Patents

Literature

125 results about "Reversal film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

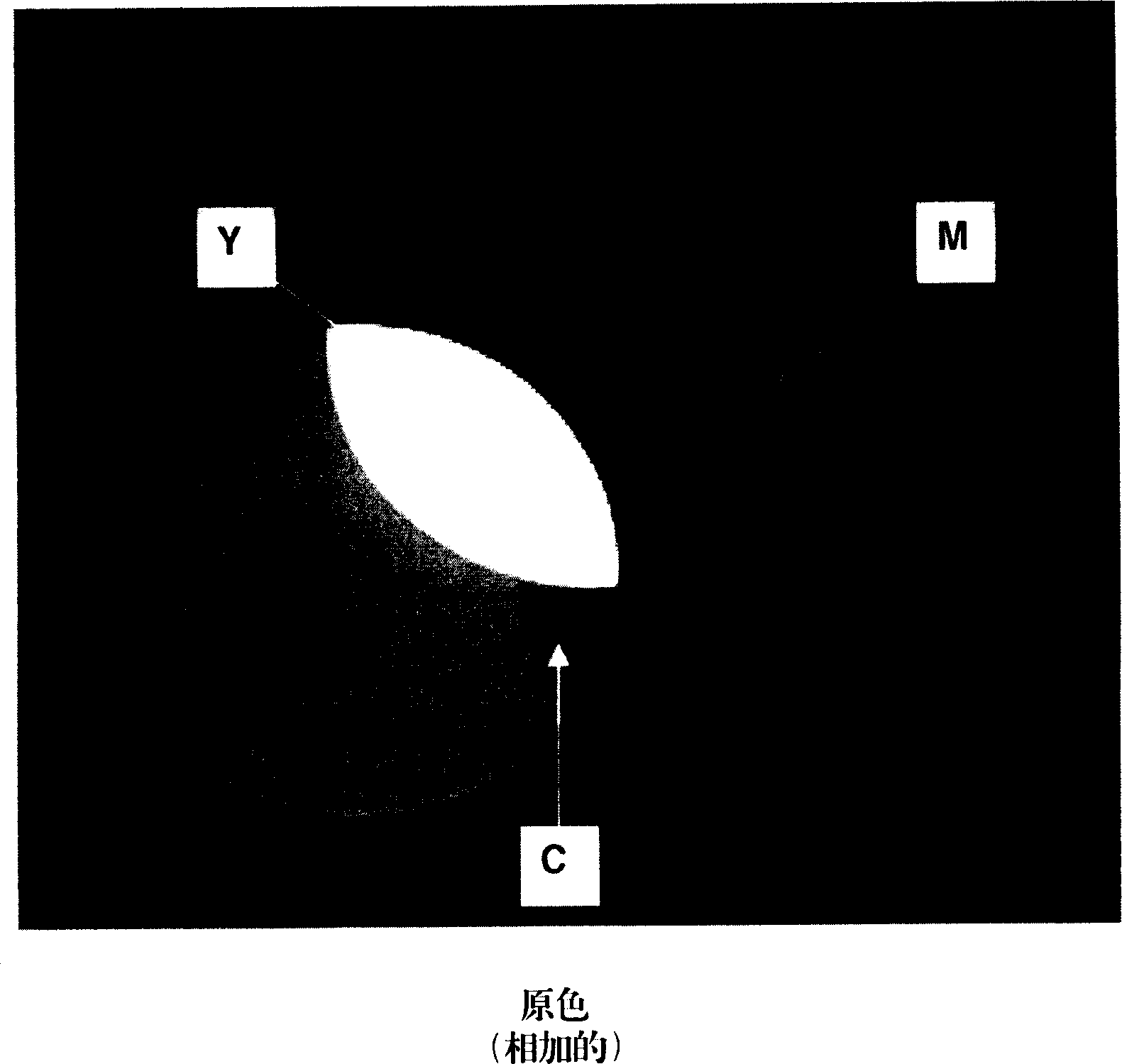

In photography, reversal film is a type of photographic film that produces a positive image on a transparent base. The film is processed to produce transparencies or diapositives (abbreviated as "diafilm" in many countries) instead of negatives and prints. Reversal film is produced in various sizes, from 35 mm roll film to 8×10 inch sheet film.

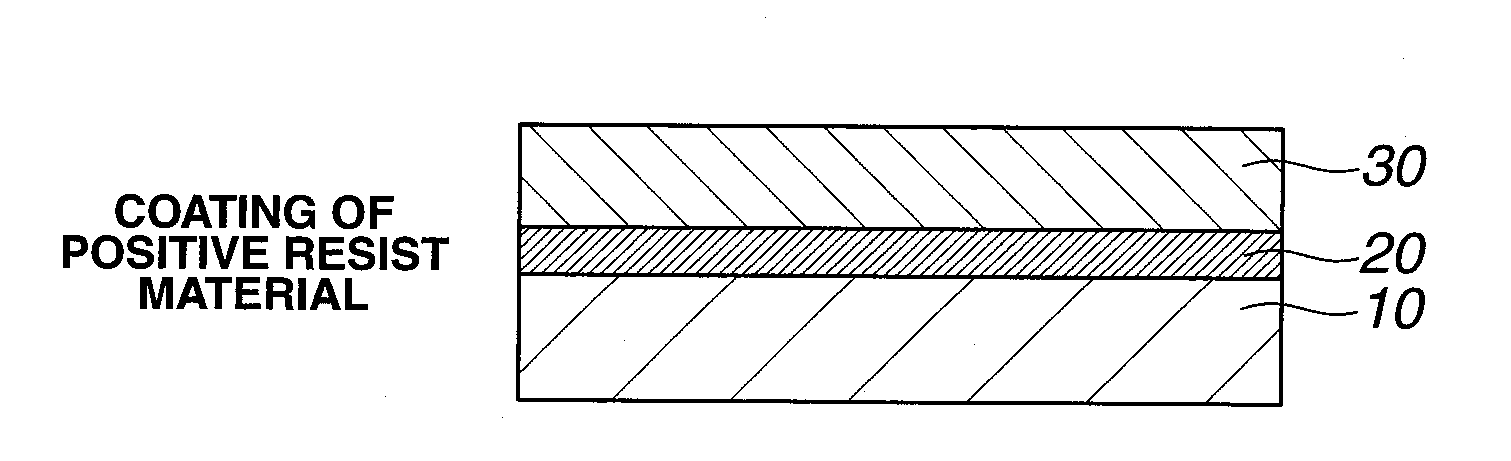

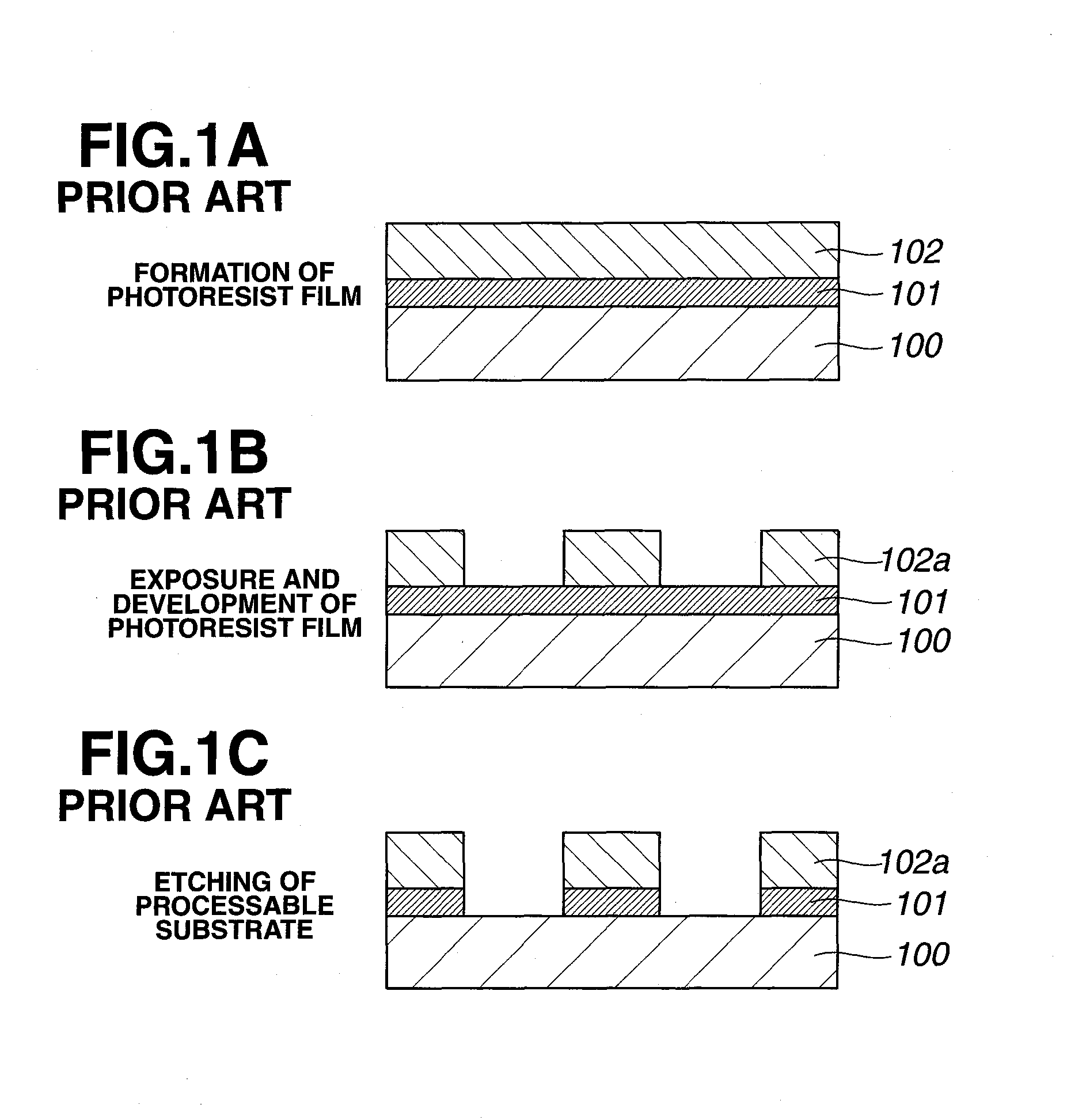

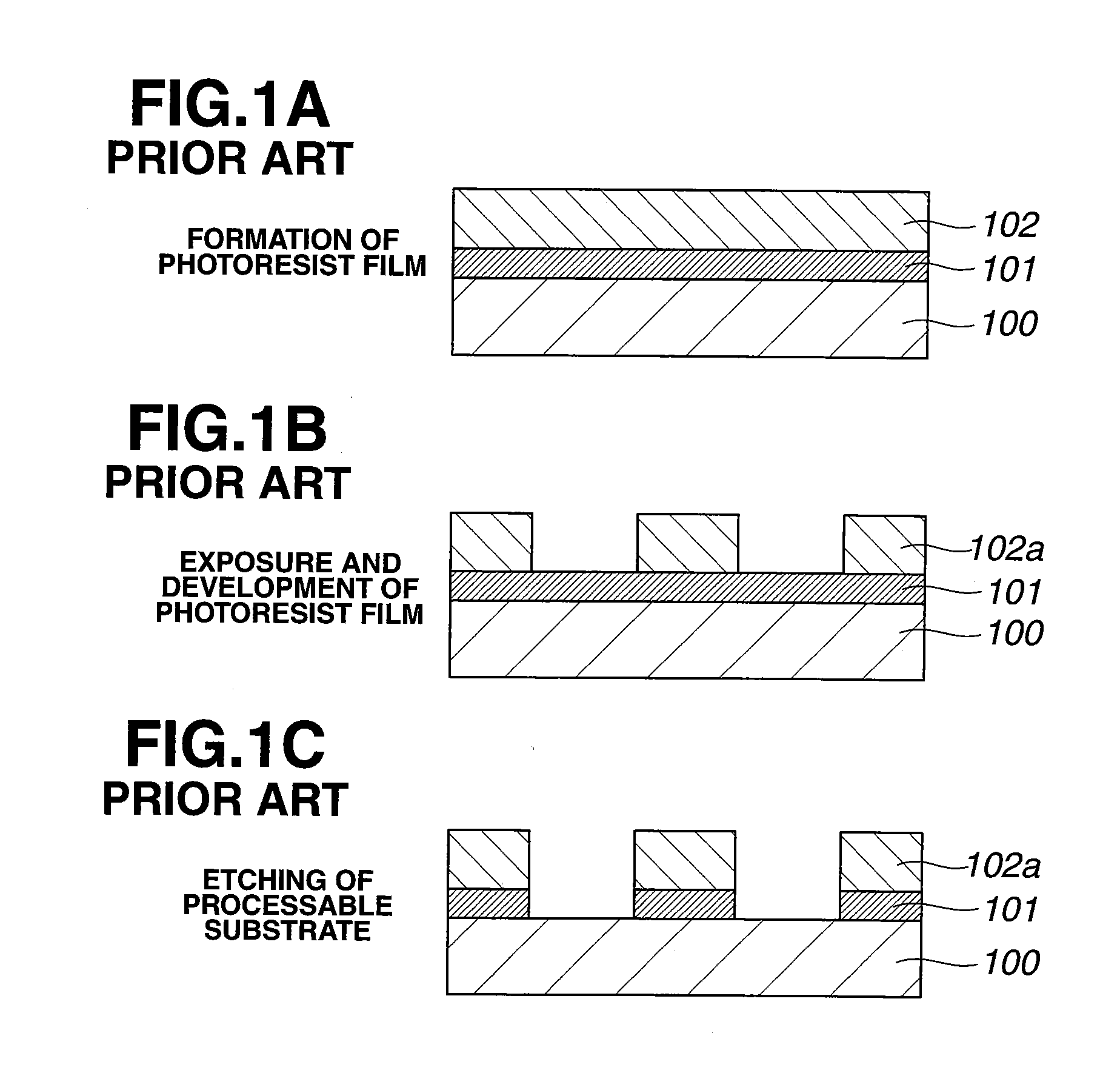

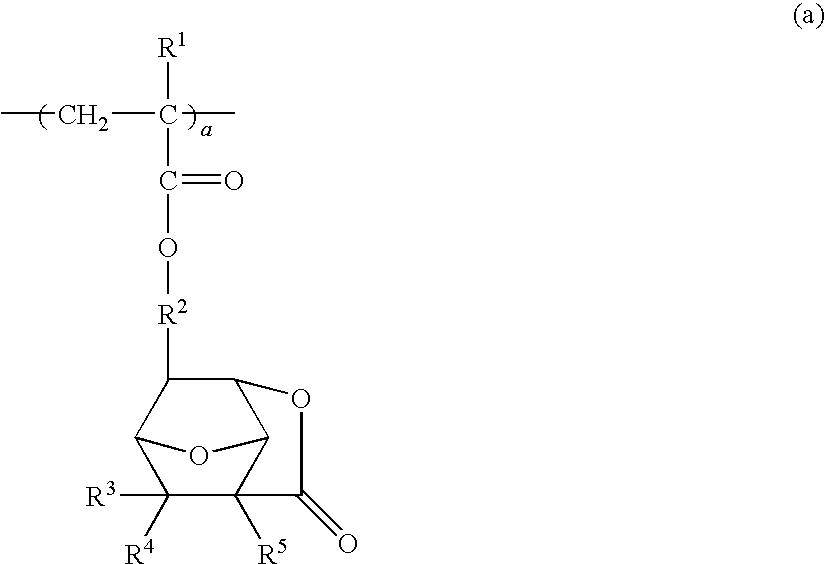

Method of forming patterns

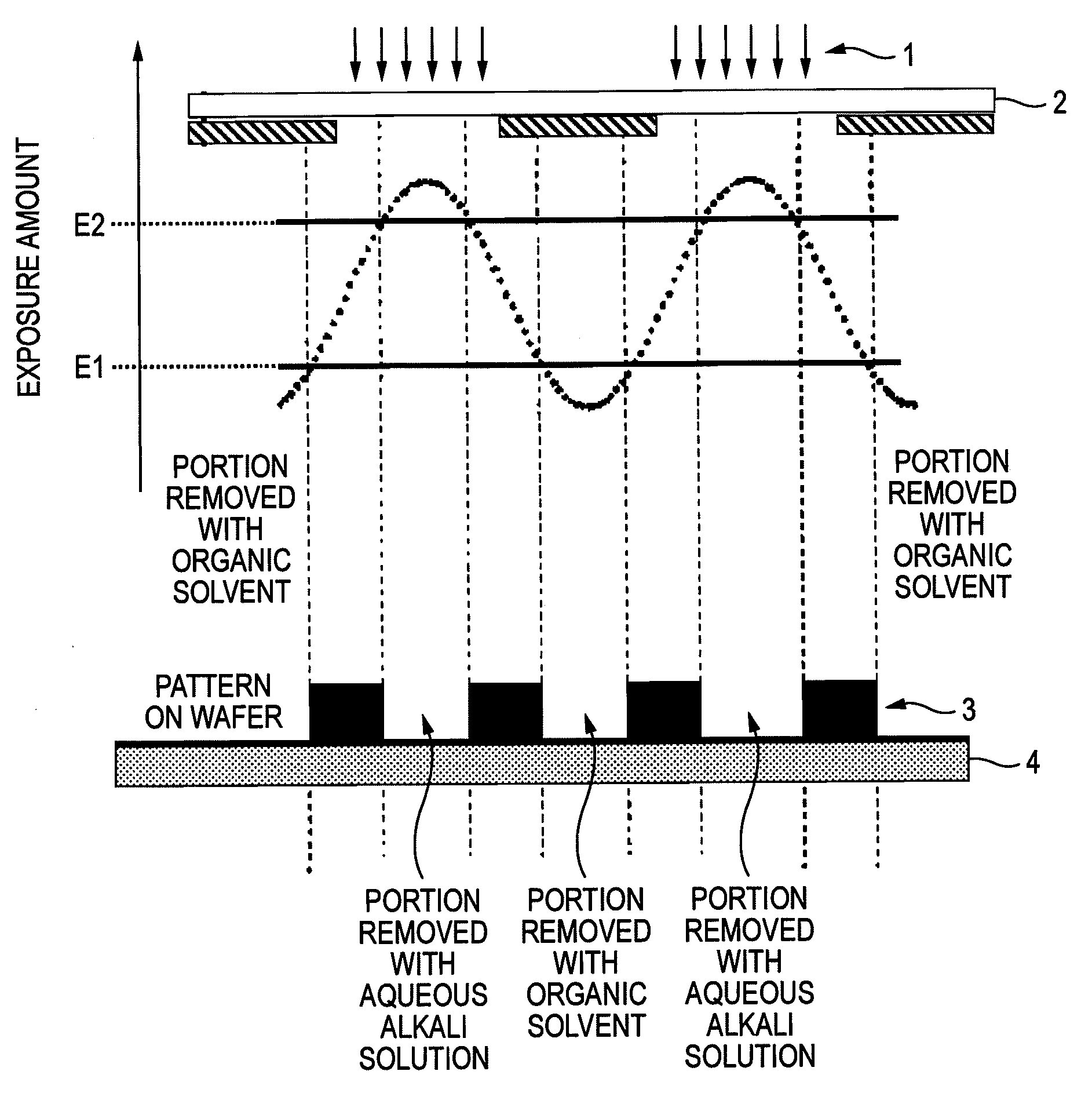

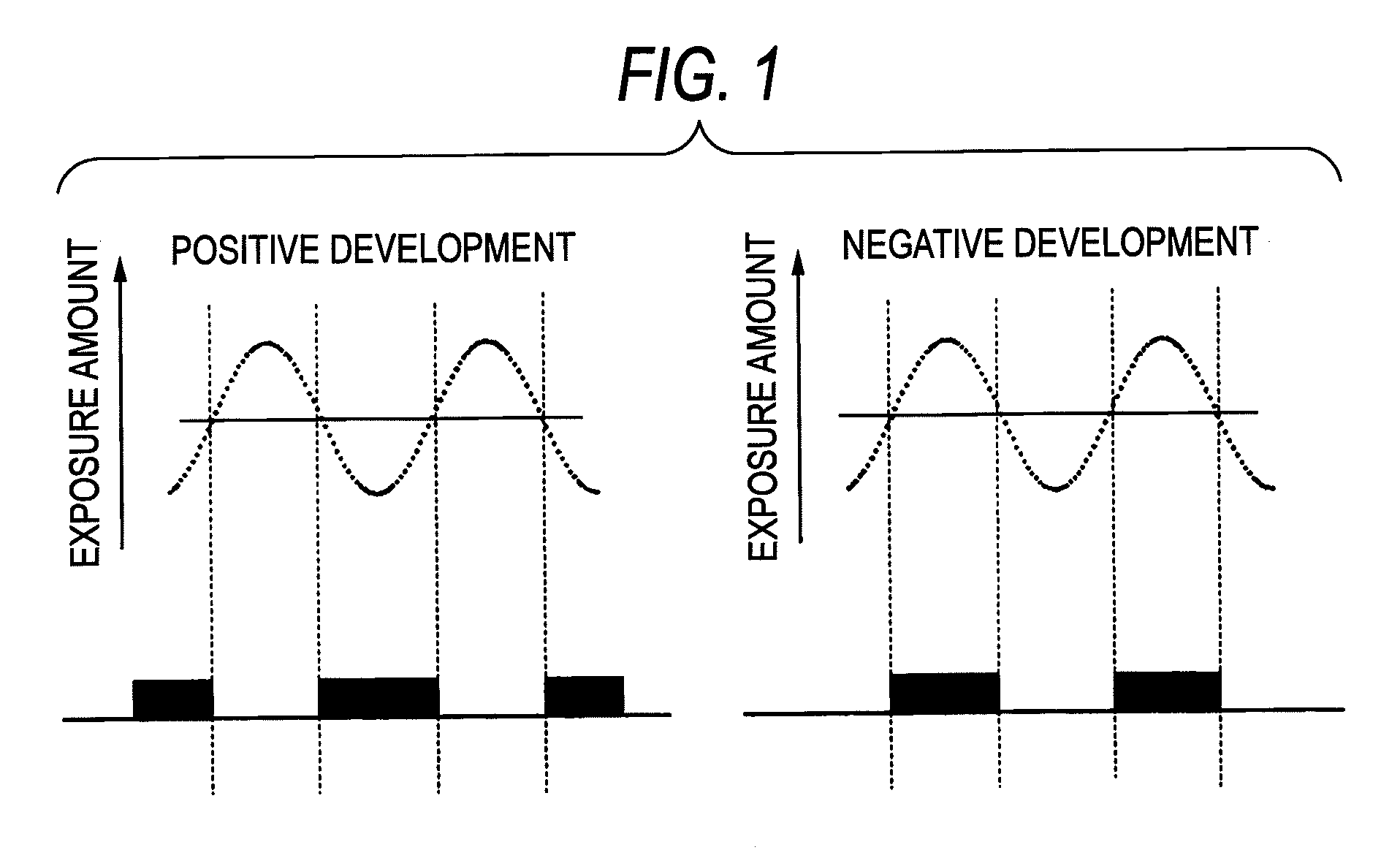

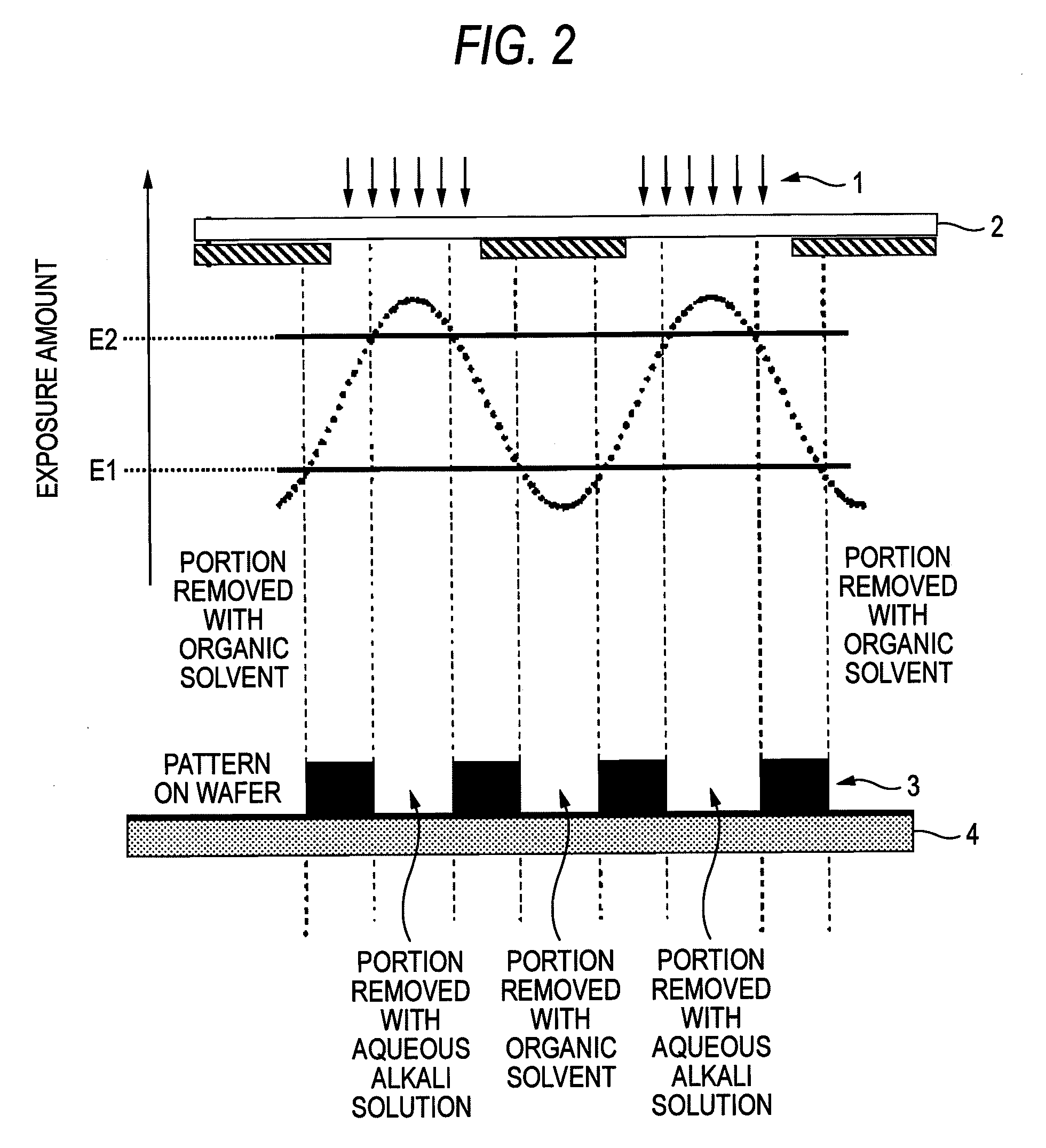

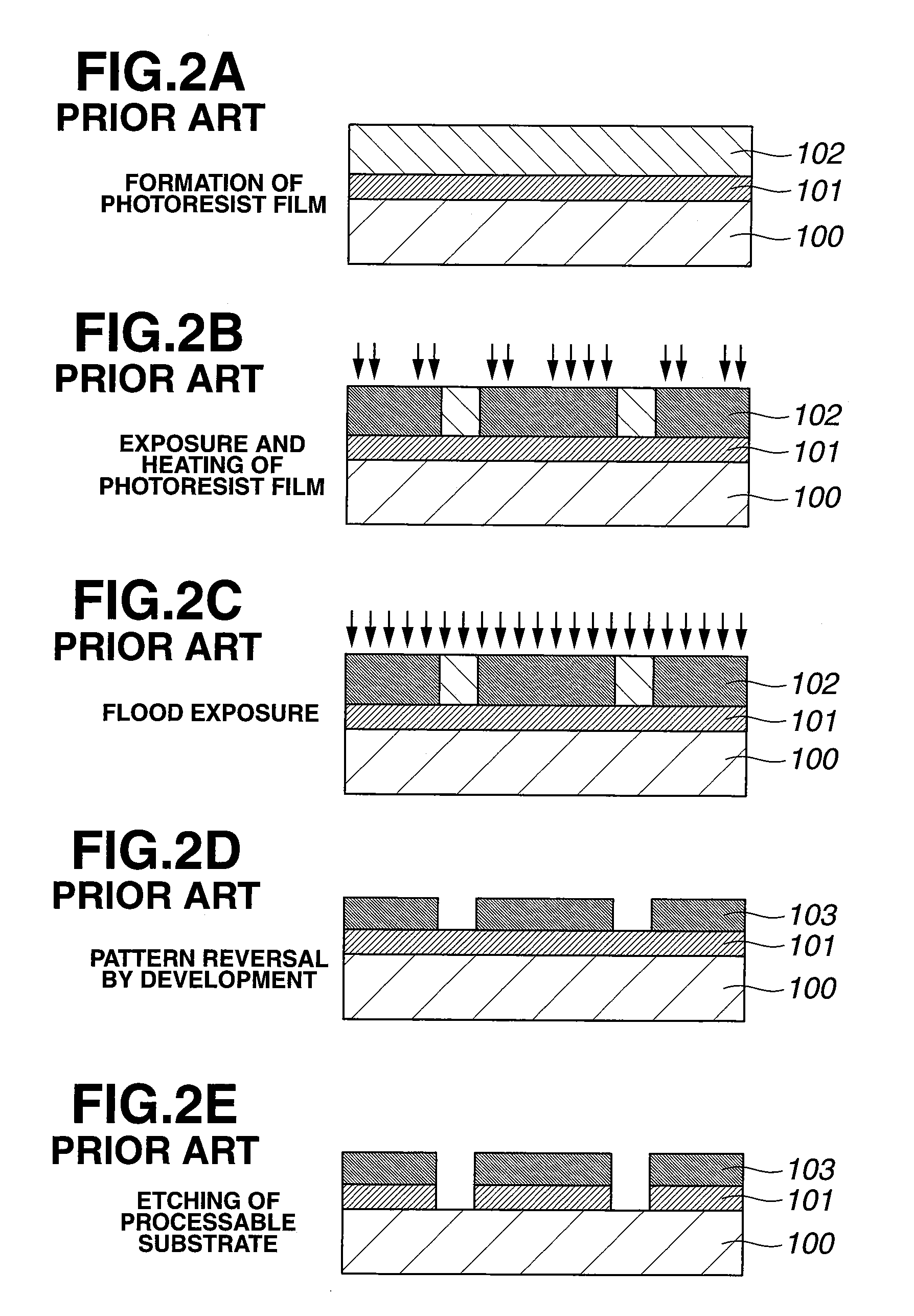

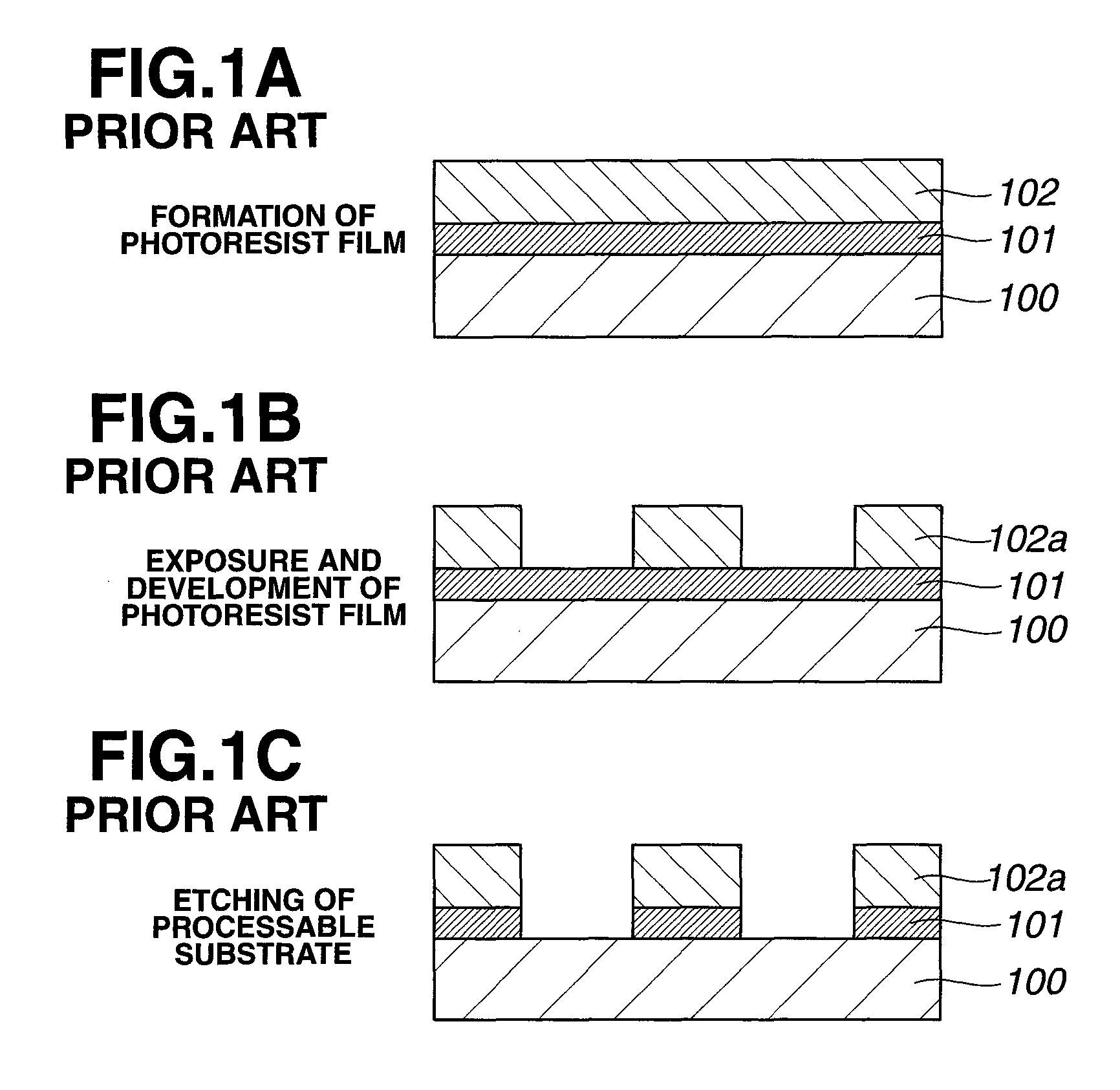

ActiveUS20090042147A1Development defect can be reducedReduced line edge roughnessPhotosensitive materialsPhoto-taking processesActinic RaysChemistry

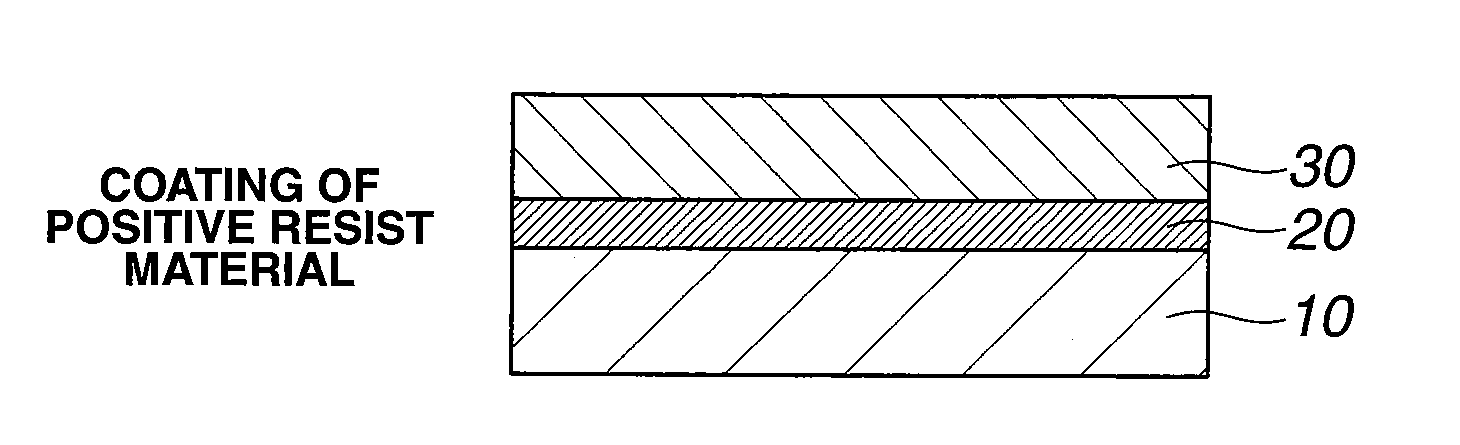

A method of forming patterns includes (a) coating a substrate with a resist composition for negative development to form a resist film, wherein the resist composition contains a resin capable of increasing the polarity by the action of the acid and becomes more soluble in a positive developer and less soluble in a negative developer upon irradiation with an actinic ray or radiation, (b) forming a protective film on the resist film with a protective film composition after forming the resist film and before exposing the resist film, (c) exposing the resist film via an immersion medium, and (d) performing development with a negative developer.

Owner:FUJIFILM CORP

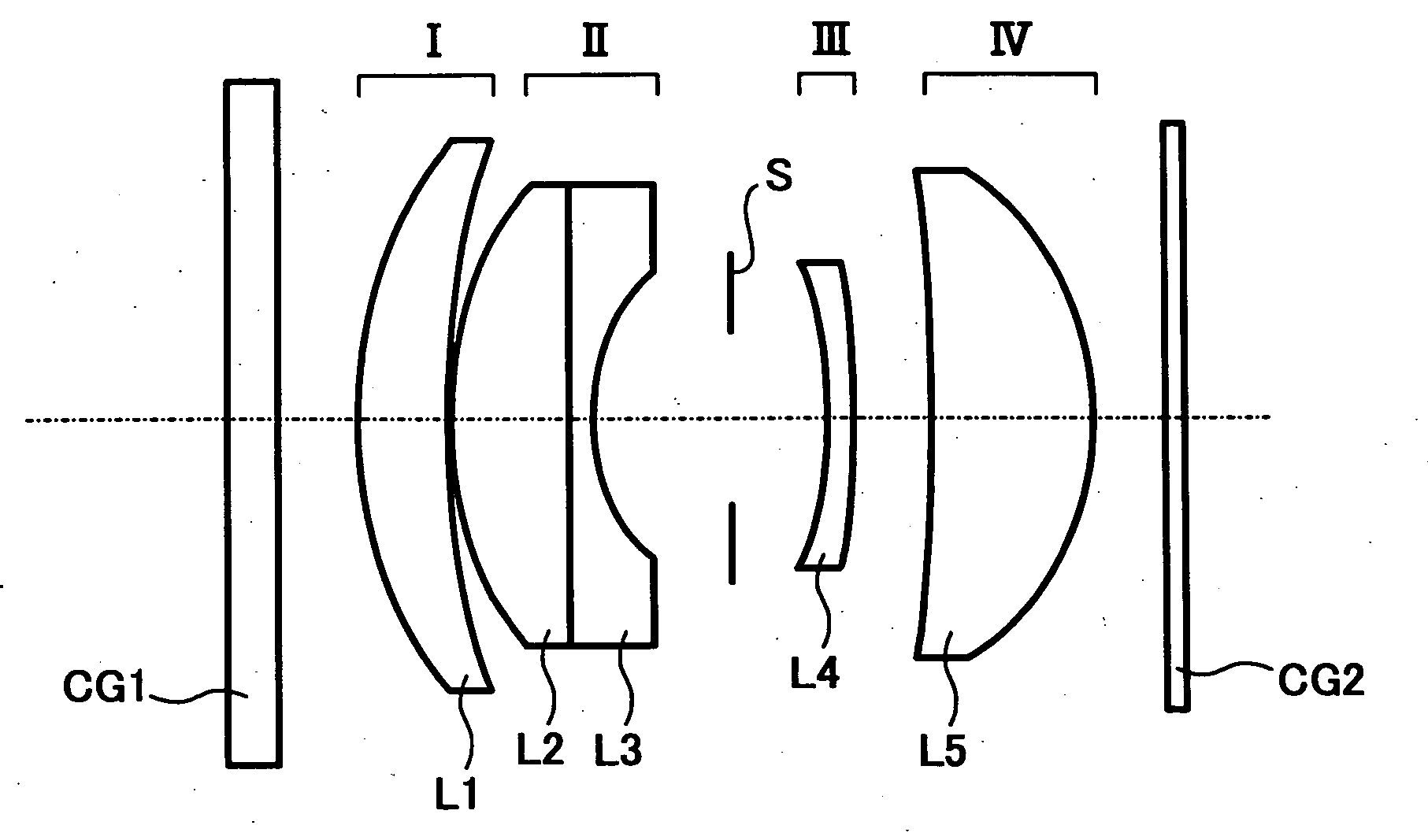

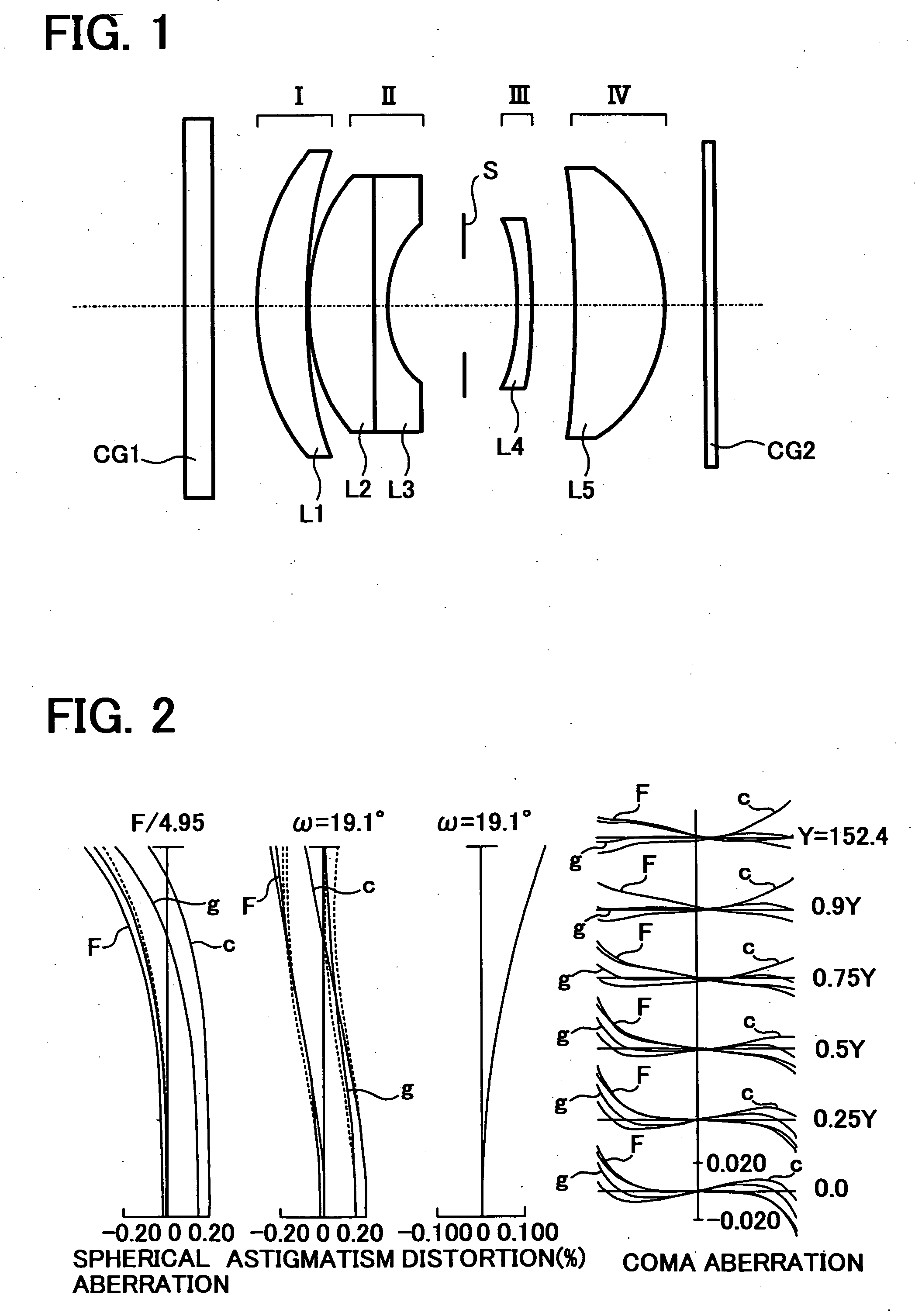

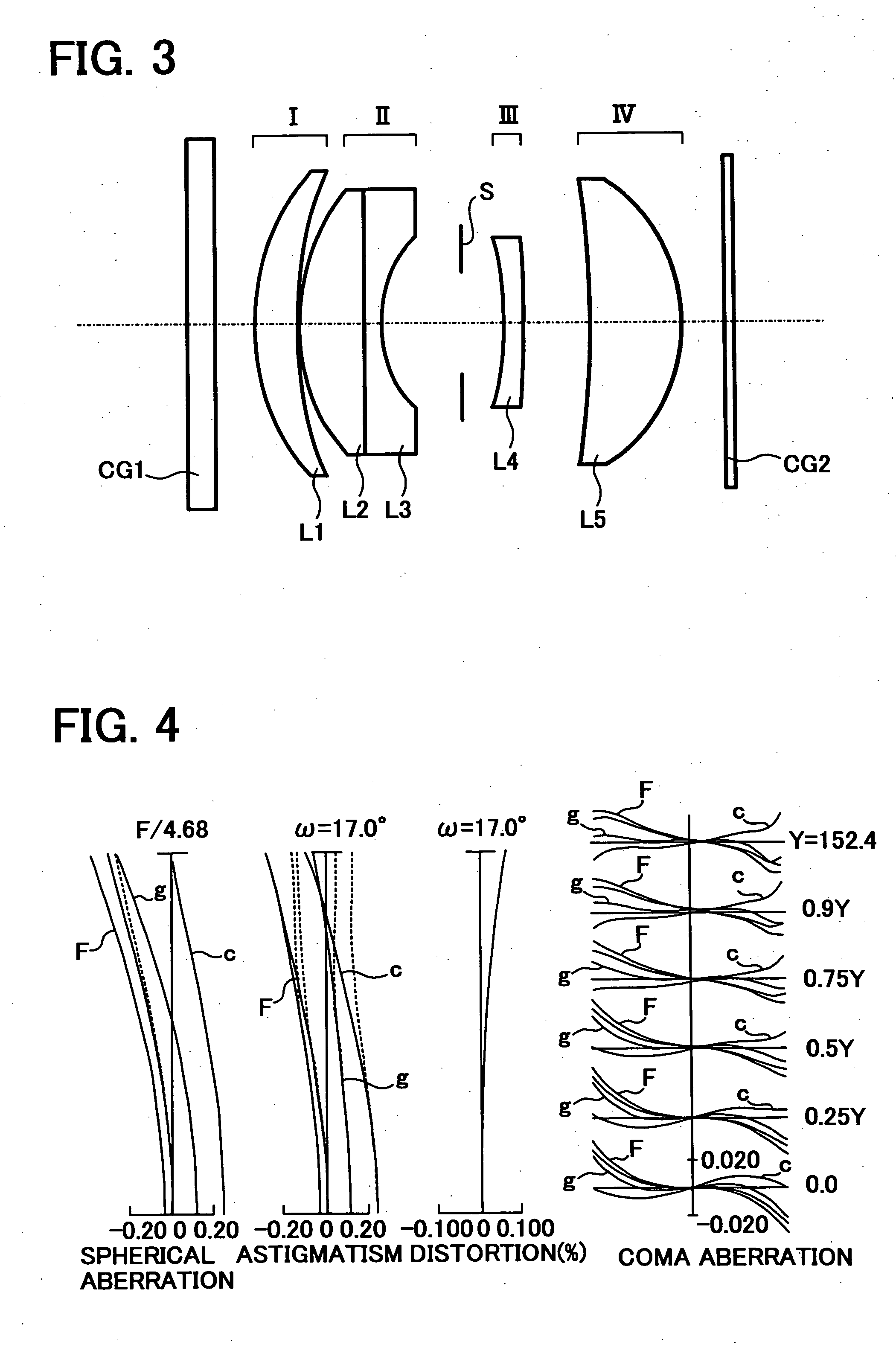

Original reading lens, original reading lens unit, original reading device, and image forming device

InactiveUS20050141103A1Small and readingSmall differencePictoral communicationLensRefractive indexImage formation

An original reading lens includes a four-group, five-element lens configuration including three positive lenses and two negative lenses, wherein the positive lens is constructed by a glass material of low dispersion, and the negative lens is constructed by a glass material of high dispersion, a partial dispersion θ gd is defined by θ gd=(ng−nd) / (nF−nc) by a refractive index nd of d line (587.56 nm), a refractive index nc of c line (656.27 nm), a refractive index nF of F line (486.13 nm), and a refractive index ng of g line (435.83 nm), a straight line connecting a coordinate point of a reference glass material K7, K7 (θ gd, ν d) and a coordinate point of a reference glass material F2, F2 (θ gd, ν d) on a plane with a coordinate system including the partial dispersion θ gd and an Abbe number ν d as orthogonal two axes is adopted as a reference line, and a partial dispersion deviation δθ gd which is the deviation from the reference line of the partial dispersion θ gd of the material is positive in one or more positive lens.

Owner:RICOH KK

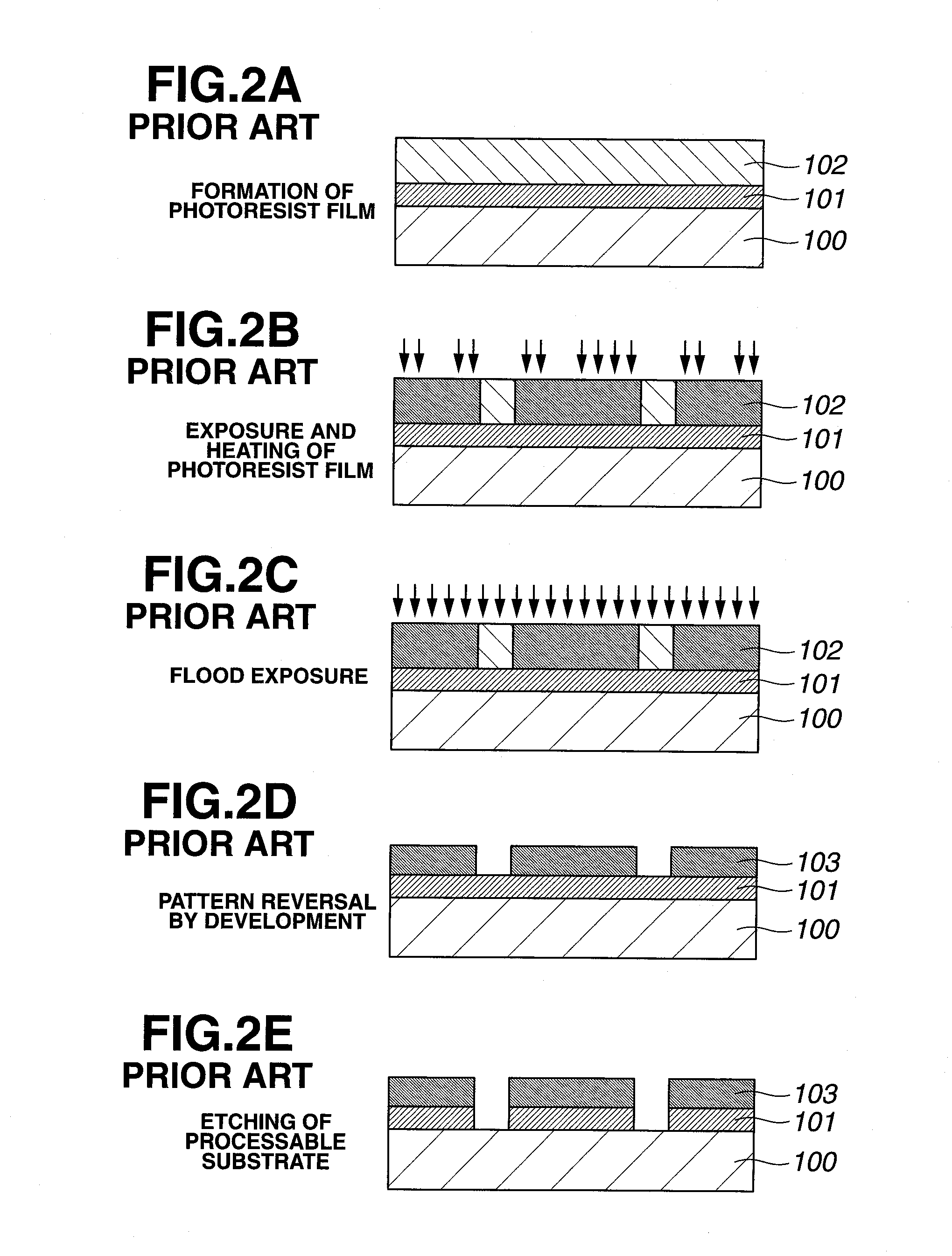

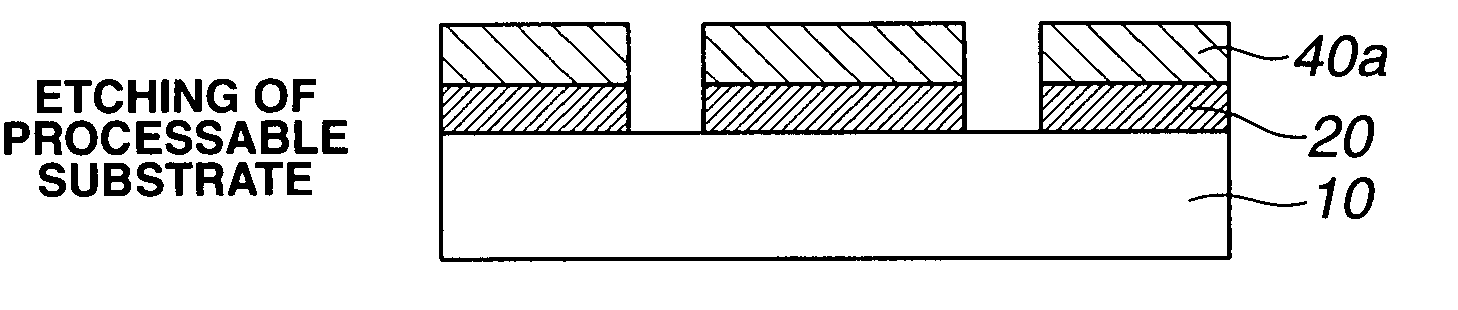

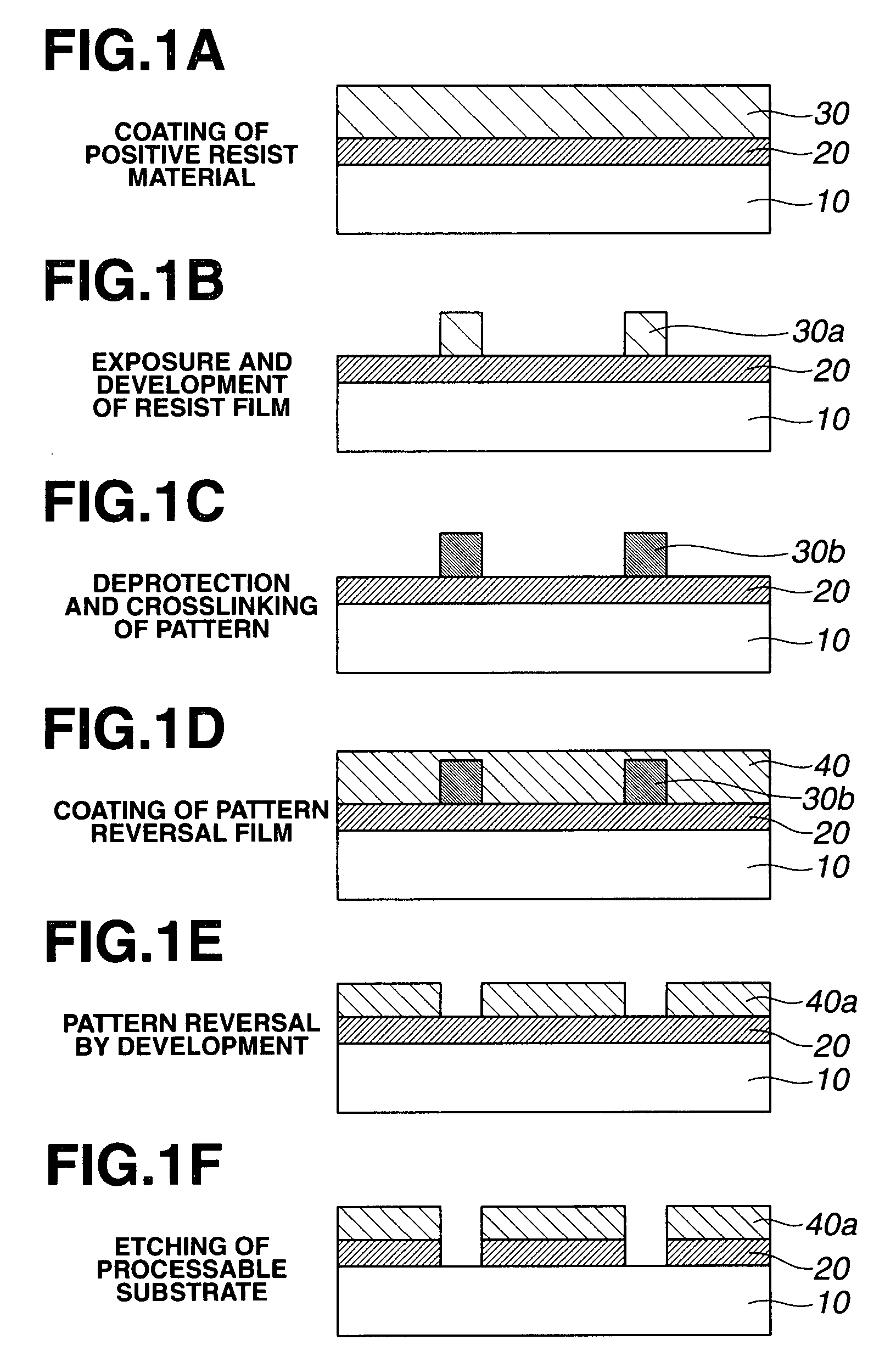

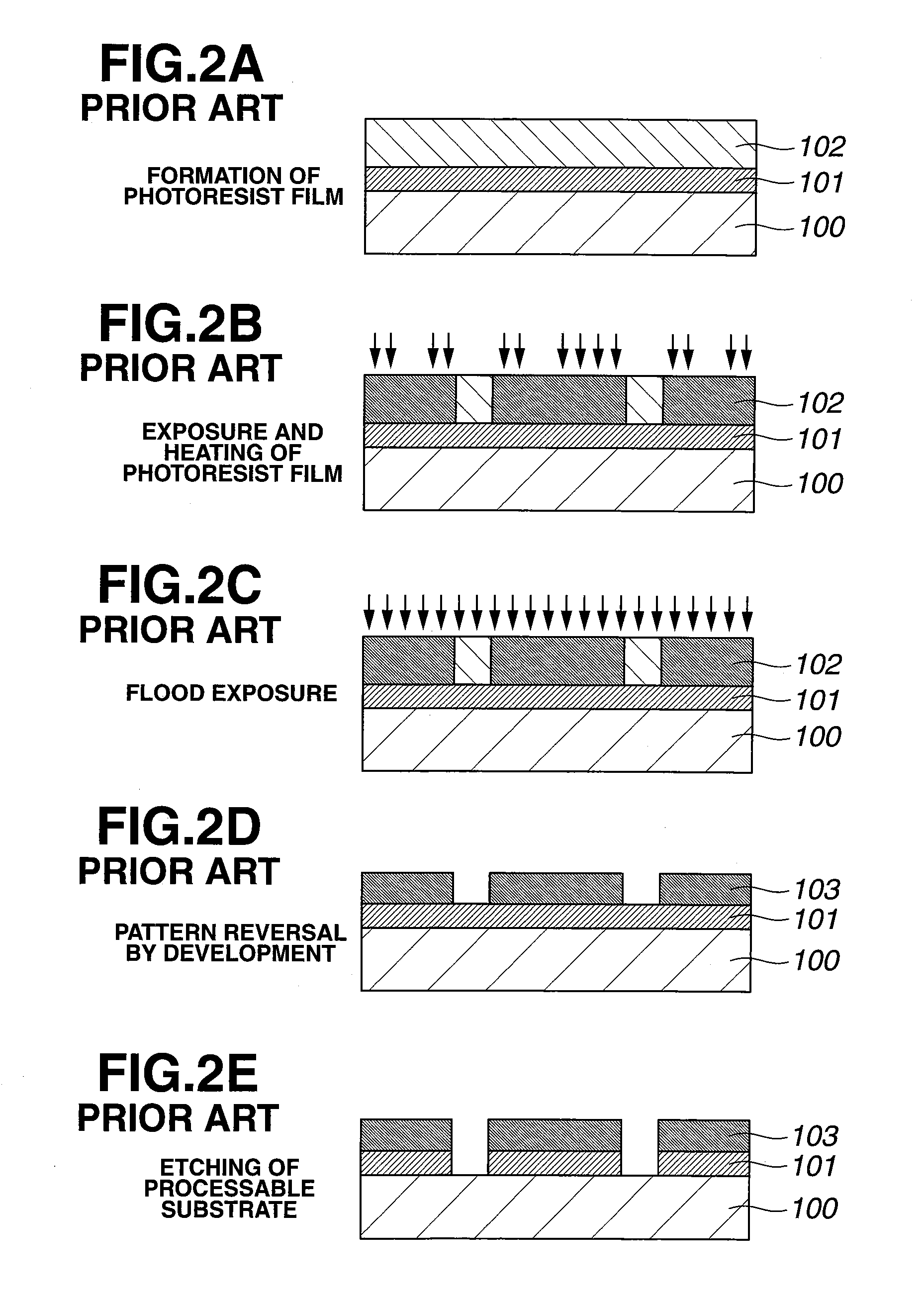

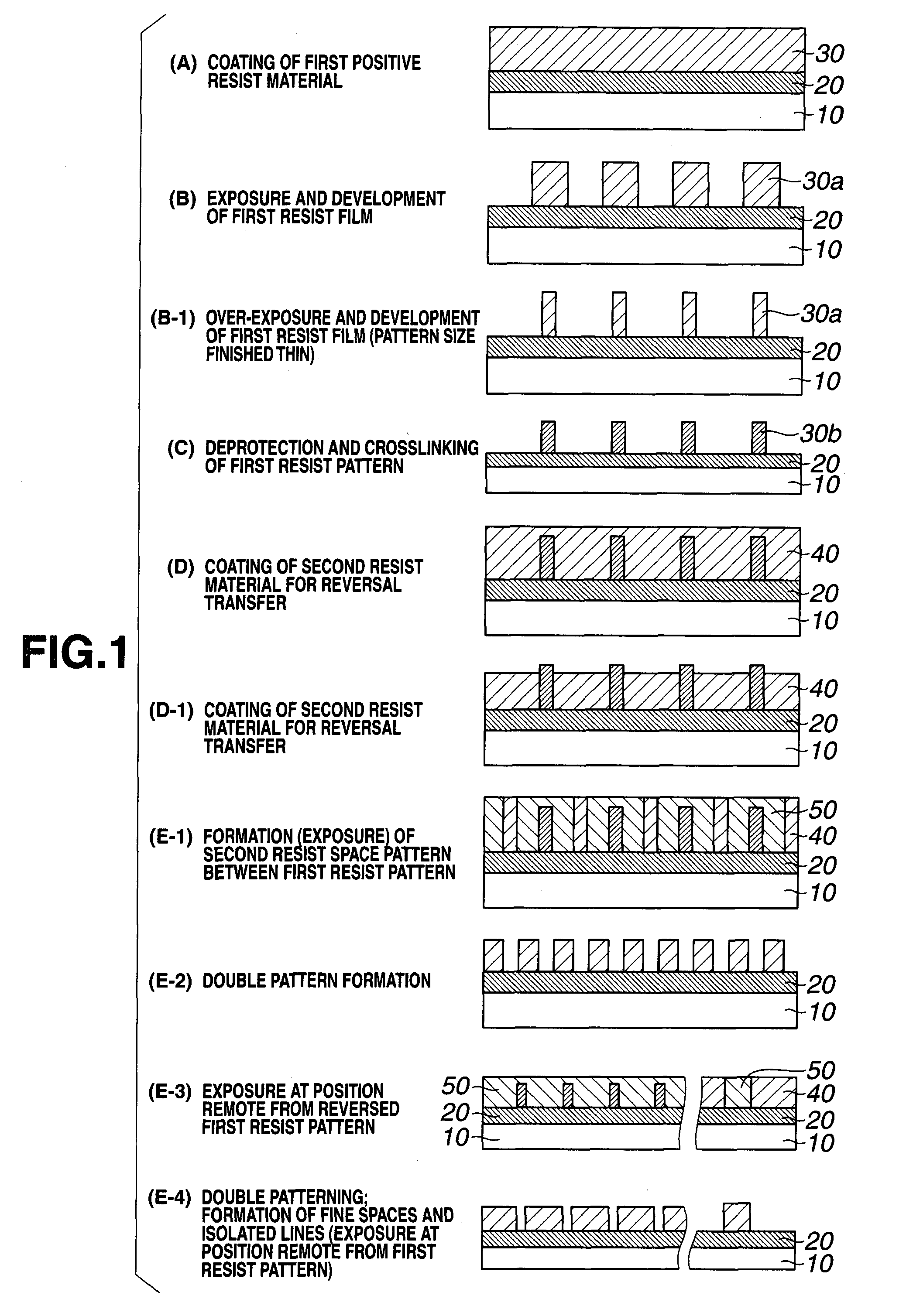

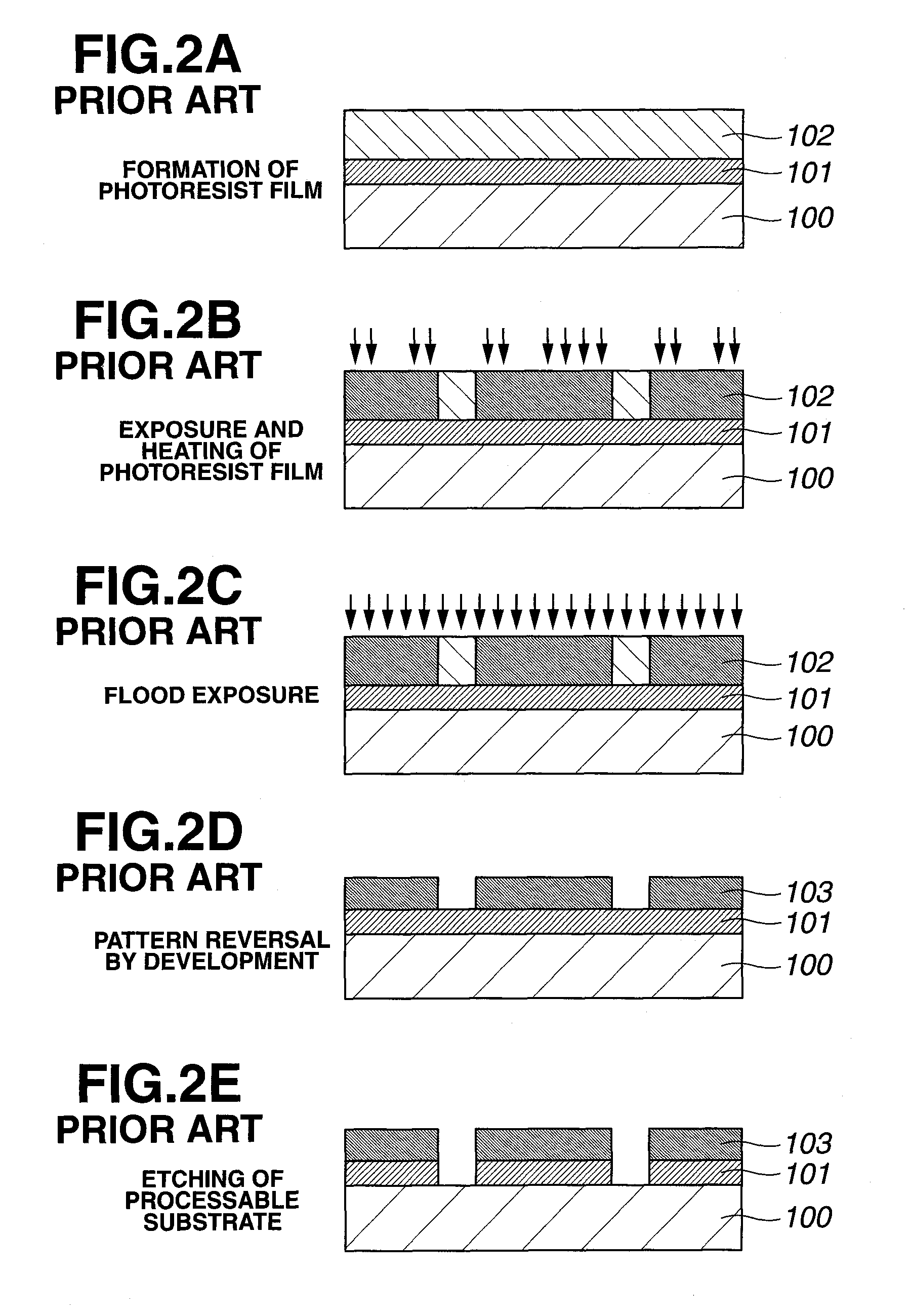

Patterning process

ActiveUS20100203457A1High resolution performanceIncrease process marginSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusSolubilityResist

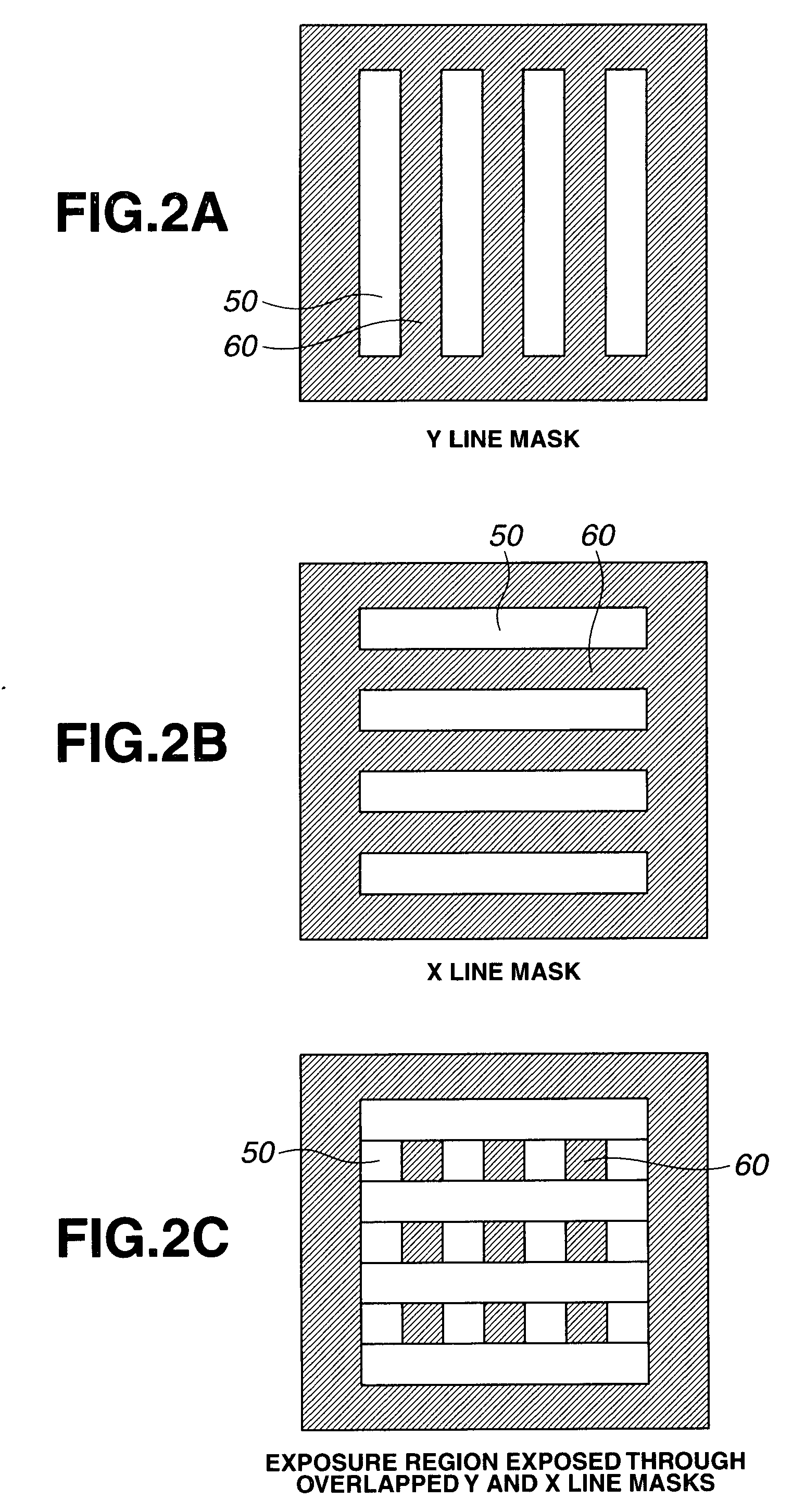

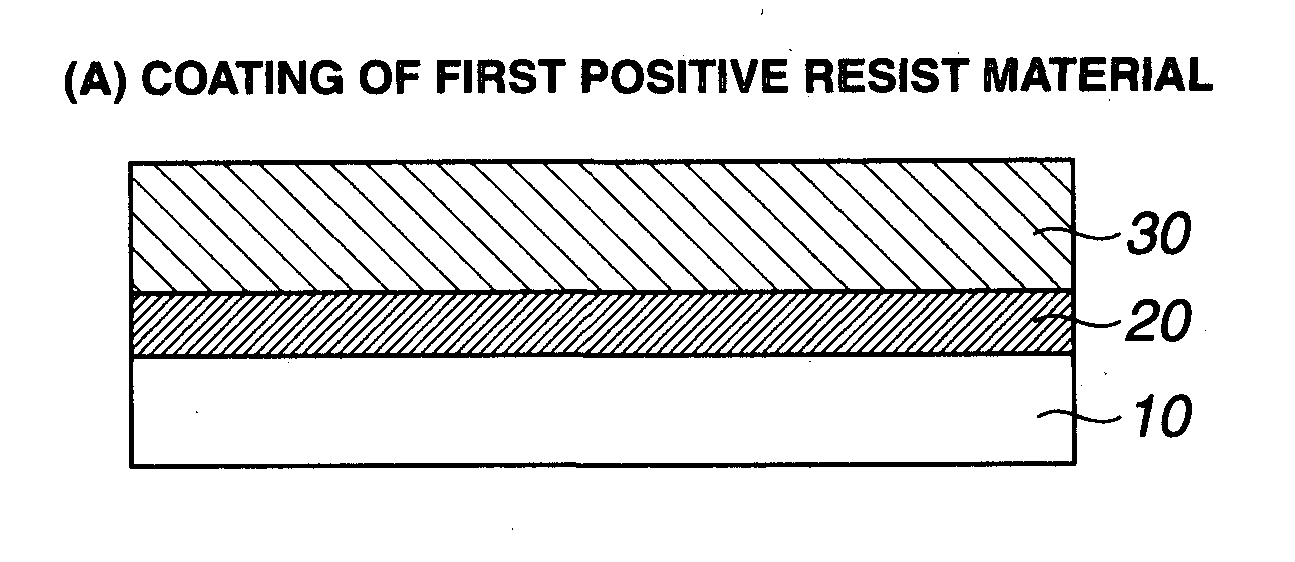

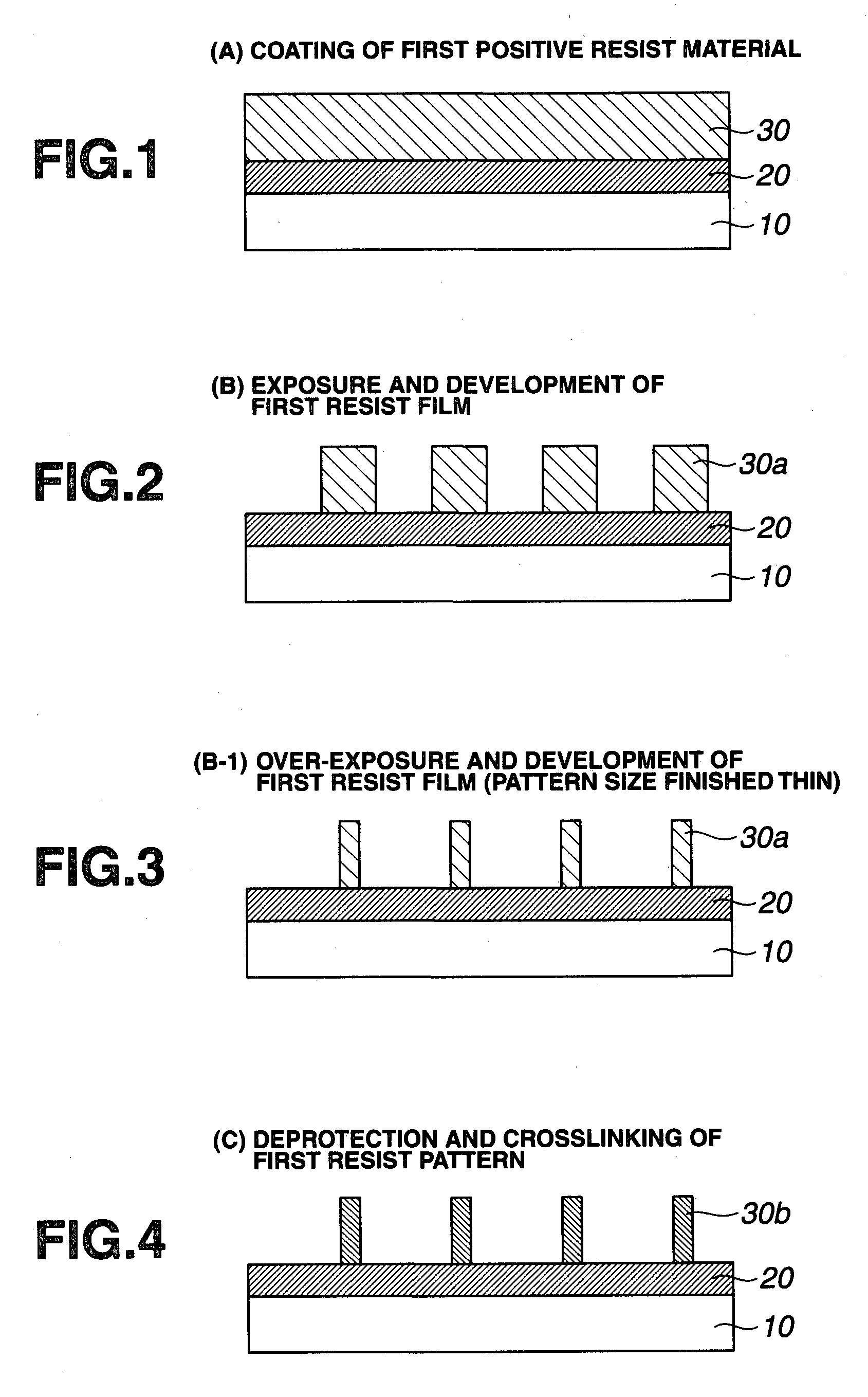

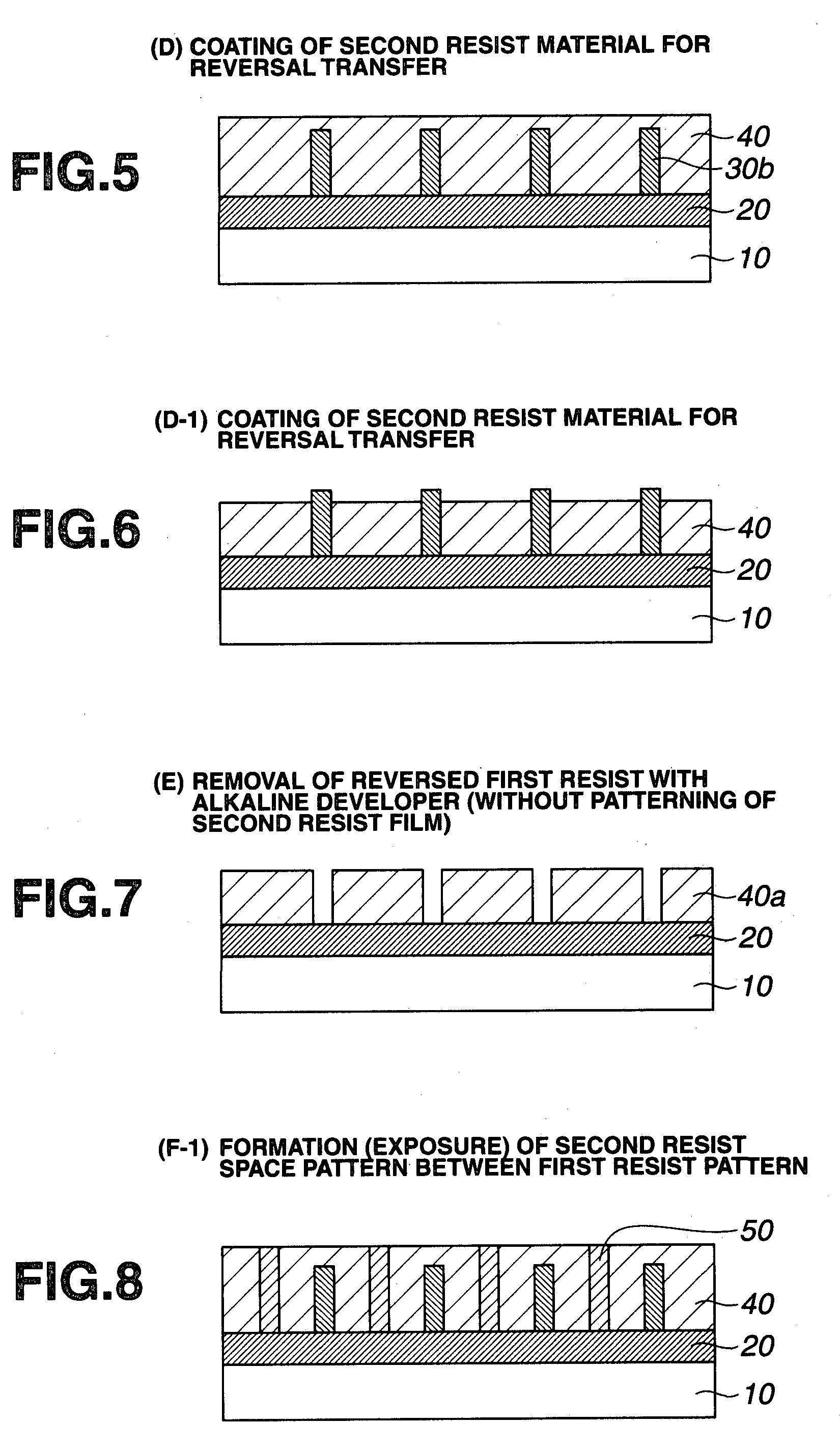

A pattern is formed by coating a chemically amplified positive resist composition comprising a resin comprising acid labile group-containing recurring units and a photoacid generator onto a substrate, drying to form a resist film, exposing the resist film to high-energy radiation through a phase shift mask including a lattice-like first shifter and a second shifter arrayed on the first shifter and consisting of lines which are thicker than the line width of the first shifter, PEB, developing to form a positive pattern, illuminating or heating the positive pattern to eliminate acid labile groups for increasing alkaline solubility and to induce crosslinking for imparting solvent resistance, coating a reversal film, and dissolving away the positive pattern in an alkaline wet etchant to form a pattern by way of positive / negative reversal.

Owner:SHIN ETSU CHEM IND CO LTD

Patterning process

ActiveUS20090081595A1Increase contrastFunction increaseResist coatingPhotosensitive materialsSolubilityResist

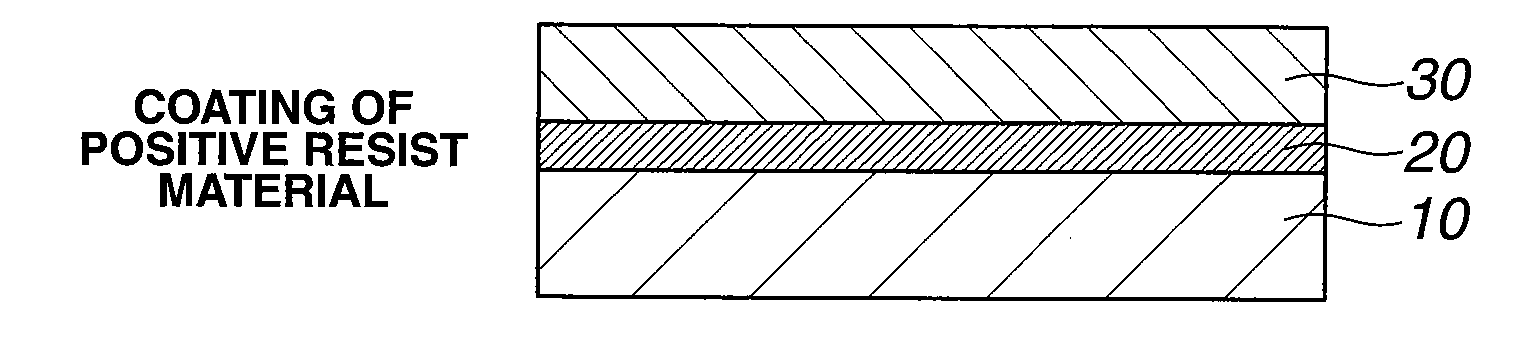

A pattern is formed through positive / negative reversal by coating a chemically amplified positive resist composition comprising an acid labile group-bearing resin, a photoacid generator, and an organic solvent onto a substrate, prebaking the resist composition, exposing the resist film to high-energy radiation, post-exposure heating, and developing the exposed resist film with an alkaline developer to form a positive pattern; irradiating or heating the positive pattern to facilitate elimination of acid labile groups and crosslinking for improving alkali solubility and imparting solvent resistance; coating a reversal film-forming composition thereon to form a reversal film; and applying an alkaline wet etchant thereto for dissolving away the positive pattern.

Owner:SHIN ETSU CHEM IND CO LTD

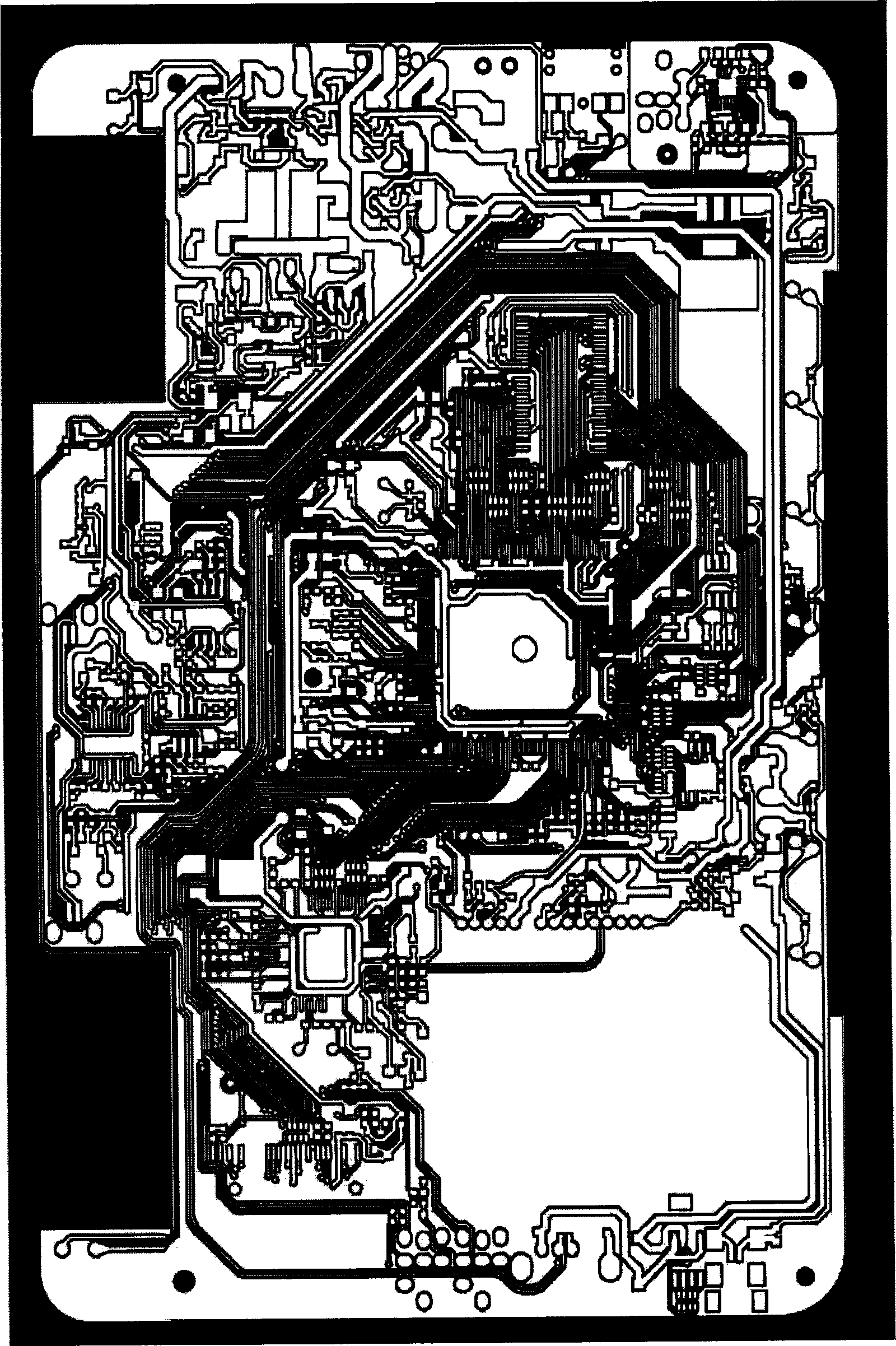

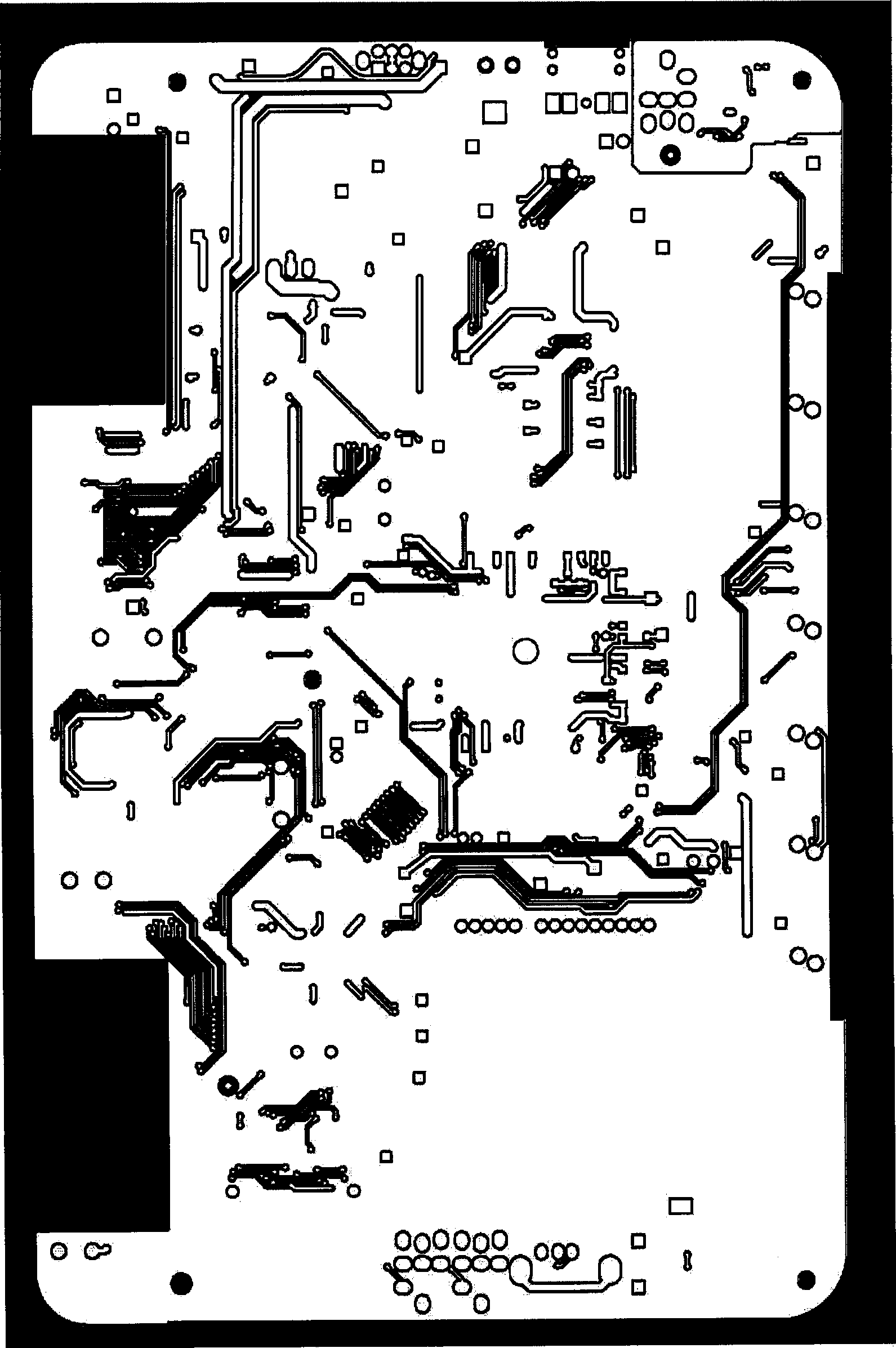

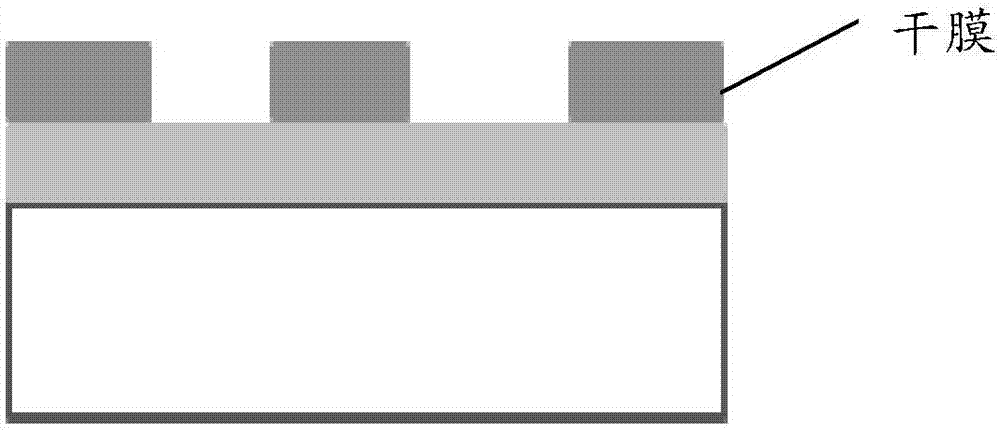

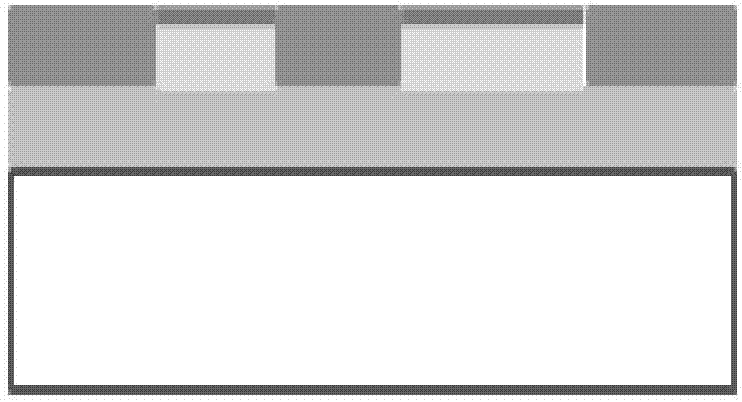

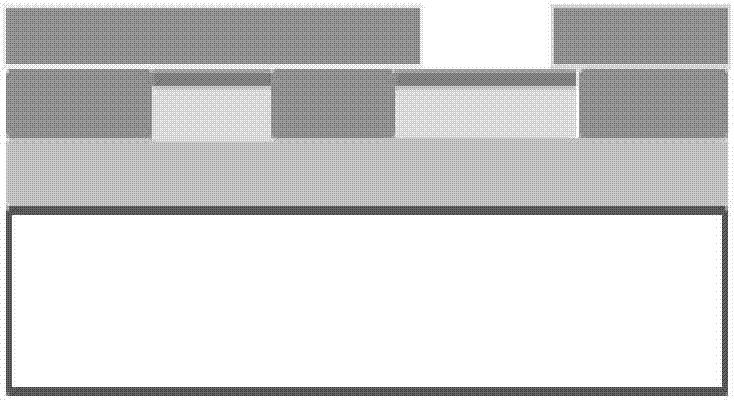

Manufacturing process for step circuit of PCB (Printed Circuit Board)

InactiveCN102651946AReduce copper thickness dropEliminate poor quality defectsConductive material chemical/electrolytical removalProduction scheduleEngineering

The invention discloses a manufacturing process for a step circuit of a PCB (Printed Circuit Board). According to the manufacturing process, different film patterns are adopted twice for manufacturing the circuit, during the primary film pattern circuit manufacture, a positive film circuit pattern is adopted, compensation is carried out a film substrate circuit at different positions according to copper thickness so as to manufacture a special circuit, and sunk copper plate electrification is carried out on the special circuit, so that the copper thickness meets the requirement; then board grinding is carried out by a twice board grinding mode so as to reduce the copper thickness difference of step positions; a dry film is enabled to be fully combined with the step positions by virtue of a film attaching and air compressing mode; and finally, normal circuit pattern manufacturing is carried out by utilizing a high-precision LDI (Laser Direct Imaging) exposure machine. Compared with the prior art, the manufacturing process for the step circuit can be used for eliminating the defects of open circuit at the position of the step circuit, notches, large deckle edges, serious lateral erosion, halfway etching and poor quality of thin lines and the like existing in the step circuit manufacturing process, improving the production efficiency and the production quality, quickening the production schedule and lowering the production cost.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

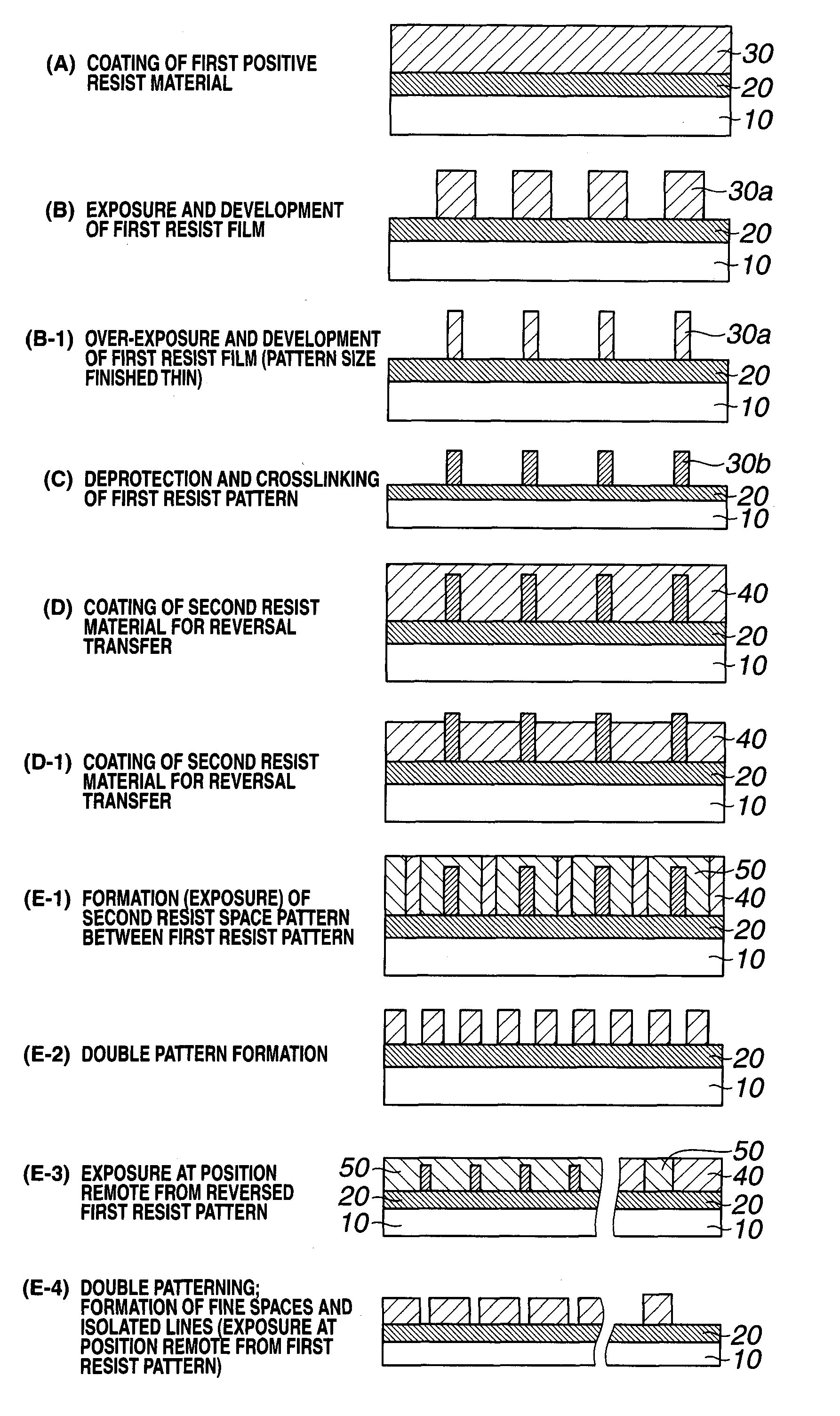

Double patterning process

ActiveUS20090208886A1Improve accuracySimple stepsSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistHigh energy

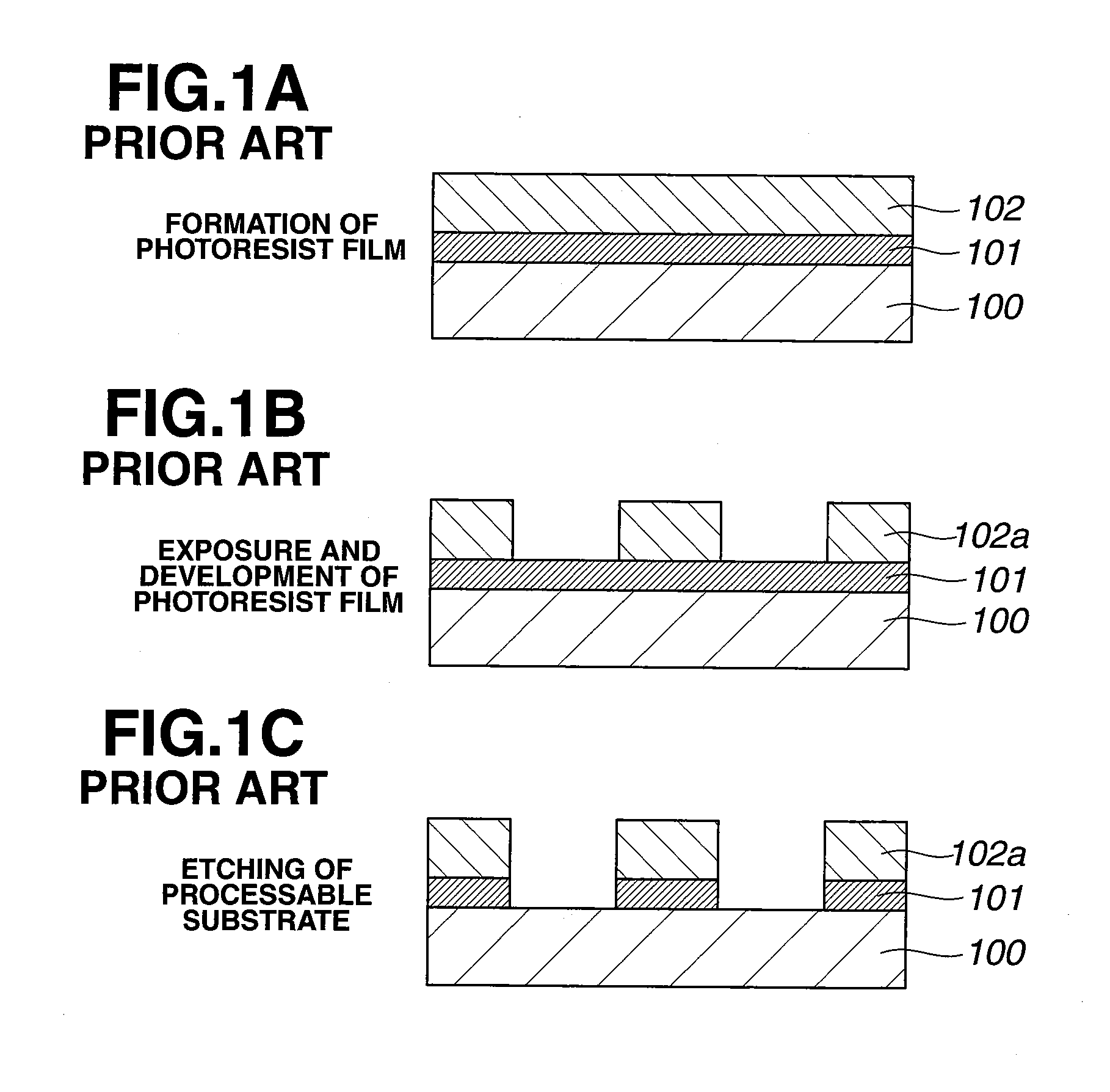

Double patterns are formed by coating a first chemically amplified positive resist composition comprising an acid labile group-bearing resin and a photoacid generator and prebaking to form a resist film on a processable substrate, exposing the resist film to high-energy radiation, PEB, and developing with an alkaline developer to form a first positive resist pattern, treating the first resist pattern to be alkali soluble and solvent resistant, coating a second resist composition and prebaking to form a reversal film, and exposing the reversal film to high-energy radiation, PEB, and developing with an alkaline developer to form a second positive resist pattern. The last development step includes dissolving away the reversed first resist pattern and achieving reversal transfer.

Owner:SHIN ETSU CHEM IND CO LTD

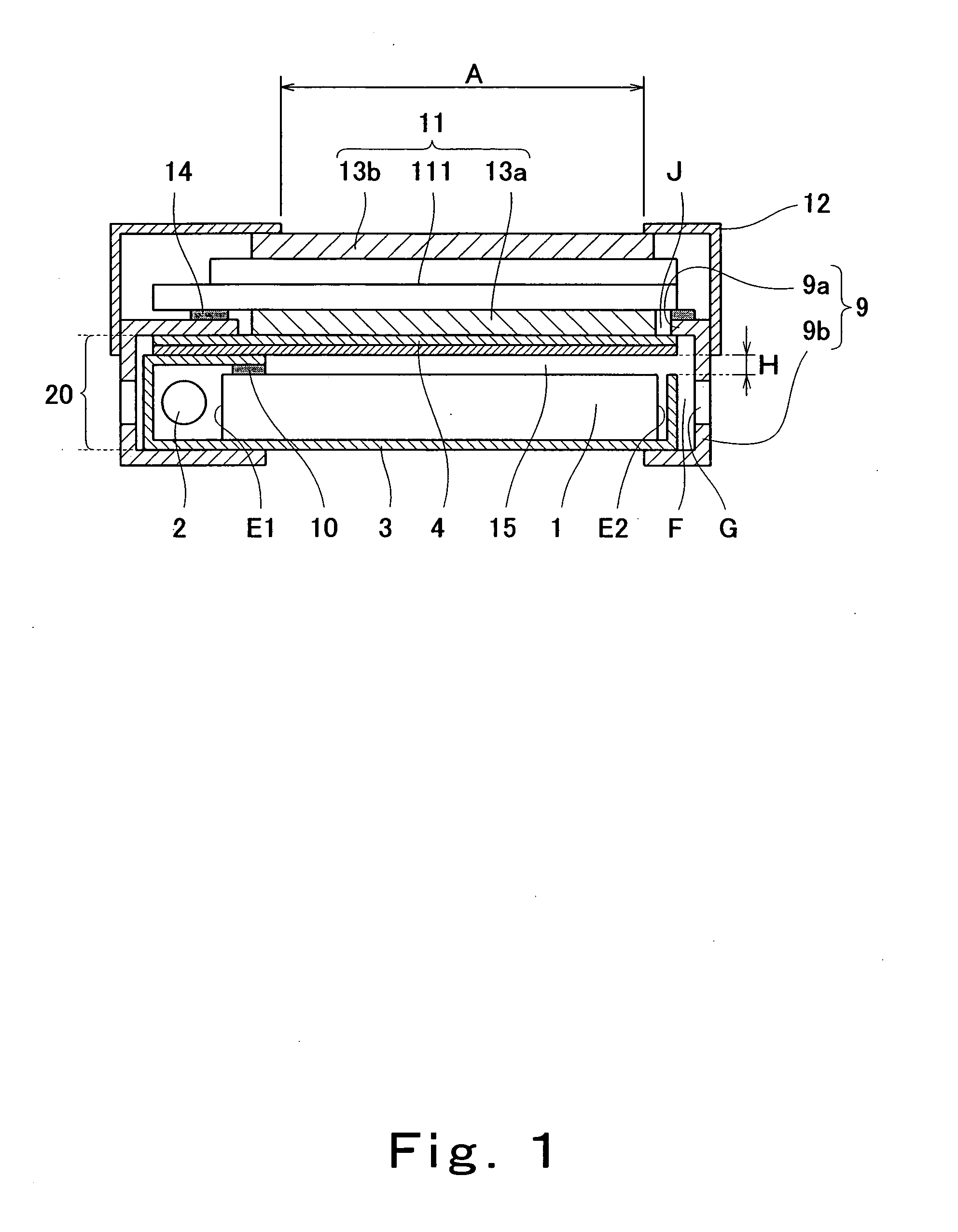

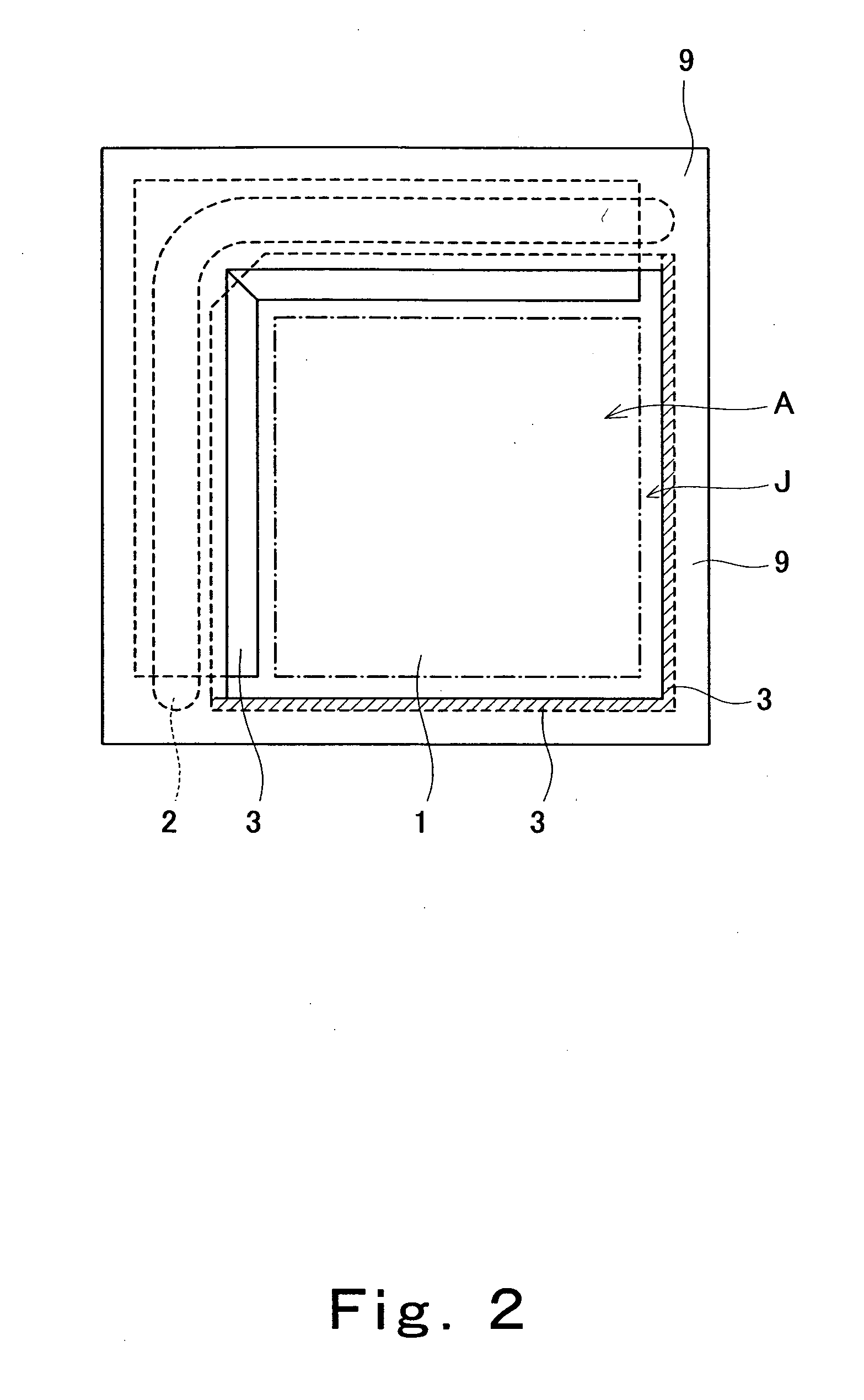

Illumination unit and liquid crystal display apparatus comprising same

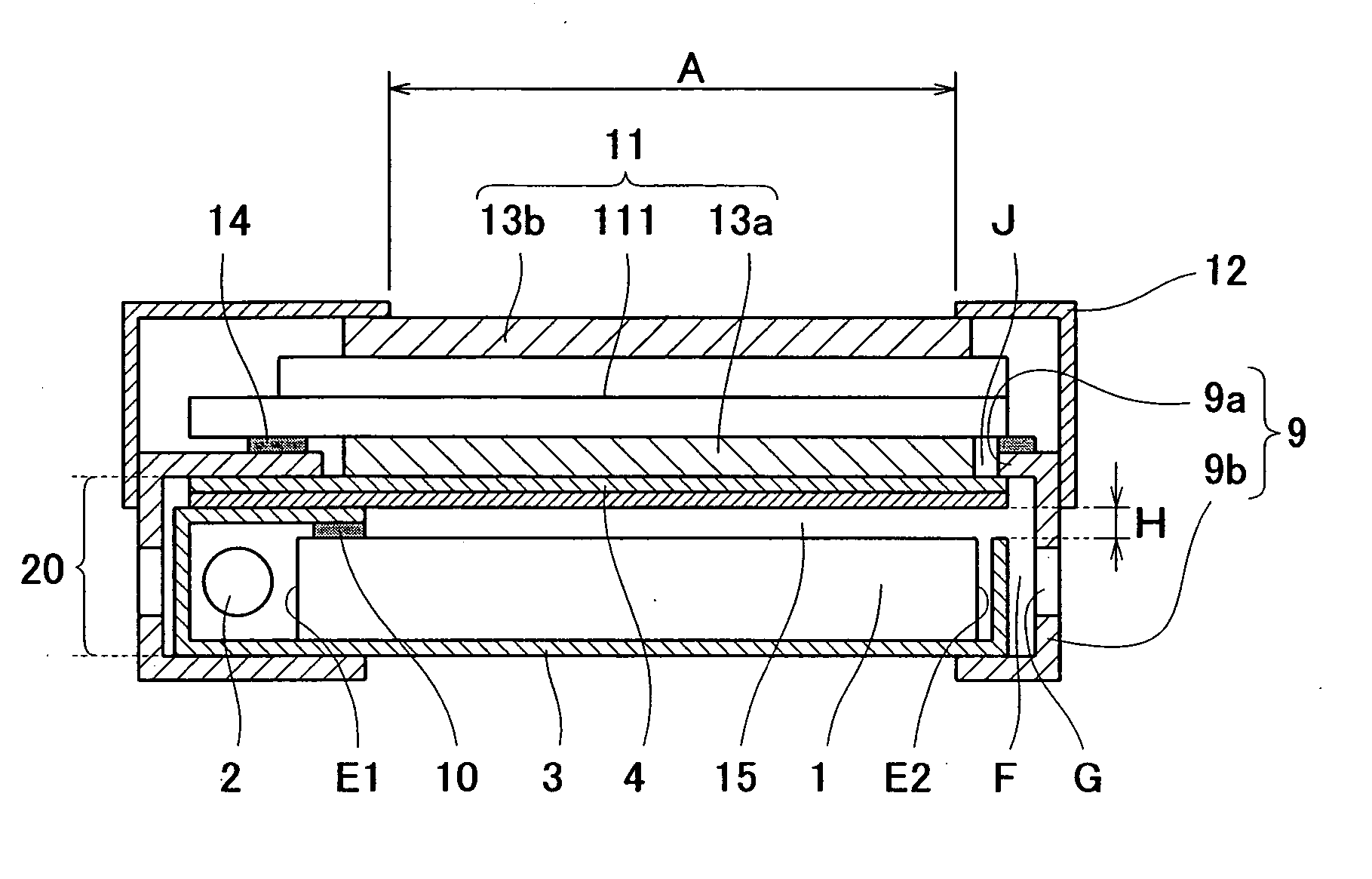

A liquid crystal display device comprising a lighting unit of the present invention is aimed to inhibit a liquid crystal panel 111 from breaking by a pressure from a display surface side of a liquid crystal cell 111, and to inhibit entry of dust having influence on display. Such lighting unit is structured in a way that a fluorescent discharge tube 2 is disposed close to an incident side end face E1 of a light guiding plate 1, and the end face E1 of the light guiding plate 1 and the fluorescent discharge tube 2, an end face E2 and a bottom surface of the light guiding plate 1 are covered with a reflecting sheet 3. A light correction sheet 4 is disposed on an emanating surface of the light guiding plate 1, and these components are stored in an electrically conductive casing 9. A spacing H of a space between the light correction sheet 4 and the light guiding plate 1 is set to not larger than one pixel dimension of the liquid crystal cell 111. The casing 9 has an opening portion J on a light emanating surface side, and a display rear surface side polarizer 13a of a liquid crystal panel 11 is disposed in direct contact with a front surface of the light correction sheet 4 within the opening portion J.

Owner:JAPAN DISPLAY CENTRAL CO LTD

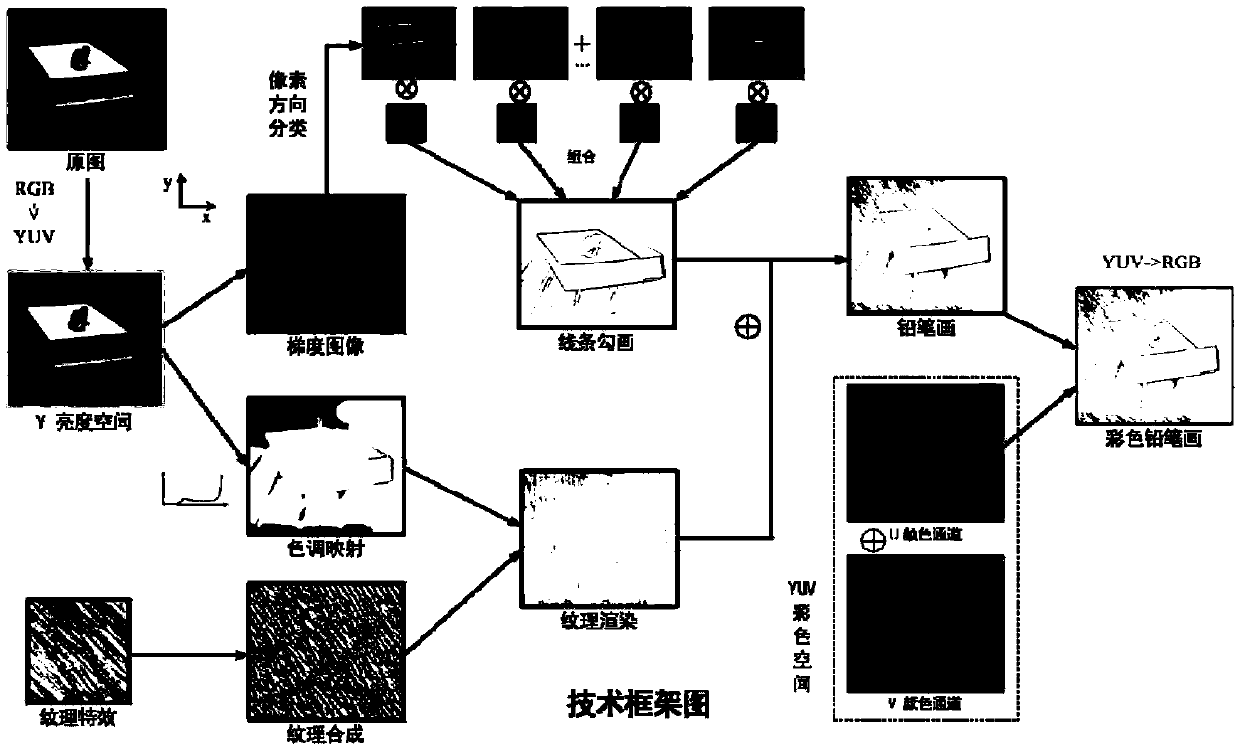

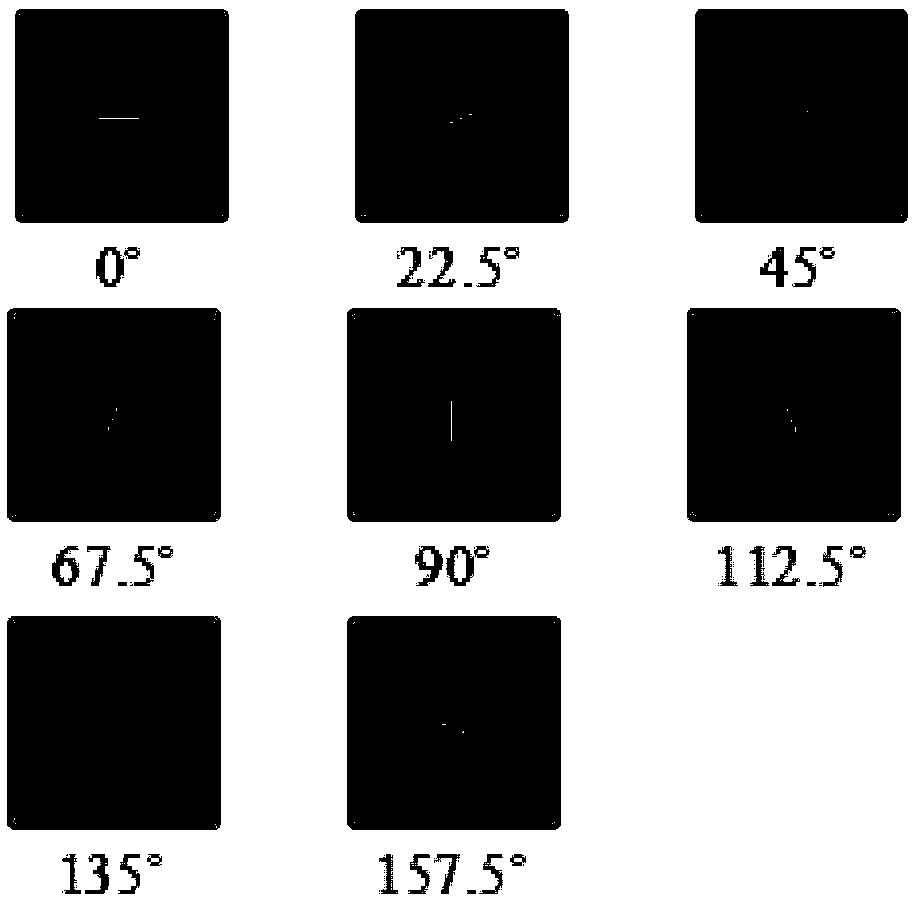

Generation method and generation device of pencil drawing fusing skeleton strokes and textural features

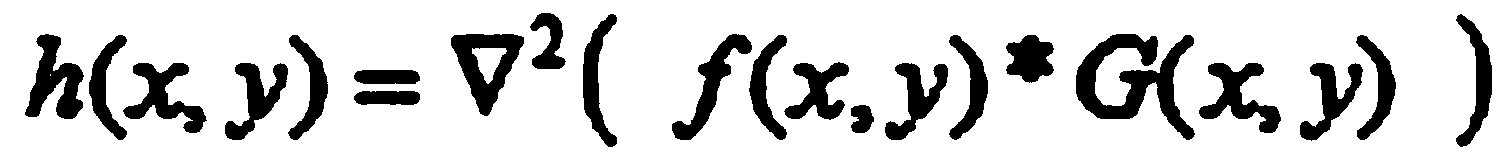

ActiveCN105374007ARealistic hand-painted artistic effectsImprove computing efficiencyGeometric image transformationTone mappingMathematical model

The present invention provides a generation method and generation device of a pencil drawing fusing skeleton strokes and textural features. The generation device of a pencil drawing comprises an original image acquisition unit, a gray image generation unit, a gradient image generation unit, a skeleton stroke layer generation unit, a tone layer generation unit, a texture feature rendering layer generation unit and a pencil drawing image generation unit. The generation method provided by the invention comprises: a gradient image is obtained through graying, deburring processing and edge detection of and inputted image; the gradient image is processed to be a skeleton stroke layer; the skeleton stroke layer is processed to be a tone layer; a texture feature rendering layer is obtained through texture synthesis and establishment of a tone mapping mathematical model; and multiply mixing of the skeleton stroke layer and the texture feature rendering layer is performed to obtain a final pencil drawing with a pencil hand-painting drawing effect. According to the invention, the step of generation of a pencil drawing is simple, the efficiency is high and the hand-painting effect is outstanding.

Owner:HUAQIAO UNIVERSITY

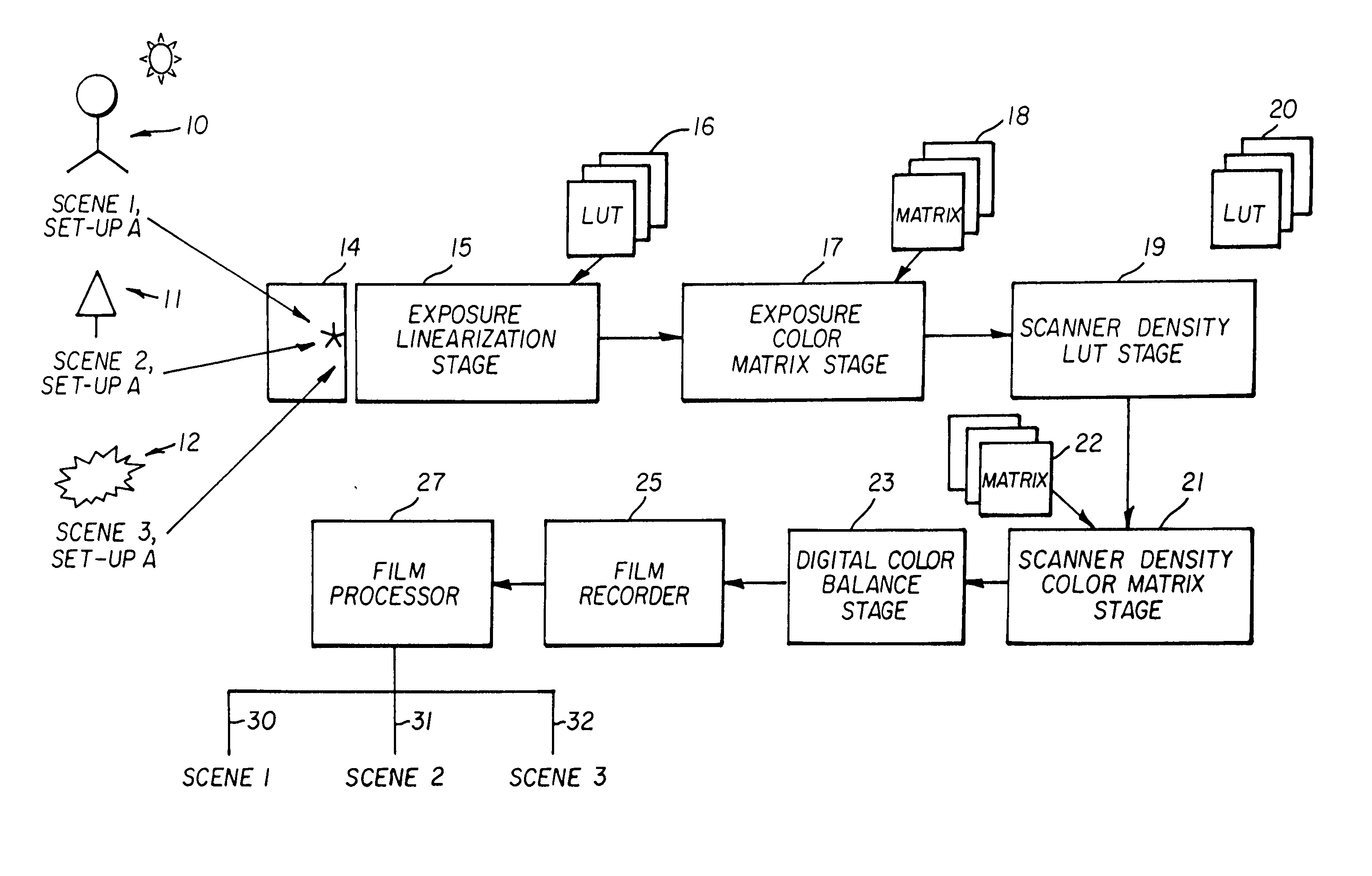

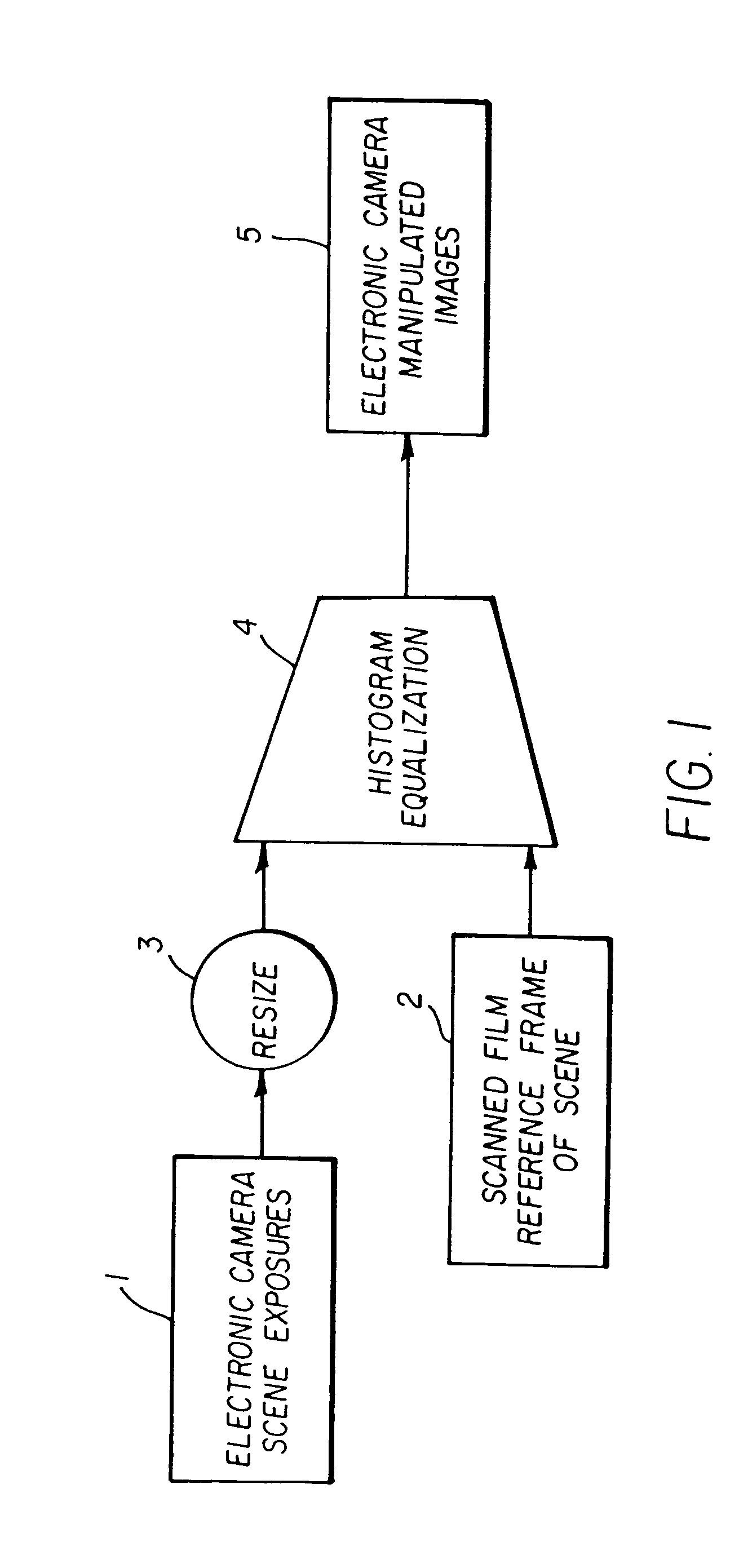

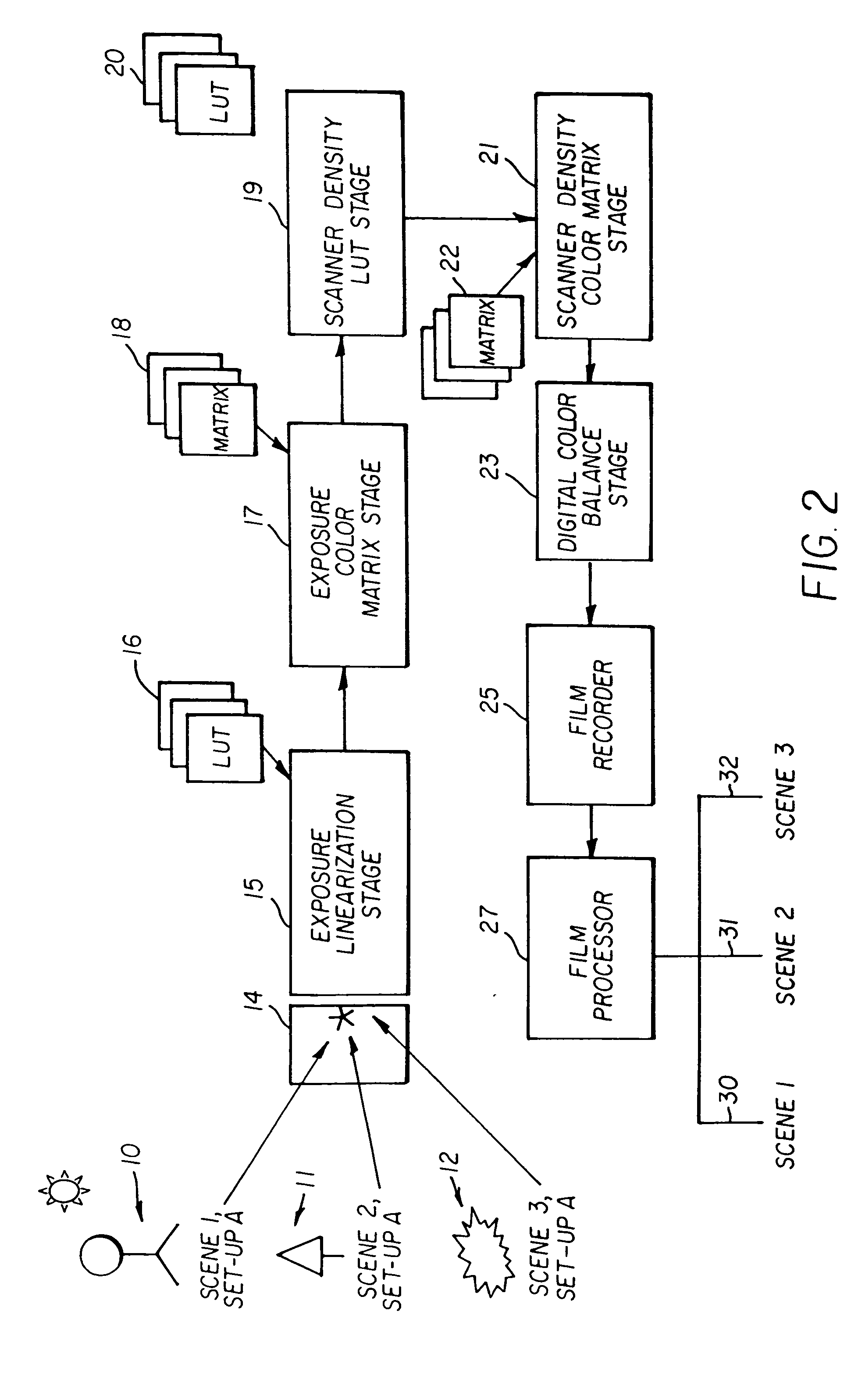

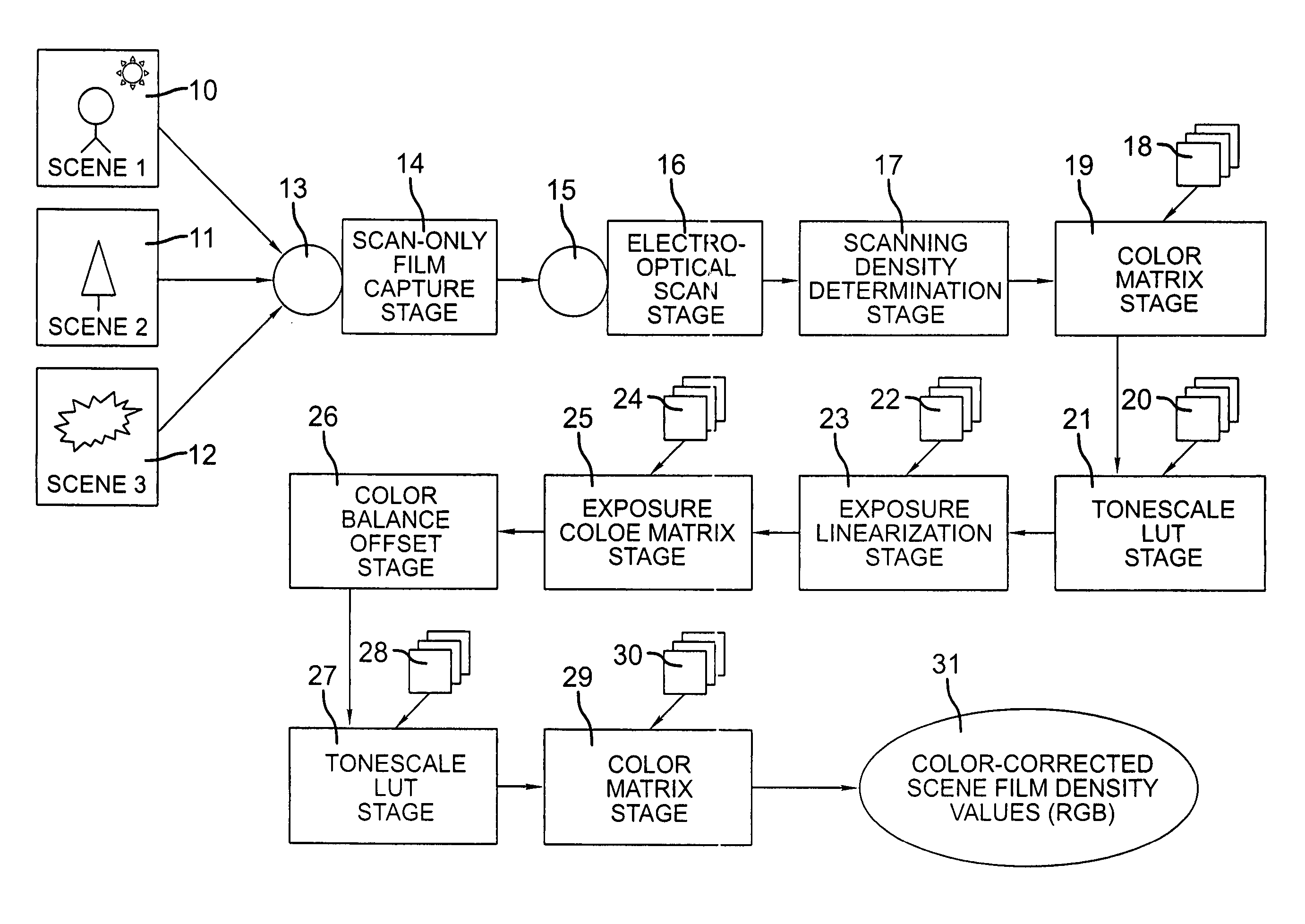

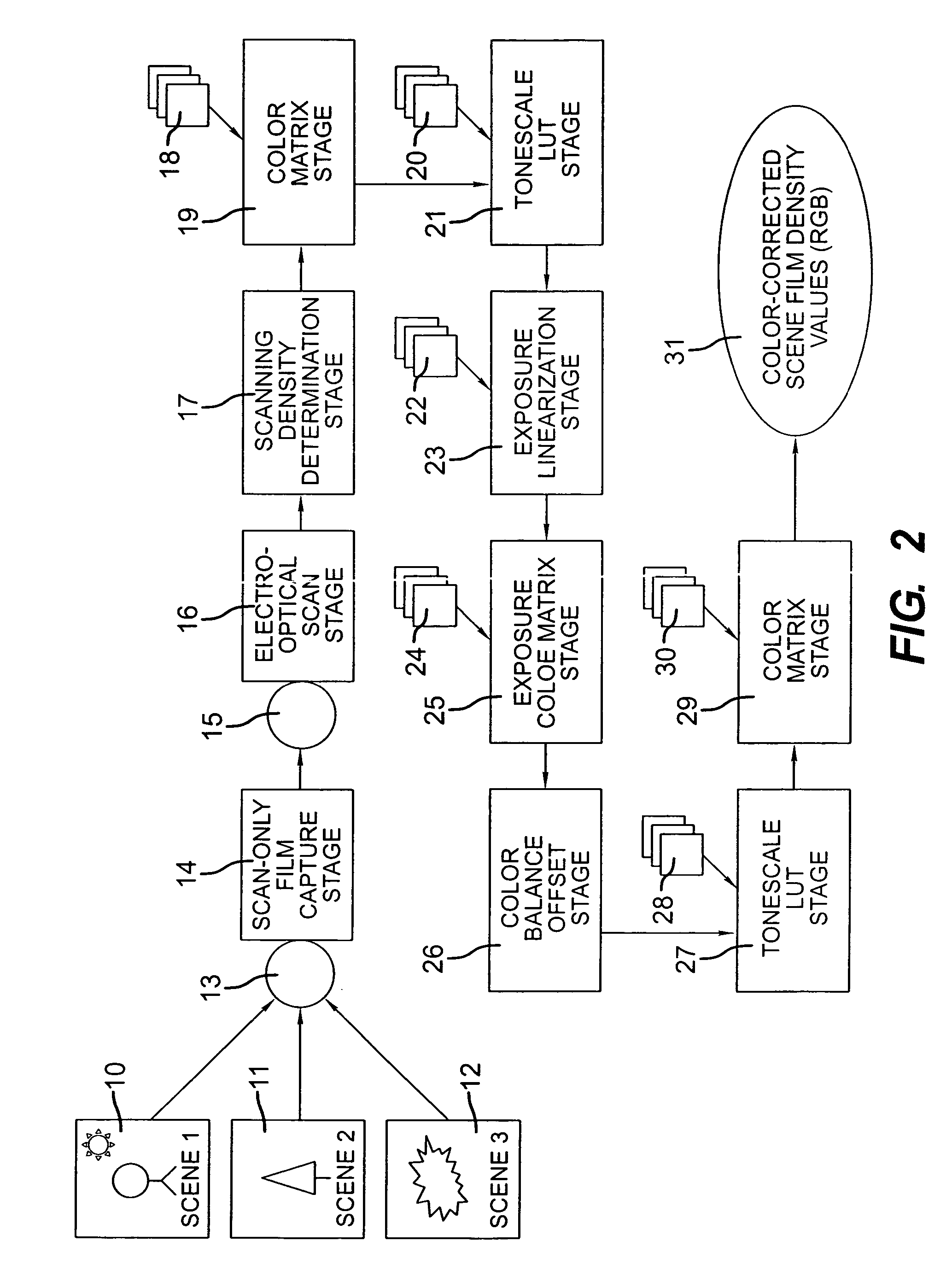

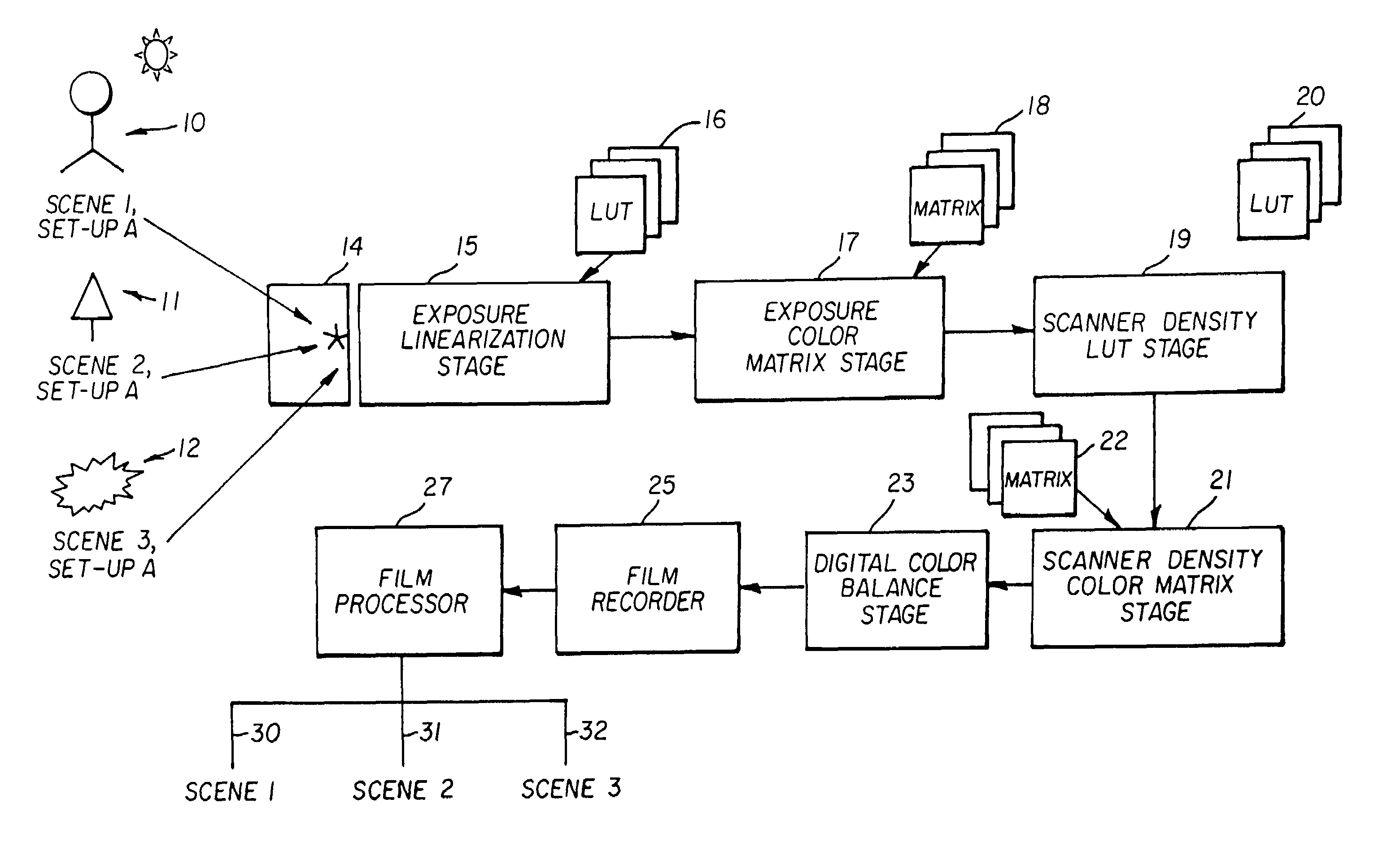

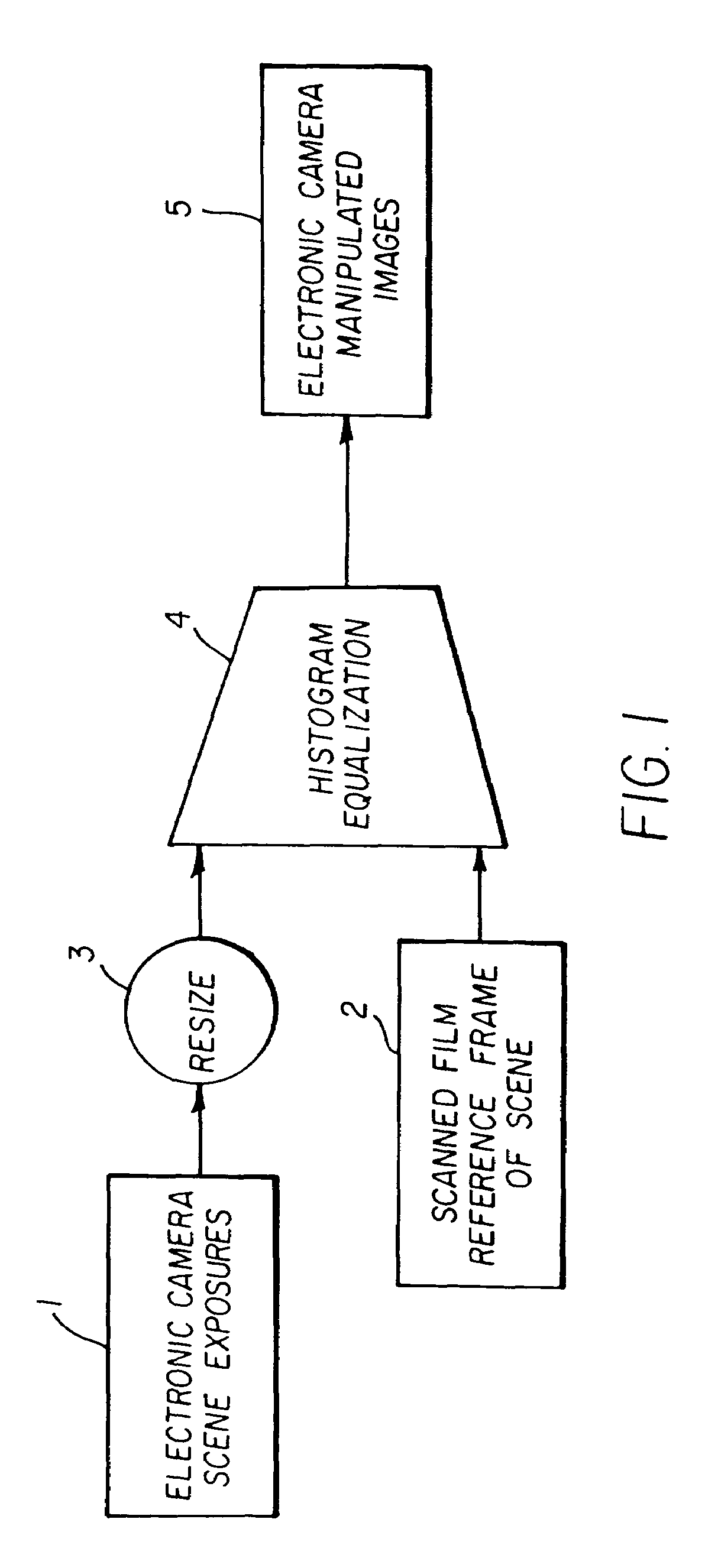

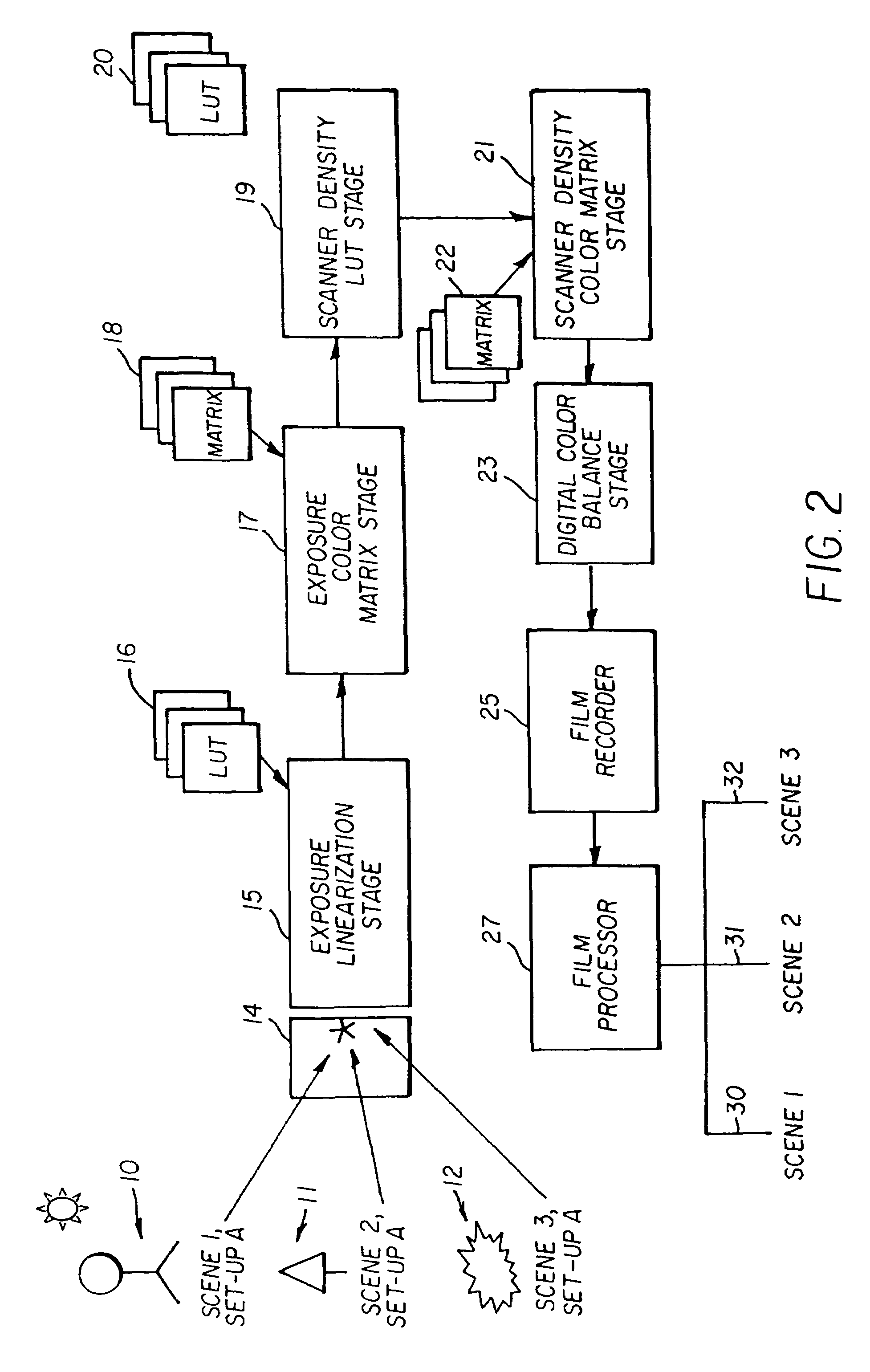

System and method for processing electronically captured images to emulate film tonescale and color

InactiveUS20050179775A1Change colorImage enhancementTelevision system detailsDigital dataDigital master

A method for converting a sequence of electronically captured images into a sequence of modified images for providing the appearance of images captured by a film reproduction system. The film reproduction system being includes motion picture negative film printed onto a motion picture print film that is displayed, or a reversal motion picture system in which the reversal film is displayed, or a motion picture film electro-optically scanned to standard format video by a telecine and further displayed, or a motion picture film electro-optically scanned by a scanner suitable for producing digital data intended for additional digital image manipulation. A digital master is prepared from the aforementioned film formats for electronic distribution or recording out to another film to be used as a printing master for producing distribution optical prints for theatrical projection.

Owner:INTELLECTUAL VENTURES FUND 83 LLC

Patterning process

ActiveUS20100178617A1Improve adhesionImprove accuracyPhotosensitive materialsSemiconductor/solid-state device manufacturingSolubilityResist

A pattern is formed by coating a chemically amplified positive resist composition comprising a resin comprising acid labile group-containing recurring units and a photoacid generator onto a substrate, drying to form a resist film, exposing the resist film to high-energy radiation, PEB, developing to form a positive pattern, illuminating or heating the positive pattern to eliminate acid labile groups for increasing alkaline solubility and to induce crosslinking for imparting solvent resistance, coating a reversal film, forming a space pattern, and shrinking the space pattern.

Owner:SHIN ETSU CHEM IND CO LTD

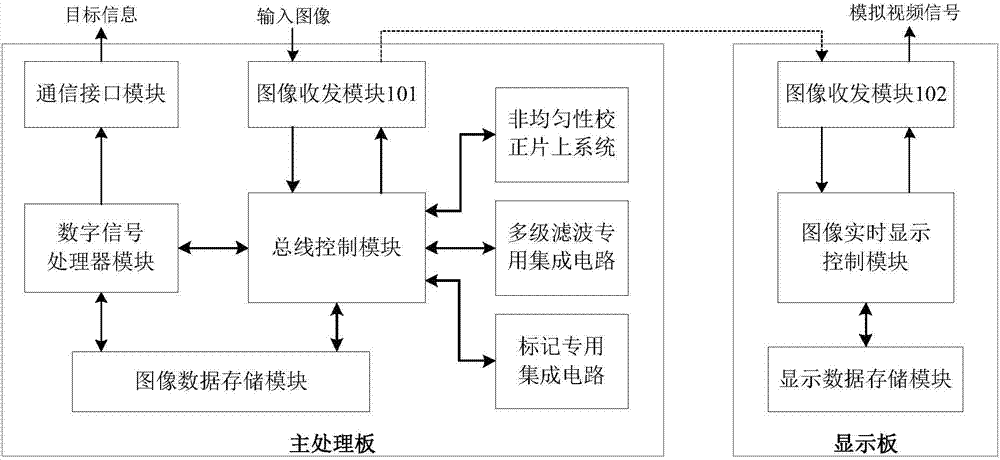

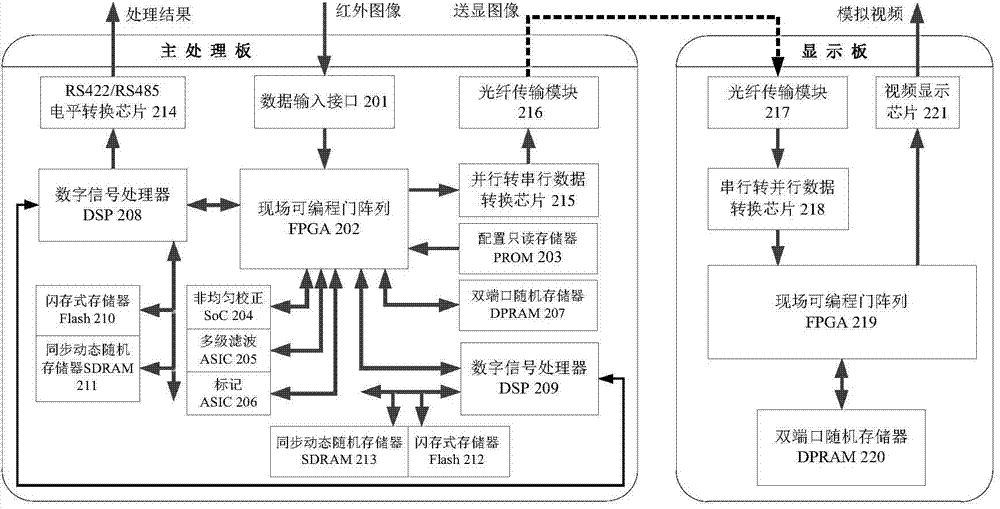

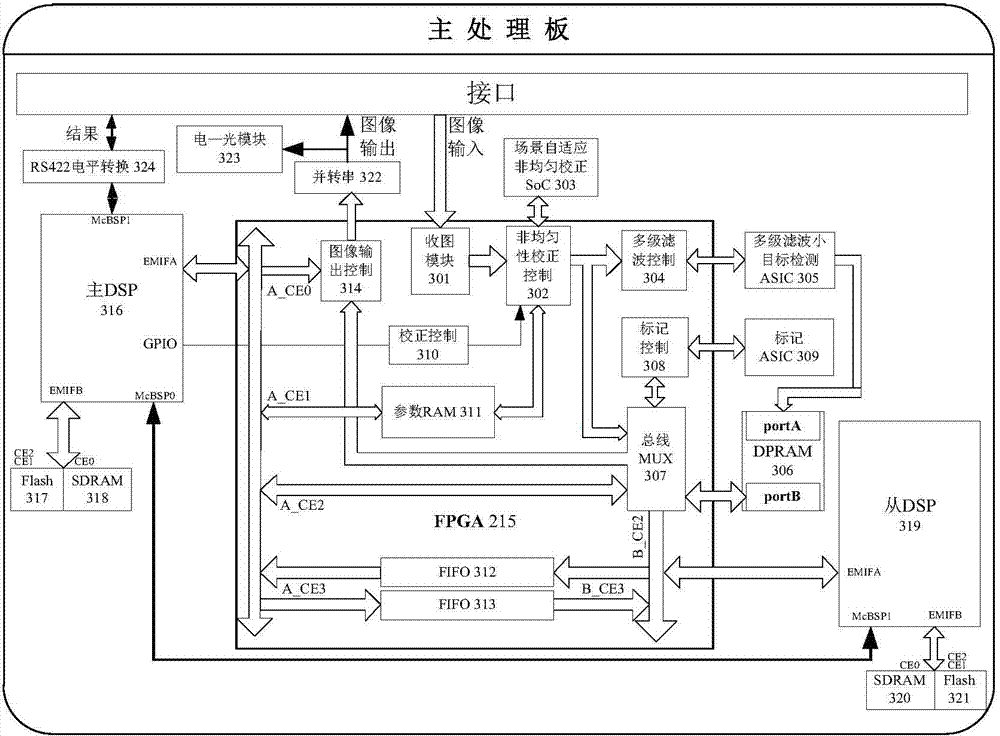

A sea target infrared imaging identification apparatus

InactiveCN103679134AFlexible structureImprove reliabilityCharacter and pattern recognitionMain processing unitCommunication interface

The invention discloses a sea target infrared imaging identification apparatus comprising a main processing panel and a display panel. The main processing panel comprises an image transmit-receive module (101), a bus control module, a digital signal processor module, an image data storage module, a communication interface module, a non-uniformity correction system-on-a-chip (SoC), a multistage filtering application specific integrated circuit (ASIC) and a mark application specific integrated circuit (ASIC), and the main processing panel completes pretreatment of images and identification and tracking of objects. The display panel comprises an image transmit-receive module (102), an image real time display control module and a display data storage module. According to the invention, the real-time performance, the stability and the reliability of sea target automatic object identification on a moving platform are effectively guaranteed, and at the same time, because the utilization of the Soc / ASICs, the power consumption of the apparatus is effectively reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

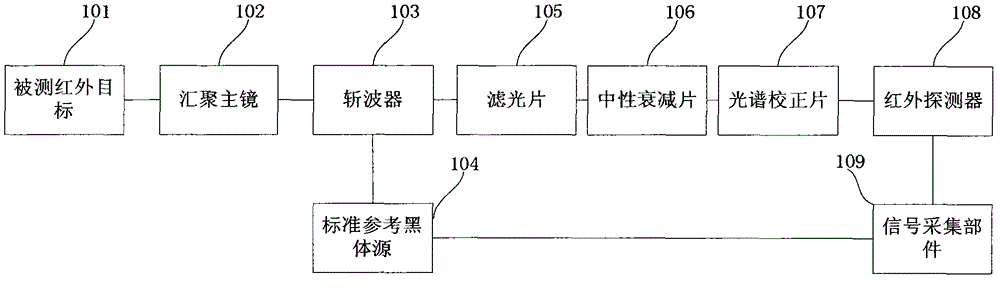

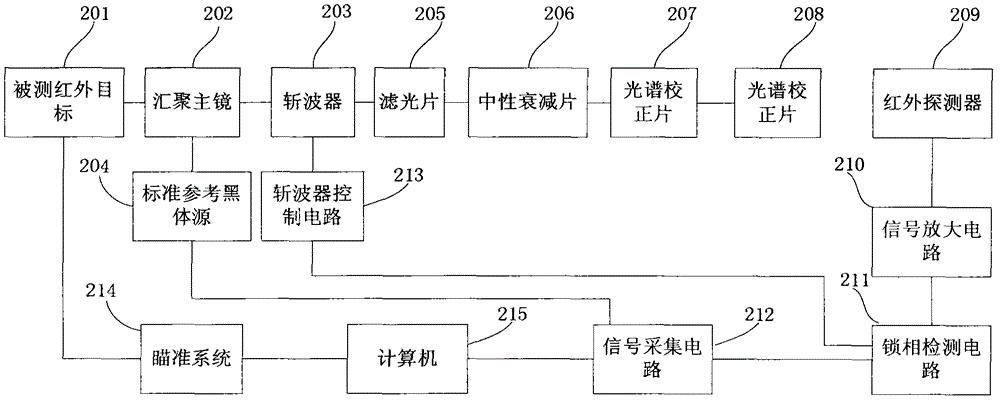

External field type infrared radiometer

The invention relates to the technical field of optical tests, in particular to an external field type infrared radiometer. According to the infrared radiometer, a main convergence mirror is connected with a wave chopper; the wave chopper is connected with a standard reference black body source and light filters; the light filters are connected with neutral attenuation pieces; the neutral attenuation pieces are connected with optical spectrum correcting pieces; the optical spectrum correcting pieces are connected with an infrared detector; a signal acquisition part is connected with the infrared detector and the wave chopper respectively. Through the embodiment, a corresponding optical spectrum curve of a whole system in a measurement waveband can be enabled to be a flat curve through the optical spectrum correcting piece, the linearity and the measurement accuracy of the whole system are improved, and the influence of a radiation spectrum of a tested object on a measurement structure is avoided; the neutral light filters with different attenuation ratios are adopted and the dynamic range of equipment is expanded. Therefore, the equipment has a plurality of ranges and strong and weak radiation targets can be measured.

Owner:BEIJING ZHENXING METROLOGY & TEST INST

Color copying method

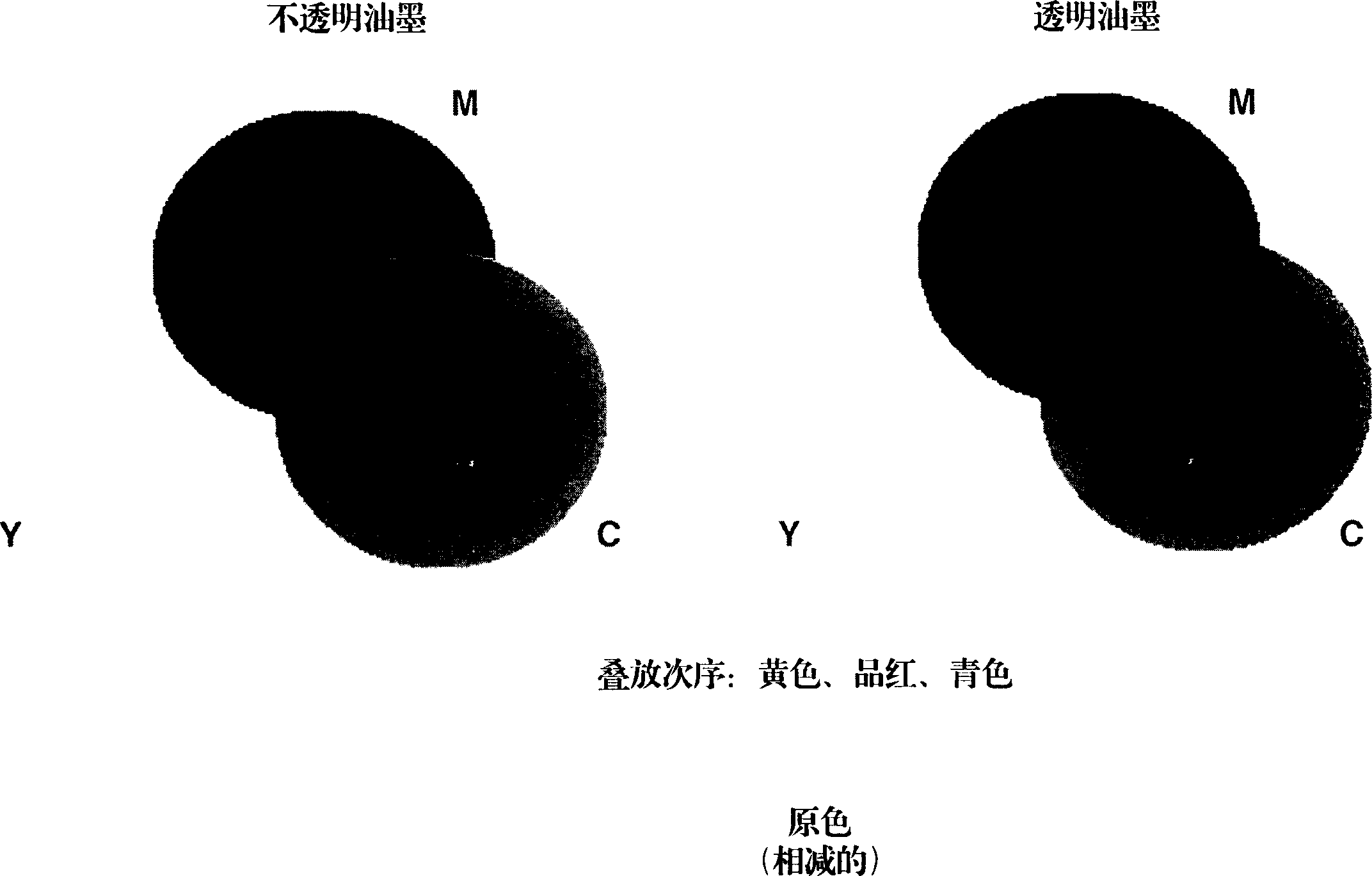

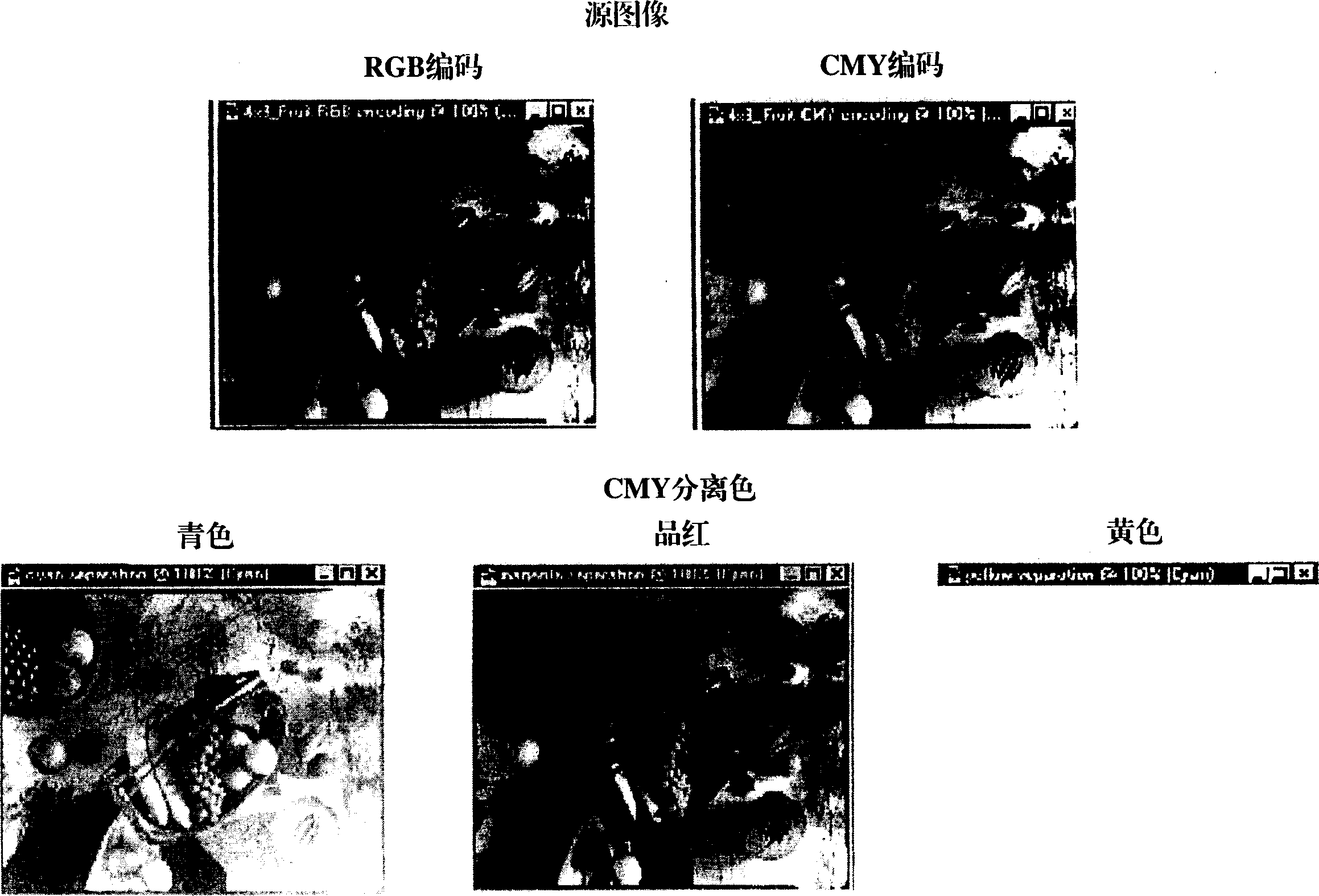

InactiveCN1509895AImprove color levelsLess inkMeasurement apparatus componentsPattern printingColor printingDigital image

A color print method using only two transparent inks to copy original image includes such steps as regulating the contrast, brightness and color balance of original digital image coded by red, green and blue, coverting it to be coded by green, fuchsin and yellow, choosing two channels from these channels for representing the channels of the master colours of original image to the best, determining the key colors to be precisely copied in original image, choosing the relative colors from the ink palette, designing the colors to chosen channels, overlapping two channels to form a synthetic image, regulating gray scale, generating the separated colors of positive film, and transforming to image on negative film.

Owner:WEYERHAEUSER CO

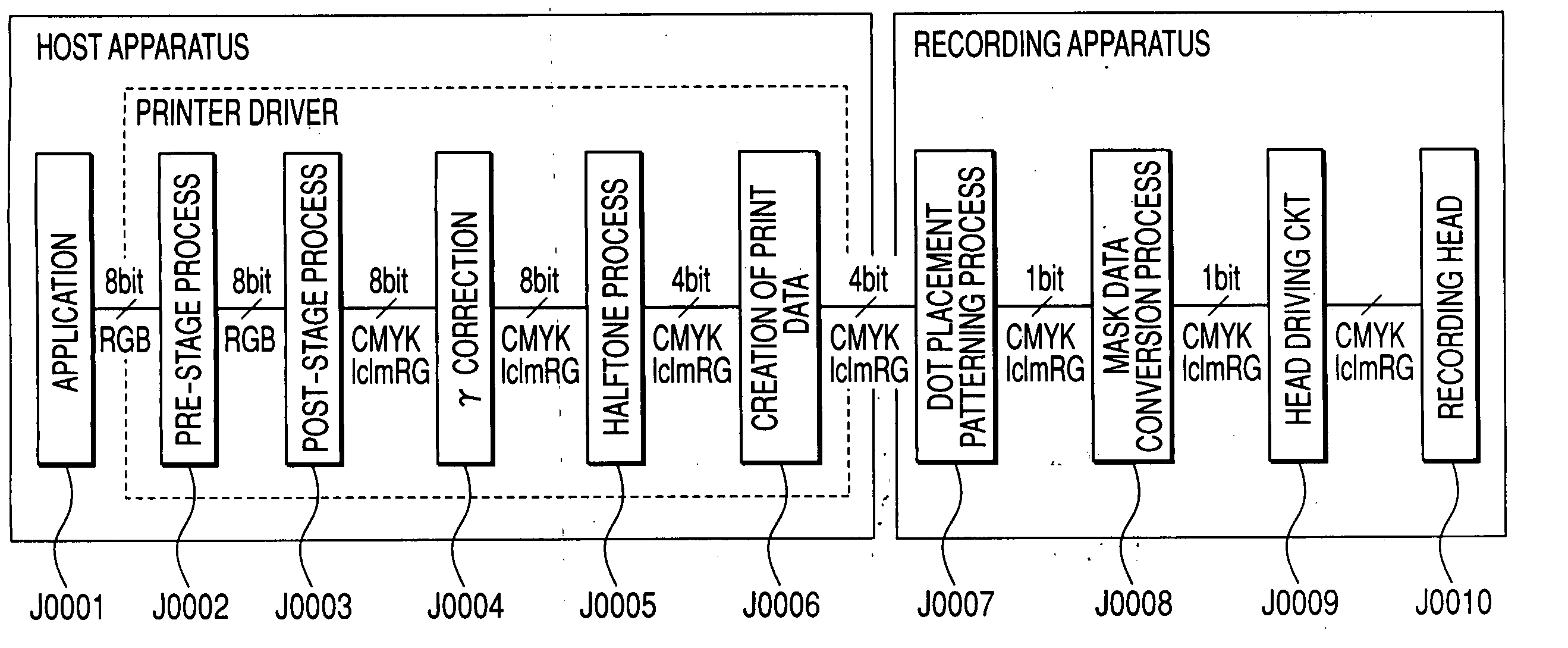

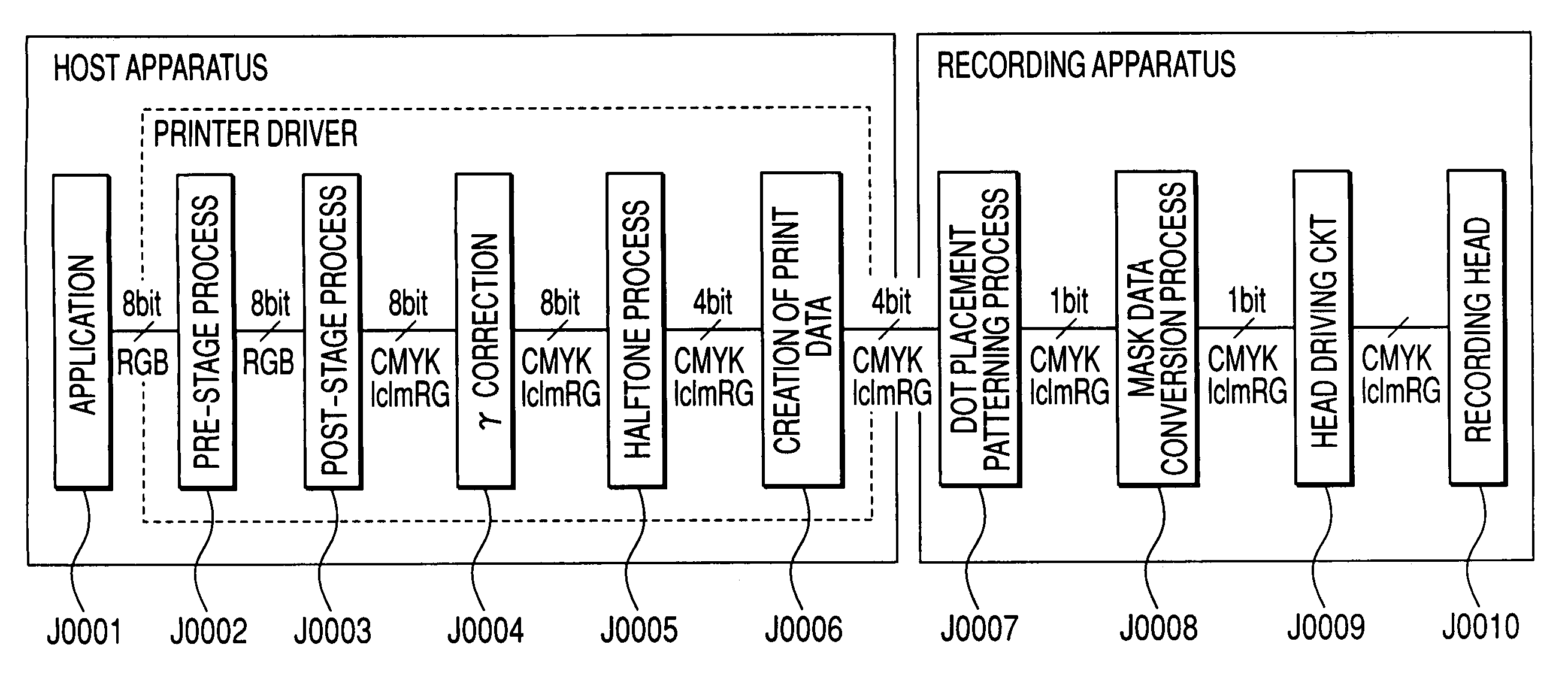

Image forming method, image processing method and ink jet recording apparatus

InactiveUS20050168762A1Improve clarityImprove vividnessDigitally marking record carriersMeasurement apparatus componentsHueReversal film

Owner:CANON KK

Patterning process

ActiveUS20100178618A1High resolution performanceIncrease process marginSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistSolubility

A pattern is formed by coating a chemically amplified positive resist composition comprising a resin comprising acid labile group-containing recurring units and a photoacid generator onto a substrate, drying to form a resist film, exposing the resist film to high-energy radiation through a phase shift mask having a lattice-like array of shifters, PEB, developing to form a positive pattern, illuminating or heating the positive pattern to eliminate acid labile groups for increasing alkaline solubility and to induce crosslinking for imparting solvent resistance, coating a reversal film, and dissolving away the positive pattern in an alkaline wet etchant to form a pattern by way of positive / negative reversal.

Owner:SHIN ETSU CHEM IND CO LTD

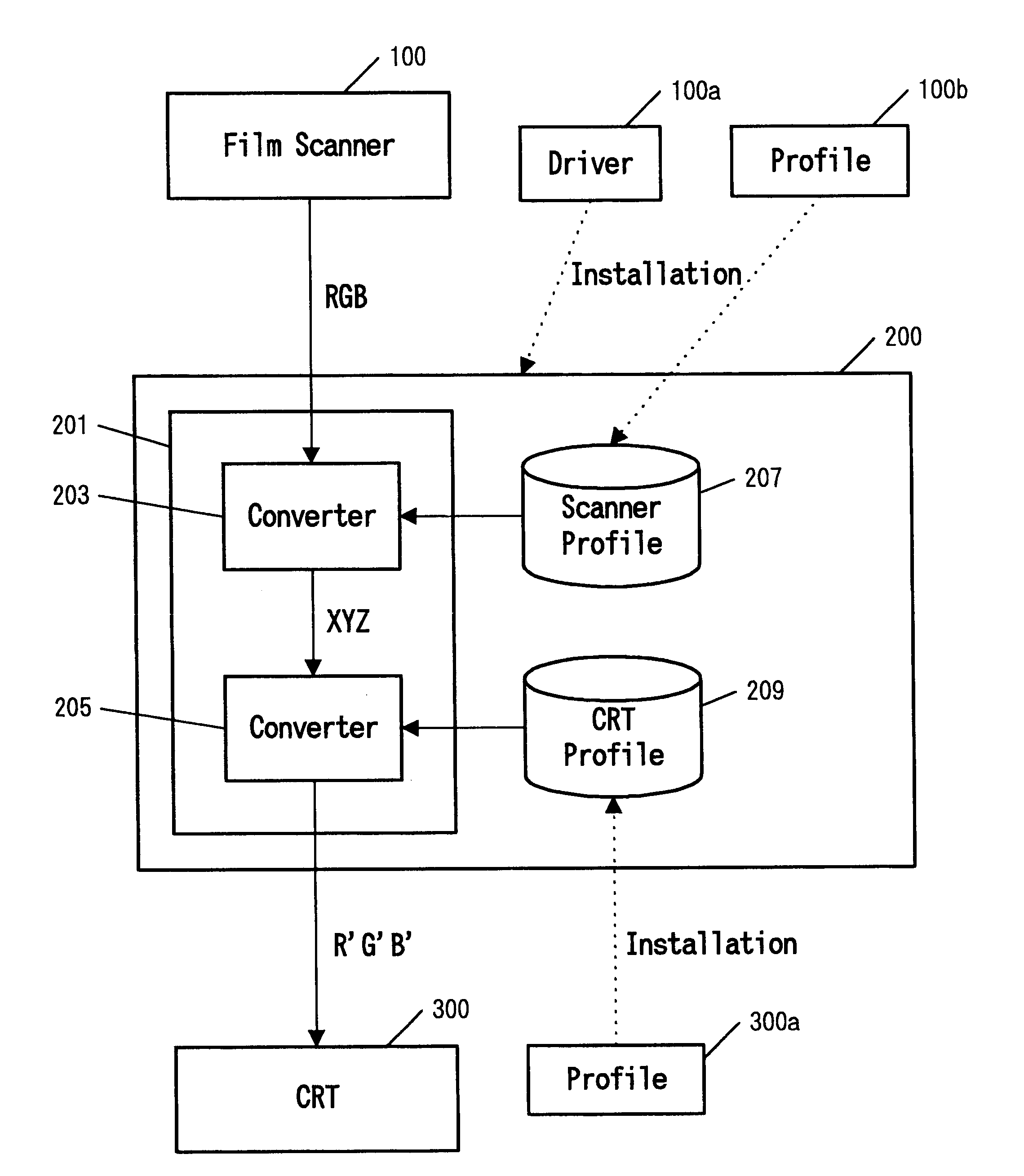

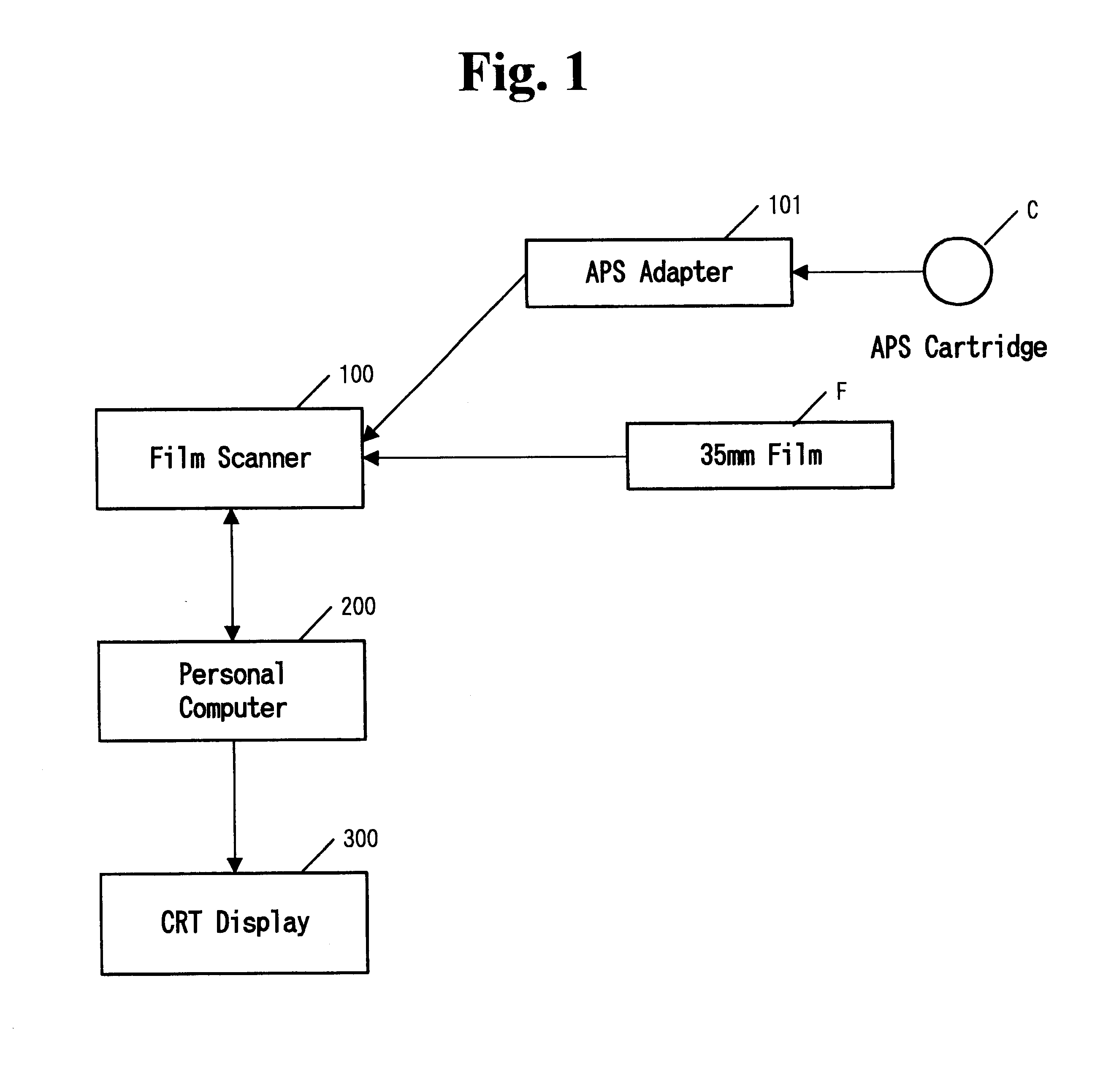

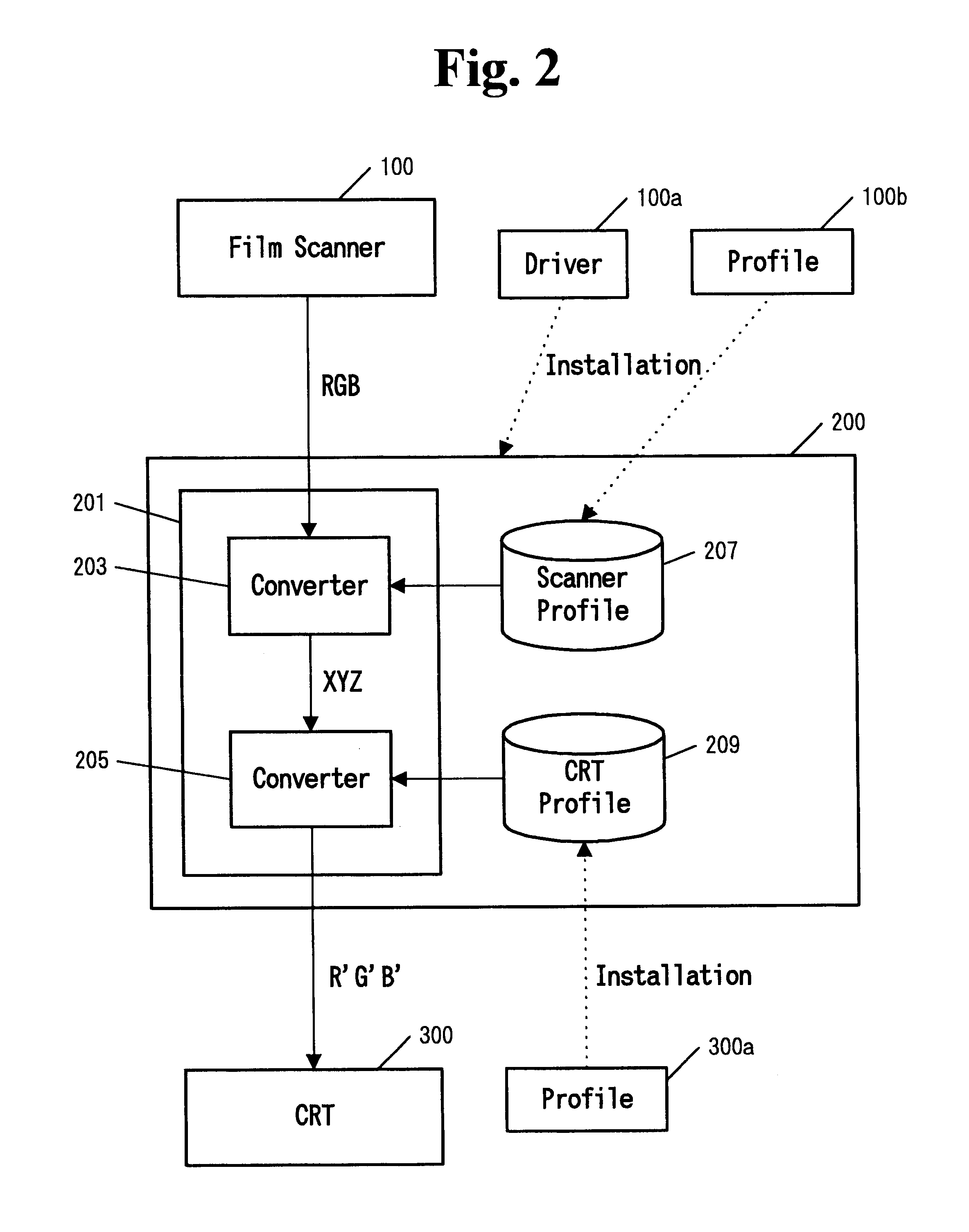

Film scanning system

InactiveUS6762863B1Image data processing detailsColour-separation/tonal-correctionUser inputInput selection

A user inputs whether a reading object film is negative film, positive film, or monochrome film. A suitable profile for use in color matching is selected based on this input.

Owner:MINOLTA CO LTD

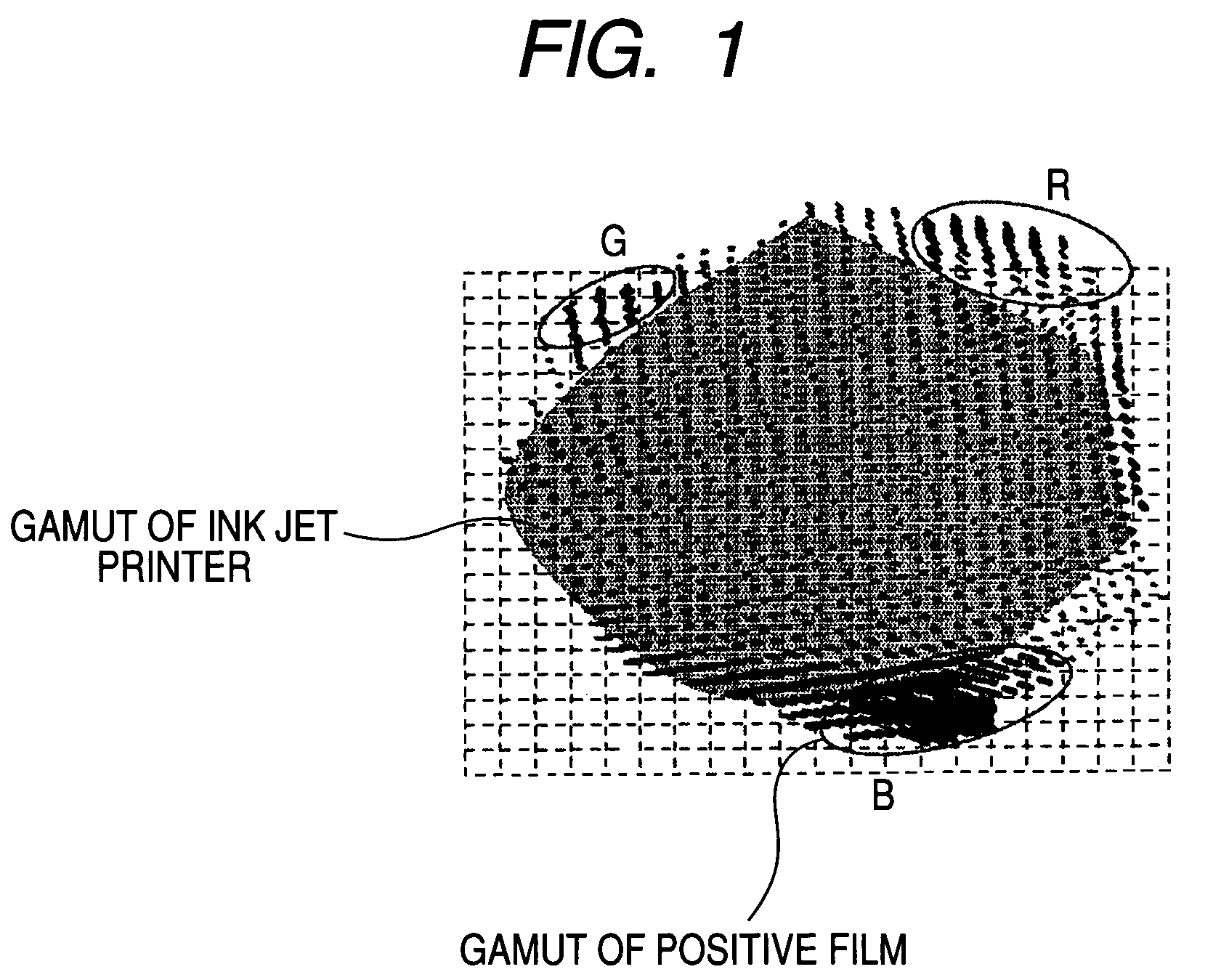

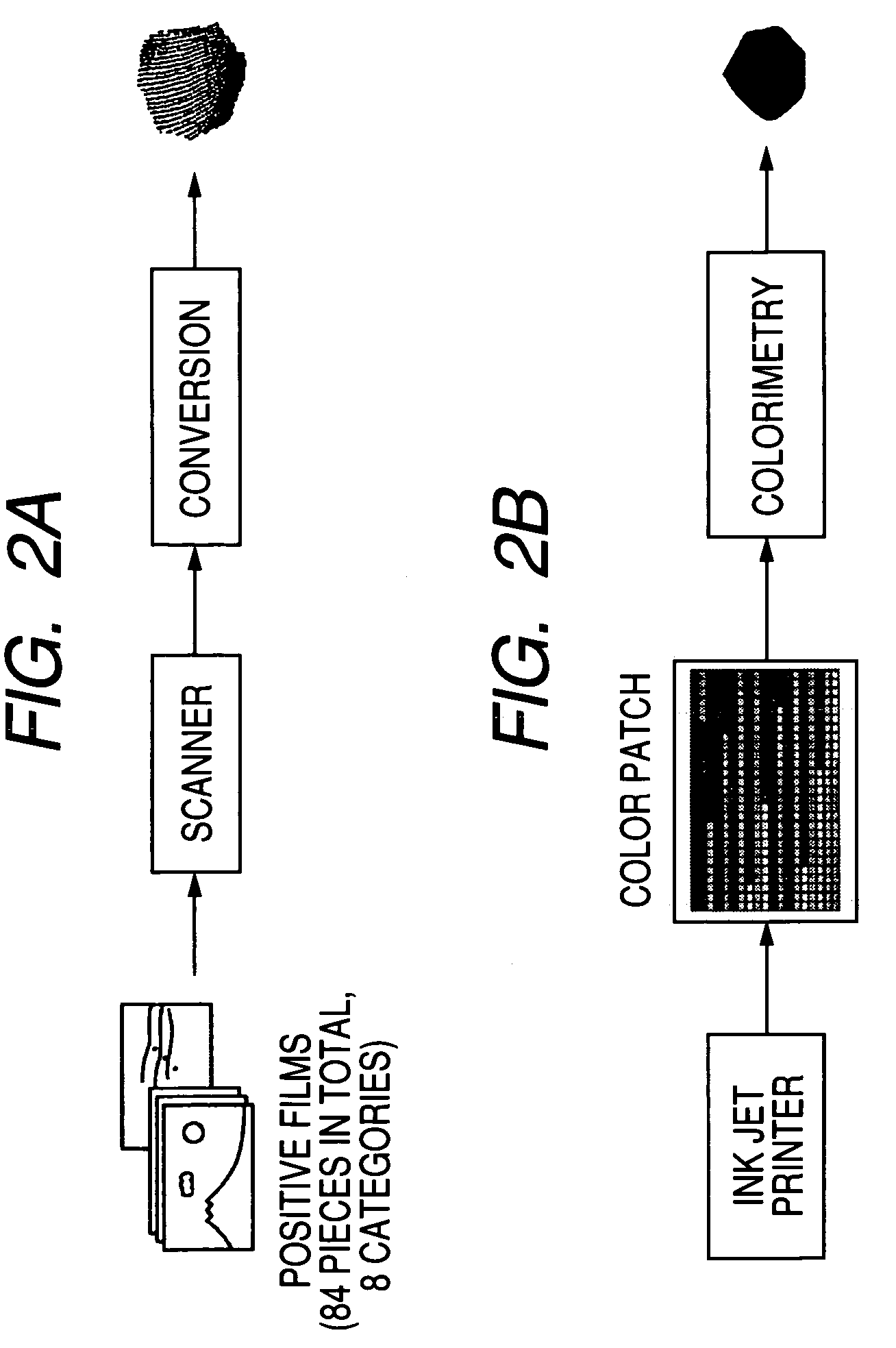

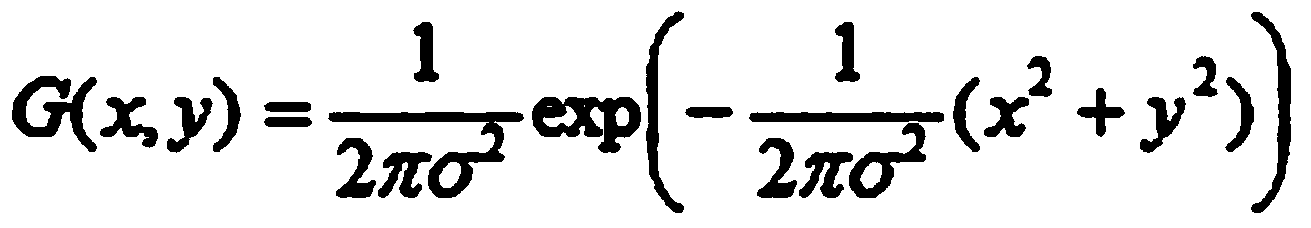

Image forming method, image processing method and ink jet recording apparatus

InactiveUS7463384B2Digitally marking record carriersMeasurement apparatus componentsImaging processingImage formation

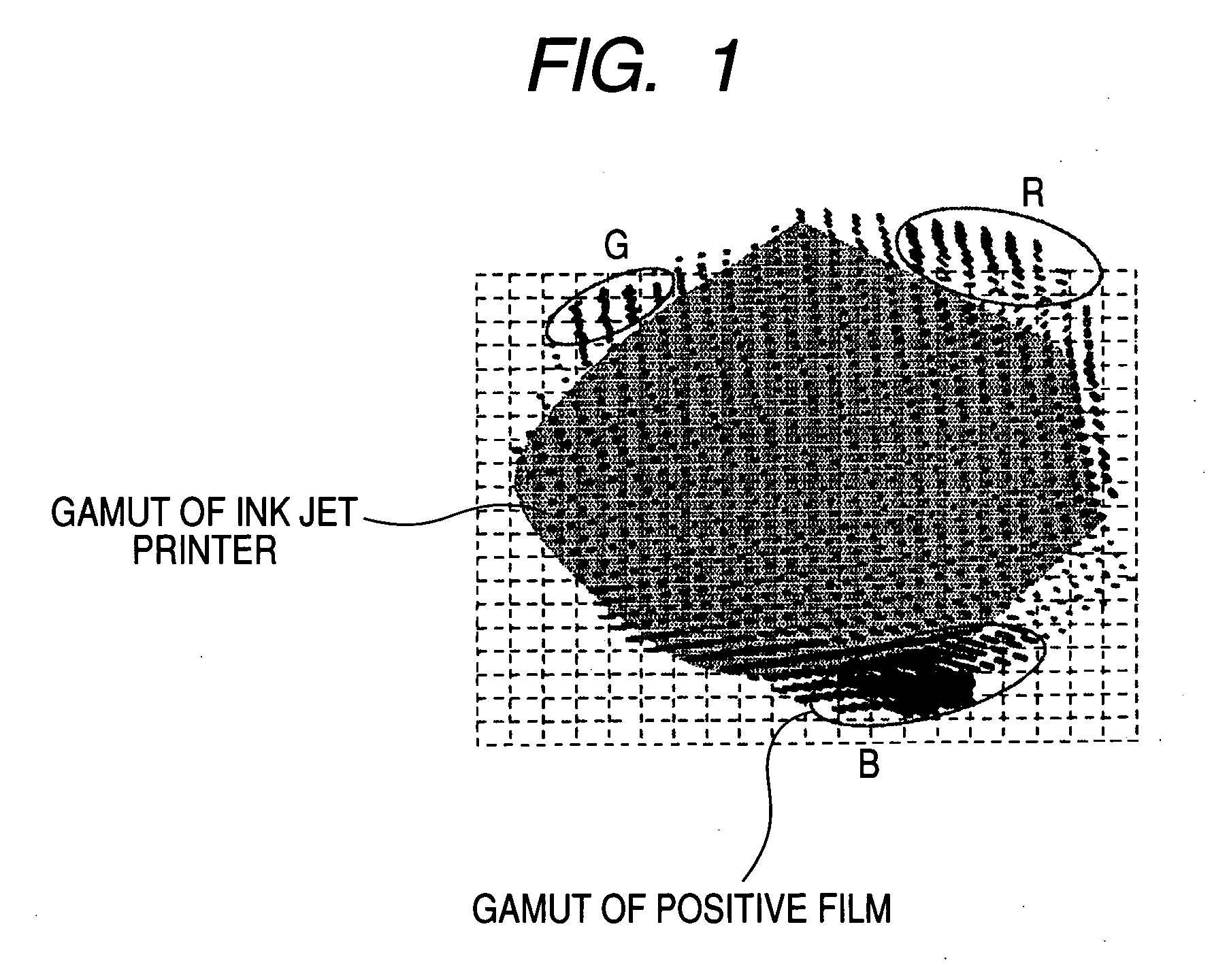

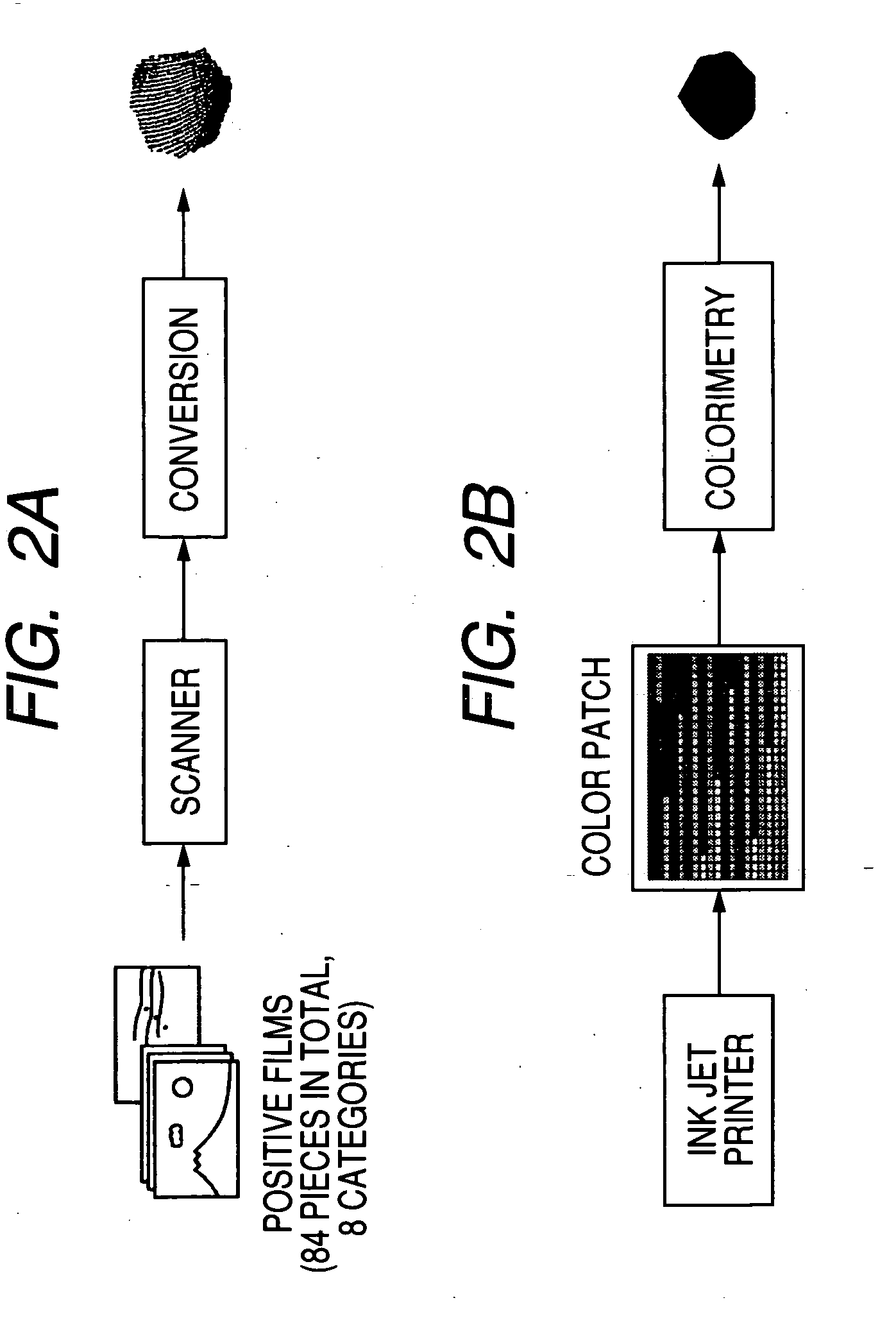

For obtaining a color reproduction range of a printer closer to the color reproduction range of the positive film, a mere addition of a specific color recording material in the same manner as the recording materials of other colors is insufficient, and, for a specific color showing a large gap from the color reproduction range of the positive film, an application amount different from that of the recording materials of other colors is required for such specific color, in consideration of color developing property. Therefore, in case of forming an image on a recording medium with recording materials of basic colors of cyan, magenta and yellow and recording materials of specific colors different in hue from such basic colors, a maximum application amount per unit area is made larger in at least a recording material of specific color than the application amount of the recording materials of the basic colors.

Owner:CANON KK

Method for converting scalar image into vector image

The invention discloses a method for converting a scalar image into a vector image. Lining is carried out on an original image so that an edge skeleton map of the image can be obtained; color gradation standardization adjusting is carried out on the edge skeleton map to obtain a skeleton map with enhanced lines; an image threshold value is calculated, and binaryzation is carried out on the image threshold value; edge skeleton points are acquired, and a polygon is formed by the continuous edge skeleton points; curve fitting is carried out on the points of each polygon; the polygons on which curve fitting is carried out are drawn through a bezier curve and filled with black, and a vector edge image is obtained; the original image is smoothened based on the bilateral filter iteration to obtain an image with the smooth plane; positive bottom overlaying operation is carried out on the plane image and the vector edge image, and the vectorization cartoon image with the clear skeleton is obtained. The method has the advantages that the processing speed is high, the algorithm of the method can be achieved on a smart phone, the processing effect is good, the image is smooth, colors are abundant, the skeleton is clear, the expanding performance is high, and the scalar image can be changed into various special vector effects.

Owner:CHENDU PINGUO TECH CO LTD

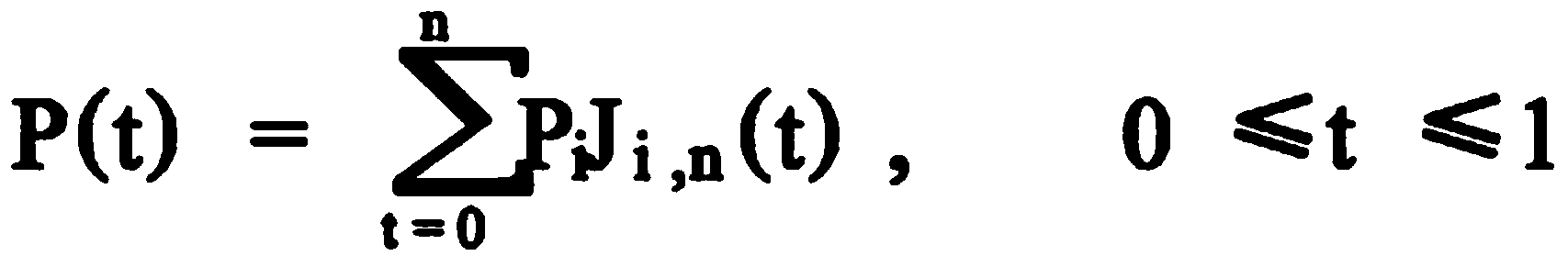

System and method for processing images to emulate film tonescale and color

A method for converting a sequence of scan-only film captured images into a sequence of modified images that provide the appearance of images captured by a photographic film reproduction system; the photographic film reproduction system being includes photographic motion picture negative film printed onto a motion picture print film that is displayed, or a reversal motion picture system in which the reversal film is displayed, or a photographic motion picture film electro-optically scanned to standard format video by a telecine and further displayed, or a photographic motion picture film electro-optically scanned by a scanner suitable for producing digital data intended for additional digital image manipulation and further preparation as a digital master for electronic distribution such as digital theatrical projection or various types of broadcast video; or recorded out to another photographic film to be used as a printing master for producing distribution optical prints for theatrical projection.

Owner:MONUMENT PEAK VENTURES LLC

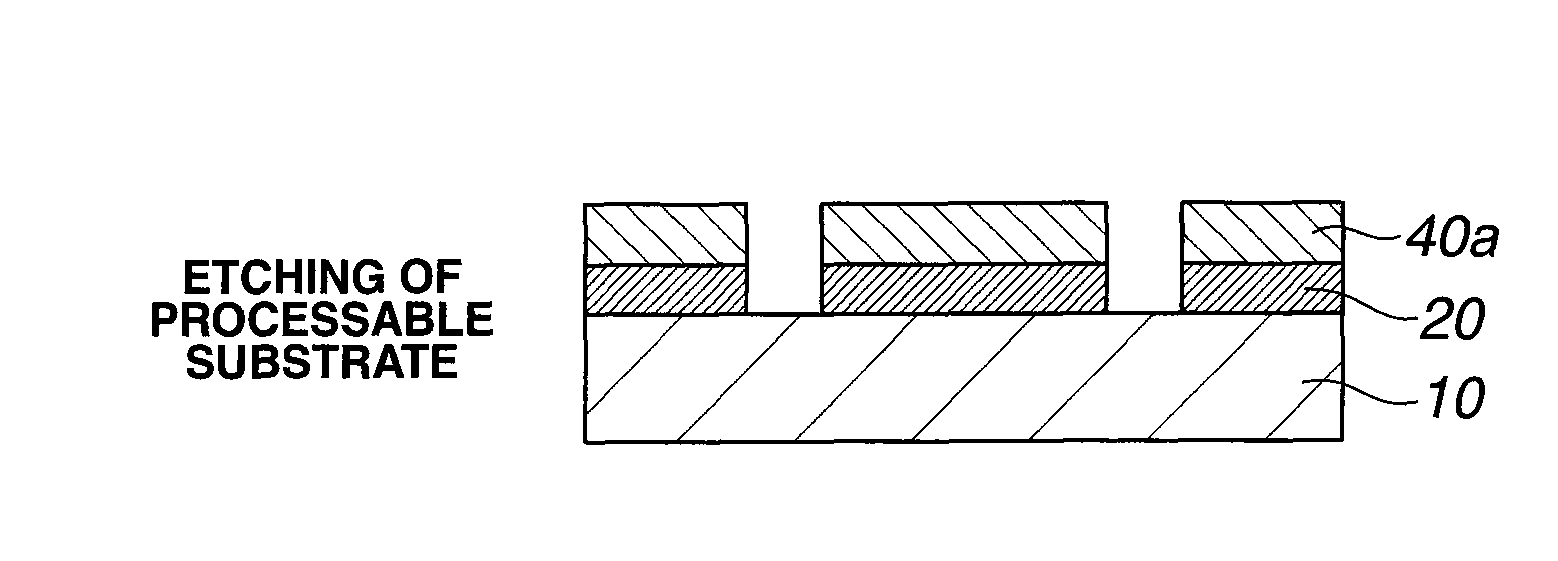

Double patterning process

ActiveUS20090253084A1Improve accuracySimple stepsPhotosensitive material processingOriginals for photomechanical treatmentResistHigh energy

Double patterns are formed by coating a chemically amplified positive resist composition comprising an acid labile group-bearing resin and a photoacid generator and prebaking to form a resist film on a processable substrate, exposing the resist film to high-energy radiation, PEB, and developing with an alkaline developer to form a positive resist pattern, treating the positive resist pattern to be alkali soluble and solvent resistant, coating a negative resist composition and prebaking to form a reversal film, and exposing the reversal film to high-energy radiation, PEB, and developing with an alkaline developer to form a negative resist pattern. The last development step includes the reversal transfer step of dissolving away the positive resist pattern which has been converted to be soluble in developer.

Owner:SHIN ETSU CHEM IND CO LTD

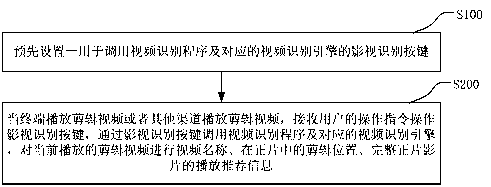

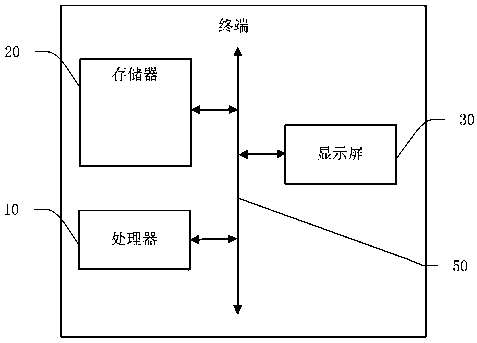

Method, terminal and medium for acquiring positive film correlation data based on short video

ActiveCN108989856AImprove viewing experienceImprove click-through rateSelective content distributionPattern recognitionIdentification key

The invention discloses a processing method, a terminal and a medium for acquiring positive film correlation data based on a short video. The method comprises the following steps: a video identification key for calling a video identification program and a corresponding video identification engine is preset; when the terminal plays the clip video or other channels play the clip video, receiving anoperation instruction of a user; operating a video recognition key; calling a video recognition program and a corresponding video recognition engine through the video recognition key; providing playback recommendation information of video name, the clip position in the feature film and complete positive film of the currently played clip video; and completing the playback recommendation information of the feature film at. The patent of the invention solves the painful point that it is difficult for a user to but find a positive film while watching a short video, provides a new method for the operation of the positive film, improves the click-through rate of the positive film, improves the viewing experience of the user, and greatly provides convenience for the user.

Owner:KONKA GROUP

Manufacturing method of circuit board with selectively plated copper and tin

InactiveCN101521991AReduce plating areaReduce pollutionConductive material chemical/electrolytical removalPrinted element electric connection formationElectricityOptoelectronics

The invention relates to a manufacturing method of a circuit board with selectively plated copper and tin, comprising the following steps: coating a plating-resistant cover film on a copper precipitation circuit board or a circuit board plated with copper at first time, and then bonding positive sheets of all metal holes and hole rings, which are contained in circuit diagrams, on the plating-resistant cover film to form a primary circuit after exposure and development; plating copper and tin on the hole walls of all the metal holes and the hole rings and then carrying out film de-coating; coating a corrosion-resistant cover film on the de-coated circuit board, and then bonding negative sheets of the circuit diagrams on the corrosion-resistant cover film to form a secondary circuit after exposure and development; etching the circuit diagrams and then carrying out film de-coating and tin de-coating; and manufacturing a circuit board product after welding prevention, exposure, development, element mark printing, tin spraying, anti-oxidation process or turmeric and outline process. The invention selectively plates copper and tin, thereby greatly reducing the amount of copper and tin to greatly reduce the environmental pollution from tin de-coating process, effectively saving the copper, tin, water, electricity, chemical materials, energy charges and manpower and effectively reducing the production costs for enterprises.

Owner:深圳市源基电子科技有限公司 +1

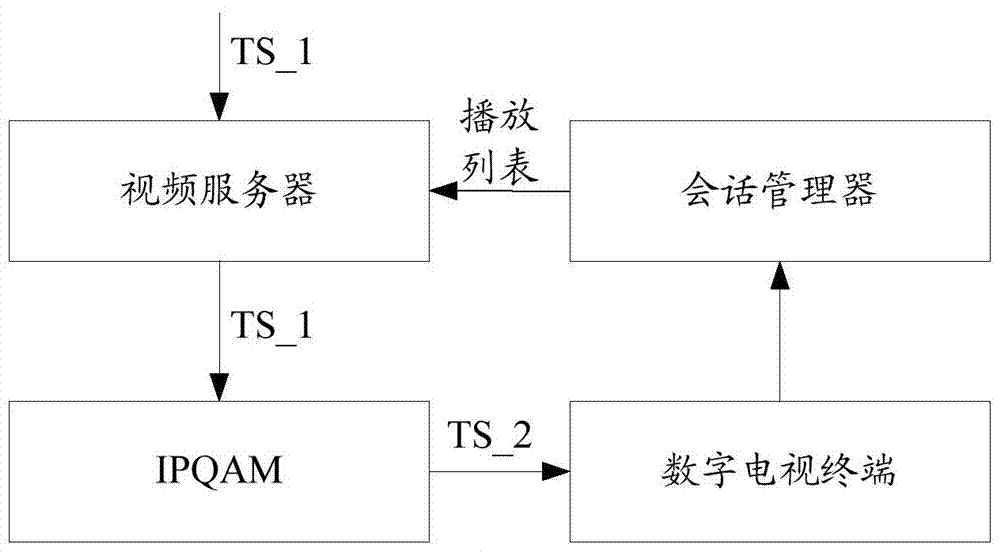

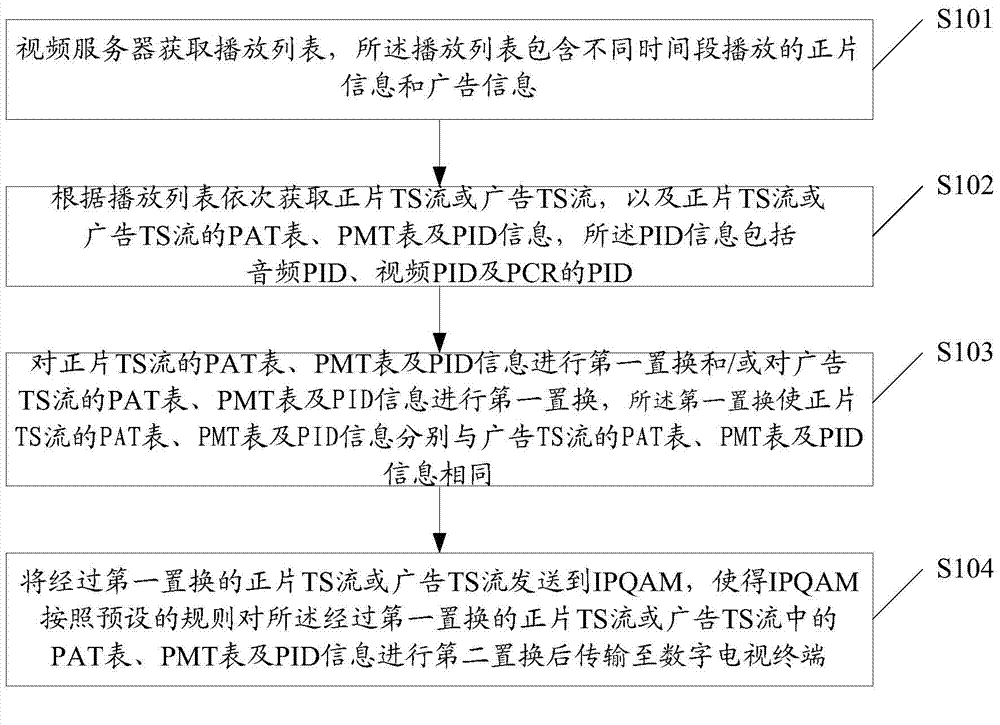

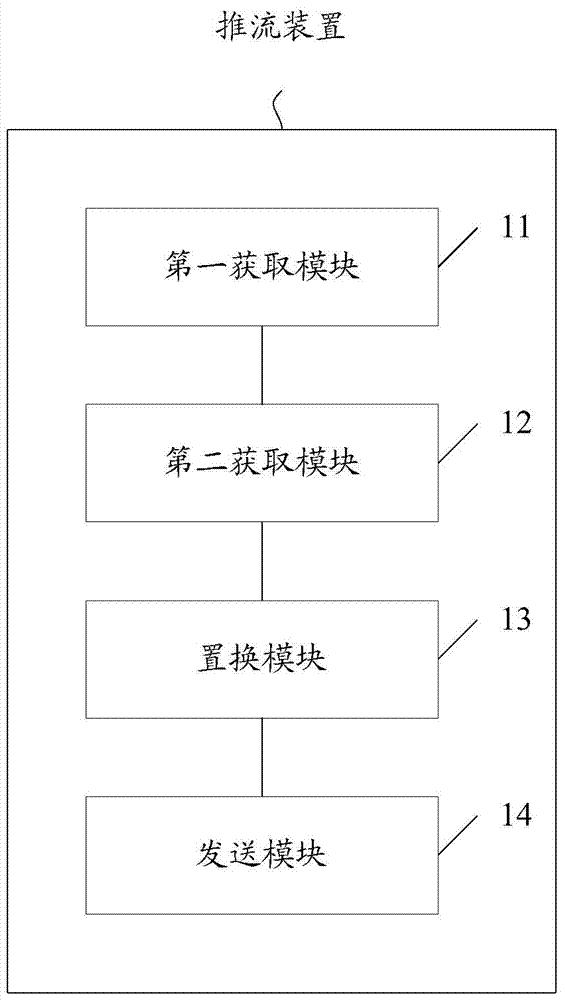

Stream forwarding method, device, server and system for video advertising insertion

InactiveCN103763588AImprove experienceThere will be no blurred screenSelective content distributionVideo advertisingVideo server

The invention provides a stream forwarding method, device, server and system for video advertising insertion. The method includes the steps that a video server obtains a play list, wherein the play list comprises feature film information and advertisement information played at different time periods; according to the play list, a feature film TS stream or an advertisement TS stream, a PAT table, a PMT table and PID information of the feature film TS stream or the advertisement TS stream are sequentially obtained; first permutation is carried out on the PAT table, the PMT table and the PID information of the feature film TS stream and / or the advertisement stream, and by means of first permutation, the PAT table, the PMT table and the PID information of the feature film TS stream are the same as those of the advertisement TS stream; the feature film TS stream or the advertisement TS stream after first permutation is sent to an IPQAM. By means of the stream forwarding method, device, server and system, the blurred screen phenomenon occurring when a feature film and advertisement are switched during video advertising insertion is eliminated.

Owner:SHENZHEN COSHIP ELECTRONICS CO LTD

Circuit board manufacturing method without tin plating, tin retreating and capable of saving copper and nickle

InactiveCN101489355AAvoid heavy pollutionSave potionConductive material chemical/electrolytical removalTinningElectricity

A method for manufacturing circuit board which is free of tin plating and tin removing and can save the using amounts of copper and nickel comprises the following steps: a. coating plating-resistant covering film on the circuit board after copper deposition or the first time of copper plating, then adhibiting the positive film of all metal holes and hole rings in the circuit pattern on the covering film for forming a primary circuit after exposing and developing; b. electroplating copper and nickel on the hole wall and hole ring of all metal holes, then removing the covering film; c. coating etching-resistant covering film on the circuit board after film removing, adhibiting the negative film of circuit pattern on the etching-resistant covering film, and forming the secondary circuit after exposing and developing; d. etching the circuit pattern, then removing film and checking erosion; and e. forming the finished product of circuit board through executing the steps of resistance welding, exposing, developing, printing component symbol or tin spraying or executing oxidation prevention procession. The method of the invention can reduce environment pollution and realize clean production through eliminating electrotinning and tin removing technique, effectively saves metal, water, electricity and chemical material and reduces production cost of enterprise through selectively electroplating copper and nickel.

Owner:陈国富

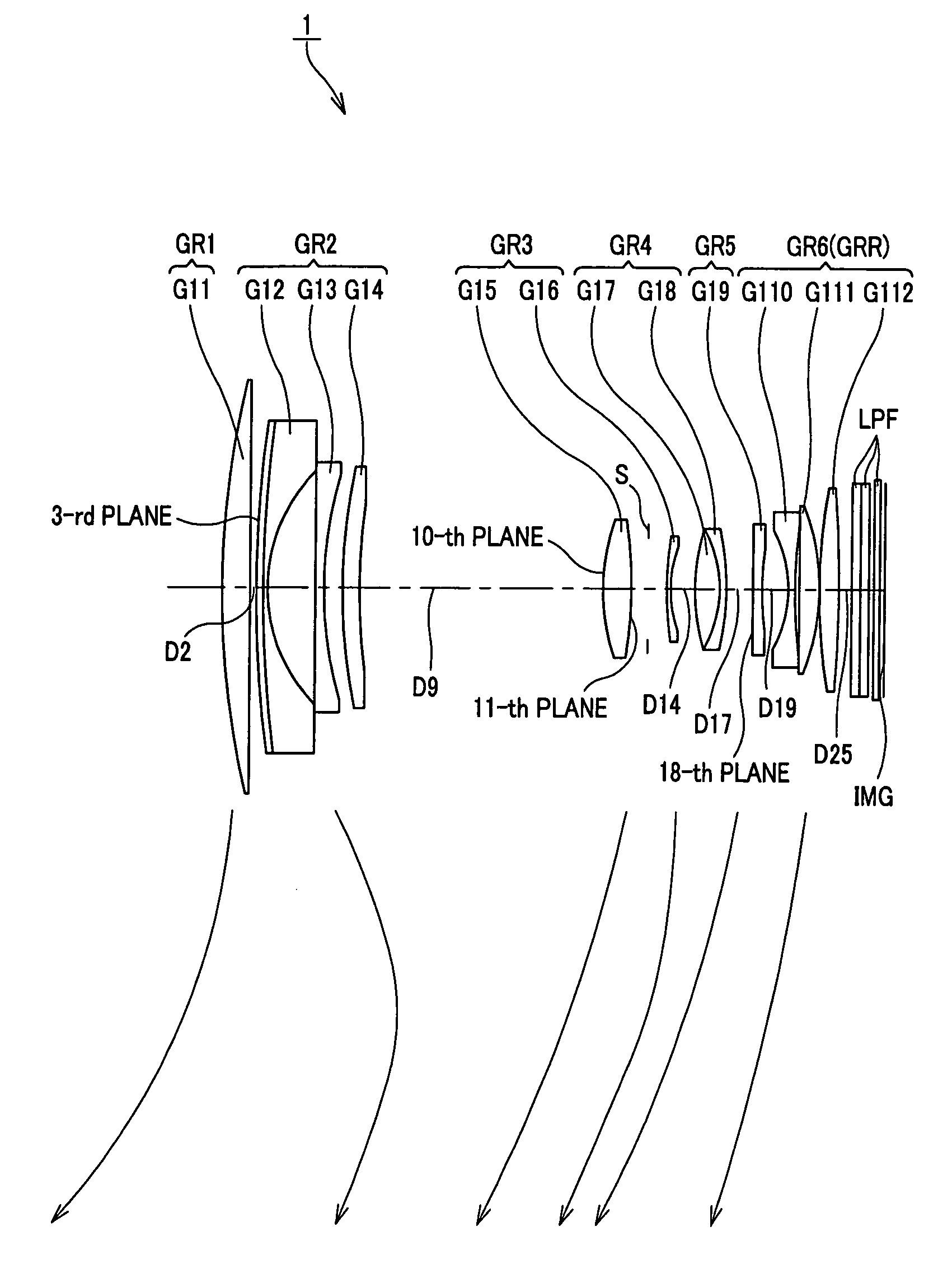

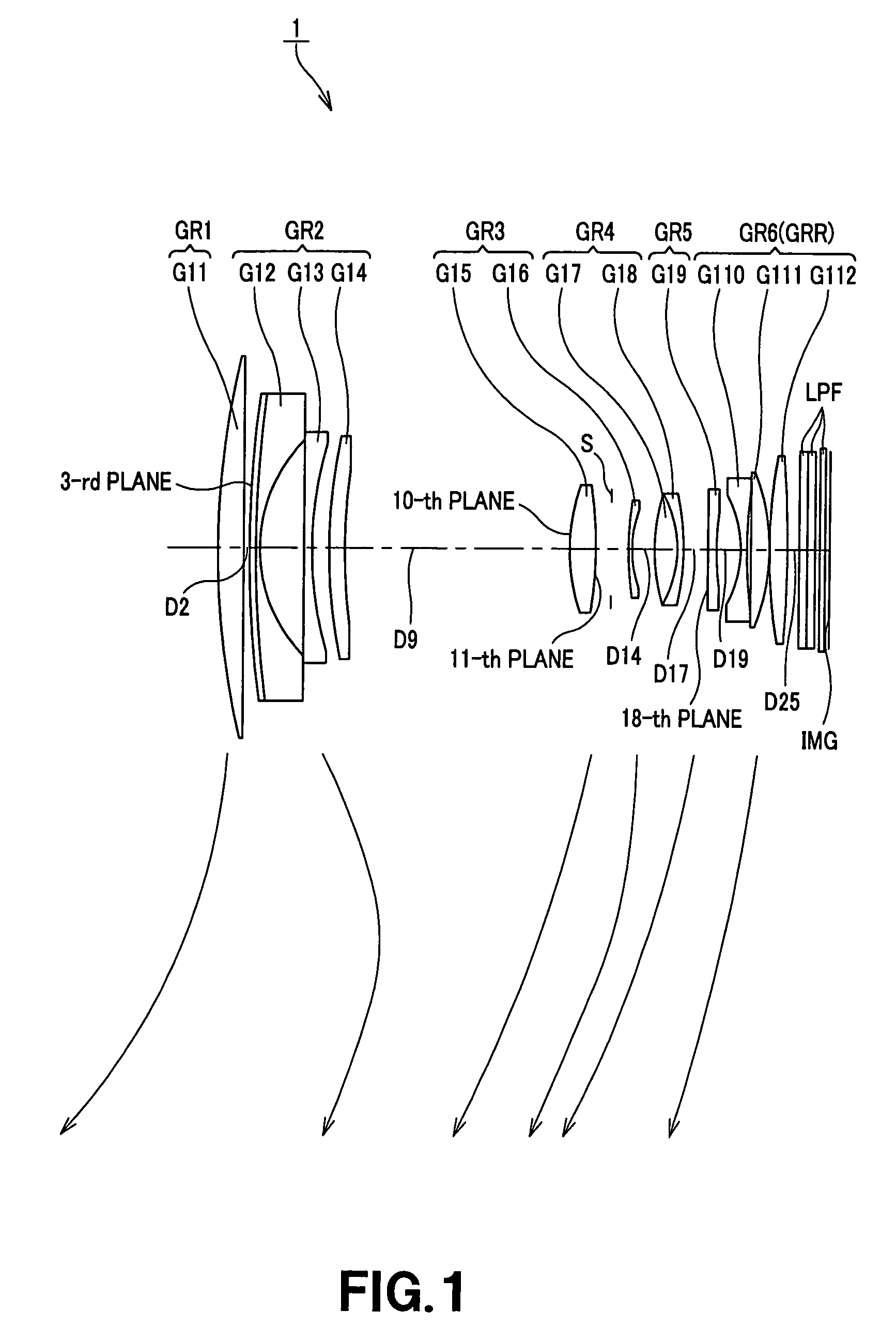

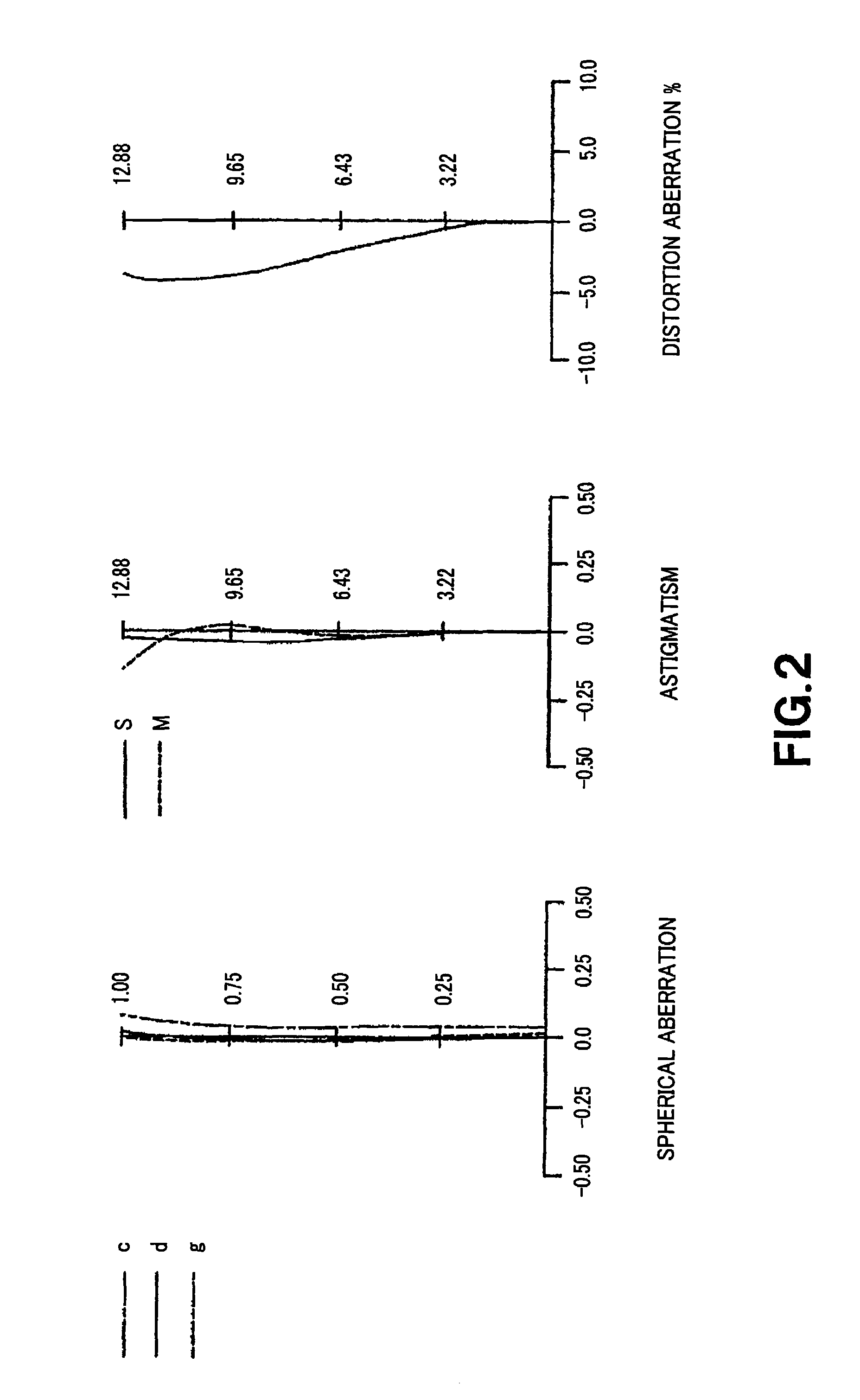

Zoom lens and image pick-up apparatus

A zoom lens including a broad picture angle of 60 to 100 degrees as a photographic picture angle of the wide-angle end state, and having a magnification ratio of about three to six times, small front gem diameter, excellent compactness and high image formation performance, which is used in a video camera or a digital still camera, and an image pick-up apparatus using such a zoom lens. A zoom lens (20), consisting of plural groups and serving to change group spacing or spacings to thereby perform a magnification changing or adjusting operation, comprises a first lens group GR1 having positive refractive power, a second lens group GR2 having negative refractive power and a third lens group GR3 having positive refractive power which are arranged in order from the object side, and a last group GRR arranged at the side closest to the image surface and having negative refractive power, wherein the first lens group GR1 is constituted by single positive lens G1, and satisfies the following conditional formulas.0.5<Ymax / FW<1.3 (1)VdG1>40 (2)In the above formula,Ymax: maximum image height on image pick-up surface;FW: focal length at the wide-angle end state of the lens entire; and systemVdG1: Abbe number at d line of the first lens group GR1.

Owner:SONY CORP

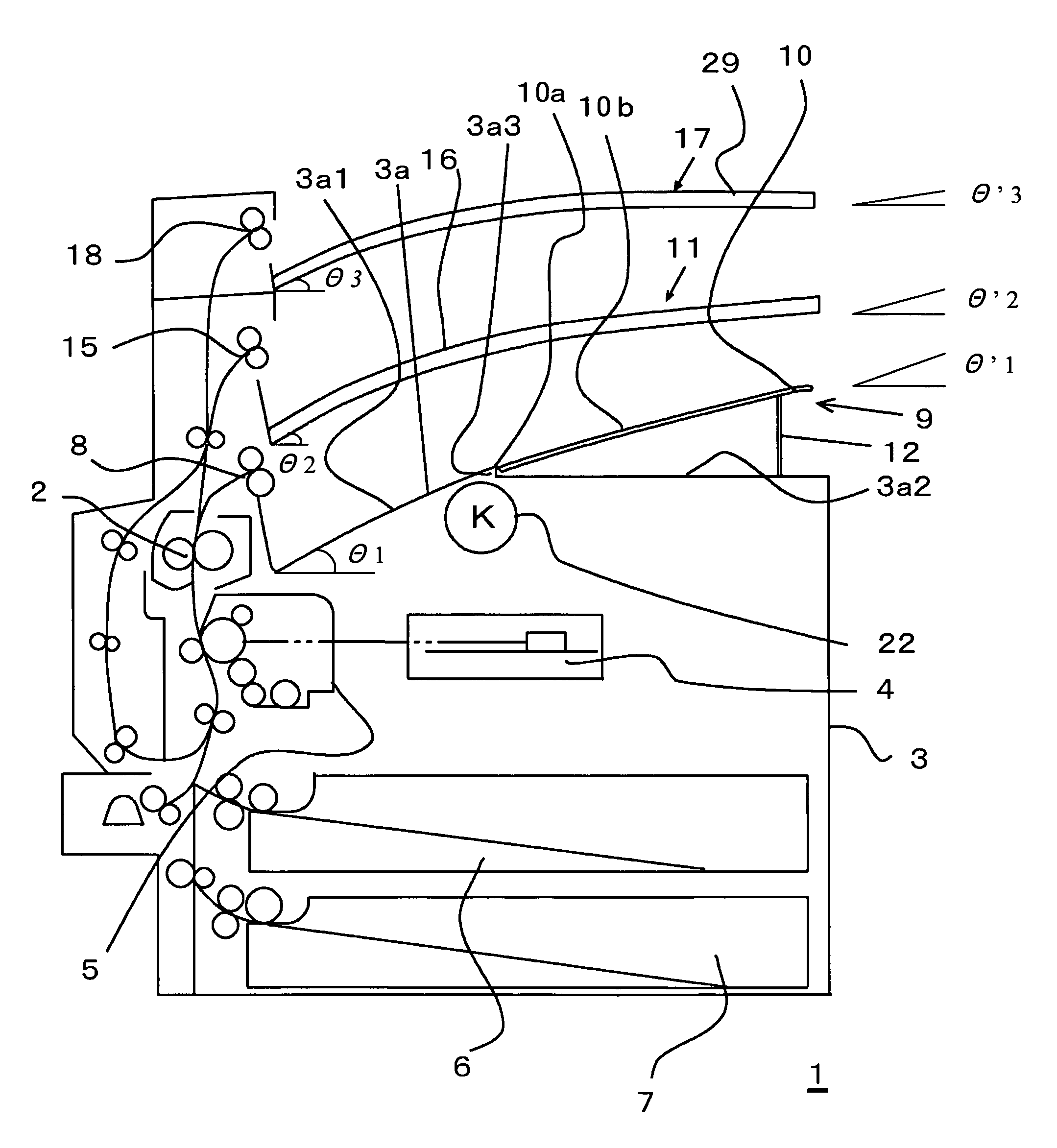

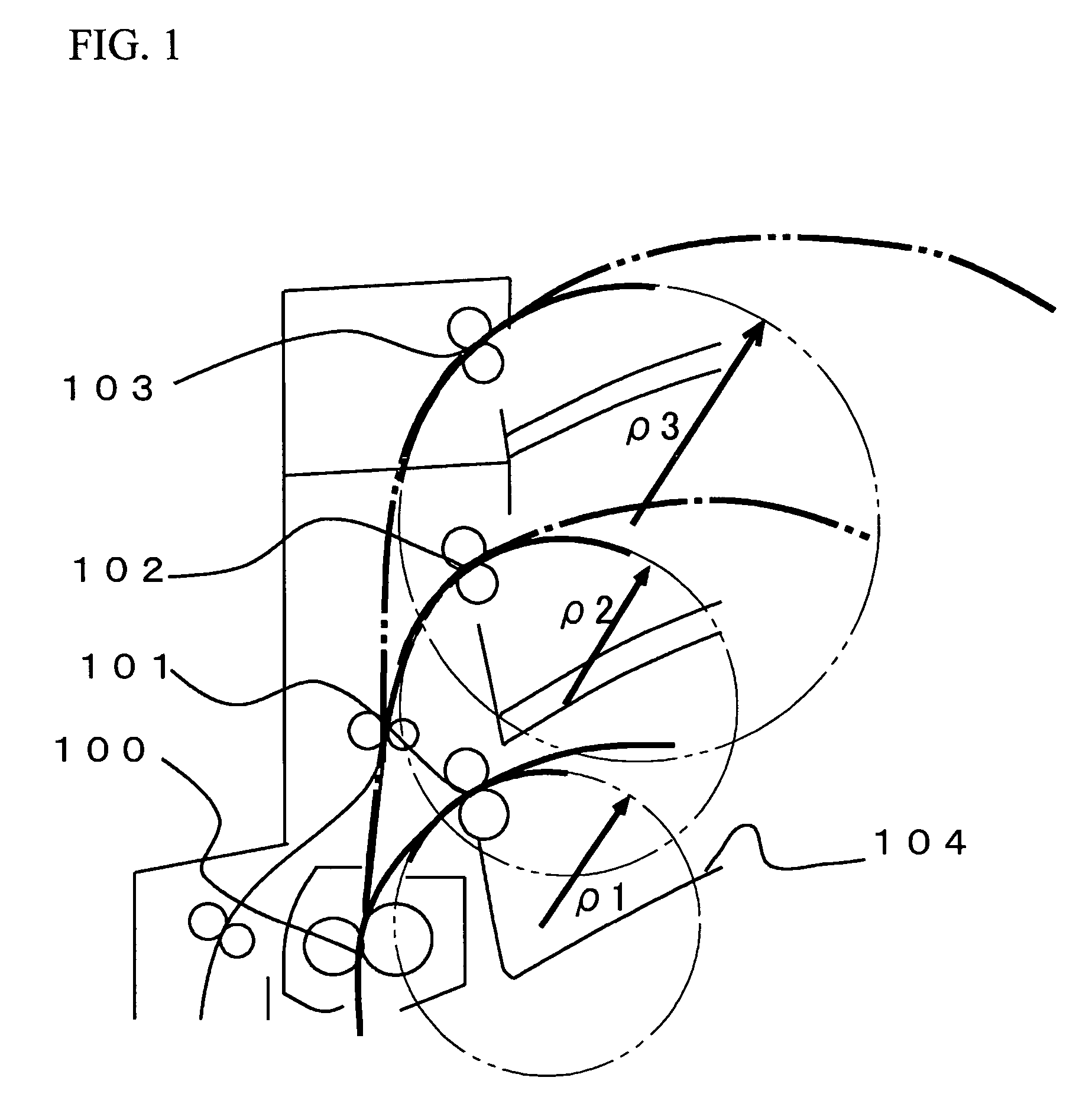

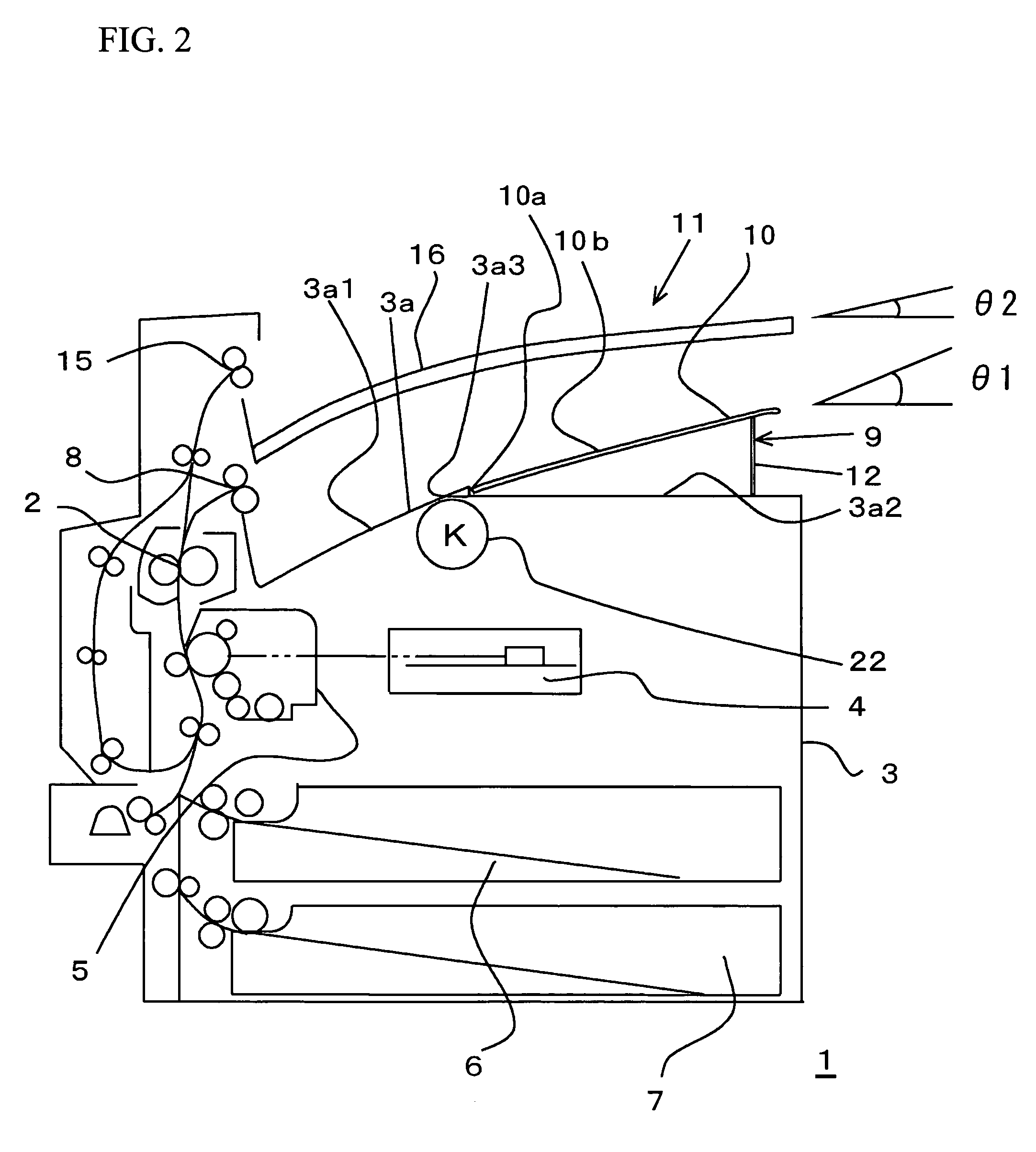

Image-forming apparatus and multiple sheet curl correcting sheet-receiving units

InactiveUS7711310B2Prevent a stacking state of discharged sheets from degradingElectrographic process apparatusPile receiversImage formationEngineering

An image-forming apparatus includes multiple sheet discharge trays arranged on a downstream of a fixing unit in a layer structure, and multiple sheet-receiving units provided corresponding to the multiple sheet discharge trays arranged in the layer structure. Each of the sheet-receiving units respectively includes a climbing slope from a sheet discharge direction start point to a sheet discharge direction end point, and an angle of the climbing slope of a sheet-receiving unit is close to plane, as the sheet-receiving unit is arranged on a further downstream. It is thus possible to provide the image-forming apparatus in which discharged sheets of paper are not piled up on the sheet-receiving unit in a curled state or the discharged sheet does not push out the sheet piled on the sheet-receiving unit.

Owner:FUJIFILM BUSINESS INNOVATION CORP

System and method for processing electronically captured images to emulate film tonescale and color

A method for converting a sequence of electronically captured images into a sequence of modified images for providing the appearance of images captured by a film reproduction system. The film reproduction system being includes motion picture negative film printed onto a motion picture print film that is displayed, or a reversal motion picture system in which the reversal film is displayed, or a motion picture film electro-optically scanned to standard format video by a telecine and further displayed, or a motion picture film electro-optically scanned by a scanner suitable for producing digital data intended for additional digital image manipulation. A digital master is prepared from the aforementioned film formats for electronic distribution or recording out to another film to be used as a printing master for producing distribution optical prints for theatrical projection.

Owner:INTELLECTUAL VENTURES FUND 83 LLC

Preparation method and equipment of copper-thickening printed circuit board

InactiveCN107493658AAvoid bad phenomenon of tin platingImprovement of tin plating defectsConductive material chemical/electrolytical removalDirectly printed exposure masksCopper platingEtching

The invention discloses a preparation method and equipment of a copper-thickening printed circuit board. After external light imaging is performed for the first time, selective copper thickening treatment is performed firstly, so that the problems in the prior art as follows can be avoided: the lower side wall of a dry film in a winding region in secondary external light imaging suffers from medicinal liquid attack and corrosion to be hollowed out to hide medicinal water, and a poor tin plating phenomenon is caused in the secondary copper plating and tin plating due to the hidden medicinal liquid; by adoption of the preparation method, the selective copper thickening flow is performed on the dry film firstly to satisfy the partial copper thickness requirement; and the subsequent production is performed based on the normal board flow, so that the poor tin plating phenomenon caused by the previous two times of copper plating and tin plating and an open-circuit phenomenon in the subsequent etching can be relieved.

Owner:珠海杰赛科技有限公司 +1

Patterning process

ActiveUS8216774B2High resolution performanceSimple processSemiconductor/solid-state device manufacturingPhotosensitive material processingResistSolubility

A pattern is formed by coating a chemically amplified positive resist composition comprising a resin comprising acid labile group-containing recurring units and a photoacid generator onto a substrate, drying to form a resist film, exposing the resist film to high-energy radiation through a phase shift mask including a lattice-like first shifter and a second shifter arrayed on the first shifter and consisting of lines which are thicker than the line width of the first shifter, PEB, developing to form a positive pattern, illuminating or heating the positive pattern to eliminate acid labile groups for increasing alkaline solubility and to induce crosslinking for imparting solvent resistance, coating a reversal film, and dissolving away the positive pattern in an alkaline wet etchant to form a pattern by way of positive / negative reversal.

Owner:SHIN ETSU CHEM IND CO LTD

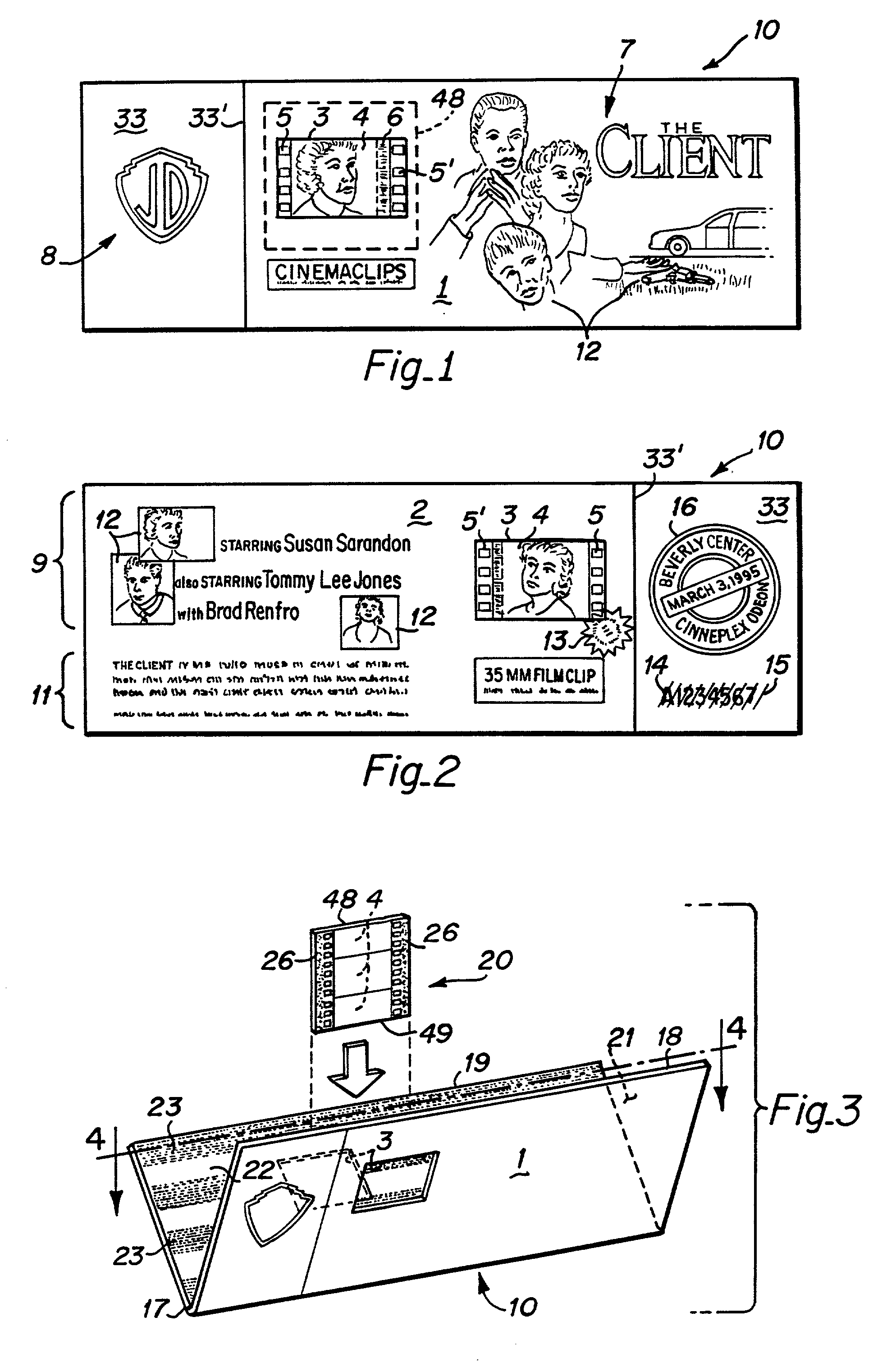

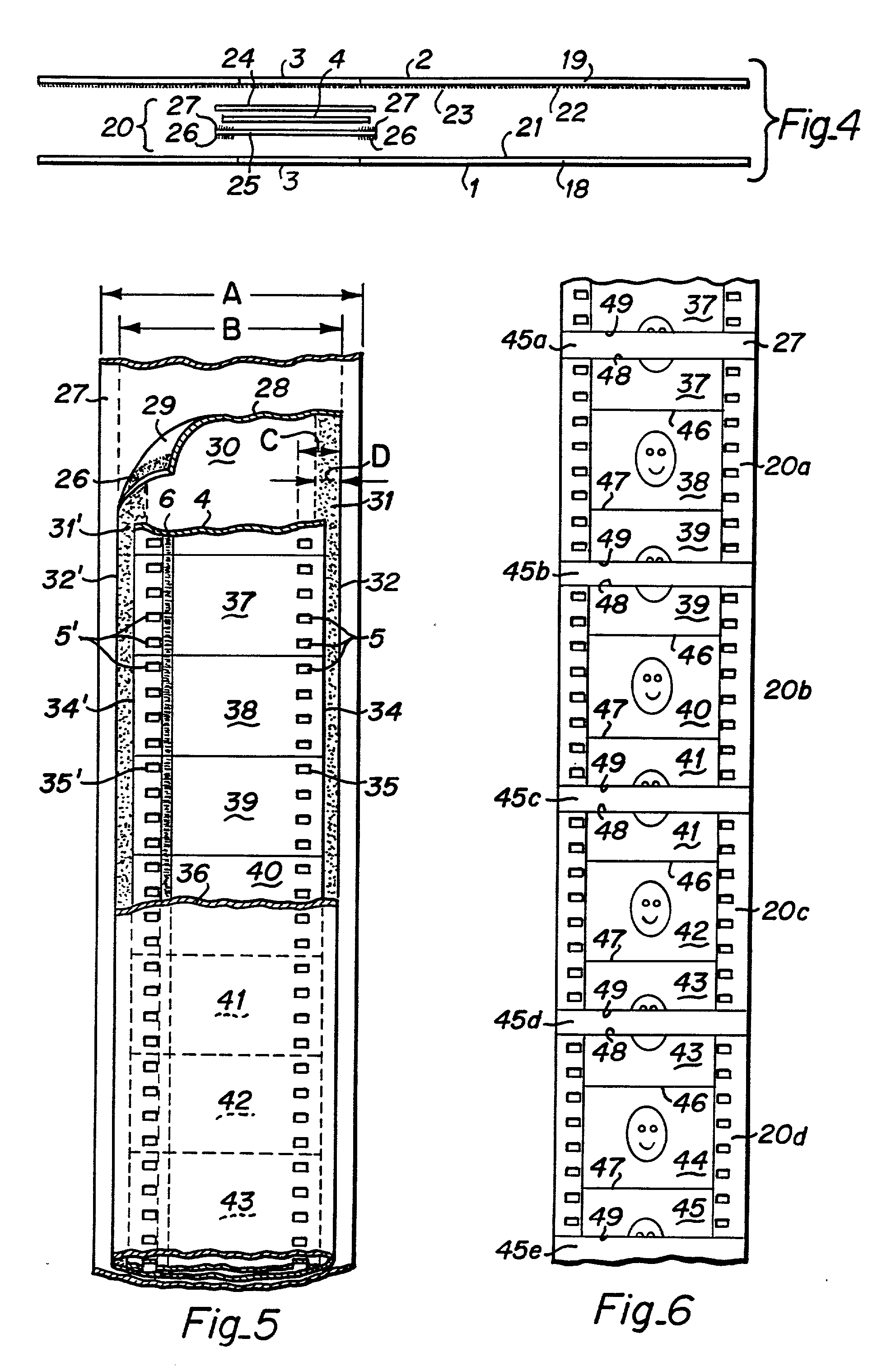

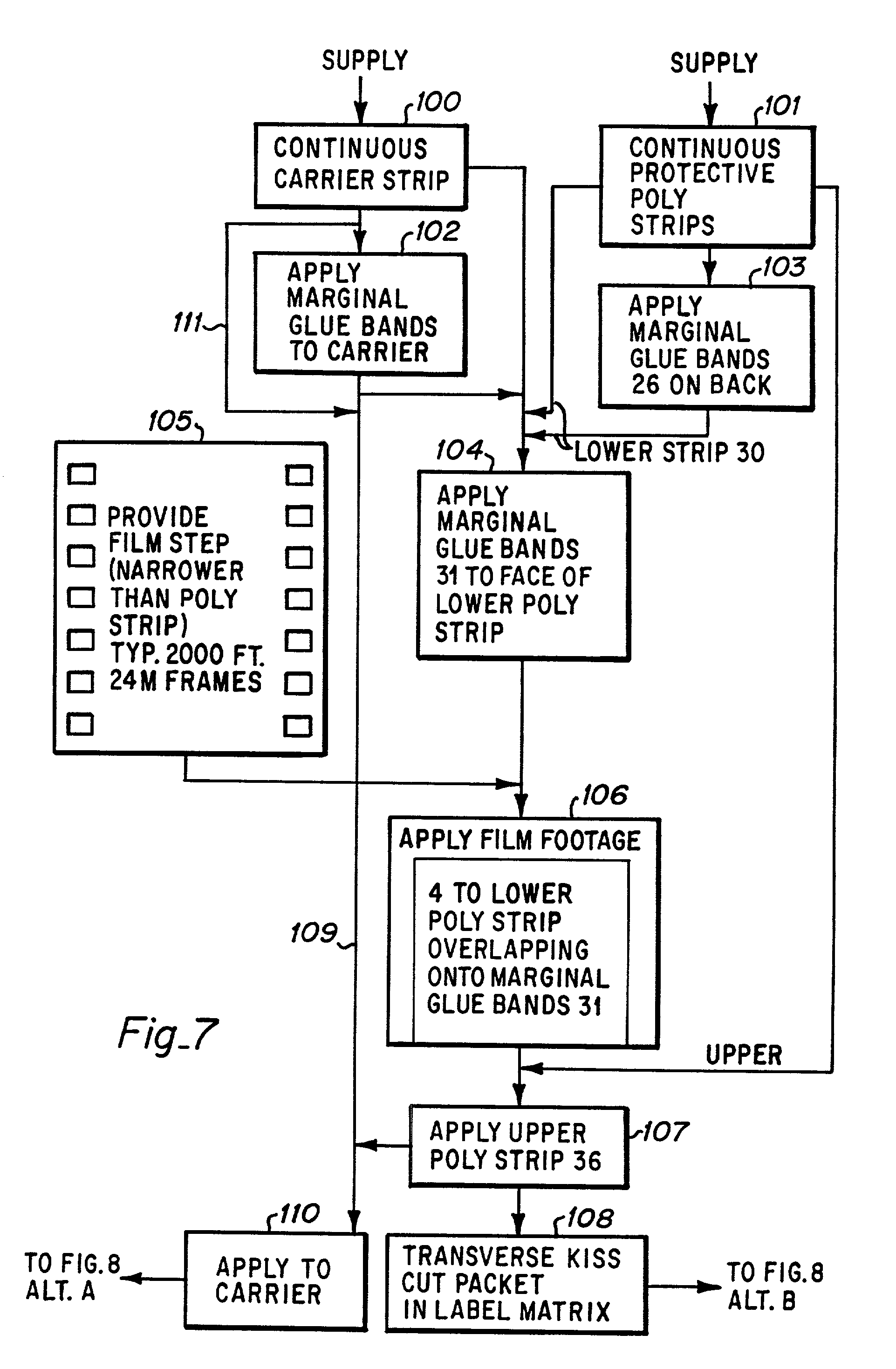

Collectible commemorative display ticket containing film clip

InactiveUS20010049897A1Quality improvementIncrease valueStampsPicture framesPolyesterPlastic materials

Collectible, rectangular ticket-type display device having a window in which is mounted a transparency type film frame or multi-frame clip for see-through type viewing. The display device preferably includes security and / or authentication indicia, and is fabricated from archival-quality materials. The ticket is formed from a single folded sheet of heavy paper or plastic material and scored along one edge for a fold to define a front and back panel. The film frame or clip is secured in an envelope or packet of non-bleed, non-yellowing transparent polyester plastic which is mounted to one inner face of the ticket panels. Preferably the ticket window is of sufficient size to exhibit the sprocket holes of the film frame or clip for authenticity. The transparency images may be of a motion picture or performance event such as a concert, sporting or historical event, and may be reproduced from a film positive or negative, or from video tape. Methods for manufacture of the collectible ticket and the archival envelope are disclosed. The collectible ticket may be retained for archival purposes or for display in an album having special plastic pages having a plurality of pocket-type sleeves for retainingly engaging the tickets. A transportable sleeve is also disclosed.

Owner:JACQUES M DULIN ESQ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com