Patents

Literature

47results about "Directly printed exposure masks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

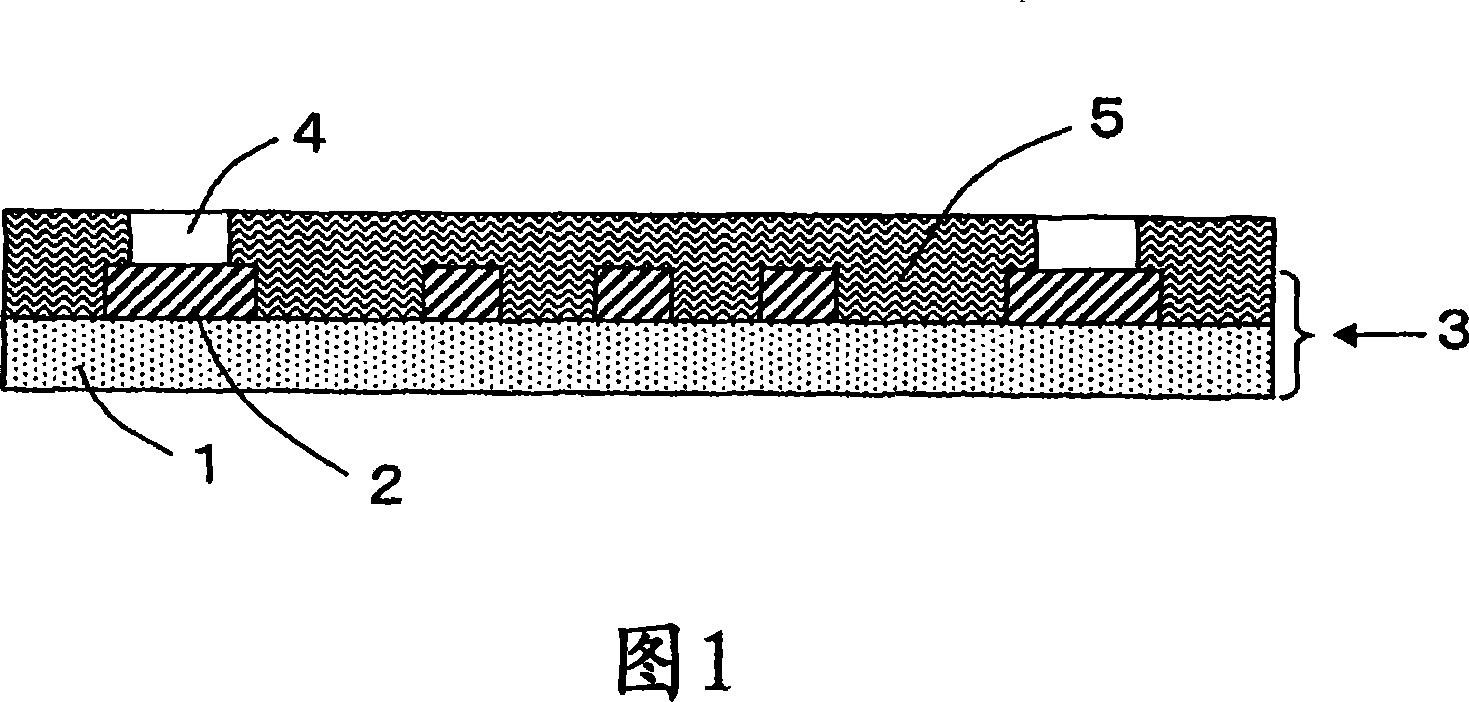

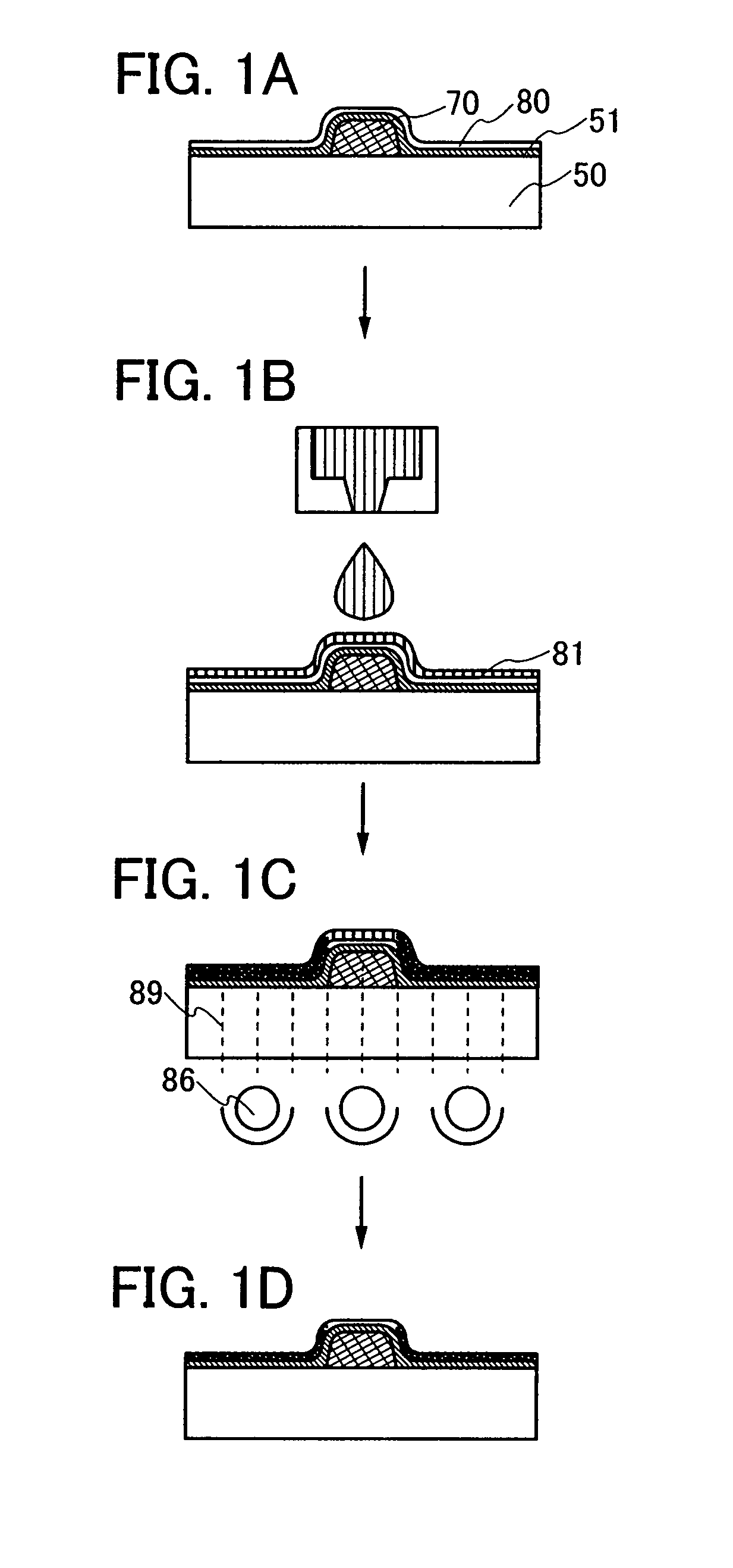

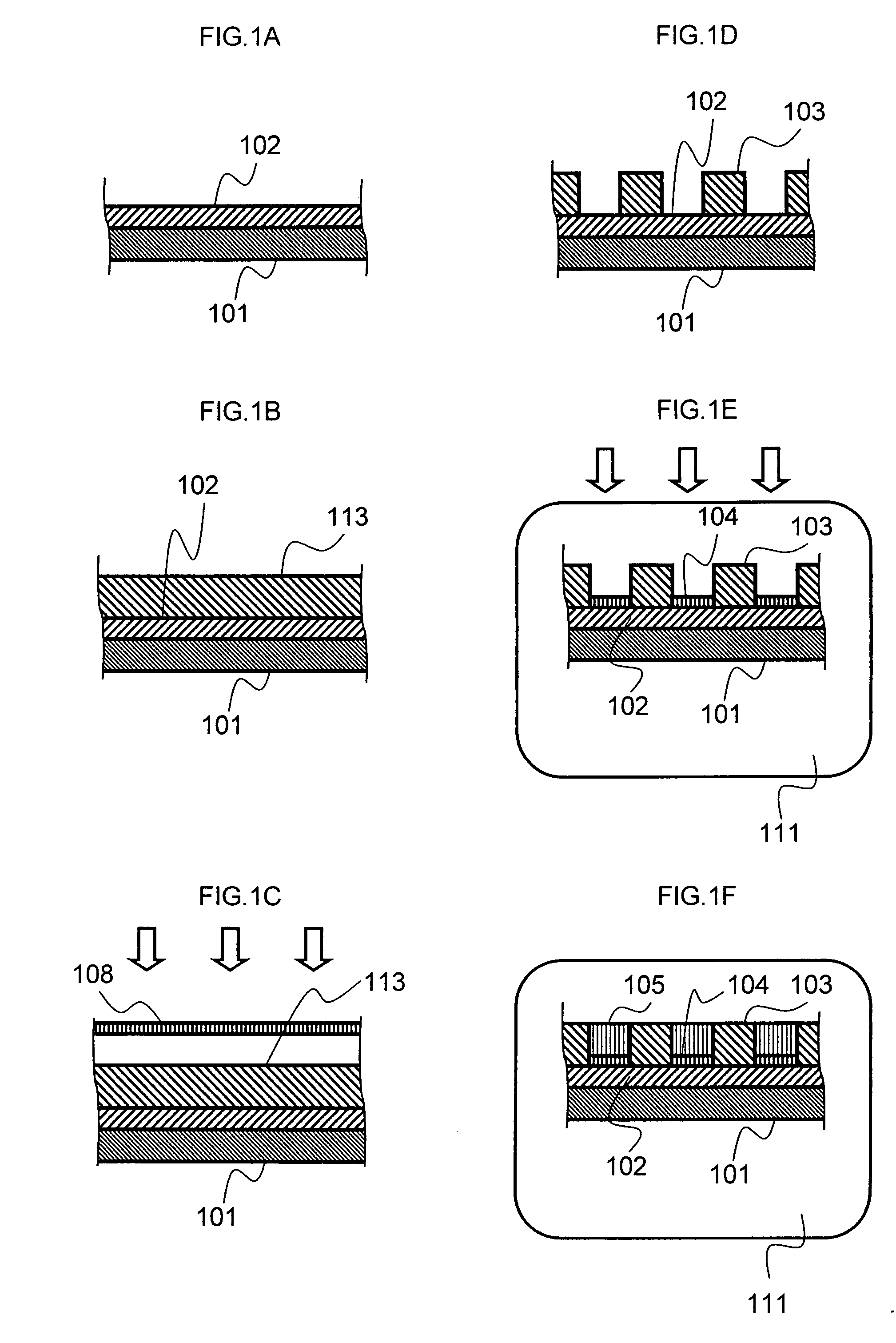

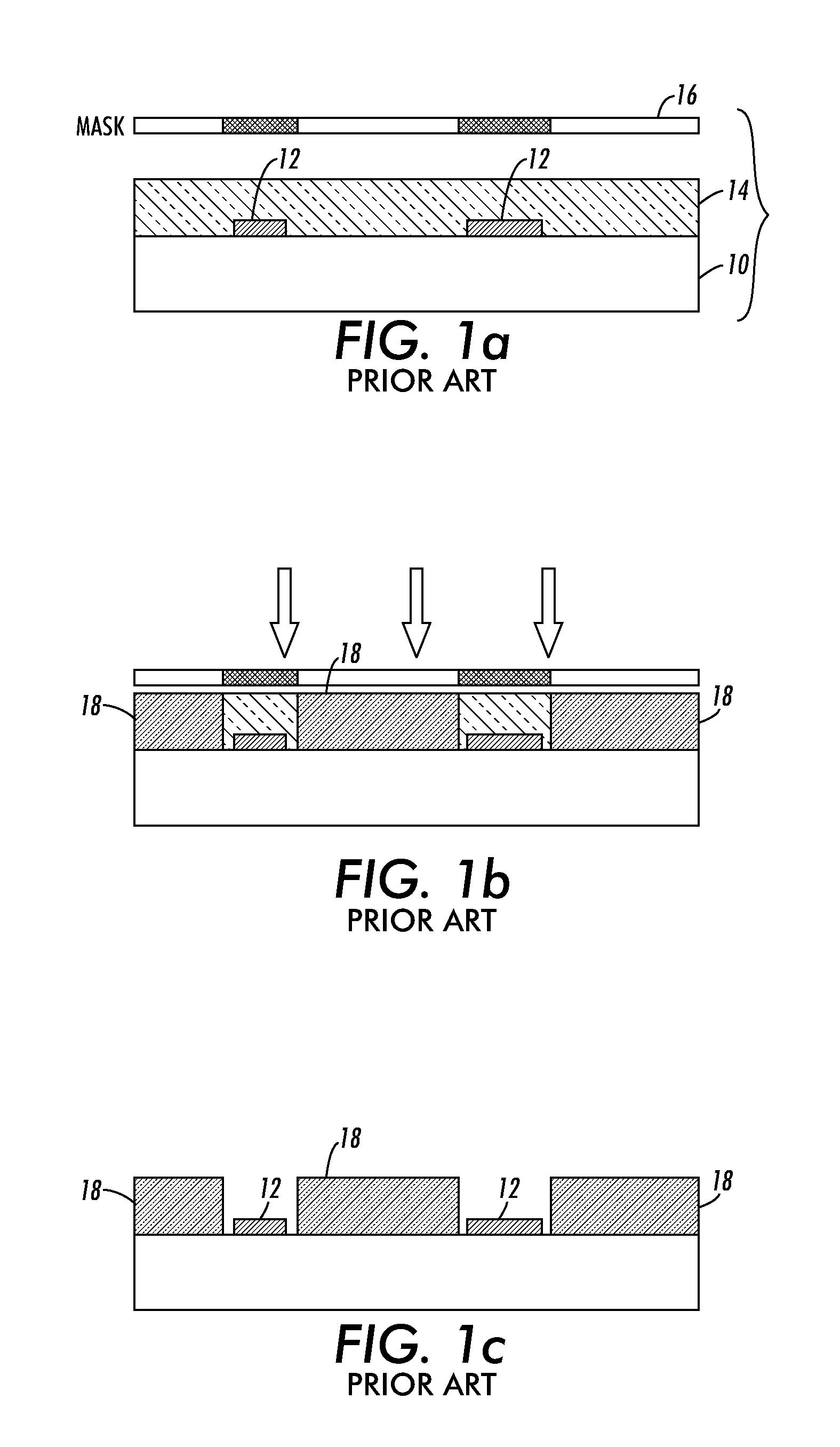

Lamination for Printed Photomask

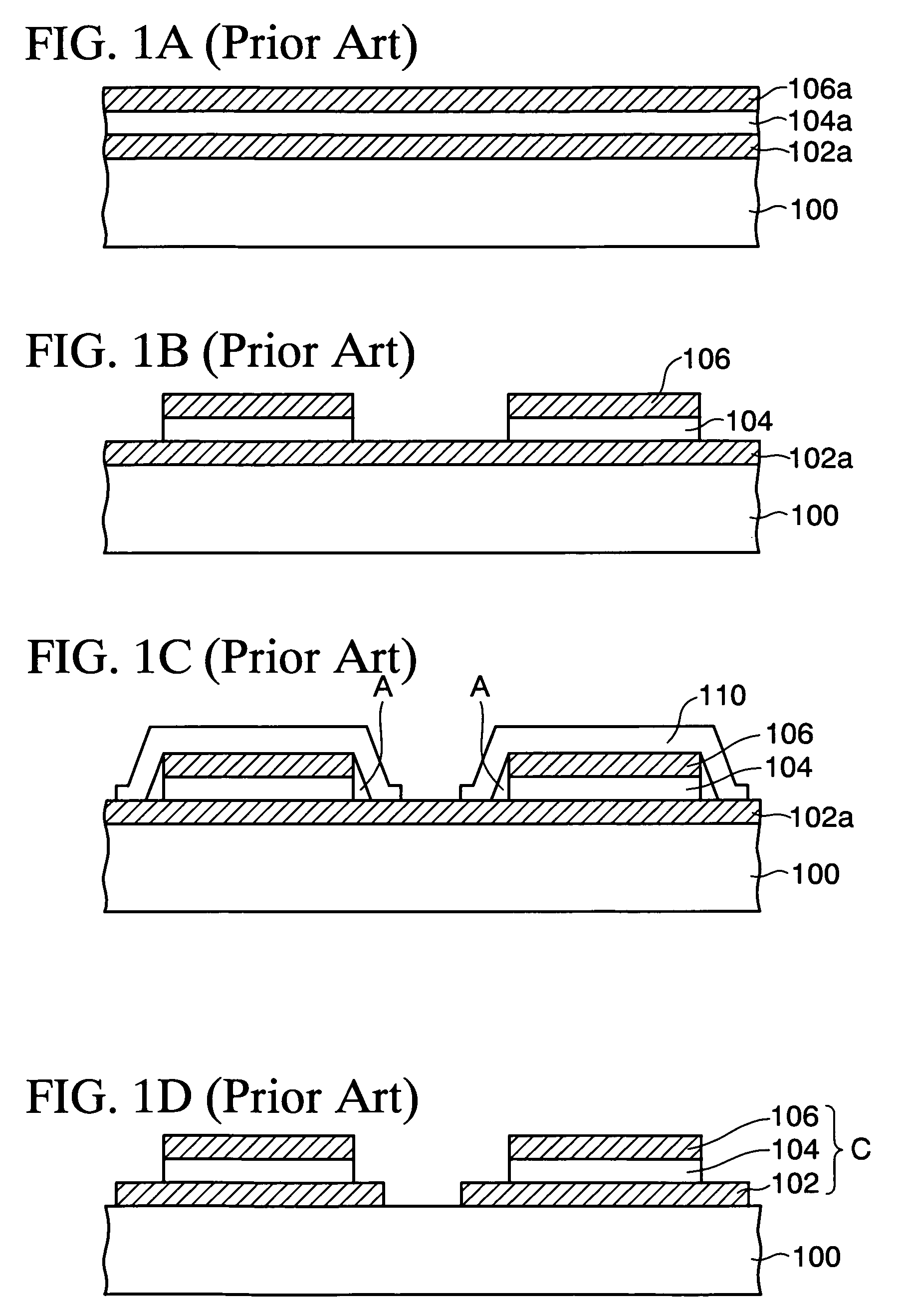

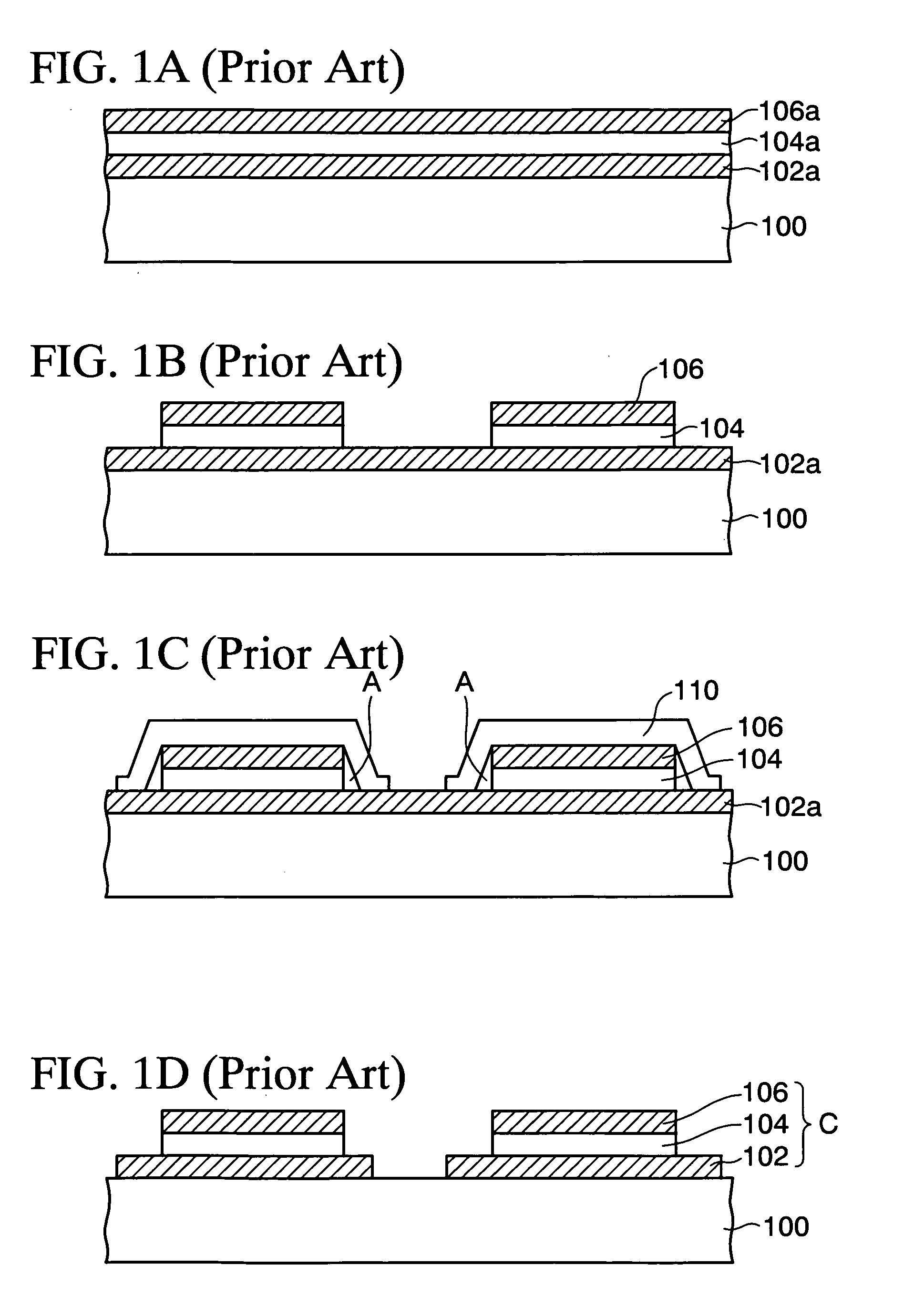

InactiveUS20090123873A1Increase costExtended production timePhotosensitive materialsPrinted circuit aspectsResistAdhesive

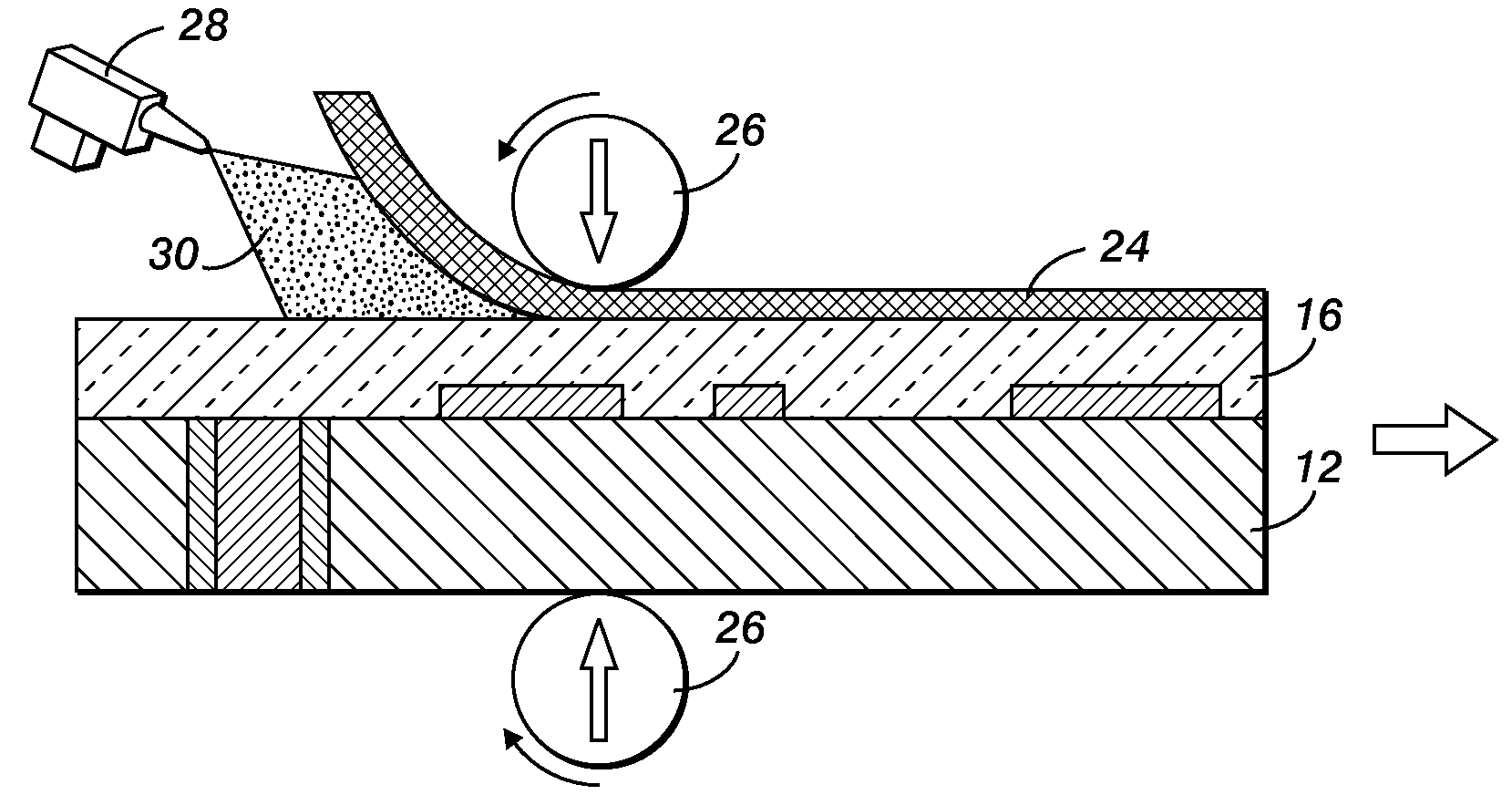

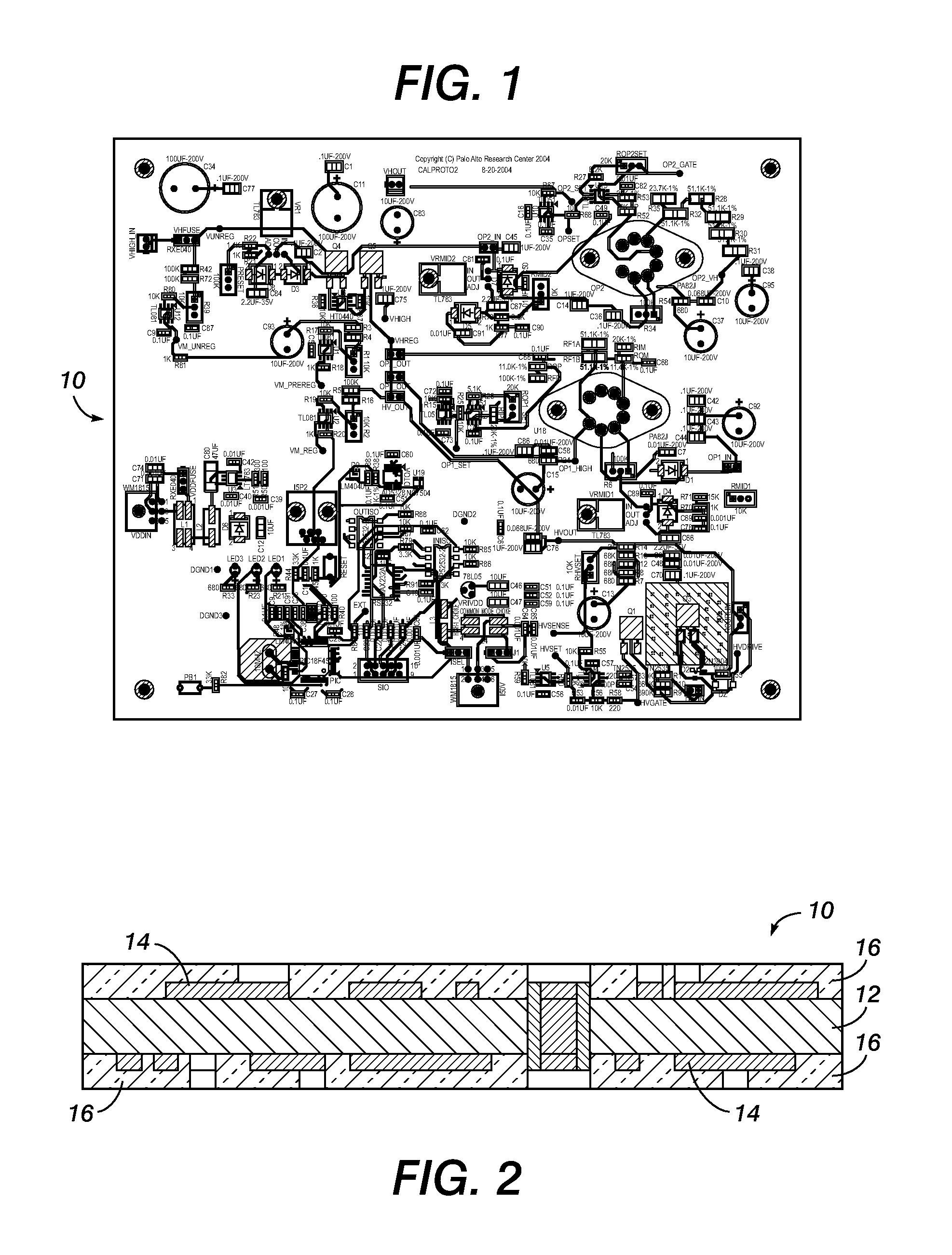

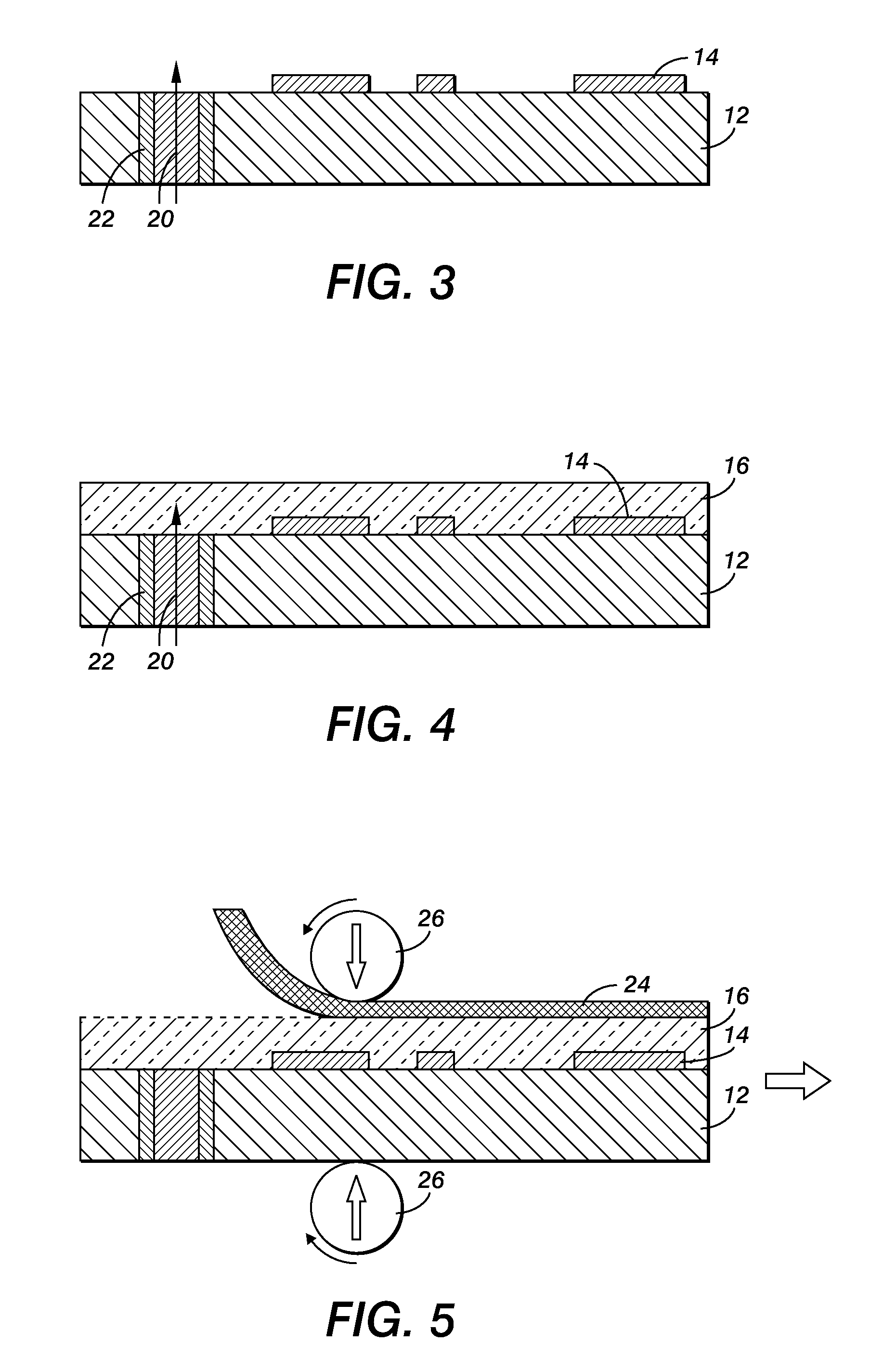

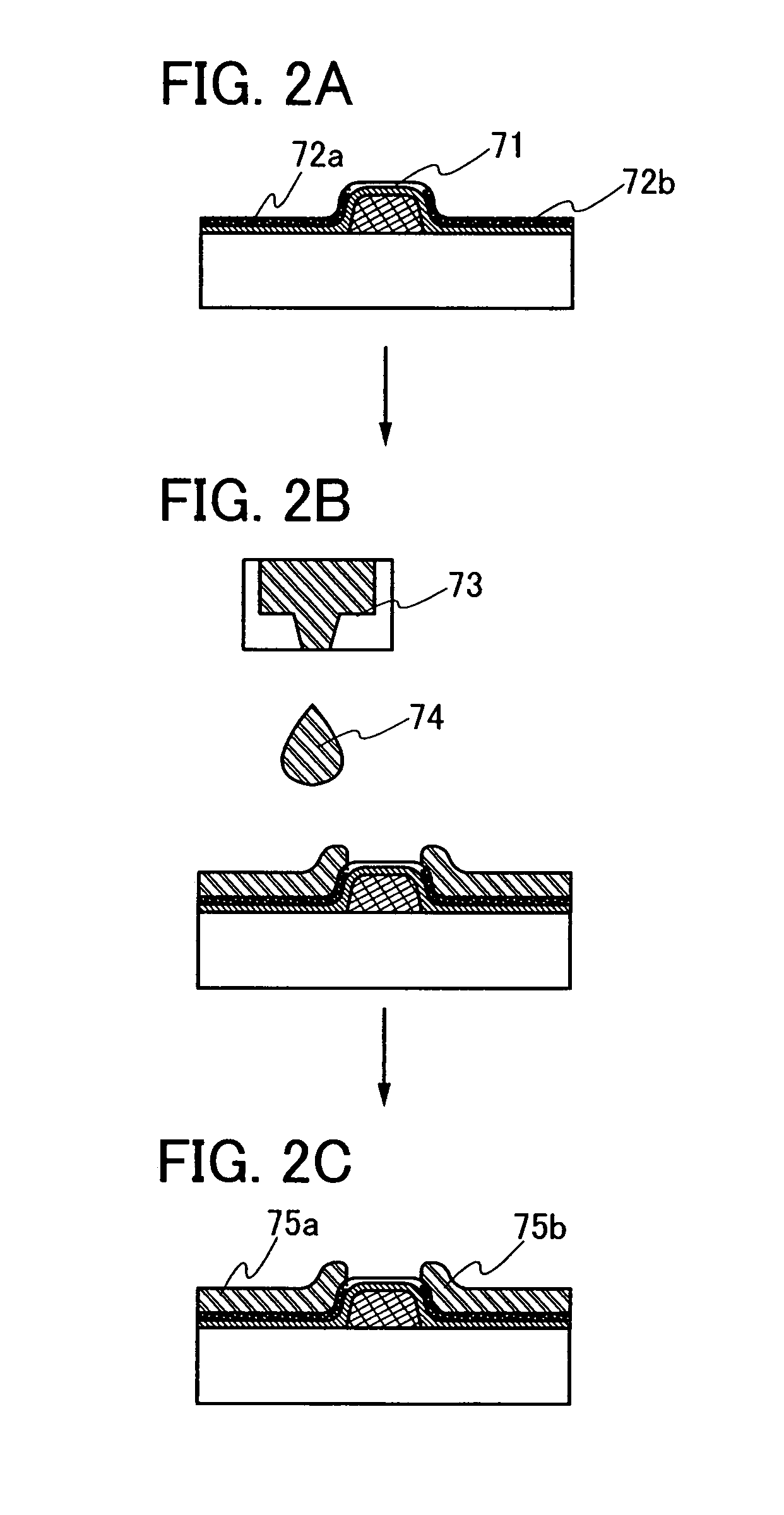

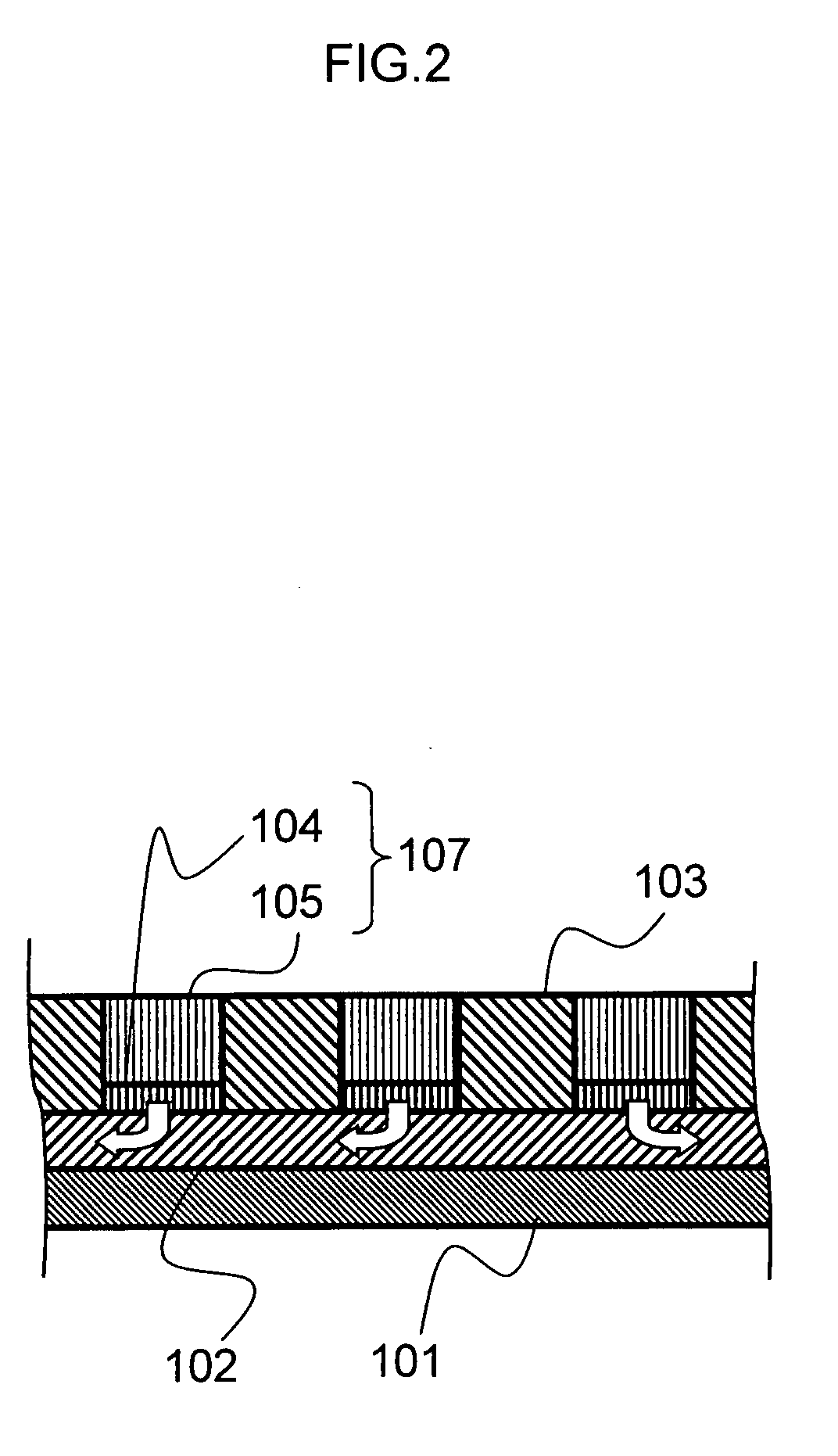

A method for masking regions of photoresist in the manufacture of a soldermask for printed circuit boards is disclosed. Following application of photoresist over patterned traces on a substrate, a sheet-like thin film is applied over the photosensitive material. The thin film may adhere to the photosensitive material by way of the adhesive state of the photosensitive material or by way of an adhesive applied to the photosensitive material or the thin film or carried by the thin film. Digital mask printing may proceed on the surface of the thin film. The photosensitive material may then be exposed through the printed photomask, the thin film (with photomask) removed, and the photosensitive material developed.

Owner:PALO ALTO RES CERNTER

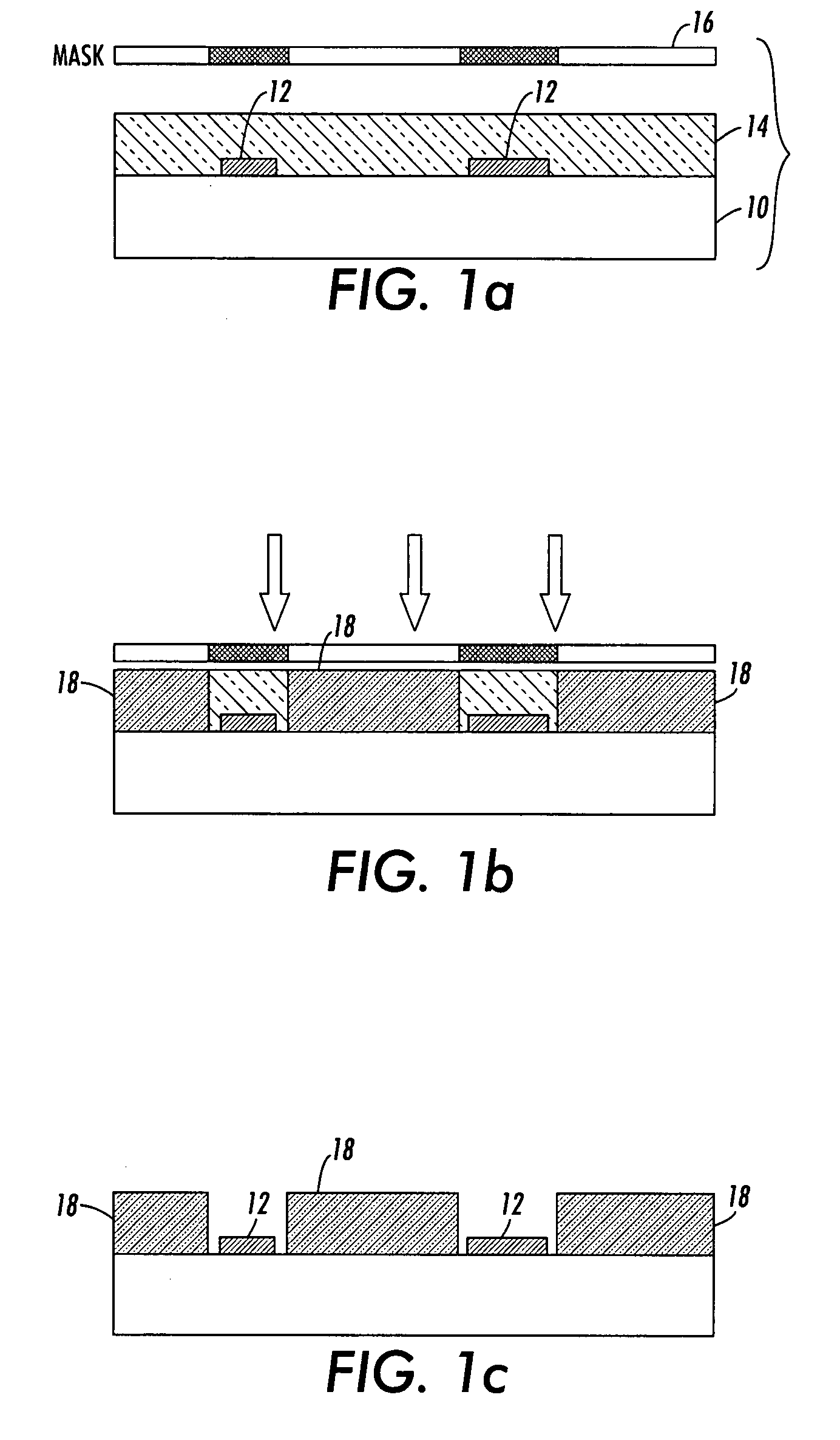

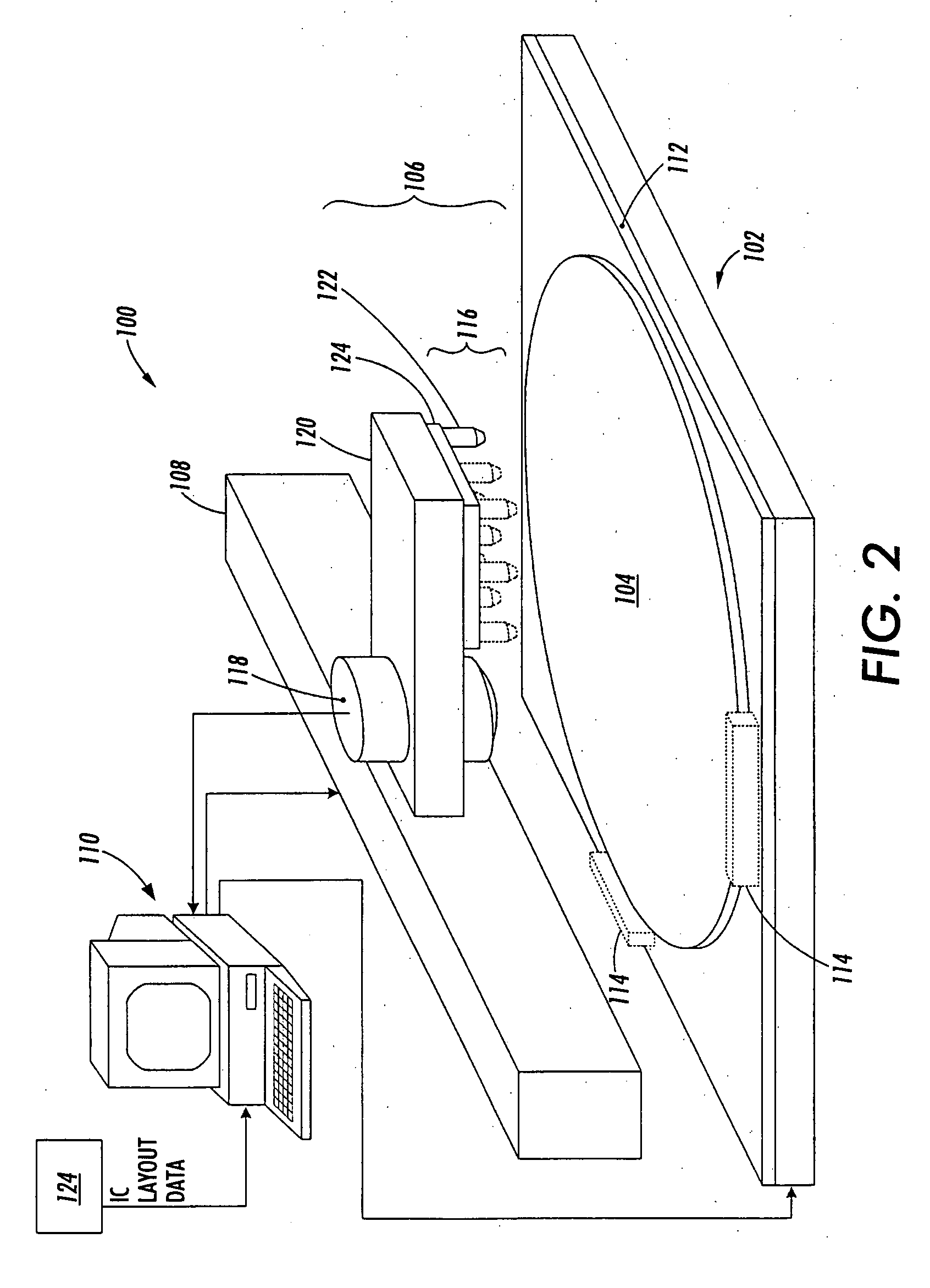

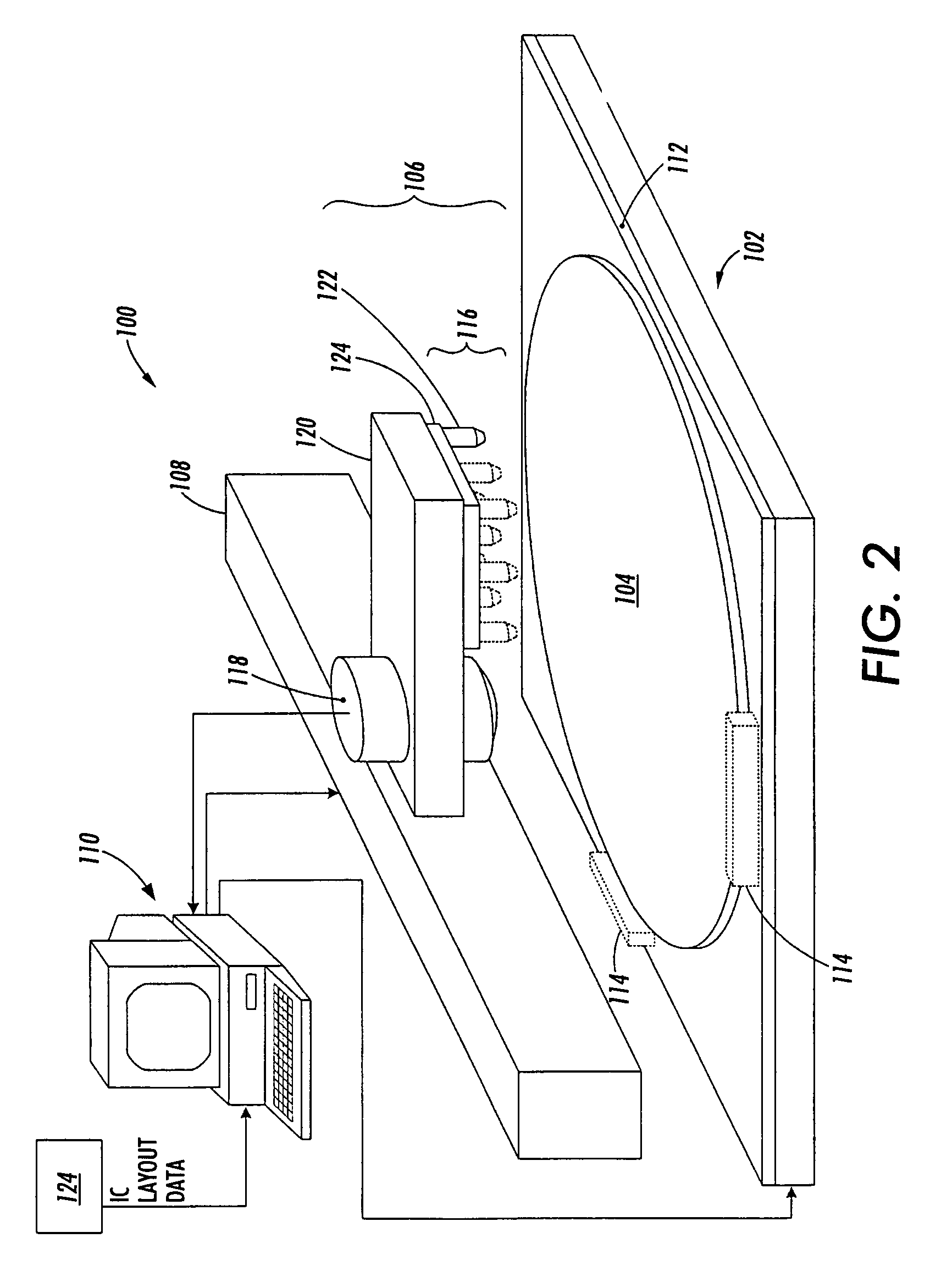

Method and system for patterning a mask layer

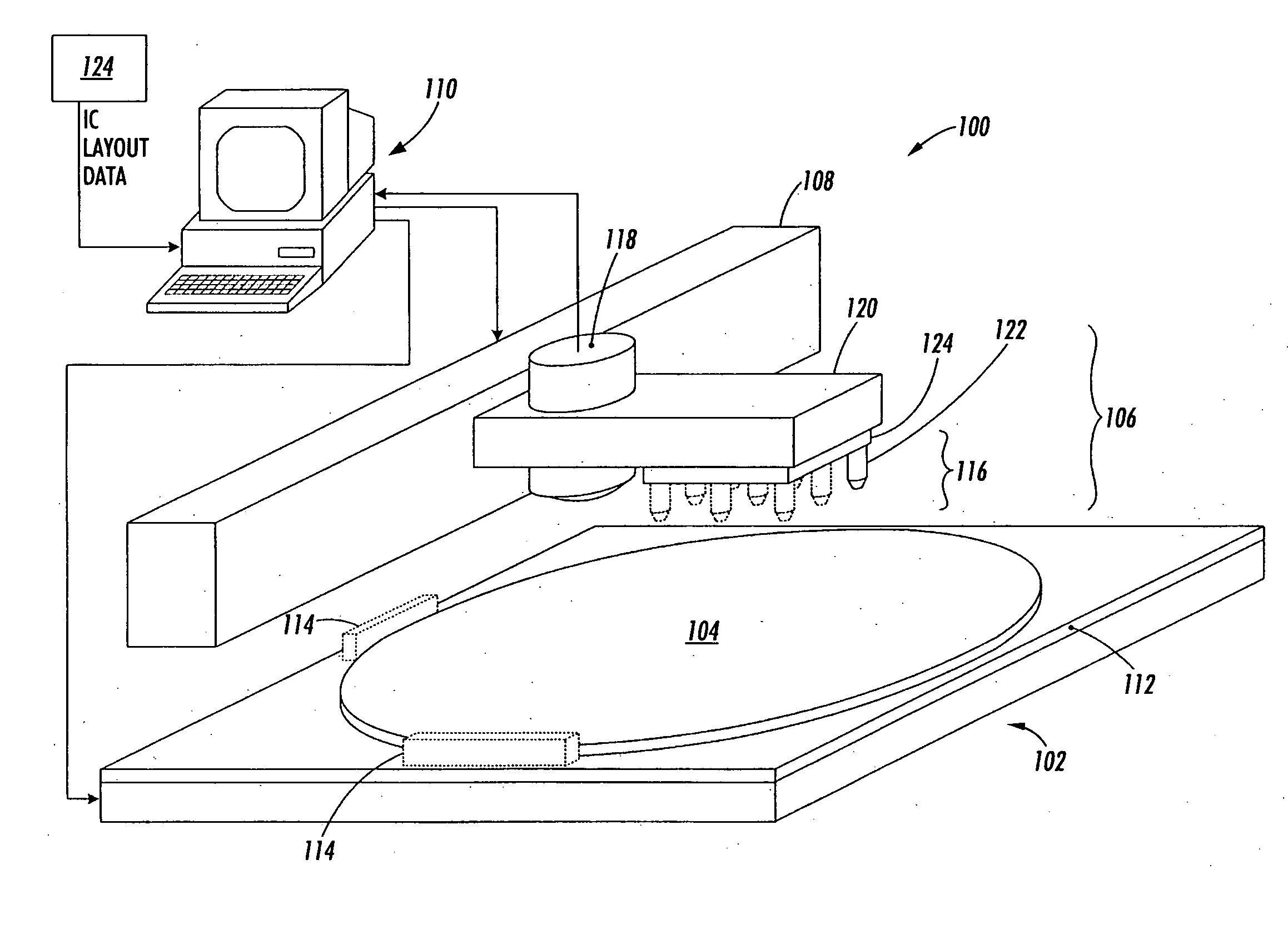

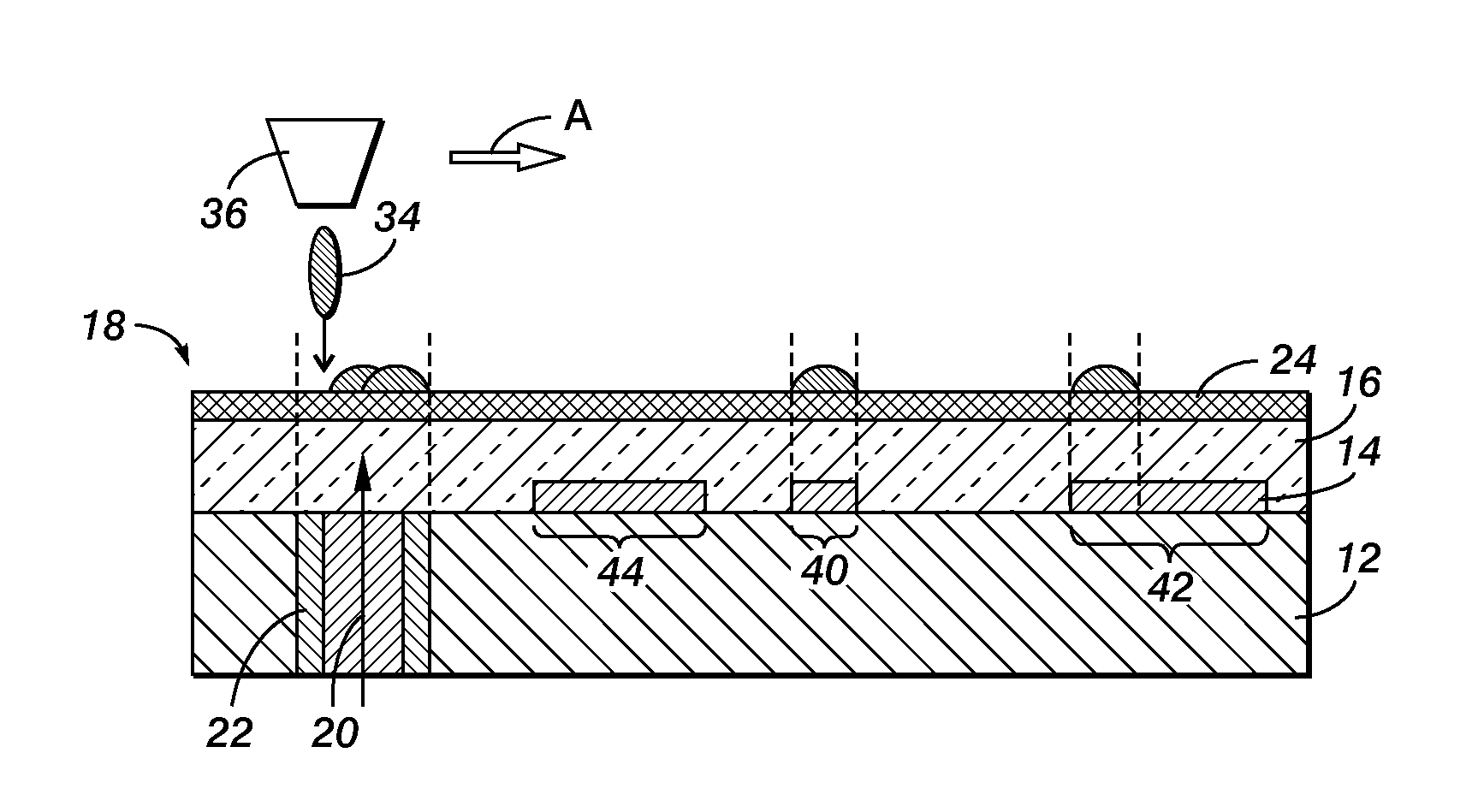

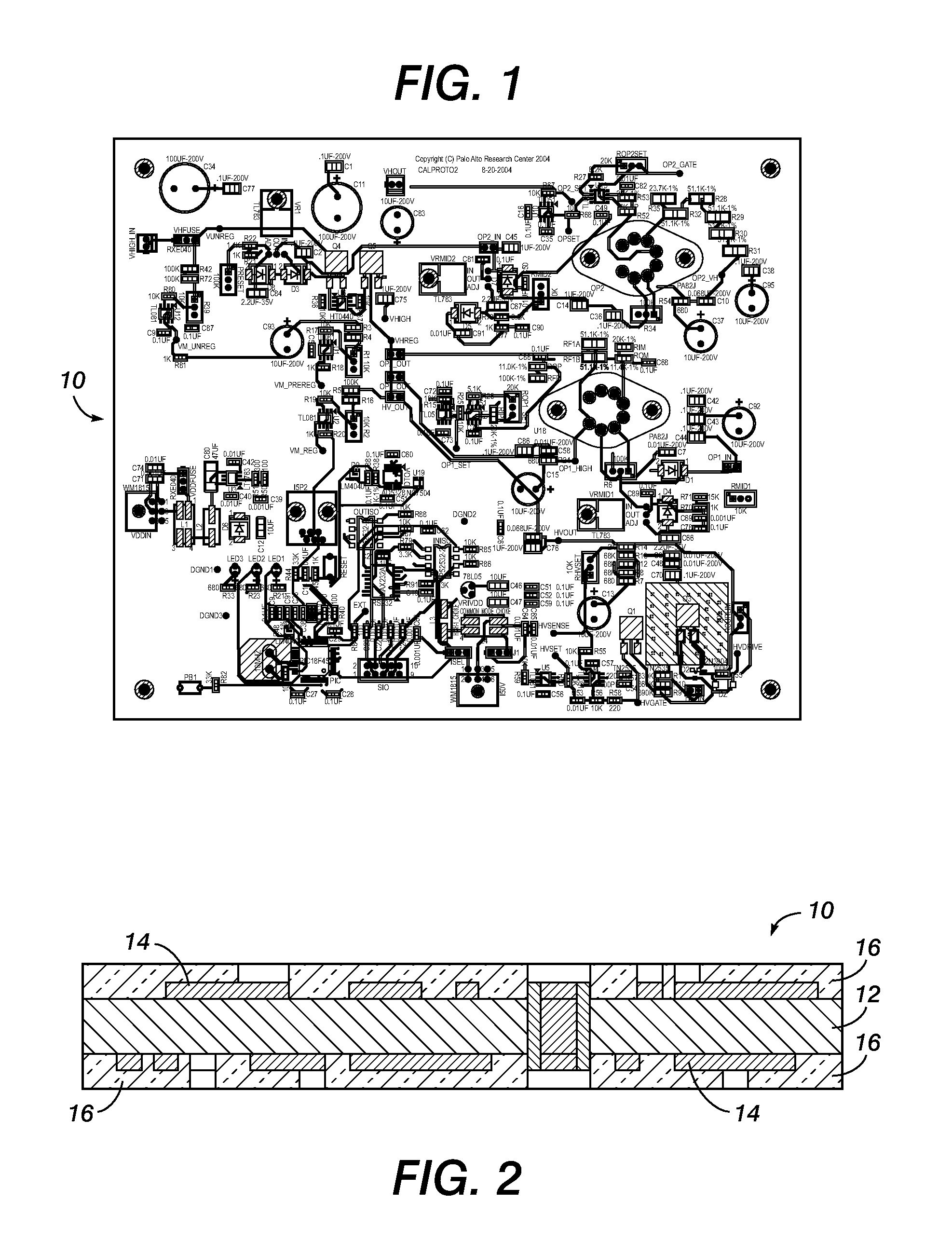

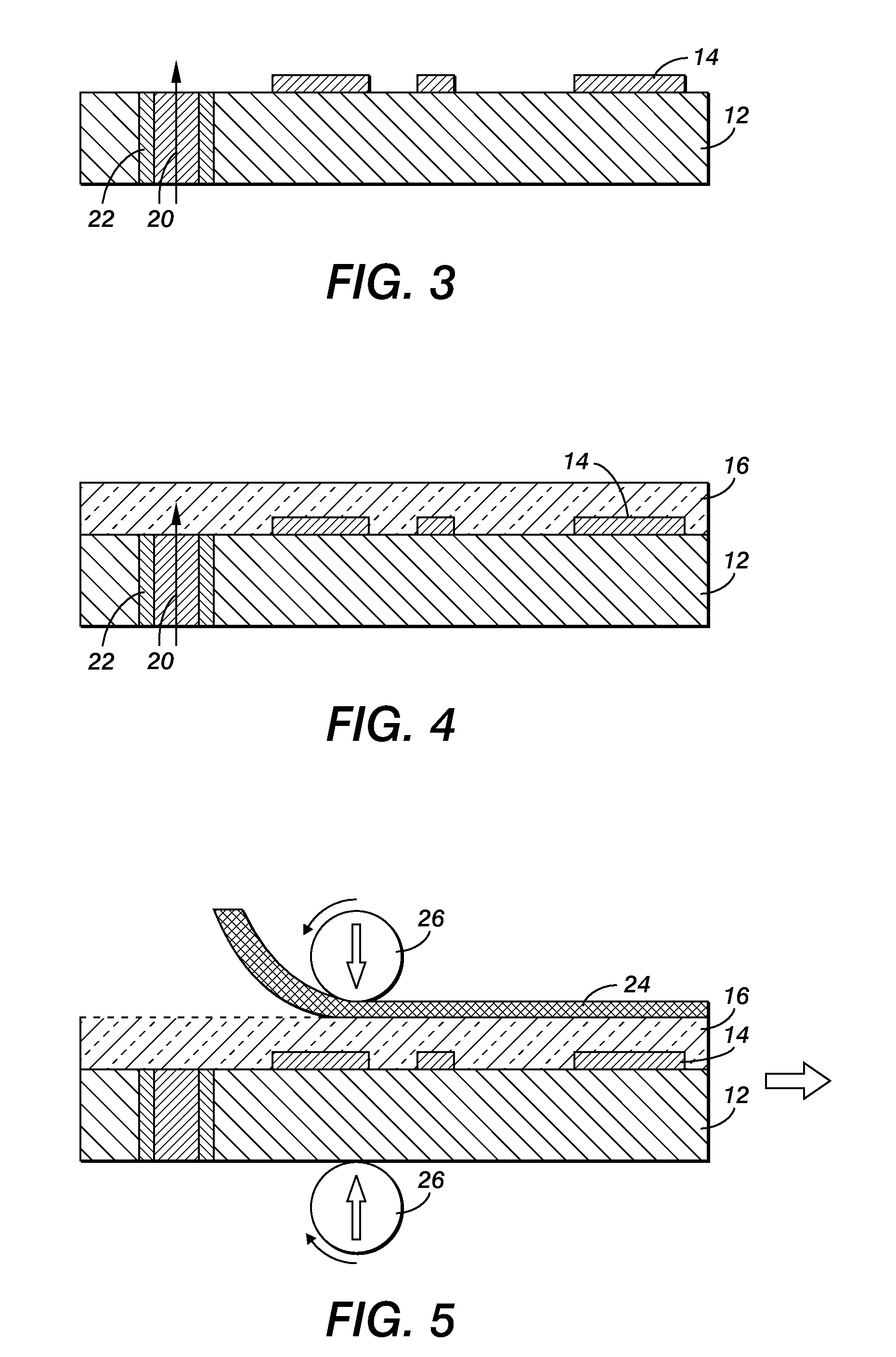

The presently described embodiments use a printing process, e.g. a wax printing technique, to pattern a mask layer (such as a soldermask layer) of, for example, a printed circuit. Substantially all other conventional processes in developing soldermask and exposure processes can be maintained. According to the presently described embodiments, each printed circuit will have a unique pattern that matches uniform and non-uniform runout. In one form, the pattern is comprised of wax single drops having a specified gap to make the process transparent to the current industry practice. Furthermore, the single drops can be used for both large and small areas without any development time differences. In at least one form, the wax pattern and the soldermask in the gap are removed during development.

Owner:XEROX CORP

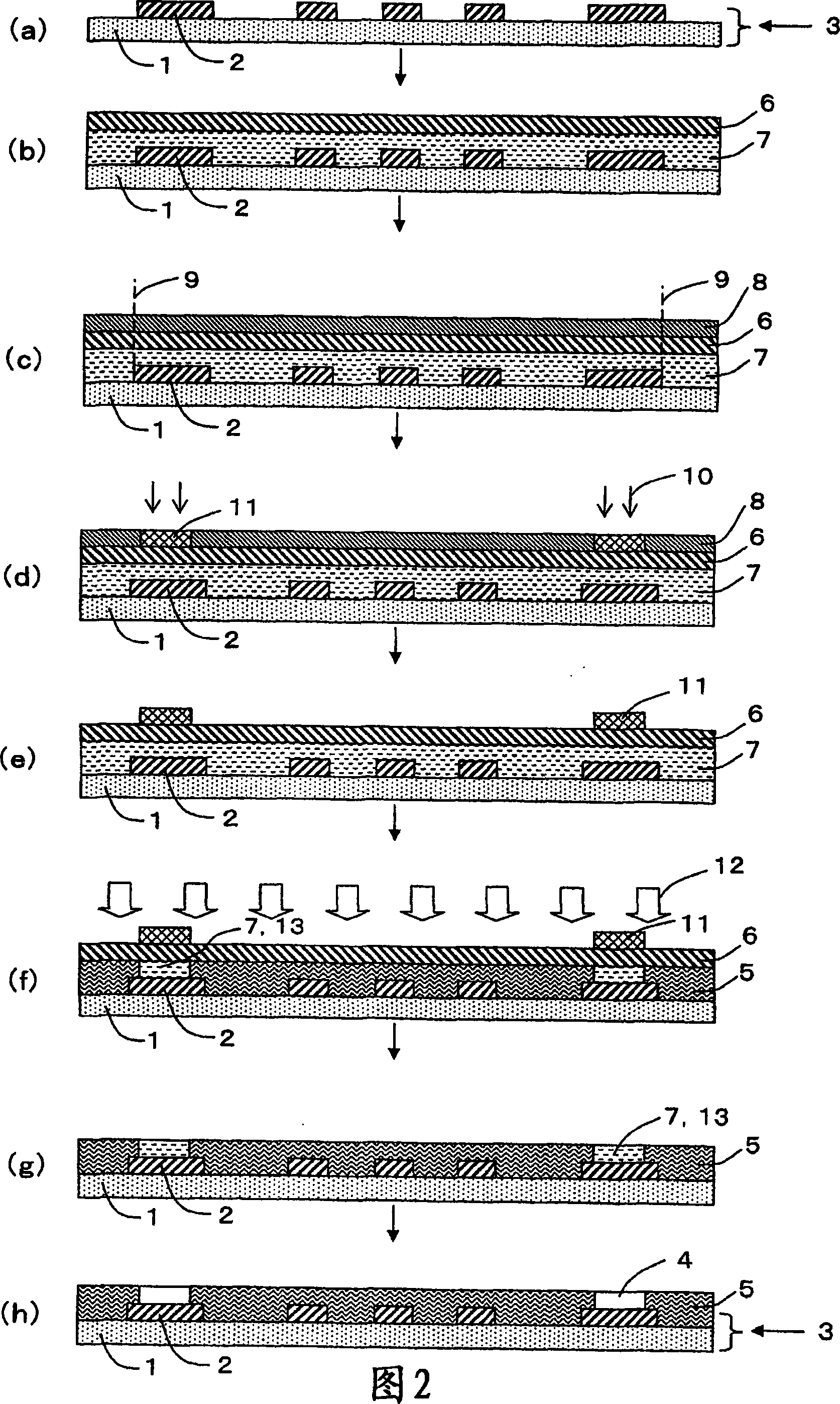

Forming method for protecting image

ActiveCN101126893ANo position deviationNo protection position deviationSemiconductor/solid-state device manufacturingDouble resist layersResistSemiconductor chip

Production of a resist pattern involves applying first then second photohardenable resist films (F1, F2), sensitive to light in first and second wavelength regions (WL1, WL2) respectively, to a semiconductor chip or a circuit board, where film F2 blocks light of WLR1. Laser light in WL2 is applied through a screen onto part of F2 followed by applying a developer solution, to form a mask pattern. F1 is illuminated with light in WL1 through a membrane mask, and finally F1 is developed.

Owner:SANEI KAGAKU KK

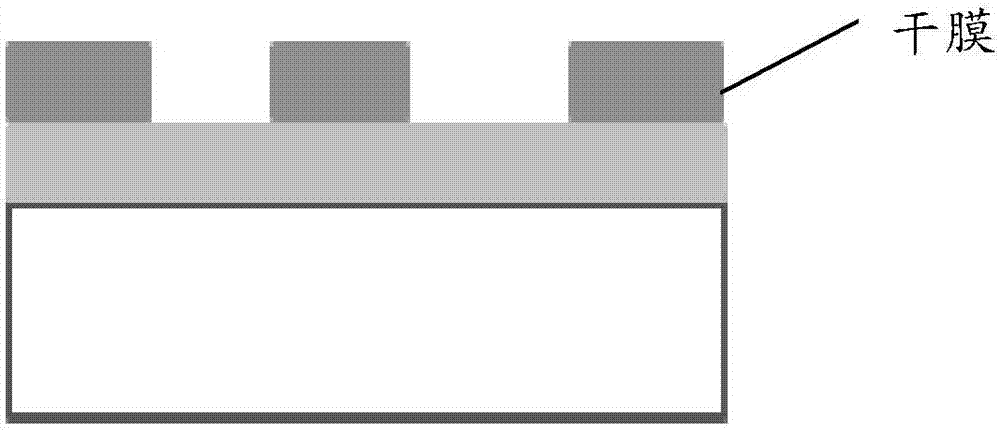

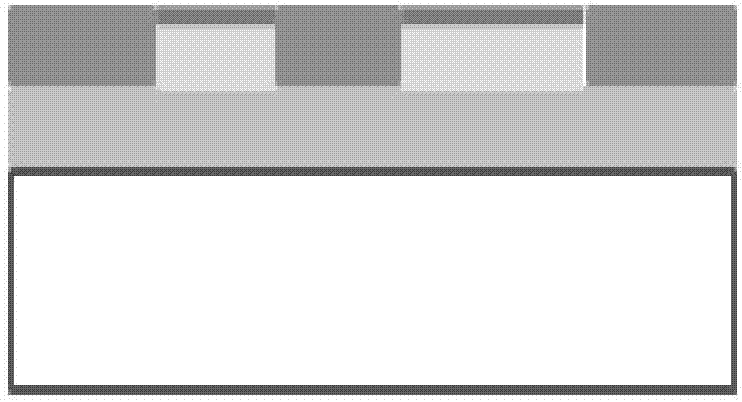

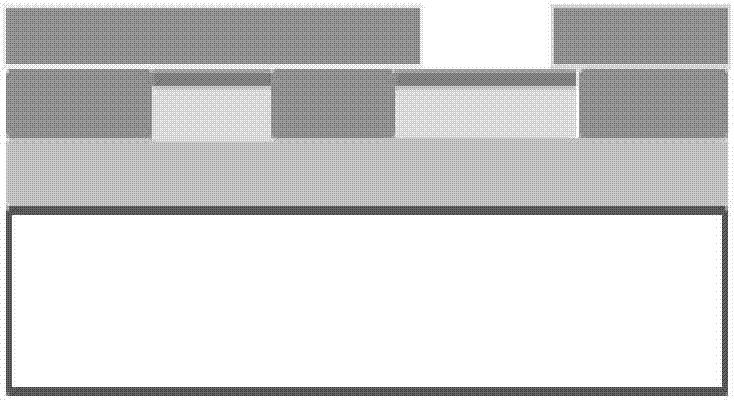

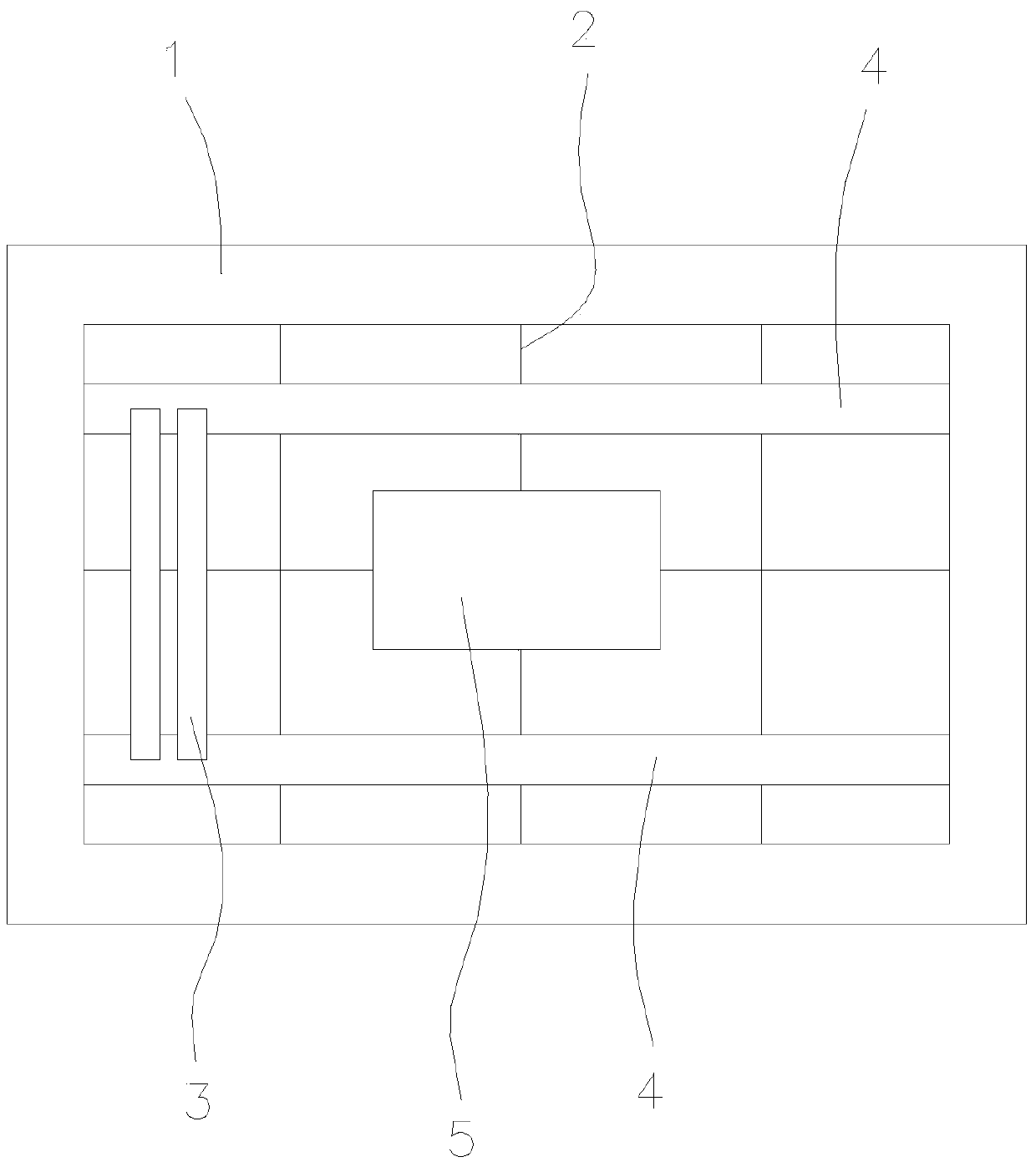

Preparation method and equipment of copper-thickening printed circuit board

InactiveCN107493658AAvoid bad phenomenon of tin platingImprovement of tin plating defectsConductive material chemical/electrolytical removalDirectly printed exposure masksCopper platingEtching

The invention discloses a preparation method and equipment of a copper-thickening printed circuit board. After external light imaging is performed for the first time, selective copper thickening treatment is performed firstly, so that the problems in the prior art as follows can be avoided: the lower side wall of a dry film in a winding region in secondary external light imaging suffers from medicinal liquid attack and corrosion to be hollowed out to hide medicinal water, and a poor tin plating phenomenon is caused in the secondary copper plating and tin plating due to the hidden medicinal liquid; by adoption of the preparation method, the selective copper thickening flow is performed on the dry film firstly to satisfy the partial copper thickness requirement; and the subsequent production is performed based on the normal board flow, so that the poor tin plating phenomenon caused by the previous two times of copper plating and tin plating and an open-circuit phenomenon in the subsequent etching can be relieved.

Owner:珠海杰赛科技有限公司 +1

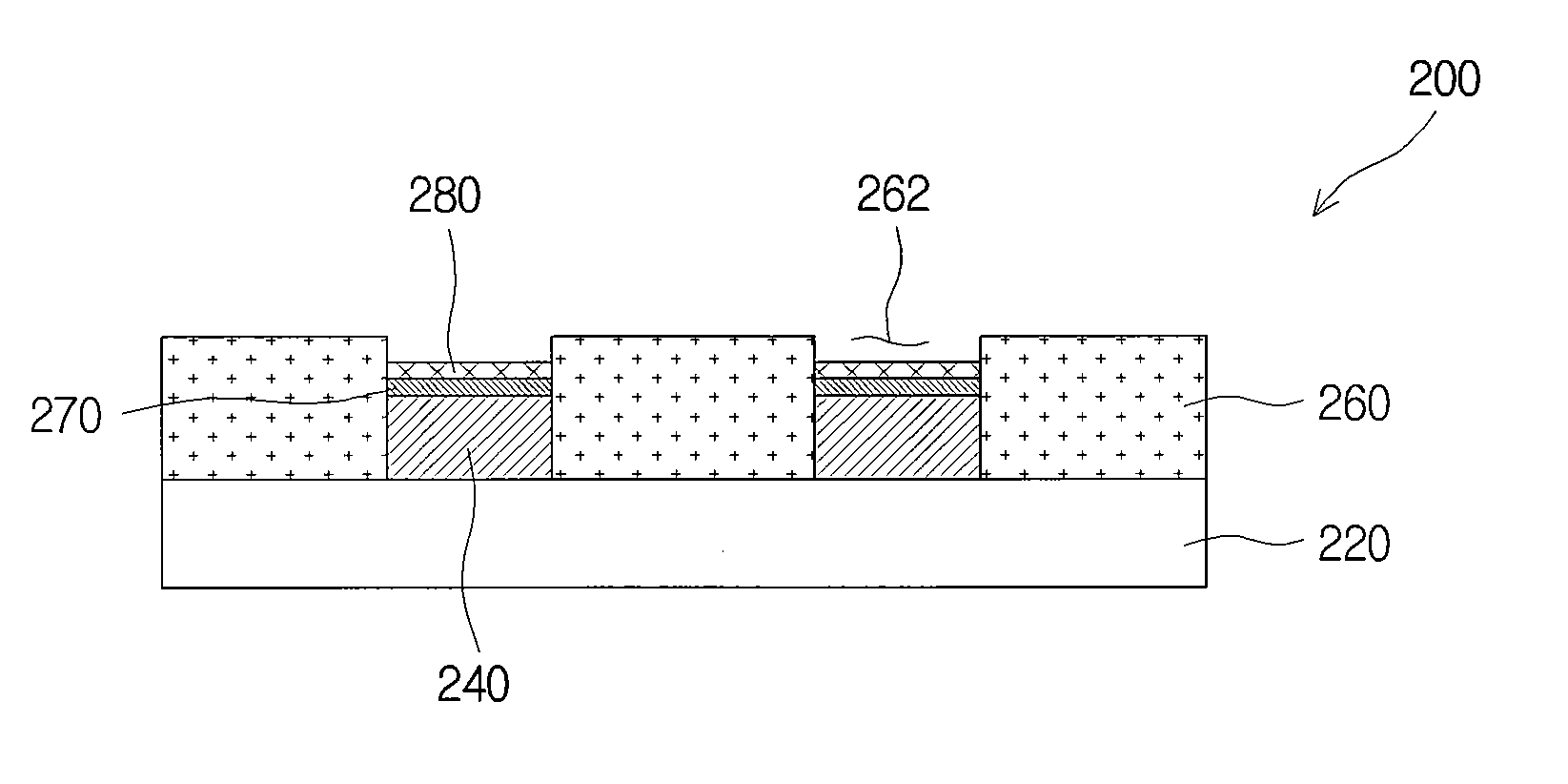

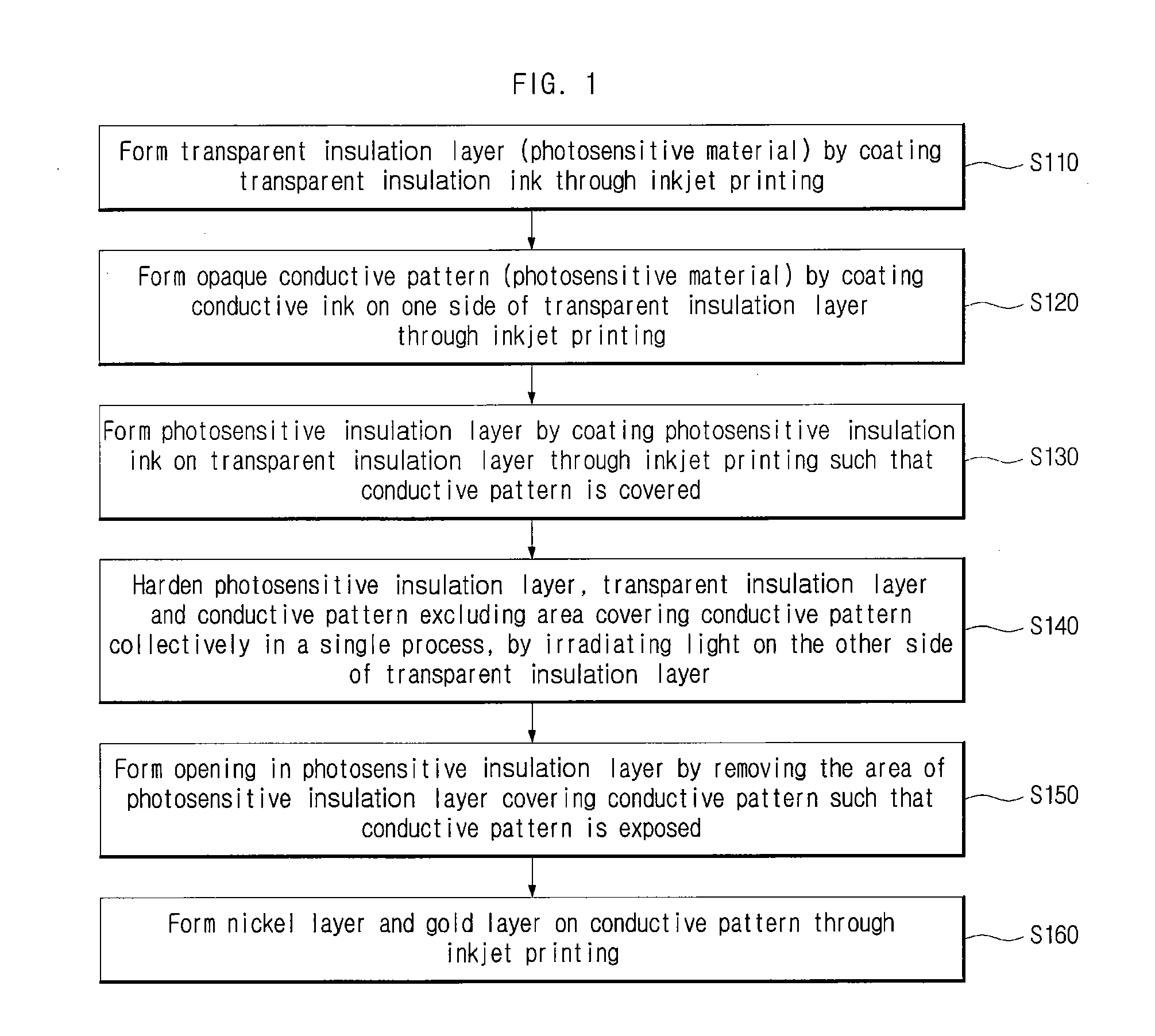

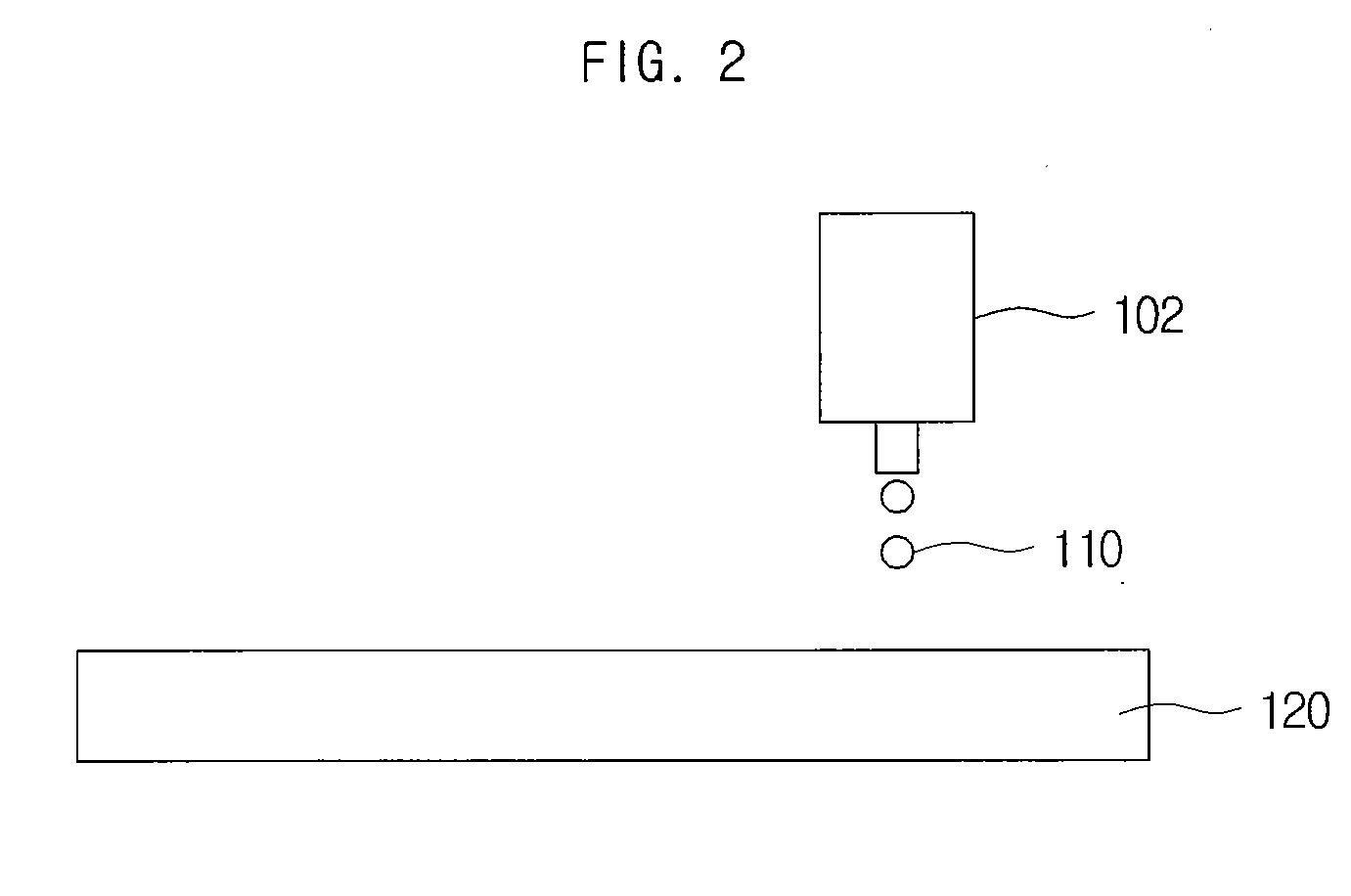

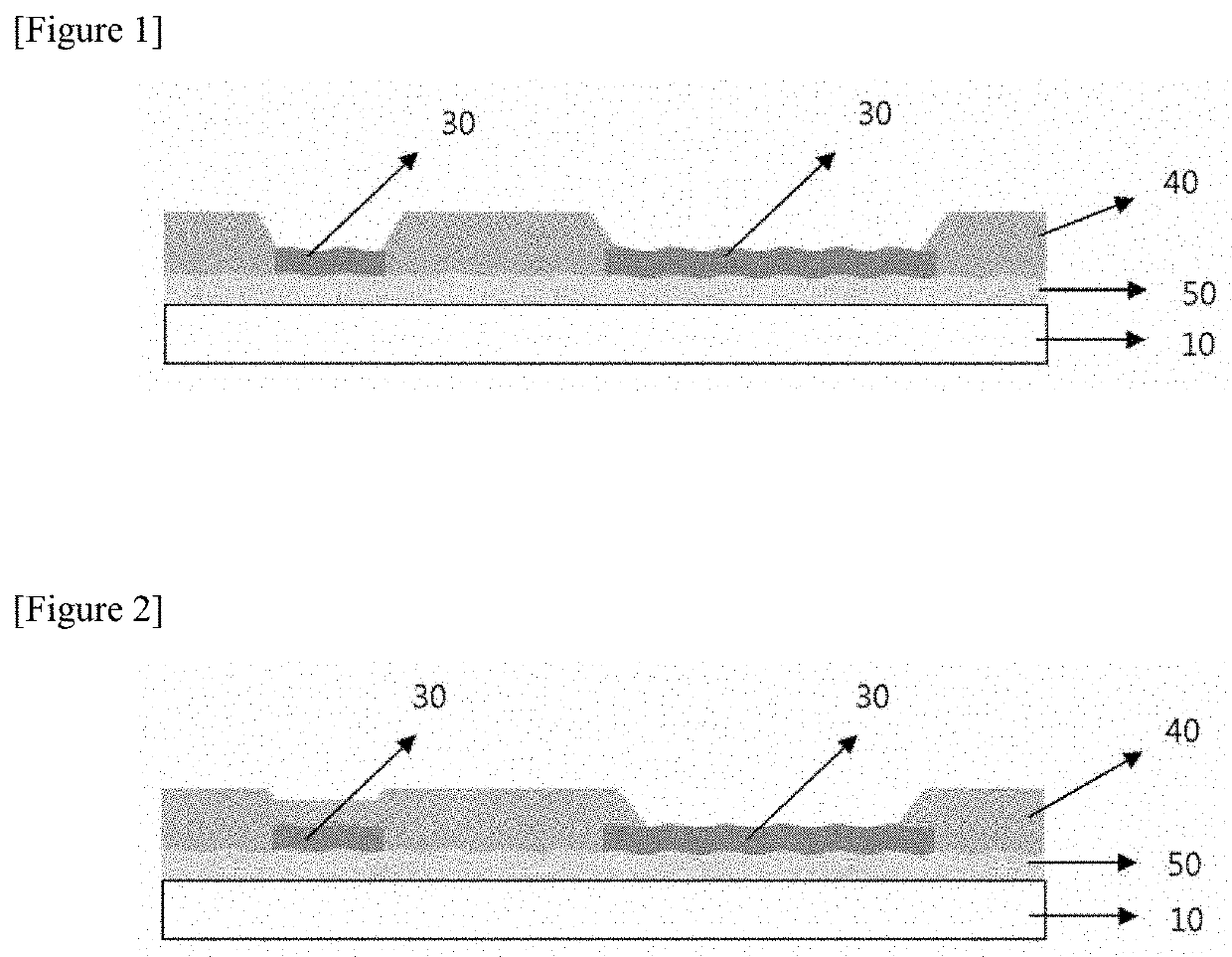

Printed circuit board and method of manufacturing the same

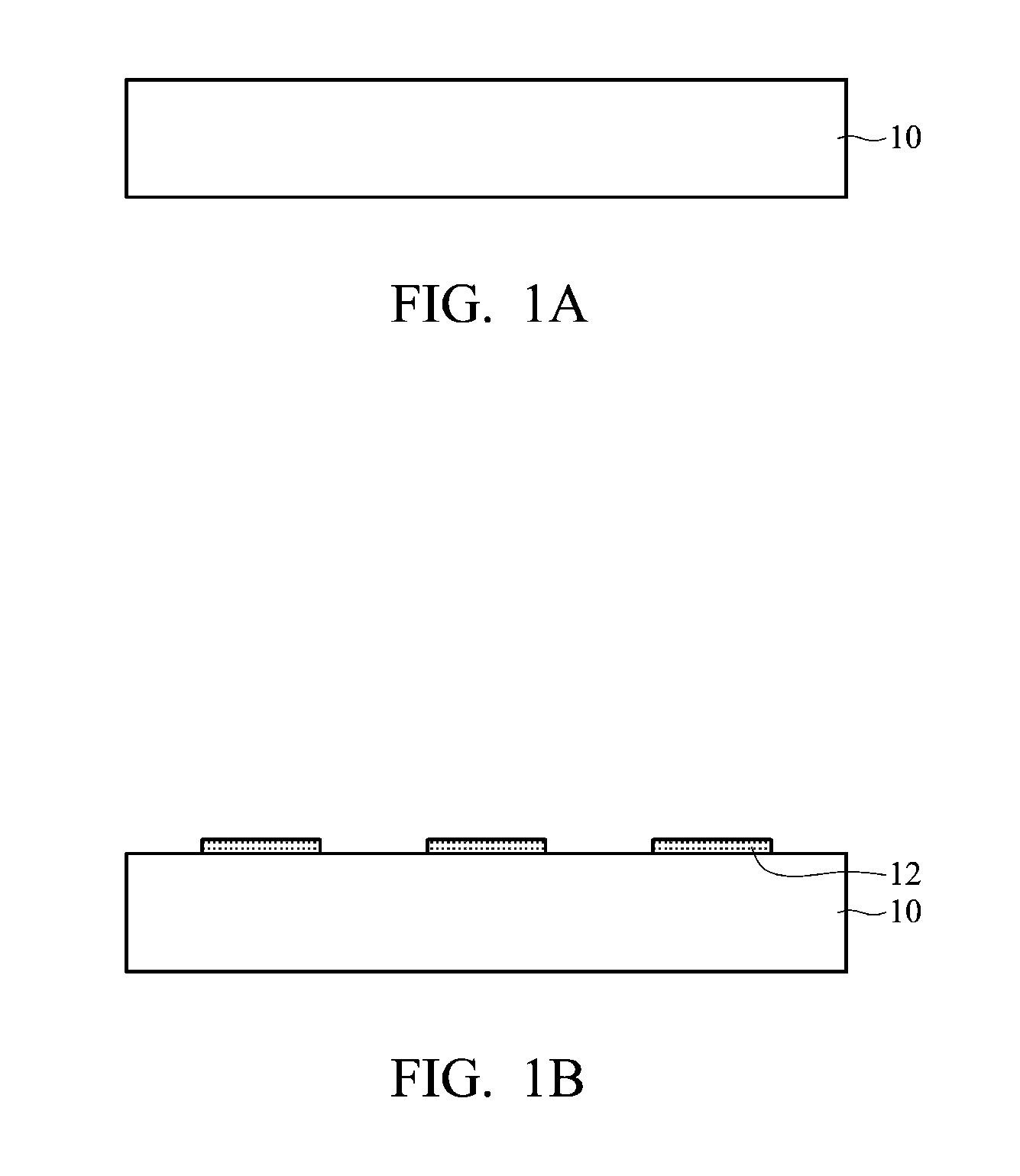

InactiveUS20100055605A1Shorten production timeReduce manufacturing costPhotosensitive materialsSemiconductor/solid-state device manufacturingInsulation layerEngineering

A printed circuit board and a method of manufacturing the printed circuit board are disclosed. The method of manufacturing the printed circuit board in accordance with an embodiment of the present invention can include: forming an opaque conductive pattern on one side of a transparent insulation layer; forming a photosensitive insulation layer on the transparent insulation layer such that the conductive pattern is covered; hardening the photosensitive insulation layer excluding an area covering the conductive pattern by irradiating light on the other side of the transparent insulation layer; and forming an opening on the photosensitive insulation layer by removing the area of the photosensitive insulation layer covering the conductive pattern such that the conductive pattern is exposed.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Printed wiring board and manufacturing method of the same

InactiveCN101888745ASimplify the manufacturing processReduce manufacturing costTransparent dielectricsConductive pattern reinforcementManufacturing cost reductionResist

Owner:HITACHI CABLE

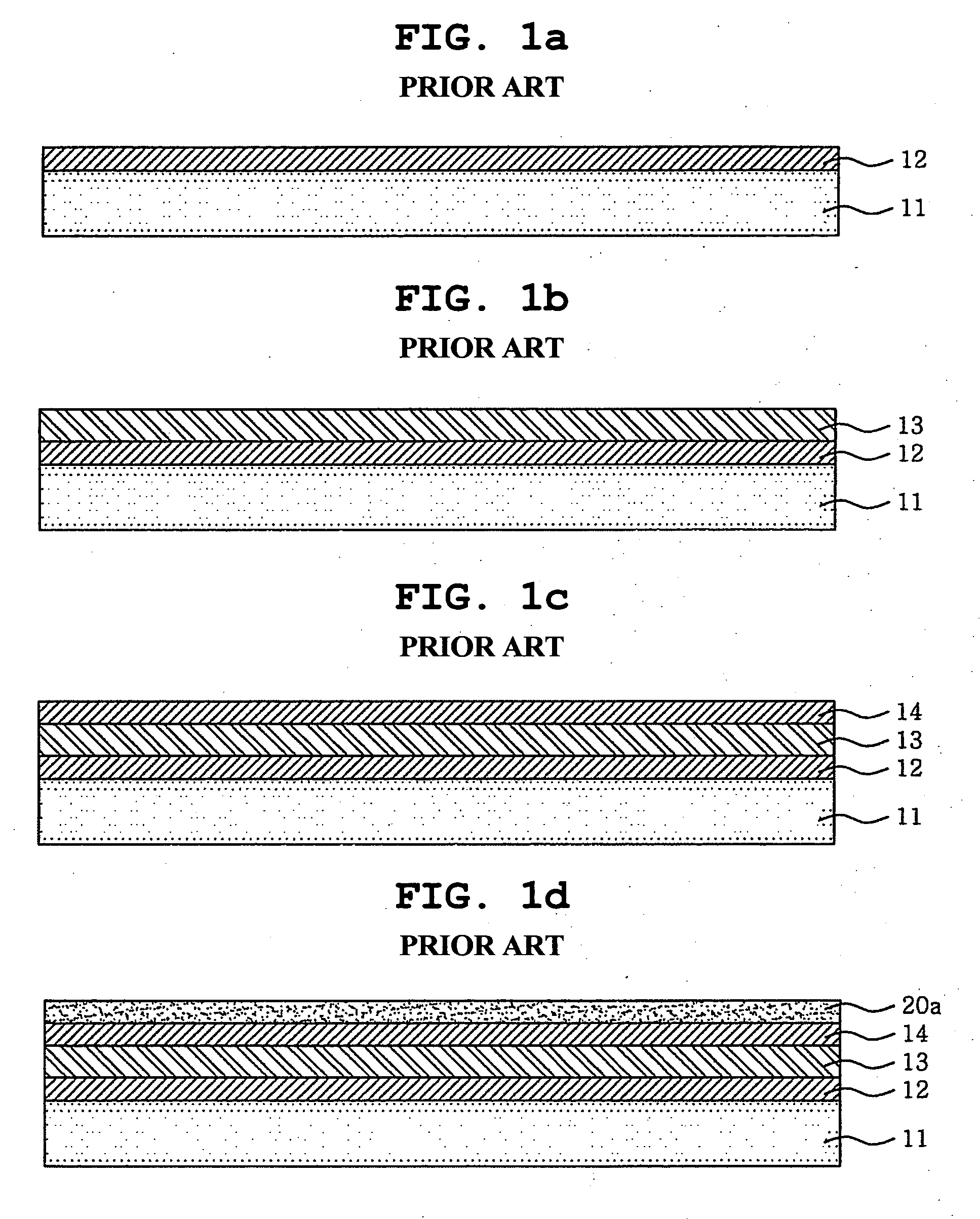

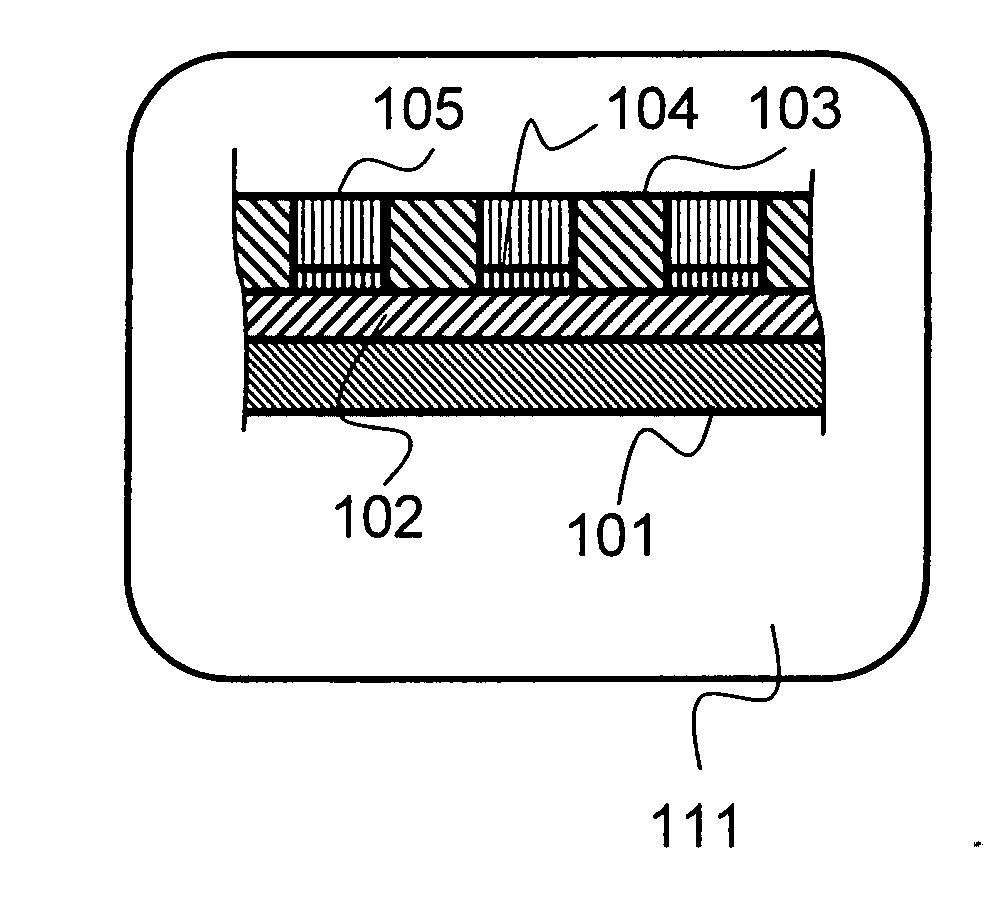

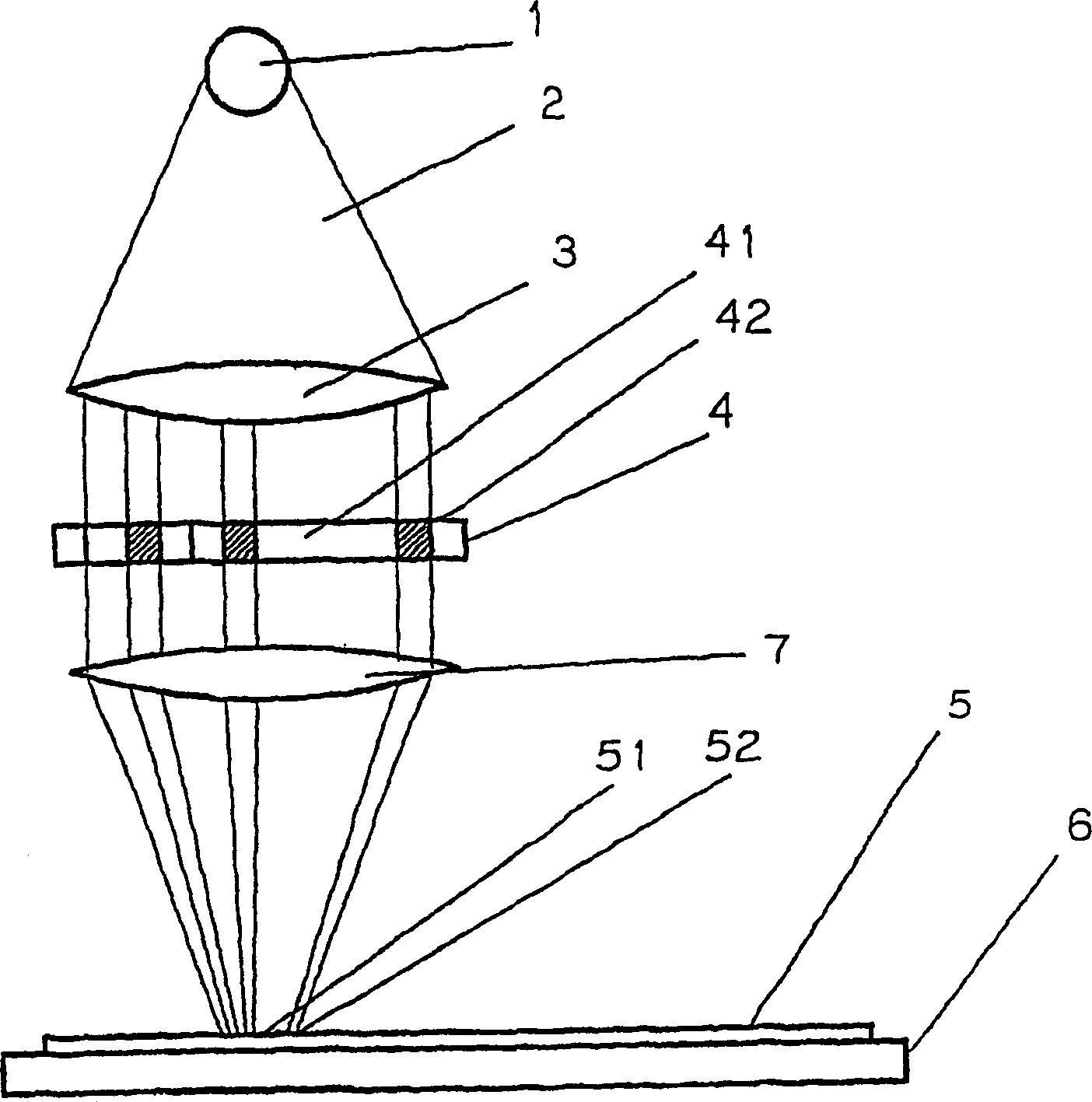

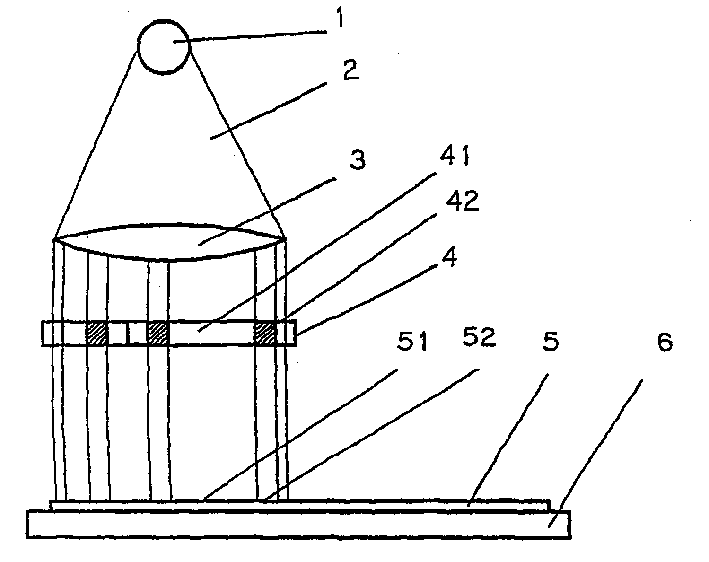

Manufacturing method for a circuit pattern, a thin film transistor and an electronic appliance

InactiveUS7820465B2Reduce the number of stepsExcellent electrical propertiesMolten spray coatingSolid-state devicesLight irradiationElectron

A circuit pattern is formed by following steps: forming a light-blocking mask over a major surface of a light-transmitting substrate, forming a first film in a first region over the substrate and the mask, forming a photocatalytic film in at least a part of the first region over the first film, changing wettability of the first film in a second region which is in the first region, being in contact with the photocatalytic film, and not overlapping the mask, by light irradiation from a back surface opposite to the major surface of the substrate, removing the photocatalytic film, and forming a composition including a pattern forming material in the second region.

Owner:SEMICON ENERGY LAB CO LTD

Printed circuit board including embedded capacitor and method of fabricating same

InactiveUS20060115770A1Avoid it happening againPrinted circuit aspectsPhotomechanical apparatusEngineeringDielectric layer

Disclosed is a PCB including an embedded capacitor, in which a dielectric layer and an upper electrode layer are formed after a lower electrode layer of the embedded capacitor is formed, thereby providing a microcircuit pattern on a circuit layer having a lower electrode layer formed thereon, and a method of fabricating the same.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

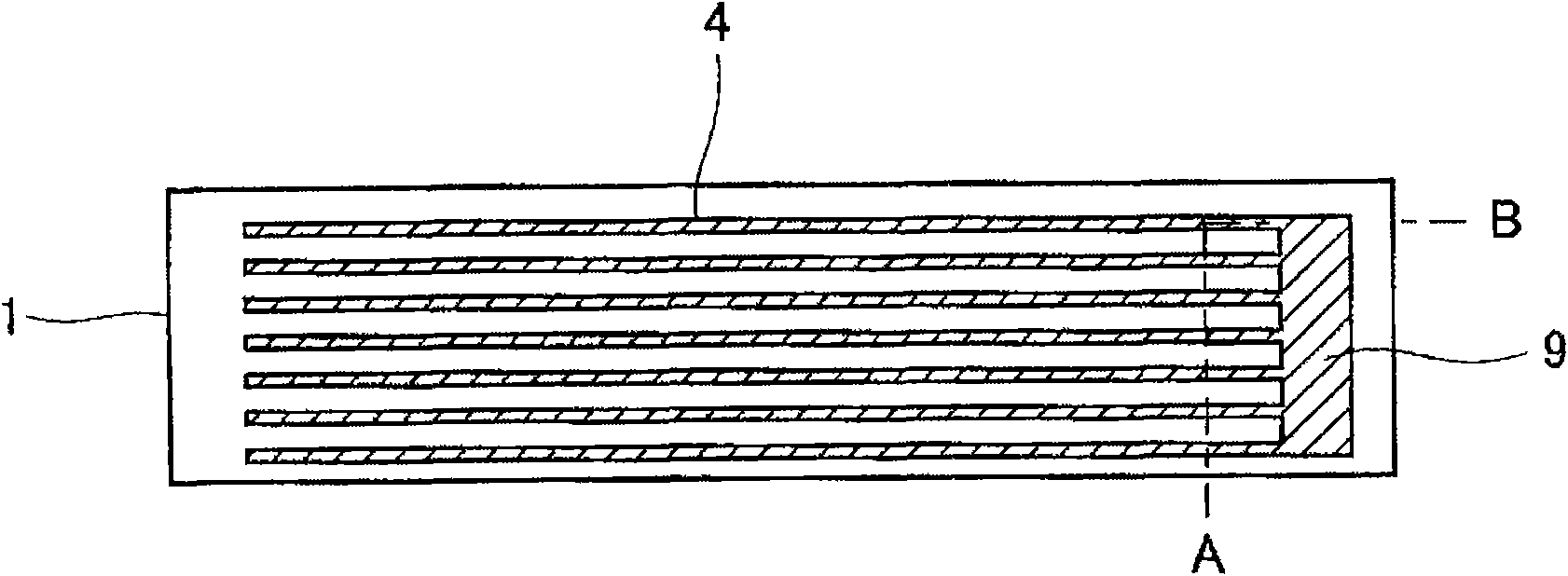

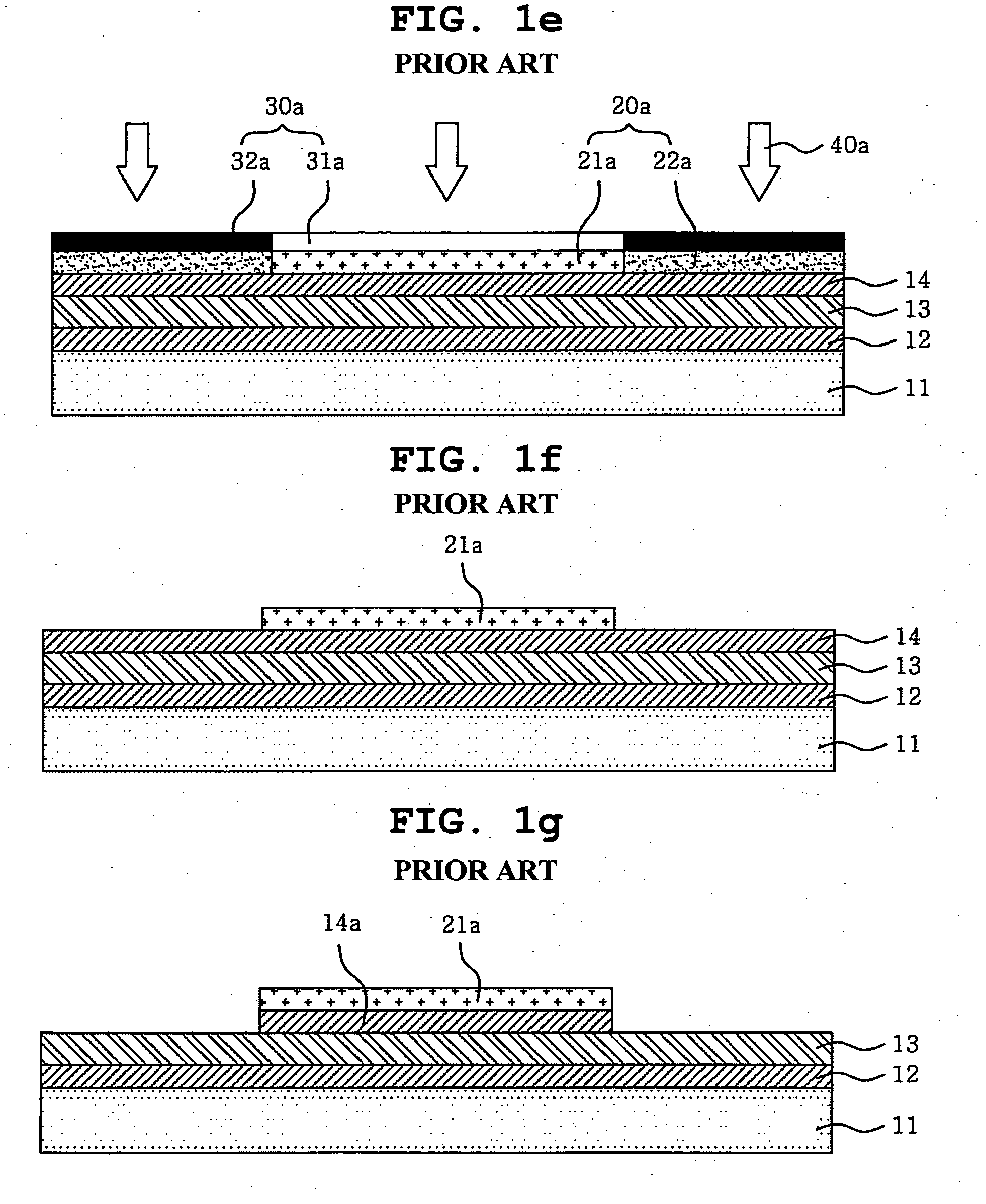

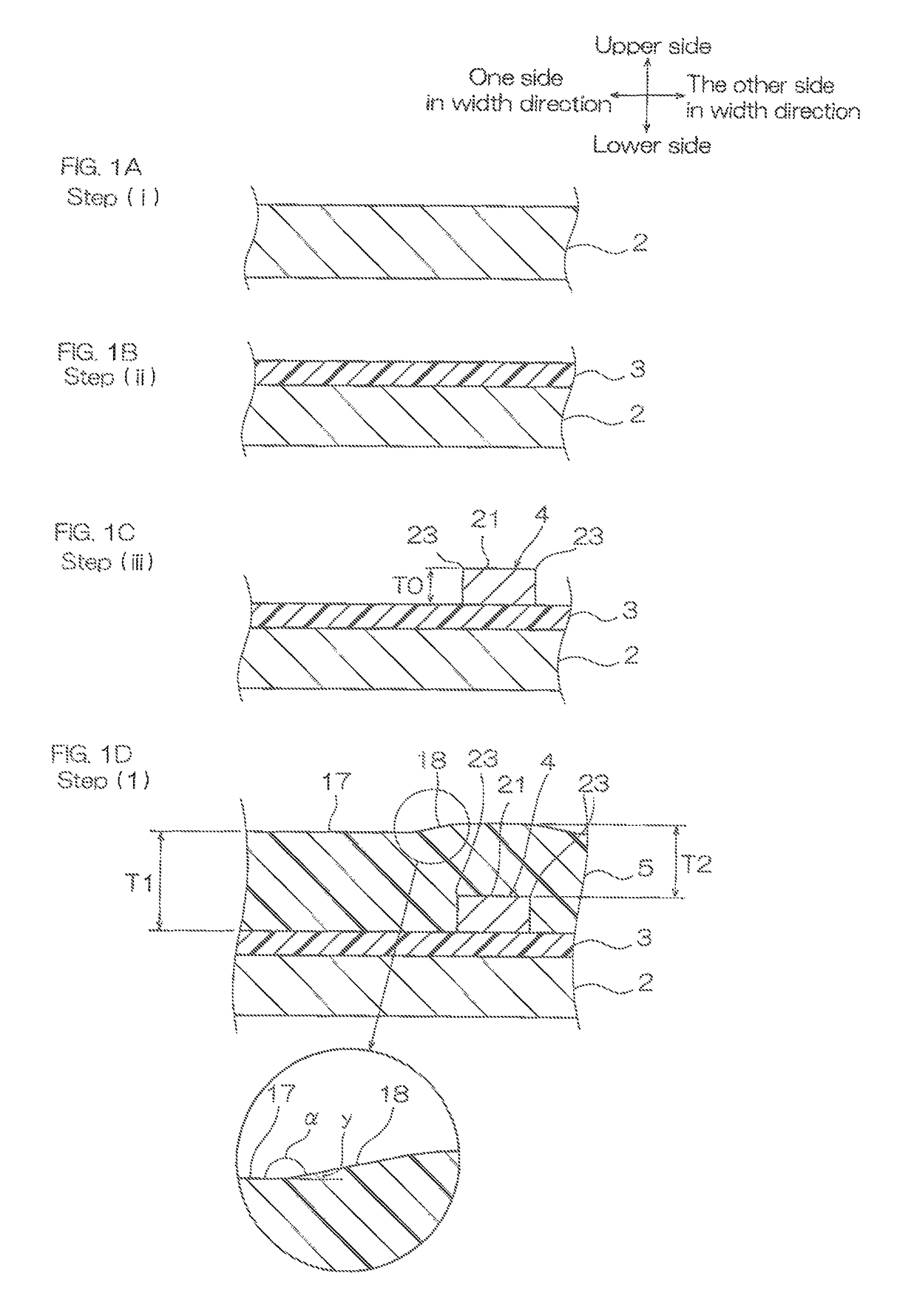

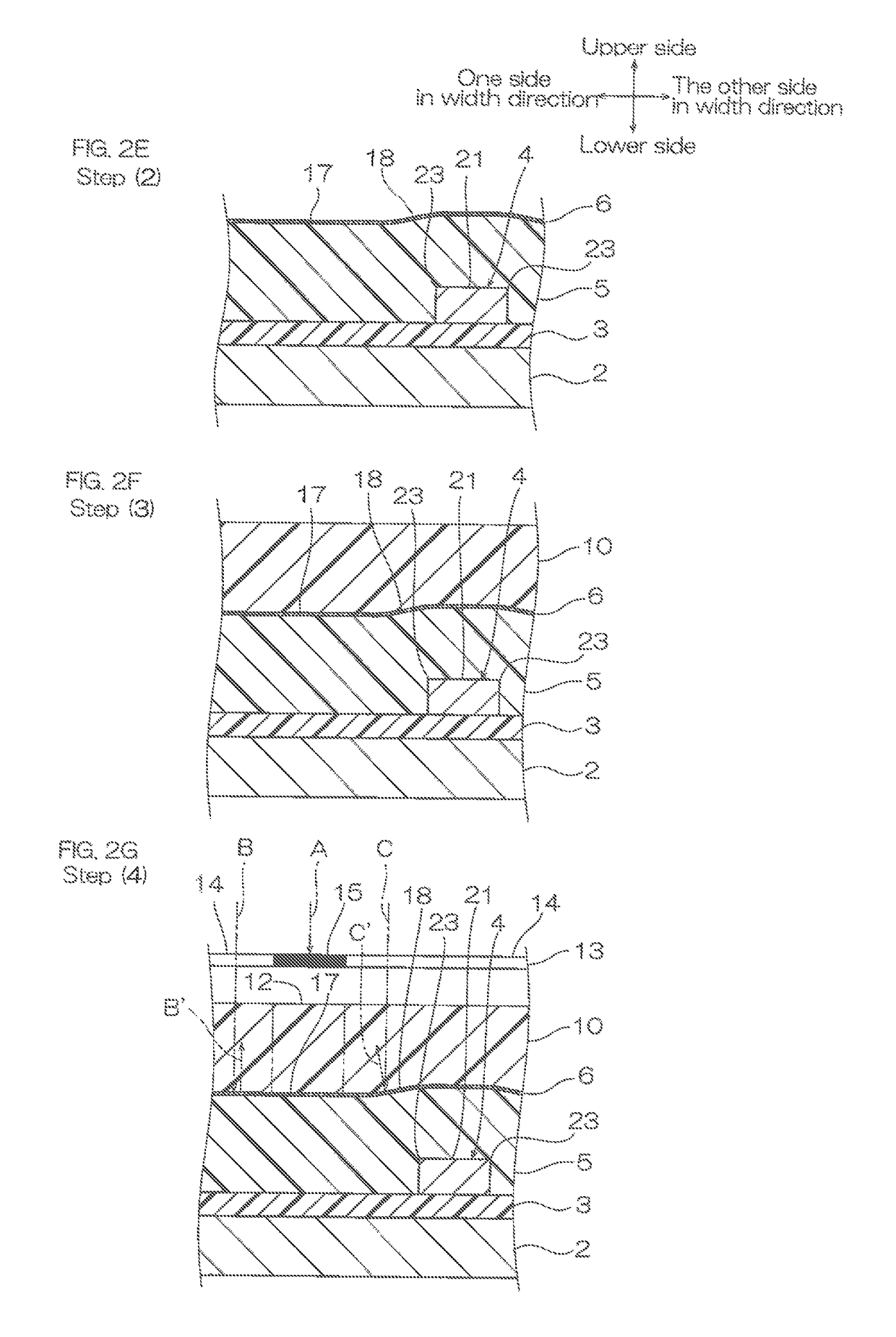

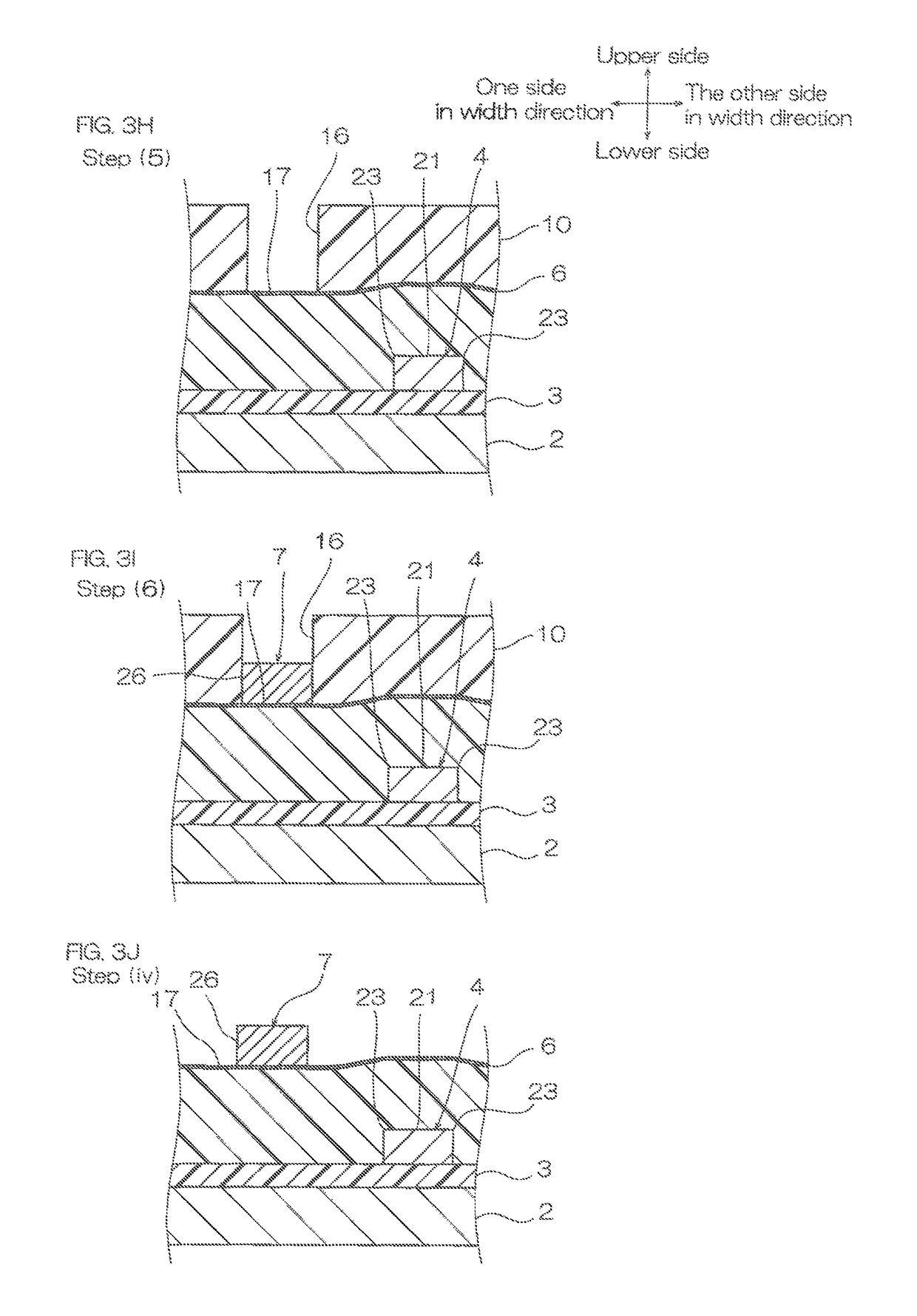

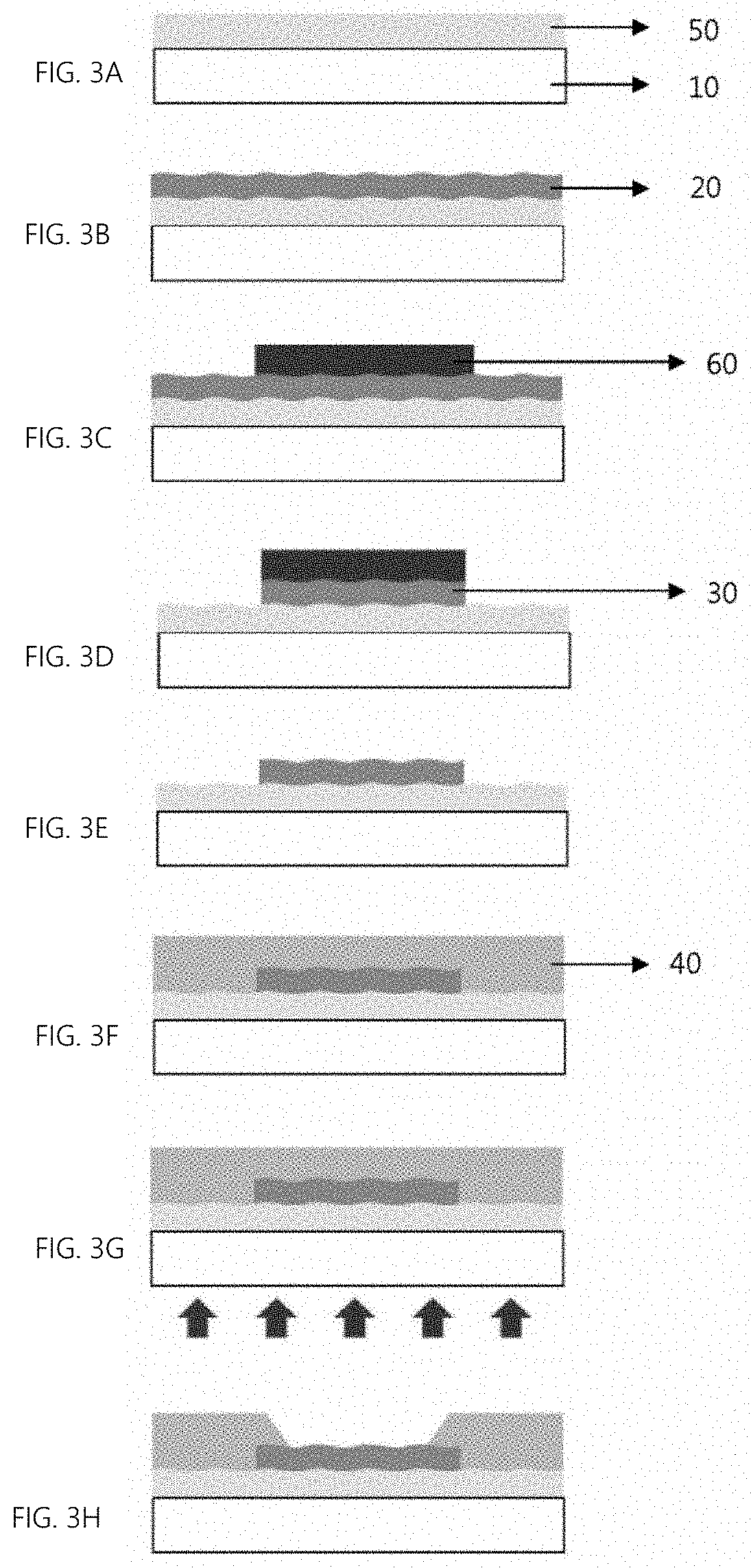

Method for producing wired circuit board

ActiveUS10143088B2Inadequate formation of conductive pattern can be suppressedImprove connection reliabilityResist detailsPrinted circuit aspectsThin membraneEngineering

The method for producing a wired circuit board including an insulating layer and a conductive pattern provided on the insulating layer includes the steps of the following: a step (1), in which the insulating layer is provided; a step (2), in which a metal thin film is provided on an inclined face of the insulating layer; a step (3), in which a photoresist is provided on the metal thin film; a step (4), in which a photomask is disposed so that in the photoresist, a portion where the conductive pattern is to be provided is shielded from light, and the photoresist is exposed to light through the photomask; a step (5), in which the portion of the photoresist shielded from light by the photomask is removed to expose the metal thin film corresponding to the portion; and a step (6), in which the conductive pattern is provided on the metal thin film exposed from the photoresist. When exposing the photoresist, reflection is caused by the metal thin film positioned on the inclined face to reduce light projected to the portion.

Owner:NITTO DENKO CORP

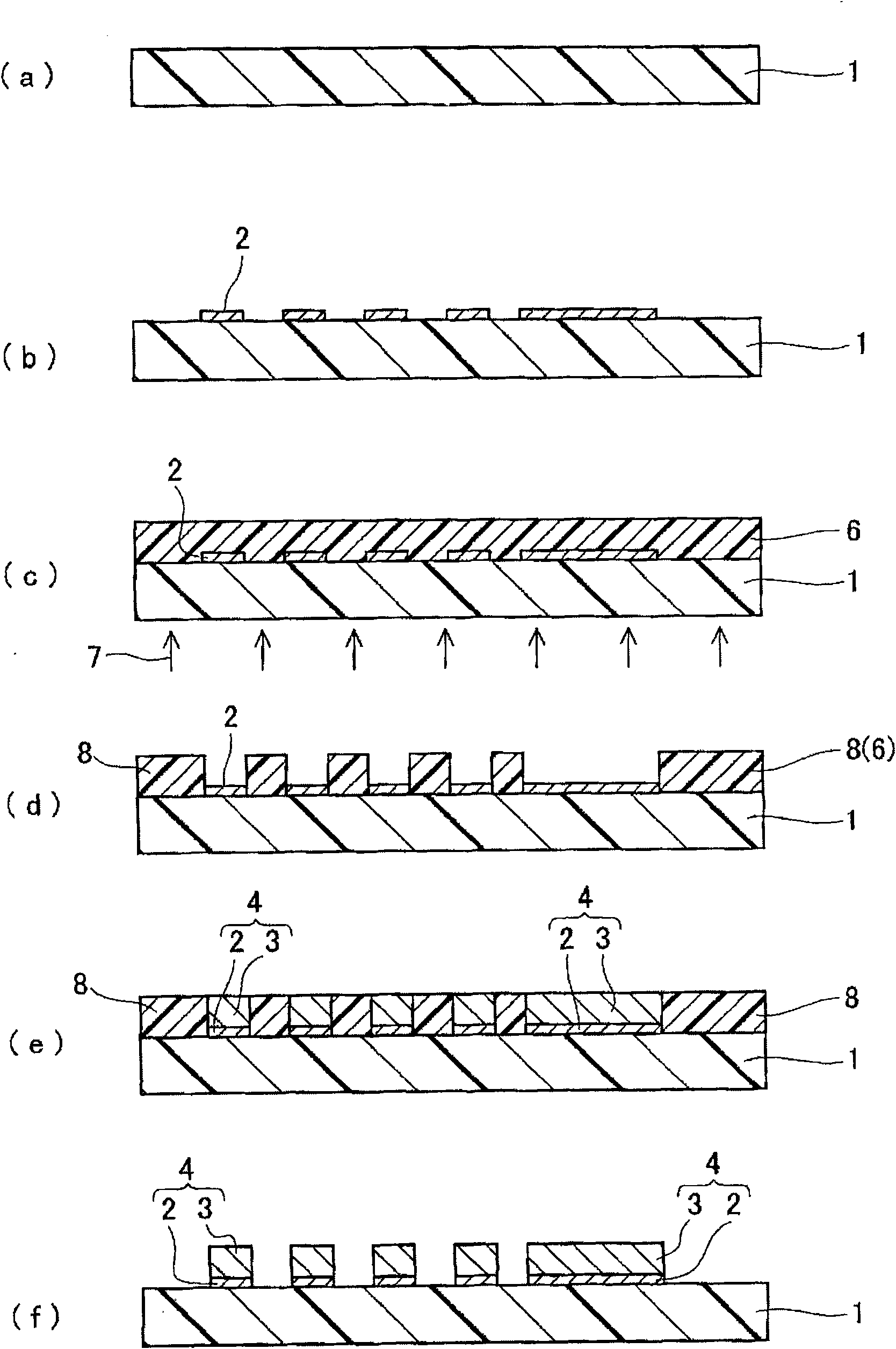

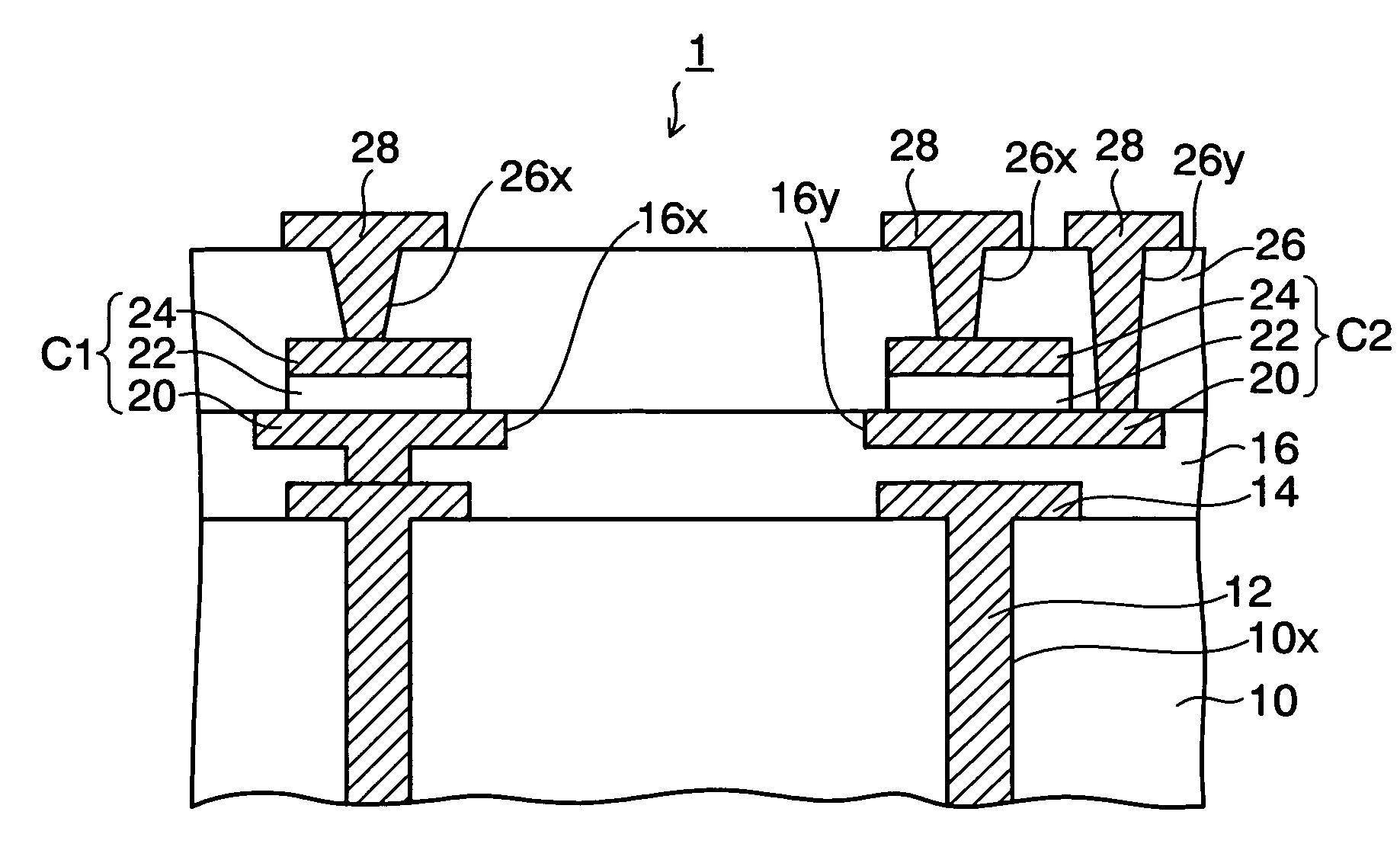

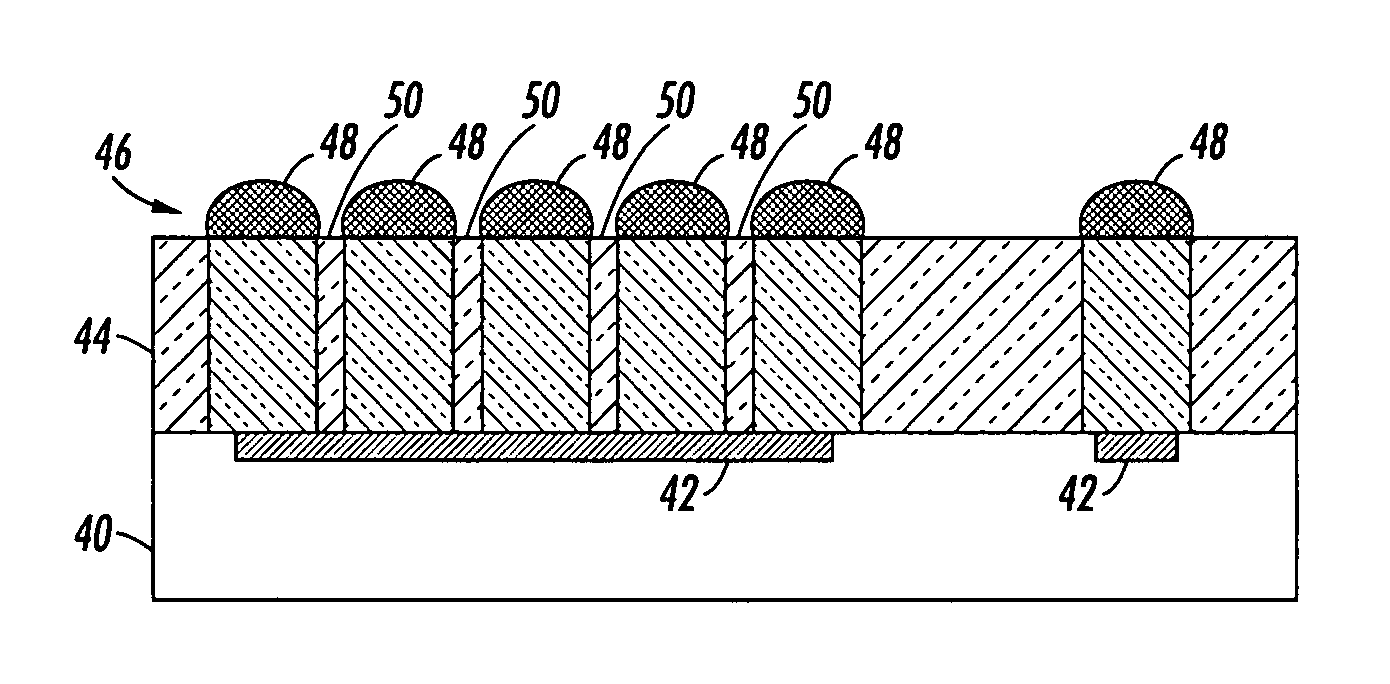

Capacitor device and method of manufacturing the same

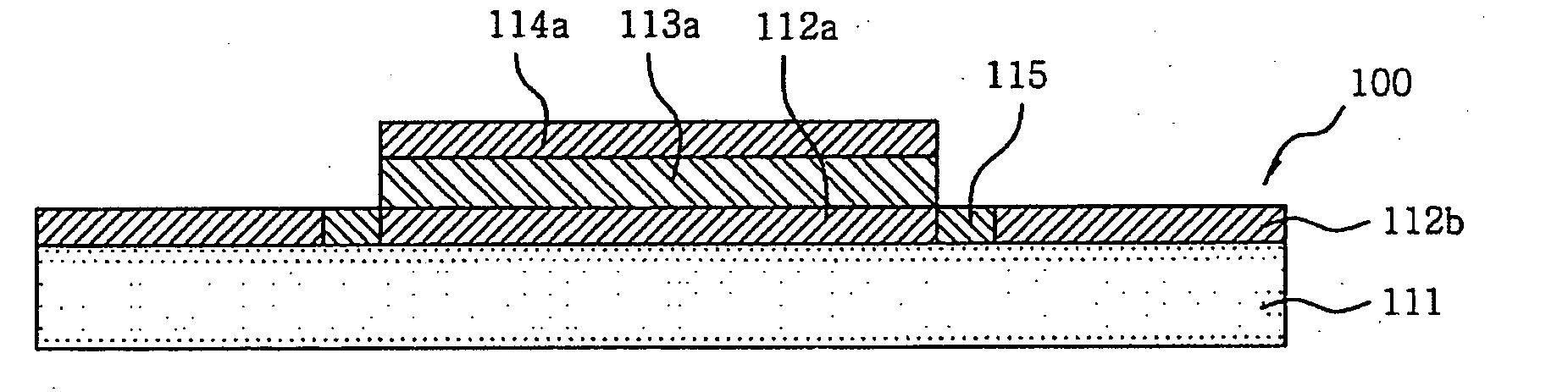

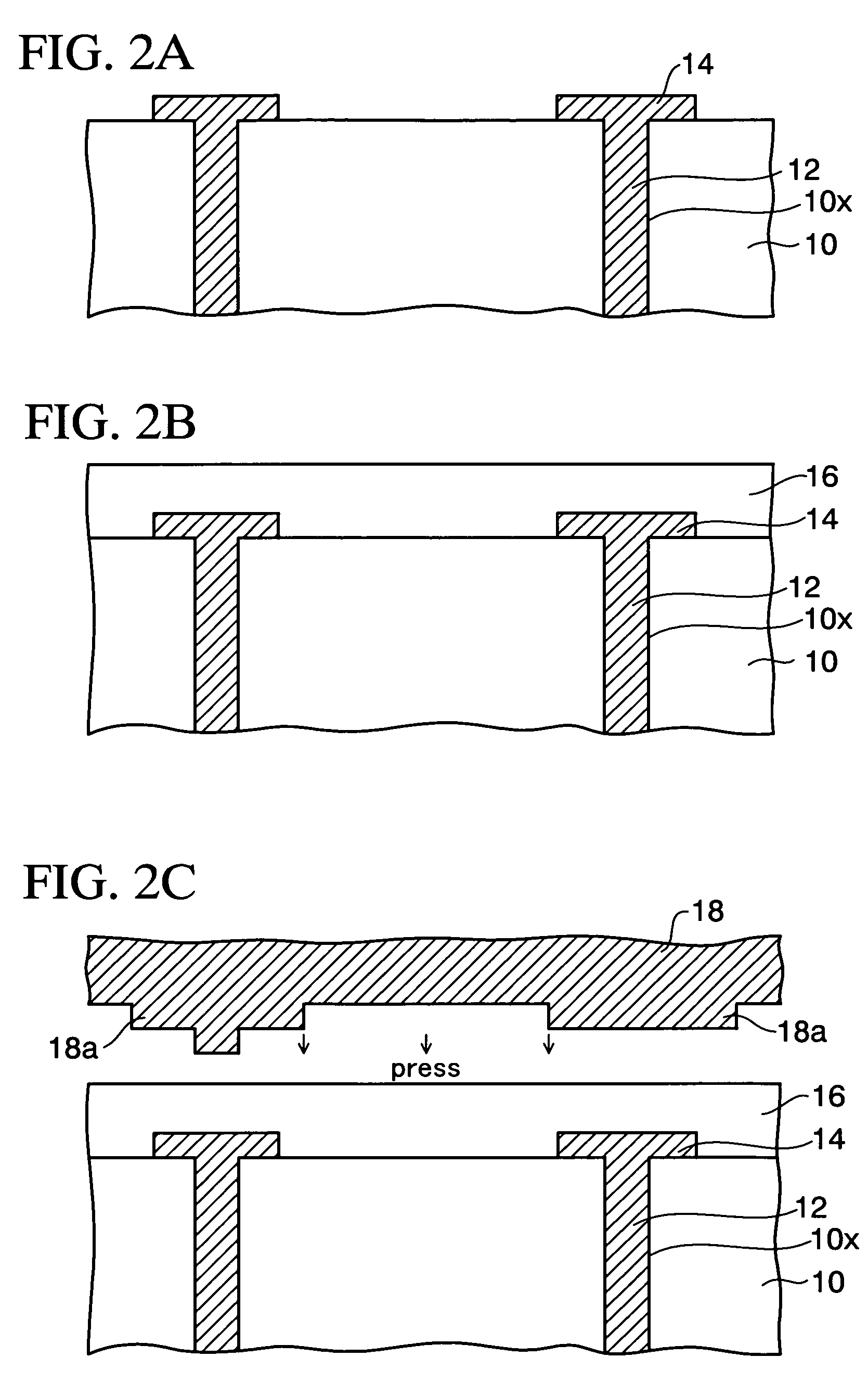

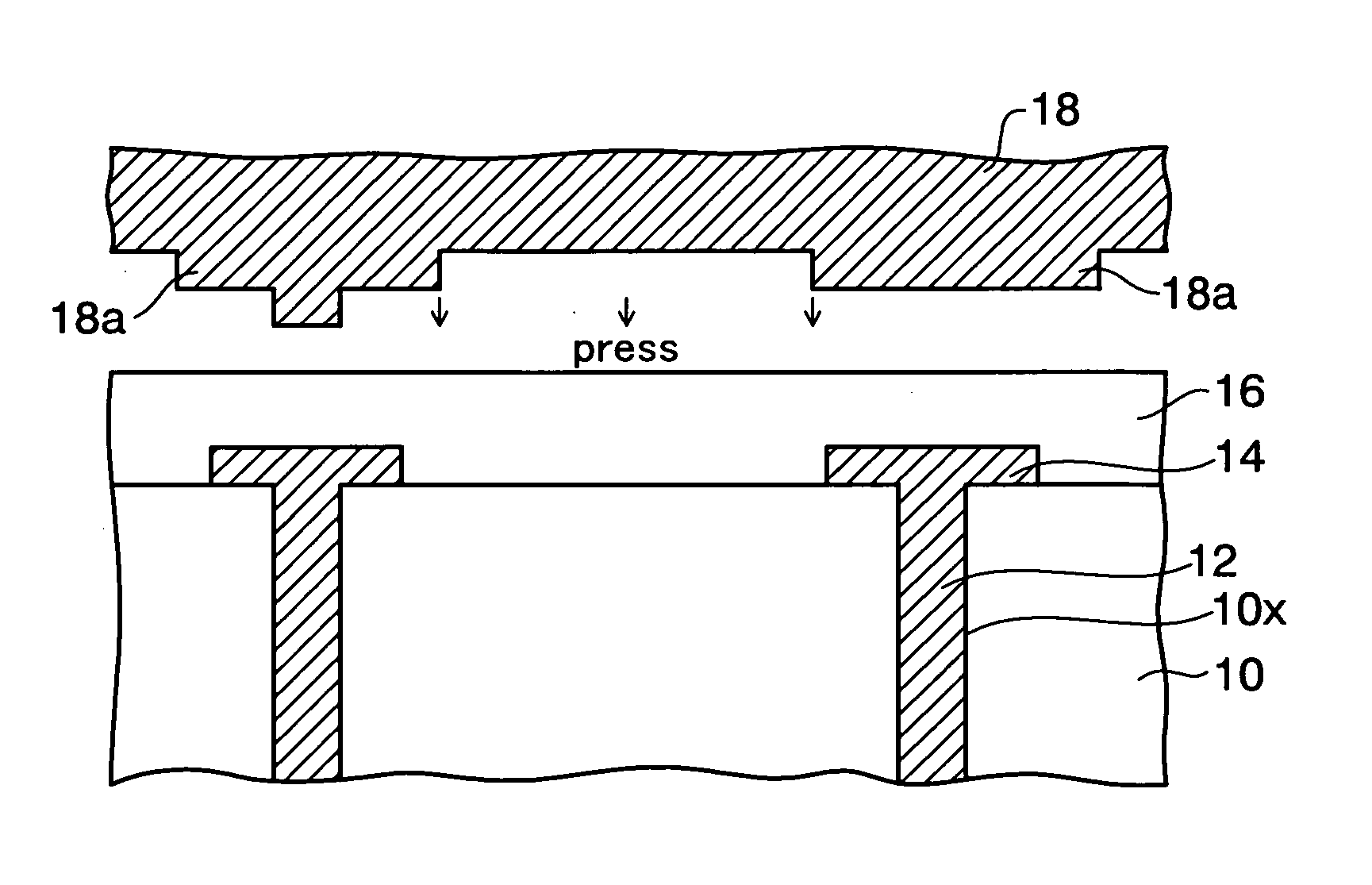

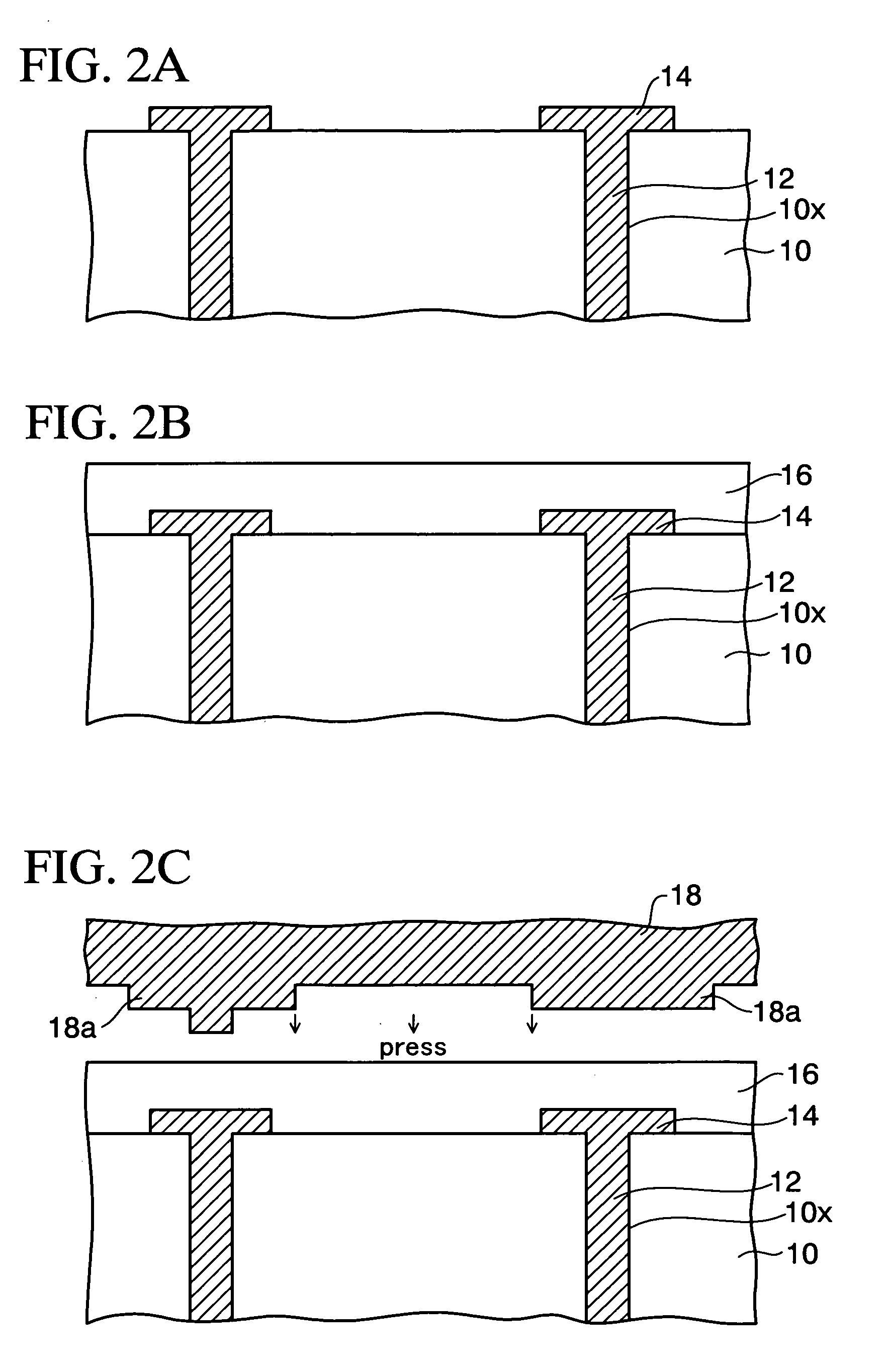

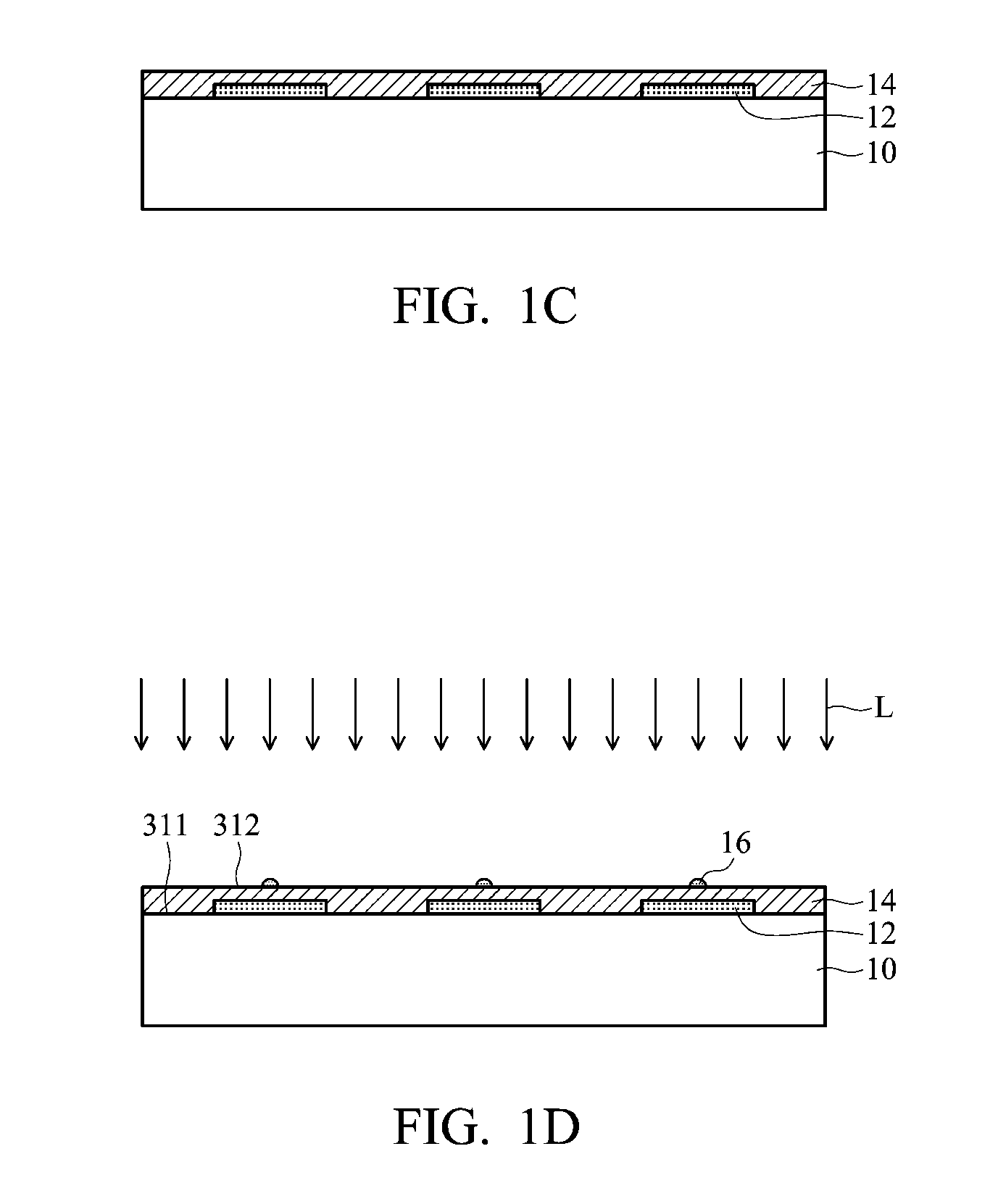

ActiveUS7678660B2Semiconductor/solid-state device detailsPrinted circuit aspectsCapacitanceFiller metal

A method of manufacturing a capacitor device of the present invention, includes the steps of, forming an insulating layer on a substrate, forming a recess portion in the insulating layer by an imprinting process, forming a lower electrode by filling a metal layer in the recess portion in the insulating layer, forming a photosensitive dielectric layer on the lower electrode, forming an upper electrode on the dielectric layer, and forming a dielectric layer pattern under the upper electrode by exposing / developing the dielectric layer while using the upper electrode as a mask.

Owner:SHINKO ELECTRIC IND CO LTD

Capacitor device and method of manufacturing the same

ActiveUS20060086964A1Reduced Tolerance RequirementsImprove responseTransistorSemiconductor/solid-state device detailsOptoelectronicsDielectric layer

A method of manufacturing a capacitor device of the present invention, includes the steps of, forming an insulating layer on a substrate, forming a recess portion in the insulating layer by an imprinting process, forming a lower electrode by filling a metal layer in the recess portion in the insulating layer, forming a photosensitive dielectric layer on the lower electrode, forming an upper electrode on the dielectric layer, and forming a dielectric layer pattern under the upper electrode by exposing / developing the dielectric layer while using the upper electrode as a mask.

Owner:SHINKO ELECTRIC IND CO LTD

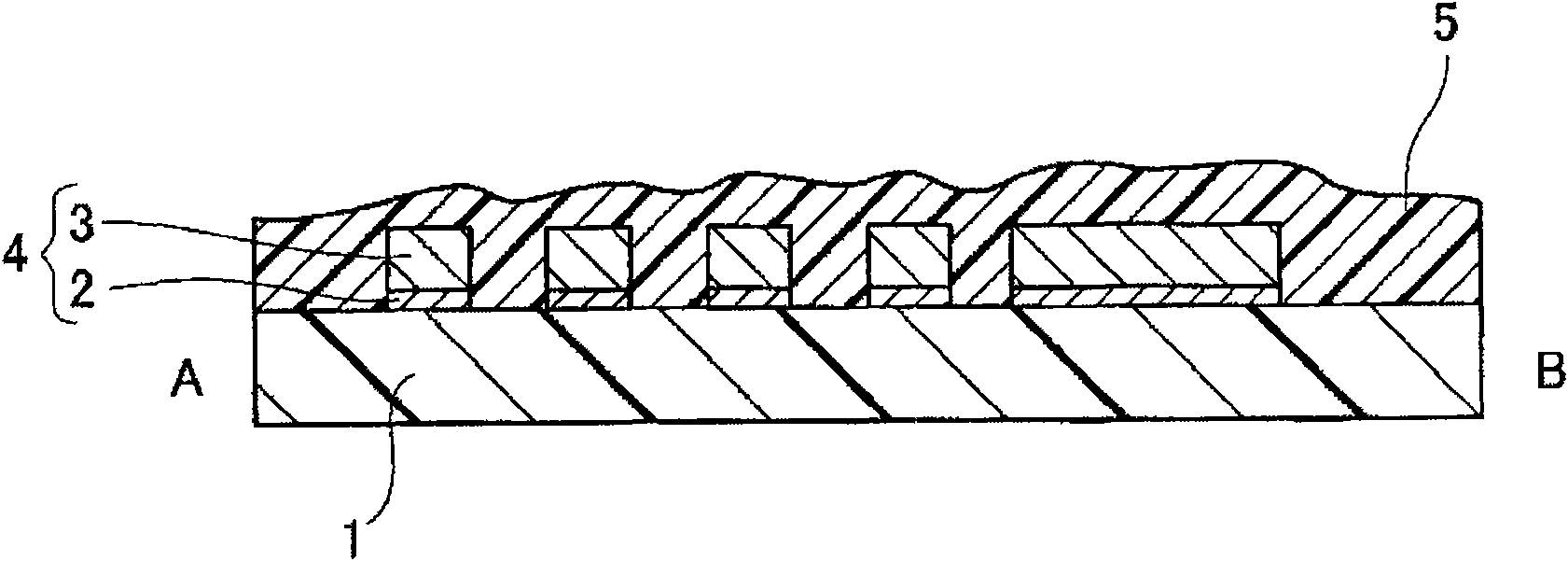

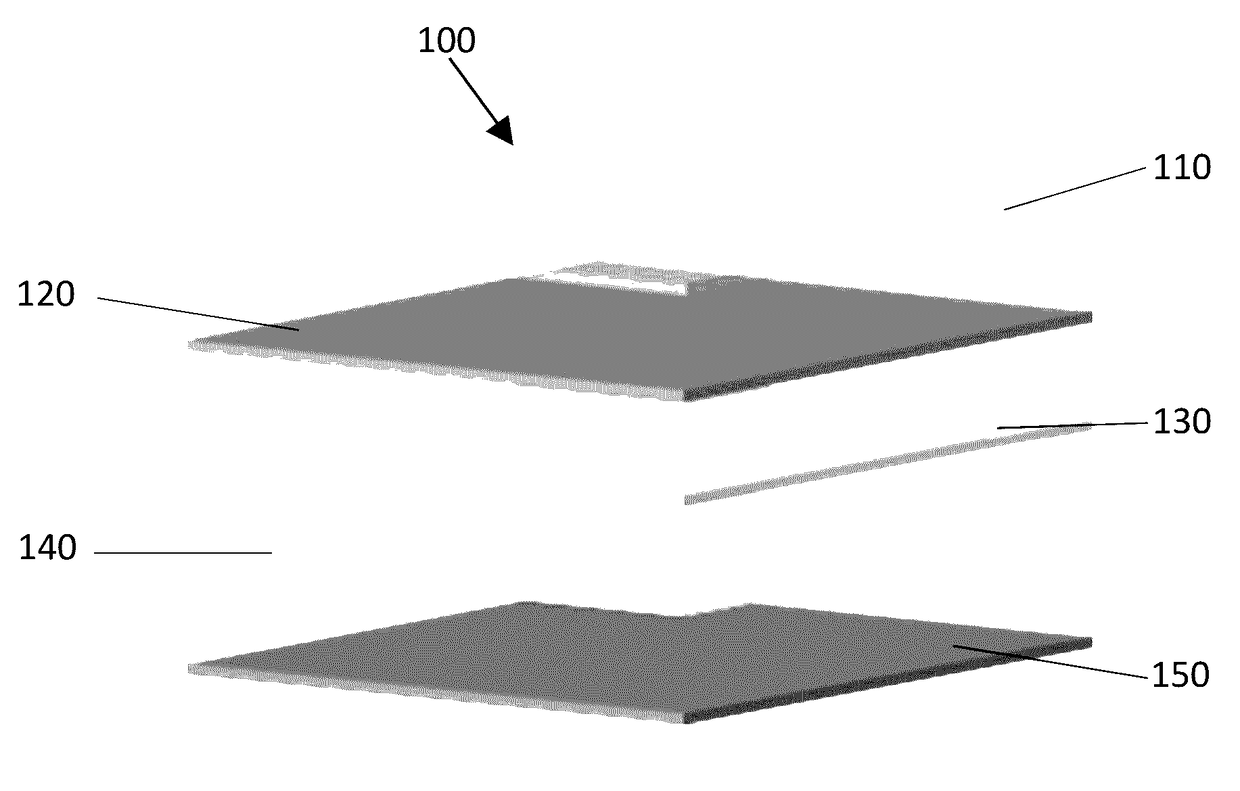

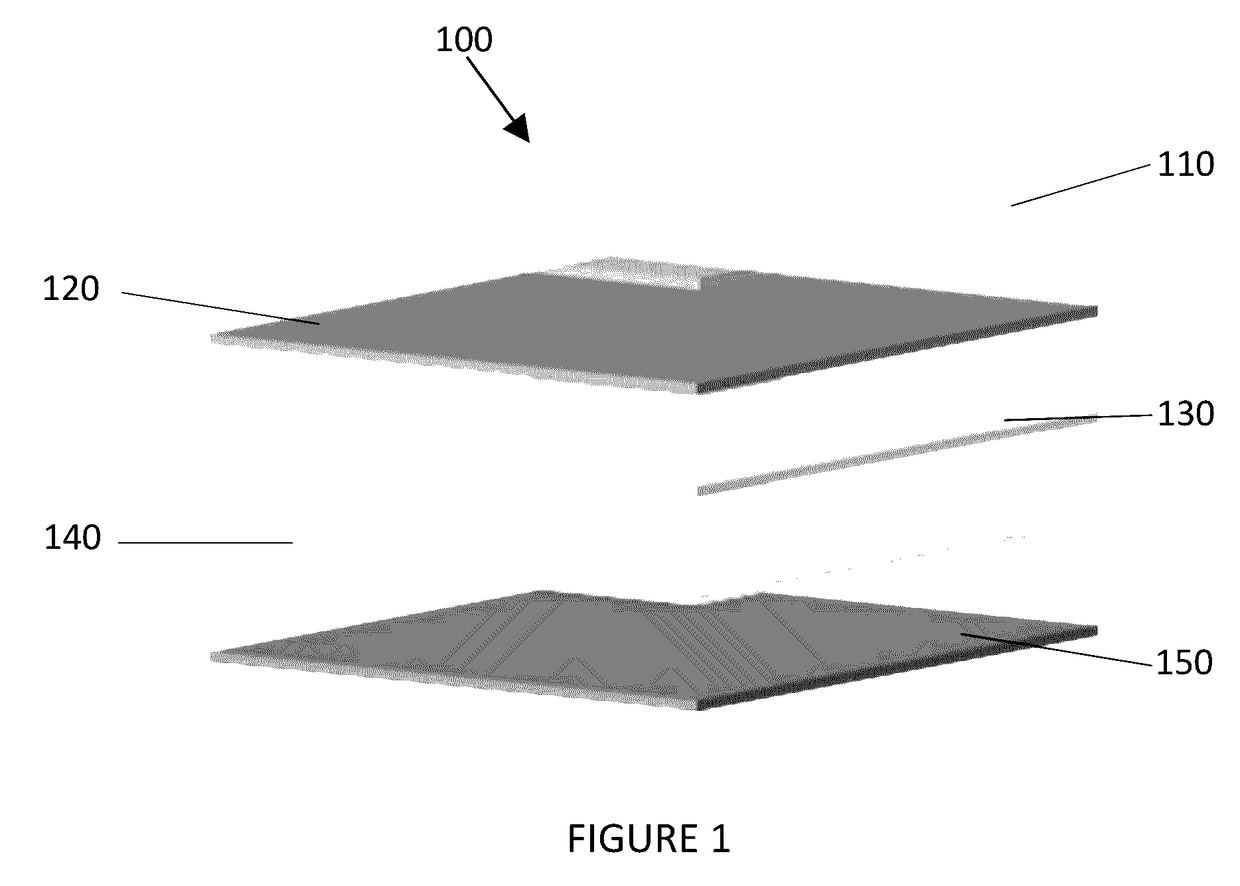

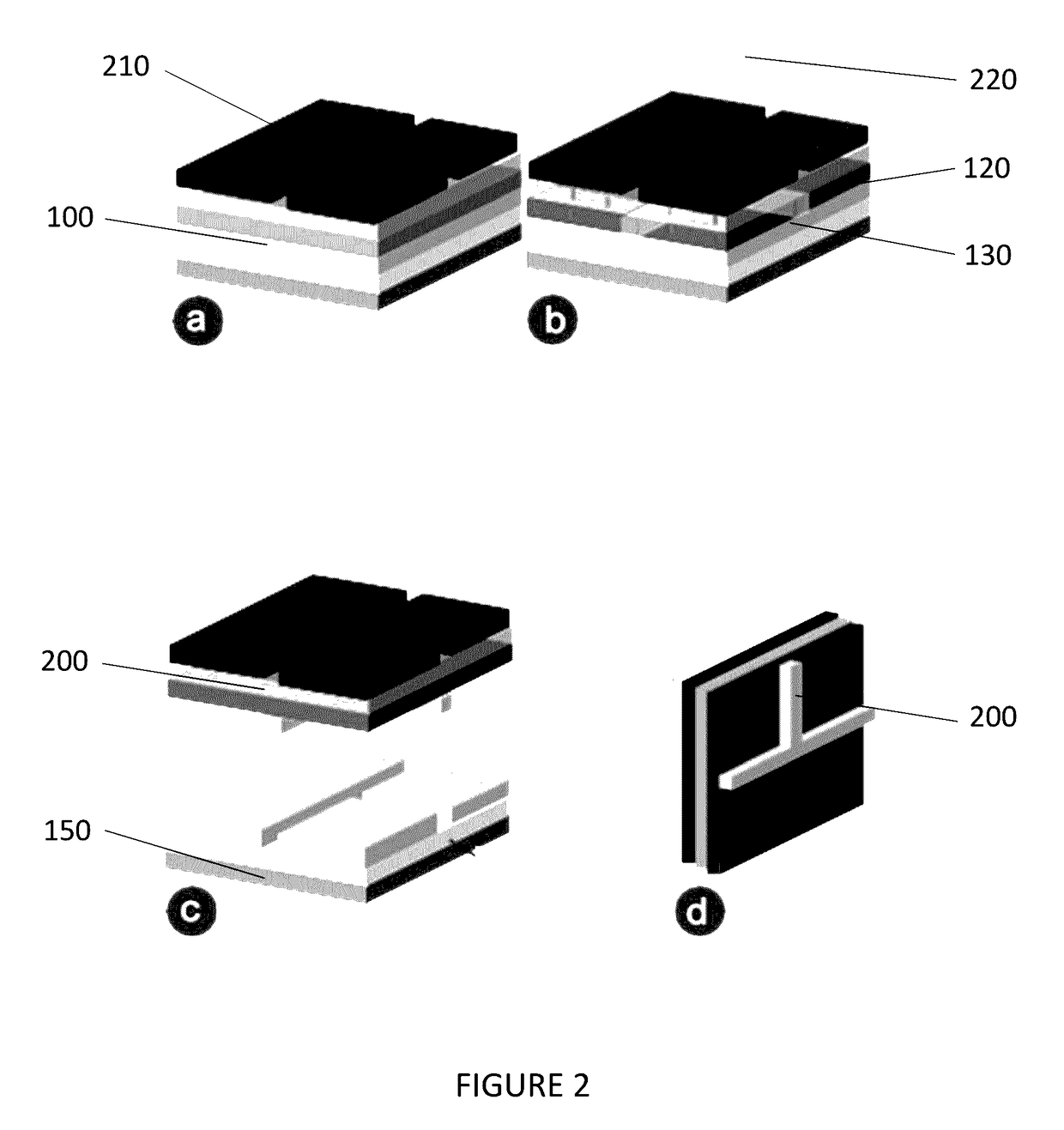

Printable Films for Printed Circuit Boards and Processes for Making Same

InactiveUS20170135220A1Phototackifying patterningTransparent dielectricsConductive materialsEngineering

Film for use in preparing a printed circuit board (PCB) along with methods for making a PCB and producing a printable film are described herein. The film includes a first layer formed of a radiation-transparent material, a second layer formed of a curable adhesive material, a third layer formed of an electrically conductive material, and optionally, a fourth layer formed of an adhesive and a fifth layer formed of a removable material. Through the adhesive layers, the layers are bonded together to produce the printable film. To produce a PCB, the first layer is covered in ink distributed in a pattern representing the PCB, and the ink-covered film is exposed to radiation until the non-ink-covered portions of the second layer have cured. Then, the fifth layer is removed tearing away the electrically conductive material associated with the non-ink-covered portions of the second layer producing the PCB.

Owner:ADDEM LABS INC

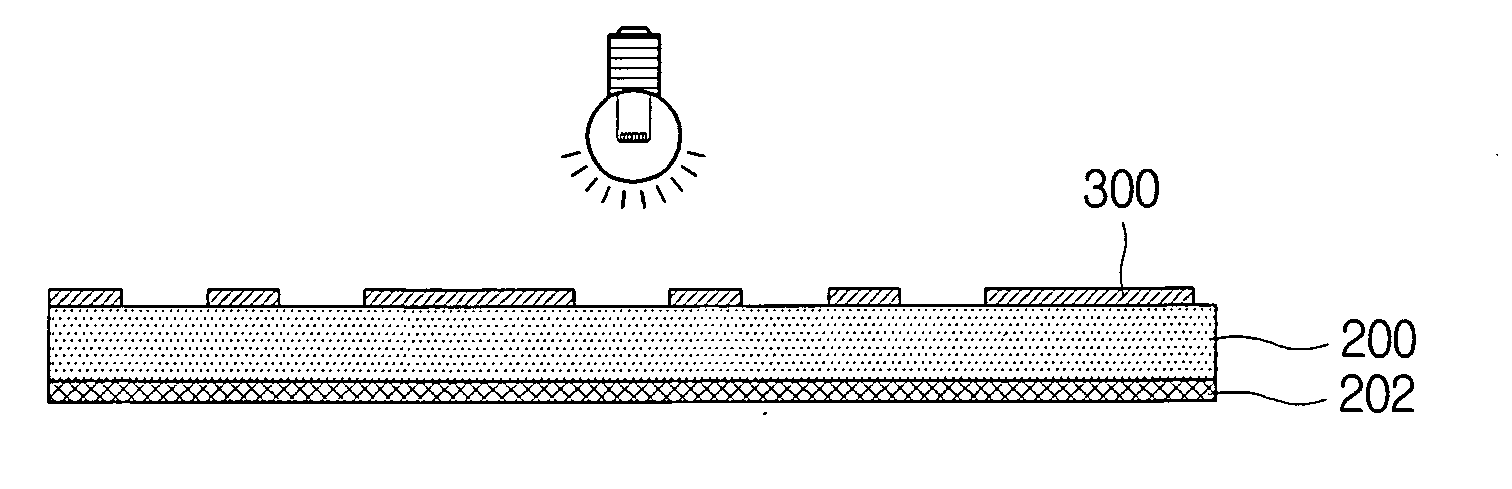

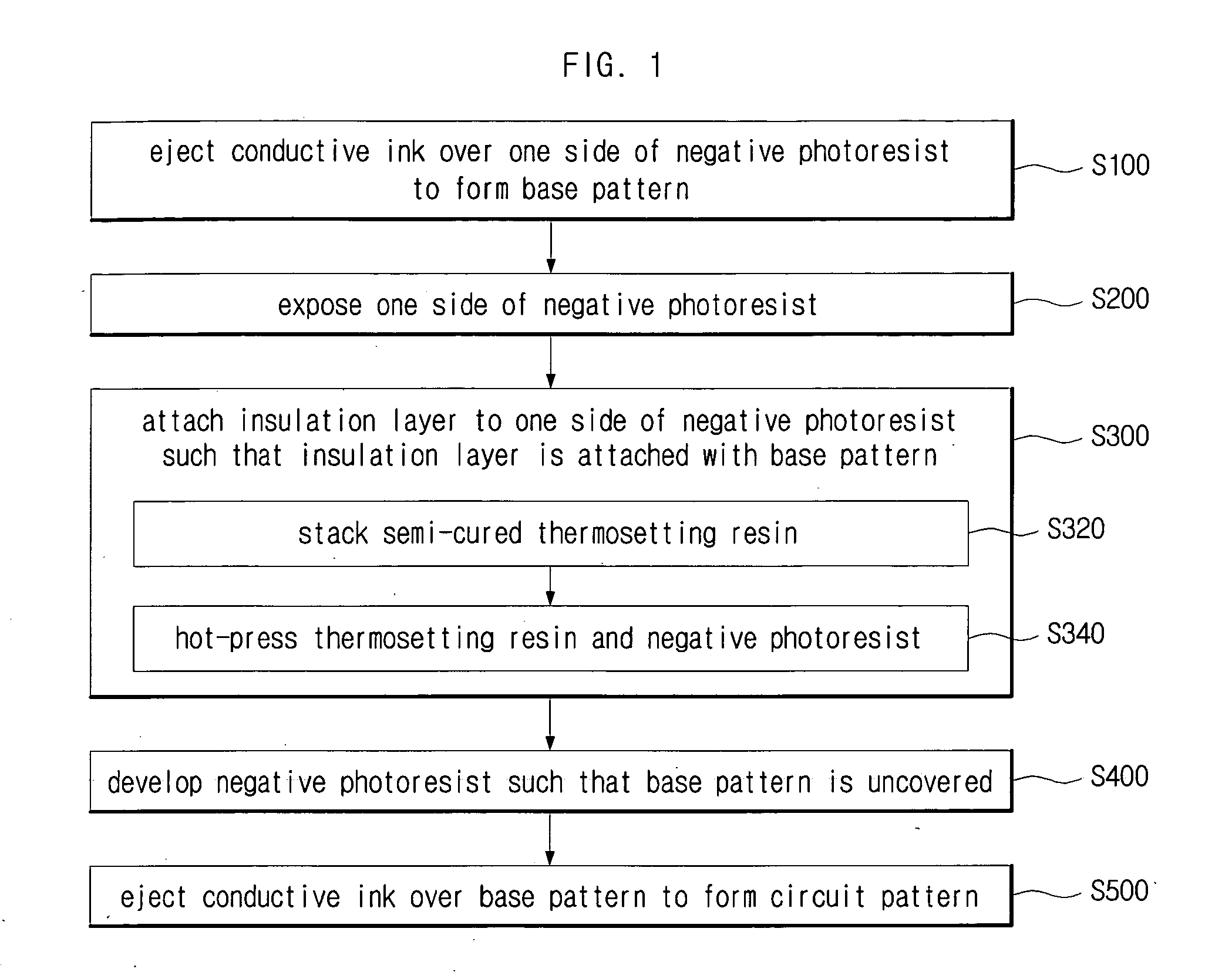

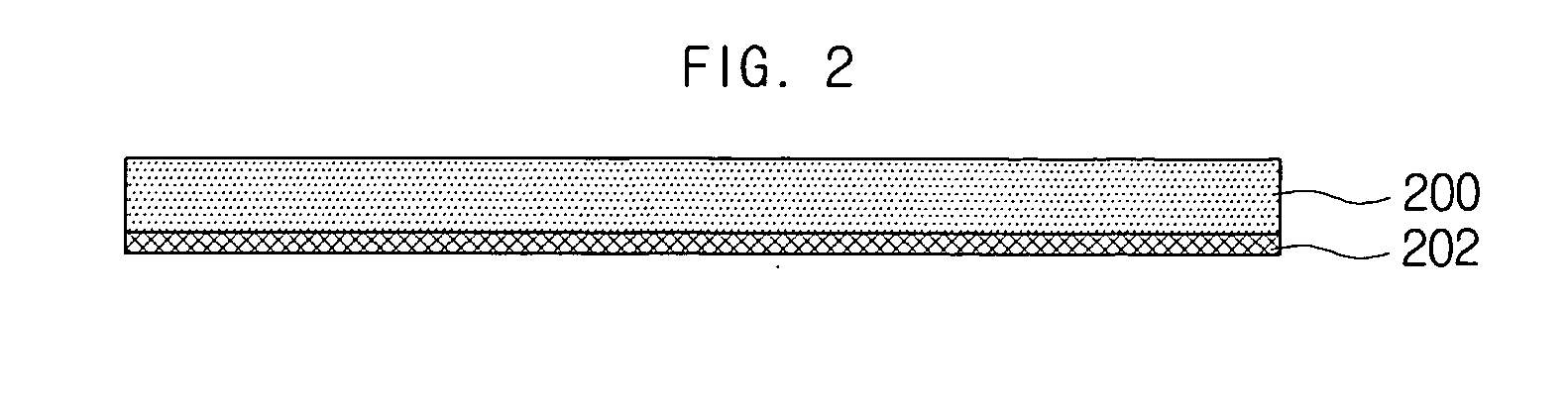

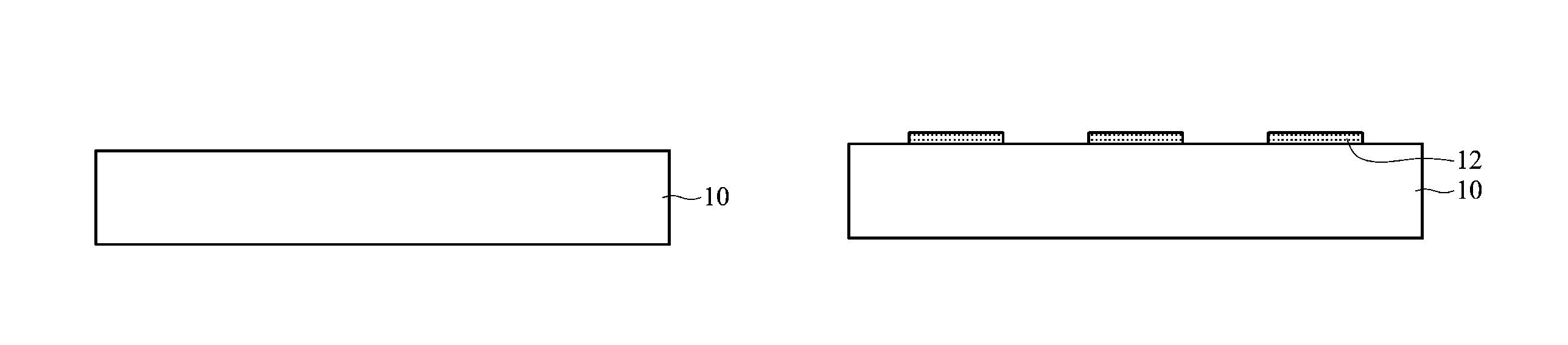

Method for manufacturing printed circuit board

InactiveUS20090136874A1Increasing the thicknessImprove adhesionSemiconductor/solid-state device manufacturingPhotosensitive material processingResistInsulation layer

A method of manufacturing a printed circuit board is disclosed. The method, which includes forming a base pattern over one side of a negative photoresist, exposing the one side, attaching an insulation layer on the one side, developing the negative photoresist such that the base pattern is uncovered, and forming a circuit pattern over the base pattern, can increase the thickness of the circuit pattern and strengthen the adhesion between the circuit pattern and the insulation layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Fabrication methods for electronic devices with via through holes and thin film transistor devices

InactiveUS8216898B2Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectron

Owner:IND TECH RES INST

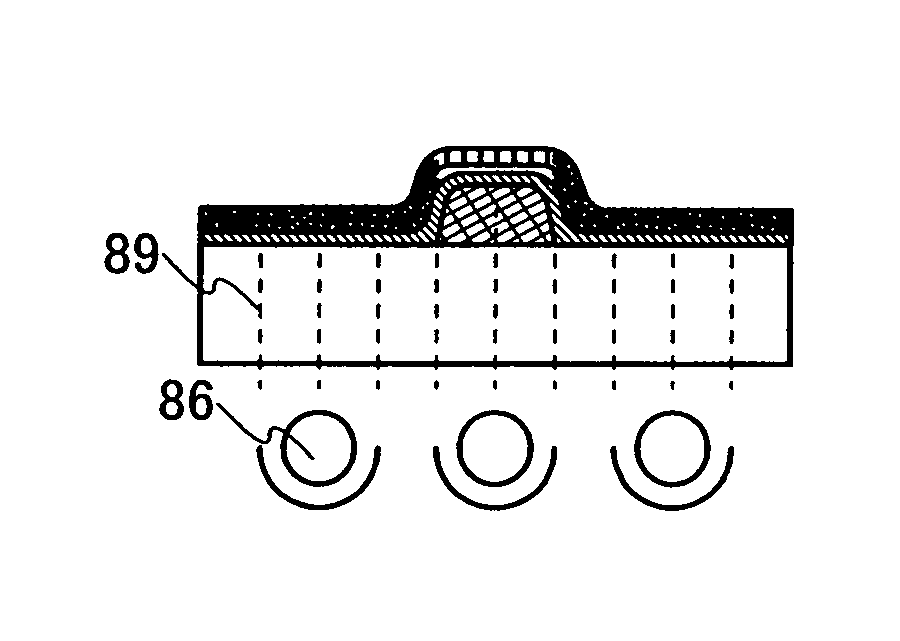

Method of manufacturing wiring substrate, and liquid ejection head manufactured by same

InactiveUS20070222079A1Well formedImprove cooling effectInking apparatusSemiconductor/solid-state device detailsUltraviolet lightsReagent

The method of manufacturing a wiring substrate includes the steps of: forming a photocatalyst containing layer which is made of a material containing a photocatalytic material, on a substrate made of an insulating material; forming a resin layer in regions other than wire regions on the photocatalyst containing layer; radiating ultraviolet light on the photocatalyst containing layer while the substrate provided with the resin layer and the photocatalyst containing layer is immersed in a solution containing at least a metal ion and a sacrificial reagent, in such a manner that metal is deposited on exposed regions of the photocatalyst containing layer.

Owner:FUJIFILM CORP

Lamination for printed photomask

Owner:PALO ALTO RES CERNTER

Aluminum substrate resistance welding screen making method for preventing photosensitive slurry from falling off

ActiveCN105517366AImprove the problem of easy falling offAvoid abnormal qualityNon-metallic protective coating applicationDirectly printed exposure masksSpray coatingPulp and paper industry

An aluminum substrate resistance welding screen making method for preventing photosensitive slurry from falling off comprises the following steps: (1) using double-sided adhesive to paste a PET protective film to each of the positions, corresponding to the running tracks at the two ends of a scraper, on the front of a screen mesh; (2) applying glue water to the positions, corresponding to the PET protective films, on the back of the screen mesh, and naturally drying the glue water for a period of time after glue water applying to make the PET protective films cured on the screen mesh; (3) before photosensitive slurry is applied, adding boiling oil water to the photosensitive slurry according to the ratio of 30ml boiling oil water to 1kg photosensitive slurry, manually stirring the boiling oil water and the photosensitive slurry, and letting the mixture stand for a period of time; (4) spray-coating a given photosensitive slurry applying position of the screen mesh with the photosensitive slurry added with boiling oil water; and (5) after the photosensitive slurry is applied, baking the screen in an oven for a period of time to make the photosensitive slurry cured on the screen mesh. By using the method, the problem that the photosensitive slurry on the mesh in the positions of the two ends of the scraper is easy to fall off is improved effectively, the product quality is improved, and the service life of the screen is increased.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

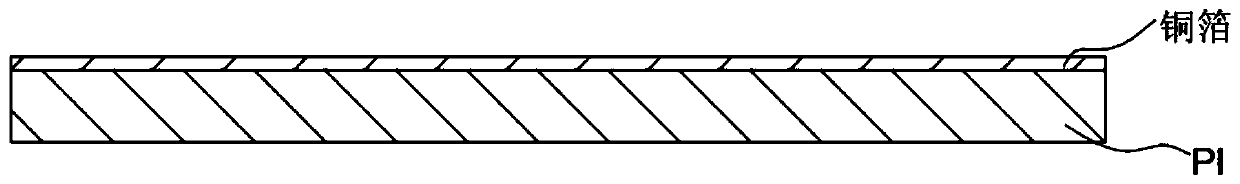

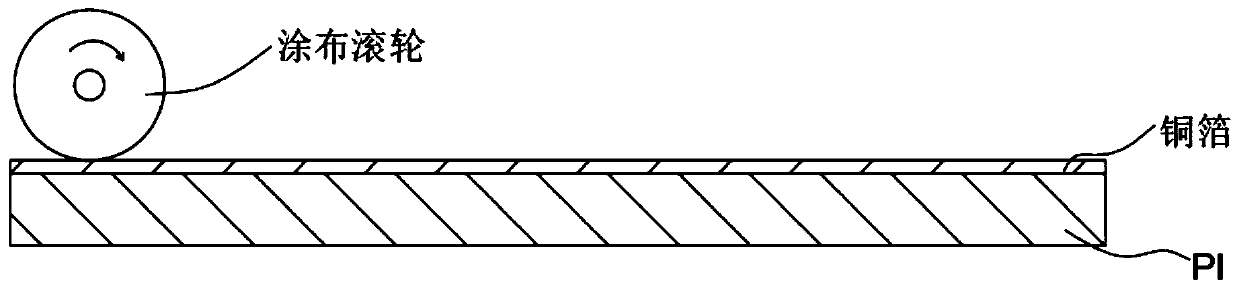

Novel circuit forming method

InactiveCN110856357ALow costThe production process steps are simpleConductive material chemical/electrolytical removalDirectly printed exposure masksCopper foilPhotoresist

The invention provides a novel circuit forming method, and relates to the technical field of circuit forming. The new circuit forming method comprises the following steps: S1, pretreating a product substrate; S2, coating photoresist on the pre-treated substrate by using a coating roller to obtain a product with a photoresist pattern; S3, baking the product coated with the photoresist pattern to cure the photoresist; and S4, etching the baked product with the cured photoresist pattern to remove a copper foil which is not covered by the photoresist, and then, carrying out development to remove the photoresist on the surface of the product to obtain a required circuit pattern. According to the invention, the circuit board is manufactured by using a roller pattern coating method, so that the processes of exposure, development and the like are omitted, the original production process steps can be simplified, the labor and equipment costs are greatly reduced, adverse effects caused by manualoperation are avoided, the product quality can be ensured, and the production efficiency is improved.

Owner:江苏上达半导体有限公司

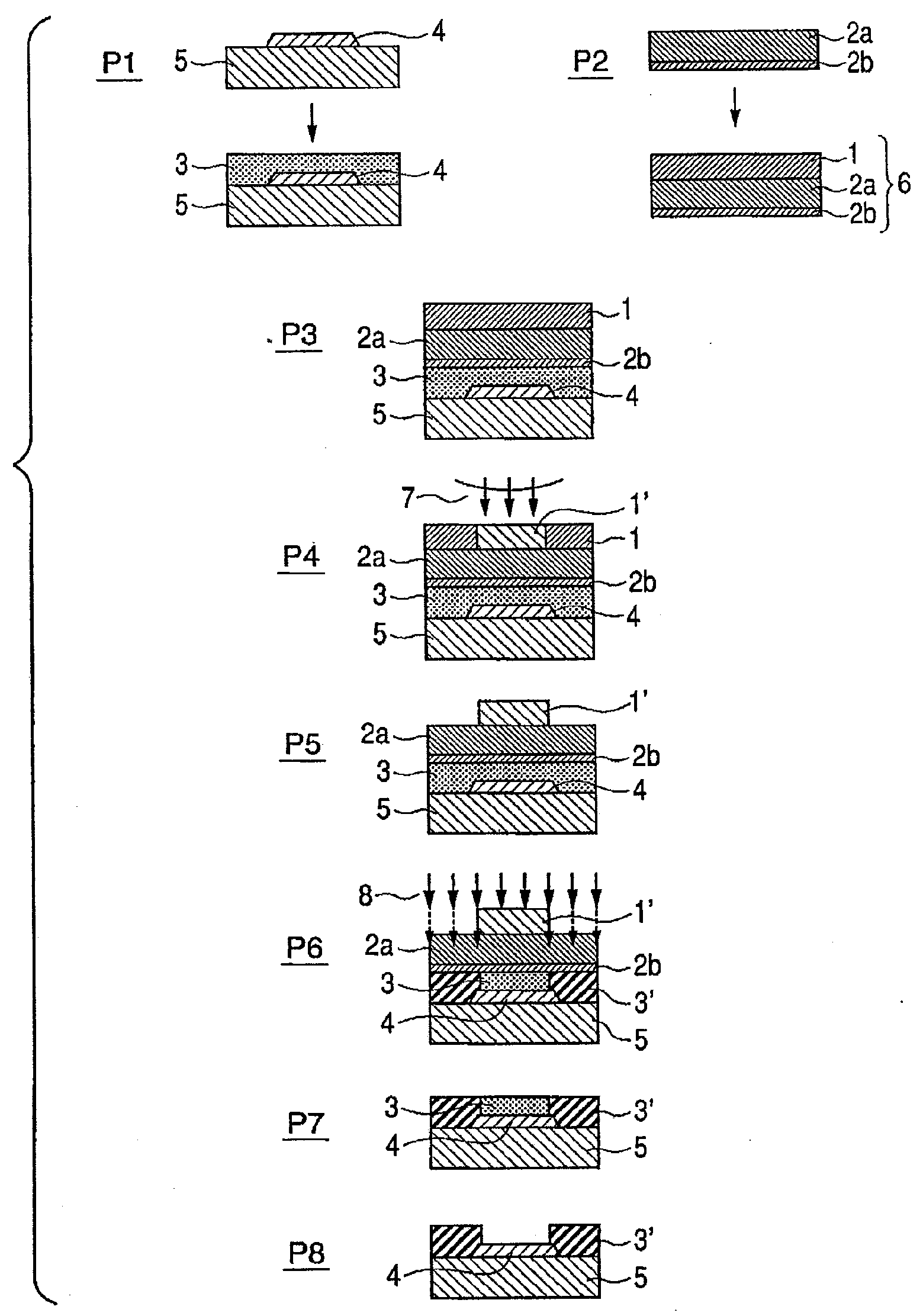

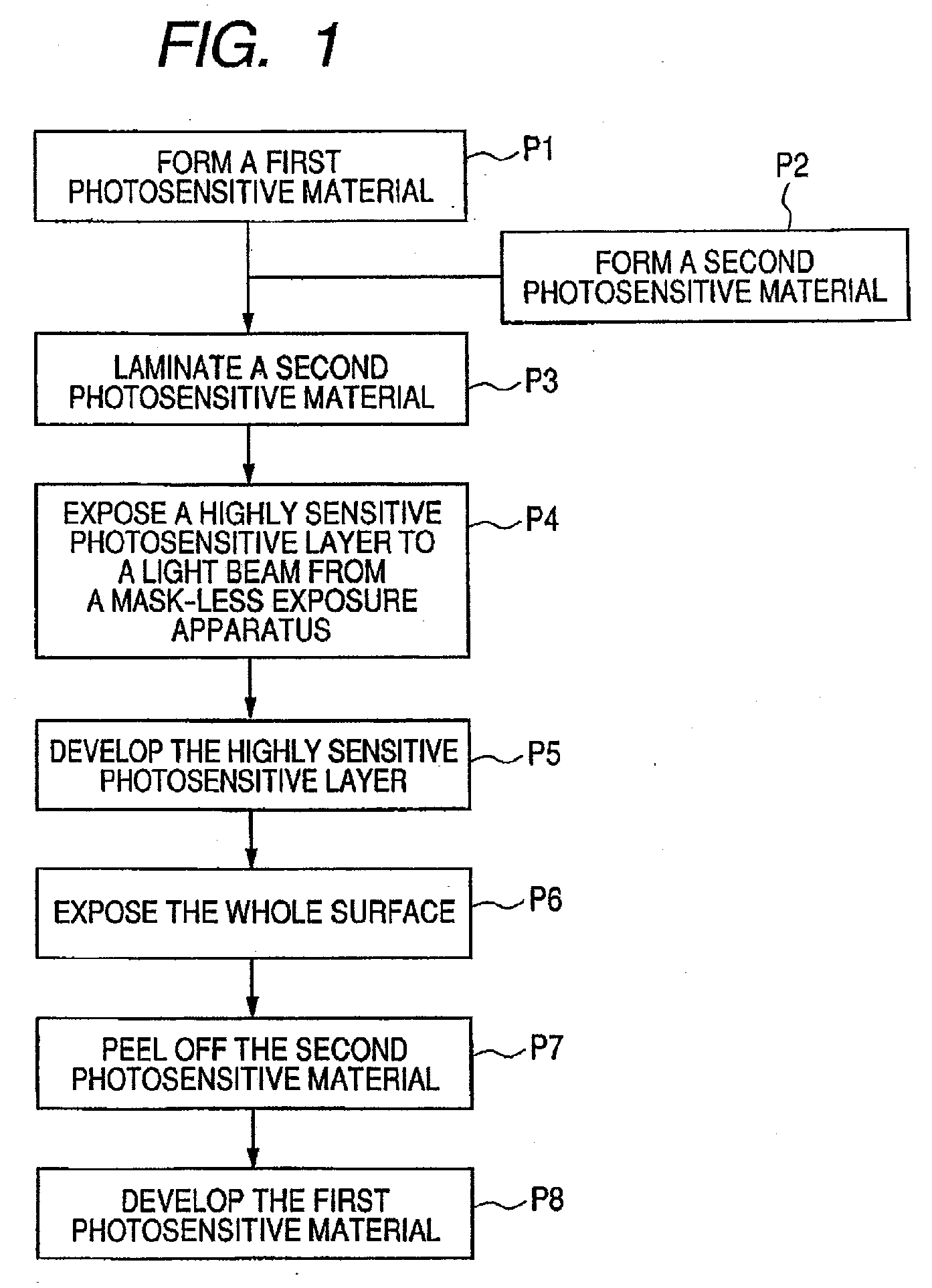

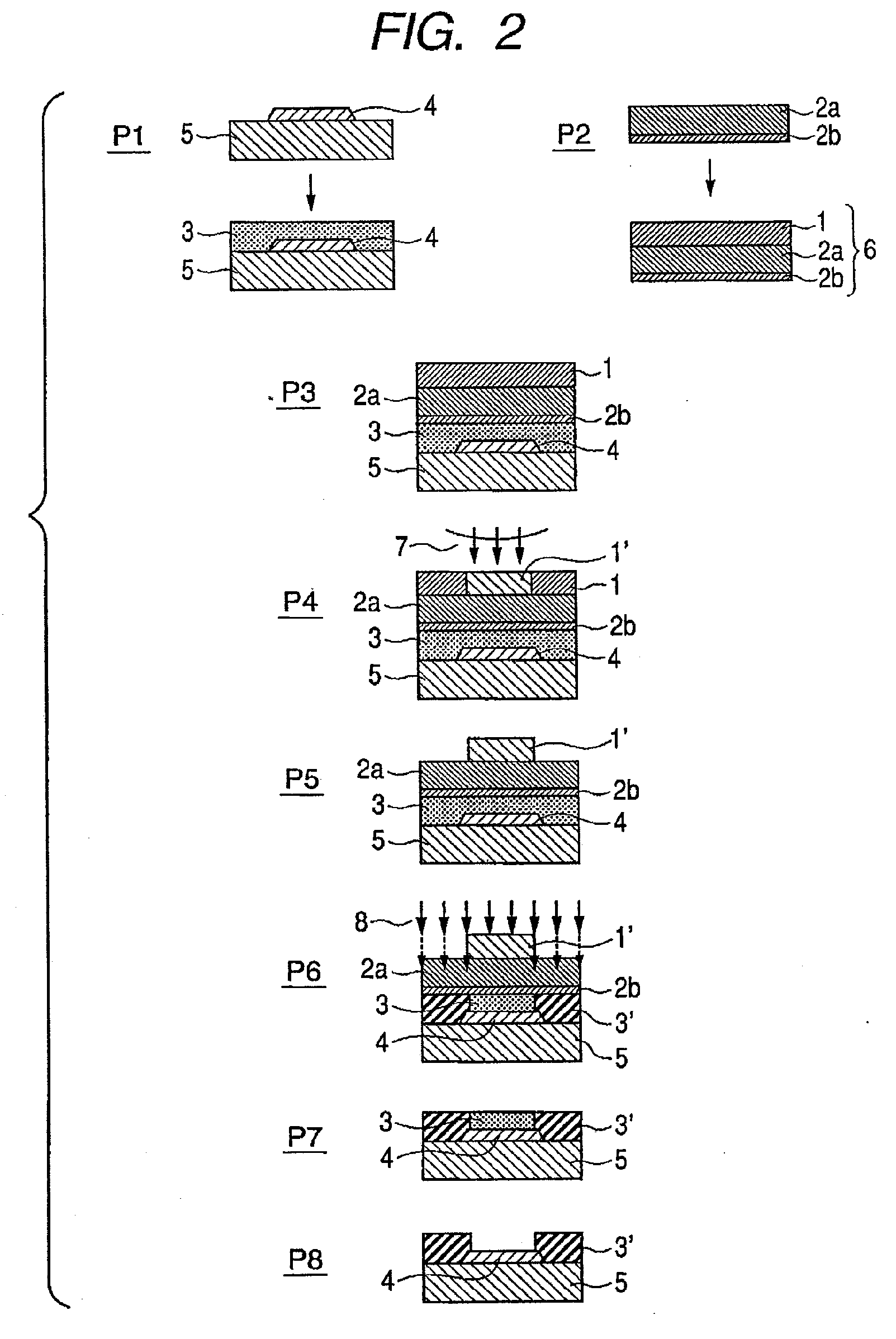

Pattern Formation Method

InactiveUS20090111062A1Low efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusLight beamUltraviolet lights

The present invention provides a pattern formation method comprising a step of forming on a substrate a film of a first photosensitive material having low sensitivity to a light beam with a main wavelength at h-line emitted from a mask-less drawing exposure apparatus but having high sensitivity to an energy light beam containing ultraviolet light; a step of forming on the first photosensitive material a film of a second photosensitive material having higher sensitivity to a light beam with the main wavelength at h-line; a step of drawing a second pattern on the second photosensitive material with the mask-less direct drawing exposure apparatus; a step of developing the second photosensitive material; and a step of exposing to a light beam the second photosensitive material with the second pattern formed thereon and the first photosensitive material in batch to form a target first pattern on the first photosensitive material.

Owner:HITACHI SEIKO LTD

A method for individualised marking of circuit boards

InactiveCN1437713APhotography auxillary processesPrinted circuit aspectsEngineeringElectronic component

A method for individualised marking of electronic components in electronics manufacture, such as circuit boards. On the photosensitive surface required for manufacturing the blanks is exposed, on each blank, a machine-readable pattern, which is subsequently used in the manufacture of the product itself, for individualising the blanks in question.

Owner:芳诺・萨尔米

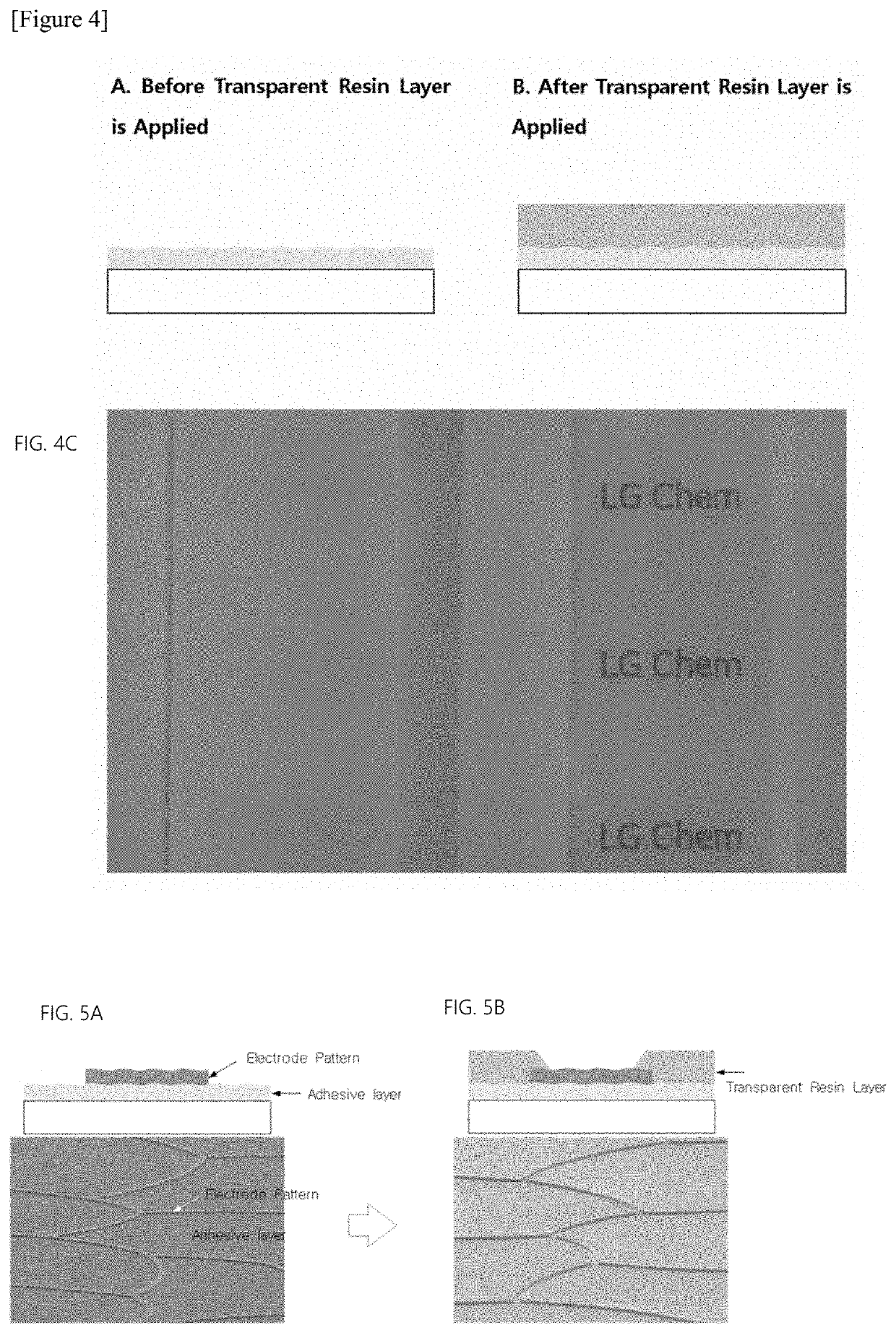

Electrode substrate for transparent light-emitting device display, and manufacturing method therefor

ActiveUS20200091392A1Low raw material costReduce smogCircuit optical detailsSolid-state devicesDisplay deviceEngineering

Owner:LG CHEM LTD

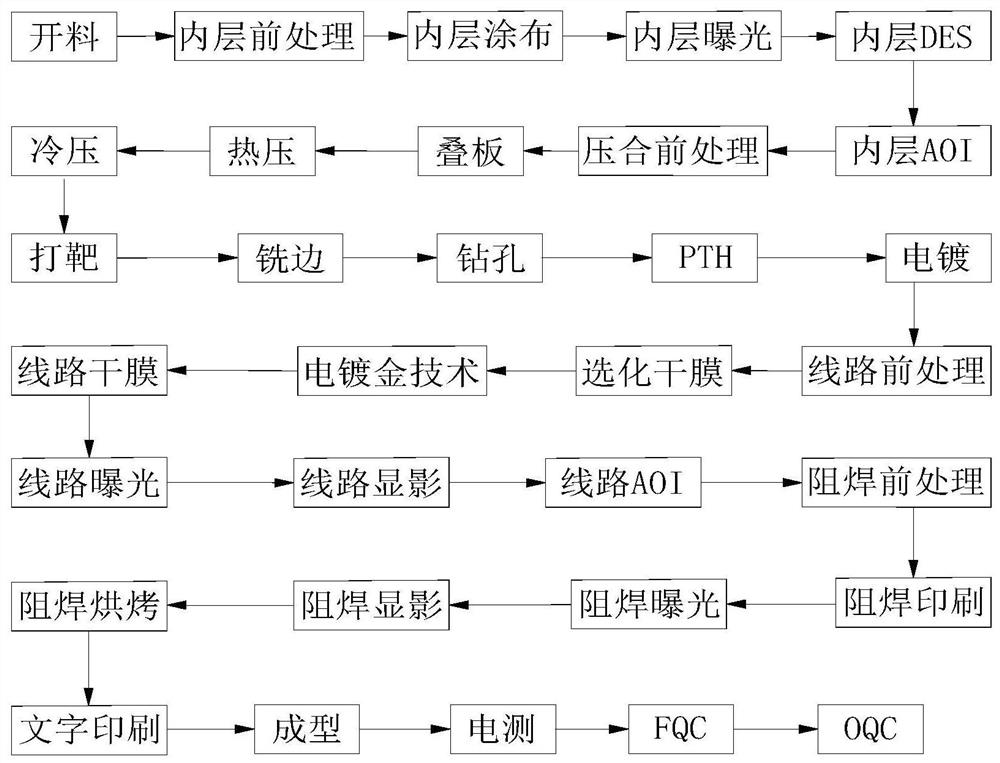

High-electromagnetic-compatibility circuit board and manufacturing method thereof

InactiveCN111698830AReduce manufacturing costImprove reliabilityCircuit masks application/removalRadiation-sensitive masks exposureMaterial consumptionProcess engineering

The invention belongs to the technical field of printed circuit boards, and particularly relates to a high-electromagnetic-compatibility circuit board and a manufacturing method thereof. The manufacturing method includes the steps: after a circuit pretreatment procedure, protecting the positions, not needing gold plating, on the circuit board through a selective dry film; plating the whole board with gold, and then processing the circuit board through the circuit dry film. According to the invention, the problems of more personnel, large material consumption, low product percent of pass and quality, heavy pollution and high cost caused by a redundant and complex production process are solved, the reliability of the product is greatly improved, and the manufacturing cost of the circuit board is reduced.

Owner:GUANGDE SANSN TECH CO LTD

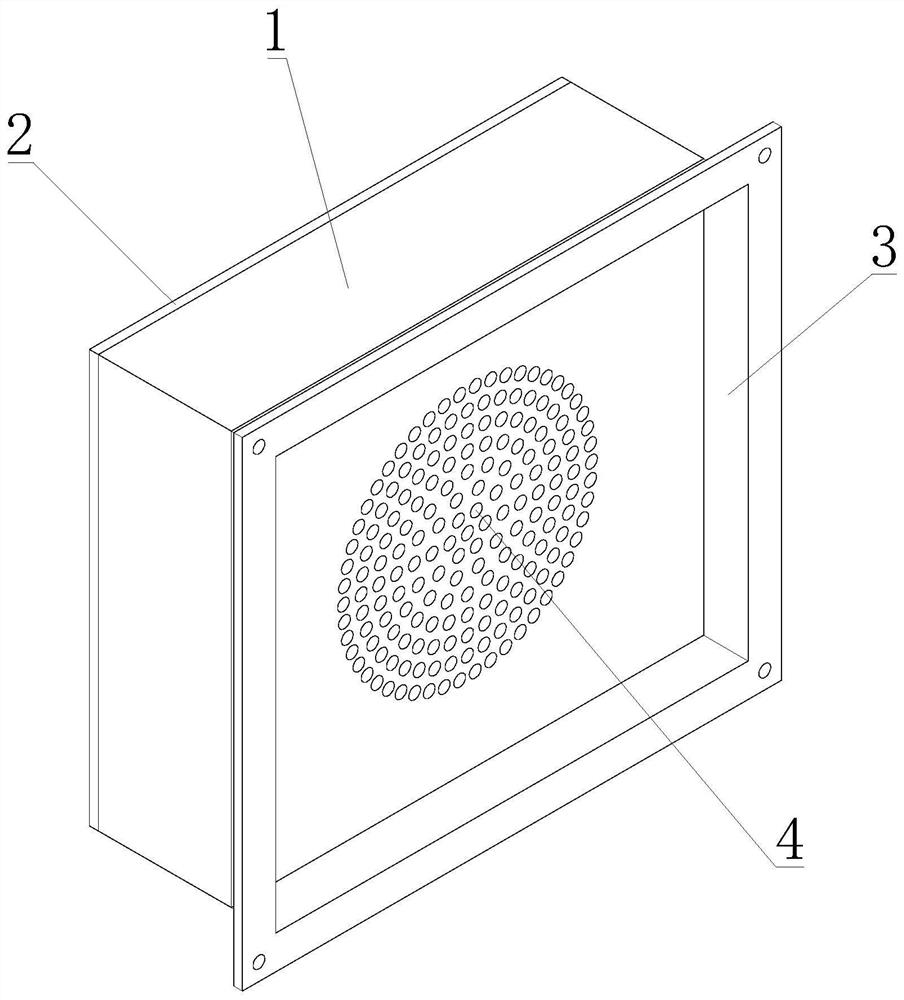

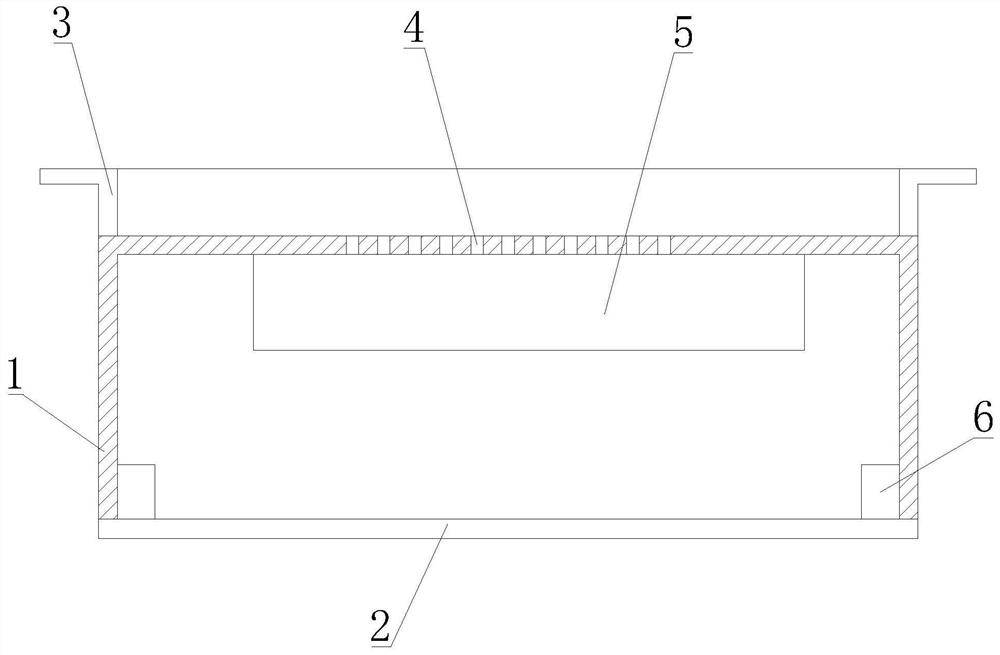

Moisture-proof stain-resistant composite circuit board and production process thereof

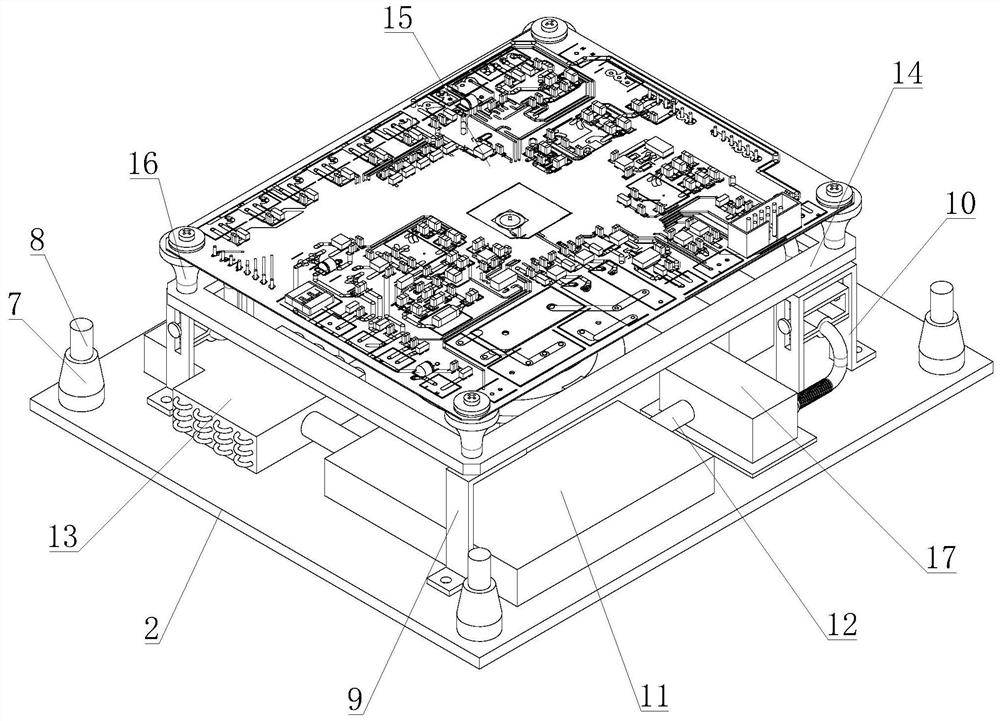

PendingCN111757640AEnsure usabilityEnsure cooling effectSupport structure mountingCooling/ventilation/heating modificationsEngineeringStructural engineering

The invention discloses a moisture-proof stain-resistant composite circuit board and a production process thereof. A plurality of groups of heat dissipation through holes are formed in the side wall of the rear end of the circuit board box body; and fixed seats are arranged at four corners of the inner side of the front end of the circuit board box body. A box body mounting frame is fixedly mounted at the rear end of the circuit board box body; positioning sleeves are arranged at four corners of a circuit board mounting base; positioning holes matched with the positioning sleeves are formed inthe fixed seats; mounting screw holes are formed in the bottoms of the positioning holes; a rotating cover drives a sealing baffle to rotate to seal or open an air hole, heat dissipation is started when the circuit board works, the use performance and the heat dissipation effect of the circuit board are ensured, and the sealing baffle seals the air holes when the circuit board does not work, so that external dust and impurities are effectively prevented from entering the circuit board, impurities are prevented from adhering to the surface of the circuit board, and the use performance is prevented from being affected.

Owner:昆山顺灏电子科技有限公司

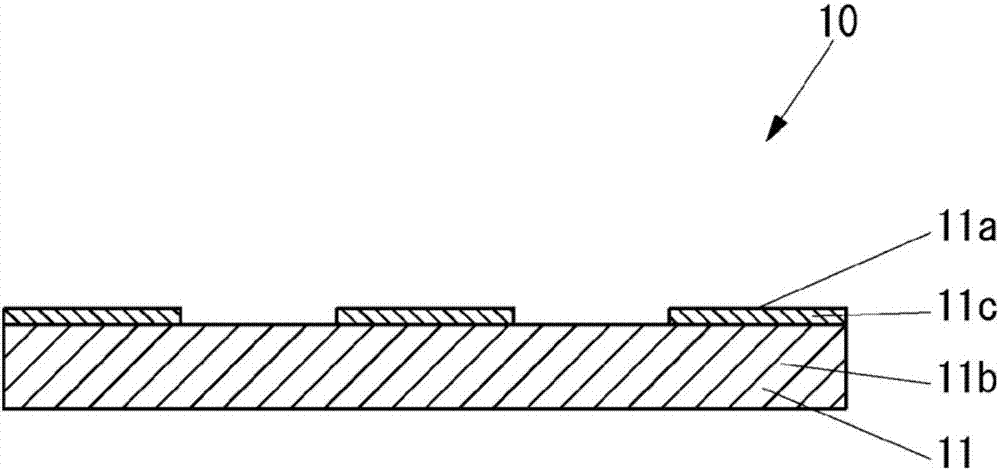

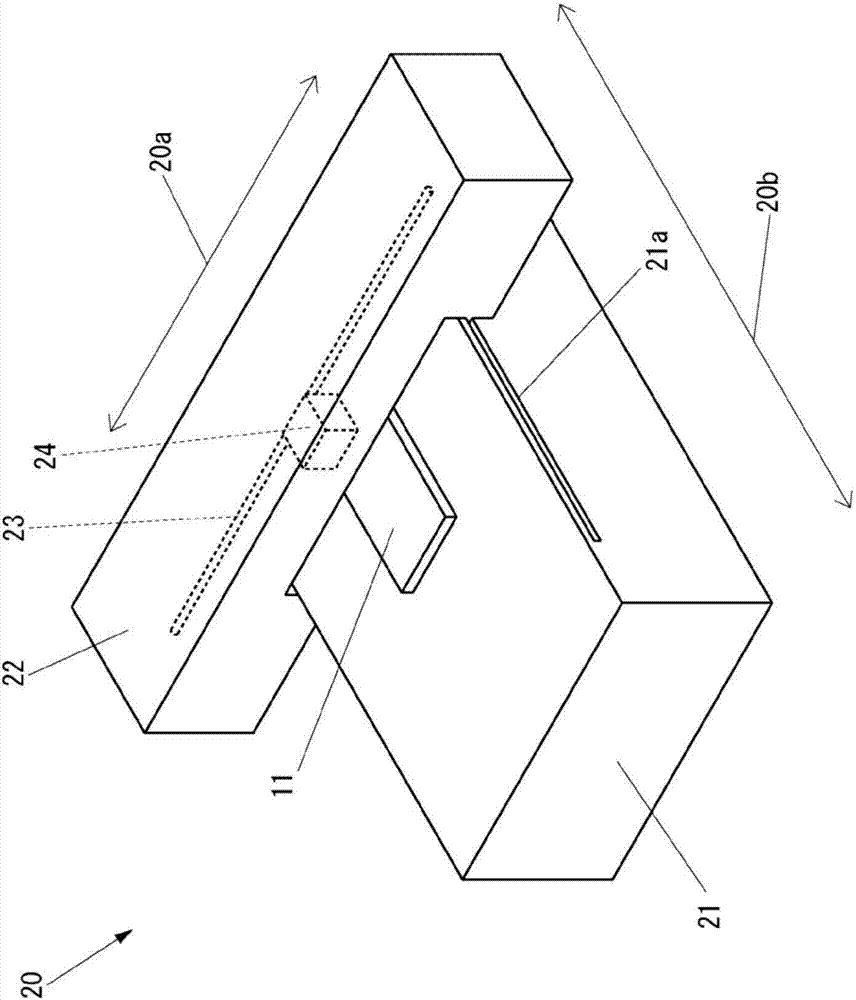

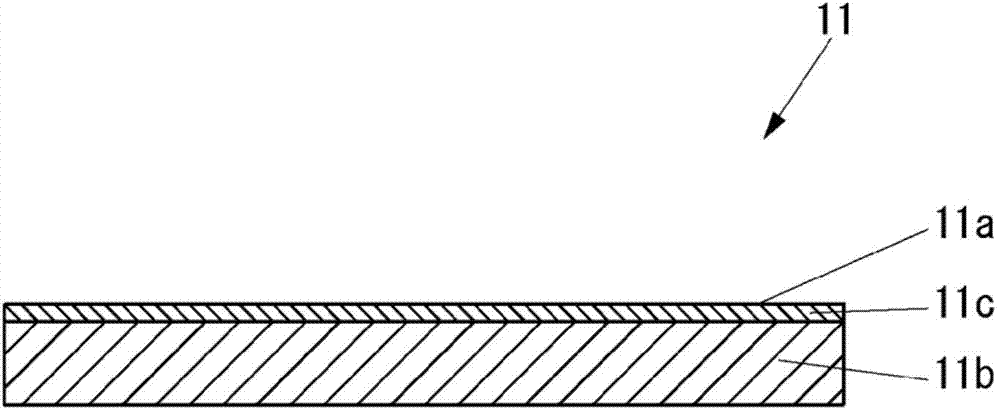

Etching method

In this etching method, the surface (11a) of a target object (11) is processed by using a corrosive agent to corrode said surface (11a) as a means of solving the problem addressed by the present invention. The etching method comprises: a resist formation step in which resist liquid is inkjet-printed on the surface (11a) so that the resist liquid forms a resist (12); a surface corrosion step in which the side (11a) of the target object (11) on which the resist (12) was formed by the resist formation step is brought into contact with a corrosive agent so that the part of the surface (11a) not having the resist (12) formed thereon is corroded; and a resist peeling step in which the resist (12) is peeled from the surface (11a) after the surface corrosion step. The etching method is characterized by the resist formation step being a step in which the resist (12) is formed using a resist liquid containing a monofunctional monomer or a monofunctional oligomer and a polyfunctional monomer or a polyfunctional oligomer.

Owner:MIMAKI ENG

Method and system for patterning a mask layer

ActiveUS8968985B2Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusWaxEngineering

The presently described embodiments use a printing process, e.g. a wax printing technique, to pattern a mask layer (such as a soldermask layer) of, for example, a printed circuit. Substantially all other conventional processes in developing soldermask and exposure processes can be maintained. According to the presently described embodiments, each printed circuit will have a unique pattern that matches uniform and non-uniform runout. In one form, the pattern is comprised of wax single drops having a specified gap to make the process transparent to the current industry practice. Furthermore, the single drops can be used for both large and small areas without any development time differences. In at least one form, the wax pattern and the soldermask in the gap are removed during development.

Owner:XEROX CORP

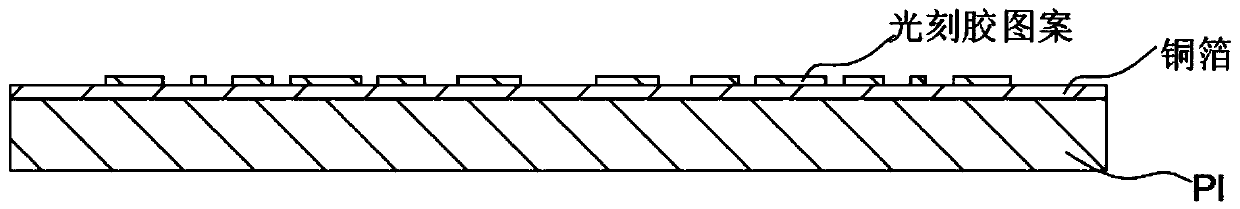

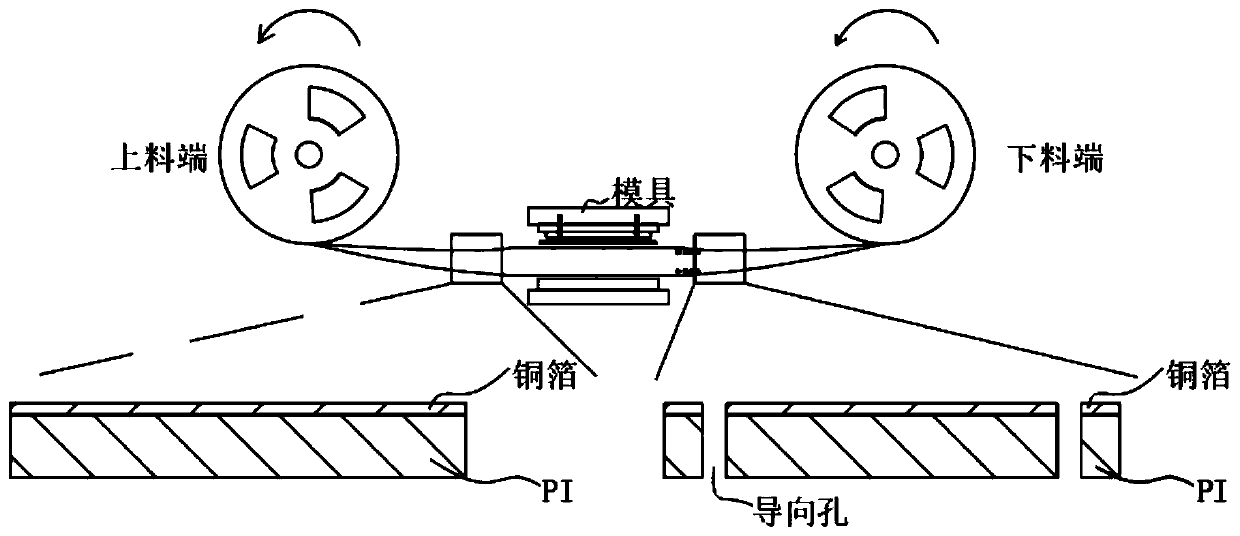

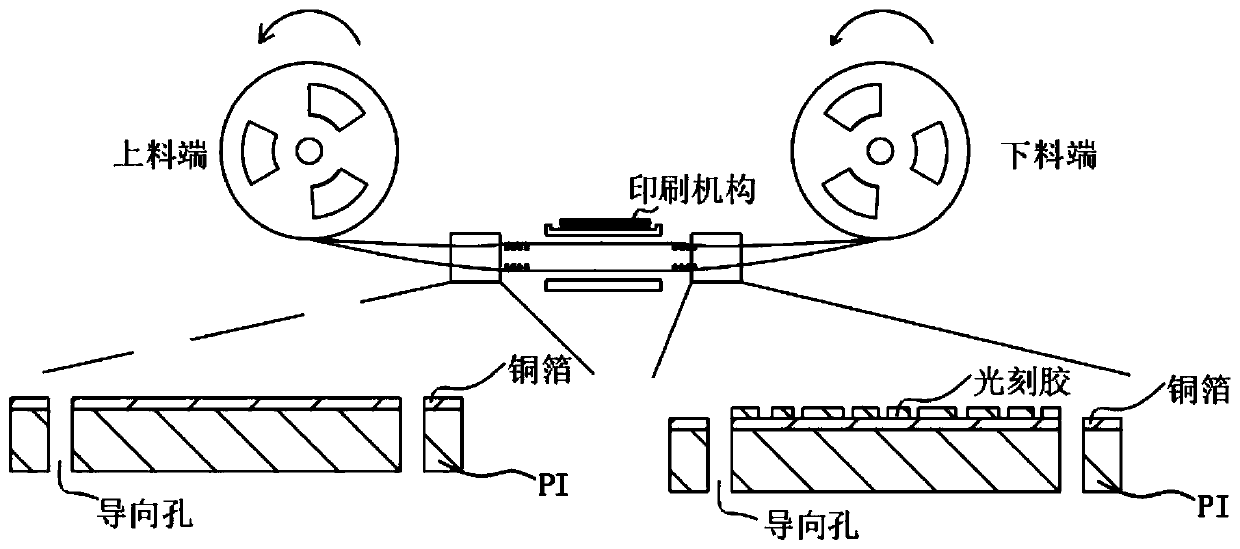

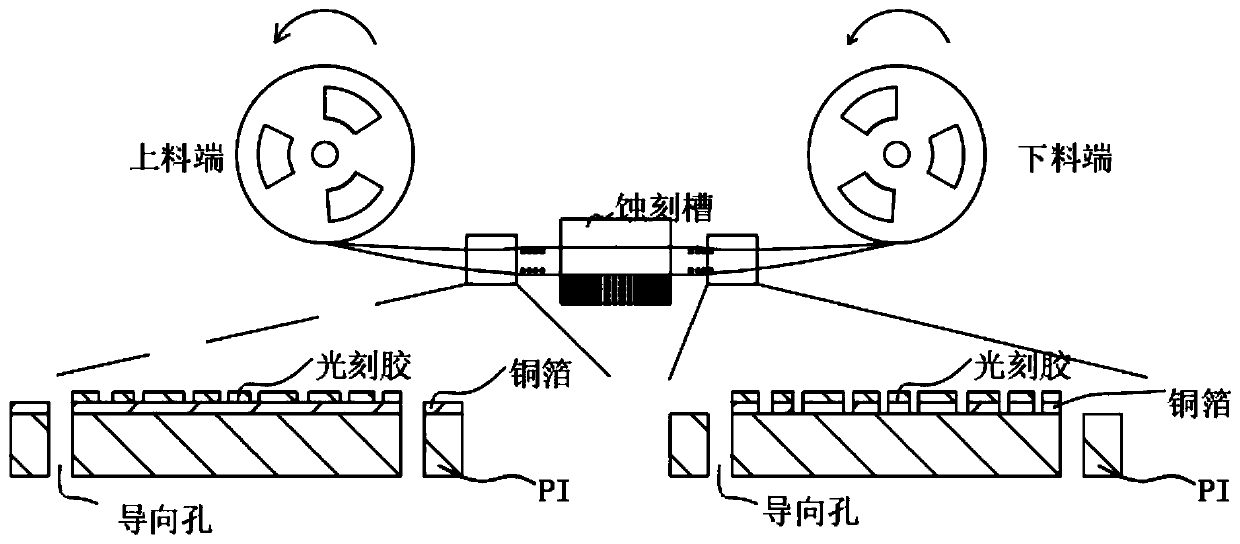

Method for forming COF circuit

InactiveCN110856358AReduce short circuit bad situationLow costConductive material chemical/electrolytical removalDirectly printed exposure masksCopper foilPhotoresist

The invention provides a method for forming a COF circuit and relates to the technical field of integrated circuits. The method for forming the COF circuit comprises steps that S1, a base material ispunched, and guide holes on two sides of the base material are punched; S2, photoresist printing of a punched product is performed, and a required photoresist pattern is printed on a surface of a copper foil and cured; S3, the product printed with the photoresist pattern is etched, and the copper which is not covered by the photoresist under the action of an etching solution is removed; and S4, afilm of the etched product is stripped, the photoresist pattern protected on the copper surface is removed, and the circuit pattern is exposed. The method is advantaged in that circuit forming is carried out in a printing manner, operations of exposure and development processes are omitted, so occurrence of bad short circuit conditions is reduced, cost of the exposure and development processes isgreatly saved, a product processing period can be shortened, and equipment cost is greatly reduced.

Owner:江苏上达半导体有限公司

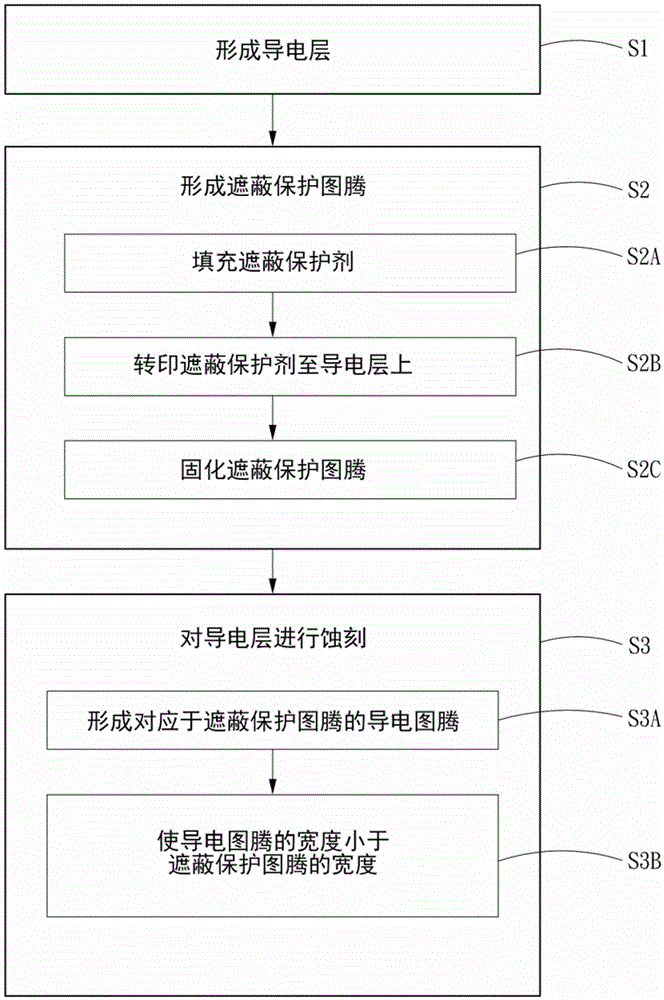

Method of forming conductive totem by using gravure printing mode

InactiveCN106817845AReduce usageLow costConductive material chemical/electrolytical removalDirectly printed exposure masksLight exposureEngineering

The invention discloses a method of forming a conductive totem by using a gravure printing mode. A conductive layer is firstly formed on a substrate; the gravure printing mode is then used to form a shielding protection totem on the conductive layer; and finally, the conductive layer is etched, and the conductive layer forms a conductive totem corresponding to the shielding protection totem. With the help of the gravure printing mode, the shielding protection totem can be formed directly without processes such as yellow light exposure and development, and thus, the process complexity can be reduced to improve the process speed, and the stock use is reduced to reduce the cost.

Owner:CHEESHIN TECHNOLOGY CO LTD

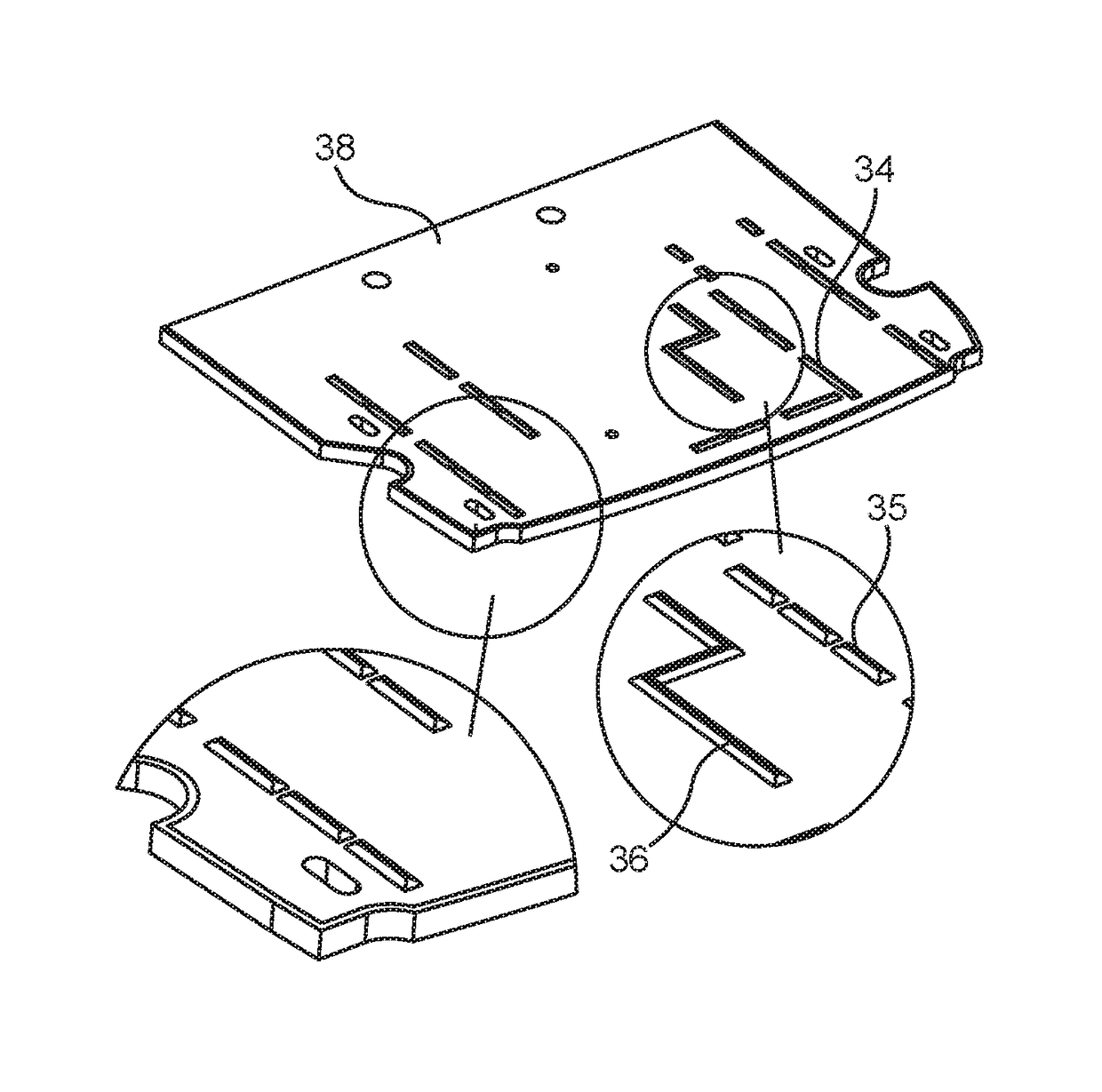

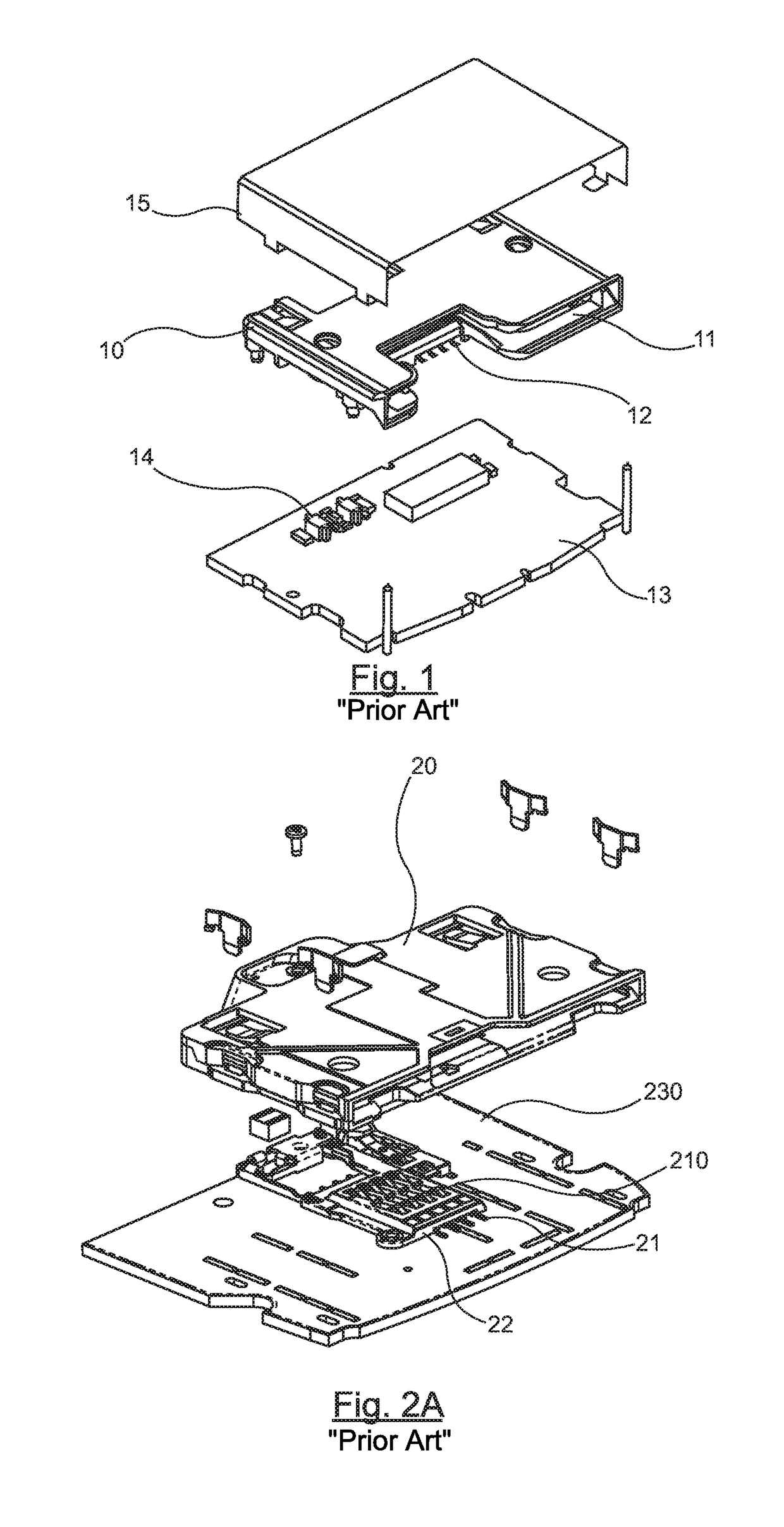

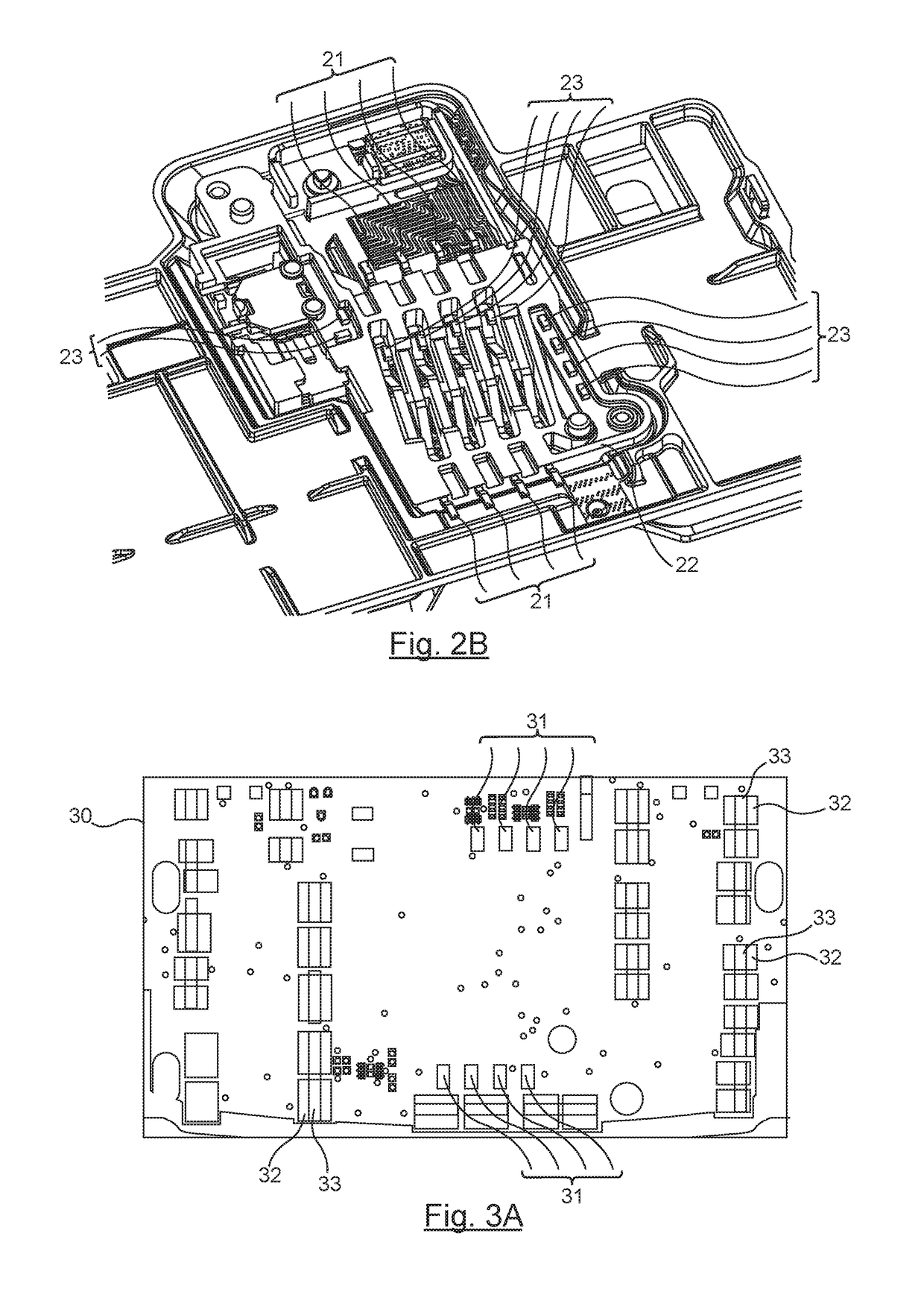

Support entering into the fabrication of an electronic device, corresponding memory card connector, memory card read terminal and manufacturing method

ActiveUS9980374B2Increased riskPrinted circuit assembling3D rigid printed circuitsEngineeringElectronic component

Owner:BANKS & ACQUIRERS INT HLDG

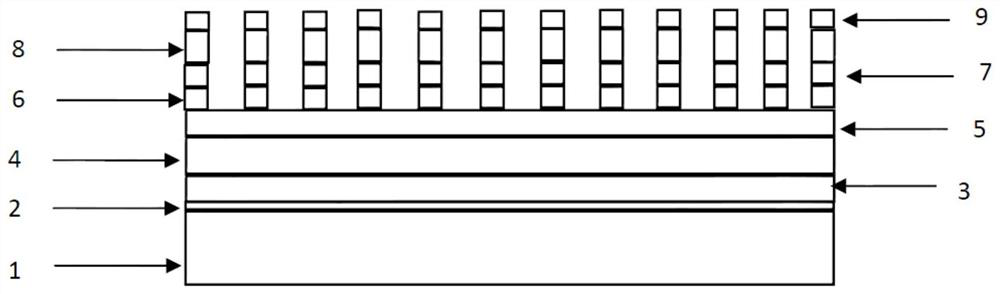

Flexible circuit board and manufacturing method thereof

ActiveCN112291917AImprove adhesionHigh visible light transmittancePrinted circuit detailsPrinted circuit aspectsFlexible circuitsHemt circuits

The invention relates to a flexible circuit board and a manufacturing method thereof. The flexible circuit board comprises a flexible base material 1 which is provided with a transition layer 2, an optical antireflection layer 3, an optical antireflection layer 4, a protective transition layer 5, a transition layer 6, a seed layer 7, a copper layer 8 and a protective layer 9 from bottom top to top. The manufacturing method comprises the steps of (1) plating and (2) etching the circuit. According to the invention, the transition layer, the protective layer and the seed layer are introduced between the flexible substrate 1 and the conductive copper layer 8, so that the adhesive force between the substrate and the conductive copper is improved, the copper foil with the thickness of 20-30 microns can be electroplated on the surface of the substrate, and the drawing force of the bonding pad can reach more than 1N. According to the invention, the optical antireflection layer 3 and the optical antireflection layer 4 are introduced and form an optical anti-reflection structure, so that the visible light transmittance of the circuit board is improved, and the loss value of the transmittancecan be reduced to less than 5%.

Owner:深圳市顺华智显技术有限公司

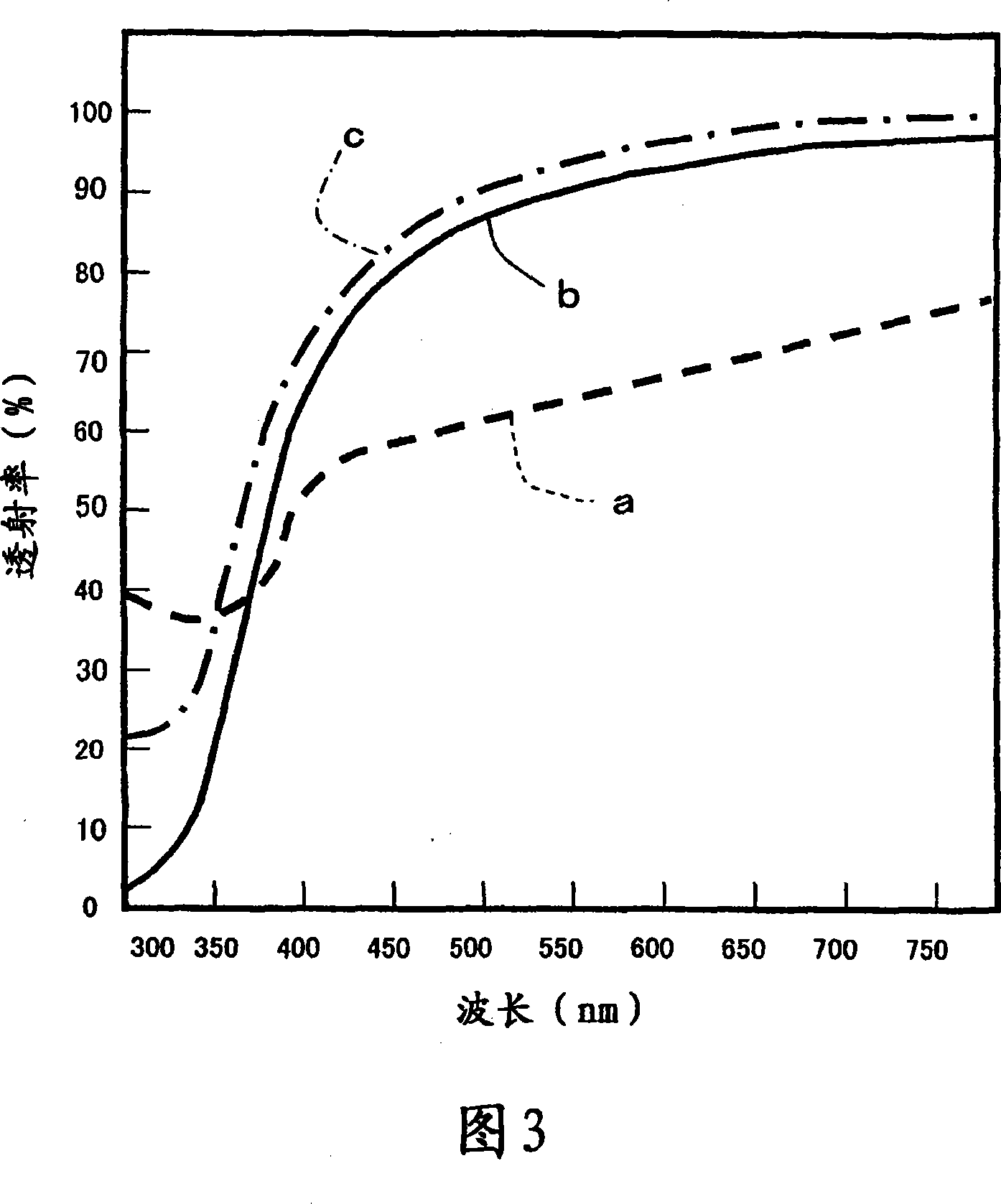

Imaging on substrates with alkaline strippable UV blocking compositions and aqueous soluble UV transparent films

ActiveUS20160353577A1Fast and economicalDifficult and time-consume to removeSecond resist masksPhotomechanical exposure apparatusWater solubleUv blocking

Substrates, such as printed circuit boards, are coated with an aqueous alkaline developable UV photosensitive material followed by applying an aqueous soluble UV transparent film to coat the UV photosensitive material. An aqueous alkaline strippable UV blocking composition is selectively applied to the surface of the UV transparent film to function as a mask. UV light is applied to portions of the UV photosensitive material not covered by the mask. The UV blocking composition, UV transparent film and selective sections of the UV photosensitive material are simultaneously removed with an aqueous alkaline developer solution to form an image on the substrate.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Popular searches

Originals for photomechanical treatment Metallic pattern materials Printed element electric connection formation Photosensitive materials for photomechanical apparatus Glass/slag layered products Natural mineral layered products Superimposed coating process Metal layered products Resistive material coating Printed capacitor incorporation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com