Patents

Literature

106 results about "Film-out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

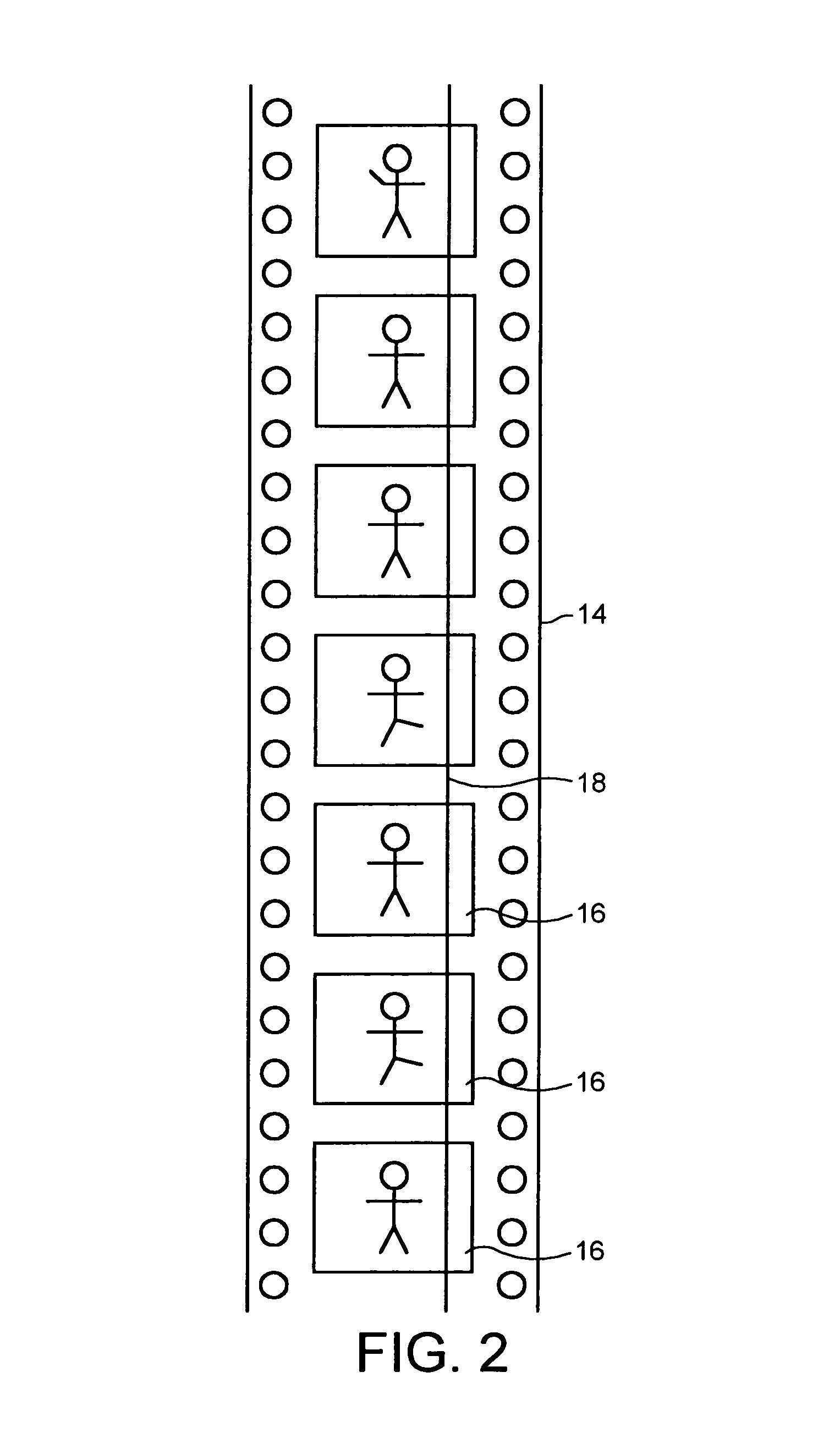

Film-out is the process in the computer graphics, video production and filmmaking disciplines of transferring images or animation from videotape or digital files to a traditional film print. "Film-out" is a broad term that encompasses the conversion of frame rates, color correction, as well as the actual printing, also called scanning or recording.

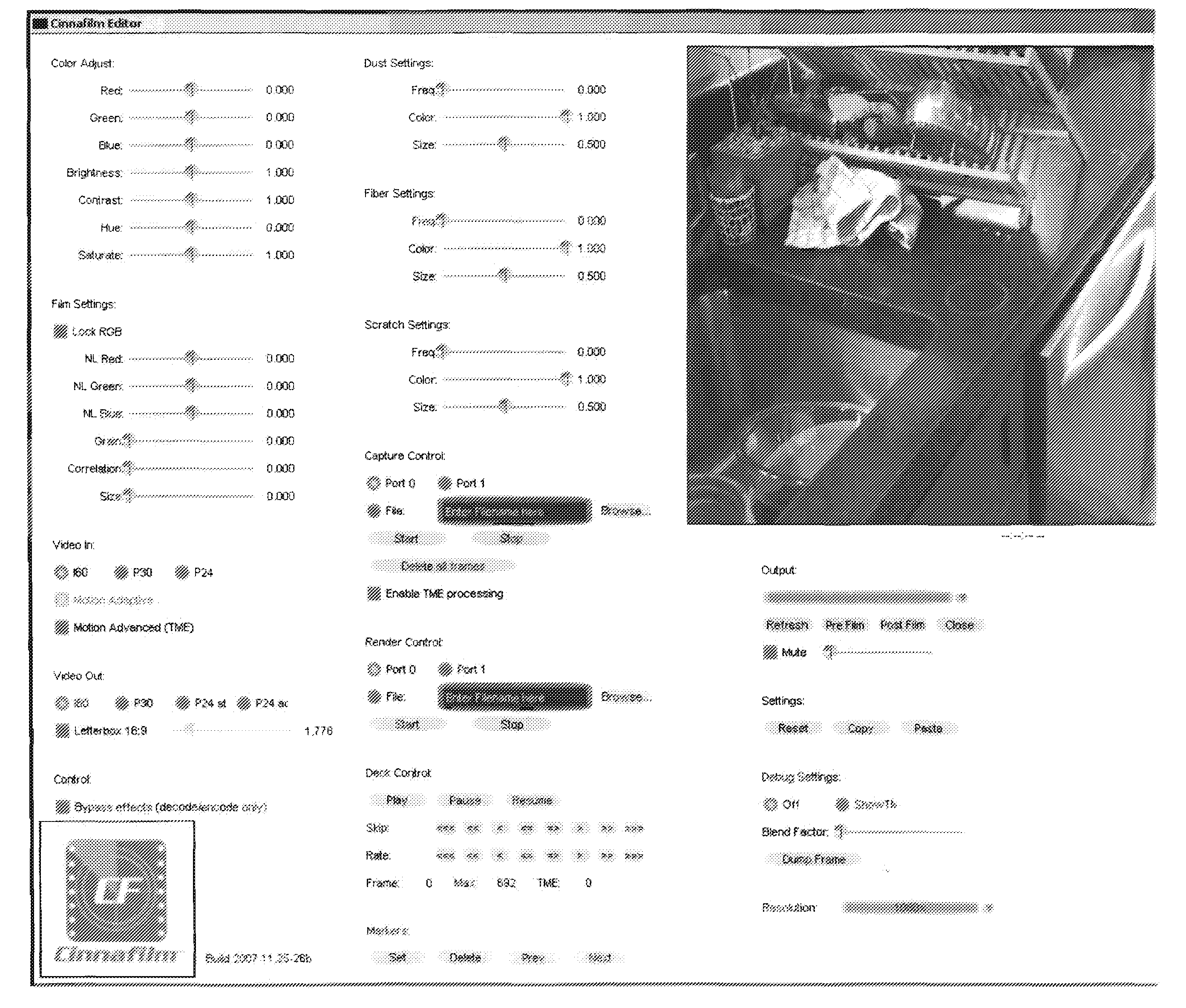

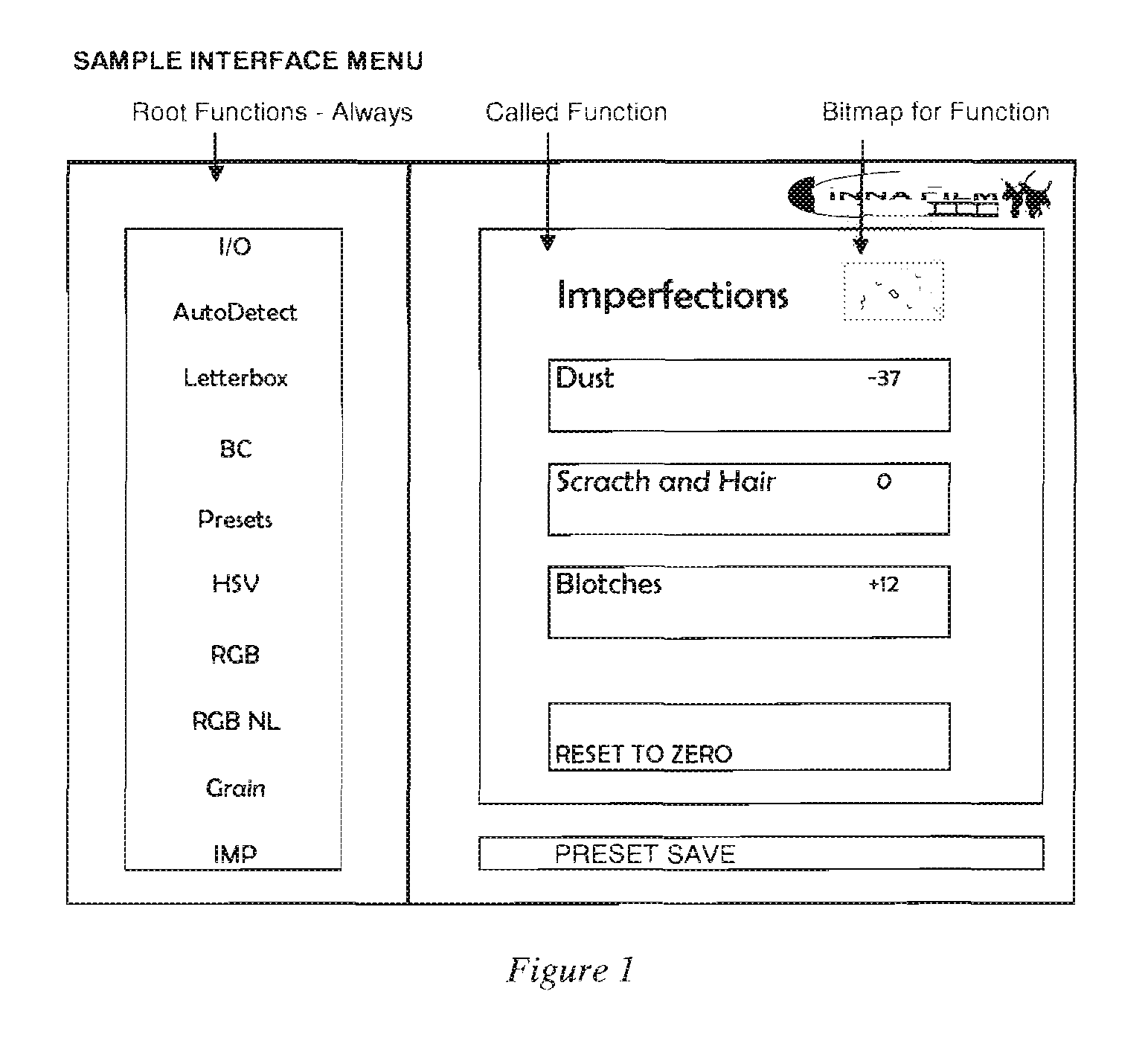

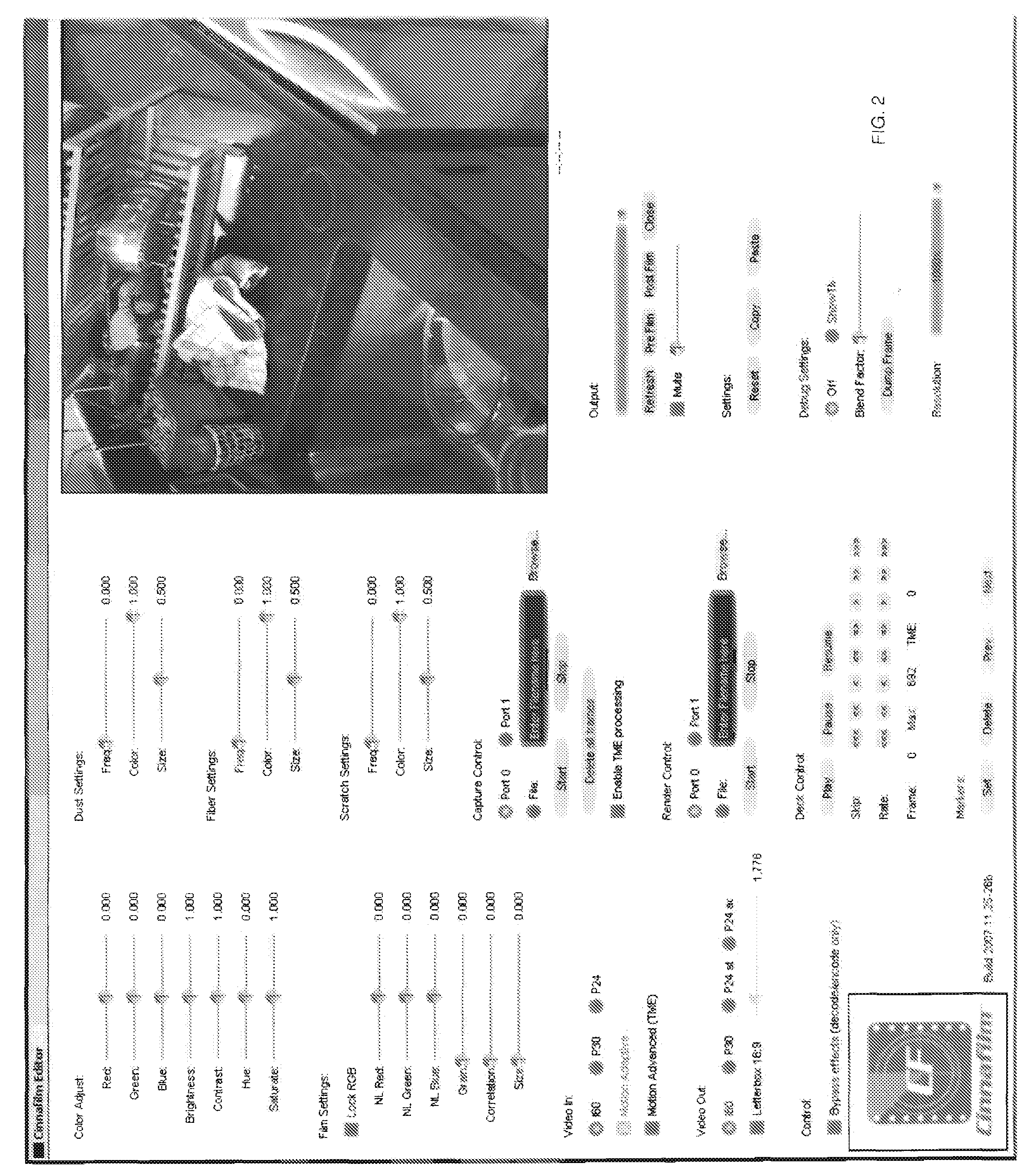

Real-time film effects processing for digital video

InactiveUS20080204598A1Avoid stutter artifactAvoid artifactsColor signal processing circuitsElectronic editing digitised analogue information signalsDigital videoComputer graphics (images)

A method, apparatus, and computer software for applying in real time imperfections to streaming video which causes the resulting digital video to resemble cinema film.

Owner:MAURER LANCE +2

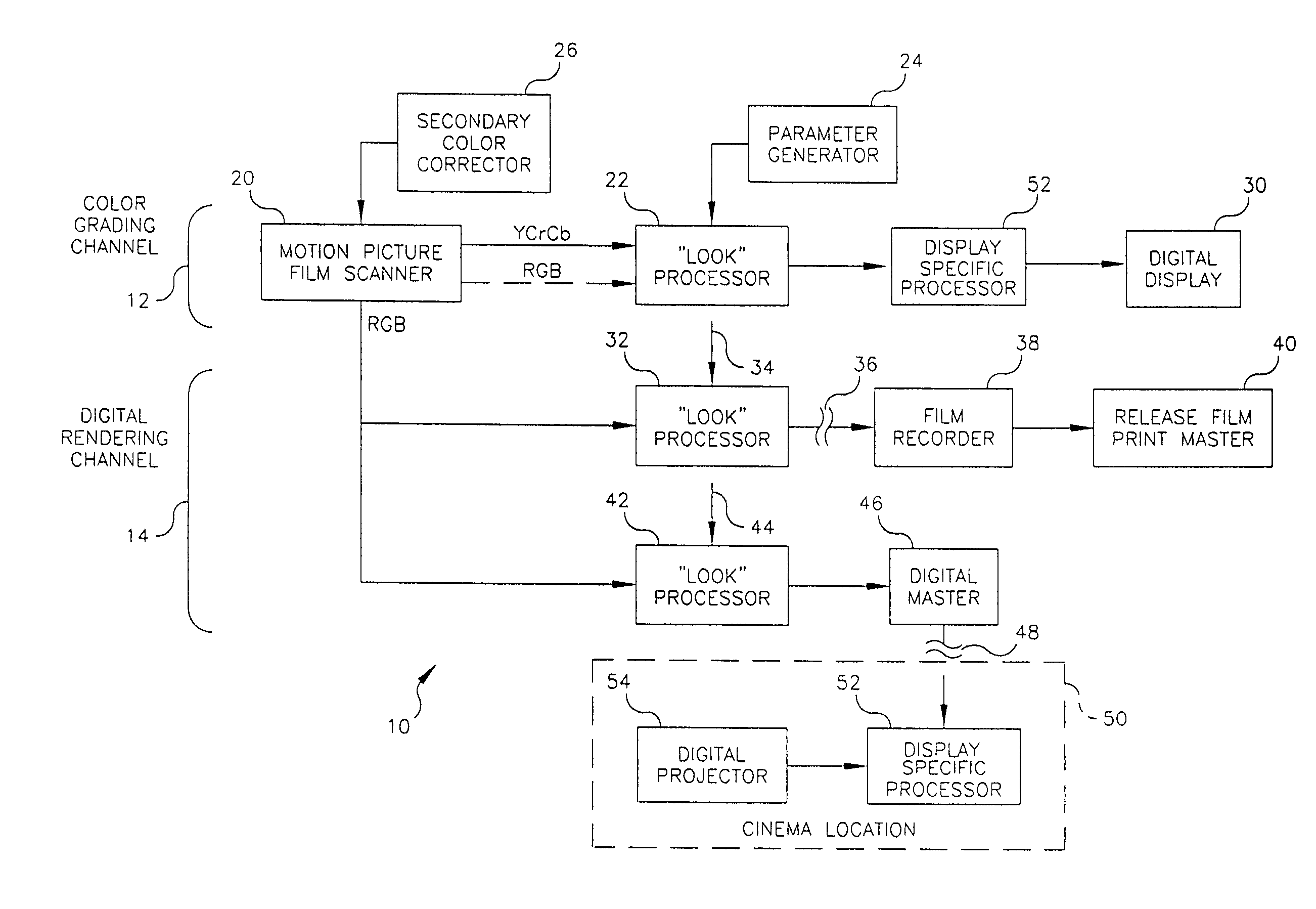

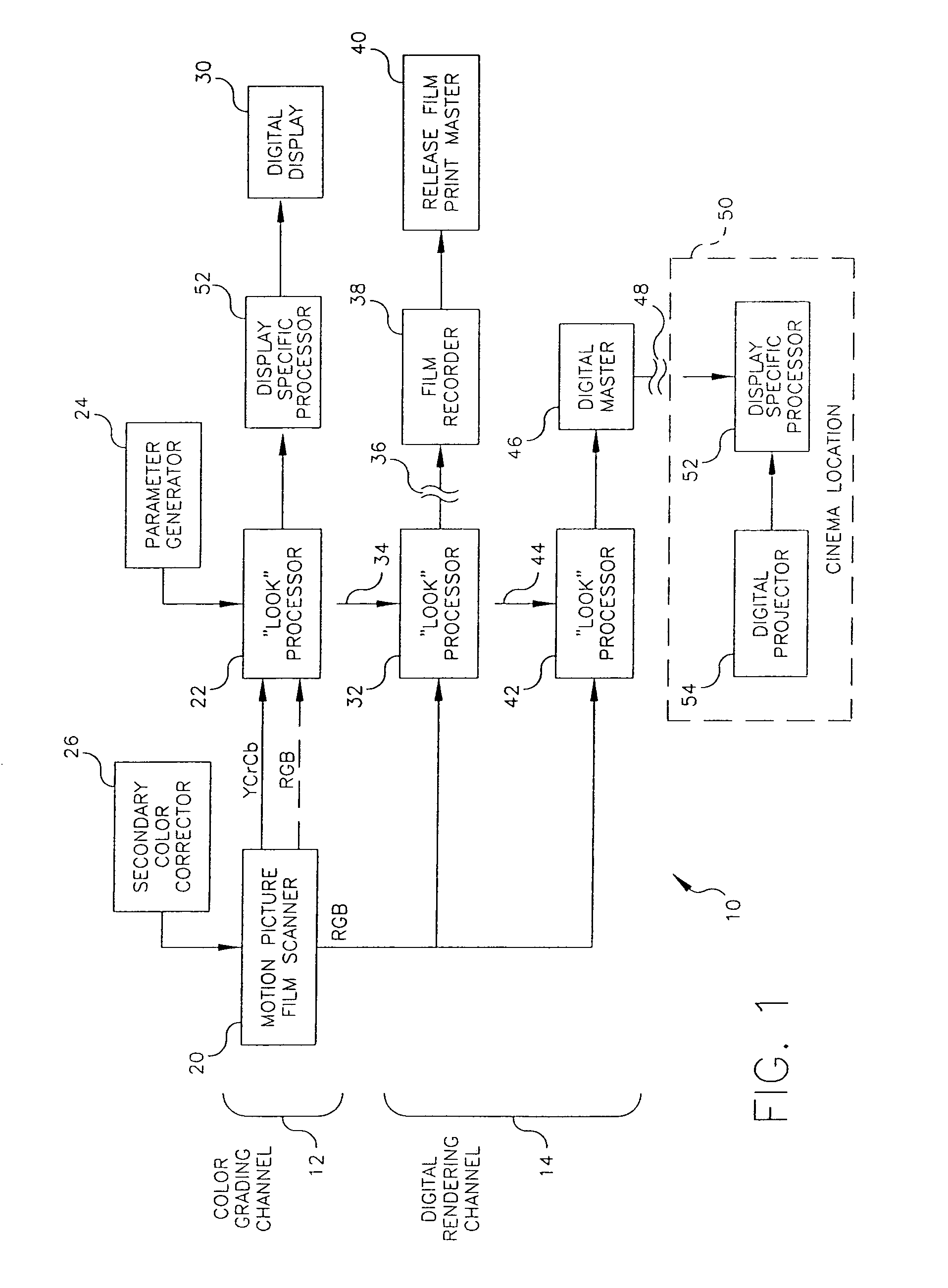

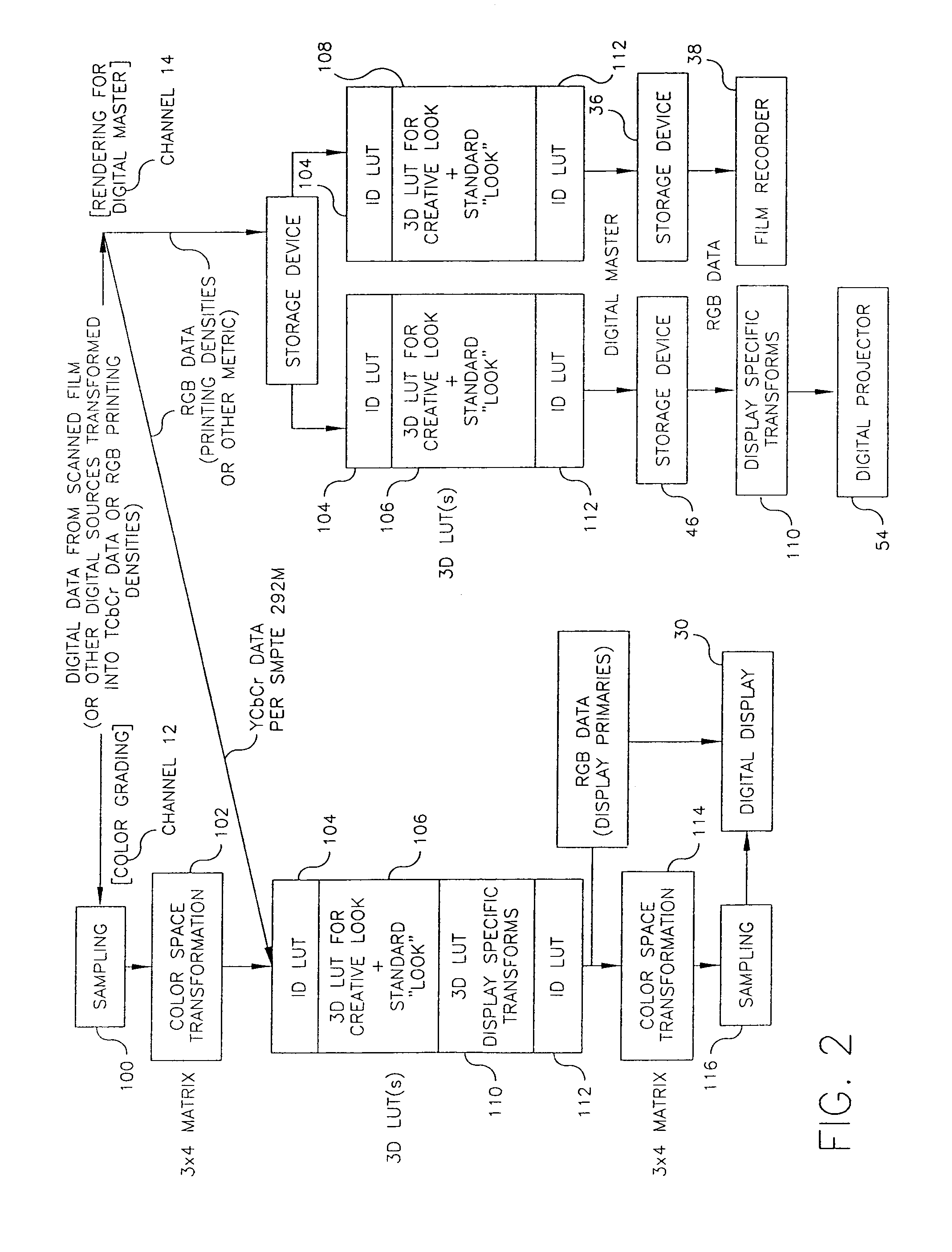

System for optimizing the display and rendering of digital images for digital mastering

ActiveUS7053927B2True colorImprove visualizationTelevision system detailsTelevision system scanning detailsDigital masterComputer graphics (images)

Owner:EASTMAN KODAK CO

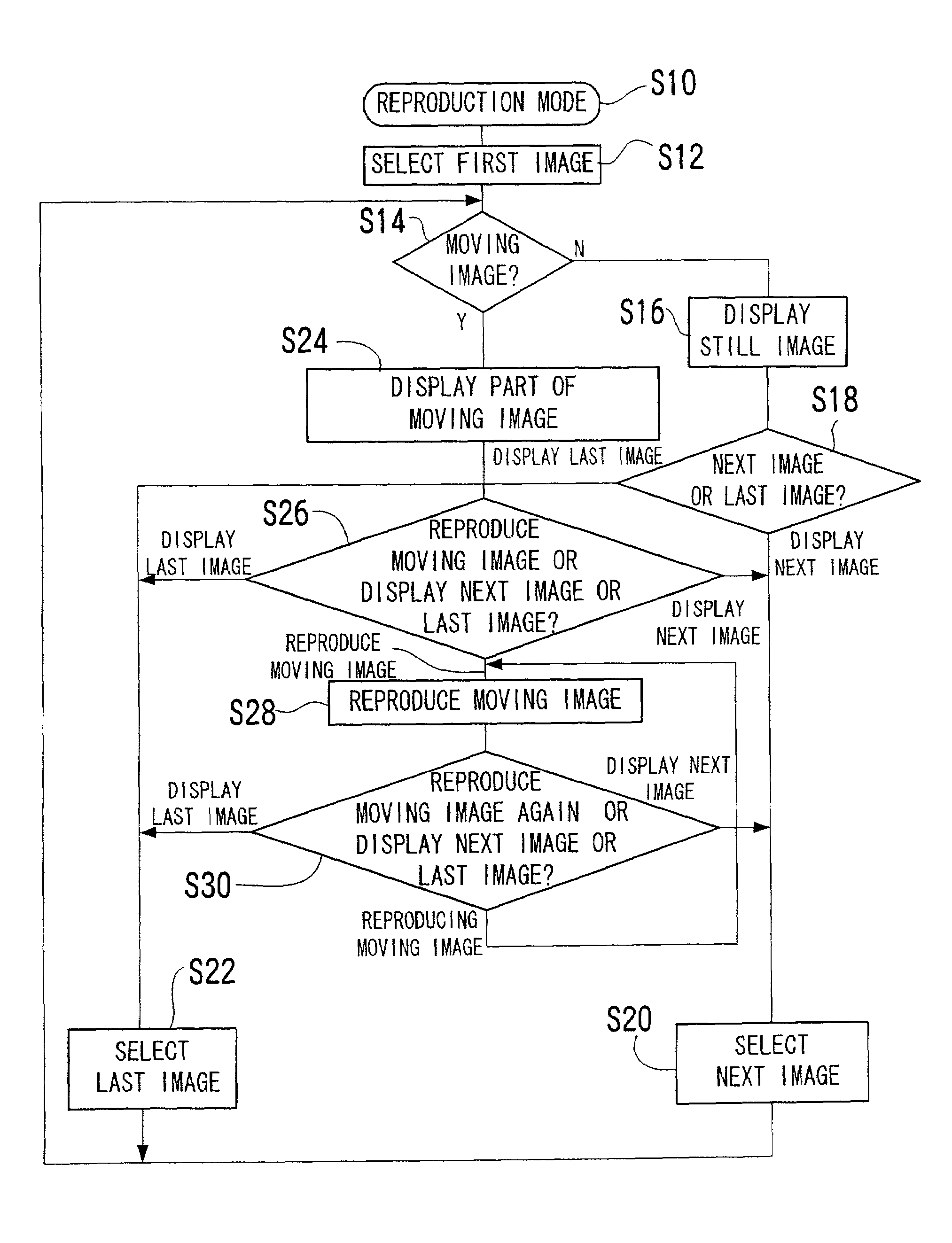

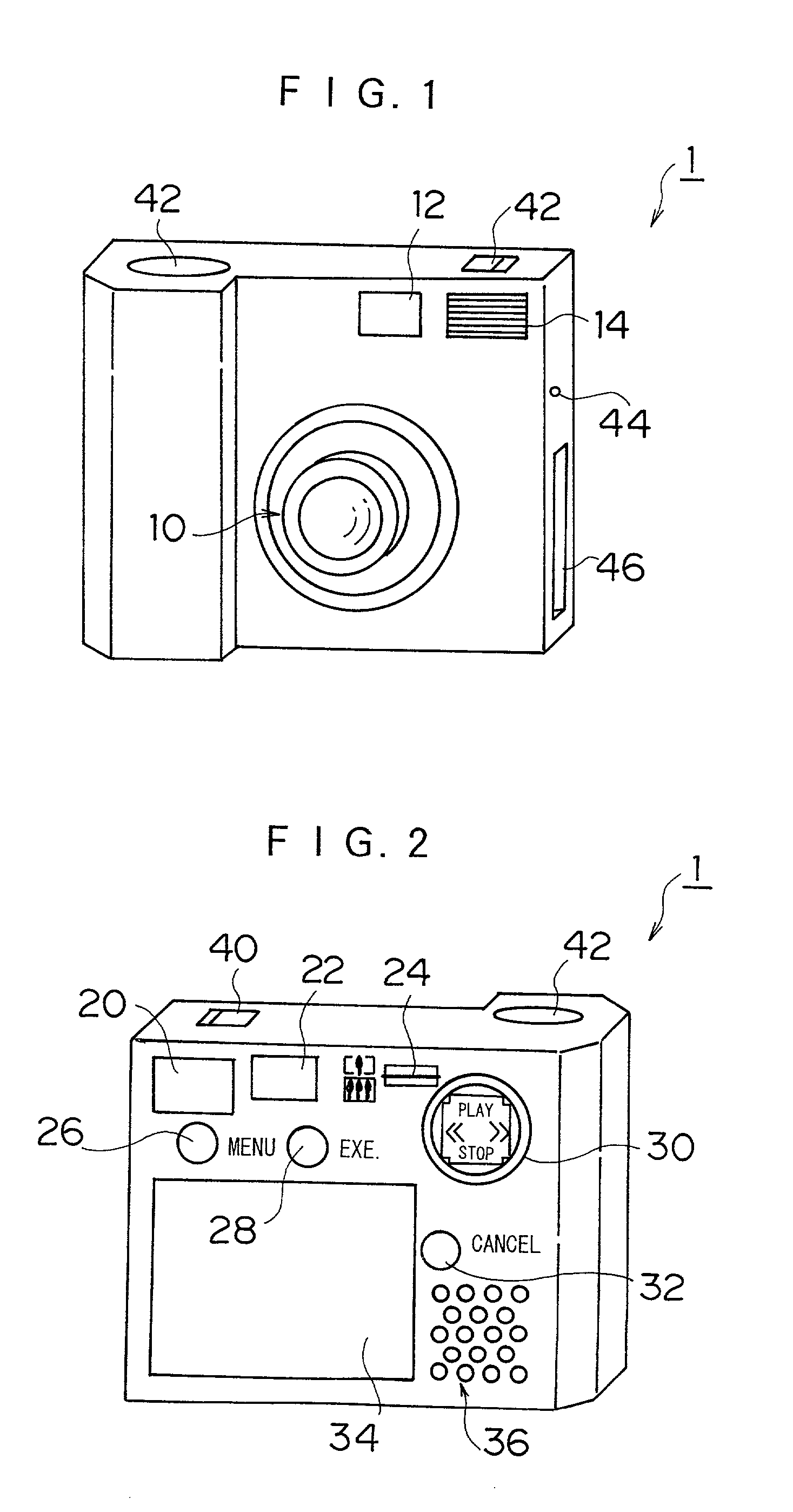

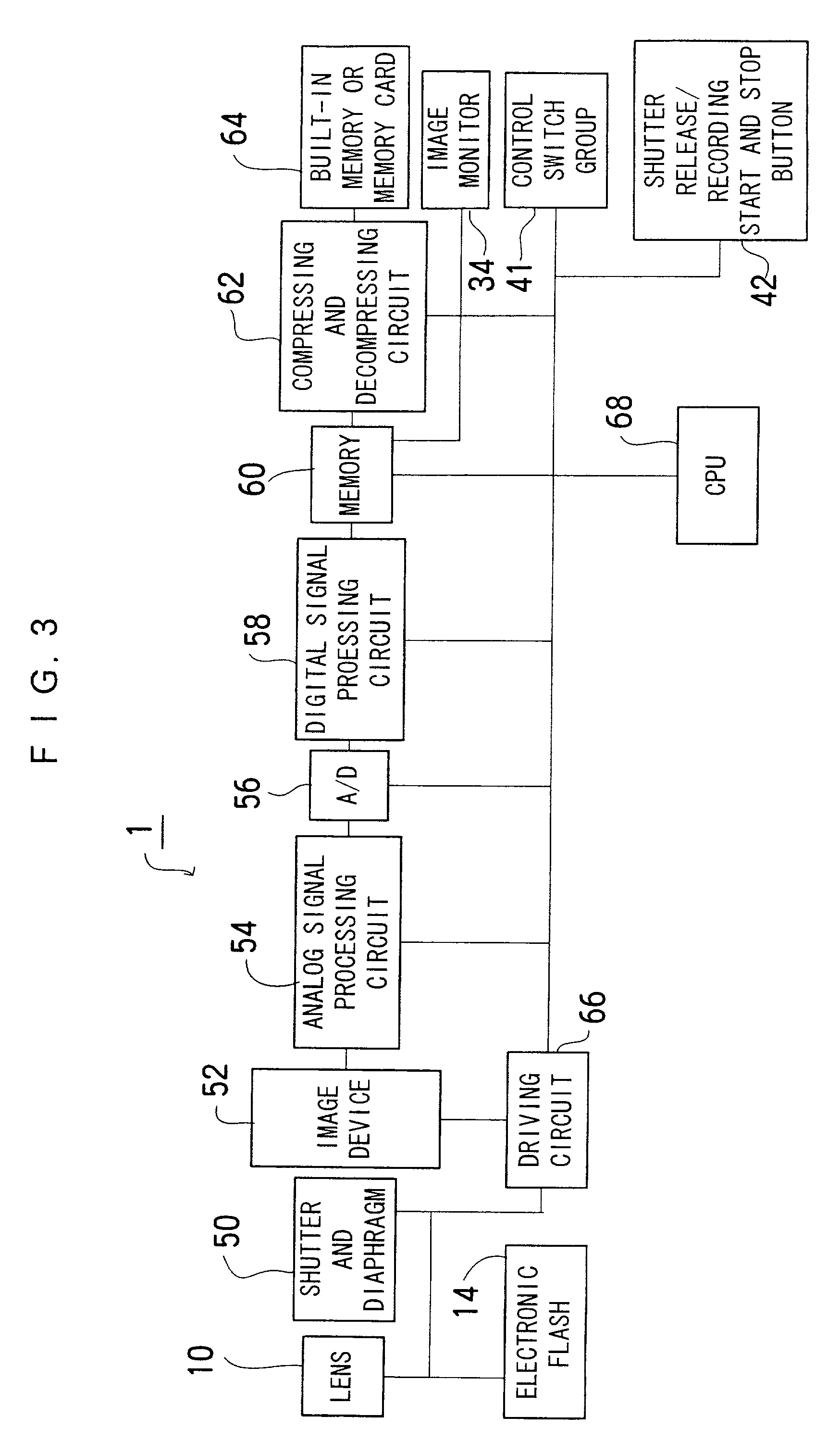

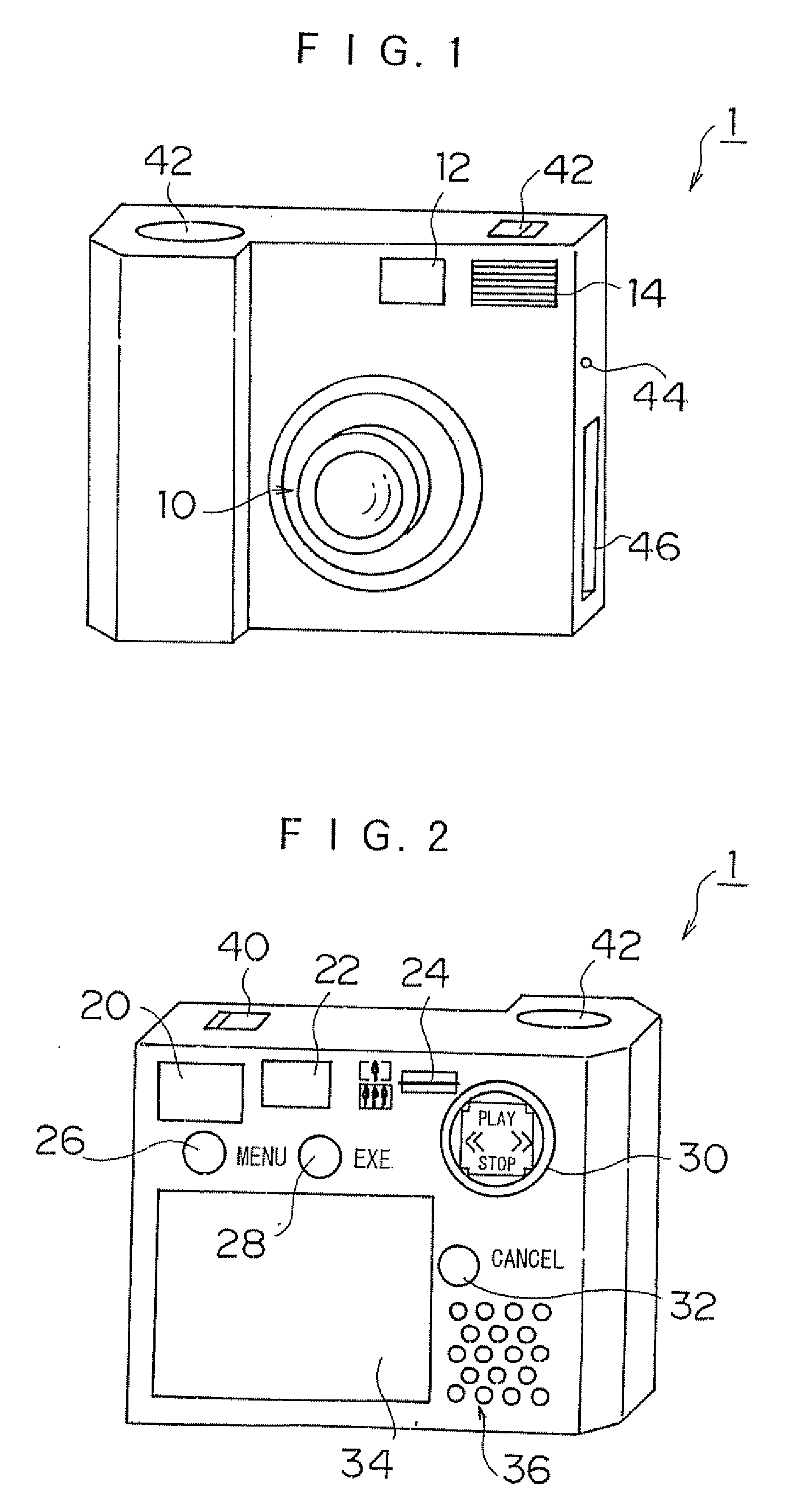

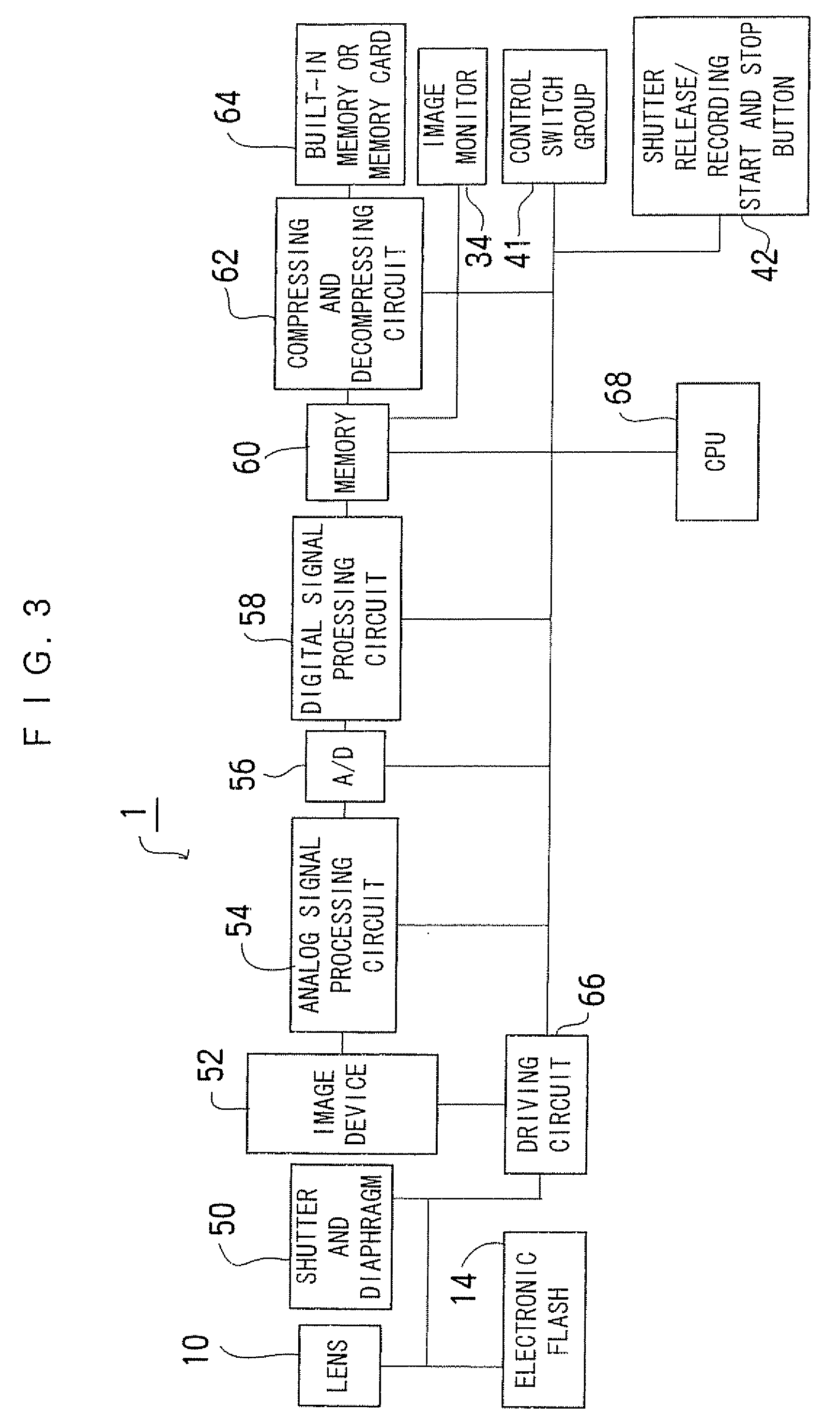

Multi-modal reproducing apparatus and digital camera

Owner:FUJIFILM CORP

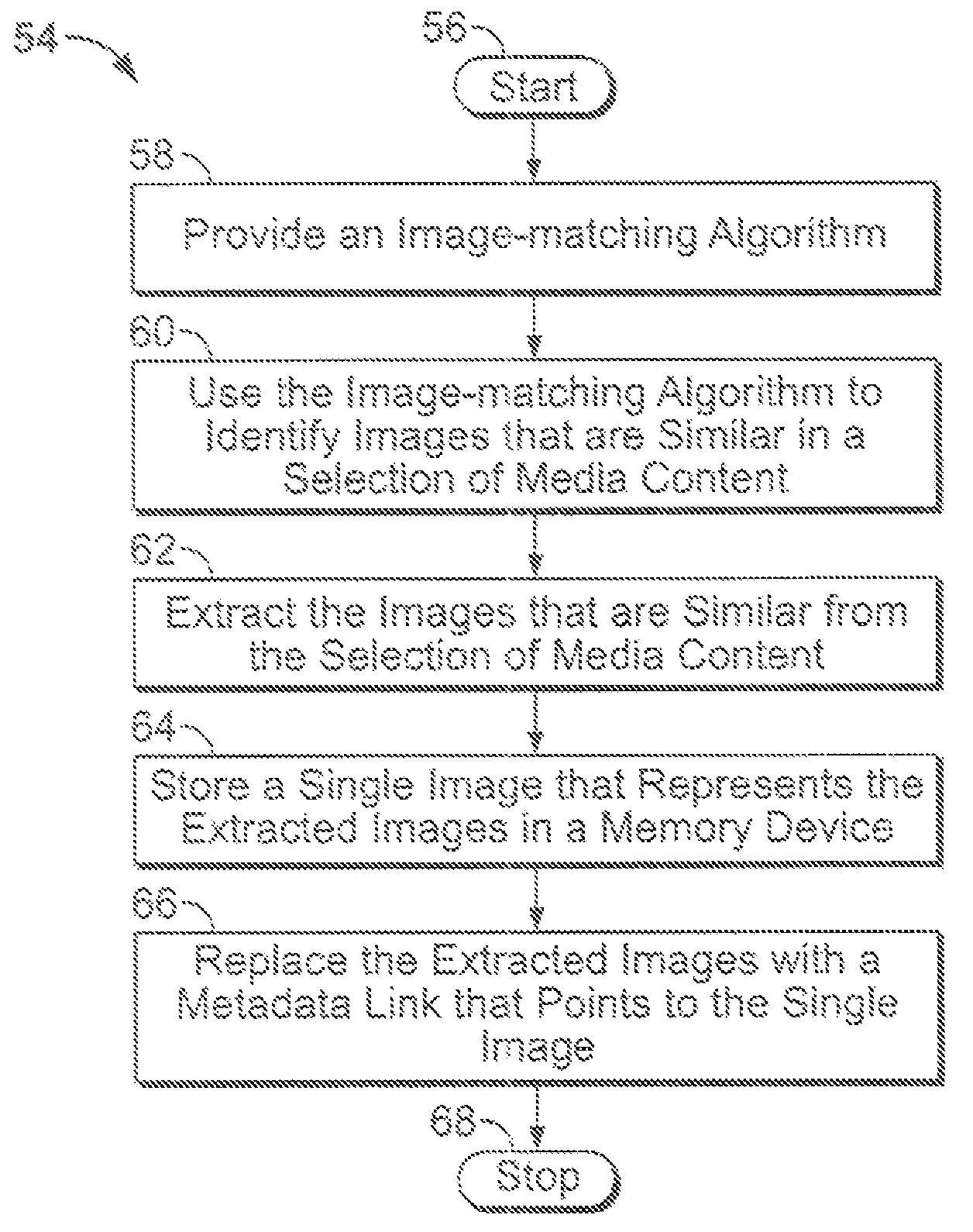

Method And Apparatus For Providing Lossless Data Compression And Editing Media Content

ActiveUS20080063287A1Electronic editing digitised analogue information signalsRecord information storageMatch algorithmsComputer graphics (images)

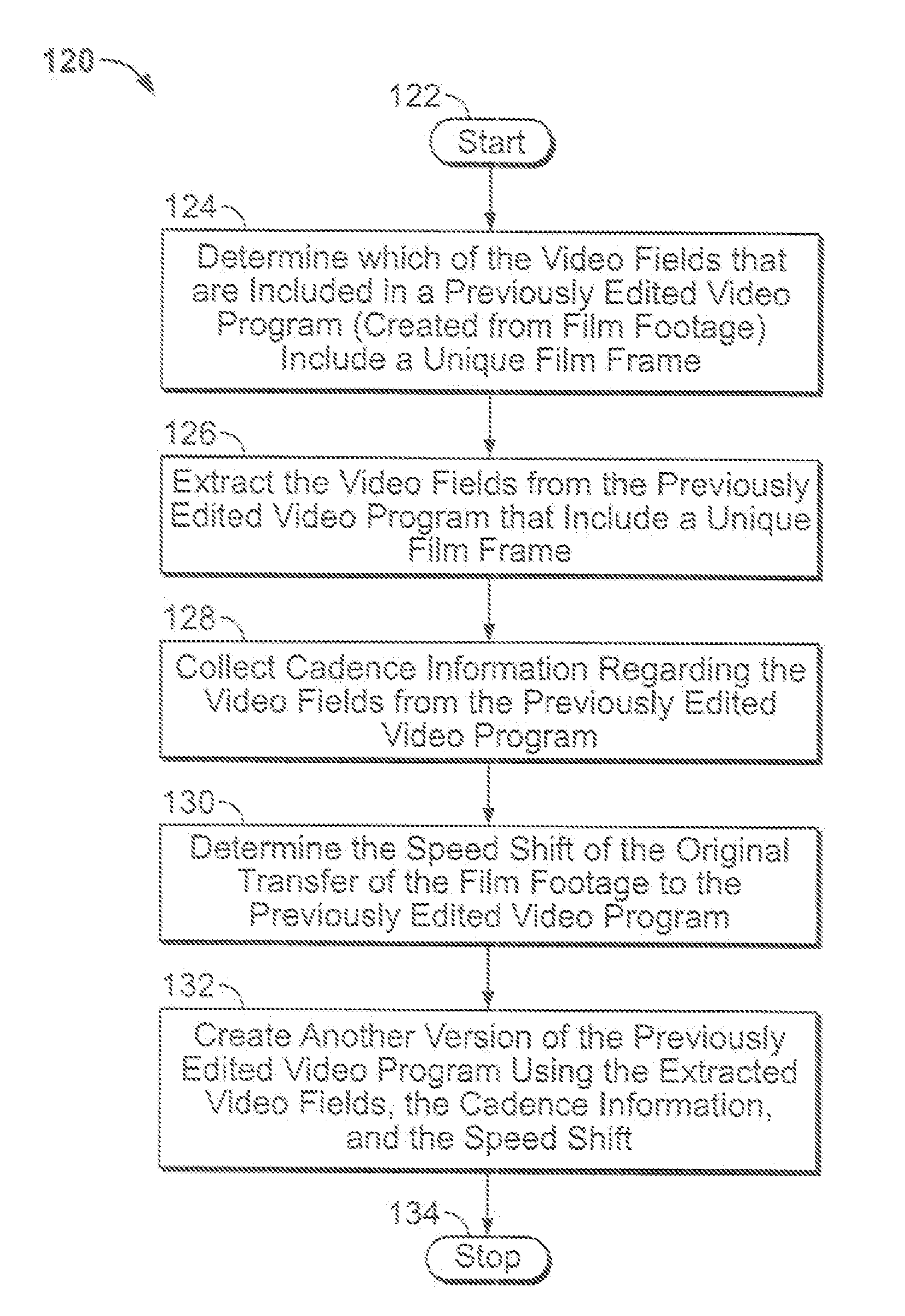

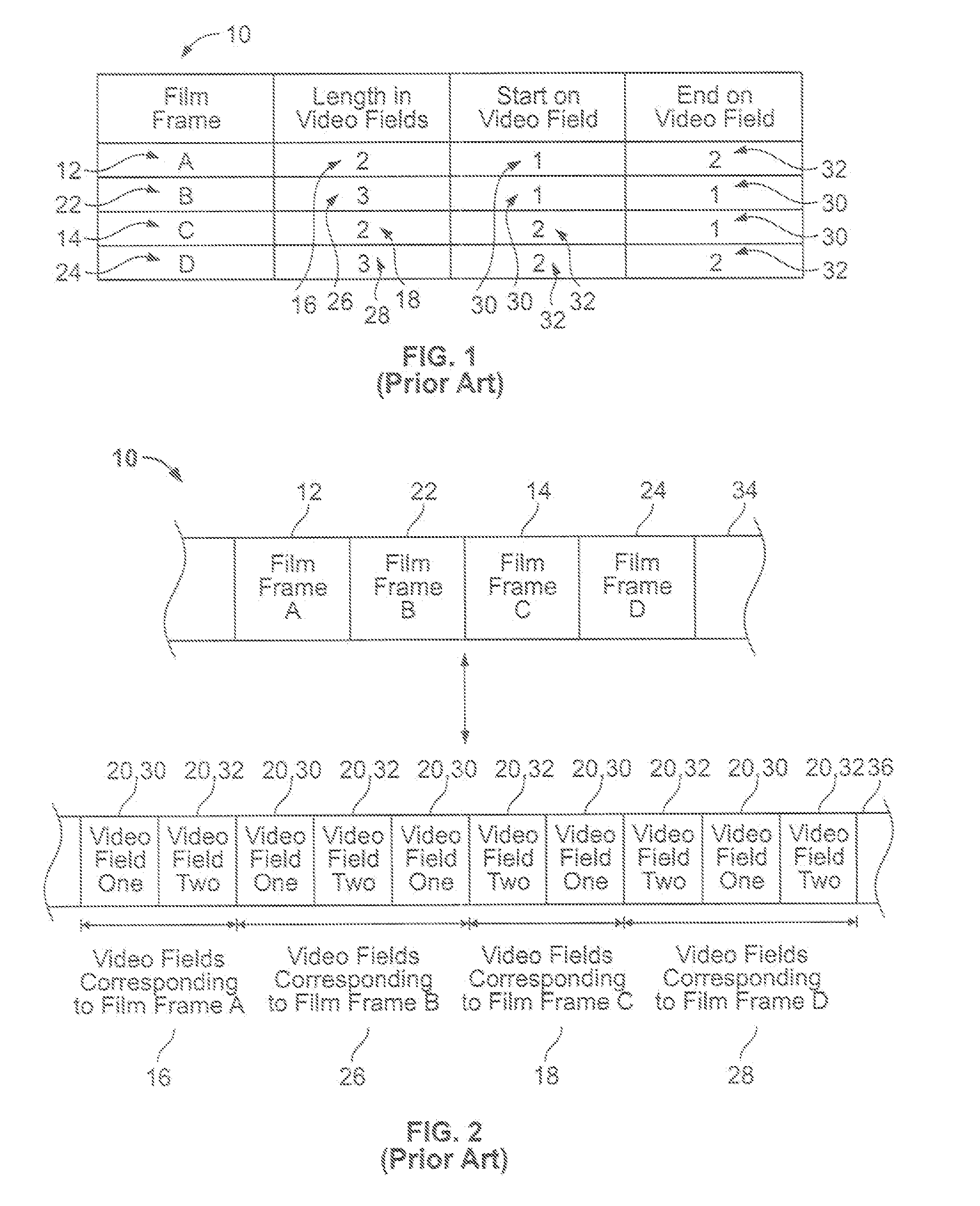

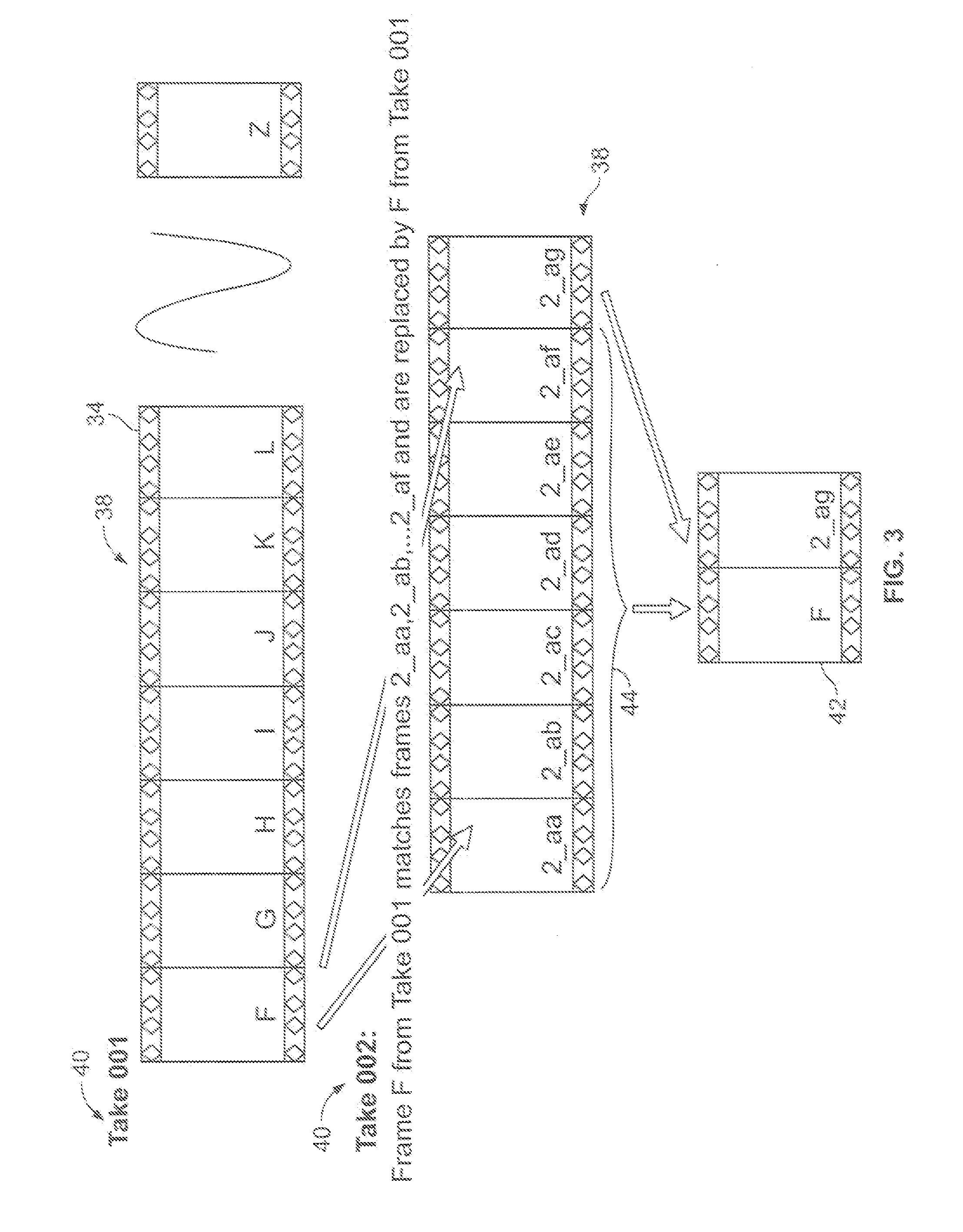

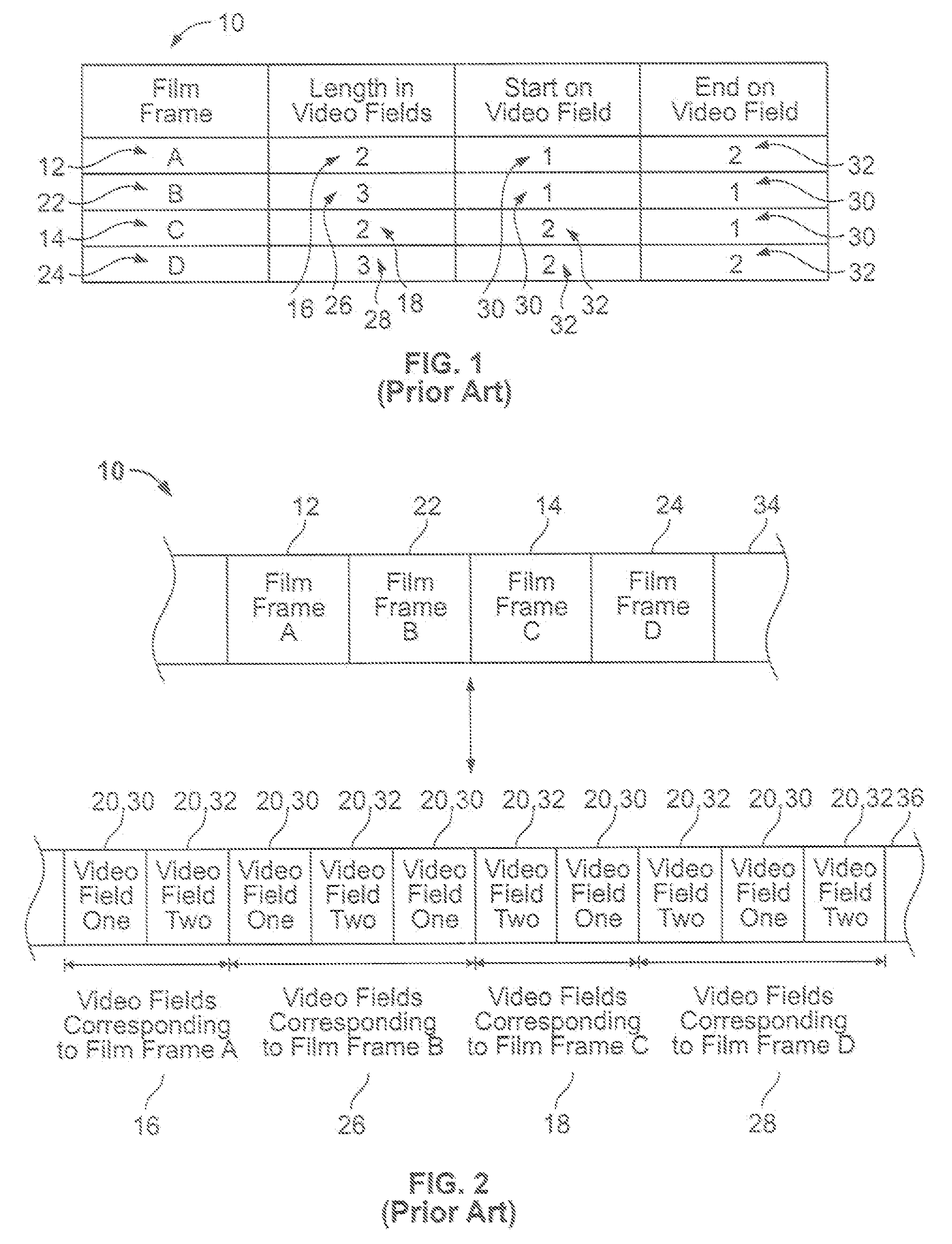

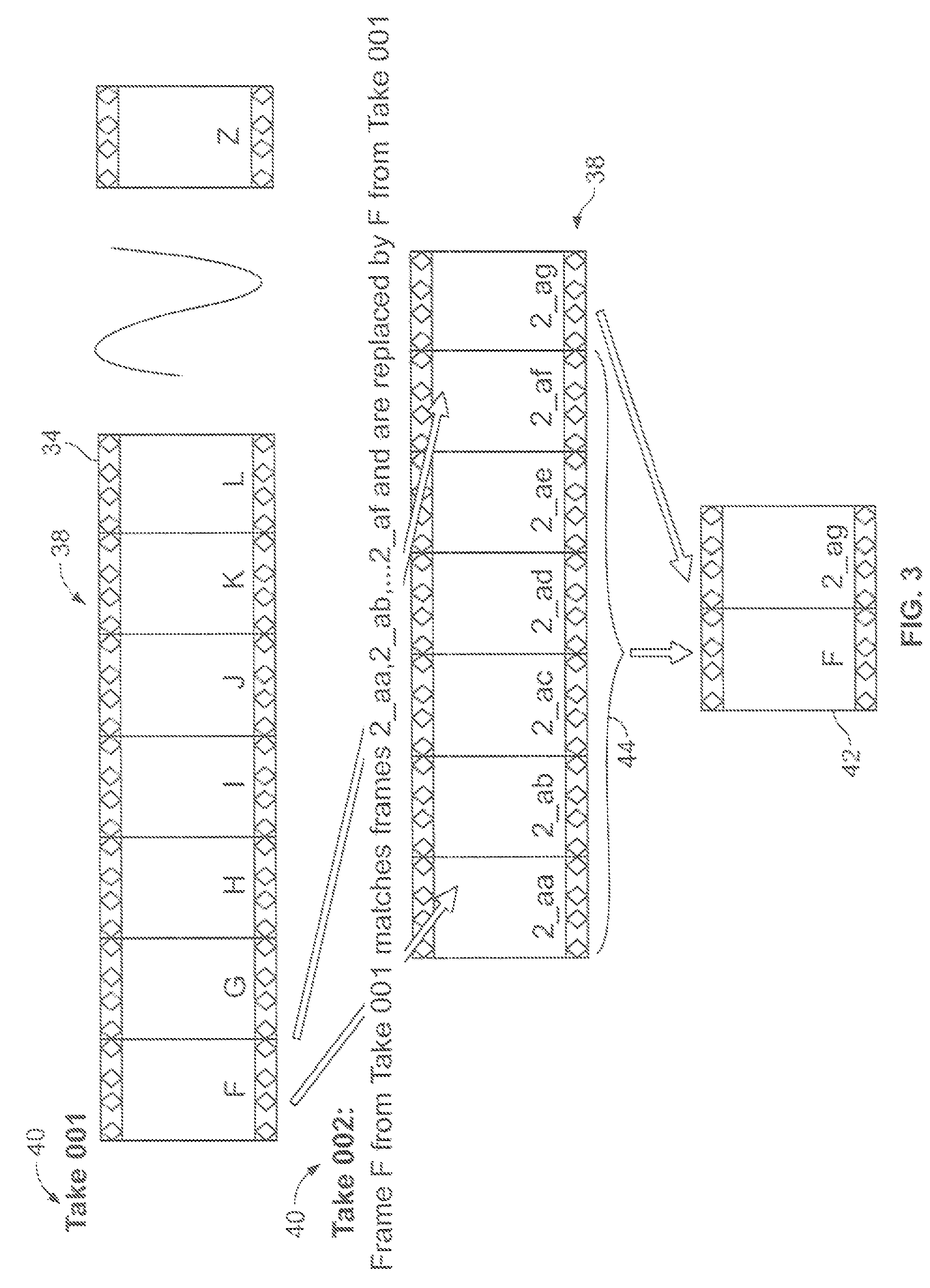

A method and a related apparatus for compressing images included in media content and editing the media content. The method can include providing an image-matching algorithm and a memory device, using the image-matching algorithm to identify images that are similar in a selection of media content extracting the images that are similar from the selection of media content, storing a single image that represents the extracted images in the memory device, and replacing the extracted images in the selection of media content with a metadata link that points to the single image. The method can further include providing a previously edited video program that originally was created from film footage, determining which of the video fields from the program include a unique film frame from the footage, and extracting the video fields from the program that include a unique film frame.

Owner:WARNER BROS ENTERTAINMENT INC

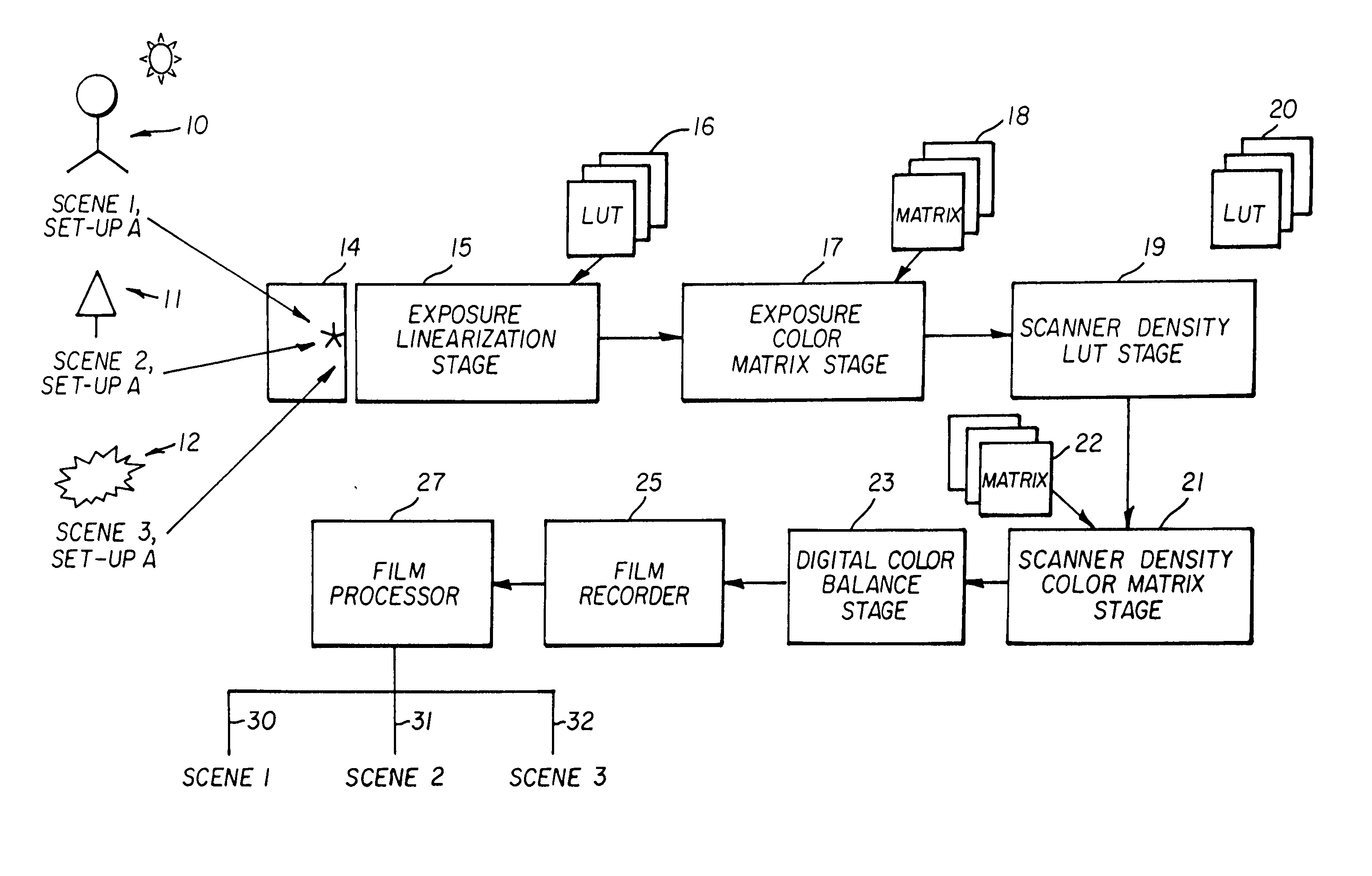

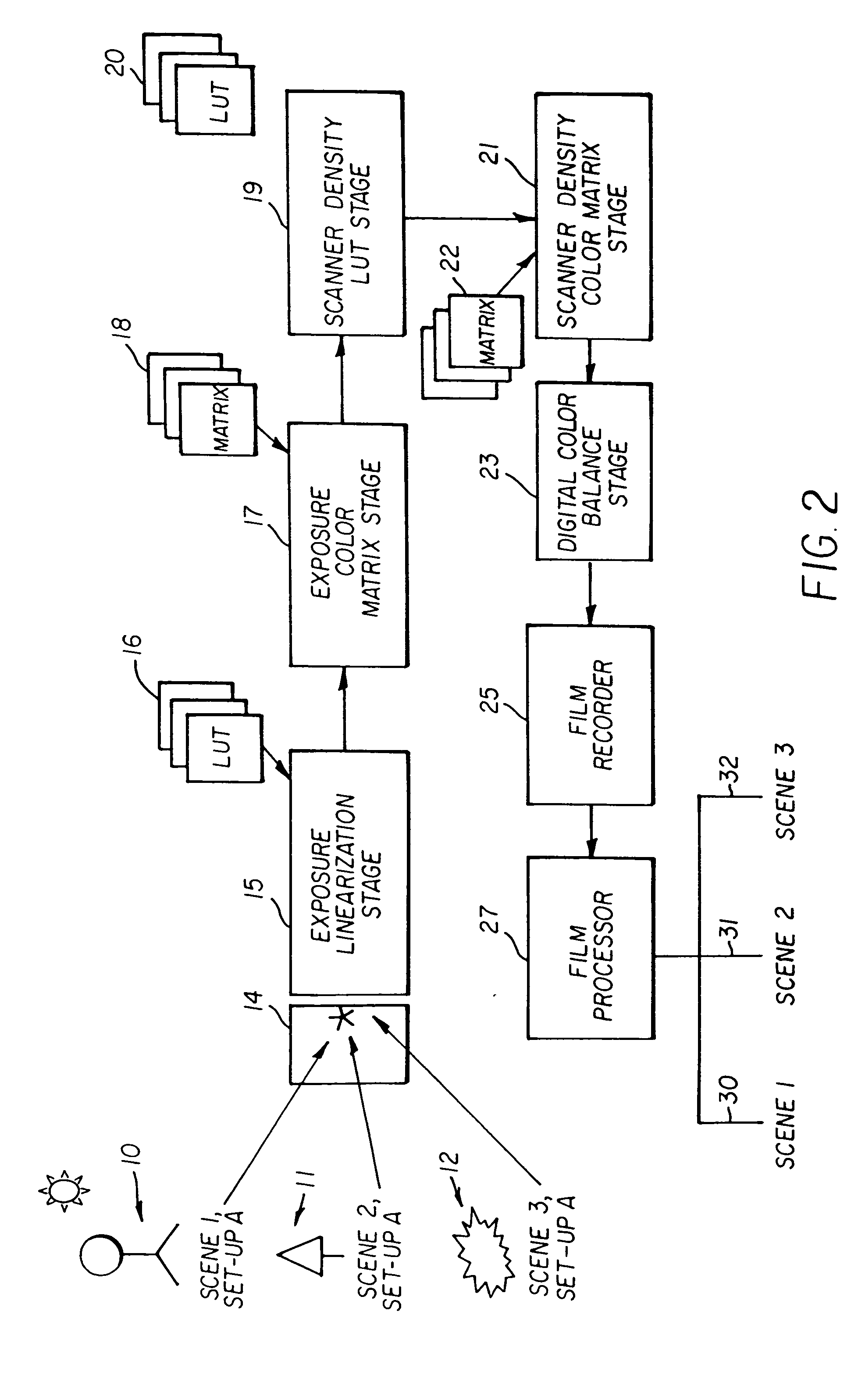

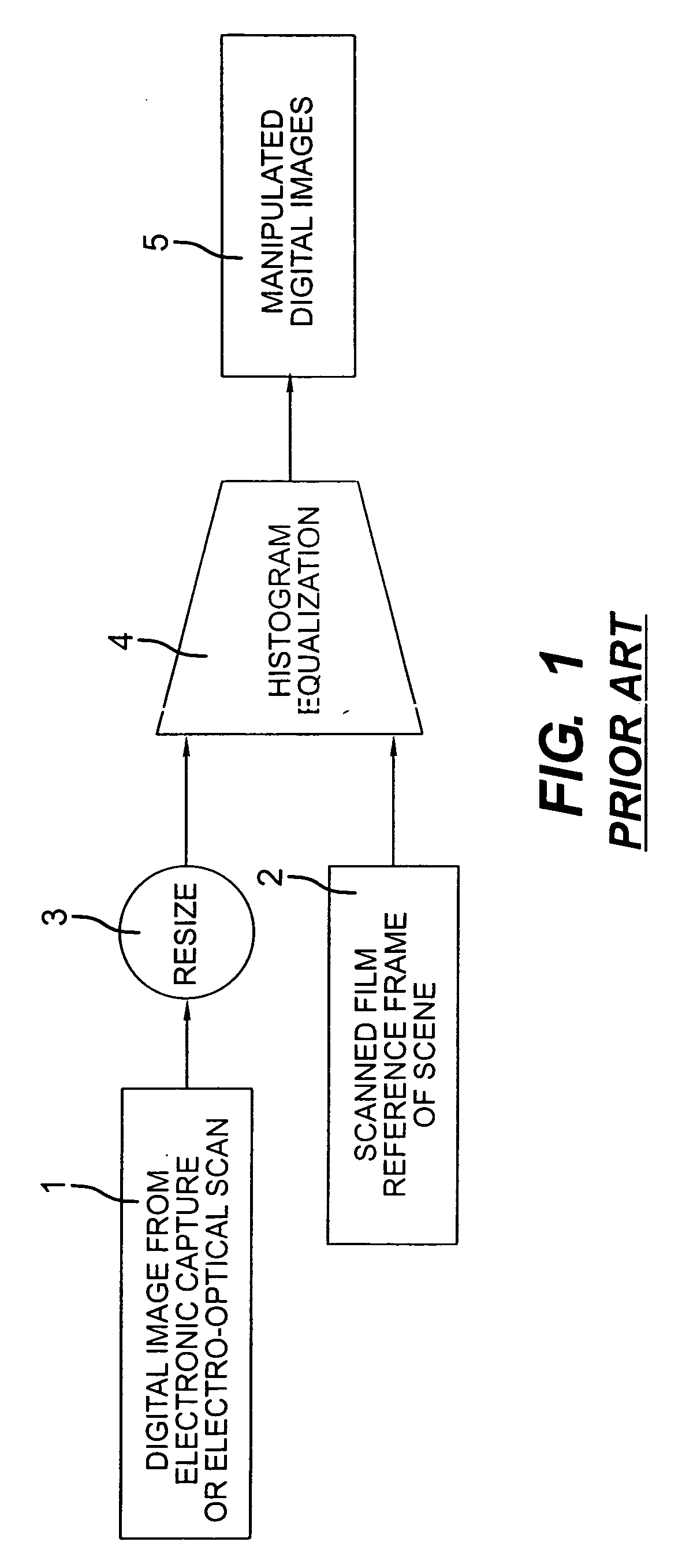

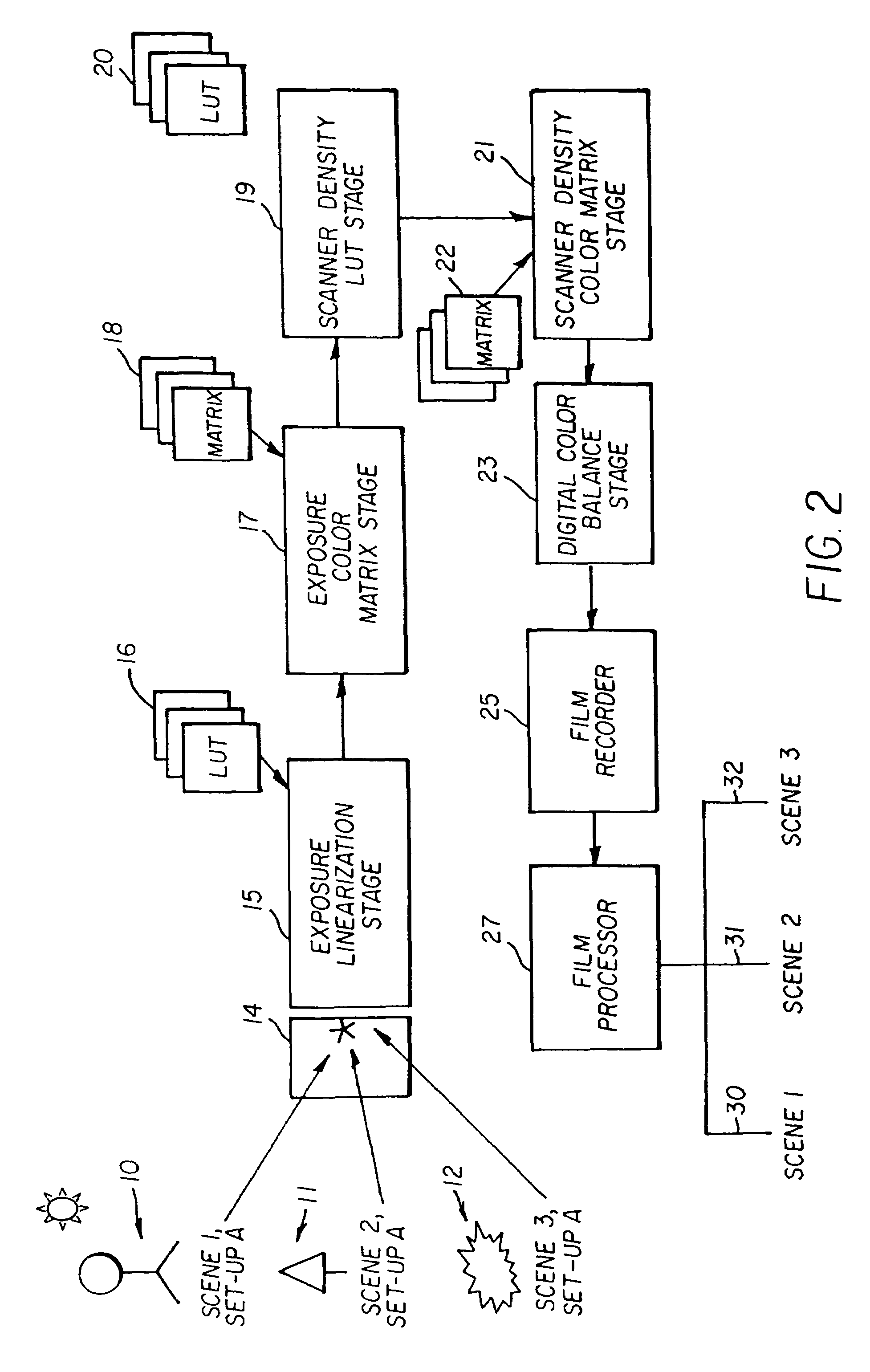

System and method for processing electronically captured images to emulate film tonescale and color

InactiveUS20050179775A1Change colorImage enhancementTelevision system detailsDigital dataDigital master

A method for converting a sequence of electronically captured images into a sequence of modified images for providing the appearance of images captured by a film reproduction system. The film reproduction system being includes motion picture negative film printed onto a motion picture print film that is displayed, or a reversal motion picture system in which the reversal film is displayed, or a motion picture film electro-optically scanned to standard format video by a telecine and further displayed, or a motion picture film electro-optically scanned by a scanner suitable for producing digital data intended for additional digital image manipulation. A digital master is prepared from the aforementioned film formats for electronic distribution or recording out to another film to be used as a printing master for producing distribution optical prints for theatrical projection.

Owner:INTELLECTUAL VENTURES FUND 83 LLC

Method and apparatus for providing lossless data compression and editing media content

ActiveUS7805011B2Electronic editing digitised analogue information signalsRecord information storageMatch algorithmsComputer graphics (images)

A method and a related apparatus for compressing images included in media content and editing the media content. The method can include providing an image-matching algorithm and a memory device, using the image-matching algorithm to identify images that are similar in a selection of media content extracting the images that are similar from the selection of media content, storing a single image that represents the extracted images in the memory device, and replacing the extracted images in the selection of media content with a metadata link that points to the single image. The method can further include providing a previously edited video program that originally was created from film footage, determining which of the video fields from the program include a unique film frame from the footage, and extracting the video fields from the program that include a unique film frame.

Owner:WARNER BROS ENTERTAINMENT INC

Method for adjusting digital images to compensate for defects on film material

InactiveUS7012642B1Shorten the timeCompensation effectTelevision system detailsTelevision system scanning detailsFilm-outDigital image

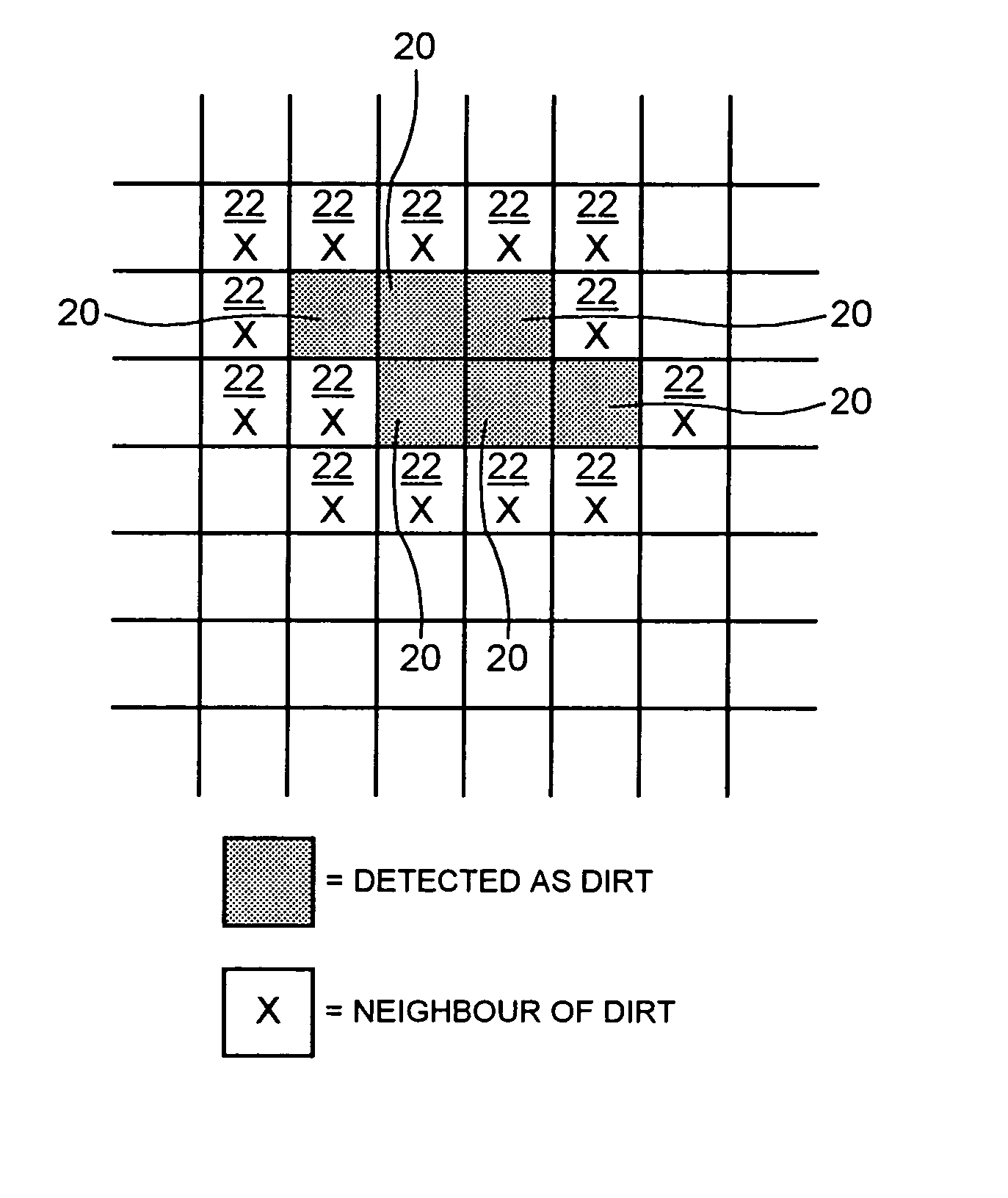

A method of scanning frames of cinematographic film to generate digital values of pixels constituting images on the film frames is provided in which pixels corresponding to defects on the film are identified and the values of such pixels are adjusted to compensate for the defects, the identification of the pixels corresponding to defects on the film being carried out by identifying pixels whose value is beyond a predetermined threshold.A method of correcting for flicker in digital images obtained by scanning cinematographic film is also provided. This method comprises the steps of identifying frames in which flicker is present; identifying relatively bright regions in those frames whose brightness is above a predetermined level, and correcting digital pixels in those relatively bright regions so as to compensate for the effect of flicker.

Owner:PANDORA INT

Method for processing motion pictures at high frame rates with improved temporal and spatial resolution, resulting in improved audience perception of dimensionality in 2-D and 3-D presentation

InactiveUS20090027549A1Same image claritySame smoothnessPicture reproducers using cathode ray tubesProjectorsHigh frame rateFilm-out

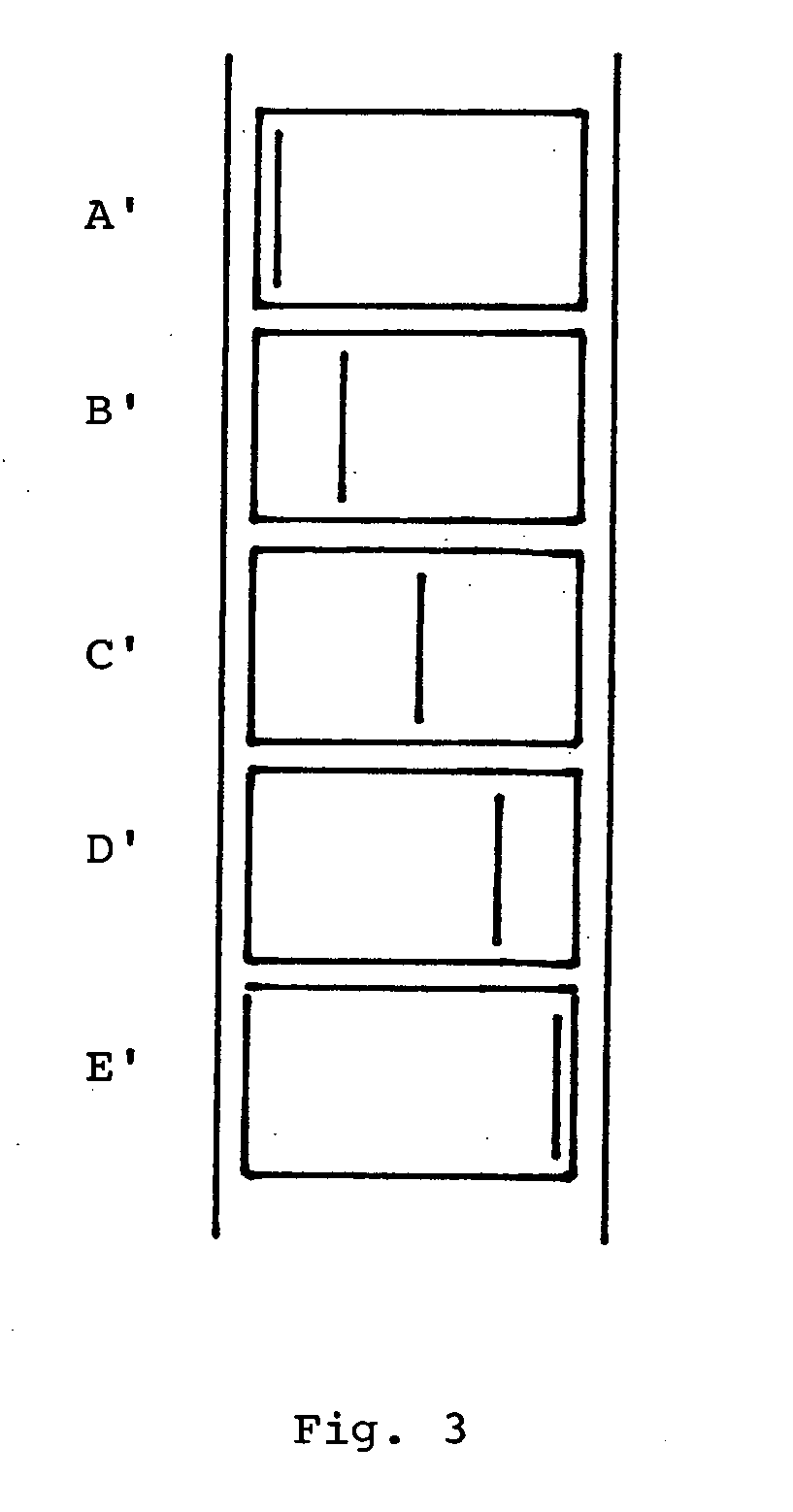

Previously-produced motion picture films are enhanced for theatrical exhibition, at double the frame rate at which they were originally produced. New images are interpolated between each of the images of the original film. These interpolated images are generated through the use of computer software that analyzes the actual horizontal and vertical displacement of each pixel of every image of the original motion picture, so the interpolated images accurately depict the exact image that would have been captured, if the original motion picture had been produced at double the actual frame rate of production. This enhancement technique can be used selectively for certain scenes or sequences of a motion picture, and not for others. Film or digital projection is suitable. Two-dimensional or three-dimensional motion pictures can be enhanced according to the method described, and motion pictures photographed at high frame rates can be converted to conventional frame rates for general release.

Owner:WEISGERBER ROBERT C

High-thermal-conductive moisture permeable film and preparation method thereof

InactiveCN103194058AImprove thermal conductivityHigh standardChemical industryPolymer scienceFilm base

The invention discloses a high-thermal-conductive moisture permeable film and a preparation method of the high-thermal-conductive moisture permeable film. The high-thermal-conductive moisture permeable film comprises a film base material and a high-thermal-conductive filler, wherein the high-thermal-conductive filler accounts for 1-10wt% of the total weight of the film base material and the high-thermal-conductive filler, and the film base material is as balance. The preparation method of the high-thermal-conductive moisture permeable film comprises the following steps of 1. casting liquid preparation: dissolving the film base material and the high-thermal-conductive filler into corresponding solvents according to the proportion to prepare the casting liquid, heating, and uniformly stirring through ultrasonic shaking for spare; 2. film preparation with a dry method: performing film wiping treatment on the casting liquid, wherein the thickness of the film is controlled to be 150-250mum, placing the film in the air for 24 hours to enable the solvent to volatilize naturally; or film preparation with a wet method: performing film wiping treatment on the casting liquid, wherein the thickness of the film is controlled to be 150-250mum, and then placing the film into a coagulation bath for film formation with the wet method, taking the film out after 5-10 minutes, placing the film into purified water and standing for 30-50 hours to remove the solvent, and then drying. The high-thermal-conductive moisture permeable film has high thermal conductive coefficient, and has high total heat recovery efficiency while having high selectivity.

Owner:GUILIN UNIV OF ELECTRONIC TECH

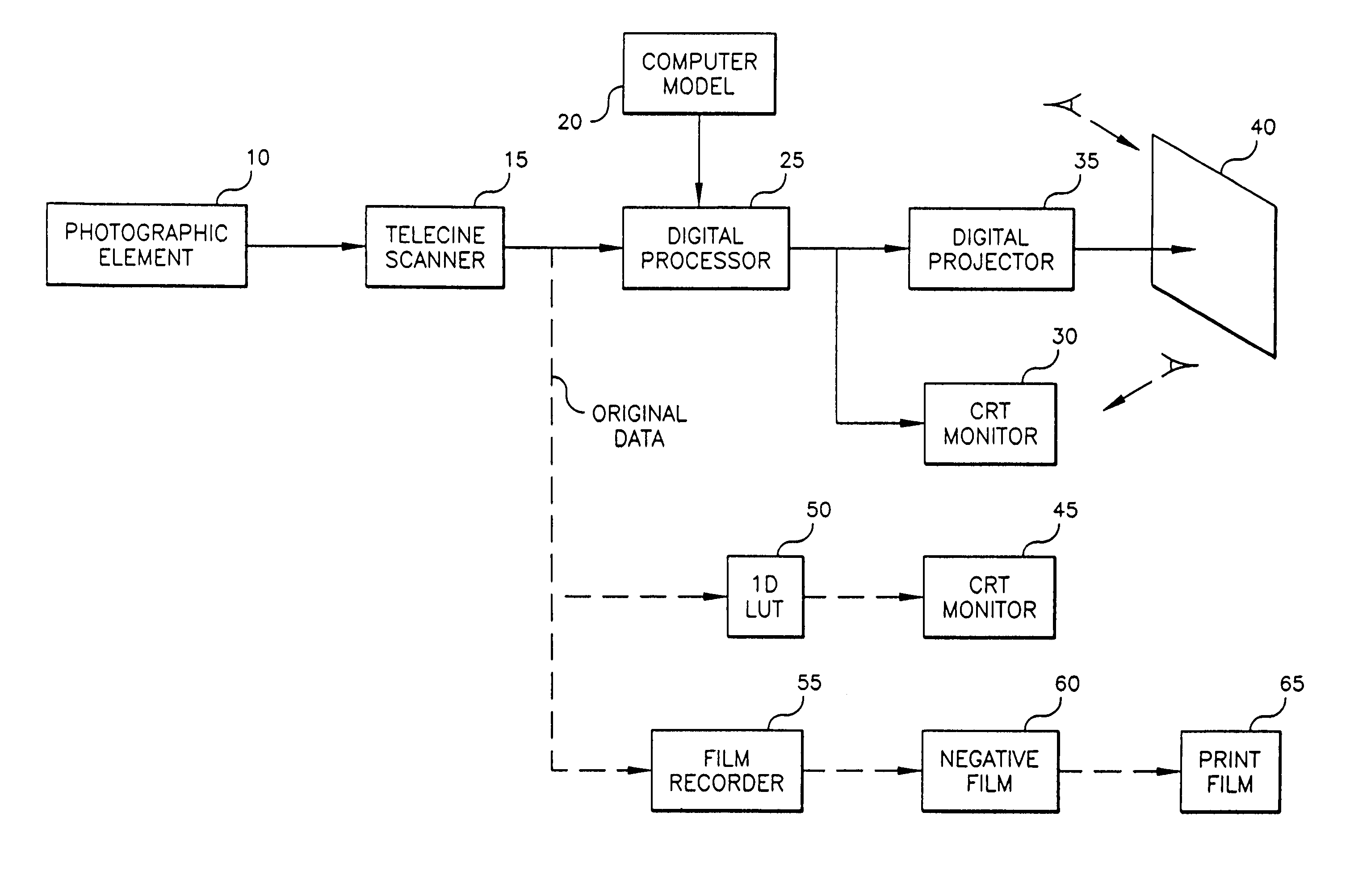

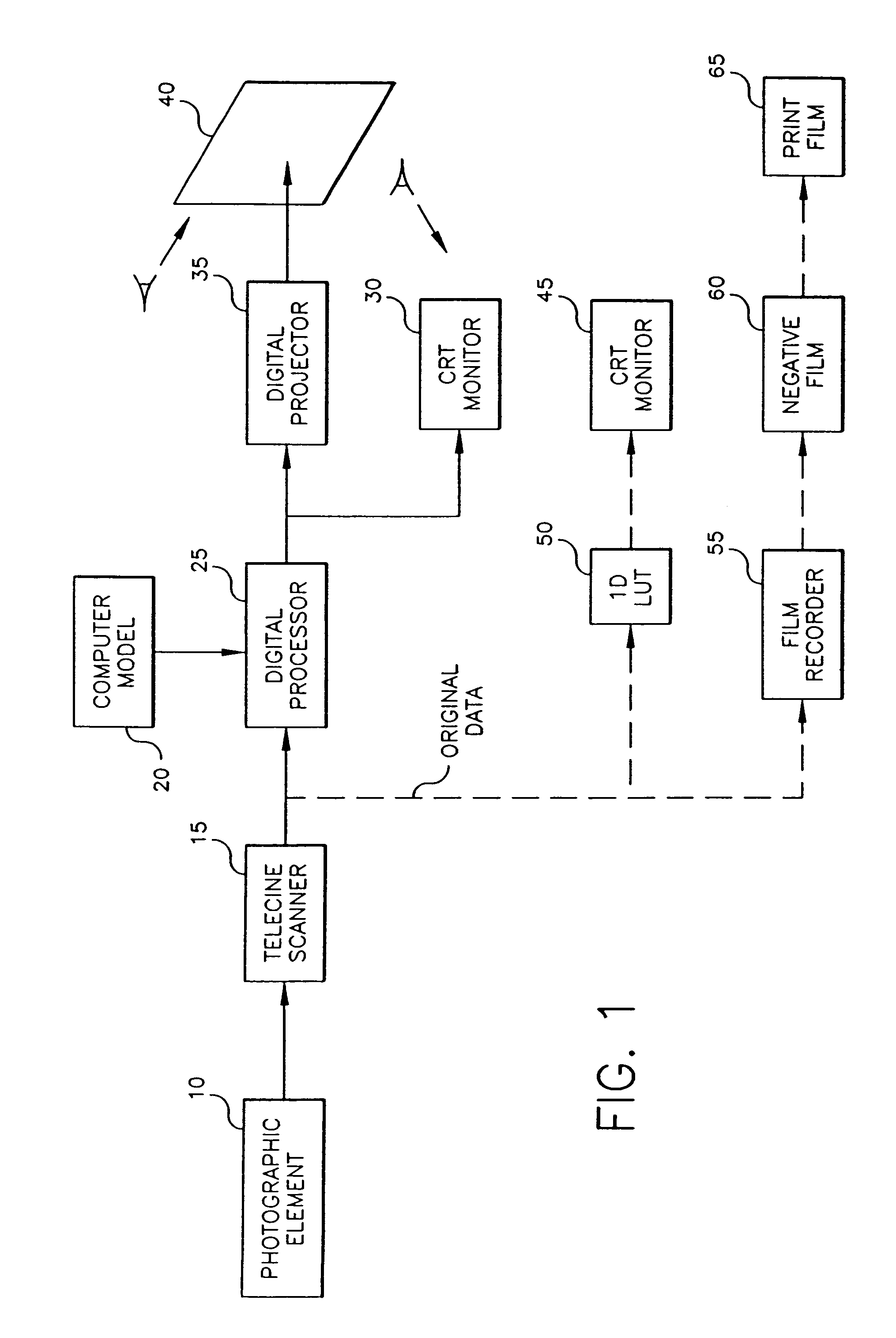

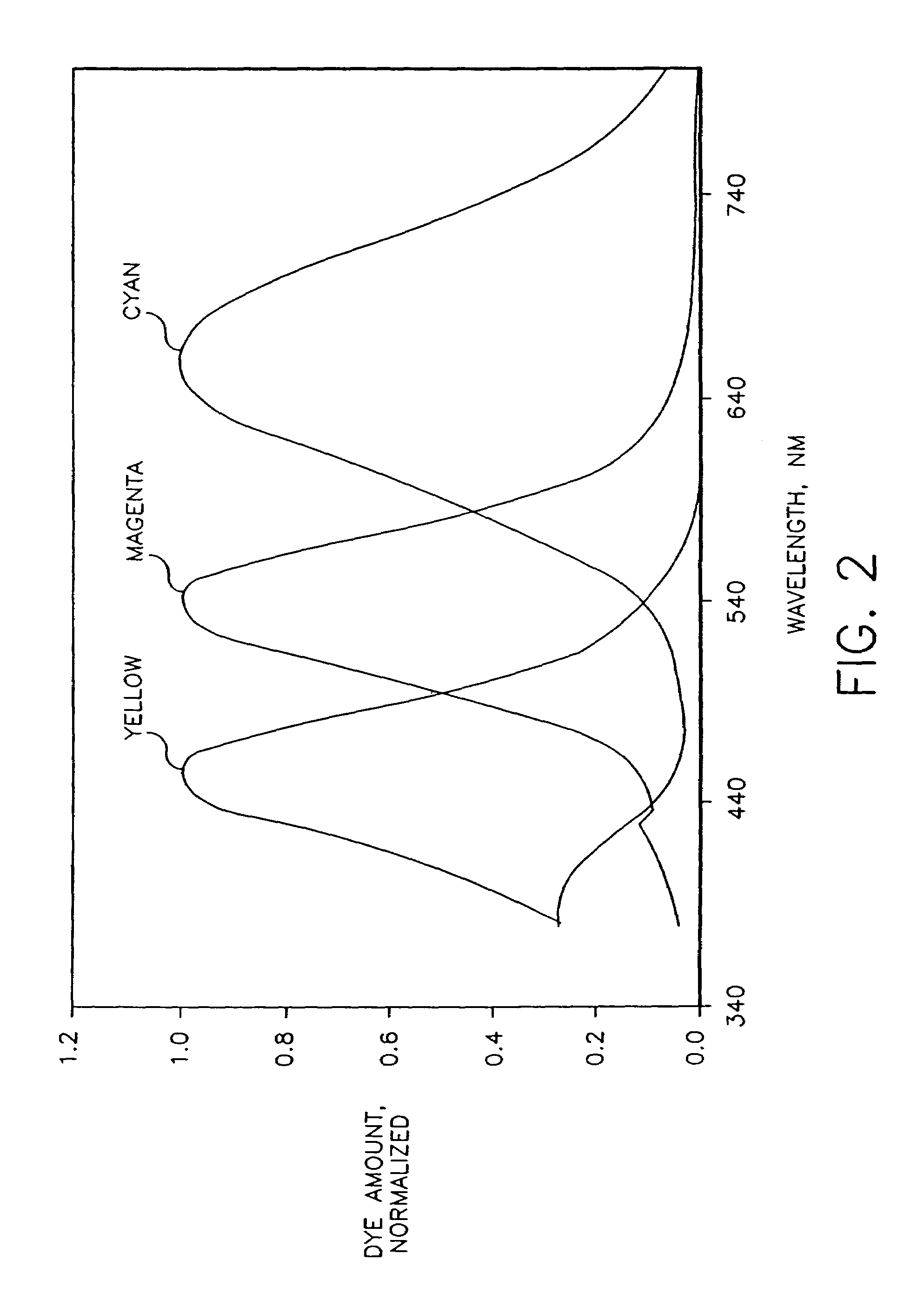

Method of digital processing for digital cinema projection of tone scale and color

InactiveUS6987586B2Digitally marking record carriersColor television signals processingComputer graphics (images)Radiology

A method for processing a sequence of digital image signals in order to match the appearance of a particular display medium, such as a motion picture print film, includes the steps of (a) converting the digital image signals into signal values in an analytical dye amount space where the signal values are proportional to a dye set corresponding to the particular medium; and (b) converting the signal values in analytical dye amount space into output values suitable for a display device, such as a digital projector. Moreover, the signal values in analytical dye amount space may be corrected for viewing conditions, such as printing flare, gamma, contrast ratio or neutrality.

Owner:IMAX THEATERS INT

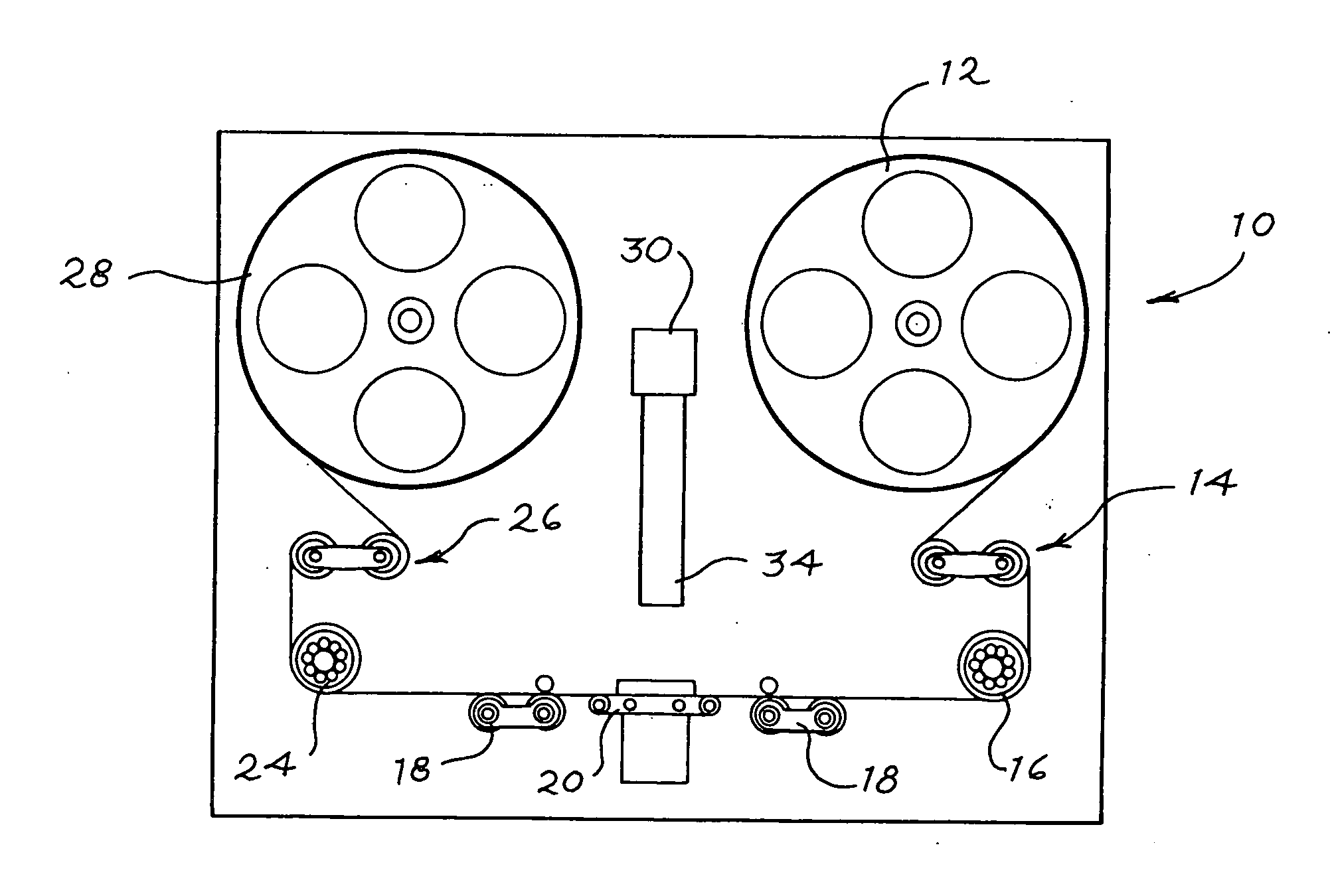

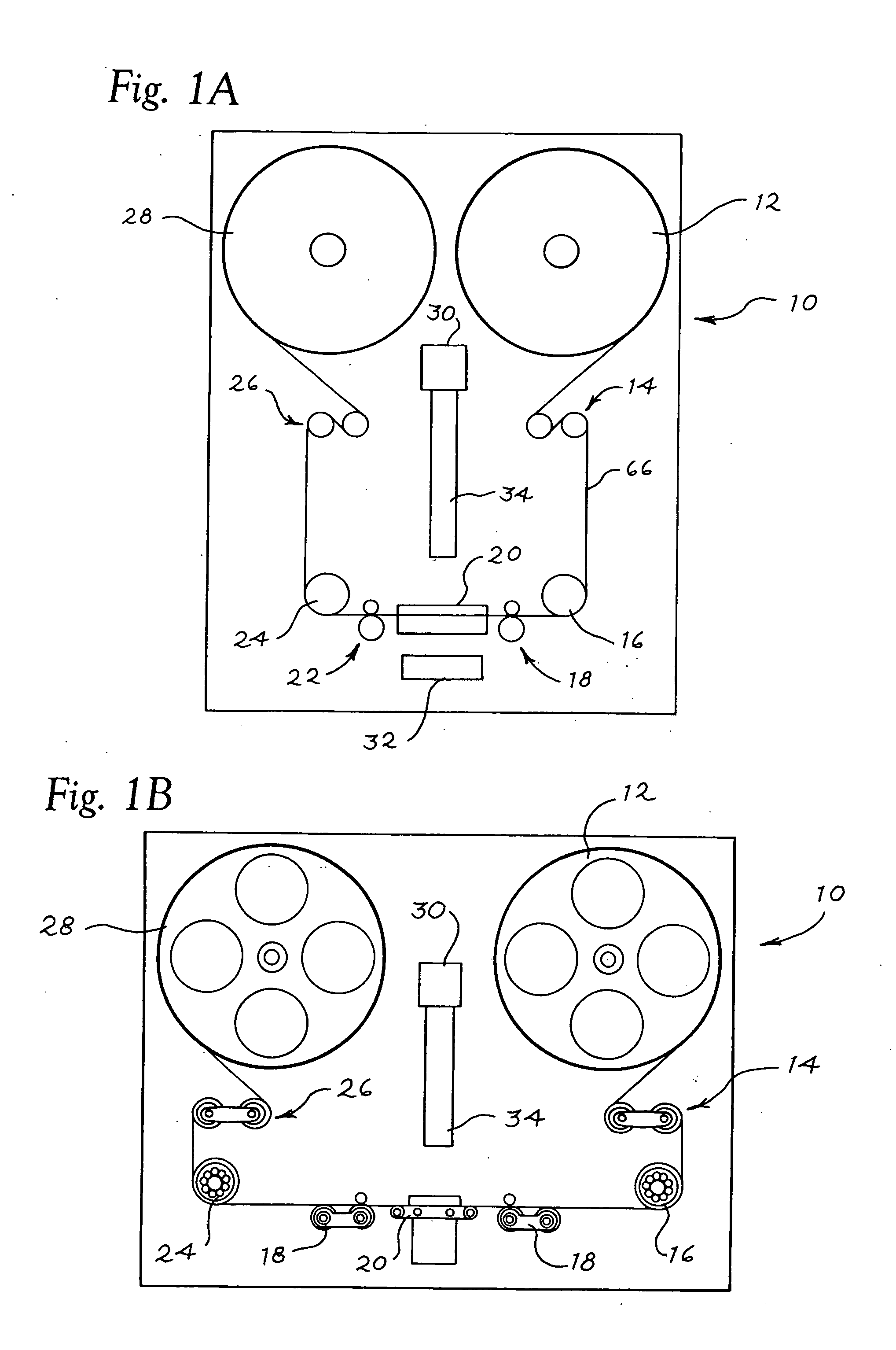

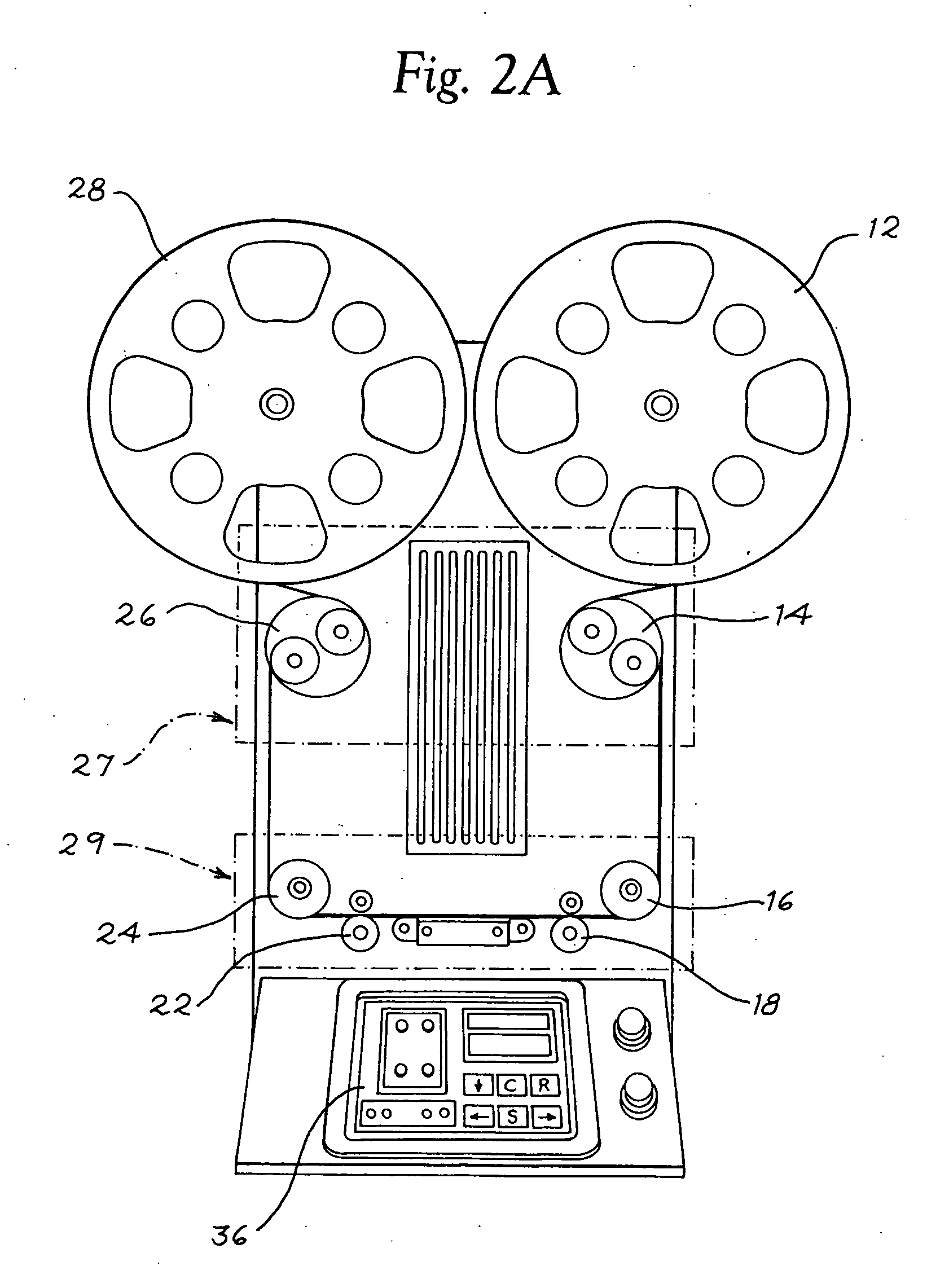

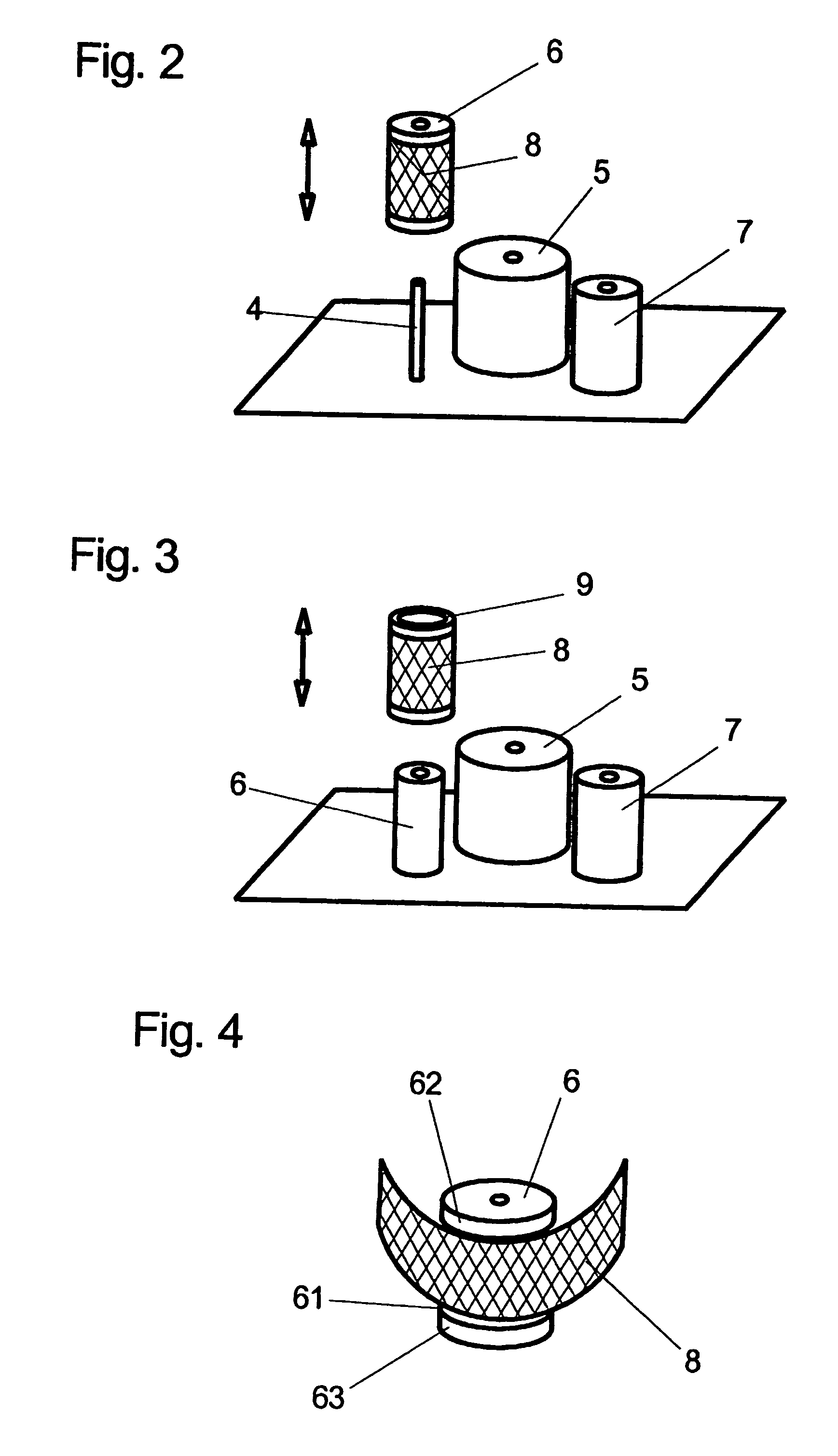

Method and apparatus for continuous motion film scanning

ActiveUS20130076890A1Facilitates high resolution digital duplicationSignificant informationTelevision system detailsTelevision system scanning detailsFilm-outDigital image

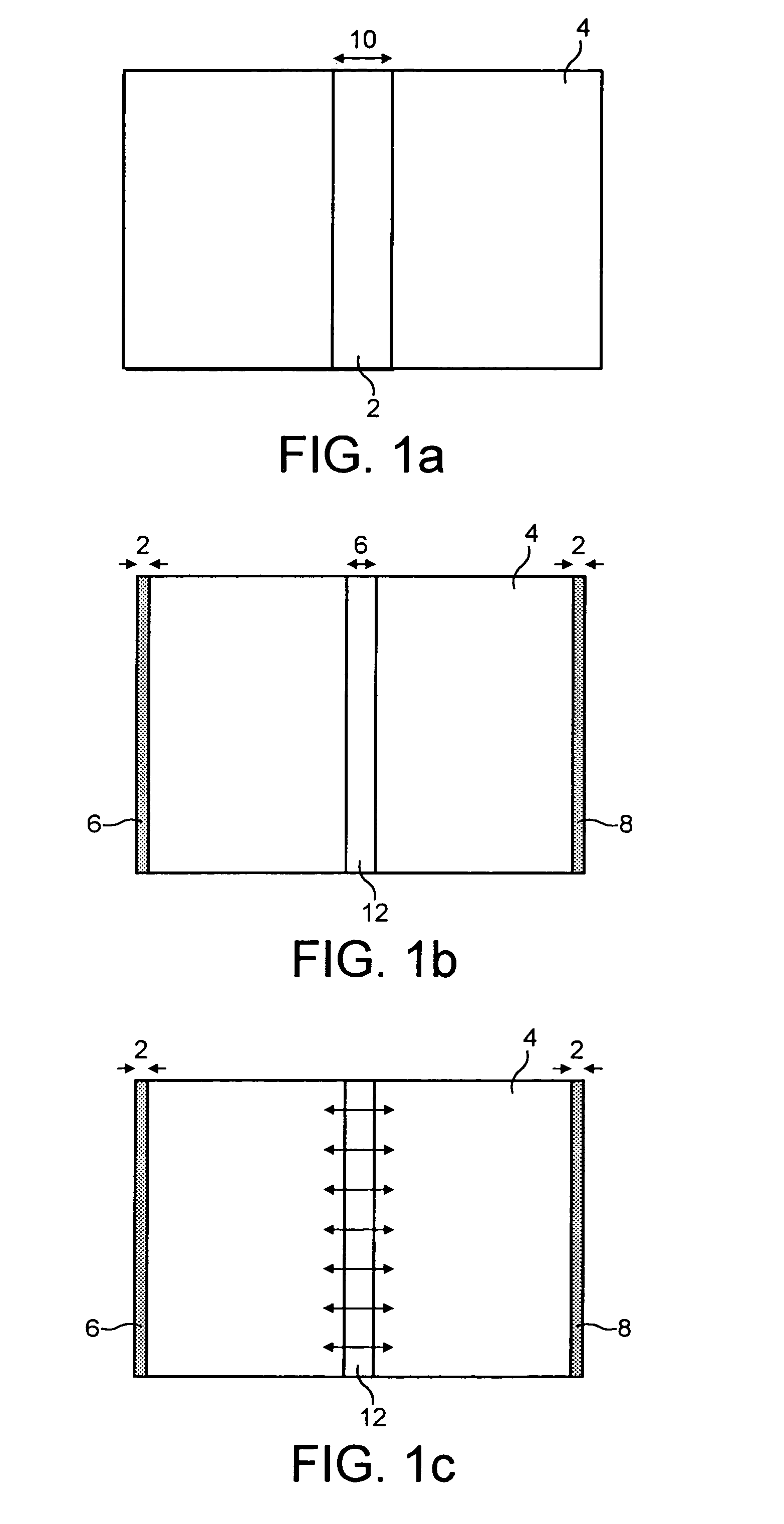

A continuous film scanning system for high resolution digital archival and duplication of motion picture film on a frame by frame basis. Film is driven through the film scanning system through the use of rollers and maintained at a consistent tension throughout the scanning process. Optical interrogation of the perforations associated with each film frame is used to trigger digital image capture. The continuous film scanning system is particularly well adapted to safely handle imperfect or damaged film stock.

Owner:REFLEX TECH

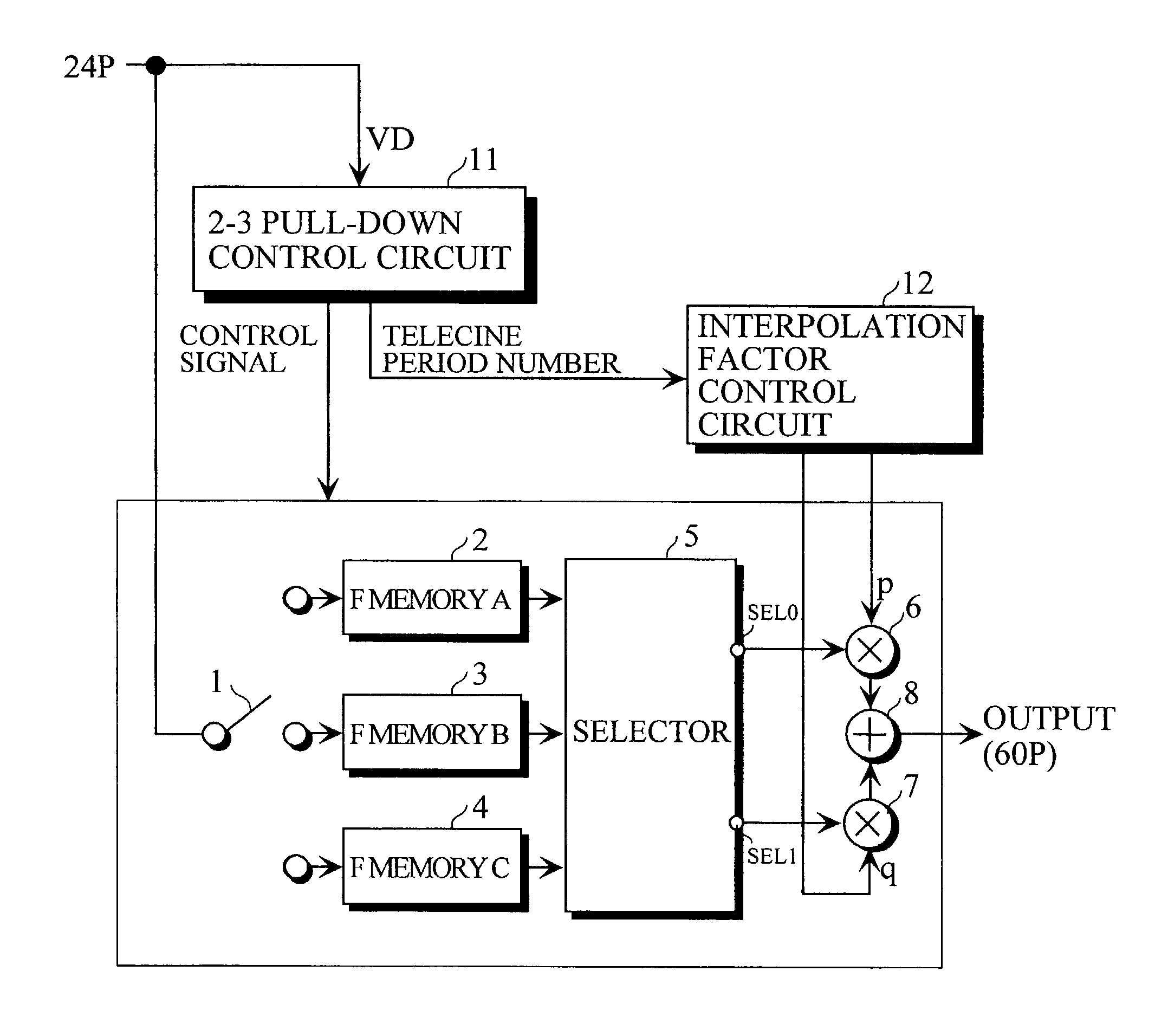

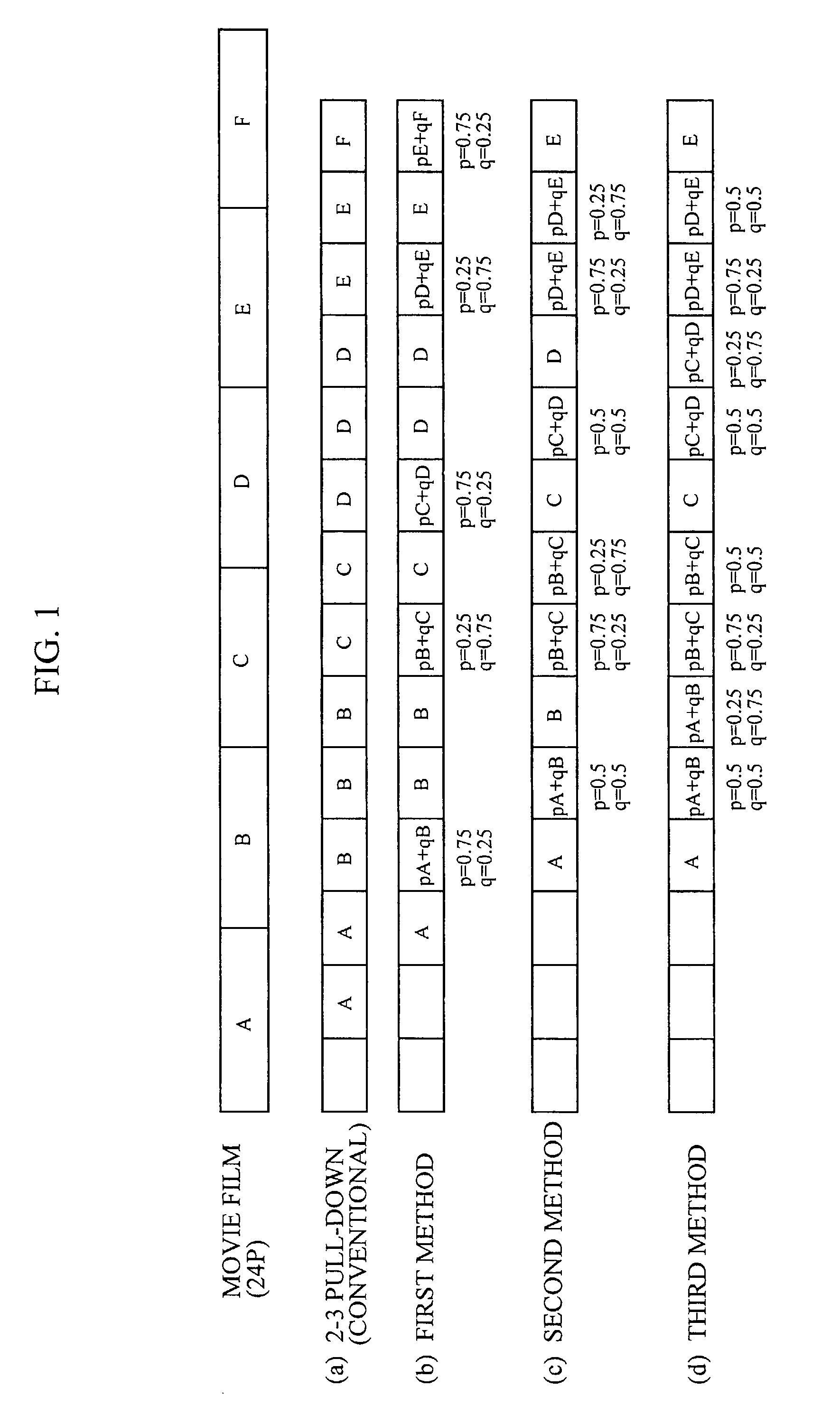

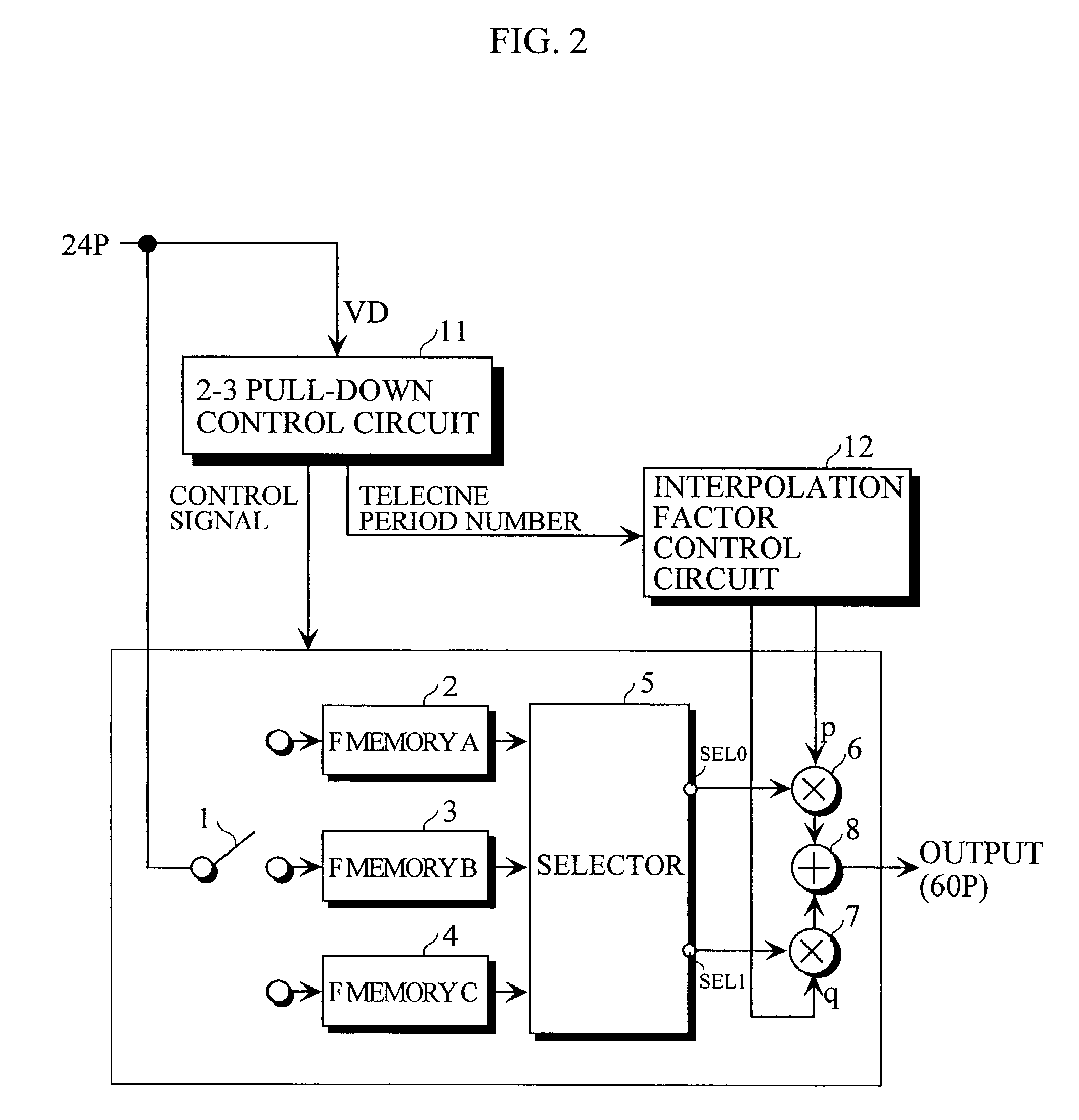

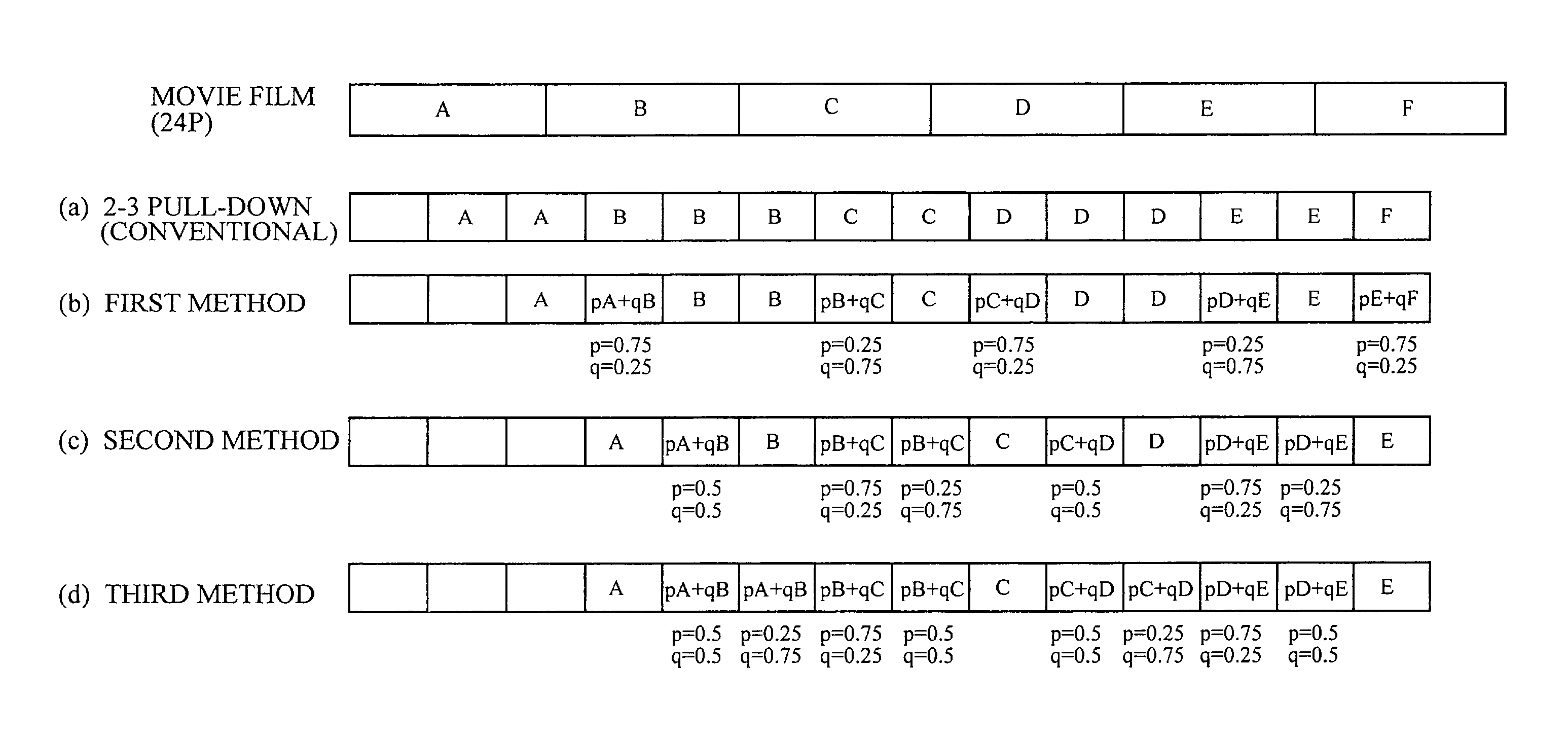

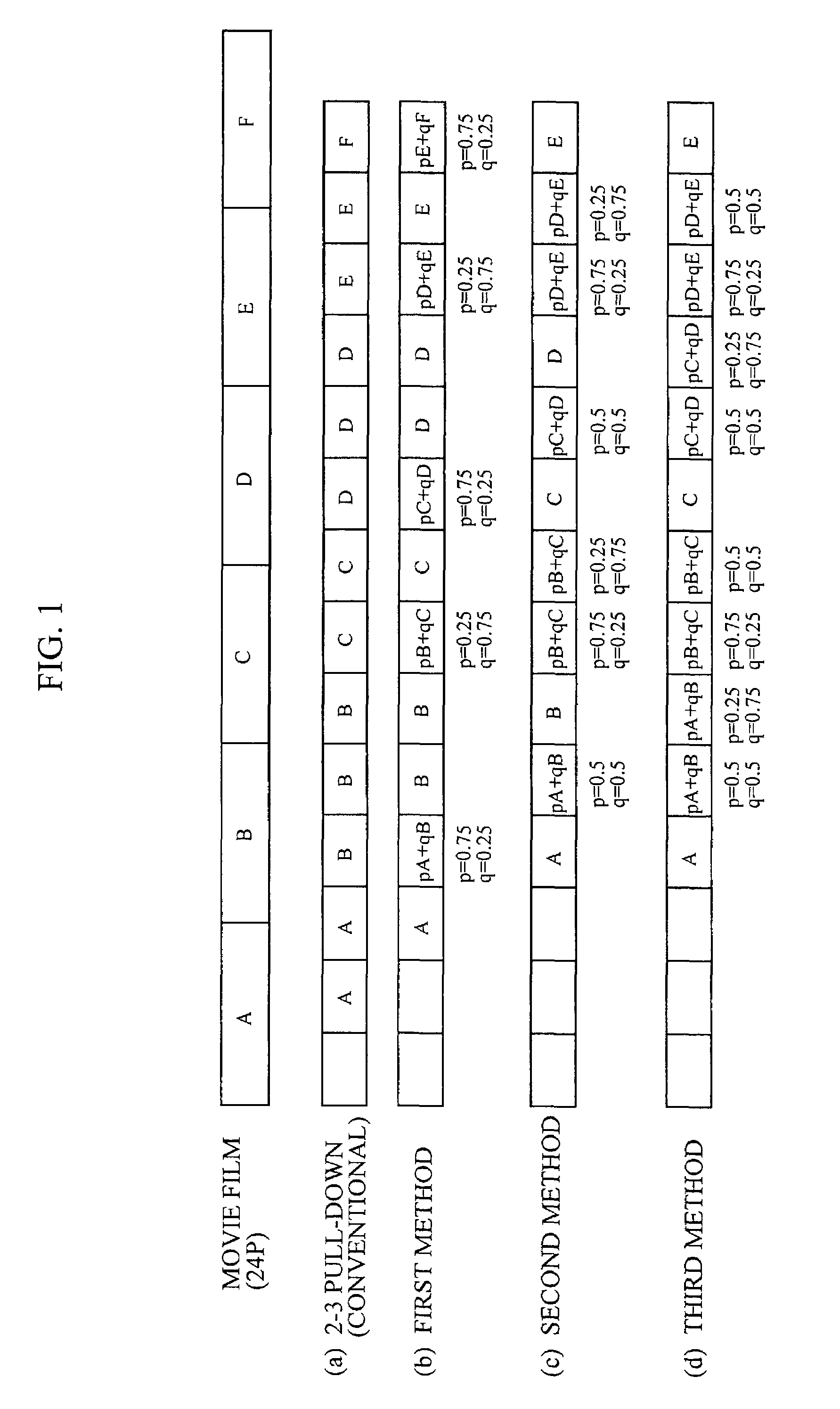

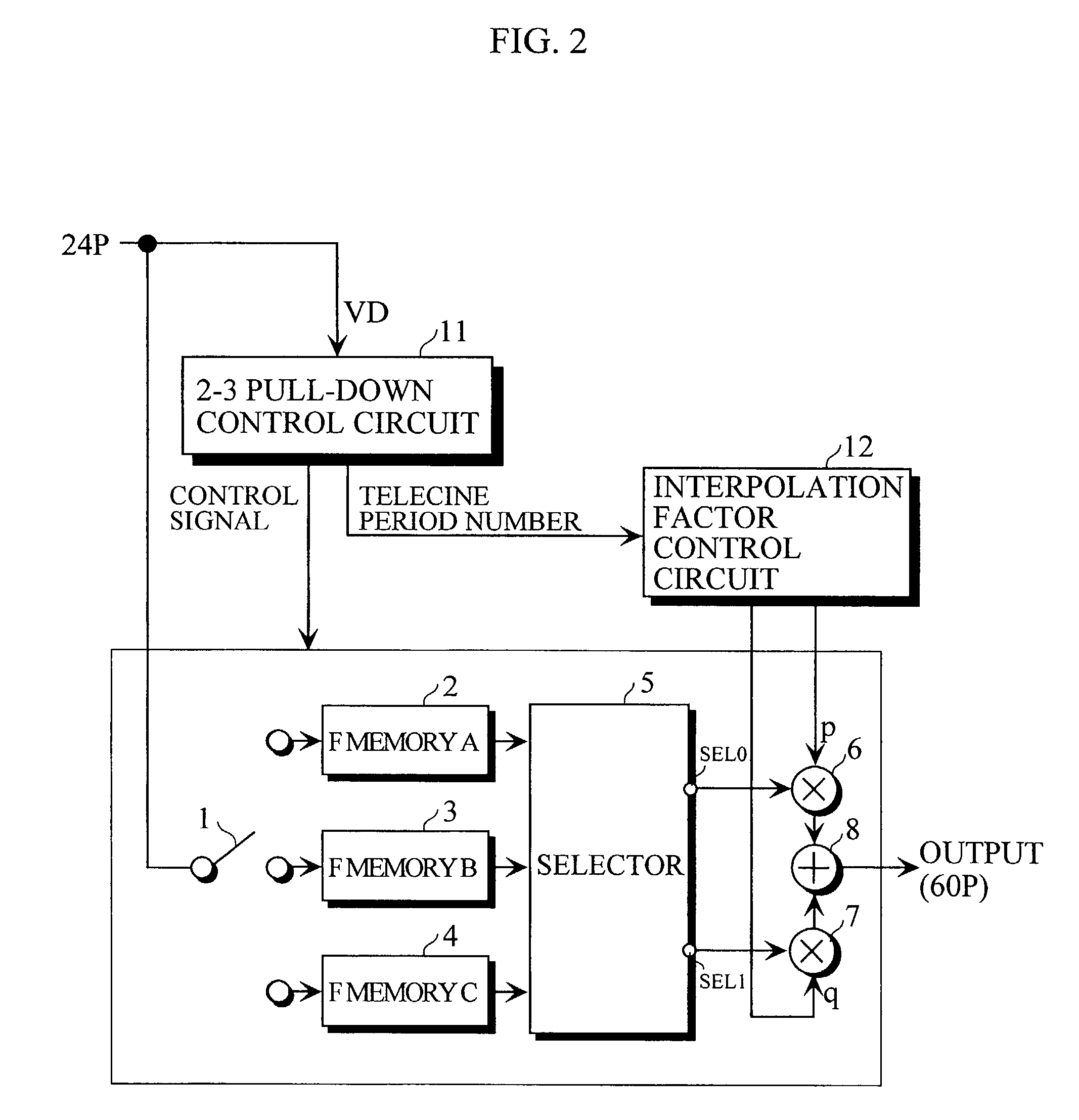

Telecine converting method

InactiveUS20040012673A1Suppress flickerSmooth movementTelevision system detailsTelevision system scanning detailsFilm-outTelecine

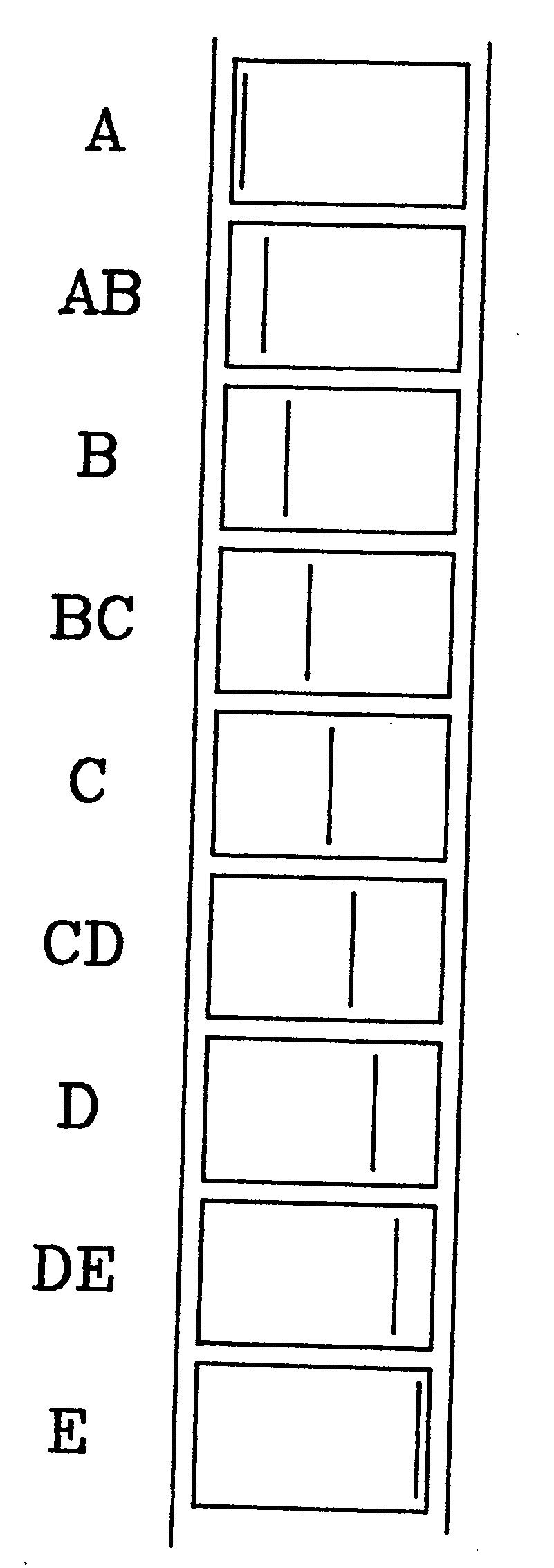

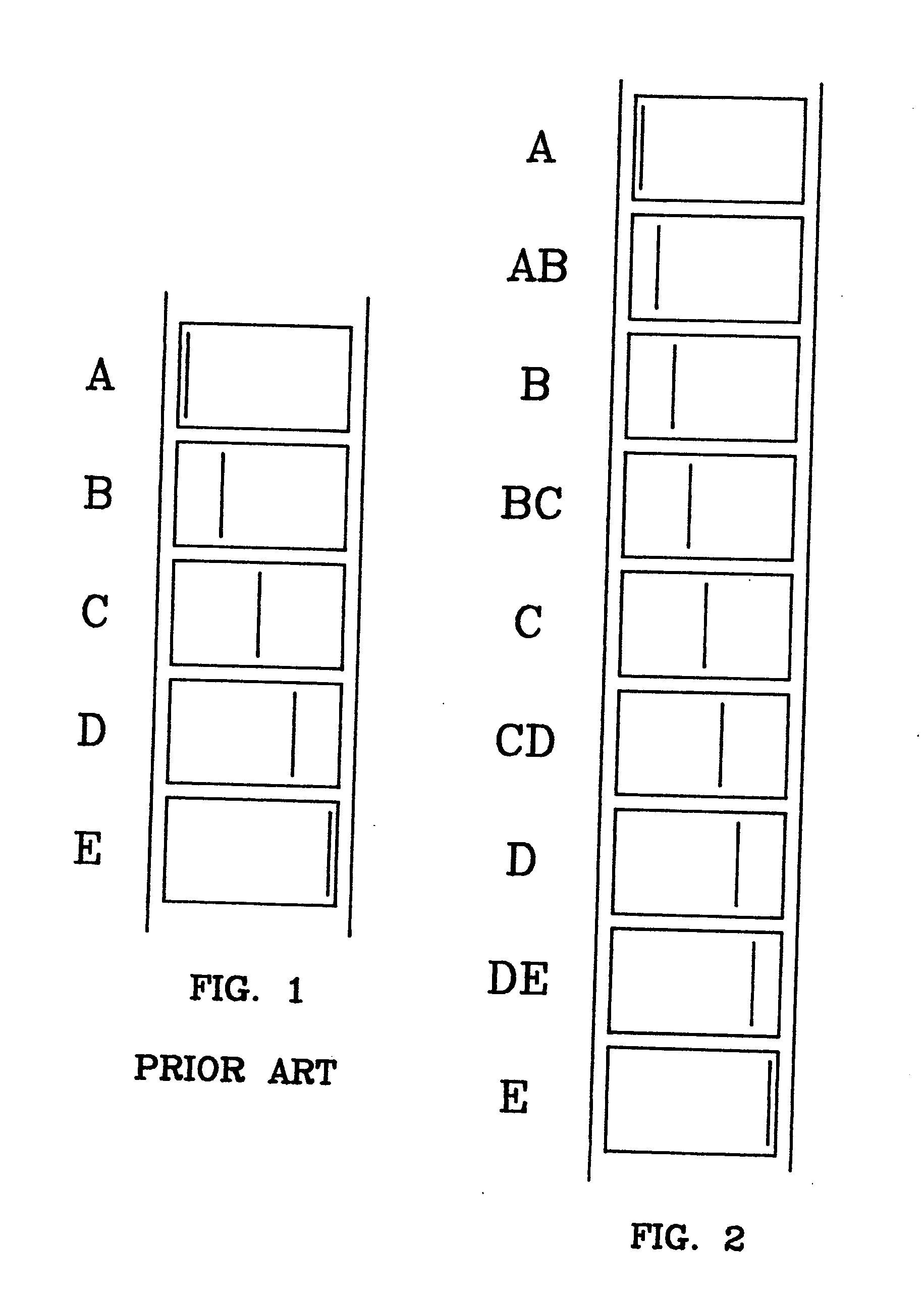

In a telecine converting method for converting a video in a movie film composed of 24 frames per second into a video signal composed of 60 frames per second, a telecine converting method is characterized in that in order that respective integration values of display time periods of frame videos in the movie film become equal after the telecine conversion, used as a video in the predetermined frame after the conversion is an interpolated video obtained by interpolating the frame videos ahead of and behind the video in the movie film.

Owner:SANYO ELECTRIC CO LTD

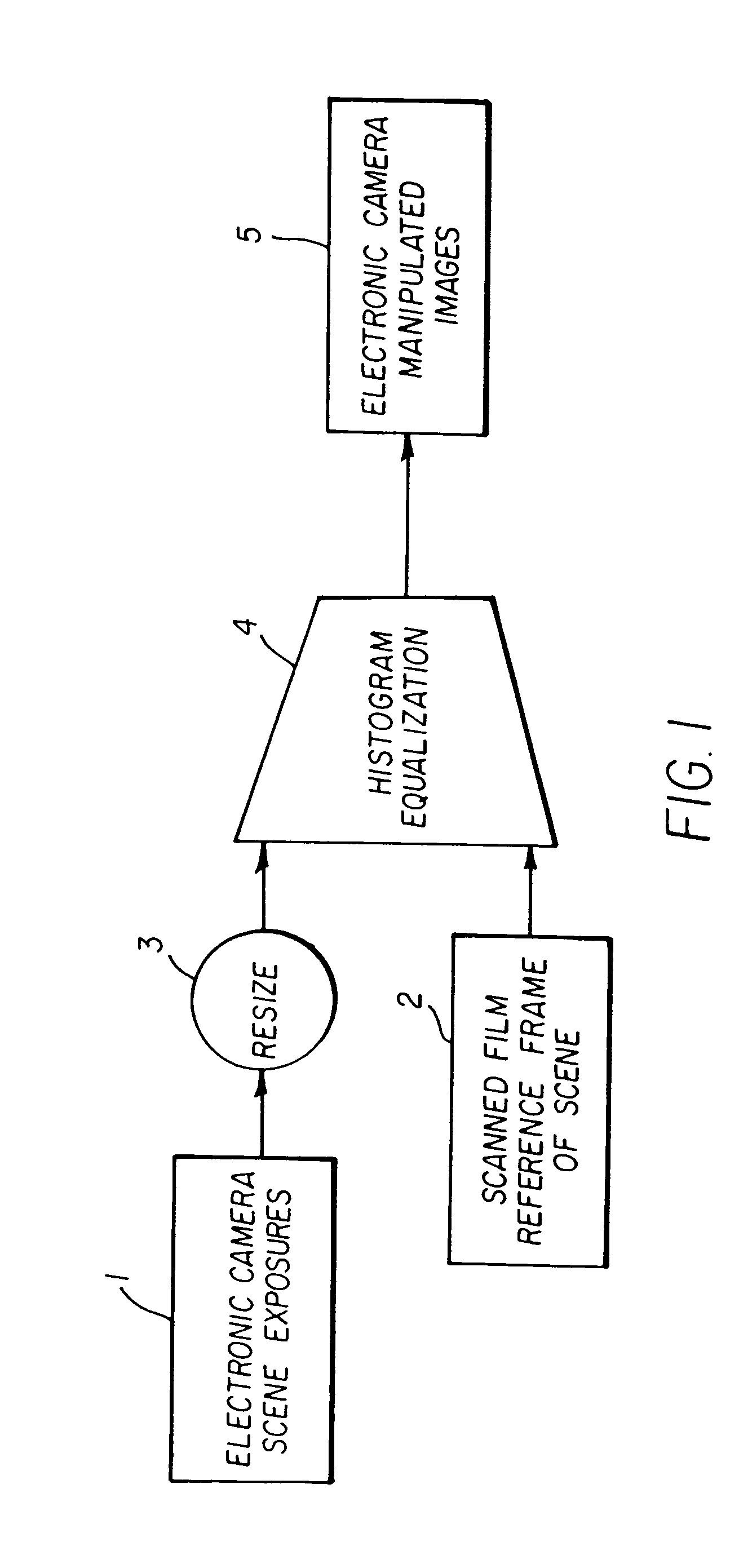

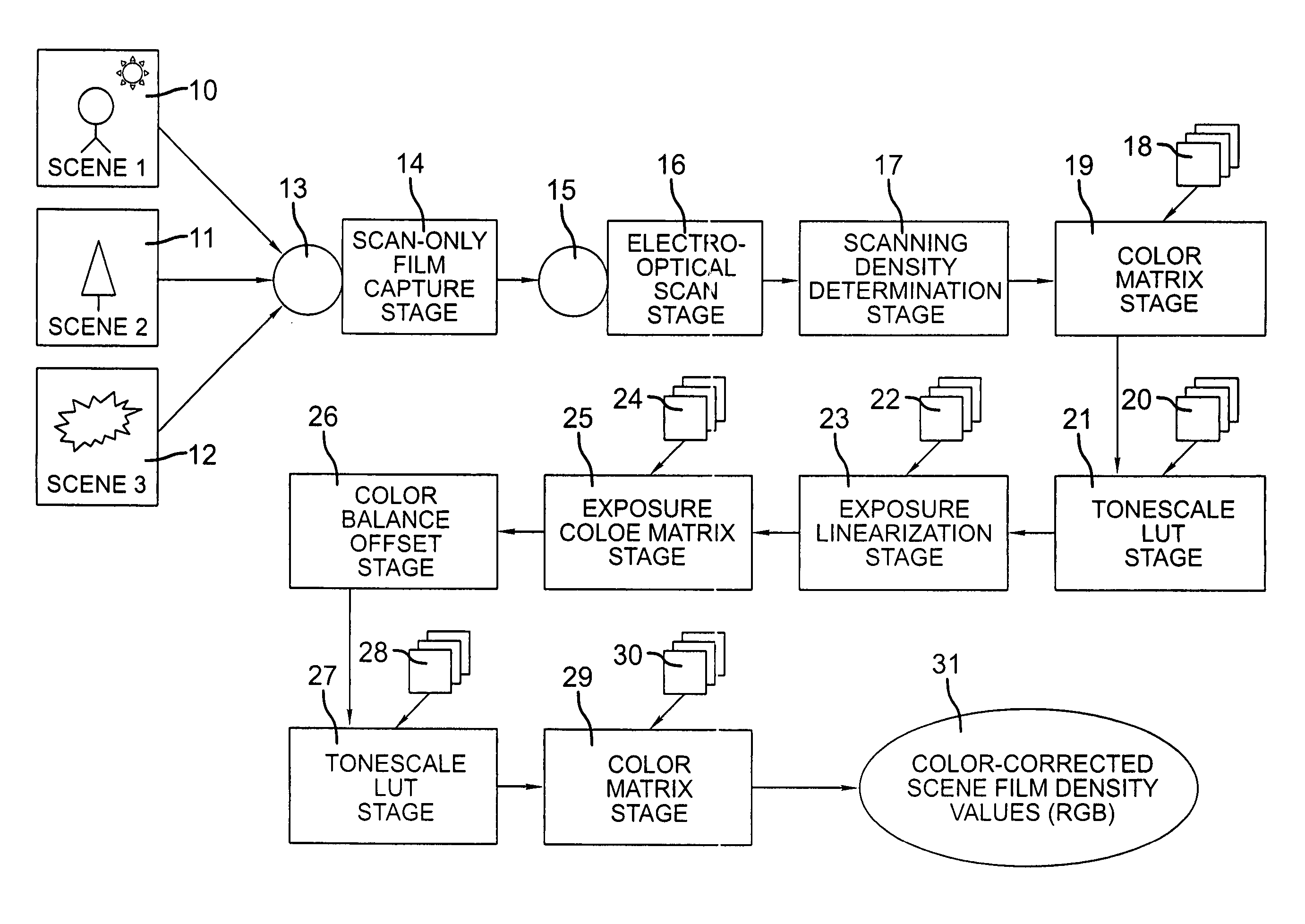

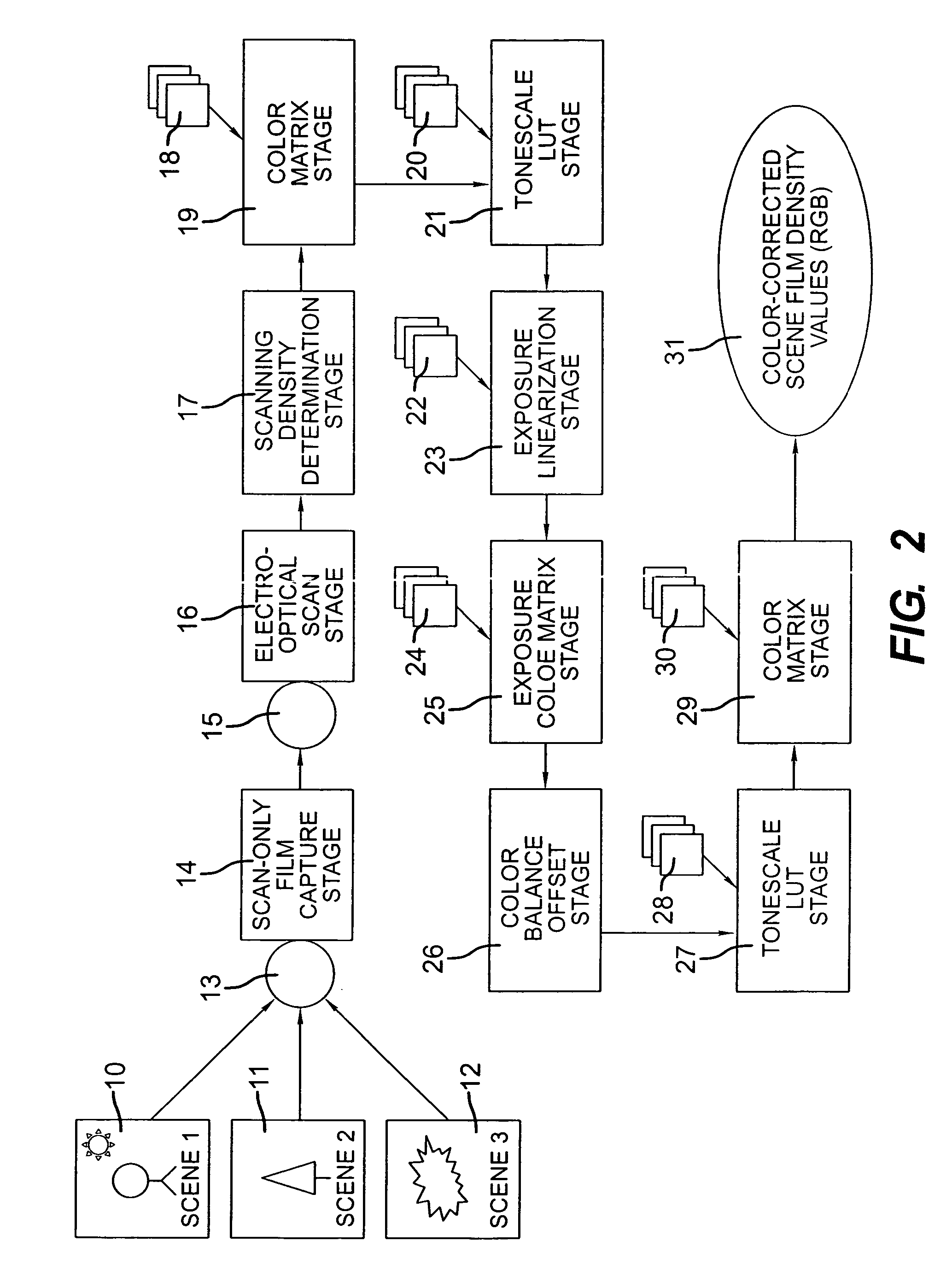

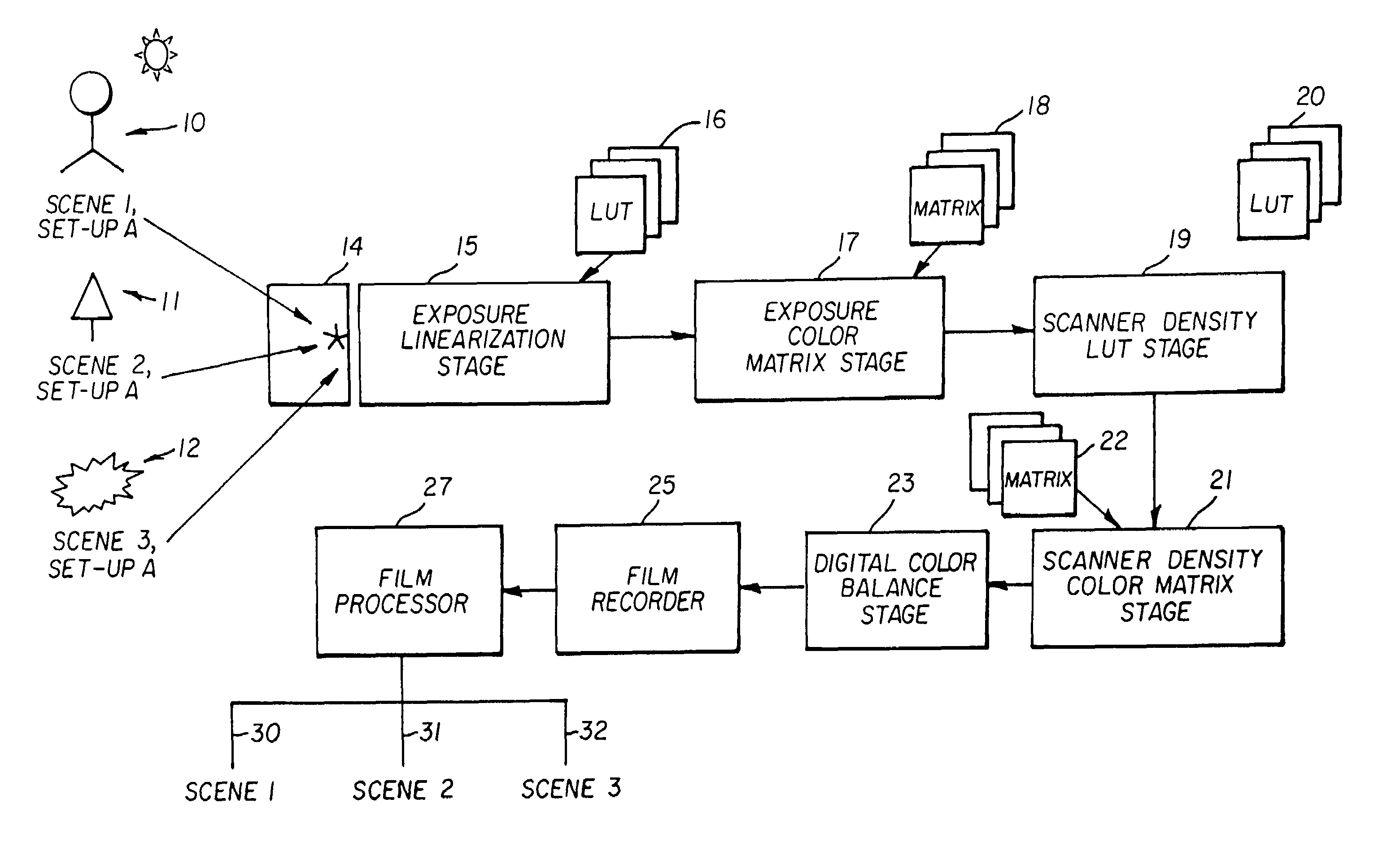

System and method for processing images to emulate film tonescale and color

A method for converting a sequence of scan-only film captured images into a sequence of modified images that provide the appearance of images captured by a photographic film reproduction system; the photographic film reproduction system being includes photographic motion picture negative film printed onto a motion picture print film that is displayed, or a reversal motion picture system in which the reversal film is displayed, or a photographic motion picture film electro-optically scanned to standard format video by a telecine and further displayed, or a photographic motion picture film electro-optically scanned by a scanner suitable for producing digital data intended for additional digital image manipulation and further preparation as a digital master for electronic distribution such as digital theatrical projection or various types of broadcast video; or recorded out to another photographic film to be used as a printing master for producing distribution optical prints for theatrical projection.

Owner:MONUMENT PEAK VENTURES LLC

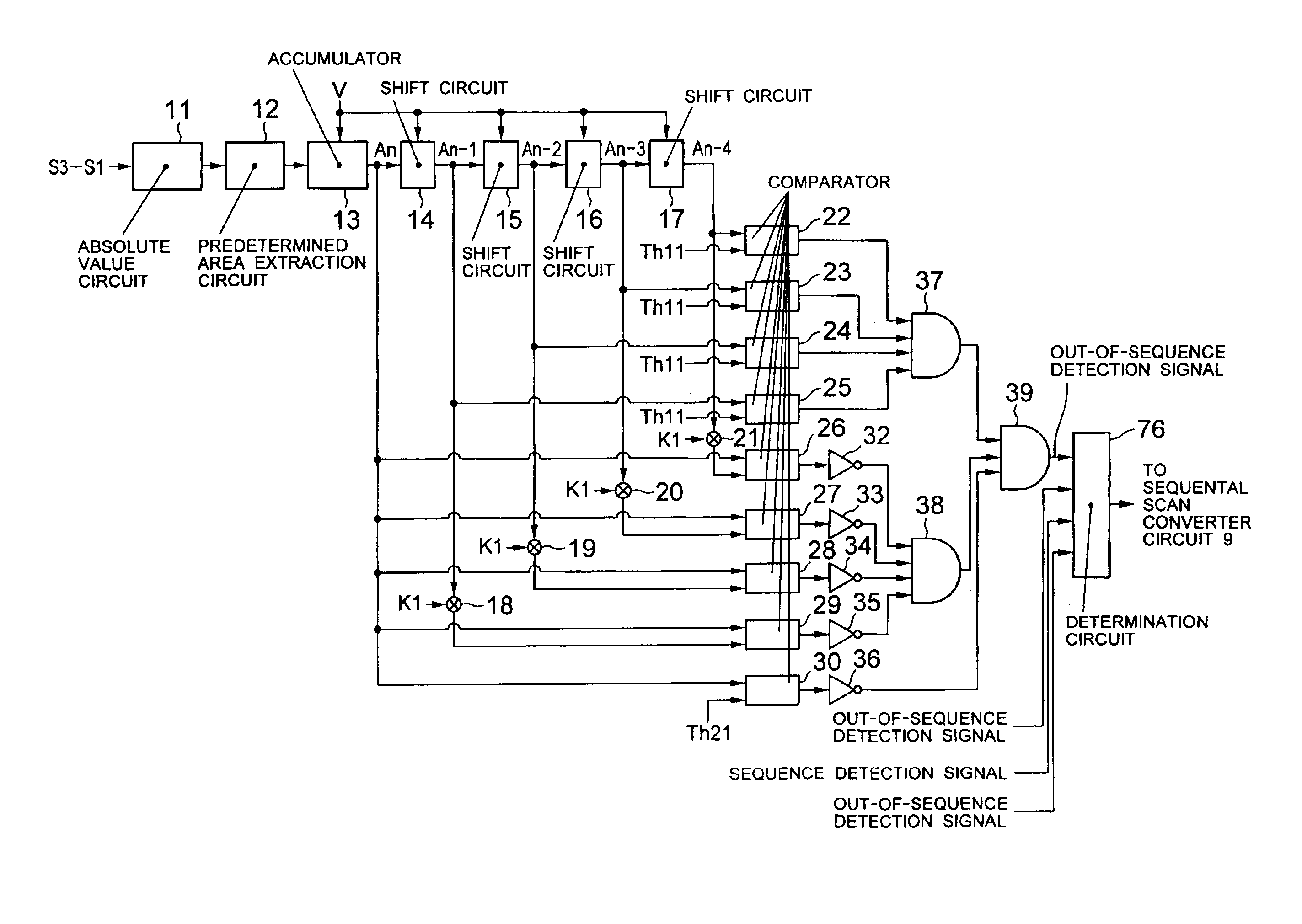

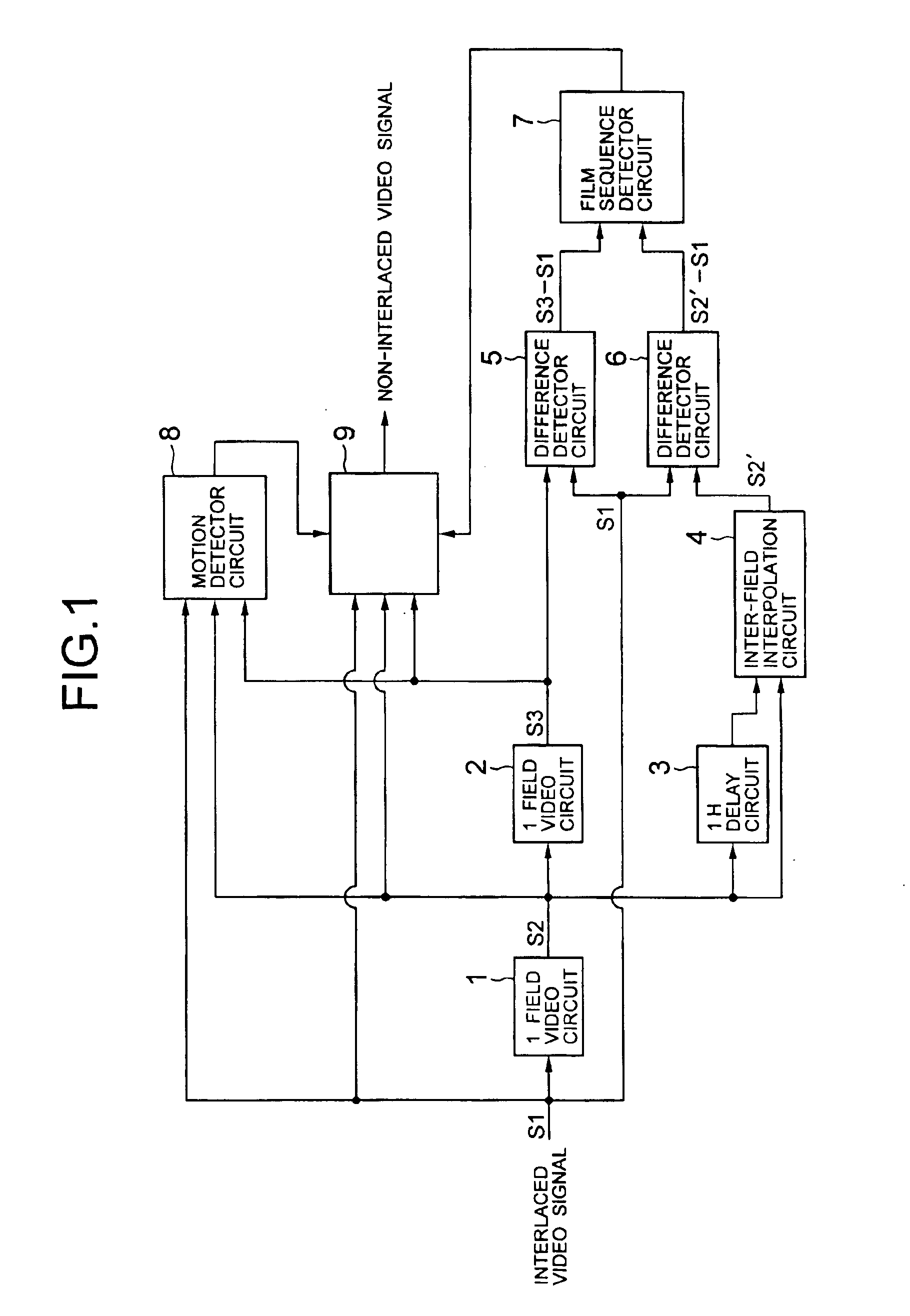

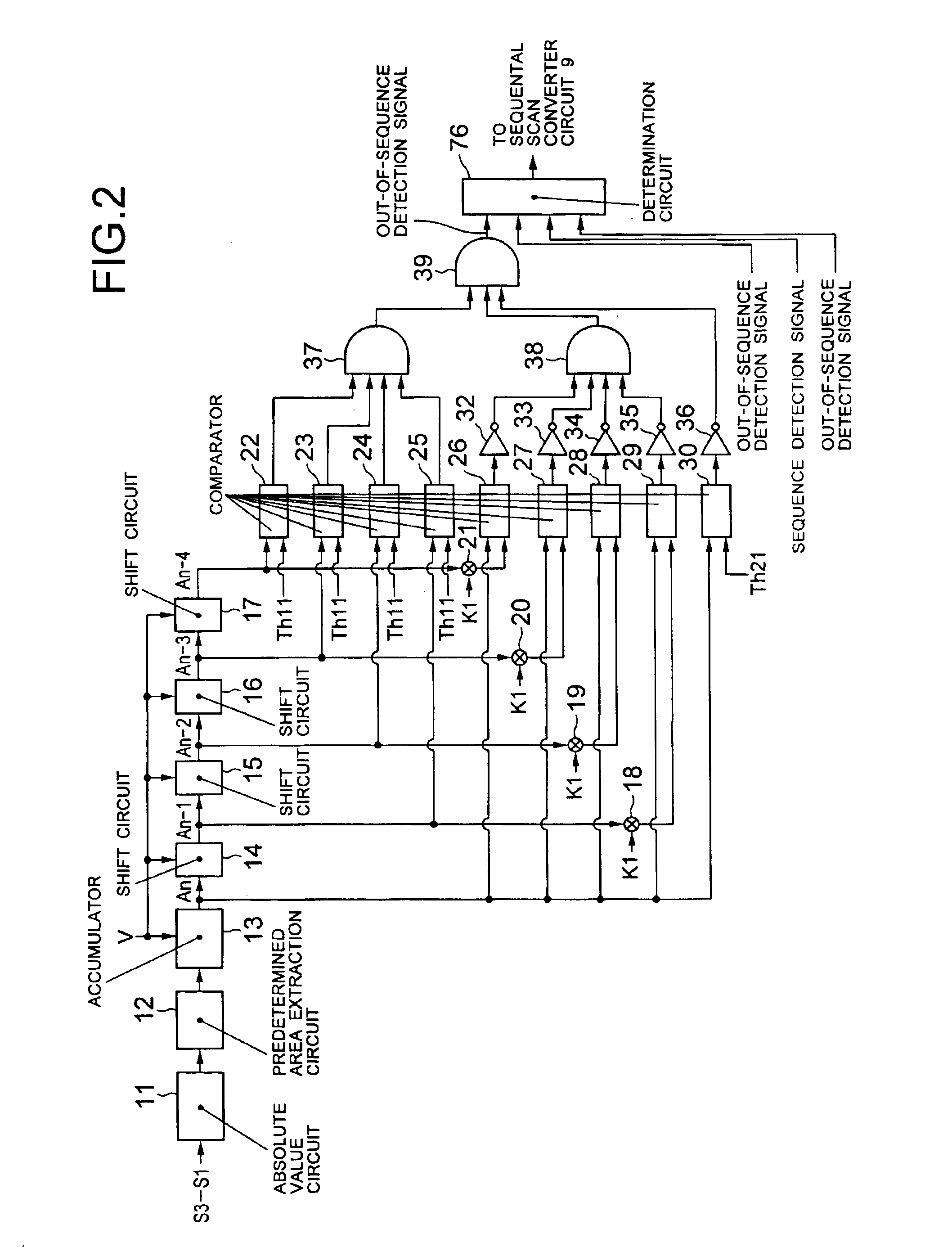

Apparatus for detecting telecine conversion method of video signal

InactiveUS6965414B2Accurate methodTelevision system detailsTelevision system scanning detailsMotion fieldFilm-out

A telecine conversion method detecting apparatus which determines that an input video signal is a telecine converted video signal generated from a movie film in accordance with a 2-3 pull-down method when detecting that an inter-frame difference accumulated value of a current field of the input video signal is equal to or less than a threshold value for still field determination, that each inter-frame difference accumulated value of four fields preceding the current field is equal to or greater than a threshold value for motion field determination, and that the inter-frame difference accumulated value of the current field is less than each corrected value calculated by multiplying each of the inter-frame difference accumulated values of the four preceding fields by a predetermined coefficient.

Owner:PIONEER MICRO TECH CORP +1

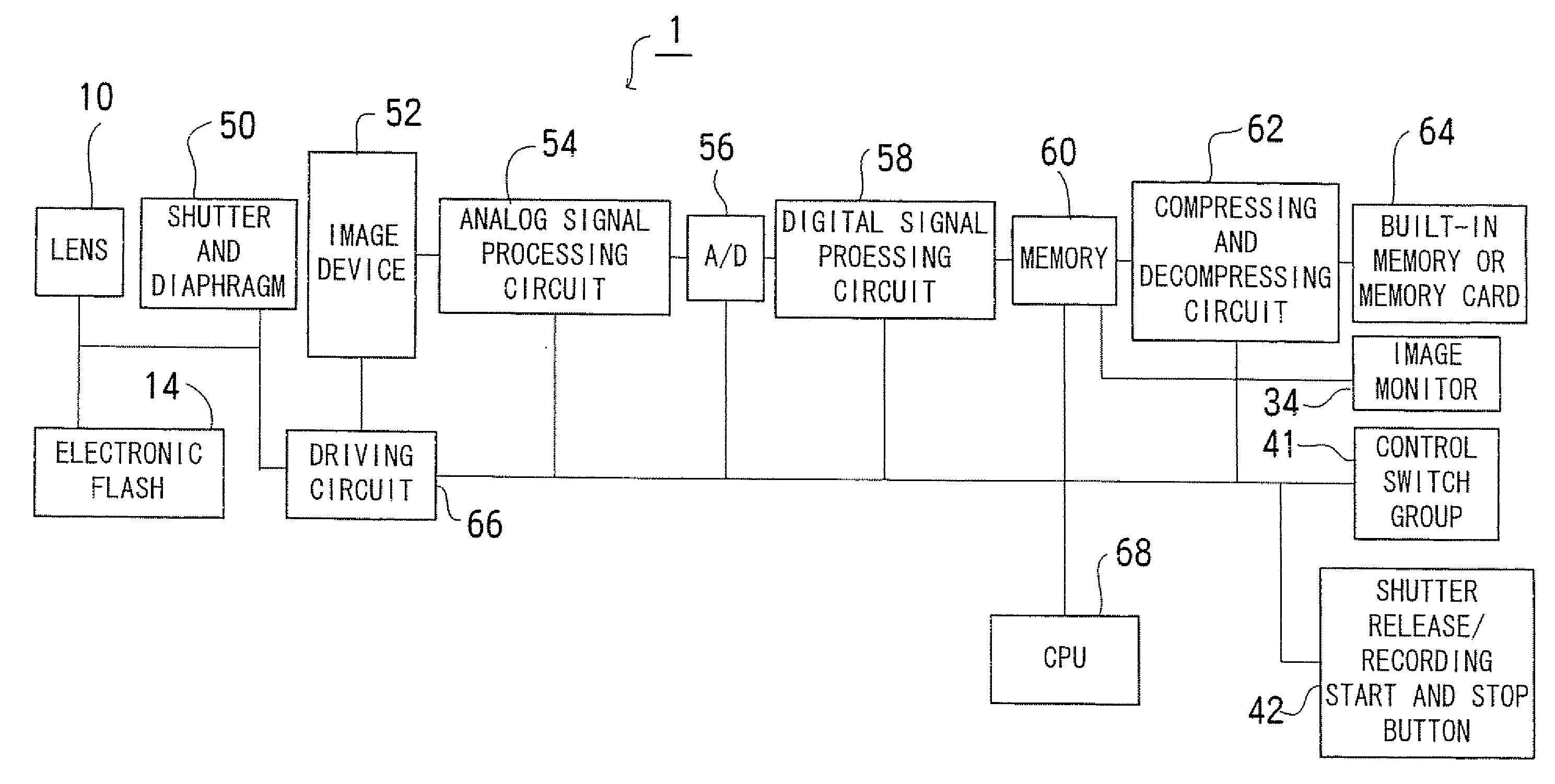

Image Reproducing Apparatus and Digital Camera

Owner:FUJIFILM CORP

Telecine converting method

InactiveUS7020197B2Smooth movementSuppress flickerTelevision system detailsTelevision system scanning detailsFilm-outTelecine

In a telecine converting method for converting a video in a movie film composed of 24 frames per second into a video signal composed of 60 frames per second, a telecine converting method is characterized in that in order that respective integration values of display time periods of frame videos in the movie film become equal after the telecine conversion, used as a video in the predetermined frame after the conversion is an interpolated video obtained by interpolating the frame videos ahead of and behind the video in the movie film.

Owner:SANYO ELECTRIC CO LTD

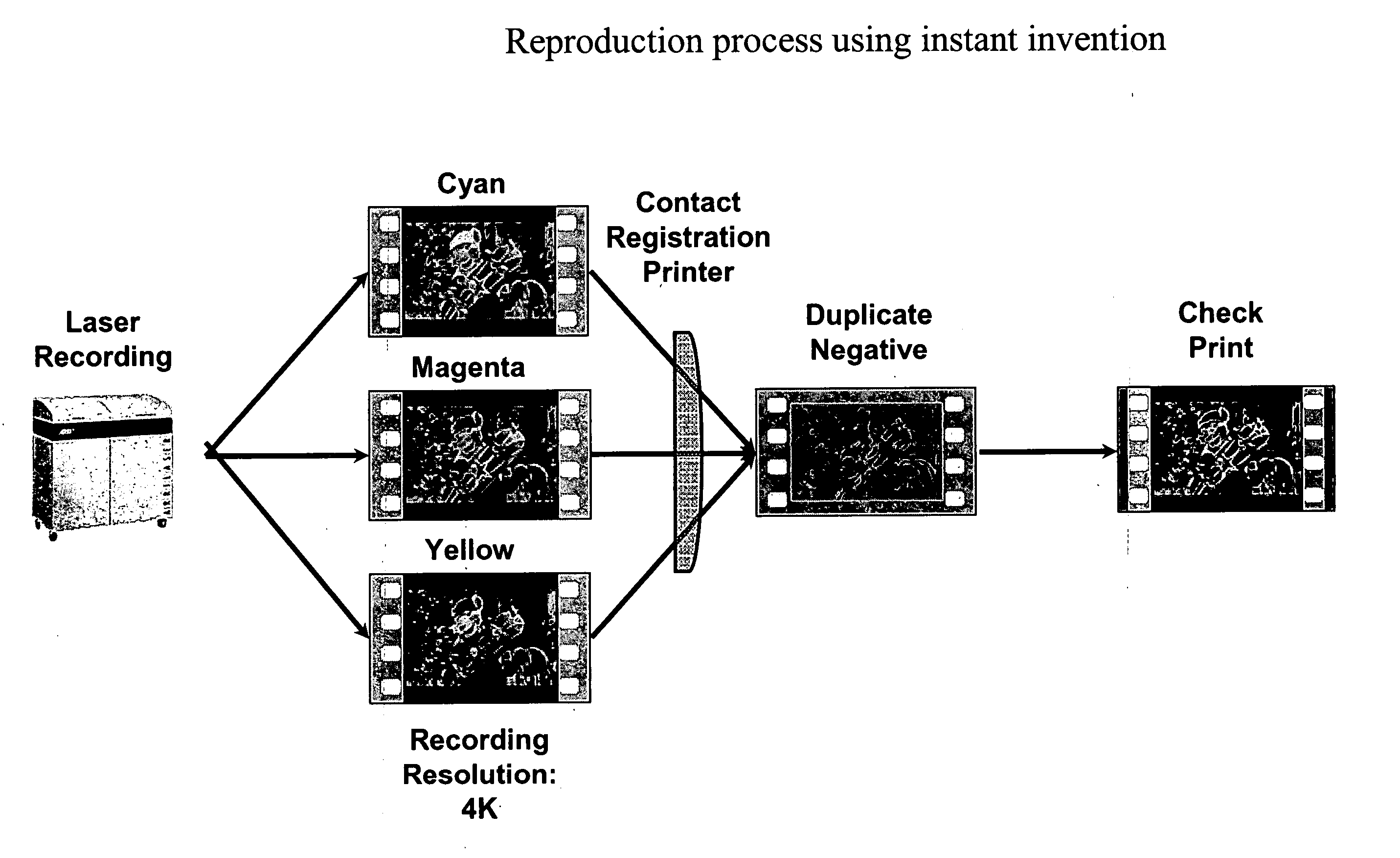

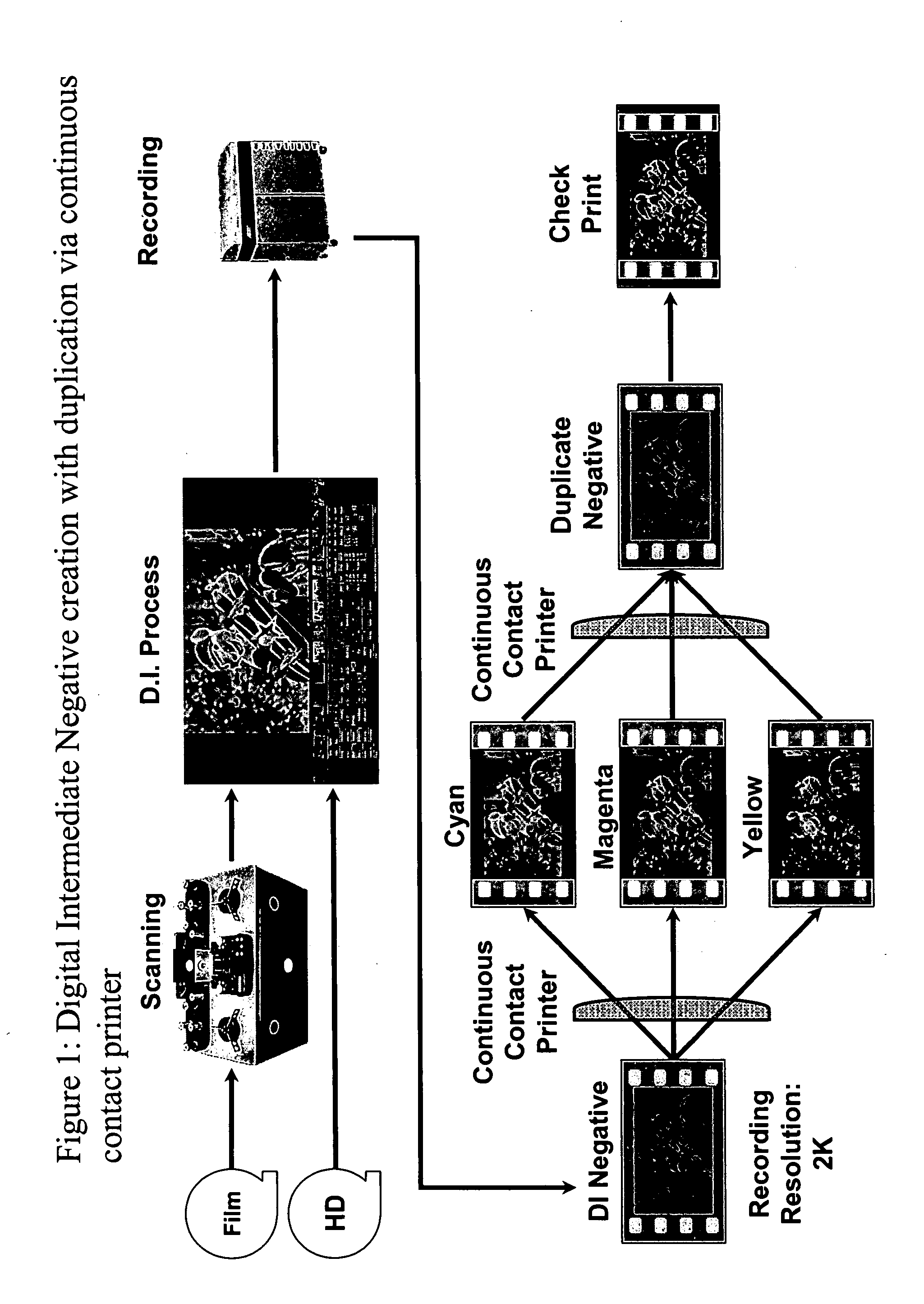

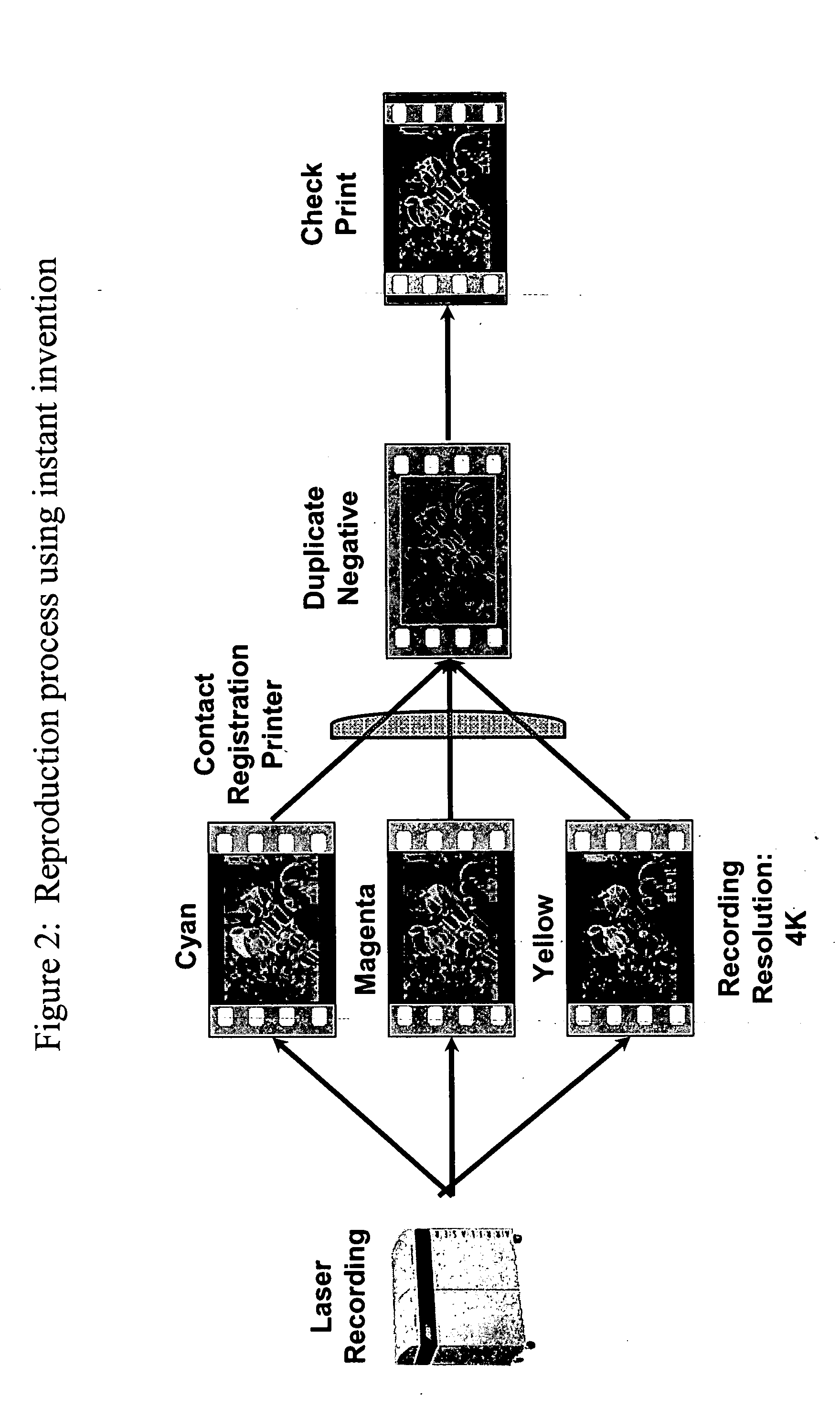

Method for conversion and reproduction of film images through a digital process

InactiveUS20060023275A1Few stepsRetaining moreTelevision system detailsColor photographyComputer graphics (images)Film-out

Owner:PJF PRODIONS

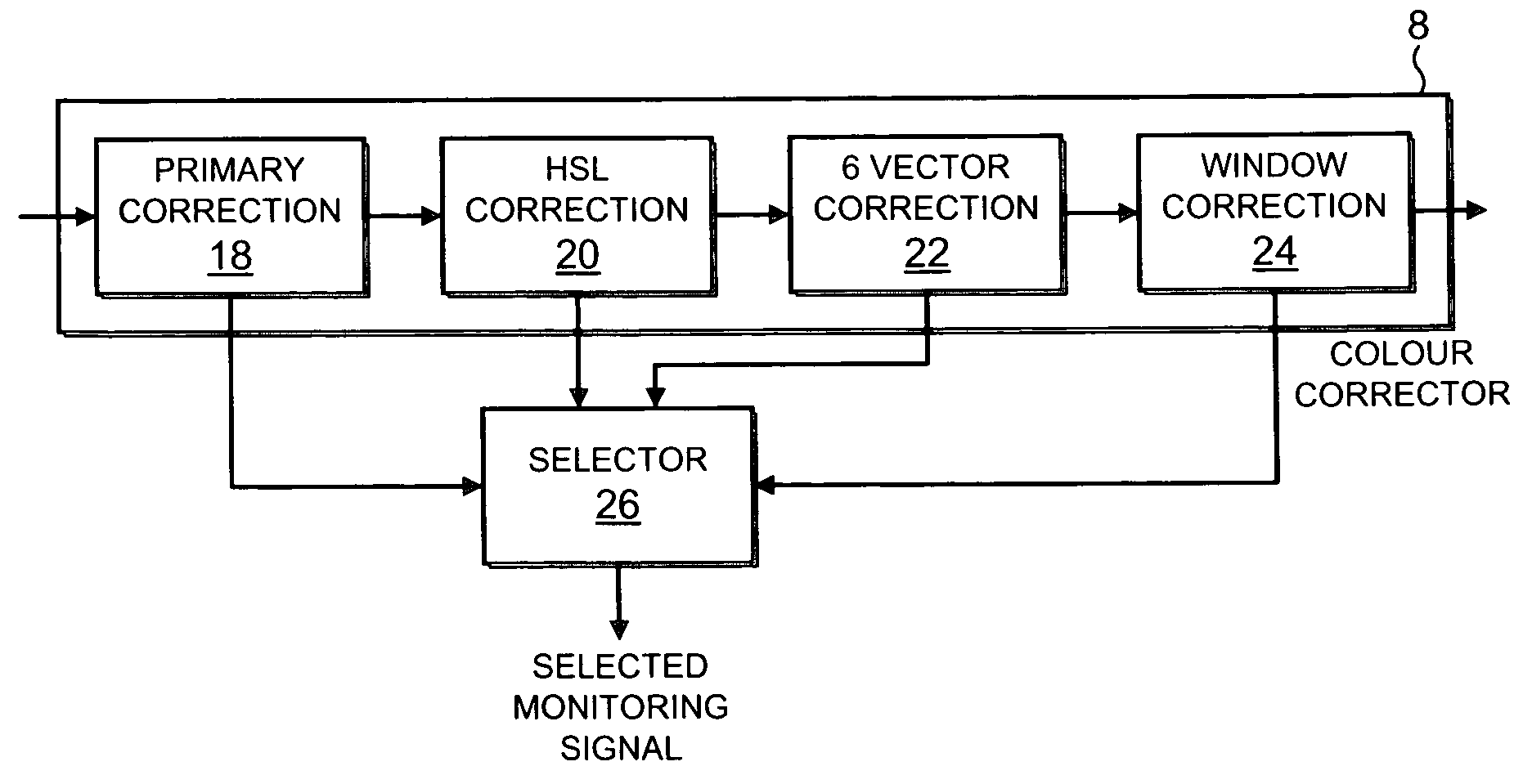

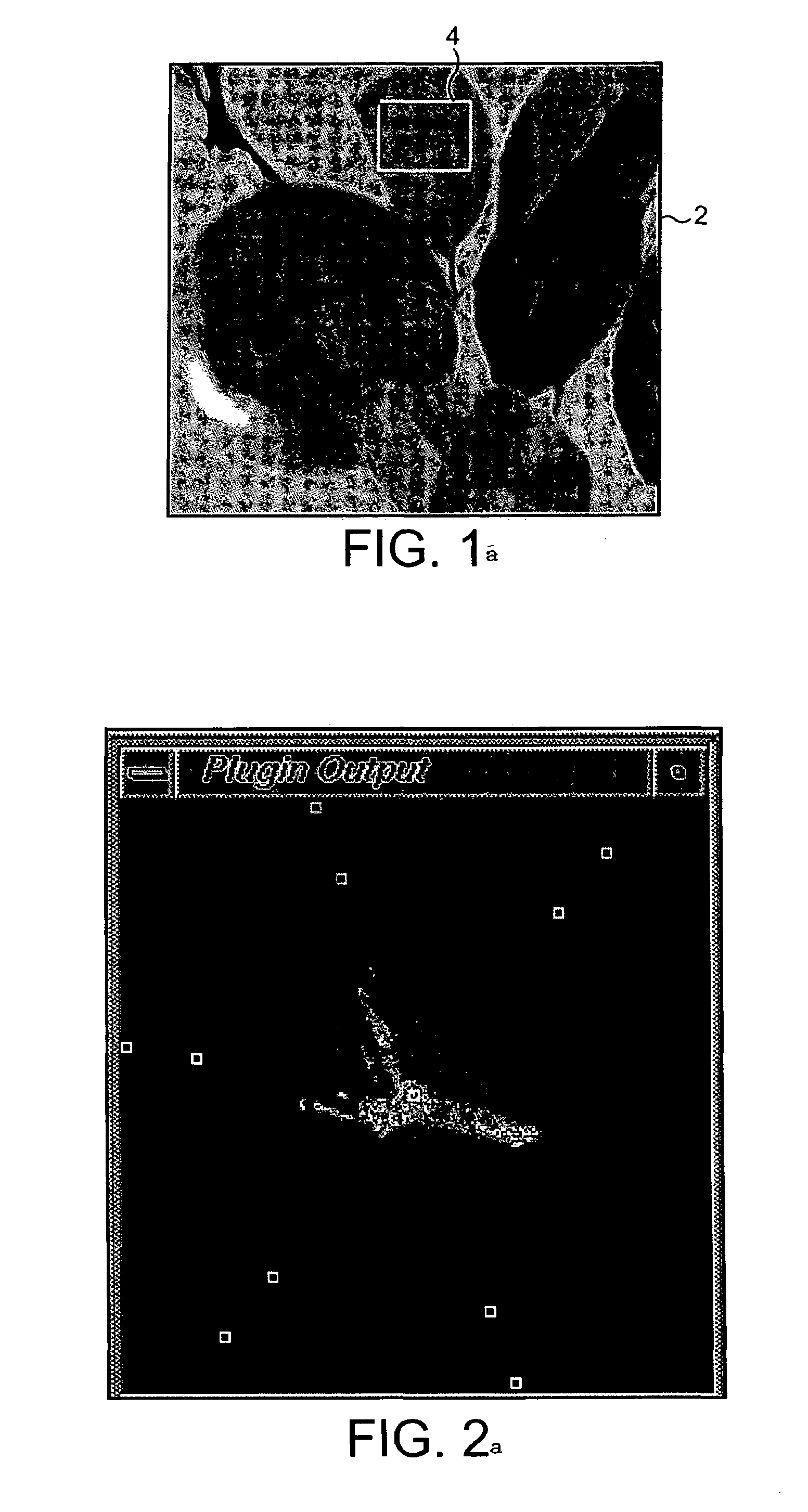

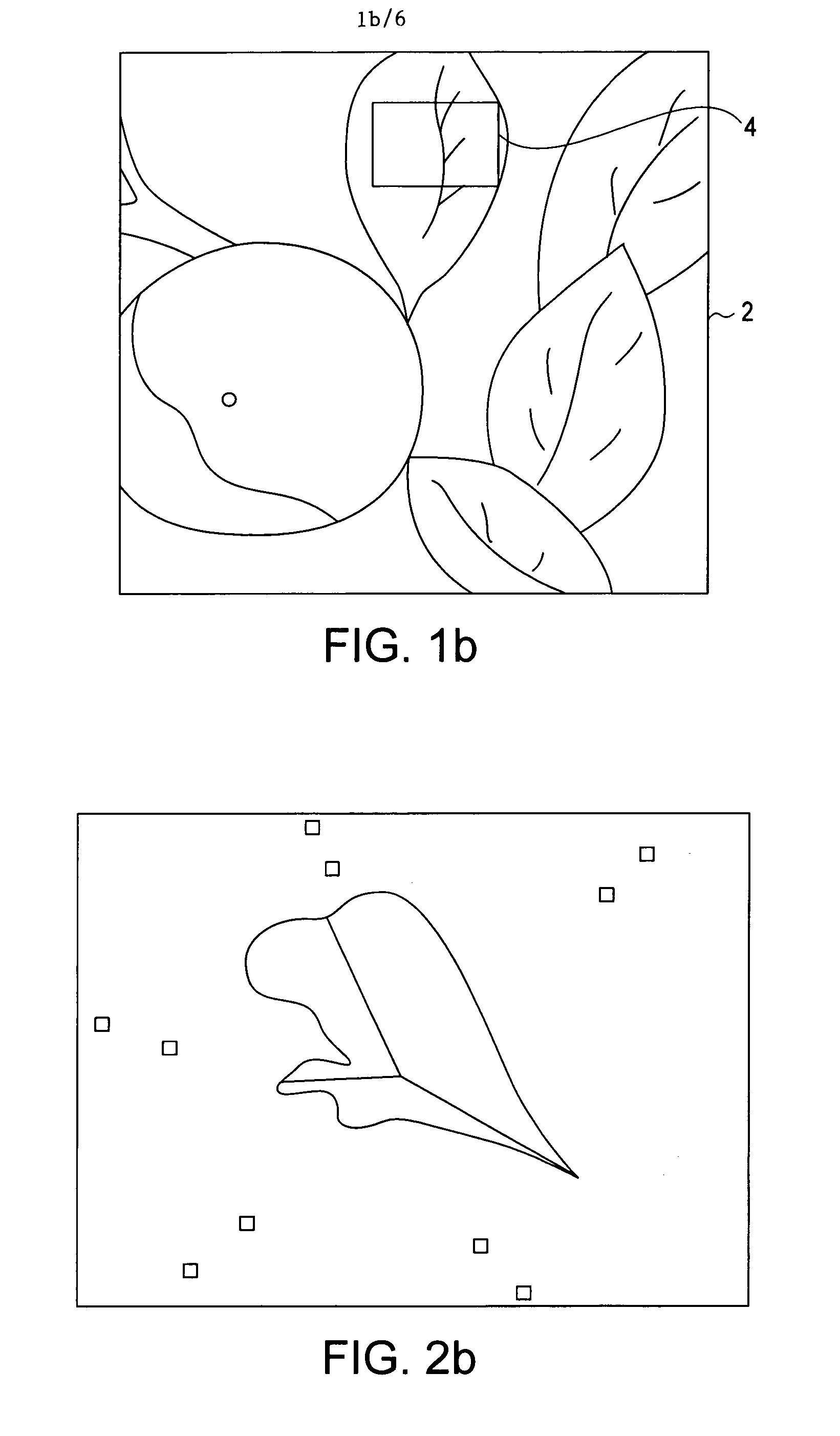

Image processing

InactiveUS7042489B2Choose accuratelyEasy to makeTelevision system detailsTelevision system scanning detailsGraphicsImaging processing

A system for scanning cinematographic film so as to produce digital images corresponding to the images on frames of the film is provided. The system includes means for scanning the film, means for displaying the digital images obtained by scanning the film, and image processing means. The image processing means includes means for adjusting the appearance attributes of the digital images obtained and further includes (a) means for displaying the output signal level versus time in graphical form for the images obtained, and / or (b) means for displaying the luminance, chrominance and saturation of the images obtained in graphical form on polar axes.

Owner:PANDORA INT

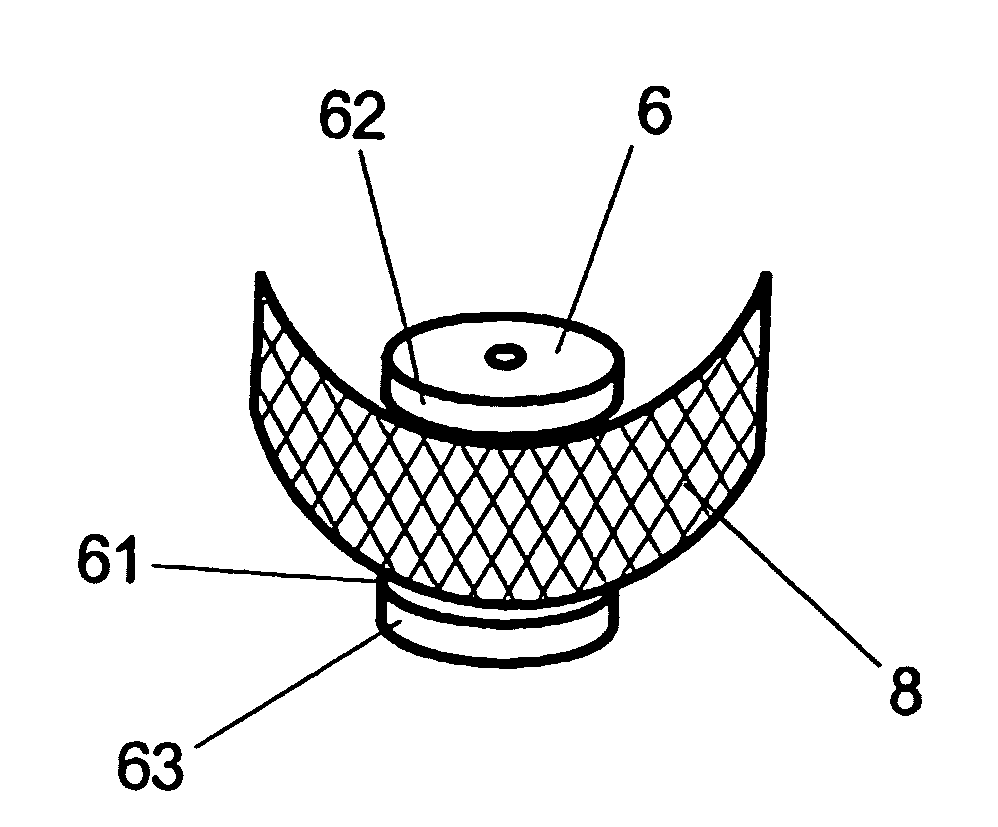

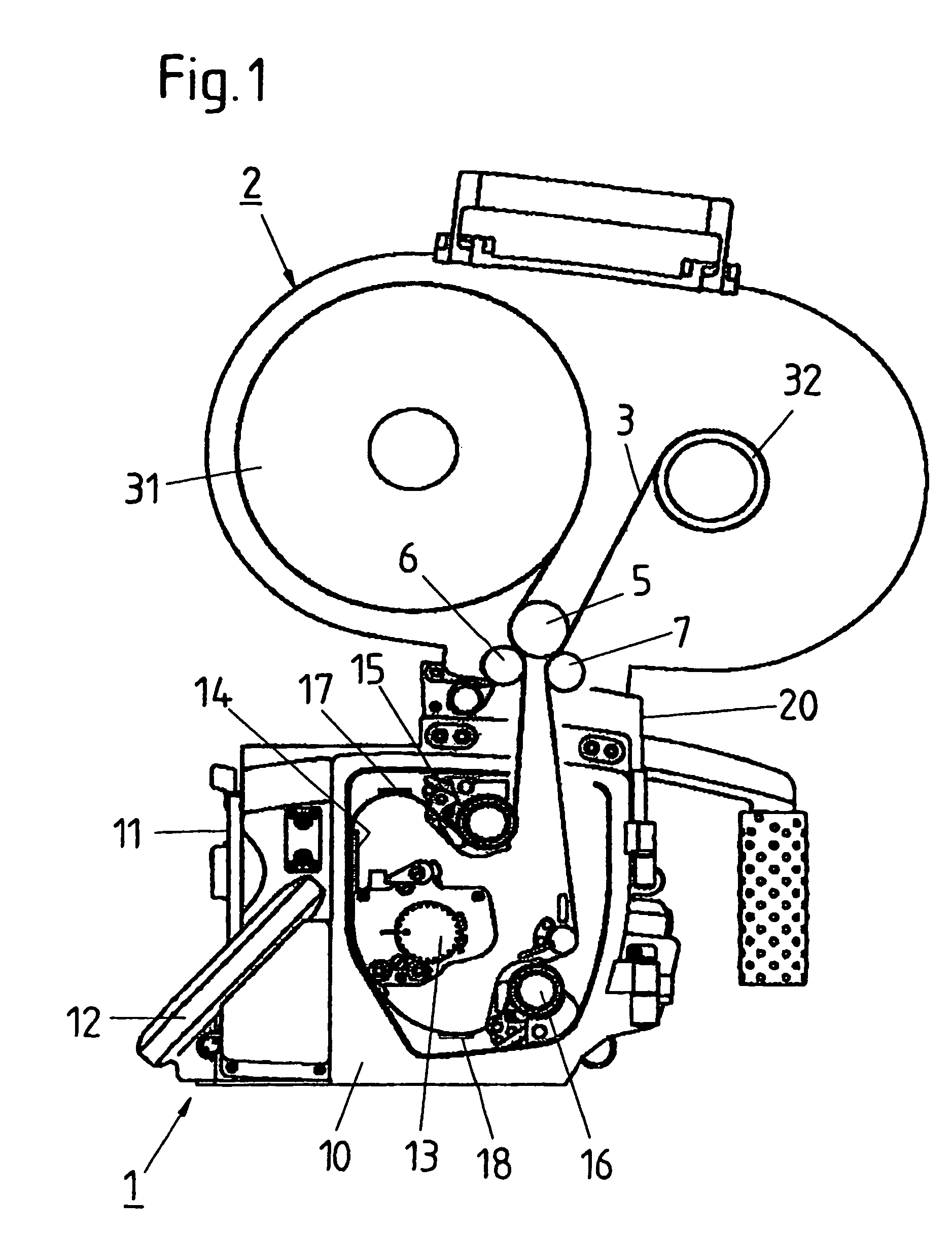

Motion picture camera having a film magazine and means for cleaning the film

InactiveUS7751024B2Low costEasy to operateProcessed material treatmentLiquid processingSheet filmFilm-out

A motion picture camera is provided having a film magazine inside of which a film supply reel, from which a motion picture film to be exposed having a supporting layer and a light-sensitive emulsion layer is unwound and moved over a film conveying path past a picture window for picture exposure and a film winding reel are placed, onto which the exposed motion picture film is wound. A device, which serves to remove foreign bodies located on one or both surfaces of the motion picture film, is placed in the film conveying path between the film supply reel inside the film magazine and the picture window.

Owner:ARNOLD & RICHTER CINE TECH GMBH & CO BETRIEBS KG

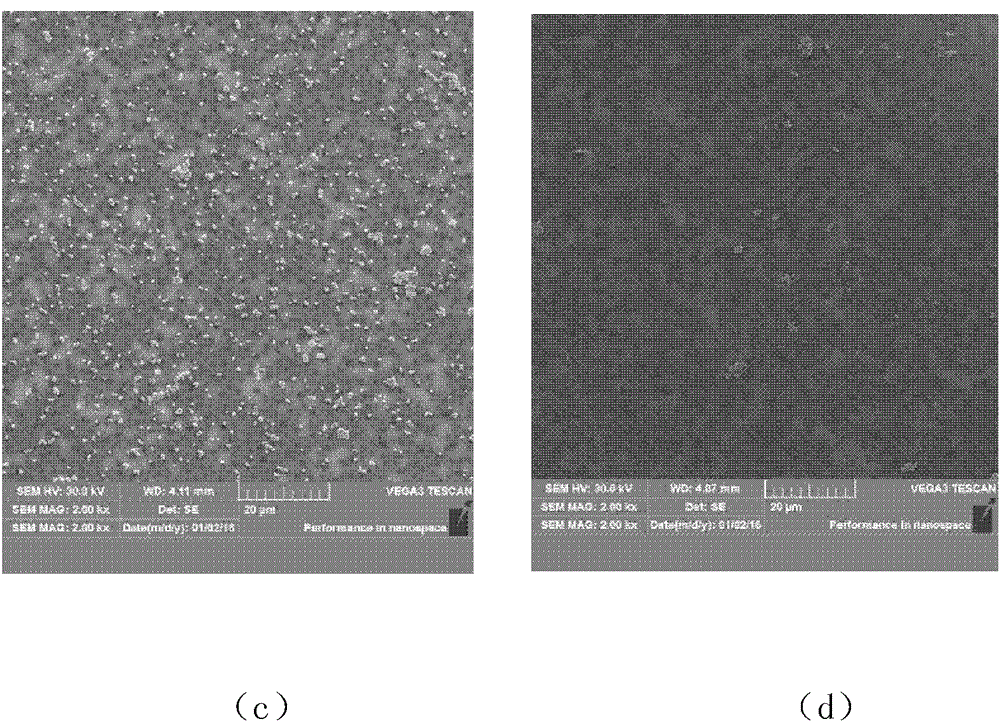

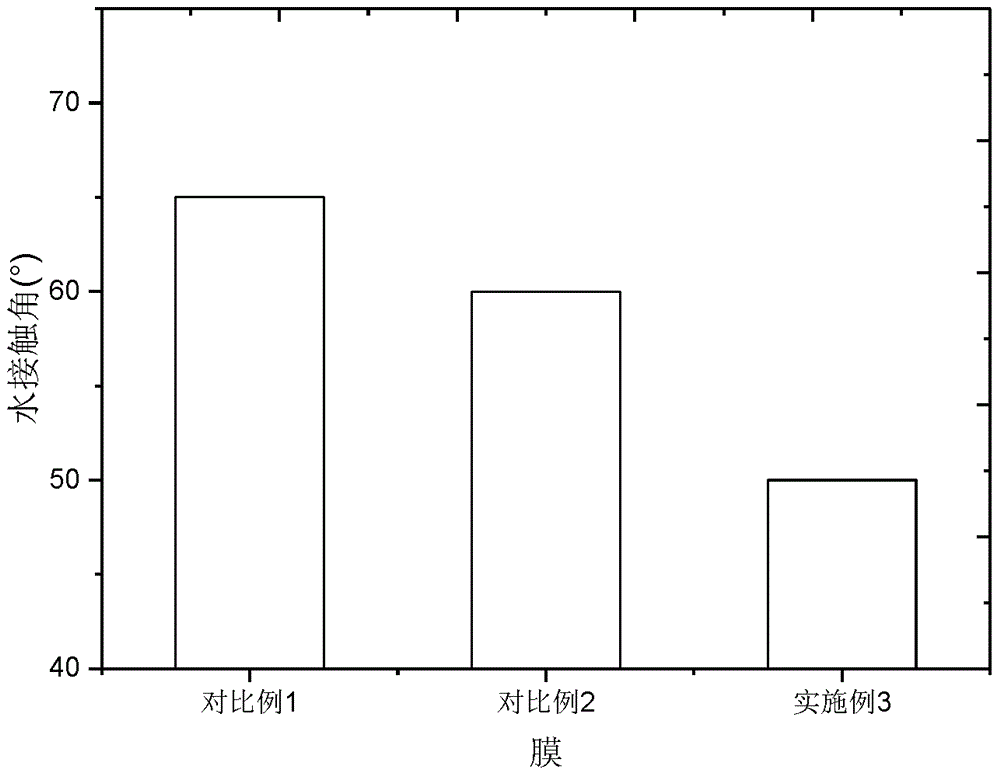

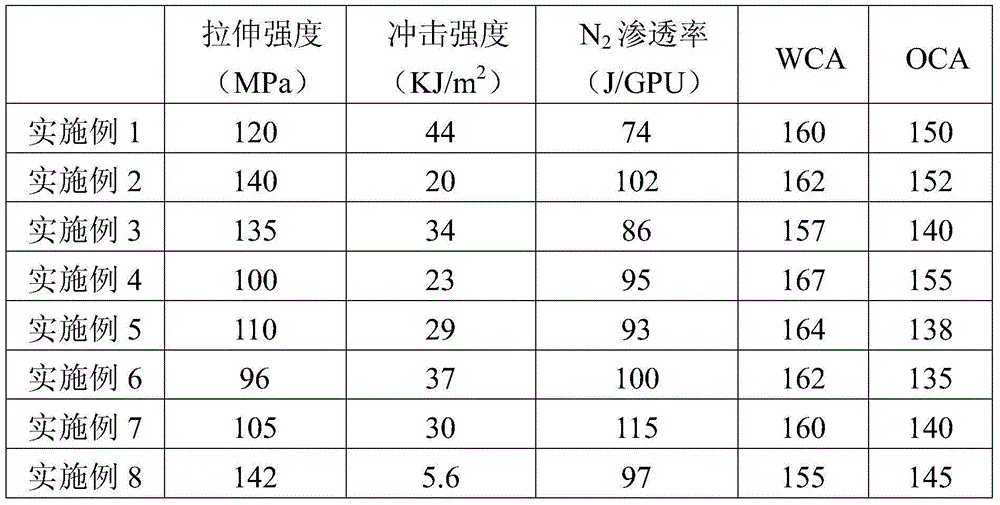

Method for improving antifouling property of polyimide film and product

ActiveCN105771699AImprove hydrophilicityImprove anti-pollution performanceMembranesSemi-permeable membranesMicroorganismPolyimide membrane

The invention discloses a method for improving the antifouling property of a polyimide film and a product, belonging to the field of modification of polyimide films. The method comprises the following steps: immersing the polyimide film in a diamine solution for 0.1h-24h, taking the film out and cleaning the film; and immersing the cleaned polyimide film in an acid solution for 1-48h, taking the film out and cleaning the film. According to the method, by use of good hydrophilicity of zwitter-ions, the zwitter-ions are successfully grafted on the surface of the polyimide film to endow the polyimide film with high hydrophilic performance, obviously improve the hydrophilicity of the film and further improve the antifouling property of the film, and the microorganism adsorption and biological membrane formation inhibition are reduced, and the antifouling ability is stably and reliably improved. The preparation process is simple, can be operated easily and can realize industrial application.

Owner:HUAZHONG UNIV OF SCI & TECH

Self-cleaning aramid fiber film, preparation method thereof, and applications thereof in gas separation

ActiveCN103908903AAchieve decentralizationImprove the problem of using concentrated sulfuric acidSemi-permeable membranesDispersed particle separationEpoxyOrganic solvent

The invention belongs to the technical field of aramid fiber film preparation, and discloses self-cleaning aramid fiber film, a preparation method thereof, and applications thereof in gas separation. The method includes steps of: adding aramid fiber into a mixed solution of an organic solvent and a strong alkali, stirring to obtain a uniform solution, adding a pore-forming agent, stirring and degassing, casting on a substrate to form film, immersing the film together with the substrate into water, allowing the film to gel in water and be separated from the substrate so as to obtain gel film, drying the gel film to obtain aramid fiber film, dipping the prepared aramid fiber film into fluorine-containing epoxy resin dispersed by a solvent, taking the aramid fiber film out, and heating the aramid fiber film to obtain the self-cleaning aramid fiber film. A film casting liquid is prepared by dispersing the aramid fiber through the strong alkali, and then the aramid fiber film is prepared by a solution phase transfer method, thus maintaining the good molecular structure integrity of the aramid fiber, and preserving inherent performances of the aramid fiber, thus as high-temperature resistance, solvent tolerance and high strength. Then the fluorine-containing epoxy resin is grafted into the aramid fiber film to obtain the aramid fiber film with hydrophobicity or amphiphobicity, thus obtaining the self-cleaning aramid fiber film.

Owner:国科广化(南雄)新材料研究院有限公司 +1

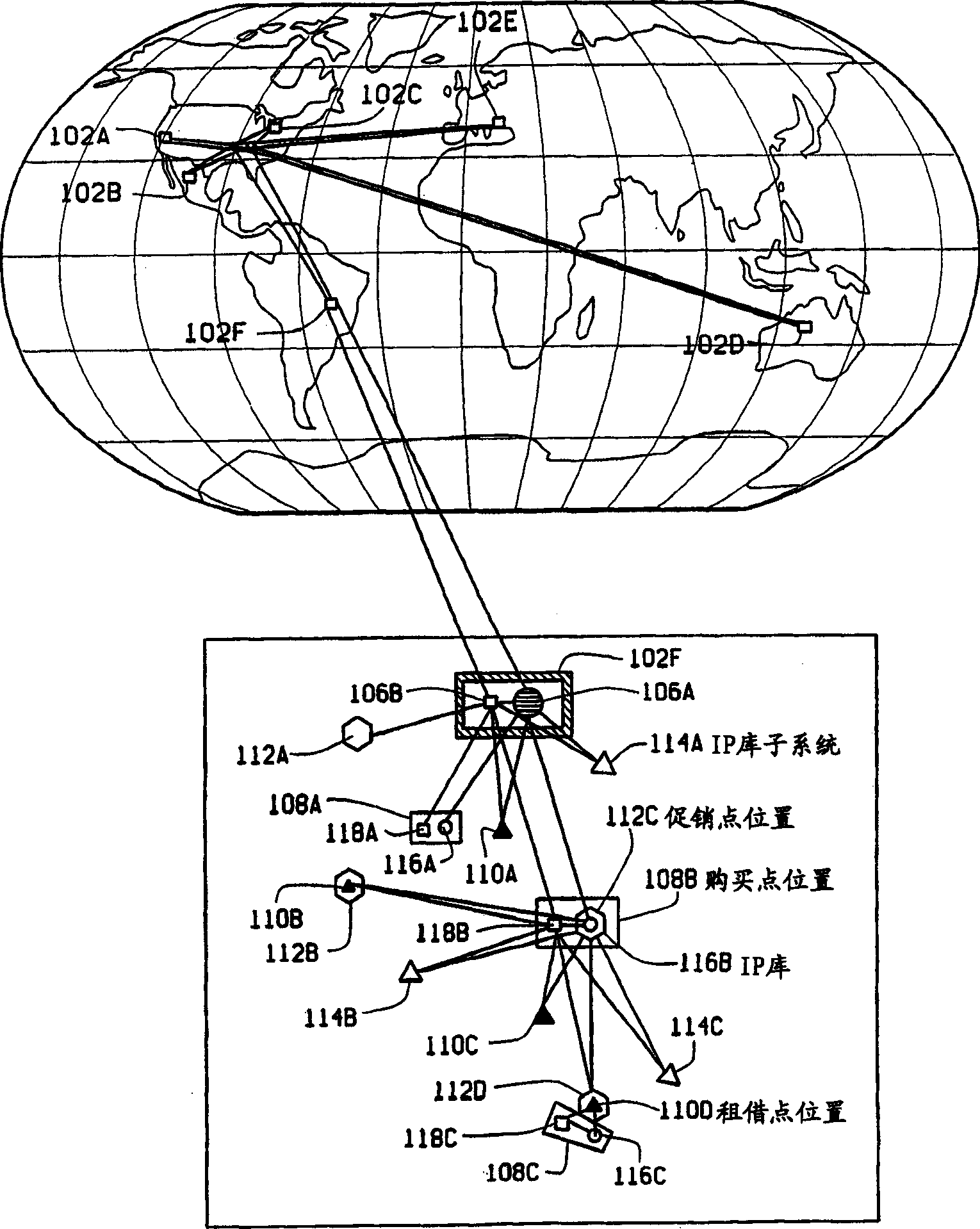

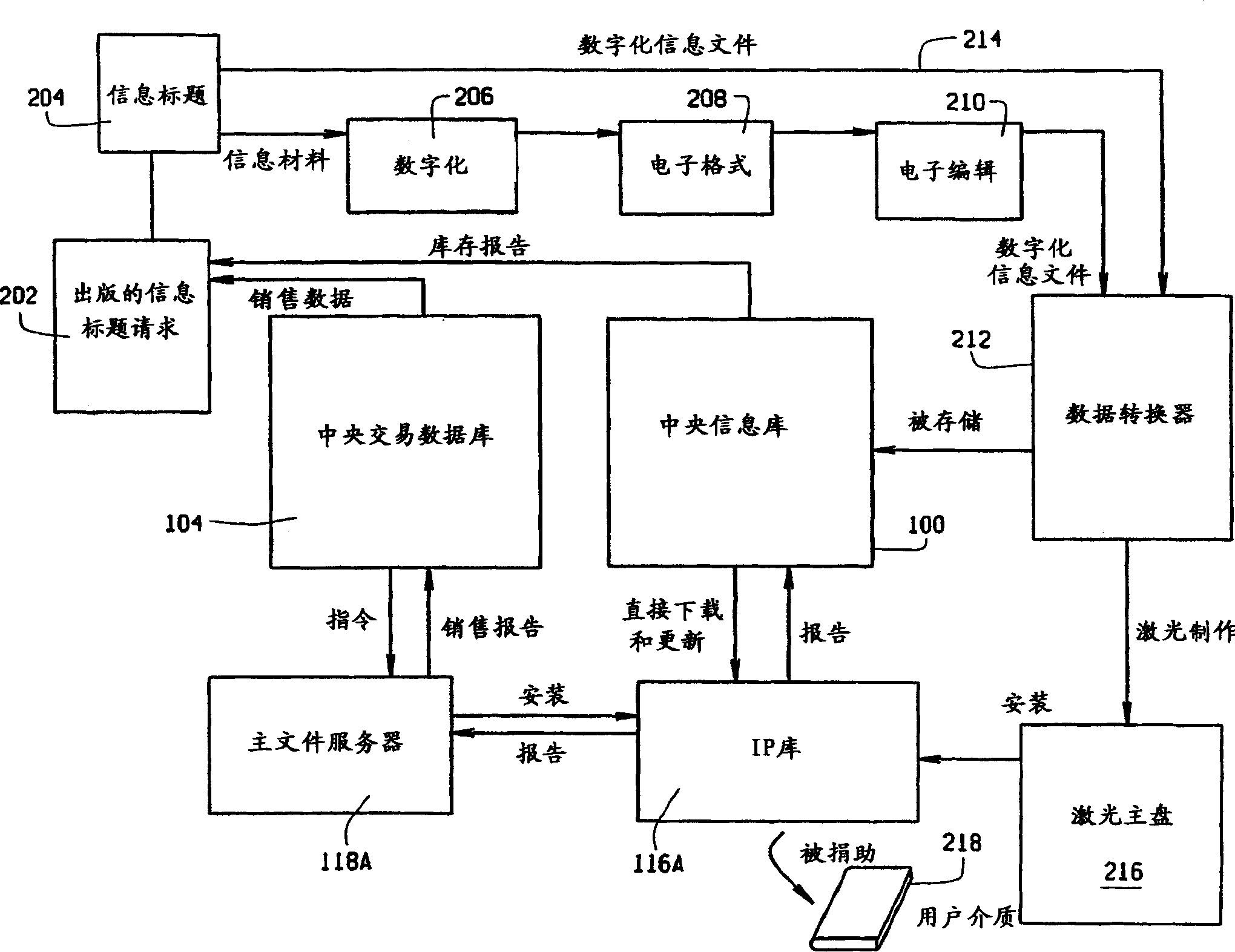

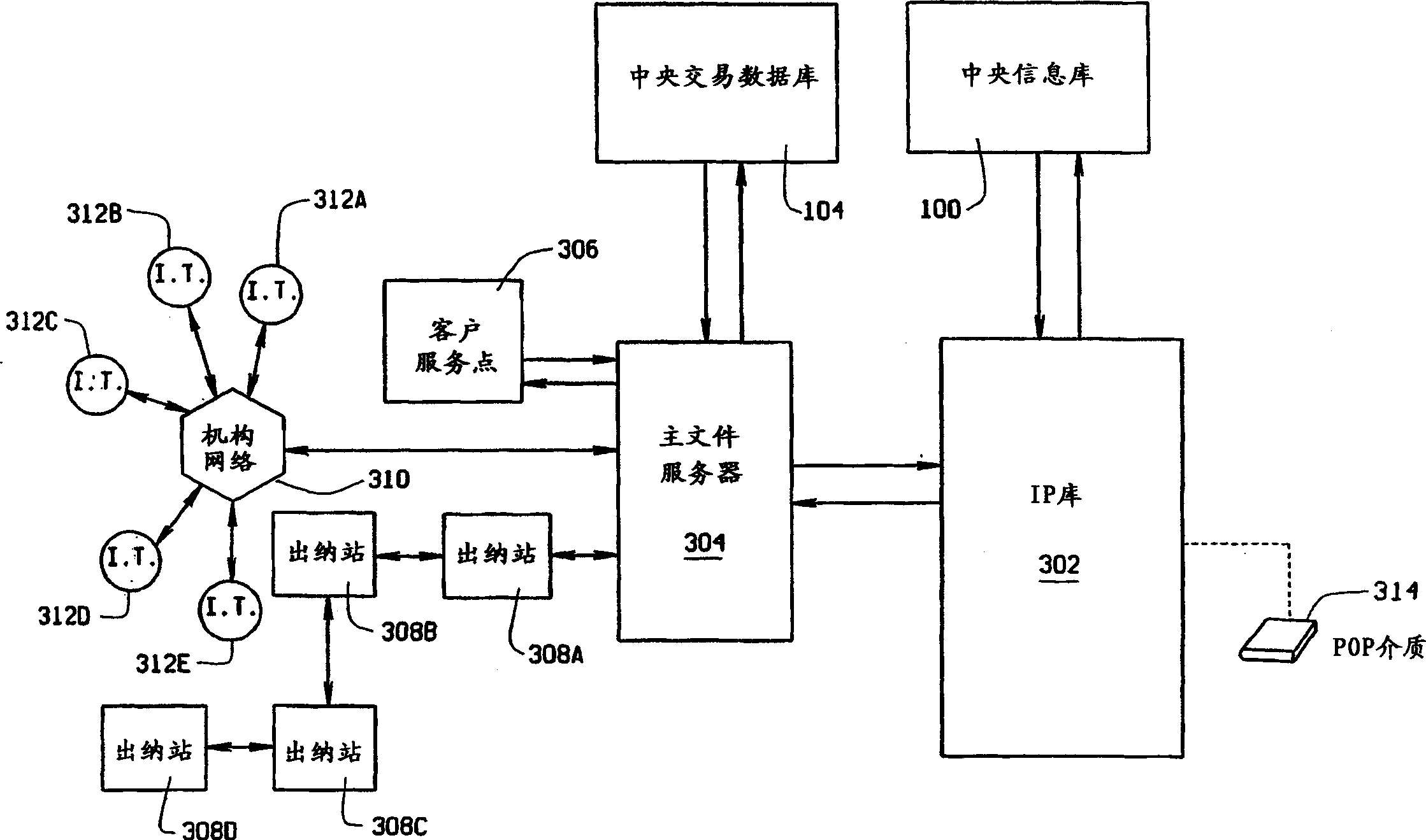

Methods and devices for storing, distributing and accessing intellectual property in digital form

In one embodiment, the present invention is an apparatus for conveniently obtaining the text of an IP, the apparatus comprising a storage device (116A) storing the text of a plurality of IPs, wherein the text includes various electronically stored representations, these representations represent printed works, films, films, video representations, television programmes, music, audio works, audio representations, radio programs, graphic material, artistic works, plays, operas, novels, articles, photographs, pictures, images ( all types of electronic images including virtual images), advertising copies, or computer games, or parts and combinations thereof; a processor (118A) connected to the storage device (116A), the storage device (116A) A program is further stored for controlling the processor to: receive an IP selection request; receive a user identification associated with the IP selection request; and if the user identification and IP selection are valid, output the selected IP using the determined IP encryption level The encrypted text of the selected IP.

Owner:IPDN

System and method for processing electronically captured images to emulate film tonescale and color

A method for converting a sequence of electronically captured images into a sequence of modified images for providing the appearance of images captured by a film reproduction system. The film reproduction system being includes motion picture negative film printed onto a motion picture print film that is displayed, or a reversal motion picture system in which the reversal film is displayed, or a motion picture film electro-optically scanned to standard format video by a telecine and further displayed, or a motion picture film electro-optically scanned by a scanner suitable for producing digital data intended for additional digital image manipulation. A digital master is prepared from the aforementioned film formats for electronic distribution or recording out to another film to be used as a printing master for producing distribution optical prints for theatrical projection.

Owner:INTELLECTUAL VENTURES FUND 83 LLC

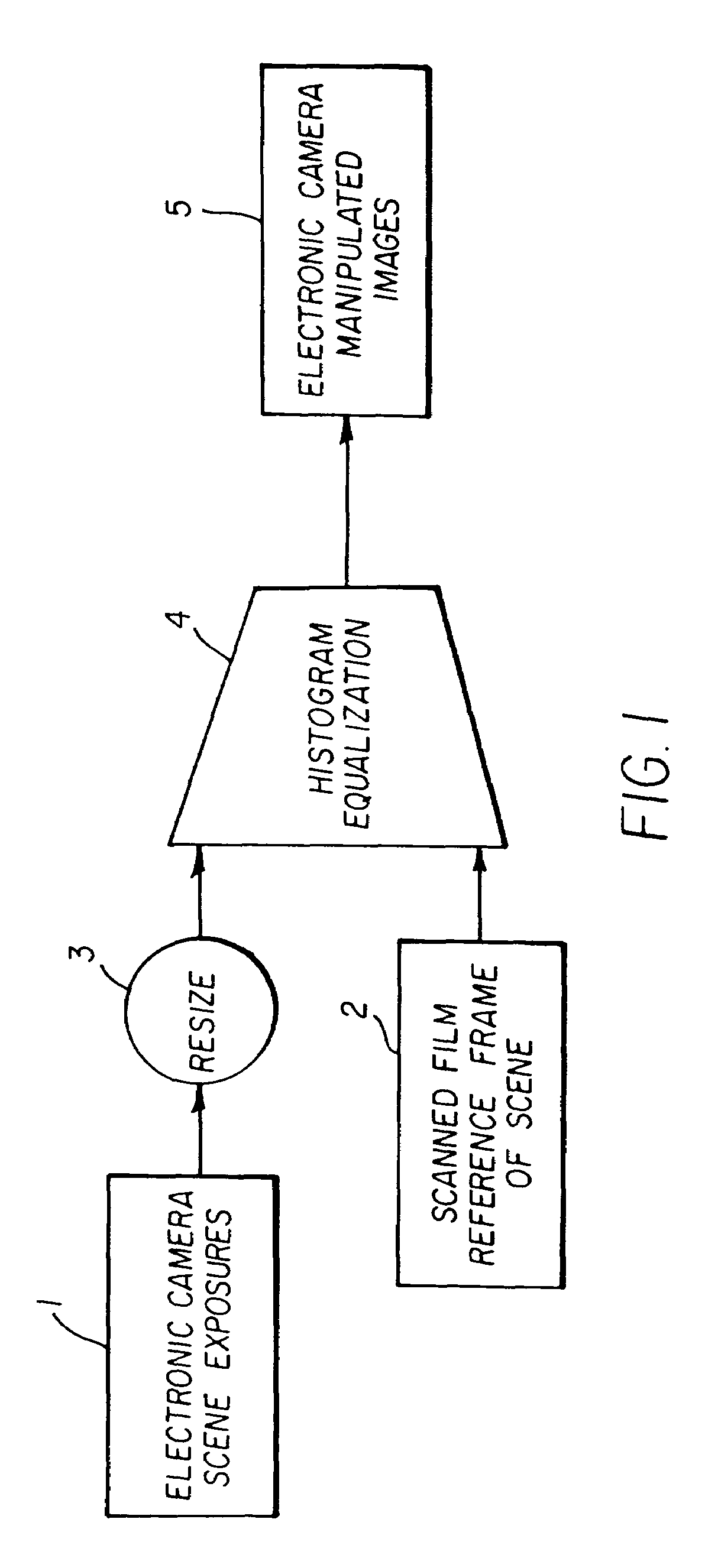

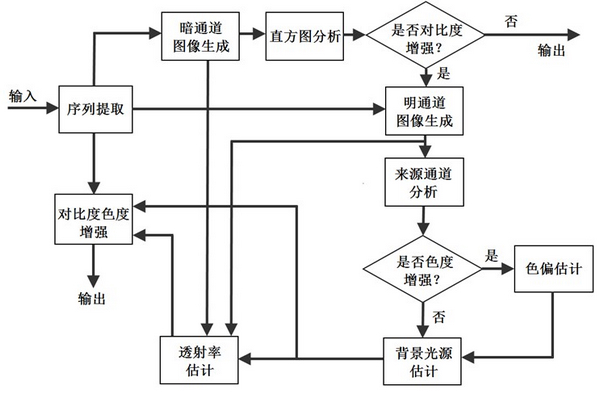

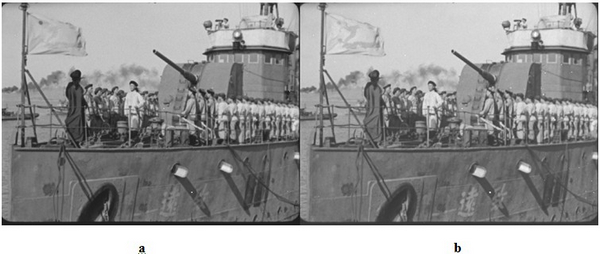

Method for automatically enhancing contrast ratio and chrominance of movie

ActiveCN102427538AImplement auto-enhancementEfficient removalColor signal processing circuitsPhysicsFilm-out

The invention discloses a method for automatically enhancing contrast ratio and chrominance of a movie; the method comprises the following steps of: reading a frame image sequence of the same scene in a video, and calculating a bright channel image and a dark channel image of each frame; carrying out column diagram analysis on the dark channel image, judging whether the contrast ratio is needed to enhanced; carrying out source analysis on the bright channel image, and judging whether the chrominance is needed to enhanced; if the contrast ratio is needed to enhanced, carrying out transmissivity estimation through an original image, the bright channel image and the dark channel image; and determining a threshold value of the transmissivity according to the bright channel and the dark channel; and enhancing the contrast ratio and the chrominance. According to the degradation principle of cine films, the method can be used for automatically distinguishing whether the contrast ratio and the chrominance of the movie are needed to be enhanced, and automatically enhancing the contrast ratio and chrominance of images needing to be enhanced.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of low temperature plasma grafted protein modified polyvinylidene fluoride film

InactiveCN102512973AGood biocompatibilityImprove hydrophobic defectsSemi-permeable membranesWater savingProtein solution

The invention discloses a preparation method of a low temperature plasma grafted protein modified polyvinylidene fluoride film. The preparation method comprises the following steps: putting a polyvinylidene fluoride film into a plasma working chamber for 10-600 seconds, and carrying out plasma surface treatment; taking the film out, exposing in air for 0-10 minutes, immersing into protein solution, and carrying out grating reaction; and taking the film out, and rinsing by distilled water repeatedly. The depth of the action of the low temperature plasma to the material surface is only 10 nanometers, so that the properties of a matrix cannot be affected. The preparation method has a simple process, is convenient to operate, has low chemicals consumption, is water-saving and energy-saving, and has higher reliability and safety, small environment pollution and broad application prospect.

Owner:DONGHUA UNIV

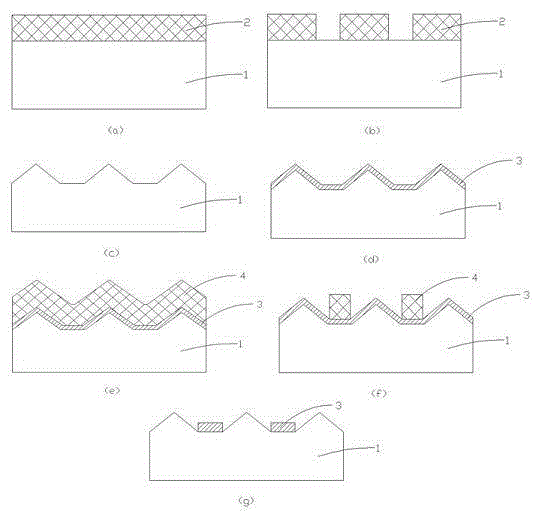

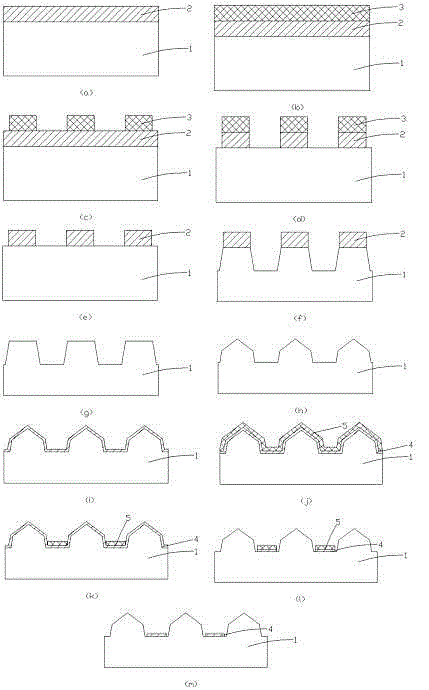

Producing method for graphical sapphire substrate

The invention discloses a producing method for a graphical sapphire substrate. A flat substrate is provided; a mask layer is formed on the surface; a graphical mask layer is produced on the surface of the mask layer by utilizing a photolithography; a graph is formed on the surface of the substrate by adopting a wet process corrosion or dry process etching technology by utilizing the graphical mask layer; the mask layer is removed; an insulating medium film is formed on the surface of the graphical substrate; the insulating medium film in the clearance of the graphical substrate is protected by utilizing the photolithography; the insulating medium film out of the photolithography protection is removed by adopting the wet process corrosion or dry process etching technology. According to the invention, epitaxy cannot grow on the surface of the insulating medium film; the epitaxial growth in the vertical direction is avoided; lateral epitaxial growth is increased; the dislocation density in a glowing area is reduced; the insulating medium film with certain film thickness is adopted to fill the clearance of the graphical substrate; the depth of the clearance is reduced; epitaxial growth cycle is reduced.

Owner:SHENZHEN DESUN PHOTOELECTRICITY

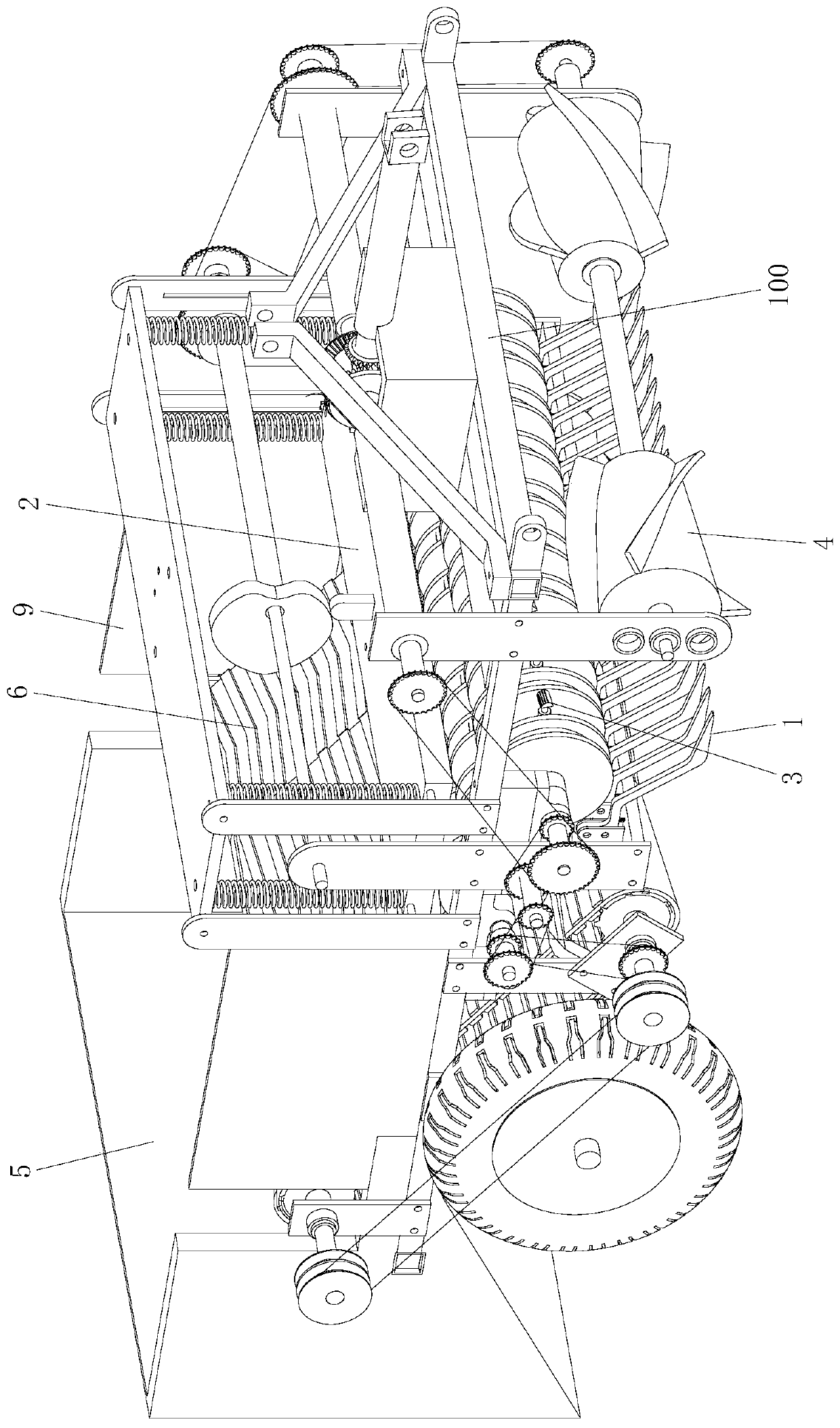

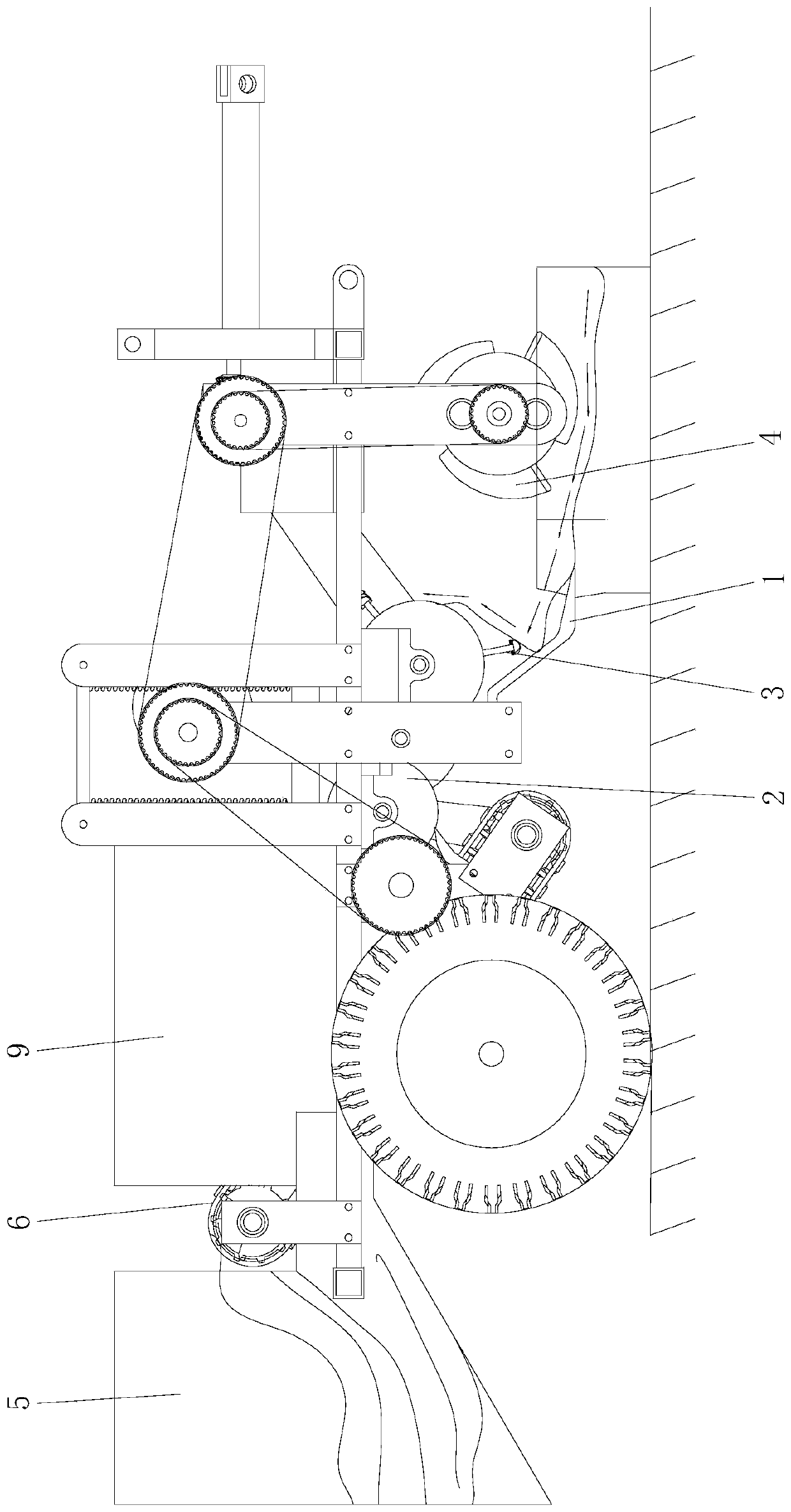

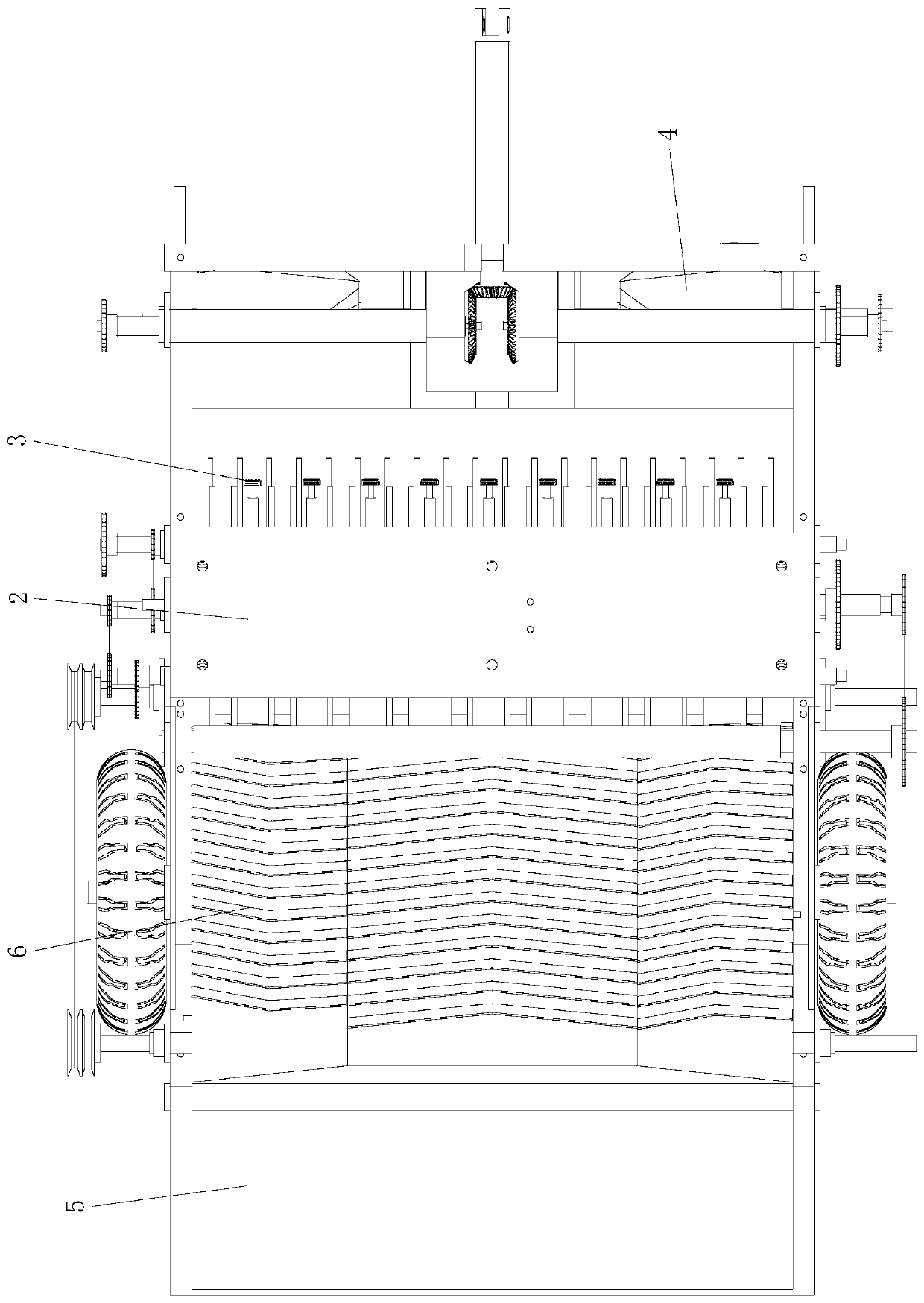

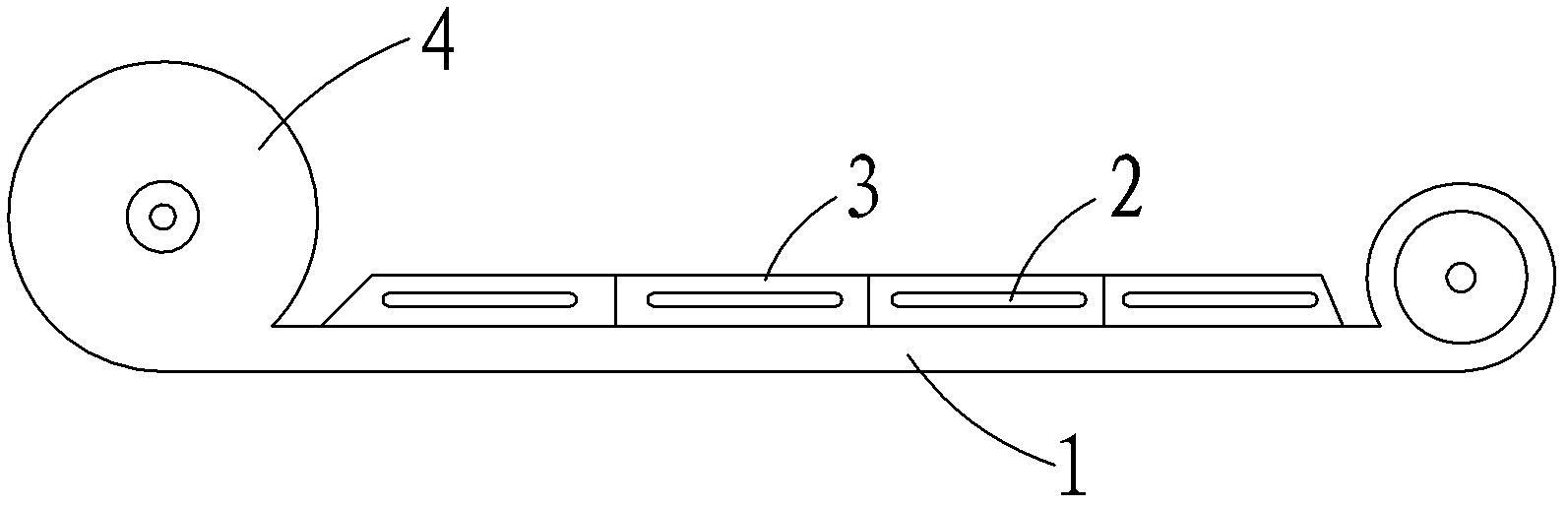

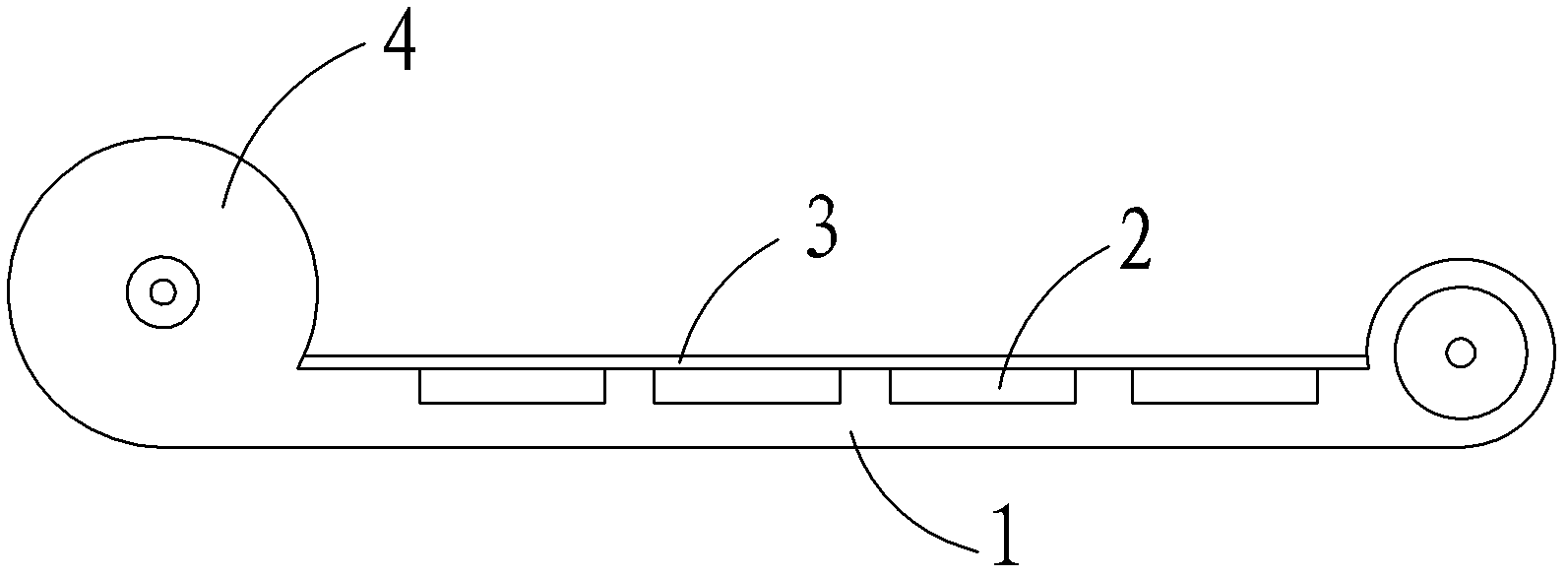

Farmland residual film recovery machine

The invention discloses a farmland residual film recovery machine, which comprises a frame, a plurality of film picking shovels, a film-soil separation device and a film feeding device. The film picking shovels are mounted at intervals on the frame sequentially and used for picking residual films out of soil, the film-soil separation device is used for separating soil from residual films, and thefilm feeding device is used for feeding the residual films picked by the film picking shovels into the film-soil separation device. A soil breaking device for breaking the soil on the residual films is arranged on the frame and in front of the film picking shovels and comprises a soil breaking shaft, the soil breaking shaft is driven to rotate by a soil breaking driving component, and two soil breaking rollers for breaking soil lumps on two sides of the residual films correspondingly are mounted on the soil breaking shaft and mounted at an interval on the soil breaking shaft. The farmland residual film recovery machine has advantages of simple structure, easiness in manufacturing, low cost, great soil breaking effects, low residual film breakage and soil entrainment quantity and the like.

Owner:HUNAN AGRICULTURAL UNIV

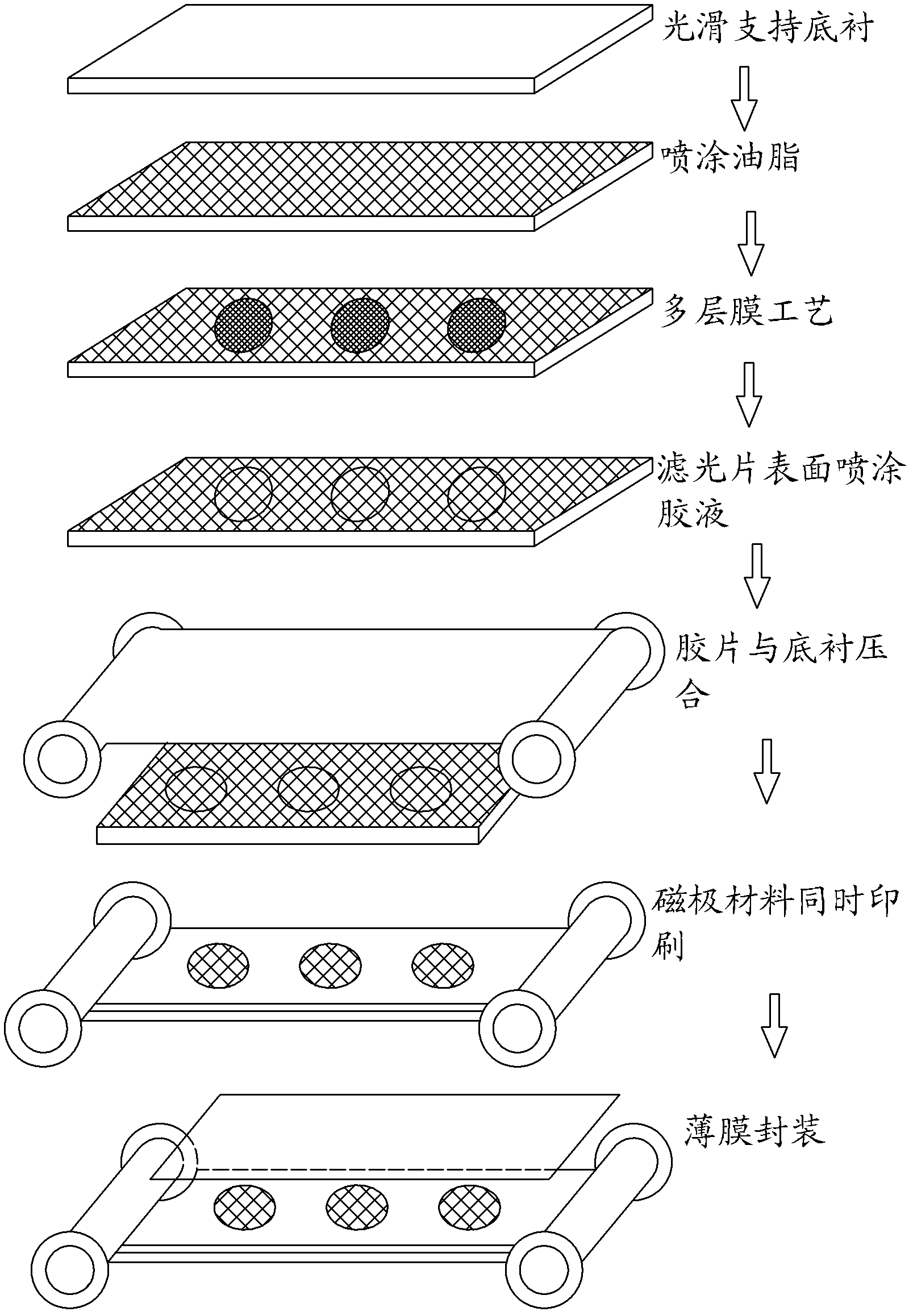

Filtering thin film, filtering thin film device and manufacture method thereof

The invention discloses a filtering thin film which comprises a support bottom liner and at least two optical fibers with different transmission bandwidths, wherein the optical fibers are arranged on the support bottom liner according to the single queue, and transparent layers are arranged on surface layers of the optical fibers. The invention has the advantages that the optical fibers are coated or adhered on a shooting cinema film or common photographic film by adopting a vacuum multilayer coating process technology or multiple-spectrum optical fiber soft bottom liner adhesion process technology to form the filtering thin film, and the filtering thin film can be bent into a coil which is similar to a film used for shooting or photographing. The filtering thin film has the advantages of convenience for operation, low cost, small occupation space, light weight and high transmission rate, thus the spectral resolution is greatly increased.

Owner:孔令华

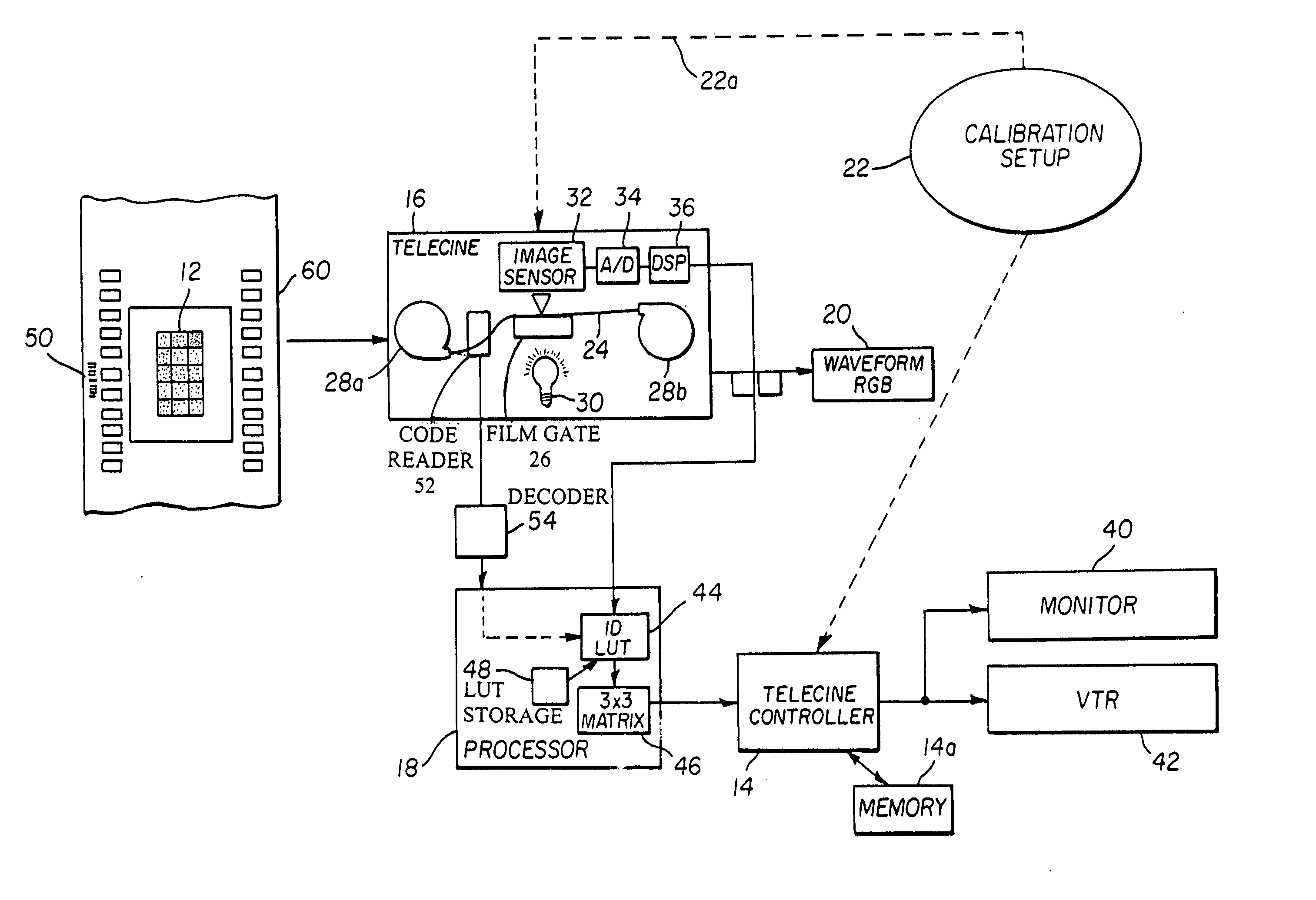

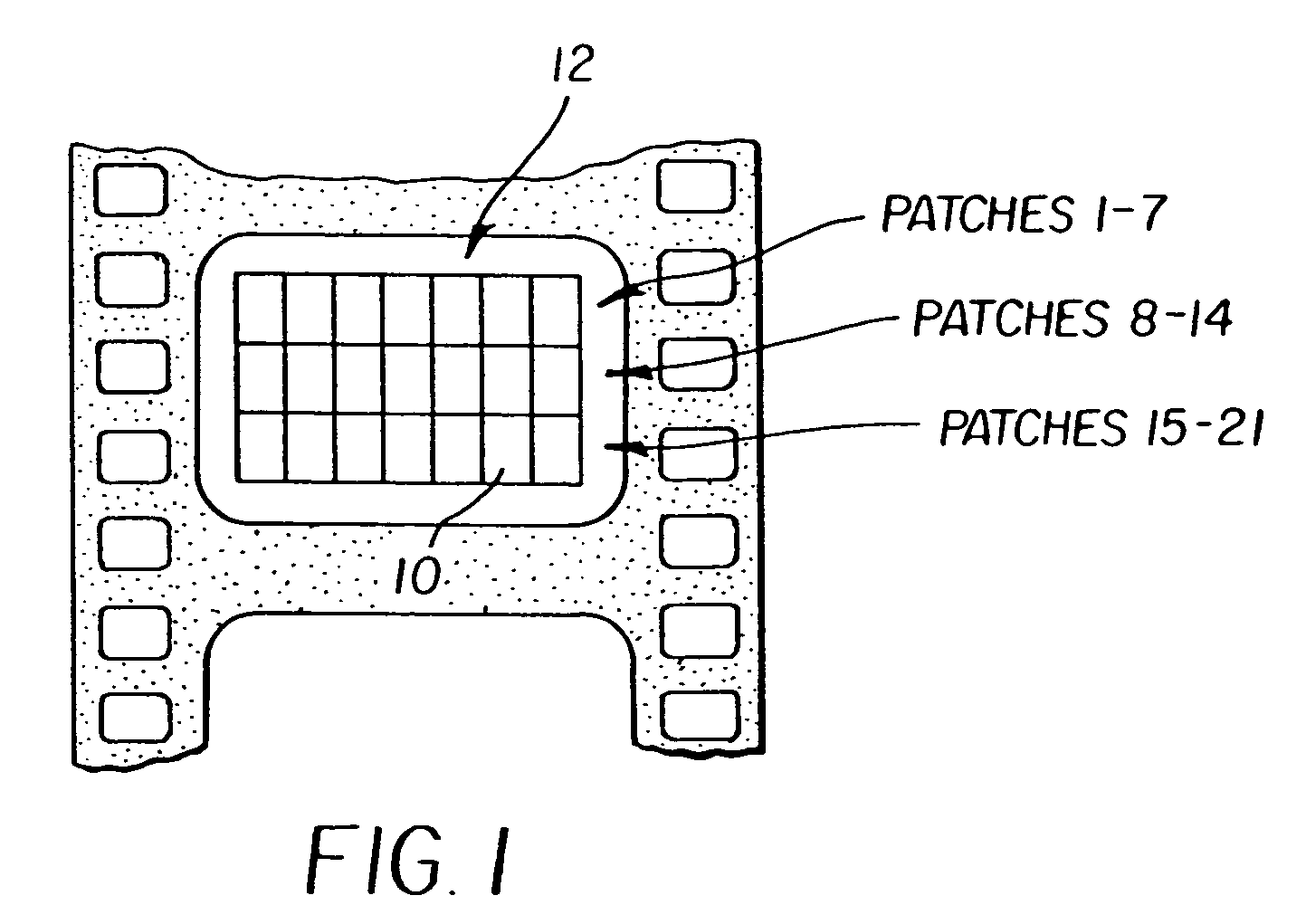

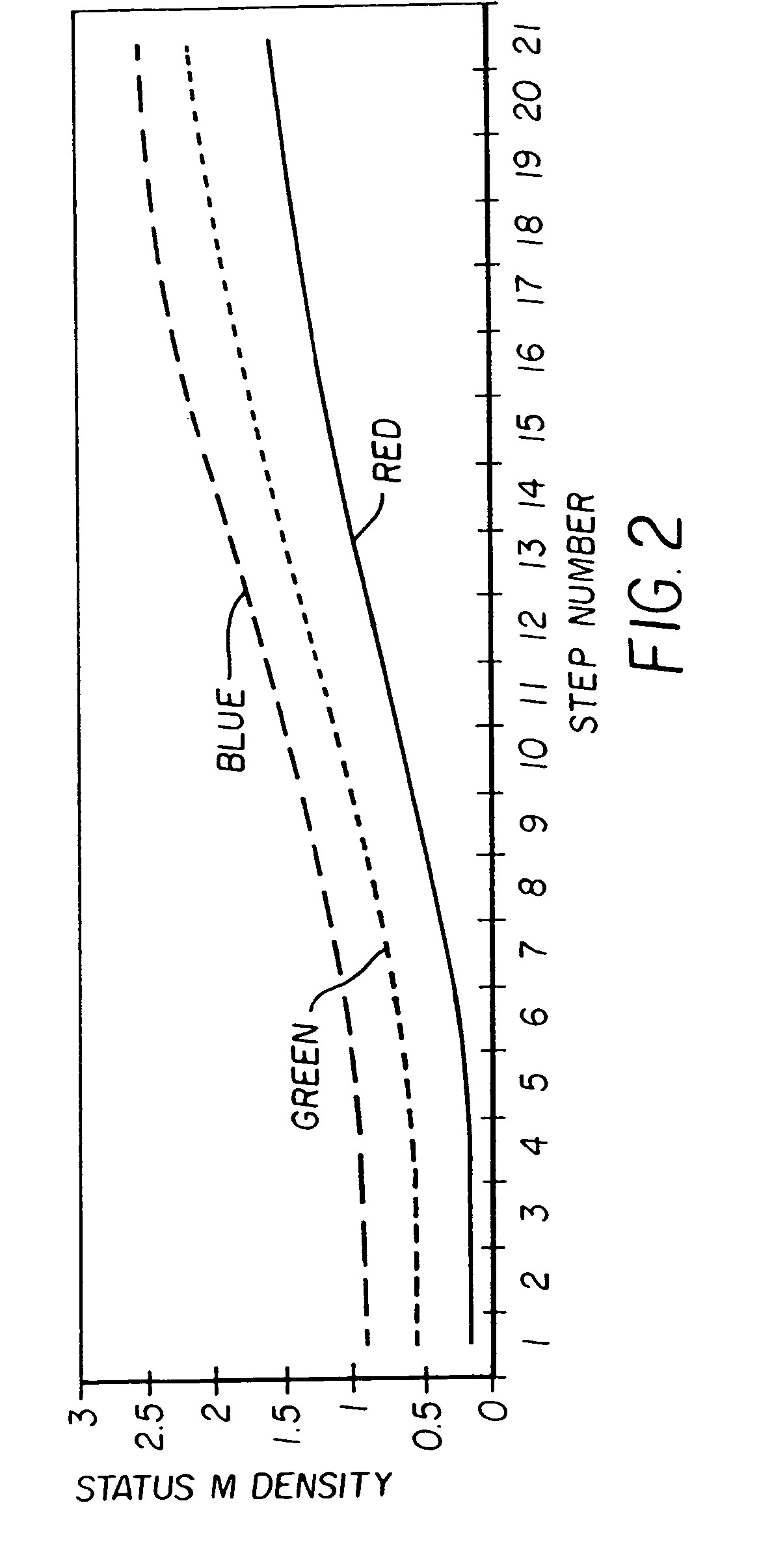

Calibration of a telecine transfer device for a best light video setup

InactiveUS20060146130A1Simple processImprove automationTelevision system detailsColor motion picture films scanningPhysicsFilm-out

In calibrating a motion picture film scanner, a calibration element is provided that is composed of a multi-step neutral gray series comprised of a plurality of known density patches, each corresponding to one or more prescribed aim voltages, that substantially represent the full density vs. exposure range of a photographic element. The calibration element is scanned with the motion picture film scanner and one or more signal voltages are generated for each density patch. The motion picture film scanner is then adjusted to bring the signal voltages toward the prescribed aim voltages, thereby generating one or more adjustments that compensate for errors from the prescribed aim voltages and capture substantially the full range of the motion picture film. Since each motion picture film that is scanned by the film scanner is a particular film stock, i.e., a particular film type, the calibration further includes applying a custom correction to the output of the motion picture film scanner for the particular film type being scanned. The custom correction may be a neutral scale correction provided by a one-dimensional look up table.

Owner:CIRULLI ROBERT J +2

Method of plating non-conductive film in vacuum

InactiveCN102505110AImprove the decorative effectDoes not affect deliveryVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceFilm-out

The invention provides a method of plating a non-conductive film in vacuum. The method comprises the following steps: providing a glass substrate; pre-treating the glass substrate so as to realize that the surface of the glass substrate is clean; loading the pre-treated glass substrate on a substrate rack, delivering the substrate rack to a vacuum chamber by virtue of a transmission system; setting a film material or a target material in the vacuum chamber, heating the film material or bombarding the target material so as to deposit the film material or the target material on the surface of the glass substrate to form a film, wherein the thickness of the film is between 10nm and 2,000nm, and the resistance of the film is more than 1M omega; and delivering the glass substrate with the plated film out of the vacuum chamber by virtue of the transmission system. The method provided by the invention has the following beneficial effects: 1, strong decoration, wherein different optical interference can be formed by controlling the thickness of the film and the proportion of materials in the film, so that decorative films of various colors can be produced; and 2, excellent insulation, wherein the resistance of the film is more than 1M omega by controlling the thickness of the film and the proportion of materials in the film, so that excellent insulation is formed, and contact and remote signal transfer are not influenced.

Owner:深圳市杰瑞表面技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com