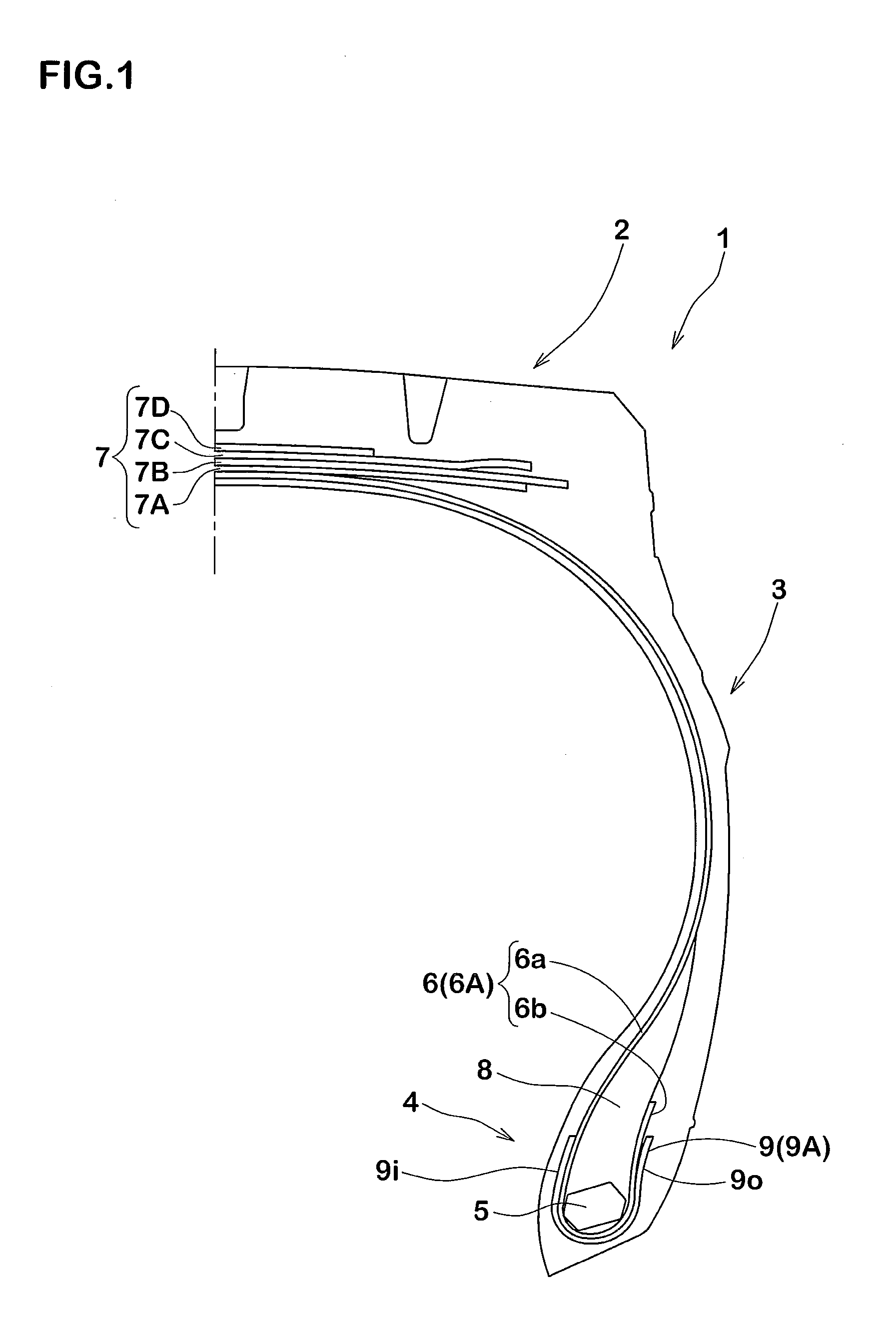

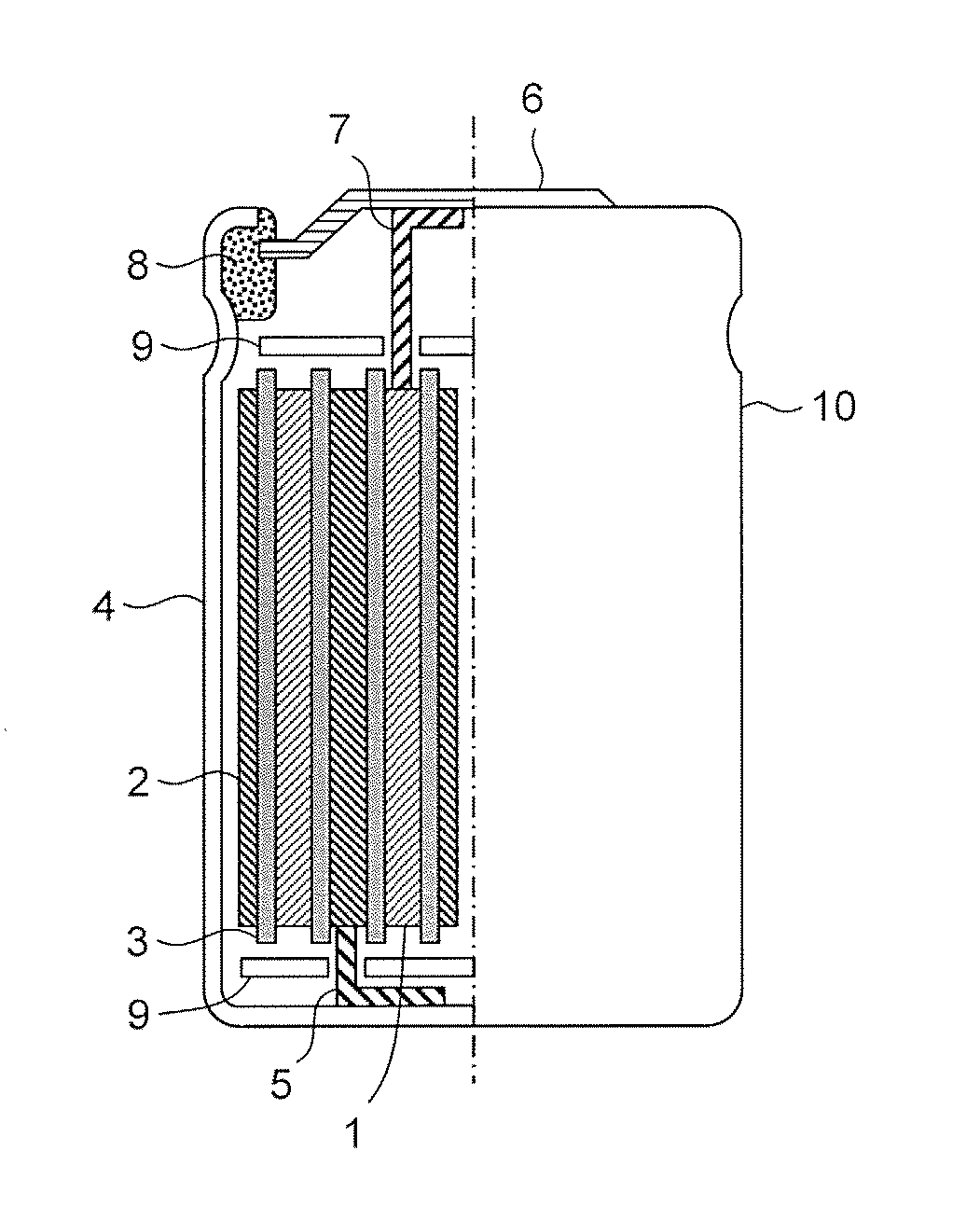

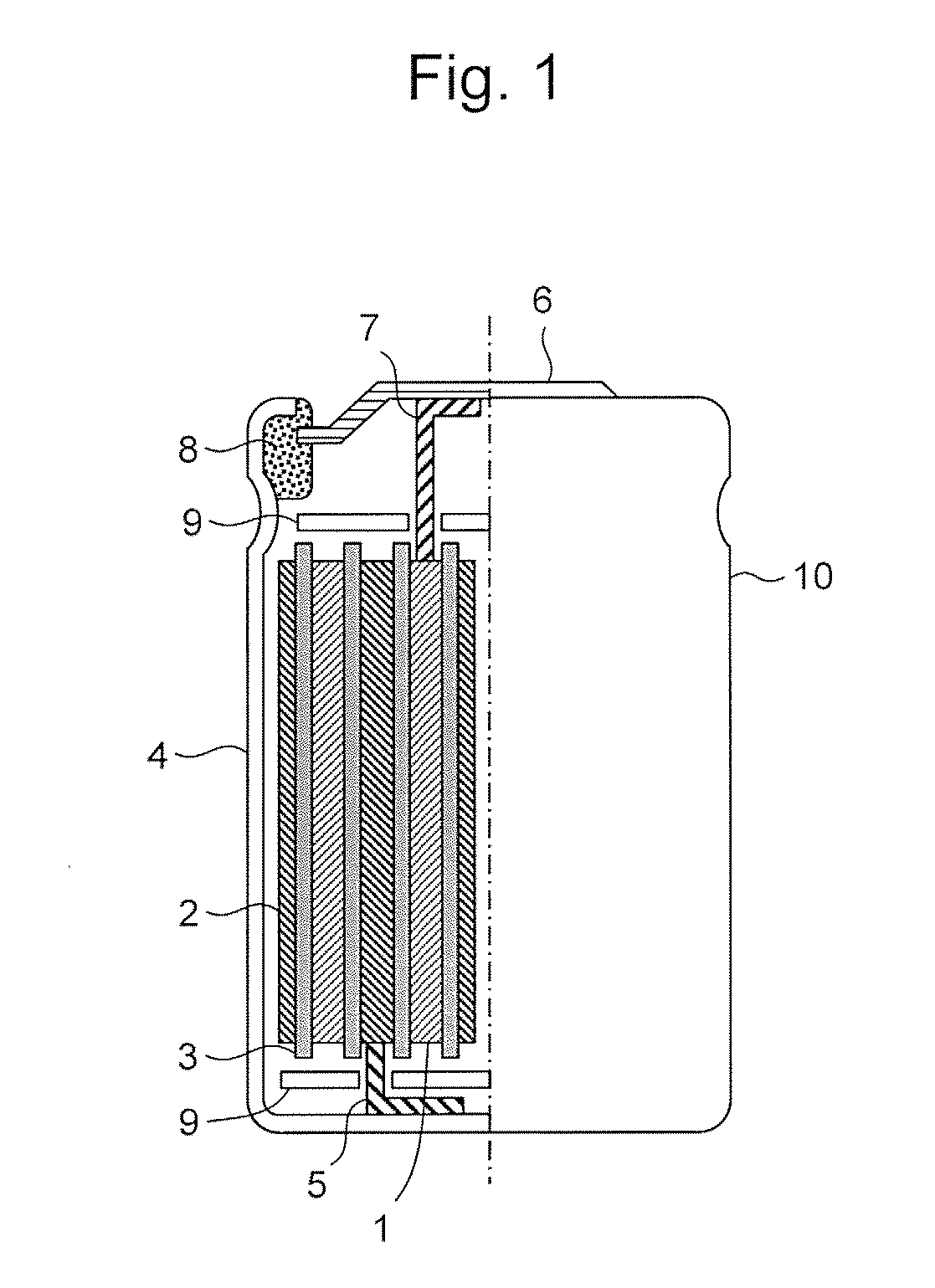

Acoustic Wave Device and Method for Production of Same

ActiveUS20110018389A1Stably keep tight sealImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical conductorAcoustic wave

A small and highly reliable acoustic wave device and a method for production of the same will be provided. The acoustic wave device has a piezoelectric substrate 1; a SAW element 2 on one main surface of the piezoelectric substrate 1; an outside connection-use conductor 3 formed on the one main surface of the piezoelectric substrate 1 and electrically connected to the SAW element 2; a columnar electrode 10 on the outside connection-use conductor 3; and a protective cover 6 defining inner walls of a vibration space 7 for vibration of the SAW element 2 and planarly surrounding a side surface of the columnar electrode 10.

Owner:KYOCERA CORP

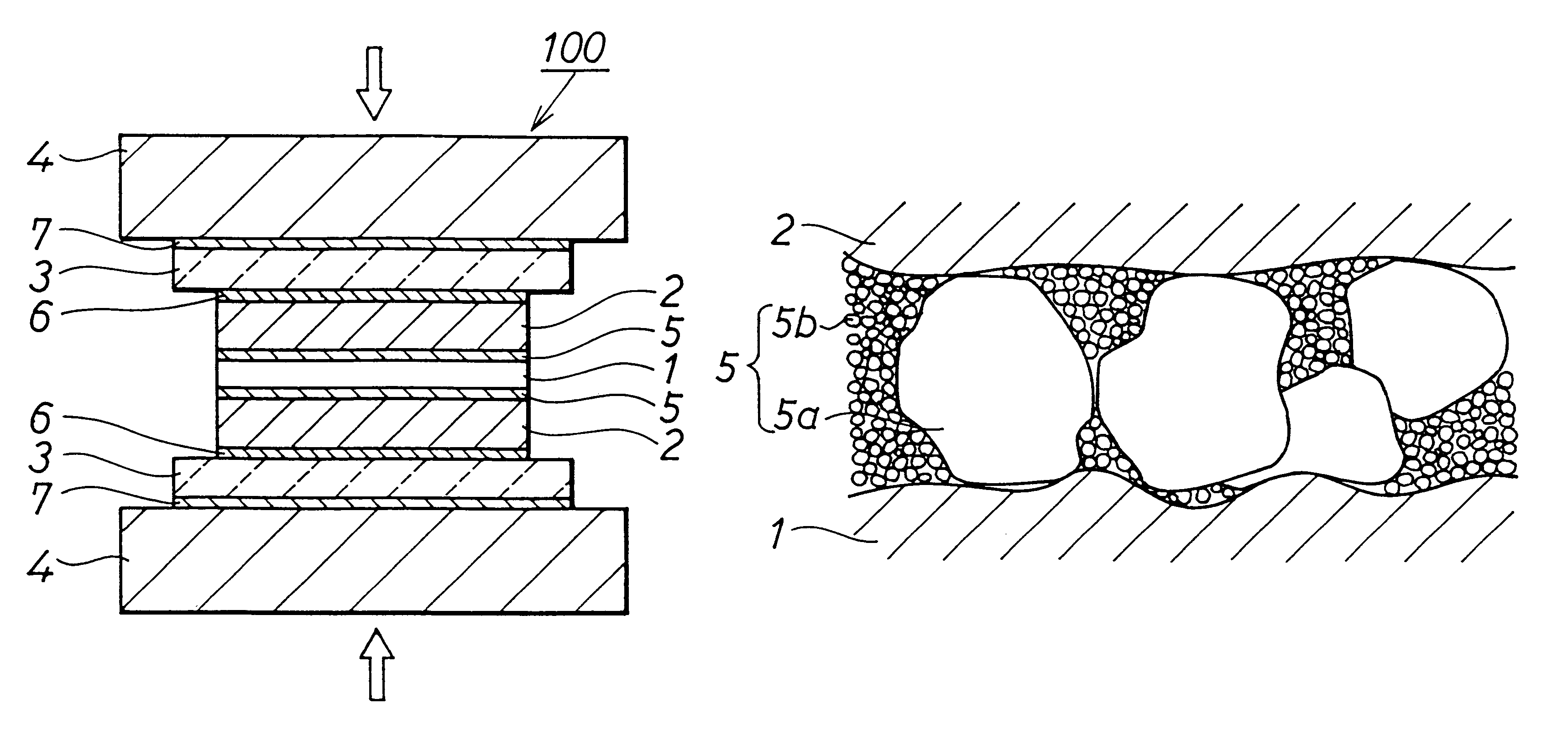

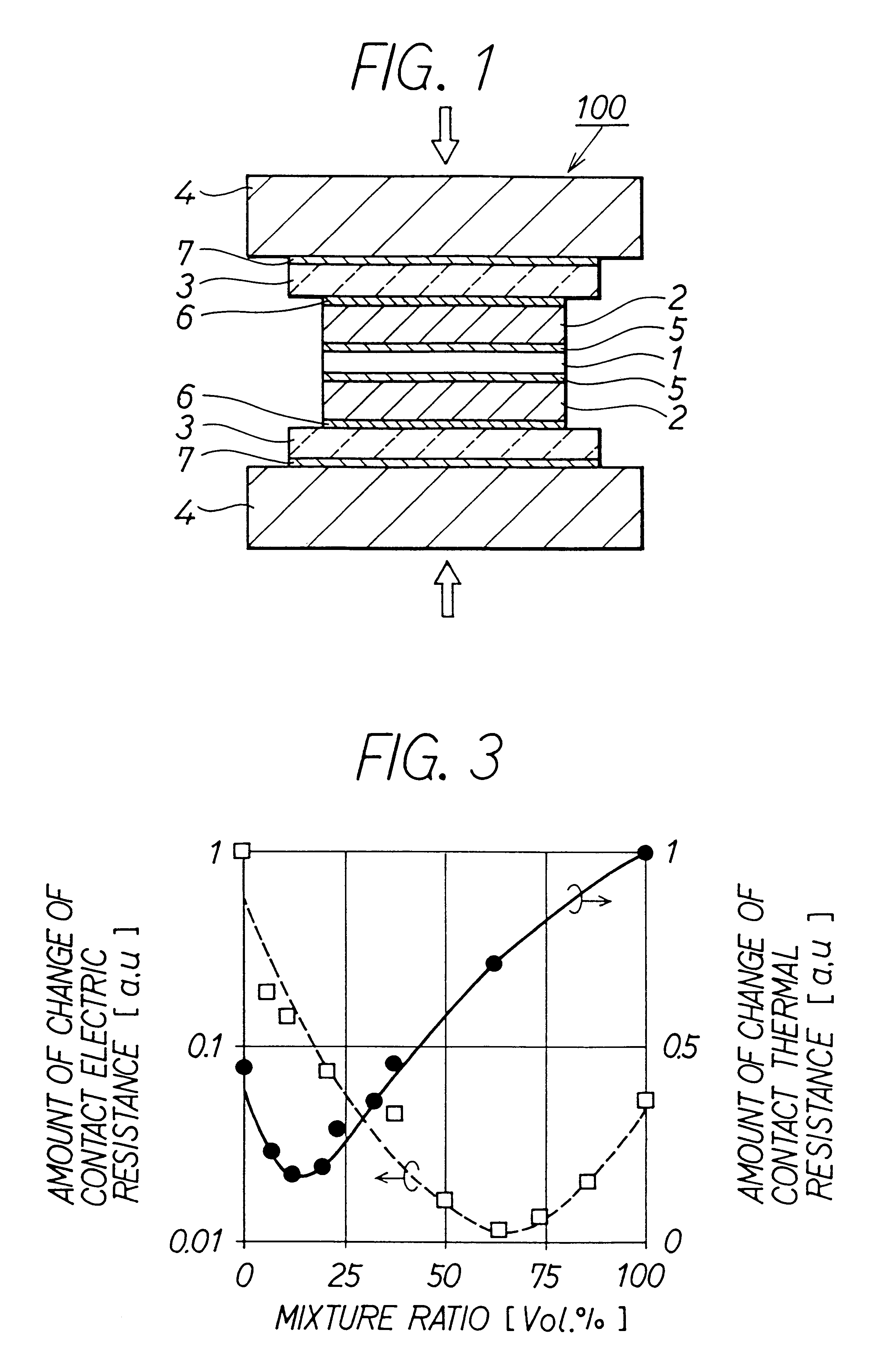

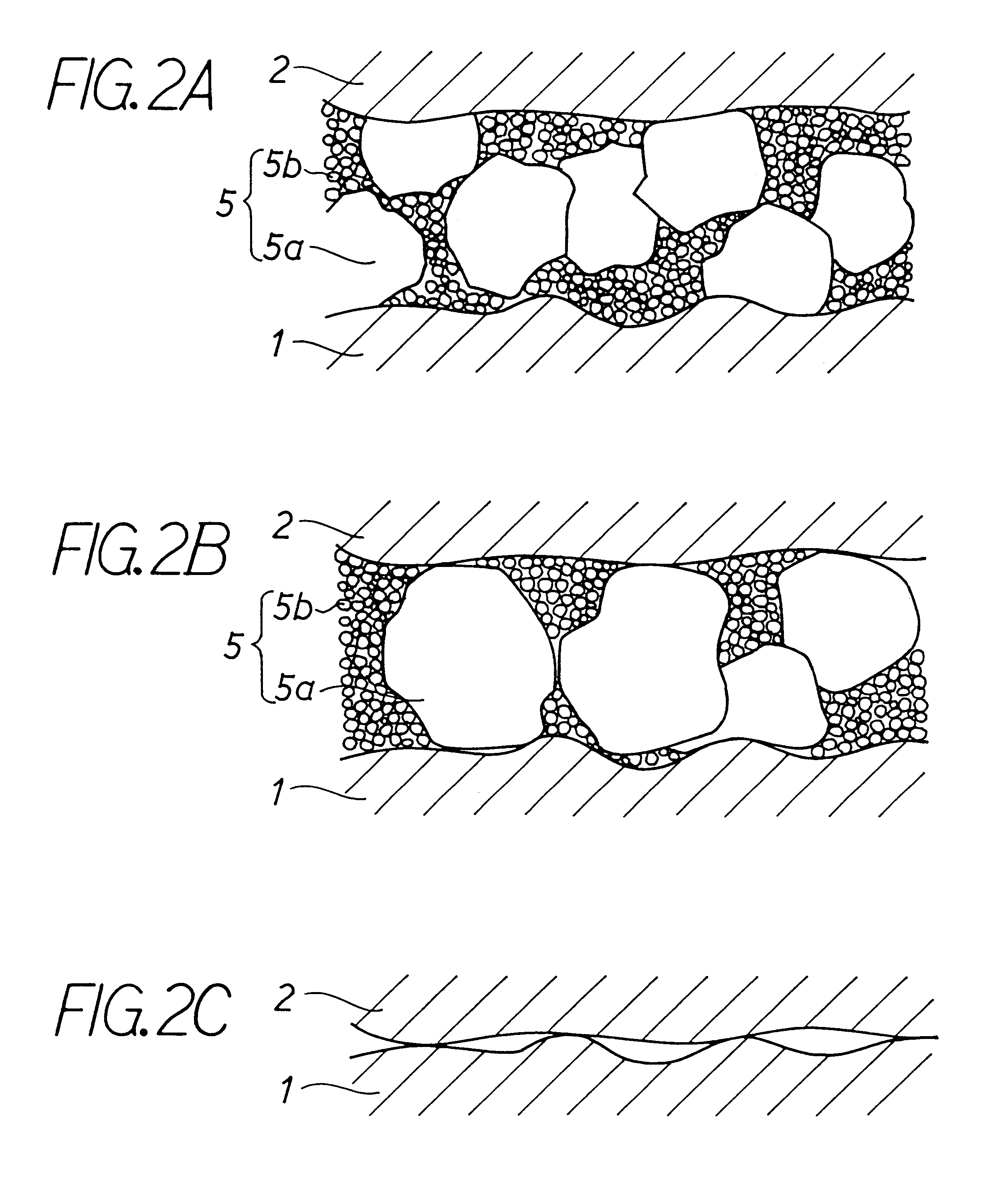

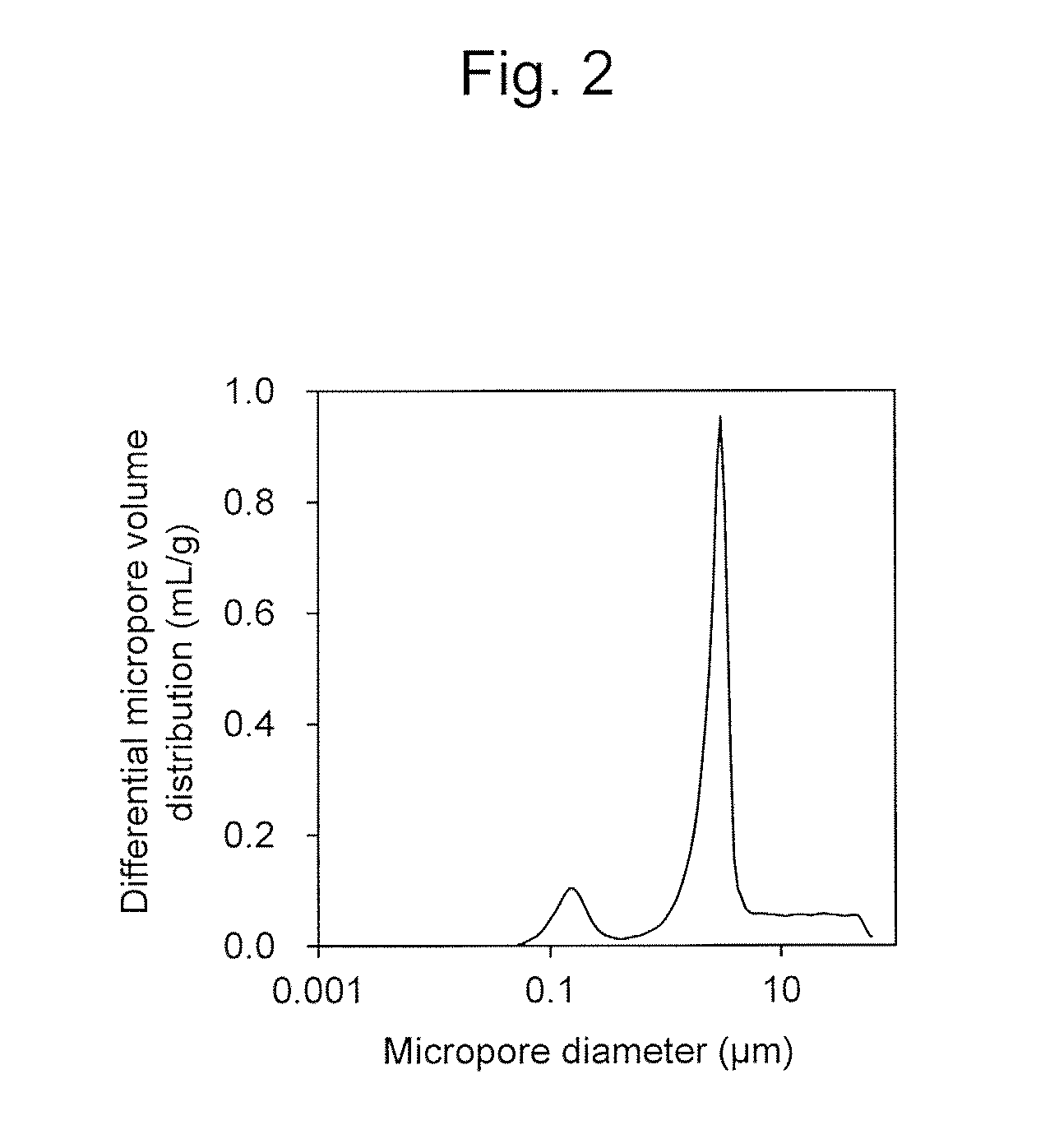

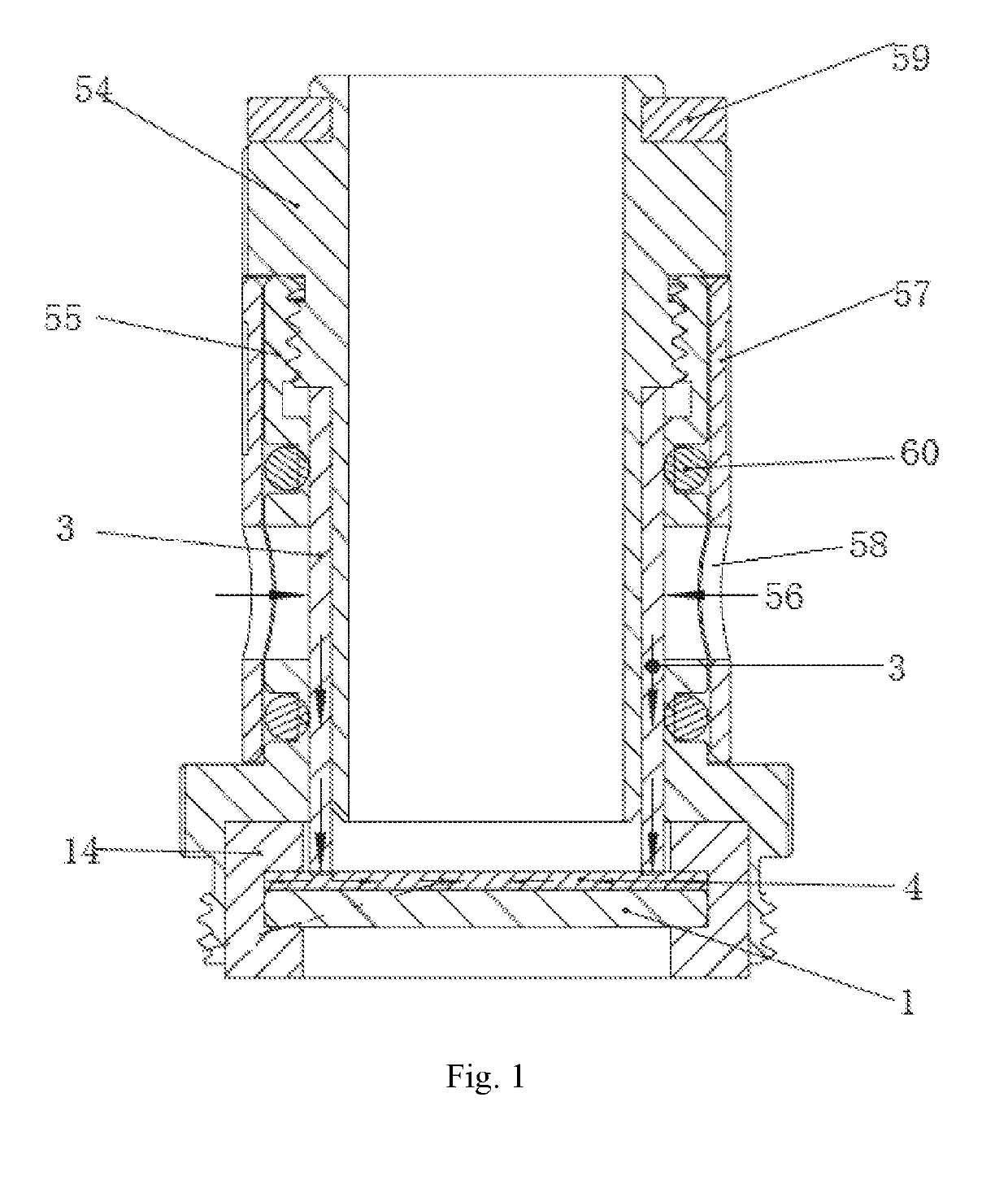

Electric apparatus having a contact intermediary member and method for manufacturing the same

InactiveUS6380622B1Reduce resistanceLower resistanceLayered productsSemiconductor/solid-state device detailsElectrical resistance and conductanceDevice material

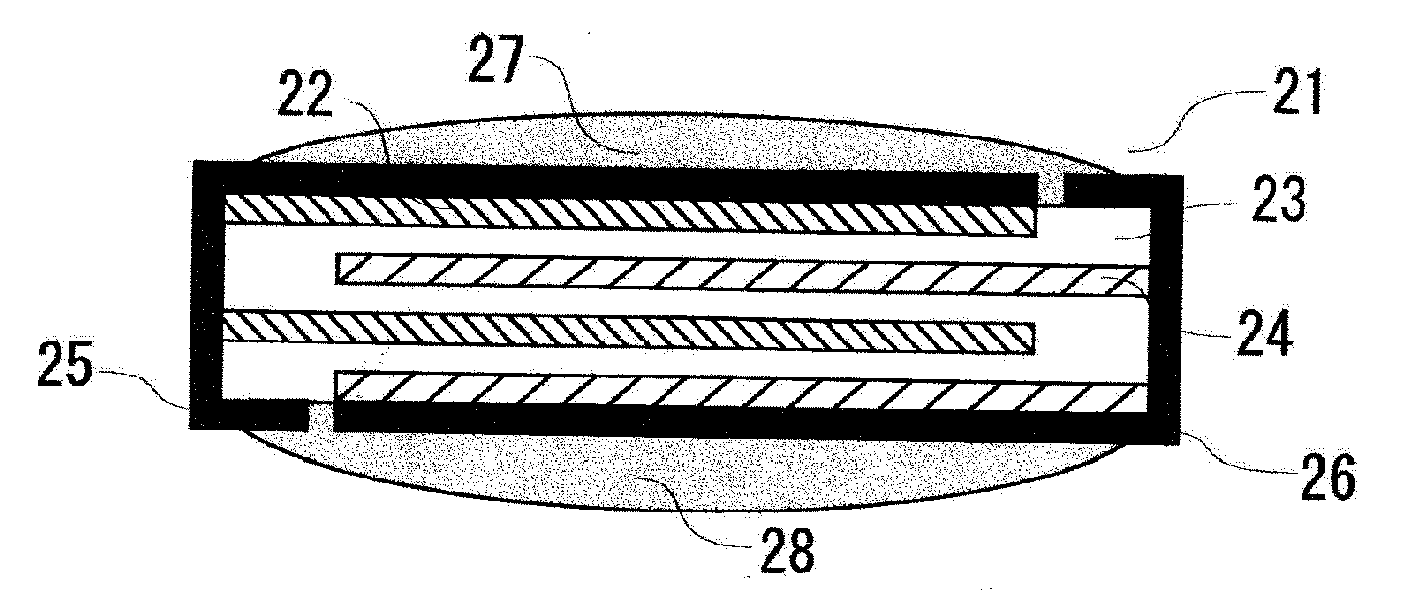

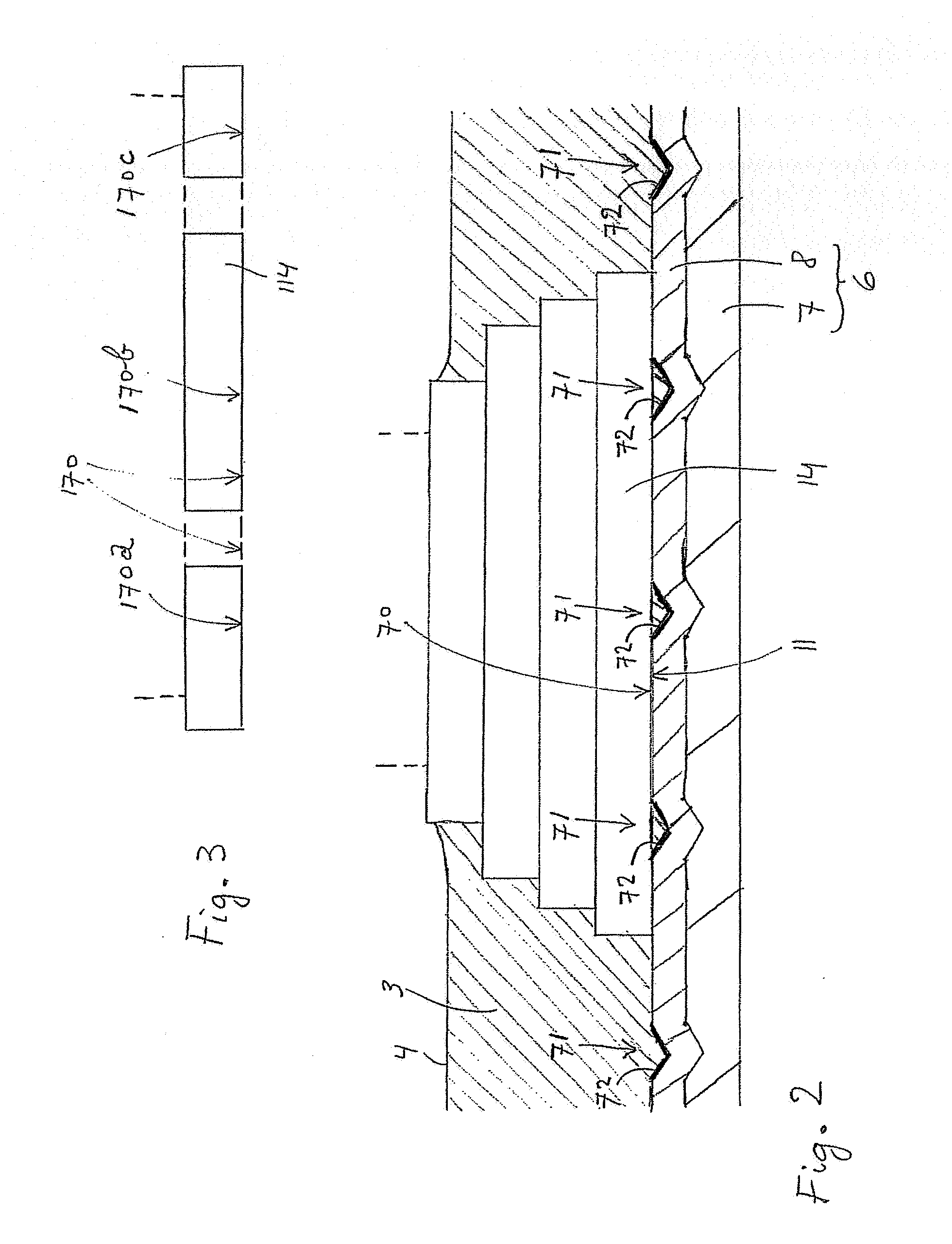

A pressed-contact type semiconductor device in which a main electrode surface of a semiconductor element is contacted with an electrode plate by a pressed-contact, which can reduce both an electric resistance and a thermal resistance between the main electrode surface of the semiconductor element and the electrode plate. The pressed-contact type semiconductor device (100) is provided with a semiconductor element (1) having electrode surfaces, a pair of electrode plates (2) contacted with the electrode surfaces by the pressed-contact, a pair of insulating plates (3) contacted with the outer side of the pair of the electrode plates by the pressed-contact, and a pair of radiating plates (4) contacted with the outer side of the pair of the insulating plates by the pressed-contact. A contact intermediary member (5), which is made up of particle member having at least thermal conductivity and electric conductivity, is intercalated between the semiconductor element and the electrode plate. The particle member of the contact intermediary member includes large particles 5a having an average particle diameter of more than 2 mum, and small particles 5b having an average particle diameter of to or less than 2 mum. Contact intermediary members (6, 7) are intercalated into gaps generated between the electrode plate and the insulating plate, and between the insulating plate and the radiating plate so as to fill up these gaps. The contact intemediary members are made of powder material having at least thermal conductivity.

Owner:DENSO CORP

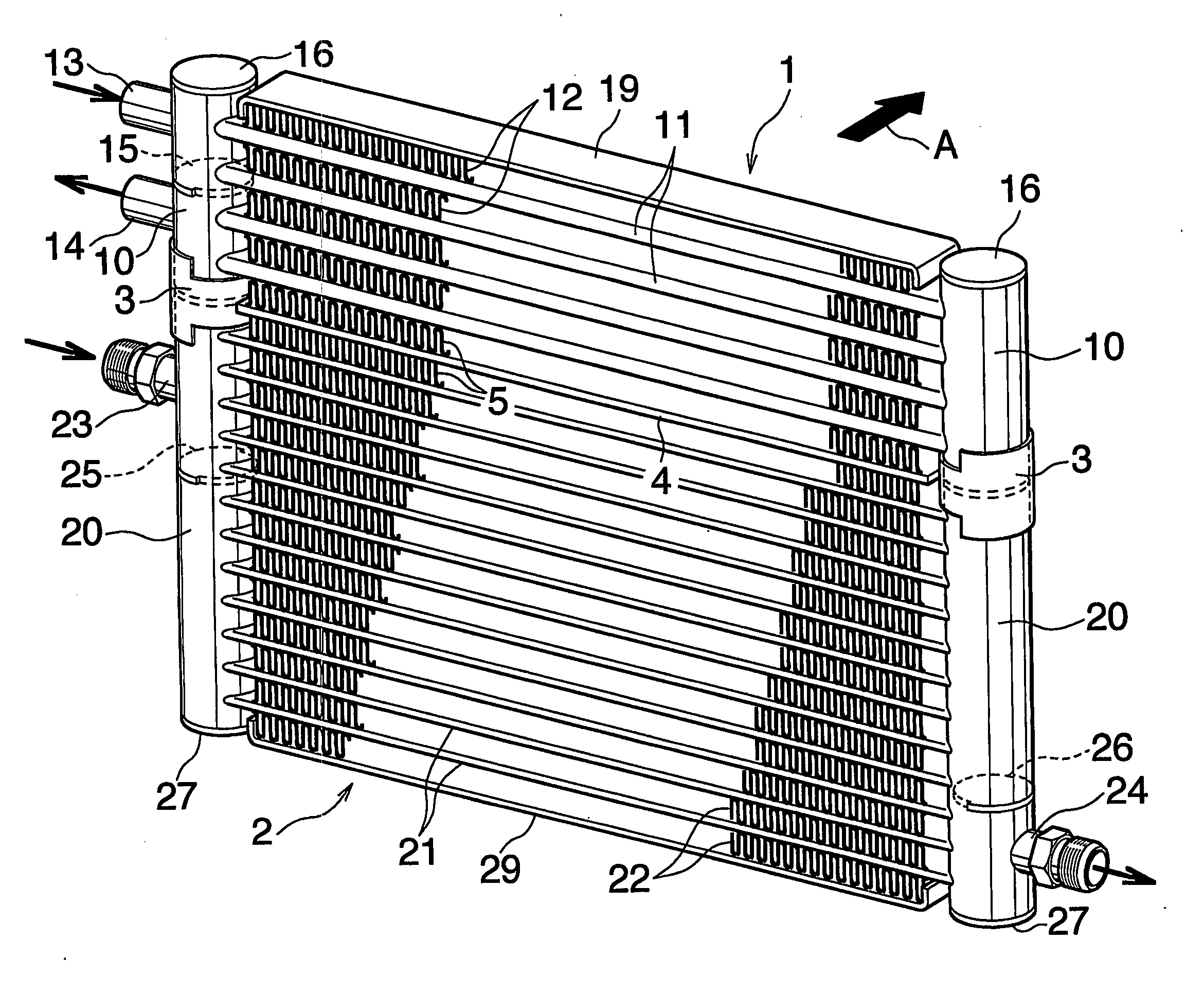

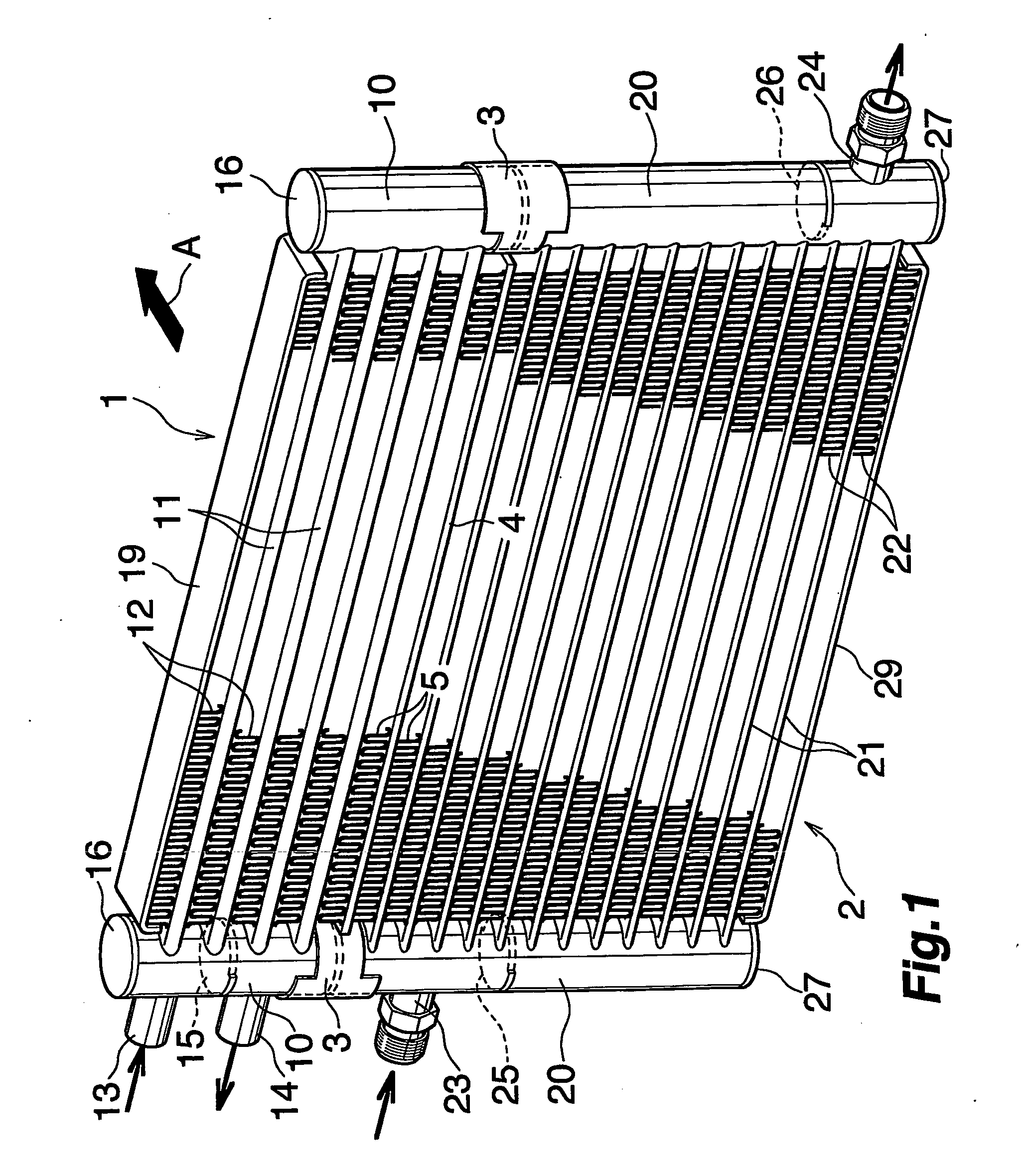

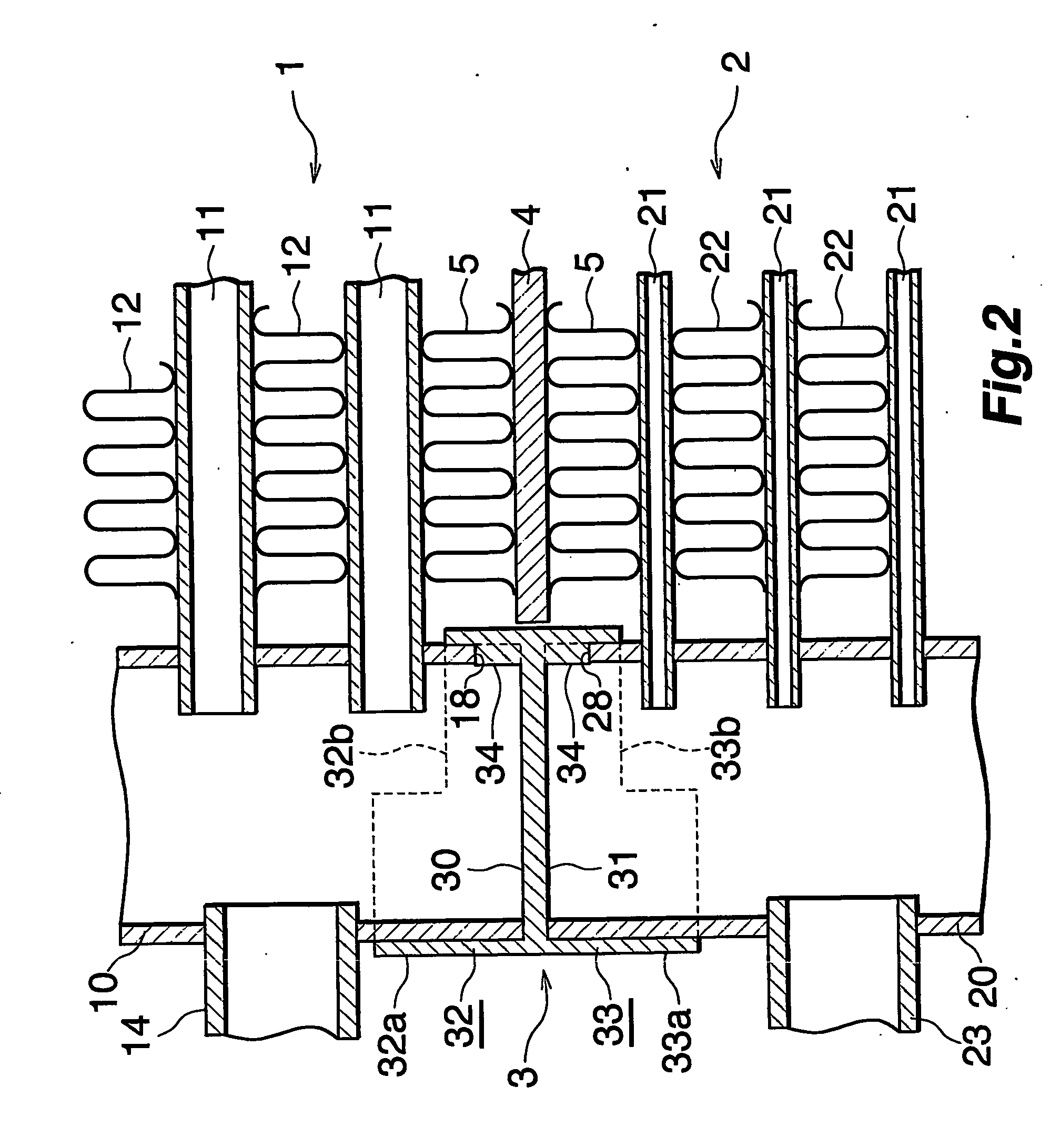

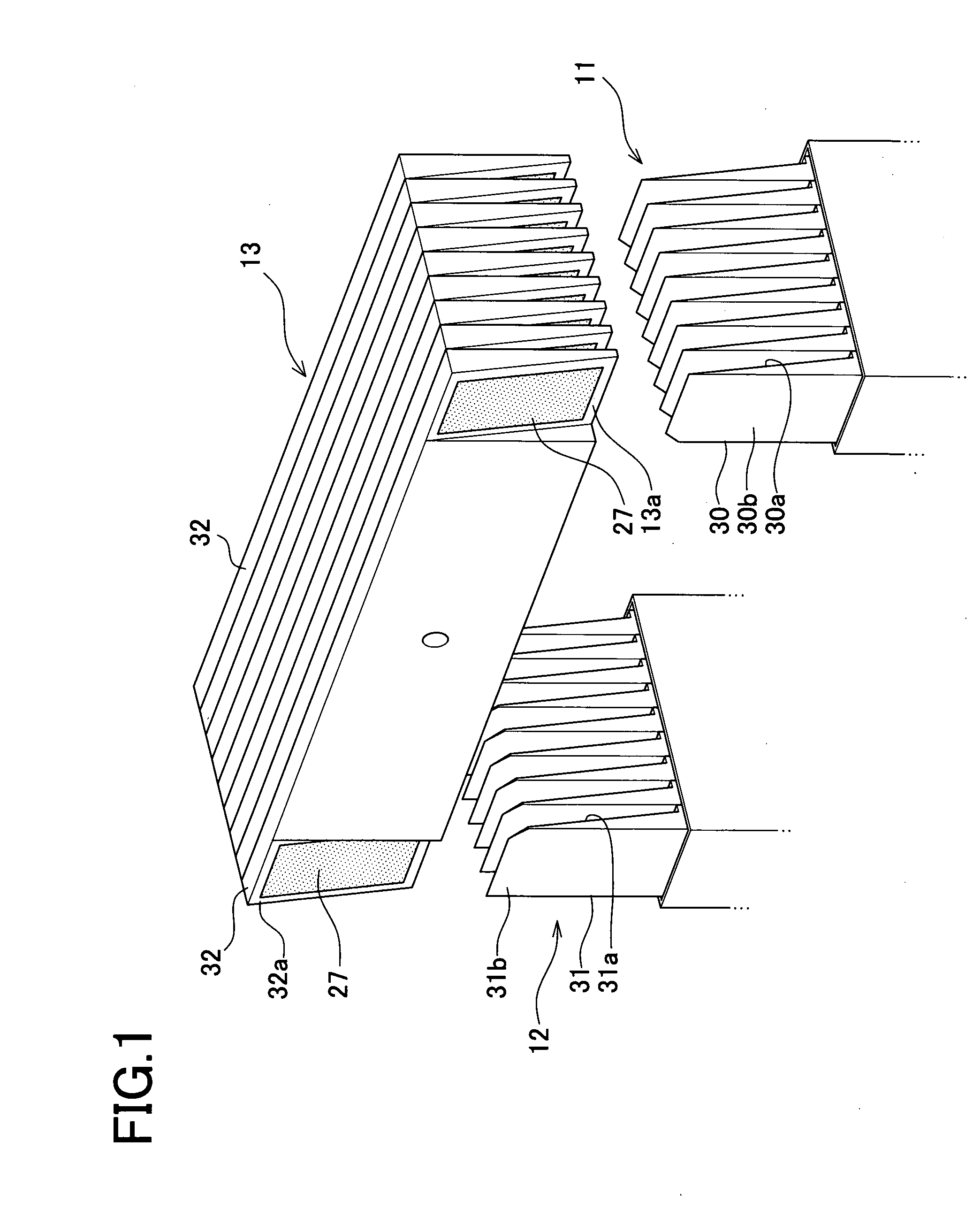

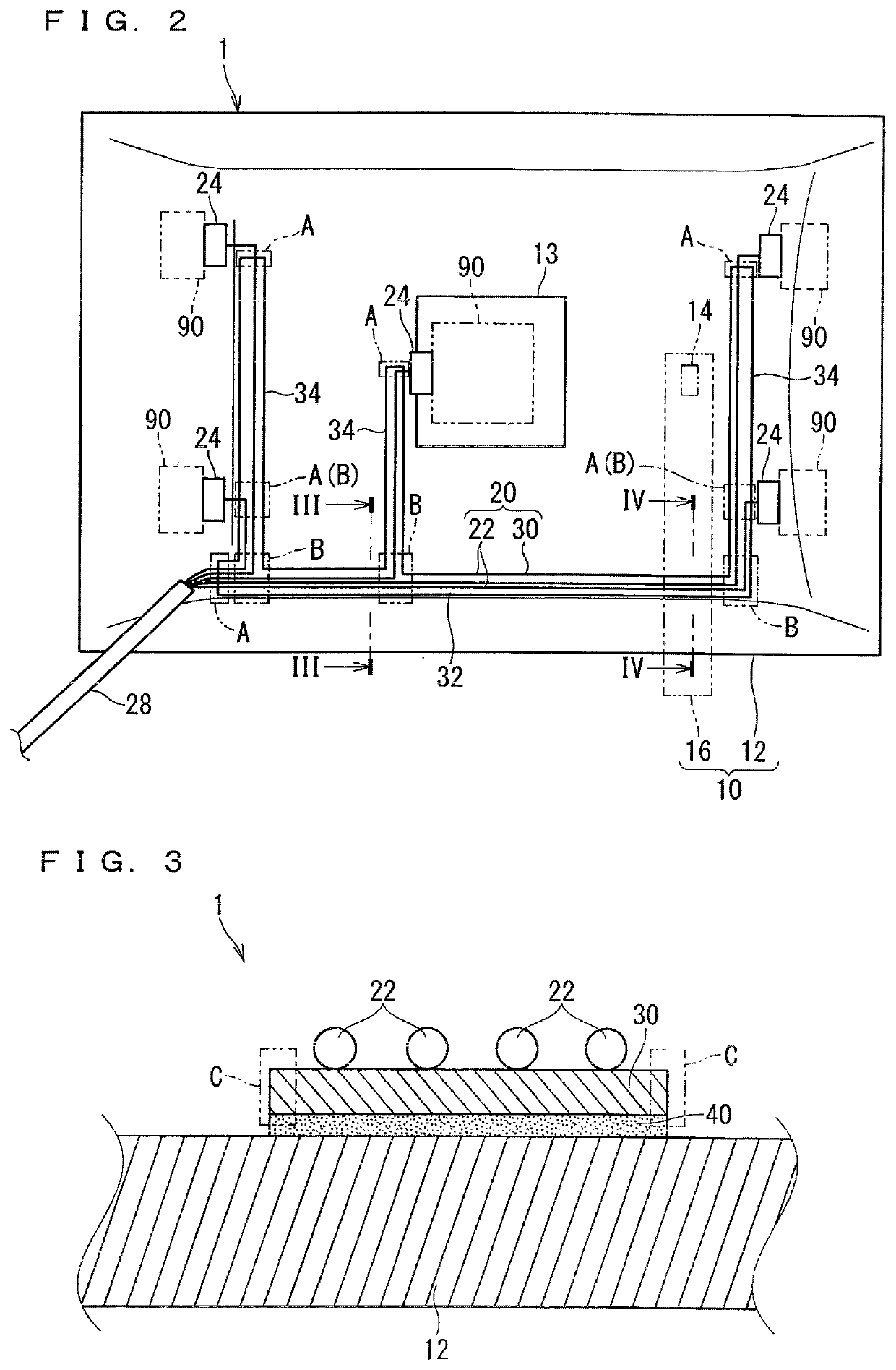

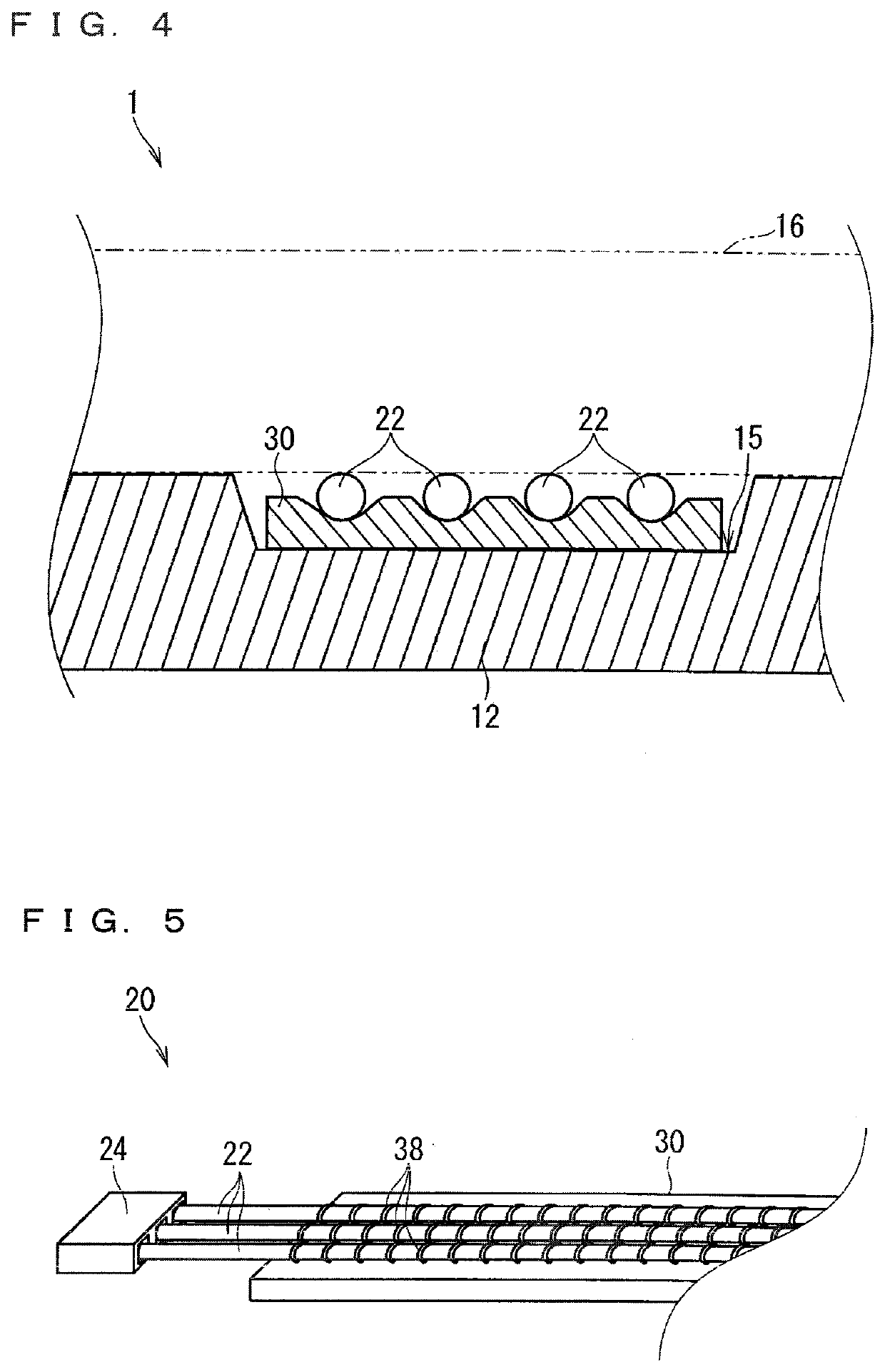

Unit-type heat exchanger

InactiveUS20050217831A1Precise positioningEasy to useStationary conduit assembliesHeat exchanger casingsEngineeringMechanical engineering

A unit-type heat exchanger for use as a condenser in motor vehicle air conditioners and an oil cooler for various oils use in motor vehicles. An oil cooler 1 and a condenser 2 are arranged one above the other and assembled into a unit. Each of these components 1, 2 has two pipelike headers 10, 20 arranged in parallel to each other at a spacing, and a plurality of parallel heat exchange tubes 11, 21 joined at opposite ends thereof to the two headers 10, 20. The adjacent oil cooler 1 and condenser 2 have ends thereof positioned in proximity to each other and connected to each other by connectors 3. Each of the connectors 3 is provided at opposite sides thereof with respective recessed portions 30, 31 for opposed ends of the headers 10, 20 to be fitted therein, and these header ends are fined in the respective recessed portions 30, 31 and joined to the connector 3. The unit-type heat exchanger is adapted to prevent mixing of the fluids flowing inside the oil cooler 1 and the condenser 2, respectively.

Owner:KEIHIN THERMAL TECH CORP

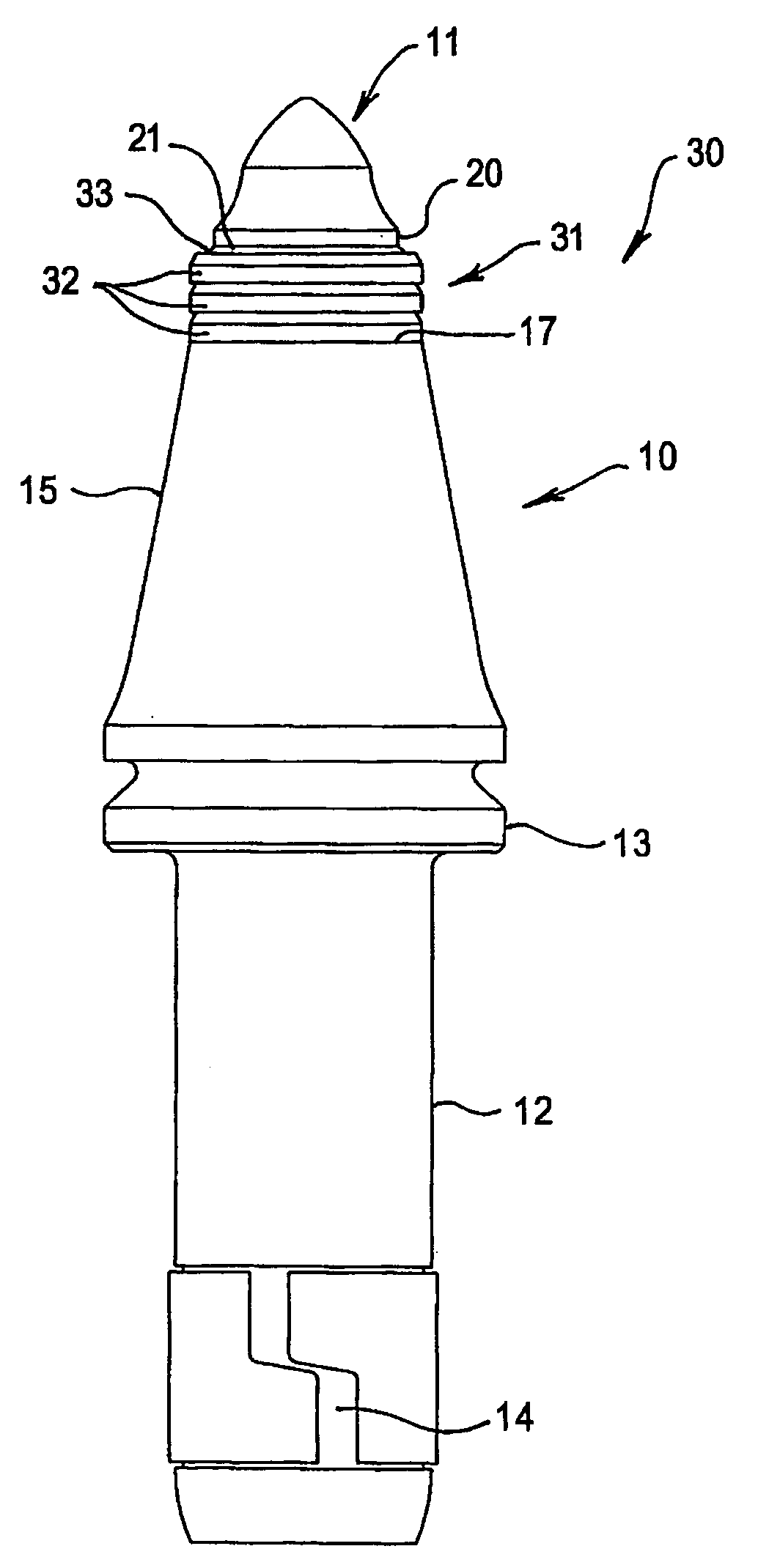

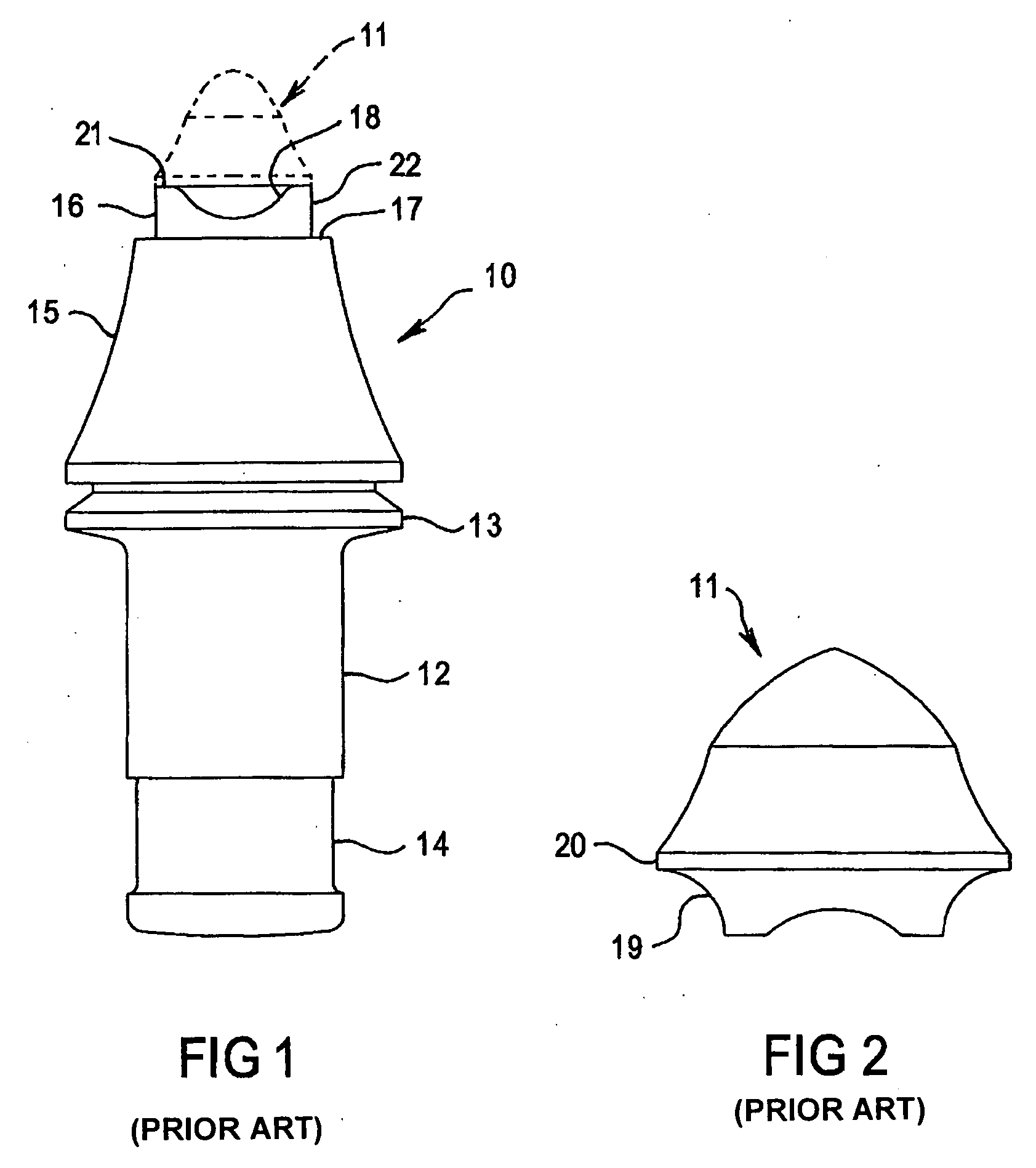

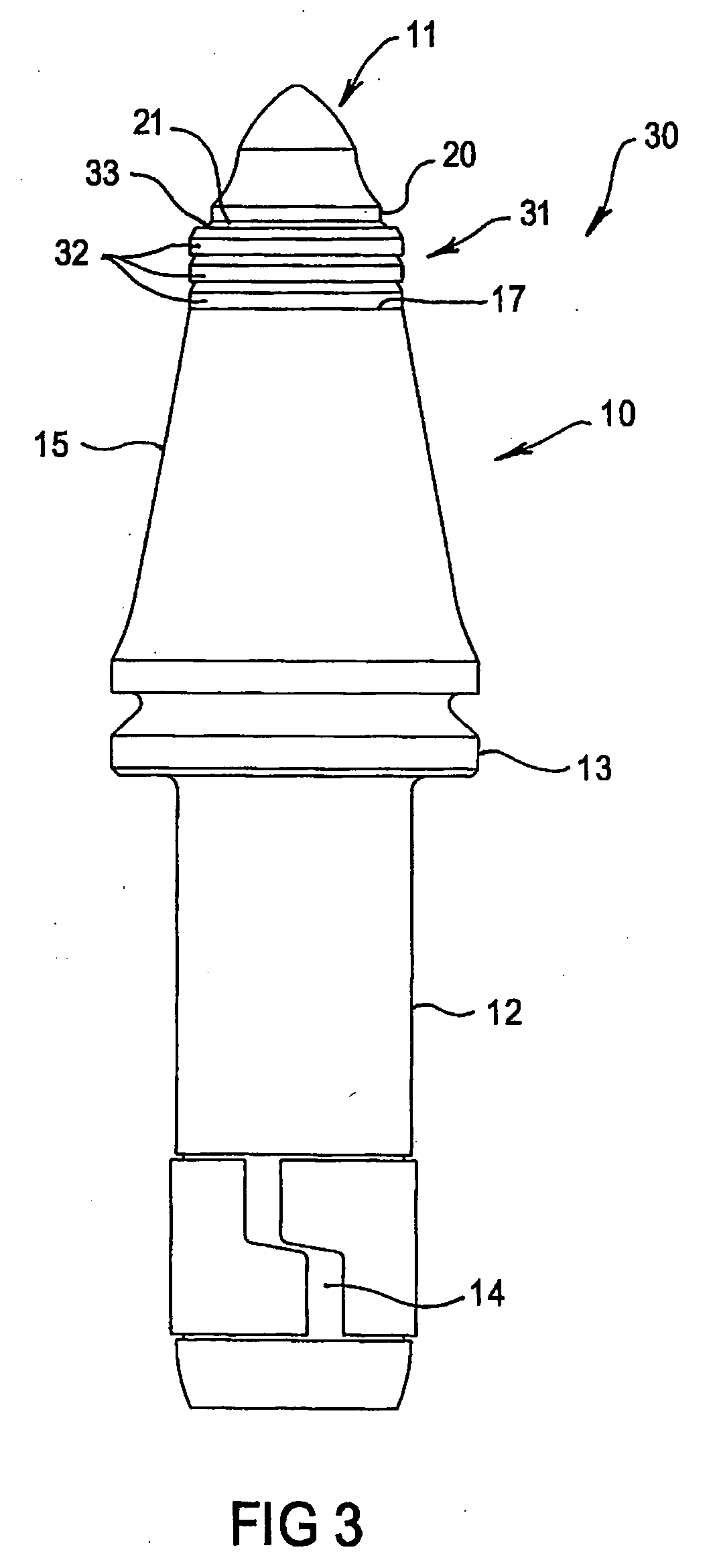

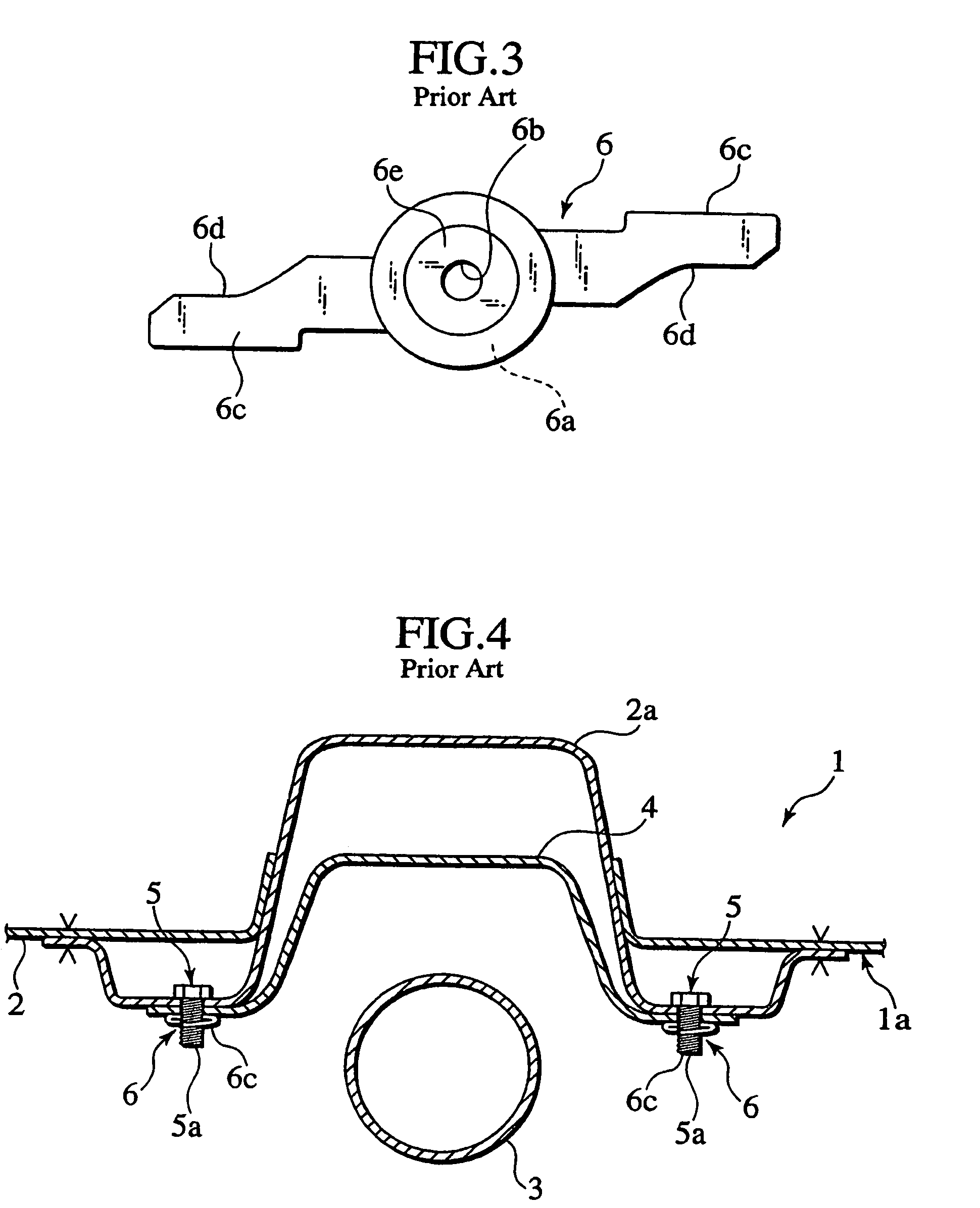

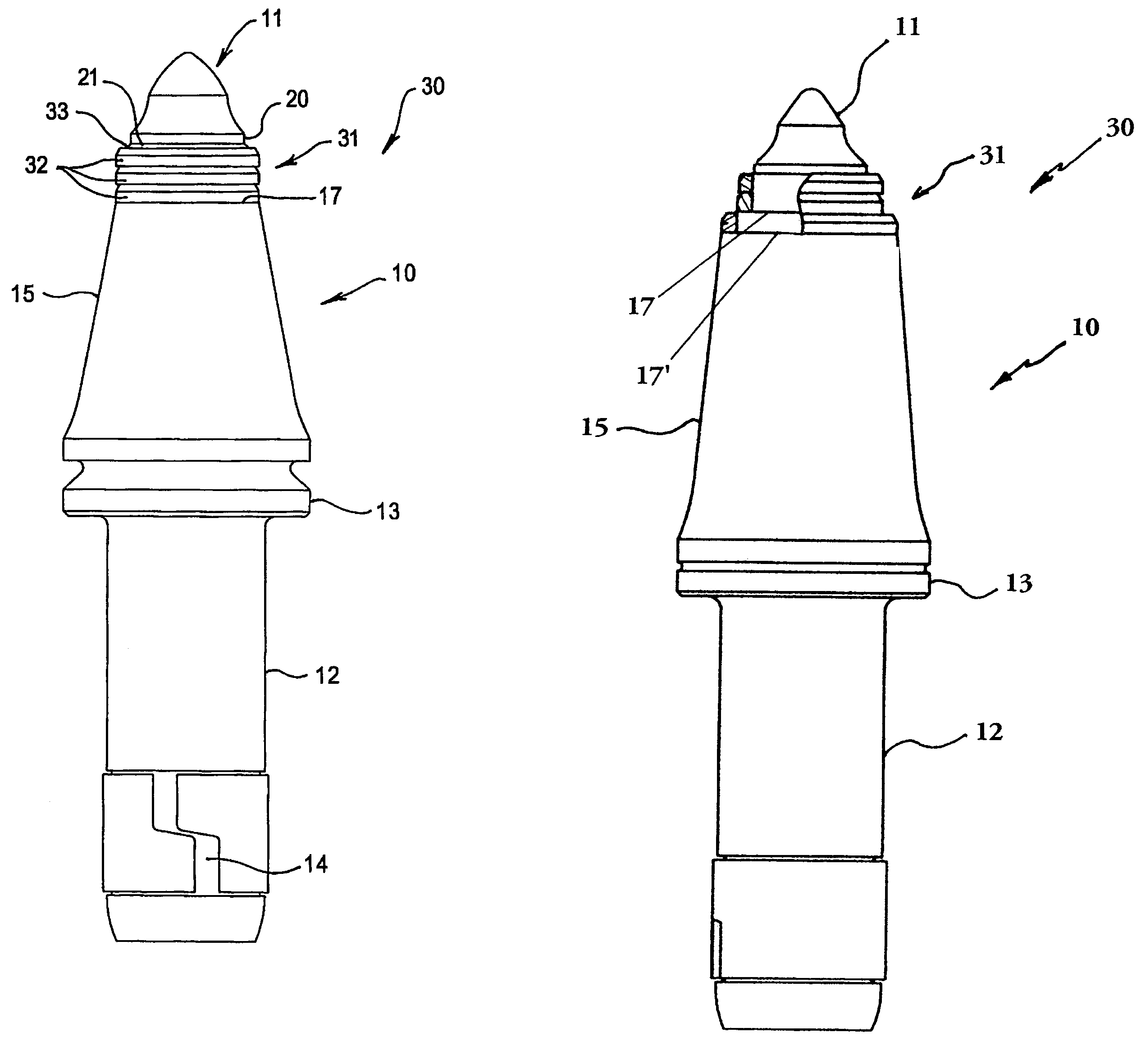

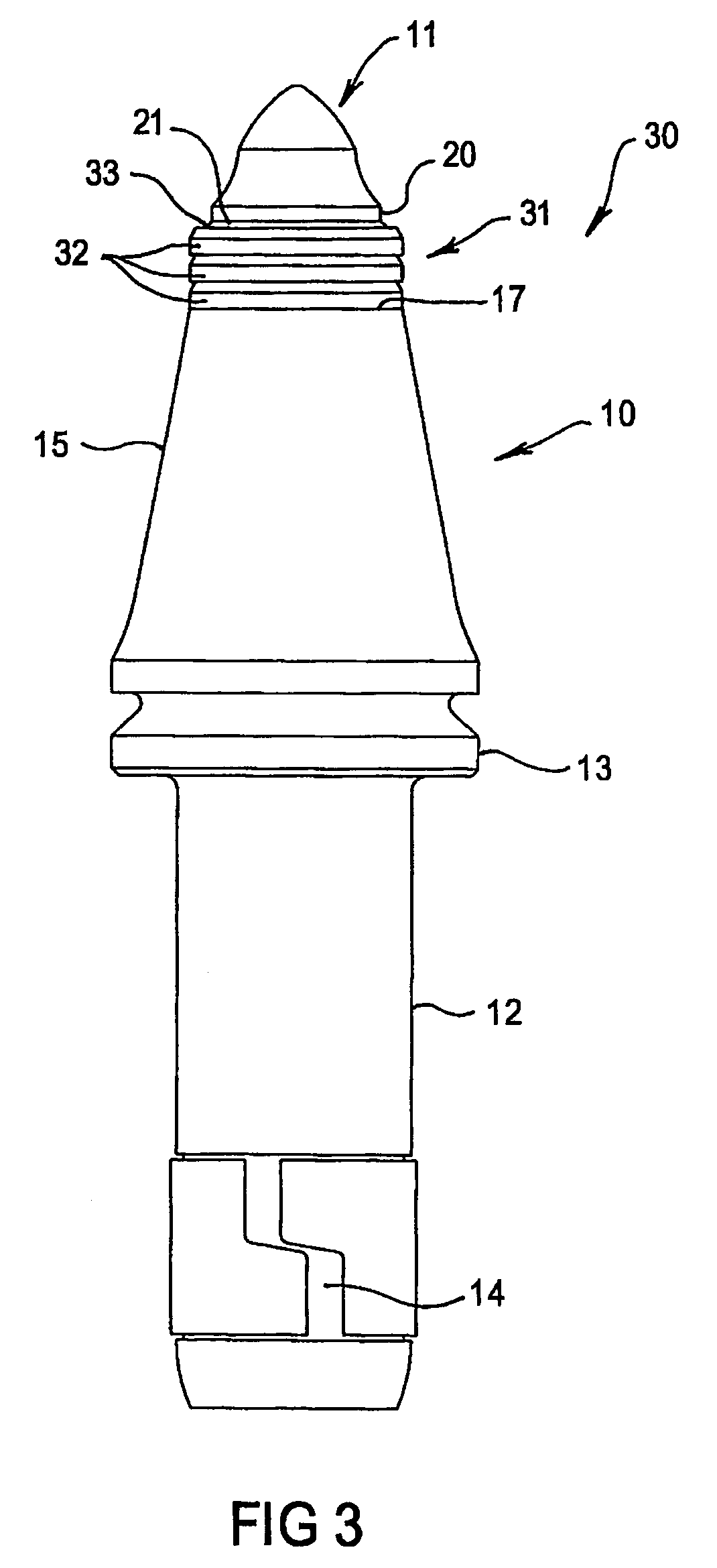

Rotary cutting bit having spark suppression sleeve

InactiveUS20050212345A1Reduction tendencyReduce the possibilityDust removalFire preventionEngineeringMechanical engineering

A cutting pick includes an elongate shank, a cutting tip fixed to one end of the shank to project from that end and which is of a material that is harder than the material of the shank, and an annular sleeve which is attached about the shank adjacent the cutting tip. The sleeve is of a material (e.g., tungsten carbide) which is harder than the material of the shank and which has a lower propensity for incendive spark production during a cutting operation than the material of the shank. The sleeve includes a plurality of annular sleeve portions which are attached about the shank immediately adjacent to each other.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

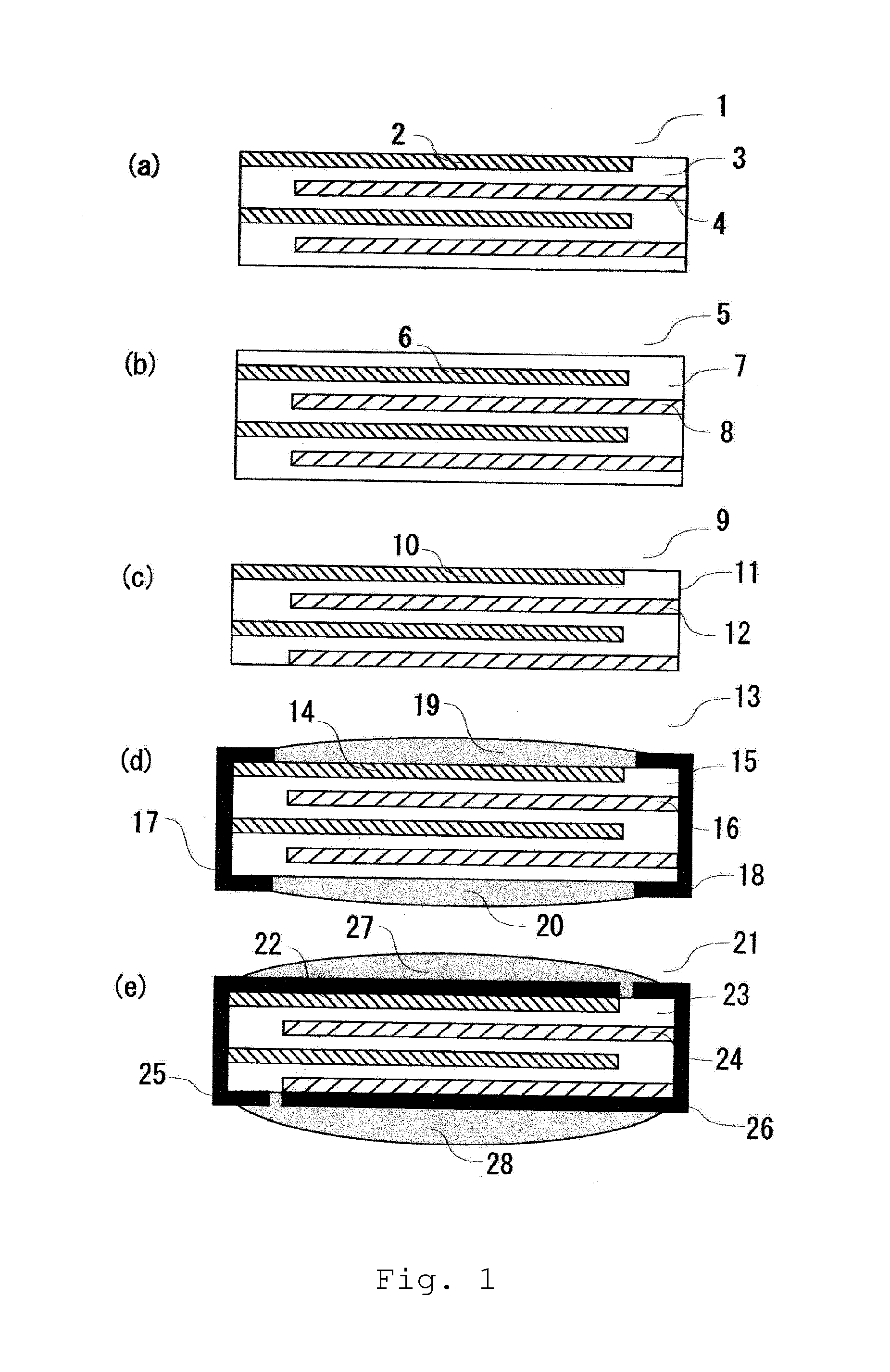

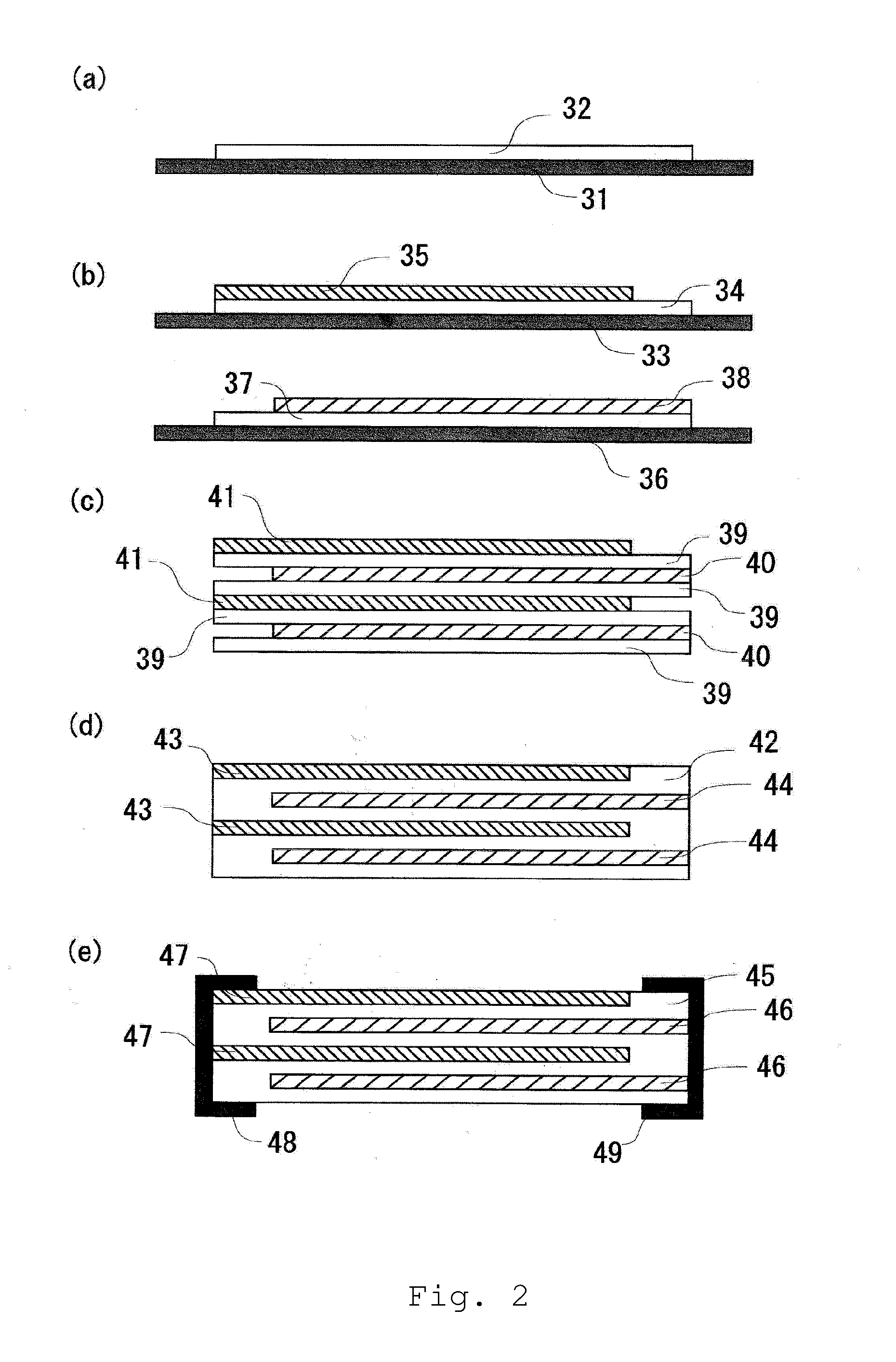

Lithium ion secondary battery and method for manufacturing same

ActiveUS20120015234A1Lower internal resistanceImprove discharge performanceSolid electrolytesFinal product manufactureAll solid stateElectrical battery

A conventional, multilayer, all-solid-state, lithium ion secondary battery where an electrode layer and an electrolyte layer are stacked has a problem that it has a high interface resistance between the electrode layer and the electrolyte layer and has a difficulty in increasing the capacity of the battery. A battery has been manufactured by applying pastes of a mixture of an active material and a solid electrolyte to form electrode layers and baking a laminate of electrode layers and electrolyte layers at a time. As a result, a matrix structure including the active material and the solid electrolyte has been formed in the electrode layers, so that a battery with a large capacity and a reduced interface resistance between the electrode layer and the electrolyte layer has been successfully achieved.

Owner:NAMICS CORPORATION

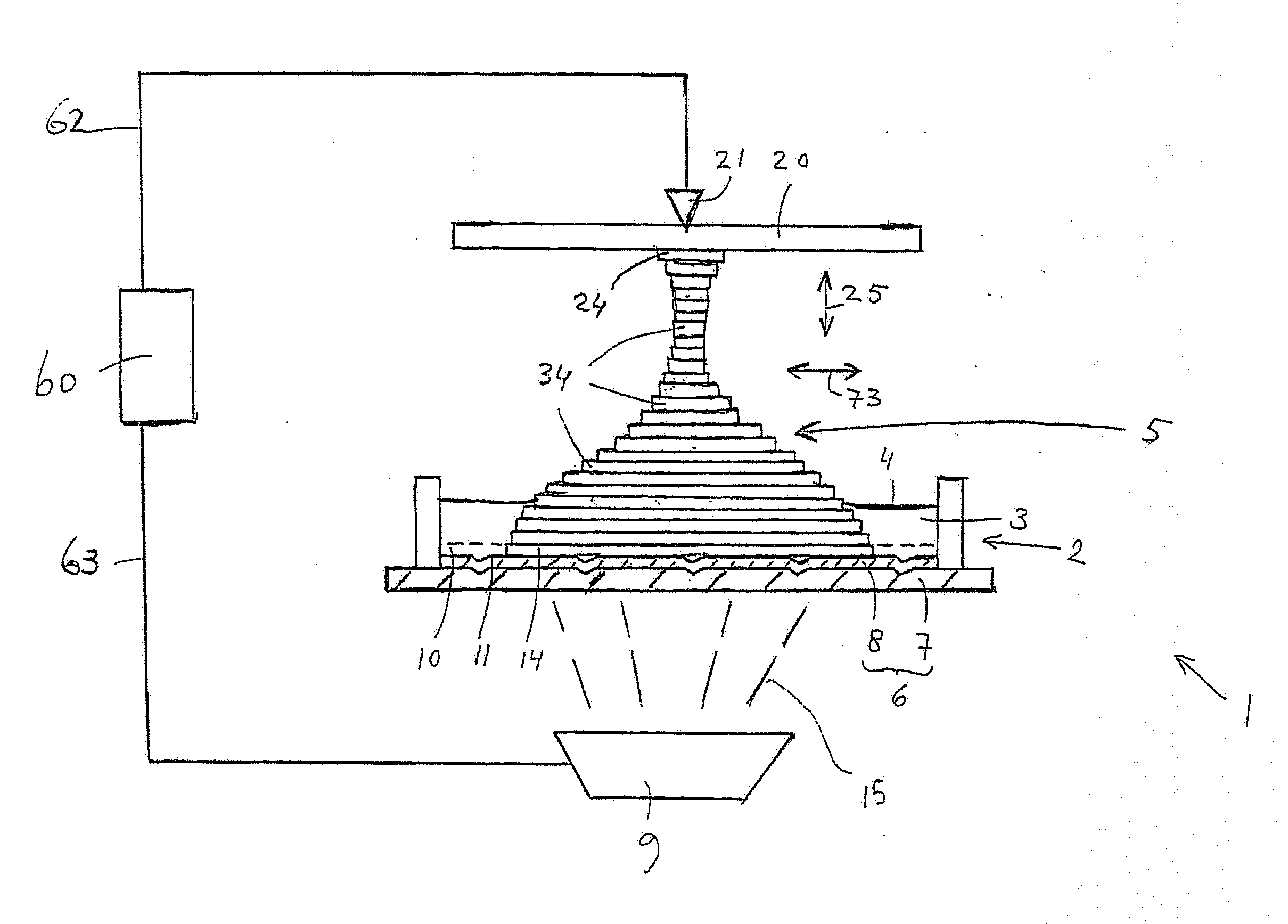

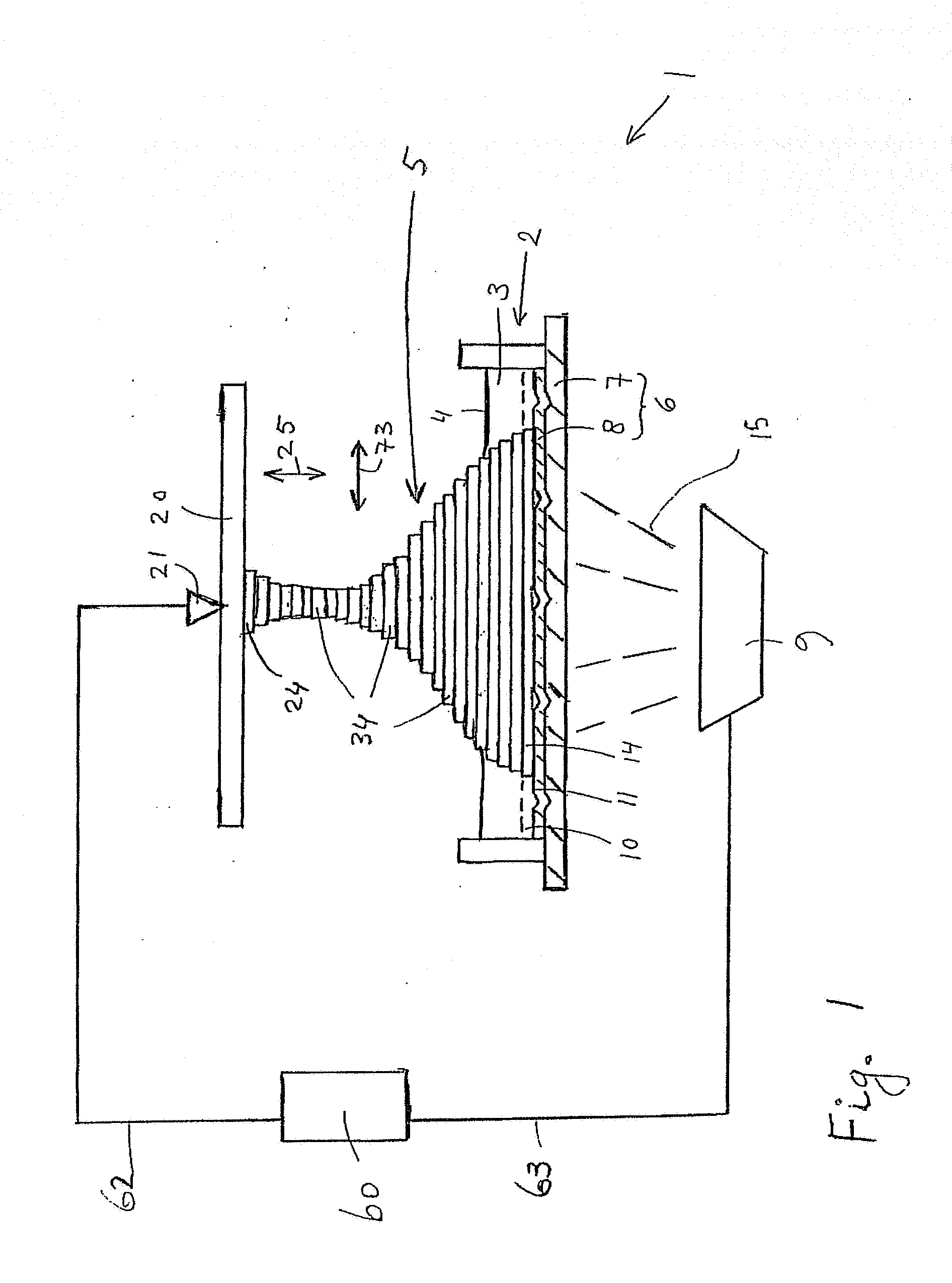

Method and system for layerwise production of a tangible object

ActiveUS20090309267A1Reduce differential pressureEasy to separateAdditive manufacturing apparatusTailstocks/centresTangible objectMechanical engineering

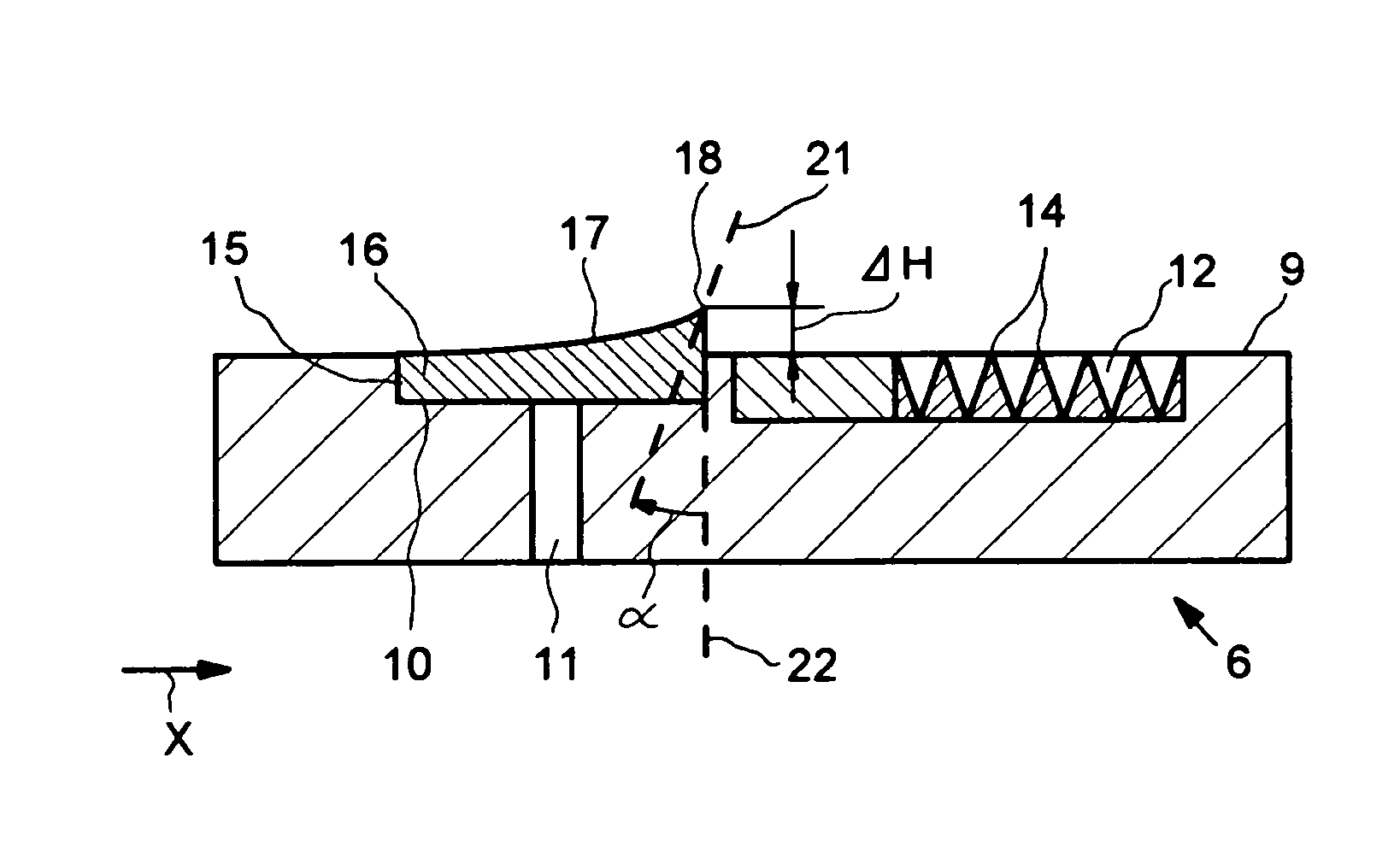

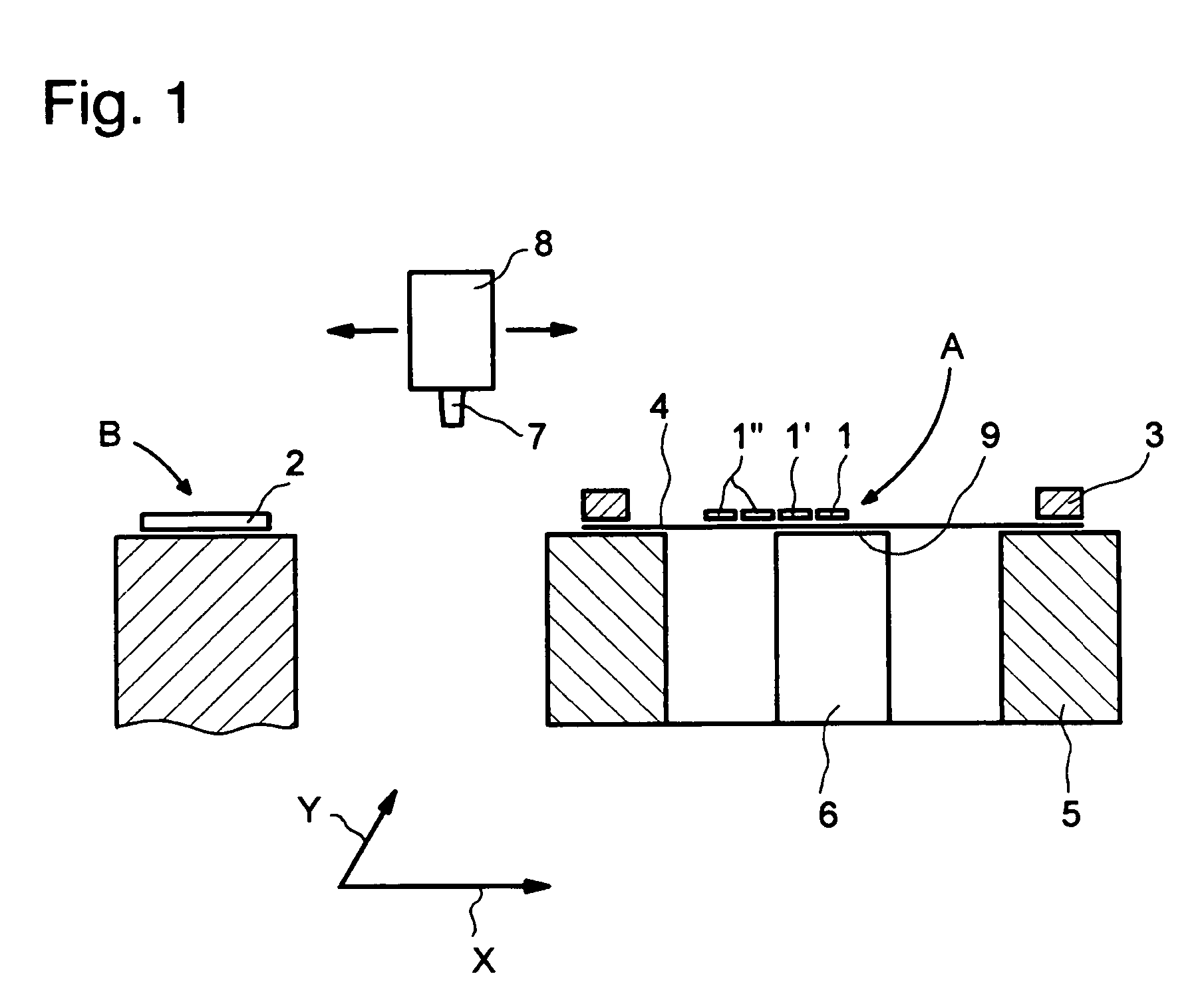

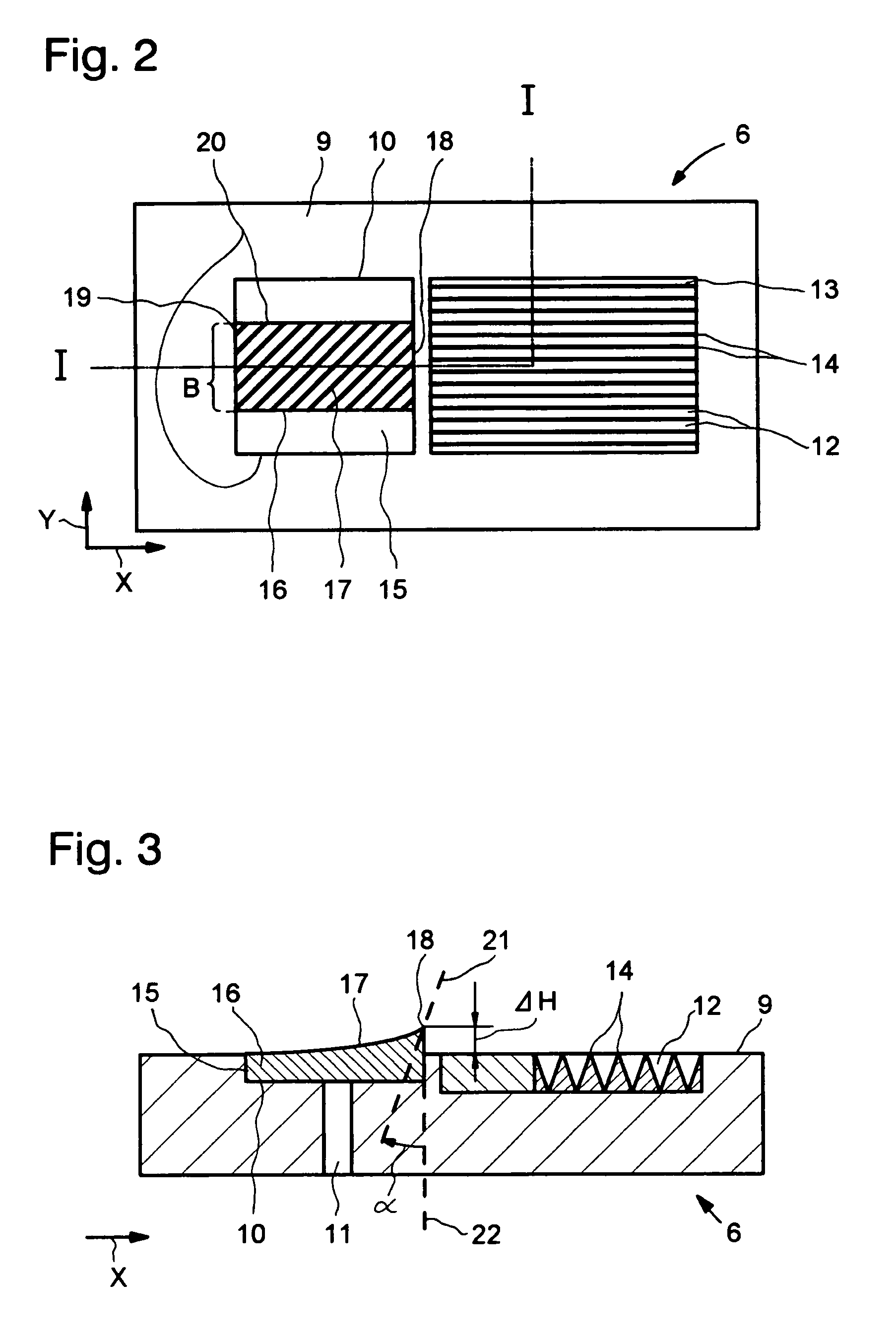

A method cycle of a method for layerwise production of a tangible object (5) comprises the successive steps of: solidifying predetermined parts of a liquid so as to obtain a solid layer (14) having a predetermined shape; separating said solid layer from a construction shape (6); and moving, relative to one another, the separated solid layer and the construction shape to a predetermined position relative to one another. Solidifying is carried out such that the solid layer and the construction shape have nonmatching shapes in the sense that all surface portions of a solid layer side (70) that are or have been in contact with a liquid contacting side (11) of the construction shape can not simultaneously be brought in full contacting engagement with the liquid contacting side.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

Method for detaching a semiconductor chip from a foil and device for mounting semiconductor chips

InactiveUS7238593B2Reduce adhesionEasily be pickedSemiconductor/solid-state device detailsLighting elementsSemiconductor chipMental detachment

Owner:ESEC

Keyboard

ActiveUS20110042195A1High sensitivityContact areaEmergency actuatorsElectric switchesEngineeringMembrane configuration

Owner:CHICONY ELECTRONICS

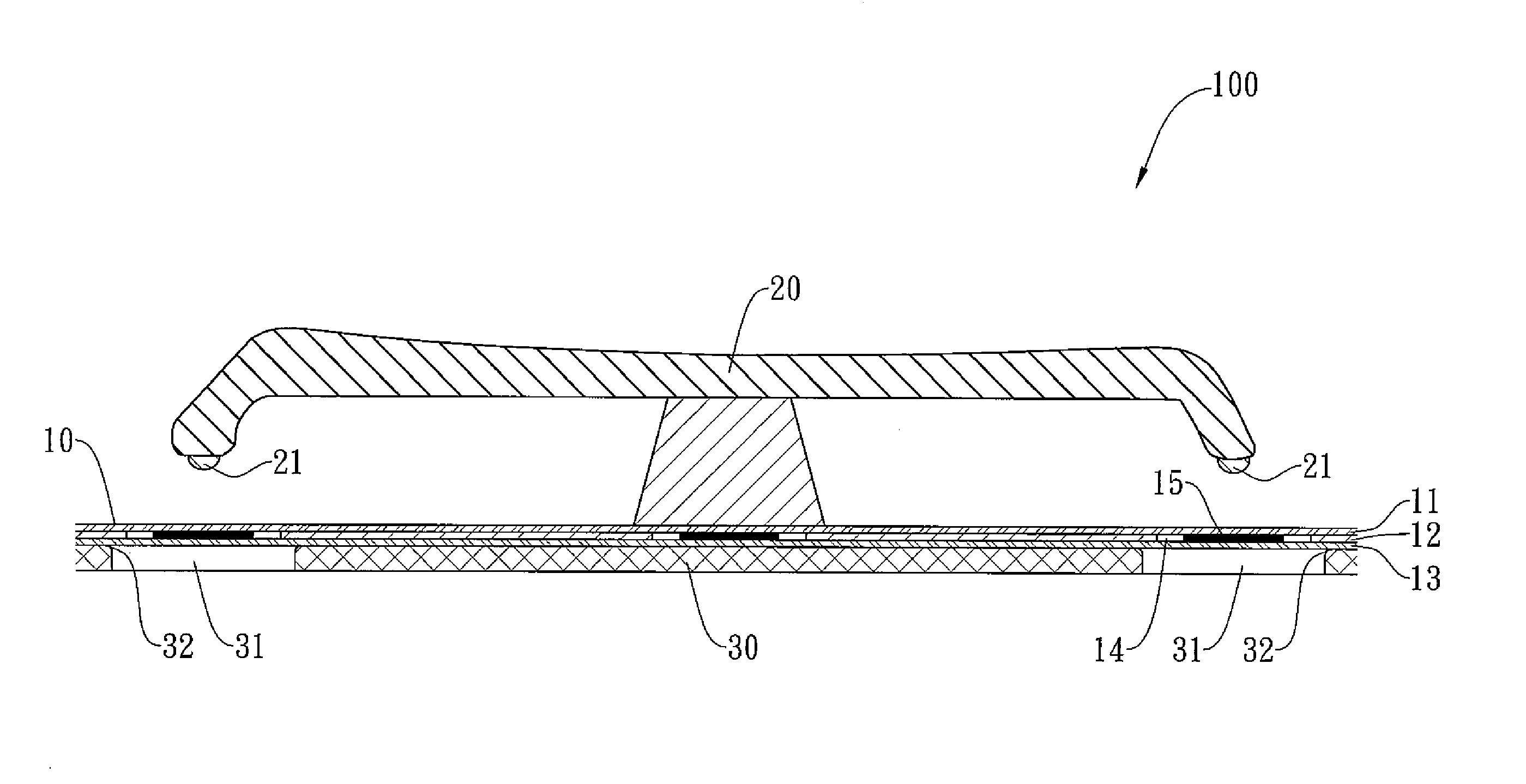

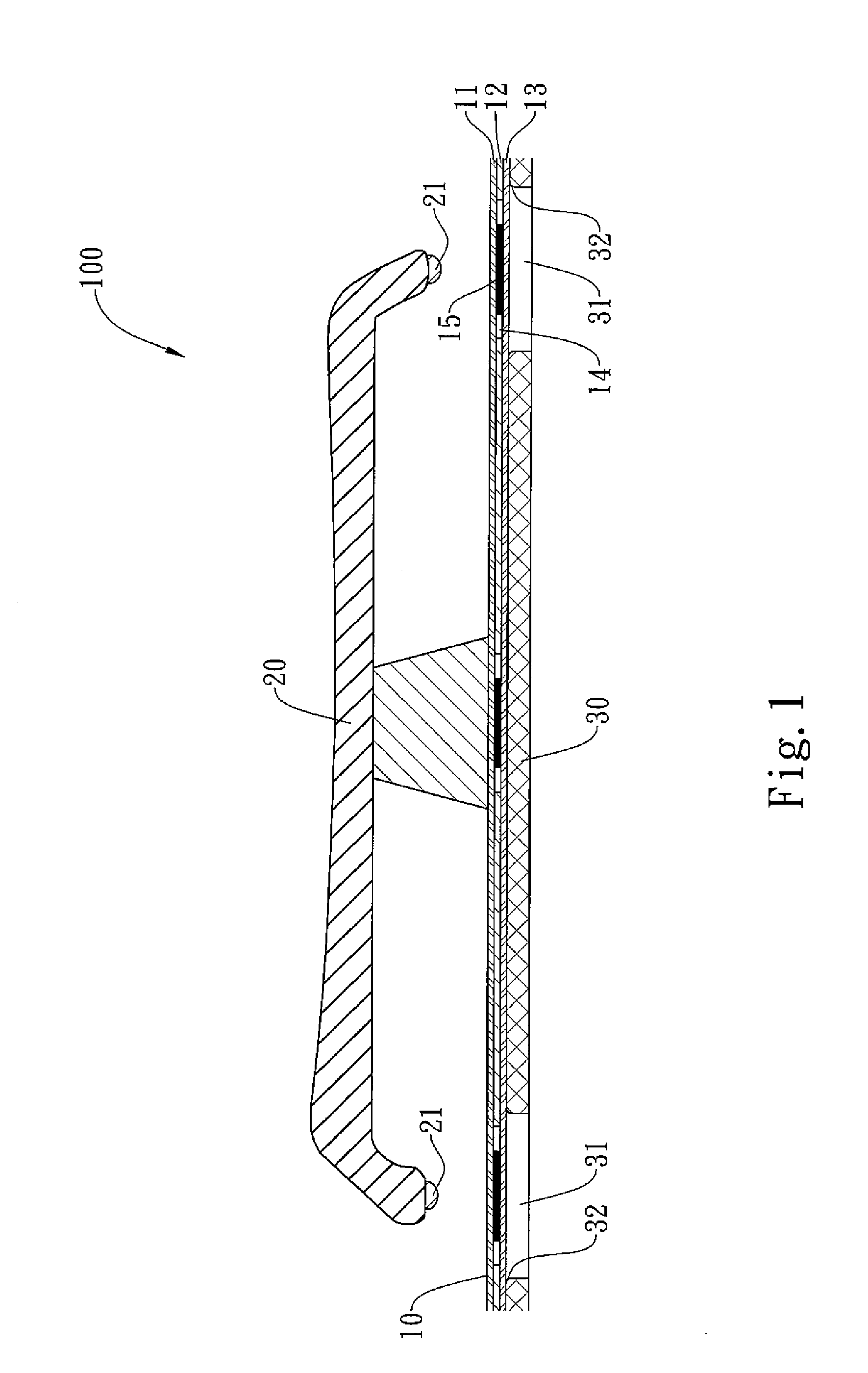

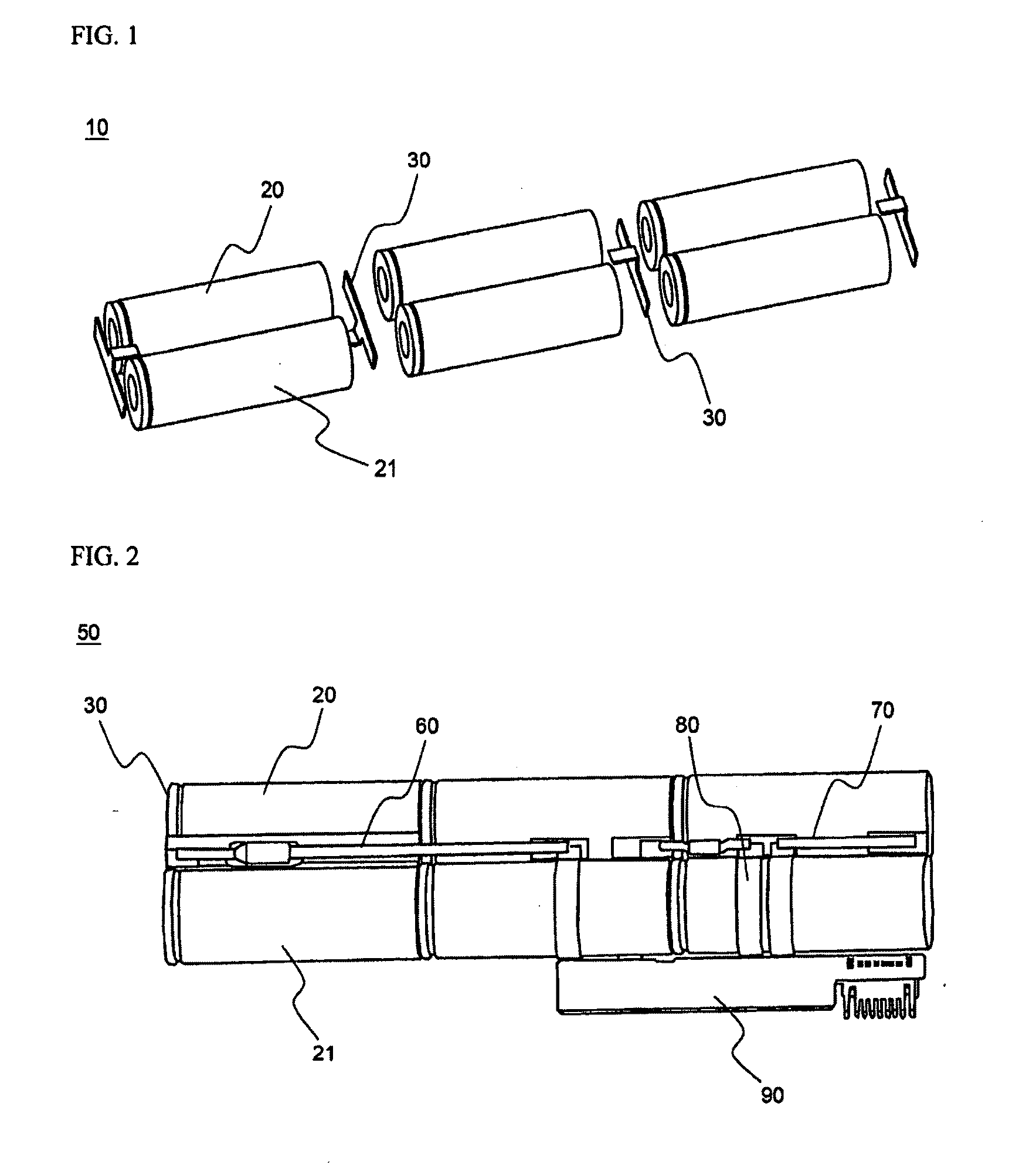

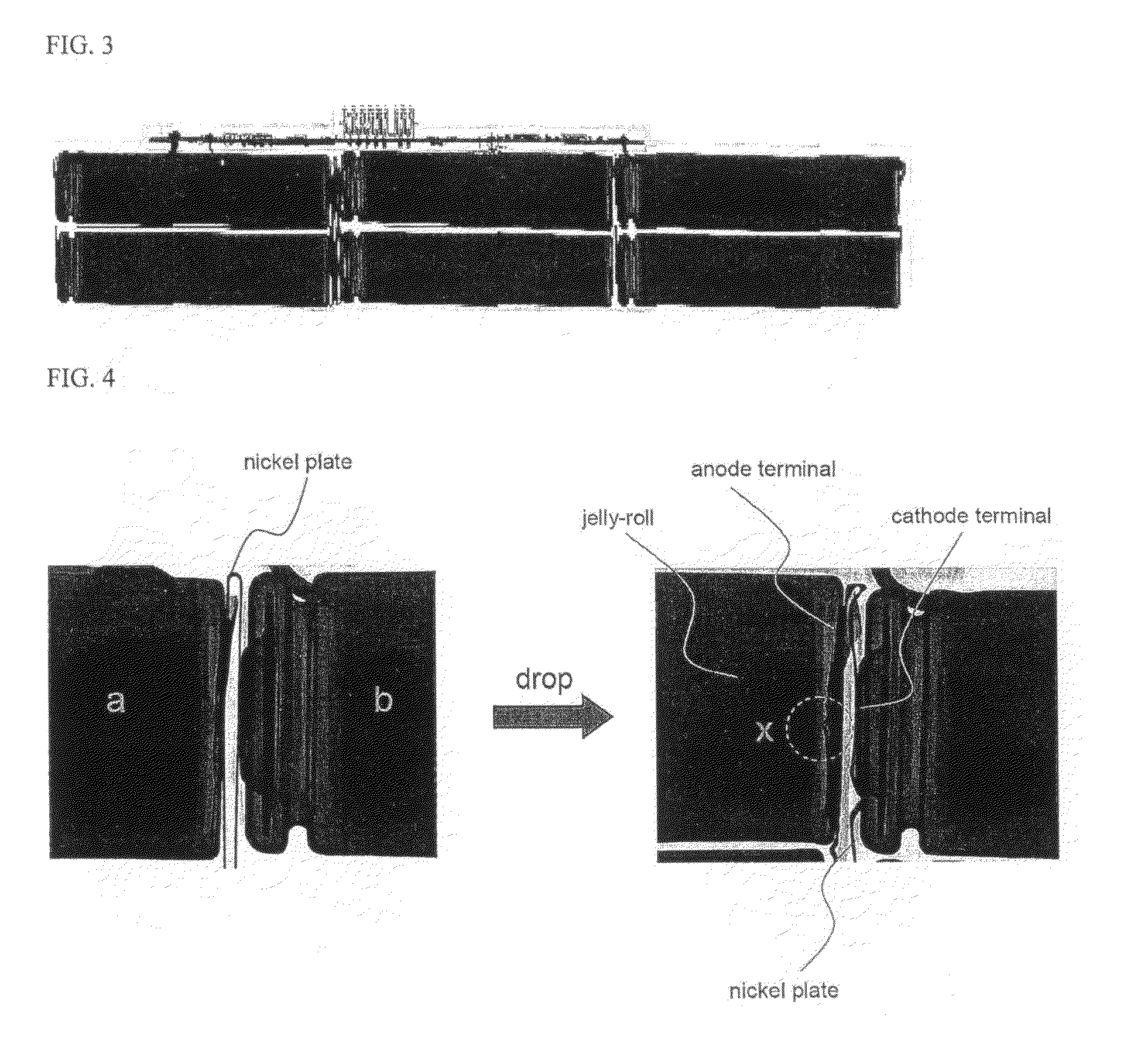

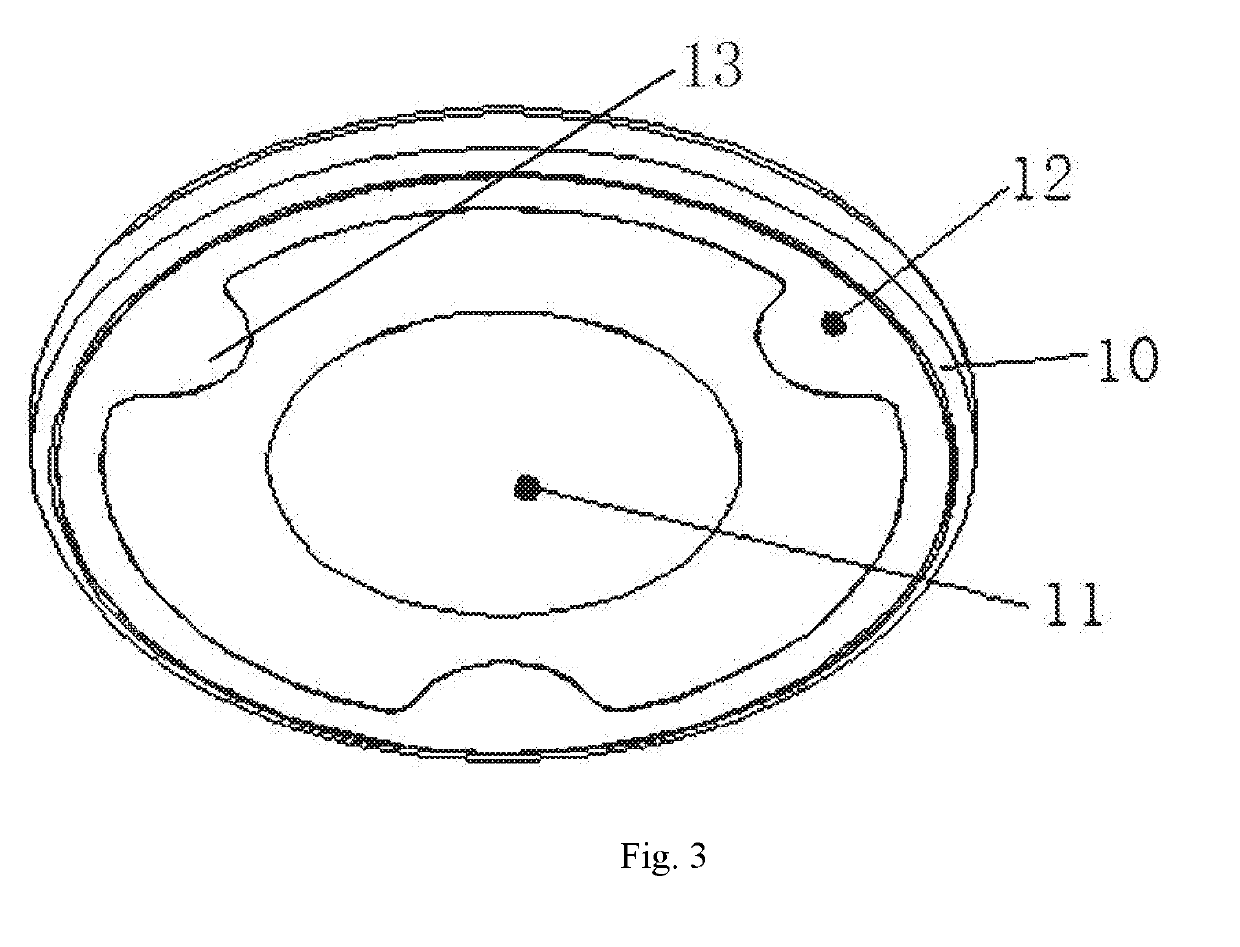

Electrical connecting member for secondary battery

ActiveUS20110104958A1Easy to manufactureContact areaCoupling device detailsCell component detailsElectricityElectrical connection

Disclosed herein is a connection member for secondary batteries to achieve the electrical connection in a battery pack including two or more cylindrical secondary batteries in a physical contact manner, the connection member including an outer circumferential contact part contacting an electrode terminal of a lower battery cell along the outer circumferential region of the electrode terminal of the lower battery cell, such that the outer circumferential contact part can be electrically connected to the electrode terminal of the lower battery cell in a surface contact manner, for minimizing the change of resistance at the contact region against an external force and restraining a possibility that the electrode terminal of the lower battery cell is depressed, and a central contact part contacting an electrode terminal of an upper battery cell or the central region of a sidewall of the battery pack for providing an elastic contact force to the entire connection member mounted between the electrode terminals of the respective battery cells or between the electrode terminals of the battery cells and the sidewall of the battery pack.

Owner:LG ENERGY SOLUTION LTD

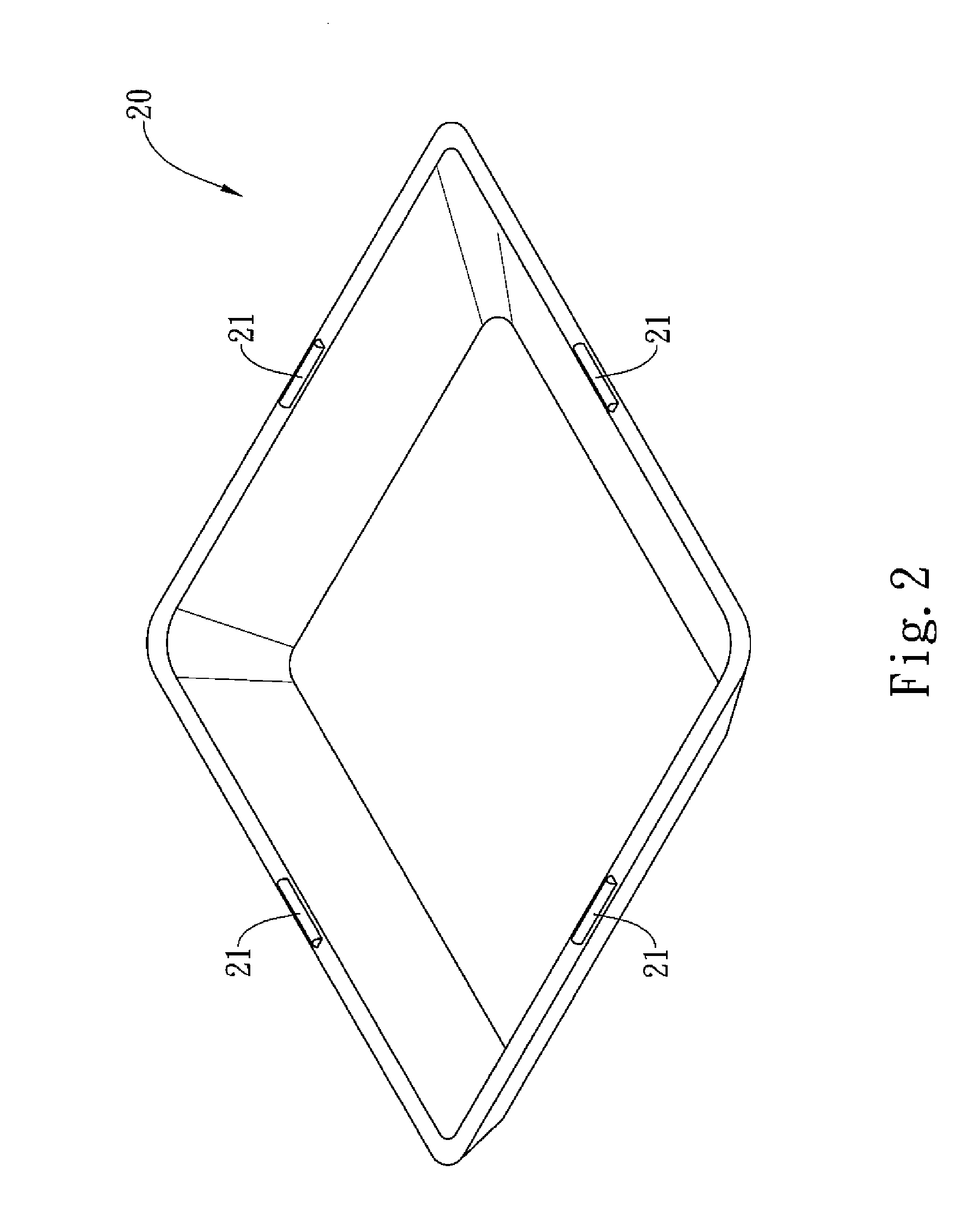

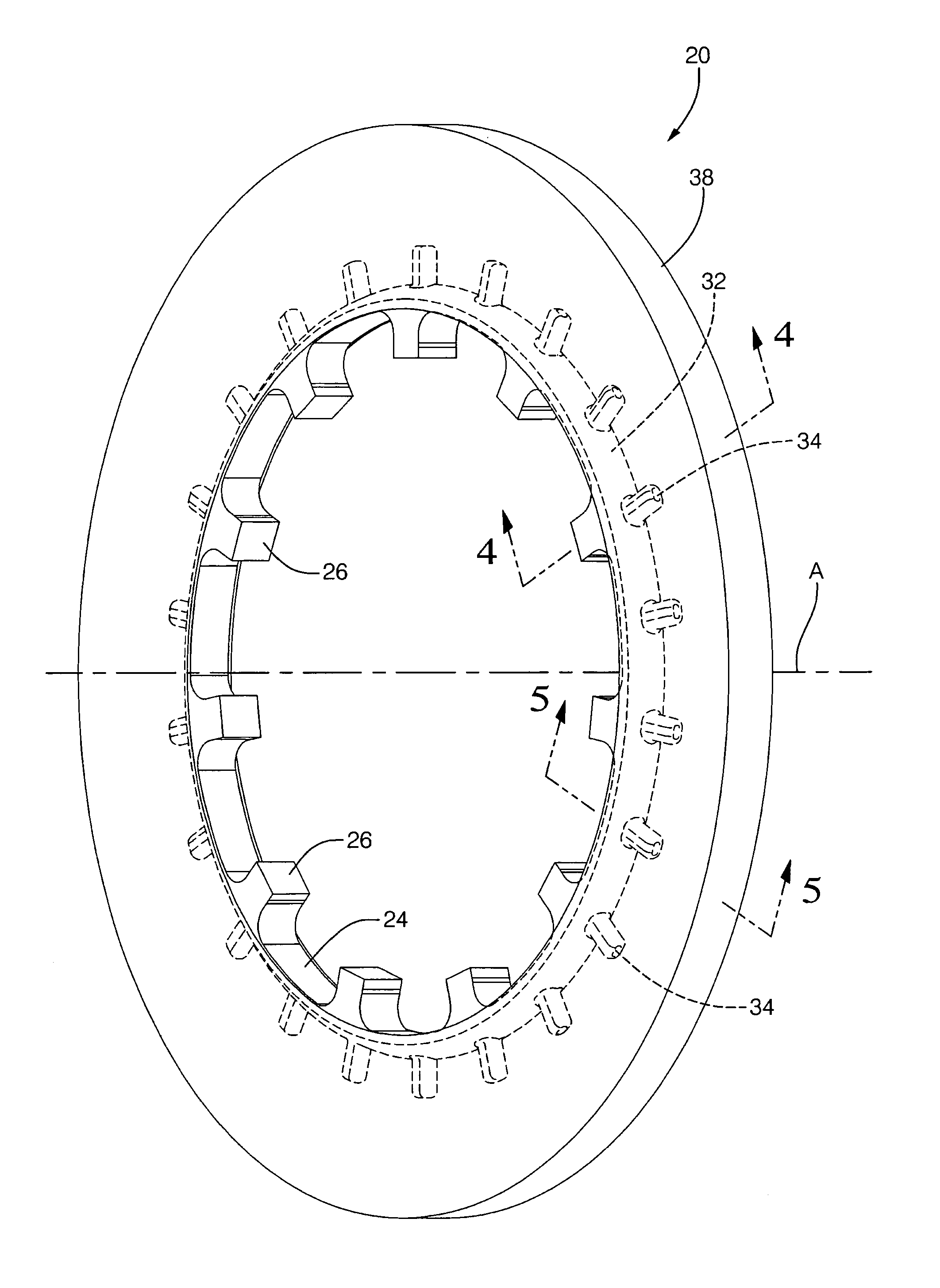

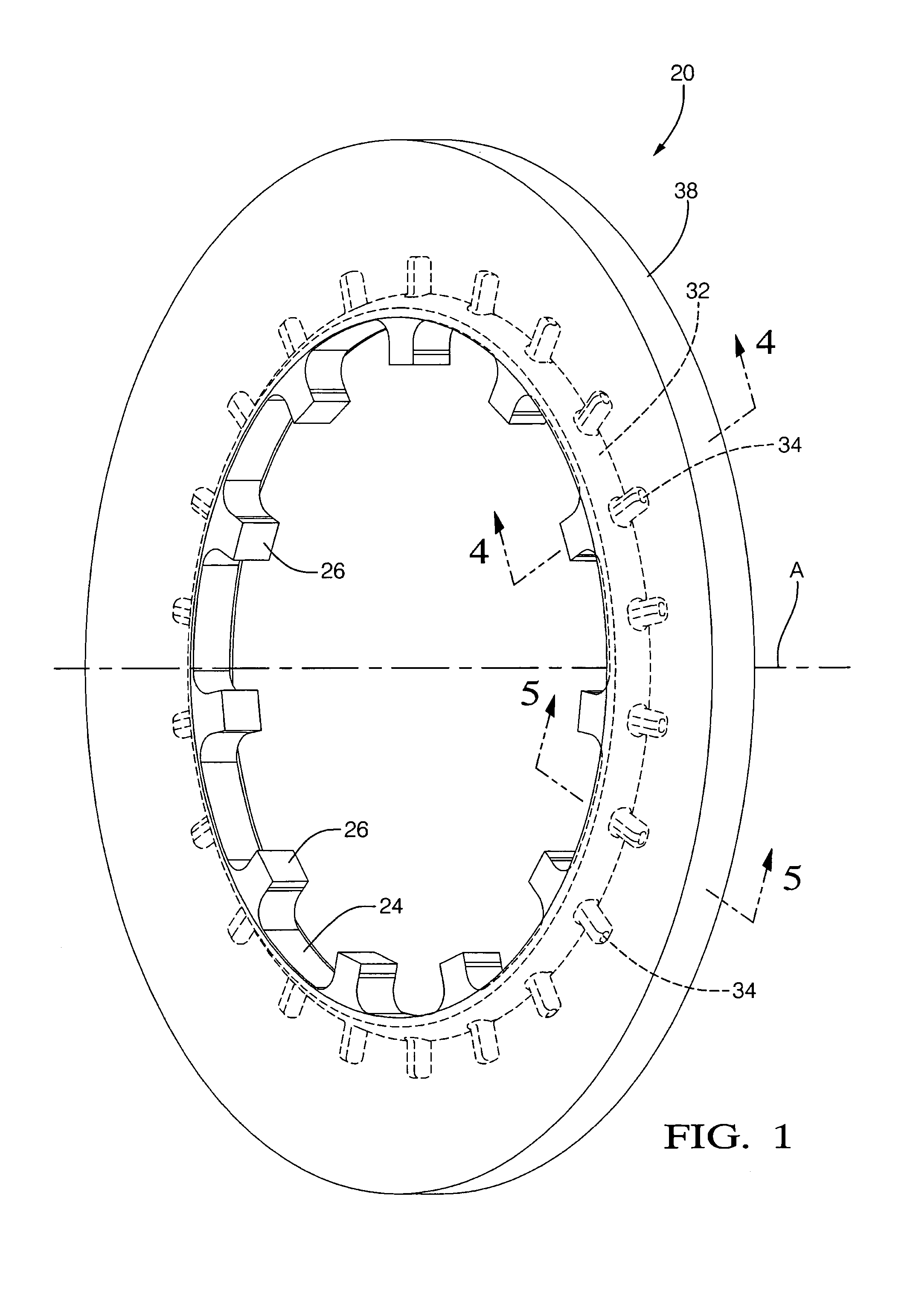

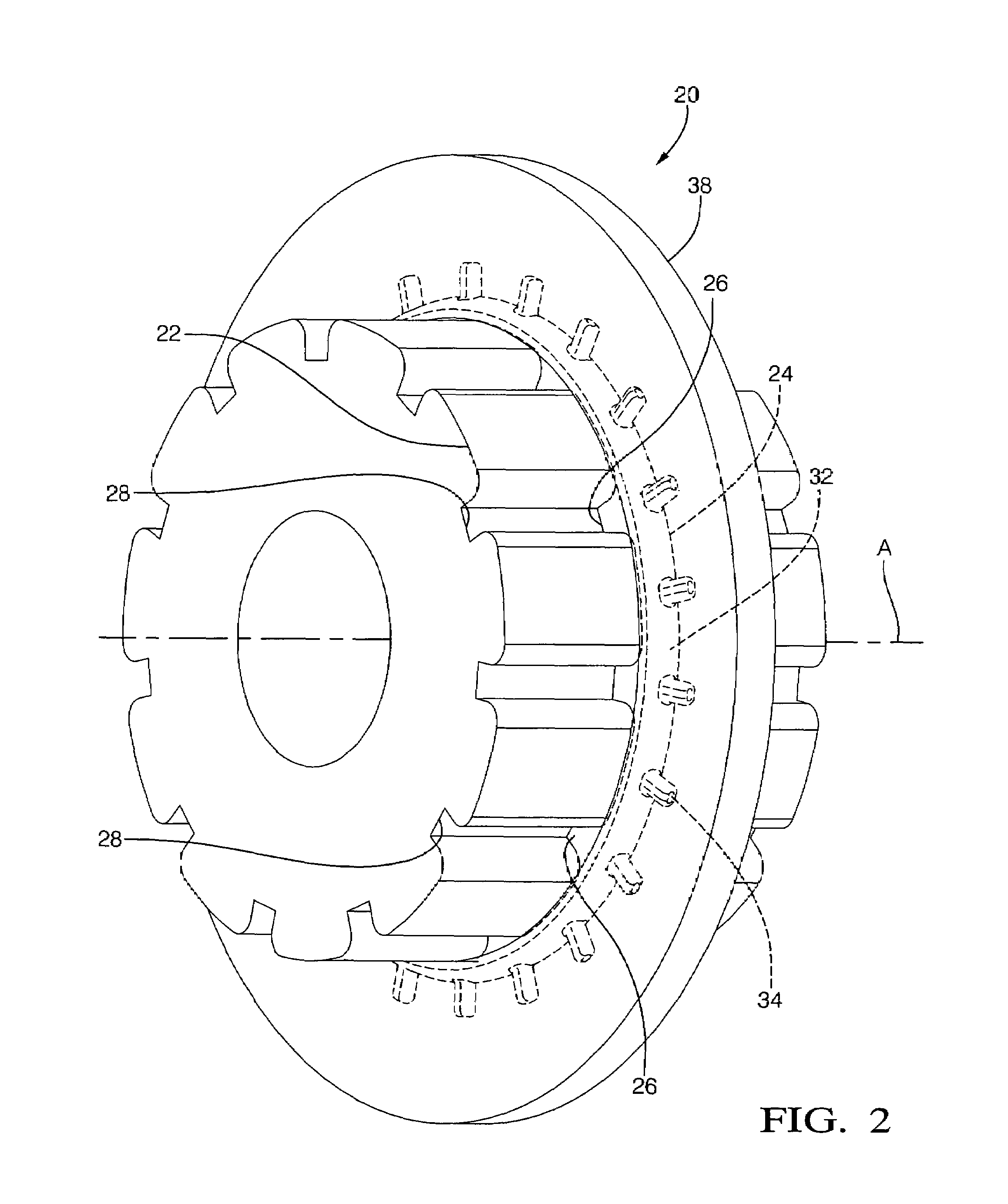

Brake rotor assembly

A brake rotor assembly for a dual brake disc braking system includes an annular ring having a plurality of teeth. The teeth are disposed radially about a central axis of the annular ring, and extend inward toward the central axis. The teeth are for slideably engaging a hub (wheel end) having a plurality of channels. The annular ring includes a plurality of pins extending outwardly from the annular ring. A friction disc is disposed radially about the annular ring, and is in interlocking engagement with the plurality of pins. The annular ring and the plurality of teeth are integrally cast from a high strength corrosion resistant material having a tensile strength greater than 260 megapascals to resist fracture during high stress braking conditions and high thermal loads. The friction disc is cast around the annular ring from a grey cast iron.

Owner:BWI CO LTD SA

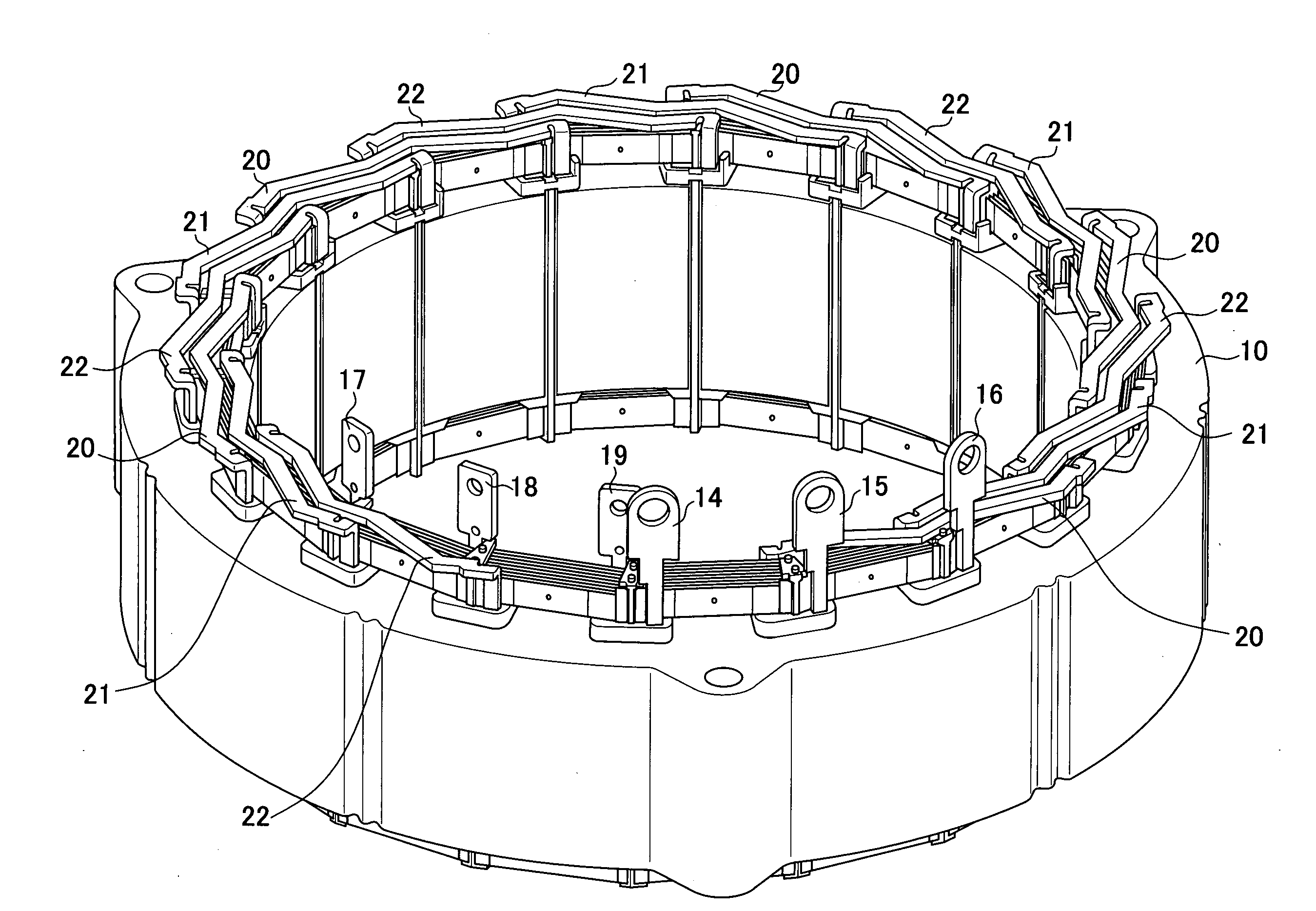

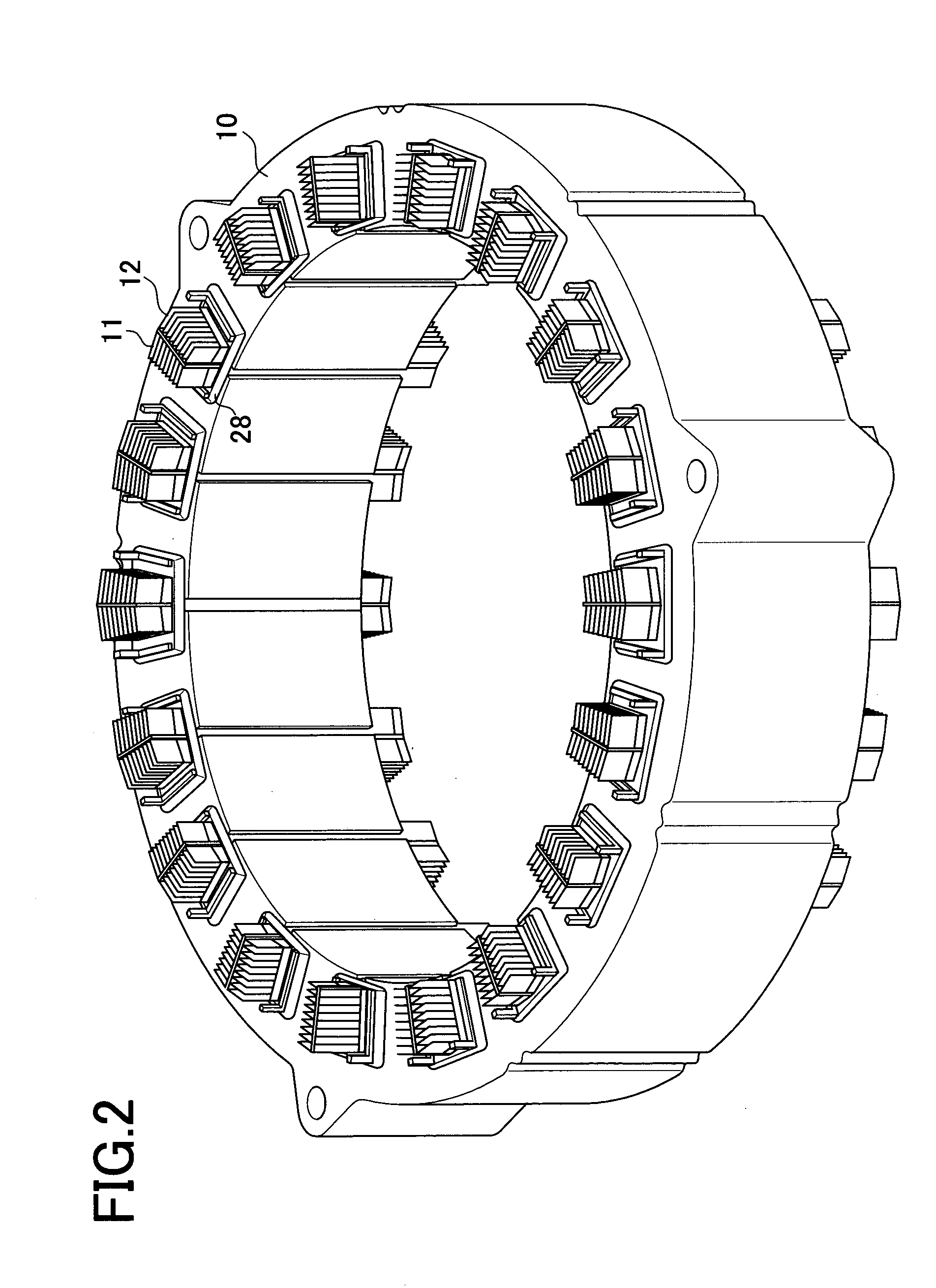

Motor stator and motor stator manufacturing method

InactiveUS20090230808A1Reduce contact resistanceIncrease the areaWindings insulation shape/form/constructionSynchronous machinesElectrical conductorEngineering

A stator for motor comprises a stator core formed with a plurality of slots in an inner periphery thereof, a plurality of first laminated conductors each including a plurality of laminated thin plates in each slot, a plurality of second laminated conductors each including a plurality of laminated thin plates inserted in each slot, and an end connecting conductor including a plurality of connecting thin plates each having a connecting portion for connecting an end portion of each laminated thin plate of the first laminated conductor in one slot and an end portion of each laminated thin plate of the second laminated conductor in another slot. The thin plates and the connecting portion of each connecting plate are tapered in thickness.

Owner:TOYOTA JIDOSHA KK

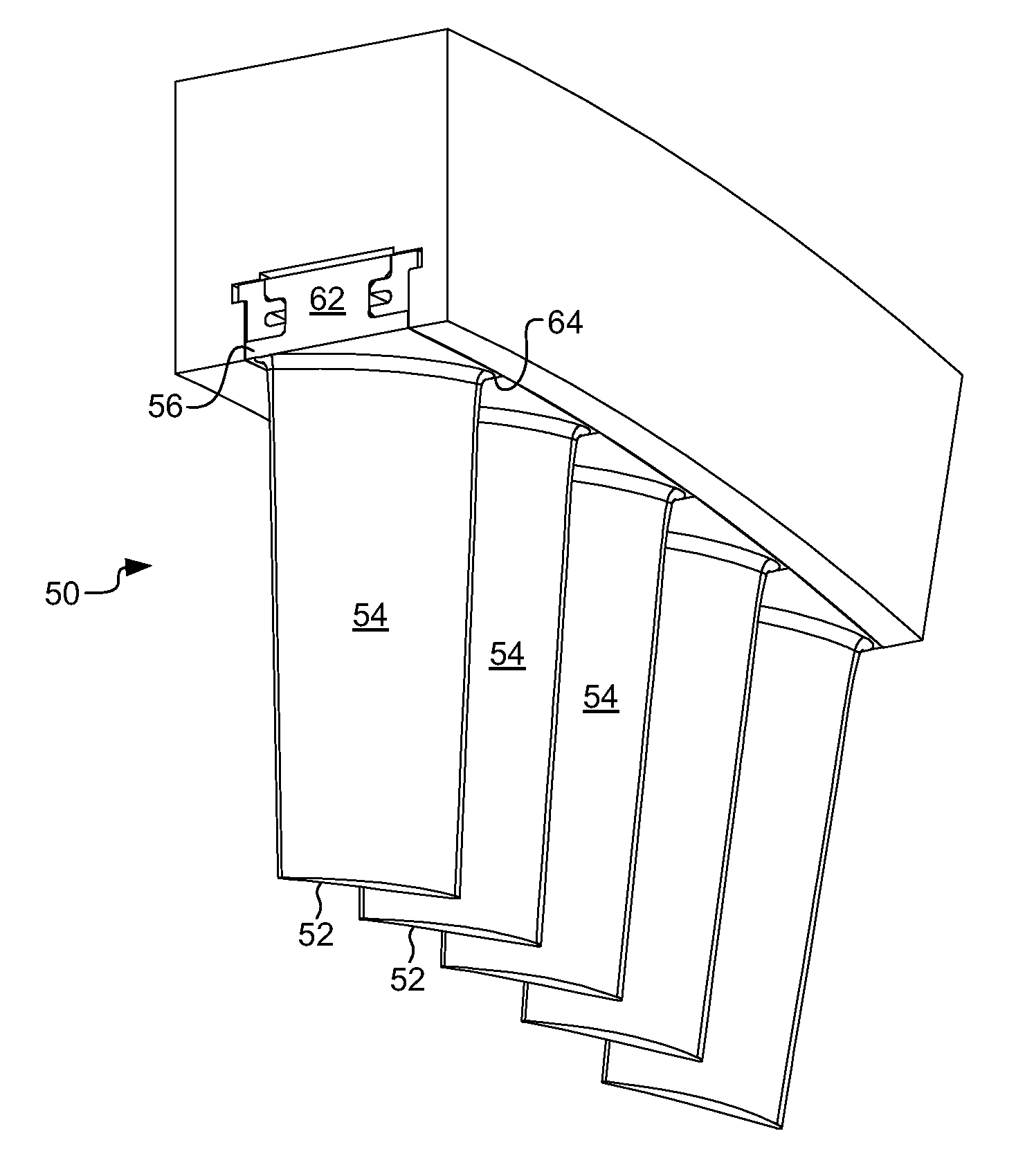

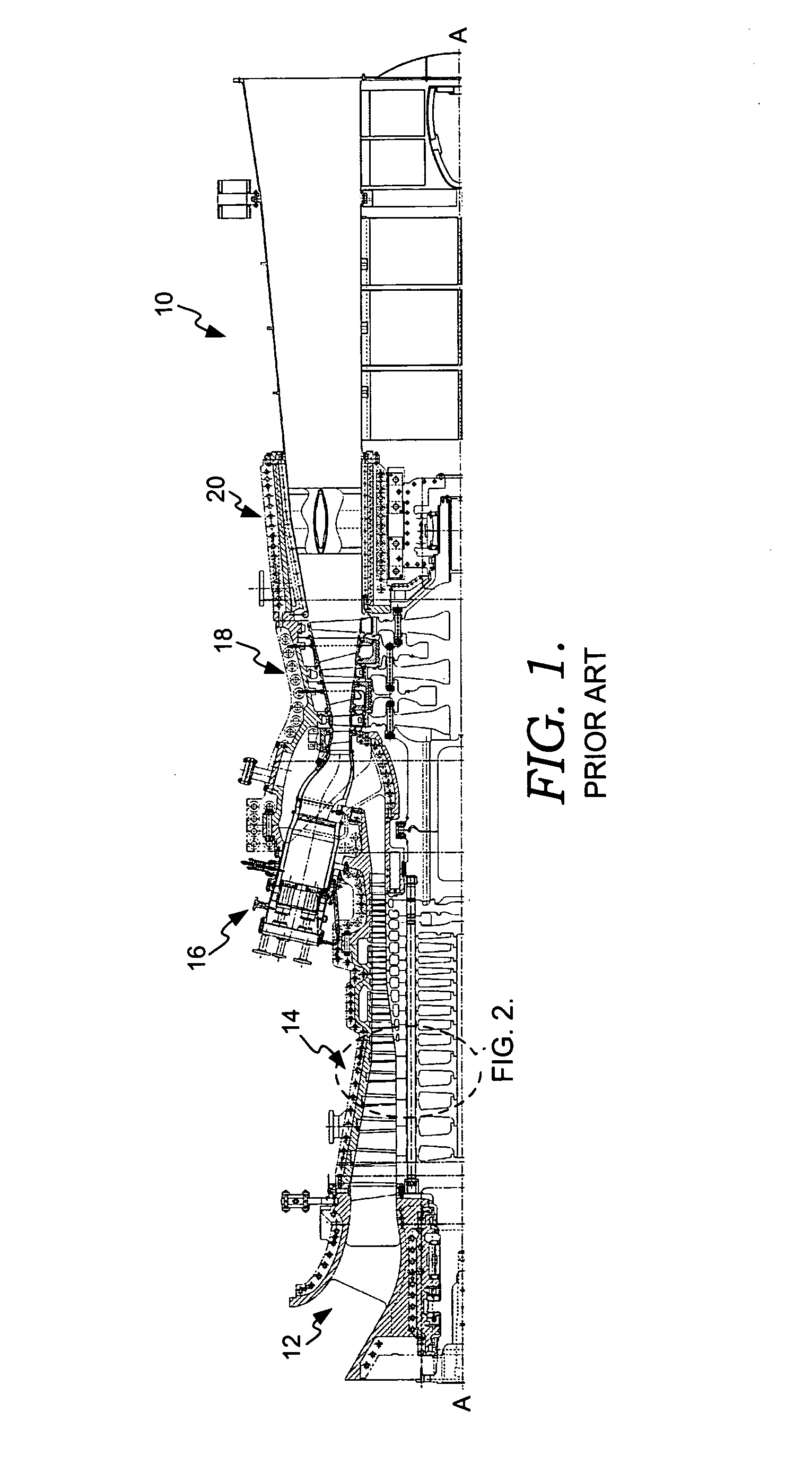

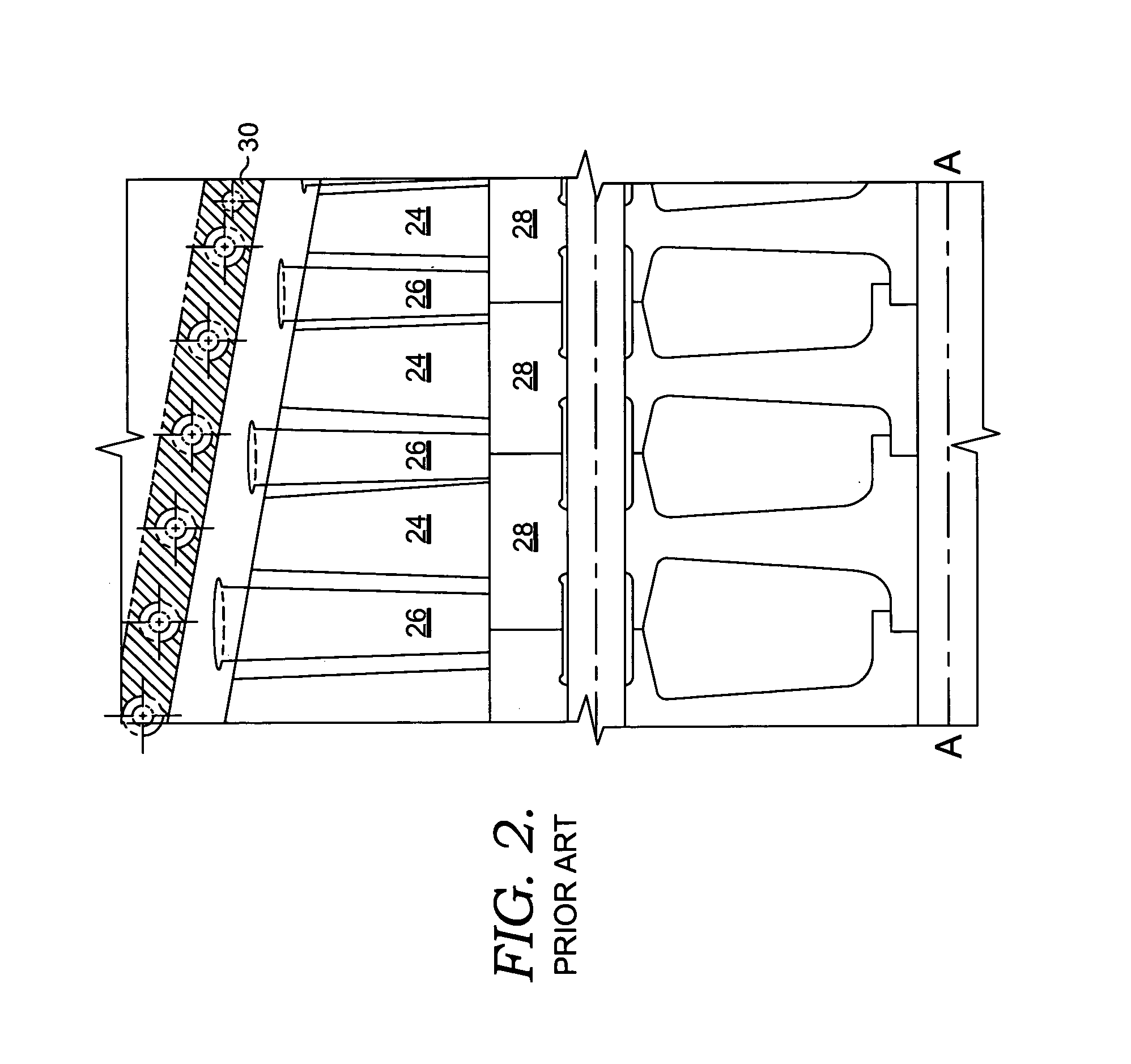

Hook ring segment for a compressor vane

ActiveUS7618234B2Contact areaIncrease contact areaPump componentsReaction enginesEngineeringGas turbines

Owner:ANSALDO ENERGIA SWITZERLAND AG

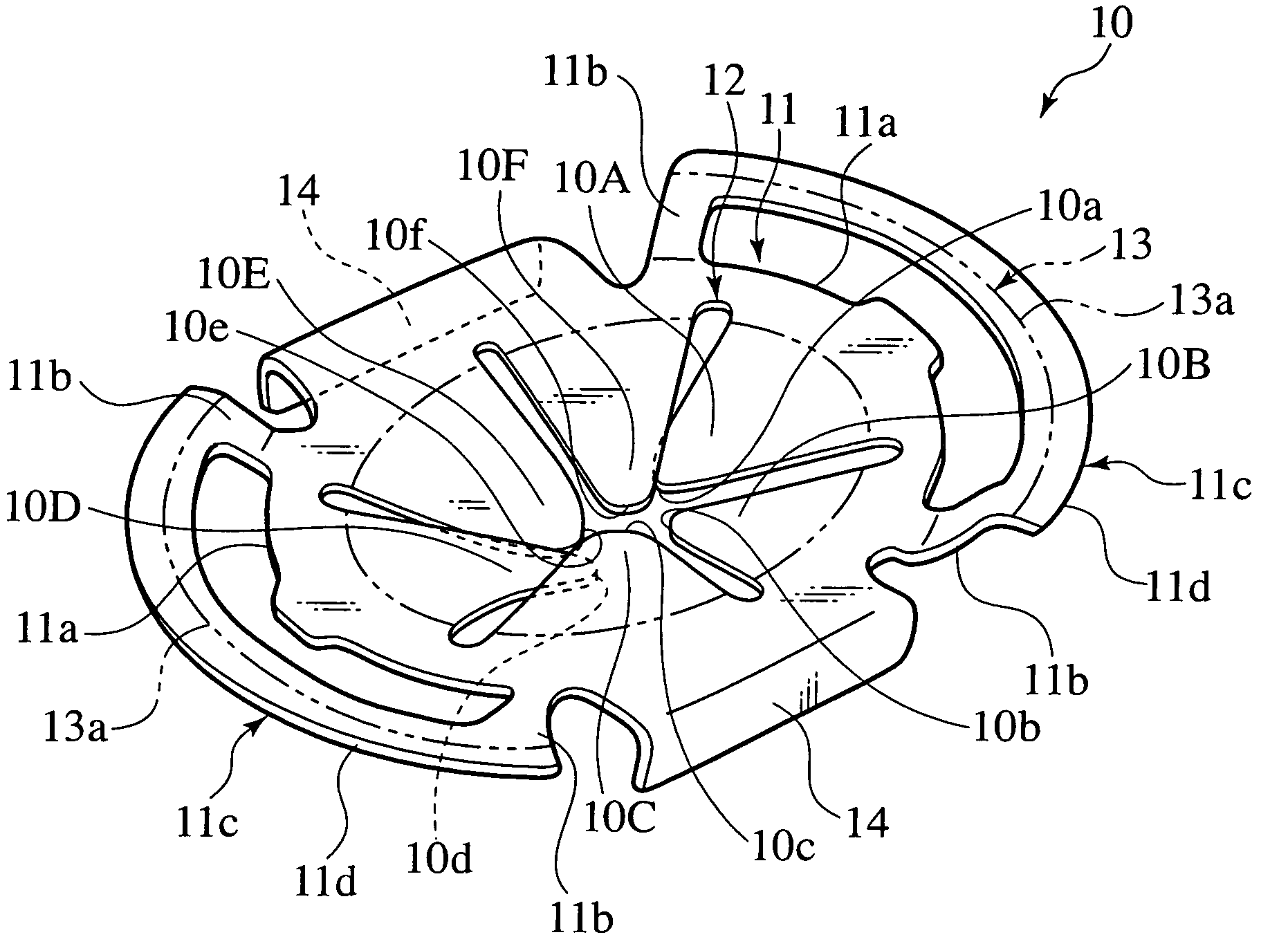

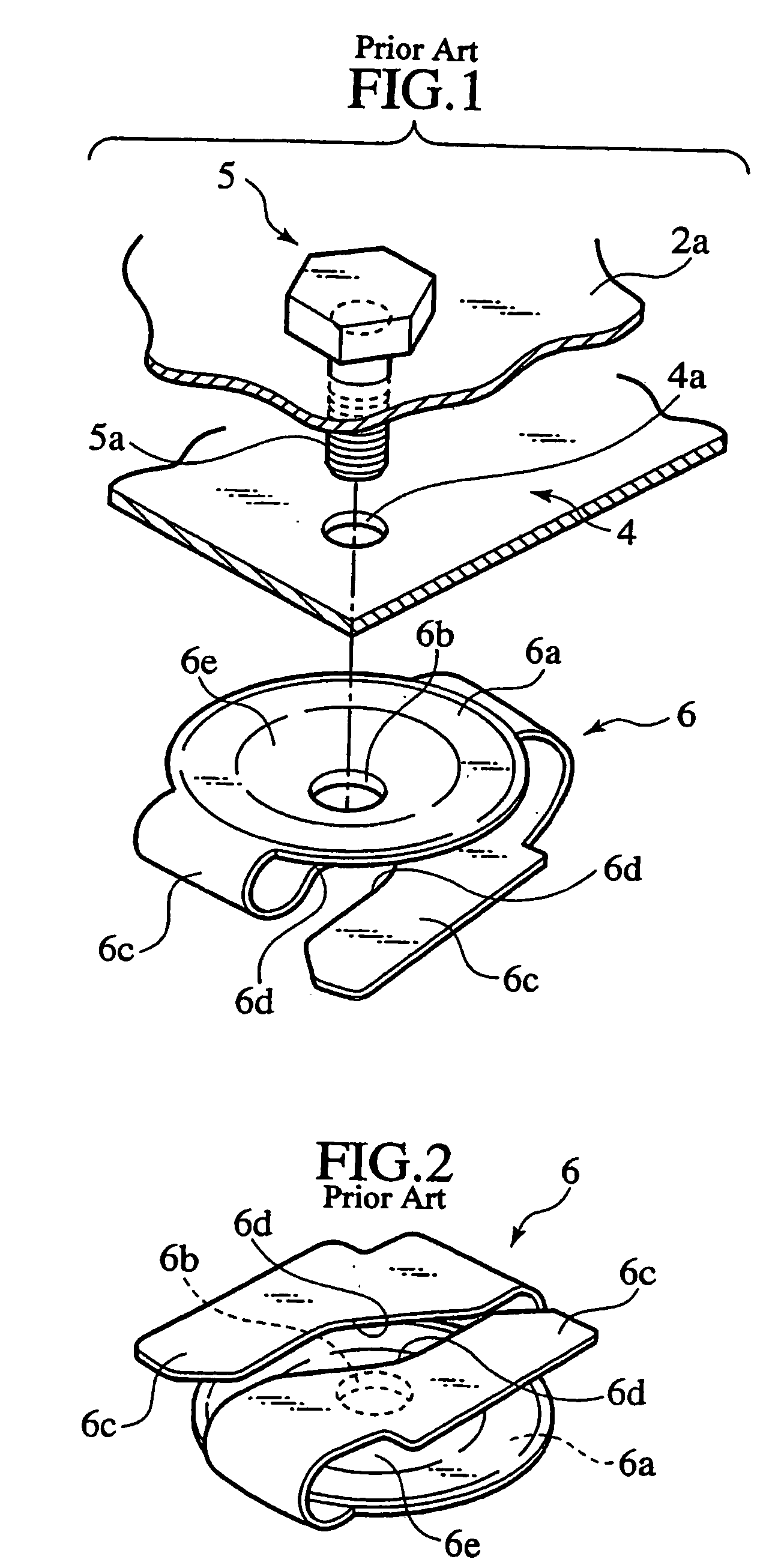

Attachment clip and attachment structure using same

An attachment clip 10 is provided to attach a heat shielding plate 4 to an under-panel 2. The under-panel 2 has a bolt 5 projecting from a floor tunnel 2a. The heat shielding plate 4 has a bolt hole 4a formed to allow passage of a shank 5a of the bolt 5. The attachment clip 10 has a clip body 11 having an abutting part 13 for abutment on the heat shielding plate 4. The abutting part 13 has a shank hole 12 for passage of the shank 5a of the bolt 5. The attachment clip 10 further includes six engagement claws 10A–10F projecting from the inner periphery of the clip body 11 inwardly. The engagement claws 10A–10F have respective engagement tips 10a–10f formed to depart from the clip body 11 along the axial direction of the attachment chip 10, providing a substantial cone-shaped configuration. The engagement claws 10A–10F elastically engage with threads of the shank 5a while urging the heat shielding plate 4 toward the under-panel 2 along the axial direction of the bolt 5.

Owner:NISSAN MOTOR CO LTD

Rotary cutting bit having spark suppression sleeve

InactiveUS7172256B2Reduction tendencyReduce the possibilityDust removalFire preventionMechanical engineeringDrill bit

Owner:SANDVIK INTELLECTUAL PROPERTY AB

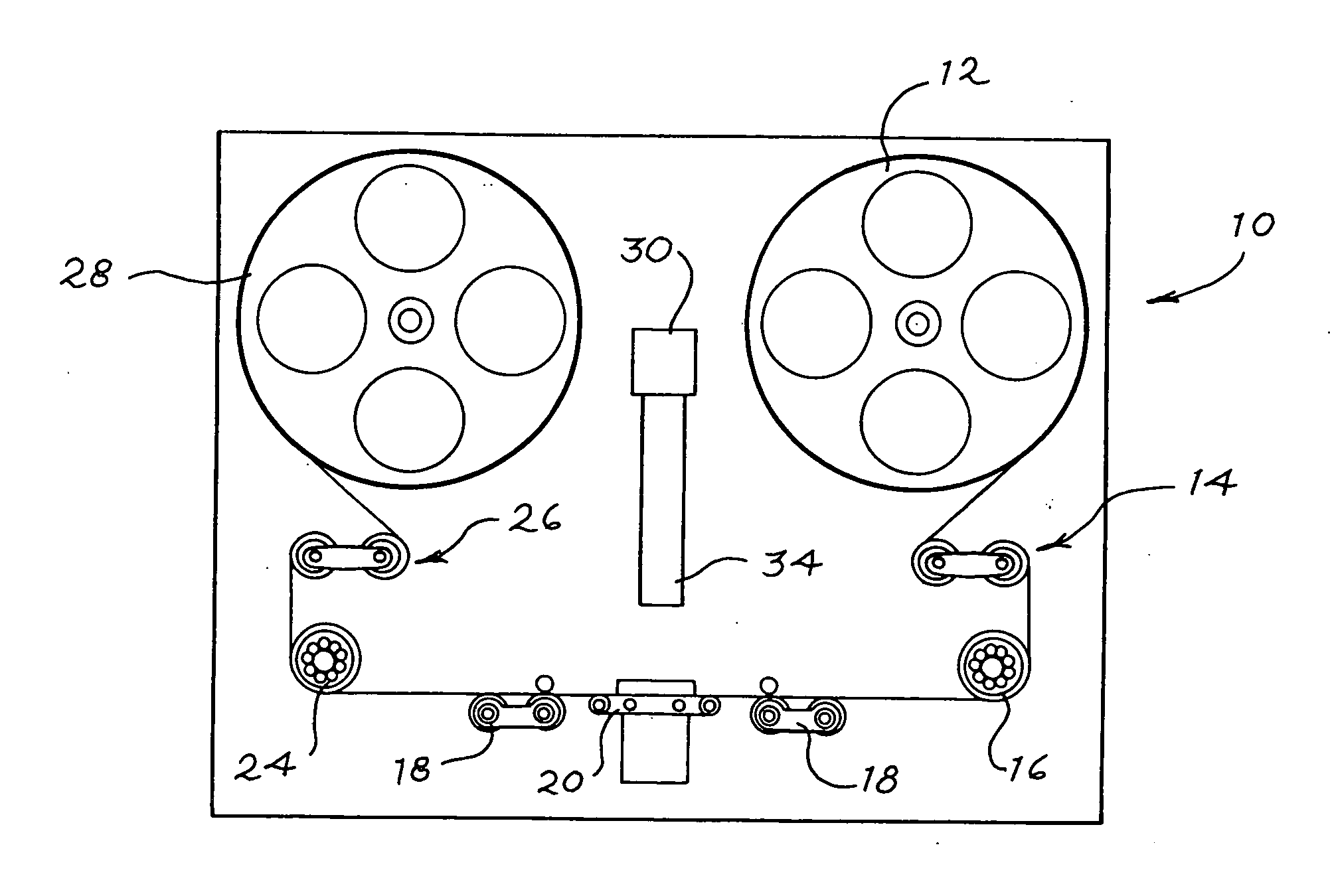

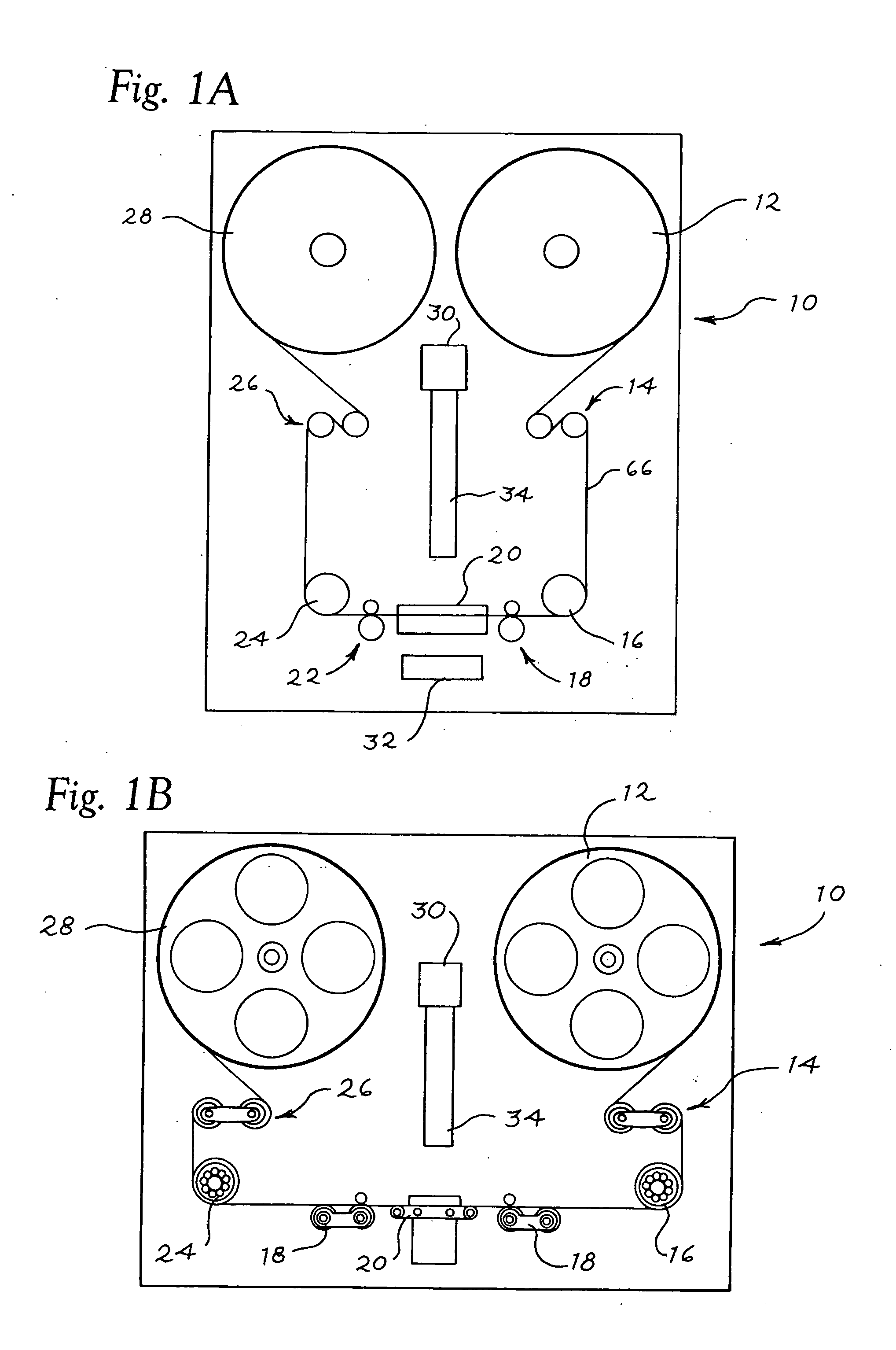

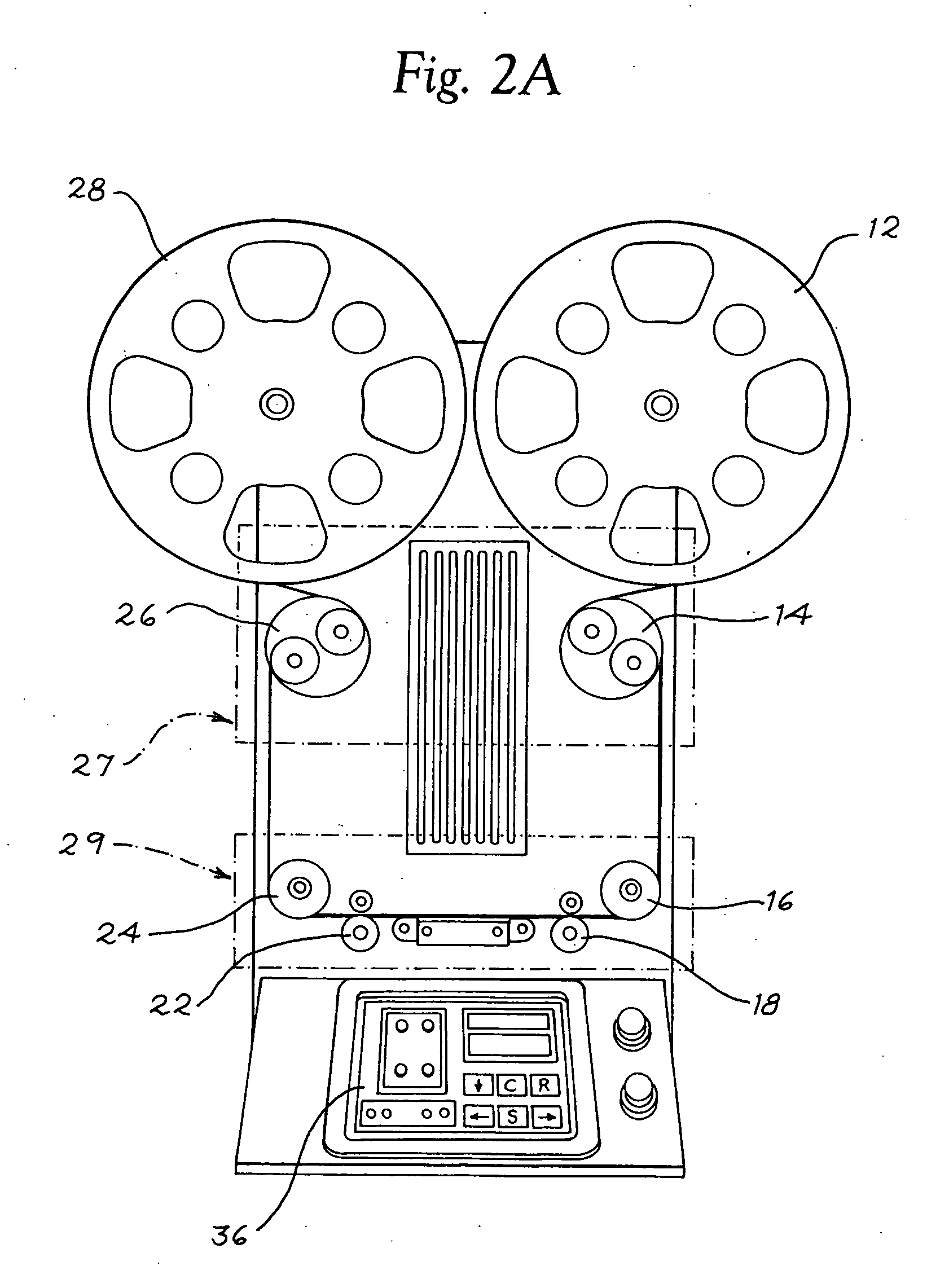

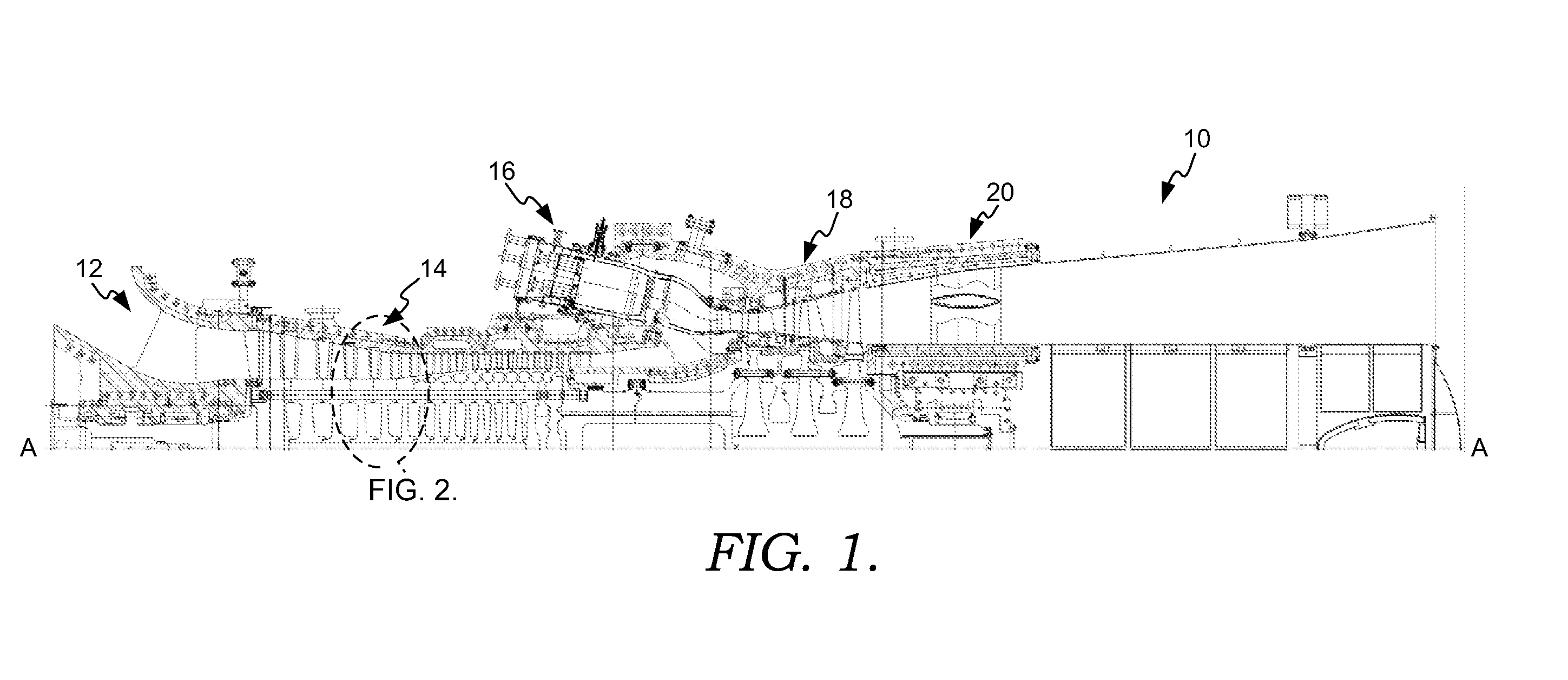

Method and apparatus for continuous motion film scanning

ActiveUS20130076890A1Facilitates high resolution digital duplicationSignificant informationTelevision system detailsTelevision system scanning detailsFilm-outDigital image

A continuous film scanning system for high resolution digital archival and duplication of motion picture film on a frame by frame basis. Film is driven through the film scanning system through the use of rollers and maintained at a consistent tension throughout the scanning process. Optical interrogation of the perforations associated with each film frame is used to trigger digital image capture. The continuous film scanning system is particularly well adapted to safely handle imperfect or damaged film stock.

Owner:REFLEX TECH

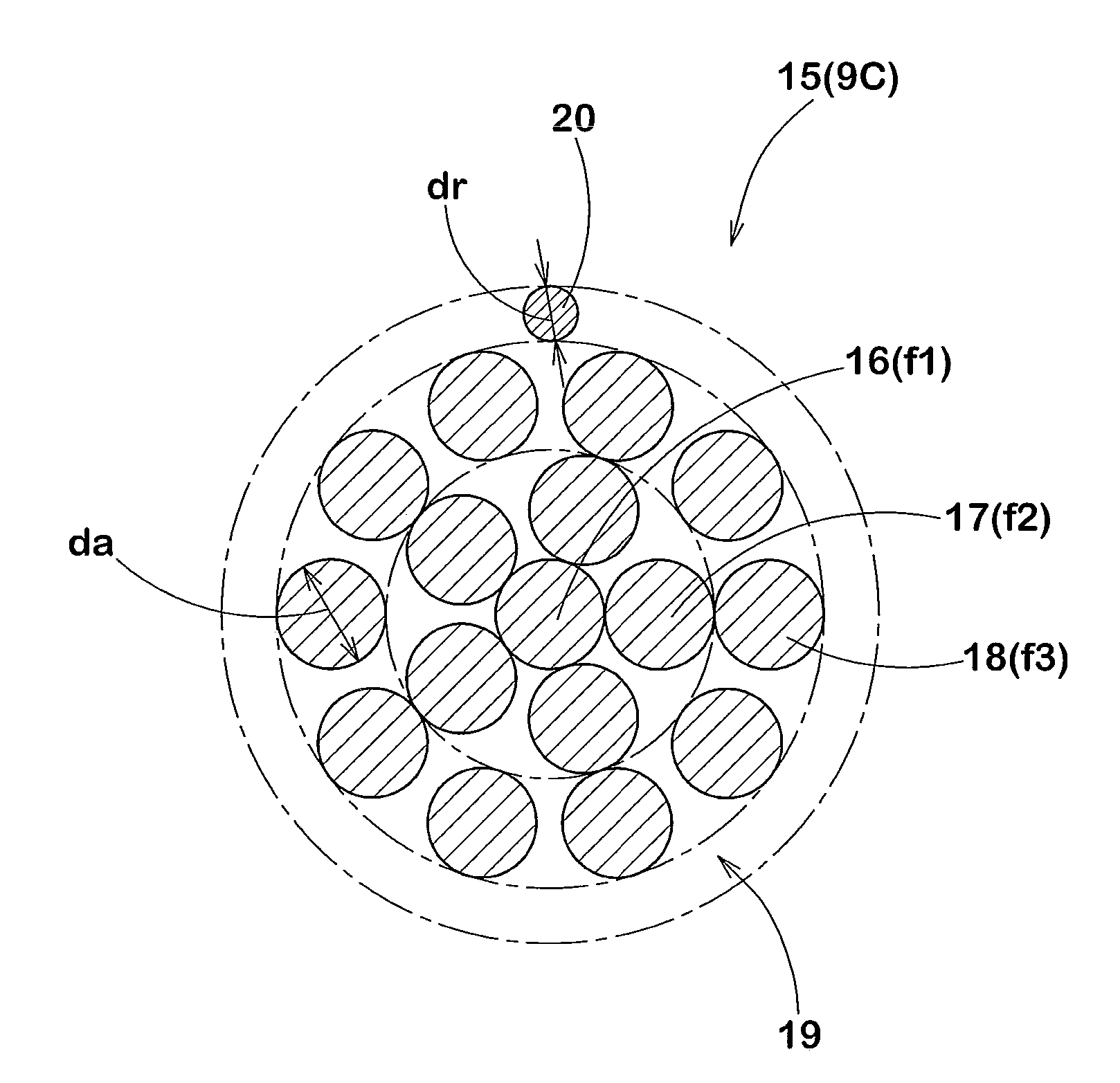

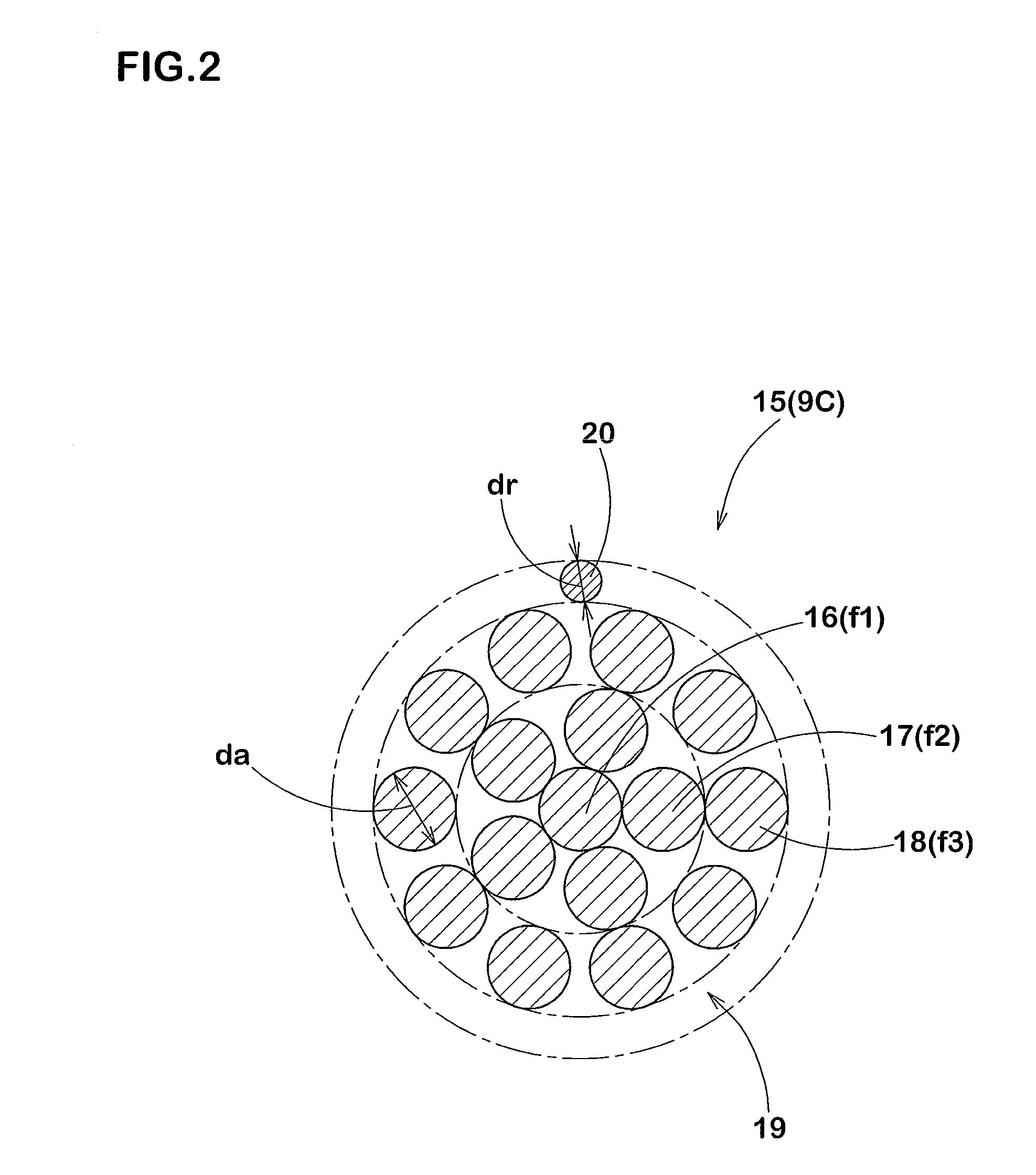

Steel cord for tire and pneumatic tire using the steel cord

InactiveUS20100300592A1Strong penetrating powerLow tensile strengthPneumatic tyre reinforcementsTyre beadsFrettingEngineering

It is an object of the present invention to reduce fretting between strands in a steel cord, to suppress reduction in cord strength caused by running, to enhance rubber penetrability, and to improve tire durability. The steel cord includes a cord main portion 19 of a triple layer-stranding structure including: a core 16 formed from one core strand f1, an inner sheath 17 including N (2 to 5) inner sheath strands f2 stranded with a stranding pitch Pi around the core; and outer sheath 18 formed from M (6 to 11) outer sheath strands f3 stranded with a stranding pitch Po around the inner sheath. Diameters of the strands f1, f2 and f3 are equal to each other, and stranding directions of the sheaths 17 and 18 are the same. A difference (|Ai−Ao|) between a stranding angle Ai of the inner sheath strand f2 and a stranding angle Ao of the outer sheath strand f3 is greater than 1° and smaller than 3°.

Owner:SUMITOMO RUBBER IND LTD

Positive electrode active material for lithium ion secondary battery, and positive electrode for lithium ion secondary battery and lithium ion secondary battery comprising the same

ActiveUS20160099460A1Lower resistanceLarge capacitySecondary cellsPositive electrodesLithium hydroxideLithium carbonate

A positive electrode active material includes a primary particle represented by Compositional Formula (1): Li1+xNiyCozM1−x−y−zO2 (1), where x is a number satisfying a relation represented by an expression −0.12≦x≦0.2; y is a number satisfying a relation represented by an expression 0.7≦y≦0.9; z is a number satisfying a relation represented by an expression 0.05≦z≦0.3; and M is at least one element selected from the group consisting of Mg, Al, Ti, Mn, Zr, Mo, and Nb; or a secondary particle into which the primary particle aggregates. The primary particle or the secondary particle includes a free lithium compound in a weight proportion of 0.1% or more and 2.0% or less, and the weight of lithium hydroxide in the free lithium compound is 60% or less of the weight of lithium carbonate in the free lithium compound.

Owner:HITACHI METALS LTD

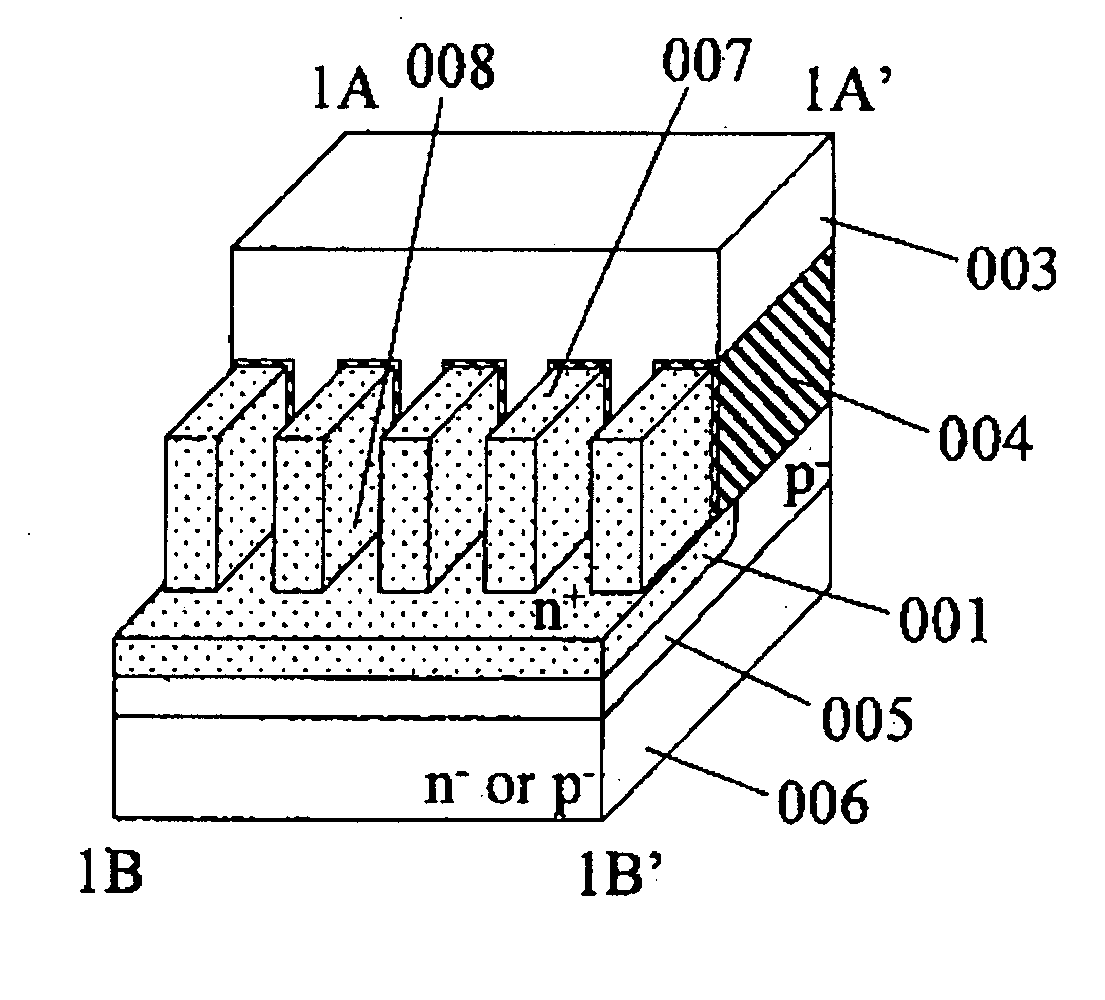

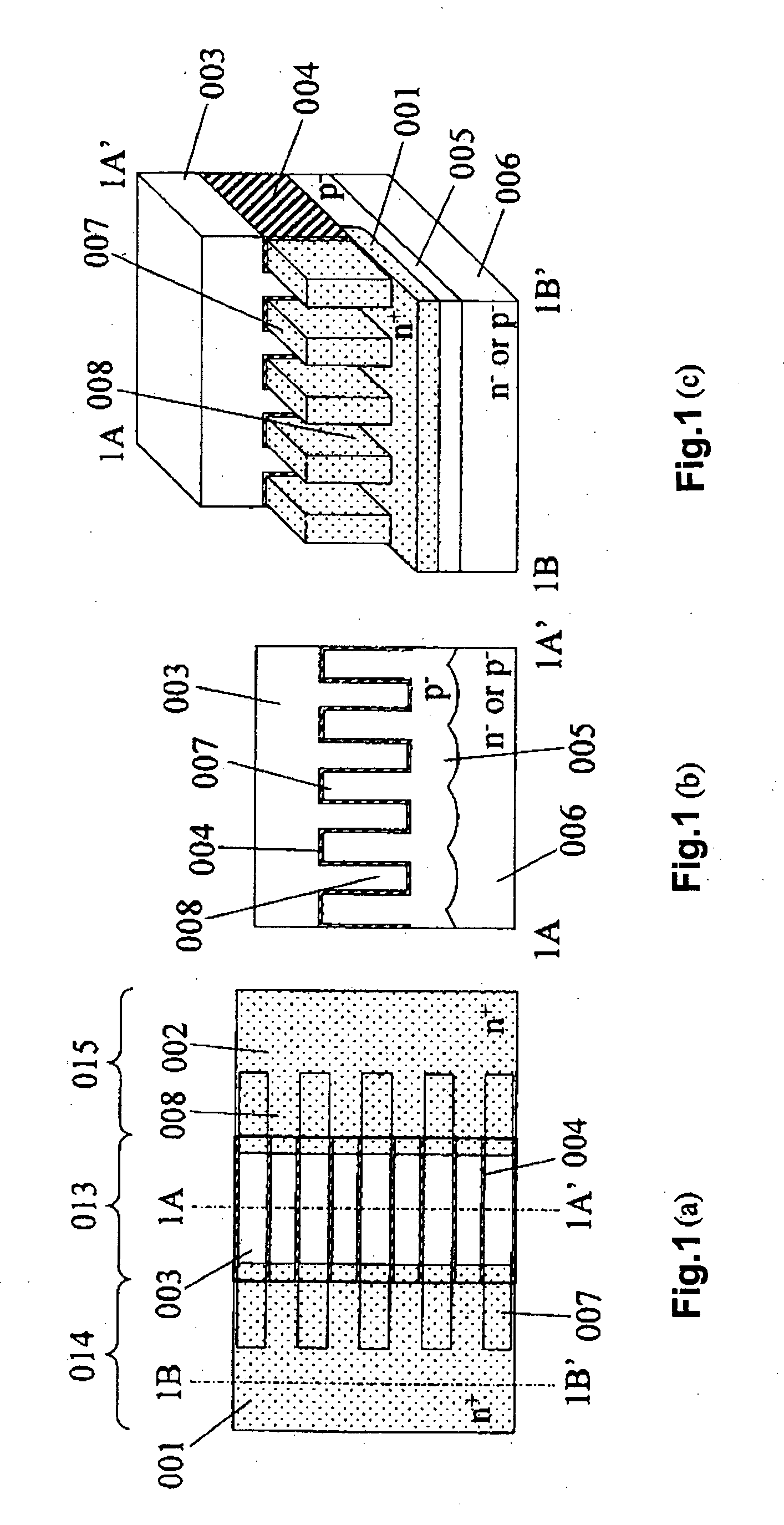

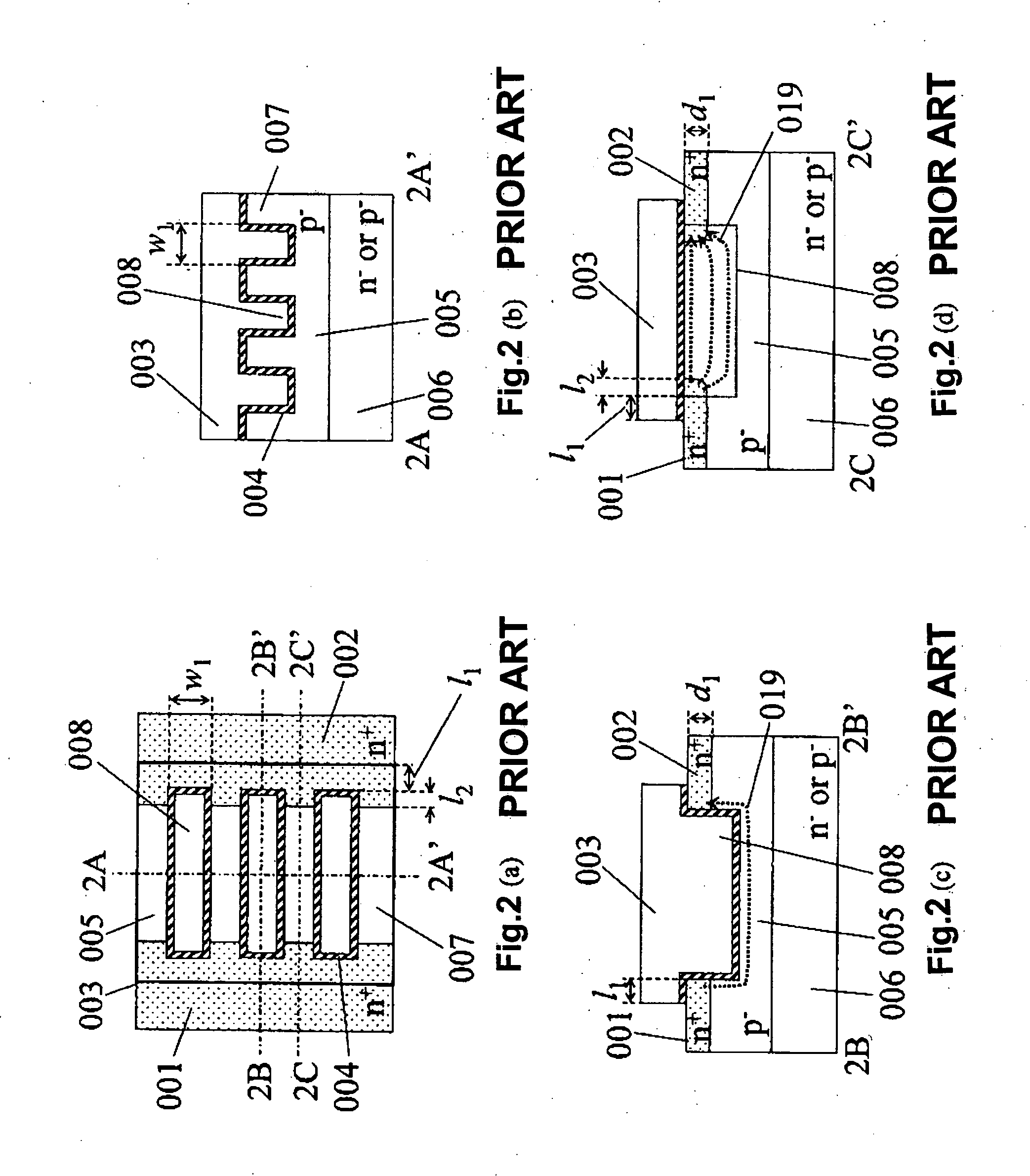

Lateral semiconductor device using trench structure and method of manufacturing the same

ActiveUS20060001085A1Lower resistanceImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

A lateral trench MOS transistor is provided in which trenches extending to the source and drain regions are disposed parallel to the gate length direction, agate oxide is disposed on the trenches, a well is disposed under the trench region and the source and drain regions by using oblique ion implantation, a gate electrode is disposed on the gate oxide, and source and drain regions are disposed on the same plane as a bottom surface of a concave portion of the trenches self-aligned to the gate electrode by using oblique ion implantation.

Owner:ABLIC INC

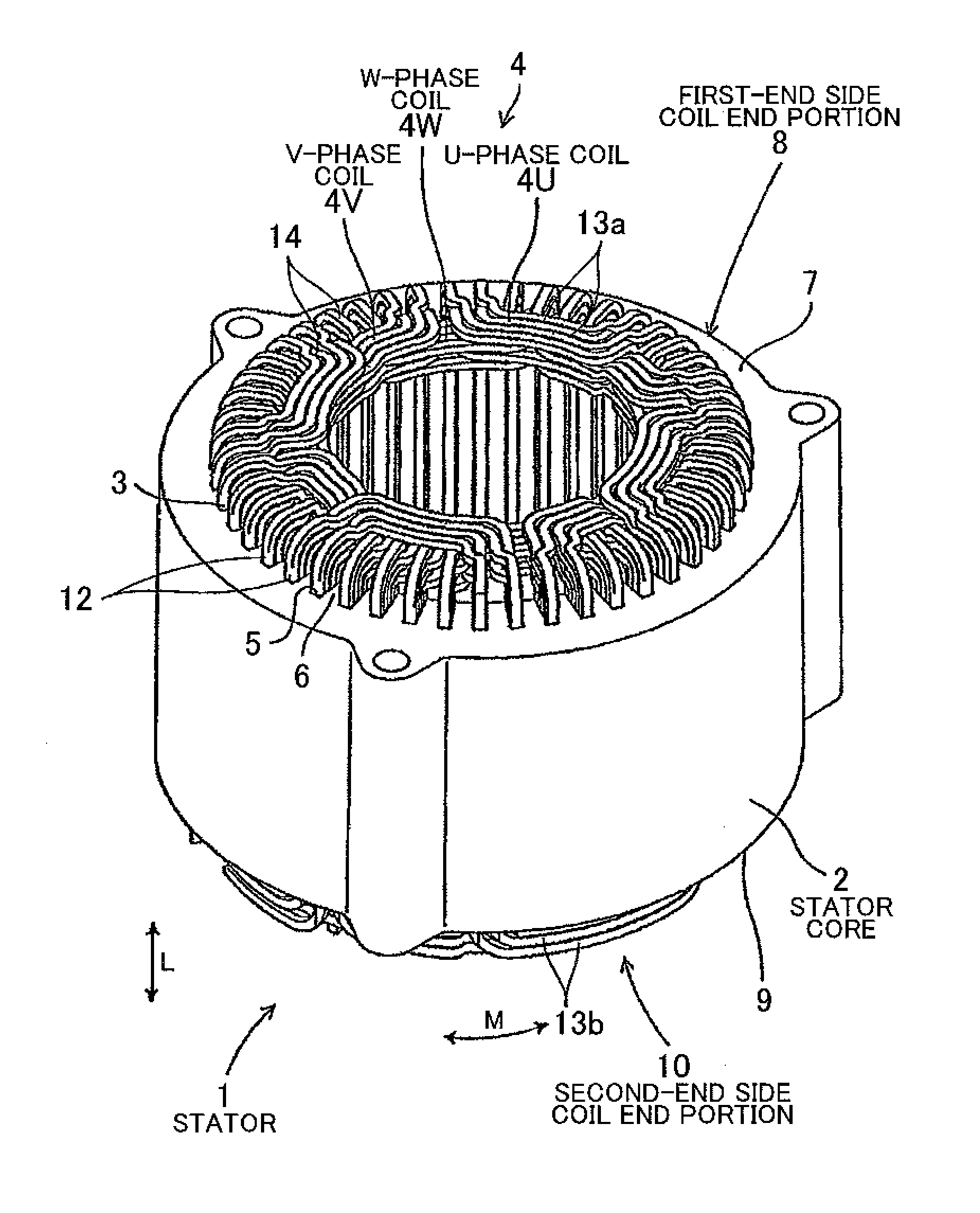

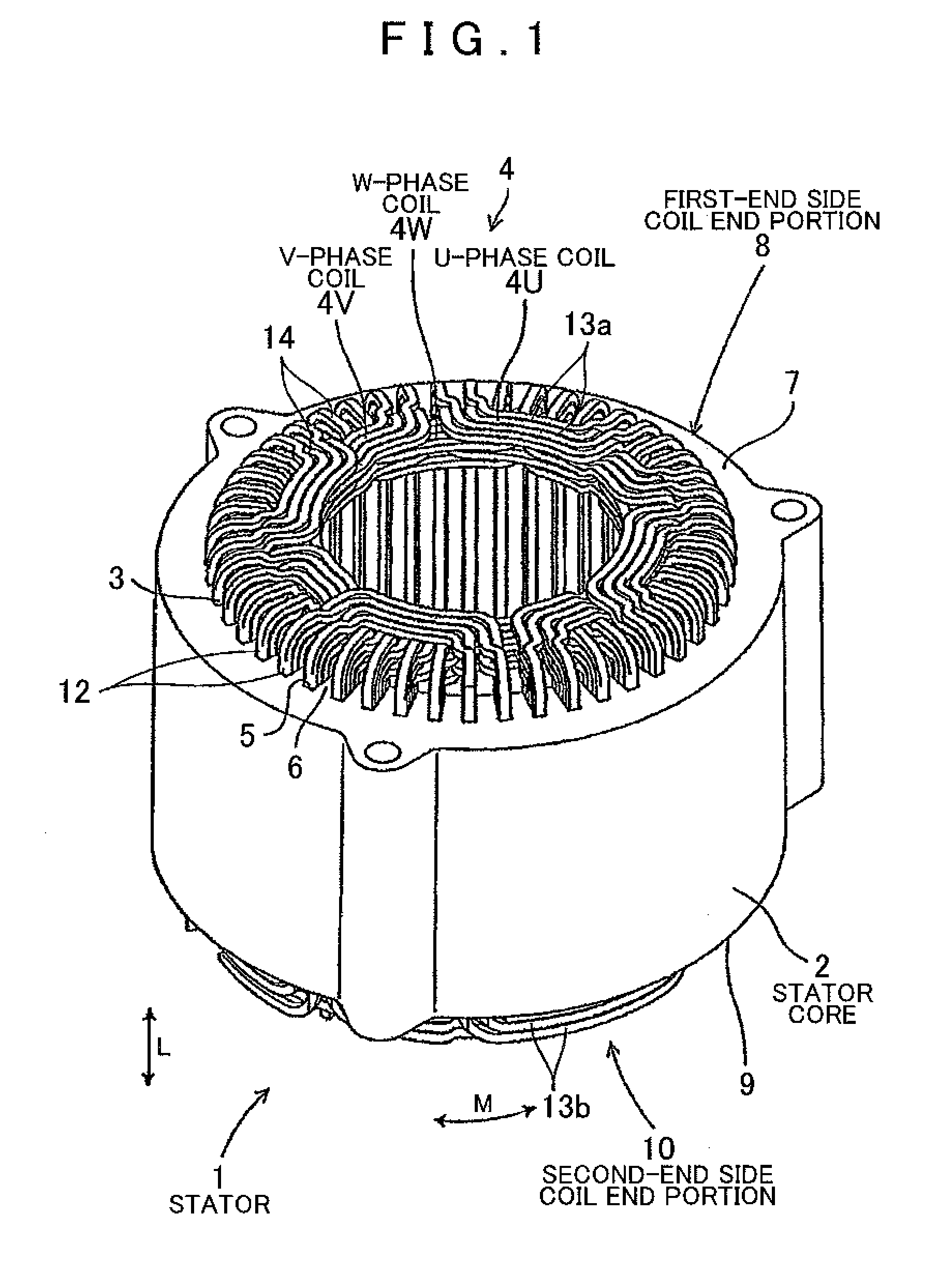

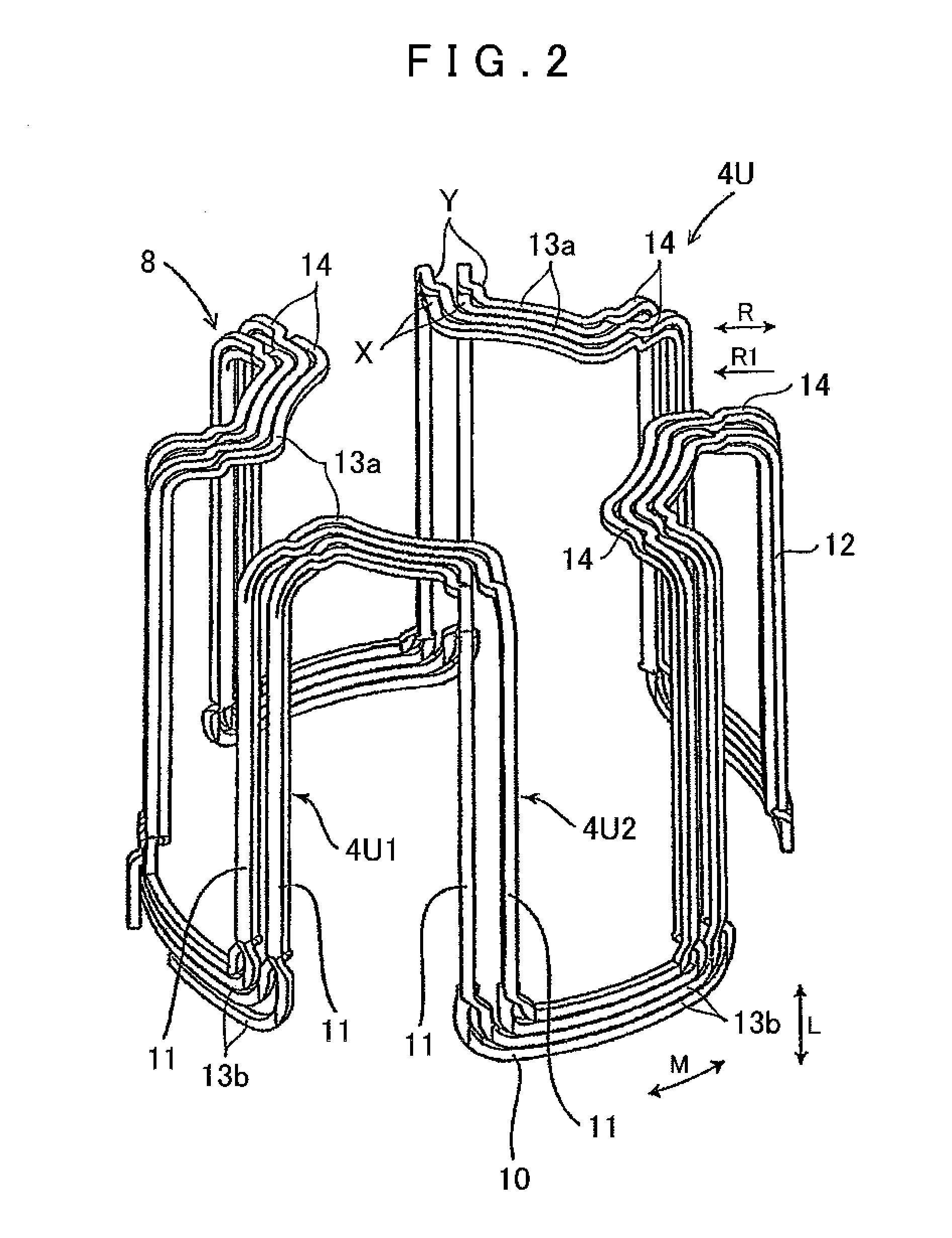

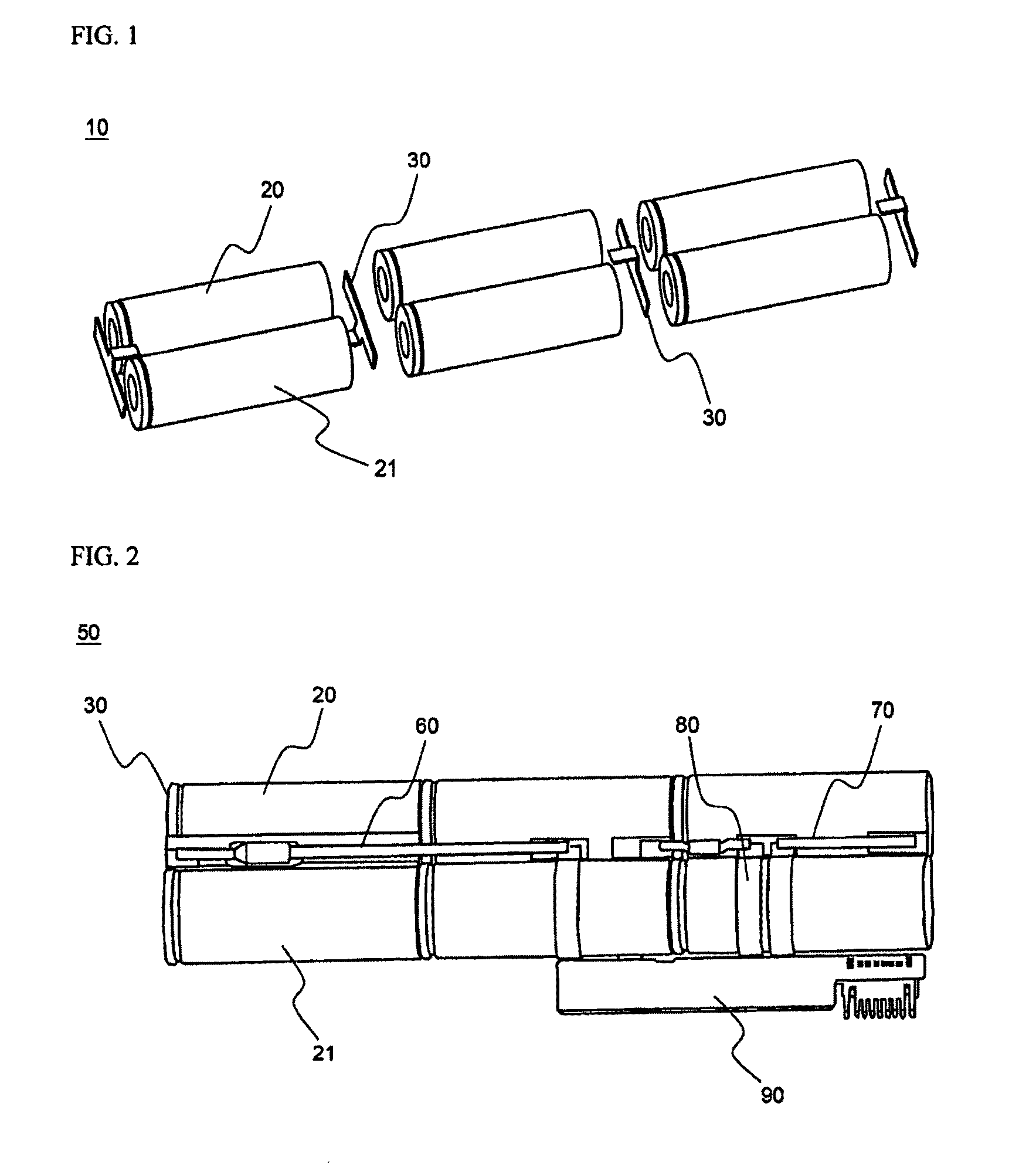

Manufacturing method and manufacturing apparatus for stator

InactiveUS20110099797A1Contact areaReduce contact areaManufacturing dynamo-electric machinesEngineeringMechanical engineering

An apparatus and a method for manufacturing a stator is disclosed. The stator includes a stator core having slots formed along an axial direction at a plurality of locations in a circumferential direction, and a coil formed by combining a plurality of rectangular wires that have a plurality of straight portions being disposed in the slots and arranged side by side in the circumferential direction and in a radial direction. A restriction jig having a number of restriction pieces is disposed on a first-end side of the coil in the axial direction. The coil is inserted into the stator core from the first-end side in the axial direction to dispose the straight portions in the slots. Circumferential positions of the straight portions are restricted along the axial direction through contact with the restriction pieces by relatively moving the restriction jig and the coil in the axial direction.

Owner:AISIN AW CO LTD

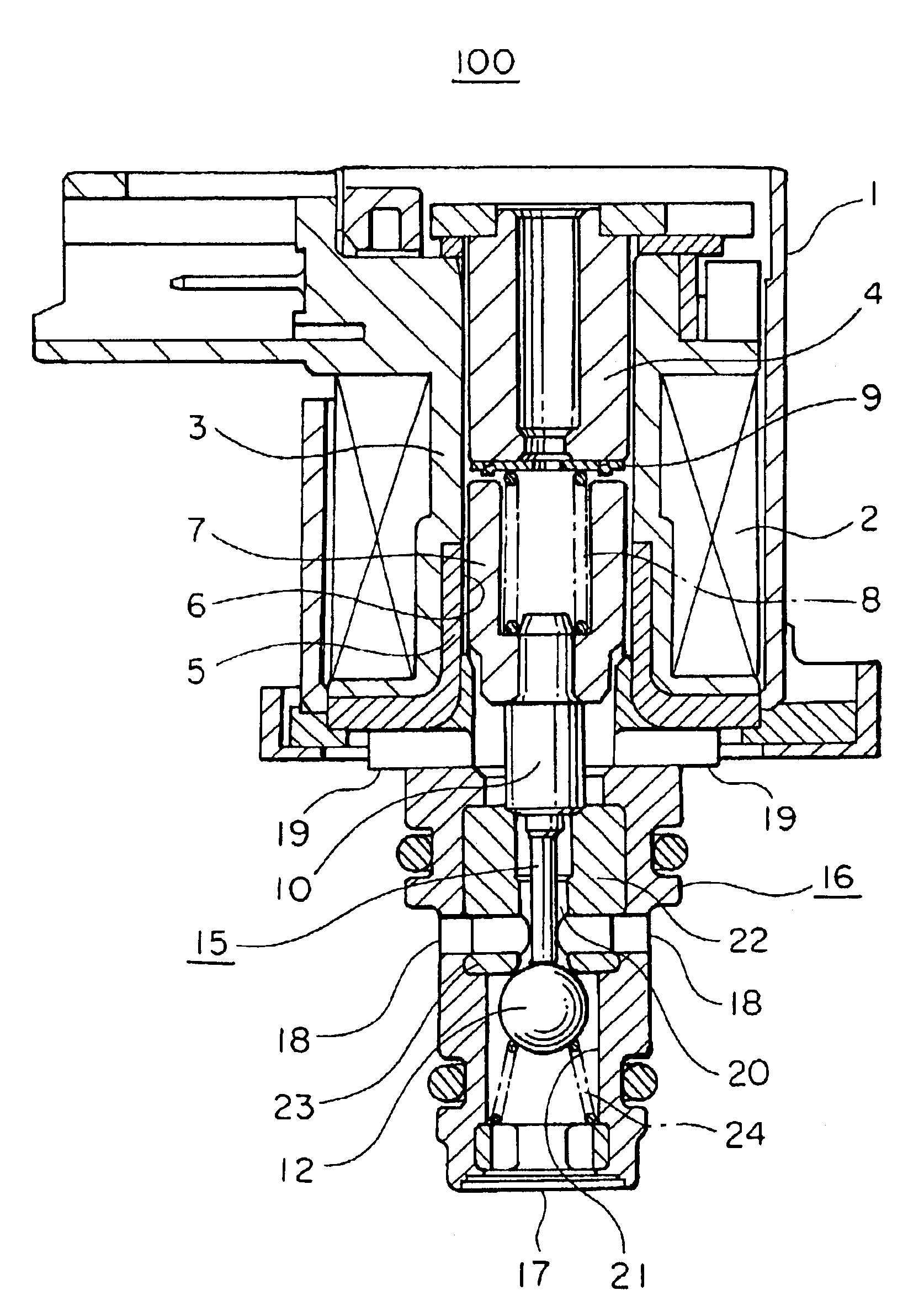

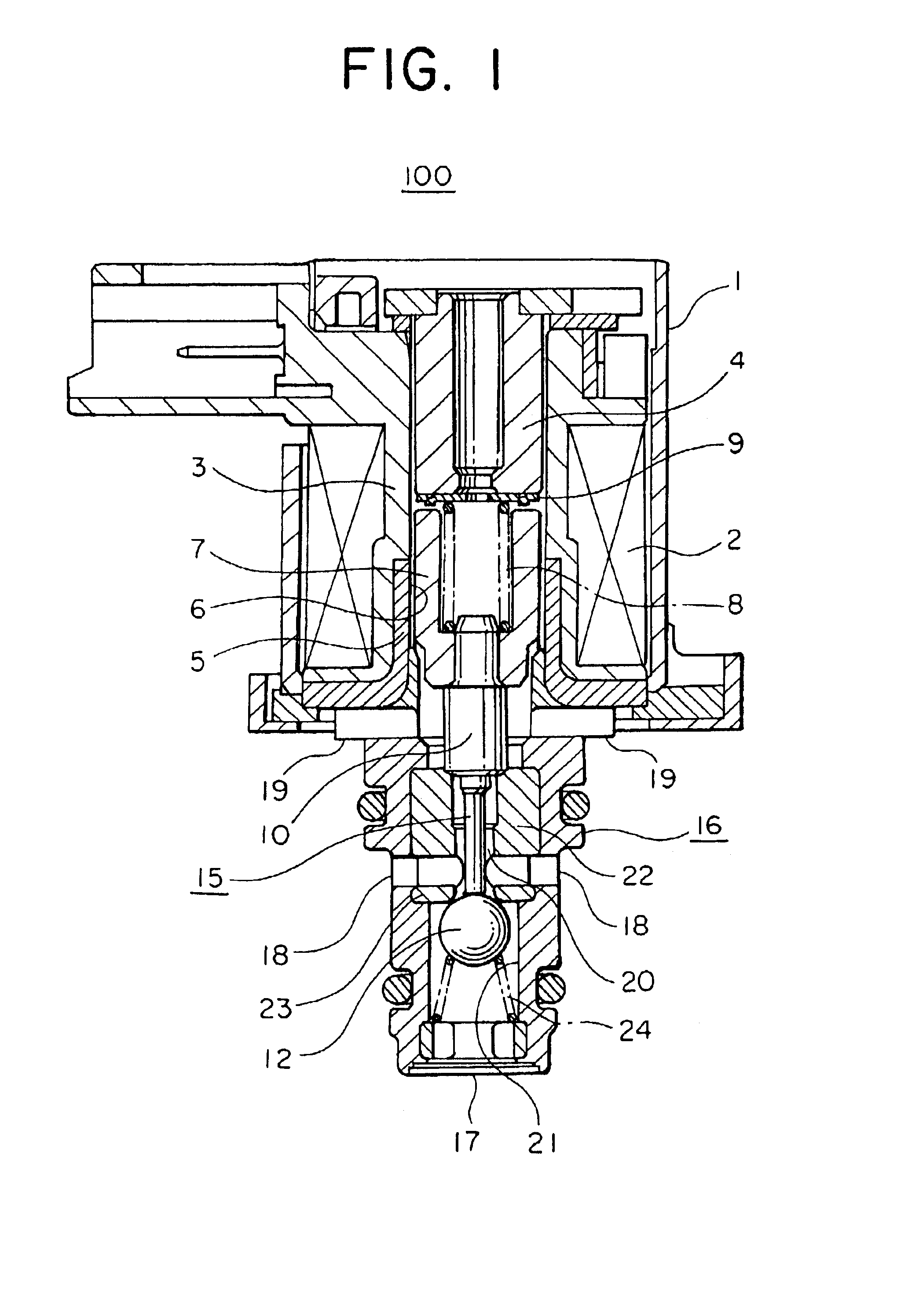

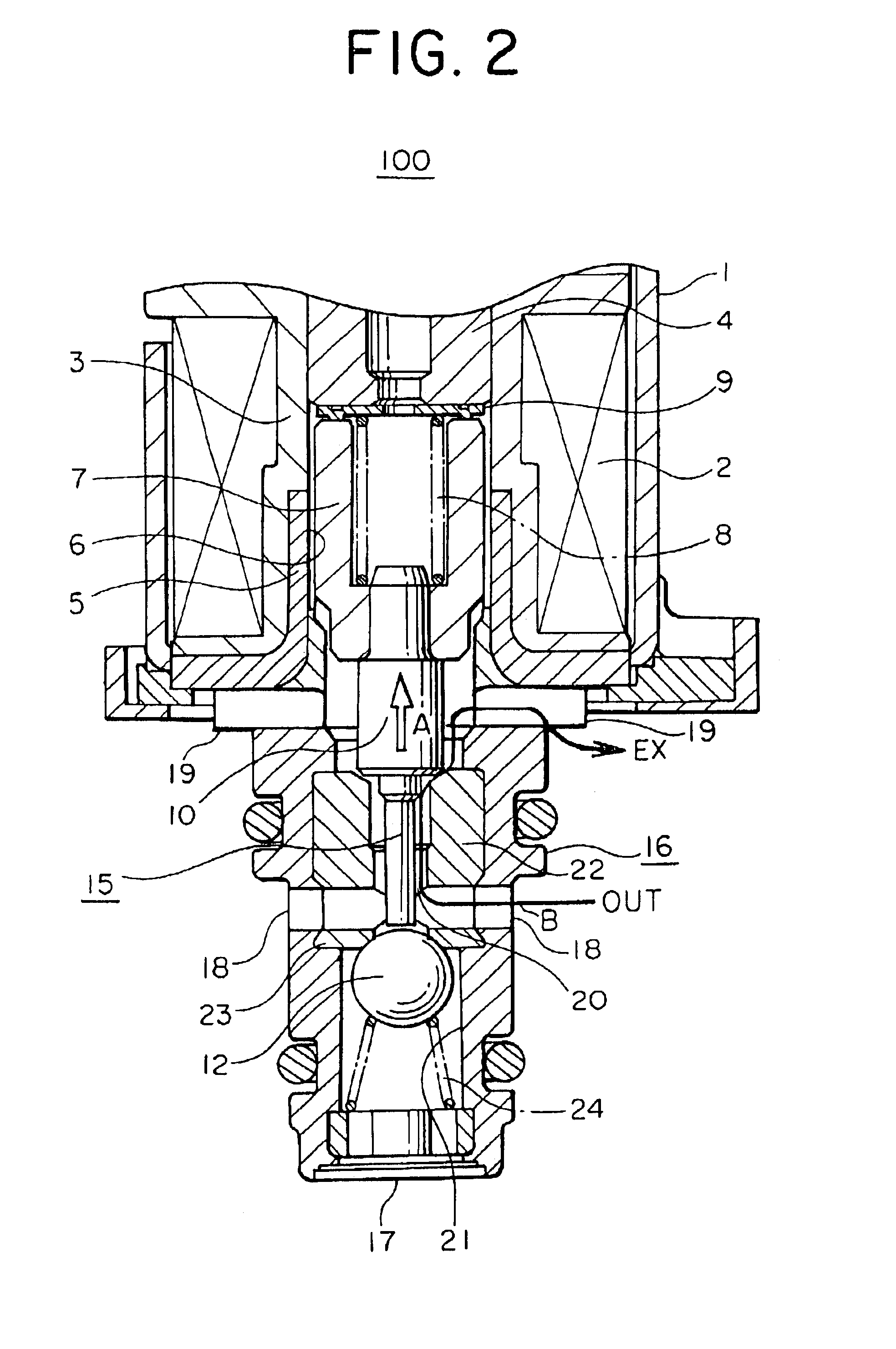

Electromagnetic valve

InactiveUS6874751B2Ensure controlSuppress noiseOperating means/releasing devices for valvesMachines/enginesSolenoid valveEngineering

An electromagnetic valve (100) which can ensure a predetermined response behavior while sustaining a desired control performance with operation noise being suppressed even after operation over an extended time includes a plunger assembly (15) having a plunger (7), a coil (2) for driving the plunger (7), a fixed core (4) disposed in a direction in which the plunger (7) is displaced for attracting the plunger assembly (15) to a retracted position upon electrical energization of the coil (2) to thereby hold the plunger at that position, a resilient member (8) disposed, being compressed, between the plunger (7) and the fixed core (4) to resiliently urge the plunger assembly (15) to an advanced position, and a spacer (9; 39) interposed between the plunger (7) and the fixed core (4). The spacer (9; 29; 39; 49) is provided with a protrusion (9a; 29a).

Owner:MITSUBISHI ELECTRIC CORP

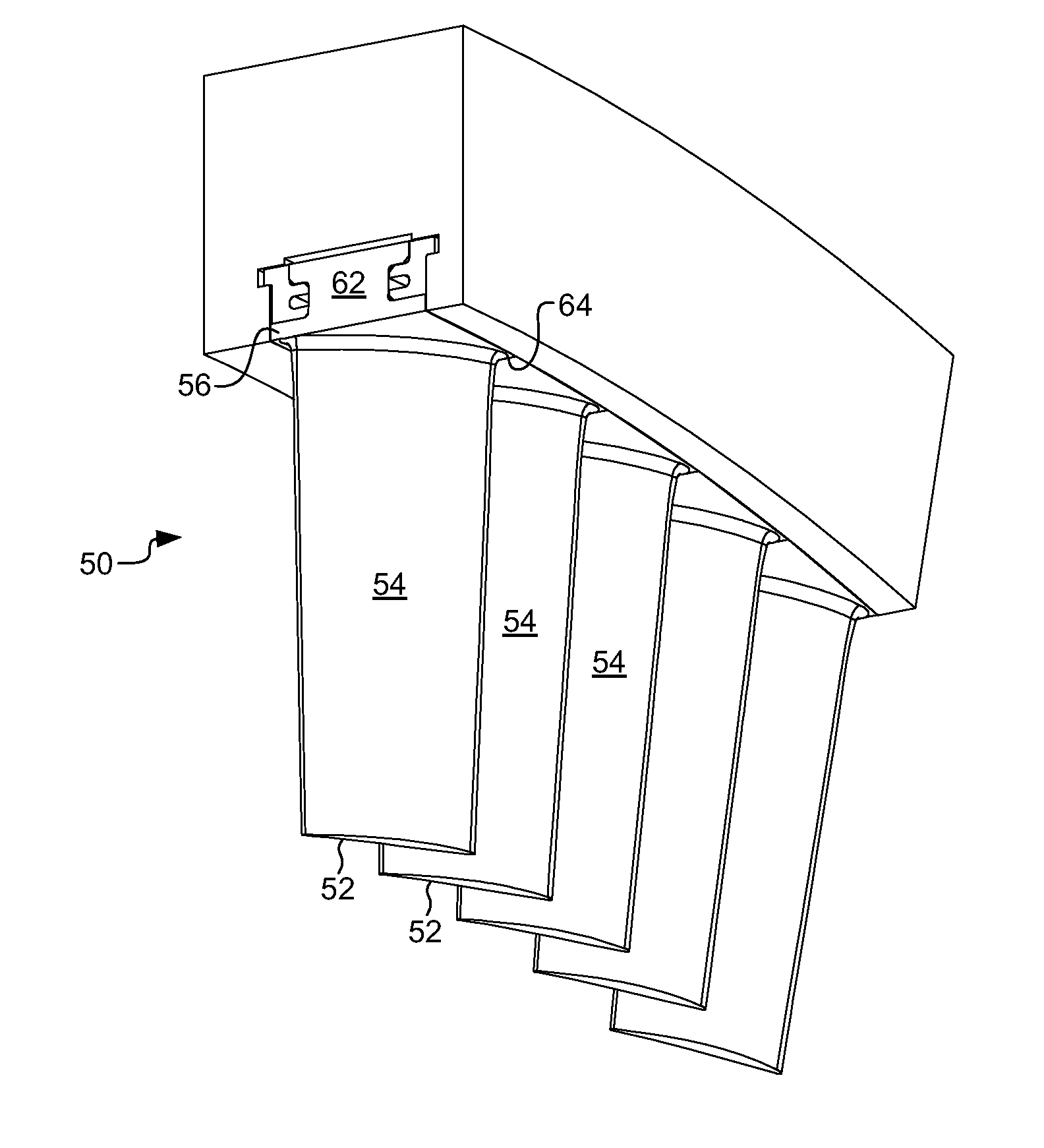

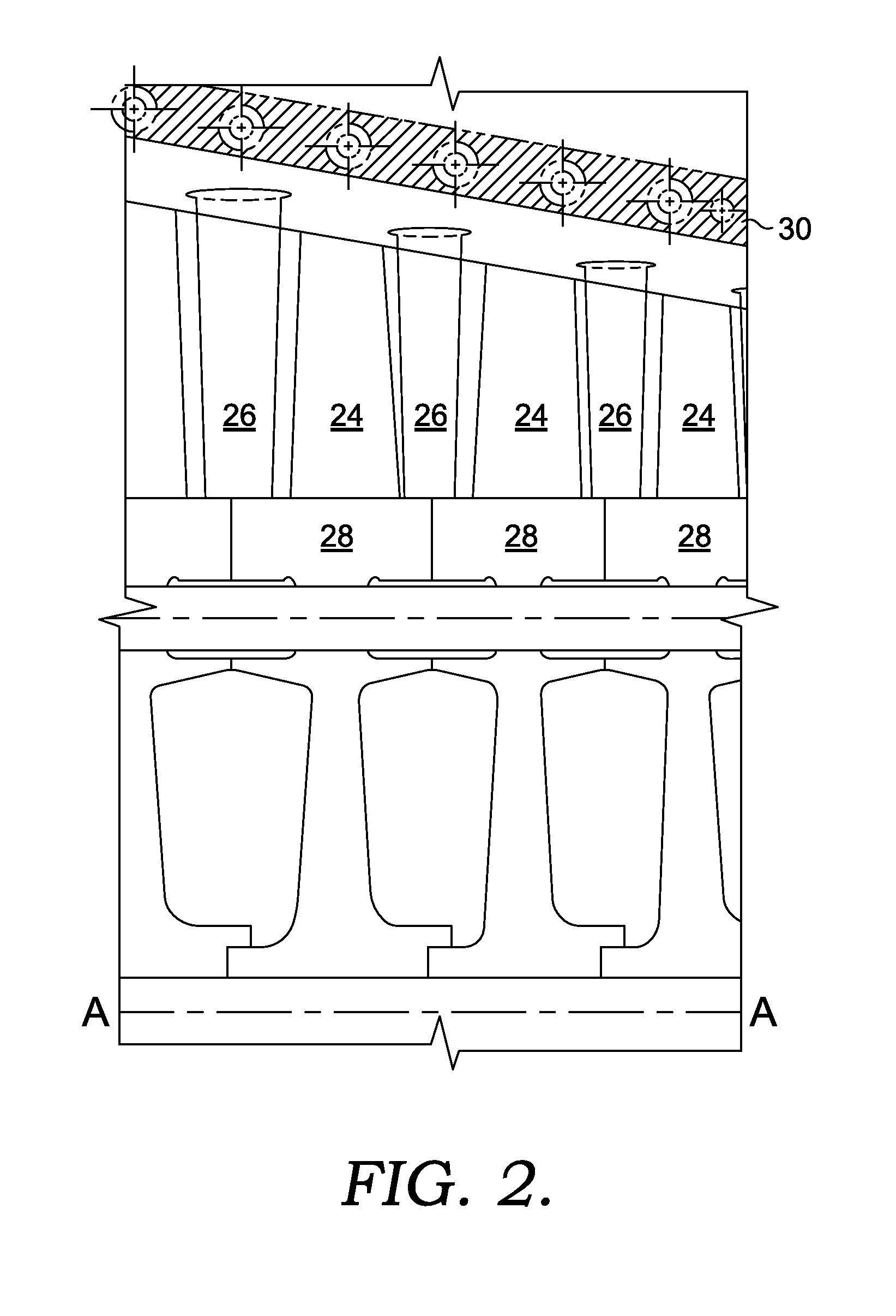

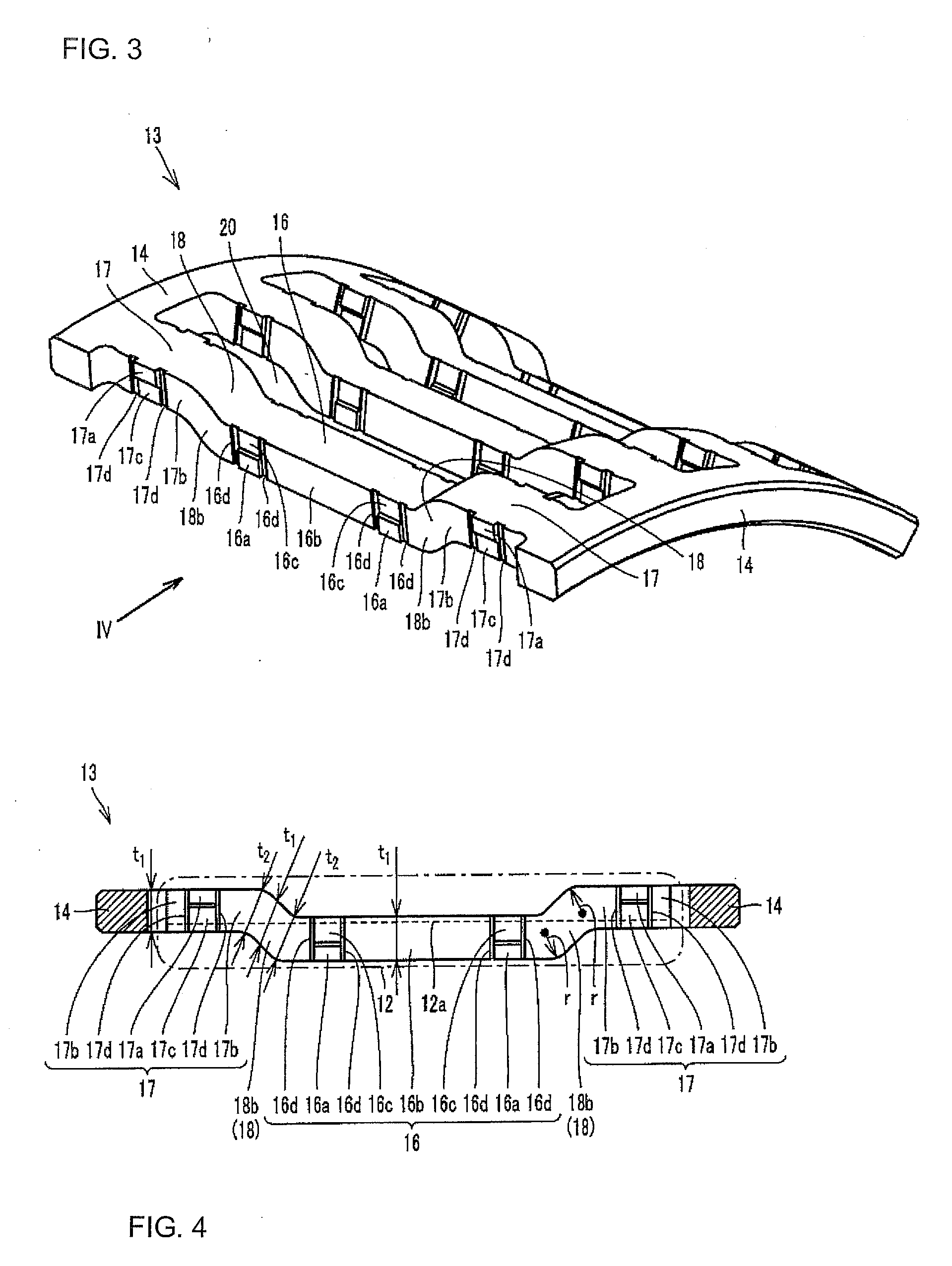

Hook Ring Segment For A Compressor Vane

ActiveUS20080193290A1Contact areaIncrease contact areaPump componentsReaction enginesEngineeringGas turbines

Embodiments for a compressor stator vane assembly in a gas turbine engine are disclosed. In an embodiment of the present invention a stator vane assembly is provided having a plurality of vanes each with an attachment and channels machined into the forward and aft walls of the attachment. A forward hook ring segment is pressfit into the channel in the forward wall of the attachment and an aft hook ring is pressfit into the channel in the aft wall of the attachment. The hook ring segments join a plurality of vanes together so as to provide a uniform engagement of mounting slots in the compressor case. Such an arrangement increases the contact area between the hook rings and the compressor case such that damping of individual vane vibrations are improved and operating stresses are reduced.

Owner:ANSALDO ENERGIA SWITZERLAND AG

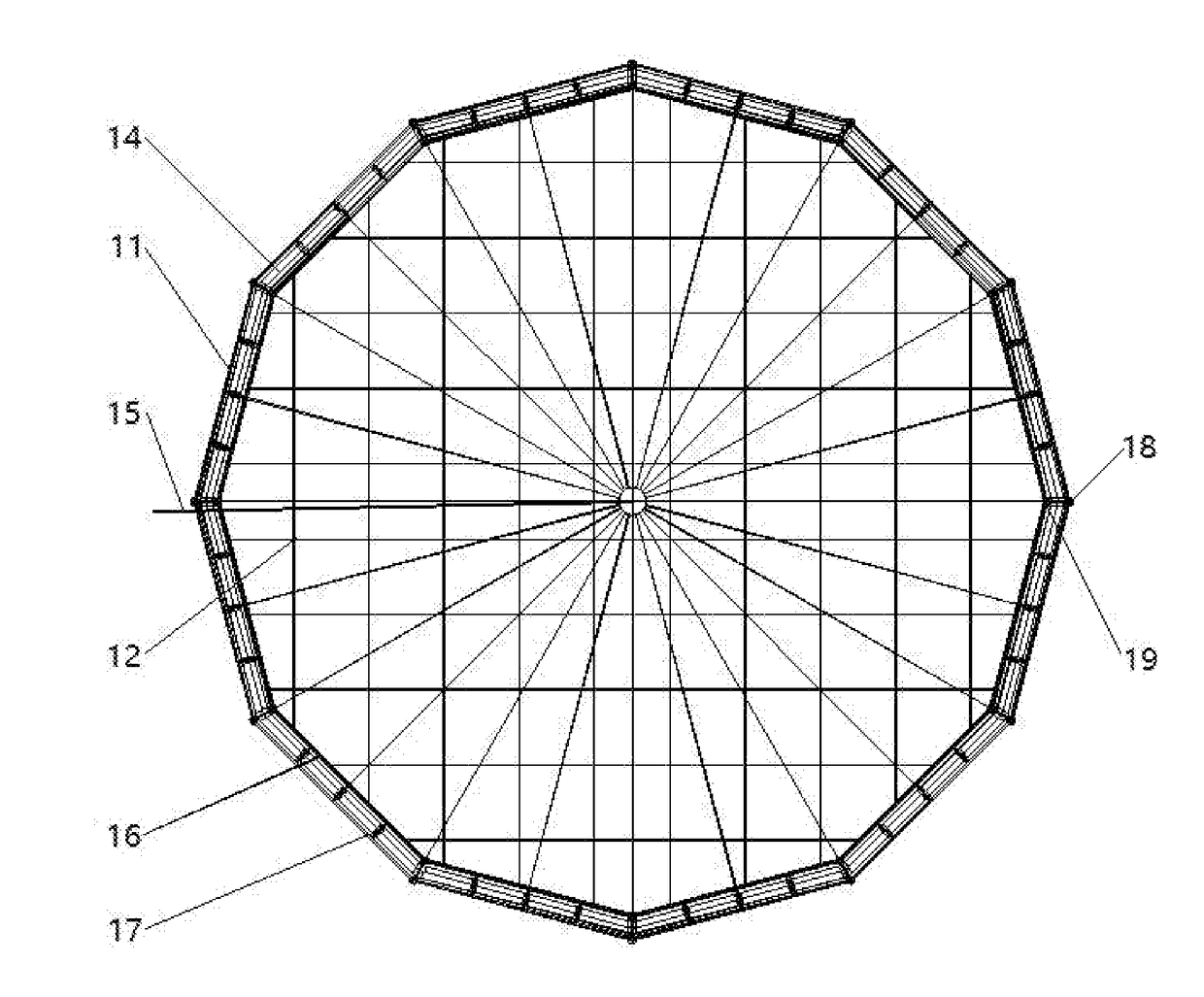

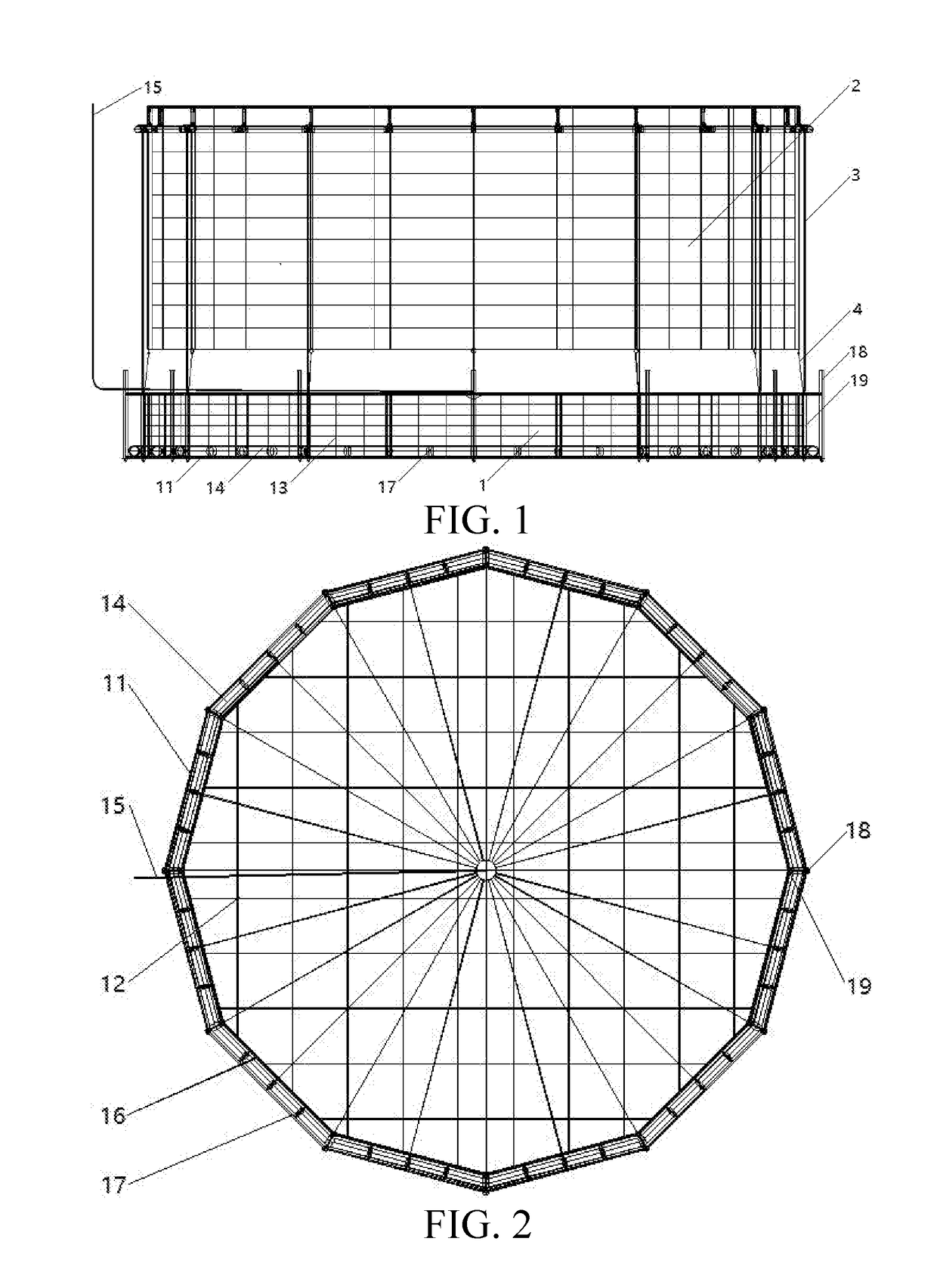

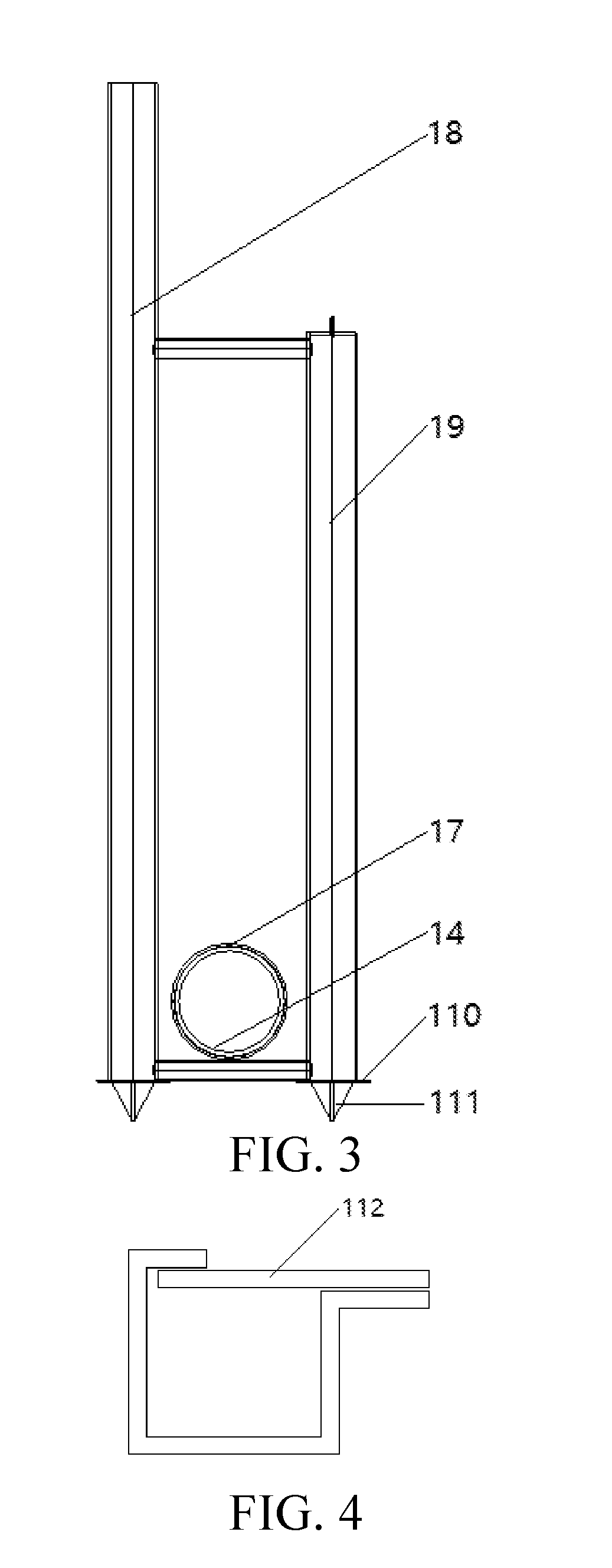

Steel structure cage for marine crustacean aquaculture and integration thereof into vertical fish-crustacean aquaculture system

ActiveUS20180139935A1Remarkable environment benefit benefitRemarkable benefit economic benefitClimate change adaptationPisciculture and aquariaPrawnSteel frame

A steel structure cage for marine crustacean aquaculture and integration thereof into a vertical fish-crustacean aquaculture system are disclosed. The steel structure cage includes a steel frame, top, side and bottom net systems, a ballast tank system, and steel grooves. The steel frame includes internal and external steel frames. The steel grooves are fixed on upper and lower ends of the internal steel frame. Edges of the top and bottom net systems are respectively fixed into the corresponding steel grooves. The side net is welded on the internal steel frame. The ballast tank system is arranged between the internal and external steel frames. A HDPE cage is moored to the steel structure cage to form a vertical aquaculture system. Whereby, an ideal culturing environment for marine crustaceans is given and the objective of vertical aquaculture “culturing fish at top water layers and culturing prawns (crabs or cowries) at bottom water layers” can be fulfilled.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Ultrasonic atomization piece, electronic cigarette atomization core and electronic cigarette atomizer

ActiveUS20190142063A1Simple structureWork at highMedical devicesTobacco devicesElectricityElectrical connection

Disclosed are an ultrasonic atomization piece, an electronic cigarette atomization core and an electronic cigarette atomizer. The ultrasonic atomization piece includes a piezoelectric ceramic main body; one surface of the piezoelectric ceramic main body is in contact with a positive electrode conducting layer, and the other surface of the piezoelectric ceramic main body is in contact with a negative electrode conducting layer, the negative electrode conducting layer extends to the surface of the piezoelectric ceramic main body on which the positive electrode conducting layer is located along a side edge of the piezoelectric ceramic main body, and a plurality of convex point areas, which cover the edge of the positive electrode conducting layer are provided on an edge of the negative conductive layer. The ultrasonic atomization piece, the electronic cigarette atomization core and the electronic cigarette atomizer have the advantages of simple structure, reliable electrical connection, reliable work, high atomization speed, good smoke taste and long service life.

Owner:CHINA TOBACCO HUNAN INDAL CORP

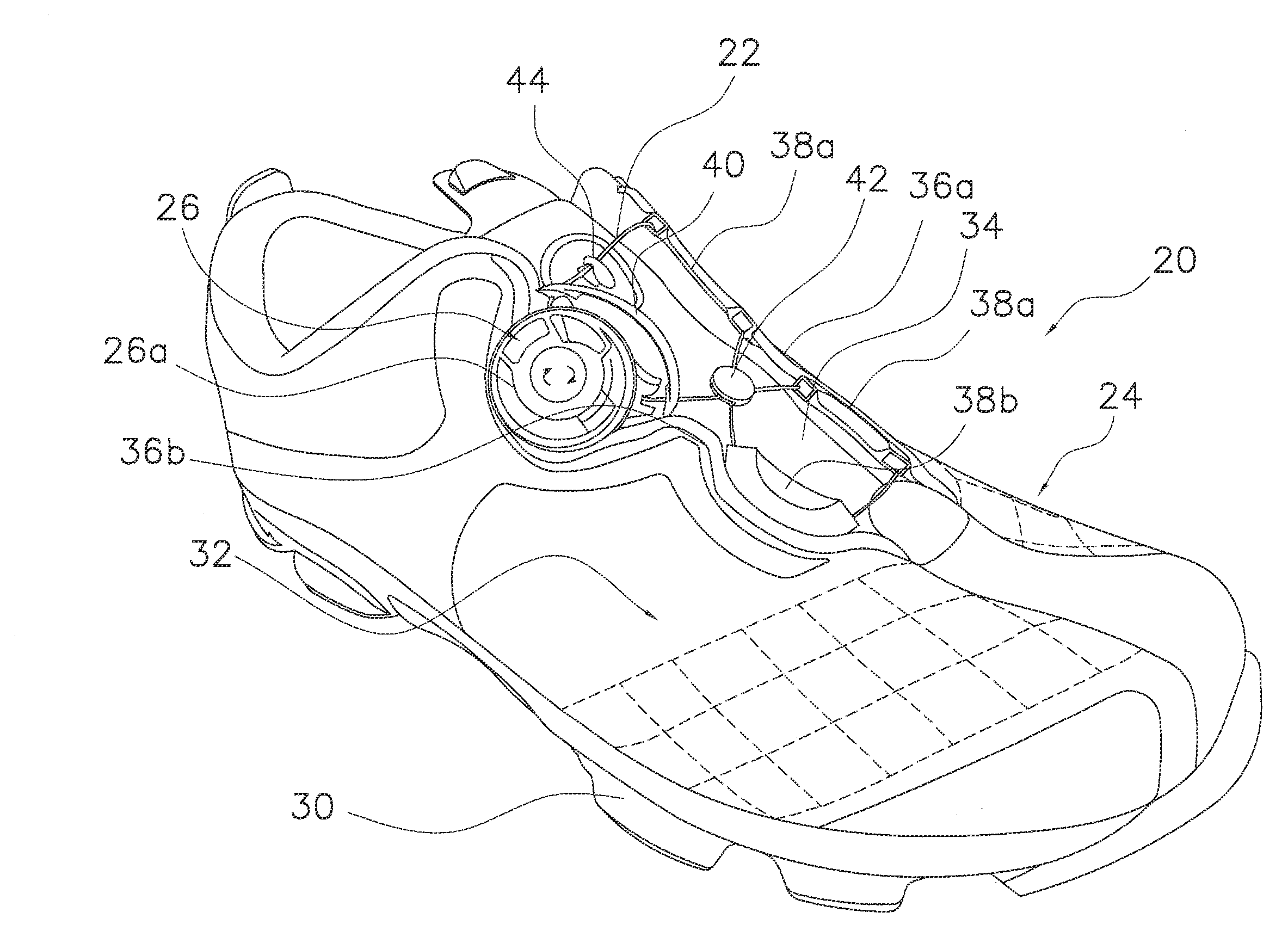

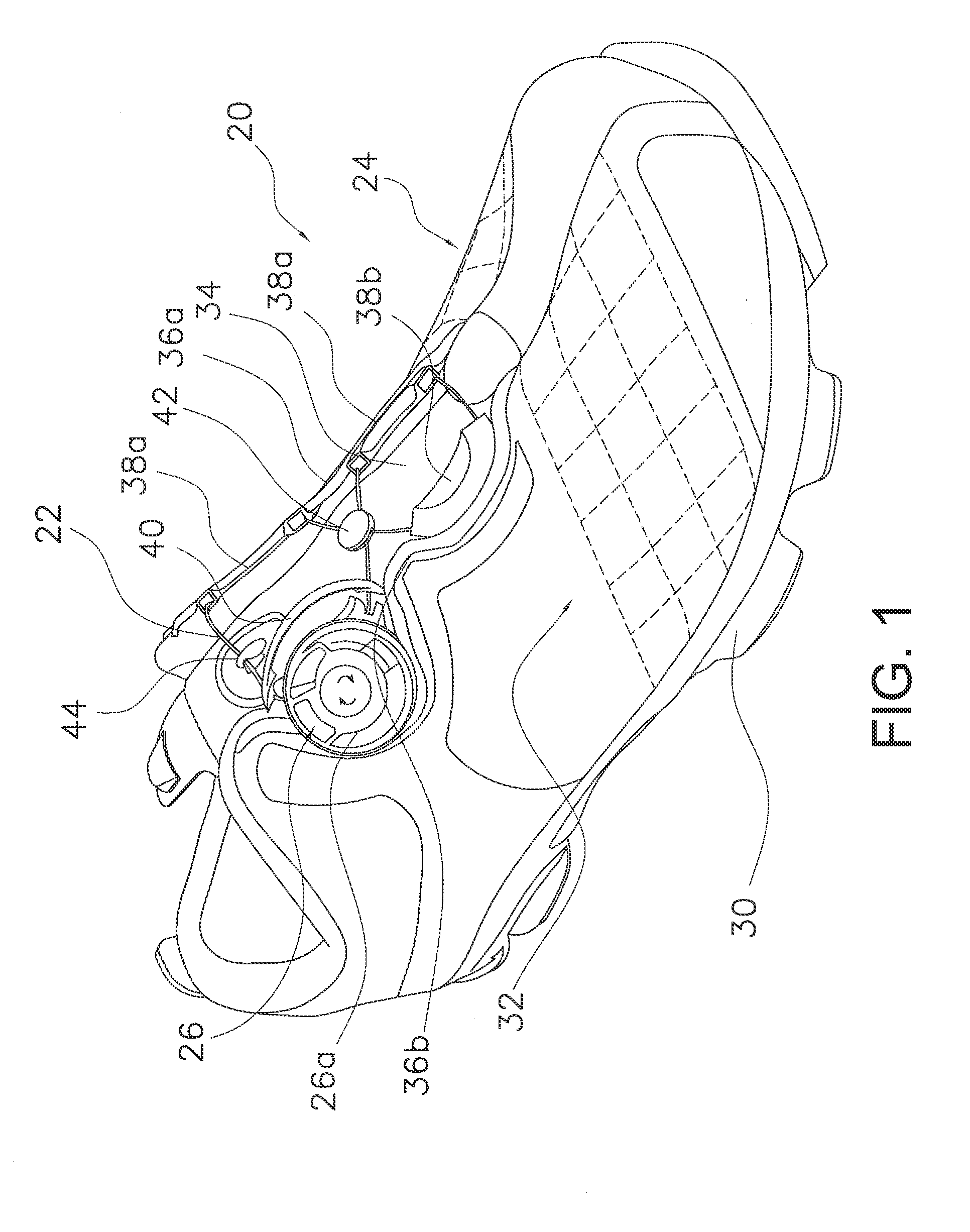

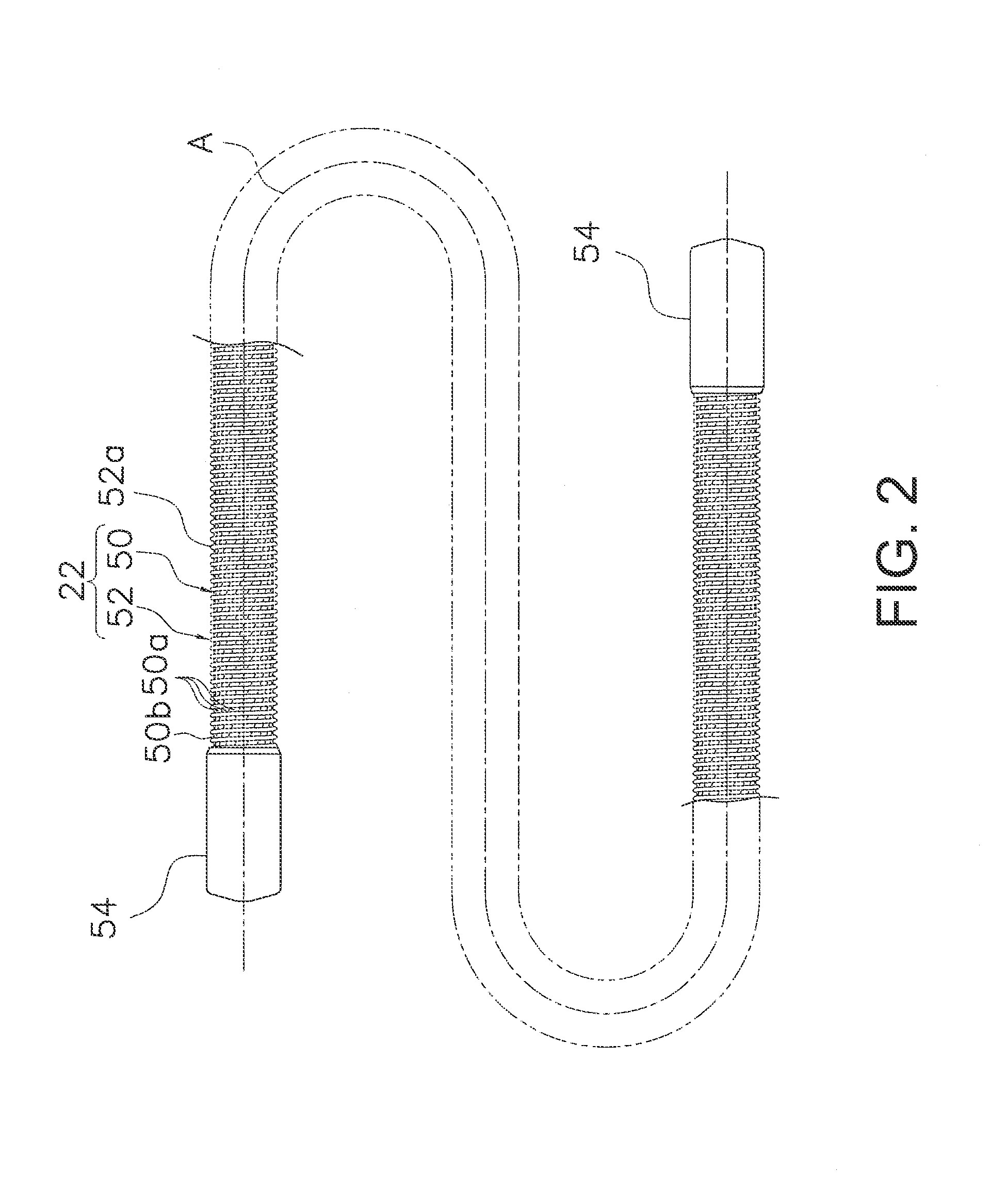

Lacing cord and shoes using the same

ActiveUS20140196312A1Little strengthMinimized contact areaTravelling sacksShoe lace fasteningsEngineeringElectrical and Electronics engineering

A lacing cord is used in an article to be laced that includes shoes, clothing and bags. The lacing cord basically includes a core wire and at least one protruding part. The core wire includes at least one wire member. The at least one protruding part is provided to a peripheral section of the core wire so as to intersect with an axial direction of the core wire and to protrude radially outward from the peripheral section of the core wire.

Owner:SHIMANO INC

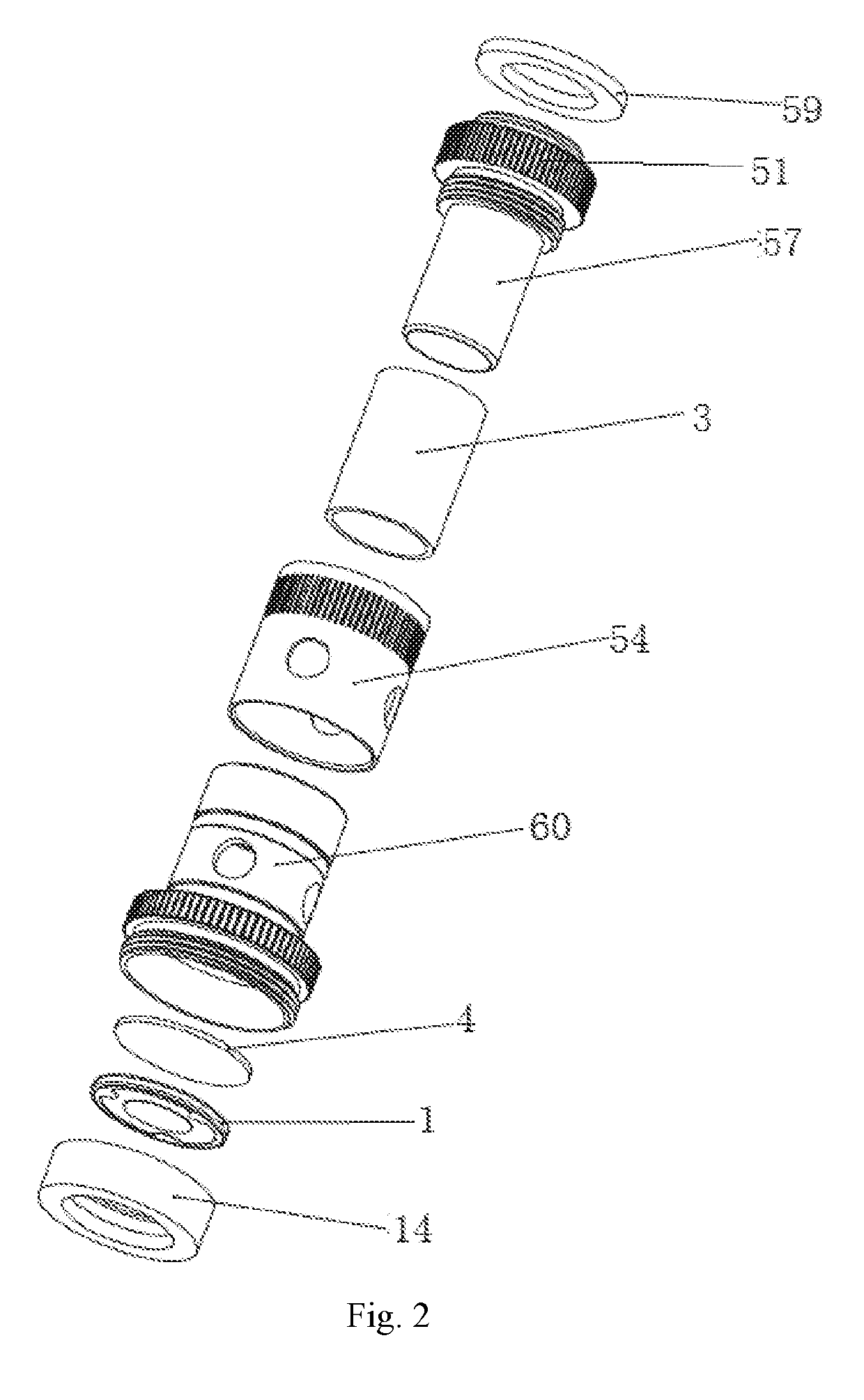

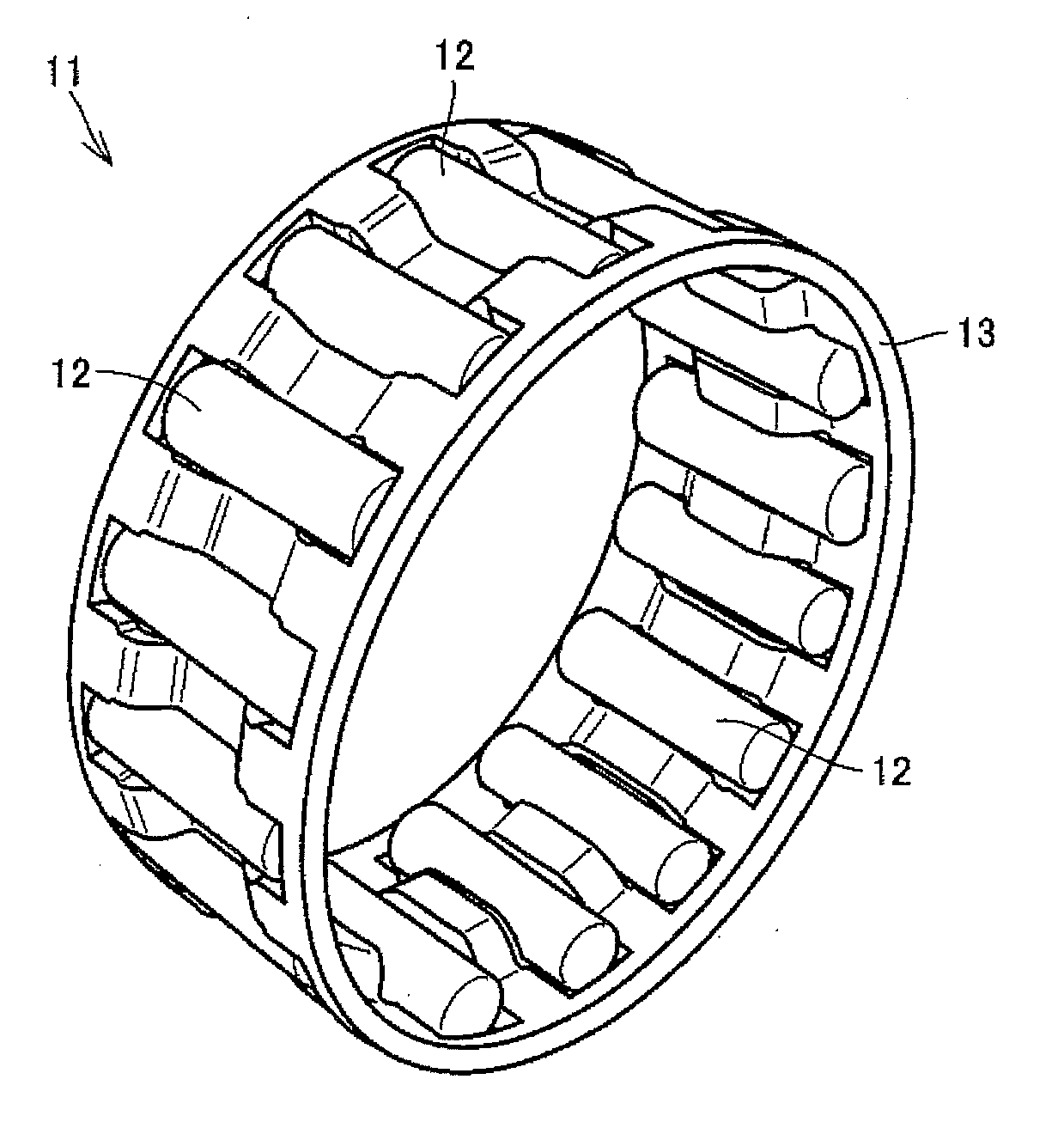

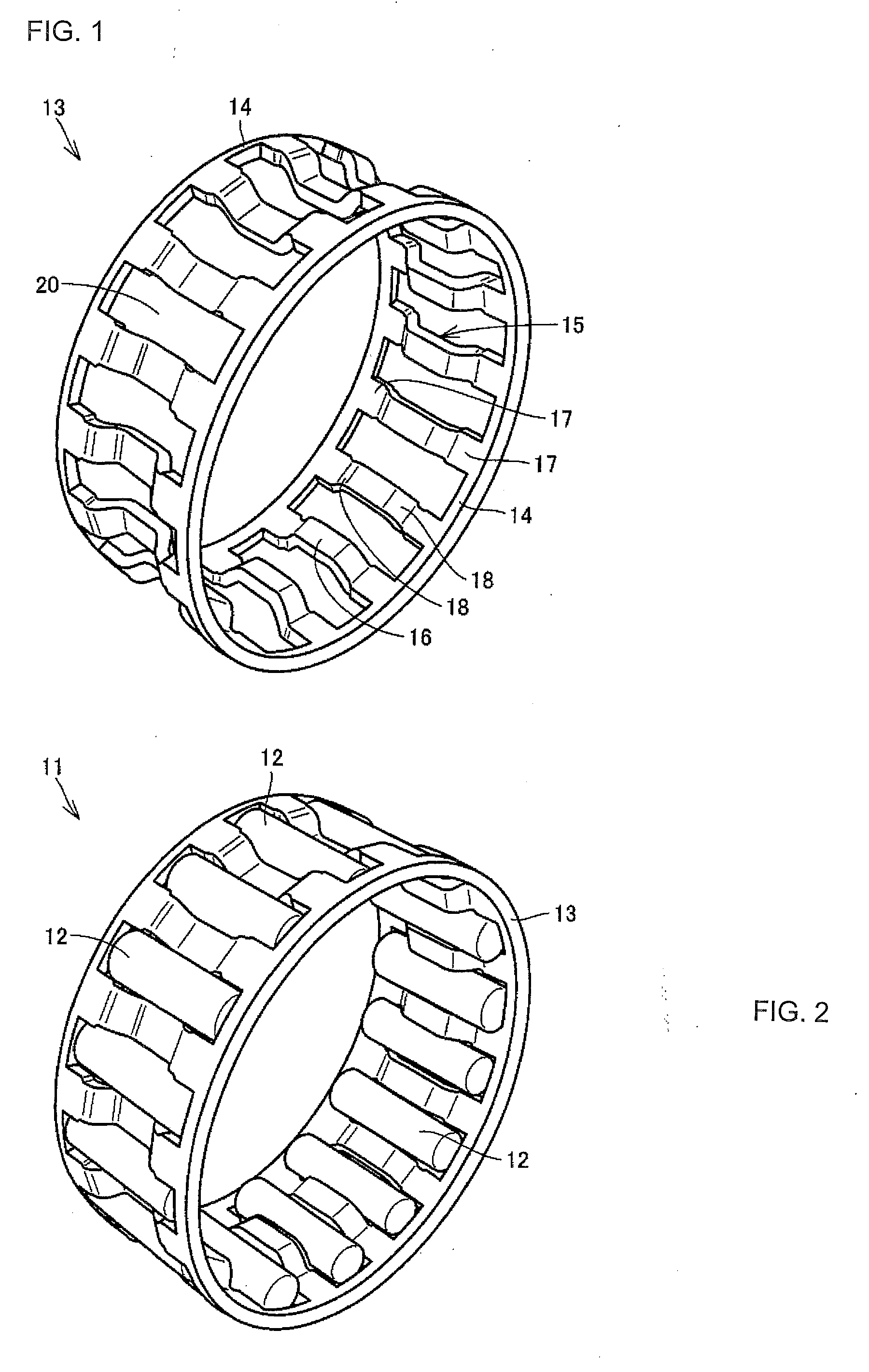

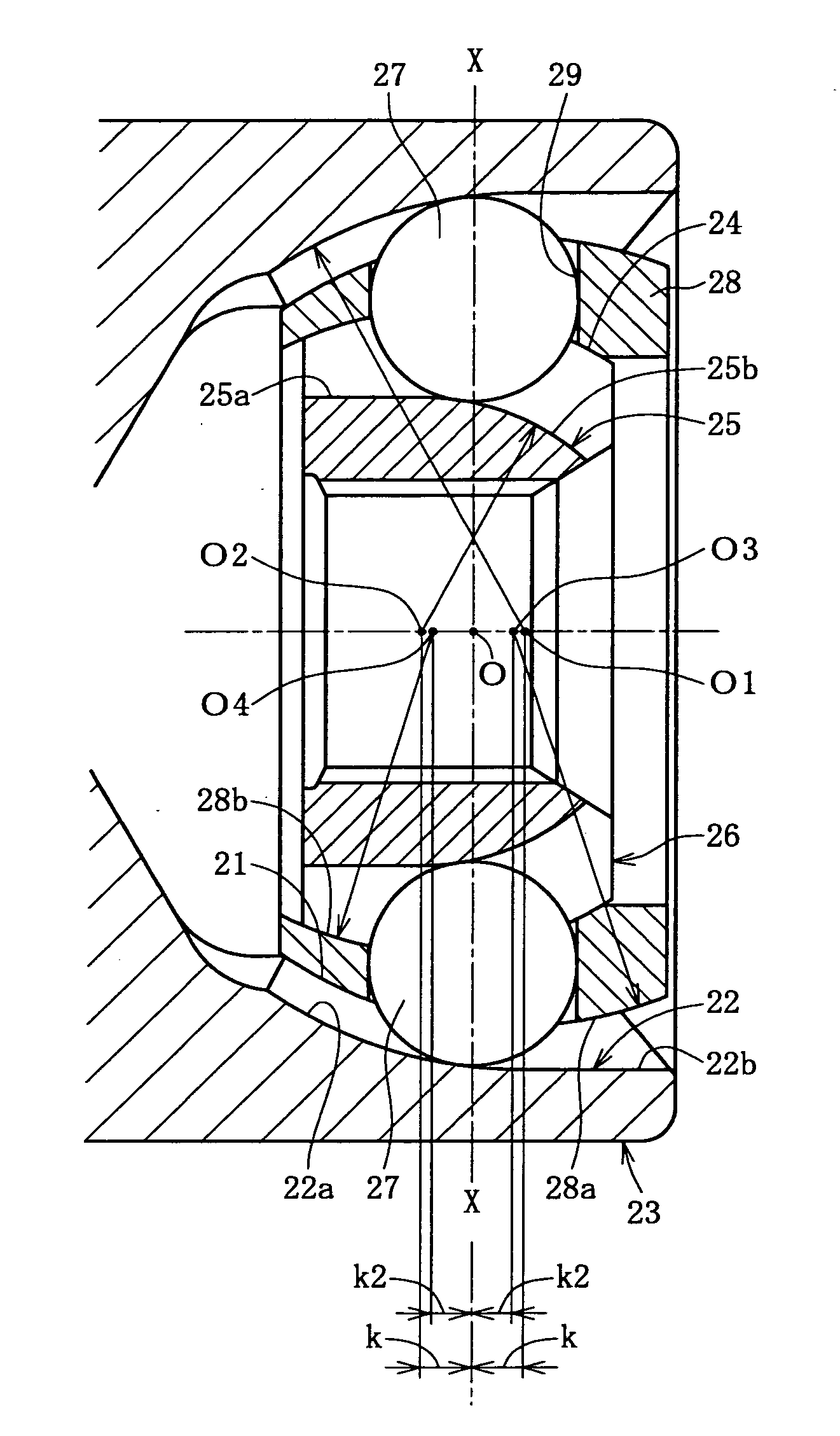

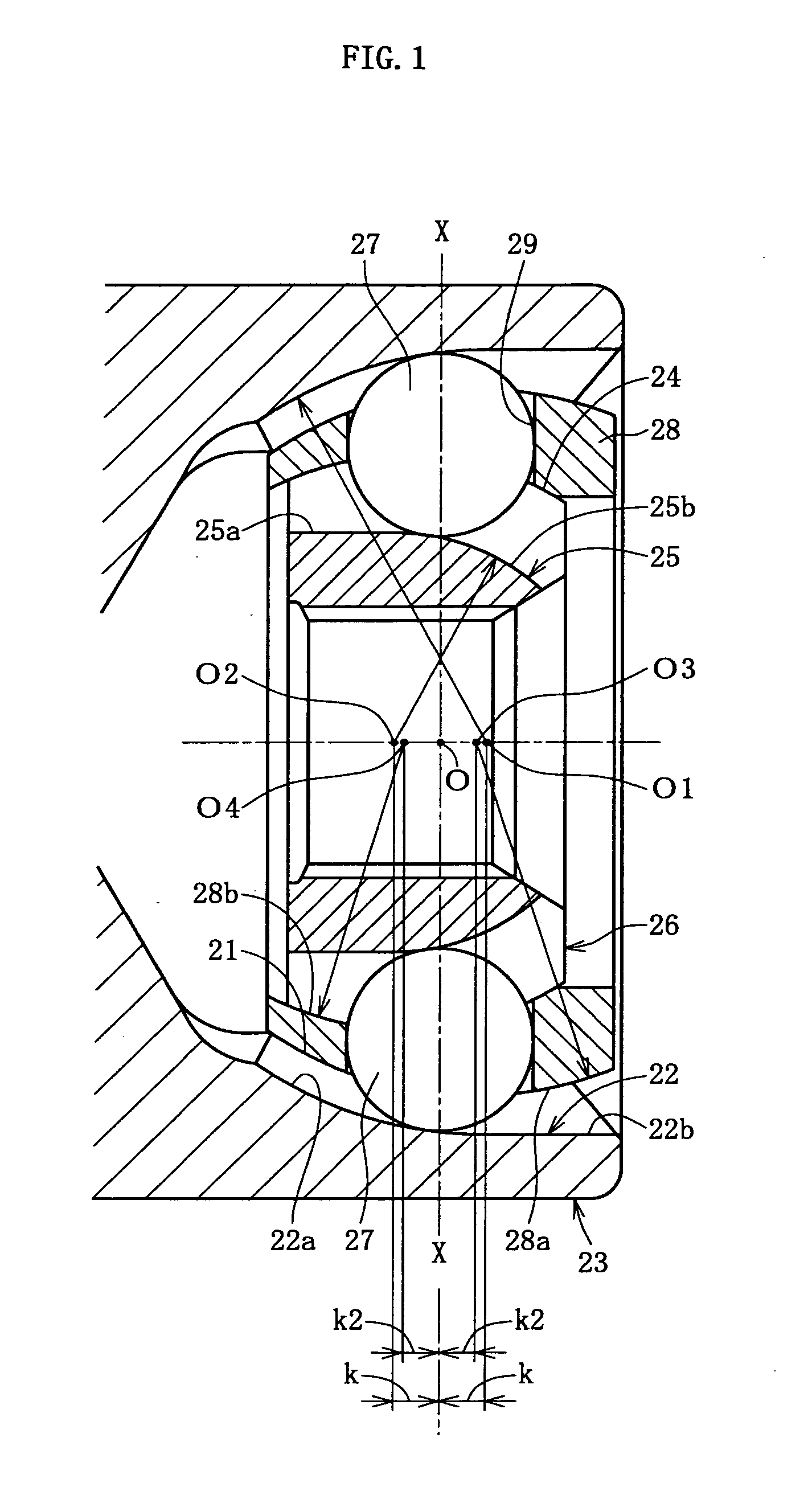

Roller bearing retainer and needle roller bearing

ActiveUS20100278471A1Reduced contact areaAvoid abrasionsShaftsBearing componentsNeedle roller bearingEngineering

A roller bearing retainer (13) includes a pair of annular ring parts (14) and a plurality of column parts (15) each including a column center part (16) provided in an axial center region so as to be positioned relatively on the radial inner side, a pair of column end parts (17) provided in axial end regions so as to be positioned relatively on the radial outer side, and a pair of column sloped parts (18) positioned between the column center part (16) and the pair of column end parts (17), and connecting the pair of ring parts to each other. A thickness of each part of the column center part, the pair of column end parts, and the pair of column sloped parts is smaller than a thickness of a boundary part between the adjacent parts.

Owner:NTN CORP

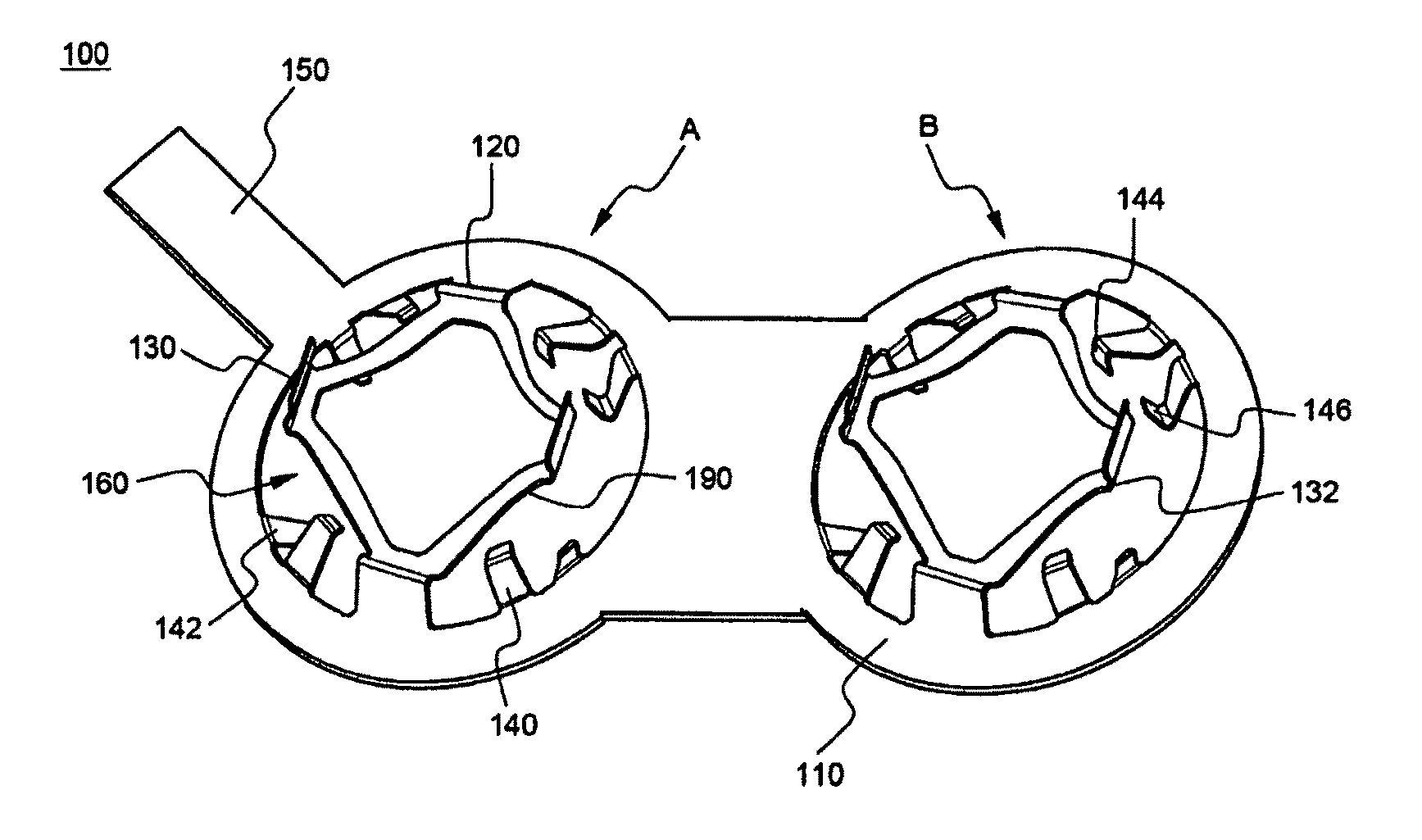

Electrical connecting member for secondary battery

ActiveUS8287313B2Stably achieving electrical connectionEasy to implementElectric discharge tubesCoupling device detailsElectricityElectrical connection

Disclosed herein is a connection member for secondary batteries to achieve the electrical connection in a battery pack including two or more cylindrical secondary batteries in a physical contact manner, the connection member including an outer circumferential contact part contacting an electrode terminal of a lower battery cell along the outer circumferential region of the electrode terminal of the lower battery cell, such that the outer circumferential contact part can be electrically connected to the electrode terminal of the lower battery cell in a surface contact manner, for minimizing the change of resistance at the contact region against an external force and restraining a possibility that the electrode terminal of the lower battery cell is depressed, and a central contact part contacting an electrode terminal of an upper battery cell or the central region of a sidewall of the battery pack for providing an elastic contact force to the entire connection member mounted between the electrode terminals of the respective battery cells or between the electrode terminals of the battery cells and the sidewall of the battery pack.

Owner:LG ENERGY SOLUTION LTD

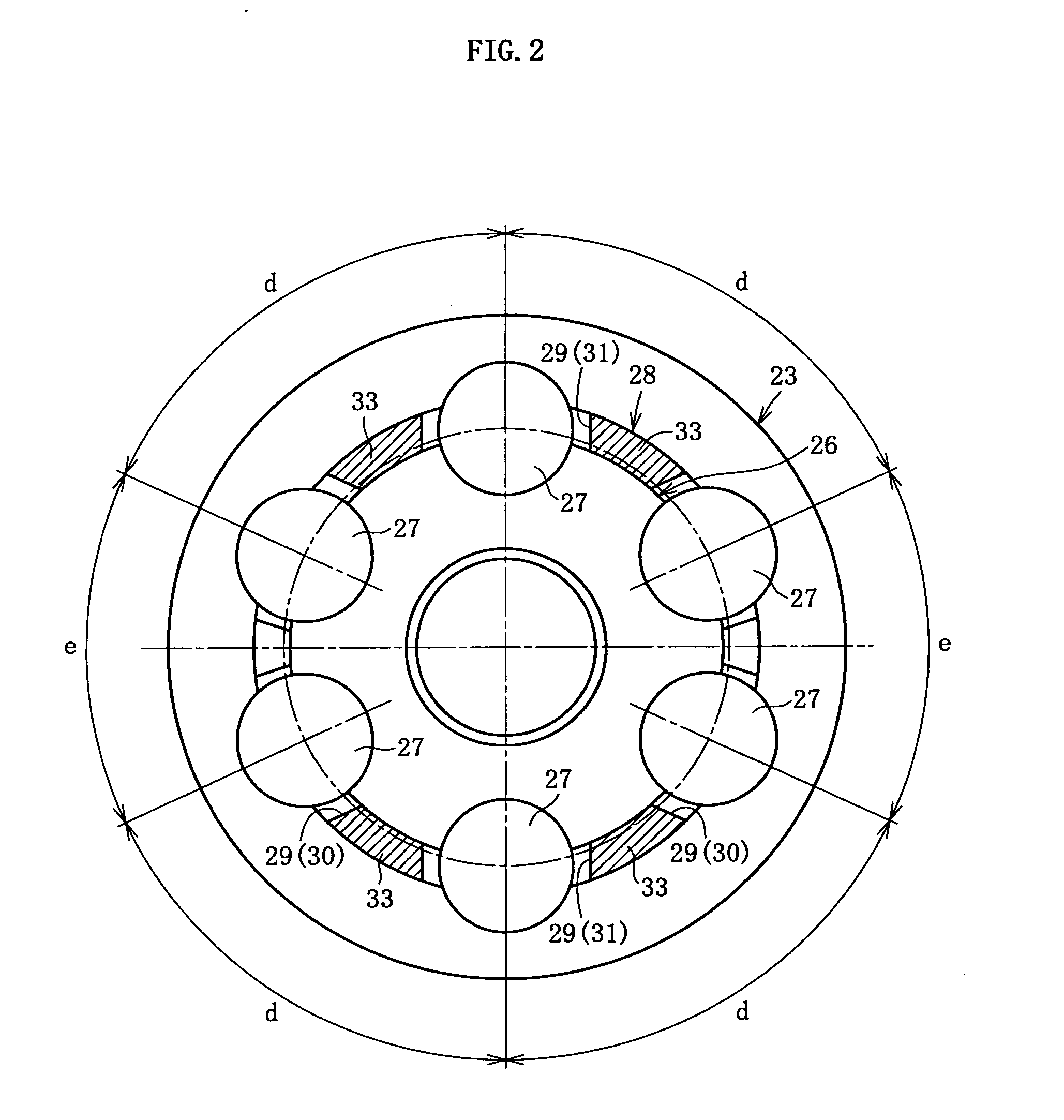

Fixed constant-velocity universal joint

ActiveUS20100029396A1Increase rigidityImprove operabilityClutchesYielding couplingHigh angleEngineering

The present invention provides a fixed constant velocity universal joint that can be made compact, has little decrease in load capacity even when the fixed constant velocity universal joint is made compact and is at an operating angle, and can improve high angle strength and durability through lessening instances in which a ball runs over a track at a high angle. In the fixed constant velocity universal joint of the present invention, a cage 28 includes four pockets 29, the pockets 29 being a pair of long pockets 30 of which a circumferential direction spacing is wide and a pair of short pockets 31 of which the circumferential direction spacing is narrow. The pair of long pockets 30 are shifted by 180 degrees along a circumferential direction and a pair of short pockets 31 are shifted by 180 degrees along the circumferential direction. As a result, the long pockets 30 and the short pockets 31 are alternately disposed along the circumferential direction. A long pocket 30 houses two balls 27. A short pocket 31 houses one ball. Two ball housing sections 38 connected by a slit 37 are formed in the long pocket 30 by projections 36 that project towards a long pocket inner side being provided on opposing long sides 35 of the long pocket 30.

Owner:NTN CORP

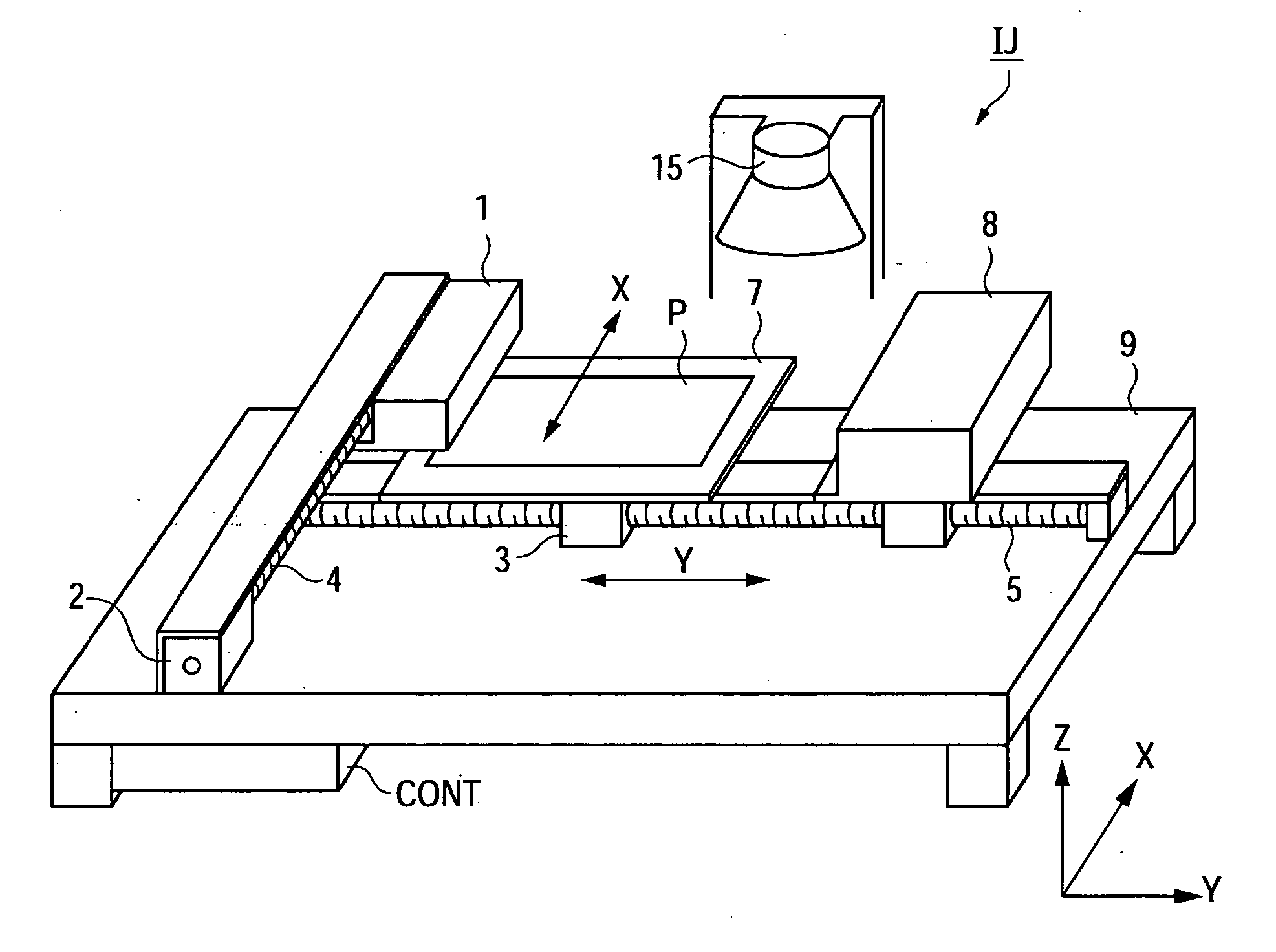

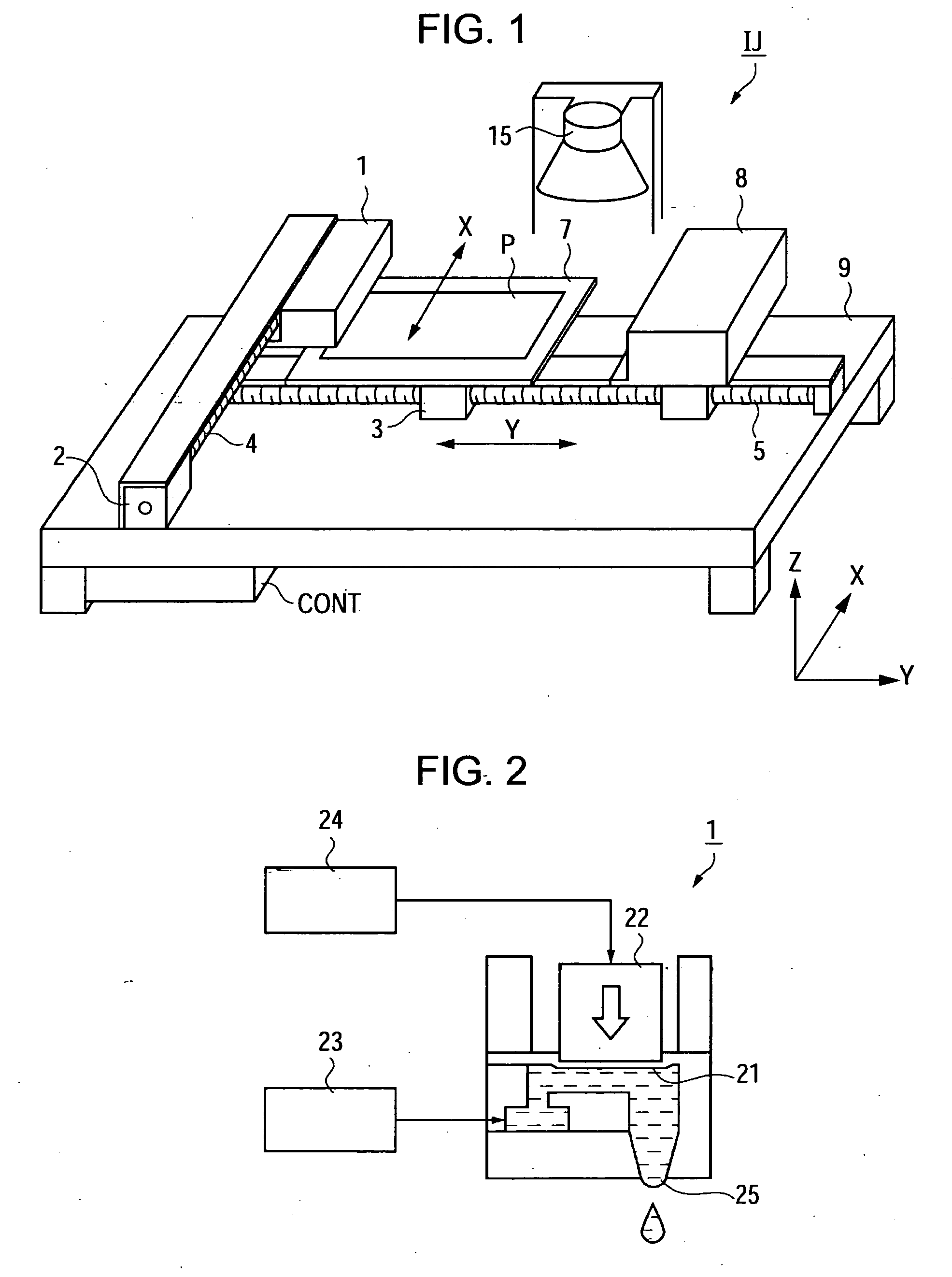

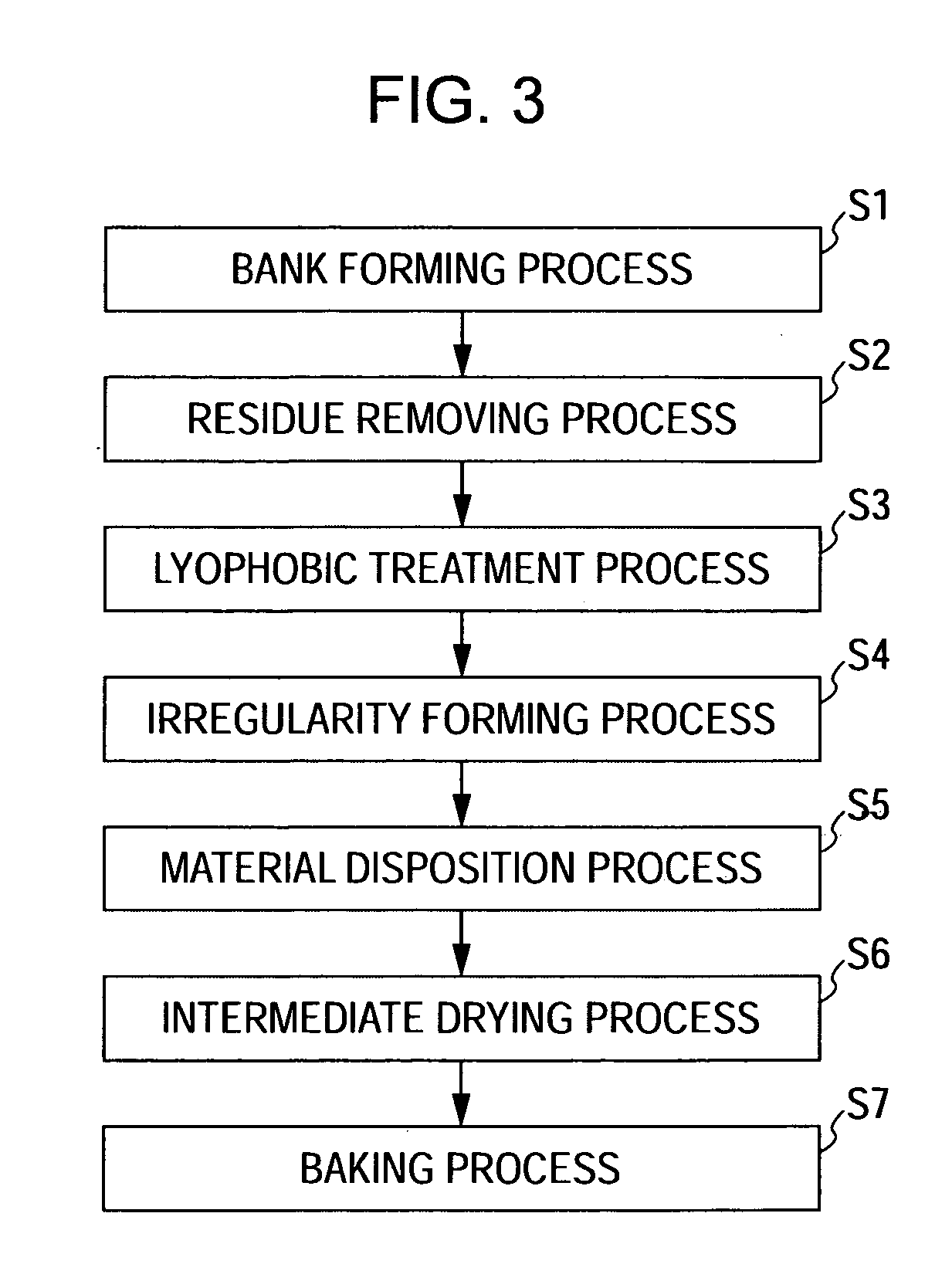

Method of forming film pattern, method of manufacturing device, electro-optical device, and electronic apparatus

InactiveUS20060183036A1Improve performanceImprove film adhesionPicture framesSolid-state devicesEngineeringElectronic equipment

A method of forming a film pattern by disposing a functional liquid on a substrate includes: forming banks corresponding to the film pattern on the substrate; forming irregularities on bottoms between the banks by using the banks as a mask; and disposing the functional liquid between the banks and on the bottoms formed with the irregularities.

Owner:SEIKO EPSON CORP

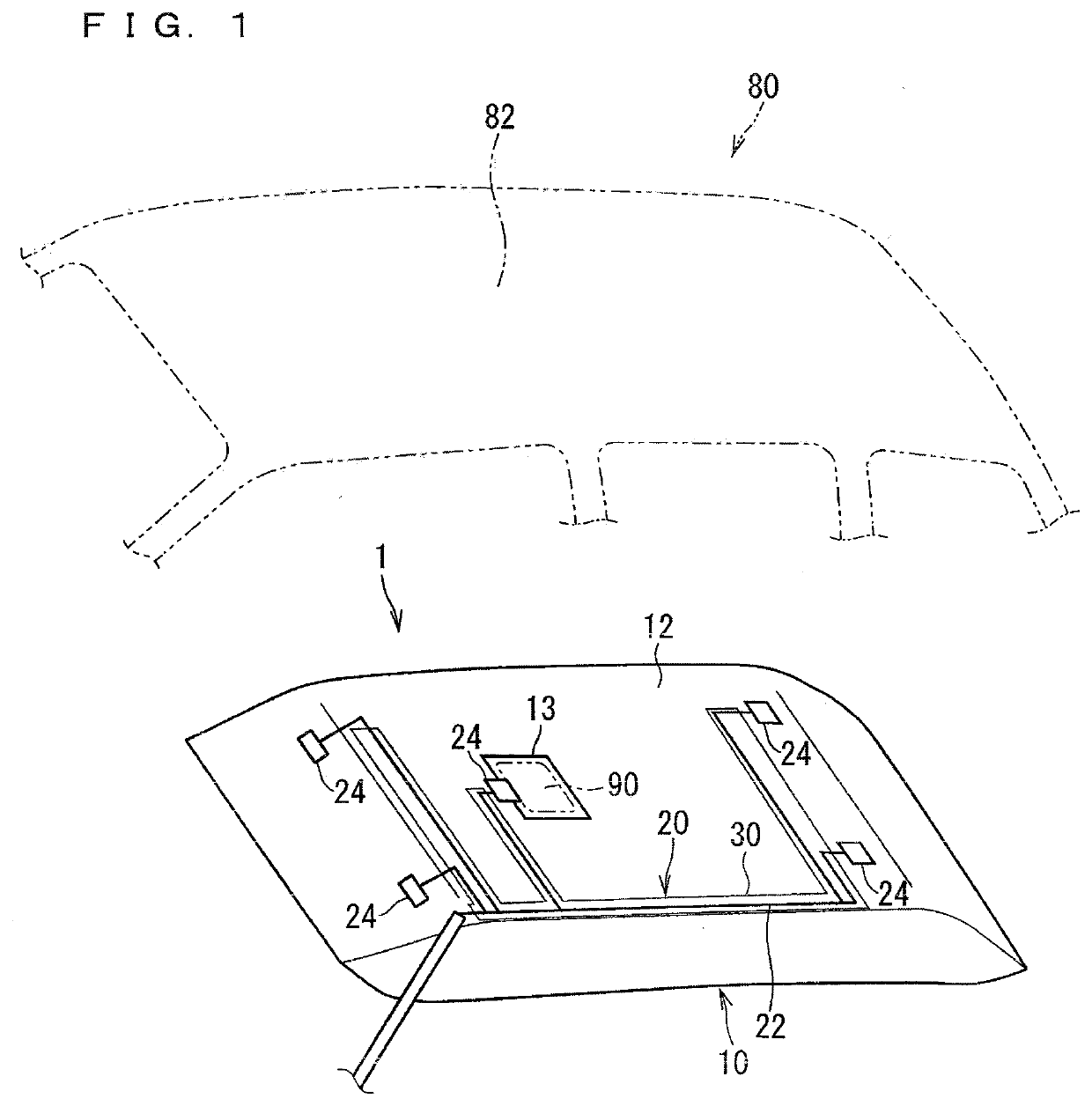

Wire harness fixing structure

InactiveUS20200062198A1Contact areaIncrease contact areaElectrical apparatusElectric/fluid circuitStructural engineeringElectric wire

A wire harness fixing structure includes an interior member including a plate-like member and interiorly mounted on a vehicle and a wire harness including an electrical wire disposed along the plate-like member and a sheet material to which the electrical wire is fixed by sewing or welding. The wire harness is fixed to the interior member while the sheet material is spread.

Owner:AUTONETWORKS TECH LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com